Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Not easy to shrink and deform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

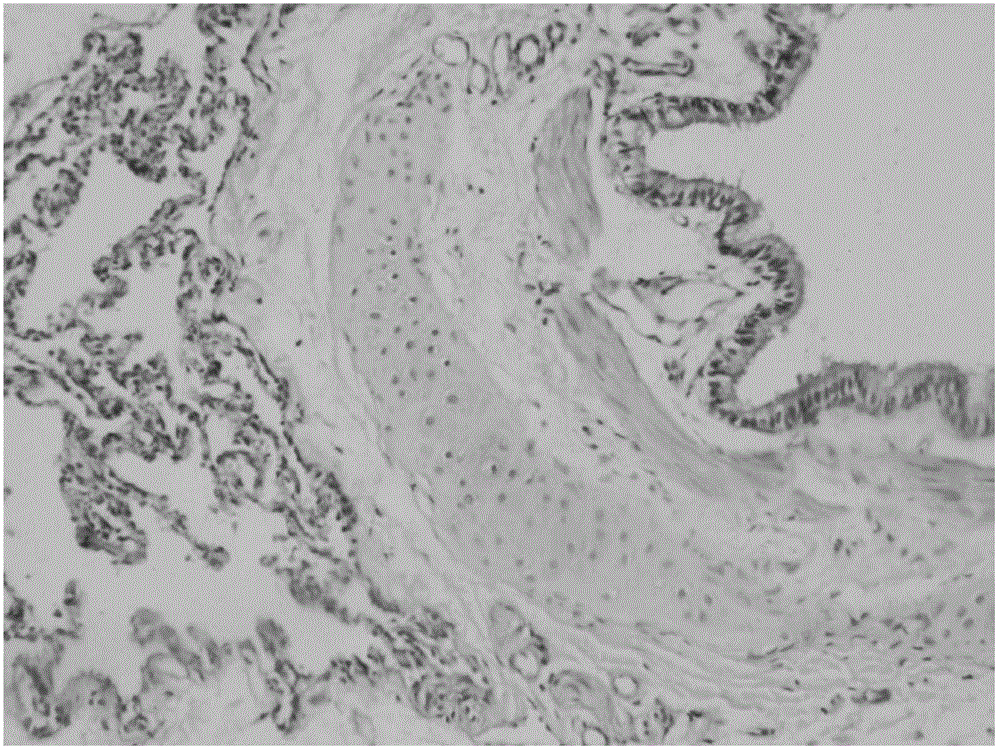

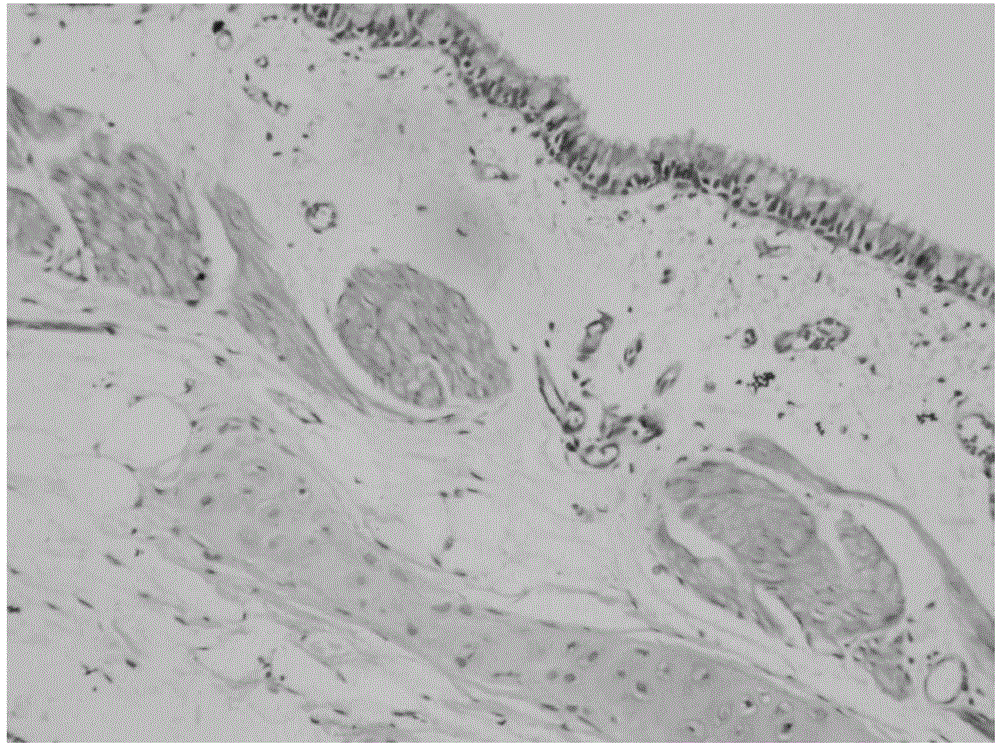

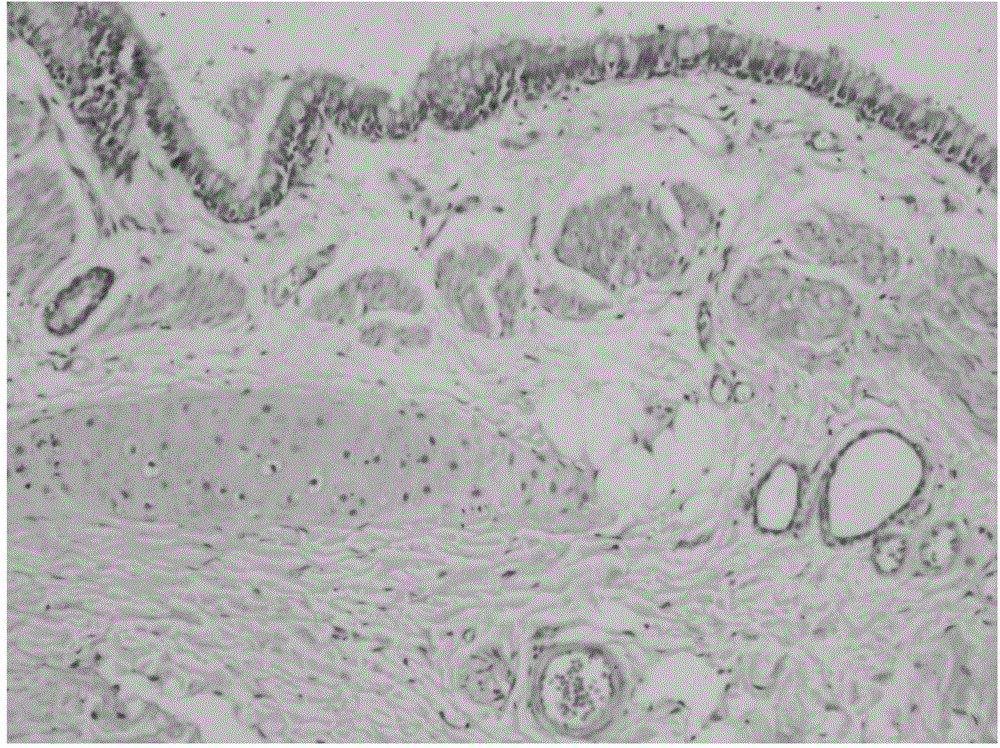

Tissue dewaxing transparent agent free of benzene

InactiveCN104155160ASoft effectNot easy to shrink and deformPreparing sample for investigationLiquid base cytologyStaining

The invention relates to a tissue dewaxing transparent agent free of benzene, which is used in biological histology, histopathology or forensic science, can make a tissue transparent, and can make the tissue dewaxed. The tissue dewaxing transparent agent belongs to the technical field of in vitro diagnostic reagents. The tissue dewaxing transparent agent mainly contains 95%-100% of alicyclic hydrocarbon, and the balance of accessories; the alicyclic hydrocarbon is a monocyclic alicyclic hydrocarbon or a bicyclic alicyclic hydrocarbon. The tissue dewaxing transparent agent free of benzene has the advantages of being non-toxic, soft in effect, and not easy to cause shrinkage, deformation, hardening and embrittlement of a tissue material, capable of improving the section intact rate, insensitive to the humid environment, not easy to muddy due to absorption of moisture in the air, and the like; not only can be used for liquid based cytology, immunohistochemistry, biological histology, routine pathological diagnosis, and immunohistochemical diagnostic techniques, is also suitable for special staining method and histochemical techniques. The refractive index of used alicyclic hydrocarbon transparent agent (cyclohexane) is 1.42, the (methyl cyclohexane) refractive rate is 1.42, and is basically consistent with the tissue refractive index (1.418), and the transparent effect is better.

Owner:陆可望 +1

Method for producing automotive rear shelf

The invention relates to a method for producing an automotive rear shelf. The method is characterized by comprising the following steps of: (1) heating: hanging polypropylene sheets in a two-layer drying oven and heating, wherein the temperature of an upper-layer drying oven of the two-layer drying oven is between 240 and 260 DEG C; the temperature of a lower-layer drying oven of the two-layer drying oven is between 325 and 345 DEG C; and the heating time is 85 to 95 seconds; (2) pressing and forming: laying a fabric on two layers of PP sheets flatly, and pressing and forming the fabric in a die to obtain a half-finished product, wherein the pressure during pressing and forming is 70 to 90kg / cm<2>, and the forming time is 60 to 70 seconds; (3) cooling and shaping: cooling and shaping the half-finished product at the normal temperature, wherein the cooling time is 30 to 50 seconds; (4) installing accessories: installing the accessories on the half-finished product to obtain an automotive rear shelf finished product; and (5) examining and packing, wherein the fabric is a non-woven fabric, and the PP sheets are PP wood powder sheets with glue. The method ensures the performance indexes of light weight, high strength, difficult contraction distortion and the like of a rear shelf, greatly reduces the weight of the rear shelf, and meets the requirement for lightweight vehicle design; and as the material has a double-layer wood powder sheet structure, the product is fuller.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Production method of vehicular coat and hat rack

InactiveCN101357612AReduce weightNot easily deformedRacks dispositionEnvironmental resistanceWork in process

The invention relates to a method for manufacturing a coatrack of an automobile, which pertains to the technical field of automobile interior trim parts; the method comprises the steps: a natural fiberboard is taken as a board body of the coatrack; press forming, cool setting, fabric attaching, die cutting and accessory mounting are carried out to the board body of the coatrack. The board body is claimed as a finished product after passing the examination. The method of the invention achieves the performance indexes of a coatrack assembly, such as heat resistance, light weight, high strength, low contractility and low deformability and reaches the Grade 3 of the international leading level, thereby reducing the weight of the coatrack and meeting the design requirement of light weight of the whole automobile; the process adopts the double-oven suspension heating and molding line production, with stable technique; a semi-automatic assembling fixture is adopted in the installation, thereby ensuring safe accuracy and improving working efficiency. No semi-manufactured goods accumulate during the course so that the manufacturing cost can be saved. No harmful substance is generated in the whole production process so that the coatrack produced by the method of the invention is environment-friendly.

Owner:WUXI GISSING AUTO PARTS CO LTD

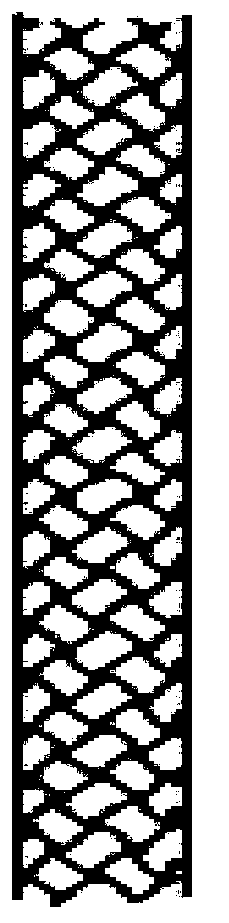

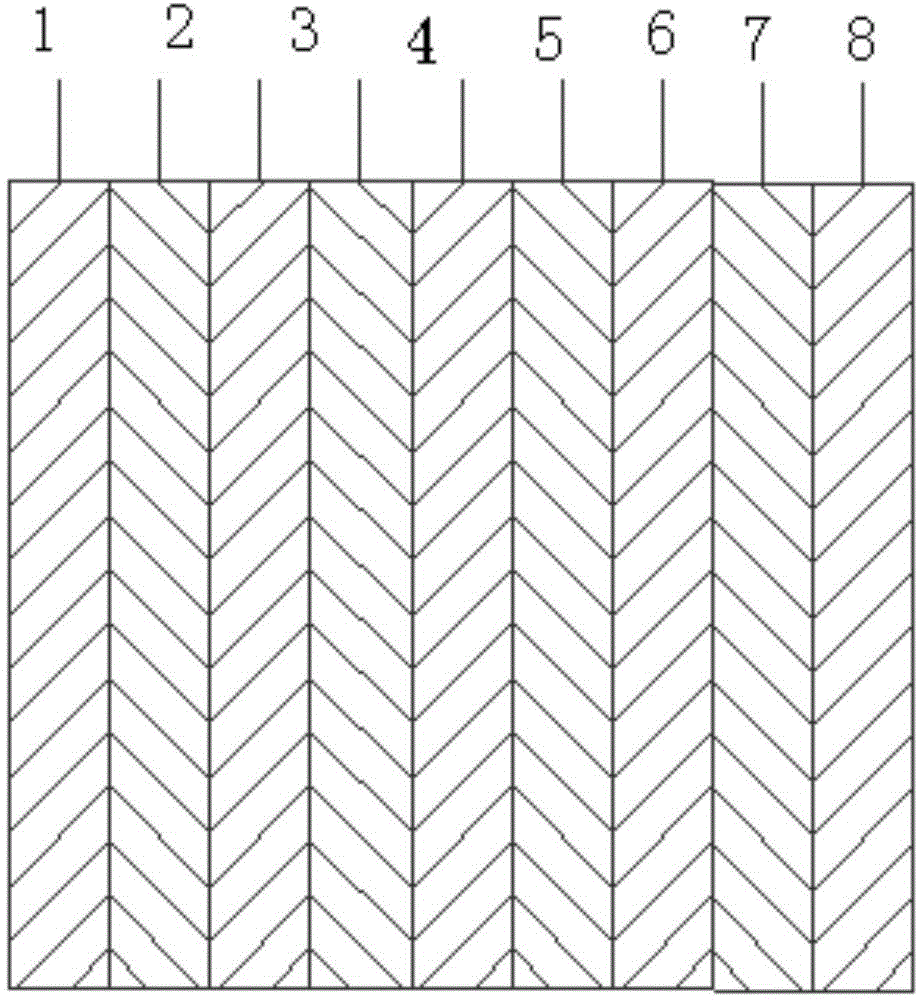

Production process of basalt gridding cloth

ActiveCN104342929AGood alkali resistanceGood flexibilityFibre treatmentGauze-woven fabricsBond propertiesBasalt fiber

The invention discloses a production process of basalt gridding cloth. The basalt gridding cloth is prepared by adopting fiber woven fabrics of basalt as base materials, soaking in acrylic polymer emulsion for coating, carrying out twist-weaving of gauze weaves, and then carrying out alkali-resistant treatment with an alkali-resistant penetrating agent and high-temperature heat setting treatment with an enhancing agent. The production process is characterized in that the fiber woven fabrics of the basalt are adopted as base materials and are soaked by the acrylic polymer emulsion, so that the alkali resistance, the flexibility and the tensile strength of the warp-direction and weft-direction heights are good; and then the alkali-resistant treatment with the alkali-resistant penetrating agent and high-temperature heat setting treatment with the enhancing agent are carried out, and finally, by amino silicon oil, the handfeel and the flexibility of a product are greatly improved. The basalt gridding cloth is good in chemical stability, resists alkali, acid, water, cement erosion and other chemical corrosion, is strong in bonding property with resin, is easily dissolved in styrene and the like, is high in strength and modulus and light in weight, is good in size stability, is stiff and flat, is not easily shrunk and deformed, is excellent in positioning performance and better in impact resistance, is anti-mildew and insect-resistant, and is fireproof, heat-insulating, sound-insulating and insulated.

