Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

641 results about "High fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal-ceramic composite articulation

InactiveUS6881229B2Minimal productionImprove flexural strengthBone implantJoint implantsHigh fractureIn vivo

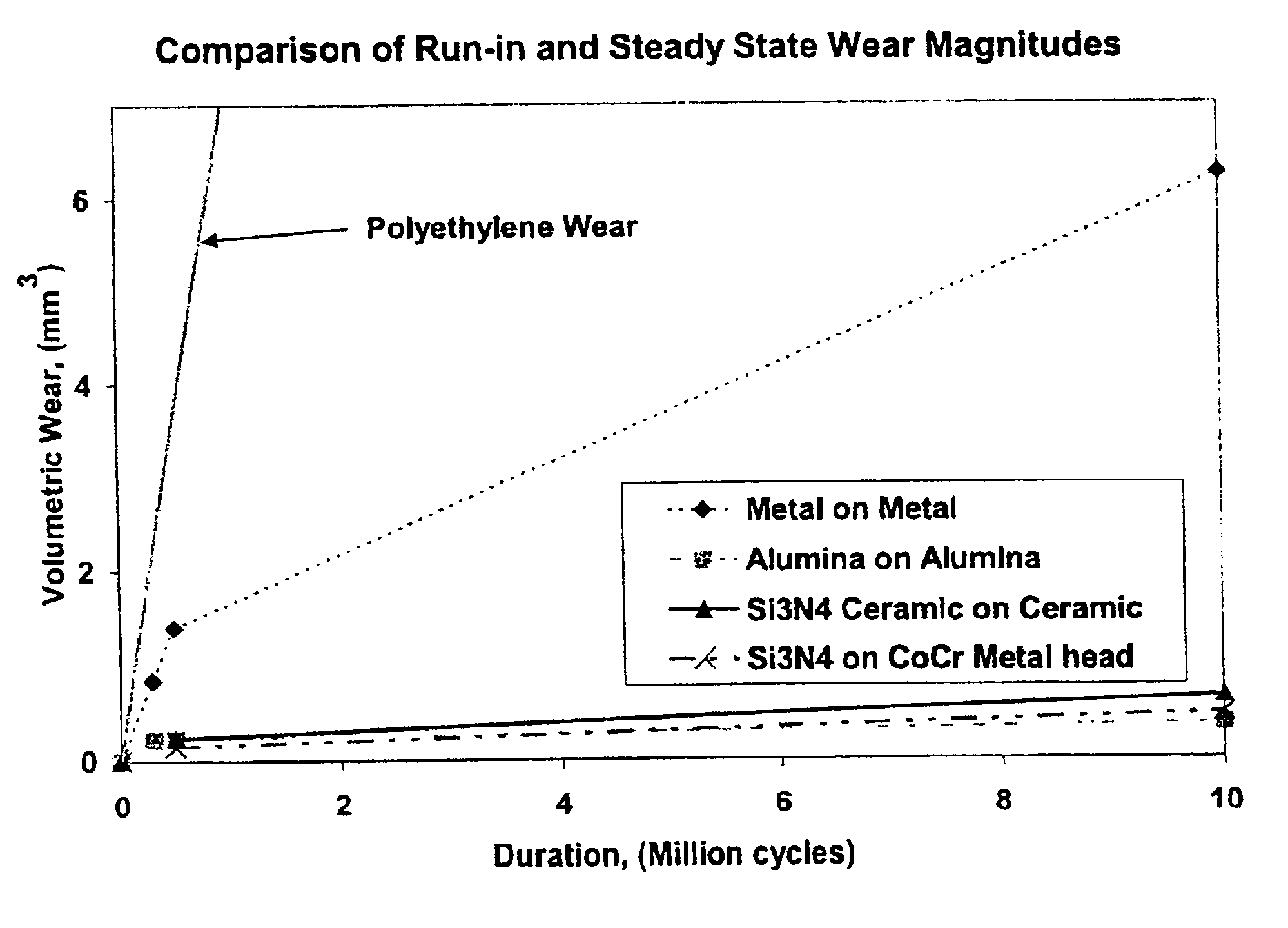

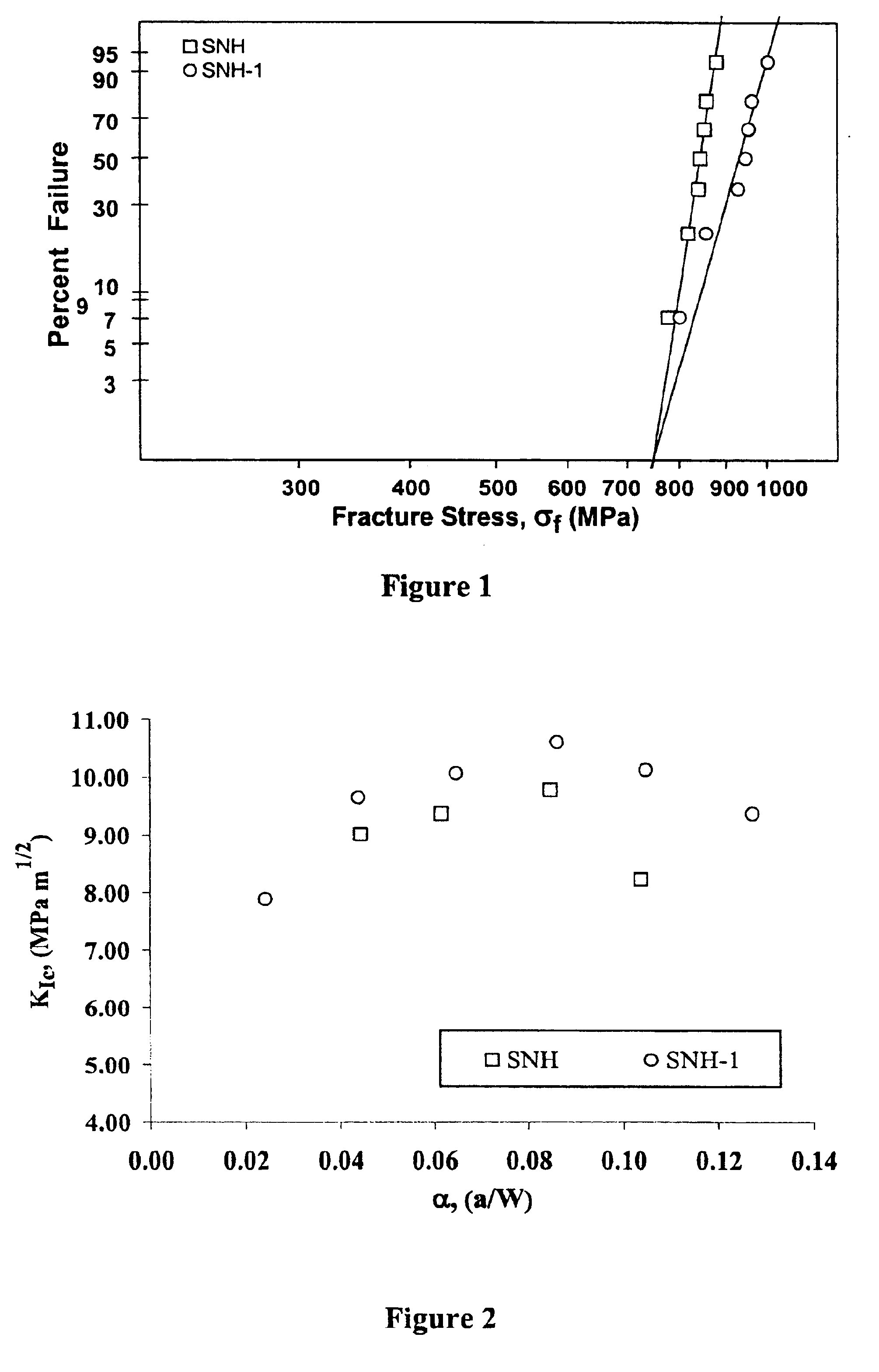

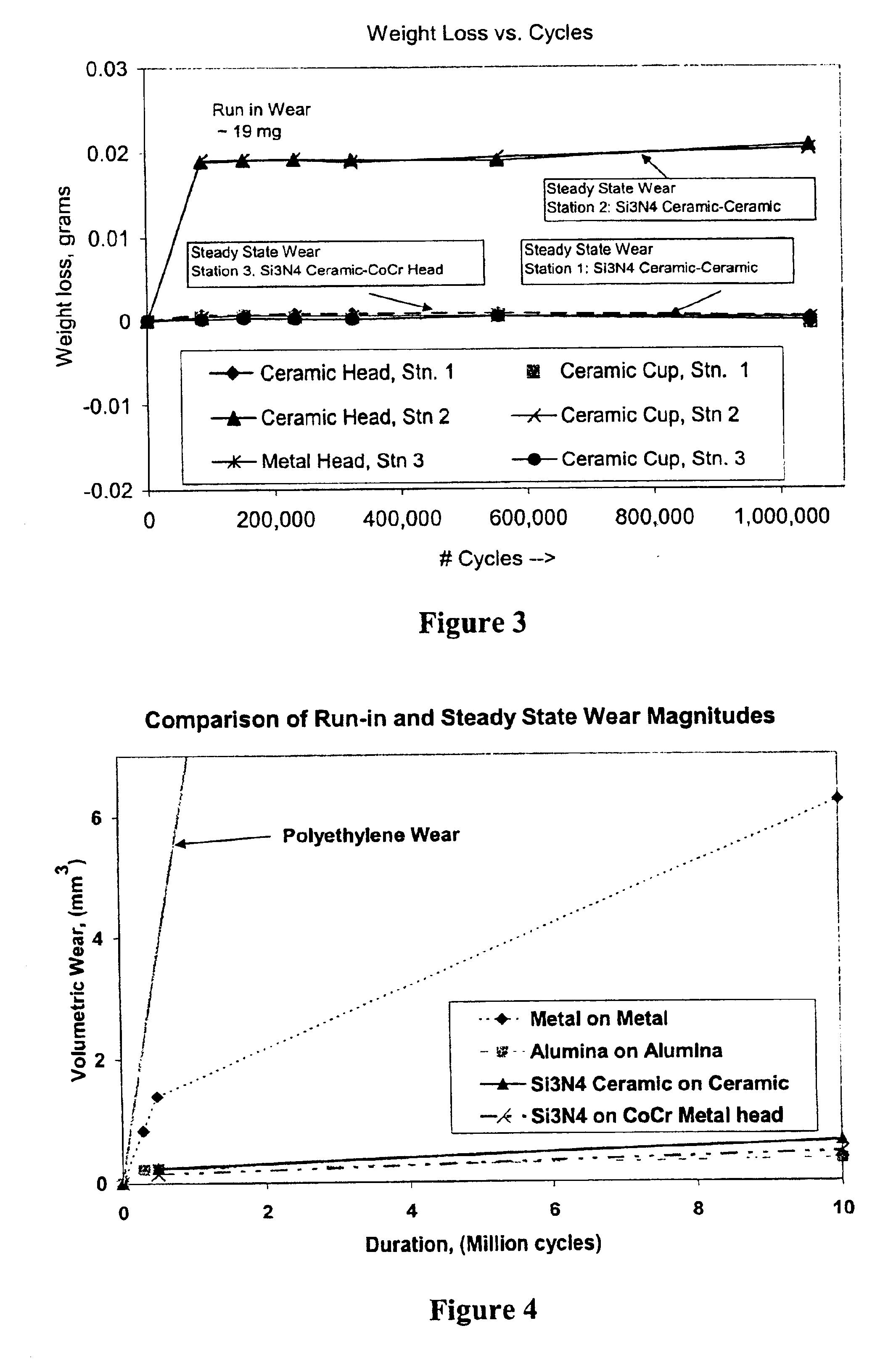

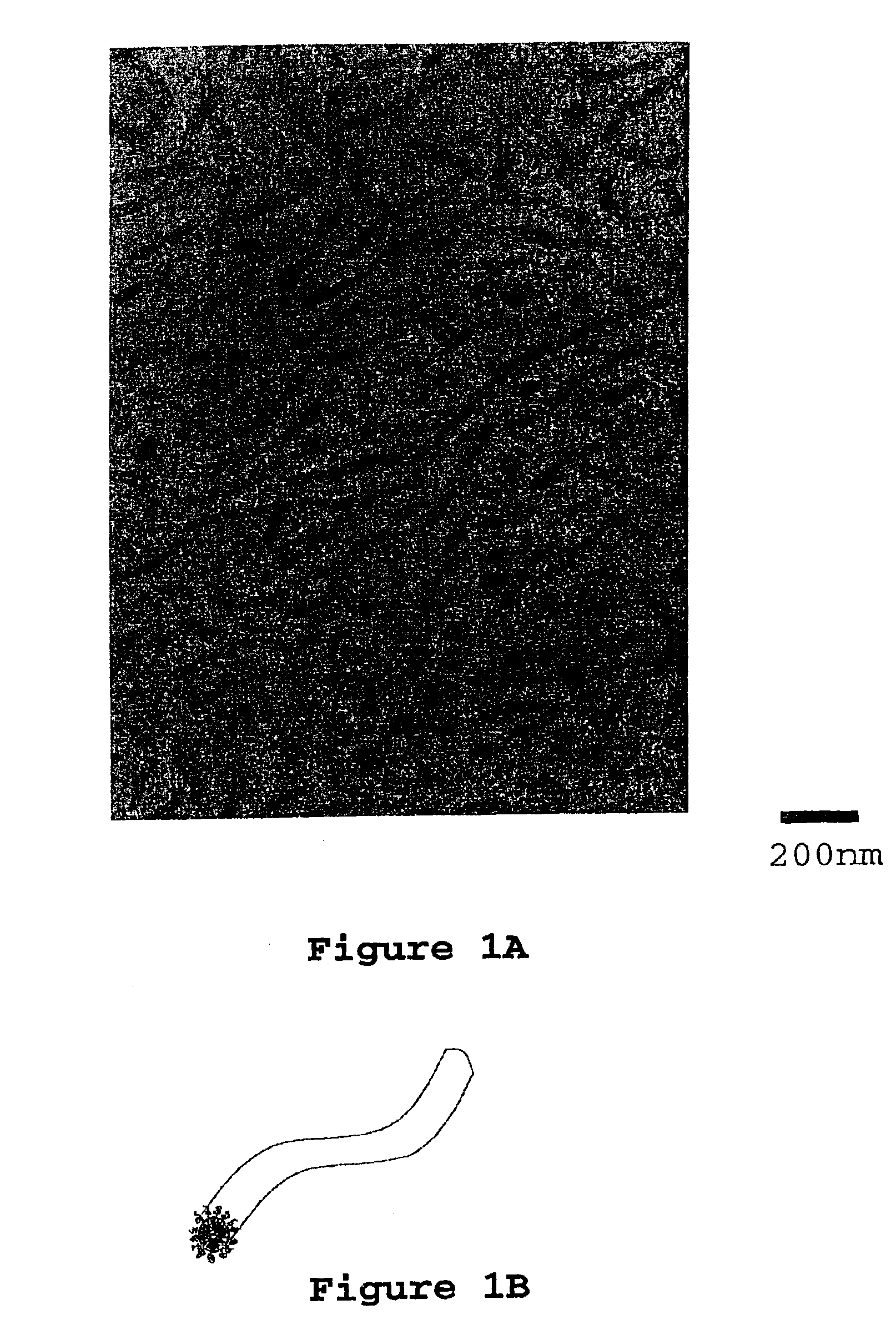

A ceramic-metal composite articulation is provided with substantial elimination of wear debris, wherein a ceramic material is provided with superior mechanical properties tailored for articulating with ceramic articulations having high flexural strength (greater than about 700 MPa), high fracture toughness (greater than about 7 MPa1 / 2) and a high Weibull modulus (greater than about 20), in comparison with presently available bio-ceramics such as alumina or zirconia. The mechanical property enhancement enables ceramic materials with greater reliability and significantly reduced in-vivo fracture risk to be obtained. Preliminary in-vitro wear performance, to several million cycles using established test protocols, of head / cup components in a prosthetic hip joint made from these ceramics also demonstrates the ultra low wear characteristics. These material properties substantially eliminate polyethylene (PE) wear debris mediated implant failures by offering an optimal combination of bio-mechanical safety and reliability with ultra low wear performance.

Owner:SINTX TECH INC

Curable flame retardant epoxy compositions

InactiveUS6887574B2Improve fracture resistanceModulus is reducedSynthetic resin layered productsPrinted circuit aspectsEpoxyHigh fracture

A curable flame retardant epoxy resin composition including (a) at least one flame retardant epoxy resin; (b) at least one amphiphilic block copolymer; and (c) a curing agent. Such components are present in the curable composition in the appropriate amounts and ratios such that, upon curing, the block copolymer self-assembles into a nano structure morphology, such as a worm-like micelle morphology. The resulting cured product made from the composition of the present invention has a remarkably increased high fracture resistance; and allows the use of flame retardant epoxies in applications where fracture resistance is an issue.

