Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "High process flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

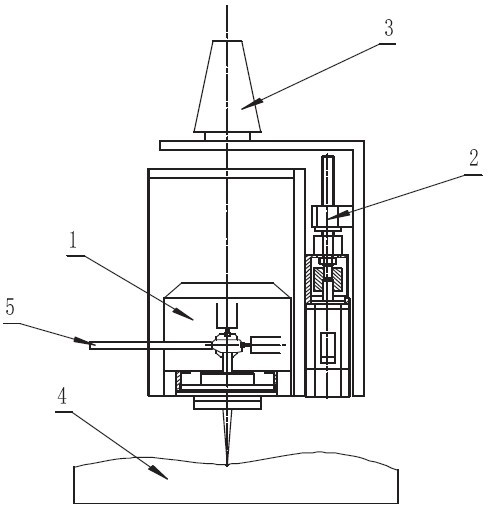

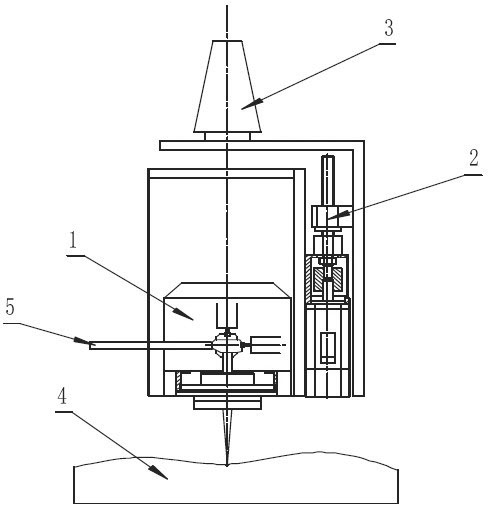

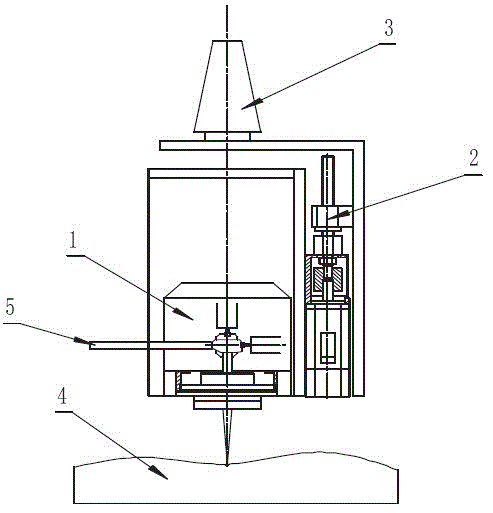

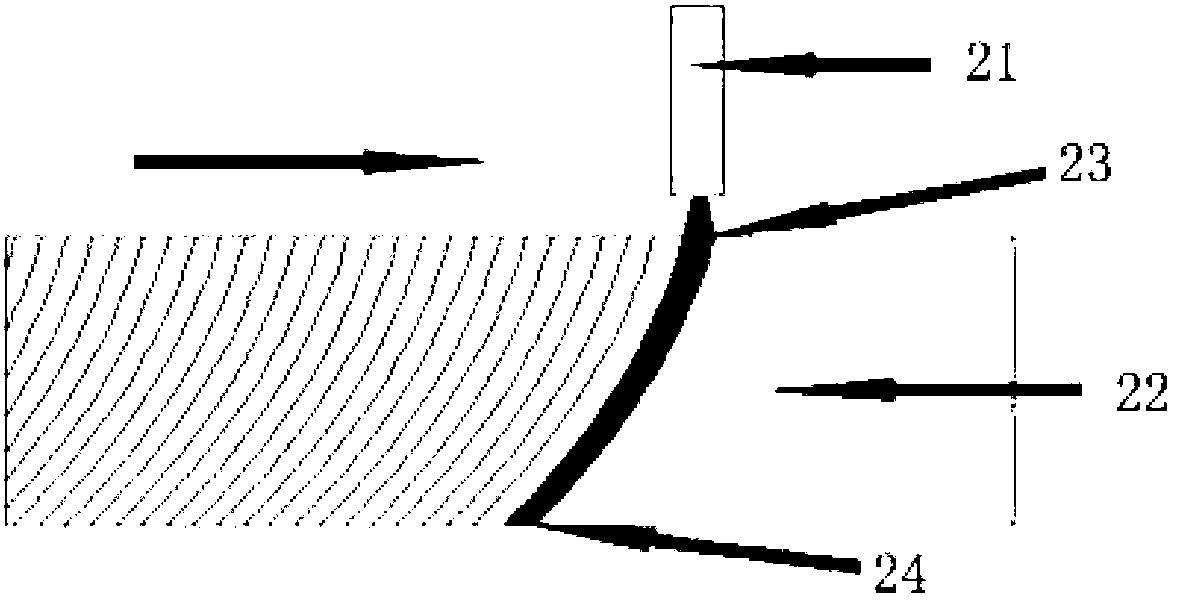

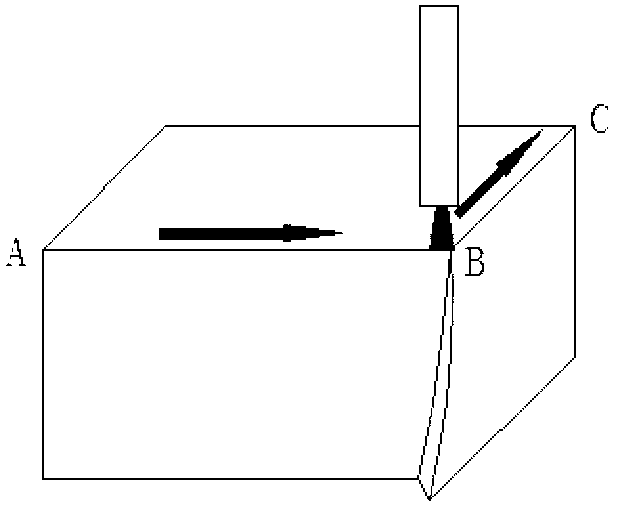

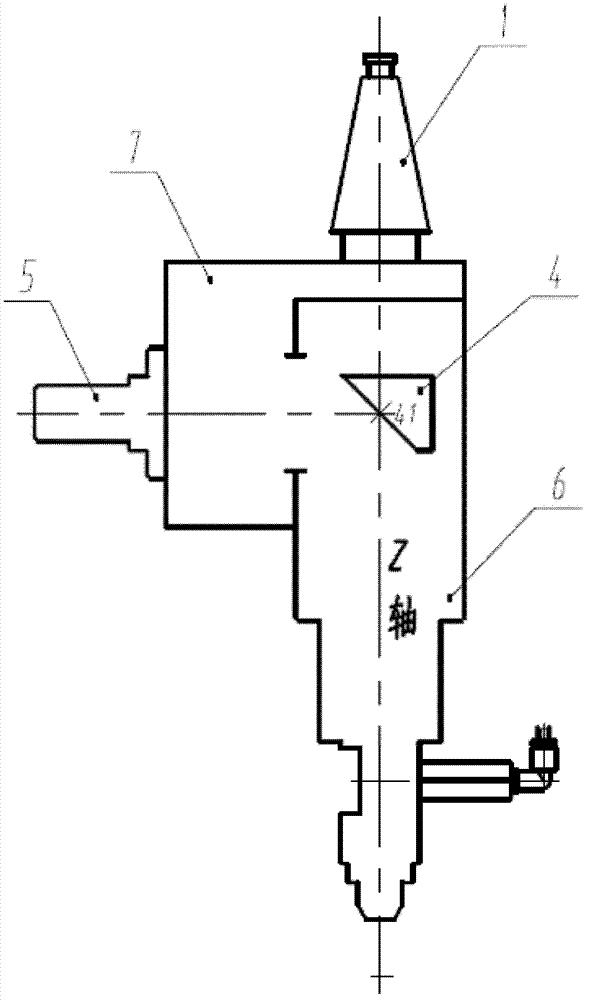

Laser machining method and device applicable for complicated curved surface

ActiveCN102151984AReduce the overall heightImprove energy consumptionLaser beam welding apparatusLaser etchingLaser processing

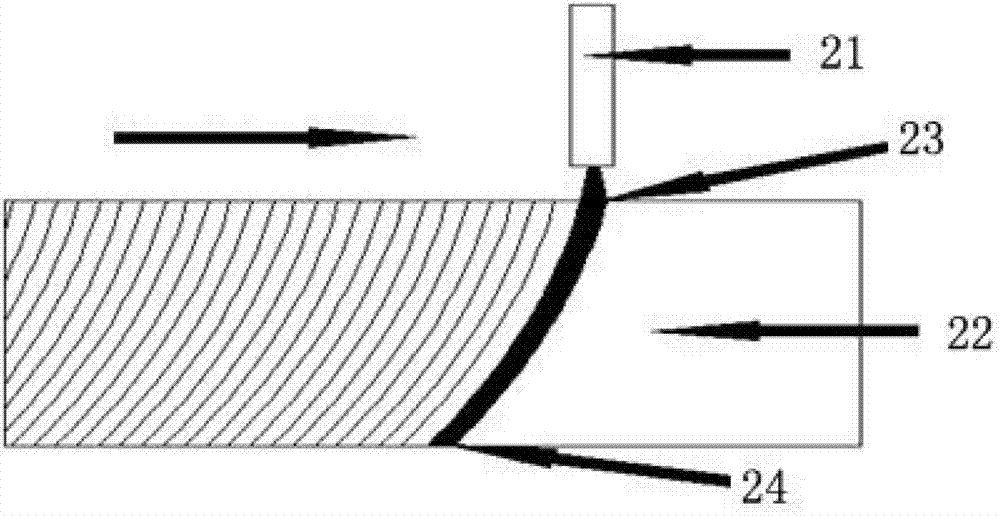

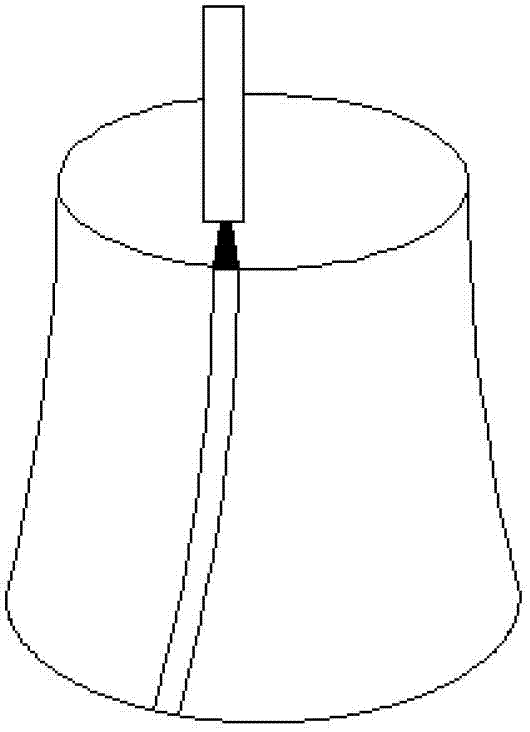

The invention provides a laser machining method applicable for a complicated curved surface. By adopting processing steps of dividing the complicated curved surface into curved surface sheets and establishing a coordinate system of each curved surface sheet, the subsequent processing steps of dividing sub blocks and machining pattern parallel projection can be implemented according to the coordinates of the curved surface sheets respectively, so the limit that a machining molded surface backing to a laser incident direction or a steep surface parallel to an optical axis direction cannot be machined because only one coordinate system is adopted to perform whole injection in the prior art can be overcome, the machining efficiency is improved and the machining applicable range is extended. The invention also provides a laser machining device. The laser machining device has a three-axis laser machining head structure provided with a two-axis laser polarization mirror and a Z-axis mobile mechanism, so the problem that the conventional system depends on a three-axis lathe is solved; therefore, a machining unit is independent and compact, and is easy to assemble and disassemble; the conventional five-axis linkage milling machine can be changed into a laser-etching machining lathe so that the functions are compatible; and the laser machining device has a significant practical value.

