Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

703results about How to "Fusion well" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

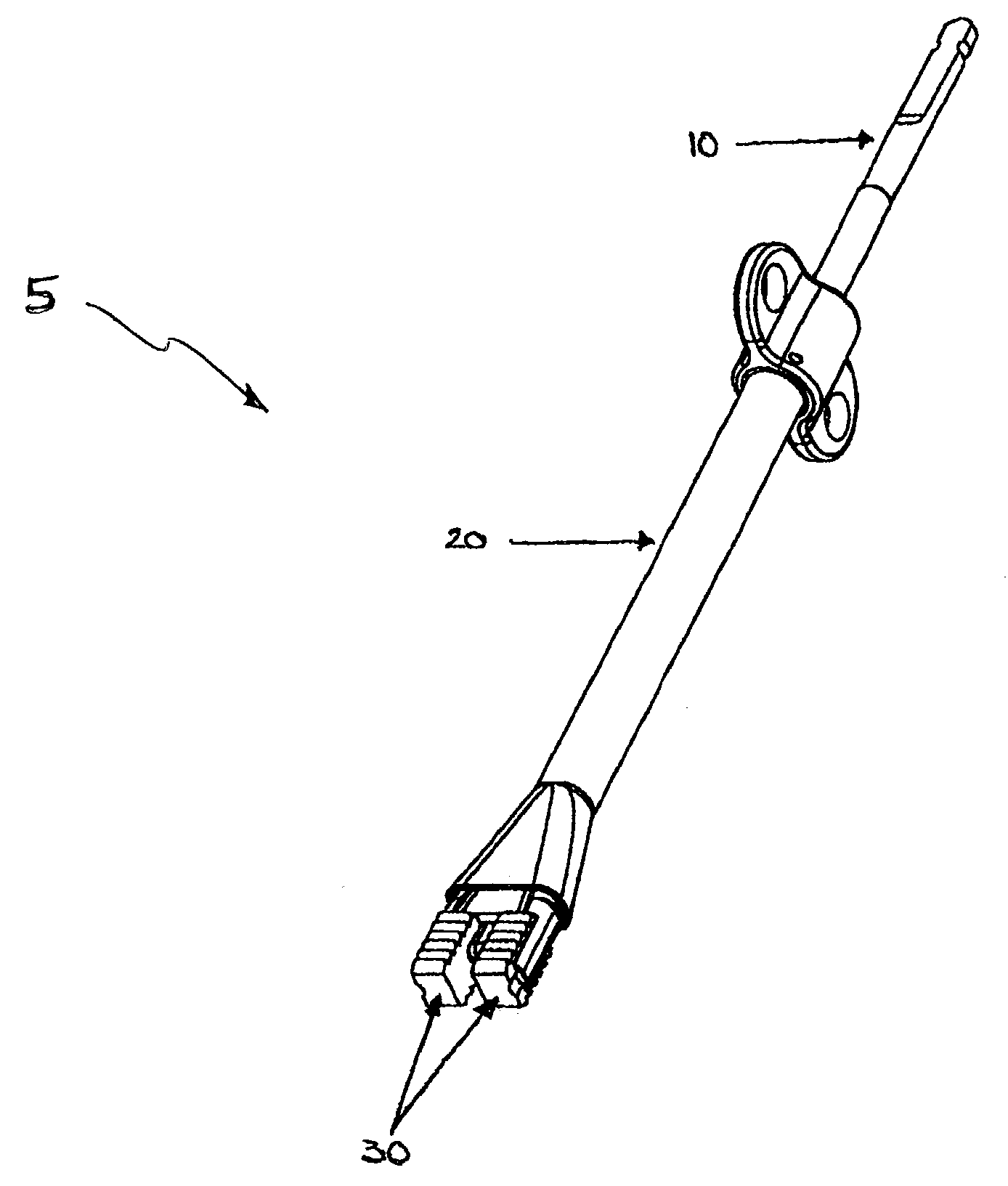

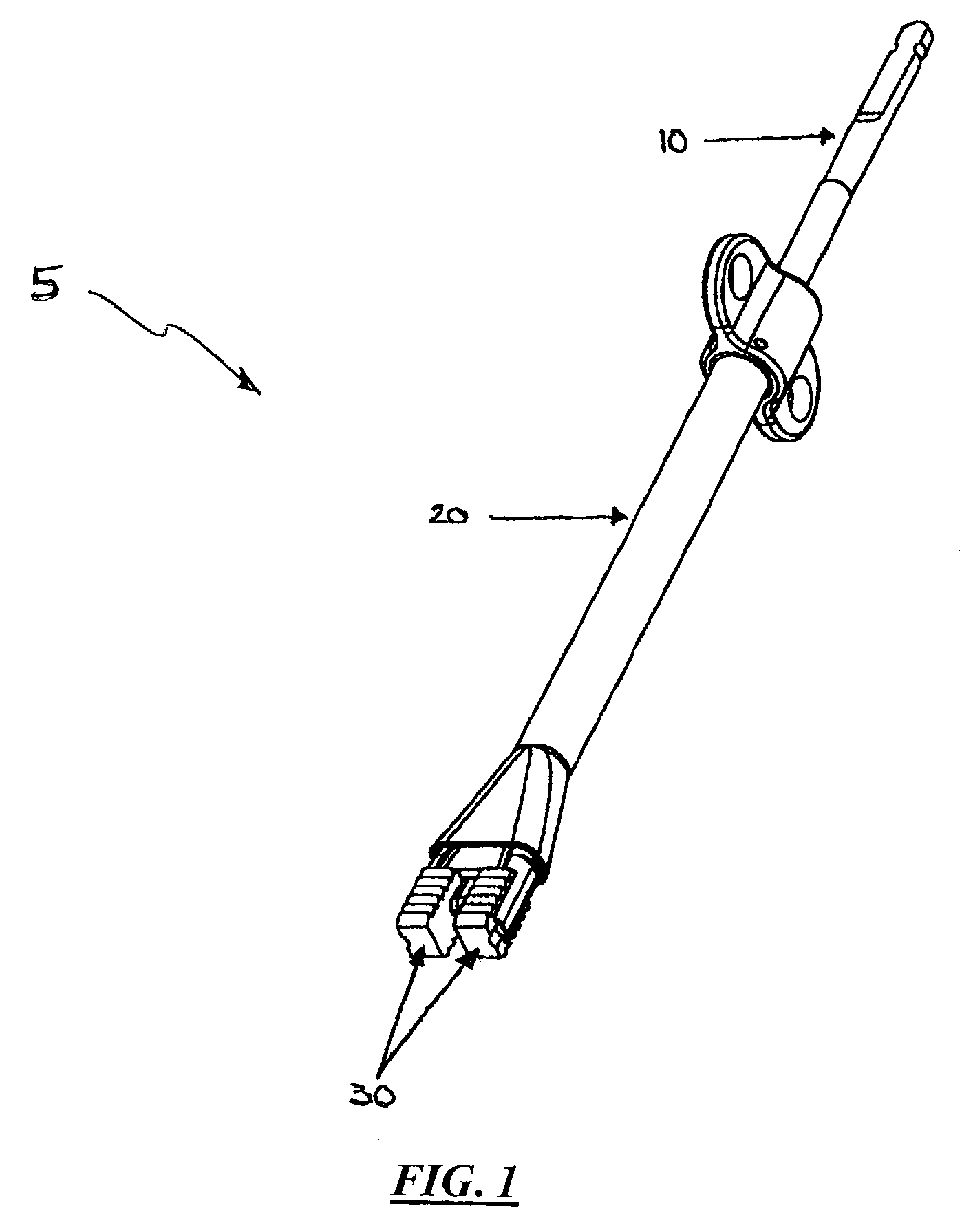

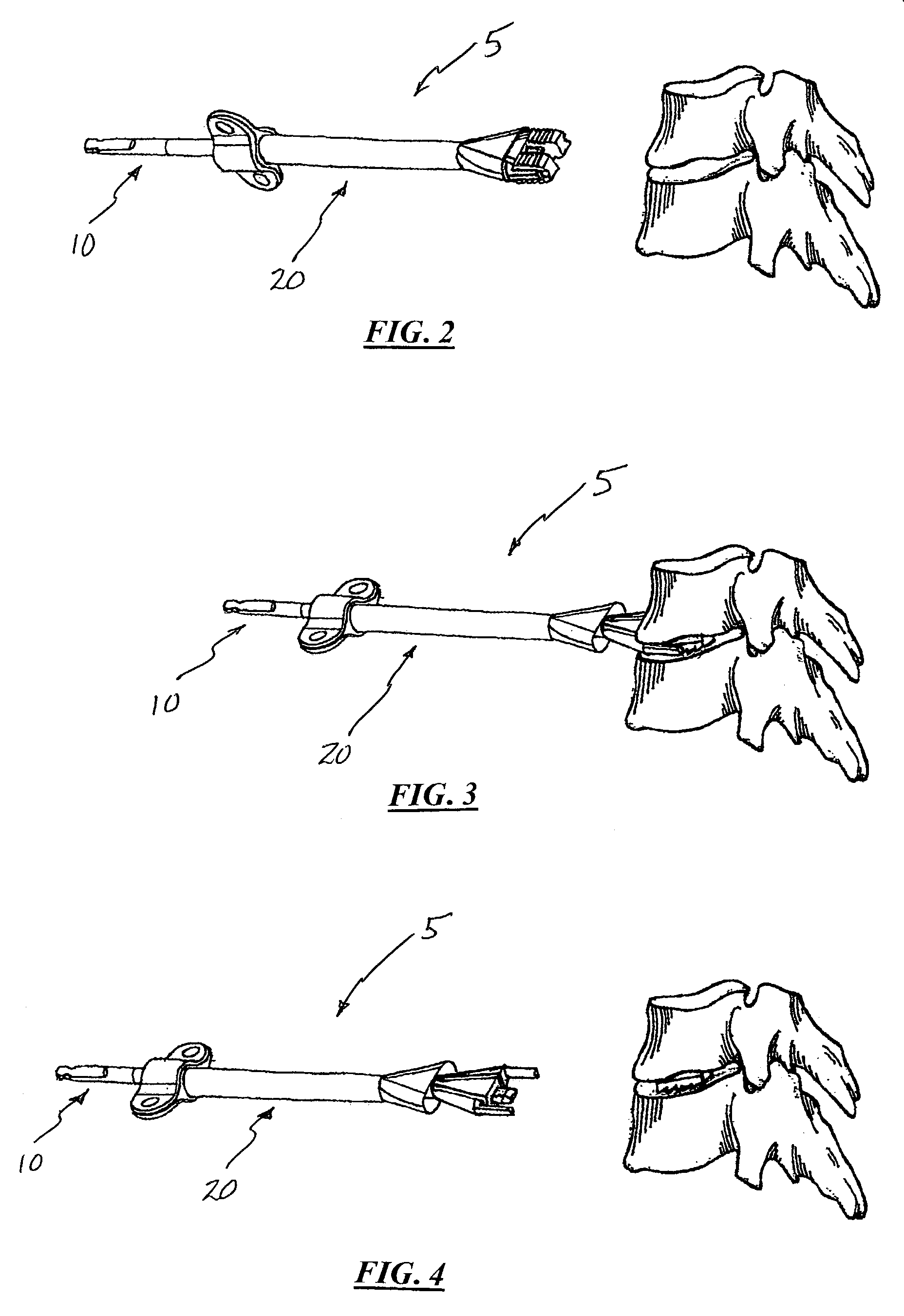

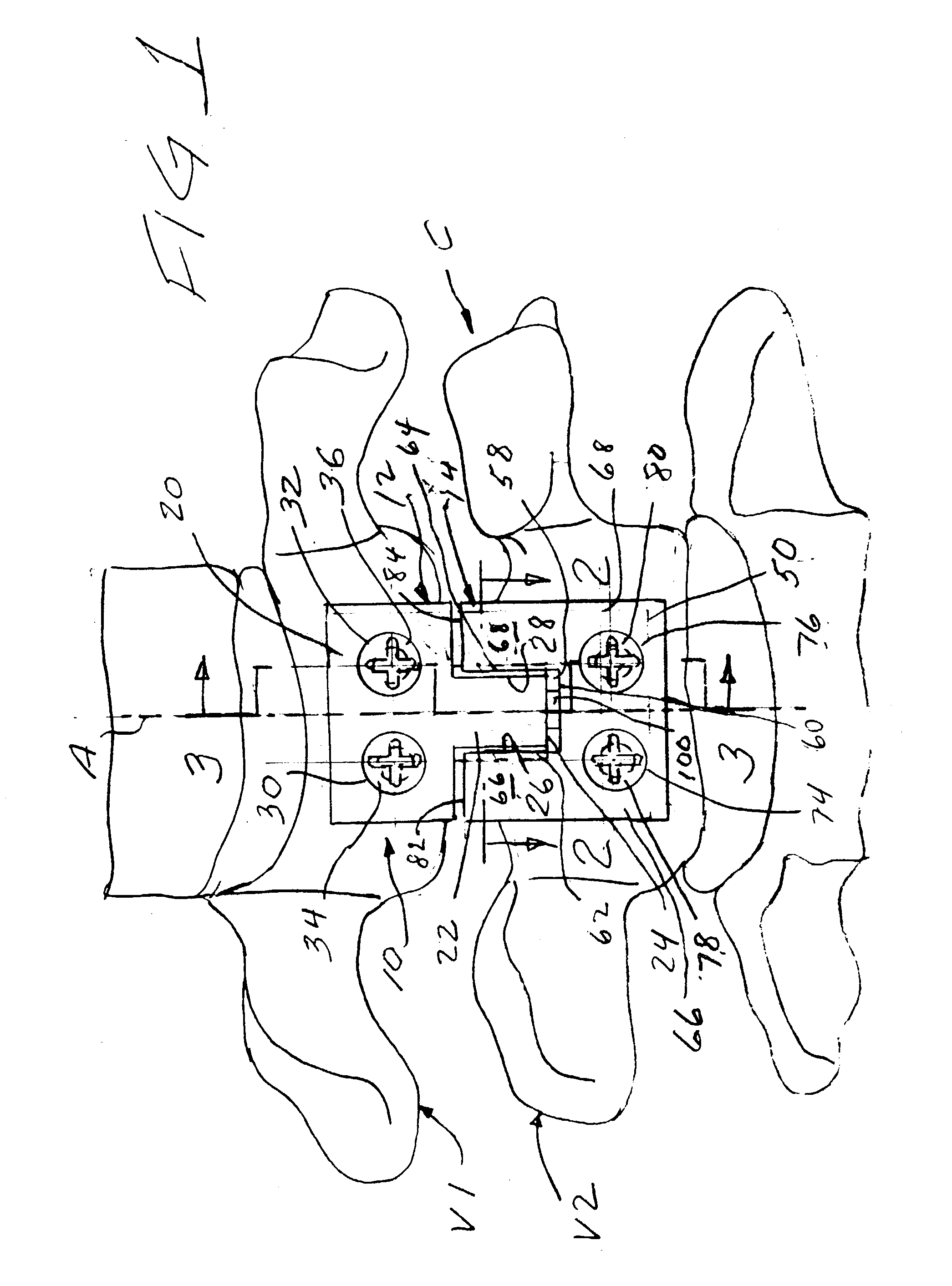

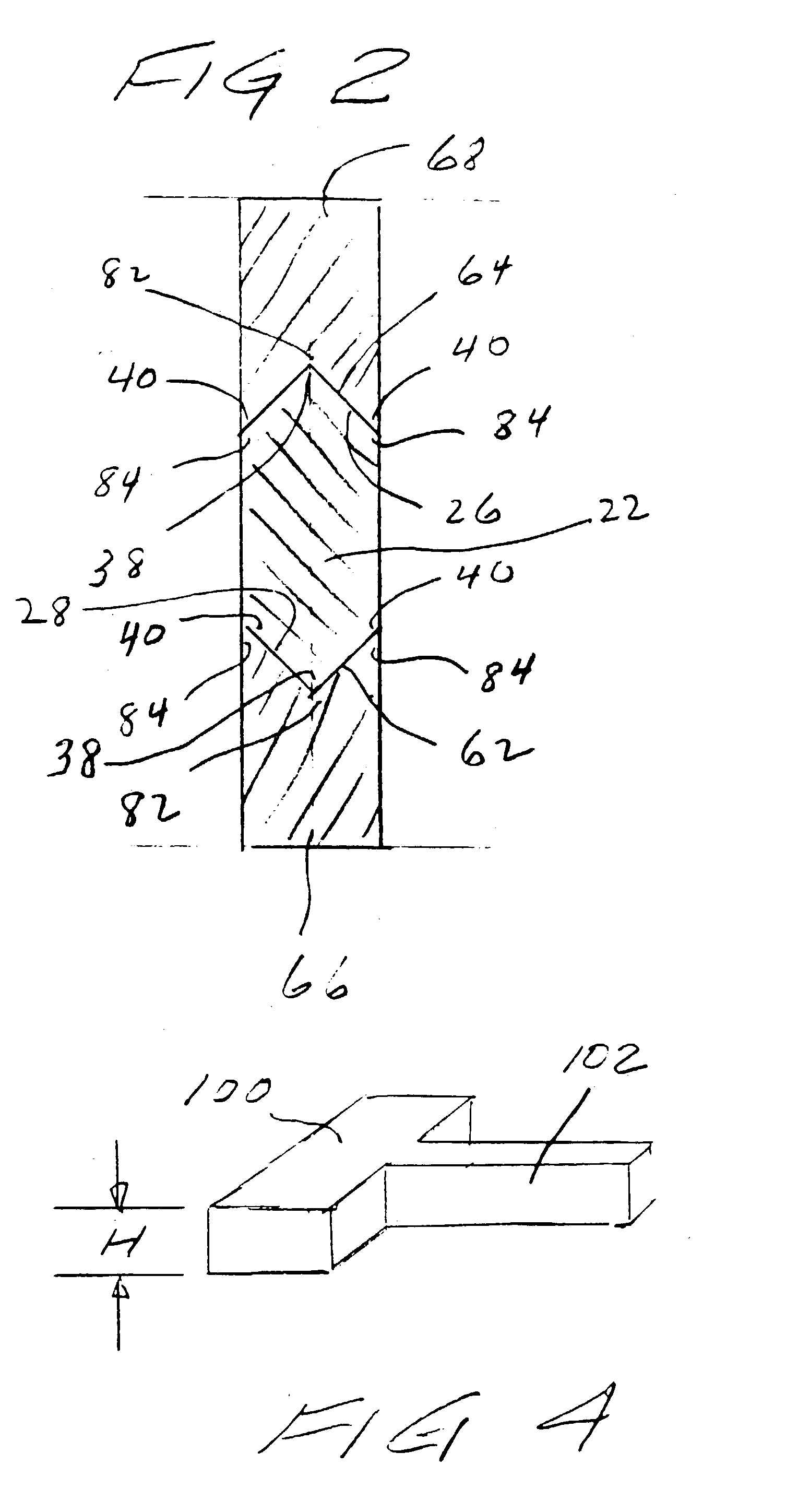

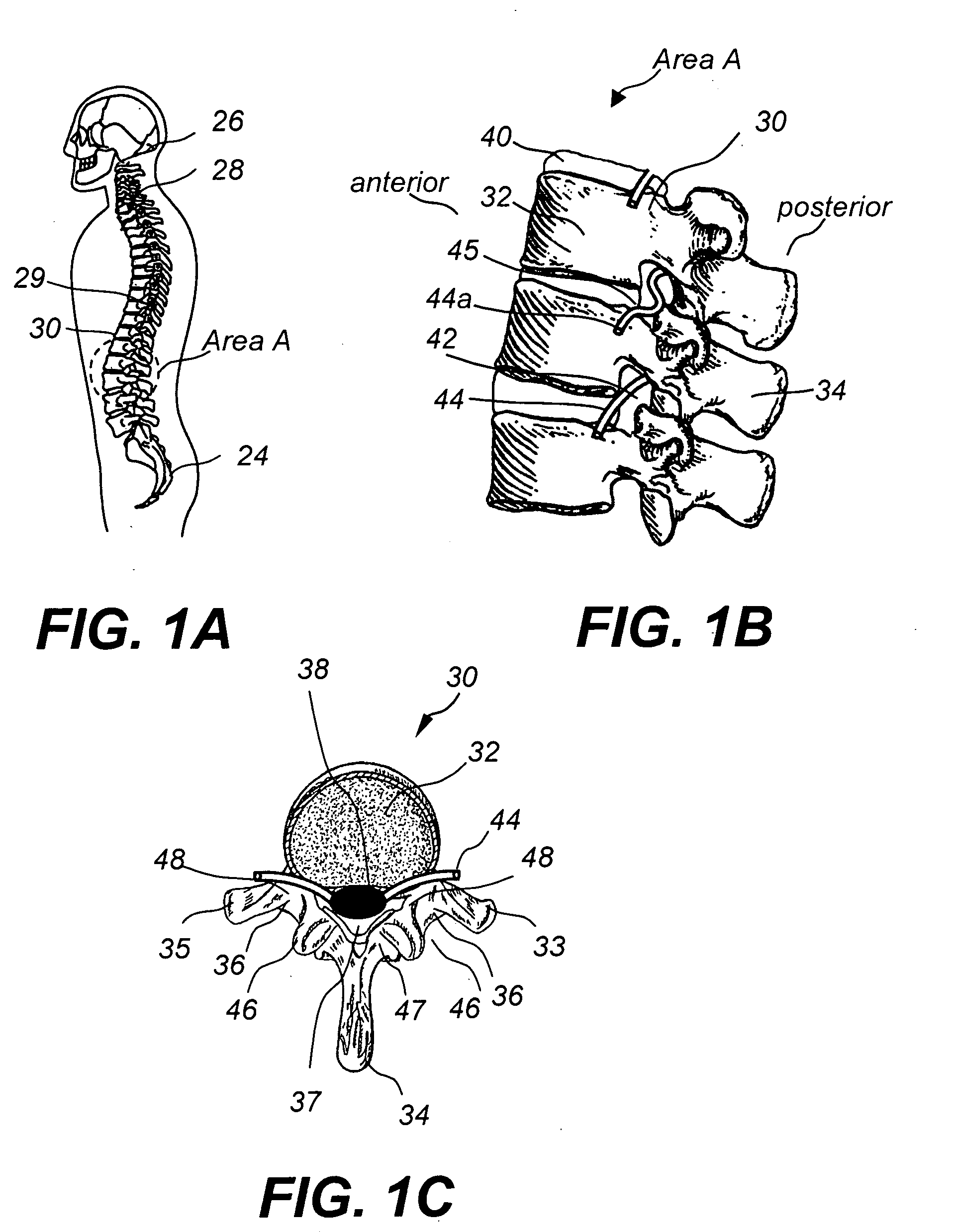

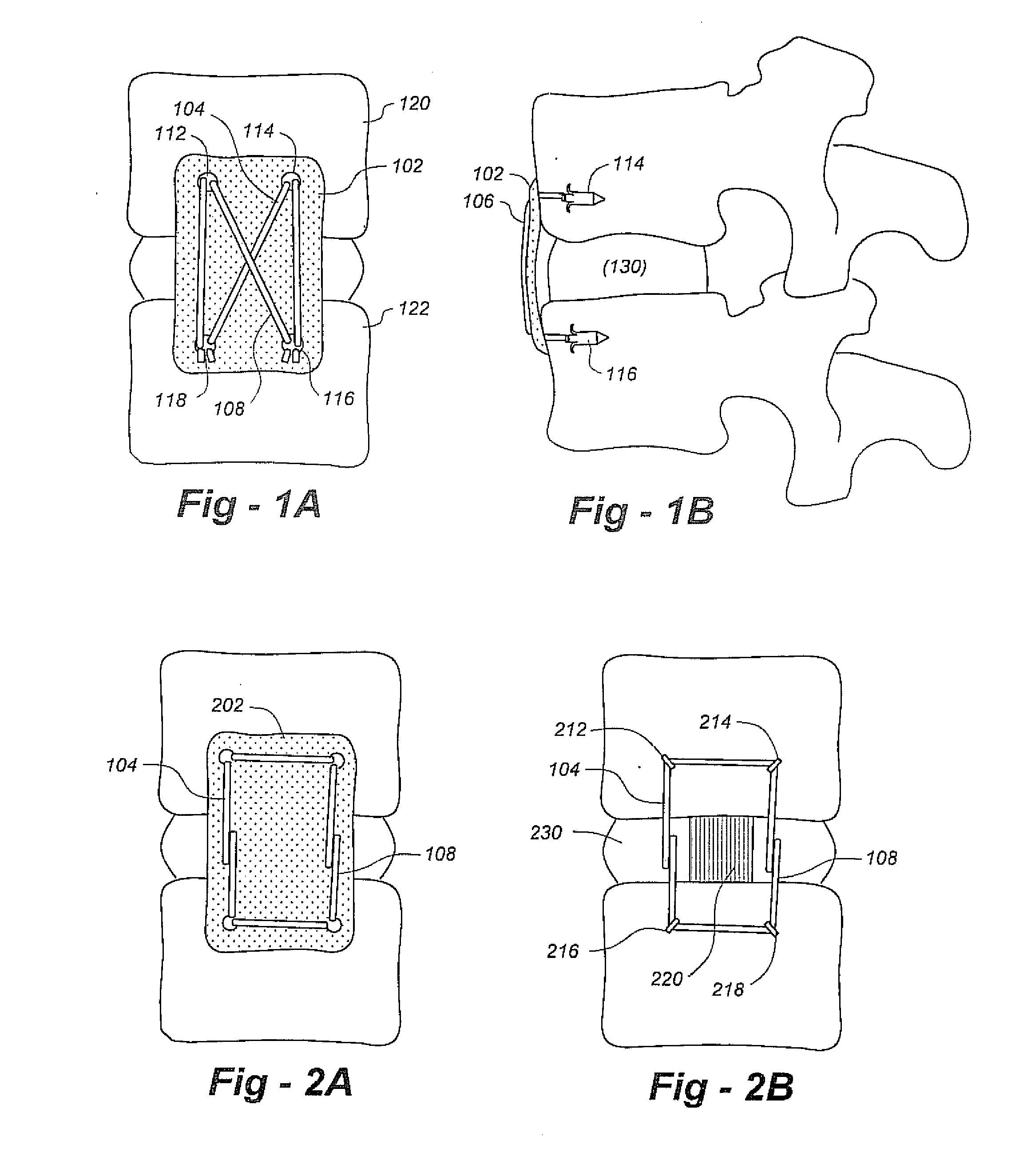

