Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

396results about How to "Resolve uncertainty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

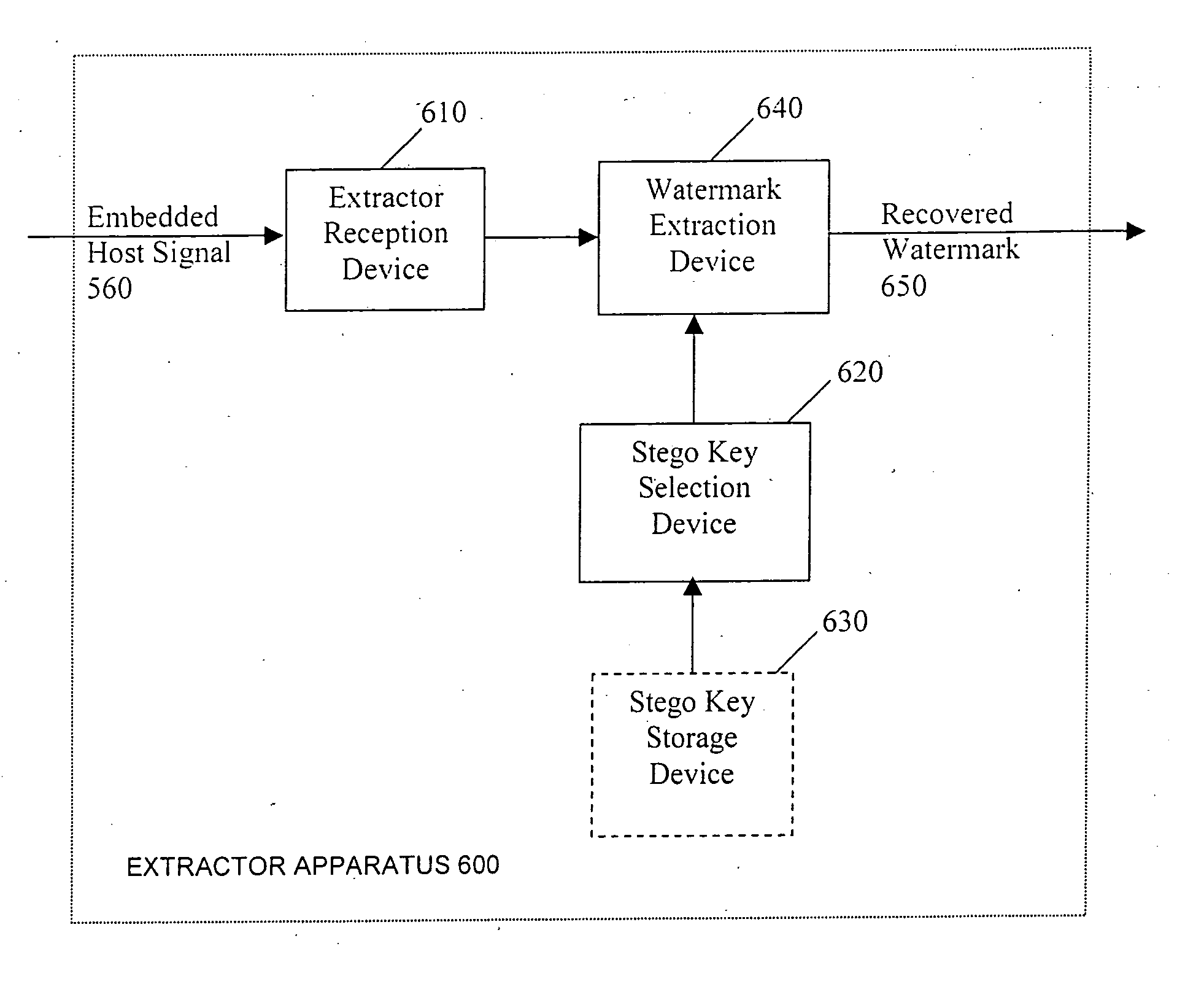

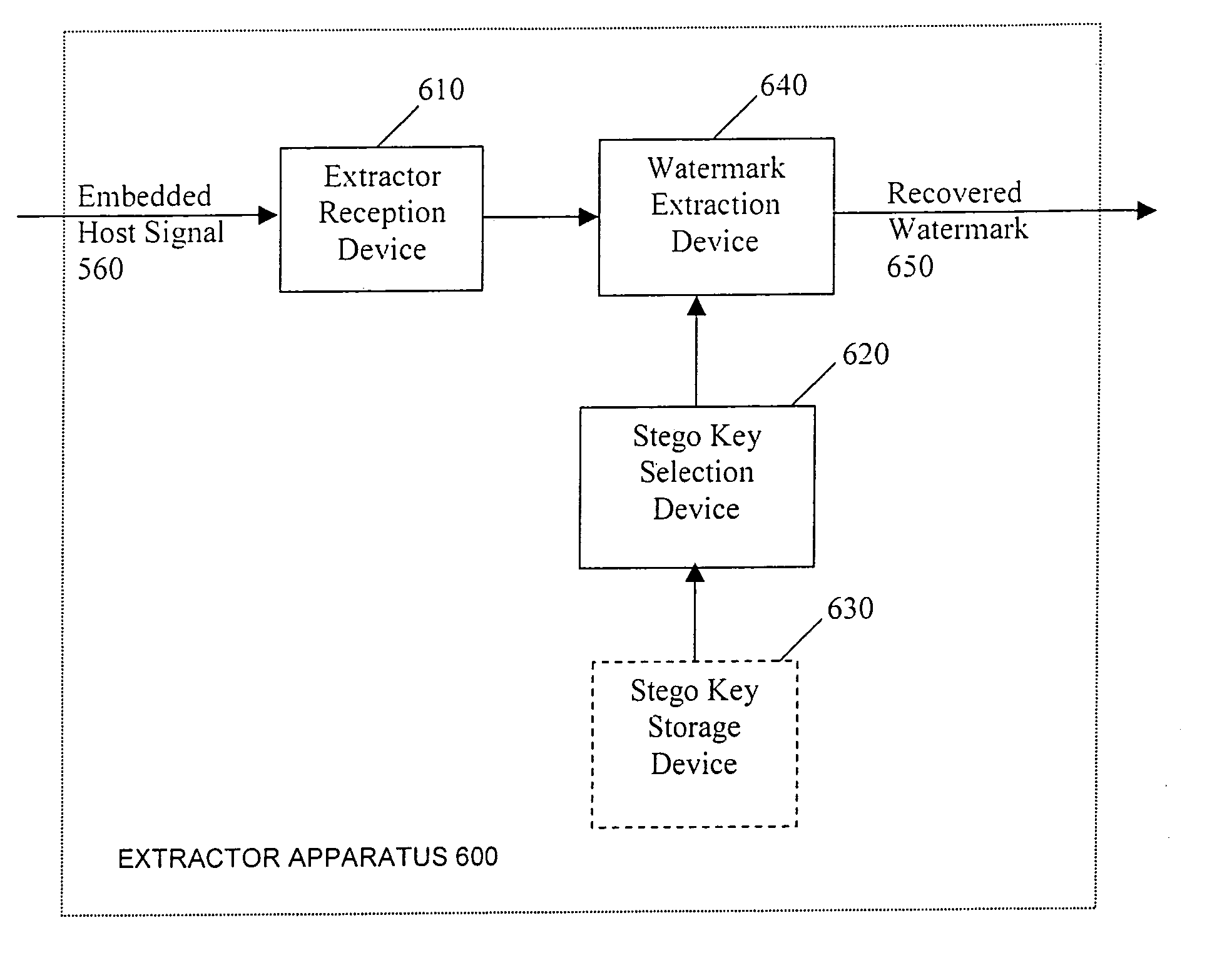

System reactions to the detection of embedded watermarks in a digital host content

InactiveUS20060239503A1Increase payload capacityIncreased payload capacityUser identity/authority verificationSpeech analysisSystem requirementsSystem recovery

Methods for adapting the operation of a system in response to the detection of embedded watermarks from a digital host content are provided. A digital host content is received and examined for the presence of watermarks. In response to the detection of embedded watermarks and in accordance with the value, type, density or spacing of the detected watermarks, one or more system reactions may take place. These reactions include conditionally allowing the system to resume its normal operation, prohibiting the system from resuming its normal operation, degrading the quality of the digital host content or changing the security status of the digital host content. In response to the extraction of weak watermarks that do not meet the desired system requirements, the extraction operation may be modified or extended to enable the detection of strong watermarks.

Owner:IP ACQUISITIONS LLC

System reactions to the detection of embedded watermarks in a digital host content

InactiveUS7369677B2Increase payload capacitySacrificing complexityUser identity/authority verificationSpeech analysisSystem requirementsSystem recovery

Methods for adapting the operation of a system in response to the detection of embedded watermarks from a digital host content are provided. A digital host content is received and examined for the presence of watermarks. In response to the detection of embedded watermarks and in accordance with the value, type, density or spacing of the detected watermarks, one or more system reactions may take place. These reactions include conditionally allowing the system to resume its normal operation, prohibiting the system from resuming its normal operation, degrading the quality of the digital host content or changing the security status of the digital host content. In response to the extraction of weak watermarks that do not meet the desired system requirements, the extraction operation may be modified or extended to enable the detection of strong watermarks.

Owner:IP ACQUISITIONS LLC

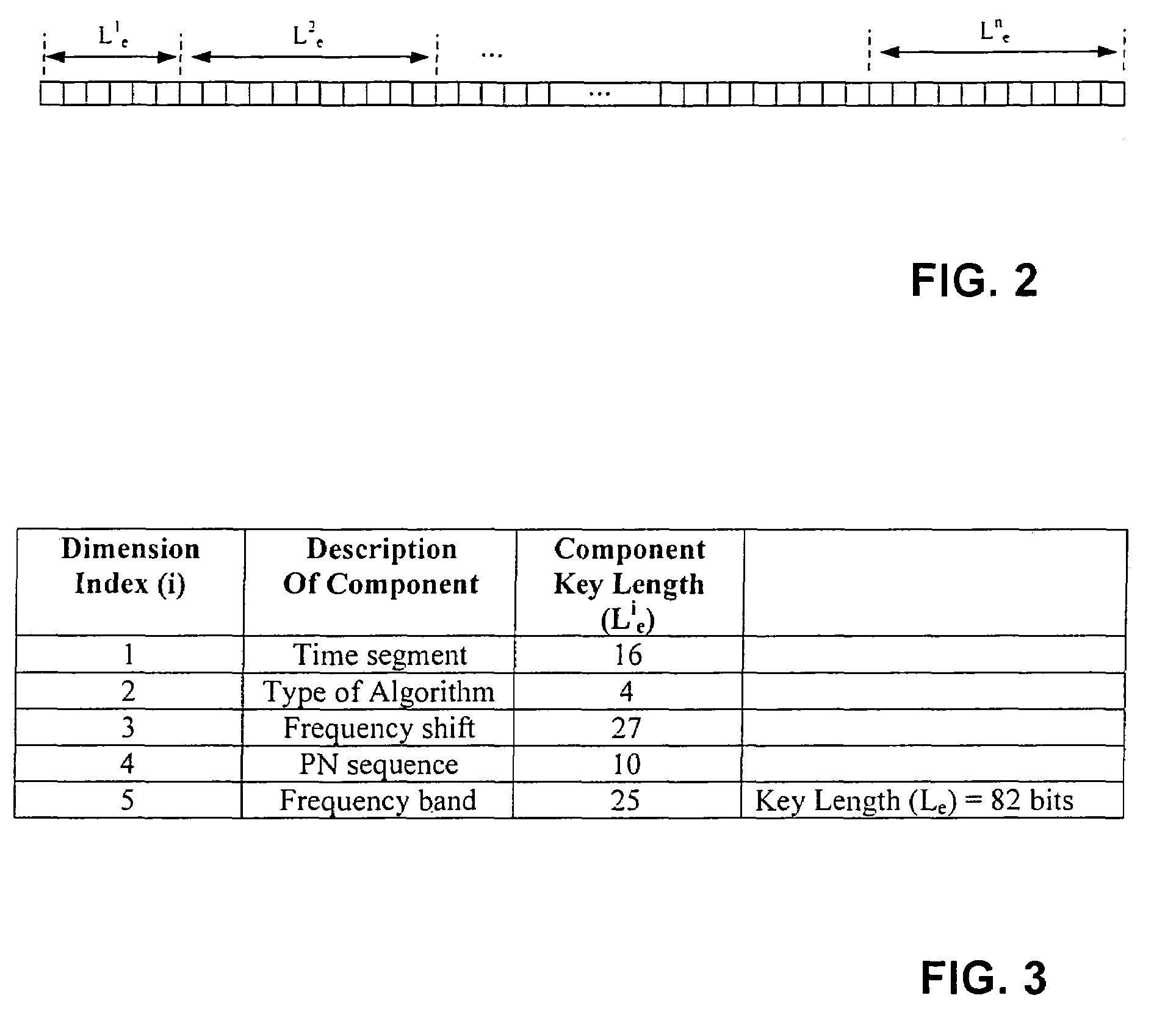

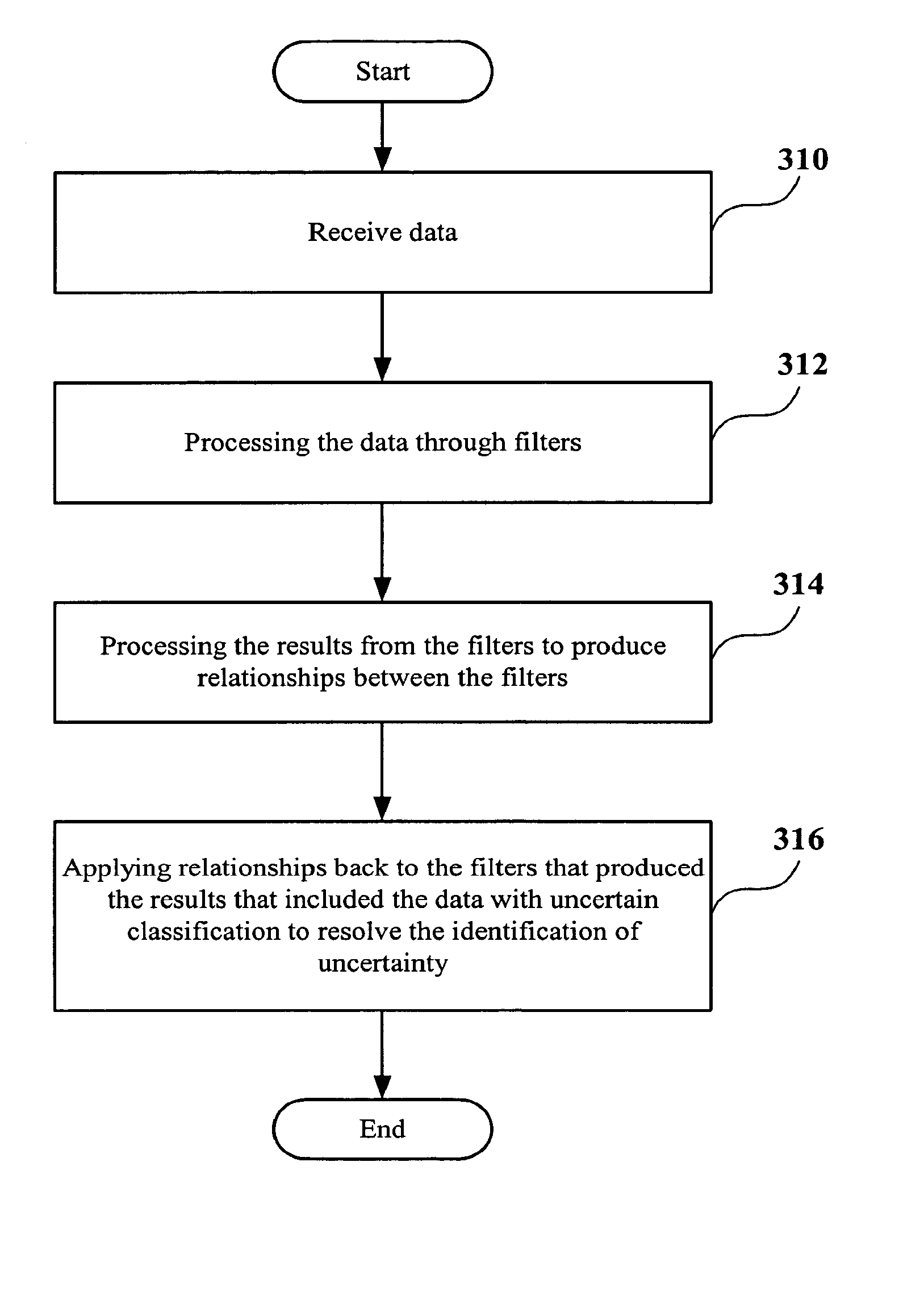

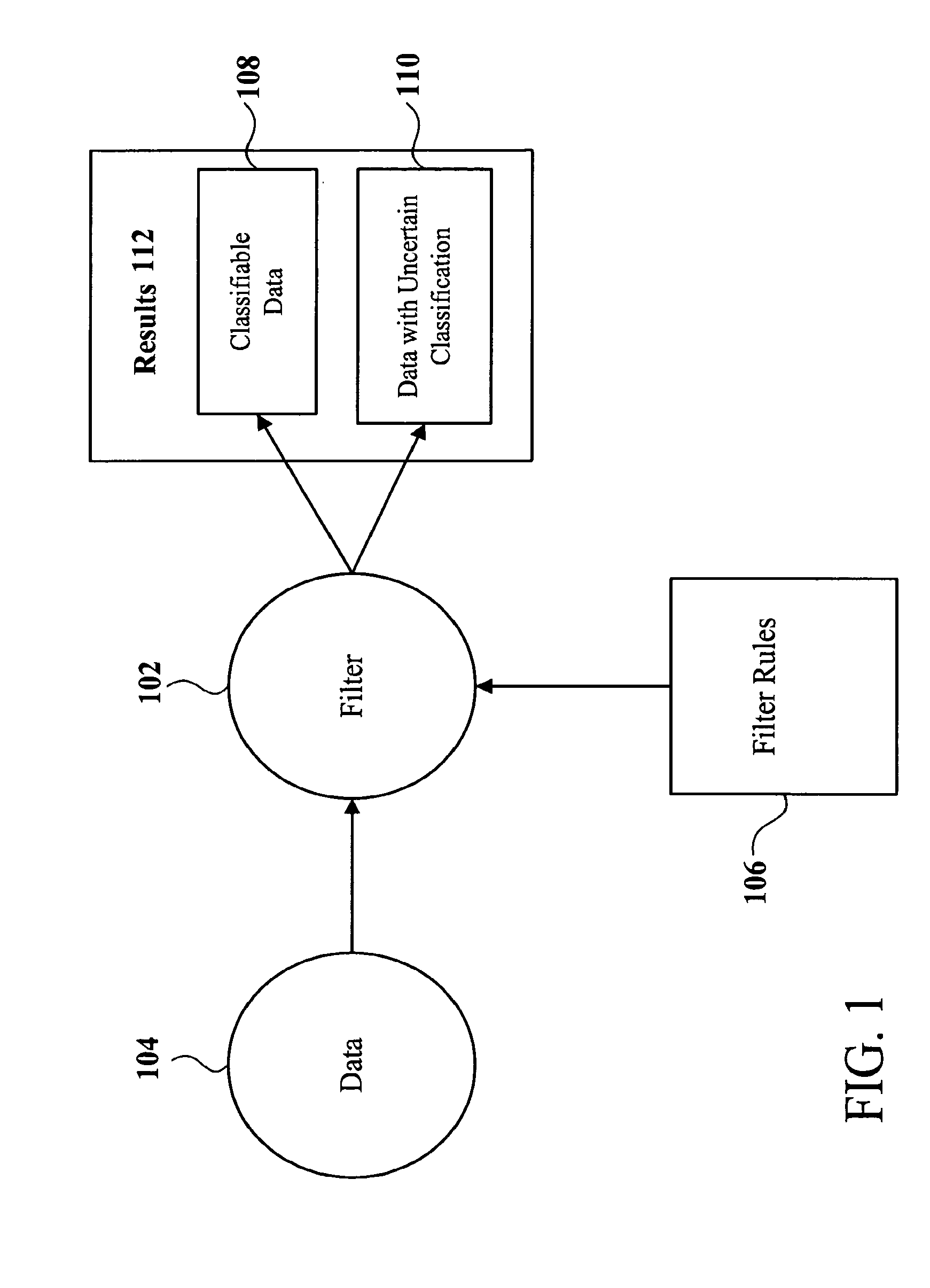

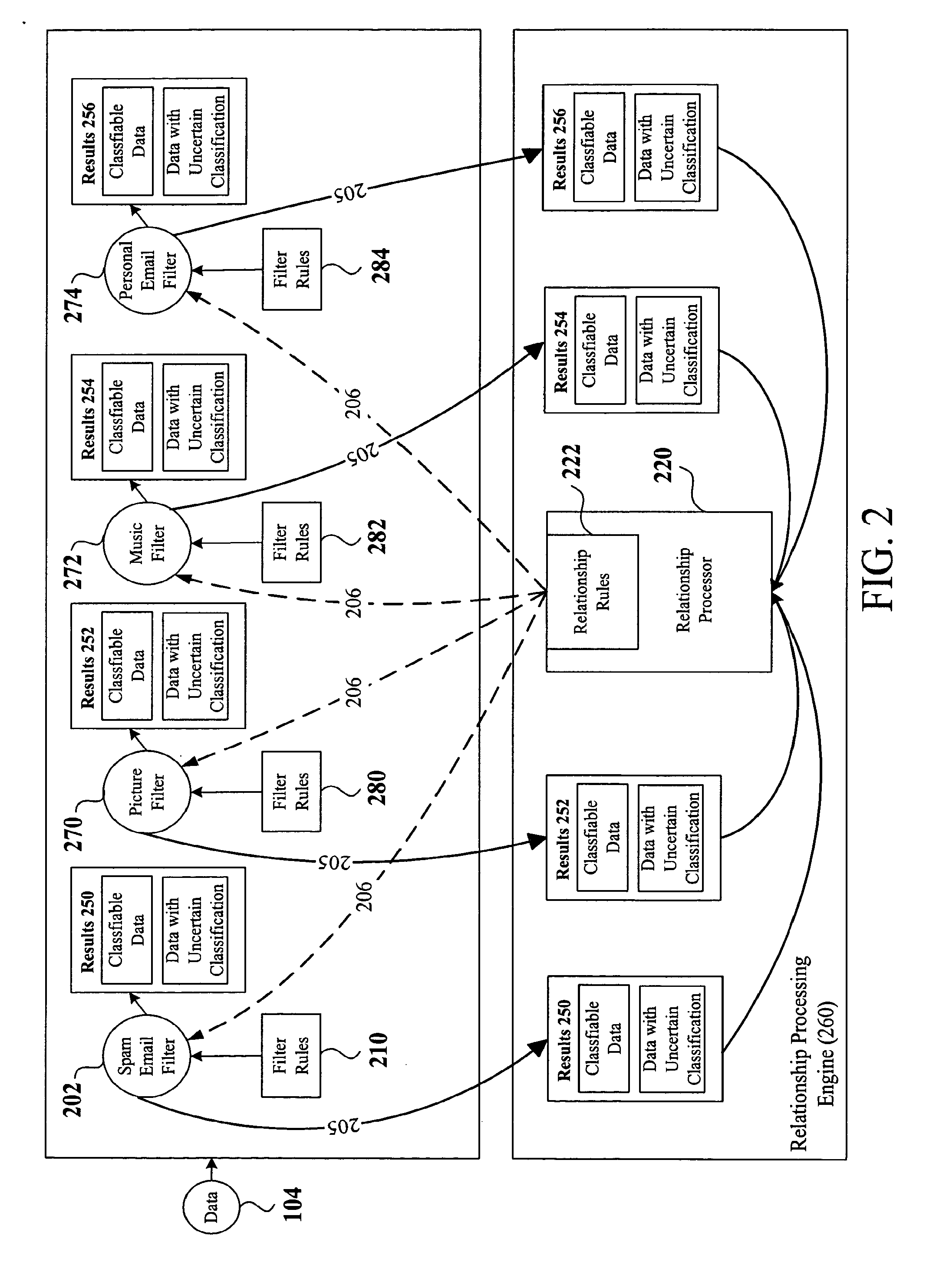

Methods and systems for training content filters and resolving uncertainty in content filtering operations

InactiveUS20050015452A1Resolve uncertaintyDigital data information retrievalCharacter and pattern recognitionContent filteringPattern recognition

A method for resolving uncertainty resulting from content filtering operations is provided. Results produced by a plurality of filters are received whereby the results include classification of filtered data and identification of uncertainty in the classification. Thereafter, relationships between the plurality of filters are established and the relationships are applied. The application of the relationships enables the identification of uncertainty to be resolved. Systems for resolving the uncertainty resulting from content filtering operations are also described.

