Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

387results about "Solvent-treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mirror face synthetic leather and production method thereof

InactiveCN101498106AImprove wear resistanceIncrease brightnessSolvent-treatmentSynthetic resin layered productsPolyesterSurface layer

The invention relates to a mirror face synthetic leather and a manufacturing method thereof, belonging to the technical filed of synthetic leather and manufacturing methods. The manufacturing method is characterized in that the manufacturing method comprises the following steps: manufacturing polyester or daiamid short fiber and sea-island fiber into non-woven fabrics, immersing the non-woven fabrics in polyvinyl alcohol or ironing the non-woven fabrics by hot pressing, processing raw fabrics, immersing and coating polyurethane, solidifying, extracting, obtaining basic fabrics, embossing, removing film by a dry method, curing and inspecting for entering warehouses. The mirror face synthetic leather manufactured by the manufacturing method has high wearing resistance, high brightness, excellent performance and technological improvements on base layers and surface layers, effectively develops the use valve that the original single sea-island fiber does not have, and combines the characteristics of sea-island fiber and daiamid or polyester fiber. The manufacturing method widens the technical routes of synthetic leather development and has wide prospects of popularization and application.

Owner:QUANZHOU WANHUA SEWANG MICRO FIBER CO LTD

Preparation method of antibacterial nanofiber membrane

ActiveCN105200663AImprove antibacterial propertiesOvercome mechanical propertiesSolvent-treatmentSucessive textile treatmentsFiberCross-link

The invention provides a preparation method of an antibacterial nanofiber membrane. The method comprises the procedures of preparation of a nanofiber membrane, preparation of germicide solutions and modification of the nanofiber membrane by the germicide solutions. The method is characterized in that the antibacterial nanofiber membrane is prepared by soaking the nanofiber membrane in the germicide solutions of different concentrations; the nanofiber membrane is formed by being subjected to a polymerization reaction in an organic monomer or a solution of the organic monomer and an inorganic germicide, or is formed by being directly soaked in a polymer solution or a germicide solution of a polymer and an inorganic mixed solution. The preparation method comprises the following steps: step (1), preparing the germicide solutions; step (2), preparing a polymer electrostatic spinning solution and preparing the nanofiber membrane; step (3), modifying the nanofiber membrane by the germicide solutions; an obtained hierarchical-pore nanofiber cross-linked-structure thin film of a core-shell structure is an antibacterial nanofiber membrane finished product.

Owner:上海展恒环保科技有限公司

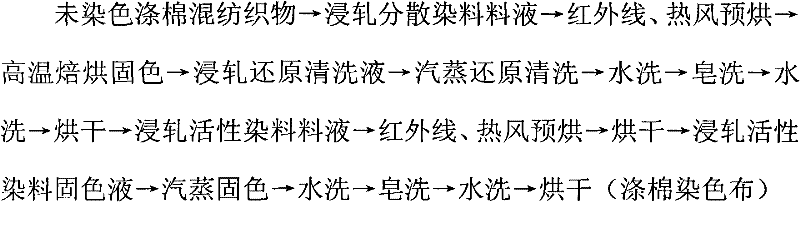

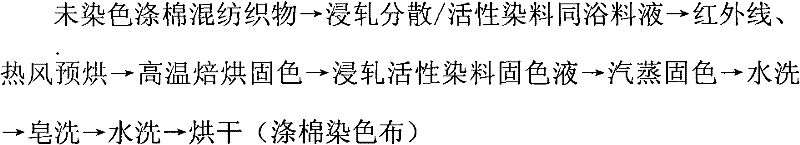

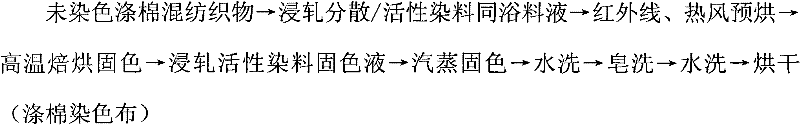

One-bath one-step process for dispersing/reactive dye of cotton-polyester blended fabric

InactiveCN102409565AReduce contentReduce consumptionSolvent-treatmentLiquid/gas/vapor removalFiberPolyester

The invention relates to a one-bath one-step process for a dispersing / reactive dye of a cotton-polyester blended fabric. The one-bath one-step process mainly comprises the following steps performed on the cotton-polyester blended fabric: dispersing / reactive dye one-bath pad dyeing; infrared and hot-air drying in advance; high-temperature baking fixation; padding in a reactive dye fixation solution; steam fixation; water washing; soaping; water washing; drying; terylene dyeing; and obtaining finished cloth. The one-bath one-step process is characterized by fully padding an unstained cotton-polyester blended fabric in a dispersing / reactive dye one-bath solution, introducing infrared and hot air so as to dry 60-70% of water in the fabric in advance, baking at high temperature so as to dye and fix color for polyester fibers, fully padding in the reactive dye fixation solution, performing steam fixation so as to dye and fix color for cotton fibers, and performing the processes of water washing, soaping and water washing so as to fully develop color on the fabric and fully wash off the surface dyeing on the fabric, thereby finishing a dyeing process. The dry and wet grinding fastness can fully meet the customer demand.

Owner:XIANGFAN NEW NO 45 PRINTING & DYEING

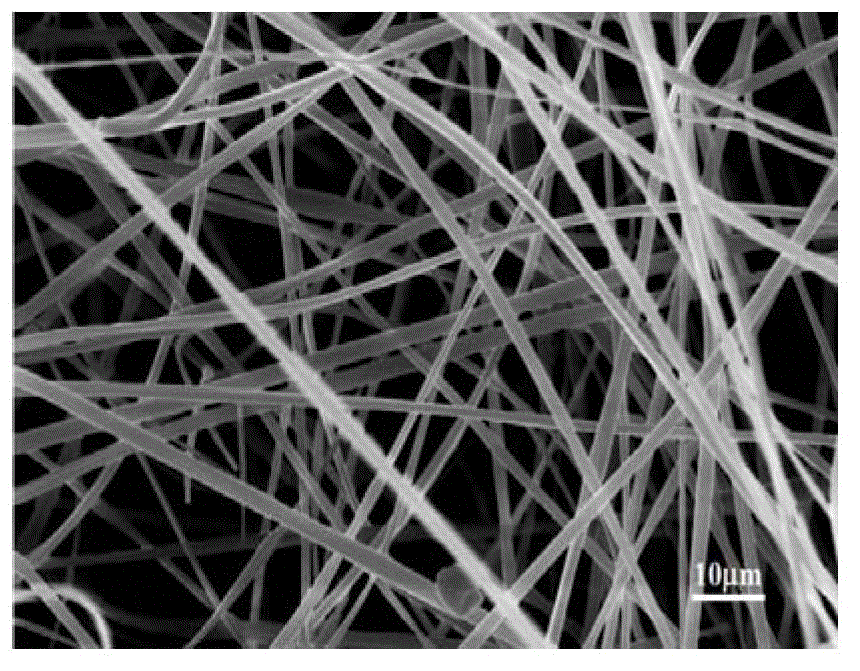

Scratch resistant processing method of non-figured island ultrafine fiber napped leather

ActiveCN101591860AChange the distribution status of the islandHigh process flexibilityFabric breaking/softeningSolvent-treatmentLow-density polyethylenePolyamide

The invention relates to a scratch resistant processing method of non-figured island ultrafine fiber napped leather, which comprises the following steps: taking PA6 as an island; taking PE with low density as the sea; adding a small amount of ionic polymer; and spinning an ultrafine fiber by a single-screw blending method. The ultrafine fiber is needled into non-woven fabrics, impregnated with PU resin, reduces toluene contents, and is expanded for drying, sliced, ground, and the like to manufacture ultrafine fiber napped leather. The islands of the ultrafine fiber are partially crosslinked due to the function of ionic compound in a production flow so as to prevent the fiber in the napped leather from falling when the napped leather is used as a material to be made into products of gloves, shoes, clothing, bags, suitcases, and the like, thereby greatly improving the scratch resistance of the napped leather.

Owner:HUAFON MICROFIBER SHANGHAI

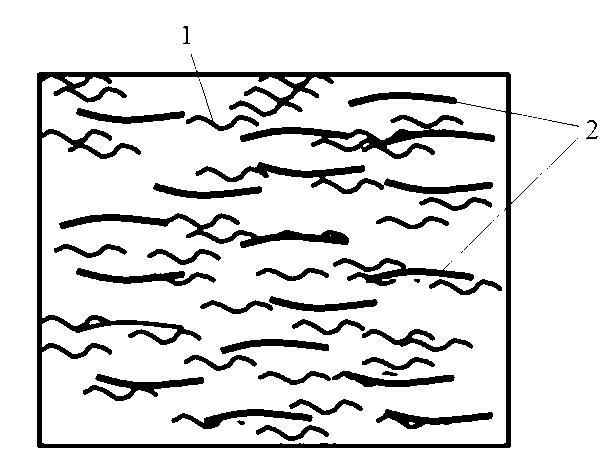

Micro-fiber knitted fabric synthetic leather and manufacturing method thereof

ActiveCN101629387AIncrease elasticitySoft textureSolvent-treatmentWeft knittingPolyurethane coatingBiomedical engineering

The invention relates to the technical fields of micro-fiber knitted fabric synthetic leather synthetic leather base fabrics, especially relates to a micro-fiber knitted fabric synthetic leather of which the micro-fiber knitted fabrics are base fabrics and a manufacturing method thereof. The base fabrics of the micro-fiber knitted fabric synthetic leather of the invention are sea-island type micro-fiber knitted fabrics, the thickness of which is 0.03-3.0mm, and the structure of which is warp knitting or weft knitting; the base fabrics have one layer or two layer or more than two layers between which are formed by knitting, the color is homochromy or polychrome, the base fabrics also contain soaking elastic porous polyurethane which accounts for 10-65% of the total weight of the base fabrics, 25-40% is preferred, and at least one surface is suede or elastic porous polyurethane coating.