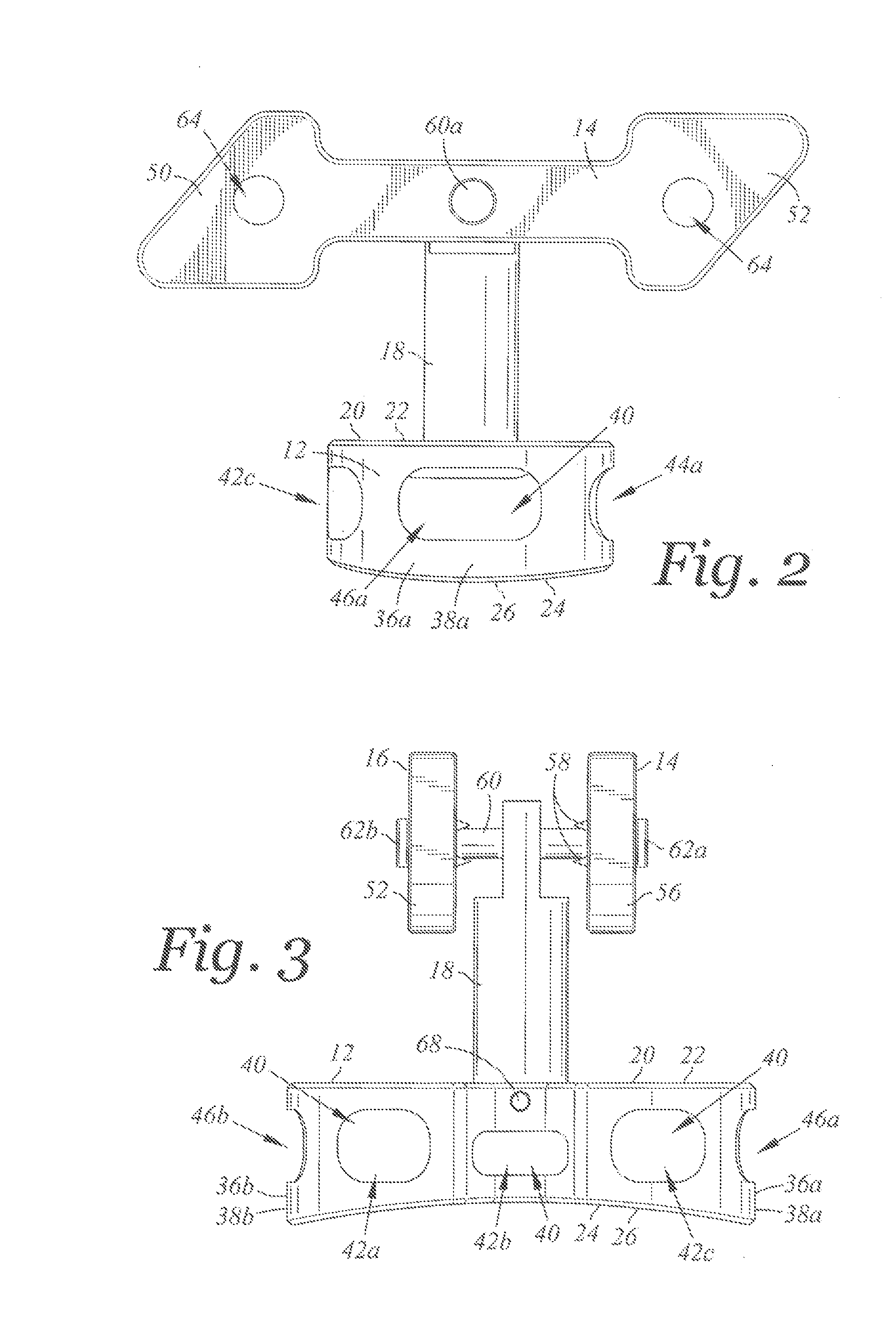

System and method for performing spinal fusion

InactiveUS7618423B1Adequate disk heightSolve the lack of heightBone implantSpinal implantsSpinal columnSpinal fusion

A system and associated methods for performing spinal fusion, involving the use of a graft holder assembly, a locking assembly, and a pair of bone graft implants to simultaneously introduce the bone graft implants into a disc space to thereafter effect spinal fusion.

