Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Fully fed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cast magnesium alloy of low linear shrinkage

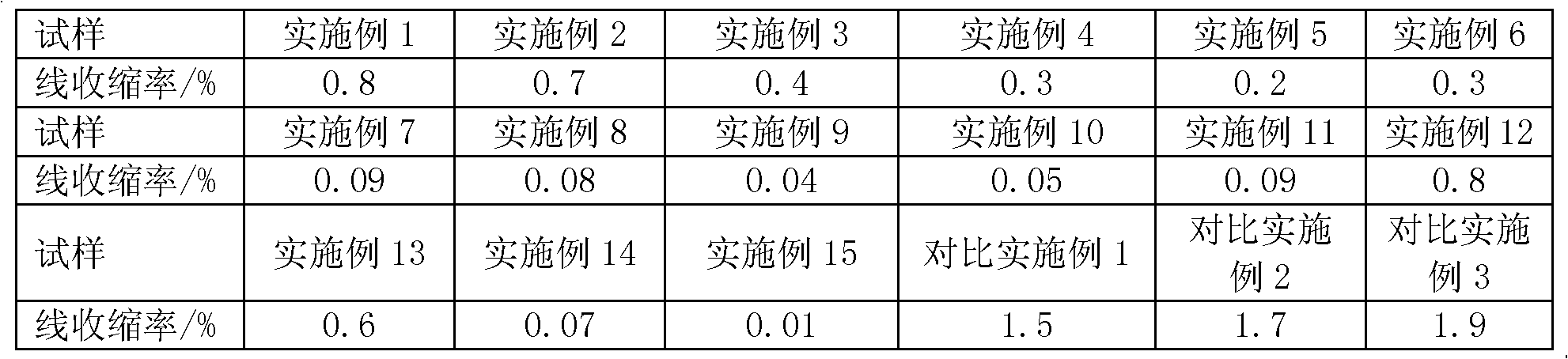

The invention discloses a cast magnesium alloy of low linear shrinkage, which belongs to the field of magnesium alloys. The magnesium alloy consists of Mg, Al, Zn, Mn, rare earth, Nb, Li and M element, wherein the materials have the following weight percentage composition: 1.5-25 percent of Al, 0.1-3.5 percent of Zn, 0.1-2.2 percent of Mn, 0.0002-16 percent of rare earth, 0.0002-4 percent of Nb, 0.0002-9 percent of Li, 0.0002-2 percent of M element and the balance Mg; and the M element is at least one of Zr, Ti, Sr, Ca, C and B. According to the heat-resistant magnesium alloy, the rare earth element and the Nb element are added into the magnesium alloy, so that the structure of beta phase is changed; the Zr element and the M element are added to refine crystal grains; due to combined action of the elements, latent heat of crystallization during alloy solidification is changed; and the magnesium alloy which has superior mold-filling capacity, low shrinkage, superior mechanical property and good machinability, fluidity and die-cast performance and is suitable for casting is obtained.

Owner:嘉兴佳斯贝特新材料有限公司

Method for producing ultrahigh pressure switch pressure-bearing aluminum alloy tanks under low pressure through V method

ActiveCN102941333ASpeed up the flowReduce scour forceFoundry mouldsFoundry coresVacuum castingUltra high pressure

The invention discloses a method for producing ultrahigh pressure switch pressure-bearing aluminum alloy tanks under low pressure through a V method in the technical field of vacuum casting, which comprises the following processing steps: jig manufacture, low-temperature gating system manufacture, upper tank molding, lower tank molding, lower core mould assembling, casting and pressure removing and picking. The method solves the defects of slag inclusion, pores, pinholes and the like of cast caused by intensive scouring of molten metal to cast, and simultaneously can solve the problems that the cavity casting system occupies excessive molten metal, and particularly the product yield of cast with low wall thickness and large size is low.

Owner:NANYANG HUISEN PRECISION INSTR CASTING

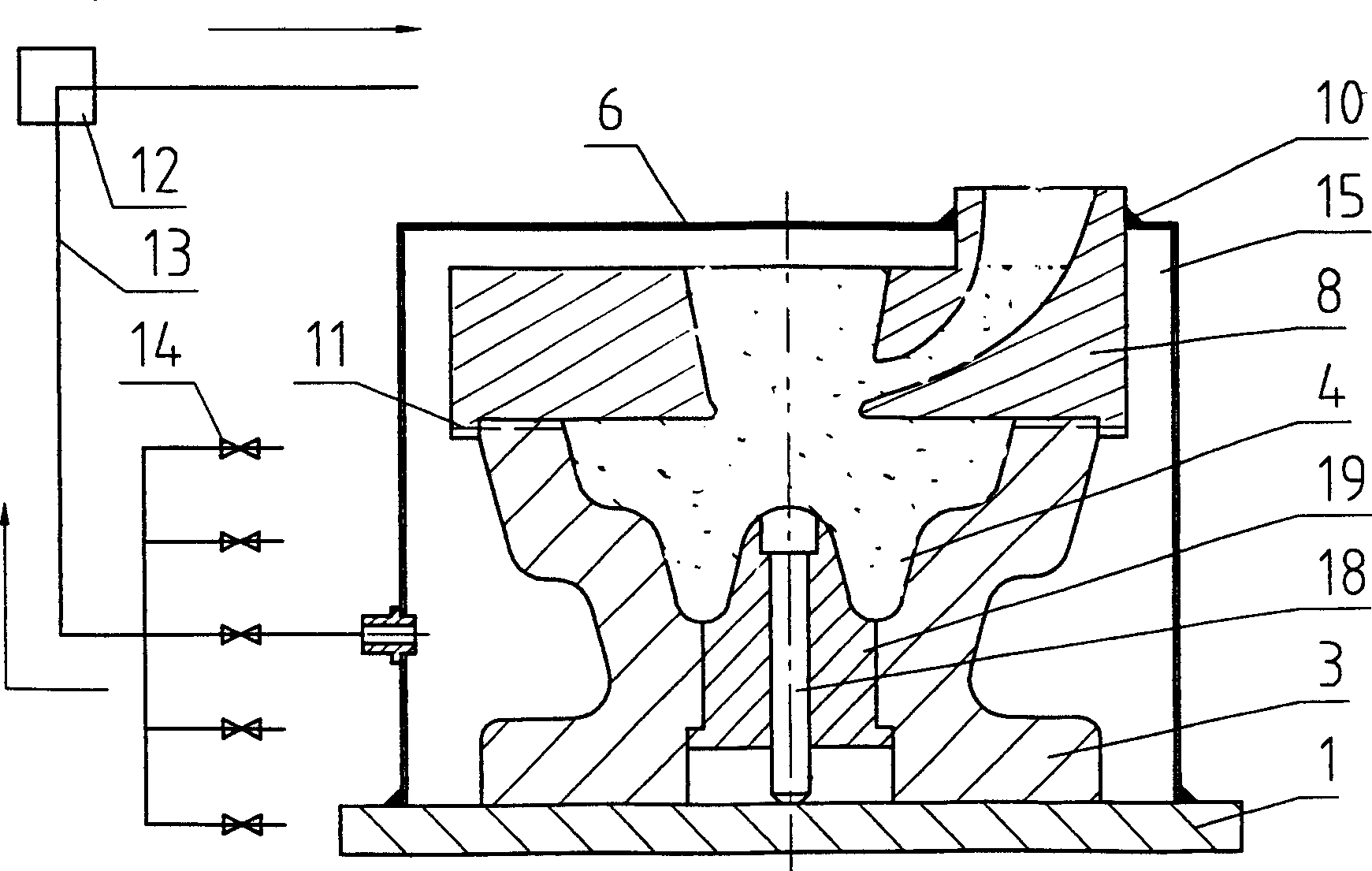

Multi-element combined-type low-pressure pouring method and combined-type sand core

ActiveCN103008612AEasy to shapeImprove filling abilityFoundry mouldsFoundry coresMulti elementMaterials science

The invention discloses a multi-element combined-type low-pressure pouring method and a combined sand core. The method comprises the following steps of A, preparing the combined sand core which is formed by combining a plurality of branch sand cores according to the structural shape of a member to be poured; B, adopting the combined sand core to carry out the low-pressure pouring, wherein metal liquid for pouring enters a transverse pouring gate on the bottom of the combined sand core from a main pouring port of the combined sand core, partial metal liquid enters a plurality of sprues on a shower pouring gate from the transverse pouring gate, and then enters a die cavity, the shower pouring gate is arranged on the inner side of the combined sand core, and is used for pouring an inner skin of a casting; and the other part of the metal liquid enters a gap pouring gate from a gap pouring gate sprue which is arranged on the outer side of the transverse pouring gate and then enters a die cavity of an outer skin of the casting. The combined sand core comprises an inner sand core, an outer sand core and a sprue sand core, wherein the sprue sand core is provided with a main sprue, the transverse pouring gate, the shower pouring gate and the gap pouring gate sprue. Due to the adoption of the method and the sand core, the advantages of multiple pouring gates are integrated, the process is more reasonable, and the qualification rate of the casting is increased.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Compound feed for the polyculture of Litopenaeus vannamei and Trachinotus ovatus and a preparation method thereof

ActiveCN103385382AMeet all needsEasy feedingAnimal feeding stuffAdditive ingredientMonocalcium phosphate

The present invention provides compound feed for the polyculture of Litopenaeus vannamei and Trachinotus ovatus and a preparation method thereof. The compound feed is characterized by comprising the following ingredients in parts by weight: 15-25 parts of fish meal, 5-10 parts of meat and bone meal, 1-5 parts of maggot powder, 15-25 parts of soybean meal, 5-10 parts of peanut bran, 1-5 parts of soybean protein concentrate, 1-5 parts of cottonseed meal, 1-5 parts of corn gluten meal, 1-3 parts of molasses yeast, 1-3 parts of corn DDGS, 1-3 parts of squid paste, 1-3 parts of shrimp shell powder, 20-25 parts of high-gluten flour, 1-2 parts of sea fish oil, 1-2 parts of soybean oil, 1-2 parts of soy lecithin, 0.5-1 parts of calcium dihydrogen phosphate, 0.1-0.3 parts of choline chloride, 0.1-0.3 parts of cholesterol, 0.05-0.1 parts of L-ascorbate-2-monophosphate, 0.1-0.3 parts of coated lysine, 0.1-0.3 parts of coated methionine, 0.1-0.3 parts of Bacillus subtilis, 0.1-0.3 parts of mannan, 0.1-0.5 parts of complex vitamins, 0.1-0.5 parts of complex mineral salts. Experiments show that the compound feed for the polyculture of Litopenaeus vannamei and Trachinotus ovatus of the present invention can effectively meet the comprehensive nutrient needs of both Litopenaeus vannamei and Trachinotus ovatus, significantly improves the effective utilization of the feed, and has a relatively low food coefficient.

Owner:广西粤海饲料有限公司

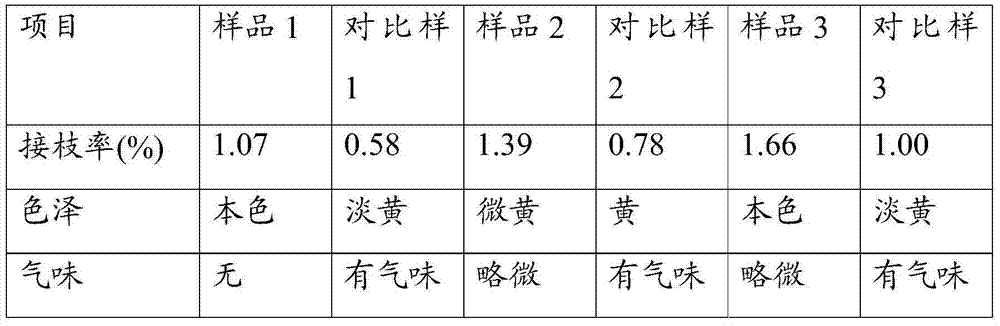

High-grating-rate and low-odor polypropylene resin composition and preparation method thereof

The invention provides a high-grating-rate and low-odor polypropylene resin composition and a preparation method thereof. The polypropylene resin composition consists of the following components in parts by weight: 100 parts of polypropylene resin, 1-3 parts of a polar monomer, 0.01-1 part of an initiator A, 0.01-1 part of an initiator B and 0.5-2 parts of a second monomer. The preparation method comprises the steps of weighing raw materials according to the weight part, mixing the raw materials in a high-speed mixer for 2-5min and discharging materials; and implementing reactive extrusion grafting on the mixed raw materials through a dual-screw extruder. The polypropylene resin composition disclosed by the invention, through selecting initiator and comonomer, reduces pungent odor of materials and improves grafting efficiency. The prepared polypropylene disclosed by the invention has the advantages of light product odor, high grating rate and low gel rate, and is applicable to a flexibilizer and a compatilizer of polar monomer and non-polar polymer alloy; the polypropylene resin composition is used for filling or strengthening polypropylene, and is capable of improving the mechanical performance and the heat resistance of the material.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

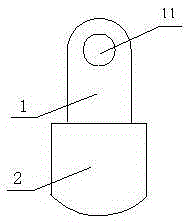

Dual-compound wear-resisting hammer and manufacturing method thereof

The invention discloses a dual-compound wear-resisting hammer comprising a hammer handle and a hammer body; the hammer body is formed by compound casting of two kinds of metal liquids, and the hammer body is in casting connection with the solid hammer handle to form the hammer. The manufacturing method includes the following steps: step 1, manufacturing and casting a sand mold according to a structure of the hammer; step 2, processing the hammer handle with a low-alloy steel blank material, and preburying one end of the hammer handle into the casted sand mold of the hammer; step 3, selecting high-chromium cast iron and carbon steel, and carrying out quantitative pouring in sequence; and step 4, carrying out heat treatment. The dual-compound wear-resisting hammer not only can improve wear resistance of the hammer but also allows the hammer body and the hammer handle to be combined closely and not generate cracks, casting defects are overcome, the product yield is improved, the cleaning workload is reduced, and the quality and the service life of the hammer are improved substantially.

Owner:江苏长友特钢机械有限公司

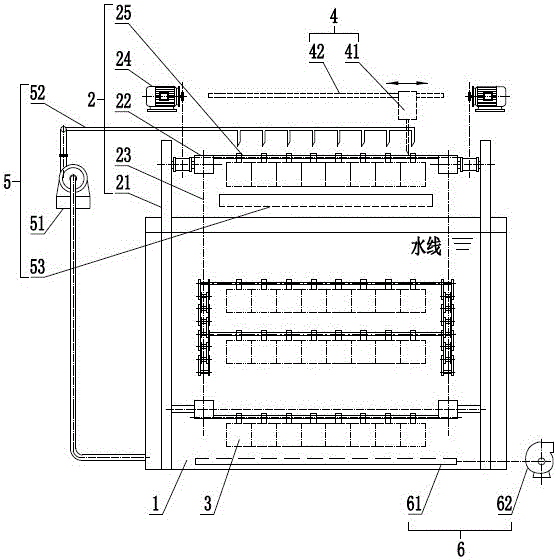

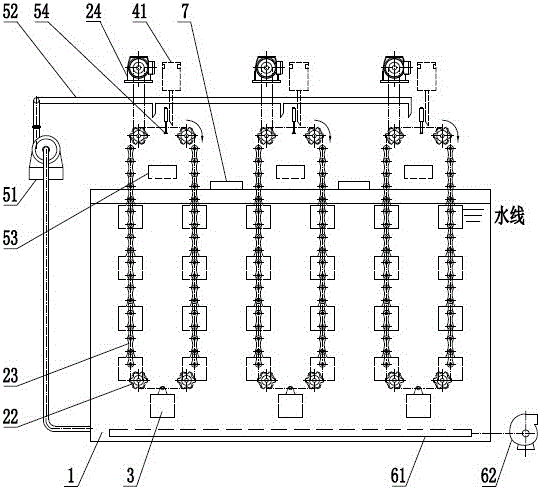

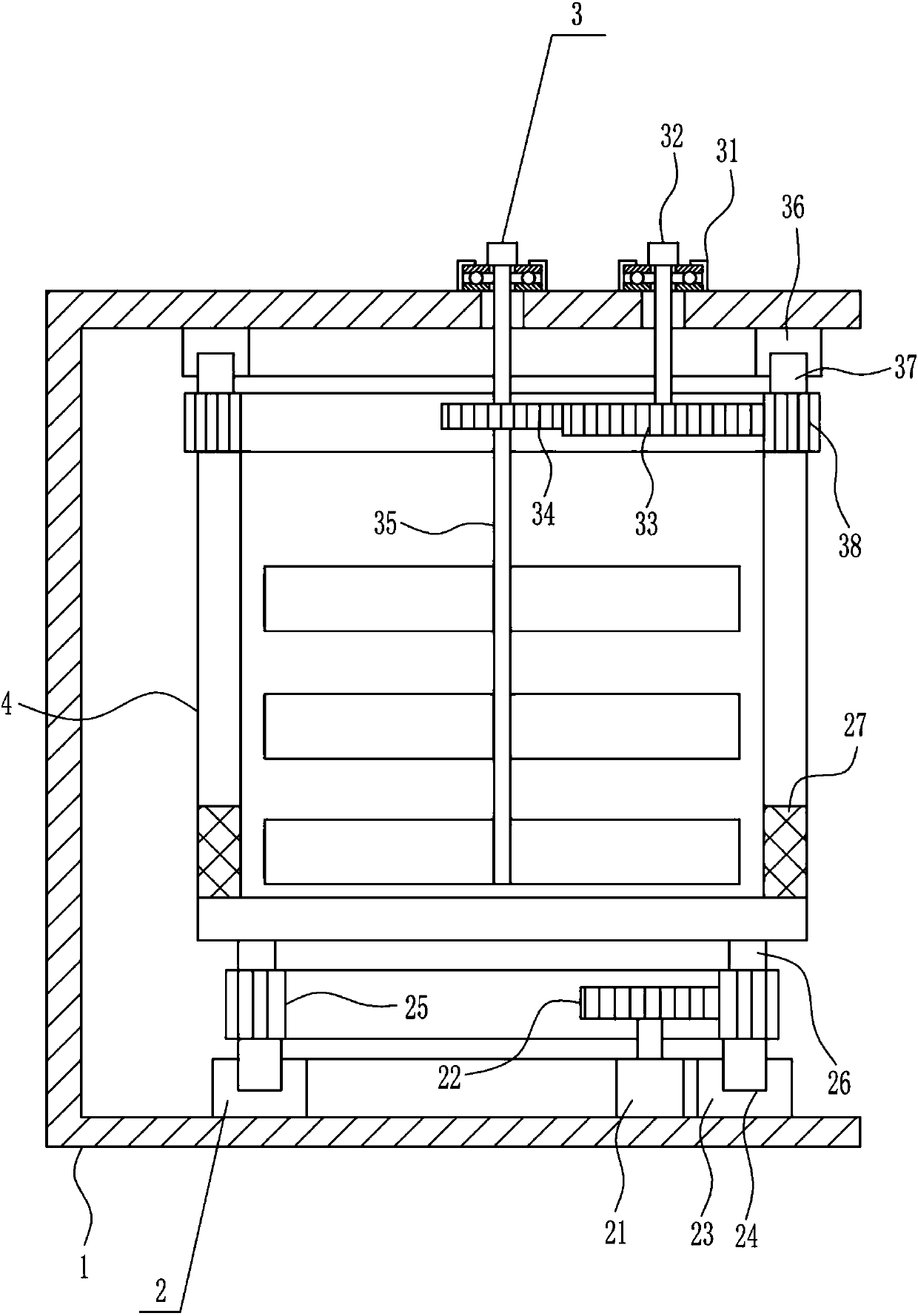

Intensive three-dimensional crab raising system

InactiveCN106818576AEasy feedingTake advantage ofClimate change adaptationPisciculture and aquariaEconomic benefitsEngineering

