Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Excellent long-term heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Granular polyurethane resin composition and molded article of the same

InactiveUS20100227985A1Fusion wellImprove production efficiencyVehicle componentsCoatingsThermoplastic polyurethanePolymer chemistry

Disclosed is a granular polyurethane resin composition containing a thermoplastic polyurethane resin which contains a hard segment obtained by a reaction between a polyisocyanate and a chain extender. The polyisocyanate contains isocyanate groups of 1,4-bis(isocyanatomethyl)cyclohexane in an amount of not less than 50% by more relative to the total mole number of isocyanate groups.

Owner:MITSUI CHEM INC

Heat-curable powder coating composition

InactiveUS20090270533A1Excellent long-term heat resistanceOutstanding flexibilityAnti-corrosive paintsEpoxy resin coatingsPolymer sciencePolymer chemistry

Disclosed is a heat-curable powder coating composition that allows the formation of a coating film having outstanding long-term corrosion resistance, as well as outstanding chipping resistance, flexibility, and adhesion.The disclosed heat-curable powder coating composition is characterized by a resin having crosslinkable functional groups that are solid at room temperature (A), a curing agent capable of reacting with said crosslinkable functional groups (B), a fibrous filler (C), and heat-expandable resin particles (D).

Owner:BASF COATINGS JAPAN

Raw materials for preparing corrugated dual-wall hard PVC pipe

InactiveCN1346844AImprove the lubrication effectExcellent long-term heat resistanceParaffin waxPolyvinyl chloride

A material used for making hard corrugated PVC pipe is prepared from PVC (100 pts.wt.), trisalt (6.4-6.8 pts.wt.), lead stearate (0.42-0.47 pts.wt.), barium stearate (1.4-1.7 pts.wt.), stearic acid (0.42-0.47 pts.wt.), microcrystal paraffin (0.36-0.41 pts.wt.), polyvinyl wax (0.58-0.62 pts.wt.), ACR (401) (1.9-2.1 pts.wt.), chlorinated polyethylene (5.8-6.3 pts.wt.), superfine calcium carbonate (9-11 pts.wt.) and AC 316 (0.28-0.33 pts.wt.). Its advantages are high lubricating performance, impact strength, ring rigidity and Vicat softening temp, good demoulding nature, and excellent low-temp plasticity.

