Fabrication technology of face fabric

A manufacturing process and fabric technology, used in dry cleaning fiber products, textiles and papermaking, fabric surface trimming, etc., can solve the problems of insufficient comfort, softness, affecting the service life of swimsuits, poor aesthetics, etc., and achieve bright color and feel. Thick, glossy soft finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

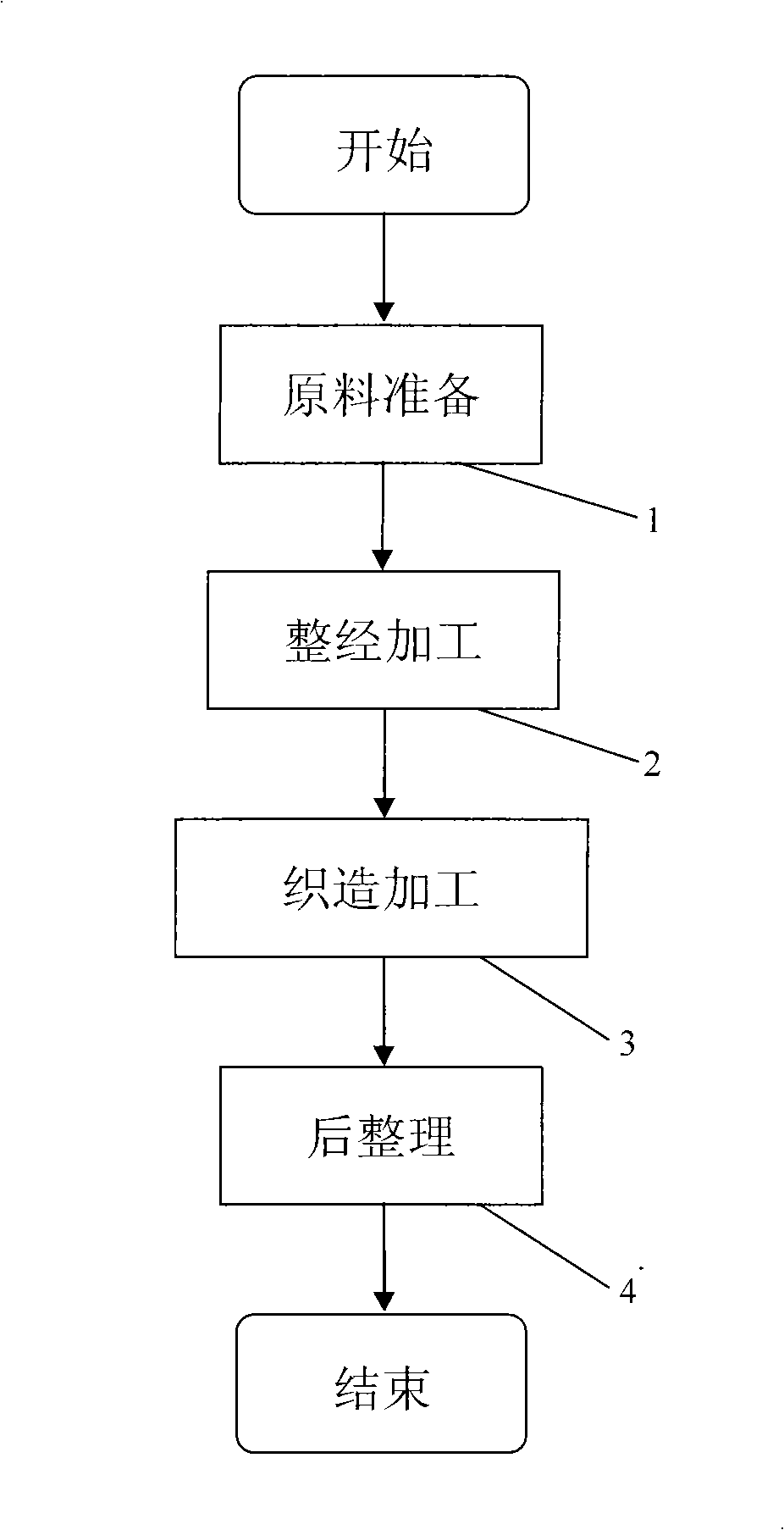

[0025] refer to figure 1 , a fabric manufacturing process, comprising the steps in turn:

[0026] Raw material preparation 1: 40D / 24F polyester semi-gloss cationic filament and 40D spandex are used as two raw materials, and the mass percentages of 40D / 24F polyester semi-gloss cationic filament and 40D spandex are 80.41% and 19.59% respectively. Imported Korean Hyosung polyester cationic and Invista's chlorine-resistant Lycra are interwoven. Cationic polyester has high dye exhaustion rate, good color permeability; good color fastness, bright color, soft luster, and good moisture absorption performance. Chlorine-resistant Lycra has good chlorine resistance and excellent elasticity and recovery properties. The surface is combed with cationic polyester, and the rear combed spandex is 26 threads and 1 empty, forming a beautiful stripe effect, and the finished product has good air permeability.

[0027] Warping processing 2: segmental warping is used, and the indoor environment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com