Owner:武汉飞能达激光技术有限公司

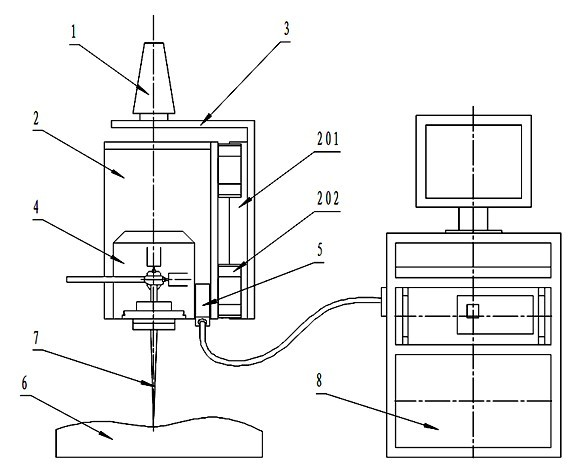

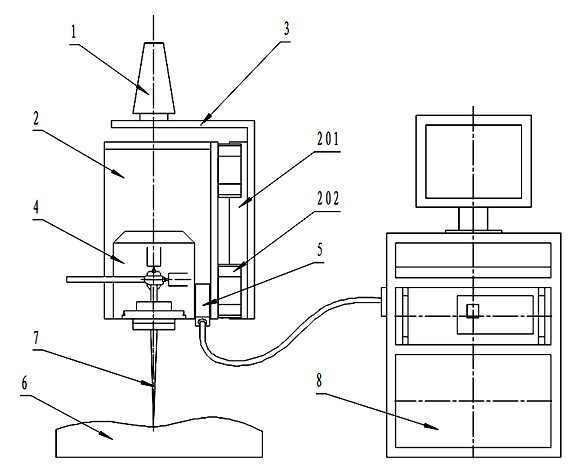

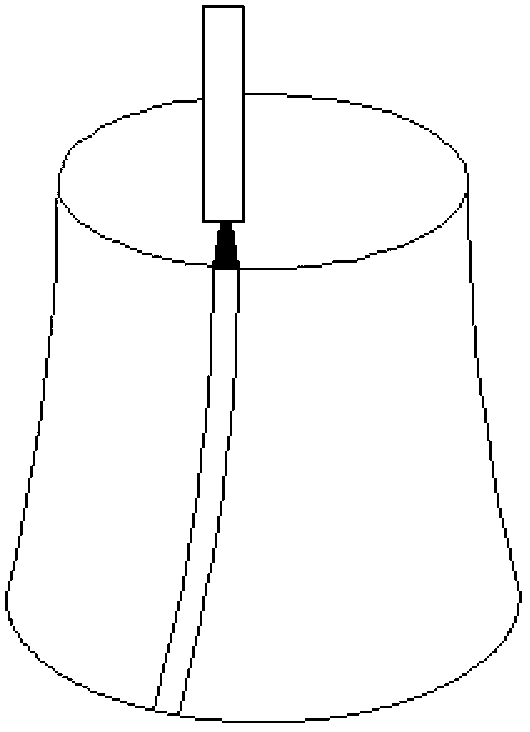

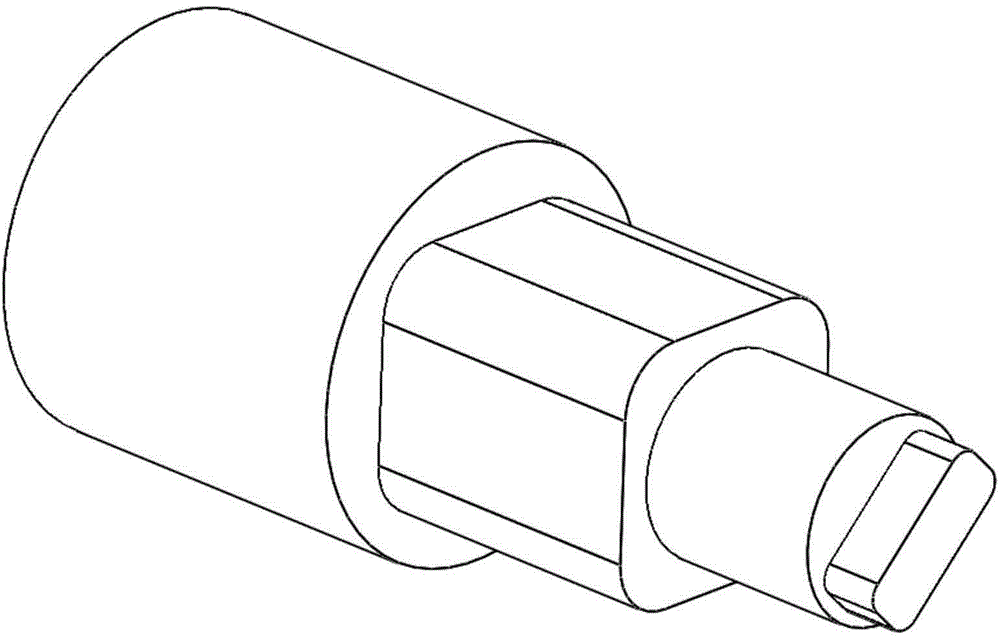

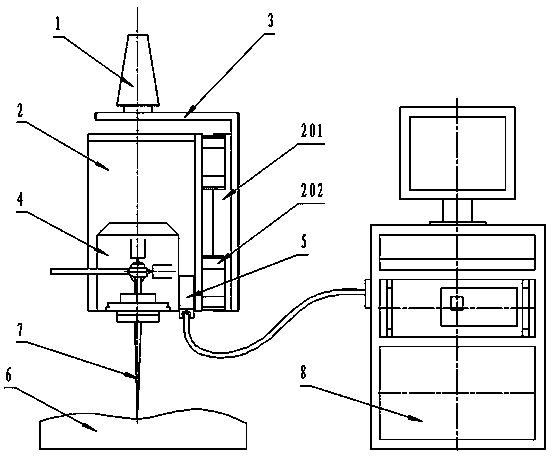

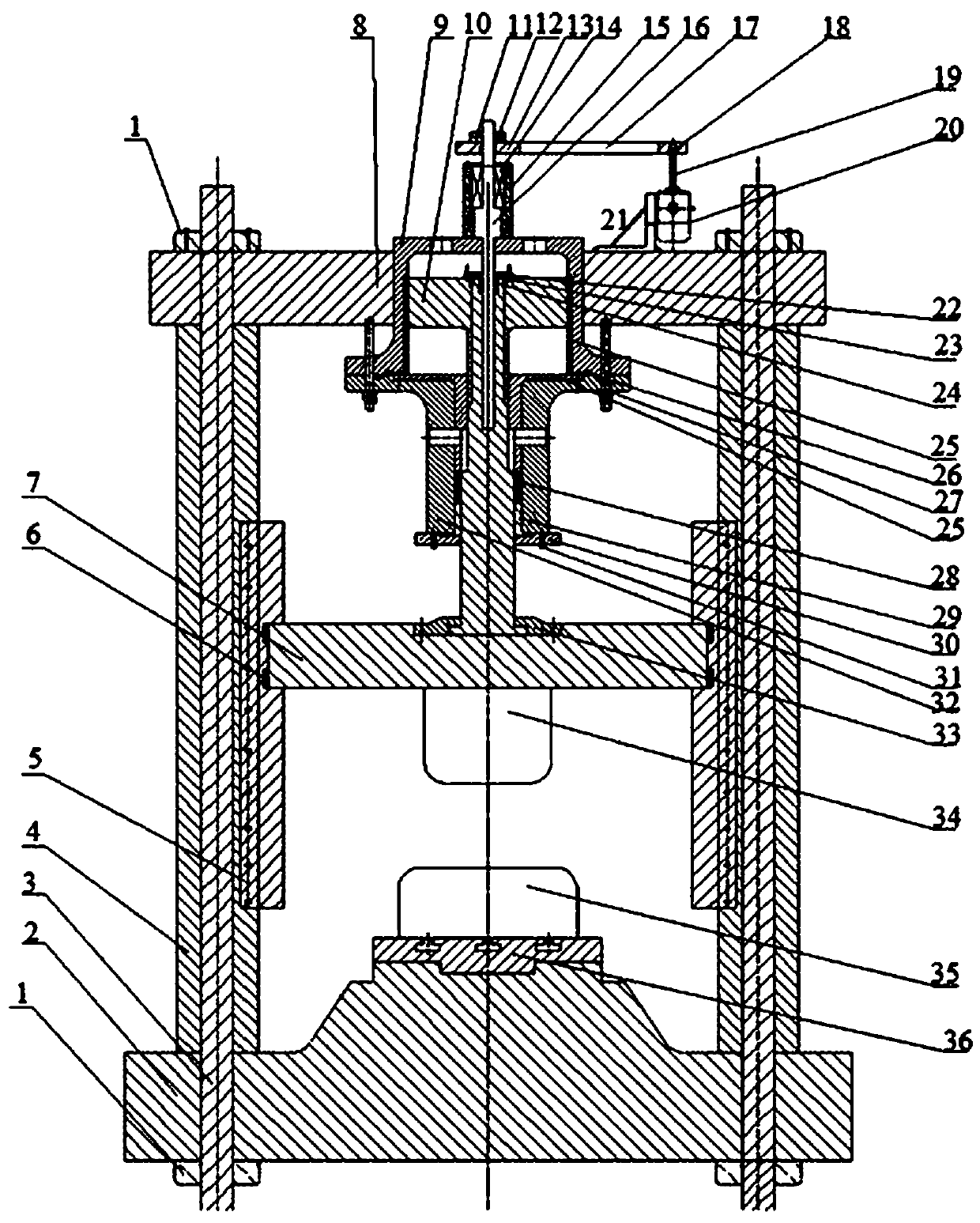

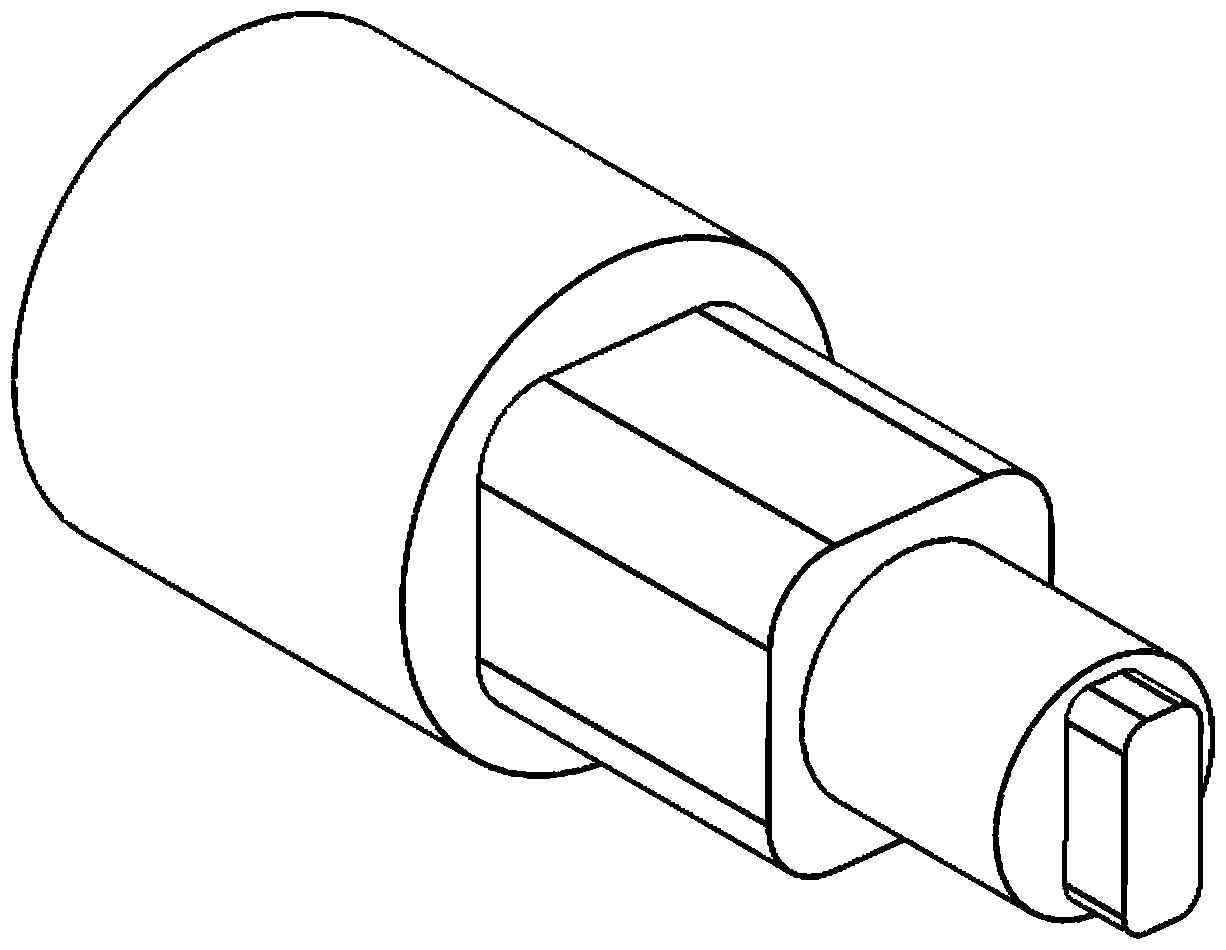

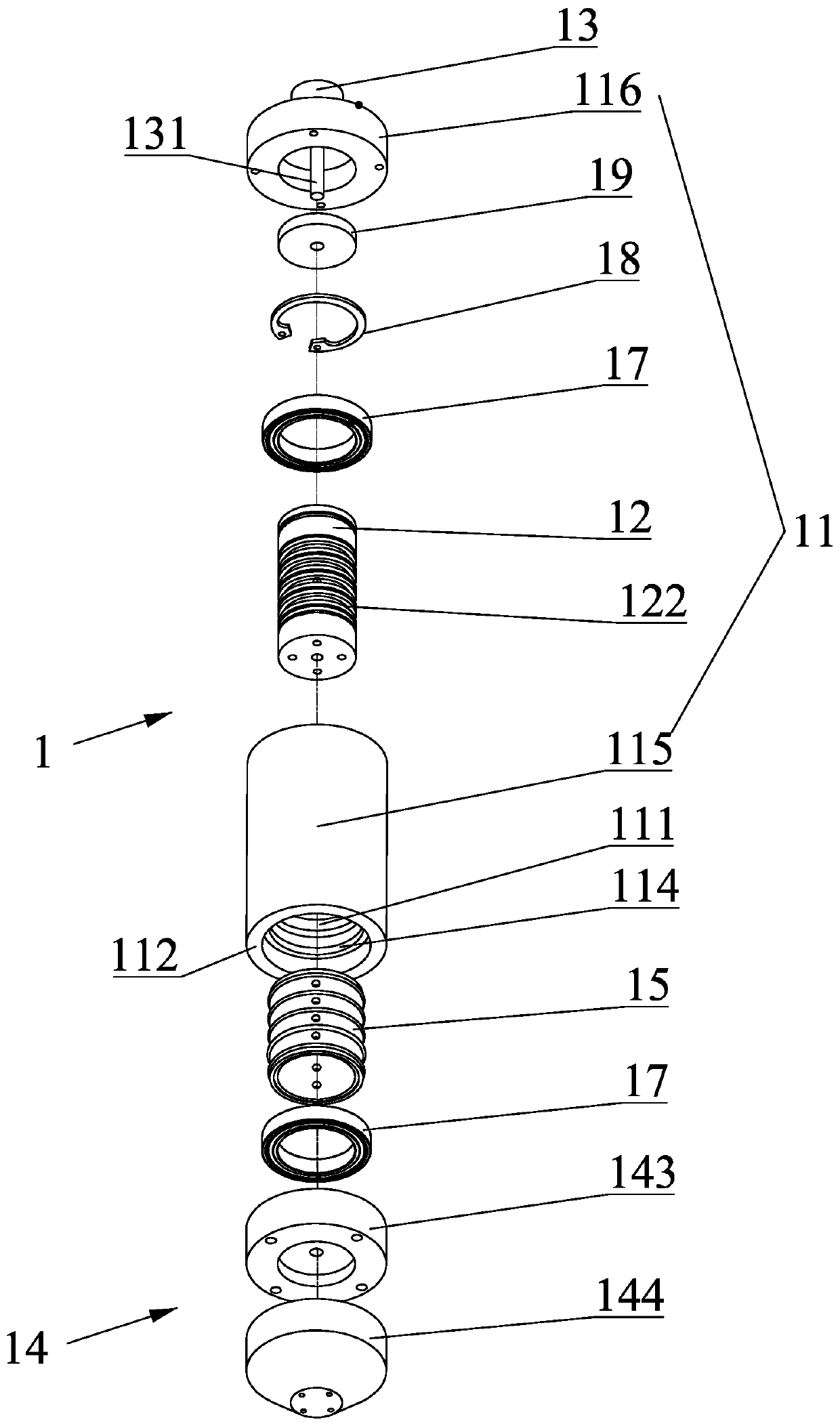

Three-coordinate galvanometer scanning laser processing head

ActiveCN102166685ARealize the self-adjustment function of processing focal lengthCombined processing is simpleLaser beam welding apparatusNumerical controlLaser processing

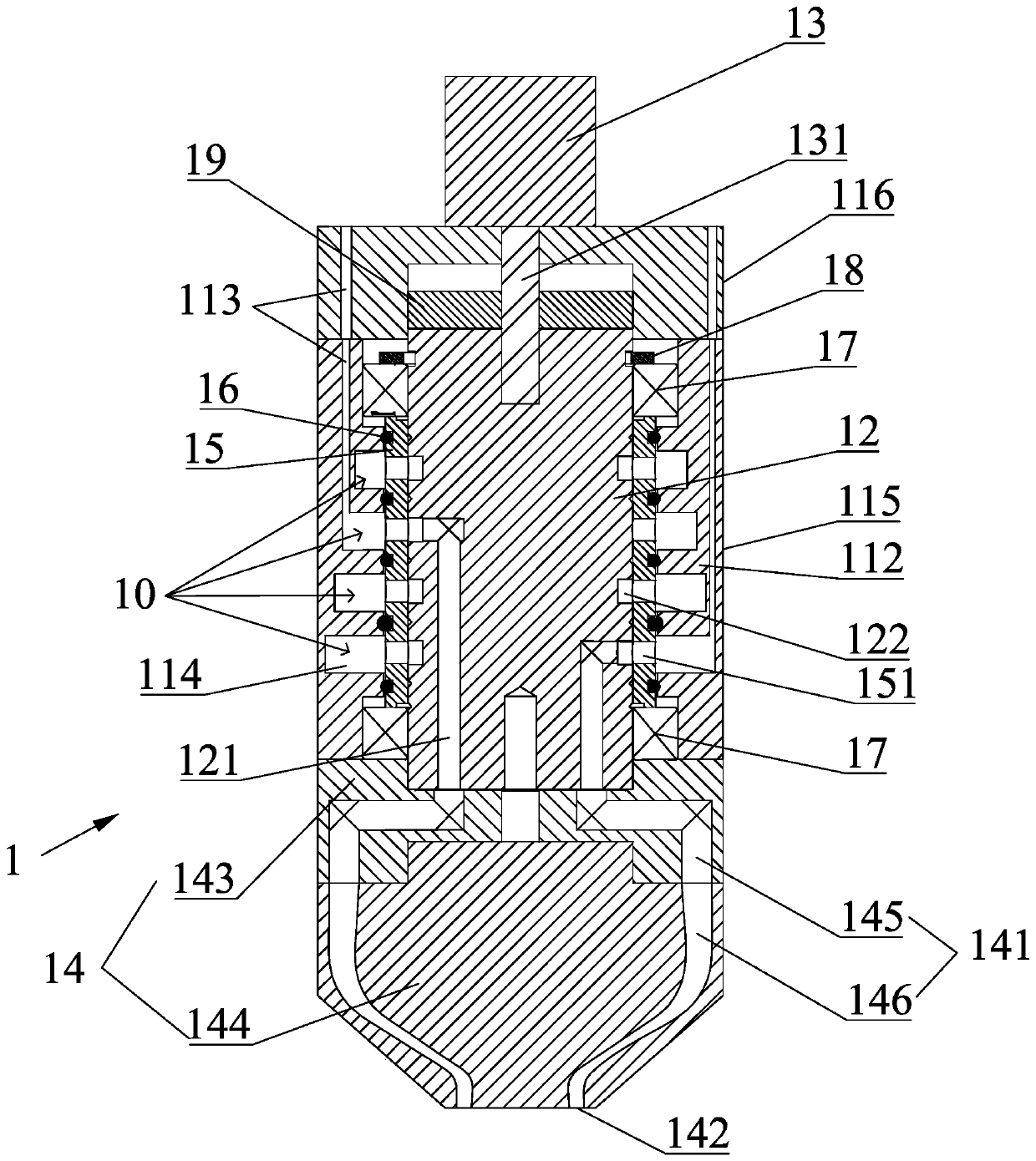

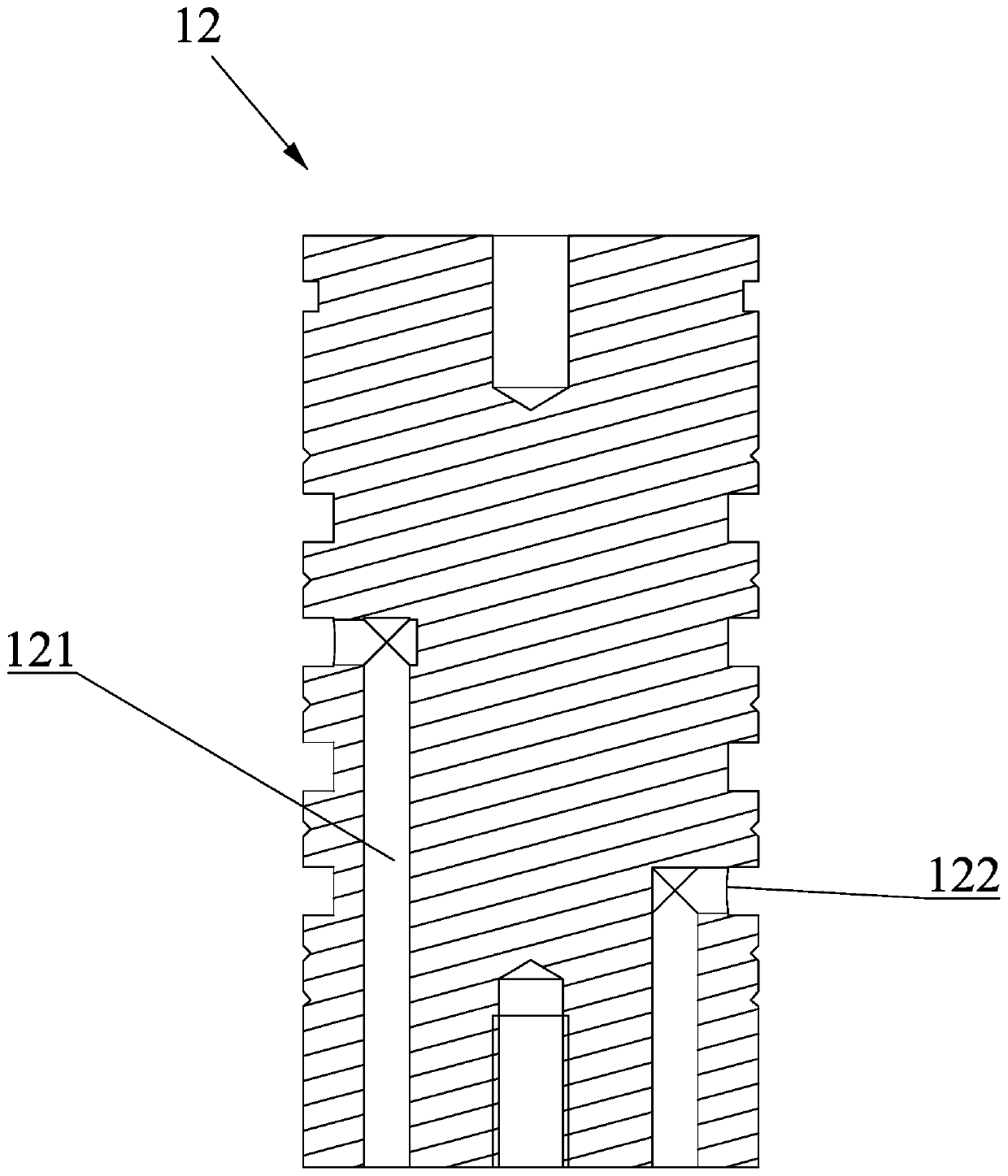

The invention provides a three-coordinate galvanometer scanning laser processing head, which comprises an XY two-axis laser galvanometer system, a clamping mechanism, a Z-axis moving mechanism, a laser displacement sensor and a control system, wherein the Z-axis moving mechanism comprises a fixed part and a moving part, and the clamping mechanism is fixedly mounted on the fixed part of the Z-axis moving mechanism; and the XY two-axis laser galvanometer system and the laser displacement sensor are fixedly mounted on the moving part of the Z-axis moving mechanism, and the laser displacement sensor, the Z-axis moving mechanism and the XY two-axis laser galvanometer system are all electrically connected with the control system. The laser processing head has the function of dynamic focal length setting, and has an independent and compact structure; the laser processing head has the broach interface design of a standard numerically-controlled machine tool, which enables the laser processing head to be easily assembled for processing with commercialized multi-axis synchronous numerically-controlled machine tools of a three-axis type, a five-axis type, and the like; and technological flexibility is greatly enhanced, and a conventional multi-axis synchronous numerically-controlled machine tool can be conveniently changed into a galvanometer scanning laser processing machine tool with compatible functions, thereby the three-coordinate galvanometer scanning laser processing head has important practical value.

