Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1473results about How to "Guaranteed hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon rubber with high refractive index and high transparency for optical encapsulation and preparation method thereof

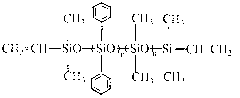

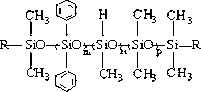

ActiveCN103122149AHigh refractive indexImprove mechanical propertiesSemiconductor devicesHydrogenPolymer science

The invention relates to silicon rubber with high refractive index and high transparency for optical encapsulation and a preparation method thereof. The silicon rubber is prepared from a phenyl vinyl polysiloxane component A, a silicon resin component B containing phenyl vinyl, a phenyl component C containing hydrogen polyoxyalkylene, a platinum catalyst component D, a catalytic inhibitor component E, a modified polysiloxane component F, and a water remover component G in a mixing manner. The silicon rubber not only has over 1.50 of refractive index, but also is good in transparency, excellent in adhesion, and stable in performance, can resist heat and ultraviolet radiation for a long period of time, can meet various requirements of LED (light-emitting diode) encapsulation, and is an ideal encapsulation material of the LED. The silicon rubber can be packaged into a bi-component product; the product has good storage stability; and high transparency is still kept after the product is stored for over 6 months.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

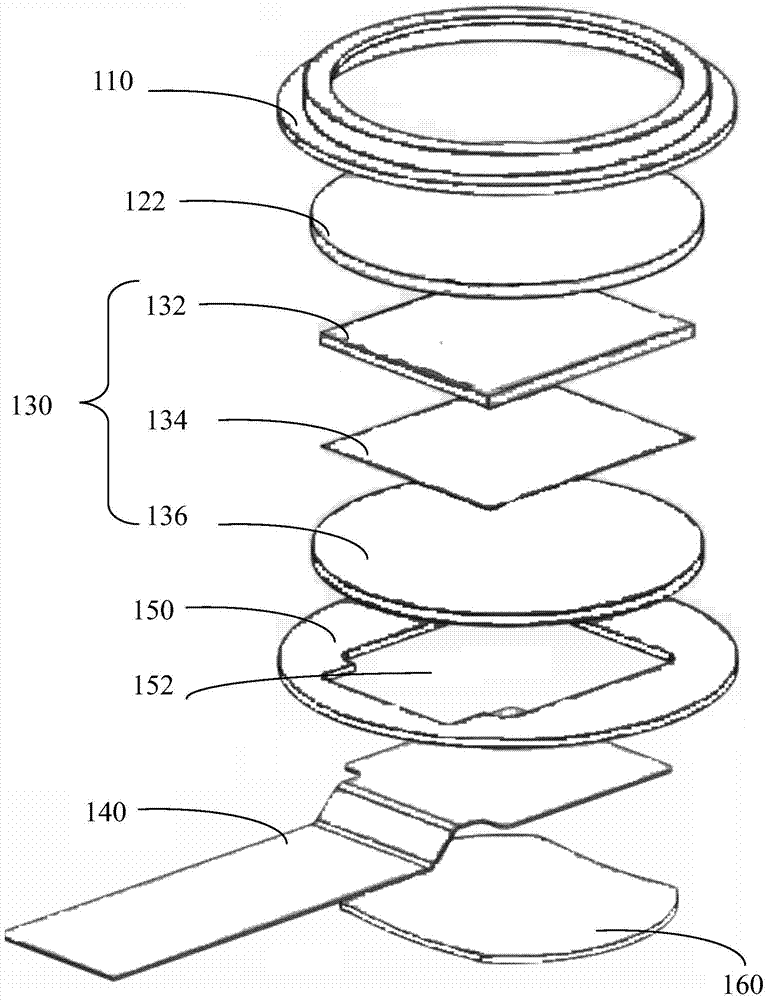

Fingerprint recognition sensor packaging structure, electronic device and method for manufacturing fingerprint recognition sensor

ActiveCN103793689ADoes not affect thicknessDoes not affect thickness designCharacter and pattern recognitionDielectricGlass cover

The invention relates to a fingerprint recognition sensor packaging structure and an electronic device with the fingerprint recognition sensor packaging structure. The fingerprint recognition sensor packaging structure comprises a control button and a fingerprint recognition sensor arranged below the control button, wherein the control button comprises a glass cover plate and a thin film which coats the surface of the glass cove plate and is made of non-anisotropic dielectric materials. The mode of combining the glass cover plate and the coated film is adopted by the control button, the hardness of the control button is ensured, meanwhile, cost is reduced, in addition, the thickness of the fingerprint recognition sensor packaging structure is not affected, and when the fingerprint recognition sensor packaging structure is embedded into the electronic device, the thickness design of the electronic device is not affected.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

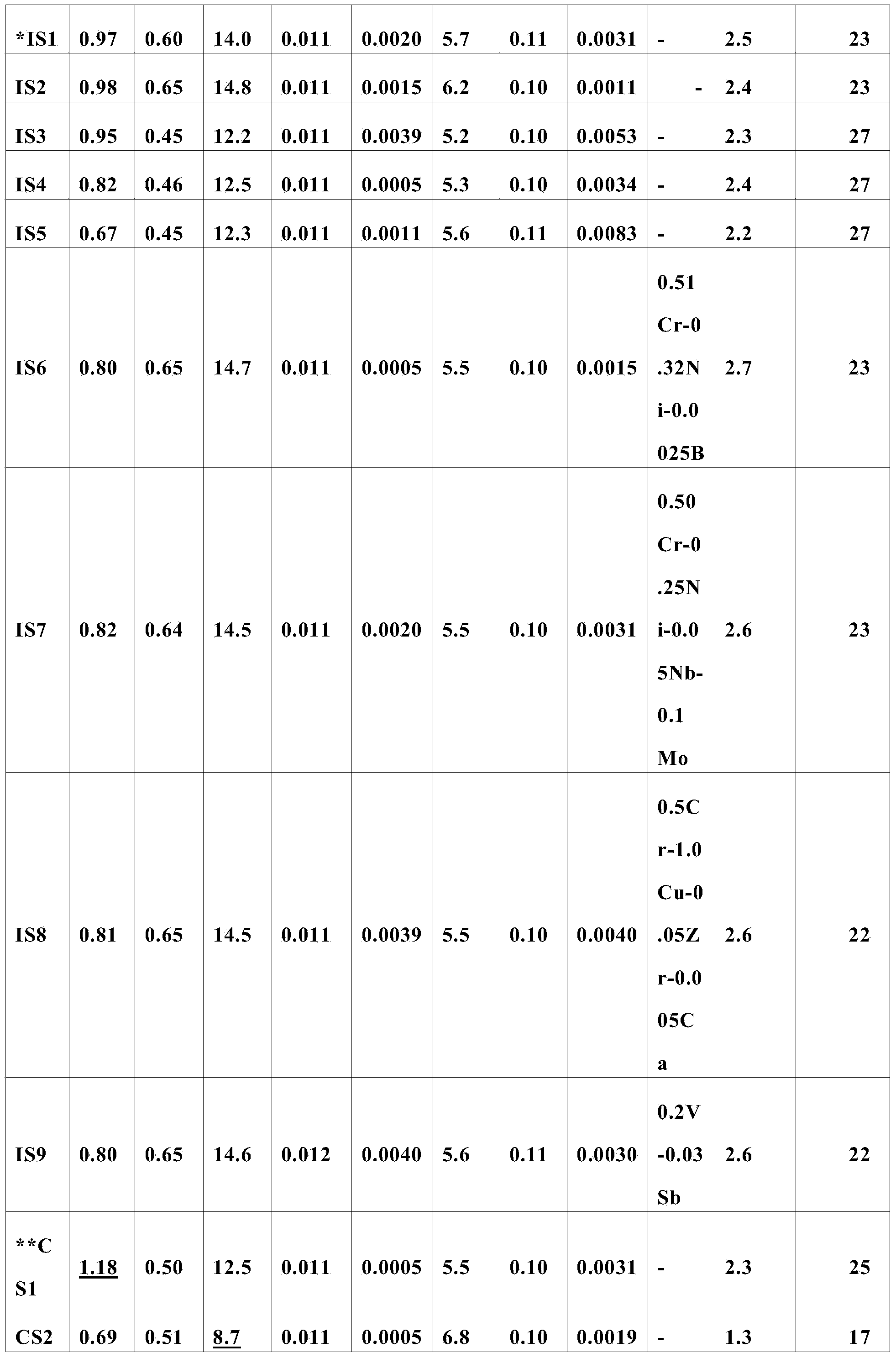

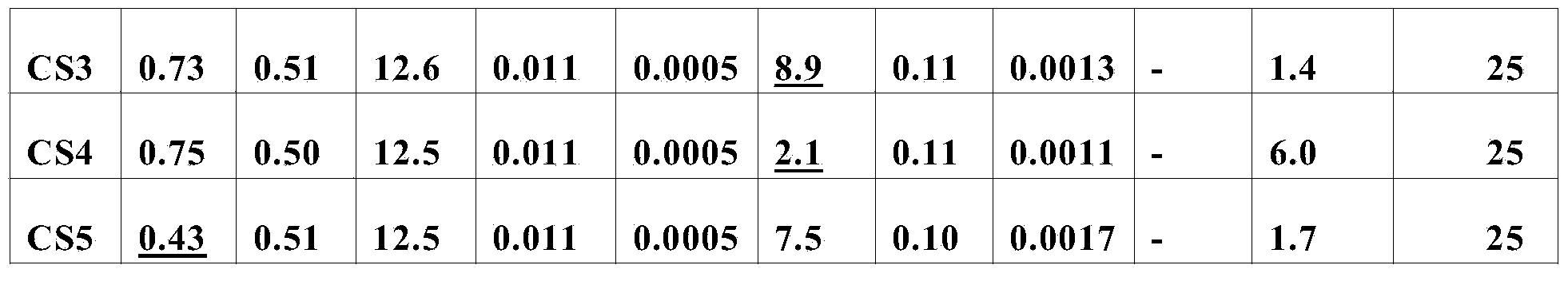

Austenitic, lightweight, high-strength steel sheet of which the yield ratio and flexibility are outstanding and a production method therefor

ActiveCN103370434AHigh yield ratioImprove ductilityHot-dipping/immersion processesThin material handlingPliabilityManganese

The present invention relates to an austenitic, lightweight, high-strength steel sheet having a high yield ratio and ductility and a method for producing the same, and more particularly, to a high-strength steel sheet for automotive interior panels, exterior panels, and structural parts, and a method for producing the steel sheet. An aspect of the present invention provides austenitic, lightweight, high-strength hot rolled steel sheet , cold rolled steel sheet and coated steel sheet having a high yield ratio and ductility and a method for producing thereof including appropriate concentrations of alloying elements such as Mn, Si, and Al to obtain a tensile strength of 800 MPa or greater, an elongation of 30% or greater, and a yield ratio of 60% or greater that are difficult to obtain from high-carbon, high-manganese steel sheets or high-manganese, lightweight steel sheets of the related art. The present invention provides a steel sheet having a low specific gravity, a high yield ratio, and high ductility as compared to high-strength steel sheets of the related art such as advanced high strength steels (AHSS). The steel sheet of the present invention is effective in maintaining the rigidity of a structural member and have good press processing characteristics so that the steel sheet can be used for manufacturing automotive parts to reduce the weight of automobiles and combining a plurality of parts into a single module or as one part to simplify machining or assembly processes.

Owner:POSCO CO LTD

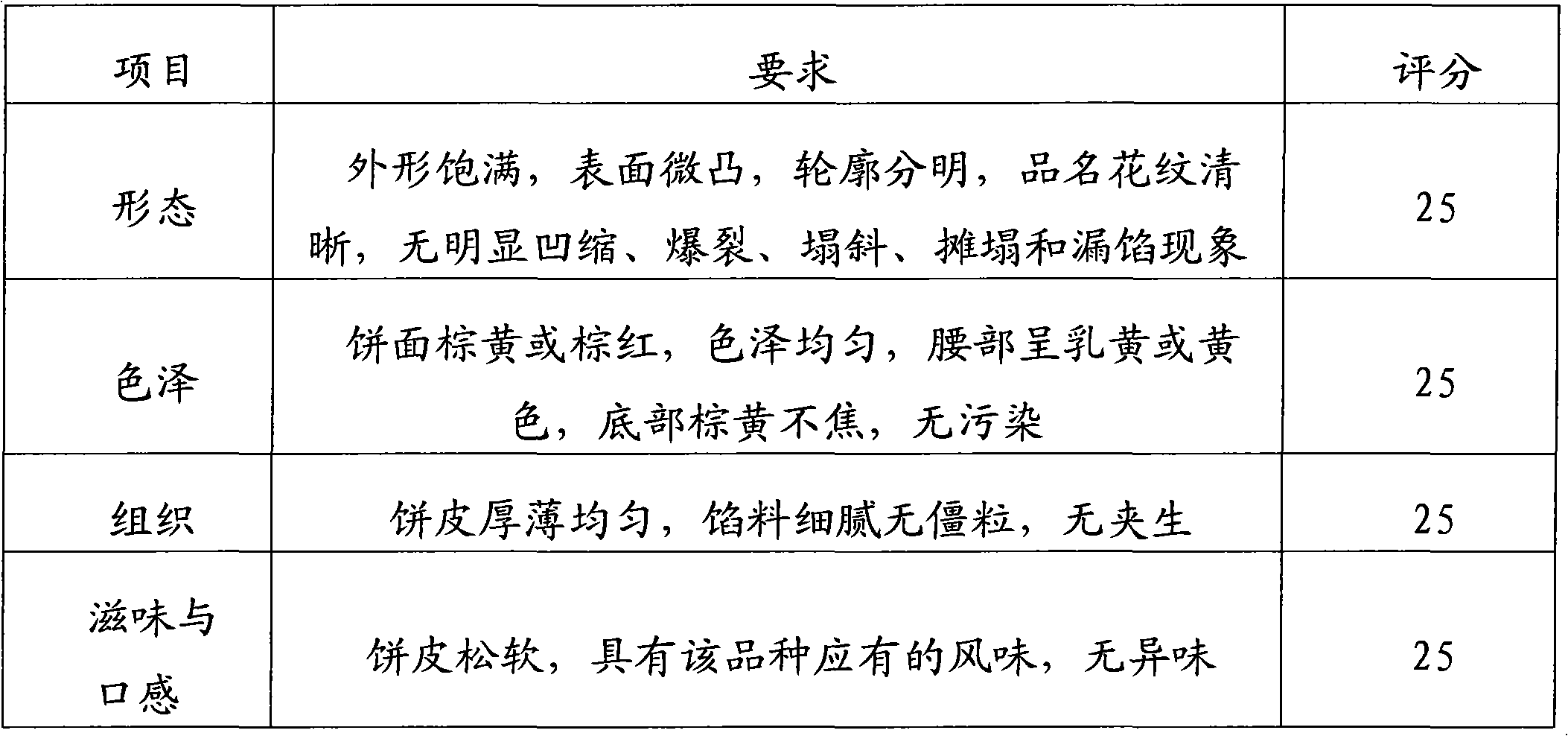

Moon cake

ActiveCN101889600AEasy to shapeImprove plasticityDough treatmentBakery productsAlkaline waterVegetable oil

The invention discloses a moon cake. The moon cake comprises a moon cake cladding and a moon cake filling, wherein the moon cake cladding comprises the following raw materials: 40 to 70 percent of wheat flour, 20 to 45 percent of sugar alcohol, 2 to 8 percent of L-arabinose, 5 to 20 percent of animal and vegetable oil or hydrogenated animal and vegetable oil and 0.2 to 2 percent of alkaline water. The technical problems of soft cladding and poor plasticity caused by the low viscosity of a sugar-free moon cake which takes maltitol solution as a cladding in the prior art are solved. Therefore, the moon cake has the characteristics of easily-shaped cladding, high plasticity and stable texture in baking process.

