Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110 results about "Stellite alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stellite is a range of cobalt-chromium alloys designed for wear resistance. The alloys may also contain tungsten or molybdenum and a small but important amount of carbon.

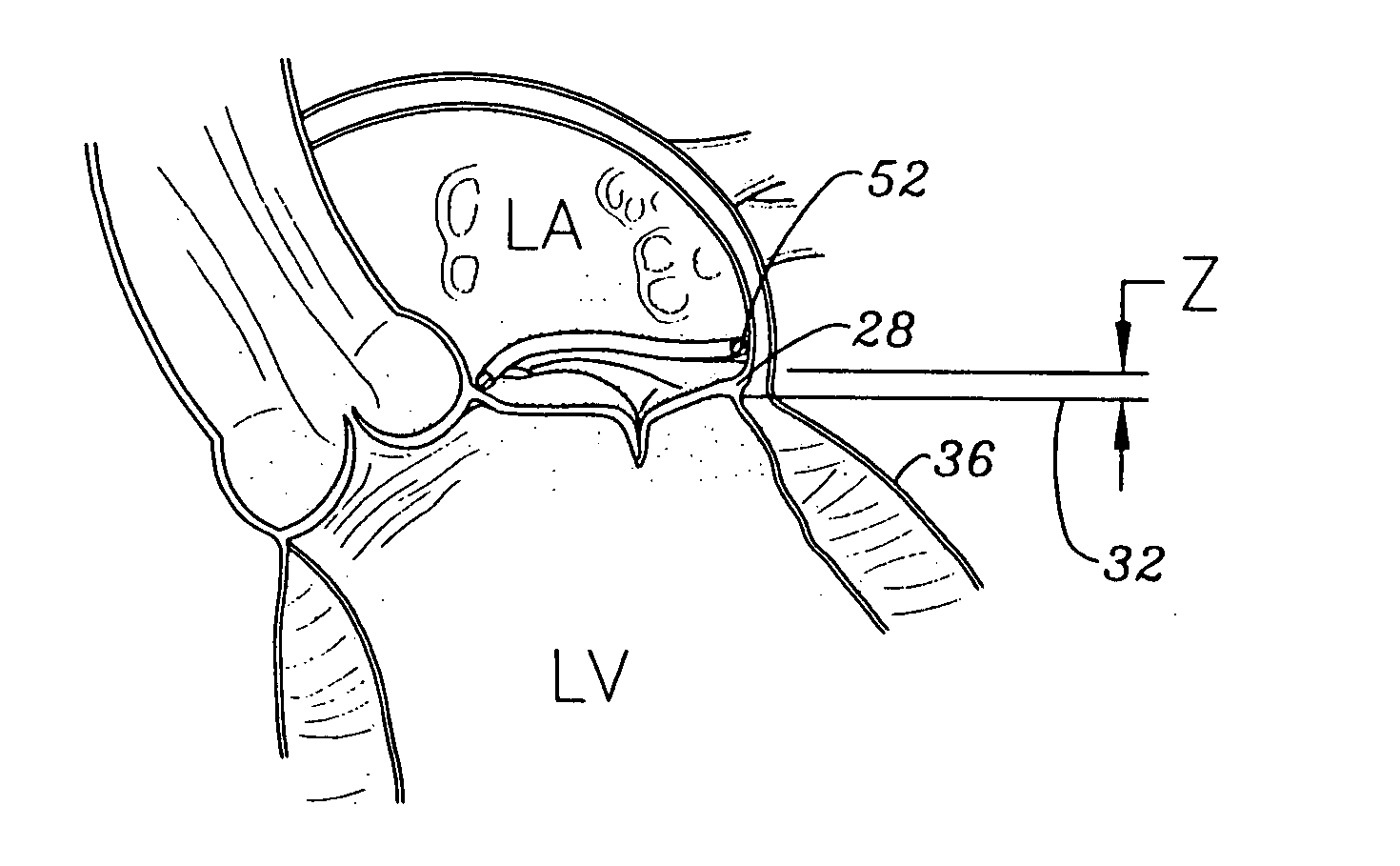

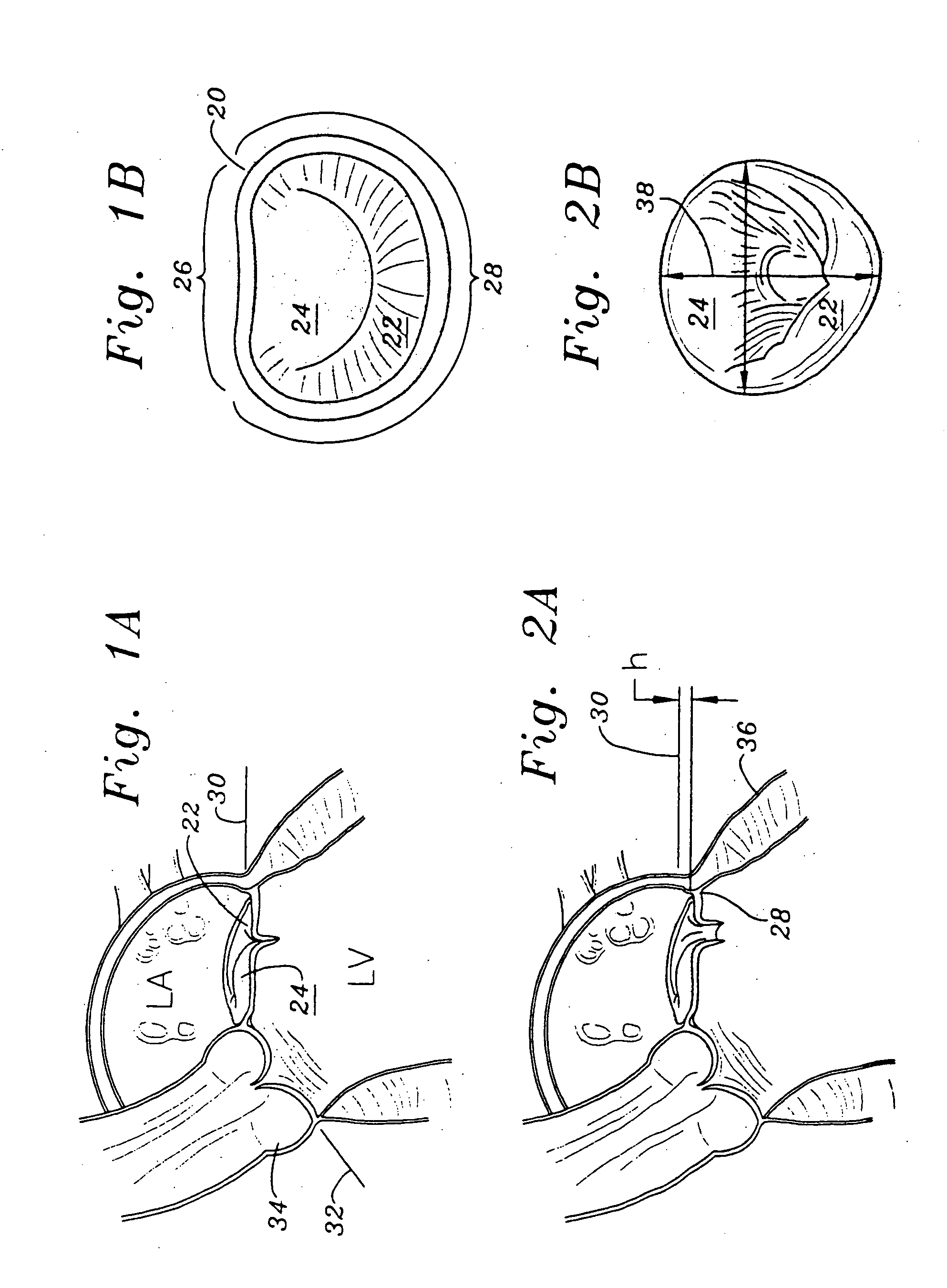

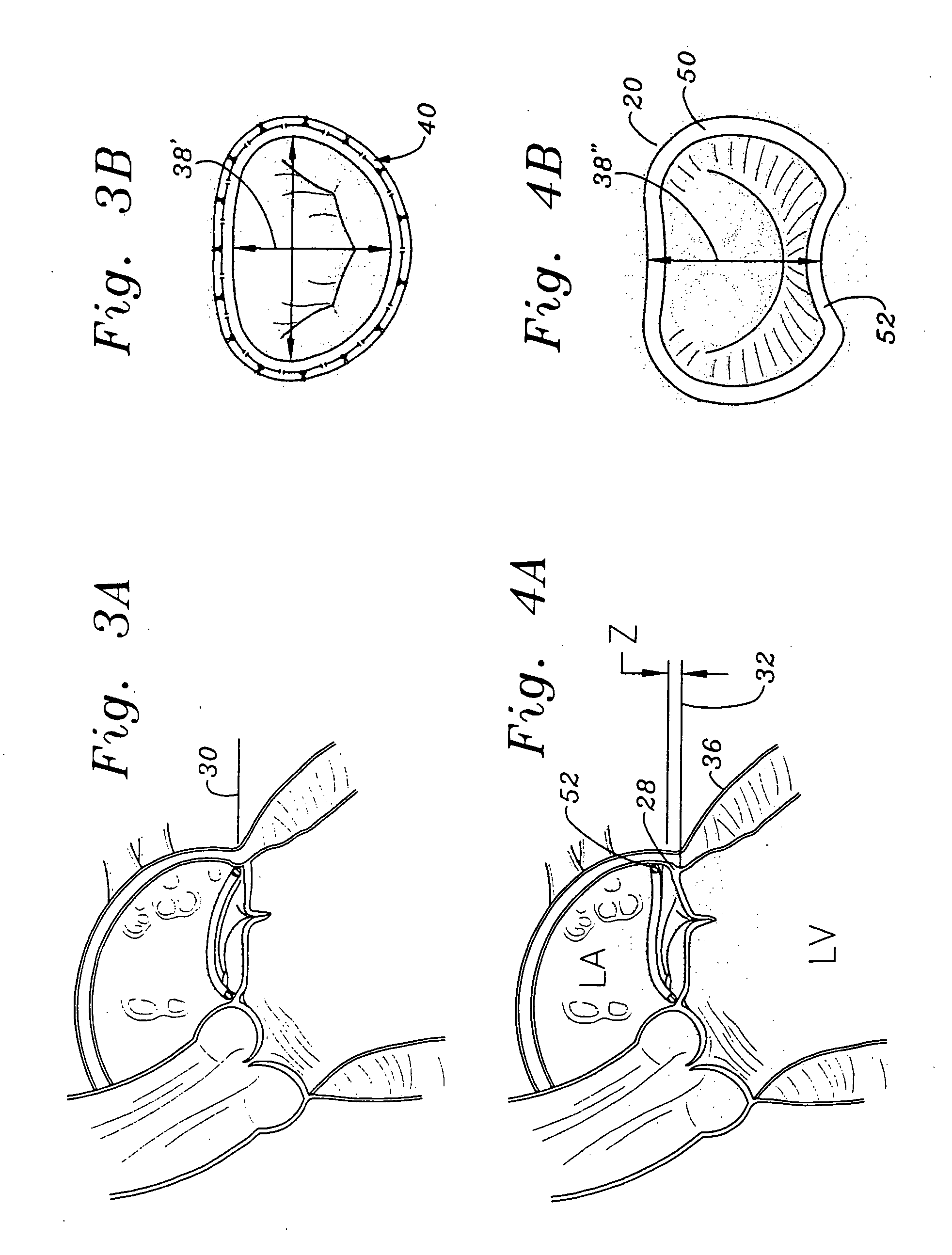

Methods of implanting a mitral valve annuloplasty ring to correct mitral regurgitation

ActiveUS20050049698A1Reduce the impactReduce impactBone implantAnnuloplasty ringsStellite alloyMitral annuloplasty ring