Owner:山东瑞恒纺织有限公司

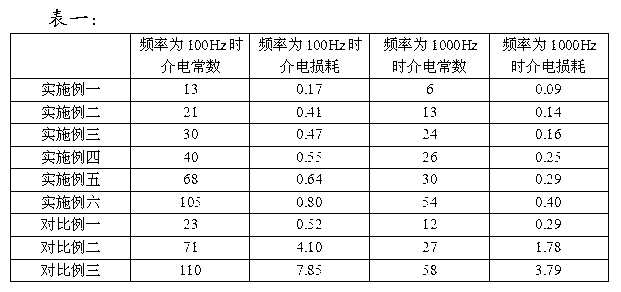

Elastomer composite with high dielectric constant and low dielectric loss and preparation method thereof

ActiveCN103194858AIncrease contentIncrease percolation valueSolvent-treatmentFilament/thread formingElectricityElastomer composites

The invention relates to elastomer composite with high dielectric constant and low dielectric loss and a preparation method thereof. The preparation method includes the steps of suspension allocation, electrospinning and post-treatment. Percolation value of the composite is increased by controlling directional arrangement of carbon nanotubes in substrate, so that dielectric constant of the composite is increased by increasing the content of the carbon nanotubes, the dielectric loss is kept low, and the problem that the high dielectric constant and the low dielectric loss are not balanced for the dielectric composite is solved.

Owner:BEIJING UNIV OF CHEM TECH

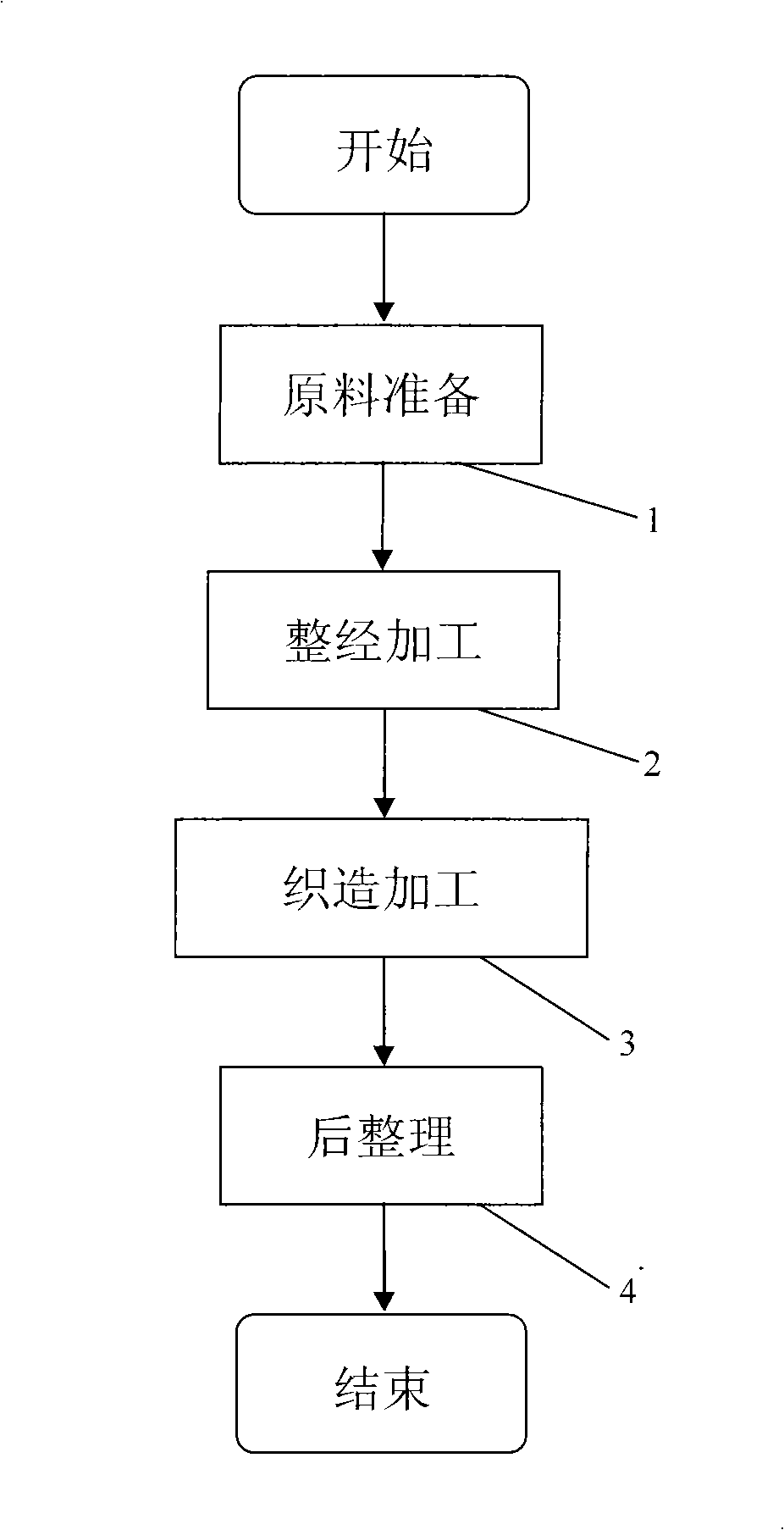

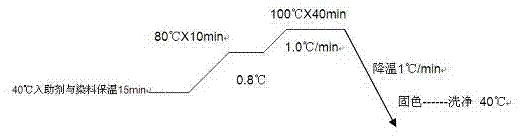

Fabrication technology of face fabric

InactiveCN101338480AHigh dye exhaustionGood color penetrationSolvent-treatmentFibre typesDye absorptionYarn

The present invention discloses a fabric manufacturing process, which includes the procedures as follows: preparing raw materials, warping, weaving, after treatment, etc. The cation terylene provided by the present invention has the advantages of high dye absorption, good color permeability, good dyeing color fastness, bright color, soft luster and good moisture absorption. Surface combed cation terylene is fully woven and back combed polyurethane adopts 26 ditches and one gap, thus forming the pleasant strip effect. The finished product has good air permeability; the unique polyurethane hollow weaving process forms graceful horizontal strip and ensures the fabric has the unique characteristics of dense structure, thick hand feeling, appropriate stretch and modulus, etc.; the cation terylene yarn with good dyeing performance and dyeing permeability ensures that the color penetrates the interior of fabric. When the fabric is made into the printing swimsuit, the plush and the surface area of the same color even if the fabric pills due to multiple wear and abrasion of swimming wall and beach, thus prolonging the service life of the swimsuit.