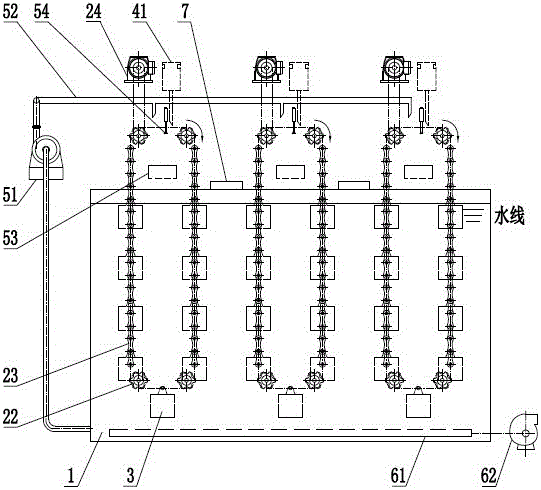

The invention discloses an intensive three-dimensional crab raising system, which comprises a culture pond and a control device, wherein a vertical conveying device capable of annularly circulating is arranged in the culture pond; the conveying device comprises a transport segment and a vacant segment; a plurality of crab pots are uniformly suspended on the transport segment at intervals and the vacant segment is vacant; the culture pond is provided with a feeding device and a waste discharge device which are arranged at the upper part of the top of the conveying device; the control device is used for controlling the conveying device, the feeding device and the waste discharge device. Multi-layer placement of crab pots in the culture pond is achieved by adopting the vertical conveying device capable of annularly circulating; feeding and drainage work can be conveniently completed by using the feeding device and the waste discharge device; aquatic water is fully utilized; and the intensive three-dimensional crab raising system has the characteristics of high culture density and high automatic degree, has relatively economic benefits and is beneficial to popularization.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

3D printing forming casting method for large-scale complex thin-wall high-temperature metal component

InactiveCN107598095ASolving the Difficulties of Investment Casting Shell ManufacturingAchieve rapid productionAdditive manufacturing apparatusFoundry mouldsWaxInvestment casting

Owner:安徽恒利增材制造科技有限公司

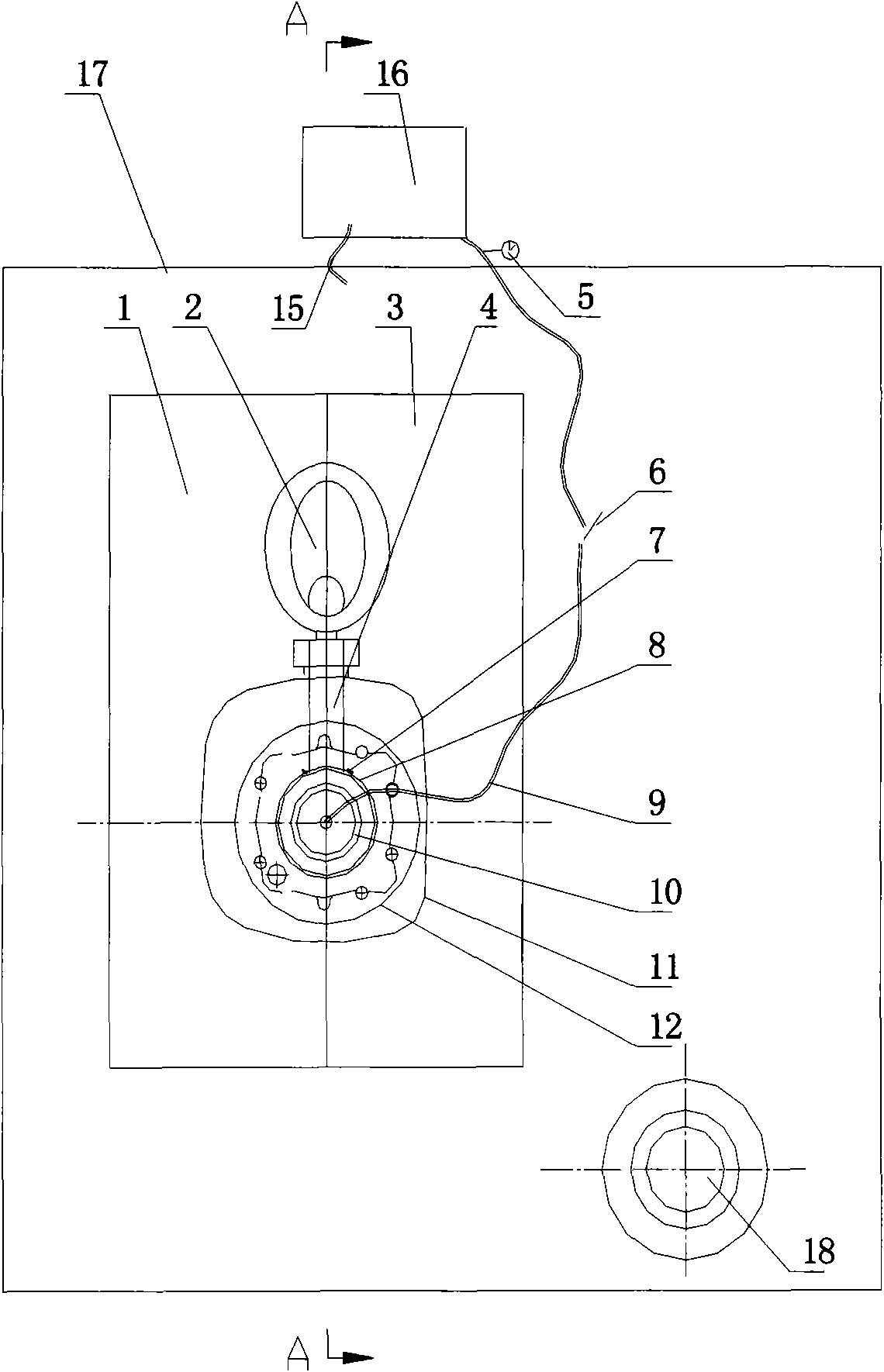

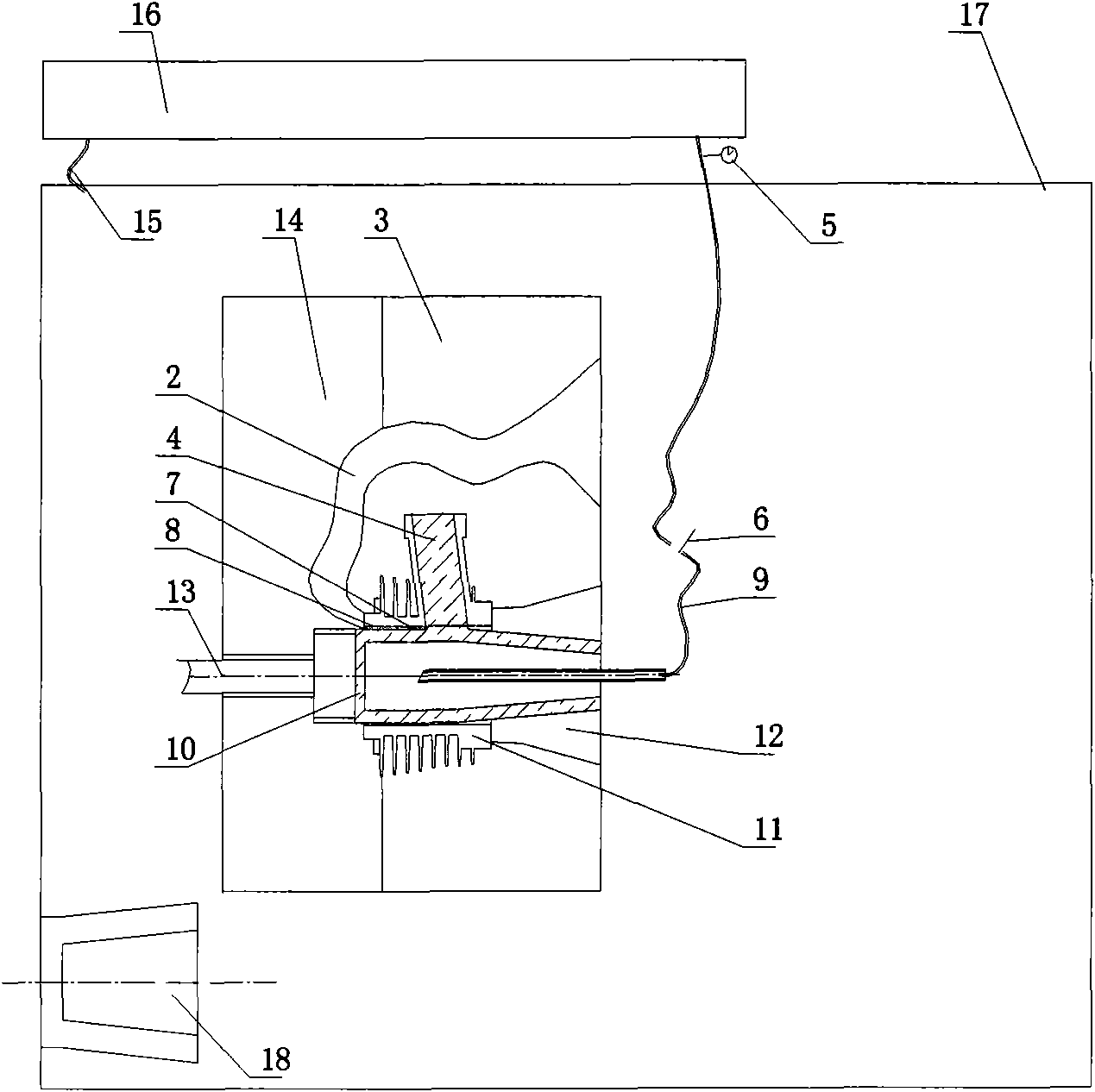

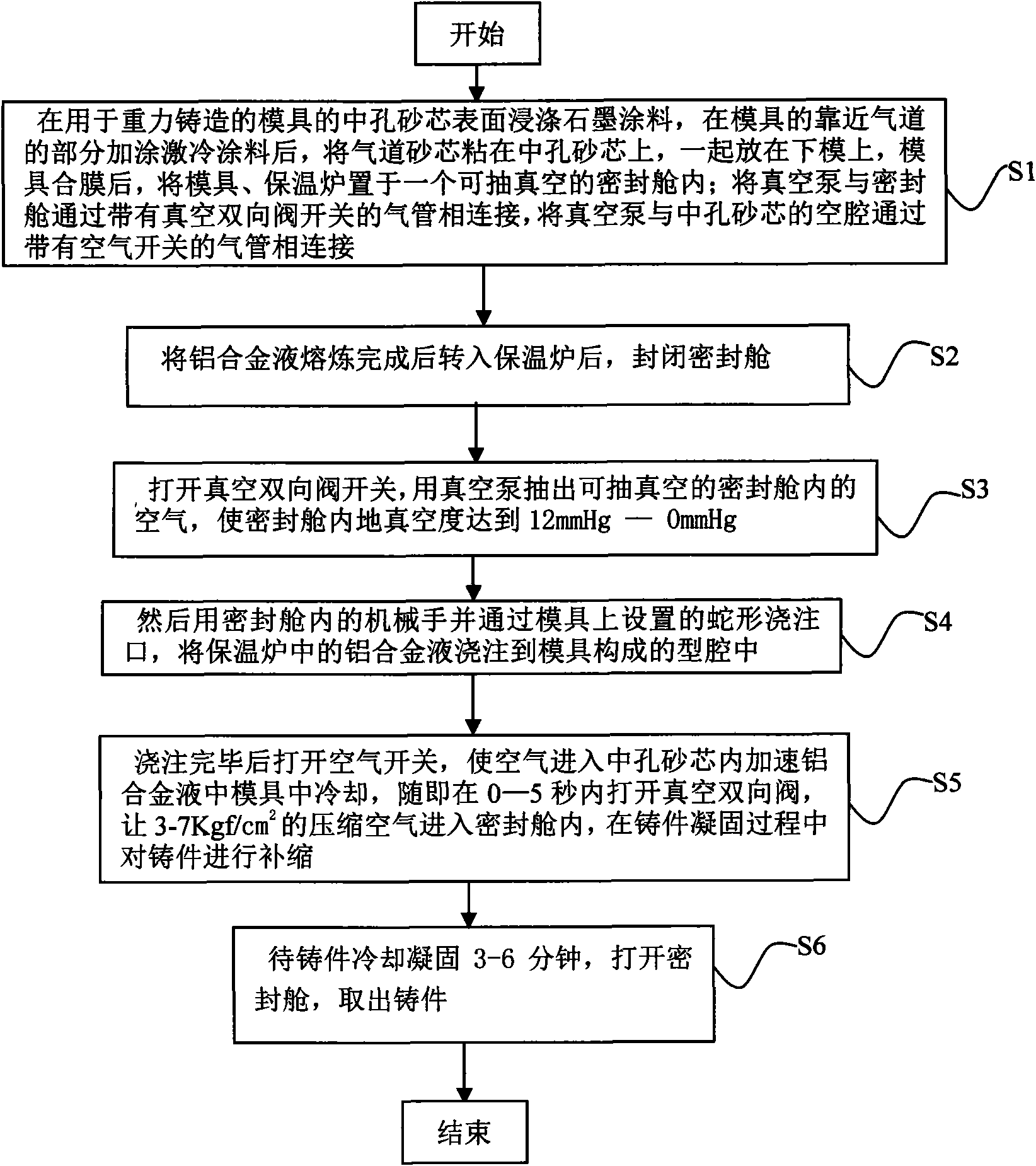

Vacuum gravity casting method of aircraft engine block

The invention relates to a vacuum gravity casting method of an aircraft engine block. The method comprises the following steps: graphite paint is dipped on the surface of a mesoporous sand core of a die used for gravity casting, chilling coating is coated at the part of the die used for gravity casting close to an air passage, a sealing cabin provided with the die is vacuumized before casting through a snake-shaped casting opening, and the mesoporous sand core and the sealing cabin are filled with compressed air after casting. Due to the adoption of the closed vacuum casting, the casting is performed through the snake-shaped casting opening, and as the graphite paint and the chilling coating are adopted, the compressed air is blown in the mesopore to carry the heat away, the shrinkage cavities in the casting part are greatly reduced, the qualification rate of the finished products of the casting part is improved to about 90 percent from 20 percent and the production cost is greatly reduced.

Owner:CHONGQING CONSTR ELECTROMECHANICAL CO LTD

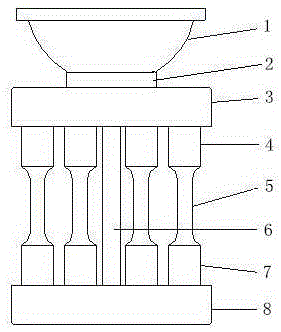

Casting mold and casting method of high aluminum zinc alloy annular casting parts

The invention discloses a casting mold of high aluminum zinc alloy annular casting parts. A metal outer mold of the casting mold is positioned on a metal bottom plate, a metal core mold is positioned in the center of the metal bottom plate, a casting mold cavity with an annularly opened upper opening is formed by a cavity among the upper side of the metal bottom plate, the inner edge of the metal outer mold and the outer edge of the metal core mold, a casting mold sand core is fixed on the upper side of the metal core mold, a metal cover plate is covered on the upper side of the metal outer mold, and knurling is arranged on the bottom surface of the casting mold cavity. The invention also discloses a casting method for the high aluminum zinc alloy annular casting parts. The method includes 1) injecting liquid-state high aluminum zinc alloys into the casting mold cavity until the high temperature liquid level rises to the upper side of the metal outer mold; 2) lifting the metal cover plate to the upper side of the metal outer mold, continuing casting, compensating cooled the upper lateral surfaces of casting parts until the casting parts are formed finally. The casting mold and casting method reduces dendrite segregation and pinholes among dendrites, improves mechanical property of the casting parts and greatly increases qualified rate of the casting parts.