Owner:HONGXIANG NEW GEO MATERIAL

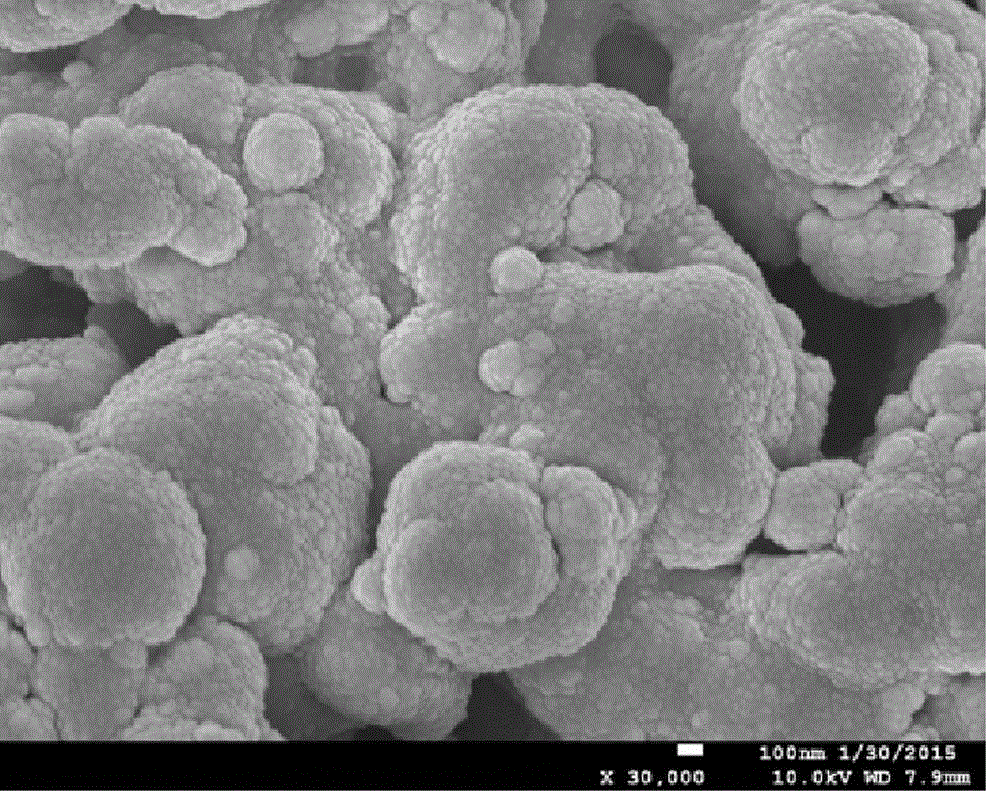

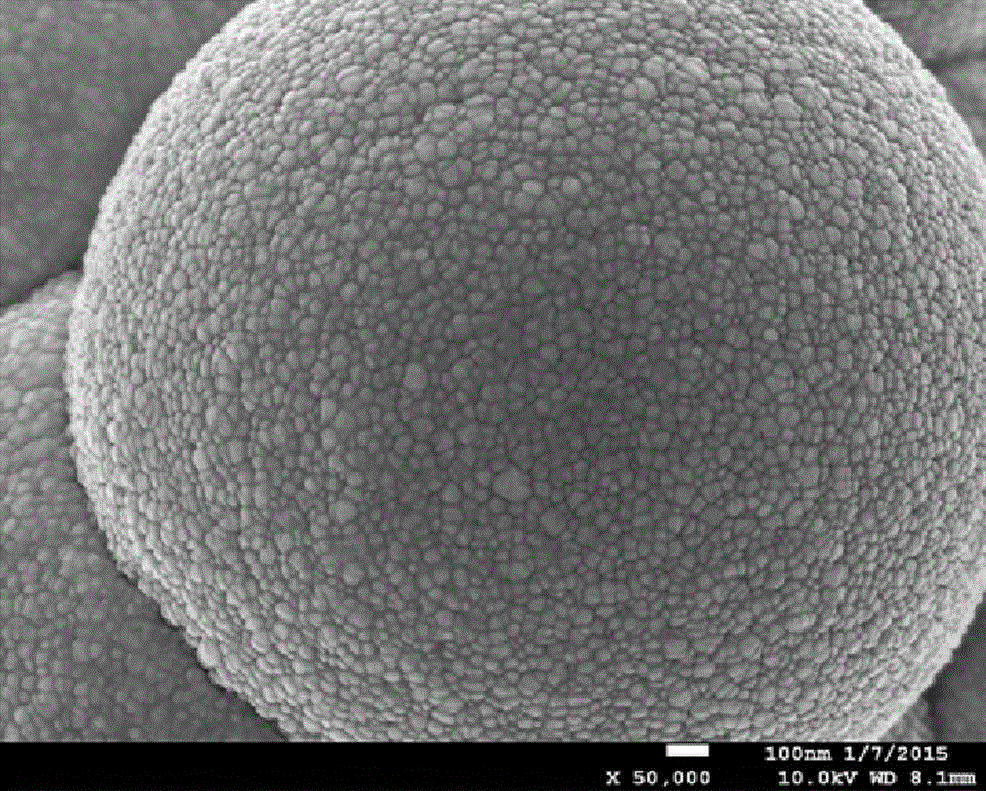

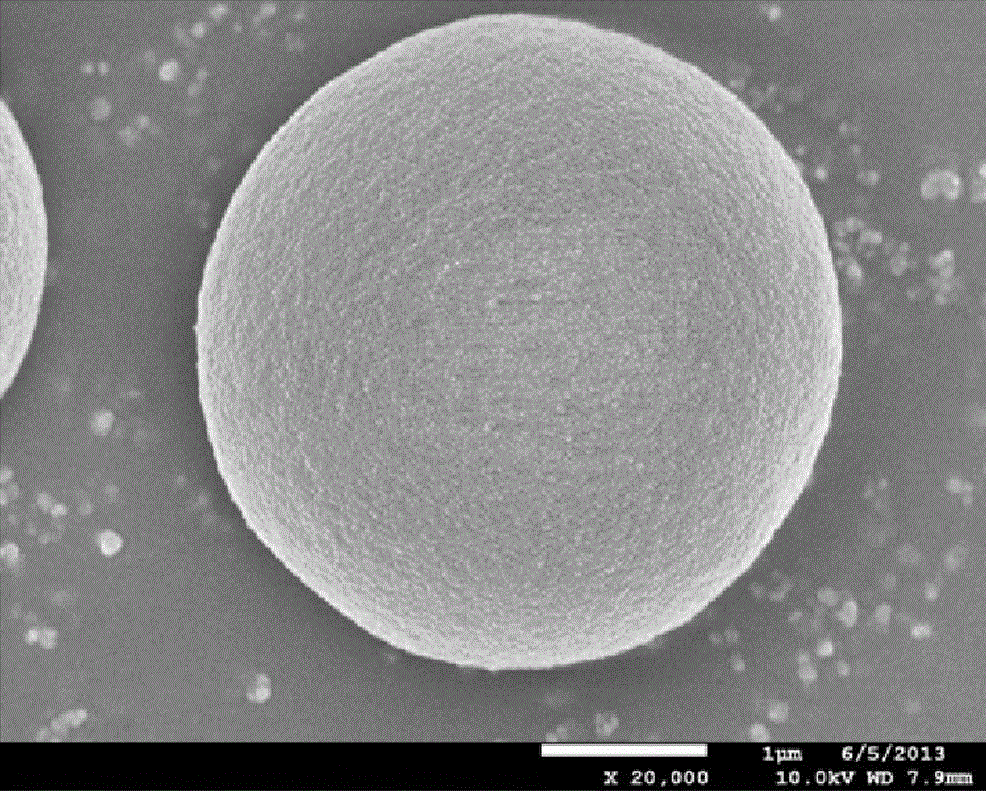

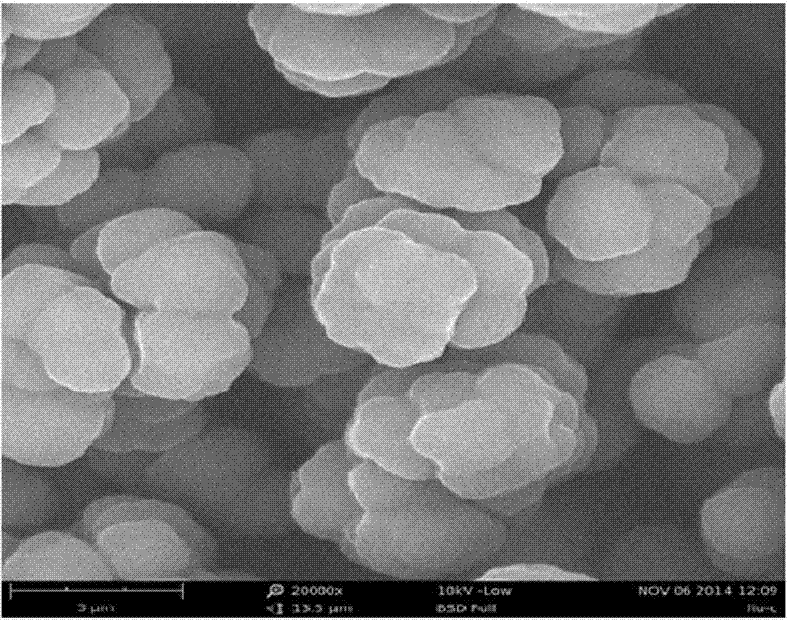

Preparation method for ionic liquid hybrid imprinted material

ActiveCN105131181ASolve complexityResolve separabilityOther chemical processesFunctional monomerDouble bond

The invention discloses a preparation method for an ionic liquid hybrid imprinted material. The preparation method comprises the following steps: uniformly mixing a silylating reagent containing an electronegative group at the tail end of an alkyl chain and an imidazole compound in a molar ratio of 1:(1-3) and carrying out a reaction to obtain an ionic liquid; sequentially adding template molecules, functional monomers, a crosslinking agent containing 2-3 double-bond functional groups and an initiator into the ionic liquid, and fully dissolving the components to obtain an organic phase; dissolving a silane crosslinking agent in an organic solvent, and sequentially adding water and ammonia water to dissolve to obtain an inorganic phase; introducing nitrogen, adding the organic phase into the inorganic phase, and carrying out a reaction at 60-80 DEG C for 8-36 hours; washing out the template molecules; and washing the liquid to neutral and drying the liquid to obtain the ionic liquid hybrid imprinted material. The material prepared by the preparation method disclosed by the invention can be used for extracting and separating various and multiple types of targets and the whole preparation process is mild in reaction condition, relatively low in equipment demand, simple in process, convenient to operate, environmental-friendly and suitable for large-scaled production, popularization and application.

Owner:HEBEI UNIVERSITY

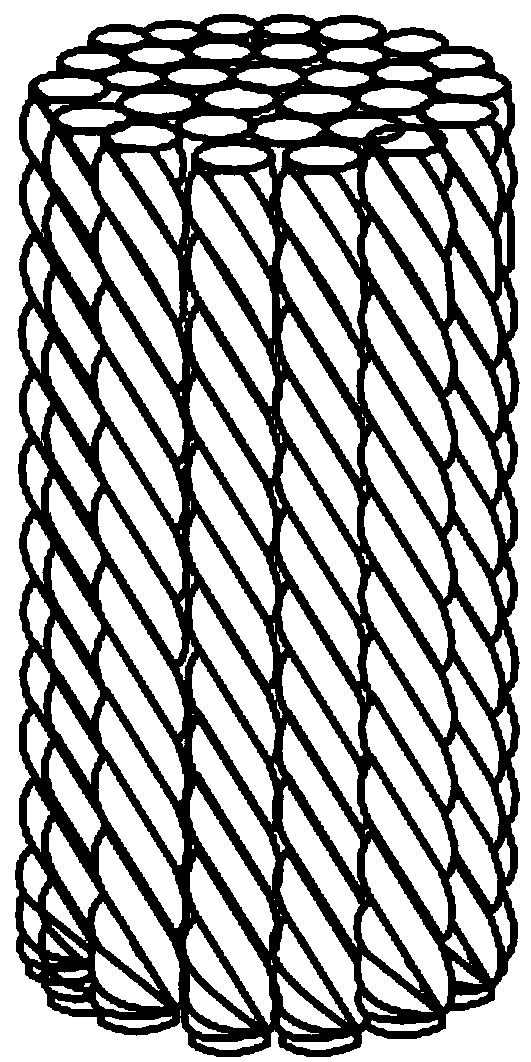

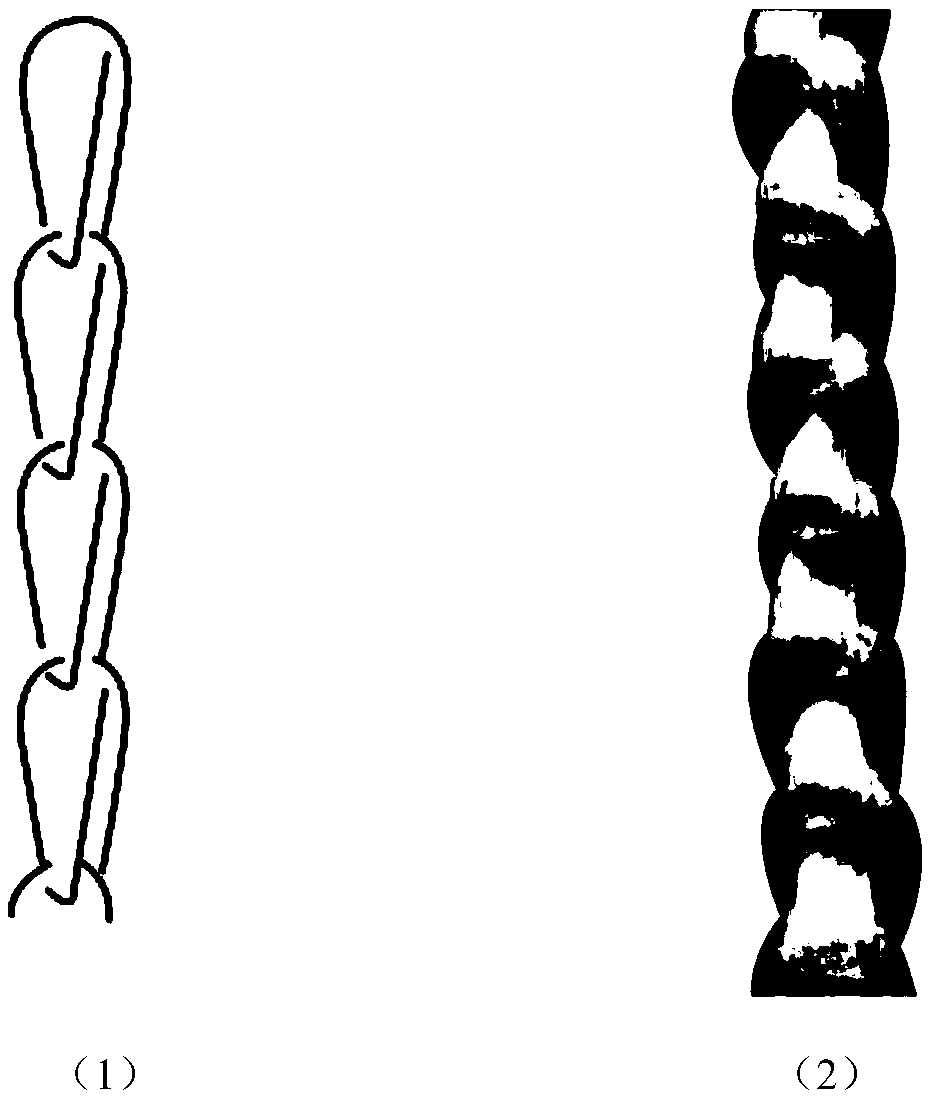

Degradable odor generation element for non-burned cigarette and cigarette product