Owner:NUVASIVE

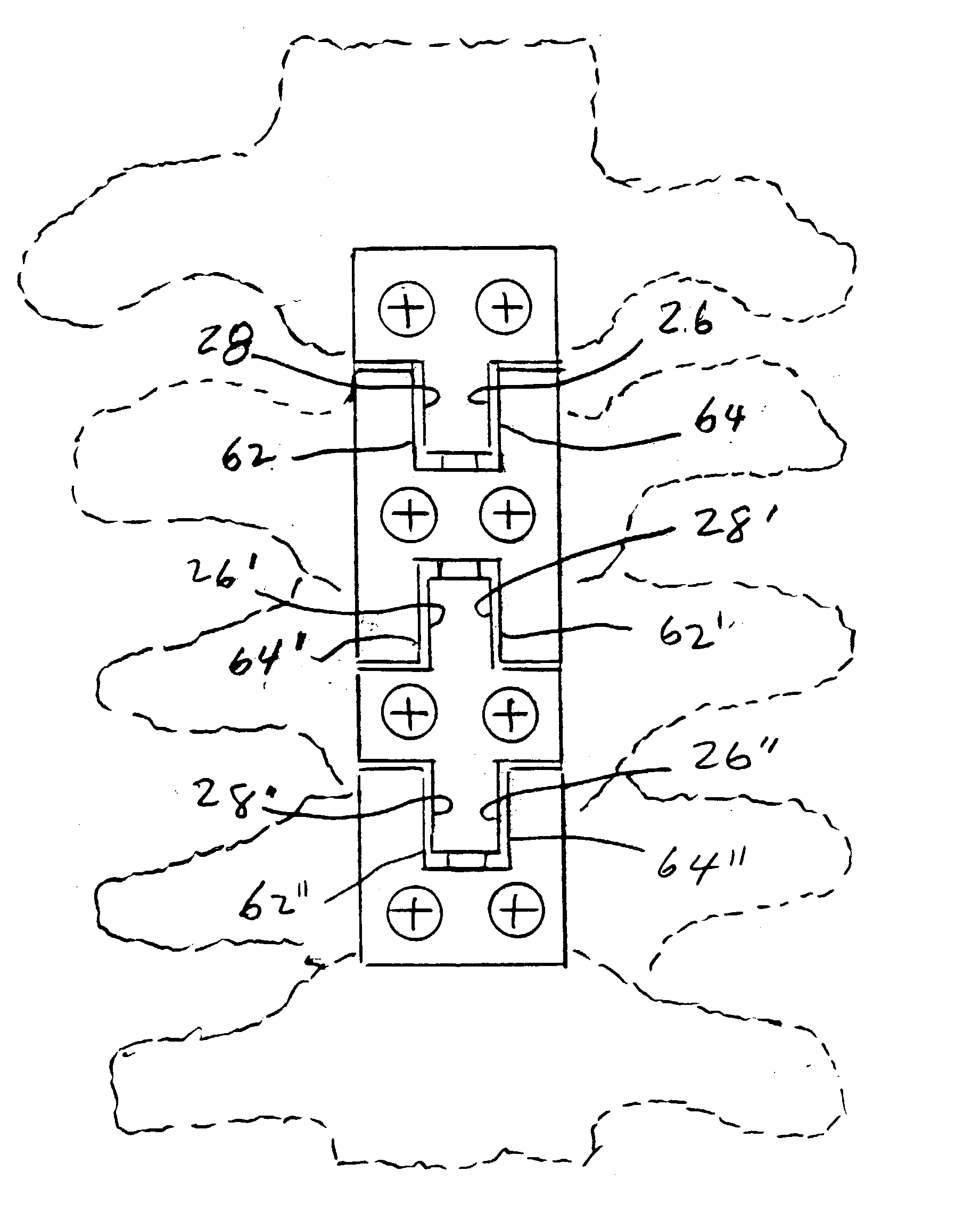

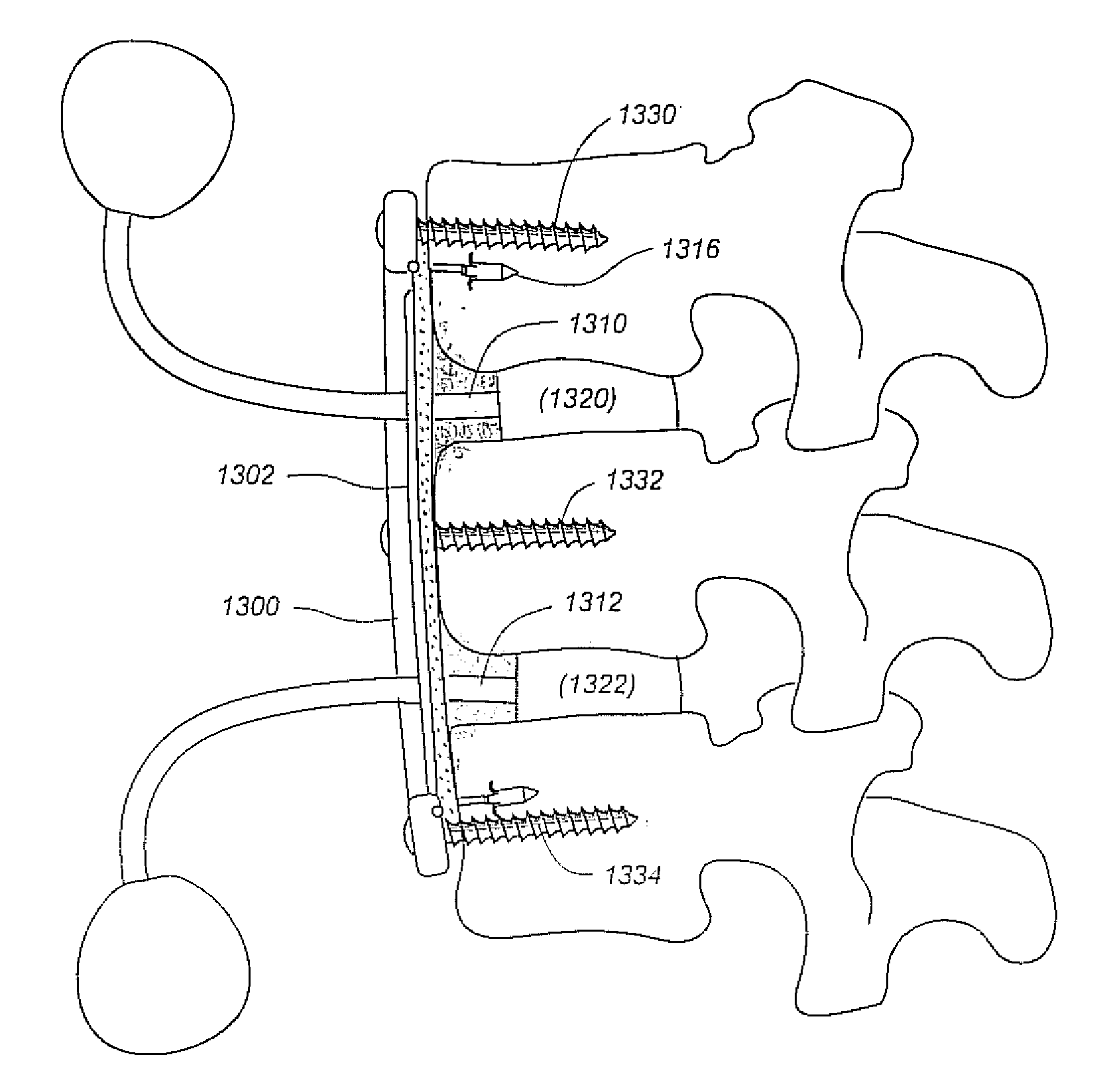

Methods and apparatuses for promoting fusion of vertebrae

Methods and apparatuses for promoting fusion of vertebrae are provided. The apparatuses comprise interconnecting plates that fixate vertebrae to each other and provide for a predetermined amount of subsidence where the fusion occurs. Allowing for this predetermined amount of subsidence increases bone to bone contact at the graft, which promotes fusion without having excessive settling of the two vertebrae onto the graft. The predetermined amount of subsidence is achieved by the placement of a plate spacer between each of two interconnecting plates when the plates are attached to the vertebrae. The plate spacer has a height equal to the maximum amount of subsidence desired. After affixing the plates to the vertebrae, the plate spacer is removed, leaving a space between the plates, which allows the vertebrae to subside by a distance equal to the height of the plate spacer.

Owner:DINH DZUNG H +1

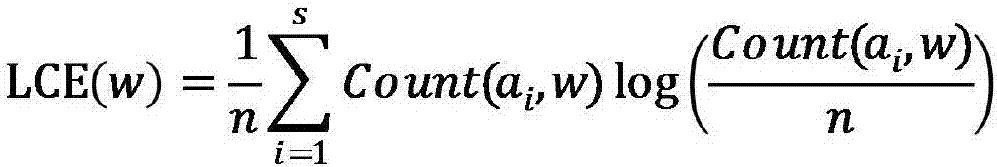

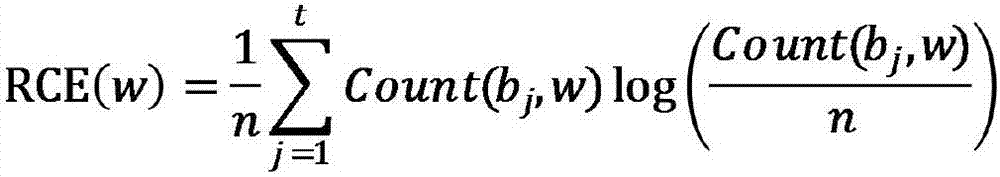

Geographical science domain named entity recognition method

ActiveCN107133220AEntity recognition implementationCorrect mislabeling issueSemantic analysisSpecial data processing applicationsDomain nameConditional random field

The invention discloses a geographical science domain named entity recognition method, which is used for recognizing geographical science core term entities and geographical location entities. The method mainly comprises three steps of (1) establishing a geographical science domain dictionary, and using a new word discovery algorithm to identify new words in the geographical science domain in an unsupervised way; (2) training and testing based on a conditional random field (CRF) model and a multichannel convolutional neural network (MCCNN) model; (3) carrying out error correcting and fusion on entities recognized by the models by using a rule-based method. According to the geographical science domain named entity recognition method, the new words of the domain are identified as the dictionary in an unsupervised way by using the new word discovery algorithm, so that the work distinguishing effect is improved. The semantic vectors of the words are learnt from large-scale unmarked data in an unsupervised way, and basic characteristics of the words are synthesized and are taken as the input characteristics of the MCCNN model, so that manual selection and construction of the characteristics are avoided. The predicting results of the two models are fused by means of a custom rule, so that the problem of error marking in a recognition process can be corrected.

Owner:SOUTHEAST UNIV

Fluxless heat-and wear-resistant cast iron alloy surfacing welding electrodes and manufacture thereof

InactiveCN1530201AReduce labor intensityImprove welding productivityArc welding apparatusWelding/cutting media/materialsWear resistantRefractory

An uncoated refractory antiwear welding cast iron alloy electrode for build-up welding contains C (2.5-6.5 wt.%), Si (0.8-2.5), Mn (0.4-1.5), Cr (16-35), Nb (0-1.5), Mo (0-3.5), Ni (0-2.0), W (0-2.5), V (0.1-2.0), Ti (0-0.8), Cu (0-1.0), S (0-0.08), P (0-0.1), O (0-0.08), N (0-0.08), Al (0-0.1) and Fe (rest), and is made up by casing method. Its advantages are high hardness of welded layer (more than 42 HRC), and low cost.

Owner:攀钢集团钢城企业总公司溶解乙炔厂

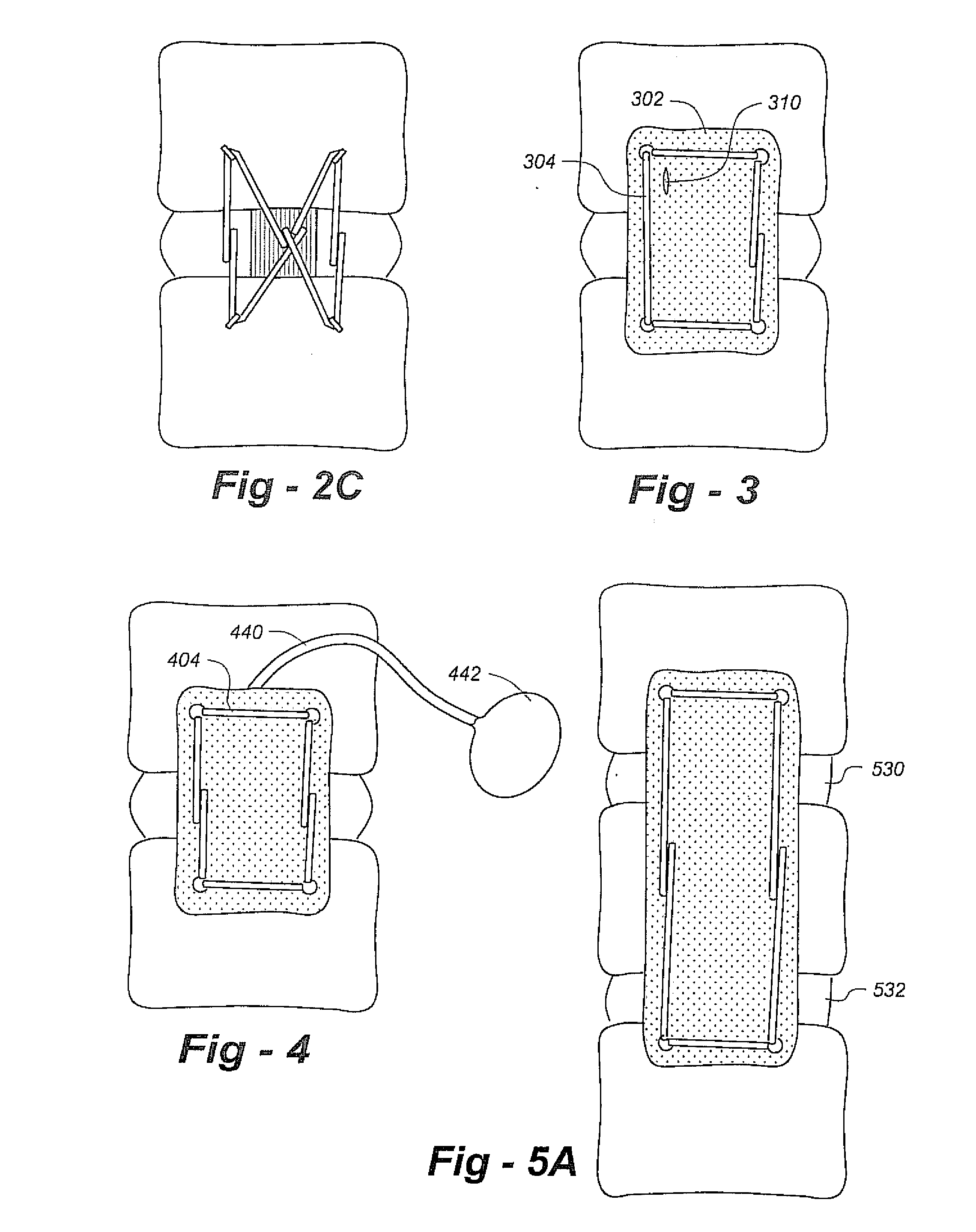

Method and device for kinematic retaining cervical plating

InactiveUS20060009845A1Retain flexibilityEasily placeInternal osteosythesisBone implantSpinal implantVertebra

A spinal implant assembly for replacing intervertebral elements between a first spinal vertebra and an adjacent second spinal vertebra includes an intervertebral implant for inserting between the first and second spinal vertebrae and a first kinematic retaining plate. The intervertebral implant comprises a body having a top surface, a bottom surface, and a first appendage extending from the top surface of the intervertebral implant. The first appendage is adapted to fit within and form a tongue and groove attachment with a first opening formed in the first spinal vertebra. The first kinematic retaining plate is attached to the first spinal vertebra so that it secures the first appendage in the first opening. The intervertebral implant further comprises a second appendage extending from the bottom surface and the second appendage is adapted to fit within and form a tongue and groove attachment with a second opening formed in the second spinal vertebra. A second kinematic retaining plate is attached to the second spinal vertebra so that it secures the second appendage in the second opening.

Owner:SPINEFRONTIER LLS

Prepn process of collagen-based surface wound repairing membrane possessing tissue induction

InactiveCN101020077AShorten wound healing timeGood fusionAbsorbent padsBandagesBiocompatibility TestingBiology

The present invention is preparation process of collagen-based surface wound repairing membrane possessing tissue induction function, and features that the collagen-based surface wound repairing membrane modified physically and chemically has introduced gelatin-base slow releasing microsphere containing cell growth factor, pores of 20-200 micron size, pore rate not smaller than 80 %, tensile strength not smaller than 1 MPa, pH 5.0-6.0, and excellent degradation and biocompatibility. It has the functions of absorbing wound diffusate, induce the adhesion, proliferation and differentiation of autocell, induce the growth of blood vessel, release cell growth factor to the wound for long time, speed wound healing and avoid scar. The present invention is used for injury, burns, scalds, skin ulcer, etc.

