Machining cutter abrasion state identification method of numerical control machine tool

A tool wear, CNC machine tool technology, applied in the direction of program control, computer control, general control system, etc., can solve the problem of low recognition accuracy of tool wear state, and achieve the improvement of recognition accuracy, productivity, and tool life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

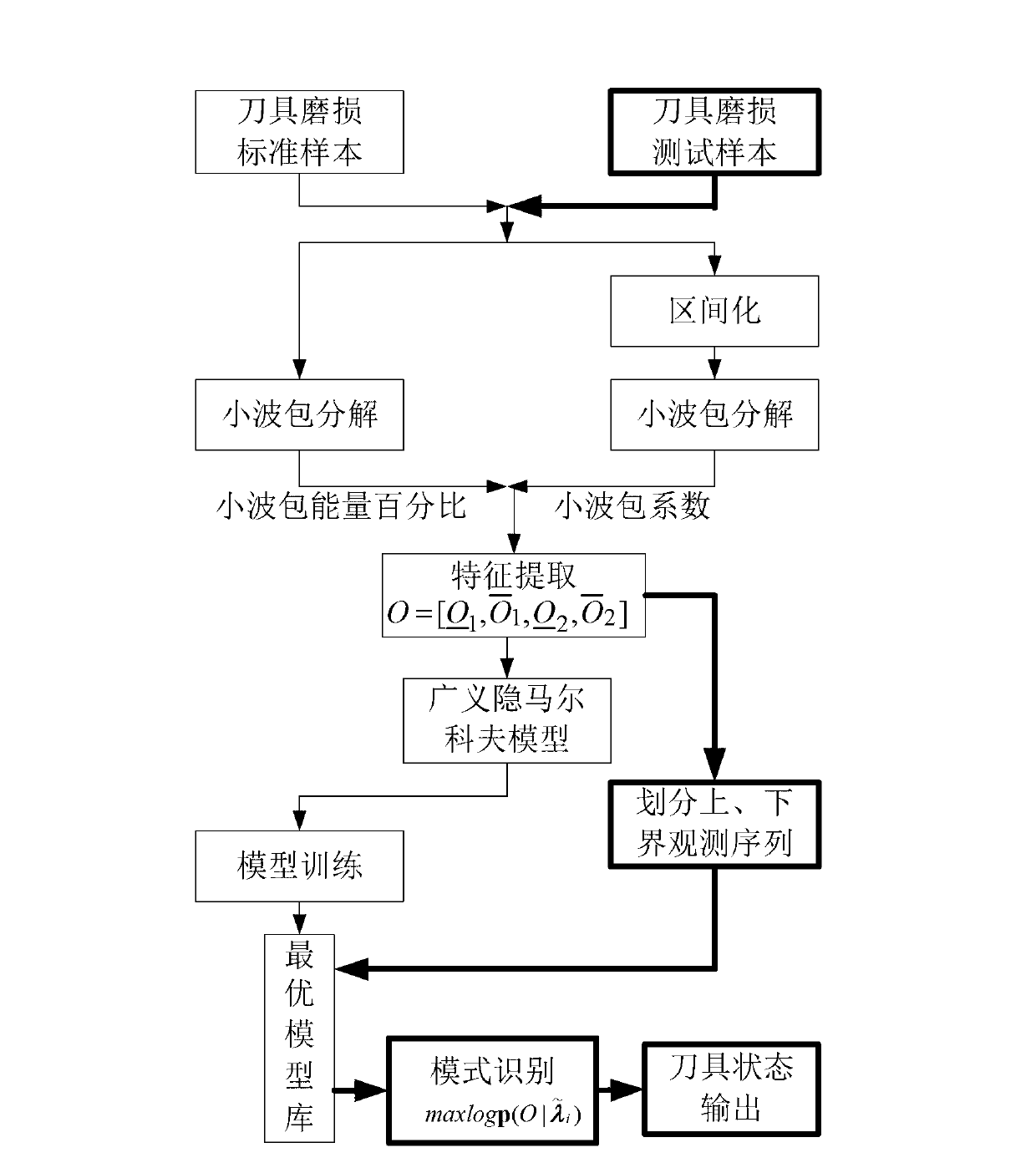

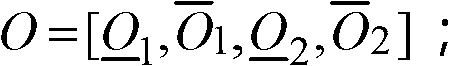

[0034] See attached figure 1 , the tool wear state identification method of the present invention comprises the following steps:

[0035] (1) Data collection

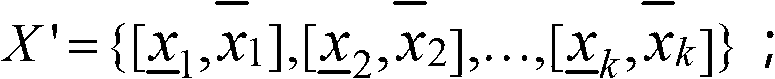

[0036]Tool wear is closely related to cutting force. The measurement tool used in this embodiment is a dynamometer, and the measurement data under various wear states of CNC machine tool cutting are obtained through the dynamometer, which is used as the tool wear force signal data set X={x 1 , x 2 ,...,x k}, where k=1, 2, ..., m, m is the number of measured data, x 1 , x 2 ,...,x k Refers to the multiple measurement values of measurement data, that is, sampling values.

[0037] There are generally four types of tool wear states, namely normal, light wear, severe wear and damage. The measurement data can be one of cutting force, acceleration, acoustic emission, torque, current a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com