InactiveCN108685192ASimple processIncrease productivityTobacco devicesEnvironmental chemistryAfter treatment

The invention provides a degradable odor generation element for a non-burned cigarette. The odor generation element is made of biodegradable polylactic acid monofilaments, and is formed by preparing several polylactic acid monofilaments into a rope or knitted fabric structure through one or more processes of weaving, knitting and twisting and then carrying out cutting. The odor generation elementfurther comprises polylactic acid monofilaments without perfume and polylactic acid monofilaments with perfume adhering to the surfaces after treatment, and when a hot airflow passes through a longitudinal extension channel defined by the polylactic acid monofilaments, the original odor of smoke and a generated volatile aroma are kept respectively. The process is simple, and the production efficiency is high; the adopted polylactic acid monofilaments have good biodegradability and environmental friendliness.

Owner:CHANGZHOU LOONG TOP NEW MATERIALS TECH

Cotton cloth embroidery anti-deformation processing technology

InactiveCN105040300AComplete embroideryNot offlineEmbroidering machines apparatusCotton clothHot melt

The invention relates to a cotton cloth embroidery anti-deformation processing technology. the technology comprises the following steps: (1) subjecting cotton cloth to a preshrinking treatment; (2) fixedly arranged a layer of hot melt glue on the backside of the processed cotton cloth; (3) artificially embroidering required patterns on the front side of the cotton cloth, knotting the thread residues, and after embroidery, removing the hot melt glue that face the blank area on the front side of the cotton cloth; (4) pressing and heating the residual hot melt glue, drying in the air, and cooling. In the provided technology, the patterns and hot melt glue are adhered together, the adhesion is quickly, the operation is simple, the completeness of embroidery on the cotton cloth can be guaranteed, moreover, the phenomenon of loose thread is avoided, after washing, the cotton cloth does not shrink or deform, the cotton cloth cannot be wrinkled easily, the overall cotton cloth is flat, and the technology has a good application prospect therefore.

Owner:苏州尊赢会展服务有限公司

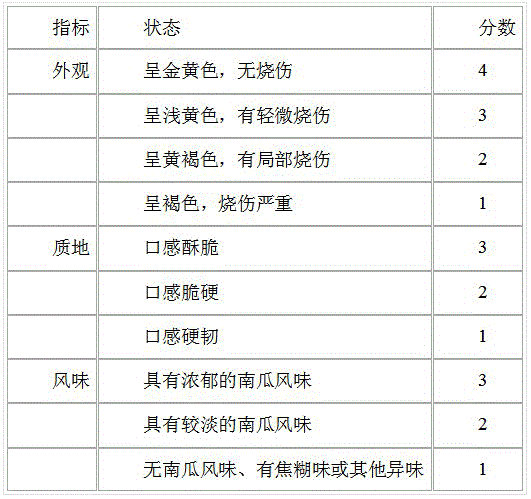

Processing method for instant crisp pumpkin chip

The invention specifically relates to a processing method for an instant crisp pumpkin chip, which belongs to the technical field of further processing of agricultural products. According to the method, pumpkin is used as a raw material and is subjected to selecting, cleaning, cutting and blanching at first and then to microwave vacuum drying until water content in a wet basis is 4 to 6%. The product of the instant crisp pumpkin chip has a yellow color, crisp taste, no burns, a plump shape, high retention of nutritional components and rich flavor of pumpkin, does not use any additive and is natural, healthy and safe; the processing method provided in the invention has the advantages of simple operation, healthiness, environment friendliness, a short production period, low operation cost, a high utilization rate of energy and capacity of assisting further processing of pumpkin and improving the quality and market competitiveness of a dried pumpkin product.

Owner:FUJIAN AGRI & FORESTRY UNIV

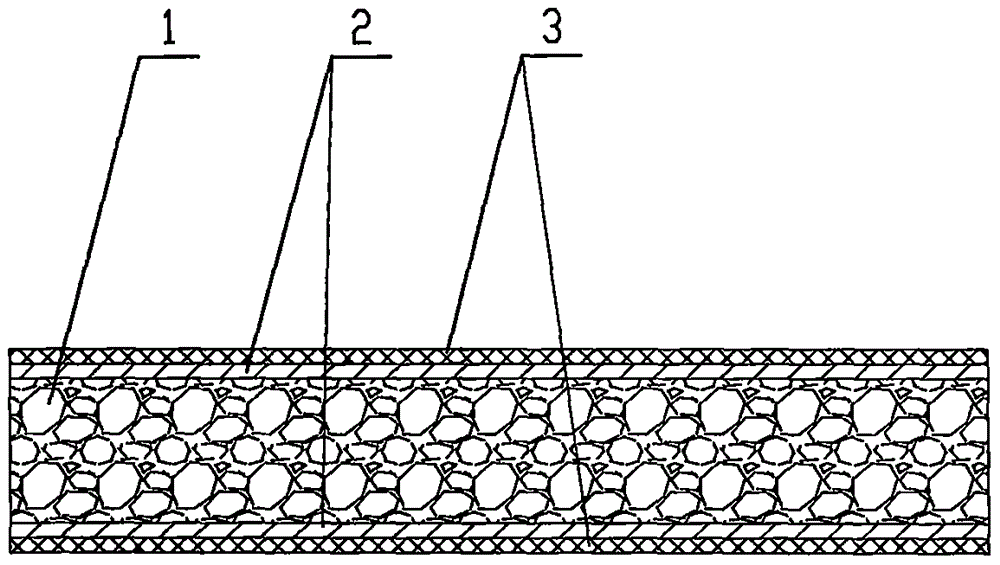

Mortar caul plate formed by stacking glass fiber felt and glass fiber net

InactiveCN103982022AGood alkali resistanceGood flexibilityCovering/liningsGlass/slag layered productsGlass fiberBrick

The invention discloses a mortar caul plate formed by a stacking glass fiber felt and a glass fiber net. At present, building external wall decoration materials mainly include external wall coating, external wall bricks, stones, a glass curtain wall and the like and have different advantages and disadvantages. According to the mortar caul plate, the glass fiber felt and the glass fiber net are stacked and are wrapped by composite grout formed by emulsion, cement, quartz powder, dispersing agents, early strength agents, water-retaining agents, antifoaming agents and water, and the mortar caul plate is obtained after drying. The mortar caul plate has the advantages of being soft, light, thin, anti-cracking, anti-folding, anti-aging, resistant to moisture, environmentally friendly, safe, low in production cost, easy to construct and low in construction cost, saving energy and the like; the motor caul plate overcomes the defects that existing external wall decoration plates are large in self-weight, high in construction cost, high in manufacturing cost and the like.

Owner:广西启利新材料科技股份有限公司

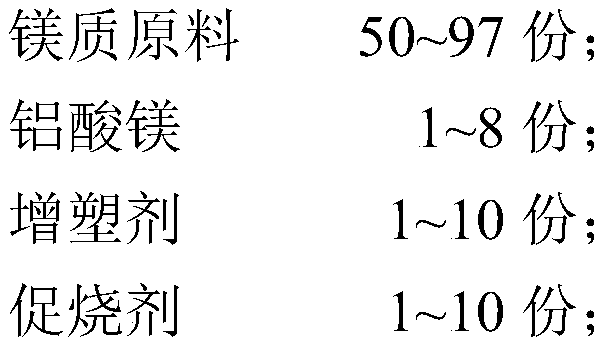

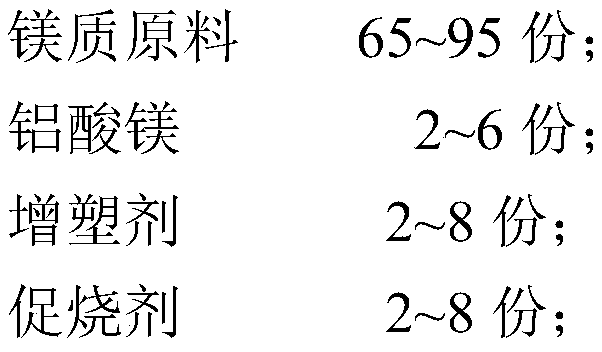

Magnesian high-strength gunning mix

PendingCN111170723AImprove adhesion performanceImprove high temperature sintering strengthMagnesium AluminateSlag

The invention discloses a magnesian high-strength gunning mix, which comprises the following raw materials in parts by weight: 50-97 parts of a magnesian raw material, 1-8 parts of magnesium aluminate, 1-10 parts of a plasticizer and 1-10 parts of a burning promoter, wherein the magnesium raw material is selected from sintered magnesia, high-calcium magnesia and a magnesium-chromium reclaimed material. According to the gunning mix, magnesium aluminate and a magnesian raw material quickly react to generate a gel on the premise that water exists, so that the bonding strength is generated while the adhesion performance of the gunning mix is improved; a small amount of a sintering promoter is added, so that sintering can be promoted at a high temperature, and the high-temperature sintering strength is effectively improved; and the gunning mix is limited in liquid phase quantity formed at a high temperature, small in shrinkage, good in steel slag permeability resistance and not easy to formstructural peeling.

