Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

814results about How to "Difficult to disperse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

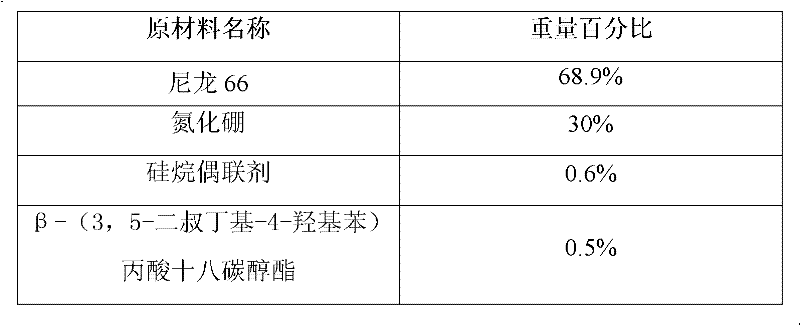

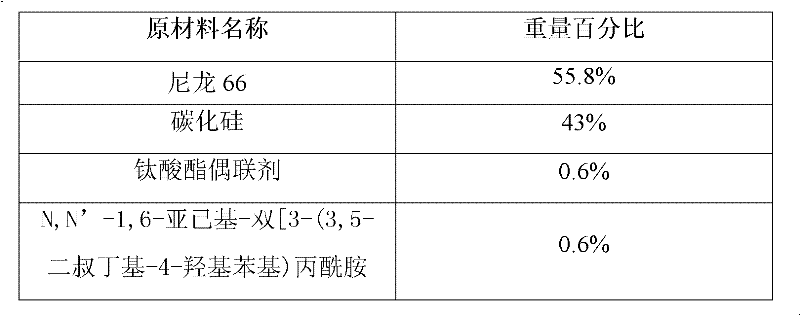

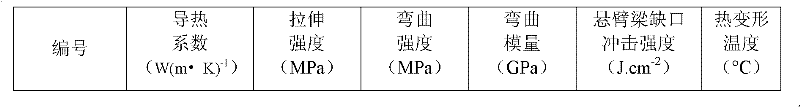

Nylon 66 composite material with high heat conductivity and preparation method thereof

ActiveCN102408710AGood dispersionEvenly dispersedHeat-exchange elementsStrength of materialsNylon 66

The invention discloses a nylon 66 composite material with high heat conductivity, comprising the following substances based on weight percentages: 70-42% of nylon 66, 27-55% of heat conduction filler, 0.5-1.5% of coupling agent and 0.5-1.5% of anti-oxidant. In addition, the invention also discloses a preparation method for the nylon 66 composite material with high heat conductivity, wherein the method adds a processing step on the heat conduction filler based on the conventional method. The nylon 66 composite materials with high heat conductivity prepared by the invention can better keep themechanical property of the nylon 66 composite material and largely raise the heat conductivity at the same time. In comparison with the heat conductivity of the nylon 66 composite material prepared from the heat conduction filler without processing, the heat conductivity of the nylon 66 composite material prepared from the processed heat conduction filler is raised by about 30-50%.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Glass fibre reinforced nylon colorful heat insulation stripe for al-alloy door & window and method for preparing same

InactiveCN101307147ADifficult to disperseSolve easy discolorationDoors/windowsMasterbatchGlass fiber

The invention discloses a glass fiber reinforced nylon colored insulated strip used for an aluminum alloy door and window. The compositions by weight portion of the glass fiber reinforced nylon colored insulated strip are: 100 portions of nylon resin, 5 to 50 portions of glass fibers, 0 to 50 portions of inorganic filler, 5 to 25 portions of toughening agent, 0.3 to 5 portions of coupling agent, 0.3 to 5 portions of dispersing lubricant, 0.2 to 5 portions of antioxidant, 0.1 to 1 portion of light stabilizer, 0.1 to 1 portion of heat stabilizer and 2 to 10 portions of colored masterbatch. The invention also discloses a method for preparing the colored insulated strip. The glass fiber reinforced nylon colored insulated strip solves the problems that the masterbatch and the filler are difficult to disperse and nylon 66 is easy to change color during the processing procedure; the insulated strip products have various colors, superior performance and beautiful appearance; and the glass fiber reinforced nylon colored insulated strip realizes perfect matching with the window color, can achieve the beautility effect, meets and enlarges the demand of clients and the market, and is favorable for promotion, use and development of the glass fiber reinforced nylon 66 insulated strip.

Owner:FOSHAN NANHAI YILE ENG PLASTICS

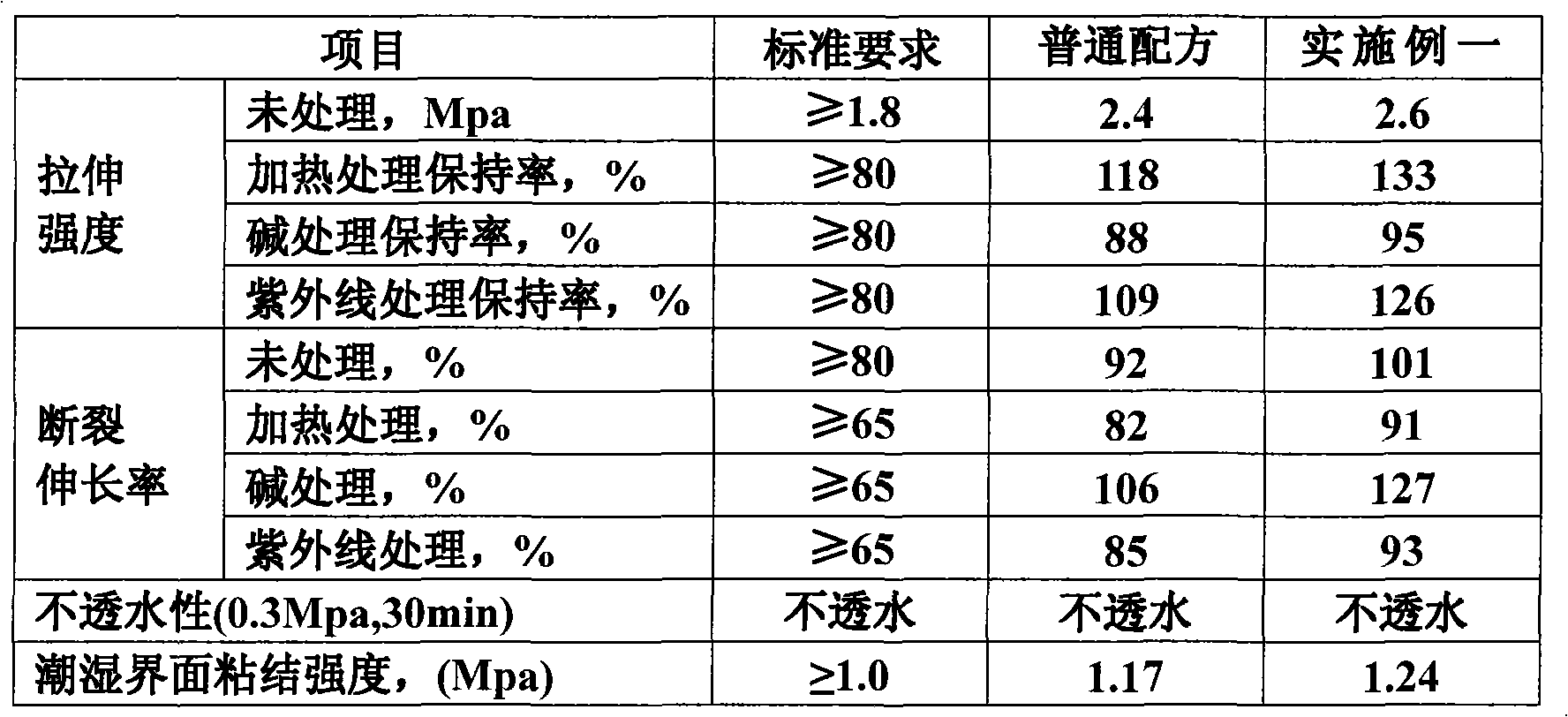

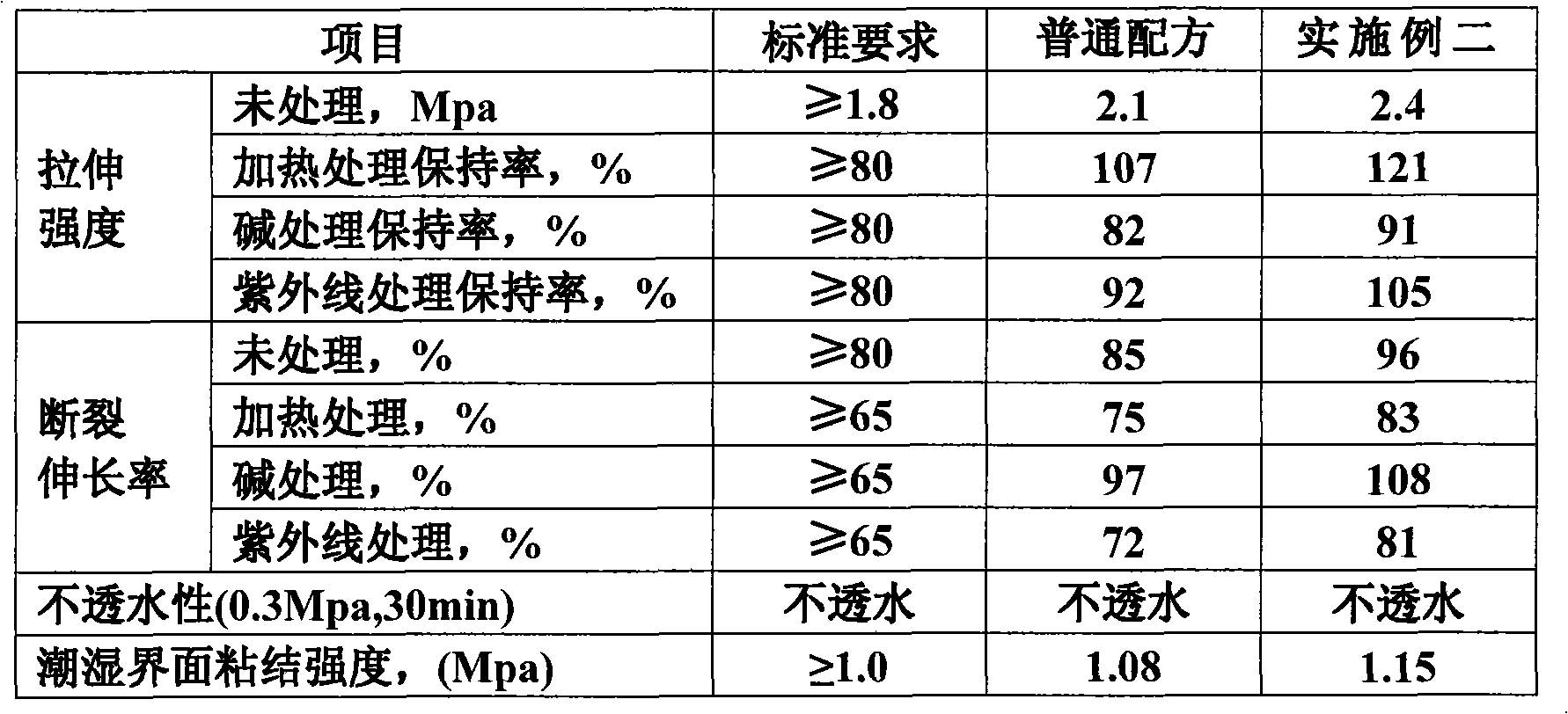

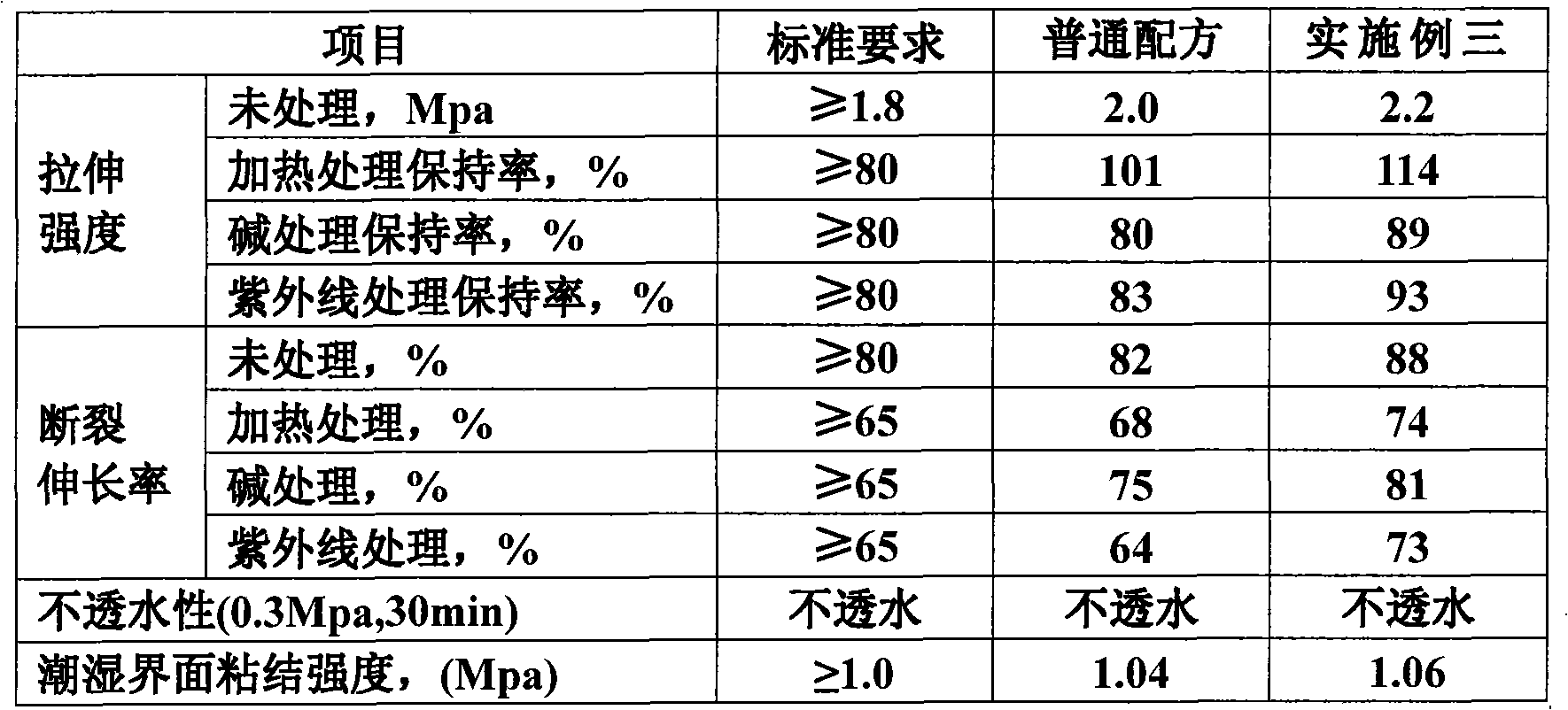

II-type polymer cement waterproofing coating modified by nano materials and preparation method thereof

ActiveCN101550309AImprove thixotropyPrevent saggingAntifouling/underwater paintsPaints with biocidesPlasticizerPolymer

The invention discloses a II-type polymer cement waterproofing coating modified by nano materials, which consists of a liquid material component and a powder material component, wherein the liquid material component comprises the following ingredients by weight: 85-95 percent of acrylic ester latex, 0.5-2 percent of plasticizer, 0.2-0.4 percent of dispersant, 0.2-0.5 percent of silicone antifoam agent, 0.1-0.3 percent of preservative, 0.3-0.6 percent of active ingredient content of pre-dispersed nano silicon dioxide solution, 0.02-0.06 percent of active ingredient content of pre-dispersed nano alumina solution, and the balance of water. The mixture ratio of the liquid material component to the powder material component is 10:14-20 according to proportions by weight. The invention greatly improves the thixotropy of the coating, prevents coating elevation construction from sagging, reduces loss in coating construction, simultaneously enhances all properties of the coating such as water resistance, alkaline resistance and the like, and obtains obvious effects.