Owner:武汉飞能达激光技术有限公司

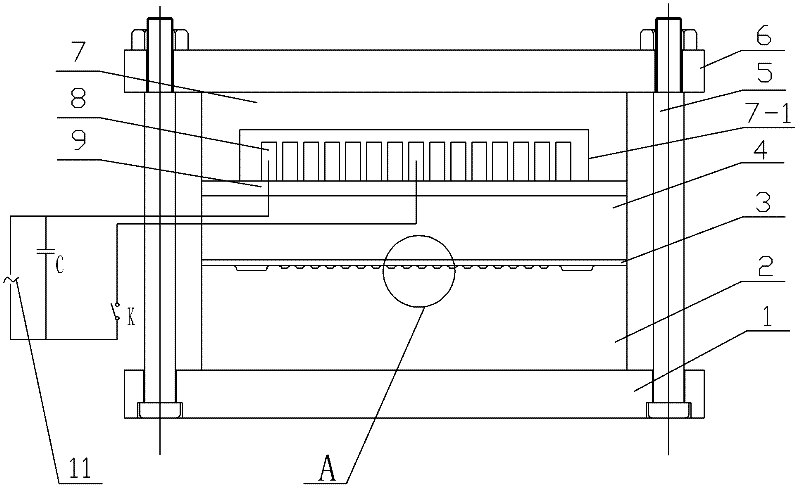

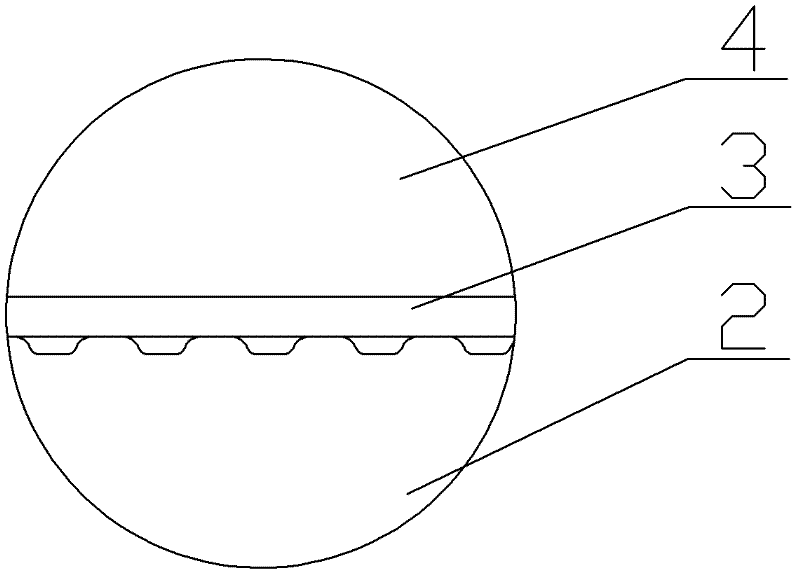

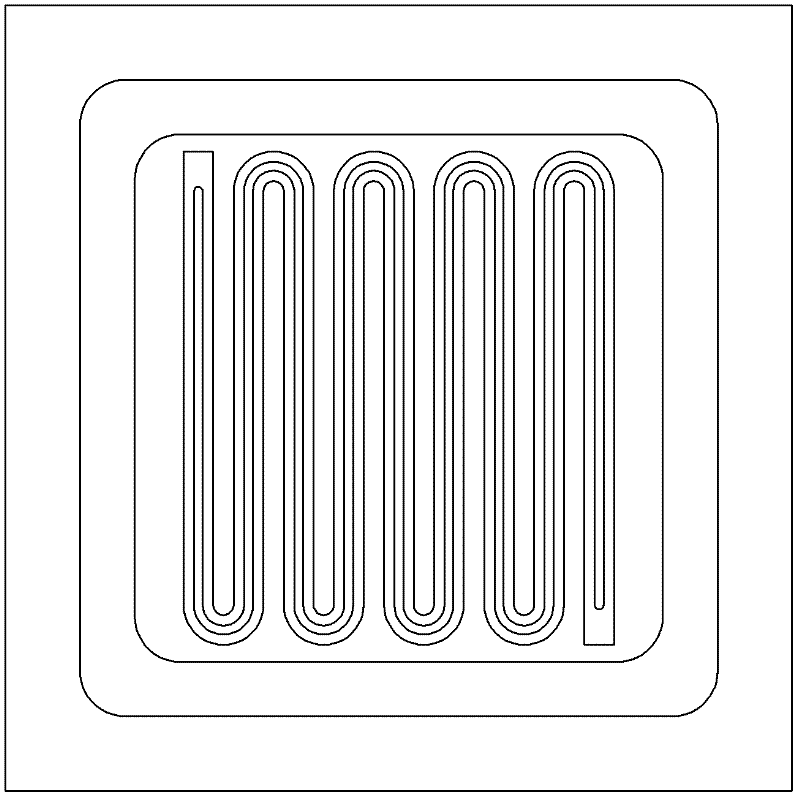

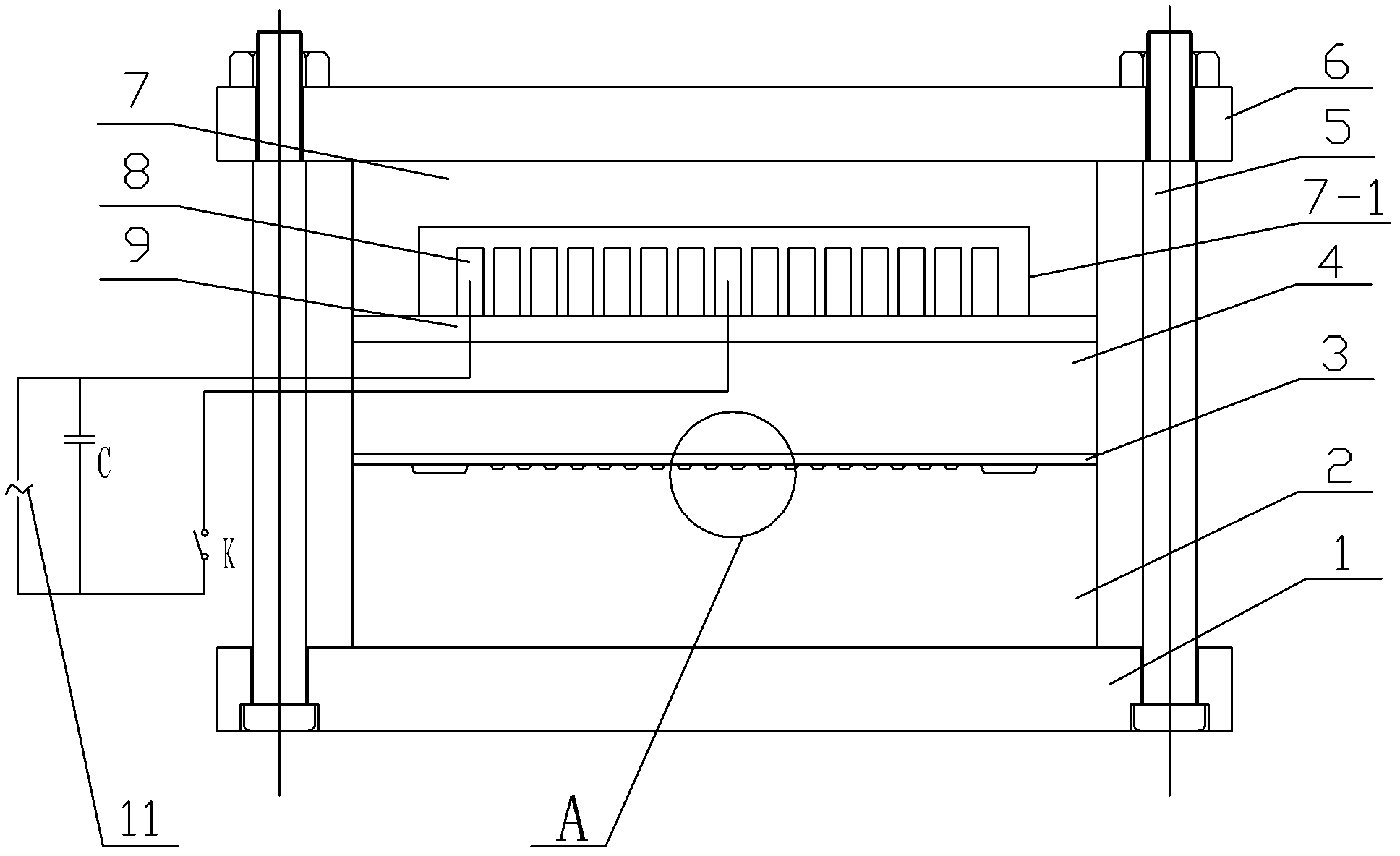

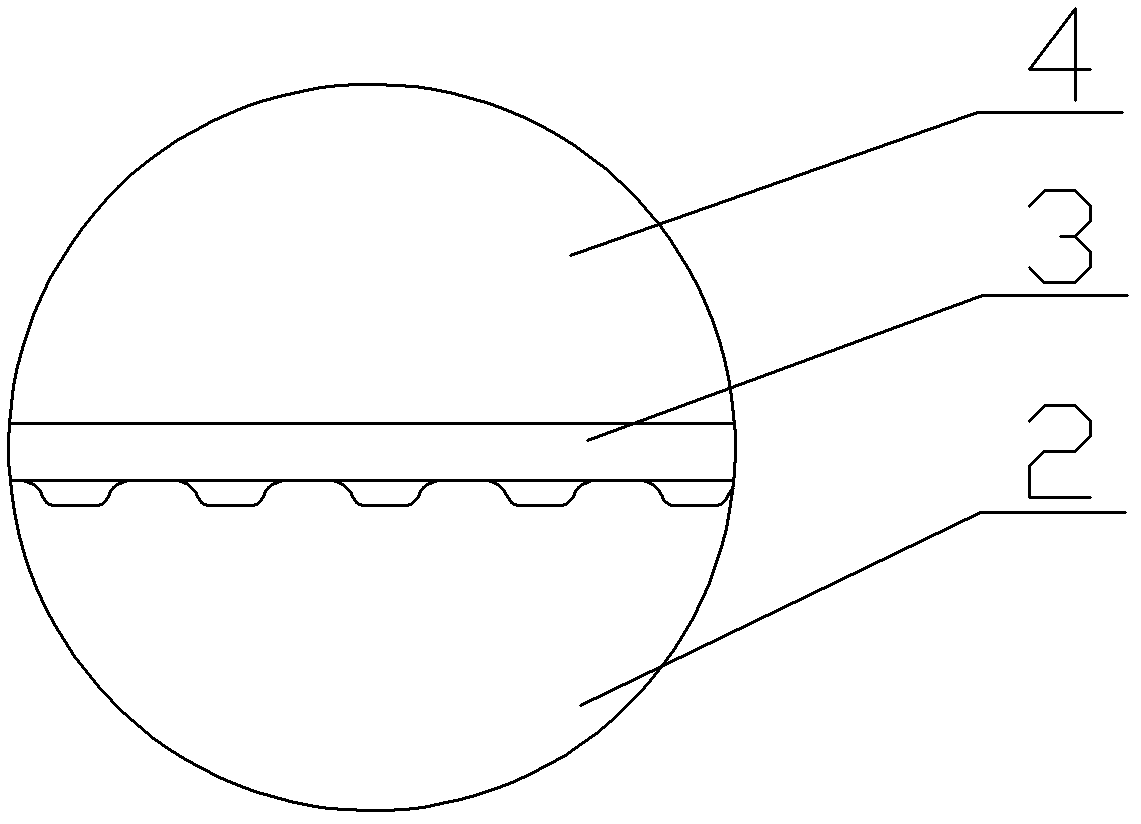

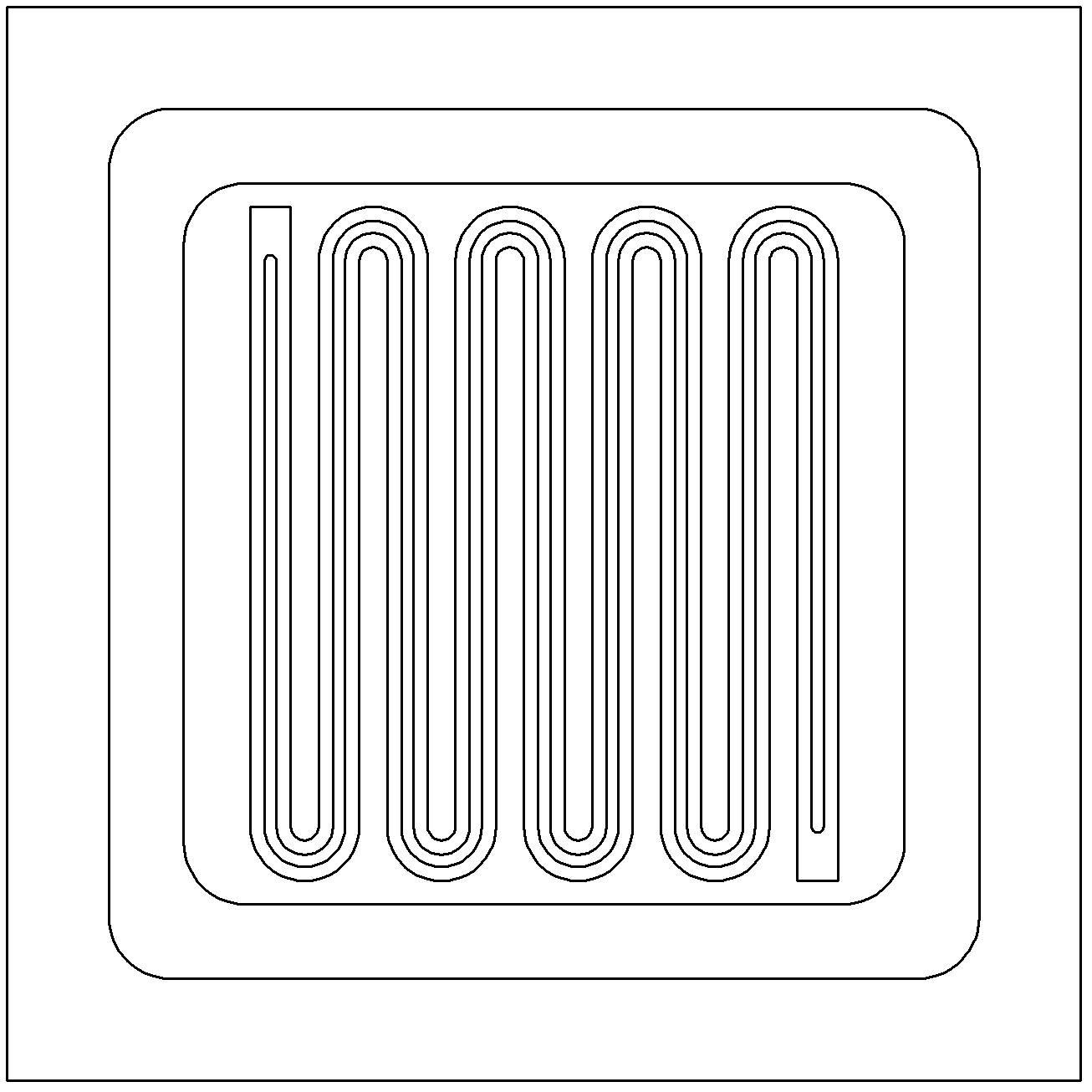

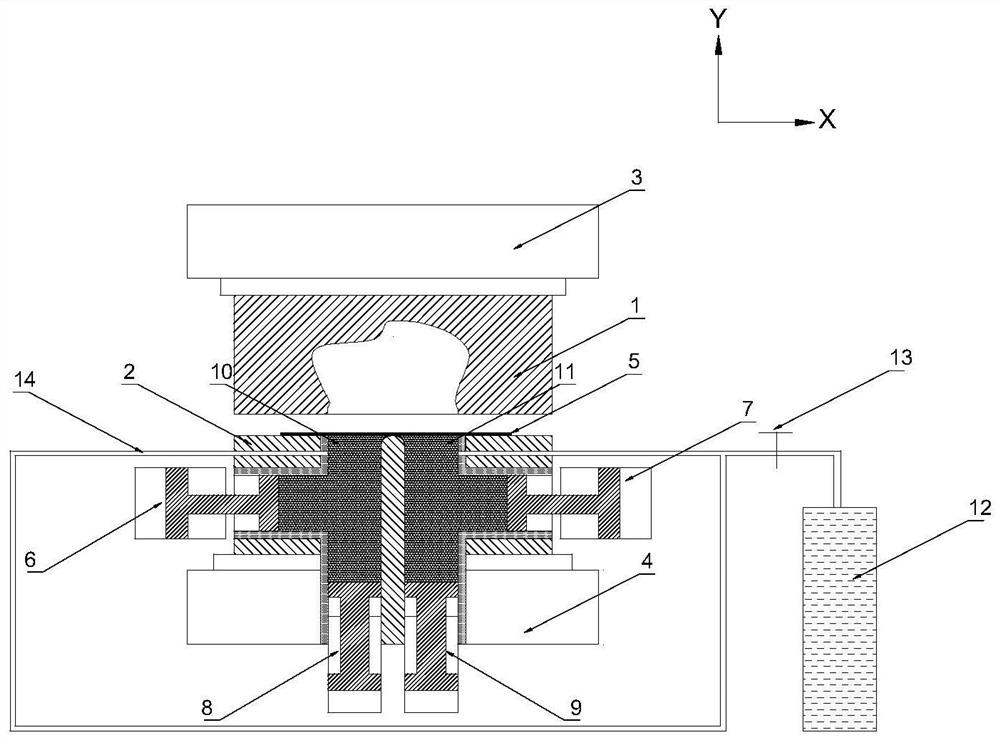

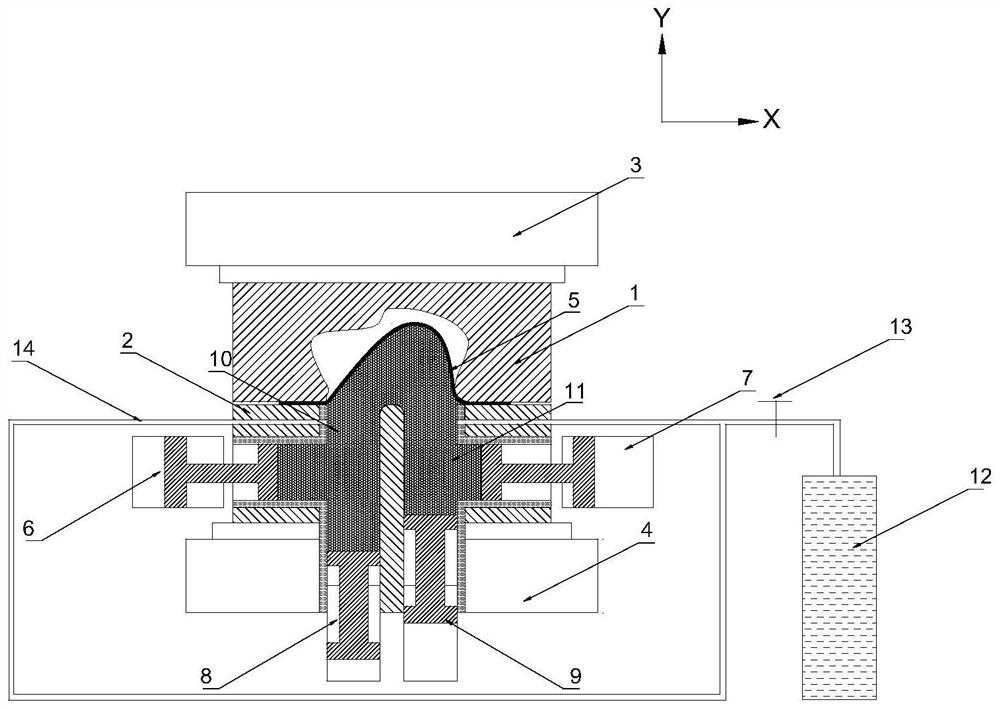

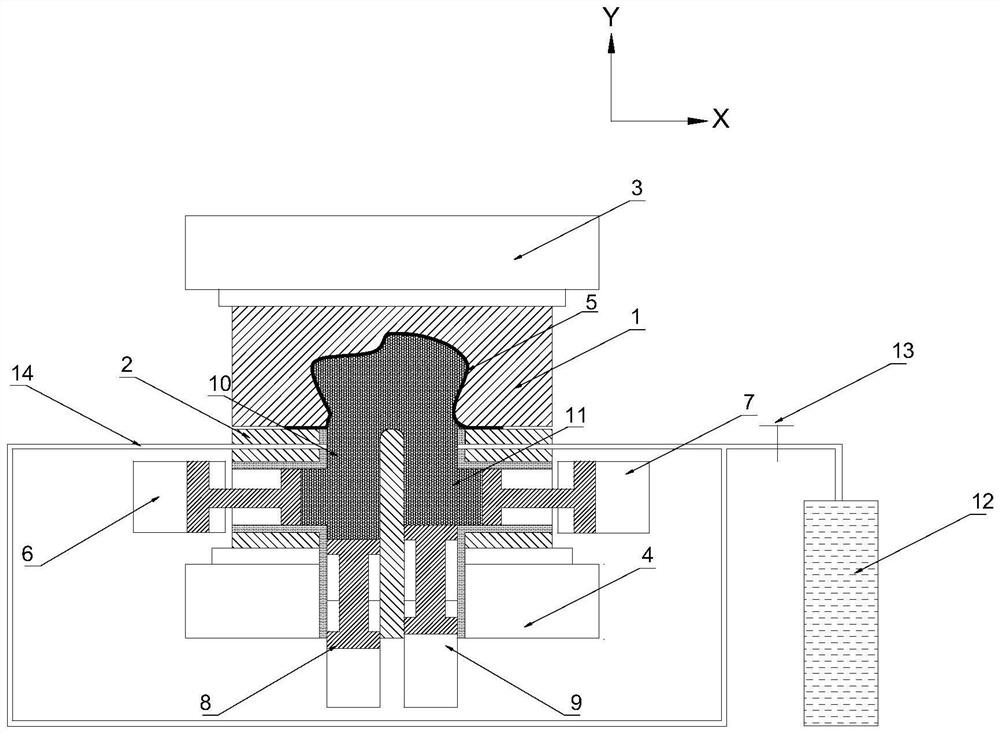

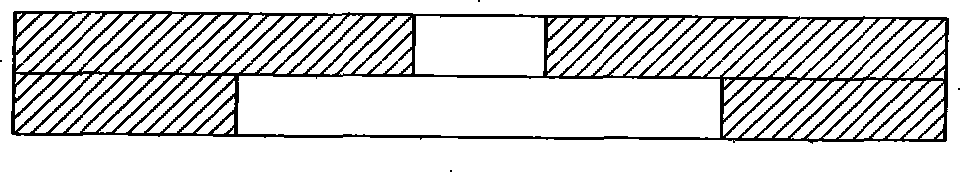

Electromagnetic force driven soft mold forming device and method for metal bipolar plate of fuel cell

The invention relates to a method for forming a fuel cell metal bipolar plate. The invention aims at the problems of a conventional plastic deformation means (such as a punching forming means) for forming a metal sheet that a raised mould and a concave mould are difficult to match with each other and a driving sheet cannot be reused in a process of electromagnetically forming a metal bipolar plate. The device is characterized in that a forming mould, a flexible mould, a driving plate, a support frame and an upper fixing plate are stacked on a lower fixing plate from bottom to top, wherein a coil is arranged in a groove on a lower end face of the support frame; two adjacent circles of leads are separated by high-pressure isolating material; high-pressure high-strength isolating materials are filled between the groove and the coil and on the surface of the coil, thereby forming a flat coil; two ends of the coil are serially connected to a capacitor bank; and the upper fixing plate and the lower fixing plate are fixedly connected through a fastening bolt. The method comprises the following steps: placing a plate blank on the forming mould and fastening the upper fixing plate and the lower fixing plate; and performing discharging forming; and taking out a formed piece, thereby acquiring the metal bipolar plate. The device and the method provided by the invention are used for forming the fuel cell metal bipolar plate.

Owner:HARBIN INST OF TECH

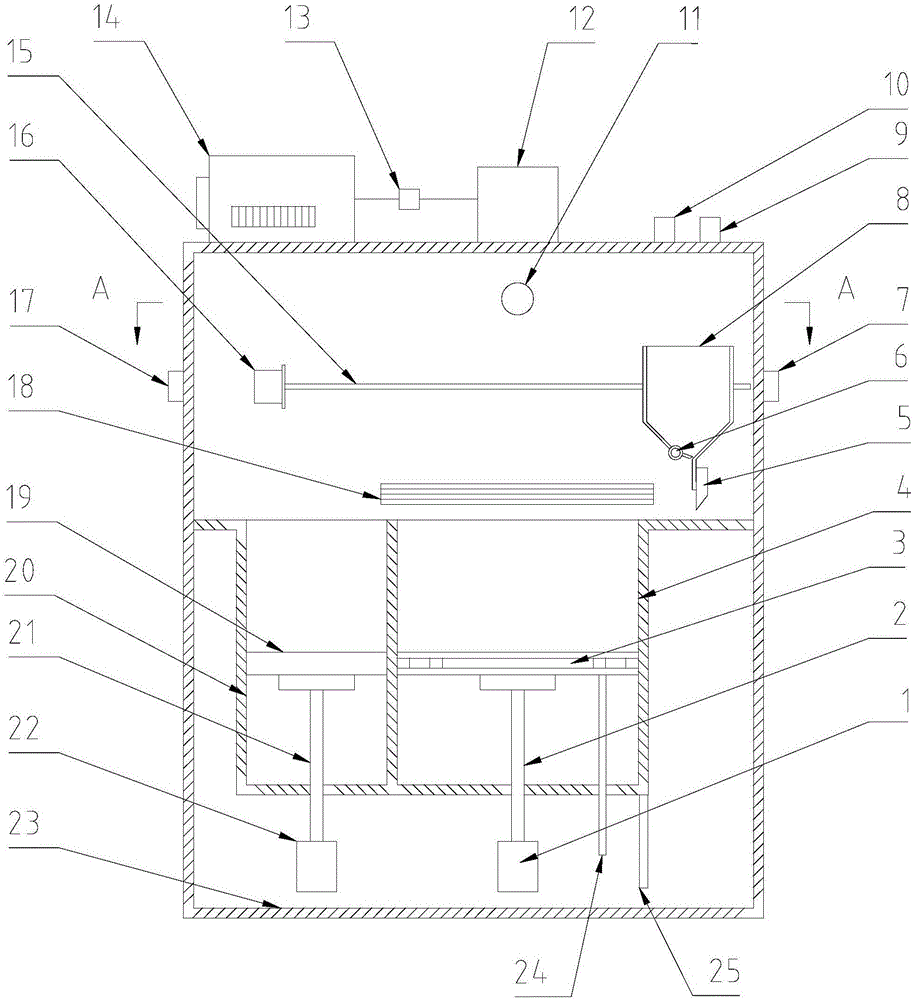

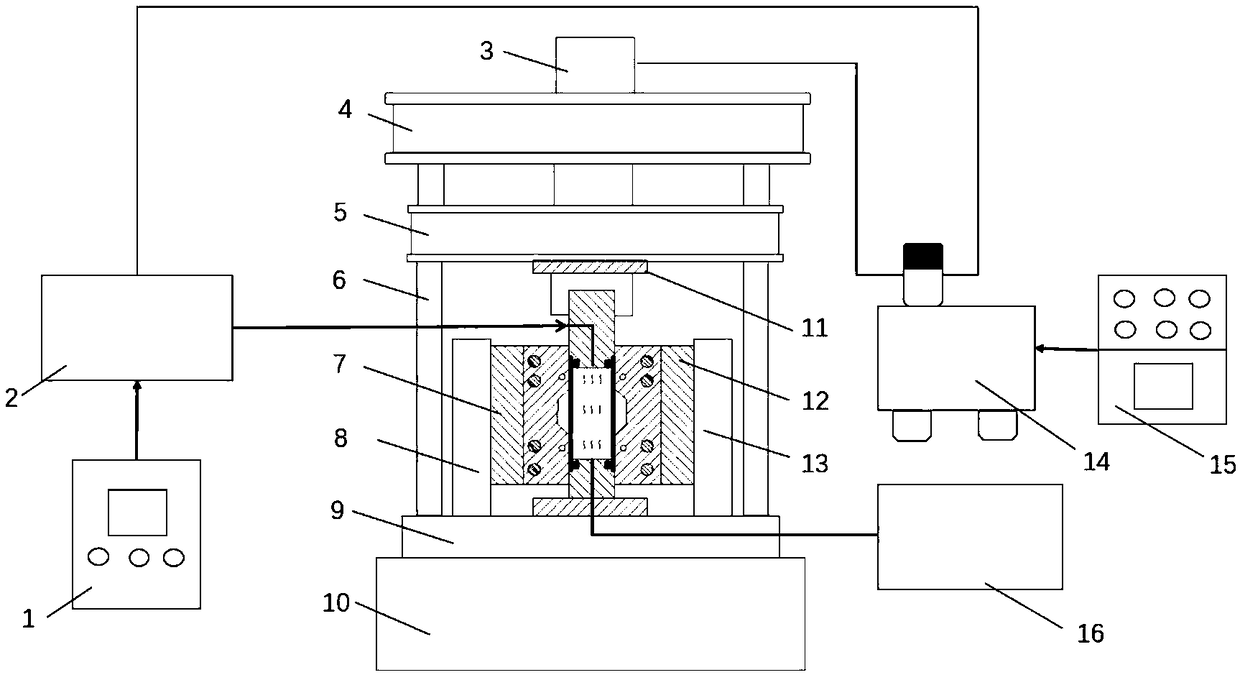

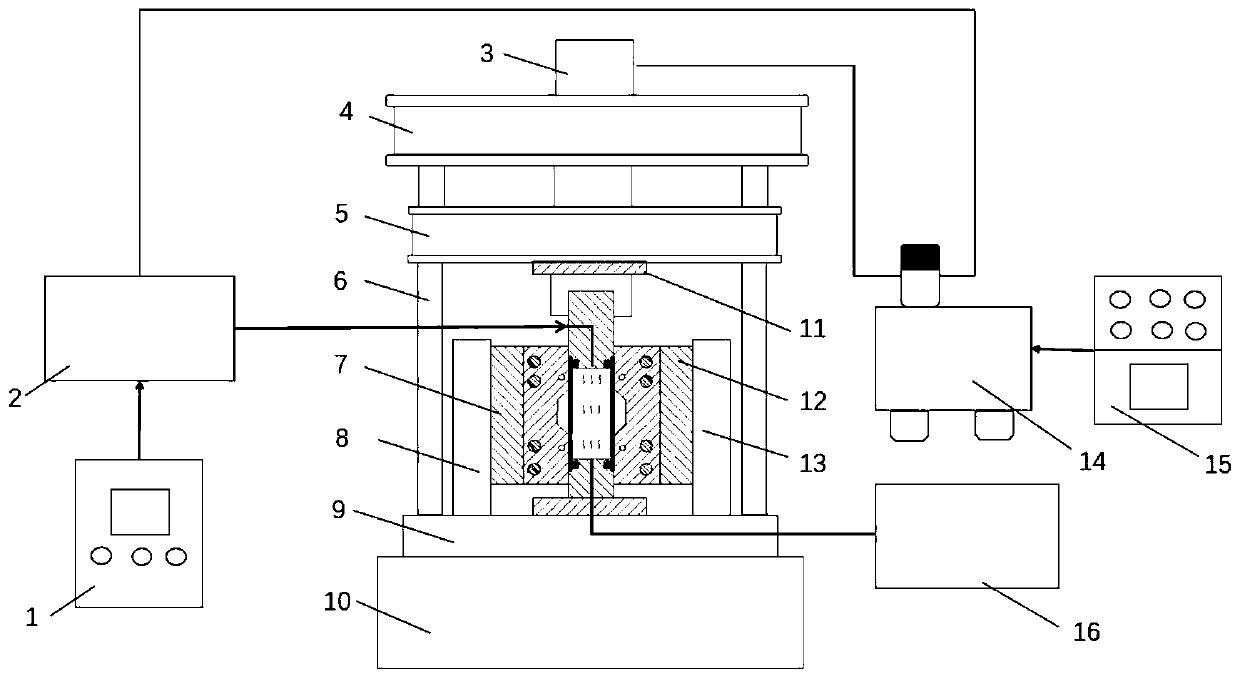

Special laser selecting area melting equipment for directly manufacturing metal orthopedics implant

ActiveCN105945282AImprove powder utilizationImprove cleanlinessAdditive manufacturing apparatusIncreasing energy efficiencyGratingOxygen

The invention discloses special laser selecting area melting equipment for directly manufacturing a metal orthopedics implant. The equipment is characterized by comprising a forming system, a powder recovery system, a powder paving system, a laser transmission system, a dust filter and water / oxygen purification double-circulation system, and a sealing cavity; the forming system, the powder recovery system and the powder paving system are all positioned in the sealing cavity; the laser transmission system is positioned at the upper part of the sealing cavity; the dust filter and water / oxygen purification double-circulation system is positioned out of the sealing cavity; the forming system includes a forming cylinder, a forming cylinder piston, a ball screw, a servo motor and a grating ruler; a heating copper plate, a water cooling system and a temperature sensor are arranged in the forming cylinder piston; the powder paving system paves powder by an upper powder paving mode; and the forming process is performed under argon protection, and is provided with the dust filter and water / oxygen purification double-circulation system. The equipment is high in atmosphere cleanness of the forming cavity and high in forming part size precision, can form such bionic structures as porous structures and biological channels, and is suitable for quick and personalized customization of artificial hip joints.

