Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94results about How to "Solve lightweight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

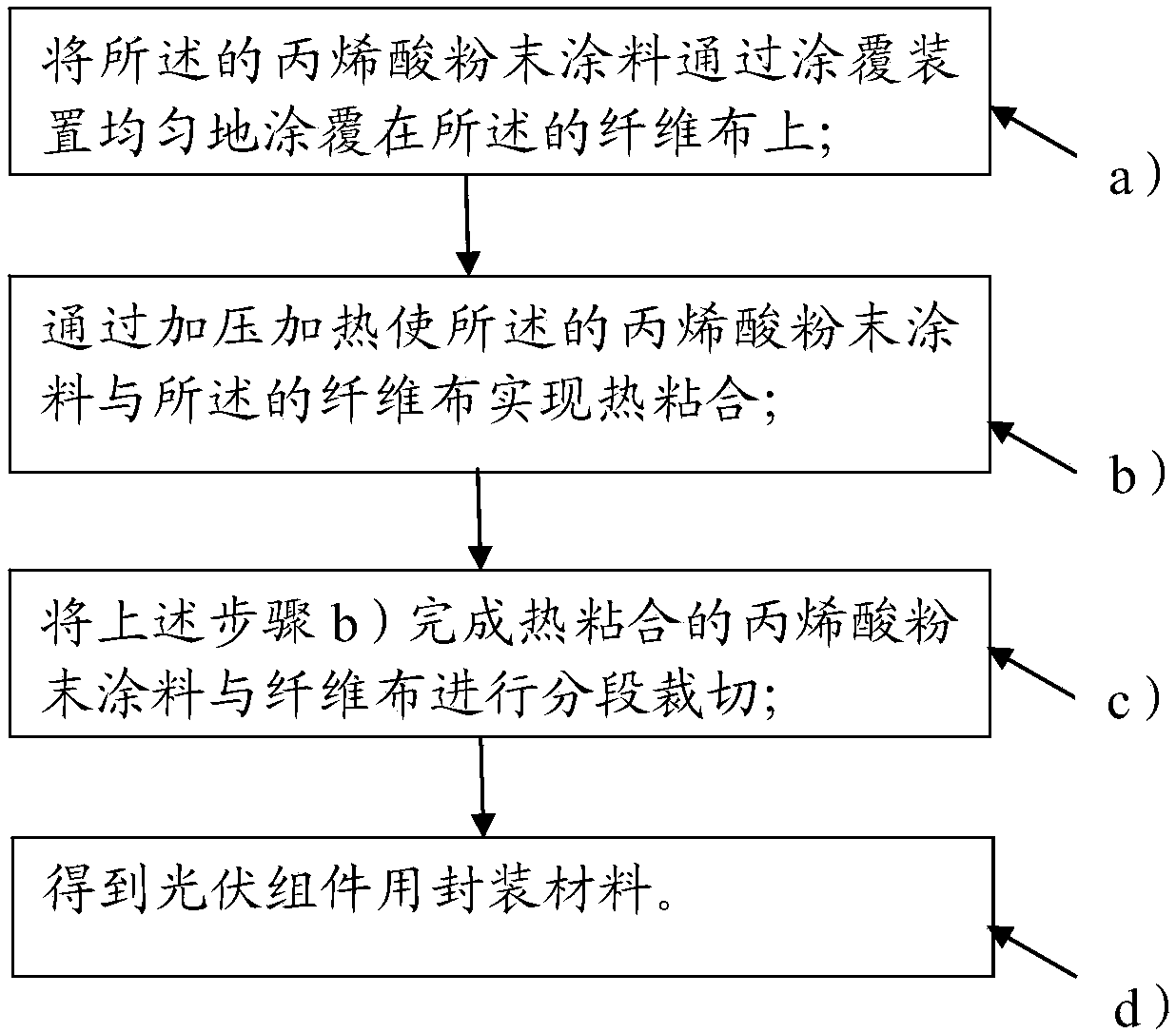

Packaging material for photovoltaic module and preparation method of the packaging material

ActiveCN106299000AReduce weightReduce installation costsFinal product manufactureFibre treatmentFiberPhotovoltaic industry

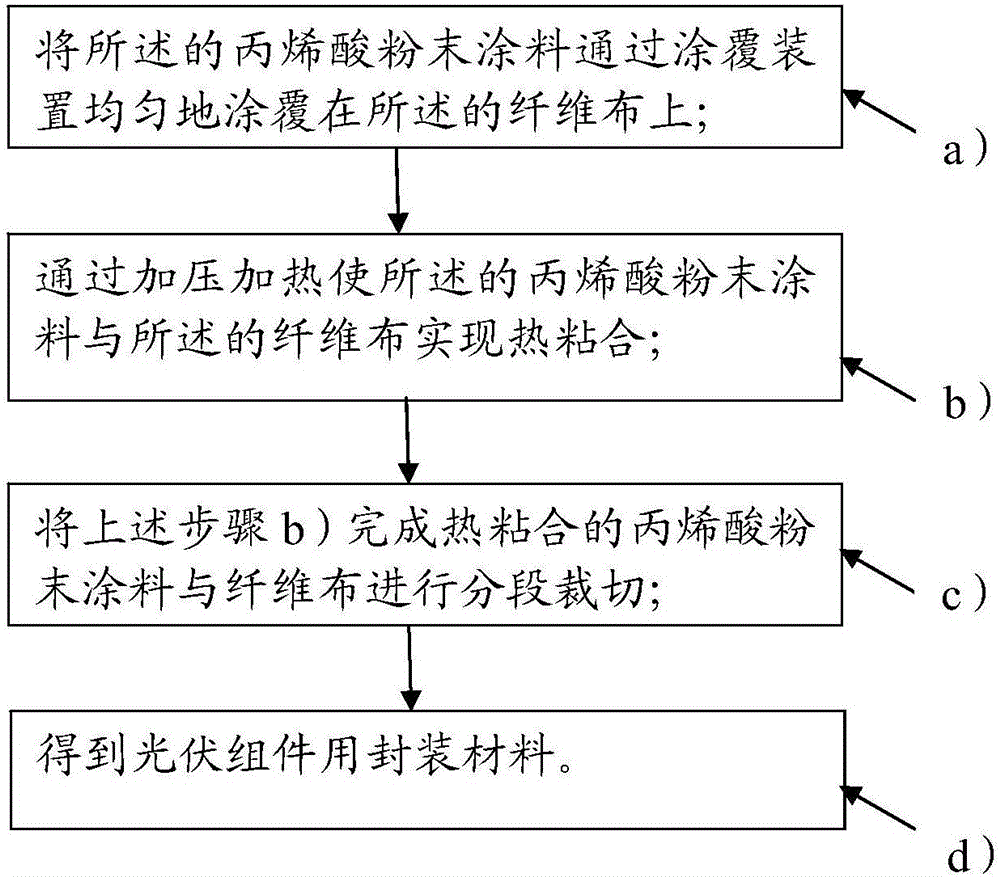

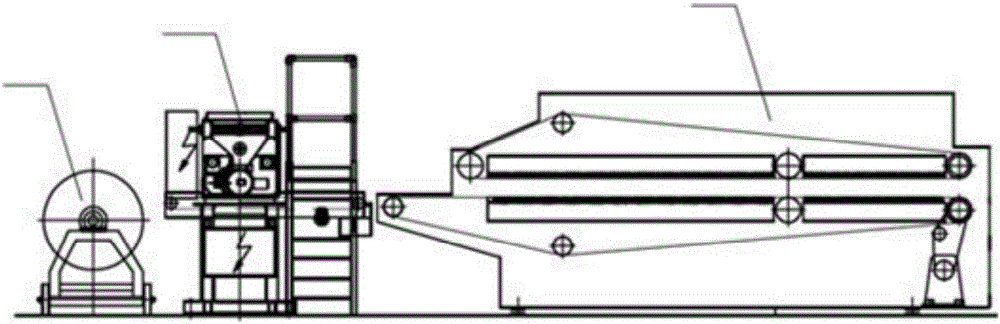

The invention discloses a packaging material for a photovoltaic module. The packaging material comprises the following raw materials in parts by weight: 30-50 parts of fiber cloth produced from fiber material through weaving; and 50-70 parts of acrylic powder coating including acrylic resins and a curing agent. The acrylic powder coating is evenly spread on the fiber cloth. The packaging material is low in manufacturing cost. While meeting the prerequisites of resistance to ultraviolet, aging, impact and fire which are standard requirements of the photovoltaic industry, the packaging material solves the problem of lightweight photovoltaic module packaging material, makes installation more convenient, reduces the installation cost, and thus is very suitable for large-scale promotion and application in the photovoltaic field. The invention also discloses a preparation method of the packaging material for a photovoltaic module. The method meets installation requirement for changing the packaging size of a photovoltaic module at will to adapt to different buildings and thus further facilitates installation and application of photovoltaic modules.

Owner:TIGER DRYLAC TAICANG +1

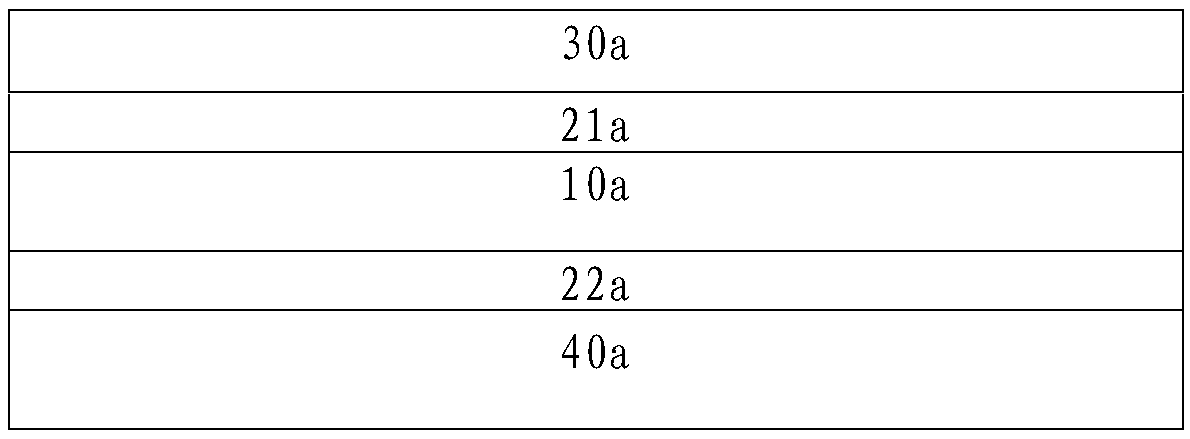

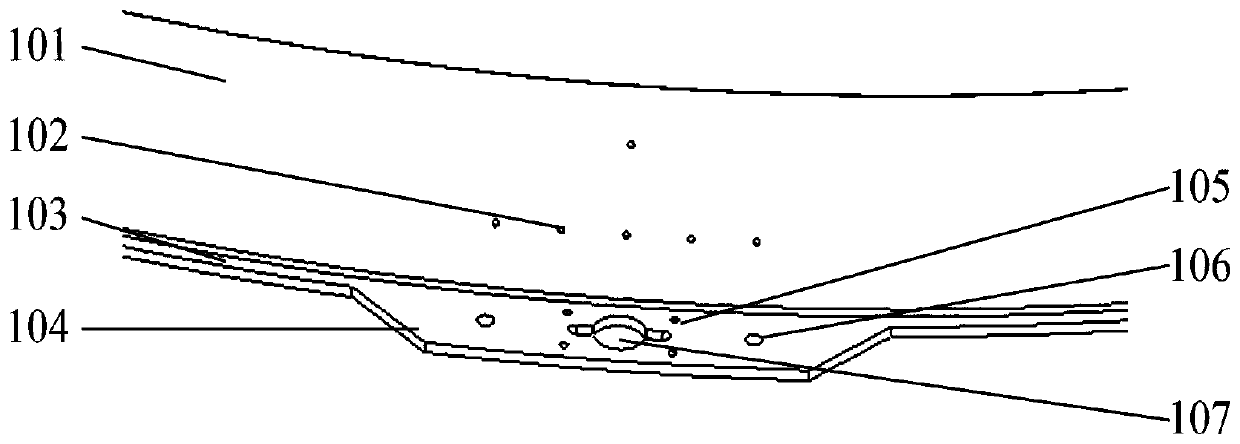

Photovoltaic assembly, lamination structure thereof and preparation method of lamination structure

ActiveCN108022988ALow manufacturing costReduce weightLaminationLamination apparatusPolyesterEngineering