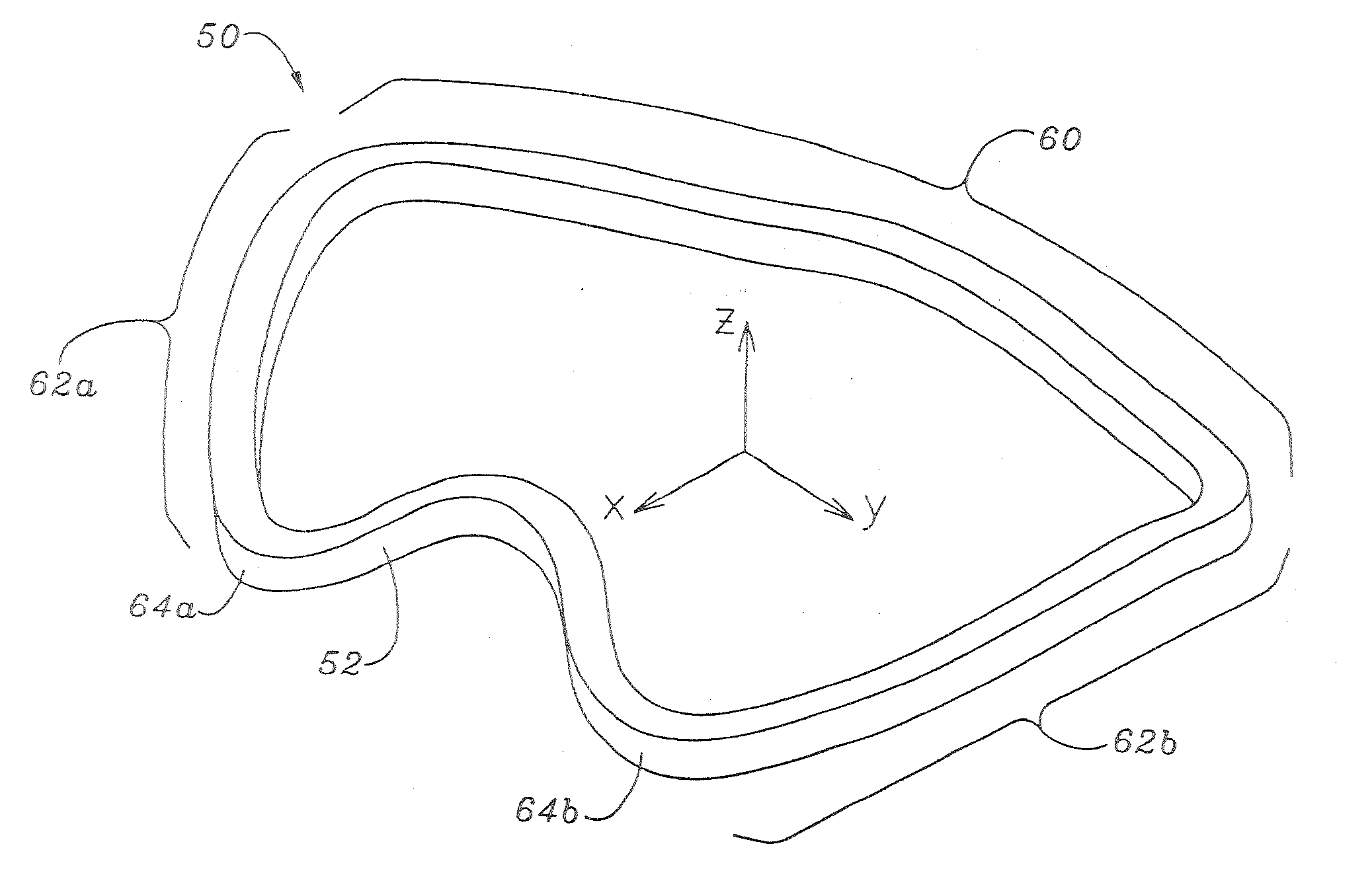

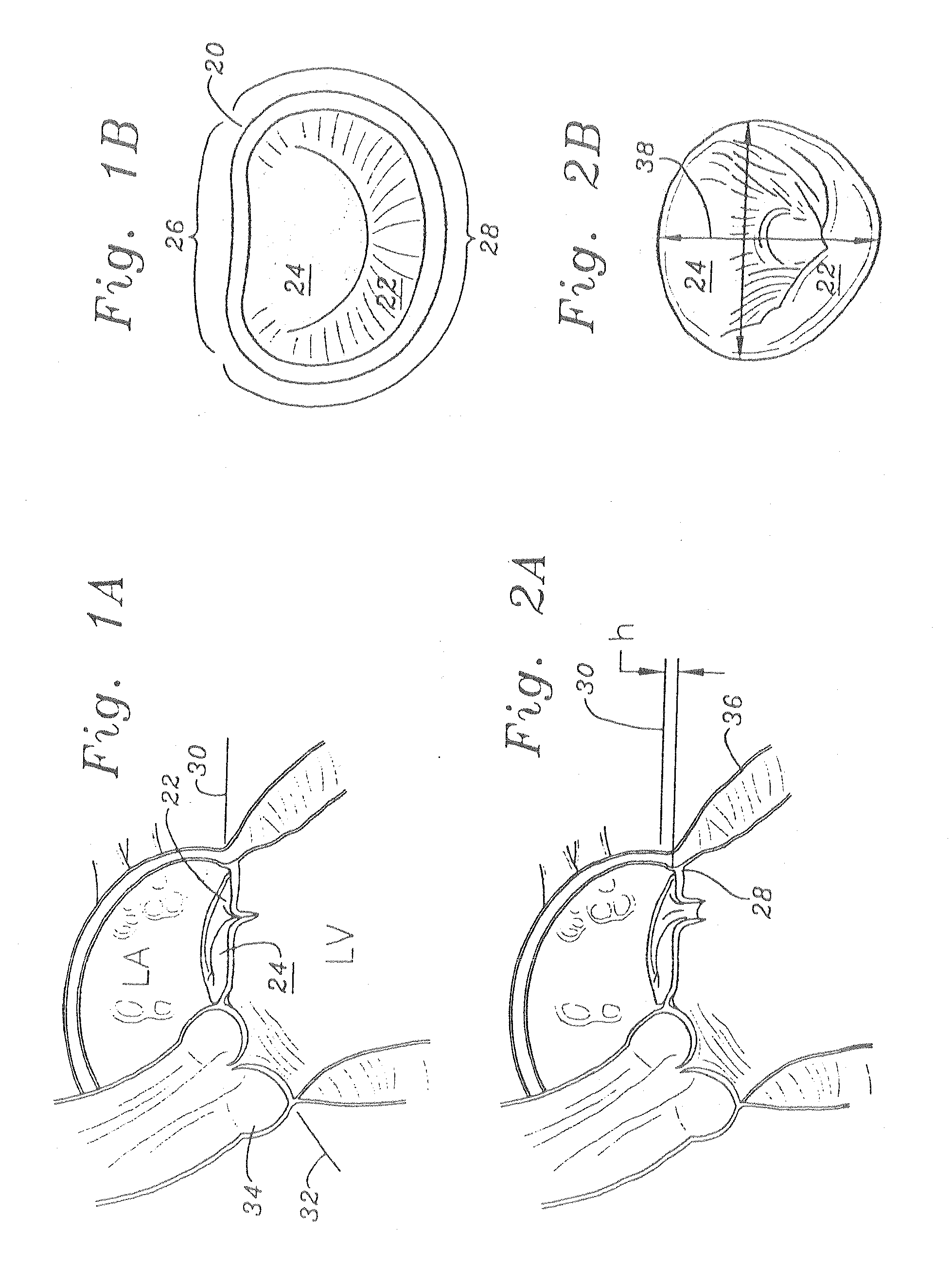

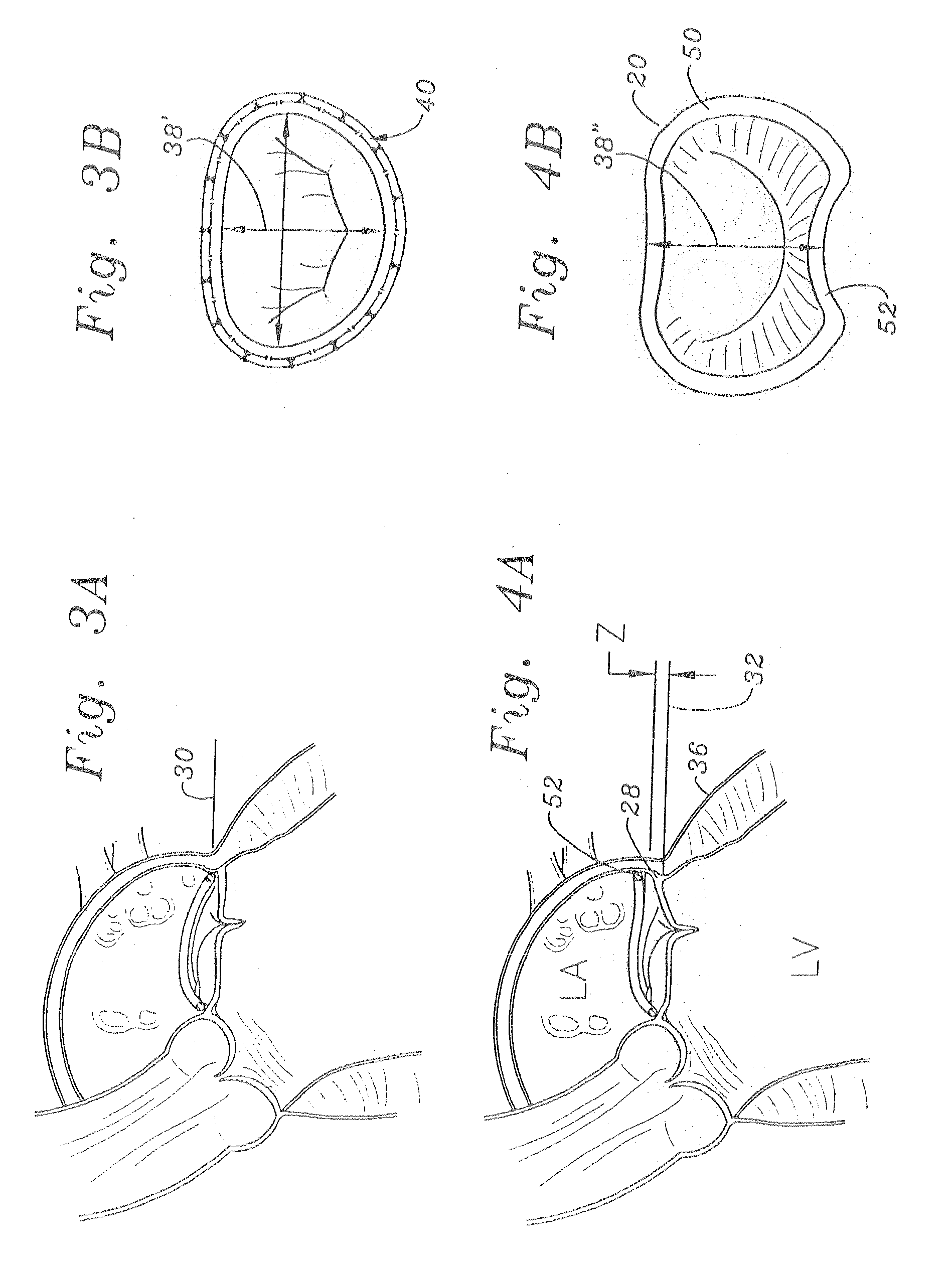

Methods of implanting an annuloplasty ring to correct maladies of the mitral annulus that not only reshapes the annulus but also reconfigures the adjacent left ventricular muscle wall. The ring may be continuous and is made of a relatively rigid material, such as Stellite. The ring has a generally oval shape that is three-dimensional at least on the posterior side. A posterior portion of the ring rises or bows upward from adjacent sides to pull the posterior aspect of the native annulus farther up than its original, healthy shape. In doing so, the ring also pulls the ventricular wall upward which helps mitigate some of the effects of congestive heart failure. Further, one or both of the posterior and anterior portions of the ring may also bow inward. The methods include securing the annuloplasty ring with the anterior portion against the annulus anterior aspect and the posterior portion against the annulus posterior aspect so that the ring posterior portion elevates and may also pull radially inward, the annulus posterior aspect and corrects the mitral regurgitation.