Owner:镇江汇通金属成型有限公司

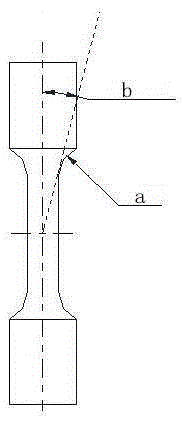

Method for reducing microporosity during casting of high-temperature alloy test bar

ActiveCN105290328AReduce non-metallic inclusionsLower narrowFoundry mouldsFoundry coresFilter systemAlloy

The invention belongs to the technical field of precision casting and particularly relates to a method for reducing microporosity during casting of a high-temperature alloy test bar. According to the method, by enlarging a feeding channel of molten steel in the test bar pouring process, the pouring temperature and a mode of heat dissipation of the test bar are improved, too quick solidification on the surface of the test bar is reduced, and the feeding effect of a pouring system is improved. The smoothness of the feeding channel of a test bar detection part is achieved, the microporosity defect in the middle of the test bar is completely introduced into the pouring system, and the microporosity caused by too many impurities in alloy liquid is reduced by utilizing a filtering system.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Vacuum, gravity and precision casting method with metallic mould

A vacuum-gravitational precise casting technology with metallic mould includes such steps as preparing metallic mould, putting it in a cover, sealing the cover, vacuumizing, pouring molten metal while vacuumizing, immediately taking the cast workpiece out and cooling.

Owner:王一诚

Magnesium alloy with hot cracking resistance and low linear shrinkage

The invention discloses a magnesium alloy with hot cracking resistance and low linear shrinkage, and belongs to the magnesium alloy field. The magnesium alloy is composed of elements of Mg, Al, Zn, Mn, rare earths, Nb and Li, and comprises, by weight, 1.5 to 25 percents of Al, 0.1 to 3.5 percents of Zn, 0.1 to 2.2 percents of Mn, 0.0002 to 16 percents of rare earths, 0.0002 to 4 percents of Nb, 0.0002 to 9 percents of Li, and the balance Mg. According to the magnesium alloy, the structure of Beta phase is changed by adding rare earth elements and the Nb element into the magnesium alloy; grains are refined by adding the Li element; and crystallization latent heat is changed when the magnesium alloy is solidified by the combined action of the elements, so that the heat resistant magnesium alloy which has good mold-filling capacities, low shrinkage rate, good mechanical properties, machinability, mobility and die-casting properties and is suitable for casting is obtained.

Owner:JIANGHAN UNIVERSITY

Magnesium alloy with hot cracking resistance and low linear shrinkage

The invention discloses a magnesium alloy with hot cracking resistance and low linear shrinkage, and belongs to the magnesium alloy field. The magnesium alloy is composed of elements of Mg, Zn, rare earths, Nb, Al and Li, and comprises, by weight, 0.2 to 9 percents of Zn, 0.0002 to 2 percents of Zr, 0.0002 to 16 percents of rare earths, 0.0002 to 4 percents of Nb, 0.001 to 1.49 percents of Al, 0.0002 to 9 percents of Li, and the balance Mg. According to the magnesium alloy, the structure of Beta phase is changed by adding rare earth elements and the Nb element into the magnesium alloy; grains are refined by adding the Li and Zr elements; and the crystallization latent heat is changed when the magnesium alloy is solidified by the combined action of the elements, so that the heat resistant magnesium alloy which has good mold-filling capacities, low shrinkage rate, good mechanical properties, machinability, mobility and die-casting properties and is suitable for casting is obtained.

Owner:嘉兴佳斯贝特新材料有限公司

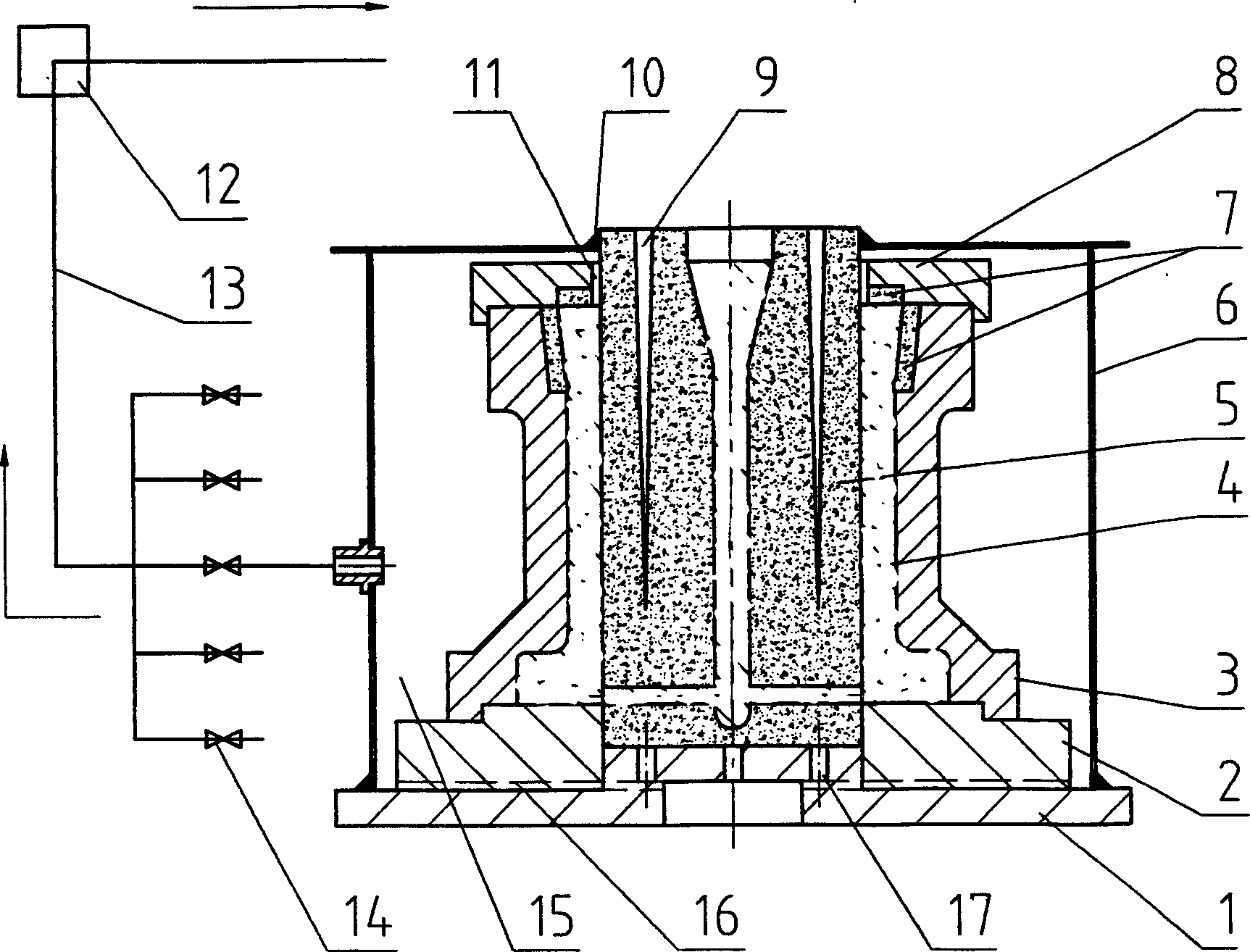

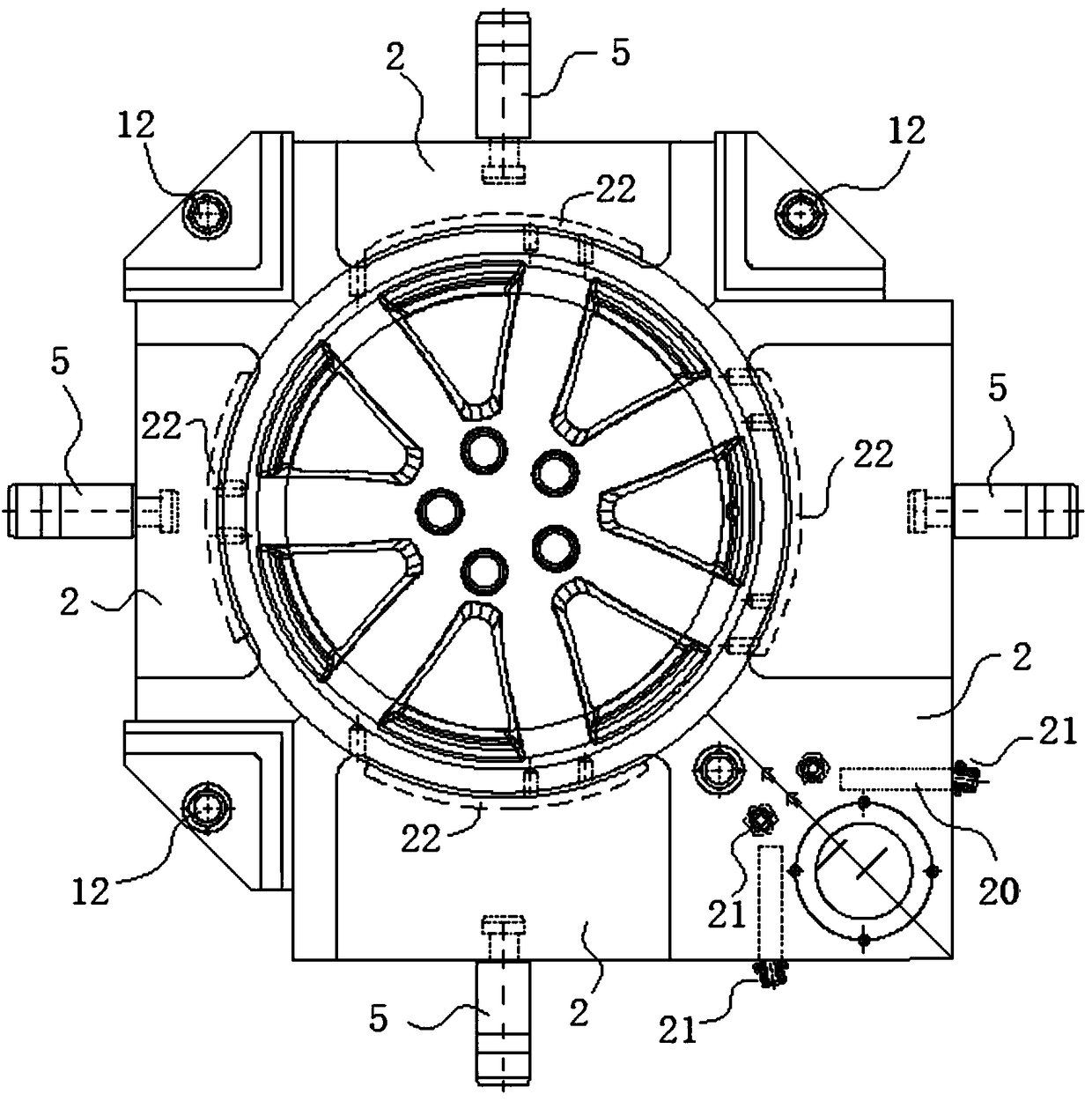

High-pressure hub casting mold and casting method thereof

PendingCN108543914AIncrease profitIncrease productivityFoundry mouldsFoundry coresCasting moldHigh pressure

The invention provides a high-pressure hub casting mold. The high-pressure hub casting mold comprises an upper mold body, a side mold body, a bottom mold body and a gas pressurization system, whereinthe upper mold body, the side mold body and the bottom mold body form a casting cavity for a hub to be cast after being assembled; the center of the upper mold body is connected with a liquid storagehopper; a metal liquid storage chamber communicating with the casting cavity is formed in the liquid storage hopper; the gas pressurization system is connected with the liquid storage hopper through aventilation pipe and communicates with the metal liquid storage chamber; the side mold body is provided with a runner, and a pouring gate is arranged at the outer end of the runner; and after metal liquid is poured into the casting cavity, the gas pressurization system is used for applying high pressure to the metal liquid in the metal liquid storage chamber, and the metal liquid in the metal liquid storage chamber carries out feeding on a hub casting in the casting cavity under the high pressure applied by the gas pressurization system. The high-pressure hub casting mold further comprises aheating system, a cooling system and a demolding system used for demolding the formed hub casting. According to the high-pressure hub casting mold, a working allowance is reserved for the casting, thedeformation amount of the casting is reduced, the production efficiency is improved, and the rejection rate is low.