Owner:THYTEC SHANGHAI

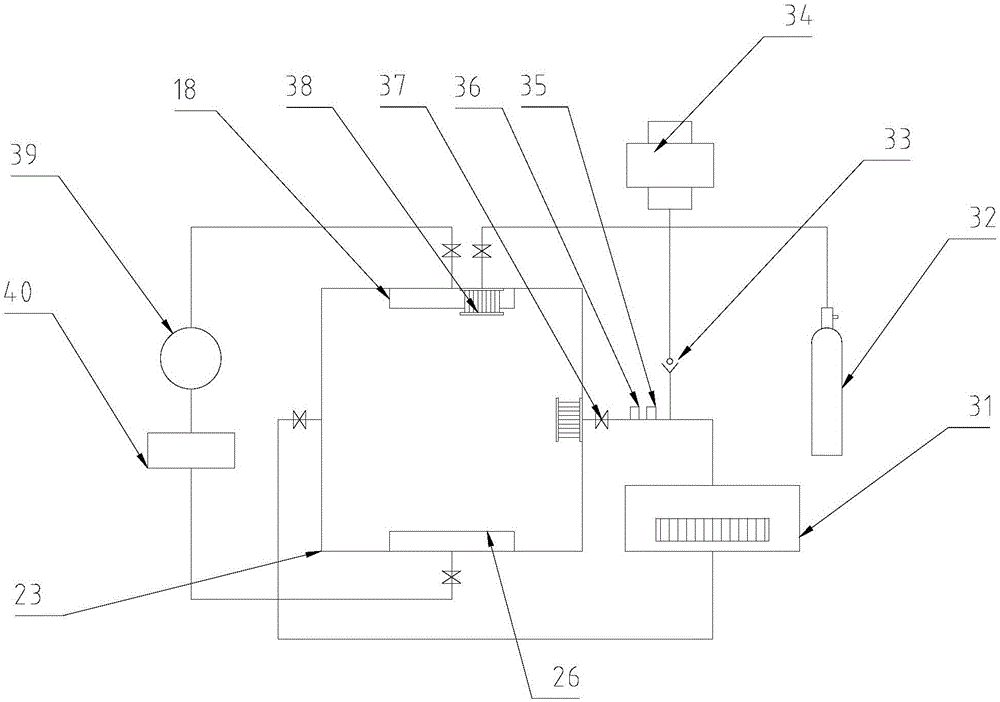

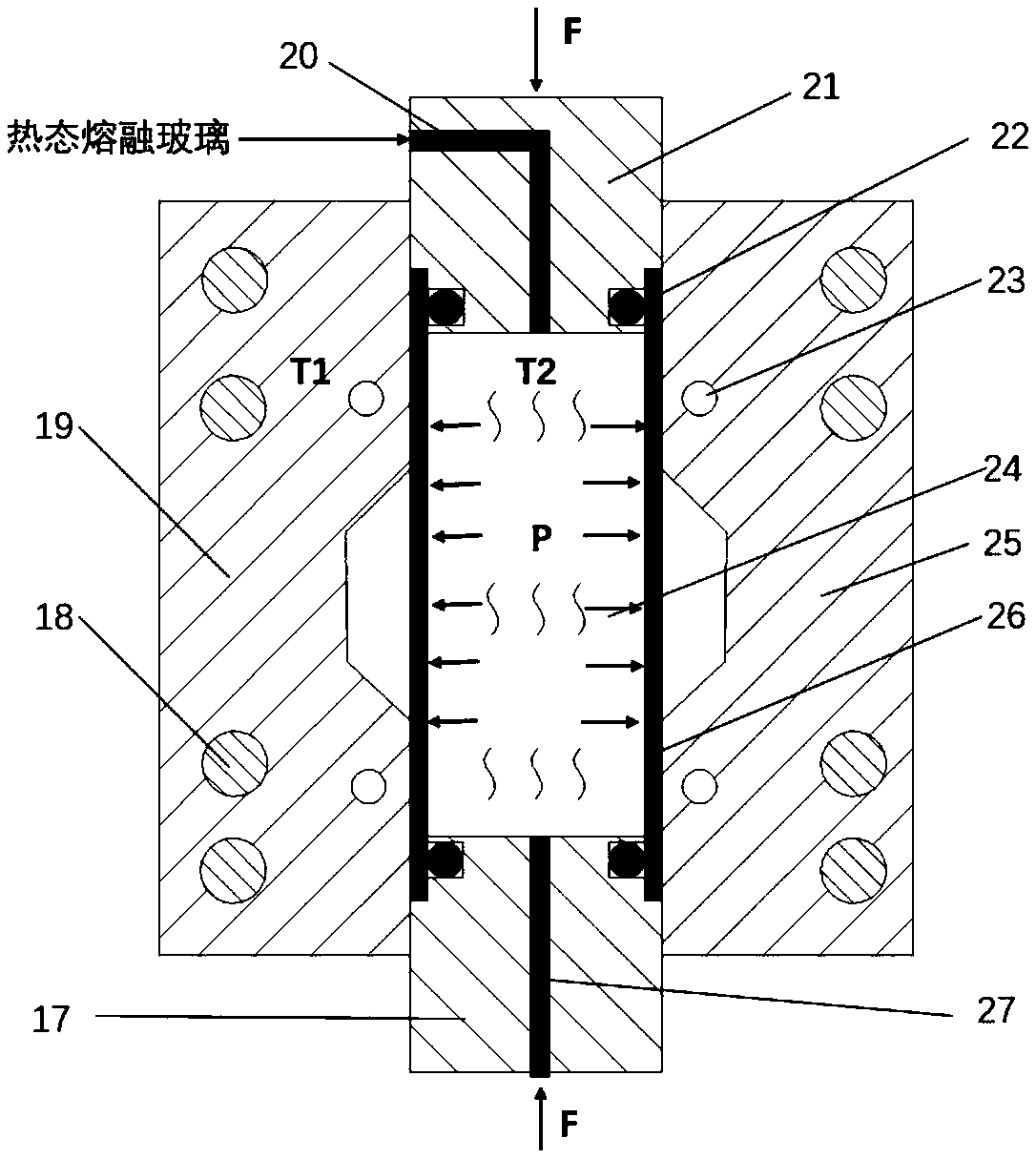

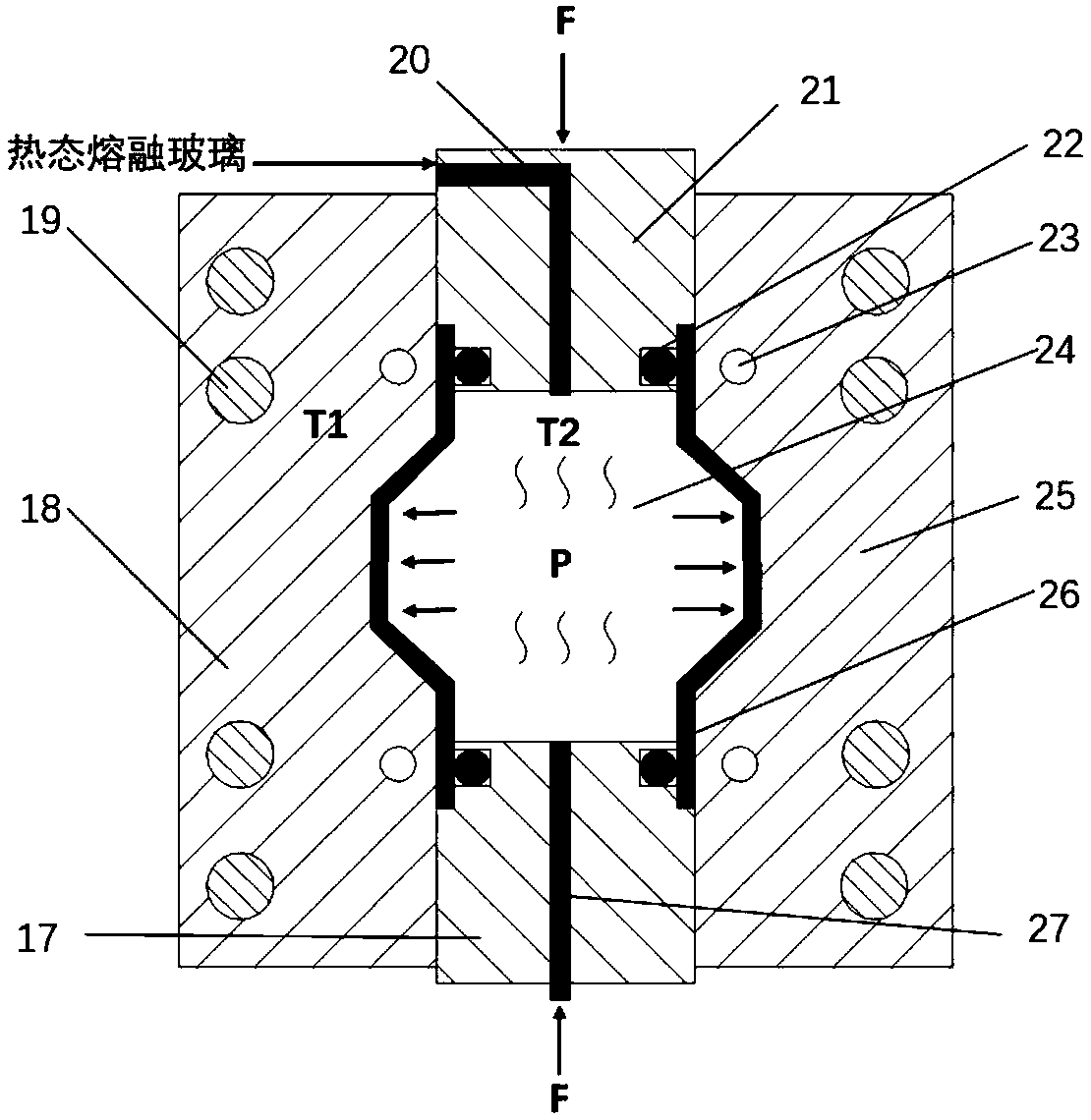

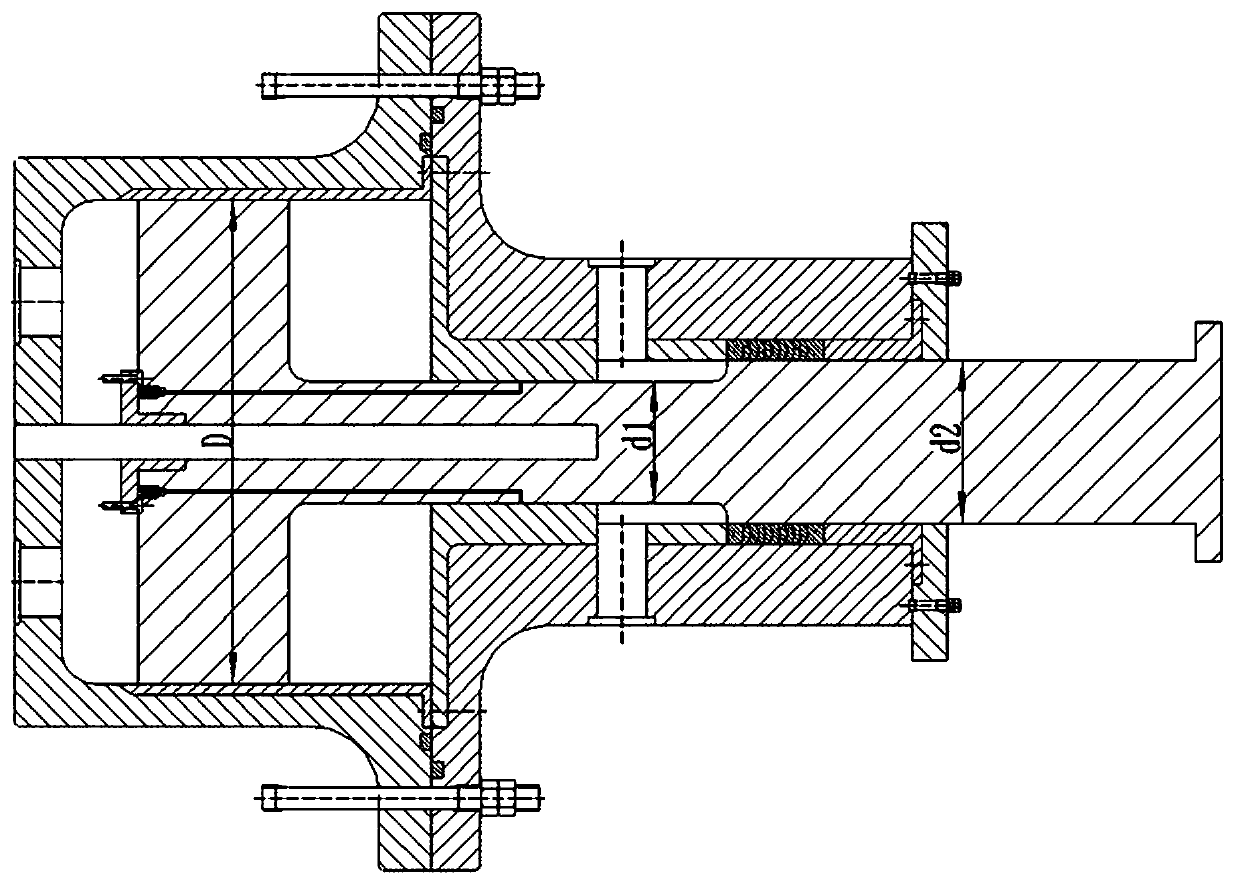

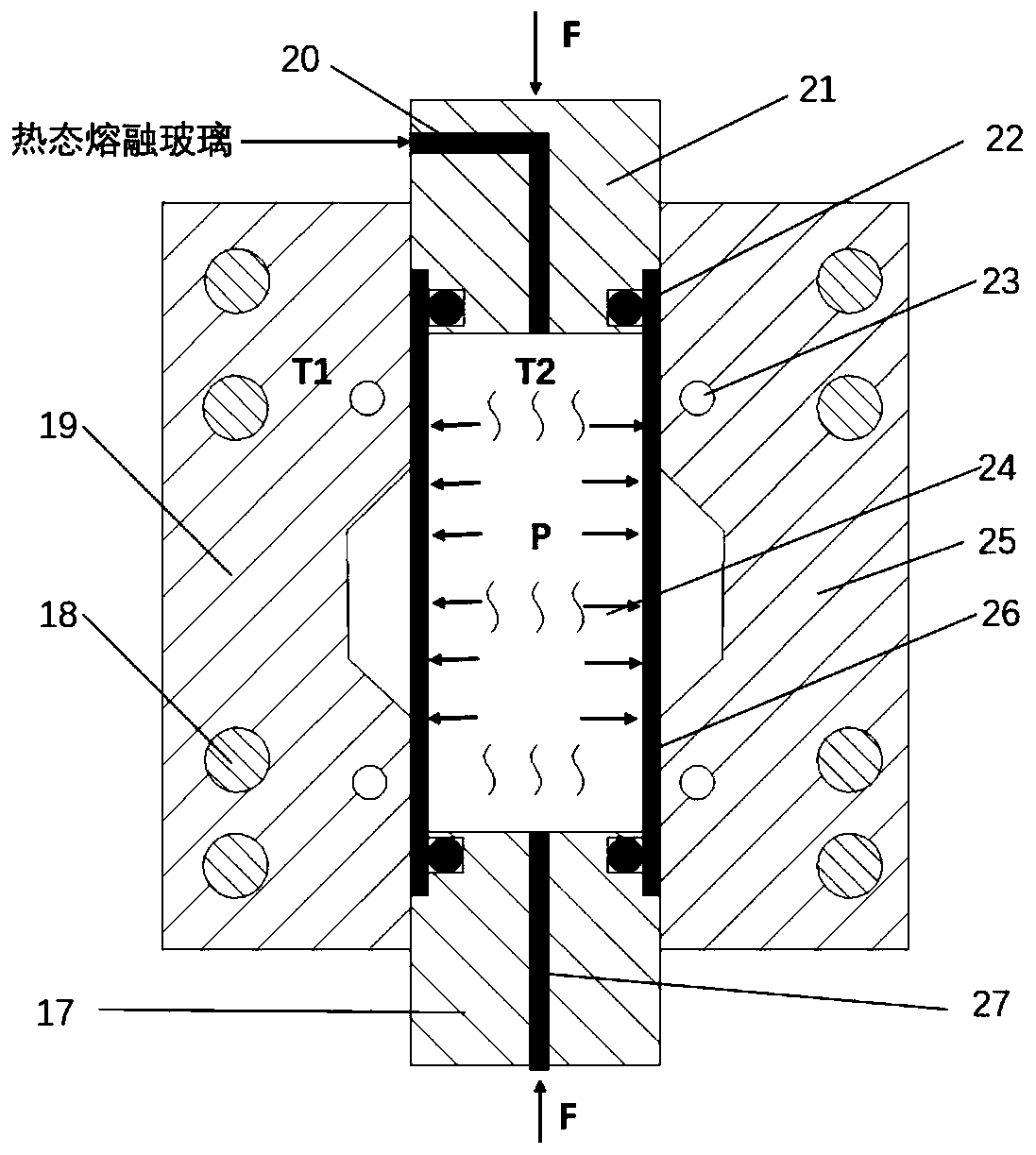

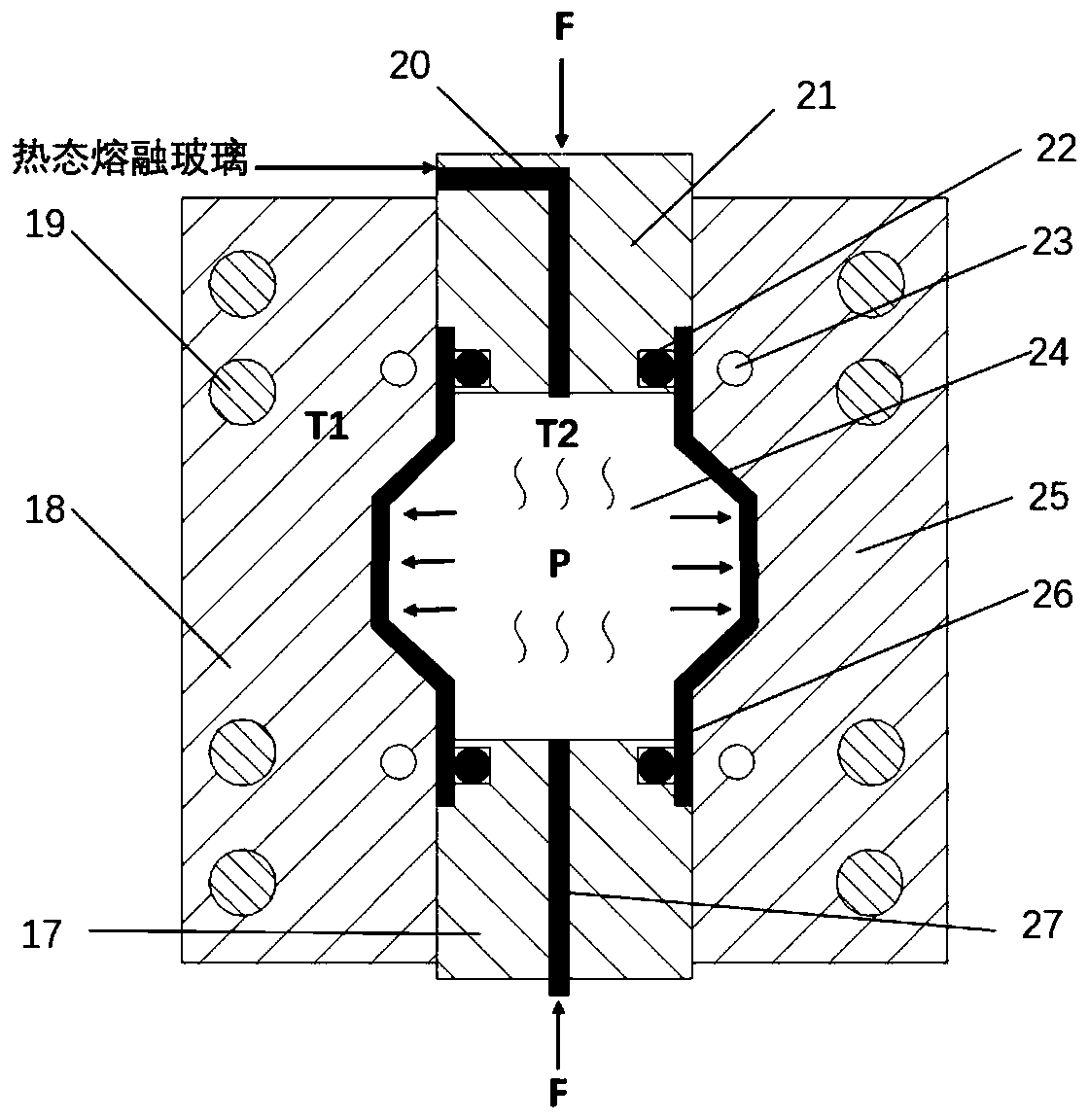

Pipe hot medium internal pressure forming method based on molten glass

ActiveCN108856441AMeet the forming temperature process requirementsReduce compressionInternal pressureHeat conducting

The invention discloses a pipe hot medium internal pressure forming method based on molten glass, and relates to a metal pipe forming method. The problems that according to existing hot medium internal high pressure forming methods, the heating speed is low, heat conducting coefficients are low, sealing is difficult, and forming pressure only can reach about 0-50MPa are solved. The method comprises the steps that 1, a pipe internal high pressure forming temperature interval is determined according to the pipe variety; 2, according to the pipe internal high pressure forming temperature, glass materials are selected; 3, a pipe to be formed is preheated; 4, a pipe blank is vertically placed into a forming die, and die closing and sealing are carried out; 5, the glass materials are heated to obtain molten glass; 6, the glass media are injected into the sealed pipe blank; 7, the pipe blank is heated to internal high pressure forming temperature under high-temperature filling; and 8, material supplementing is carried out; and 9, pressure maintaining is carried out, the molten glass flows out through an overflow valve, die opening is carried out, and the formed deformed-section pipe partis obtained. The pipe hot medium internal pressure forming method is used in the field of internal high pressure forming.

Owner:HARBIN INST OF TECH

Integrated mixed driving type double-cylinder serial pressurizing oil press

ActiveCN107457340AFulfillment requirementsRealize boost functionForging press detailsForging press drivesMotor driveControl system

The invention discloses an integrated mixed driving type double-cylinder serial pressurizing oil press and belongs to the field of forging and pressing equipment. A driving mode of a three-phase asynchronous motor is replaced by a servo motor driving mode and a transmission mode of a nut pair of a ballscrew of an electric spiral press is applied to a conventional oil pressure. First, higher stroke and return speed demand is achieved by the conventional oil pressure, so that the fast forging frequency of the conventional oil pressure is improved; second, the response speed, precision and flexibility of the press process of a control system are improved by means of the servo driving technology, the process range of the control system is expanded, the energy is saved and the emission is reduced, and the structure of the conventional hydraulic system is simplified; then, a one-way plunger type cylinder structure of the conventional oil press is replaced by the double-cylinder serial pressurizing one-way plunger type cylinder, so that the pressurizing function can be achieved and the forging efficiency is increased; and finally, an alternating servo motor drives the nut pair of the lead screw to move, so that the return cylinder and return structure of the conventional press are cancelled, and therefore, the press is simple in structure and small in load of a movable cross beam.

