Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2611results about "Gas-turbine engine testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and apparatus for model based diagnostics

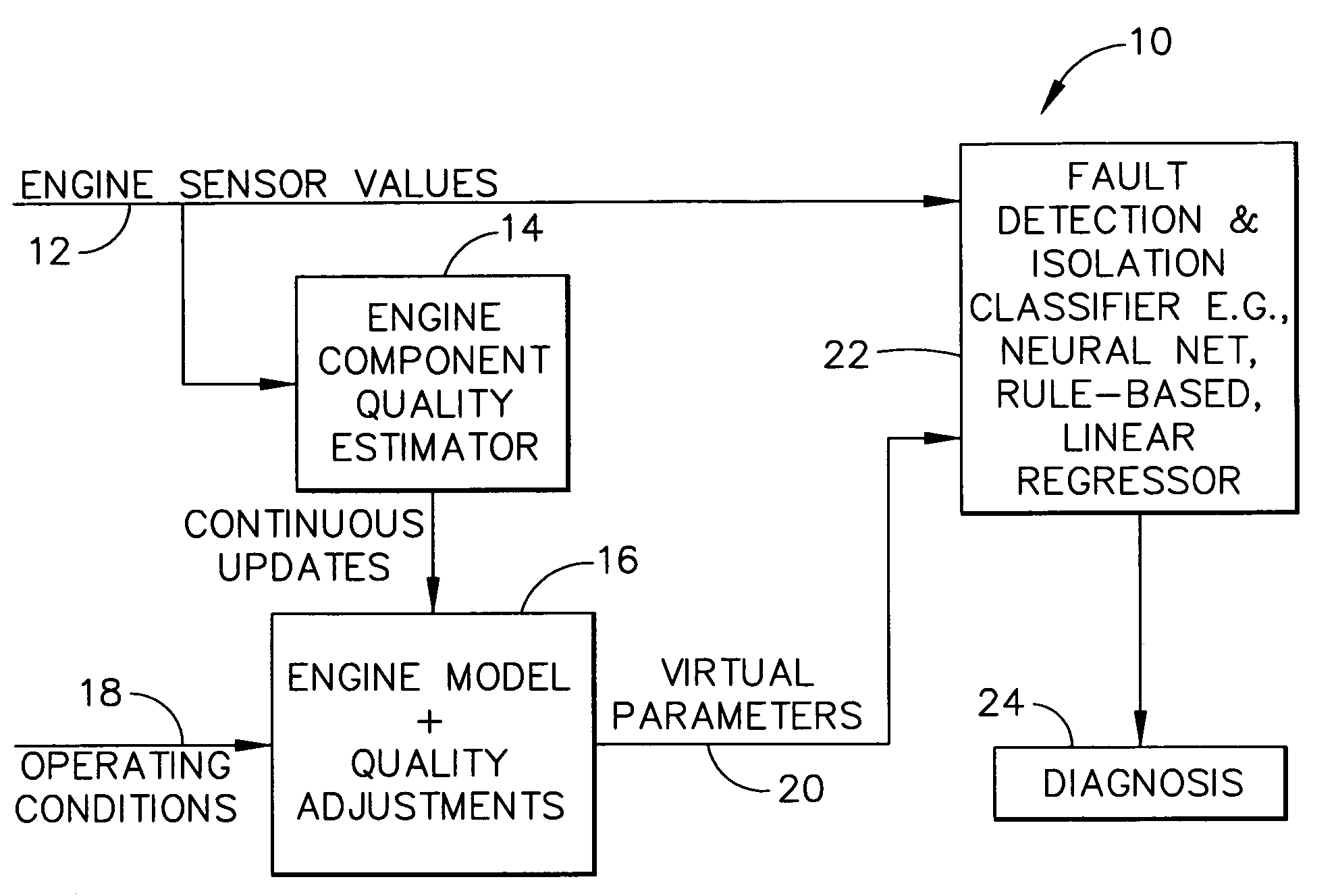

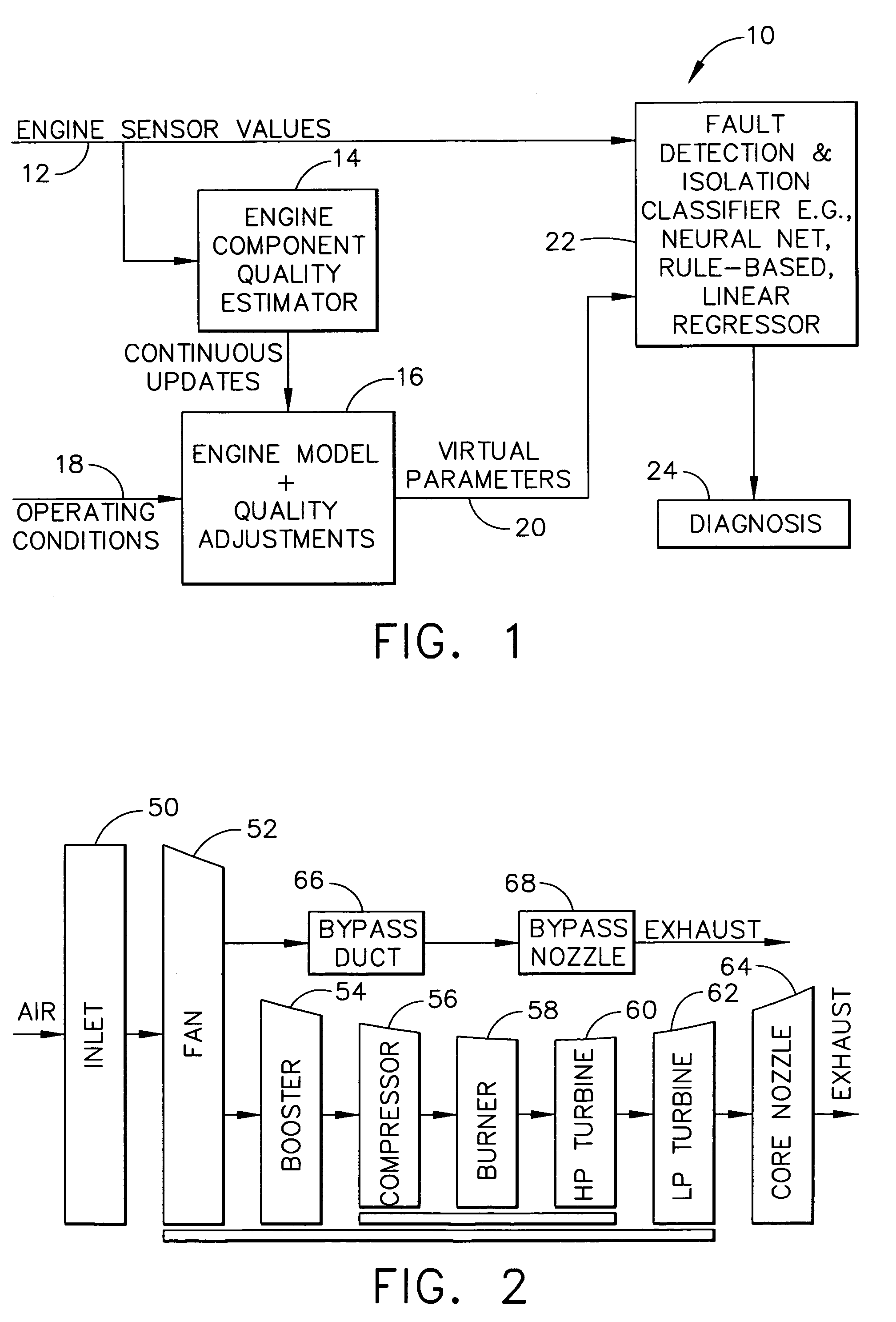

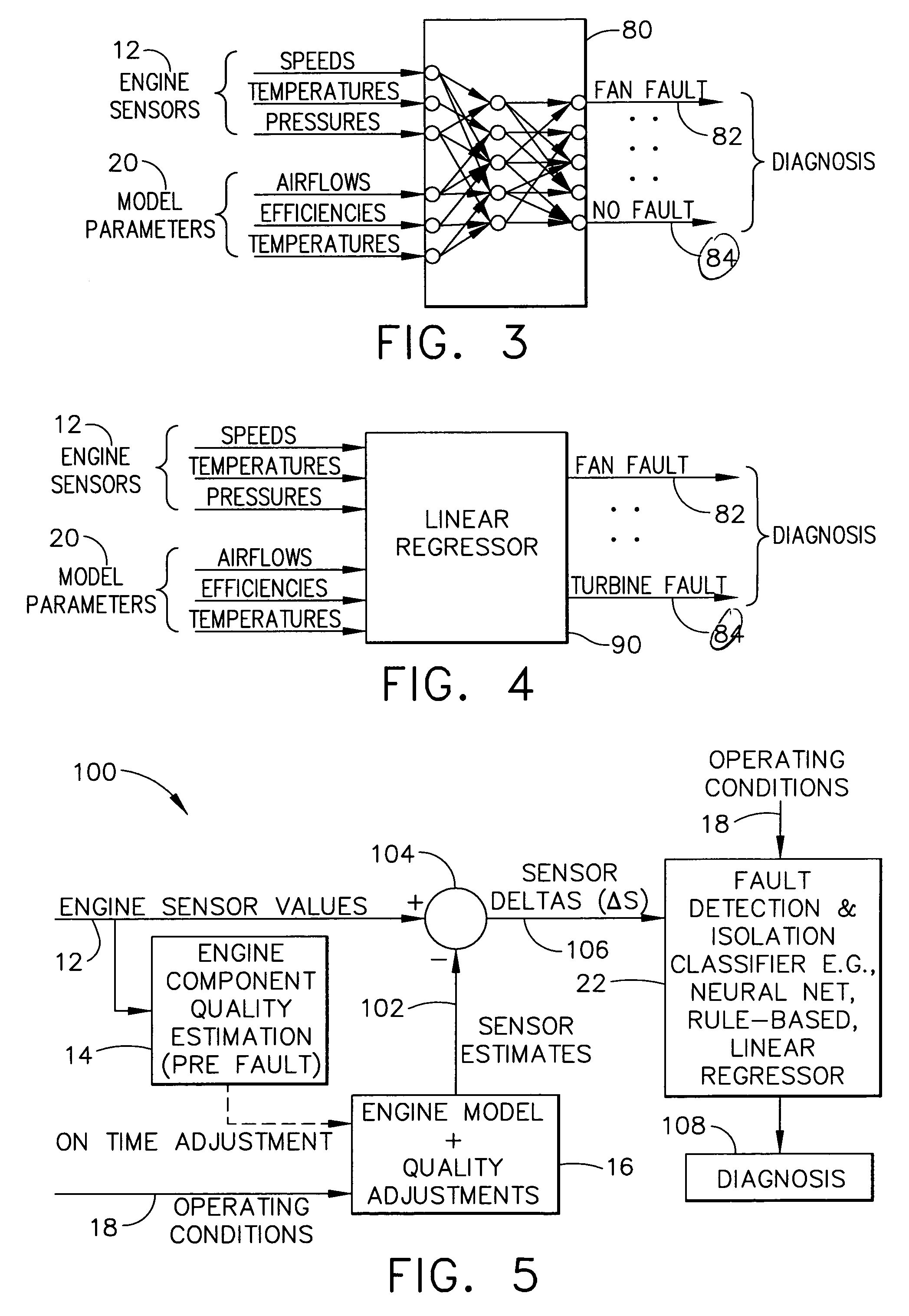

Systems and methods for performing module-based diagnostics are described. In an exemplary embodiment, sensor values from an actual engine plant are input to an engine component quality estimator which generates performance estimates of major rotating components. Estimated performance differences are generating by comparing the generated performance estimates to a nominal quality engine. The estimated performance differences, which are indicative of component quality, are continuously updated and input to a real-time model of the engine. The model receives operating conditional data and the quality estimates are used to adjust the nominal values in the model to more closely match the model values to the actual plant. Outputs from the engine model are virtual parameters, such as stall margins, specific fuel consumption, and fan / compressor / turbine efficiencies. The virtual parameters are combined with the sensor values from the actual engine plant in a fault detection and isolation classifier to identify abnormal conditions and / or specific fault classes, and output a diagnosis.

Owner:GENERAL ELECTRIC CO

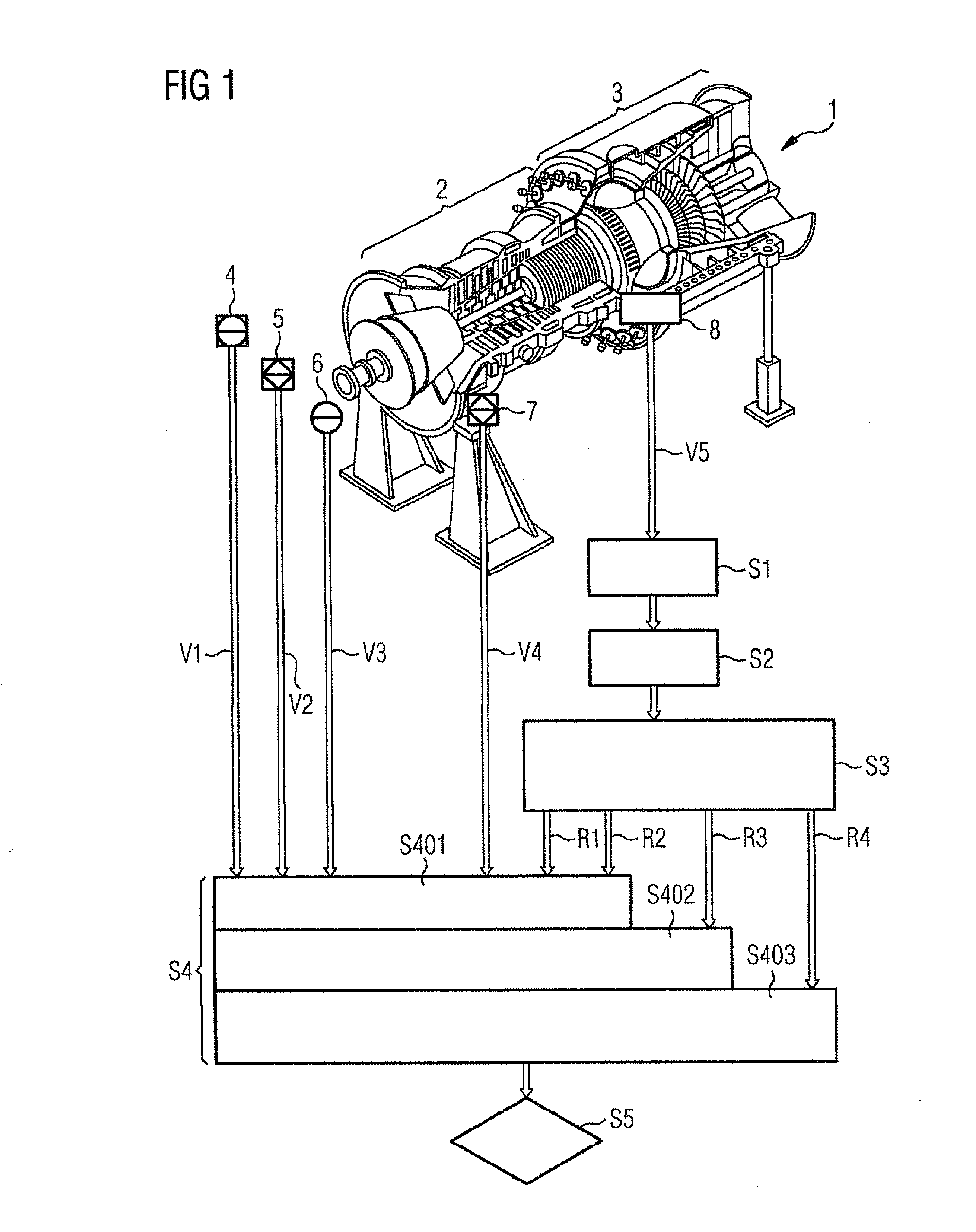

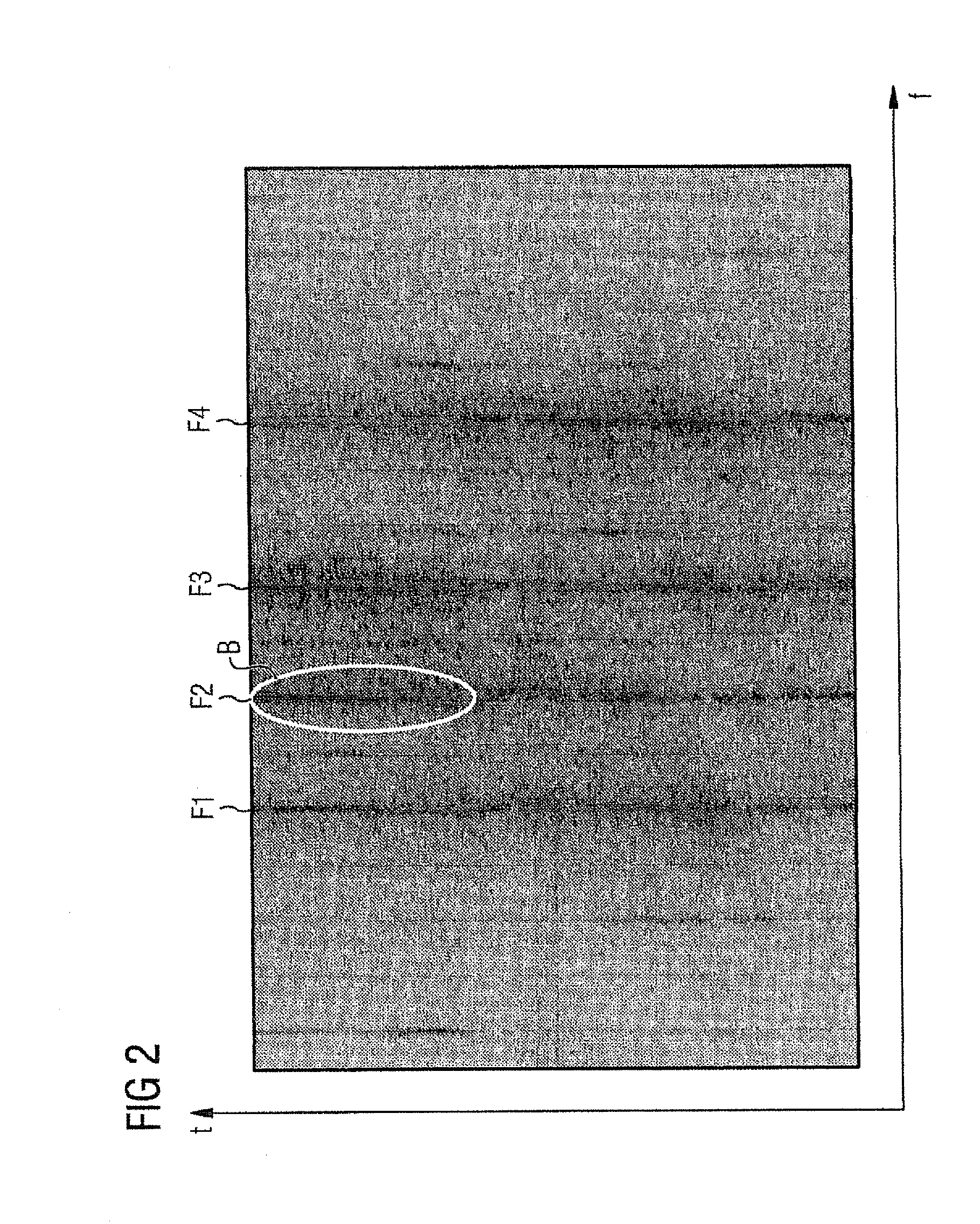

Method for analysis of the operation of a gas turbine

ActiveUS20100262401A1Accurate diagnosisLess sensorsGas-turbine engine testingEngine fuctionsFrequency spectrumEngineering

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

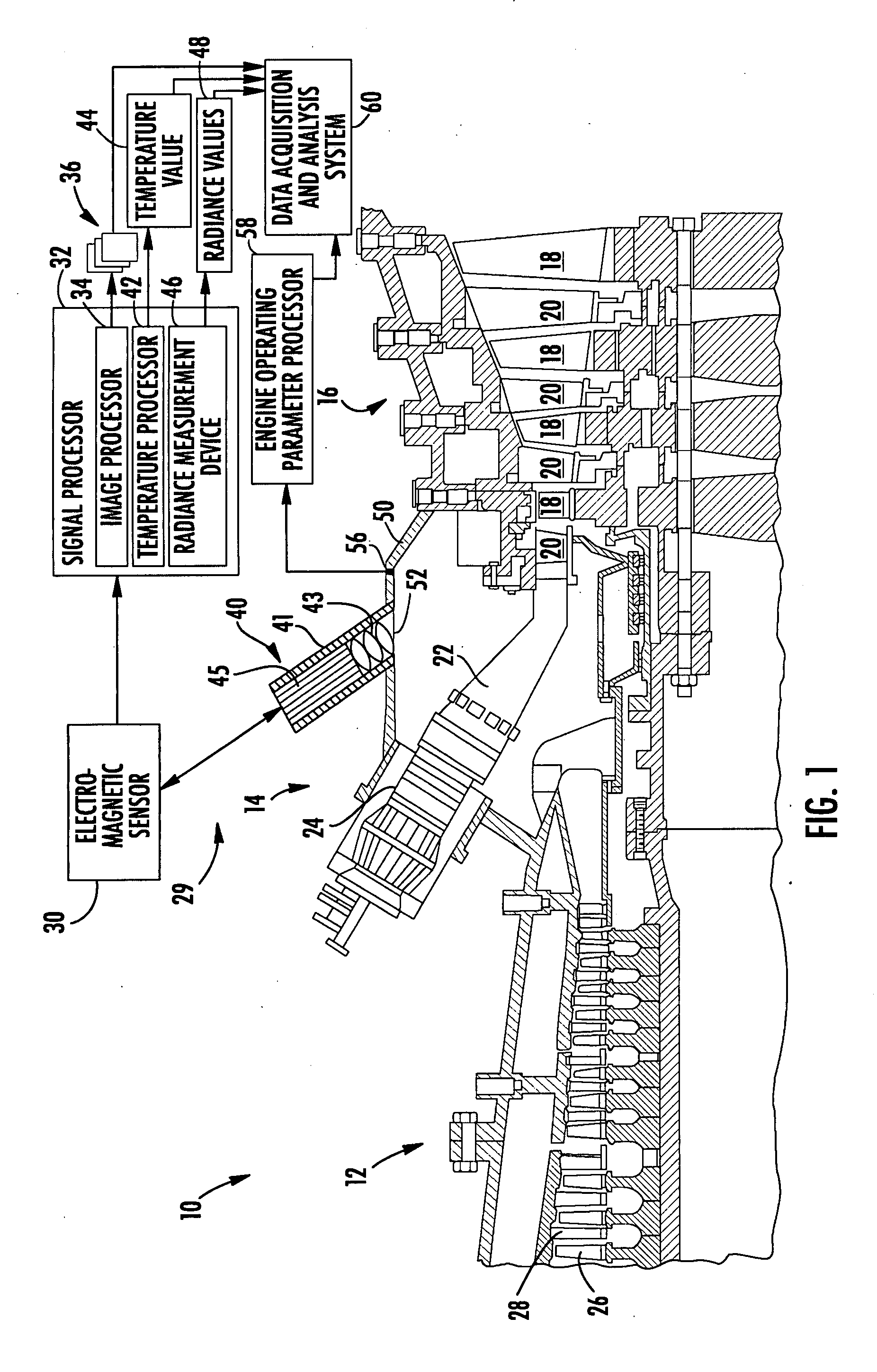

System and method of evaluating uncoated turbine engine components

InactiveUS20080101683A1Gas-turbine engine testingMaterial analysis by optical meansNon destructiveVision based systems

Aspects of the invention are directed to a visual-based system and method for non-destructively evaluating an uncoated turbine engine component. Aspects of the invention are well suited for high speed, high temperature components. Radiant energy emitted from an uncoated turbine engine component can be captured remotely and converted into a useful form, such as a high resolution image of the component. A plurality of images of the component can be captured over time and evaluated to identify failure modes. The system can also measure and map the temperature and / or radiance of the component. The system can facilitate the non-destructive evaluation of uncoated turbine components during engine operation without disassembly of the engine, thereby providing significant time and cost savings. Further, the system presents data to a user with sufficient context that allows an engine operator can evaluate the information with an increased degree of confidence and certainty.