Owner:HAINING DEJUN KNITTING & DYEING GROUP

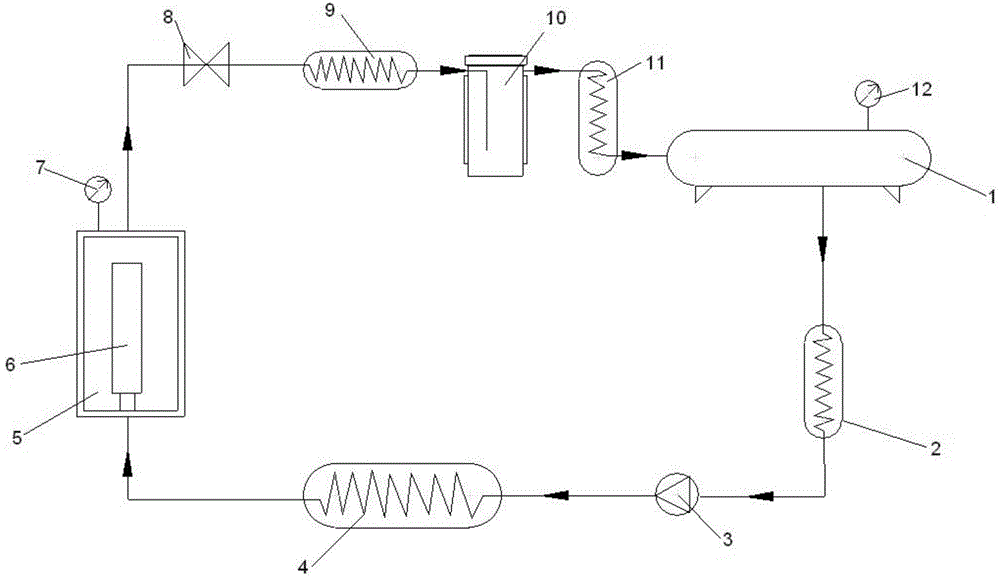

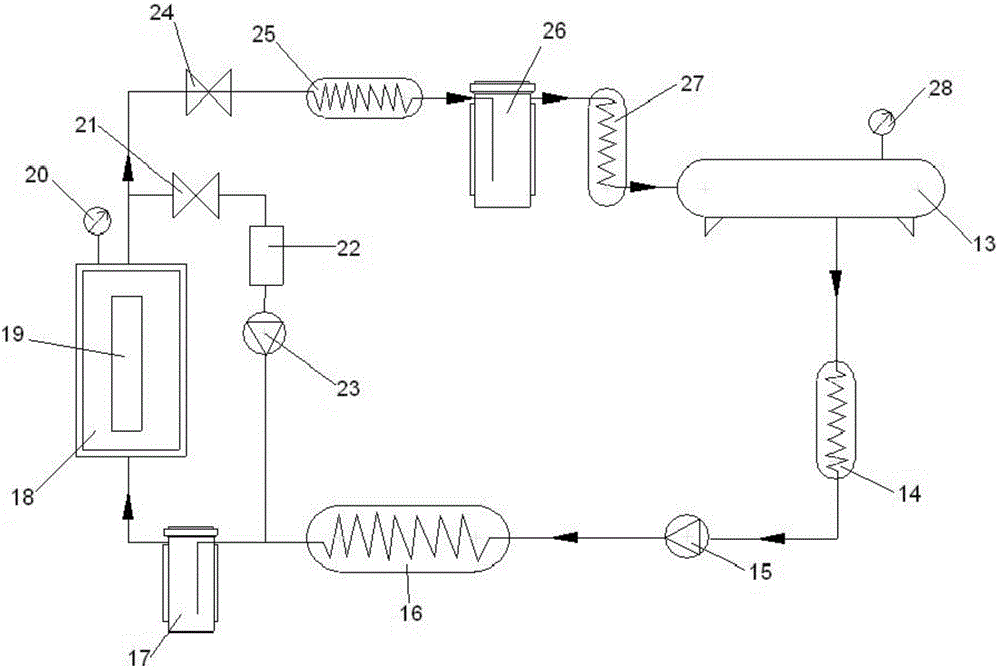

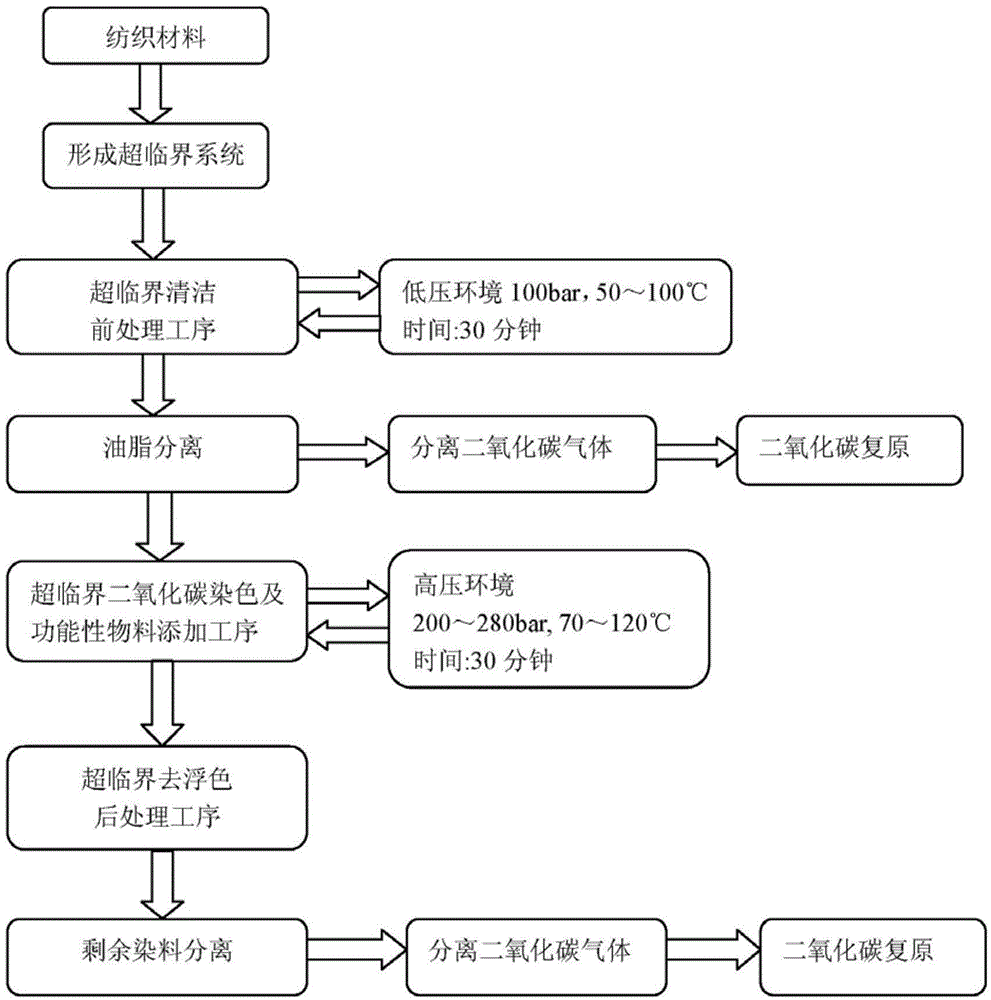

Anhydrous arranging method for supercritical fluid textile materials

InactiveCN104420096AImprove efficiencyImprove cleaning efficiencySolvent-treatmentFibre treatmentPolymer chemistryIntegrated technology

The present application is directed to a method of waterless processing of textile materials using supercritical fluid, including the use of supercritical fluid to dye the textile materials, the use of supercritical fluid for a pre-processing procedure of cleansing the textile materials, and the use of supercritical fluid to wash off unfixed dyes and cleansing of the textile materials and to perform the post-processing procedure of adding functional materials after the use of supercritical fluid to dye the textile materials. The present application provides an integrated technology of pre-processing, dyeing and post-processing of textile materials using supercritical fluid. At the same time, cleansing and dyeing are performed which effectively raises the efficiency.

Owner:HONG KONG PRODUCTIVITY COUNCIL +1

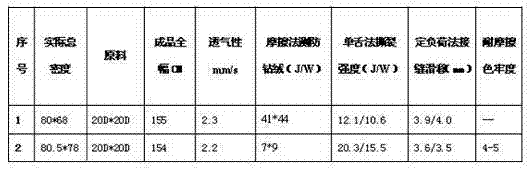

Production process of ventilated and anti-velvet fine-denier shell fabric

ActiveCN102828372AFeel goodEnhance downproof performanceSucessive textile treatmentsSolvent-treatmentProcess engineeringAqueous solution

Owner:WUJIANG FUHUA WEAVING

Manufacturing method of underwear fabric

InactiveCN101643970AThe effect of unidirectional stretching is obviousHave flexibilitySolvent-treatmentWarp knittingEngineeringRaw material

The invention discloses a manufacturing method of an underwear fabric. The manufacturing method adopts 40D / 12F nylon bright filament yarn, 210D spandex and 100D / 72F terylene stretch yarn with the weight percentage of 62 percent, 22 percent and 16 percent as raw materials. By adopting the technical scheme, the raw materials adopt the nylon bright filament yarn, the spandex and the terylene stretchyarn for weaving so as to lead the fabric to have comfort and softness of pure cotton fabric and also have luster of the nylon fabric and flexibility of the spandex fabric. The weaving process adoptsthe terylene stretch yarn as weft insertion so as to lead wrap drawing to be minimum and larger weft drawing and lead the unidirectional drawing effect of the fabric to be more obvious.

Owner:HAINING DEJUN KNITTING & DYEING GROUP

Method for preparing dewatering oil absorption silicon carbide ceramic fiber felt

ActiveCN102877218AHigh porosityImprove adsorption capacitySolvent-treatmentFilament/thread formingElectrospinningCeramic

The invention discloses a method for preparing a dewatering oil absorption silicon carbide ceramic felt and relates to a ceramic fiber felt. According to the dewatering oil absorption silicon carbide ceramic fiber felt prepared by the method, the phenomena of melting and aging under severe conditions such as high temperature and acid and alkaline are avoided, the technology is simple, the specific surface area is large, the adsorption efficiency is high, the fiber felt is light and soft, has good strength and toughness, and the preparation method can be used repeatedly in the water treatment field. The method comprises the following steps of: (1) preparing silicon-containing polymer solution, (2) electrostatic spinning, (3) thermal treatment and (4) surface treatment.

Owner:LVNA TECH CO LTD

Method for dyeing and finishing polyester and nylon composite filament corduroy

InactiveCN102605584ADamage intensityHigh strengthSolvent-treatmentFibre typesDisperse dyeNylon material

The invention discloses a method for dyeing and finishing polyester and nylon composite filament corduroy, which comprises the following processes: checking a gray fabric; sewing the gray fabric; pre-shrinking in full width; splitting; pre-shaping; dyeing; soft finishing shaping; and packaging an end product, wherein a full width water washing machine is used for performing the process of pre-shrinking in full width; the process of splitting is performed according to a thermal treatment method and an alkali treatment method; during the process of pre-shaping, the temperature is 195 DEG C-200 DEG C and an assembly line turning speed is 30m / min-35m / min; dye liquor in the process of dyeing is aqueous solution of disperse dye or mixed aqueous solution of disperse dye and acidic dye; and the process of the soft finishing shaping is as follows: the corduroy passes through a material chute containing 10-15g / l softening agent aqueous solution, and then the corduroy is dried and shaped at high temperature, wherein the drying temperature is 165 DEG C-175 DEG C, the assembly line turning speed is 30m / min-35m / min and the softening agent is an organic silicon softening agent. The end product prepared according to the method provided by the invention has the advantages of high strength, full and mild velvet feeling, excellent shape-keeping property, convenience in washing and finishing, uniform dyeing effect, and capability of obtaining specific gigging effects such as frostwork or polyester peach skin, and the like.

Owner:杭州天宇印染有限公司

Dyeing and processing method of all-cotton satin weave brushed fabric

InactiveCN105040340AWith brushed effectNot easy to shed hairFabric breaking/softeningSolvent-treatmentEngineeringDyeing

The present invention discloses a dyeing and processing method of all-cotton satin weave brushed fabric. The method is as below: gray fabric singeing, rolled enzyme cold heap, scouring, bleaching, tentering whitening, sanding, printing ageing washing, softening fixing and pre-shrinking. The brushed fabric has soft fine hair, napping effect and no hair loss; and dyeing and finishing not only retain the loose and soft characteristics of the satin weave but also protect the mightiness of the fabric.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Moisture absorbing and deodorizing and ultraviolet resisting fabric

InactiveCN102776691AMoisture absorption and deodorant haveUV resistant withSolvent-treatmentWeft knittingSurface layerUltraviolet

The invention discloses a moisture absorbing and deodorizing and ultraviolet resisting fabric. The fabric comprises a surface layer and an internal layer, wherein the surface layer is natural fiber blended woven fabric which has functions on quick absorbing and diffusing moisture, resisting bacterium, deodorizing and resisting ultraviolet ray; and the internal layer is polyester filament yarn with excellent functions on moisture absorbing, and perspiring. The fabric is prepared via a knitting technology. The invention discloses the moisture absorbing and deodorizing and ultraviolet resisting fabric, and the fiber is reasonable in preparation, and simple and convenient in preparation technology; with the special double-face compound structure, the fabric has the functions on moisture absorbing, perspiring, resisting bacterium, deodorizing and resisting ultraviolet ray; and the fabric is very suitable for manufacturing sports and casual wear.