Owner:苏州市姑苏新型建材有限公司

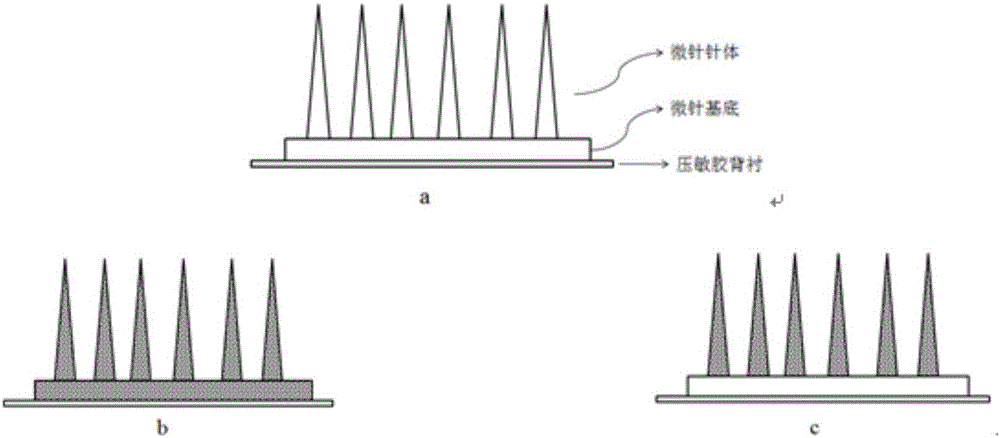

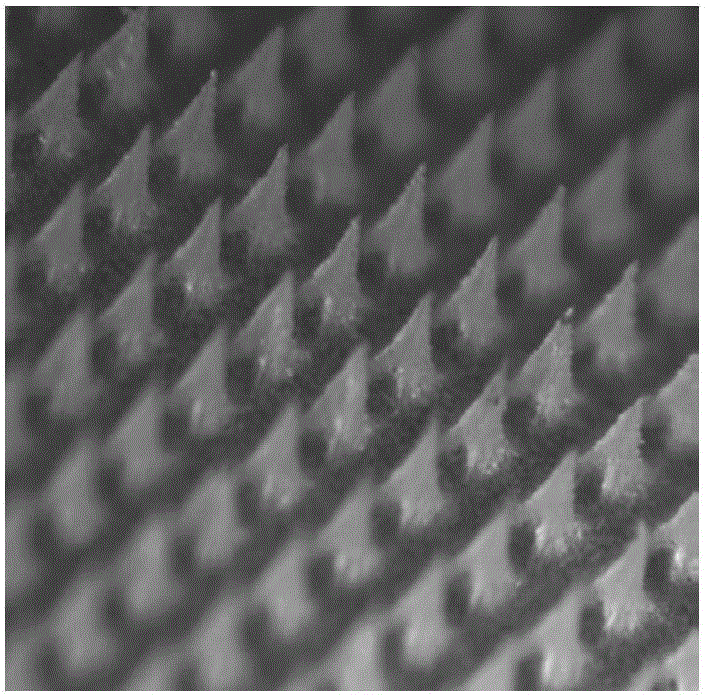

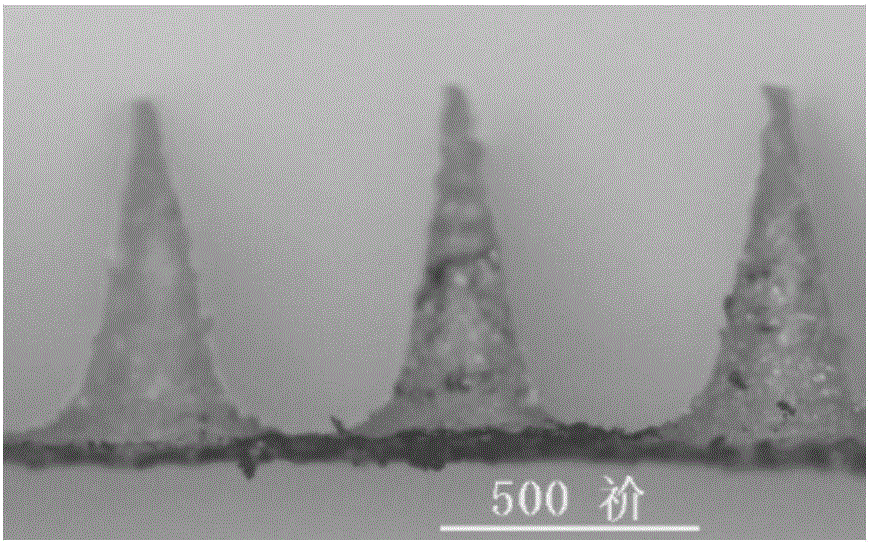

Flexible slow-release micro-needle patch and preparation method thereof

InactiveCN106422045AGood dispersionGood sustained releaseOrganic active ingredientsMicroneedlesSolubilityMedicine

The invention discloses a flexible slow-release micro-needle patch and a preparation method thereof. The micro needle patch comprises a micro-needle, a substrate and a back lining, wherein the micro-needle and the substrate form a micro-needle array; a base material of the micro-needle or a base material of the micro-needle array contains a drug in a crystal form; the solubility of the drug in the crystal form in water is less than 100 microgram / ml. The micro-needle patch has the characteristics of simple process, high preparation safety, low process cost and high drug loading capacity.

Owner:BEIJING CAS MICRONEEDLE TECH LTD

Preparation method of high-rate lithium ion battery anode slurry

ActiveCN106207129ALower internal resistanceIncrease energy densityElectrode manufacturing processesSecondary cellsDispersityHigh rate

The invention provides a preparation method of high-rate lithium ion battery anode slurry. The preparation method includes the steps of firstly, performing drying treatment on each component; secondly, dissolving an adhesive in a solvent, and stirring and dispersing to obtain an adhesive solution A; thirdly, taking one part of the adhesive solution A, adding one part of an conductive agent into the part of the adhesive solution A, and stirring and dispersing to obtain slurry B; fourthly, adding the other part of the conductive agent and the rest of the adhesive solution into the slurry B, and stirring and dispersing to obtain slurry C; fifthly, adding anode active materials into the slurry C in twice, stirring and dispersing, using a solvent to perform viscosity regulation, filtering, and performing vacuum defoaming to obtain the high-rate lithium ion battery anode slurry. The high-rate lithium ion battery anode slurry has the advantages that after a current collector is coated with the high-rate lithium ion battery anode slurry, the components of the high-rate lithium ion battery anode slurry are good in dispersity, electrochemical performance consistency between single batteries is guaranteed, and the rate capability of the batteries can be brought into play favorably; a lithium ion battery prepared by the slurry is low in internal resistance, high in energy density and good in circulation performance.

Owner:CALB CO LTD

High-safety lithium ion battery cathode paste and preparation method thereof

InactiveCN105514417AImprove securityReduce internal gassingCell electrodesSecondary cells servicing/maintenanceLithium carbonateAcrylonitrile

The invention provides a high-safety lithium ion battery cathode paste and a preparation method thereof. The high-safety lithium ion battery anode paste comprises 80-99 parts of positive active materials, 0.2-10 parts of a binder, 0.5-5 parts of a conductive agent and 0.3-10 parts of a positive additive, wherein the positive additive is lithium carbonate; the binder is one or two of a acrylic acid acrylonitrile copolymer and polyvinylidene fluoride (PVDF). According to the high-safety lithium ion battery cathode paste and the preparation method thereof, as analytically pure lithium carbonate is added to react with alkali and water remained in a battery, internally produced gas is reduced, and the battery safety is improved; besides, with the adoption of the improved dry high-viscosity mixing technology, the stirring time of the paste is obviously shortened, the production efficiency is improved, the dispersing effect of the paste is enhanced, the quality of the paste is improved, and the safety performance of lithium ion batteries is further improved.

Owner:先进储能材料国家工程研究中心有限责任公司

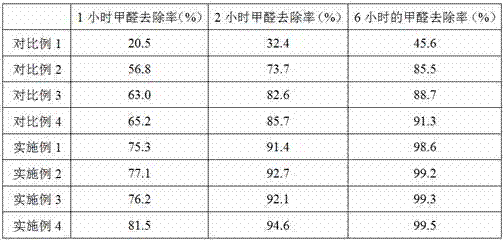

Preparation method of modified activated carbon for removing formaldehyde in air in high efficiency

InactiveCN107282003AStable stateRaw material safetyGas treatmentOther chemical processesActivated carbonChemical reaction

The invention discloses a preparation method of modified activated carbon for removing formaldehyde in air in high efficiency. The preparation method comprises the steps of utilizing general activated carbon as base carbon, weighing nitrogen substance and deionized water, dissolving the nitrogen substance into the deionized water, then adding the base carbon, evenly mixing, standing for several hours, then performing ultrasound-assisted treatment, flatly paving the obtained base carbon, air drying the base carbon, then stoving the base carbon and naturally cooling to room temperature to obtain the modified activated carbon. The modified activated carbon for removing formaldehyde disclosed by the invention has safe raw material, low price and low cost; the method is convenient and easy to operate and can be easily expanded in industry; a method in which physical adsorption fixation and chemical reaction elimination are combined is utilized, so that a formaldehyde removing effect is obvious; furthermore, the modified activated carbon has safety, stability, no secondary pollution and convenience in use; ability for adsorbing formaldehyde in the air is larger than 90% and reaches a level of superior formaldehyde removing dedicated carbon.

