Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Improve hole making efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

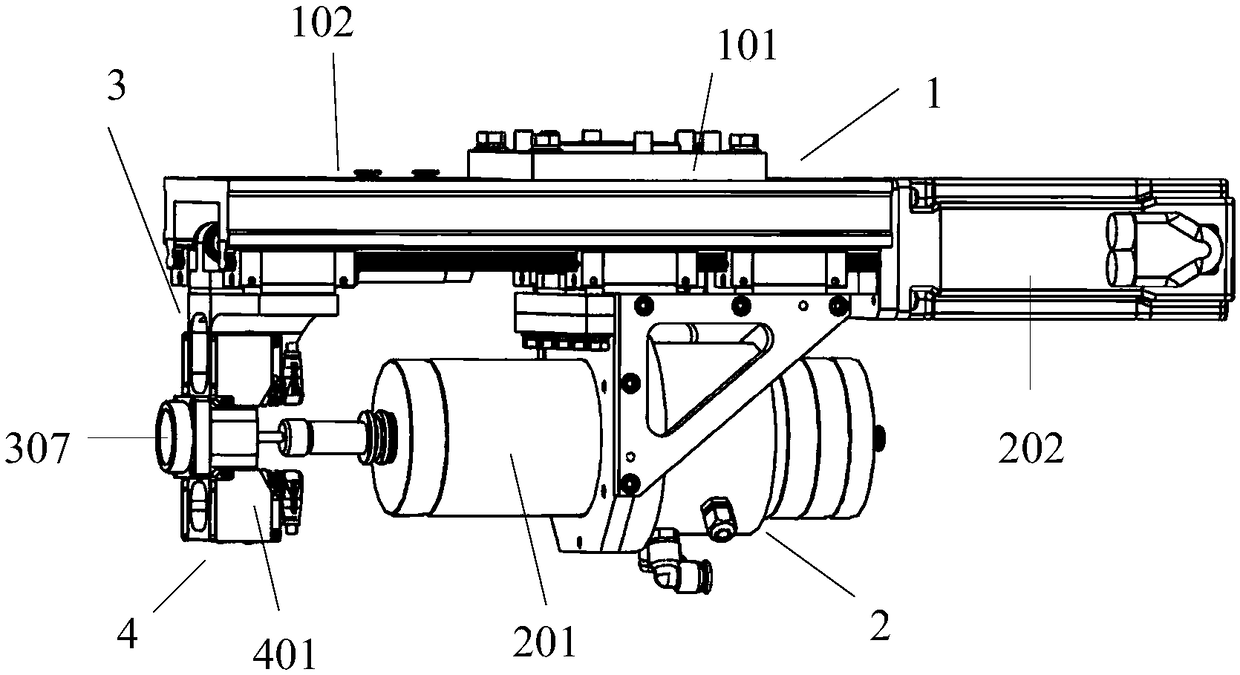

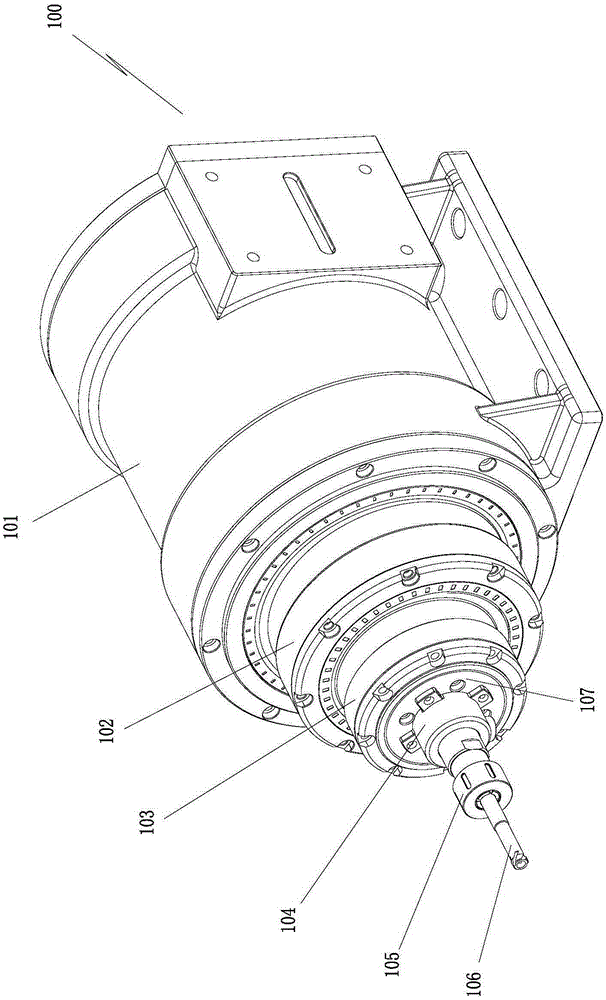

Aviation hole-forming robot end effector capable of adjusting attitude

InactiveCN102513575AFree replacementImprove hole making efficiencyPositioning apparatusBoring/drilling componentsAviationRotary stage

The invention provides an aviation hole-forming robot end effector which is suitable for plane skin drilling and can be used for automatically adjusting the attitude. The end effector comprises a leading screw feeding module, a binary angle adjusting mechanism, a compacting chip-absorbing module, a drilling module and a sensor module. The leading screw feeding module mainly comprises a leading screw driving motor, a synchronous transmission component and a dual-ball leading screw and is used for realizing feeding motion of drilling; the binary angle adjusting mechanism mainly comprises a stepping motor, a transmission gear, a wedge-shaped turn table and a spherical hinge and is used for realizing the automatic adjustment of the tail end attitude; the compacting chip-absorbing module mainly comprises a cylinder, a pressing cylinder, a cylinder connecting rod and a compacting head and is used for realizing compaction of a skin and the absorption of metal drill chips; the drilling module mainly comprises a drilling servo motor, a transmission shaft, a drill chuck and a drill bit and is used for realizing high-accuracy drilling; and the sensor module comprises a proximity sensor and a laser distance-measuring sensor and is used for realizing zero addressing and limiting of the movement of a main shaft, and the measurement of the normal line of a drilling point.

