Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Less affected by heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

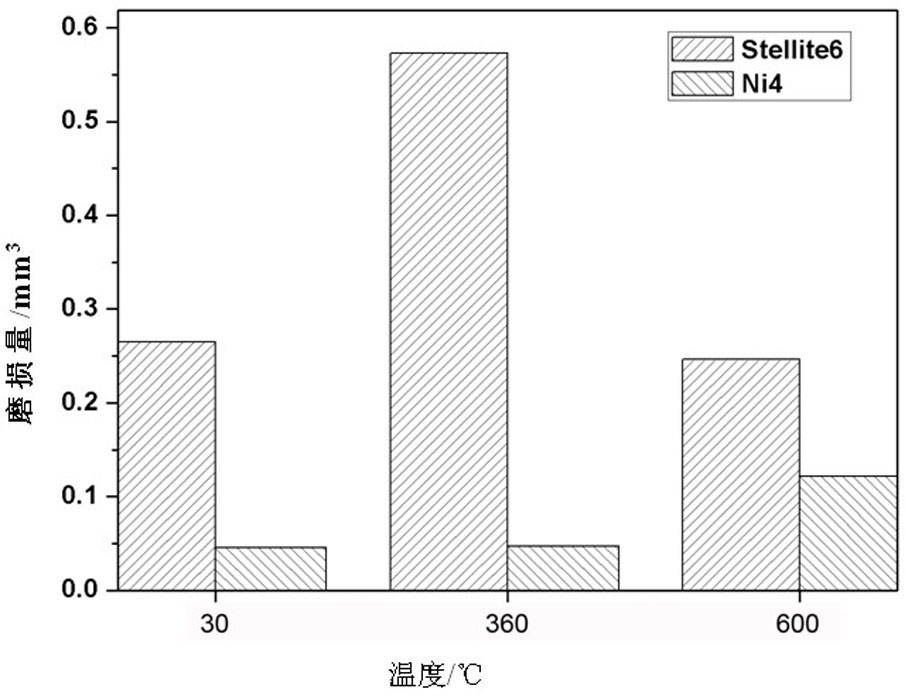

Nickel chromium alloy for sealing face of nuclear power valve

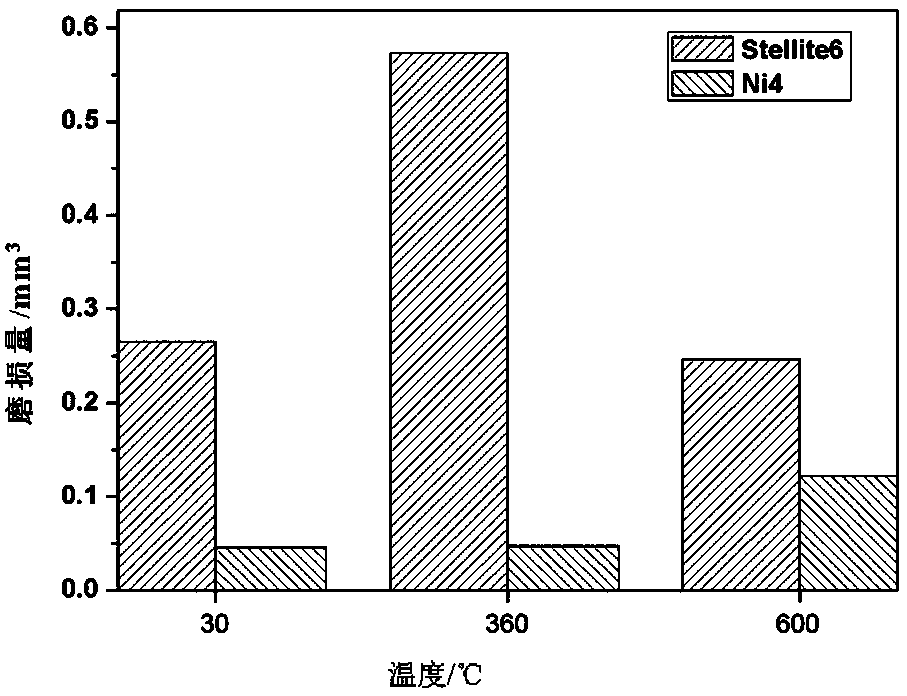

InactiveCN101629256ALess affected by heatHigh bonding strengthMetallic material coating processesPlasma jetNuclear power

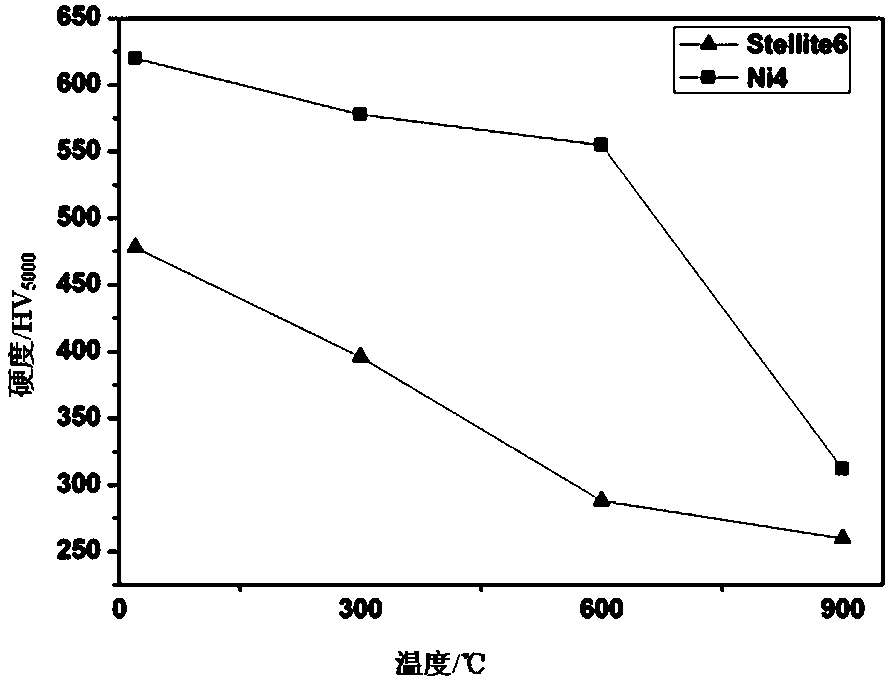

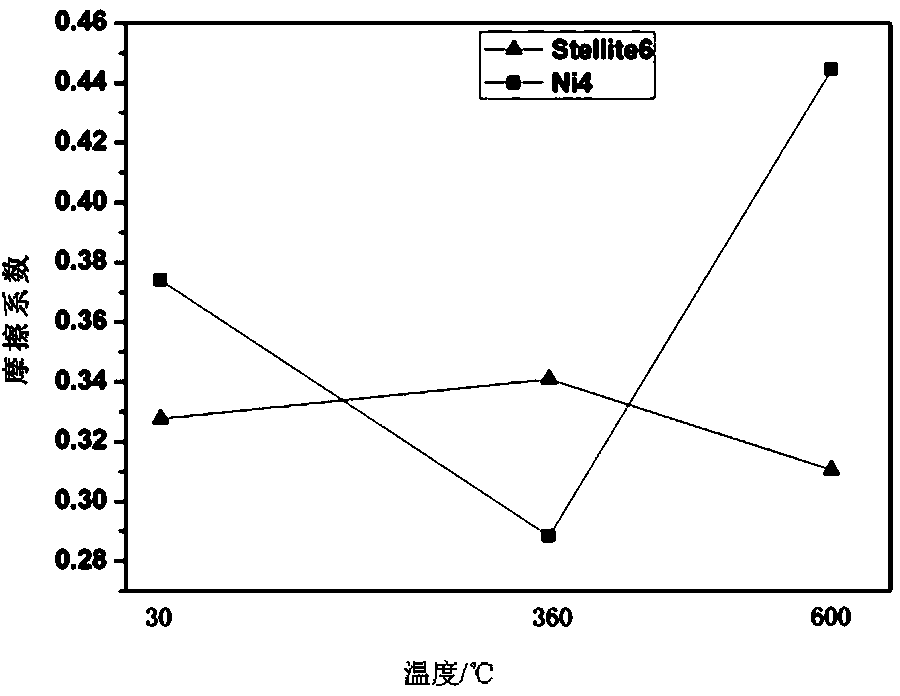

The invention discloses a nickel chromium alloy for a sealing face of a nuclear power valve. The nickel chromium alloy comprises the following components in percentage by weight: 26.0-28.0 percent of chrome, 2.0-2.5 percent of silicon, 1.1-1.3 percent of boron, 4.5-5.5 percent of molybdenum, 3.0-4.0 percent of tungsten, 0.9-1.1 percent of carbon and the balance of nickel. Meanwhile, a coating layer is prepared by a laser cladding technology so as to obtain a sealing face coating layer of a nickel-based alloy nuclear power valve, which has the following relevant parameters: the rigidity is HRC 42-46 which is slightly higher than HRC39-43 of a Stellite-6 cobalt-based alloy coating layer; the tissue grain fineness number of the coating layer is 11-12 grades which is superior to 9-10 grades of a general plasma jet welding layer and 8-9 grades of a flame resurfacing welding layer; and the width of a combination band of the coating layer and a basal body is 10-30 micrometers which is superior to 80-120 micrometers of a plasma jet welding combination band and 200-300 micrometers of a flame resurfacing welding combination band.

Owner:SUZHOU UNIV

Nickel-base alloy coating for sealing surface of nuclear power valve and preparing method for nickel-base alloy coating

InactiveCN102534606AMeet the needs of the jobGood high temperature performanceMetallic material coating processesPowder mixtureNuclear power

The invention discloses a nickel-base alloy coating for a sealing surface of a nuclear power valve, and is characterized in that the nickel-base alloy coating is prepared according to a method of conducting laser-cladding on nickel-base alloy powder. The nickel-base alloy powder comprises the following constituents by weight percent: 20.0 to 24.0 percent of Cr, 4.0 to 4.2 percent of Si, 3.0 to 3.5 percent of P, 3.0 to 3.2 percent of Mo, 8.0 to 8.5 percent of Fe, 1.0 to 1.2 percent of C, 0.8 to 1.0 percent of yttrium oxide, and Ni in balancing amount. The laser-cladding process adopts a synchronous powder feeding method and a pre-coating method. The nickel-base alloy powder mixture contains no noble metal Co, thereby particularly meeting requirements on valves under nuclear environments; and due to the formulation design of the mixture, and the advantage of the laser-cladding technology in coating preparing, the coating on the sealing surface has a favorable high-temperature property.

Owner:SUZHOU UNIV

Thermochromic polypropylene composition and its preparation method and use

The invention discloses a thermochromic polypropylene composition. The thermochromic polypropylene composition comprises, by weight, 95-99 parts of polypropylene resin and 0.5-3 parts of thermochromicmicrocapsules. The core of the thermochromic microcapsule is prepared from a triphenylmethane-metal complex and the wall of the thermochromic microcapsule is synthesized from formaldehyde and melamine through polymerization according to a mole ratio of 2.5 / 1 to 3 / 1. The preparation method of the thermochromic microcapsule comprises that formaldehyde and melamine undergo an addition reaction at pHof 7.5-8.5 to produce a methylol melamine prepolymer, a triphenylmethane-metal complex is dispersed in a sodium dodecyl sulfate aqueous solution with a concentration of 0.2-1.0 wt%, the methylol melamine prepolymer is added into the solution, the pH is adjusted to 5.5-6.5 so that a microcapsule emulsion is obtained, the microcapsule emulsion undergoes a reaction at 80-90 DEG C for 3h, and the reaction product is washed, is subjected to suction filtration and is dried so that the thermochromic microcapsule is obtained. The thermochromic polypropylene composition can resist heat in a long termand can be widely used in automobile dashboards, accessory dashboards, seats, door plates, bumpers or stand columns.

