Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120results about How to "Good thermal crack resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cast magnesium alloy of low linear shrinkage

The invention discloses a cast magnesium alloy of low linear shrinkage, which belongs to the field of magnesium alloys. The magnesium alloy consists of Mg, Al, Zn, Mn, rare earth, Nb, Li and M element, wherein the materials have the following weight percentage composition: 1.5-25 percent of Al, 0.1-3.5 percent of Zn, 0.1-2.2 percent of Mn, 0.0002-16 percent of rare earth, 0.0002-4 percent of Nb, 0.0002-9 percent of Li, 0.0002-2 percent of M element and the balance Mg; and the M element is at least one of Zr, Ti, Sr, Ca, C and B. According to the heat-resistant magnesium alloy, the rare earth element and the Nb element are added into the magnesium alloy, so that the structure of beta phase is changed; the Zr element and the M element are added to refine crystal grains; due to combined action of the elements, latent heat of crystallization during alloy solidification is changed; and the magnesium alloy which has superior mold-filling capacity, low shrinkage, superior mechanical property and good machinability, fluidity and die-cast performance and is suitable for casting is obtained.

Owner:嘉兴佳斯贝特新材料有限公司

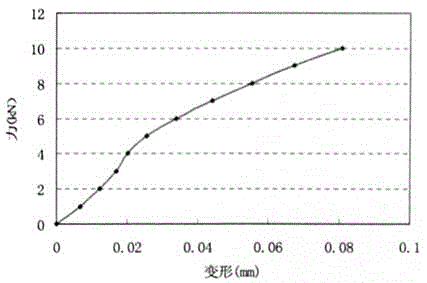

Friction material of brake sheet for rail transit vehicle brake system, and preparation method and application of friction material

InactiveCN102560183ALow costStable coefficient of frictionFriction liningRail transitMaterials science

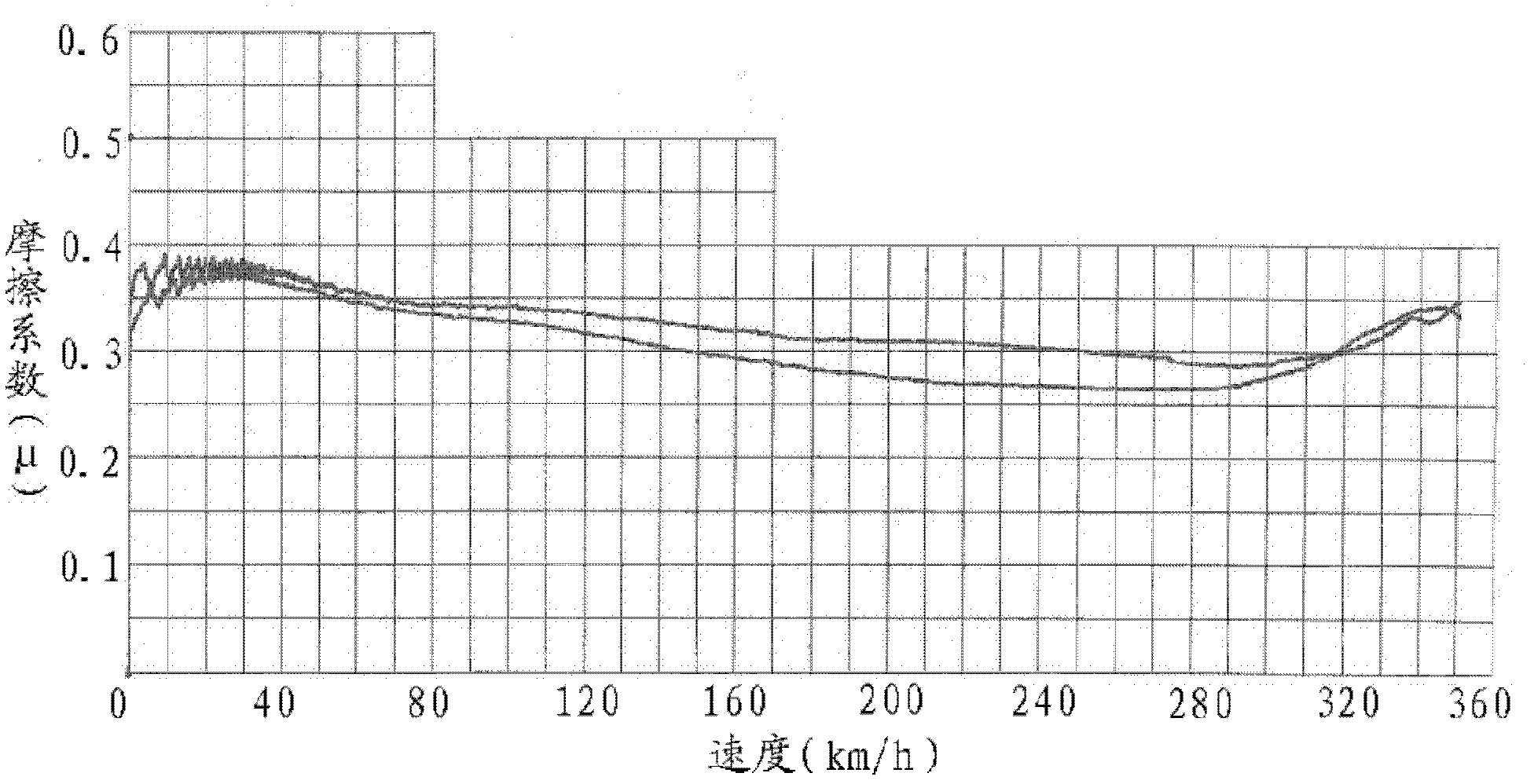

The invention discloses a friction material of a brake sheet for a rail transit vehicle brake system, and a preparation method and application of the friction material. The friction material comprises the following components in parts by weight: 40 to 60 parts of Cu, 6 to 15 parts of Fe, 6 to 10 parts of Sn, 2 to 5 parts of Ni, 1 to 5 parts of Mn, 1 to 6 parts of Cr, 8 to 16 parts of C, 2 to 8 parts of Sic and 2 to 8 parts of Mo. The preparation method for the friction material comprises the following steps: mixing the components to obtain a mixture; placing the mixture into a die and pressing; and sintering the pressed mixture to obtain the friction material of the brake sheet for the rail transit vehicle brake system. The invention overcomes the defects in the prior art, has the advantages of stable friction coefficient and low wear rate, can safely brake rail transit vehicles, and can reduce the using cost and the maintenance cost of the rail transit vehicles.

Owner:MIN OF RAILWAY TRANSPORT BUREAU +2

Ceramic part and production method thereof

PendingCN106977184AHigh densityImprove uniformityCeramic shaping apparatusInjection molding machineHigh heat

The invention relates to the technical field of powder metallurgy and particularly relates to a ceramic part and a production method thereof. The production method comprises (1) mixing granulation: putting ceramic powder into a mixer, heating the ceramic powder, adding a binder into the ceramic powder, carrying out mixing, and carrying out granulation through an extruder to obtain feed, (2) injection molding: placing the feed in an injection molding machine and carrying out injection molding to obtain an injected blank, (3) degreasing: placing the injected blank into an air furnace, carrying out hot degreasing, carrying out heating pre-sintering, carrying out furnace cooling and taking out a blank, and (4) sintering: putting the blank in a sintering furnace, carrying out sintering, and carrying out grinding and polishing to obtain a ceramic part. Through powder injection molding process and final degreasing and high temperature sintering, a fine ceramic part having a complex shape is obtained, the product has high compactness and good uniformity and is obtained by one step molding, the operation and control are simple, product quality is stable, production efficiency is high, a production cost is low and large-scale industrial production is realized.

Owner:深圳市星迪伟业科技有限公司

Hot rolling roller for rolling nonferrous metal, and manufacturing method thereof

The present invention discloses a hot rolling roller for rolling a nonferrous metal, and a manufacturing method thereof. Chemical components of the roller comprise, by weight, 0.50-0.80% of C, 0.30-1.20% of Si, 0.20-1.00% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 4.50-6.00% of Cr, 0.20-0.80% of Ni, 0.20-1.00% of Mo, 0.10-0.50% of V, and the balance of Fe and unavoidable impurities. The manufacturing method of the roller comprises the following process steps: a, refining a steel ingot; b, forging a roller blank; c, carrying out quenching and tempering, and carrying out mechanical processing; d, carrying out a quenching heat treatment; and e, carrying out a tempering treatment. The hot rolling roller has characteristics of high wear resistance, good thermal cracking resistance and good electrochemical corrosion resistance, and a service life of the hot rolling roller can be increased by more than 50% compared with the ordinary Cr3 roller.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Sintered flux for 9Ni steel welding and preparation method thereof

ActiveCN106238965AImprove low temperature toughnessGood thermal crack resistanceWelding/cutting media/materialsSoldering mediaTO-18Crack resistance

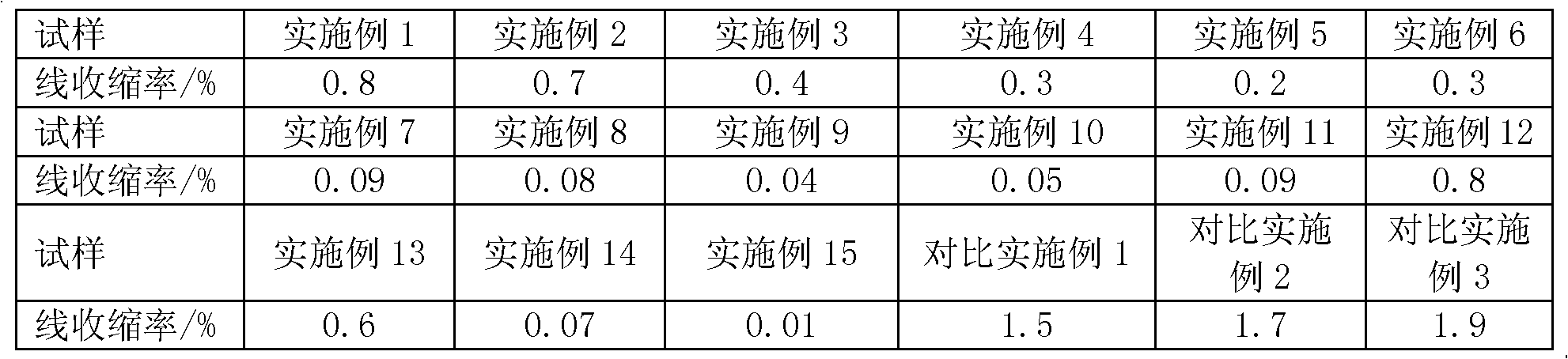

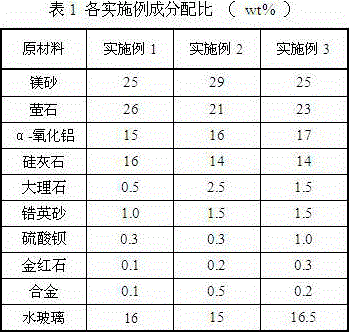

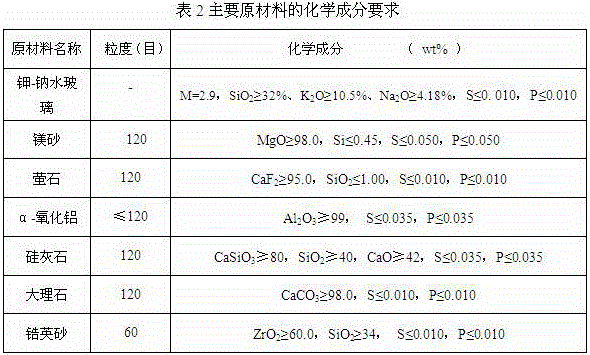

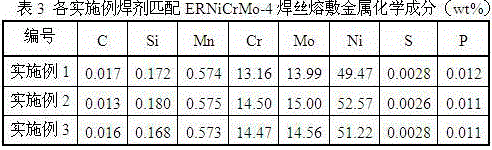

The invention discloses sintered flux for 9Ni steel welding, and relates to the technical field of welding materials. The sintered flux comprises the following components in parts by weight: 20 to 28 parts of CaF2, 23 to 33 parts of MgO, 15 to 18 parts of Al2O3, 8 to 12 parts of CaO, 4 to 10 parts of SiO2, 0.5 to 2 parts of BaO, 0.5 to 2 parts of TiO, 0.5 to 2 parts of ZrO2, 0.5 to 2 parts of alloy and 15 to 20 parts of water glass, wherein the alloy is ferrosilicon or manganese-silicon or a combination of ferrosilicon and manganese-silicon. The preparation method comprises the steps of uniformly mixing the components according to the proportion; carrying out granulation; drying at the low temperature of 300 to 400 DEG C; and sintering at the high temperature of 660 to 750 DEG C, so as to obtain a flux finished product. According to the sintered flux, the flux is matched with a solid welding wire ERNiCrMo-4, the welding manufacturability is relatively good, the mechanical property of weld joints is good, the ultra-low temperature toughness of deposited metals is stable and excellent, the hot crack resistance sensitivity is good, and the sintered flux is applicable to submerged arc flat welding and horizontal welding of 9Ni steel.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