Owner:EDWARDS LIFESCIENCES CORP

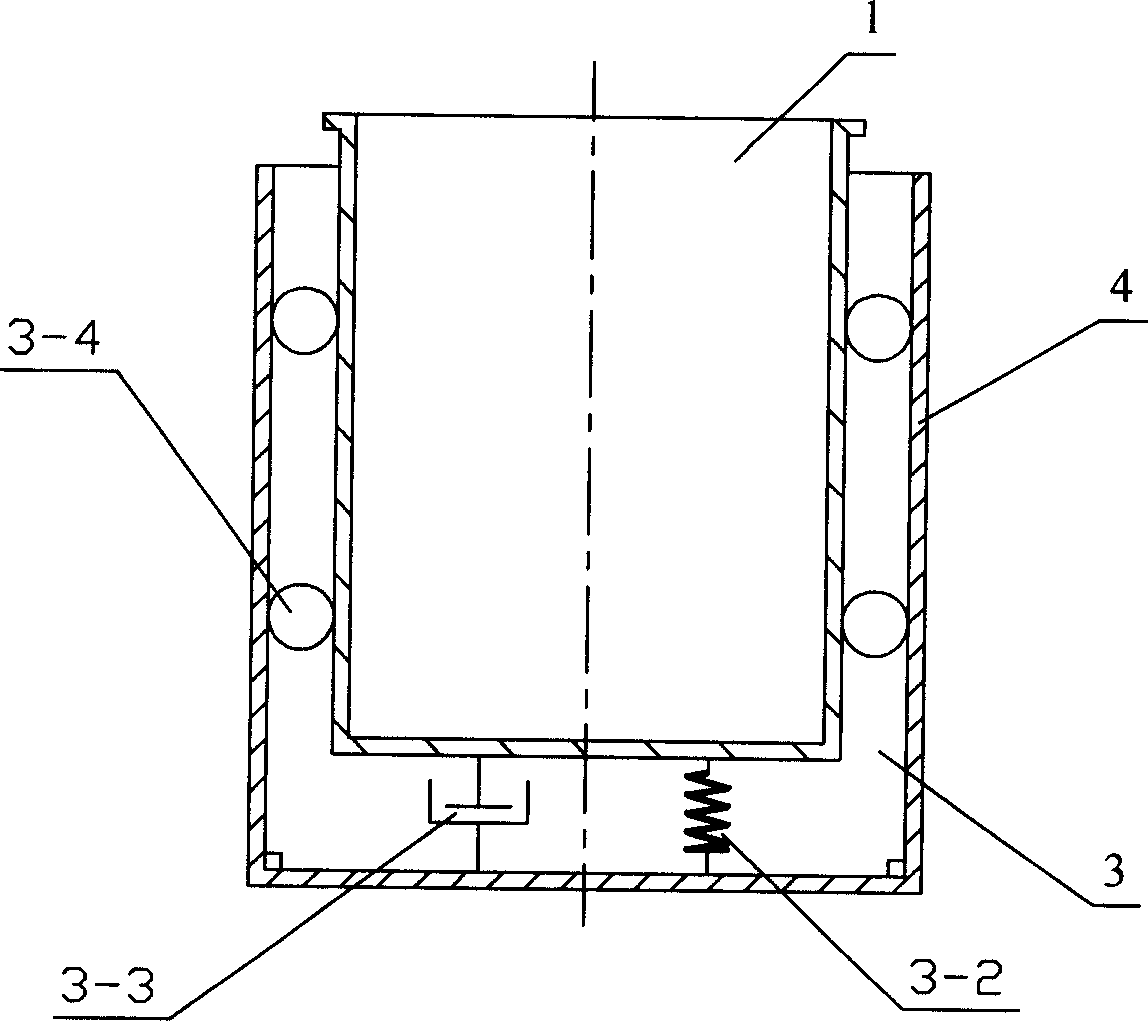

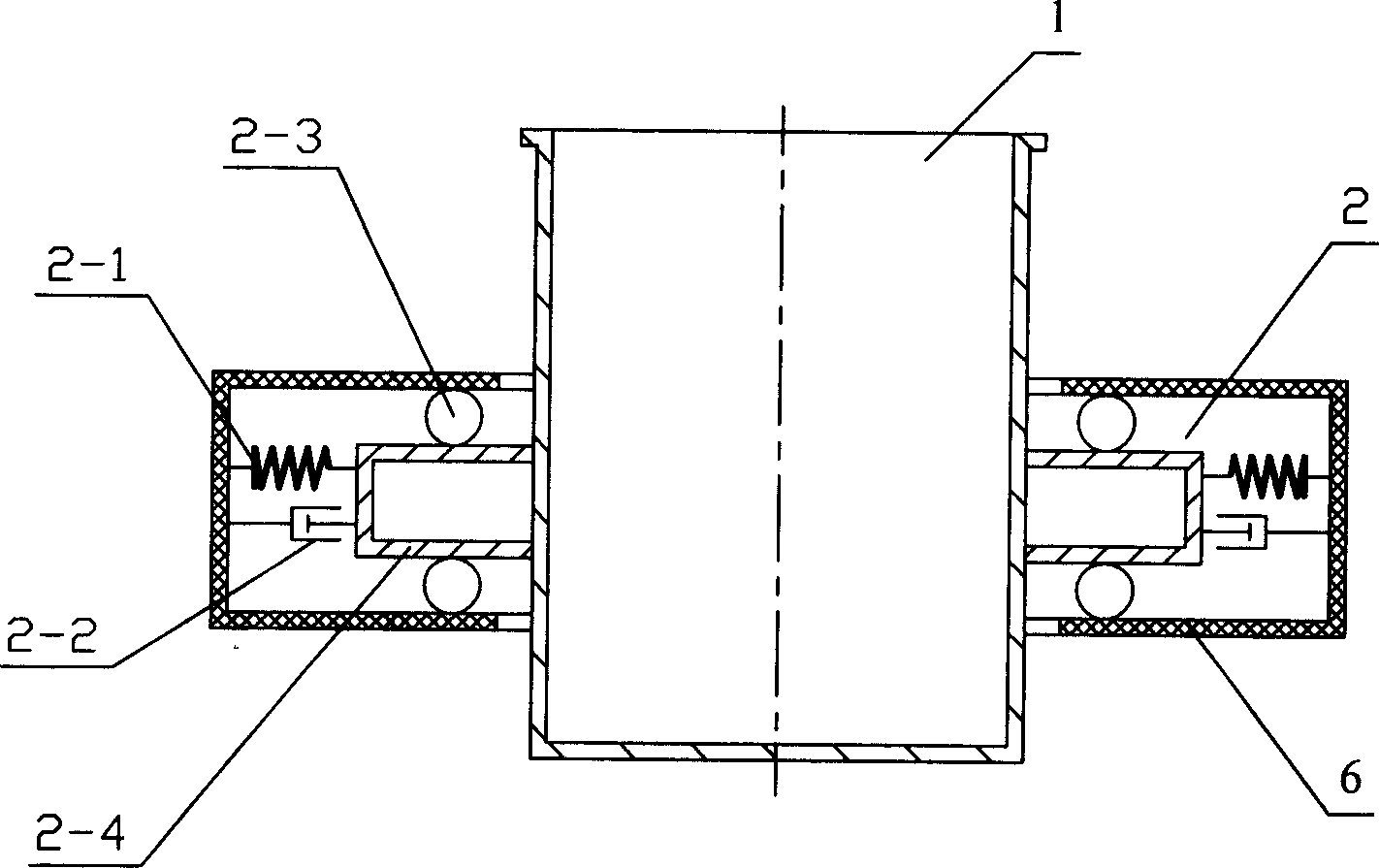

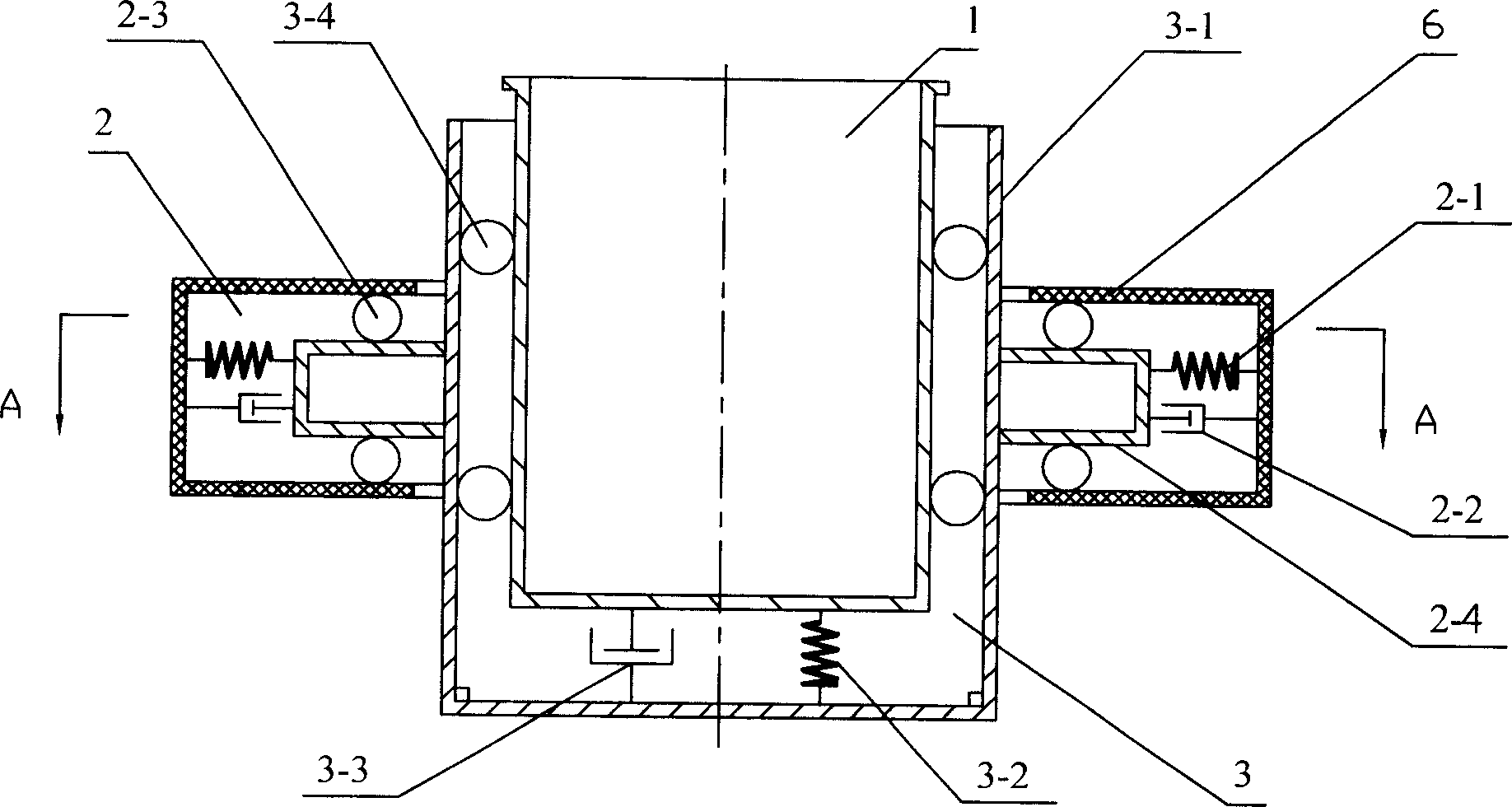

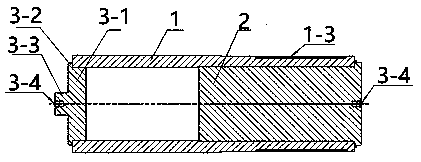

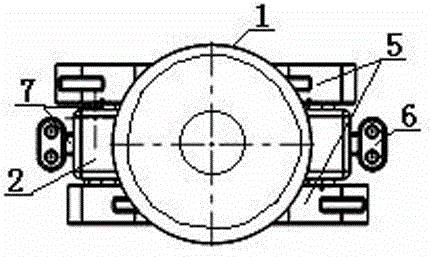

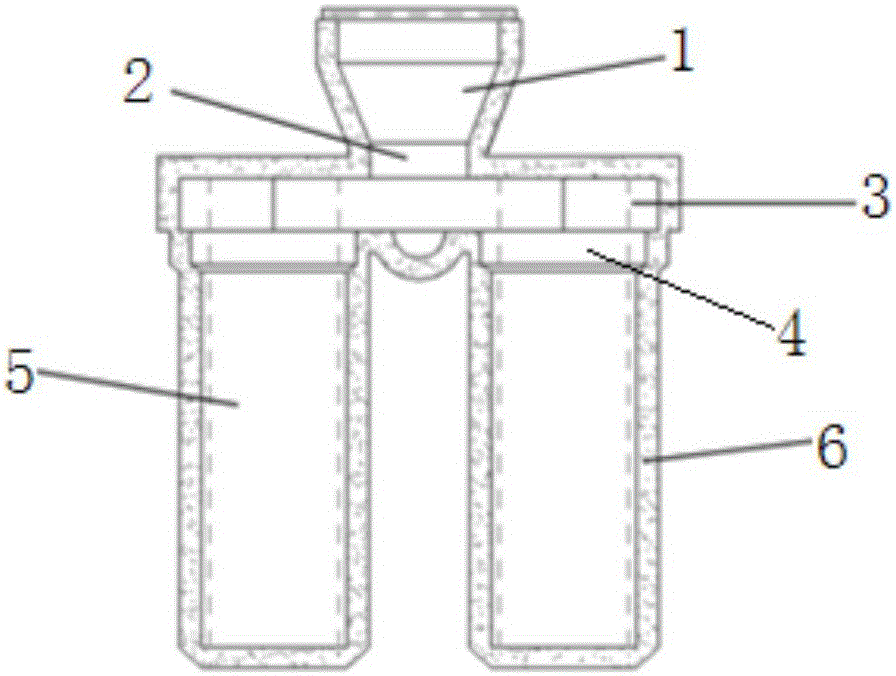

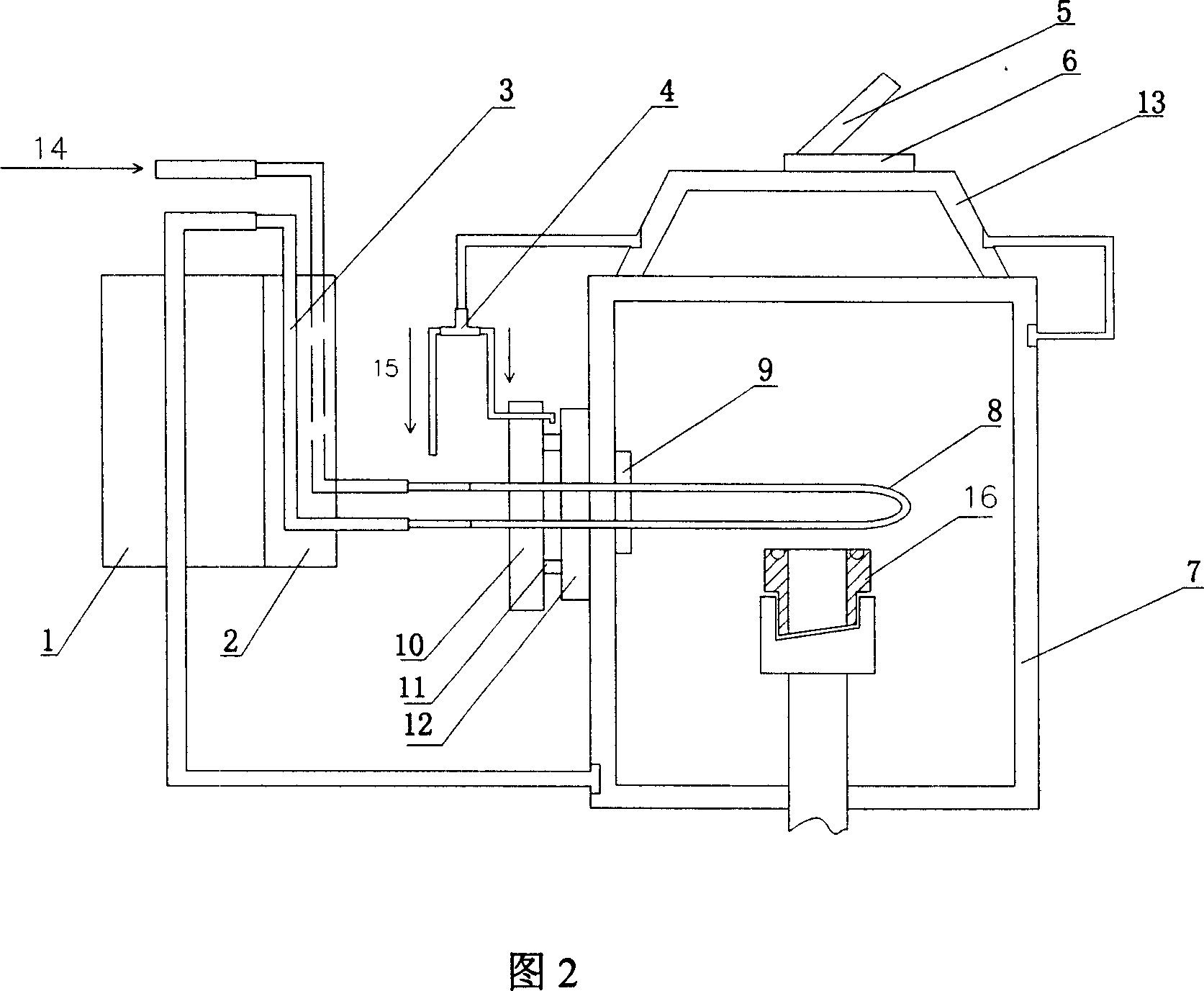

Integrated shock absorbing vibrating isolation device for stellite

InactiveCN1911734ASo as not to damageLower launch costsCosmonautic vehiclesCosmonautic partsStellite alloyIsolating mechanisms

Owner:郑钢铁 +3

Zirconium oxide full-porcelain dental repair material and its preparing method

InactiveCN1813654AImprove molding qualityReduce the difficulty of operationImpression capsDentistry preparationsPolymer sciencePolyvinyl alcohol

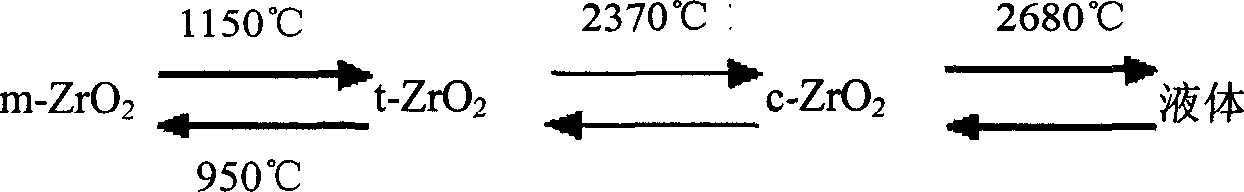

The present invention belongs to a ceramic material and its preparation field. In the particular, it relates to a zirconia full-porcelain dental repairing material and its preparation method. Its raw material composition contains (by wt%) 86-92% of tetragonal-phase zirconia stabilized by 3.0-5.15% of yttrium oxide, 5-10% of flux and 3-4% of adhesive, in which the flux is one kind of boron-aluminum-silicon system glass, hydroxyapatite and beta-stellite or more than one kind of them, and the adhesive is one or more than one kind of polyvinyl alcohol, carboxyl methyl cellulose and polyacrylic acid. Its preparation method includes the following steps: mixing raw materials, garanulating, cold isostatic compaction, moulding and sintering.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Mitral Annuloplasty Ring Having Upward Bows

Methods of implanting an annuloplasty ring to correct maladies of the mitral annulus that not only reshapes the annulus but also reconfigures the adjacent left ventricular muscle wall. The ring may be continuous and is made of a relatively rigid material, such as Stellite. The ring has a generally oval shape that is three-dimensional at least on the posterior side. A posterior portion of the ring rises or bows upward from adjacent sides to pull the posterior aspect of the native annulus farther up than its original, healthy shape. In doing so, the ring also pulls the ventricular wall upward which helps mitigate some of the effects of congestive heart failure. Further, one or both of the posterior and anterior portions of the ring may also bow inward. The methods include securing the annuloplasty ring with the anterior portion against the annulus anterior aspect and the posterior portion against the annulus posterior aspect so that the ring posterior portion elevates, and may also pull radially inward, the annulus posterior aspect and corrects the mitral regurgitation.