Owner:RGT UNIV OF MINNESOTA

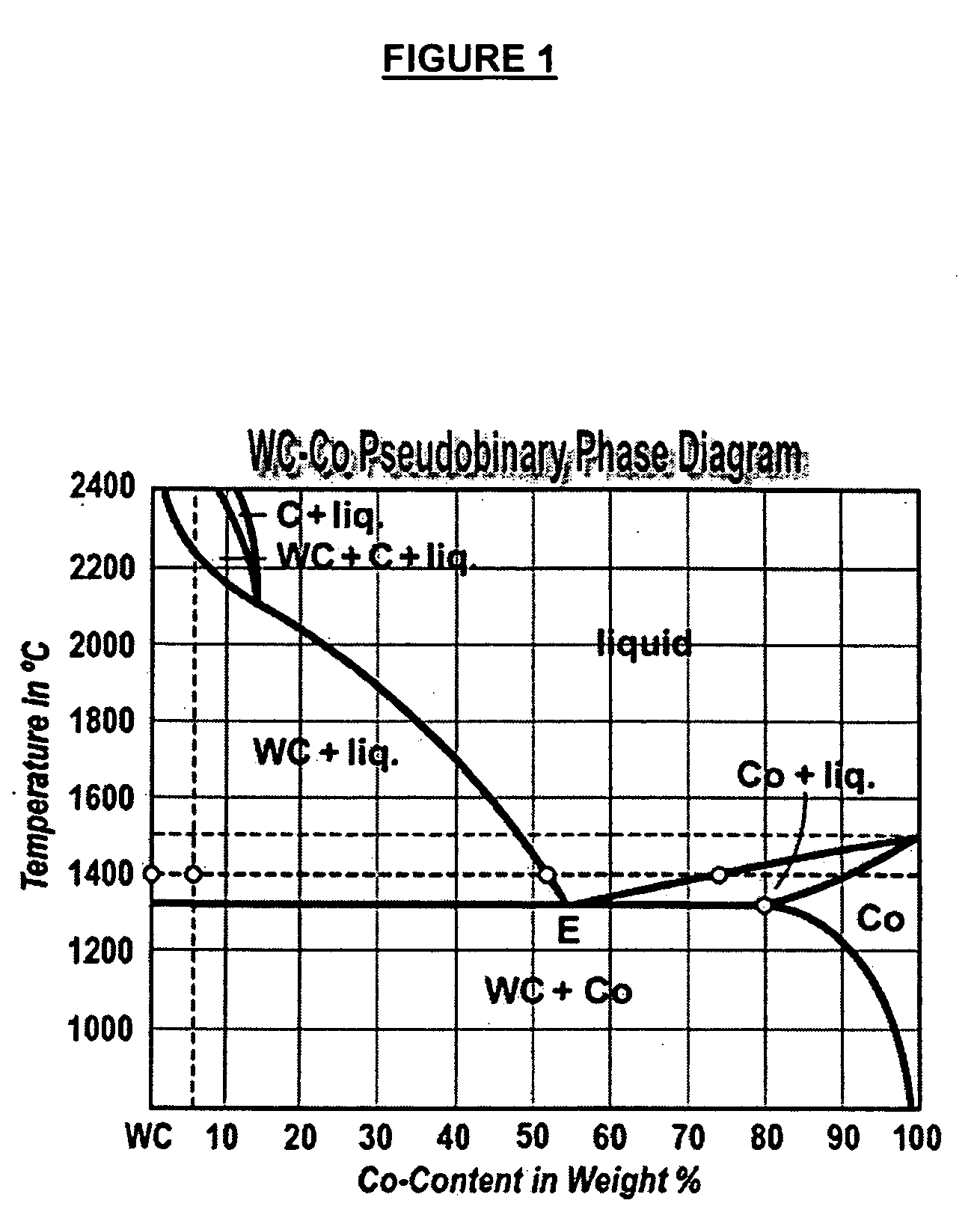

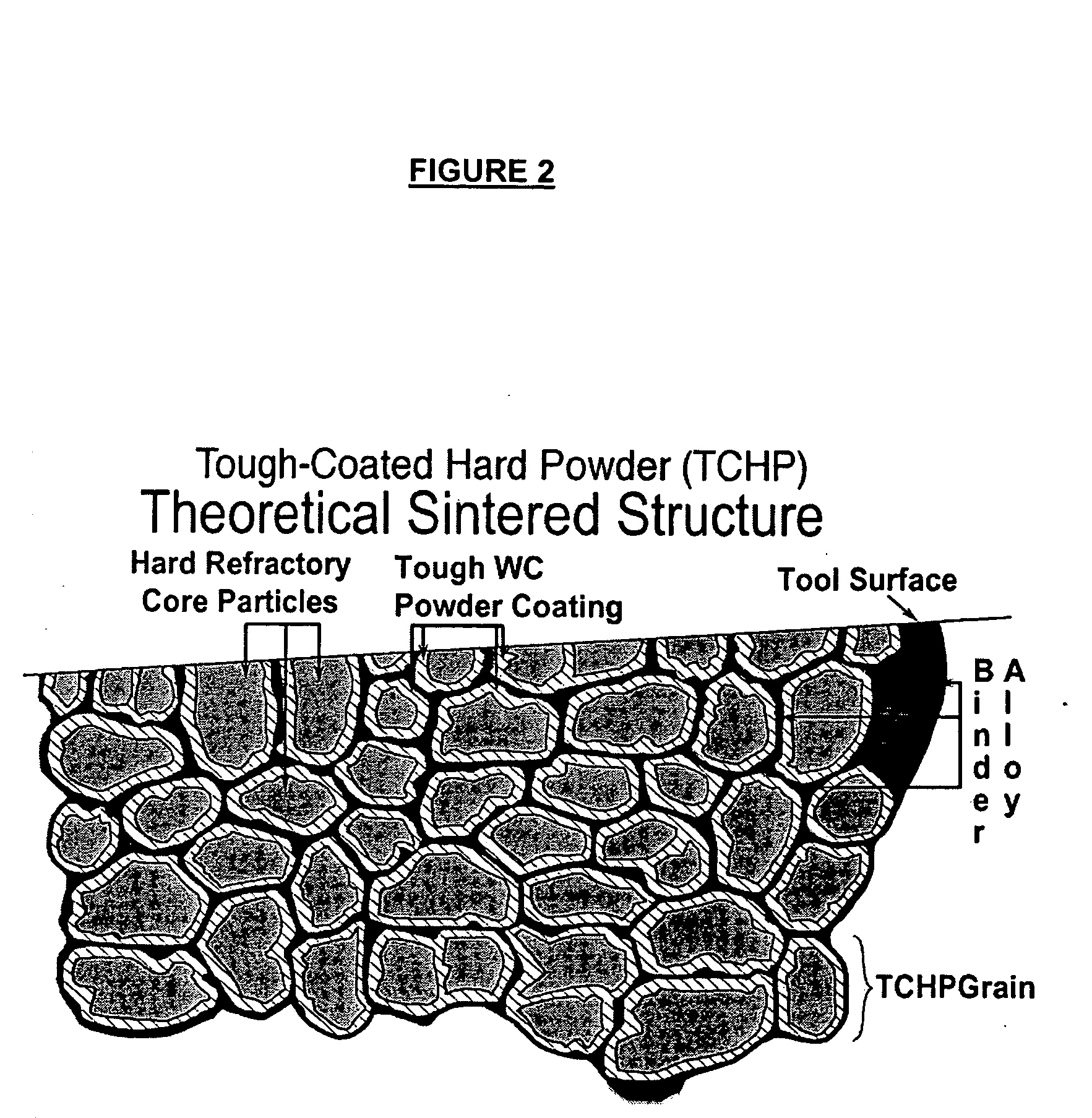

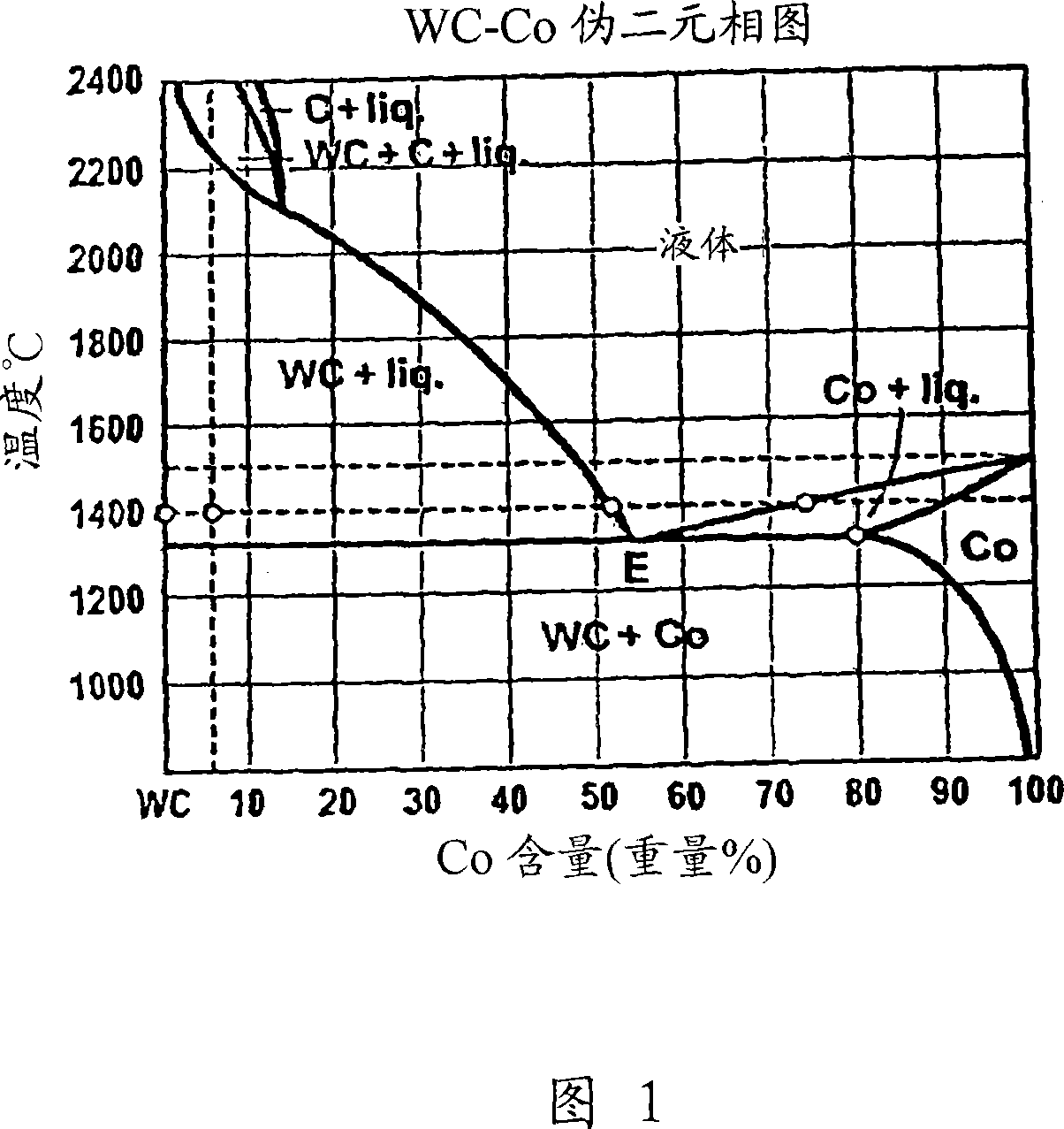

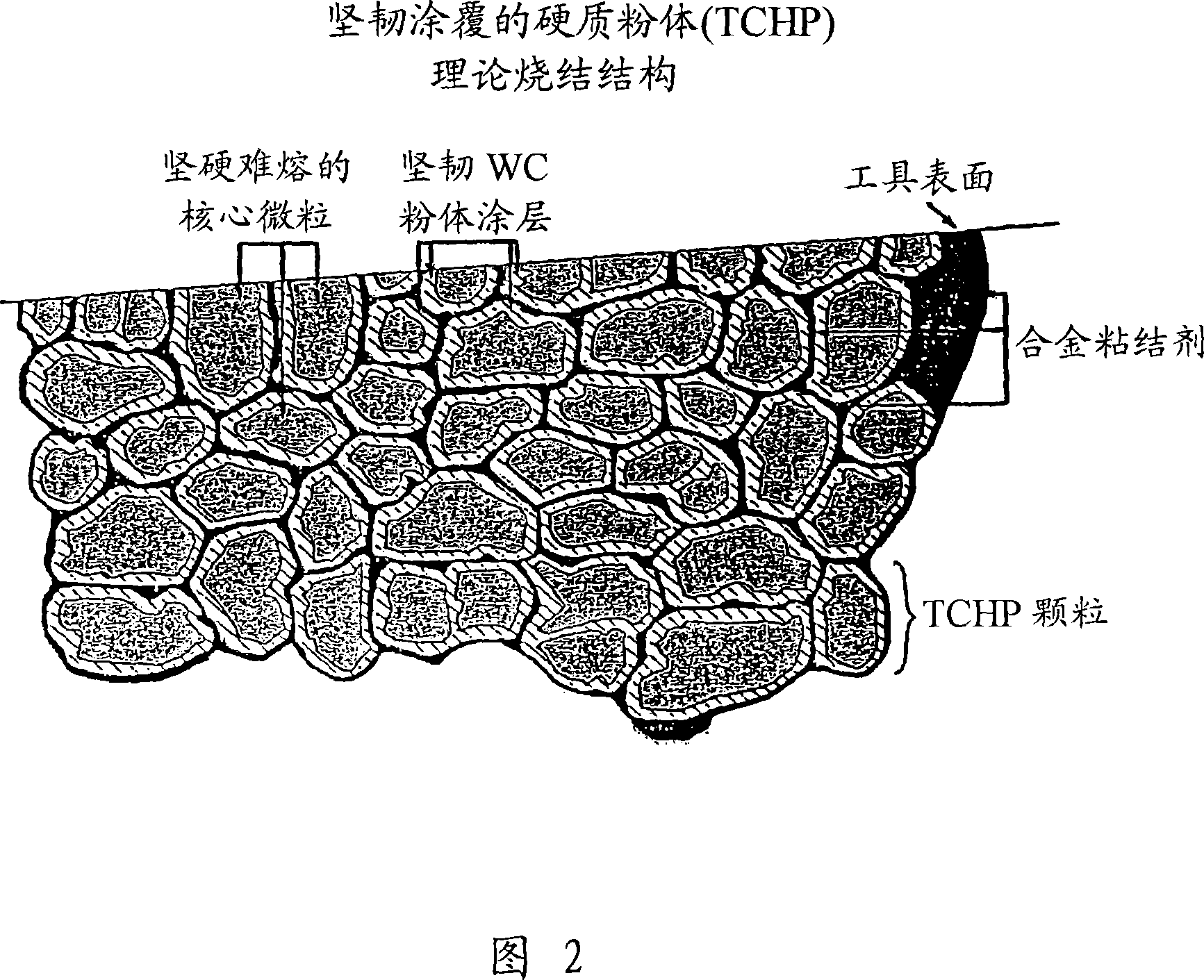

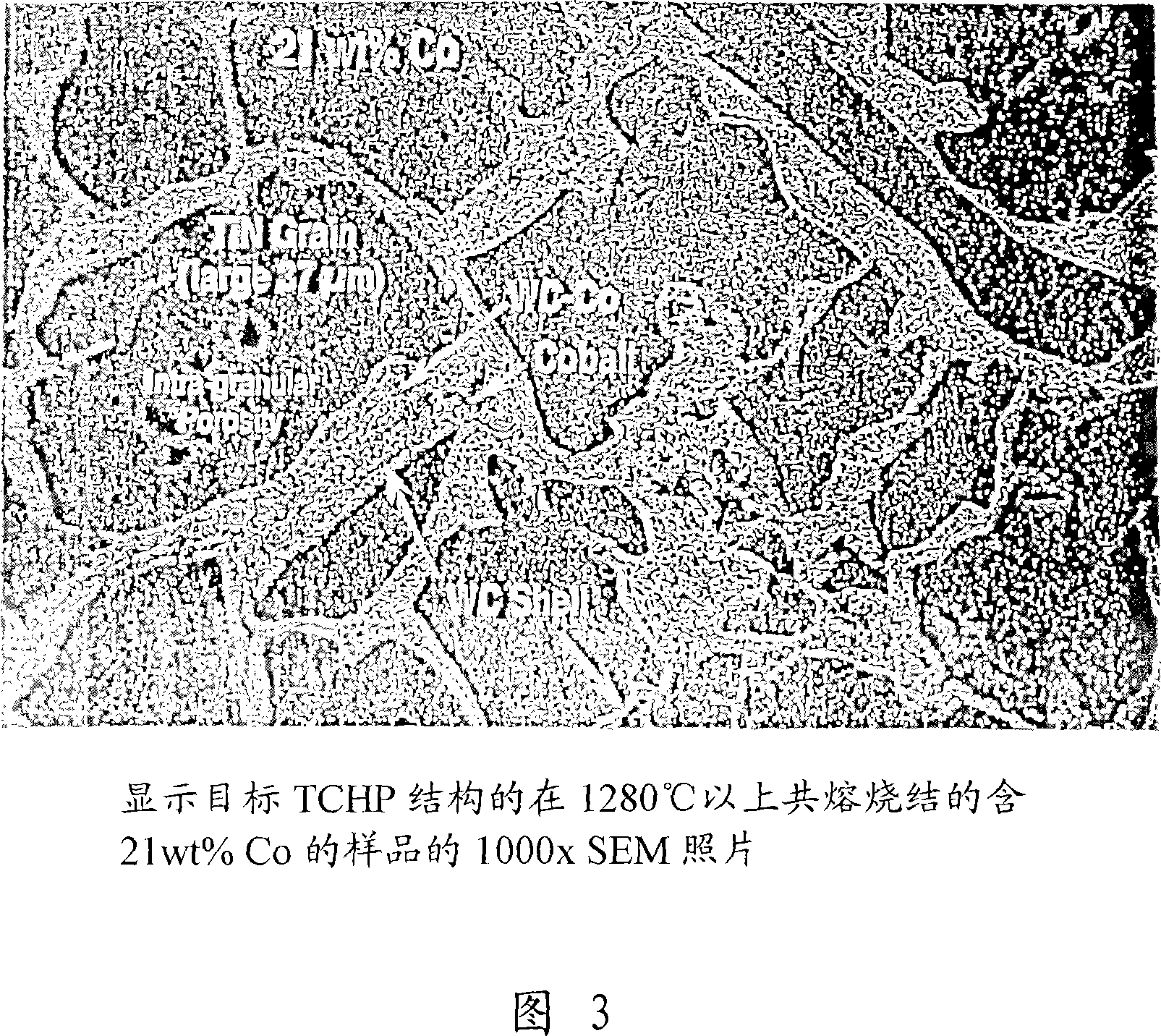

Method for consolidating tough coated hard powders

A method of consolidating particulate materials into articles having combinations of properties not available by conventional processes by liquid phase sintering. These particulate materials are comprised of core particles individually coated with layers of a metal compound having a relatively higher fracture toughness than the core, such as WC or TaC. These coated particles include an outer layer comprised a metal, such as Co or Ni. The particles with these coatings are pressed to form an article and the article densified at pressures and temperatures where full density is achieved without the degradation of the material forming the core particle.

Owner:ETERNALOY HLDG GMBH

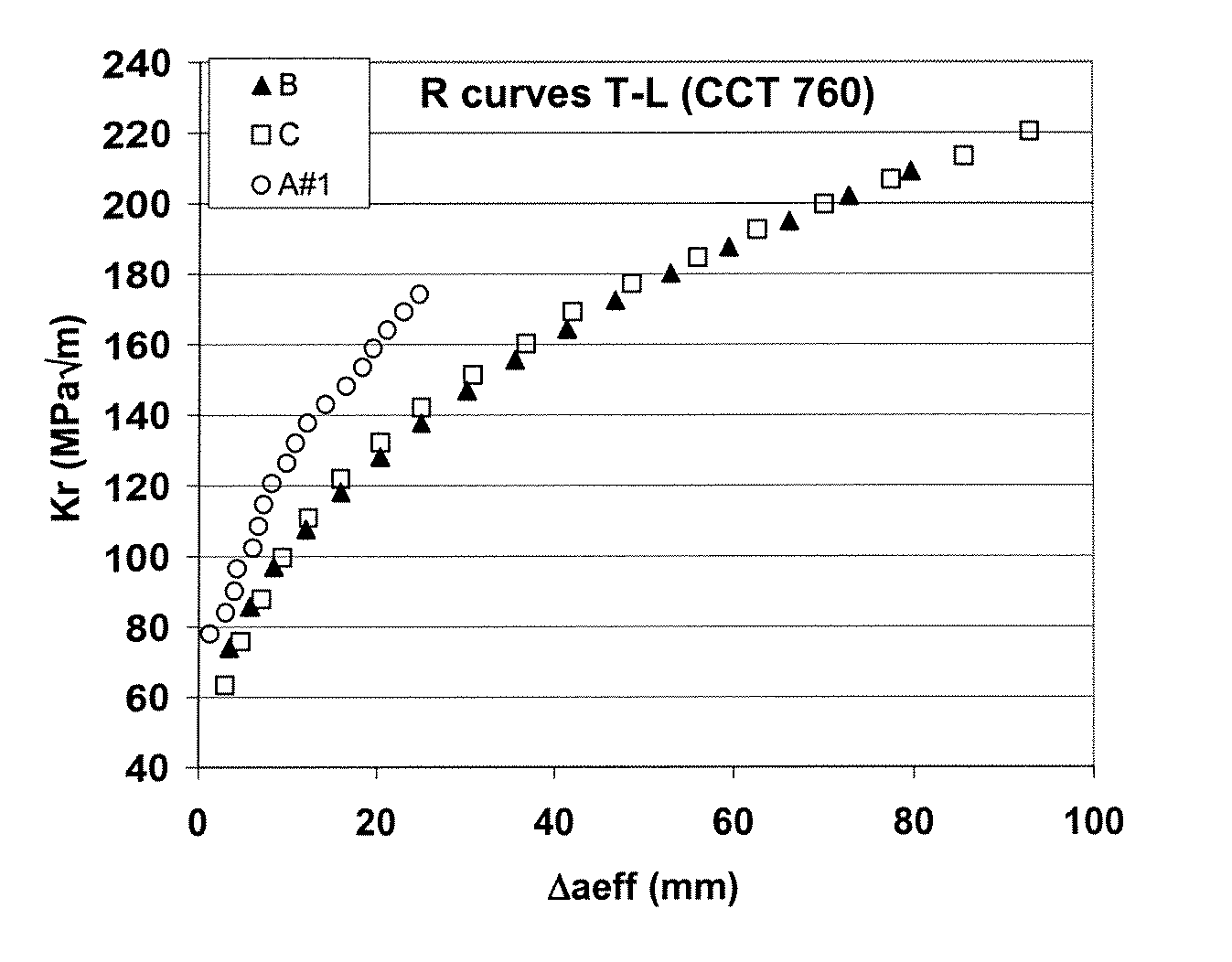

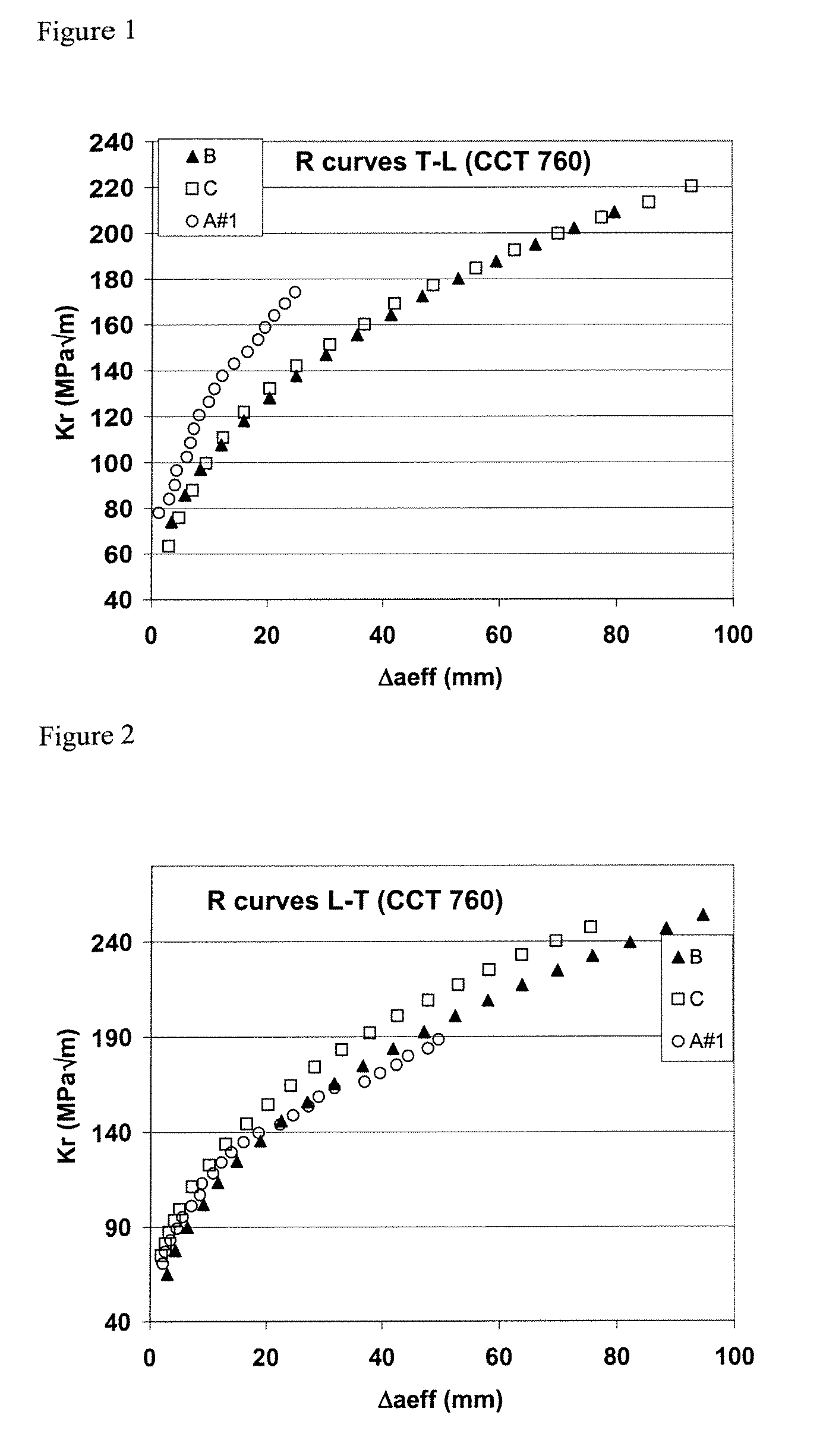

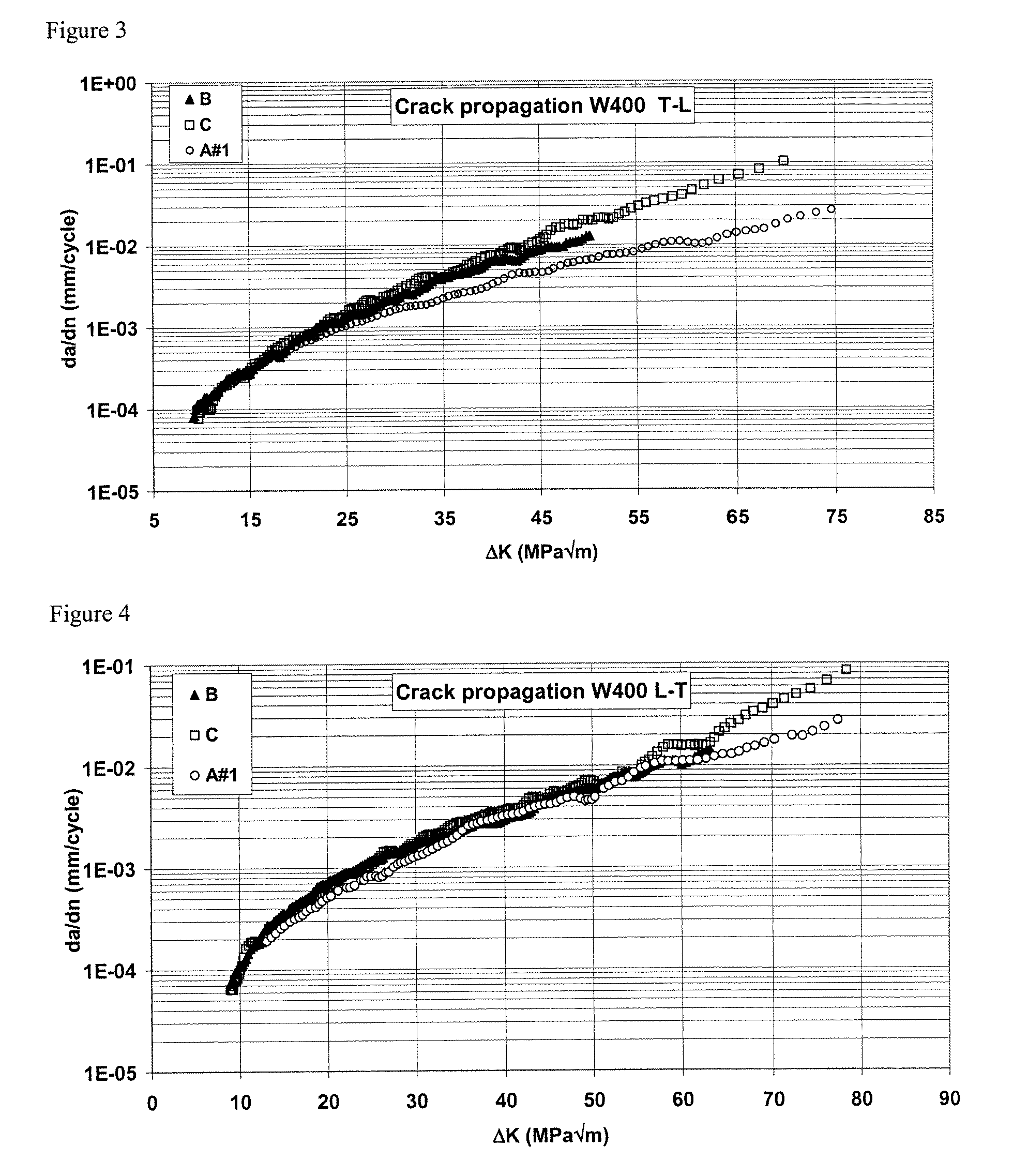

Al-Cu-Li-Mg-Ag-Mn-Zr alloy for use as structural members requiring high strength and high fracture toughness

An improved aluminum lithium alloy comprising 0.1 to 2.5 wt. % Li, 2.5 to 5.5 wt. % Cu, 0.2 to 1.0 wt. % Mg, 0.2 to 0.8 wt. % Ag, 0.2 to 0.8 wt. % Mn, up to 0.4 wt. % Zr or other grain refiner such as chromium, titanium, hafnium, scandium or vanadium, the balance aluminum. The present alloy exhibits an improved combination of strength and fracture toughness, over any thickness range. The present invention is further directed to methods for preparing and using Al—Li alloys as well as to products comprising the same.