Owner:田平康

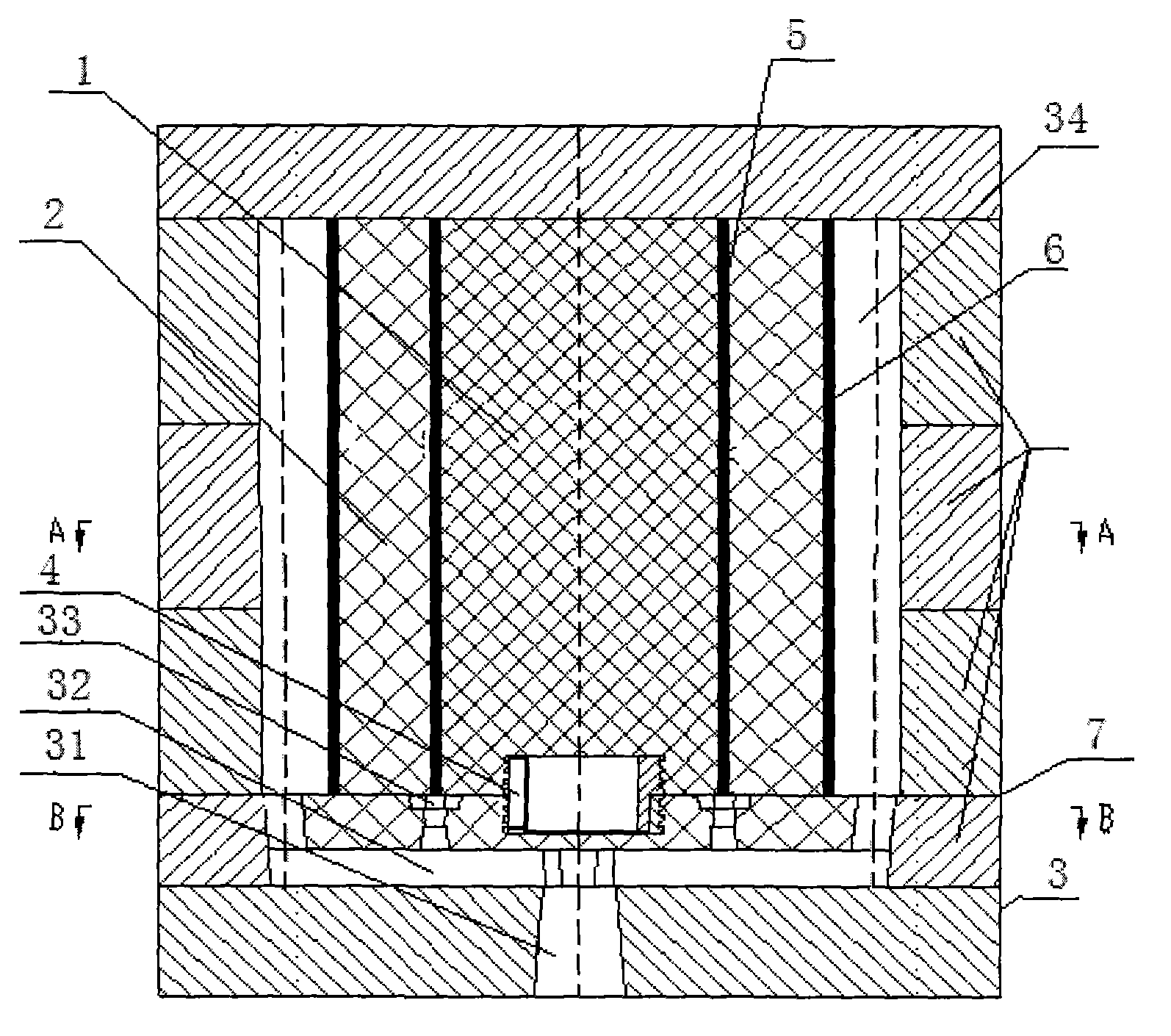

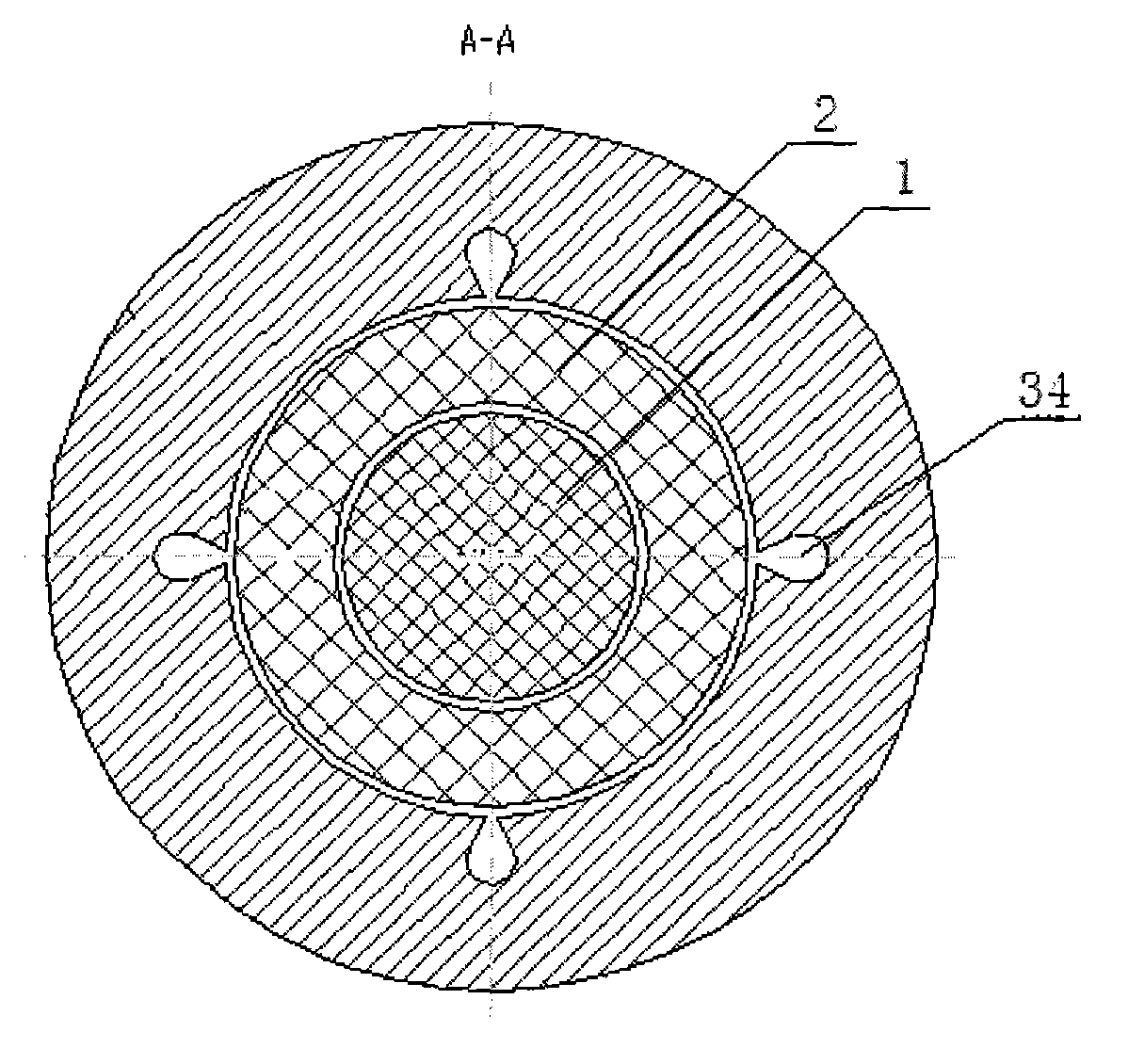

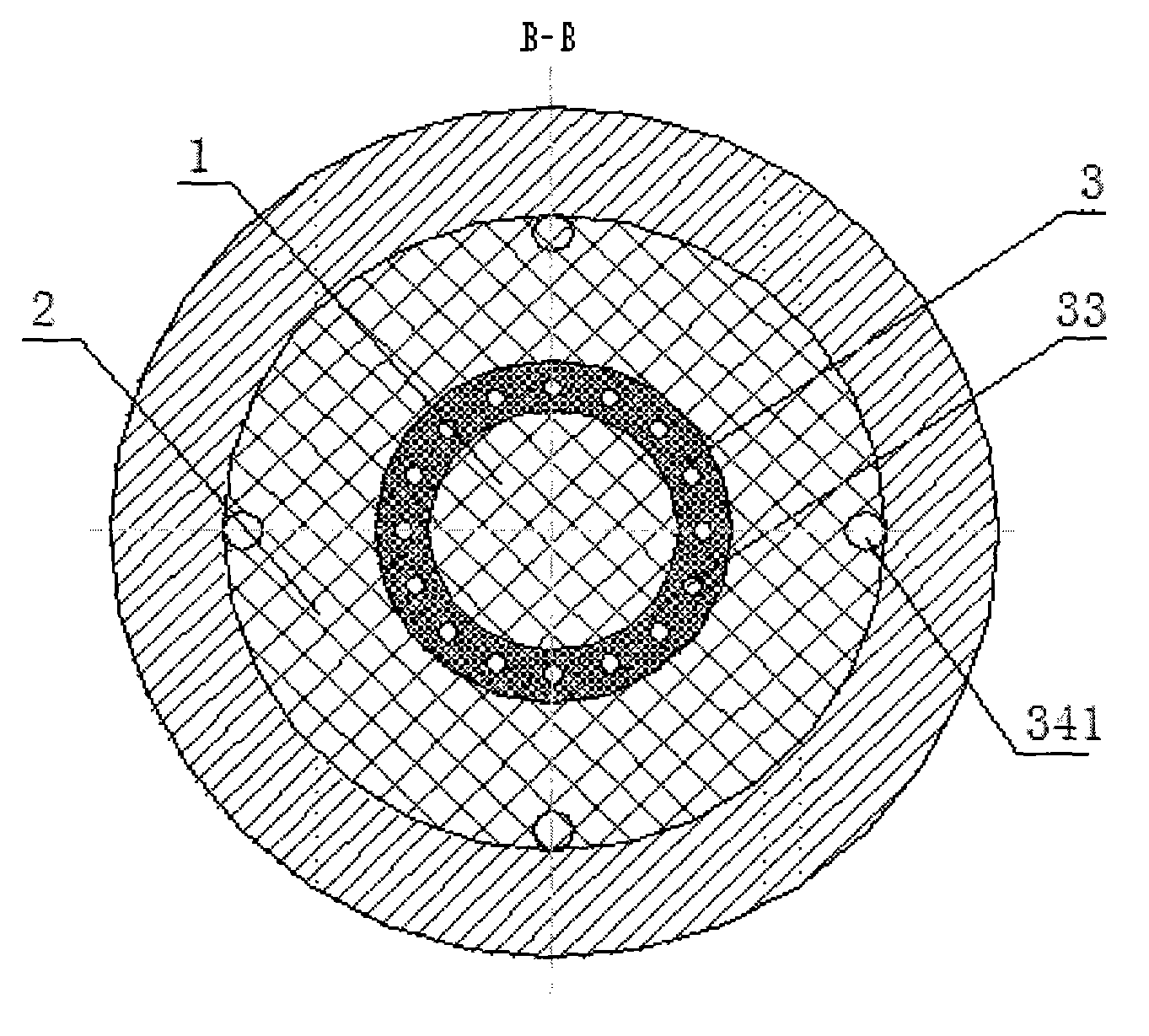

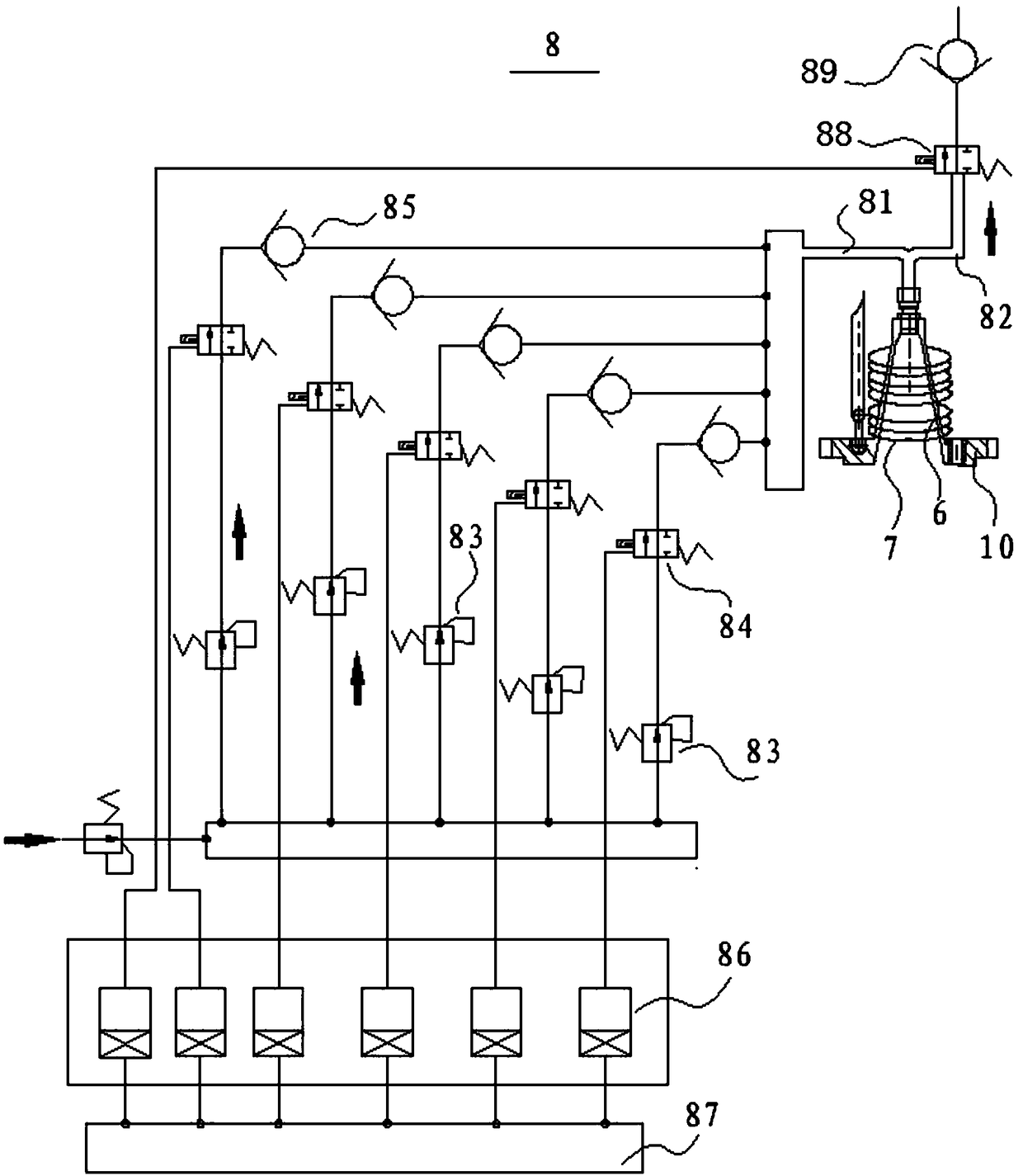

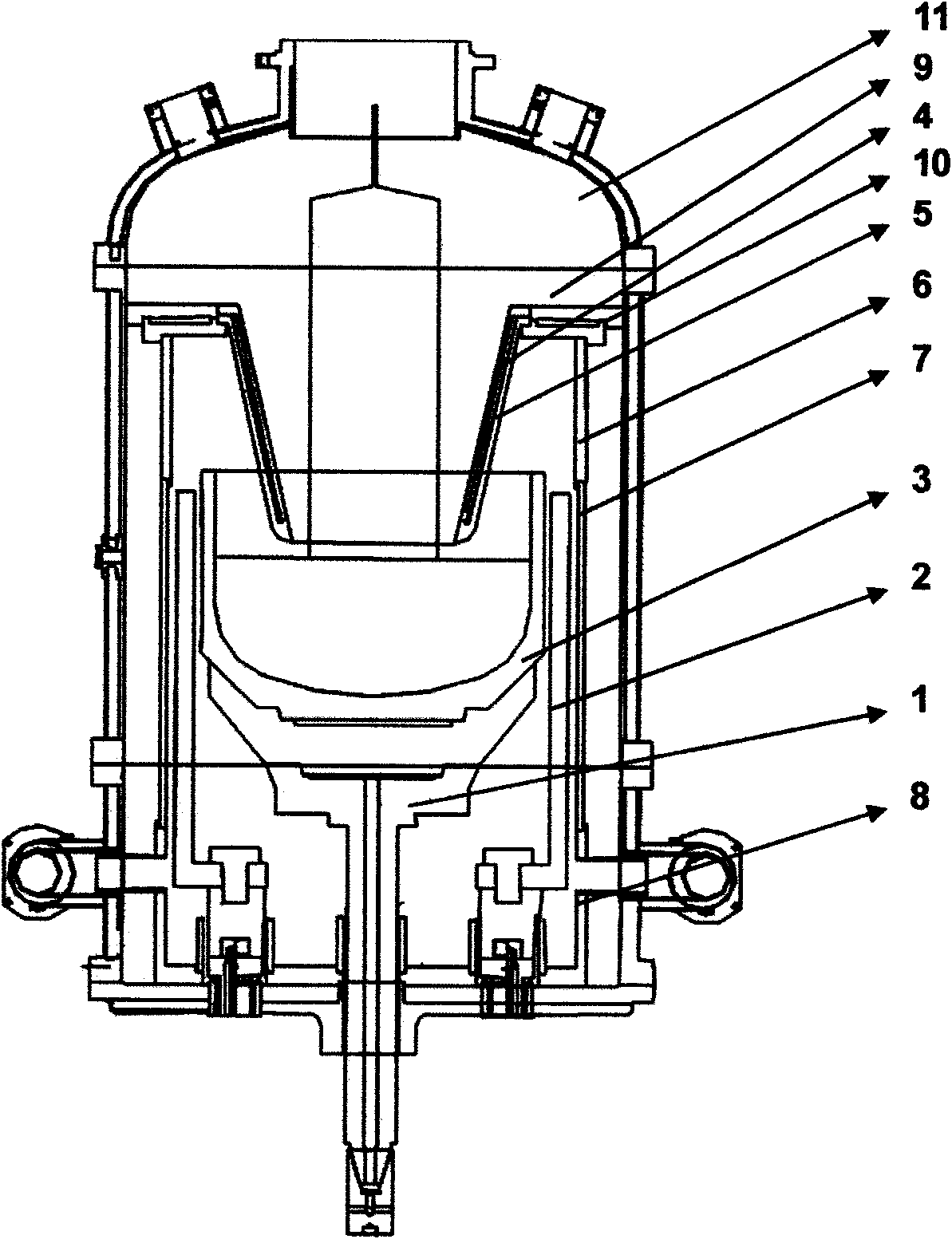

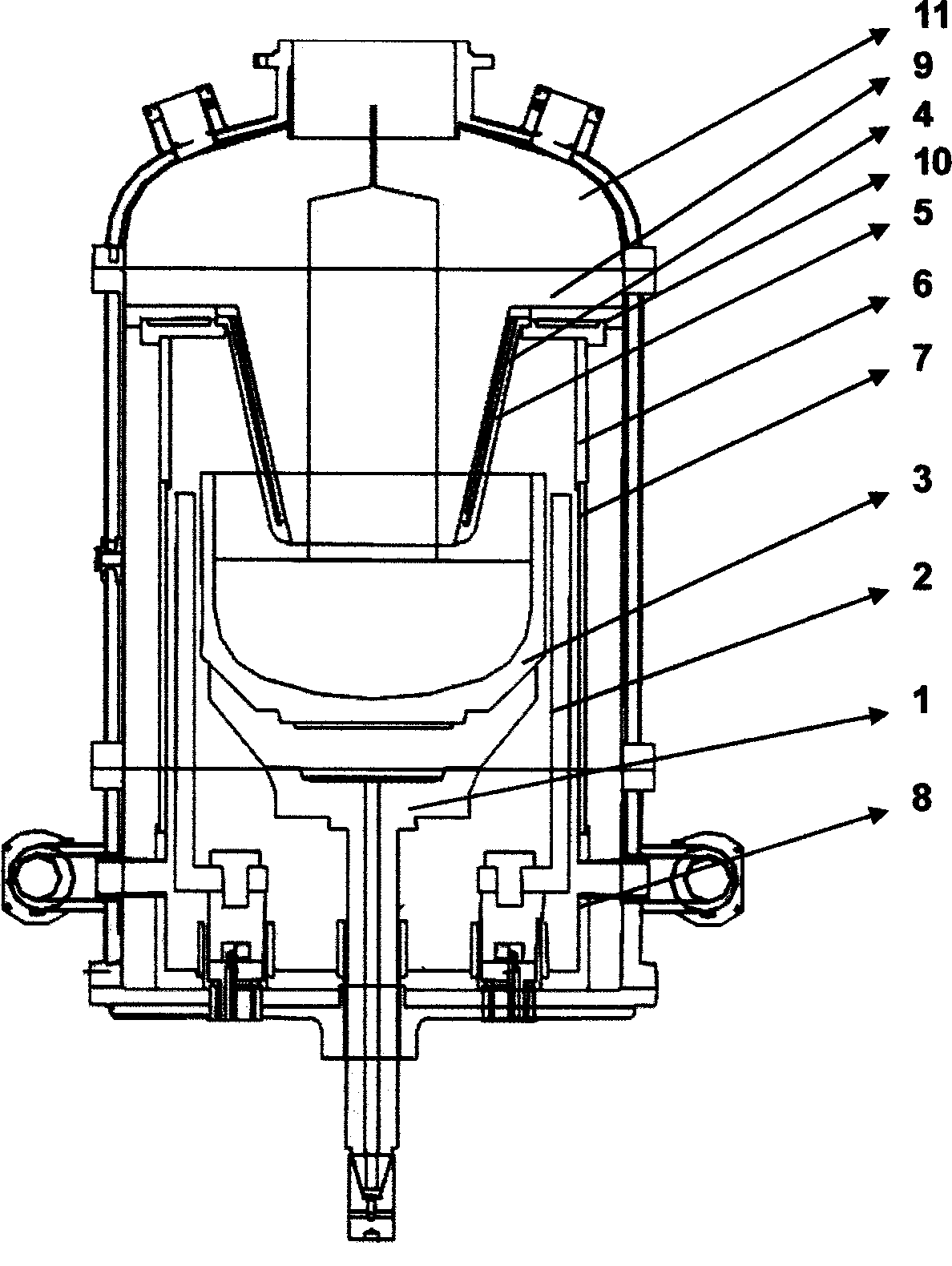

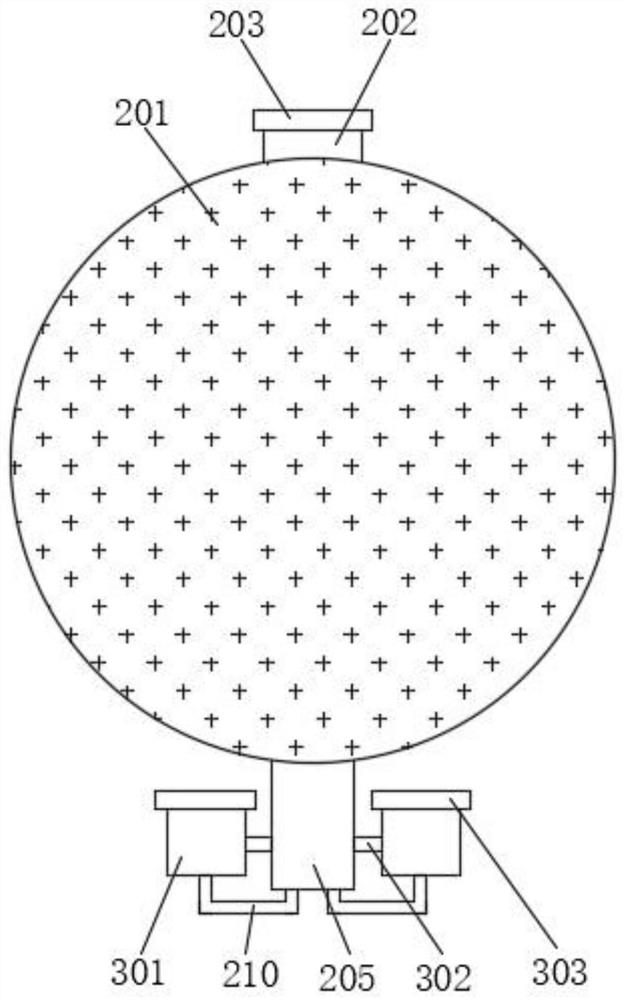

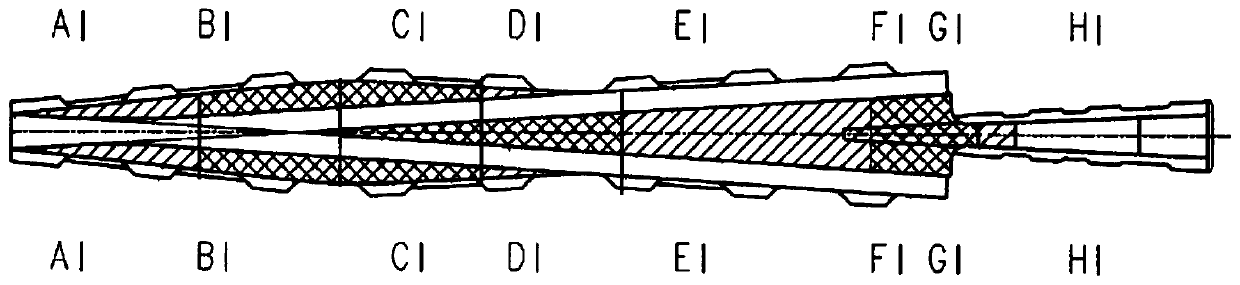

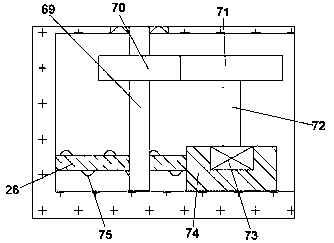

Thermal field system suitable for large charge amount of 90t furnace

InactiveCN102108545AFully fedIncrease heating capacityBy pulling from meltThermal insulationEngineering