Owner:SHENGQUAN HEALTANG

Method for preparing ultra-high hardness cladding layer through synchronous ultrasonic vibration assisting laser technology

InactiveCN104451673AIncreased microhardnessImprove wear resistanceMetallic material coating processesCeramic coatingLiquid metal

The invention provides a method for preparing an ultra-high hardness cladding layer through the synchronous ultrasonic vibration assisting laser technology. According to the specific scheme, the method includes the steps that ultrasonic vibration is synchronously introduced in the Ni-based metal ceramic coating cladding process, mobility of liquid metal can be improved in the mode, tissue distribution is more uniform, in the solidification process, a growing dendrite net can be broken and made to be dispersed to all portions of melt, small crystal nucleuses which are uniformly distributed are formed, segregation of metal ceramic is avoided, and therefore it is guaranteed that the cladding layer is not prone to cracking when ultra-high hardness is acquired; equipment is simple, calibration and installation are facilitated, energy consumption is low, the working environment is good, and acquired coating metal ceramic particles are uniform in distribution, high in hardness and good in abrasion resistance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

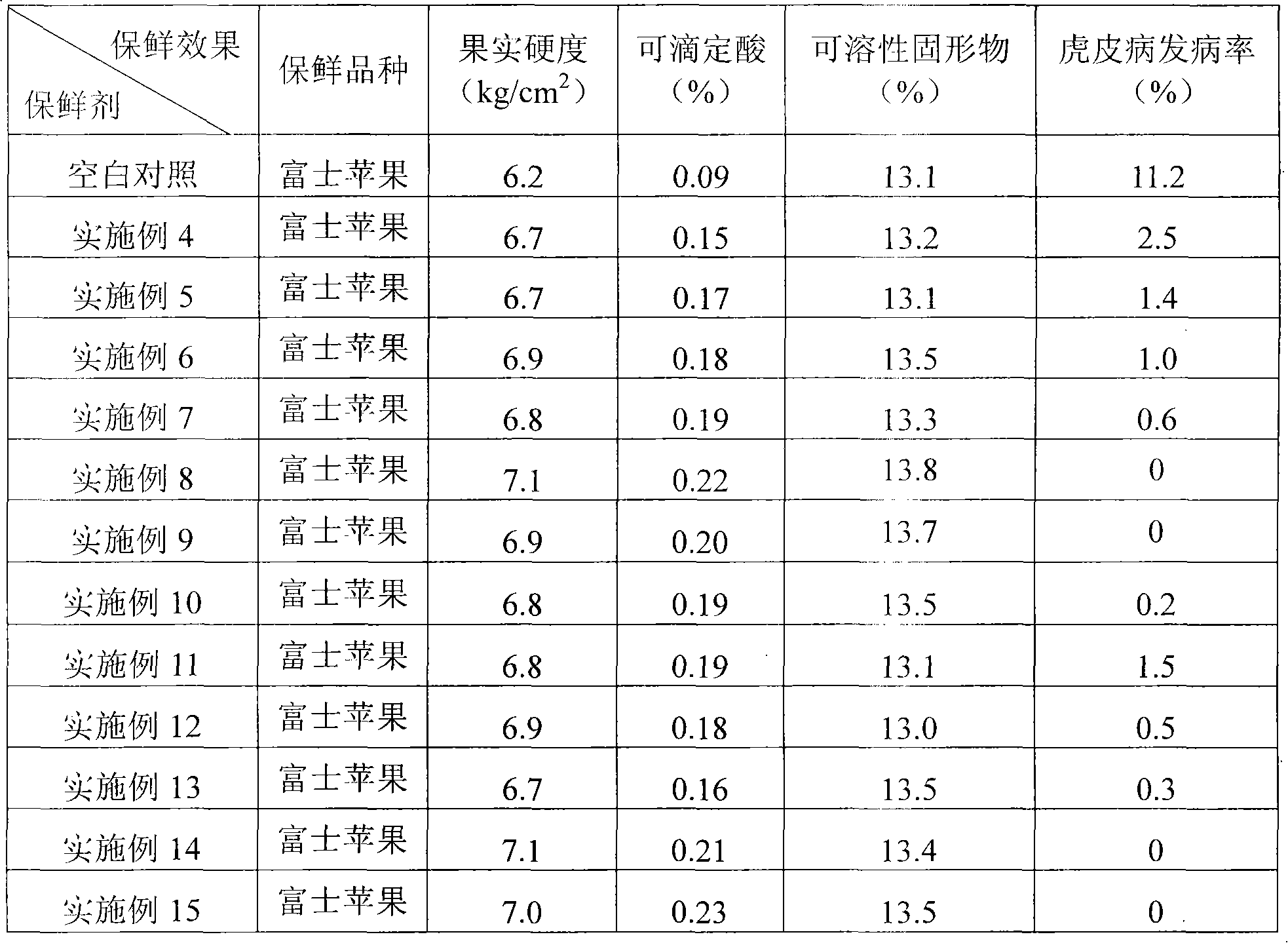

Cyclopropene preservative, and preparation and packaging methods thereof

ActiveCN102119719AExtended storage timeImprove qualityDead plant preservationFruit and vegetables preservationChemistryCyclopropene

The invention provides a cyclopropene preservative, which is characterized by containing 0.1 to 99 mass percent of cyclopropene coating material powder, 0.1 to 98 mass percent of compound, composition or material releasing water molecules, and 0 to 98 mass percent of one or more assistants. The invention also provides the preparation method and packaging method of the cyclopropene preservative. The preservative is convenient for use and has a remarkable preservation effect.

Owner:山东营养源食品科技有限公司

Branched/block copolymer for treatment of keratinous substrates

InactiveCN1337974AKeep your hairGuaranteed stickinessCosmetic preparationsHair removalPersonal carePolymer science

A block copolymer for hair styling compositions includes hydrophilic and hydrophobic blocks which allow for optimization of desirable characteristics of the hair styling composition, such as style retention at high humidity, tack, hardness, resistance to flaking, and washability from the hair. The copolymer includes a polyacrylate backbone of hydrophobic blocks, with hydrophilic acrylate side chains. The copolymer is suitable for the formulation of a number personal care, household, hair care, skin care and other formulation. The copolymer is suited to incorporation into low VOC hydra-alcoholic hair styling compositions to meet reduced VOC regulations.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Steel for a plastic molding die

To provide a steel for plastic molding die which possesses enough hardness, wear resistance and corrosion resistance, and is excellent in high-precision processability and mirror polishing properties. The steel for a plastic molding die contains not more than 0.80 wt% C, not less than 0.01 wt% and less than 1.40 wt% Si, not less than 0.05 wt% and not more than 2.0 wt% Mn, not less than 0.005 wt% and not more than 1.00 wt% Ni, not less than 13.0 wt% and not more than 20.0 wt% Cr, not less than 0.20 wt% and not more than 4.0 wt% Mo + 1 / 2 W, not less than 0.01 wt% and not more than 1.00 wt% V, not less than 0.36 wt% and not more than 0.80 wt% N, not more than 0.02 wt% O, not more than 0.80 wt% A1, and the remainder substantially including Fe and unavoidable impurities.

Owner:DAIDO STEEL CO LTD

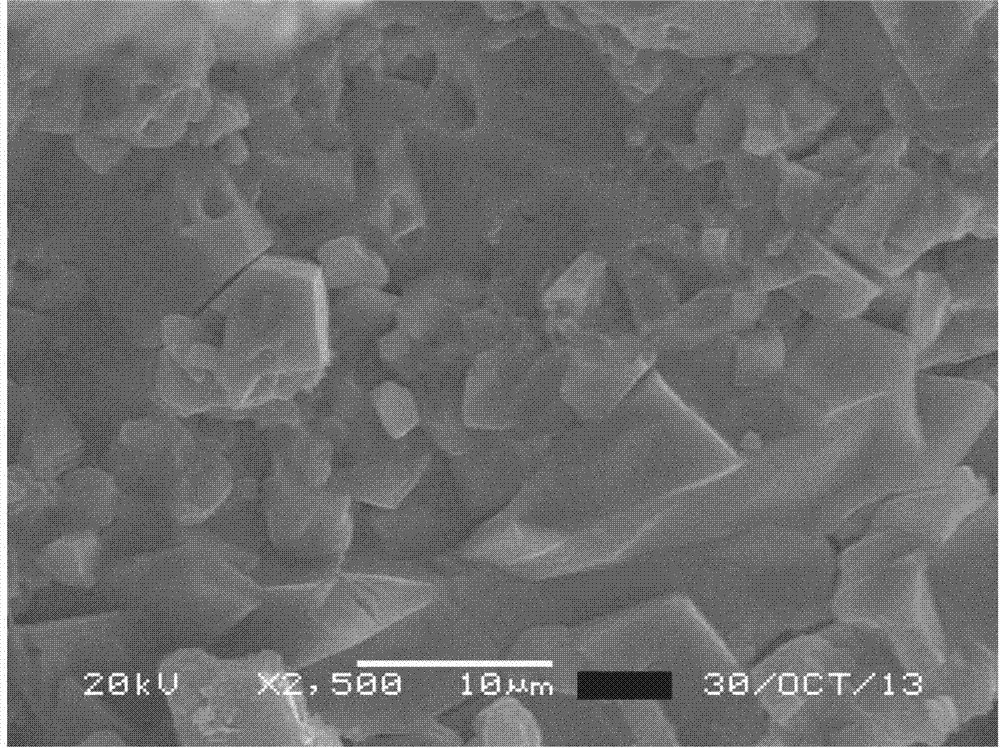

Stone-plastic composite powder for laser sintering 3D manufacturing technology and preparation method of stone-plastic composite powder

ActiveCN103881371ALow costReduce consumptionAdditive manufacturing apparatus3D object support structuresManufacturing technologyNylon 12

The invention provides stone-plastic composite powder for laser sintering 3D manufacturing technology and a preparation method of the stone-plastic composite powder, and relates to composite powder for laser sintering 3D manufacturing technology as well as a preparation method and a use method of the composite powder. The stone-plastic composite powder provided by the invention is used for solving the technical problems of low strength of a sintered workpiece prepared from a wood-plastic composite material and a rice husk powder-hot melt adhesive composite material for the existing laser sintering, and high cost of a sintered workpiece prepared from metal powder or ceramic powder. The stone-plastic composite powder for laser sintering 3D manufacturing technology provided by the invention is composed of nylon 12 powder and limestone powder. The preparation method comprises the steps of adding the nylon 12 powder and the limestone powder into a ceramic grinding tank for grinding and mixing to obtain the stone-plastic composite powder. During laser sintering, a laser beam scans a sub-region in a manner of scanning on a horizontal plane, and the laser power is 15-20 W, so that the laser power is low. The stone-plastic composite powder provided by the invention is applied to the laser sintering 3D manufacturing field.

Owner:NORTHEAST FORESTRY UNIVERSITY +2

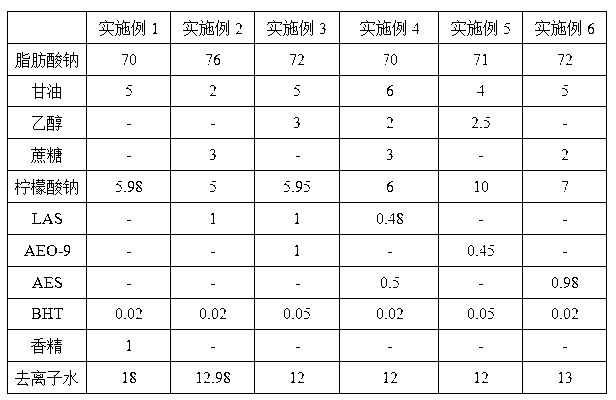

Transparent soap

InactiveCN103013715AHigh transparencyHigh hardnessSoap detergents with organic compounding agentsAlkali/ammonium soap compositionsActive agentFatty acid

The invention discloses a transparent soap, which is mainly prepared by fatty acid, a transparent reagent, sodium citrate, a surfactant and deionized water, wherein the content of sodium citrate based on weight is 0.1-15%. The transparent soap has appropriate hardness and transparency; and the washing capability is not influenced by calcium ions and magnesium ions when in use.

