Method for preparing hard particle coating on hard substrate through laser-assisted cold spraying

A hard particle, laser-assisted technology, applied in the field of laser technology and cold spraying, can solve problems such as inability to apply hard particle coating, and achieve the effect of improving plastic deformation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

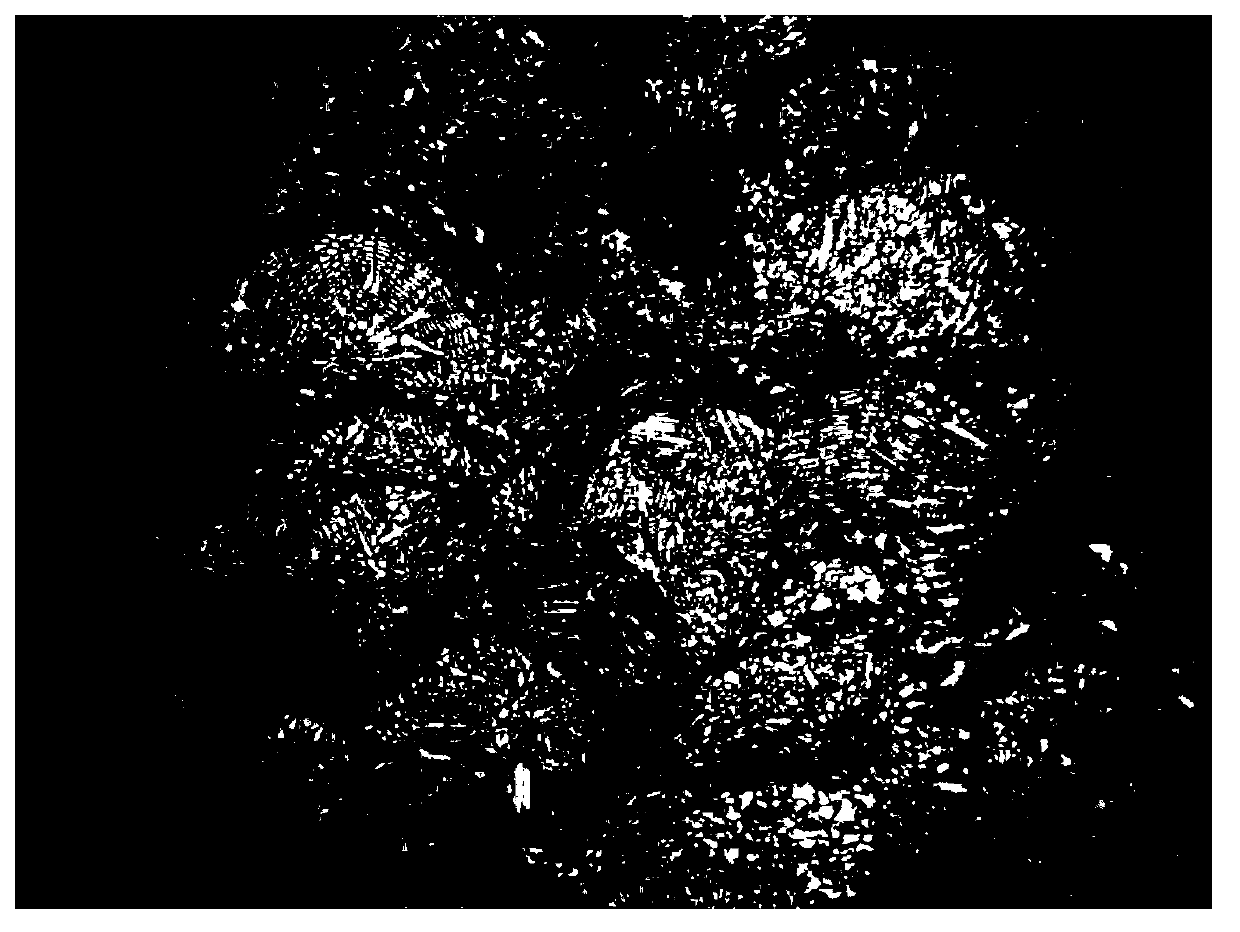

[0021] The 45 steel cylinder was sandblasted as the substrate, and Ni45 spherical particles with a particle diameter of 30 microns were selected for laser-assisted cold spraying. The laser is a fiber laser with a power density of 3×10 5 W / cm 2 . The high-pressure gas is 1.5MPa compressed air, and the particles are preheated to a temperature of 600°C. The 45 steel cylinder is rotated through the machine tool control, and at the same time, the powder is fed, and the laser is activated to heat the spraying area synchronously, forming a hard particle coating on the surface of the 45 steel cylinder. Metallographic photographs of Ni45 deposited coatings as figure 1 As shown, it can be clearly seen that the particles collide, deform and bond together.

[0022] However, when no laser heating was added, no deposition was formed on the substrate no matter how the parameters were adjusted.

Embodiment 2

[0024] S43C low-carbon steel was sandblasted as the substrate, and Ni60 material with a particle diameter of 40 microns was selected for laser-assisted cold spraying. The laser is a semiconductor laser with a power density of 4×10 5 W / cm 2 . The high-pressure gas is 3.0MPa compressed air, the preheating temperature of the particles is 500°C, start the powder feeding, use the Staubli manipulator to control the nozzle to the starting point, start the laser, and complete the flat spraying. During the spraying process, the laser heats the spraying area synchronously. The metallographic photos of the prepared hard particle coating are as follows: figure 2 As shown, it can be clearly seen that the particles are plastically deformed by impact and combined together, and the microhardness is measured to be 610HV.

[0025] However, when no laser heating was added, no deposition was formed on the substrate no matter how the parameters were adjusted.

Embodiment 3

[0027] The 45 steel plate was sandblasted as the substrate, and the Ni60 material with a particle diameter of 50 microns was selected for laser-assisted cold spraying. The laser is a semiconductor laser, and the power density used is 5×10 5 W / cm 2 . The high-pressure gas is 3.0MPa compressed air, and the particle preheating temperature is 600°C. At the same time, the Staubli manipulator is controlled to control the nozzle movement and start powder feeding, and start the laser to synchronously heat the spraying area to form a deposited coating on the surface of the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com