Owner:WUGANG REFRACTORY CO LTD

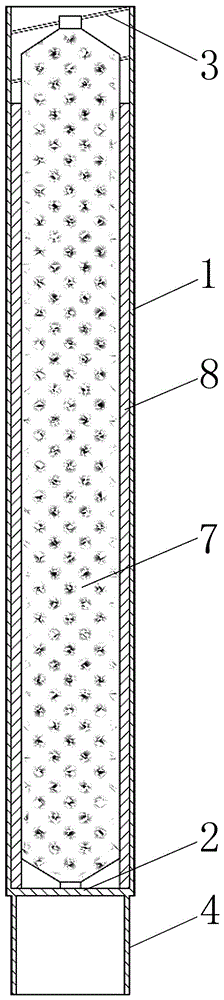

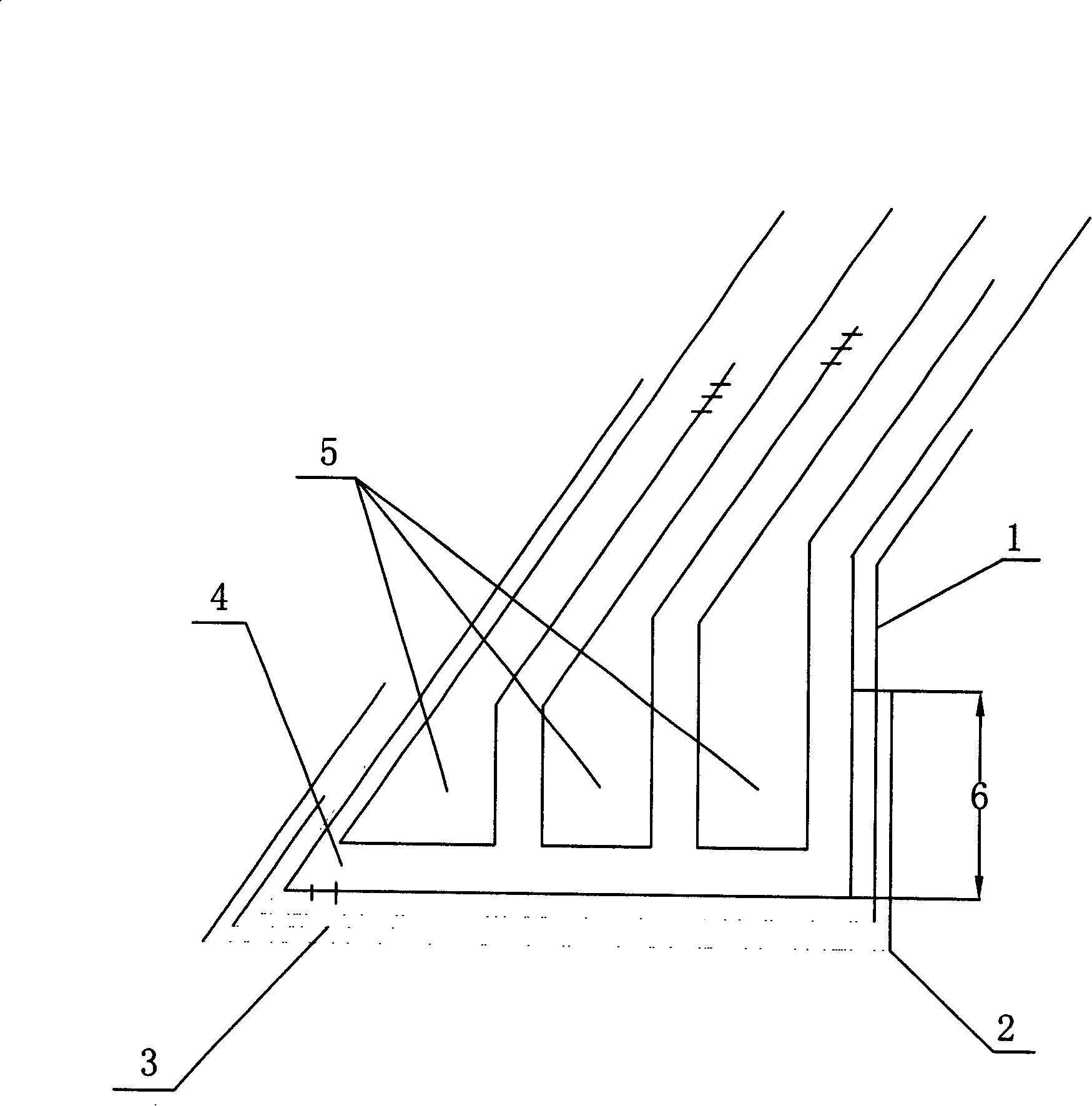

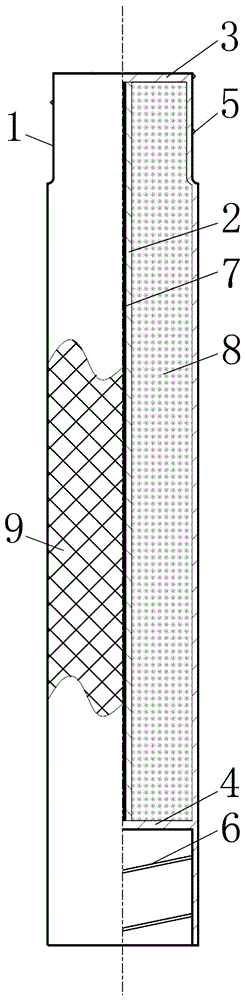

Novel coal mine anchoring agent installing device and method

The invention relates to an anchoring agent installing technology in coal mine roadway support, in particular to a novel coal mine anchoring agent installing device and a novel coal mine anchoring agent installing method. According to the novel coal mine anchoring agent installing device and the novel coal mine anchoring agent installing method, the problems that an anchoring agent easily breaks, easily deflects and easily falls off in an installing process are solved. The novel coal mine anchoring agent installing device comprises a cylindrical brittle plastic protective shell, wherein an opening is formed in each of the upper end and the lower end of the cylindrical brittle plastic protective shell; a partition plate is arranged in the inner cavity of the cylindrical brittle plastic protective shell, and partitions the inner cavity of the cylindrical brittle plastic protective shell into an upper primary cavity and a lower secondary cavity; the length of the upper primary cavity is greater than that of the lower secondary cavity; internal screw threads are formed in the inside surface of the upper part of the cylindrical brittle plastic protective shell; external screw threads are formed in the outside surface of the lower part of the cylindrical brittle plastic protective shell; grid stripes are rolled on the outside surface of the cylindrical brittle plastic protective shell; two axial cutting seams are formed in the side surface of the cylindrical brittle plastic protective shell in a penetrating manner, and directly face each other. The novel coal mine anchoring agent installing device and the novel coal mine anchoring agent installing method are applicable to the coal mine roadway support.

Owner:TAIYUAN UNIV OF TECH

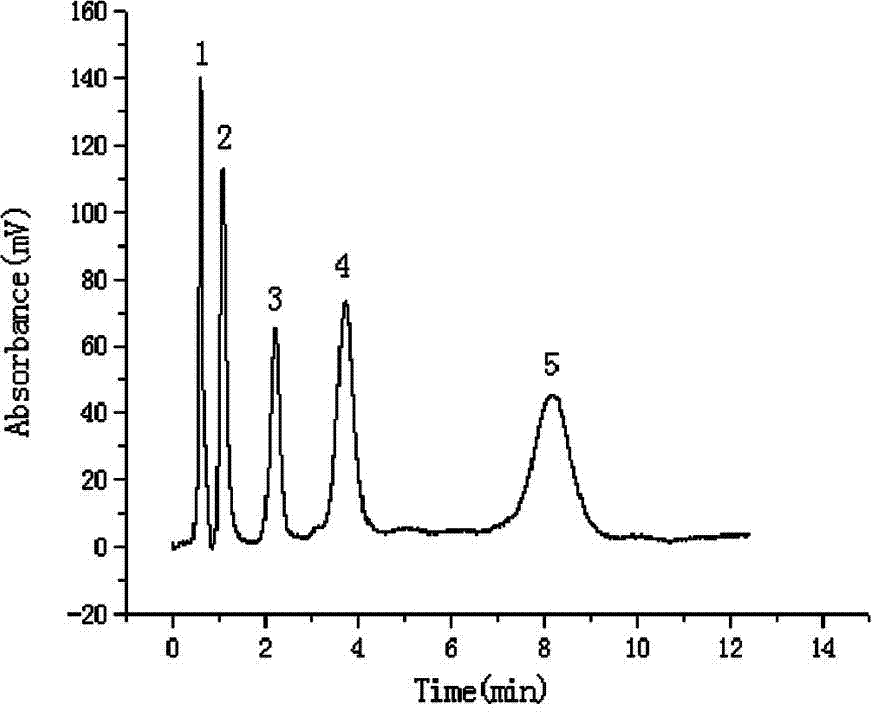

Preparation method of inorganic-organic hybrid monolithic column

InactiveCN104492122AUniform skeletonUniform pore sizeOther chemical processesSolid sorbent liquid separationFoaming agentAlcohol

The invention relates to a preparation method of an inorganic-organic hybrid monolithic column. The preparation method comprises the following steps: A. adjusting the pH value of Fe<2+> compound containing aqueous solution, adding with nano-diamond, adding with H2O2 and reacting to obtain hydroxyl nano diamond; B. mixing the hydroxyl nano diamond with KH570, dissolving into ethyl alcohol, carrying out ultrasonic treatment, reacting, centrifuging, washing, and drying to obtain the coupled hydroxylized nano diamond; C. mixing the coupled hydroxylized nano diamond, dipentaerythritolhexaacrylate, a cross-linking agent, an initiator and a pore-foaming agent, injecting the mixture into a stainless steel column, and reacting for 1-1.5h; and D. connecting the stainless steel column with a high-pressure infusion pump, flushing, and drying to obtain the inorganic-organic hybrid monolithic column. The preparation method has simple process, the reaction condition can be realized easily, the operability is good, the prepared monolithic column has uniform framework and pore diameter, has good separation effect and can be used for separating complex samples under a wide-temperature-range condition, and the application field of the monolithic column can be expanded greatly.

Owner:HEBEI UNIVERSITY

Tubeless diagonal tyre

The invention relates to a tubeless oblique crossing tire, comprising tyre foundation which comprises a tyre bead section. Tyre bead wires are arranged in inner of the tyre bead section. Bead fabric is arranged on rebate of the tyre bead section. Bead toe fabric is arranged on bead toe of the rebate and the bead fabric. An outside end of the bead toe fabric centre justifies to the tyre bead wires which in the innermost of the tyre foundation, and clings to an outside end of the toes of the bead fabric, and another end goes around and clings in the tyre foundations to extend into inner side of the tyre foundations. A masking adhesive tape which can fully cover the bead fabric and the bead toe fabric is arranged outside of the bead fabric and the bead toe fabric. The bead fabric generally is singles cloth and the bead toe fabric is canvas materiel. According to different tyre specifications, the bead fabric can be singles cloth of nylon, urethane elastic fiber, chinlon and polypropylene fiber, and the width of the bead toe fabric also selects out a suitable size according to tyre specification. Because the bead toe fabric clings to the outside of the singles cloth, the invention handles out the singles cloth shrinkage strain and knotting problems in process of vulcanization, and also improves air tightness of the tyre.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

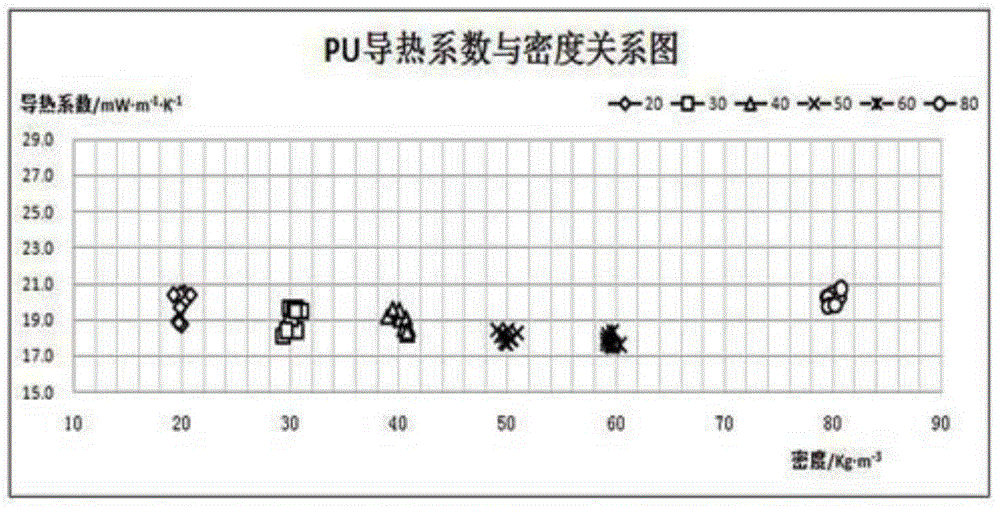

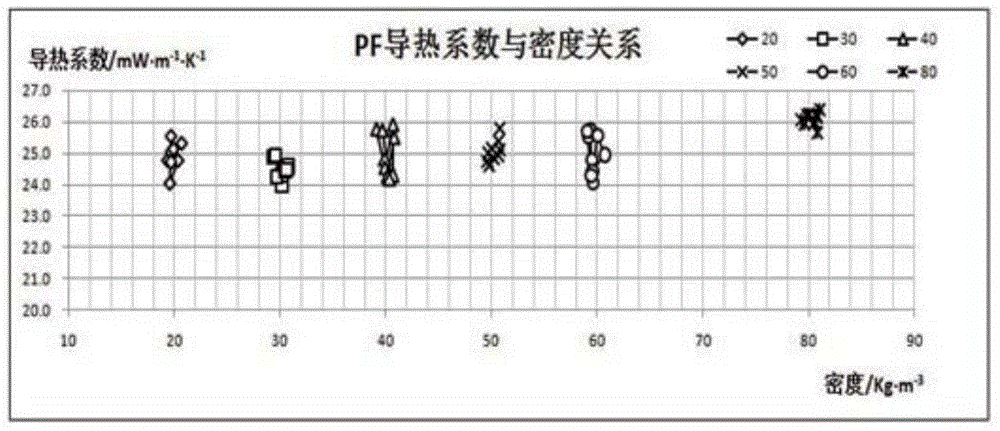

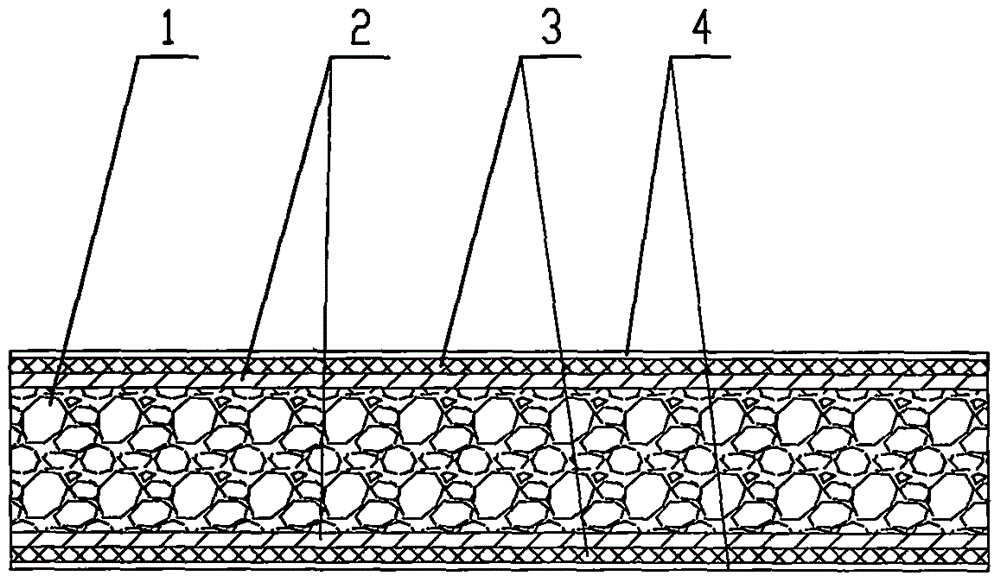

Heat-preservation heat isolation panel with VIP

ActiveCN104975660AEnhanced external mechanical strengthExtended service lifeThermal insulationClimate change adaptationPorosityThermal isolation

Provided is a thermal insulation board with a vacuum thermal isolation plate, comprising a porous foam body (2) and a flexible vacuum thermal isolation plate (1). The porous foam body (2) is a hard polyurethane foam body or phenolic resin foam body having a density of 20 - 80 kilograms / cubic metre, and the porous foam body (2) is directly combined into a whole with at least one major surface and all side faces of the vacuum thermal isolation plate (1) in a foaming process. In the porous foam body, the dimensions of various foam pores are less than 0.3 millimetre and the closed porosity rate is more than 60%. The porous foam body (2) at the outside of the major surface of the vacuum thermal isolation plate (1) has a thickness of 1 - 50 millimetres.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

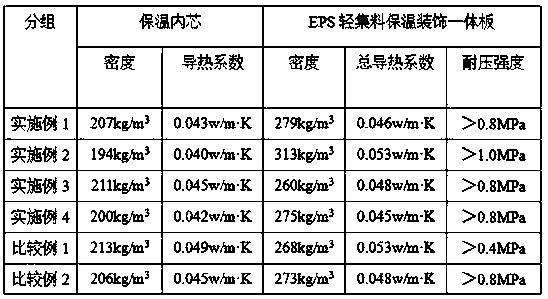

EPS lightweight aggregate thermal-insulation decorative all-in-one board, and preparation method thereof

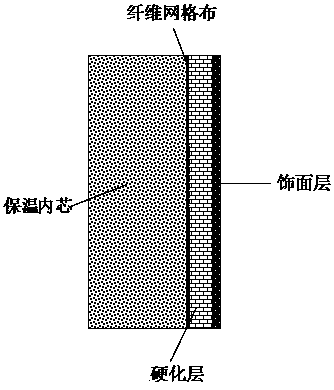

The invention discloses an EPS lightweight aggregate thermal-insulation decorative all-in-one board, and a preparation method thereof. The EPS lightweight aggregate thermal-insulation decorative all-in-one board comprises a thermal insulation inner core, a fiber grid cloth, a hardened layer, and a stone-like coating decorative layer successively from inner to outer; by weight, the thermal insulation inner core comprises 30 to 50 parts of EPS foam particle, 40 to 80 parts of iron tailing sand, 200 to 300 parts of Portland cement, 10 to 20 parts of rubber powder, and 10 to 20 parts of hydroxymethyl cellulose. According to the preparation method, the flame-retardant EPS foam particle is taken as a lightweight aggregate to prepare the thermal insulation inner core, EPS foam is ultra low in heat conductive coefficient, so that the whole board is provided with excellent thermal insulation performance. The EPS lightweight aggregate thermal-insulation decorative all-in-one board is excellent in thermal insulation effect, and low in density, is simple in preparation technology, and is convenient for large scale production.