Owner:SICHUAN UNIV

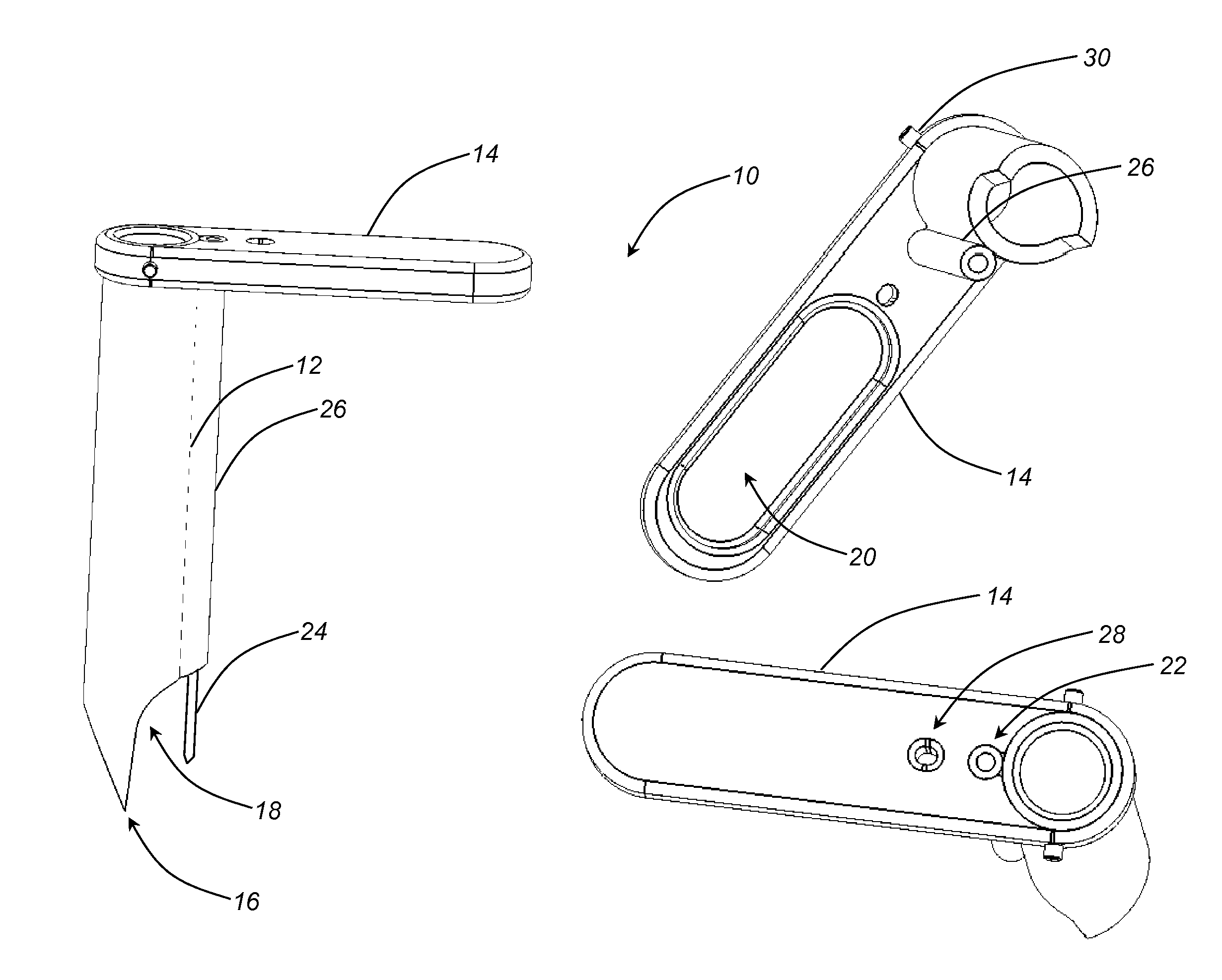

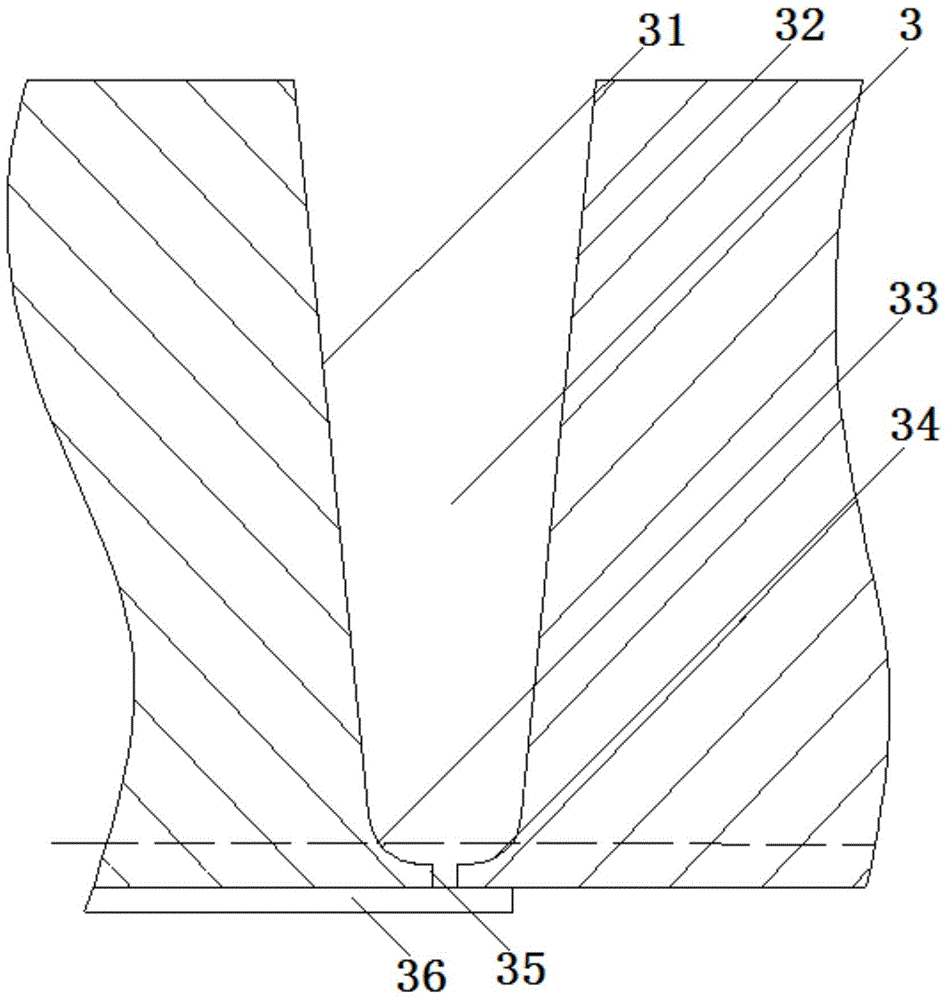

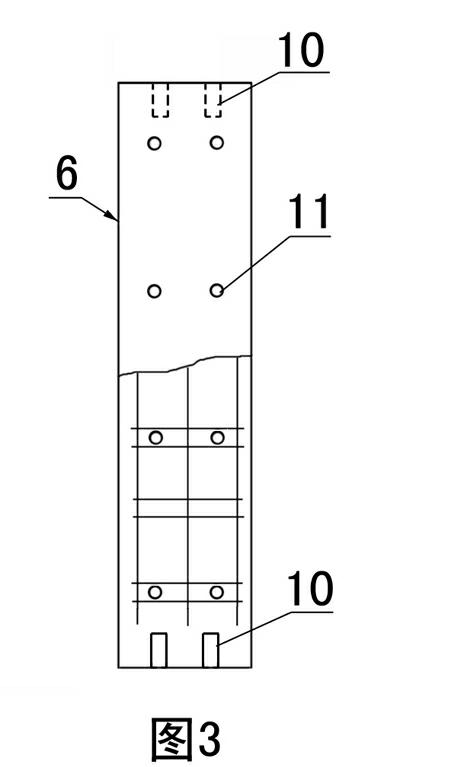

Anterior lumbar lag plate

InactiveUS20060229618A1Maximize effectivenessFusion wellInternal osteosythesisJoint implantsVertebraNuclear medicine

An anterior lumbar plate for attachment with bone screws to selected vertebrae of a person's spine is combined: (a) with separate L5 and S1 drill guides separately and removably attachable to the lumbar plate, and (b) with lock plates removably attachable to the lumbar plate to prevent unscrewing of installed bone screws. This invention further provides a method for implanting and locking in place the L5 and S1 bone screws. This invention is adaptable for L4-L5, L4-L5-S1, and L5-S1 lumbar plates.

Owner:STRYKER EURO OPERATIONS HLDG LLC

Stainless steel compound welding steel pipe and manufacturing method thereof

ActiveCN102889434AImprove corrosion resistanceImprove structural strengthRigid pipesStainless steel electrodeUltimate tensile strength

The invention discloses a stainless steel compound welding steel pipe and a manufacturing method thereof. The stainless steel compound welding steel pipe is formed by welding stainless steel compound hotly-rolled rolling plates through a welding line, wherein the welding line is formed by a stainless steel compound welding line and a carbon steel welding line. The manufacturing method comprises the following steps of: milling an edge and arranging a groove; when putting a stainless steel compound layer on the inner layer, firstly utilizing gas shield welding to weld a middle layer; then, utilizing a stainless steel welding strip to weld a stainless steel compound layer welding line in an argon arc welding manner; then, utilizing a carbon steel welding strip to weld the carbon steel welding line by a submerged-arc welding manner; when the stainless steel layer is less than 0.9 mm, directly welding a stainless steel welding line by submerged-arc welding; and when the stainless steel compound layer is located at the outer layer, firstly welding the carbon steel welding line by adopting the carbon steel welding strip and the submerged-arc welding, and adopting the stainless steel welding strip and the argon arc welding manner to weld the stainless steel compound layer welding line. According to the stainless steel compound welding steel pipe and the manufacturing method thereof, the manufactured stainless steel compound welding steel pipe has high structural strength and strong corrosion resistance; and the bonding strength of an inner pipe and an outer pipe is not less than 200 MPa.

Owner:ZHEJIANG KINGLAND & PIPELINE TECH

Multi-layer multiplex hydraulic valve mold and casting technique thereof

The invention discloses a mould for a multilayer multi-way hydraulic valve and a casting process thereof. The casting process comprises: cleaning a mould, adjusting the mould, selecting a shell mold and a sand core material, then entering a manufacturing and molding working procedure, and finally casting and mold stripping. The process matched with the mould for the multilayer multi-way hydraulic valve adopts a method with the shrinkage characteristic of the process to control shrinkage amount of a casting, namely controlling the shrinkage amount of the casting by placing a plurality of layers of asbestos cloth at a sand core head of a main flow passage of the casting, finely adjusts the tolerance of the dimension of the casting by adjusting the layer number of the asbestos cloth, smoothly solves the problem of requirement on the dimensional precision of a CAT casting, and is a casting process which can manufacture the multilayer multi-way hydraulic valve with higher precision requirement and stable quality.