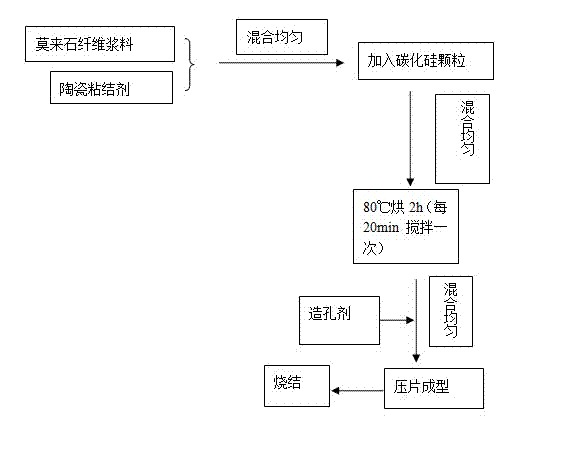

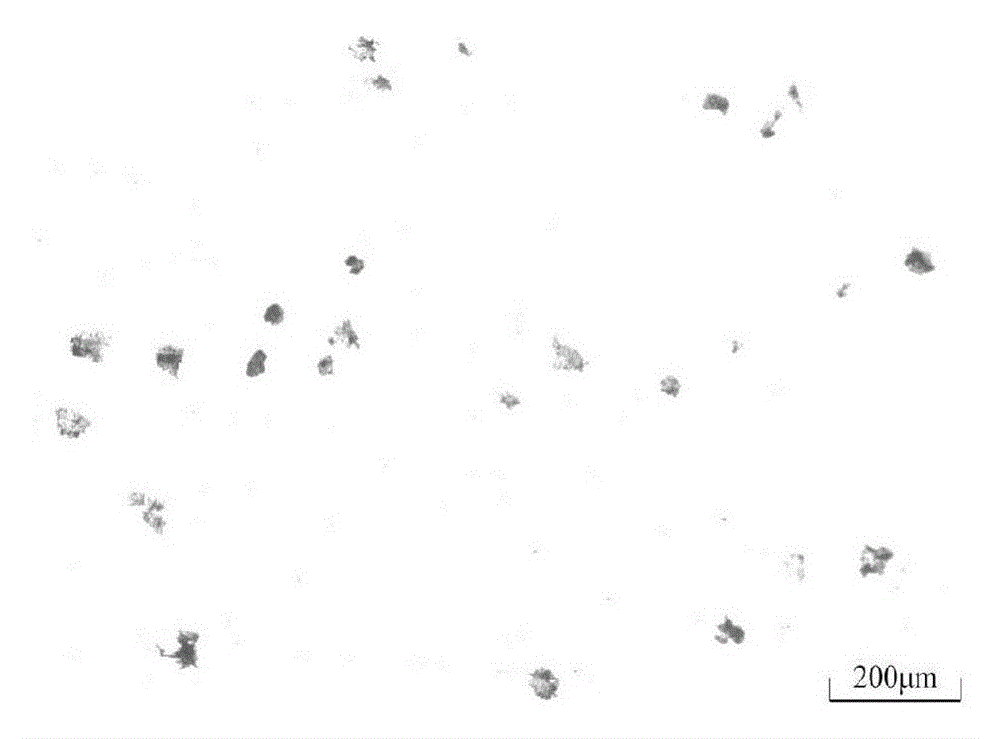

Fiber enhanced silicon carbide porous ceramic and preparation method and application thereof

InactiveCN103086732AGood thermal crack resistanceImprove flexural strengthDispersed particle filtrationCeramicwareCarbide siliconMullite

The invention discloses fiber enhanced silicon carbide porous ceramic which is composed of the following components in part by weight: 1 part of a ceramic binder, 1-3 parts of mullite fiber pulp, 8 parts of silicon carbide particles with an average particle size being about 230microns, and 1 part of a pore-forming agent. The preparation method is implemented through the steps that firstly, homogeneous mullite fiber pulp is prepared, so that when the mullite fiber pulp is mixed with a binder and silicon carbide particles with large particle sizes, mullite fibers can be uniformly dispersed but not agglomerated, thereby achieving a good toughening effect in a ceramic matrix. The invention further discloses an application of the fiber enhanced silicon carbide porous ceramic in the aspects of preparing silicon carbide porous ceramics and improving the toughness of silicon carbide porous ceramics.

Owner:TIANJIN NORMAL UNIVERSITY

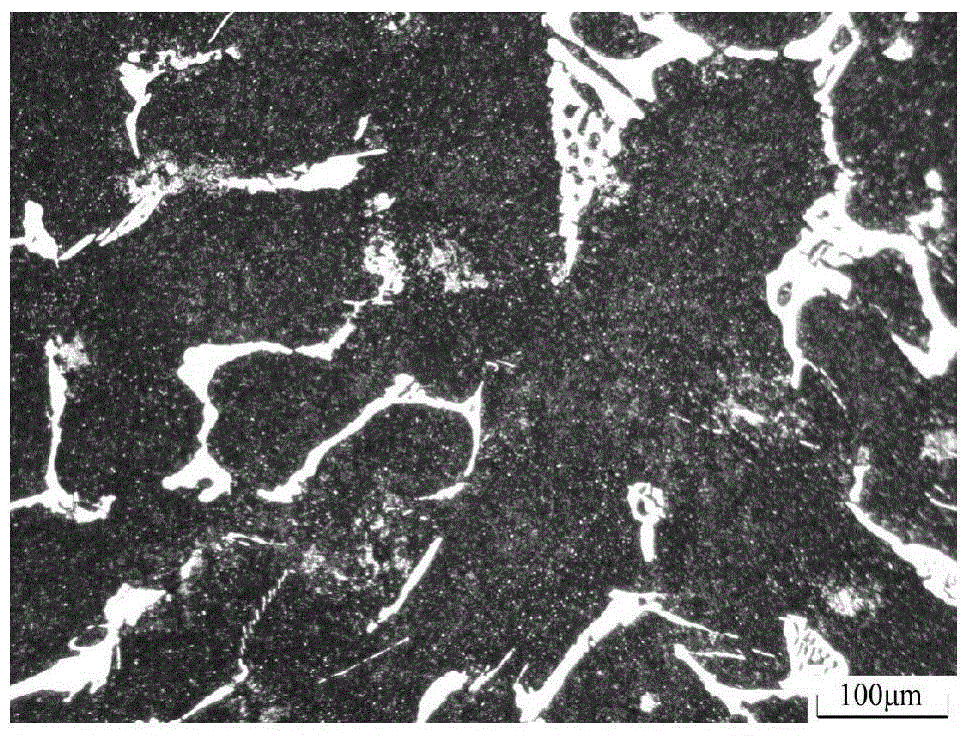

High-carbon graphitic steel roller ring for profile steel universal mill and manufacturing method of high-carbon graphitic steel roller ring

The invention discloses a high-carbon graphitic steel roller ring for a profile steel universal mill and a manufacturing method of the high-carbon graphitic steel roller ring. The outer layer of the roller ring is composed of, by mass, 1.70%-2.30% of C, 1.50%-2.20% of Si, 0.50%-1.20% of Mn, 0.03% of P or less, 0.03% of S or less, 1.00%-1.80% of Cr, 0.20%-1.20% of Ni, 0.20%-0.80% of Mo and the balance Fe. A core is composed of, by mass, 1.00%-2.00% of C, 1.00%-2.00% of Si, 0.50%-1.50% of Mn, 0.03% of P or less, 0.03% of S or less, 0.5% of Cr or less and the balance Fe. The manufacturing method comprises the steps of smelting, inoculation and spheroidizing, centrifugal casting and heat treatment. Spheroidizing is carried out at least two times. The metallographic structure of the roller ring obtained after heat treatment comprises a pearlite base body, carbide with the area rate of 10.36% and graphite, the form of the graphite is in a mass shape or a mass insect shape, and the area rate of the graphite is 1.7%. The high-carbon graphitic steel roller ring has high wear resistance, breaking resisting strength, toughness, hot crack resistance and accident impact resisting capacity, and the steel bonding tendency is avoided.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

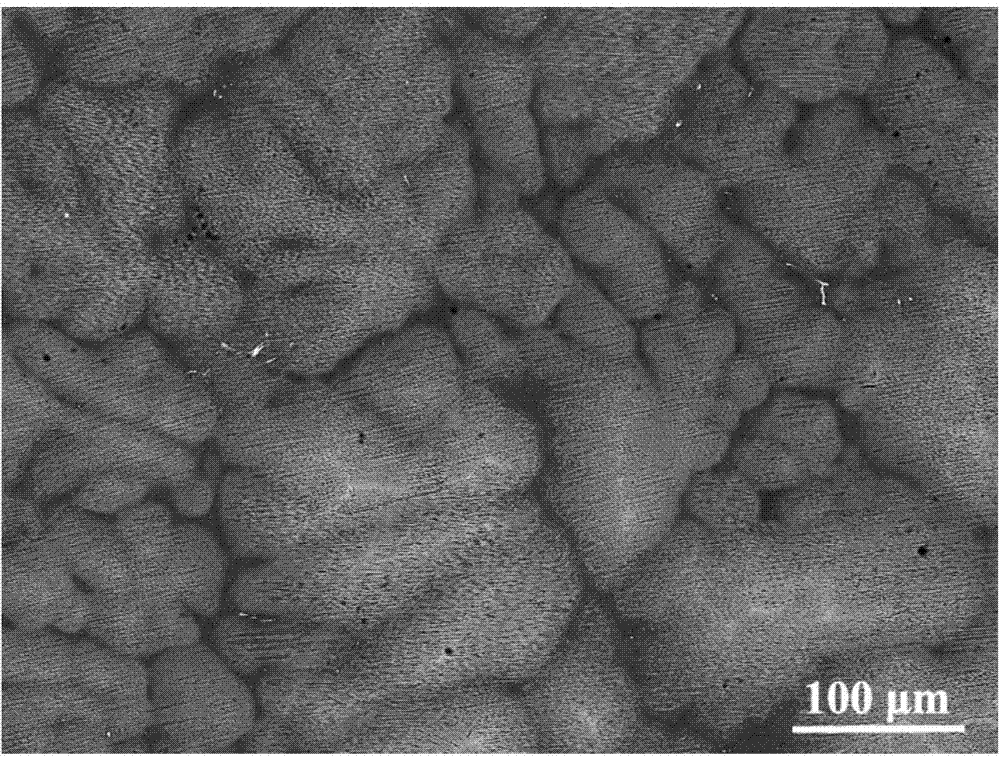

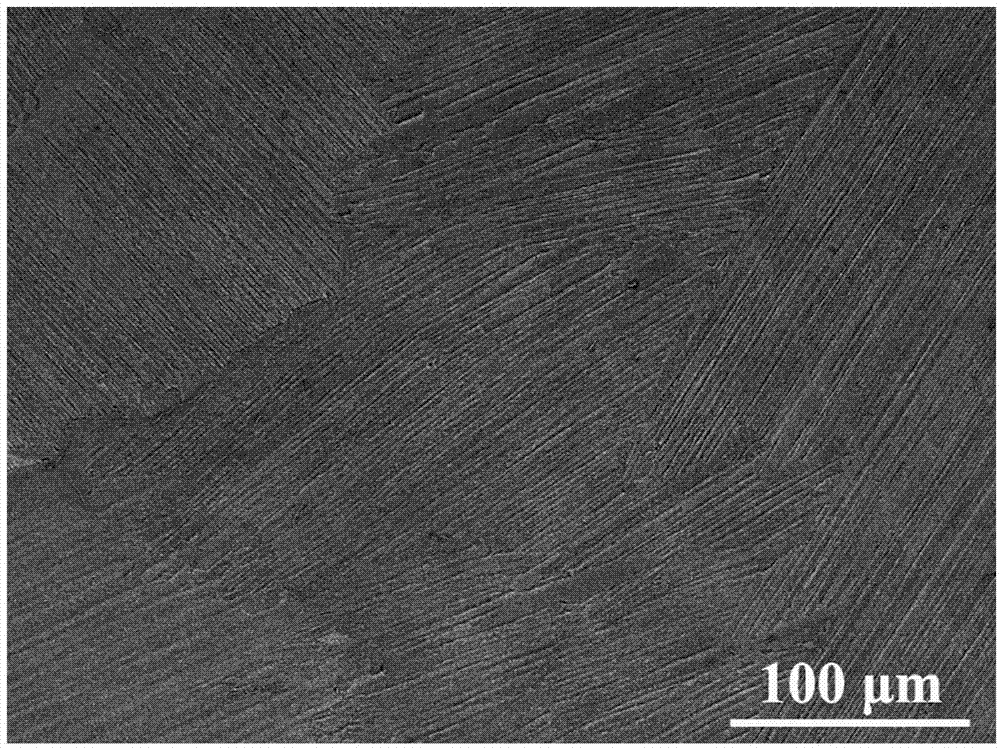

Preparation technique of continuous casting crystallizer copper plate surface cermet coating

ActiveCN103614687AUniform and flat microscopic surfaceImprove corrosion resistanceMolten spray coatingCrack resistanceHeat treated