Owner:ZHEJIANG UNIV OF TECH

Method for manufacturing automobile damper with polyurethane composite material

Belonging to the technical field of auto part manufacturing, the invention relates to a method for manufacturing an automobile damper with a polyurethane composite material. The method comprises: adding a component C catalyst into component A, and stirring them uniformly, then pouring them into the machine tank of a low pressure casting machine, and conducting thermal insulation; then adding component B and the above mixed solution into a low pressure machine and carrying out stirring, injecting the mixture into a damper die for foaming, then spraying a release agent, thus obtaining an automobile damper. The polyurethane composite material prepared in the invention has the advantages of low viscosity, good fluidity, fewer dark bubbles, wide foaming scope, and no need for heating before use. And the automobile damper product manufactured with the polyurethane composite material is characterized by light weight, good strength, good elasticity, good smooth finish, fewer dark bubbles, no shrinkage, easy processing, and good elasticity, thus being very popular with automobile manufacturers.

Owner:无锡双象新材料有限公司

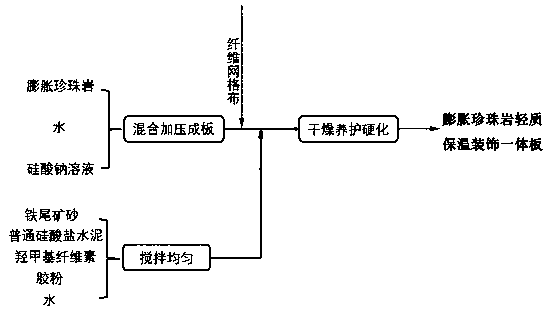

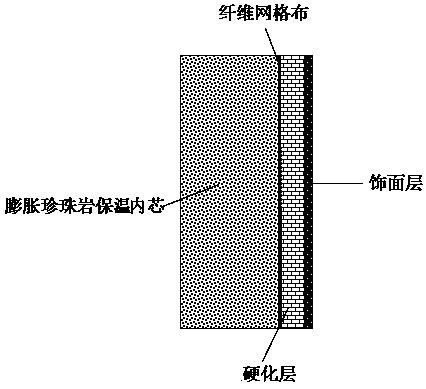

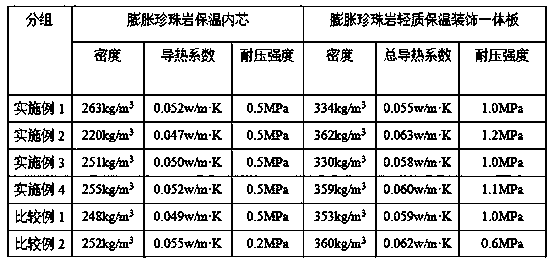

Expanded perlite light heat-insulation decorative integrated plate and preparation method thereof

InactiveCN110451916AAvoid fireRemove uncertaintyCovering/liningsSolid waste managementFiberThermal insulation

The invention discloses an expanded perlite light heat-insulation decorative integrated plate and a preparation method thereof. The expanded perlite light heat-insulation decorative integrated plate sequentially comprises an expanded perlite heat-insulation inner core, fiber mesh cloth, a hardening layer and a real stone paint finish coat from inside to outside. The preparation method of the expanded perlite heat-insulation inner core comprises the following steps: 1) wetting expanded perlite with water, and uniformly stirring for later use; 2) mixing the wetted expanded perlite in the step 1)with a sodium silicate aqueous solution, and uniformly stirring for later use; and 3) transferring the uniformly stirred mixture in the step (2) into a mold, integrally compressing the mixture in themold until the volume of the mixture reaches 60-80% of the original volume, demolding, and naturally drying until the moisture is completely evaporated to obtain the expanded perlite heat-insulationinner core. The expanded perlite light heat-insulation decorative integrated plate is integrally made of an inorganic material, is high in fireproof and flame retardant grade, meanwhile has functionsof light weight, heat insulation, decoration and the like, and can be directly applied to the fields of heat insulation of external walls of industrial and civil buildings.

Owner:ZHEJIANG UNIV OF TECH

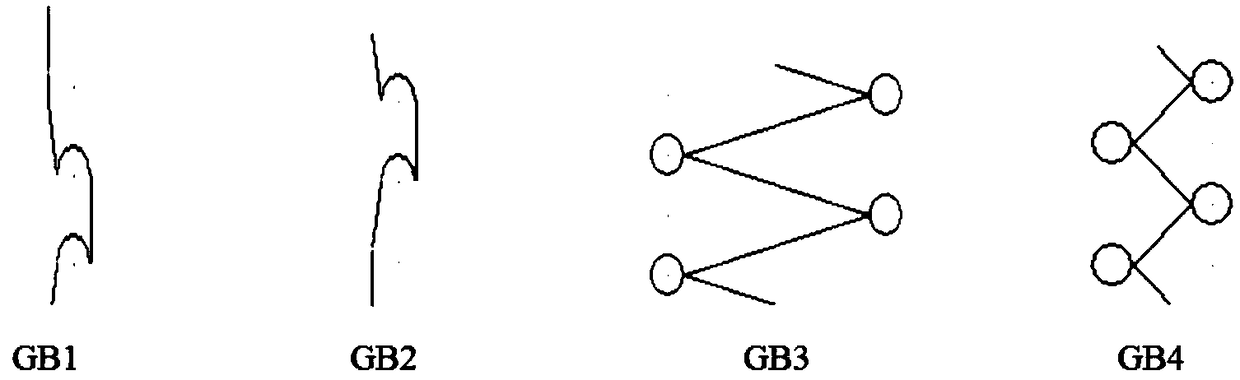

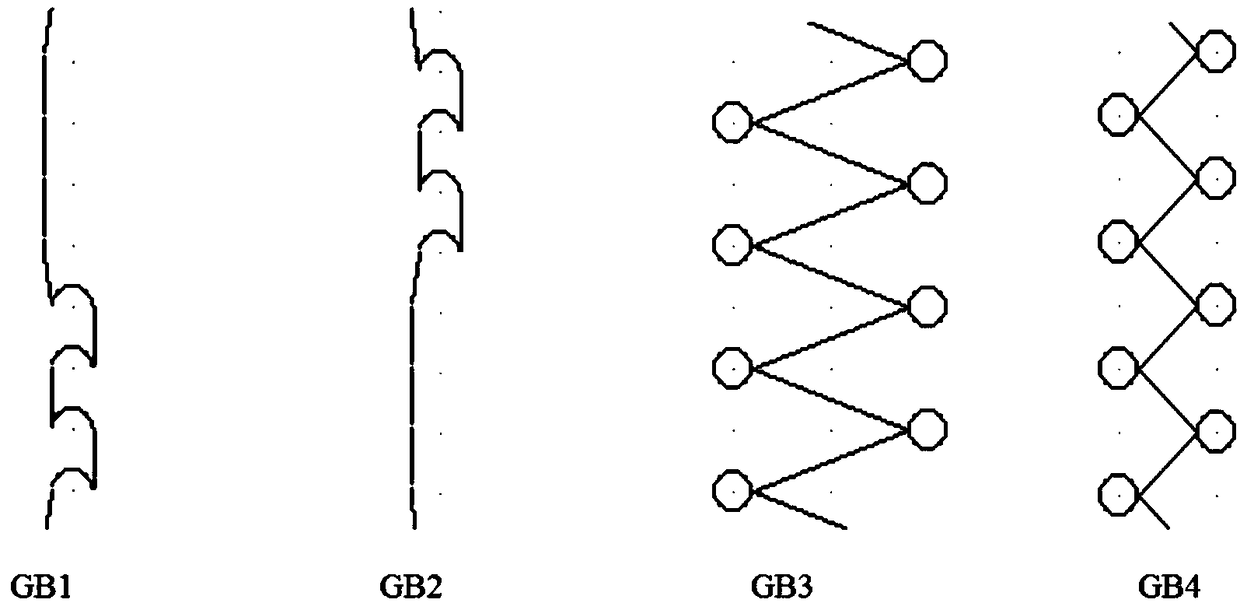

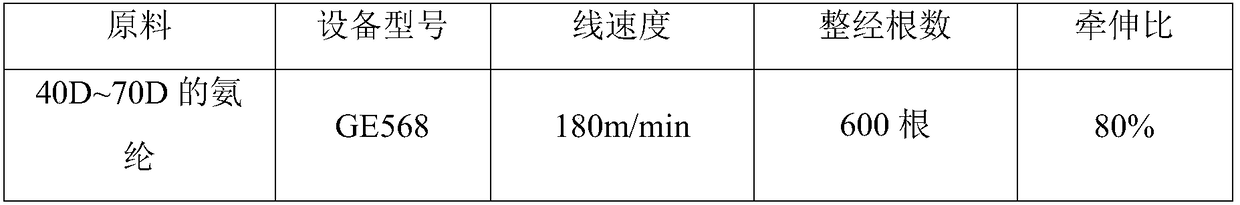

Warp knitted elastic fabric imitating pique and preparation method thereof

The invention discloses a warp knitted elastic fabric imitating pique and a preparation method thereof, and belongs to the field of clothing fabrics. The method comprises the steps that two guide barsin the front of a warp knitting machine penetrate through cotton yarn and pass through a miss-lapping texture, the miss-lapping yarn is in a straight line shape on the technological front face and ishung on the front face of the fabric, the front two guide bars are utilized to perform penetrating and symmetrical lapping to form the effect of the pique; and the last spandex guide bar is utilizedto perform two-needle warp flatting, so that the cloth cover generates elasticity in the longitudinal and transverse directions. The prepared warp knitted elastic fabric imitating the pique contains 16-53% of cotton yarn, 35-70% of chinlon and 8-23% of spandex. The weight of the finished warp knitted elastic fabric product imitating the pique is 140-265 g / m<2>, and the warp knitted elastic fabricimitating the pique has the advantages of good hygroscopicity and gas permeability of the pique, and overcomes the disadvantages that the fabric made from the pique is poor in size stability and easyto contract and deform.

Owner:JIANGNAN UNIV

Anti-deformation embroidering method

InactiveCN106283442AGuaranteed comfortGuaranteed aestheticsEmbroidering machines apparatusEngineeringHot-melt adhesive

The invention discloses an anti-deformation embroidering method. The method comprises the following steps: carrying out pre-shrinking treatment on embroidering base cloth at first; (2) fixedly arranging a layer of hot melt adhesive on the back surface of the embroidering base cloth after the embroidering base cloth is subjected to pre-shrinking treatment; (3) embroidering required patterns on a front surface of the embroidering base cloth with silk threads manually, tying a knot at an end of a thread end, and removing the hot melt adhesive except the patterns on the back surface of the embroidering base cloth after embroidery of the patterns is finished; and (4) carrying out pressing treatment on the residual hot melt adhesive, then air-drying and cooling. The pattern part of the embroidering base cloth is adhered by the hot melt adhesive, is adhered rapidly and is simple to operate, completeness of embroidery on the embroidering base cloth can be guaranteed, thread loosening is avoided, the embroidering base cloth cannot shrink or deform easily after being washed, and cannot wrinkle, so that integral embroidery keeps flat, comfort level and attractiveness of embroidery are guaranteed, and application prospect is good.