Owner:袁培江

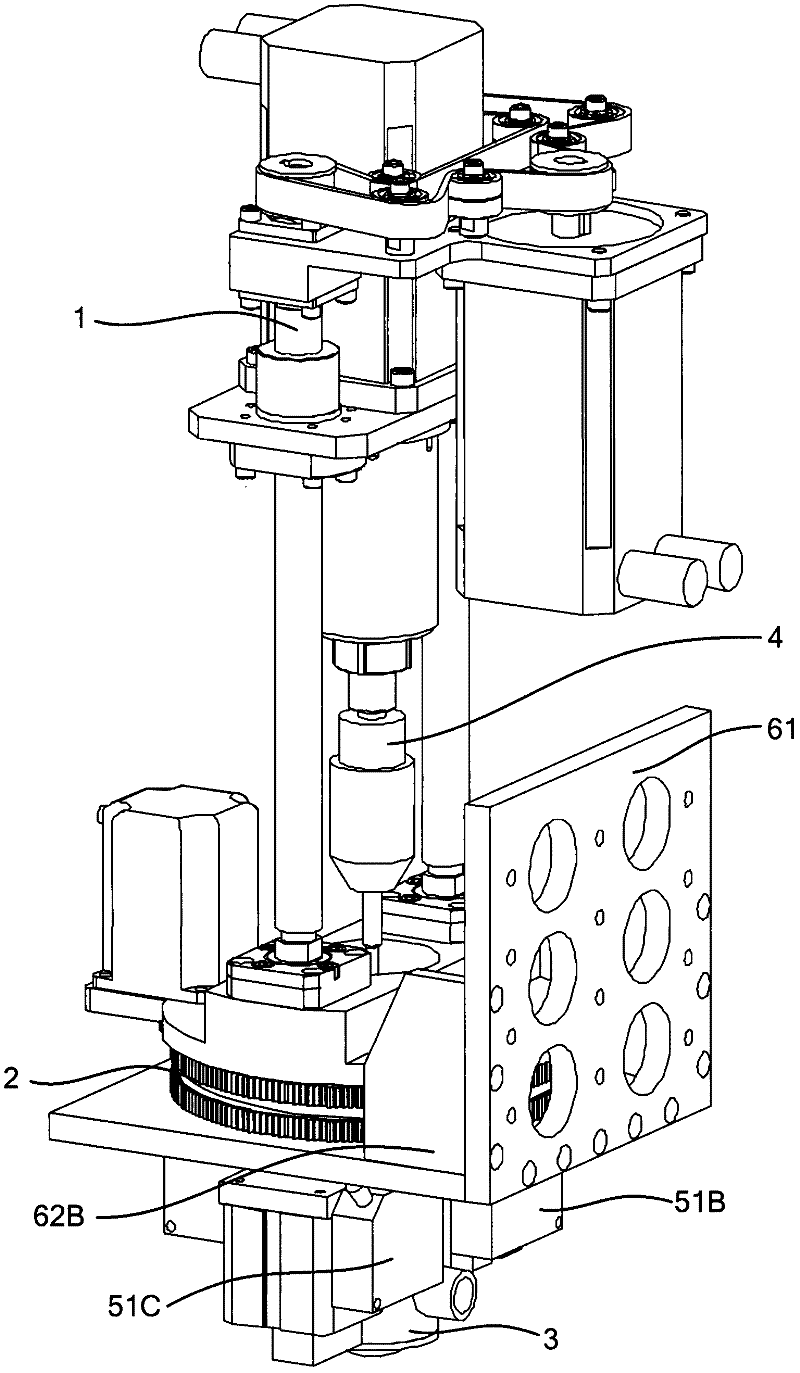

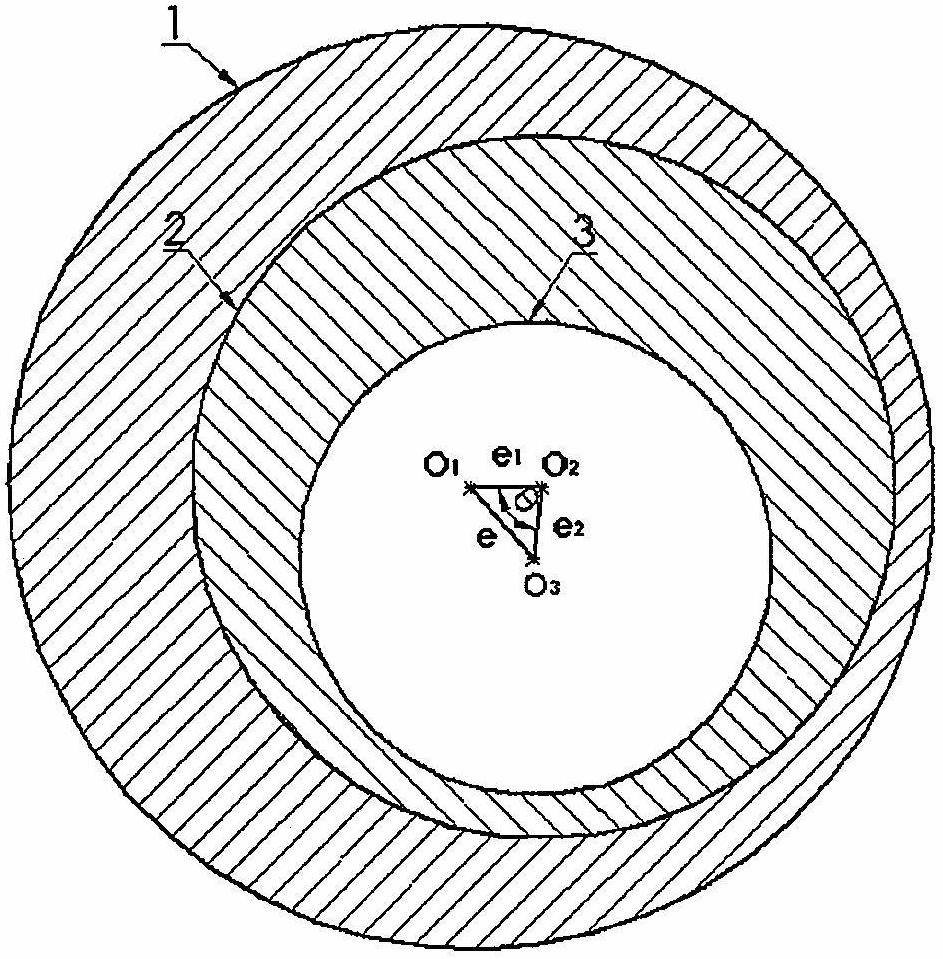

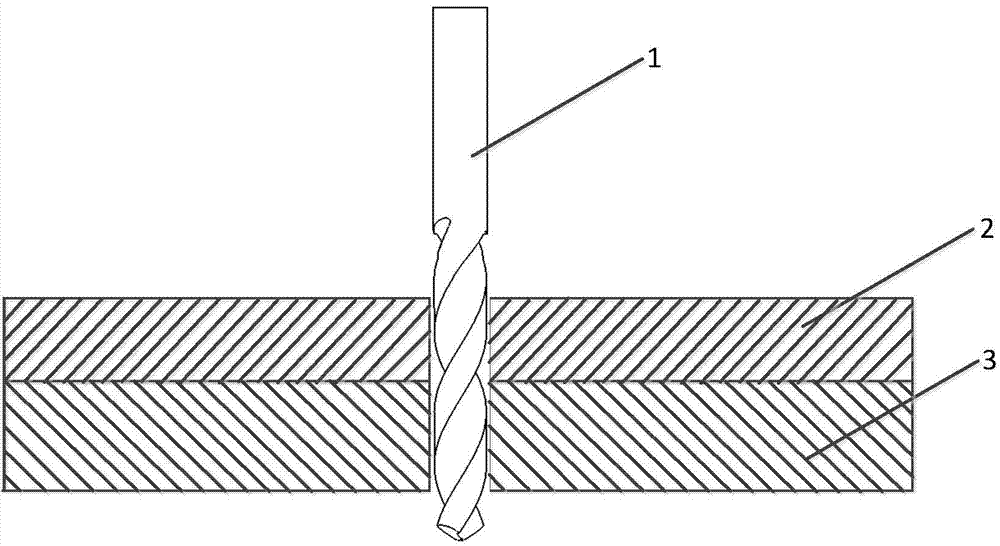

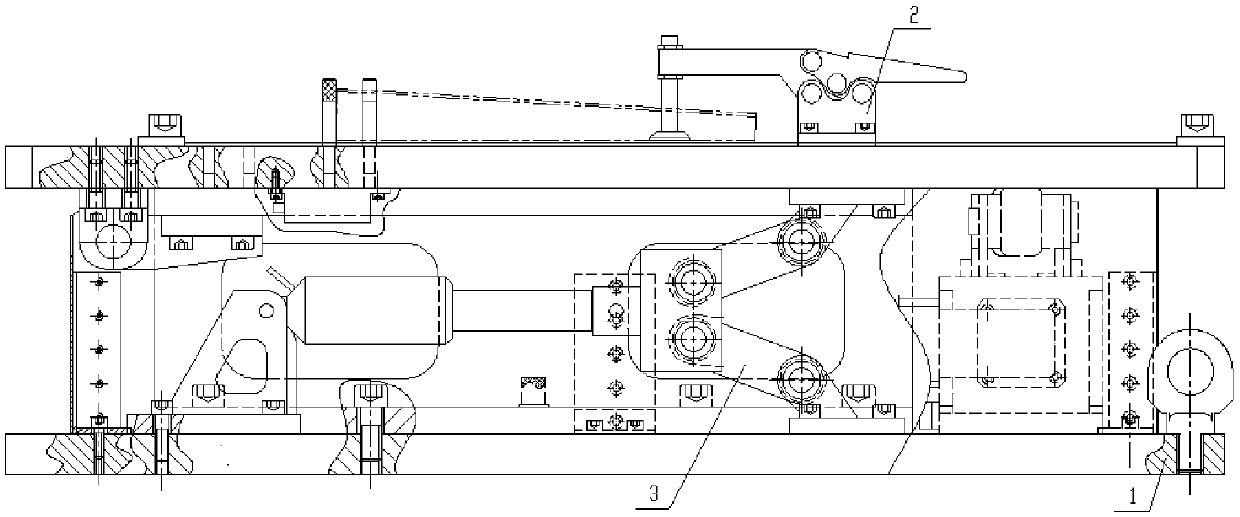

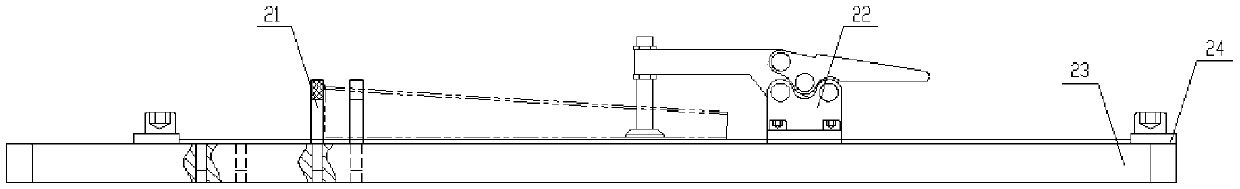

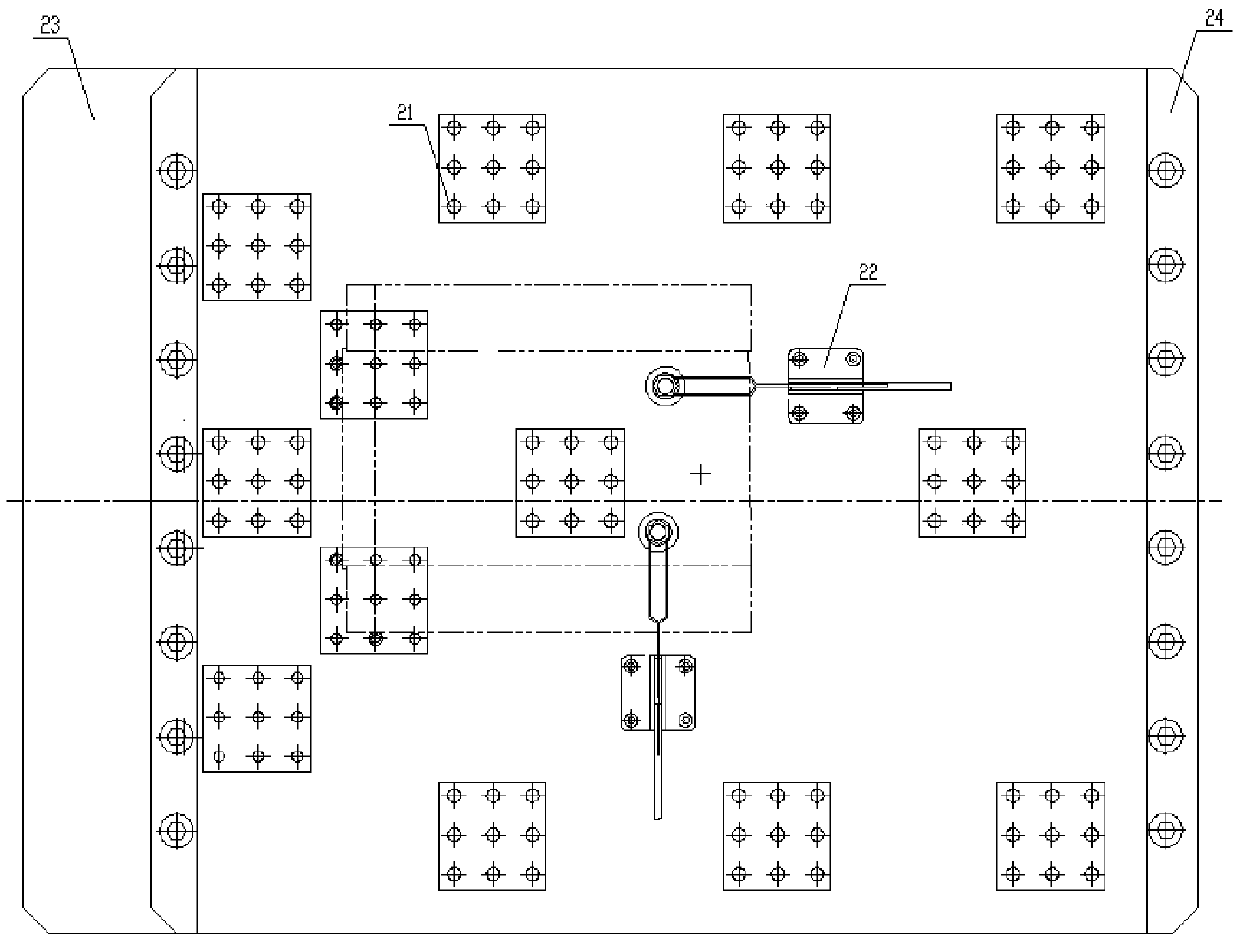

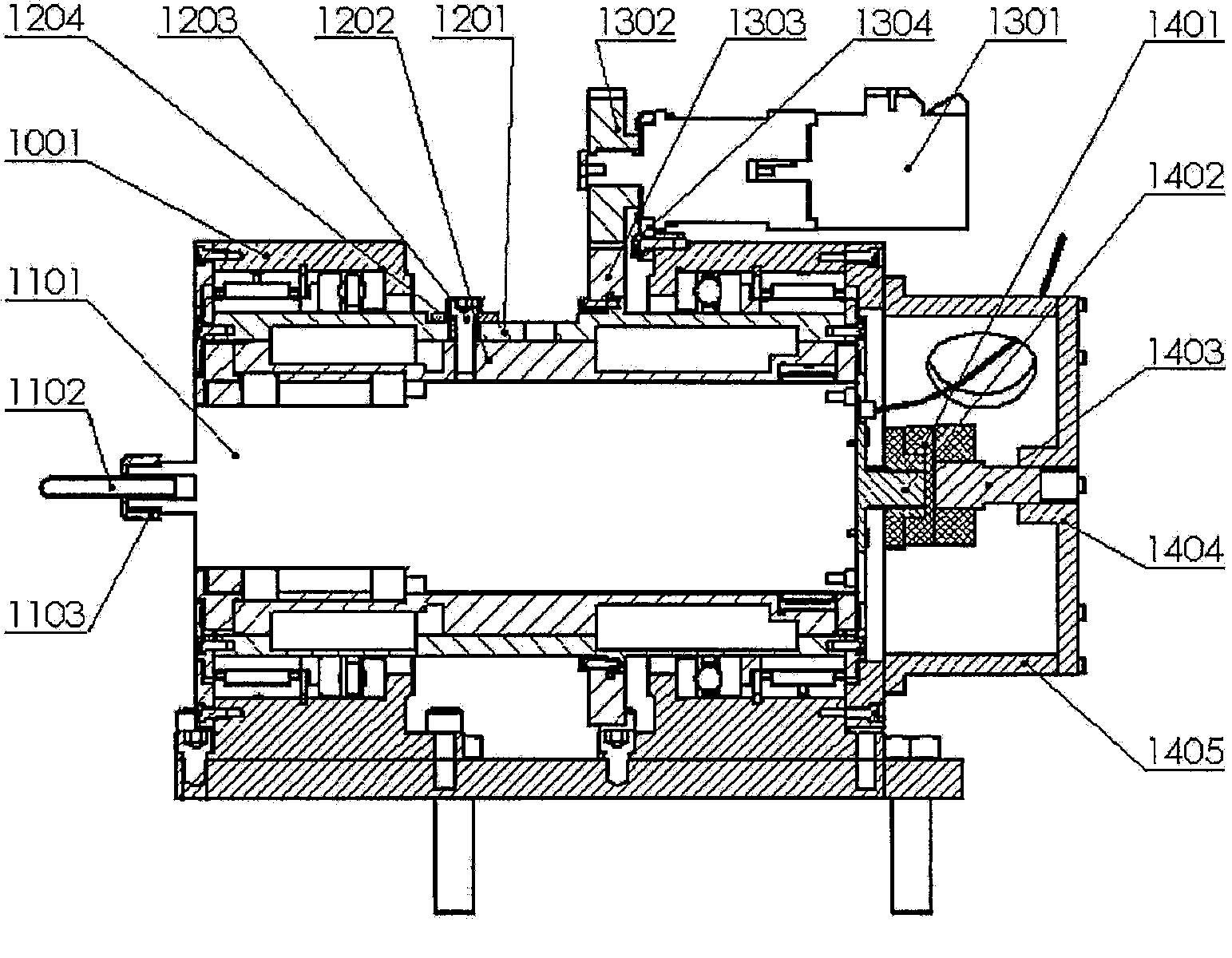

Hole forming device capable of adjusting aperture of formed hole on line

ActiveCN103659403ARealize processingSolve the entanglementFeeding apparatusLarge fixed membersFrequency changerEngineering

The invention discloses a hole forming device capable of adjusting the aperture of a formed hole on line. The hole forming device comprises an eccentric hole-forming machine head component, an eccentric head feeding platform component, an aperture adjusting driving component, a main shaft cable winding-preventing component and a pressing foot component. According to the hole forming device, an inner eccentric sleeve and an outer eccentric sleeve are used for achieving high-speed self rotating of a tool and revolution of the tool around a changeable center in a hole forming process, and then compound motion needed by tool eccentric hole forming is provided. The self-rotating speed of the tool is achieved by the fact that an outer frequency changer controls the frequency of an electric main shaft. Aperture adjusting, tool revolution speed and tool axial feeding speed can be accurately controlled by programs through servo control motors. The hole forming device can achieve on-line formed hole aperture adjusting, hole forming efficiency is improved, meanwhile, machining of taper hole can be achieved, the problem of cable winding during main shaft high-speed rotating is avoided through a main shaft cable winding-preventing mechanism, and the stability and the safety of the whole hole forming device are improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