Owner:BEIJING FORESTRY UNIVERSITY +2

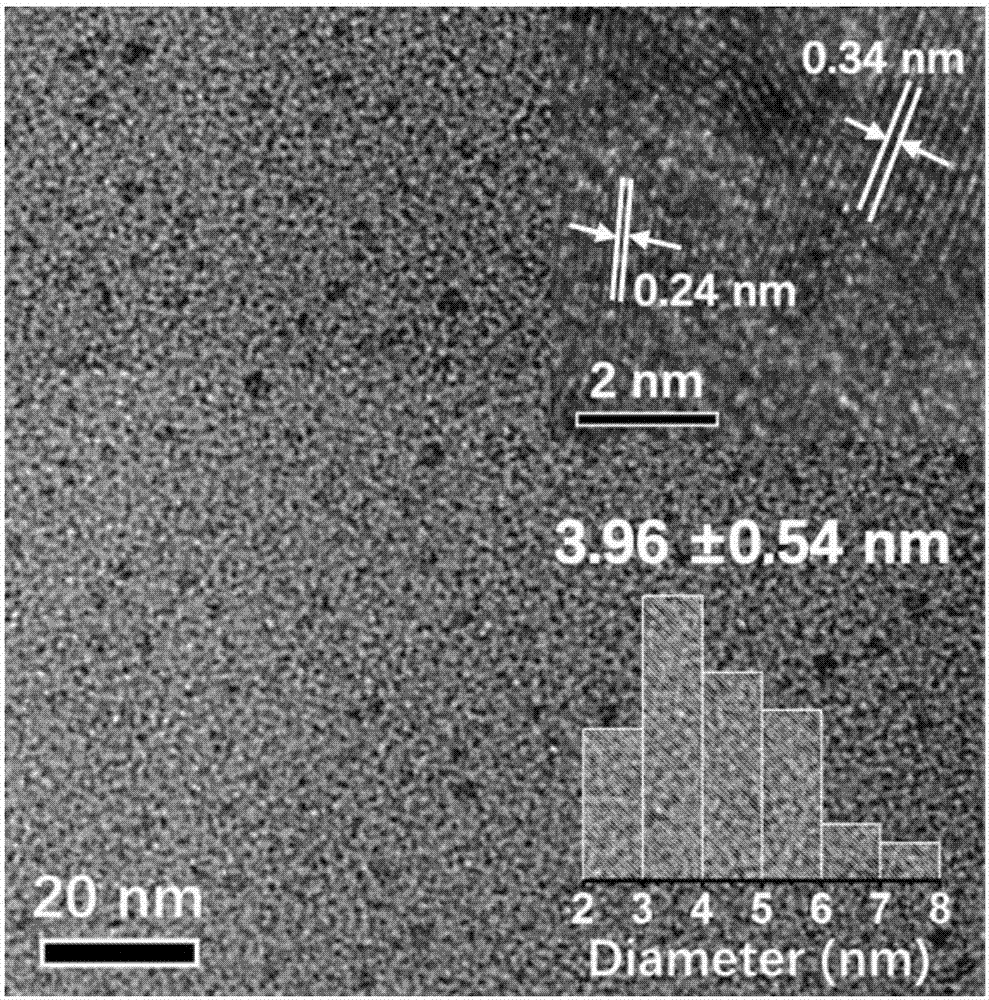

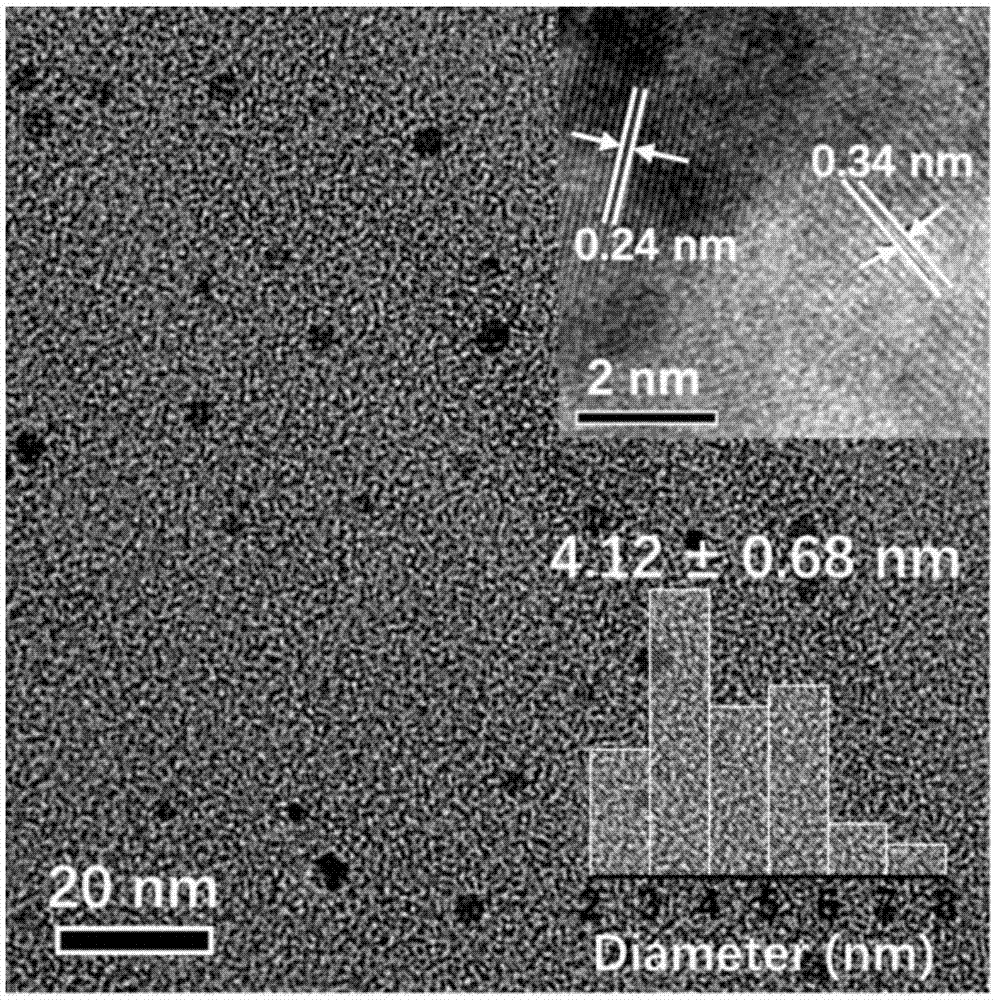

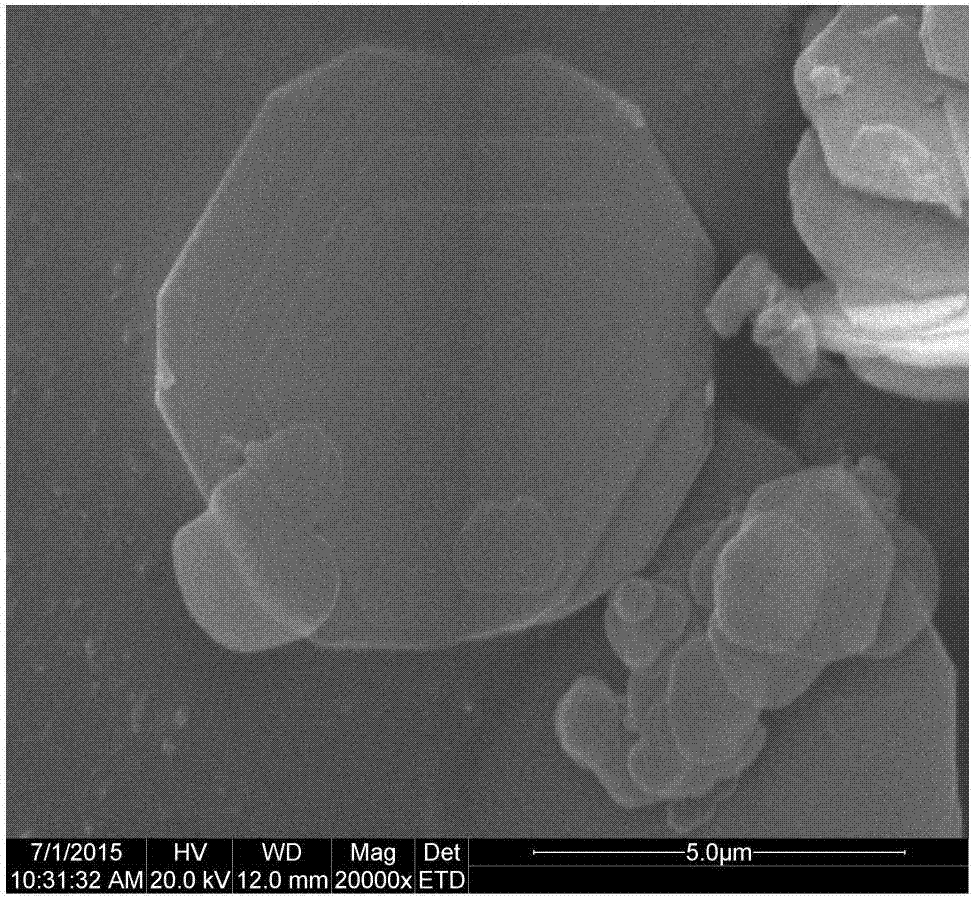

Qunatum carbon, and preparation method and implementation apparatus thereof

ActiveCN104261383AGood dispersionSynthetic size controllableMaterial nanotechnologyMixing methodsDouble bondElectromotive force

The invention relates to a qunatum carbon which comprises carbon particles with the particle size of 0.6-100nm, wherein the carbon particles are mono carbon and / or graphene particles; and the surface layer of the carbon particles contain carbon, hydrogen, oxygen and nitrogen compounds, which comprise condensed aromatics, compounds containing carbon-oxygen single bond, compounds containing carbon-oxygen double bond and compounds containing carbon-hydrogen bond. The invention also relates to a qunatum carbon solution which is a water solution containing qunatum carbon. The ORP of the qunatum carbon solution is 280-380mv, the electric conductivity sigma is 1-5ms / cm, the electromotive force is 280-380mv, the pH value is 1.5-3.2, and the concentration is 0.1-0.45%. The invention also relates to a device and method for preparing the qunatum carbon. The method has the advantages of simple technique, low cost, no generation of three wastes, uniform carbon particle size and stable product quality, is easy to control, and can easily implement large-scale production.

Owner:北京三昌宇恒科技发展有限公司

Particulate ferric oxide red pigment and method for producing the same

InactiveCN1521220ASolving Dispersion ProblemsSolve the problem of easy cakingPigmenting treatmentPolyvinyl alcoholSulfate

The present invention is granular iron oxide red pigment of grain size of 5-100 mesh and its preparation process. The preparation process includes the following steps: compounding water solution of additive in the concentration of 0.3-10 % and heating to 30-100 deg.c; spraying the water solution to iron oxide red in a pelletizing machine to form the granular pigment gradually with the weight ratio of iron oxide red to the water solution being 100 to 15-40; and vibration sieving and stoving to obtain the product. The additive is the combination of two or more of CMCNa, PVA, sodium silicate, glutin, sodium lignosulfonate and ferrous sulfate. The granular iron oxide red pigment has the same performance and use effect as the powdered iron oxide red pigment and is favorable to prevent dust pollution, and may be used to replace powdered iron oxide red pigment.

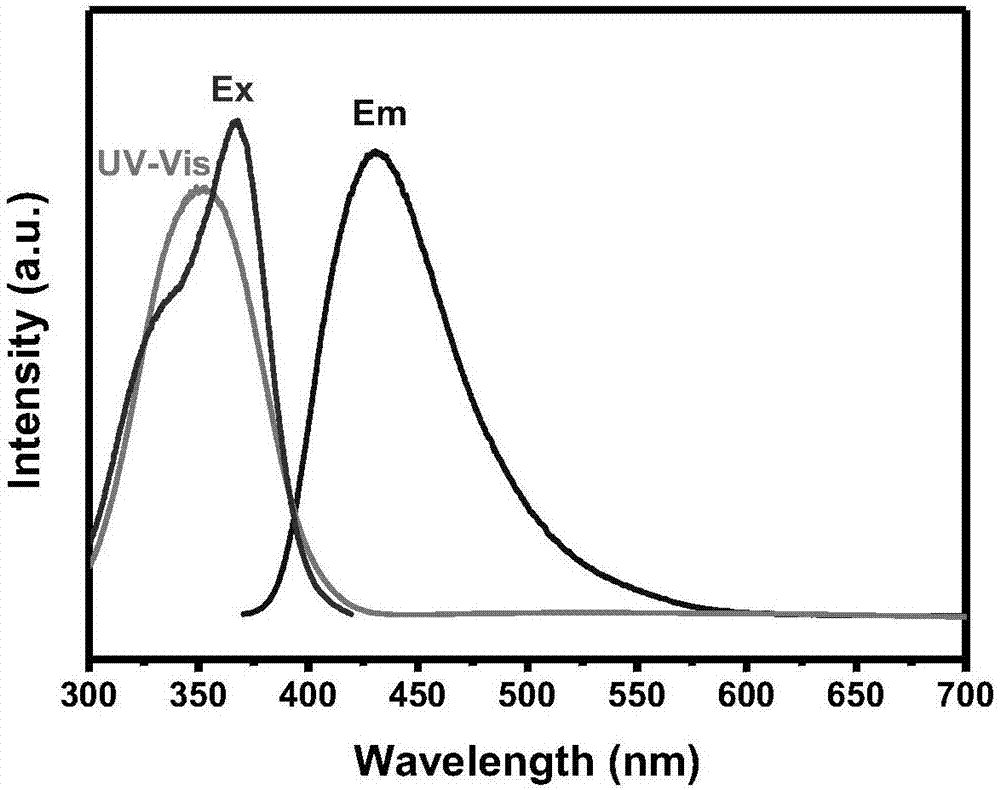

Preparation method of multicolor fluorescent carbon dots and application of multicolor fluorescent carbon dots in aspect of LED (light-emitting diode)

InactiveCN107418569ACheap way to prepareCheap manufacturingMaterial nanotechnologyNanoopticsEpoxyN dimethylformamide

The invention discloses a preparation method of multicolor fluorescent carbon dots and application of the multicolor fluorescent carbon dots in the aspect of LED (light-emitting diode), and relates to the field of luminescent materials. The efficient multicolor fluorescent carbon dots can be obtained through regulating the proportion and reaction temperature of a reactant. The carbon dots are prepared by the following method: citric acid and urea, in different proportions, are dissolved in N,N-dimethylformamide, the reaction temperature is controlled to be 140 to 200 DEG C to carry out solvothermal reaction, the fluorescent carbon dots with the maximum emission peak covering 400 to 650nm are obtained, and the fluorescent carbon dots with the fluorescence quantum efficiency all being 10% or above are obtained, wherein the blue light is 52%, the green light is 35% and the red light is 13%. The carbon dots can be used as luminescent powder of an LED to be directly added into an encapsulating material epoxy resin of the diode, and used for preparing LED devices with blue light, green light, red light and white light.

Owner:BEIJING UNIV OF TECH

Preparation method of antique bricks with 3D relief

The invention discloses a preparation method of antique bricks with 3D relief, wherein the preparation method includes the steps: preparing a bottom glaze on the surface of the body and carrying out ink-jet printing, overglazing, drying and firing in turn, and thus obtaining the finished product. The rich and lifelike 3D relief is prepared on the antique brick surface by an ink jet and infiltration technology. The preparation process is simple, a die is not needed to be replaced according to different designs of the antique bricks, and the production cost is saved greatly. Correspondingly, theinvention also discloses the antique bricks with 3D relief, wherein the antique bricks have the advantages of low surface glossiness, clear texture, strong stereoscopic sense, and excellent anti-fouling and anti-skid performance.