Owner:KUSN ZHOUSHI HUIHONG GARMENT FACTORY

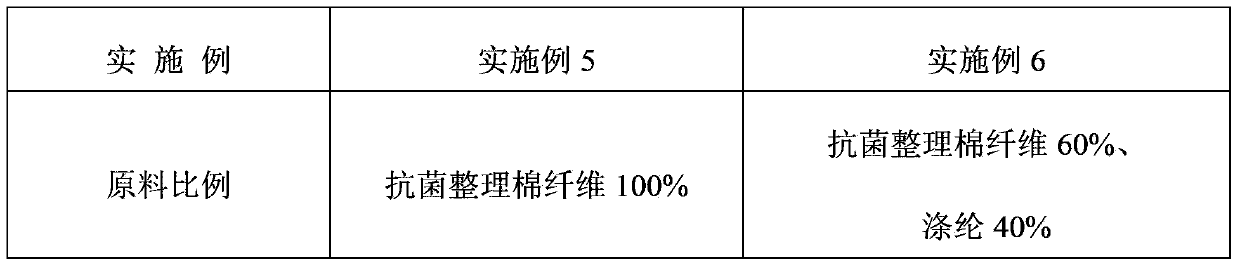

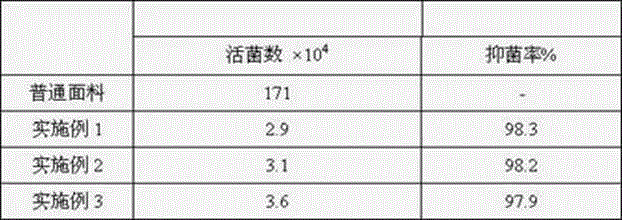

Antibacterial spun-dyed yarn and colored spinning process of antibacterial spun-dyed yarn