Owner:兰州兰石重工有限公司

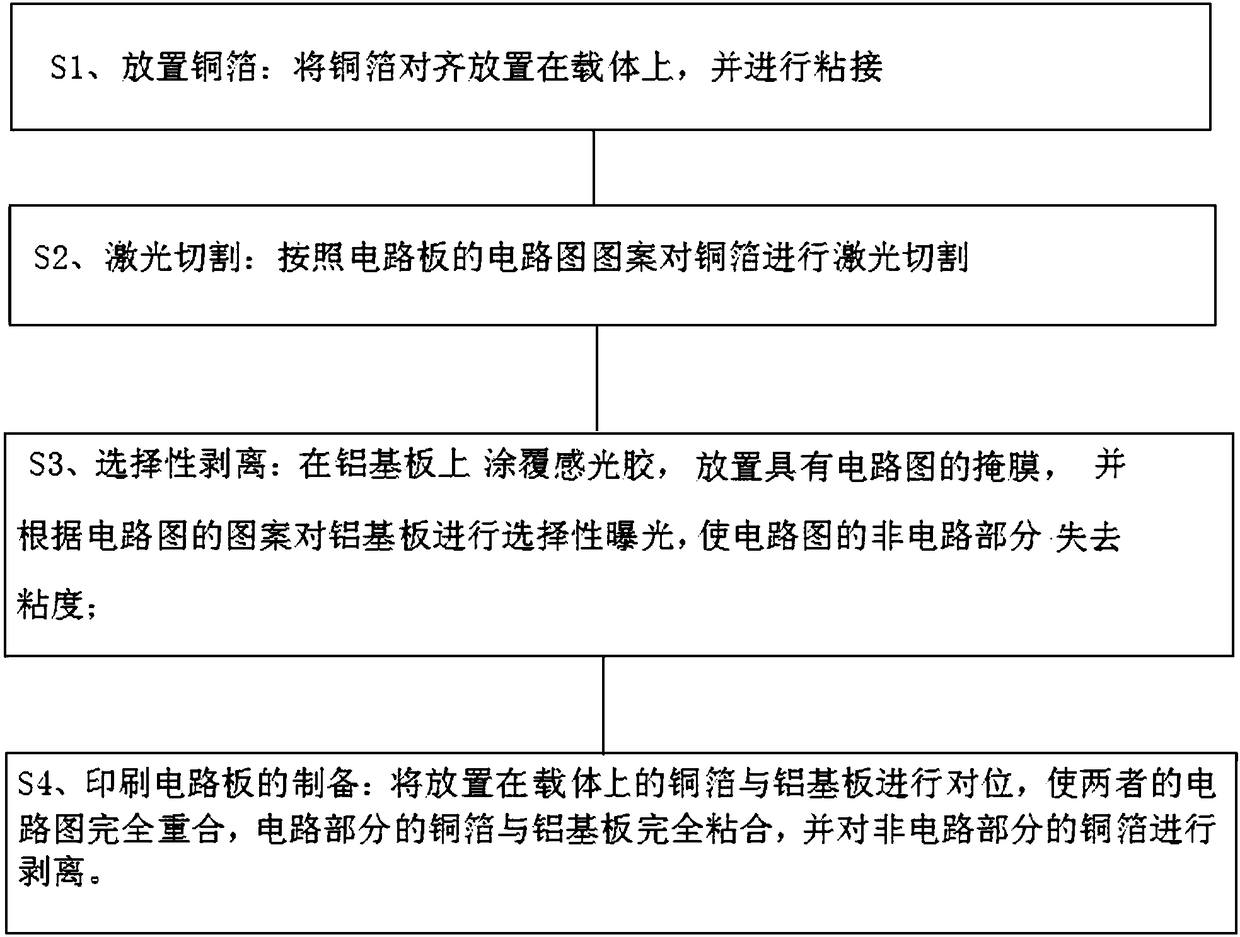

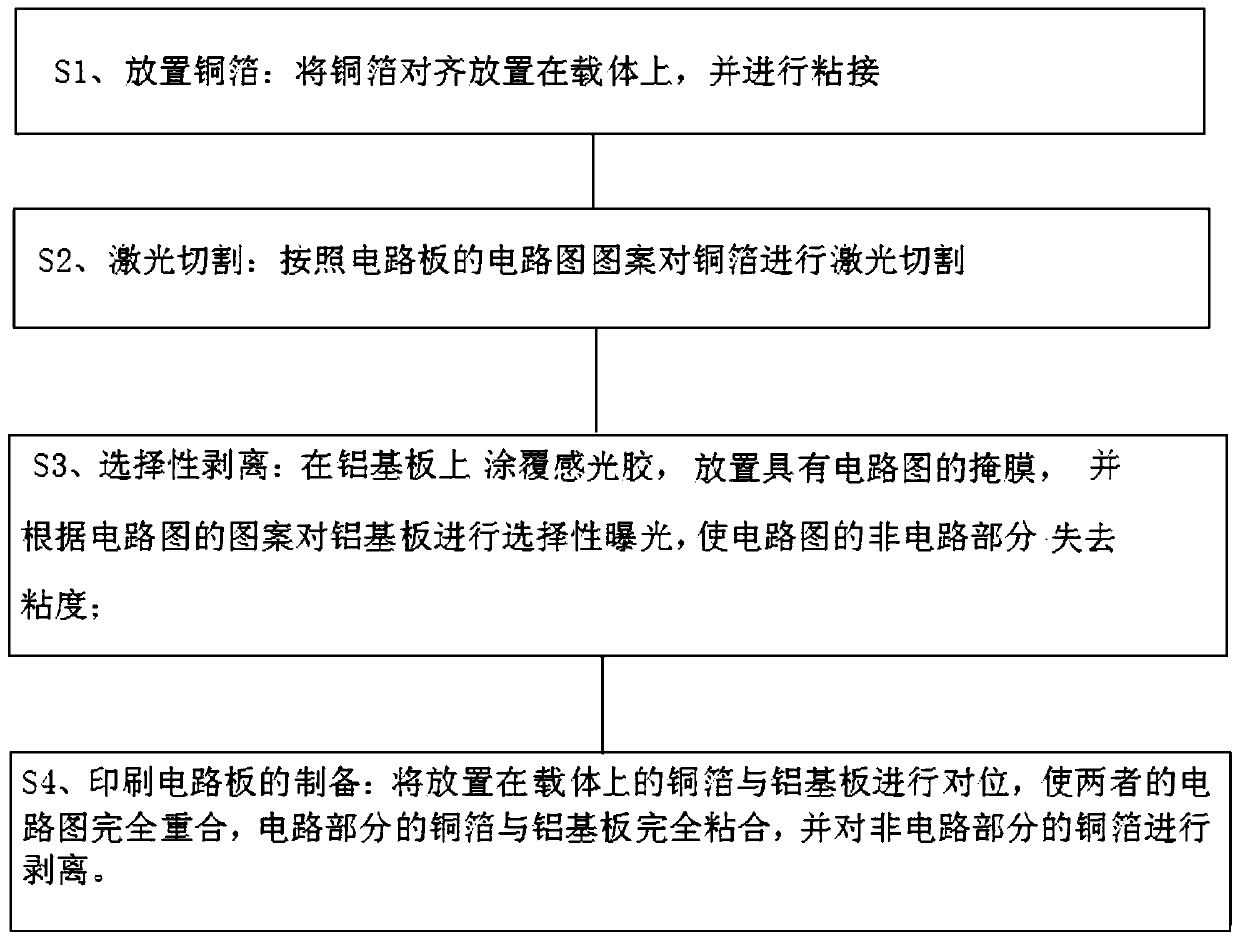

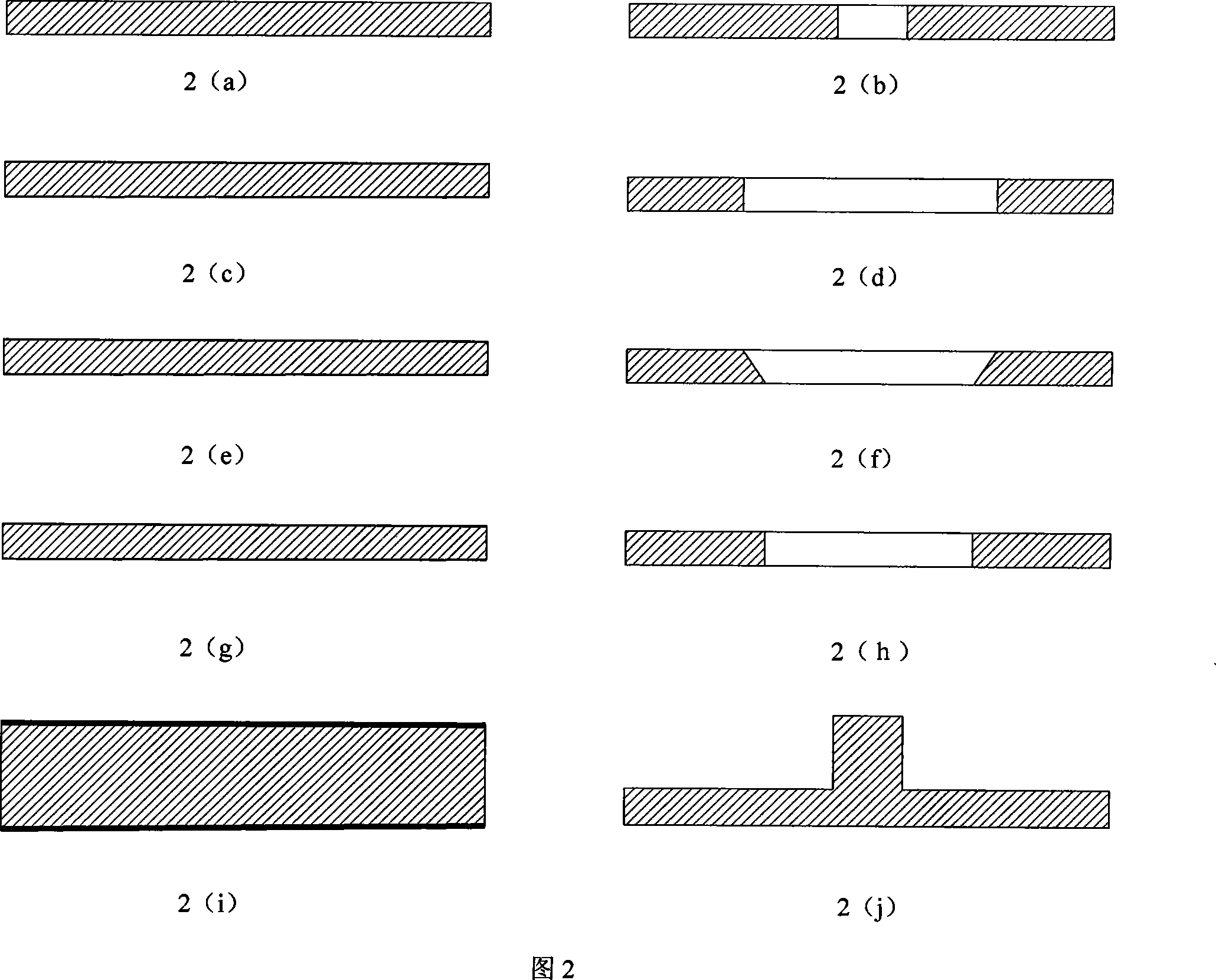

Preparation method of printed circuit board and copper foil for processing

ActiveCN108323025AImprove protectionAvoid infringementPrinted circuit manufacturePhotosensitive materials for photomechanical apparatusEtchingLaser cutting

The invention provides a preparation method of a printed circuit board. The method includes the following steps of: S1, copper foil arrangement: copper foil is arranged on a carrier in a manner that the copper foil is aligned with the carrier, and the copper foil and the carrier are composited; S2, laser cutting: laser cutting is performed on the pattern of the circuit diagram of a circuit board;S3, selective peeling: an aluminum substrate is coated with photoresist, and a mask with a circuit diagram is arranged on the aluminum substrate, and the aluminum substrate is selectively exposed according to the pattern of the circuit diagram, so that the non-circuit portion of the circuit diagram loses viscosity; and S4, printed circuit board preparation: the copper foil arranged on the carrieris aligned with the aluminum substrate, so that the circuit diagrams of the copper foil and the aluminum substrate are completely overlapped with each other, and the copper foil of a circuit portion is completely bonded to the aluminum substrate, and the copper foil of a non-circuit portion is peeled off. According to the preparation method of the invention, the circuit board is inscribed by a laser cutting method, so that chemical etching can be avoided in a production process; and waste copper can be directly recycled, and therefore, a great environmental protection value can be realized with cost reduced. With the method adopted, a new idea is provided for the production of copper foil for circuit board.

Owner:北京启创驿讯科技有限公司

Laser machining method and device applicable for complicated curved surface

ActiveCN102151984BReduce the overall heightImprove energy consumptionLaser beam welding apparatusLaser etchingLaser processing

The invention provides a laser machining method applicable for a complicated curved surface. By adopting processing steps of dividing the complicated curved surface into curved surface sheets and establishing a coordinate system of each curved surface sheet, the subsequent processing steps of dividing sub blocks and machining pattern parallel projection can be implemented according to the coordinates of the curved surface sheets respectively, so the limit that a machining molded surface backing to a laser incident direction or a steep surface parallel to an optical axis direction cannot be machined because only one coordinate system is adopted to perform whole injection in the prior art can be overcome, the machining efficiency is improved and the machining applicable range is extended. The invention also provides a laser machining device. The laser machining device has a three-axis laser machining head structure provided with a two-axis laser polarization mirror and a Z-axis mobile mechanism, so the problem that the conventional system depends on a three-axis lathe is solved; therefore, a machining unit is independent and compact, and is easy to assemble and disassemble; the conventional five-axis linkage milling machine can be changed into a laser-etching machining lathe so that the functions are compatible; and the laser machining device has a significant practical value.

Owner:武汉飞能达激光技术有限公司

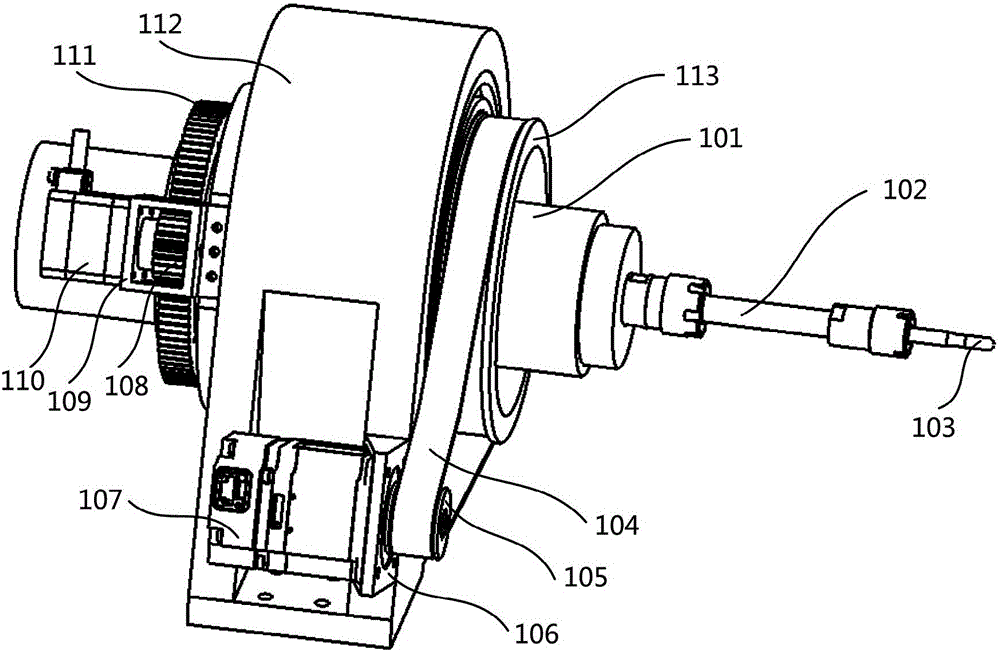

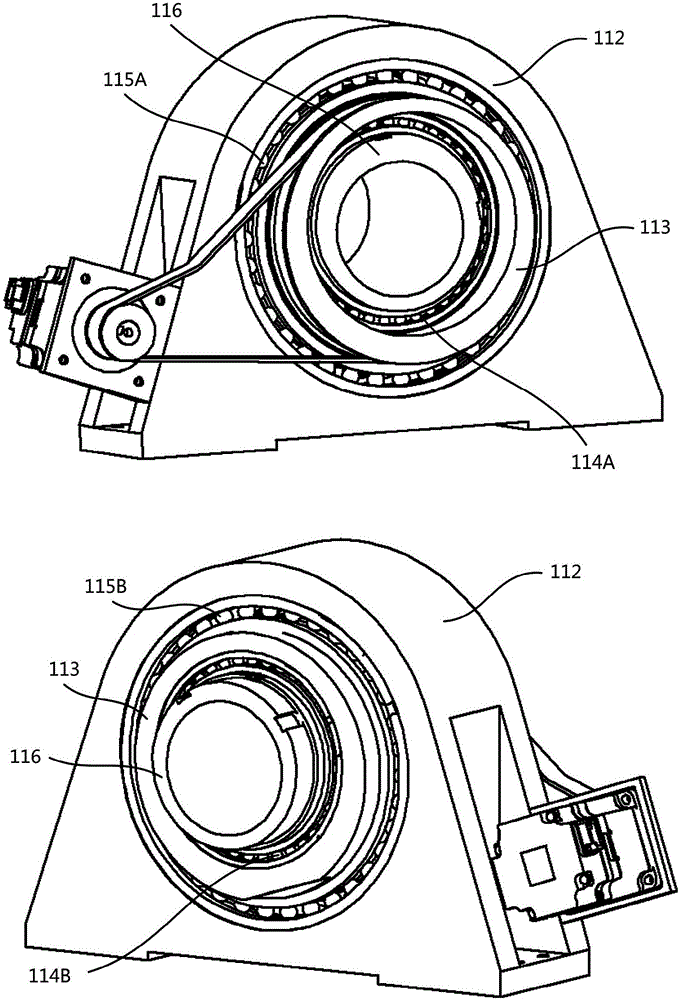

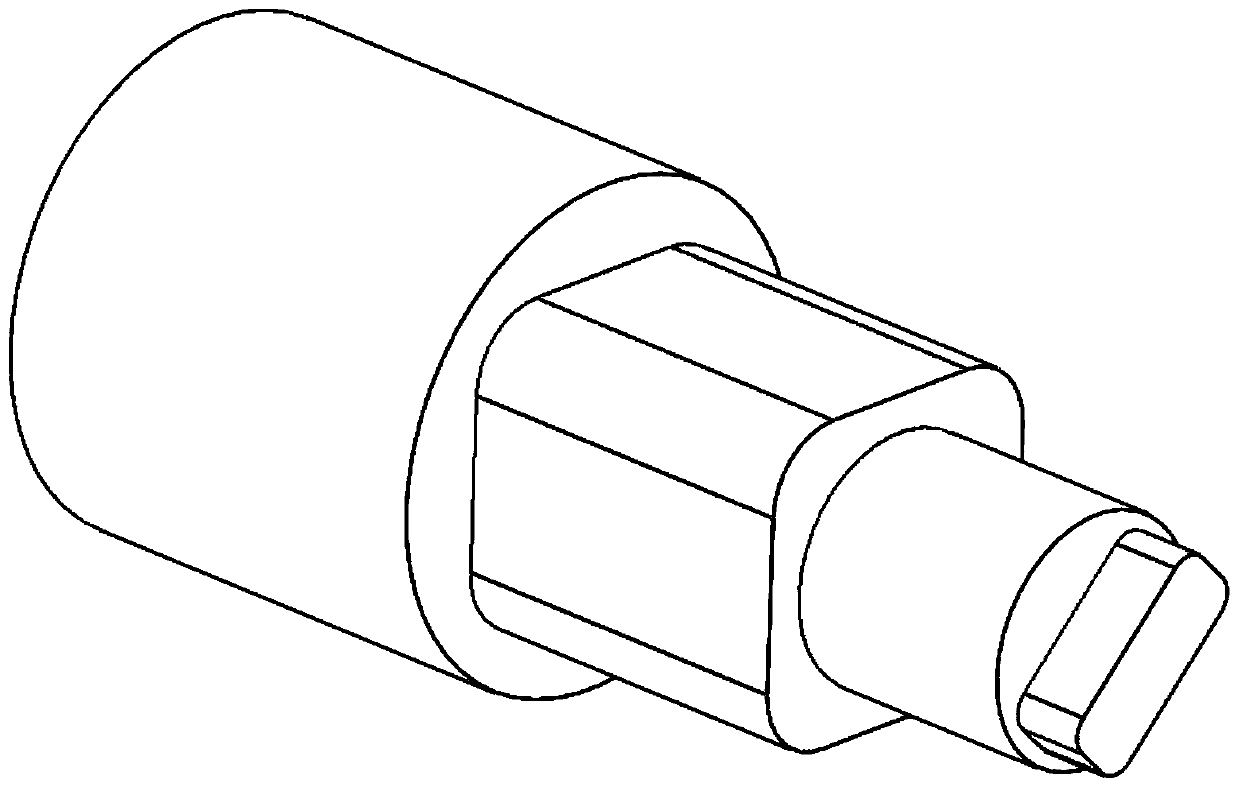

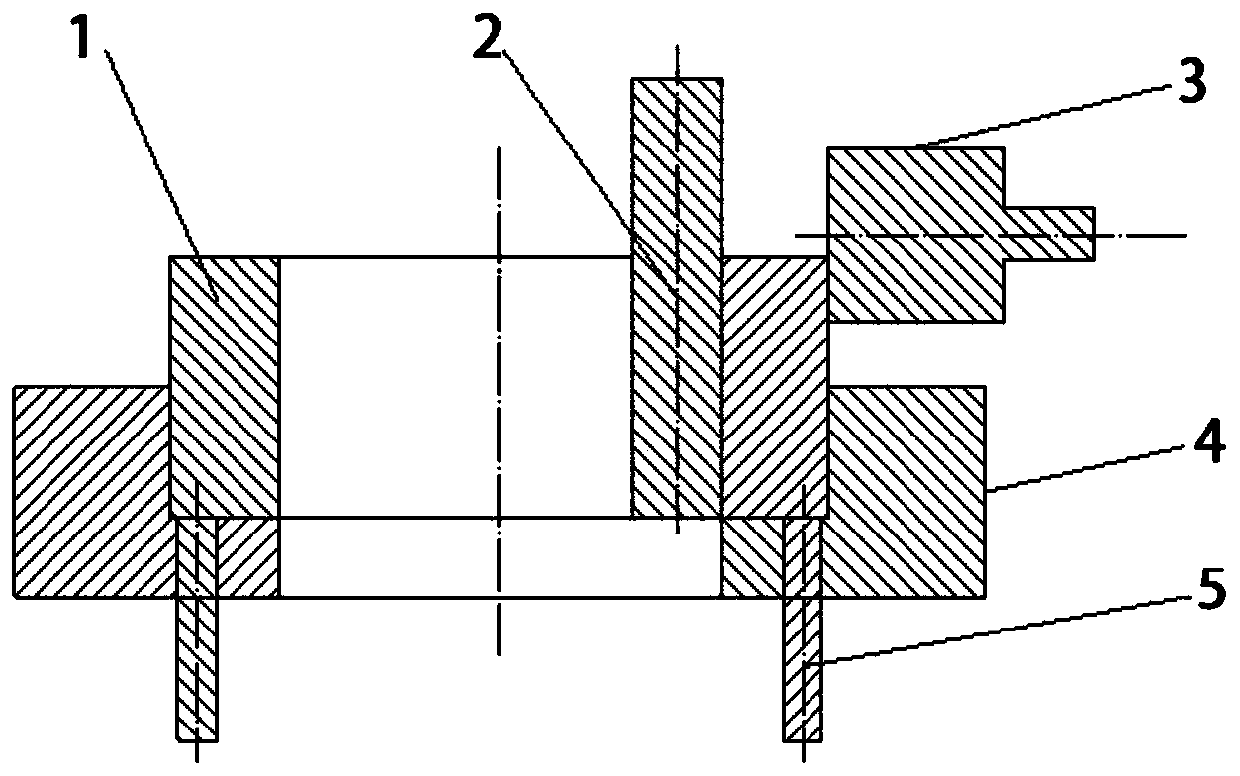

Dual-core concurrent universal swing mechanism

ActiveCN102848110AHigh process flexibilityAvoid Winding ProblemsWelding/cutting auxillary devicesShearing machinesDual coreEngineering

The invention provides a dual-core concurrent universal swing mechanism which comprises a first drive unit, a second drive unit, a rotating arm, a clamping device and a medium channel, wherein the output end of the first drive unit is connected with the rotating arm; the clamping device is mounted on the rotating arm and is linked with the rotating arm; the output end of the second drive unit is connected with the clamping device; the clamping device is used for clamping a cutting head; and the medium channel is used for feeding a working medium into the cutting head. According to the invention, corner and arc errors and cutting conicity errors caused by different fluid states of a high energy beam at an entrance point and an exit point can be eliminated. Meanwhile, the medium channel composed of at least four rotating joints forms a rigidly connected four-link mechanism, and the four-link mechanism can be matched with the random swing of the cutting head to realize the transmission of the high energy beam medium. Due to the absence of a vertical rotating axis or an approximately vertical rotating axis, in the process of continuous circumferential conical cutting, the cutting head can not rotate around the self axis, thereby avoiding the problem that a pipeline connected with the cutting head is wound around a cable.

Owner:柔锋机械科技(江苏)有限公司

Intelligent plastic forming process method and intelligent plastic forming equipment used for same

ActiveCN105478641AStrong flexibilityImprove forging precisionForging press detailsManipulatorAutomatic programming

The invention discloses an intelligent plastic forming process method and intelligent plastic forming equipment used for the same. The process method sequentially comprises the steps that three-dimensional modeling and plastic deformation digital simulation are conducted, an automatic programming system with a machine learning function is adopted for completing analysis and programming of the forming step of a forge piece, a steel ingot is heated, closed-die upsetting is conducted on the steel ingot, and plastic forging forming is conducted by squeezing a blank on an intelligent plastic forming hydraulic machine through rolling tools. According to the equipment, intelligent manipulators installed on the intelligent plastic forming hydraulic machine drive intelligent pressing heads to rotate around the axes in the horizontal direction or the vertical direction, and wedging angles larger than zero degree are formed by the squeezing surfaces of the rolling tools on the intelligent pressing heads and the surface of the forge piece; a supporting device can drive the forge piece to rotate and move; a sensing system can obtain data of the temperature of the forge piece, the pressure of the rolling tools on the forge piece and the forge piece metal flowing displacement and send the data to a control system; the control system controls actions of all components. According to the intelligent plastic forming process method and the intelligent plastic forming equipment used for the same, the forging precision is high, materials are saved, no special molds are needed, the forging flexibility is high, and the cost is low.