Owner:肇庆乐华陶瓷洁具有限公司

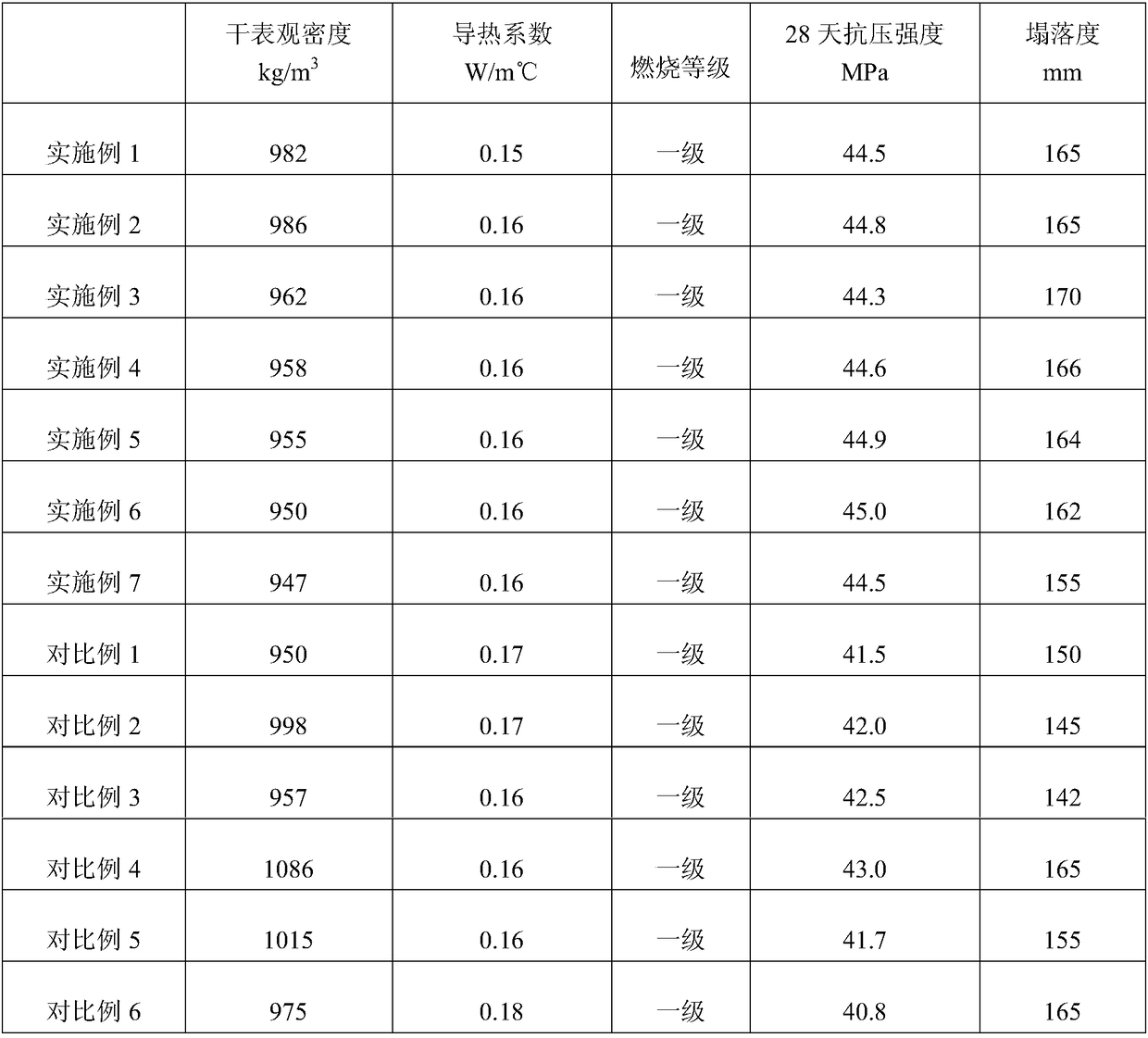

High-strength lightweight aggregate concrete and preparation method thereof

The invention provides high-strength lightweight aggregate concrete. The concrete comprises the following raw materials in parts by weight: 350 to 550 parts of cementing material, 450 to 600 parts oflightweight fine aggregate, 500 to 650 parts of lightweight coarse aggregate, 5 to 7 parts of an additive, and 150 to 170 parts of water. The lightweight fine aggregate comprises 60 to 80 percent of fine aggregate ceramsite in mass percent, and 20 to 40 percent of active construction waste powder in mass percent; the lightweight coarse aggregate comprises the following components in mass percent:50 to 75 percent of coarse aggregate ceramsite, 10 to 30 percent of stone gangue, 10 to 20 percent of ceramic waste residue, and 3 to 8 percent of expanded graphite. The concrete reasonably utilizes the stone gangue, construction waste, urban sludge and ceramic waste residue into a gel material and aggregate, not only improves the mechanical strength and stability of the concrete, but also provides a novel approach for the reuse of solid waste, and is beneficial to energy saving and environmental pressure relieving.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

Nano metal titanium dioxide sol negative oxygen ion finishing method for fabric

InactiveCN101481874ASimple operation processLow baking temperatureVegetal fibresAnimal fibresAnhydrous ethanolOxygen ions

The invention relates to a finishing method of fabric by nano-metal titanium dioxide sol negative oxygen ions. The finishing method comprises the following steps: (1) dissolving butyl titanate in 2 / 3 of ethanol, mixing evenly, adding ethanol aqueous solution dropwise, and adjusting pH value to 2 by concentrated inorganic acid after finishing adding dropwise, and continuing to stir for 2h to obtain transparent nano-TiO2 sol, wherein, the butyl titanate, an inhibitor, an anhydrous ethanol and water are at a mol ratio of 1:1:10-30:2-4; and (2) soaking the fabric in the sol finishing agent for 3min, then predrying at the temperature of 80 DEG C, baking at the temperature of 120 DEG C for a plurality of 150s, washing and drying at the temperature of 80 DEG C. The method has simple operation process and low baking temperature of 100-180 DEG C and can help realize industrial production.

Owner:DONGHUA UNIV

Microscopic carbon fiber with a variety of structures

A microscopic carbon fiber formed of a fiber-like substance of such a structure that cylindrical graphen sheets are stacked on each other in a right-angled direction to the axis thereof, wherein the sheets forming a cylinder comprise a polygonal cross section perpendicular to the axis thereof, the maximum diameter of the cross section is 15 to 100 nm, an aspect ratio is 10<5>or less, and I / I measured by Raman spectroscopic analysis is 0.1 or less. By adding a small amount of carbon fiber, physical properties such as electric characteristics, mechanical properties, and thermal properties can be increased without impairing the characteristics of a matrix.

Owner:MITSUI & CO LTD

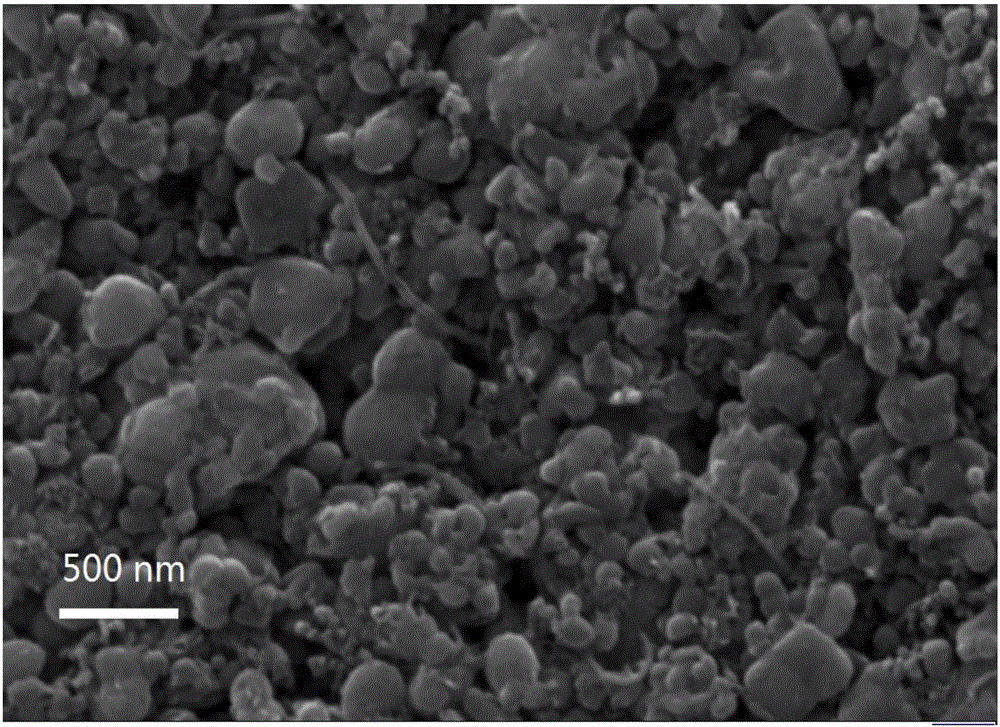

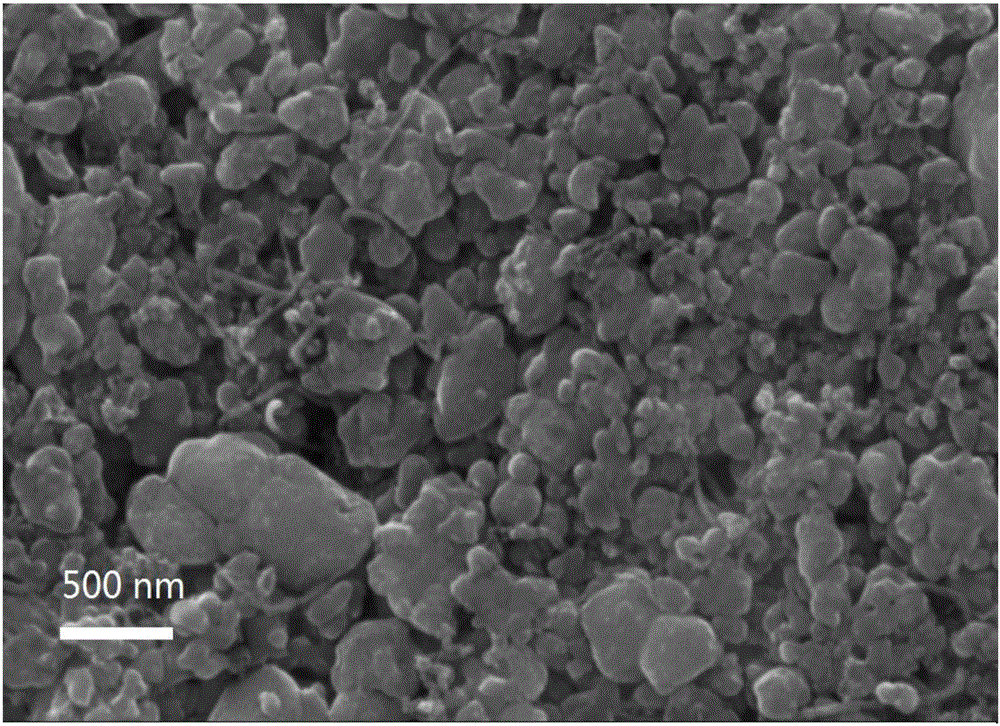

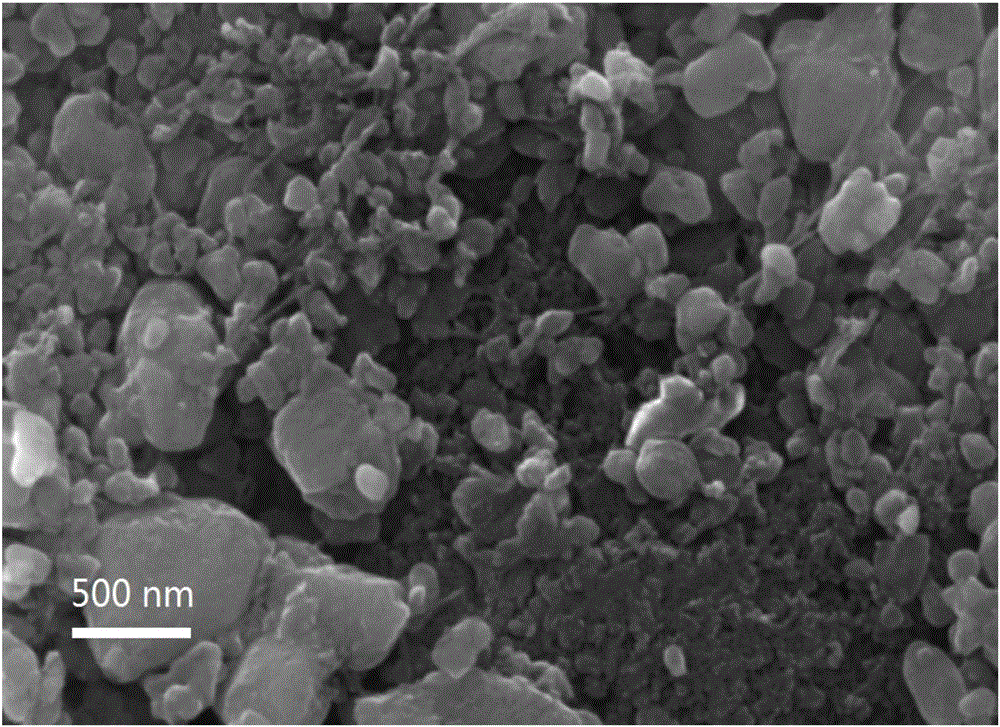

Rubber composition for tire tread and preparation method of rubber composition

ActiveCN107266750ASmall particle sizeLarge specific surface areaSpecial tyresSilica particlePolymer science

The invention provides rubber composition which is used for a tire tread and prepared from modified nano-silica filled butadiene styrene rubber. Nano-silica is modified with aliphatic diisocyanate, then water-soluble polymers are added for a grafting reaction, a barrier layer with a high dispersion structure is formed on surfaces of nano-silica particles for preparation of modified nano-silica, the modified nano-silica and butadiene styrene rubber are mixed and coagulated, and the high-performance rubber composition for tire tread rubber is prepared. The problem that nano-silica is prone to agglomeration is effectively solved, the problems that nano-silica has poor binding force with a rubber matrix and is non-uniform in dispersion are solved, and the composition has high wear resistance, low friction and wet-skid resistance. The invention further provides a preparation method of the composition.

Owner:PETROCHINA CO LTD

Method for preparing zirconium oxide ceramic

The invention relates to a method for preparing zirconium oxide ceramic, which comprises the following steps of: preparing high solid phase slurry by adopting low-toxicity gel and dispersant, then adding an initiator, performing vacuum deaeration, injecting the slurry into a mold, curing and stripping to obtain a green body, and drying and sintering the green body to obtain the ceramic. The method is used for preparing the green body which has good surface finishment, peeling resistance, cracking resistance, good uniformity and high strength, the strength of the green body is 20 to 40MPa, andthe green body can be directly machined so as to effectively reduce the subsequent processing cost; and the green body can be sintered into the ceramic at one time, the yield reaches 100 percent, theceramic has excellent performance and good stability, the strength is 800 to 1,200MPa, the fracture toughness is 10 to 20MPa.m1 / 2, the average strength is 550MPa compared with the strength of the drypressing molded ceramic, the average fracture toughness is 8MPa.m1 / 2, and the performance of the ceramic is greatly improved.