Owner:EDWARDS LIFESCIENCES CORP

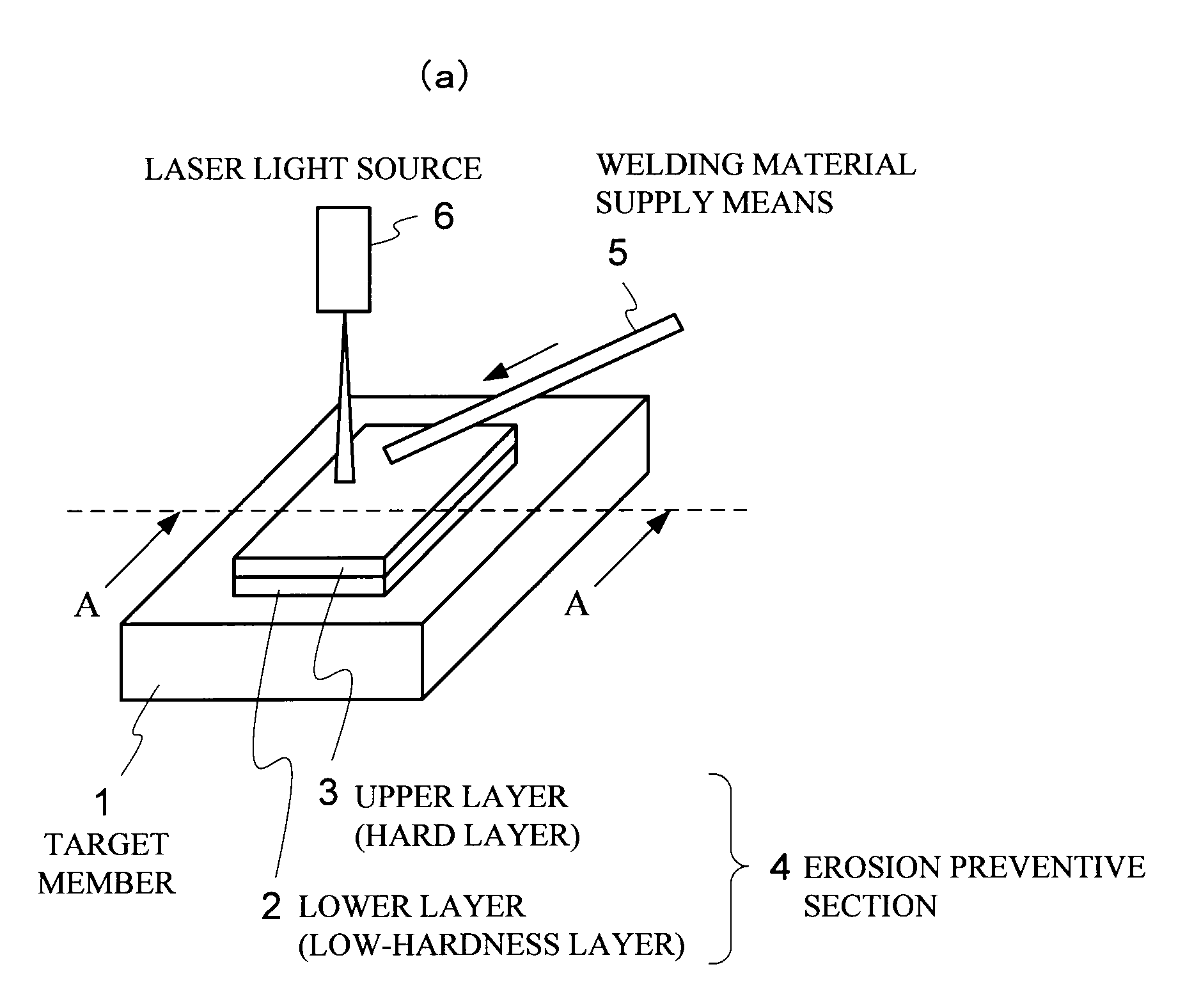

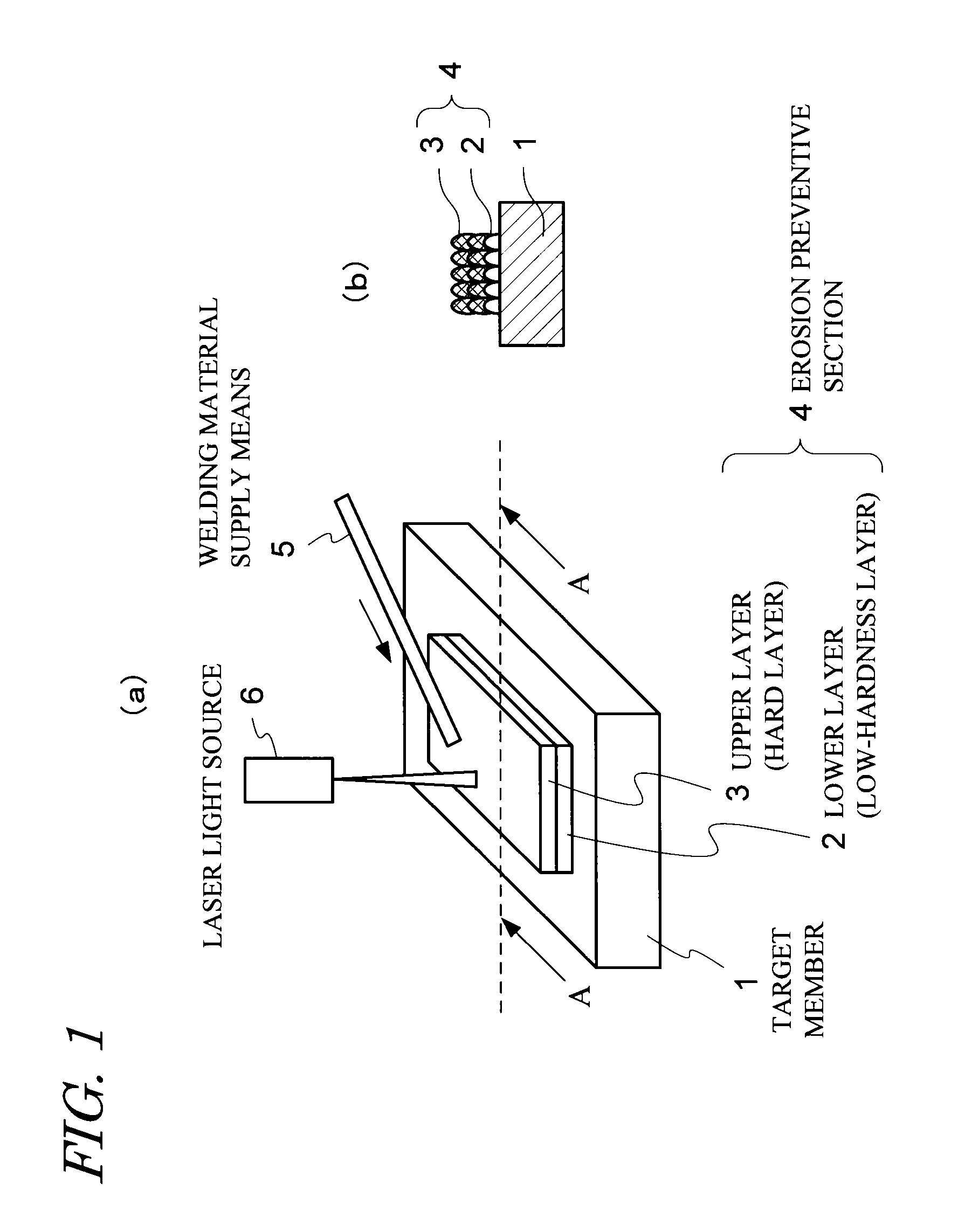

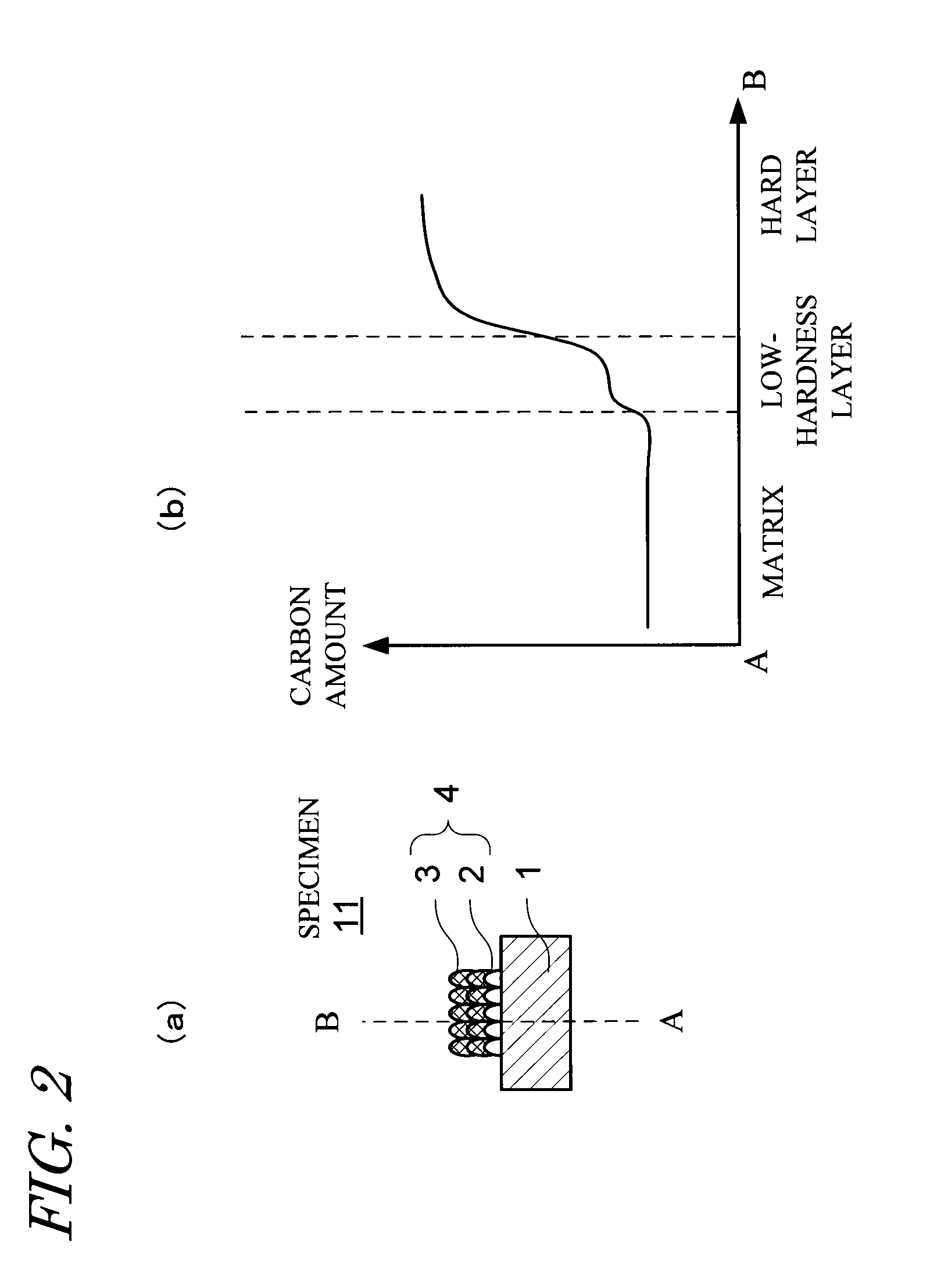

Erosion prevention method and member with erosion preventive section

InactiveUS20090308847A1Good economy and reliabilityEasy to provideTurbinesArc welding apparatusStellite alloyLaser light

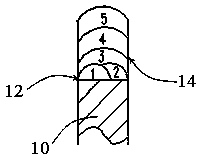

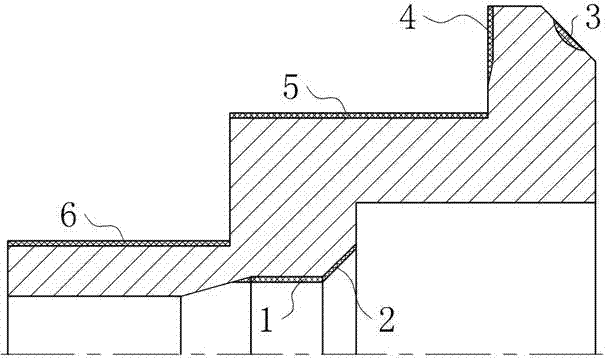

A method is provided, which ensures reliability during manufacture and in the use environment, and allows affording erosion prevention capability in an inexpensive manner, to an erosion-susceptible portion such as turbine rotor blades. An erosion preventive section 4, comprising a lower layer (low-hardness layer) 2 of an austenitic material, and an upper layer (hard layer) 3 of a hard material, such as stellite, harder than the low-hardness layer 2, is formed by laser build-up welding on a portion, which is susceptible to erosion caused by liquid droplets and solid particles in a use environment, of a target member 1 such as a turbine rotor blade. Laser build-up welding is carried out through irradiation of a laser beam from a laser light source 6 while a welding material supply means 5 supplies an austenitic material and a hard material in the form of, for instance, a rod, powder or the like.

Owner:KK TOSHIBA

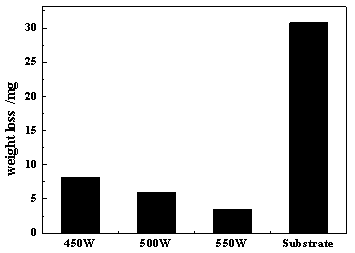

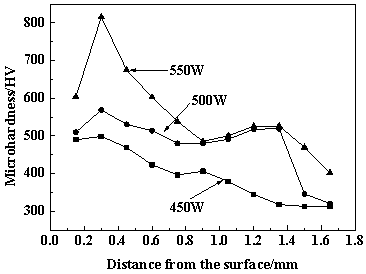

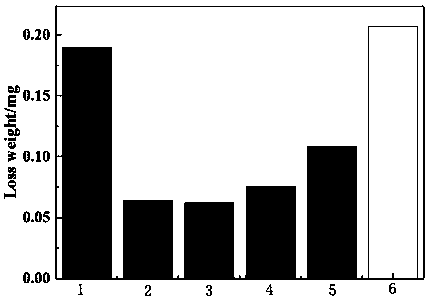

Preparation method for wear-resistant and corrosion-resistant composite coating layer

InactiveCN108611636AHigh hardnessAccelerated corrosionAdditive manufacturing apparatusMetallic material coating processesStellite alloySurface layer

The invention discloses a preparation method for a wear-resistant and corrosion-resistant composite coating layer. The preparation method specifically comprises the following steps: S1. carrying out pretreatment on a cladding matrix; S2. carrying out drying treatment on a cladding material; S3. melting the cladding material and the surface layer of the cladding matrix simultaneously through a laser device and in combination with a coaxial powder feeding method to form an alloy coating layer, that is, the high-hardness corrosion-resistant layer, wherein the cladding matrix in the step S1 is made from Q960 steel; and the cladding material in the step S2 is made from the mixture of tungsten carbide powder and Stellite 6 alloy powder. According to the preparation method disclosed by the invention, the composite coating layer is creatively prepared on the surface of the Q960 steel through a laser cladding technology; the tungsten carbide powder and the Stellite 6 alloy powder are mixed as the cladding material in a specific ratio; and the process parameters of the laser cladding technology are scientifically and reasonably designed, so that the problems of low hardness and short servicelife under the working condition of abrasive wear, of a laser cladding coating layer made from Stellite 6 cobalt alloy, are effectively solved.

Owner:HUNAN UNIV OF TECH +2

Machining technology of turbine blade with water corrosion prevention achieved by means of laser cladding

ActiveCN103659201AGuarantee the requirements of machining dimensional accuracyGuarantee cladding qualityStellite alloyDistressing

The invention provides a machining technology of a turbine blade with water corrosion prevention achieved by means of laser cladding. According to the machining technology of the turbine blade, the machining precision of the blade can be guaranteed, the fusion cladding amount is small, and tool loss is reasonable. The machining technology of the turbine blade with the water corrosion prevention achieved by means of laser cladding comprises the steps of (1) blank manufacturing; (2) forming through die forging; (3) heat treatment; (4) rough milling of the molded surface of a blank and milling of a laser cladding groove, wherein a certain redundant amount of a forge piece is removed through milling, and the laser cladding groove is machined until the laser cladding groove is within a certain tolerance range; (5) laser cladding of stellite in the laser cladding groove; (6) correction of a blade by means of a pressing machine after laser cladding; (7) radiographic and penetration inspection of a laser cladding area; (8) repairing welding of an unqualified portion, in the laser cladding area, of the blade through argon arc welding; (9) distressing and heat treatment; (10) comprehensive milling, wherein the blade is machined until the blade is within the tolerance range; (11) polishing, wherein machining tool marks on the surface of the blade are removed through polishing; (12) shot blasting of the surface of the blade.

Owner:WUXI TURBINE BLADE

Nickel chromium alloy for sealing face of nuclear power valve

InactiveCN101629256ALess affected by heatHigh bonding strengthMetallic material coating processesPlasma jetNuclear power

The invention discloses a nickel chromium alloy for a sealing face of a nuclear power valve. The nickel chromium alloy comprises the following components in percentage by weight: 26.0-28.0 percent of chrome, 2.0-2.5 percent of silicon, 1.1-1.3 percent of boron, 4.5-5.5 percent of molybdenum, 3.0-4.0 percent of tungsten, 0.9-1.1 percent of carbon and the balance of nickel. Meanwhile, a coating layer is prepared by a laser cladding technology so as to obtain a sealing face coating layer of a nickel-based alloy nuclear power valve, which has the following relevant parameters: the rigidity is HRC 42-46 which is slightly higher than HRC39-43 of a Stellite-6 cobalt-based alloy coating layer; the tissue grain fineness number of the coating layer is 11-12 grades which is superior to 9-10 grades of a general plasma jet welding layer and 8-9 grades of a flame resurfacing welding layer; and the width of a combination band of the coating layer and a basal body is 10-30 micrometers which is superior to 80-120 micrometers of a plasma jet welding combination band and 200-300 micrometers of a flame resurfacing welding combination band.

Owner:SUZHOU UNIV

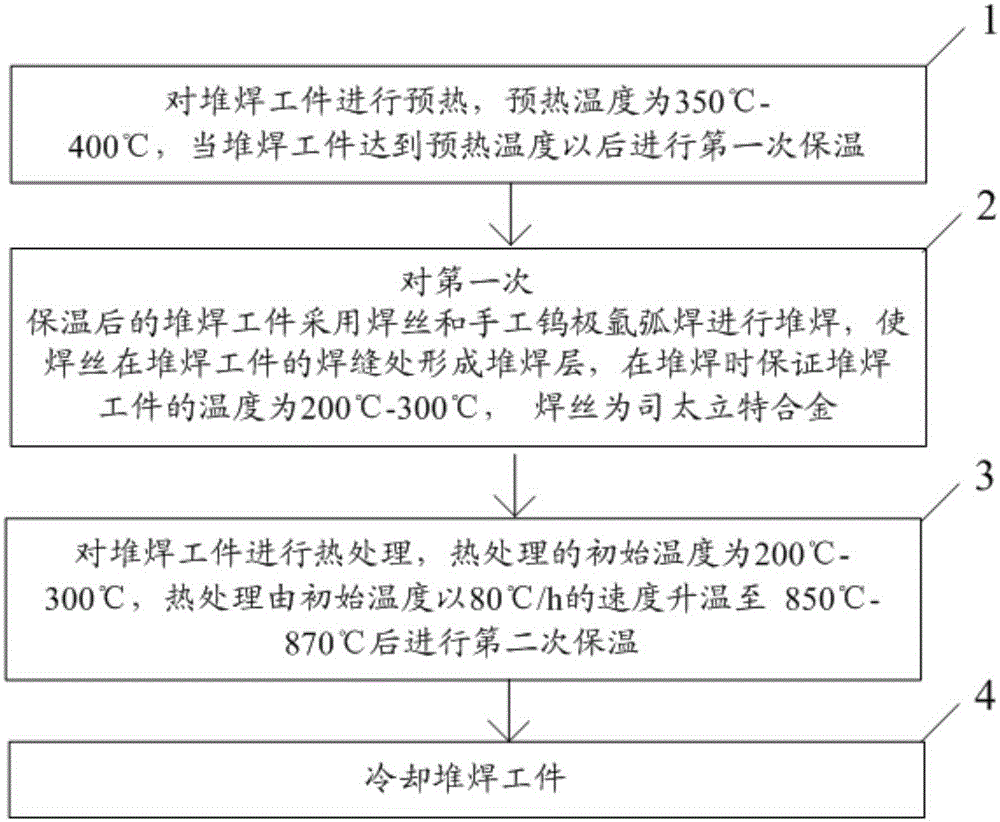

Welding method for conducting build up welding through stellite alloy

InactiveCN105171186AReduce cooling rateSlow coolingArc welding apparatusWelding/cutting media/materialsStellite alloyAlloy

The invention discloses a welding method for conducting build up welding through stellite alloy, and belongs to the field of welding. The method includes the steps that the first time of heat preservation is conducted after a build up welded workpiece is preheated; build up welding is conducted through a welding wire and manual argon tungsten-arc welding by means of the build up welded workpiece after the first time of heat preservation so that the welding wire can form a build up welded layer at the weld joint of the build up welded workpiece, wherein it is ensured that the build up welded workpiece is 200 DEG C to 300 DEG C in the build up welding process, and the welding wire is made of stellite alloy; after welding is completed, thermal treatment is conducted on the build up welded workpiece, wherein the initial temperature of thermal treatment is 200 DEG C to 300 DEG C, and the second time of heat preservation is conducted after the initial temperature of thermal treatment is raised to 850-870 DEG C at the speed of 80 DEG C per hour; and cooing is conducted. According to the method, the build up welded workpiece is preheated, the cooling speed of the weld joint can be decreased through preheating, the welded build up welded workpiece can be slowly cooled, a product is prevented from generating welding cracks especially cold cracks, and meanwhile it can be ensured that the build up welded layer has high strength.

Owner:WUHAN MARINE MACHINERY PLANT

Nickel base alloy powder for intaking and exhausting valve sealing surface weld deposit of automobile

InactiveCN101342646ALow costImprove performanceWelding/cutting media/materialsSoldering mediaStellite alloyRoom temperature

The invention discloses nickel base alloy powder for overlaying welding of the sealing surface of the intake and outlet valve of automobiles. The nickel base alloy powder comprises the components with the following weight portions of 25-27 percent of Cr, 4-6 percent of Mo, 10-15 percent of Fe, 2-3 percent of Si, 1.5-2 percent of B, 0.65-0.75 percent of C and Ni for the rest. The beneficial effects of the invention are (1) low cost, (2) good technological properties and (3) high hardness. The nickel base alloy powder can take the place of cobalt base alloy powder and has low cost. The price of the nickel base alloy powder is one third of the price of the cobalt base alloy powder. The nickel base alloy powder is especially suitable for plasma overlaying welding technology and vacuum furnace melting technology of the sealing surface of the intake and outlet valve of automobiles and locomotives. Compared with Stellite No. 6 cobalt base alloy powder, the welding layer of the invention processed by the same plasma arc overlaying welding technology has a same volume loss (mm <3>) in wear test. By comparing the hardness of the nickel base alloy powder with the hardness of the Stellite No. 6 cobalt base alloy powder, the two powders have the same hardness HRC which is 43 after the powders are cooled to room temperature. The two powder after being welded have the same hardness under 400-700 centigrade temperature in the furnace, while the nickel base alloy powder has better red-hardness.