Owner:南通华东液压铸业有限公司

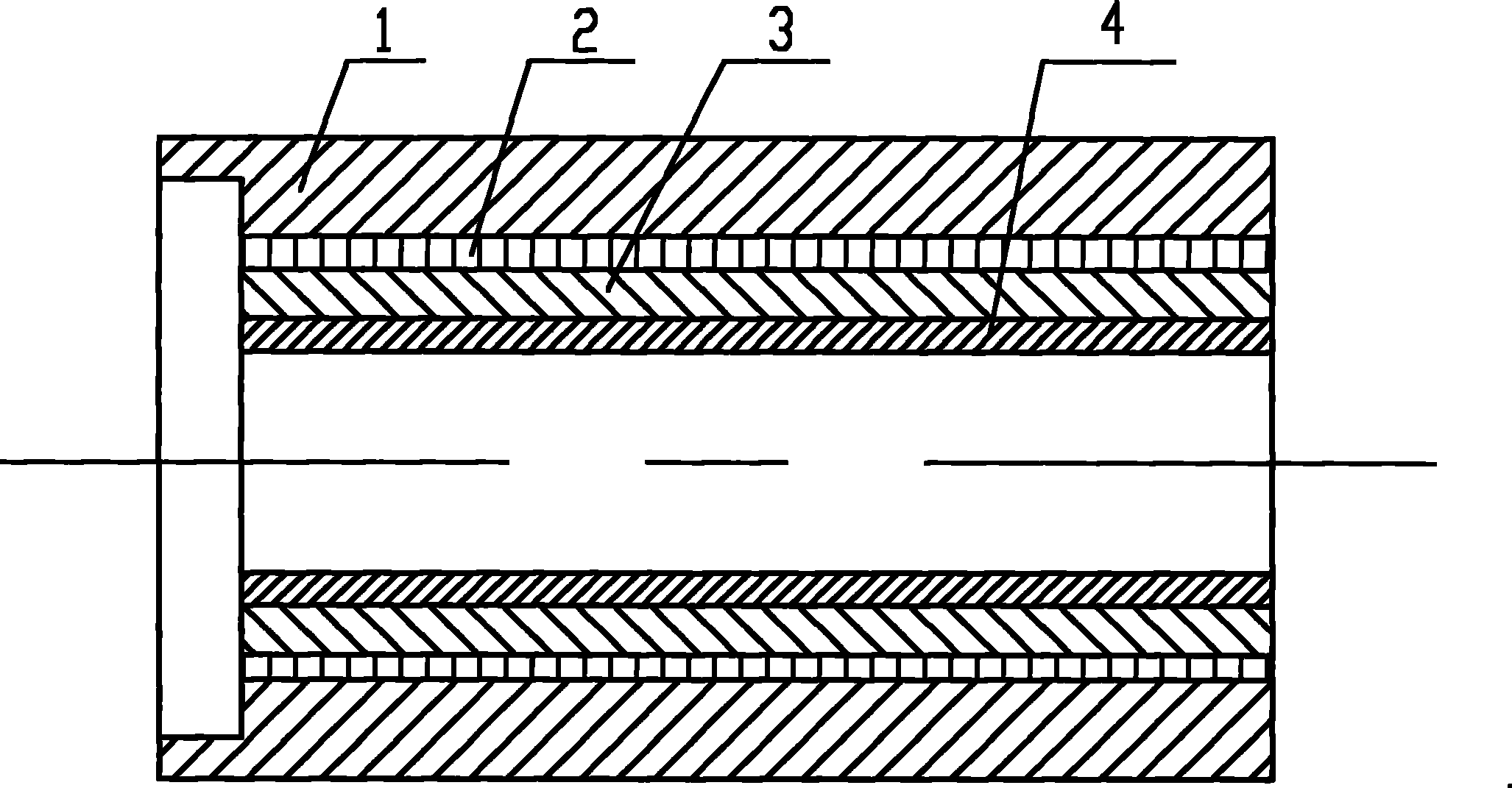

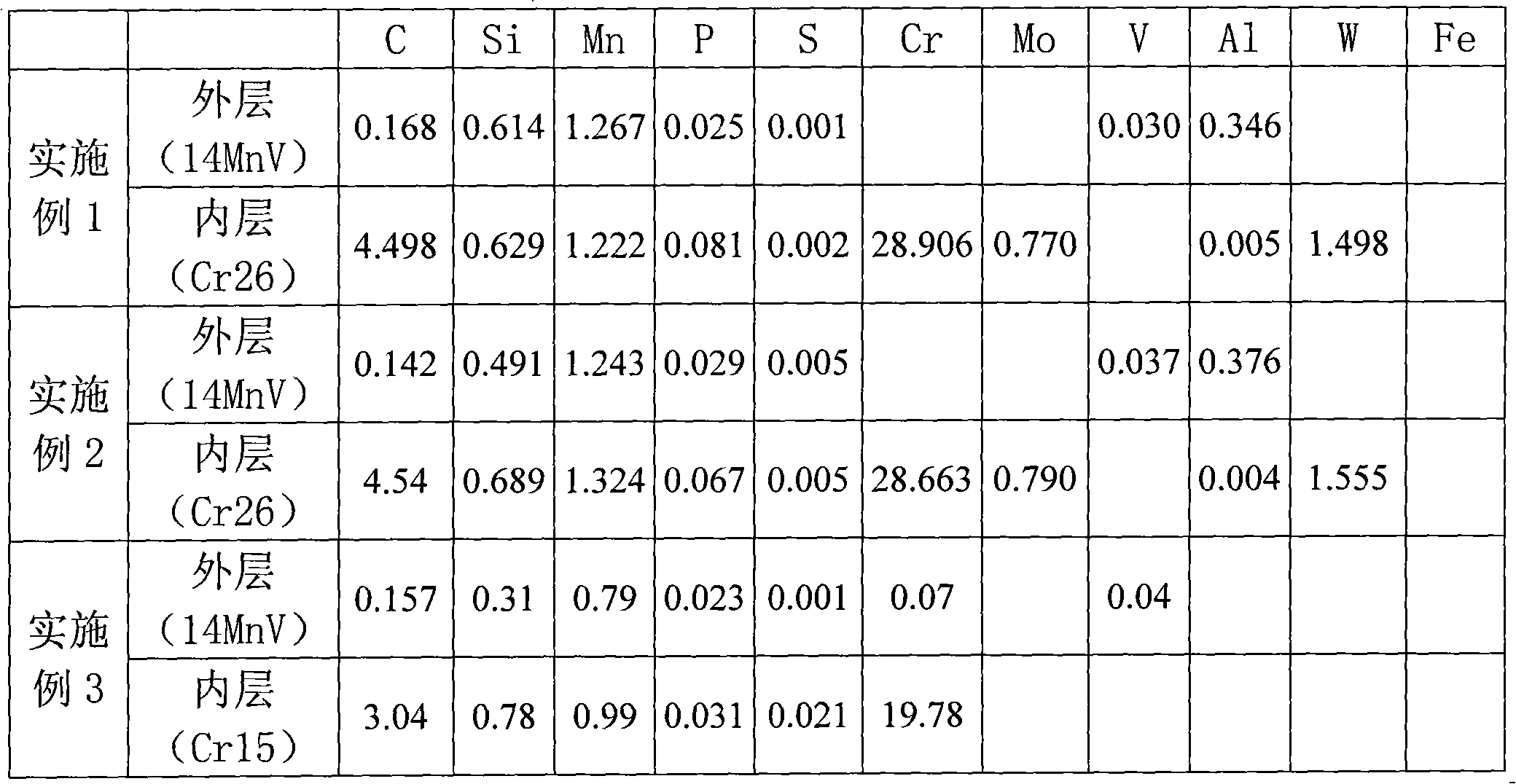

Bimetallic metallurgical composite wear-resisting tube blank and manufacturing method thereof

The invention discloses a method for manufacturing a bimetallic metallurgical composite wear-resisting tube blank, which comprises the following steps: firstly, spraying a water-based zircon powder coating onto a metal tube die after being baked to between 200 and 300 DEG C, wherein the spraying thickness is 1.0 to 3.0mm; secondly, centrifugally casting external liquid metal on the metal tube die after being baked to between 200 and 350 DEG C, cooling the metal tube die after casting, beginning to cast internal liquid metal into the metal tube die when an internal surface temperature of the outer layer is cooled to a temperature lower than a solidus temperature of the external metal; and finally, pouring the internal liquid metal into the metal tube die for centrifugal casting, cooling the metal tube die after casting, and stopping cooling when the outer layer and the inner layer are completely solidified, then the outer layer and the inner layer are metallurgically fused completely, wherein the outer layer is made of a plain carbon steel material or a low-alloy high-strength steel material and the inner layer is made of a high-chromium white cast iron material. The invention also discloses the bimetallic metallurgical composite wear-resisting tube blank manufactured by the method. The outer-layer metal and the inner-layer metal of the tube blank manufactured by the method can be metallurgically fused completely; the qualification rate is improved; and the use safety is high.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

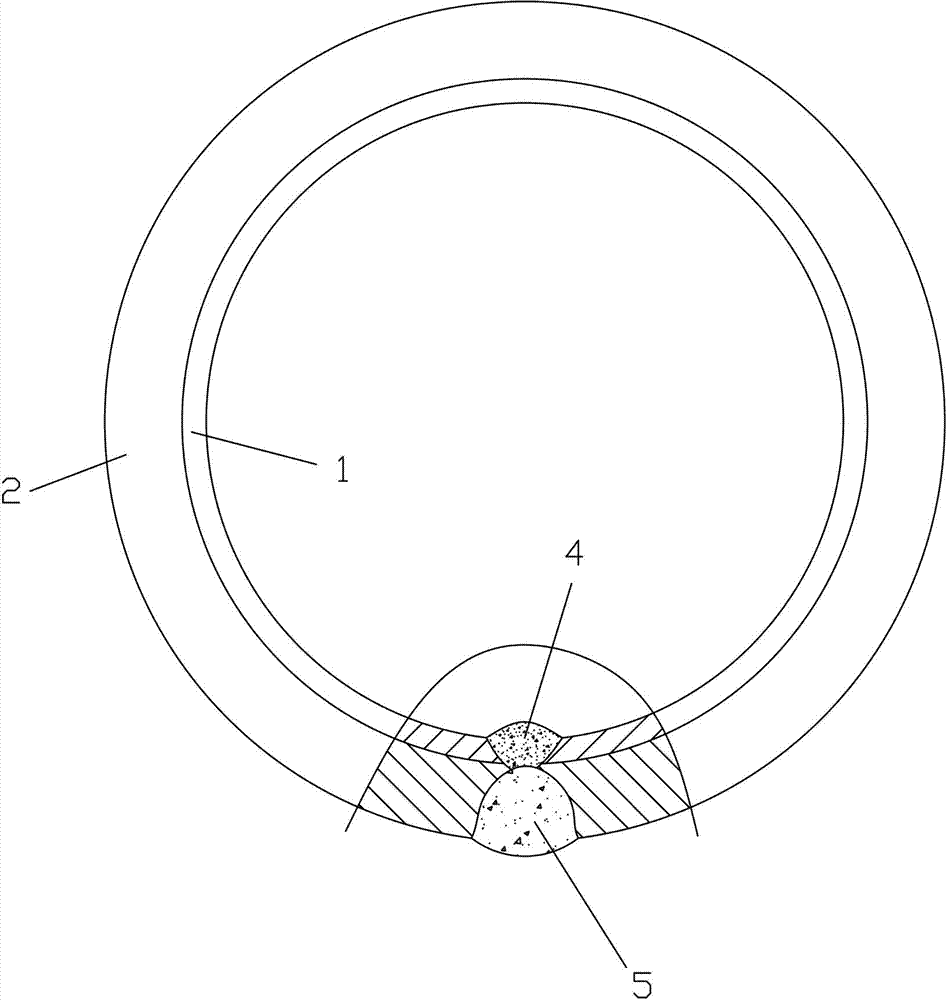

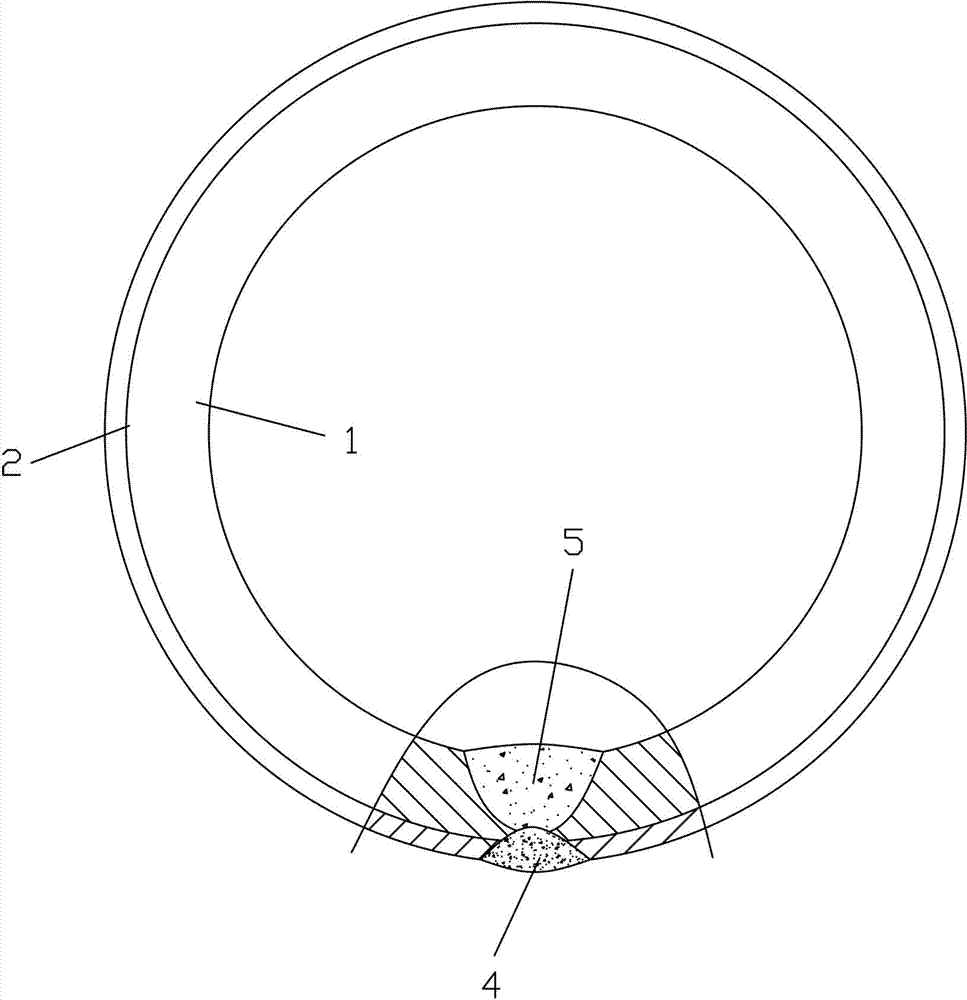

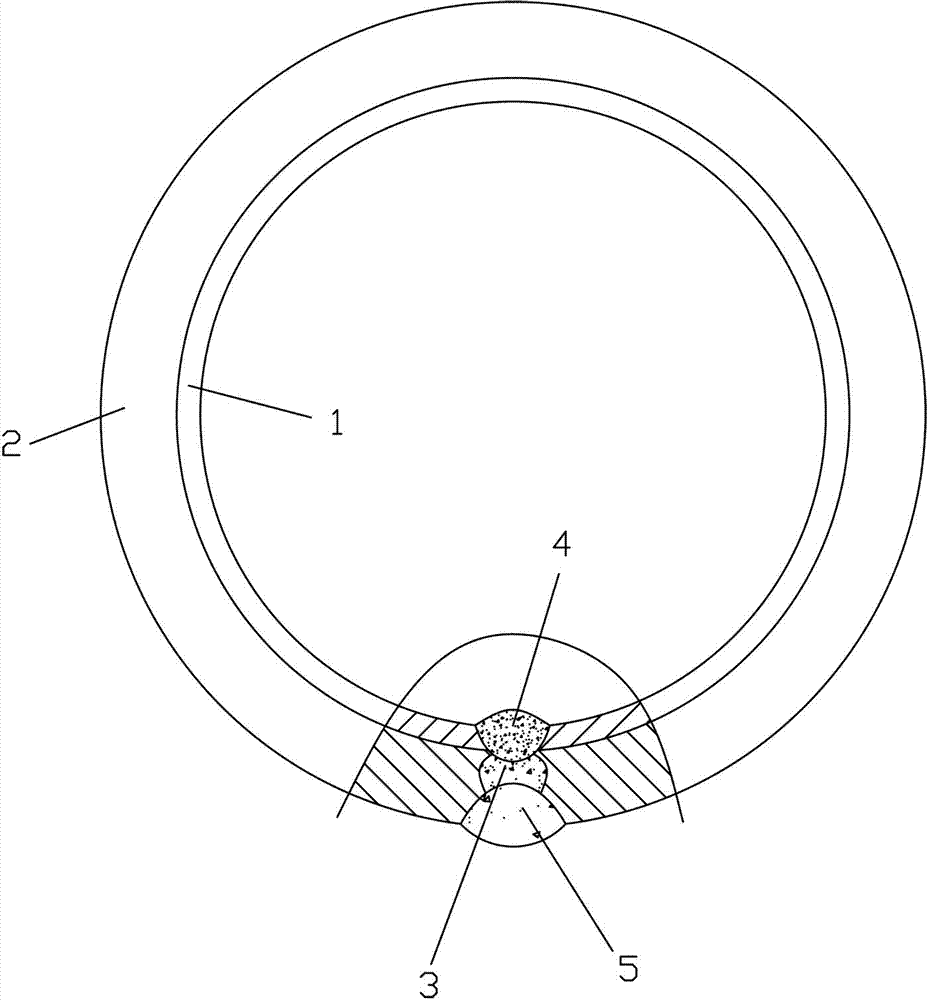

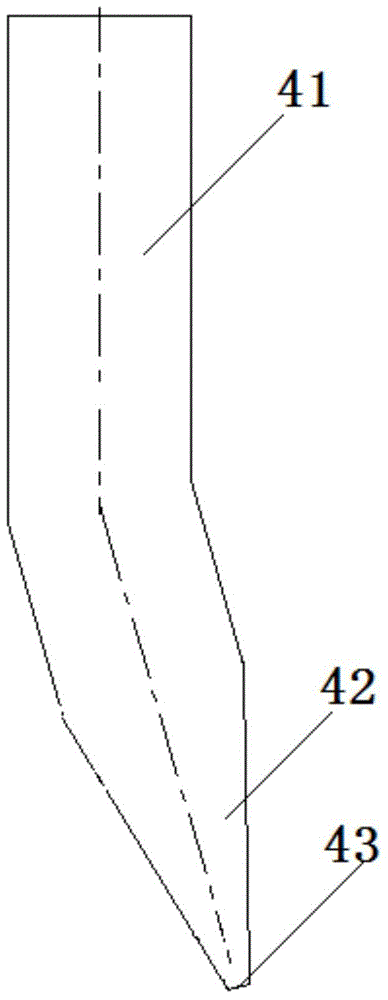

Sacroiliac joint fusion systems and methods

ActiveUS20160175113A1Easy accessImprove visualizationInternal osteosythesisCannulasSacroiliac jointBiomedical engineering

Joint fixation systems and methods, enabling: drilling one or more major bores in a joint; drilling one or more minor bores in the joint, wherein the one or more minor bores are disposed about a periphery of and partially overlap the major bore(s); and disposing an implant in the major bore(s) and the one or more minor bores, wherein a cross-sectional shape of the implant substantially conforms to a collective cross-sectional shape of the major bore(s) and the one or more minor bores. Prior to drilling the major bore(s) or the one or more minor bores, a portal tube is disposed adjacent to the joint, thereby providing access to and stabilizing the joint. A drill guide tube is disposed concentrically within the portal tube, and a drill guide is disposed concentrically within the drill guide tube. Subsequent to drilling the major bore(s) and the one or more minor bores, an implant guide tube is disposed concentrically within the portal tube.