The invention discloses a thermal field system used for manufacturing solar monocrystalline silicon, which comprises a mono-crystal furnace chamber, a graphite crucible, a support rod, a heater, a three-segment crucible, a guiding cylinder, a thermal insulation cylinder and a thermal insulation cover, wherein the thermal insulation cylinder is arranged in the mono-crystal furnace chamber, and is provided with the thermal insulation cover; the guiding cylinder is arranged in the thermal insulation cylinder and is connected with the thermal insulation cover together; the upper end port of the guiding cylinder is connected with the thermal insulation cover, while the lower end port extends into the graphite crucible; the heater is positioned between the three-segment crucible and the side wall of the thermal insulation cylinder and is arranged around the three-segment crucible; the lower end of the three-segment crucible is provided with the support rod; the inner diameter of the guiding cylinder ranges from phi 260 to phi 300mm and the height of the guiding cylinder ranges from 330 to 410mm; the inner diameter of the heater ranges from phi 620 to phi 680mm; and the inner diameter of the three-segment crucible ranges from phi 538 to phi 578mm. The thermal field system can promote thermal insulation of the furnace chamber and increase the charge amount.

Owner:WINSUN NEW ENERGY

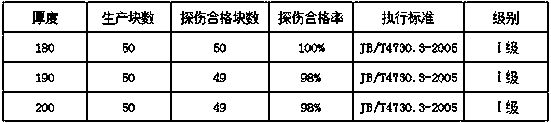

Alloy constructional steel 27SiMn with 180-200mm thickness and manufacturing technology thereof

ActiveCN109609840AImprove hardenabilityHigh strengthProcess efficiency improvementSmeltingHeat treated

The invention discloses alloy constructional steel 27SiMn with 180-200mm thickness and a manufacturing technology thereof. The alloy constructional steel 27SiMn is prepared from the chemical raw materials in percentage by mass: 0.27-0.30% of C, 1.2-1.4% of Si, 1.2-1.3% of Mn, no more than 0.030% of P, no more than 0.030% of S, 0.0008-0.001% of B, 0.020-0.030% of Ti, and the balance of Fe and residual elements. The manufacturing technology comprises the following steps of converter smelting, LF refining, VD vacuum degassing, die casting, heating, rolling, stacking cooling, and heat processing.The components of the alloy constructional steel 27SiMn are rationally designed, the manufacturing technology is improved, and parameters are accurately controlled, so that the alloy constructional steel 27SiMn with 180-200mm thickness and with a good combination property is obtained, and requirements of customers are better met.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Process method of lost-foam casting double-liquid compound crusher hammer

InactiveCN104475683AImprove bindingMaterial molten steel feedingFoundry mouldsFoundry coresCasting moldCrusher

The invention provides a process method of a lost-foam casting double-liquid compound crusher hammer. The process method is characterized in that a hammer handle is arranged downwards and a hammer end is arranged upwards in a module formed by foam patterns, and the module is formed by connecting a riser, an inner gate and a pouring gate; when two metal materials are melted to respective tapping temperature in two furnaces respectively at the same time, two types of molten metal are poured into the same casting mold one after another, after a casting is solidified and cooled, a casting head is cut, and the double-liquid compound hammer is obtained. The process is simple, the cost is reduced by 20%, the production efficiency is increased by 50%, the quality is stable, and the energy-saving effect is remarkable.

Owner:王会岑

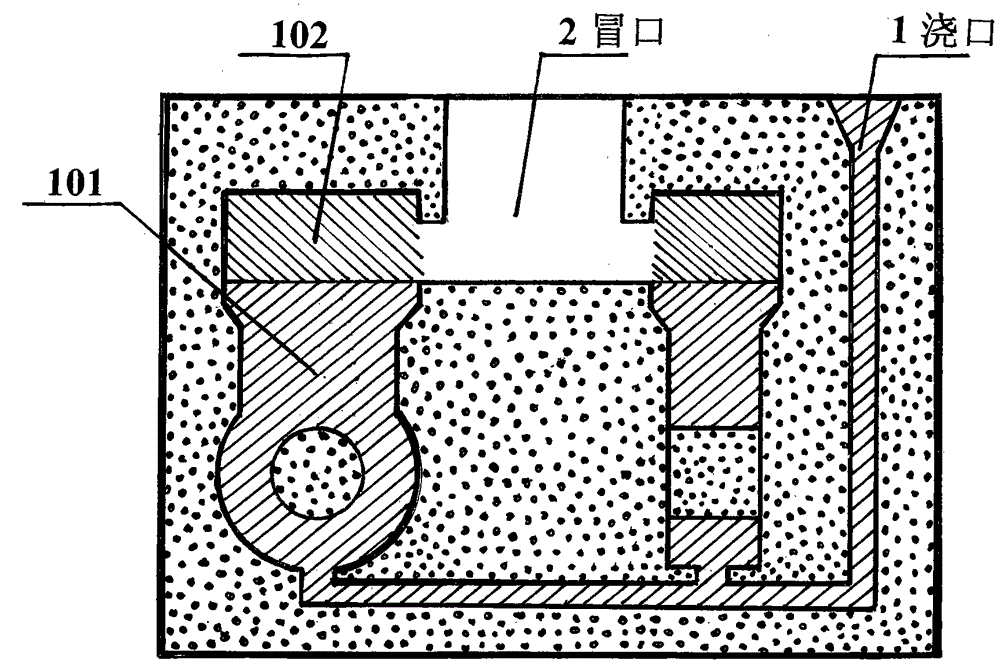

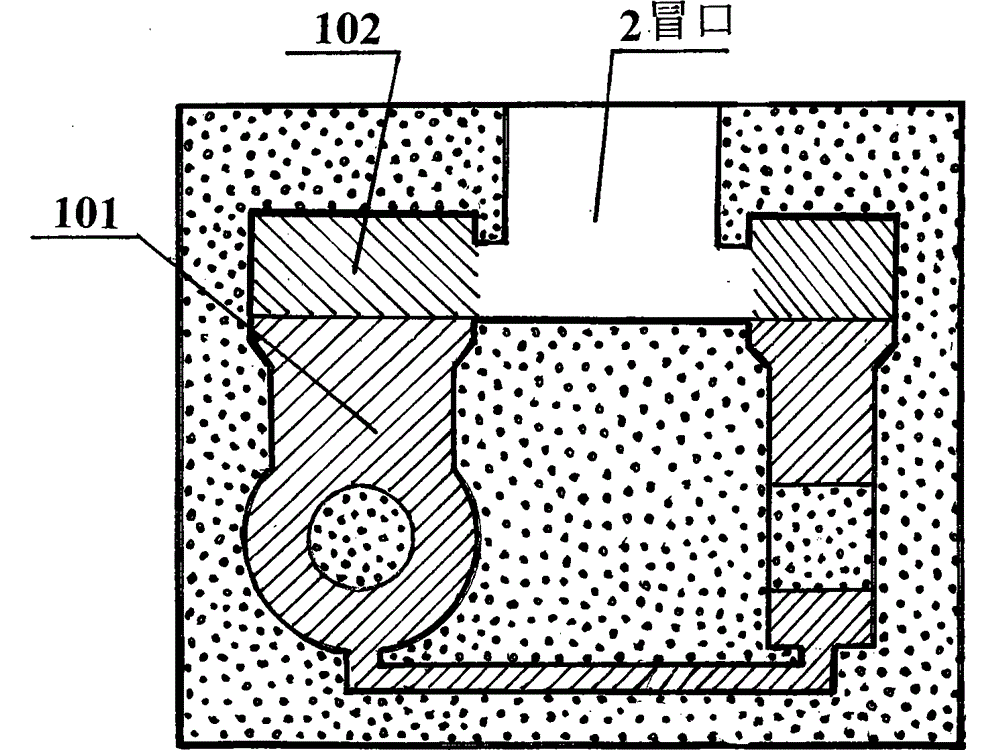

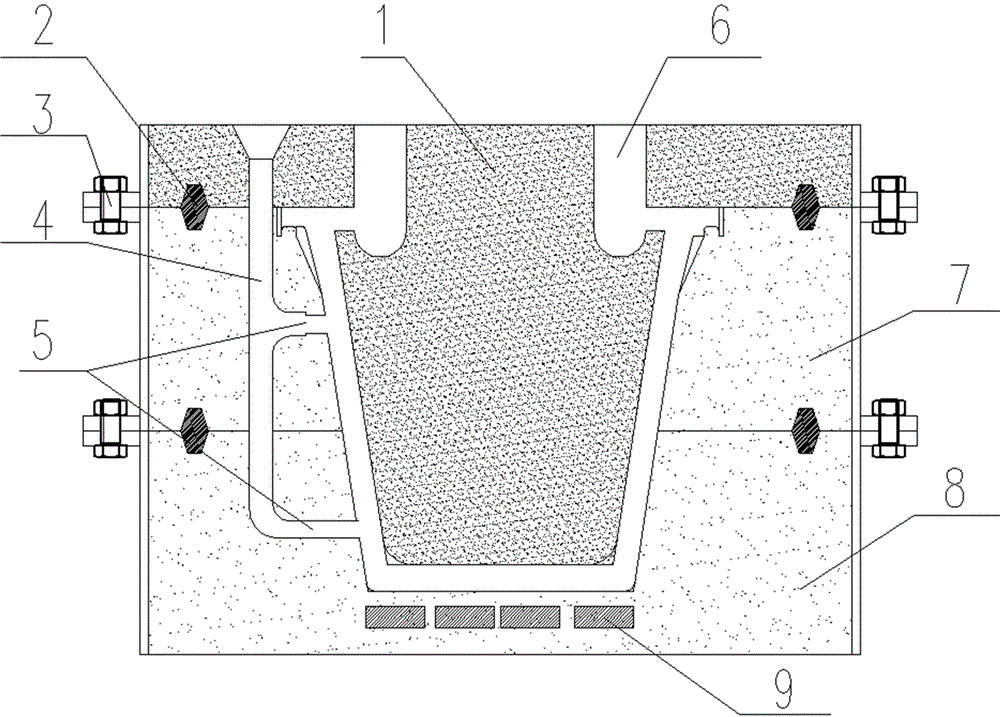

Large-scale casting device for aluminum-water utensil

InactiveCN104607595APrecise positioningFirmly connectedFoundry mouldsFoundry coresThermal insulationMetallurgy

The invention relates to a casting device and in particular to a large-scale casting device for an aluminum-water utensil. The large-scale casting device consists of an upper sand mould, a metal positioning cone, a fastening bolt, a straight pouring gate, inner pouring gates, a dead head, a lower part of the lower sand mould, an upper part of the lower sand mould and cold iron. The large-scale casting device is characterized in that the straight pouring gate is perpendicular to the ground, the upper and the lower inner pouring gates are in angled design; molten water forms two different pressure differences in the inner pouring gates to ensure that the molten iron can fill up a utensil mould cavity within the shortest time; the straight pouring gate and the inner pouring gates consist of ceramic tubes with inner wall diameter of 120 mm; the upper sand mould and the lower sand mould are positioned through the metal positioning cone, and are connected through the fastening bolt after being closed; the dead head is a heating thermal-insulation dead head with diameter of 180 mm; feeding for casting pieces is relatively sufficient, and a self-utilization rate of the molten iron is greatly increased. The large-scale casting device has the advantages of being simple in structure, reasonable in design, time-saving and labor-saving, high in molten iron utilization rate, high in efficiency, good in casting piece surface quality, and the like.

Owner:SHANDONG HAOAN GOLDTECH NEW MATERIALS

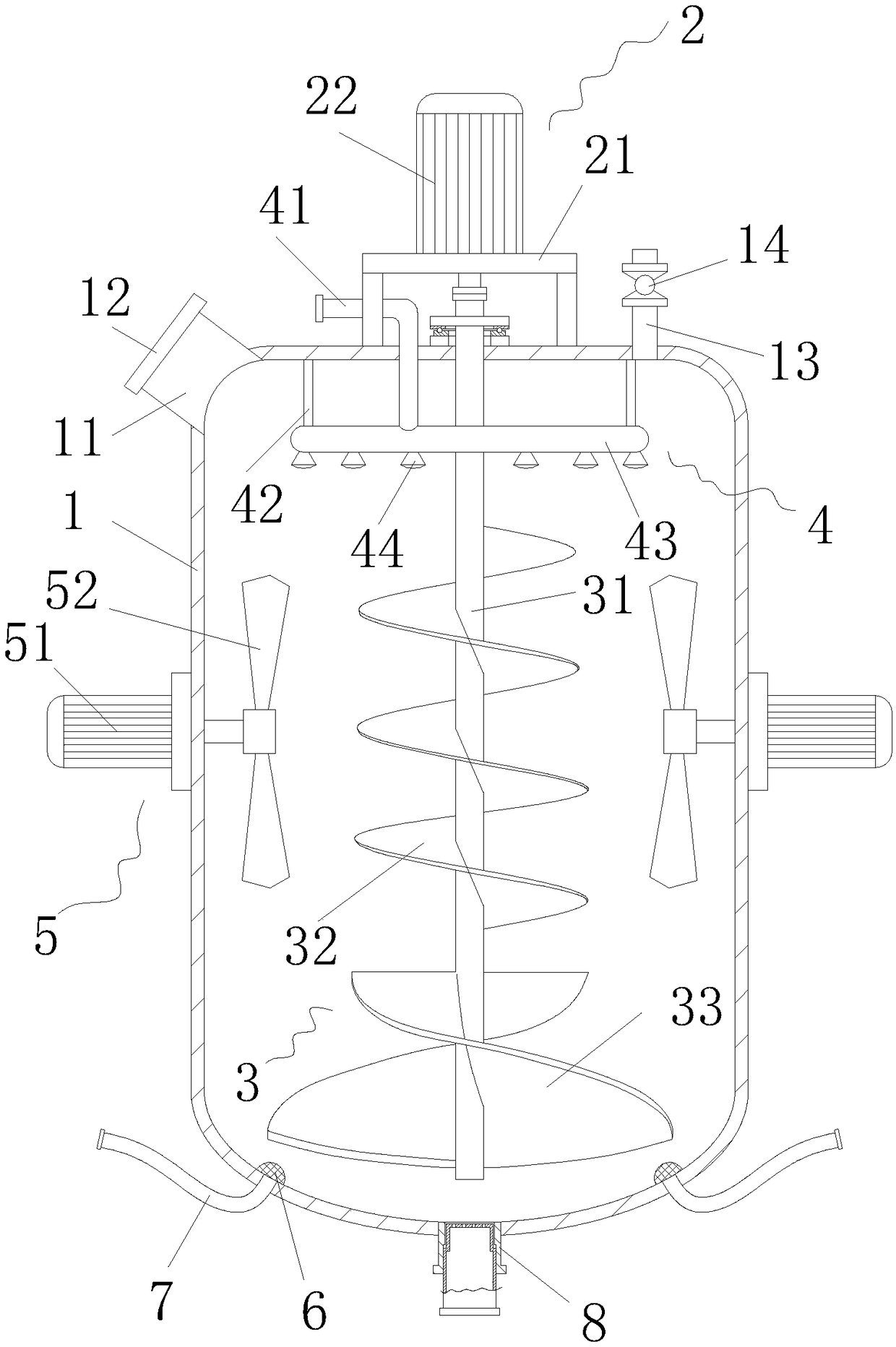

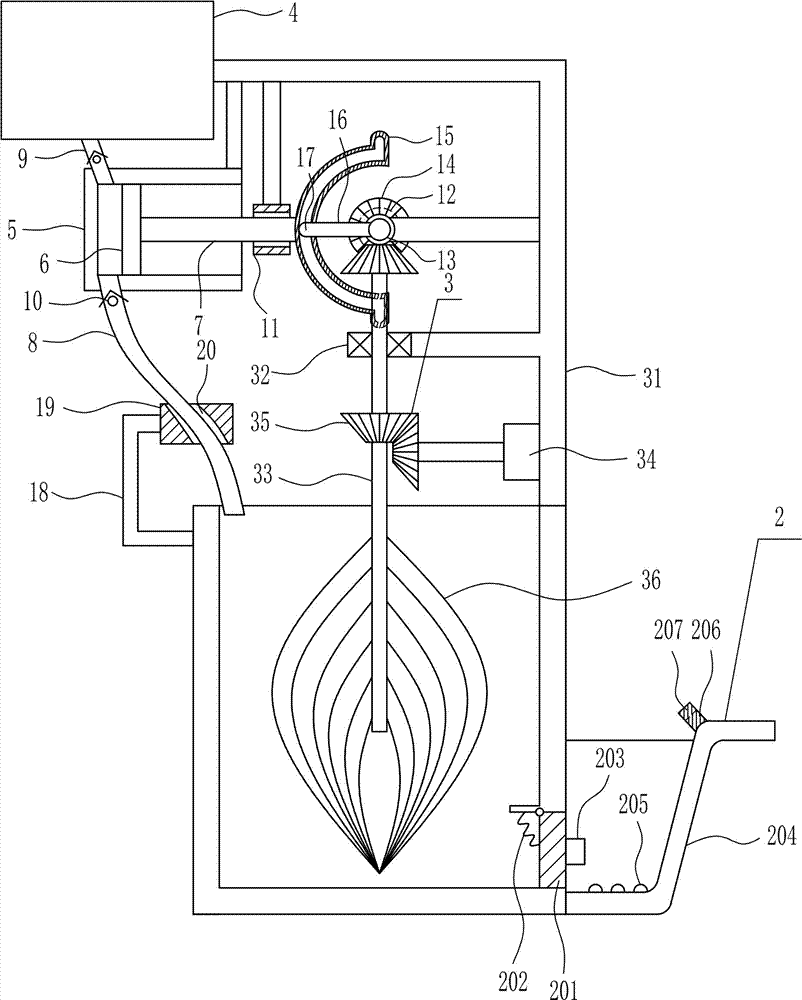

Feeding device for aquaculture fertilizer

InactiveCN107711661AStir wellFully fedRotating receptacle mixersTransportation and packagingAquatic animalEngineering

The invention relates to a feeding device, in particular to a feeding device for an aquaculture fertilizer. Against the technical problem to be solved, the invention provides the feeding device for the aquaculture fertilizer, which saves time and labor and can evenly feed baits. In order to solve the technical problem, the invention provides the feeding device for the aquaculture fertilizer, whichincludes a mounting frame and the like. The inner bottom of the mounting frame is connected with a feeding mechanism, the upper portion inside the mounting frame is connected with a stirring mechanism, and the inner middle of the mounting frame is connected with a feeding box. The feeding device for the aquaculture fertilizer achieves effects of being capable of saving time and labor and evenly feeding the baits. The feeding mechanism is arranged, so that the baits in the feeding box are fully stirred, and the well-stirred baits are continuously and evenly fed into a cultivation farm under the filtering action of a filter screen, so that aquatic animals and plants can be fully fed; The stirring mechanism is arranged to fully stir the baits in the feeding box, and thus the feeding device saves time and labor and is high in stirring efficiency.

