Feeder head coating structure and treatment method of aluminum alloy low-pressure cast

A coating treatment, aluminum alloy technology, applied in the direction of coating, mold, mold composition, etc., can solve the problems of increasing on-site pouring operation procedures, unrealizable mold size, difficulty in customizing riser sleeves, etc., and achieves good thermal insulation effect. , Excellent thermal insulation effect, good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

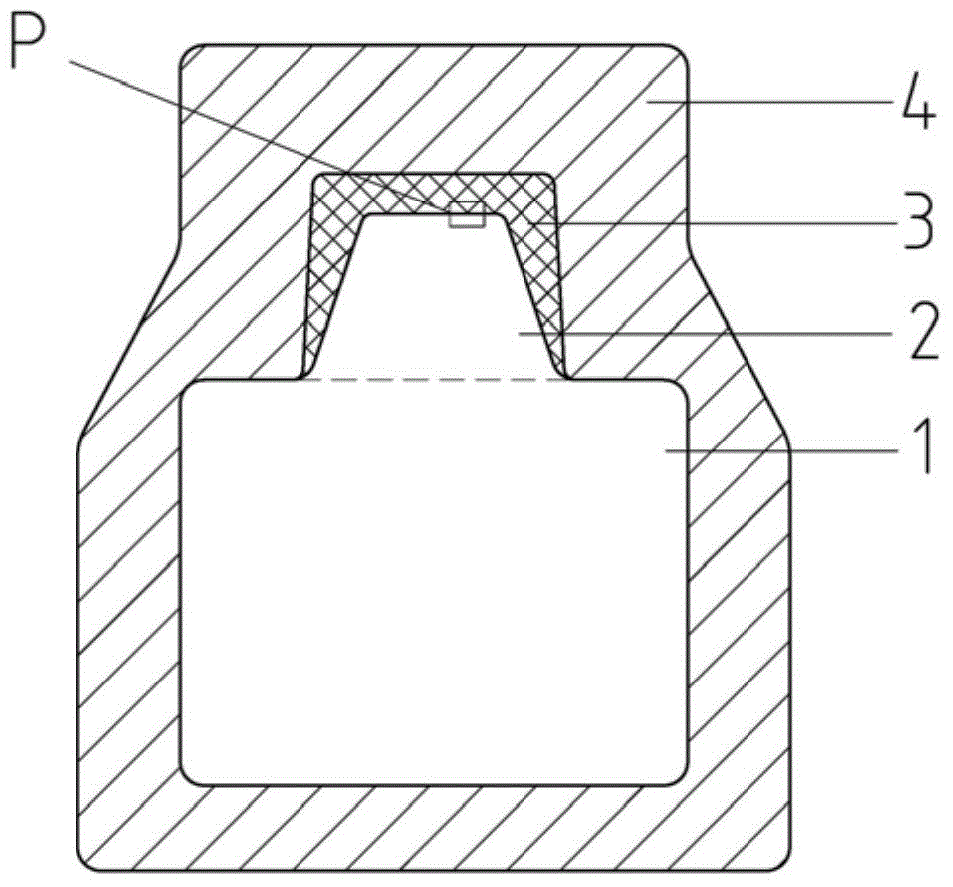

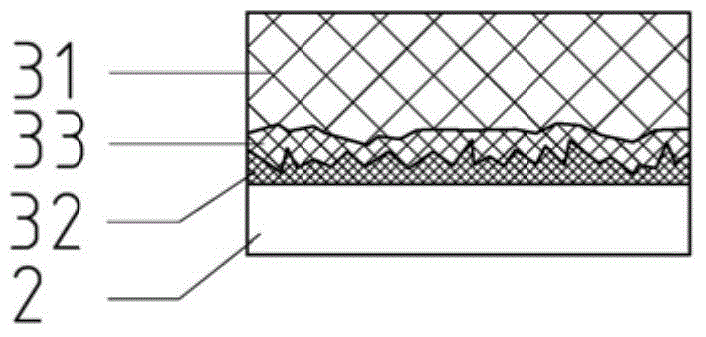

[0025] refer to figure 1 and figure 2 , the present invention comprises a die 4 and a riser 2 formed by a cavity thereon, the riser 2 is open on one side and communicates with the mold cavity forming the casting body 1, and a sintered riser is arranged between the mold 4 and the riser 2 Coating 3, riser The coating 3 includes a layer of No. 1 refractory material 31 and a layer of No. 2 refractory material 32 bonded to each other. The No. 1 refractory material 31 is bonded on the mold 4 and extends from the bottom of the riser 2 to the opening. The thickness of the refractory gradually decreases, forming a slope of 30-60°, and the thickness of the coating at the bottom is 5-10mm; at the same time, the transition layer 33 formed between the two refractory materials can increase the combination between the two refractory materials and effectively prevent coating. Laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com