Owner:SUNMAN (ZHENJIANG) CO LTD

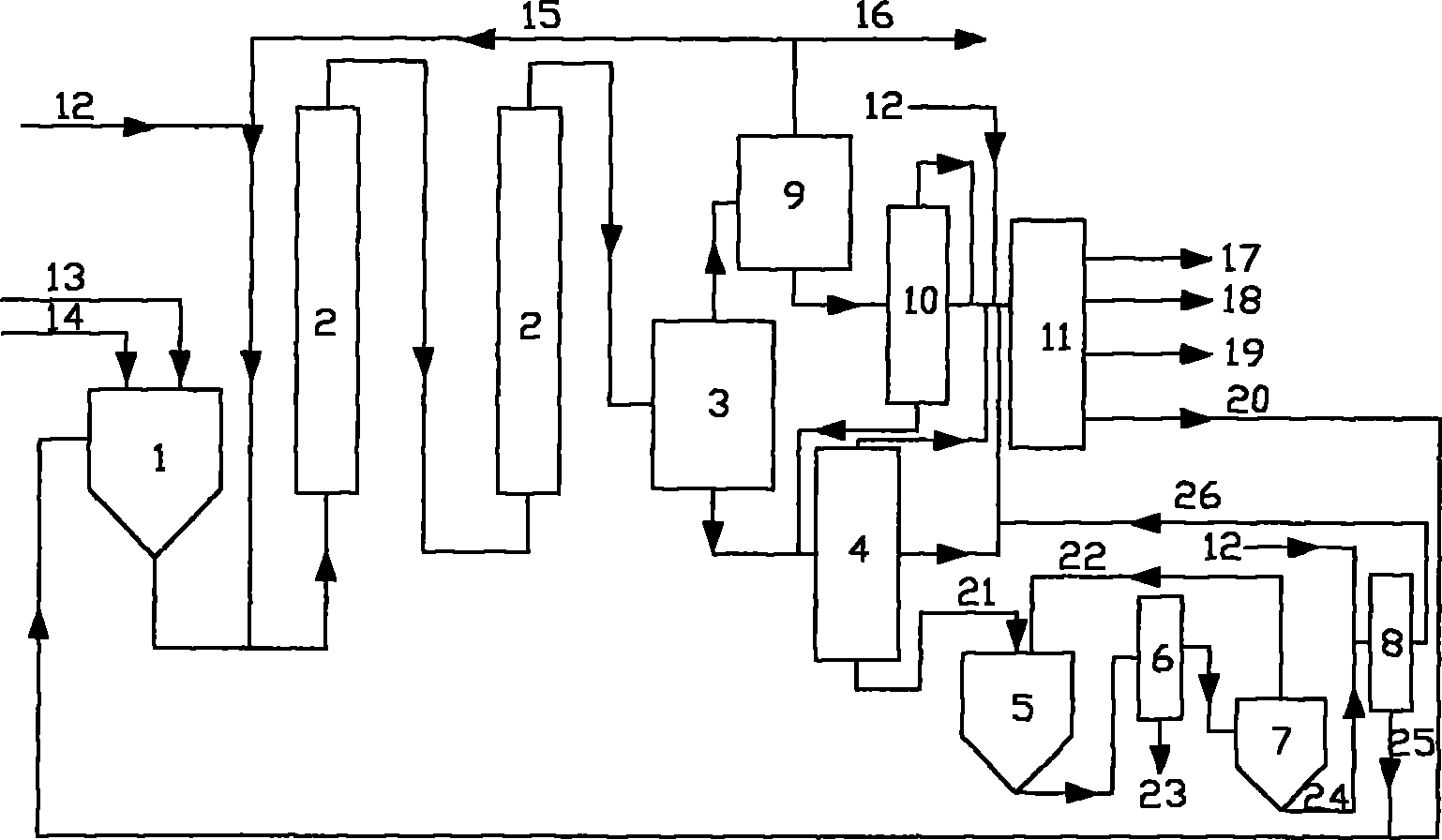

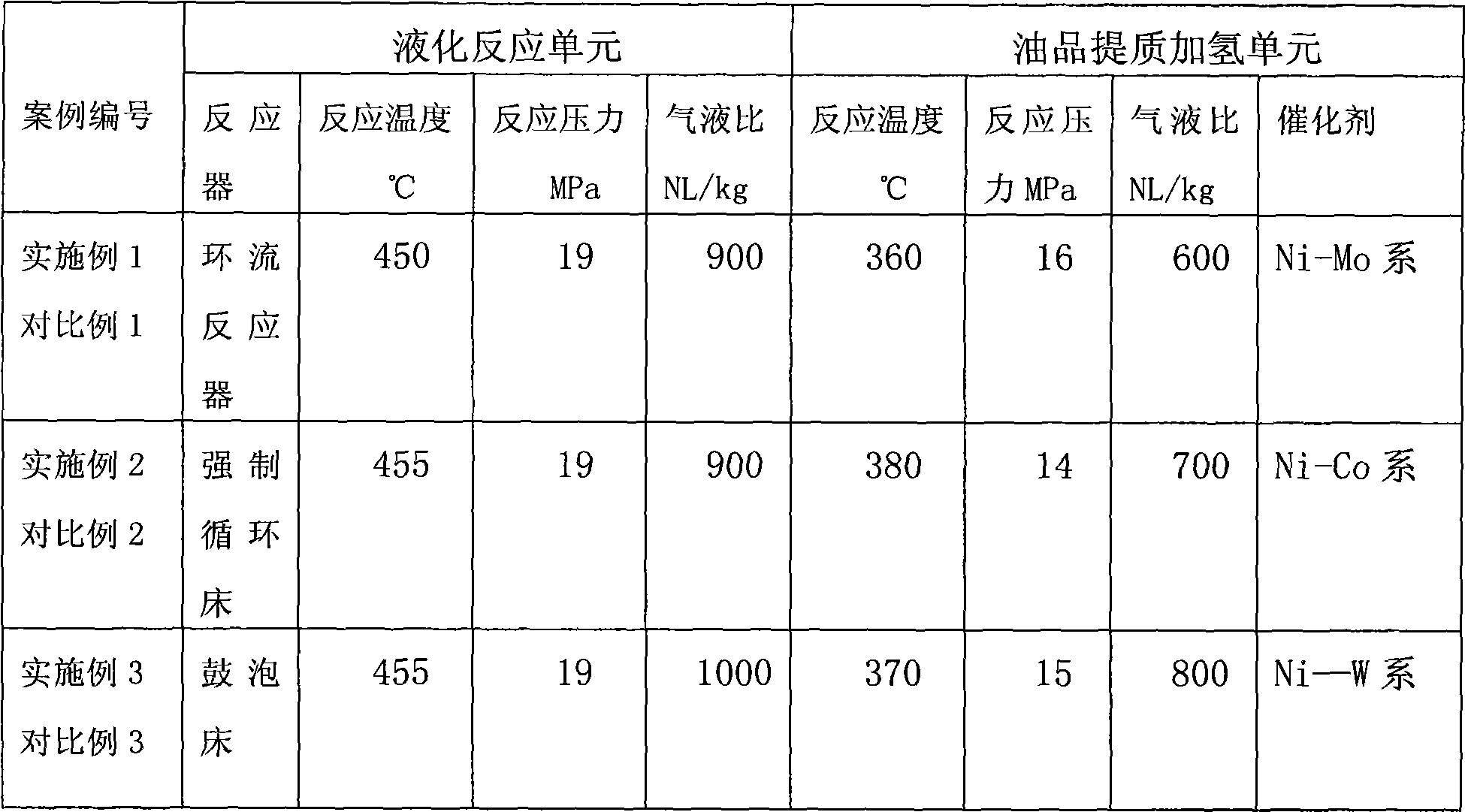

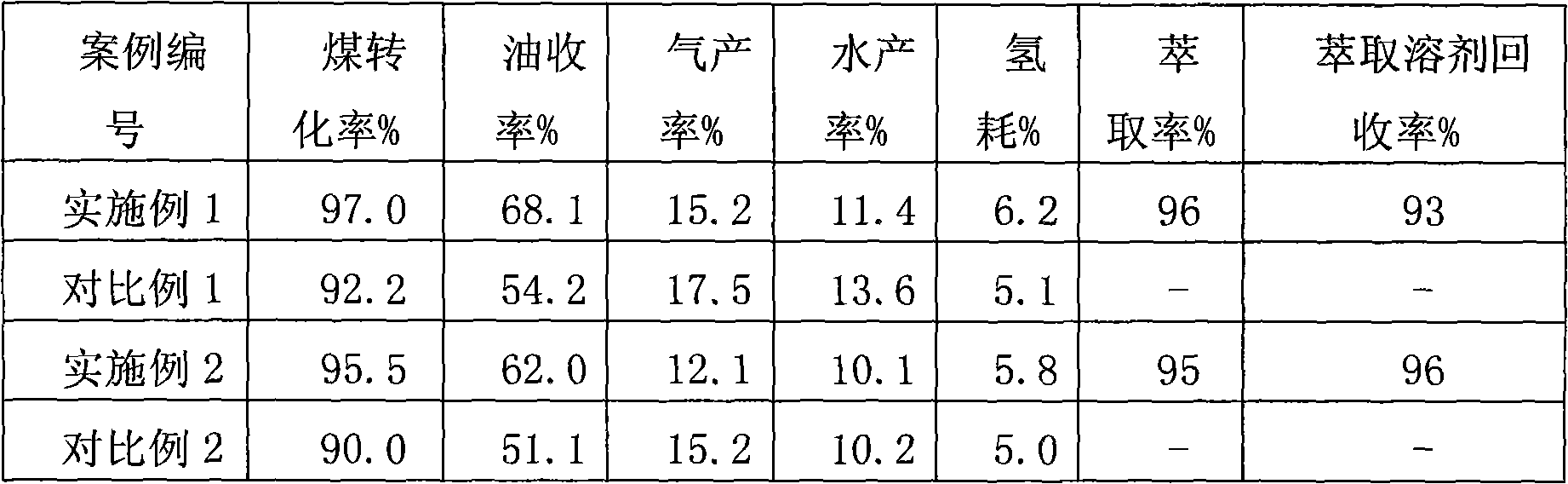

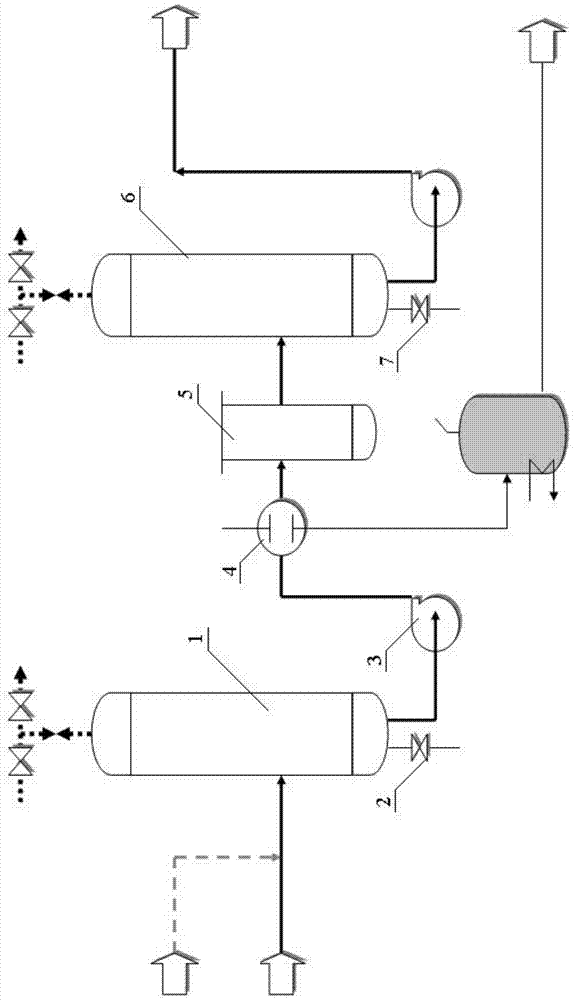

Method for directly liquefying coals with function of maximizing utilization of liquefied residues

ActiveCN102010741AGreat operating flexibilityHigh air hold-upLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesEconomic benefitsOil separation

The invention relates to a method for directly liquefying coals with a function of maximizing utilization of liquefied residues. The method comprises the following technical steps: preparing coal paste; carrying out hydrotreating and liquefaction on the coal paste; carrying out oil separation treatment on the obtained oil product; carrying out upgrading and hydrotreating on the obtained product; carrying out hot extraction on the residues and then carrying out solid-liquid separation on the residues; and recovering the solvent; and carrying out hydrotreating treatment on the mixture of heavy oils and asphalt materials so as to obtain the final product, then taking the heavy oils as recycled solvent to prepare the coal paste, and the like. The method provided by the invention has the advantages that because of organically combining the liquefaction process and the residue extraction, the utilization of liquefied residues is maximized, the conversion rate of coal is improved, the yieldsof light and middle oils subjected to coal liquefaction are improved by 10 to 60 percent, and the quality of oil is improved, thereby greatly enhancing the economic benefits of direct coal liquefaction plants and improving environment protection; and the method provided by the invention has important economic and social significances, and can widely be applied to the field of coal direct liquefaction.

Owner:CHINA COAL RES INST

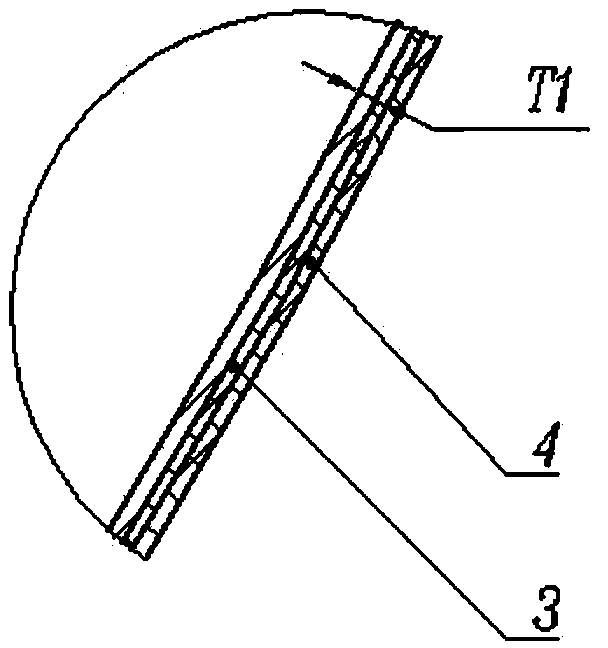

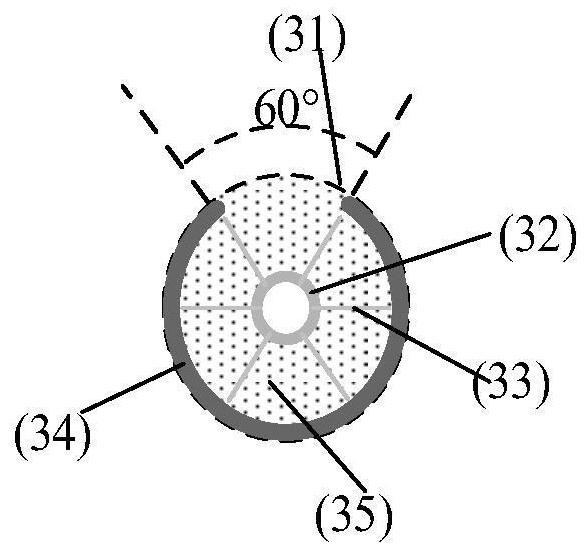

Metal diaphragm storage box made of carbon-fiber composite materials and manufacturing method thereof

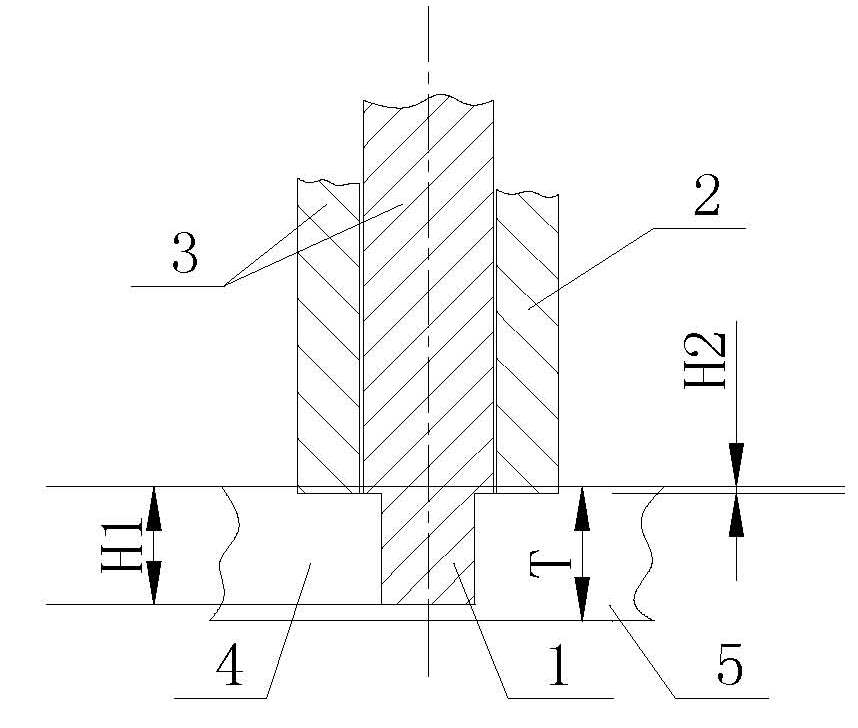

ActiveCN103437913ASimple structureGood manufacturing processRocket engine plantsCarbon fiber compositeFlange