Owner:TIANJIN ZHUJIN METAL SURFACE ENG MATERIALTECH DEV

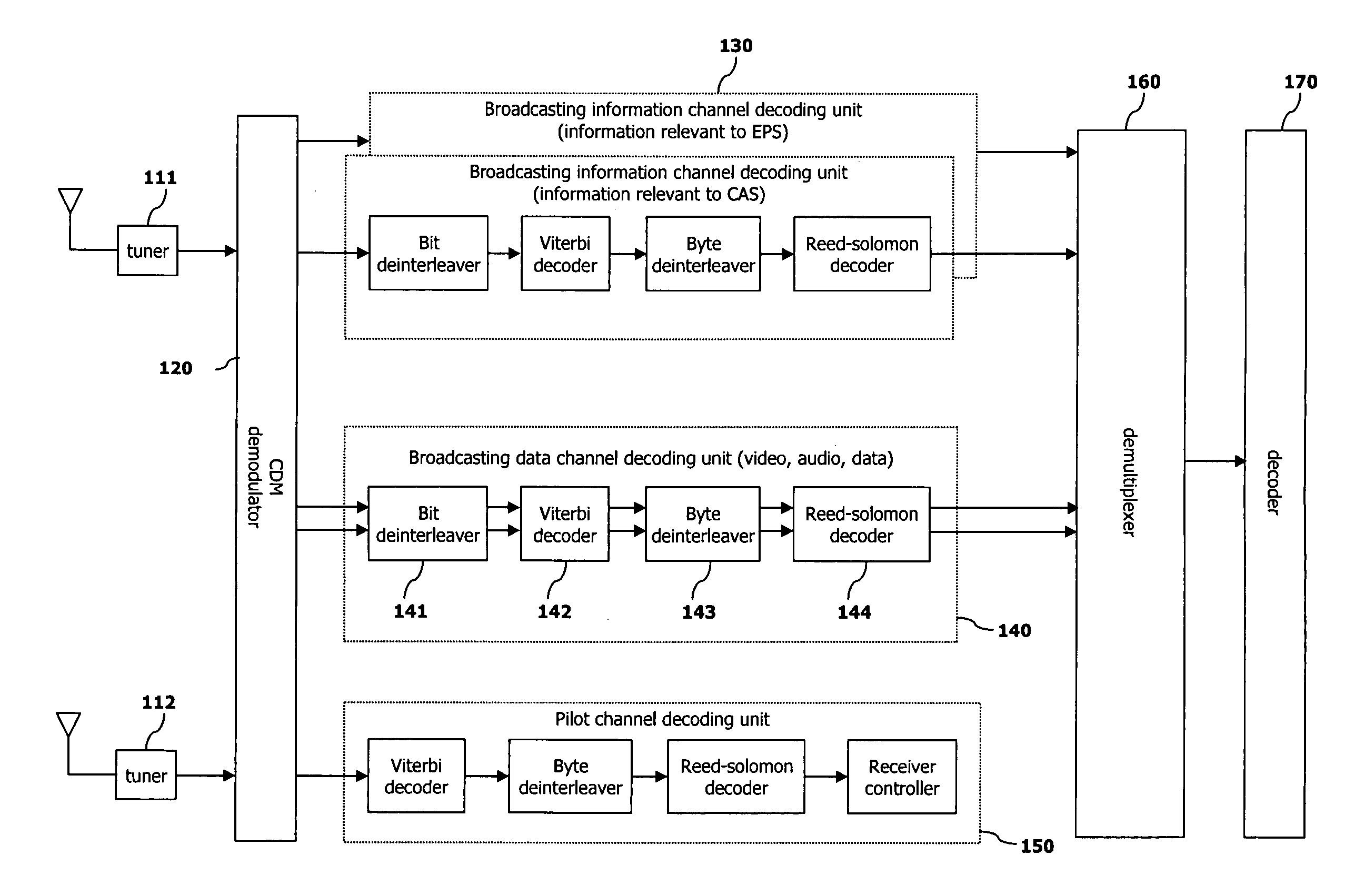

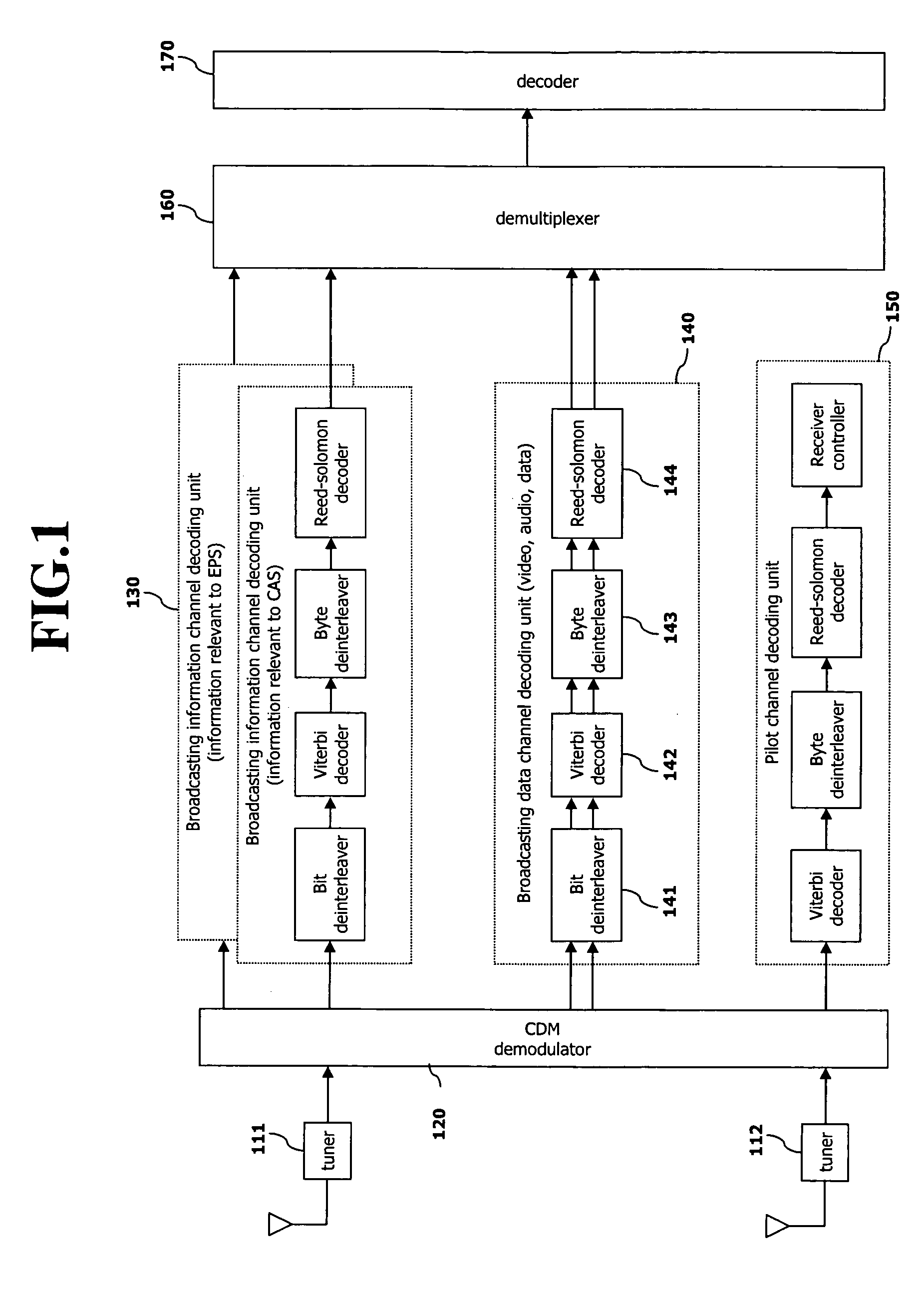

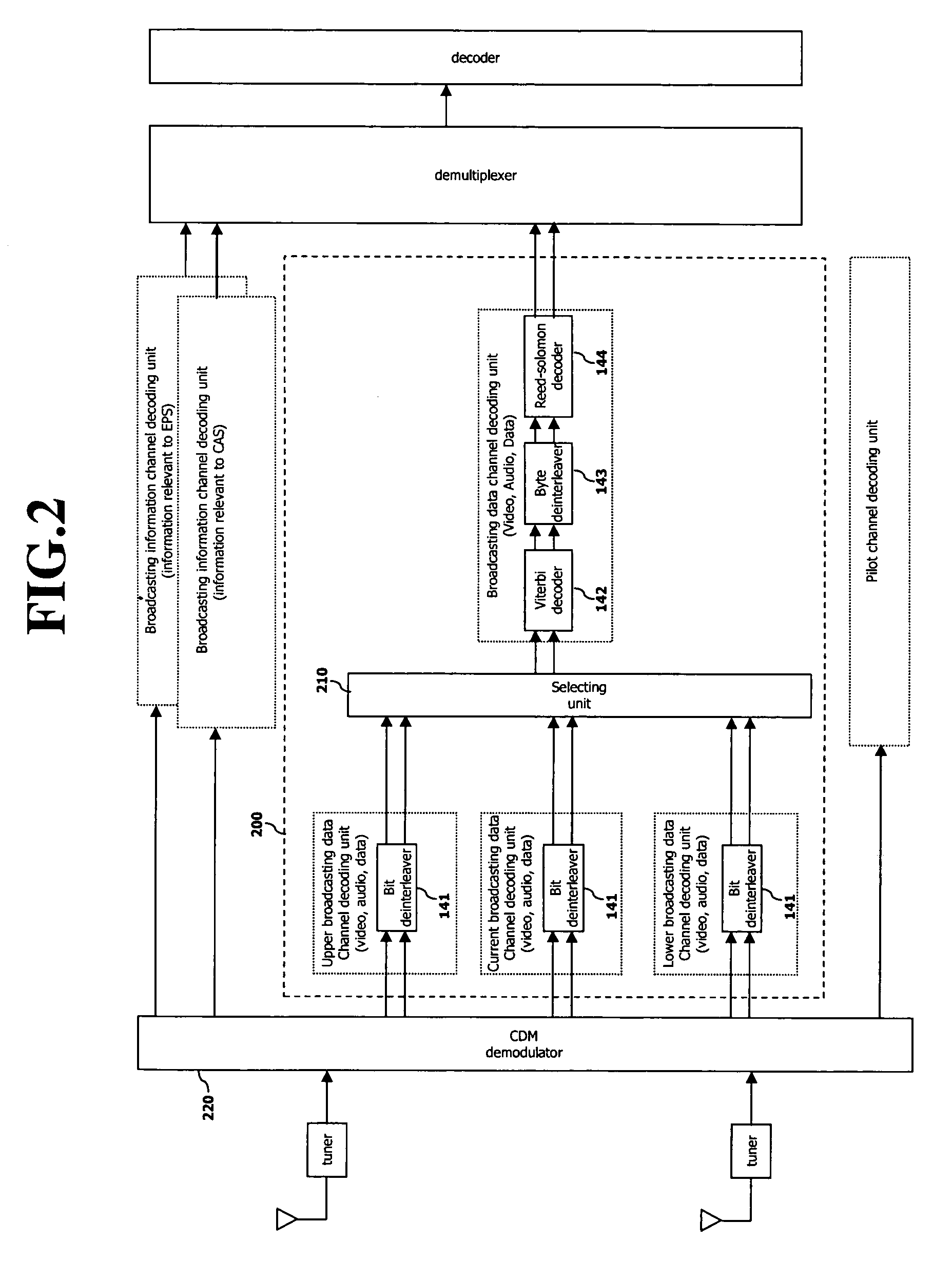

Apparatus for receiving stellite DMB and method thereof

InactiveUS20060064727A1Minimize delay timeMinimize timeTelevision system detailsSatellite broadcast receivingBroadcast channelsStellite alloy

Disclosed are an apparatus for receiving a satellite DMB capable of minimizing a video broadcast channel switching time and a method thereof. In the method, time taken to bit de-interleave broadcasting data of the video broadcast channel is reduced thereby to minimize a delay time generated at the time of switching channels. In a satellite DMB receiver having a CDM demodulator for demodulating broadcasting data coded by a Walsh code and having a broadcasting data channel decoding unit for decoding the coded broadcasting data, the satellite DMB receiving apparatus comprises a CDM demodulator for demodulating a Walsh code of at least one broadcast channel, and at least one broadcasting data channel decoding unit for decoding more than one broadcast channel, and a selecting unit for selecting a channel to be viewed by a user.

Owner:LG ELECTRONICS INC

Rolling bearing

An improved rolling bearing, in particular one being used in aqueous environment, such as water and steam, comprising an outer race, an inner race, rolling elements, and a retainer holding said rolling elements in a spaced relation from each other, wherein the races of the bearing are made of stellite, the rolling elements are made of hot-isostatic-pressed alumina-zirconia composites, and the retainer is made of poly-ether ether ketone comprising graphite fibers, graphite powder, and polytetrafluoroethylene.

Owner:AB SKF

Machining technology of thin-wall sleeve with surfacing hard stellite

ActiveCN110449848AGuaranteed mechanical propertiesGuarantee welding qualityStellite alloyLarge deformation

The invention relates to a machining technology of a thin-wall sleeve with surfacing hard stellite. The machining technology comprises steps as follows: blanking, heat treatment, size processing before turning and welding, mounting of a welding support device, welding, mounting of a coarse grinding tool for coarse grinding of welding position excircle, semi-finish turning as well as mounting of amandrel device for accurate grinding and finish turning. With the adoption of the welding support device, the coarse grinding tool and an accurate grinding tool, welding quality is guaranteed, the problems of welding cracks and large deformation in conventional welding process are solved, the heat treatment is performed after welding, stress produced by welding is eliminated, a shaft sleeve blankis subjected to heat treatment, mechanical properties of materials are guaranteed, the problem of deformation of the shaft sleeve in the grinding process of the conventional shaft sleeve with thinnerwall is solved, and machining precision is greatly improved.

Owner:SHENYANG SANKE HYDRAULIC MACHINERY MANUFACTORY

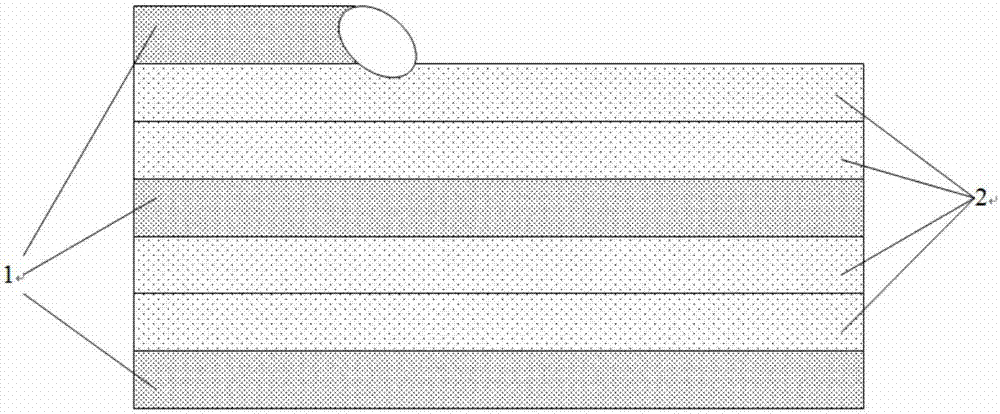

Laser additive manufacturing technology for K465 nickel-base high-temperature alloy structure piece

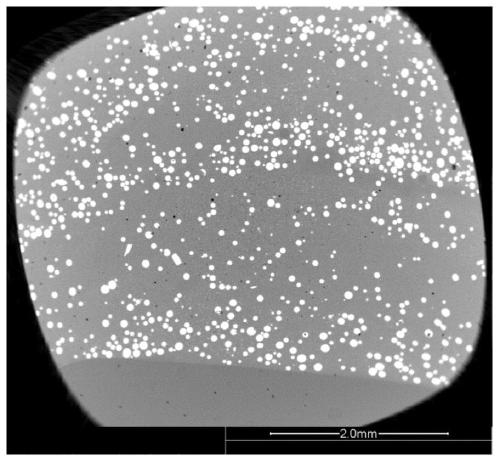

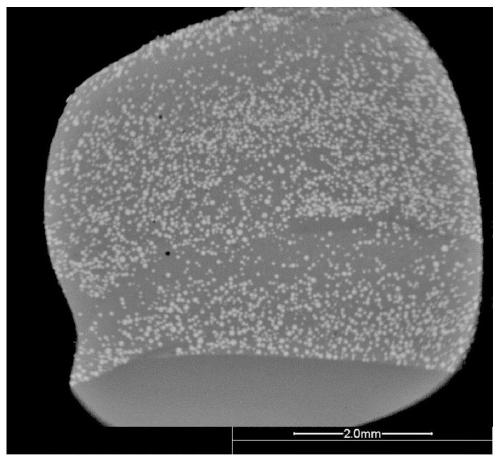

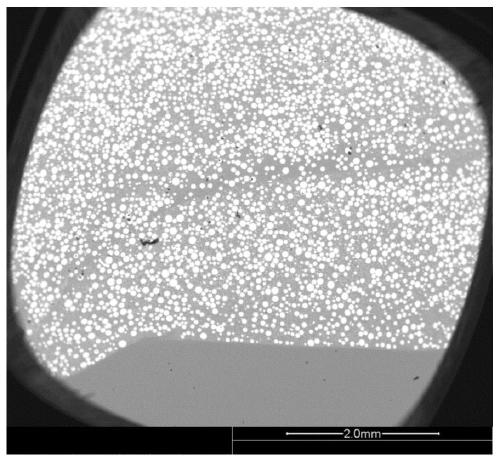

ActiveCN107338370AStable formMeet structural strengthAdditive manufacturing apparatusIncreasing energy efficiencyStellite alloyCrack free

