As-cast high-toughness die-cast aluminum-silicon alloy and preparation method and application thereof

A technology of aluminum-silicon alloy and silicon alloy, which is applied in the field of as-cast high-toughness die-casting aluminum-silicon alloy and its preparation, can solve the problems of difficult heat treatment, increase the production cost of castings, and low absolute strength, meet the requirements of high mechanical properties and extend the service life The effect of long life and good thermal cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

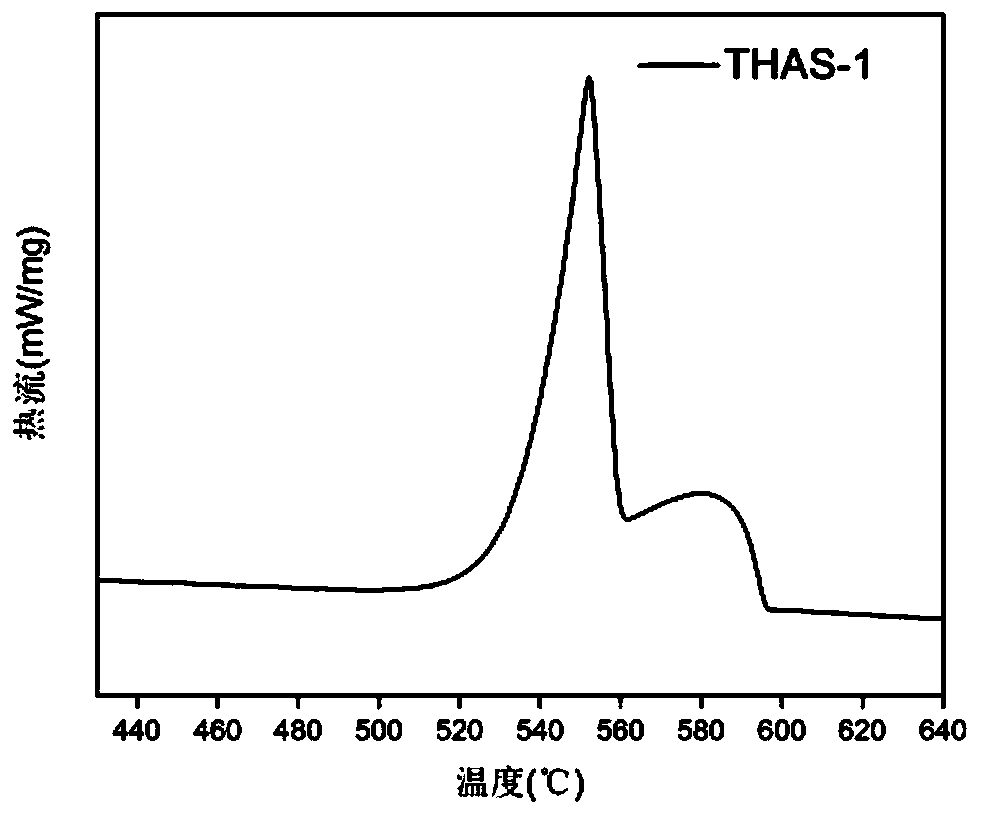

[0047] Aluminum-silicon alloy dies were prepared by as-cast high-strength and toughness die-casting Al-silicon alloy THAS-1. Among them, the composition of the as-cast high-strength and toughness die-cast aluminum-silicon alloy THAS-1 is: Si: 9.004wt%; Mg: 0.0047wt%; Mn: 0.558wt%; V: 0.160wt%; Zr: 0.198%wt; wt%; Cu: 0.004wt%; Fe: 0.144wt%; Zn: 0.018wt%; Sr: 0.0205wt%;

[0048] (1) Cut the THAS-1 aluminum alloy ingot into small pieces of about 2kg, put the THAS-1 small alloy ingot into the furnace, and quickly heat up to 700-720°C. After the alloy is melted, keep it warm for 30 minutes, and then pass in argon. And the melt was continuously stirred for 30 minutes to remove the gas in the melt and make the components homogeneous; after the above operations were completed, the temperature was lowered to 680°C, kept for 10 minutes, and the slag was removed.