Owner:GUANGDONG PENGJIN INDUSTRY CO LTD

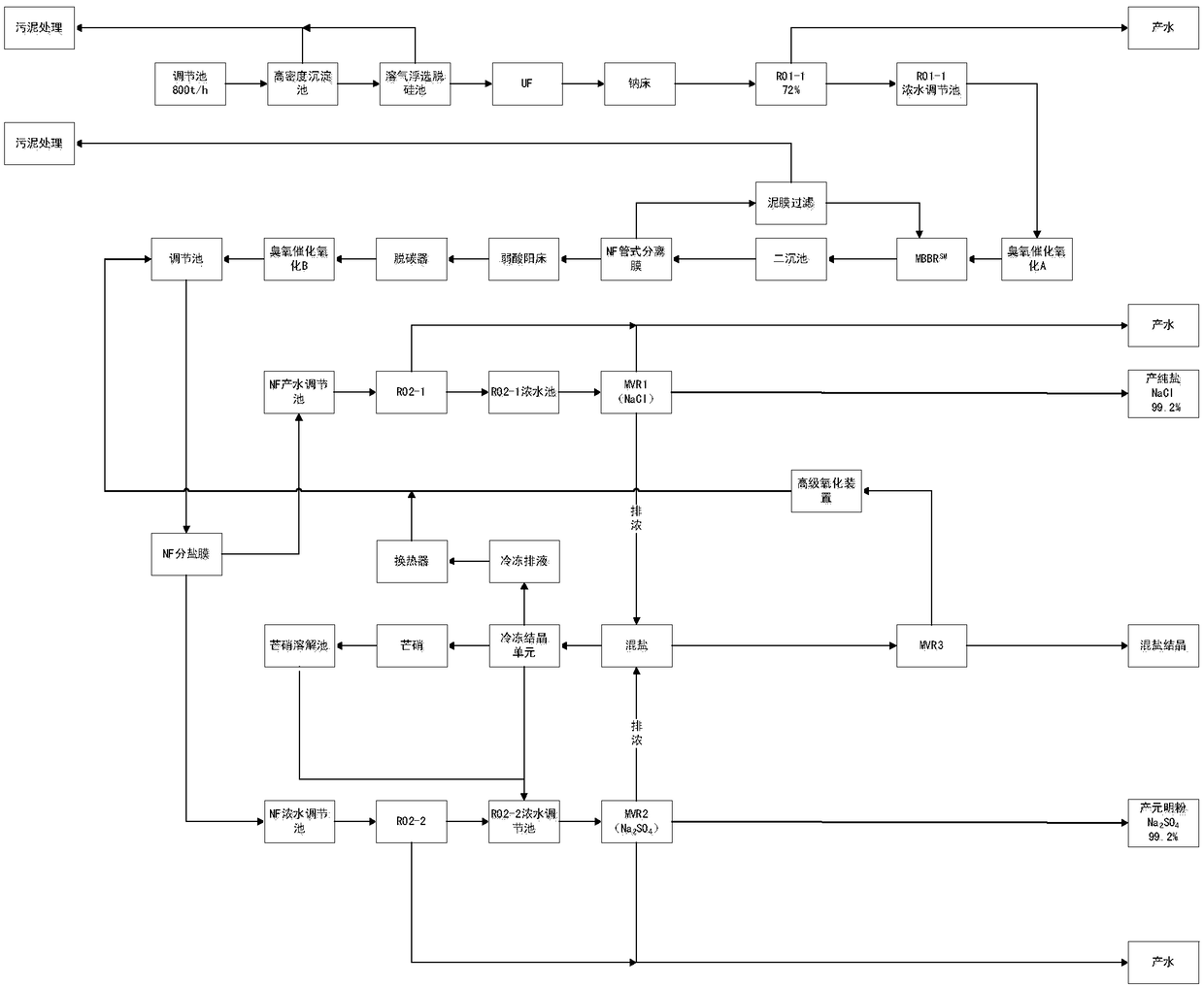

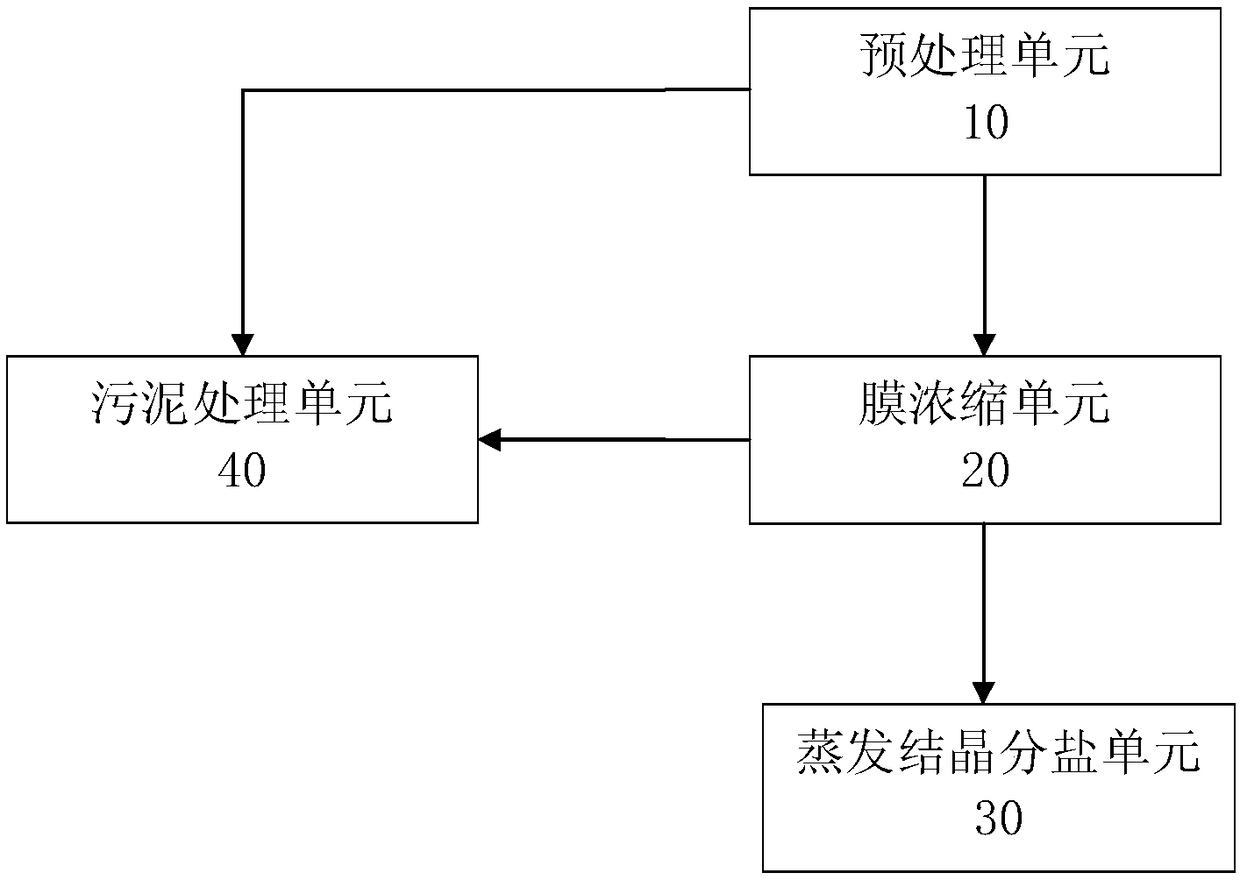

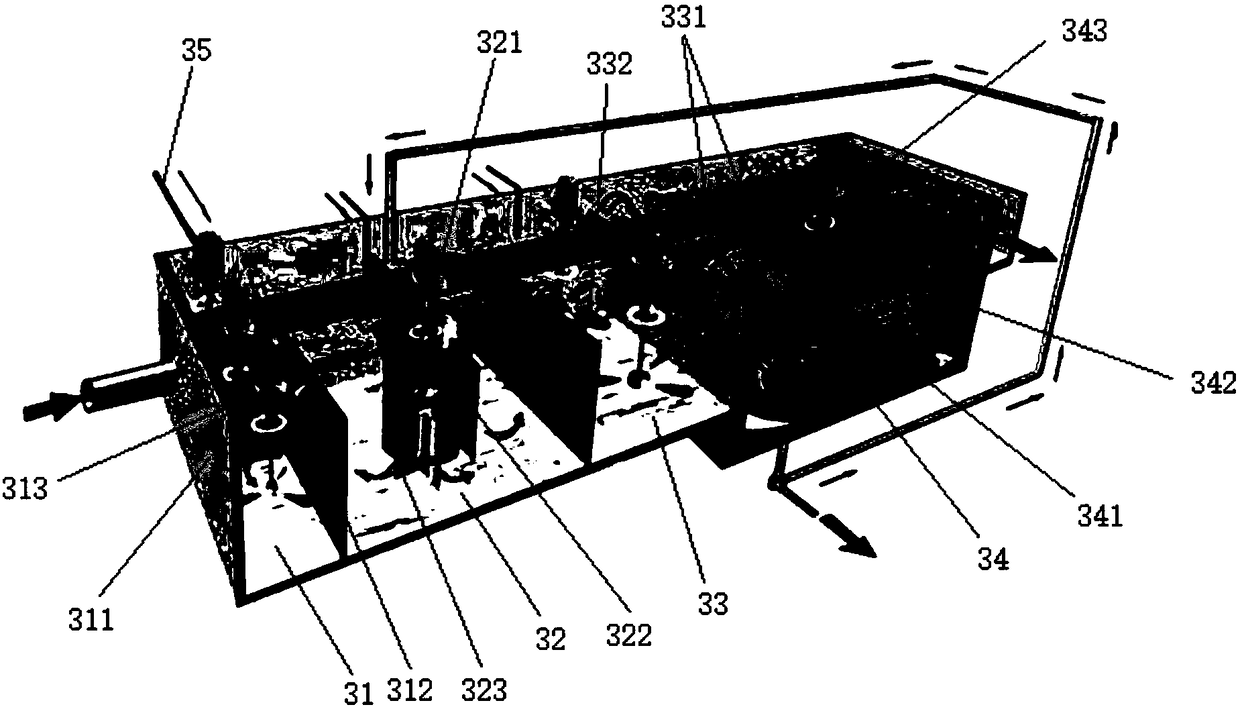

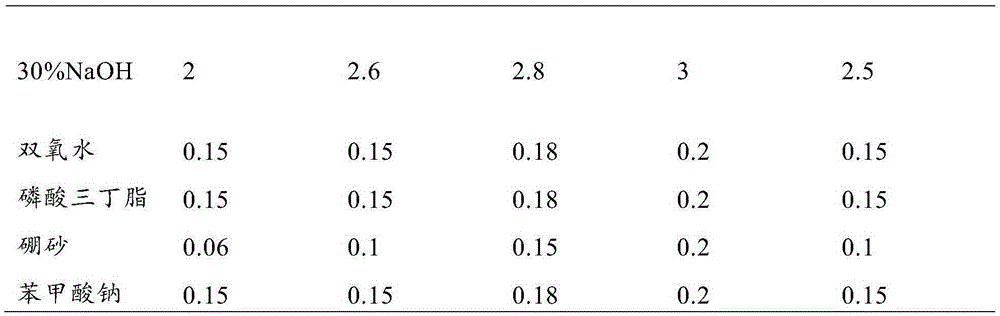

Salinity wastewater zero-discharging method and system

PendingCN108128961AImprove adsorption capacityGuaranteed purityGeneral water supply conservationTreatment involving filtrationDissolved gas flotationFiltration

The invention relates to a salinity wastewater zero-discharging method and system. The method comprises the following steps: further hardness and silicon removal treatment is performed on suspension-removed degummed body by adopting a lime-sodium carbonate softening method and dissolved gas flotation filtration; the hardness is removed deeply through ion exchange; deep treatment is performed by adopting RO concentrated water; COD and NO3- are further reduced by adopting an advanced oxidation and hypersaline microorganism combination technology; an NF membrane salt separation process is adopted; multi-effect Mechanical Vapor Recompression (MVR) is adopted to perform a constant-temperature evaporative crystallization process to concentrate and separate salt; before MVR drained concentrated water is put into catalytic oxidation or an NF membrane, or all is put into carnallite MVR, carnallite is generated; a mother liquor of an MVR device is discharged, and enters a low-temperature refrigeration method to product a large amount of mirabilite to eliminate COD interference; a refrigerating fluid is subjected to advanced oxidization to eliminate COD in a discharged mother liquor outside acrystallization device. A pretreatment technology of the salinity wastewater zero-discharging method is efficient and stable; membrane concentration pretreatment, NF membrane salt pre-separation andreverse osmosis membrane concentration technologies are energy-saving and reliable; total product water and the finished product salt yield are high; the pretreatment technology is an energy-saving technology for reducing the carnallite yield.

Owner:东莞市圆明生物科技有限公司

POSS (Polysilsesquioxane)-containing antireflective film coating liquid and preparation method and application thereof

The invention discloses a POSS (Polysilsesquioxane)-containing antireflective film coating liquid and a preparation method and application thereof, and belongs to the field of film coating liquids. The preparation method of the POSS-containing antireflective film coating liquid comprises the following steps of: adding the following raw materials in percentage by weight: 0.01%-20% of POSS derivatives, 0-10% of nanometer silicon dioxide granules, 0%-10% of hollow silicon dioxide, 0%-5% of non-silicon nanometer oxide granules, 0%-10% of organic silicon compounds, 0%-50% of deionized water and 0%-2% of catalysts into a solvent; and reacting at 20-150 DEG C for 0-45 hours to obtain the POSS-containing antireflective film coating liquid. The POSS-containing antireflective film coating liquid disclosed by the invention can be applied to photovoltaic glass, display screen base plate glass, building glass and automobile glass; and the obtained antireflective film has the advantages of good film layer uniformity, high adhesive force and rigidity and good weather resistance.