The invention discloses a laser additive manufacturing technology for a K465 nickel-base high-temperature alloy structure piece, and belongs to the technical field of high-temperature alloy laser additive manufacturing. According to the technology forming technology parameters, the laser power ranges from 1,300 W to 1,600 W, the scanning speed ranges from 3 mm / s to 6 mm / s, the powder feeding rate ranges from 1 g / min to 2 g / min, the scanning manner is linear scanning or staggered scanning, and the overlap rate ranges from 40% to 50%. In the forming process, crack forming and expanding are controlled through a laminated structure, and the laminated structure is a structure piece formed through alternated arrangement of a layer of K465 high-temperature alloy and two layers of Stellite 6 high-temperature alloys. According to the technology, crack-free forming manufacturing of the K465 alloy structure piece is achieved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

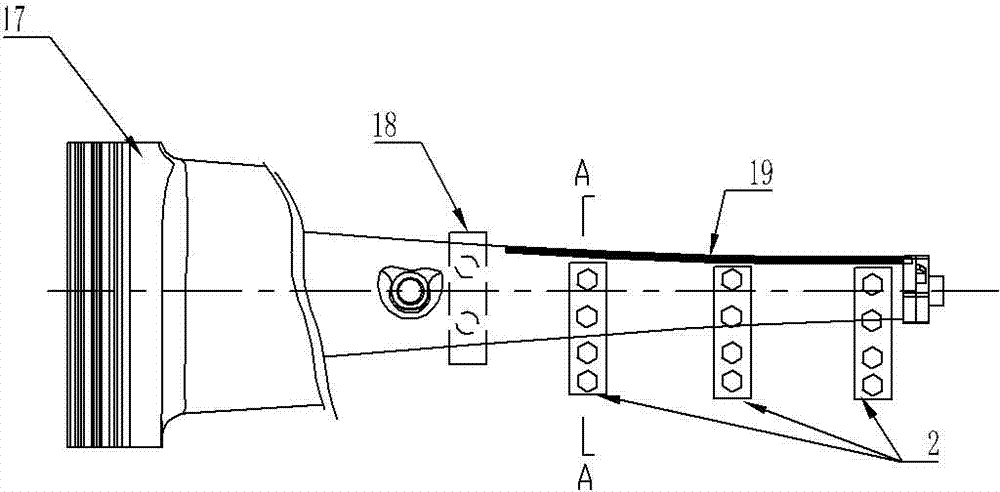

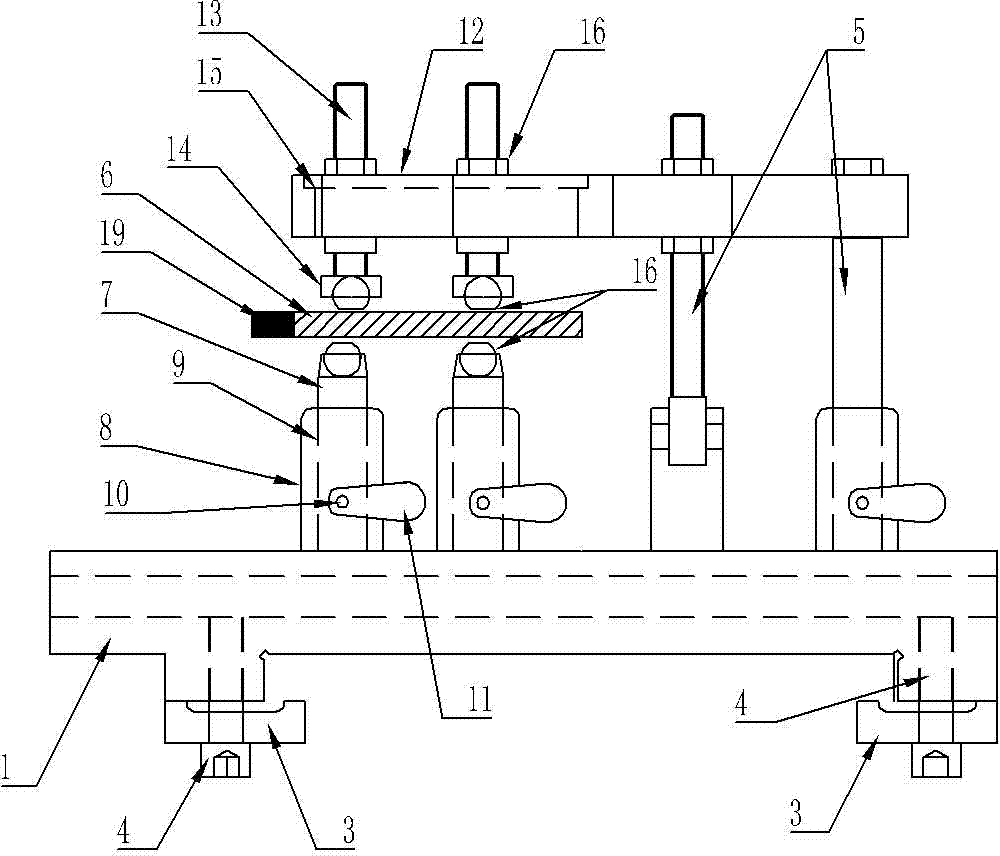

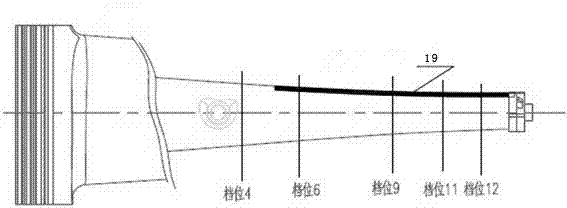

Hard-soldering deformation control method for turbine blade and special fixture for hard-soldering

ActiveCN103752983ABrazing Distortion ControlEasy clampingSoldering auxillary devicesStellite alloyTurbine blade

The invention provides a hard-soldering deformation control method for a turbine blade. The hard-soldering deformation control method for the turbine blade can effectively reduce the hard-soldering deformation of stellite alloy sheets at the steam inlet sides of last-stage large blades of a turbine. The hard-soldering deformation control method for the turbine blade is characterized by comprising the following steps: detecting the hard-soldering deformation and deformation tendency of a test blade by comparing the blade hard-soldering area of the blade before and after the hard-soldering with a blade theoretical model, obtaining a main hard-soldering deformation area and hard-soldering deformation direction of the test blade, and when performing hard-soldering of the stellite alloy sheets to the product blade having the same specification with the test blade, using a special fixture for hard-soldering to apply an over-deformation stress with direction opposite to the hard-soldering deformation direction to the main deformation area of the product blade corresponding to the test blade. The special fixture for hard-soldering comprises a machine tool guide rail connecting seat and multiple groups of chuck mechanisms, wherein the multiple groups of chuck mechanisms are mounted on the machine tool guide rail connecting seat, and the multiple groups of chuck mechanisms are uniformly arranged along the length direction of the hard-soldering area of the stellite alloy sheet of the blade.

Owner:WUXI TURBINE BLADE

Method for preparing anti-corrosion coating by means of laser cladding technology

InactiveCN108823564AImprove corrosion resistanceQuality improvementMetallic material coating processesStellite alloySurface layer

The invention discloses a method for preparing an anti-corrosion coating by means of a laser cladding technology. The method specifically includes the following steps that 1, cladding matrix pre-treatment is conducted; 2, a cladding material is subjected to drying treatment; 3, a laser in combination with a coaxial powder feeding method is adopted to make the cladding material and a cladding matrix surface layer melt simultaneously, and a layer of alloy coating is formed, so that the anti-corrosion coating is obtained; the cladding matrix in step 1 is Q960 steel; the cladding material in step2 is Stellite 6 alloy powder. According to the method for preparing the anti-corrosion coating by means of the laser cladding technology, the Q960 steel with good wear resistance is used as the cladding matrix, the Stellite 6 alloy powder with high corrosion resistance is used as the cladding material, the coaxial powder feeding method is adopted for conducting laser cladding under the action of the laser, and by means of synergistic cooperation between the cladding matrix and the cladding material, not only is the corrosion resistance of the Q960 steel improved, but also the quality of the Stellite 6 alloy laser cladding coating can be improved.

Owner:HUNAN UNIV OF TECH +2

Valve seat face surfacing technology

InactiveCN104534165AStrong corrosion resistanceImprove plasticityValve arrangementsStellite alloyEngineering

The invention relates to a valve seat face surfacing technology. The technology comprises the steps of performing rough turning on a valve seat and a valve core base material of a valve to be machined through a lathe to form the rough machining size before welding; surfacing austenitic stainless steel on the rough turned valve seat and valve core base material of the valve to form a stainless steel transition layer; putting the surfaced valve seat and valve core base material of the valve on the lathe, and turning the surfaced stainless steel layer on the valve seat of the valve flat; surfacing Stellite alloy on the valve seat stainless steel surface to form a Stellite alloy layer, which is the valve seat seal face; tempering the Stellite alloy surfaced valve seat and valve core. The surfacing technology has the advantages that the austenite stainless steel layer which is high in corrosion resistance and good in material plasticity is stacked on the valve seat to serve as the transition layer, and Stellite alloy is surfaced on the transition layer, accordingly, the surfacing yield reaches more than 98%.

Owner:NANTONG LONGYUAN POWER STATION VALVE

Precise CRDM part casting forming method

ActiveCN104874739AImprove yieldUniform structure and long-term wear resistanceFoundry mouldsFoundry coresStellite alloyInvestment casting

The invention discloses a precise CRDM part casting forming method. The precise CRDM part casting forming method comprises the steps that 1, a ceramic mold shell matched with design shape is manufactured in an investment mode according to the design shape of a CRDM claw and / or a connecting rod; 2, the ceramic mold shell is preheated under the condition of the temperature ranging from 850 DEG C to 1100 DEG C, the temperature is kept for 1-5 hours, and temperature uniformity of all positions of the ceramic mold shell is ensured; a stellite ingot is molten under the condition of the temperature ranging from 1400 DEG C to 1500 DEG C and is cast into the well-preheated ceramic mold shell, and a casting is formed after solidification; 3, mold shell is cleaned, and the casting is subjected to heat preservation under the condition of the temperature ranging from 850 DEG C to 950 DEG C and then is subjected to air cooling for 610 hours. The forming of the connecting rod and / or the claw part for a CRDM is reliably achieved by means of an investment casting technology, forming operation is easy, finished product rate is high, and a formed connecting rod and / or the claw part has even texture, is long-acting and abrasion-resistant, is reliable and stable in use and can effectively meet the technological requirements.

Owner:DONGFANG TURBINE CO LTD

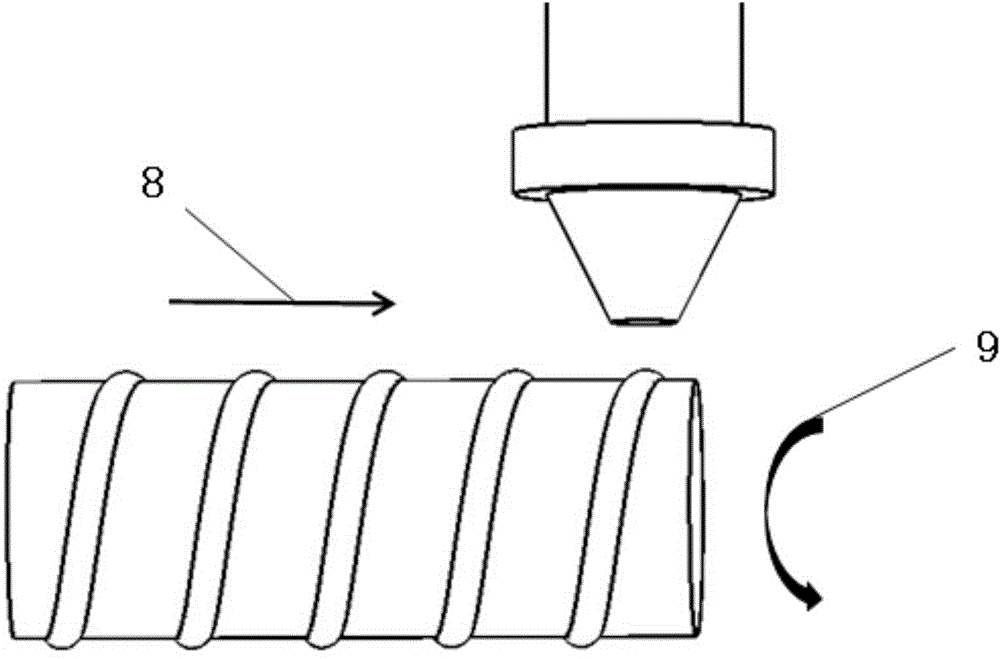

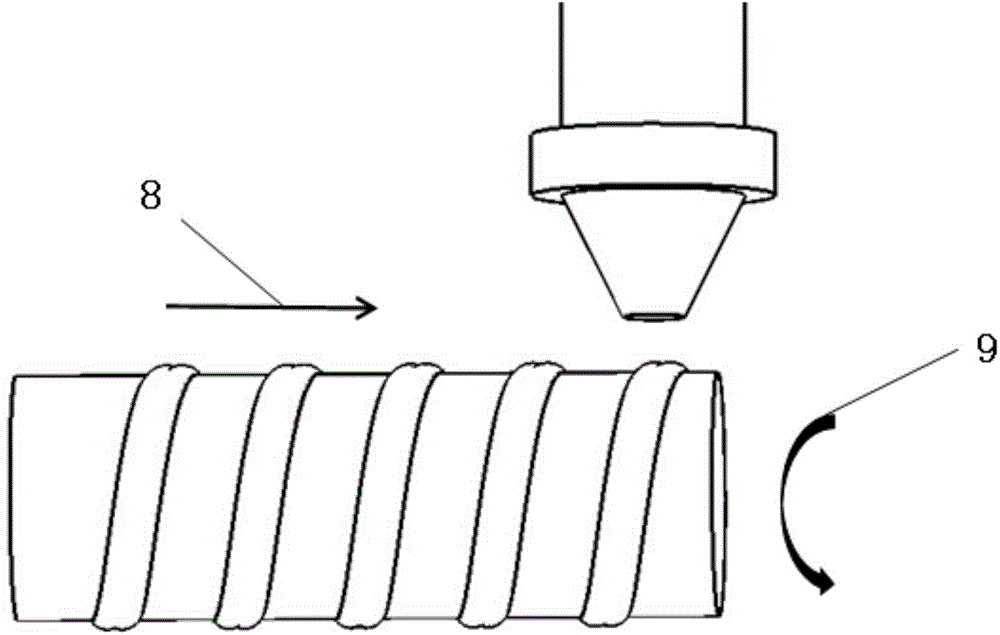

Stellite cobalt-based alloy outer circle large-area plasma surfacing method

The invention discloses a Stellite cobalt-based alloy outer circle large-area plasma surfacing method. The method comprises the following steps of S1, forming a cylindrical workpiece to be subjected to surfacing through machining; S2, removing impurities on the to-be-welded surface of the workpiece to be subjected to surfacing, wherein impurity cleaning includes removing greasy dirt, rust and oxide; S3, conducting liquid permeation detection on the surface of the workpiece to be subjected to surfacing, and repairing the workpiece if detection is not passed; S4, preheating the workpiece to be subjected to surfacing to a specified temperature if detection is passed; S5, conducting plasma surfacing on Stellite 12 powder special for a cobalt-based alloy; S6, conducting post-heating treatment on the workpiece subjected to surfacing; S7, conducting rough machining on a surfacing layer; S8, conducting liquid permeation detection on the surfacing layer, and repairing the surfacing layer if detection is not passed; S9, conducting final heat treatment if detection is passed; and S10, conducting finish machining to form a finished product by using a cobalt-based alloy special tool. The Stellite cobalt-based alloy outer circle large-area plasma surfacing method has the beneficial effects that the workpiece subjected to surfacing is free of cracks, uniform in hardness, high in qualified rate and short in construction period, and the labor intensity of welders is relieved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