Owner:KINGFA SCI & TECH CO LTD +1

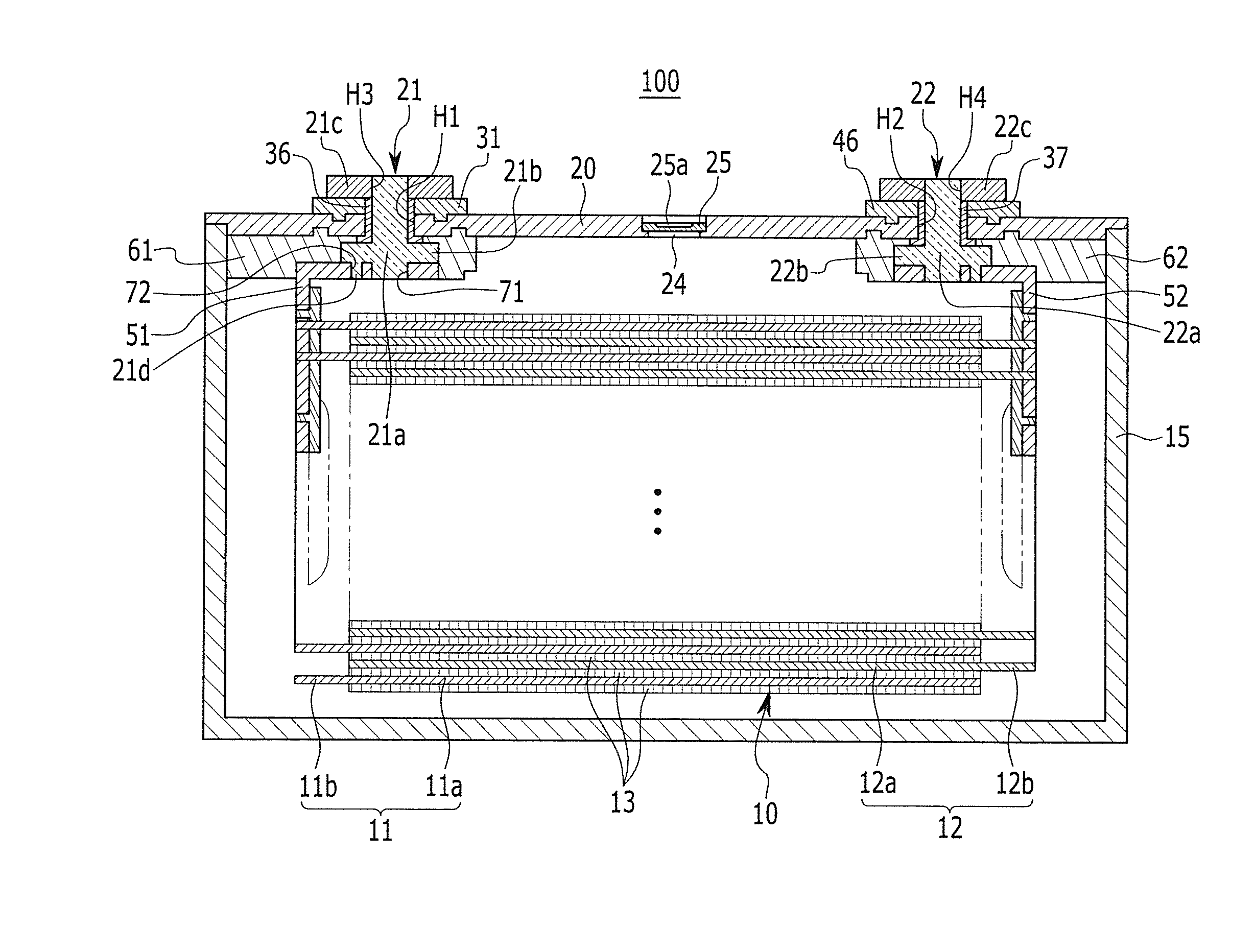

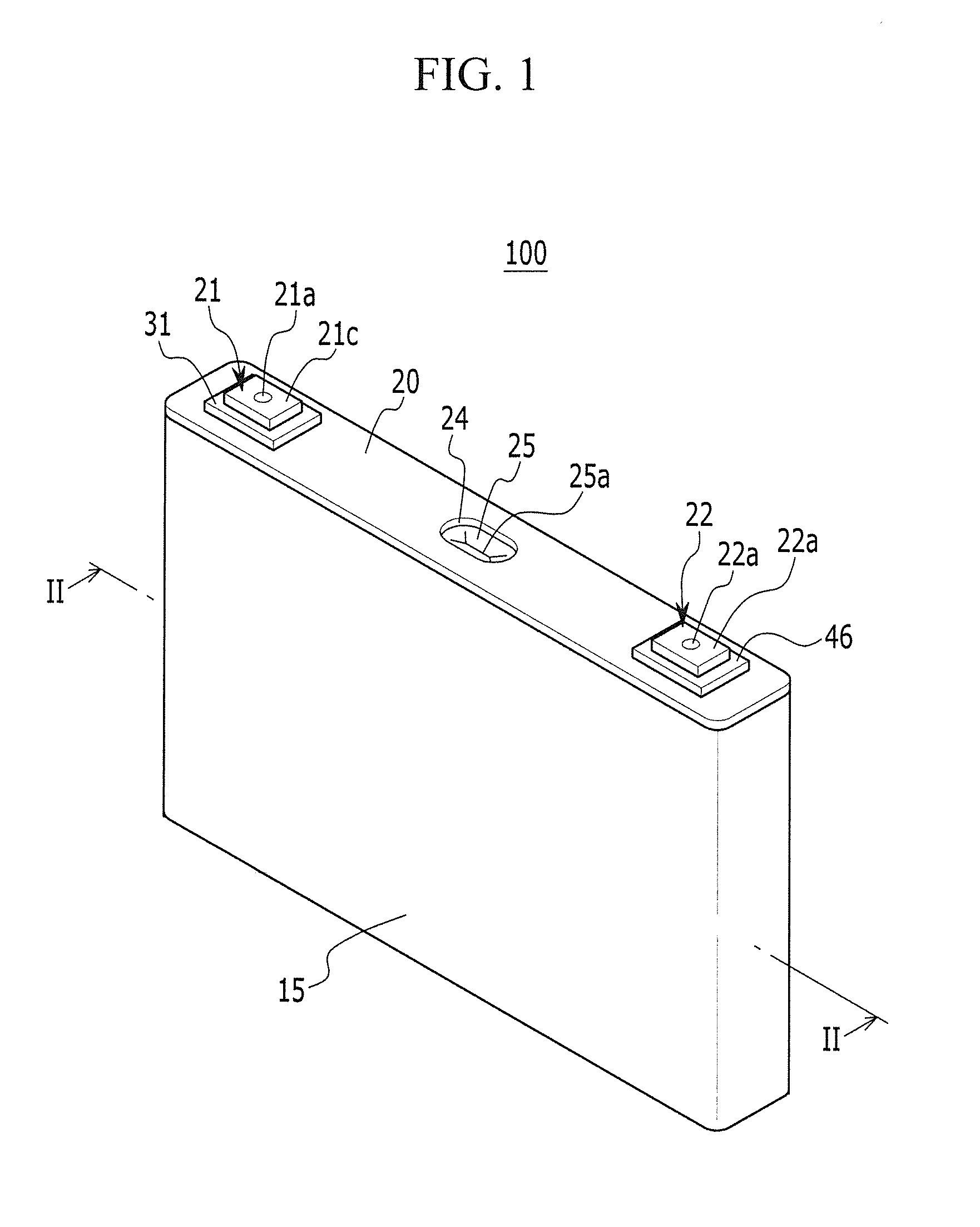

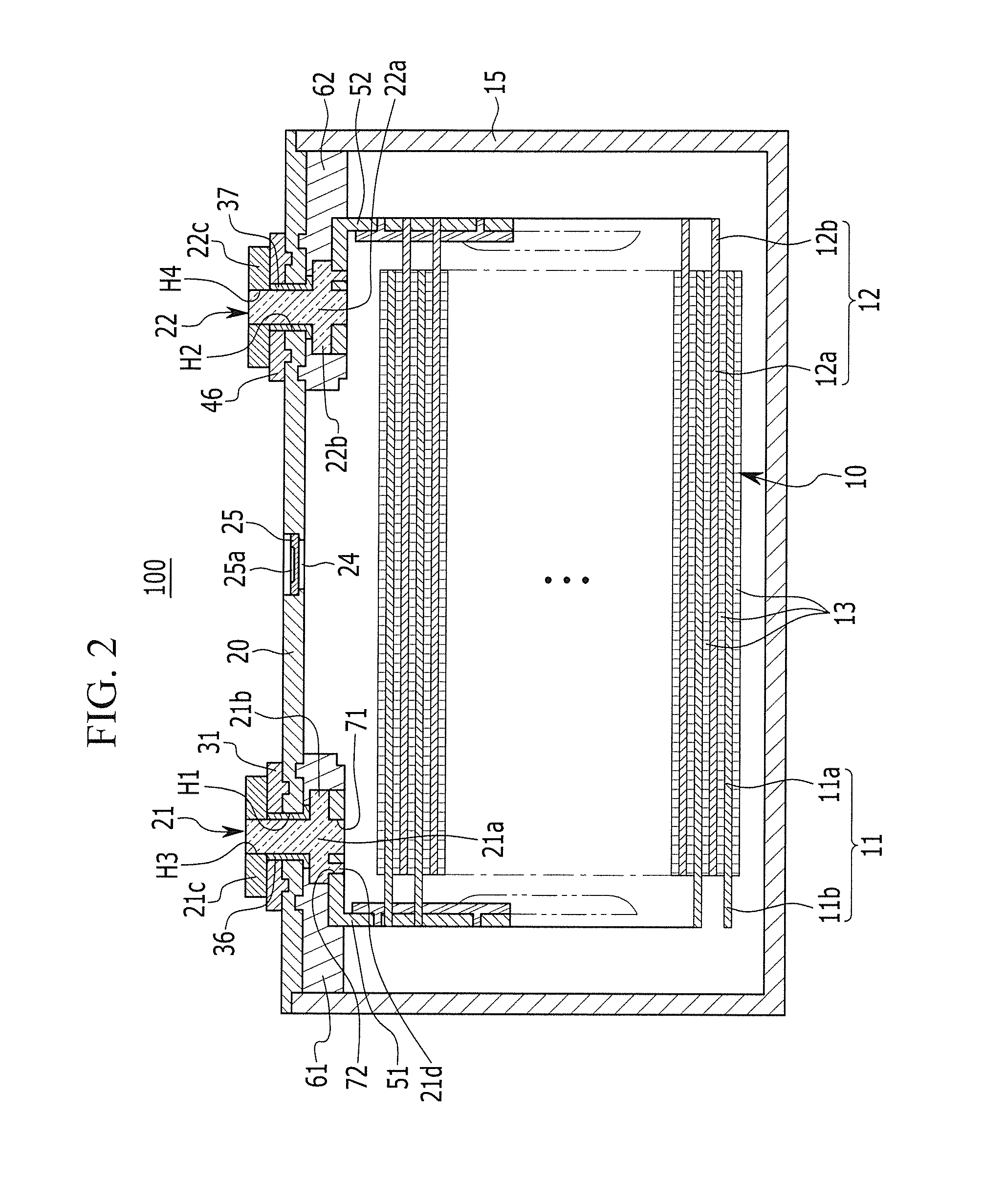

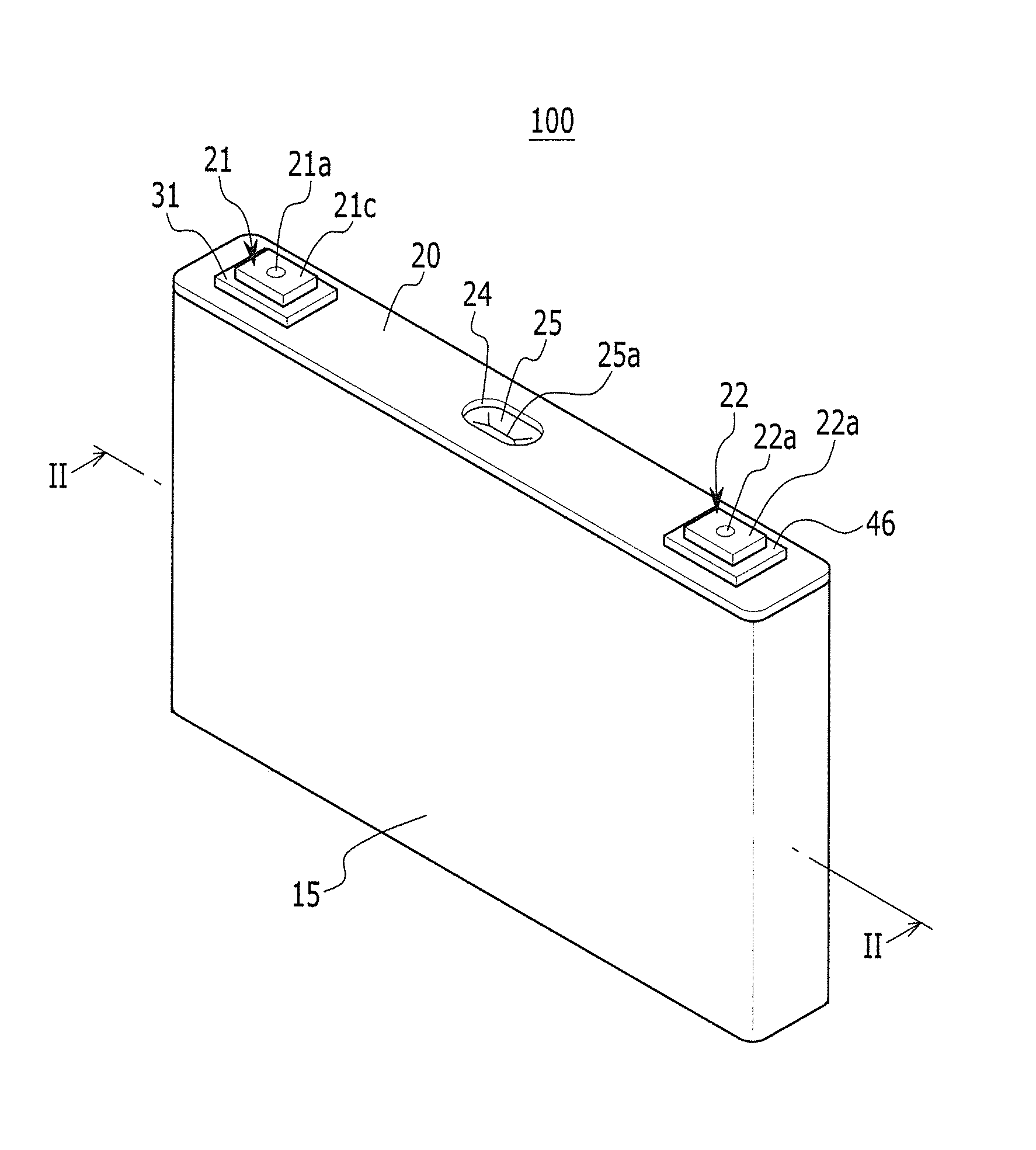

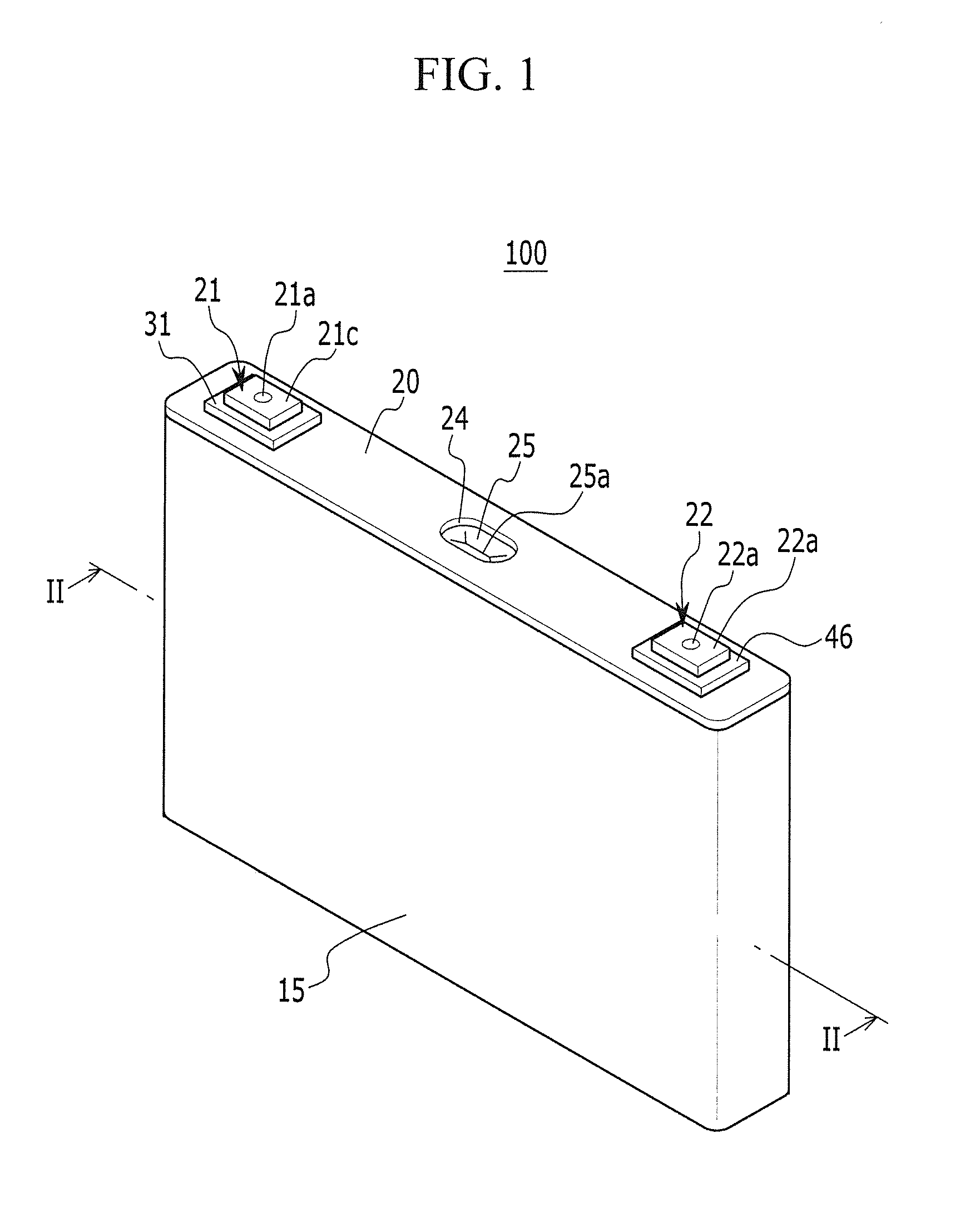

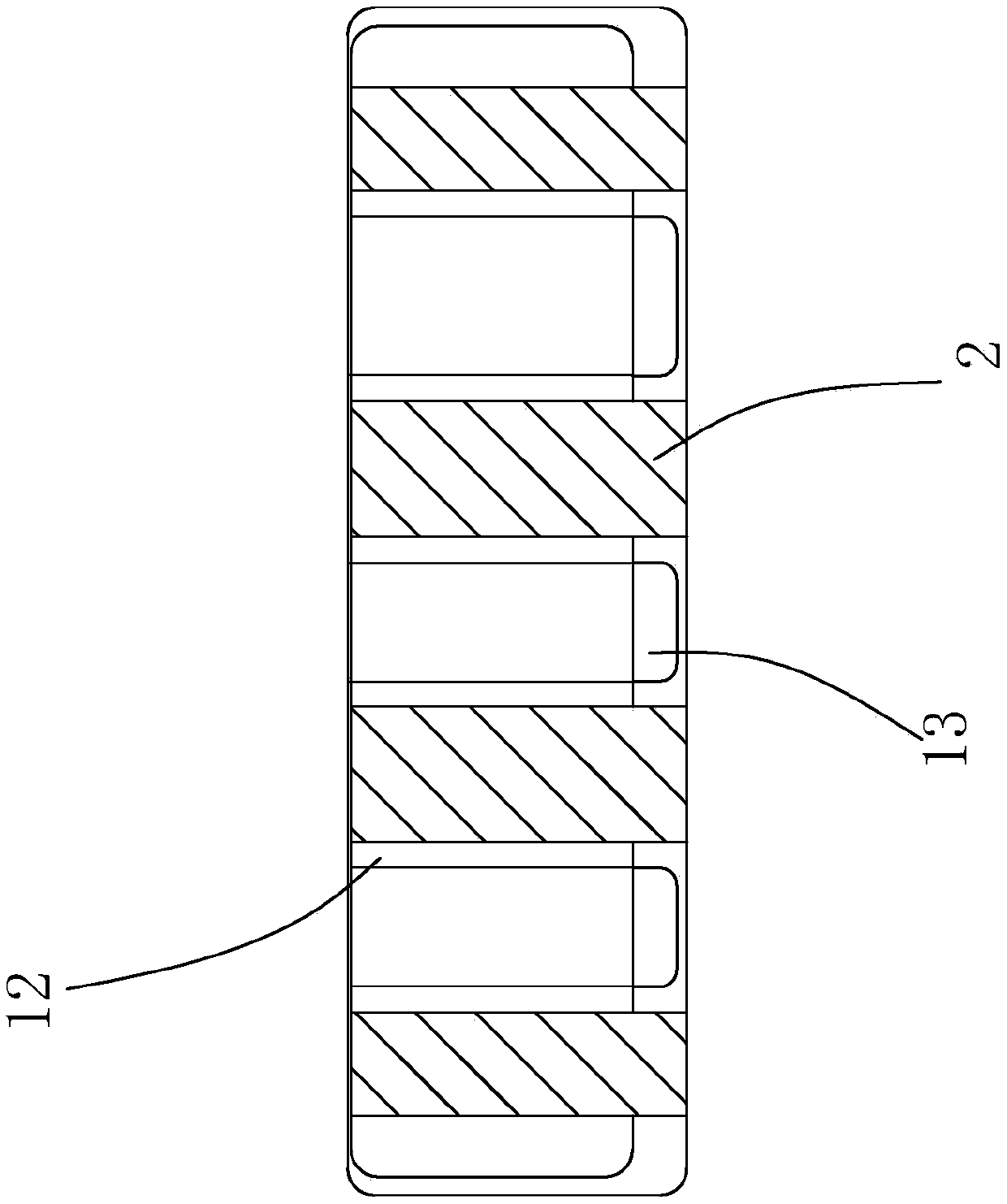

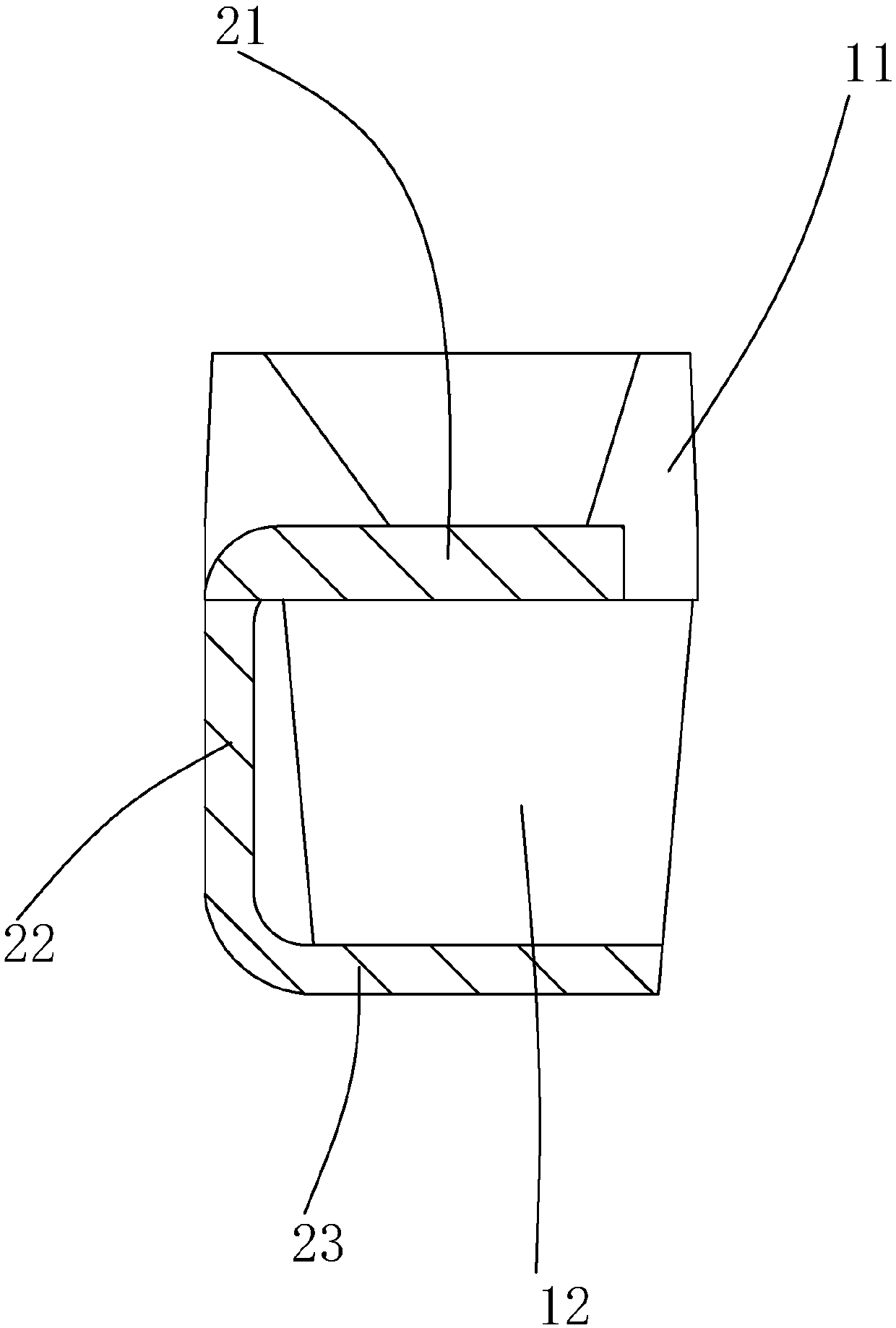

Rechargeable battery

ActiveUS20140242426A1Increase heatReduce heatSecondary cellsCell component detailsElectrical batteryRechargeable cell

A rechargeable battery including an electrode assembly, a case housing the electrode assembly, a cap plate coupled to the case, a first electrode terminal on the cap plate, and a first lead tab electrically connecting the electrode assembly and the first electrode terminal, wherein the first lead tab has a cell fuse and a heat dissipating member coupled to the first lead tab and spaced from the cell fuse.