Owner:SINOMACH GENERAL MACHINERY SCIENCE & TECHNOLOGY CO LTD

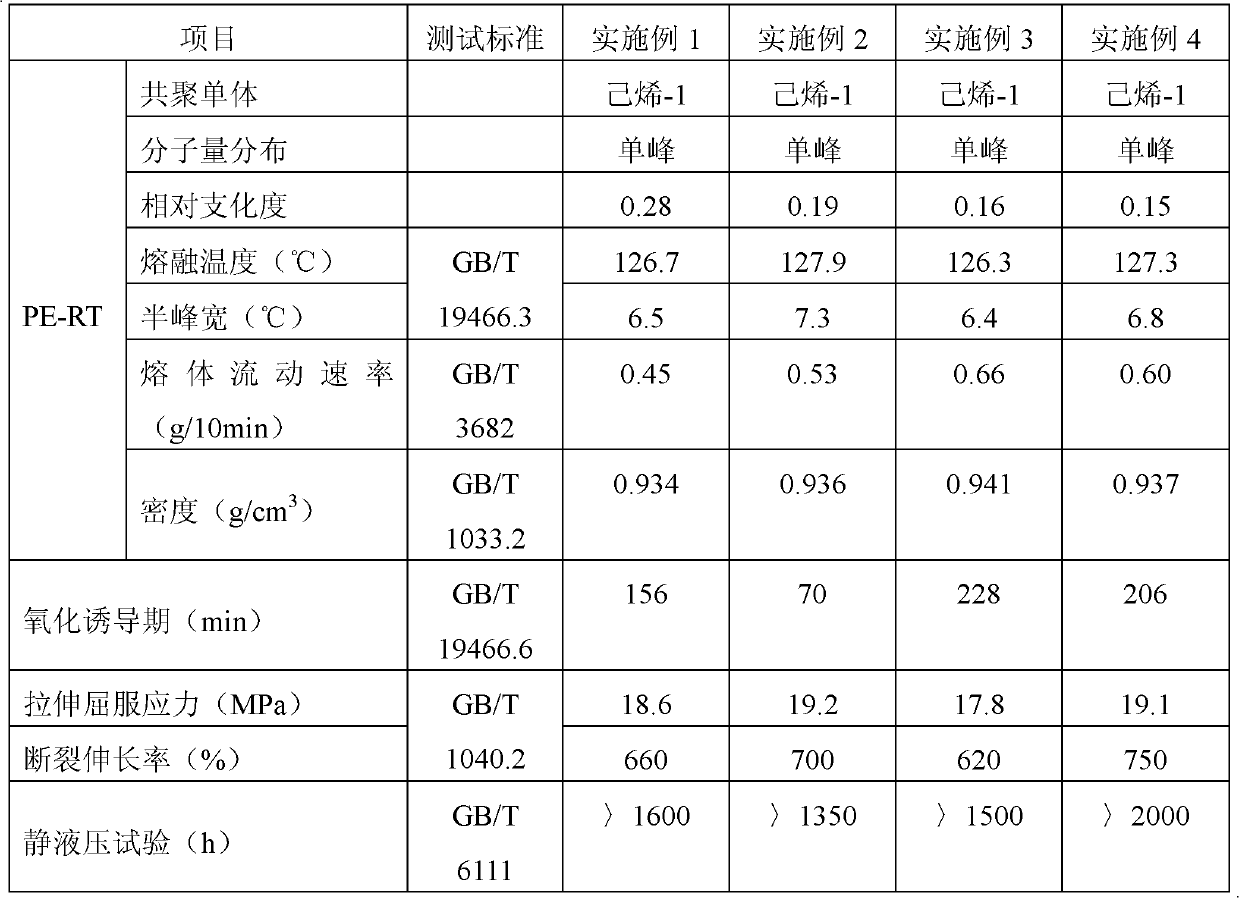

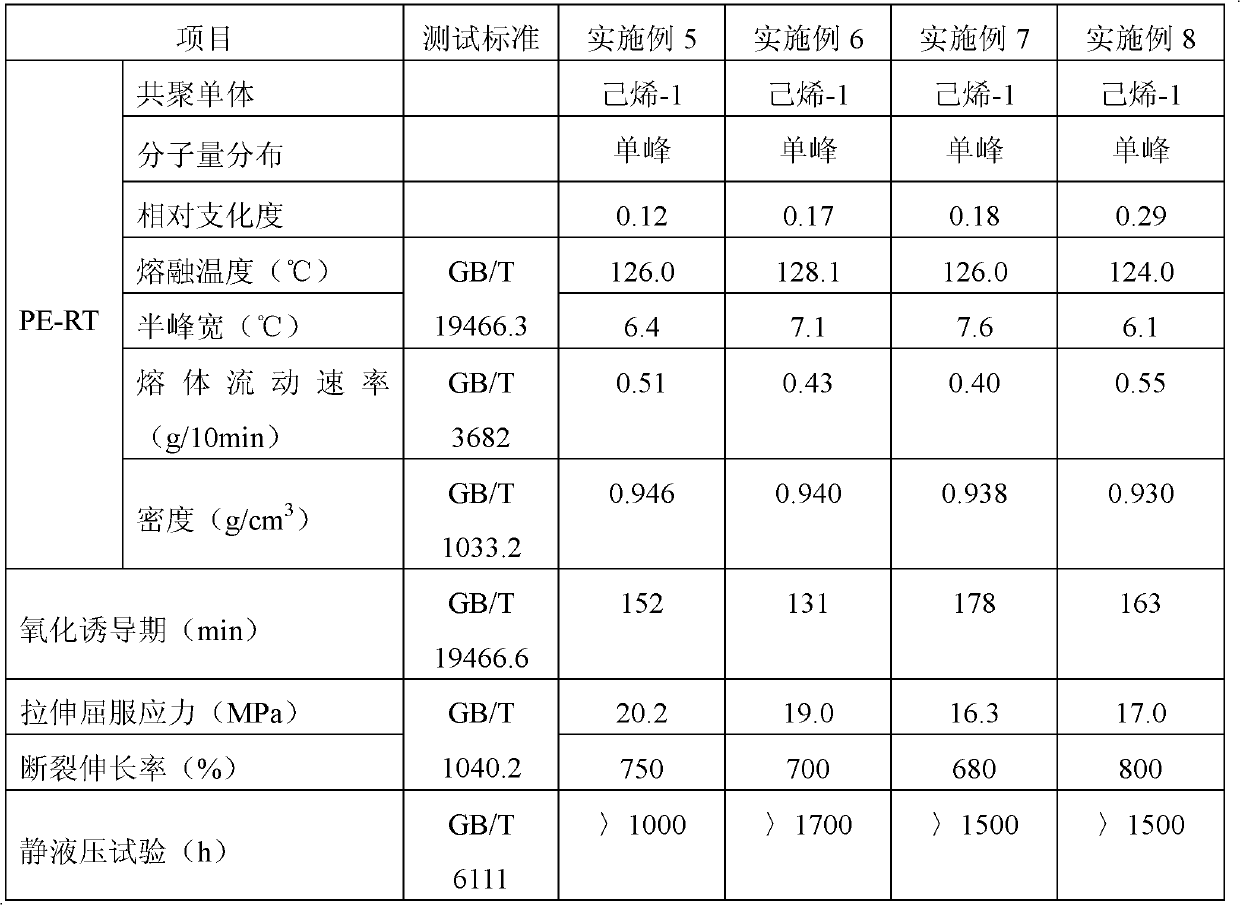

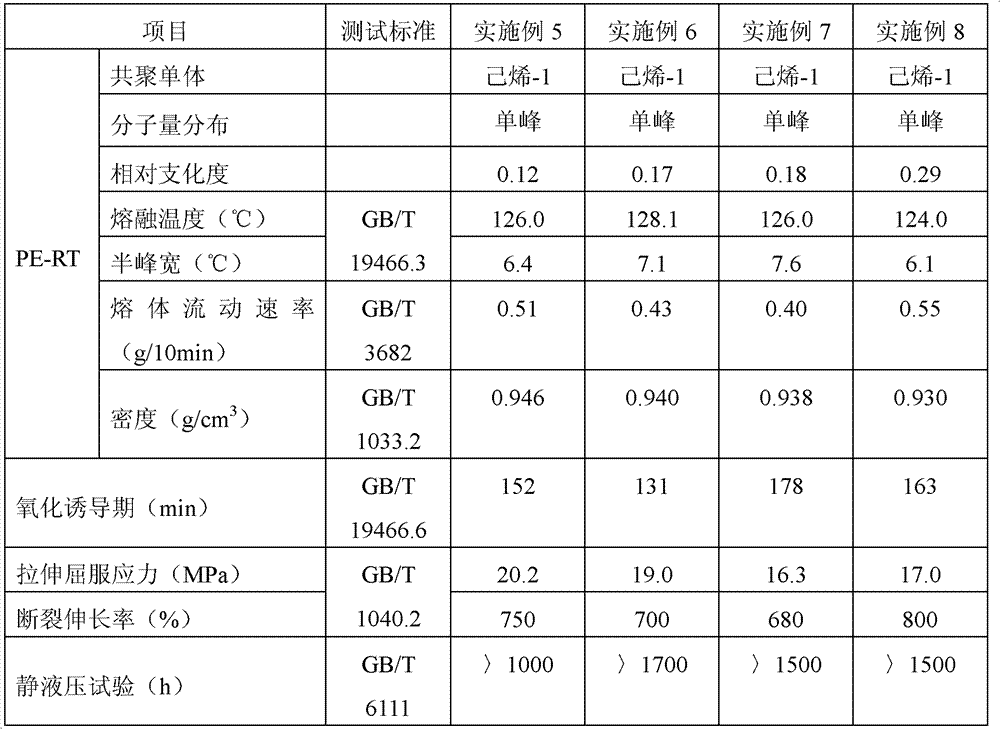

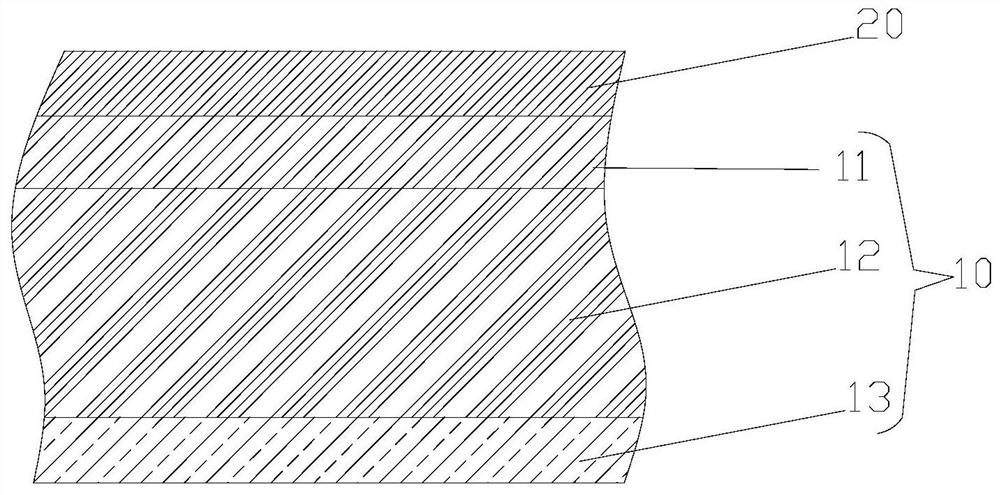

PE-RT (polyethylene of raised temperature resistance) composition and application thereof

ActiveCN102952323AExcellent long-term heat resistanceImprove oxidation resistanceFlexible pipesPhenolMechanical property

The invention relates to a PE-RT (polyethylene of raised temperature resistance) composition and application thereof, belonging to the field of polyethylene pipelines. The PE-RT composition is characterized by comprising the following components in parts by weight: 100 parts of PE-RT and 0.1-1.5 parts of antioxidant, wherein the PE-RT is an ethylene-hexene-1 copolymer which has a density of 0.926-0.950 g / cm<3>, a melt flow rate of 0.1-2 g / 10min (190 DEG C, 2.16Kg of weights), unimodal molecular weight distribution and a relative branching degree of 0.08-0.50; and the antioxidant comprises a hindered phenol antioxidant and a phosphite antioxidant. According to the invention, the PE-RT composition having excellent mechanical properties, high-temperature creep resistance, heat aging resistance and extrusion processability is prepared from the heat-resistant ethylene-hexene copolymer, the antioxidant and other components, thereby further improving the practical performance of PE-RT pipe products. Thus, the PE-RT composition can be used for the preparation of pipe products and pipe fittings for a hot water pipeline system.