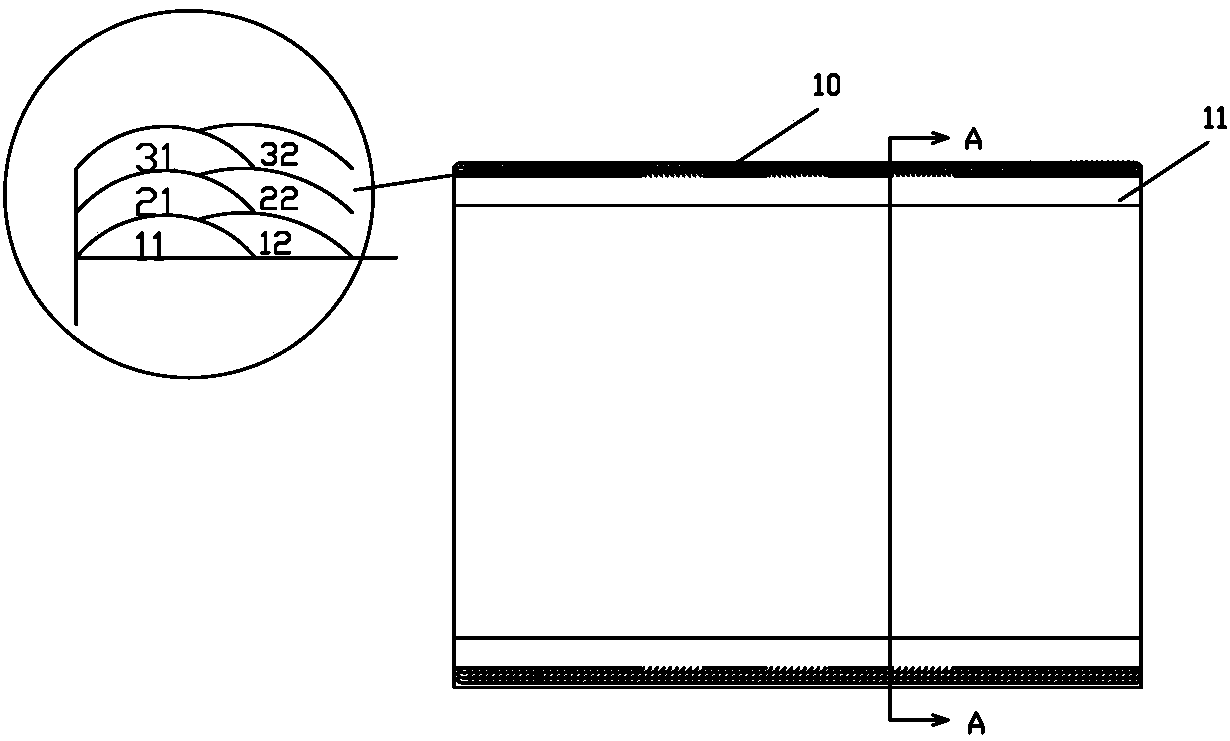

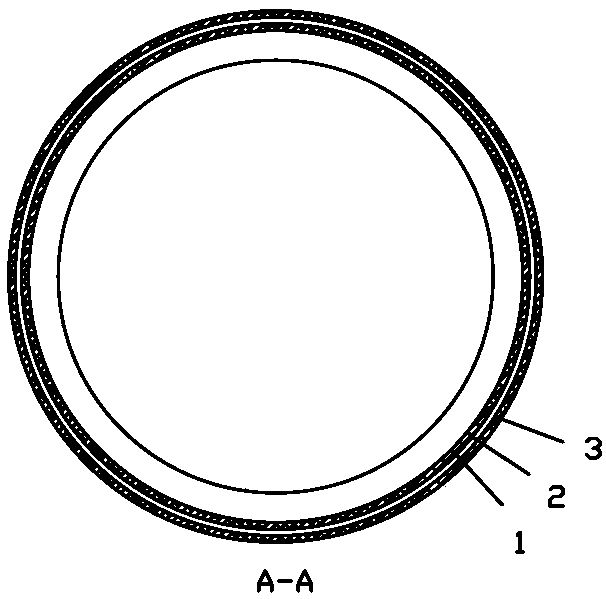

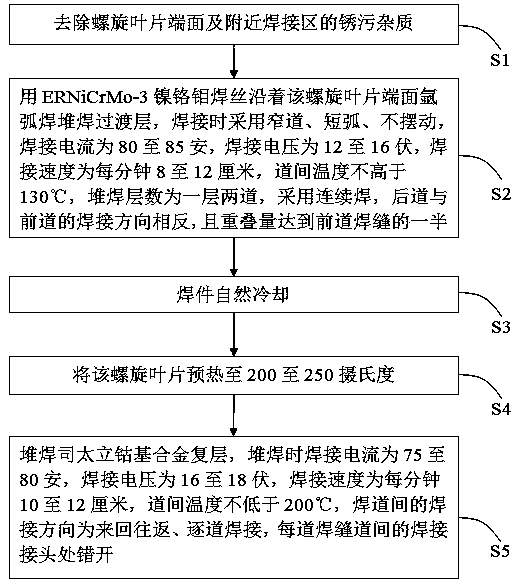

Spiral blade wear resisting layer alloy overlaying process

ActiveCN109623099AImprove wear resistanceAccelerated corrosionWelding/cutting media/materialsSoldering mediaImpurityMetallic Nickel

The invention provides a spiral blade wear resisting layer alloy overlaying process. Rust impurities on the end surfaces of spiral blades and in nearby welding areas are removed; transition layers areoverlaid along the end surfaces of the spiral blades by using ERNiCrMo-3 nickel chromium molybdenum welding wires through argon arc welding; during welding, narrow beads and short arcs are adopted without swinging; the welding current is 80-85 A; the inter-bead temperature is not higher than 130 DEG C; the overlaying layer number is two beads in each layer; the continuous welding is adopted; thewelding directions of two beads are opposite; the overlap quantity of the latter bead is one half of welding lines of the previous bead; welded parts are naturally cooled; the spiral blades are preheated to 200-250 DEG C; Stellite cobalt base alloy cladding layers are overlaid; during overlaying, the welding current is 75-80 A; the inter-bead temperature is not lower than 200 DEG C; the welding direction between the beads is reciprocating bead-by-bead welding; and welding joints between the welding beads are staggered. The service life of the blades can be greatly prolonged.

Owner:JIANGSU XINHONGDA GROUP

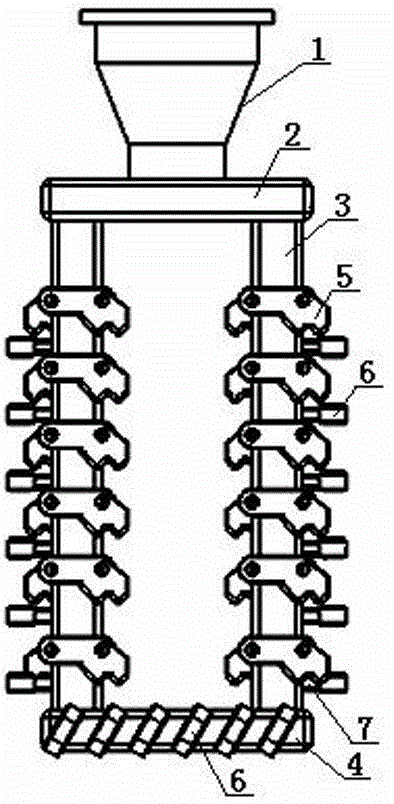

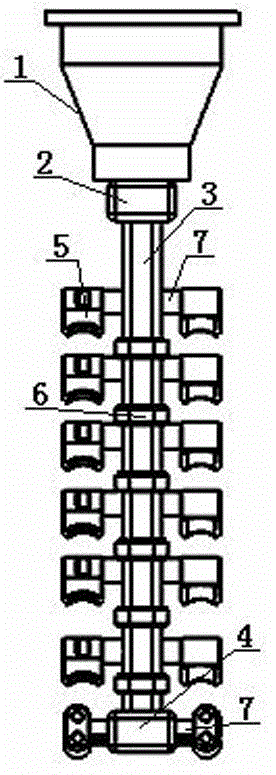

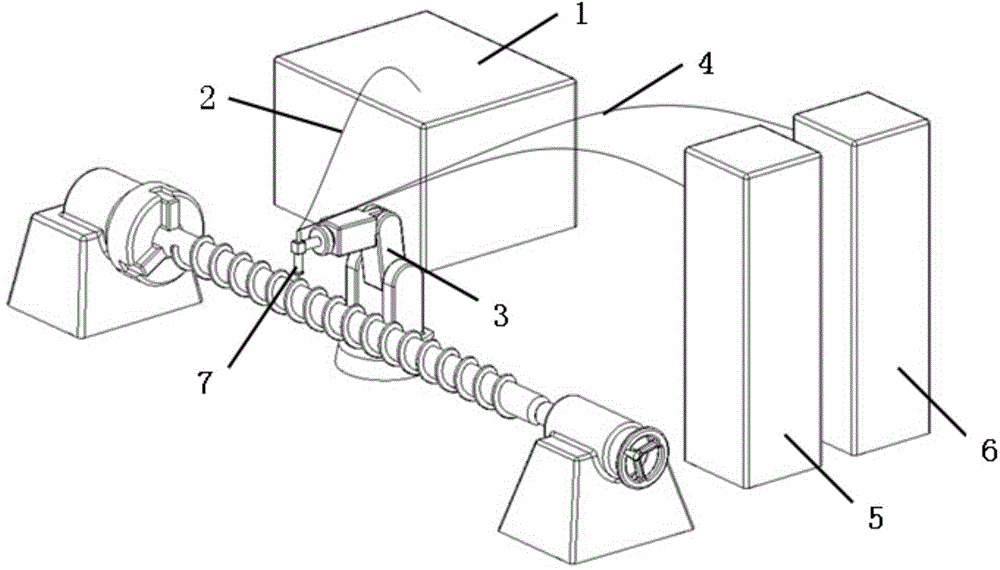

Technological method for screw manufacturing through laser combination

ActiveCN104550955AFine grainImprove anti-wear performanceIncreasing energy efficiencyManufacturing technologyHigh energy

The invention relates to the field of material science and laser processing, in particular to a technological method for screw manufacturing through laser combination. The technological method sequentially comprises the following steps of determining a laser combination additive manufacturing material; cleaning the surface of a polished rod of a screw; carrying out laser combination additive manufacturing on the screw; and carrying out subsequent milling on the primarily formed screw. The technological method disclosed by the invention has the beneficial technical effects that the polished rod of the screw is subjected to additive manufacturing by using a laser combination additive manufacturing technology; the surface to be processed is rapidly scanned by a laser beam with high-energy density; due to extremely rapid heating and cooling speeds, crystal particles are not easy to grow, so that a high-performance surfacing layer which has extremely fine crystal grains and is in firm metallurgical bonding with a matrix body is obtained on the screw flight surface formed by laser combination additive manufacturing. When a material of a superficial layer is changed (for instance, Ni60 is changed into Stellite 6 and 316L combination), the performances of the superficial layer can be changed, and the technological method can be applied in other occasions (such as large-size gears).

Owner:ZHEJIANG UNIV OF TECH +1

Valve disc multi-position plasma stellite spray welding process method

ActiveCN106975830ALow weld dilutionImprove toughnessPlasma welding apparatusStellite alloyHeat-affected zone

The invention discloses a stellite spray welding process method, in particular to a valve disc multi-position plasma stellite spray welding process method, and belongs to the technical field of welding process methods. The method comprises the following steps that firstly, the to-be-spray-welded inner round face, the to-be-spray-welded inner conical face and the to-be-spray-welded outer conical face of a valve disc are subjected to plasma stellite spray welding; secondly, the valve disc is subjected to postwelding stress relief heat treatment for the first time; thirdly, the to-be-spray-welded outer end face, the to-be-spray-welded outer large round face, the to-be-spray-welded outer small round face and the like of the valve disc are subjected to plasma stellite spray welding; and fourthly, the valve disc is subjected to postwelding stress relief heat treatment for the second time. The process flow is simple, the working efficiency can be improved, the production cost is reduced, through reasonable welding and heat treatment process orders and in combination with matched welding process parameters, direct stellite spray welding on all the to-be-spray-welded faces of the valve disc can be performed, welding cracks can be avoided, the toughness of the heat affected zone is good, the weld seam dilution rate is low, and the weld seam pass percent is high.

Owner:DONGFANG TURBINE CO LTD

Composite structure coating and spraying method thereof

ActiveCN101613852AAccelerated corrosionImprove high temperature wear resistanceMolten spray coatingStellite alloyFunctional composite

The invention discloses a composite structure coating which is characterized by comprising a stellite alloy layer coated on the surface of a roller body, a MoB / CoCr metal ceramic layer coated on the surface of the stellite alloy layer and a barrier layer arranged on the surface of the MoB / CoCr metal ceramic layer. In the invention, the functional composite structure coating manufactured by the thermal spraying technology and special coating after being subjected to hole sealing can ensure single use time and accumulative service life of a sinking roller and stable roller to be increased by 1-3 times of roller bodies without coatings, so that steel plants improve use efficiency of high value roller bodies, thus improving production efficiency and product quality.

Owner:SHANGHAI JUSN SURFACE TECH ENG +1

Laser cladding coating for improving water erosion resistance of brazed stellite and preparation method

ActiveCN110424010AImprove water erosion resistanceImprove service performanceMetallic material coating processesPorosityStress concentration

The invention discloses a laser cladding coating for improving the water erosion resistance of brazed stellite and a preparation method. A coating is laser-cladded on the surface of a stellite substrate brazed on a steam turbine blade, the coating is composed of a continuous phase nickel-based alloy material and dispersion strengthening phase wolfram carbide particles, the WC particles are spherical, stress concentration caused by sharp corners is effectively eliminated, the coating cannot crack, wolfram oxide with certain thickness is arranged on the surfaces of the WC particles, excessive dissolution of a WC melted nickel-based alloy is avoided, optimum dispersion strengthening of a nickel-based alloy phase is achieved, the coating is prepared through the laser cladding technology, the efficiency is high, the operation is easy, and the prepared coating is dense, free of cracks and low in porosity. The laser cladding coating for improving the water erosion resistance of the brazed stellite and the preparation method of the laser cladding coating can be used for water-erosion-resistant coatings on the surfaces of blades of large nuclear steam turbines and thermal power steam turbines and manufacturing, repairing and re-manufacturing, the service performance of parts is effectively improved, and the service life of the parts is effectively prolonged.

Owner:HAINAN NUCLEAR POWER +1

Method for preparing quasi-crystallized composite through laser processing

ActiveCN106544672AImprove wear resistanceImprove surface topographyMetallic material coating processesStellite alloyLaser processing

The invention discloses a method for preparing a quasi-crystallized composite through laser processing. The method comprises the specific steps that a certain mass proportion of Stellite SF 12-NB-Mo mixed powder is dried and fully mixed, and argon is adopted as the protective gas; a laser, a coaxial powder feeder and a synchronous wire feeder are adopted for conducting laser melting deposition treatment on the surface of a titanium alloy, wherein according to process parameters, the laser power is 1.00-4.80 kW, the spot diameter is 0.3-4.0 mm, the laser beam scanning speed is 12-18 mm / s, the powder feeding rate is 6-32 g / min, the multichannel overlapping rate is 18-55%, and the wire feeding speed is 8-15 mm / s; and meanwhile, La2O3-coated TC11 wires are fed to the edge of a molten bath at a certain angle, and after the powder and the wires are subjected to laser processing at the same time, a laser melting deposition composite can be obtained. The laser coaxial powder feeding mode is adopted for melting a SiMn powder laser alloy to the surface of the composite, so that the quasi-crystallized composite is formed. By adoption of the method for preparing the quasi-crystallized composite through laser processing, the composite with the surface appearance and the microhardness remarkably improved can be obtained.

Owner:SHANDONG JIANZHU UNIV

Concreting system for thin-walled cylindrical part and precision casting formation method

ActiveCN104999037ALess stringent requirementsImprove yieldFoundry mouldsFoundry coresStellite alloyWax

The invention discloses a concreting system for a thin-walled cylindrical part and a precision casting formation method. The concreting system comprises a wax tree formed by welding a sprue cup, a straight sprue, a horizontal sprue, an inner sprue and a casting together in sequence, wherein the wax tree is coated with a mould case. The precision casting formation method comprises the following steps: forming the mould case without a parting surface, coating the mould case, preheating the mould case, smelting and pouring, cleaning the casting, performing heat treatment, and the like. The precision casting formation method can replace the conventional widely-applied centrifugal casting forming method, mother alloy can be remarkably saved, the yield can be remarkably improved, the harsh requirements on equipment, environment and personnel can be reduced, the processing amount can be reduced, the cost is only 60% of that of the centrifugal casting, and as Stellite neck bush is high in consumption and multiple in variety each year, very considerable economic benefits are achieved.

Owner:DONGFANG TURBINE CO LTD

Combustion engine crankshaft electric spark overlaying repairing process

InactiveCN101920429ASmall color differenceArc welding apparatusMaterial magnetic variablesEngineeringInternal combustion engine

The invention relates to a combustion engine crankshaft electric spark overlaying repairing process. The process includes that: oil removing and rust removing are carried out on the surface of crankshaft at room temperature; magnetic powder and liquid penetrating test are utilized to determine crack position and polishing is carried out to remove the crack; 3kW electric spark repairing machine is selected, a working gun is manually rotated, the clamped nickel base or stellite electrode is utilized, under the protection of argon, microarc overlaying is carried out by a consumable electrode, the technological parameters thereof are that: output voltage is 70-80V, frequency is 70-2000Hz, argon flow is 4-5L / min, and strengthening speed is 2-3min / cm; and crankshaft magnetic powder defect detector is utilized to detect magnetic powder inspection at the repairing position. The fatigue strength and wear resisting property of the repaired crankshaft can meet the requirement, minimum chromatism between electric spark overlaying layer and base material can be realized, and no related magnetic track is produced in magnetic powder detection. The invention can realize magnetic powder inspection generally adopted by railway system.

