Composite filament strand filter tip for cigarettes

A technology of composite tow and filter rods, which is applied in the fields of e-liquid filter elements, applications, tobacco, etc., can solve the problems of unsatisfactory equilibrium adsorption and the use of filters with excellent functions, and achieves low price, easy industrial production, and convenient The effect of industrial processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Raw materials: Acetate fiber tow (specification 3.0Y / 30000), water-based polyester filament tow (specification 300D / 72F (POY))

[0030] Water-based polyester filament monofilament cross-section Y-shaped, glass transition temperature 58 ° C, melting point 170 ° C, containing sodium isophthalic acid-5 sulfonate and polyethylene glycol water-soluble groups, intrinsic viscosity 0.55 dl / g, Under standard conditions, the moisture absorption rate is 6%.

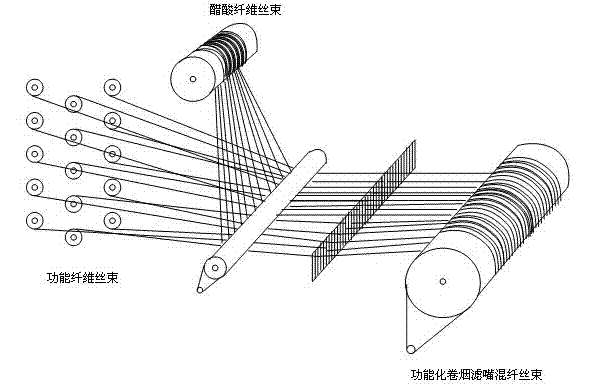

[0031] according to figure 2 Mixed fiber tow bundling process, the uncrimped acetate tow and 20 bobbins of water-based polyester filament are compositely bundled, and the ratio of the total denier of the acetate tow to the water-based polyester filament tow is 5 / 1 , the water-based polyester filaments are evenly arranged radially in the acetate tow, and the composite tow is obtained after the bundle is completed, according to figure 1 In the technical process, the composite tow is subjected to dry heat crimping at 145°C, a...

Embodiment 2

[0034] Raw materials: Acetate fiber tow (specification 3.0Y / 30000), polyvinyl alcohol filament tow (specification 300D / 72F (POY))

[0035] Polyvinyl alcohol filament monofilament has a Y-shaped cross section, a glass transition temperature of 78°C, contains hydroxyl water-soluble groups, an alcoholysis degree of 99%, a polymerization degree of 1700, and a moisture absorption rate of 7% under standard conditions.

[0036] according to figure 2 Mixed fiber tow bundling process, the uncrimped acetate tow and 300D / 72F are combined and bundled in 20 bobbins, the ratio of the total denier of the acetate tow to the polyvinyl alcohol filament tow is 5 / 1, The polyvinyl alcohol filaments are arranged radially and evenly in the acetate tow, and the composite tow is obtained after the bundling is completed, and then according to figure 1 In the technical process, the composite tow is subjected to dry heat crimping at 145°C, and then relaxed, dried and shaped at 140°C for 4 minutes to be...

Embodiment 3

[0039] Raw materials: acetate tow (specification 2.8Y / 28000), polylactic acid filament tow (specification 300D / 72F (POY))

[0040] Polylactic acid filament monofilament cross-section is approximately circular, glass transition temperature is 53°C, initial melting temperature is 150°C, contains ester groups, terminal hydroxyl groups are acetylated with acetic anhydride, intrinsic viscosity is 1.75dl / g (chloroform), and absorbs moisture under standard conditions The rate is 5%.

[0041] according to figure 2 Mixed fiber tow bundling process, the uncrimped acetate tow and polylactic acid filament tow are compositely bundled with 30 bobbins, the ratio of the total denier of acetate tow to polylactic acid filament tow is 3.1 / 1. The polylactic acid filaments are evenly spaced in the radial direction in the acetate tow, and the composite tow is obtained after the bundle is completed, and then according to figure 1 In the technical process, the composite tow is subjected to dry he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com