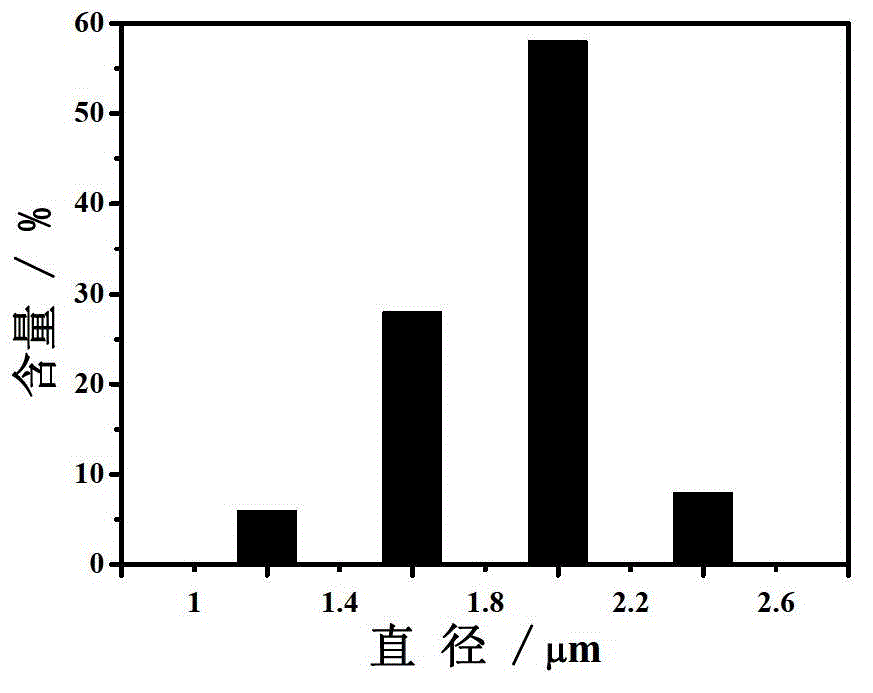

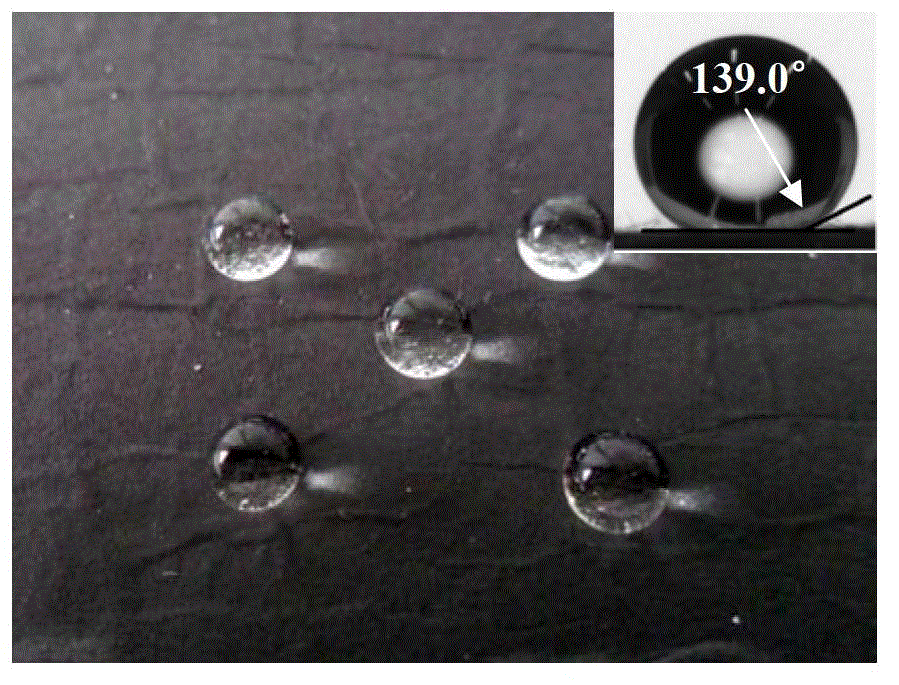

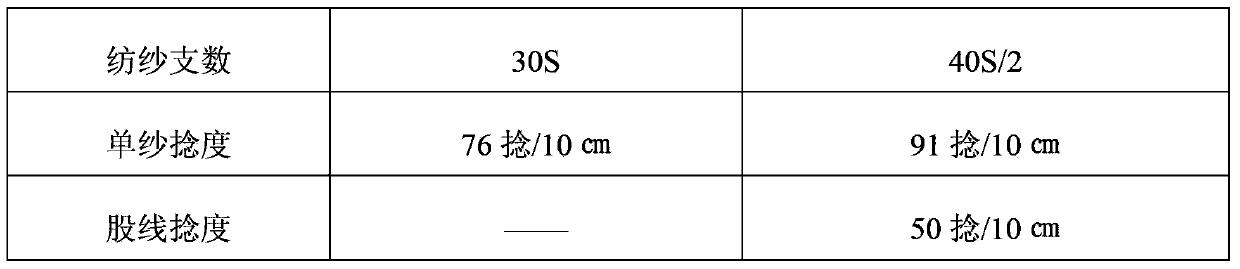

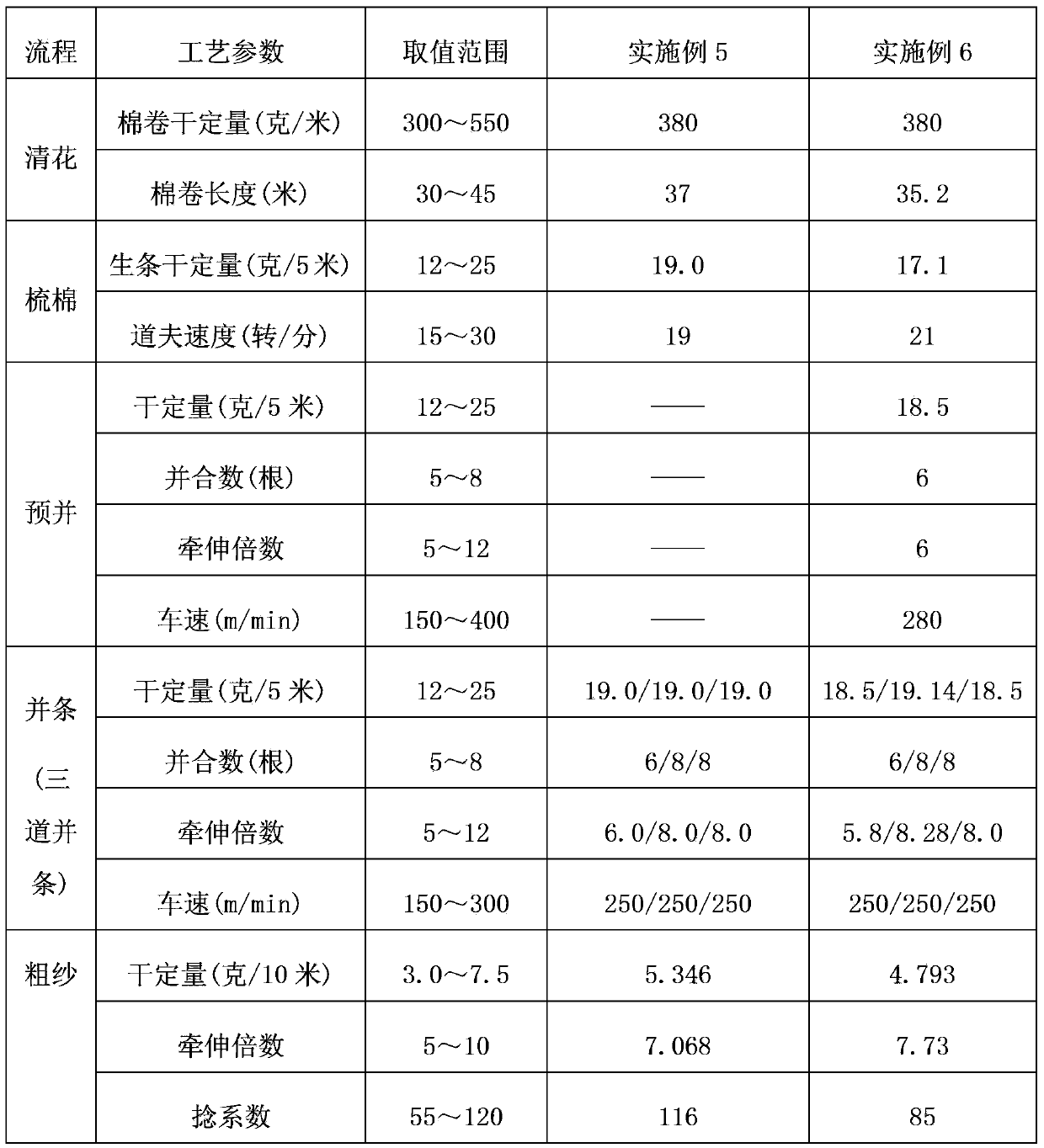

The invention provides antibacterial spun-dyed yarn. On the basis of a total mass of the antibacterial spun-dyed yarn, at least 10 wt% of loose fibers used for the antibacterial spun-dyed yarn are subjected to antibiotic finish; the thread count of the antibacterial spun-dyed yarn is 10S-60S of single yarn or plied yarn, wherein the twist of the single yarn is 300-1300 per meter, and the twist of the plied yarn is 150-1300 per meter. A spinning process of the antibacterial spun-dyed yarn comprises the following steps: first, the loose fibers are subjected to preprocessing and dyeing; all or a part of the loose fibers are subjected to the antibiotic finish according to a ratio; then, the antibacterial spun-dyed yarn is produced through a colored spinning process. A fabric woven through the antibacterial spun-dyed yarn has the advantages of being excellent in antibacterial performance, lasting in antibacterial effect, and quite good in washability, and the fibers subjected to the antibiotic finish do not cause spinnability problems.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

Short-flow processing method for beamed plush fabric

ActiveCN103757812AQuick contactEmission reductionSolvent-treatmentSucessive textile treatmentsPolyesterProcess engineering

The invention discloses a short-flow processing method for s beamed plush fabric. The processing method comprises the steps of weaving of a polyester drawn textured yarn raw material, air current dyeing, decolorizing and soft shaping. By adopting the short-flow processing method, the process flow is shortened by 60 percent, the processing cost is saved by 65 percent, energy is saved by 70 percent, water is saved by 50 percent, and sewage disposal is reduced by 50 percent.

Owner:JIANGSU WEIMIAO TEXTILE TECH CO LTD

Bedding fabric with antibacterial and cool functions and post-finishing process thereof

InactiveCN103132196AGood hygroscopicityRefreshingSolvent-treatmentBiochemical fibre treatmentPolymer scienceSpinning

The invention discloses bedding fabric with antibacterial and cool functions and a post-finishing process thereof. The bedding fabric is formed by weaving blended yarn with antibacterial and cool functions. The blended yarn with antibacterial and cool functions is formed by blending linen fiber, chitin fiber staple and polyester filament yarn according to sirofil spinning technology. In the blended yarn with antibacterial and cool functions, the linen fiber and the chitin fiber staple are both wrapped on the surface of the polyester filament yarn. The post-finishing process includes the following steps: desizing and scouring-singeing-bleaching repeatedly through chlorine oxygen-cellulase washing-dying-washing and gentle stretching-preshrinking-finished products. The fabric finished products has cool touch, excellent antibacterial performance and good crease resistance. Compared with pure linen fabric, the fabric is soft. Simultaneously compared with chitin fabric, the fabric has a certain body and is appropriate for bedding fabric in spring and summer.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

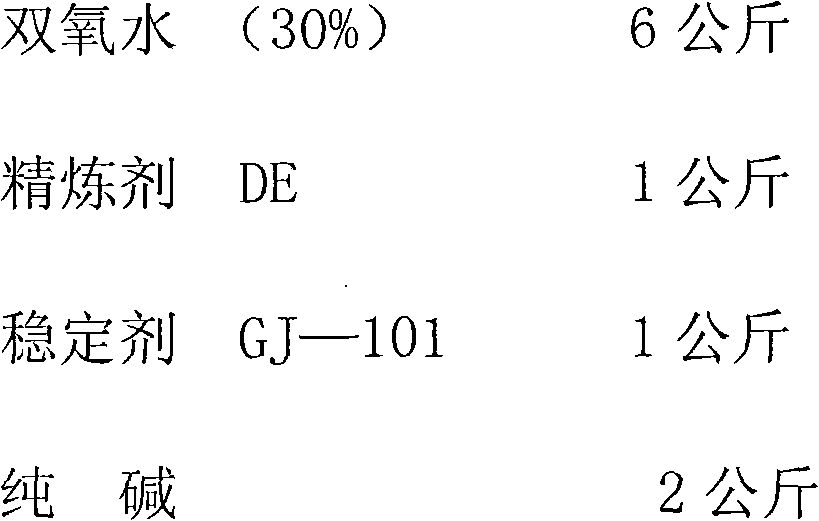

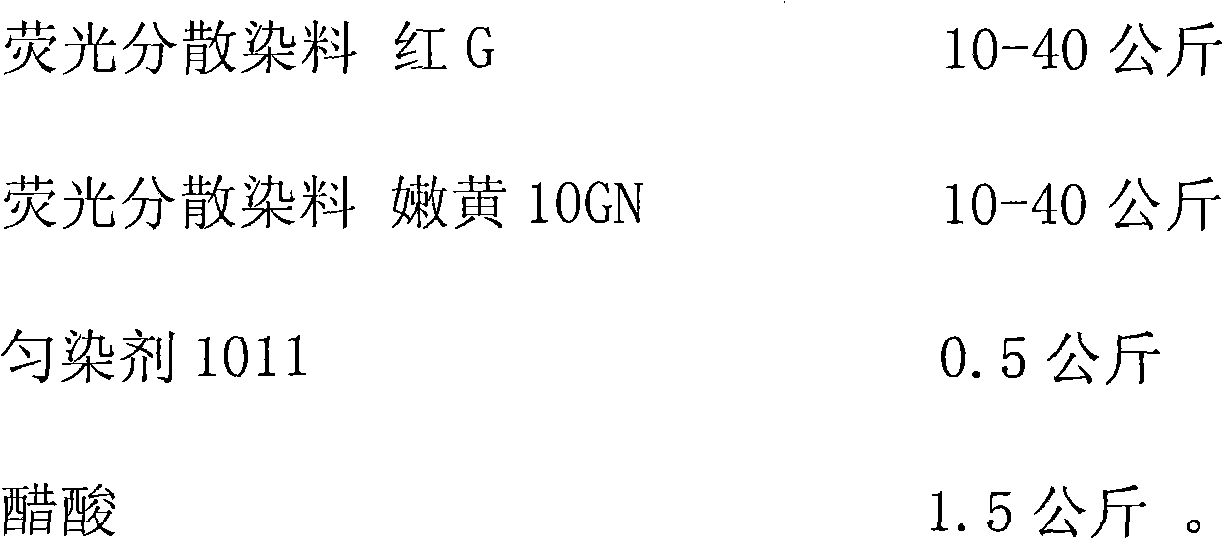

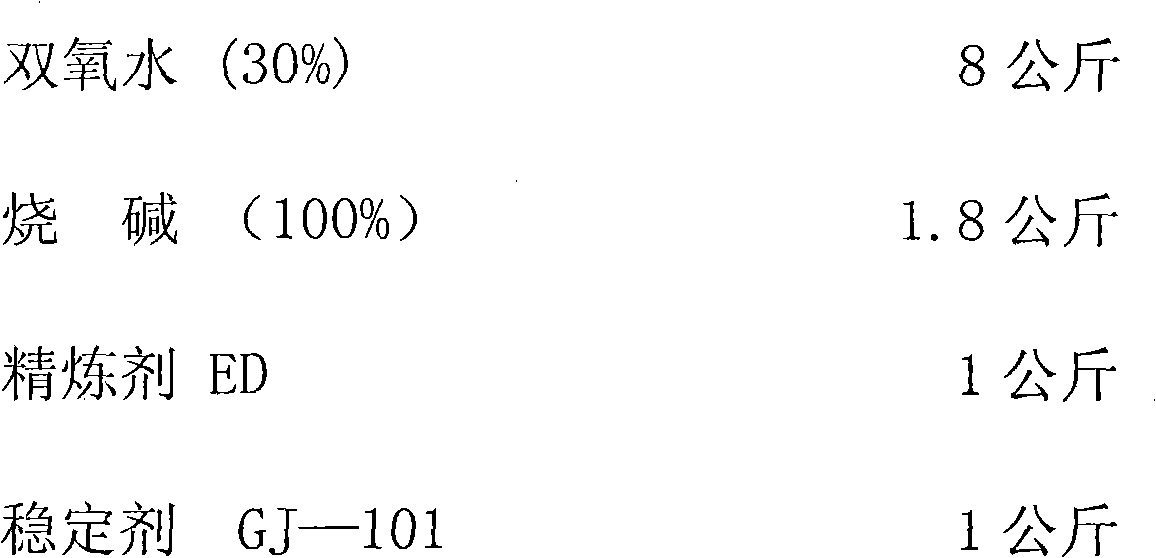

Technology for producing high-standard fluorescent safe protective polyester and cotton interwoven fabric by using domestic fluorescent disperse dye

ActiveCN102704282AImprove fluorescence vividnessHigh color fastnessSolvent-treatmentBiochemical fibre treatmentDisperse dyeFluorescence

The invention relates to dyeing of fluorescent safe protective polyester and cotton interwoven fabrics, in particular to a technology for producing a high-standard fluorescent safe protective polyester and cotton interwoven fabric by using a domestic fluorescent disperse dye. The technology comprises the following steps of: (1) bleaching pretreatment: enhancing bleaching of a polyester and cotton interwoven fabric by adopting a jig dyeing machine, and removing residual hydrogen peroxide on the interwoven fabric by using a hydrogen peroxide removing enzyme to improve the dyeing uniformity of the fabric; (2) high-temperature and high-pressure dyeing: [1] performing heat preservation level dyeing for 4 times at the temperature of 60 DEG C, so that the fluorescent disperse dye is absorbed uniformly on the surface of the fabric as much as possible; [2] strictly controlling the dyeing rate and the pH value by adopting a method for controlling a dyeing temperature rise curve to satisfy the level dyeing conditions; and (3) reductive washing: performing reductive cleaning, oxygen rinsing and acid washing neutralization after dyeing, rewashing, drying, performing after finishing, tentering, sizing and inspecting the finished product, wherein a mixed solution of rongalite and caustic soda is adopted in the reductive cleaning. The domestic fluorescent disperse dye is produced by adopting high-temperature and high-pressure jig dyeing equipment, has obvious advantages, and is detected through quality standards of EN-471.