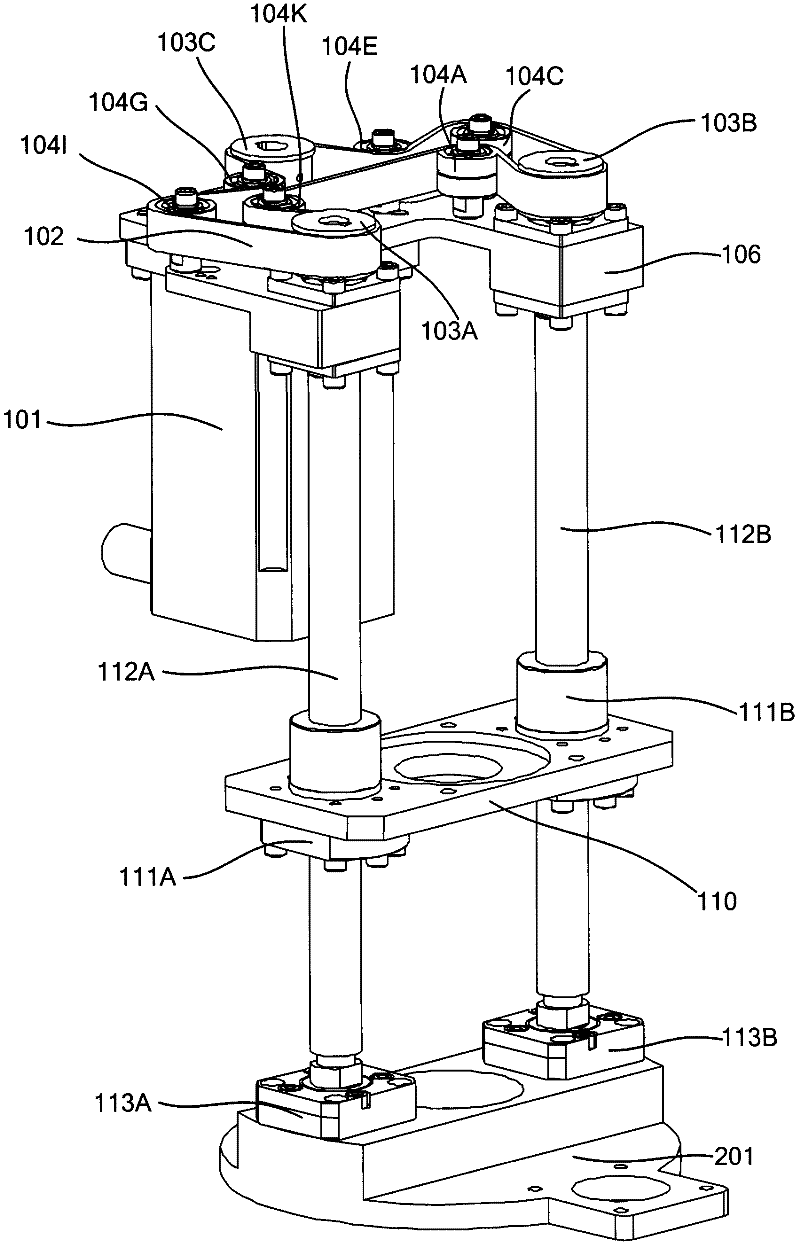

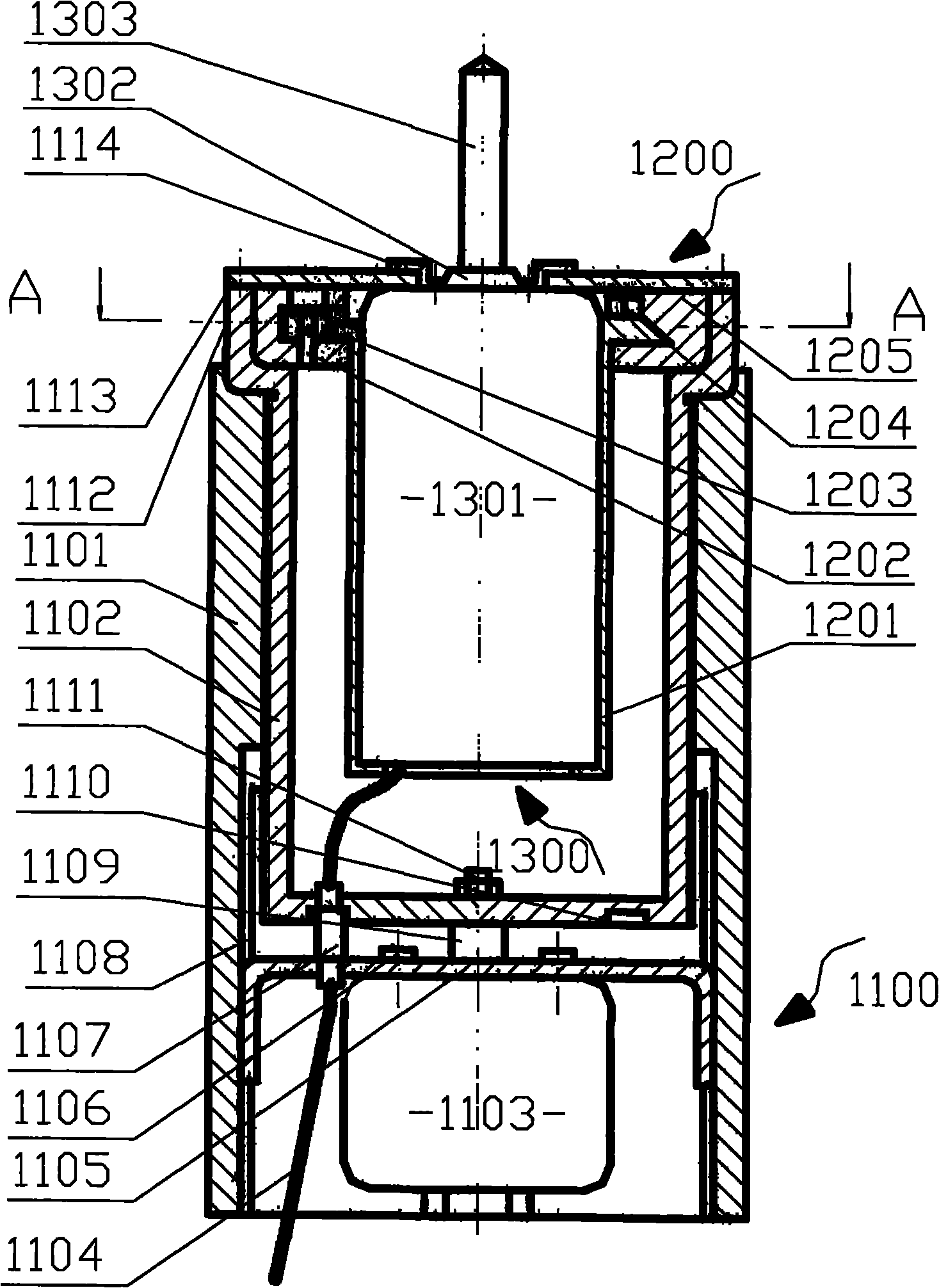

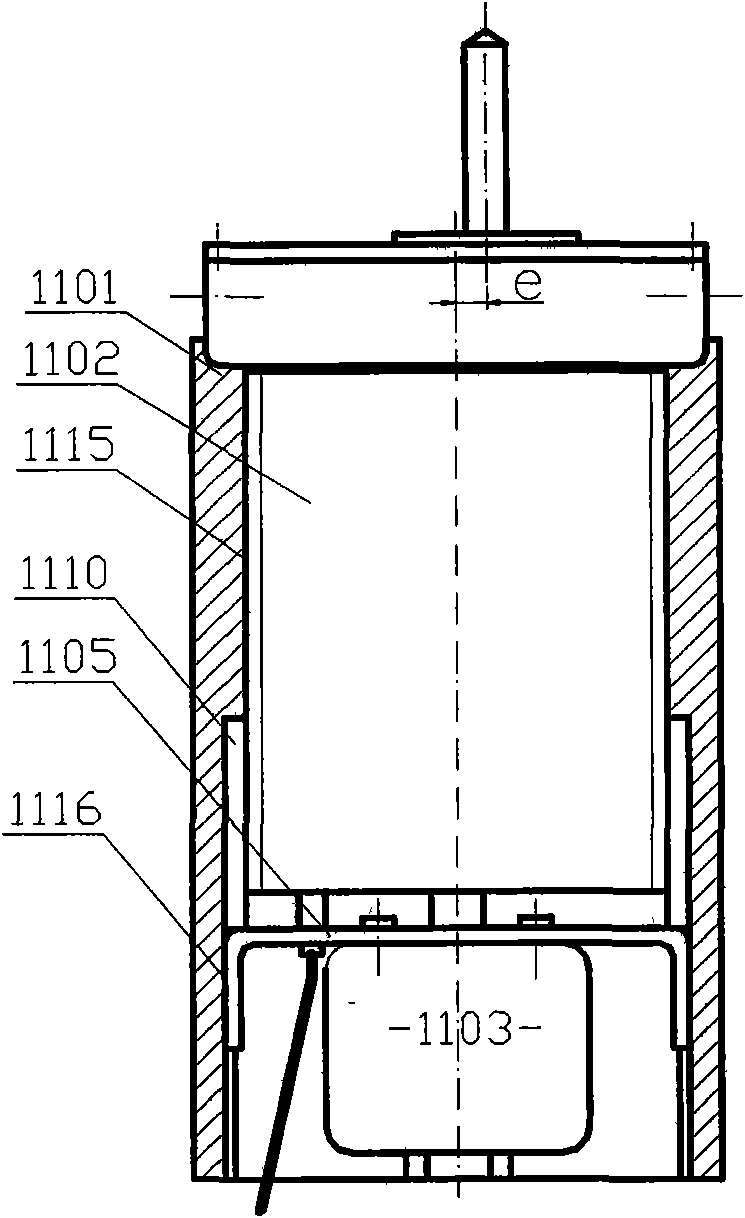

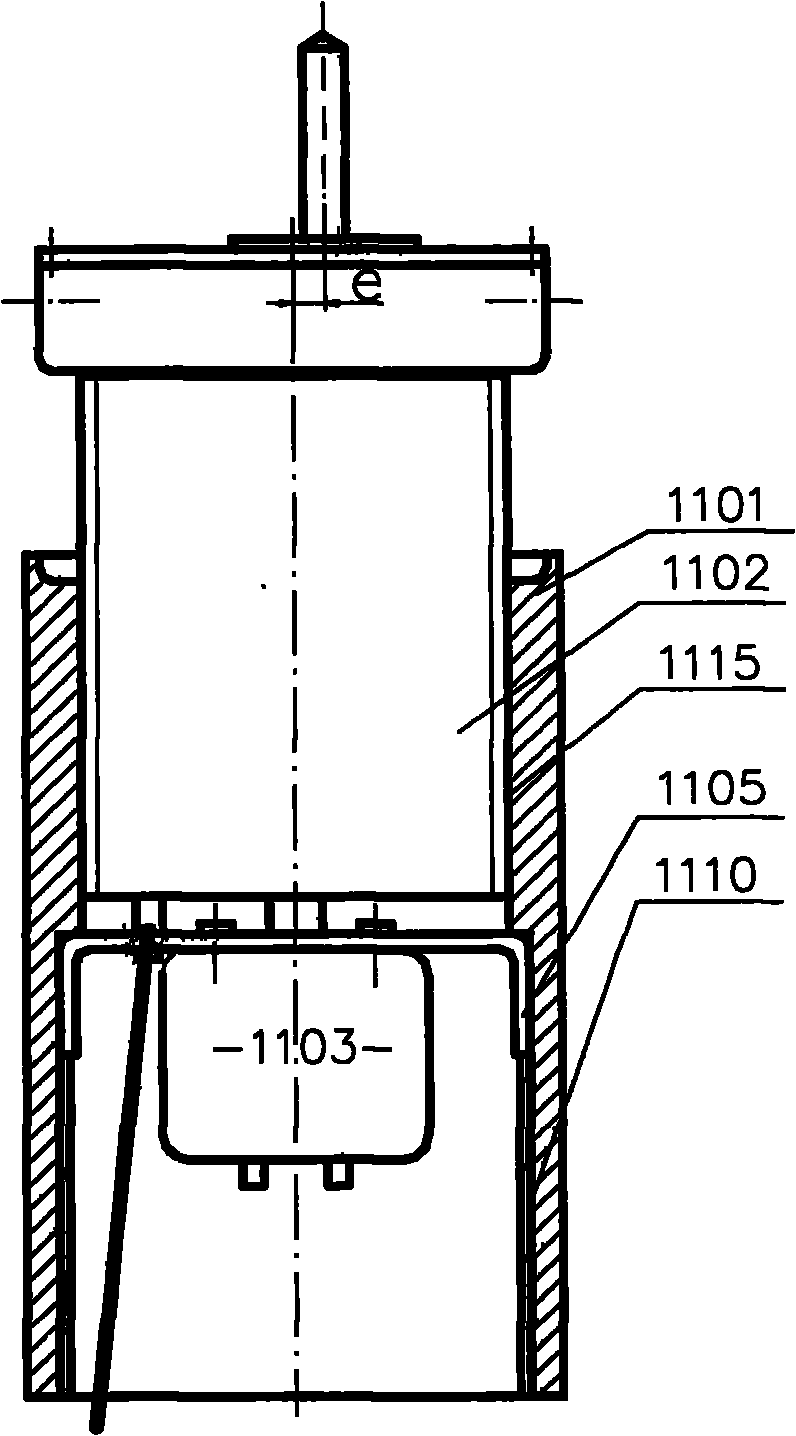

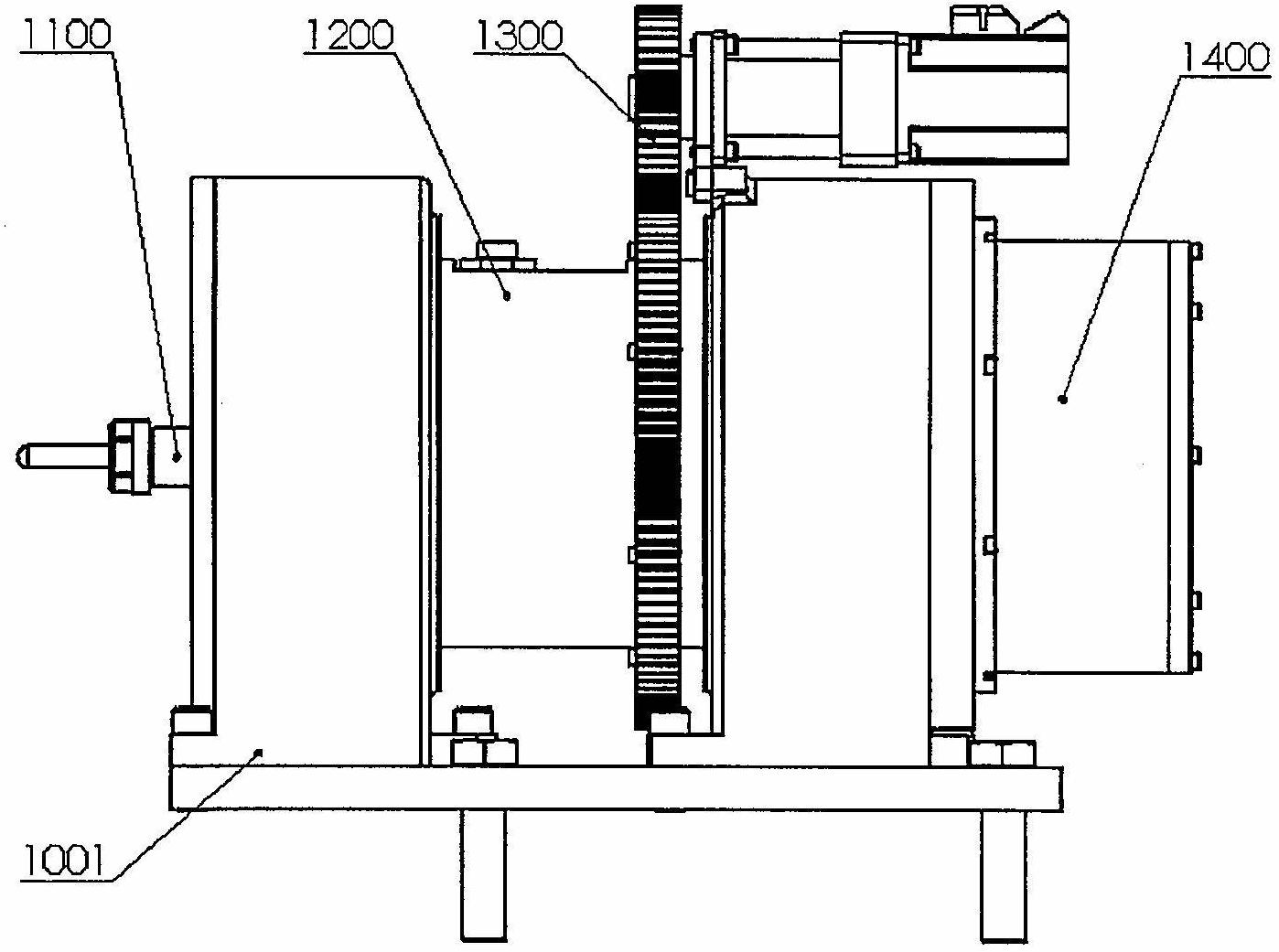

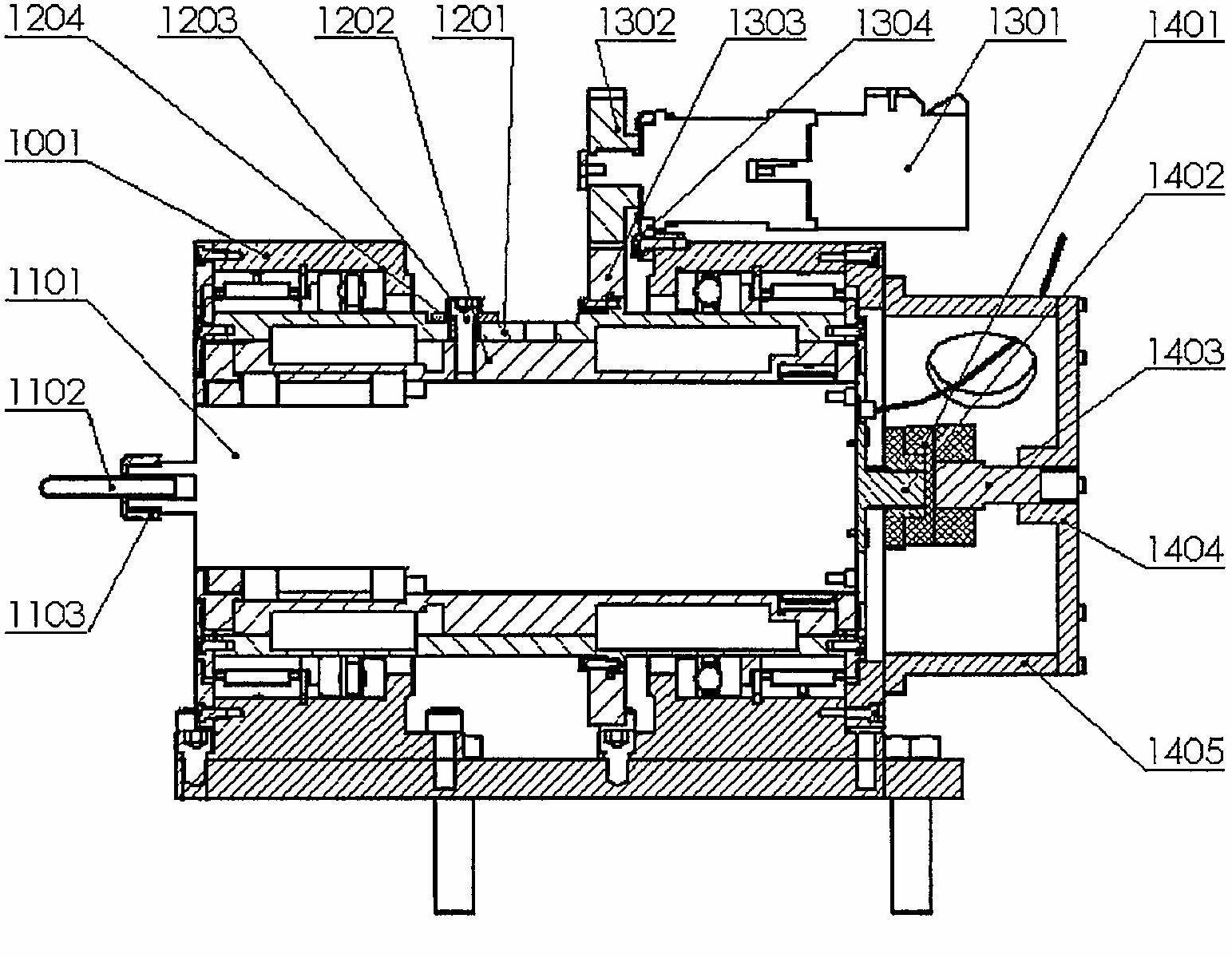

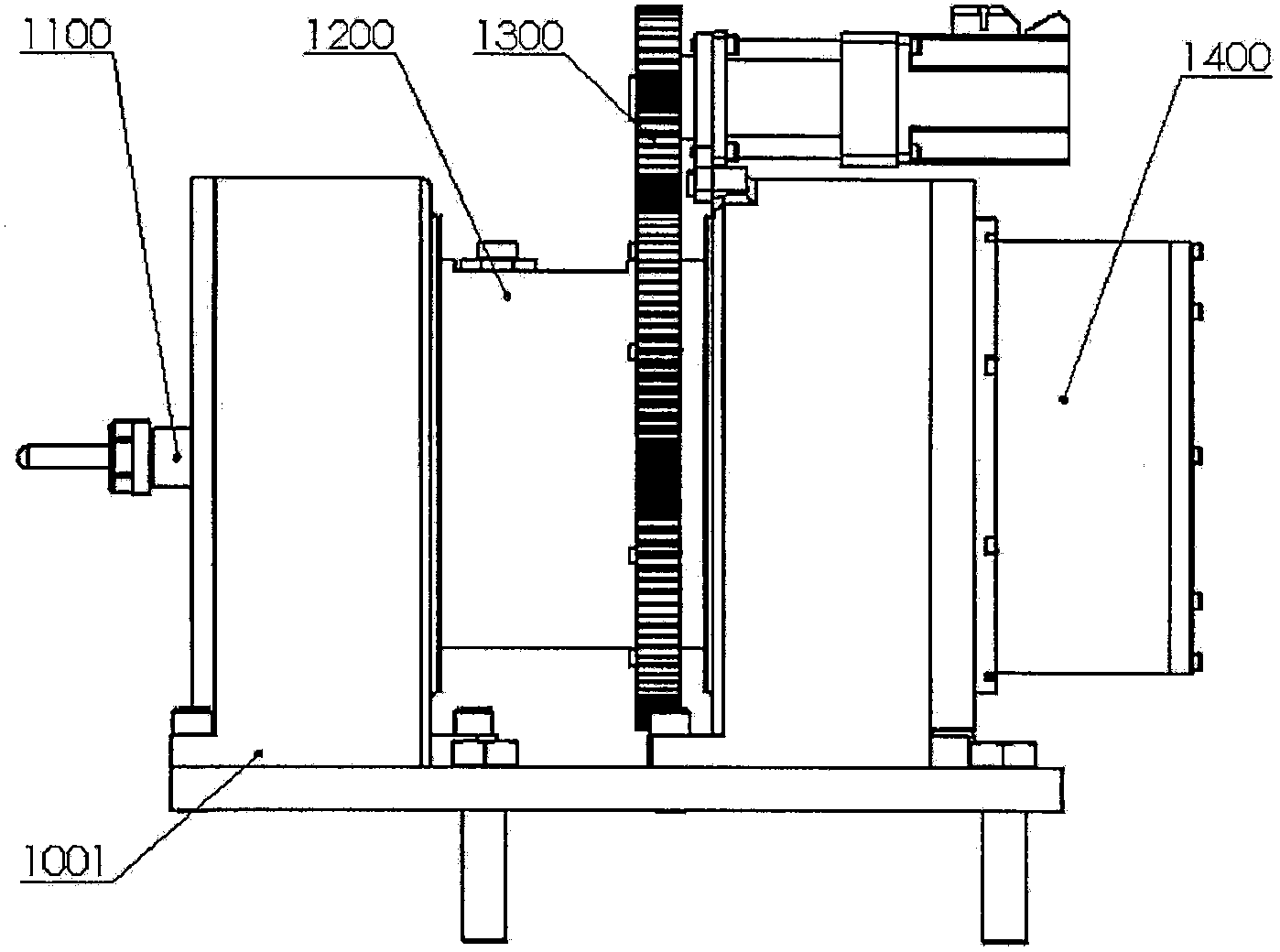

Helical milling device and method

InactiveCN101786180ASimple structureReduce weightFeeding apparatusMilling equipment detailsEngineeringRadial deviation

The invention relates to a helical milling device and a helical milling method, and belongs to the technical field of machining. The device mainly comprises a helical feed mechanism (1100) used for realizing the axial feeding and revolution of a cutter (1303), a radial deviation mechanism (1200) used for adjusting the revolution radius of the cutter (1303) relative to axes of pores and a rotation mechanism (1300) used for driving the cutter to rotate. The device and the method of the invention can greatly improve the manufacturing quality and machining efficiency of complex pore series on surfaces of large-scale workpieces.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