Owner:SAMSUNG SDI CO LTD

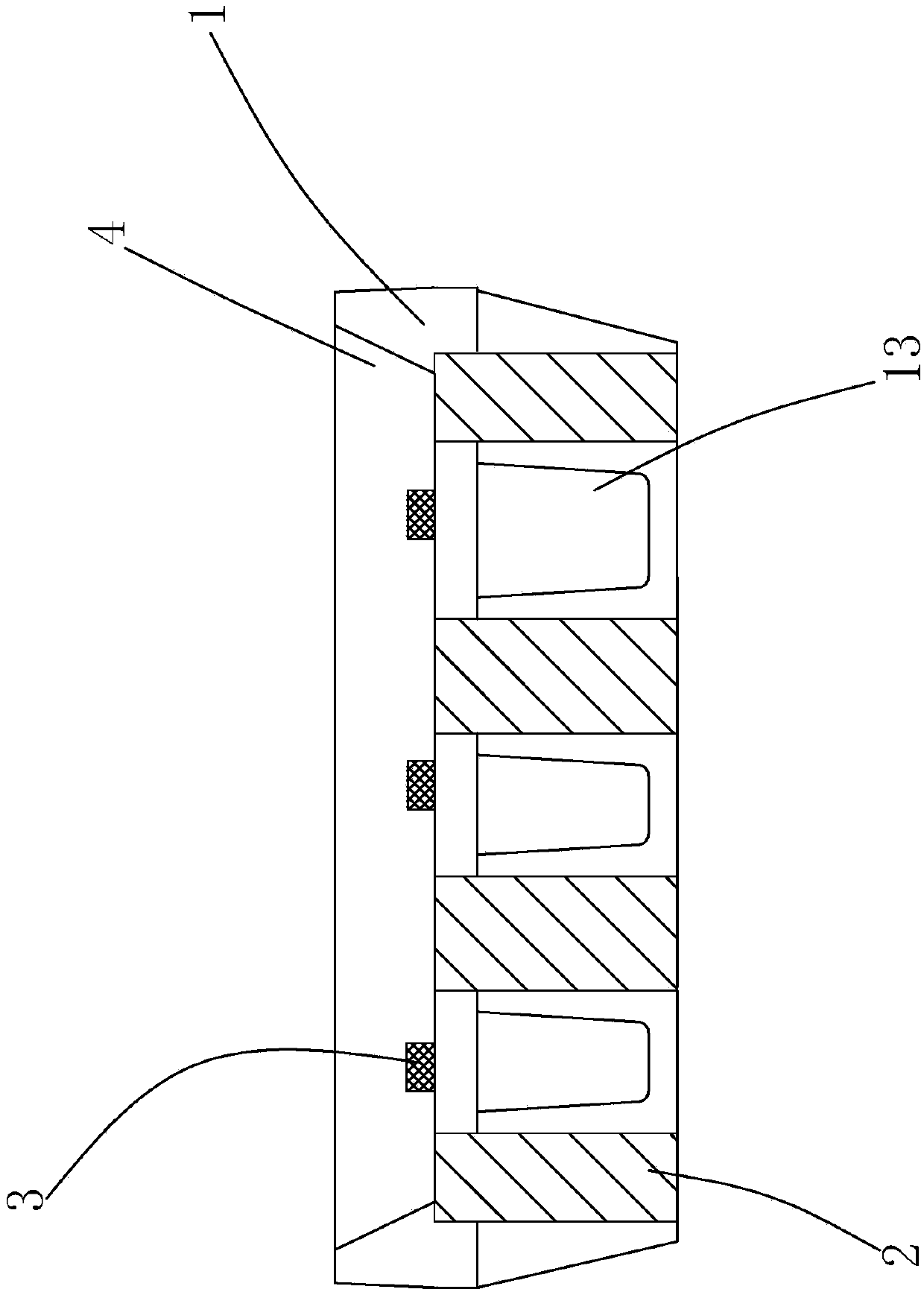

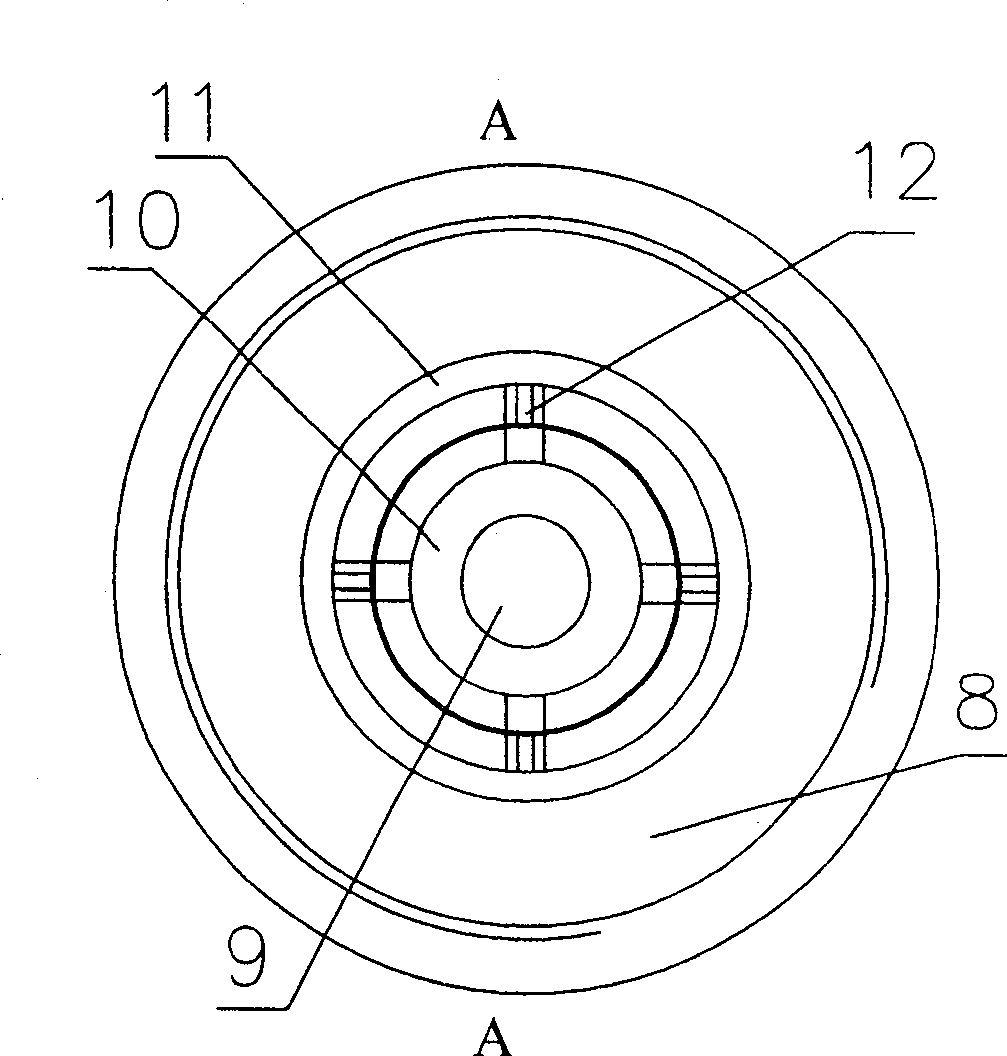

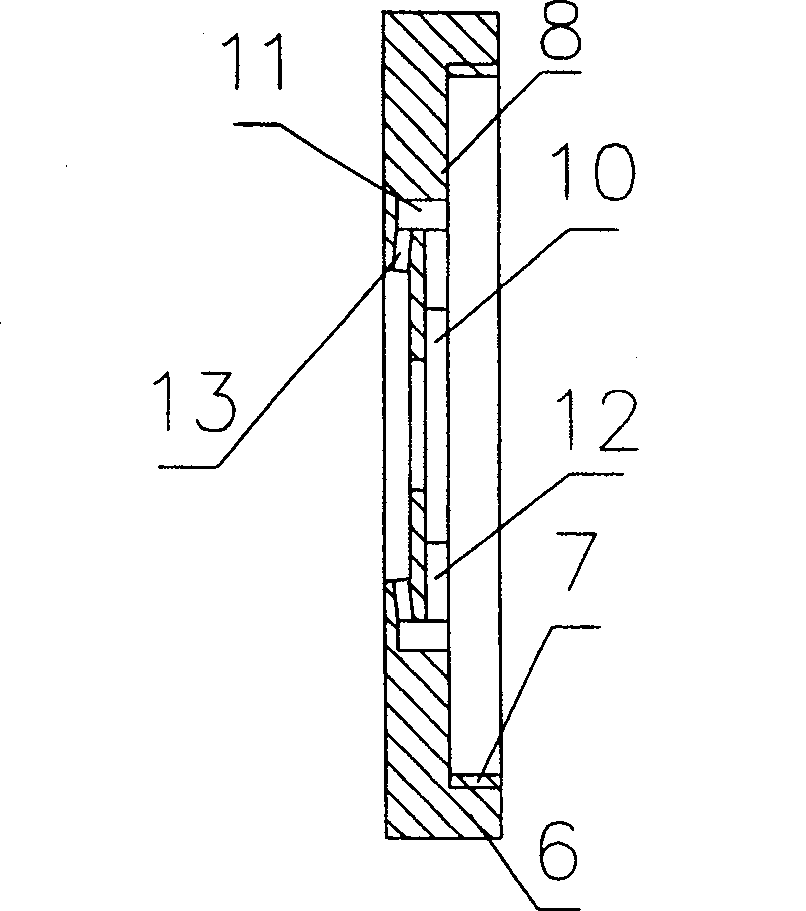

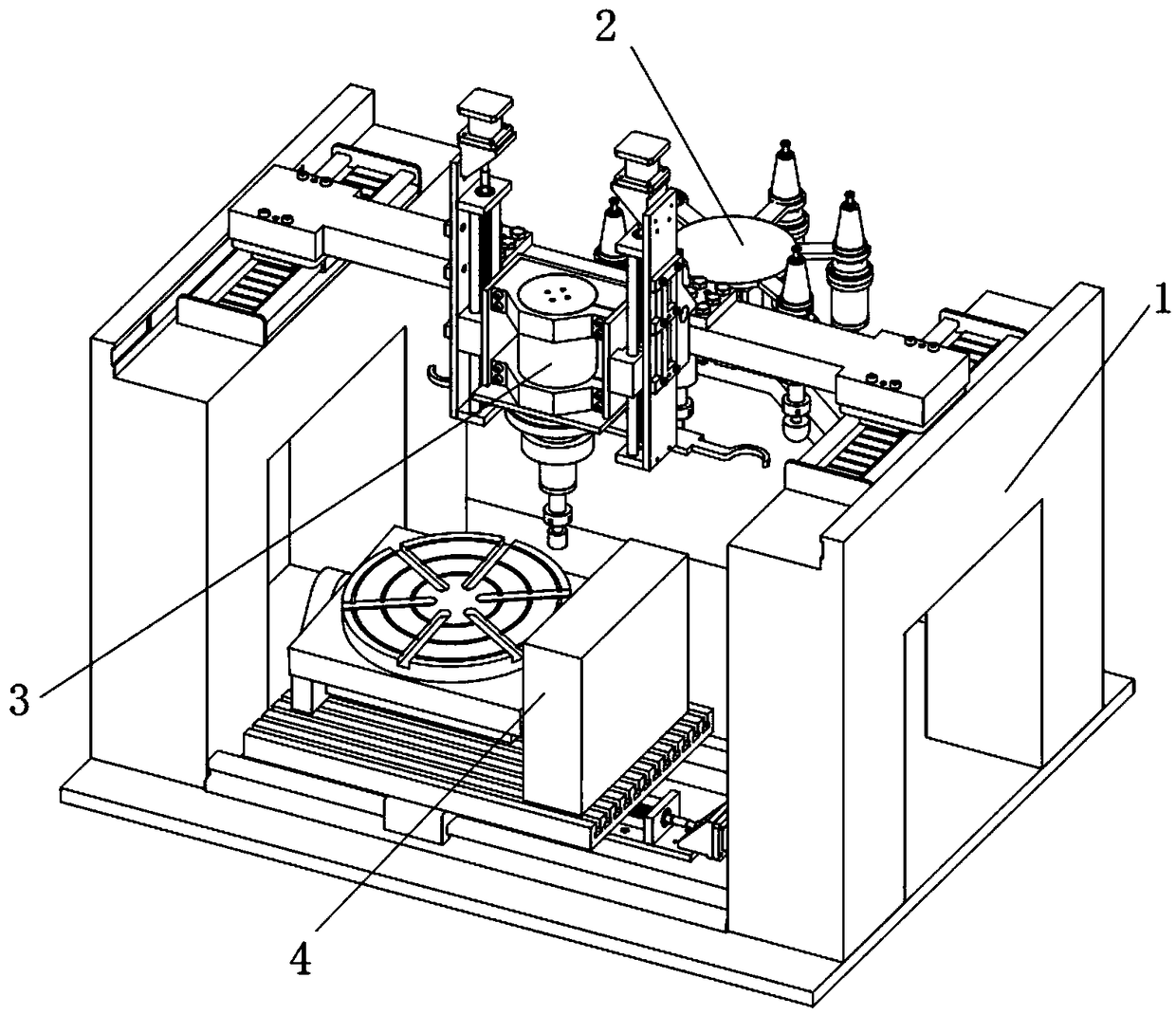

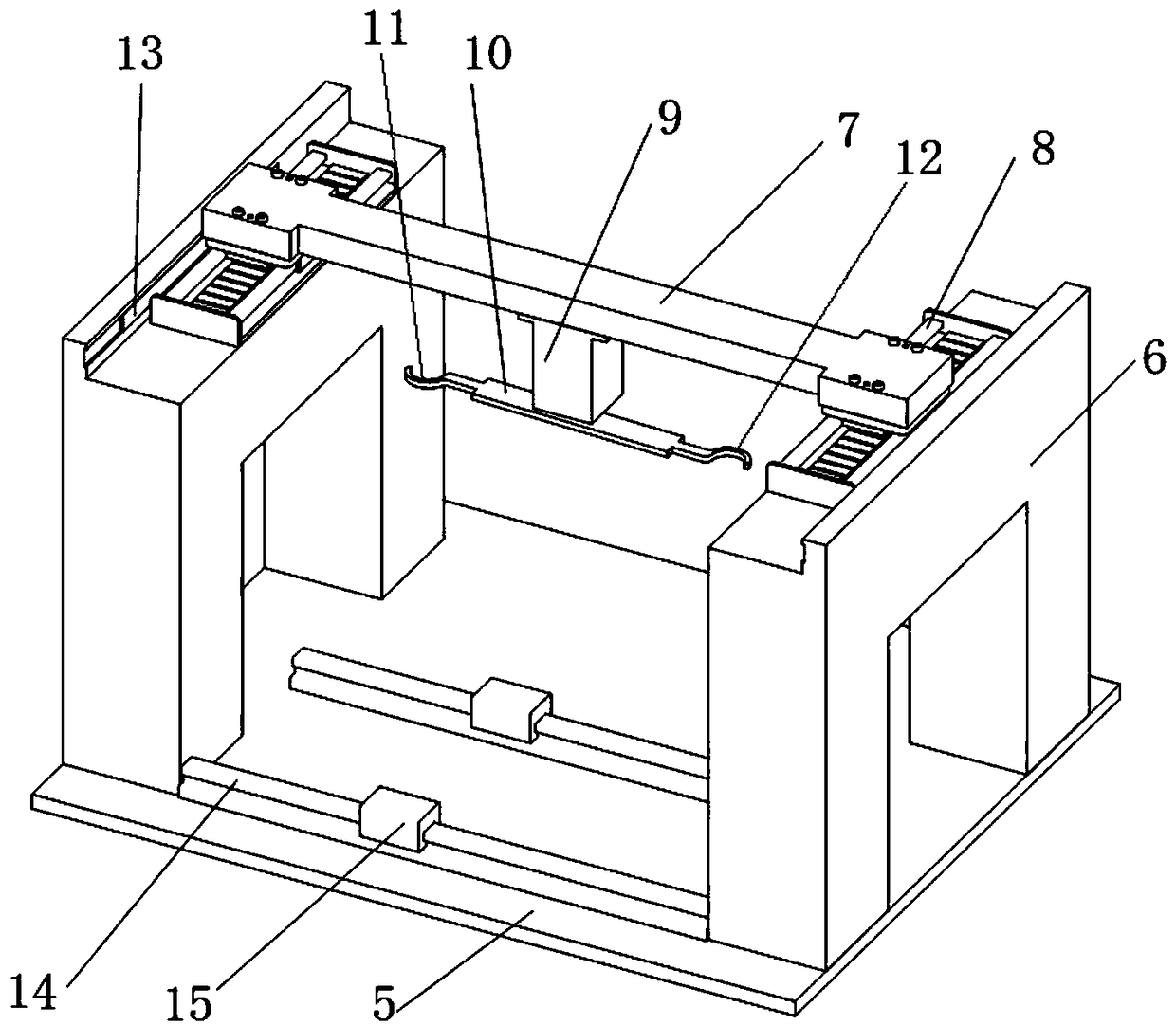

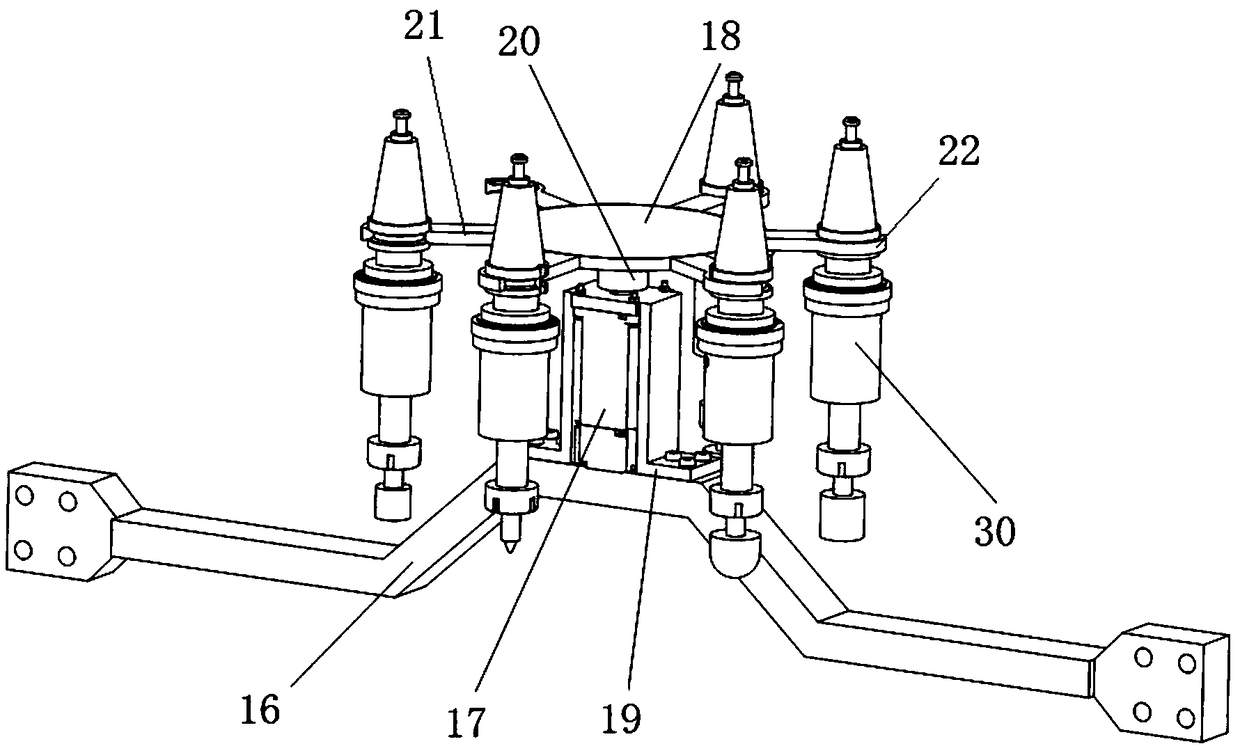

Multi-end laser cutting head

InactiveCN104889564ACompact structureExtended service lifeLaser beam welding apparatusBeam splittingLight beam

The invention discloses a multi-end laser cutting head and belongs to the technical field of application of laser cutting machinery. The multi-end laser cutting head comprises a base, a collimating mirror is mounted on one side of the base, the top end of the collimating mirror is connected with a laser with a connector, a beam splitter and reflectors are arranged in the base, and the beam splitter is communicated with the inside of the collimating mirror. Cutting ends are mounted at the bottom of the base and nozzles are mounted at the bottom ends of the cutting ends. Focus lenses are arranged in the cutting ends and are connected with adjusting nuts on the side walls of the cutting ends, and a beam adjuster is arranged between the cutting ends and the base and is communicated with the beam splitter and the reflectors. The multi-end laser cutting head is added into a beam splitting system and a beam quality adjusting system, so that on the premise of the same cutting quality, efficiency is improved by several times, machining cost is greatly reduced, laser cutting kerf is narrow, workpiece deformation is small, operation efficiency is high, and the nozzles can well protect the focus lenses.

Owner:无锡信欧光电科技有限公司

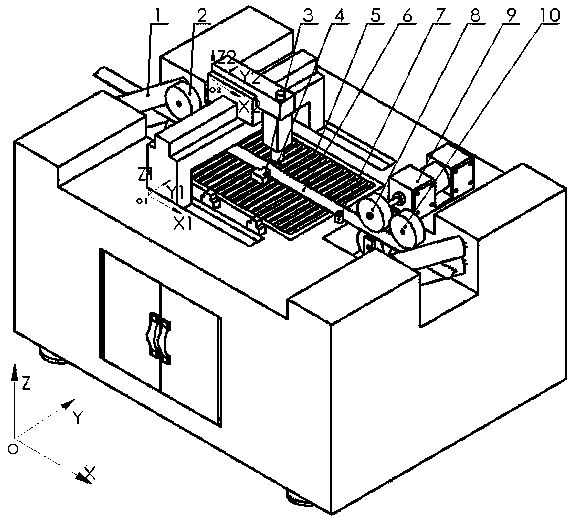

Laser continuous cutting device used for cutting saw belt and cutting method

ActiveCN104014938ANo thermal deformationNo damageWelding/soldering/cutting articlesMetal working apparatusMilling cutterLaser cutting

The invention discloses a laser continuous cutting device used for cutting a saw belt and a cutting method. The laser continuous cutting device aims to solve the problems that continuous cutting and forming of sawteeth can not be achieved, tool auxiliary time accounts for a high percentage, and cutting efficiency is low in the prior art. The laser continuous cutting device comprises a base which is sequentially provided with a driving friction roller used for regulating feeding speed of the saw belt, a pressing wheel set used for pressing the saw belt, a work platform and a driving wheel set driven by a driving device; a laser head which is arranged on a Z shaft for cutting the saw belt is arranged above the work platform; the work platform is provided with a feeler block and a transverse locating mechanism used for locating the saw belt; during cutting work, the speed of a sliding platform X1 is the same as the feeding speed of the saw belt. The laser cutting sawtooth continuous forming technique does not need a milling cutter, and the sawteeth in any two-dimensional shapes can be correspondingly manufactured very rapidly.