Owner:辽宁宏润源印染有限公司

Anti-radiation antibacterial deodorizing fabric and preparation method thereof

The invention provides anti-radiation antibacterial deodorizing fabric. The anti-radiation antibacterial deodorizing fabric comprises a base fabric layer, a fabric layer and an anti-radiation antibacterial deodorizing layer arranged between the base fabric layer and the fabric layer. The anti-radiation antibacterial deodorizing layer is composed of warps, wefts and wool yarns by cross knitting. The warps are antibacterial fibers containing nano-silver particles, and the nano-silver particles account for 0.015-0.020%o of the antibacterial fibers. The wefts are antibacterial fibers treated by deodorizing finishing liquid, and the wool yarns are silver-plated fiber filament, and the silver-plated fibers use chinlon filaments as carrier. Silver is arranged on fibers on the surface of the carrier by the electrolysis method. The anti-radiation antibacterial deodorizing fabric is simple in structure, low in cost, excellent in antibacterial effect, long in antibacterial time and convenient in raw-material sourcing and has wide-spectrum antibacterial function.

Owner:广州傲加科技有限公司

Production method for singeing and mercerizing single yarn

InactiveCN102021778AStrong noveltyUniqueMercerising of yarns/threads/filamentsSolvent-treatmentYarnPolymer science

The invention provides a production method of singeing and mercerizing a single yarn. In the method, appropriate cotton is selected, a singeing and mercerizing process is studied and confirmed, and a process appropriate for the mercerizing of the single yarn is obtained to ensure that the breaking strength loss of the single yarn after the mercerizing is little; the single yarn is not easy to break in the weaving process; and the pattern of the fabric weaved with the single yarn has novelty and peculiarity. The production method for singeing and mercerizing a single yarn is characterized by sequentially comprises the processes of combing the single yarn, singeing, reeling, mercerizing, dyeing, wringing, drying, and rewinding; the singeing process specifically comprises the step of singeing the single yarn by a singeing machine to burn up the hairiness on the surface of the single yarn at a singeing temperature of 800 DEG C-1050 DEG C; and the mercerizing process specifically comprises the step of mercerizing the processed single yarn by a mercerizing machine, wherein the processing temperature is 18 DEG C-22 DEG C, the processing time is 6 minutes 30 seconds to 6 minutes 50 seconds, the processing tension of the single yarn maintains -1.0%-0% of stretching, and the alkali concentration in the processing fluid is 26 baume degrees to 30 baume degrees.

Owner:WUXI NATURAL GREEN FIBER TECH

Preparation technology of alkali-resisting PTFE (polytetrafluoroethylene) and PPS (polyphenylene sulfide) fiber blended needled felt

InactiveCN110130116ASmall filter resistanceImprove breathabilitySolvent-treatmentNon-woven fabricsEmulsionFiltration

The invention belongs to the technical field of industrial dedusting application and particularly discloses a preparation technology of alkali-resisting PTFE (polytetrafluoroethylene) and PPS (polyphenylene sulfide) fiber blended needled felt. The preparation technology comprises following steps: step 1, fiber opening; step 2, fiber carding; step 3, lapping; step 4, needling compaction; step 5, postprocessing: (1), calendering; (2), singeing; (3), impregnation with an emulsion; (4), high-temperature setting; (5), film covering. The preparation technology of the alkali-resisting PTFE and PPS fiber blended needled felt has beneficial effects as follows: 1, a PTFE fiber+PPS fiber needled felt filter material is a filter material with a stereoscopic fiber structure, and the filter material isformed by covering two sides of base cloth with stereoscopically staggered PTFE fibers and PPS fibers respectively, compacting and fixing the base cloth and then needling the base cloth by a needlingmachine; 2, the needled felt filter material has a small bore diameter, low filtration resistance, good breathability and high dust capturing efficiency. The filtration efficiency can reach 99.99% orabove.

Owner:JIANGSU XI YANGYANG ENVIRONMENTAL PROTECTION EQUIP SCI & TECH CO LTD

Cotton-real silk XLA intertexture and producing method thereof

InactiveCN101381919AIncrease elasticityFeel goodSolvent-treatmentDry-cleaning apparatus for textilesYarnEngineering

The invention provides a cotton-silk XLA mixed fabric and a production method thereof, and relates to a process for dyeing, weaving and finishing cheese of textile fabrics. The production method comprises the following steps: silk cheese is wound, degummed, dyed and then doubled with XLA so as to form weft; cotton yarn is wound, warped and sized so as to form warp; and the weft and the warp are interwoven, singed, desized, set, preshrunk and then made into the cotton-silk XLA mixed fabric. The cotton-silk XLA mixed fabric is an all-natural green elastic fabric which has the advantages of good hand feeling, luster, elasticity and serviceability.

Owner:JIANGSU LIANFA TEXTILE

Preparation method of protective clothing blended fabric

ActiveCN105862204AImprove insulation effectImprove antistatic performanceSolvent-treatmentFibre cleaning/openingPolyesterEnvironmental resistance

The invention provides a preparation method of a protective clothing blended fabric. The fabric is formed by blending modified polyester fibers, wool and linen fibers, and the modified polyester fibers are formed by adding raw vermiculite powder to the preparation process of polyester fibers, cost is low, the modification effect is excellent, and in addition, the whole preparation process is environmentally friendly; the heat preservation performance of the fabric can be improved by adding the wool; antistatic performance and anti-ultraviolet performance of the fabric can be improved by adding the linen fibers.

Owner:SHENZHEN ELLASSAY FASHION CO LTD

Continuous processing technology for non-shrink treatment of chlorine-free wool top and wool product

ActiveCN105986484AQuick contactAct quicklySucessive textile treatmentsSolvent-treatmentWater chlorinationPulp and paper industry