Owner:晏思文

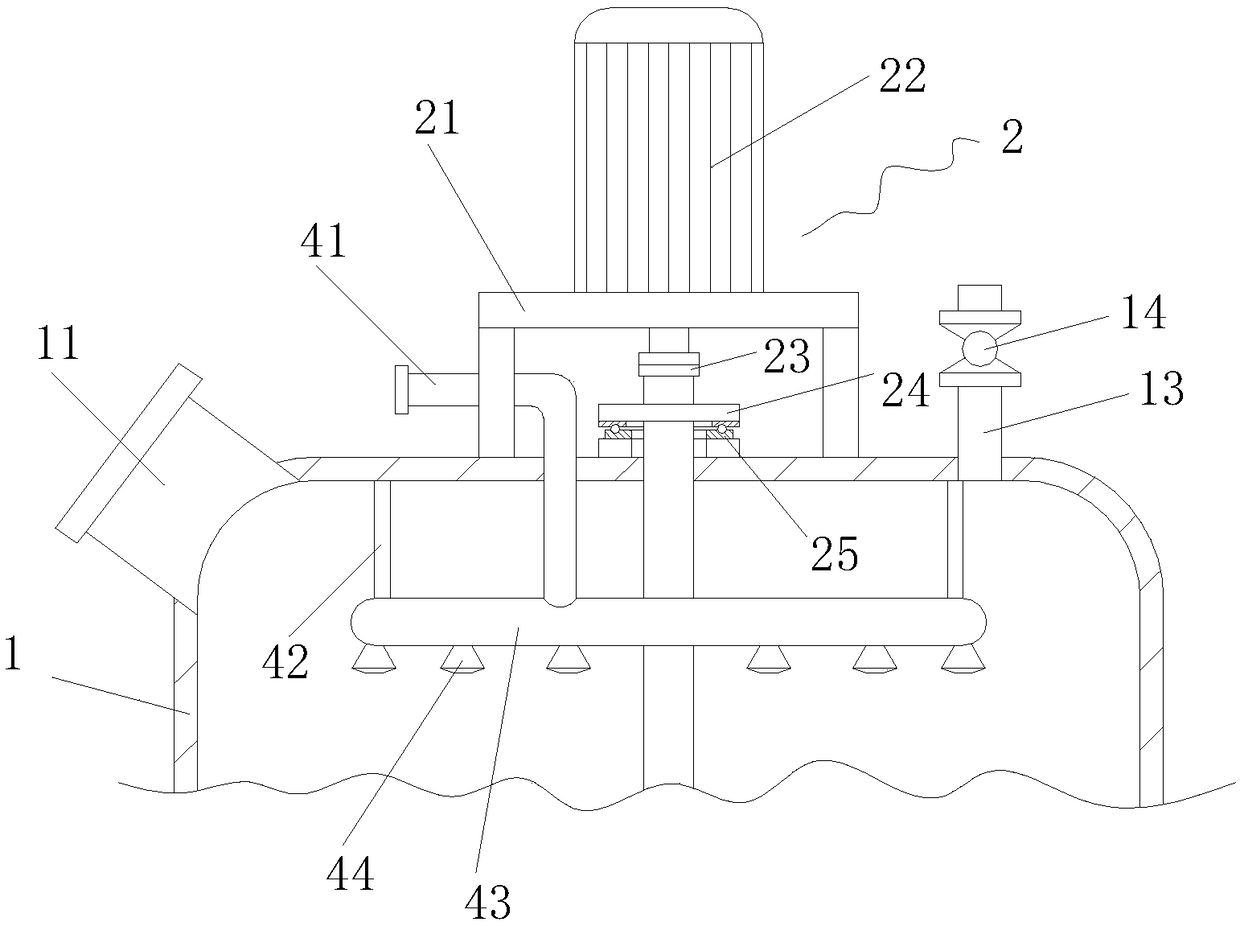

Raw material cooking apparatus for producing soy sauce

The invention discloses a raw material cooking apparatus for producing soy sauce. The raw material cooking apparatus comprises a cooking pot body, wherein a spiral stirring apparatus for stirring a raw material up and down is installed inside the cooking pot body, the top of the cooking pot body is provided with an overturning driving mechanism for driving the spiral stirring apparatus, the upperend of the cooking pot body is provided with a feeding pipe orifice and a pressure relief pipe, the feeding pipe orifice is provided with a feeding sealing cover, the pressure relief pipe is providedwith a safety valve, the inner lower end of the cooking pot body is circumferentially provided with a plurality of steam heads, the steam heads are connected with a steam conveying pipe extending outof the cooking pot body, the bottom of the cooking pot body is provided with an unloading pipe orifice, and the unloading pipe orifice is provided with a filtering apparatus for discharging the washing water and impurities. The raw material cooking apparatus is reasonable in structure layout, integrates the soaking and cooking, facilitates the reduction of treatment time of the raw material, and can improve the subsequent production efficiency of the soy sauce.

Owner:安徽朱隆记食品有限公司

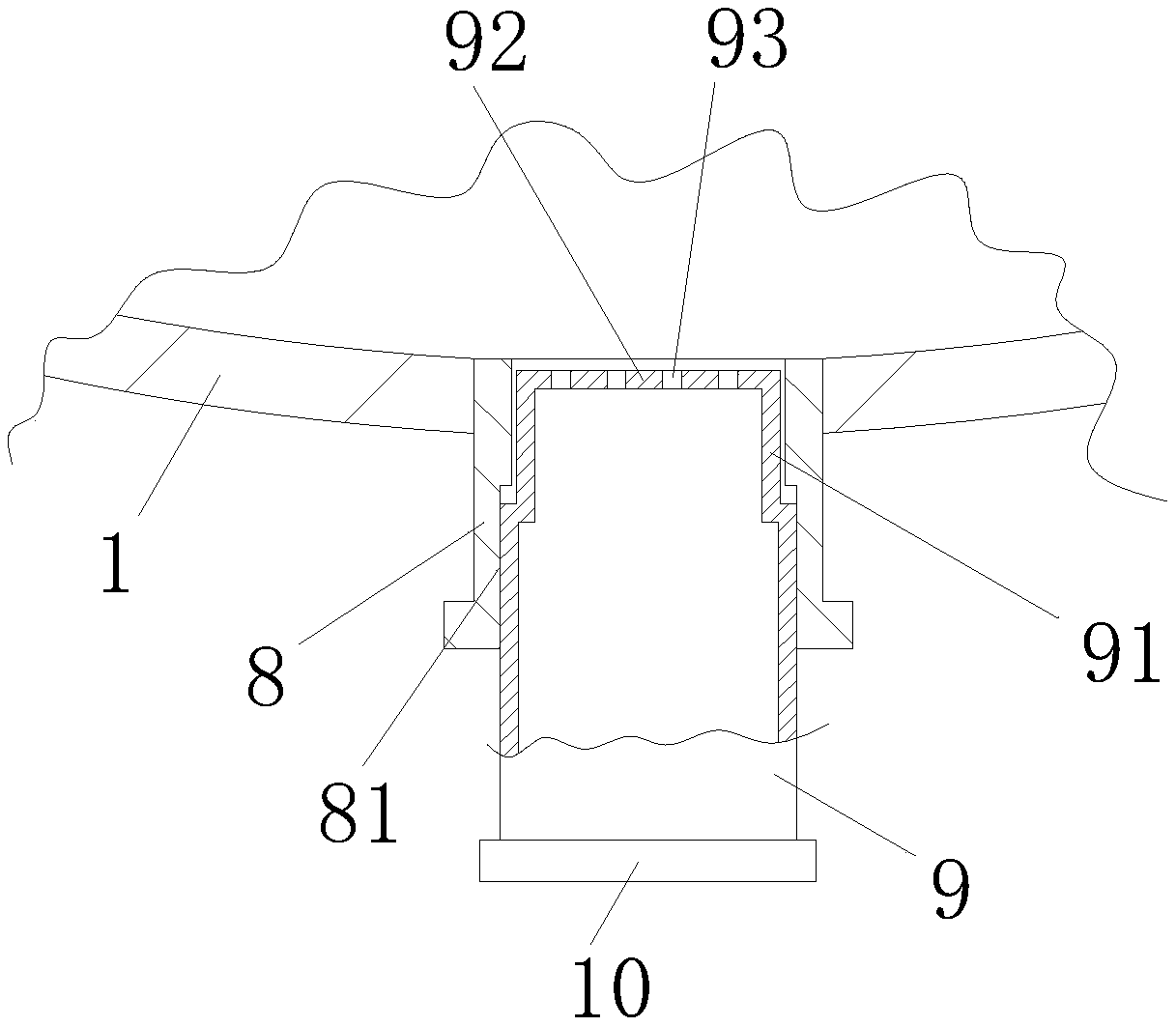

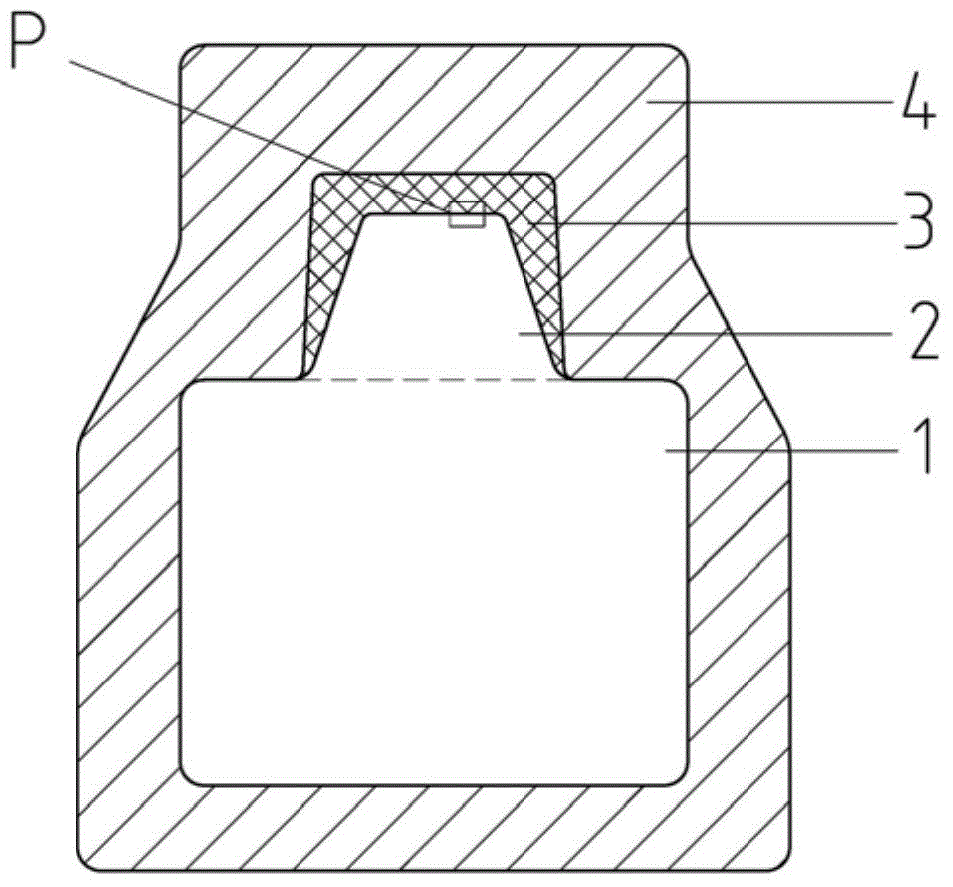

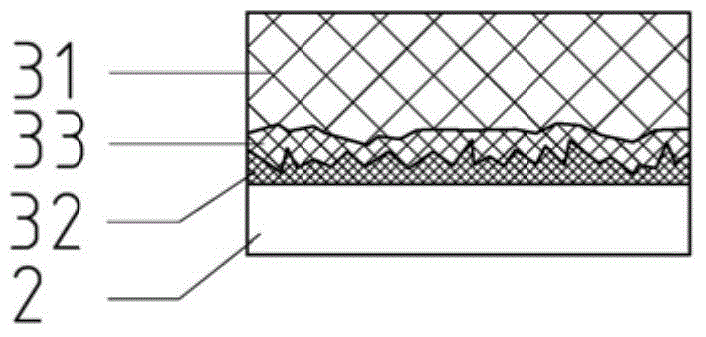

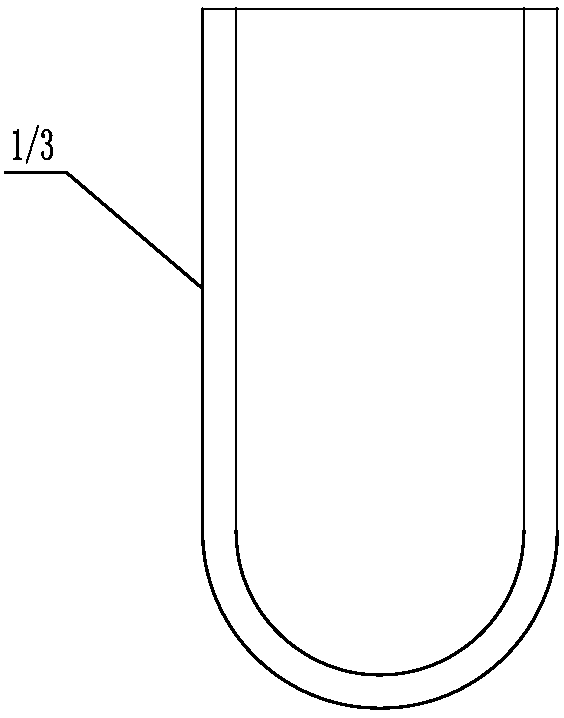

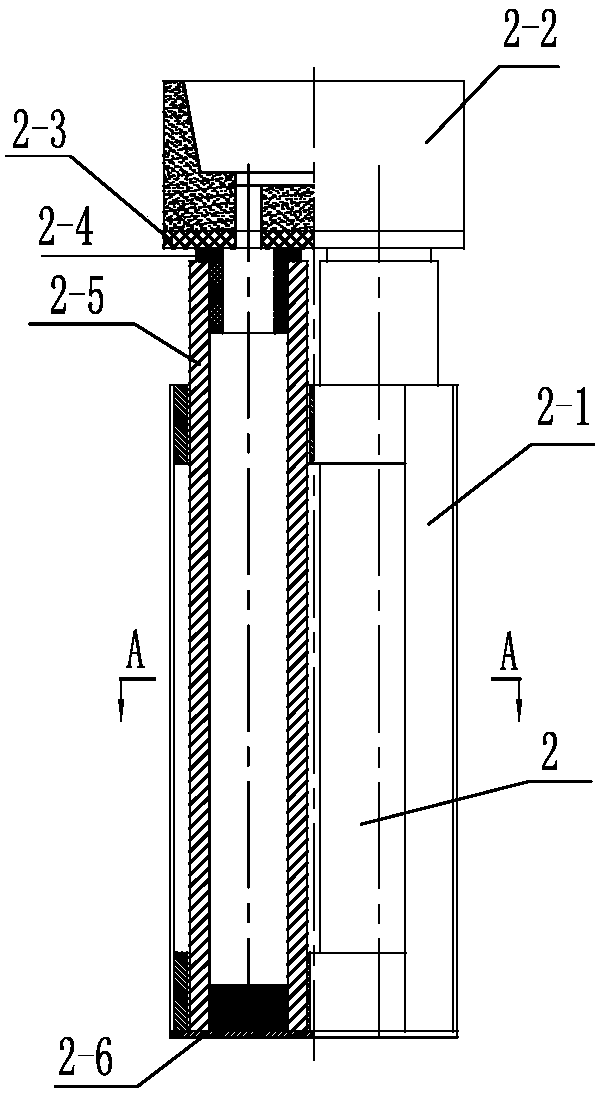

Feeder head coating structure and treatment method of aluminum alloy low-pressure cast

ActiveCN104148612AInhibit sheddingWon't fall offFoundry mouldsFoundry coresThermal insulationUltimate tensile strength

The invention relates to a feeder head coating structure and treatment method of an aluminum alloy low-pressure cast. The feeder head coating structure comprises a mold and a feeder head formed by a cavity in the mold. The feeder head is communicated with a mold cavity forming a cast body, and a sintered feeder head coating is arranged between the mold and the feeder head. The thicknesses, from the bottom of the feeder head to an opening, of the feeder head coating are gradually decreased to form a gradient. The feeder head coating with the gradient is adopted for making the coating at the bottom of the feeder head be thick, the thicknesses from the bottom of the feeder head to the opening are gradually decreased, in this way, the thermal insulation effect is excellent, molten metal at the bottom of the feeder head is prevented from solidifying firstly in the process of feeding, it can be effectively guaranteed that sufficient feeding is performed on the cast through the feeder head, the feeder head coating has certain surface strength and smoothness after sintering, the adhesion property of the coating on the mold is good, the combination between coatings is good, the possibility that in the casting process, the high-temperature molten aluminum erodes the coating is lowered, and the feeder head coating is effectively prevented from falling off in the process of cast stripping.