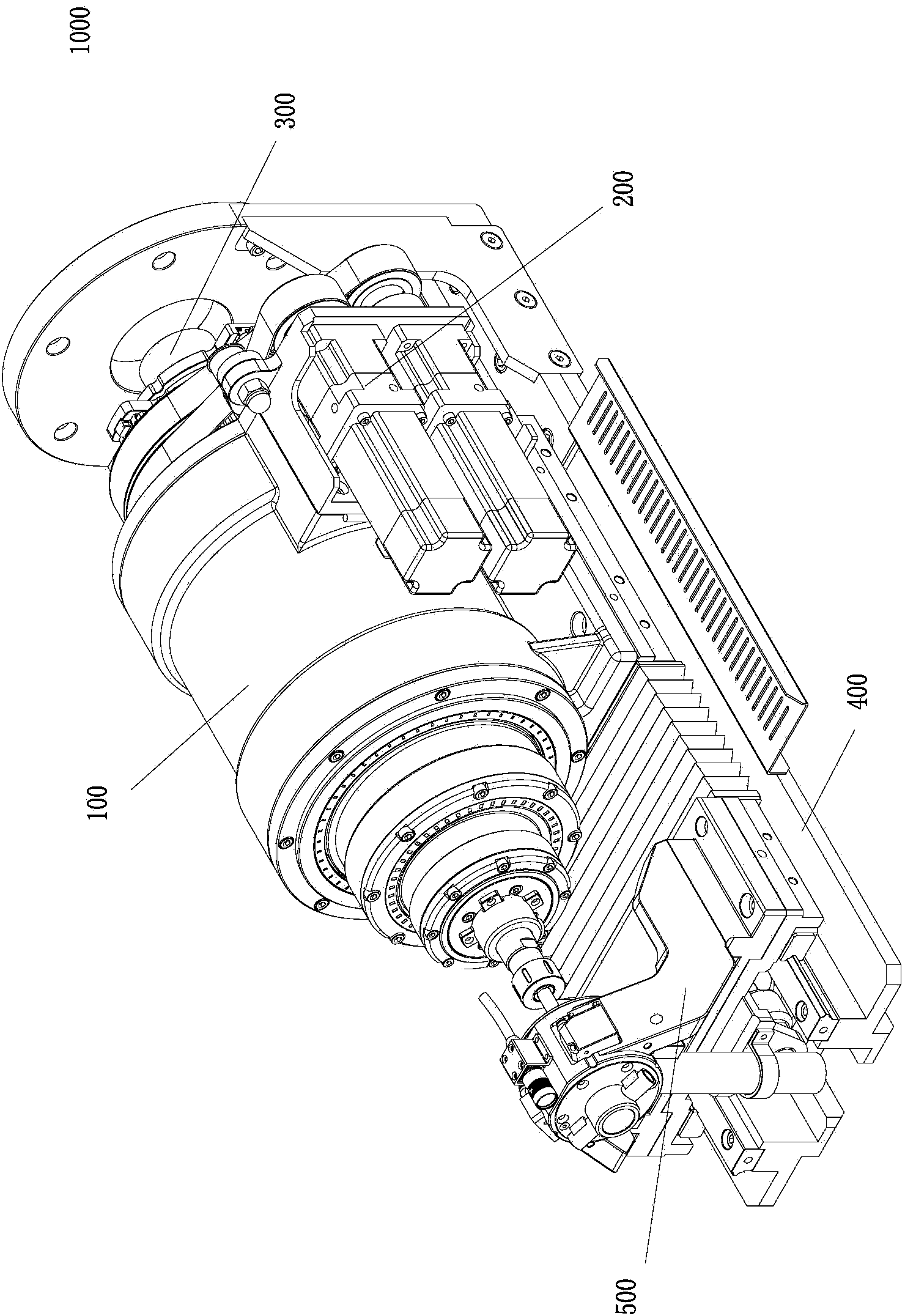

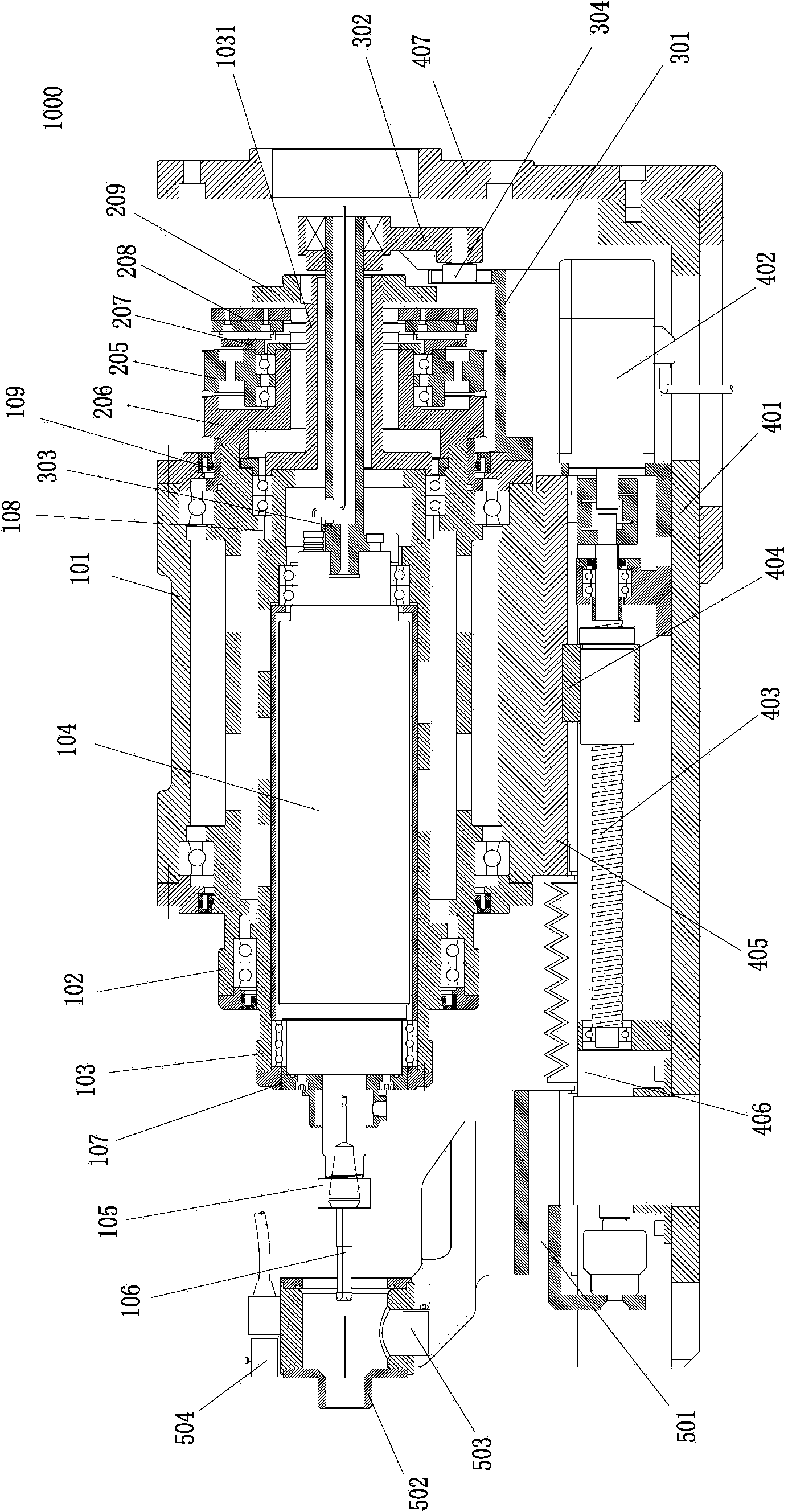

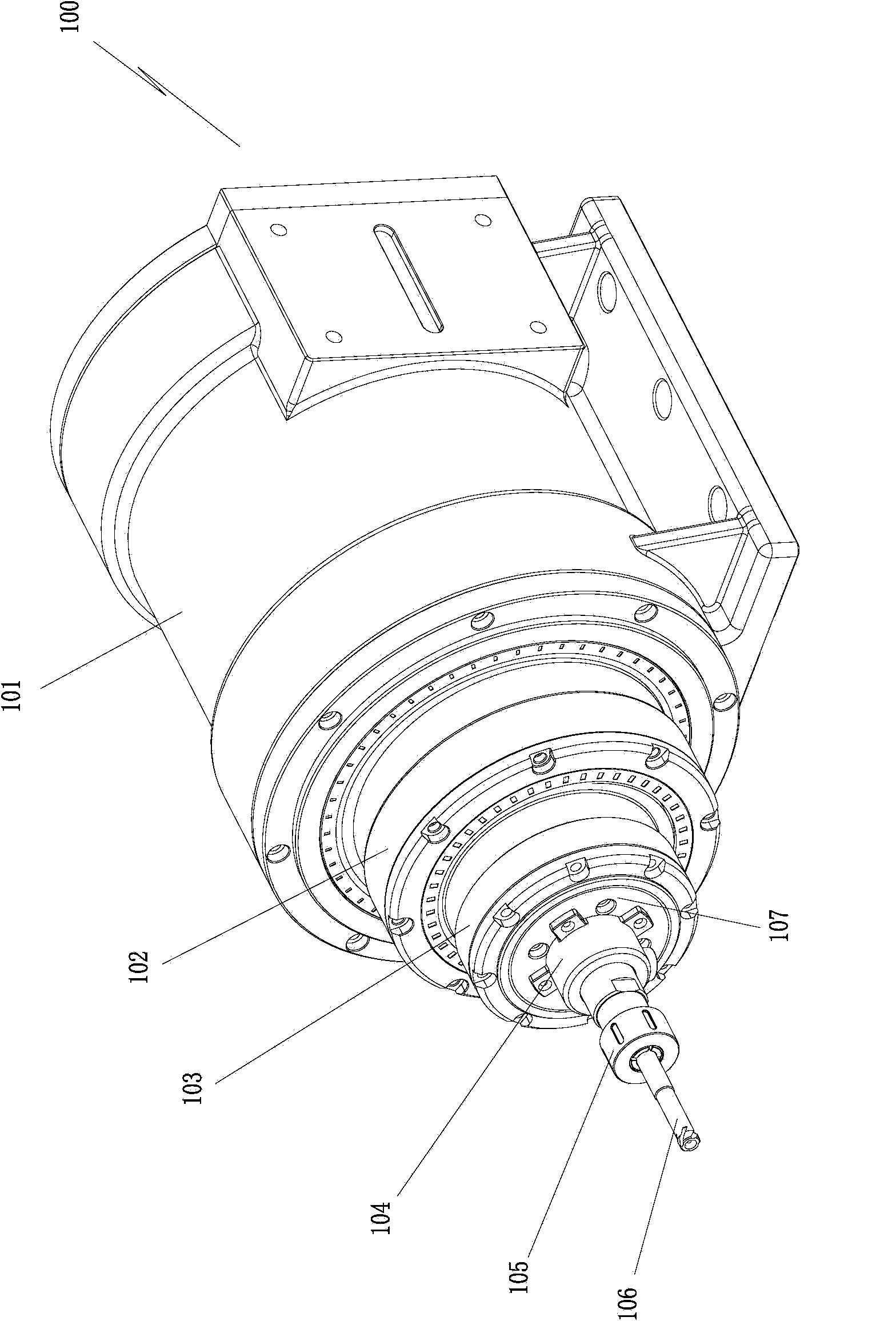

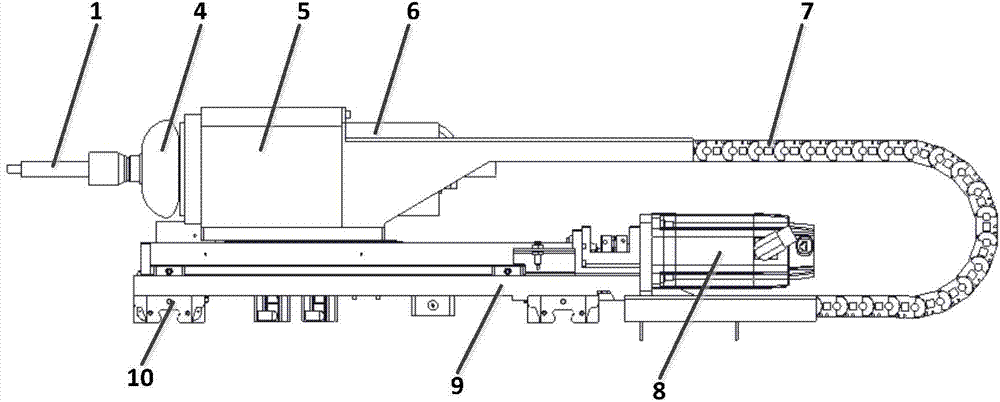

