Film-coated tablet of glycyrrhizinic acid monopotassiium salt and method for preparing the same

A technology of glycyrrhizic acid monopotassium salt and film-coated tablets, which is applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, and pill delivery, etc. Uniformity, sugar-coated tablets take a long time to produce and other problems, to achieve the effect of improving bioavailability, improving appearance and stable properties of the main drug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

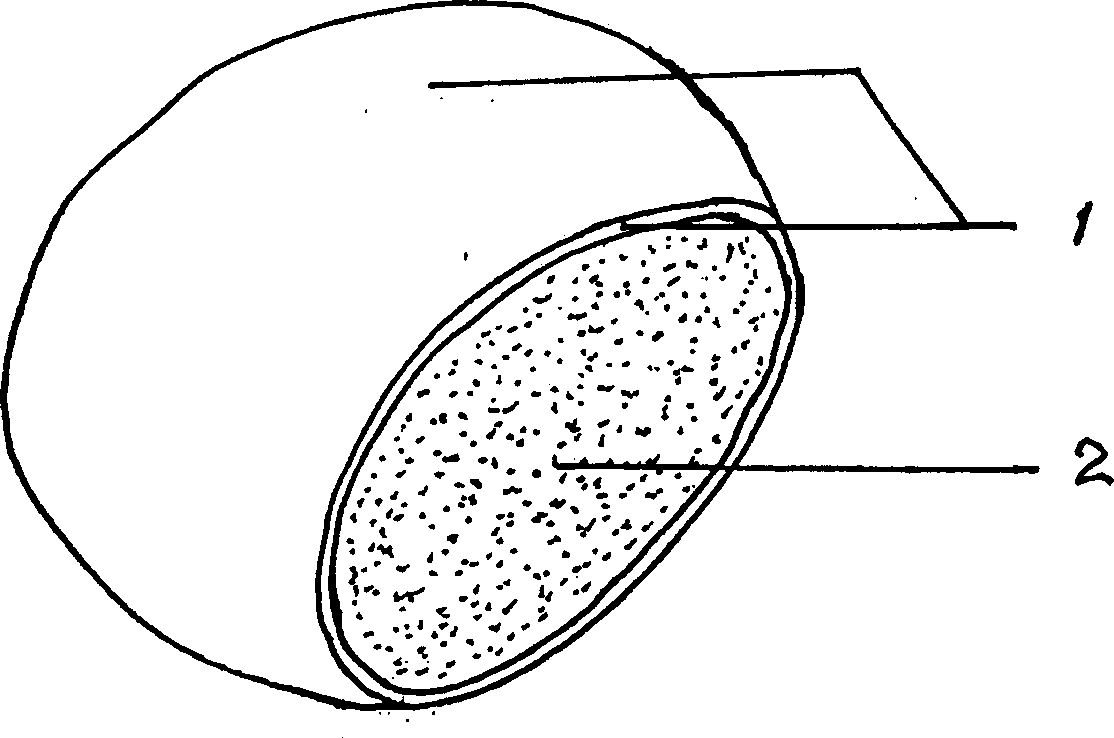

[0030] Glycyrrhizinic acid monopotassium salt film-coated tablet, with oblate glycyrrhizic acid monopotassium salt tablet with a diameter of 0.8-1.0 cm as the tablet base, the surface of the tablet is spray-coated with a layer of coating material film-coating layer with a thickness of 0.4-0.5 mm.

[0031] The components of the monopotassium glycyrrhizinate tablet are as follows: monopotassium glycyrrhizinate 5g, starch 50g, sucrose 40g, micronized silica gel 5g, magnesium stearate 120g, sodium carboxymethyl starch 130g, sodium lauryl sulfate 50g, 150g of talcum powder, 6g of alcohol 50% by volume. Coating material Opadry 100.0g was added with 900ml of ethanol with a volume percentage of 80% to make slurry.

[0032] The preparation method is as follows:

[0033] Preparation of oblate monopotassium glycyrrhizic acid tablets with a diameter of 0.8 to 1.0 cm: (1) crushing and sieving: the main drug monopotassium glycyrrhizic acid was passed through a 100 mesh sieve, magnesium ste...

Embodiment 2

[0036] Glycyrrhizic acid monopotassium salt film-coated tablet, with oblate glycyrrhizic acid monopotassium salt tablet with a diameter of 0.9-1.1 cm as the tablet base, the surface of the tablet is spray-coated with a layer of coating material film-coating layer with a thickness of 0.5-0.6 mm. (Such as figure 1 shown)

[0037] The components of the monopotassium glycyrrhizinate tablet are as follows: monopotassium glycyrrhizinate 8g, starch 80g, sucrose 70g, micropowder silica gel 8g, magnesium stearate 150g, sodium carboxymethyl starch 170g, sodium lauryl sulfate 80g, 180g of talcum powder, 8g of alcohol 50% by volume. 200.0 g of the coating material Opadry was mixed with 2000 ml of 80% ethanol by volume.

[0038] The preparation method is as follows:

[0039] Preparation of oblate monopotassium glycyrrhizic acid tablets with a diameter of 0.9 to 1.1 cm: (1) crushing and sieving: the main drug monopotassium glycyrrhizic acid was passed through a 100 mesh sieve, magnesium st...

Embodiment 3

[0042] Glycyrrhizic acid monopotassium salt film-coated tablet, with oblate glycyrrhizic acid monopotassium salt tablet with a diameter of 1.0-1.15 cm as the tablet base, the surface of the tablet is spray-coated with a layer of coating material film-coating layer with a thickness of 0.6-0.7 mm.

[0043] The components of the monopotassium glycyrrhizic acid tablet are as follows: monopotassium glycyrrhizinate 10g, starch 100g, sucrose 100g, micronized silica gel 10g, magnesium stearate 200g, sodium carboxymethyl starch 200g, sodium lauryl sulfate 100g, talcum powder 200g, 50% alcohol by volume percentage 10g. Coating material Opadry 300.0g, add 3600ml of ethanol with a volume percentage of 80% to prepare slurry.

[0044] The preparation method is as follows:

[0045] Preparation of oblate monopotassium glycyrrhizic acid tablets with a diameter of 1.0 to 1.15 cm: (1) crushing and sieving: the main drug monopotassium glycyrrhizic acid was passed through a 100 mesh, magnesium st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com