Owner:CHINA PETROLEUM & CHEM CORP

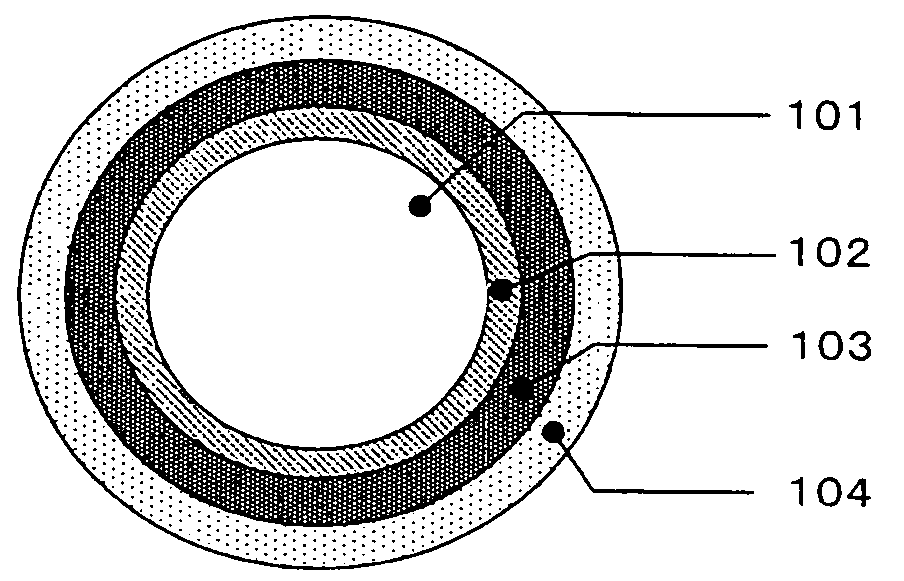

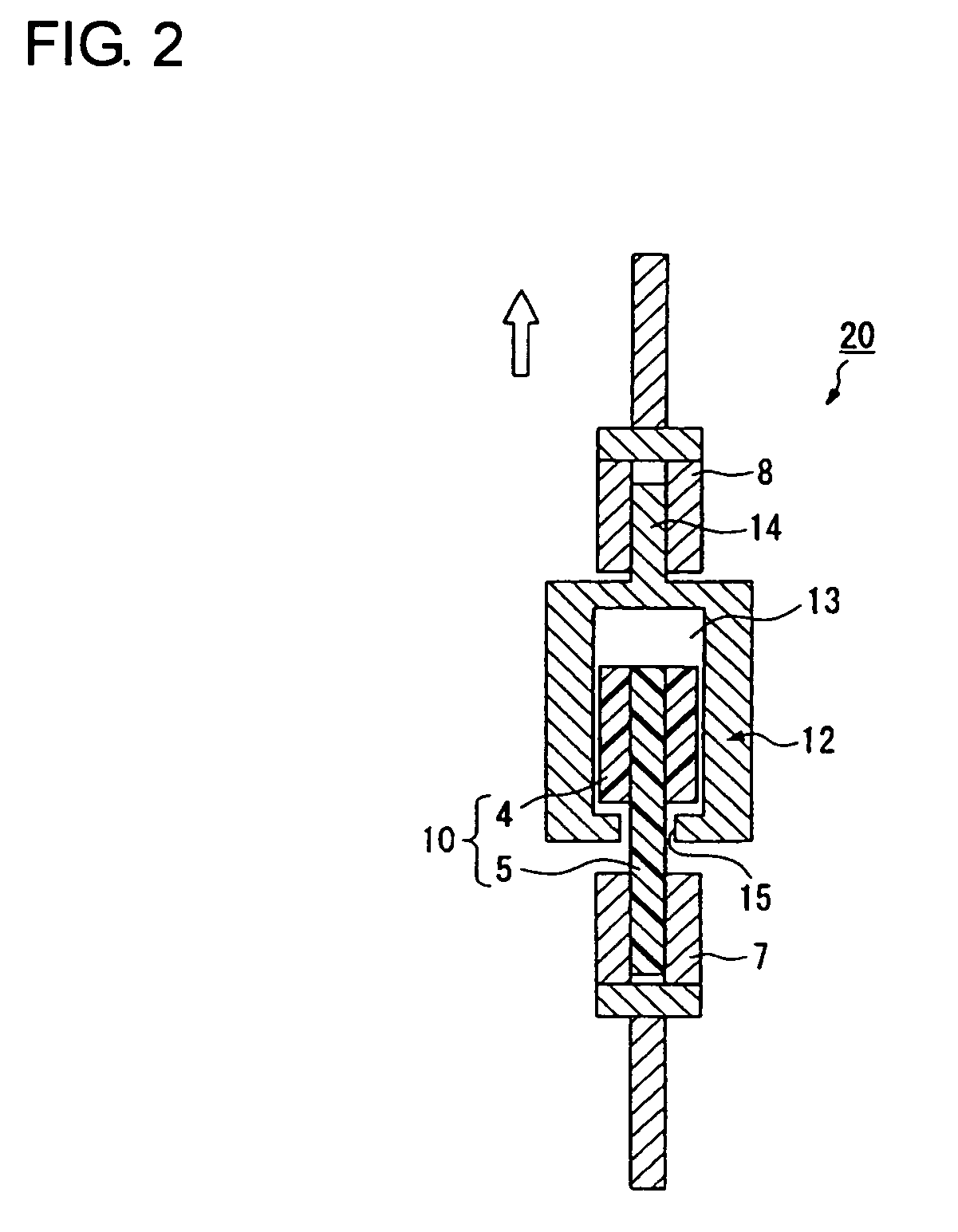

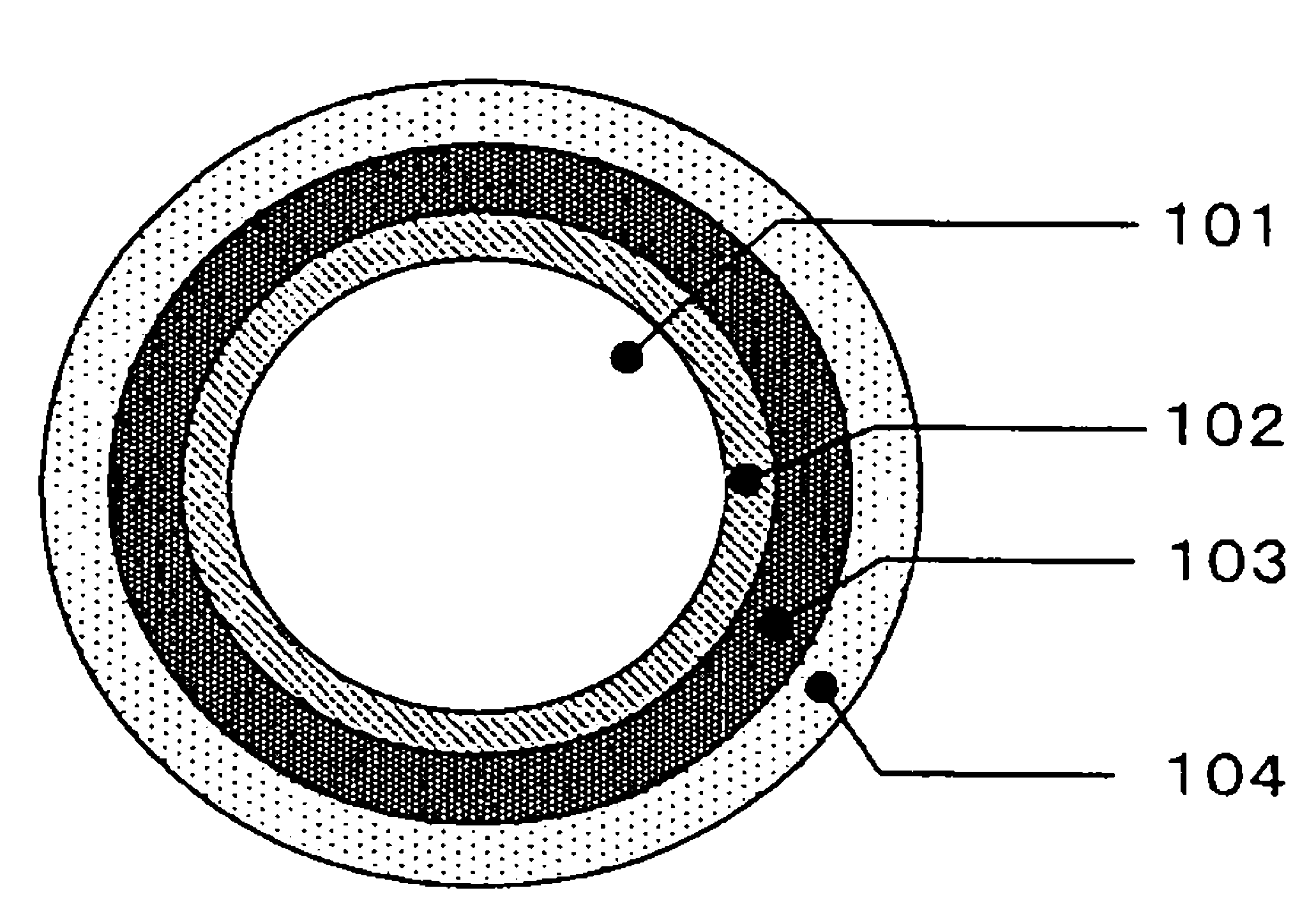

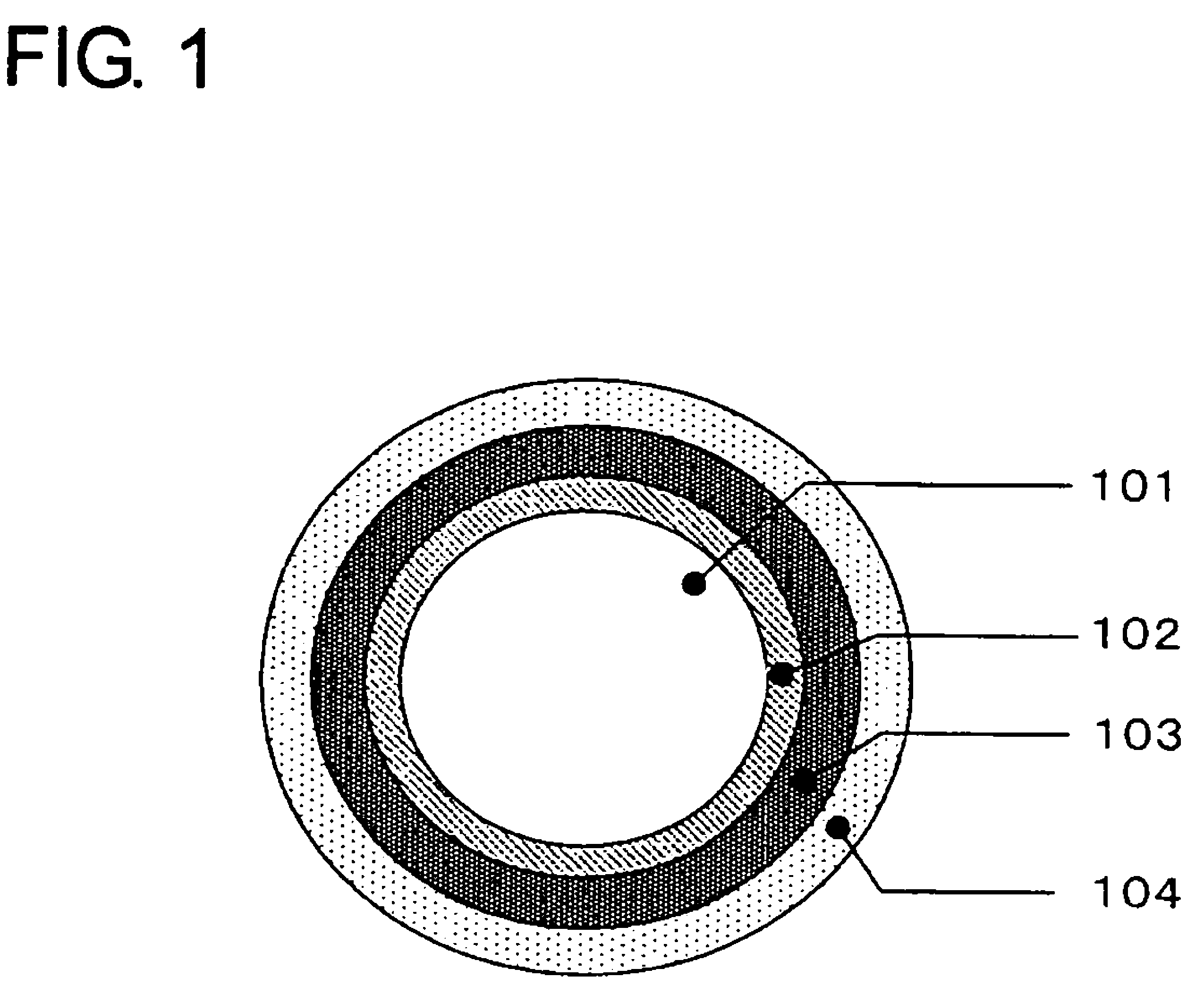

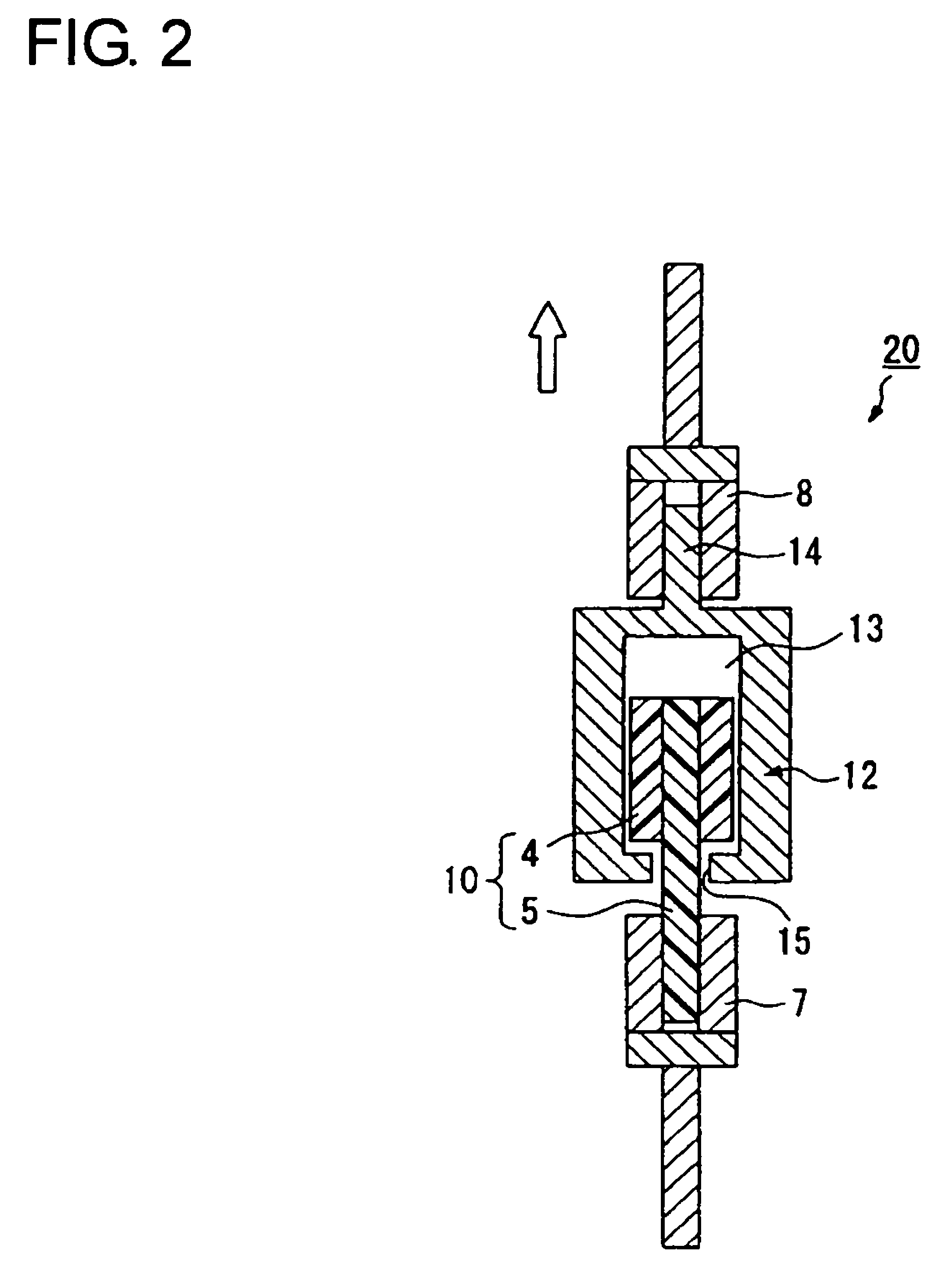

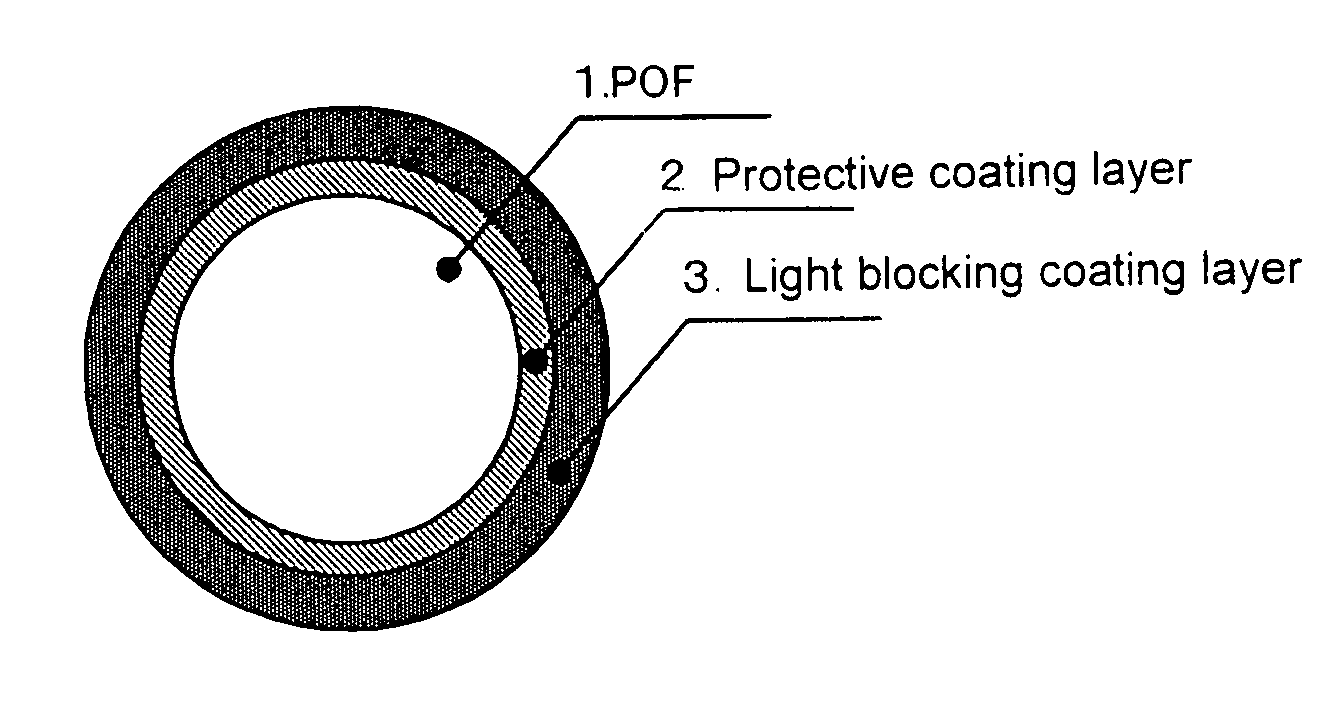

Plastic optical fiber cable and method of signal transmission using the same

ActiveUS20090279837A1Improve transmission lossExcellent long-term heat resistanceOptical fibre with multilayer core/claddingFibre mechanical structuresBare fiberPolymethyl methacrylate

A plastic optical fiber cable includes: a bare optical fiber including a core made of a poly(methyl methacrylate) or a copolymer including methyl methacrylate as a major component and a cladding layer including, at least in the outermost layer, a layer made of a certain fluorine-containing olefin-based resin; and a coating layer provided on the outer surface thereof. The coating layer includes a protective coating layer, a light blocking coating layer, and a functional coating layer, the layers being provided in the order mentioned from inner side. The protective coating layer is made of a certain resin material. The light blocking coating layer is made of a nylon-based resin including, as a major component, nylon 11 or nylon 12, the nylon-based resin containing monomer and oligomer compounds derived from the nylon-based resin in an amount of a certain range. The functional coating layer is made of a nylon-based resin composition having a crystalline melting point within a certain range, the nylon-based resin composition containing a certain amount of melamine cyanurate or bromine atoms and further containing a certain amount of inorganic chromatic pigments, or the layer is made of a nylon-based resin composition having a crystalline melting point of within a certain range and an oxygen transmission rate within a certain range.

Owner:MITSUBISHI CHEM CORP

Polyurethane resin composition for reaction injection molding and molded article

InactiveUS20100305294A1Good light fastnessExcellent long-term heat resistancePolymer chemistryReaction injection molding

Disclosed is a polyurethane resin composition for reaction injection molding, which contains an isocyanate component containing at least one of an alicyclic polyisocyanate and an aralkyl polyisocyanate and a trimer of hexamethylene diisocyanate, and a polyol component.