Owner:武汉绿凯科技有限公司

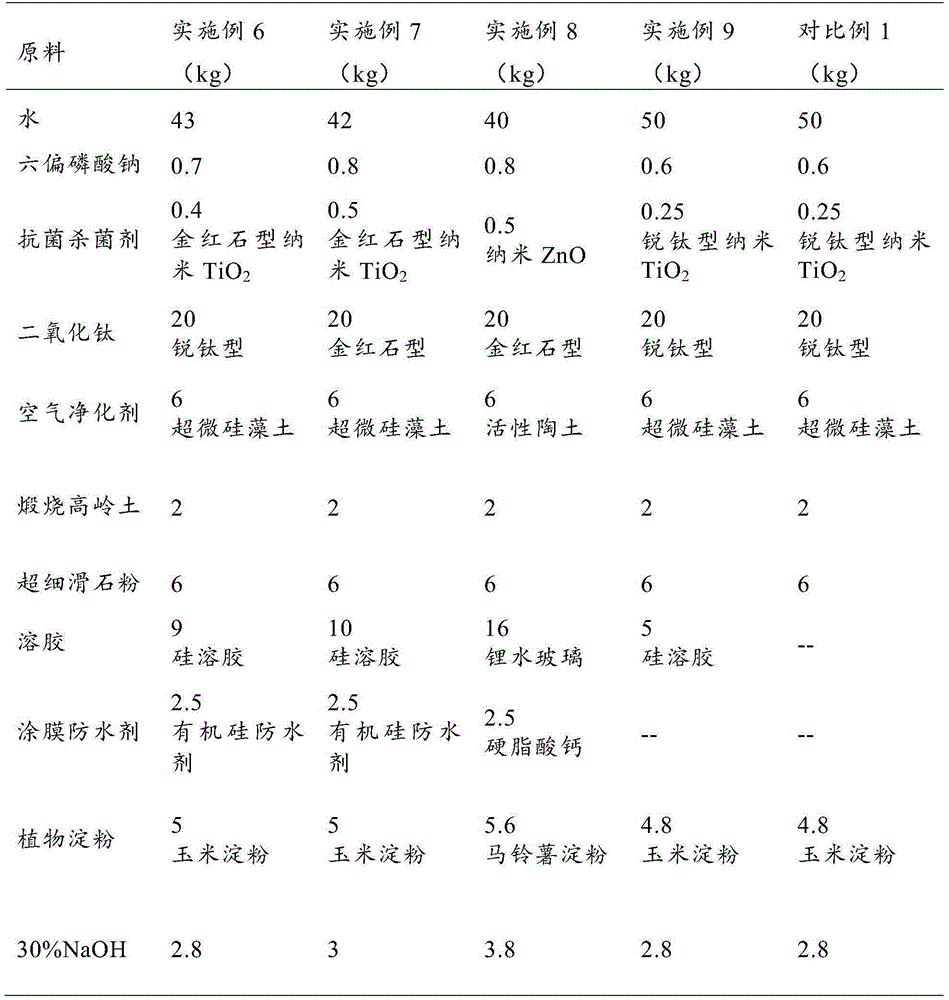

Plant ecological interior wall coating and preparation method thereof

ActiveCN105368164ALow NaOH contentImprove water resistanceStarch coatingsEcological environmentBinding force

The invention discloses a plant ecological interior wall coating and a preparation method thereof. The plant ecological interior wall coating is characterized by being prepared from a titanium dioxide filler, a borax crosslinking agent, an oxidizing agent, water, plant starch serving as a binding agent and sol serving as a binding agent modifier. According to the plant ecological interior wall coating, the plant starch is utilized as the binding agent, no synthetic resin emulsion is contained, complete biodegradation can be achieved, and the coating is an ecological environment-friendly interior wall coating in the true sense; the sol is added to serve as the binding agent modifier, the higher film coating binding force and film coating strength are achieved, and the technical property can reach the GB / T9756-2009 standard of a qualified synthetic resin emulsion interior wall coating product and is obviously suprior to the JC / T423-91 technical requirements for a water-soluble interior wall coating.

Owner:烟台阳光新材料技术有限公司

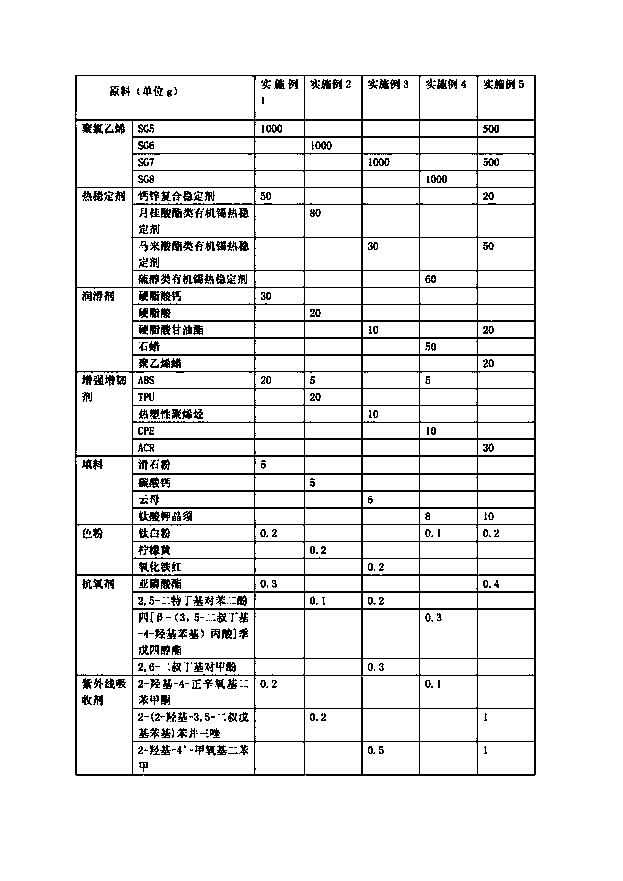

Environmental thermoplastic PVC table tennis material and its preparation method of table tennis

An environmental thermoplastic PVC table tennis material comprises the following materials, by weight, 100 parts of polyvinyl chloride, 3-8 parts of a heat stabilizer, 1-5 parts of a lubricant, 10-30 parts of a reinforcing flexibilizer, 5-10 parts of a filling material, 0.1-0.2 part of a toner, 0.1-0.5 part of an anti-oxidant and 0.1-2 parts of an ultraviolet ray absorber. The preparation method of the environmental thermoplastic PVC table tennis comprises the following steps: firstly carrying out injection moulding to form two hemispheres, splicing the two hemispheres by the use of an adhesive to form a complete sphere, polishing, swelling in a die cavity to form a uniform table tennis, and carrying out aftertreatment to prepare a finished product ball. Thickness of the hemispheres, from top to bottom, is divided into five stages. The environmental thermoplastic PVC table tennis material has advantages of low cost, high hardness, excellent elastic modulus, good eccentricity and good environmental protection property, and can meet requirements of a game ball.

Owner:JIANGNAN UNIV +1

Wear-resistant steel with high resistance to tempering and manufacturing method thereof

ActiveCN101555574AEasy access to strengthGuaranteed StrengthTemperature control deviceMetal rolling arrangementsTemperingHardness

The invention relates to wear-resistant steel with high resistance to tempering and a method for manufacturing steel plates made of the same. The wear-resistant steel with high resistance to tempering comprises the following components according to the weight percent: 0. 10 to 0.24 of C, 0.15 to 1.40 of Si, 1.20 to 2.00 of Mn, 0.40 to 1.60 of Cr, 0.15 to 0.50 of Mo, not more than 0.30 of Ni, not more than 0.12 of V, not more than 0.03 of Ti, not more than 0.05 of Al, not more than 0.015 of P, not more than 0.010 of S and the balanced Fe and inescapable impurities. The wear-resistant steel with high resistance to tempering can keep the strength and the rigidity at higher temperature, remarkably improves the use temperature, has simple process and saves the cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Cyclopropene preservative and preparation method thereof

ActiveCN102119718AExtended storage timeImprove qualityDead plant preservationFruit and vegetables preservationPreservativeCyclopropene

The invention provides a cyclopropene preservative, which is characterized by containing 0.1 to 99 mass percent of cyclopropene coating material powder, 0.1 to 98 mass percent of compound, composition or material releasing water molecules, and 0 to 98 mass percent of one or more assistants. The invention also provides the preparation method and using method of the cyclopropene preservative. The preservative is convenient for use and has a remarkable preservation effect.

Owner:山东营养源食品科技有限公司

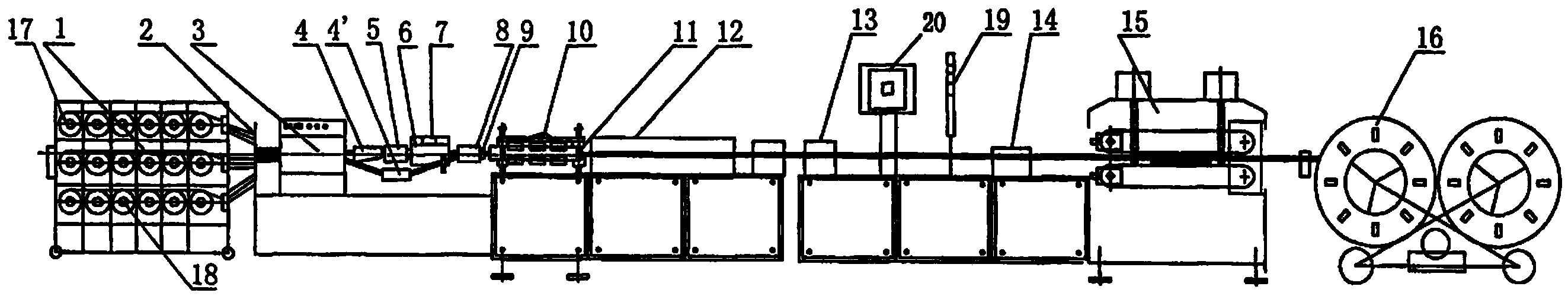

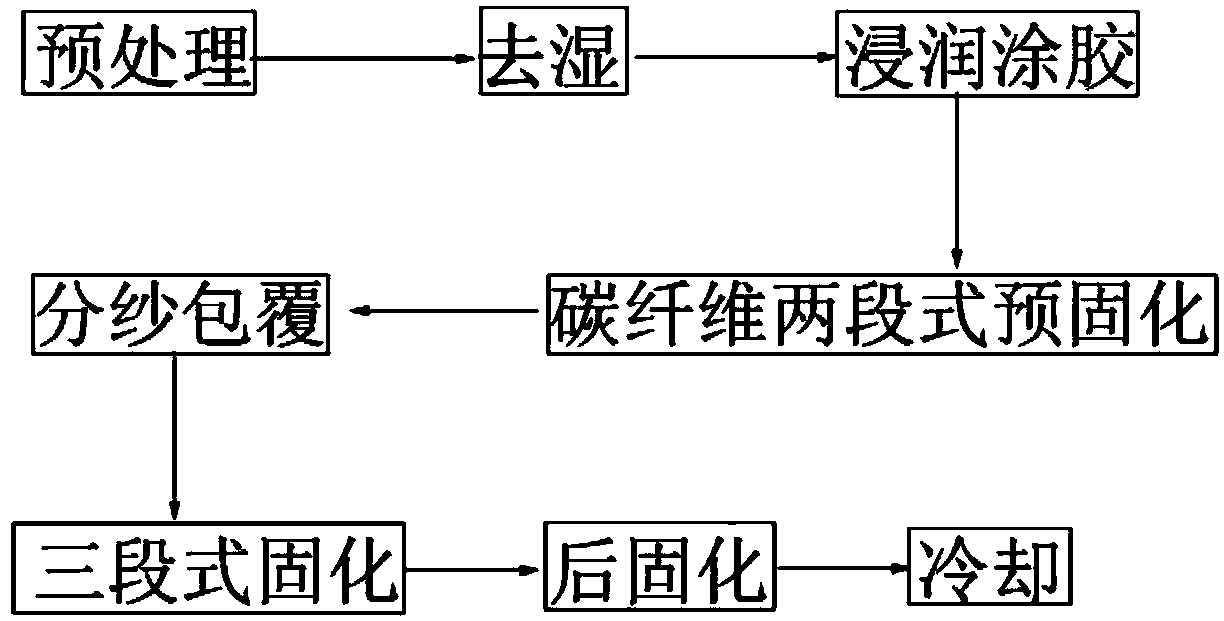

Electric transmission line carbon fiber composite core manufacturing method

InactiveCN103413629AImprove conductivityImprove performanceCable/conductor manufactureElectric power transmissionBasalt fiber

An electric transmission line carbon fiber composite core manufacturing method mainly includes the following steps of conducting preprocessing, dehumidification and glue infiltration, pre-hardening carbon fibers in a two-section heating mode, enabling high-strength glass fibers or basalt fibers to cover a pre-hardened carbon fiber core according to certain rules, hardening the carbon fiber core covered by the high-strength glass fibers or the basalt fibers in a three-section mode, and conducting post curing and cooling, wherein consumed epoxy resin is high-temperature-resistant special type pultrusion epoxy resin which is prepared by adding modified anhydride compounds in the glue infiltration process. The electric transmission line carbon fiber composite core manufacturing method has the advantages that the carbon fibers are preformed in a pultrusion mode to be in a semi-hardened state after being infiltrated, heating temperature sections are controlled so that the carbon fiber core with excellent performance can be obtained, particularly, heating and hardening are conducted in the three-section mode in the final covering and forming process, therefore, the rigidity of final products is ensured, the smoothness of production and production efficiency are improved, and the carbon fiber composite core produced through combination can completely meet the requirements of electric power transmission.