Owner:NANJING UNIV OF TECH

Thermoplastic polyurethane hollow fiber membrane and preparation method thereof

InactiveCN102000515AHigh strengthImprove throughputSemi-permeable membranesHollow filament manufactureFiltrationMelt extrusion

The invention discloses a thermoplastic polyurethane hollow fiber membrane and a preparation method thereof. The hollow fiber membrane is made of polyurethane and prepared by adopting a thermally induced phase separation process. The preparation method comprises the following steps of: mixing thermoplastic polyurethane, thinner, inorganic pore-forming agent and antioxidant uniformly by using a high-speed stirrer, melting and extruding the mixture into granules by using a double-screw extruder, then melting and extruding the granules into hollow fibers by using a single-screw extruder, performing cooling molding, and finally extracting the thinner and the inorganic pore-forming agent in the hollow fibers. The prepared thermoplastic polyurethane hollow fiber membrane has the advantages of high flux, tensile strength and compressive strength, good flexibility of membrane silks, high elongation of the membrane silks at break, good chemical tolerance, permanent hydrophilic property, dry storage and the like. The fiber membrane can be applied to filtration of household and commercial drinking water, filtration and purification of brewed wine, food and medicaments, municipal tap water and sewage treatment, industrial sewage treatment, sea water desalinization pretreatment and the like.

Owner:HUIZHOU QIXIN MEMBRANE PURIFICATION & ENVIRONMENTPROTECTION

Graphene-inorganic nanometer particle composite fiber and preparing method thereof

ActiveCN106032585AEasy to settleNot easy to precipitateInorganic material artificial filamentsArtifical filament manufactureFiberNanoparticle

A graphene-inorganic nanometer particle composite fiber and a preparing method thereof are disclosed. The method includes (1) continuously injecting a mixture of a graphene oxide solution, inorganic nanometer particles and a soluble reductant into a tubular reactor, (2) heating the tubular reactor in the step (1) at the same time of continuous injecting in the step (1) to obtain water-containing graphene-inorganic nanometer particle composite gel, and (3) continuously pulling the water-containing graphene-inorganic nanometer particle composite gel prepared in the step (2) out, and drying. Through continuous injecting into the tubular reactor and continuous pulling out, a procedure of continuously preparing a large amount of the composite fiber is achieved. The procedure is simple in process and mild in conditions. The prepared composite fiber combines application characteristics of a graphene fiber material and an inorganic nanometer material, is uniform in structure and excellent in mechanical performance and has potential application value in the fields of energy, catalysis, and the like.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

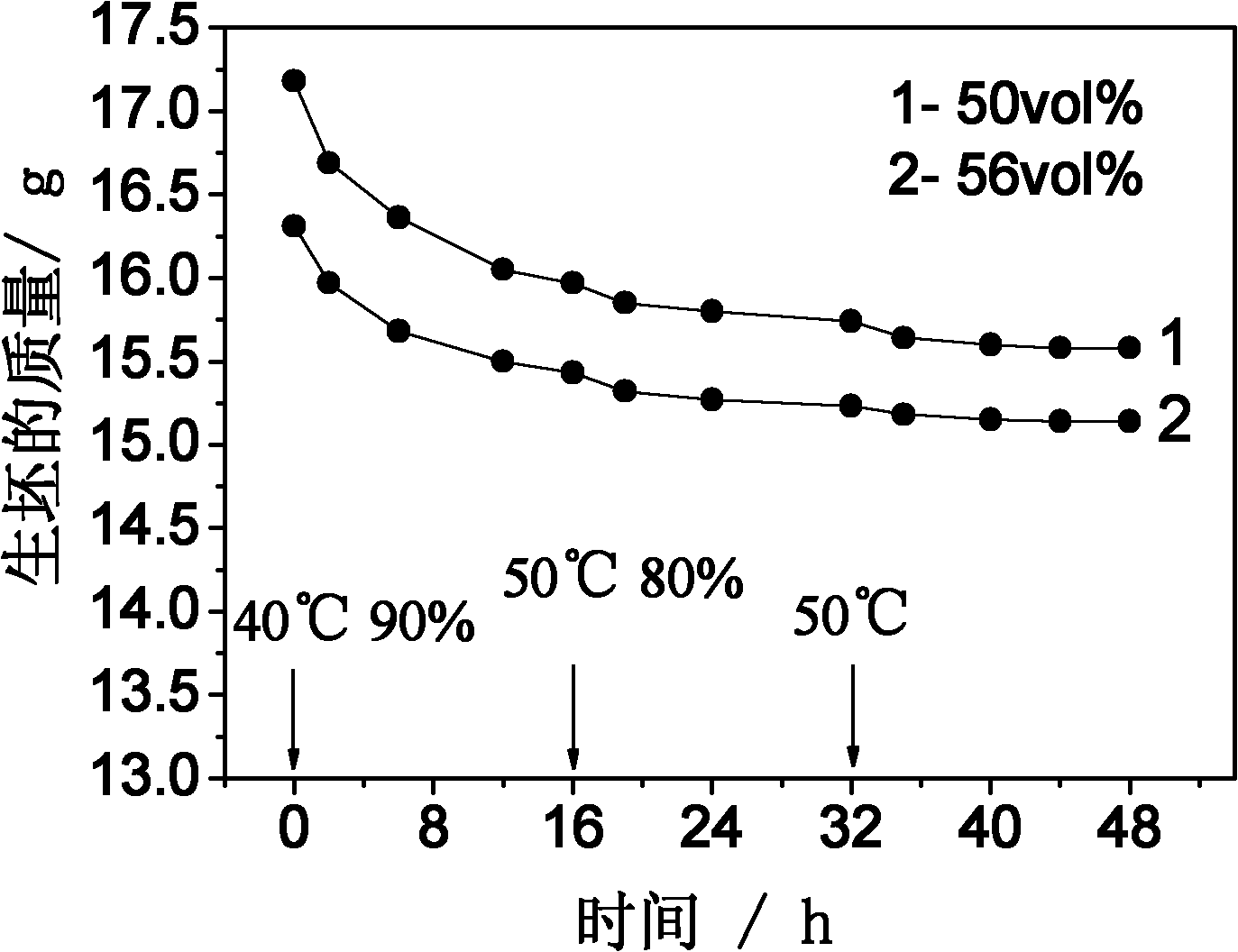

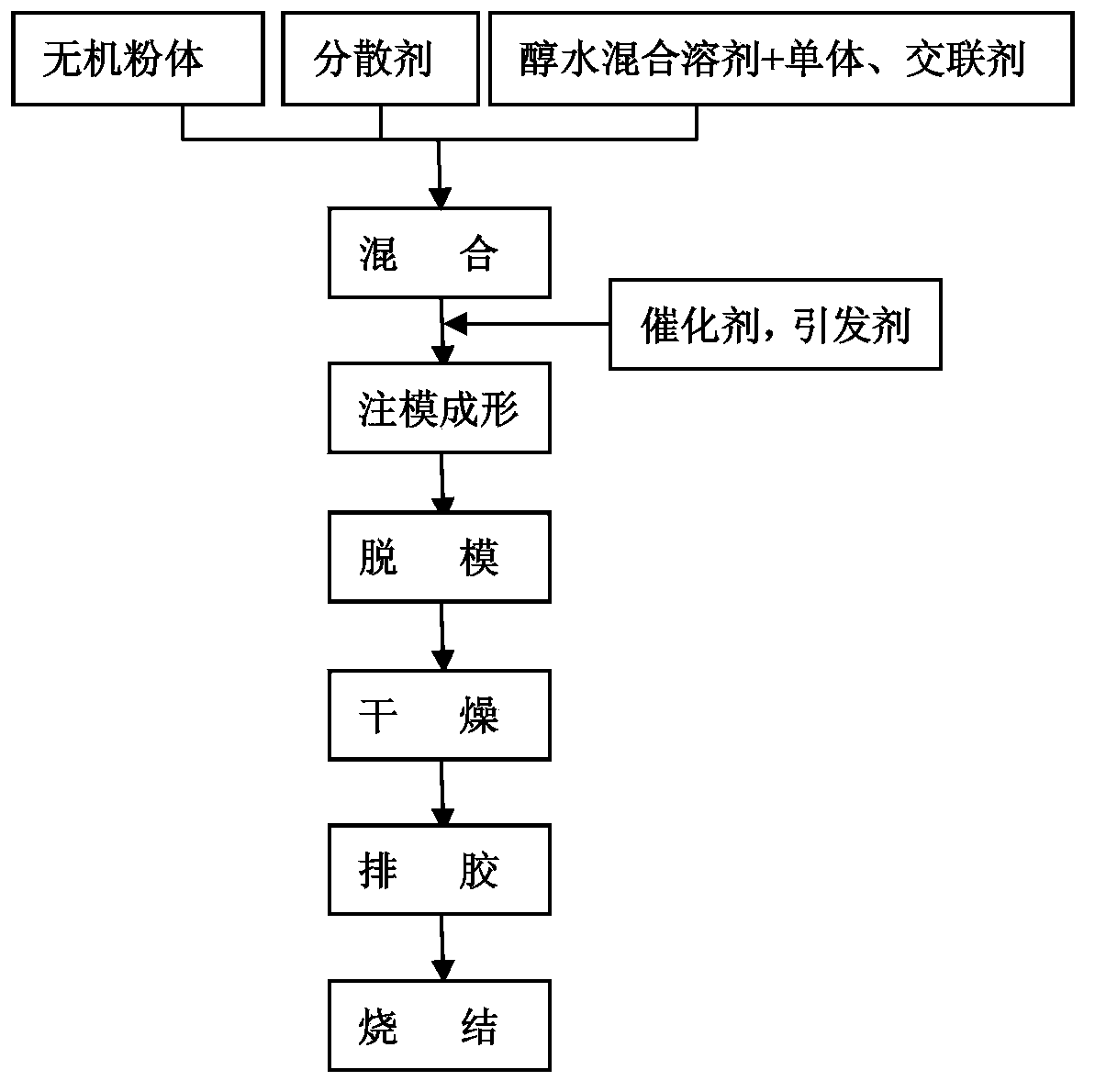

Formation technology for preparation of porous or compact material with gel-casting of alcohol-water basic material slurry

ActiveCN103406973ANot easy to shrink and deformGood dispersionCeramic shaping apparatusCross-linkAlcohol

The invention discloses a formation technology for preparation of porous or compact material with gel-casting of alcohol-water basic material slurry, which comprises the following steps: adding polymerized monomer and cross-linking agent to alcohol-water mixed solvent to premix to mixed solution, and dispersing ceramic powders or powder metallurgy powders in the obtained mixed solution through dispersing agent to prepare ceramic or powder metallurgy slurry; injecting the obtained ceramic or powder metallurgy slurry into a mould, and demoulding after solidification to obtain a wet body; conducting slowly heating up drying for the obtained wet body to obtain a dry body; and glue removing and sintering the dry body to obtain porous or compact ceramic or powder metallurgy material. According to the technology, the dry body with small shrinkage distortion and accurate size is obtained through the control for the alcohol-water ratio of the alcohol-water mixed solvent to prepare the wet body and then the combination of a special method to dry the wet body; the glue removing and the sintering can be conducted through a conventional method; the porous or compact ceramic or powder metallurgy material is prepared through the ceramic or powder metallurgy slurry cable of adapting to different solid content; the prepared porous or compact ceramic or powder metallurgy material has the advantages of uniform distribution, high bending-resistant and compressive strength, good repeatability, low cost, and the like, and facilitates the industrial production.