Owner:纪慧娟

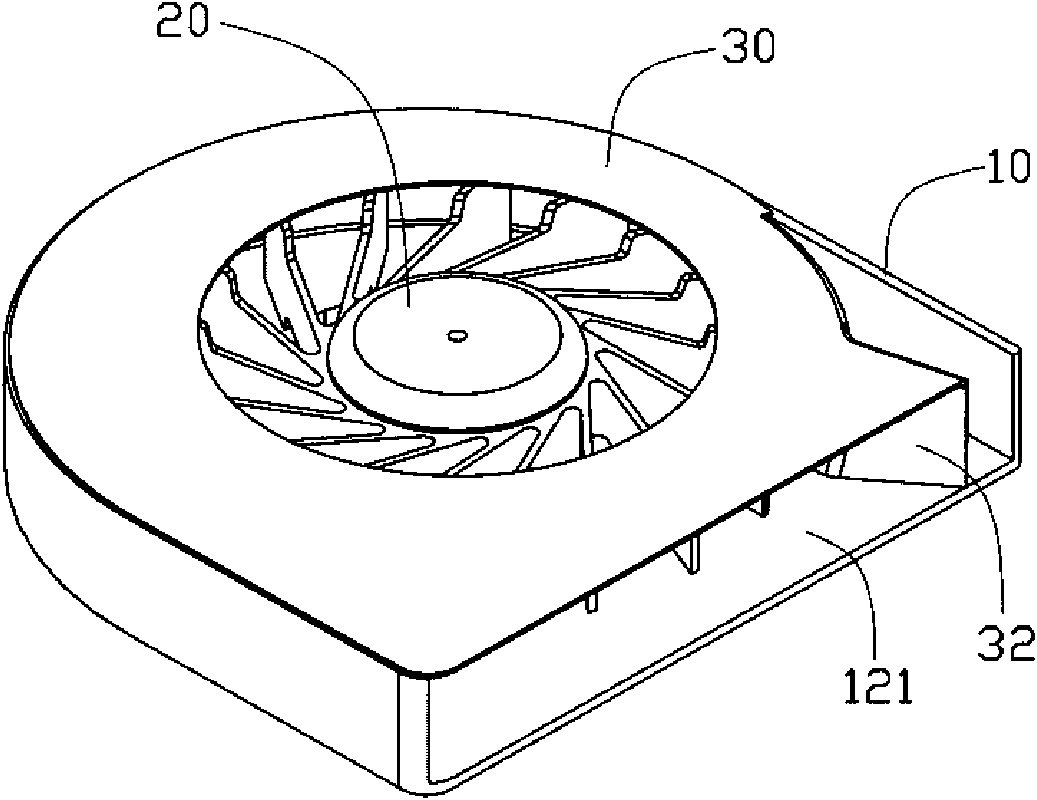

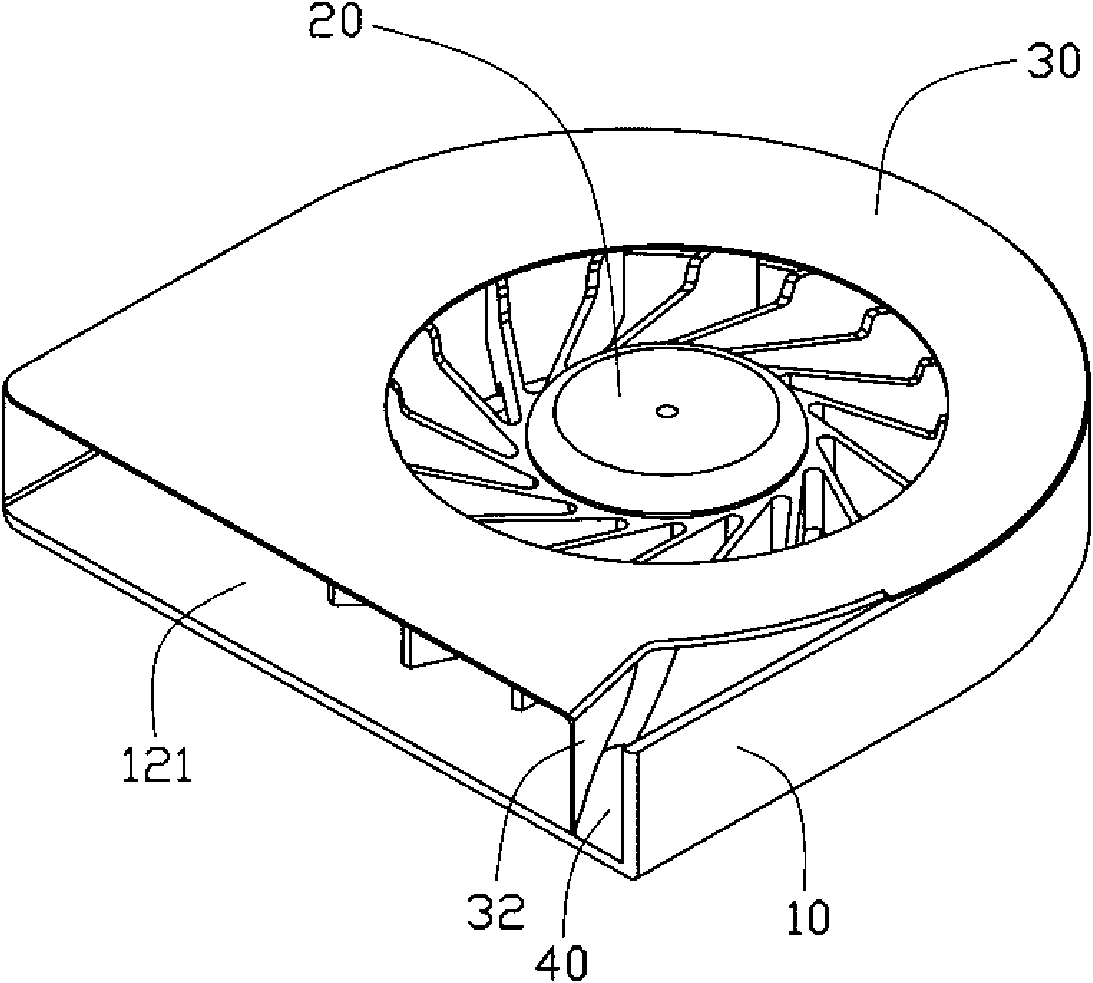

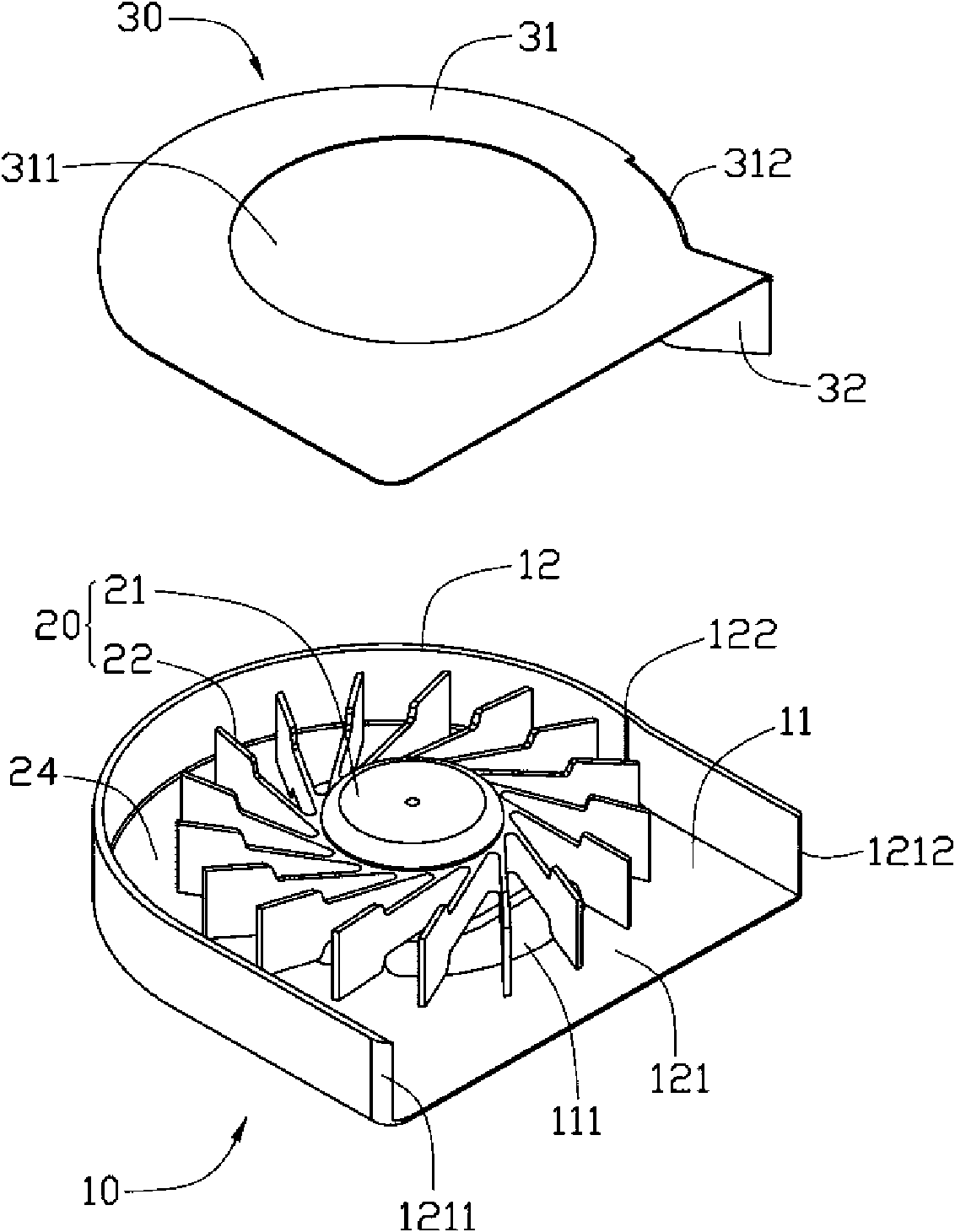

Eccentric fan

InactiveCN101672299AReduce manufacturing costSave raw materialsPump componentsDigital data processing detailsEngineeringRaw material

Owner:FU ZHUN PRECISION IND SHENZHEN +1

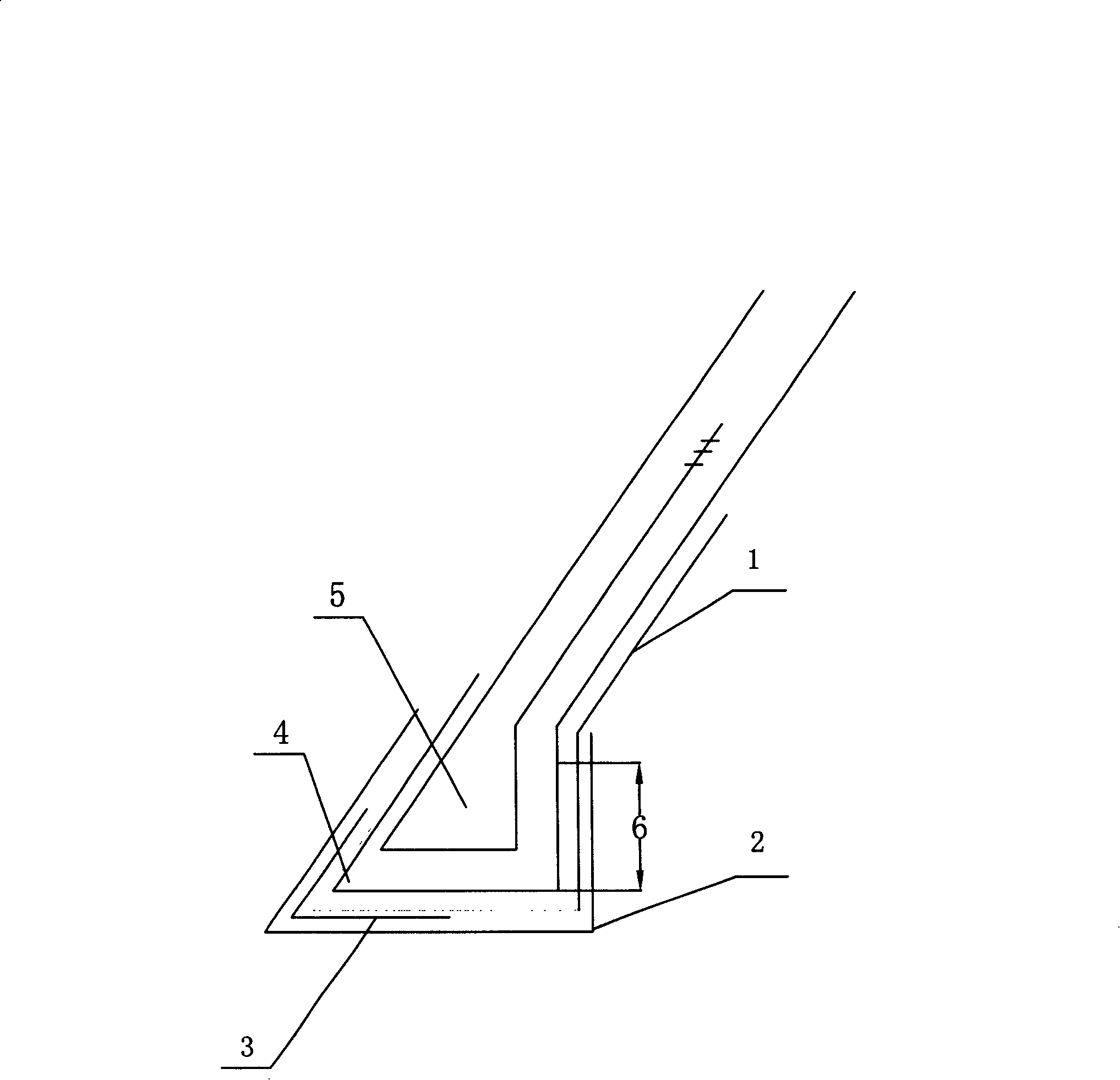

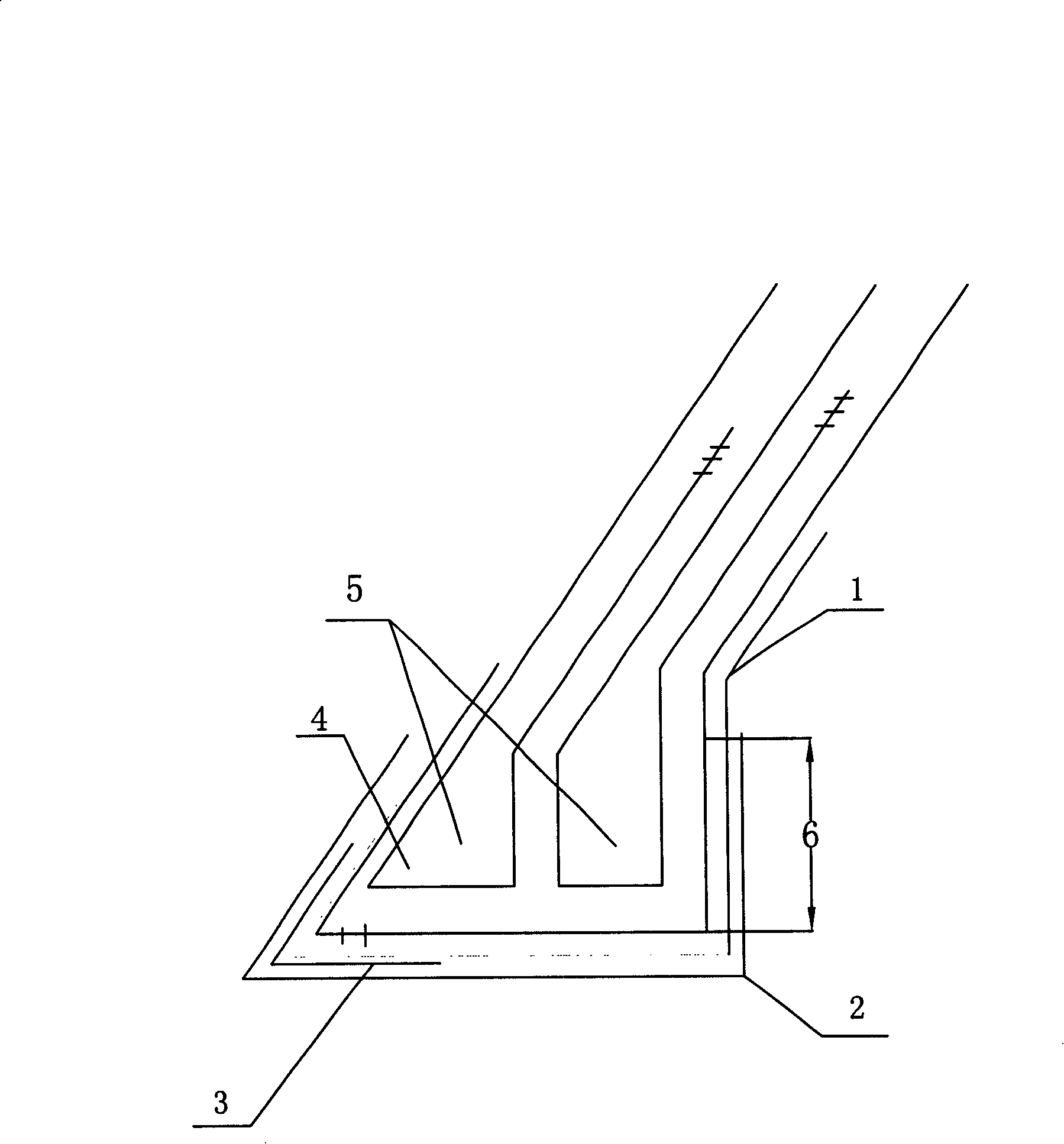

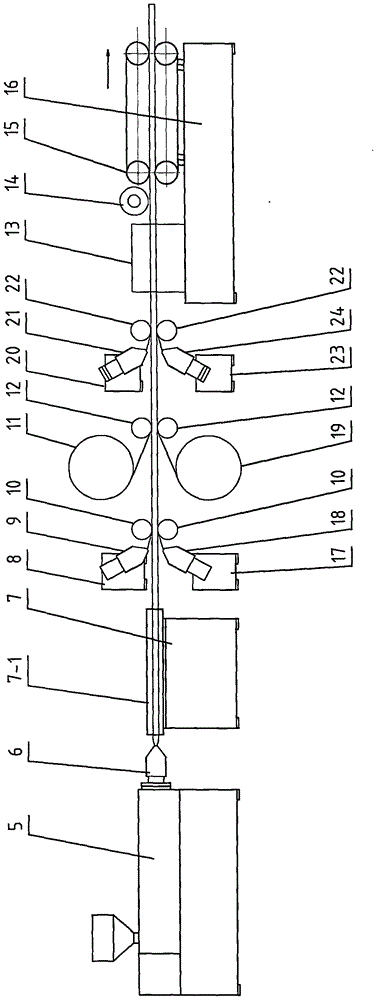

Delicate fragrance-type health laser tipping paper

InactiveCN103981774AAvoid deformationStable tensionSpecial paperPaper/cardboardChitosan coatingControl system

The invention discloses a delicate fragrance-type health laser tipping paper. The delicate fragrance-type health laser tipping paper orderly comprises a PET film (1), a molded layer (2), an aluminized layer (3), a hollowed-out printed layer (4), a NaOH layer (5), a transfer adhesive layer (6), a tipping paper (7), a chitosan coating (8) and a perfume layer (9) from inside to outside. The delicate fragrance-type health laser tipping paper utilizes the PET film having very small shrinkage and thickness of 20 microns, utilizes an advanced tension force control system and guarantees tension force stability in the whole process. According to the delicate fragrance-type health laser tipping paper, the film deforms difficultly, size stabilization is kept and each filter tip is provided with only one icon. The delicate fragrance-type health laser tipping paper does not need latter printing and can be provided with very flashy patterns by aluminum washing, and the bright aluminum washing patterns of the tipping paper can be seen by light.