Owner:MITSUI CHEM INC

Plastic optical fiber cable and method of signal transmission using the same

ActiveUS8023789B2Improve transmission lossExcellent long-term heat resistanceOptical fibre with multilayer core/claddingFibre mechanical structuresPoly(methyl methacrylate)Engineering

Owner:MITSUBISHI CHEM CORP

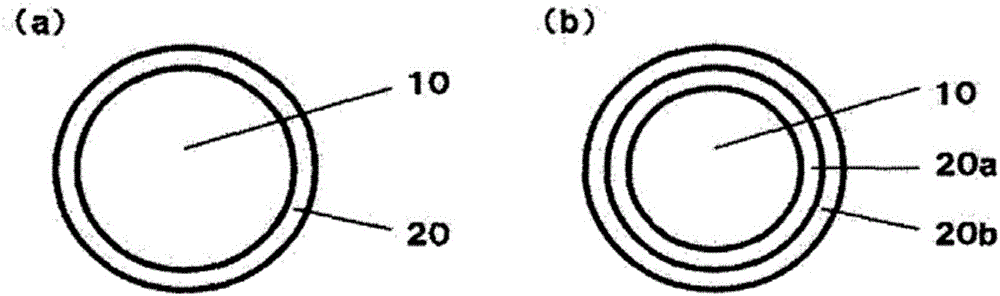

Plastic optical fiber cable

ActiveUS20090067794A1Excels in long-term heat resistanceSmall increase in transmission lossOptical fibre with multilayer core/claddingOptical waveguide light guideTetrafluoroethylenePolymer science

The invention provides a plastic optical fiber cable comprising a plastic optical fiber having a core / clad structure, a light blocking coating layer provided around the plastic optical fiber, and a protective coating layer provided between the outermost layer of the core / clad structure and the light blocking coating layer. The outermost layer of the core / clad structure is made of a fluorine-containing olefin polymer containing at least a tetrafluoroethylene unit, the crystal melting heat of the fluorine-containing olefin polymer being 59 mJ / mg or lower. The light blocking coating layer is made of a resin primarily containing a polyamide resin, the content of polyamide resin-derived monomers and oligomers being 1.5% by weight or lower.

Owner:MITSUBISHI CHEM CORP

Thermochromic polypropylene composition and its preparation method and use

The invention discloses a thermochromic polypropylene composition. The thermochromic polypropylene composition comprises, by weight, 95-99 parts of polypropylene resin and 0.5-3 parts of thermochromicmicrocapsules. The core of the thermochromic microcapsule is prepared from a triphenylmethane-metal complex and the wall of the thermochromic microcapsule is synthesized from formaldehyde and melamine through polymerization according to a mole ratio of 2.5 / 1 to 3 / 1. The preparation method of the thermochromic microcapsule comprises that formaldehyde and melamine undergo an addition reaction at pHof 7.5-8.5 to produce a methylol melamine prepolymer, a triphenylmethane-metal complex is dispersed in a sodium dodecyl sulfate aqueous solution with a concentration of 0.2-1.0 wt%, the methylol melamine prepolymer is added into the solution, the pH is adjusted to 5.5-6.5 so that a microcapsule emulsion is obtained, the microcapsule emulsion undergoes a reaction at 80-90 DEG C for 3h, and the reaction product is washed, is subjected to suction filtration and is dried so that the thermochromic microcapsule is obtained. The thermochromic polypropylene composition can resist heat in a long termand can be widely used in automobile dashboards, accessory dashboards, seats, door plates, bumpers or stand columns.

Owner:KINGFA SCI & TECH CO LTD +1

Plastic optical fiber cable

ActiveUS7609930B2Small increase in transmission lossExcellent long-term heat resistanceOptical fibre with multilayer core/claddingOptical waveguide light guideTetrafluoroethyleneOligomer

The invention provides a plastic optical fiber cable comprising a plastic optical fiber having a core / clad structure, a light blocking coating layer provided around the plastic optical fiber, and a protective coating layer provided between the outermost layer of the core / clad structure and the light blocking coating layer. The outermost layer of the core / clad structure is made of a fluorine-containing olefin polymer containing at least a tetrafluoroethylene unit, the crystal melting heat of the fluorine-containing olefin polymer being 59 mJ / mg or lower. The light blocking coating layer is made of a resin primarily containing a polyamide resin, the content of polyamide resin-derived monomers and oligomers being 1.5% by weight or lower.

Owner:MITSUBISHI CHEM CORP

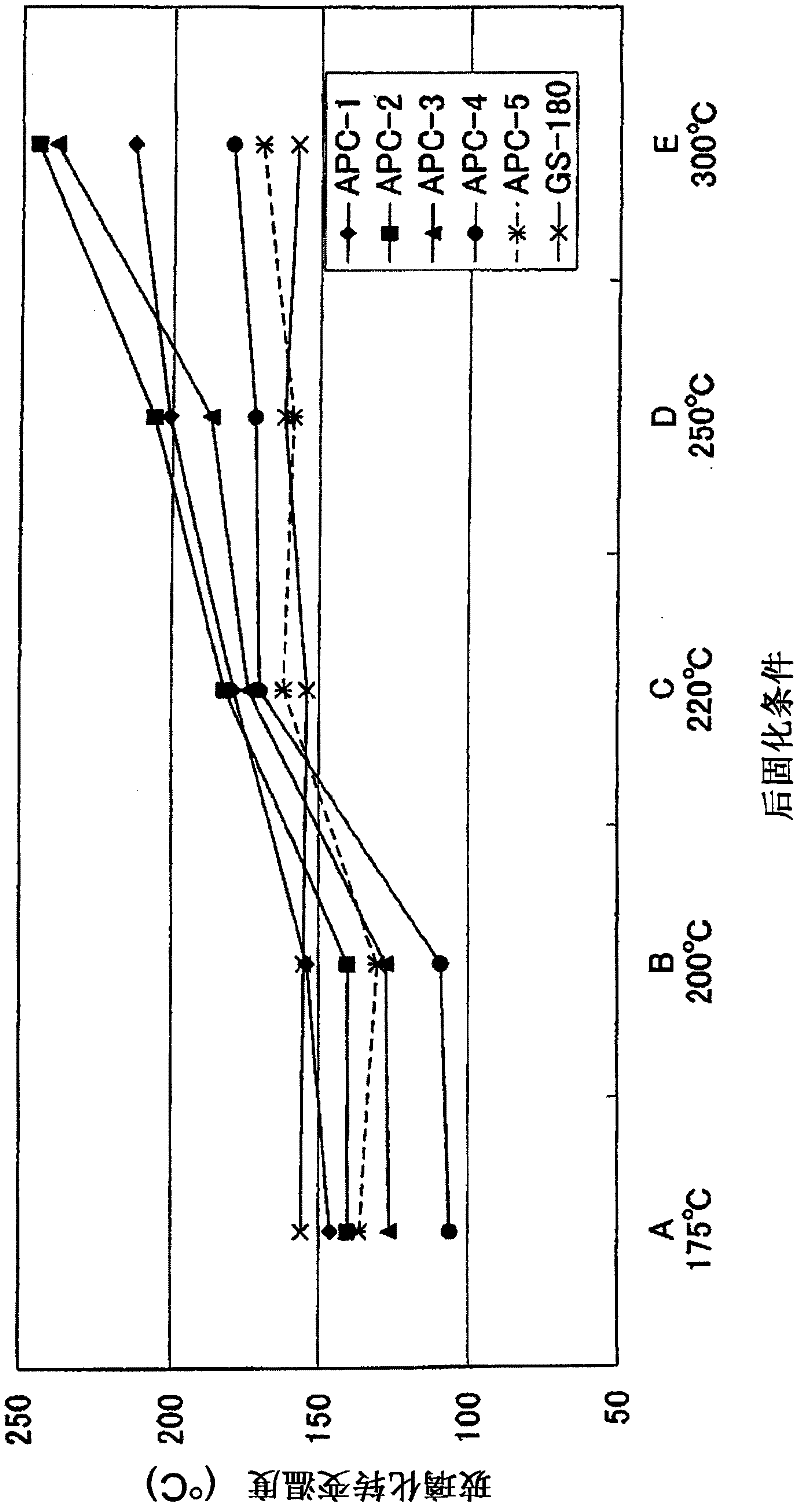

Method for manufacturing cured product of thermosetting resin composition and cured product obtained thereby

InactiveCN102372835AHigh glass transition temperatureExcellent long-term heat resistanceSemiconductor devicesEpoxyChemistry

The present invention relates to a method for producing a cured product of a thermosetting resin composition and a cured product obtained thereby. The method includes: heating a thermosetting resin composition including the following ingredients (A) to (C) at a temperature of 100 to 200 DEG C for 1 to 60 minutes; and then further heating the thermosetting resin composition at a temperature of 220 to 350 DEG C for 10 to 6,000 minutes, thereby curing the thermosetting resin composition: (A) an allyletherified phenol resin; (B) an epoxy resin; and (C) a curing accelerator.

Owner:NITTO DENKO CORP

Method for manufacturing cured product of thermosetting resin composition and cured product obtained thereby

InactiveCN102372836AHigh glass transition temperatureExcellent long-term heat resistanceSemiconductor/solid-state device detailsSolid-state devicesPhenolChemistry

The present invention relates to a method for producing a cured product of a thermosetting resin composition and a cured product obtained thereby. The method includes: heating a thermosetting resin composition including the following ingredients (A) to (C) at a temperature of 100 to 200 DEG C for 1 to 60 minutes; and then further heating the thermosetting resin composition at a temperature of 220 to 350 DEG C for 10 to 6,000 minutes, thereby curing the thermosetting resin composition: (A) an allylated phenol resin; (B) an epoxy resin; and (C) a curing accelerator.

