Technological method for screw manufacturing through laser combination

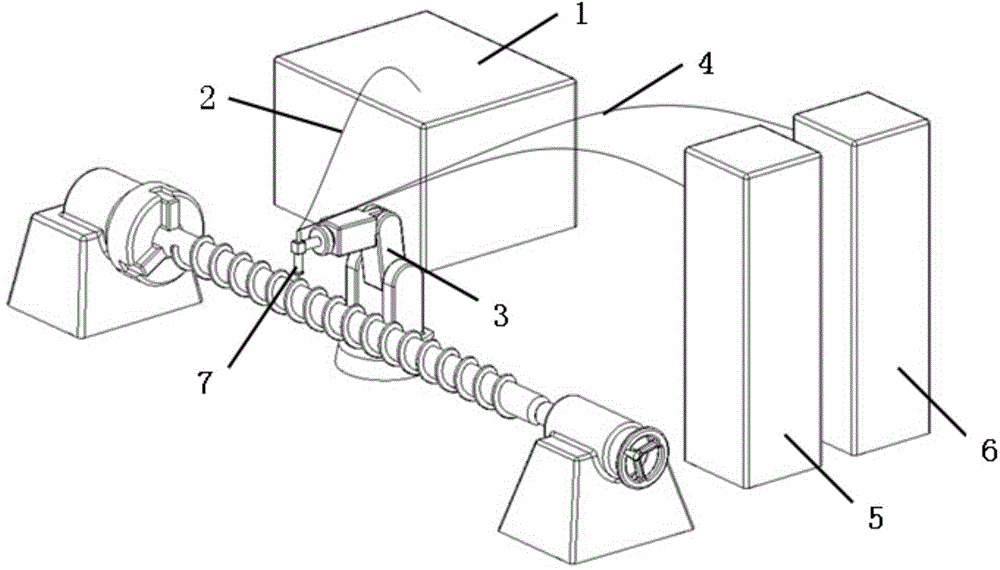

A process method and screw technology, applied in the field of screw laser combination manufacturing, can solve the problems of easy wear of metal screws, short service life, large machining allowance, etc., and achieve simple process method and manufacturing cost, improved service life, and anti-wear performance. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