The invention discloses a preparation technique of a continuous casting crystallizer copper plate surface cermet coating, which comprises the following steps: copper plate surface oil removal, copper plate surface sandblasting, coating preparation and hot spraying subsequent treatment, wherein the hot spraying subsequent treatment is vacuum heat treatment or hole sealing treatment. The preparation technique of the technical scheme is simple to operate, and has the advantages of fewer steps and high efficiency. After being subjected to vacuum heat treatment or hole sealing treatment, the cermet coating has the advantages of high microhardness, small internal stress, favorable wear resistance, favorable thermal crack resistance, high bonding strength, favorable bonding property and low thermal conductivity, can lower the thermal crack of the crystallizer copper plate in the high-temperature region, can effectively decelerate the heat conduction inside crystallizer (especially the meniscus surface), and can be widely used in continuous casting of a medium / low-speed continuous caster.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

Universal type steel ball unthreaded ball iron roller ring and manufacturing method thereof

The invention discloses a universal type steel ball unthreaded ball iron roller ring which comprises an outer layer and an inner core. The proportion between the outer layer and the inner core is 2:1. The alloy component of the outer layer comprises, by weight, 3.0-3.5% of C, 1.2-2.0% of Si, 0.5-1.2% of Mn, 0.1% or less of P, 0.02% or less of S, 0.2-1.0% of Cr, 0.5-1.5% of Ni, 0.2-1.0% of Mo, and the balance Fe and inevitable impurities. The alloy component of the inner core comprises, by weight, 1.0-1.5% of C, 1.3-1.7% of Si, 0.5-1.0% of Mn, 0.08% or less of P, 0.03% or less of S, 0.5% or less of Cr, 0.3% or less of Ni, 0.13% or less of Mo, and the balance Fe and inevitable impurities. A manufacturing method comprises the steps of A, smelting, B, inoculation and spheroidizing, and C, casting. By means of the universal type steel ball unthreaded ball iron roller ring and the manufacturing method thereof, the hardness fall of rollers can become small, the steel adhesion tendency is relieved, and the comprehensive using performance of the roller ring is improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Hard aluminum alloy for metal die casting of precision electronic product structural member

The invention discloses a hard aluminum alloy for metal die casting of a precision electronic product structural member. The hard aluminum alloy is prepared by antigravity metal die casting and natural ageing heat treatment. The hard aluminum alloy comprises, by mass, 21-30% of zinc, 5.7-7.2% of silicon, 2.0-2.4% of copper, 0.17-0.35% of manganese, 0.2-0.6% of trace alloy element and the balance aluminum and unavoidable impurities with iron content of 0.27% or less. The invention also discloses a preparation method of the hard aluminum alloy. The hard aluminum alloy can be prepared by high precision die casting, has high strength, can be subjected to high quality surface treatment, can be used for production of a high precision structural member of small, thin and light electronic products, and is suitable for large parts of spaceflight and aviation, automobiles, high-speed railway, steamships and yachts and daily hardware products.

Owner:陈灿

Copper-free friction material and brake pad

ActiveCN105670564AImprove stabilityReduce wearOther chemical processesFriction liningButadiene-styrene rubberMagnesium

The invention discloses a copper-free friction material and a brake pad. The copper-free friction material comprises the following raw materials by weight: 30-40 parts of steel fiber, 5-15 parts of modified phenolic resin, 5-10 parts of nitrile butadiene rubber, 10-15 parts of styrene butadiene rubber, 10-15 parts of graphite, 3-4 parts of molybdenum disulfide, 5-10 parts of cryolite, 5-8 parts of barium sulfate, 1-5 parts of aramid fiber, 1-5 parts of heavy calcium carbonate, 1-5 parts of heavy magnesium oxide, 1-3 parts of aramid fiber, and 3-4 parts of silicon carbide. The brake pad made of the copper-free friction material provided by the invention has good hot cracking resistance and wear resistance, and low wear rate, thereby prolonging the service life. And reasonable control of the friction material composition proportion can ensure no abnormal wear to a brake disc.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

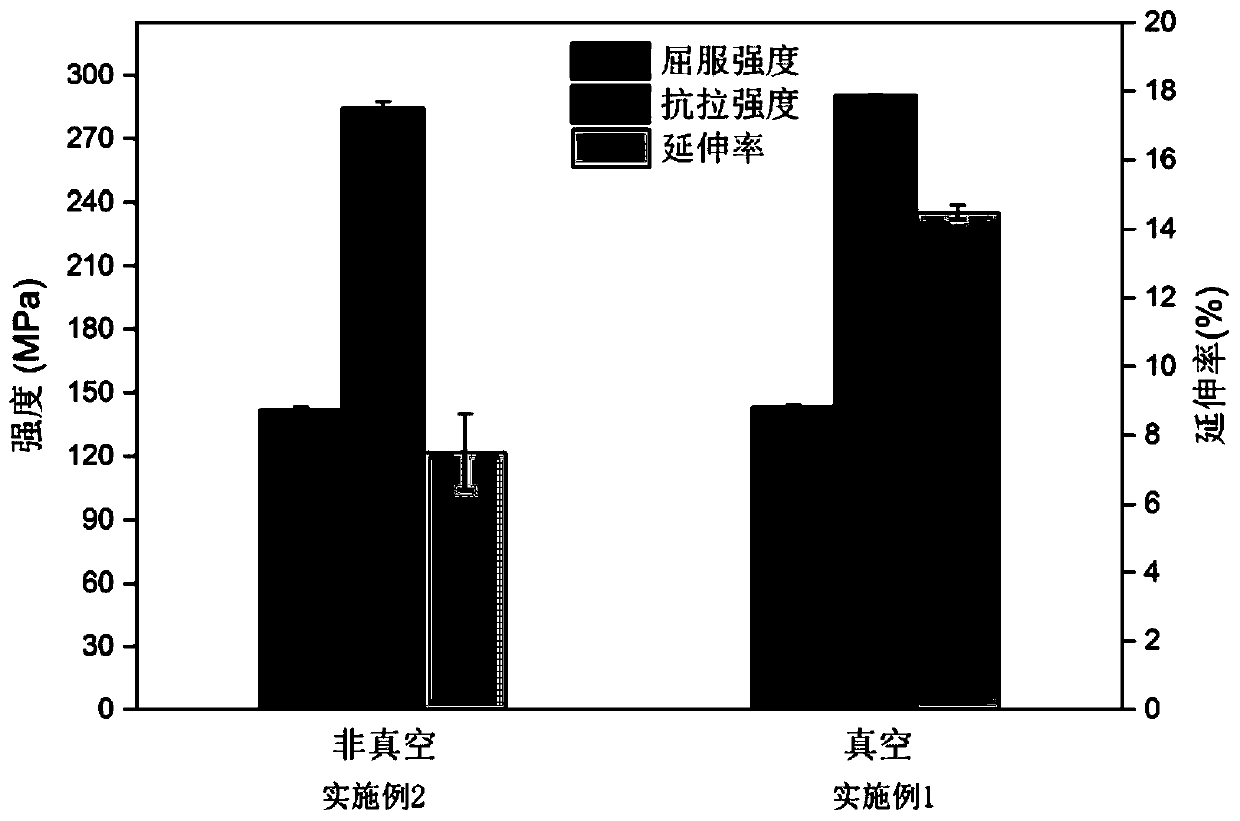

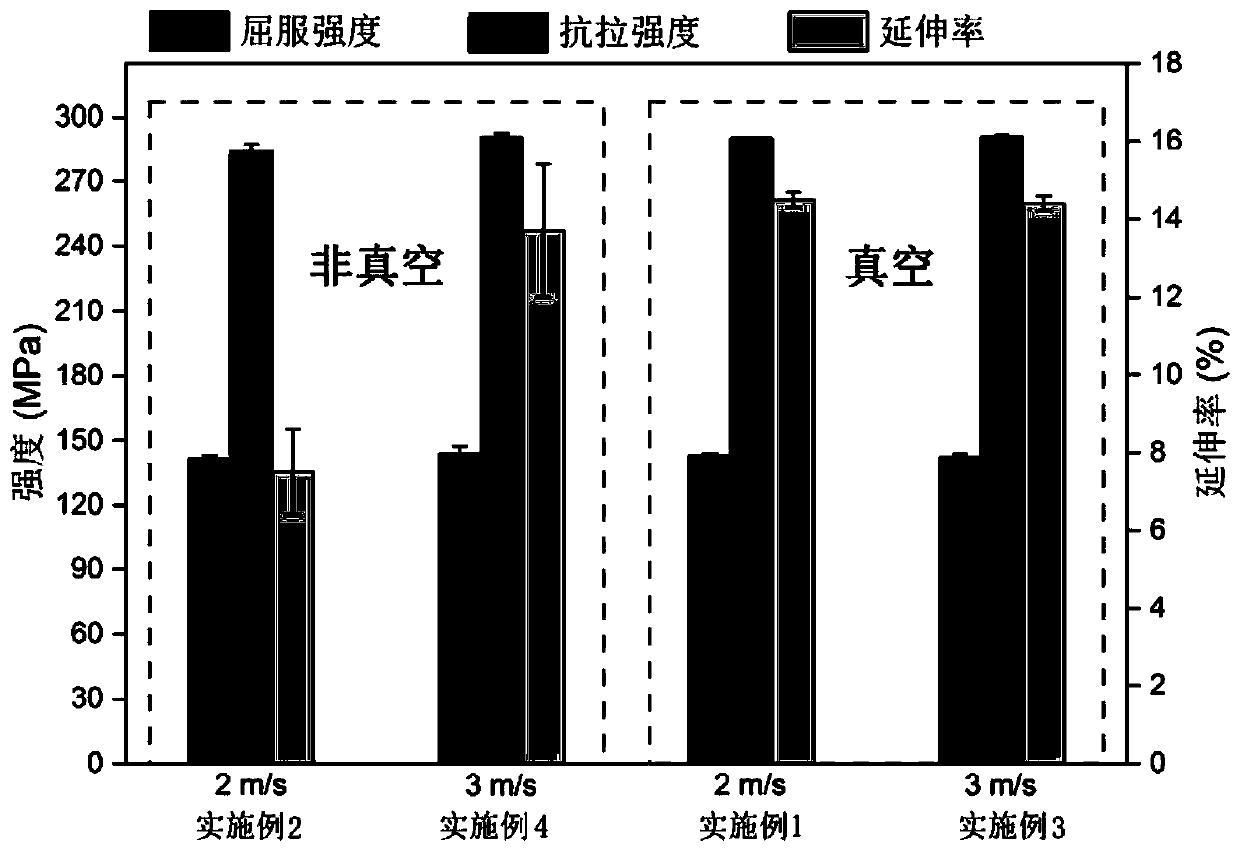

As-cast high-toughness die-cast aluminum-silicon alloy and preparation method and application thereof

The invention discloses an as-cast high-toughness die-cast aluminum-silicon alloy and a preparation method and an application thereof, wherein the as-cast high-toughness die-cast aluminum-silicon alloy comprises 8-11wt% of silicon, 0.4-0.8wt% of manganese, 0.1-0.4wt% of vanadium, 0.1-0.4wt% of zirconium, 0.01-0.04wt% of bismuth, not more than 0.2wt% of iron, not more than 0.1wt% of inevitable inclusions and the balance of aluminum. The aluminum-silicon alloy not only exhibits high toughness and good thermal crack resistance, but also has good fluidity. When the melt is die-casted, the structural defects caused by the die-cast process can be significantly reduced and avoided; and subsequent alloy heat treatment process can be avoided; the production cost can be reduced while the mechanicalproperties of aluminum-silicon alloy castings are improved significantly.

Owner:TSINGHUA UNIV +1

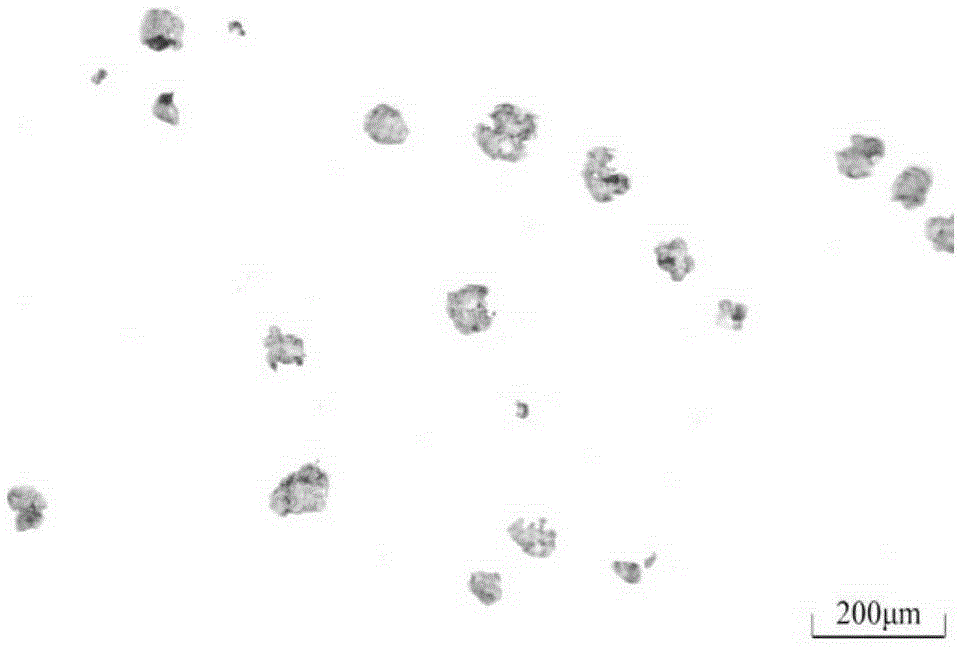

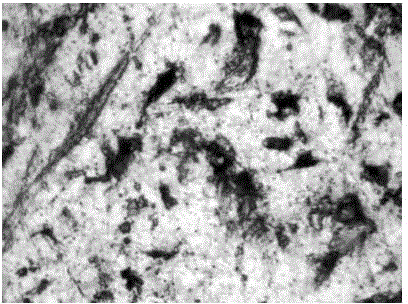

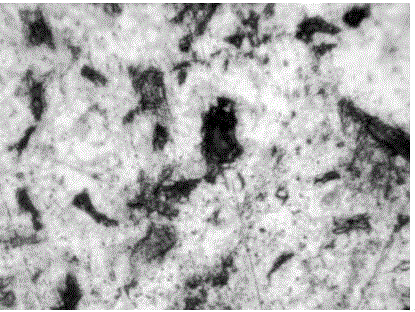

Hot cracking resistant mixed-crystal hard alloy and preparation method thereof

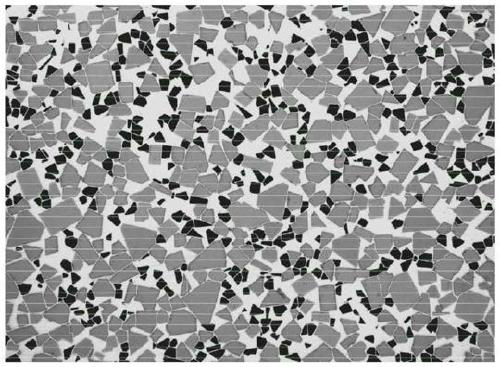

PendingCN109487142AThe average crystal diameter ratio is accurately controlledHigh strengthGranularityDiameter ratio

