Material for hollow blow-molded micro-foamed tool box and preparation method thereof

A toolbox and micro-foaming technology, which is applied in the field of toolbox materials and its preparation, can solve the problem of difficult control of the wall thickness of blow molding toolboxes, poor transverse tensile properties of polypropylene melts, and easy deformation of toolboxes, etc. problems, to achieve the effect of improving the stability and uniformity of cell growth, good heat resistance, improving sag resistance and transverse tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

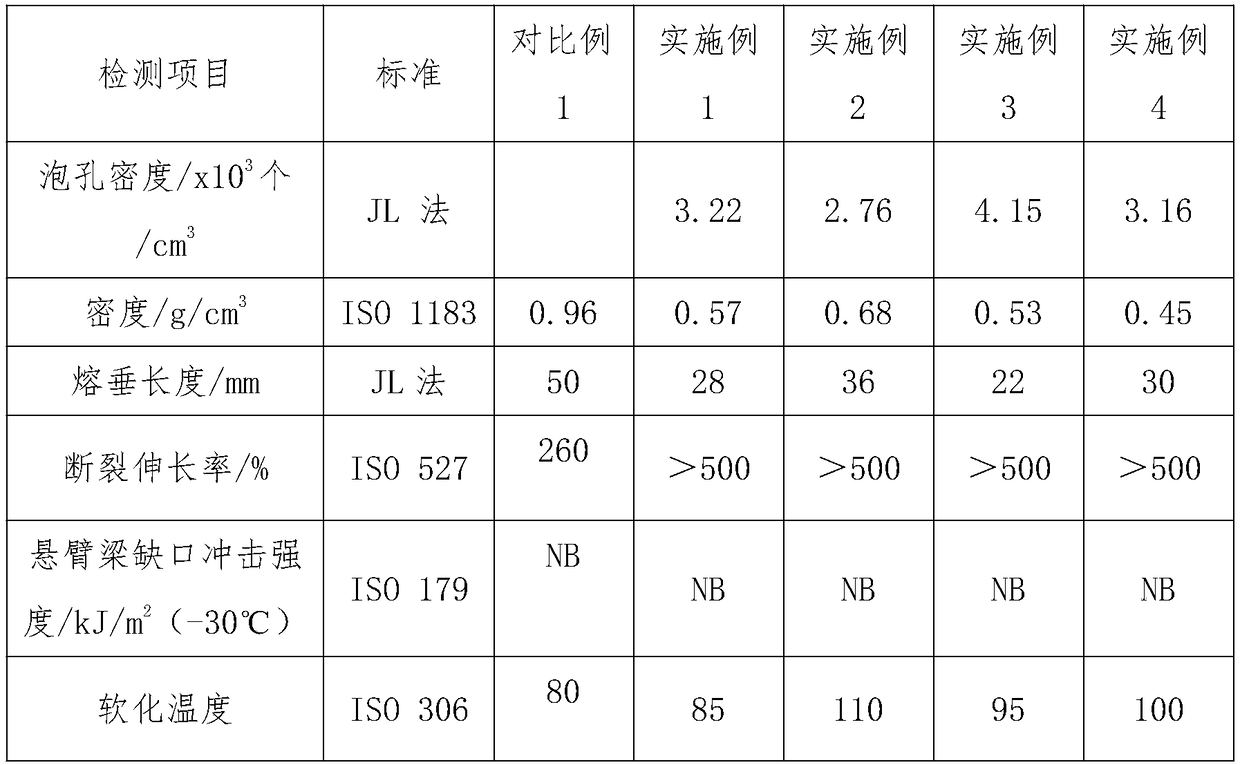

Examples

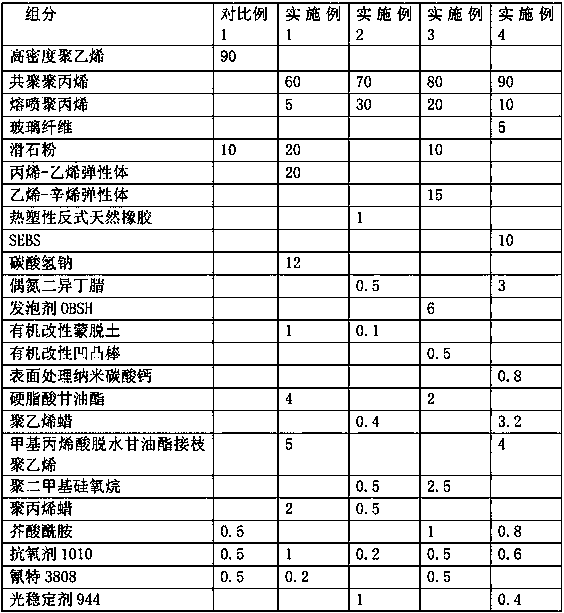

Embodiment 1

[0036] Described material component sees table 1;

[0037] The production method is step 1: 60 parts of copolymerized polypropylene, 5 parts of melt-blown polypropylene, 20 parts of talcum powder, 20 parts of propylene-ethylene elastomer, 1 part of organically modified montmorillonite, and 4 parts of glyceryl stearate , 5 parts of dehydrated glyceryl methacrylate grafted polyethylene, 2 parts of polypropylene wax, 1 part of antioxidant 1010, 0.2 part of Cytec 3808, mixed in a mixer for 2 minutes according to a certain number of parts by weight, and added to the double In the screw extruder, granulate at a temperature of 200-250°C, and the screw speed is 400r / min, to obtain a blow moldable toolbox polypropylene composite material;

[0038] Step 2: Add 12 parts of sodium bicarbonate into the single-screw blow molding machine from the side feeding port according to parts by weight; at the same time, add the toolbox polypropylene composite material obtained in step 1 to the barrel...

Embodiment 2

[0041] Described material component sees table 1;

[0042]The production method is step 1: 70 parts of copolymerized polypropylene, 30 parts of melt-blown polypropylene, 1 part of thermoplastic trans natural rubber, 0.1 part of organically modified montmorillonite, 0.4 part of polyethylene wax, polydimethylsiloxane 0.4 part of alkane, 0.4 part of polypropylene wax, 0.2 part of antioxidant 1010; 1 part of light stabilizer 944 was mixed in a mixer for 10 minutes according to a certain number of parts by weight, and was added into a twin-screw extruder through a hopper. Pelletizing at -250°C, with a screw speed of 700r / min, to obtain a polypropylene composite material for blow molding toolboxes;

[0043] Step 2: Add 0.5 parts of azobisisobutyronitrile into the single-screw blow molding machine from the side feeding port according to the weight part; at the same time, add the tool box polypropylene composite material obtained in step 1 to the single-screw blow molding machine mate...

Embodiment 3

[0046] Described material composition sees table 1;

[0047] The production method is step 1: 80 parts of copolymerized polypropylene, 20 parts of melt-blown polypropylene, 10 parts of talcum powder, 15 parts of ethylene-octene elastomer, 0.5 parts of organically modified attapulgite, and 2 parts of glyceryl stearate , 2.5 parts of polydimethylsiloxane, 1 part of erucamide, 0.5 part of antioxidant 1010, and 0.5 part of Cytec 3808 were mixed in a mixer for 6 minutes according to a certain number of parts by weight, and added to the twin-screw extruder through a hopper. In the machine, granulate at a temperature of 200-250°C, and the screw speed is 500r / min, to obtain a polypropylene composite material that can be blow molded;

[0048] Step 2: Add 6 parts of foaming agent OBSH into the single-screw blow molding machine from the side feeding port according to the parts by weight; at the same time, add the toolbox polypropylene composite material obtained in step 1 to the barrel o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com