Owner:CONSTELLIUM ROLLED PROD RAVENSWOOD

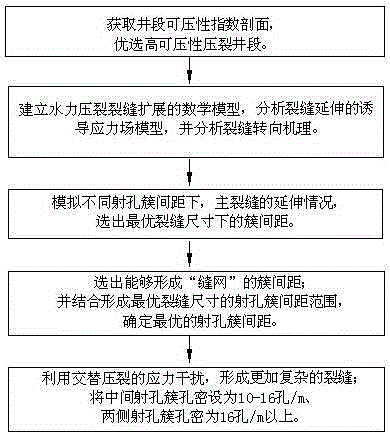

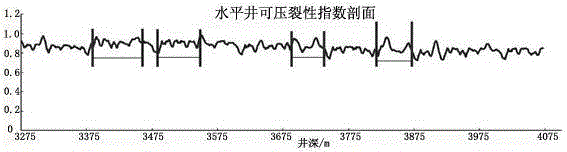

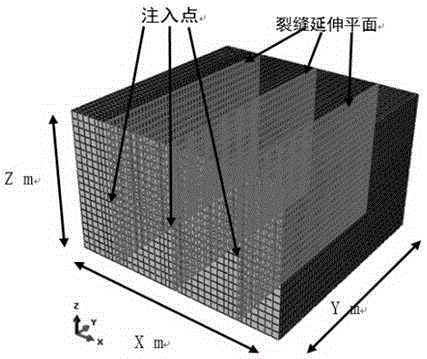

Optimum design method for staged fracturing perforation cluster parameters of horizontal well of shale reservoir

ActiveCN105201479AGuaranteed outputAchieve mutual interferenceFluid removalSpecial data processing applicationsPrincipal stressHigh fracture

The invention relates to an optimum design method for staged fracturing perforation cluster parameters of a horizontal well of a shale reservoir. The optimum design method includes the following steps of S1, selecting high-fracture-performance fracturing well sections; S2, building a mathematical model for hydrofracture fracture progressing, analyzing an induction stress field model for fracture extension, and analyzing a fracture diverting mechanism; S3, analyzing extending conditions of main fractures, and selecting cluster distances capable of allowing the main fractures to evenly extend forwards; S4, analyzing change conditions of stress fields around the main fractures, selecting the perforation cluster distances with the horizontal principal stress ratios smaller than 1.3, and determining the optimal perforation cluster distances in cooperation with the step S3; S5, further improving the complexity of the fractures through an alternate fracturing principle, and setting the perforation density of perforation clusters in the middle to range from 10 to 16 per m and the perforation density of perforation clusters in the two sides to be larger than 16 per m. By means of the optimum design method, the perforation cluster distances can be optimized, largest fracture transforming sizes can be obtained, the practical effect of reservoir transforming can be improved, and high construction cost and the poor fracturing effect which are caused by aimlessly setting the perforation cluster distances can be avoided.

Owner:SOUTHWEST PETROLEUM UNIV

Drug formulations

InactiveUS20120202838A1Improve fracture toughnessImprove fracture resistancePowder deliveryBiocideHigh fractureMedicine

In one embodiment, the present invention relates to abuse-deterrent drug formulations comprise a plurality of discrete domains uniformly dispersed in a pharmaceutically acceptable matrix, wherein said domains have high fracture toughness and comprise at least one polymer and at least one abuse-relevant drug. In another embodiment, the present invention relates to a formulation comprising a plurality of discrete mechanically reinforcing particles uniformly dispersed in a pharmaceutically acceptable matrix, wherein said matrix has high fracture toughness and comprises at least one polymer and at least one active agent, at least one abuse-relevant drug or a combination of at least one active agent and at least one abuse-relevant drug.

Owner:ABBVIE INC

Alumina/zirconia ceramics and method of producing the same

InactiveUS7148167B2Excellent abrasionHigh hardnessCeramic shaping apparatusClaywaresHigh fractureHardness

Owner:KYOCERA CORP

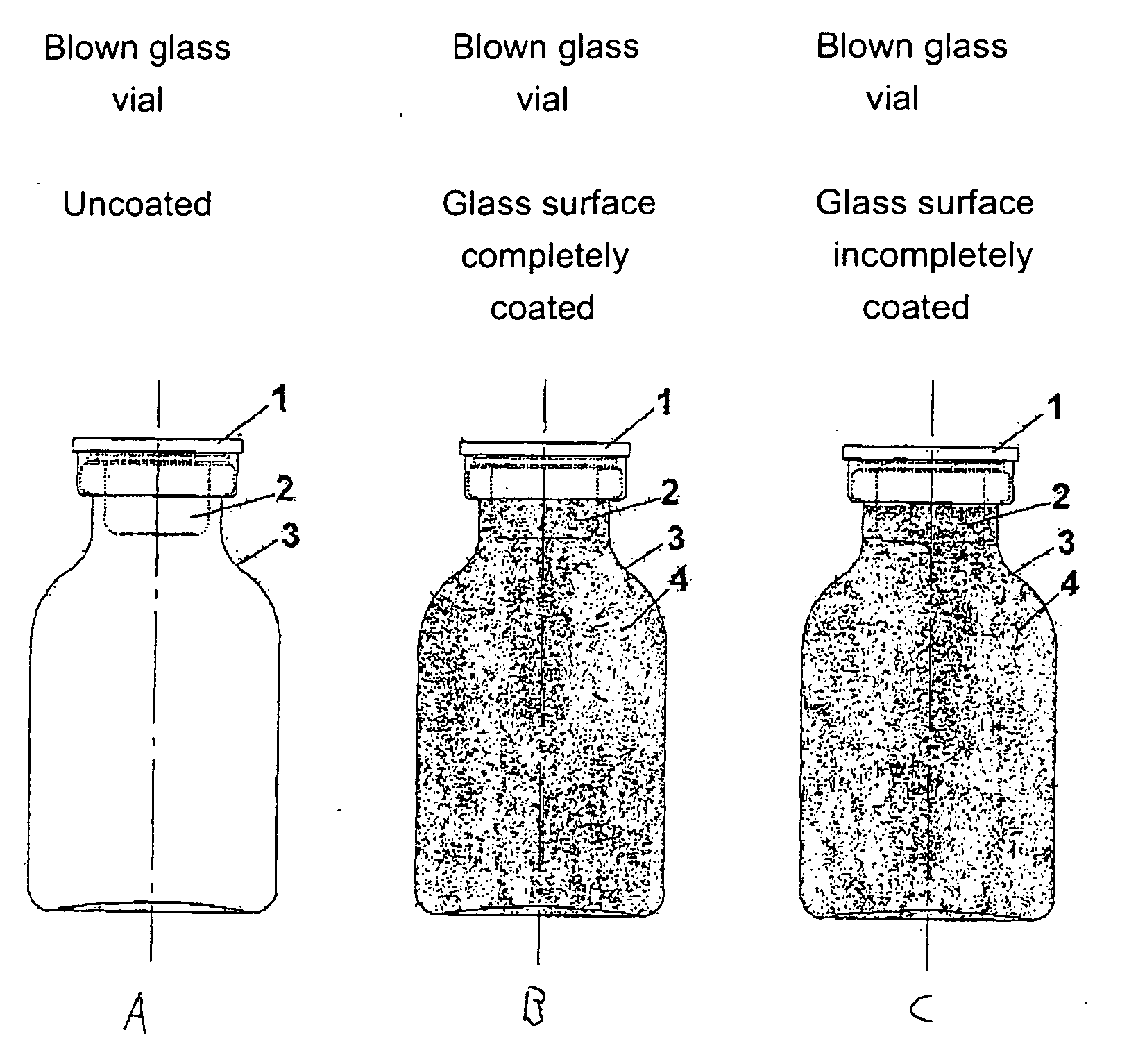

Safety containers for biologically active substances and method for producing said container

InactiveUS20070010700A1Increased and high fracture strengthSimple and rapid to carry-outClosure capsCoverings/external coatingsHigh fractureUltimate tensile strength

The invention relates to safety containers for biologically active substances, in particular cytostatic agents, said container having increased or higher fracture strength and shatterproof qualities, in addition to an uncontaminated exterior. The invention also relates to a method for producing said containers and to the use of a medium containing at least one polymer for decontaminating the exterior of a container that is filled with a biologically active substance, sealed and optionally labelled.