Owner:SIEMENS ENERGY INC

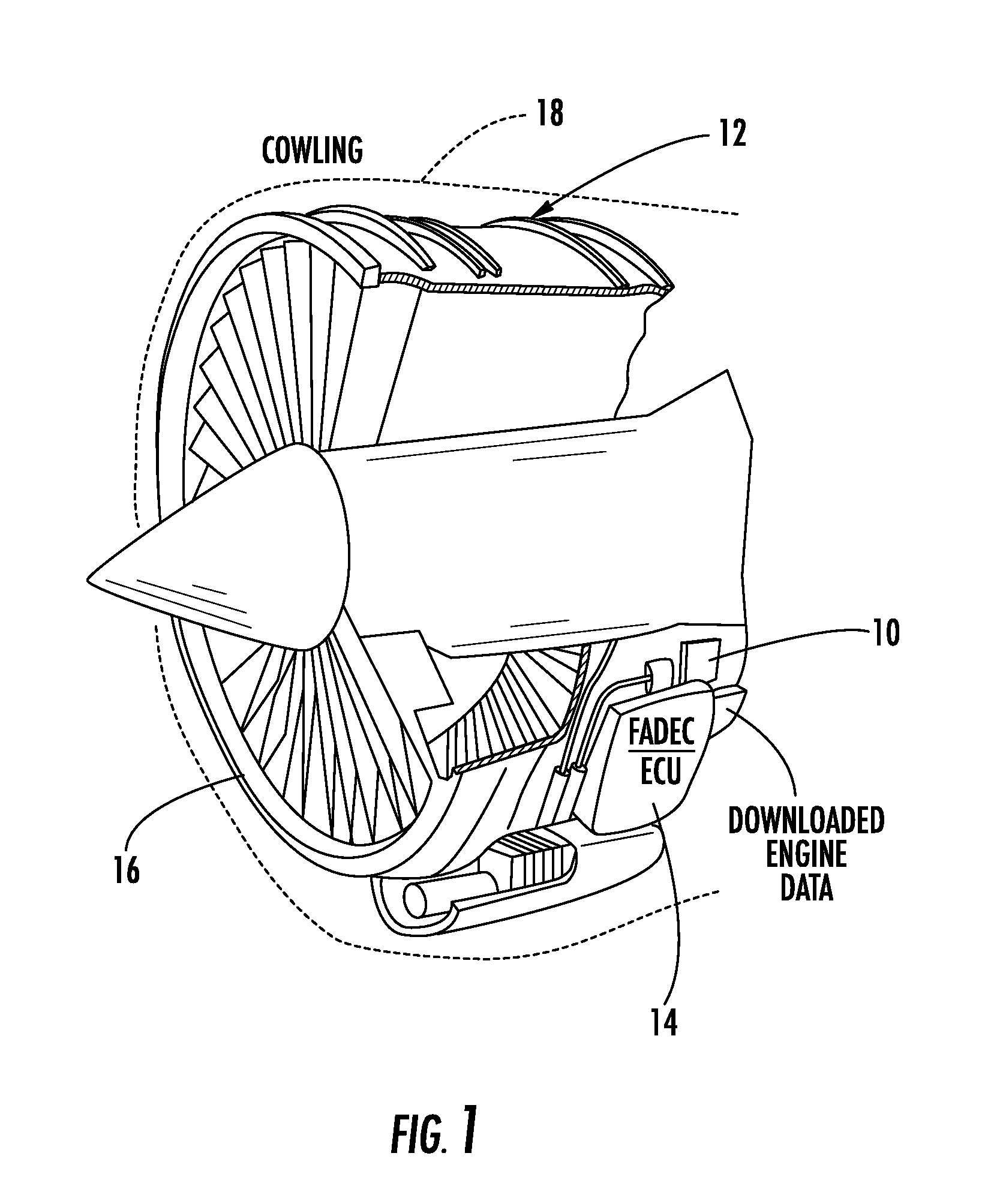

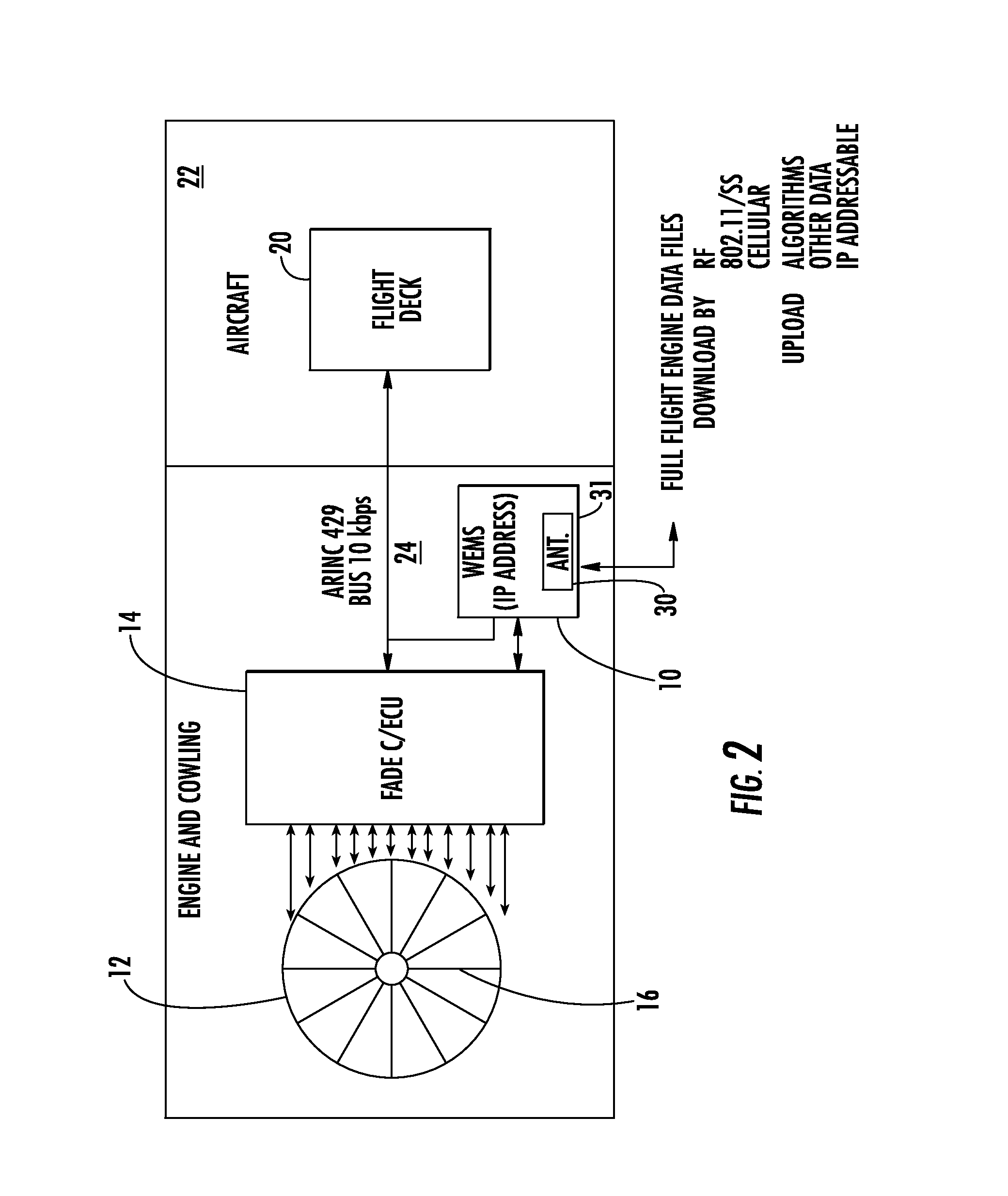

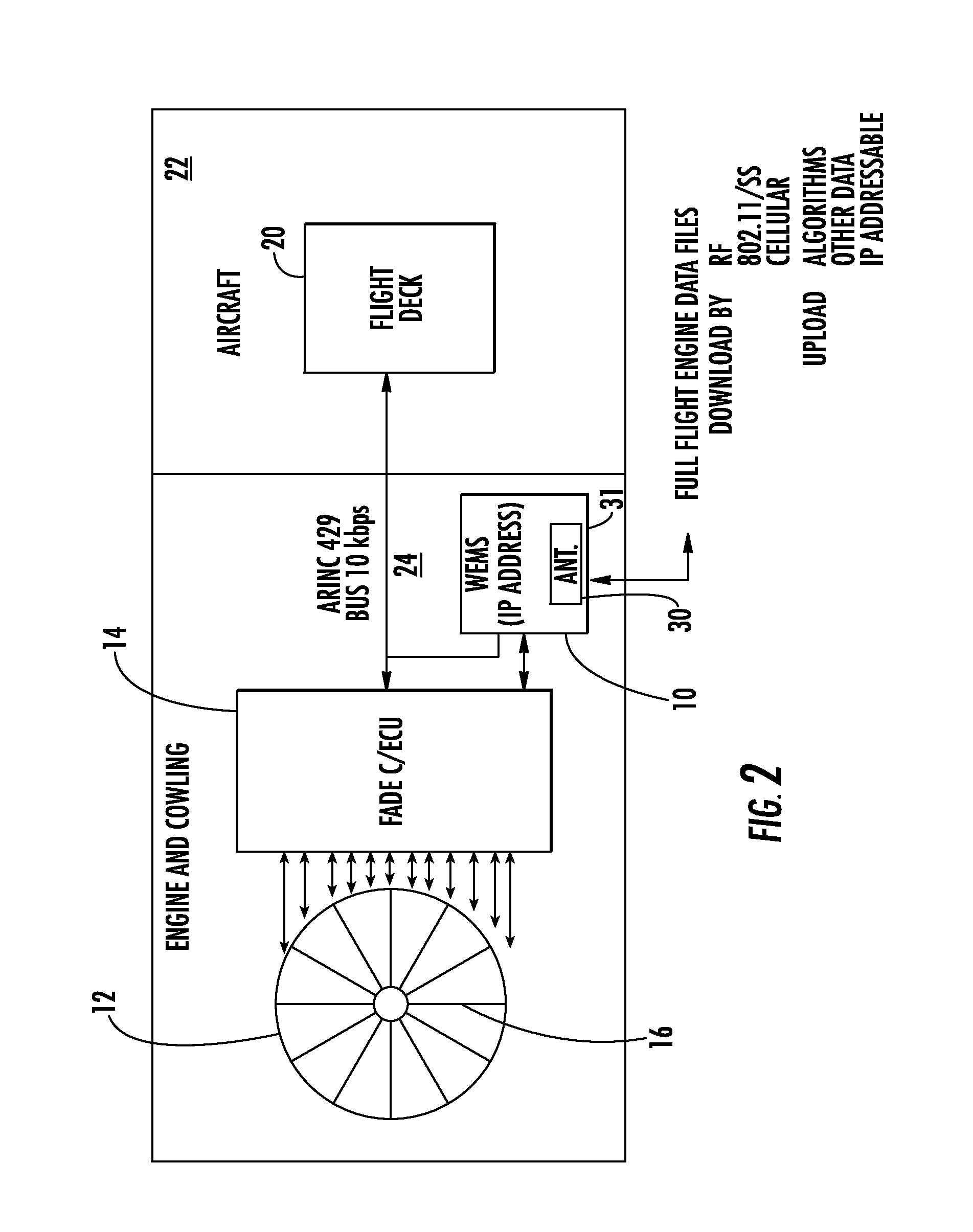

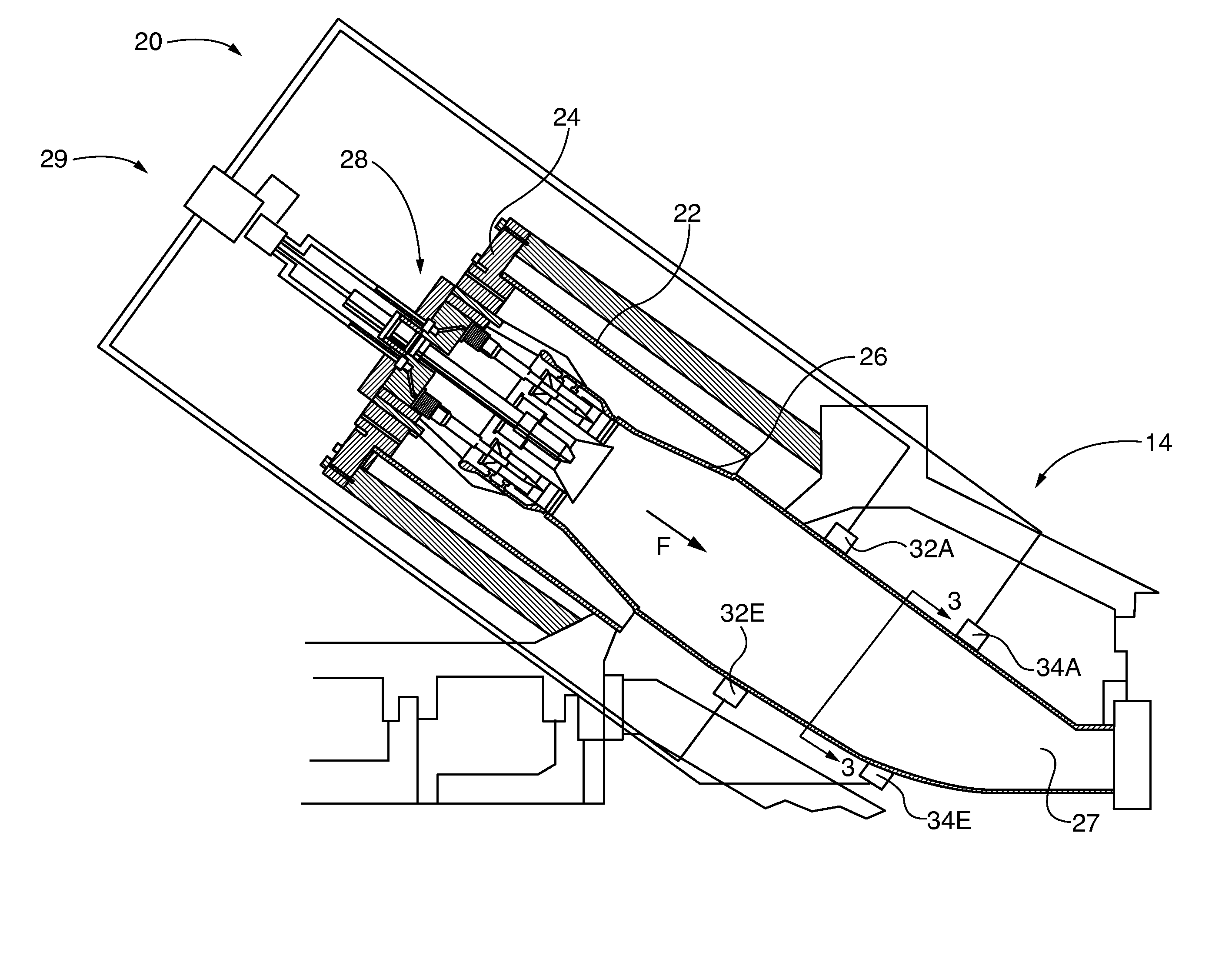

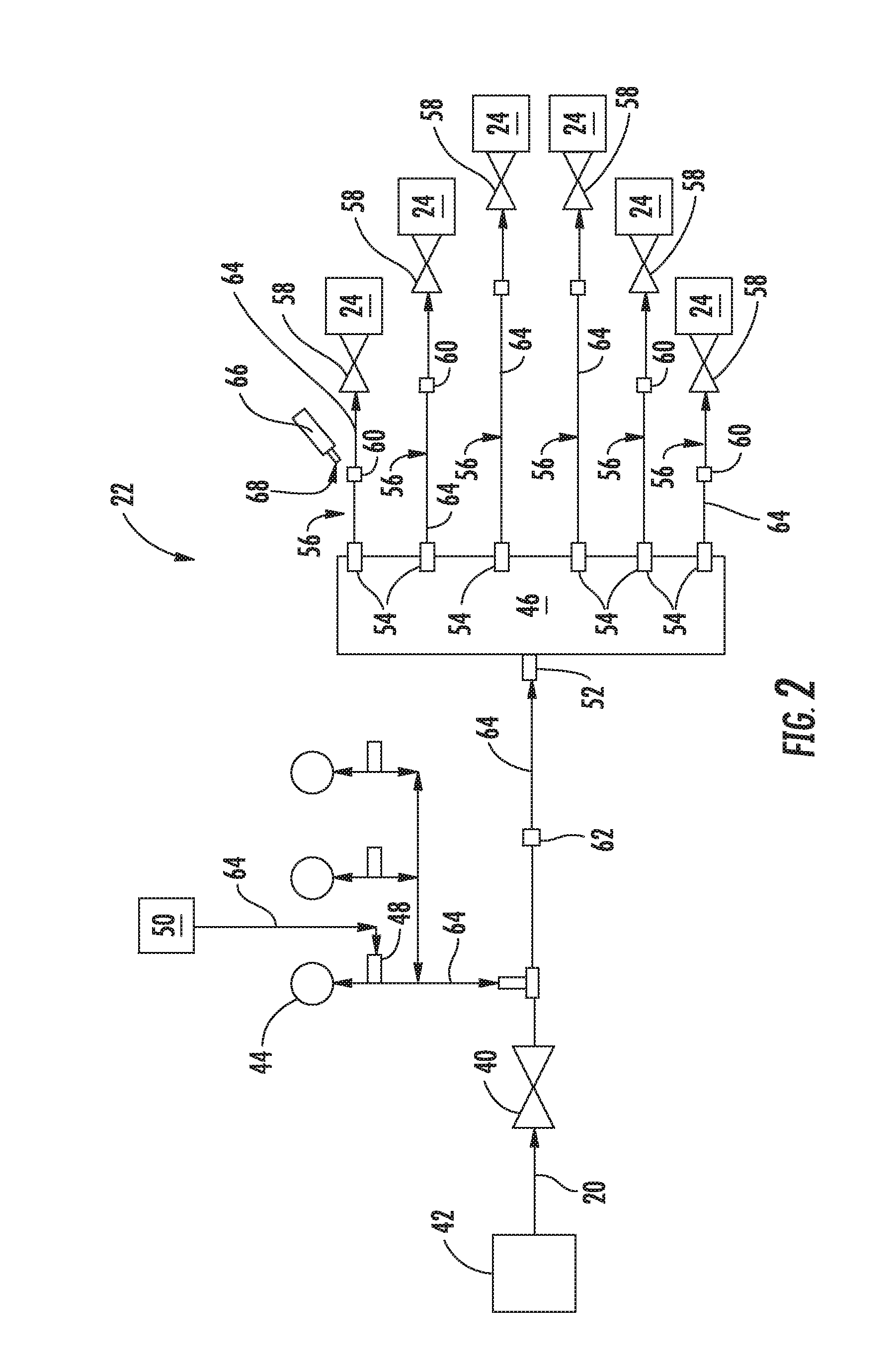

Wireless engine monitoring system and associated engine wireless sensor network

ActiveUS20150330869A1Vehicle testingGas-turbine engine testingWireless sensor networkingMonitoring system

A monitoring system for an aircraft engine includes a plurality of wireless engine sensors that sense engine parameters based on an engine sampling algorithm. The wireless engine sensors receive a new engine sampling algorithm to change the engine parameter sensing and generate engine data based on the new engine sampling algorithm. An engine monitoring module is mounted at the aircraft engine and collects and stores in a memory the engine data and transmits the engine data over a wireless communications signal into the aircraft and receives a new engine sampling algorithm and transmits it to the wireless engine sensors. A wireless LAN is within the aircraft and receives the new engine sampling algorithm from a ground based control center and transmits the new engine sampling algorithm to the engine monitoring module.

Owner:HARRIS CORP

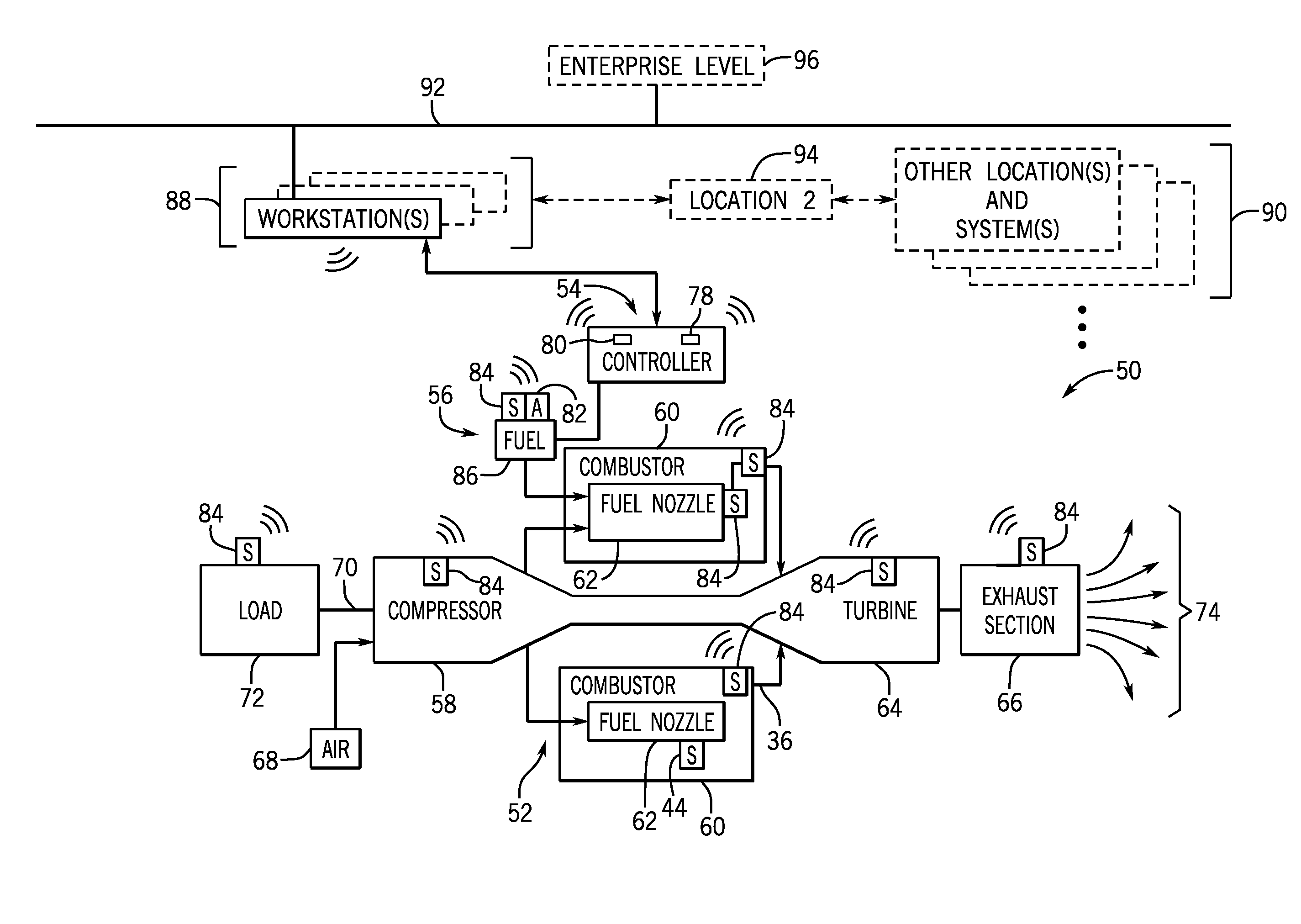

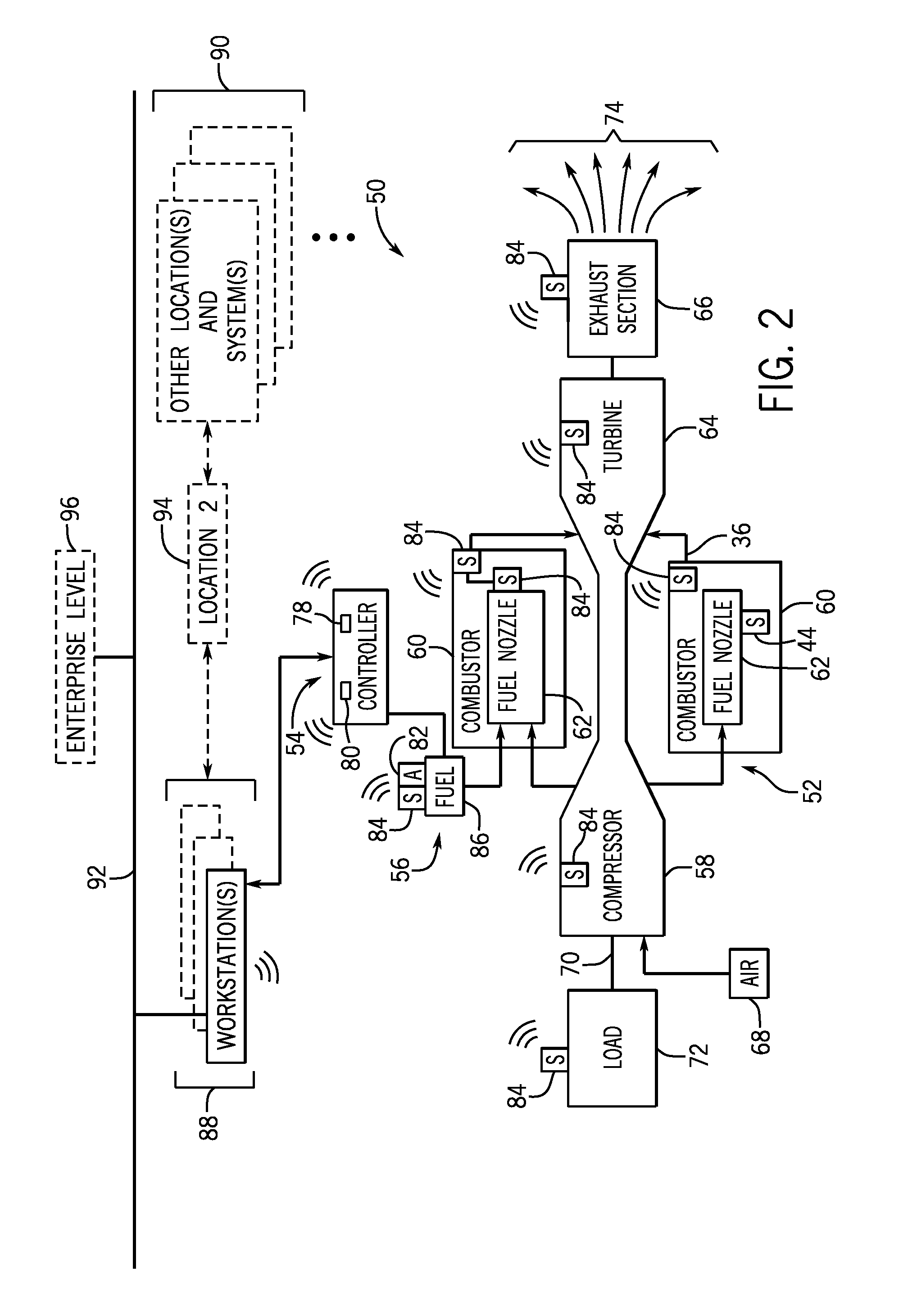

Gas turbine combustor diagnostic system and method

In an embodiment, a method includes performing a turbine combustor diagnostic routine including operating a first turbine combustor of a plurality of turbine combustors at a substantially steady state of combustion; adjusting an operational parameter of the first turbine combustor to cause a change in combustion products produced by the first turbine combustor; identifying a first sensor response of a first subset of a plurality of sensors disposed within or downstream from a turbine fluidly coupled to the turbine combustor, the first sensor response being indicative of the change in the combustion products, and wherein the first subset comprises one or more first sensors; correlating the first subset of sensors with the first turbine combustor; and diagnosing a condition of the first subset of the plurality of sensors, the first turbine combustor, or a combination thereof, based on the first sensor response.

Owner:GENERAL ELECTRIC CO +1

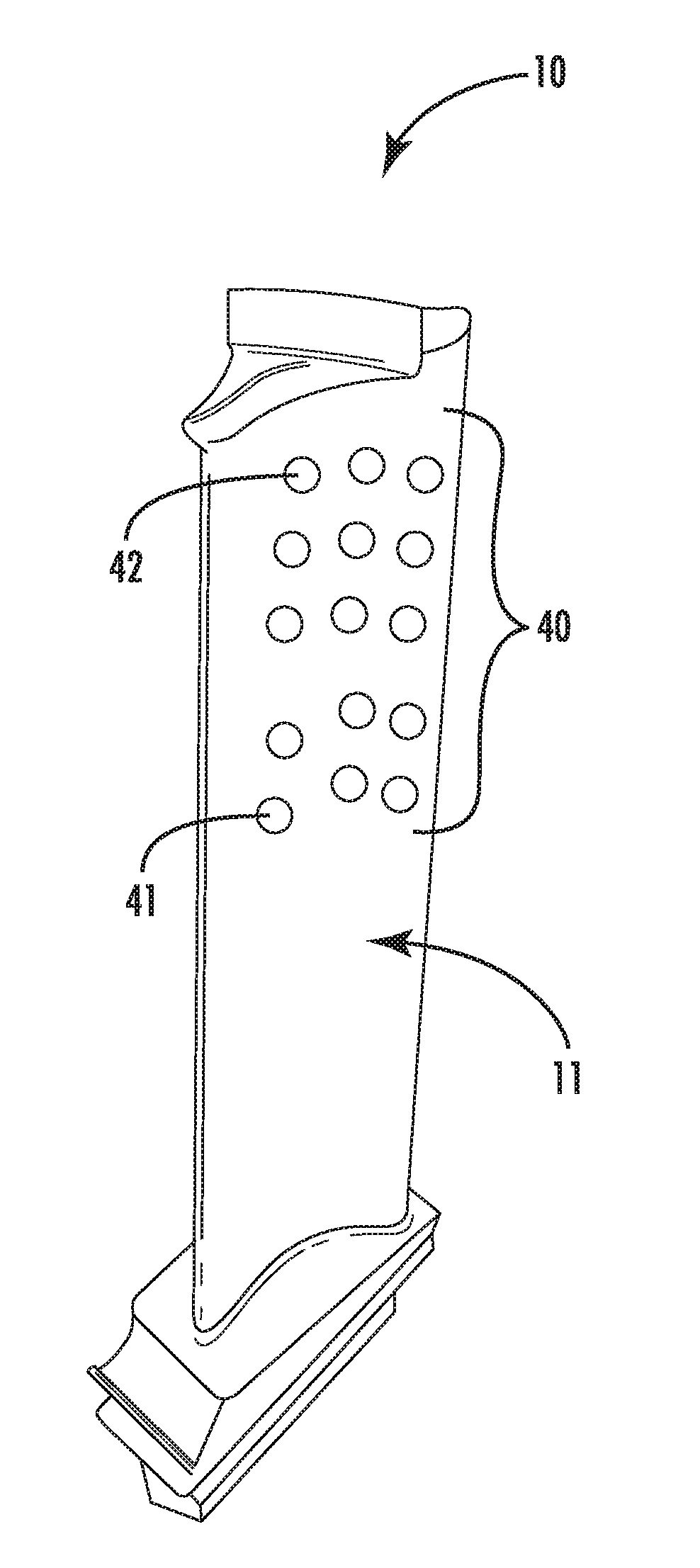

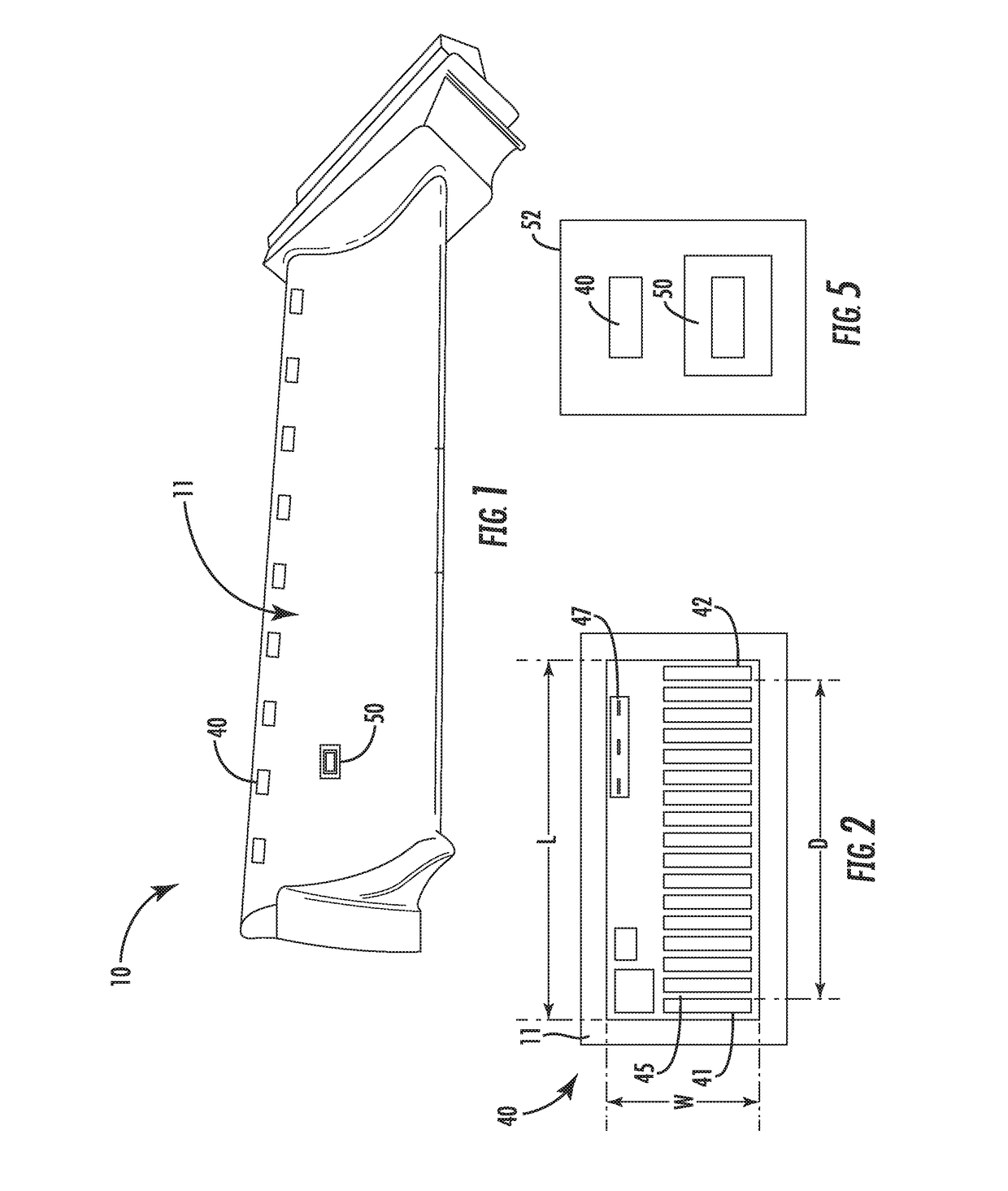

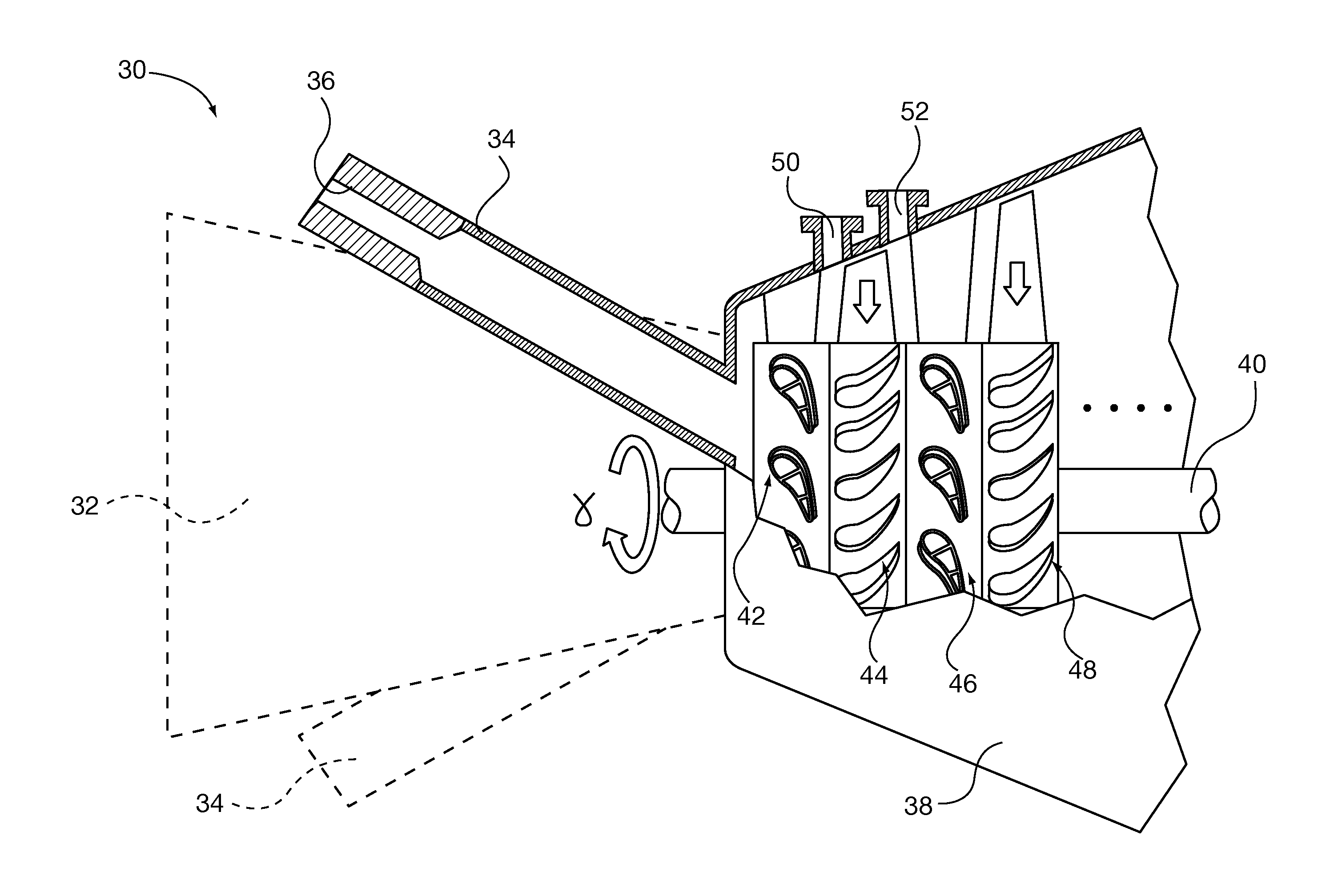

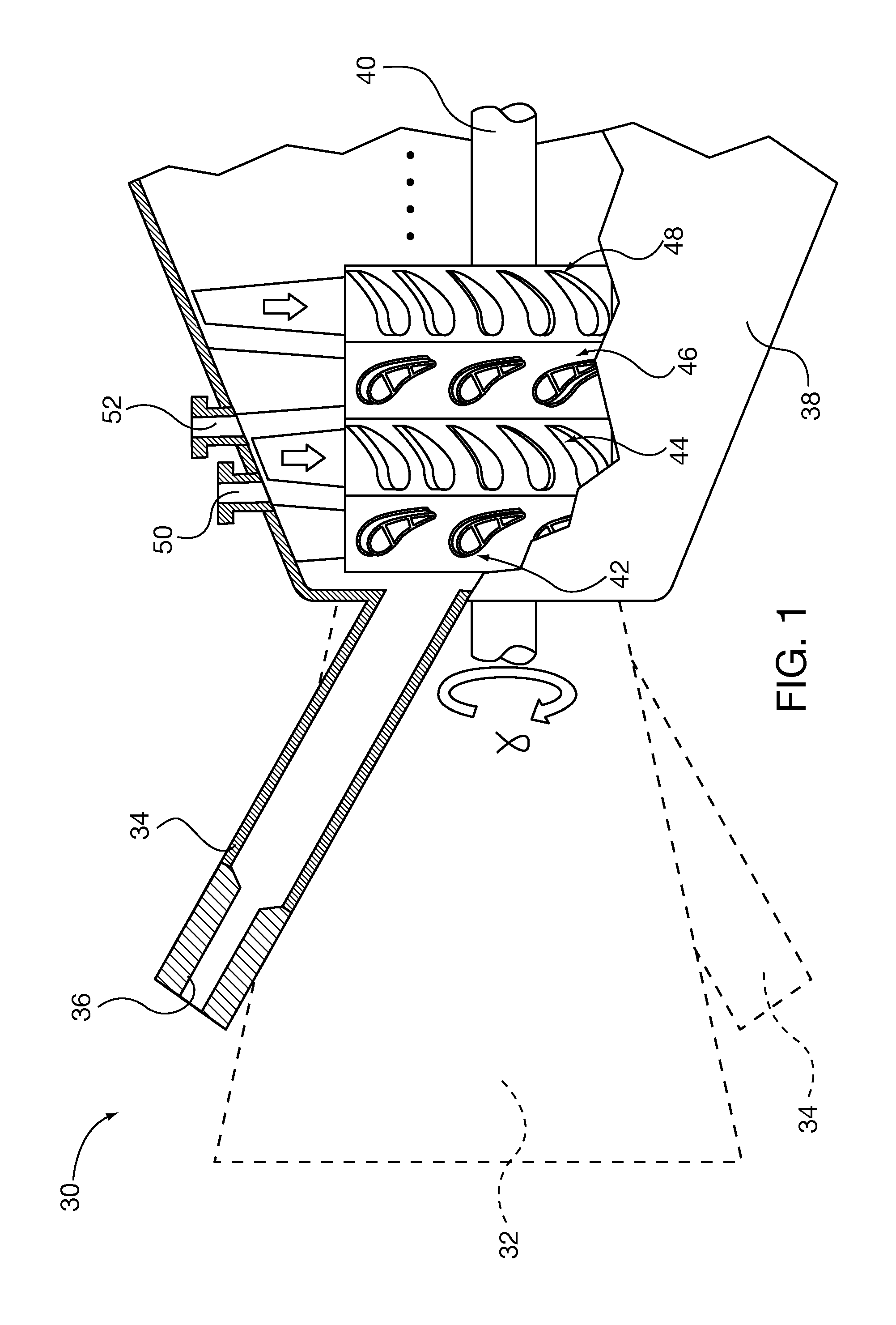

Systems and methods for evaluating component strain

A system and related methods for evaluating a component using a reference feature and a replicate of the reference feature. The component has an exterior surface with a reference feature thereon. The method includes determining an initial condition of the reference feature, subjecting the component to at least one duty cycle after determining the initial condition, determining a subsequent condition of the reference feature after the at least one duty cycle while the component is in a service position, and forming a replicate of the reference feature while the reference feature is in one of the initial condition or the subsequent condition. One of the initial condition or the subsequent condition may be determined based on the replicate of the reference feature.

