Fingerprint recognition sensor packaging structure, electronic device and method for manufacturing fingerprint recognition sensor

A fingerprint recognition and packaging structure technology, applied in character and pattern recognition, instruments, computer parts, etc., can solve the problems of large thickness of electronic equipment, easy brittleness of fingerprint imaging sensors, and expensive production of fingerprint recognition sensors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

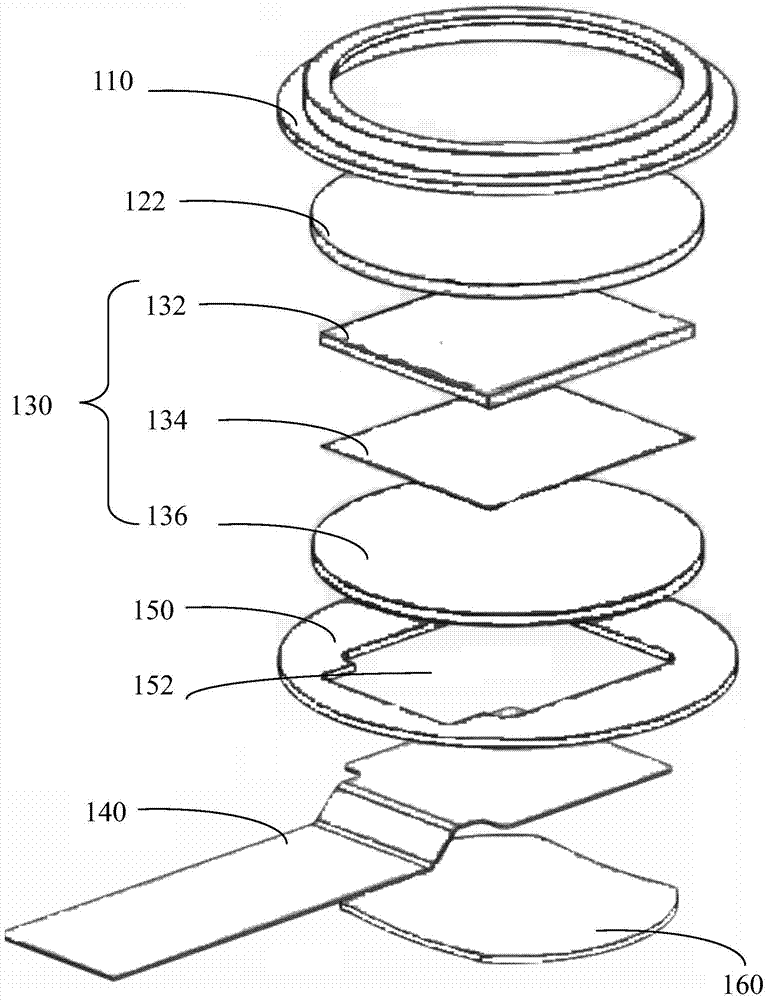

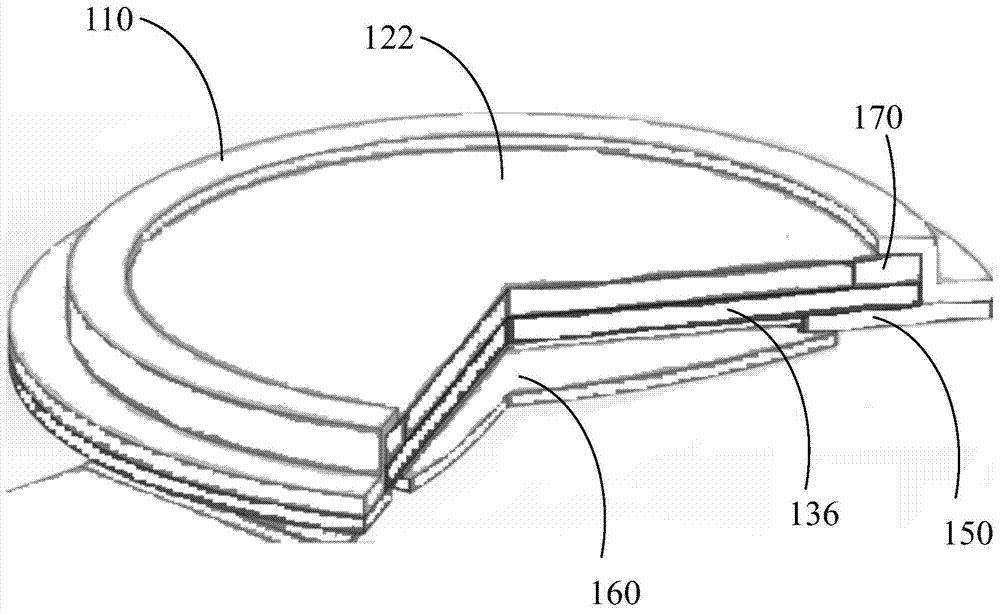

[0026] Please refer to figure 1 , Illustrates the explosive state of a fingerprint recognition sensor packaging structure used in electronic equipment. The electronic device here should be understood in a broad sense, and can be a smart phone, a touchpad, a mobile computing device, an electrical appliance, a panel or body of a vehicle, etc.

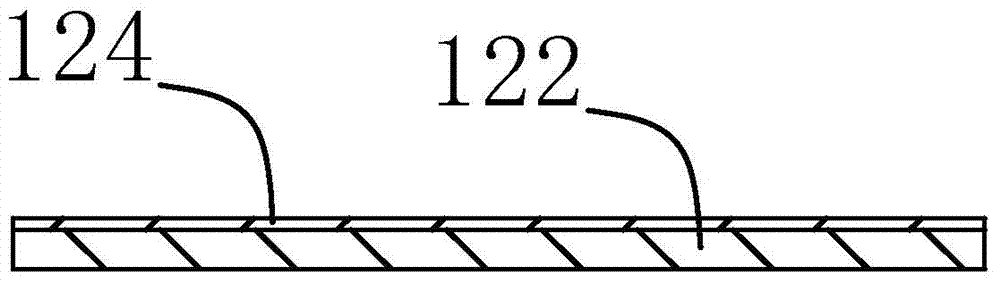

[0027] The fingerprint recognition sensor package structure includes a base ring 110 made of metal material, a control button surrounded by the base ring 110, a fingerprint recognition sensor 130 placed under the control button, a flexible element 140 and a reinforcing element 150 placed under the fingerprint recognition sensor 130 , And a spring switch 160 placed under the reinforcing element 150.

[0028] The control button is arranged above and coupled to the circuit of the fingerprint recognition sensor 130. In the electronic device, the control button can be arranged relative to the display element of the electronic device, for example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com