The invention discloses a hot cracking resistant mixed-crystal hard alloy and a preparation method thereof. The hot cracking resistant mixed-crystal hard alloy comprises a hard phase, a bonding phraseand optional temperature resistant components. The hard phase comprises coarse tungsten carbide (WC) and fine WC. The ratio of the average crystal diameter of the coarse WC to the average crystal diameter of the fine WC is (1.7: 2.1). The average grain size of the hard alloy is between 2.4 Mu m and 3.4 Mu m. According to the hot cracking resistant mixed-crystal hard alloy provided, control over the average crystal diameter ratio of of the coarse WC to the fine WC is accurate; intensity is high; rigidity is high; and the hot cracking resistant property is good. When the hard alloy is used in an environment of thermal mechanical corrosion fatigue, crack initiation is late; hot crack growth is slow; the hard alloy is especially suitable for rolling of threaded steel on a small profile rolling mill; blocks are not easy to drop; rolled steel is good in quality; and the service life is improved by more than 20%.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

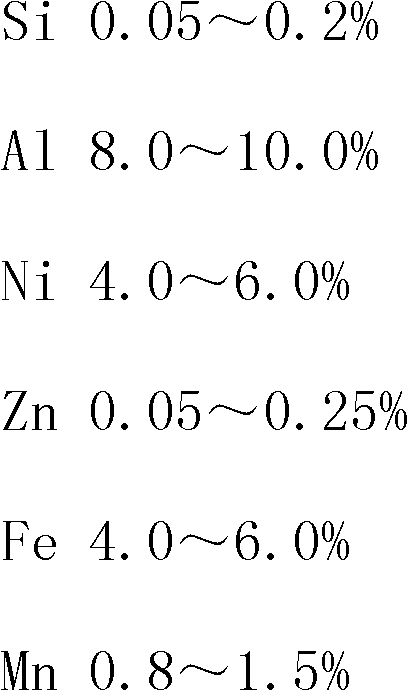

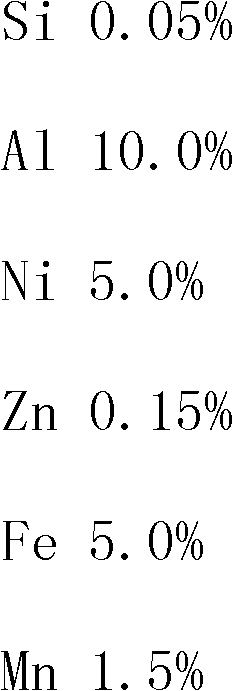

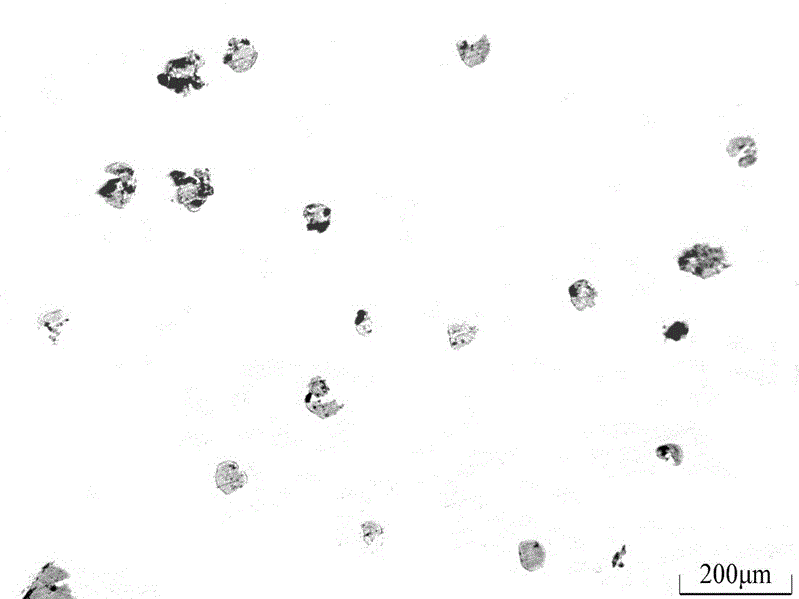

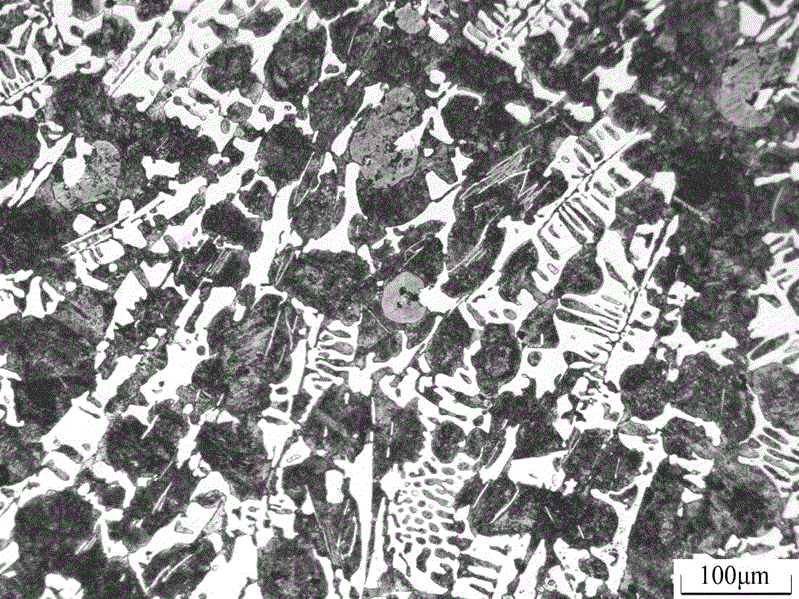

Low-nickel and high-iron copper alloy glass mould and manufacturing method thereof

ActiveCN102628119AOptimal active stateConducive to the distribution and fusion of elementsFurnace temperatureCrack resistance

The invention relates to a low-nickel and high-iron copper alloy glass mould and a manufacturing method thereof. The mould has better oxidization resistance, heat fatigue resistance, heat conductivity, enhanced toughness, good heat cracking resistance, and has the advantages of easiness of machining, reduced cost and long service life. The low-nickel and high-iron copper alloy glass mould comprises the following components in weight percentage: 0.05-0.2% of Si, 8.0-10.0% of Al, 4.0-6.0% of Ni, 0.05-0.25% of Zn, 4.0-6.0% of Fe and 0.8-1.5% of Mn; after the components are smelted, the smelted components are cast at 1250-1280 DEG C; the heat-preservation time of heat treatment is 6 hours and the temperature is controlled at 680 DEG C; and the mixture is reduced to 150 DEG C along the furnacetemperature, the furnace temperature is raised to the room temperature and then the product is taken out to obtain the glass mould which has the properties that the tensile strength is 400-450 N / mm<2>, the Brinell hardness is 175-200, the bending strength is 350 N / mm<2>, the thermal conductivity is 0.12-0.15 k / M*S*DEG C, the thermal expansion coefficient is 17*10<-6> m / k and the service life is 1.3-1.5 million times.

Owner:常熟市兄弟玻璃模具有限公司

Cast iron material pinch roll used for hot strip mill and manufacturing method of cast iron material pinch roll

InactiveCN106367664AImprove wear resistanceGood thermal crack resistanceFurnace typesHeat treatment furnacesStrip millAlloy

The invention discloses a cast iron material pinch roll used for a hot strip mill. The pinch roll comprises alloy components including, by weight percent, 2.90%-3.60% of C, 1.30%-2.00% of Si, 0.40%-1.00% of Mn, 0. 50%-1.00% of Cr, 1.50%-2.50% of Ni, 0.30%-1.00% of Mo, smaller than or equal to 0.10% of P, smaller than or equal to 0.05% of S and the balance Fe and inevitable impurities. The invention further discloses a manufacturing method of the cast iron material pinch roll used for the hot strip mill. The manufacturing method includes the steps of smelting, inoculation and spheroidizing treatment, casting and heat treatment. The pinch roll can have the high wear resistance, the good heat crack resisting performance, the accident impact resisting capability and other comprehensive performance, and complex rolling conditions of the pinch roll before a reeling machine of the hot strip mill can be met.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

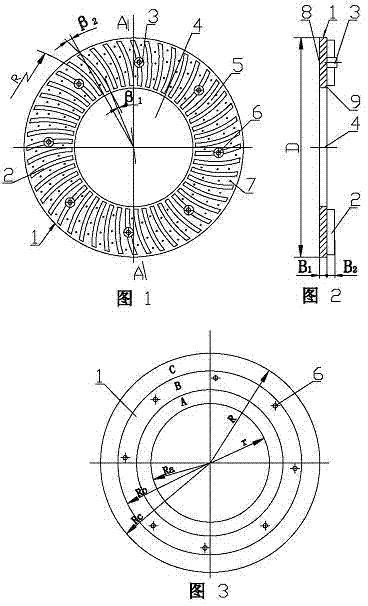

High-speed train brake disc and brake disc material thereof

ActiveCN103925316AImprove wear resistanceGood thermal crack resistanceOther chemical processesBraking discsEngineeringUltimate tensile strength

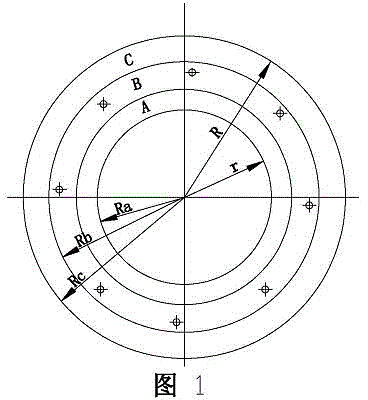

The invention discloses a high-speed train brake disc. A disc body center hole and radiating ribs are arranged on a disc body, the ratio R / D of the circular arc radius R of each radiating rib to the outer diameter D of the disc body ranges from 0.4 to 0.6, the inflow angle beta 1 of each radiating rib ranges from 0 degree to 15 degrees, the outflow angle beta 2 of each radiating rib ranges from 25 degrees to 35 degrees, and the ratio B2 / B1 of the height B2 of each radiating rib to the thickness B1 of the disc body ranges from 1.0 to 1.2. A brake disc material of the high-speed train brake disc comprises, by weight, 0.16% to 0.25% of C, 0.25% to 0.60% of Si, 0.80% to 1.30% of Mn, 0.70% to 1.20% of Cr, 0.01% to 0.03% of W, 0.80% to 1.30% of Ni, 0.40% to 0.70% of Mo, 0.05% to 0.20% of Cu, 0.18% to 0.25% of SiC, 0.20% to 0.30% of Al2O3, 0.03% to 0.15% of V, 0.0050% to 0.025% of N, 0.005% to 0.20% of Re, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% of S, and the balance Fe. According to the high-speed train brake disc, forced guiding of a radiating air field can be achieved, the radiating speed is high, overall strength is high, and the high-speed train brake disc is widely applicable to braking systems of various high-speed trains.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +3

Hot roll for rolling aluminium products and manufacturing method thereof

ActiveCN103436789AImprove wear resistanceGood thermal crack resistanceFurnace typesRollsAluminiumThermal treatment

The invention discloses a hot roll for rolling aluminium products and a manufacturing method thereof. The hot roll is prepared from the following chemical constituents in percentage by weight: 0.50-0.80% of C, 0.20-1.50% of Si, 0.20-1.00% of Mn, no more than 0.025% of P, no more than 0.025% of S, 4.50-6.00% of Cr, 0.50-2.00% of Mo, 0.10-1.00% of V and the balance of Fe and inevitable impurities. The manufacturing method for the hot roll for rolling aluminium products includes the technological steps of steel ingot refining, roll blank forging, hardening and tempering as well as machining, quenching thermal treatment, tempering and the like. The hot roll for rolling aluminium products, which is provided by the invention, has high wearing resistance, excellent hot cracking resistance and electrochemical corrosion resistance, and the service life of the hot roll is prolonged by 50% above in comparison with that of a common hot roll made of Cr3 material.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