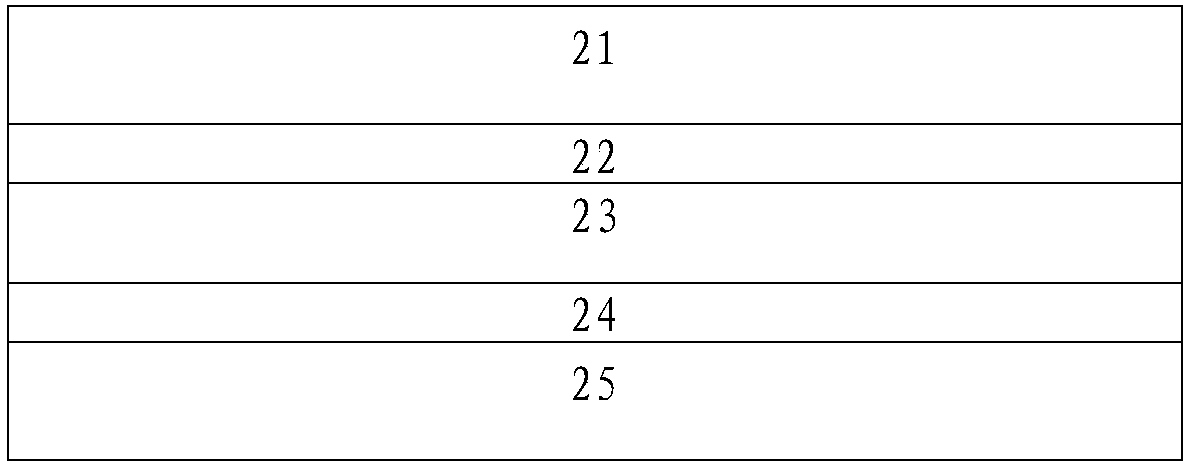

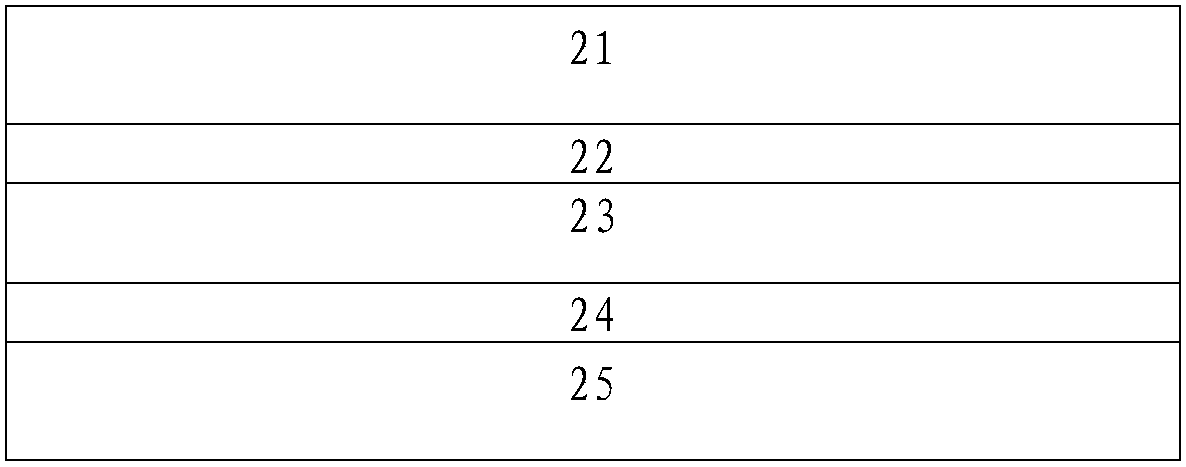

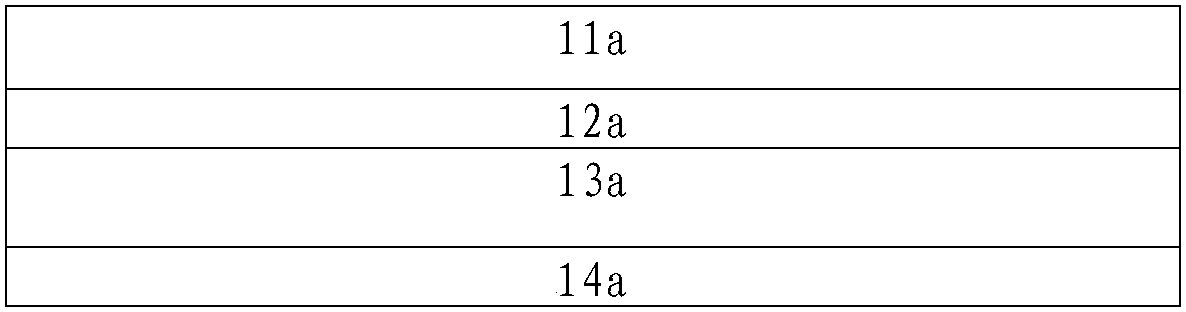

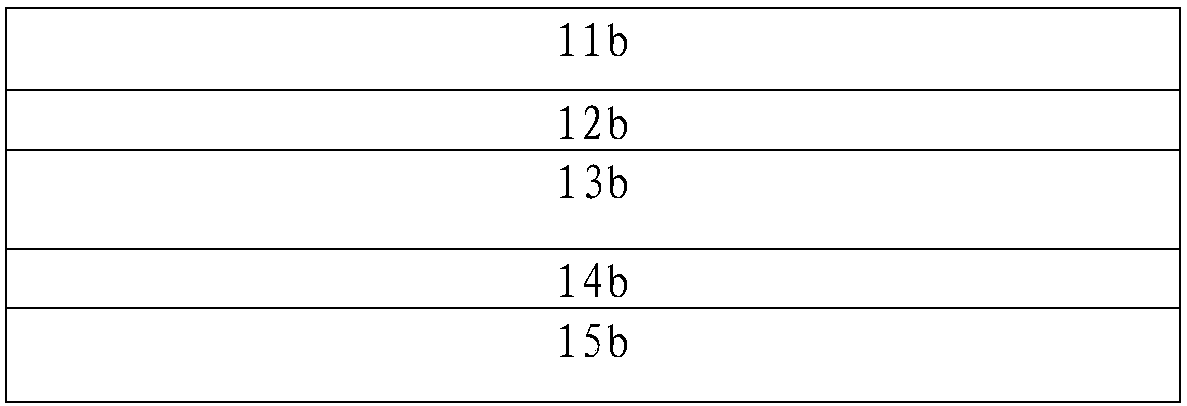

The invention provides a metal diaphragm storage box made of carbon-fiber composite materials and a manufacturing method thereof. The metal diaphragm storage box comprises a liner 1 and a metal diaphragm 2 and also comprises an insulating layer 3 and a carbon-fiber composite material layer 4, wherein the liner 1 comprises an upper flange 11, an upper hemisphere 12, a connecting ring 13, a lower hemisphere 14 and a lower flange 15; the upper hemisphere 12 and the lower hemisphere 14 are connected by the connecting ring 13; the upper flange 11 is connected with the upper hemisphere 12; the lower flange 15 is connected with the lower hemisphere 14; the metal diaphragm 2 is butted with the connecting ring 13; the outer surface of the liner 1 is coated with the insulating layer 3; the outer surface of the insulating layer 3 is wound with the carbon-fiber composite material layer 4, and is connected with the carbon-fiber composite material layer 4 in a bonding manner. The metal diaphragm storage box provided by the invention has the advantages that the problems of large weight and low structure efficiency of the metal diaphragm storage box are solved, the light-weight design of the metal diaphragm storage box is realized, the cost is reduced and the performance of a product is improved.

Owner:SHANGHAI INST OF SPACE PROPULSION

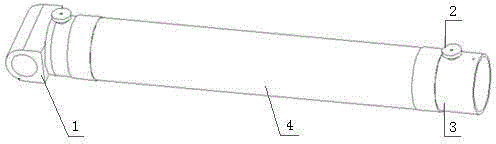

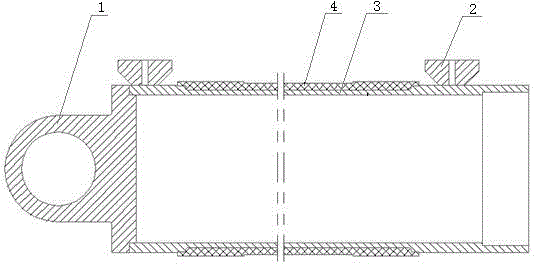

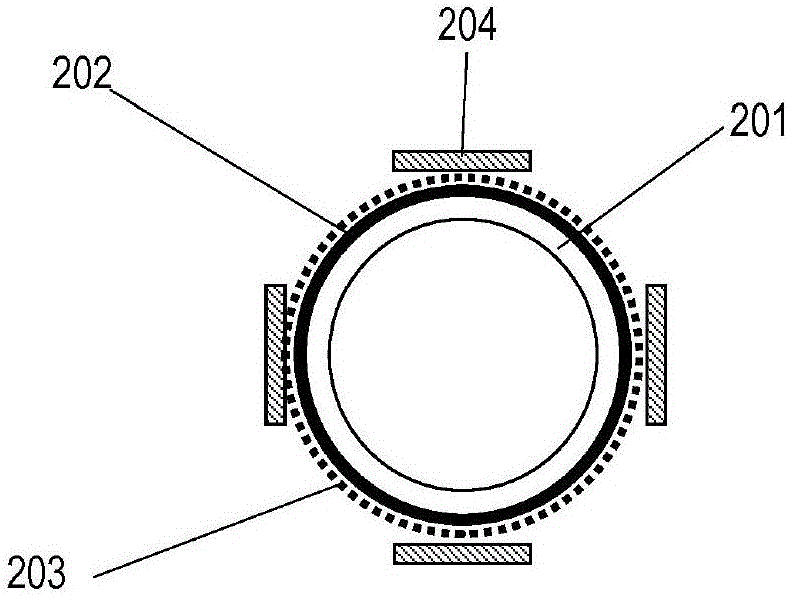

Carbon fiber composite material reinforcing hydraulic oil cylinder

InactiveCN102720721AImprove securityReduce energy consumptionFluid-pressure actuatorsTruckMetal cylinder

The invention provides a carbon fiber composite material reinforcing hydraulic oil cylinder, comprising a base, a cylinder barrel and oil openings. The oil openings are arranged at the both ends of the cylinder barrel; the cylinder barrel is a thinned metal cylinder barrel; a reinforcing layer is coated outside the cylinder barrel; the reinforcing layer is a carbon fiber composite material reinforcing layer; the carbon fiber composite material reinforcing layer uses heat convertible resin as a base body and a carbon fiber as a reinforcing material; and the carbon fiber composite material reinforcing layer contains the resin with a mass ratio of 23-55%. Compared with the full-metal hydraulic oil cylinder in the prior art, the strength, the rigidity and the anti-fatigue property of the carbon fiber composite material reinforcing hydraulic oil cylinder in various working conditions are improved by more than 20%, so that not only can the security of the product be effectively improved in the working conditions, but also more than 30% of the weight is reduced. Therefore, a mechanical pump truck is lightened, and the entire cost is reduced.

Owner:HENGSHEN

Small butt locking device for space

ActiveCN105000199ASolve lightweightSolve the miniaturization problemCosmonautic component separationFace detectionLocking mechanism

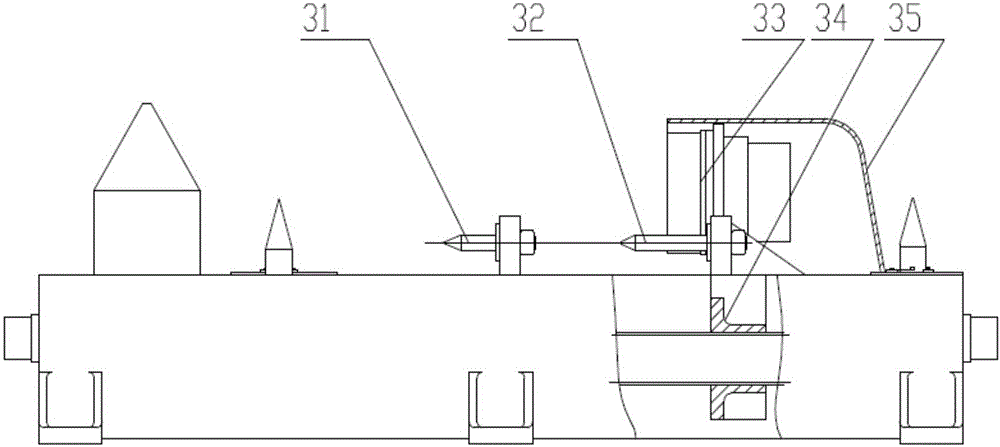

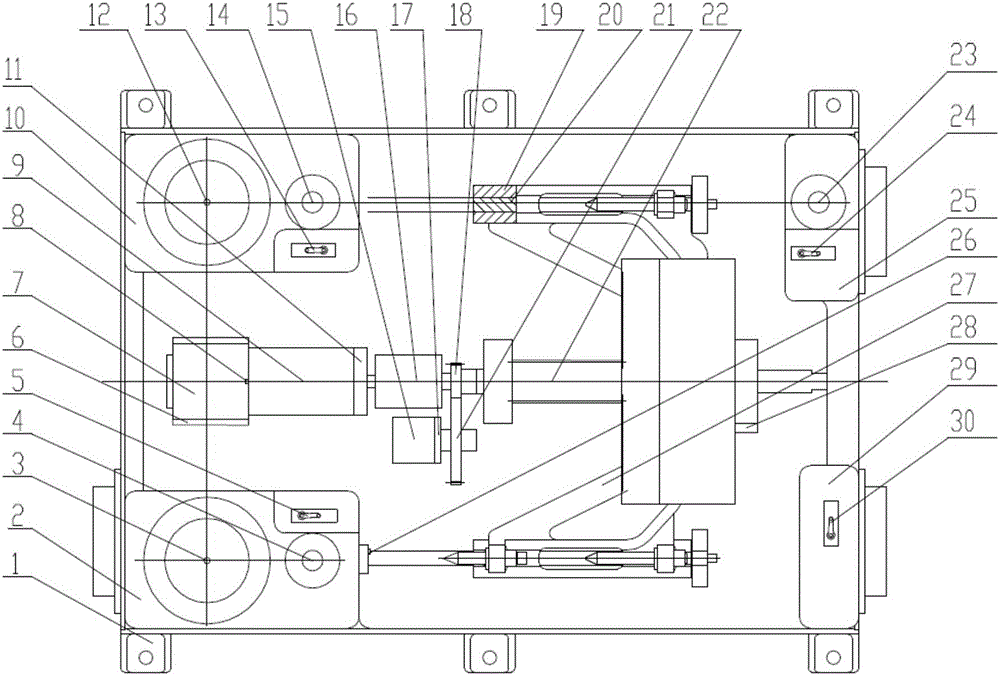

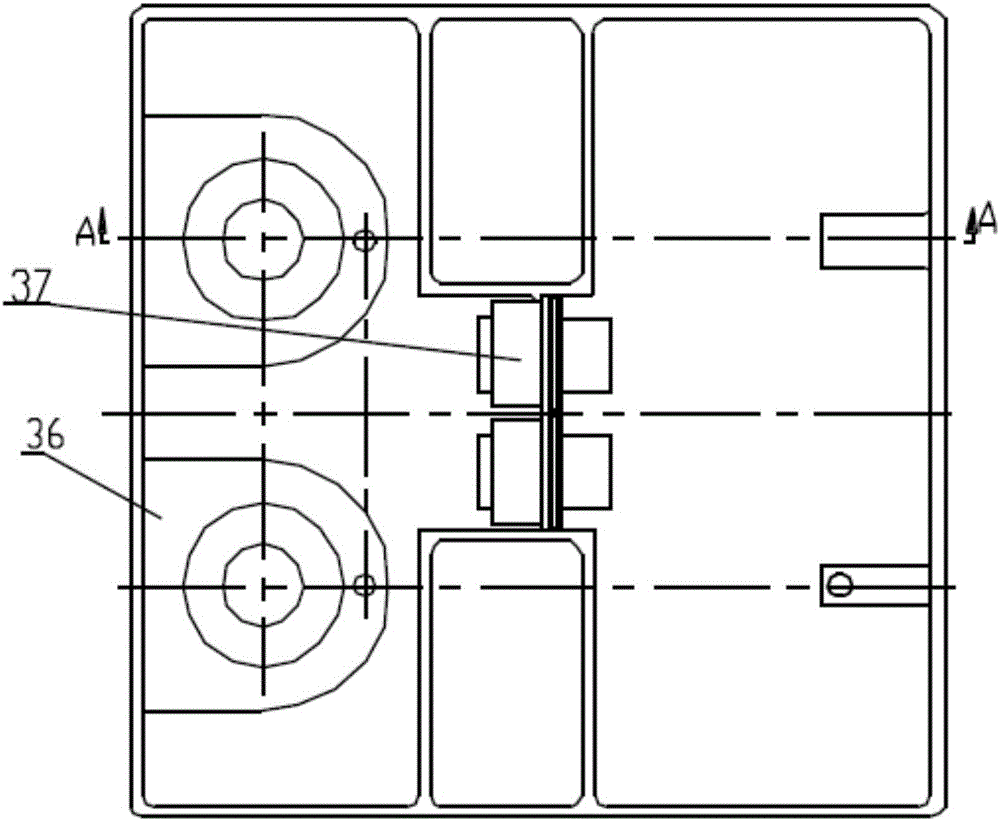

The invention provides a small butt locking device for a space. The small butt locking device comprises a diving mechanism installed on a space station and a shell installed on a space test load. The diving mechanism comprises a fame, a positioning pin installation plate A, a coarse positioning pin A, a fine positioning pin A, a face detection switch A, a heating device, a motor, a temperature sensor, a speed reducer, a positioning pin installation plate B, a speed reducer support, a coarse positioning pin B, a face detection switch B, a fine positioning pin B, a potentiometer, a coupling, a potentiometer support, a pinion, a sliding guide bush, an optical axis, a bull gear, a screw, a fine positioning pin C, a face detection switch C, a positioning pin installation plate C, a locking detection switch, a drive rack, an unlocking detection switch, a switch installation plate, a face detection switch D, a locking pin A, a locking pin B, a floating connector socket and a nut. The small butt locking mechanism for the space is miniature and lightweight, and an astronaut does not need to participate in operation.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Method for producing automotive rear shelf