Owner:CENT SOUTH UNIV

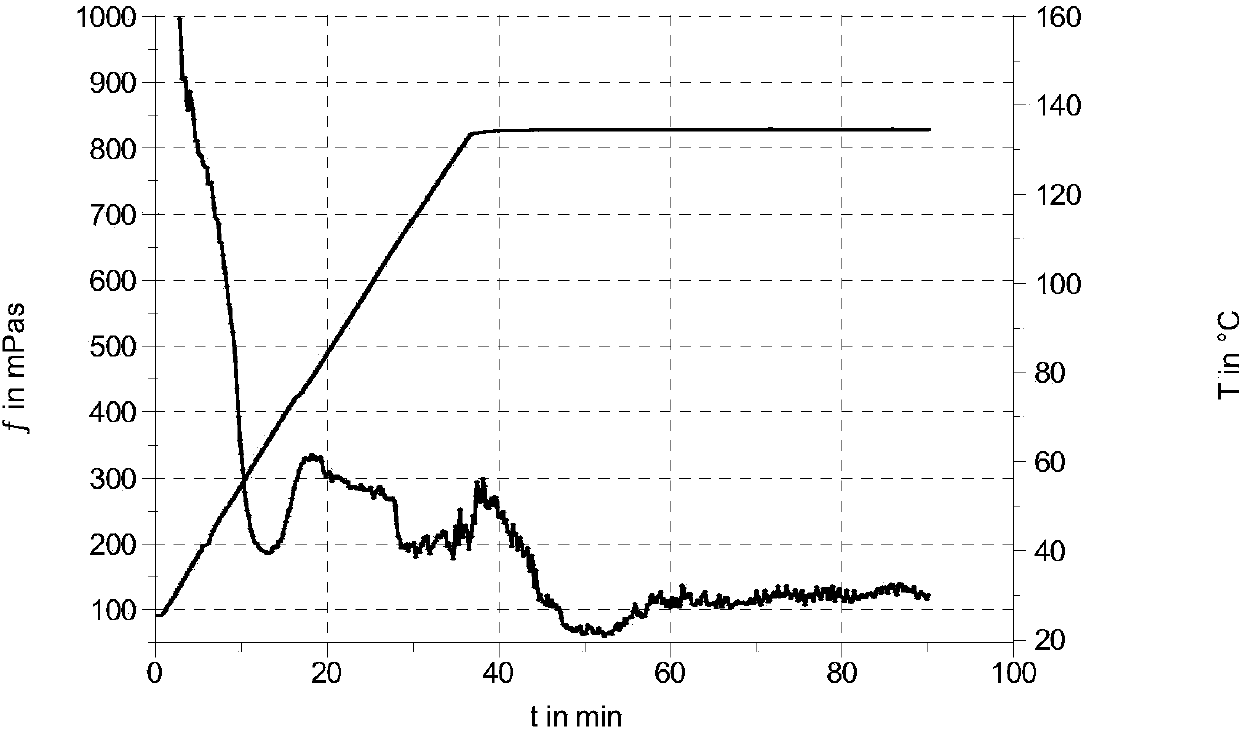

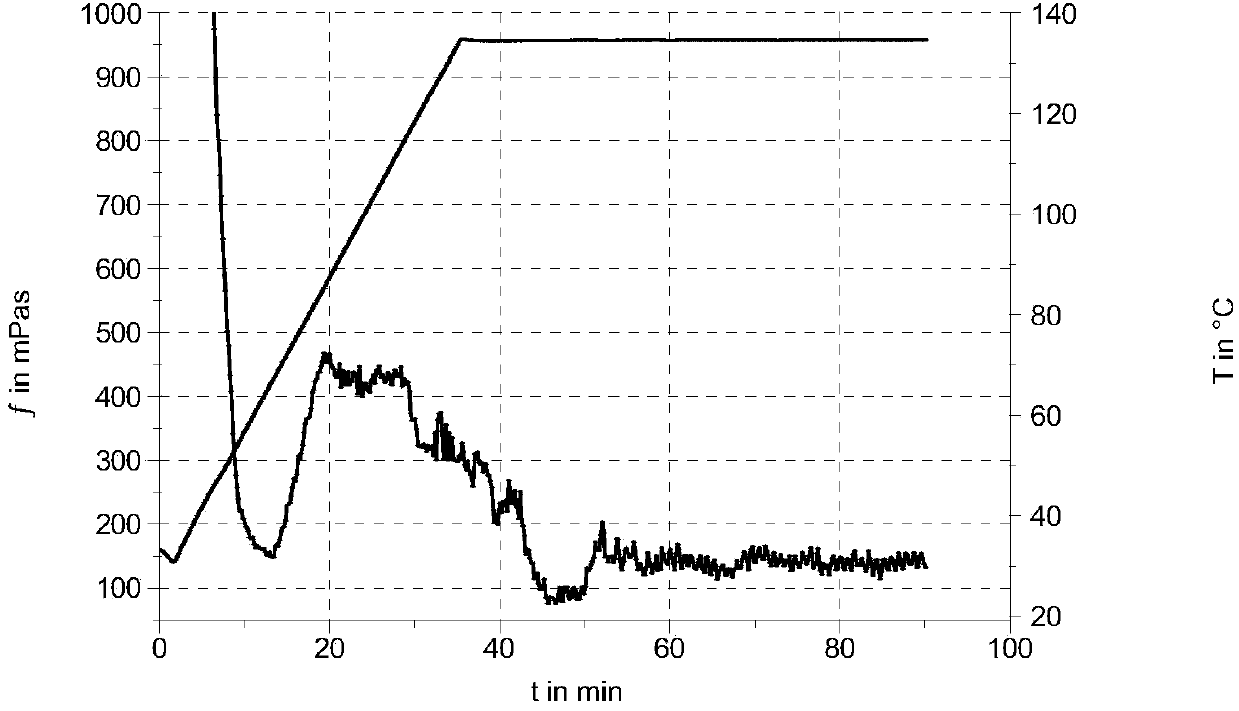

Continuously blended liquefied polymer thickener for fracturing construction

InactiveCN104194765AOvercoming Fisheyes and ClumpingDifficult to disperseDrilling compositionSolventLiquid polymer

The invention discloses a continuously blended liquefied polymer thickener for fracturing construction. The liquid polymer comprises a hydrophilic polymer, a hydrophobic oily organic solvent and other additives, wherein the additives comprise quaternary ammonium modified organic clay, a polar solvent and a surfactant. The liquid polymer is prepared by feeding each component according to a certain feeding sequence and stirring. The prepared liquid polymer can be rapidly dissolved or swollen in water and can be used as the thickener in the fracturing fluid.

Owner:CNPC BOHAI DRILLING ENG

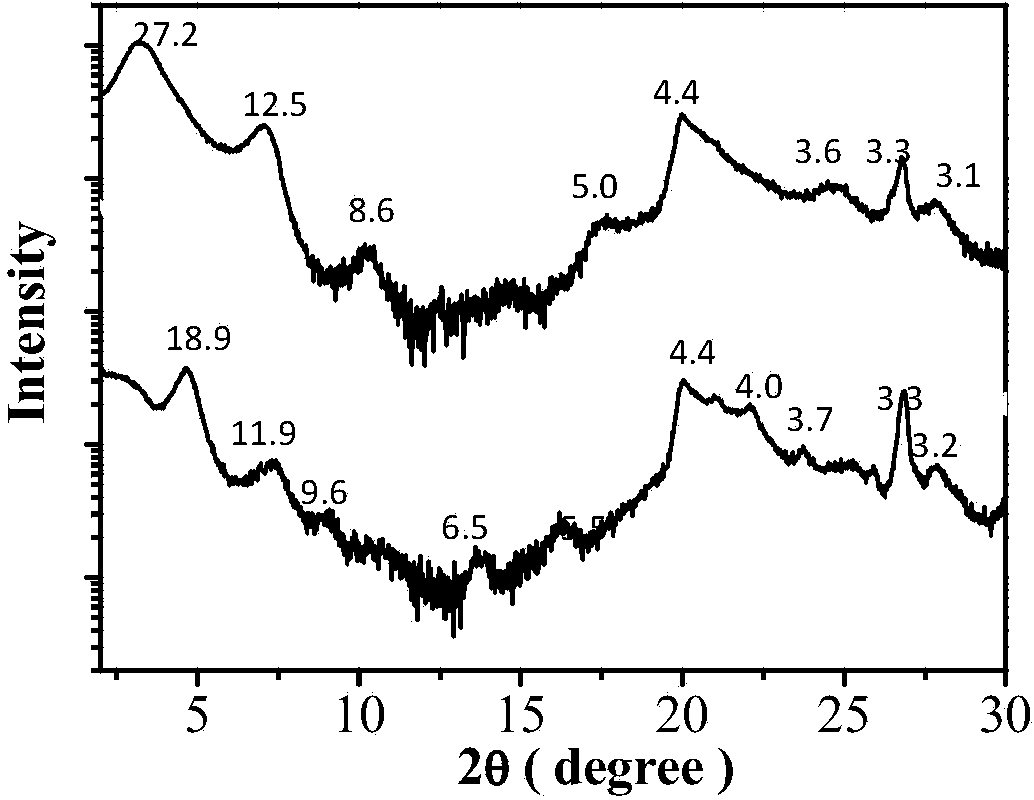

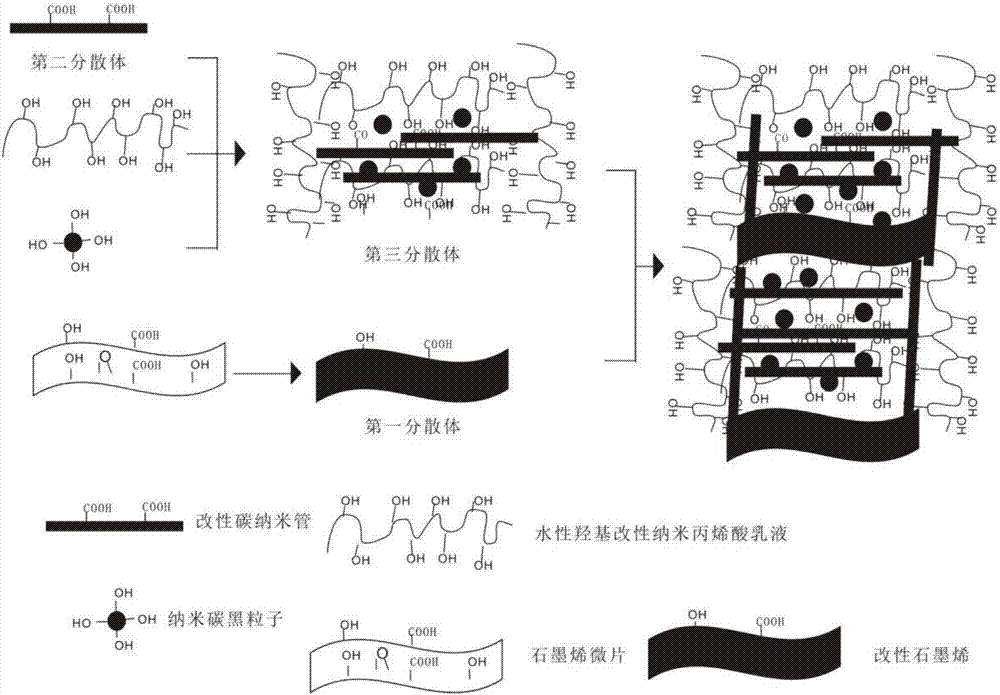

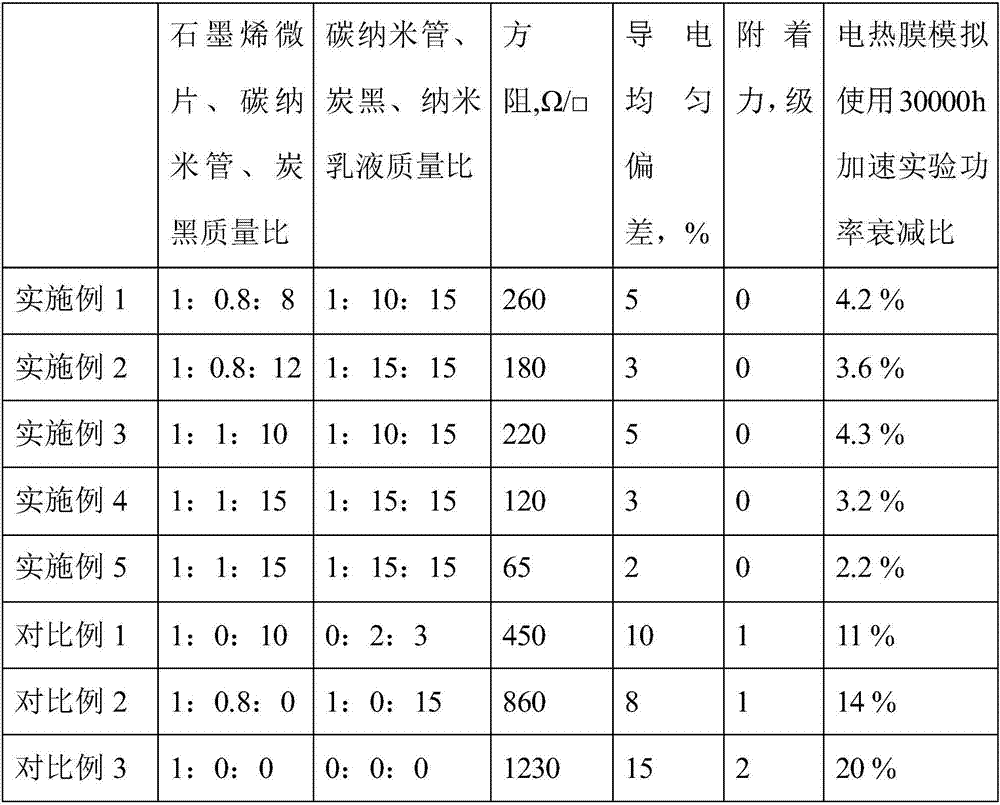

Water-based graphene/carbon nanotube composite electric-heating conversion printing ink and preparation method thereof

The invention discloses water-based graphene / carbon nanotube composite electric-heating conversion printing ink and a preparation method thereof. The preparation method comprises the following steps: uniformly stirring a graphene microchip, a water-based non-ionic high-polymer dispersant and water, and then dispersing so as to obtain a first dispersion; putting one-dimensional nano-powder into inorganic strong acid, carrying out heating reflux, carrying out ultrasonic treatment, washing with water, and drying, so as to obtain a second dispersion; uniformly mixing the second dispersion with carbon black powder, a water-based anionic dispersant, sodium dodecyl benzene sulfonate, a water-based hydroxyl-modified nano-acrylic emulsion and dimethylethanolamine, and then dispersing so as to obtain a third dispersion; and mixing the first dispersion, the third dispersion and water-based resin, grinding, adding a flatting agent, a defoamer, a pH adjusting agent, a preservative and an anti-settling agent, and uniformly mixing, so as to obtain the water-based graphene / carbon nanotube composite electric-heating conversion printing ink. The invention further discloses the water-based graphene / carbon nanotube composite electric-heating conversion printing ink.