Owner:NITTO DENKO CORP

Material special for modified polypropylene loose tubes

The invention discloses a material special for modified polypropylene loose tubes. The material comprises, by weight, 80-90% of polypropylene, 3-9% of polyethylene, 5-15% of filling materials, 0.3-1% of antioxidant, 1-3% of nucleating agent, 0.1-0.6% of heat stabilizer, 0.1-1% of lubricating agent, 0.1-1% of oil resistant penetrant, and 0.1-1% of anti coagulation agent. As the material special for the optical cable loose tubes, the material is high in hardness and toughness, good in extrusion performance and appropriate in extrusion press; optical fiber extra length is stably controllable; good processing stability can be provided at wide cable outlet speed, and good long-term heat resistance, pressure resistance and oil resistance are provided; molecular structure is modified via material rheological property and crystallization property, so that shrinkage is reduced, the optical fiber extra length is stably controlled; relative to PBT (polybutylece terephthalate), the material is good in hydrolytic stability, needless for drying before being extruded, and is convenient to use and cost-saving.

Owner:江阴爱科森博顿聚合体有限公司

Plastic optical fiber cable and method of transmitting signal

ActiveUS8422844B2Little increase in transmission-lossExcellent long-term heat resistanceOptical fibre with multilayer core/claddingElectromagnetic transmittersPolytetramethylene terephthalatePlastic optical fiber

A plastic optical fiber cable includes: a bare plastic optical fiber including a core formed of a polymer containing a methyl methacrylate unit, and a clad layer including a layer formed of a specific fluorine-containing olefin resin at least in the outermost layer; and a coating layer around the bare plastic optical fiber, the coating layer including a light-shielding coating layer formed of a specific nylon resin composition, a functional coating layer (C) and a functional coating layer (D) in this order, where one of the functional coating layer (C) and the functional coating layer (D) is formed of a resin composition (I) containing a polybutylene terephthalate resin as a major component or an ethylene-vinyl alcohol copolymer as a major component; the other is formed of a specific nylon resin composition (II); and a ratio of the thickness of the functional coating layer (C) to the thickness of the functional coating layer (D) is set to fall within a specific range.

Owner:MITSUBISHI CHEM CORP

Heat stabilizer and composite material containing same

ActiveCN111205637AExcellent long-term heat resistanceImprove floating fiber conditionZinc compoundsBoronic acid

The invention belongs to the technical field of polymer modification, and provides a heat stabilizer. The heat stabilizer is composed of N,N'-bis(2,2,6,6-tetramethyl-4-piperidyl)-1,3-benzenedicarboxamide and a zinc compound, wherein the zinc compound is selected from any one or a mixture of more of zinc carboxylate, zinc carbonate, zinc titanate, zinc molybdate, zinc ferrite, zinc sulfate, zinc phosphate, zinc oxide, zinc borate and zinc halide. Compared with the prior art, the heat stabilizer provided by the invention has the advantages that a resin base material is endowed with good long-term heat resistance; the heat stabilizer has better dispersity in resin; the fiber floating condition of the surface of the glass fiber reinforced injection molding part is improved; long-term injectionmolding does not corrode the mold; and the CTI value (relative tracking index) of the product is not influenced.

Owner:BENSONG ENG PLASTICS HANGZHOU

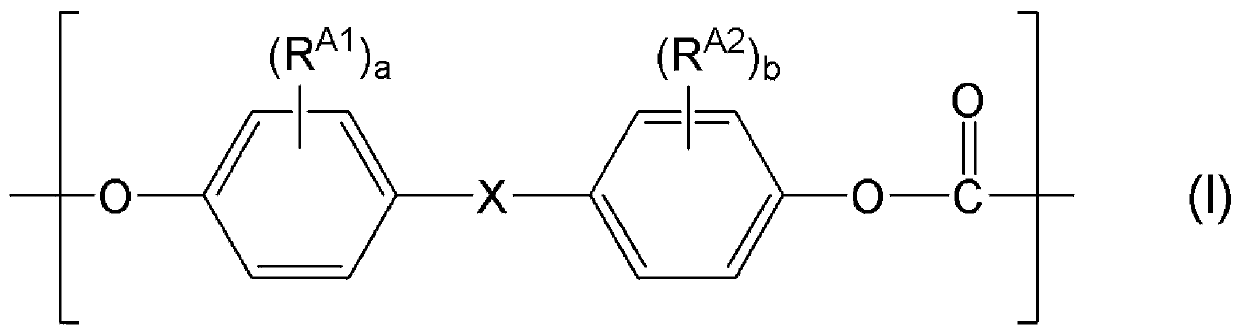

Aromatic polycarbonate resin composition and optical molded article

InactiveCN110997808AExcellent initial YI valueExcellent long-term heat resistancePlanar/plate-like light guidesEpoxyPolymer science

Provided is an aromatic polycarbonate resin composition containing 0.01-0.1 part by mass of an alicyclic epoxy compound (B), 0.2-0.6 part by mass of a polyether compound (C) having a polyoxyalkylene structure, and 0.005-1 part by mass of a phosphorus compound (D) per 100 parts by mass of an aromatic polycarbonate resin (A), wherein the difference between the YI value of a 5-mm-thick molded articleobtained by molding the aromatic polycarbonate resin composition at 320 DEG C after 3000 hours in an environment at 85 DEG C and 85% RH and an initial YI value is 3.0 or less.

Owner:IDEMITSU KOSAN CO LTD

Polyimide resin composition

A polyimide resin composition contains a polyimide resin (A) including repeating constituent units represented by formula (1) and repeating constituent units represented by formula (2), having a content ratio of repeating constituent units of formula (1) to the total repeating constituent units of formula (1) and repeating constituent units of formula (2) of 20-70 mol%; and a nanocarbon material (B). (R1 is a C6-22 divalent group including at least one alicyclic hydrocarbon structure. R2 is a C5-16 divalent chain aliphatic group. X1 and X2 are each independently a C6-22 tetravalent group including at least one aromatic ring.).

Owner:MITSUBISHI GAS CHEM CO INC

Polymer composition based on polypropylene/propylene copolymer having semi-homogeneous phase

ActiveUS20190185648A1Increase flexibilityImprove bendabilityPower cables with screens/conductive layersInsulated cablesSolventPolypropylene

Disclosed is a polymer composition having a semi-homogeneous phase that exhibits excellent electrical, mechanical and thermal properties while satisfying flexibility, bendability and impact resistance. More specifically, disclosed is a polymer composition having a morphology in which a rubber-phase filler of a propylene copolymer is dispersed in a matrix of polypropylene, wherein an elution rate of the rubber-phase filler in a xylene-based solvent is less than 50%, based on the content of the rubber-phase filler such that the rubber-phase filler forms a semi-homogeneous phase with the matrix.