Owner:湖南泰嘉智能科技有限公司

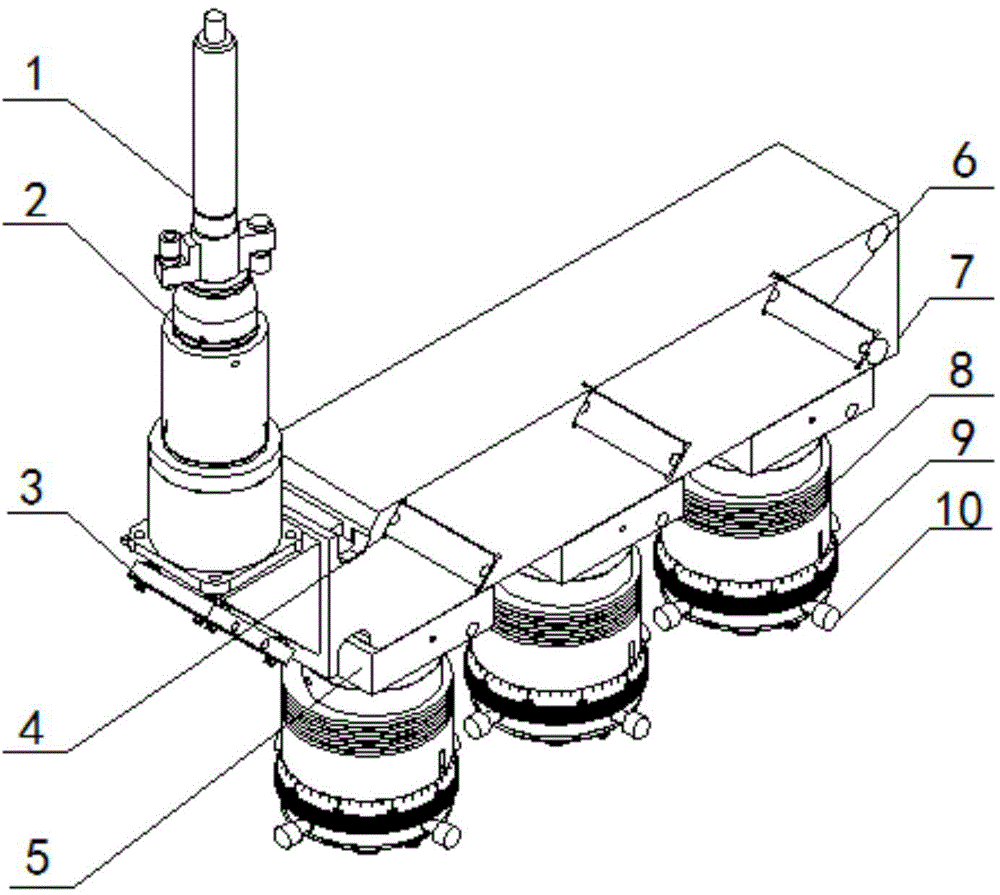

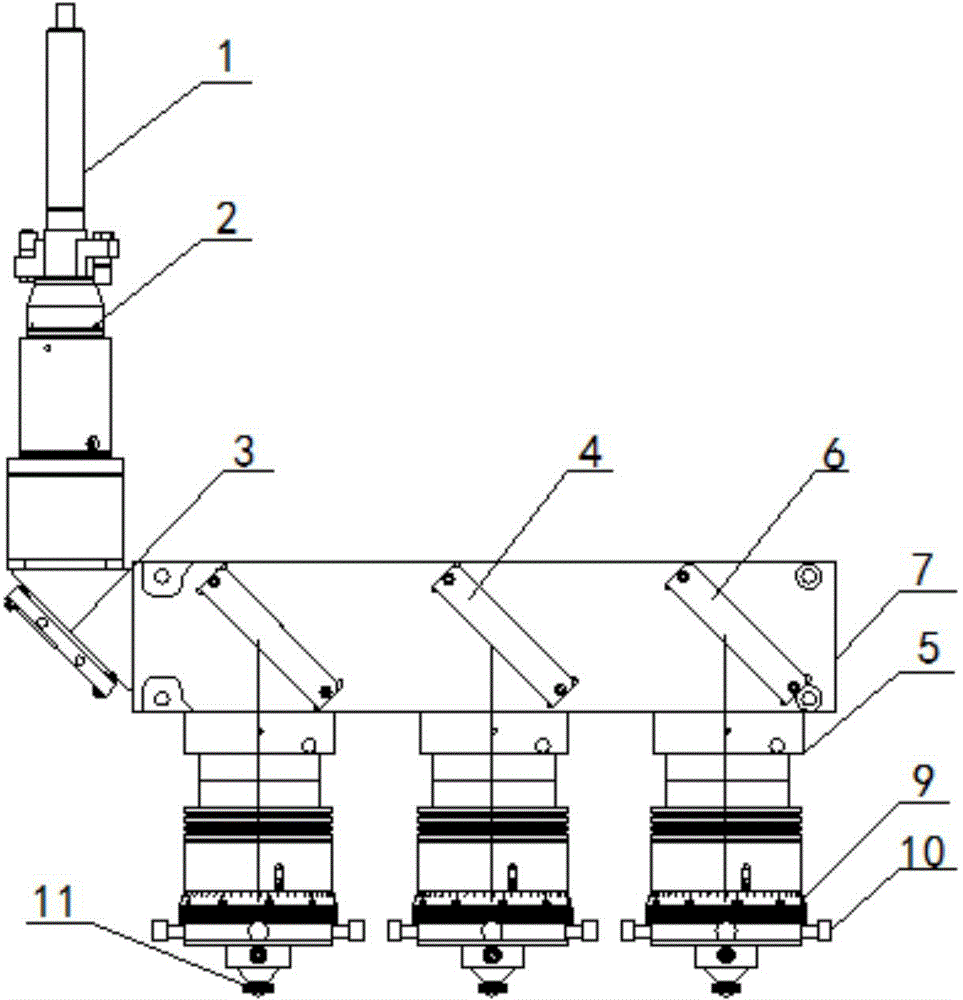

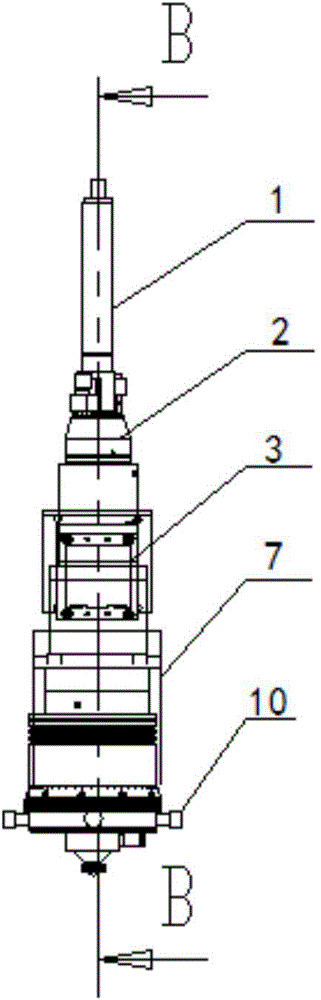

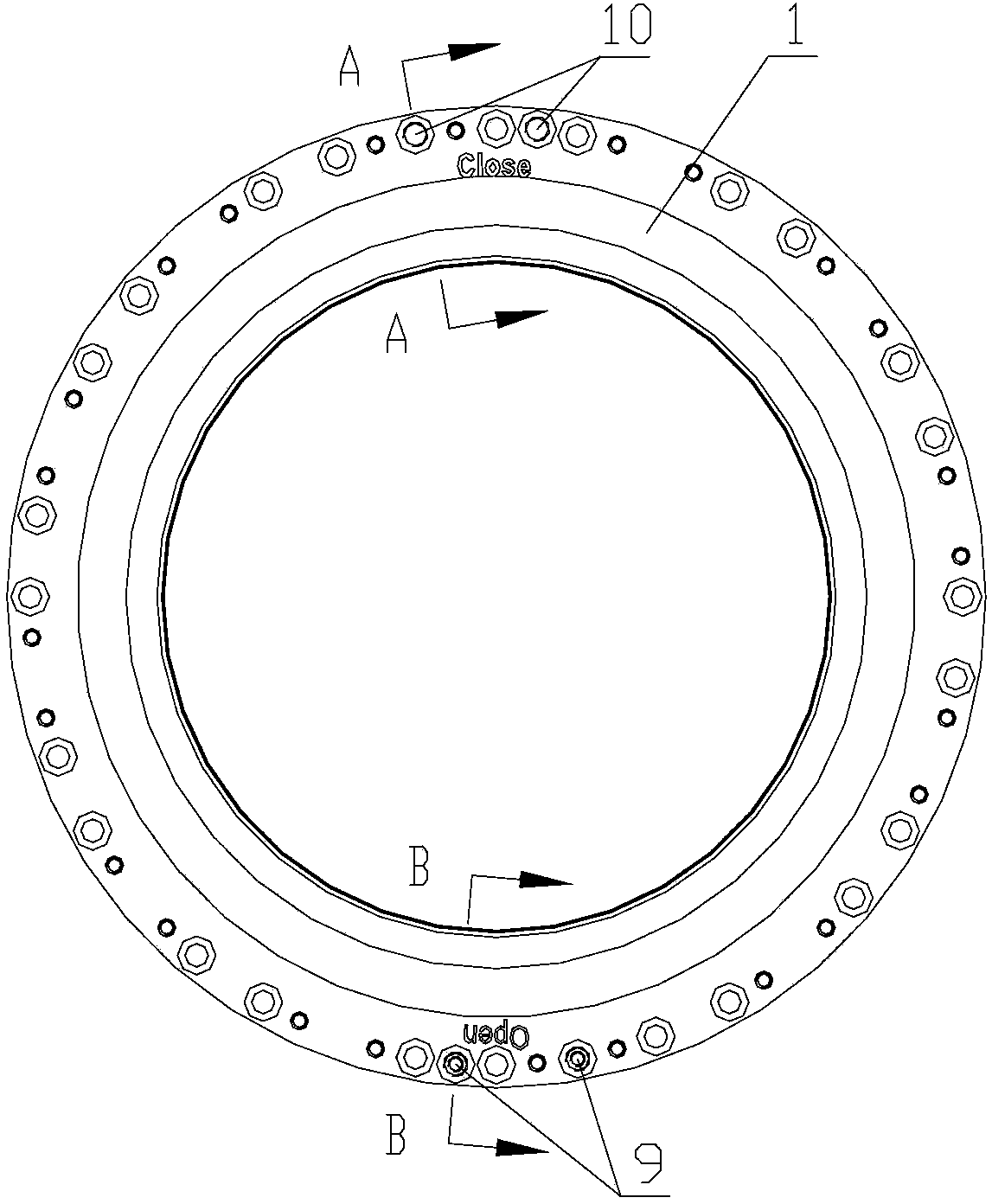

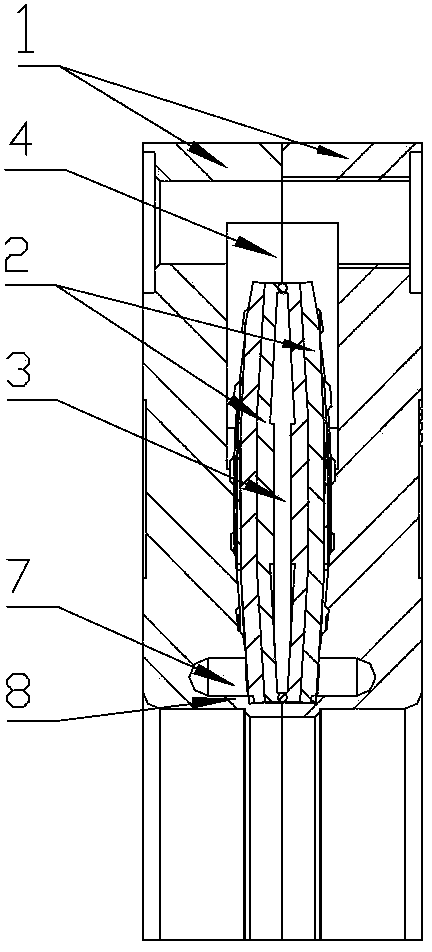

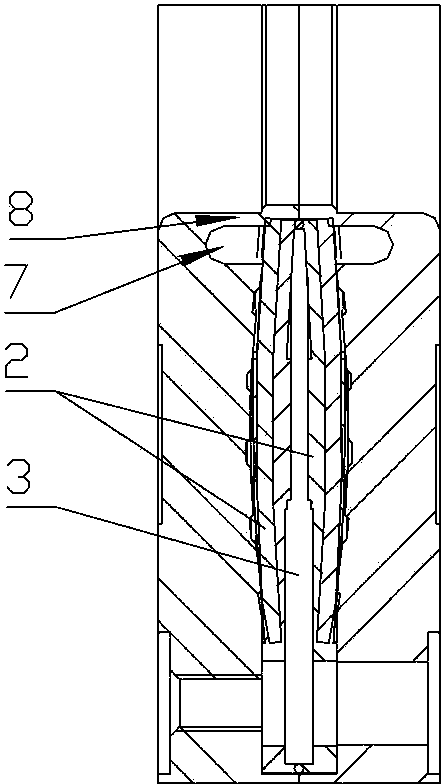

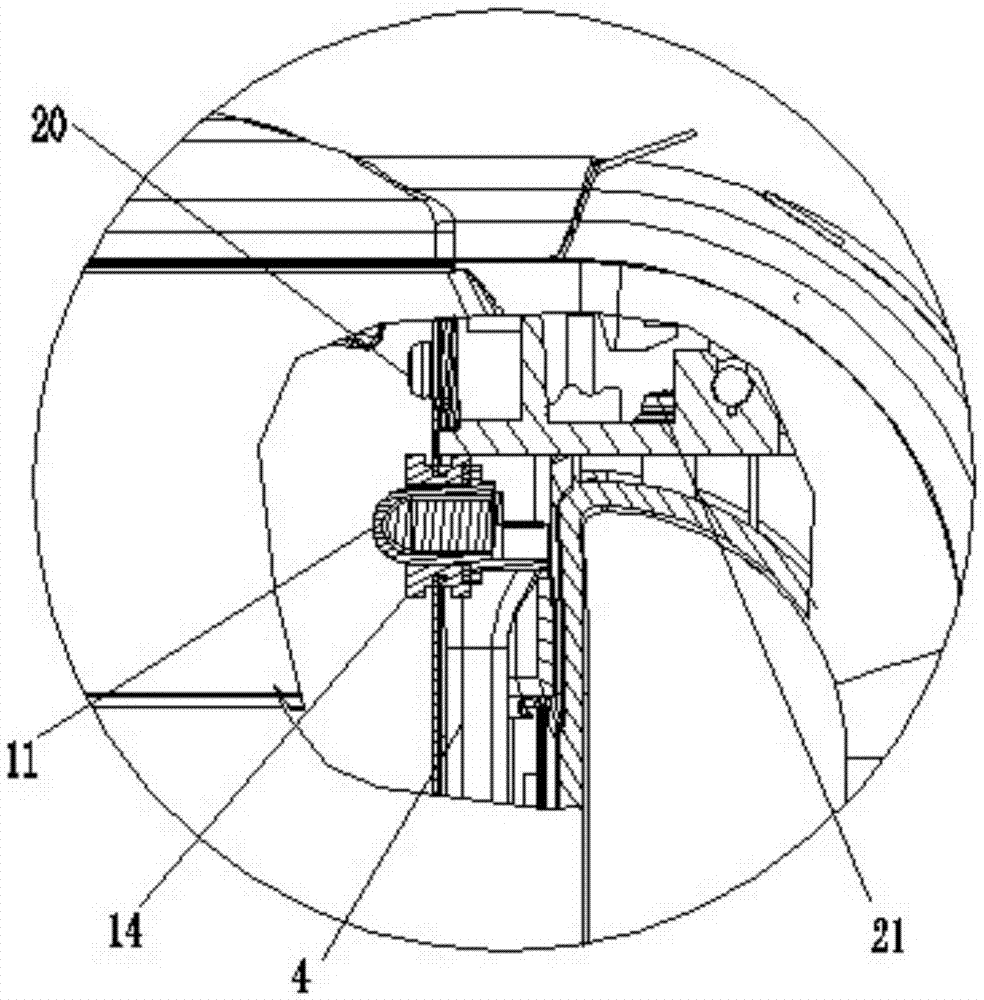

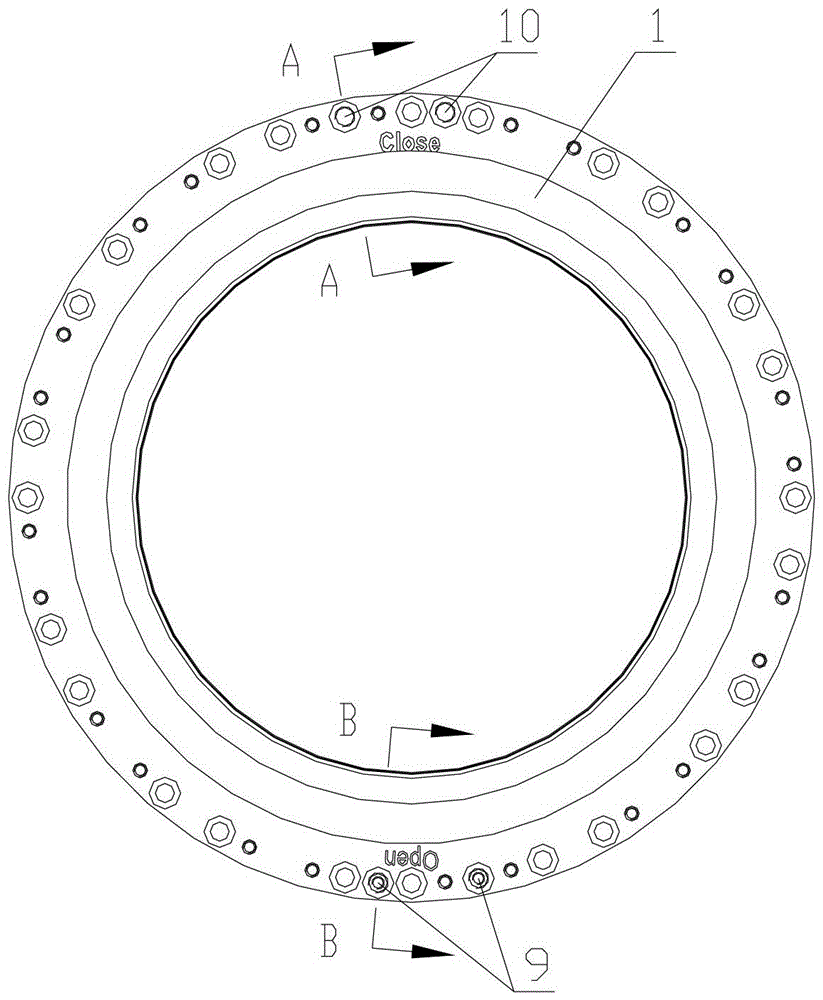

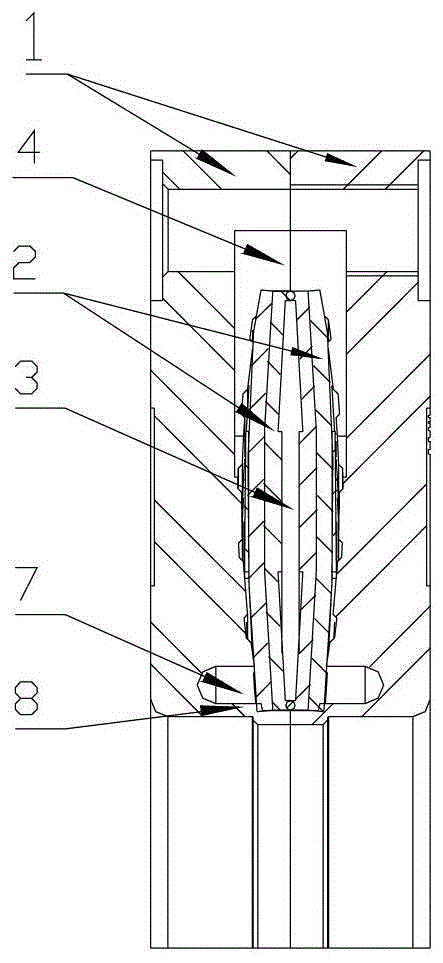

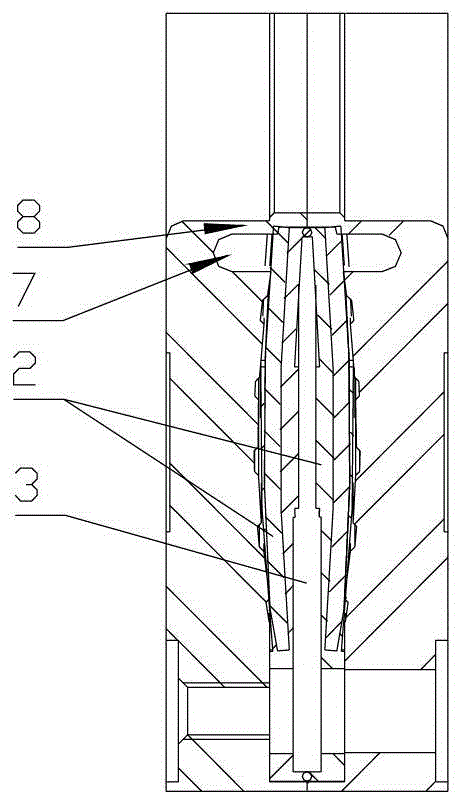

Pneumatic forceps holder

ActiveCN103410884AEasy to installLess affected by heatDrum brakesBrake actuating mechanismsLife lengthForceps

The invention discloses a pneumatic forceps holder, relates to the forceps holder for motor braking, and belongs to the novel pneumatic forceps holder both economic and practical. The pneumatic forceps holder is characterized by comprising two symmetrical shells same in size and two symmetrical spring bellows same in size; the spring bellow are oppositely combined and arranged in the shells and fixed through bolts; an inner cavity is formed between the spring bellows, and an outer cavity is formed between the shells and the spring bellows; one outer side face of the shells serves as a level surface to be processed. The pneumatic forceps holder has the advantages that the pneumatic forceps holder is novel in structure, convenient to process, small in size, convenient to mount and use, less n processing difficulty and precision, long in service life, convenient to maintain and replace and the like.

Owner:KEDE NUMERICAL CONTROL CO LTD

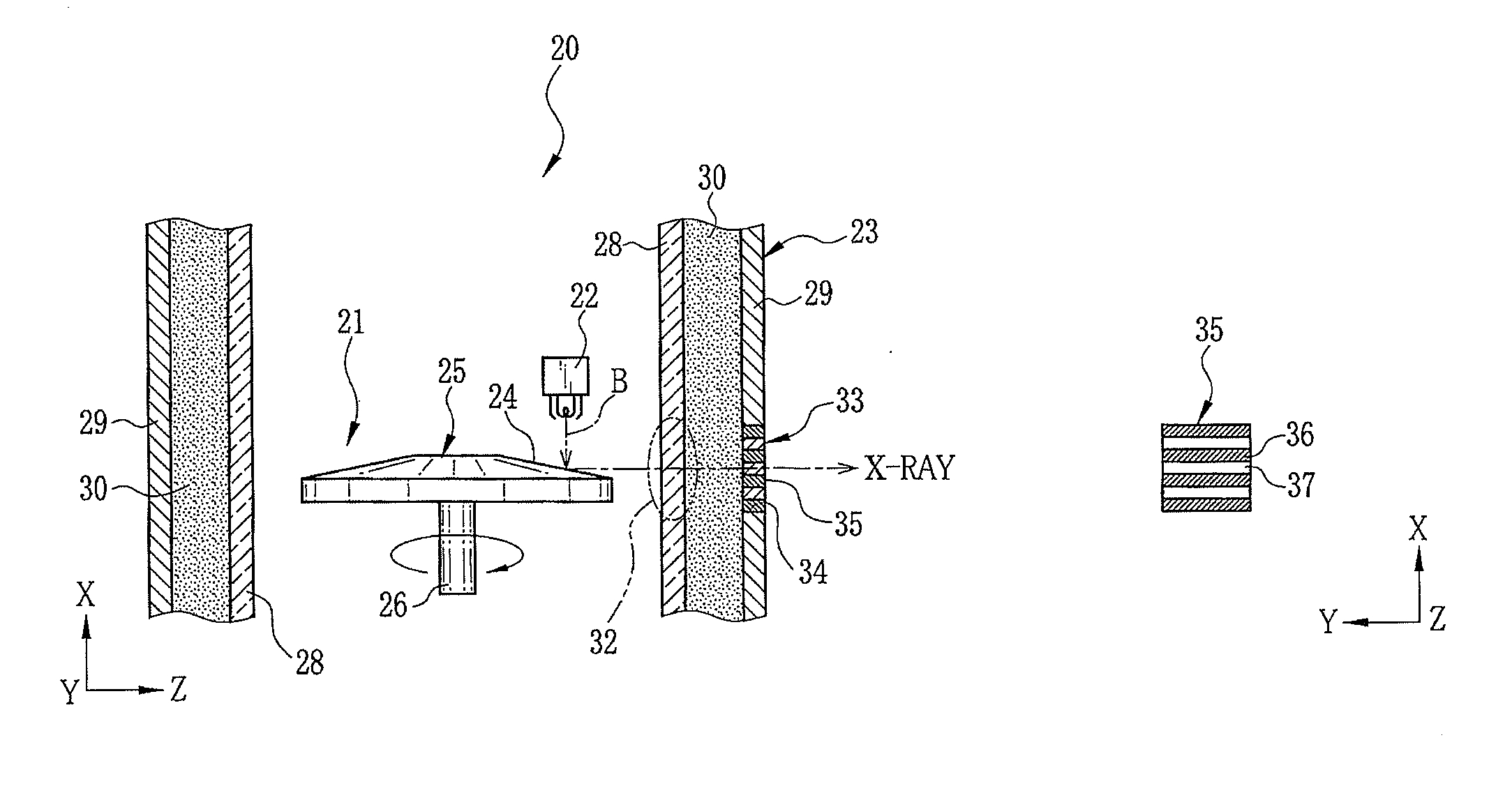

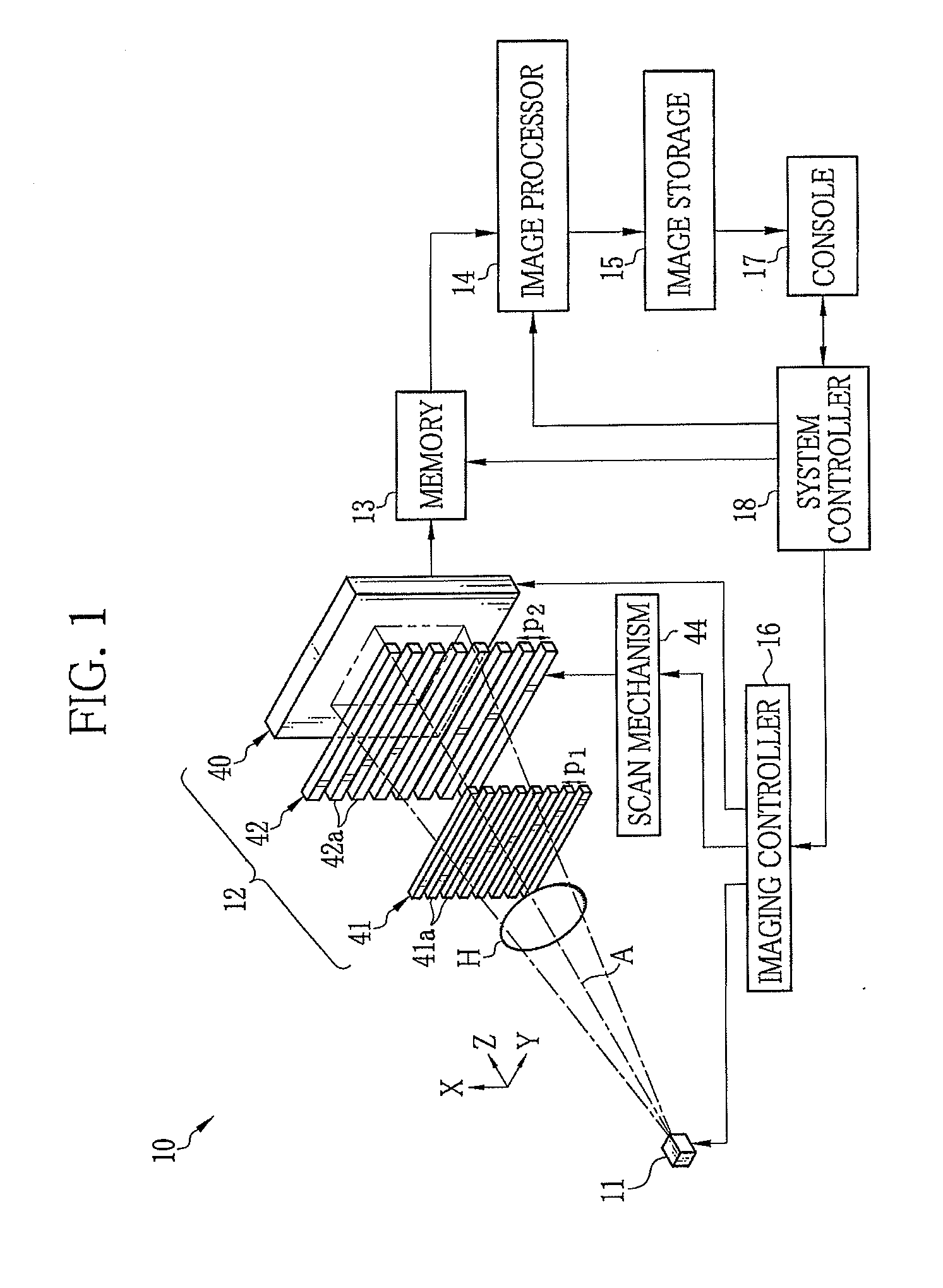

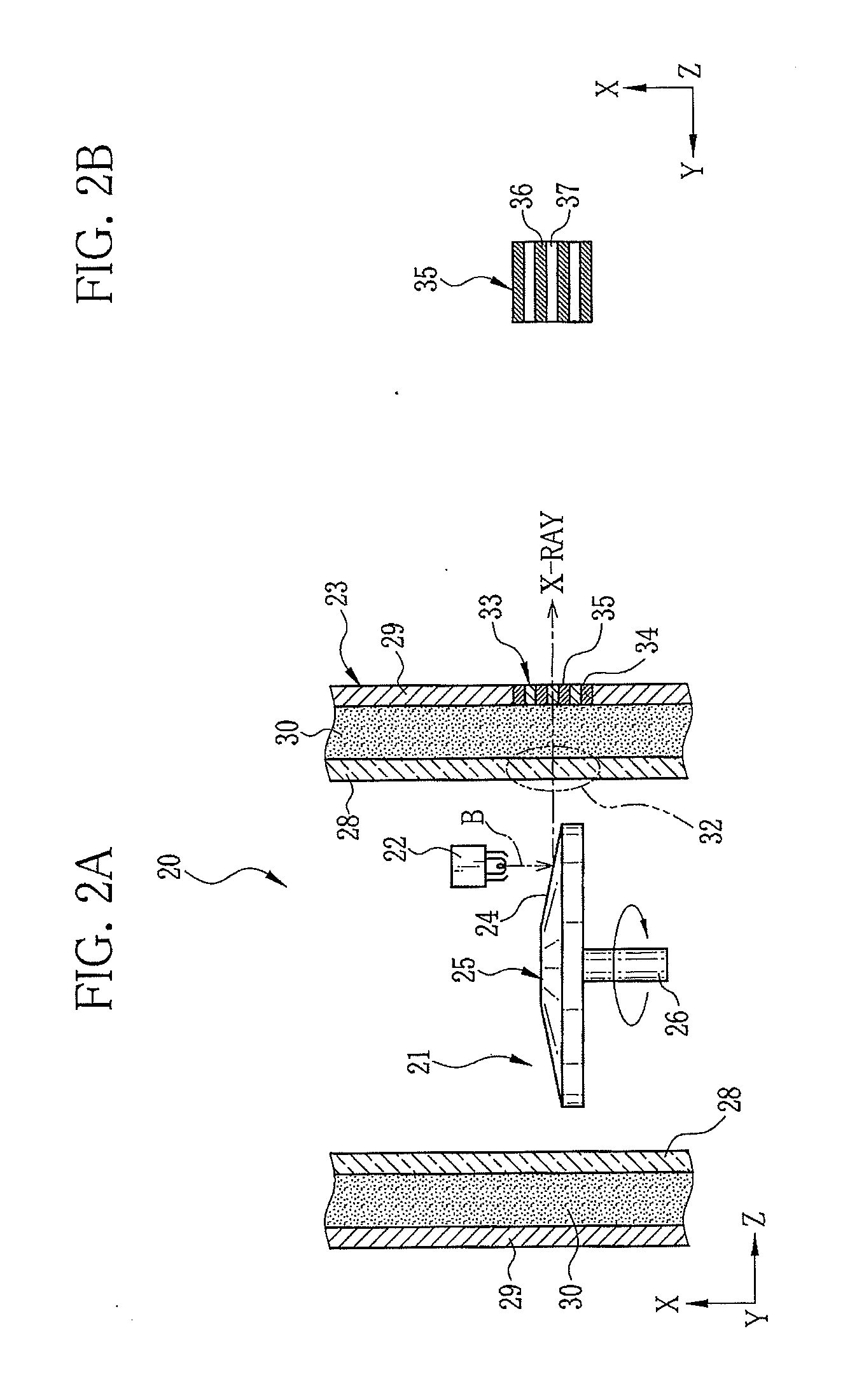

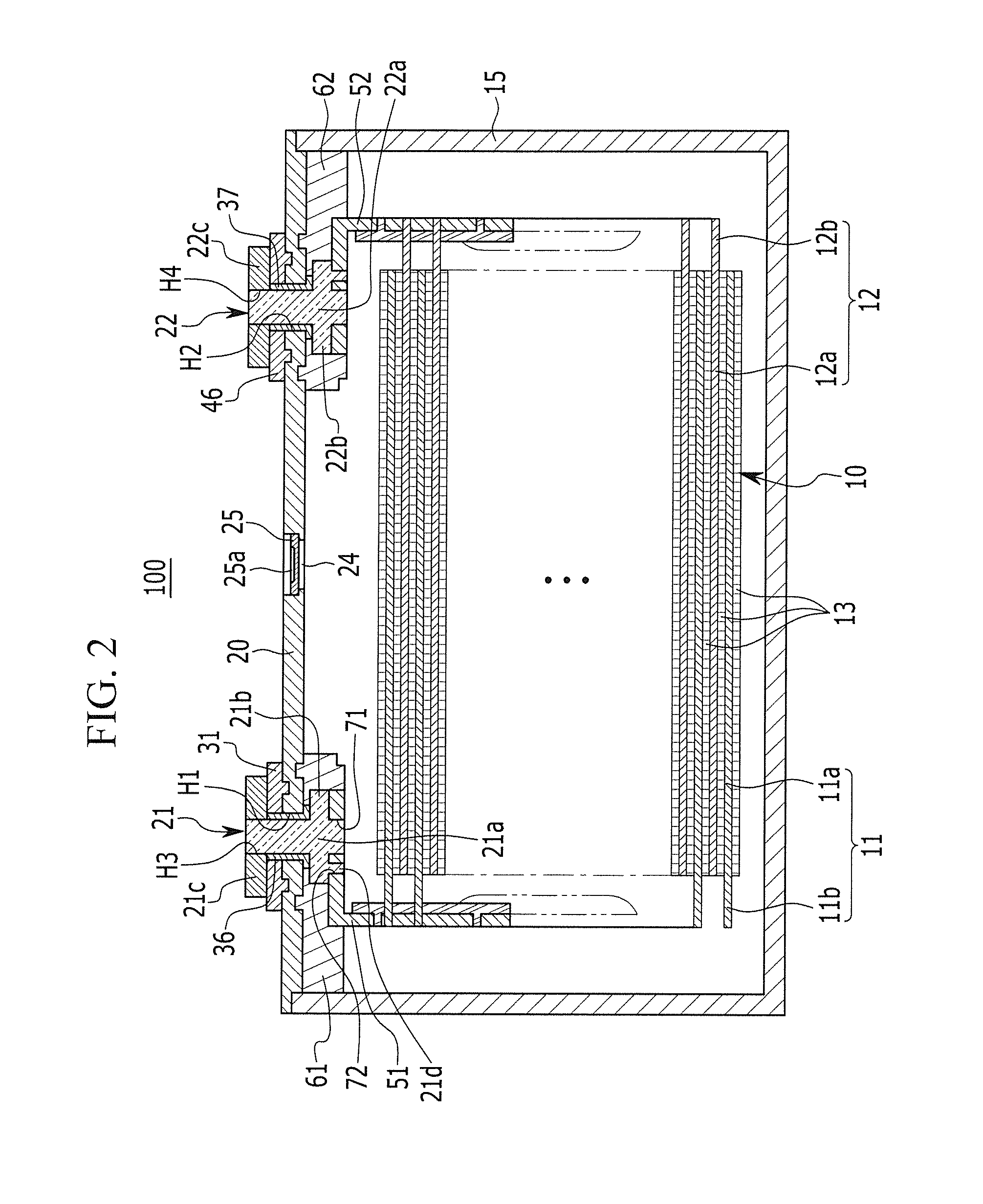

Radiation tube and radiation imaging system

InactiveUS20120134463A1Without affecting cost and sizeImprove cooling effectImaging devicesX-ray tube electrodesRadiation imagingX-ray

An X-ray tube has a cathode, a rotating anode, and a case for enclosing the cathode and the rotating anode. The rotating anode generates X-rays due to emission of electron beams from the cathode. The case includes a vacuum envelope for enclosing the cathode and the rotating anode, and a housing for enclosing the vacuum envelope. Inside of the vacuum envelope is maintained vacuum. The vacuum envelope has an X-ray passing portion for passing the X-rays therethrough. The housing is provided with a radiation window for radiating the X-rays, passed through the X-ray passing portion, to the outside of the case. The radiation window includes an opening and a multi-slit arranged in the opening. The multi-slit partly shields the X-rays, generated by the rotating anode, to form a plurality of virtual linear light sources.