Owner:BEACON BIOMEDICAL

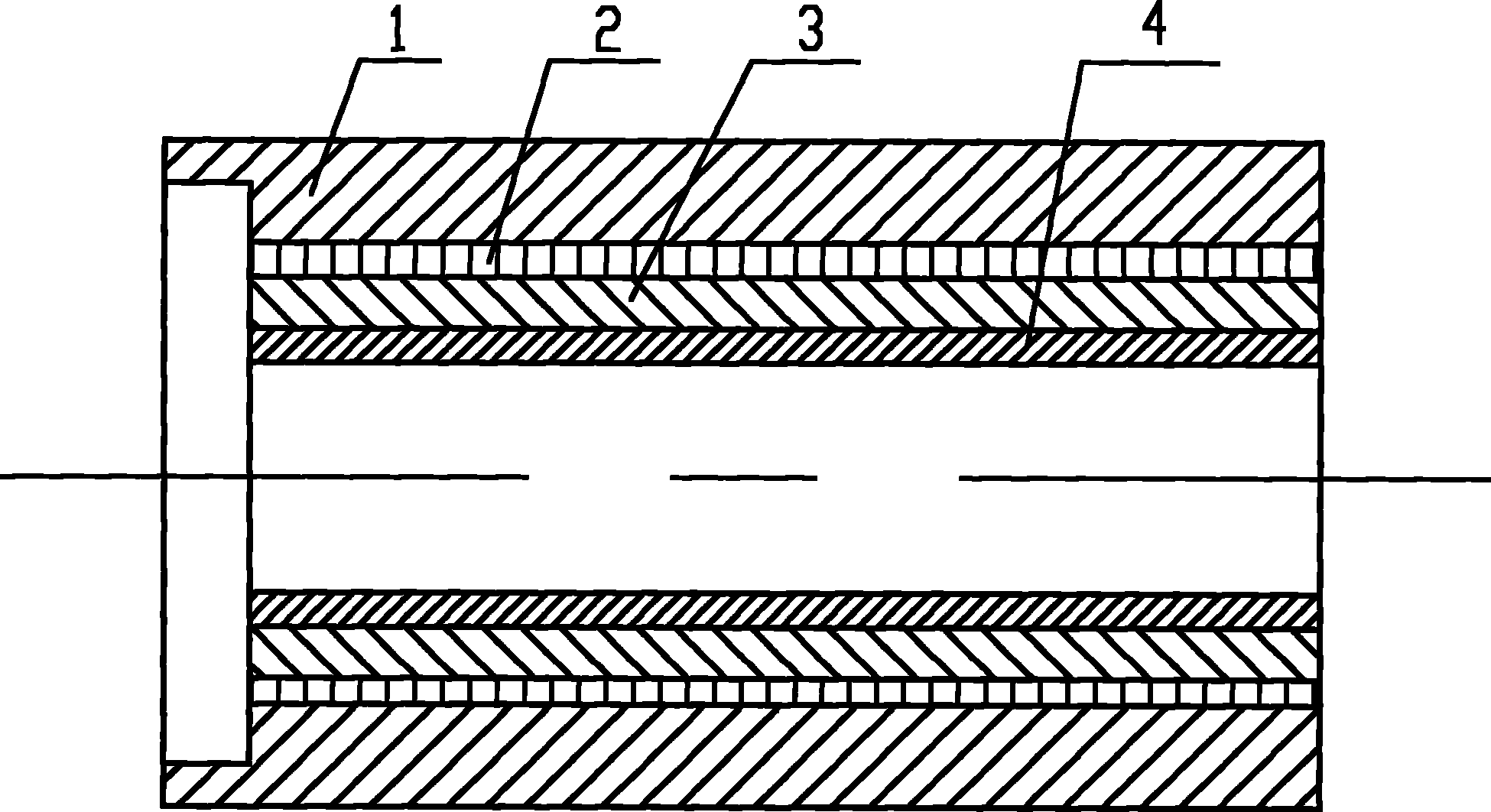

Pneumatic tire and method of manufacturing the same

ActiveUS20090199942A1Improve adhesionGuaranteed maintenance effectWithout separate inflatable insertsTyresElastomerThermoplastic elastomer

Provided is a pneumatic tire in which the adhesion of a noise absorbing member formed of a porous material is improved. A pneumatic tire according to the present invention includes a resin layer, a noise absorbing member and a locking member. The resin layer is formed of any one of a thermoplastic resin and a thermoplastic elastomeric composition obtained by dispersing an elastomer in a thermoplastic resin, and is formed on at least a part of the inner surface of the tire. The noise absorbing member is formed of a porous material, and is disposed on the resin layer. The locking member is formed of a thermoplastic resin, and is bonded to the resin layer through the noise absorbing member by thermal fusion.

Owner:THE YOKOHAMA RUBBER CO LTD

Methods and apparatus for repairing and/or replacing intervertebral disc components and promoting healing

InactiveUS20110034975A1Increase riskFacilitates reconstructionInternal osteosythesisBone implantHerniated discsSurgical department

Disclosed embodiments provide for treatment of the anulus fibrosus (AF) and intevertebral disc (IVD), including herniated discs, anular tears of the disc, or disc degeneration, while enabling surgeons to contain blood, fluid, proteins, or other materials that are placed into or migrate into or near defective regions of the spine. The invention also concentrates mesenchymal stem cells (MSCs) in the surgical area and increases the area of bone to be fused. Other aspects of the invention may be used to raise the temperature of tissues, including surgical tissues, to stimulate inflammation, thereby stimulating tissue healing. According to these embodiments, the invention places a heating element below the skin and adjacent to the tissue to stimulate the healing thereof.

Owner:FERREE BRET A

Granular polyurethane resin composition and molded article of the same

InactiveUS20100227985A1Fusion wellImprove production efficiencyVehicle componentsCoatingsThermoplastic polyurethanePolymer chemistry

Disclosed is a granular polyurethane resin composition containing a thermoplastic polyurethane resin which contains a hard segment obtained by a reaction between a polyisocyanate and a chain extender. The polyisocyanate contains isocyanate groups of 1,4-bis(isocyanatomethyl)cyclohexane in an amount of not less than 50% by more relative to the total mole number of isocyanate groups.

Owner:MITSUI CHEM INC

Laser differential confocal LIBS, Raman spectrum-mass spectrum imaging method and Raman spectrum-mass spectrum imaging device

InactiveCN105136750AImplement focus detectionRealize functionMaterial analysis by electric/magnetic meansRaman scatteringLaser-induced breakdown spectroscopyMass spectrometry imaging

The invention relates to a laser differential confocal LIBS, a Raman spectrum-mass spectrum imaging method and a Raman spectrum-mass spectrum imaging device and belongs to the technical fields of confocal microscopy imaging, mass spectrum imaging and spectral measurement. In the invention, the differential confocal microscopy imaging technology is combined with a spectrum and mass spectrum detection technology; a high-spatial-discrimination differential confocal system is used for axially focusing and imaging a sample; a mass spectrum detection system is used for performing mass spectrum detection to charged molecules and atoms in a sample microcell; and a spectral detection system is used for performing microcell spectrum detection to focal spot excitation spectrums (Raman spectrum and induced breakdown spectrum) of a differential confocal microscopy system, thereby achieving high-spatial discrimination and high-sensitivity imaging and detection of complete component information and configuration parameters of the sample microcell. The invention achieves advantage complement and structure and function fusion of laser poly-spectrum component imaging detection (mass spectrum, Raman spectrum and laser-induced breakdown spectrum). The method and the device have wide application prospect in the fields of biology, physical chemistry, micro-fabrication and nano-fabrication and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Thermoplastic elastomer composition and process for producing the same

InactiveUS20050038186A1Improve mechanical propertiesImprove scratch resistanceMeth-Thermoplastic elastomer

A thermoplastic elastomer composition of the invention, formed by dynamically crosslinking a polymer composition including a rubber and an olefinic resin and having an average particle size of rubber particles within a specific range, shows an excellent balance of mechanical properties such as flexibility and elastic recovery, and a moldability. Also an inclusion of a (meth)acrylate resin and a hydrogenated diene polymer provides a composition particularly excellent in scratch resistance. Also an inclusion of a maleimide compound provides a composition particularly excellent in injection fusibility. Also an inclusion of an undenatured organopolysiloxane of a specific viscosity and a denatured organopolysiloxane provides a composition particularly excellent in initial slidability and durable slidability.

Owner:ENEOS MATERIALS CORP

Low-alloy high-strength steel welding process

InactiveCN101337298ASolving the Elimination of Welding Residual StressHigh tensile strengthArc welding apparatusWelding/cutting media/materialsWelding residual stressAlloy

The invention discloses a technological method for welding low-alloy high-strength steel, which comprises the following steps: a divided edge is formed, a welding area is polished and cleaned, and the strength of welding material is equivalent to that of steel to be welded; Ar+CO2 mixed gas protective welding is adopted, preheating is performed before welding, and the welding speed is 250-300mm / min; a 800MPa solid welding wire is adopted to perform multilayer multirun welding; the interlayer temperature is kept at 150 DEG C plus or minus 20 DEG C during the welding process, a preheating spray gun is used from time to time for temperature compensation, the welding line energy is 16-18KJ / cm, low temperature aging is performed to the whole after welding, and the temperature is 300-400 DEG C. The welding technological method prevents welding cracks from being generated, eliminates residual stress generated during welding large-sized structural members, and serves the purpose that the tensile strength of weld joins equals the tensile strength of parent metal.

Owner:四川航天神坤装备有限公司

Horizontal position welding method

The invention discloses a horizontal position welding method, which butts an upper plate and a lower plate. The back of the butted position of the plates is provided with and fixed with a pad, under the condition of a small gap, a monofilament automatic horizontal position welding trolley which swings welding sticks up and down is directly used for back welding; under the condition of a large gap, firstly, semi-automatic CO2 shielded welding or the monofilament automatic horizontal position welding trolley is adopted to carry out back welding on one or more channels on the side of the lower plate at the gap position under the condition of not swinging the welding sticks, when the gap turns smaller, then monofilament automatic horizontal position welding trolley swinging the welding sticks up and down is used for back wielding of the remained gap, finally the whole welding line is filled fully by diplonema automatic welding. The invention widens the suitable range of the back wielding mode using the automatic horizontal position welding trolley, and improves the efficiency and the wielding quality of the horizontal position welding.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

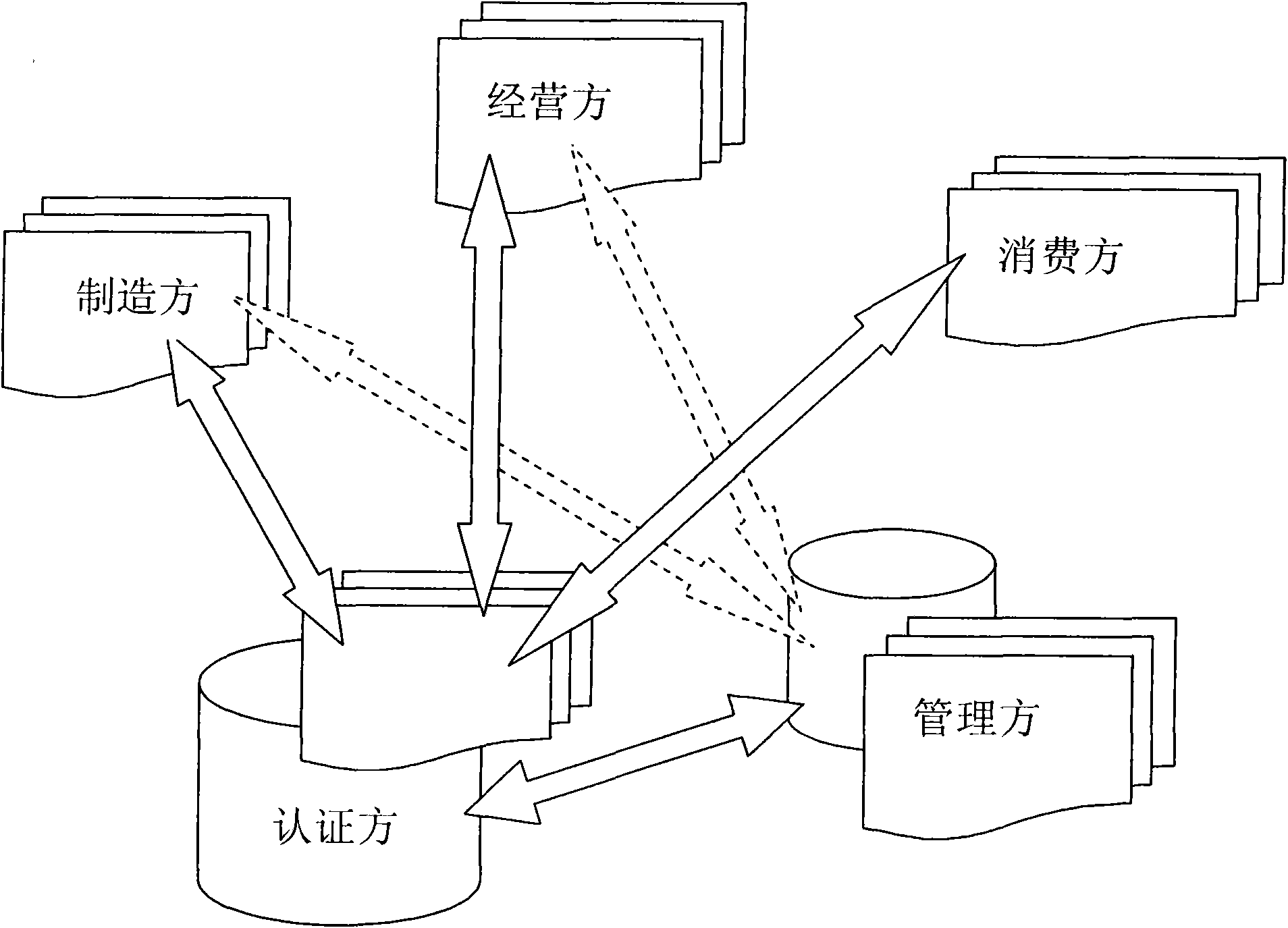

Method for interactive dynamic forgery prevention and verification

InactiveCN101807285AImprove anti-counterfeiting performanceEasy to processCommerceInformation networksComputers technology

The invention relates to a method for interactive dynamic forgery prevention and verification, which realizes the dynamic forgery prevention and verification with the effects of low cost, easy implementation, forgery prevention and cross-territory selling prevention. The method comprises a manufacturing party, a management party, a consuming party, a certification party and an administration party, and is characterized in that the manufacturing party which produces and processes anti-counterfeit articles, the management party which carries out transactions and provides service based on the anti-counterfeit articles, the consuming party which ultimately holds and uses the articles, the certification party which is responsible for verifying whether the articles are true or false, and the administration party which stores and processes the circulation information of the anti-counterfeit articles carry out the interaction and inquiry and verification processing on the anti-counterfeit information of the articles based on the computer technology, communication equipment and the information network. By using the method, all the parties can realize the information interaction and the dynamic data update, thereby achieving the purposes of cross-territory selling prevention and forgery prevention.

