Technology for producing high-standard fluorescent safe protective polyester and cotton interwoven fabric by using domestic fluorescent disperse dye

A technology for disperse dyes and safety protection, which is applied in the processing of textile materials, dyeing methods, and biochemical fiber processing, etc. It can solve problems such as unstable performance, narrow dyeing temperature range, and non-uniform pH range of dyeing baths, and achieve cost reduction. Low, high product quality, high reflective brightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Fabrics, dyes and auxiliaries used:

[0028] ① Fabric specification: T70 / C30 150D×12 S 103×70 162CM

[0029] T50 / C50 200D×10 S 114×50 150CM

[0030] ② Domestic fluorescent disperse dyes: "Shanyu" brand and "Hua Die" brand fluorescent disperse dyes produced in Taizhou, Zhejiang Province.

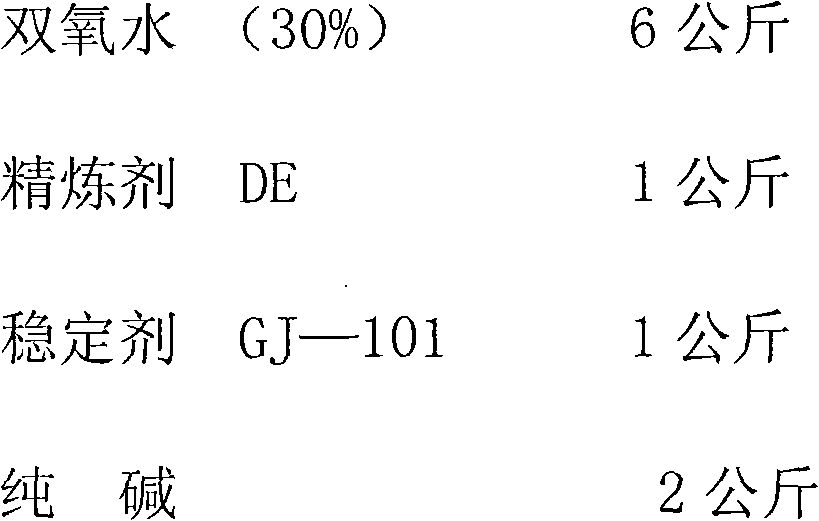

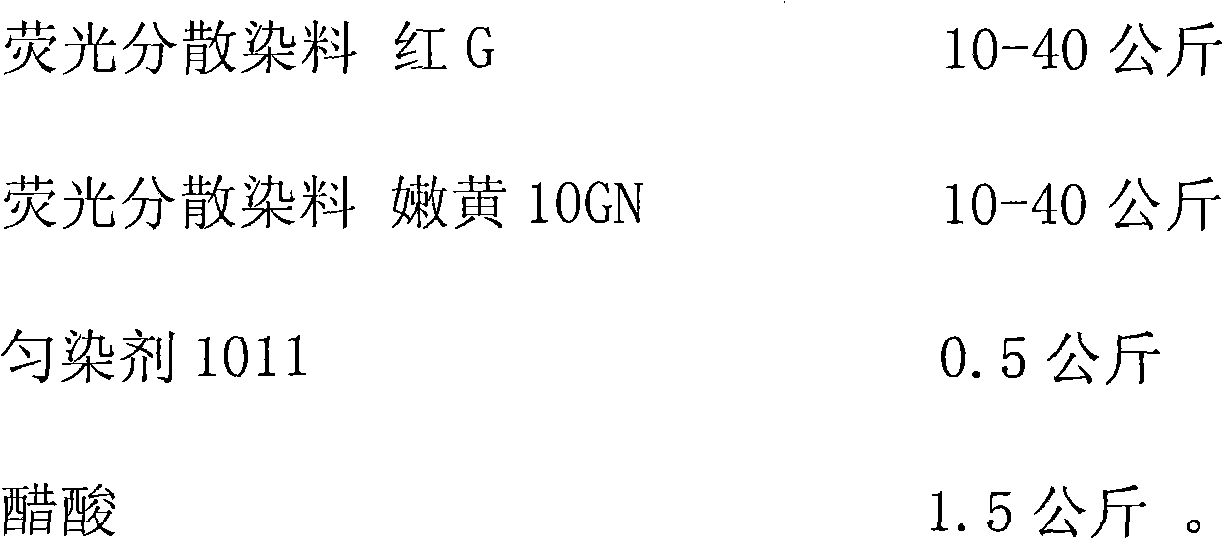

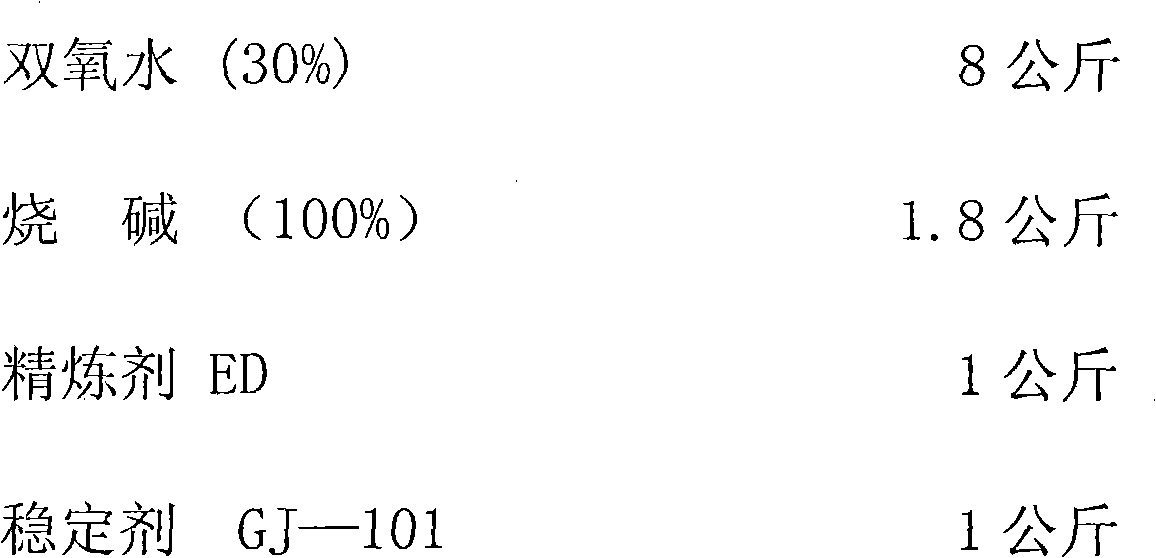

[0031] ③Auxiliaries: leveling agent 1011, refining agent ED, hydrogen peroxide, stabilizer GJ-101, acetic acid, caustic soda, etc.

[0032] Production equipment and testing instruments:

[0033] ①GOTMEI high temperature and high pressure dyeing jigger and normal temperature dyeing jigger.

[0034] ② Testing instruments: DaTa color600 color matching instrument, Madal pilling tester, washing color fastness tester, rubbing color fastness tester, standard shrinkage test washing machine, perspiration color fastness tester, breaking strength tester, Heavy Hammer Tear Tester.

[0035] The specific process steps are as follows:

[0036] (1) Pre-bleaching treatment: inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com