Owner:BAXTER INT INC +1

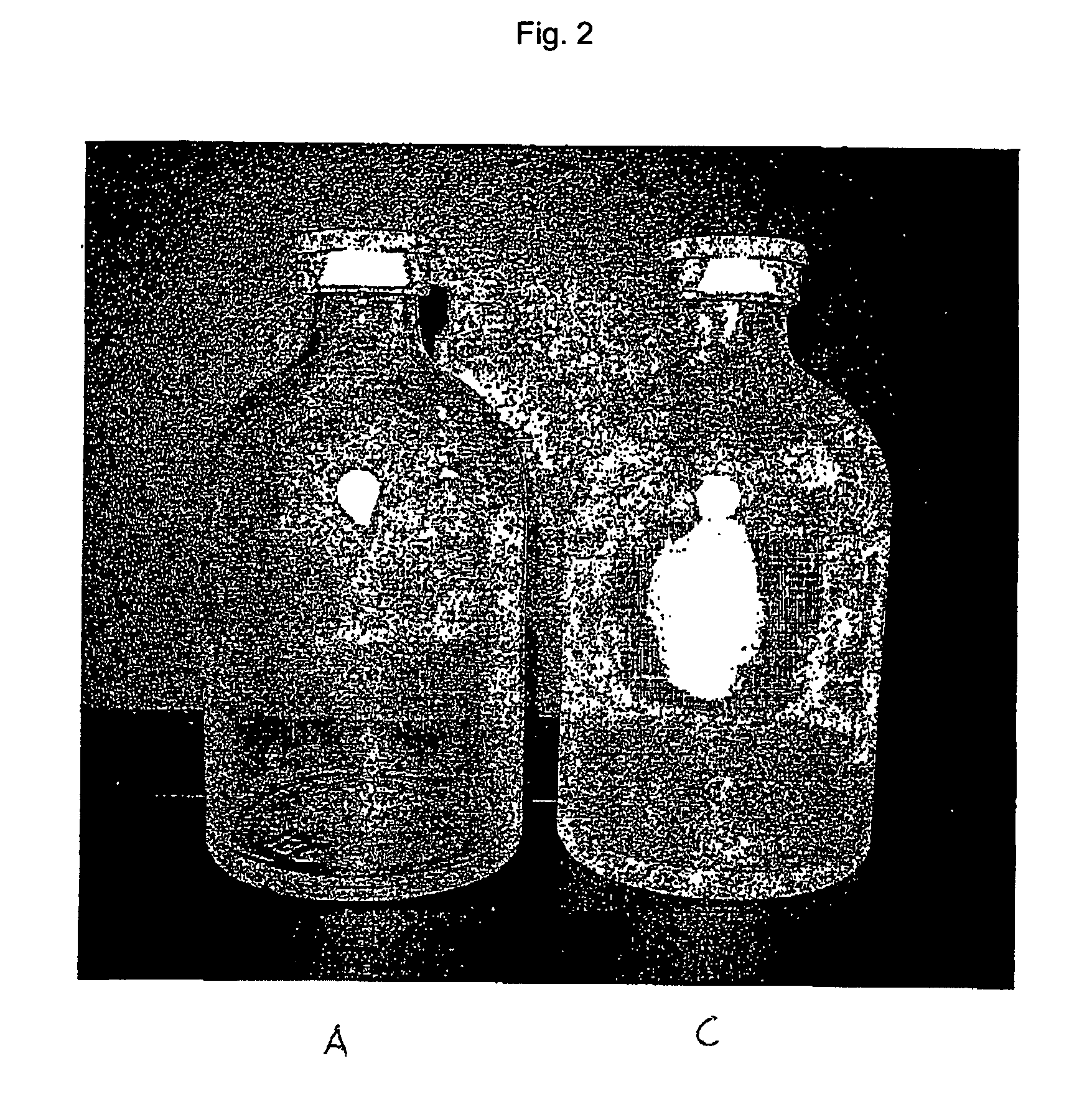

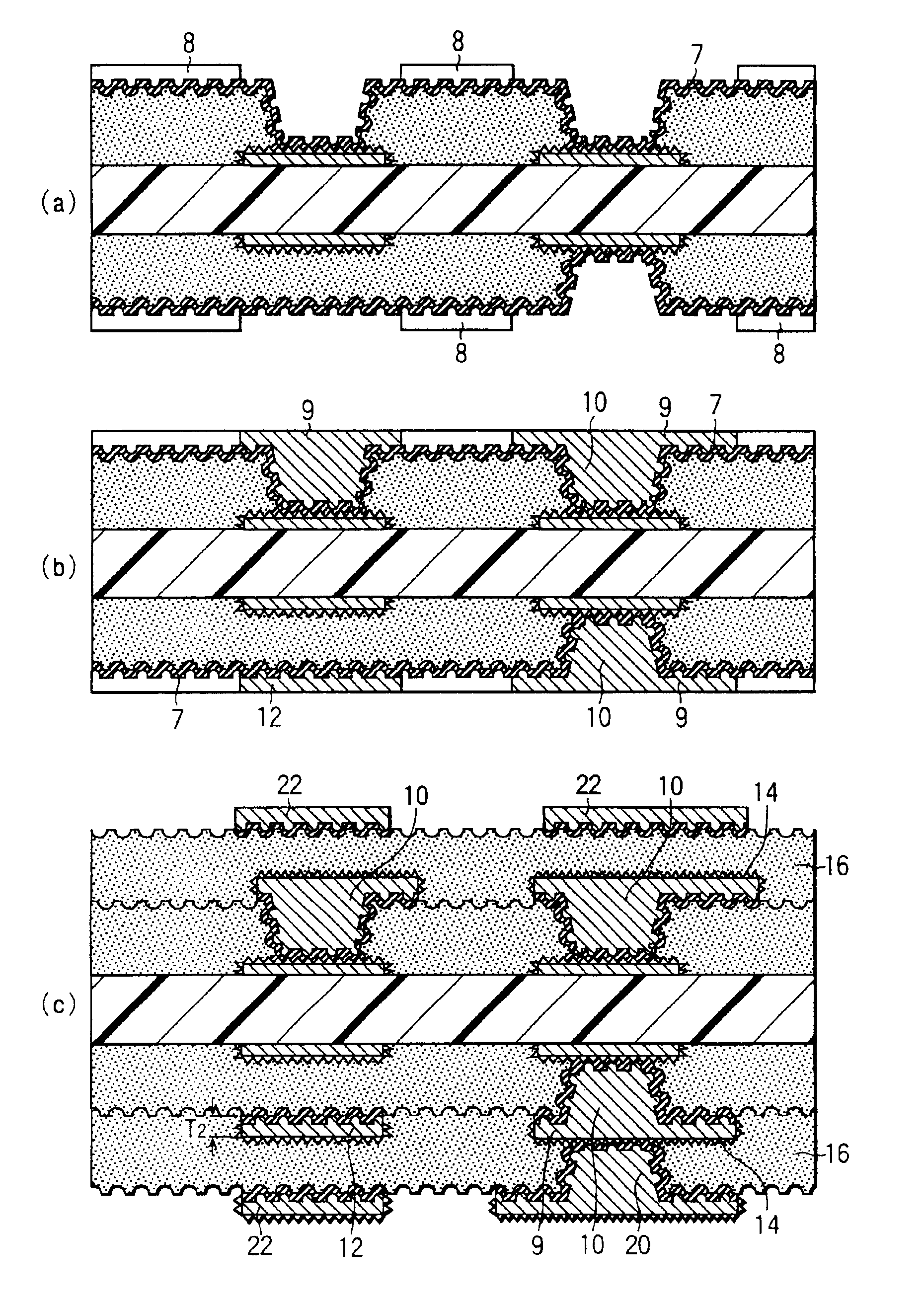

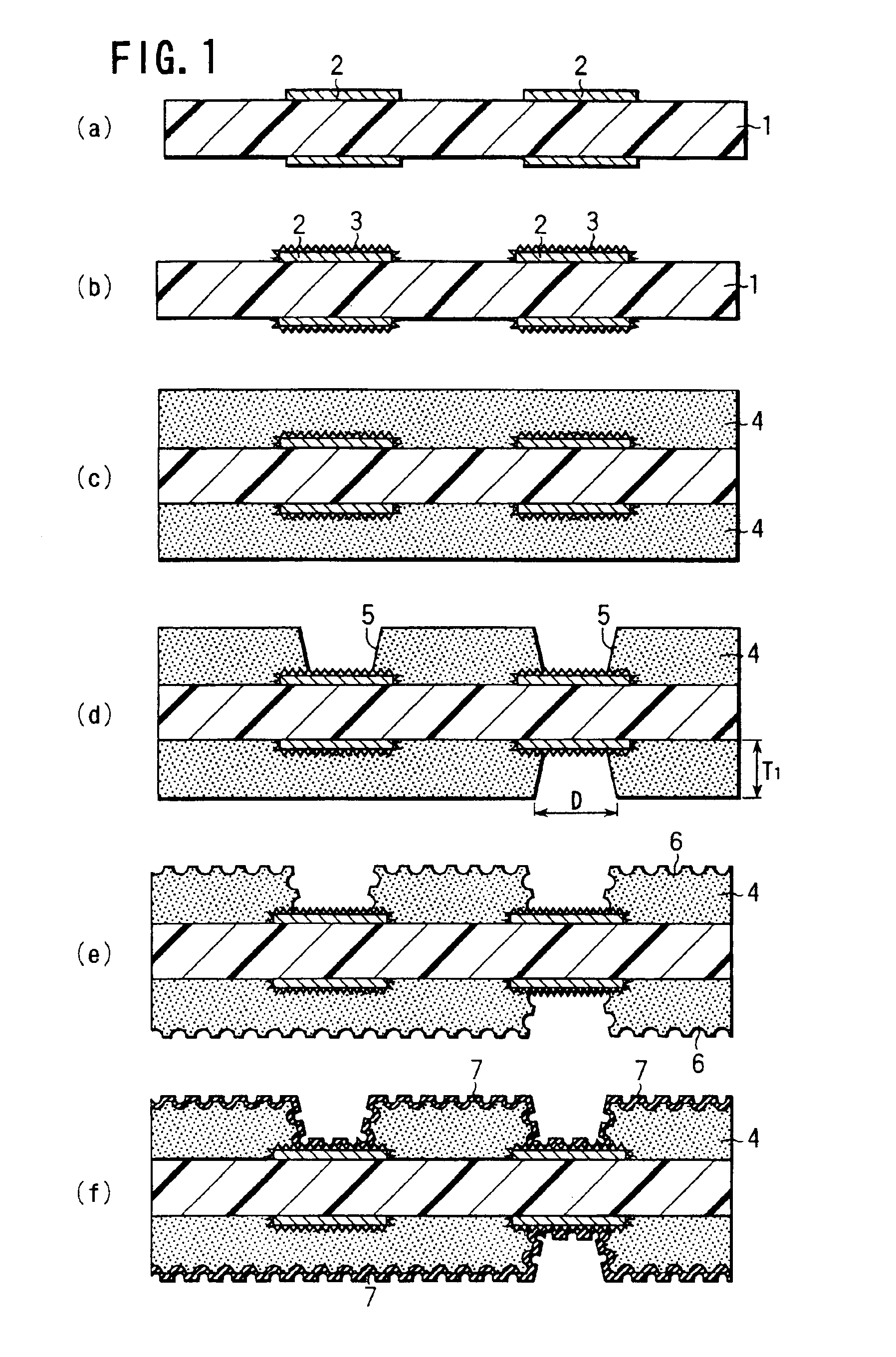

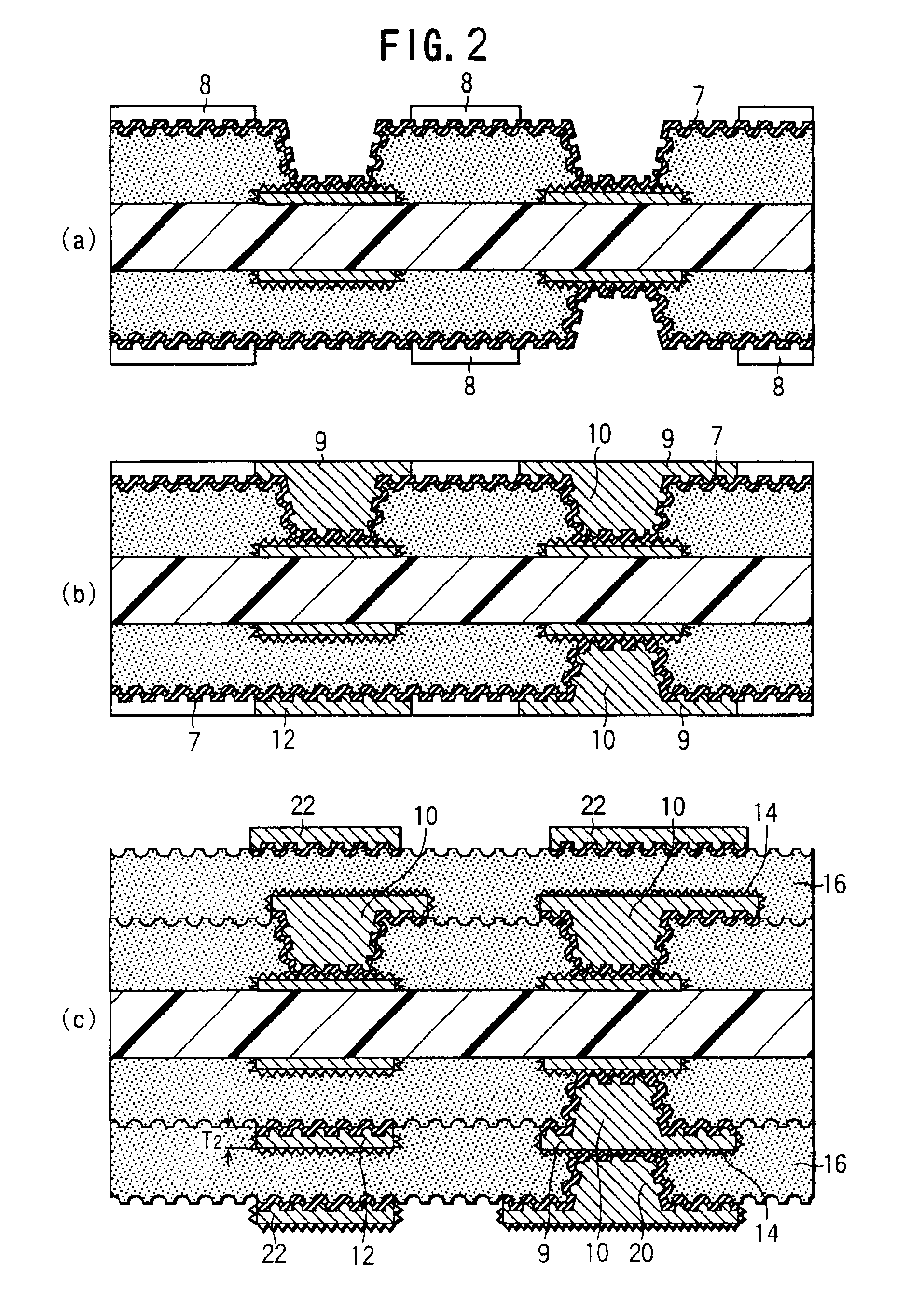

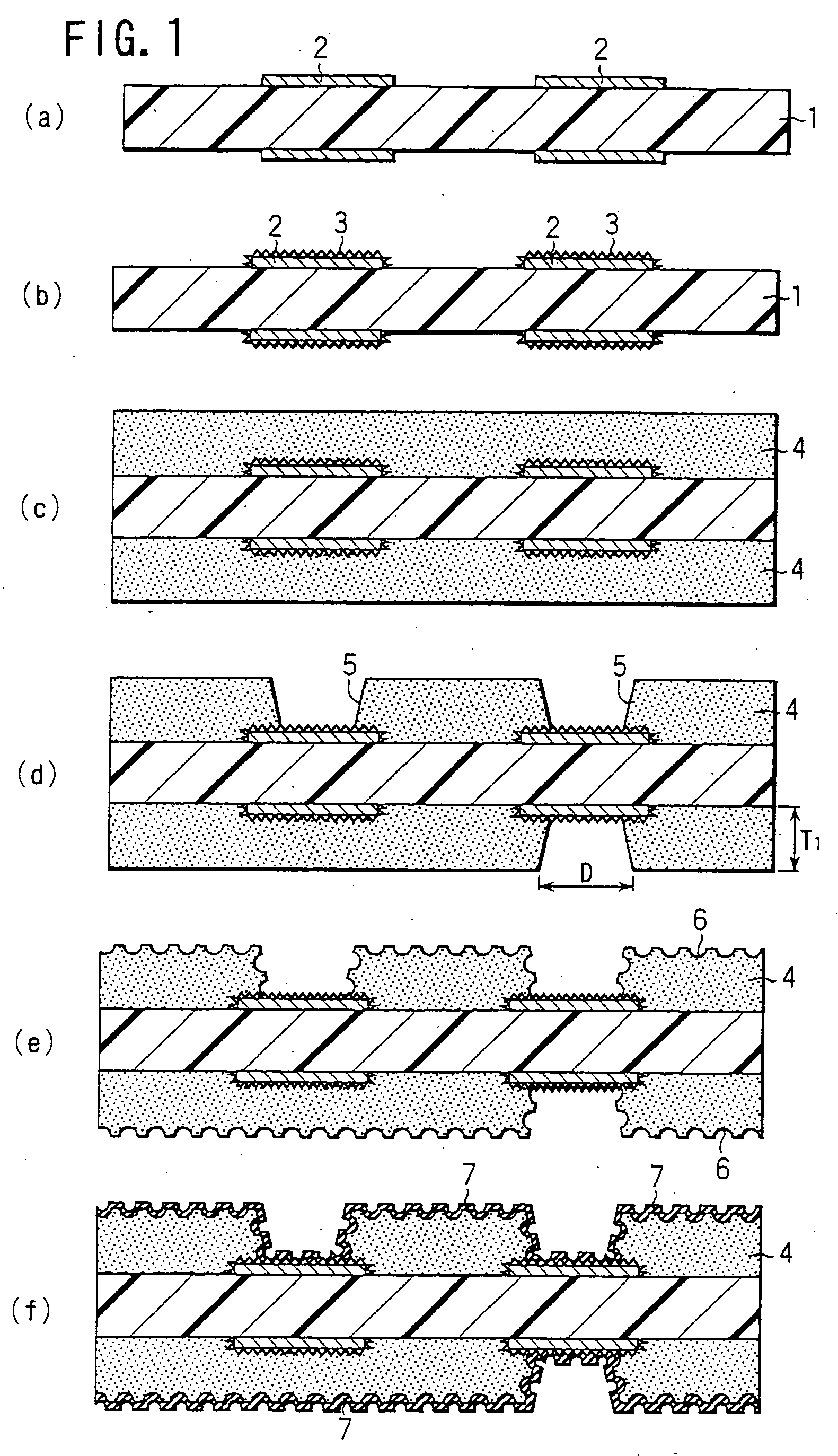

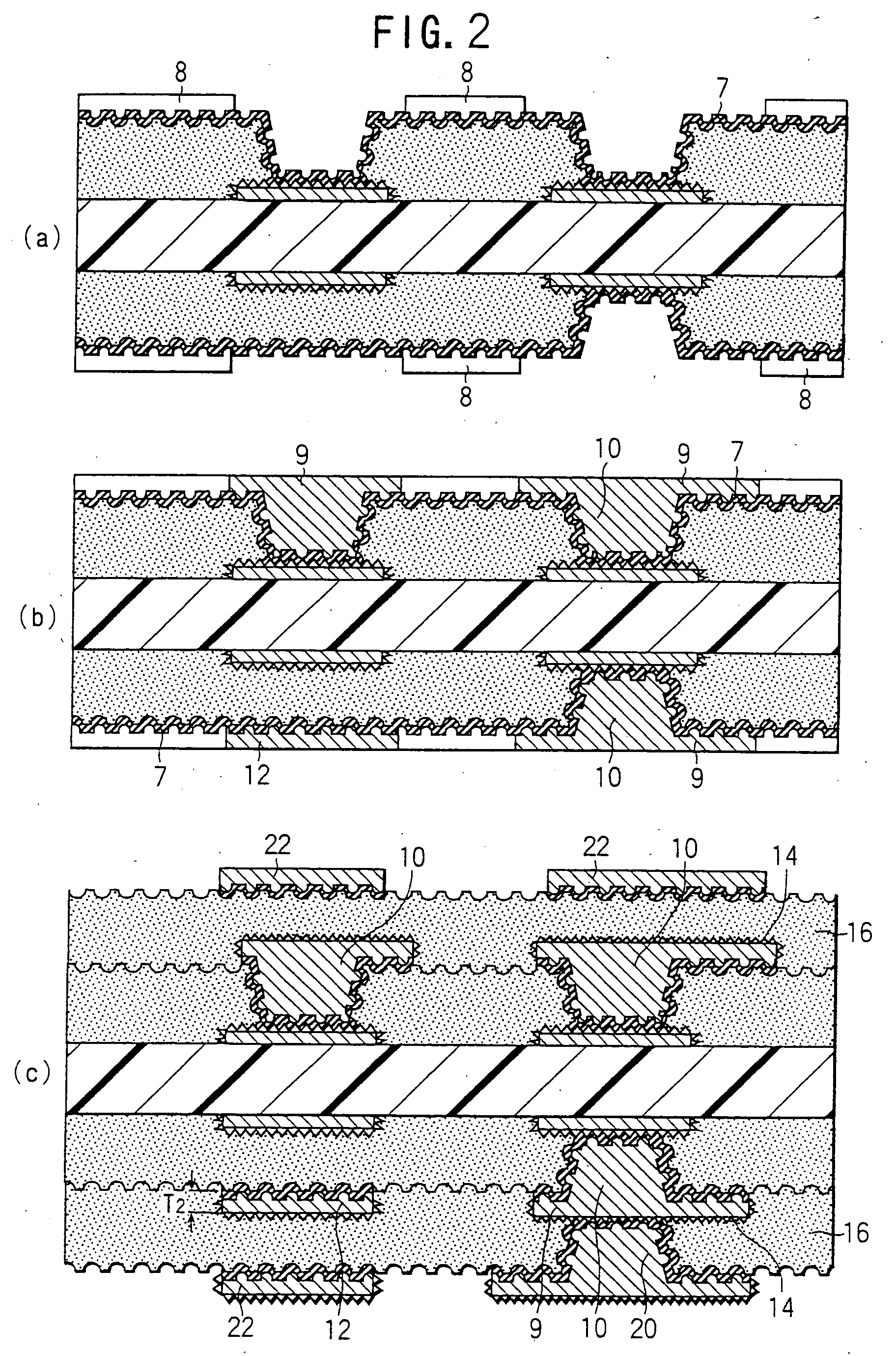

Multilayer printed wiring board having filled-via structure

InactiveUS7071424B1More highly reliableUniform thicknessInsulating substrate metal adhesion improvementDielectric materialsHigh fractureElectrical conductor

The present invention provides a multilayer printed wiring board having a filled viahole structure advantageously usable for forming a fine circuit pattern thereon, and having an excellent resistance against cracking under a thermal shock or due to heat cycle. The multilayer printed wiring board is comprised of conductor circuitry layers and interlaminar insulative resin layers deposited alternately one on another, the interlaminar insulative resin layers each having formed through them holes each filled with a plating layer to form a viahole. The surface of the plating layer exposed out of the hole for the viahole is formed substantially flat and lies at a substantially same level as the surface of the conductor circuit disposed in the interlaminar insulative resin layer. The thickness of the conductor circuitry layer is less than a half of the viahole diameter and less than 25 μm. The inner wall of the hole formed in the interlaminar insulative resin layer is roughened and an electroless plating layer is deposited on the roughened surface. An electroplating layer is filled in the hole including the electroless plating layer to form the viahole. The interlaminar insulative resin layer is formed from a composite of a fluororesin showing a high fracture toughness and a heat-resistant thermoplastic resin, a composite of fluororesin and thermosetting resin or a composite of thermosetting and thermoplastic resins.

Owner:IBIDEN CO LTD

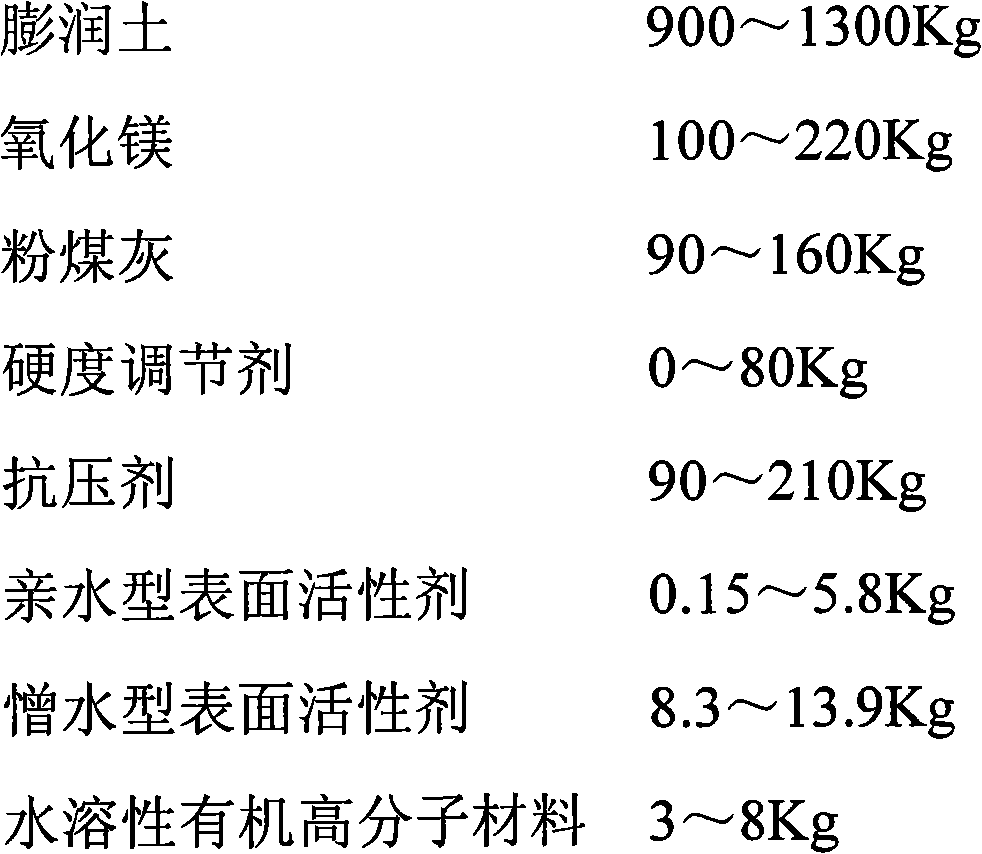

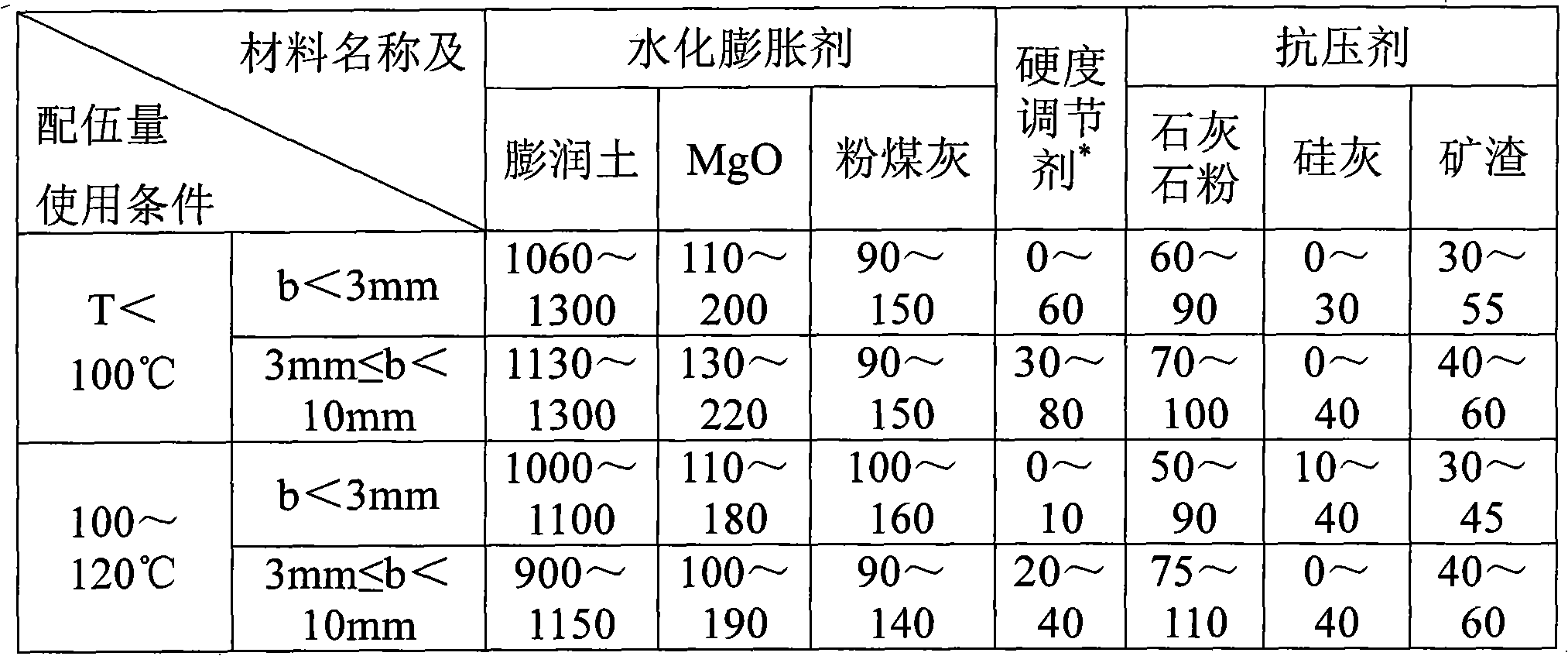

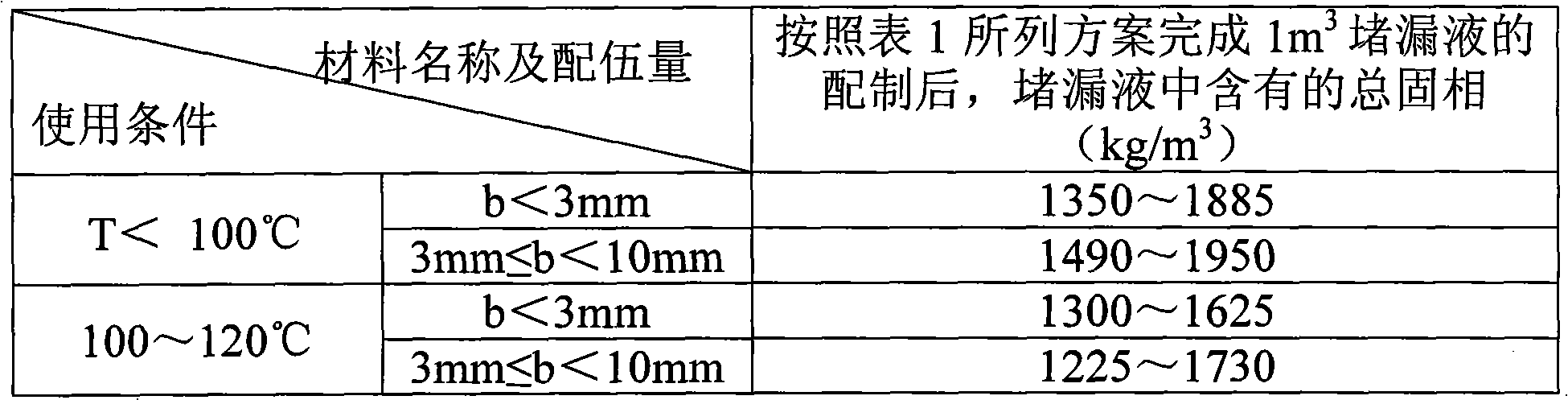

Plugging bearing material for petroleum drilling, and preparation method and application thereof

ActiveCN102061151ASuitable for lipophilic and hydrophilic propertiesGuaranteed preparationDrilling compositionSealing/packingHigh fracturePetroleum

The invention provides a plugging bearing material for petroleum drilling, and a preparation method and application thereof. The plugging bearing material comprises the following components: 900 to 1,200 kilograms of bentonite, 100 to 220 kilograms of magnesium oxide, 90 to 160 kilograms of fly ash, 0 to 80 kilograms of hardness regulator, 90 to 210 kilograms of compression resisting agent, 0.15 to 5.8 kilograms of hydrophilic surfactant, 8.3 to 13.0 kilograms of hydrophobic surfactant and 3 to 8 kilograms of water-soluble organic high polymer material. A plugging material formed by the plugging bearing material has high fracture plugging capability, and a plugging belt formed by the plugging bearing material plays a certain stable role in fracturing rocks. The plugging bearing material, and the preparation method and the application thereof are suitable for processing formation leakage of various forms.