Owner:SUZHOU SUYUE NEW MATERIAL

High-carbon gray cast iron automobile brake disk and production method thereof

ActiveCN103225037AShorten the lengthConvenient lengthBraking discsFriction liningChemical compositionHigh carbon

The invention relates to a high-carbon gray cast iron automobile brake disk and a production method thereof. The high-carbon gray cast iron automobile brake disk comprises the following chemical components in percentage by weight: 3.7-3.8% of C, 0.5-0.8% of Mn, 0.3-0.5% of Cu, 0.1-0.2% of Cr, 0.2-0.4% of Mo, 1.6-2.0% of Si, 0.1-0.2% of N, 0.01-0.12% of P, 0.05-0.12% of S and the balance of Fe. The brake disk provided by the invention has the outstanding characteristics of small brake temperature rise, abrasion resistance, favorable heat fatigue resistance effect and the like; the performance of an automobile brake system can be obviously improved, and the service life can be obviously prolonged; and meanwhile, the potential safety hazard caused by ineffective brake due to high temperature can be effectively eliminated. Thus, the high-carbon gray cast iron automobile brake disk has high economic value.

Owner:河南淮海精诚工业科技有限公司

High-speed low-shrink low-smoke zero-halogen tight-buffered material used for 4G optical cable and preparation method of high-speed low-shrink low-smoke zero-halogen tight-buffered material

ActiveCN103897256AHigh melting pointHigh softening temperatureFibre mechanical structuresLinear low-density polyethyleneFire retardant

The invention discloses a high-speed low-shrink low-smoke zero-halogen tight-buffered material used for a 4G optical cable and a preparation method of the high-speed low-shrink low-smoke zero-halogen tight-buffered material. The tight-buffered material is composed of the following raw materials in parts by weight: 30-60 parts of ethylene-vinyl acetate copolymer, 10-20 parts of linear low density polyethylene, 20-30 parts of high density polyethylene, 10-30 parts of compatilizer, 100-150 parts of filler-type flame retardant, 25-60 parts of synergistic flame retardant, 1-2 parts of silane coupling agent, 2-5 parts of ultra-high molecular weight silicone master batch, 0.5-1 part of amides high-performance lubrication dispersant and 0.2-0.5 part of compound antioxygen through stirring, mixing and extruding steps. The tight-buffered material prepared by elaborate formula selection and processing is low in shrinking percentage, strong in rigidity, high in hardness, high in extrusion molding speed, low in rejection rate and good in high / low temperature cycling resistance. When the tight-buffered material is processed, die orifice stacking and salivation are less, the surface of the optical cable is smooth, fine and particle-free, and the tight-buffered material is easy to peel.

Owner:JIANGSU LINRY NEW MSTAR TECH

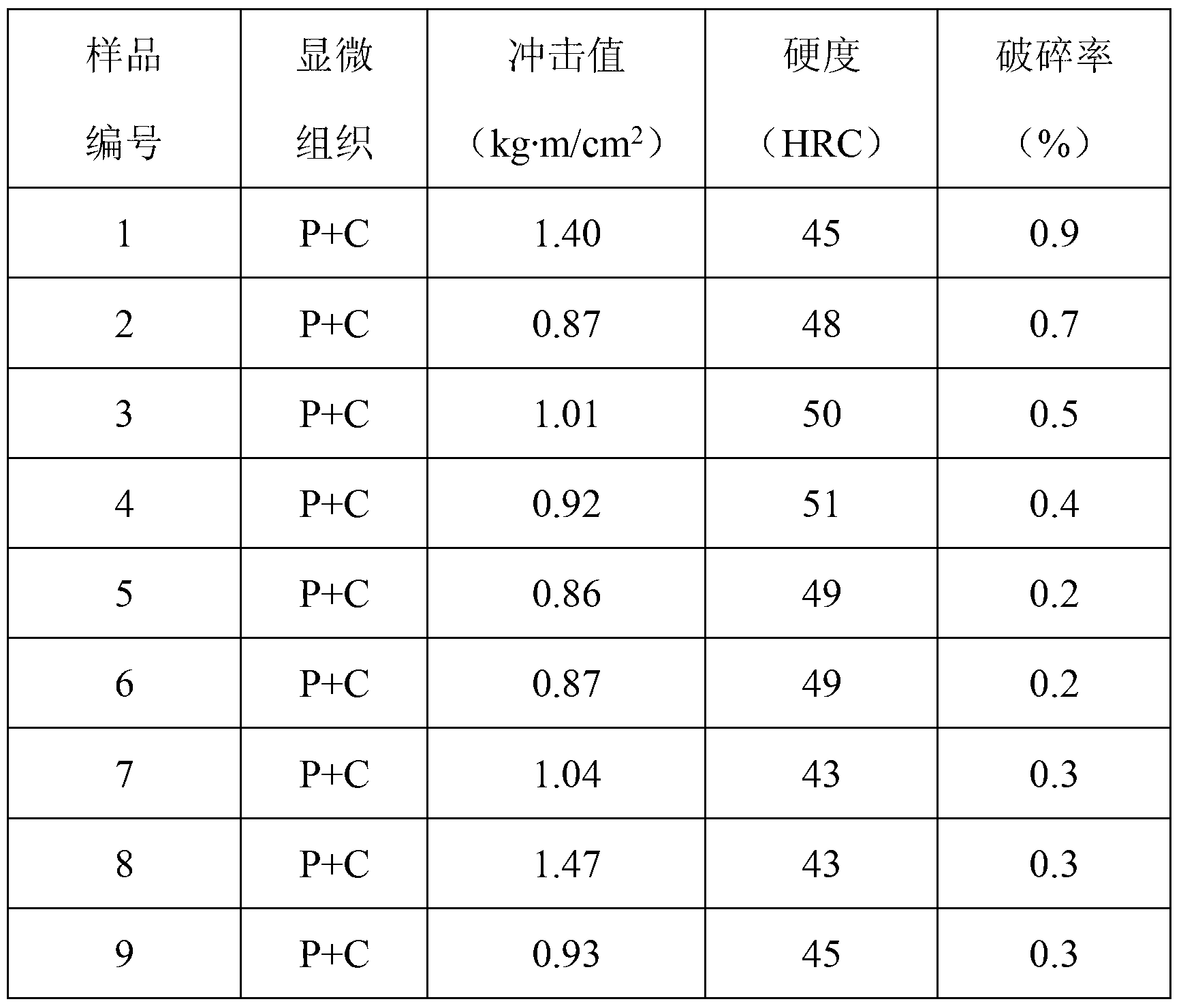

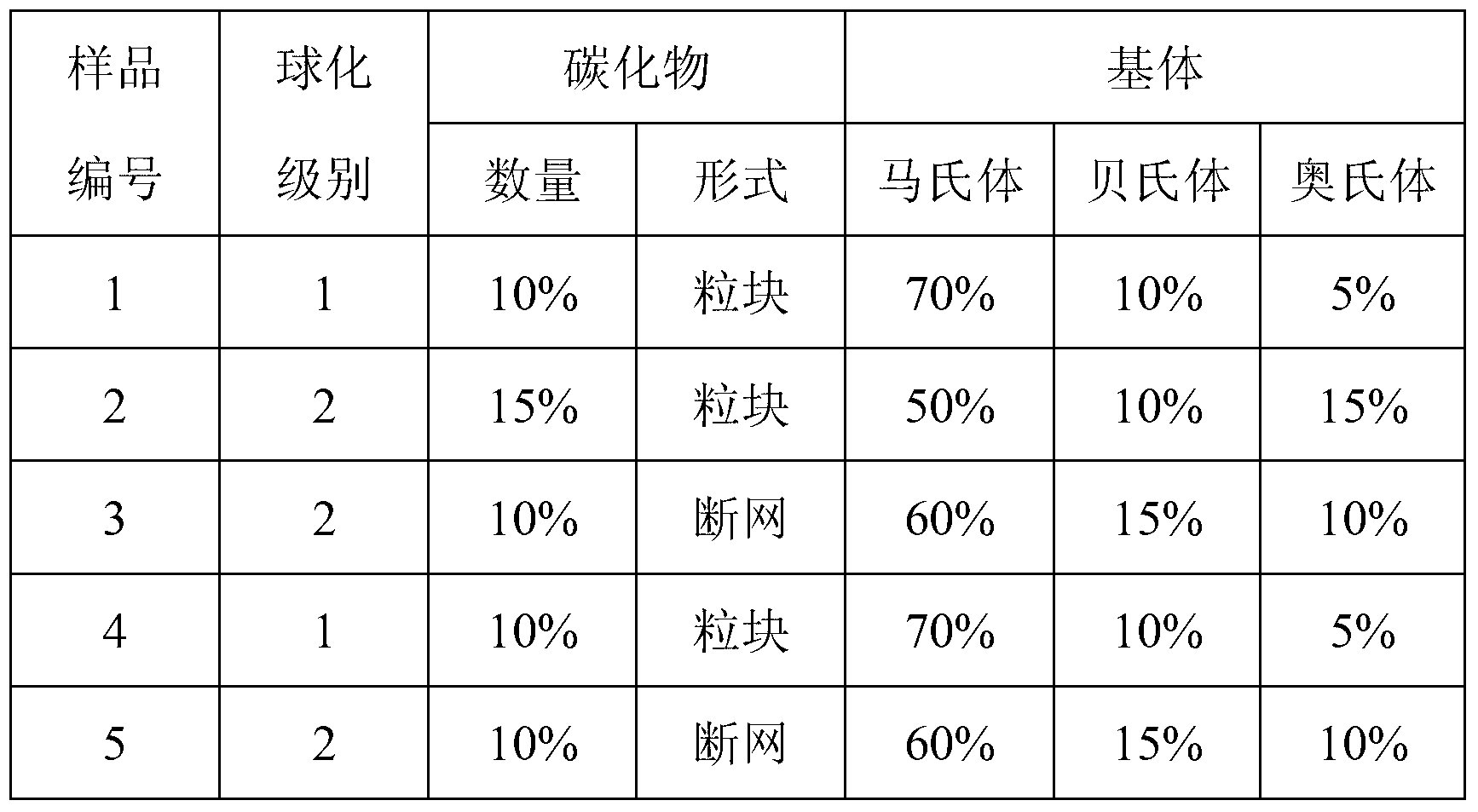

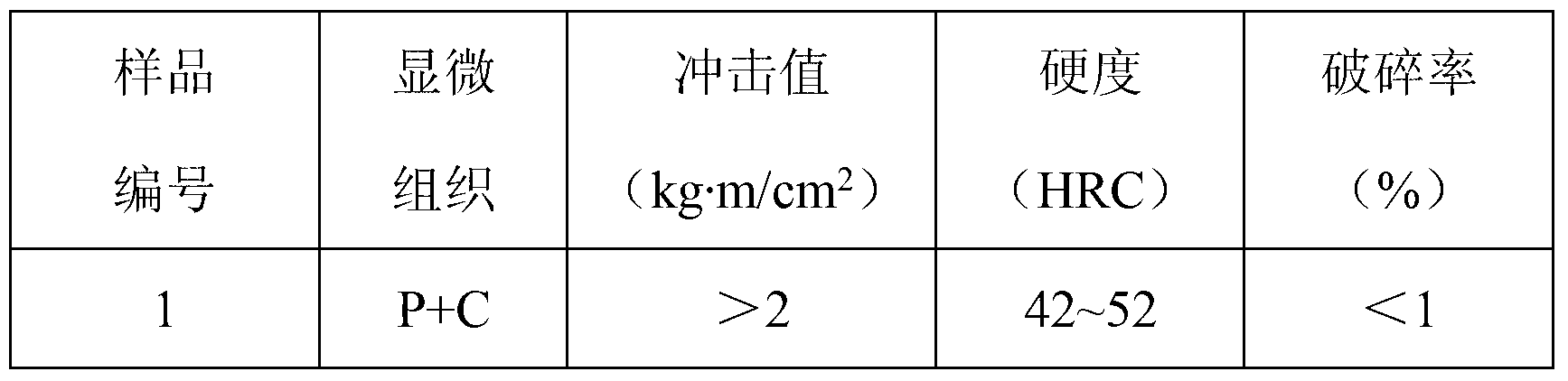

Multi-component alloy casting ball

The invention discloses a multi-component alloy casting ball which comprises the following main chemical components in percentage by weight: 1.8-3.2% of carbon (C), 0.5-1.0% of silicon (Si), 0.4-0.8% of manganese (Mn), 2.0-3.8% of chromium (Cr), no more than 0.5% of molybdenum (Mo), no more than 0.5% of copper (Cu), no more than 0.5% of nickel (Ni), no more than 0.2% of niobium (Nb), no more than 0.5% of zirconium (Zr), no more than 0.5% of vanadium (V), no more than 0.01% of boron (B), no more than 0.15% of phosphorus (P), no more than 0.15% of sulfur (S), 0.5-0.6% of rare earth yttrium (Y-Re) and the balance of iron (Fe). According to the invention, the cost is saved, the corrosion resistance and high temperature resistance of the multi-component alloy casting ball in a wet grinding environment can be improved, the breakage rate can be reduced, and the hardness and shock resistance of the multi-component alloy casting ball in a dry grinding environment can be ensured.