Owner:GENERAL ELECTRIC CO

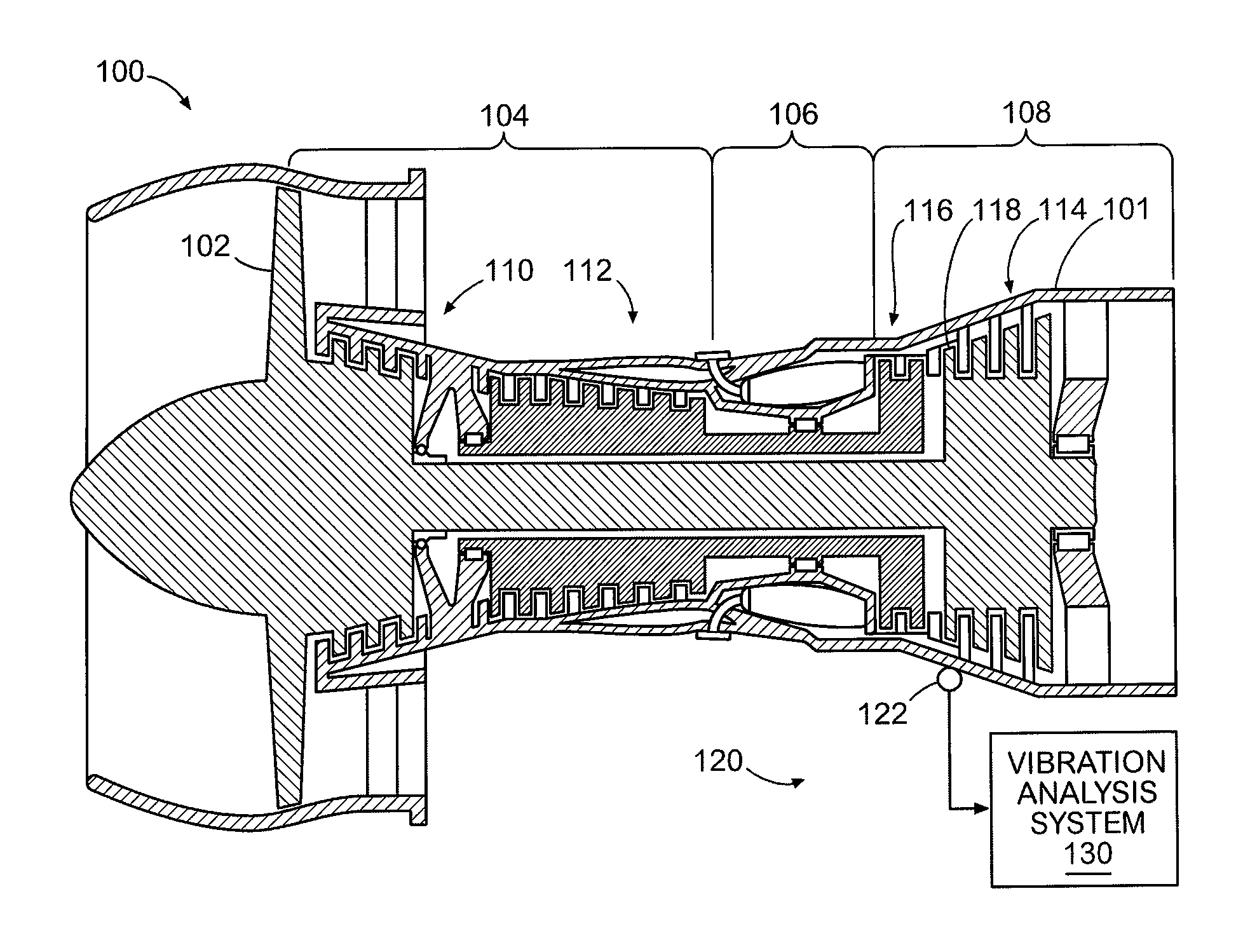

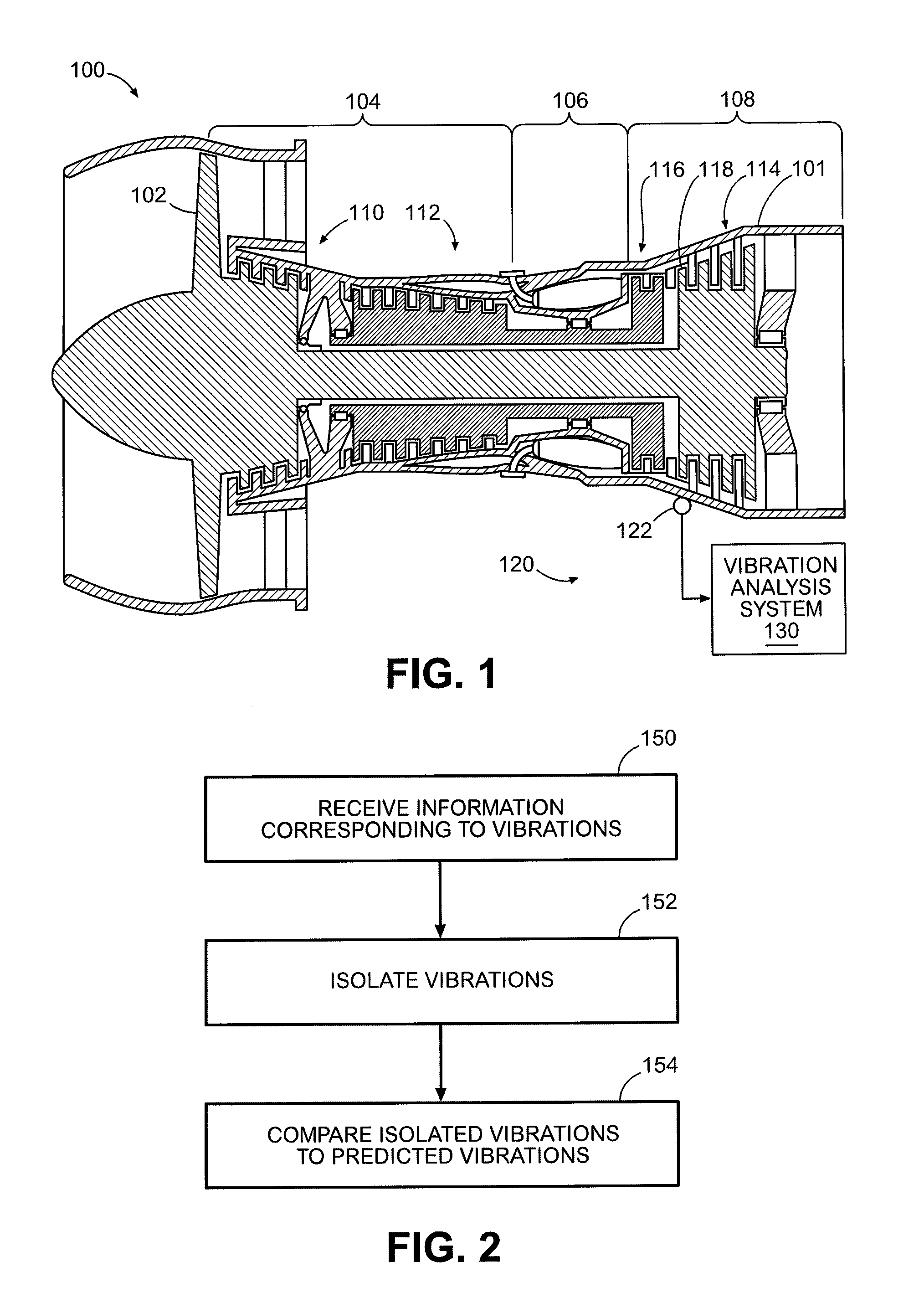

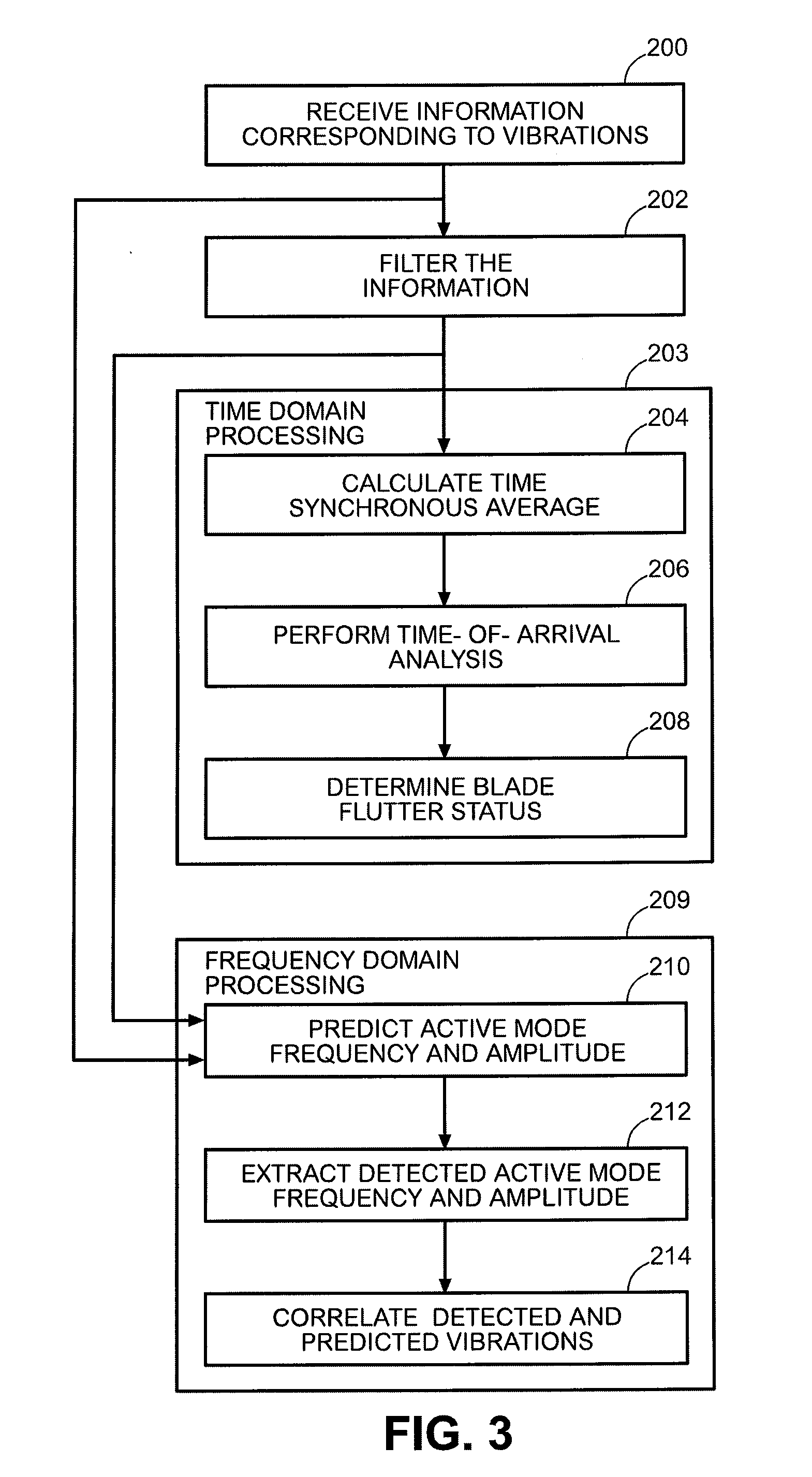

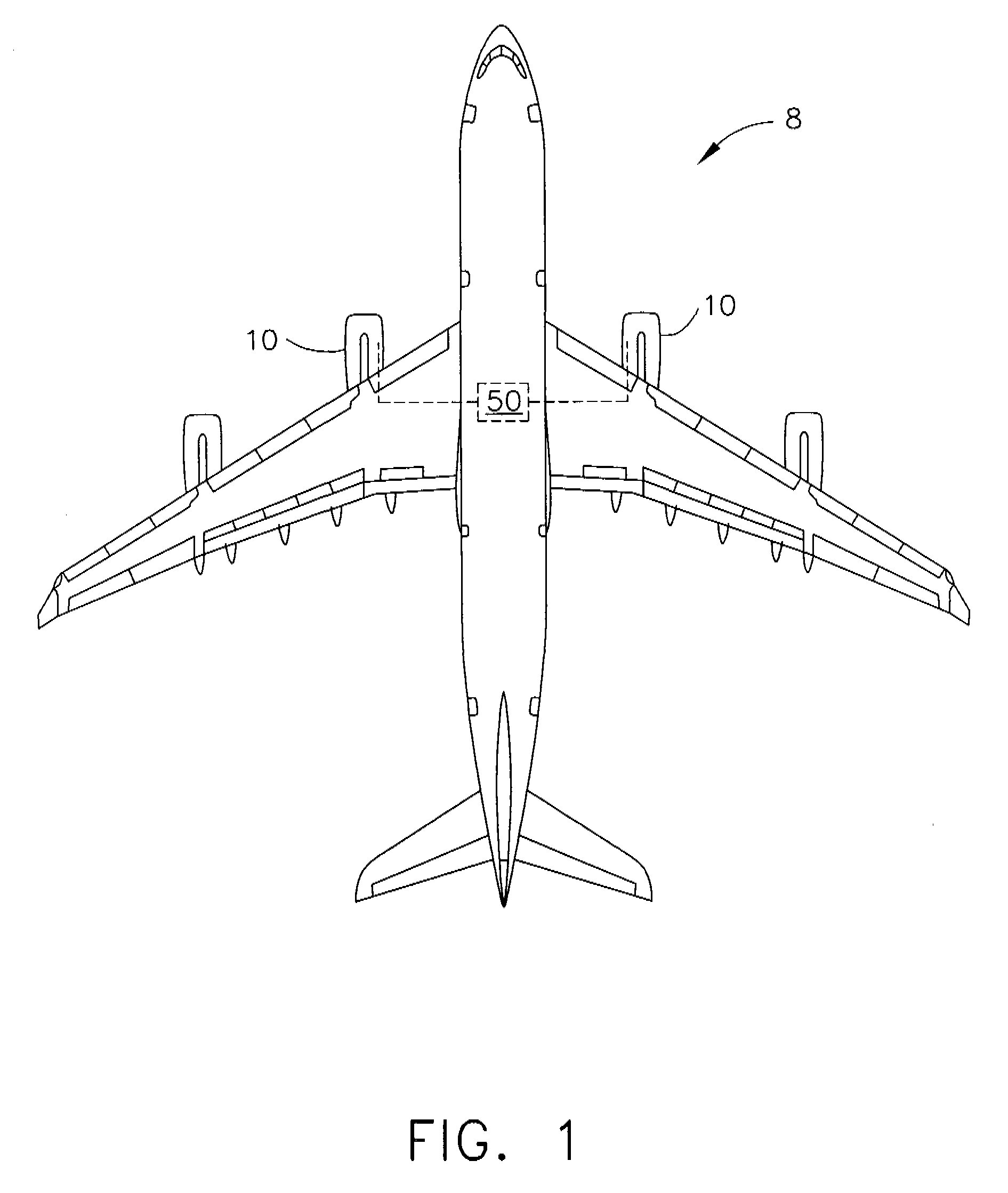

Gas Turbine Engine Systems and Methods Involving Vibration Monitoring

InactiveUS20090301055A1Vibration measurement in solidsMachine part testingMonitoring methodsGas turbines

Gas turbine engine systems and methods involving vibration monitoring are provided. In this regard, a representative vibration monitoring method for a gas turbine engine includes: receiving information corresponding to detected vibrations of a gas turbine engine; isolating vibrations attributable to rotating blades of the gas turbine engine from the detected vibrations; and comparing the isolated vibrations to information corresponding to predicted vibrations of the rotating blades.

Owner:UNITED TECH CORP

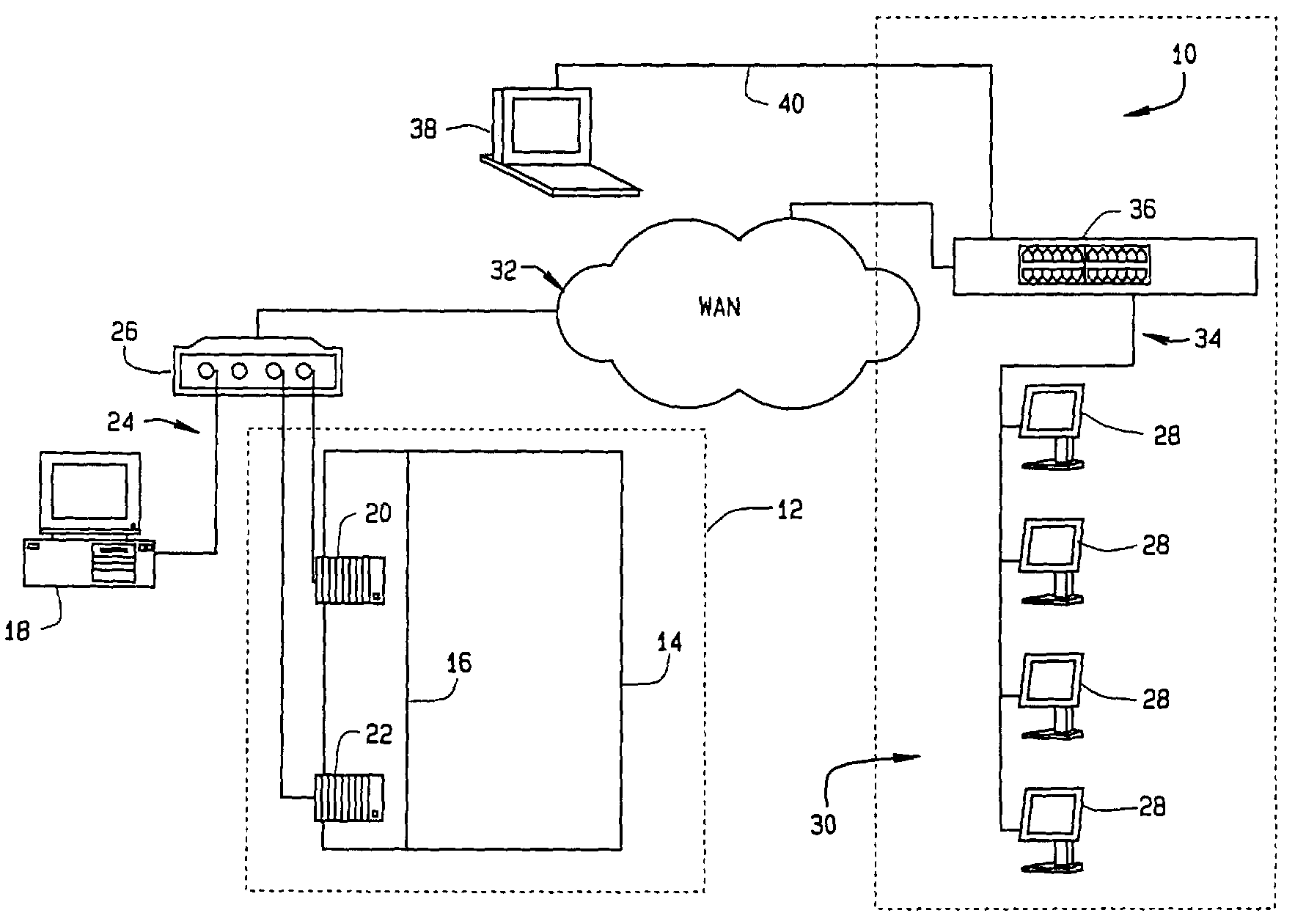

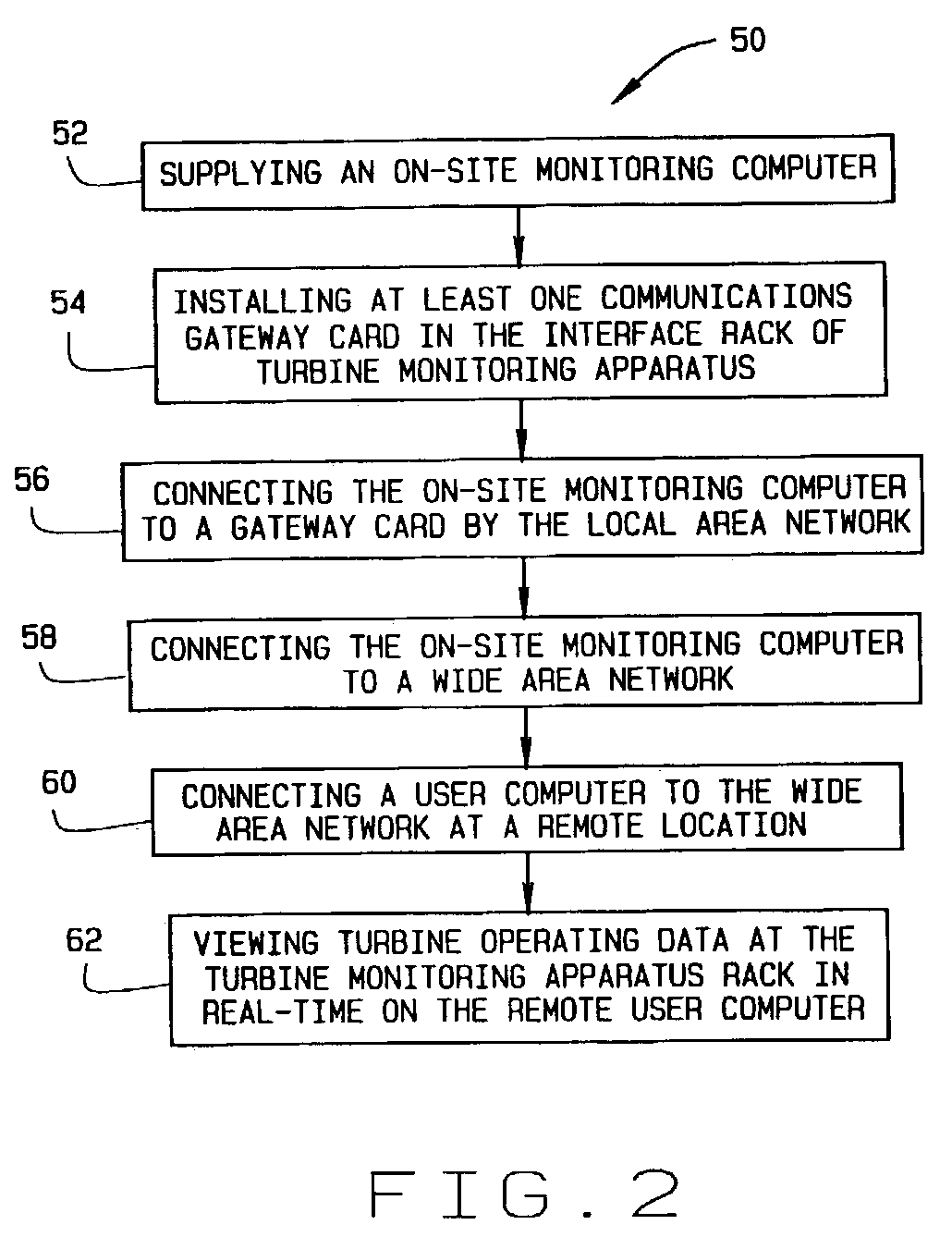

System and method for real-time viewing of monitoring system data

ActiveUS7299279B2Optimize dataAnalogue computers for vehiclesGas-turbine engine testingSite monitoringProgrammable logic controller

A method of viewing data of a turbine monitoring system from a remote location is provided. The turbine monitoring system includes a programmable logic controller having an interface rack. In an exemplary embodiment, the method includes supplying an on-site monitoring computer, installing at least one communications gateway card in the interface rack, connecting the on-site monitoring computer to the at least one gateway card by a local area network, and connecting the on-site monitoring computer also to a wide area network.

