A kind of alloy quantum dot and preparation method thereof

A technology of quantum dots and alloys, applied in the field of alloy quantum dots and their preparation, can solve the problems of complex preparation process of core-shell quantum dots, time-consuming and laborious, and difficulty in applying white light QLEDs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

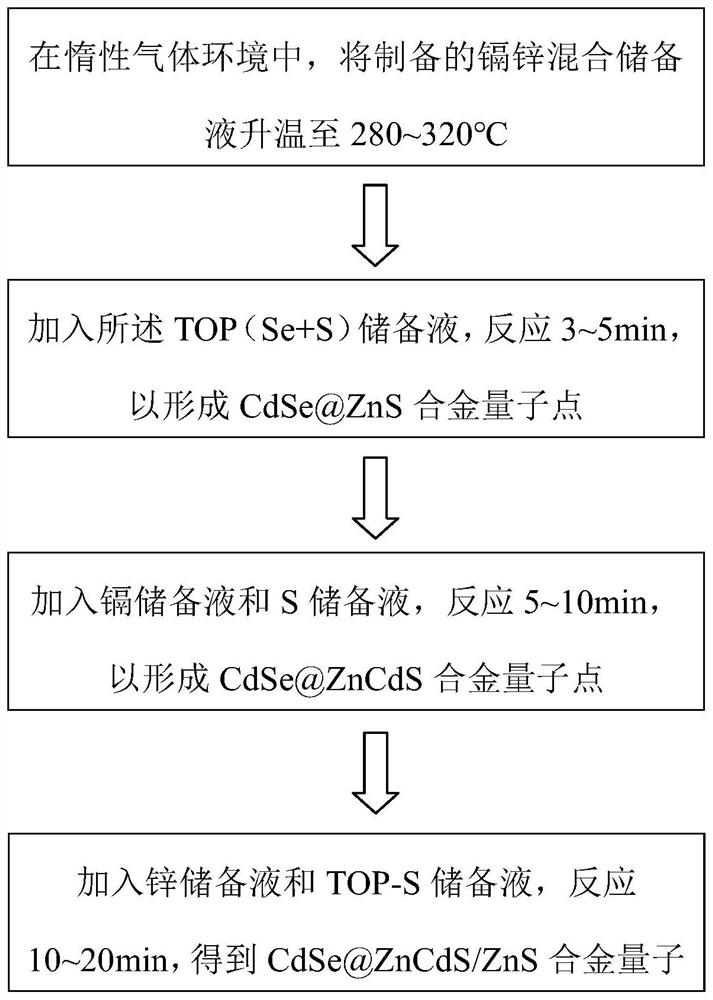

Method used

Image

Examples

Embodiment 1

[0034] Get 0.1mmol Se powder and 4mmol S powder and dissolve in 1.5mL trioctylphosphine under the protection of an inert gas to prepare a TOP (Se+S) stock solution, in the TOP (Se+S) stock solution, the Se: S mole The ratio is 1:40.

[0035] Take 0.0256g of cadmium oxide, 0.878g of zinc acetate, 5mL of oleic acid, and 15mL of octadecene in a round-bottomed flask, and raise the temperature to 200-300°C for 0.5h under the protection of an inert gas to prepare a mixed stock solution of zinc and cadmium. Raise the temperature to 280-320° C., add the above TOP (Se+S) stock solution, and grow at 290-310° C. for 3-10 minutes to obtain CdSe@ZnS alloy quantum dots.

[0036] Take 0.256g of cadmium oxide, 2mL of oleic acid and 2mL of octadecene and raise the temperature to 200-300°C under the protection of inert gas to prepare a cadmium stock solution. Take 0.176g of zinc acetate, 4mL of oleic acid and 4mL of octadecene under the protection of inert gas Raise the temperature to 200-300°...