Owner:FUJIFILM CORP

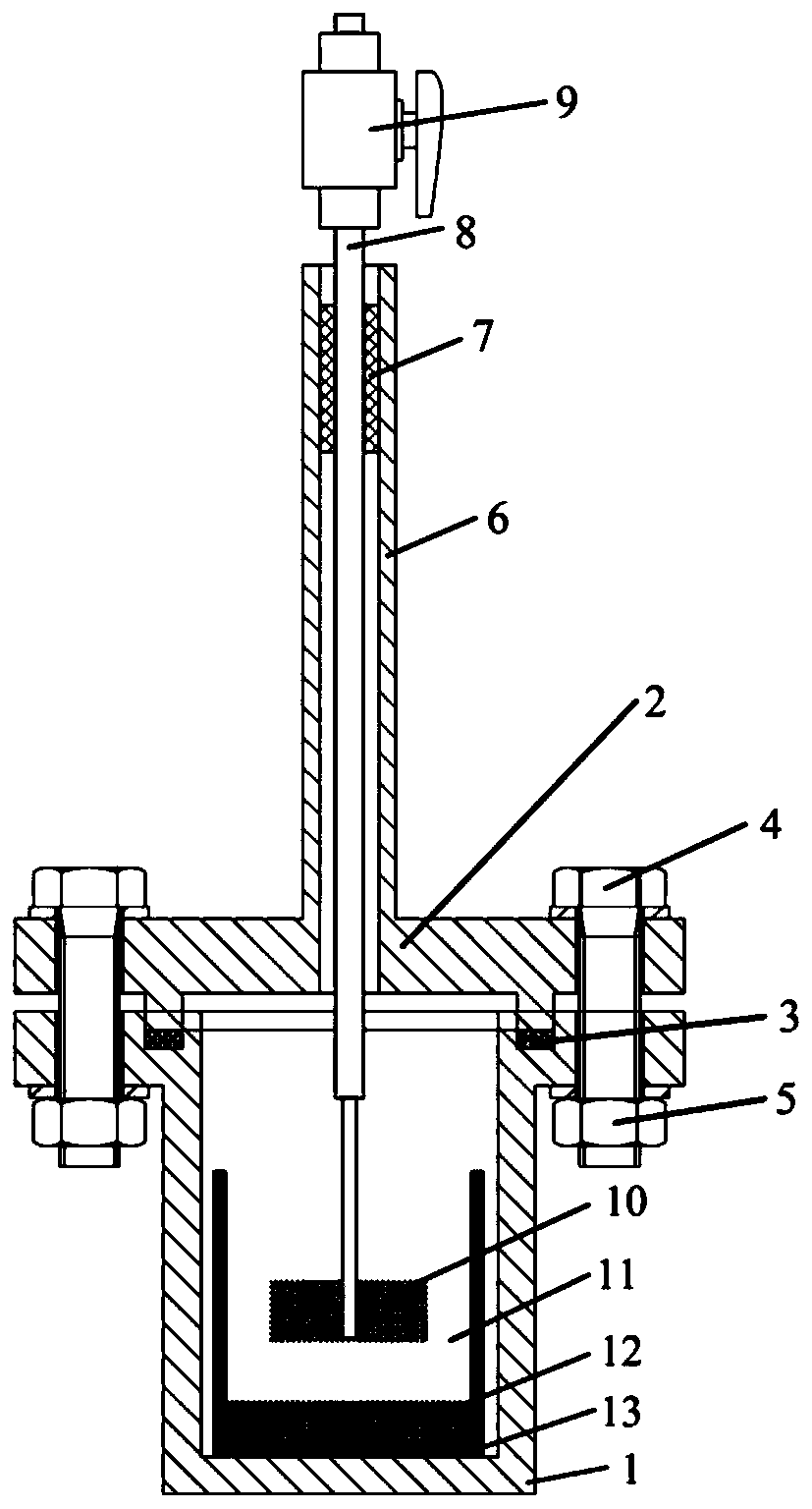

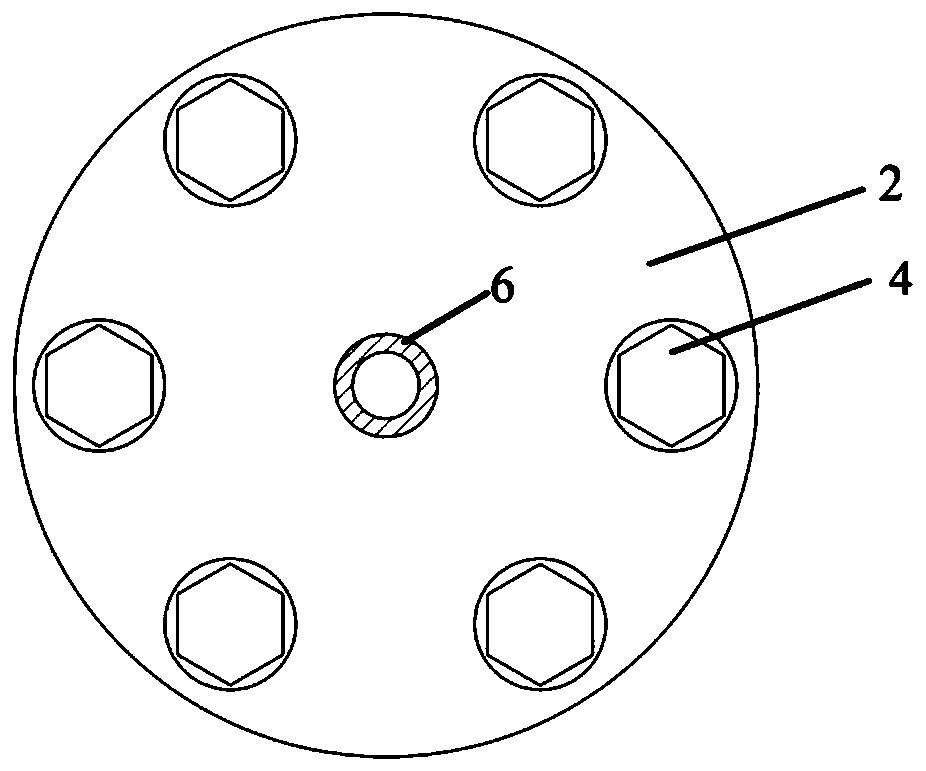

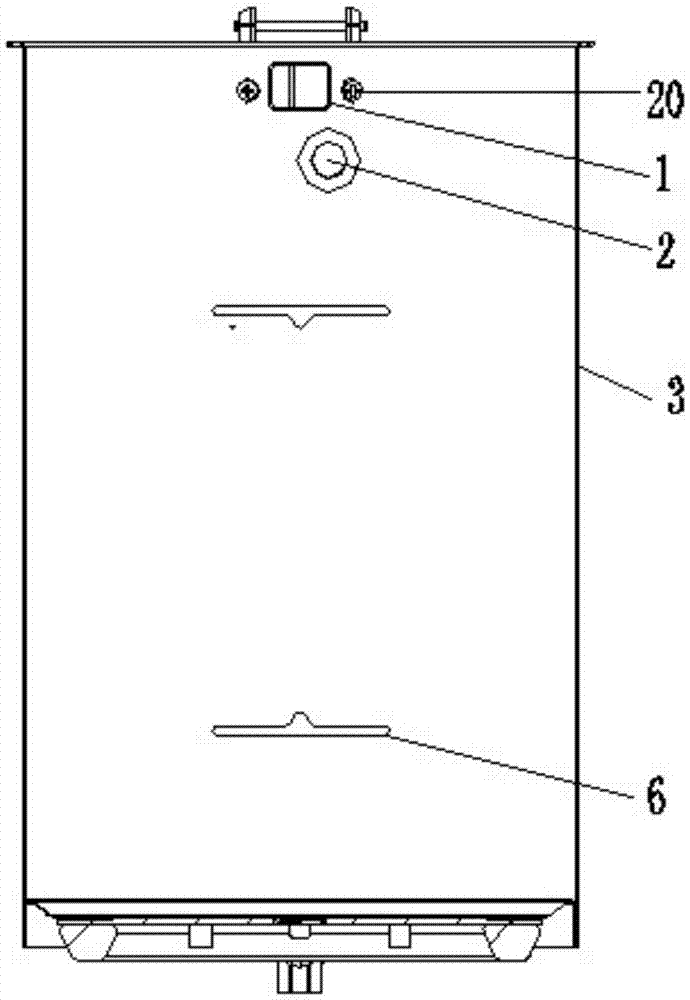

Reusable liquid metal battery device

PendingCN110429350AAchieve reuseReduce wasteSpecific condition cell workingSecondary cellsElectrical batteryCurrent collector

The invention relates to a reusable liquid metal battery device, comprising: a battery casing, a top cover, a metal sleeve, an insulating sealing material, a negative electrode conductive tube and a valve, wherein a negative electrode current collector, an electrolyte, a positive electrode material and a positive electrode current collector are successively placed in the battery casing; the positive electrode material is placed in the positive electrode current collector; the negative electrode material is placed in the negative electrode current collector; the negative electrode current collector is connected to the negative electrode conductive tube through a negative electrode lead wire; the negative electrode conductive tube passes through the metal sleeve at the center of the top cover to be connected with the valve; and the battery casing and the top cover are in detachable connection. The liquid metal battery device provided by the invention can be disassembled to be reused, isadapted to the optimal adjustment of an active material inside the battery, can simplify the configuration process of the battery, reduces the research and development cost of the liquid metal battery, and detects the air impermeability of the battery casing through the valve.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

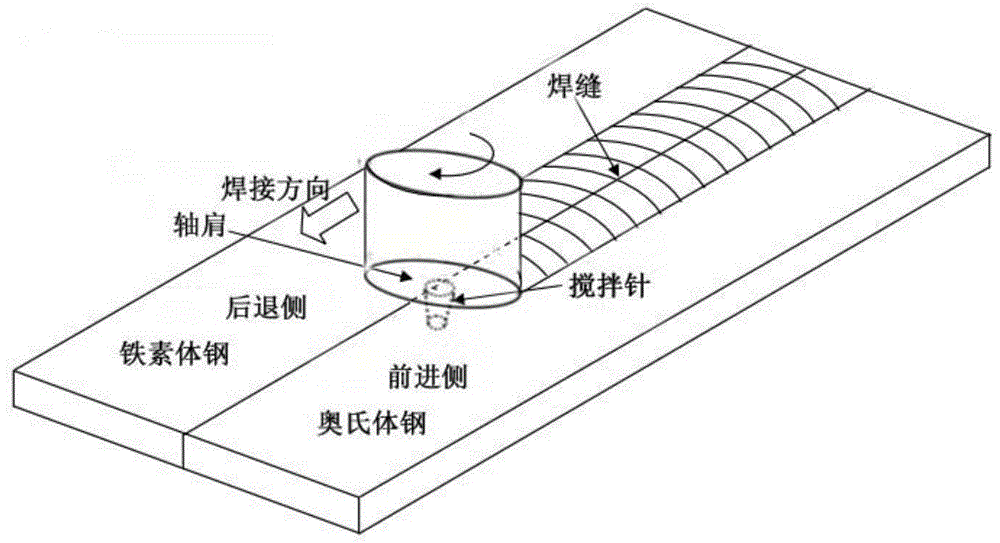

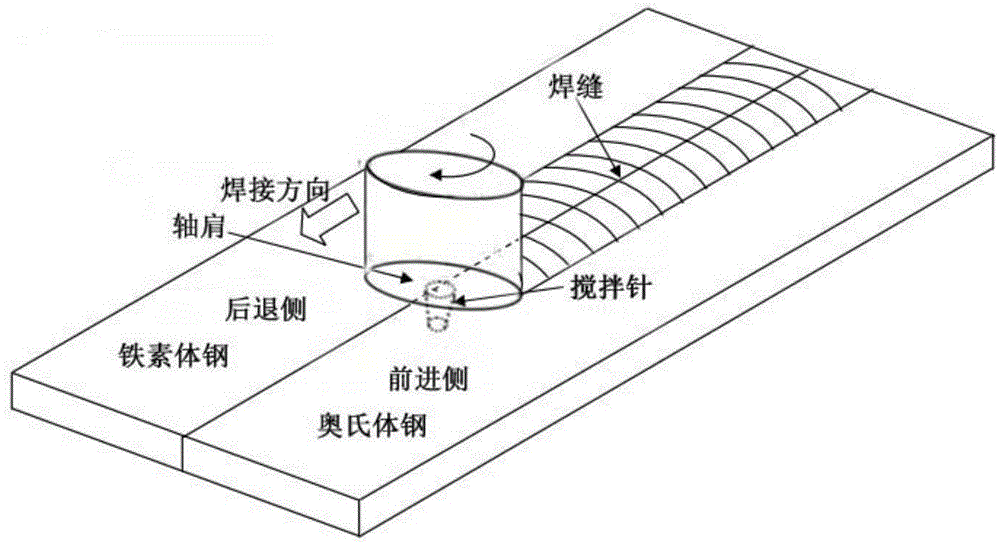

Friction-stir welding method of ferrite/austenite dissimilar steel

InactiveCN104400207AImprove performanceHigh strengthWelding/soldering/cutting articlesMetal working apparatusMetallic materialsEngineering

The invention relates to friction-stir welding method of ferrite / austenite dissimilar steel, and belongs to the technical field of welding of metal materials. The method comprises the steps that a ferrite steel plate and an austenite steel plate are fixed in an abutting-joint manner through a fixing device and are fixed to a friction-stir welding device through a clamp; the distance from a stirring head of the friction-stir welding device to an abutting-joint surface is set, that is, the offset amount and the shaft shoulder pushing amount are set; and the inclined angle, the rotating speed and the advancing speed of the stirring head are adjusted, and then welding is carried out. According to the method, in the welding process, heat input is small, an overheated area existing in fusion welding cannot be generated, and common defects, such as impurity blending and cold and heat cracks, do not exist. A welding joint with the more excellent performance can be obtained. The technology problem of welding of a dissimilar steel plate is solved.

Owner:UNIV OF SCI & TECH BEIJING

Tripterygium hypoglaucum film coated tablets and preparation method thereof

InactiveCN101874816ALess affected by heatReduce breakageAntipyreticAnalgesicsMagnesium stearatePharmacology

The invention discloses film coated tablets of tripterygium hypoglaucum tablets and a preparation method thereof. The film coated tablets are characterized in that: oblate or elliptic tripterygium hypoglaucum tablets with the diameter of 0.8 to 1.2 centimeters are used as tablet bases, and a film coating with the thickness of 0.1 to 0.3 millimeter is sprayed and coated on the tablet surface; and the tripterygium hypoglaucum tablet cores comprise the following components in part by weight: 40 to 80 parts of tripterygium hypoglaucum, 10 to 40 parts of starch, 0 to 30 parts of microcrystalline cellulose, 10 to 30 parts of 1 to 10 percent hydroxypropyl methyl cellulose methanol solution, 0.5 to 5 parts of magnesium stearate and 1 to 5 parts of carboxymethyl starch sodium. The preparation method for the tripterygium hypoglaucum film coated tablets has the advantages of simple preparation, easy operation, easy mastery, low equipment investment and short production period; and the prepared tablets have stable main medicinal property, are favorable for improving the medicinal quality, and ensure the effect of the tablets.

Owner:昆明梓橦宫全新生物制药有限公司

Preparation method of moisture-proof traditional Chinese medicine coated film

InactiveCN104587481AChemically stableDry fastPharmaceutical delivery mechanismOil/fats/waxes non-active ingredientsSugar Coated TabletMoisture resistance

The invention discloses a preparation method of a moisture-proof traditional Chinese medicine coated film, which relates to a coating technology of the traditional Chinese medicine and belongs to the medicinal preparation field. The moisture-proof traditional Chinese medicine coated film comprises the following components: 30-40 parts of hydroxypropyl methyl cellulose, 5-8 parts of triethyl citrate, 6-10 parts of xylitol, 4-8 parts of castor oil, 4-8 parts of tween-80, 14-18 parts of dextrin, 6-10 parts of aerosol, 6-10 parts of zein, 5-10 parts of 1% of artificial food coloring solution, 350-420 parts of distilled water (40-50 DEG C) and balance of ethanol with 95% of concentration; wherein weight unit of solid is gram, and volume unit of liquid is milliliter. The moisture-proof traditional Chinese medicine coated film has the beneficial effect of stable chemical property of a film forming substance, inertia to an enzyme system, no physiological toxicity and no usage of cane sugar; the coated film has the advantages of moisture resistance, heat resistance, cold resistance and abrasion resistance which are better than that of the sugar coated tablets, so that the stability of the coated film is increased, and storage period is prolonged.

