Cast iron material pinch roll used for hot strip mill and manufacturing method of cast iron material pinch roll

A manufacturing method and technology for pinch rolls, which are applied in the field of roll casting, can solve problems such as cracks and wear resistance, and achieve the effects of improved wear resistance, high wear resistance, and guaranteed thermal crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

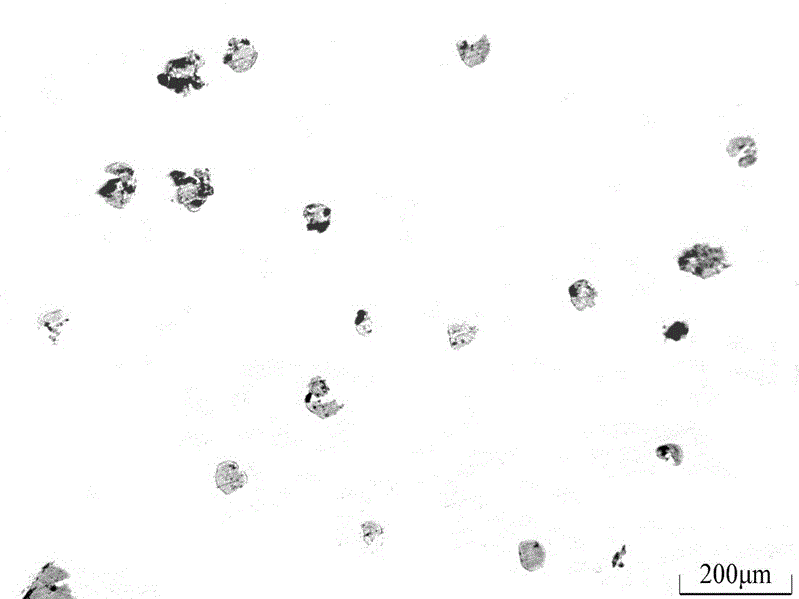

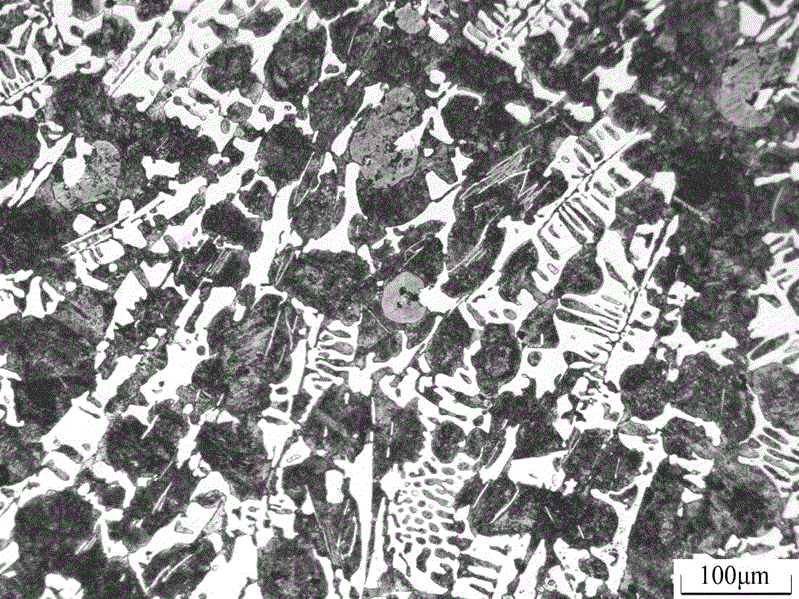

Image

Examples

Embodiment 1

[0032] A pinch roll made of cast iron used in a hot strip rolling mill in this embodiment, the alloy composition and weight percentage content target of the set pinch roll is C 3.15-3.25%, Si 1.65-1.75%, Mn 0.75- 0.85%, Cr 0.65~0.75%, Ni1.85~1.95%, Mo 0.75~0.85%, P≤0.10%, S≤0.05%, and the rest are Fe and unavoidable impurities.

[0033] In this implementation, cast iron pinch rolls for hot strip mills are prepared through the steps of smelting, inoculation, spheroidization, pouring, and heat treatment. Each step is specifically,

[0034] 1) For smelting, the raw materials are placed in the induction furnace according to the proportion of the alloy composition and its weight percentage. The specific input raw materials are pig iron, scrap steel, ferromanganese, ferrochromium, ferronickel and ferromolybdenum. Electromagnetic stirring is used. Set the smelting temperature to 1400°C~1500°C, and start smelting.

[0035] 2) Inoculation and spheroidization treatment, add inoculant ...

Embodiment 2

[0041] A pinch roll made of cast iron used in a hot strip rolling mill in this embodiment, the alloy composition and weight percentage content target of the set pinch roll is C 3.55-3.60%, Si 1.95-2.00%, Mn 0.50- 0.60%, Cr 0.50~0.60%, Ni2.30~2.40%, Mo 0.95~1.00%, P≤0.10%, S≤0.05%, and the rest are Fe and unavoidable impurities.

[0042] In this implementation, cast iron pinch rolls for hot strip mills are prepared through the steps of smelting, inoculation, spheroidization, pouring, and heat treatment. Each step is specifically,

[0043] 1) For smelting, the raw materials are placed in the induction furnace according to the proportion of the alloy composition and its weight percentage. The specific input raw materials are pig iron, scrap steel, ferromanganese, ferrochromium, ferronickel and ferromolybdenum. Electromagnetic stirring is used. Set the smelting temperature to 1400°C~1500°C, and start smelting.

[0044] 2) Inoculation and spheroidization treatment, add inoculant in...

Embodiment 3

[0049] A pinch roll made of cast iron used in a hot strip rolling mill in this embodiment, the alloy composition and weight percentage content target of the set pinch roll is C 3.35-3.45%, Si 1.75-1.85%, Mn 0.50- 0.60%, Cr 0.50~0.60%, Ni1.60~1.70%, Mo 0.50~0.60%, P≤0.10%, S≤0.05%, and the rest are Fe and unavoidable impurities.

[0050] In this implementation, cast iron pinch rolls for hot strip mills are prepared through the steps of smelting, inoculation, spheroidization, pouring, and heat treatment. Each step is specifically,

[0051] 1) For smelting, the raw materials are placed in the induction furnace according to the proportion of the alloy composition and its weight percentage. The specific input raw materials are pig iron, scrap steel, ferromanganese, ferrochromium, ferronickel and ferromolybdenum. Electromagnetic stirring is used. Set the smelting temperature to 1400°C~1500°C, and start smelting.

[0052] 2) Inoculation and spheroidization treatment, add inoculant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com