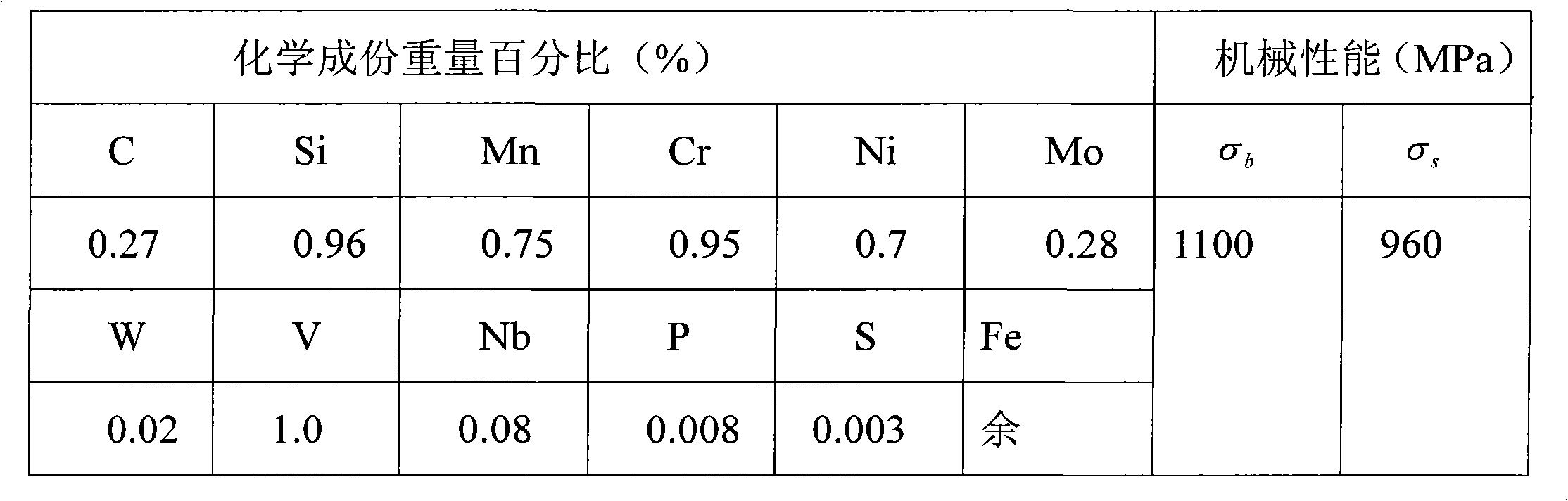

Alloy structural steel material for brake discs of high-speed motor train unit vehicles

InactiveCN102102165AImprovement of the problem of thermal crack damageSufficient thermal fatigue performanceNiobiumManganese

The invention discloses an alloy structural steel material for brake discs of high-speed motor train unit vehicles, which belongs to the technical field of materials for brake discs. The alloy structural steel material comprises the following chemical components in percentage by weight: 0.26 to 0.30 percent of carbon, 0.8 to 1.0 percent of silicon, 0.7 to 0.9 percent of manganese, 0.9 to 1.0 percent of chromium, 0.6 to 0.8 percent of nickel, 0.2 to 0.4 percent of molybdenum, 0.01 to 0.02 percent of tungsten, 0.09 to 1.0 percent of vanadium, 0.07 to 0.08 percent of niobium, less than 0.2 percent of phosphorus, less than 0.1 percent of sulfur, and the balance of iron. The alloy structural steel material solves the problem of thermal crack damage of the conventional brake disc friction surface due to poor heat conductivity, and meanwhile, the brake disc material has enough thermal fatigue performance, high and stable friction coefficient, good abrasion resistance and thermal cracking resistance and light weight.

Owner:北京建筑工程学院

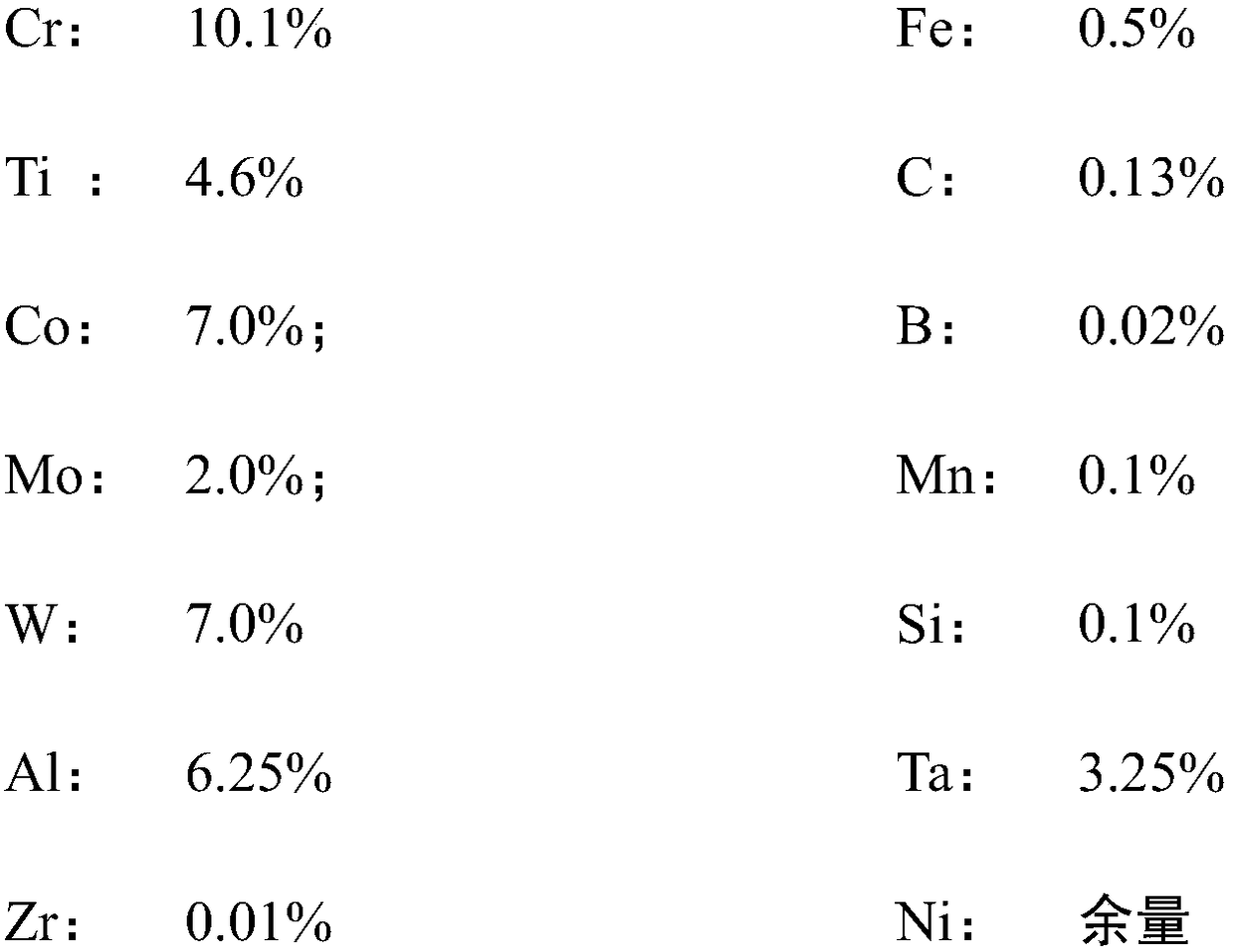

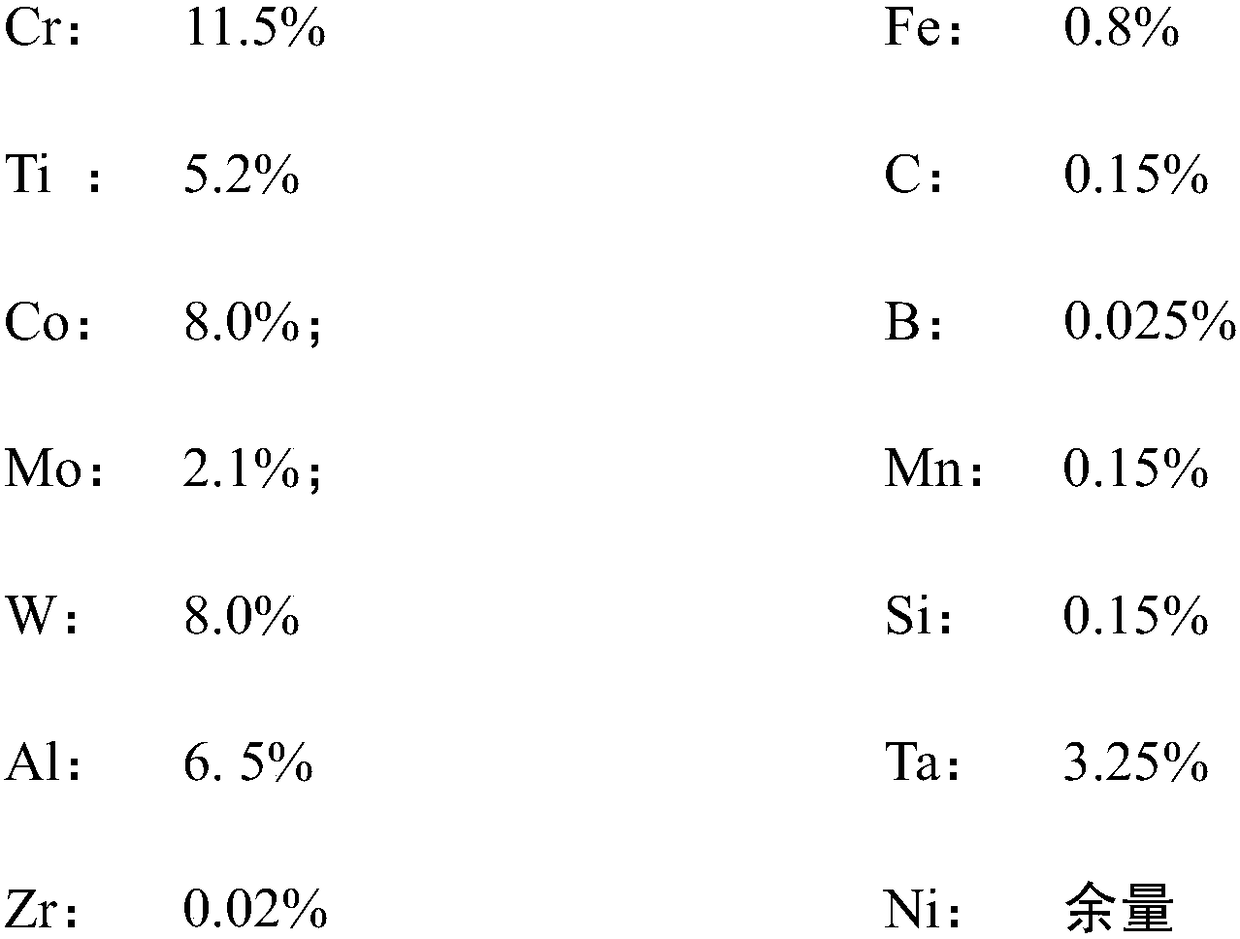

High-temperature alloy and preparation method thereof

The invention discloses a high-temperature alloy. The high-temperature alloy comprises the following raw materials of, by mass percent, 10.1-12.5% of Cr, 4.6-5.8% of Ti, 7.0-9.0% of Co, 2.0-2.25% of Mo, 7.0-9.0% of W, 6.25-6.75% of Al, less than or equal to 0.03% of Zr, less than or equal to 1.0% of Fe, 0.13-0.17% of C, 0.02-0.03% of B, less than or equal to 0.2% of Mn, less than or equal to 0.2%of Si, 3.25-3.75% of Ta, and the balance Ni. The invention further discloses a preparation method of the high-temperature alloy and belongs to the technical field of the high-temperature alloys. Compared with a similar formed material, the high-temperature alloy obtained by the preparation method has higher high-temperature endurance life and has the advantage of excellent resistance to thermal crack, and the thermal crack problem of the high-temperature alloy is solved greatly.

Owner:ANHUI TATSU PRECISION ALLOY

Magnesium alloy with hot cracking resistance and low linear shrinkage

The invention discloses a magnesium alloy with hot cracking resistance and low linear shrinkage, and belongs to the magnesium alloy field. The magnesium alloy is composed of elements of Mg, Zn, rare earths, Nb, Al and Li, and comprises, by weight, 0.2 to 9 percents of Zn, 0.0002 to 2 percents of Zr, 0.0002 to 16 percents of rare earths, 0.0002 to 4 percents of Nb, 0.001 to 1.49 percents of Al, 0.0002 to 9 percents of Li, and the balance Mg. According to the magnesium alloy, the structure of Beta phase is changed by adding rare earth elements and the Nb element into the magnesium alloy; grains are refined by adding the Li and Zr elements; and the crystallization latent heat is changed when the magnesium alloy is solidified by the combined action of the elements, so that the heat resistant magnesium alloy which has good mold-filling capacities, low shrinkage rate, good mechanical properties, machinability, mobility and die-casting properties and is suitable for casting is obtained.