Owner:安徽华惠福科技有限公司

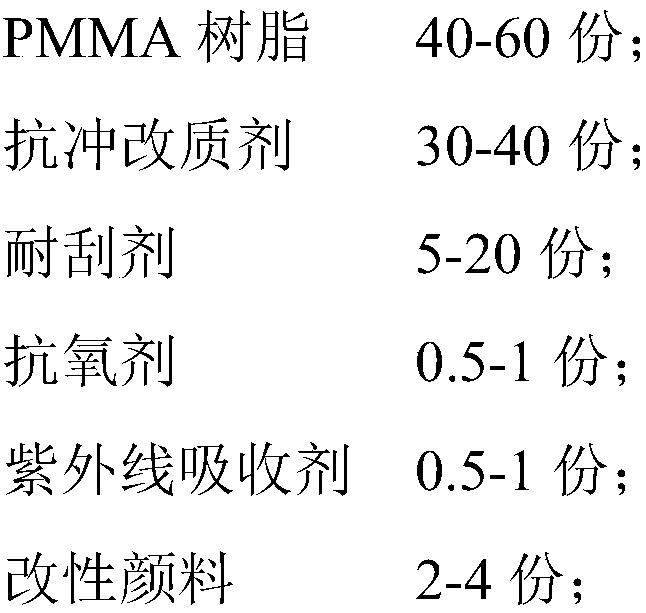

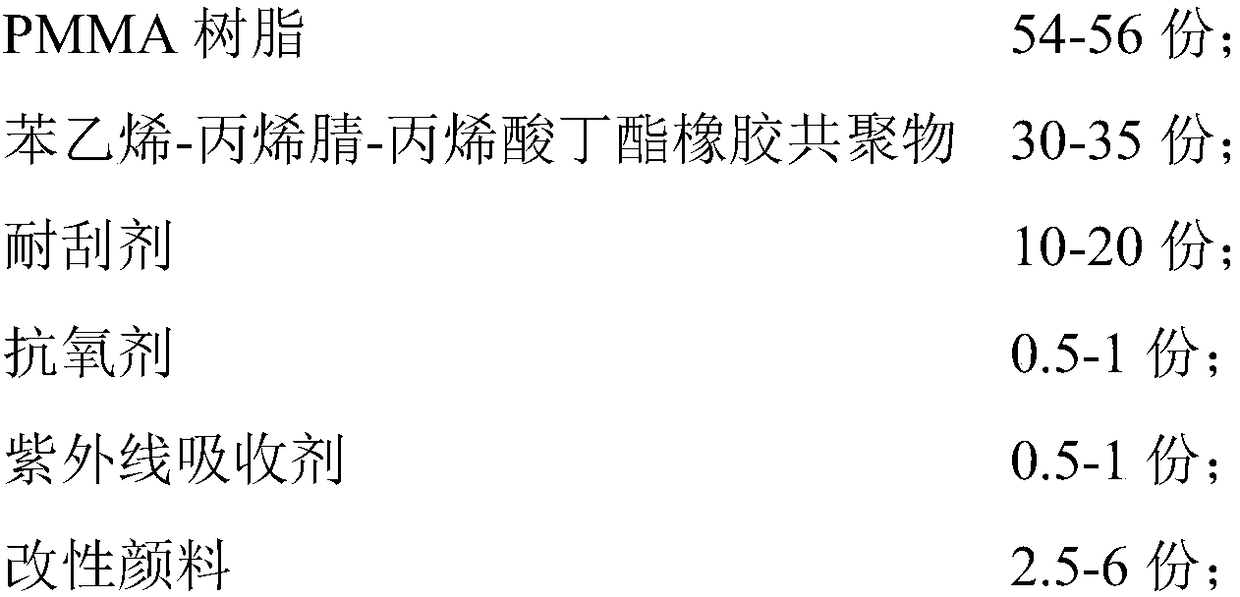

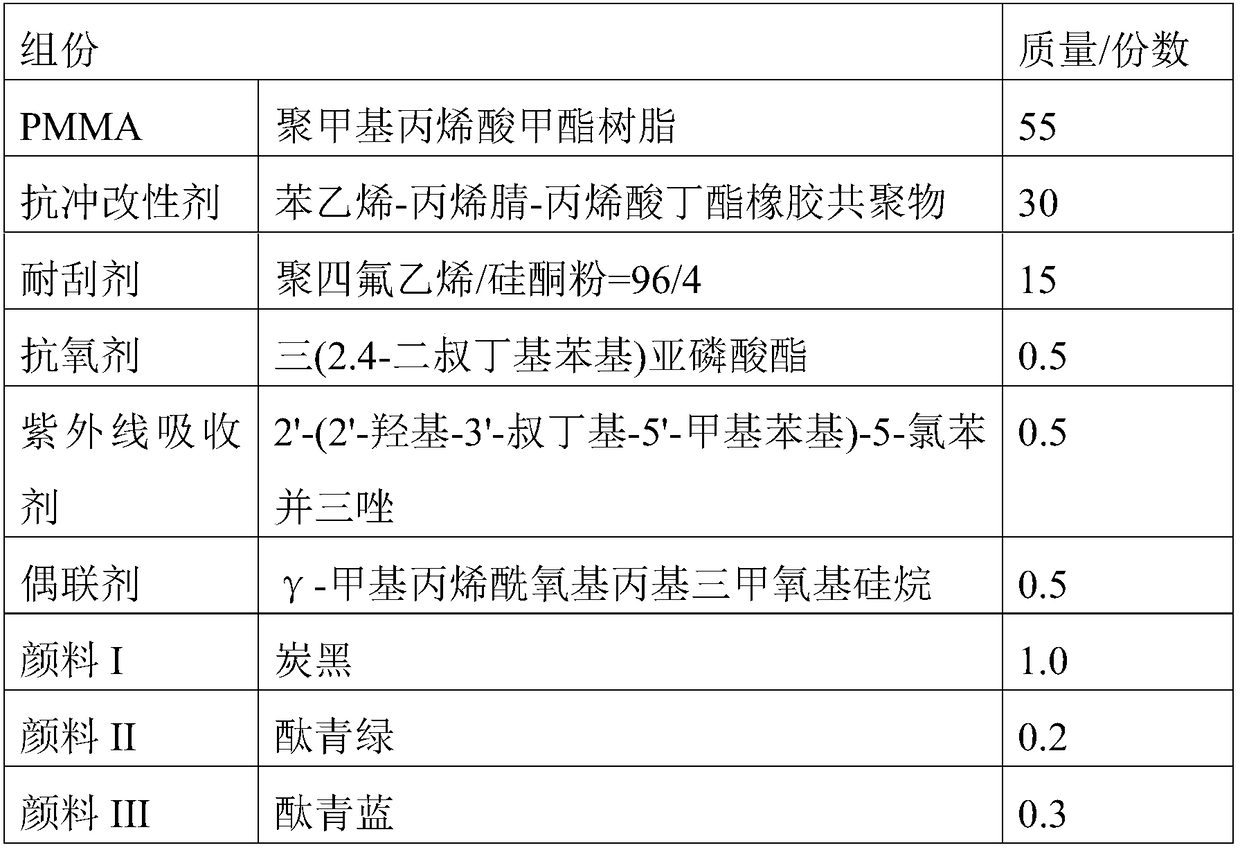

Spray-free, high-weather-resistant and scratch-resistant PMMA material and preparation method thereof

The invention relates to a spray-free, high-weather-resistant and scratch-resistant PMMA material and a preparation method thereof. The PMMA material comprises, by mass, the following raw materials: 40-60 parts of PMMA resin; 30-40 parts of an impact modifier; 5-20 parts of a scratch-resistant agent; 0.5-1 part of an antioxidant; 0.5-1 part of an ultraviolet absorbent; 2-4 parts of modified pigment; the scratch-resistant agent is prepared from, by mass, 95-98 parts of fluororesin and 2-5 parts of silicone powder. The PMMA material has excellent weather resistance and scratch resistance, and can meet the quality requirements of automobile exterior parts on the weather resistance and the scratch resistance.

Owner:FOSHAN KAIYUE GRAND SKY PLASTIC TECH CO LTD

Organic-inorganic compound fertilizer for high-yield paddy rice

InactiveCN105384527AIncrease productionProduct environmental protectionFertilizer mixturesSeabirdPesticide residue

The invention discloses an organic-inorganic compound fertilizer for high-yield paddy rice. The organic-inorganic compound fertilizer is prepared from the following raw materials in parts by weight: 20 to 50 parts of urea, 5 to 20 parts of monoammonium phosphate, 30 to 50 parts of potassium polyphosphate, 30 to 50 parts of seabird droppings, 15 to 35 parts of fermented paddy rice straws, 5 to 18 parts of fermented cow dung, 15 to 30 parts of bone dregs, 5 to 15 parts of humic acid, 2 to 8 parts of modified turf, 1 to 7 parts of paddy rice straws, 15 to 19 parts of coal ash, 5 to 12 parts of attapulgite, 1 to 6 parts of kaolin, 1 to 3 parts of manganese sulfate, 1 to 2 parts of ferrous sulfate, 1 to 4 parts of carbonic lime, 0.01 to 0.07 part of compound enzyme and 0.01 to 0.05 part of compound bacteria. A product of the organic-inorganic compound fertilizer is environment-friendly, less in pesticide residue, balanced in nutrition and high in yield of paddy rice.

Owner:高青山

Transparent and environment-friendly underwater consolidated solvent-free epoxy grouting material and preparation method and application thereof

The invention discloses a transparent and environment-friendly underwater consolidated solvent-free epoxy grouting material. The transparent and environment-friendly underwater consolidated solvent-free epoxy grouting material is prepared from a first component and a second component. The weight ratio of the first component to the second component is 100:(0.5-100). The first component is prepared from, by weight, 20-85 parts of epoxy resin, 25-80 parts of reactive diluent and 0.5-5 parts of interfacial modifier. The second component is prepared from, by weight, 10-95 parts of amine curing agent, 0-40 parts of waterproof dispersant and 0-20 parts of accelerant. The invention further discloses a preparation method and application of the transparent and environment-friendly underwater consolidated solvent-free epoxy grouting material. The grouting material is high in strength, good in water plugging and leakage preventing effect, good in waterproof performance and comprehensive mechanical property and low in toxicity, the preparation method is simple, and the application range is wide.

Owner:GUANGZHOU YINGTIAN BUILDING MATERIAL TECH CO LTD

Water plugging agent for carbonatite and preparation method and using method thereof

InactiveCN101712863AHigh densityLow densityDrilling compositionSealing/packingHigh densityVolumetric Mass Density

The invention provides a water plugging agent for carbonatite and a preparation method and a using method thereof. The water plugging agent consists of the following raw materials in part by weight: 5 to 14 parts of cement, 4 to 8 parts of quartz, 0.1 to 0.5 part of cement flocculating agent, 4 to 11 parts of density lightening admixture, 1 to 2 parts of grid structure agent and 72 to 74 parts of water. The water plugging agent has high bonding strength and low density, and is suitable for high-temperature and high-mineralization carbonatite oil wells so as to solve the problem that the water plugging agent in the prior art is not suitable for the high-temperature and high-mineralization environment, has poor bonding strength and high density, and cannot effectively control water or improve the oil recovery ratio.

Owner:北京德美高科科技股份有限公司

Environmental-friendly disposable plant fiber tableware and preparation method thereof

The invention discloses an environmental-friendly disposable plant fiber tableware which comprises the following raw materials in parts by weight: 10-18 parts of rice husk, 15-25 parts of corn straw, 10-20 parts of dried straw, 2-4 parts of starch, 8-14 parts of an adhesive, 4-10 parts of processing aids, 2-4 parts of plant albumen glue and 1-3 parts of plant polysaccharide. The disposable tableware disclosed by the invention is non-toxic and harmless, is relatively good in mechanical property, relatively good in mechanical strength and toughness, green and environmental-friendly in raw material, relatively good in degradability, wide in raw material source, safe and reliable in component, harmless to human bodies, low in cost, safe and convenient, simple in preparation process and has relatively high practical values and good application prospects, both resources are saved and environment pollution is reduced, and comprehensive utilization of agricultural wastes is achieved.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

