Processing method of interleaving paper product and interleaving paper

A technology of intermediate isolation and processing methods, applied in chemical instruments and methods, paper/cardboard layered products, paper, etc., can solve problems such as affecting normal use, increasing manufacturing costs, failing to achieve use effects, and achieving broad marketization Prospects, increase manufacturing costs, and facilitate the effect of popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

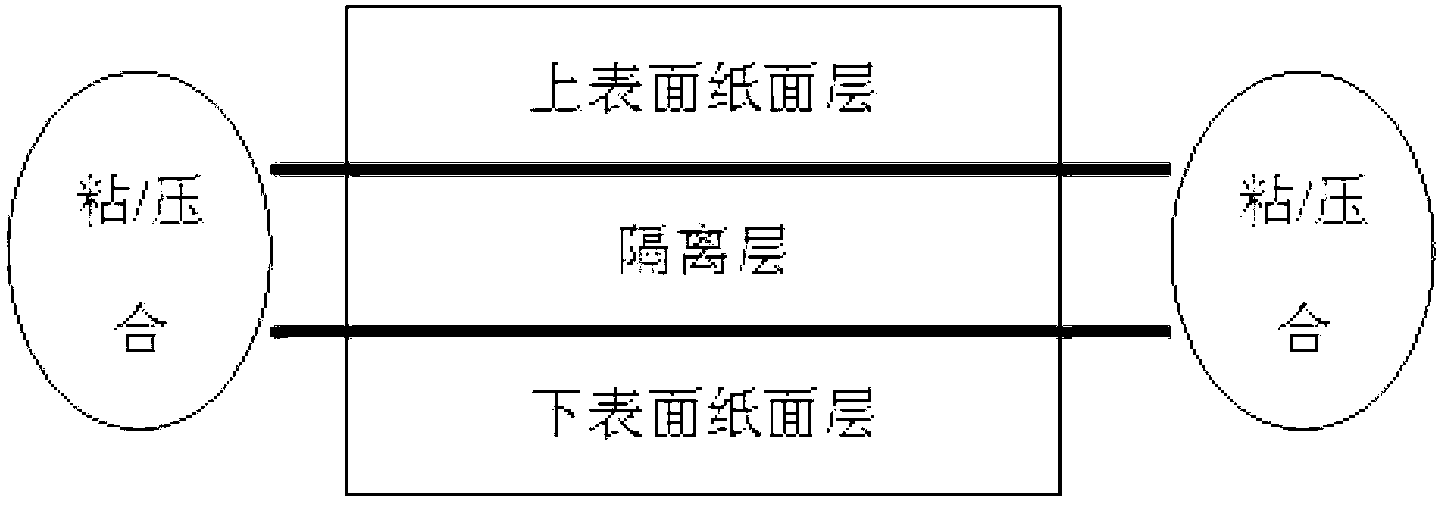

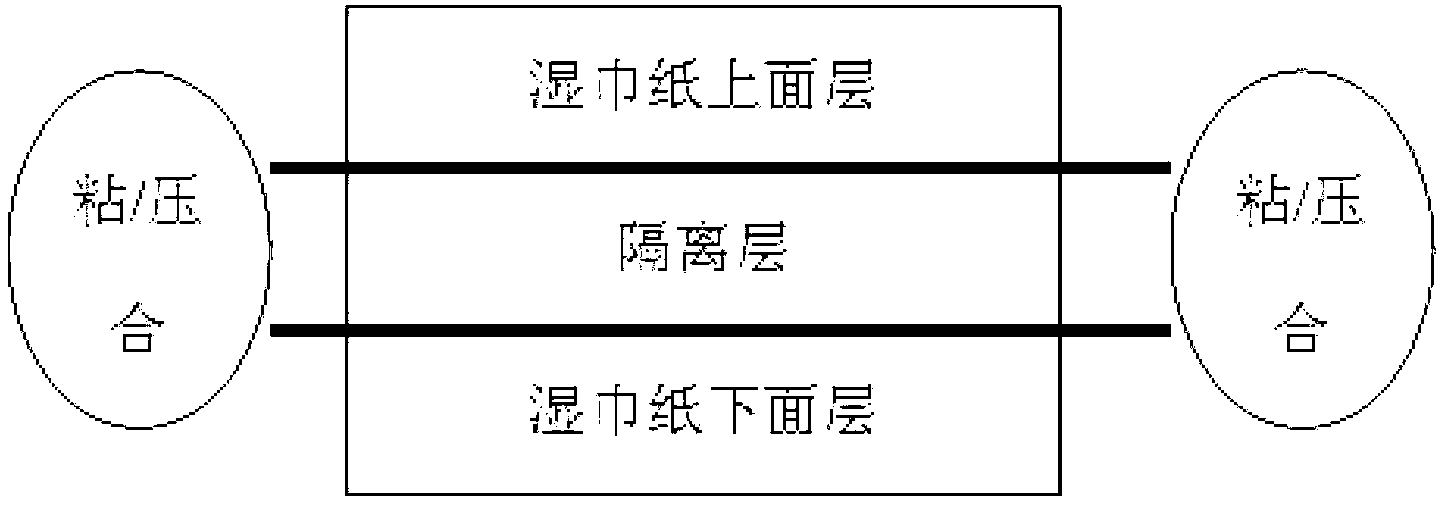

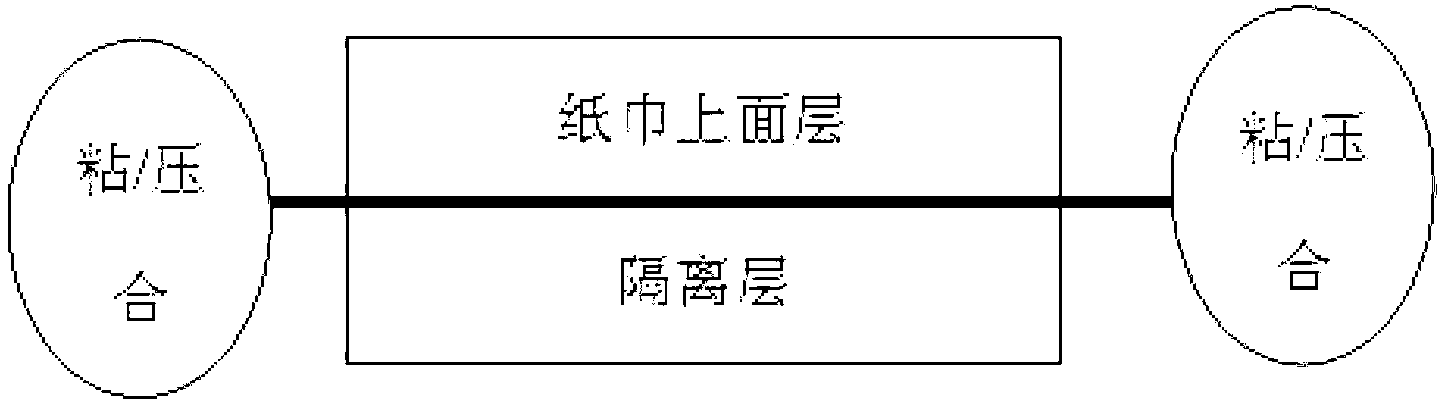

[0031] Such as figure 1 , Figure 4 and Figure 5 As shown, the intermediate isolated paper processing method provided by the present embodiment comprises the following steps:

[0032] (1) Isolation layer manufacturing: polyacrylate is mixed with fluorocarbon chains to form a waterproofing agent, and dried after impregnated with auxiliary agents to form a waterproof film; the polyacrylate is formed into a film with high gloss and strong water resistance alone, Moreover, the film has adhesiveness, and is copolymerized with the fluorocarbon chain to form a surface active compound to jointly realize the composition of the waterproof layer of the fluorocarbon chain polymer. Features such as water are fully combined to realize the manufacture of the isolation layer. The auxiliary auxiliary agent includes various inorganic auxiliary agents, and the papermaking auxiliary agent includes pulp auxiliary agent, papermaking additive and coating auxiliary agent. Specifically, the mass r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com