Owner:BAKER HUGHES INC

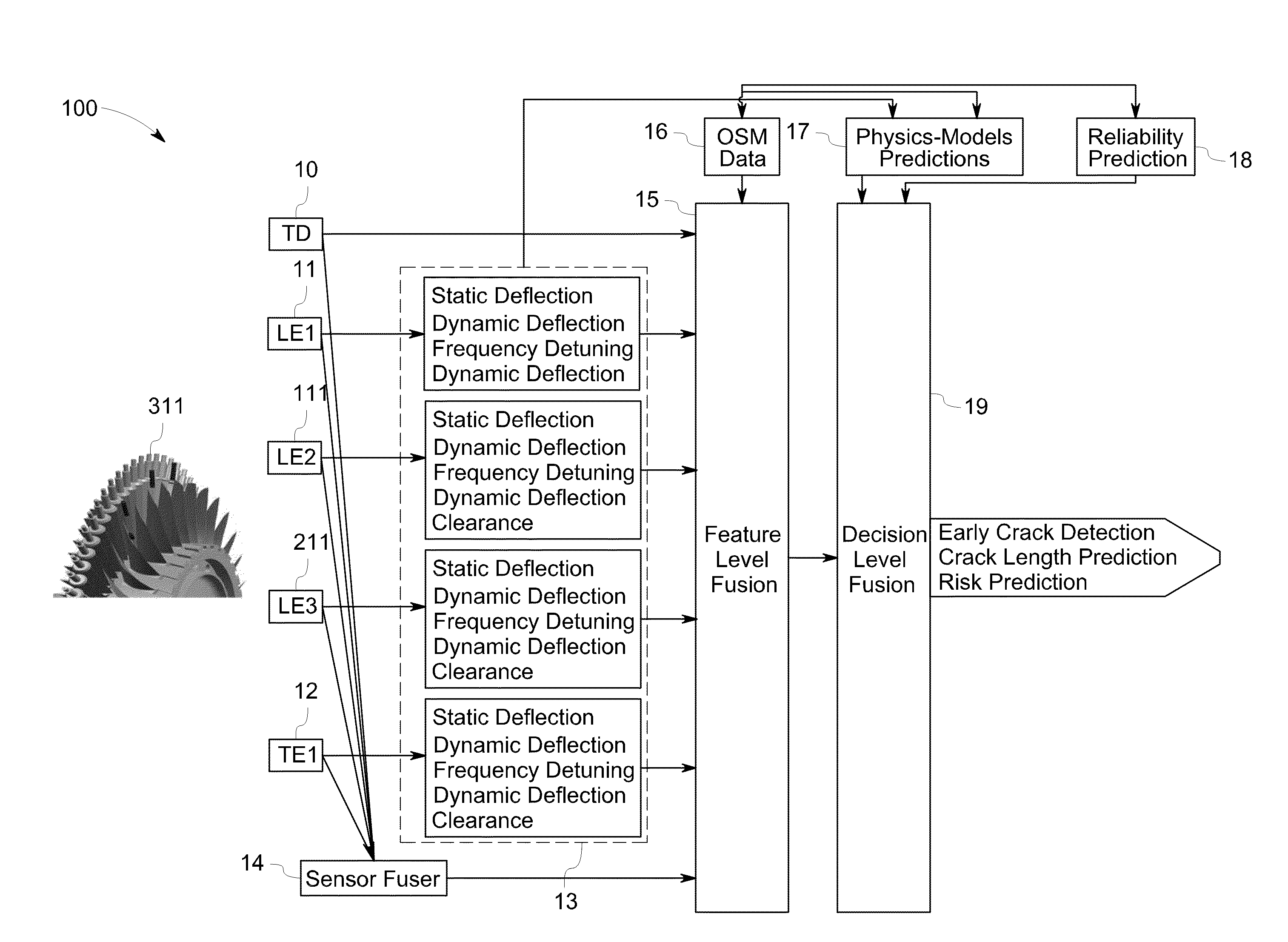

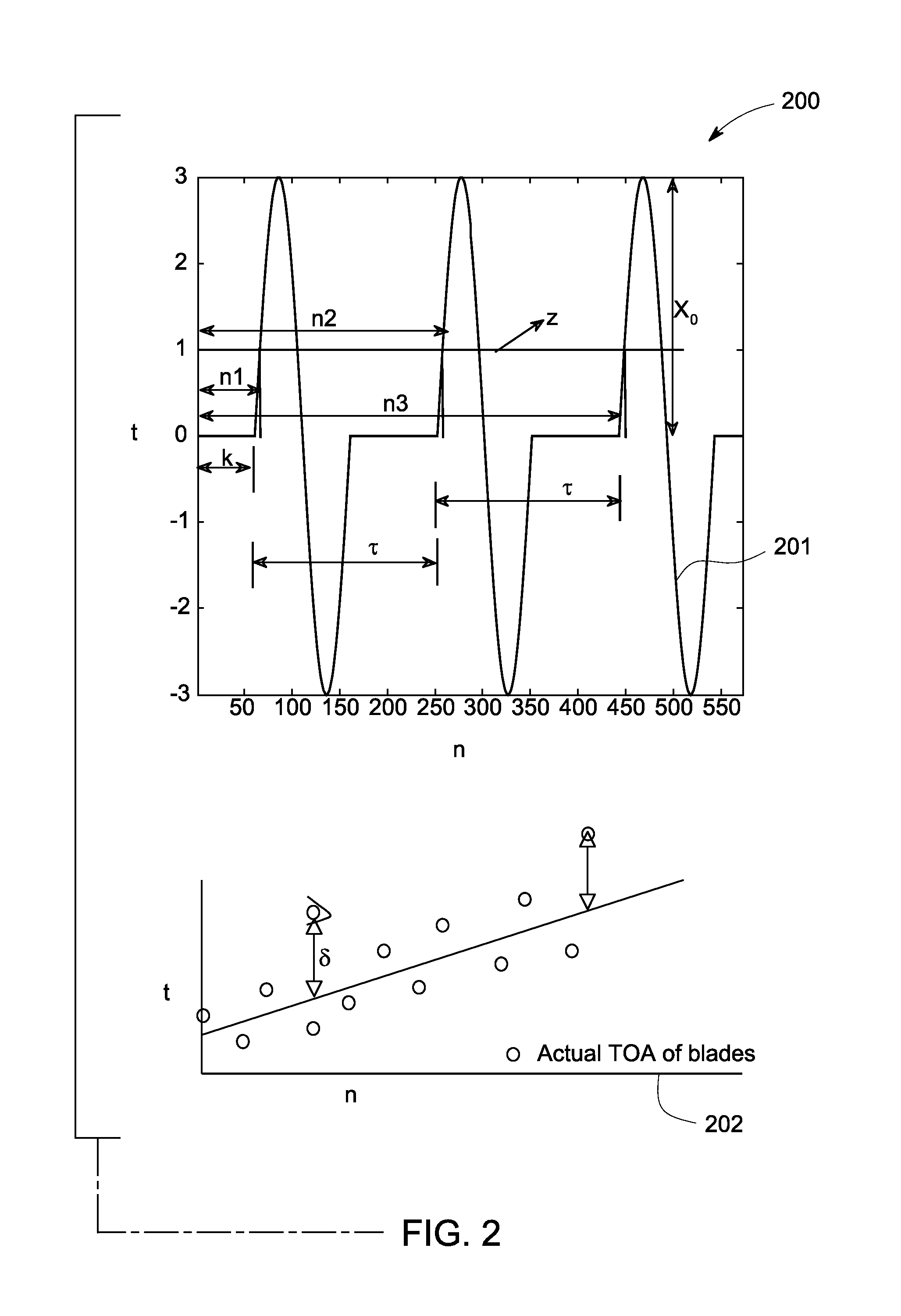

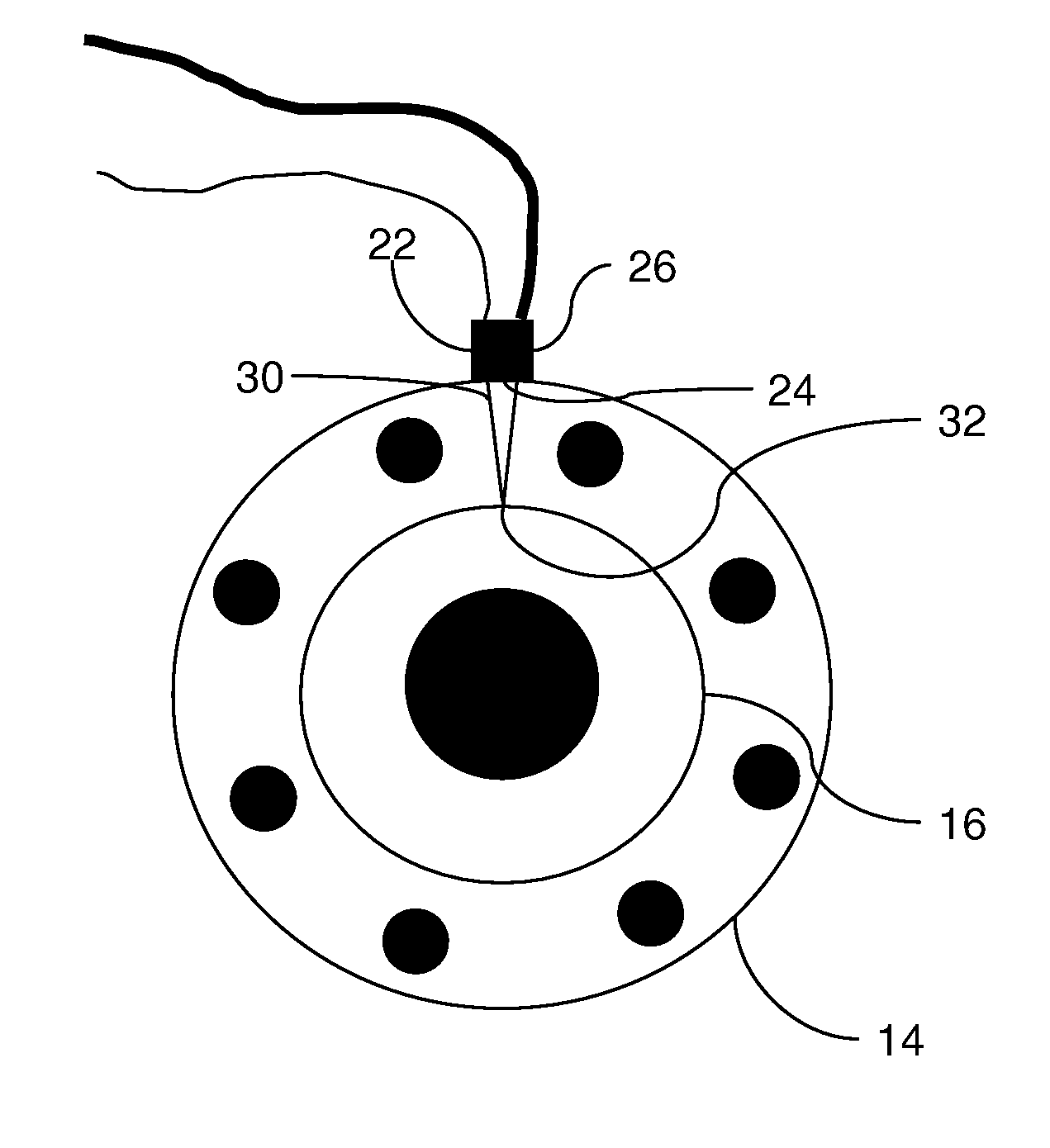

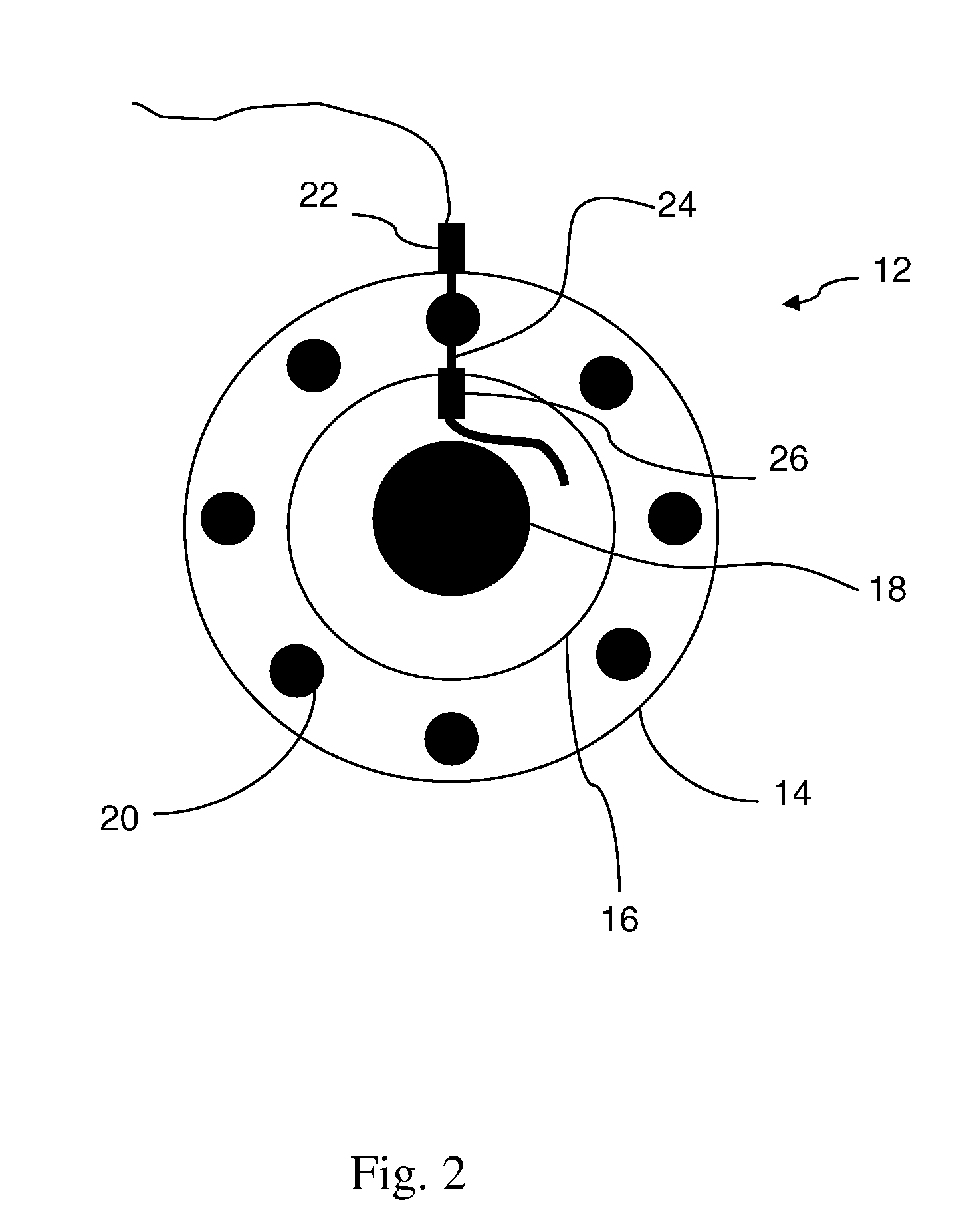

System and method for rotor blade health monitoring

A system for rotor blade health monitoring include time of arrival (TOA) sensors and a controller comprising a processor configured for obtaining TOA signals indicative of times of arrival of rotating rotor blades from the respective TOA sensors and for determining initial features from the TOA signals; and a feature level fuser configured for fusing the initial features received from the processor for use in evaluating health of the rotating rotor blades.

Owner:GENERAL ELECTRIC CO

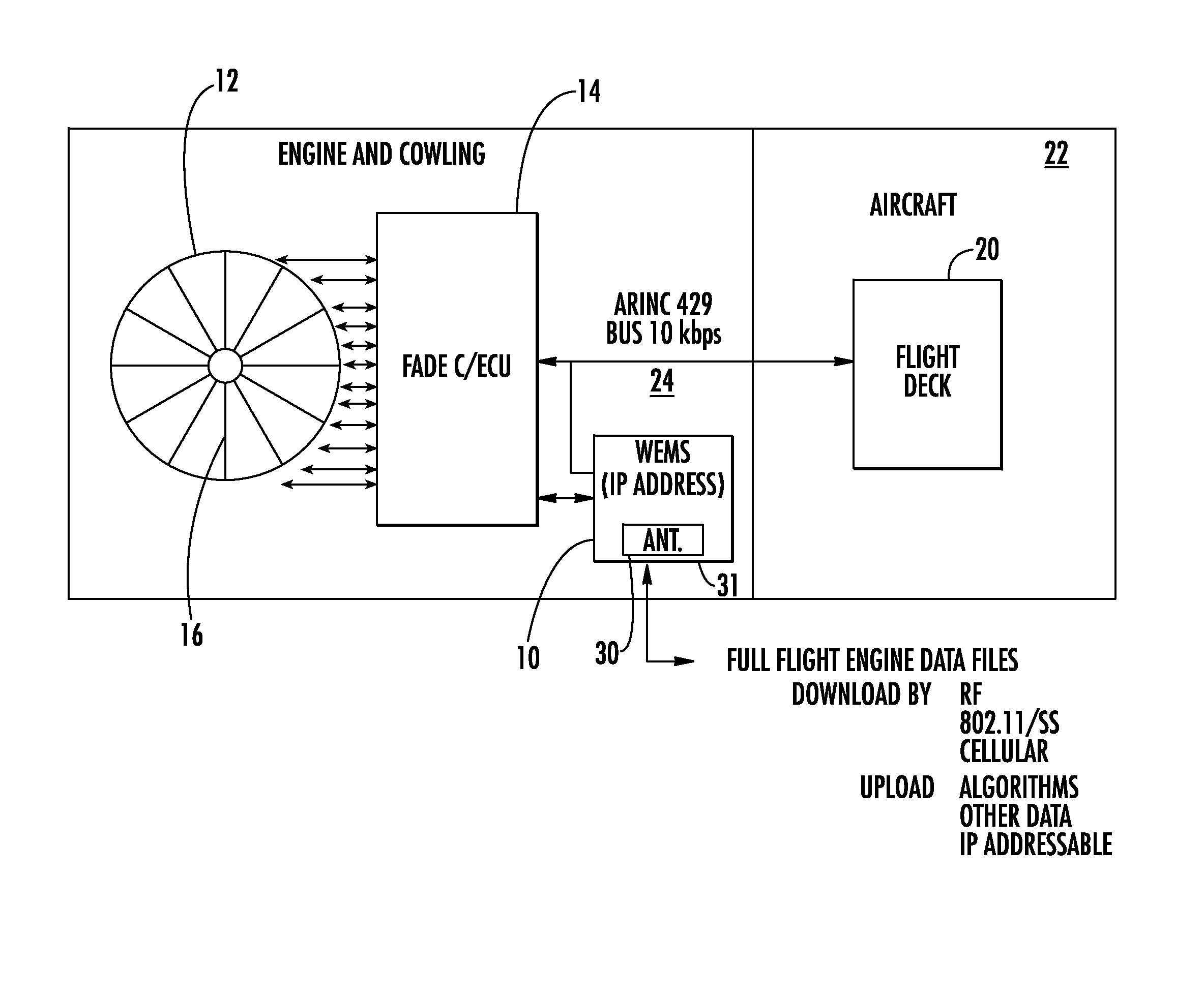

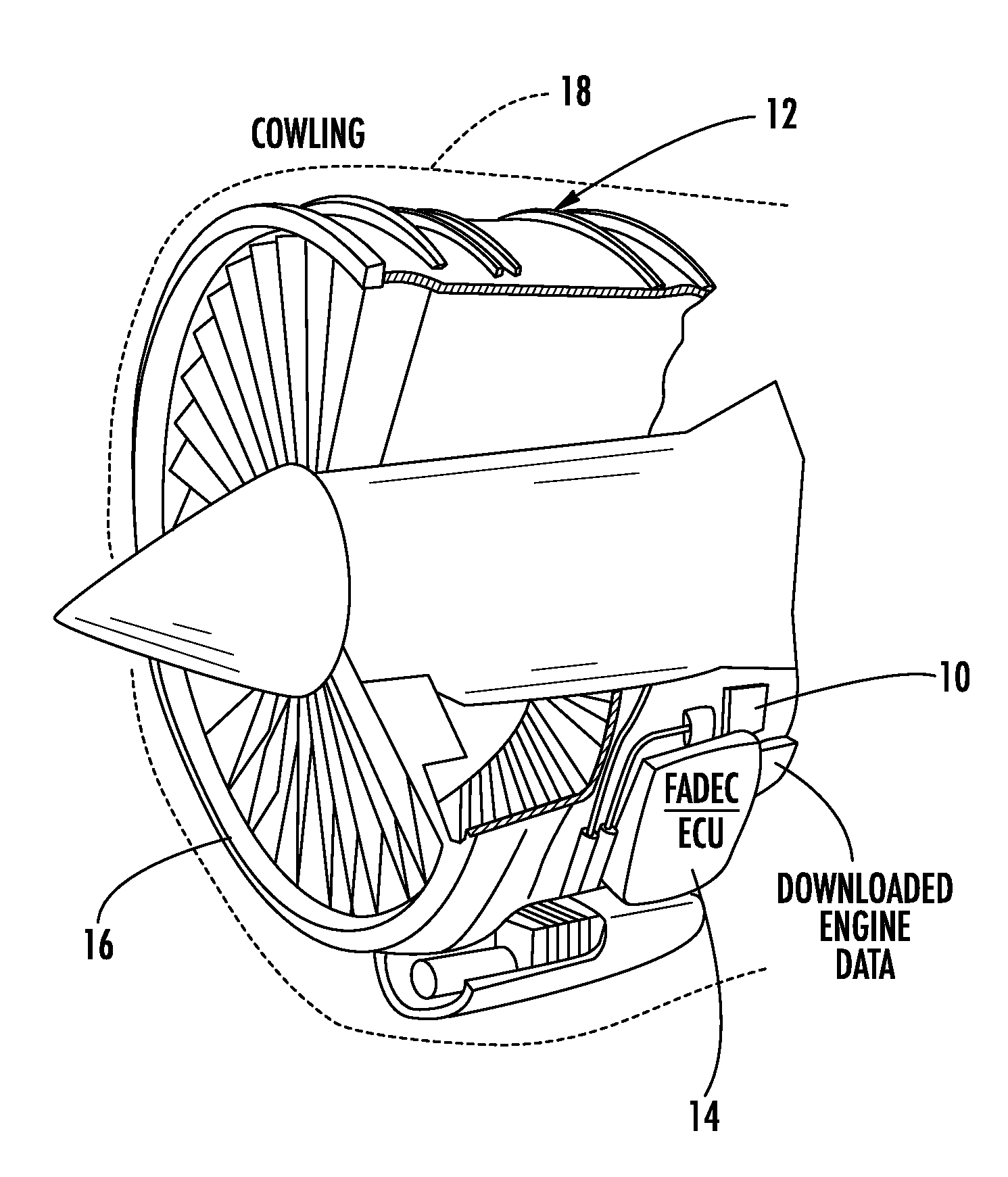

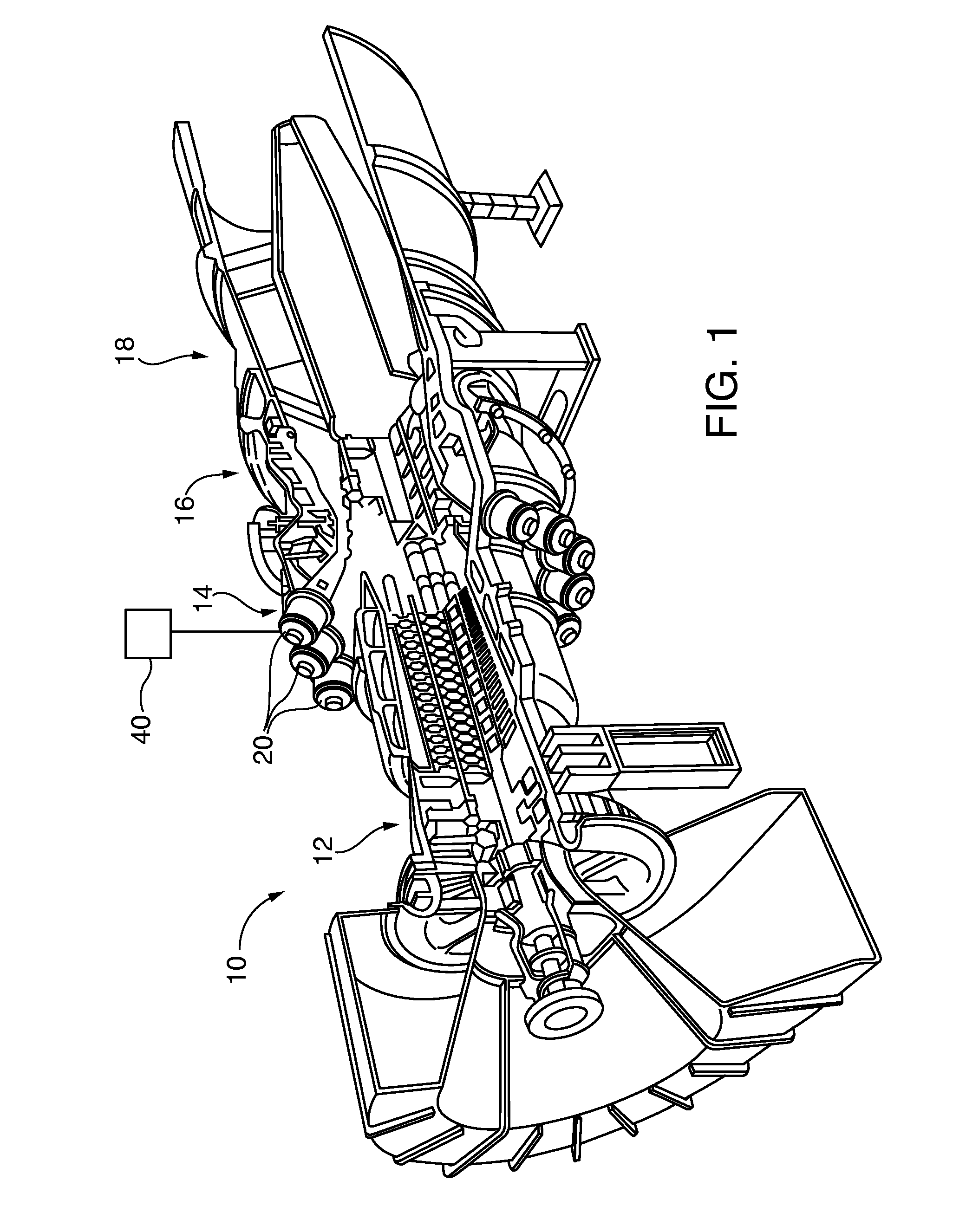

Wireless engine monitoring system and associated engine wireless sensor network

ActiveUS20130332011A1Aircraft health monitoring devicesGas-turbine engine testingTransceiverWireless sensor networking

A plurality of wireless engine sensors each includes a sensing circuit that senses an engine parameter as engine data. A radio transceiver receives and transmits the engine data regarding the sensed engine parameters. An engine monitoring module includes a housing configured to be mounted at the aircraft engine. A sensor receiver is mounted within the housing and receives the engine data from the wireless engine sensors. A first wireless transmitter is carried by the housing. A memory is carried by the housing and a processor is carried by the housing and coupled to the memory and the first wireless transmitter and configured to collect and store in the memory engine data related to engine parameters sensed during operation of the aircraft engine by the plurality of wireless engine sensors and transmit the engine data via the first wireless transmitter.

Owner:HARRIS CORP

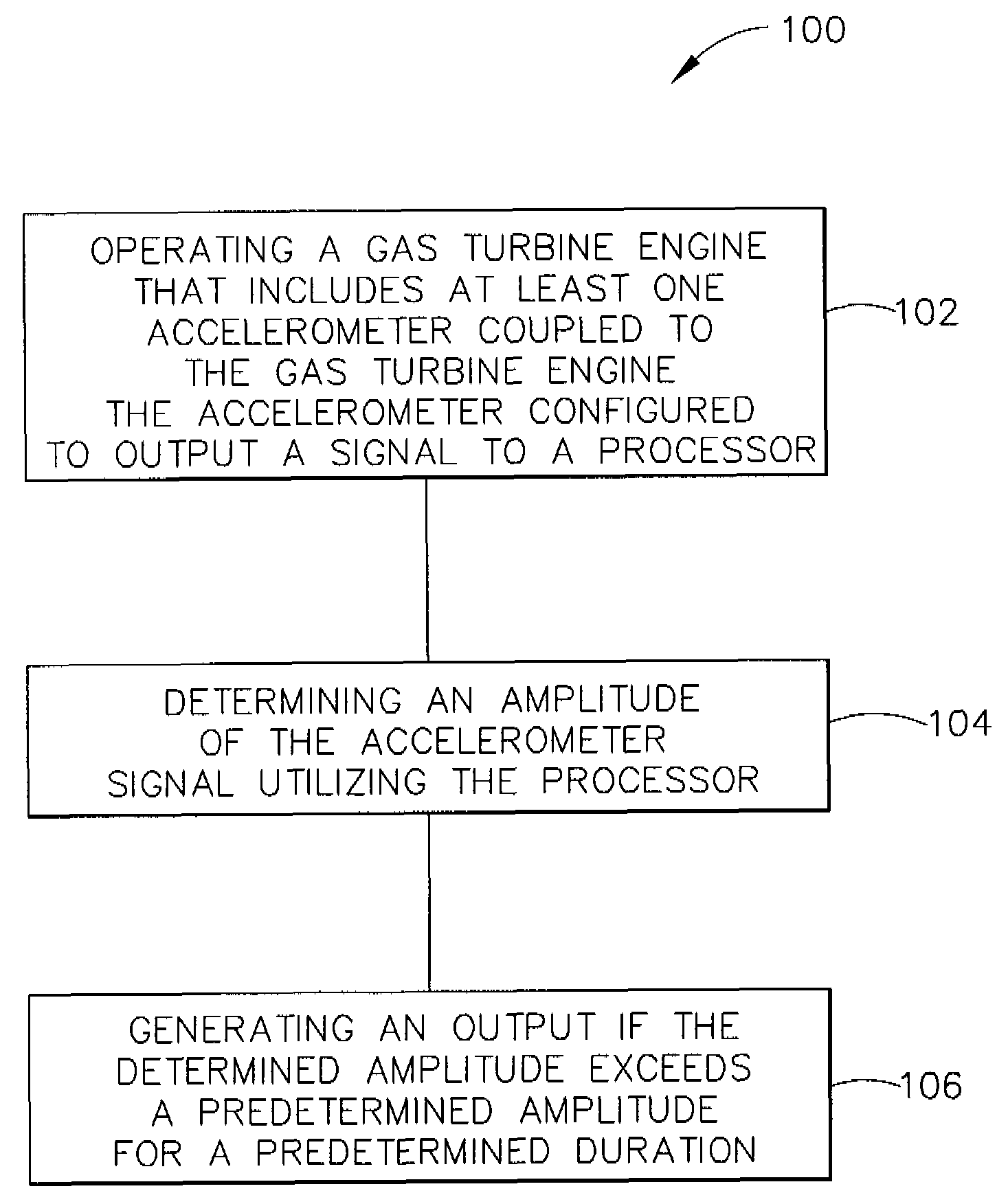

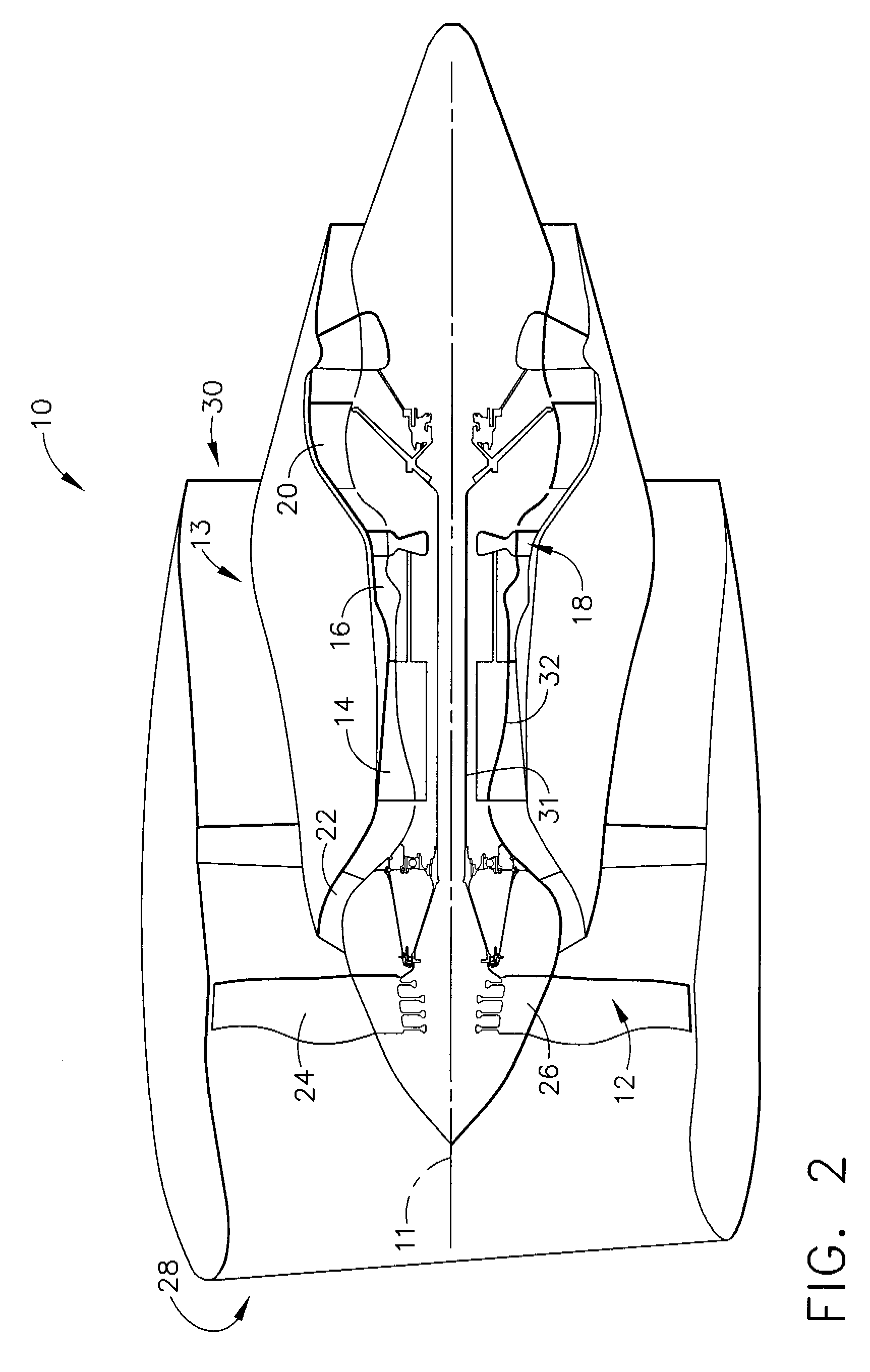

Method and apparatus for operating a gas turbine engine

InactiveUS20070250245A1Easy to identifyVibration measurement in solidsAnalogue computers for vehiclesVibration amplitudeTurbine

A method for operating a gas turbine engine includes coupling at least one sensor within the gas turbine engine to transmit a signal indicative of a vibration level of a rotor assembly within the gas turbine engine, detecting the vibration level of the rotor assembly based on the signal transmitted from the at least one sensor, comparing the detected vibration level to a predetermined vibration threshold, and generating an output if the detected vibration amplitude exceeds the threshold amplitude for a predetermined duration to facilitate identifying a gas turbine engine impulse event.

Owner:GENERAL ELECTRIC CO

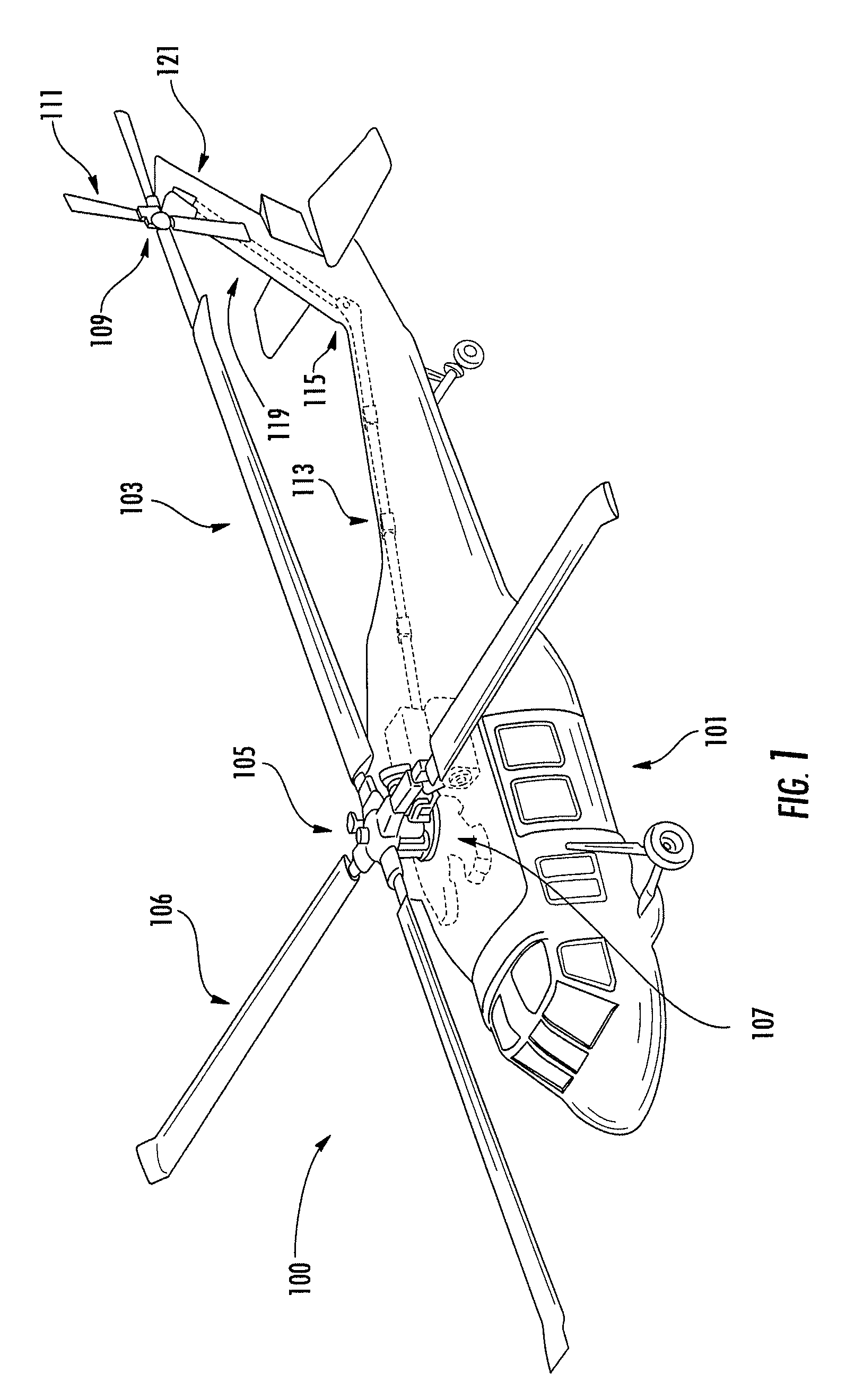

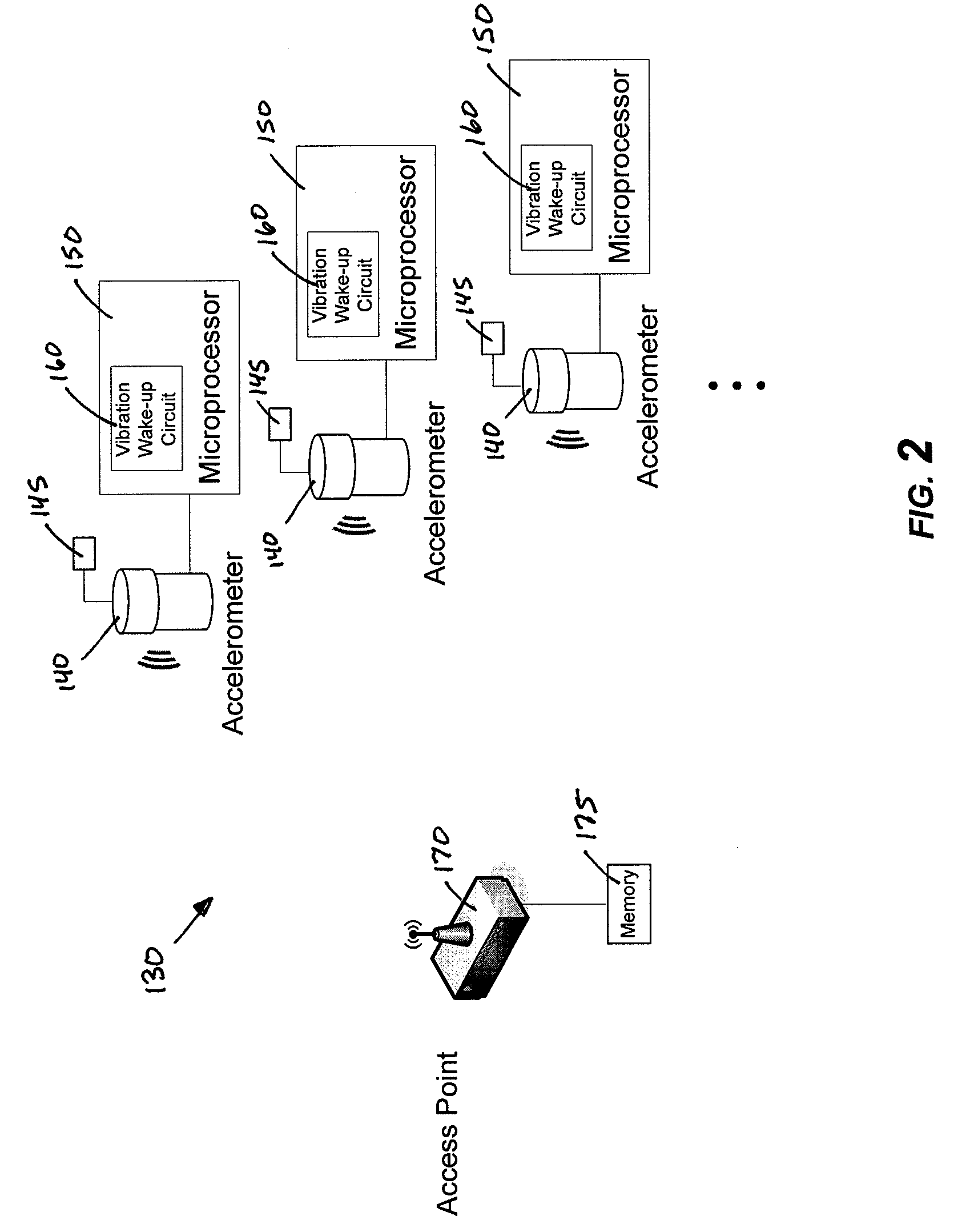

Vehicle health and usage monitoring system and method

ActiveUS20090216398A1Reducing unscheduled downtimeMitigate catastrophic failureVehicle testingGas-turbine engine testingLine sensorHealth and usage monitoring systems

A health and usage monitoring system (HUMS) and method for monitoring the health and / or usage of one or more components of a vehicle. In various embodiments, the present invention uses a plurality of wireless sensors configured, when activated by a vibration of the vehicle, to monitor one or more components of the vehicle and to communicate health and / or usage data of the one or more components of the vehicle to a data access point. The data access point may relay real-time health and / or usage data to an operator of the vehicle, or the health and / or usage data may accessed later. Such a system allows critical components of the vehicle to be monitored so as to reduce failures, and so that repairs to, or replacements of, the critical components of the vehicle may be planned, thus reducing unscheduled downtime.