Embodiment 2

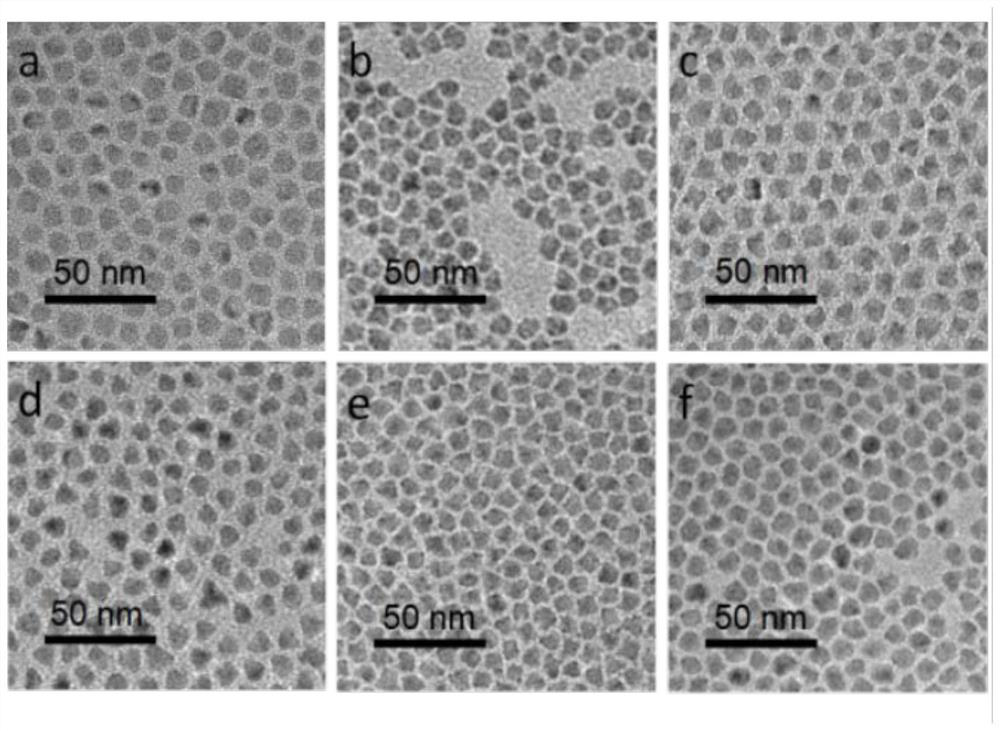

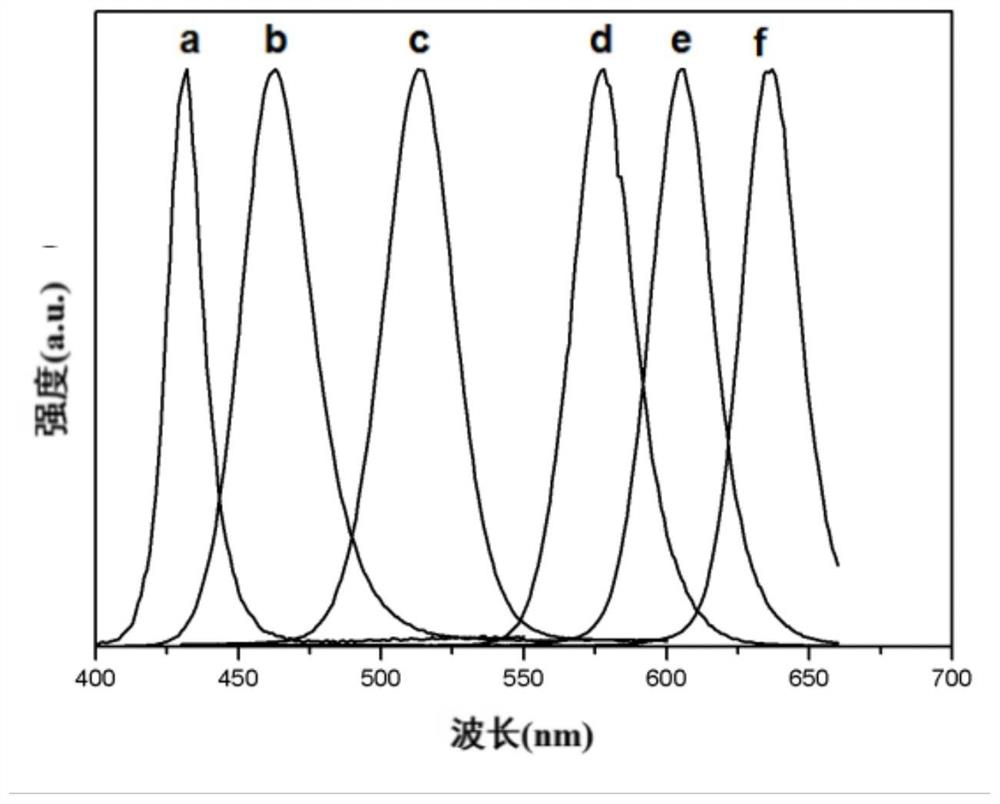

[0041] Get alloy quantum dot a, alloy quantum dot b, alloy quantum dot c, alloy quantum dot d, alloy quantum dot e and alloy quantum dot f in embodiment 1, its transmission electron microscope figure is as figure 2 As shown, the emission spectrum is shown as image 3 shown. according to figure 2 and image 3 It is known that the average quantum dot size and the corresponding fluorescence peak position corresponding to different alloy quantum dots are respectively: alloy quantum dot a corresponds to 8.3nm and 431nm, alloy quantum dot b corresponds to 8.3nm and 462nm, alloy quantum dot c corresponds to 8.4nm and 514nm, alloy quantum dot d corresponds to 8.1nm and 575nm, alloy quantum dot e corresponds to 8.2nm and 606nm, alloy quantum dot f corresponds to 8.5nm and 638nm. From the data results, it can be concluded that the average size of the six alloy quantum dots is in the range of 8.3±0.3nm, but the position of the fluorescence emission peak changes with the change of th...

Embodiment 3

[0043] Get 0.1mmol Se powder and 0.4mmol S powder and dissolve in 2mL trioctylphosphine under the protection of an inert gas to prepare a TOP (Se+S) stock solution, in the TOP (Se+S) stock solution, the Se:S mole The ratio is 1:4, take 0.0256g of cadmium oxide, 0.878g of zinc acetate, 5mL of oleic acid, and 15mL of octadecene in a round-bottomed flask, and raise the temperature to 200-300°C for 0.5h under the protection of an inert gas to prepare zinc Mix cadmium stock solution, then raise the temperature to 280-320°C and add the above TOP(Se+S) stock solution, grow at 290-310°C for 3-10min to obtain CdSe@ZnS alloy quantum dots, then add cadmium stock solution and S stock solution Liquid reaction 5-20min, then add zinc stock solution and TOP-S stock solution, react 10-20min to obtain alloy quantum dot A, described cadmium stock solution, S stock solution, zinc stock solution and TOP-S stock solution and embodiment 1 is the same. Adjusting the addition of Se powder and S powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com