Owner:CHINA PETROLEUM & CHEM CORP +1

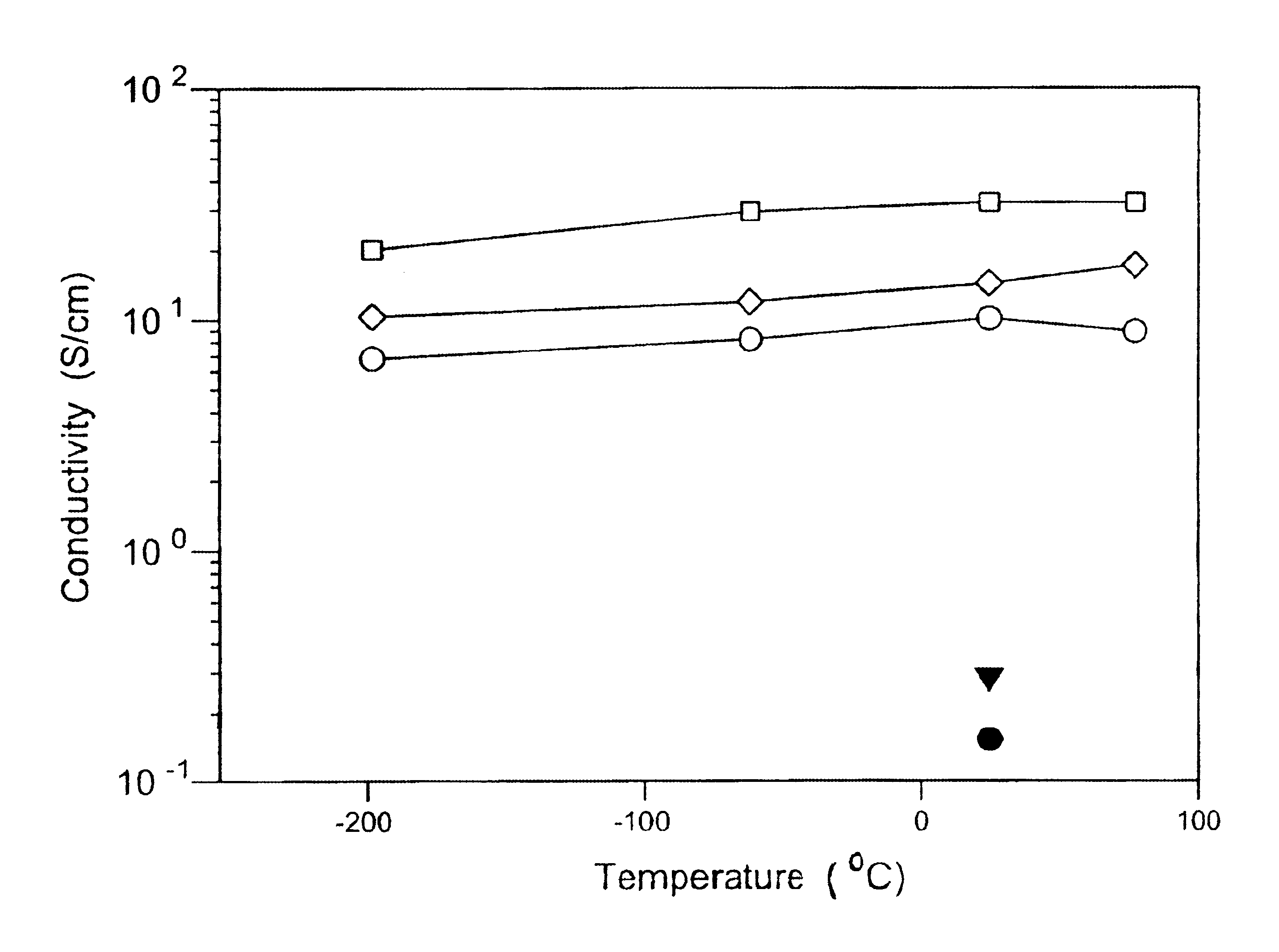

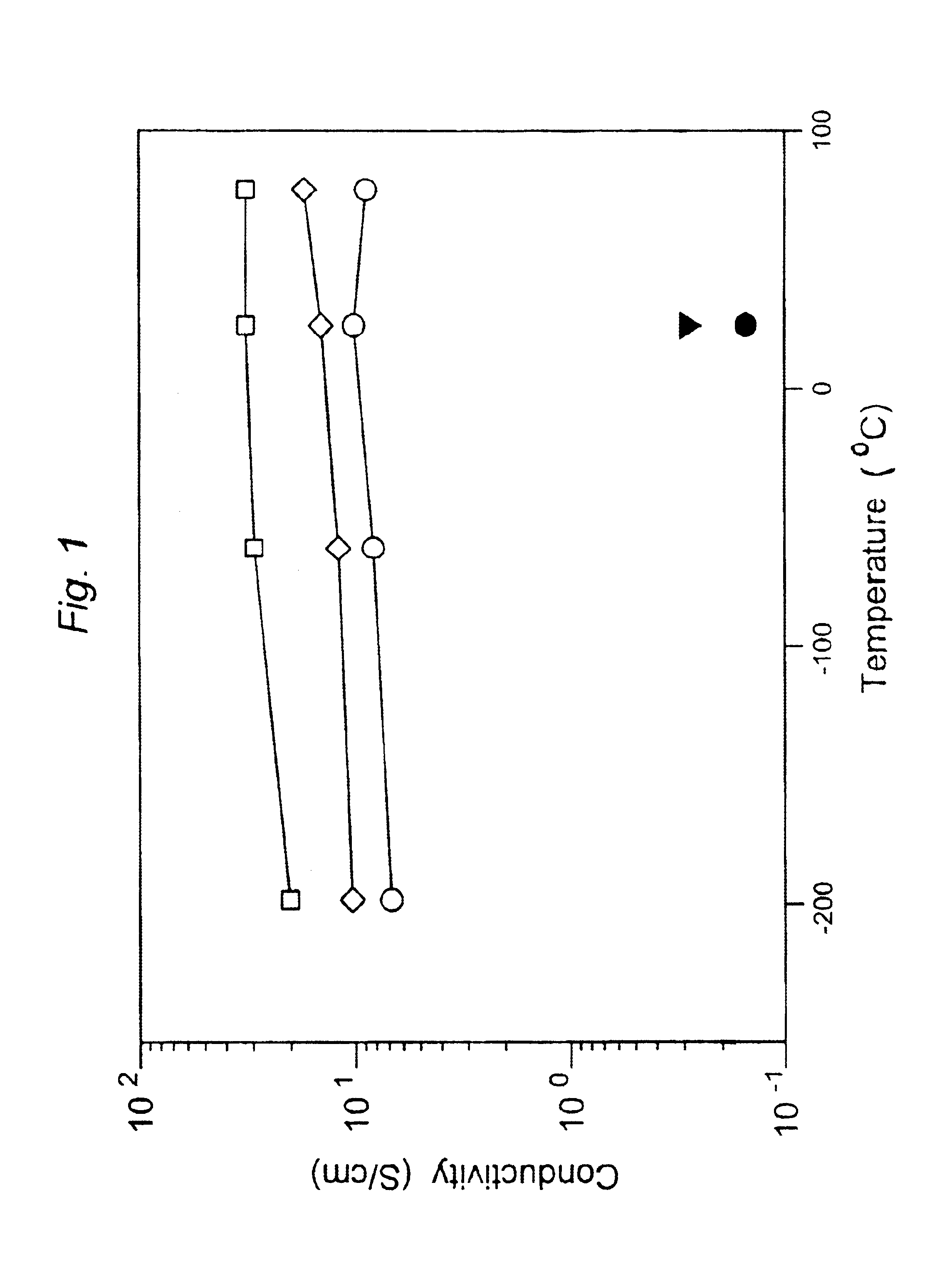

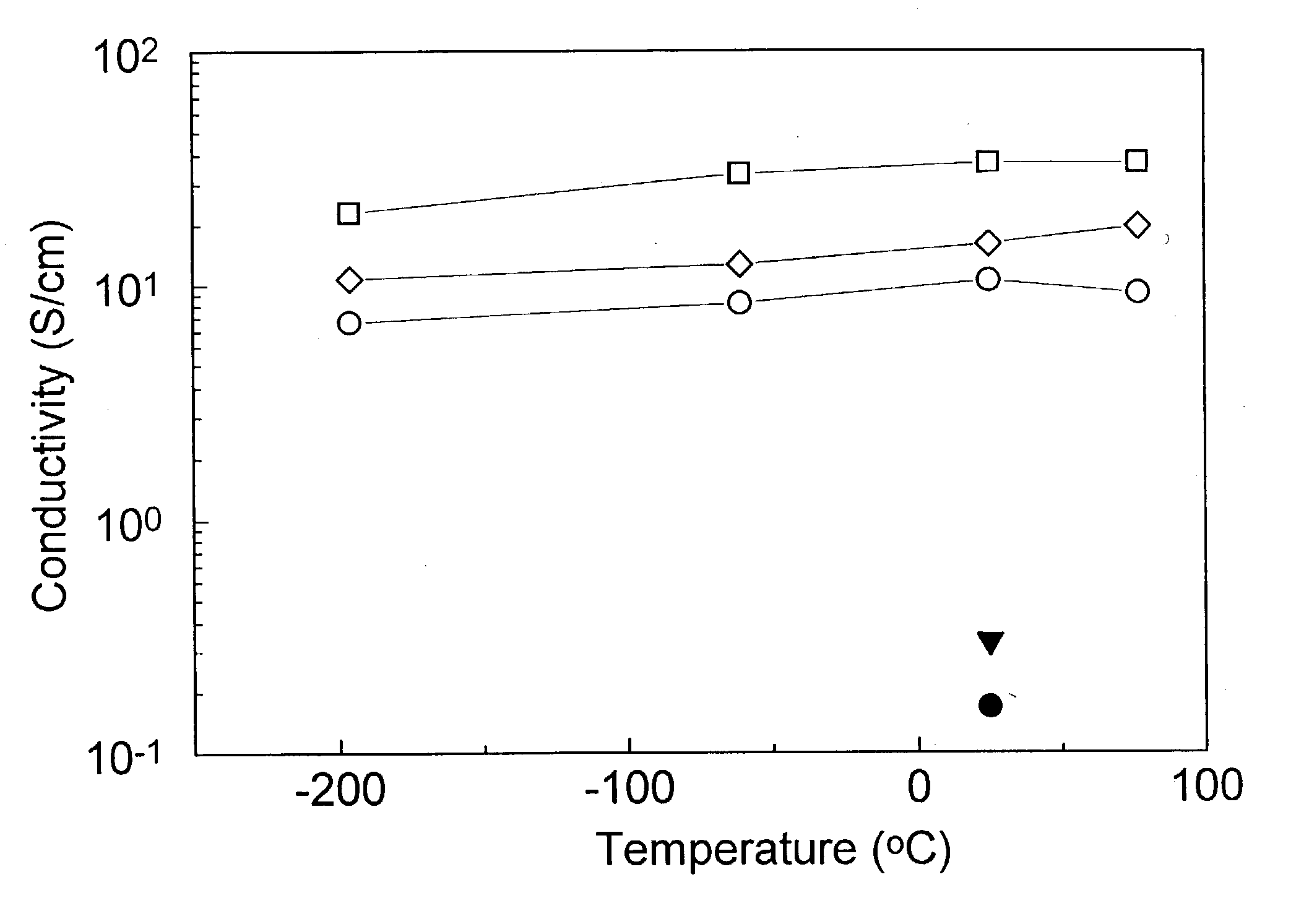

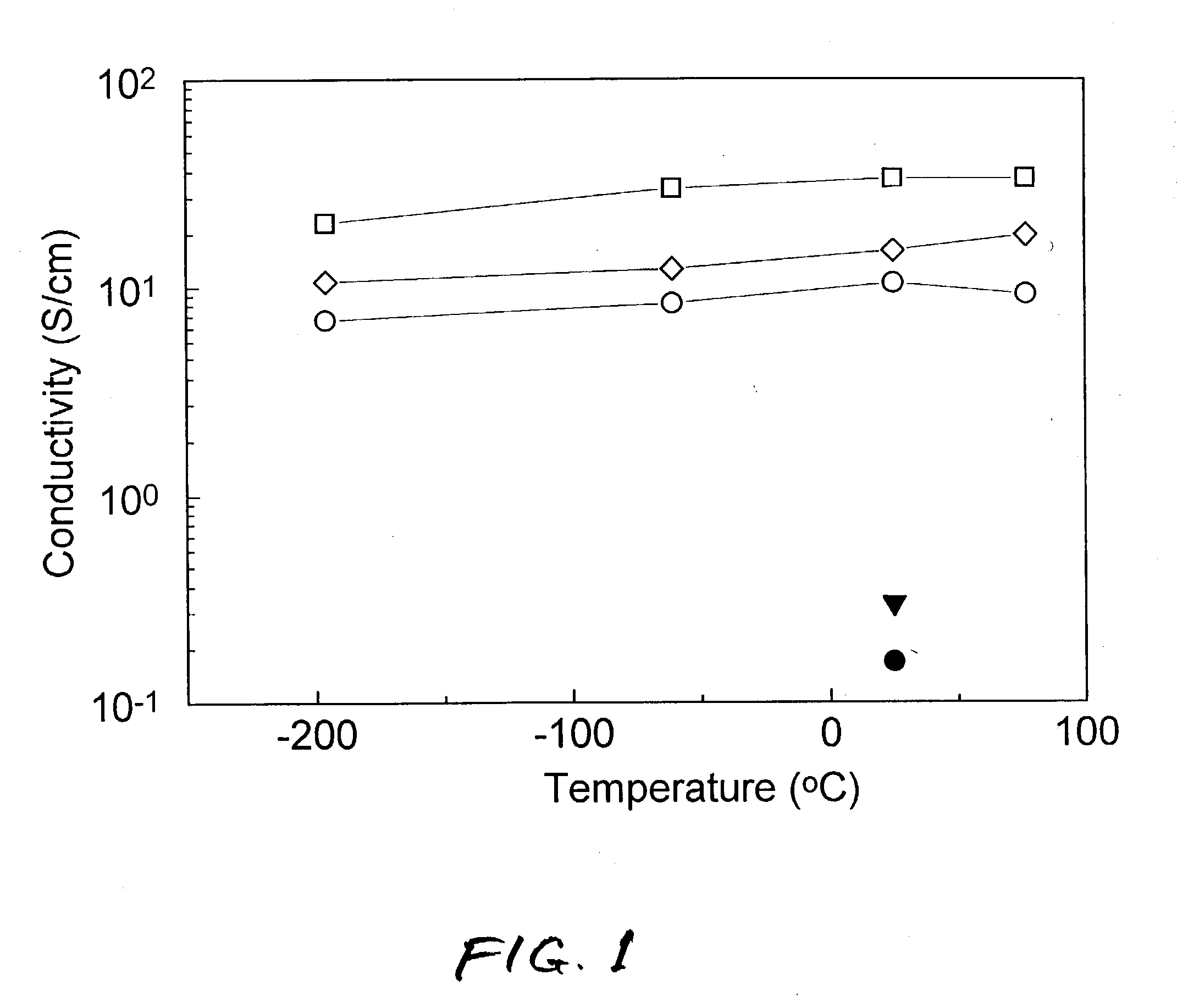

Ceramic materials reinforced with single-wall carbon nanotubes as electrical conductors

InactiveUS6875374B1Reduce processing timeMaterial nanotechnologyOxide/hydroxide preparationHigh fractureElectrical conductor

Composite materials formed of a matrix of fused ceramic grains with single-wall carbon nanotubes dispersed throughout the matrix and a high relative density, notably that achieved by electric field-assisted sintering, demonstrate unusually high electrical conductivity in combination with high-performance mechanical properties including high fracture toughness. This combination of electrical and mechanical properties makes these composites useful as electrical conductors in applications where high-performance materials are needed due to exposure to extreme conditions such as high temperatures and mechanical stresses.

Owner:RGT UNIV OF CALIFORNIA

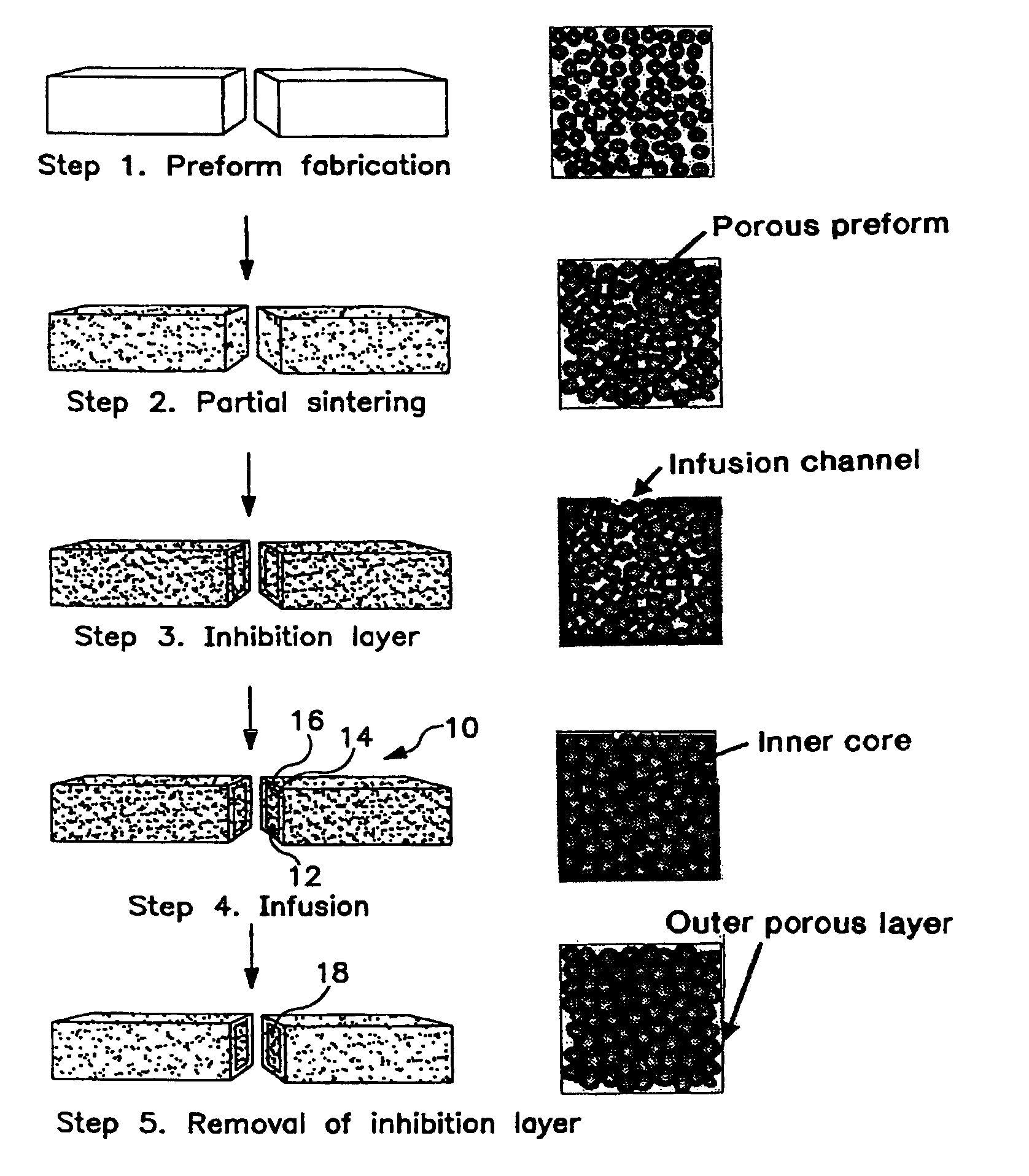

Polymer re-inforced anatomically accurate bioactive protheses

InactiveUS7052710B2Improve mechanical propertiesImprove abilitiesPowder deliveryImpression capsHigh fractureCustom made implant

Customized implants for use in reconstructive bone surgeries where anatomical accuracy and bone adaptation are important, such as plastic and craniomaxillofacial reconstructions. This implant comprises a porous surface layer and a tough inner core of interpenetrating phase composite. The porous surface layer enhances the biocompatibility, tissue ingrowth, and implant stability. The tough inner core improves the mechanical properties of the implant with a high fracture toughness and a low modulus. The anatomical accuracy of the implants will minimize the intra-operative manipulation required to maintain a stable host bone-implant interface.

Owner:TRUSTEES OF BOSTON UNIV

New Al-Cu-Li-Mg-Ag-Mn-Zr alloy for use as structural members requiring high strength and high fracture toughness

An improved aluminum lithium alloy comprising 0.1 to 2.5 wt. % Li, 2.5 to 5.5 wt. % Cu, 0.2 to 1.0 wt. % Mg, 0.2 to 0.8 wt. % Ag, 0.2 to 0.8 wt. % Mn, up to 0.4 wt. % Zr or other grain refiner such as chromium, titanium, hafnium, scandium or vanadium, the balance aluminum. The present alloy exhibits an improved combination of strength and fracture toughness, over any thickness range. The present invention is further directed to methods for preparing and using Al—Li alloys as well as to products comprising the same.

Owner:CONSTELLIUM ROLLED PROD RAVENSWOOD

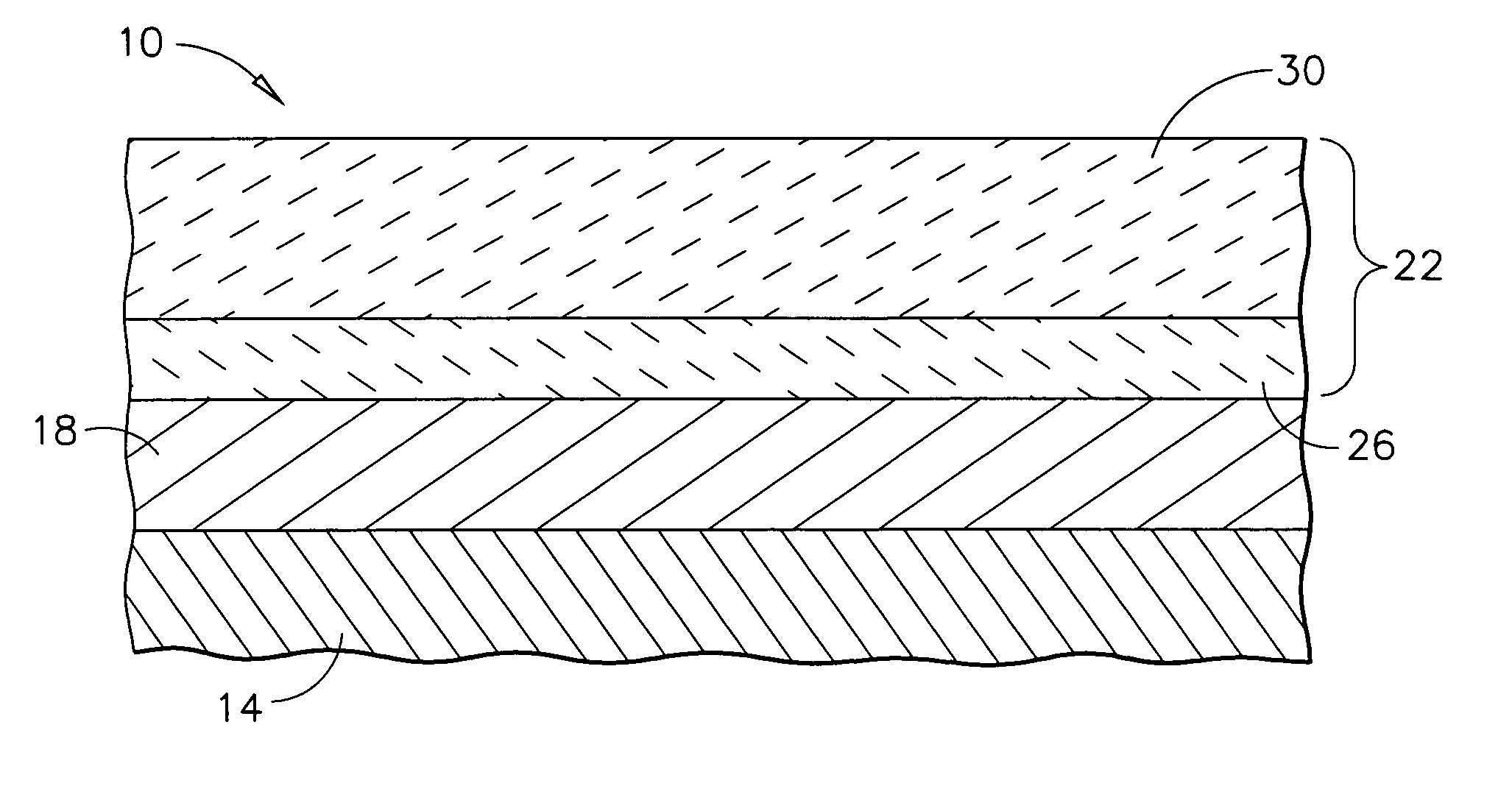

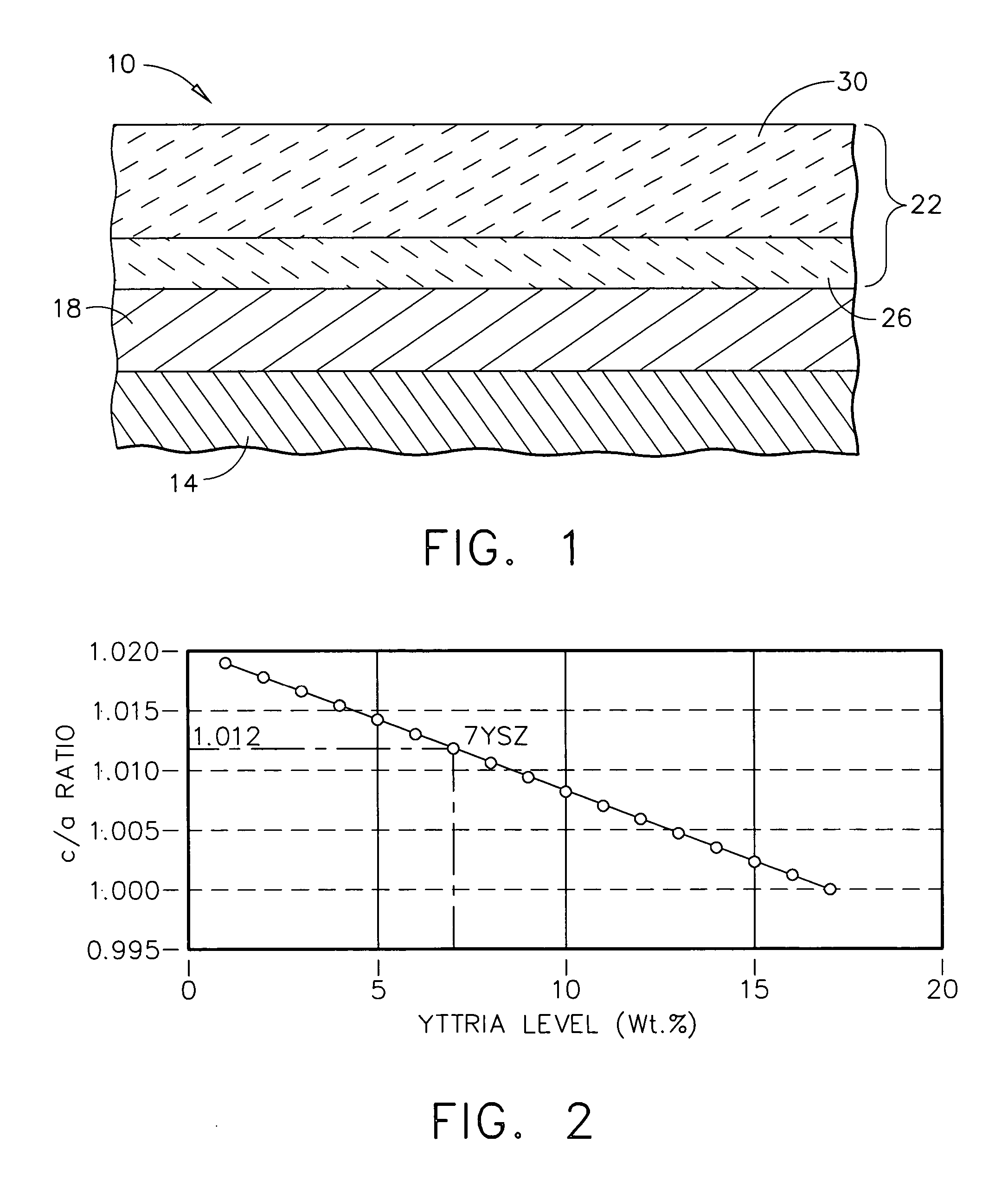

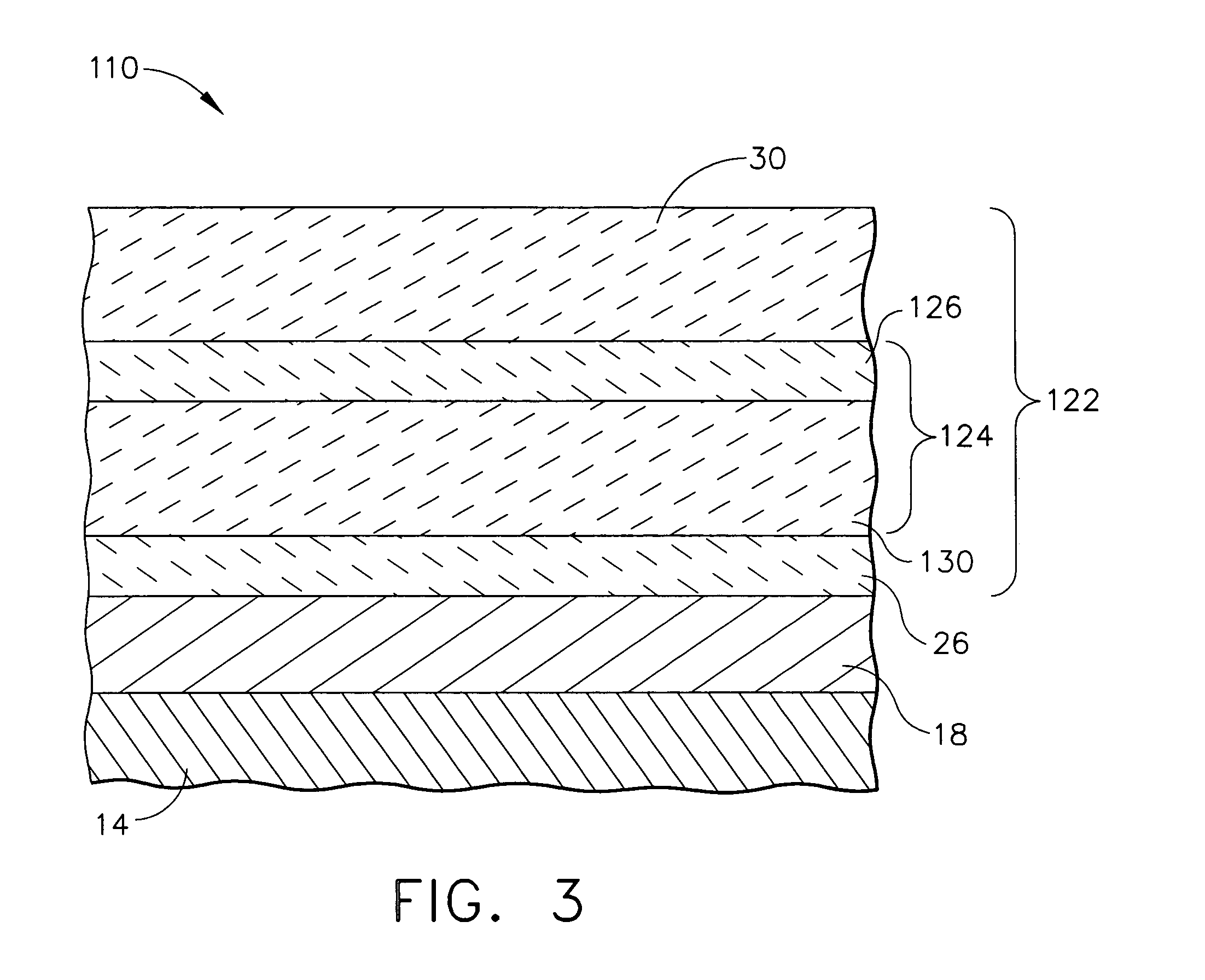

Thermal barrier coatings with high fracture toughness underlayer for improved impact resistance

InactiveUS20060019119A1Improve fracture toughnessIncrease impactVacuum evaporation coatingSputtering coatingHigh fractureBond coat

A reduced thermal conductivity thermal barrier coating having improved impact resistance for an underlying substrate of articles that operate at, or are exposed to, high temperatures. This coating comprises an inner high fracture toughness layer nearest to the underlying substrate and having a thickness up to about 5 mils (127 microns) sufficient to impart impact resistance to the thermal barrier coating, and comprises a zirconia-containing ceramic composition having a c / a ratio of the zirconia lattice in the range of from about 1.011 to about 1.016 and stabilized in the tetragonal phase by a stabilizing amount of a stabilizing metal oxide selected from the group consisting of yttria, calcia, ceria, scandia, magnesia, india, lanthana, gadolinia, neodymia, samaria, dysprosia, erbia, ytterbia, europia, praseodymia, and mixtures thereof. The thermal barrier coating further includes an outer thermal insulating layer adjacent to and overlaying the inner layer and comprising a ceramic thermal barrier coating material. The thermal barrier can be used to provide a thermally protected article having a substrate (e.g., metal substrate) and optionally a bond coat layer adjacent to and overlaying the substrate. The thermal barrier coating can be prepared by forming the inner high fracture toughness layer, followed by forming on the inner layer the outer thermal insulating layer.