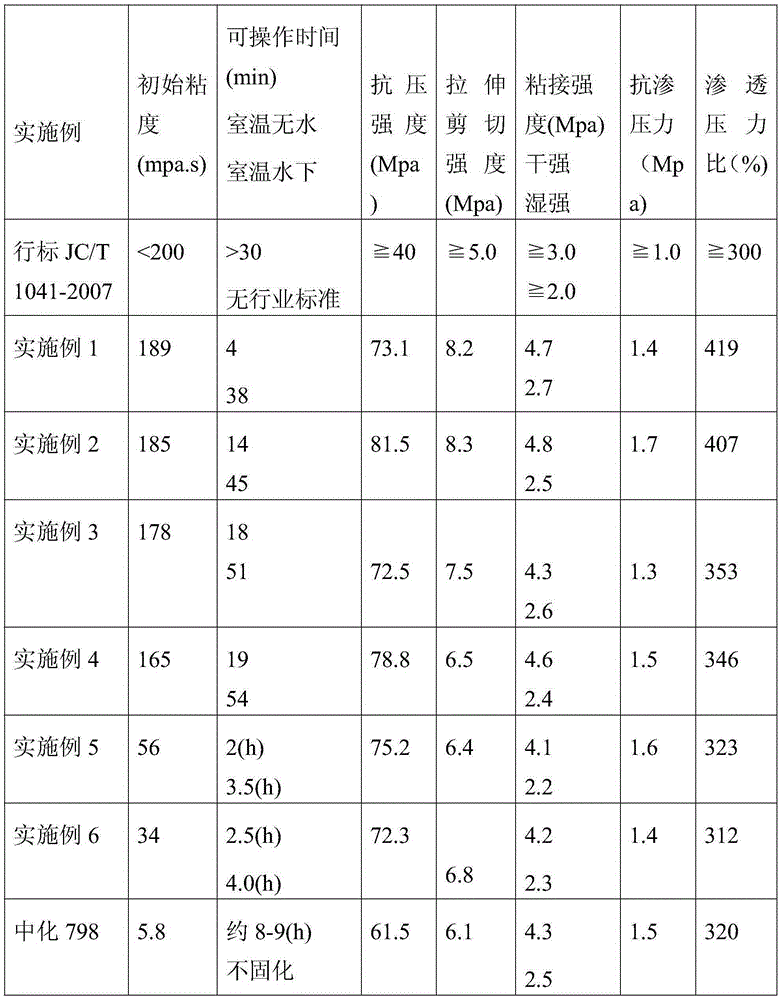

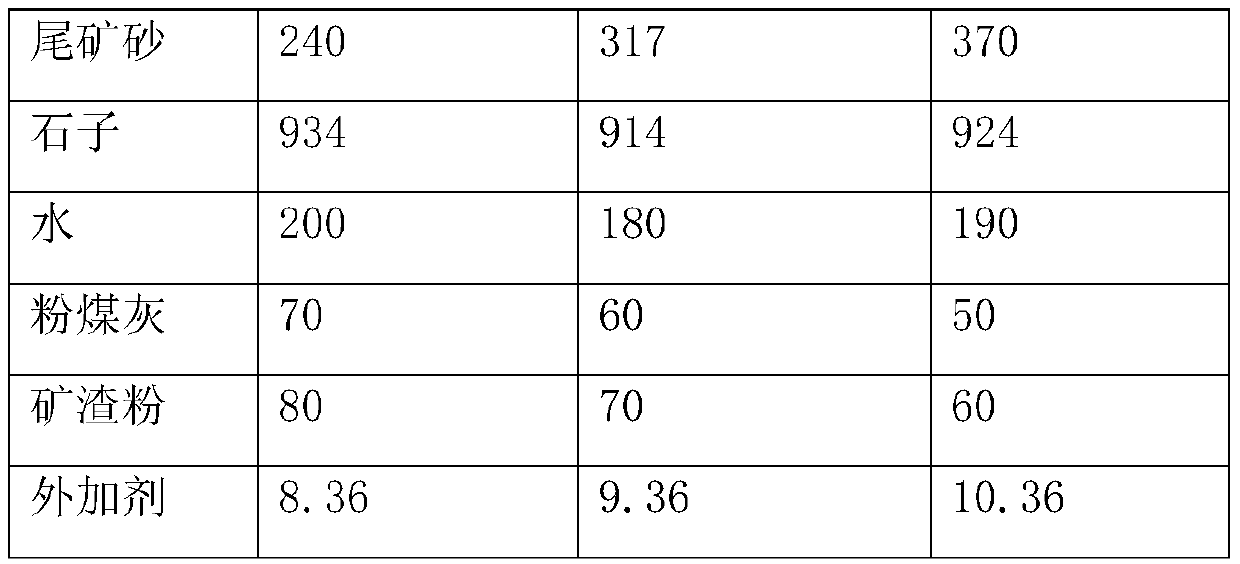

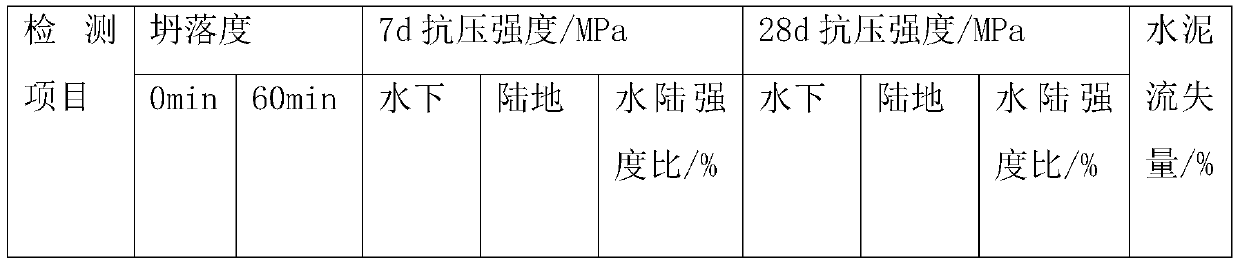

C30 tailing sand concrete and preparation method thereof

The invention discloses a C30 tailing sand concrete and a preparation method thereof. The C30 tailing sand concrete includes cement, sands, tailings sands, broken stones, water, fly ash, slag powder and an admixture; the tailing sands have a fineness modulus of 2.1-2.3 and a mud content of below 5%; the admixture is prepared by mixing a water reducer, a flocculant, a reinforcing component and modified bentonite according to a mass ratio of 1:(0.8-1.2):(4.5-5.5):(0.04-0.06); and the reinforcing component is prepared by mixing triethanolamine, polydimethylsiloxane and modified coal gangue powderaccording to a mass ratio of 1:(0.4-0.6):(1.2-1.5). The C30 tailing sand concrete of the invention has the advantages of good workability, small slump loss, and low dispersibility during underwater construction.

Owner:青岛中建富兴商砼有限公司

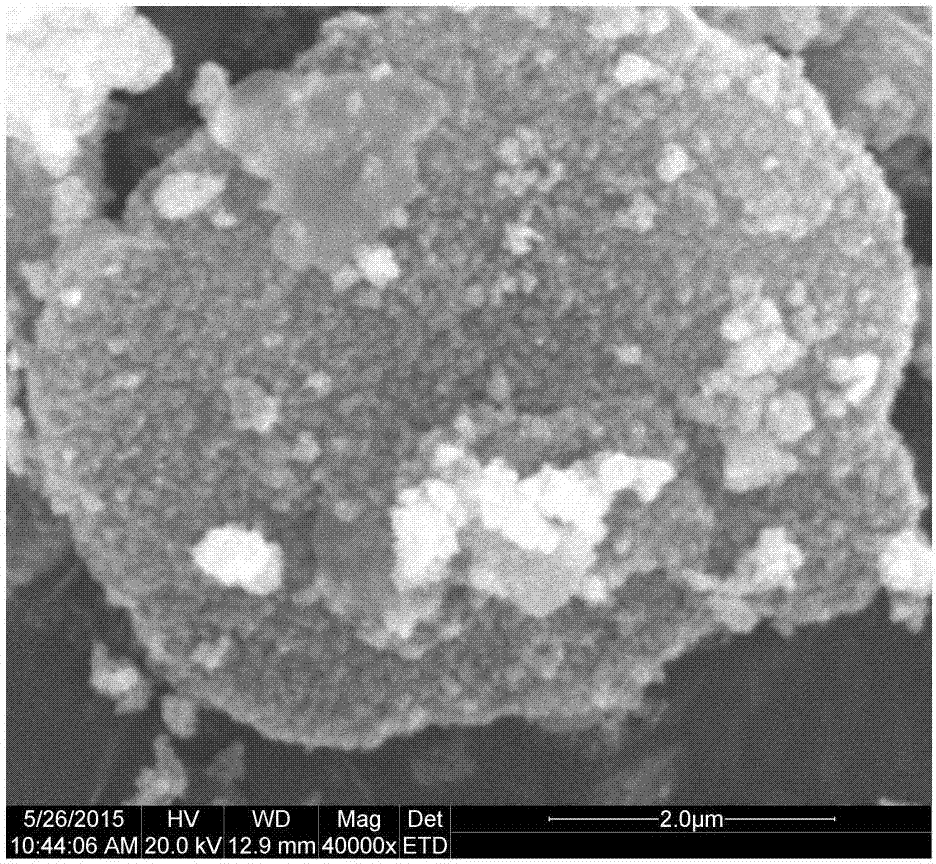

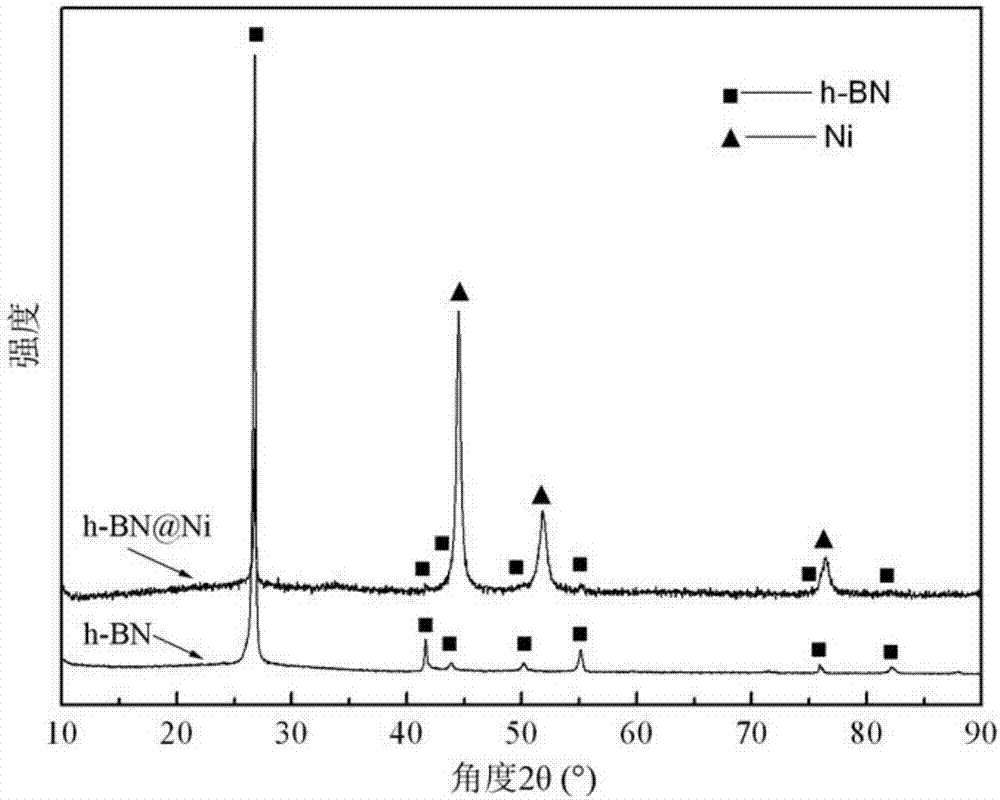

Self-lubricating ceramic cutter material with h-BN@Ni core-shell structure composite powder added and preparation method of self-lubricating ceramic cutter material

ActiveCN106904947AGood dispersionImprove mechanical propertiesChemical platingHexagonal boron nitride

The invention relates to a self-lubricating ceramic cutter material with h-BN@Ni core-shell structure composite powder added and a preparation method of the self-lubricating ceramic cutter material. The self-lubricating ceramic cutter material is prepared from components in percentage by mass as follows: 25%-45% of alpha-Al2O3, 50%-70% of (W,Ti)C, 2%-10% of h-BN@Ni composite powder in terms of the mass of h-BN and 0.4%-1.5% of MgO. The preparation method comprises the steps as follows: sensitizing and activating h-BN powder, preparing h-BN@Ni composite powder through chemical plating, preparing alpha-Al2O3, (W,Ti)C and h-BN@Ni suspensions respectively, performing ball milling and vacuum drying, placing obtained mixed powder into a mold, and performing cold-press forming and hot-press sintering. The breaking tenacity of the self-lubricating ceramic cutter material can be improved substantially, the sintering temperature of the ceramic cutter material can be decreased, energy is saved, and environmental protection is facilitated.

Owner:QILU UNIV OF TECH

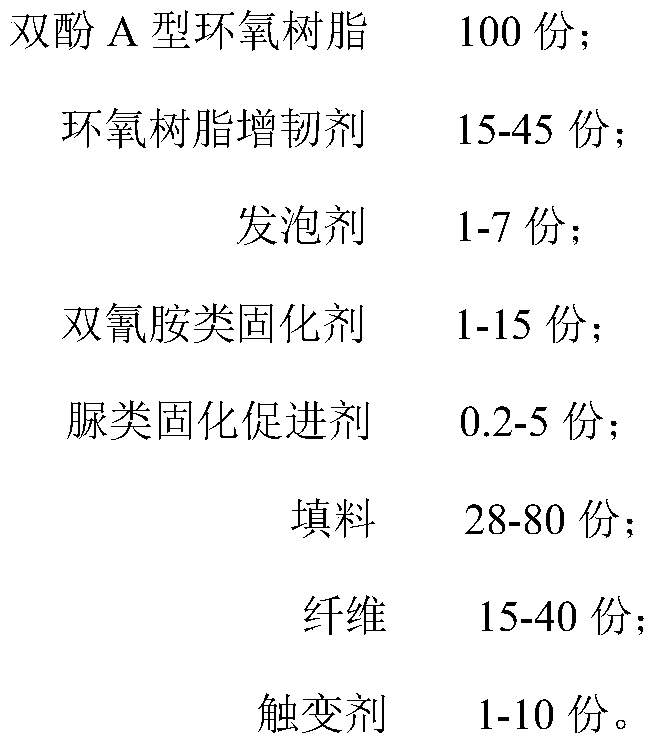

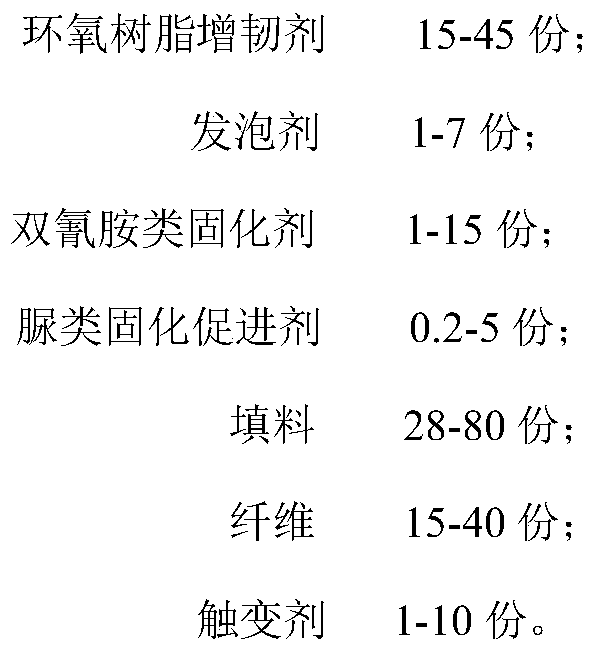

Foam composition with epoxy group structure and preparation method and application thereof

Th invention discloses a foam composition with an epoxy group structure and a preparation method and application thereof. The foam composition with the epoxy group structure is prepared from, by weight, 100 parts of bisphenol-A epoxy resin, 15-45 parts of epoxy resin toughening agent, 1-7 parts of foaming agent, 1-15 parts of dicyandiamide curing agent, 0.2-5 parts of urea curing accelerator, 28-80 parts of filler, 15-40 parts of fibers and 1-10 parts of thixotropic agent. The foam composition is prepared by adding the raw materials step by step and then conducting processing kneading and curing foaming. Compared with an existing epoxy foaming material, the foam composition has higher shearing strength and compressive strength, and meanwhile the processing method is simple; the foam composition can serve as structural foam to be used as a reinforcing material in automobiles or planes, when the foam composition is used in a whole automobile, the weight of the whole automobile can be reduced, energy absorption of an automobile framework can further be improved under the collision situation, and therefore the safety of the whole automobile is improved. In addition, the foam composition can be applied to other transportation and mechanical equipment which are possibly subjected to collisions.

Owner:YOULIAN NEW MATERIAL TECH SHANGHAI CO LTD

Catalytic cracking catalyst and its preparation

The invention relates to a preparation method of catalytic cracking catalyst, which comprises a step of mixing a matrix, a molecular sieve with water for beating. The invention is characterized in that the matrix includes at least one component having a fibrous structure and taking the weight of the solid in the slurry as reference, the content of the matrix in the slurry is 40 to 95 percent by weight, and the content of the molecular sieve is 5 to 60 percent by weight, wherein, the content of the component having a fibrous structure is 1 to 50 percent by weight. The catalytic prepared by themethod has less surface crack, high strength and strong anti-Ni pollution capability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com