Owner:JIANGSU YONGNIAN LASER FORMING TECH

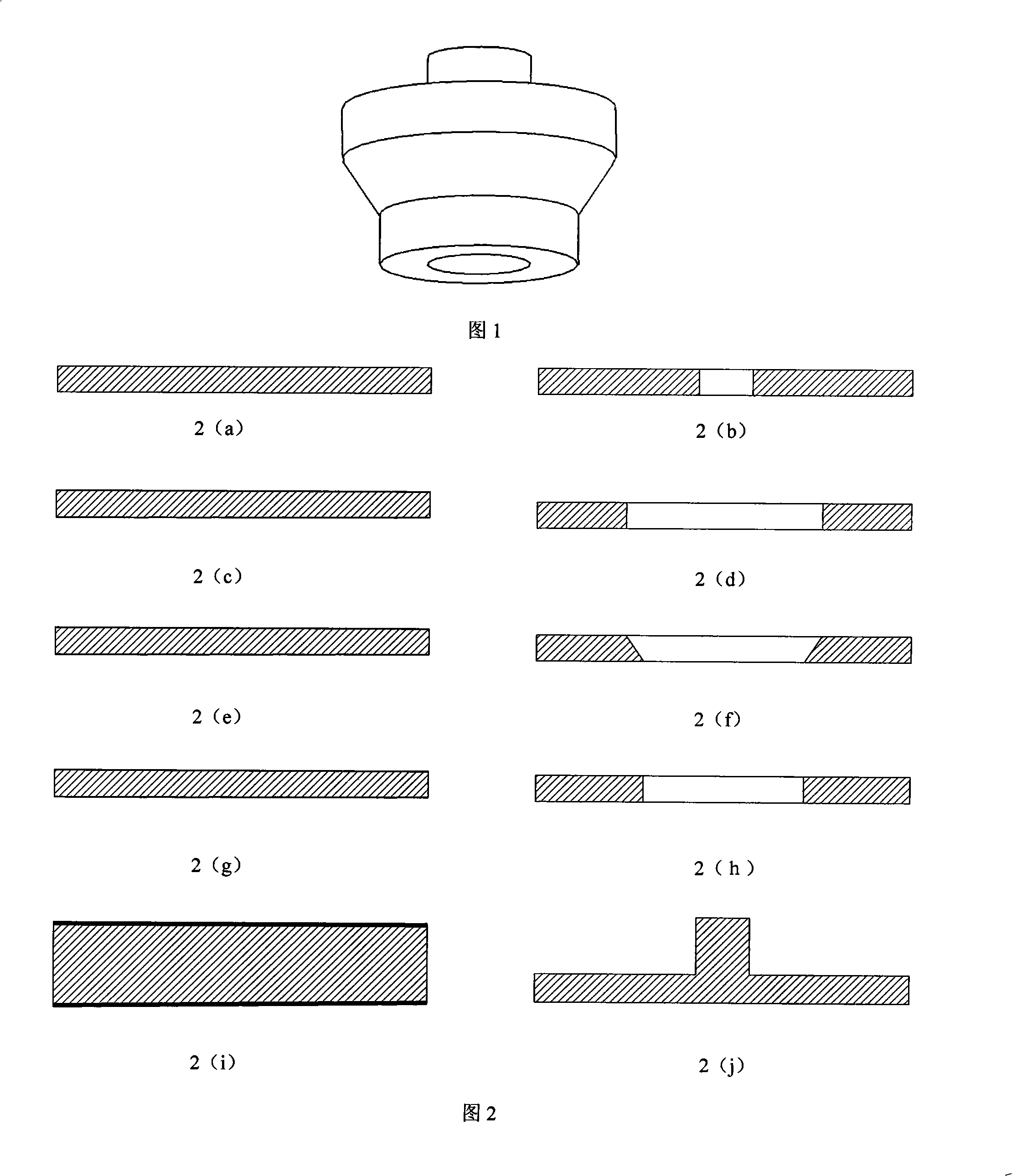

Process for manufacturing three-dimensional miniature mold

InactiveCN101293628AHigh precisionHigh process flexibilitySemi-permeable membranesPiezoelectric/electrostrictive/magnetostrictive devicesMicroelectromechanical systemsWidth ratio

The invention provides a method for manufacturing a three-dimensional minitype die; patterns corresponding to each layer structure of the parts to be manufactured are respectively etched on each silicon wafer; H2SO4 with the weight percentage of 98% and H2O2 with the weight percentage of 98% are mixed by the volume ratio of 2-4:1; the mixed solution is then used for cleaning all silicon wafers; the silicon wafers are then activated and dried; the silicon wafers are then rapidly aligned and bonded by layer; finally, the three-dimensional die cavity is gained by the annealing disposal. The method of the invention can manufacture the three-dimensional minitype die with micron meter dimension, has the advantages of high precision, low cost and large flexibility and is applicable to the processing and manufacture of micro electro-mechanical system device dies such as micro-gear shafts, micro-step shafts and high depth-width-ratio three-dimensional minitype structure, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

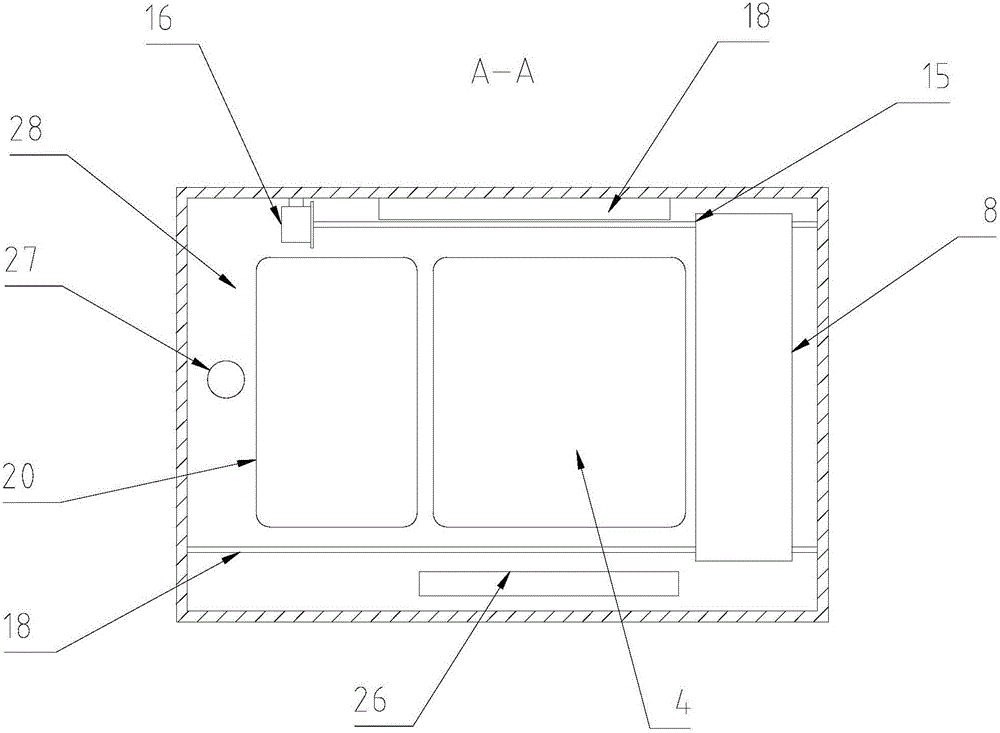

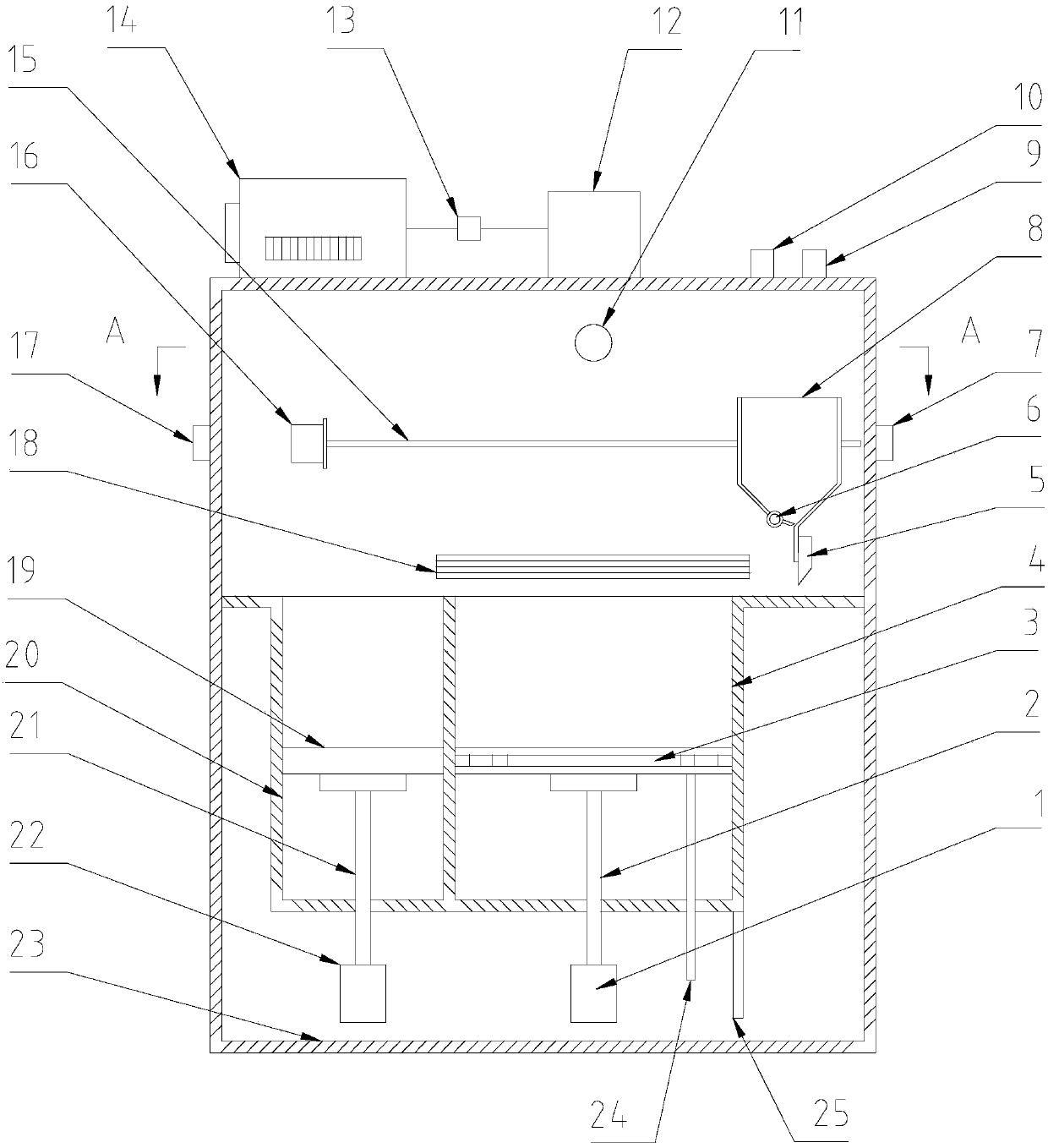

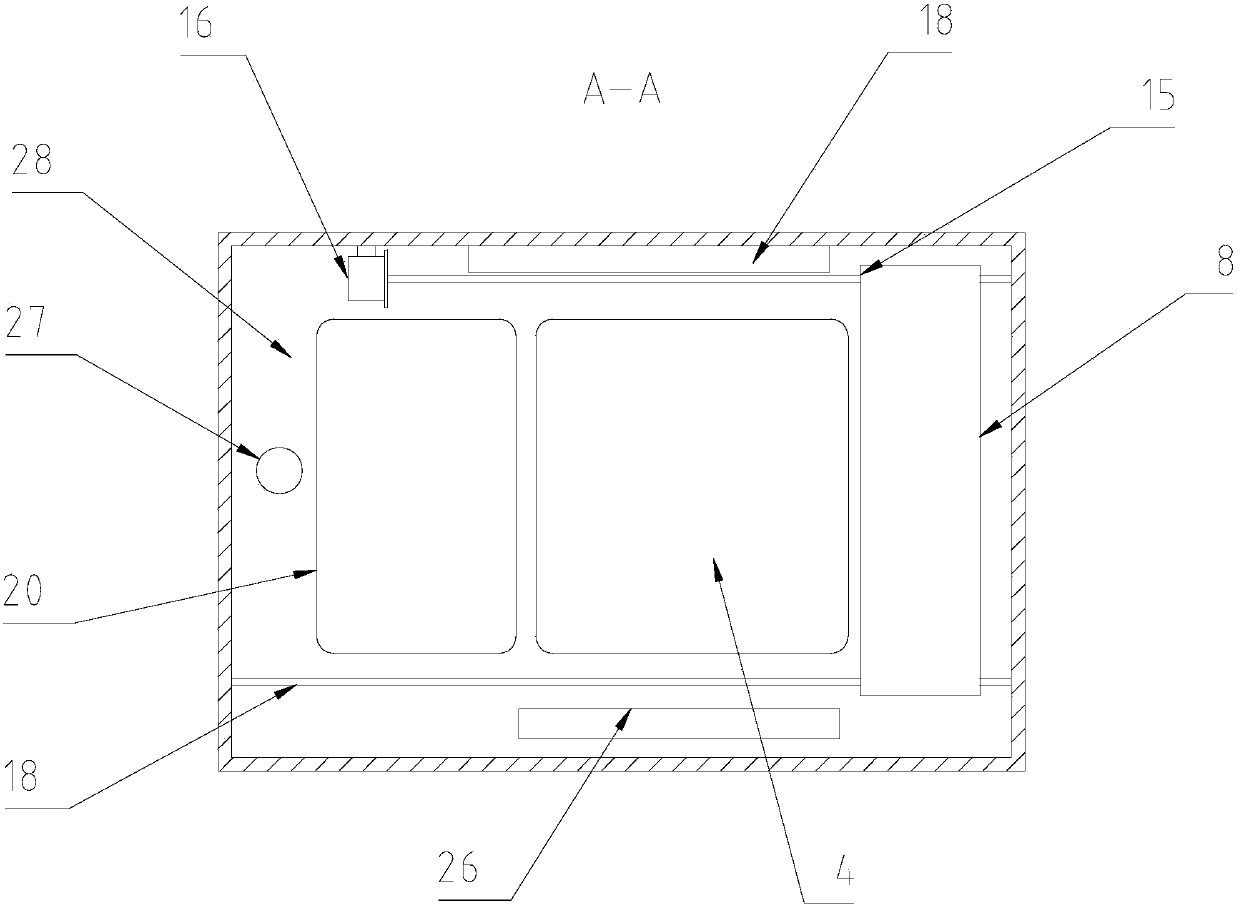

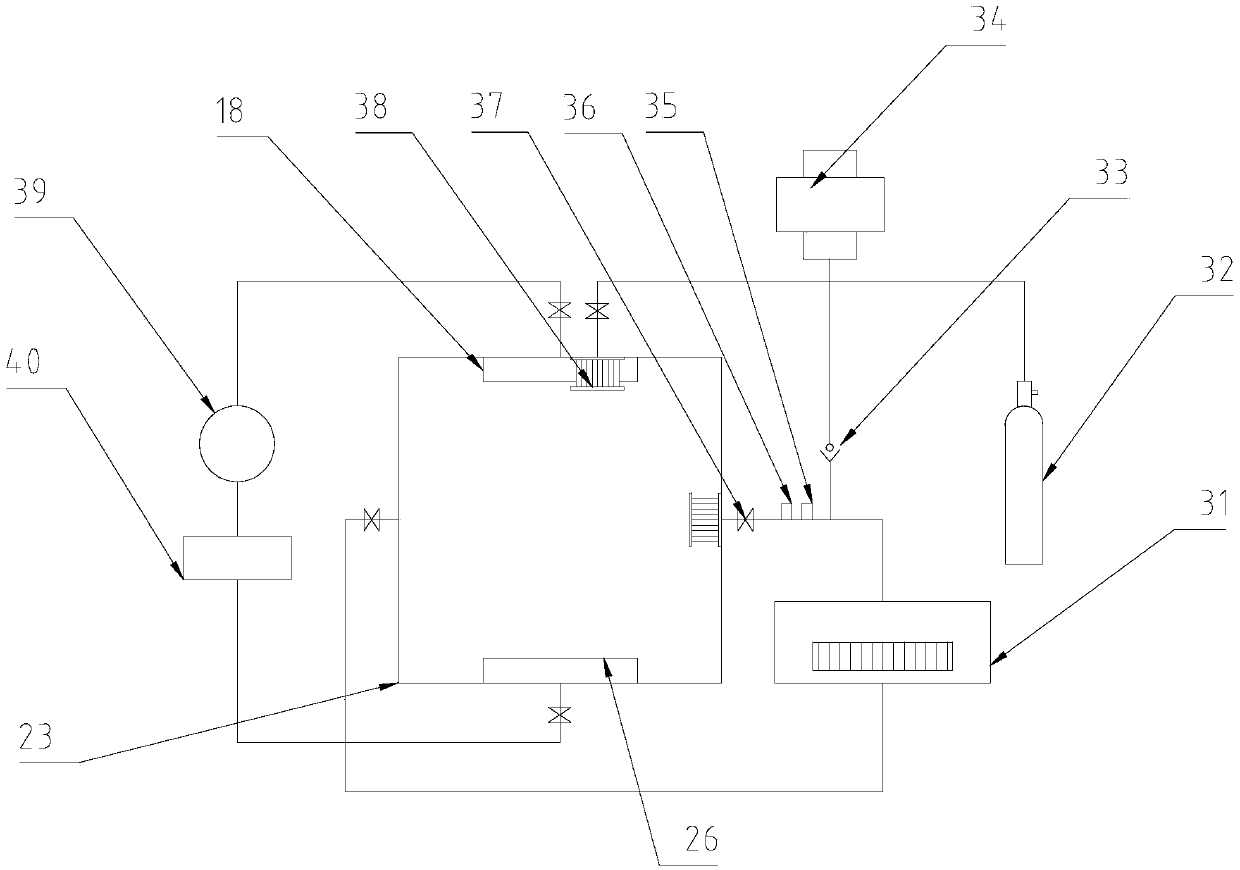

A special equipment for laser selective melting for direct manufacturing of metal orthopedic implants

ActiveCN105945282BImprove powder utilizationImprove cleanlinessAdditive manufacturing apparatusIncreasing energy efficiencyArtificial hip jointsEngineering

A laser selective melting special equipment for directly manufacturing metal orthopedic implants, characterized in that it includes a forming system, a powder recovery system, a powder spreading system, a laser transmission system, a dust filtration and water / oxygen purification double circulation system, and a sealing cavity; the forming system, powder recovery system, and powder spreading system are all placed in the sealed cavity, the laser transmission system is placed on the upper part of the sealed cavity, and the dust filtration and water / oxygen purification double circulation system is placed outside the sealed cavity ; The forming system includes a forming cylinder, a forming cylinder piston, a ball screw, a servo motor and a grating scale; the inside of the forming cylinder piston is provided with a heating copper plate, a water cooling system and a temperature sensor; The way of powder spreading; the forming process is carried out under the protection of argon, and it is equipped with a double circulation system of dust filtration and water / oxygen purification. The invention has high cleanliness of the atmosphere in the forming chamber, high dimensional accuracy of the forming parts, can form bionic structures such as porous structures and biological channels, and is suitable for rapid and personalized customization of artificial hip joints.

Owner:THYTEC SHANGHAI

Scratch resistant processing method of non-figured island ultrafine fiber napped leather

ActiveCN101591860BChange the distribution status of the islandHigh process flexibilitySolvent-treatmentFabric breaking/softeningLow-density polyethyleneFiber

Owner:HUAFON MICROFIBER SHANGHAI

Forming method of electromagnetic driving flexible-mould for fuel cell metal bipolar plate

The invention relates to a method for forming a fuel cell metal bipolar plate. The invention aims at the problems of a conventional plastic deformation means (such as a punching forming means) for forming a metal sheet that a raised mould and a concave mould are difficult to match with each other and a driving sheet cannot be reused in a process of electromagnetically forming a metal bipolar plate. The device is characterized in that a forming mould, a flexible mould, a driving plate, a support frame and an upper fixing plate are stacked on a lower fixing plate from bottom to top, wherein a coil is arranged in a groove on a lower end face of the support frame; two adjacent circles of leads are separated by high-pressure isolating material; high-pressure high-strength isolating materials are filled between the groove and the coil and on the surface of the coil, thereby forming a flat coil; two ends of the coil are serially connected to a capacitor bank; and the upper fixing plate and the lower fixing plate are fixedly connected through a fastening bolt. The method comprises the following steps: placing a plate blank on the forming mould and fastening the upper fixing plate and the lower fixing plate; and performing discharging forming; and taking out a formed piece, thereby acquiring the metal bipolar plate. The device and the method provided by the invention are used for forming the fuel cell metal bipolar plate.

Owner:HARBIN INST OF TECH

Three-coordinate galvanometer scanning laser processing head

ActiveCN102166685BRealize the self-adjustment function of processing focal lengthCombined processing is simpleLaser beam welding apparatusNumerical controlLaser processing

The invention provides a three-coordinate galvanometer scanning laser processing head, which comprises an XY two-axis laser galvanometer system, a clamping mechanism, a Z-axis moving mechanism, a laser displacement sensor and a control system, wherein the Z-axis moving mechanism comprises a fixed part and a moving part, and the clamping mechanism is fixedly mounted on the fixed part of the Z-axis moving mechanism; and the XY two-axis laser galvanometer system and the laser displacement sensor are fixedly mounted on the moving part of the Z-axis moving mechanism, and the laser displacement sensor, the Z-axis moving mechanism and the XY two-axis laser galvanometer system are all electrically connected with the control system. The laser processing head has the function of dynamic focal length setting, and has an independent and compact structure; the laser processing head has the broach interface design of a standard numerically-controlled machine tool, which enables the laser processing head to be easily assembled for processing with commercialized multi-axis synchronous numerically-controlled machine tools of a three-axis type, a five-axis type, and the like; and technological flexibility is greatly enhanced, and a conventional multi-axis synchronous numerically-controlled machine tool can be conveniently changed into a galvanometer scanning laser processing machine tool with compatible functions, thereby the three-coordinate galvanometer scanning laser processing head has important practical value.

Owner:武汉飞能达激光技术有限公司

An integrated hybrid drive double-cylinder series booster hydraulic press

ActiveCN107457340BFulfillment requirementsRealize boost functionForging press detailsForging press drivesMotor driveThree phase asynchronous motor

The invention discloses an integrated mixed-drive double-cylinder series booster hydraulic press, which belongs to the field of forging equipment. It replaces the driving mode of the three-phase asynchronous motor with the driving mode of the servo motor, and applies the transmission mode of the ball screw nut pair of the electric screw press to the traditional hydraulic press. First, it makes the traditional hydraulic press achieve faster stroke and return speed requirements, the rapid forging frequency of the traditional hydraulic press is increased; secondly, the servo drive technology improves the response speed, precision, and process flexibility of the control system, expands its process range, saves energy and reduces consumption, and simplifies the structure of the traditional hydraulic system; again , replacing the one-way plunger cylinder structure of the traditional hydraulic press with a double-cylinder series-type supercharged single-pass plunger cylinder, which can realize the pressurization effect and improve the forging efficiency; finally, the AC servo motor drives the screw nut pair to move, eliminating the need for the traditional press. The return cylinder and return structure of the press make the structure of the press simple and the load of the movable beam is small.

Owner:兰州兰石重工有限公司

Robotic hole making end effector

InactiveCN103639471BImprove hole qualityImprove hole making efficiencyMeasurement/indication equipmentsFeeding apparatusEngineeringActuator

The invention discloses a drilling end actuator suitable for an industrial robot. The drilling end actuator comprises a cutting unit, a connecting unit, a feeding unit, a pressing unit and a measuring unit. The cutting unit mainly comprises a motorized spindle, a cutter handle, a cutter, a servo motor and a cutting transmission assembly and is used for achieving planetary drilling and cutting; the connecting unit mainly comprises a connecting plate and tool fast-switching devices and is used for achieving three installation modes and fast switching between the different installation modes; the feeding unit mainly comprises a lead screw nut pair, a feed motor and a feed transmission assembly and is used for achieving feed movement of planetary drilling and cutting; the pressing unit mainly comprises an air cylinder, a pressing plate, a pressing pipe and a pressing head and is used for pressing a workpiece; the measuring unit comprises a photoelectricity distance sensor and a force sensor and is used for detecting the perpendicularity of the cutter before and after pressing and monitoring the state of the cutter during the drilling process in real time. The drilling end actuator can form a flexible drilling system when used in cooperation with the industrial robot, and precise drilling of stacked materials can be achieved.