Owner:GENERAL ELECTRIC CO

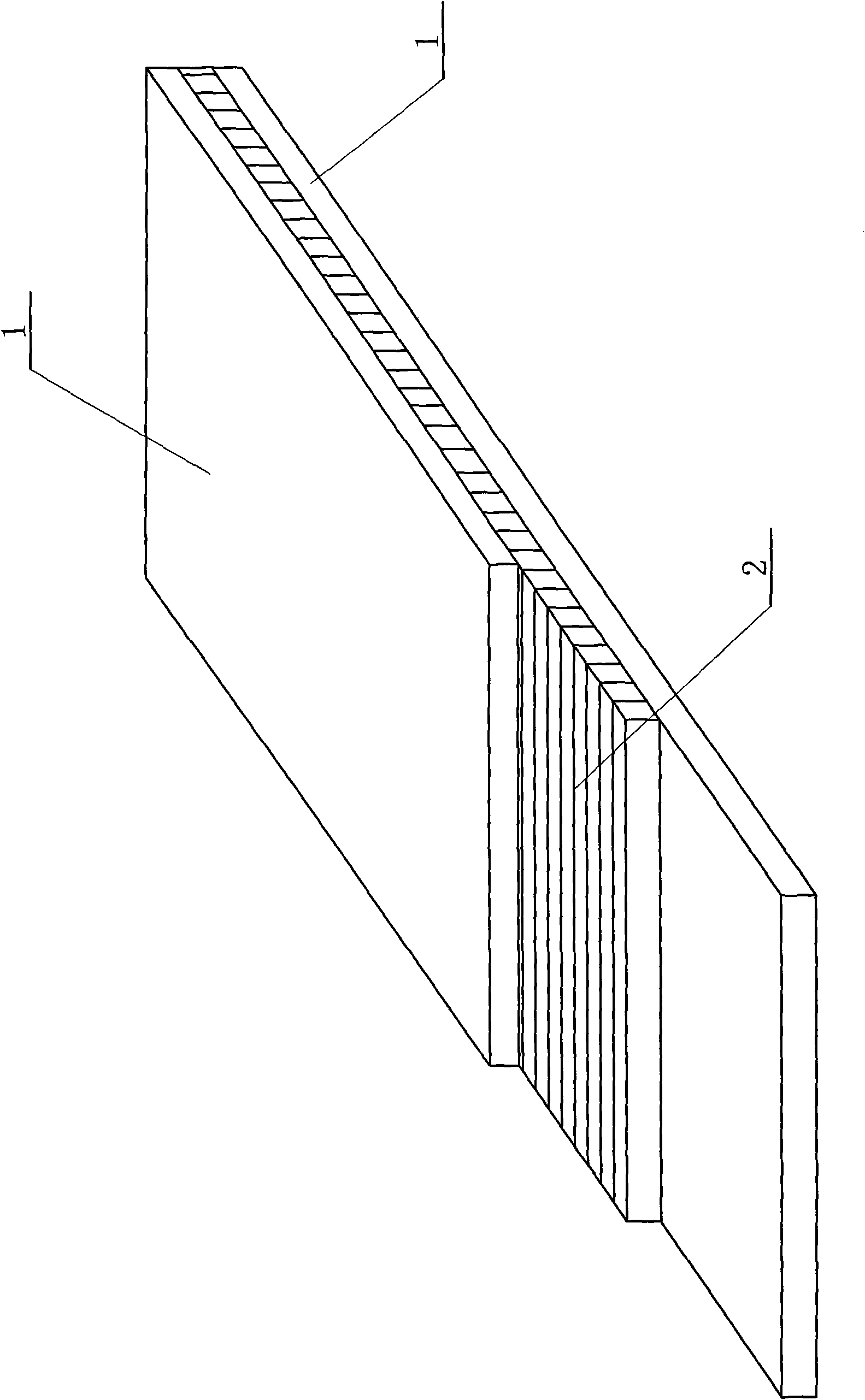

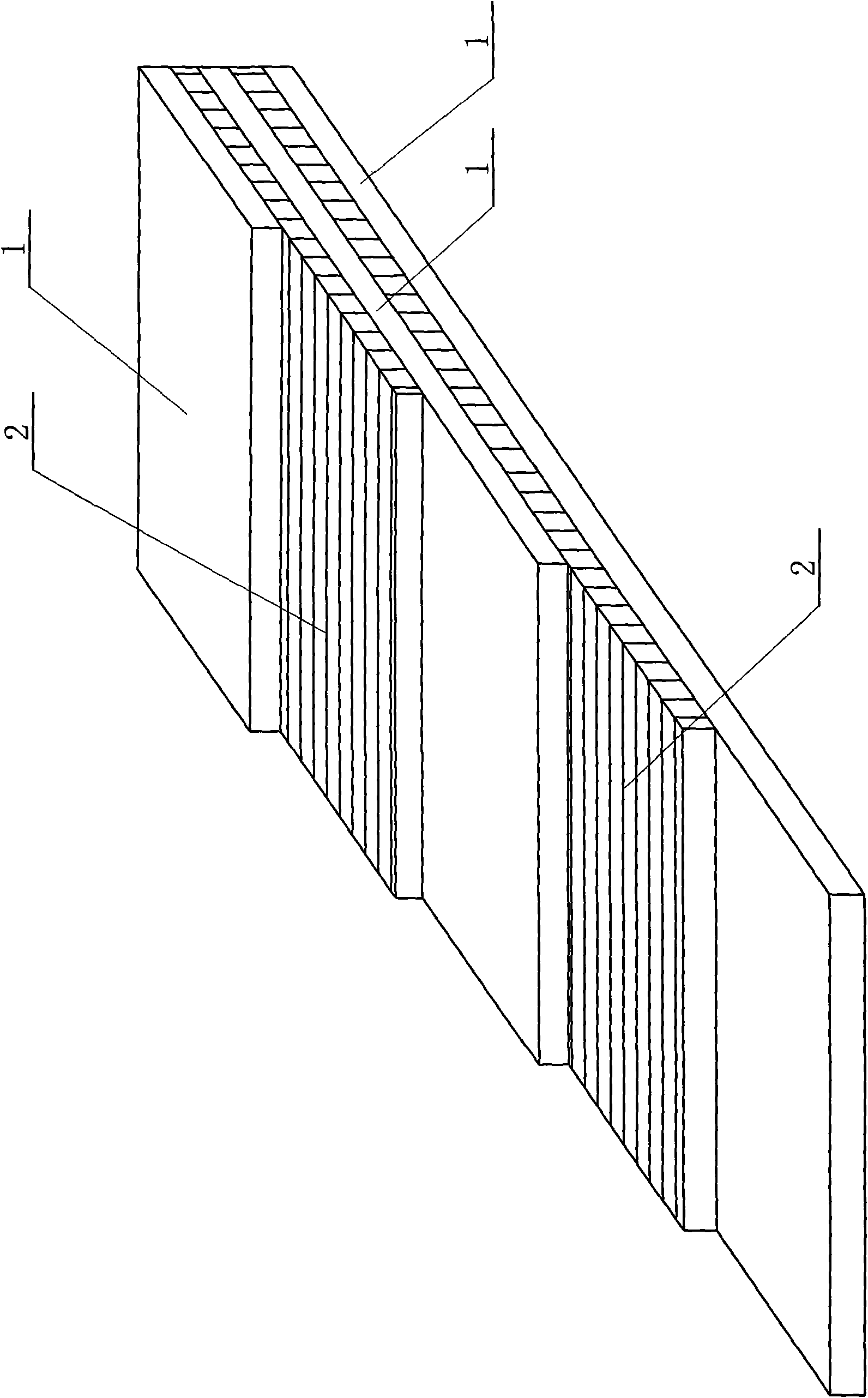

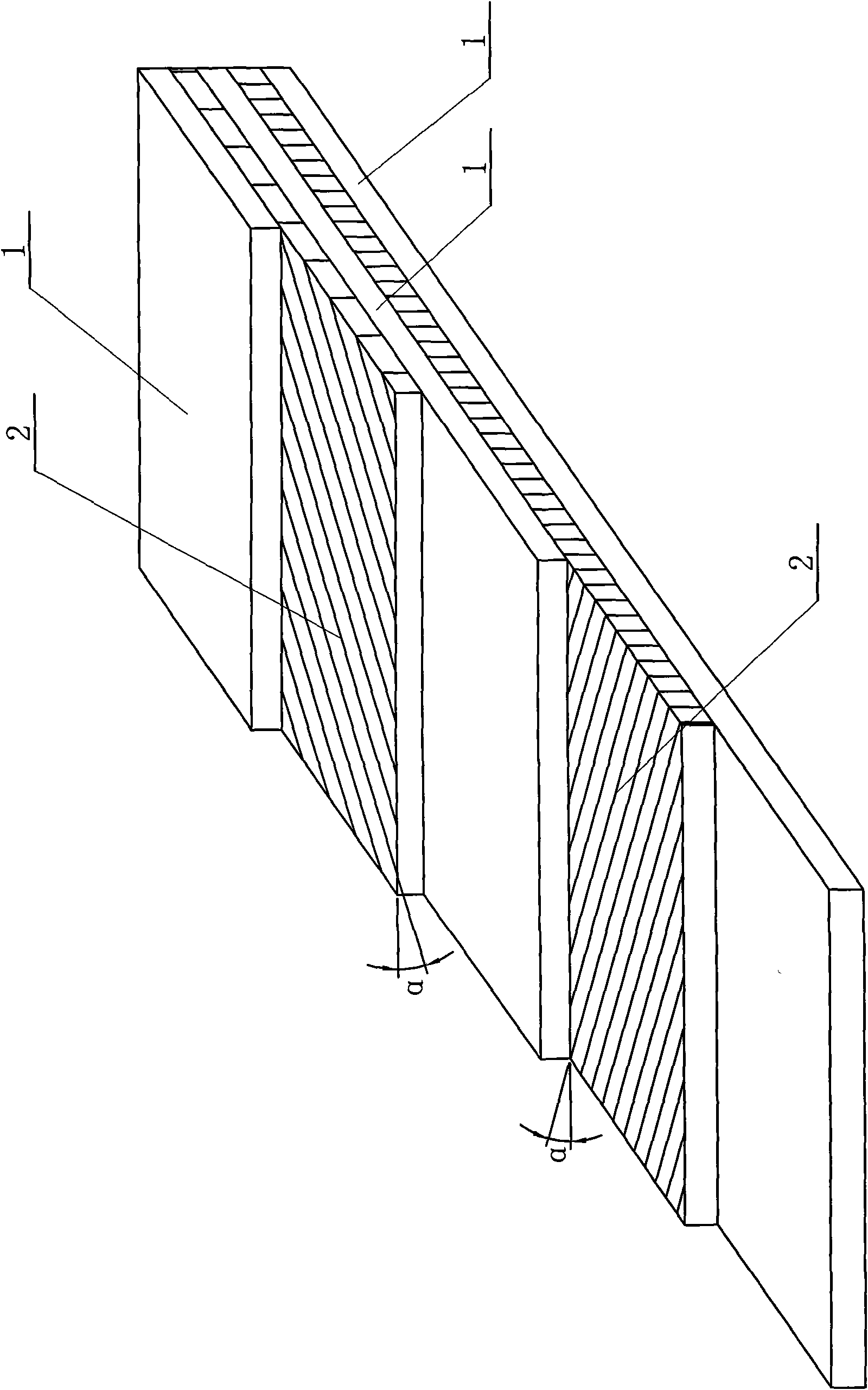

Carbon fiber metal laminate

InactiveCN101524903AImpact resistantImprove fatigue performanceSynthetic resin layered productsMetal layered productsHigh fractureFiber metal laminate

The invention relates to a carbon fiber metal laminate. The invention aims at the problem that, so far, flight vehicle structure materials, which not only has high specific strength and high specific stiffness, but also has high fracture toughness and processability, are non-existent. The inventive laminate is composed of at least two metal plates and at least one carbon fiber composite material layer; at least two metal plates are superposed together, a carbon fiber composite material layer which is adhesively bonded with the two adjacent metal plates are laid between the two adjacent metal plates; the thickness of the metal plate is 0.2m-0.4m and the thickness of the carbon fiber composite material layer is 0.15mm. The inventive laminate has high specific strength and specific stiffness, high fracture toughness and processability, and is also excellent in fatigue property and loss tolerance property. The invention can be used as a structure material for aerospace flights, such as a skin material of large civil planes, and can also be used as alternative material of metal auto panels, magnetically levitated train, light bulletproof armor and ship, etc.

Owner:HARBIN INST OF TECH

Diamond-silicon carbide composite and method

Uniformly dense, diamond-silicon carbide composites having high hardness, high fracture toughness, and high thermal stability are prepared by consolidating a powder mixture of diamond and amorphous silicon. A composite made at 5 GPa / 1673K had a measured fracture toughness of 12 MPa·m1 / 2. By contrast, liquid infiltration of silicon into diamond powder at 5 GPa / 1673K produces a composite with higher hardness but lower fracture toughness.