Owner:SIMMONDS PRECISION PRODS

Method and Apparatus for Spectroscopic Measurements in the Combustion Zone of a Gas Turbine Engine

ActiveUS20080289342A1Improve reflectivityAffect engine performanceGas-turbine engine testingEngine fuctionsLight beamEngineering

A method for measuring combustion parameters within a combustion zone of a gas turbine engine, the combustion zone being defined between an inner and outer casing. The method comprises transmitting a beam from a transmit optic optically coupled to a bore in the outer casing off a portion of the inner casing and receiving a portion of the beam reflected off the inner casing with a receiving optic optically coupled to a bore in the outer casing. An apparatus for practicing the method comprises a laser generating a beam and a transmitting / receiving optics pair, the transmitting / receiving optics pair being configured for operative association with a port in an outer casing of a gas turbine engine, whereby the transmitting / receiving optics are in optical communication by reflecting the beam off a portion of an inner casing.

Owner:ONPOINT TECHNOLOGIES LLC

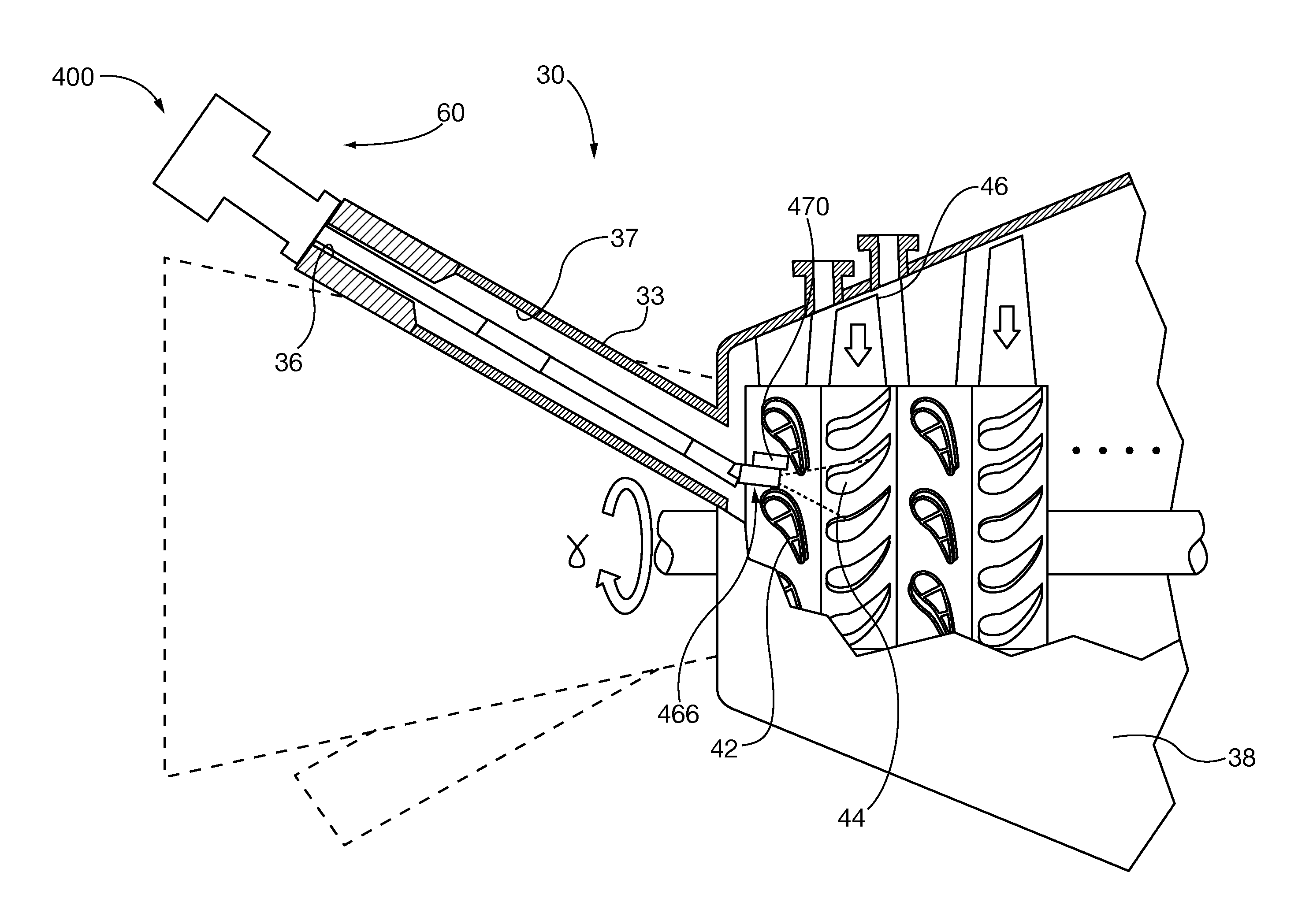

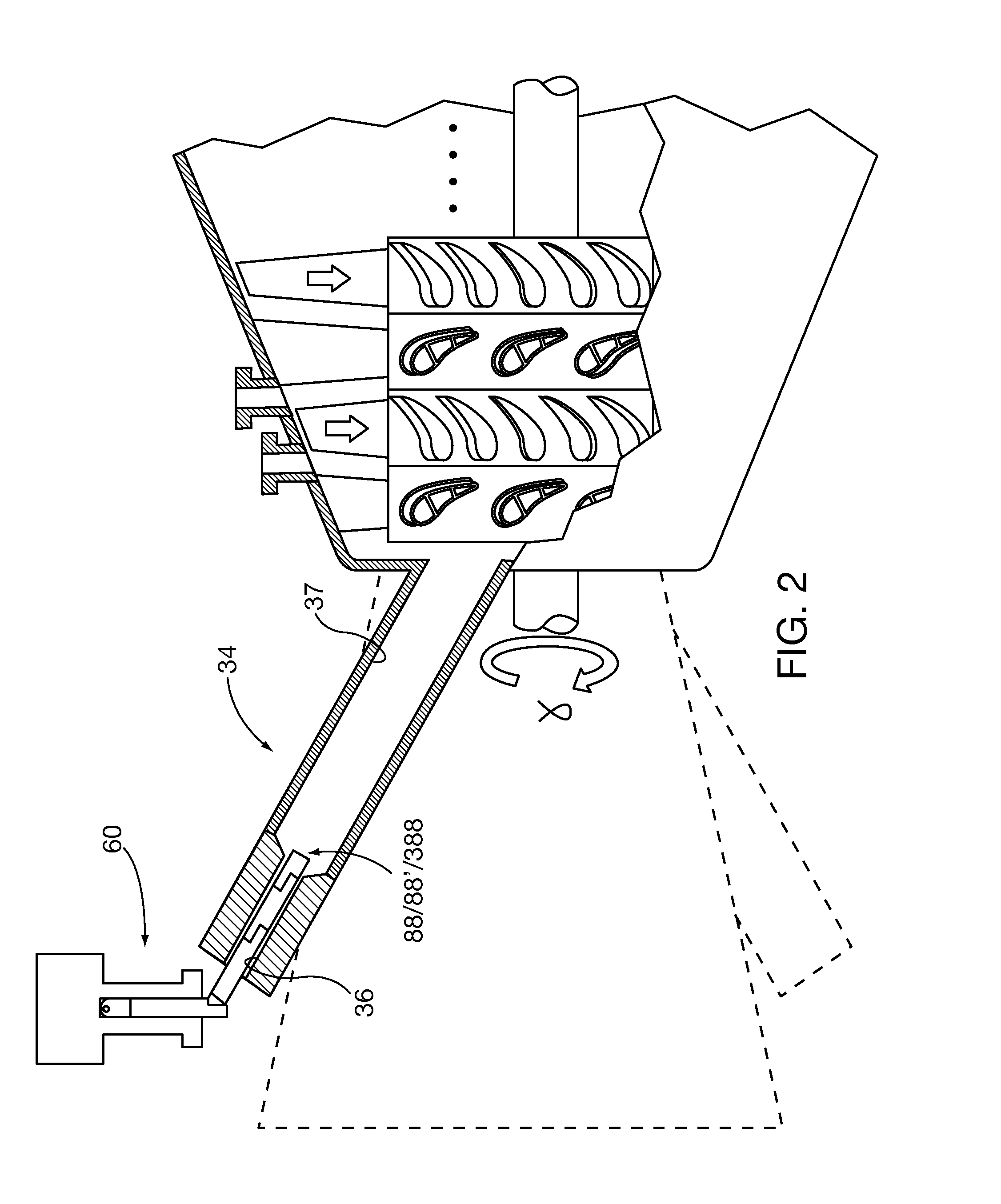

Method and system for surface profile inspection of off-line industrial gas turbines and other power generation machinery

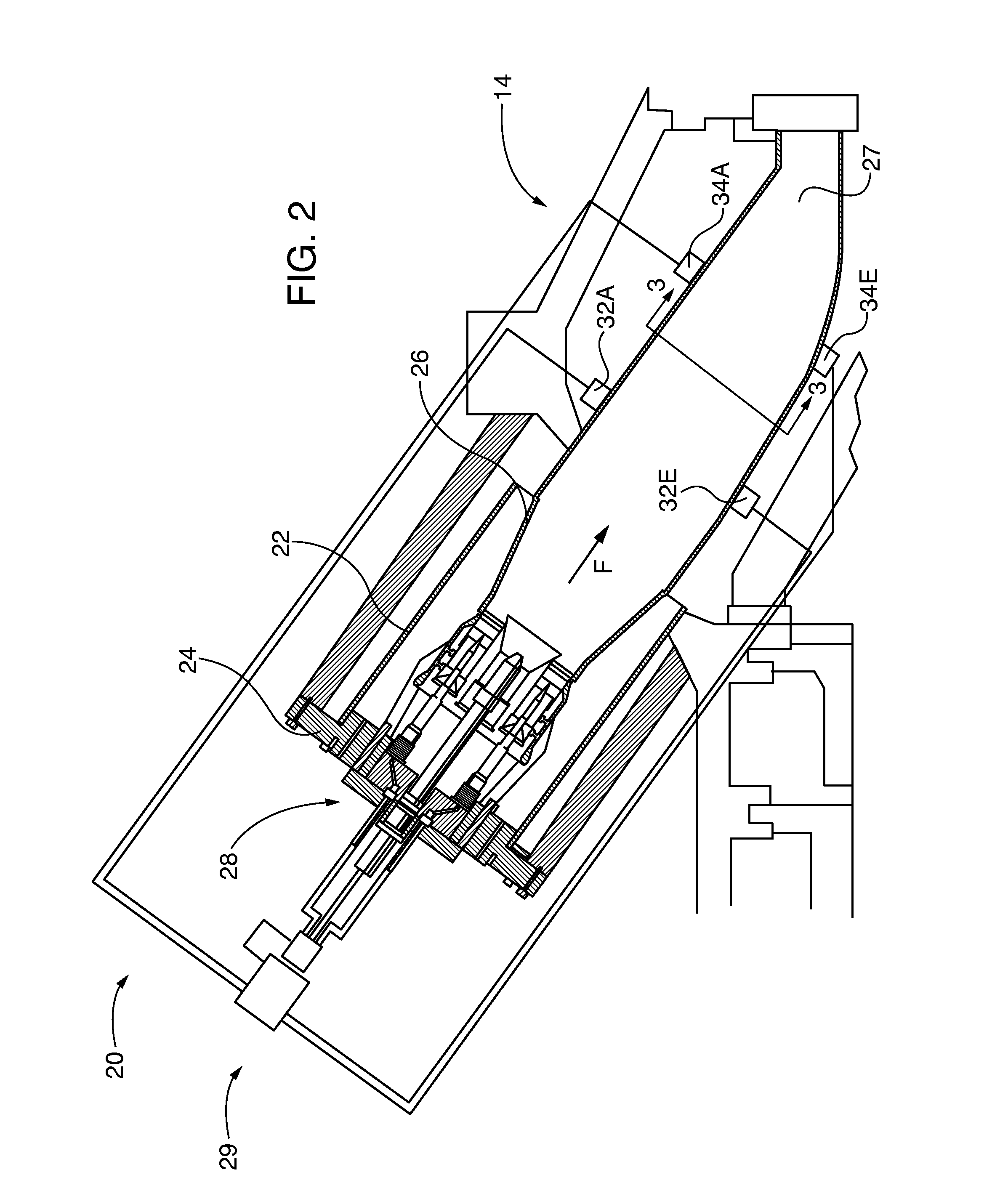

ActiveUS20150300920A1Facilitates of dimensionalGathering informationGas-turbine engine testingMaterial analysis by optical meansIndustrial gasTime profile

Internal components of power generation machines, such as gas or steam turbines, are inspected with a laser profilometer inspection system that is inserted and positioned within the turbine, for example through an inspection port that is in communication with an open inter-row spacing volume between an opposing turbine vane and turbine blade row. Component surface profile scans are performed to determine relative profile heights along a two-dimensional scan line generated by the profilometer. Three-dimensional profile information is obtained by translating the scan line across the surface. Real time profile information is gathered without physical contact, which is helpful for extracting off-line engineering information about component surface conditions, including surface spallation, perforation, and gaps between components. The system is capable of determining blade tip gap between a turbine blade tip and its opposing abradable surface in the turbine casing.

Owner:SIEMENS ENERGY INC

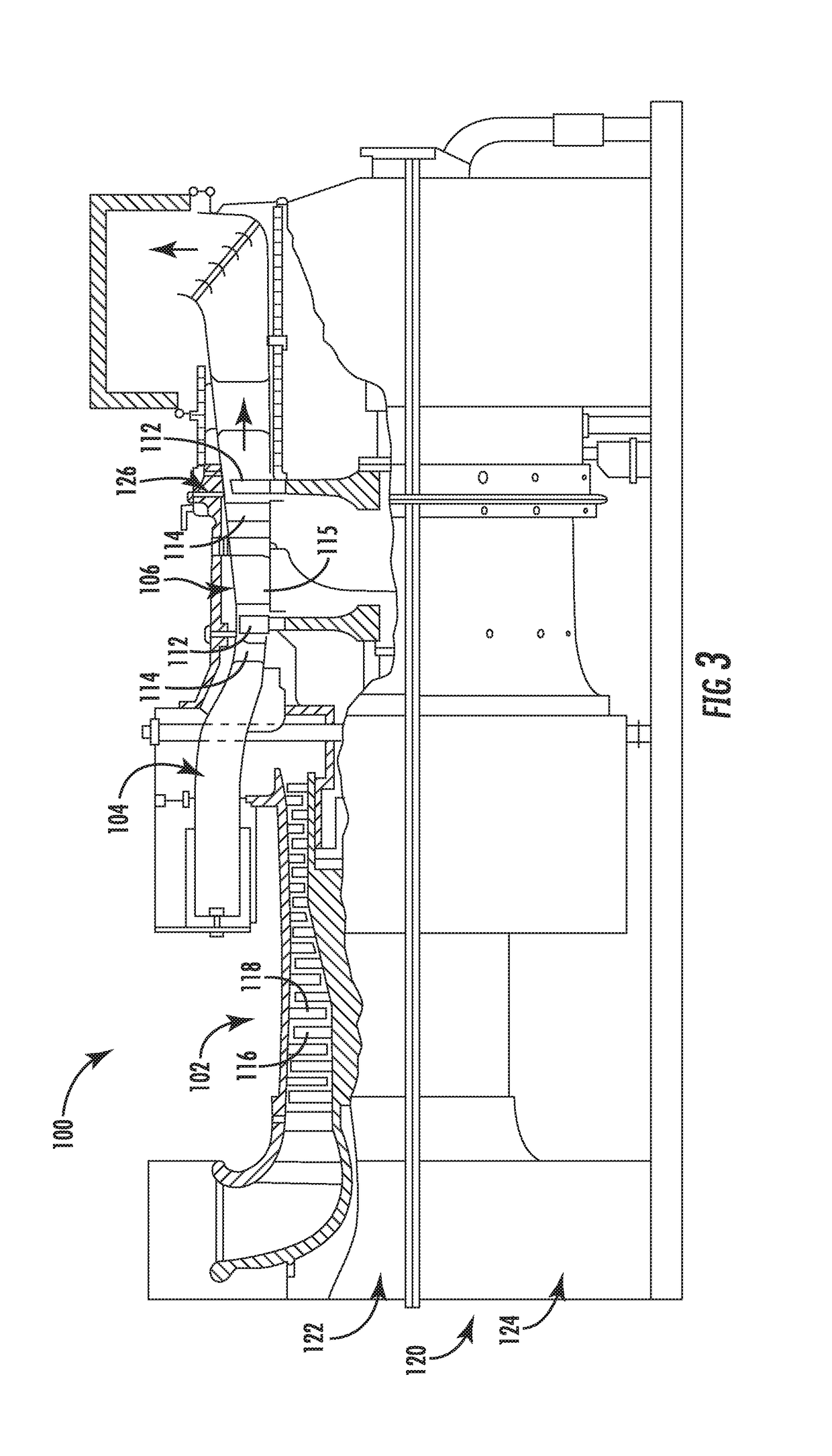

Creep life management system for a turbine engine and method of operating the same

A creep life management system includes at least one sensor apparatus coupled to a first component. The at least one sensor apparatus is configured with a unique identifier. The creep life management system also includes at least one reader unit coupled to a second component. The at least one reader unit is configured to transmit an interrogation request signal to the at least one sensor apparatus and receive a measurement response signal transmitted from the at least one sensor apparatus. The creep life management system further includes at least one processor programmed to determine a real-time creep profile of the first component as a function of the measurement response signal transmitted from the at least one sensor apparatus.

Owner:GENERAL ELECTRIC CO

System and method for automated optical inspection of industrial gas turbines and other power generation machinery with articulated multi-axis inspection scope

ActiveUS20130194412A1Minimize damageEqualize levelGas-turbine engine testingMaterial analysis by optical meansEngineeringVideo camera

Internal components of power generation machinery, such as gas and steam turbines are inspected with an optical camera inspection system that is capable of automatically positioning the camera field of view (FOV) to an area of interest within the machinery along a pre-designated navigation path and capturing images without human intervention. Automatic camera positioning and image capture can be initiated automatically or after receipt of operator permission. The pre-designated navigation path can be defined by operator manual positioning of an inspection scope within the power machine or a similar one of the same type and recording of positioning steps for future replication. The navigation path can also be defined by virtual simulation. The inspection system includes an articulated multi-axis inspection scope.