Owner:嘉兴佳斯贝特新材料有限公司

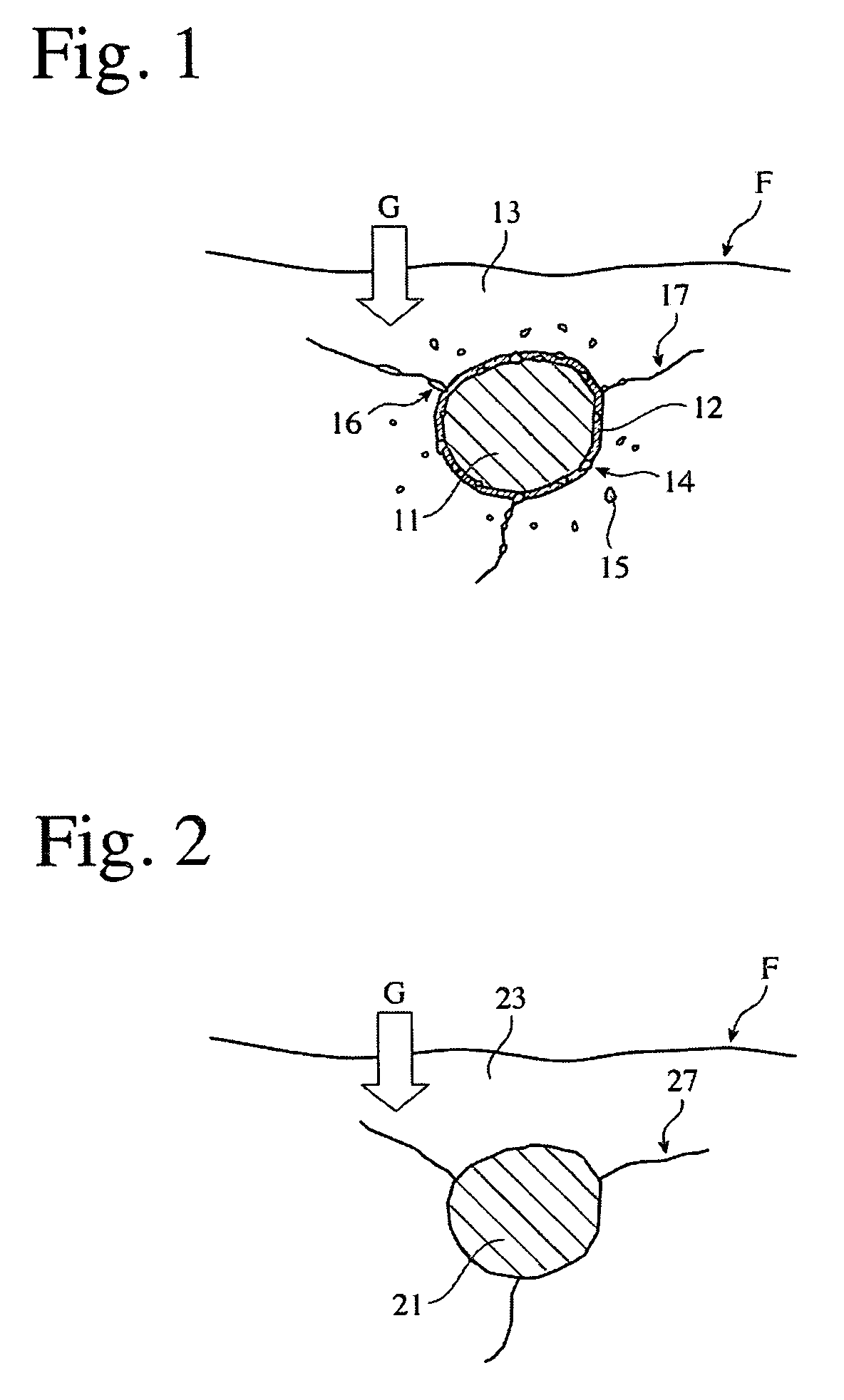

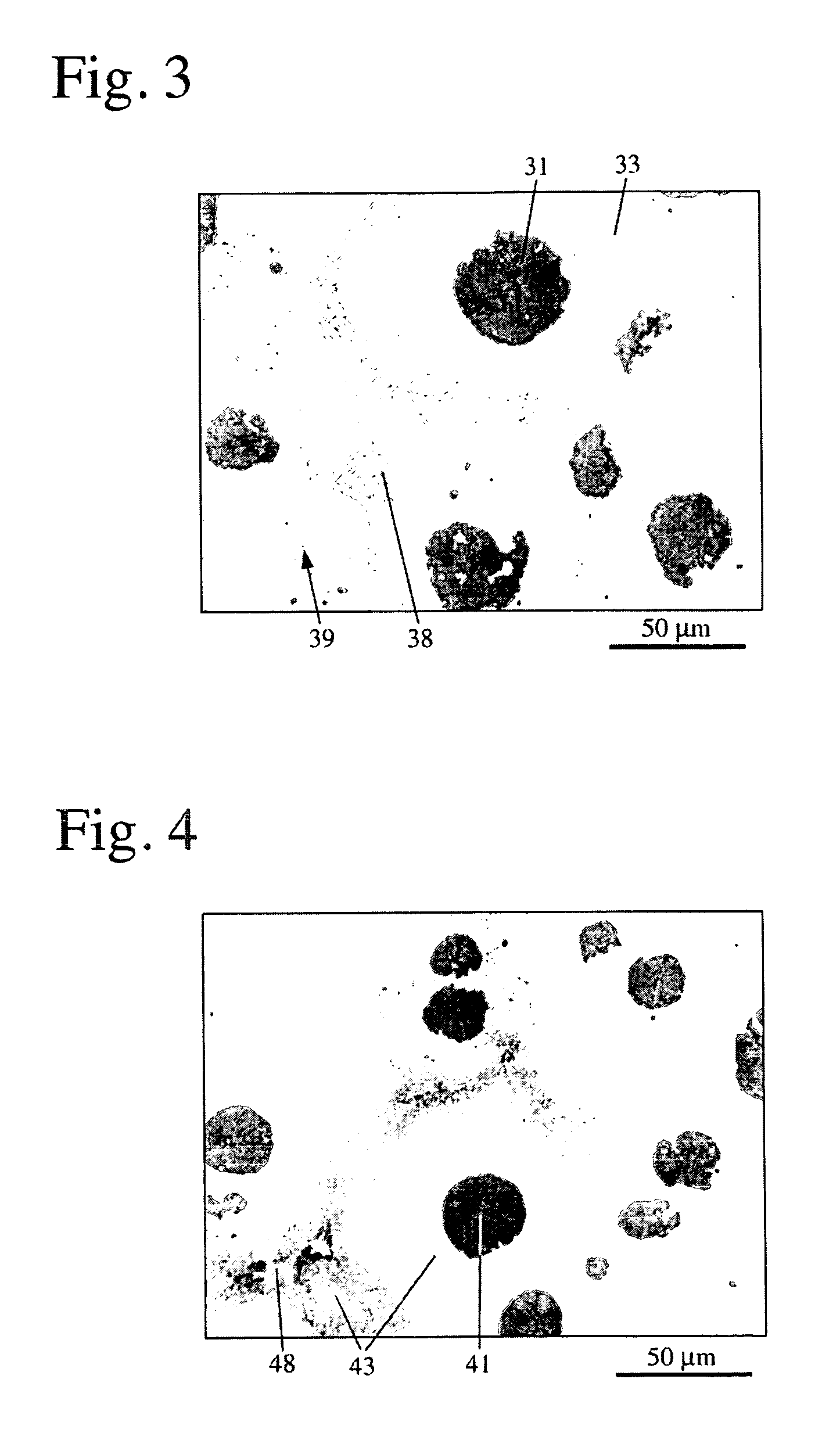

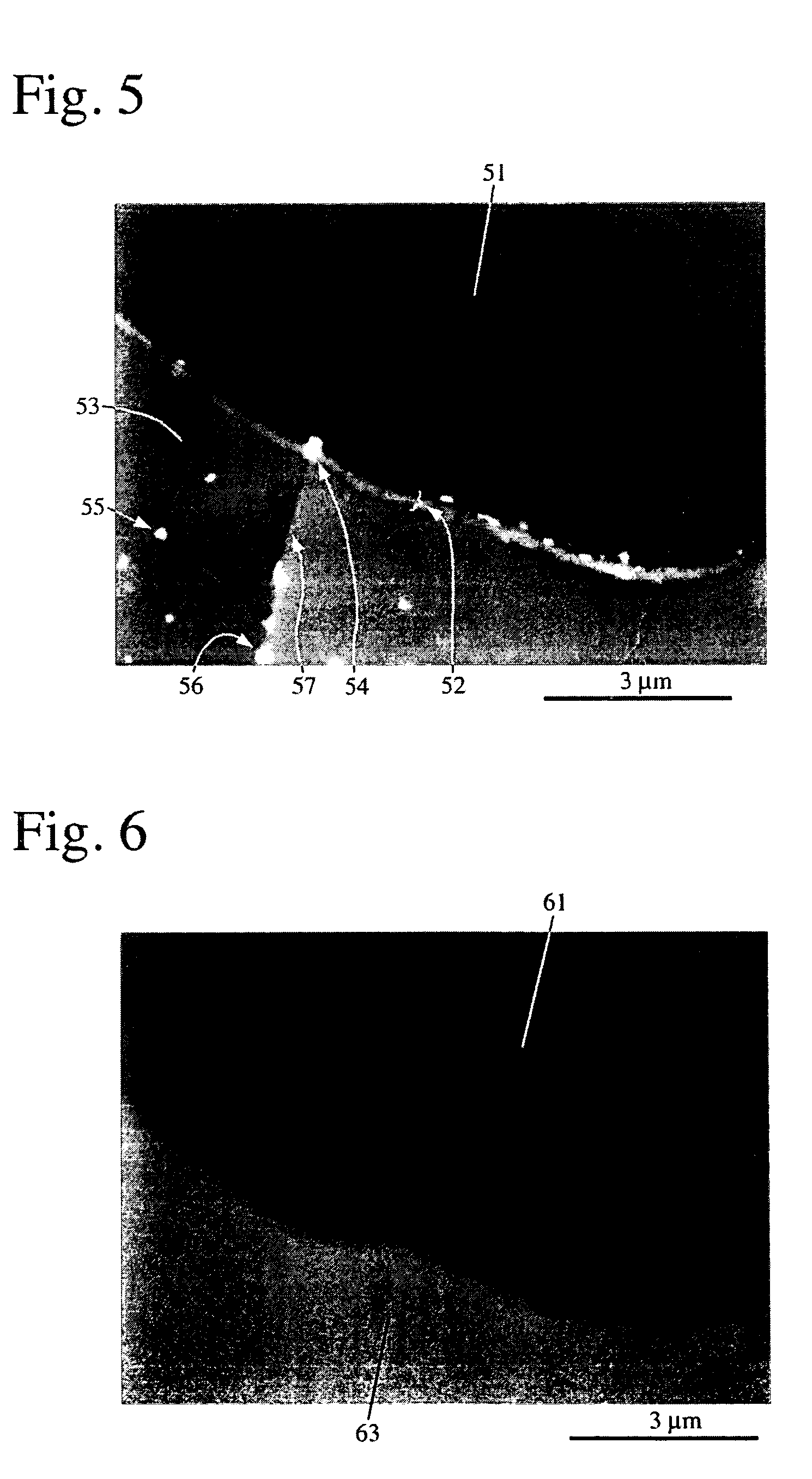

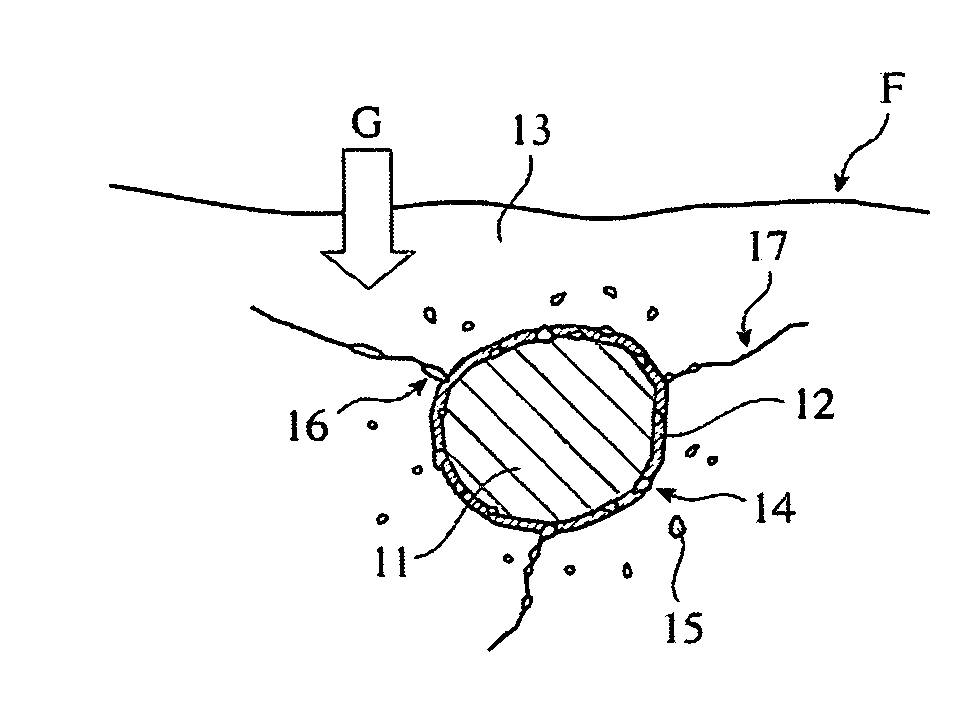

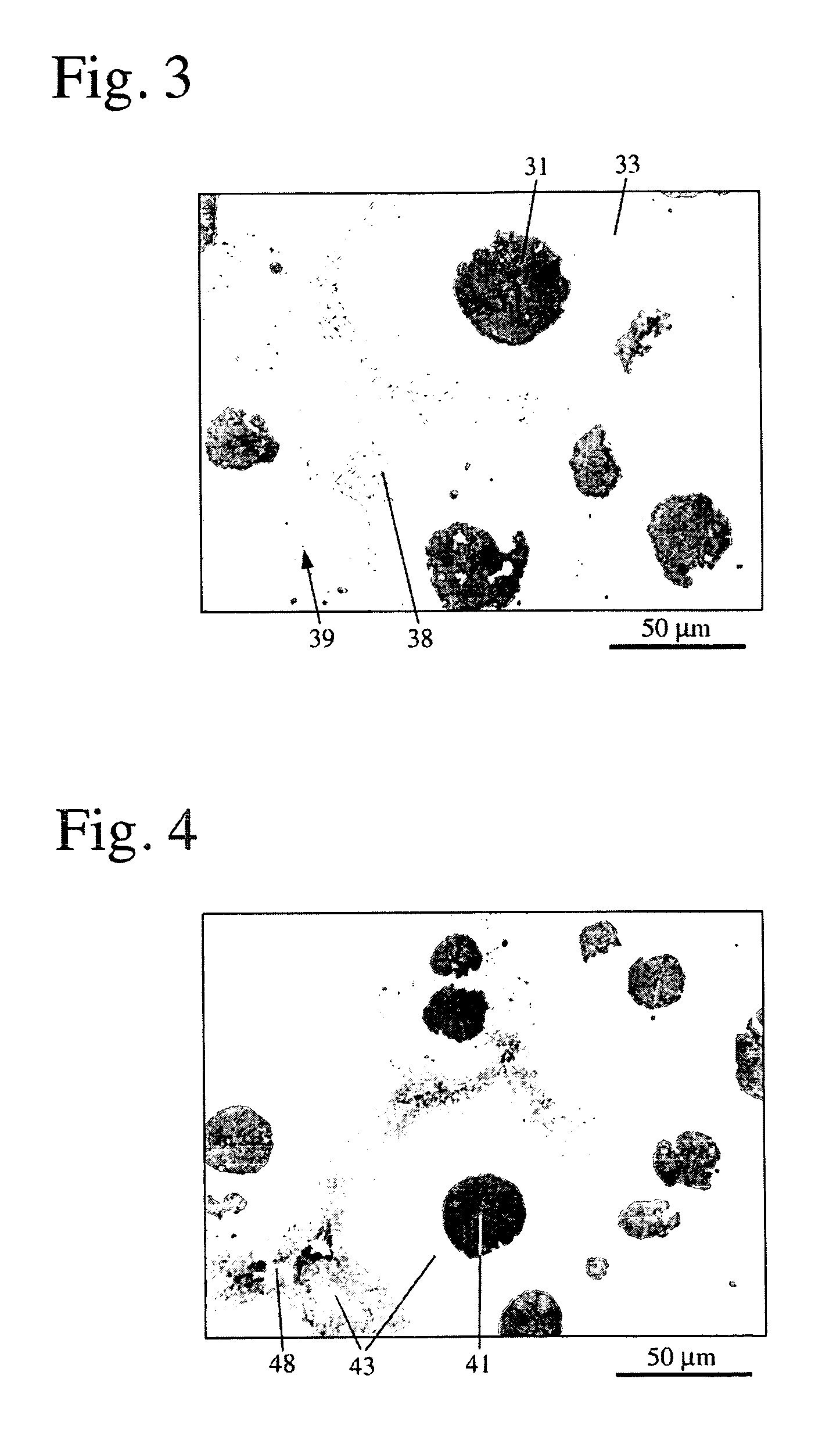

Heat-Resistant Cast Iron And Exhaust Equipment Member Formed Thereby

ActiveUS20080308193A1Low costGood thermal crack resistanceExhaust apparatusSilencing apparatusCast ironGraphite particle

A graphite-containing, heat-resistant cast iron for exhaust equipment members used at temperatures exceeding 800° C., comprising 3.5-5.6% of Si and 1.2-15% of W on a weight basis, and having intermediate layers, in which W and Si are concentrated, in the boundaries of graphite particles and a matrix. An exhaust equipment member formed by this heat-resistant cast iron has an AC transformation point is 840° C. or higher when measured from 30° C. at a temperature-elevating speed of 3° C. / minute, and a thermal cracking life of 780 cycles or more in a thermal fatigue test, in which heating and cooling are conducted under the conditions of an upper-limit temperature of 840° C., a temperature amplitude of 690° C. and a constraint ratio of 0.25.

Owner:HITACHI METALS LTD

Heat-resistant cast iron and exhaust equipment member formed thereby

ActiveUS7794650B2Low costGood thermal crack resistanceExhaust apparatusSilencing apparatusThermal fatigueGraphite particle

A graphite-containing, heat-resistant cast iron for exhaust equipment members used at temperatures exceeding 800° C., comprising 3.5-5.6% of Si and 1.2-15% of W on a weight basis, and having intermediate layers, in which W and Si are concentrated, in the boundaries of graphite particles and a matrix. An exhaust equipment member formed by this heat-resistant cast iron has an AC1 transformation point is 840° C. or higher when measured from 30° C. at a temperature-elevating speed of 3° C. / minute, and a thermal cracking life of 780 cycles or more in a thermal fatigue test, in which heating and cooling are conducted under the conditions of an upper-limit temperature of 840° C., a temperature amplitude of 690° C. and a constraint ratio of 0.25.

Owner:HITACHI METALS LTD

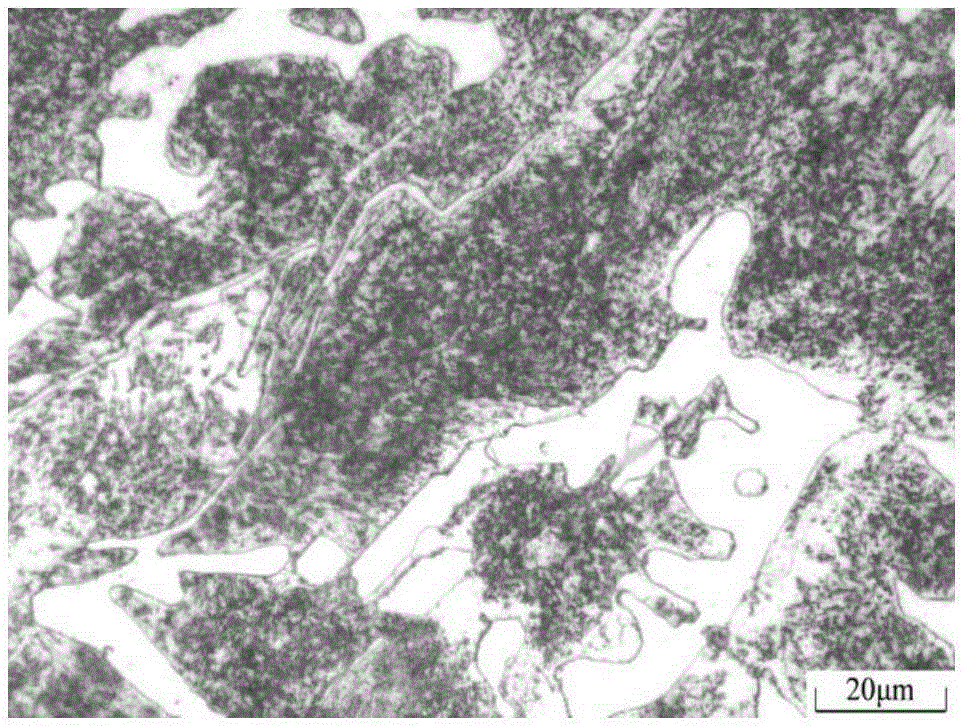

High-nitrogen high-speed steel centrifugal composite roller and preparation process thereof

ActiveCN112743064AImprove wear resistanceExcellent thermal fatigue crack resistanceFurnace typesProcess efficiency improvementThermal fatigueCrack resistance