Owner:天津市诺奥科技发展股份有限公司

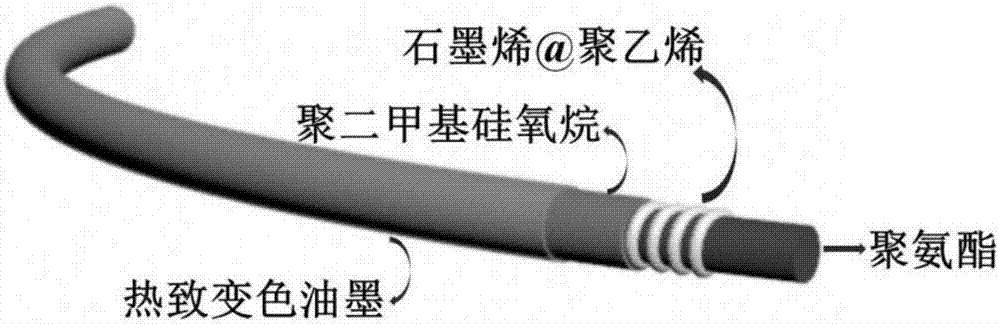

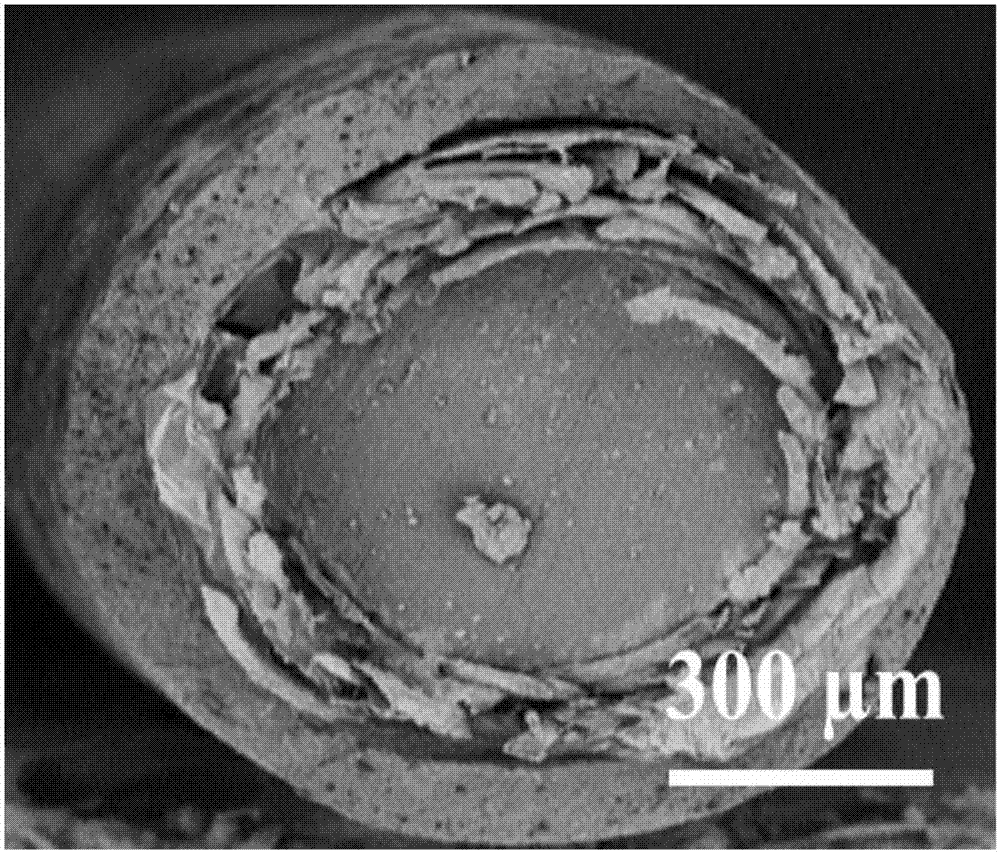

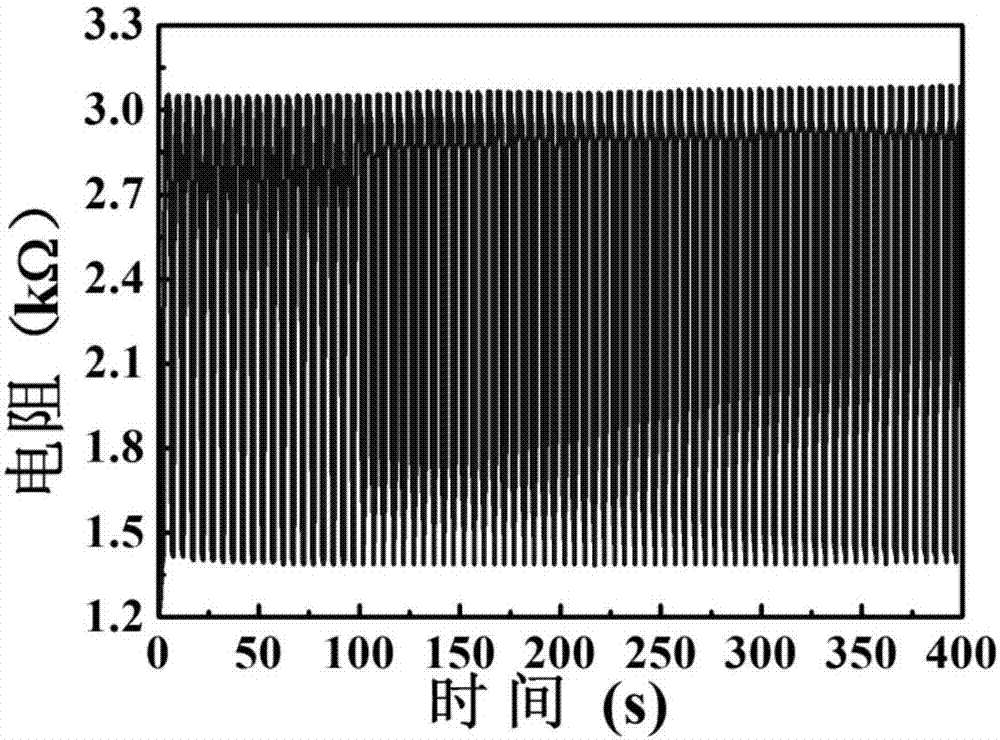

Stretchable electric-heating-induced chameleon fiber and preparing method thereof

The invention relates to stretchable electric-heating-induced chameleon fiber. Core-spun yarn serves as an elastic substrate, and a conducting layer, a protection layer and a chameleon layer are prepared on the surface of the substrate in sequence. A preparing method comprises the steps of pre-treatment of the core-covering yarn, synthesis of the core-spun yarn modified by multilayer graphene oxide, synthesis of the core-spun yarn modified by multilayer graphene, and synthesis of stretchable electric-heating-induced chameleon fiber. According to the stretchable electric-heating-induced chameleon fiber and the preparing method thereof, the method is simple, the condition is mild, the cost is low, and thus the stretchable electric-heating-induced chameleon fiber is suitable for scale production. The obtained stretchable electric-heating-induced chameleon fiber can be changed into multiple colors, has good electroconductivity and cycling stability, and meanwhile shows excellent stretchable performance; basis is provided for functionalization and intellectualization of fiber, and the stretchable electric-heating-induced chameleon fiber has high application value in the aspect like military camouflage, intelligent wearability and visual sensors.