Owner:JIANGSU KINGHENG PACKAGE MATERIAL CO LTD

Method for producing car heat insulating pad

InactiveCN101654084AReduce weightFull productLamination ancillary operationsSynthetic resin layered productsWork in processWoven fabric

The invention belongs to the technical field of interior parts of cars, in particular to a method for producing a car heat insulating pad which is installed in a car engine bin and plays roles of sound absorption and heat insulation. The method for producing the car heat insulating pad comprises the following steps: (1) baking: baking the upper molded surface and the lower molded surface of prefabricated polyurethane in a double-oven suspending type; (2) pressing and molding: pressing and molding composite hot rolling non-woven fabrics on the upper molded surface and the lower molded surface of the baked polyurethane respectively to form a semi-finished product; (3) cooling and shaping: cooling and shaping the pressed and molded semi-finished product at normal temperature; (4) cutting andtrimming: carrying out peripheral cutting and hole position cutting on the cooled and shaped semi-finished product according to the shape requirement of the heat insulating pad; (5) inspecting: inspecting the finished product; and if the finished product is qualified, packaging into a box to be delivered into a warehouse.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

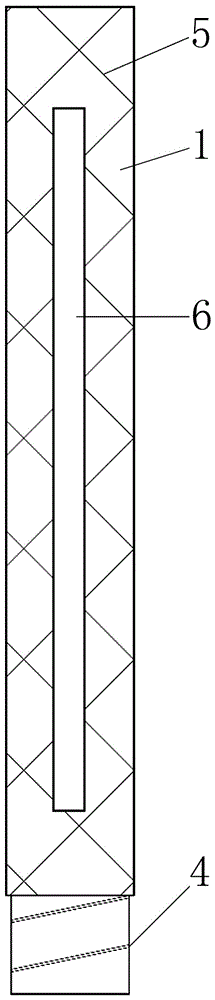

Novel hard shell anchoring agent

The invention relates to an anchoring agent for coal mine roadway support, and specifically discloses a novel hard shell anchoring agent. The novel hard shell anchoring agent solves the problem that the anchoring agent is easy to break, deviate and slip in installation. The novel hard shell anchoring agent comprises a cylindrical outer shell and a cylindrical inner shell, wherein an end plate is arranged at the upper end of the cylindrical outer shell, and an opening is formed at the lower end; a division plate is arranged in the inner cavity of the cylindrical outer shell; the division plate divides the inner cavity of the cylindrical outer shell into an upper main cavity and a lower secondary cavity, and the upper main cavity is longer than the lower secondary cavity; external threads are formed on the outer surface of the upper part of the cylindrical outer shell; internal threads are formed on the inner surface of the lower secondary cavity; openings are respectively formed at the upper and lower ends of the cylindrical inner shell; the upper end of the cylindrical inner shell is vertically fixed in the center of the lower surface of the end plate; the lower end of the cylindrical inner shell is vertically fixed in the center of the upper surface of the division plate; the inner cavity of the cylindrical inner shell is filled with a curing agent; and daub fills the gap between the cylindrical outer shell and the cylindrical inner shell. The novel hard shell anchoring agent is suitable for coal mine roadway support.

Owner:TAIYUAN UNIV OF TECH

Plastic plate and molding equipment

InactiveCN106273311AImprove efficiencyLow costSynthetic resin layered productsLaminationPolymer adhesivePolystyrene

The invention discloses plastic plate molding equipment. The equipment comprises a first plastic extruding machine, a second plastic extruding machine, a third plastic extruding machine, first guide rollers, an upper-layer nonwoven fabric layer unwinding equipment first unwinding device, a lower-layer nonwoven fabric layer unwinding equipment second unwinding device, second guide rollers and traction devices which are arranged sequentially, wherein the first plastic extruding machine is used for extruding a middle-layer heat-insulation plate; the second plastic extruding machine is used for extruding an upper plastic sheet layer; the third plastic extruding machine is used for extruding a lower plastic sheet layer; a setting mold is fixedly connected onto a first setting device; a heat-insulation plate machine head is mounted on the first plastic extruding machine, an extruded heat-insulation plate blank is cooled and set by the setting mold of the first setting device, and a continuous heat-insulation plate is formed; the middle-layer heat-insulation plate, the modified plastic sheet layer on the upper side, the modified plastic sheet layer on the lower side and grid fabric or nonwoven fabric are bonded together in a hot-melt manner respectively; the heat-insulation plate is made of polystyrene (PS), polyvinyl chloride (PVC), polyurethane (PU), polypropylene (PP), polyethylene (PE) and ethylene-vinyl acetate (EVA); and the plastic sheet layers are made of PVC, PP, PE and PU. The grid fabric or the nonwoven fabric or a polymer adhesive layer has the good bonding property to a wall and does not fall off easily, and the service life is long.

Owner:DALIAN HUAGONG INNOVATION TECH

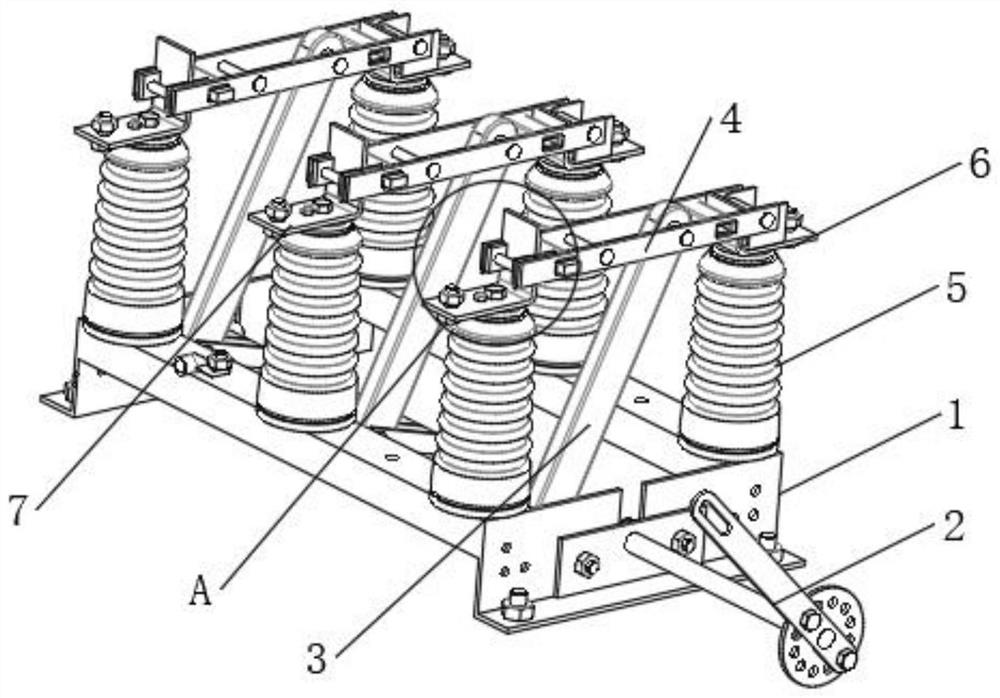

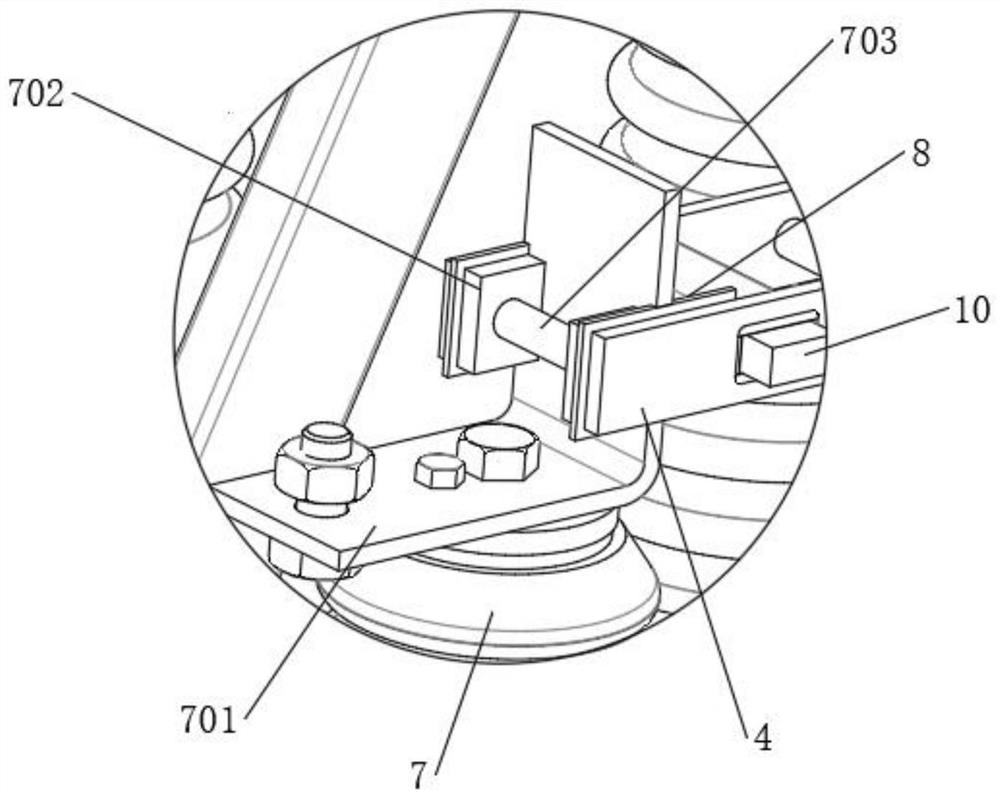

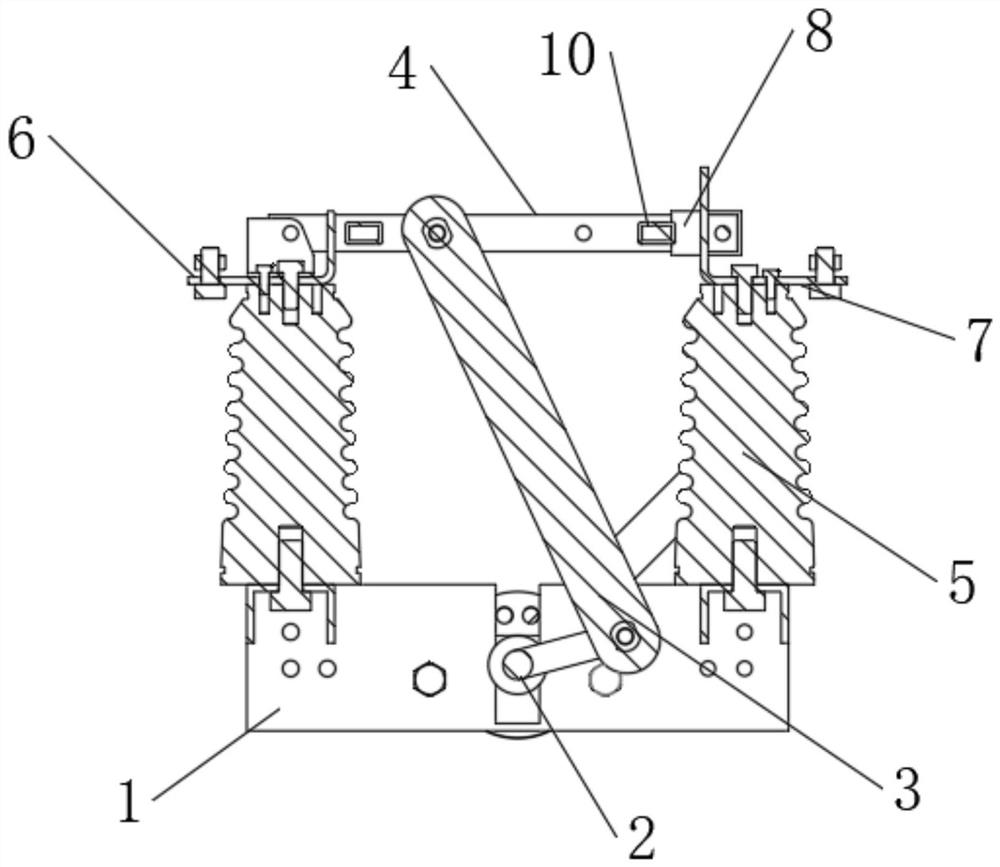

High-voltage isolating switch with high-temperature protection function

InactiveCN113178351AAvoid harmPrevent shrinkage deformationAir-break switch detailsStructural engineeringKnife switch

The invention discloses a high-voltage isolating switch with a high-temperature protection function, and belongs to the field of isolating switches, the high-voltage isolating switch with a high-temperature protection function comprises a base, a plurality of isolating switches are fixedly connected to the base, each isolating switch comprises a pair of insulators, and the top ends of the pair of insulators are connected with a fixing frame plate and a connecting plate respectively; a knife switch is hinged to the fixing frame plate and comprises a pair of flashboards, the opposite ends of the pair of flashboards are fixedly connected with arc-shaped conducting strips, a rotating shaft is rotationally connected to the base, a connecting rod is hinged between the rotating shaft and the knife switch, the connecting plate comprises an L-shaped connecting plate matched with the knife switch, and the upper end of the L-shaped connecting plate is fixedly connected with a pair of protruding plates. And the insulating cylinder is connected between the pair of protruding plates, so that pressure detection and temperature detection can be carried out on the contact of the disconnecting link, the damaged disconnecting link can be independently disconnected after an insulator on a single disconnecting switch is damaged, and further damage to the disconnecting switch caused by high temperature due to a fault is prevented.