Owner:TRIAD NAT SECURITY LLC

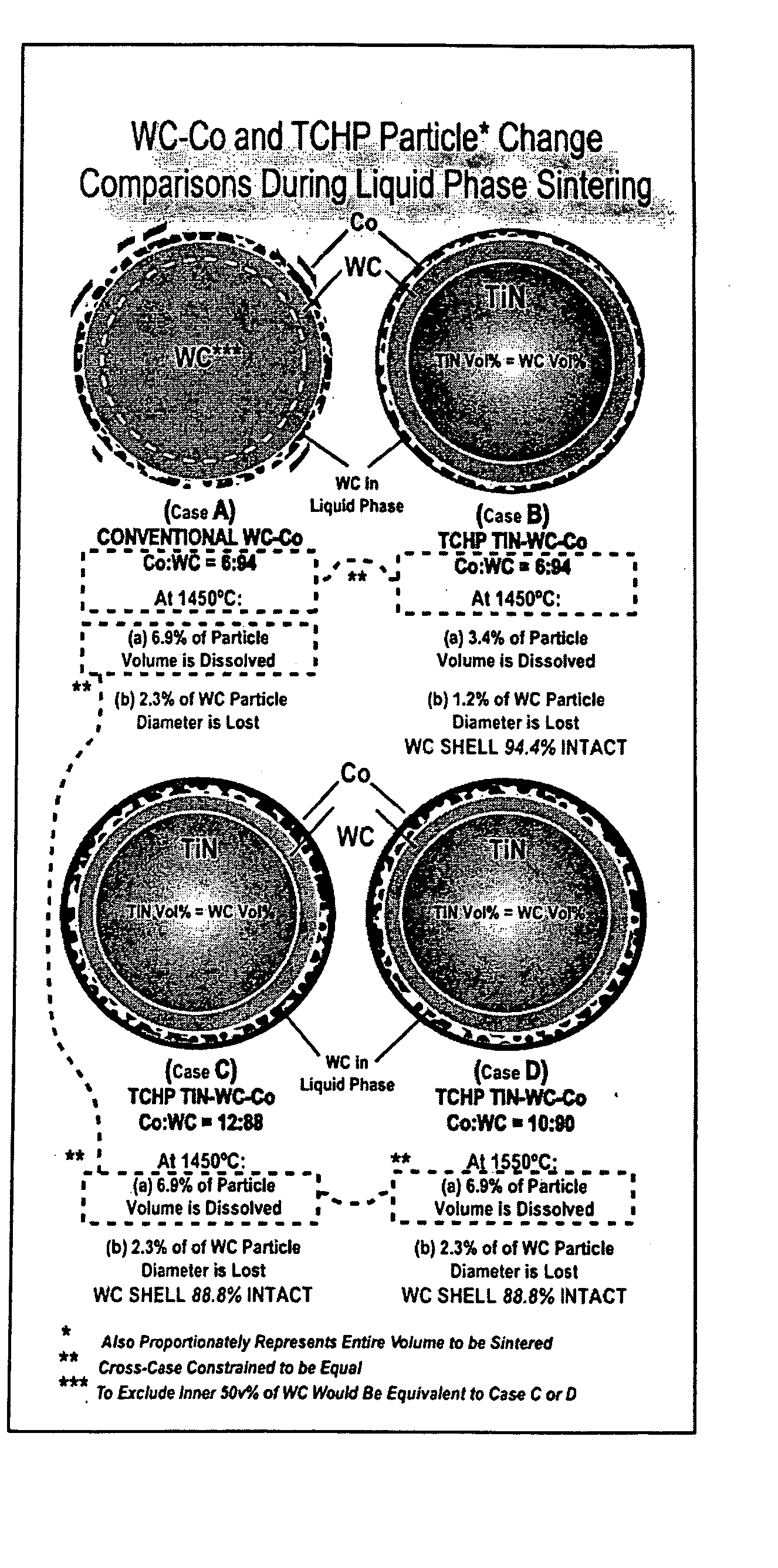

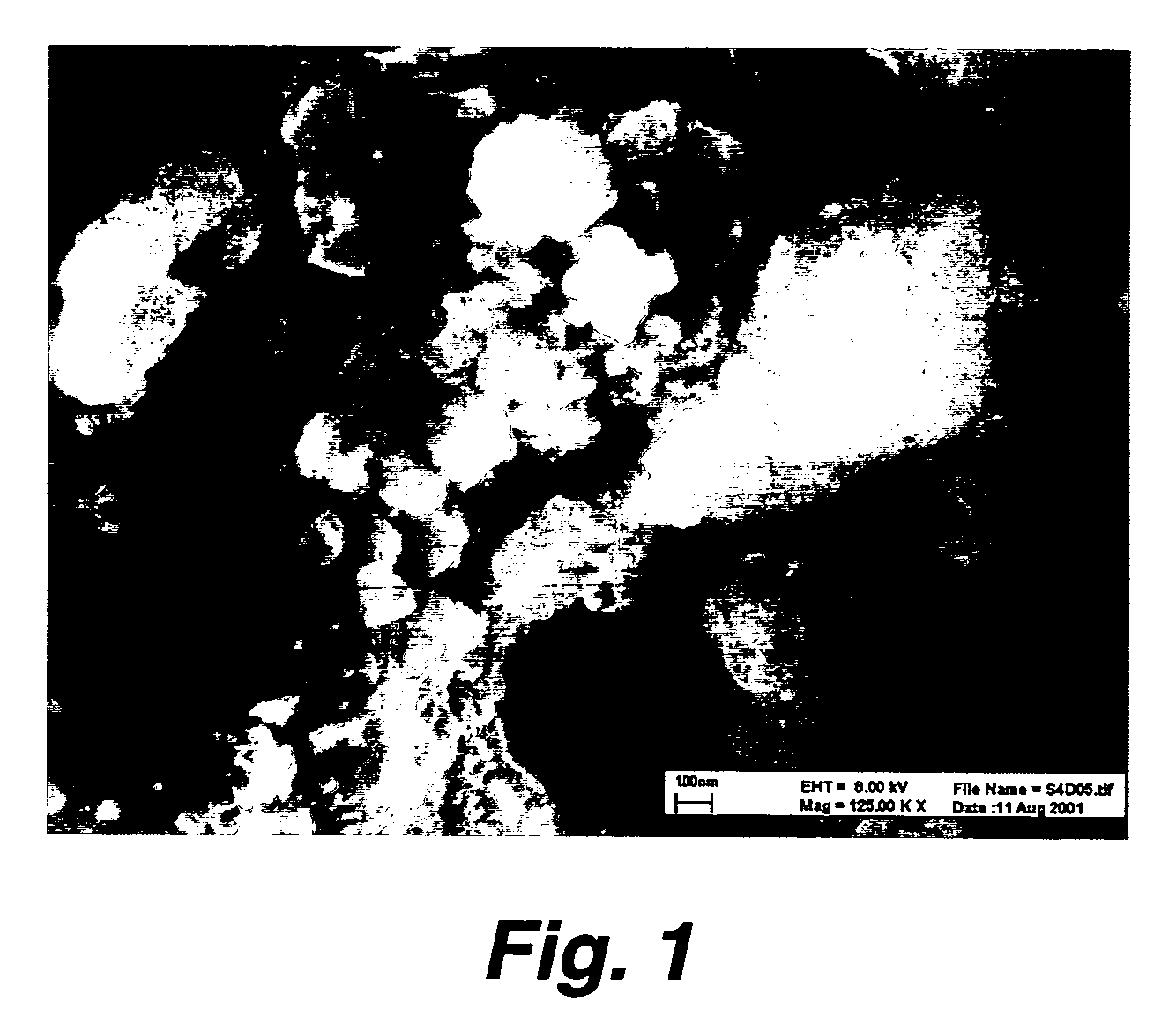

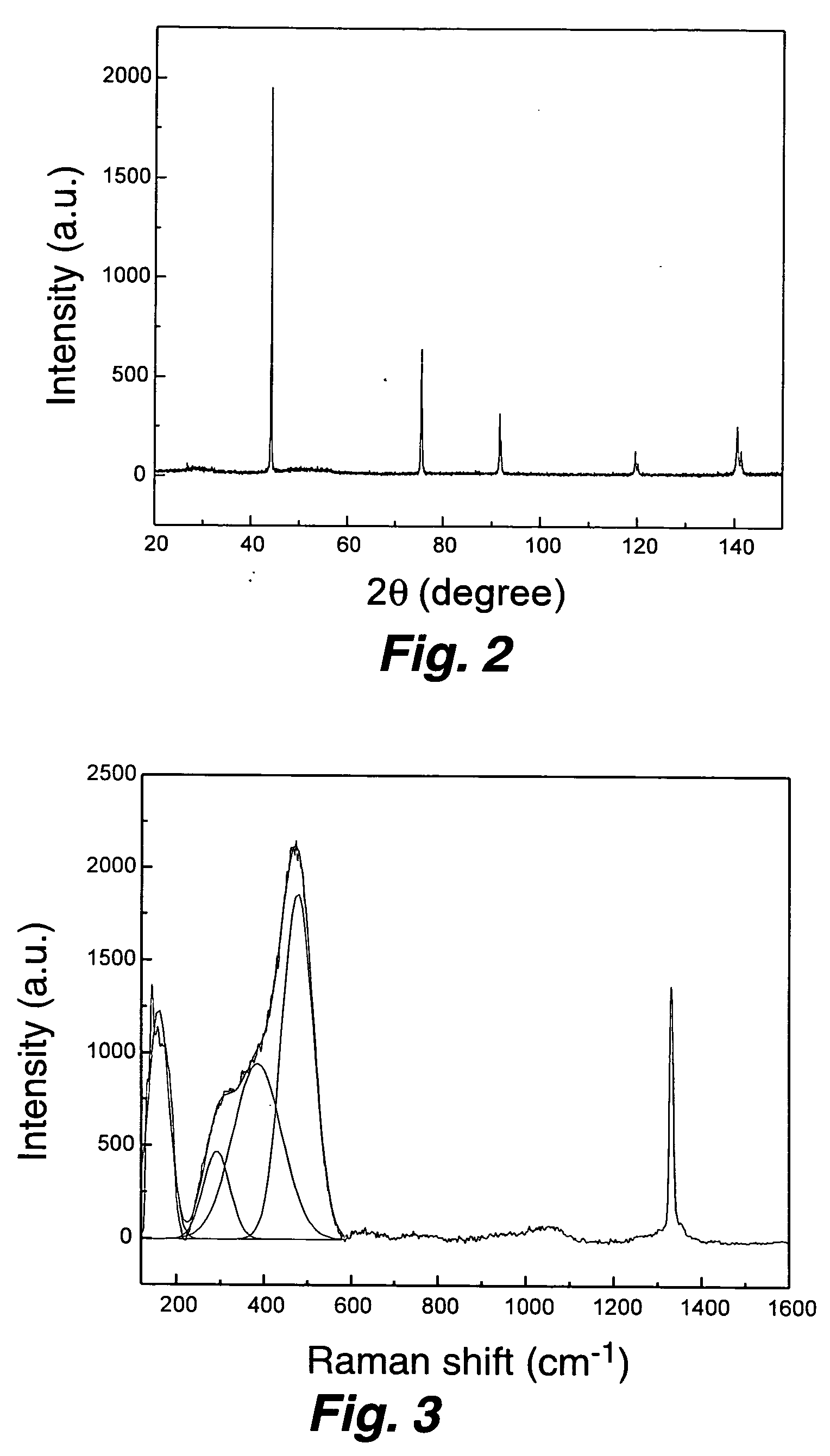

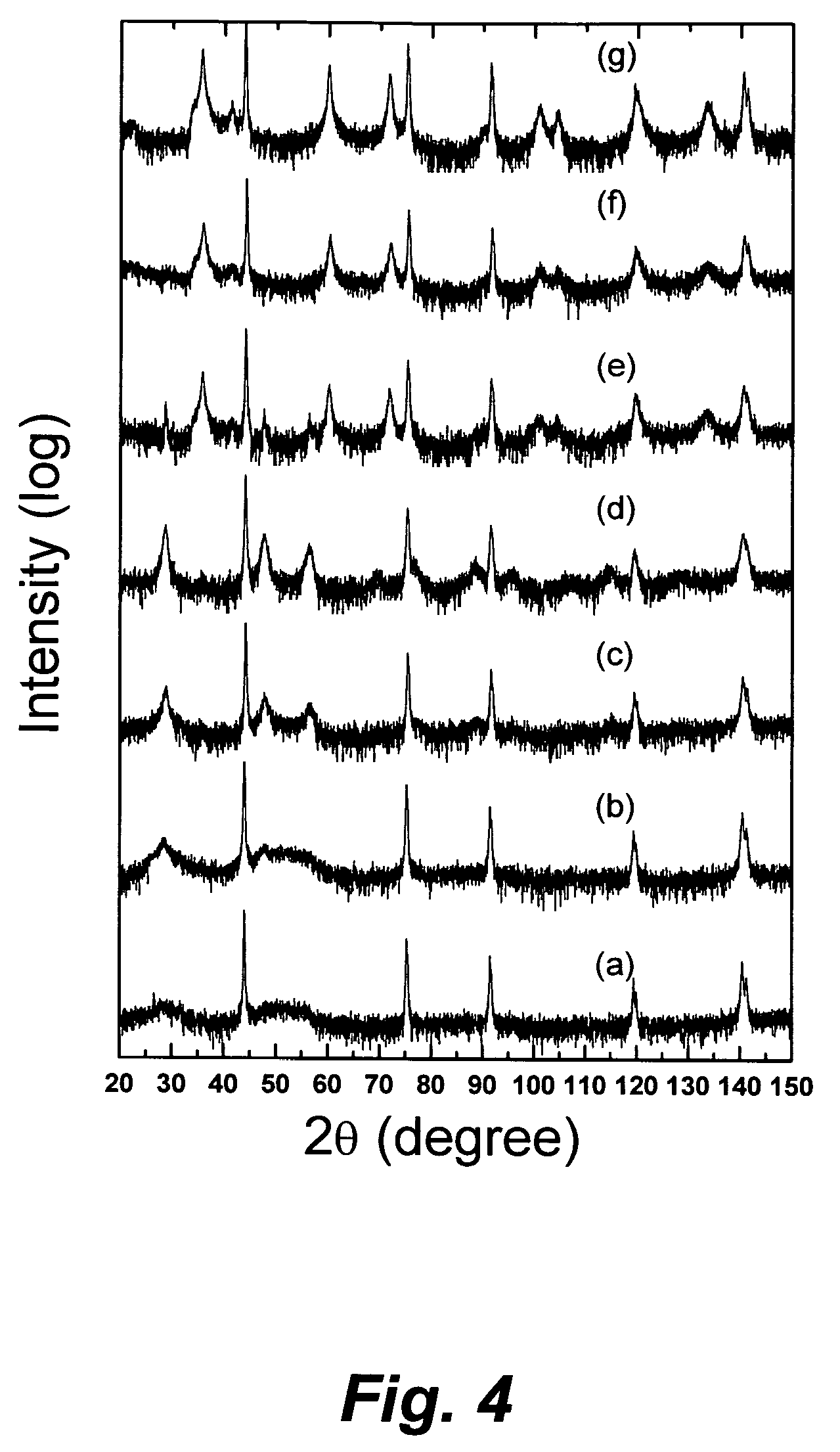

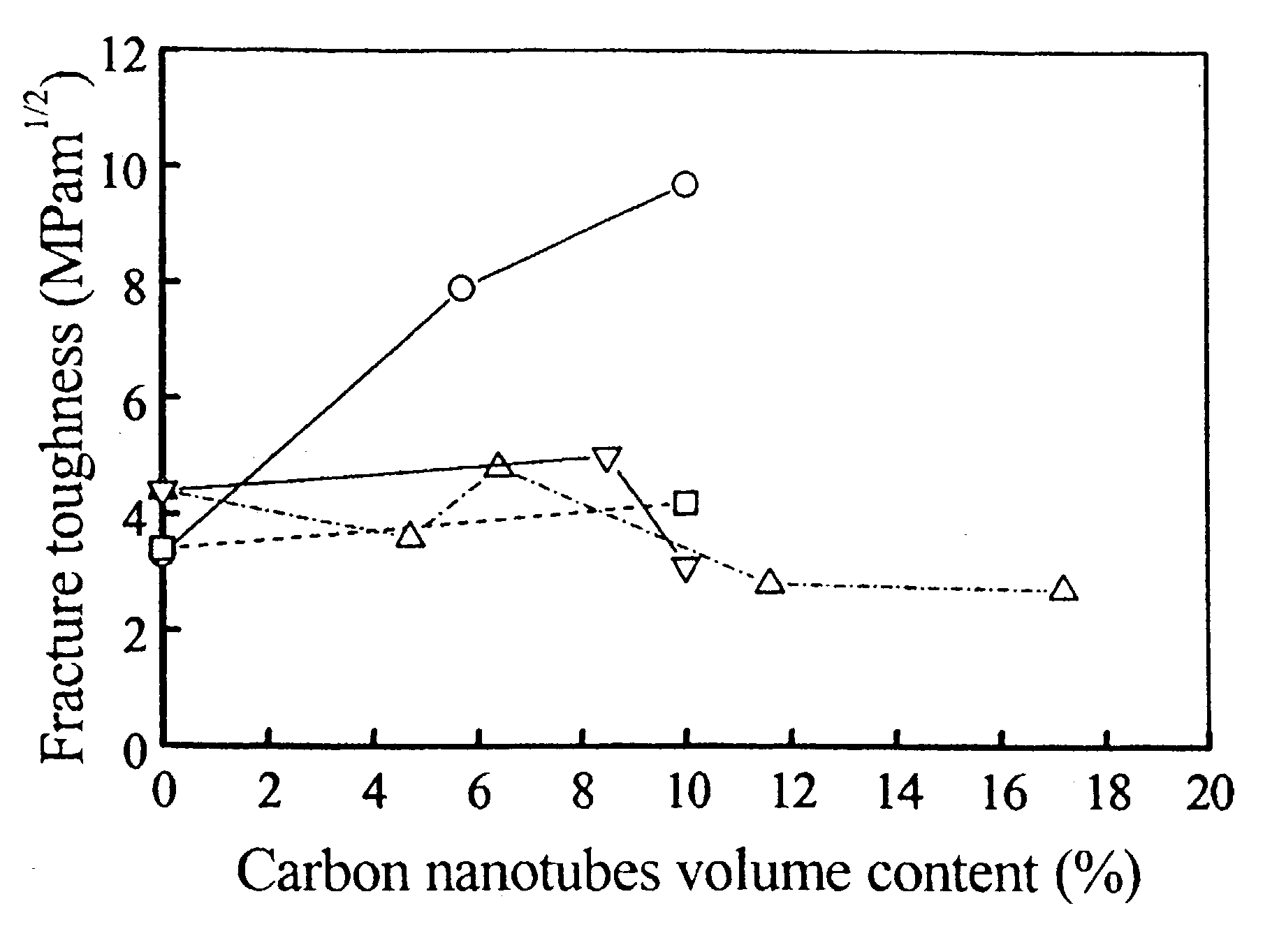

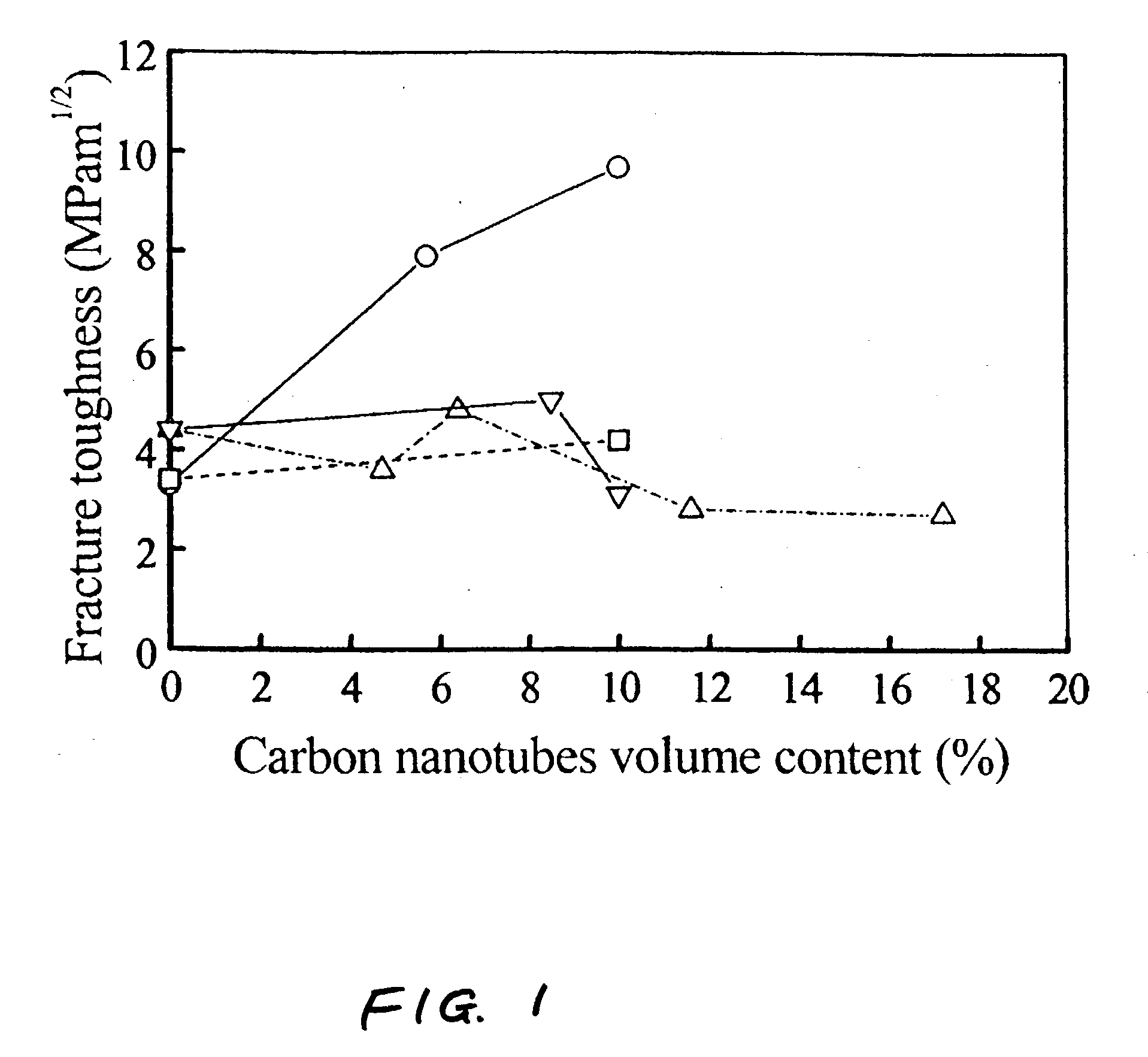

Nanocrystalline ceramic materials reinforced with single-wall carbon nanotubes

InactiveUS6858173B2Improve fracture toughnessImprove mechanical propertiesMaterial nanotechnologyTitanium dioxideHigh fractureCarbon nanotube

Composites of ceramic materials, notably alumina or metal oxides in general, with single-wall carbon nanotubes are consolidated by electric field-assisted sintering to achieve a fully dense material that has an unusually high fracture toughness compared to the ceramic alone, and also when compared to composites that contain multi-wall rather than single-wall carbon nanotubes, and when compared to composites that are sintered by methods that do not include exposure to an electric field.

Owner:RGT UNIV OF CALIFORNIA

Nanocrystalline ceramic materials reinforced with single-wall carbon nanotubes

Composites of ceramic materials, notably alumina or metal oxides in general, with single-wall carbon nanotubes are consolidated by electric field-assisted sintering to achieve a fully dense material that has an unusually high fracture toughness compared to the ceramic alone, and also when compared to composites that contain multi-wall rather than single-wall carbon nanotubes, and when compared to composites that are sintered by methods that do not include exposure to an electric field.

Owner:RGT UNIV OF CALIFORNIA

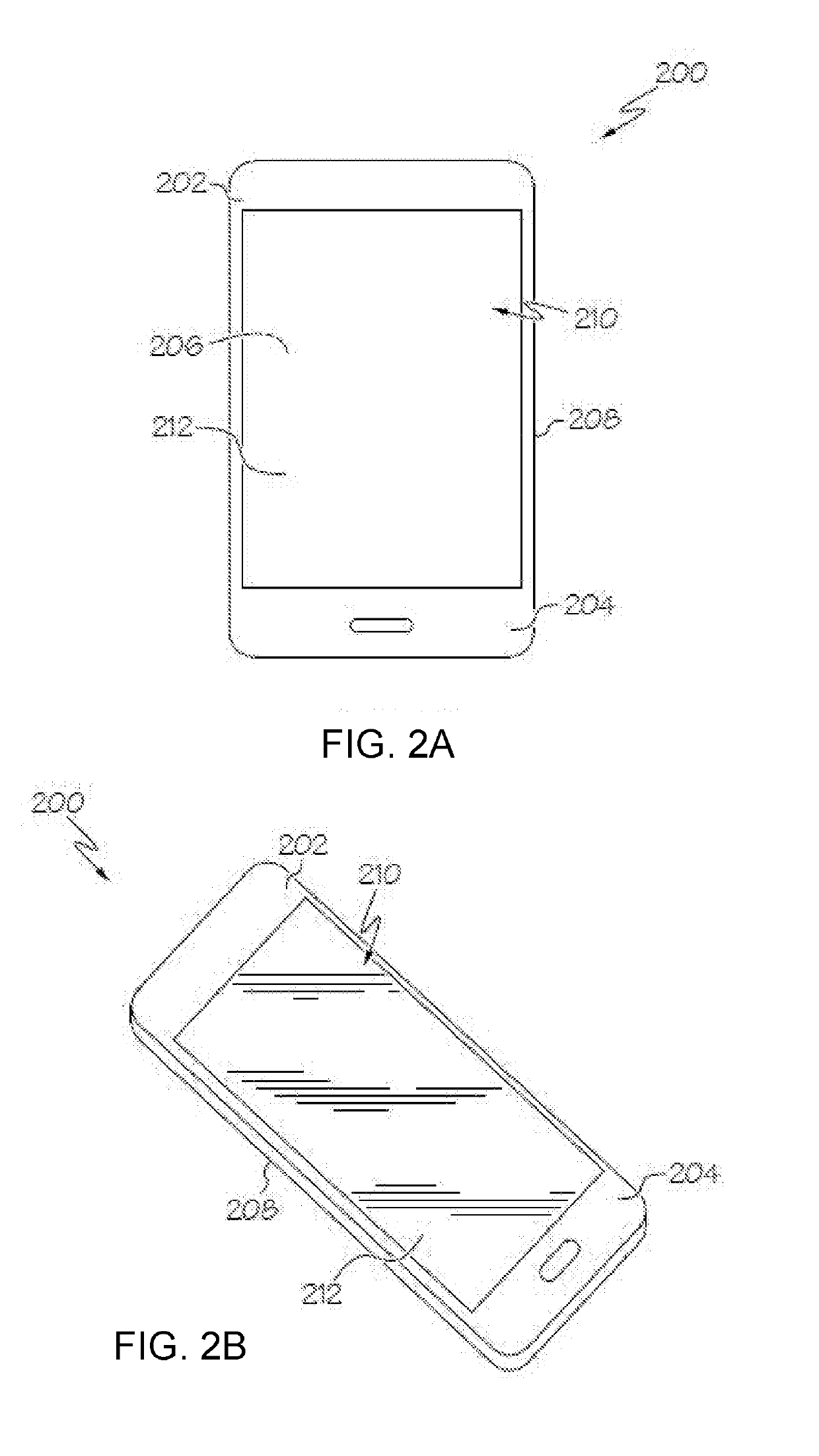

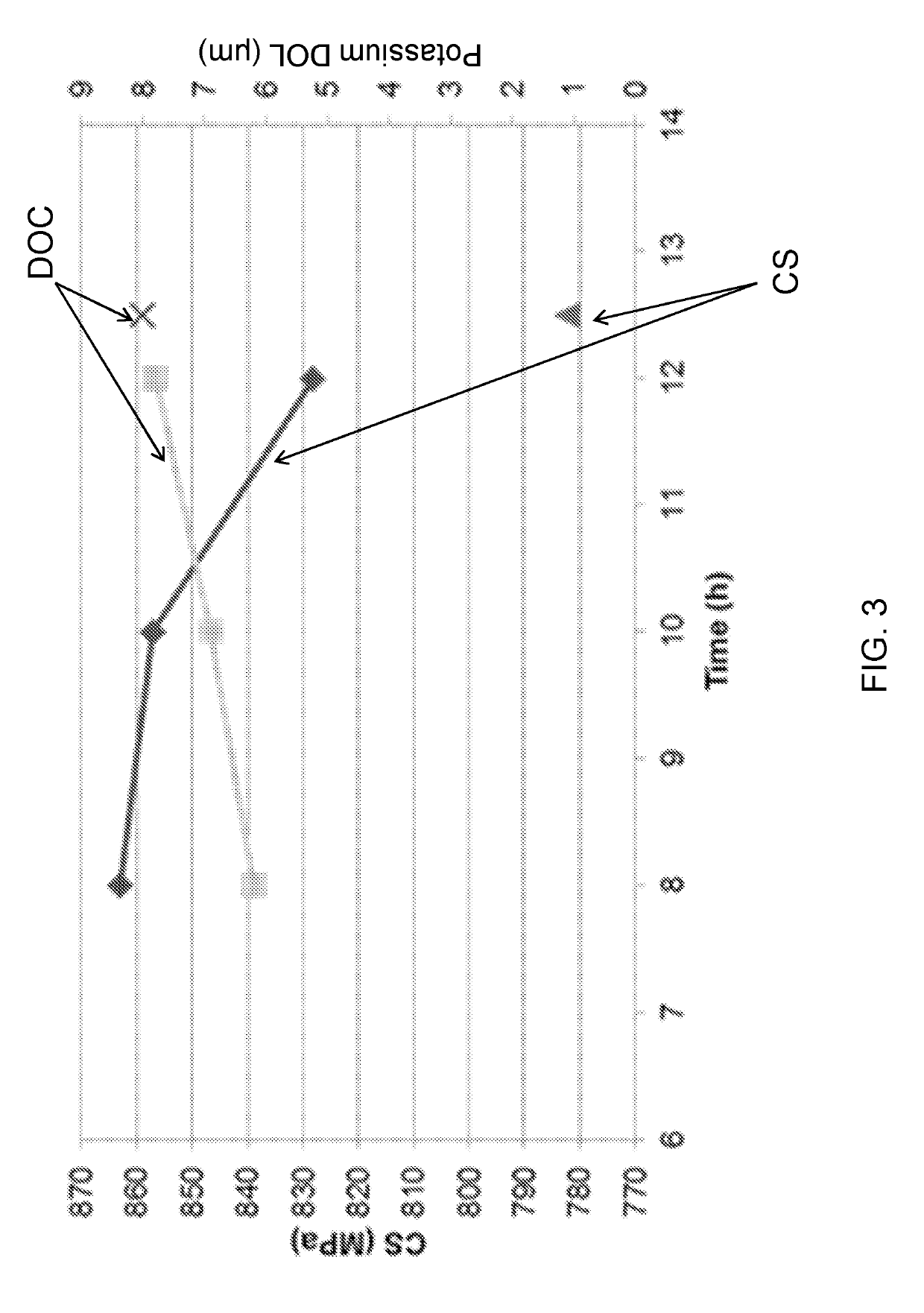

Glasses having high fracture toughness

A glass composition includes: 50 mol % to 69 mol % SiO2; 12.5 mol % to 25 mol % Al2O3; 0 mol % to 8 mol % B2O3; greater than 0 mol % to 4 mol % CaO; greater than 0 mol % to 17.5 mol % MgO; 0.5 mol % to 8 mol % Na2O; 0 mol % to 2.5 mol % La2O3; and greater than 8 mol % to 18 mol % Li2O, wherein (Li2O+Na2O+MgO) / Al2O3 is from 0.9 to less than 1.3; and Al2O3+MgO+Li2O+ZrO2+La2O3+Y2O3 is from greater than 23 mol % to less than 50 mol %. The glass composition may be characterized by at least one of the following: a K1C value measured by a chevron short bar method of at least 0.75; and a K1C value measured by a double torsion method of at least 0.8. The glass composition is chemically strengthenable. The glass composition may be used in a glass article or a consumer electronic product.