Owner:周锡卫

Full-position connecting pipe and safety end circular seam welding method achieved through tungsten electrode inert gas arc welding

ActiveCN104084678AImprove welding efficiencyReduce welding distortionArc welding apparatusWorkpiece edge portionsSpin weldingArchitectural engineering

The invention discloses a full-position connecting pipe and safety end circular seam welding method achieved through tungsten electrode inert gas arc welding. According to the method, nickel base alloy serves as an isolating layer to carry out machining on a connecting pipe and a safety end so that a welding groove can be formed by the connecting pipe and the safety end during assembling, and the welding groove is welded. A plurality of weld beads are welded during welding, the bottom end of a part to be welded is arced during welding, spin welding is carried out along one side of the part to be welded to the top end of the part to be welded, arcing is stopped, the bottom end of the part to be welded is arced again, spin welding is carried out along the other side of the part to be welded to the top end of the part to be welded, and arcing is stopped. When the welding groove is a double-faced U-shaped narrow gap groove, an outer groove is welded but not completely welded, back chipping and complete welding are carried out on an inner groove, and then complete welding is carried out on the outer groove. When the welding groove is a single-faced narrow gap groove, the groove is completely welded, a cushion plate is removed, and back chipping is carried out.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

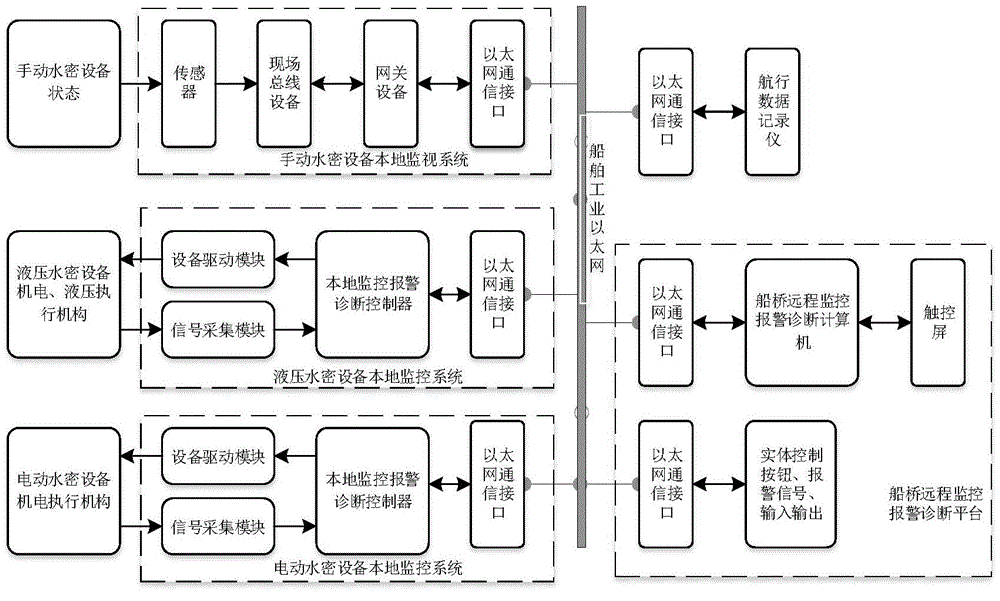

Ship or offshore mobile platform watertight equipment monitoring and fault diagnosis system

InactiveCN105988457AImprove transmission efficiencyHigh transmission accuracyElectric testing/monitoringIndustrial EthernetNon real time

The invention discloses a ship or offshore mobile platform watertight equipment monitoring and fault diagnosis system. The ship or offshore mobile platform watertight equipment monitoring and fault diagnosis system includes a watertight equipment monitoring local monitoring system, a ship industrial Ethernet and a bridge remote monitoring alarm diagnosis platform, wherein the watertight equipment monitoring local monitoring system is used for acquiring the state signals of watertight equipment so as to generate monitoring signals, carrying out fault diagnosis on the state signals so as to generate corresponding real-time monitoring signals, and generating corresponding pre-diagnosis information according to diagnosed non-real-time complex faults; the bridge remote monitoring alarm diagnosis platform is connected with the watertight equipment monitoring local monitoring system through the ship industrial Ethernet; the pre-diagnosis information is inputted into the bridge remote monitoring alarm diagnosis platform through the ship industrial Ethernet so as to be applied to final fault diagnosis; and when a fault occurs, shutdown control signals are emitted, so that maintenance information can be further obtained. With the ship or offshore mobile platform watertight equipment monitoring and fault diagnosis system of the invention adopted, two-stage fault diagnosis can be carried out on a whole ship and an offshore mobile platform, and comprehensive monitoring and operation maintenance of watertight integrity and the watertight equipment can be realized.

Owner:刘炎

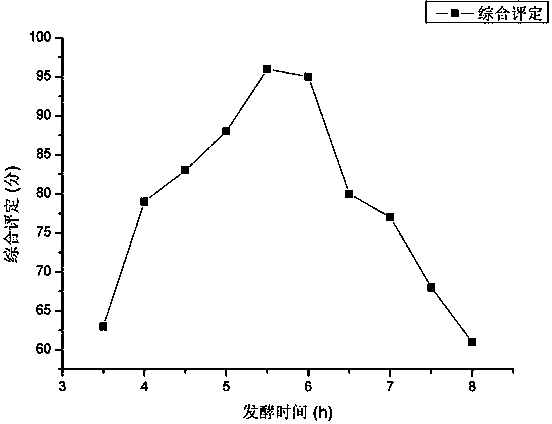

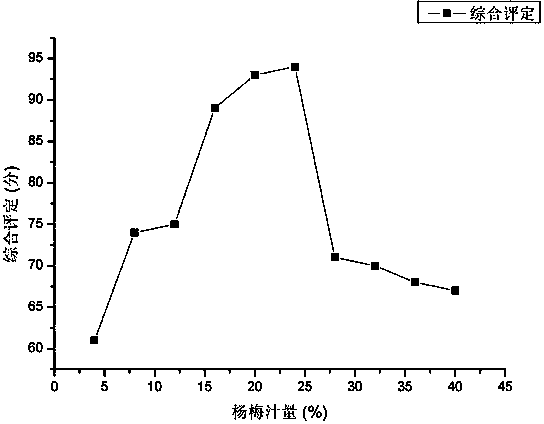

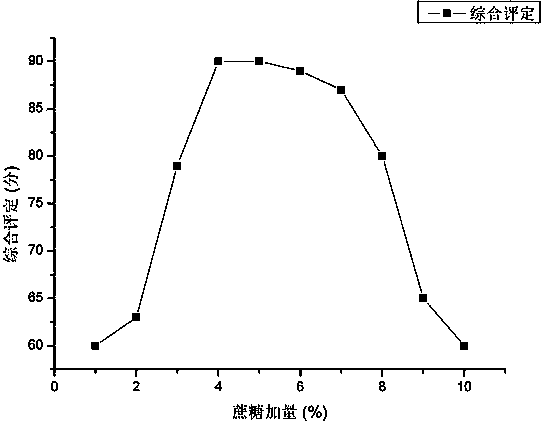

Honey-waxberry yoghourt and production method thereof

InactiveCN103549003AHarmonious and suitable aromaCoordinated and suitable milk flavorMilk preparationSaccharumSucrose

The invention relates to honey-waxberry yoghourt and a production method thereof. The honey-waxberry yoghourt is characterized by comprising a component A, a component B and a component C, wherein the component A is milk; the component B comprises the following components according to the weight percent of the component A: 4%-8% of honey water solution, 8%-24% of waxberry juice and 4%-8% of cane sugar; the component C is strain powder, and the adding amount of the strain powder is equal to 2%-3% of the component A according to weight percent. According to the production method, the honey, the waxberry and the milk are processed into a yoghourt beverage in certain proportion, the nutrition and the taste are integrated, the honey-waxberry yoghourt has the nutrition and healthcare functions of the honey, the waxberry and the yoghourt, the assortment of yoghourt products are enriched, and particularly, the market blank of honey-waxberry yoghourt is made up. Specifically, the honey-waxberry yoghourt has the advantages that the color is uniform and is pale violet red, the aroma of the waxberry and the honey and the milk fragrance are properly coordinated, the sweetness is moderate, the taste is fine, the honey-waxberry yoghourt is in a uniform curdled milk state, and no or few whey is separated out.

Owner:SUZHOU POLYTECHNIC INST OF AGRI

Pulsar/starlight angle combination navigation method of high orbit satellite

InactiveCN104006813AReduce precisionGood navigationInstruments for comonautical navigationNavigation by astronomical meansEnvironmental geologyMarine navigation

The invention discloses a pulsar / starlight angle combination navigation method of a high orbit satellite. The method comprises the following steps: establishing an orbital dynamic equation of a near earth satellite; establishing a pulsar navigation observation equation; establishing a starlight angle observation equation; using a dynamic filter to process a dynamic model and starlight angle distance information; and fusing the obtained filter result with the pulsar observation information by using a static filter. The combination navigation method uses the dynamic and static nonlinear filter to realize the optimal fusion of the original observation information of the pulsar with the starlight angle distance information, so compared with a pulsar navigation system, a combination navigation system has the advantages of small size, less power consumption short measurement period; and compared with CNS, the combination navigation system can obtain high precision navigation information.

Owner:NAT UNIV OF DEFENSE TECH

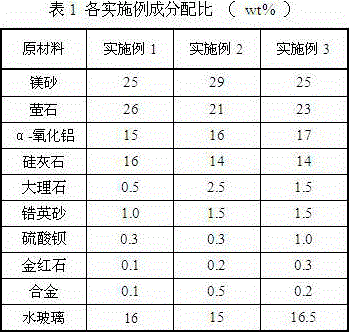

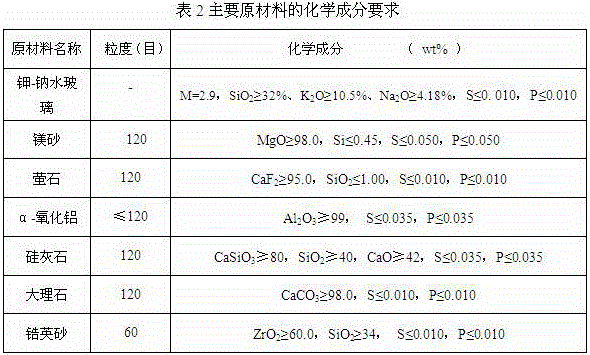

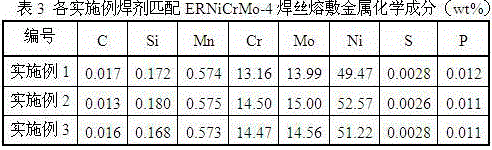

Sintered flux for 9Ni steel welding and preparation method thereof

ActiveCN106238965AImprove low temperature toughnessGood thermal crack resistanceWelding/cutting media/materialsSoldering mediaTO-18Crack resistance

The invention discloses sintered flux for 9Ni steel welding, and relates to the technical field of welding materials. The sintered flux comprises the following components in parts by weight: 20 to 28 parts of CaF2, 23 to 33 parts of MgO, 15 to 18 parts of Al2O3, 8 to 12 parts of CaO, 4 to 10 parts of SiO2, 0.5 to 2 parts of BaO, 0.5 to 2 parts of TiO, 0.5 to 2 parts of ZrO2, 0.5 to 2 parts of alloy and 15 to 20 parts of water glass, wherein the alloy is ferrosilicon or manganese-silicon or a combination of ferrosilicon and manganese-silicon. The preparation method comprises the steps of uniformly mixing the components according to the proportion; carrying out granulation; drying at the low temperature of 300 to 400 DEG C; and sintering at the high temperature of 660 to 750 DEG C, so as to obtain a flux finished product. According to the sintered flux, the flux is matched with a solid welding wire ERNiCrMo-4, the welding manufacturability is relatively good, the mechanical property of weld joints is good, the ultra-low temperature toughness of deposited metals is stable and excellent, the hot crack resistance sensitivity is good, and the sintered flux is applicable to submerged arc flat welding and horizontal welding of 9Ni steel.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