The invention relates to the technical field of rollers, and provides a high-nitrogen high-speed steel centrifugal composite roller. The high-nitrogen high-speed steel centrifugal composite roller comprises an outer layer and a core part. The outer layer is made of high-nitrogen high-speed steel and is prepared from the following components in percentage by weight: 0.8-1.8% of C, 0.3-1.0% of Si, 0.4-1.0% of Mn, less than or equal to 0.030% of P, less than or equal to 0.025% of S, 5.0-15.0% of Cr, 0.5-4.0% of Mo, less than or equal to 2.0% of Ni, less than or equal to 5.0% of V, less than or equal to 3.0% of Nb, less than or equal to 5.0% of W, 60-300ppm of [N] and the balance of Fe. The core part is made of high-strength nodular cast iron and comprises the following components in percentage by weight: 2.5-3.5% of C, 2.0-3.0% of Si 2, 0.3-0.8% of Mn, less than or equal to 0.10% of P, less than or equal to 0.03% of S, less than or equal to 0.5% of Mo, less than or equal to 0.5% of Cr, more than or equal to 0.04% of Mg and the balance of Fe. Through the technical scheme, the problems of poor toughness, wear resistance and thermal fatigue crack resistance of the outer layer in the prior art are solved.

Owner:TANGSHAN XIANLONG ROLL INDAL

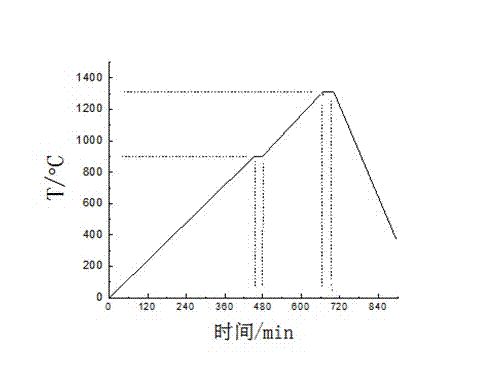

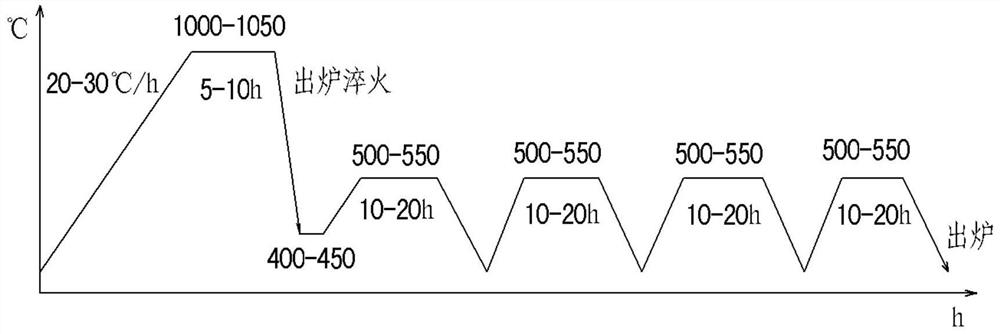

Heat treatment process of hot-work-die steel for aluminum die-casting mould

The invention discloses a heat treatment process of hot work die steel. The hot work die steel consists of the following components in percentage by weight: 0.30 to 0.50 percent of C, 0.80 to 1.20 percent of Si, 1.50 to 1.70 percent of Mn, 4.50 to 5.50 percent of Cr, 1.60 to 2.00 percent of W, 0.10 to 0.30 percent of Mo, 1.60 to 1.80 percent of V, 1.20 to 1.60 percent of Ni, 0.2 to 0.4 percent of Co, 0.5 to 0.7 percent of Nb, less than or equal to 0.05 percent of S, less than or equal to 0.03 percent of P and the balance of Fe. The heat treatment process comprises the following steps of: (1) quenching, namely heating a die steel blank to the temperature of between 630 and 650 DEG C at a temperature rise speed of 60 to 90 DEG C per minute, and preserving the temperature for 90 to 120 minutes, and heating the die steel blank to the temperature of between 1080 and 1120 DEG C at a temperature rise speed of 30 to 60 DEG C per minute, preserving the temperature for 150 to 180 minutes, and cooling through oil quenching; and (2) tempering, namely carrying out primary tempering, heating the die steel blank to the temperature of between 480 and 500 DEG C at a temperature rise speed of 60 to 90 DEG C per minute, performing air cooling to room temperature, carrying out secondary tempering, heating the die steel blank to the temperature of between 430 and 450 DEG C at a temperature rise speed of 30 to 60 DEG C per minute, and performing air cooling to room temperature.