Owner:SONY COMPUTER ENTERTAINMENT INC

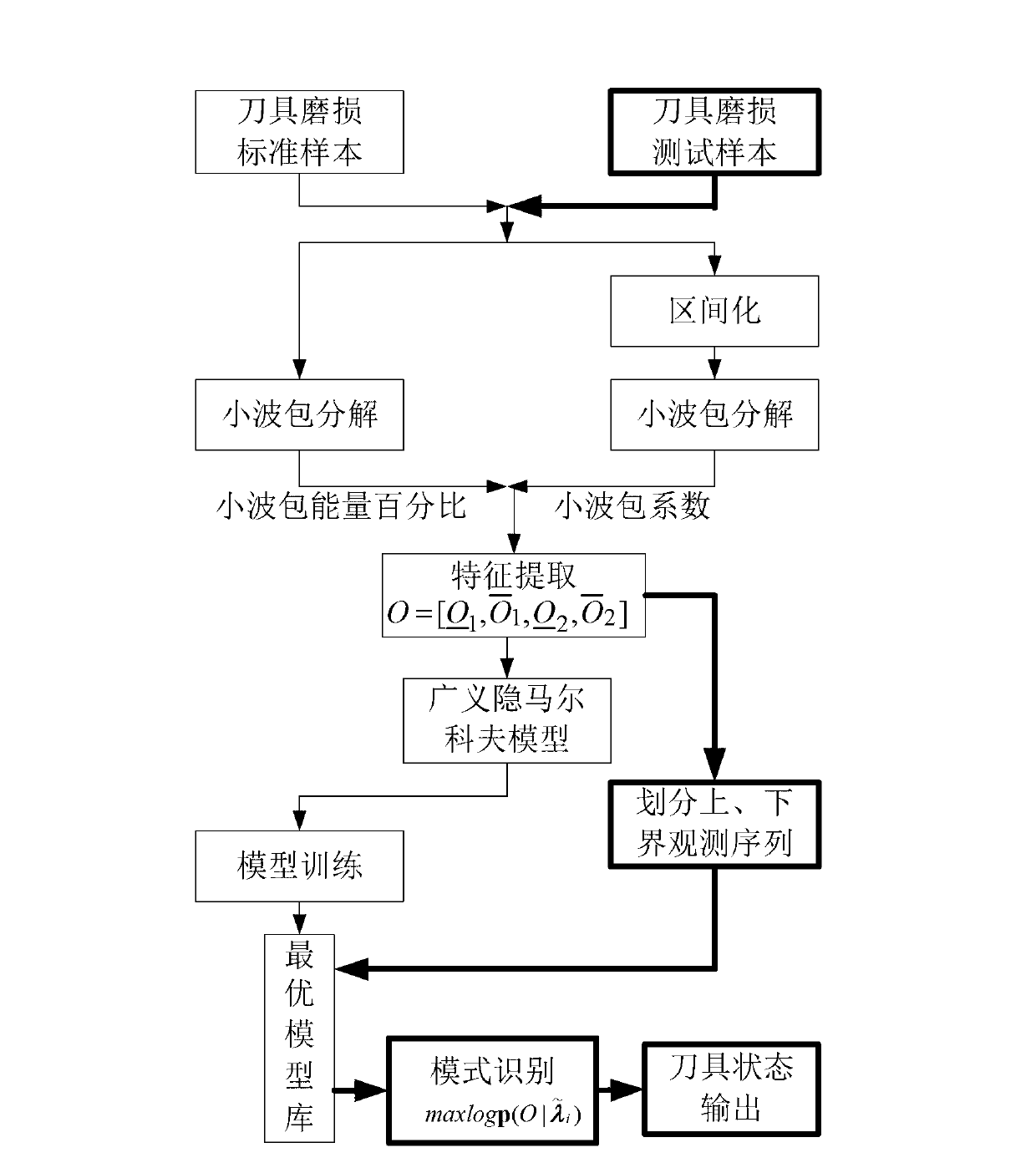

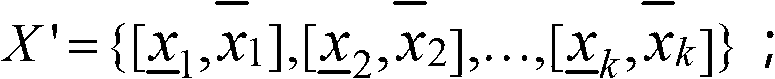

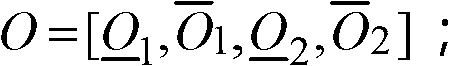

Machining cutter abrasion state identification method of numerical control machine tool

ActiveCN103105820ALong tool lifeImprove productivityProgramme controlComputer controlWavelet packet decompositionCollections data

The invention discloses a machining cutter abrasion state identification method of a numerical control machine tool. The method comprises a first step of data collection, a second step of regionalizing the collection data and obtaining an interval dataset, a third step of conducting wavelet packet decomposition of a collection signal and obtaining an energy percentage of each frequency range and an upper bound wavelet packet coefficient and a lower bound wavelet packet coefficient corresponding to each frequency range, a fourth step of obtaining a multiple observation sequence, a fifth step of obtaining a general hidden Markov original model lambada=(A, B, pi), a sixth step of model training and obtaining an optimal model base lambada=(lambada 1, ..., lambada n), and a seventh step of regarding the to-be-identified cutter abrasion signal data as multiple observation input, substituting into the optimal model base and identifying the cutter abrasion state. The method solves the problem of uncertainty in data processing when the cutter abrasion state is studied in the numerical control machine tool machining through a general interval probability and identifying accuracy rate is greatly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

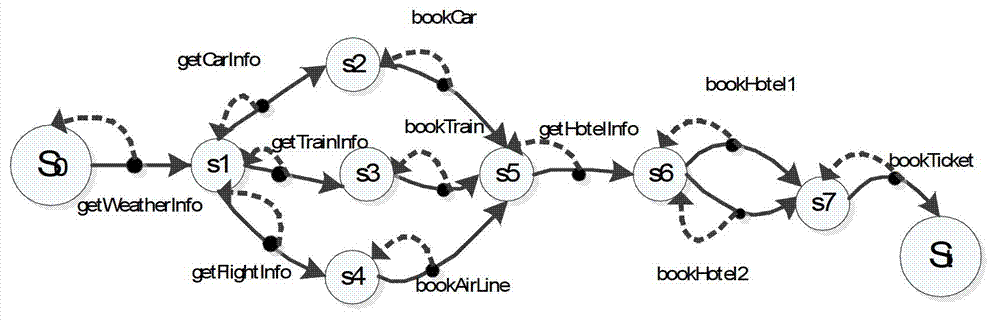

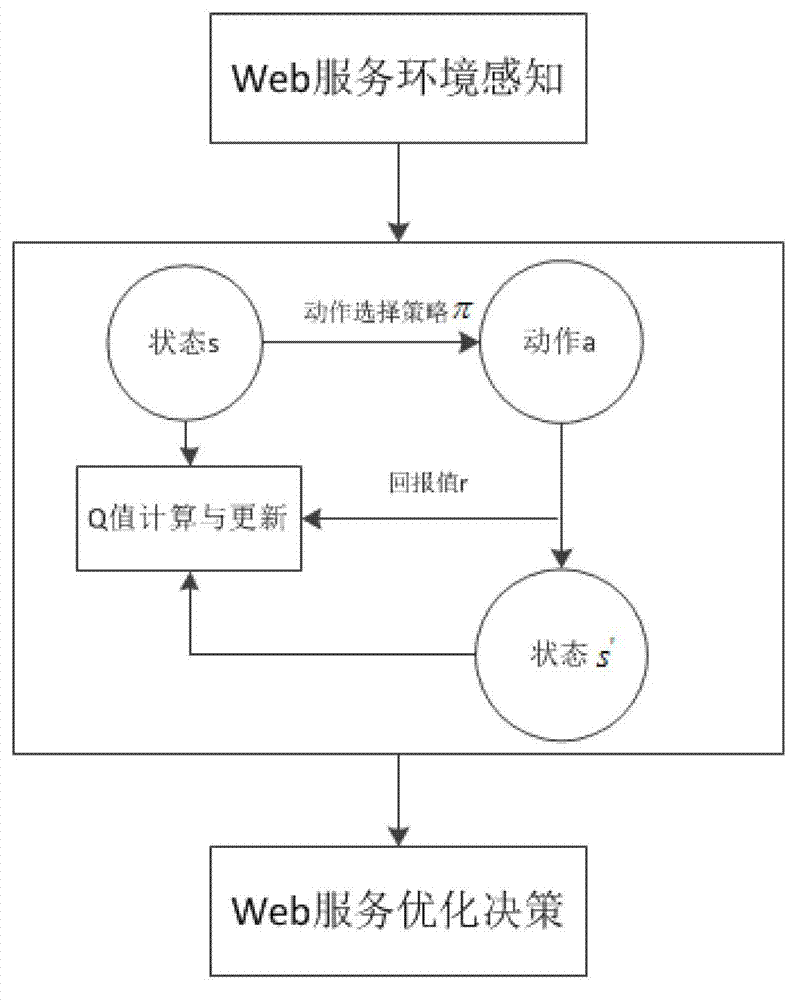

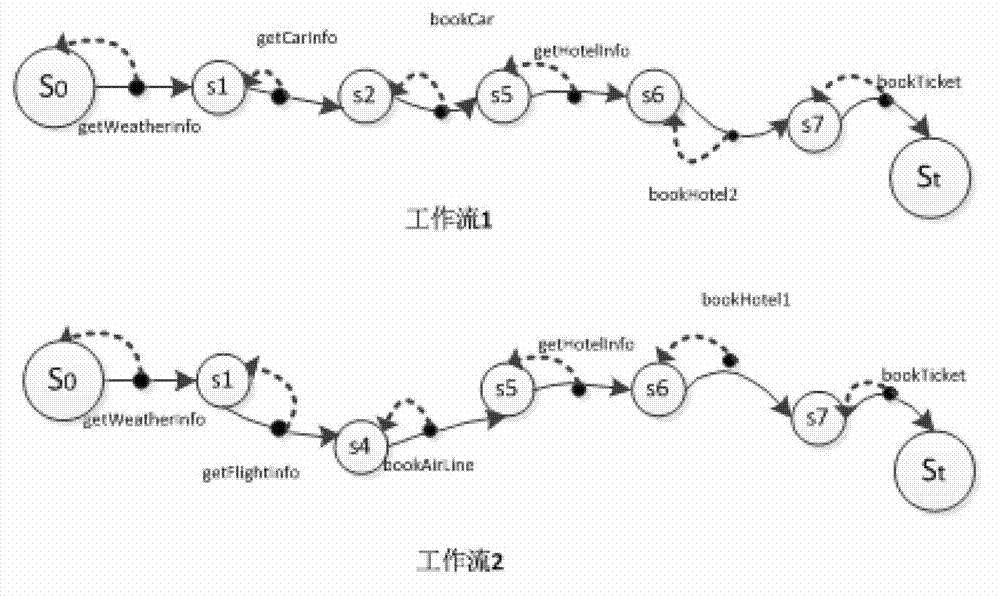

Large-scale self-adaptive composite service optimization method based on multi-agent reinforced learning

InactiveCN103248693AAdd coordinatorMeet individual needsTransmissionComposite servicesCombinatorial optimization

The invention discloses a self-adaptive composite service optimization method based on multi-agent reinforced learning. The method combines conceptions of the reinforced learning and agents, and defines the state set of reinforced learning to be the precondition and postcondition of the service, and the action set to be the Web service; parameters for Q learning including the learning rate, discount factors and Q value in reinforced learning are initialized; each agent is used for performing one composite optimizing task, and can perceive the current state, and select the optimal action under the current state as per the action selection strategy; the Q value is calculated and updated as per the Q learning algorithm; before the Q value is converged, the next round learning is performed after one learning round is finished, and finally the optimal strategy is obtained. According to the method, the corresponding self-adaptive action strategy is worked out on line as per the environment change at the time, so that higher flexibility, self-adaptability and practical value are realized.

Owner:SOUTHEAST UNIV

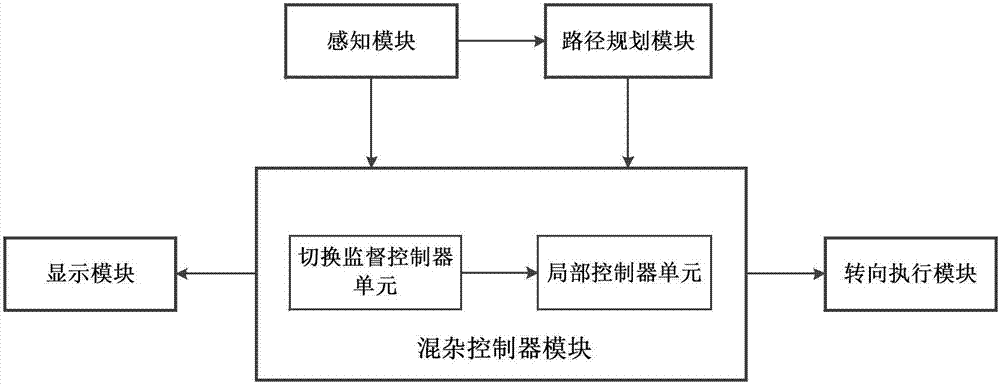

Traversal control system and method of driverless automobile based on hybrid theory

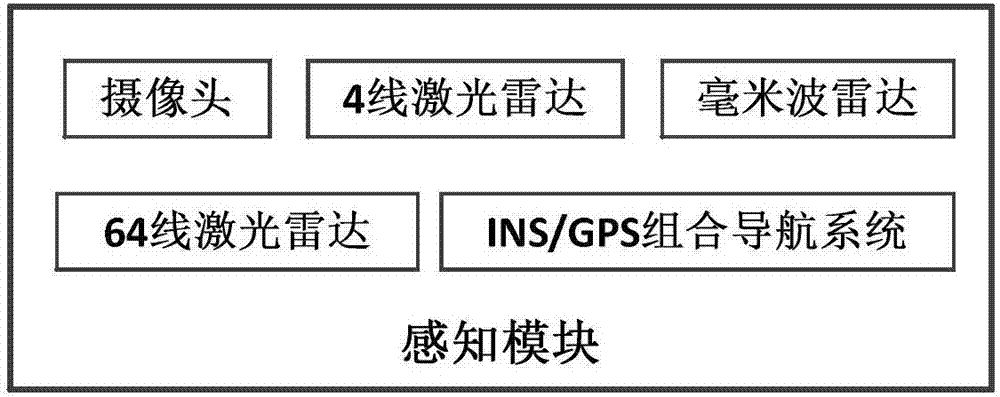

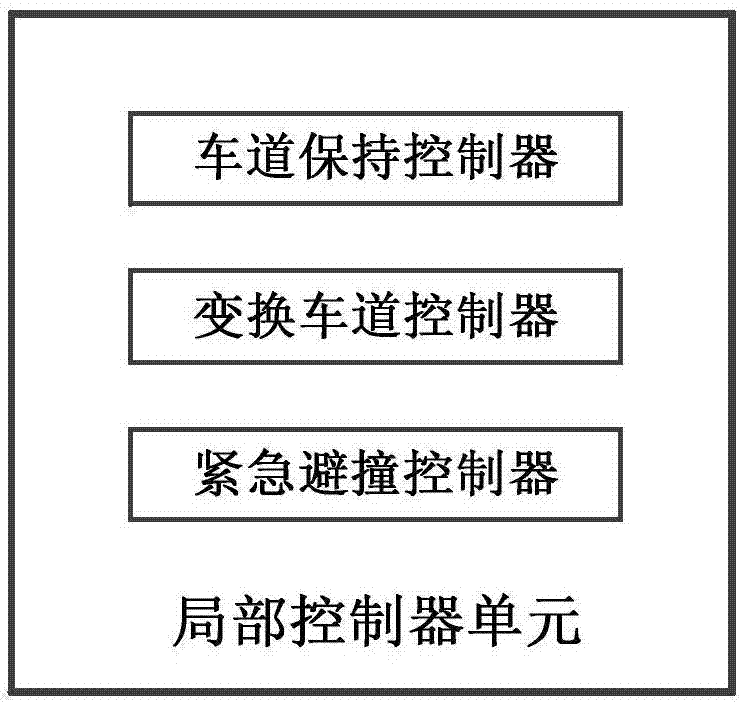

ActiveCN107139917AGuaranteed stabilityImplementation complexityExternal condition input parametersAutomatic steeringControl system

The invention discloses a traversal control system and method of a driverless automobile based on a hybrid theory. The system comprises a sensing module, a path planning module, a hybrid controller module, a steering executing module and a display module. The sensing module is used for acquiring the vehicle travelling environment and the vehicle operating state; the path planning module is used for planning a path based on the absolute position of a vehicle in a map and the position of the vehicle relative to peripheral obstacles and a lane line; the hybrid controller module comprises a local controller unit and a switching monitoring controller unit; the local controller unit designs a controller meeting a target for working conditions of lane-keeping, lane conversion and emergent collision avoidance; the switching monitoring controller unit driven by different discrete events drives effective mode switching, so that the switching stability is guaranteed; the steering executing module drives a steering motor according to a signal of the hybrid controller so as to realize automatic steering of the driverless automobile; and the display module is used for displaying sensing information, path planning information and control mode information.

Owner:JIANGSU UNIV

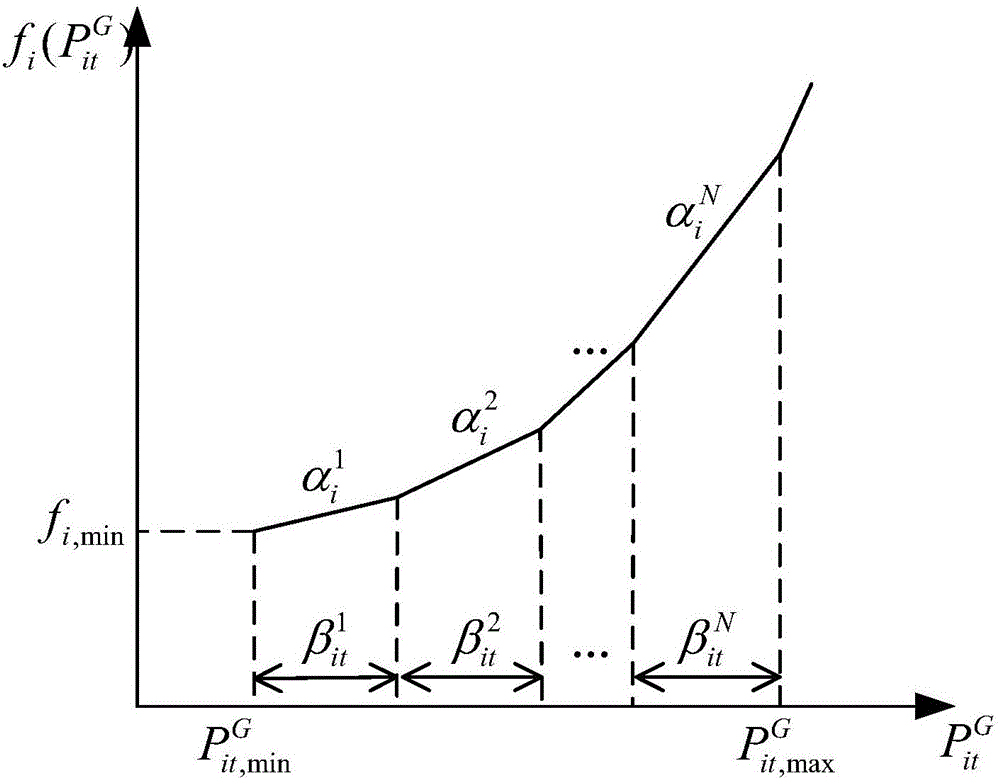

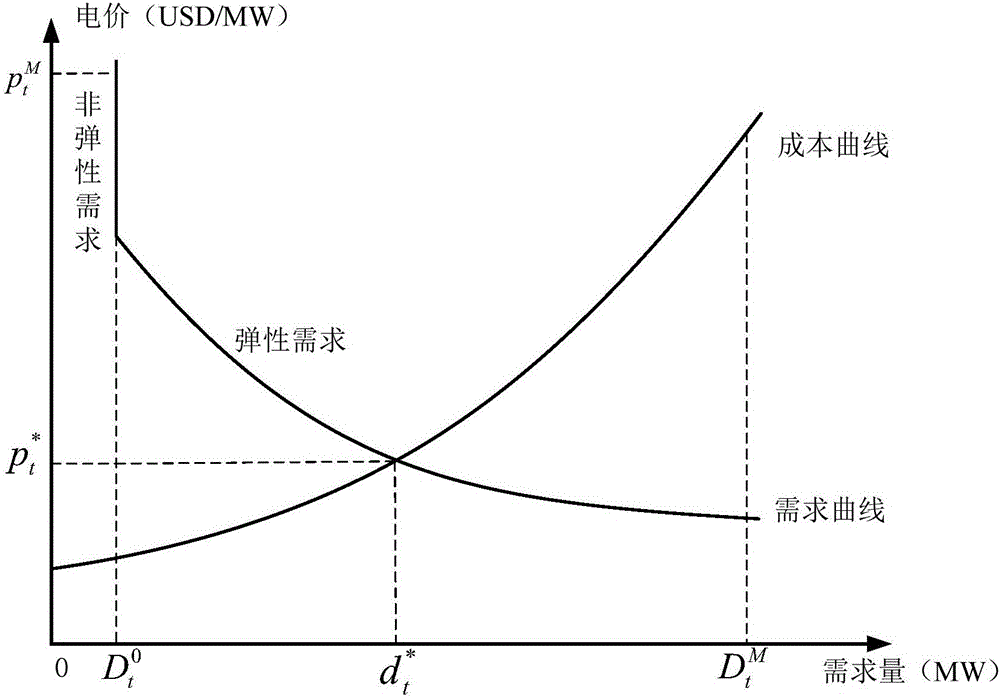

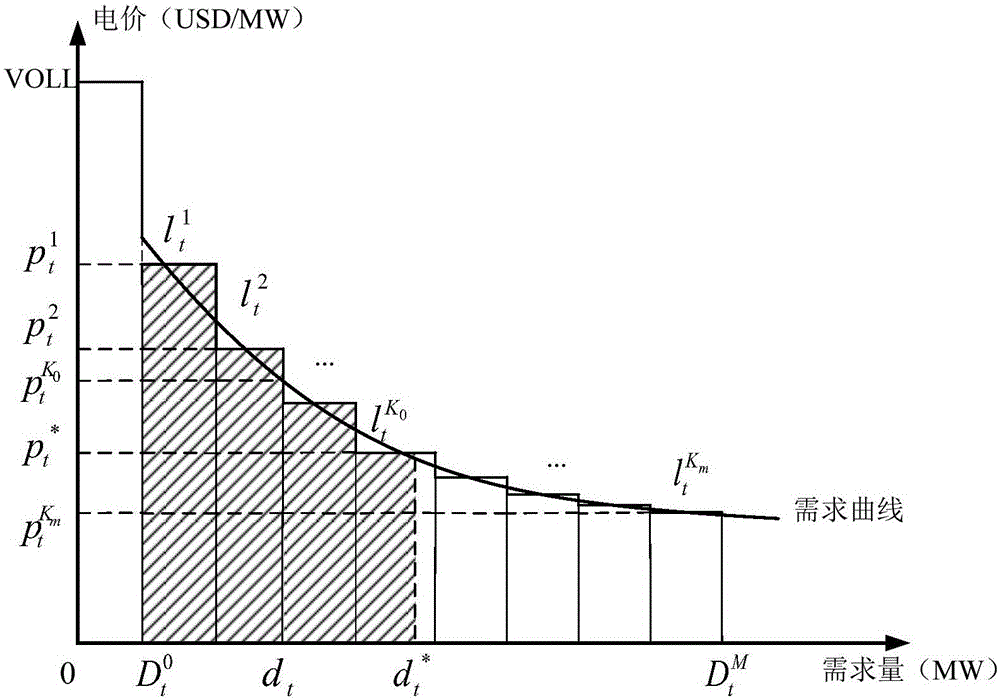

Method of solving robust two-layer optimization model based on wind power prediction and demand response

ActiveCN106655246AImprove consumption levelResolve uncertaintySingle network parallel feeding arrangementsWind energy generationBilevel optimizationDemand response

The invention provides a method of solving a robust two-layer optimization model based on wind power prediction and demand response. The robust two-layer optimization model comprises a unit combination optimization model and an economic dispatching optimization model. The method comprises steps: the unit combination optimization model is built; according to the unit combination optimization model, the economic dispatching optimization model is built; and according to the economic dispatching optimization model, the robust two-layer optimization model is built and solved. The robust two-layer optimization model provided by the invention comprises the unit combination optimization part and the economic dispatching optimization part, and considered from two aspects of a power generation side and a demand side, the method of the invention improves the wind power absorption level and solves the problem of uncertainty of wind power output.