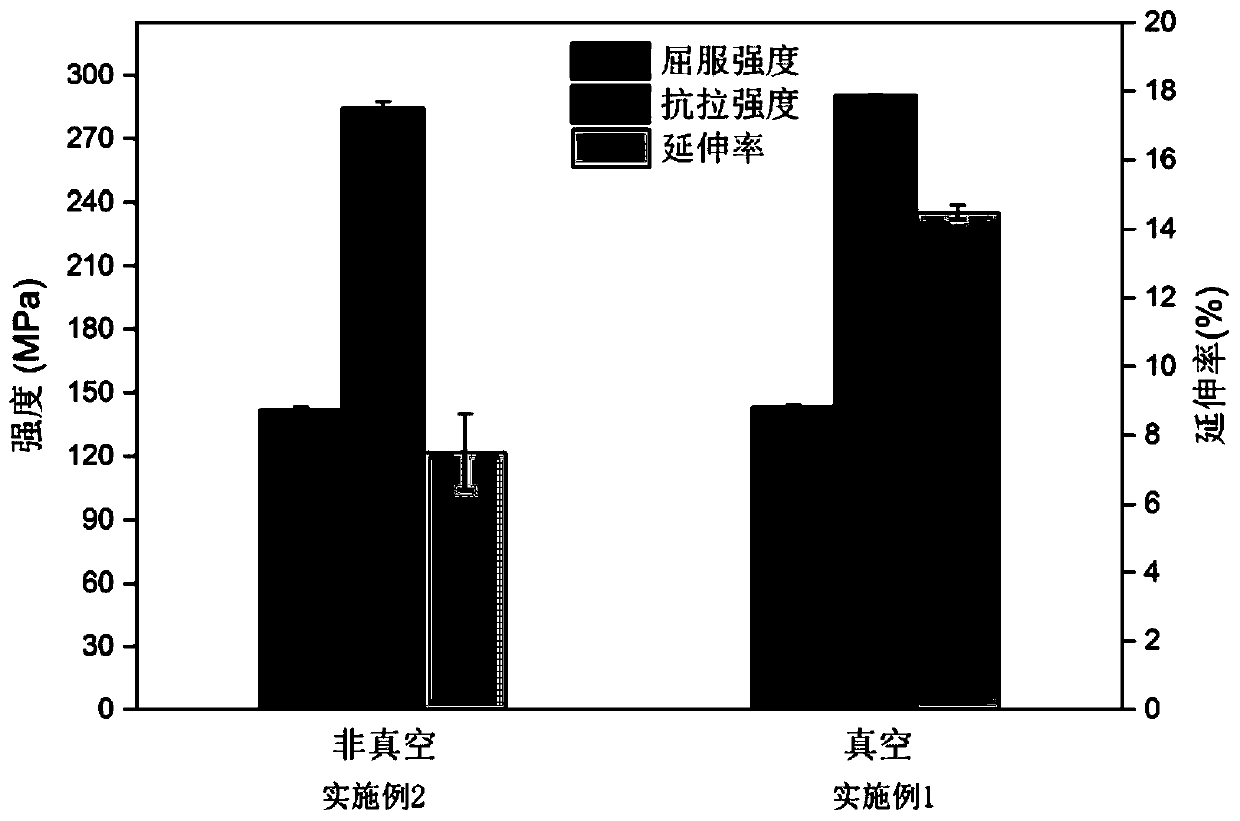

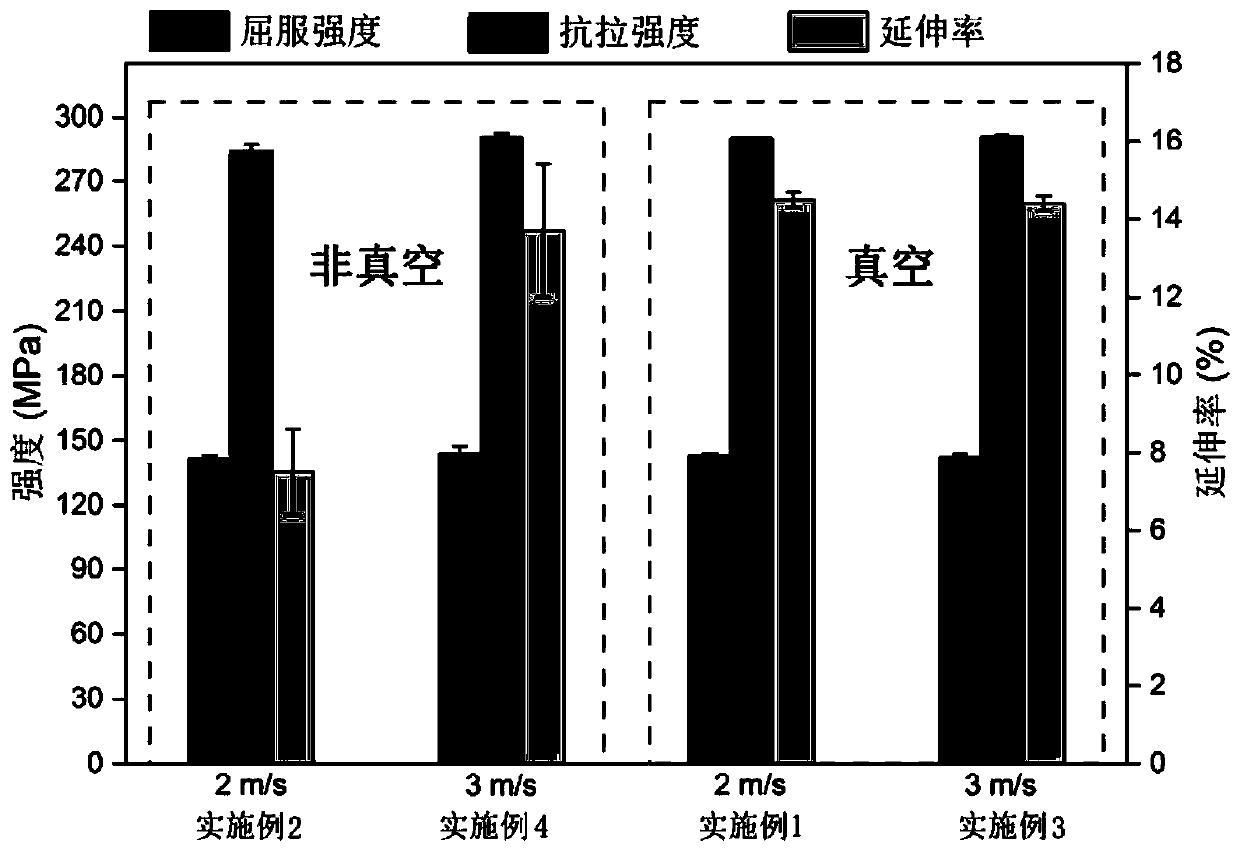

[0049] (2) Perform die-casting treatment on the melt after slag removal, the melt pouring temperature is 680°C, the mold te...

Embodiment 2

[0050] The differences between Embodiment 2, Embodiment 3, Embodiment 4, Embodiment 5 and Embodiment 6 and Embodiment 1 are shown in Table 1.

[0051] The difference between table 1 embodiment 2-6 and embodiment 1

[0052]

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| solidus temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com