Owner:HUINNOVATION

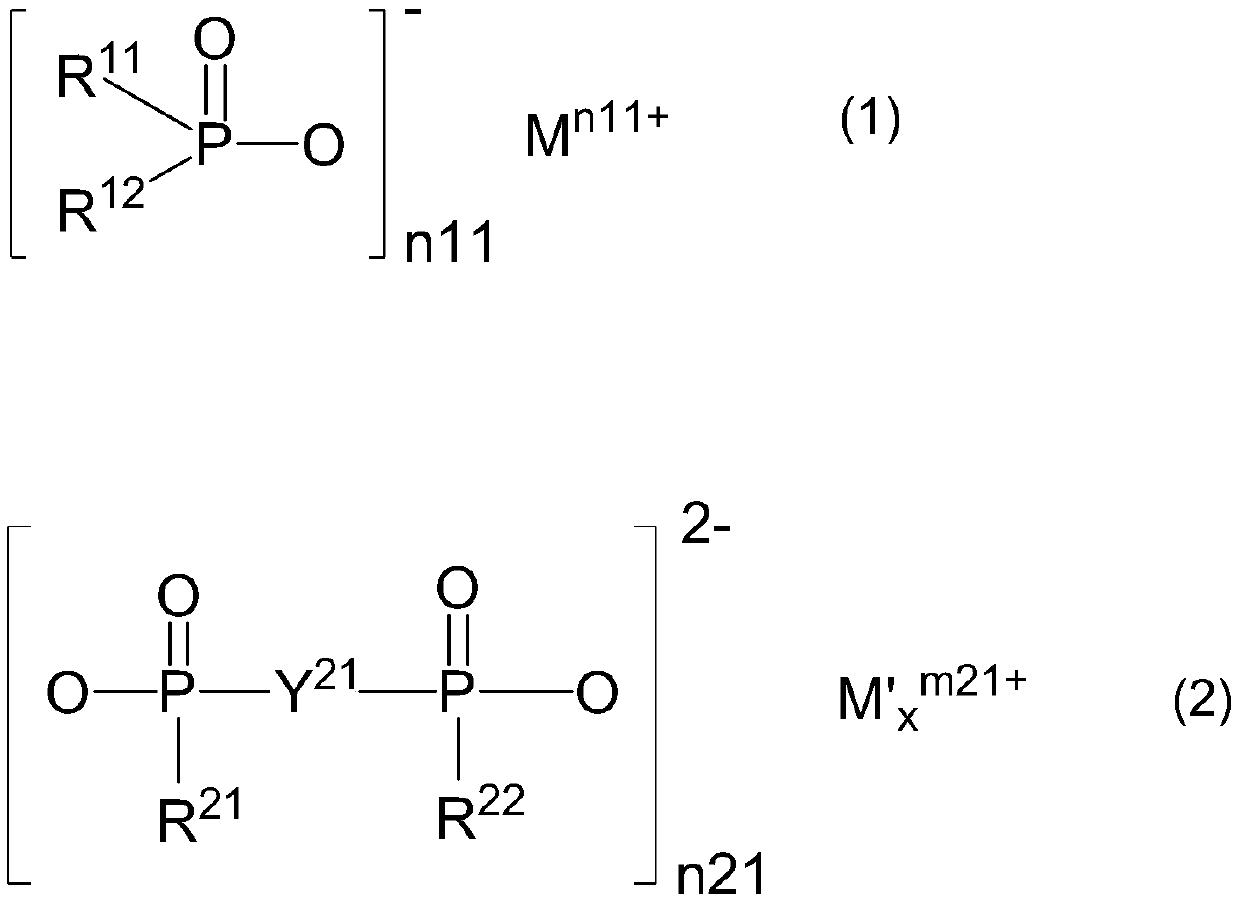

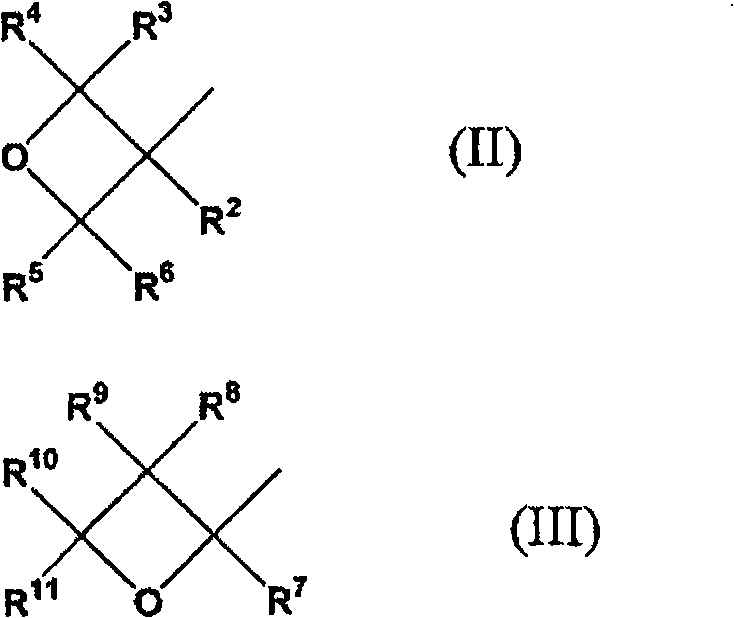

Polyamide composition, method for producing same, and molded article

PendingCN110964315AGood flame retardancyExcellent long-term heat resistancePhosphinic AcidsPhosphinidene

The invention relates to a polyamide composition, a method for producing the same, and a molded article. Provided is a polyamide composition which does not contain halogen, but has excellent flame retardancy and good long-term heat resistance when formed into a molded article. The polyamide composition containes (A) an aliphatic polyamide; (B) a semi-aromatic polyamide containing a diamine unit and a dicarboxylic acid unit; (C) at least one phosphinic acid salt selected from the group consisting of phosphinic acid salts represented by general formula (1), diphosphinic acid salts represented bygeneral formula (2), and condensates thereof; and (D) a polymer having an oxygen index of 27% or more and having an aromatic group in the main chain, the content of the polymer (D) being 0.1-8% by mass relative to the total mass of the aliphatic polyamide (A), the semi-aromatic polyamide (B), the phosphinic acid salt (C), and the polymer (D).

Owner:ASAHI KASEI KK

A heat-resistant polyethylene composition and its application

ActiveCN102952323BExcellent long-term heat resistanceImprove oxidation resistanceFlexible pipesPhenolMechanical property

The invention relates to a PE-RT (polyethylene of raised temperature resistance) composition and application thereof, belonging to the field of polyethylene pipelines. The PE-RT composition is characterized by comprising the following components in parts by weight: 100 parts of PE-RT and 0.1-1.5 parts of antioxidant, wherein the PE-RT is an ethylene-hexene-1 copolymer which has a density of 0.926-0.950 g / cm<3>, a melt flow rate of 0.1-2 g / 10min (190 DEG C, 2.16Kg of weights), unimodal molecular weight distribution and a relative branching degree of 0.08-0.50; and the antioxidant comprises a hindered phenol antioxidant and a phosphite antioxidant. According to the invention, the PE-RT composition having excellent mechanical properties, high-temperature creep resistance, heat aging resistance and extrusion processability is prepared from the heat-resistant ethylene-hexene copolymer, the antioxidant and other components, thereby further improving the practical performance of PE-RT pipe products. Thus, the PE-RT composition can be used for the preparation of pipe products and pipe fittings for a hot water pipeline system.