Owner:CORNING INC

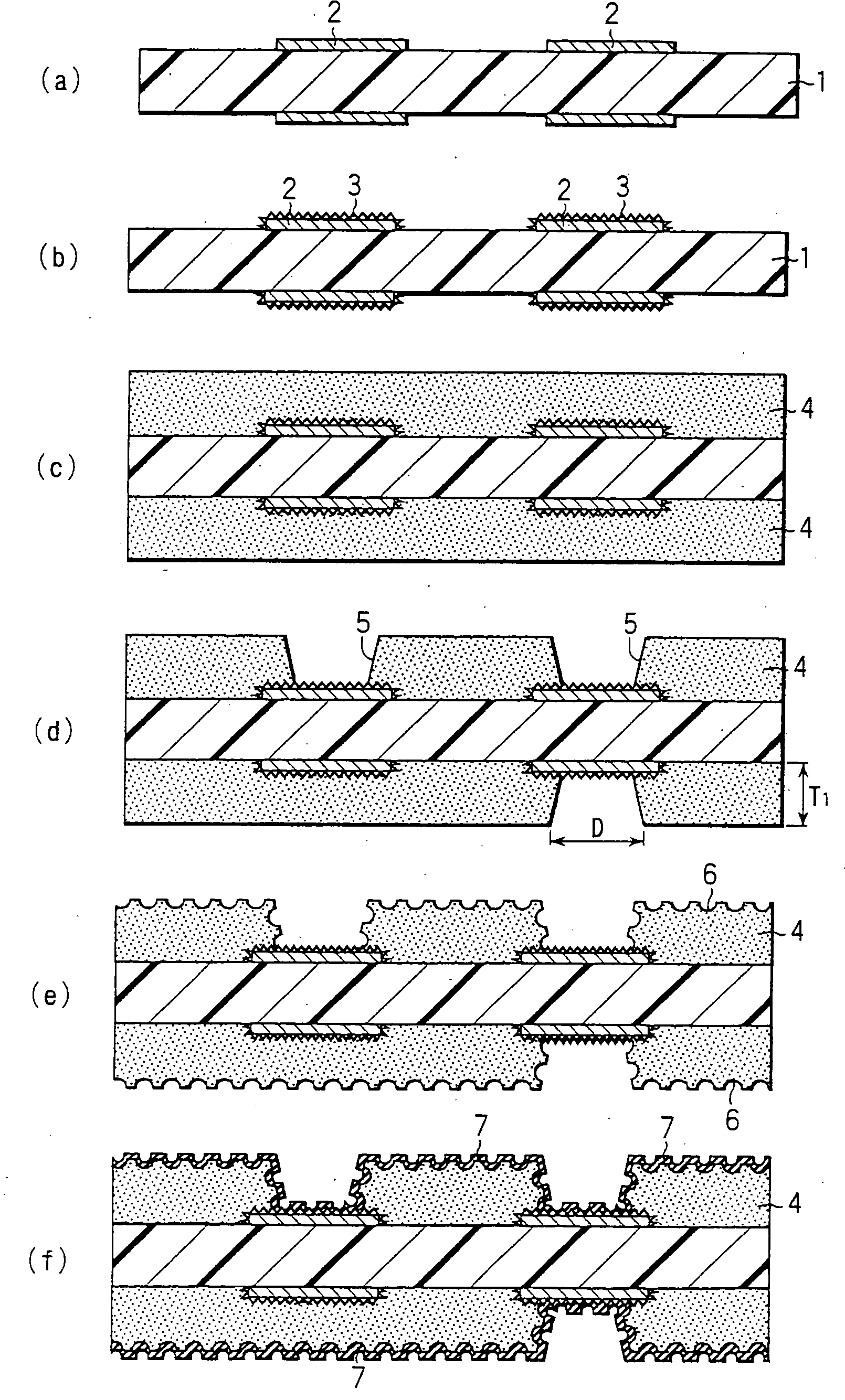

Multilayer printed wiring board with filled viahole structure

InactiveUS20050100720A1Large malleabilityAdhesionInsulating substrate metal adhesion improvementDielectric materialsElectrical conductorHigh fracture

The present invention provides a multilayer printed wiring board having a filled viahole structure advantageously usable for forming a fine circuit pattern thereon, and having an excellent resistance against cracking under a thermal shock or due to heat cycle. The multilayer printed wiring board is comprised of conductor circuitry layers and interlaminar insulative resin layers deposited alternately one on another, the interlaminar insulative resin layers each having formed through them holes each filled with a plating layer to form a viahole. The surface of the plating layer exposed out of the hole for the viahole is formed substantially flat and lies at a substantially same level as the surface of the conductor circuit disposed in the interlaminar insulative resin layer. The thickness of the conductor circuitry layer is less than a half of the viahole diameter and less than 25 μm. The inner wall of the hole formed in the interlaminar insulative resin layer is roughened and an electroless plating layer is deposited on the roughened surface. An electroplating layer is filled in the hole including the electroless plating layer to form the viahole. The interlaminar insulative resin layer is formed from a composite of a fluororesin showing a high fracture toughness and a heat-resistant thermoplastic resin, a composite of fluororesin and thermosetting resin or a composite of thermosetting and thermoplastic resins.

Owner:IBIDEN CO LTD

Method for consolidating tough coated hard powders

InactiveCN1997475APrevent chemical interactionsTransportation and packagingMetal-working apparatusParticulatesHigh fracture

A method of consolidating particulate materials into articles having combinations of properties not available by conventional processes by liquid phase sintering. These particulate materials are comprised of core particles individually coated with layers of a metal compound having a relatively higher fracture toughness than the core, such as WC or TaC. These coated particles include an outer layer comprised a metal, such as Co or Ni. The particles with these coatings are pressed to form an article and the article densified at pressures and temperatures where full density is achieved without the degradation of the material forming the core particle.

Owner:阿洛梅特公司

Method for manufacturing prestressed concrete tubular pile

InactiveCN101863079ASimple production equipmentProcess is easy to controlCeramic shaping apparatusHigh fracturePre stress

The invention relates to a method for manufacturing a prestressed concrete tubular pile, which belongs to the technical field of building engineering materials. The method comprises the following steps of: weighing silicate cement, composite superfine powder, sand, broken stone, water and composite water reducing agent in a ratio, pouring the weighed sand into a stirrer, adding the weighed silicate cement and the weighed composite superfine powder into the stirrer in turn, stirring the mixture, then adding the weighed water into the stirrer, stirring the mixture to form cement mortar, adding the weighed composite water reducing agent into the stirrer, and finally adding the weighed broken stone into the stirrer to obtain concrete; pouring the concrete into a tubular pile die, tensing steel bars to obtain a pre-stressing force, and centrifugally shaping the concrete to obtain the prestressed concrete tubular pile; and finally curing the prestressed concrete tubular pile by steam. The manufacturing method only needs low-temperature and normal-pressure steam curing, and has the advantages of simple production equipment, convenient process control, safe production and operation, saving of production land, reduction of product cost, improvement of production efficiency, reduction of environmental pollution, high compression-resistant push, good impact toughness, high fracture toughness and good durability.

Owner:深圳市同成新材料科技有限公司

Rear-earth-rich, niobium-rich and cand-rich rear sorted tail-ore microcrystal glass and mfg. method

The invention relates to a rare earth enriched, niobium, fluorite rare selecting tail mine micro-crystal glass and manufacture method. The feature is that the manufacture raw material of the glass is rare selecting tail mine and quartz sand. The chemical constituent includes SiO2 30-70wt%, CaO 5-20wt%, Al2O3 5-15wt%, CaF 3-15wt%, ReO 3-15wt%, Nb2O5 0-5wt%, and TiO2 0-10wt%. The advantages of the invention are that it has more refined micro-crystal, and the fracture toughness is obviously improved.

Owner:内蒙古科韵环保材料股份公司

High-strength silicon carbide ceramic pipe and manufacturing method thereof

The invention discloses a high-strength silicon carbide ceramic pipe and manufacturing method thereof, and belongs to the technical field of engineering ceramic materials. Silicon carbide ceramic powders with different granularities are used as the main raw materials, graphite powder and carbon black are used as binders, and resin is used as a binder. The materials are uniformly mixed by a spray granulation process; an organic plasticizer of cellulose and a lubrication agent are added into the mixture; and vacuum pugging, decaying and extrusion molding are conducted to obtain a pipe base substrate; and the base substrate is subjected to drying solidification, high temperature sintering reaction, sandblast and heat treatment to obtain the high strength silicon carbide ceramic pipe. The pipe biscuit manufactured by the process has high strength and length of more than 4000mm; after sintering, the pipe has strength of 300MPa or more, and has the advantages of moderate density, high thermal conductivity, high fracture toughness, good thermal shock resistance and low cost, and can be widely applied to chemical and metallurgy fields, such as acid and alkaline corrosion and high temperature erosion.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

Method for preparing aluminum oxide-titanium carbide-zirconium oxide nanocomposite ceramic material

The invention belongs to the technical field of material science and relates to a method for preparing an aluminum oxide-titanium carbide-zirconium oxide nanocomposite ceramic material. The method is characterized by comprising the following steps of: mixing 30 to 40 volume percent of submicron alpha-Al2O3, 50 to 62 volume percent of nano-TiC, 1 to 4 volume percent of nano-ZrO2, 2 to 7 volume percent of molybdenum powder and nickel powder and the balance of MgO and Y2O3; and performing vacuum hot-pressing sintering by taking polyethylene glycol as a dispersant, wherein the temperature rise is between 75 and 110 DEG C / minute at the temperature of less than 1,550 DEG C; and the temperature rise is between 30 and 50 DEG C / minute at the temperature of more than 1,550 DEG C. The composite material has the advantages of high density, uniform particle size distribution, high hardness, high strength, high fracture toughness, high temperature resistance and the like and is suitable for manufacturing and processing a cutter made of difficultly-processed materials, particularly a cutter made of low-alloy and super high intensity hardened and tempered steel.

Owner:SHANDONG UNIV

High fracture toughness aluminum-copper-lithium sheet or light-gauge plates suitable for fuselage panels

An aluminum alloy comprising 2.1 to 2.8 wt. % Cu, 1.1 to 1.7 wt. % Li, 0.1 to 0.8 wt. % Ag, 0.2 to 0.6 wt. % Mg, 0.2 to 0.6 wt. % Mn, a content of Fe and Si less or equal to 0.1 wt. % each, and a content of unavoidable impurities less than or equal to 0.05 wt. % each and 0.15 wt. % total, and the alloy being substantially zirconium free.

Owner:CONSTELLIUM ISSOIRE

Rare earth-mixing high strength lithium bisilicate sitall material and preparation method thereof

The invention relates to a rare earth-mixing high strength lithium bisilicate sitall material and a preparation method thereof. Parent glass of the invention includes the following components according to molar percentage: 61.2 to 66.0 percent of SiO2, 0 to 2.5 percent of B2O3, 0 to 1.6 percent of Al2O3, 1.0 to 3.7 percent of P2O5, 0 to 2.3 percent of ZrO2, 1.0 to 1.8 percent of K2O, 24.2 to 31.8 percent of Li2O, 0 to 2.0 percent of MgO, 0 to 2.0 percent of CaO, and 0.5 to 4.2 percent of La2O3+Y2O3. A corresponding raw material prepared from the oxidates is processed by the steps of ball milling, 80 mesh sieve sieving and uniform mixing to obtain a batch; the batch is led into a copple to be melted after the temperature from 1480 to 1520 DEG C is maintained for 2 to 3 hours, and the melted batch is cast into a stainless steel mould to be molded and then is annealed at 500 DEG C for 0.5 hour; and the step of coring is carried out in a resistance furnace at the temperature from 500 to 550 DEG C for 1 hour, and the step of crystallization is carried out at the temperature from 600 to 850 DEG C for 2 hours. The crystallization degree of the sitall is as high as 60 to 70 percent, the flexural strength is 100 MPa or more higher than the sitall to which the rare earth oxides are not added, the highest flexural strength reaches 334 MPa, the maximum elastic modulus reaches 143 GPa, and the highest fracture toughness reaches 3.34 MPa-m. The sitall of the invention has favorable stability, and the heat treatment temperature is lower and is easy to control.

Owner:CENT SOUTH UNIV

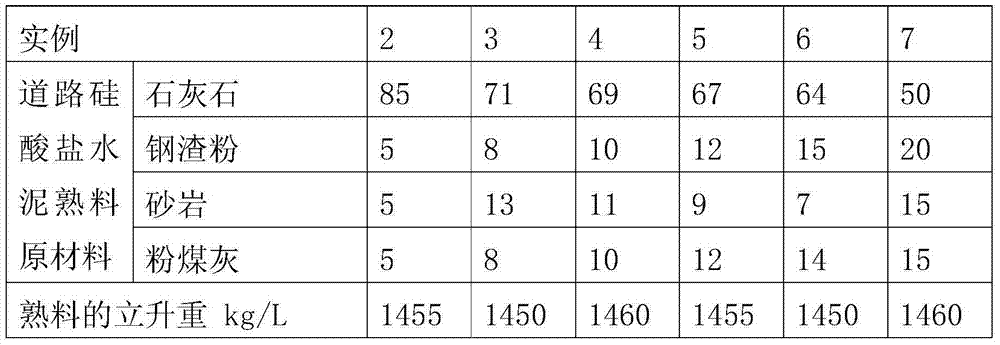

Road silicate cement clinker and preparation method thereof

InactiveCN104496228AImprove flexural performanceImprove wear resistanceCement productionHigh fractureShrinkage rate

The invention relates to road silicate cement clinker and a preparation method thereof. The preparation method for the road silicate cement clinker comprises the following steps: grinding and roasting a cement raw material, wherein the cement raw material consists of the following substances in parts by weight: 50-85 parts of lime stones, 5-20 parts of steel slag powder, 5-15 parts of sandstones and 5-15 parts of coal ash. The preparation method can be used for recycling the steel slag, grinding the steel slag into powder after drying, and adopting the prepared steel slag powder as a cement production raw material to prepare road silicate cement clinker with low heat and high fracture resistance, so that the sintering quality of the clinker can be effectively improved after the steel slag powder is added. On the basis of meeting the technical requirements specified in the road silicate cement national standards, the road silicate cement clinker can be used for improving the fracture resistance and wear resistance of the cement, and lowering the hydration heat evolution and the dry shrinkage rate.

Owner:CHINA BUILDING MATERIALS ACAD

Ceramic materials reinforced with single-wall carbon nanotubes as electrical conductors

InactiveUS20050067607A1Reduce processing timeMaterial nanotechnologyOxide/hydroxide preparationHigh fractureElectrical conductor

Composite materials formed of a matrix of fused ceramic grains with single-wall carbon nanotubes dispersed throughout the matrix and a high relative density, notably that achieved by electric field-assisted sintering, demonstrate unusually high electrical conductivity in combination with high-performance mechanical properties including high fracture toughness. This combination of electrical and mechanical properties makes these composites useful as electrical conductors in applications where high-performance materials are needed due to exposure to extreme conditions such as high temperatures and mechanical stresses.

Owner:RGT UNIV OF CALIFORNIA

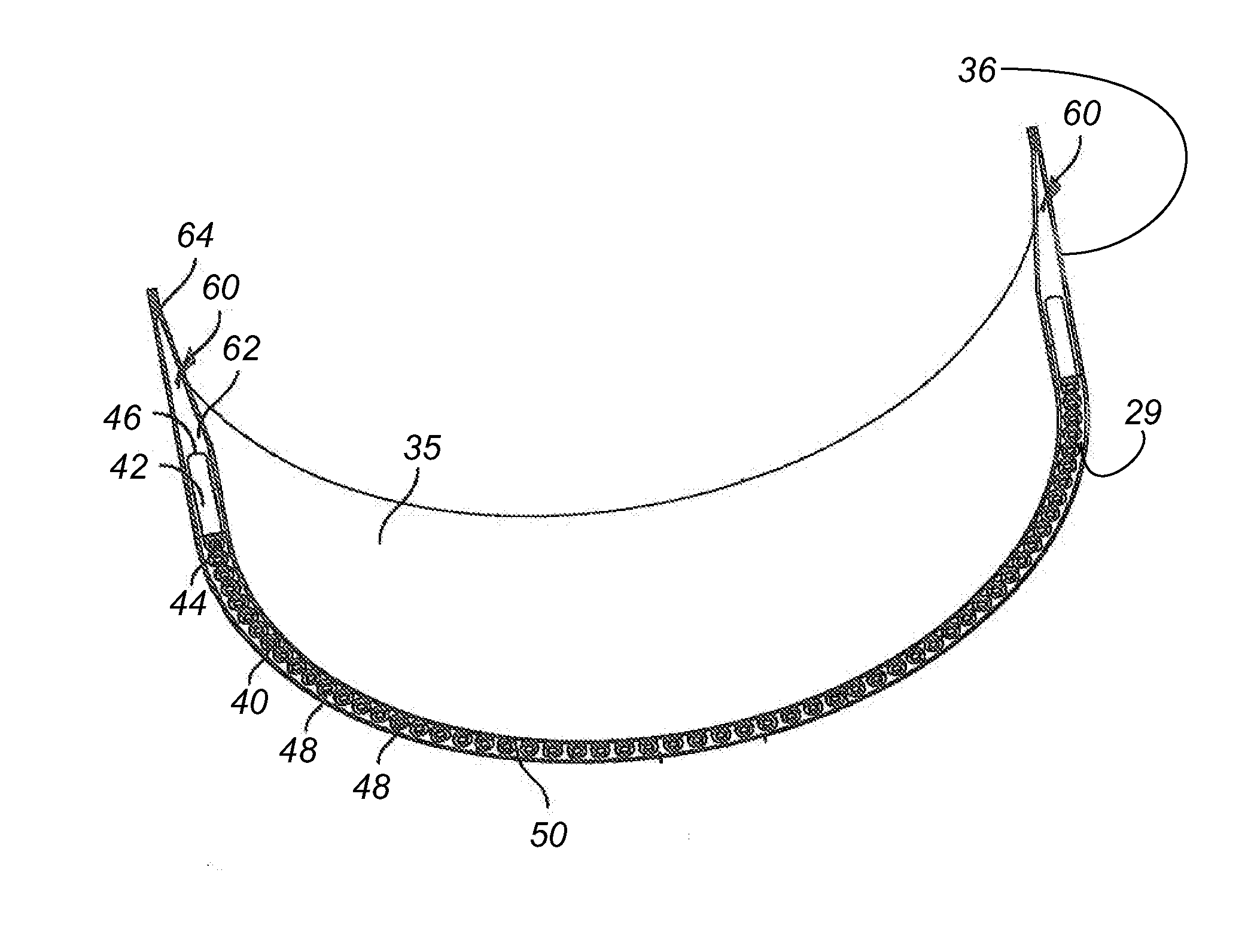

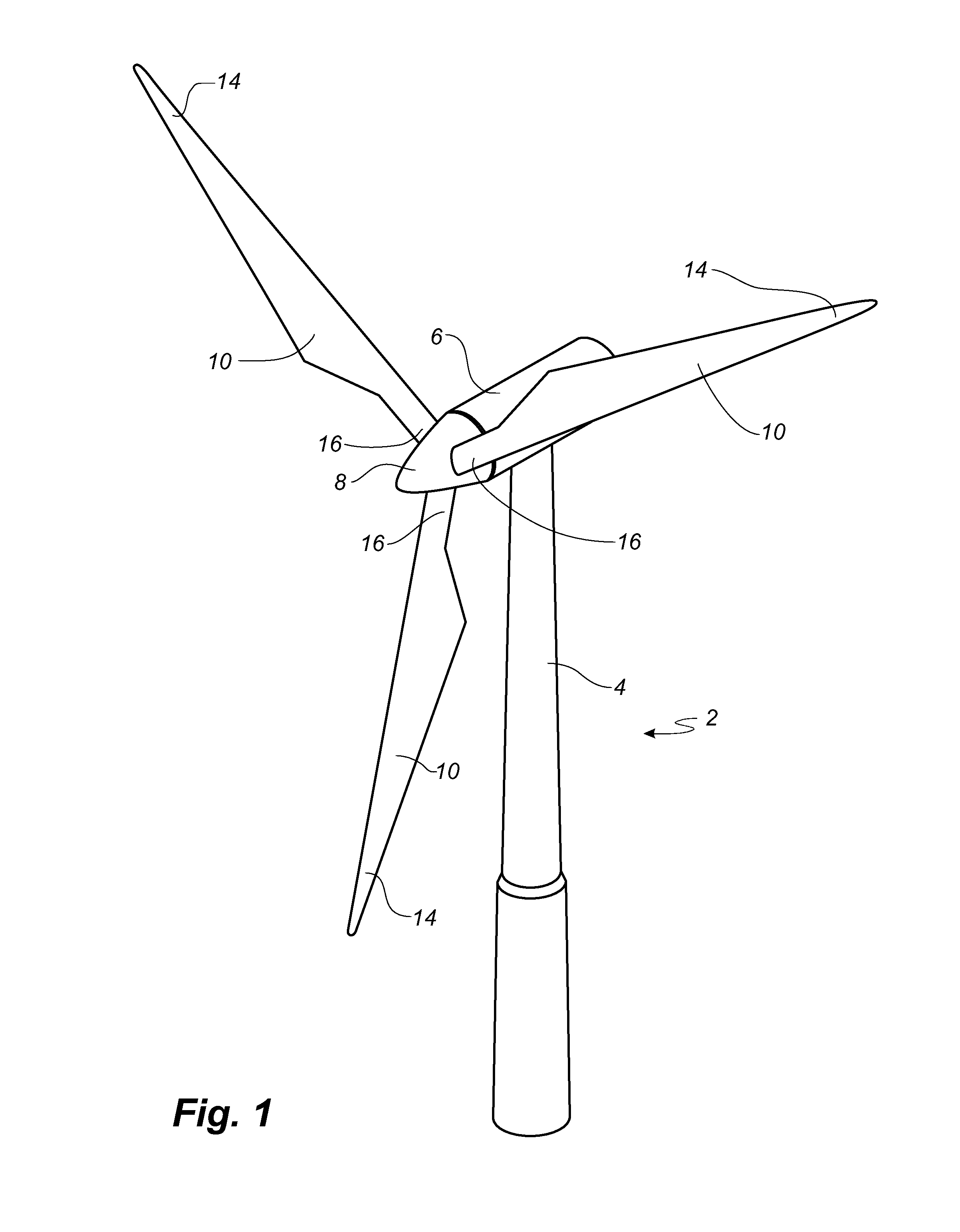

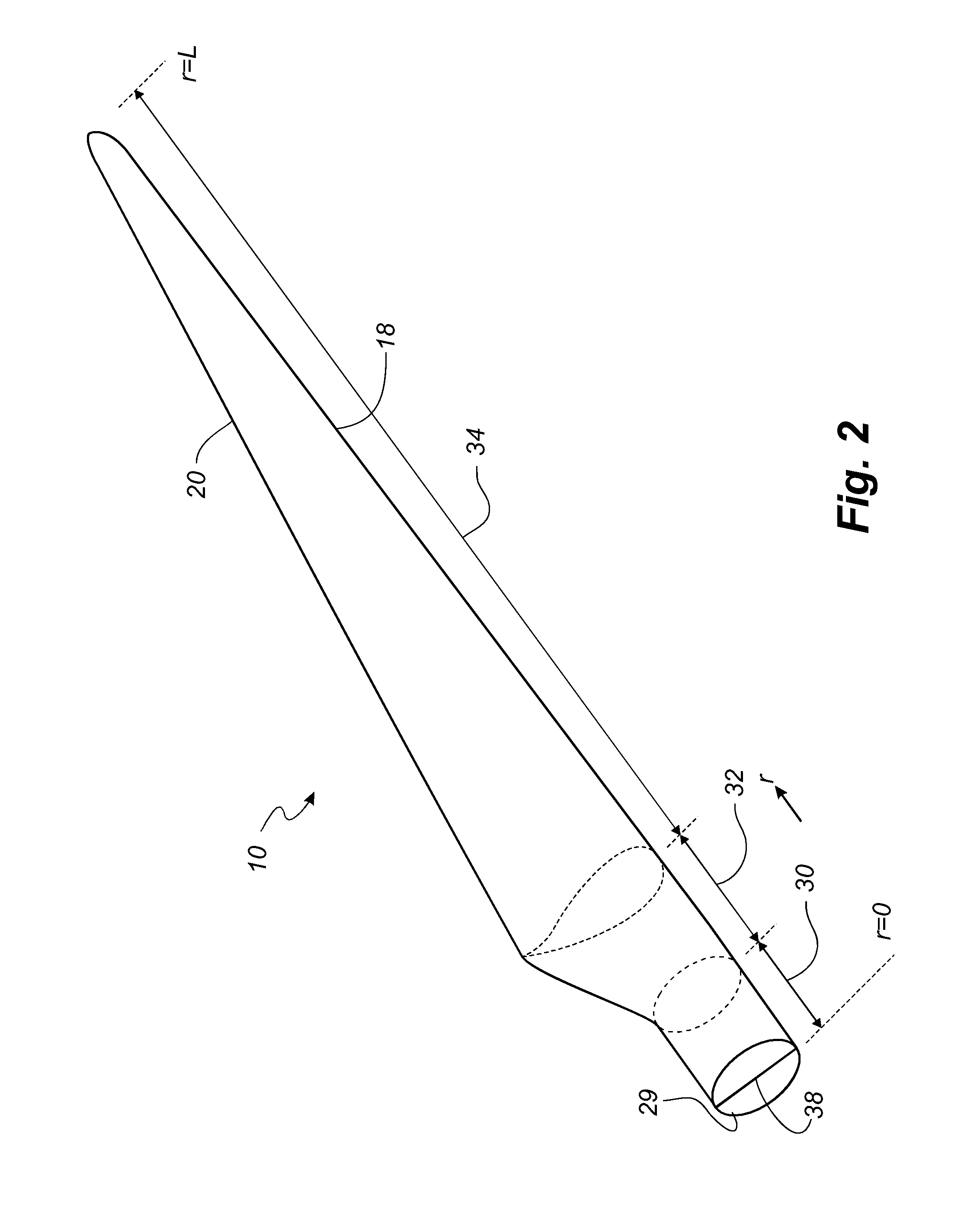

Wind Turbine Blade Bushing System

ActiveUS20170045032A1High retention rateEasy to anchorEngine fuctionsMachines/enginesHigh fractureTurbine blade

A wind turbine blade bushing system for arrangement in a root end of a wind turbine blade is described. The wind turbine blade bushing system comprises a threaded element for retaining a mounting bolt for a wind turbine blade, the threaded element being formed from a first material; and an anchor element for arrangement at the root end of the wind turbine, wherein the anchor element acts to at least partly retain the threaded element in the wind turbine blade, the anchor element being formed from a second material. The first material has a higher strength and higher fracture toughness than the second material.

Owner:LM WP PATENT HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com