Owner:刘桐言

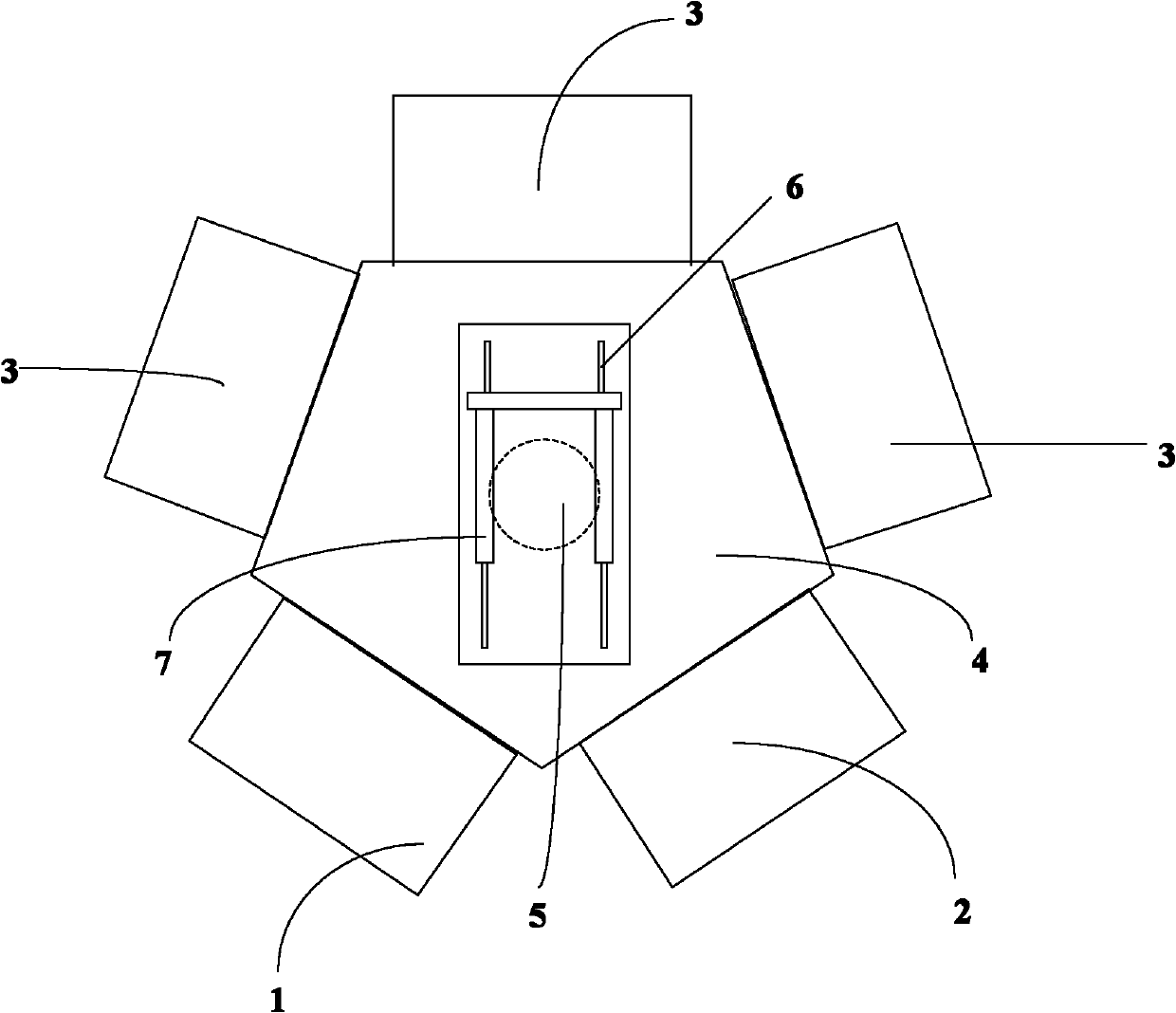

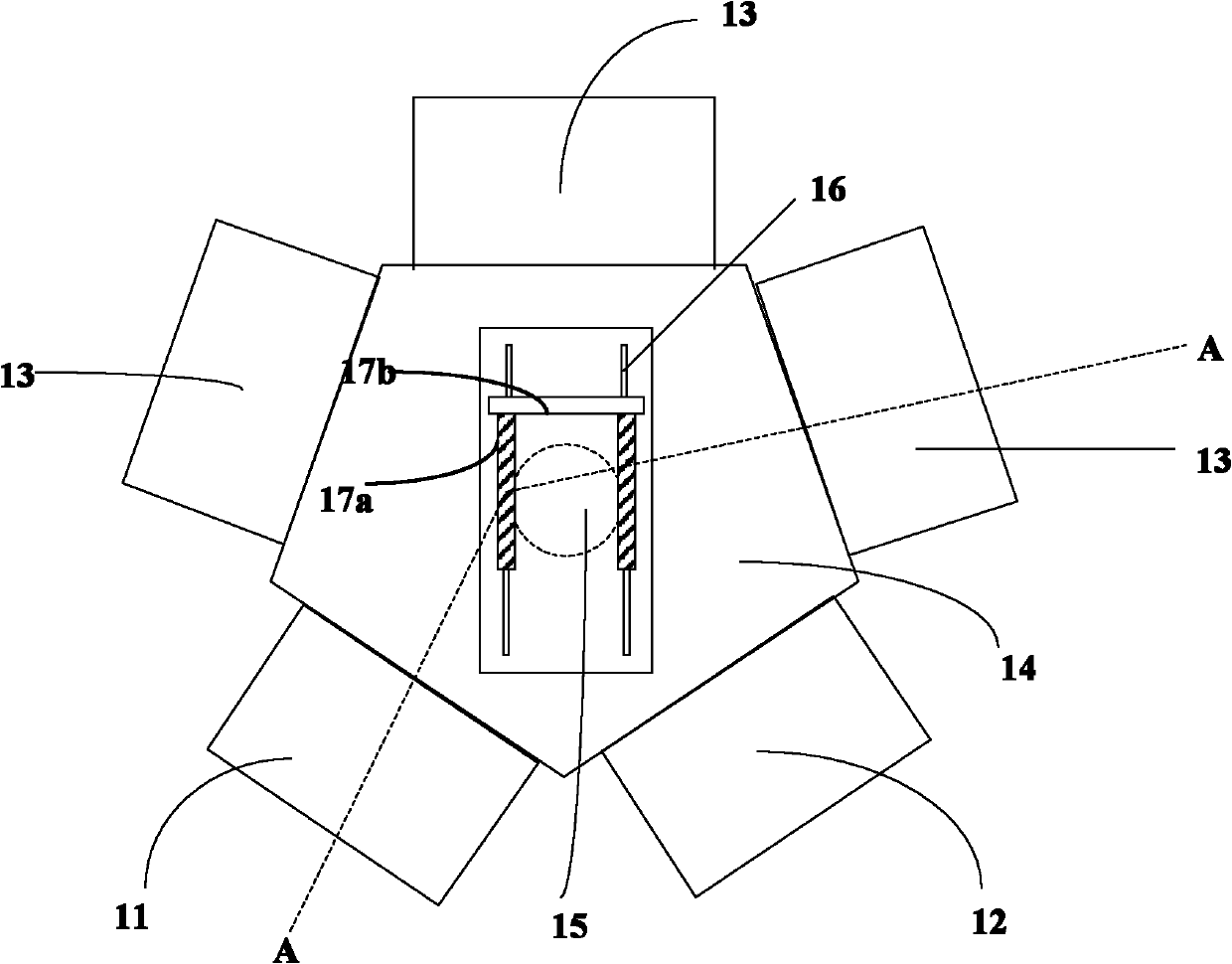

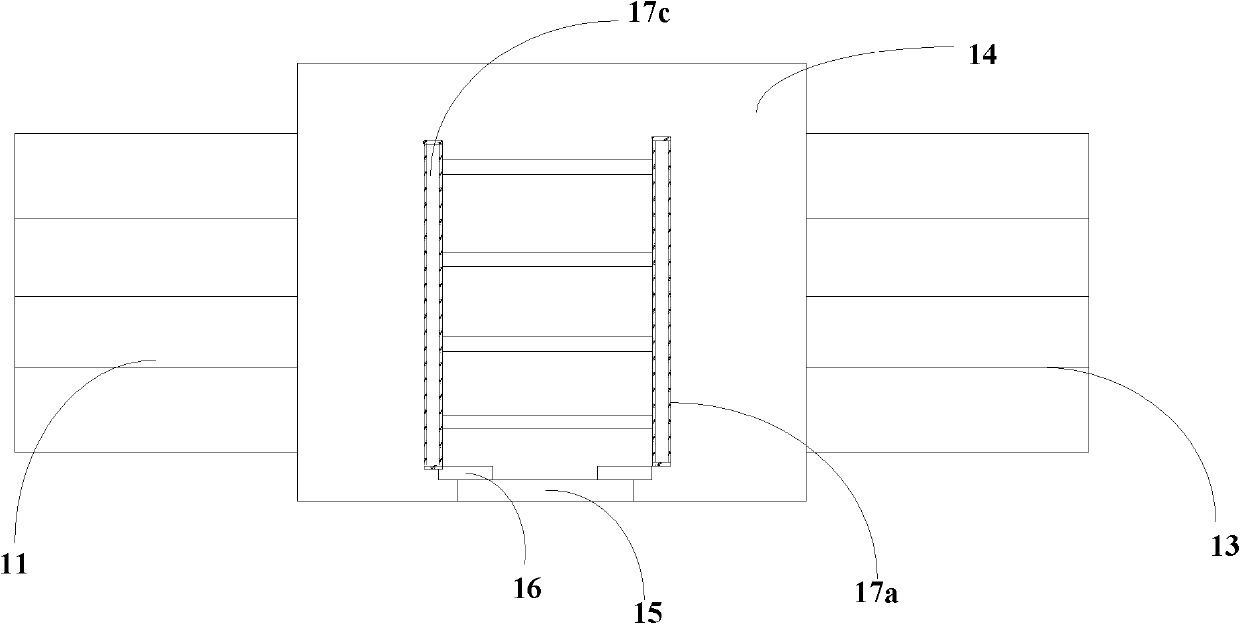

Device and method for welding target through stirring friction

ActiveCN105382404ASimple structureEasy to operateWelding/soldering/cutting articlesNon-electric welding apparatusElectrical resistance and conductanceIndium

The invention relates to a device and method for welding a target through stirring friction. The device comprises an indium binding device and an encapsulating structure. The method for welding the target through stirring friction comprises the sequential steps that firstly, binding surfaces of ceramic target and a metal substrate are each coated with a welding layer through a thermal coating method; secondly, the ceramic target coated with the welding layer and the metal substrate coated with the welding layer in the first step are horizontally placed on a horizontal table; thirdly, a metal wire rotating at a high speed is adjusted so that the metal wire can exactly face a seam of the two welding layers of the binding surfaces of the ceramic target and the metal substrate; fourthly, binding bonding welding work is started, the rotating speed of a controllable motor is adjusted, the moving speed of the horizontal table is adjusted, and the horizontal table is horizontally moved in the radial direction of the metal wire. By means of the method, the defect that when ceramic target and a metal substrate are welded through a traditional resistance heating method, deformation and cracking occur after welding due to the large difference of the coefficients of thermal expansion can be effectively overcome.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

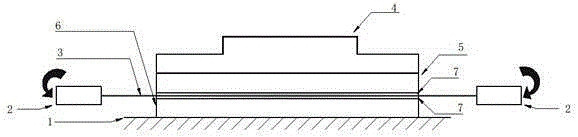

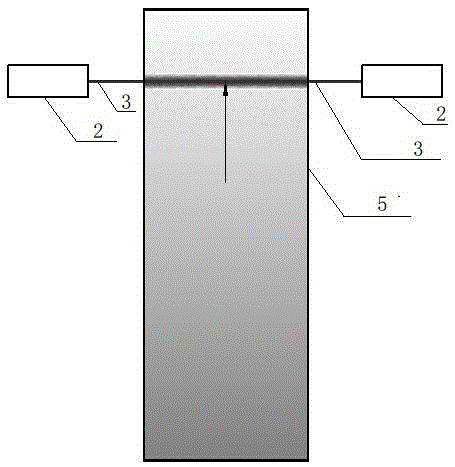

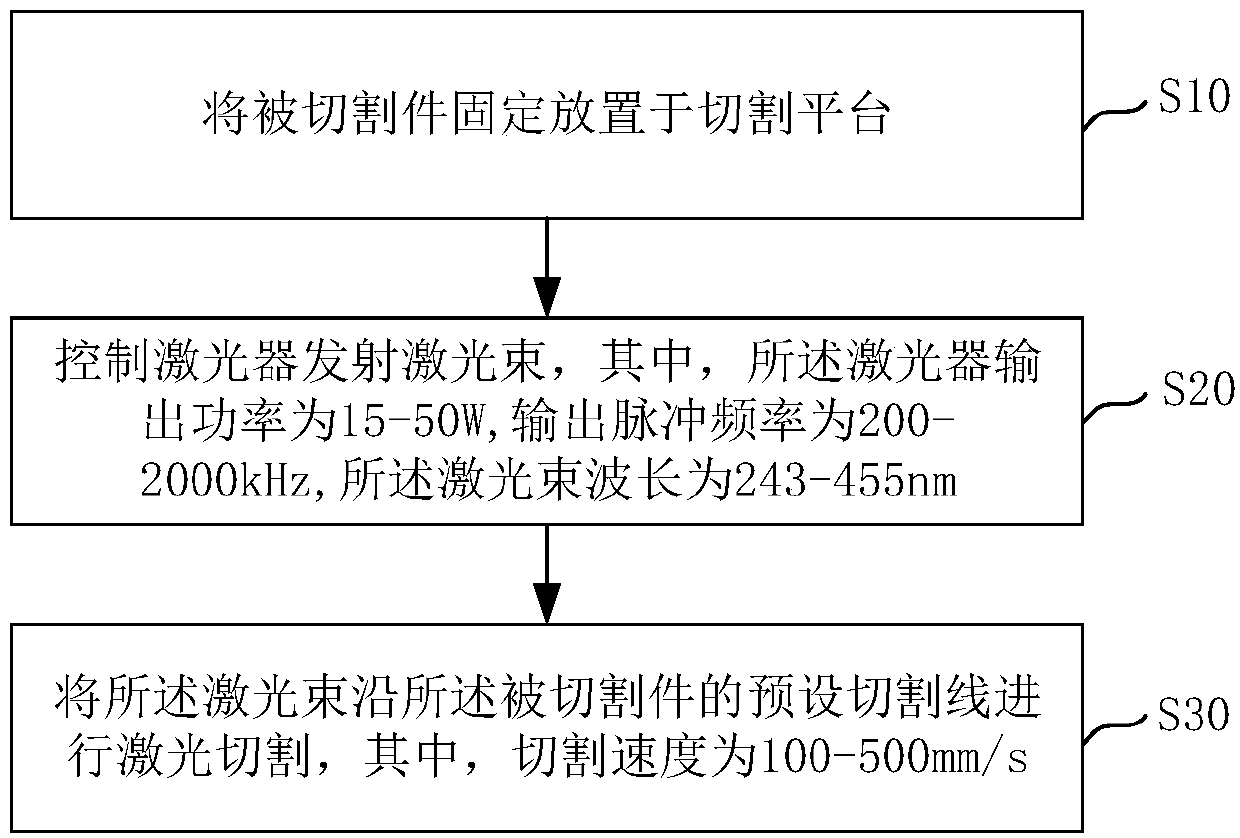

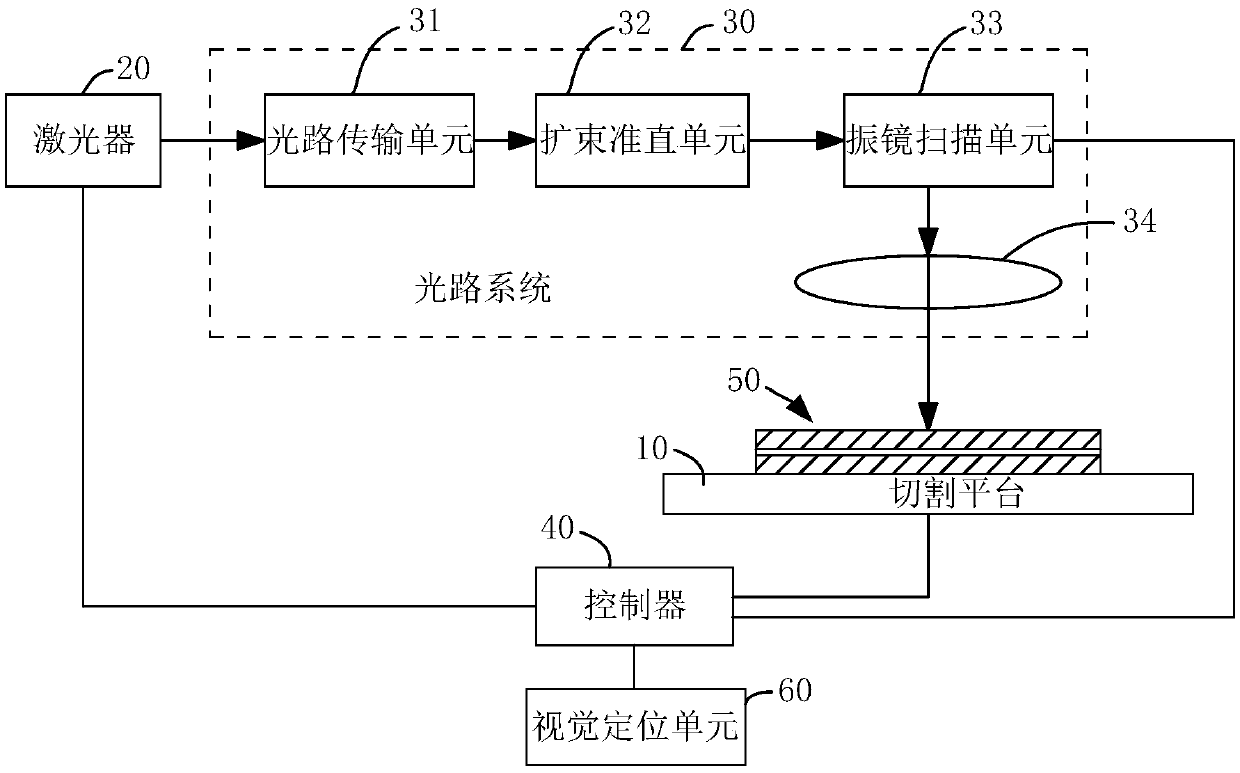

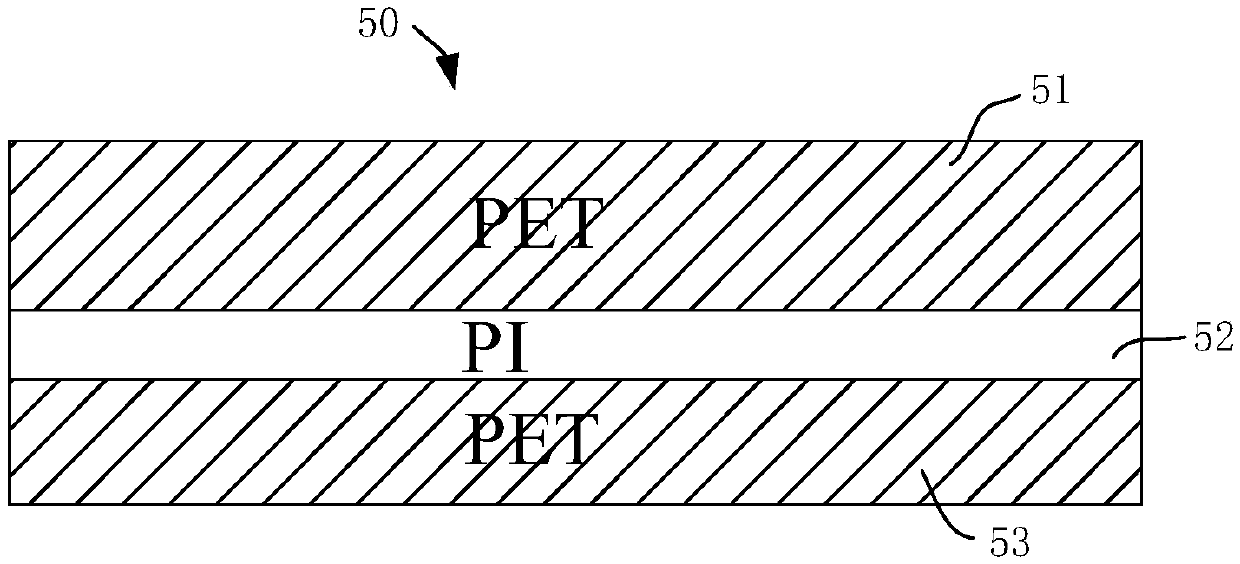

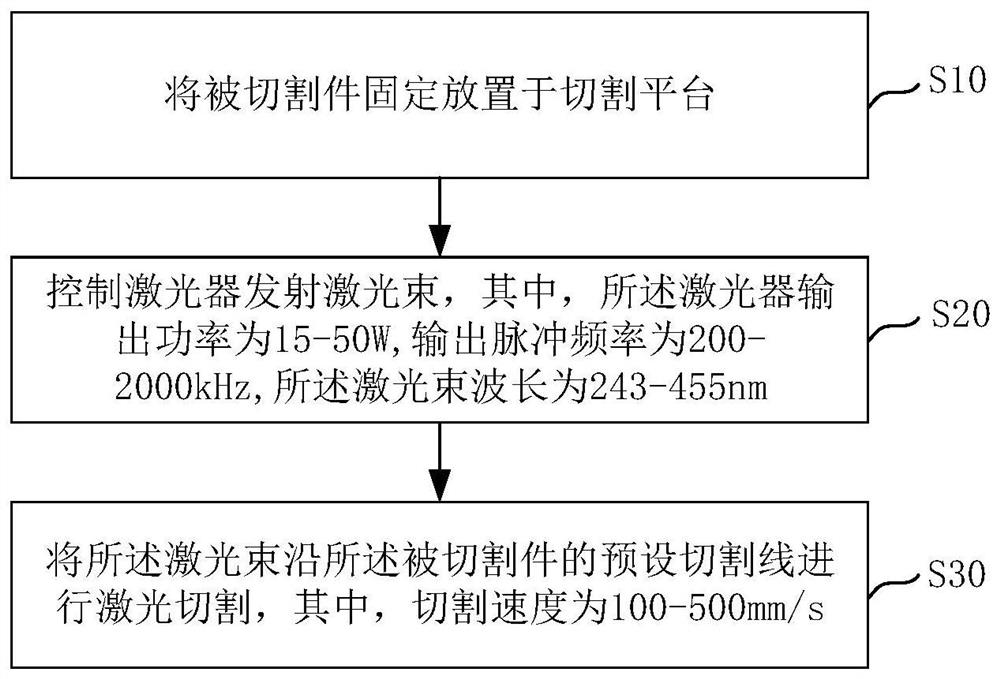

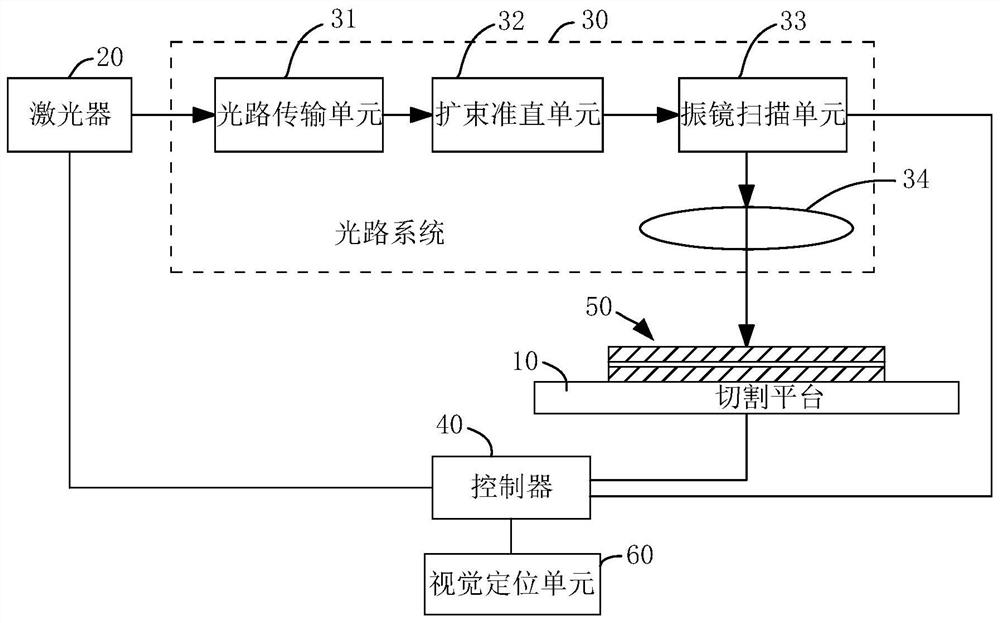

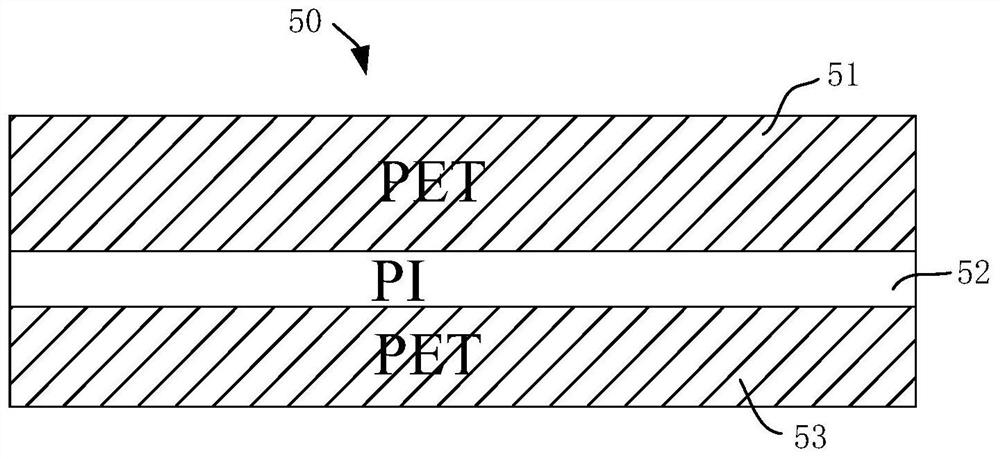

Laser cutting method and laser cutting device

ActiveCN110936027ATimely releaseLittle change in tackLaser beam welding apparatusHeat-affected zoneEngineering

The invention discloses a laser cutting method, which is applied to a cutting operation of a multilayer composite material. The laser cutting method comprises the following steps of fixedly placing acut piece on a cutting platform; controlling a laser to emit a laser beam, wherein the output power of the laser is 15-50 W, the output pulse frequency is 200-2000 kHz, and the wavelength of the laserbeam is 243-455 nm; and carrying out laser cutting along a preset cutting line of the cut piece by the laser beam, wherein the cutting speed is 100-500 mm / s. Meanwhile, the invention further discloses a laser cutting device capable of implementing the laser cutting method. According to the technical scheme, the laser cutting method is adopted, the process parameters of the laser cutting machiningare controlled, so that the temperature of the heat affected area of the cut piece along the two sides of the cutting line is not increased too much, the heat influence is small, the heat can be released in time, and the phenomenon of poor quality of the cut finished product caused by the fact that molten impurities infiltrate between the layers due to the reduced adhesion between the layers is avoided.

Owner:深圳市大族半导体装备科技有限公司

Rechargeable battery

ActiveUS9466823B2Extended operating timeGood heat dissipationSecondary cellsCell component detailsElectrical batteryRechargeable cell

A rechargeable battery including an electrode assembly, a case housing the electrode assembly, a cap plate coupled to the case, a first electrode terminal on the cap plate, and a first lead tab electrically connecting the electrode assembly and the first electrode terminal, wherein the first lead tab has a cell fuse and a heat dissipating member coupled to the first lead tab and spaced from the cell fuse.

Owner:SAMSUNG SDI CO LTD

Conveying manipulator and handling device

ActiveCN102554937AGuaranteed to workWill not deformFinal product manufactureGripping headsEngineeringManipulator

The invention relates to a conveying manipulator and a handling device used for carrying a large area baseplate. The conveying manipulator comprises a load-bearing arm and a heat protection shell positioned on the surface of the load-bearing arm, wherein the thickness range of the heat protection shell is 0.001mm-0.3mm; and preferably, the surface of the load-bearing arm or a surface at which the heat protection shell is contacted with the load-bearing arm is provided with one or more protruding parts. The invention also provides the handling device which comprises the conveying manipulator. The conveying manipulator provided by the invention adopts the heat protection shell, the conveying manipulator still can exactly operate under a hot environment, even if the conveying manipulator is positioned in the hot environment for a long time, and the conveying manipulator can not transform; and in addition, the thickness of the heat protection shell is 0.001mm-0.3mm, further the weight of the conveying manipulator is reduced, the volume of the conveying manipulator is reduced, and the conveying cost is reduced.