Owner:STATE GRID HEILONGJIANG ELECTRIC POWER CO LTD HARBIN POWER SUPPLY CO +2

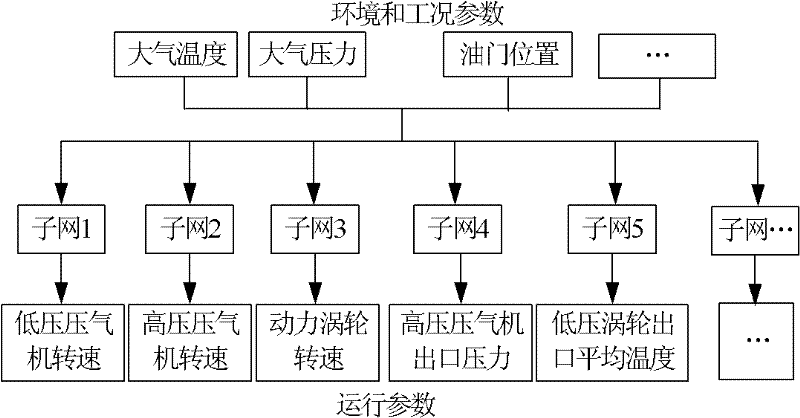

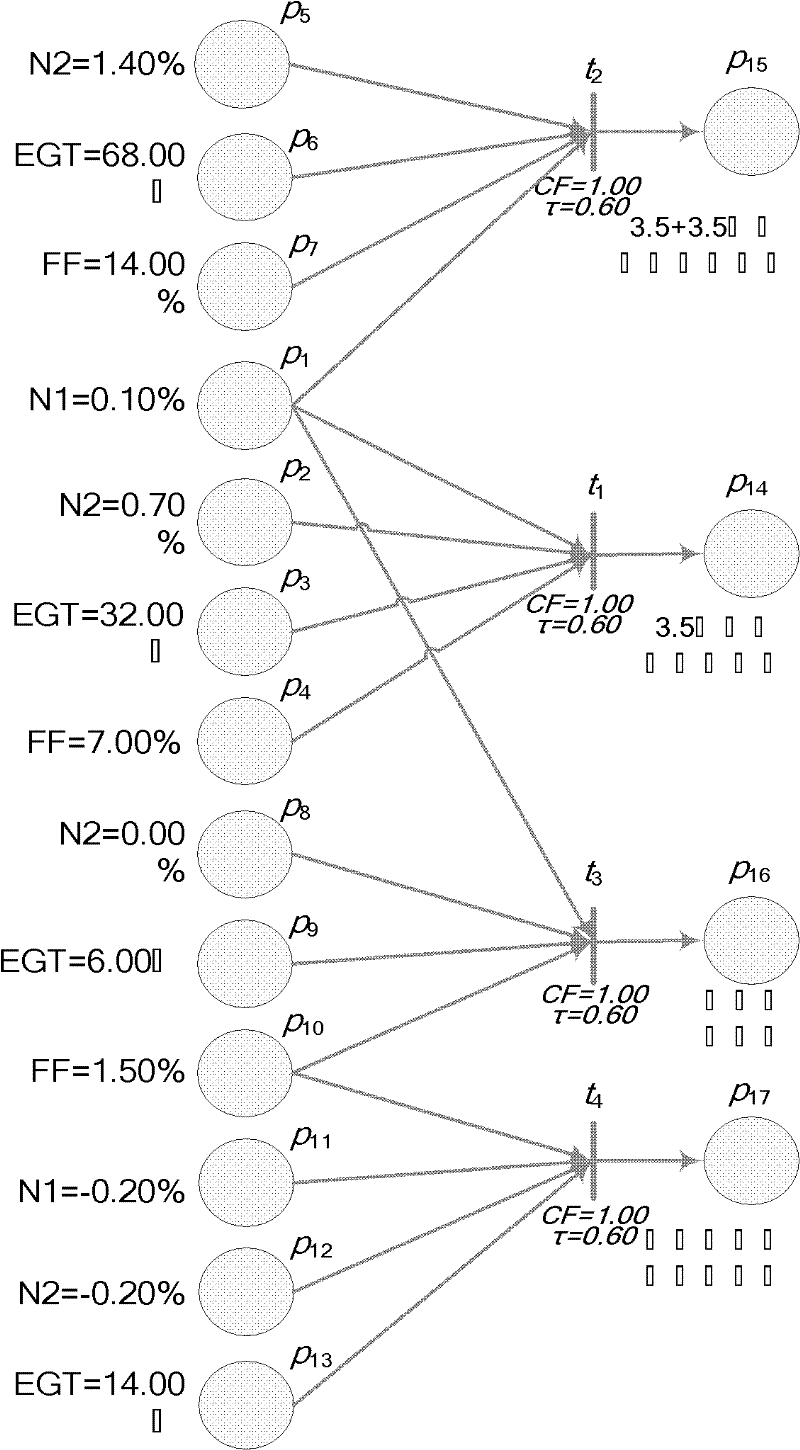

Gas path fault diagnostic method for marine gas turbine based on fuzzy Petri net (FPN)

InactiveCN102175460AResolve uncertaintyGas-turbine engine testingBiological neural network modelsReasoning algorithmEngineering

The invention discloses a gas path fault diagnostic method for a marine gas turbine based on a fuzzy Petri net (FPN), comprising the following steps of: (1) obtaining the operating standard value of the marine gas turbine; (2) based on an actually-measured value, calculating the membership grade of the actual operating parameter deviation belonging to the criterion deviation fuzzy subset by using a membership function; (3) defining the FPN in response to the characteristics of the fault diagnostic Petri net after determining the operating standard value and the deviation; and (4) determining a FPN reasoning algorithm for gas path fault diagnosis for the marine gas turbine based on related definitions of the transitional enabling and igniting rules. Through the gas path fault diagnostic method for the marine gas turbine based on the fuzzy Petri net (FPN), the defects of not strong university, wrong judgment and reasoning of the traditional method are overcome; it is actually proved that the problems of fuzziness and nondeterminacy in an gas path fault can be effectively solved by the gas path fault diagnostic algorithm for the marine gas turbine established by the gas path fault diagnostic method disclosed by the invention.

Owner:NAVAL UNIV OF ENG PLA

Preset performance ocean bottom flying node trajectory tracking control method based on disturbance observer

ActiveCN109283941AAvoid large control outputsNo overshootAdaptive controlPosition/course control in three dimensionsPerformance functionOcean bottom

The invention discloses a preset performance ocean bottom flying node trajectory tracking control method based on a disturbance observer, relates to a preset performance ocean bottom flying node trajectory tracking control method, and aims to solve the problems that an existing method does not consider modeling uncertainty and ocean environment disturbance and propeller faults affect the OBFN (Ocean Bottom Flying Node). The method comprises the following steps that: 1: establishing a Fossen outline six-degree-of-freedom nonlinear kinetic model; 2: carrying out OBFN kinetic model transformationon the nonlinear kinetic model established in S1 to obtain an OBFN kinetic model, and determining an OBFN tracking error equation according to the OBFN kinetic model; 3: establishing a performance function; 4: carrying out error transformation on the tracking error in the S3 to obtain a transformed error; and 5: according to the transformed error obtained in S4, designing an OBFN system total uncertainty observer and a preset performance trajectory tracking controller. The method is used in the field of trajectory tracking control.

Owner:HARBIN ENG UNIV

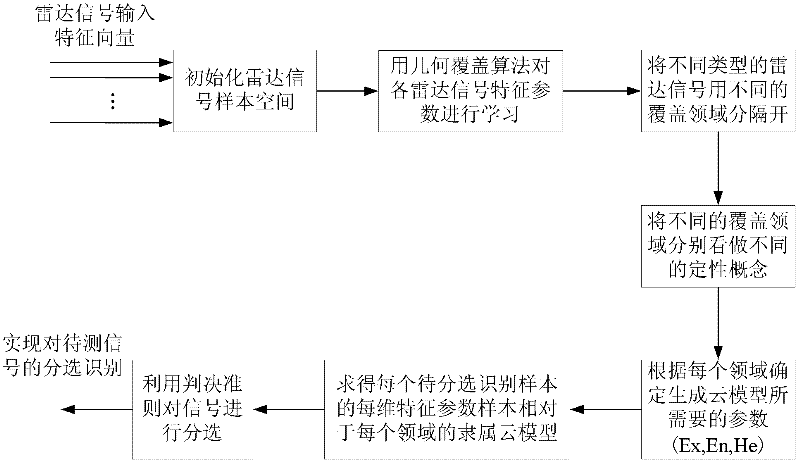

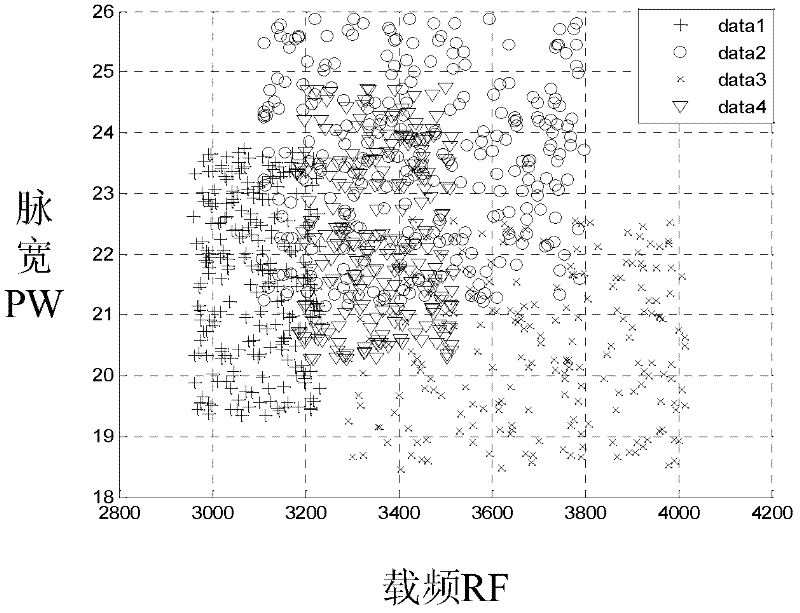

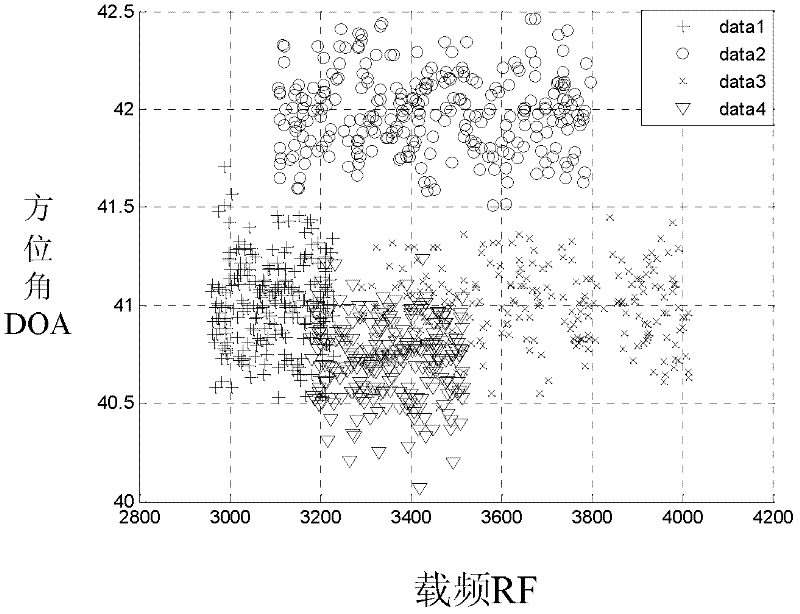

Method for sorting signals of radar radiation source by using coverage in complex dense environment

InactiveCN102590791ASolving Diverse Difficult-to-Describe ProblemsLocal minimaWave based measurement systemsFeature vectorPrior information

The method discloses a method for sorting signals of a radar radiation source by using coverage in a complex dense environment and relates to a radar radiation source signal sorting method by using coverage, aiming at solving the problem of poor sorting ability of the prior art in the complex dense environment as well as in a serious overlapping condition of characteristic parameters. The method comprises the following steps of: choosing the characteristic parameters of a radar signal capable of being standardized as input characteristic vectors, initializing a radar signal sample parameter space; carrying out supervisory learning on the radar signal with parameter prior information in the radar signal sample parameter space by using a coverage algorithm; separating the radar signals of different kinds by using different fields by using the coverage algorithm; expressing the membership degree of the characteristic parameters of each radar signal to be sorted and identified in relative with each field by using a cloud model, and obtaining the membership value of the membership degree of the radar signal to be sorted and identified in relative with each field; and sorting the signal to be detected by using decision rules. The method for sorting signals of the radar radiation source by using coverage in the complex dense environment is suitable for sorting radar radiation source signals.

Owner:HARBIN ENG UNIV

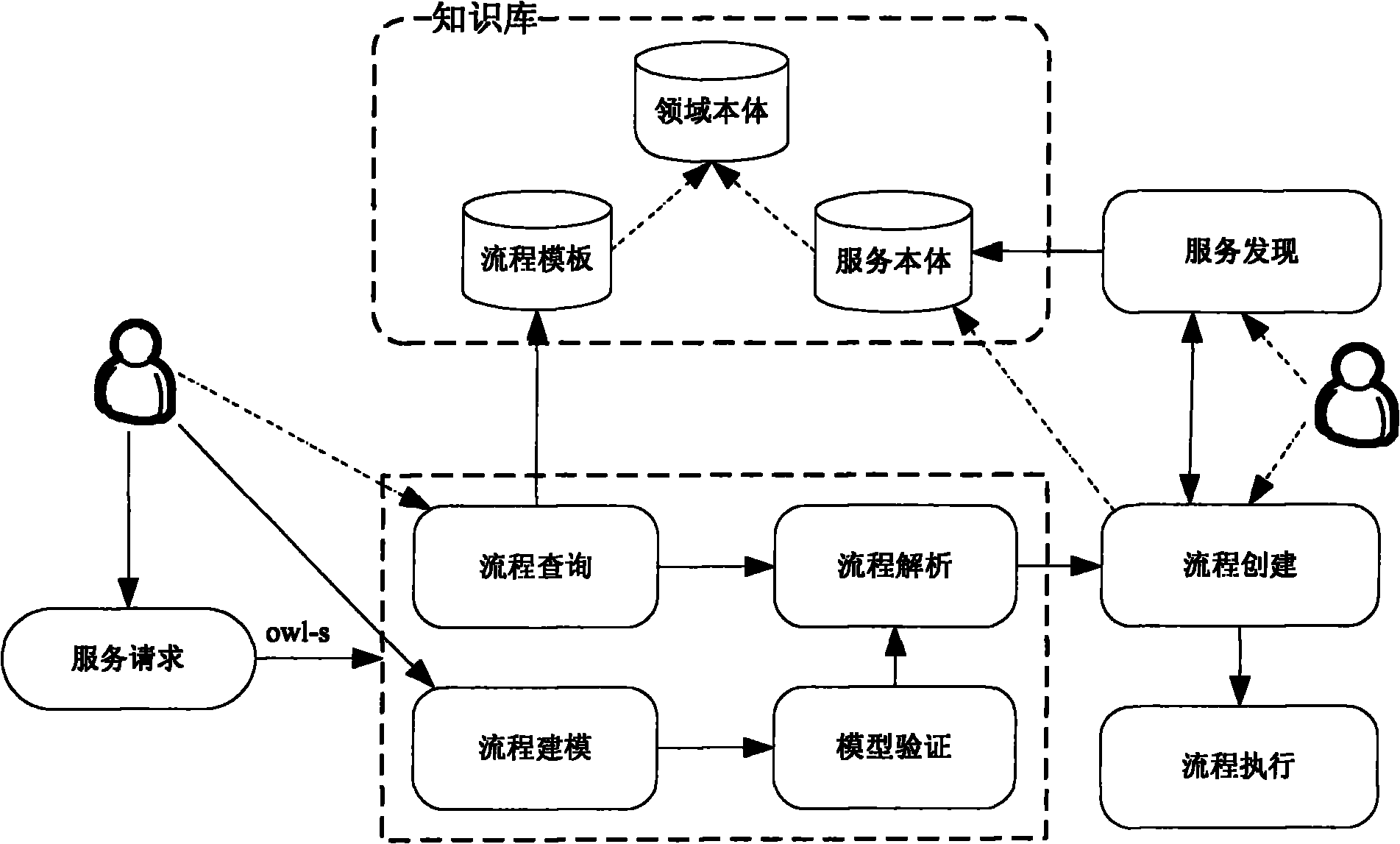

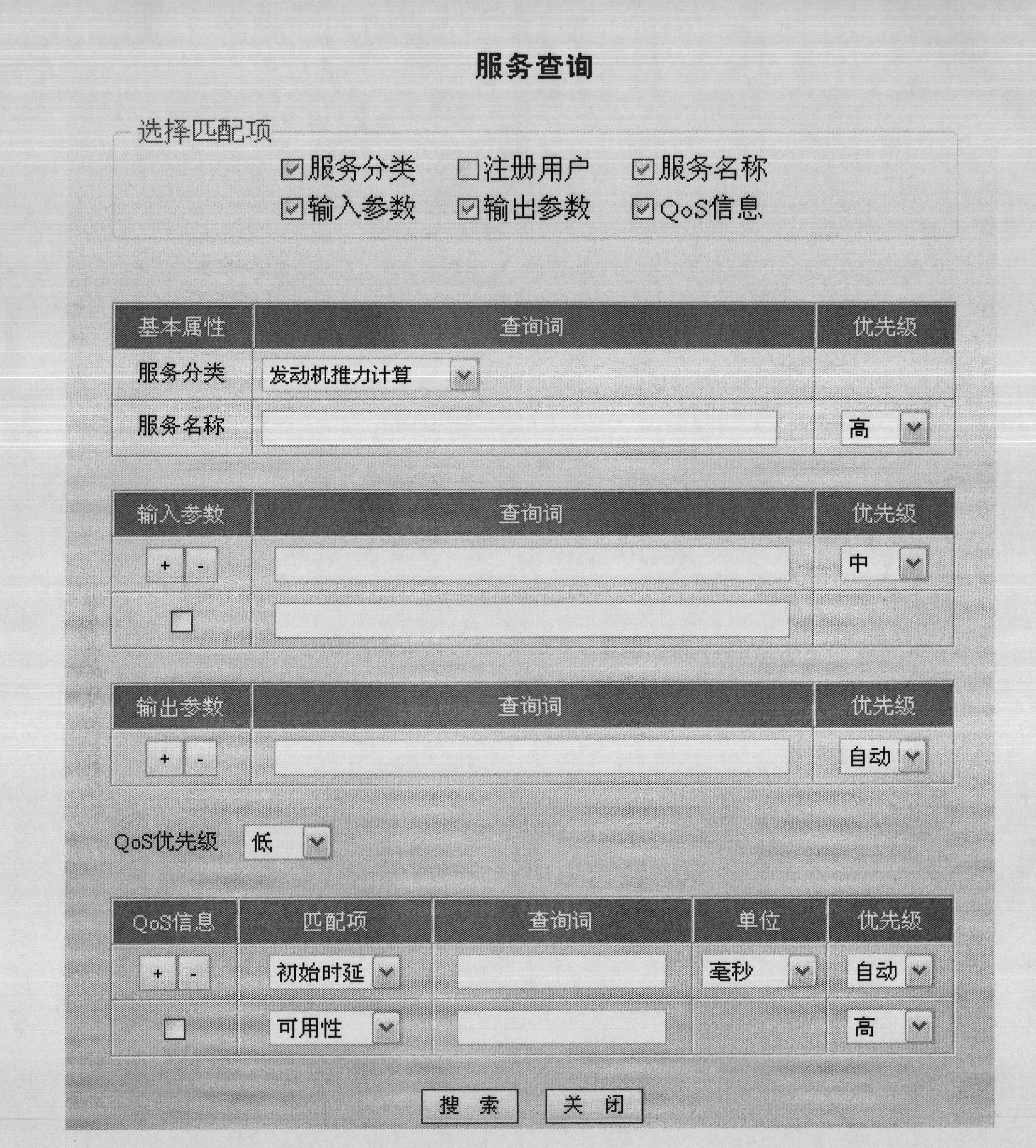

Abstract service logic-based interactive semantic Web service dynamic combination method

InactiveCN102004767AIncrease success rateImprove efficiencySpecial data processing applicationsService compositionSemantic web services

The invention discloses an abstract service logic-based interactive semantic Web service dynamic combination method. The method comprises the following steps of: separating abstract service description from specific semantic Web service instances by establishing a resource service mapping model, performing unified semantic description on Web services by using an ontology web language for services (OWL-S), realizing static binding with lower-layer services, and providing a unified interface for the service combination; performing abstract description on the combined process through combined service process modeling and providing a combined template; finishing intelligent search and match of the services by combining Chinese word segmentation technology with an ontology-based conception matching algorithm under the support of a domain ontology and a professional thesaurus; and analyzing a timing sequence relationship and a control relationship of nodes in the combined process to realize dynamic binding and executing of the services, and constructing a service combination engine.

Owner:BEIHANG UNIV

Single lithium ion battery SOC estimation method based on sliding window filtering

InactiveCN103901351AGuaranteed accuracyGuaranteed reliabilityElectrical testingModel parametersEngineering

The invention discloses a single lithium ion battery SOC estimation method based on sliding window filtering. In a novel algorithm, a battery model is composed of two RC parallel circuits, one series resistor and one nonlinear voltage source, the dynamic working state in a battery is simulated through battery terminal voltage, the RC parallel circuits and a battery SOC. The single lithium ion battery SOC estimation method is based on an electrochemistry-circuit equivalent lithium ion battery combination model, the model well describes the nonlinear function relation between battery OCV and the battery SOC, and the SMO algorithm is used for solving the nonlinear problem of the model. Meanwhile, in the single lithium ion battery SOC estimation method, the SMOS algorithm and the Kalman filtering algorithm are innovatively combined to solve the problem of uncertainty of a lithium ion battery model, and the accuracy of the battery model and the reliability of a battery control system are guaranteed. At last, the battery model parameter on-line identification method provides necessary parameter values for on-line accurate estimation of the battery SOC.