Owner:SIEMENS ENERGY INC

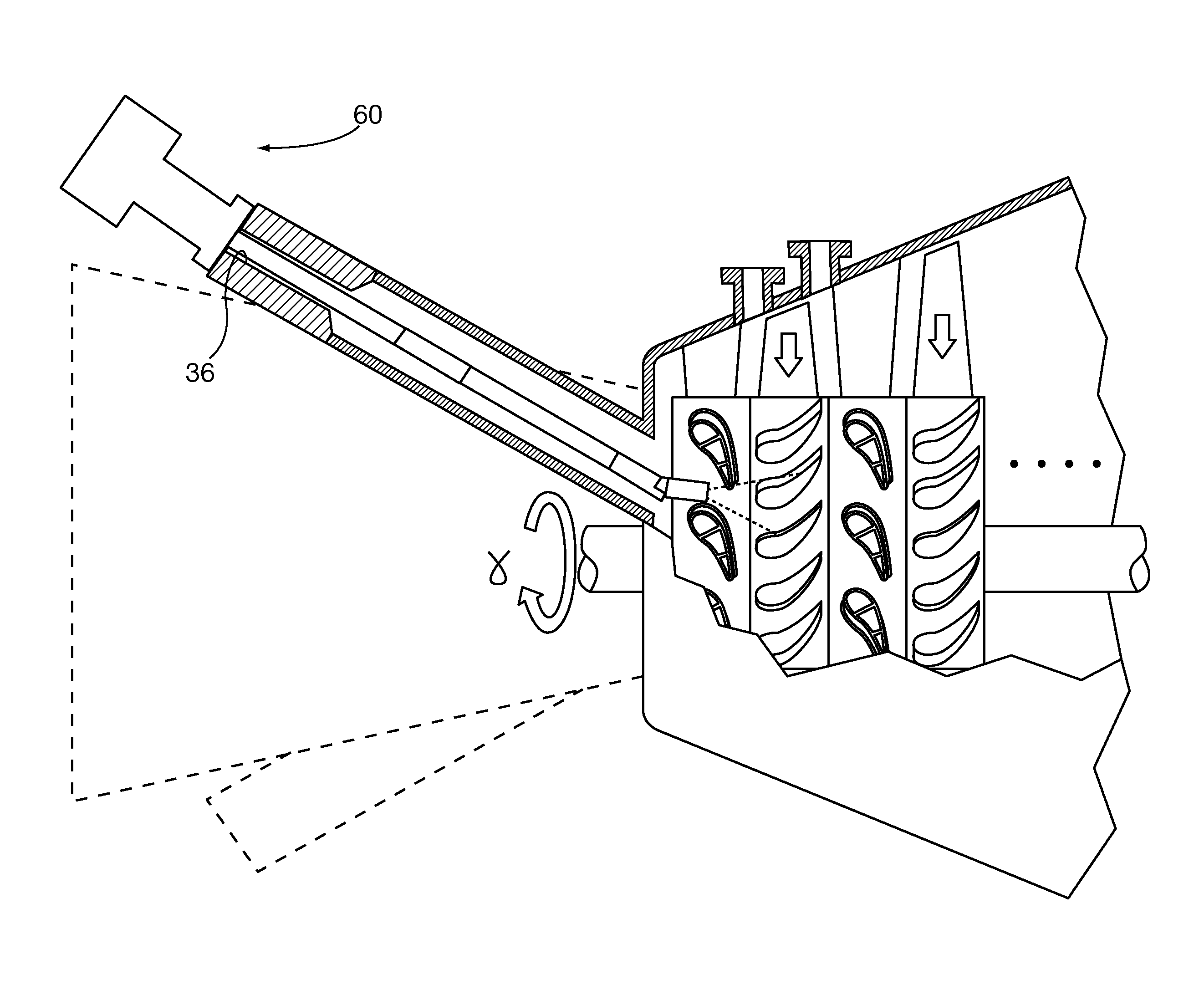

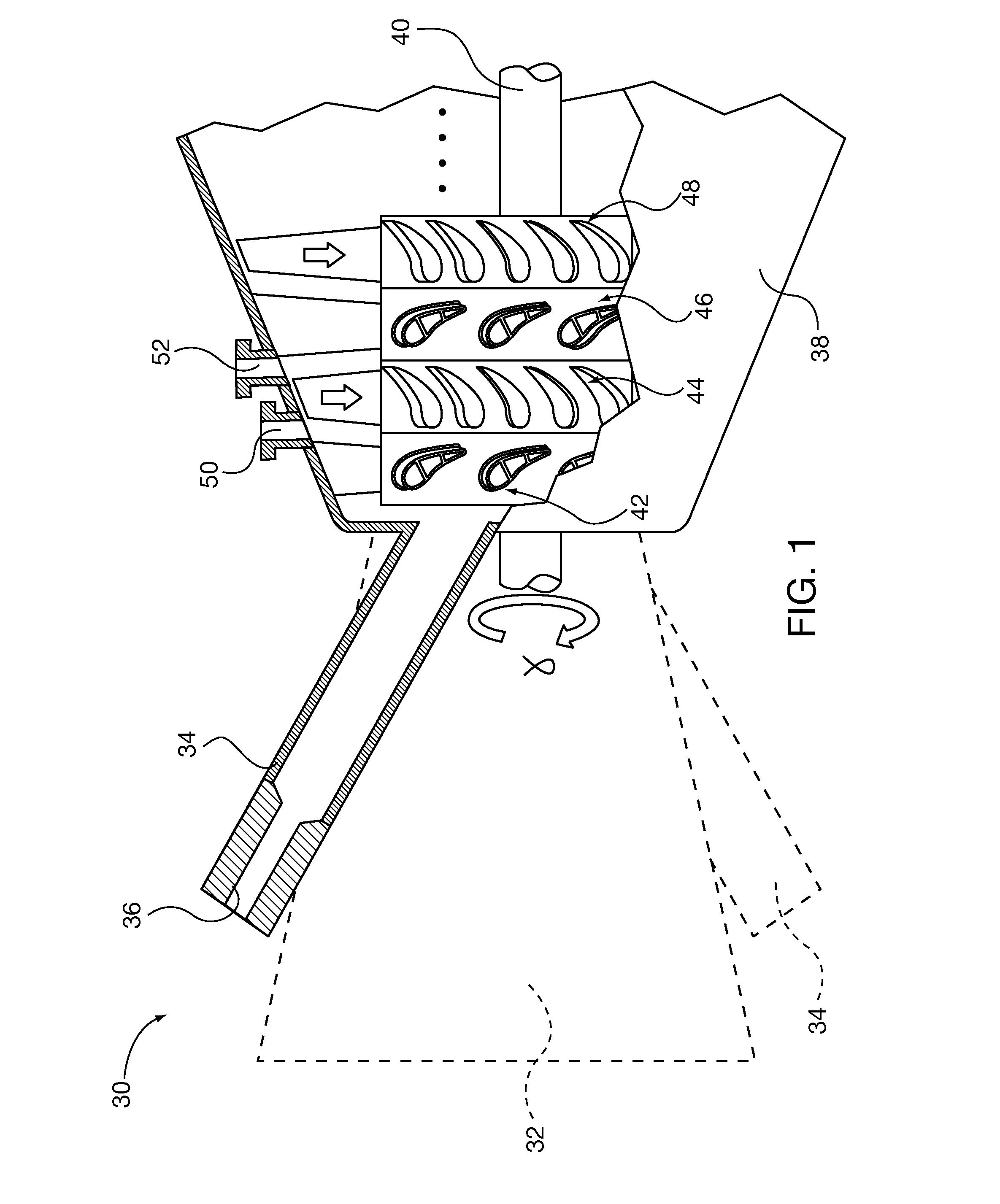

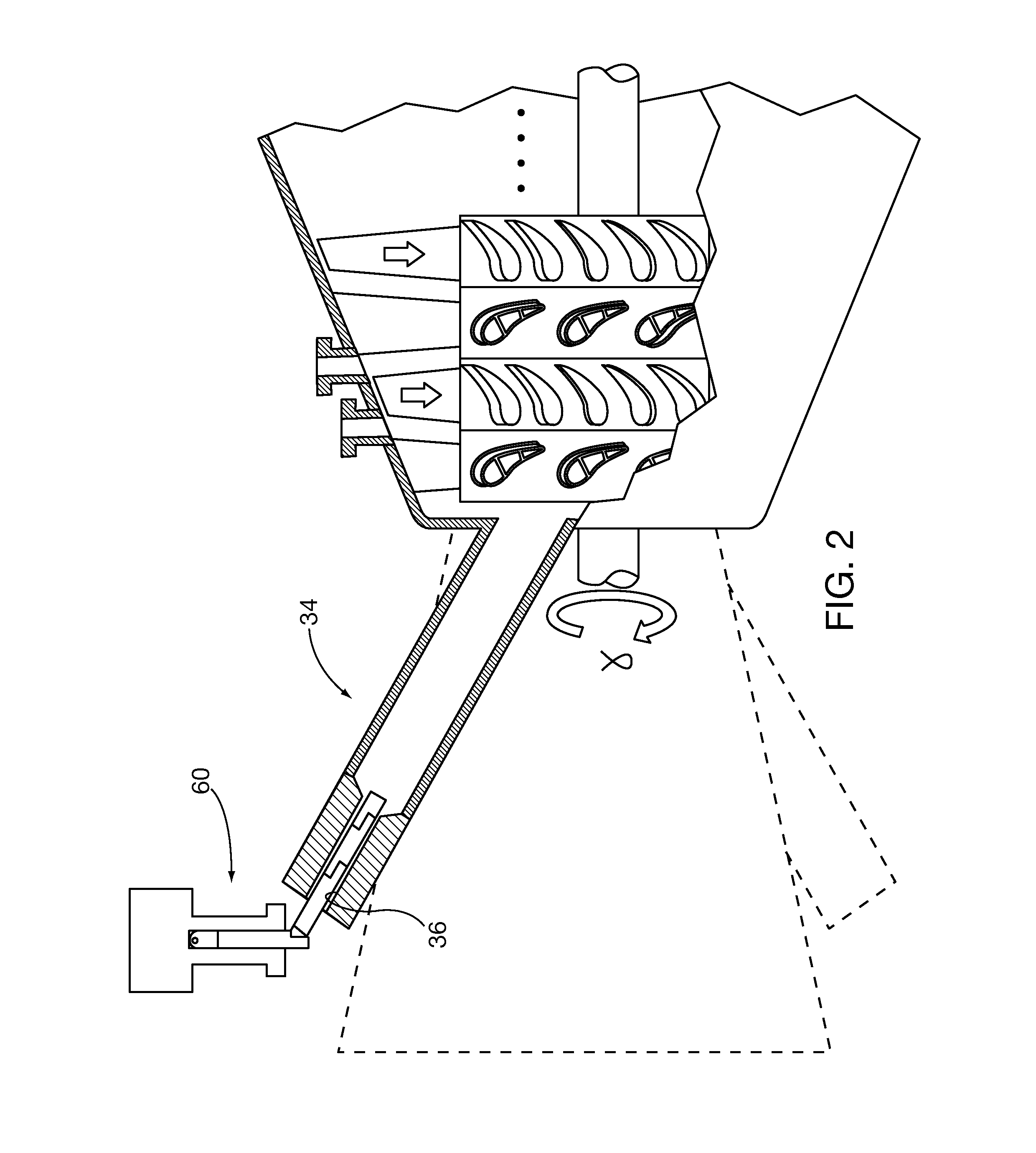

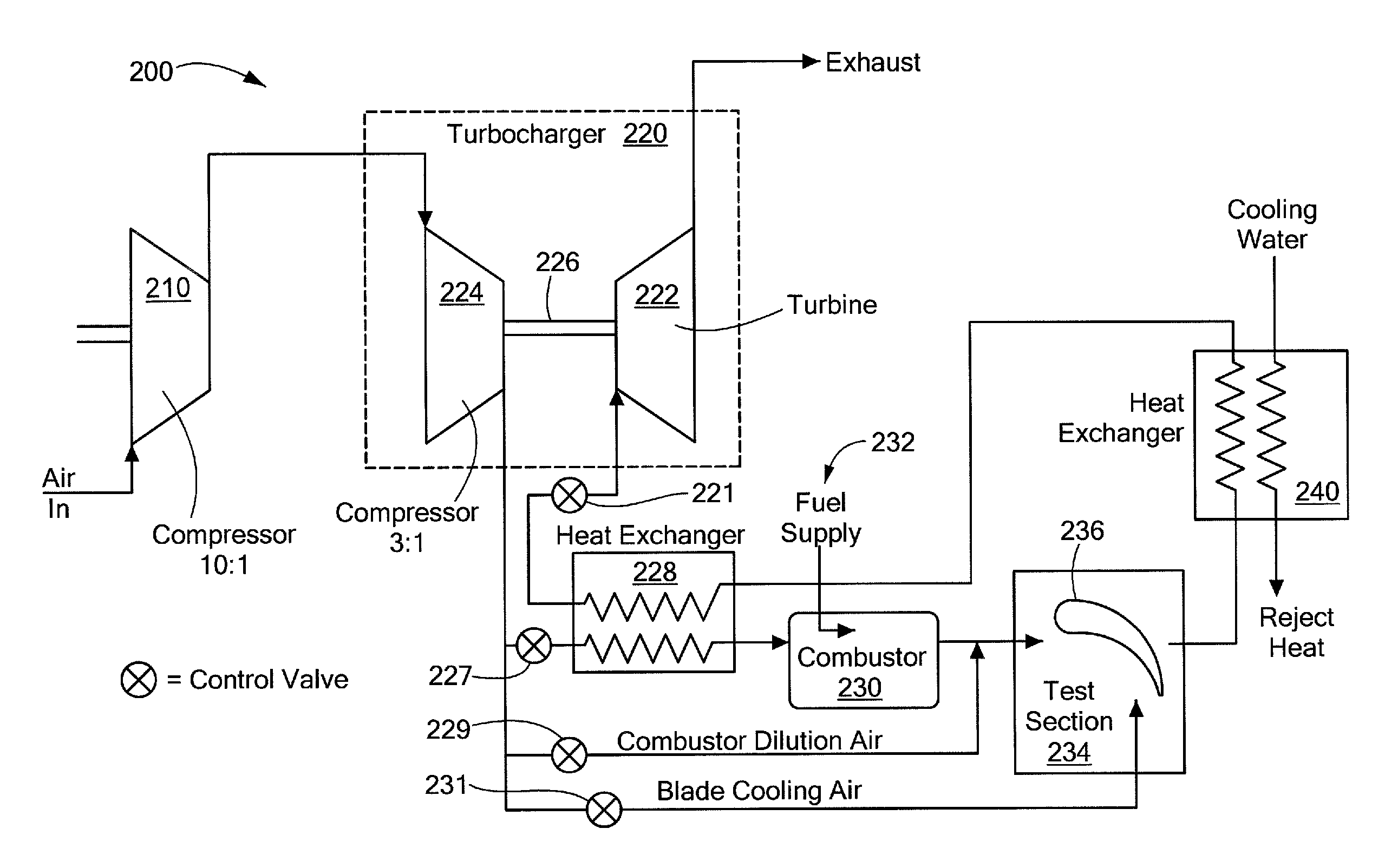

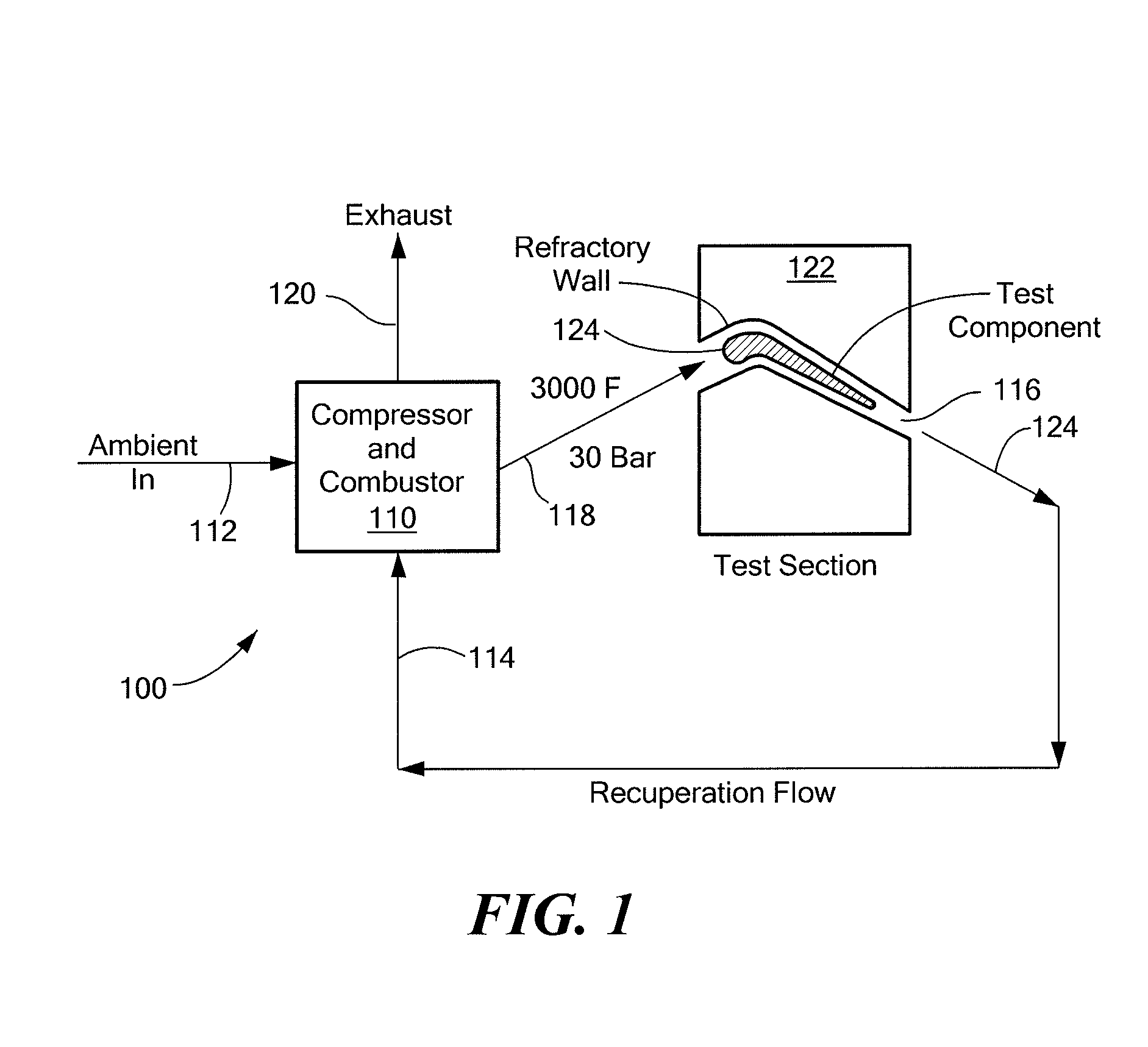

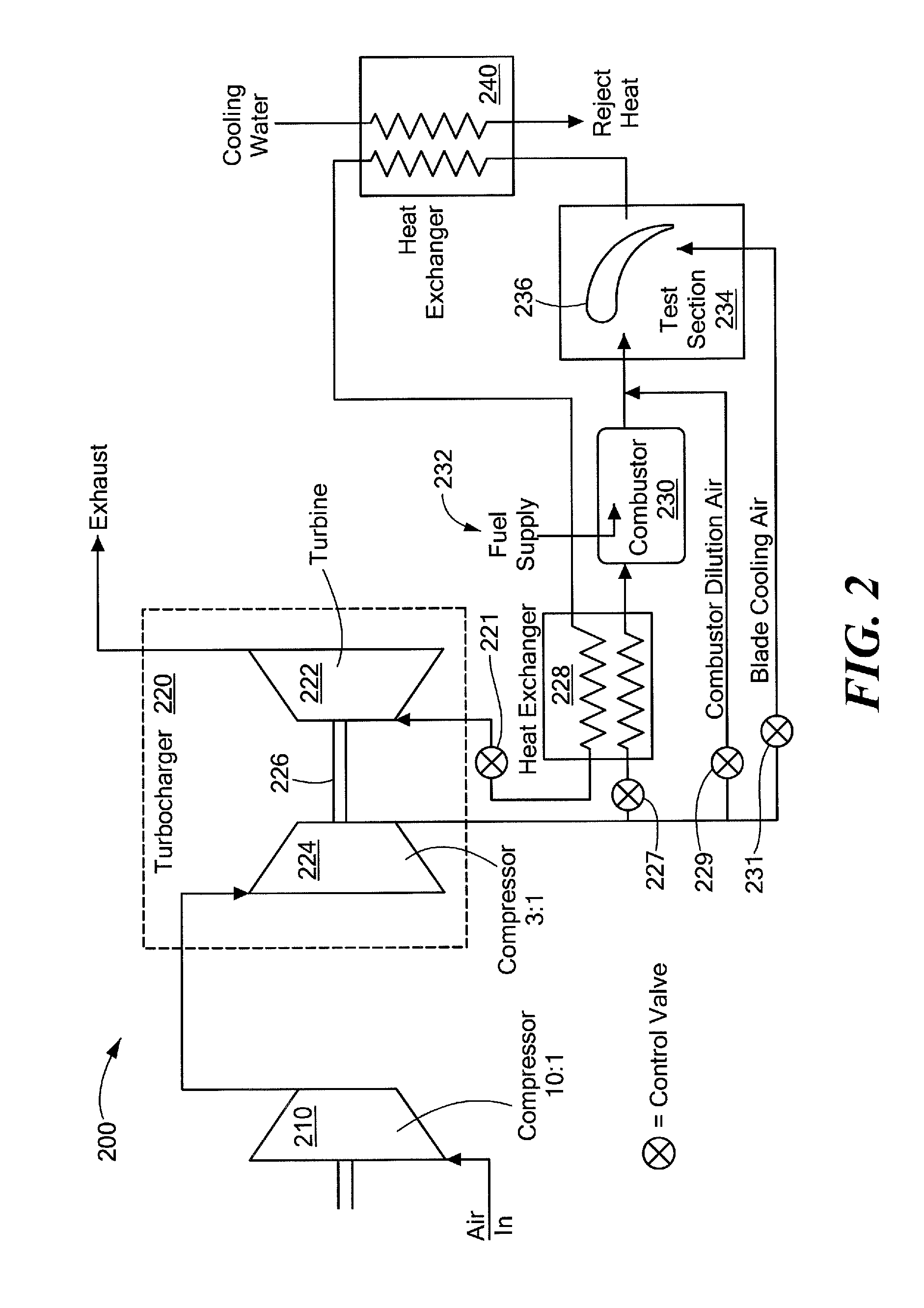

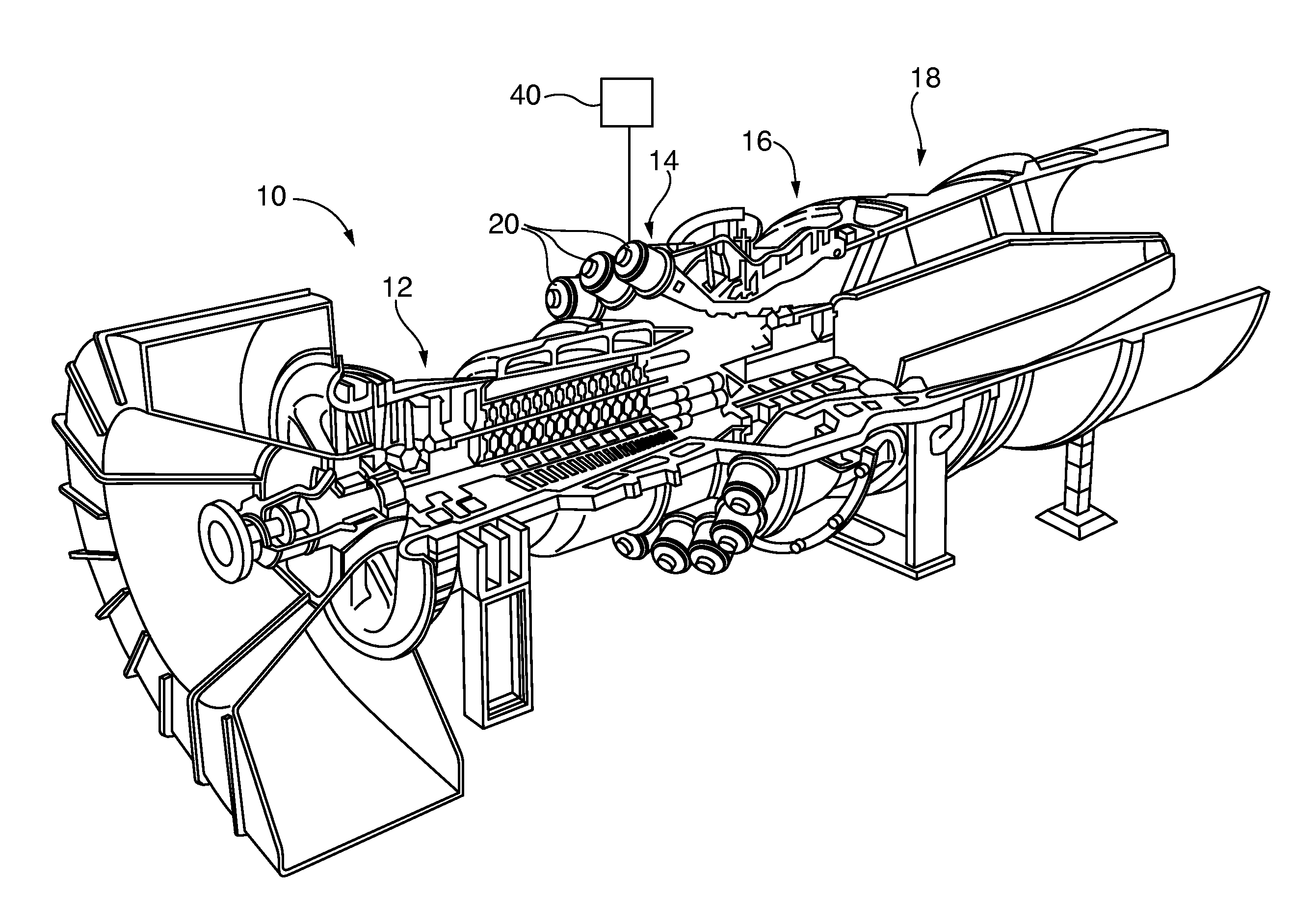

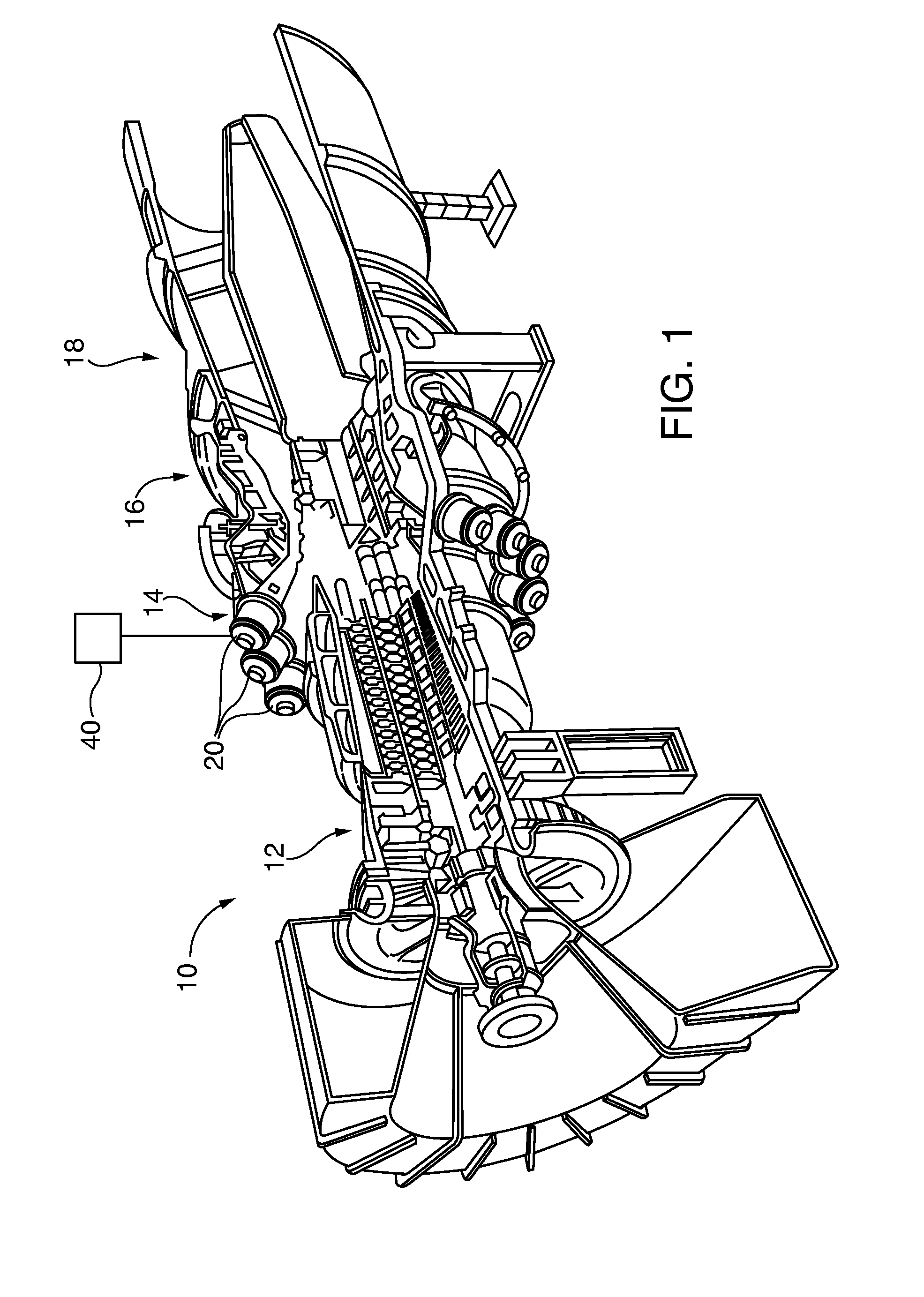

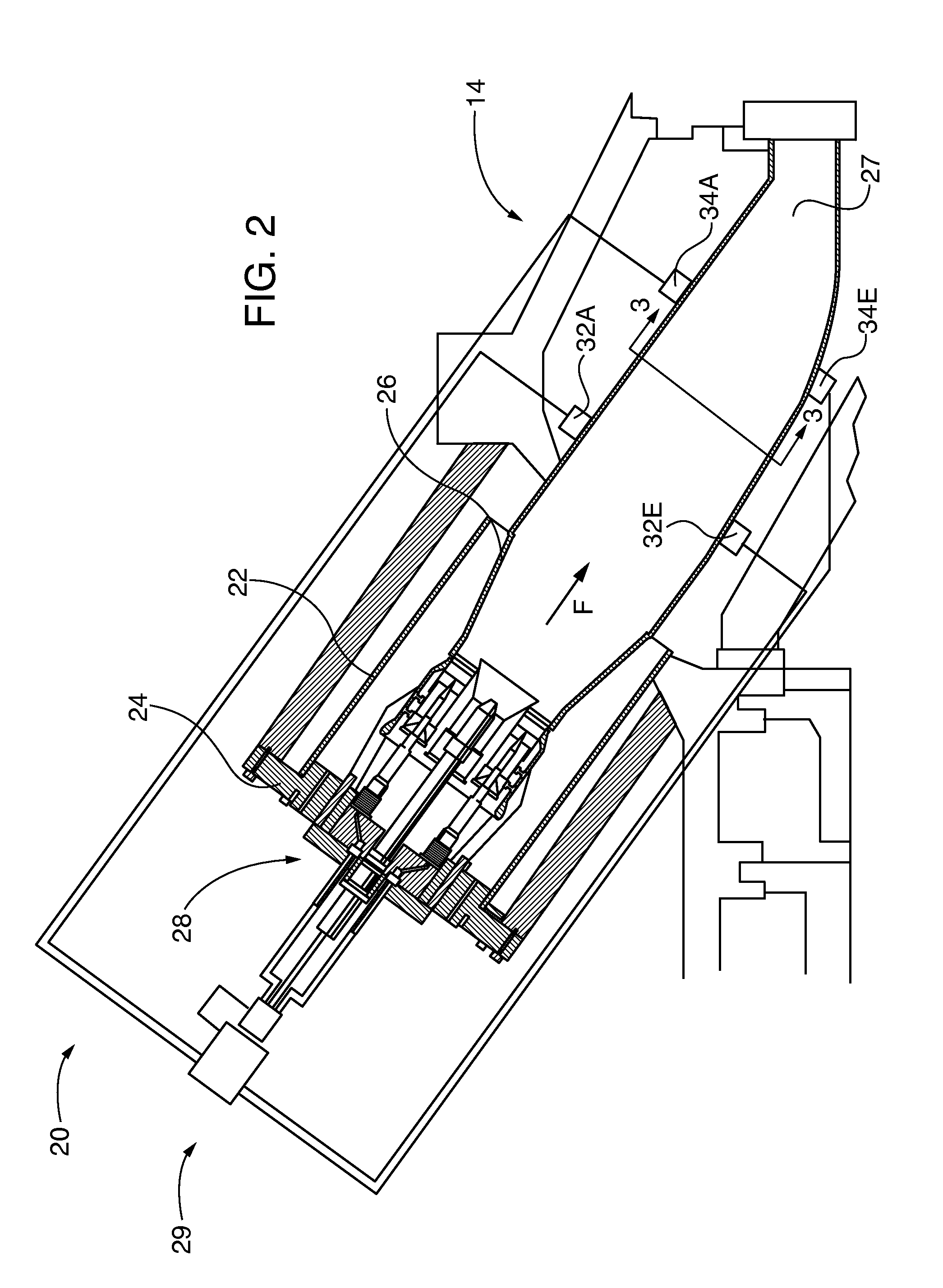

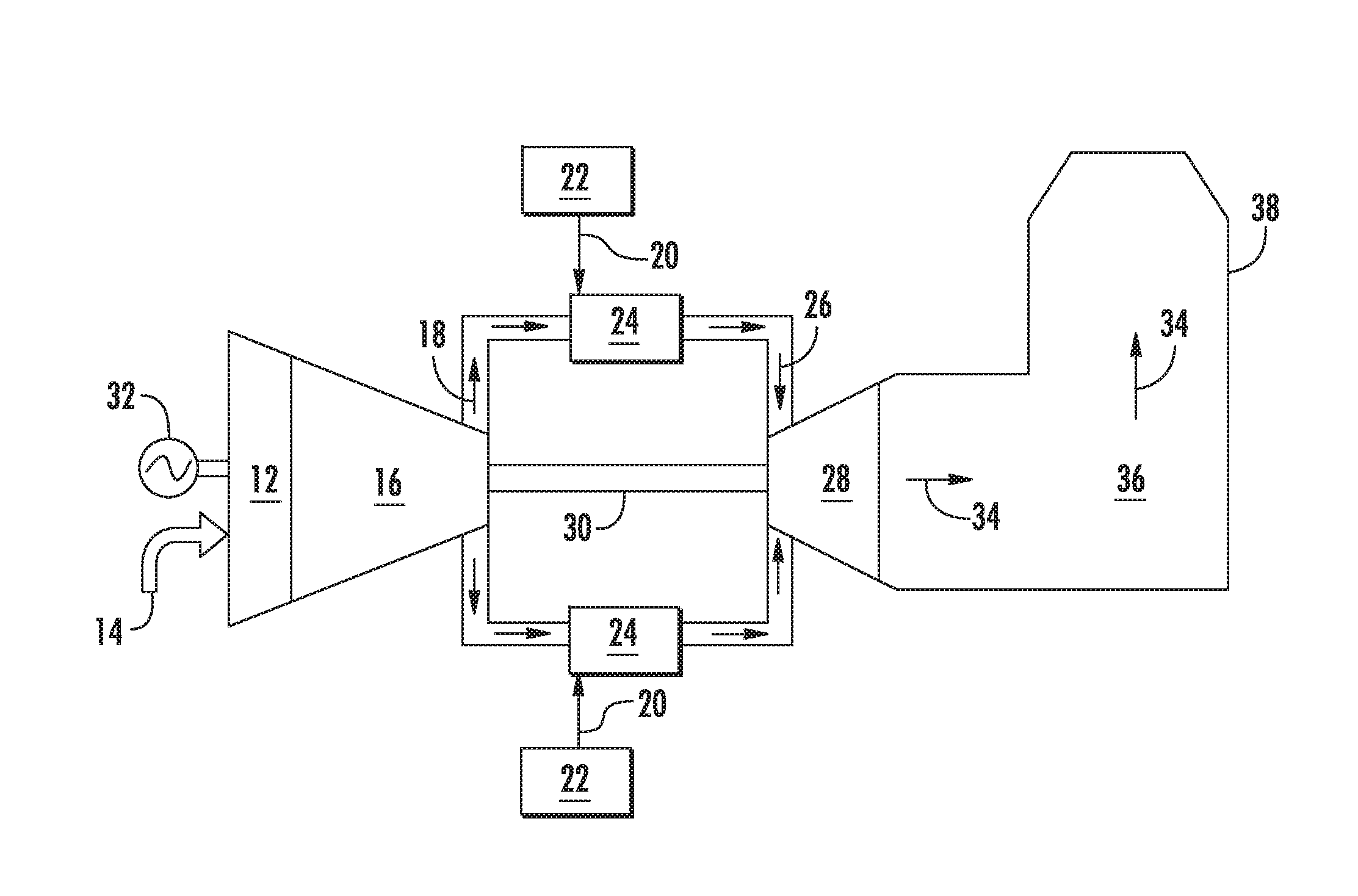

System and method for imposing thermal gradients on thin walled test objects and components

ActiveUS7966868B1Consume moreLow costGas-turbine engine testingEngine fuctionsEngineeringTest chamber

A test facility provides high temperature, high pressure and high mass flow fluid to a test object to form a relatively large thermal gradient on the object. Energy in the fluid is recuperated to drive system components, such as a heat exchanger and a turbocharger compressor. A test chamber housing the test object can be arranged to conform to a contour of the test object. A control system permits independent variation of pressure, temperature, cooling fluid and fluid velocity, as well as mechanical loading on the test object. Noncontact, optical inspection measurement techniques can be employed to measure test chamber and / or test object parameters. The test object can be configured to direct cooling airflow to permit various temperature or pressure gradients to be implemented. The test facility is relatively inexpensive to operate and provides a significant cost advantage over testing conducted in a full gas turbine engine.

Owner:SCHENCK USA CORP

System and method for automated optical inspection of industrial gas turbines and other power generation machinery with multi-axis inspection scope

ActiveUS20130192353A1Shorten the timeMore power generationGas-turbine engine testingMaterial analysis by optical meansReceiptVideo camera