Owner:SHAANXI FAST AUTO DRIVE GROUP CO LTD

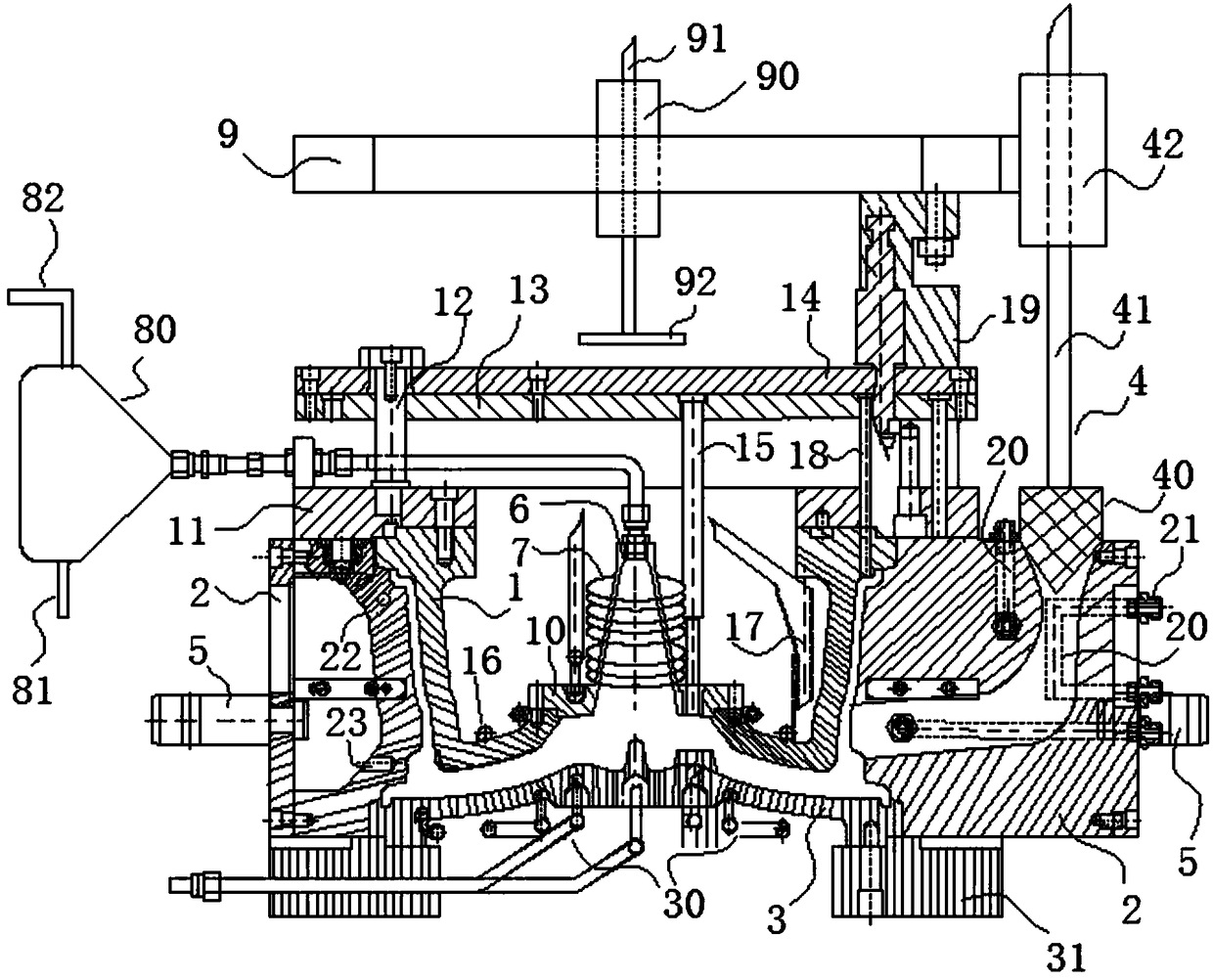

Combined smelting device capable of increasing yield of alloy castings and application of combined smelting device

The invention relates to a combined smelting device capable of increasing the yield of alloy castings and application of the combined smelting device, and belongs to the technical field of vacuum induction melting and investment casting. A crucible used for primary smelting and an ingot mold used for primary smelting are matched to prepare mother alloy cast ingots in a vacuum induction furnace, the outer surface of each mother alloy cast ingot is polished, and riser parts are cut off; and afterwards, a crucible used for secondary smelting and a refined casting mold shell used for secondary smelting are used for investment casting in the vacuum induction furnace, and thus, a precision casting is obtained. According to the combined smelting device capable of increasing the yield of the alloycastings and the application of the combined smelting device, a distribution disc is adopted for a sprue for primary smelting so that multiple mother alloy ingots can be cast at a time, ingot molds with different sizes can be used and the number of the ingot molds can be selected according to the quantity of molten materials, and the size of the ingot molds is matched with that of the crucible for secondary smelting and the material quantity. On the one hand, material waste is reduced, and the yield of materials is increased; and on the other hand, axial enlarged areas are designed at the twoends connected with the precision casting, so that sufficient feeding of the precision casting is achieved at the later casting solidification stage, and casting defects such as shrinkage cavities and shrinkage porosities are reduced.

Owner:江苏隆达超合金股份有限公司

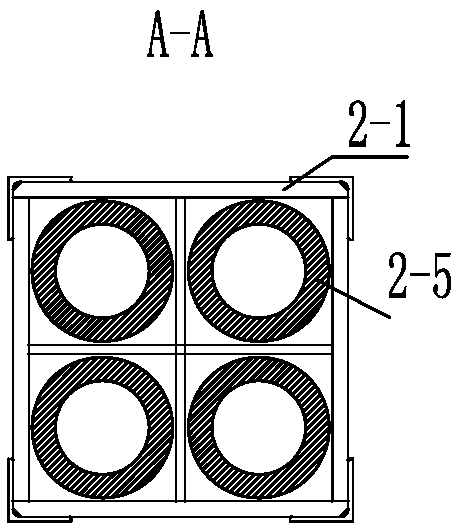

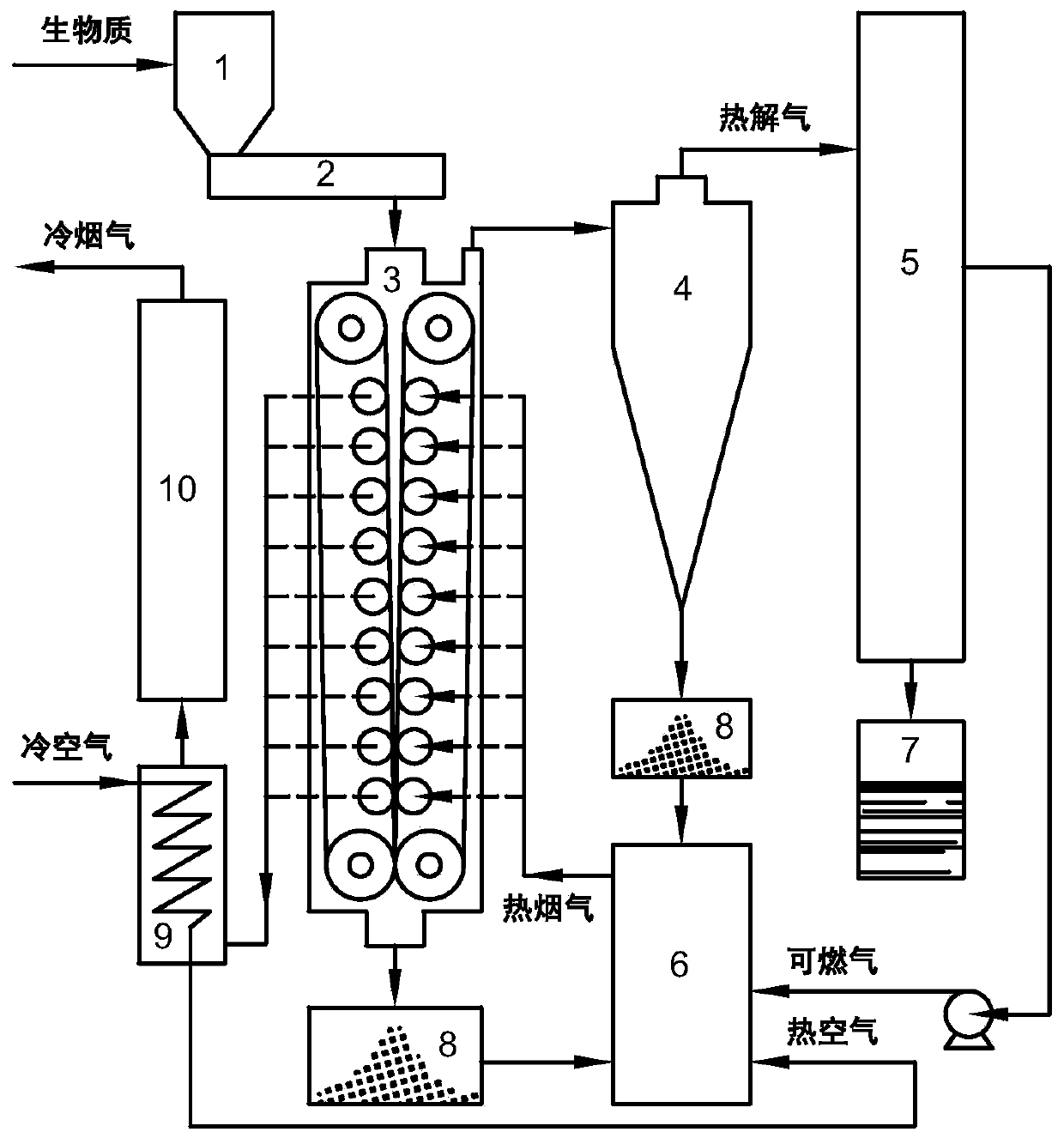

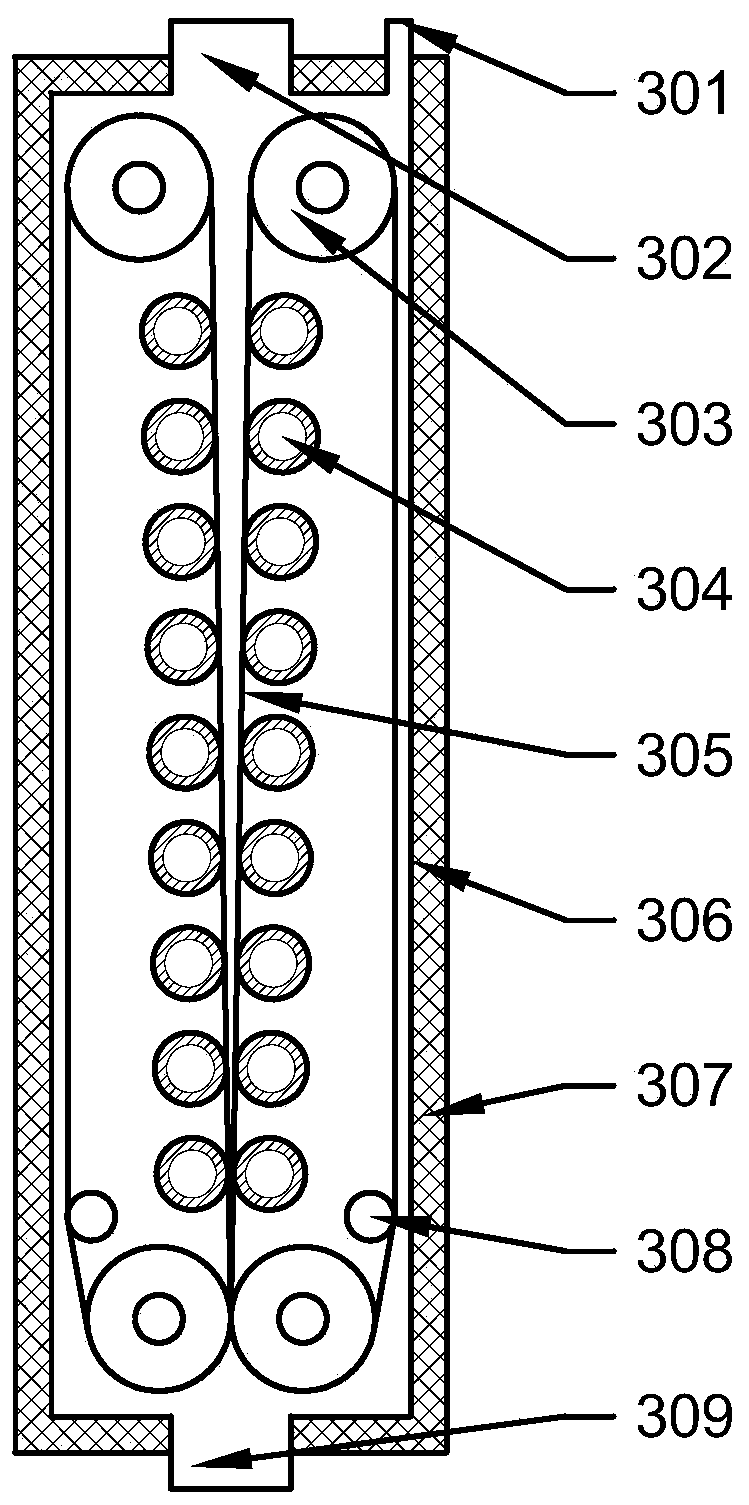

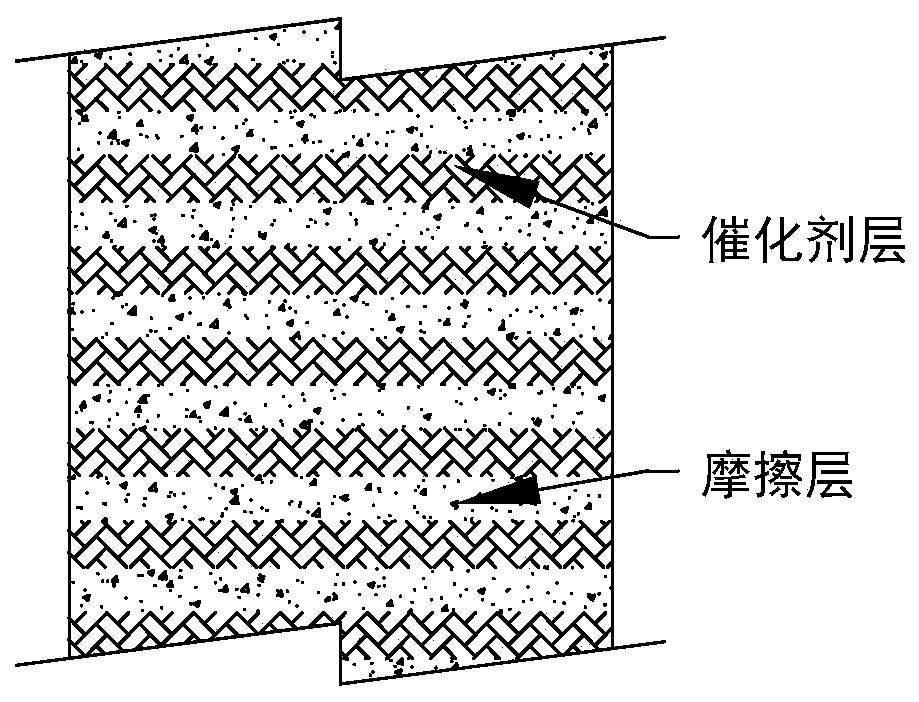

Grinding belt-type device for rapid catalytic pyrolysis of biomass and method

ActiveCN110003927ARapid condensationFully condensedBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisCombustion system

The invention belongs to the field of biomass energy utilization, and relates to a grinding belt-type device for rapid catalytic pyrolysis of biomass and a method. The device comprises a hopper, a feed system, a grinding belt-type pyrolysis reactor, a gas-solid separation system, a pyrolysis gas condensation system, a combustion system, a bio-oil collection tank, a charcoal collection tank, an airpreheating system and a flue gas purification system, wherein the grinding belt-type pyrolysis reactor comprises grinding belts, heating tubes, driving drums, tensioning devices, a sealed casing, a feed inlet, a discharge opening and a gas outlet. Pretreated material particles are continuously sheared and rubbed by the grinding belts with speed difference on two sides, and are heated by the multi-layer heating tubes to continuously pyrolyze on the surface while stripping the residual charcoal, so that a catalyst and heat can be fully fed inside the particles; the pyrolysis gas is rapidly condensed by gas-solid separation to obtain high-grade bio-oil fuel or bio-oil rich in specific high value-added products; combustible gas and coke produced by combustion generate high-temperature flue gas for heating the heating tubes, so as to achieve an autothermal pyrolysis process.