Owner:贵州省遵义市永力机电安装有限公司

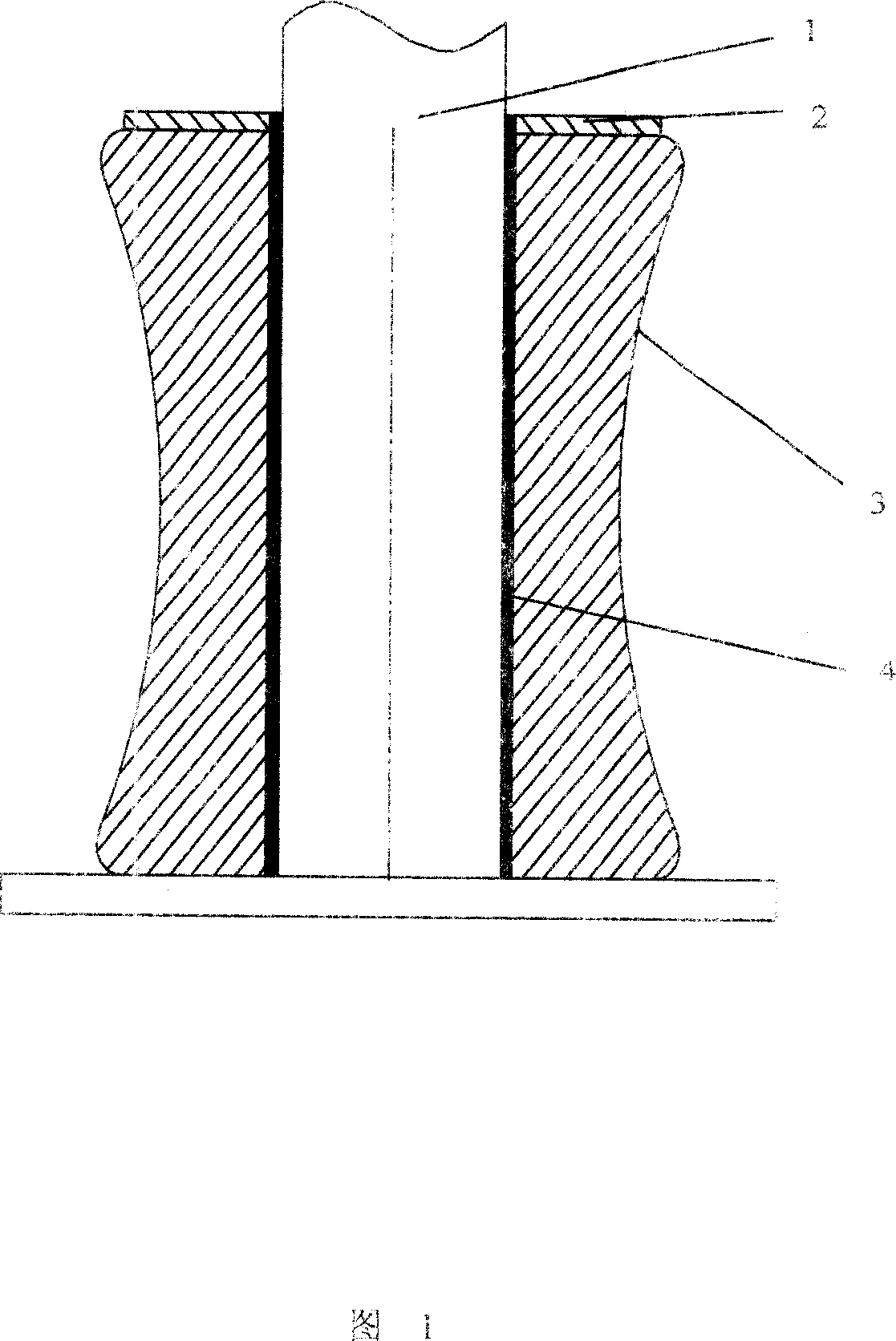

Double quenching technique for 9Cr2Mo leveler roll

InactiveCN101134996AAvoid decompositionGuaranteed hardnessFurnace typesHeat treatment process controlMartensite transformationDecomposition

The double liquid quenching process of 9Cr2Mo straightening roller includes the first quick cooling in water to avoid high temperature decomposition of overcooling austenite to the martensite transformation temperature, and the subsequent cooling in oil for martensite transformation to raise the hardness, reduce quenching deformation and avoid cracking. Before being loaded to furnace, the straightening roller has its end surfaces and central through hole covered with plates to reduce the quench cooling of these parts and ensure hardness of HRC 35-40.

Owner:CITIC HEAVY INDUSTRIES CO LTD

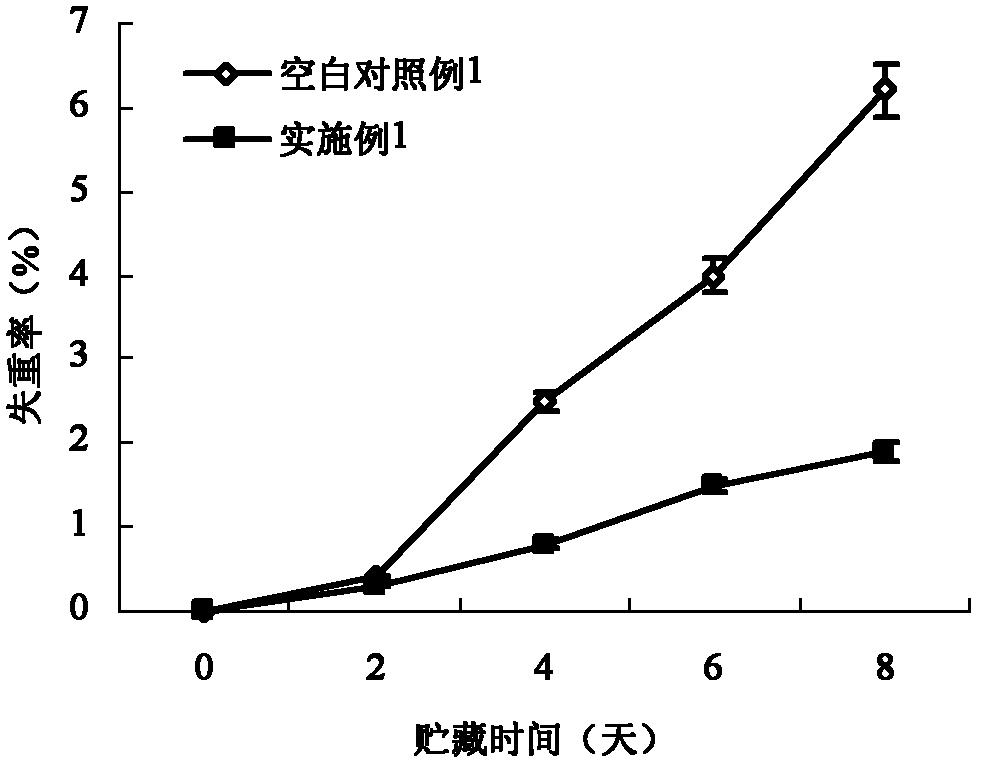

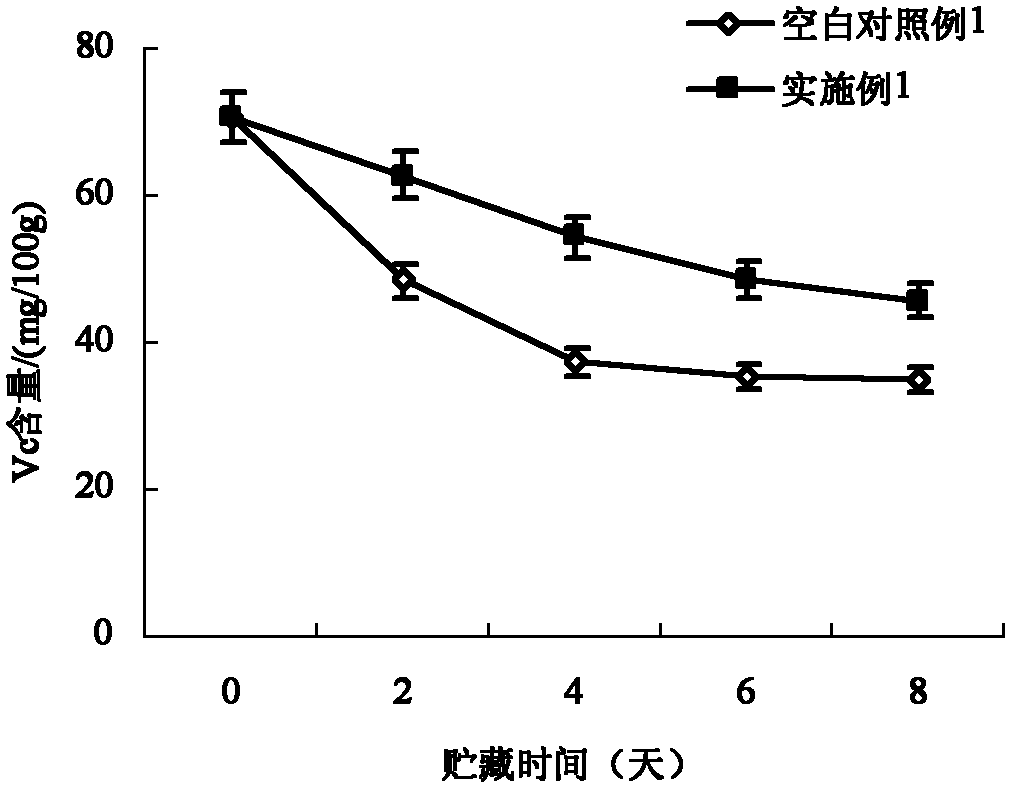

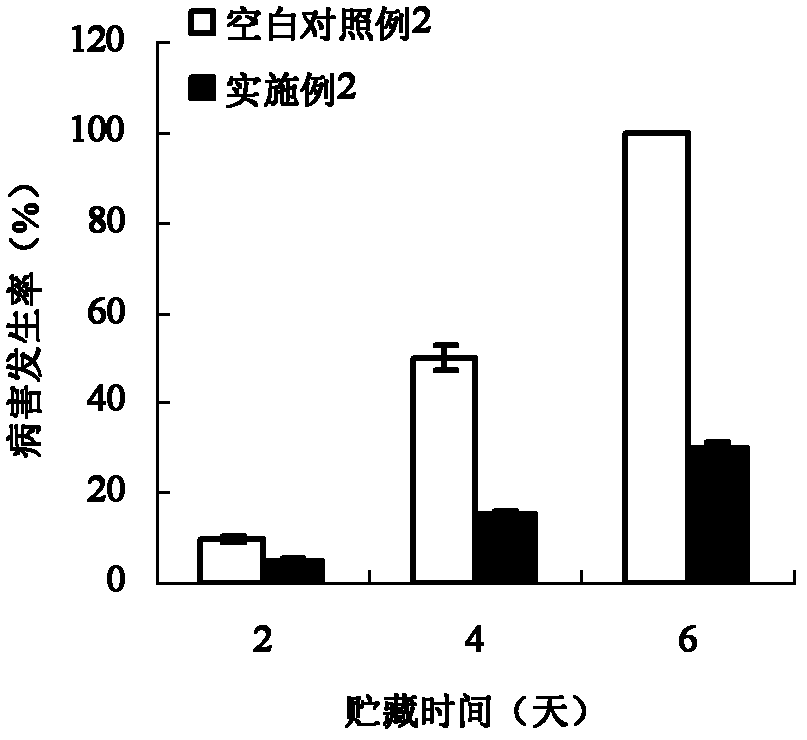

Antiseptic and fresh keeping method for oranges

ActiveCN102524363AEfficient removalInhibition of germinationFruits/vegetable preservation by heatingFruits/vegetable preservation by coatingVitamin CAntibacterial agent

The invention discloses an antiseptic and fresh keeping method for oranges. The method is characterized in that orange fruit is subjected to hot water spraying treatment on the basis of clean water soaking cleaning, then, the orange fruit is soaked into chitosan compound solution containing essential oil for carrying out film coating treatment, next, the orange fruit is packed by a fresh keeping bag containing 1.5 to 2.5 weight percent of nanometer titanium dioxide and 0.8 to 1.2 weight percent of inorganic nanometer antibacterial agents, and the hot water spraying treatment has the conditions that the water temperature is 60 to 65 DEG C, the height from the fruit surface is 0.4 to 0.6meter, the water pressure is 1.5 to 2.0 atmospheric pressure, and the spraying time is 15 to 20 seconds; and the addition quantity of essential oil is 1.8 to 2.2ml / L, volatile essential oil in the essential oil accounts for 50 to 60 percent, and the orange essential oil accounts for 50 to 40 percent. Themethod has the advantages that the hardness, the soluble solids, the titratable acid and the vitamin C content of the orange fruit can be effectively maintained, and the weight loss ratio ascending and the fungus decay occurrence after the orange picking are inhibited, so the preservation period is effectively prolonged.

Owner:NINGBO UNIV

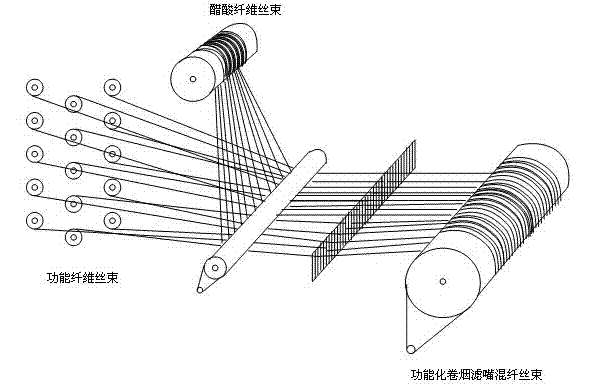

Composite filament strand filter tip for cigarettes

The invention provides a composite filament strand filter tip for cigarettes. The filter tip is composed of mixed fiber filament strands which are formed by blending cellulose acetate filament strands and degradable functional fiber filament strands, wherein the total denier ratio of the cellulose acetate filament strands to that of the functional fiber filament strands is (5-3.1):1. Since the denier ratio of the cellulose acetate filament strands and the functional fiber filament strands is better, when glyceryl triacetate is used for forming, the filter tip is more excellent in usability and processability such as adhesion effect, hardness and draw resistance to meet the requirements of the cigarettes. Due to improvement of the functional fiber proportion, the filter tip is more effective in selective adsorption and balance adsorption of harmful substances and. Further, the technological base is provided for use of various functional fibers as filter tip materials.

