Method for coloring alginate fiber stoste by adopting lake colors

A technology for coloring seaweed fiber and stock solution, which is applied in the fields of fine chemical industry and material science, and can solve the problems of fiber damage and pollution, and achieve the effects of bright coloring, overcoming damage, and good solvent migration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

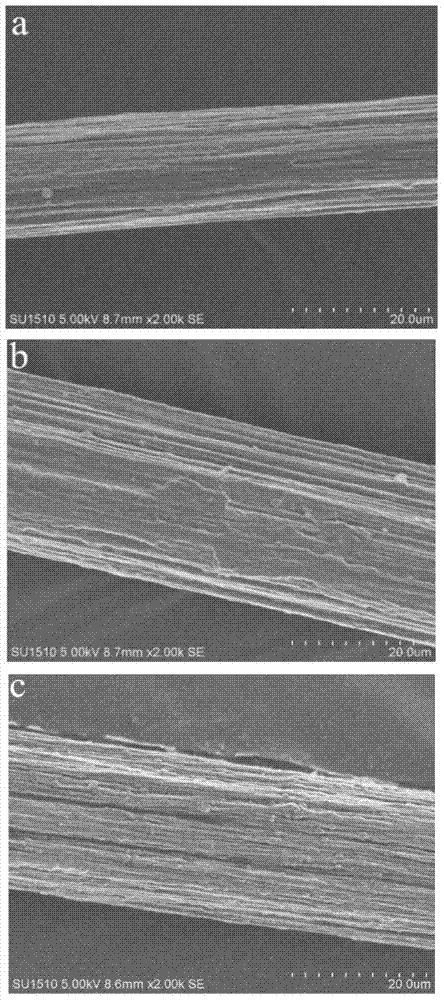

Image

Examples

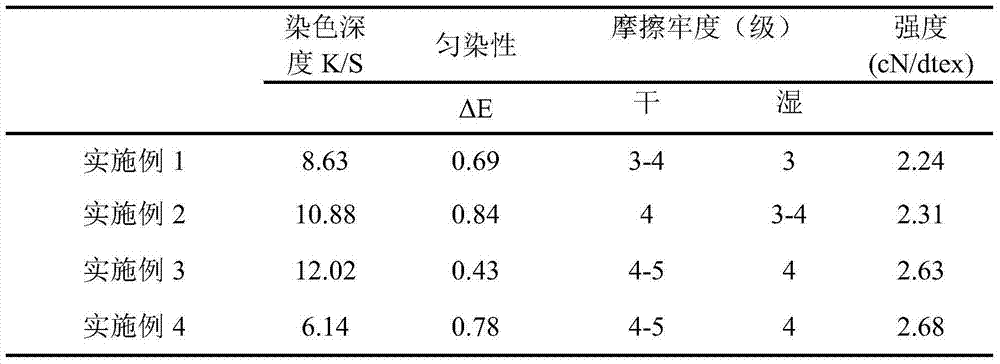

Embodiment 1

[0012] Dissolve 20g of sodium alginate into 479.6g of deionized water, stir to make it fully dissolved, and obtain the seaweed fiber spinning stock solution; take 0.4g of basic pink 6GDN, add it to the seaweed fiber spinning stock solution, stir to make it evenly mixed, Then high-pressure filtration (the filter membrane is a 100-mesh PP membrane) and vacuum degassing for 10 hours to obtain the lake dye seaweed fiber spinning solution. Adjust the temperature of the lake dye seaweed fiber spinning solution to 50°C, and extrude the spinning solution through the spinneret hole to a temperature of 20°C, CaCl 2 In the coagulation bath with a solubility of 2%, the primary seaweed fiber is obtained, and then the primary seaweed fiber is passed through a preheating bath and a drawing bath, and then stretched and shaped, and after drying and oiling, the lake dye colored seaweed fiber is obtained . The temperatures of the preheating bath and the drawing bath are 65° C. and 110° C., and ...

Embodiment 2

[0014] Dissolve 25g of sodium alginate into 473.75g of deionized water, stir to make it fully dissolved; take 1.25g of weak acid yellow 5G, add it to the seaweed fiber spinning stock solution, stir to make it evenly mixed, and then filter under high pressure (the filter membrane is 20 μm PP film), vacuum defoaming for 10 hours to obtain the lake dye seaweed fiber spinning solution. Adjust the temperature of the lake dye seaweed fiber spinning solution to 40°C, and extrude the spinning solution through the spinneret hole to a temperature of 40°C, CaCl 2 In a coagulation bath with a solubility of 5%, the primary seaweed fiber is obtained, and then the primary seaweed fiber is passed through a preheating bath and a drawing bath, and then stretched and shaped, and after drying and oiling treatment, the lake dye colored seaweed fiber is obtained . The temperatures of the preheating bath and the drawing bath are 40° C. and 70° C., and the drawing ratio of the seaweed fiber is 250%....

Embodiment 3

[0016] Dissolve 30g of sodium alginate into 469.4g of deionized water, stir to make it fully dissolved; take 0.6g of acid green 2G, add it to the seaweed fiber spinning stock solution, stir to make it evenly mixed, and then filter under high pressure (the filter membrane is 20 μm PP film), vacuum defoaming for 10 hours to obtain the lake dye seaweed fiber spinning solution. Adjust the temperature of the lake dye seaweed fiber spinning solution to 55°C, and extrude the spinning solution through the spinneret hole to a temperature of 50°C, CaCl 2 In the coagulation bath with a solubility of 4%, the primary seaweed fiber is obtained, and then the primary seaweed fiber is passed through the preheating bath and the drawing bath, and then stretched and shaped, and after drying and oiling, the colored lake algae fiber is obtained . The temperatures of the preheating bath and the drawing bath are 70° C. and 130° C., and the drawing ratio of the seaweed fiber is 110%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| draft ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com