Detection tool for rapidly detecting pitch of threaded holes of part

A technology for threaded holes and parts, which is applied in the field of inspection tools for rapid detection of threaded hole distances of parts, can solve the problems of long time wasted in detection, low detection efficiency, and only spot inspection, etc., and achieves long service life, low wear and tear, The effect of long life of the inspection tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

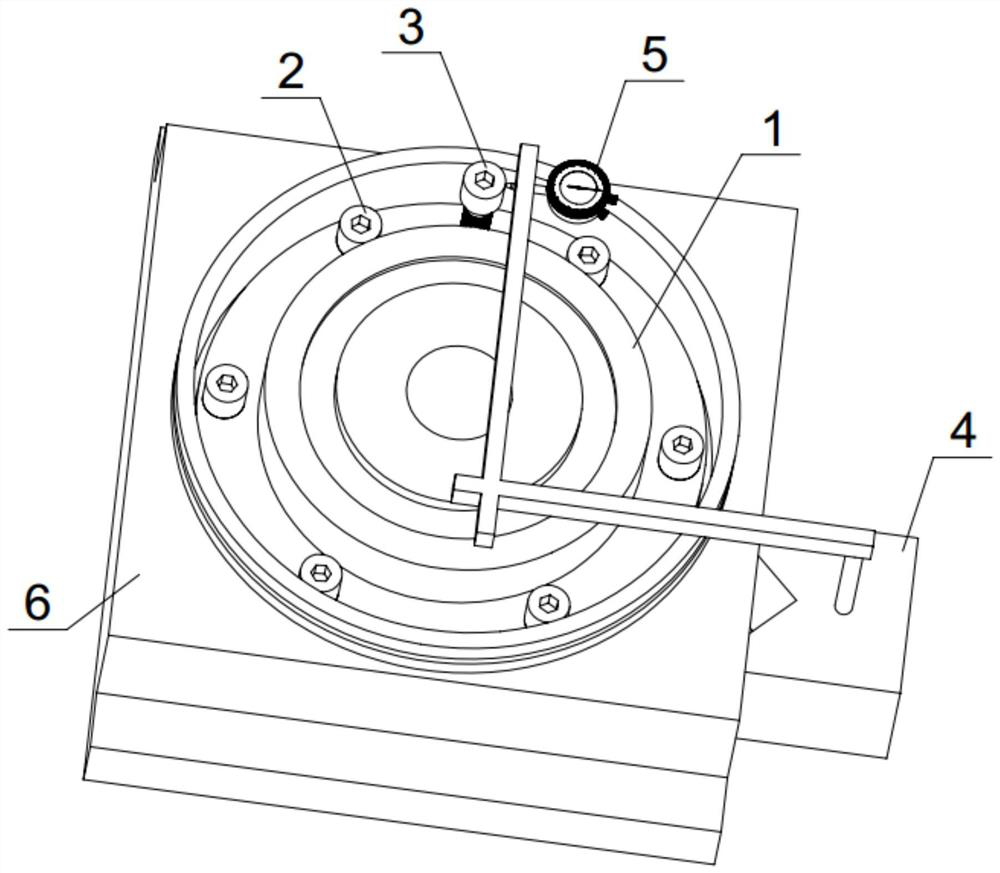

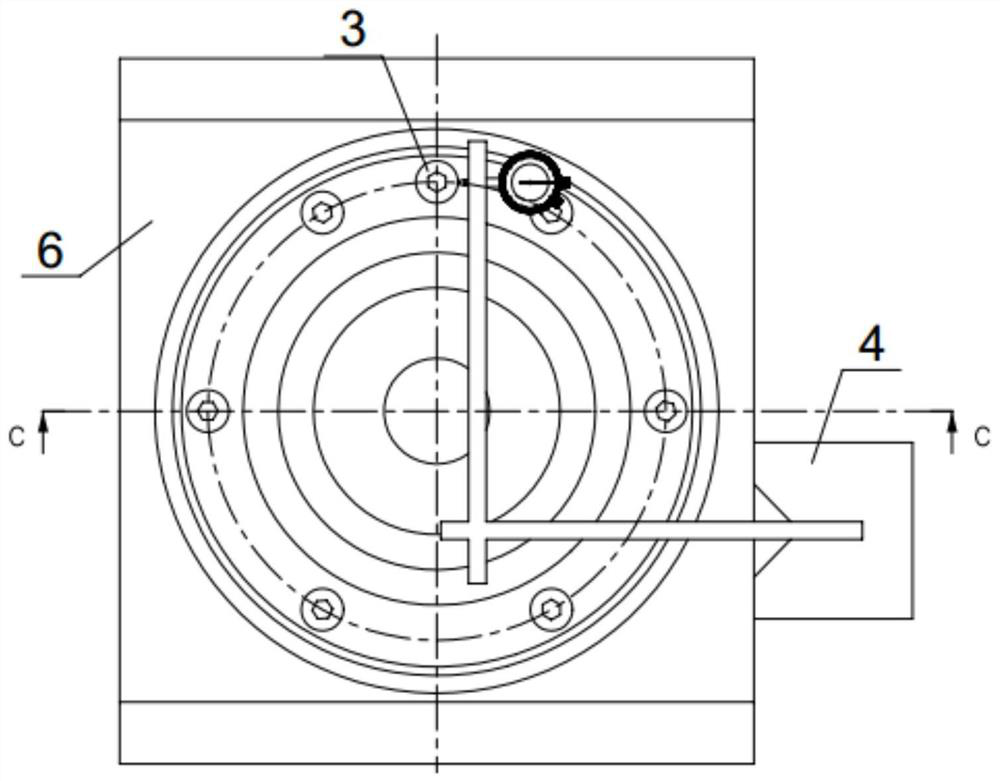

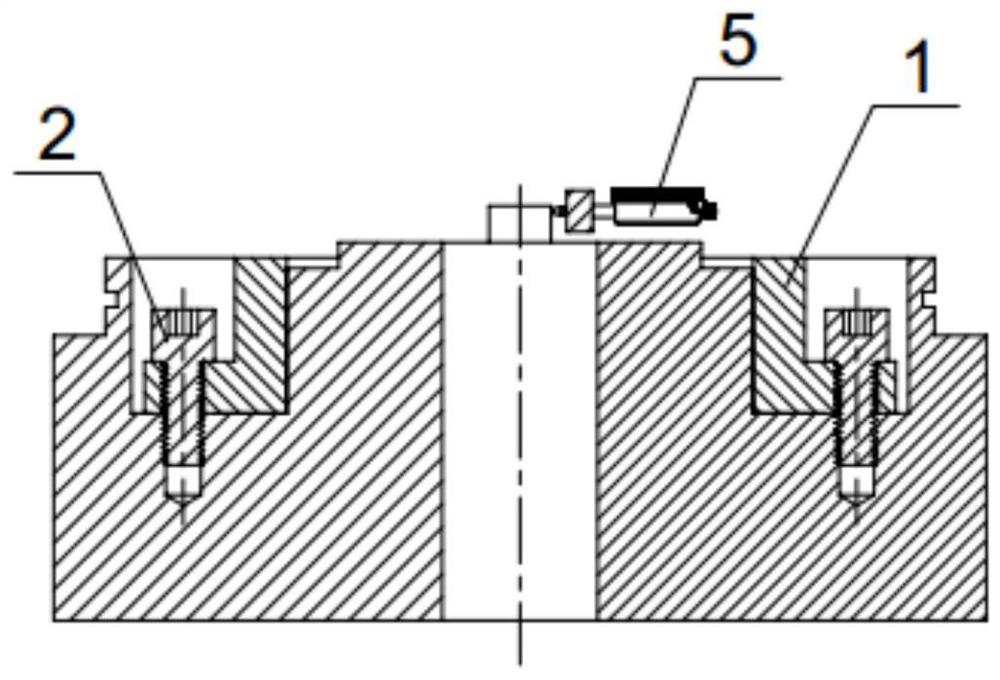

[0030] This embodiment provides a checking tool for quickly detecting the distance between threaded holes on parts. For its structure, see figure 1 As shown, it is used to realize the pair such as Figure 5 The detection of the hole distance of several measured threaded holes 7 processed on the inner annular end surface of the measured part 6 shown, the measured threaded holes 7 are located on the same circumferential line, the inspection tool includes a positioning plate 1, a contact displacement measuring piece , the detection screw 3 and the positioning screw 4, the detection hole 5 corresponding to the position of the measured thread hole 7 of the standard part is processed on the positioning plate 1, and during detection, the positioning screw 4 respectively passes through the detection and is fixedly connected to the measured thread On the hole 7, the detection screw 3 is fixed on the positioning plate 1, and the detection screw 3 and the positioning screw 4 are located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com