Owner:理想万里晖真空装备(泰兴)有限公司

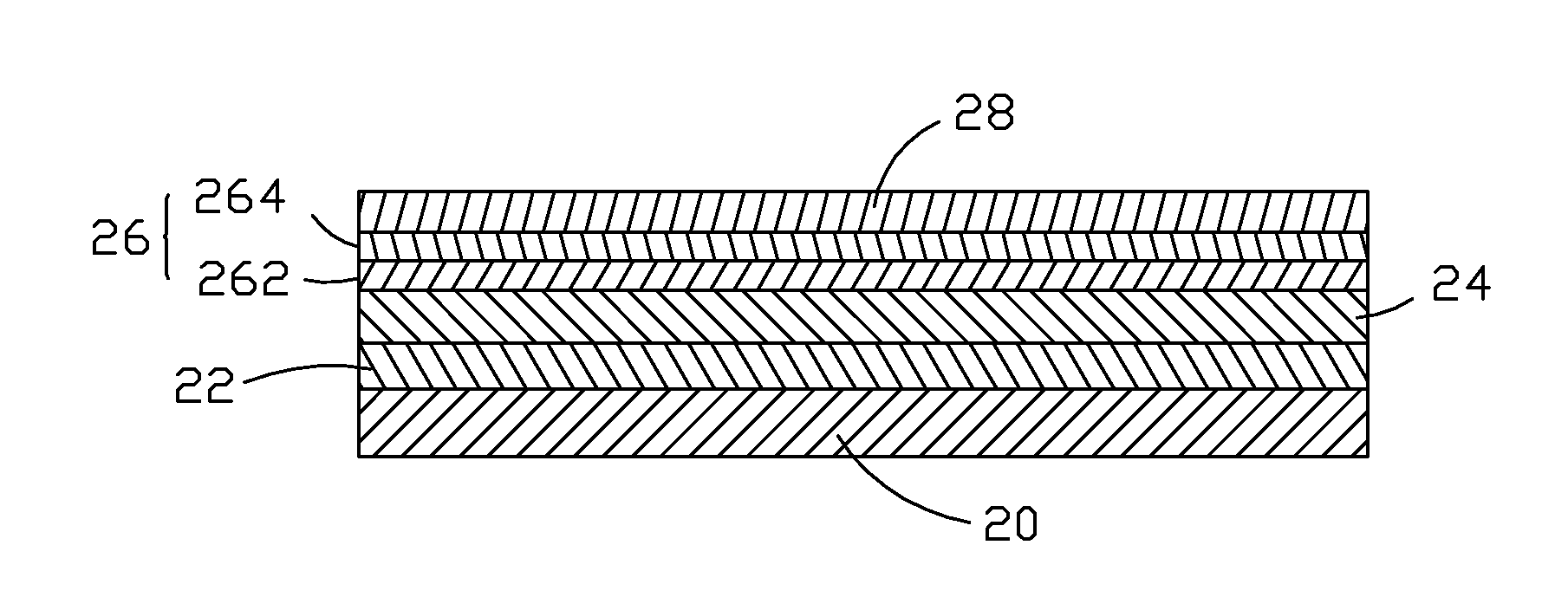

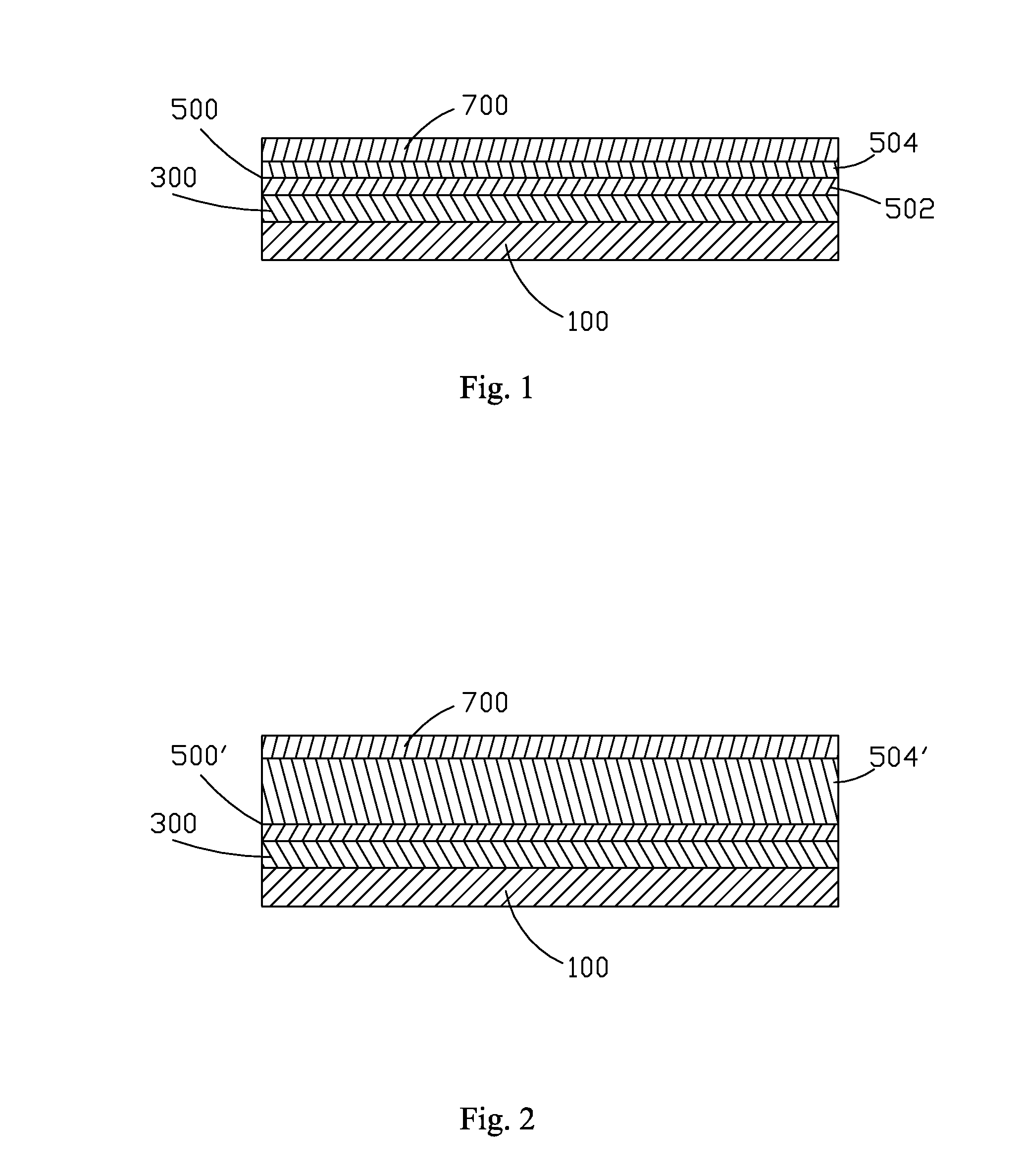

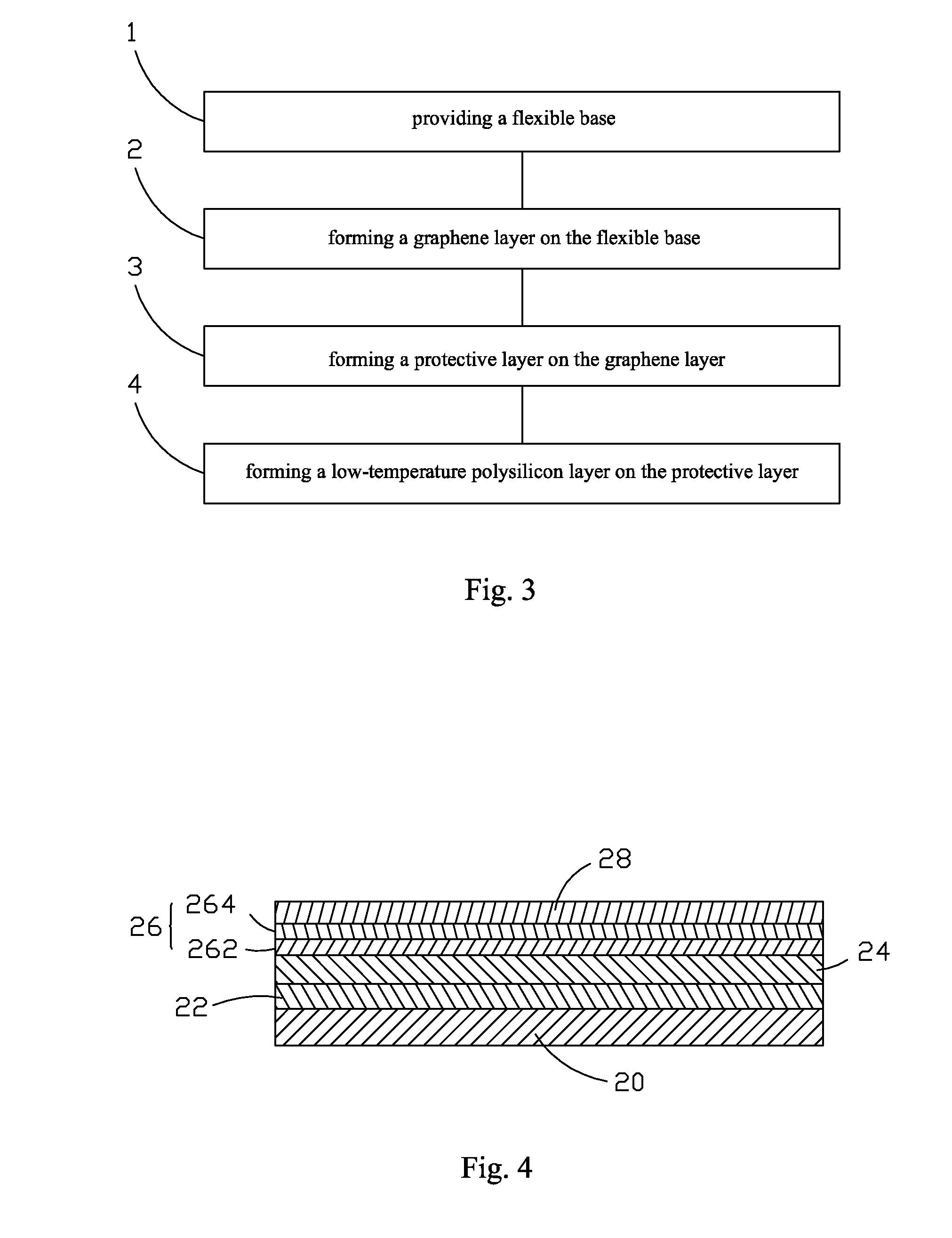

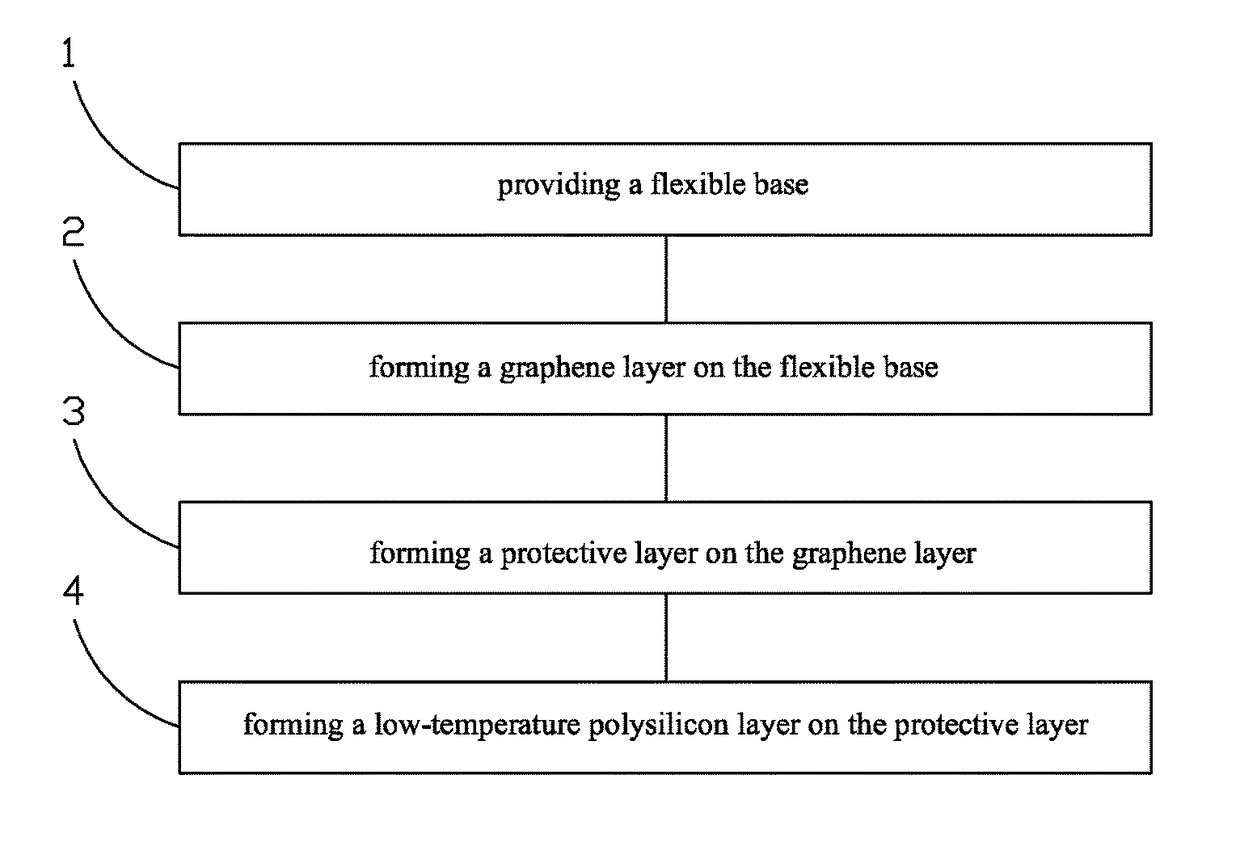

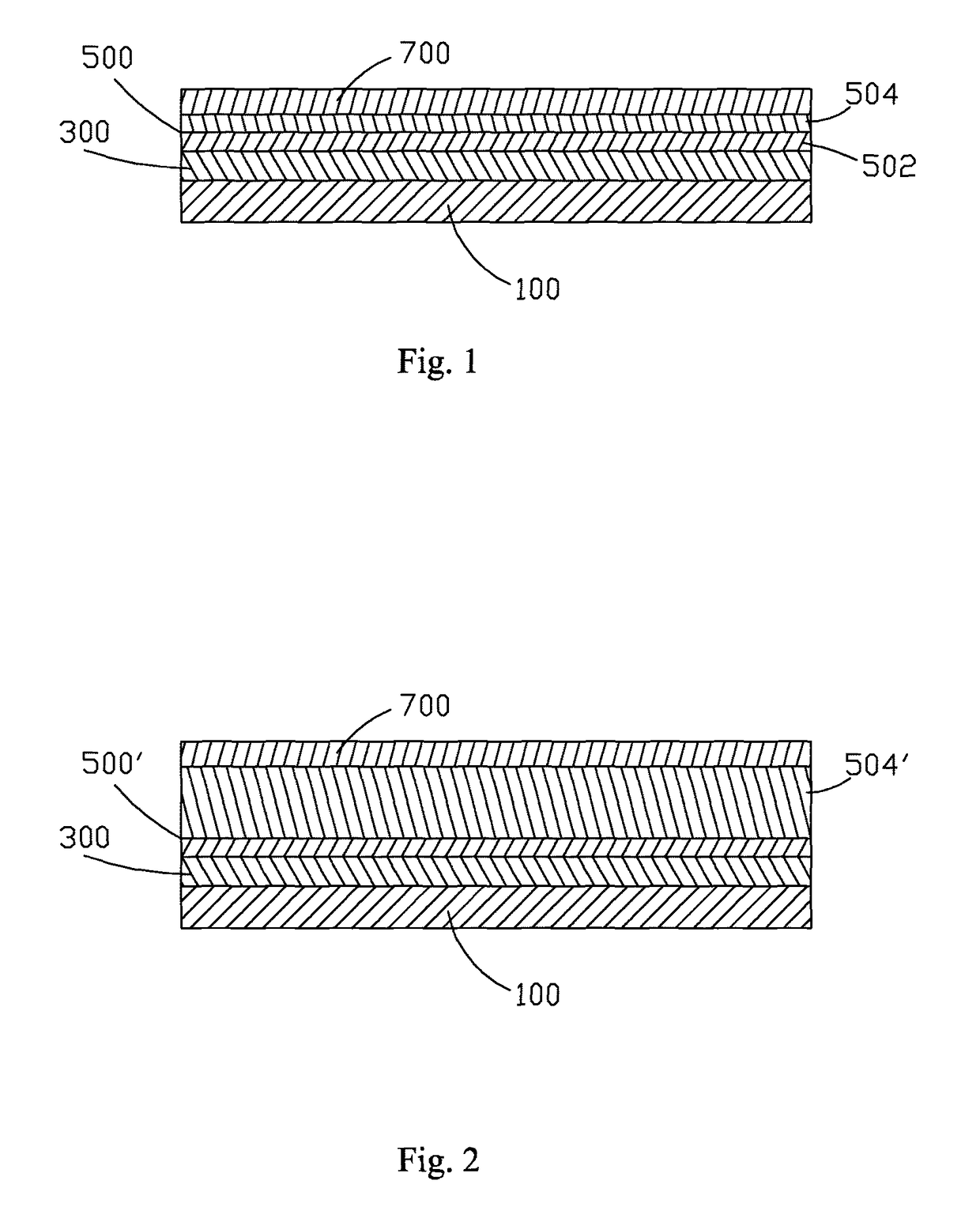

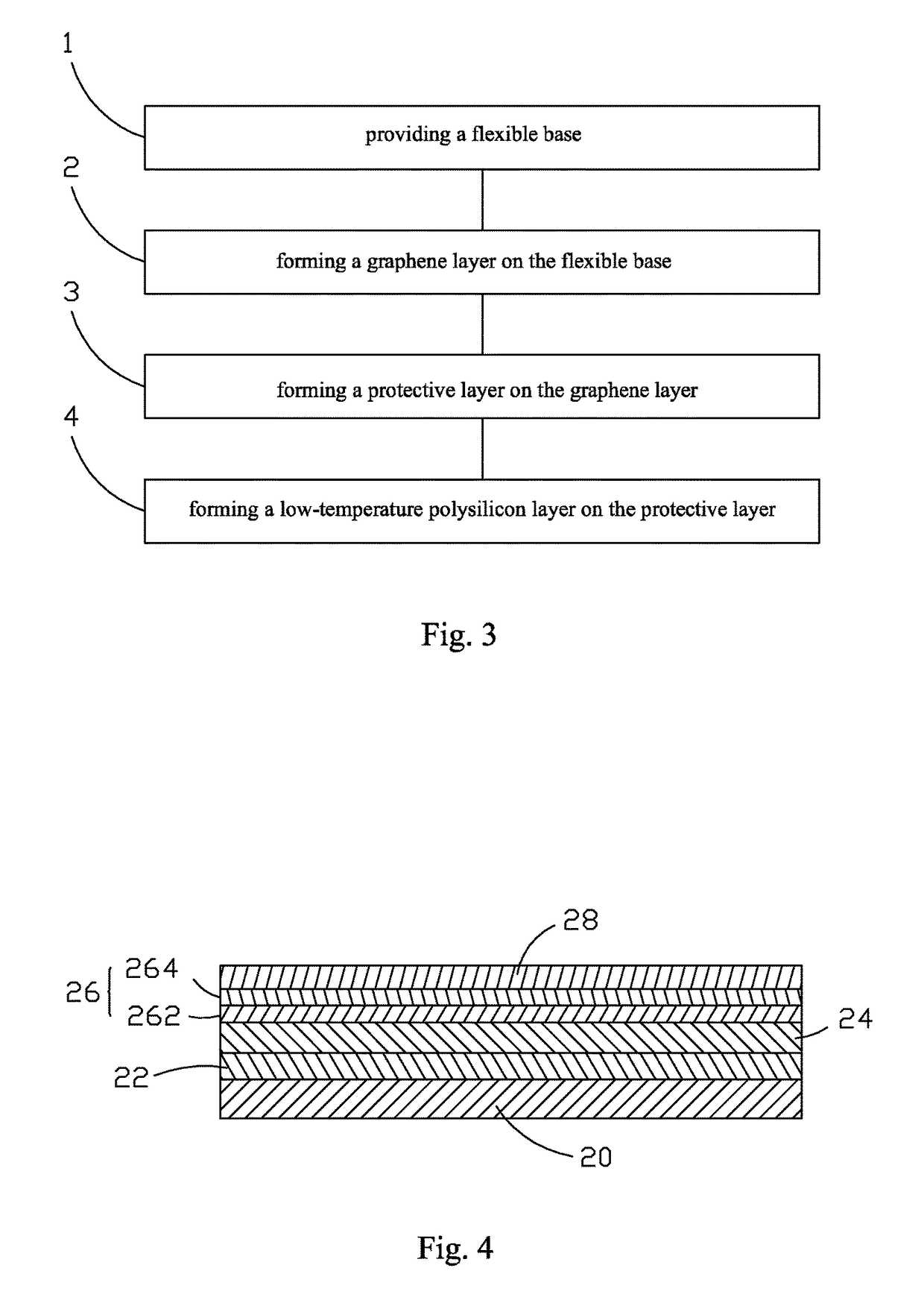

Method For Manufacturing Assembly Of Flexible Display Device And Assembly Of Flexible Display Device Manufactured With Same

The present invention provides a method for manufacturing an assembly of a flexible display device and an assembly of a flexible display device manufactured therewith. The method includes: (1) providing a flexible base (22); (2) forming a graphene layer (24) on the flexible base (22); (3) forming a protective layer (26) on the graphene layer (24); (4) forming a low-temperature polysilicon layer (28) on the protective layer (26). The method for manufacturing an assembly of a flexible display device and the assembly of the flexible display device manufactured therewith according to the present invention are such that the graphene layer is formed on the flexible base to effectively conduct out heat generated in the process of forming the low-temperature polysilicon layer so as to protect the flexible base from being affected by the heat without increasing the thickness of the protective layer thereby reducing internal stress and facilitating the realization of thinning.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

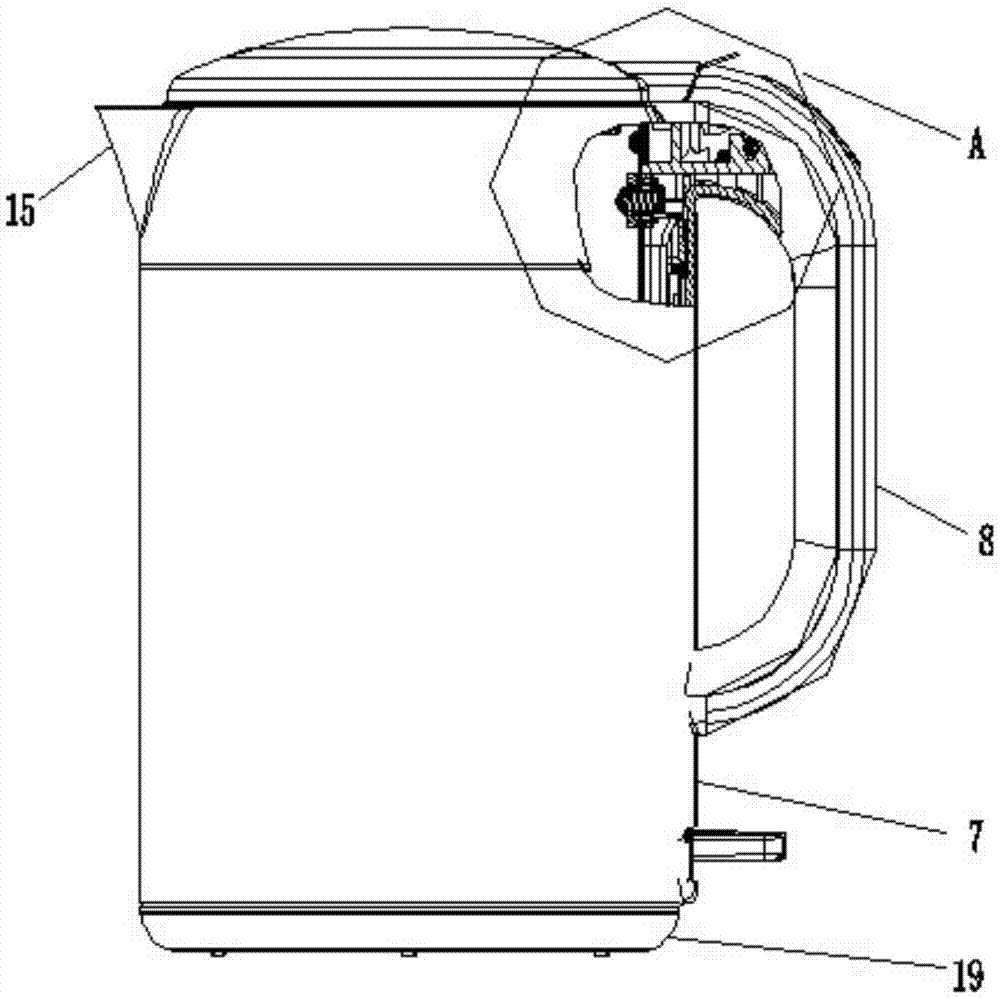

Electric kettle

The invention relates to the technical field of kitchen appliances and particularly relates to an electric kettle. The electric kettle provided by the invention comprises a kettle body, a light assembly, a handle and a switch, wherein the handle is arranged on the kettle body, the light assembly is arranged on the kettle body or the handle, and the switch is used for controlling the turn-on or turn-off of the light assembly. According to the electric kettle provided by the invention, the light assembly is arranged on the kettle body, and light irradiates forwards from the inner side part of the kettle body of the electric kettle and cannot upwards irradiate directly, so that user experience is improved; the light assembly is kept away from heat, so that the influence caused by the heat is little; the electric kettle has the advantages of simple structure and long service life.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Method for manufacturing assembly of flexible display device and assembly of flexible display device manufactured with same