Owner:SIEMENS ENERGY INC

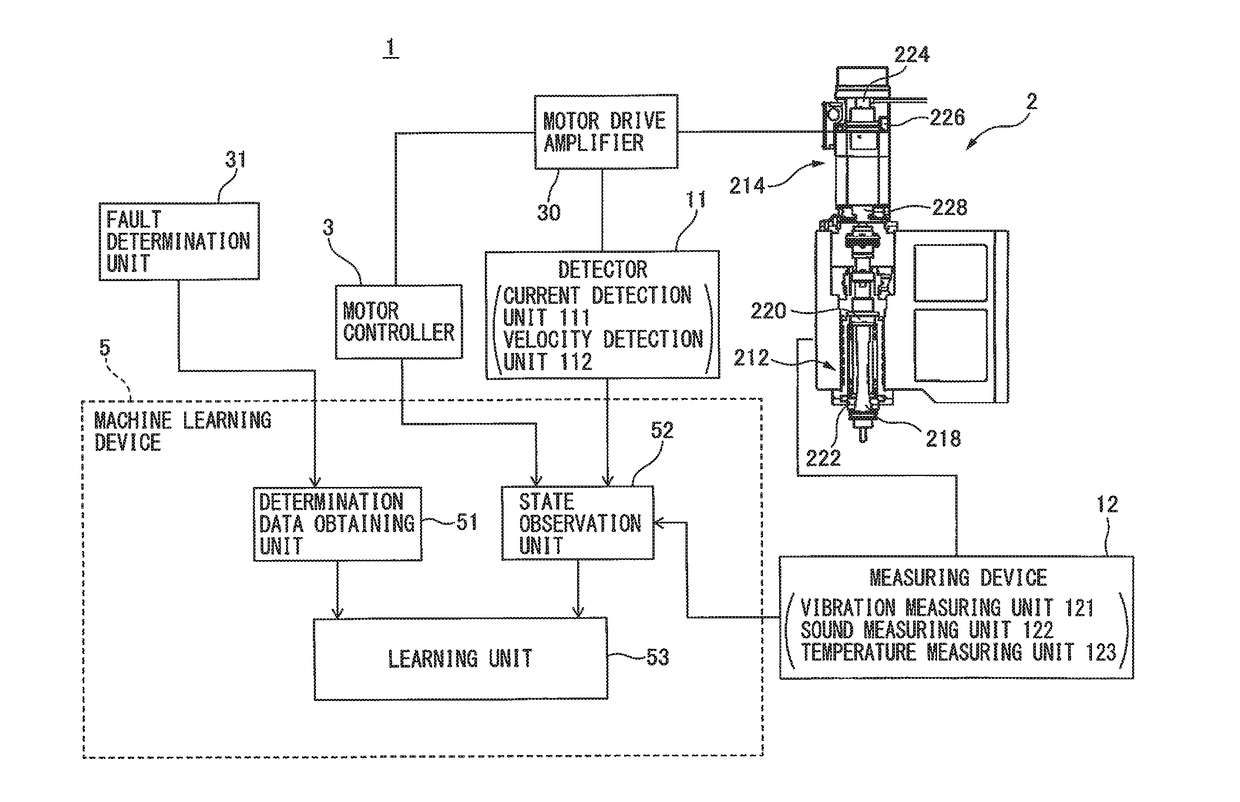

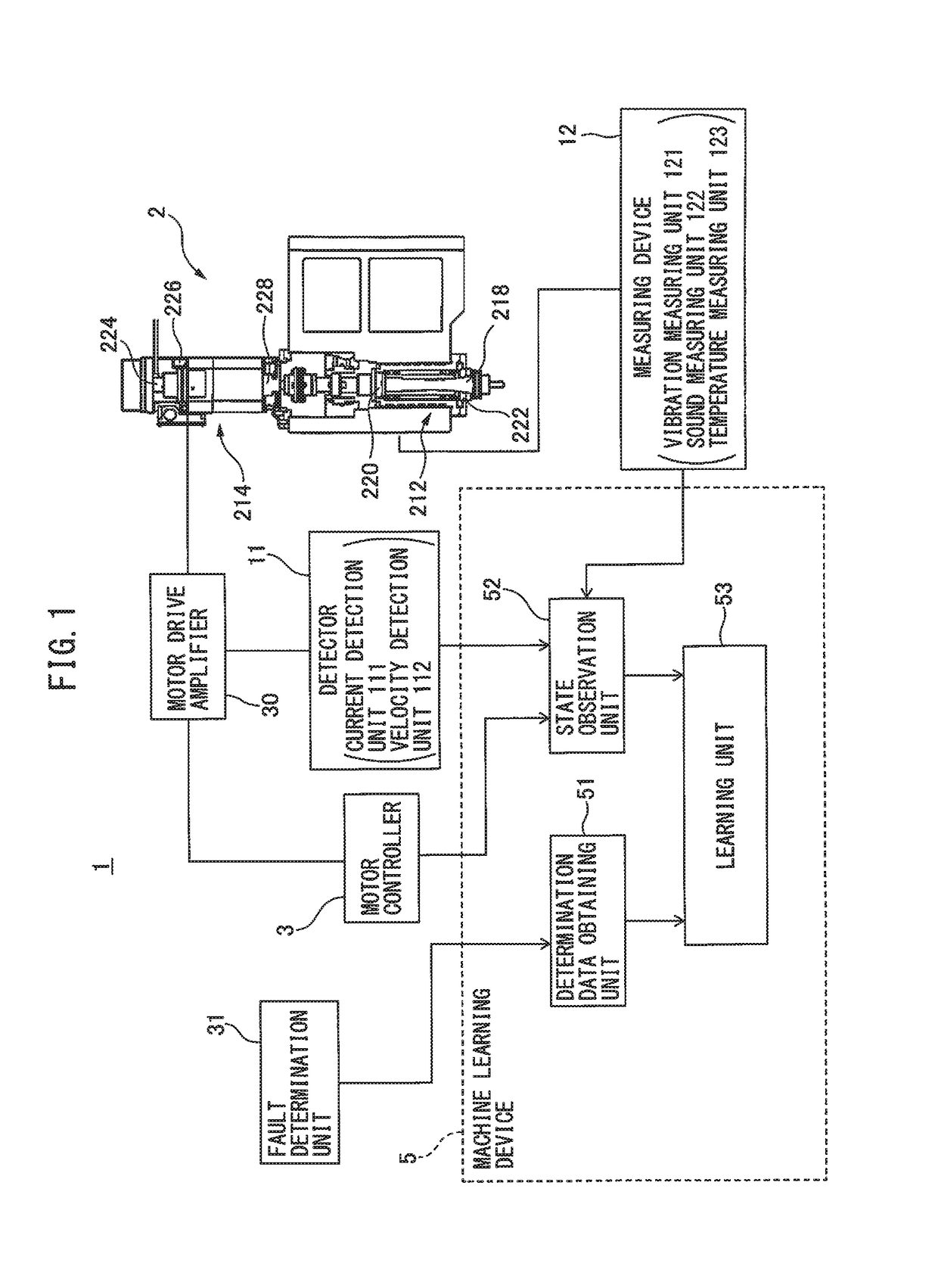

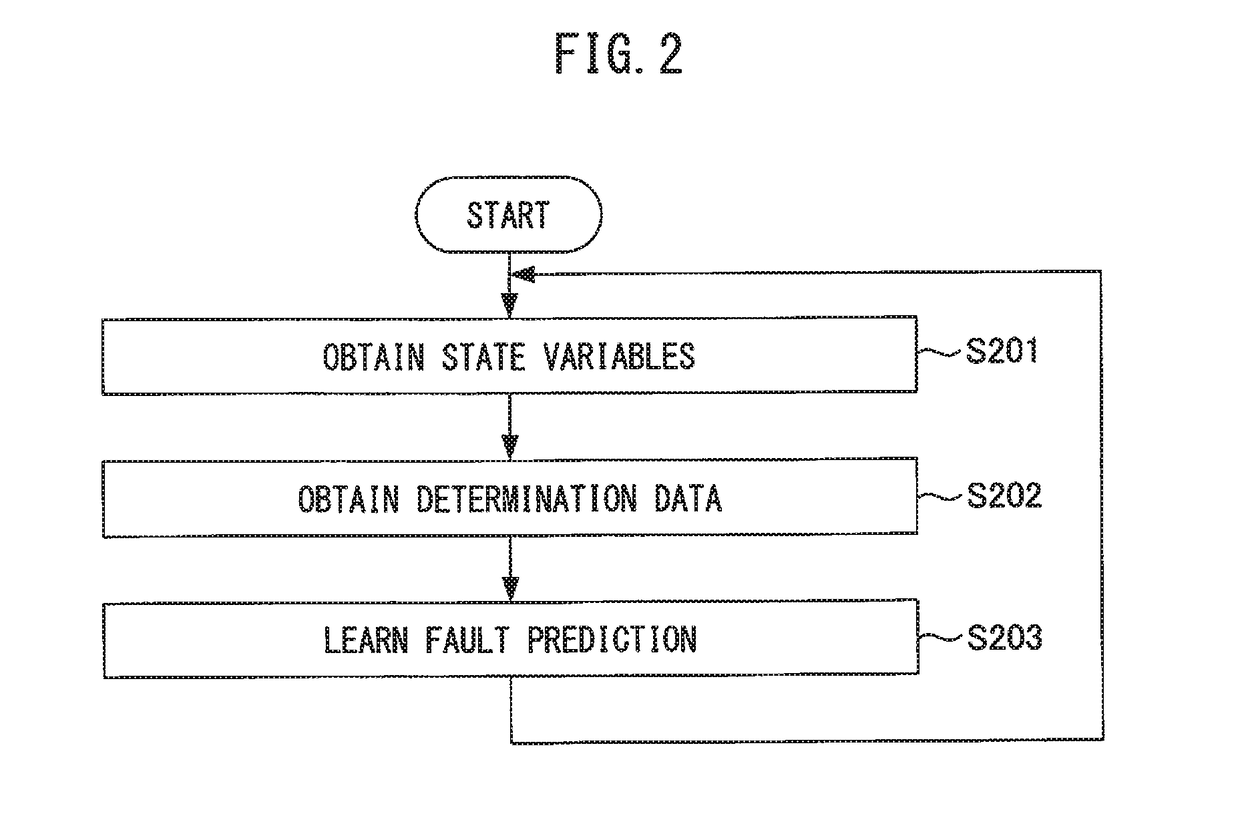

Machine learning device and machine learning method for learning fault prediction of main shaft or motor which drives main shaft, and fault prediction device and fault prediction system including machine learning device

A machine learning device which learns fault prediction of one of a main shaft of a machine tool and a motor driving the main shaft, including a state observation unit observing a state variable including at least one of data output from a motor controller controlling the motor, data output from a detector detecting a state of the motor, and data output from a measuring device measuring a state of the one of the main shaft and the motor; a determination data obtaining unit obtaining determination data upon determining one of whether a fault has occurred in the one of the main shaft and the motor and a degree of fault; and a learning unit learning the fault prediction of the one of the main shaft and the motor in accordance with a data set generated based on a combination of the state variable and the determination data.

Owner:FANUC LTD

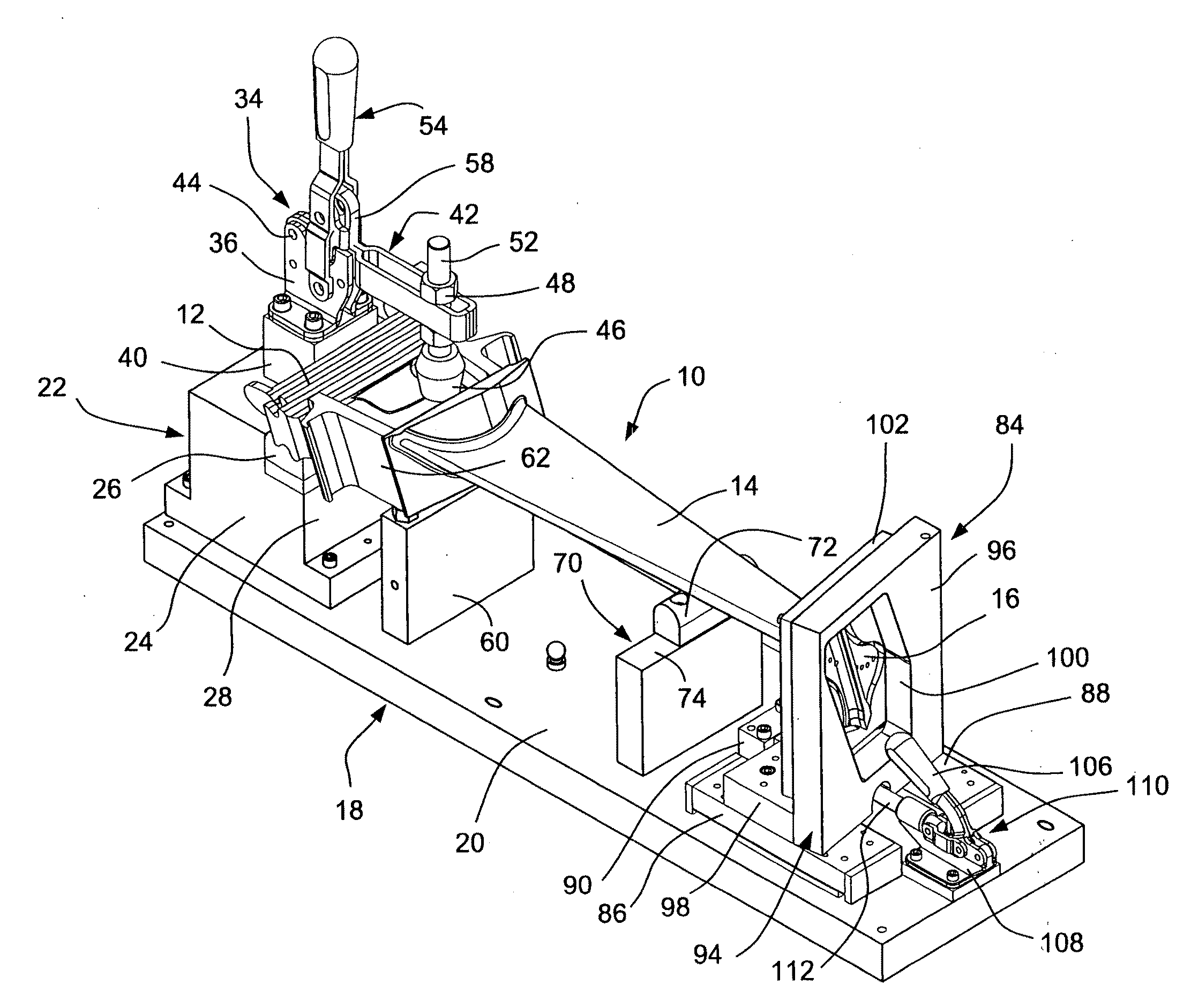

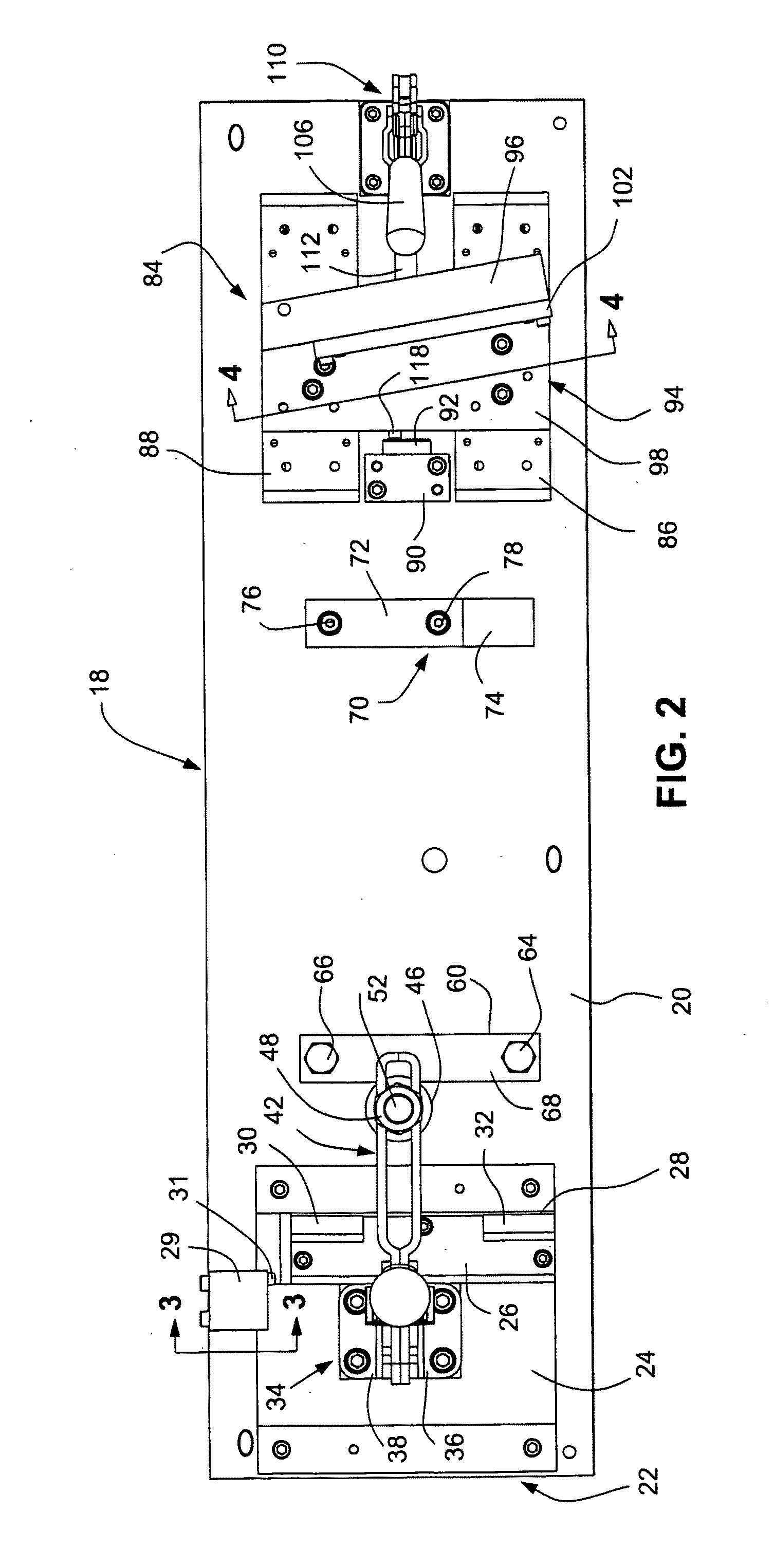

Inspection tool for measuring bucket Z notch position

An inspection tool for a turbine bucket shroud includes: a clamp device for clamping a dovetail portion of a turbine bucket; a template plate provided with an aperture defined by a edge shaped to conform to a specified shape of the turbine bucket shroud, wherein the template is moveable to a location over the turbine bucket shroud in a direction toward the clamp device, and wherein, at the location, the aperture represents a design specification location for the turbine bucket shroud relative to the dovetail portion of the bucket. A measurement gauge is provided for measuring gaps between edges of the shroud and edges of the template aperture.

Owner:GENERAL ELECTRIC CO

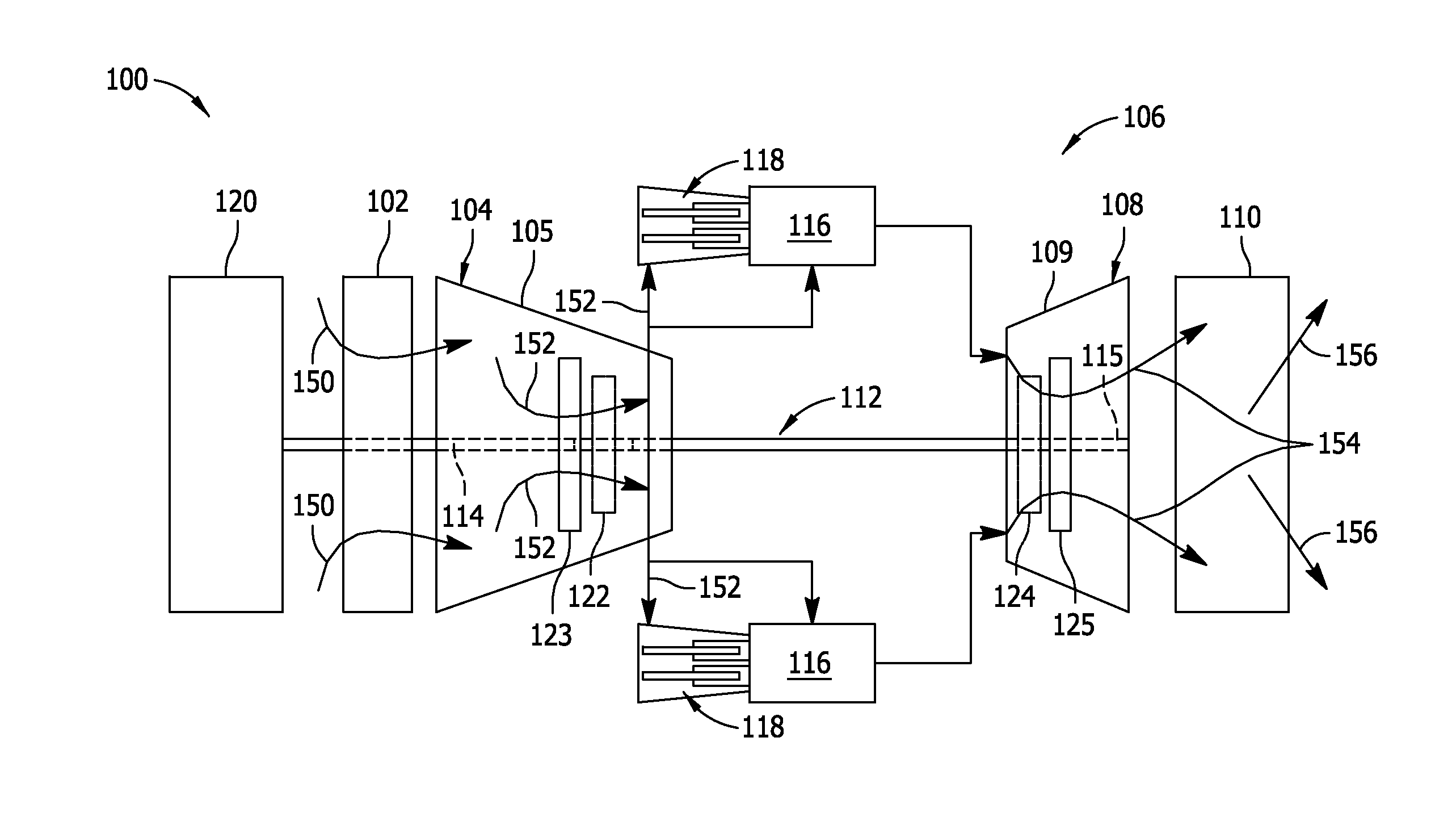

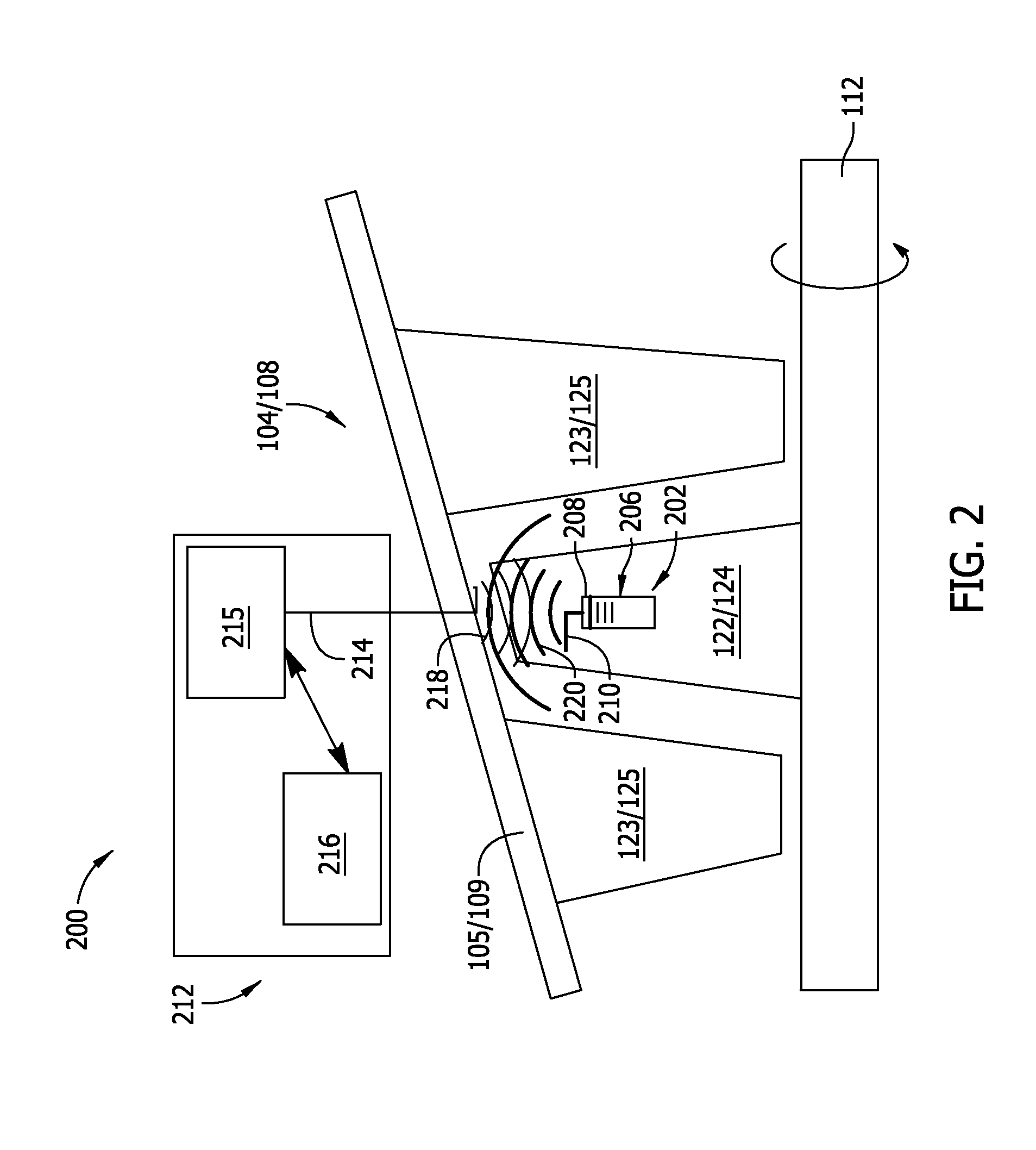

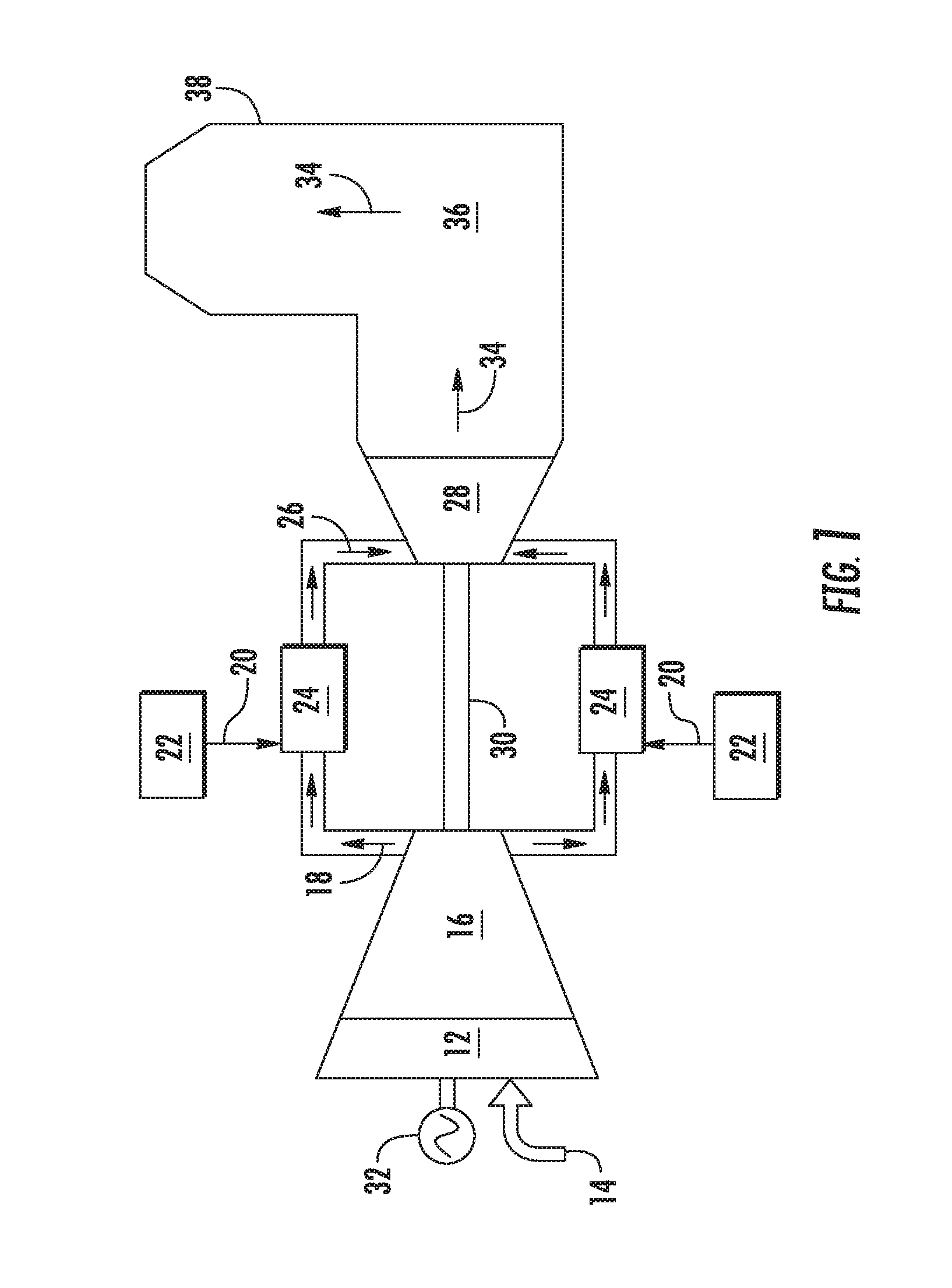

Nonintrusive performance measurement of a gas turbine engine in real time

Performance of a gas turbine engine is monitored by computing a mass flow rate through the engine. Acoustic time-of-flight measurements are taken between acoustic transmitters and receivers in the flow path of the engine. The measurements are processed to determine average speeds of sound and gas flow velocities along those lines-of-sound. A volumetric flow rate in the flow path is computed using the gas flow velocities together with a representation of the flow path geometry. A gas density in the flow path is computed using the speeds of sound and a measured static pressure. The mass flow rate is calculated from the gas density and the volumetric flow rate.

Owner:SIEMENS ENERGY INC

Condition based engine parts monitoring

Condition based engine parts (e.g., movable engine parts) monitoring is disclosed. The techniques may enable detecting cracks present in engine parts while the engine is operational. In one embodiment, a system includes a wireless sensor configured to be disposed on a movable part internal to a machine and communicate wirelessly and a controller that includes a processor. The processor may be configured to initiate communication with the wireless sensor by receiving a wireless signal indicative of a frequency of vibration of the internal movable part from the wireless sensor, to obtain an acceptable threshold range of vibrations for the internal movable part from one or more data sources, to determine whether the frequency of vibration is within the acceptable threshold range of vibrations for the internal movable part, and to initiate preventative actions when the frequency is not within the acceptable threshold range.

Owner:AI ALPINE US BIDCO INC

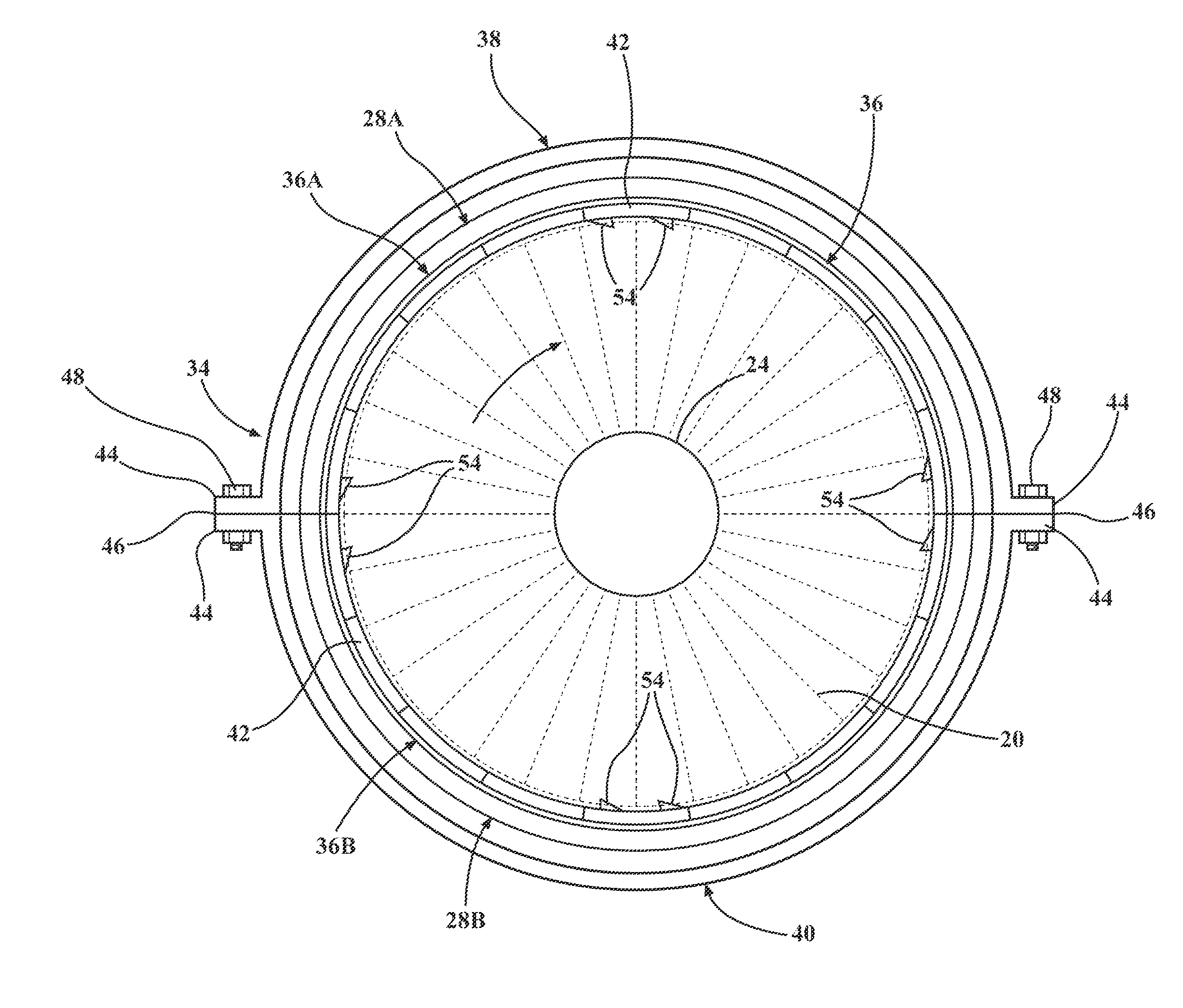

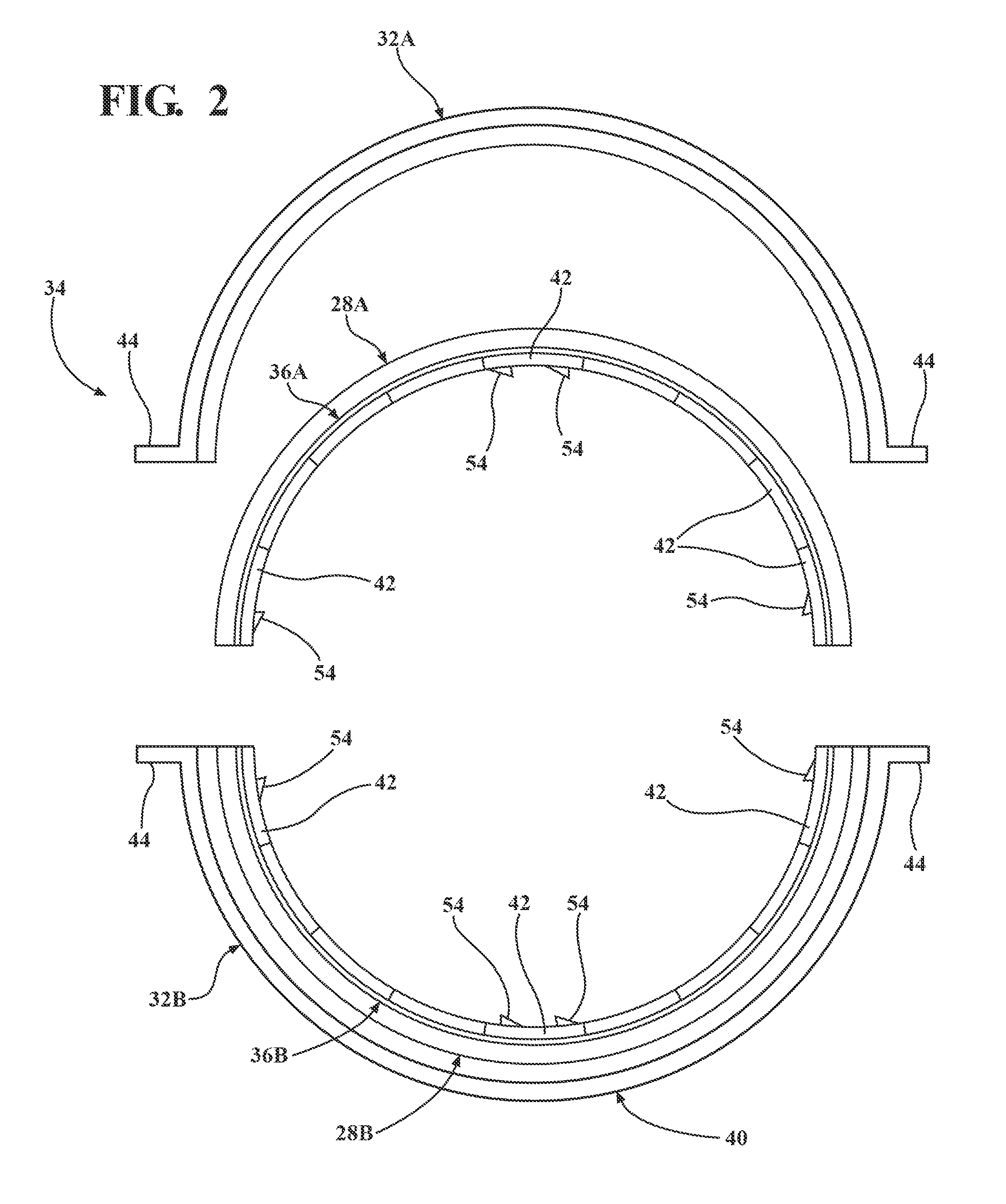

Parameter distribution mapping in a gas turbine engine

A profile map of parameter values in a region is determined based on average values along linear paths through the region. In one example, a temperature map of a region of a gas turbine engine is created based on time-of-flight measurements from acoustic transceiver pairs arranged circumferentially around the region. A speed of sound for each transceiver pair is determined based on the time-of-flight measurements. An average temperature along each path is estimated from the time of flight, and the profile map is computed from the average temperatures. The profile map may be computed using a polynomial approximation technique, a grid optimization technique or a basis function technique.