Owner:扬州道爵新能源发展有限公司

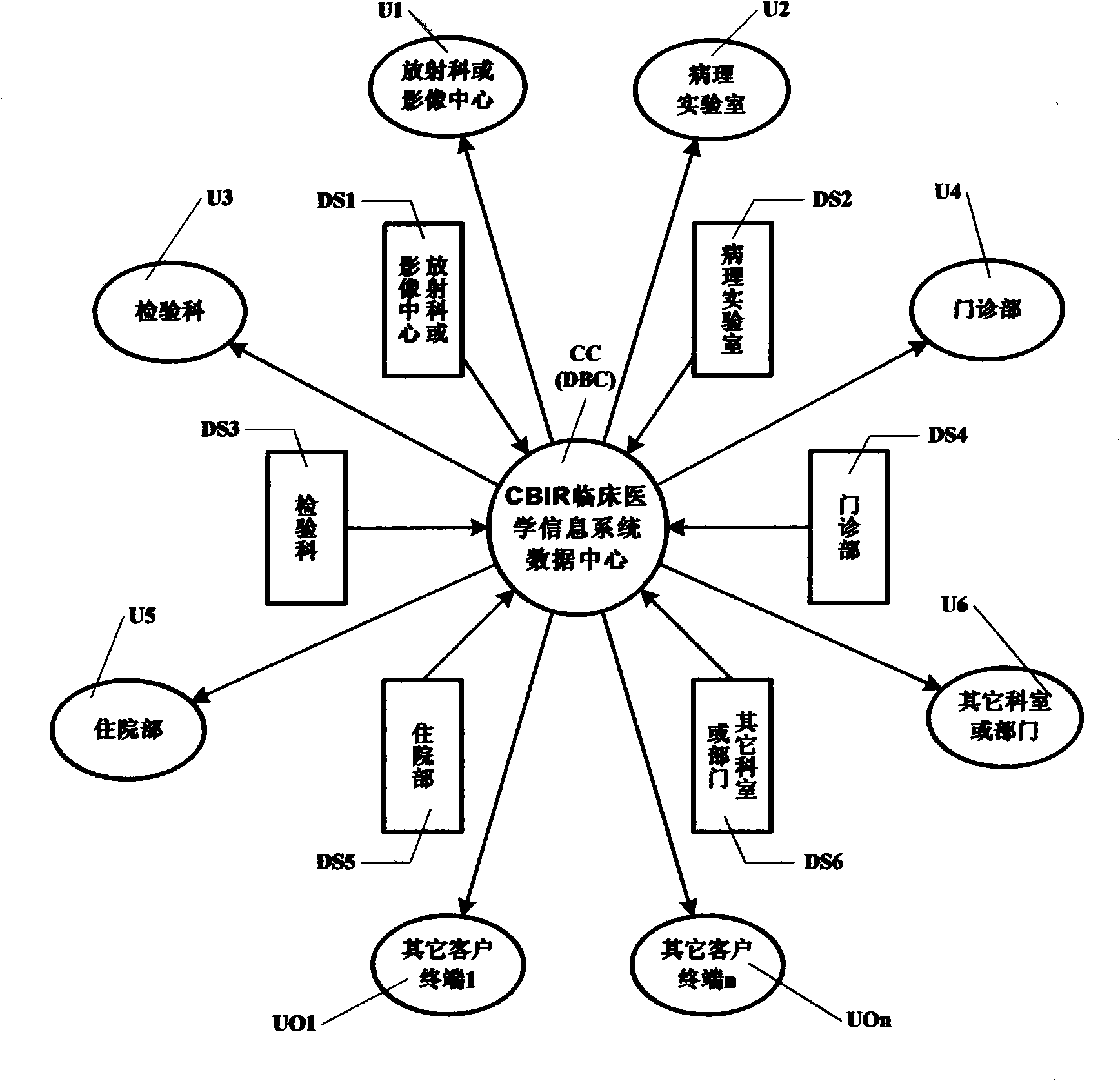

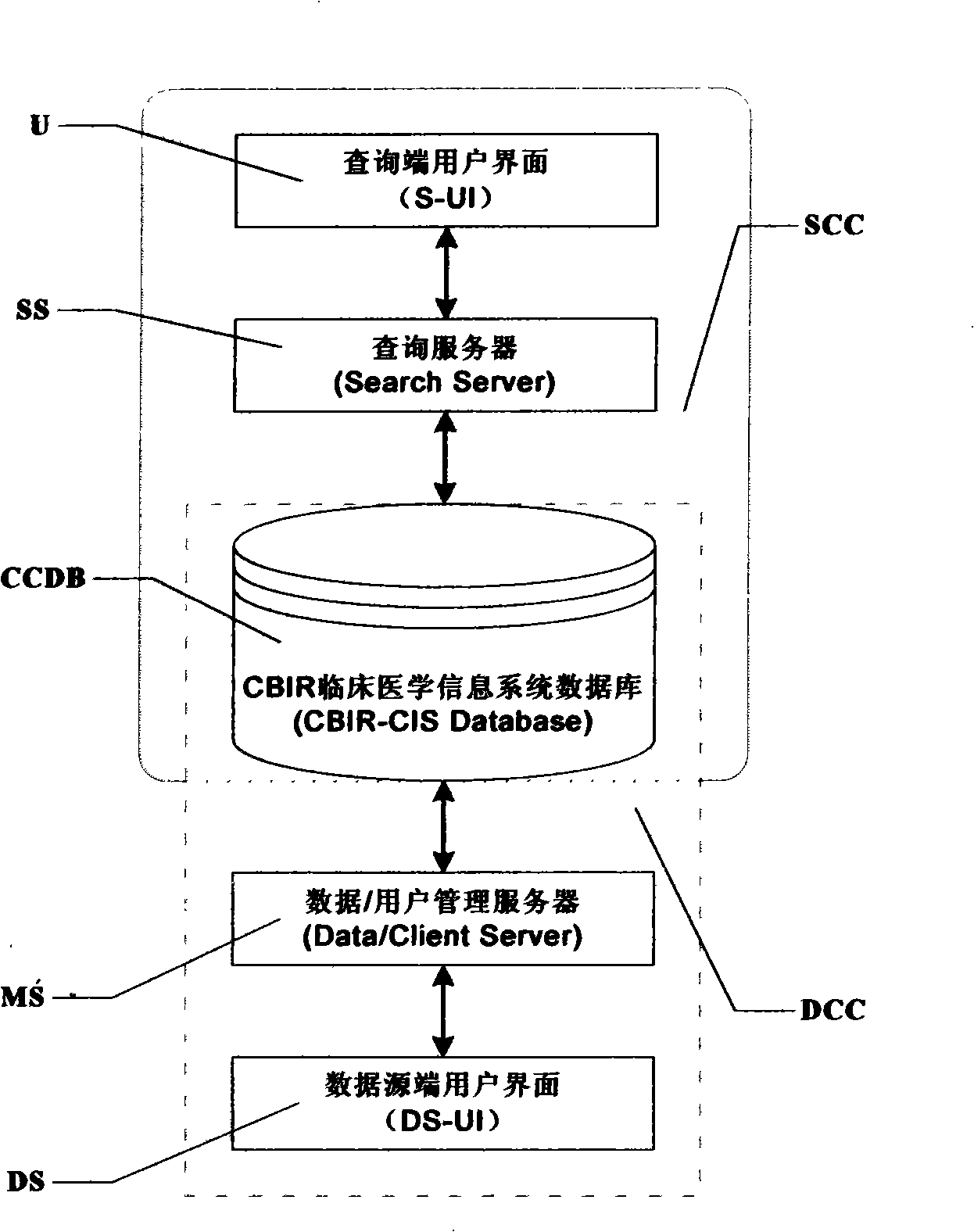

Composition and information query method of clinical medicine information system in hospital

InactiveCN101315652AReduce ambiguityHigh similaritySpecial data processing applicationsSearch engine technologyInformation system

The invention relates to a clinical medicine information management system and the application field of search engine technologies, in particular to a method which can carry out the construction of the clinical medicine information management system based on image content searching, and the inquiry of corresponding medical information in a hospital. All the component element function of the clinical medicine information management system based on the image content searching can be divided into the following parts: the processing and storage of original data information, the composition and management of a database, and the type and mode of information service; the system can carry out text inquiry based on key word searching and image inquiry based on medical image content searching, and the image inquiry mode is that: a manual label is not needed to be made for the medical image in advance, and text information such as the key words, etc. are not needed to be input while the image content is directly taken as inquiry condition, therefore, similar images and the relevant text information in the database can be directly searched out.

Owner:张小粤

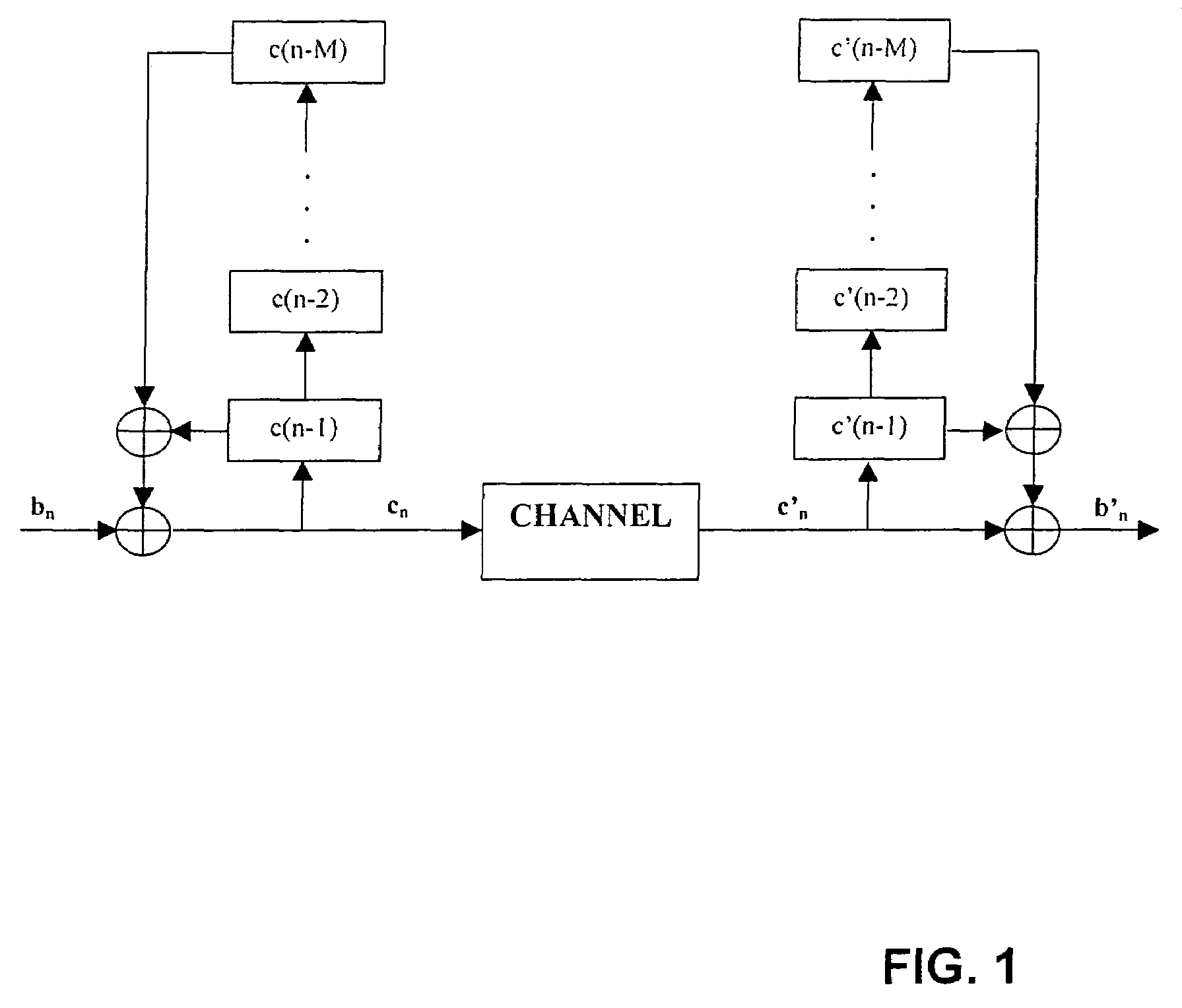

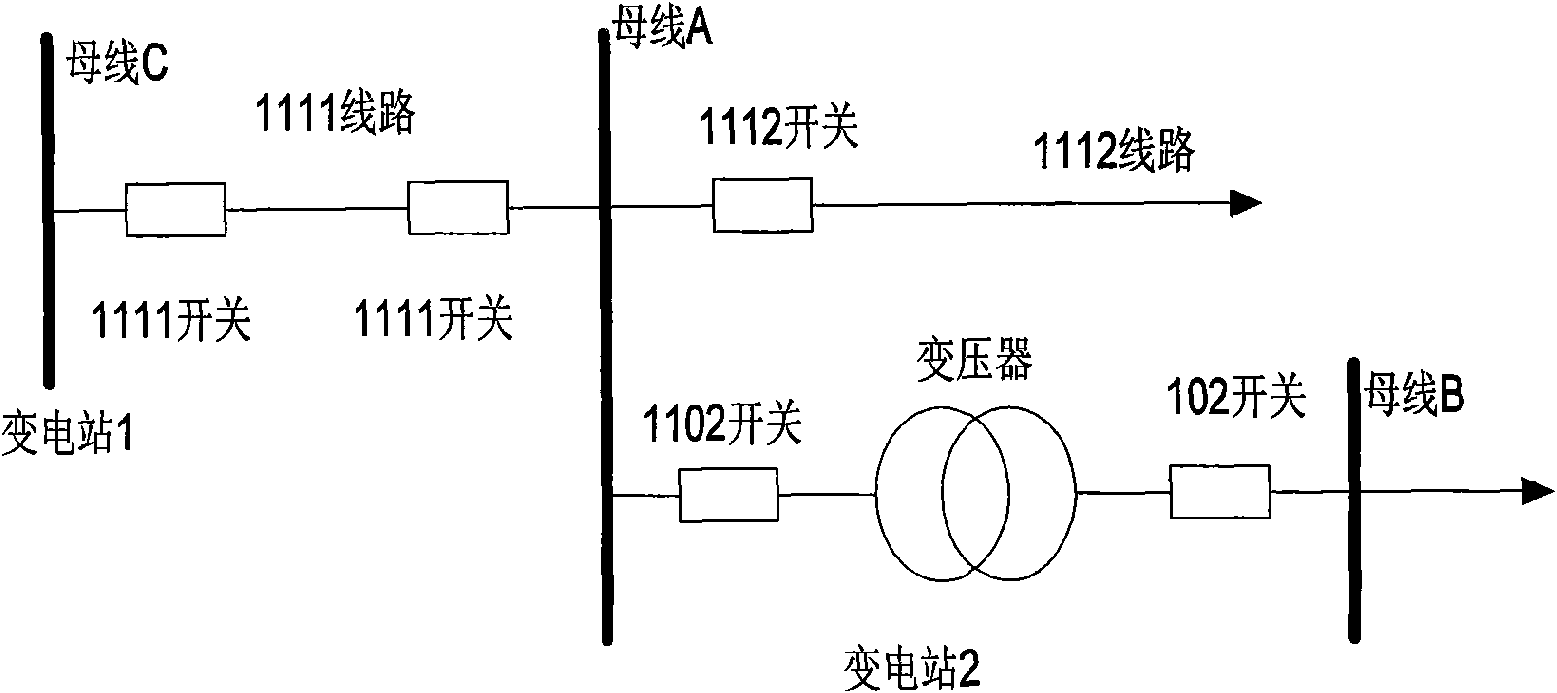

Method for conducting power system fault diagnosis by combining information theory with expert system

InactiveCN101661070APlay an auxiliary role in decision-makingSolve the disadvantages of too large solution spaceFault locationKnowledge based modelsModel implementationAction status

The invention discloses a method for conducting power system fault diagnosis by combining information theory with expert system, belonging to the technical field of power system safety treatment. Themethod includes the following steps: firstly establishing a fault diagnosis information transfer model of an actual channel, determining all possible pieces of equipment with fault through forward reasoning of the expert system according to a power cut area where the power system fails, then respectively assuming suspicious equipment, and reasoning out the corresponding action state of switching and protection reversely to obtain all possible information sources in actual communication. Finally, a control center obtains a group of data sequences consisting of the action state of switching andprotection, establishes the fault diagnosis information transfer model based on the actual channel and implements examination, repair and removal of faults according to the fault diagnosis informationtransfer model.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

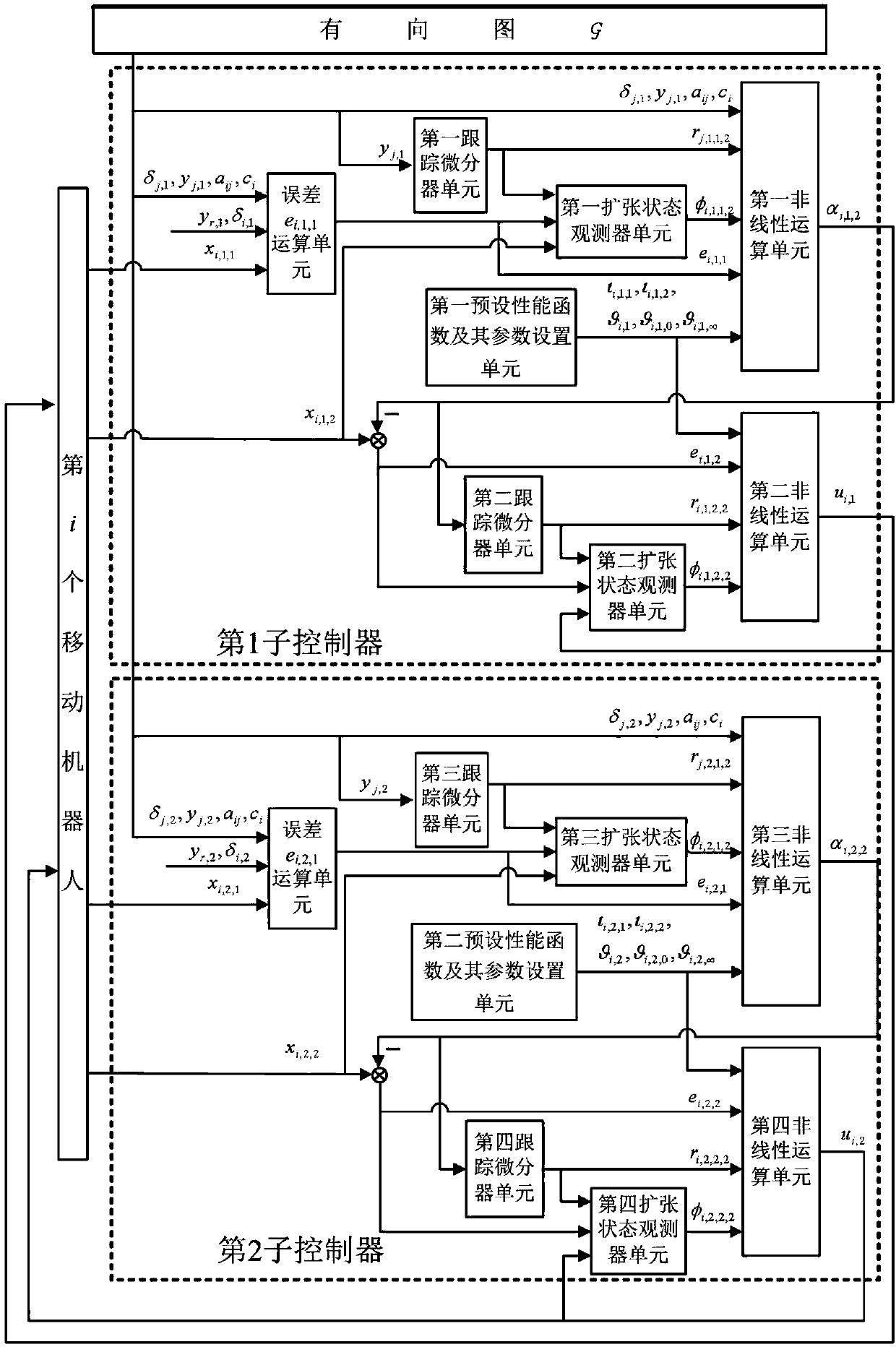

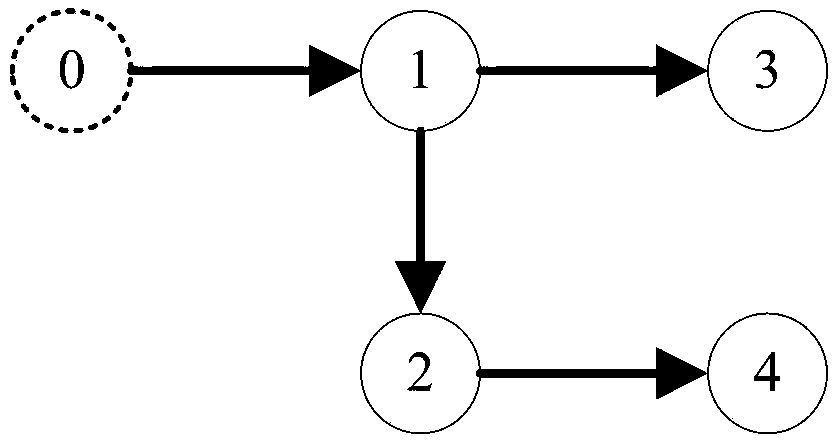

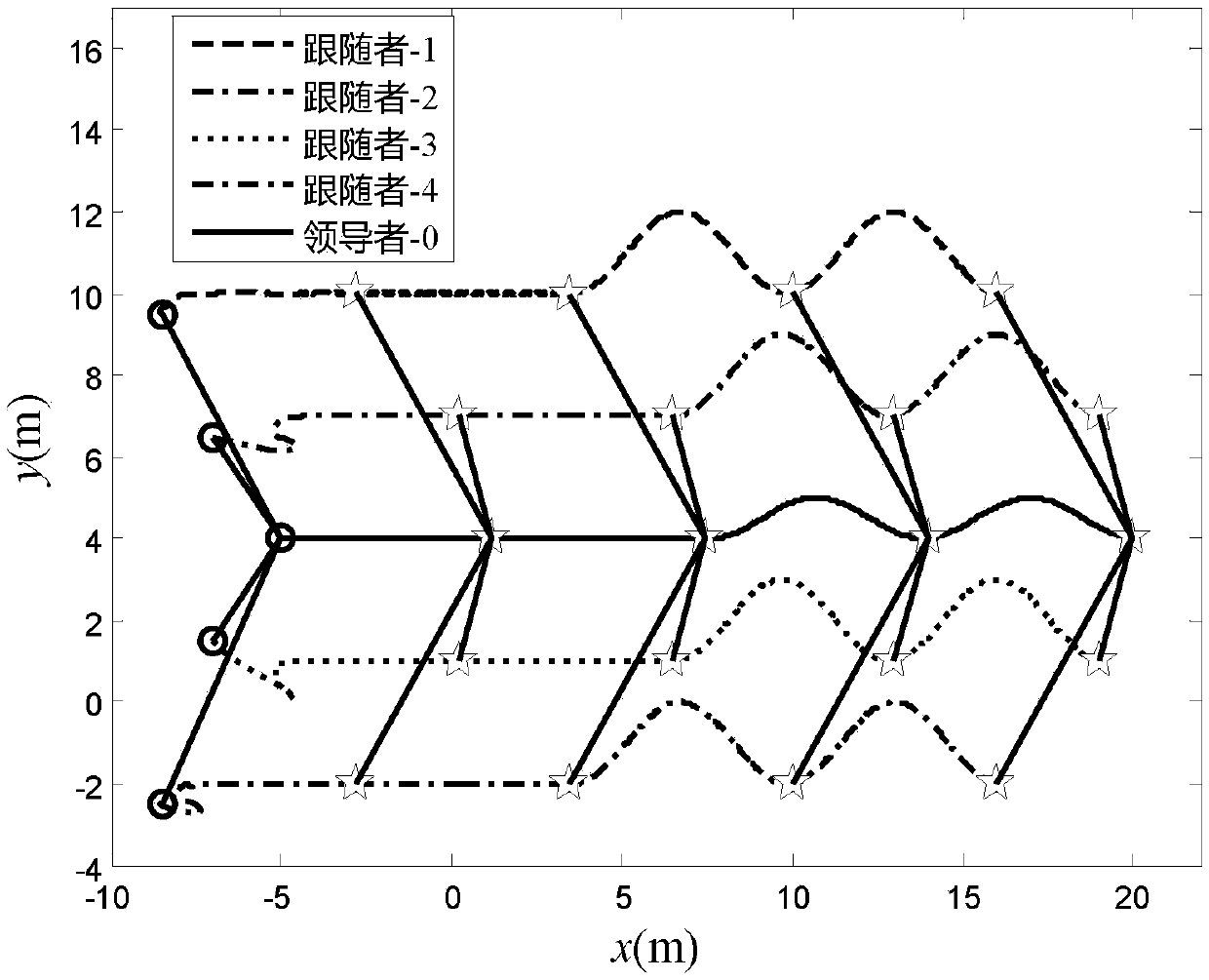

Default performance formation controller structure for multi-mobile robots and design method

ActiveCN108646758ANoise immunityHigh precisionPosition/course control in two dimensionsPerformance functionDifferentiator

The invention relates to a default performance formation controller structure for multi-mobile robots and a design method. N double-mobile robots containing unknown dynamic states are regarded as followers, the networked system formed by connecting the followers with a leader through a one-way topological graph is regarded as a controlled object, and a time-varying formation controller with default performance is designed by using the active-disturbance-rejection and inverse techniques, so that the following robots track the reference trajectory of the leader and build and keep a desired time-varying rank, and the tracking error is within a preset range. The default performance formation controller structure has the advantages that according to the characteristic that an extended state observer is independent of a precise mobile robot model, the unknown dynamic states are compensated through estimation of the extended state amount in real time, so that the designed time-varying formation controller has a disturbance rejection capacity; the derivative of a complicated nonlinear function is effectively estimated by means of a tracking differentiator; the convergence precision and rate of a formation error are improved by using a default performance function; the problems about the unknown dynamic states, complicated derivation reduction and precision control in a system can be effectively solved.