The invention relates to a method for producing an automotive rear shelf. The method is characterized by comprising the following steps of: (1) heating: hanging polypropylene sheets in a two-layer drying oven and heating, wherein the temperature of an upper-layer drying oven of the two-layer drying oven is between 240 and 260 DEG C; the temperature of a lower-layer drying oven of the two-layer drying oven is between 325 and 345 DEG C; and the heating time is 85 to 95 seconds; (2) pressing and forming: laying a fabric on two layers of PP sheets flatly, and pressing and forming the fabric in a die to obtain a half-finished product, wherein the pressure during pressing and forming is 70 to 90kg / cm<2>, and the forming time is 60 to 70 seconds; (3) cooling and shaping: cooling and shaping the half-finished product at the normal temperature, wherein the cooling time is 30 to 50 seconds; (4) installing accessories: installing the accessories on the half-finished product to obtain an automotive rear shelf finished product; and (5) examining and packing, wherein the fabric is a non-woven fabric, and the PP sheets are PP wood powder sheets with glue. The method ensures the performance indexes of light weight, high strength, difficult contraction distortion and the like of a rear shelf, greatly reduces the weight of the rear shelf, and meets the requirement for lightweight vehicle design; and as the material has a double-layer wood powder sheet structure, the product is fuller.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Encapsulation material for photovoltaic module and preparation method of the encapsulation material

ActiveCN106299000BReduce weightReduce installation costsFinal product manufactureFibre treatmentFiberPhotovoltaic industry

The invention discloses a packaging material for photovoltaic modules. The packaging material includes the following raw materials in parts by weight: 30-50 parts of fiber cloth, the fiber cloth is made of fiber materials; 50-70 parts of acrylic powder coating, and 50-70 parts of acrylic powder The coating includes an acrylic resin and a curing agent; wherein, the acrylic powder coating is evenly coated on the fiber cloth; the invention not only has low manufacturing cost, but also satisfies the requirements of photovoltaic industry technical standards such as anti-ultraviolet, anti-aging, impact resistance, and fire prevention. It effectively solves the problem of reducing the weight of the photovoltaic module packaging material, improves the convenience of installation, and reduces the installation cost, which is very suitable for large-scale promotion and application in the photovoltaic field; The package size of photovoltaic modules can be changed arbitrarily to meet the installation requirements of different buildings, which further facilitates the installation and application of photovoltaic modules.

Owner:TIGER DRYLAC TAICANG +1

Method for producing decorating part of car boot cover

InactiveCN101654080AReduce weightProcess stabilitySynthetic resin layered productsLaminationWork in processEnvironmental resistance

The invention relates to a method for producing a decorating part of a car boot cover, which belongs to the technical field of interior parts of cars. A low-density PP plate molding material is mainlyadopted as a decorating part basal body of a boot cover and is subjected to press molding, water-jet cutting and inspection to obtain a finished product. The invention solves the problem of meeting the performance indexes of sound absorption, heat resistance, light weight, high strength, and the like of a decorating part assembly of the boot cover and the three-grade international advanced level,greatly reduces the weight of the decorating part of the boot cover, meets the requirement on the lightweight design of the whole car and has stable molding process; a product has high rigidity and can not be broken and sagged; the product is produced by an automatic production line in the whole production process, thereby greatly reducing the labor intensity of workers in the production processand improving the production efficiency; no semi-finished product is stacked in the process, and the manufacture cost is saved; and the product does not generate harmful substances in the whole production process and belongs to an environmental-friendly product.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

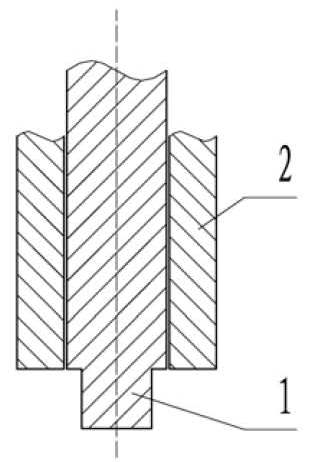

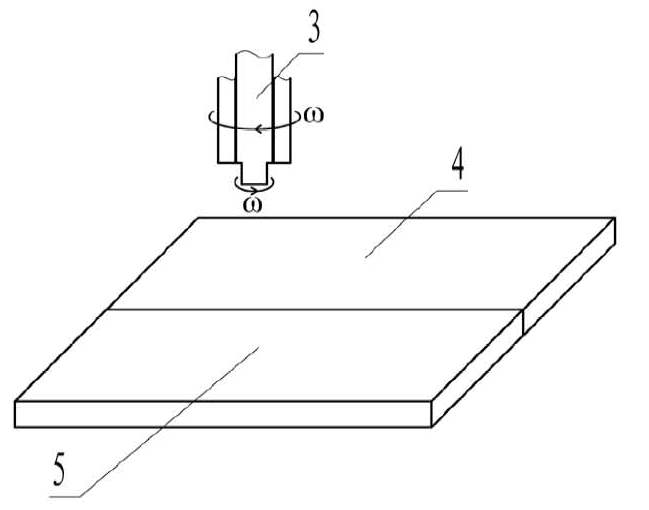

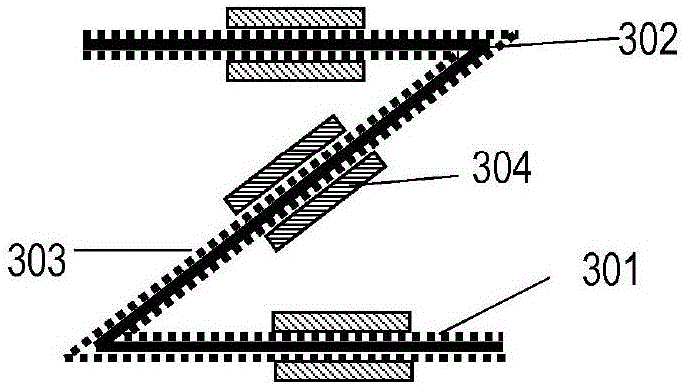

Friction stir welding method for stirring pin and shaft shoulder during differential speed rotation

InactiveCN101890573AReduce stressReduced clamping requirementsNon-electric welding apparatusRotation velocityFriction stir welding

The invention discloses a friction stir welding method for a stirring pin and a shaft shoulder during differential speed rotation, relates to the friction stir welding method and solves the problems of high downward pressure and high forward resistance and various problems caused by overcoming high speed rotation of the stirring pin and high speed rotation of the shaft shoulder in the same direction or non-rotation of the shaft shoulder existing in conventional friction stir welding. The method comprises the following steps of: inserting the stirring pin of a stirring head into a part to be welded at a rotation speed of between 3,000 and 30,000 rpm, wherein the rotation speed of the shaft shoulder of the stirring head is less than that of the stirring pin and the rotation direction of the stirring head is reverse to that of the stirring pin; the rotation speed of the shaft shoulder is 10 to 1,000 rpm; the insertion speed of the stirring head is 1 to 5 millimeter / minute; the depth of the stirring pin inserted into a workpiece is 0 to 0.5mm less than the thickness of the workpiece; and the depth of the shaft shoulder inserted into the workpiece is 0 to 0.5mm; and moving the stirring head along the horizontal direction of a butting surface of a first welded workpiece and a second welded workpiece at a speed of between 100 and 5,000 millimeter / minute. The heat required by the welding does not depend on the friction between the shaft shoulder and the welded material, so high downward pressure is not needed to ensure the friction of the shaft shoulder part to produce heat and the downward pressure is reduced.

Owner:HARBIN INST OF TECH

Cotton net bottom plastic container seedlings transplanting method

The present invention relates to a cotton net-bottom hole-plate seedling-culticating and transplanting method. Said method includes the following several main steps: preparing seedling bed, spraying carbofuran, adding protecting agent for emergence of seedlings into the soil to obtain nutrient soil, filling a half of nutrient soil into the hole of net-bottom hole plate, then placing cotton seed into said hole, making the hole be filled up with nutrient soil, placing the net-bottom hole plate into the seedling bed, watering and covering the hole-plate with a layer of fine soil, spraying glyphosate, covering the seedling bed with a layer of rice straw, film-nulching, after the seedlings are emerged, removing film, applying seedling-tonifying agent and making transplantation.

Owner:YANGZHOU UNIV

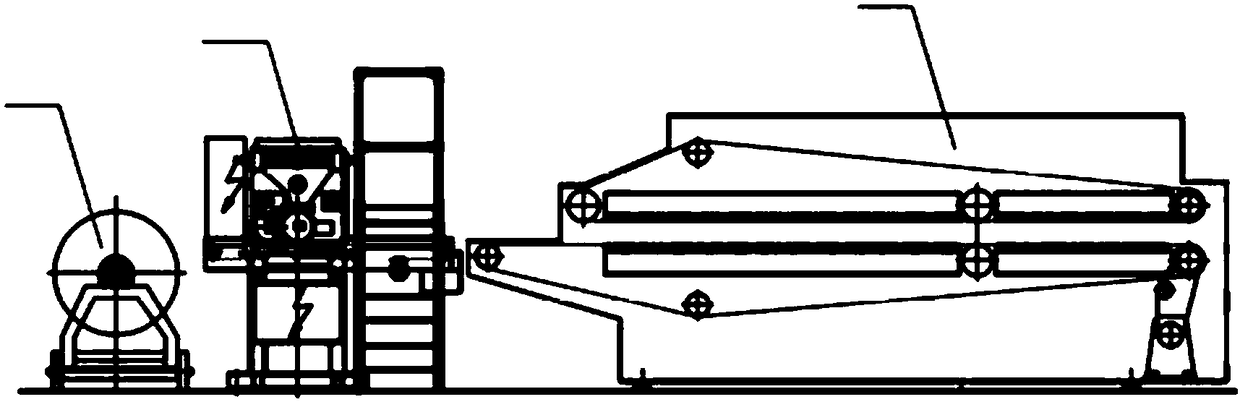

Production method of vehicular coat and hat rack

InactiveCN101357612AReduce weightNot easily deformedRacks dispositionEnvironmental resistanceWork in process

The invention relates to a method for manufacturing a coatrack of an automobile, which pertains to the technical field of automobile interior trim parts; the method comprises the steps: a natural fiberboard is taken as a board body of the coatrack; press forming, cool setting, fabric attaching, die cutting and accessory mounting are carried out to the board body of the coatrack. The board body is claimed as a finished product after passing the examination. The method of the invention achieves the performance indexes of a coatrack assembly, such as heat resistance, light weight, high strength, low contractility and low deformability and reaches the Grade 3 of the international leading level, thereby reducing the weight of the coatrack and meeting the design requirement of light weight of the whole automobile; the process adopts the double-oven suspension heating and molding line production, with stable technique; a semi-automatic assembling fixture is adopted in the installation, thereby ensuring safe accuracy and improving working efficiency. No semi-manufactured goods accumulate during the course so that the manufacturing cost can be saved. No harmful substance is generated in the whole production process so that the coatrack produced by the method of the invention is environment-friendly.

Owner:WUXI GISSING AUTO PARTS CO LTD

Method for manufacturing automobile glass wool insulating mat

InactiveCN101607460ASolve sound absorptionSolve lightweightLamination ancillary operationsLaminationHeat resistancePerformance index

The invention relates to a method for manufacturing an automobile glass wool insulating mat, which pertains to the technical filed of automotive upholstery. The method is characterized by adopting the following steps: glass wool is arranged between surface and base fabric to form base stock which is pressed, cooled and then incised by a water jet; and after being checked and proved eligible, the automobile glass wool insulating mats are packaged for storage. The insulating mat manufactured via the method has the performance indexes of sound absorption, heat resistance, light weight, high rigidity and the like, not only greatly reducing the weight of the insulating mat, but also meeting the requirements of the whole automobile on low weight design. Besides, manual arrangement of glass wool can make up for uneven glass wool density. The insulating mat manufactured via the method has the advantages of high rigidity, invulnerability, non-deformation and low cost of raw material. Therefore, the glass wool insulating mat manufactured via the method meets the requirement of the whole automobile on low cost design.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Organic solidification curing resistor slurry and preparation method thereof

ActiveCN105575464ASolve the difficulty of thinningSolve lightweightNon-conductive material with dispersed conductive materialCable/conductor manufactureSolventFire retardant

The invention discloses an organic solidification curing resistor slurry and a preparation method thereof. The organic solidification curing resistor slurry comprises a resistor function phase and an organic carrier, wherein the resistor function phase comprises super fine silver powder and super fine silicon carbide powder, the organic carrier comprises high temperature prevention resin, a high-molecular fire retardant, a solvent and an additive, the additive comprises a liquid antifoaming agent, a liquid levelling agent, a liquid anti-settling agent, a thixotropic agent, an eleaostearic acid salt heat stabilizer and an infiltration dispersant. The organic solidification curing resistor slurry can effectively solve a technical problem that thinning, lightening or specialization are not easy to realize in the prior art, 130-200 DEG C curing can be further realized, and the characteristic that the organic solidification curing resistor slurry can be used in relatively high temperature of 300 DEG C can be realized. The preparation method comprises steps that a, the resistor function phase is prepared; b, additives are prepared; c, the organic carrier is prepared; d, pre-mixing of the resistor function phase and the organic carrier is carried out; and e, a three-roller grinder is employed for grinding. Through the method, the organic solidification curing resistor slurry can be effectively prepared.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

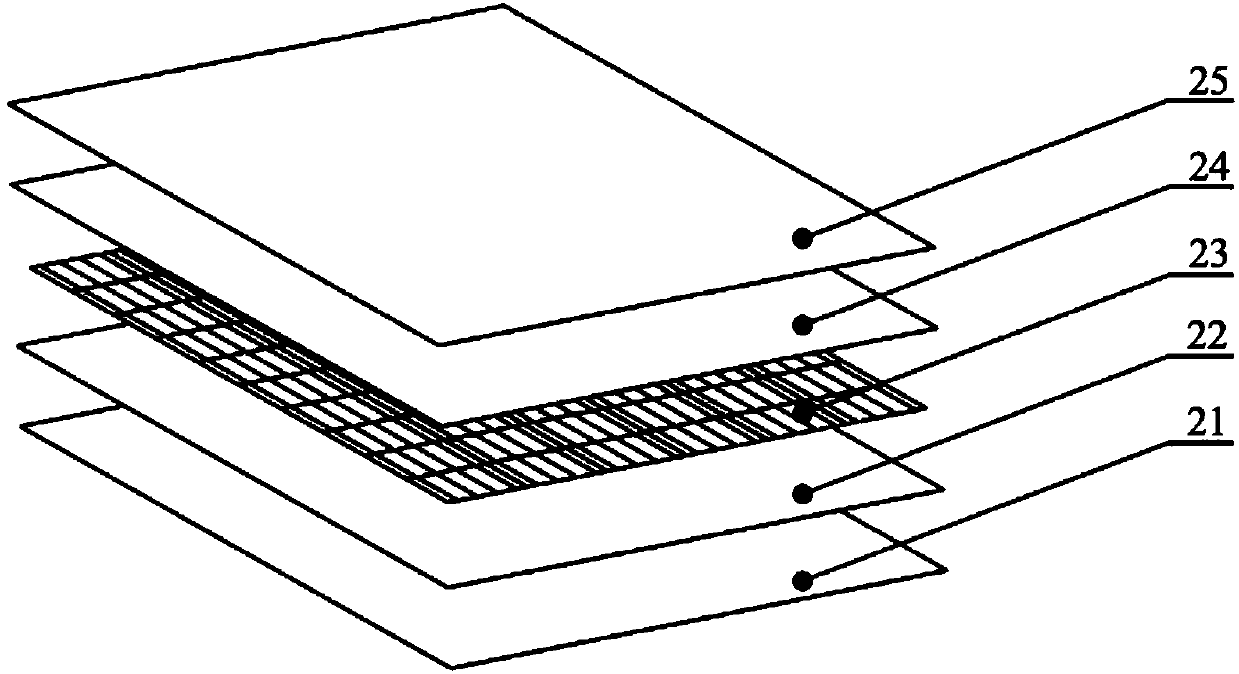

Laminated structure of a photovoltaic module and preparation method thereof, photovoltaic module