Owner:CHINA PETROLEUM & CHEM CORP

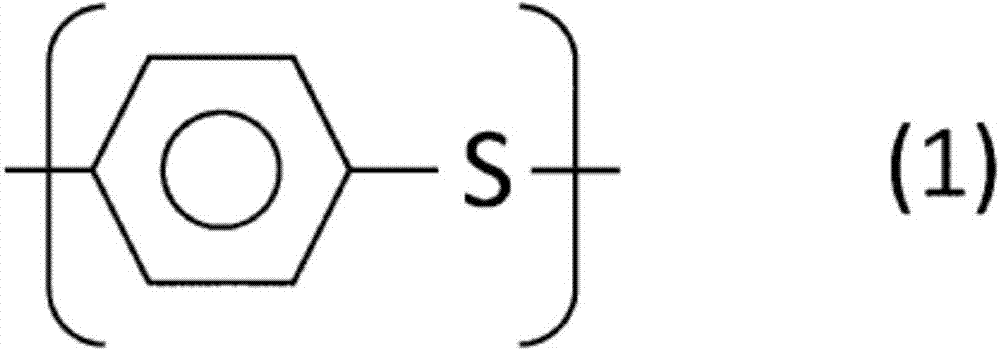

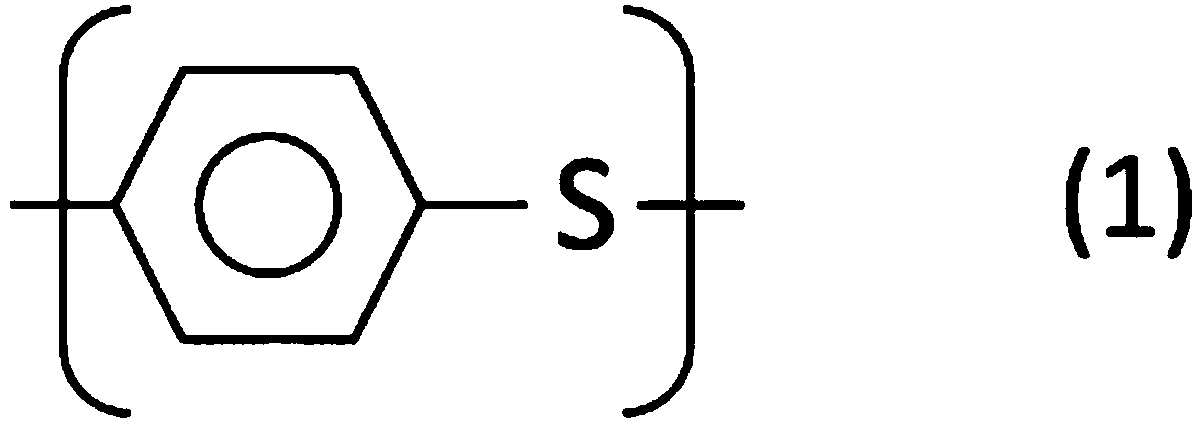

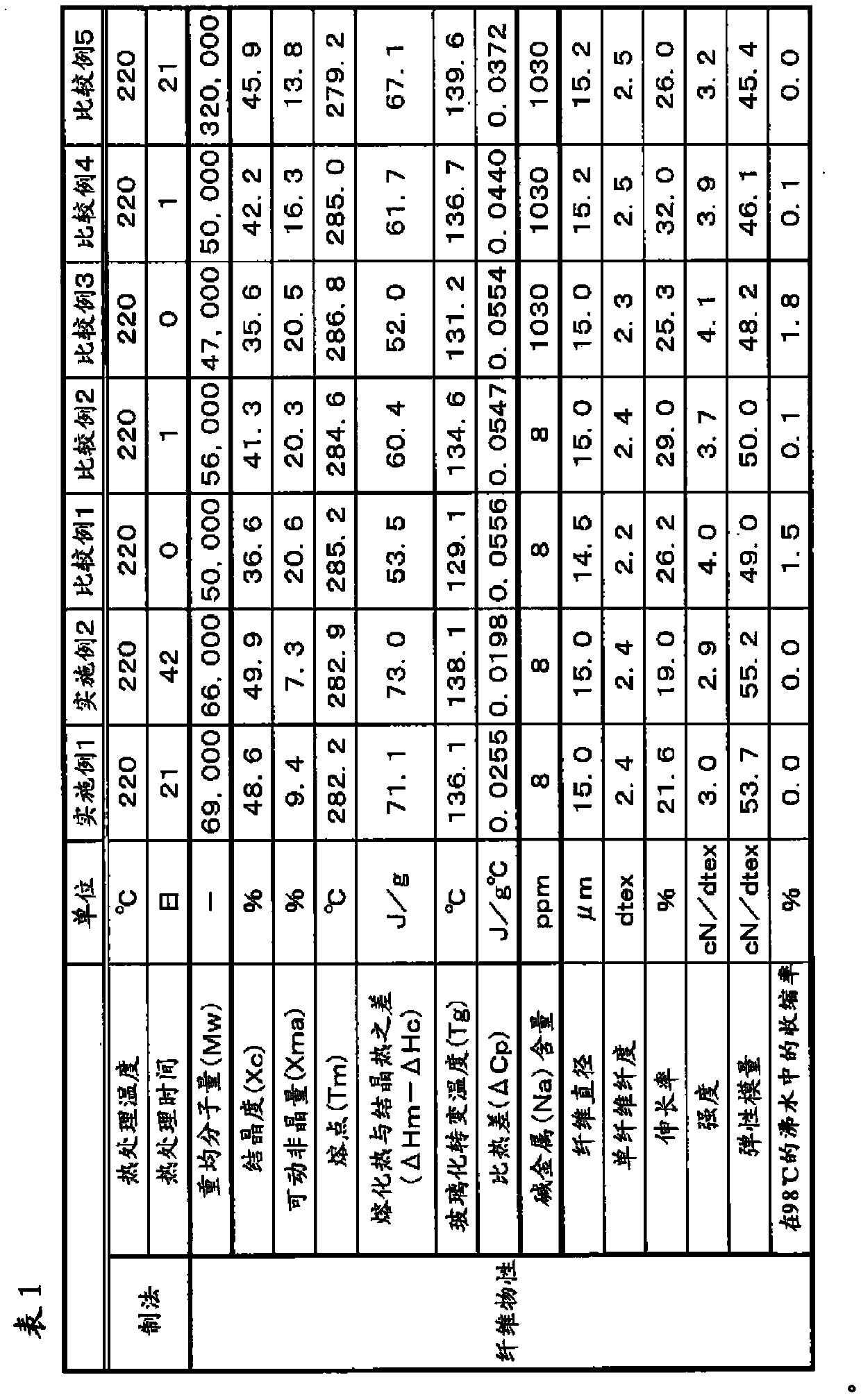

Polyphenylene sulfide fiber

ActiveCN107075742ASmall structural changesExcellent long-term heat resistanceMembrane filtersMonocomponent synthetic polymer artificial filamentFiber structureCrystallinity

Provided is a polyphenylene sulfide fiber for which changes in fiber structure are small and which has excellent long-term heat resistance. That is, the present invention is a polyphenylene sulfide fiber characterized in that the degree of crystallinity is at least 45.0%, the amount of mobile amorphous phases is not more than 15.0%, and the weight average molecular weight is not more than 300,000.

Owner:TORAY IND INC

Multi-layer co-extrusion type online hot-pressing laminated solar backboard and preparation method thereof

PendingCN111844937AStrong impact resistanceExcellent long-term heat resistanceSynthetic resin layered productsElectrical equipmentPolymer sciencePolyolefin

The invention relates to a solar backboard formed by multi-layer co-extrusion and online hot-pressing lamination of a weather-proof film. The solar backboard is formed by online hot-pressing lamination of a three-layer polyolefin co-extrusion film and the weather-proof film, wherein the thickness of the solar backboard is 350 [mu]m; the three-layer polyolefin co-extrusion film sequentially comprises a copolymerized PP functional layer, a polyolefin supporting layer and a bonding functional layer from outside to inside, and the thickness of the three-layer polyolefin co-extrusion film is 300 [mu]m; the weather-proof film is a PVF or PVDF film, and the thickness of the weather-proof film is 50 [mu]m; and the three-layer polyolefin co-extrusion film and the weather-proof film are extruded andattached synchronously on line, and the weather-proof film is located on the outer side of the copolymerized PP functional layer. The solar backboard has excellent impact resistance, long-term heat resistance, heat discoloration resistance, antistatic performance and dimensional stability, is free of layering and cracking, and achieves environmental stress cracking resistance and supporting performance of the supporting layer.

Owner:安徽省长荣新材料科技有限公司

High-polymer heat-resistant polyvinyl chloride based on multicomponent rare-earth heat stabilizer

The invention provides a high polymer heat-resistant polyvinyl chloride based on a multi-element rare earth heat stabilizer, the polyvinyl chloride includes high molecular weight polyethylene, trioctyl trimellitate, liquid barium zinc, a multi-element rare earth heat stabilizer and low Molecular polyethylene wax, wherein the preparation method of the multi-element rare earth heat stabilizer is: under an inert environment, add palladium chloride and triphenylphosphine into n-hexane, stir evenly, add 4-bromopropiophenone, and then drop three Phenyl lanthanum solution, continue to react after the dropwise addition, separate and purify to obtain the multi-element rare earth lanthanum palladium metal compound; add the multi-element rare earth lanthanum palladium metal compound into nitric acid and stir, and mix rapidly with the ethanol mixed solution of malic acid and salicylic acid, then drop Add sodium hydroxide aqueous solution, heat to react, vacuum filter, wash and dry to obtain multi-element rare earth heat stabilizer. The polyvinyl chloride prepared by the invention has a high degree of polymerization, good synergistic effect among various components, and can remarkably improve the heat resistance, mechanical properties, corrosion resistance and other properties of the polyvinyl chloride material.

Owner:SUZHOU WILDER IND & TRADE

Thermal stabilizer and composite material comprising the thermal stabilizer

ActiveCN111205637BExcellent long-term heat resistanceImprove floating fiber conditionZinc compoundsZinc titanate

The invention belongs to the technical field of polymer modification, and provides a thermal stabilizer composed of N,N'-bis(2,2,6,6-tetramethyl-4-piperidinyl)-1,3-benzene Diformamide and zinc compound, wherein the zinc compound is selected from zinc carboxylate, zinc carbonate, zinc titanate, zinc molybdate, zinc ferrite, zinc sulfate, zinc phosphate, zinc oxide, zinc borate, zinc halide Any one or a mixture of several. Compared with the prior art, the heat stabilizer provided by the present invention can: give the resin base material good long-term heat resistance; itself has better dispersion in the resin; improve the floating of the surface of the glass fiber reinforced injection molded part fiber condition; long-term injection molding does not corrode the mold; does not affect the CTI value (relative tracking index) of the product.

Owner:BENSONG ENG PLASTICS HANGZHOU

Adamantane derivative, resin composition using the same, and resin cured product

InactiveCN101652394AHigh transparencyExcellent optical propertiesOrganic chemistryHeat resistancePolyresin

Disclosed is a cured product of an adamantane derivative having a specific structure, which is excellent in transparency, optical characteristics such as (long-term) light resistance, long-term heat resistance, dielectric constant and mechanical properties. This resin cured product is suitably used in the fields of electronic / optical material.

Owner:IDEMITSU KOSAN CO LTD

Optical fiber cable and sensor

ActiveCN105940333AExcellent long-term heat resistanceExcellent mechanical propertiesFibre typesFibre mechanical structuresPolyolefinOptical fiber cable

Provided is an optical fiber cable having excellent flame retardancy, long-term heat resistance and mechanical characteristics. An optical fiber cable according to the present invention comprises an optical fiber and a cladding layer that is provided on the outer circumference of the optical fiber. The cladding layer contains a chlorinated polyolefin resin (A) and a polyolefin resin (B).

Owner:MITSUBISHI CHEM CORP

Insulating resin composition and insulated electric wire

InactiveUS20180294074A1Good flexibilityEasy wiringPlastic/resin/waxes insulatorsInsulated cablesMethacrylatePolyolefin

Owner:SUMITOMO ELECTRIC IND LTD

polyphenylene sulfide fiber

ActiveCN107075742BSmall structural changesExcellent long-term heat resistanceMembrane filtersMonocomponent synthetic polymer artificial filamentMaterials scienceFiber structure

The present invention provides a polyphenylene sulfide fiber having little change in fiber structure and excellent long-term heat resistance. That is, there is provided a polyphenylene sulfide fiber characterized by having a crystallinity of 45.0% or more, a mobile amorphous content of 15.0% or less, and a weight average molecular weight of 300,000 or less.

Owner:TORAY IND INC

Polyimide resin composition

ActiveCN113454144AExcellent long-term heat resistanceRaise the crystallization temperaturePolymer scienceAlicyclic Hydrocarbons

Owner:MITSUBISHI GAS CHEM CO INC

Polyamide acid, thermoplastic polyimide, resin film, metal-clad laminate and circuit board

ActiveUS10844175B2Improve adhesionStrong adhesionPlastic/resin/waxes insulatorsPrinted circuit aspectsImidePolymer science

Owner:NIPPON STEEL CHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com