Owner:NANJING UNIV OF POSTS & TELECOMM

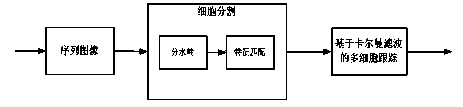

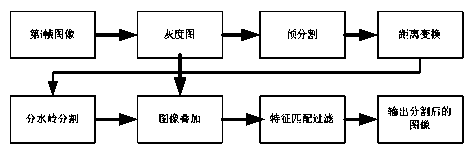

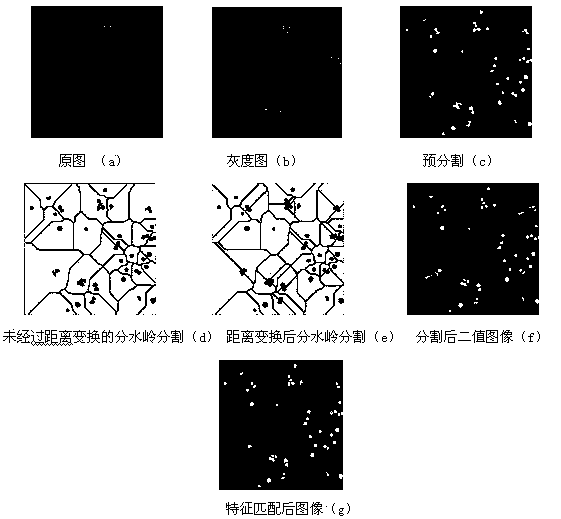

Method for synchronously tracking multiple cells in high-adhesion cell environment

InactiveCN103559724AEffective segmentationHigh precisionImage enhancementImage analysisCell synchronizationCell segmentation

The invention belongs to the field of cell tracking, and discloses a method for synchronously tracking multiple cells in a high-adhesion cell environment. In a cell sequence image, how to divide and synchronously track the cells is an unsolved problem, and especially the problem of tracking and dividing the cells under the high-adhesion condition urgently needs to be solved. An improved dividing algorithm based on watersheds and multi-feature matching is firstly provided to achieve cell dividing, then a motion model suitable for Kalman filtering is built, the multi-feature matching is added to achieve cell predication and tracking. Through experimental verification, the method is effective, the average effective rate of dividing sequence frame cells is 94.4%, and the tracking effect is superior to that of the tracking method in the prior art.

Owner:苏州相城常理工技术转移中心有限公司

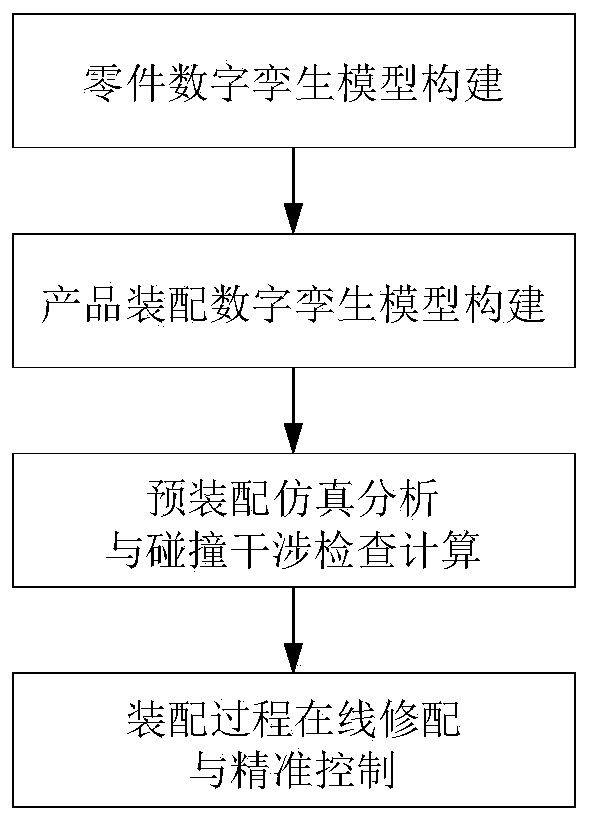

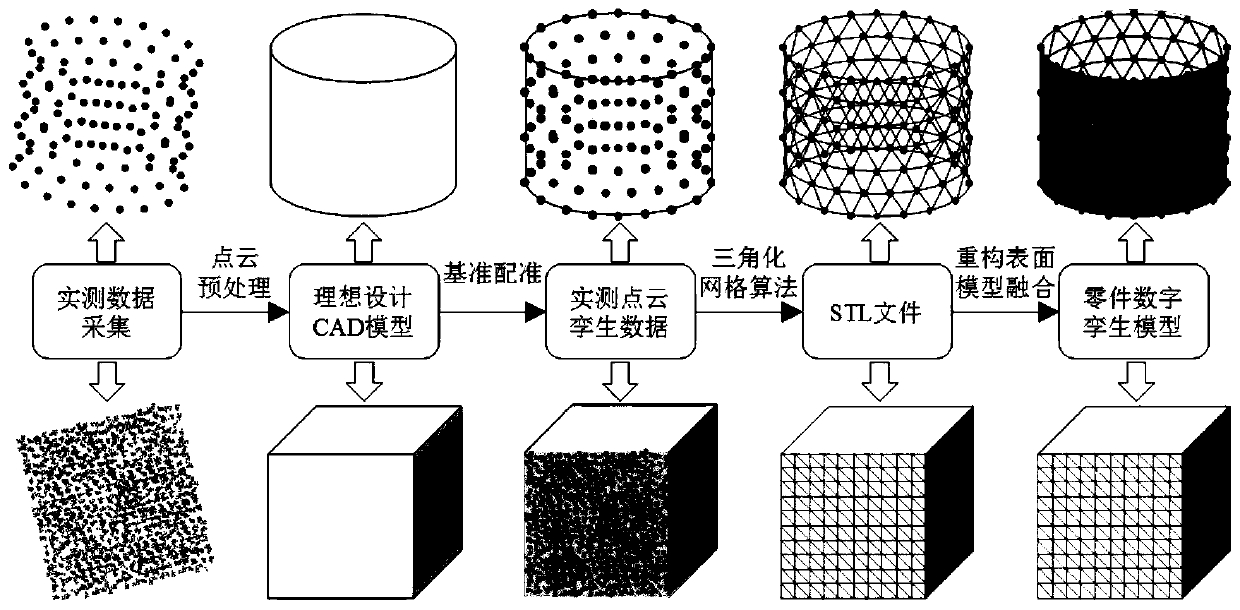

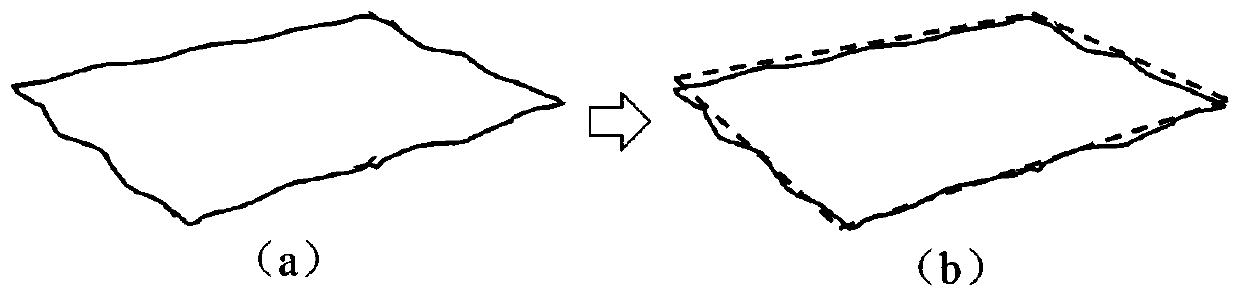

Complex product assembly process accurate repair method based on digital twinning and operation system thereof

ActiveCN111274671ARealize online precise repairRealize intelligent closed-loop controlDesign optimisation/simulationRepair timeLoop control

The invention discloses a complex product assembly process accurate repair method based on digital twinning and an operation system thereof. For the key procedures in the product assembly process, actually measured data acquisition and processing are carried out on a part assembly matching area, the actually measured data and an ideal model are deeply fused, and a part digital twinning model is constructed; solving and updating the part assembly positioning constraint in combination with the planned assembly sequence to obtain a product digital twinning model; the digital twinning model of theproduct is used for pre-assembly simulation analysis, according to an assembly simulation analysis result and an assembly collision interference check condition, position information of a matching area, needing to be repaired, of a part and the minimum repair amount are obtained through calculation, a reasonable part repair scheme is given, and online repair and precise control over the assemblyprocess are completed. Intelligent closed-loop control over the complex product assembling process can be achieved, and important engineering significance is achieved for shortening the trial assemblyand repair time in the assembling process and improving the assembling precision and efficiency.

Owner:SOUTHEAST UNIV

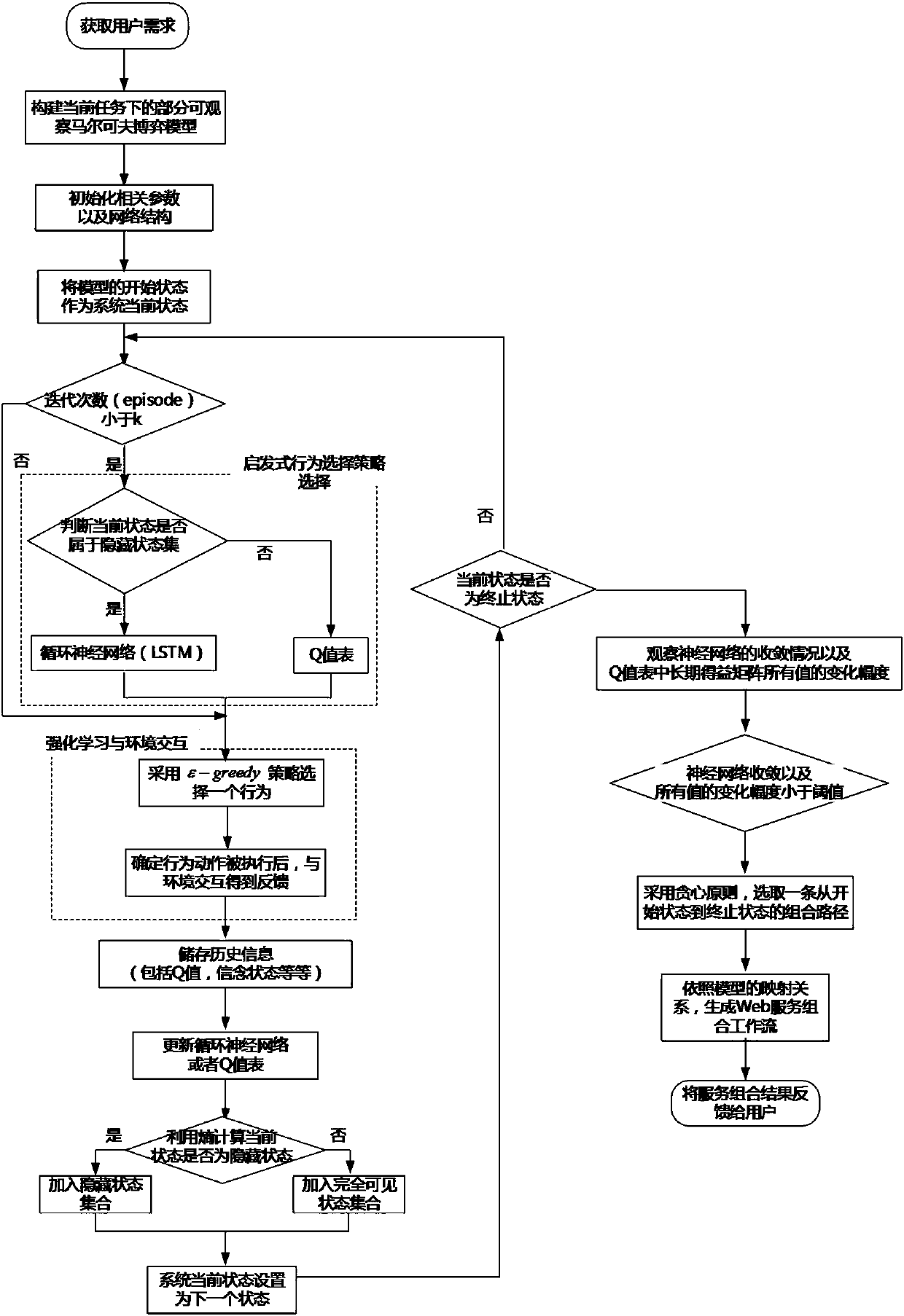

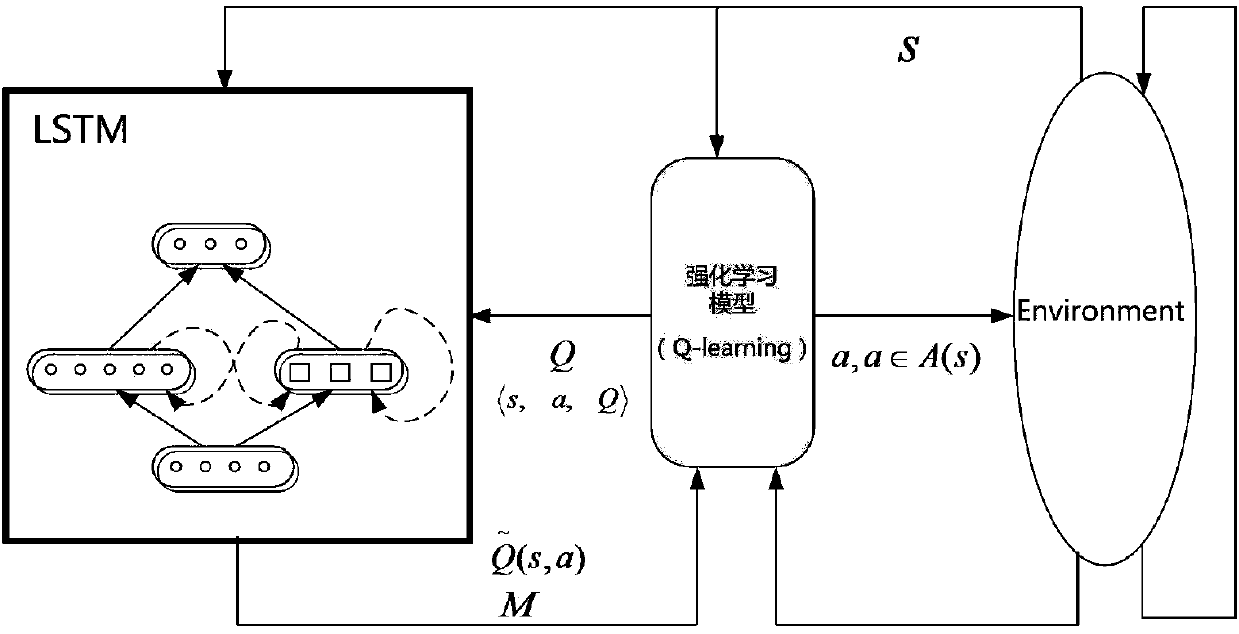

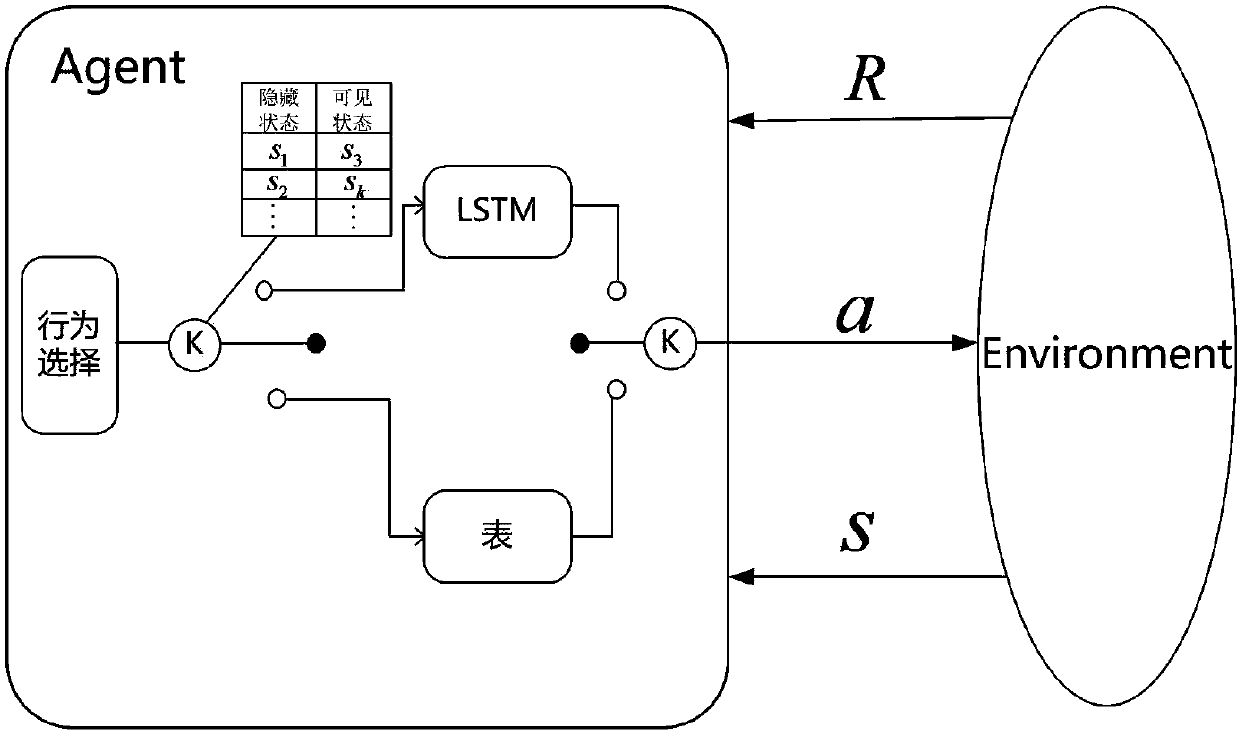

Web service combination method based on depth reinforcement learning

ActiveCN107241213ASolving Partial ObservabilityAccurately combine resultsData switching networksNeural learning methodsService compositionCurse of dimensionality

The invention discloses a web service combination method based on depth reinforcement learning for overcoming the problems of long time consumption, poor flexibility and non-ideal combination effect of the traditional service combination method in large-scale service scenes. The depth reinforcement learning technology and the heuristic thought are applied to the service combination problem. In addition, by considering the partial observability of the real environment, the service combination process is converted into a partially-observable Markov decision process POMDP, the solution problem of the POMDP is solved by using a recurrent neural network, and the method still expresses high efficiency encountering the challenge of curse of dimensionality. By adoption of the method provided by the invention, the solution speed can be effectively improved, the dynamic service combination environment is automatically adapted on the basis of ensuring the quality of the service combination scheme, and the adaptability and the flexibility of the service combination efficiency is effectively improved in a large-scale dynamic service combination scene.