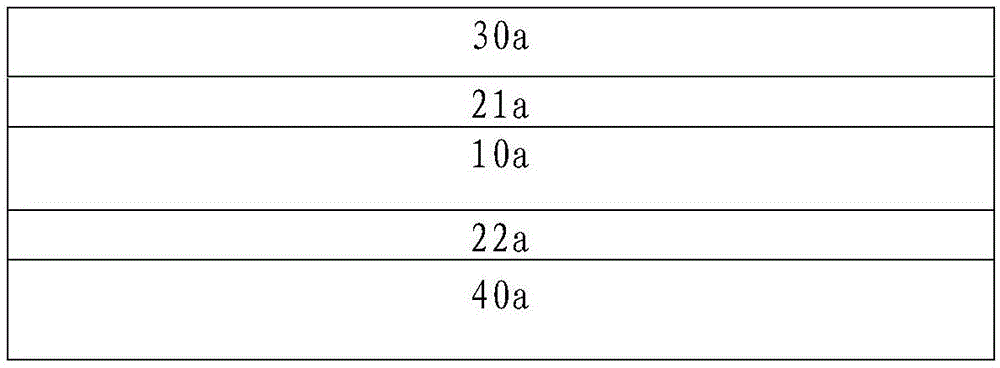

ActiveCN108022988BReduce weightReduce installation costsLaminationLamination apparatusPolyesterFiber

The invention discloses a laminated structure of a photovoltaic module, a preparation method thereof, and a photovoltaic module. The laminated structure includes a first encapsulation layer and a second encapsulation layer, wherein the first encapsulation layer consists of 30-50 parts by weight of fiber cloth and 50 parts by weight. ‑70 parts by weight of the first packaging powder coating is prepared, the first packaging powder coating is evenly coated on the fiber cloth; the second packaging layer is made of 30‑50 parts by weight of fiber cloth and 50‑70 parts by weight of the second packaging powder coating Prepared, the second packaged powder coating is evenly coated on the fiber cloth; wherein, the first packaged powder coating is acrylic powder coating or super weather-resistant polyester powder coating, and the second packaged powder coating is super weather-resistant polyester powder coating; The invention not only has low cost, but also effectively realizes the lightweight of photovoltaic module packaging materials under the premise of meeting the requirements of photovoltaic industry technical standards such as anti-ultraviolet, anti-aging, impact resistance, fire prevention, and anti-insulation, and is very suitable for use in the field of photovoltaics. Scale application.

Owner:SUNMAN (ZHENJIANG) CO LTD

Production method of car trunk carpet

InactiveCN101659229ASolve lightweightSolve performance indicators such as not easy to shrink and deformVehicle arrangementsLaminationWork in processEngineering

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

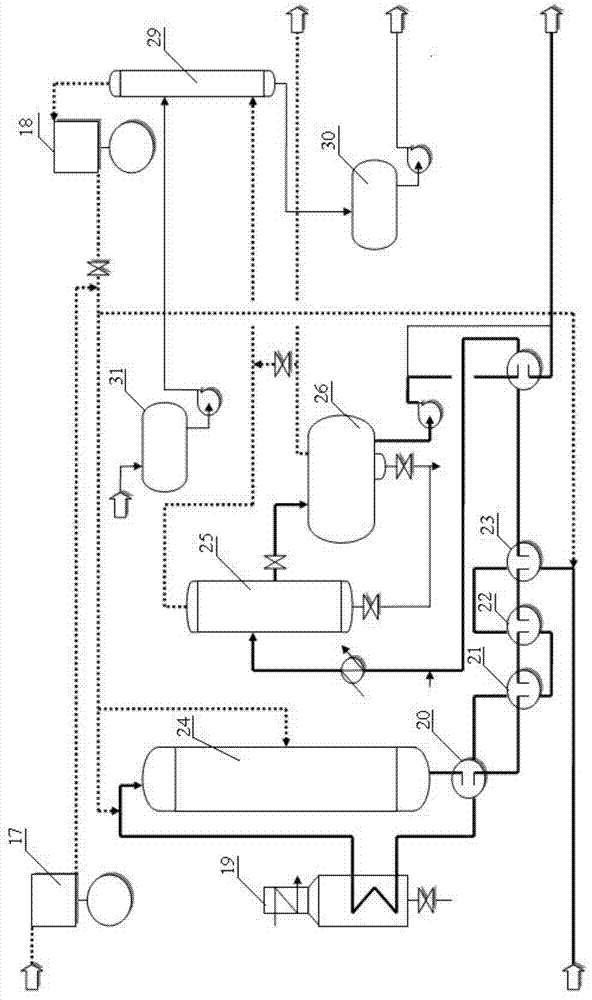

Method of producing low-sulfur low freezing point diesel by full-range shale oil

ActiveCN103497782AHigh yieldFlexible product planTreatment with hydrotreatment processesNaphthaOperational costs

The invention relates to a method of producing low-sulfur low freezing point diesel by full-range shale oil, relates to a production method of low-sulfur low freezing point diesel and solves the technical problems that the existing method of producing diesel by shale oil is complex in process and high in investment and operational cost. A material pre-fractionation unit, a reaction unit and a fraction unit are adopted in the method. The method has the advantages that finished diesel yield is high during processing of the full-range shale oil; the quality of the low-sulfur low freezing point diesel meets the national standard IV; a product scheme is flexible, the production of refined diesel and the production of the low-sulfur low freezing point diesel are both considered, and product distribution is adjusted; during the processing of the full-range shale oil, the material pre-fractionation unit is additionally provided with an absorbing column and a flash tank, lightweight shale oil is used as absorbent, LPG components in noncondensable gas can be recycled, applying a product stabilization column to the product fractionation unit to separate LPG and naphtha is avoided, and cost reduction and efficiency increasing are achieved. The invention belongs to the field of diesel production.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Preparation method of laminated structure of photovoltaic assembly, laminated structure and photovoltaic assembly

ActiveCN108376717AEasy to install and implement applicationsGuaranteed flatnessFinal product manufacturePhotovoltaic energy generationHeating timeEngineering

The invention discloses a preparation method of a laminated structure of a photovoltaic assembly, the laminated structure and the photovoltaic assembly, prepared through a laminating process. The laminating process comprises a first heating stage, a second heating stage and a third pressurization cooling stage, wherein the heating temperature of the first stage ranges from 110 DEG C to 130 DEG C,and the heating time ranges from 100 seconds to 600 seconds; the heating temperature of the second stage ranges from 131 DEG C to 200 DEG C, and the heating time ranges from 100 seconds to 1200 seconds; and the cooling temperature of the third stage ranges from 25 DEG C to 60 DEG C, and the applied pressure ranges from 0.05Mpa to 0.25Mpa. The method has the advantages that the laminating process under a low-temperature environment is realized, the energy consumption is reduced, the flatness of the laminated structure of the photovoltaic assembly is ensured, and the installation and implementation application of the photovoltaic assembly are further facilitated.

Owner:SUNMAN (ZHENJIANG) CO LTD

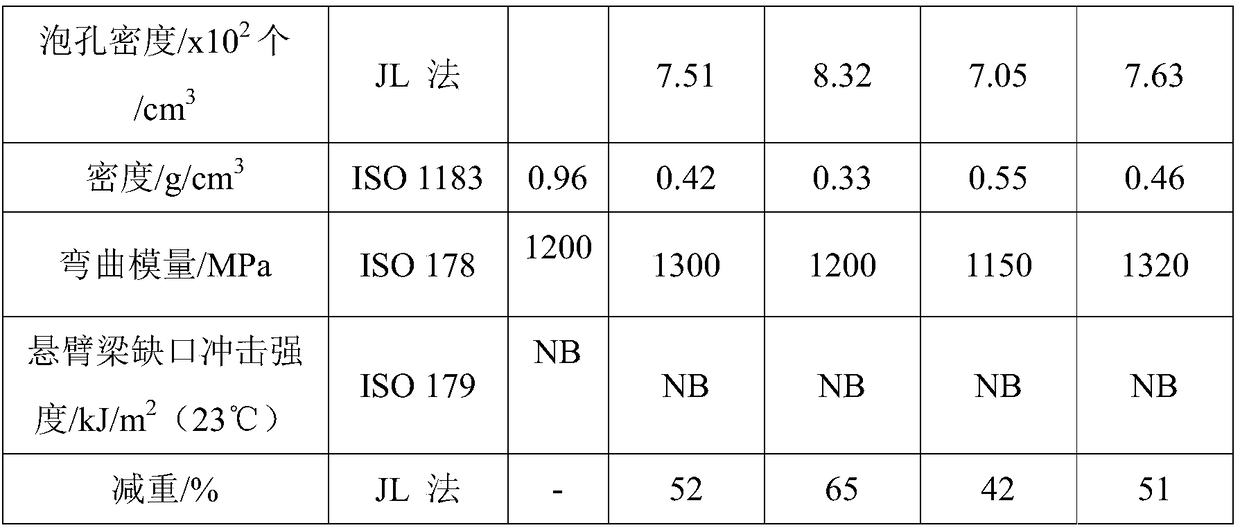

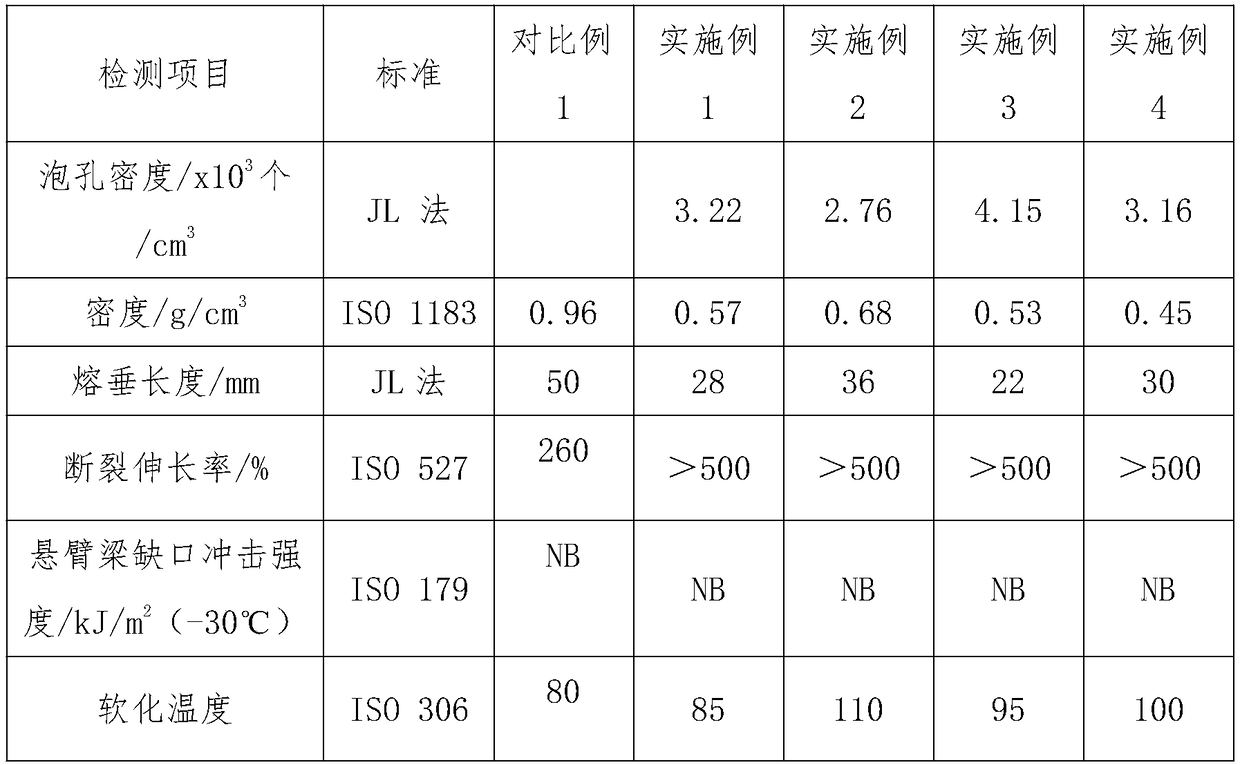

Hollow blow-molded micro-foamed automobile air duct material and preparation method thereof

InactiveCN108892830AImprove appearance qualityGood material strengthTubular articlesPolyesterMaterials science

The invention relates to an automobile air duct and a preparation method, especially to a hollow blow-molded micro-foamed automobile air duct material and a preparation method thereof. The material ofthe invention comprises the following components, by weight: 50-80 parts of polyethylene, 0-15 parts of mineral powder, 1-30 parts of polyester, 0.2-1 part of a tackifier, 0.5-10 parts of a foaming agent, 5-15 parts of a blowing promotor, 0.2-0.5 part of a lubricant, and 0.2-0.5 part of an antioxidant. The invention also discloses the preparation method of the material. The hollow blow-molded micro-foamed automobile air duct has the characteristics of high cell density and good apparent quality. An automobile engine hood product prepared by the material has the characteristics of light weight, good heat insulation effect, good dimensional stability, high yield and the like. Under the condition that the whole weight of the product is reduced by more than 40%, the normal assembly and use ofparts are not affected, and the purpose of lightweight is achieved.

Owner:NANJING JULONG SCI&TECH CO LTD +1

Building information model reconstruction method based on oblique photogrammetry technology

PendingCN111260777AExtended value and added valueIncrease productivity3D modellingInternal combustion piston enginesReconstruction methodEngineering

The invention relates to a building information model reconstruction method based on an oblique photogrammetry technology. An oblique photogrammetry technology and a three-dimensional model (BIM) roaming technology are adopted; image information in a three-dimensional building model is extracted along a certain path through a virtual camera of a three-dimensional model roaming technology and imported into corresponding real scene modeling software to be fused with an unmanned aerial vehicle oblique photography model result, and a virtual-real combined super-real scene building information model is generated. According to the invention, the oblique photogrammetry technology and the BIM modeling technology are deeply fused; on one hand, exterior facade reconstruction is carried out on a building information model through the oblique photogrammetry technology; the problems of geometric distortion, texture deformation and the like of an oblique photogrammetry technology on building modeling are solved, on one hand, the problems of low display efficiency and the like of a BIM model on a Web side are solved, and a brand-new thought is provided for display and application of the city-level BIM model.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Production method for automobile engine compartment heat-insulating cushion

InactiveCN102673084ASolve sound absorptionReduce weightLamination ancillary operationsLaminationWater jet cutterProcess engineering

The invention relates to a production method for an automobile engine compartment heat-insulating cushion and belongs to the technical field of processing of automobile interior ornament. The production method comprises the following steps: paving raw materials, placing semi-curing reconstituted cotton into a bottom layer, and placing black non-woven fabric on an upper layer; placing the paved raw materials into a die and performing hot-press forming to obtain a semi-finished product; placing aluminum foil on the surface of the product along with the shape of the product and performing hot-press forming again to obtain a semi-finished product; placing the formed semi-finished product into a cooling jig, naturally cooling and sizing; positioning the semi-finished product and performing water cutting to obtain the required engine compartment heat-insulating cushion; and after inspecting, placing the products into boxes and placing into a storage. By the method, the problems about the performance indexes such as sound absorption, sound insulation, environmental protection, light weight and the like of the engine compartment heat-insulating cushion assembly are solved; the weight of the engine compartment heat-insulating cushion is greatly reduced; and the requirement of the whole automobile on the lightweight design is met.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Method for fusing aramid/aramid fibres

InactiveCN106232895AEliminate or at least reduce the need forSave materialSolvent-treatmentFibre typesPolymer scienceAramid

A method for fusing aramid fibres, wherein (a) at least one area of an aramid fibre is treated with an ionic fluid so that the aramid is partially dissolved; (b) the aramid fibres are brought into mutual contact via the partially dissolved area, preferably with the application of pressure to the contact area, and then (c) the partially dissolved area of the aramid is recoagulated.