Owner:ZHENGZHOU UNIV

Intelligent plastic forming process method and intelligent plastic forming equipment used therein

ActiveCN105478641BSolve the accuracy problemImprove the level ofForging press detailsMachineAutomatic programming

Owner:JIANGSU YONGNIAN LASER FORMING TECH

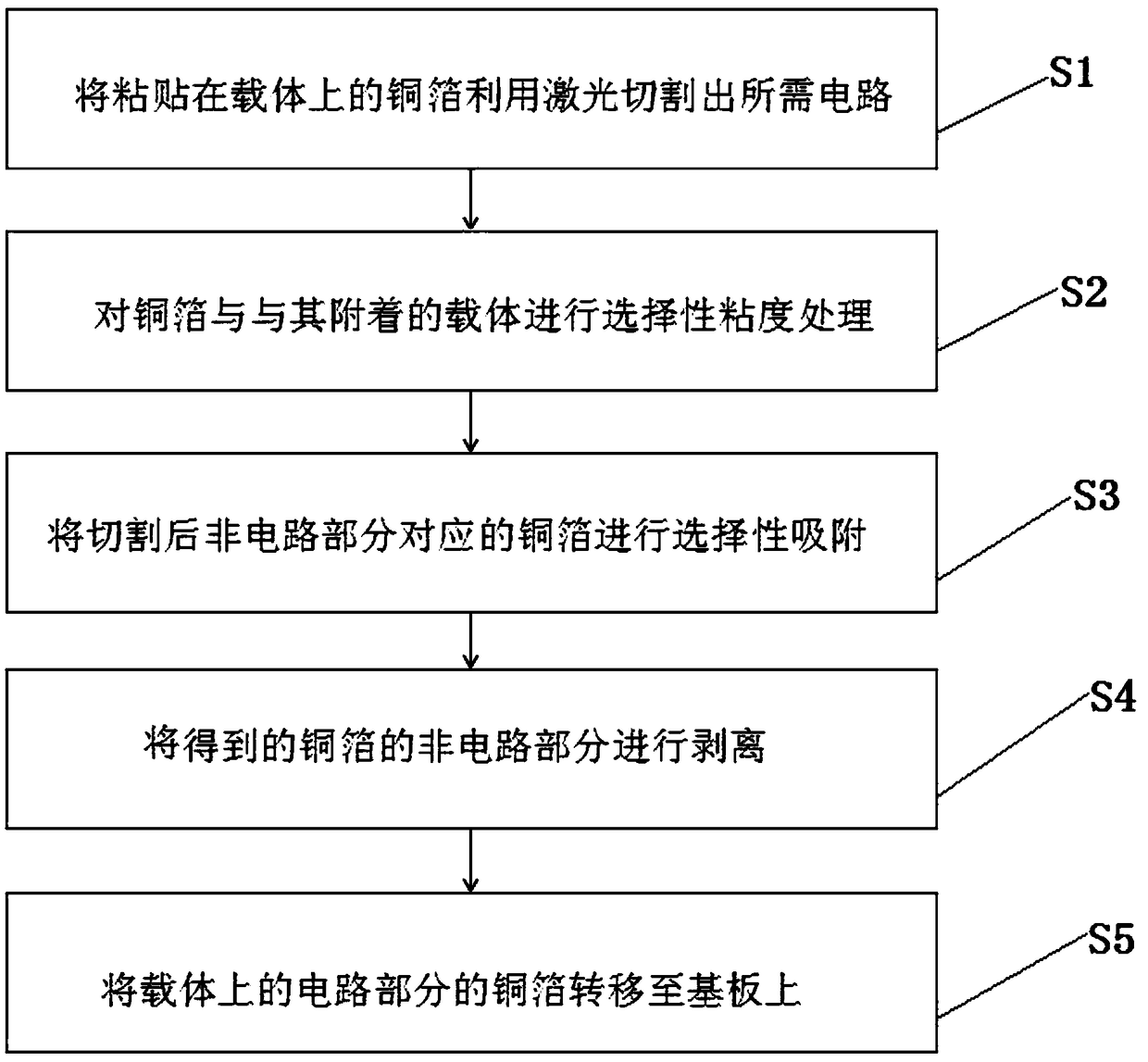

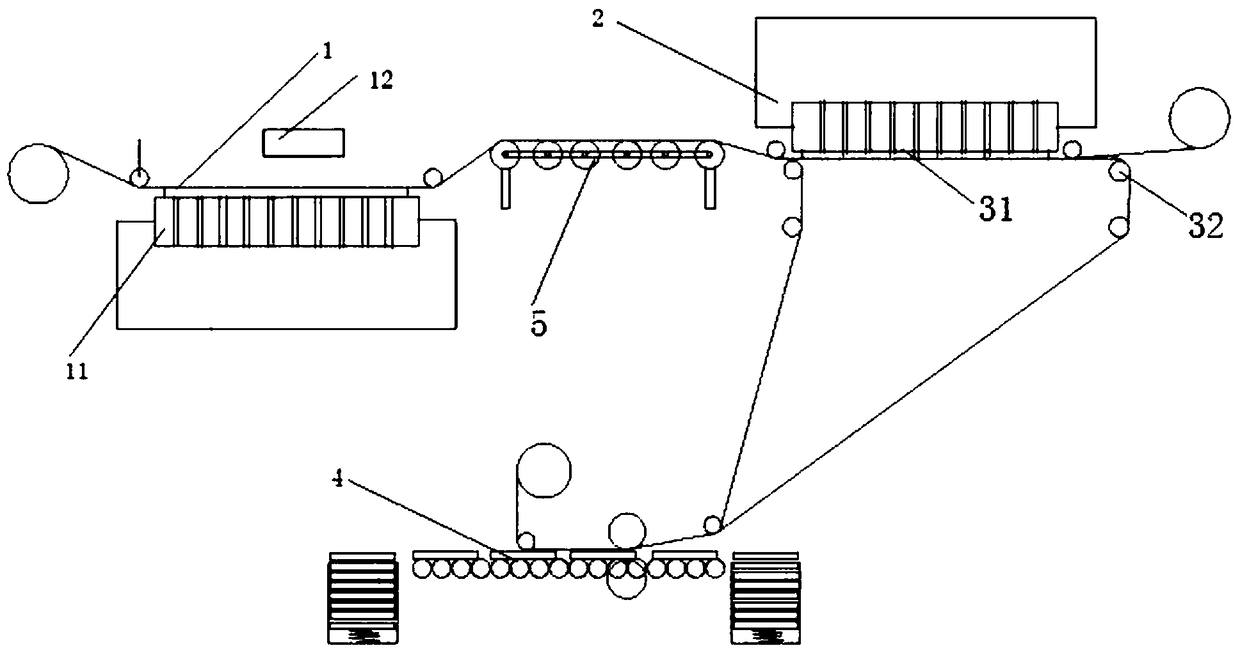

A printed circuit board processing method, system and copper foil for processing

ActiveCN106793540BImprove protectionAvoid infringementPrinted circuit manufacturePreferential adsorptionLaser cutting

The present invention provides a printed circuit board processing method, which includes the following steps: S1, laser cutting: using laser to cut out a circuit needed on the copper foil which is pasted on the carrier; S2, preferential viscosity processing: carrying out preferential viscosity processing to the copper foil and the carrier; S3, preferential adsorption: carrying out preferential adsorption to the cut copper foil corresponding to the non-circuit part; S4, peeling: peeling the non-circuit part of copper foil off the carrier to obtain the copper foil corresponding to the circuit part attached to the carrier; S5, preparation of the printed circuit board, transferring the copper foil of the circuit part on the carrier to the baseboard to obtain the printed circuit board. It is possible to use laser cutting to cut the printed circuit board, avoid chemical milling in the manufacture process, and directly recycle the waste copper, is of great value of environmental protection while reducing the cost, and a new thought for preparing printed circuit board with copper foil is provided.

Owner:曹昕

A kind of preparation method of printed circuit board and copper foil for processing

ActiveCN108323025BImprove protectionAvoid infringementPrinted circuit manufacturePhotosensitive materials for photomechanical apparatusEtchingMetallurgy

The invention provides a preparation method of a printed circuit board. The method includes the following steps of: S1, copper foil arrangement: copper foil is arranged on a carrier in a manner that the copper foil is aligned with the carrier, and the copper foil and the carrier are composited; S2, laser cutting: laser cutting is performed on the pattern of the circuit diagram of a circuit board;S3, selective peeling: an aluminum substrate is coated with photoresist, and a mask with a circuit diagram is arranged on the aluminum substrate, and the aluminum substrate is selectively exposed according to the pattern of the circuit diagram, so that the non-circuit portion of the circuit diagram loses viscosity; and S4, printed circuit board preparation: the copper foil arranged on the carrieris aligned with the aluminum substrate, so that the circuit diagrams of the copper foil and the aluminum substrate are completely overlapped with each other, and the copper foil of a circuit portion is completely bonded to the aluminum substrate, and the copper foil of a non-circuit portion is peeled off. According to the preparation method of the invention, the circuit board is inscribed by a laser cutting method, so that chemical etching can be avoided in a production process; and waste copper can be directly recycled, and therefore, a great environmental protection value can be realized with cost reduced. With the method adopted, a new idea is provided for the production of copper foil for circuit board.

Owner:曹昕

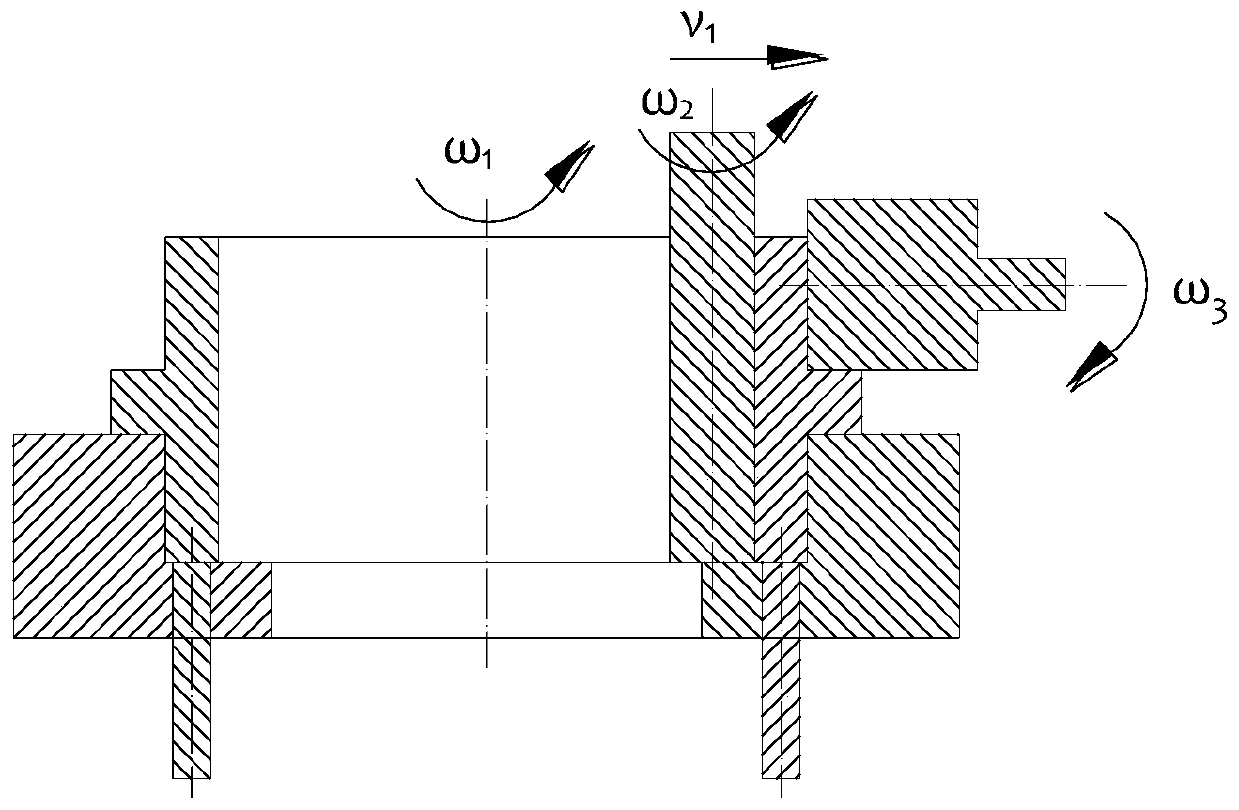

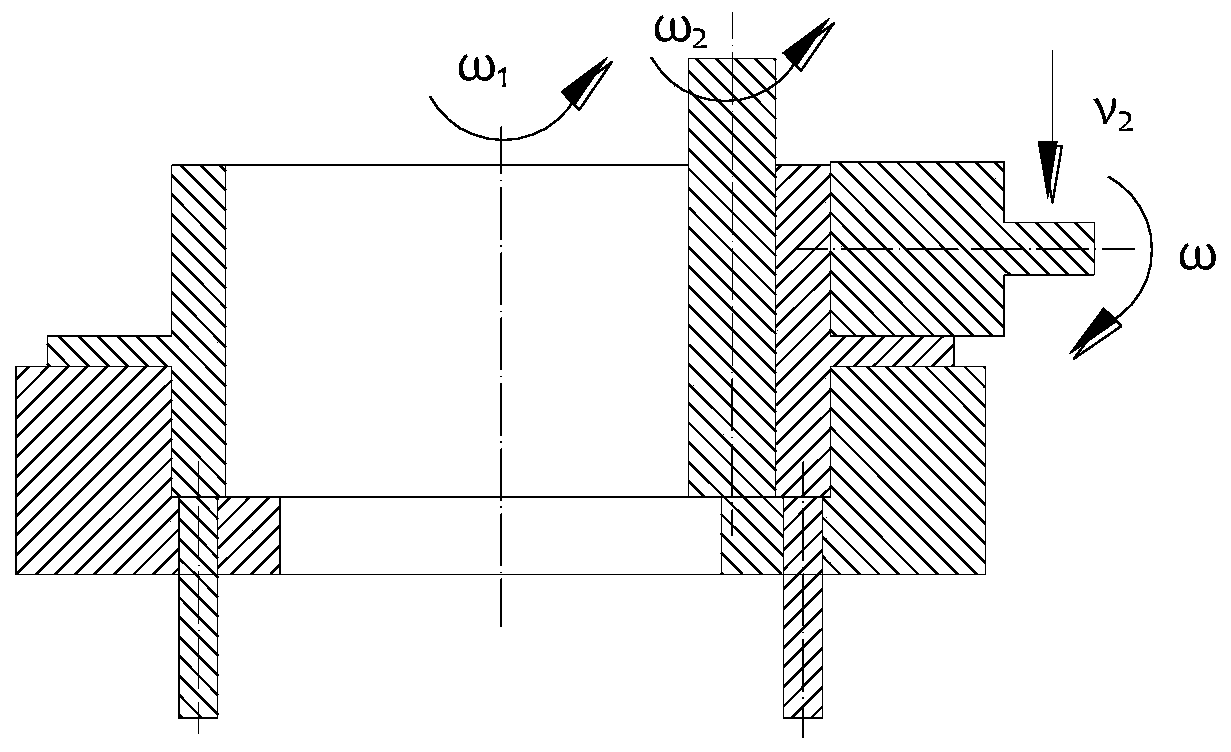

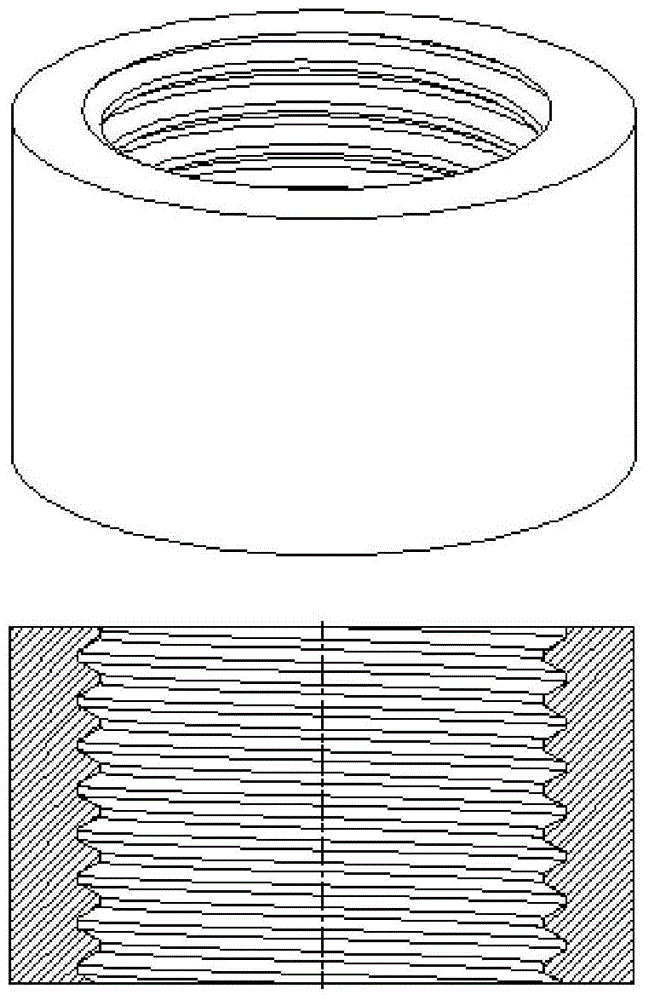

Constrained Radial-Axial Roll Forming Method for Large Thin-walled External T-shaped Ring Members

The invention relates to a constraining radial-axial roll-forming method for a large thin-wall outer T-shaped annular component. The constraining radial-axial roll-forming method comprises the following steps that S1, an annular prefabricated blank is placed in a constraint mold, the bottom face of the annular prefabricated blank is in contact with the lower end face in the constraint mold, and aradial feeding roll is arranged in the annular prefabricated blank; S2, at a radial rolling stage, after rolling is started, the constraint mold drives the annular prefabricated blank to uniformly rotate around the axis of the constraint mold at the rotating speed omega1, the radial feeding roll rotates around the axis of itself at the rotating speed omega2 and meanwhile does feeding motion at thespeed v1 in the radial direction, and an axial feeding roll uniformly rotates around the axis of itself at the rotating speed omega3 and does not do translational motion; S3, at an axial rolling stage, the constraint mold continues to uniformly rotate around the axis of itself at the rotating speed omega1, the position of the radial feeding roll is kept fixed, and the axial feeding roll starts tocarry out downward feeding at the speed v2 in the axial direction while uniformly rotating around the axis of itself; and S4, operation at a demolding stage is carried out. According to the constraining radial-axial roll-forming method, high-performance, high-efficiency, low-cost and near-net forming manufacturing of the large thin-wall complex annular component is achieved.

Owner:WUHAN UNIV OF TECH

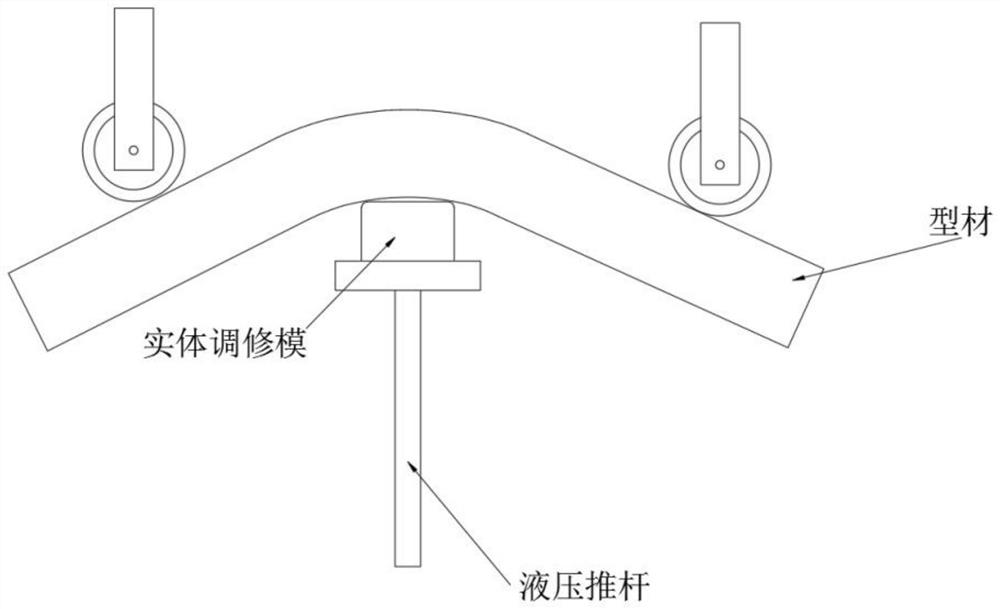

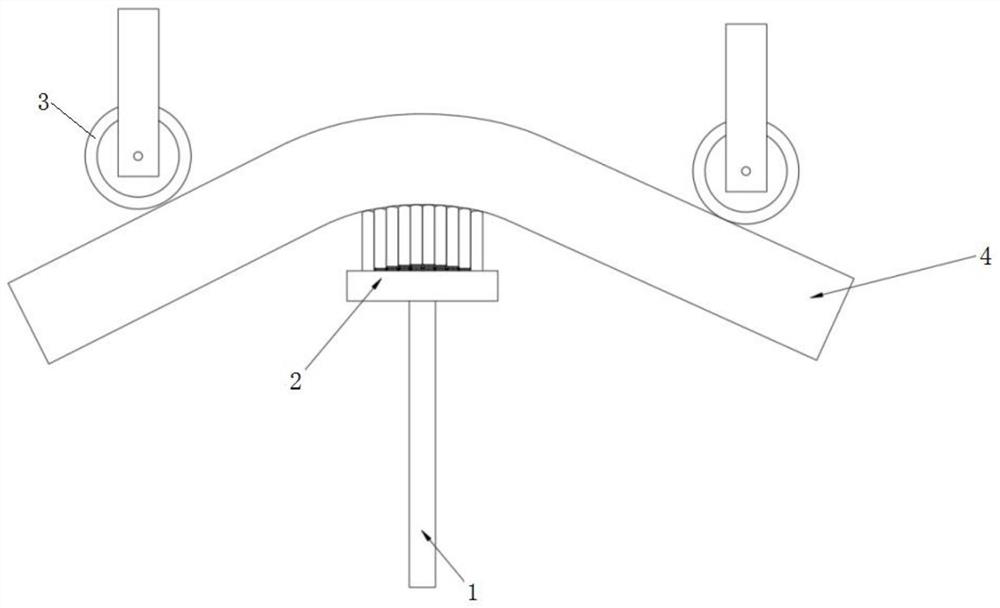

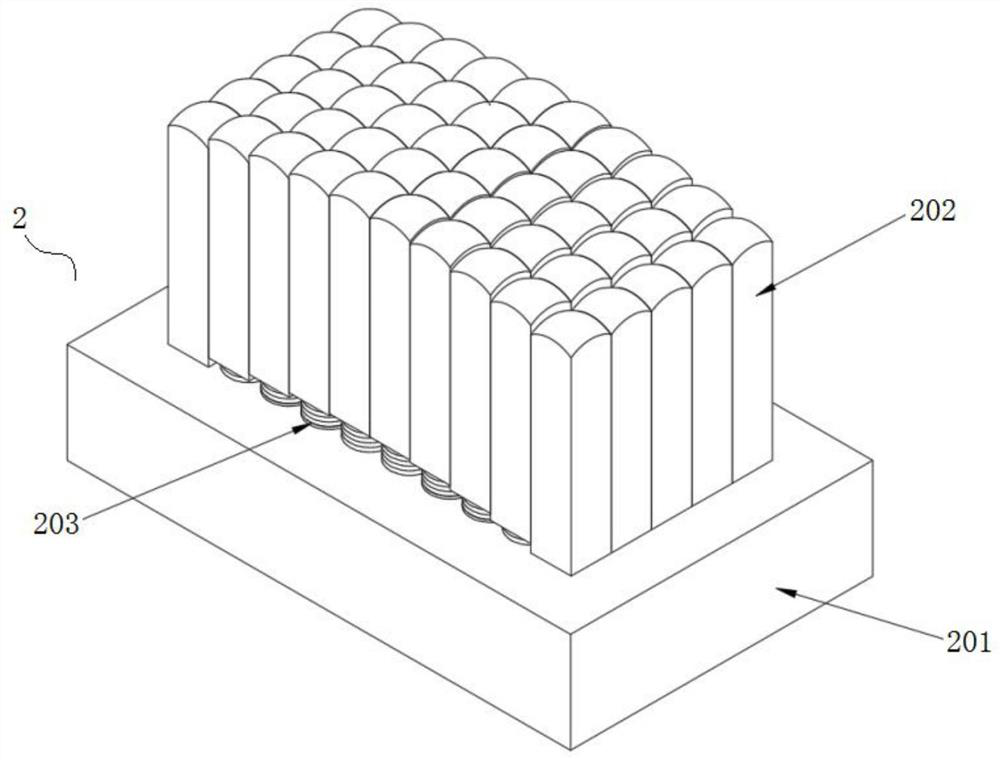

Flexible adjusting and repairing device for aluminum alloy profile of railway vehicle

PendingCN113878003AHigh process flexibilityEven by forceShaping toolsStructural engineeringMechanical engineering

The invention discloses a flexible adjusting and repairing device for an aluminum alloy profile of a railway vehicle. The flexible adjusting and repairing device comprises a hydraulic push rod and a flexible adjusting and repairing assembly connected with the hydraulic push rod; the flexible adjusting and repairing assembly comprises a base and a plurality of adjusting units connected with the base; and the adjusting units can adjust the relative distance between the adjusting units and the base, and the upper ends of the adjusting units make contact with the lower surface of the profile. According to the device, from the perspective of improving the process flexibility of the railway vehicle aluminum alloy profile adjusting and repairing device, improving the quality of the adjusted and repaired product and reducing the process defects, the adjusting and repairing device is composed of the plurality of adjusting units, different adjusting and repairing model surfaces are formed by changing the heights of the corresponding adjusting units, therefore, local contact of the aluminum alloy profile and adjusting and repairing molds is achieved in the adjusting and repairing process of the aluminum alloy profile, it is guaranteed that a workpiece is evenly stressed and deforms stably, and the problems that in the adjusting and repairing process of an existing solid sample block, the local curvature cannot be adjusted, efficiency is low, and quality is poor are solved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