Owner:SOUTHEAST UNIV

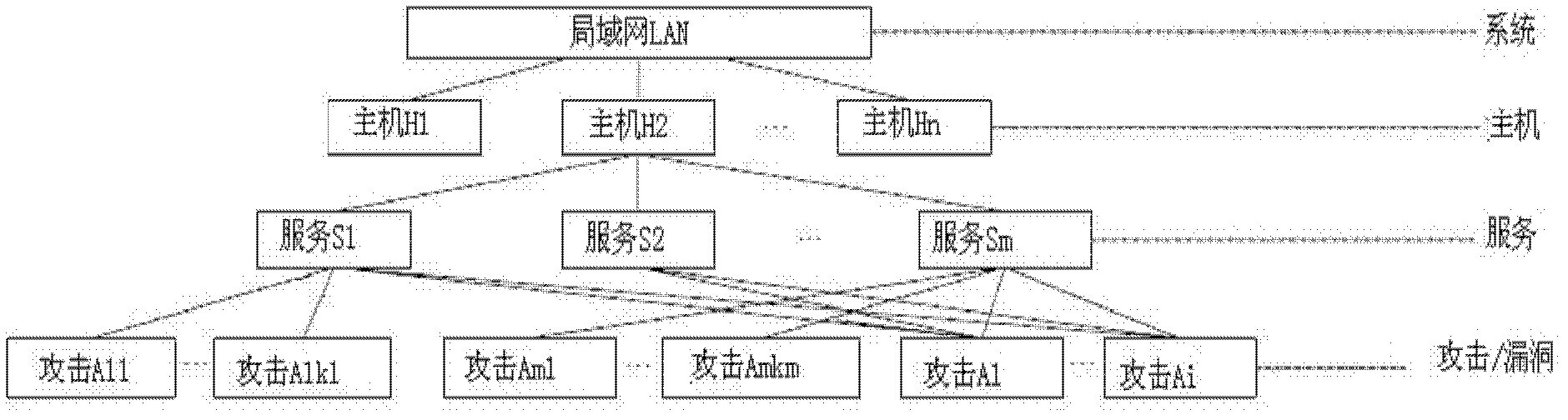

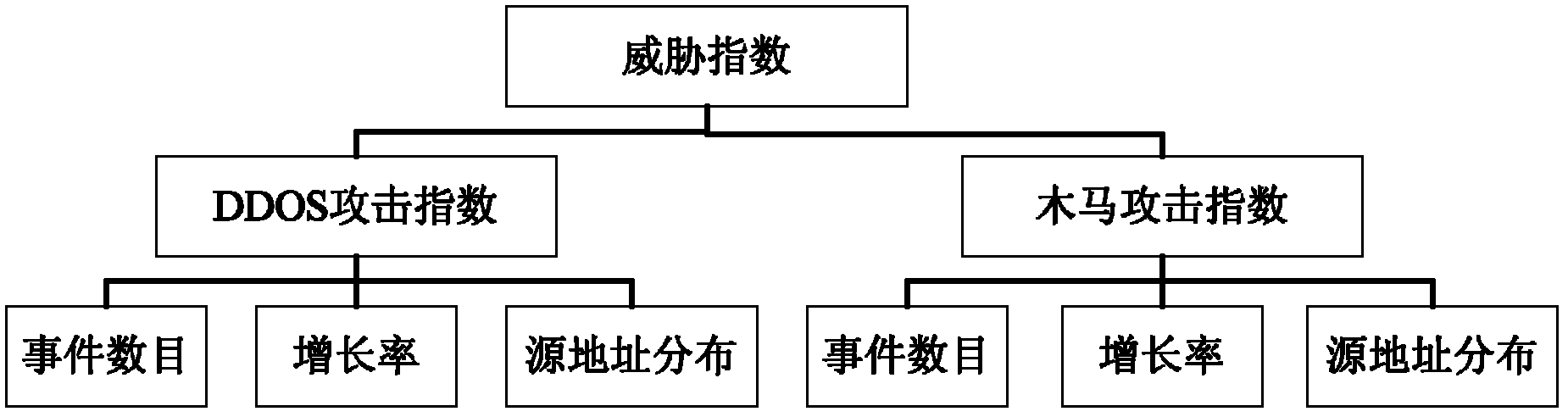

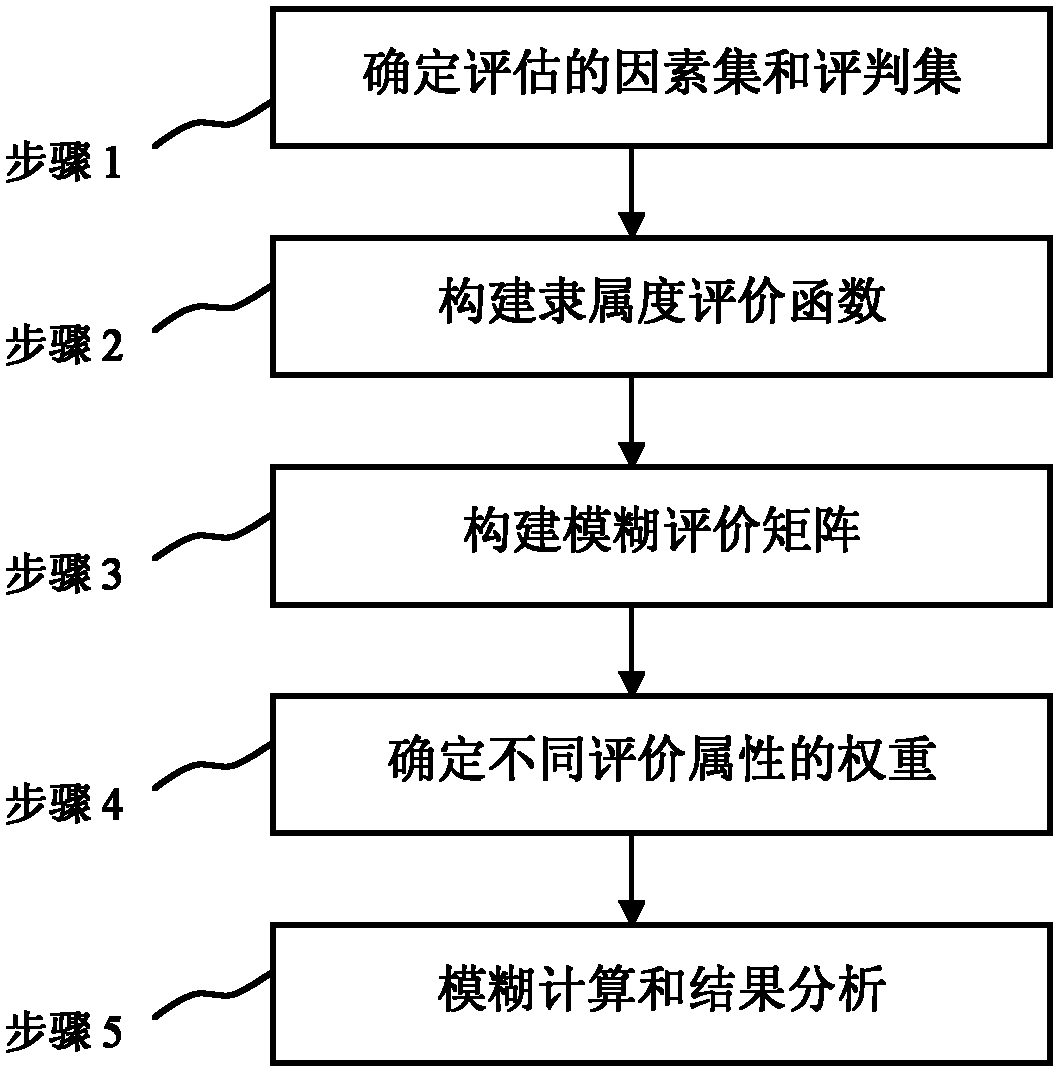

Network security situation fuzzy evaluation method based on uncertain data

The invention provides a fuzzy evaluation method used for evaluating a network security situation value of a hierarchical model, and the method comprises the steps that: an evaluation factor set and a judgment set used for evaluating network security situation indexes of a top-level node of the hierarchical model are determined; a membership function is established, and the probability that attribute data of each child node in the evaluation factor set belong to different judgment ranks in the judgment set is determined according to the membership function; a fuzzy evaluation matrix is established on the basis of the determined probability that each child node belongs to different judgment ranks; the importance weight of each child node over the top-level node of the hierarchical model isdetermined; and the network security situation indexes of the top-level node is calculated according to the established fuzzy evaluation matrix and the determined importance weight of each child nodeover the top-level node of the hierarchical model, and thereby the network security situation value of the hierarchical model is finally calculated. The fuzzy evaluation method has the advantages that the security situation of a network is evaluated through introducing fuzzy mathematics and a fuzzy analytical hierarchy process (FAHP) into the fuzzy evaluation method, and thereby the problem of data uncertainty during the evaluation of the network security situation is well solved.

Owner:NAT UNIV OF DEFENSE TECH

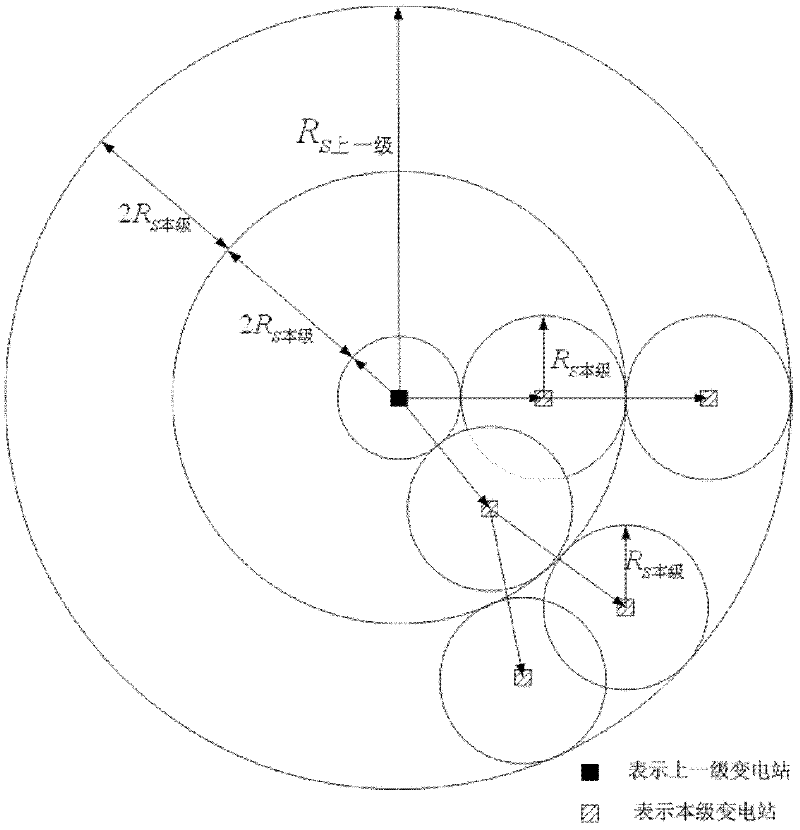

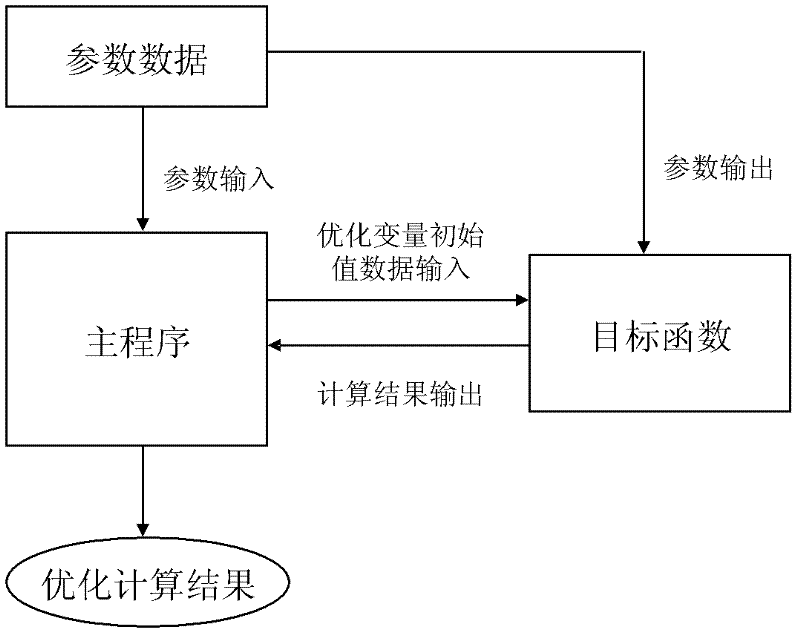

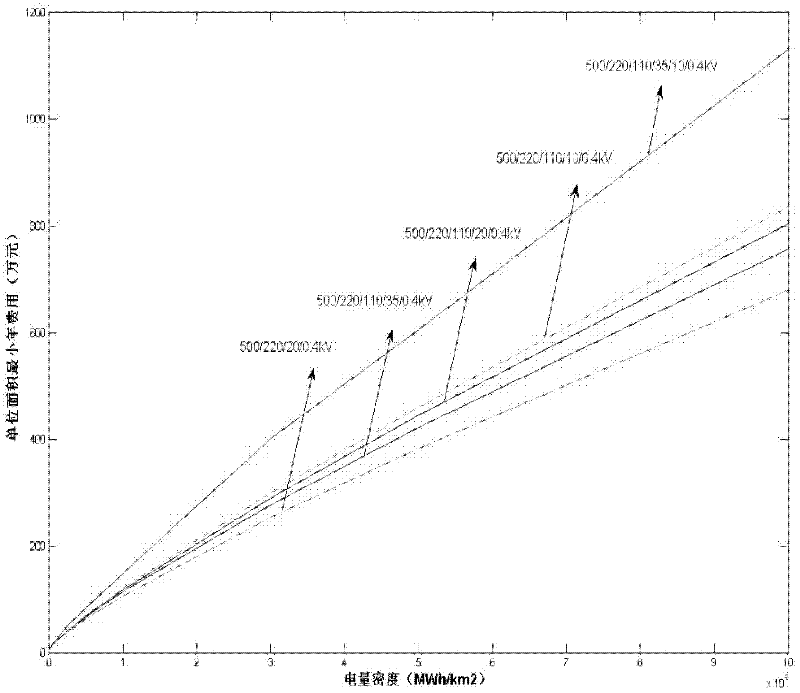

Rural electric network layout optimization method based on urban and rural integration

ActiveCN102411645APrevent scalingResolve uncertaintySystems intergating technologiesSpecial data processing applicationsPower factorElectric network

The invention provides a rural electric network layout optimization method based on urban and rural integration, which belongs to the field of rural electric network plan construction. An electric network structure model under the urban and rural integration layout, an economic power supply radius and economic power factor calculation model using the minimum annual cost as an objective function, a voltage grade sequence economic technology index optimization model and the like are built, a layered design and building method of the electric network structure model is systematically and completely provided, and in addition, the electric network annual cost optimization model is given for all voltage grade sequences. The method belongs to the electric network plan design method, which integrates the plan and the design and is applicable to the urban and rural integration.

Owner:STATE GRID CORP OF CHINA +2

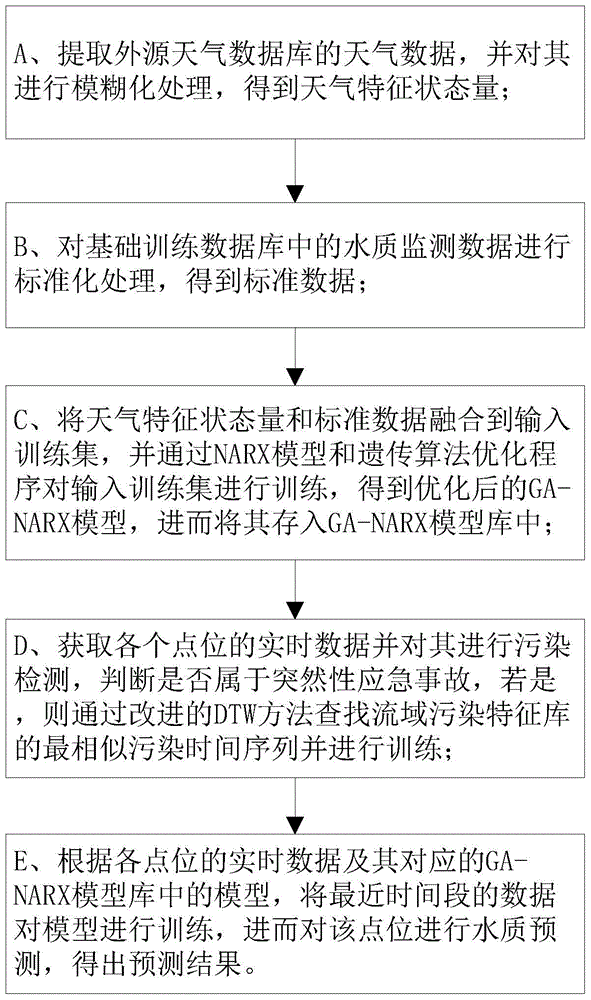

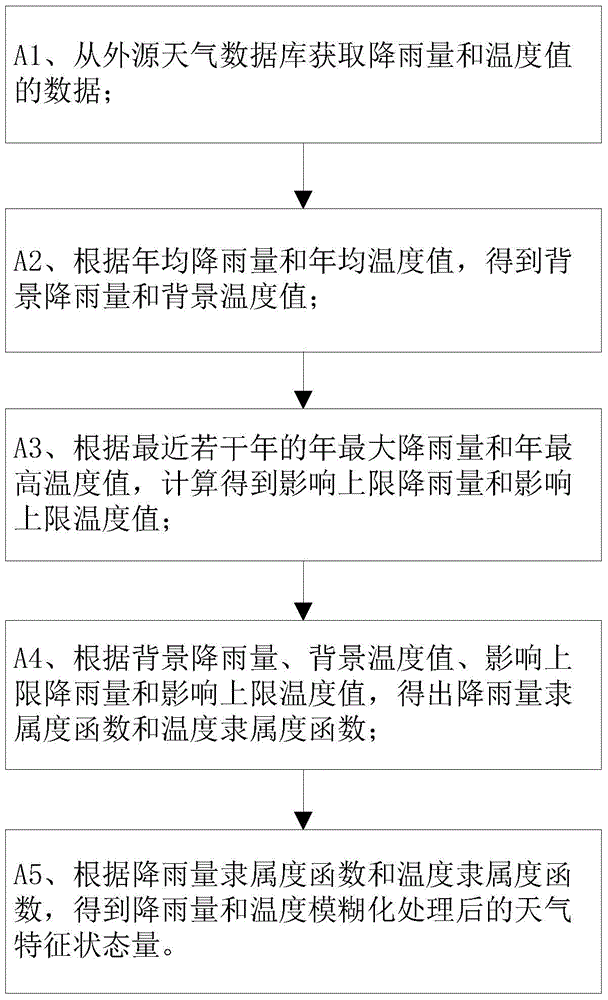

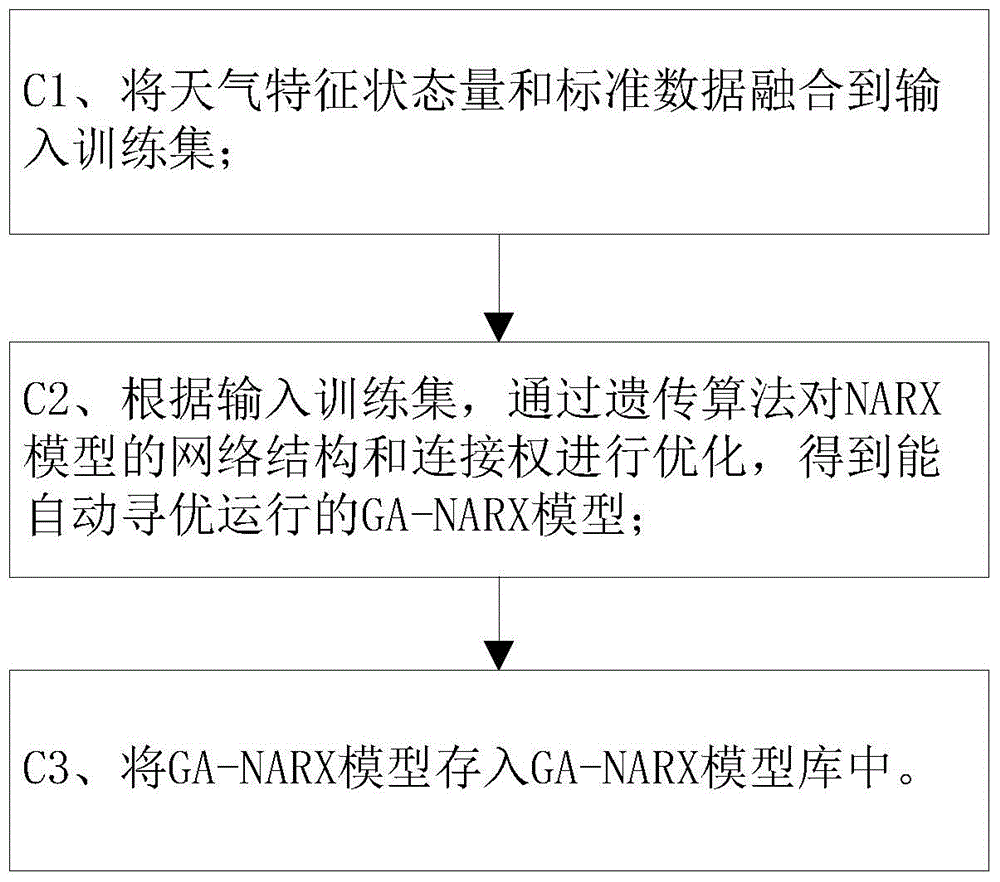

Multi-basin real-time intelligent water quality predication method and system

ActiveCN104318325AImprove accuracyImprove speed and precisionGeneral water supply conservationForecastingTraffic volumeRiver pollution

The invention discloses a multi-basin real-time intelligent water quality predication method and system. According to the multi-basin real-time intelligent water quality predication method and system, an NARX model is optimized through a genetic algorithm and a problem that earlier stage parameters of the NARX model are uncertain; a GA-NARX model is stored or called through a model storage module to predicate the multi-basin water quality condition in real time; essential data, recent data and history emergency data are performed on three-section training and accordingly an optimized GA-NARX model can basically comprise river pollution characteristics and the predication accuracy is improved; weather data replaces hydrological data and is performed on obfuscation processing and accordingly influences to the model from flow data missing are effectively solved; matching of similar pollution time sequence templates is performed through an improved DTW algorithm, a similar pollution process in the basin history is rapidly found out, experience is referred and learned, and sudden emergency accidents are accurately predicted. The multi-basin real-time intelligent water quality predication method and system can be widely applied to the water quality predication field.