Owner:北京博霖环境科技有限公司

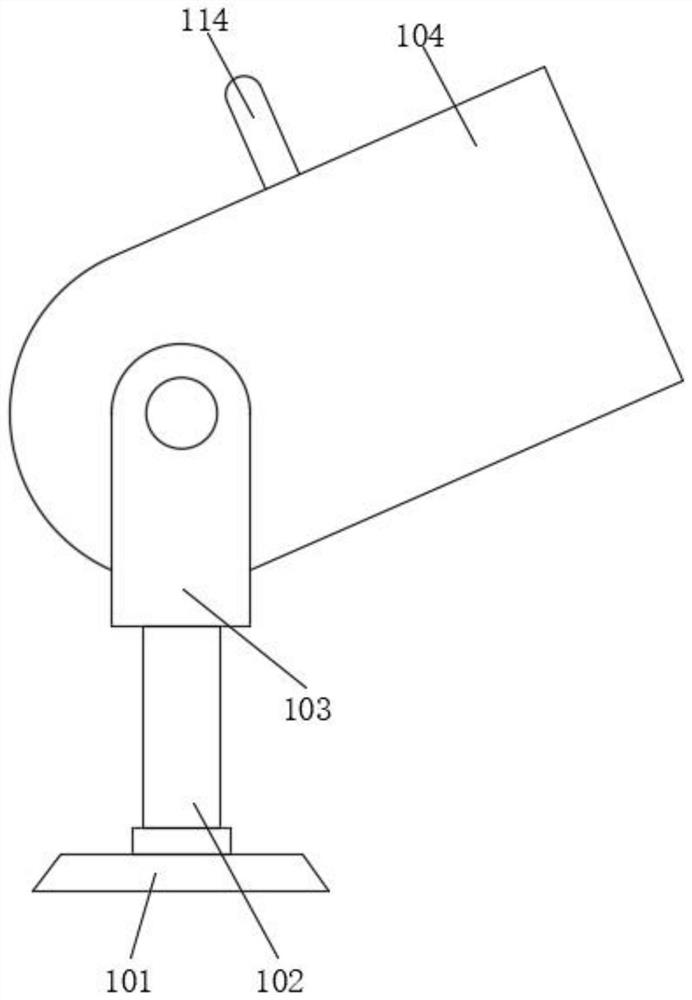

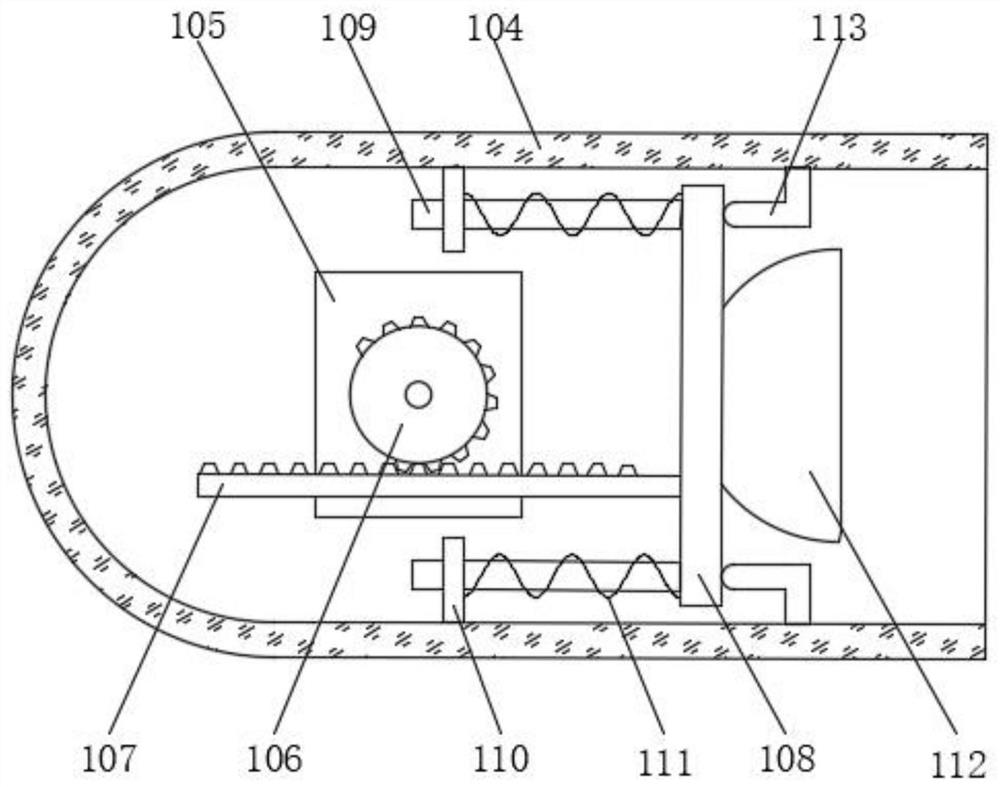

Shoreside inclined throwing type feeding device for aquaculture

ActiveCN112704037AEasy to recycleImprove feeding efficiencyClimate change adaptationPisciculture and aquariaEngineeringDrive motor

The invention discloses a shoreside inclined throwing type feeding device for aquaculture, and belongs to the technical field of aquaculture. According to the feeding device, through the arrangement of an inclined throwing assembly and self-release material storage balls, breeding personnel can continuously throw the self-release material storage balls into water of a breeding area only by standing on the shoreside to control a driving motor, the angle of an inclined throwing cylinder can be adjusted through swinging to change the falling points of the self-release material storage balls, then feeding is comprehensively conducted in the breeding area, the feeding efficiency of feed can be greatly improved, the labor cost can be effectively saved, a water contact linkage assembly is arranged, after the self-release material storage balls are thrown into water, the self-release feed storage balls can automatically release feed for feeding, a discharge pipe can face downwards all the time, outflow of the feed is facilitated, a convenient recovery assembly is arranged, the self-release feed storage balls are convenient to recover, and after the self-release feed storage balls are recovered, the self-release feed storage balls can be put into use again only by drying elastic ball bags in the sun and refilling the elastic ball bags with the feed.

Owner:徐州迈冠机械设备有限公司

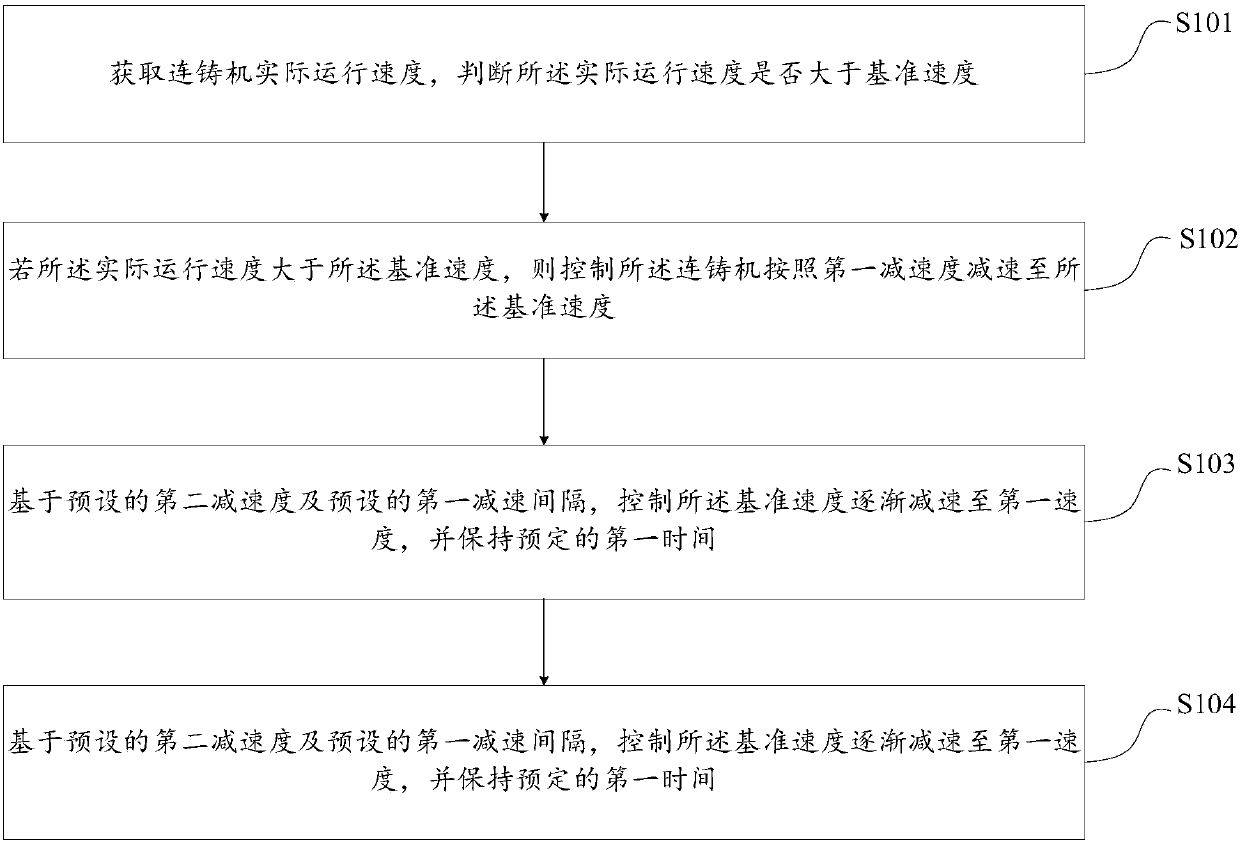

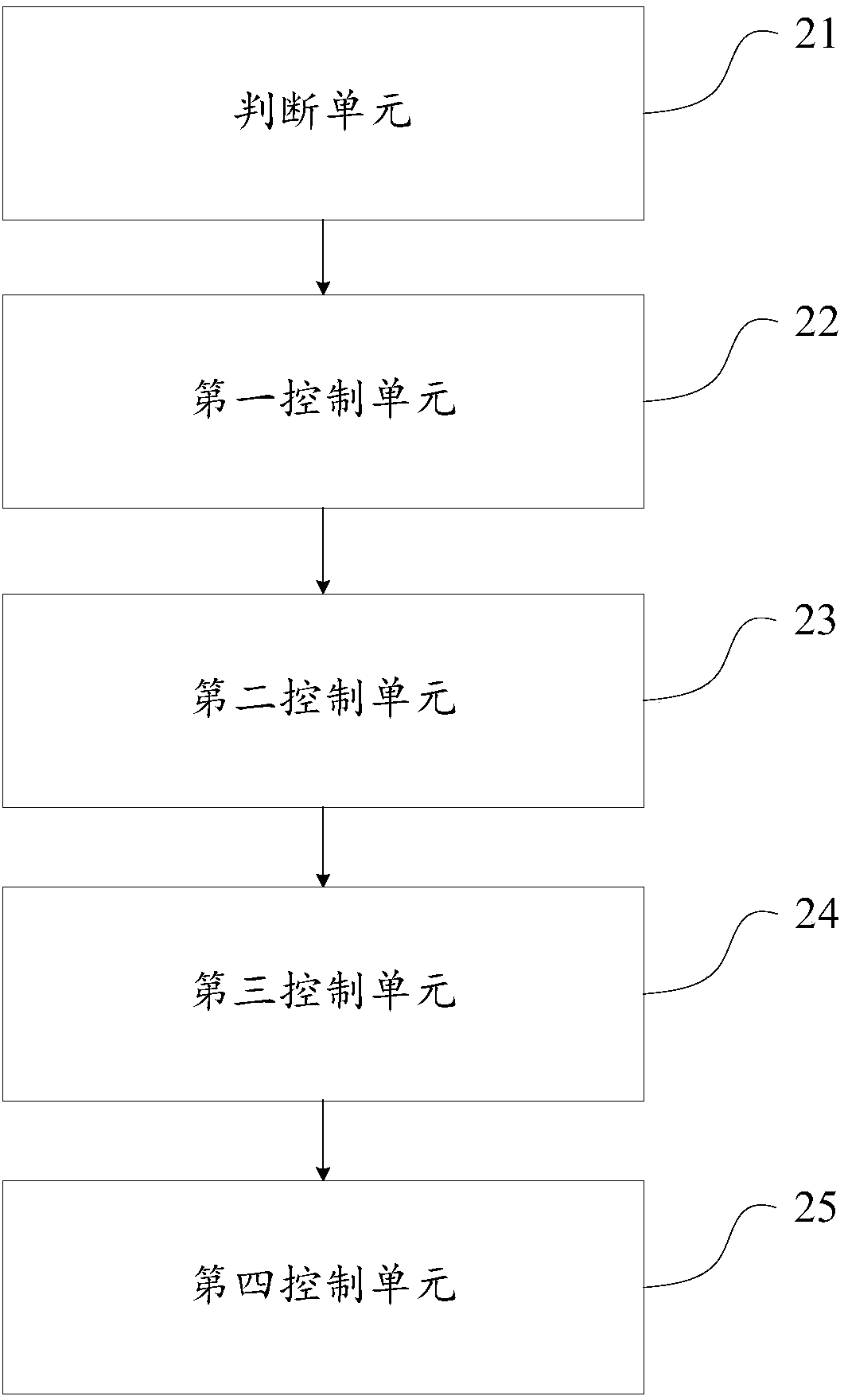

Method and device for improving quality of slab tail blank

The invention provides a method and a device for improving the quality of a slab tail blank. The method comprises that a actual running speed of a continuous casting machine is obtained, whether the actual running speed is larger than a reference speed is judged, if the actual running speed is larger than the reference speed, and the continuous casting machine is controlled to be decelerated to the reference speed according to a first deceleration speed; based on a preset second deceleration speed and a preset first deceleration interval, the reference speed is controlled to be gradually reduced to a first speed and stayed around the preset first time; based on the second deceleration speed and a preset deceleration interval, the reference speed is controlled to be gradually reduced to a second speed and stayed around a preset second time; wherein the first deceleration interval comprises 0.2 m / min, the reference speed is 1.2 m / min, and the first deceleration speed is 0.05 m / min2.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

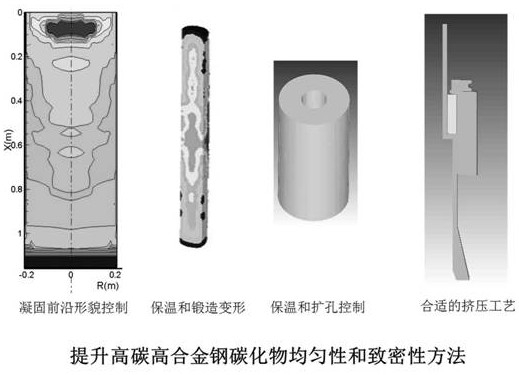

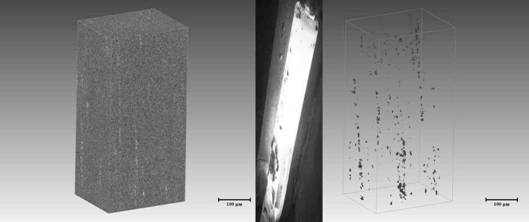

High-carbon high-alloy steel product and preparation method thereof

ActiveCN114231825AImprove uniformityImprove compactnessMetal-working apparatusIncreasing energy efficiencyThermal deformationCarbide

The invention relates to a high-carbon high-alloy steel product and a preparation method thereof, and mainly adopts the technical scheme that the preparation method of the high-carbon high-alloy steel product comprises the following steps: 1) preparing a high-carbon high-alloy steel low-segregation double-vacuum consumable blank; the preparation method is mainly used for preparing a high-carbon high-alloy steel product with fine carbides evenly distributed and hole type microdefects eliminated, and the high-carbon high-alloy steel product is prepared through the method and comprises the steps of (1) forging, (2) blank high-temperature diffusion homogenization treatment and multi-heating-number cross forging deformation cogging treatment, and (3) forging and (4) hot deformation extrusion treatment on the forged material.The preparation method is mainly used for preparing the high-carbon high-alloy steel product.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Intermittent loading and stirring type paint brushing device for decoration paint

The invention relates to a paint brushing device, and particularly relates to an intermittent loading and stirring type paint brushing device for decoration paint. The technical problem to be solved is to provide the intermittent loading and stirring type paint brushing device for decoration paint, which can mix in use at the same time and add paint intermittently. For solving the technical problem, the intermittent loading and stirring type paint brushing device for decoration paint comprises a stirring tank and others; the lower part of the right side of the stirring tank is provided with a discharging mechanism, and the upper part of the stirring tank is provided with a stirring mechanism. The intermittent loading and stirring type paint brushing device for decoration paint is provided with the discharging mechanism through which the oil paint can be discharged conveniently without worrying about the paint waste for the paint brush is dipped with too much paint; the stirring mechanism is arranged for fully stirring the paint; a cylinder and a discharging hose are arranged for intermittently loading in the stirring tank in the course of brushing.

Splicing frog casting system and casting method

ActiveCN110842150AImprove inner qualityEliminate casting defects such as shrinkage cavity and porosityFoundry mouldsFoundry coresThermal insulationEngineering

The invention discloses a splicing frog casting system and a casting method. The system comprises a pouring system, wherein the pouring system communicates with a frog toe end of a frog cavity formedin the casting mold, and the pouring system comprises a pouring gate component and a pouring and feeding open riser component. According to the splicing frog casting system, a toe end pouring system is provided with a pouring and feeding open riser, a casting is provided with a heating thermal insulation necking blind riser, the risers are arranged between holes, the rail top surface between the risers is matched with the strip-shaped bright iron, inclined pouring is carried out, and after pouring, a cold box opening process is adopted, and the casting is placed at the room temperature for hammering to remove the risers. Under the condition of inclined pouring, sequential solidification is achieved, the heating thermal insulation riser and a cold iron are matched, sufficient feeding is obtained on the frog rail surface, the risers are removed by using a hammering mode after opening, cracks caused by flame cutting are avoided, and casting defects such as shrinkage porosity are completely eliminated through ray inspection.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

Paint mixing, stirring and collecting device

InactiveCN111085128AWell mixedStir wellRotary stirring mixersTransportation and packagingMechanical engineeringEngineering

Owner:YUYAO FEIGE AUTOMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com