Owner:普罗奥尼克股份有限公司

Material for hollow blow-molded micro-foamed tool box and preparation method thereof

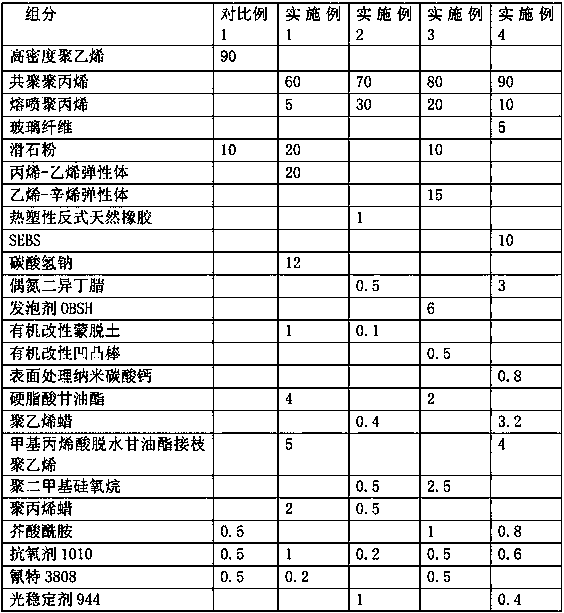

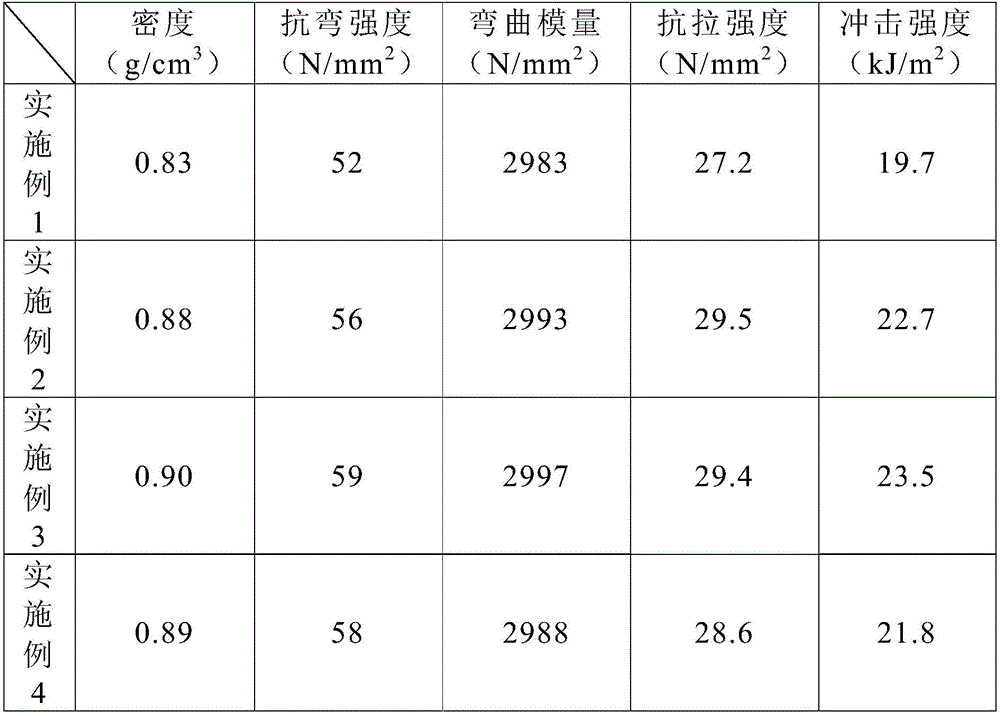

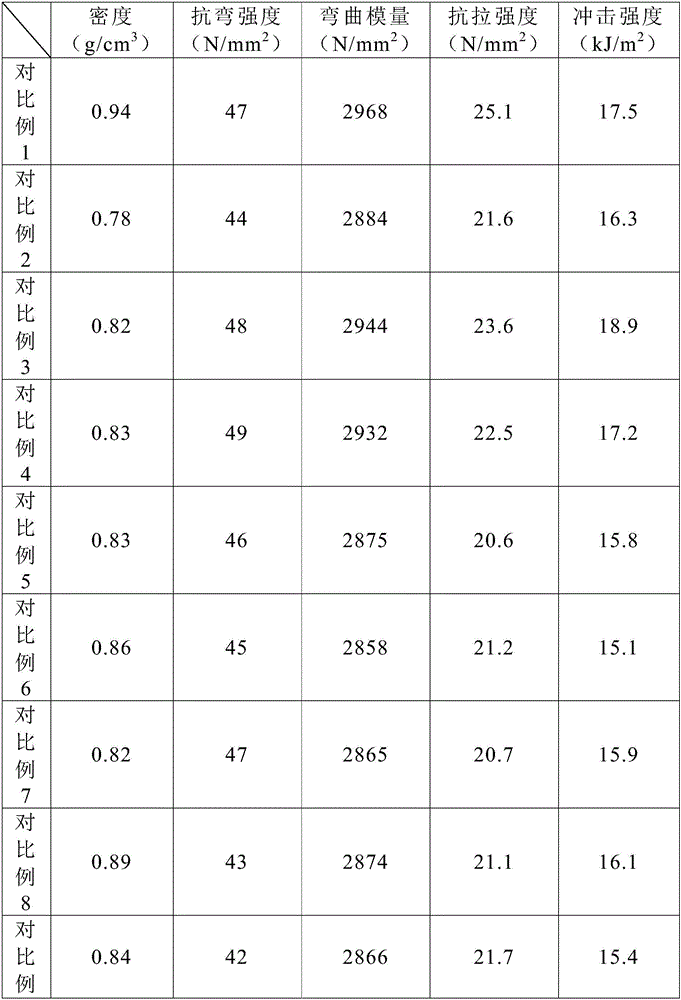

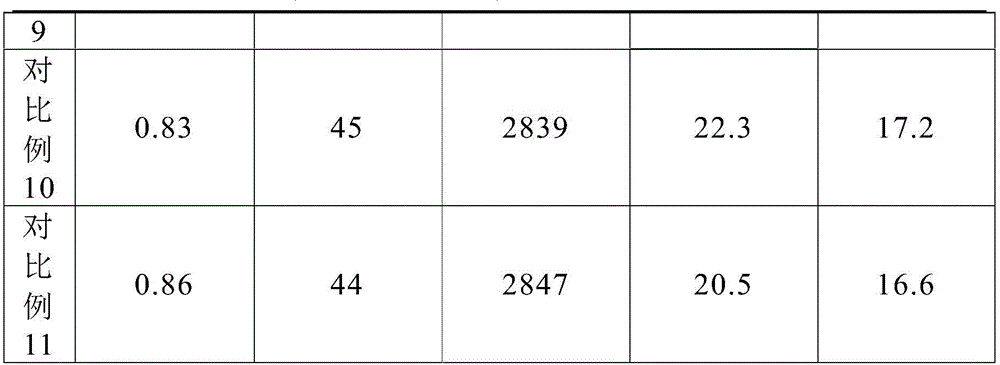

The invention relates to a tool box and a preparation method thereof, and particularly relates to a hollow blow-molded micro-foamed tool box and a preparation method of the tool box. The material related to the invention comprises the following components in parts by weight: 60-90 parts of co-polypropylene, 5-30 parts of melt-blown polypropylene, 0-20 parts of a filler, 1-20 parts of a modifier, 0.5-12 parts of a foaming agent, 1-10 parts of a foaming auxiliary agent, 0.5-2 parts of a lubricant, 0.2-1 part of an antioxidant and 0.2-1 part of a light stabilizer. The invention discloses the preparation method of the hollow blow-molded micro-foamed tool box. According to the invention, the tool box with a fine micropore structure is obtained. The anti-sagging property and the transverse stretching performance of the polypropylene melt in a blow-molding and micro-foaming process are effectively improved, the requirements of free regulation of wall thickness distribution of the product is met, the smooth operation of the polypropylene hollow blow-molding micro-foaming process is ensured, and the product has a significant characteristic of light weight. The tool box provided by the invention also has excellent dimensional stability, anti-dropping performance and anti-shocking performance. The preparation method provided by the invention has the advantages of shorter forming period, low manufacturing cost, high product qualification rate and easy realization of industrialization.

Owner:NANJING JULONG SCI&TECH CO LTD

Fibrofelt material and preparation method and application thereof

InactiveCN106087245AReduce equipment qualityGood sound absorptionNon-woven fabricsSynthetic fiberAdhesive

Owner:宁波华翔自然纤维科技有限公司

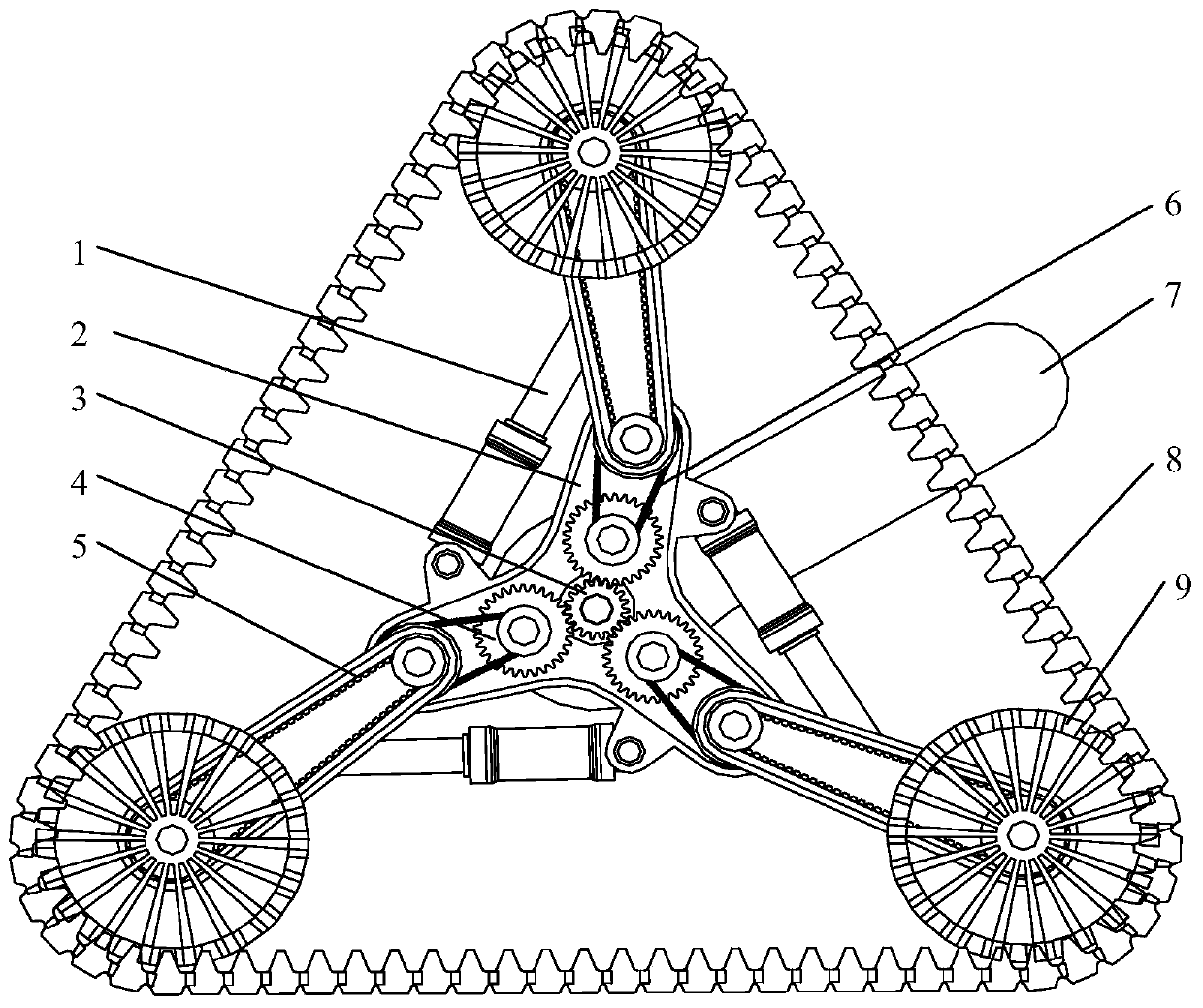

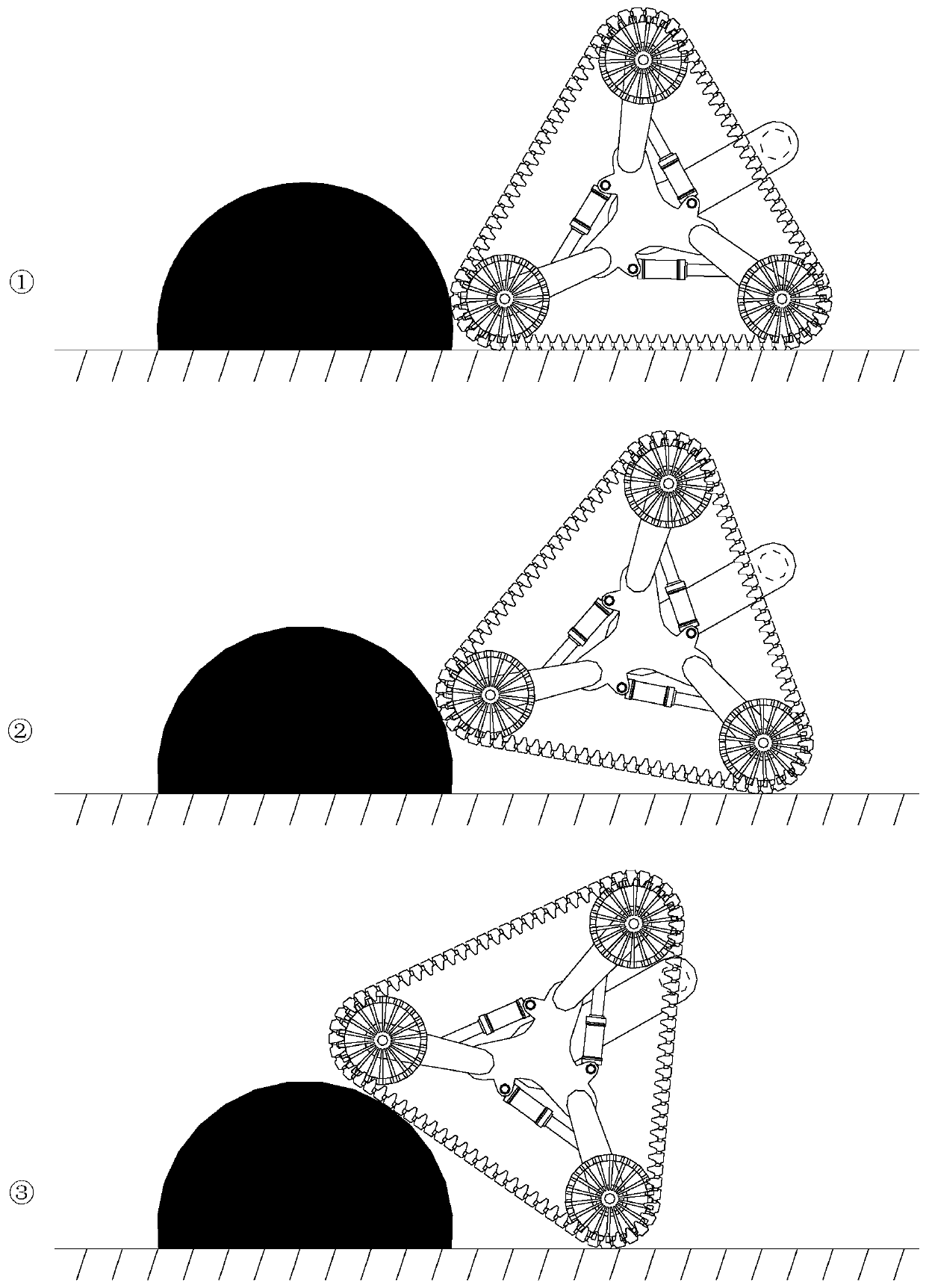

Planetary type triangular crawler running and driving device

InactiveCN109850023AImprove terrain adaptabilityCoordinate to resolve high mobilityEndless track vehiclesHydraulic cylinderTerrain

The invention discloses a planetary type triangular crawler running and driving device. The planetary type triangular crawler running and driving device is mainly used for vehicles which perform scout, transportation or combat along with soldiers under the environment with complex terrain, many obstacles and dangerous circumstances. The planetary type triangular crawler running and driving deviceis mainly composed of a rocker arm, a triangular supporting frame, gears, a driving motor, transmission devices, hydraulic cylinders, driving wheels and a crawler. The rocker arm is fixed to movable devices such as a vehicle body and supported, the driving motor transmits power to the driving wheels through the gears and the transmission devices, and the driving wheels mesh with the crawler to drive the integrity to move forward. According to the planetary type triangular crawler running and driving device, the triangular supporting frame and the rocker arm are connected through bearings and under a free rotating state, when the crawler meets an obstacle, the triangular supporting frame can overturn freely, the crawler is tightly attached to the obstacle to maintain the ground gripping force or overturn the obstacle, and the whole running device has the high terrain adapting capacity; and meanwhile, when the crawler is broken and fractured, the planetary type triangular crawler runningand driving device can still run under a wheel state due to the fact that the driving wheels have power.