Owner:广东省环境监测中心

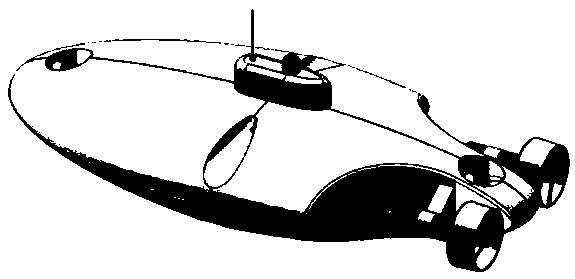

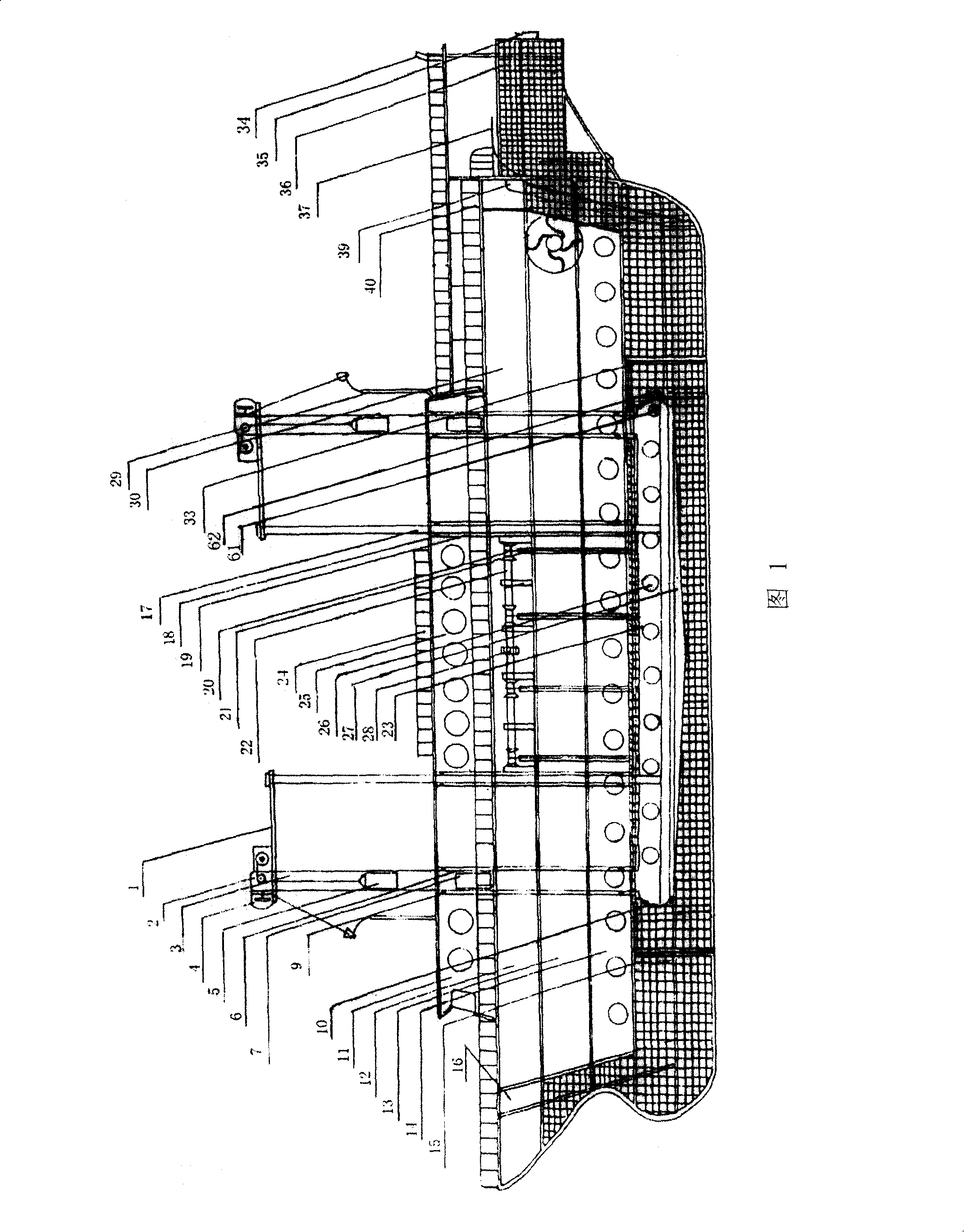

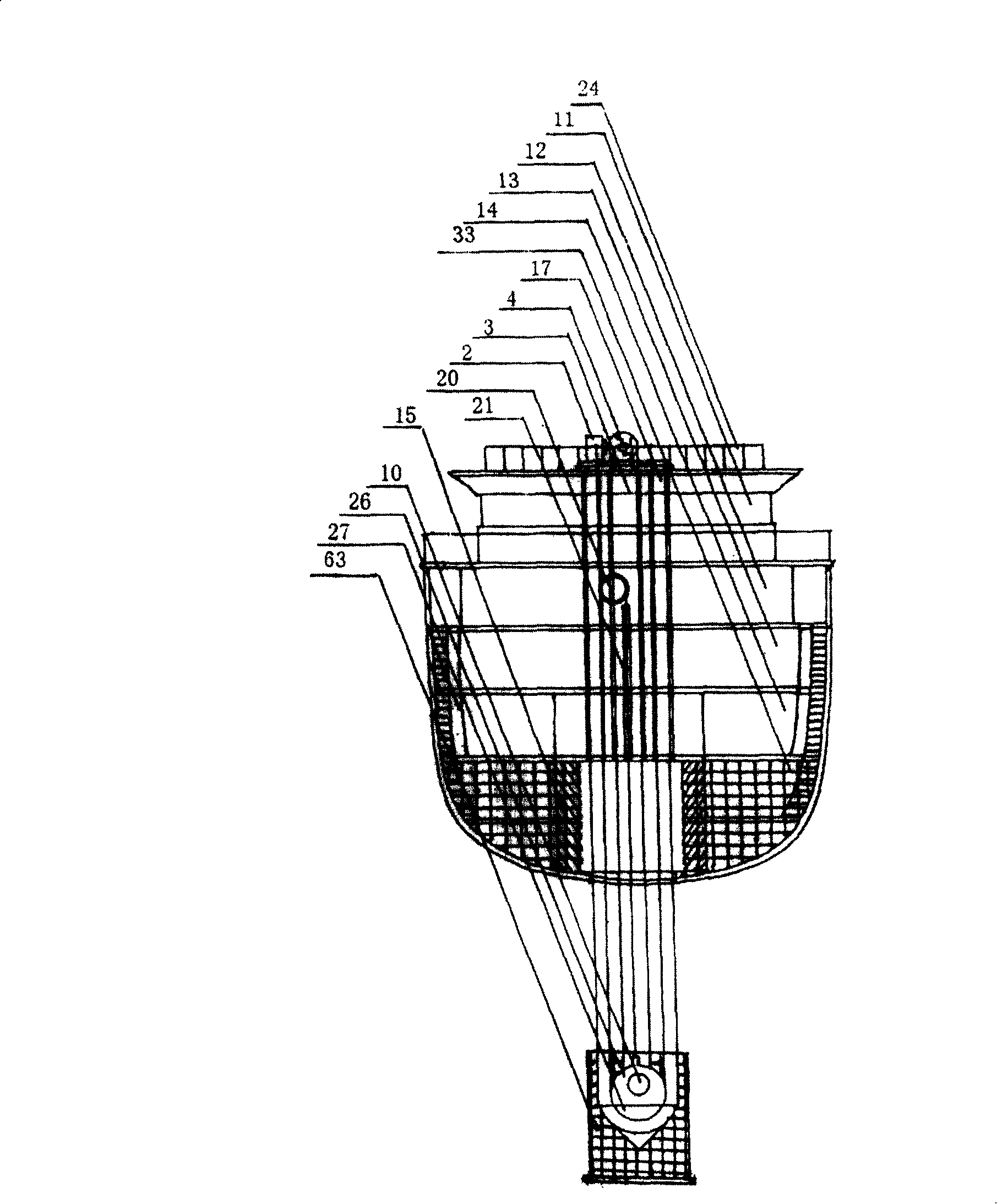

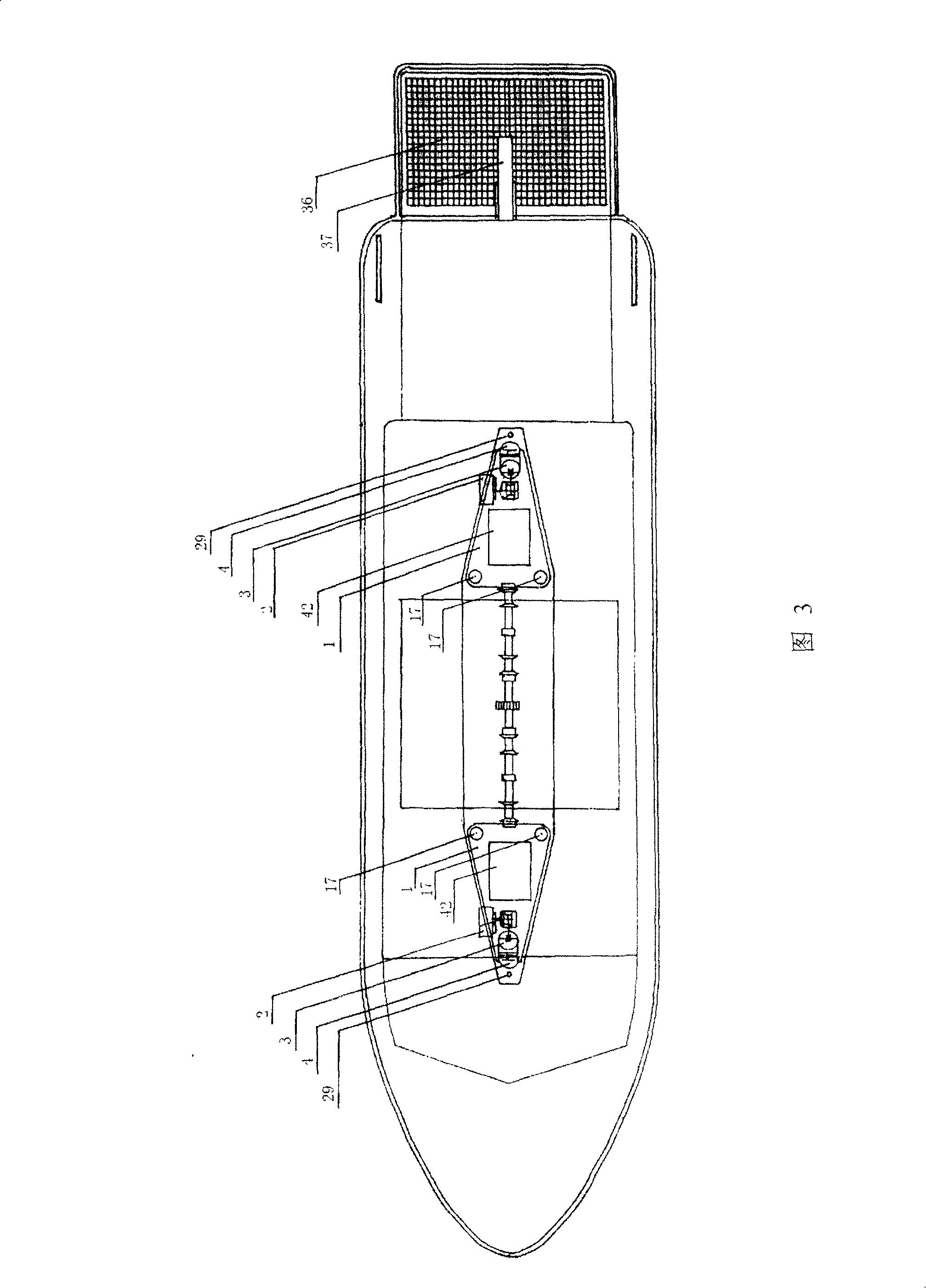

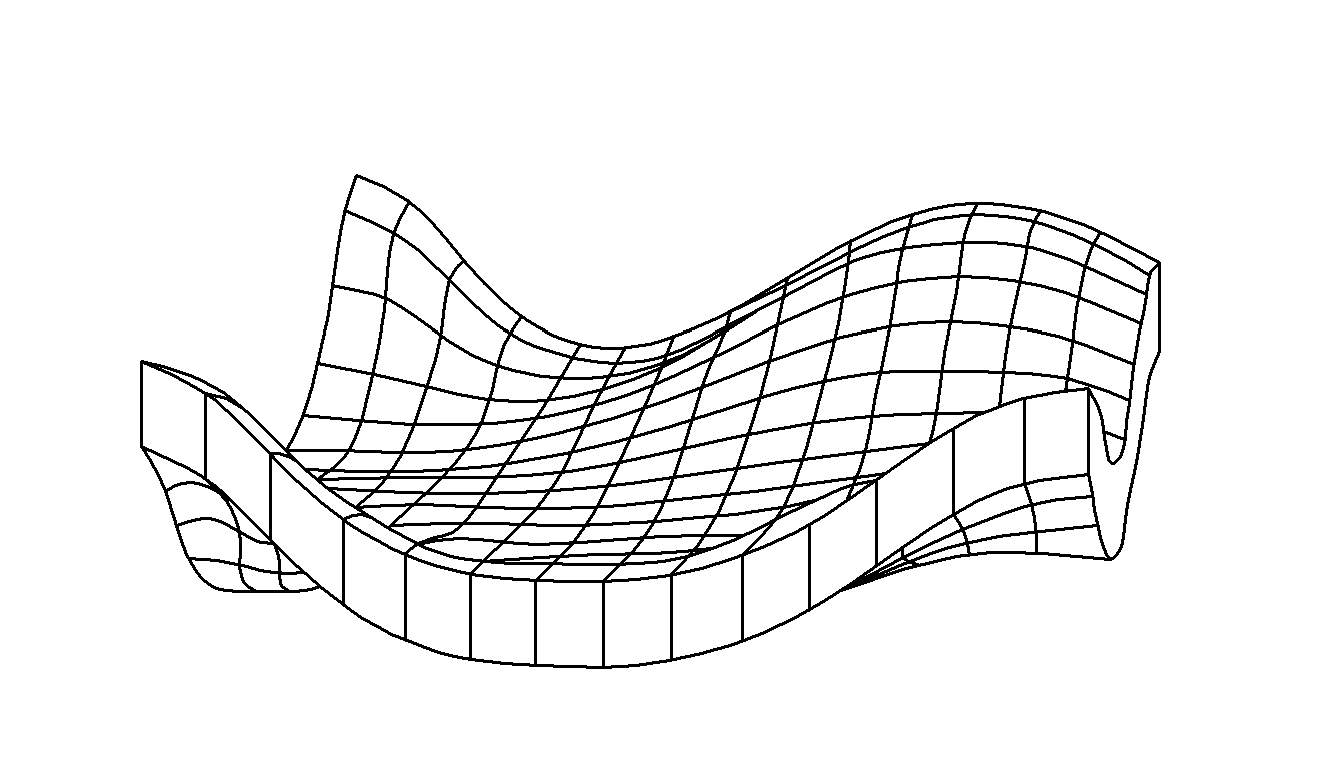

Multifunctional split underwater sightsee cruiser

InactiveCN101229842AAvoid unsafe factorsThere will be no negative consequences of over-limit sinkingUnderwater vesselsUnderwater equipmentAir cycleFlute

The invention discloses a multifunctional detachable yacht of diving and sightseeing. A lower part of the yacht on water is provided with a rise-and-fall underwater sightseeing cabin; both ends of the underwater sightseeing cabin are provided with air circulation tubes; the middle of the air circulation tubes are provided with a rise-and-fall elevator; the circumference of the underwater sightseeing cabin is provided with a meshy diving chamber which is integrated into a whole with the underwater sightseeing cabin via a rise-and-fall positioning rod; a center on the bottom of the yacht on water is provided with a flute; the underwater sightseeing cabin is hung on a yacht lifting device; when a preset limitation is reached, the underwater sightseeing cabin and the meshy diving chamber are reset synchronously inside the flute. The invention solves the complication of the underwater sightseeing facility and the uncertainty of the safety terminal technique and gets rid of the dependency on high required technical facilities. The simple and scientific structure design guarantees safety and is easy for management and control. The multifunctional detachable yacht of diving and sightseeing has the advantages of low manufacture and operating cost and safe and comfortable riding.

Owner:尤祖林

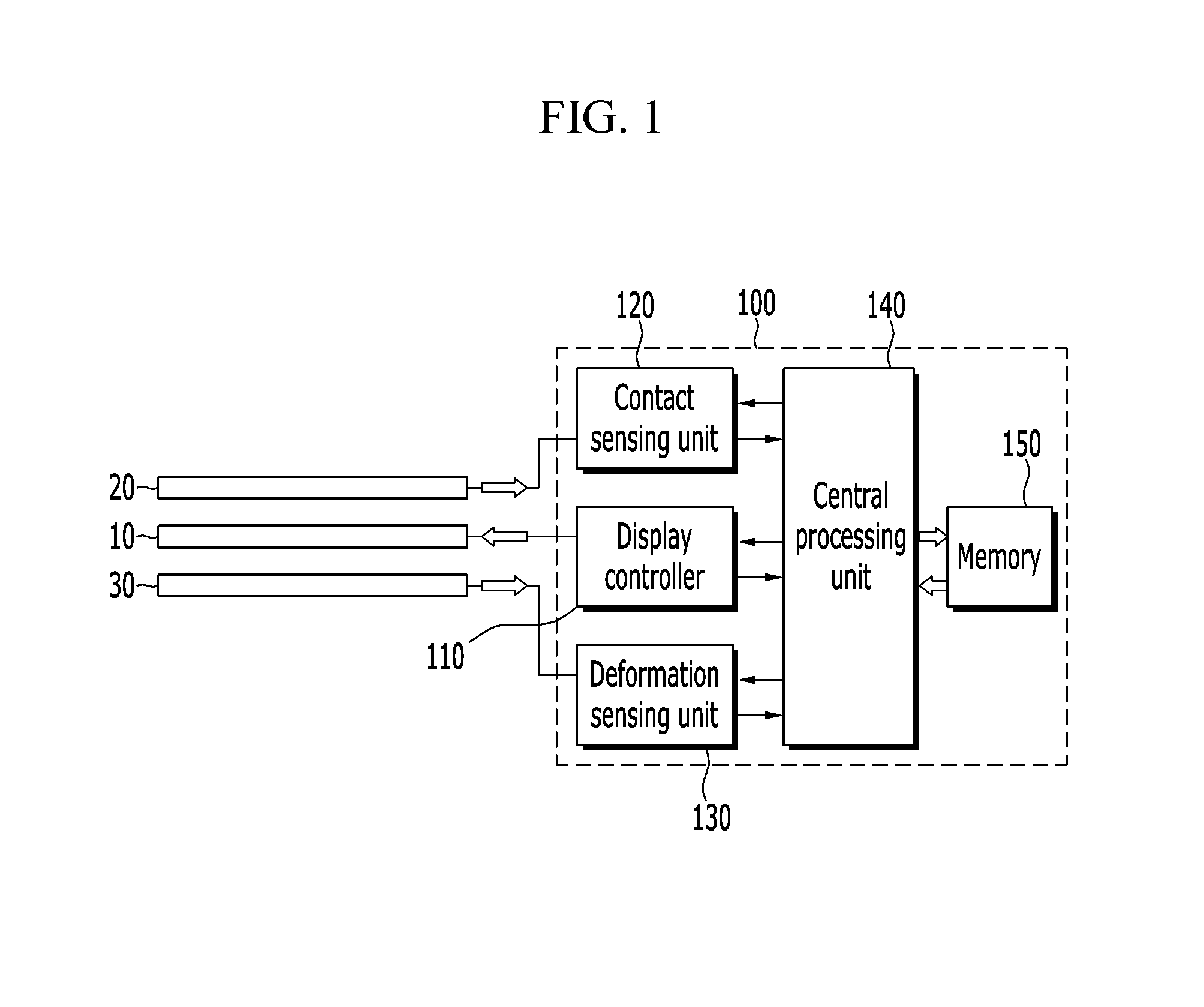

Flexible display device having guide function of gesture command and method thereof

ActiveUS20140347287A1Resolve uncertaintyDigital data processing detailsInput/output processes for data processingTouch SensesHuman–computer interaction

Provided is a flexible display device configured to include a touch sensing function and a deformation recognizing function; and a control device configured to control the flexible display panel and including an operating command database, wherein the control device is configured to identify operating command candidates from the operating command database based on at least one of a touch input data and a deformation input data received from the flexible display panel, and to instruct the flexible display panel to display the operating command candidates on the flexible display panel.

Owner:SAMSUNG DISPLAY CO LTD

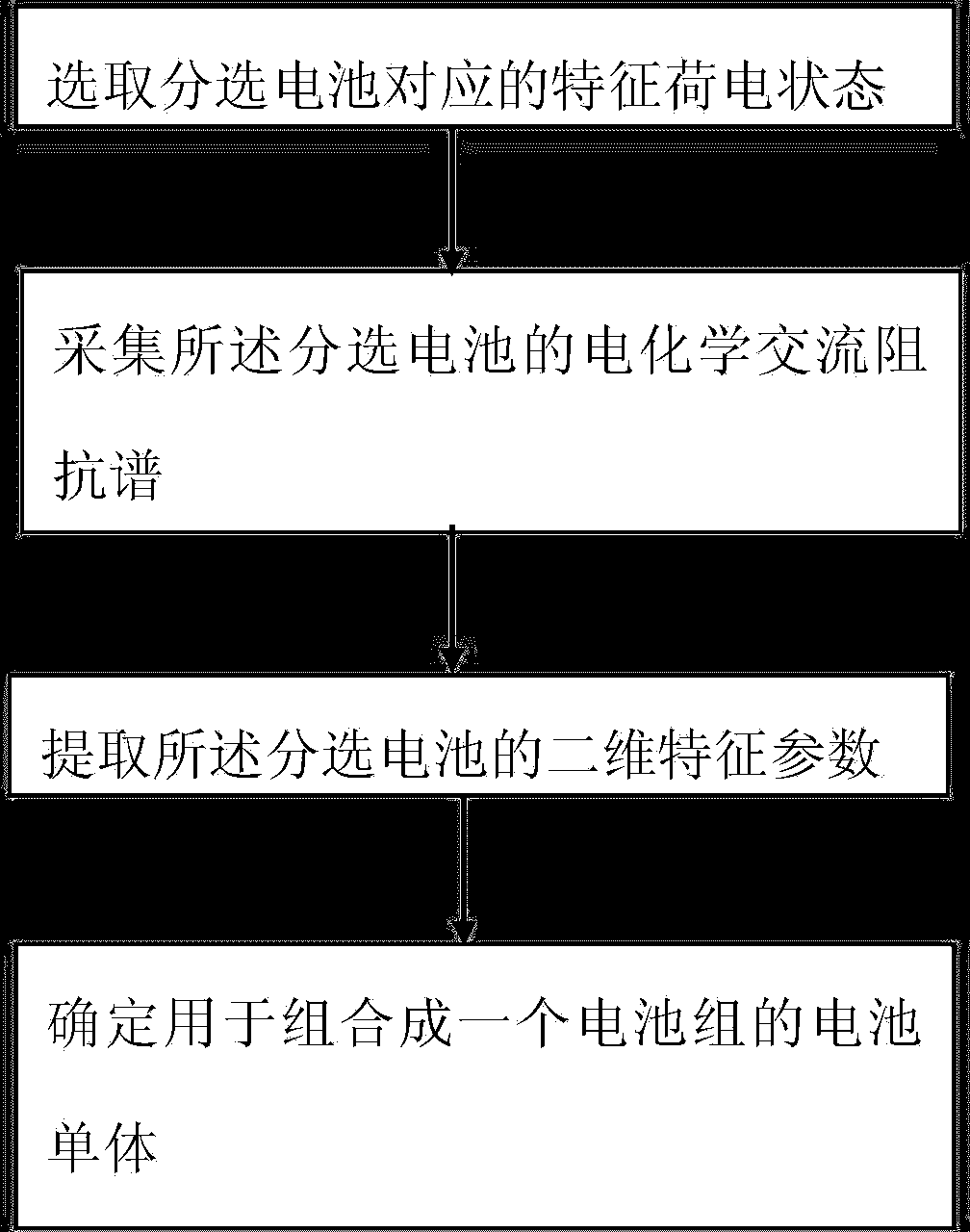

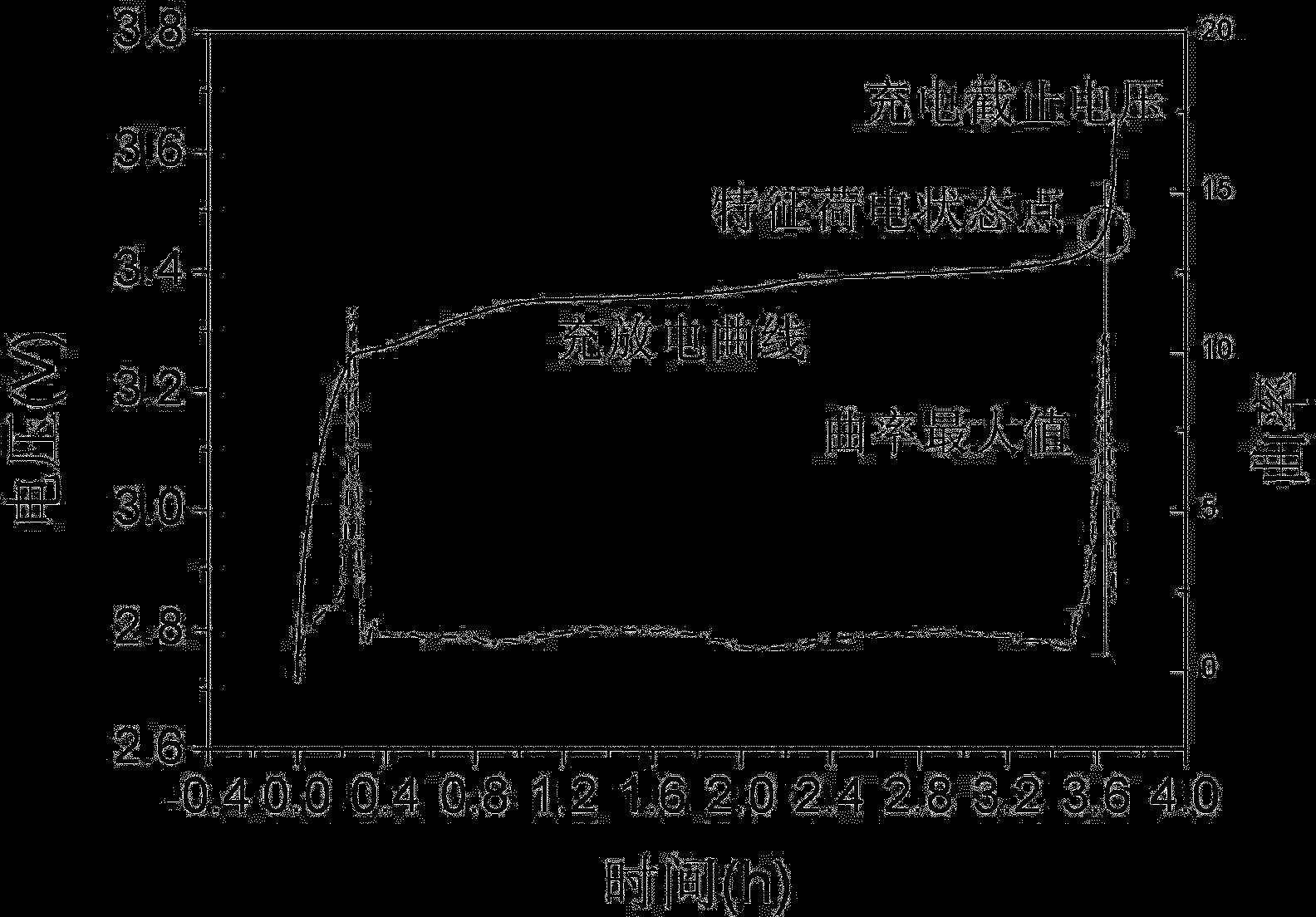

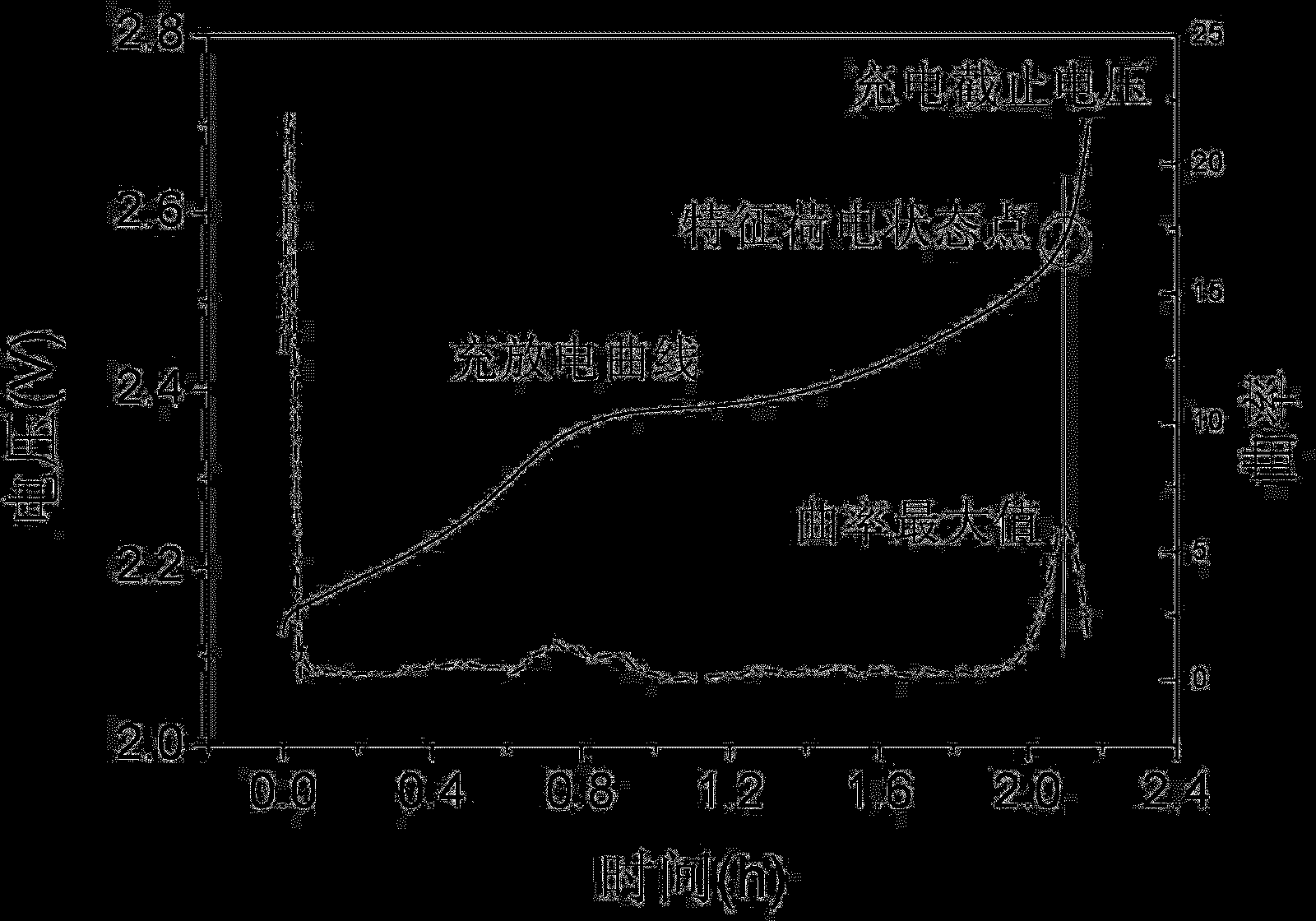

Sorting method of secondary batteries

ActiveCN103801521AImprove consistencyDifferentiate the degree of differenceSortingElectrical batterySpectroscopy

The invention relates to a sorting method of secondary batteries. The sorting method comprises the following steps: selecting featured charge states corresponding to to-be-sorted batteries, acquiring electrochemical alternating-current impedance spectroscopy of the to-be-sorted batteries, extracting two-dimensional feature parameters of the to-be-sorted batteries, and then determining battery monomers combined to form a battery pack. According to the internal features of the parts, from a charging platform to a charging cut-off voltage, of the secondary batteries, the consistency of the essentially sorted batteries is better than that of batteries sorted by a conventional method, the integral performance of the battery pack is improved, and the service life is prolonged.