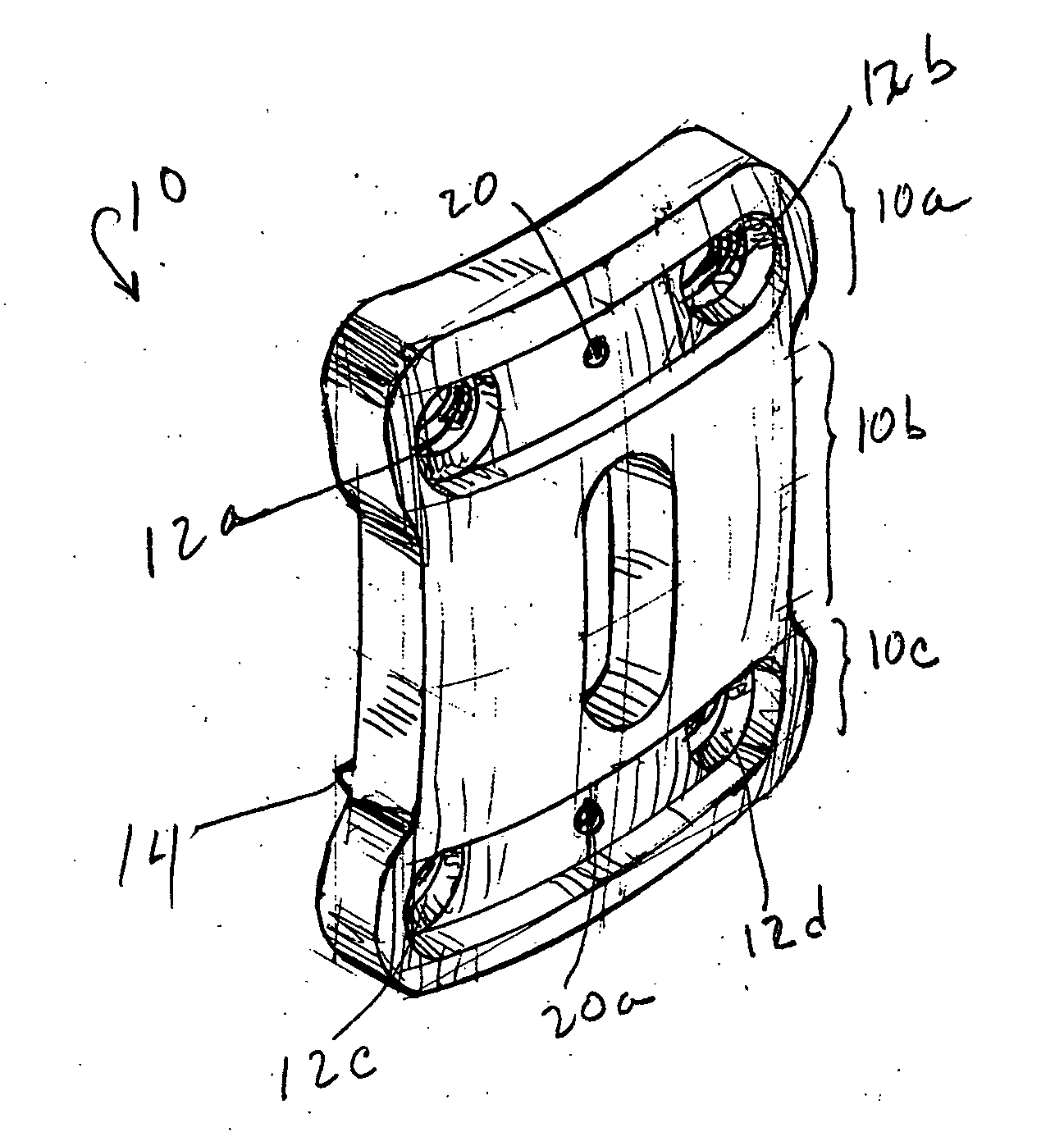

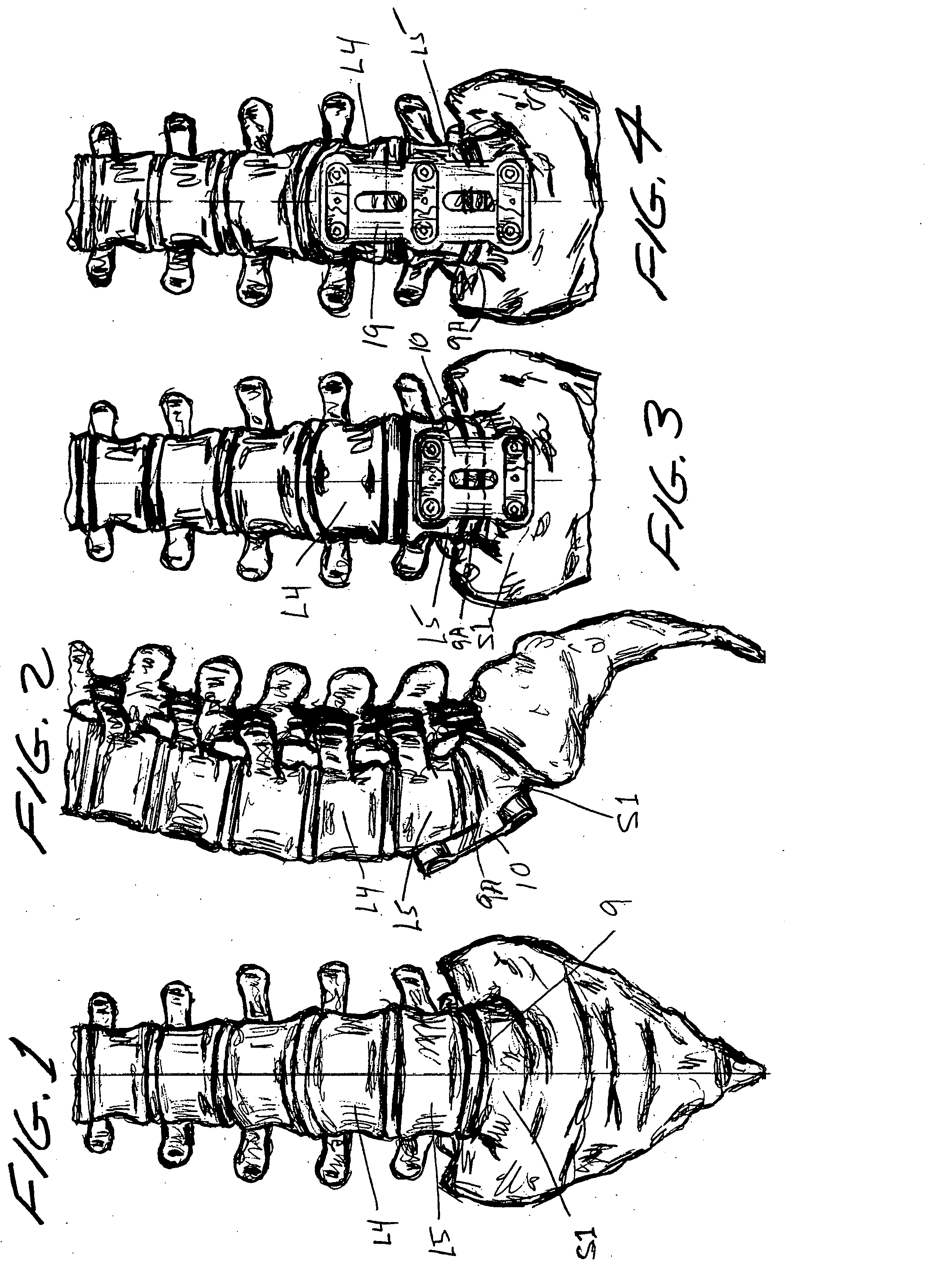

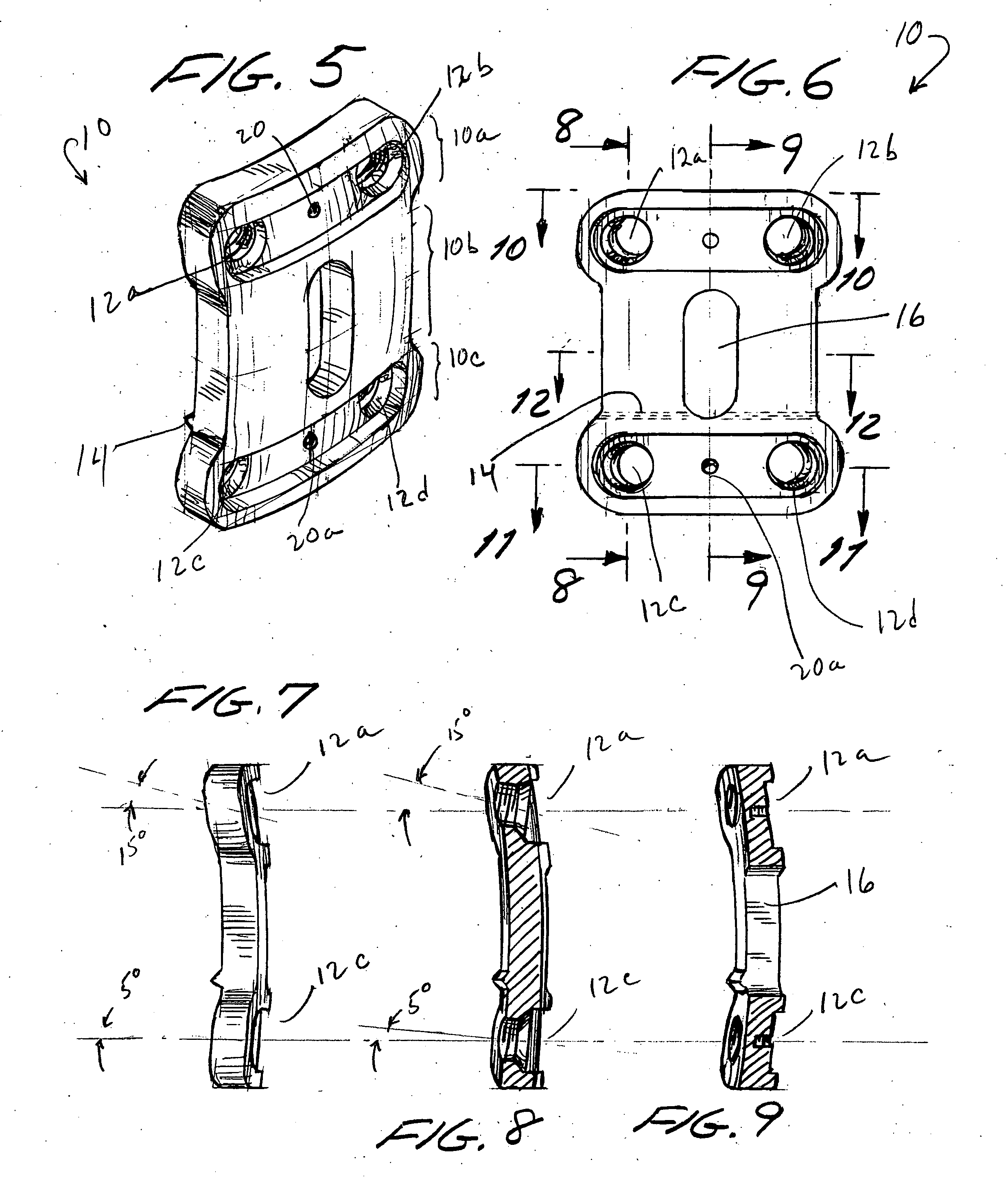

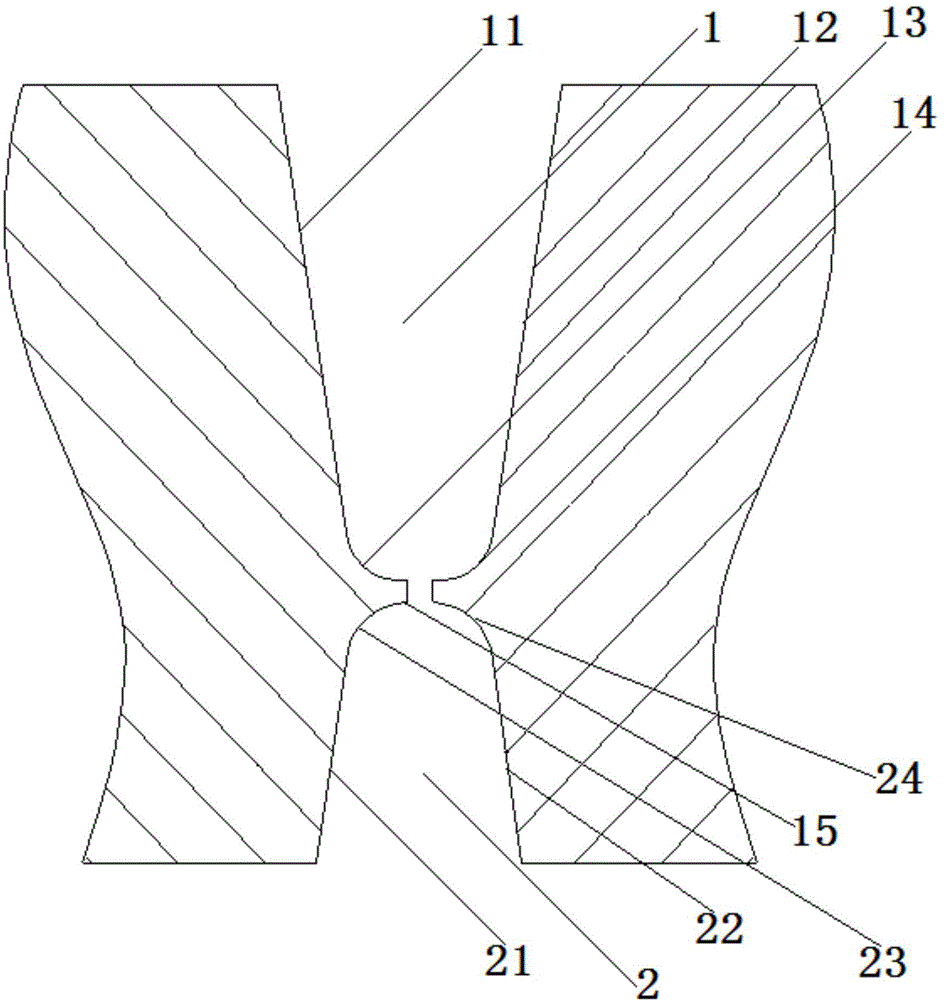

Spinal implant device with fusion cage and fixation plates and method of implanting

ActiveUS20120215261A1Easy to fixFusion wellInternal osteosythesisJoint implantsMedicineSacroiliac joint

There is provided a spinal implant device for placement between adjacent spinous processes and a pair of opposing facet joints. The spinal implant device includes a fusion cage, first and second fixation plates and a connector for connecting the cage to the plates. The fusion cage includes a superficial face, a deep face, superior and inferior saddle portions, and opposing cage ends. Each cage end defining a facet fusion surface sized and configured to respectively contact the opposing facet joints. The first and second fixation plate are sized and configured to extend along and in contact with the adjacent spinous processes. A method of implanting the device is provided. In another embodiment the device includes the fusion cage.

Owner:MASSOUDI FARZAD

Composite ceramic powder for laser cladding of high manganese steel material

InactiveCN109440101AFusion wellImprove impact toughnessMetallic material coating processesOxide ceramicComposite ceramic

The invention belongs to the technical field of material laser cladding, and relates to composite ceramic powder for laser cladding of a high manganese steel material. The composite ceramic powder isprepared from the following components in percentage by mass: 0.3-5% of C, 8-16% of Cr, 0.5-2.5% of Co, 1-4% of Mo, 0.5-1.0% of V, 0.5-3.5% of Si, 0.5-1% of Mn, 1.5-8% of Ni, 0.5-4% of B and the balance of Fe, wherein 3-5% of oxide ceramics Al2O3 and 2-4% of carbide ceramics SiC are added as an abrasion-resistant ceramic phase. The composite ceramic powder is cladded on the surface of the manganese steel material through a laser cladding remanufacturing technology, the composite ceramic powder and a matrix are fused well, the cladding surface does not produce cracks, the hardness is up to HRC55 or above, and good impact toughness and abrasion resistance are achieved.

Owner:北京奥邦新材料有限公司

Sun-proof antibacterial textile fabric

ActiveCN106884250AImprove breathabilityImprove comfortBiochemical treatment with enzymes/microorganismsWoven fabricsYarnMicrometer

The invention relates to the technical field of textile fabric manufacturing and discloses a sun-proof antibacterial textile fabric. The fabric is formed by interweaving warp and weft in a mutually perpendicular mode, the warp is sun-proof antibacterial fiber blended yarn, the weft is composed of flax fibers and polyvinyl alcohol fibers in the weight ratio of 1:(1-2), the diameter of the warp is 46.5-51.5 micrometers, the diameter of the weft is 43-44.5 micrometers, the density of the warp is 76-79 pieces per centimeter, and the density of the weft is 55-58 pieces per centimeter. The fabric has the advantages that the polyvinyl-acetal-based sun-proof antibacterial fabric is high in strength, good in toughness and excellent in moisture absorption and has the sun-proof, anti-ultraviolet and antibacterial functions, the flax fibers and the polyvinyl alcohol fibers are added so that air permeability and the comfort of the fabric can be enhanced, and the fabric is more suitable for being used in hot environments in summer.

Owner:ZHEJIANG MENGSEN CLOTHING CO LTD

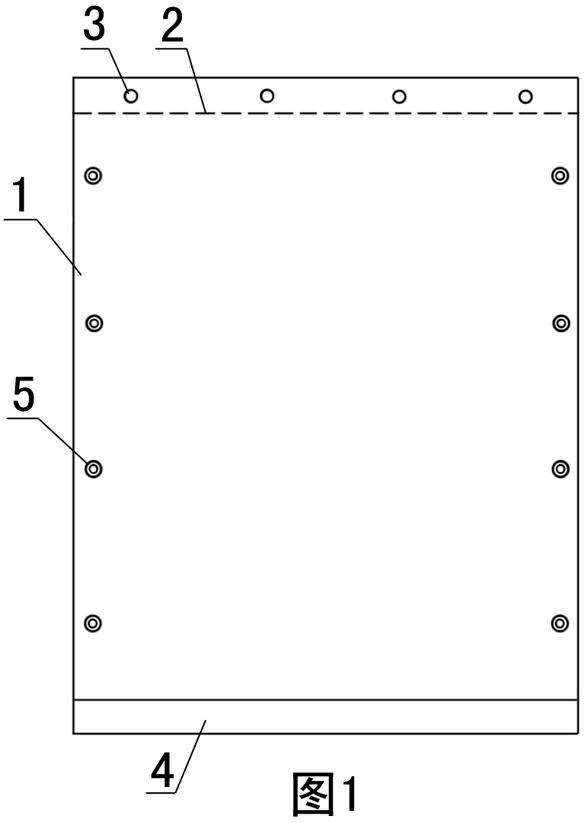

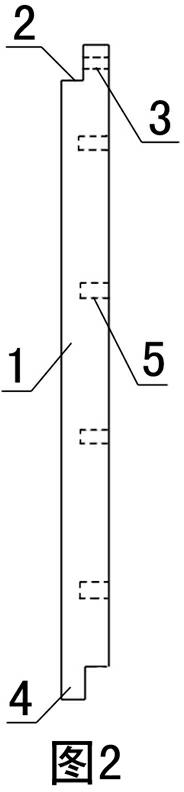

Prefabricated module board body and outer wall system of curtain wall type building as well as construction method of outer wall system

ActiveCN102535739ASimple structureEnsure safetyWallsCeramic shaping apparatusArchitectural engineeringComputer module

Owner:沈汉杰

Manual arc welding bottoming layer Z-shaped arc extinction method and application thereof in Q460 high-strength steel horizontally-fixed steel pipe butt welding

ActiveCN102922085AFusion wellNo accumulationArc welding apparatusTubular articlesShielded metal arc weldingButt welding

The invention discloses a manual arc welding bottoming layer Z-shaped arc extinction method and application of the manual arc welding bottoming layer Z-shaped arc extinction method in Q460 high-strength steel horizontally-fixed steel pipe butt welding. An arcing point is located at a position of a root part of a groove 2 to 3mm close to a truncated edge, an electric arc is lightly led to an oblique rear part of a fusing tank along the groove after being struck and then transversely swung to the other side of the groove after a pause, act extinction is carried out towards the oblique rear part of an arcing point after fusing of the groove at the side is good through observation, and a running track of an end of a welding rod is Z-shaped. As the fusing tank can be well observed in a welding process, welding defects of a bottoming layer can be reduced and technical support is provided to ensure welding quality of the bottoming layer of a butt joint. With the adoption of the arc extinction method, shaping of the root part of a welding seam can be effectively controlled and a good welding seam structure can be obtained.

Owner:CHINA ENERGY ENG GRP TIANJIN ELECTRIC POWER CONSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com