Owner:丁玉玺

Lightweight environment-friendly smokeless thermal insulation material for household appliances

PendingCN113715425AImprove structural strengthWeight increaseSynthetic resin layered productsGlass/slag layered productsPolyesterFiber

The invention discloses a lightweight environment-friendly smokeless thermal insulation material for household appliances, and relates to the technical field of thermal insulation materials. The lightweight environment-friendly smokeless thermal insulation material comprises a base material layer and a thermal insulation layer, wherein an anti-corrosion cloth layer is fixed on the upper side of the base material layer, a flame retardant layer is fixed on the upper side of the anti-corrosion cloth layer, reinforcing nets are fixed above the flame retardant layer, sound insulation layers are arranged among the reinforcing nets, and the thermal insulation layer is fixed above the reinforcing nets. The light environment-friendly smokeless thermal insulation material for household appliances is formed by pressing the carbon fiber base layer, a composite polyester fiber layer, a composite flame-retardant fiber layer, a glass fiber gridding cloth foam cotton layer and a glass cotton layer; the carbon fiber base layer is light in weight and can resist high temperature; the composite polyester fiber layer is good in elasticity and has a certain corrosion-resistant effect; thermoplastic resin is added in a preparation process, so corrosion-resistant performance is further enhanced; the composite flame-retardant fiber layer is prepared in a blended mode and has flame-retardant and heat-insulating performance; and glass fiber gridding cloth has the advantages of being high in strength and light in weight.

Owner:无锡海跃船舶新材料科技有限公司

Fireproof cable used for firefighting

InactiveCN108182994AIncrease resistanceGuaranteed normal transmissionClimate change adaptationInsulated cablesEpoxyGlass fiber

The invention discloses a fireproof cable used for firefighting. The fireproof cable is characterized by comprising a cable core, a high-temperature-resistant insulating layer, an aluminum metal sleeve, an epoxy / benzoxazine resin-based fireproof internal sheath and a low-smoke halogen-free polyolefin external sheath. The cable core is formed by four strands of insulating conductors which are mutually and externally tangent. The high-temperature-resistant insulating layer is formed by mica powder, glass fiber, teflon modified phenolic molding powder and Mg(OH)2 and wraps the cable core. The aluminum metal sleeve is formed by aluminum wires which are spirally and closely wound on the external side of the high-temperature-resistant insulating layer. The epoxy / benzoxazine resin-based fireproofinternal sheath wraps the aluminum metal sleeve. The low-smoke halogen-free polyolefin external sheath wraps the epoxy / benzoxazine resin-based fireproof internal sheath. The cable is ensured to normally operate under high temperature, and the shrinkage is close to zero without the aging phenomenon so as to have great mechanical performance and electrical insulation performance.

Owner:安徽清启系统集成有限公司

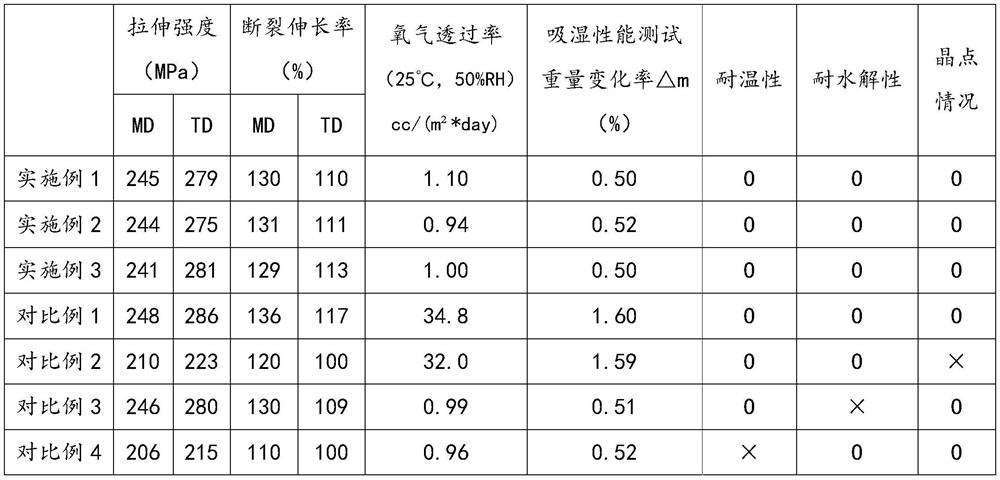

High-barrier biaxially oriented polyamide color changing film and preparation method thereof

ActiveCN112549719AWide choice of colorsSolve single colorPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyurethane dispersionColor film

The invention discloses a high-barrier biaxially oriented polyamide color changing film and a preparation method thereof. The color changing film is composed of a PU color film layer, a bonding layerand a base material layer. Slurry of the PU color film layer and slurry of the bonding layer both adopt waterborne polyurethane dispersion liquid, and the base material layer is sequentially composedof an upper surface layer, a core layer and a lower surface layer; the upper surface layer and the lower surface layer are made of a mixture of PA6 and PA12, and the core layer is made of EVOH. According to the invention, the PU color film layer coated on a release film is transferred to the surface of the biaxially oriented polyamide film obtained by three-layer co-extrusion casting stretching toobtain the biaxially oriented polyamide color changing film, and the film has the advantages of uniform color, good color coverage rate, high barrier property, scratch resistance, low moisture absorption and the like; and the PU color film layer is widely applied to packaging and decoration.

Owner:厦门长塑实业有限公司

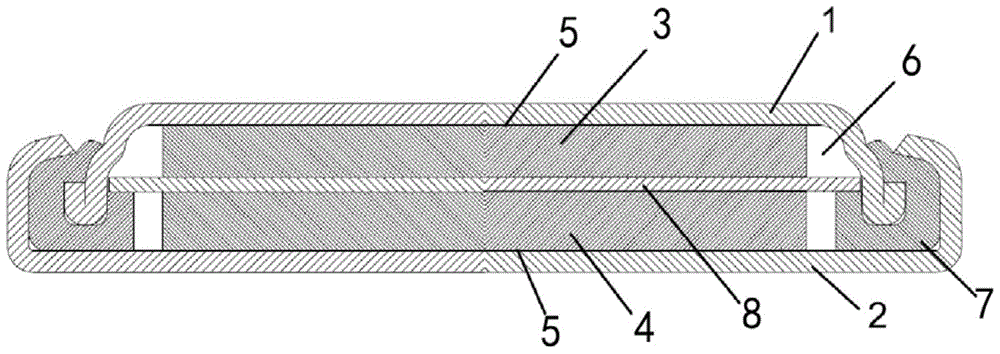

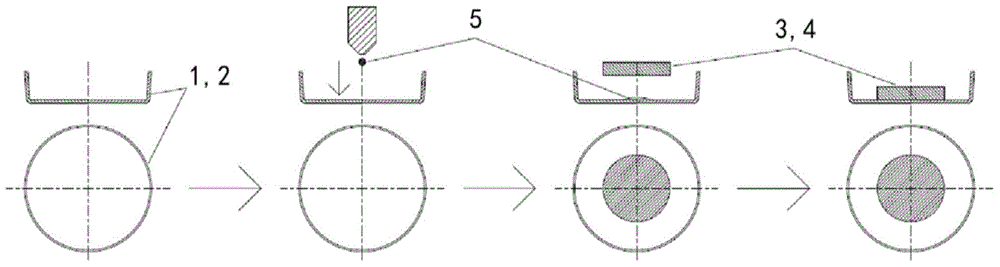

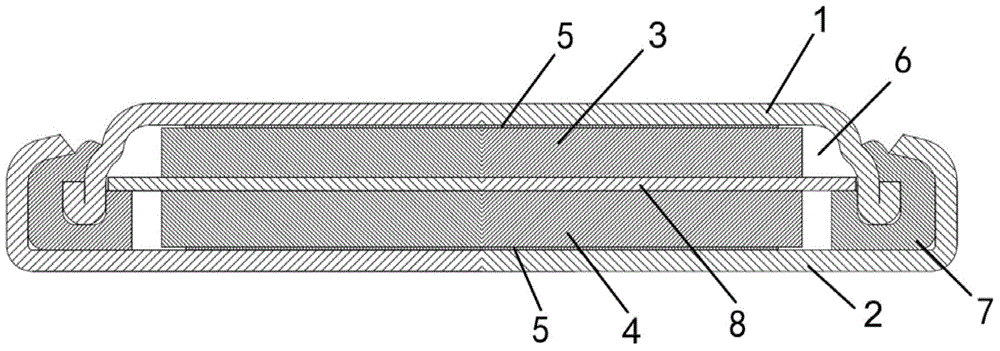

Electric double-layer capacitor and manufacturing method thereof

ActiveCN106298275AExtended service lifeLittle change in capacityHybrid cases/housings/encapsulationsHybrid/EDL manufactureScreen printingAdhesive

The invention relates to an electric double-layer capacitor and a manufacturing method thereof. A screen printing method is adopted to enable a conductive adhesive to be made into a circular conductive adhesive sheet with a certain diameter and a certain thickness, and then, the circular conductive adhesive sheet is transferred to an inner shell and an outer shell. Compared with an existing method of adopting a dispensor to inject the conductive adhesive to the inner shell and the outer shell, and then, adopting polarity electrodes to carry out flattening and shaping on the conductive adhesive, the method enables the conductive adhesive sheet prepared through the manufacturing method to be regular in shape and uniform in thickness; and the diameter of the conductive adhesive sheet can be designed to be in an optimum size. The prepared electric double-layer capacitor can work for 1000 hours under the temperature of 70 degrees and the voltage of 2.5V; the internal resistance increase rate of the double-layer capacitor is low; capacity reduction rate is low; and performance is more stable and reliable.

Owner:江苏星凯新能源科技有限公司

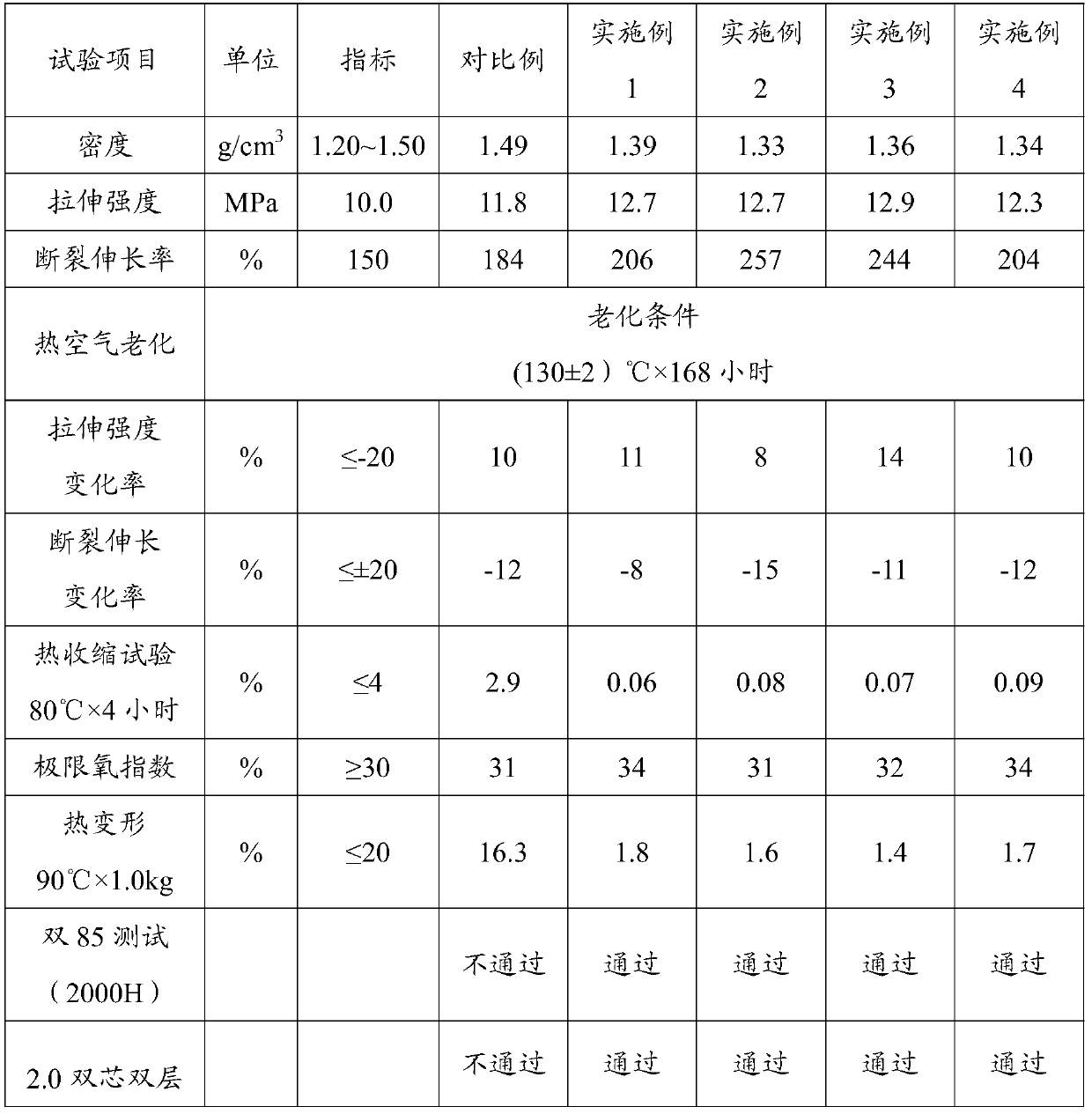

High temperature resistant, low-contraction, halogen-free, and flame-retardant sheath material and preparation method thereof

The invention discloses a high temperature resistant, low-contraction, halogen-free, and flame-retardant sheath material and a preparation method thereof, and belongs to the technical field of polymermaterials. The high temperature resistant, low-contraction, halogen-free, and flame-retardant sheath material comprises following components in parts by weight: 30 to 60 parts of thermoplastic elastomer, 16 to 30 parts of functional polyolefin resin, 16 to 25 parts of grafted linear low density polyethylene, 0.1 to 2 parts of a surface slipping agent, 0.5 to 2 parts of an antioxidant, 1 to 3 parts of a processing aid, 120 to 180 parts of a flame retardant, and 1 to 3 parts of a tubular microcrystal nano charring agent. The sheath material has the advantages of good flame retardant performance, high toughness, high temperature resistance, low contraction, and high stability, does not generate any toxic gas when being burned, and is suitable for small size cables with different structures such as single layer, multiply layers, single core, multiple cores, and the like.

Owner:WUXI JAKE PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com