Magnesium alloy extrusion combined die and casting-extrusion-shearing method thereof

A technology of extrusion die and magnesium alloy, which is applied in the field of magnesium alloy casting, can solve the problems of less slippage, limit the application of magnesium alloy, and not easy to press processing, etc., to reduce the contact area, save experimental expenses, and reduce frictional resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1 mold design and manufacture

[0062] 1. Selection of mold materials

[0063] In order to achieve the purpose of controlling the formation and development of the material microstructure, refining the sample grains and improving the performance of the material through the comprehensive process of rapid solidification, work hardening, dynamic recovery and dynamic recrystallization, a set of assembleable type mold. Combined with factors such as the temperature range and strong friction during the extrusion process, H13 hot work die steel was finally selected (the chemical composition is shown in Table 1, it is a steel grade formed by adding alloy elements on the basis of carbon steel, and the unified number code is T20502 ; Grade 4Cr5MoSiV1) as the material of the mold.

[0064] Table 1 Chemical composition of H13 steel

[0065]

[0066] 2. Mold structure design

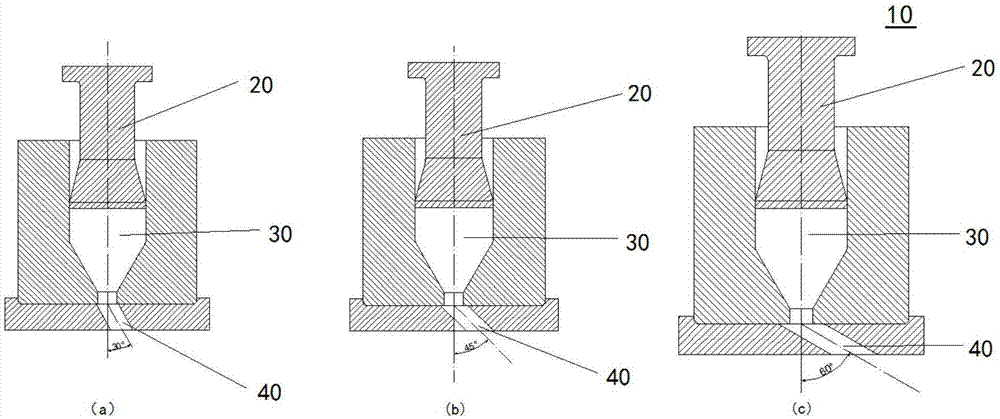

[0067] The three components of the combined die are divided into variable extrusion ratio c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com