Heavy size TRIP amorphous composite material and preparation method thereof

An amorphous composite material and large-size technology, applied in the field of amorphous alloys and their composite materials, can solve problems such as limiting engineering applications, and achieve the effects of easy engineering applications, reducing stress concentration, wide composition range and preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

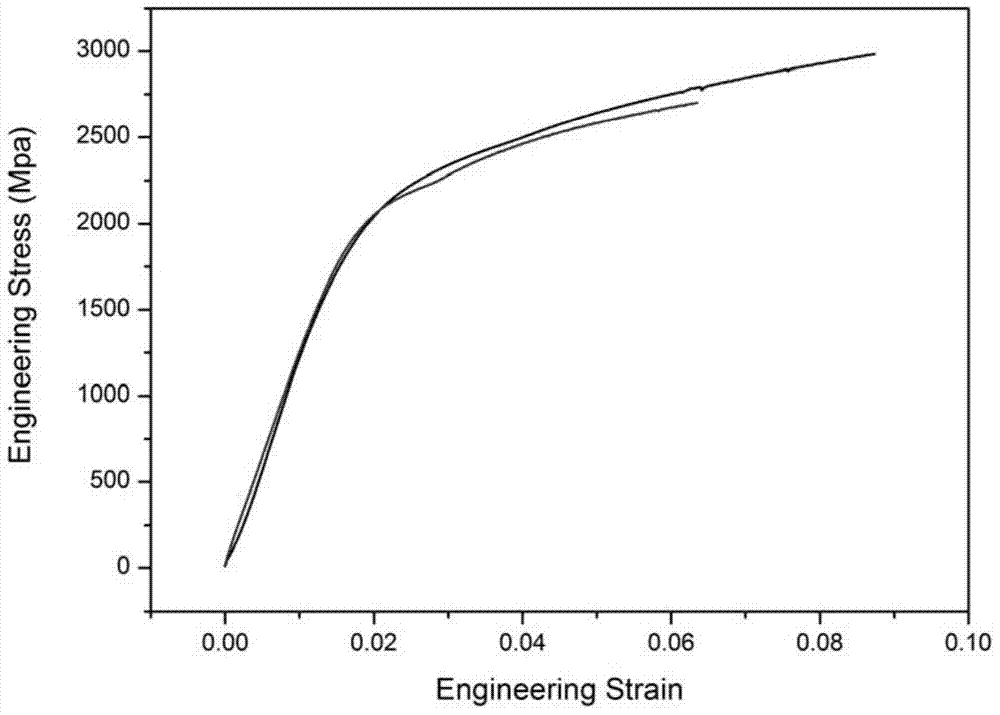

Image

Examples

Embodiment 1

[0032] Example 1 10mm×10mm large size Cu 42.25 Zr 46.5 Al 4 Ag 5 Nb 1.5 sn 0.75 Preparation and Characterization of Microstructure and Properties of Amorphous Composite Materials

[0033] (1) Alloy composition design

[0034] According to the theory of amorphous formation and alloy phase diagram, Al and Ag elements are added to the Cu-Zr binary alloy to improve the ability of the amorphous to resist crystallization and stabilize the metastable austenite phase. At the same time, Nb and Sn elements are added Elements that can react with existing alloying elements or react with added elements to form intermetallic compounds with high thermal stability, act as modifiers, promote the precipitation of crystal phases and disperse crystal phases. Specifically, the choice of Cu 42.25 Zr 46.5 Al 4 Ag 5 Nb 1.5 sn 0.75 alloy composition.

[0035] (2) Ingredients, alloy smelting and casting

[0036] Select commercially available pure metals Cu, Zr, Al, Ag, Nb, Sn with a pur...

Embodiment 3

[0048] Example 3 φ8mm large size Cu 46.25 Zr 48 Al 4 Ag 1 sn 0.75 Preparation and Characterization of Microstructure and Properties of Metallic Glass Composites

[0049] (1) Alloy composition design

[0050] According to the theory of amorphous formation and alloy phase diagram, adding Al and Ag elements on the basis of Cu-Zr binary alloy can improve the ability of amorphous to resist crystallization and stabilize the metastable austenite phase. At the same time, the added Sn element can An element that reacts with existing alloying elements to form intermetallic compounds with high thermal stability, acts as a modifier, promotes the precipitation of crystal phases and disperses crystal phases. Specifically, the choice of Cu 46.25 Zr 48 Al 4 Ag 1 sn 0.75 alloy composition.

[0051](2) Ingredients, alloy smelting and casting

[0052] Select commercially available pure metals Cu, Zr, Al, Ag, Nb, Sn with a purity higher than 99.9% (weight percentage) according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com