Owner:柳州福臻车体实业有限公司

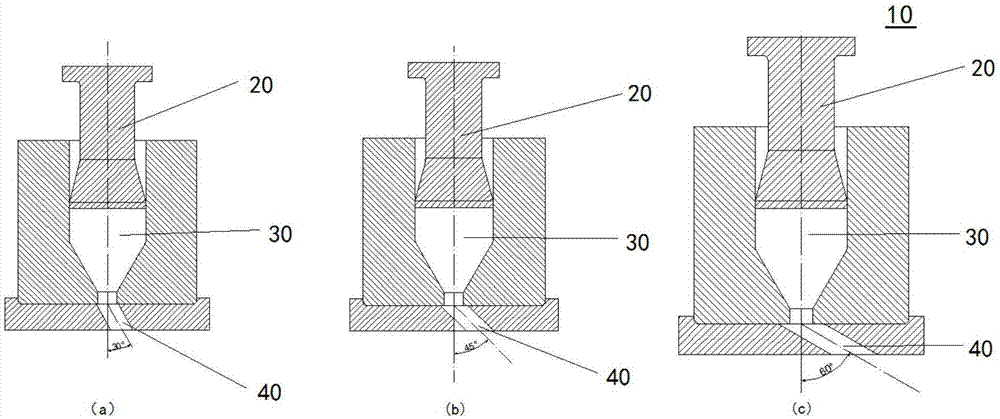

Magnesium alloy extrusion combined die and casting-extrusion-shearing method thereof

InactiveCN107475651AImprove plastic deformation abilityAchieving grain refinementMechanical propertyMagnesium alloy

The invention relates to a magnesium alloy extrusion combined die. The magnesium alloy extrusion combined die is formed in a way that a variable-extrusion ratio casting extrusion die, an equal-channel corner die and an extrusion punch are combined, wherein the variable-extrusion ratio casting extrusion die, the equal-channel corner die and the extrusion punch are detachable; the extrusion punch is installed at a feed opening of the variable-extrusion ratio casting extrusion die, and the equal-channel corner die is installed at a discharge opening of the variable-extrusion ratio casting extrusion die; and the extrusion punch is in a shape of sand glass, a funnel-shaped vertical channel is formed in a die cavity in the variable-extrusion ratio casting extrusion die, a channel of a die cavity in the equal-channel corner die forms corners from 0 to 90 degrees together with the upper and lower planes of the die, and the fillet radius of each corner is 3 mm. Magnesium alloy after chilling casting is assembled with the die and is heated and then is put on a forging press for forward extrusion, so that the grain refinement of the magnesium alloy can be realized, and the cross section of an obtained magnesium alloy bar has the advantages of small grains, uniform tissues and excellent mechanical properties.

Owner:CHONGQING UNIV

Current stabilizer sintering technology

InactiveCN101381238APromote crystallizationImproved high temperature erosion resistanceMetallurgyContinuous casting

The invention provides a firing process for a current stabilizer, which belongs to the technical field of continuous casting technology in steel production and comprises the steps of crushing, screening, batching, dry mixing, wet mixing by adding water, vibration forming, demoulding, natural curing, low temperature drying, high temperature firing, tundish baking under a table, and tundish baking before using to obtain the current stabilizer. The firing process has the characteristics of reasonable design, advanced technology, high product yield and long service life.

Owner:SHANDONG IRON & STEEL CO LTD

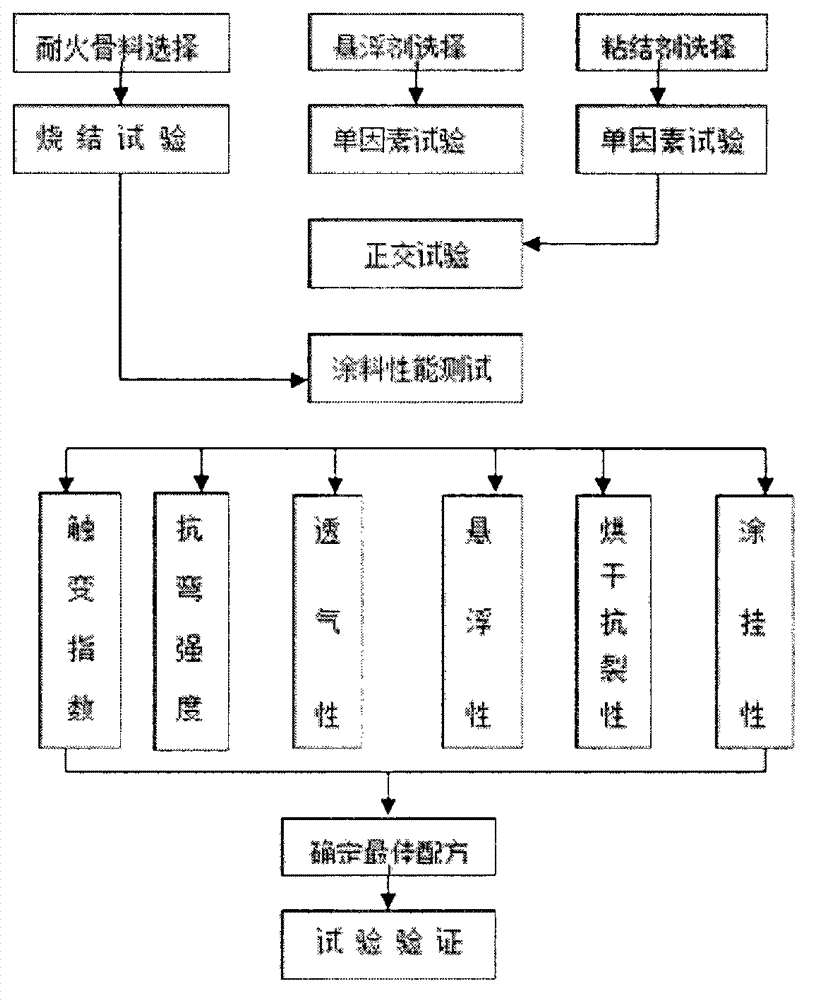

High-precision evanescent mode cast steel coating

InactiveCN104275435APromote sinteringHigh refractorinessFoundry mouldsFoundry coresSodium BentoniteSuspending Agents

The invention discloses a high-precision evanescent mode cast steel coating which consists of the following components in parts by weight: 90-120 parts of fireproof aggregates, 10 parts of auxiliaries, 3 parts of silica sol and 10-50 parts of water, wherein the water serves as a carrier; the fireproof aggregates are a combination of one or several of aluminum-silicon powder, quartz powder and bauxite clinker; the auxiliaries comprise the following internal components in percentage by mass: 15 percent of potato modified starch serving as a binder, 30 percent of Ca-based bentonite serving as a suspending agent, 50 percent of ground calcium carbonate serving as mineral adjustment powder and 5 percent of a surfactant which is FC-4430 fluorine surfactant; the fireproof aggregates are screened by a 200-300-mesh sieve. According to the coating, the surface roughness value of a casting can be reduced, casting defects are prevented, the sand falling and cleaning efficiency of the casting can be effectively improved, and gas generated by pyrolysis of a foam pattern can be effectively discharged out of a casting mold; meanwhile, permeation of metal liquid can be prevented, the strength and the rigidity of the foam pattern can be improved, and deformation of and damage to the pattern are prevented; the high-precision evanescent mode cast steel coating has good heat preservation and insulation effects.

Owner:渠县金城合金铸业有限公司

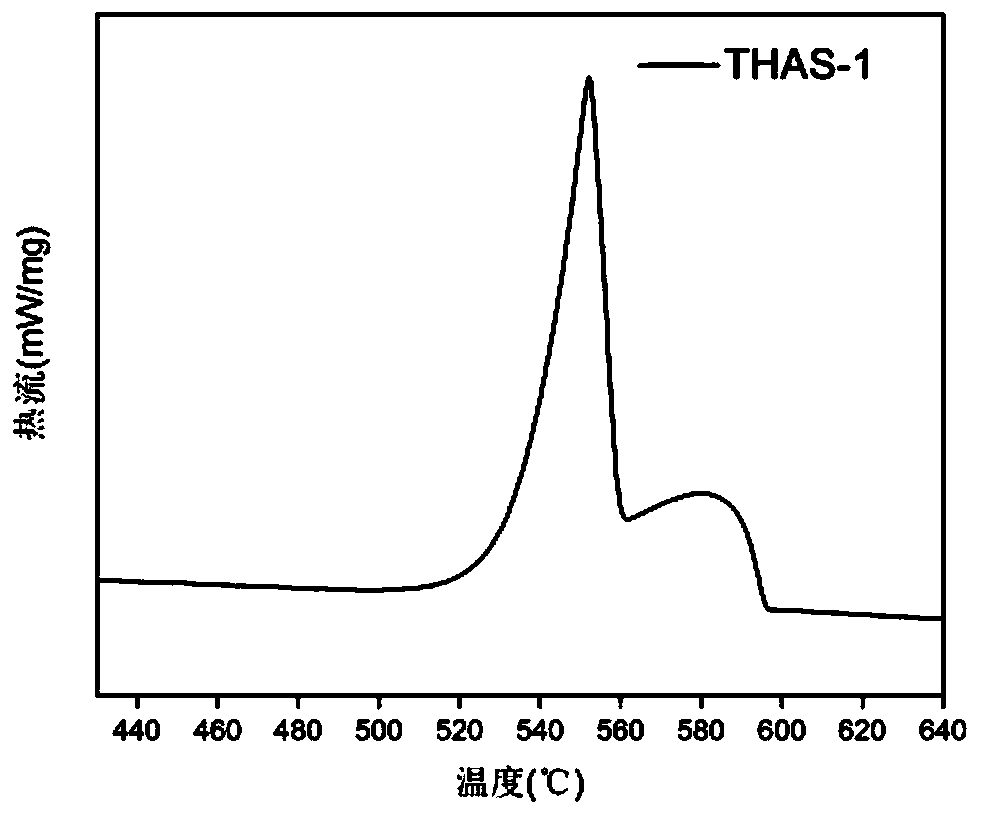

Heat-crack-resistant medium-niobium cast TiAl alloy with over-peritectic solidification characteristic

The invention relates to a heat-crack-resistant medium-niobium cast TiAl alloy with over-peritectic solidification characteristic. A medium amount of niobium element is added into a titanium-aluminum alloy with the aluminum content of 48.29-48.4 at.%, and the solidification path is over-peritectic solidification. The casting structure is an over-peritectic solidification structure which forms spherical alpha-dendrites with unobvious differentiation; no over-peritectic solidification structure with obvious peritectic corona, unobvious dendrites and unobvious dendritic segregation exists among the alpha-dendrites, thereby lowering the heat crack tendency of the niobium-containing cast titanium-aluminum alloy cast ingots and castings; and proper amounts of N and B elements are added, so that the solidification structure of the alloy is fine and uniform, thereby further lowering the crack among the lamella groups in the material. The invention provides an ideal cast titanium-aluminum alloy for titanium-aluminum alloy cast ingots and castings, which has the advantages of compact manufacturing structure, less segregation, favorable heat crack resistance and favorable properties; and the alloy can be used for manufacturing cast low-pressure turbine blades, compressor turbine blades and other heat-resistant structure components for engines.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A New Type of High Scandium Aluminum Alloy Welding Wire

ActiveCN103286471BGood electrical conductivityHigh strengthWelding/cutting media/materialsSoldering mediaManganeseWeld strength

The invention relates to the field of welding materials, in particular to a novel high-scandium aluminum alloy welding wire. The novel high-scandium aluminum alloy welding wire chemically comprises, by mass, 4.5-6.0% of Mg, 0.10-0.20% of Mn, 0.20-0.30% of Ti, 0.30-0.50% of Zn, 0.10-0.20% of Cr, 0.25-0.35% of Zr, 1.20-1.60% of Sc, not more than 0.20% of Fe, not more than 0.20% of Si, not more than 0.05% of Cu, not more than 0.0005% of Be, not more than 0.1% of other single impurity elements, not more than 0.15% of other impurity elements and the balance Al. The novel high-scandium aluminum alloy welding wire has the advantages of uniformity in texture, tiny grains, good electrical conductivity, excellent welding performance, high weld strength, good ductility and toughness, excellent mechanical property, low hot-cracking susceptibility and excellent corrosion resistance.

Owner:NORTHEASTERN UNIV LIAONING +1

Brake disc material for forging high-speed train

The invention discloses a brake disc material for forging a high-speed train. The brake disc material comprises the following components by mass percent: 0.16%-0.25% of C, 0.25%-0.60% of Si, 0.80%-1.30% of Mn, 0.70%-1.20% of Cr, 0.01%-0.03% of W, 0.80%-1.30% of Ni, 0.40%-0.70% of Mo, 0.05%-0.20% of Cu, 0.18%-0.25% of SiC, 0.20%-0.30% of Al2O3, 0.03%-0.15% of V, 0.0050%-0.025% of N, 0.005%-0.20% of Re, not more than 0.015% of P, not more than 0.010% of S and the balance of Fe. The brake disc material is high in wear resistance and good in thermal cracking resistance, the high-speed train can be safely and reliably braked, and the use and repair costs of the high-speed train are reduced.

Owner:NANJING IRON & STEEL CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com