Owner:内蒙古第一机械集团股份有限公司

Method for preparing laminated structure of photovoltaic module, laminated structure, photovoltaic module

ActiveCN108376717BEasy to install and implement applicationsGuaranteed flatnessFinal product manufacturePhotovoltaic energy generationThermodynamicsHeating time

A preparation method for a laminated structure of a photovoltaic assembly, the laminated structure and the photovoltaic assembly, which are prepared by using a lamination process. The lamination process comprises a first heating stage, a second heating stage, and a third pressurization and cooling stage. In the first stage, the heating temperature range is from 110ºC to 130ºC, and the heating time range is from 100 seconds to 600 seconds; in the second stage, the hating temperature range is from 131ºC to 200ºC, and the heating time range is from 100 seconds to 1200 seconds; and in the third stage, the cooling temperature range is from 25ºC to 60ºC, and the pressurization range is from 0.05 Mpa to 0.25 Mpa. The lamination process is implemented in a low-temperature environment, power consumption is reduced, and the flatness of the laminated structure of the photovoltaic assembly is ensured, thereby further facilitating the mounting, enforcement and application of the photovoltaic assembly.

Owner:SUNMAN (ZHENJIANG) CO LTD

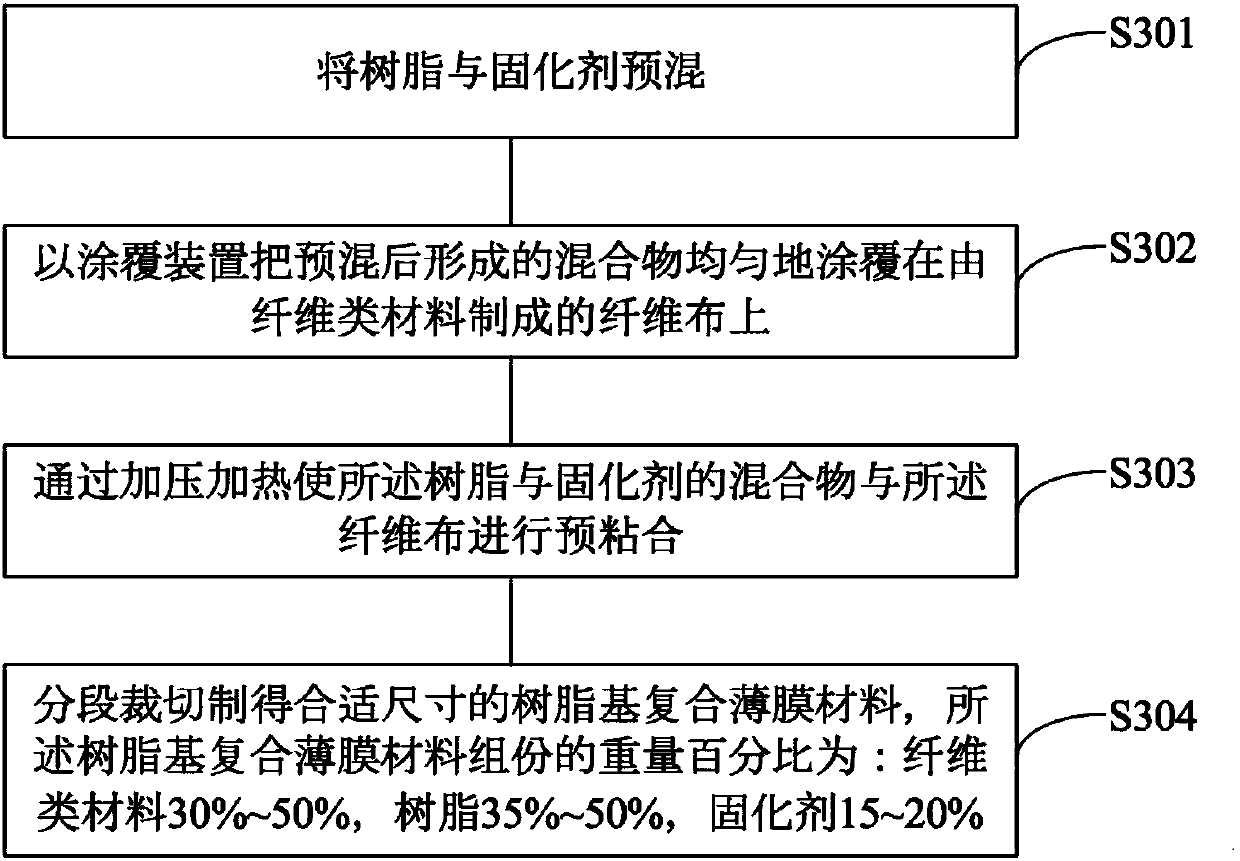

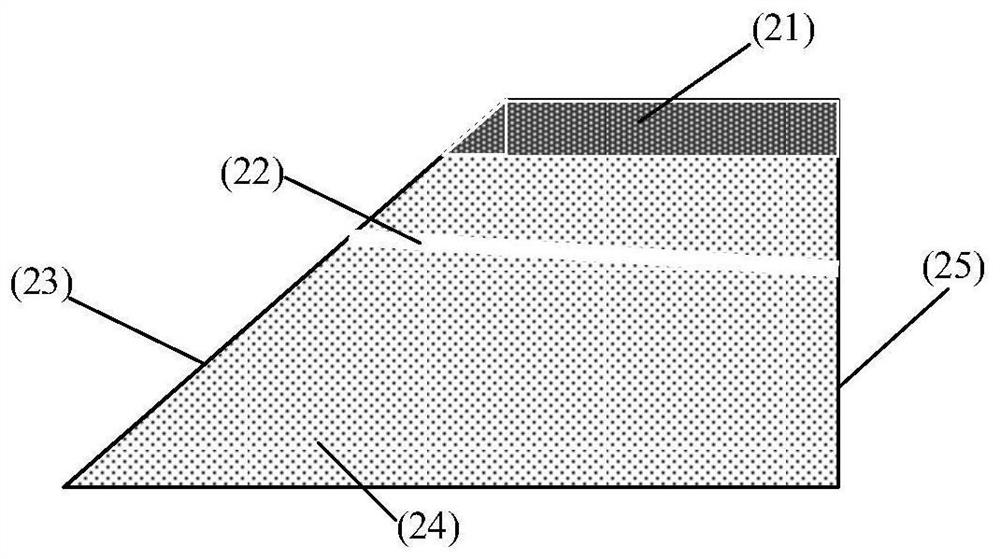

Photoelectric building material and preparation method thereof

InactiveCN108018723ASolve lightweightMeet anti-ultravioletPhotovoltaic supportsConstructions elementsFiberPlastic film

The invention provides a photoelectric building material and a preparation method thereof. A packaging material in the photoelectric building material comprises 30-50% of a fiber material, 35-50% of resin and 15-20% of a curing agent. A preparation method of the packaging material comprises the following steps: premixing the resin with the curing agent, coating a fiber cloth formed by braiding thefiber material with the mixture, pre-bonding the mixture with the fiber cloth through pressurizing and heating, and cutting the pre-bonded fiber cloth to produce the packaging material. The preparation method of the photovoltaic building material comprises the following steps: (1) sequentially stacking a fluorine plastic film, a packaging material, EVA, a solar cell, second packaging material anda green building material, and carrying out lamination and cooling to obtain the photoelectric building material; and (2) sequentially stacking the fluorine plastic film, the first packaging material, EVA, the solar cell, the second packaging material and a backing plate, carrying out lamination and cooling to obtain a laminated part, uniformly spreading an adhesive or a hot-melt adhesive film onthe surface of the green building material, pasting the laminated part, and carrying out full curing to obtain the photovoltaic building material.