Owner:DONGHUA UNIV

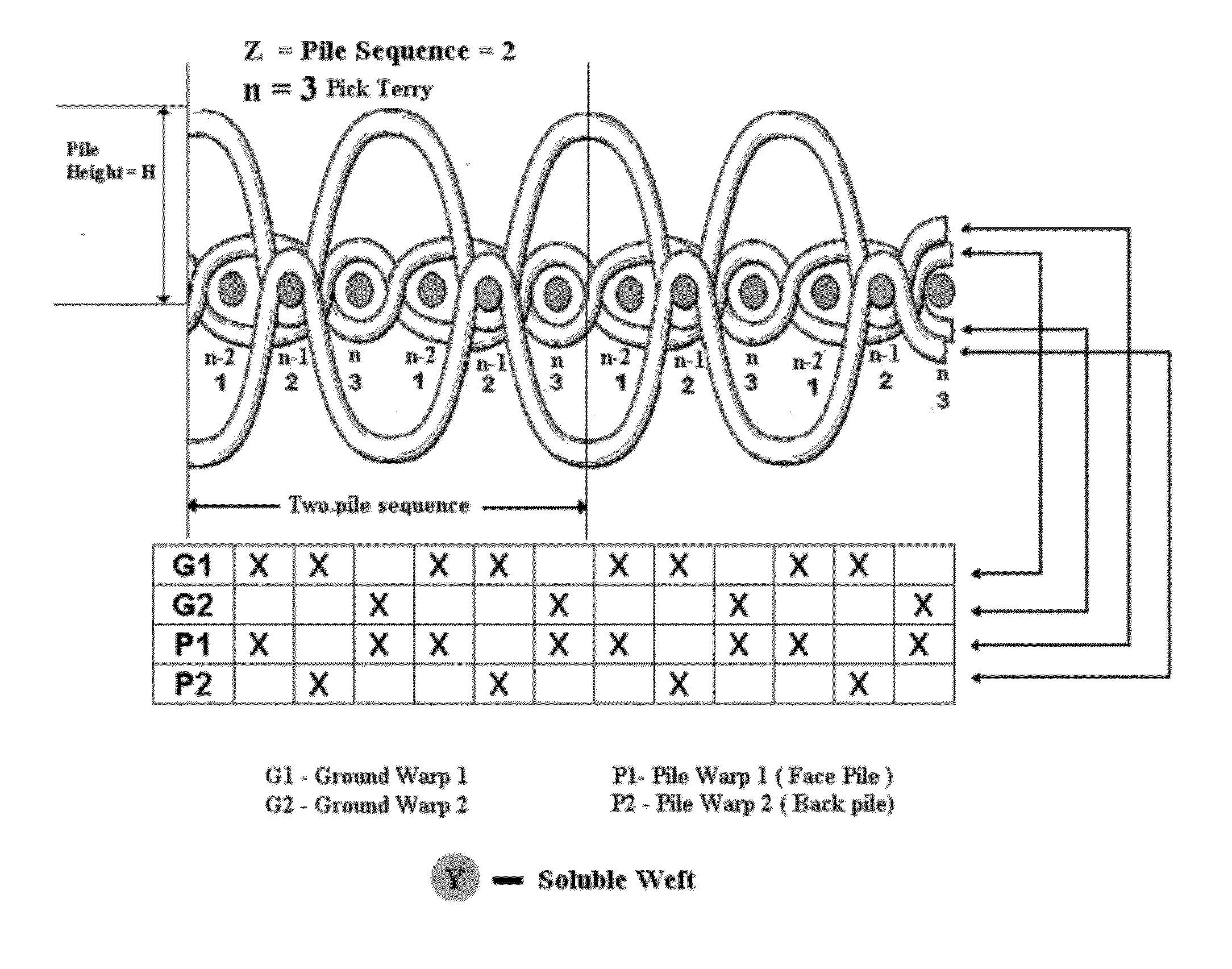

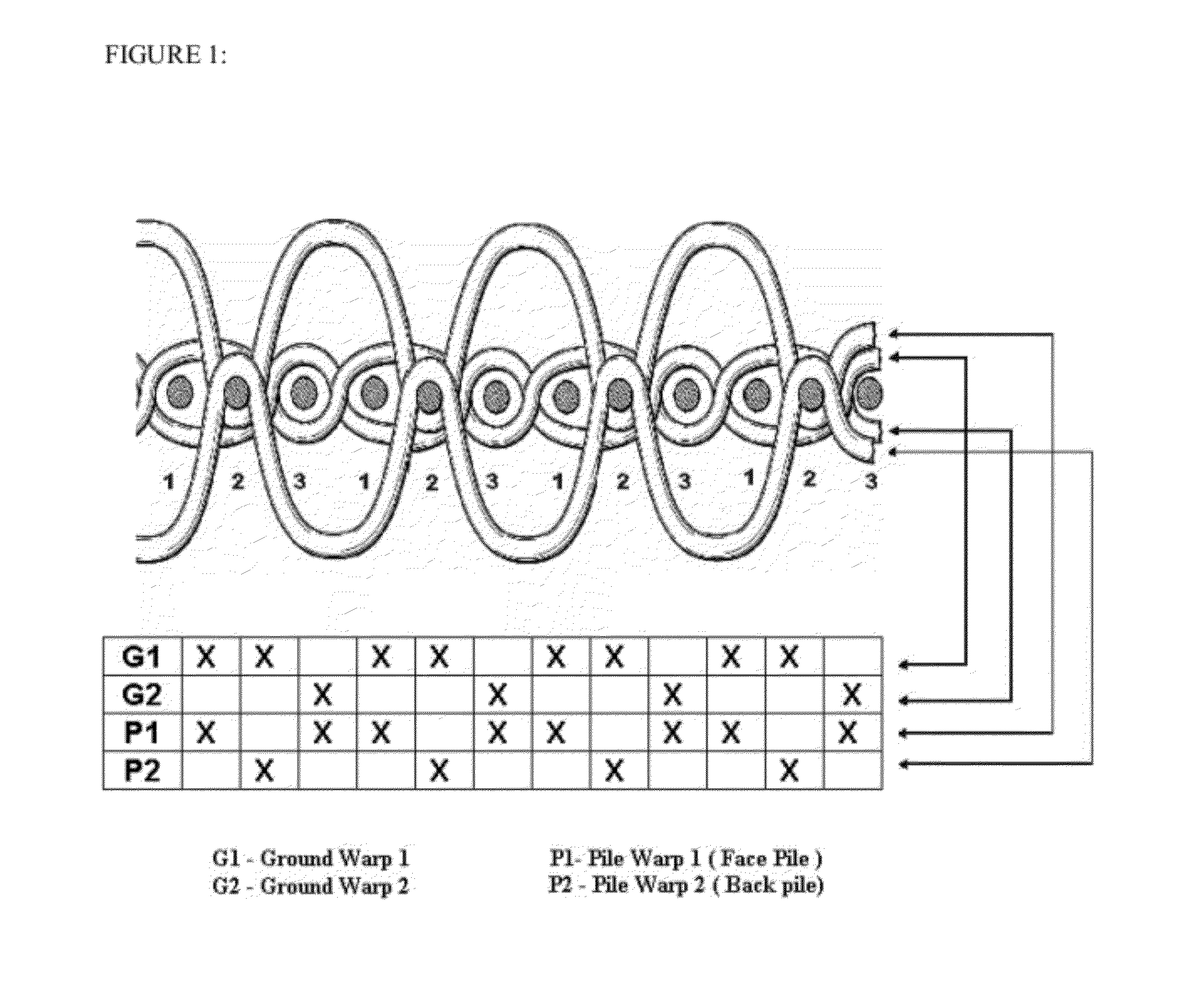

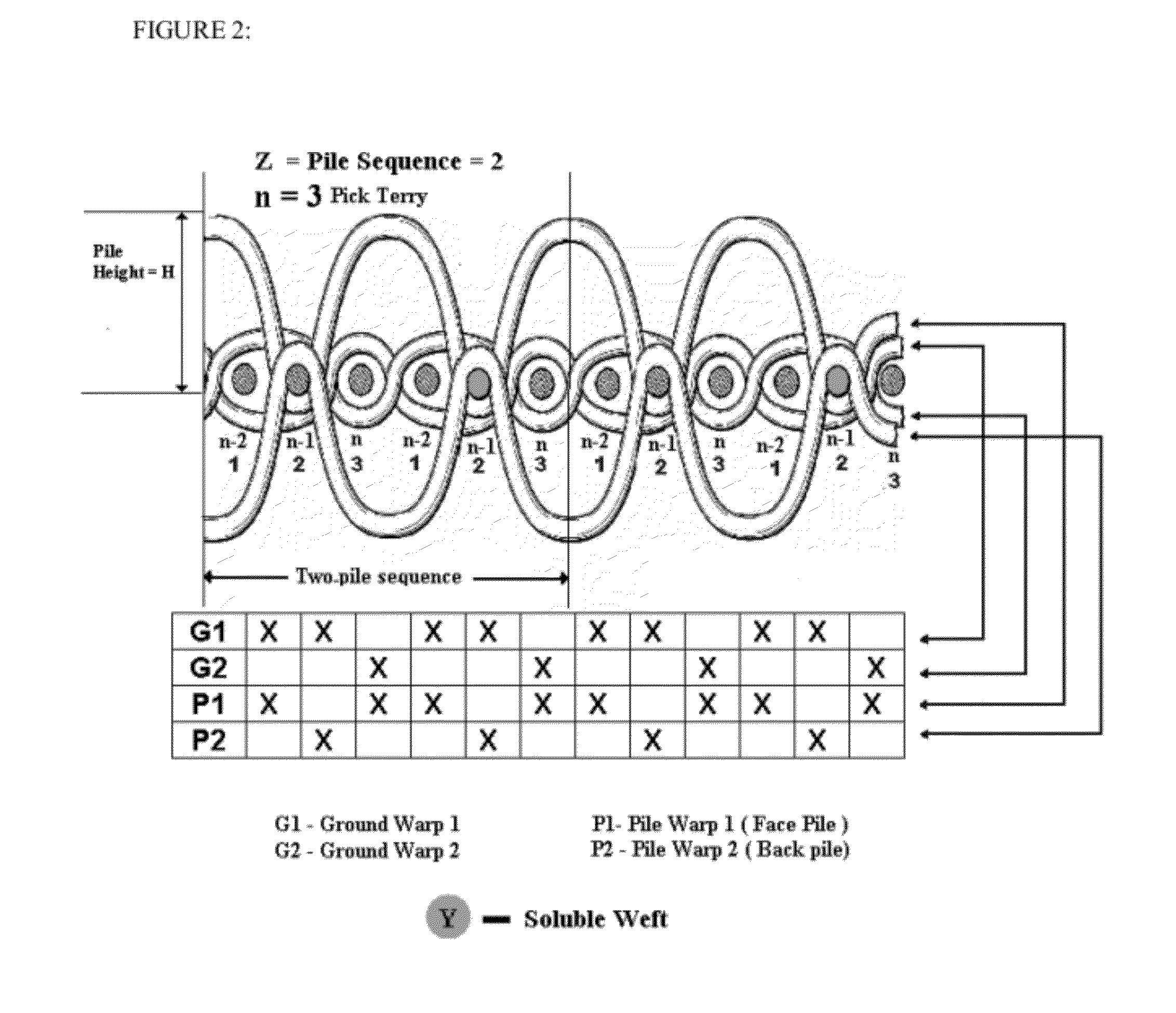

Method of weaving, processing and finishing a pile fabric

Disclosed is a method of weaving, processing and finishing a pile fabric whose pile height (H) after processing and finishing is substantially increased, thus obtaining increased pile height (H) which may be multiple of the original pile height (H) of the woven fabric. Specifically, the pile fabric is manufactured with multiple loop heights combining the original woven pile heights and / or different multiples of the original pile heights. Further, a process results in a fabric having a combination of pile heights, and designs by weaving repeats in the conventional way without soluble yarns (Y) in conjunction with repeats woven with multiple soluble yarns (Y).

Owner:GOVINDASWAMY KANNAPPAN

Anti-microbial wool fabric and manufacturing method thereof

The invention discloses an anti-microbial wool fabric. Warp and weft of the fabric are 60s high count coarse yarn formed by blending fine count wool fibers and bamboo fibers, and the weight ratio of the fine count wool fibers in the high count coarse yarn is 70%. According to the fabric, the fine count wool fibers are processed through traditional Chinese medicine anti-bacterial mixed liquid, so that the fine count wool fabric has a certain anti-bacterial function, and compared with nano silver and organic anti-bacterial agents, anti-bacterial components are safe and reliable.

Owner:JIANGSU SUNSHINE

Production technology for ultra-thin antibacterial spunlace surgery wiping material

InactiveCN104711763AResist invasionReduce stimulationSolvent-treatmentSucessive textile treatmentsPolyesterViscose

Owner:ZHEJIANG HEZHONG NONWOVEN

Blended non-woven fabric and preparation technology thereof

InactiveCN105908371ABeneficial elasticityBeneficial water absorptionSolvent-treatmentSucessive textile treatmentsRespiratorVegetable fibers

The invention discloses blended non-woven fabric and a preparation technology thereof. The blended non-woven fabric comprises the preparation raw materials of degummed silk protein fiber and degummed natural vegetable fiber, wherein the mass ratio of the degummed silk protein fiber to the degummed natural vegetable fiber is (20:80) to (80:20). The blended non-woven fabric not only has the advantages of softness, skin protection and skin favorableness of silk, but also has the elasticity and water absorption of fiber. The blended non-woven fabric is simple in preparation technology, and can be widely applied to industrials of facial masks, sanitary towels, sanitary pads, paper diapers, cosmetics, respirators, hygienic products and medical supplies.

Owner:SUZHOU YAZHOU COMMODITY TECH CO LTD

Technology for manufacturing anti-ultraviolet socks

InactiveCN103876308AUV stable and reliableSimple processSolvent-treatmentLiquid/gas/vapor article treatmentYarnPolytrimethylene terephthalate

The invention discloses a technology for manufacturing anti-ultraviolet socks. The technology includes particular steps of firstly, weaving bamboo fibers and cotton fibers via blowing, combing, silvering and fine spinning procedures to obtain bamboo fiber yarns; secondly, weaving the bamboo fiber yarns and polytrimethylene terephthalate yarns to obtain gray cloth of socks; thirdly, cutting the gray cloth according to sock manufacturing methods and requirements and then processing the cut gray cloth to obtain the socks; fourthly, soaking the socks in water with ultraviolet absorbents for 1 hour; fifthly, taking the socks out of the water, dehydrating the socks, and drying the socks in a dryer at the drying temperature of 150 DEG C for 10 minutes; sixthly, ironing the dried socks, finishing the socks and setting the socks to obtain the anti-ultraviolet socks. The proportion of the water to the ultraviolet absorbents is 10:1. The technology has the advantages that the technology is simple and is easy to understand, anti-ultraviolet components are uniformly distributed on the socks and are stably combined with the socks, and accordingly the stability and the reliability of the anti-ultraviolet performance of the socks can be guaranteed.

Owner:赵建英

Popular searches

Conjugated synthetic polymer artificial filaments Textile shaping Dyeing process Liquid/gas/vapor textile treatment Roughening Monocomponent polyamides artificial filament Heating/cooling textile fabrics Detergent mixture composition preparation Textile treatment machine arrangements Cleaning processes and apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com