Owner:成都宏亿实业集团有限公司

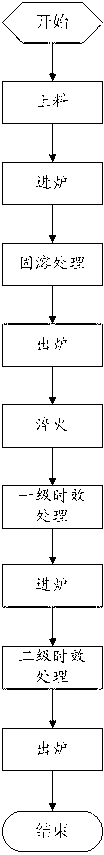

Aluminum alloy wheel heat treatment process

InactiveCN102912265AImprove overall performanceImprove plasticity and toughnessFurnace typesHeat treatment furnacesQuenchingSpoke

The invention discloses an aluminum alloy wheel heat treatment process comprising the steps of: loading, furnace feeding, solid solution treatment, discharging, quenching, primary aging treatment, feeding, secondary aging treatment, and discharging. During the solid solution treatment, a solid solution temperature is 540-550 DEG C, and a solid solution temperature maintenance time is 3.5-4.5h. During the primary aging treatment, the material is kept under room temperature for 24h. During the secondary aging treatment, the aging temperature is 115-125 DEG C, and an aging temperature maintenance time is 2.5-3.5h. With the aluminum alloy wheel heat treatment process provided by the invention, product comprehensive performance can be improved. On a basis that product hardness and tensile strength are ensured, product plasticity and toughness are substantially improved. Especially, impact toughness of the product is improved. With the process, impact strengths of thin spokes and wheels requiring lightweights can be greatly improved, such that requirements of high-requirement automotive main engine factories can be satisfied.

Owner:DARE TECH

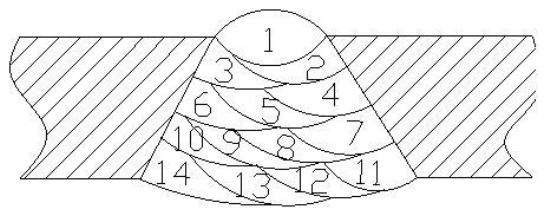

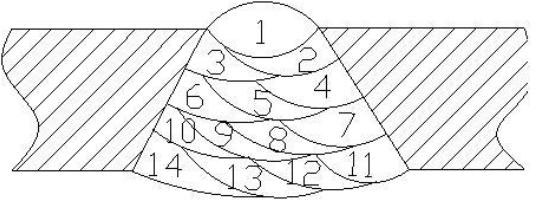

Method for welding butt-jointed seam of upward plate through manual arc welding

The invention relates to a method for welding a butt-jointed seam of an upward plate through manual arc welding, which comprises the following steps of: (1) burnishing the groove and 10-15 mm range of the surface of a test piece to have metallic luster, assembling and pairing the test piece, wherein the included angle between the groove face and the central vertical face is 30-35 DEG, the length of a root gap is 3.0-4.0 mm, the length of the truncated edge is 1.5-2.0 mm, and the unfitness of butt joint is less than 0.5 mm; (2) performing positioned welding on both ends of the test piece, wherein the length of the welding spot is 10-15 mm; and (3) adopting a layered lane welding process for the welding sequence. In the method, a linear or lateral small swing electrode manipulation manner is adopted for welding, therefore, the operation is simple and easy to master; welding joints are reduced, and the defects of porosity, slag inclusion, incomplete fusion and the like at the joints are prevented; the temperature of the molten bath is effectively controlled, and weld beading formed by the burnthrough of the root layer is prevented; the heat input of the weld seam is reduced, and the plasticity and the tenacity of the weld seam are effectively increased.

Owner:CHINA ENERGY ENG GRP TIANJIN ELECTRIC POWER CONSTR CO LTD

High-tear strength silicone rubber and preparation method thereof

The invention discloses high-tear strength silicone rubber which comprises the following raw materials: 100 parts of methylvinyl crude rubber, 30-60 parts of white carbon black, 4-6 parts of vinyl silicone oil, 0.5-2 parts of hydroxyl silicone oil, 0.5-1 part of vinyltrimethoxy silane and 0.1-0.4 part of demoulding auxiliary. The invention also discloses a preparation method of the high-strength silicone rubber, which comprises the following steps: (1) putting the methylvinyl crude rubber, hydroxyl silicone oil, vinyltrimethoxy silane and a demoulding auxiliary into a kneading machine for kneading; (2) adding the white carbon black in 3-5 batches, mixing into agglomerate, heating and vacuumizing; and (3) cooling to 60-80 DEG C, adding the vinyl silicone oil in 3-5 batches, mixing into agglomerate and discharging and packaging to obtain the high-strength silicone rubber. In the invention, by adding the vinyl silicone oil into the raw materials of the high-strength silicone rubber, the tear strength of silicone rubber is remarkably improved while guaranteeing the hardness, elasticity, heat resistance and tensile strength of the silicone rubber; and the preparation method is simple in process, and the production efficiency is high.