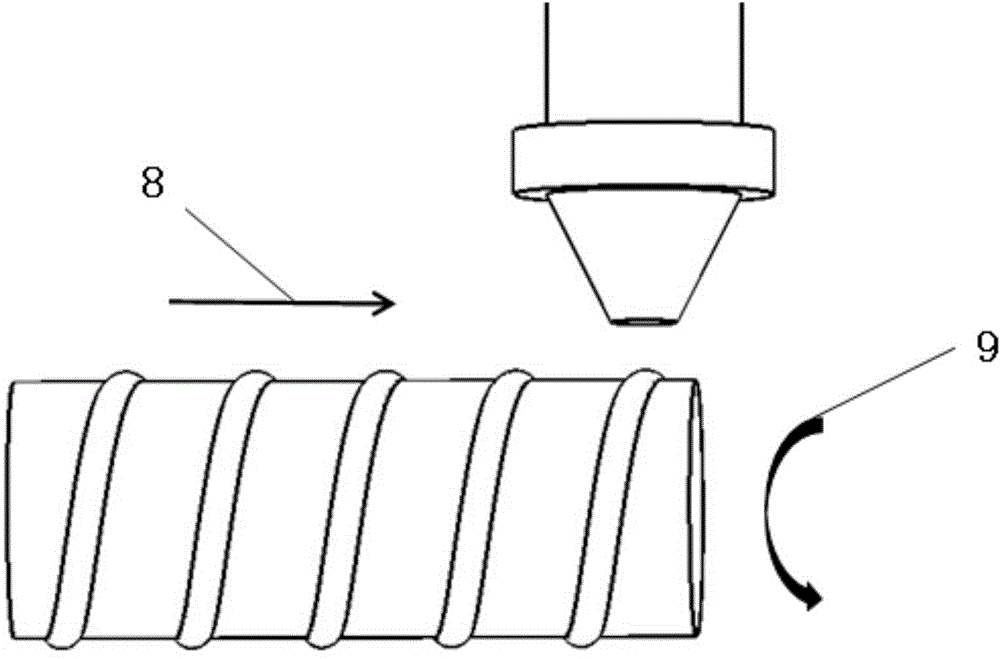

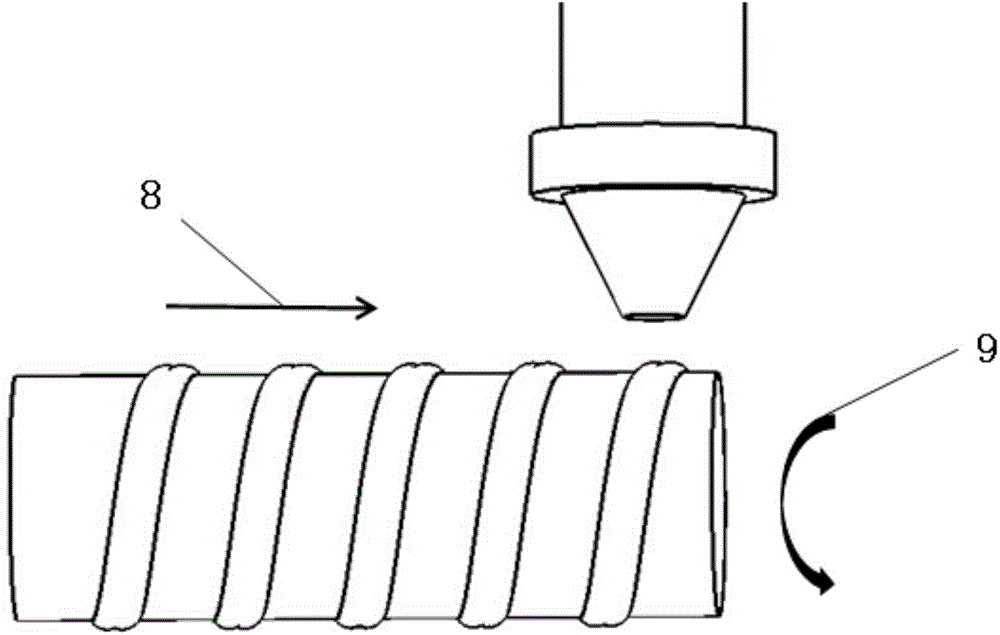

Method used

Image

Examples

Embodiment 1

[0032] The type of the processed screw is SCM, the material is 42CrMo round steel, and the processing state is quenched and tempered. Before laser treatment, customize the fixture and pre-determine the treatment area and overlap; then perform CNC programming according to the specific size of the screw to be treated; clean the area to be treated on the surface of the screw.

[0033] Put the Ni60 powder and the 42CrMo powder into the oven respectively, and carry out the drying treatment at 200°C for 2 hours. After the treatment is completed, the dried powder can be put into the first powder feeder 5 and the second powder feeder 6 respectively for use, and the particle size of the above alloy powder is spherical powder of -140~+325 mesh;

[0034] The following takes the surface treatment of the metal screw of the FT-130 injection molding machine as an example. The specific steps are as follows:

[0035] 1. Install the metal screw with a three-jaw chuck and a thimble.

[0036] 2...

Embodiment 2

[0054] The type of the processed screw is SCM, the material is 42CrMo round steel, and the processing state is quenched and tempered. Before laser treatment, customize the fixture and pre-determine the treatment area and overlap; then perform CNC programming according to the specific size of the screw to be treated; clean the area to be treated on the surface of the screw.

[0055] Put the Stellite 6 powder and 35CrMo powder into the oven, and dry them at 200°C for 2 hours. After the treatment is completed, the dried powder can be put into the first powder feeder 5 and the second powder feeder 6 respectively for standby; the particle size of the above-mentioned alloy powder is a spherical powder of -140~+325 mesh.

[0056] 1. Install the metal screw with a three-jaw chuck and a thimble.

[0057] 2. Clean the parts to be treated: remove oil stains with acetone, pine water, etc.

[0058] 3. According to the processing requirements, carry out numerical control programming accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com