Owner:SUNMAN SHANGHAI CO LTD

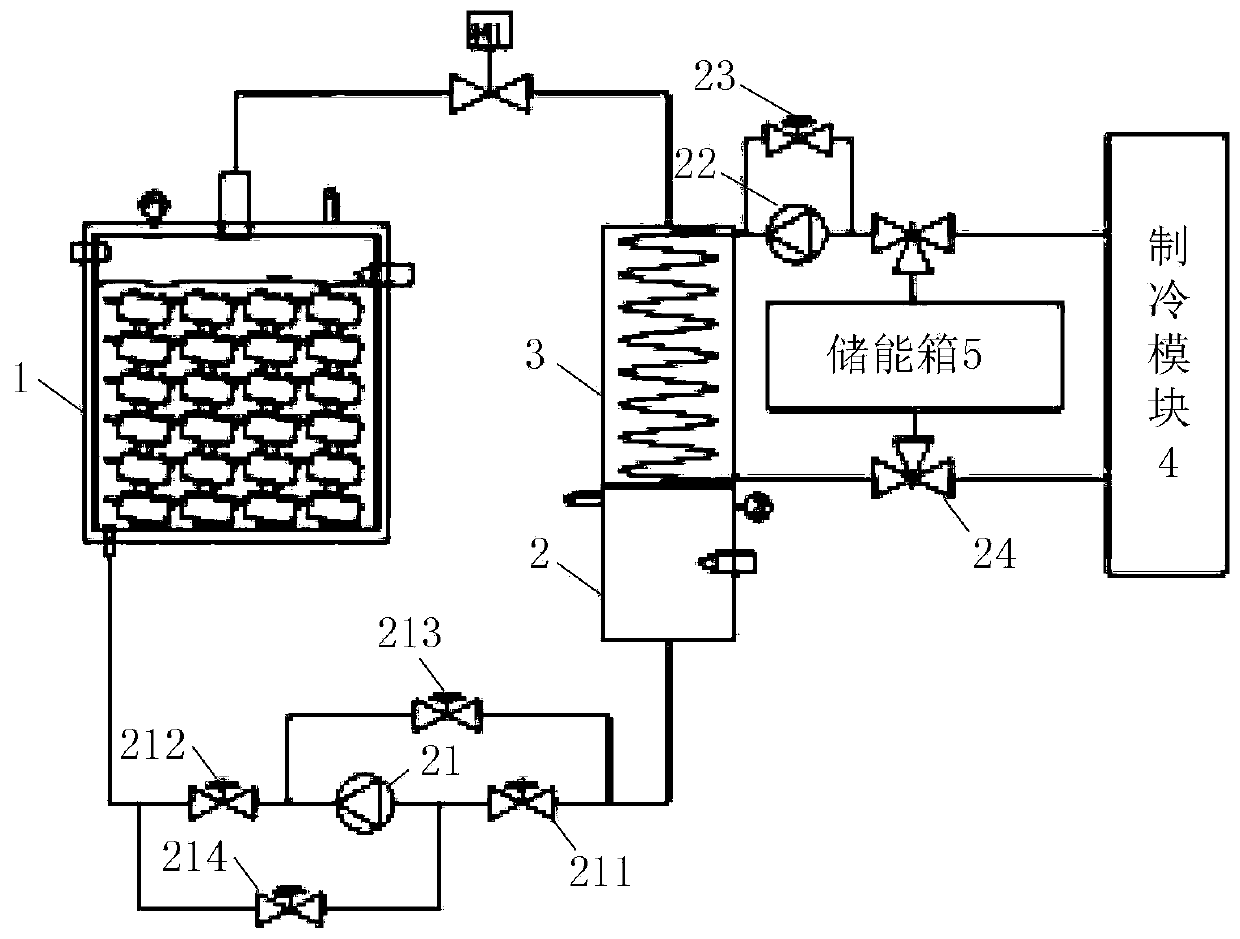

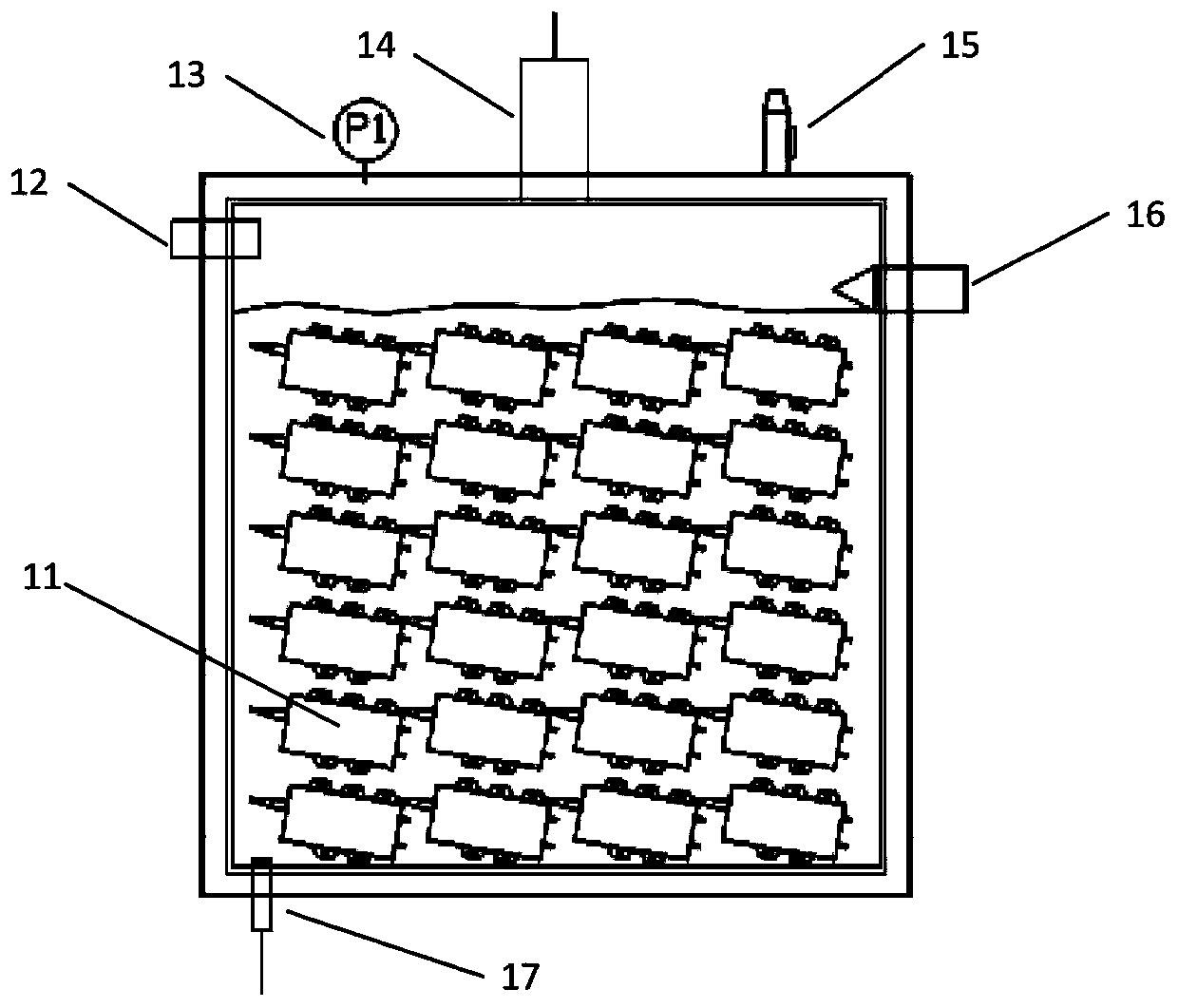

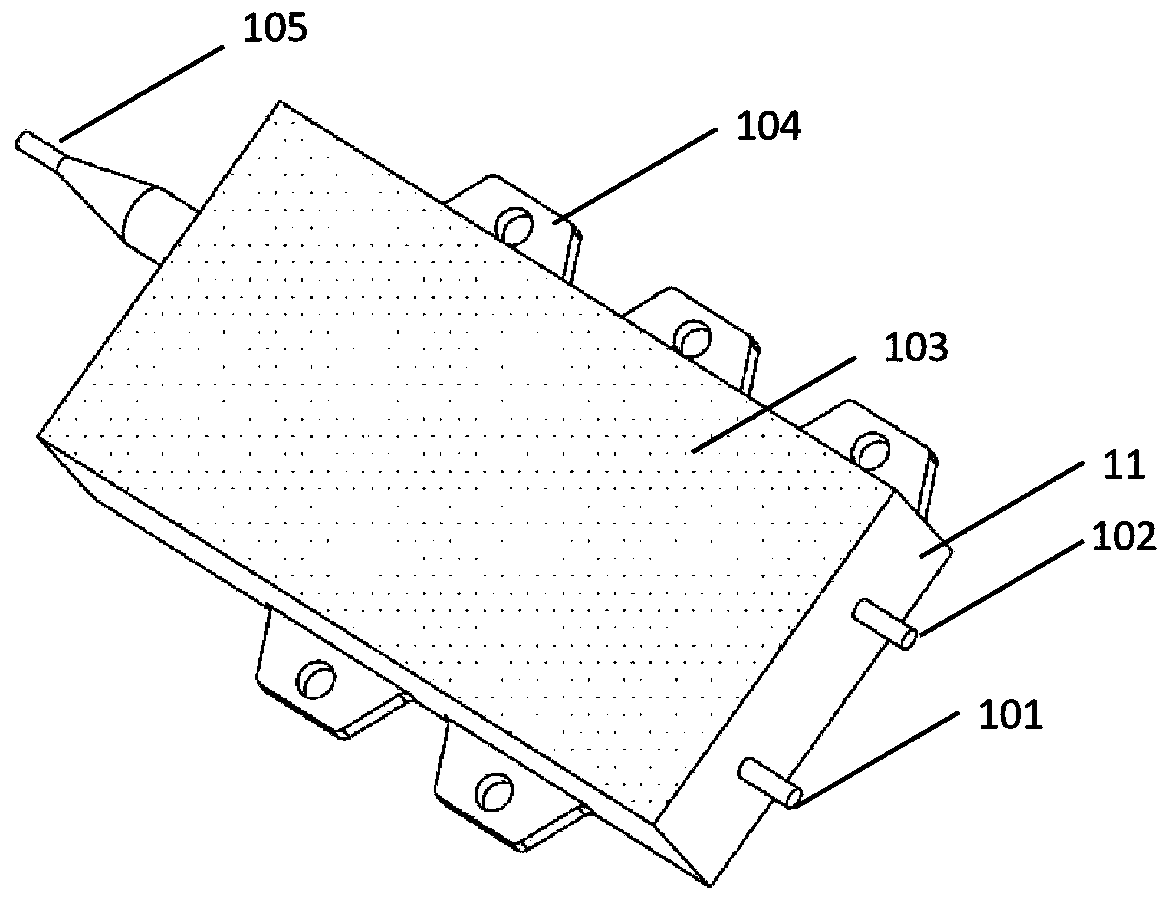

Immersion phase change liquid cooling system of laser

InactiveCN111478158AEasy to maintain stabilityGuaranteed stabilityActive medium shape and constructionLaser cooling arrangementsLaser KnivesLiquid cooling system

The invention discloses an immersion phase change liquid cooling system of a laser. The system comprises a laser knife box and a condenser, a refrigerant steam outlet is formed in the top of the laserknife box, a liquid refrigerant is arranged in the laser knife box, at least one set of laser modules are arranged in the laser knife box, the heating faces of the laser modules are immersed in the liquid refrigerant, the liquid refrigerant absorbs heat generated by the laser modules and then is converted into gas from liquid, and the gas refrigerant flows out of the laser knife box through the refrigerant steam outlet. The input end of the condenser is connected to the refrigerant steam outlet, the output end of the condenser is connected to the refrigerant liquid inlet of the laser knife box, the condenser is used for conducting heat exchange on gaseous refrigerants so that the gaseous refrigerants can be converted into liquid refrigerants through phase change, and the liquid refrigerants enter the laser knife box through the refrigerant liquid inlet. By means of the technical scheme, the heat dissipation efficiency of the laser can be improved, it is guaranteed that the laser operates in a constant-temperature environment, and the problems of miniaturization and light weight of a laser heat dissipation system are solved.

Owner:SUGON DATAENERGYBEIJING CO LTD

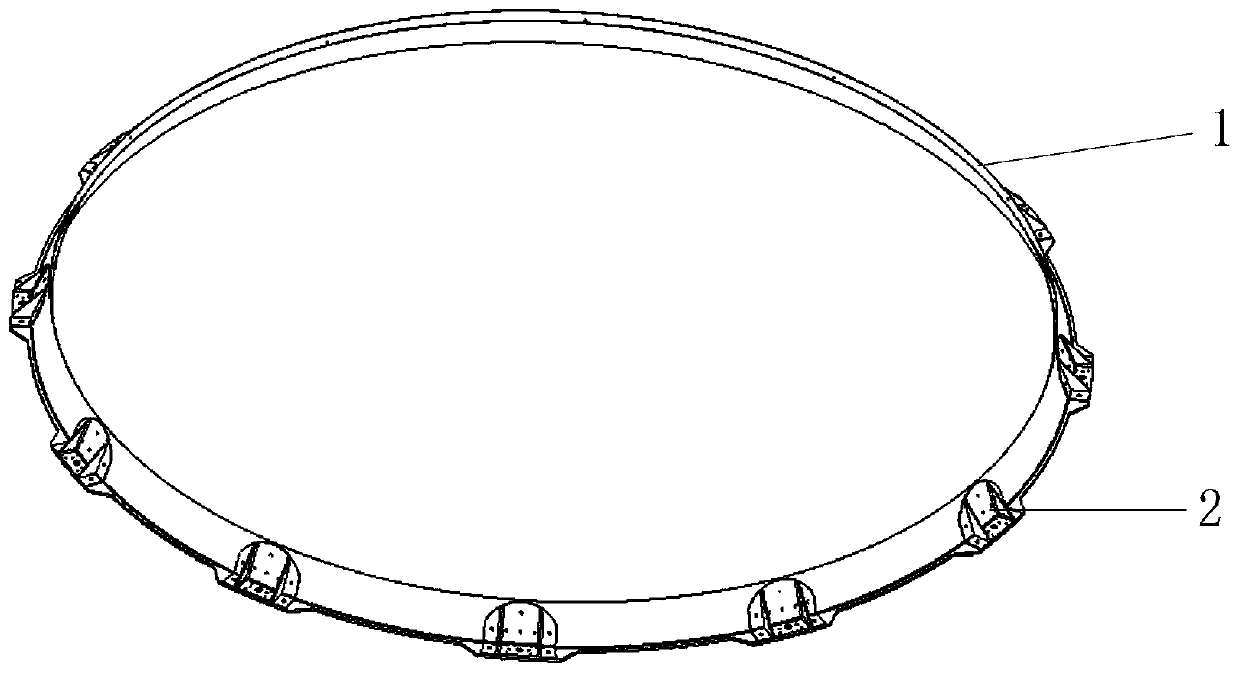

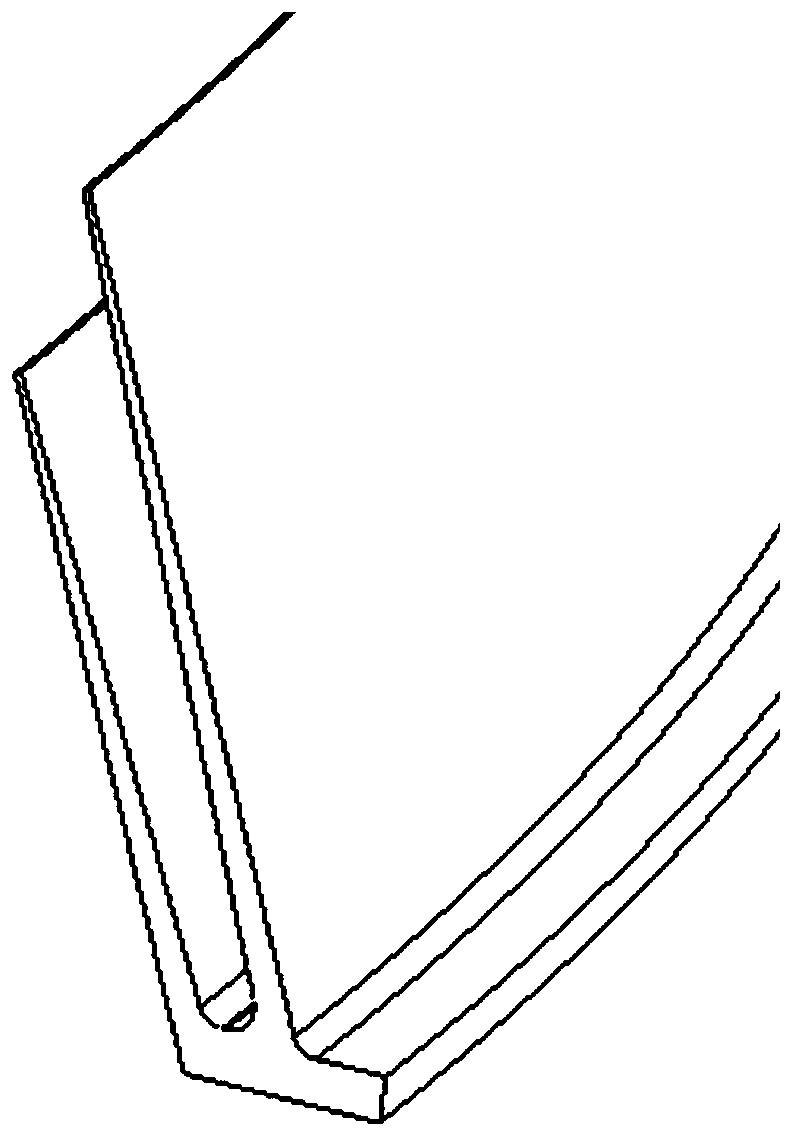

Composite material structure applicable to point-connected spacecraft

ActiveCN109911246ASolve lightweightReduce structural weightCosmonautic partsArtificial satellitesEngineeringUltimate tensile strength

The invention relates to a composite material structure applicable to a point-connected spacecraft in the field of star-arrow connecting structures. The composite material structure comprises a force-bearing barrel lower end frame and reinforcing corner boxes, wherein the section of the force-bearing barrel lower end frame is F-shaped; the force-bearing barrel lower end frame mainly comprises an inclined plane, riveting holes, a flanging flange and connecting flanges; the section of the reinforcing corner boxes is L-shaped; riveting holes are formed in the reinforcing corner boxes; the reinforcing corner boxes are riveted to the inclined plane of the lower end frame; the sections of the reinforcing corner boxes are fitted to the surfaces of the inclined plane and the connecting flanges. The composite material structure meets a lightweight design requirement of a force-bearing barrel of a new-generation Mars probe structural platform in China and also guarantees the connecting strengthand the connecting rigidity during connection with a carrier.

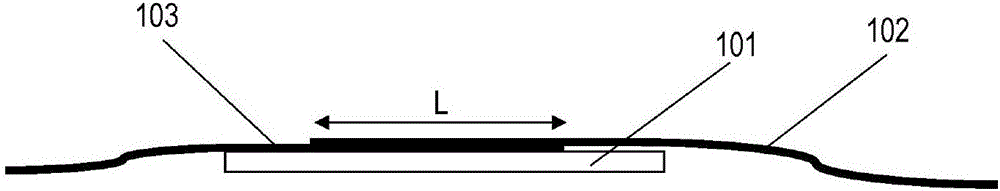

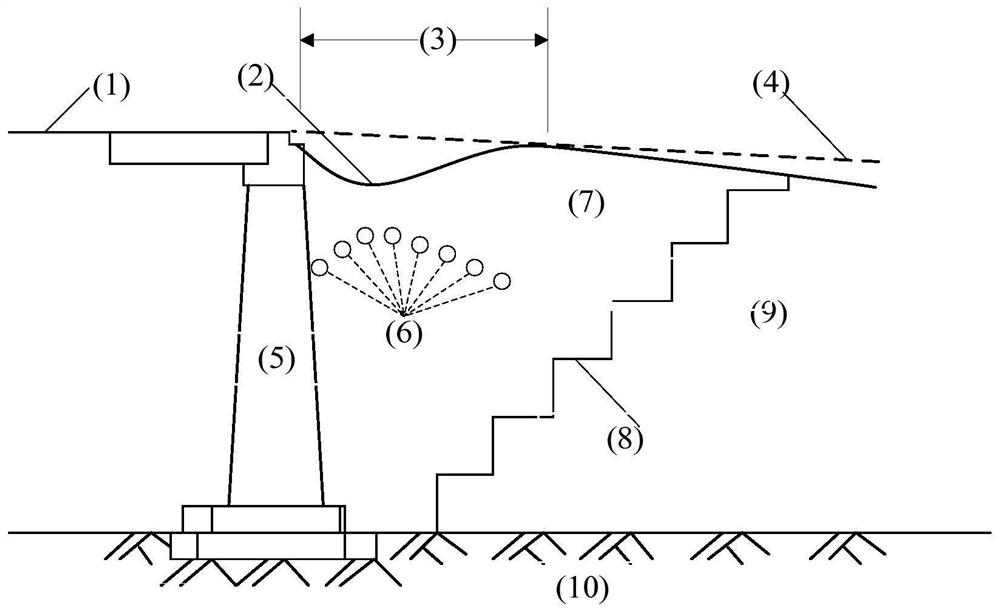

Method for treating bridgehead bumping through transverse guide hole expansion jacking

ActiveCN113235340ADoes not interfere with normal traffic operationNo hindrance to normal trafficRoadwaysArchitectural engineeringTraffic conditions

The invention discloses a method for treating bridgehead bumping through transverse guide hole expansion jacking, and belongs to an expansion jacking treatment technology for the ''bridgehead bumping disease'' induced by differential settlement of a road-bridge transition section under a traffic condition. The method comprises the following steps of 1) preparing construction; 2) measuring and setting out; 3) preparing an expansion material dry powder; 4) using a roadbed slope transverse spiral drilling machine to drill holes; 5) placing a dendritic grouting steel pipe and a directional expansion component; 6) performing high-pressure blow-filling on the expansion material dry powder, sealing holes and synchronously injecting water; and 7) carrying out side slope earthing and greening. The method is suitable for uneven settlement treatment construction of the filling subgrade of the road-bridge transition section of each grade of highway / urban road / (high-speed) railway.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com