Owner:QINGDAO HUILU SILICONE CO LTD

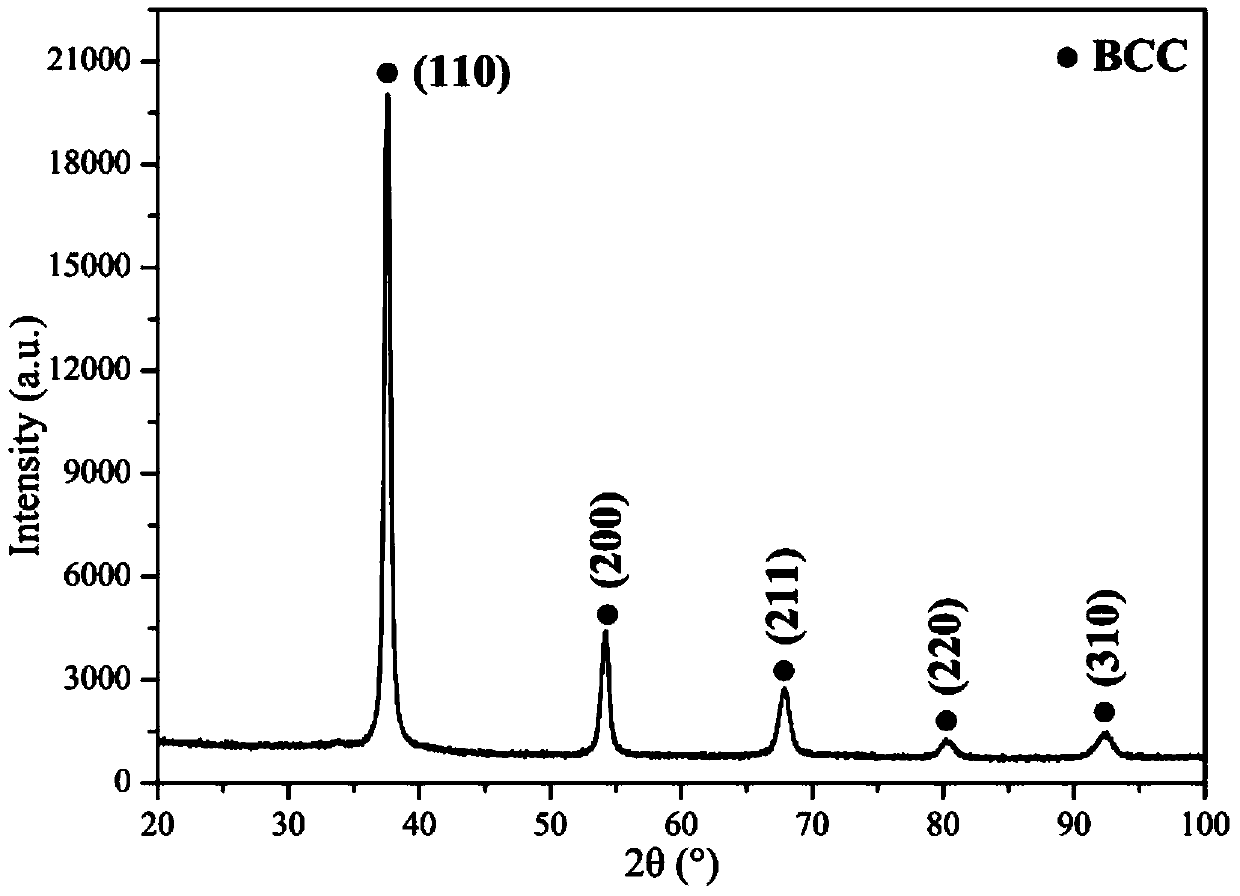

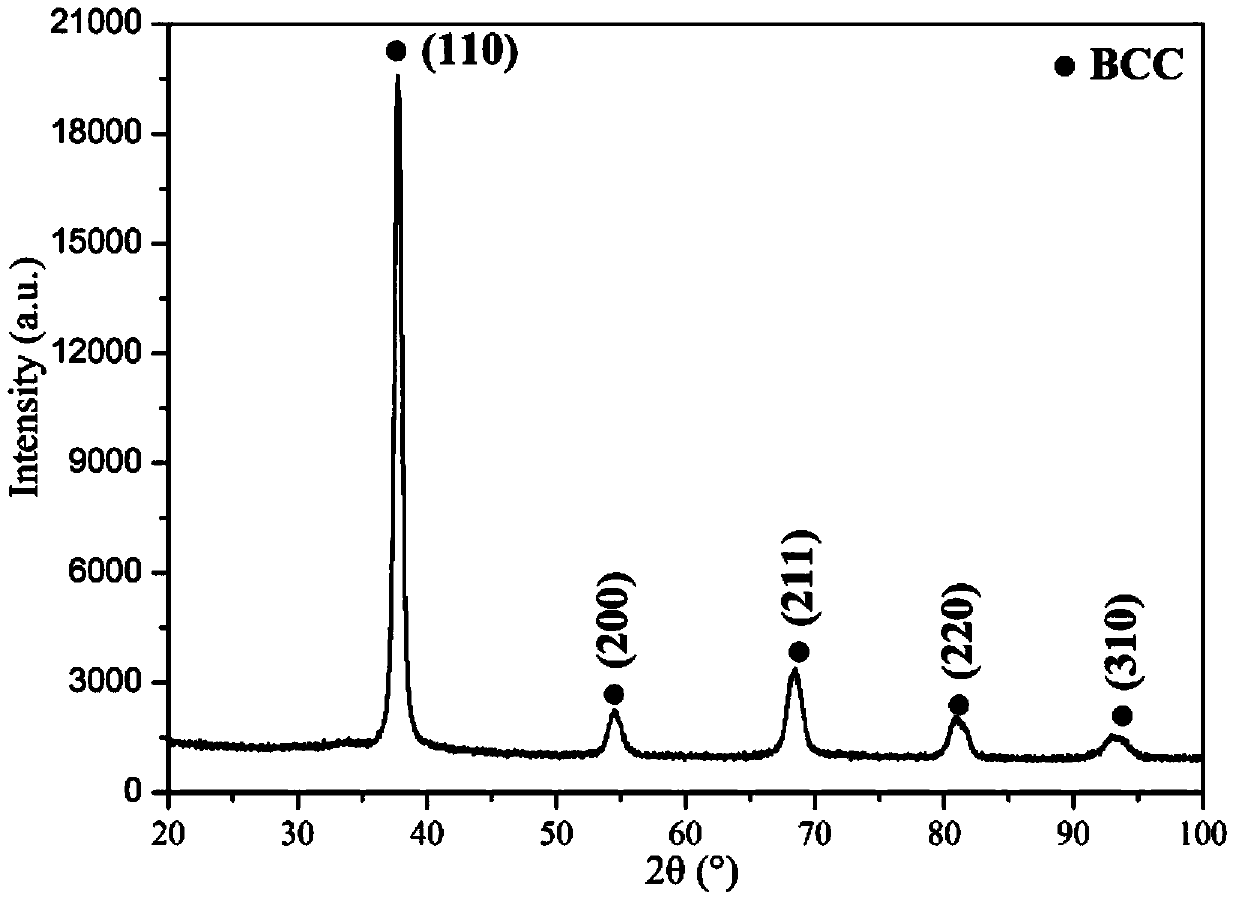

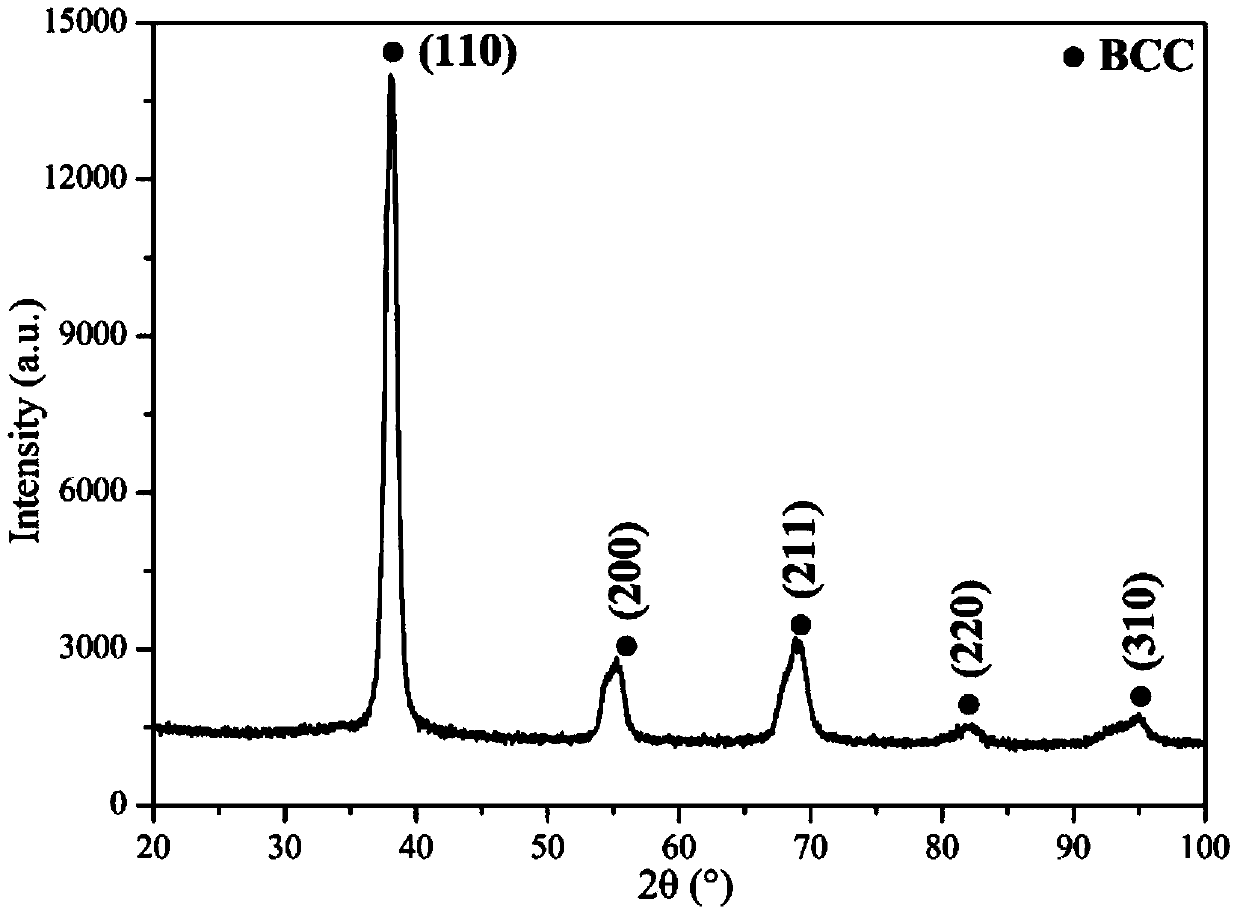

TiZrNbMoxHfy multi-principal component high temperature alloy and preparation method thereof

Owner:HARBIN INST OF TECH

Microorganism and plant derived composite fresh keeping agent for fruits and vegetables

ActiveCN106615085ABroad antibacterial spectrumStable antibacterial effectYeast food ingredientsNatural extract food ingredientsHorticultureBacillus amyloliquefaciens

The invention belongs to the technical field of fresh keeping agents, aims to develop a composite fresh keeping agent including microorganism derived effective components and plant derived effective components, is used for fresh keeping and corrosion resistance for picked fruits and picked vegetables, and provides a microorganism and plant derived composite fresh keeping agent for fruits and vegetables. The composite fresh keeping agent is prepared from a component A and a component B, wherein the component A consists of microorganism fermentation fluid and a propolis extract, and microorganisms are bacillus amyloliquefaciens Lh-1, candida intermedia and cryptococcus laurentii; and the component B consists of plant derived effective component mixed liquor and film forming liquor, wherein the plant derived effective component mixed liquor is prepared by mixing a tree peony bark water extract with a citrus peel alcohol extract, a rabdosia rubescens alcohol extract, a radix zanthoxyli water extract, a lycium ruthenicum alcohol extract, a Chinese herbaceous peony water extract, a clinopodium chinense alcohol extract and a citronella water extract, and the film forming liquor is prepared by mixing konjac glucomannan with chitosan. Through the adoption of the composite fresh keeping agent, the fruits and the vegetables are furthest prevented from mildewing and rotting, the effects for preventing the fruits and the vegetables from postharvest diseases are enhanced, the moisture dissipation of the fruits and the vegetables is reduced, the storage time of the fruits and the vegetables is prolonged, and a certain economic value is created.

Owner:AGRI BIOTECH RES CENT OF SHANXI PROVINCE

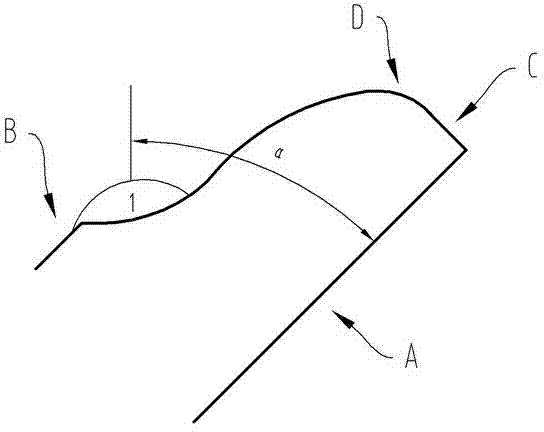

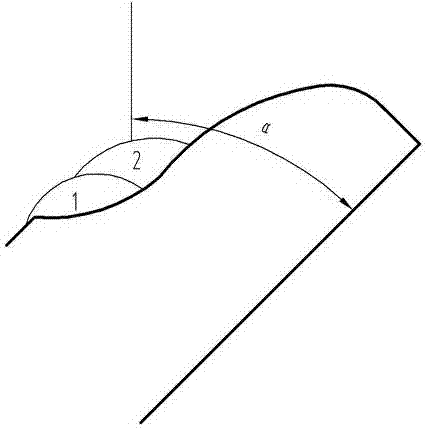

Water-erosion preventing method for turbine blade by laser cladding

ActiveCN103668188AControl deformationExtended service lifeMetallic material coating processesLaser beam welding apparatusStellite alloyAerospace engineering

The invention provides a water-erosion preventing method for a turbine blade by laser cladding. By adoption of the water-erosion preventing method, the laser cladding quality can be effectively ensured, the deformation of the laser-cladded blade can be reduced, and the requirement of different parts of the blade for the water erosion resistance can be ensured, so that the service life of the blade is prolonged. The water-erosion preventing method is characterized by comprising the following steps of: firstly carrying out roughening treatment on the surface of a blade cladding groove, then clamping the blade to a laser cladding machine tool, adopting a preheater to preheat the cladded areas of the blade, feeding powder by a side-shaft powder feeding head, and using a CO2 laser to clad stellite alloy powder in the blade cladding groove along the direction from the root of the turbine blade to the top of the turbine blade according to a mode of multilayered and multi-pass lapped cladding.

Owner:WUXI TURBINE BLADE

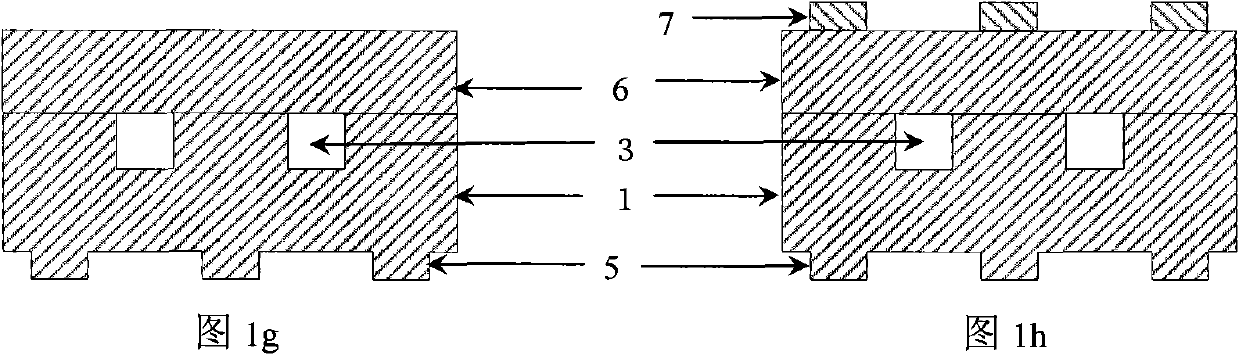

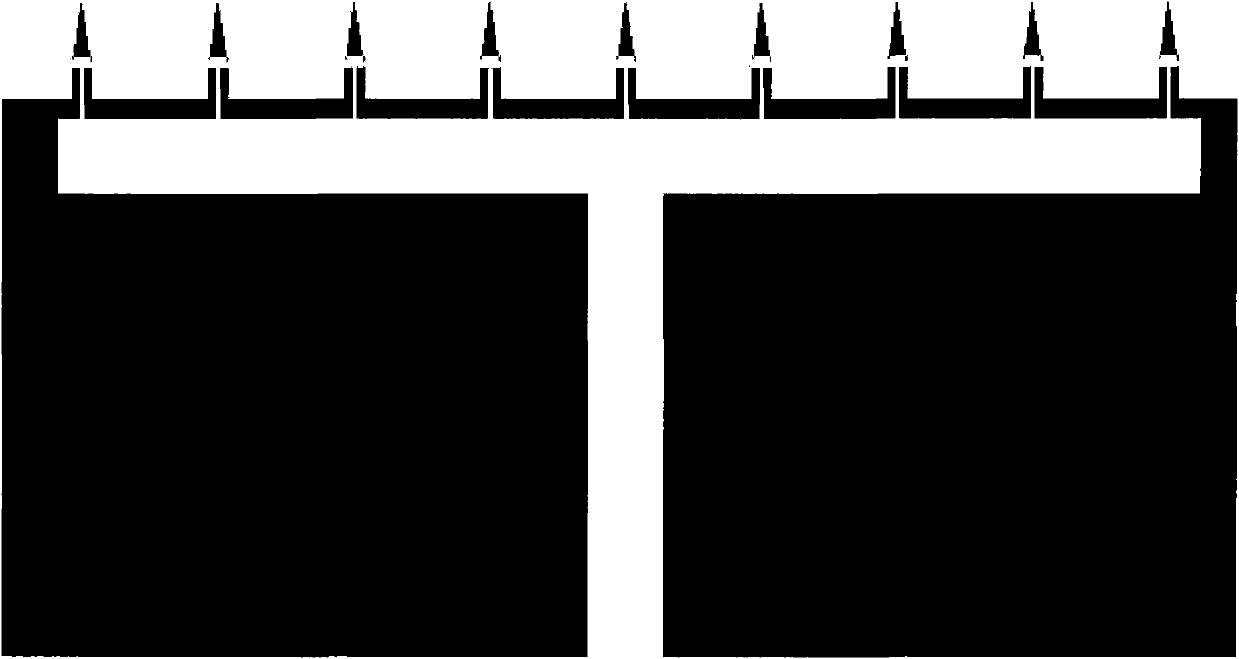

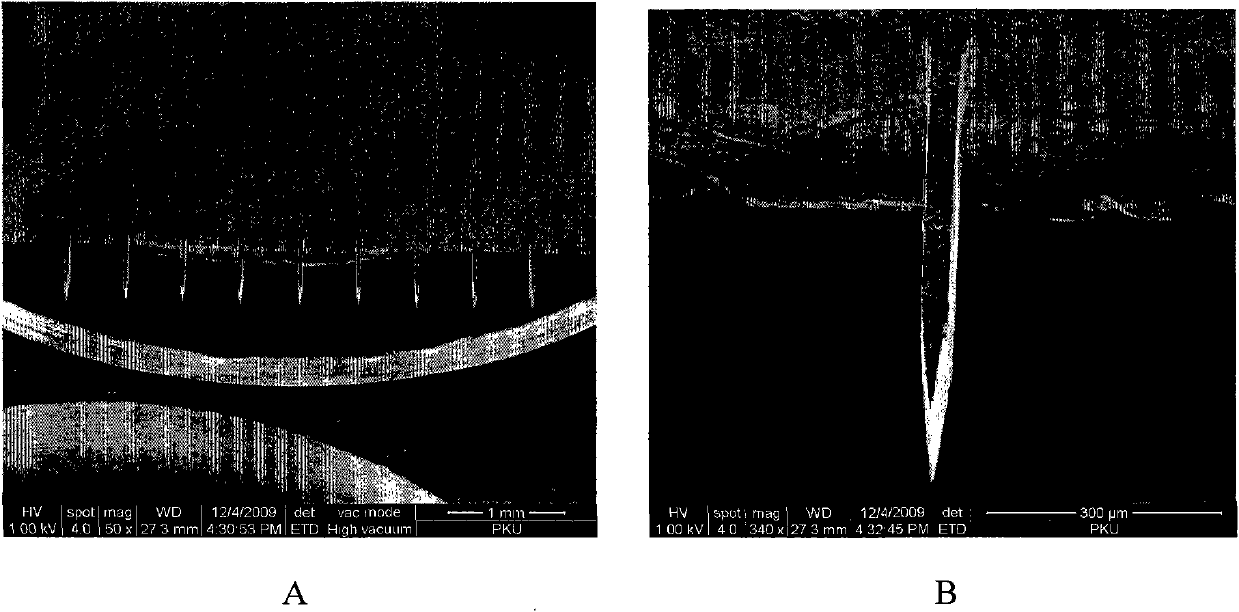

Method for preparing plane hollow microneedle for transdermal administration

InactiveCN101905856ATo achieve the purpose of sustained releasePrecise deliveryDecorative surface effectsMicroneedlesEnteral administrationChannel pattern

The invention discloses a method for preparing a plane hollow microneedle for transdermal administration, which comprises the following steps of: defining a microneedle flow channel pattern on one surface of a first metal substrate to form a trench, and defining a microneedle pattern on the other surface to form a cutting sign, wherein the central axis of the flow channel pattern is aligned with that of the microneedle pattern; bonding a second metal substrate with a trench surface of the first metal substrate; thinning a non-bonding surface of the second metal substrate, and allowing the cutting sign on the first metal substrate to align with and transfer to the non-bonding surface of the second metal substrate; and thinning a non-bonding surface of the first metal substrate, and cutting by aligning with the cutting sign on the second metal substrate to form the plane hollow microneedle. Based on the micromachining technology and by combining the conventional technology of machining and cutting at the same time, the method reduces the process difficulty, increases the using reliability of the microneedle, and is favorable for quantity production.

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com