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

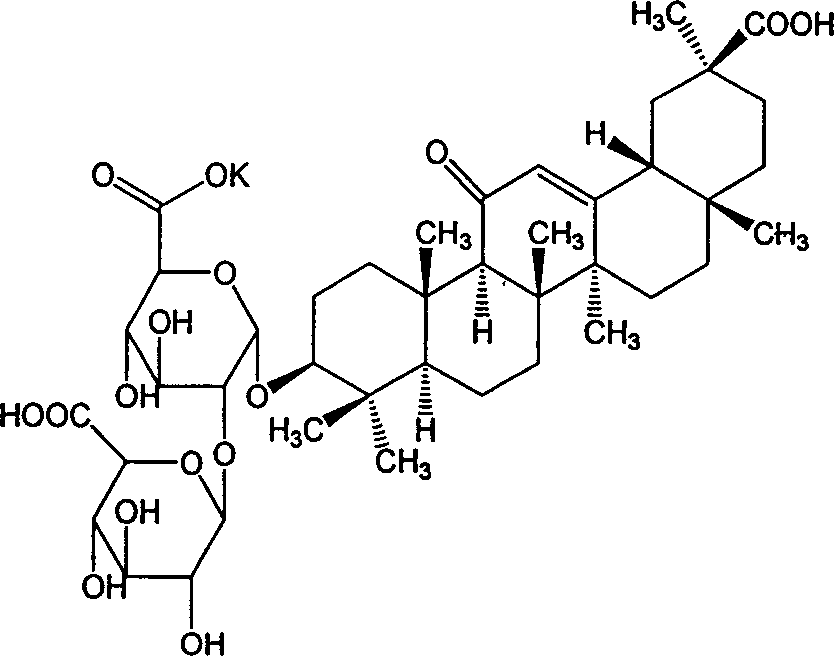

Film-coated tablet of glycyrrhizinic acid monopotassiium salt and method for preparing the same

InactiveCN1827115ALess affected by heatReduce breakageOrganic active ingredientsDigestive systemClinical efficacyLiver function

This is a glycyrrhizic single-sylvite film coating and its preparing method, which belongs to medicine technique field. Its characteristic is: it takes surbased glycyrrhizic single-sylvite plate, whose diameter is 0.8- 1.2cm as bullet base, and the bullet surface has a 0.3-0.9mm depth dressing material film coating, and the dressing material is damp-proofing. The manufacturing technique of glycyrrhizic single-sylvite film coating contains plate preparation and film coating preparation. This film coating is small, low cost, it has good damp-proofing, strong stability, it increases disintegration and dissolving rate of bullet, heightens biology availability and clinical curative effect. This glycyrrhizic single-sylvite film coating is available for auxiliary therapy in acute and chronic hepatic diseases and liver dysfunction patients, at the same time it relives the use limitation in diabetes patients.

Owner:山东山大康诺制药有限公司

LED support, LED luminescent device and LED display screen

PendingCN111354847AImprove welding effectYellowing directly affected by heatIdentification meansSemiconductor devicesLED displayEngineering

The invention discloses an LED support capable of emitting light from two sides. The LED support comprises a cup cover and metal pins. The cup cover comprises a reflection cup and a base. The number of the metal pins is more than two, all the metal pins are arranged at the same side of the cup cover; each metal pin comprises a chip placing section, a vertical welding section and a horizontal welding section, the chip placing section is arranged in the reflection cup, the vertical welding section is arranged at the outer side of the side surface of the base, and the horizontal welding section is arranged at the lower side of the bottom surface of the base. Meanwhile, the invention further provides an LED luminescent device and an LED display screen using the support. According to the invention, the metal pins of the original side light-emitting device are lengthened and bent and thus the tail ends of the metal pins can be arranged on the bottom surface of the base, so that the LED device is compatible with a side surface-mounted lamp and a back surface-mounted lamp; and the metal pins with good heat-conducting properties are arranged on the bottom surface of the base, so that the defects that the base is heated to become yellow and the stability of a product is influenced are overcome.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD

Friction stir welding method for ferritic/austenitic dissimilar steels

InactiveCN104400207BImprove performanceHigh strengthWelding/soldering/cutting articlesMetal working apparatusMetallic materialsEngineering

The invention relates to friction-stir welding method of ferrite / austenite dissimilar steel, and belongs to the technical field of welding of metal materials. The method comprises the steps that a ferrite steel plate and an austenite steel plate are fixed in an abutting-joint manner through a fixing device and are fixed to a friction-stir welding device through a clamp; the distance from a stirring head of the friction-stir welding device to an abutting-joint surface is set, that is, the offset amount and the shaft shoulder pushing amount are set; and the inclined angle, the rotating speed and the advancing speed of the stirring head are adjusted, and then welding is carried out. According to the method, in the welding process, heat input is small, an overheated area existing in fusion welding cannot be generated, and common defects, such as impurity blending and cold and heat cracks, do not exist. A welding joint with the more excellent performance can be obtained. The technology problem of welding of a dissimilar steel plate is solved.

Owner:UNIV OF SCI & TECH BEIJING

Laser cutting method and laser cutting device

ActiveCN110936027BTimely releaseLittle change in tackGlass severing apparatusLaser beam welding apparatusLaser cuttingErbium lasers

The invention discloses a laser cutting method, which is applied to the cutting operation of multi-layer composite materials, comprising the following steps: fixing and placing the cut piece on a cutting platform; 50W, the output pulse frequency is 200-2000kHz, the wavelength of the laser beam is 243-455nm; the laser beam is laser cut along the preset cutting line of the cut piece, and the cutting speed is 100-500mm / s . At the same time, the invention also discloses a laser cutting device capable of implementing the above laser cutting method. In the technical solution of the present invention, the laser cutting method is adopted to control the parameters of the laser cutting process, so that the heat-affected areas on both sides of the cut part along the cutting line are not heated up, the heat is small, and the heat can be released in time , to avoid the phenomenon that molten impurities infiltrate between layers due to the reduction of adhesion between layers, resulting in poor quality of cut products.

Owner:深圳市大族半导体装备科技有限公司

Nickel-base alloy coating for sealing surface of nuclear power valve and preparing method for nickel-base alloy coating

InactiveCN102534606BMeet the needs of the jobImprove high temperature performanceMetallic material coating processesPowder mixtureNuclear power

The invention discloses a nickel-base alloy coating for a sealing surface of a nuclear power valve, and is characterized in that the nickel-base alloy coating is prepared according to a method of conducting laser-cladding on nickel-base alloy powder. The nickel-base alloy powder comprises the following constituents by weight percent: 20.0 to 24.0 percent of Cr, 4.0 to 4.2 percent of Si, 3.0 to 3.5 percent of P, 3.0 to 3.2 percent of Mo, 8.0 to 8.5 percent of Fe, 1.0 to 1.2 percent of C, 0.8 to 1.0 percent of yttrium oxide, and Ni in balancing amount. The laser-cladding process adopts a synchronous powder feeding method and a pre-coating method. The nickel-base alloy powder mixture contains no noble metal Co, thereby particularly meeting requirements on valves under nuclear environments; and due to the formulation design of the mixture, and the advantage of the laser-cladding technology in coating preparing, the coating on the sealing surface has a favorable high-temperature property.

Owner:SUZHOU UNIV

Compound dantong tablet (film coating tablet for disorder of gallbladder) and its manufacturing method

InactiveCN1254256CLess affected by heatQuality improvementDigestive systemPharmaceutical delivery mechanismTherapeutic effectMagnesium stearate

The invention discloses a compound Dantong tablet (film-coated tablet) combined with Chinese and Western medicines and a preparation method thereof. Said compound Dantong tablets (film-coated tablets) are made of Dantong, Xihuangcao, Junchen, Andrographis paniculata, rhubarb, starch, magnesium stearate, and then filmed with special moisture-proof Opadry. Made with coating. The preparation method of the compound Dantong tablet (film-coated tablet) comprises a traditional Chinese medicine preparation process, a tablet core production process, and a film-coated coating process. The compound Dantong tablet (film-coated tablet) provided by the invention has stable quality, good therapeutic effect, low clinical dosage and is applicable to different patients. The preparation method has short production cycle, less auxiliary materials, low cost and high speed in the drying process, so that the medicine is less affected by heat and is beneficial to improve the quality of the medicine.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

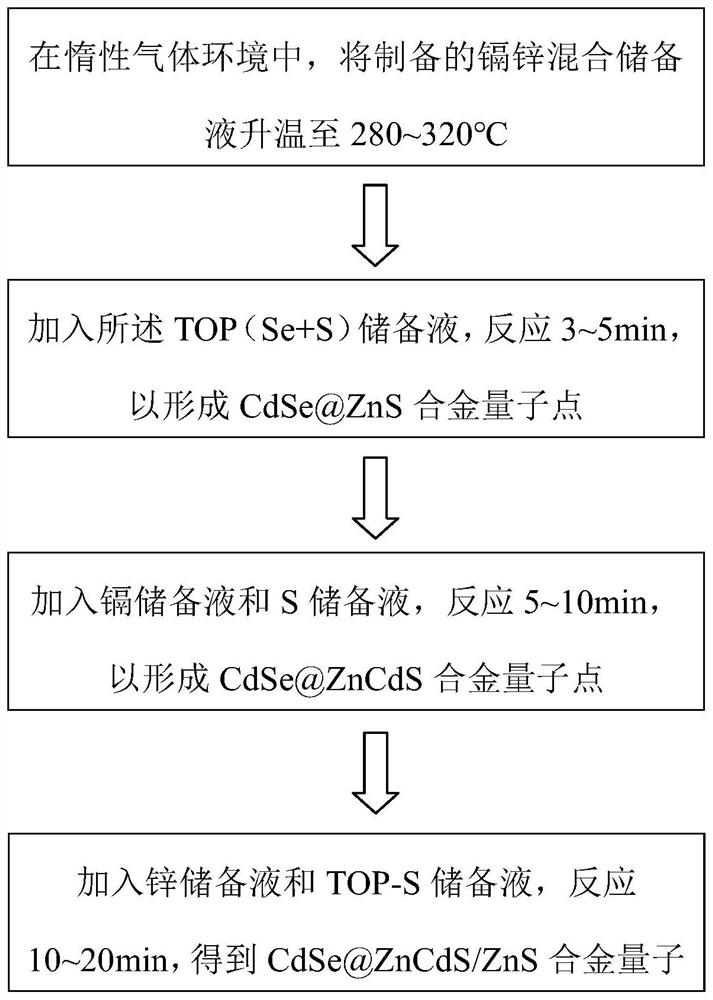

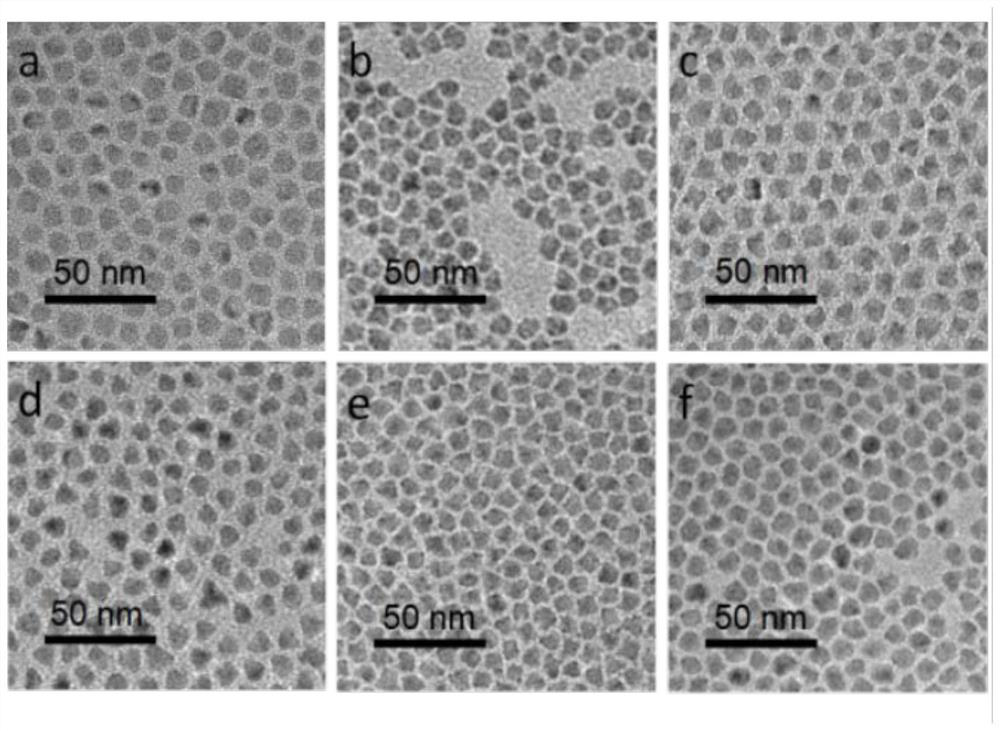

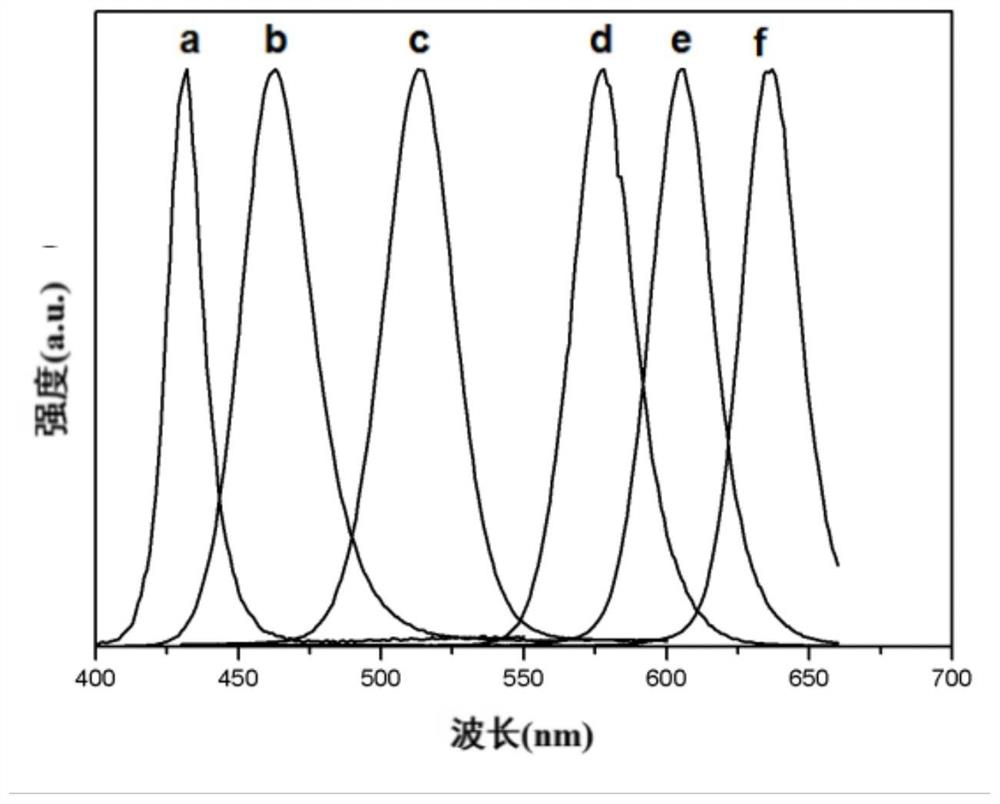

A kind of alloy quantum dot and preparation method thereof

ActiveCN107686731BHigh fluorescence quantum yieldGood optical stabilityLuminescent compositionsQuantum dotParticle physics

The invention discloses an alloy quantum dot and a preparation method thereof. By adjusting the potential barrier of the intermediate interface, the peak position of the emission light can be effectively adjusted without changing with the growth of the size of the quantum dot, so as to realize the peak position of the light emission on a specific requirement. The particle size can be continuously adjusted to meet the requirements of the quantum dot size; by adjusting the ratio of the alloy composition, the emission wavelength can be continuously adjusted under the same particle size; by adjusting the quantum dot interface barrier and element ratio , realizing the continuous change of emitted light from blue-violet light to deep red light. The preparation process of the alloy quantum dot is simple, the cost is low, and it is easy to be industrially prepared on a large scale. The prepared alloy quantum dot has high optical stability and thermal stability, and has a good application prospect in the field of QLED backlight display and lighting.

Owner:TIANJIN ZHONGHUAN QUANTUM TECH CO LTD

Process for preparing film coated brain-invigorating kidney-tonifying pills

ActiveCN1332704CChemically stableNo physiological toxicityNervous disorderAnthropod material medical ingredientsMedicinal herbsForsythia

The invention relates to a process for preparing film coated brain-invigorating kidney-tonifying pills, wherein the pills are prepared from the following Chinese medicinal herbs: gen-seng, hairy deerhorn, dog's penis, Cinnamomum cassia, lysimachia christinae, arctium fruit, cherokee rose, eucommia bark, achyranthes and cyathula root, honeysuckle flower, capsule of weeping forsythia, cicada shell, rhizoma dioscoreae, polygala root, wild jujuba seeds, amomum fruit, Chinese angelica root, dragon's bone, oyster shell, poria cocos, white atractylodes rhizome, cassia twig, licorice root, root of herbaceous peony and cardamorn.

Owner:RONGCHANG PHARM ZIBO CO LTD

Pneumatic clamp

ActiveCN103410884BShortcut structureSimple structureDrum brakesBrake actuating mechanismsForcepsBellows

Owner:KEDE NUMERICAL CONTROL CO LTD

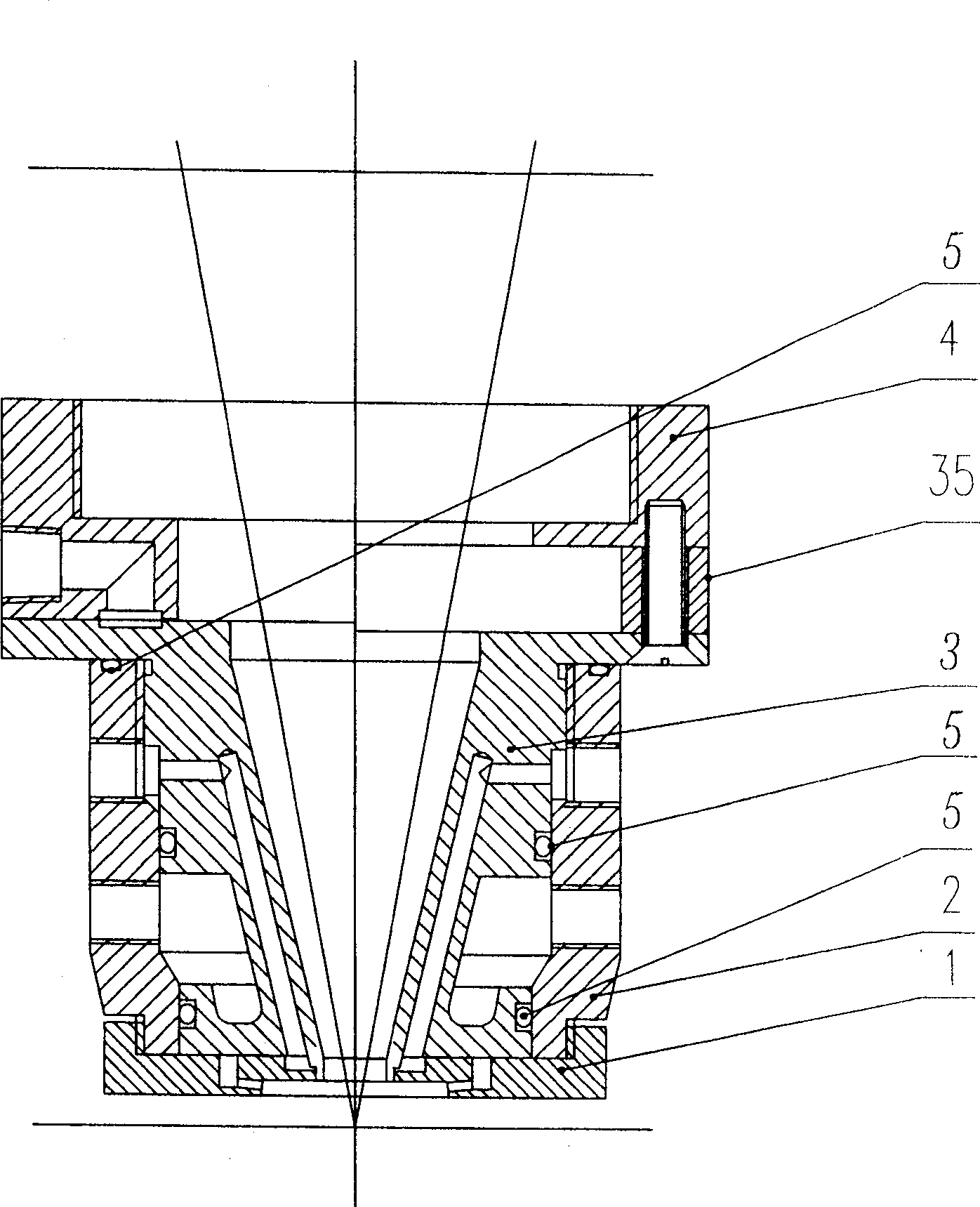

A high power laser welding head

InactiveCN100525985CLess affected by heatReasonable designLaser beam welding apparatusChemical industryAviation

A high-power laser welding head includes a guiding plate, an outer cover, an inner cover and a joint, the circumference of the guiding plate is arranged with screw thread which is connected with the sole cover of the outer cover, the center of the guiding plate is arranged with a light-pervious hole, an inner air ring and an outer air ring, the inner air ring is connected with the outer air ring with an air course and is butt-jointed with the lower end of the air course of the inner cover, the outer air ring is communicated with one end of the nozzle and the other end of the nozzle is communicated with the light-pervious hole. The present invention has the advantages of reasonable designing, compact structure, convenient installing, little maintenance amount, simple operation, small heating effect of the laser welding head as the forced cooling of air cooling and water cooling are simultaneously provided, adapting for the long-time work, insulating the welding zone from the outer air as the strong-unreactive shielding gas is sprayed during operation, smooth welding, small welding seam width, small heat affected zone, high welding efficiency, good effect, completing the fine welding which can not realized in the traditional technique, and wide adopting industries, the invention can be adopted in various industries of machine manufacturing, rubber plastic product, petroleum chemical industry, watercraft and submarine manufacturing, water conservancy and electric power, aviation and spaceflight, apparatus and instrument, communication and artwork, etc.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

A high-speed, high-precision five-axis ultrasonic machining machine tool

ActiveCN107234445BReduce wearIncrease stiffnessOther manufacturing equipments/toolsElectricityClosed loop feedback

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com