Owner:SIEMENS ENERGY INC

Method for Detecting Leaks In A Fuel Circuit of a Gas Turbine Fuel Supply System

ActiveUS20170052087A1Increased sound levelDetection of fluid at leakage pointMeasurement of fluid loss/gain rateCombustorControl valves

A method for detecting leakage at a fluid connection for a gas turbine fuel supply system is disclosed herein. The method includes closing a flow control valve at an upstream end of the fuel supply system and pressurizing the fuel supply system with a compressed medium via a compressed medium supply to a target pressure. The target pressure is less than a pressure threshold of a check valve that is disposed downstream from the compressed medium supply and upstream from a corresponding combustor of the gas turbine. The method further includes pointing a receiver portion of an ultrasonic detection device proximate to at least one tube fitting of the fuel supply system located between the flow control valve and a combustor which is fluidly coupled to the fuel supply system. Detection of an increase in sound level and / or the sound of popping at the tube fitting is indicative of a leak at the tube fitting.

Owner:GENERAL ELECTRIC CO

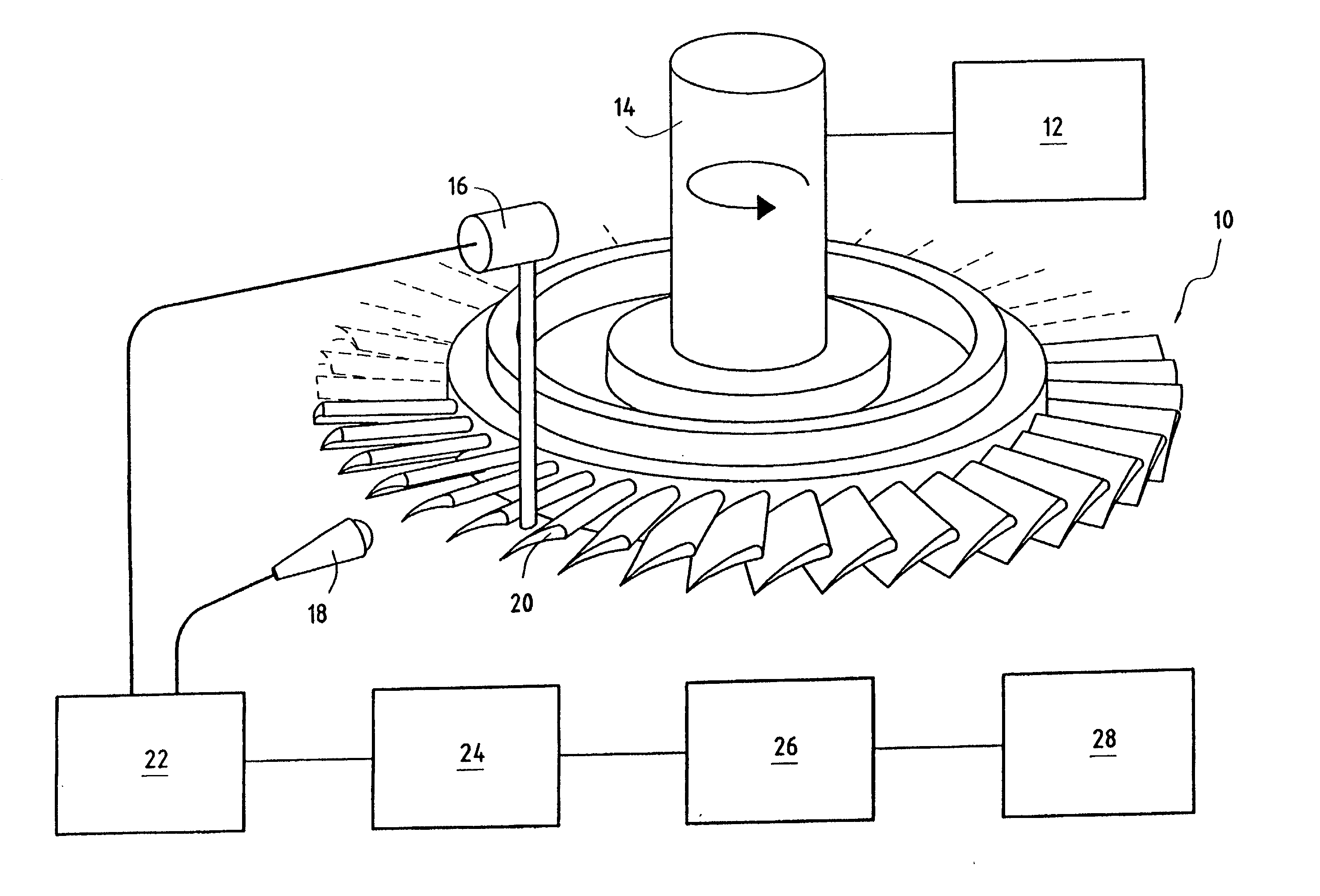

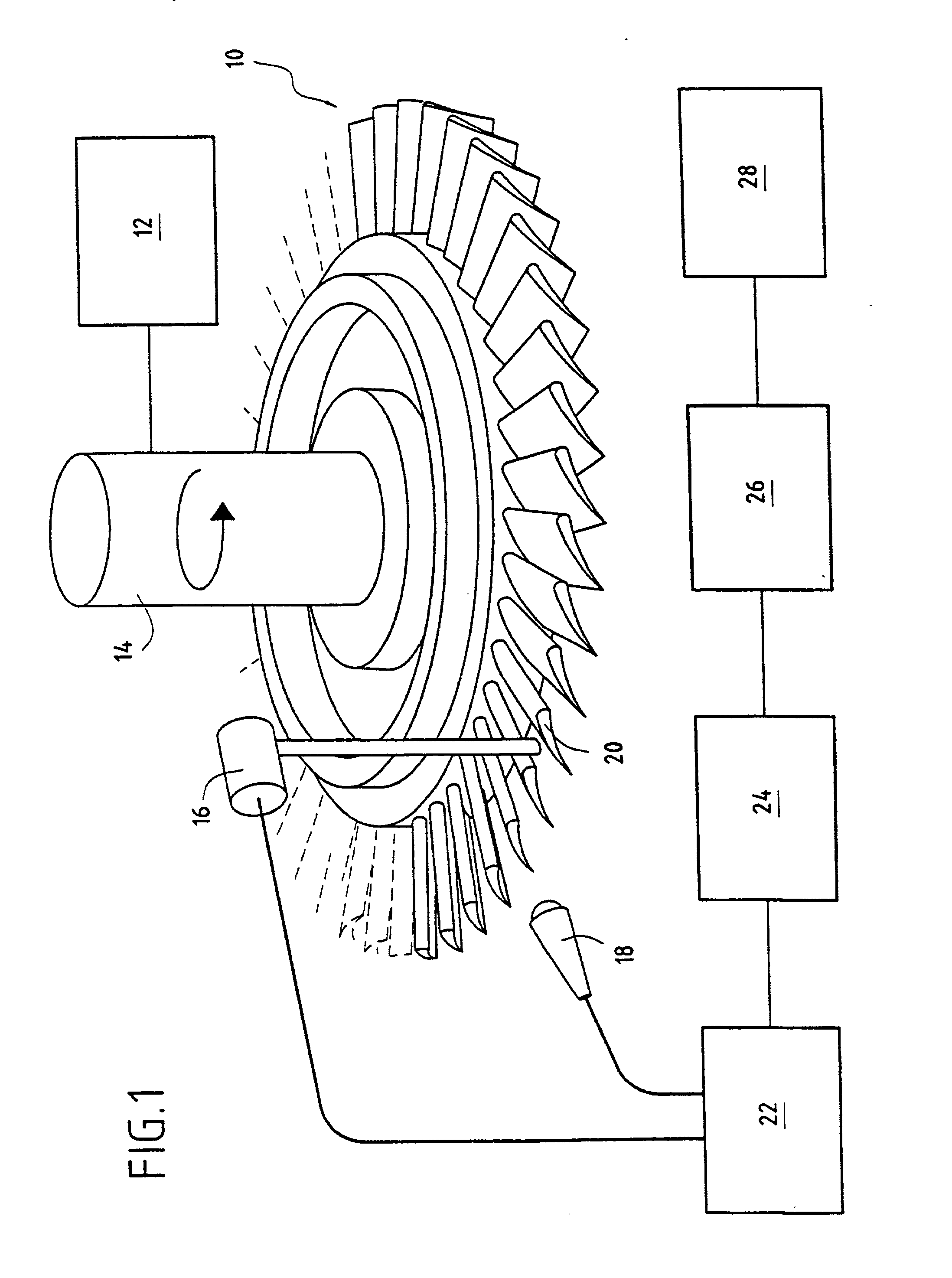

Acoustic inspection of one-piece bladed wheels

InactiveUS20020059831A1Avoid potential damageQuality inspectionVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesImpellerEngineering

These objects are achieved by a method of acoustically inspecting a one-piece bladed wheel in which the wheel is driven in rotation; each blade of the wheel is subjected to mechanical excitation; its acoustic response is picked up and a corresponding electrical signal is generated; its frequency response is determined by computing a FFT; the electrical signal and the associated frequency response are stored; the characteristic frequencies of each blade of the wheel are identified; and a wheel is rejected or accepted depending on whether or not the frequency distribution obtained in this way matches a predetermined set of forbidden frequency distributions. Advantageously, an additional step is provided in which the defects of a blade are determined by comparing its frequency response with predetermined frequency responses that are characteristic of various types of defect.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Turbine tip clearance measurement

A measuring assembly for use in a gas turbine engine includes an indicia portion that extends radially inwardly from an inner surface of a ring seal structure to a location radially inwardly from tips of blades mounted on a rotor. The indicia portion of the measuring assembly comprises a section that is abraded by the blades during rotational movement of the rotor to provide a visual indication of a distance between the tips of the blades and the inner surface.

Owner:SIEMENS ENERGY INC

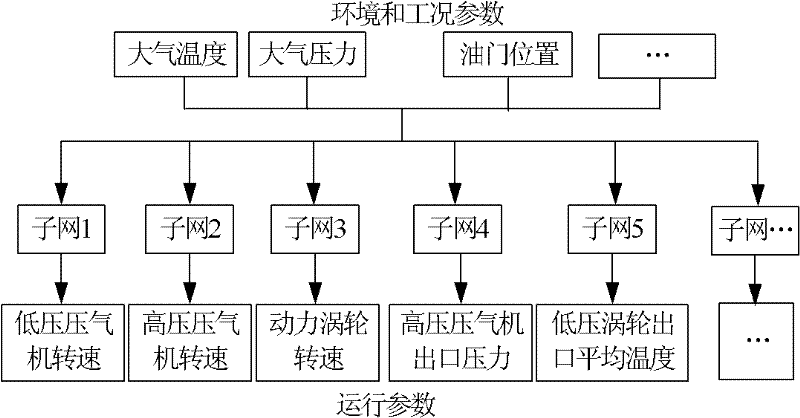

Gas path fault diagnostic method for marine gas turbine based on fuzzy Petri net (FPN)

InactiveCN102175460AResolve uncertaintyGas-turbine engine testingBiological neural network modelsReasoning algorithmEngineering

The invention discloses a gas path fault diagnostic method for a marine gas turbine based on a fuzzy Petri net (FPN), comprising the following steps of: (1) obtaining the operating standard value of the marine gas turbine; (2) based on an actually-measured value, calculating the membership grade of the actual operating parameter deviation belonging to the criterion deviation fuzzy subset by using a membership function; (3) defining the FPN in response to the characteristics of the fault diagnostic Petri net after determining the operating standard value and the deviation; and (4) determining a FPN reasoning algorithm for gas path fault diagnosis for the marine gas turbine based on related definitions of the transitional enabling and igniting rules. Through the gas path fault diagnostic method for the marine gas turbine based on the fuzzy Petri net (FPN), the defects of not strong university, wrong judgment and reasoning of the traditional method are overcome; it is actually proved that the problems of fuzziness and nondeterminacy in an gas path fault can be effectively solved by the gas path fault diagnostic algorithm for the marine gas turbine established by the gas path fault diagnostic method disclosed by the invention.

Owner:NAVAL UNIV OF ENG PLA

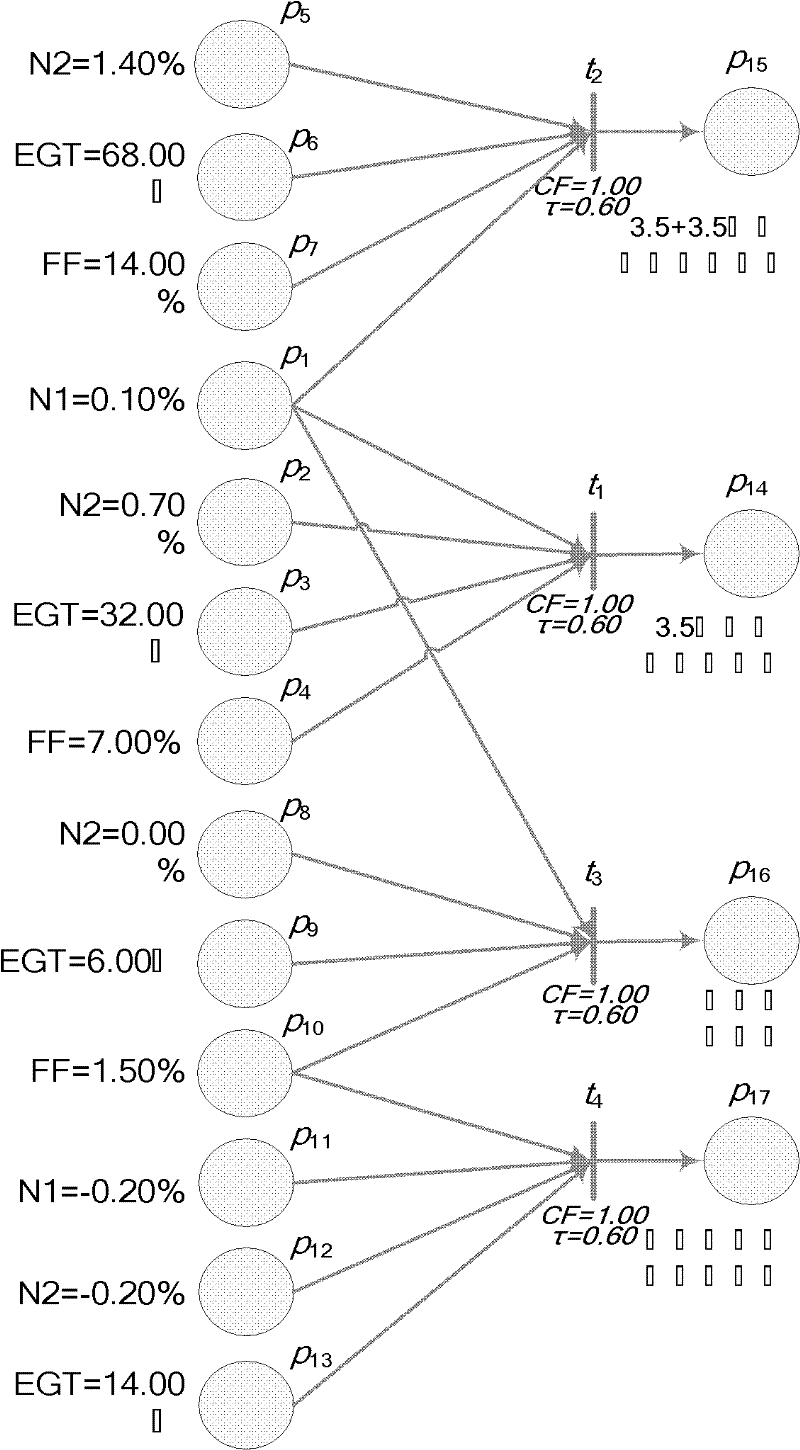

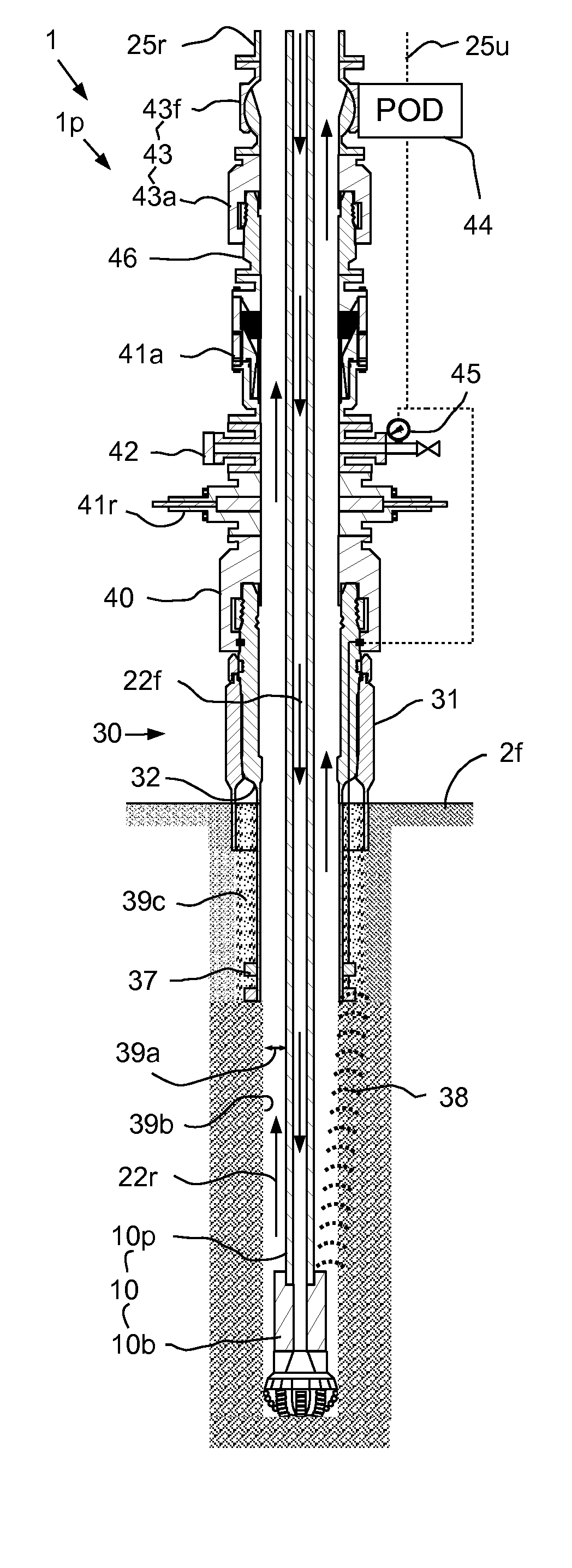

Tachometer for downhole drilling motor

A tachometer for a downhole motor includes: a tubular housing having a coupling for connection to a housing of the motor; and a probe. The probe: has a coupling for connection to a rotor of the motor, is movable relative to the tachometer housing, and has at least a portion disposed in a bore of the tachometer housing. The tachometer further includes electronics disposed in the tachometer housing and including: a battery; one or more proximity sensors for tracking an orbit of the probe; and a programmable logic controller (PLC). The PLC is operable: to receive the tracked orbit, and at least one of: to determine an angular speed of the probe using the tracked orbit, and to forecast a remaining lifespan of the motor using the tracked orbit.

Owner:WEATHERFORD TECH HLDG LLC

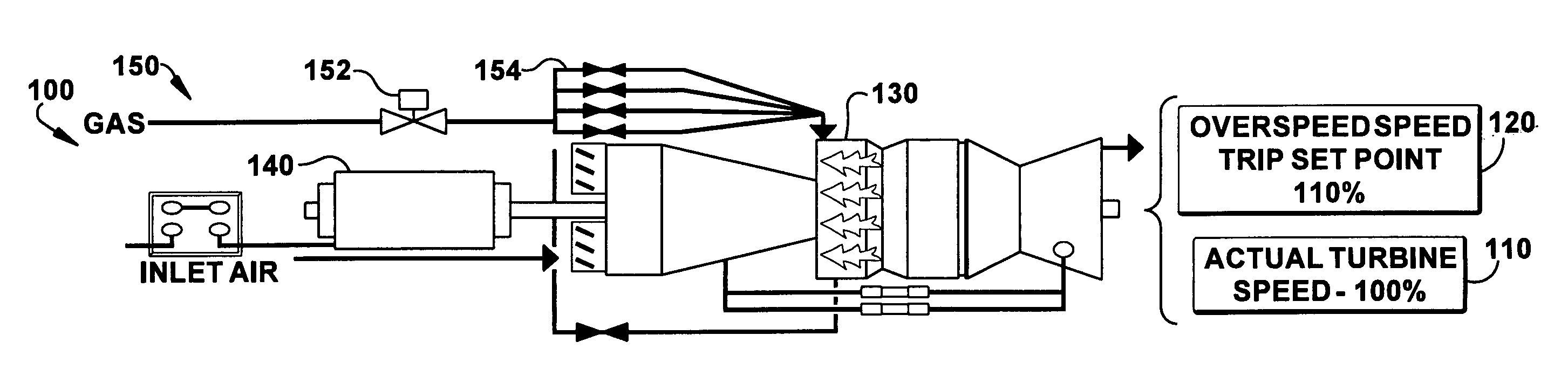

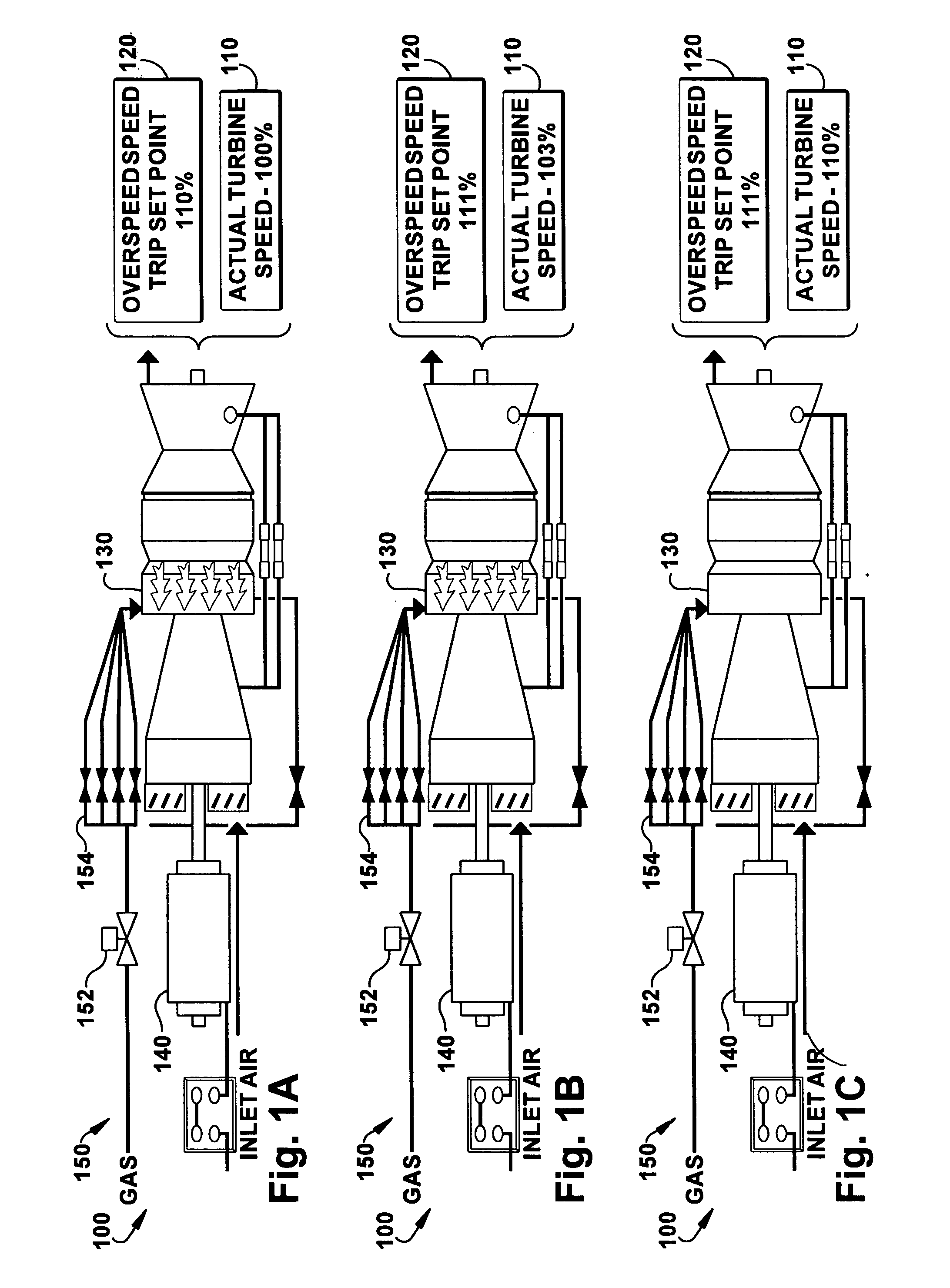

Method and system for testing the overspeed protection system of a turbomachine

A method and system of testing an overspeed protection system of a turbomachine may include providing an overspeed protection system on a turbomachine having at least one shaft. The method may: determine whether a permissive or permissive(s) is satisfied; initiate an overspeed test; automatically adjusting the speed of a shaft; determining if the speed exceeds an overspeed trip value; and automatically disabling the automatic adjustment of the speed after the test is complete.

Owner:GENERAL ELECTRIC CO

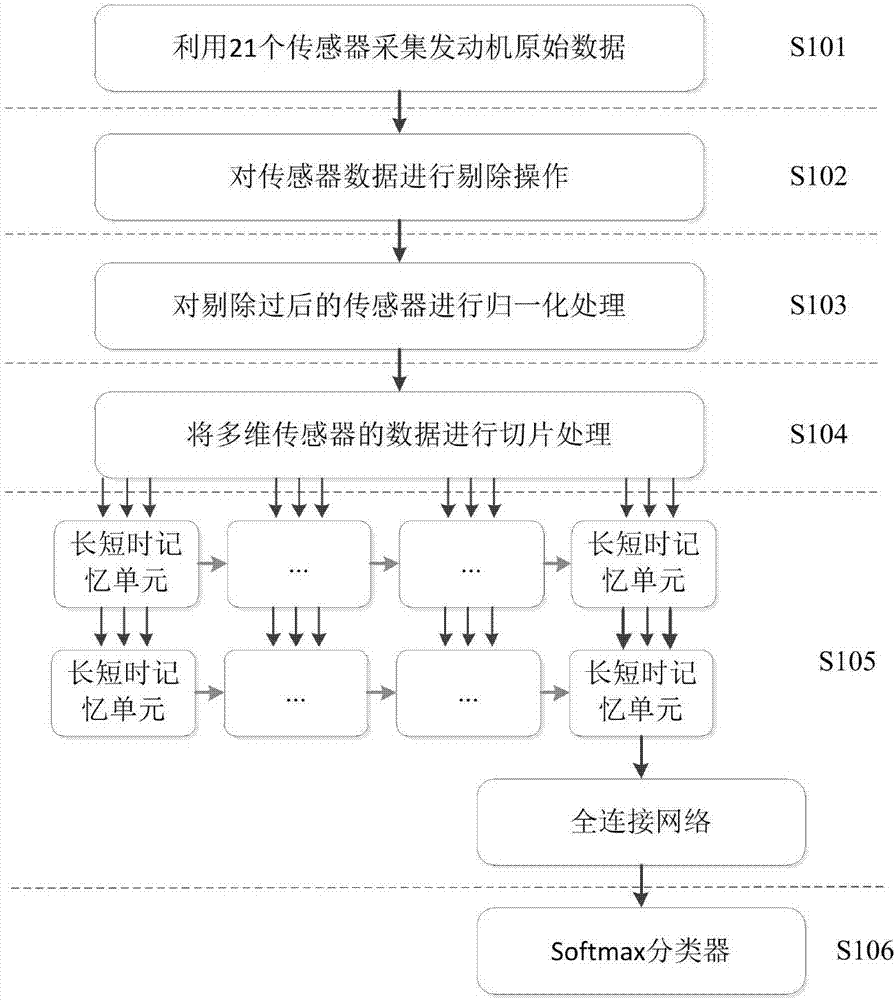

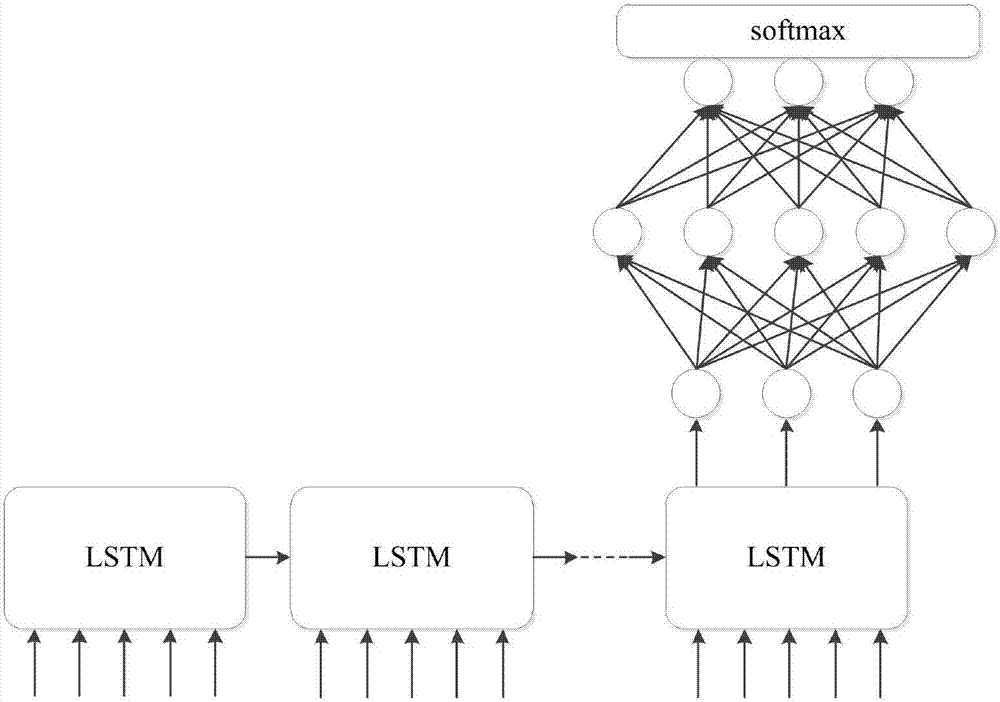

Engine fault prediction method

ActiveCN107044349AGuaranteed reliabilityForecast timeGas-turbine engine testingEngine fuctionsFeature extractionNerve network

The invention discloses an engine fault prediction method. The method comprises the following steps that effective measurement data of a plurality of sensors of an engine are obtained; the effective measurement data are subjected to normalization processing; the effective measurement data obtained after normalization processing are sliced, and a plurality of slice samples are formed; the multiple slice samples are sent into a deep nerve network to be subjected to feature extraction, and after feature extraction, the slice samples are connected to a fully-connected network; and according to output of the fully-connected network, classification is conducted through a softmax classifier, and the left service life of the engine is determined. According to the provided engine fault prediction method, the process is small, operation is easy, and the engine fault prediction method can be widely applied to various engines of aircraft.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com