Spiral molded large-deformation-resistant submerged-arc welding pipe and manufacture method thereof

A technology of anti-large deformation and spiral forming, which is applied in the direction of manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of increasing cracks, reducing the pre-strain amount of steel pipes, and large welding residual stress, so as to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail below in conjunction with accompanying drawing:

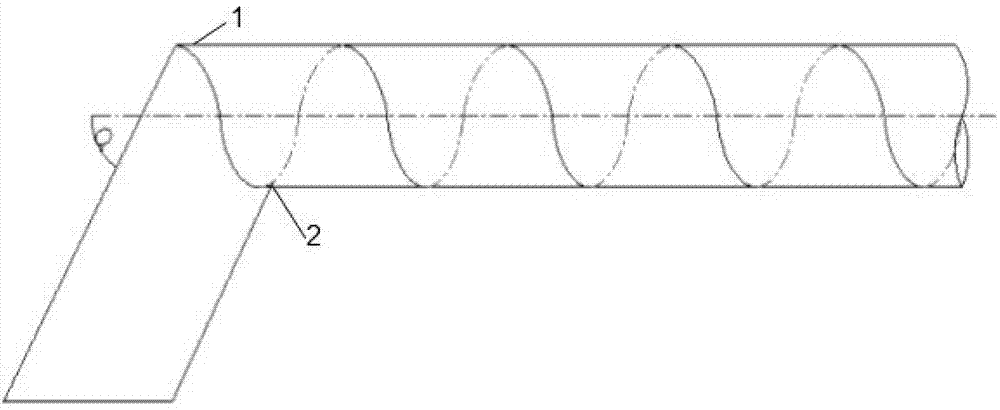

[0035] see figure 1 , the embodiment adopted by the present invention is: the X80 anti-large deformation hot-rolled coil with the structure of bainite + ferrite dual-phase structure is adopted, and it is continuously sent to the former after being leveled on the production line of the spiral welded pipe unit. , the steel strip is curled into a helical cylinder with a certain forming angle a, such as figure 1 As shown, the submerged arc welding process of three-wire internal welding and four-wire external welding is carried out at the joint position. The specific steel pipe manufacturing process steps are as follows:

[0036] 1. Uncoiling and leveling of large-deformation-resistant hot-rolled coils to prepare for the forming of steel pipes;

[0037] 2. Edge milling: including rough milling for removing excess plate edges and fine milling for X-shaped bevels. The purpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com