Owner:STATE GRID CORP OF CHINA +2

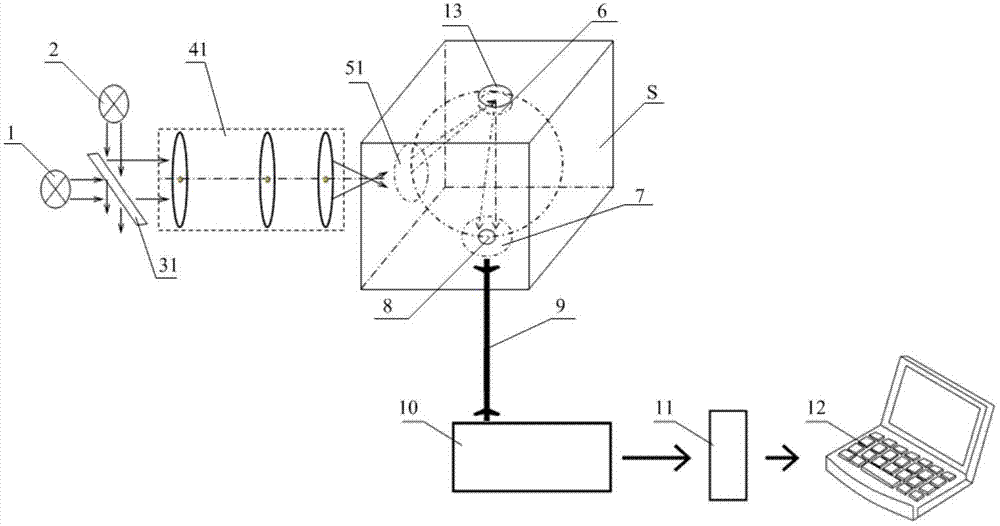

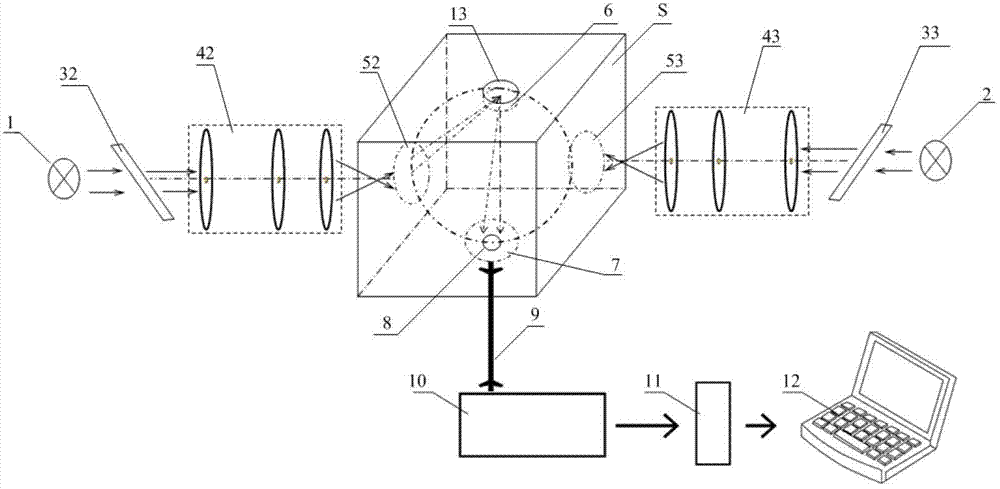

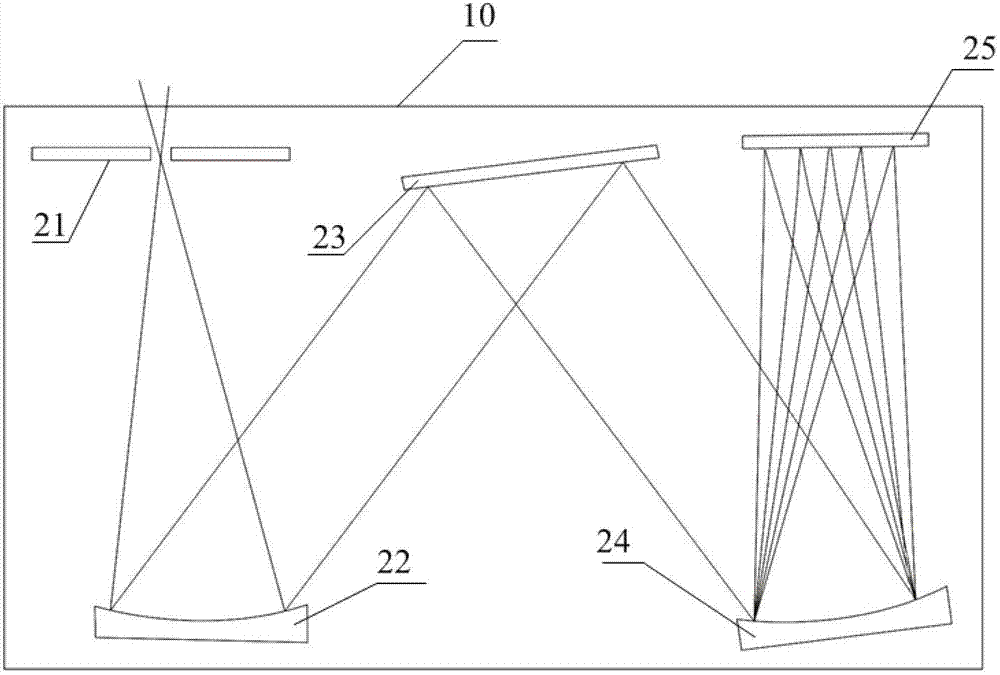

Reflectance spectrum measuring and sampling system and method used for jewel detection

ActiveCN102967604AImproving the efficiency of assay analysis testingResolve uncertaintyScattering properties measurementsInvestigating jewelsDigital conversionReflectance spectroscopy

The invention discloses a reflectance spectrum measuring and sampling system and a reflectance spectrum measuring and sampling method used for jewel detection. The reflectance spectrum measuring and sampling system comprises a first light source, a second light source, a light filtration element, an integrating sphere, an optical fiber, a spectral detection module, an analog-digital conversion module and a data processing terminal, wherein the integrating sphere has an incidence hole, a sampling port and a reflected light outgoing port. The reflectance spectrum measuring and sampling system can collect a real-time spectrum of light rays reflected by a jewel, and can efficiently obtain the full light information within the wavelength scope selected by a user, thereby solving the uncertain problems existing in the following sample measurement process, omitting the complex operation steps, such as the monochrome scanning and mechanical light splitting, and greatly improving the efficiency of a jewel detection and analysis test. The reflectance spectrum measuring and sampling system and the reflectance spectrum measuring and sampling method which have favorable performances can be widely applied to the jewel identification industry.

Owner:BIAOQI ELECTRONICS TECH

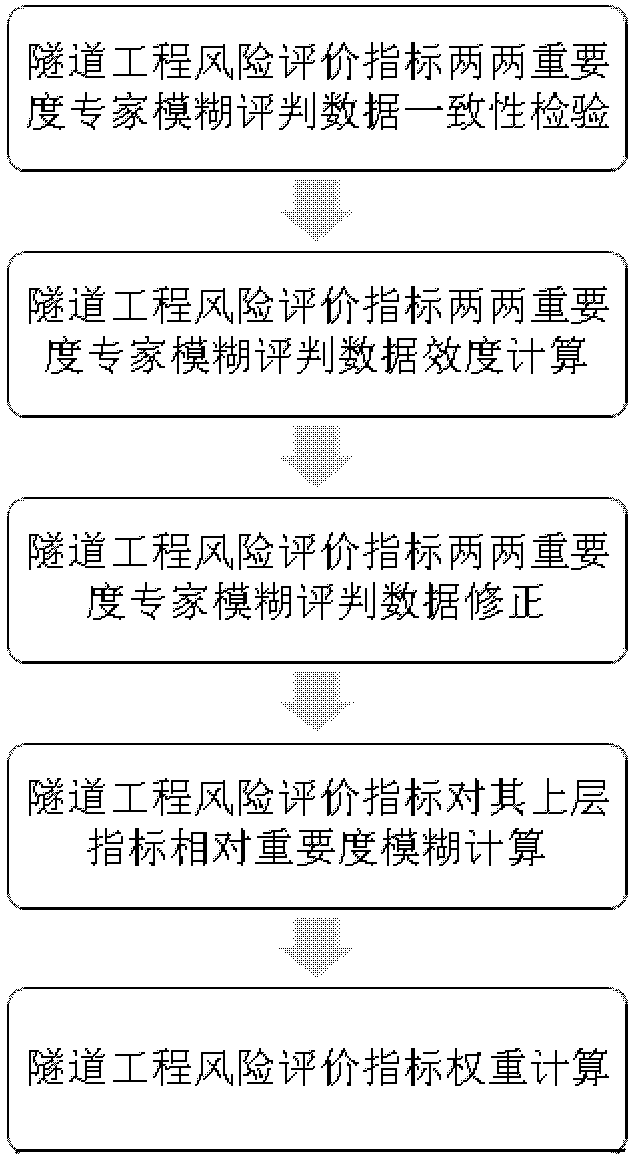

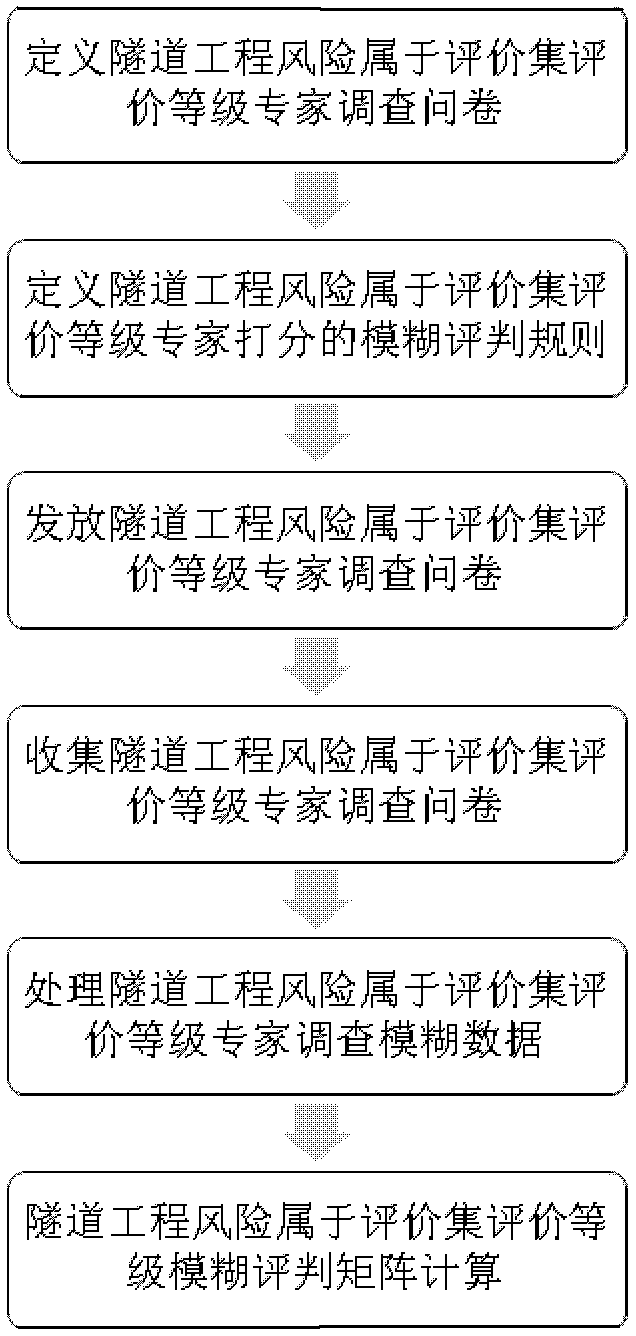

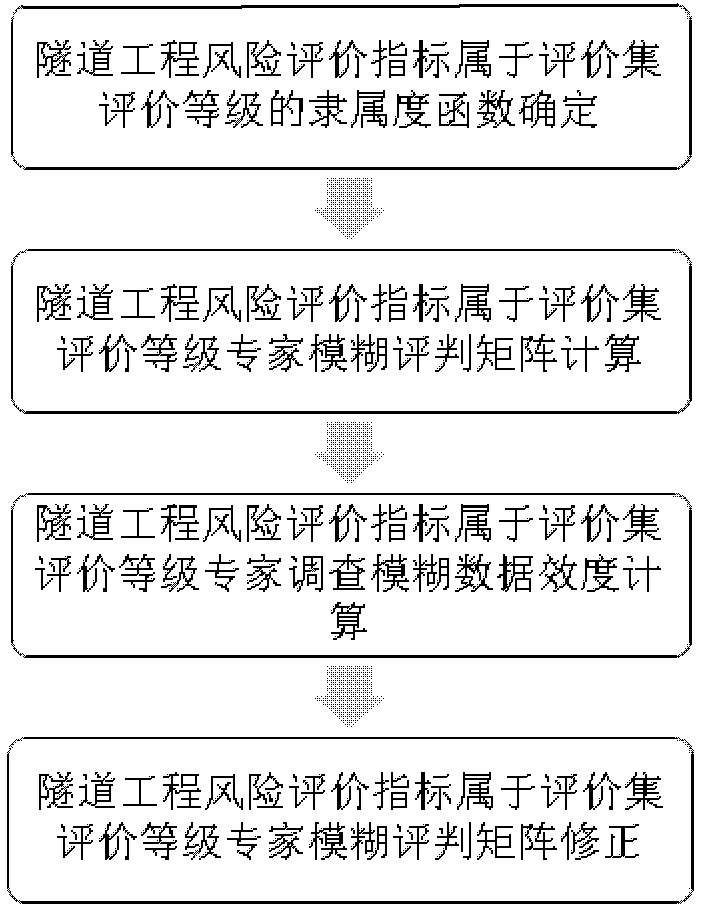

Tunnel engineering risk situation fuzzy evaluation method and system

The invention discloses a tunnel engineering risk situation fuzzy evaluation method and system. The method comprises the following steps that according to a tunnel engineering practical building environment, based on building conditions, prospective design, construction technologies and operation management factors, tunnel engineering risk evaluation indexes are determined; a tunnel engineering risk evaluation index layer is established; the tunnel engineering risk evaluation index layer is combined, a tunnel engineering risk situation fuzzy evaluation hierarchical model is established; according to expert evaluation opinions, the weight of the tunnel engineering risk evaluation indexes in the index layer obtained after validity correction processing is determined; according to the expert evaluation opinions, a fuzzy evaluation matrix obtained after validity correction is established, and according to the fuzzy evaluation matrix, bottom index layer nodes belong to risk situation evaluation index evaluation sets on a criterion layer; and tunnel engineering risk situation indexes are computed. The risk situation of tunnel engineering is evaluated by introducing fuzzy mathematics and a fuzzy layering method, and accordingly the problems of data uncertainty in tunnel engineering risk situation evaluation and influence on evaluation results are solved.

Owner:WUHAN UNIV OF TECH

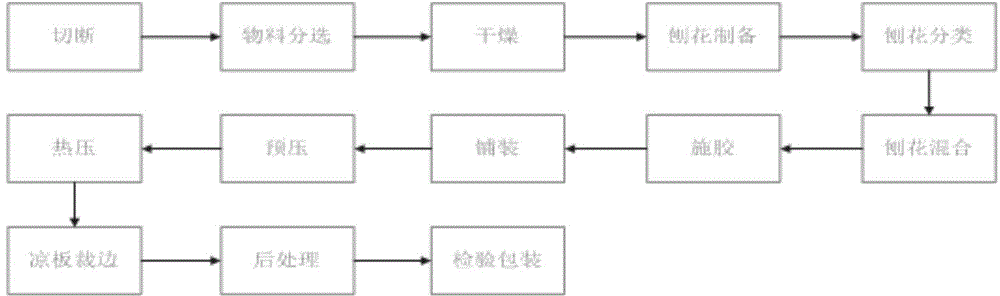

Shaving board manufacturing method

InactiveCN105171890AWidely usedBroaden the field of applicationDomestic articlesFlat articlesControl levelSizing

A shaving board manufacturing method includes the following steps of (1) cutting-off and sorting, (2) shaving preparation and classification, (3) shaving mixing, (4) sizing, (5) laying, (6) hot pressing and (7) after-treatment. Shaving boards are manufactured through puelia production. Compared with the prior art, the method has the advantages that (1) raw materials are widely used, puelia can be used independently for board manufacturing and can be mixed with other raw materials for board manufacturing, the application field of the puelia is widened, the problems of the deficiency and uncertainty of non-wood shaving board raw materials are solved, the design scale of a single production is enlarged, and production cost can be reduced; (2) various raw materials are precisely mixed through independent equipment, and the control level of the production line can be improved; (3) puelia shaving guarantees the uniformity and consistency of fibers by means of a smashing and precise grinding two-stage manufacturing mode, and the product yield is increased and subsequent processing performance is improved; (4) by means of distribution of the overall technology and equipment, the problem caused when puelia is applied to industrialization of board manufacturing is solved.

Owner:HUNAN WANHUA ECOLOGICAL PLATE IND CO LTD

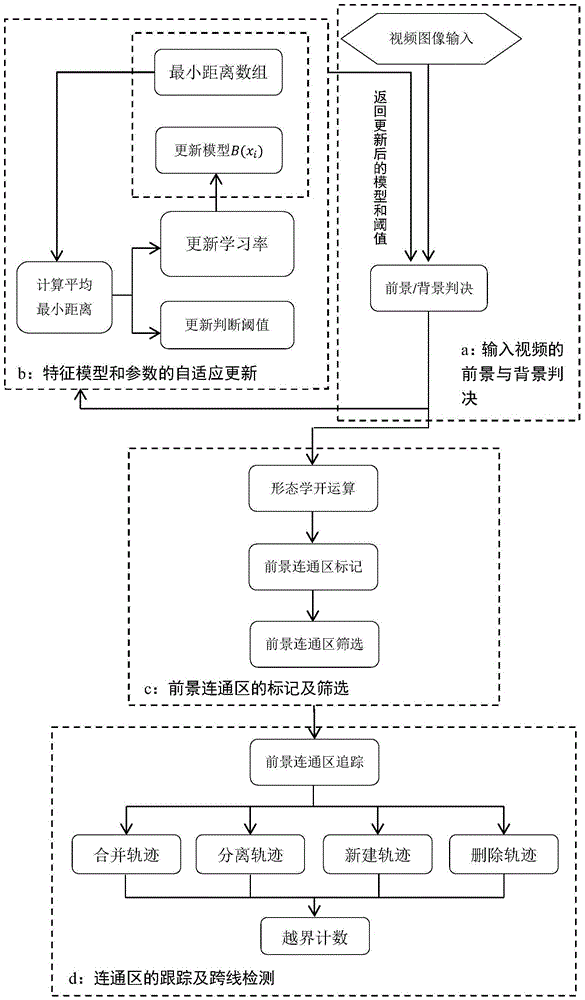

Monitoring video moving target tracking method based on self-adaptive background segmentation and system thereof

ActiveCN105654508AResolve uncertaintyGood tracking effectImage enhancementImage analysisBackground informationVideo image

The invention discloses a monitoring video moving target tracking method based on self-adaptive background segmentation and a system thereof, and is used for extracting background information in a monitoring video and realizing tracking and line crossing detection of moving targets in the video. The method mainly comprises the steps that first N frames of video images are taken to act as background models to perform background modeling according to a time sequence, and the background model of each frame of image after N frames is randomly updated so that the background models are enabled to self-adaptively change according to the change of scenes; and the foregrounds and the backgrounds are separated out according to the background models and then marking of connected regions is performed on the separated foreground targets, and the connected regions are screened so as to be adaptive to the multi-scale change of the video. The connected regions can be tracked according to the marks. The moving targets in the monitoring video can be tracked and line crossing detection can also be performed, and the number of the targets crossing the line can be recorded so that practicality is high.

Owner:WUHAN UNIV

Method for quantitatively identifying performance degradation degree of rolling bearing

InactiveCN102735447AEarly detection of initial damageEarly detection of eventual failureMachine bearings testingTime domainLife time

The invention discloses a method for quantitatively identifying the performance degradation degree of a rolling bearing. The method comprises the following steps of: extracting time domain statistical characteristics of a vibration signal of the rolling bearing, selecting a stability characteristic and a sensitivity characteristic as input vectors, establishing a fuzzy support vector description model, and calculating a fuzzy monitoring coefficient; and introducing operation time on the basis of the fuzzy monitoring coefficient to construct a monotonic damage degree index and quantitatively identify the performance degradation degree of the rolling bearing. By the method, the performance degradation degree of the rolling bearing in the whole life cycle can be quantitatively identified, initial damage and final failure are found as soon as possible, and major accidents are prevented.

Owner:XI AN JIAOTONG UNIV

Novel method for determining oil-gas migration and pool-forming periods

ActiveCN103115908AResolve uncertaintyFluorescence/phosphorescenceFluorescence spectrometryHigh resolution

The invention relates to a method for determining oil-gas migration and pool-forming periods. According to the method, oil-gas migration and the period of oil-containing gas charging are determined by carrying out high-resolution and high-precision microscopy fluorescence spectrum testing and data analysis on oil inclusions, and the oil-gas pool-forming period is determined by carrying out in-situ high-resolution and high-precision microscopy fluorescence spectrum testing and data analysis on porous oil.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com