Owner:甘肃景程光电技术有限公司

Iron-base alloy powder for high-pressure valve sealing surface weld deposit

InactiveCN101342648ALow costLow priceWelding/cutting media/materialsSoldering mediaStellite alloyRoom temperature

The invention discloses iron base alloy powder for overlaying welding of the sealing surface of a high pressure valve. The iron base alloy powder comprises the following components with the weight portions of 18-24 percent of Cr, 4-6 percent of Mo, 13 percent of Ni, 4-5 percent of Si, 1-2 percent of B, equal to or less than 0.15 percent of C, and Fe for the rest. The beneficial effects of the invention are (1) low cost, (2) good technological properties and (3) high hardness. The invention adopts the iron base alloy powder to replace the cobalt base alloy powder. The price of the iron base alloy powder is much lower than the price of the cobalt base alloy powder. The iron base alloy powder can replace Stellite No. 6 cobalt base alloy powder, and has the advantages of low cost and high properties. The welding technology of the iron base alloy powder is more advanced than the welding technology of the Stellite No. 6 cobalt base alloy powder. The Stellite No. 6 cobalt base alloy powder needs to preheat the overlaying welding base before overlaying welding, or the welding seam will split open. The overlaying welding base of the invention does not need to be preheated. The iron base alloy powder has good overlaying welding properties, has simple technologies, and is easy to be operated. After being welded and cooled to room temperature, the hardness HRC of the iron base alloy powder is 39. The hardness under 560 centigrade in a furnace is higher than the hardness under room temperature. The iron base alloy powder has sedimentation and hardening functions.

Owner:TIANJIN ZHUJIN METAL SURFACE ENG MATERIALTECH DEV

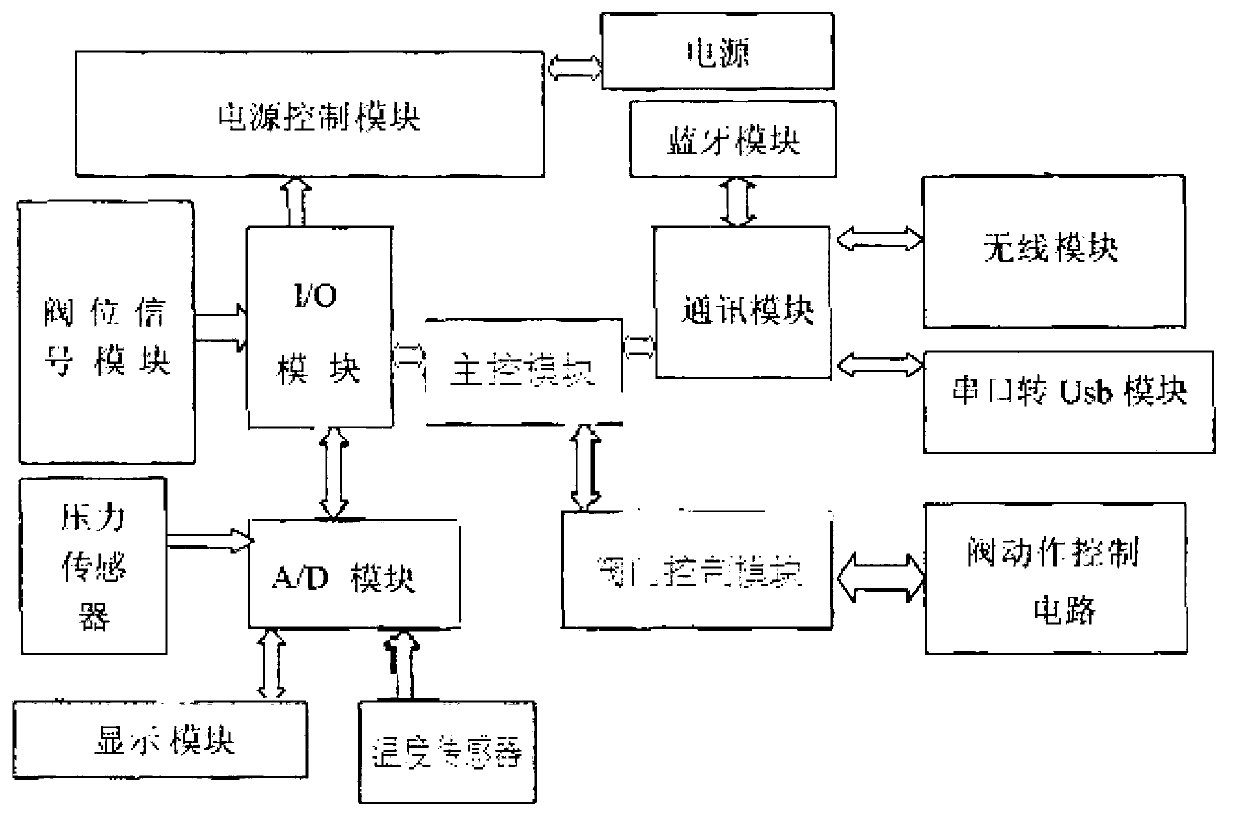

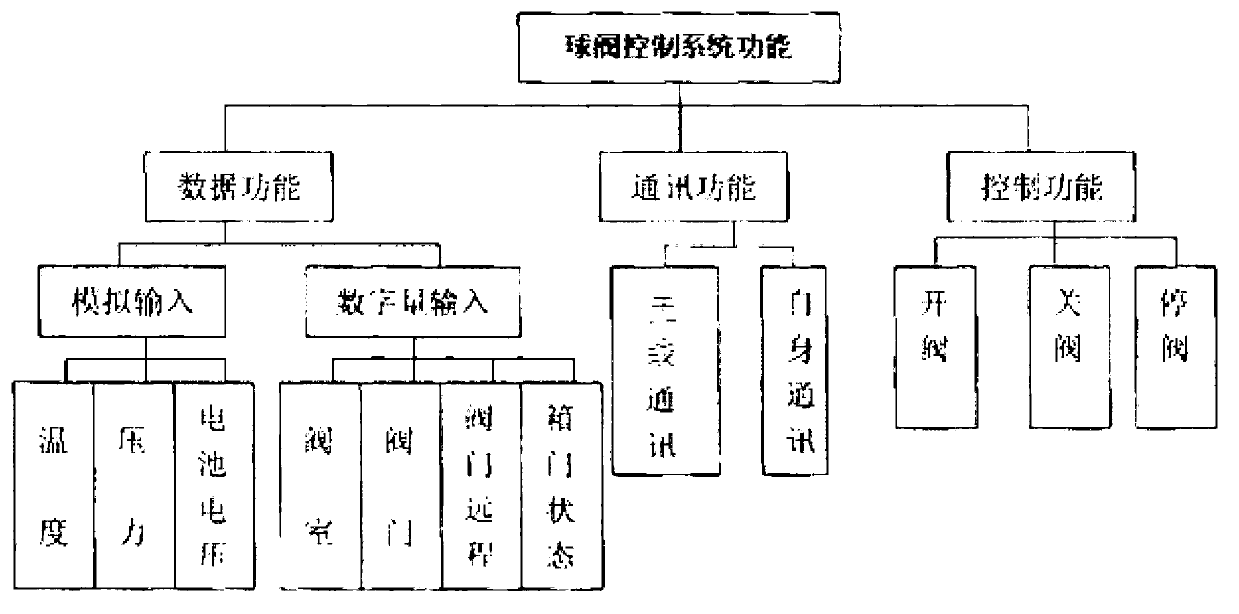

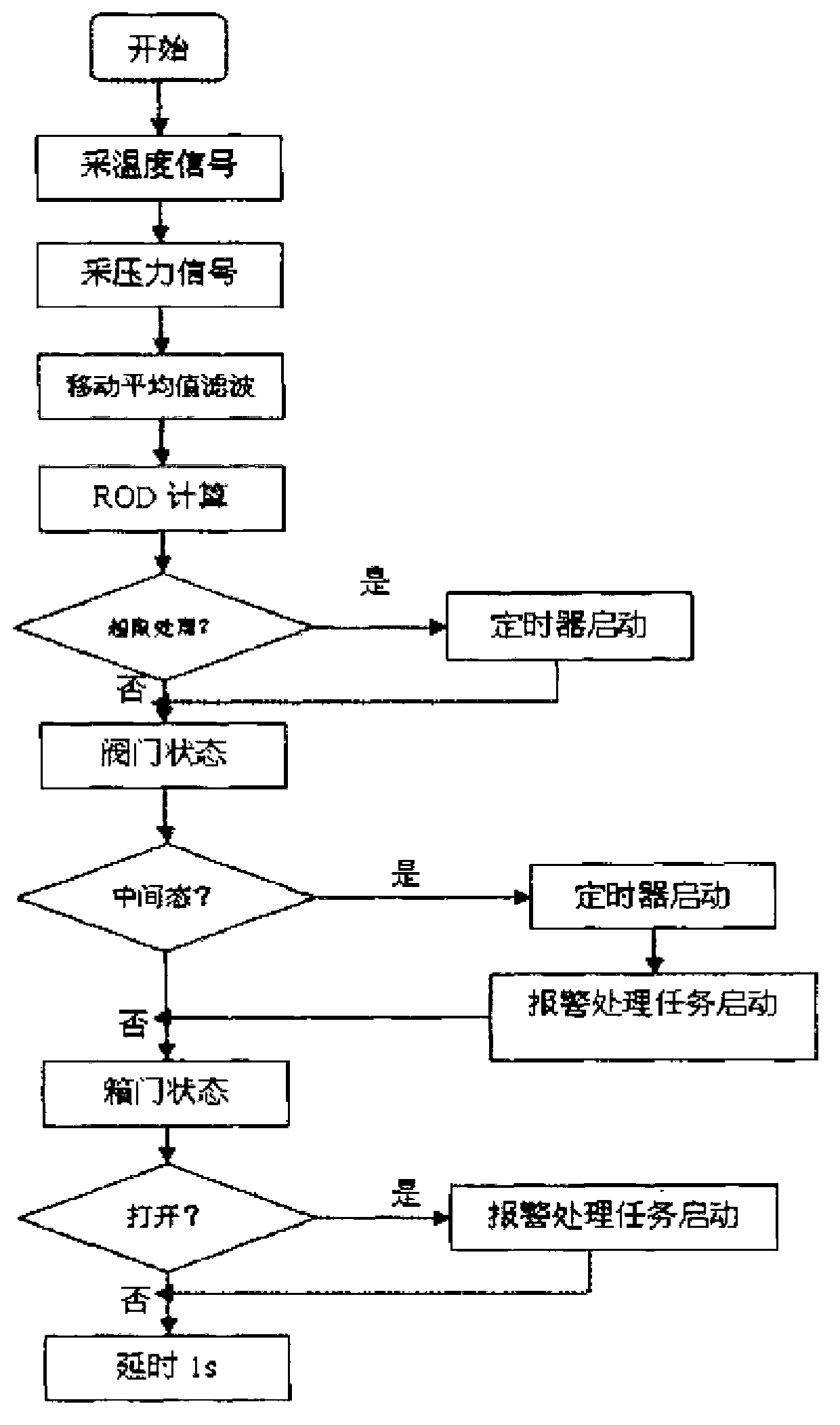

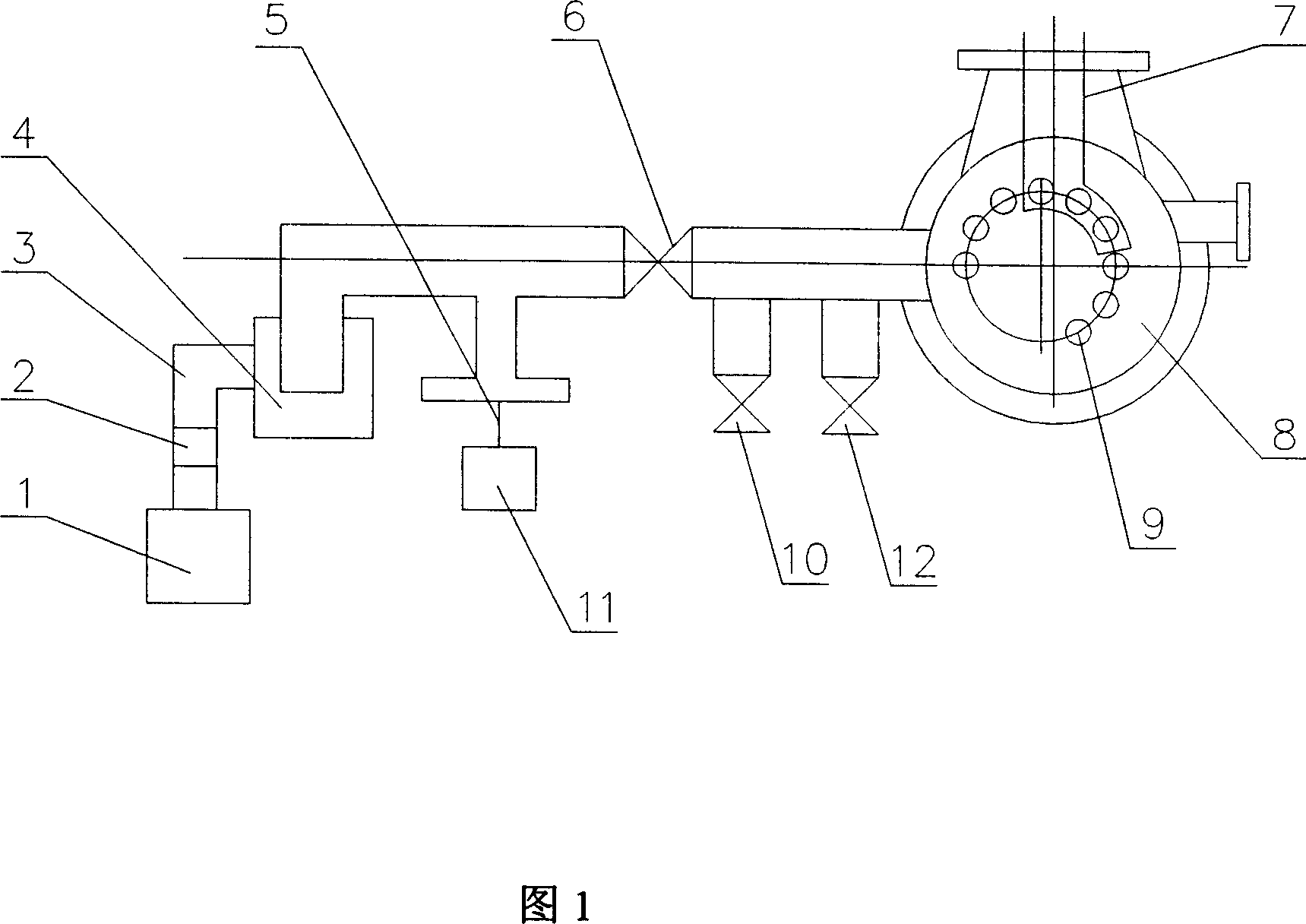

Low-temperature ball valve and control system thereof

ActiveCN103075536AReduce gapExtended service lifePlug valvesOperating means/releasing devices for valvesStellite alloyControl system

The invention discloses a low-temperature ball valve, which comprises a valve body, a valve cap, valve seat assemblies, a ball body, a valve rod and a stationary shaft, wherein the valve body and the valve cap are respectively provided with a runner; the valve body and the valve cap are connected by a gasket, a stud and a nut; the ball body is arranged in the valve body; and two sides of the ball body are respectively provided with one valve seat assembly respectively connected with the insides of the valve body and the valve cap. The low-temperature ball valve is further provided with a driving device, wherein the driving device is connected with the upper part of the valve rod by a key, and the lower end of the valve rod is connected with the ball body. According to the low-temperature ball valve disclosed by the invention, a welding line for connecting the valve body and the valve seat adopts a full-automatic welding technology, and the valve body and the valve seat adopt the U-shaped welding line so as to eliminate a leaking point in the welding line for the valve body and the valve seat. The valve sealing surface adopts Stellite hard alloy, the surface is formed by rolling, and the service life of the valve is prolonged. The sealing surface adopts automatic grinding, and the goodness fit of the sealing surface is improved.

Owner:JIANG SU YAN DIAN FA MEN CO LTD

New technology of valve sealing element vacuum induction pile-up welding hard alloy and improved equipment

InactiveCN100999032AReduce usageEasy to useMetal working apparatusSoldering auxillary devicesStellite alloyOptimization problem

The present invention relates to a new process for vacuum induction surfacing hard alloy on seal component of valve and its improved equipment. Said invention adopts the following technical measures: optimizing surfacing process: regulating U-shaped groove depth and groove wall thickness of sealing surface of sealing component to be surfaced; adopting cheap Stellite 158D and Co-L alloy powder; optimizing technological parameters of surfacing current, surfacing temperature, vacuum degree and valve seat rotating speed; improving surfacing equipment: adding and welding connecting plate and cooling device of furnace cover cooling system; intrafurnace workpiece and induction coil flange sealed position adopt heat-insulating material; a reflective mirror is mounted in the sighting window position; and on the vacuum pipeline system a leakage-detecting interface is added.

Owner:DALIAN DAGAO VALVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com