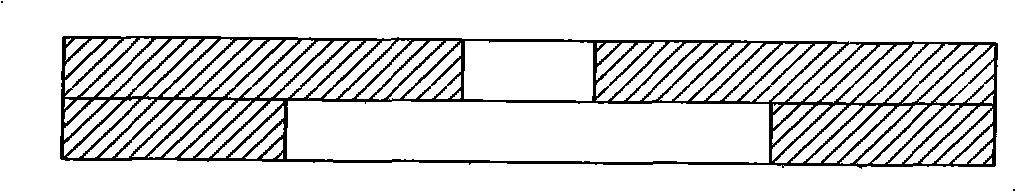

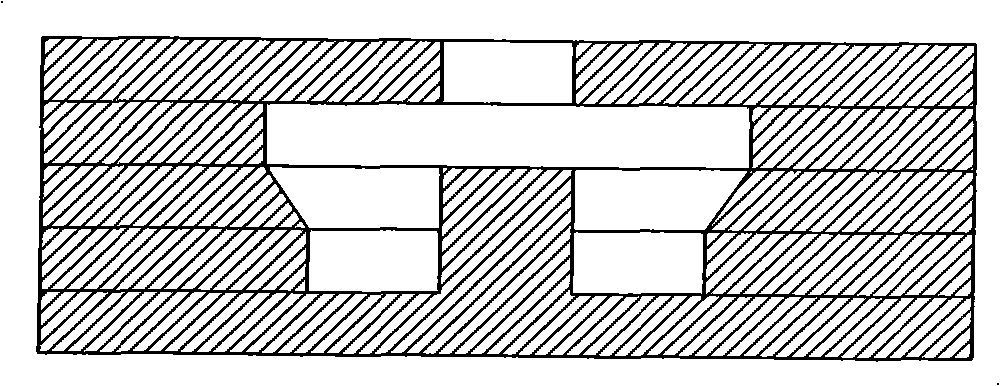

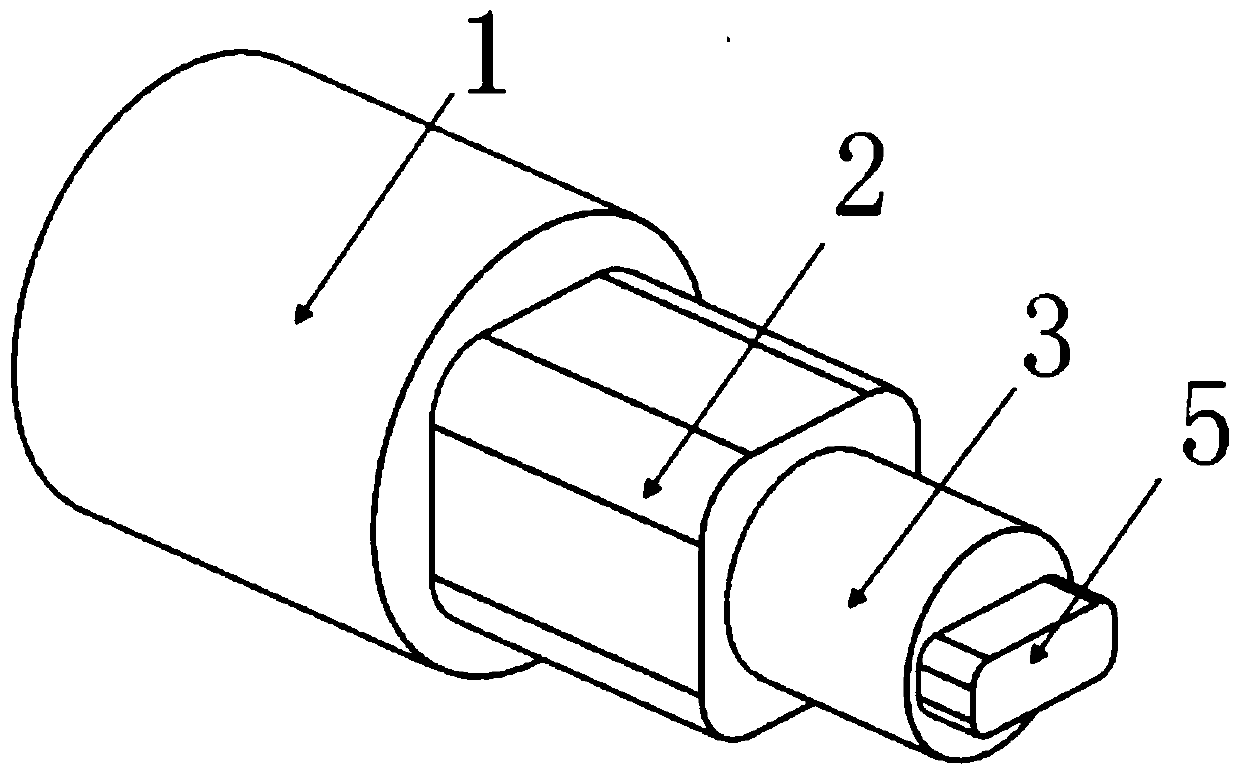

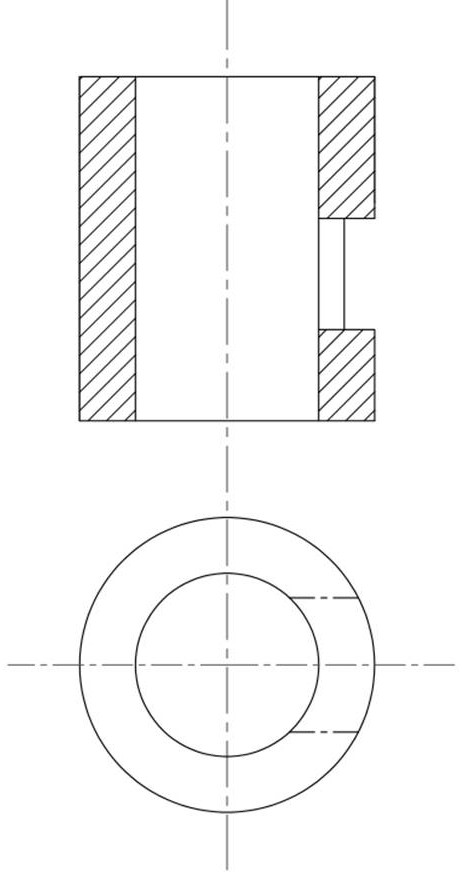

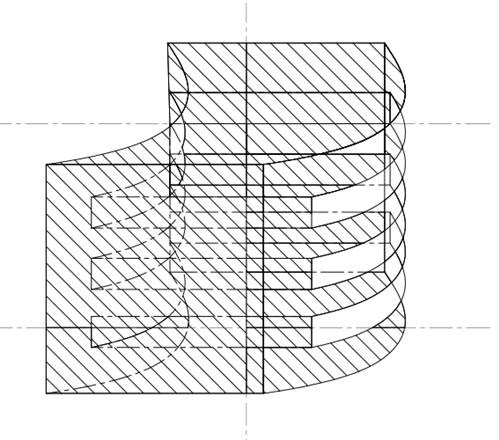

Board batch modular lateral extrusion forming device and method

The device and method for batch modularized lateral extrusion of boards relate to a device and method for high-efficiency batch lateral extrusion of boards, which can solve the long-standing problems of low production efficiency, cumbersome procedures, and complex device structures in the batch manufacturing process of boards Wait for the bottleneck. Device: the inner sleeve 5 is placed on the base 3, and the blank 2 and the punch 1 are put into the inside sequentially, the insert 4 is placed between the groove 5-1 of the inner sleeve 5 and the base 3, and the outer sleeve 6 is placed The base 3, the insert 4, and the outer side of the inner sleeve 5. Method: According to the actual requirements of the formed product, the structure of the corresponding insert 4 and the rib plate 7 is replaced by using the idea of modularization. During the extrusion process, the punch 1 is loaded downward, and the compressed deformed blank 2 flows into the insert 4 sequentially along the radial direction. The groove hole 4‑1 can be customized in batches with various specifications such as different shapes, sizes and quantities, and at the same time can realize fine-grain modification of extruded plates. The invention is suitable for extrusion molding of plates in batches.

Owner:HARBIN UNIV OF SCI & TECH

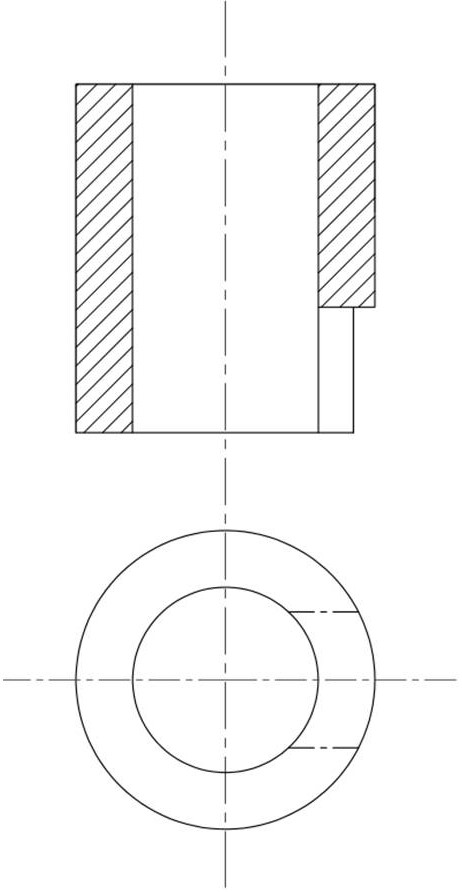

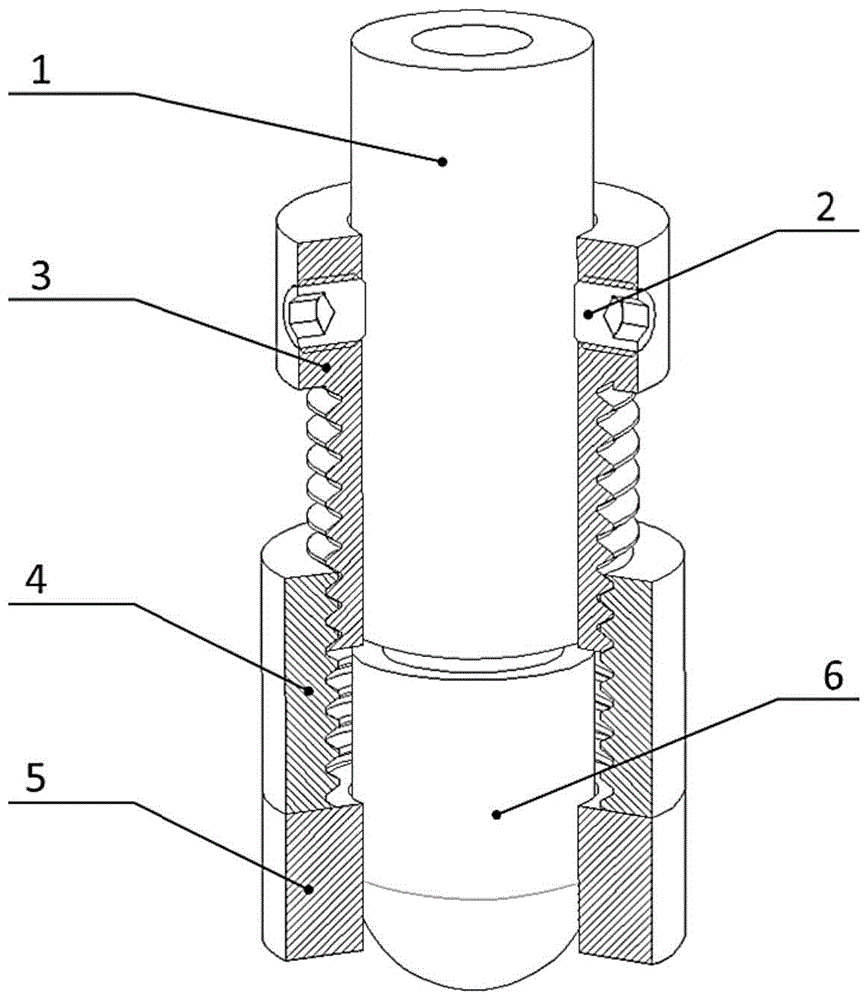

Magnetic control device for resistance spot welding with adjustable position

ActiveCN105081546BAvoid interferenceHigh precisionVehicle componentsMetal working apparatusElectrical resistance and conductanceControl system

The invention discloses a position-adjustable resistance spot welding magnetic control device. The position-adjustable resistance spot welding magnetic control device comprises a positioning guide sleeve, an annular permanent magnet fixedly connected with the positioning guide sleeve through ferromagnetic attraction force, a lining, an electrode stem, an electrode cap and positioning screws, wherein the lining is fixedly connected with the electrode stem through the positioning screws, the positioning guide sleeve is movably connected with the lining in a sleeving manner, the annular permanent magnet is fixedly connected with the positioning guide sleeve, and the electrode cap is connected with the electrode stem. The position-adjustable resistance spot welding magnetic control device has the beneficial effects that the magnetic control system has a grinding stop position, so that interference between the permanent magnet and a grinding tool is avoided; thread adjustment of the working position of the permanent magnet can be performed as needed, so that precision is high, and operation is convenient; the permanent magnet is connected with the end face of the positioning guide sleeve through ferromagnetic attraction force, so that replacement is easy, and process flexibility is high; and the inner diameter of the permanent is further reduced, so that the magnetic field intensity of a welding nuclear area is improved, and the stirring effect is enhanced.

Owner:SHANGHAI JIAOTONG UNIV

A kind of ultra-low temperature forming device and forming method of aluminum alloy component

ActiveCN112139340BImprove the cooling effectMorph coordinationShaping toolsHydraulic cylinderMetallurgy

The invention provides an ultra-low temperature forming device and forming method for aluminum alloy components, which belong to the technical field of forming thin-walled aluminum alloy components. The shape of the forming groove is matched, and the first medium cavity and the second medium cavity independent of each other are set in the lower mold, and the first medium cavity and the second medium cavity are filled with solid particle medium; the first hydraulic cylinder and the second hydraulic pressure cylinder, the first hydraulic cylinder is connected with the first medium chamber, the second hydraulic cylinder is connected with the second medium chamber; and the cold source, the cold source is connected with the first medium chamber and the second medium chamber. The invention adopts the solid particle medium as the cooling medium and the force transmission medium, which has a good cold storage effect, is easy to realize flexible loading and sealing, and is not easy to splash; and can regulate the deformation sequence and deformation amount of different regions of the aluminum alloy slab to be formed, and coordinate the slab deformation and improve the wall thickness distribution of formed components, and the process flexibility is high.

Owner:HARBIN INST OF TECH

Process for manufacturing three-dimensional miniature mold

InactiveCN101293628BHigh precisionHigh process flexibilitySemi-permeable membranesPiezoelectric/electrostrictive/magnetostrictive devicesMicroelectromechanical systemsWidth ratio

The invention provides a method for manufacturing a three-dimensional minitype die; patterns corresponding to each layer structure of the parts to be manufactured are respectively etched on each silicon wafer; H2SO4 with the weight percentage of 98% and H2O2 with the weight percentage of 98% are mixed by the volume ratio of 2-4:1; the mixed solution is then used for cleaning all silicon wafers; the silicon wafers are then activated and dried; the silicon wafers are then rapidly aligned and bonded by layer; finally, the three-dimensional die cavity is gained by the annealing disposal. The method of the invention can manufacture the three-dimensional minitype die with micron meter dimension, has the advantages of high precision, low cost and large flexibility and is applicable to the processing and manufacture of micro electro-mechanical system device dies such as micro-gear shafts, micro-step shafts and high depth-width-ratio three-dimensional minitype structure, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

A method for internal pressure forming of pipes with hot medium based on molten glass

ActiveCN108856441BMeet the forming temperature process requirementsReduce compressionMolten stateInternal pressure

The invention discloses a pipe hot medium internal pressure forming method based on molten glass, and relates to a metal pipe forming method. The problems that according to existing hot medium internal high pressure forming methods, the heating speed is low, heat conducting coefficients are low, sealing is difficult, and forming pressure only can reach about 0-50MPa are solved. The method comprises the steps that 1, a pipe internal high pressure forming temperature interval is determined according to the pipe variety; 2, according to the pipe internal high pressure forming temperature, glass materials are selected; 3, a pipe to be formed is preheated; 4, a pipe blank is vertically placed into a forming die, and die closing and sealing are carried out; 5, the glass materials are heated to obtain molten glass; 6, the glass media are injected into the sealed pipe blank; 7, the pipe blank is heated to internal high pressure forming temperature under high-temperature filling; and 8, material supplementing is carried out; and 9, pressure maintaining is carried out, the molten glass flows out through an overflow valve, die opening is carried out, and the formed deformed-section pipe partis obtained. The pipe hot medium internal pressure forming method is used in the field of internal high pressure forming.

Owner:HARBIN INST OF TECH

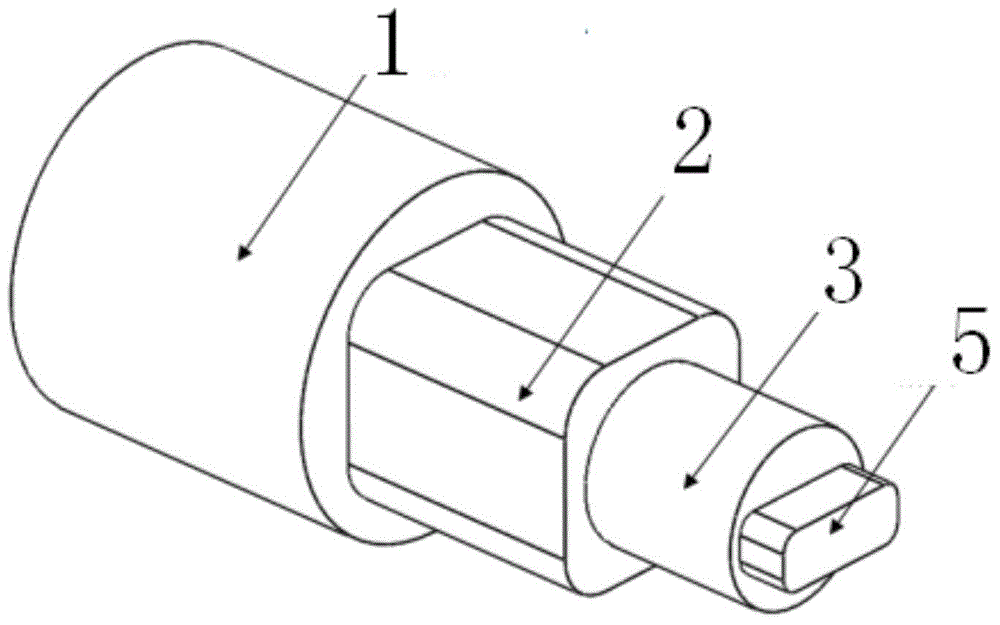

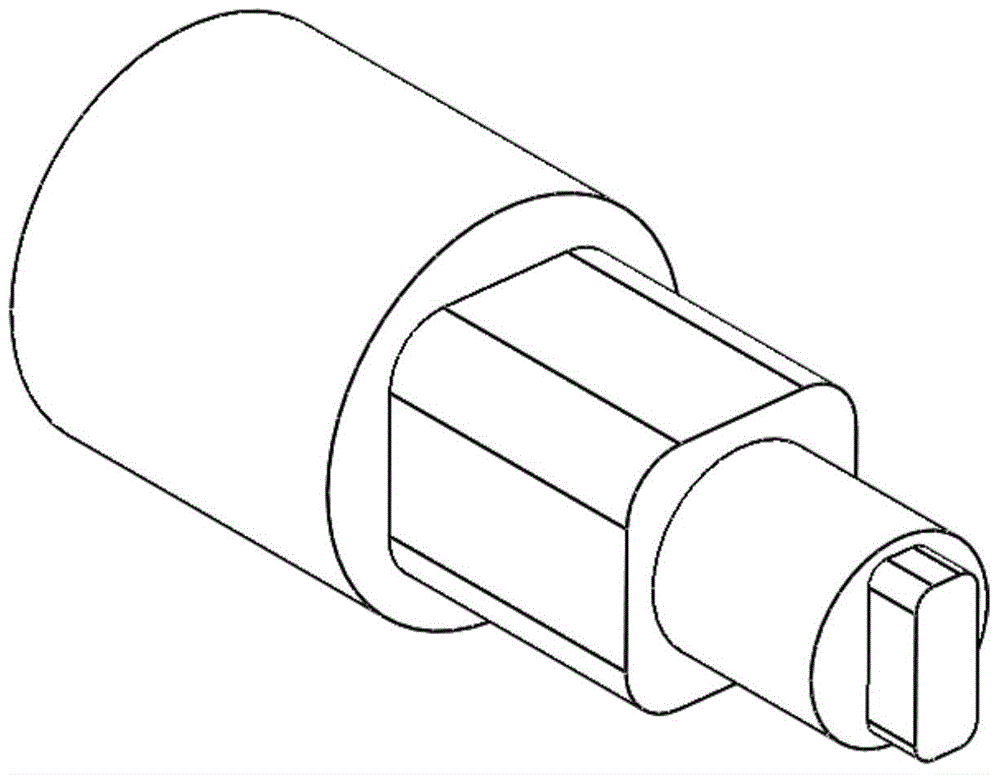

A laser processing mechanism with a shank

ActiveCN102513694BFunction extension and enhancementImprove efficiencyLaser beam welding apparatusNumerical controlLaser processing

The invention discloses a laser processing mechanism with a cutter handle. The structure of the laser processing mechanism with the cutter handle is that the cutter handle is installed at the upper portion of a frame and used for connecting a spindle of a multiaxial linkage numerical control machine and the laser processing mechanism, an optical fiber connection base is fixedly installed on one side of the frame and used for installing a transmission optical fiber connector and transmitting a laser beam emitted by a laser device into the laser processing mechanism, a laser processing head is installed at the lower portion of the frame, and a laser leading system is installed in the laser processing head and used for leading the laser beam out of the laser processing head onto a workpiece to be processed. A rotary mechanism or / and swinging mechanism can be additionally arranged on the laser processing mechanism. The laser processing mechanism is provided with the cutter handle with a standard structure so that the combination of the laser processing mechanism and the conventional multiaxial linkage numerical control machine is simple and easy, process flexibility is greatly improved, and the multiaxial linkage numerical control machine can be conveniently and quickly transformed into a multifunctional machine with a laser processing function.

Owner:武汉飞能达激光技术有限公司

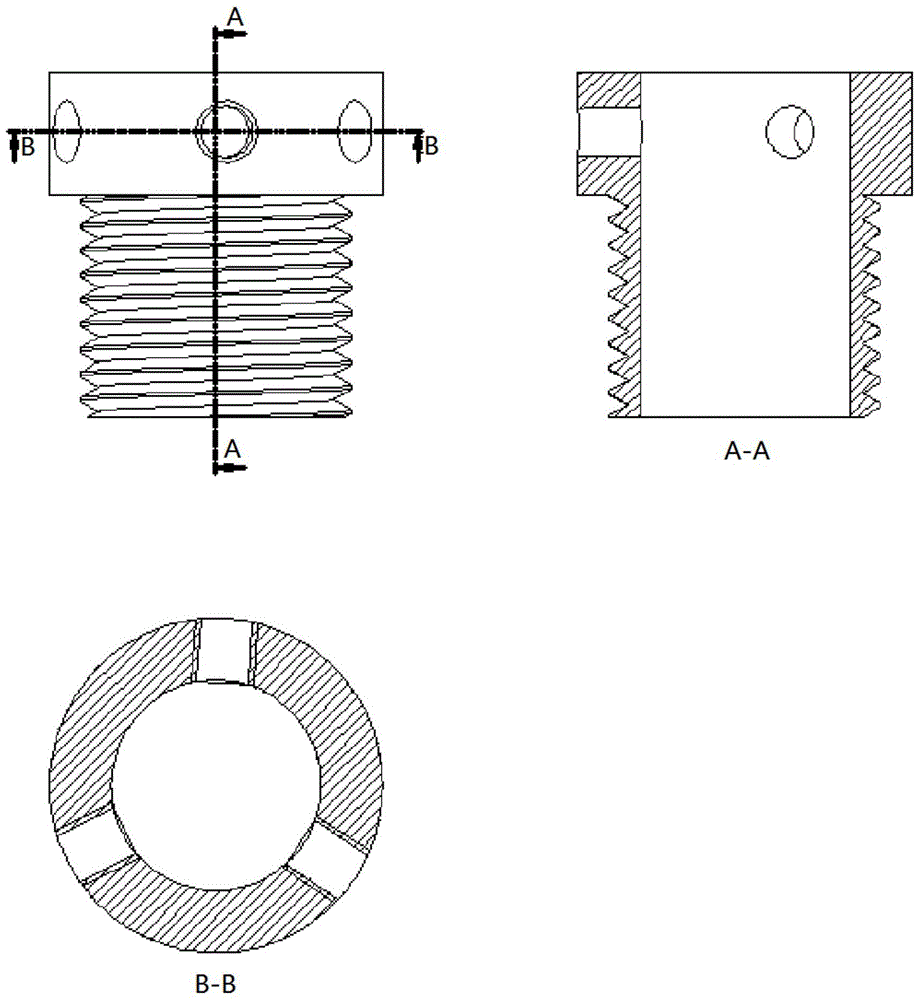

A multi-nozzle nozzle droplet spraying device

ActiveCN110560280BHigh positioning accuracySolve the problem that the injection position accuracy is difficult to guaranteeMovable spraying apparatusControl systemElectric machinery

The invention discloses micro-droplet spray equipment with a multi-nozzle spray head. The micro-droplet spray equipment comprises the multi-nozzle spray head, a workbench, an XY-axis moving device, aZ-axis moving device, a solution tank, a supporting frame and a control system, wherein the multi-nozzle spray head is mounted on the Z-axis moving device and positioned above the workbench; the workbench is mounted on the XY-axis moving device; the supporting frame is used for the mounting of all components; the multi-nozzle spray head comprises a main body, a mandrel, a motor and a multi-nozzlestructure; a plurality of solution channels which consist of solution inflow holes, ring-shaped grooves, solution outflow holes and nozzle channels are arranged in the multi-nozzle spray head; and nozzles are arranged at the outlets of the solution channels and uniformly distributed in a ring-shaped manner. Through the design that the exterior of the nozzles are stationary and the interiors of thenozzles are rotary, solution input ports can be fixed, and the change of spray materials can be rotationally completed at the output end; the complexity of a conventional multi-nozzle mechanism can be reduced; the operation can be simple; and furthermore, the problems that a solution supply pipe twists and the positioning is incorrect during the spray head conversion process of the conventional multi-nozzle device can be solved.

Owner:XIAMEN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com