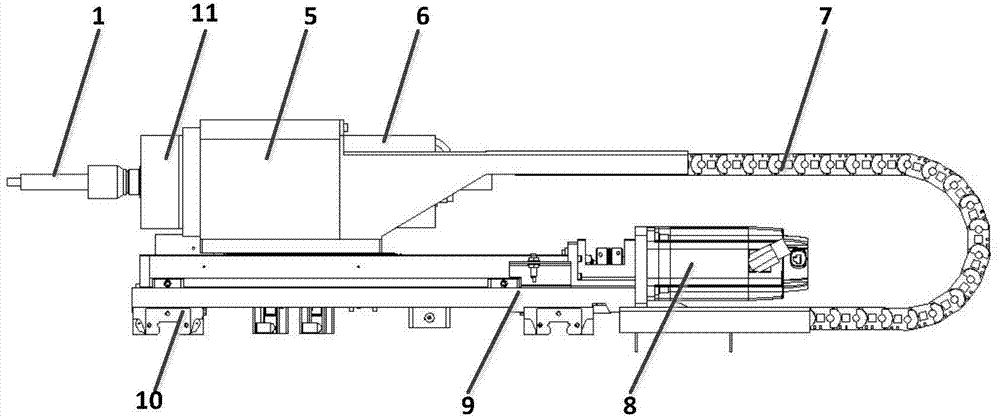

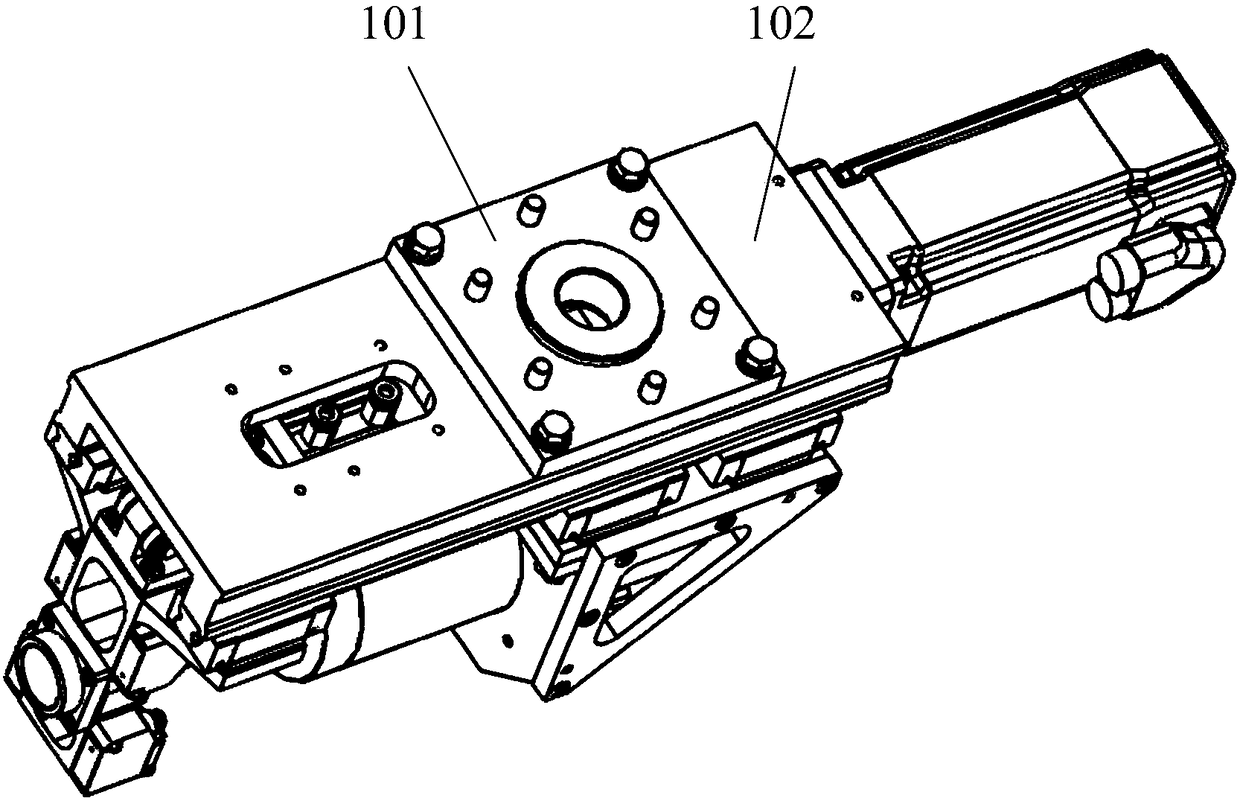

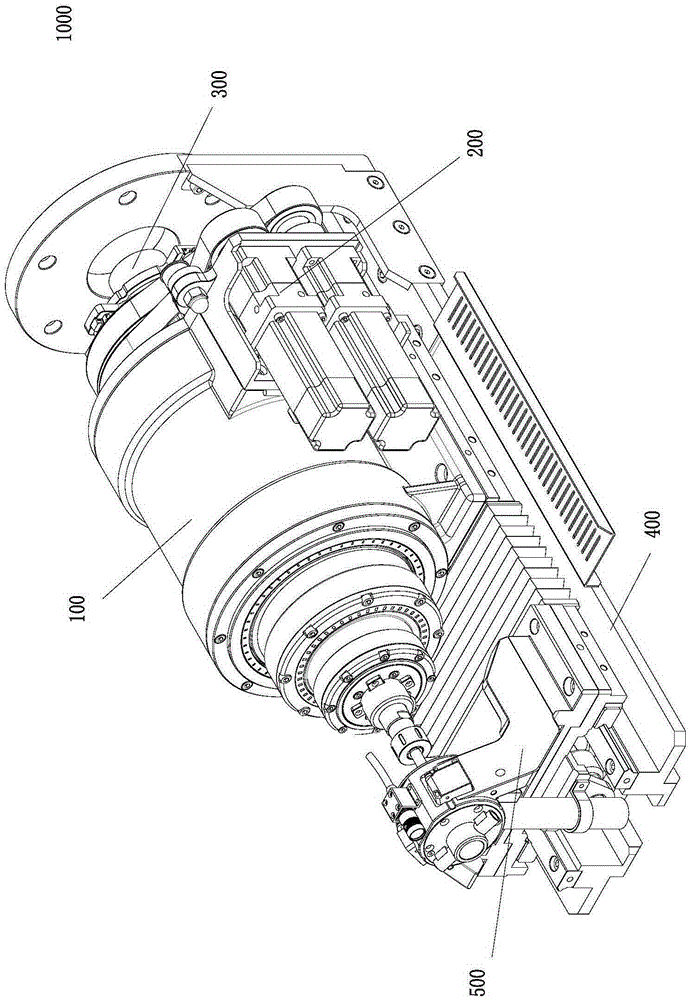

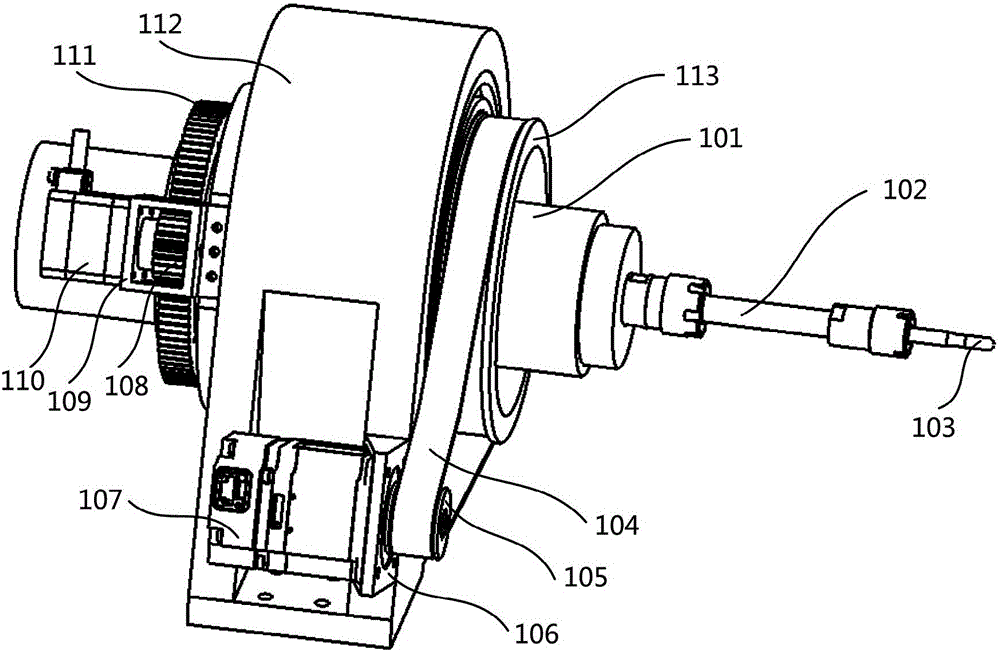

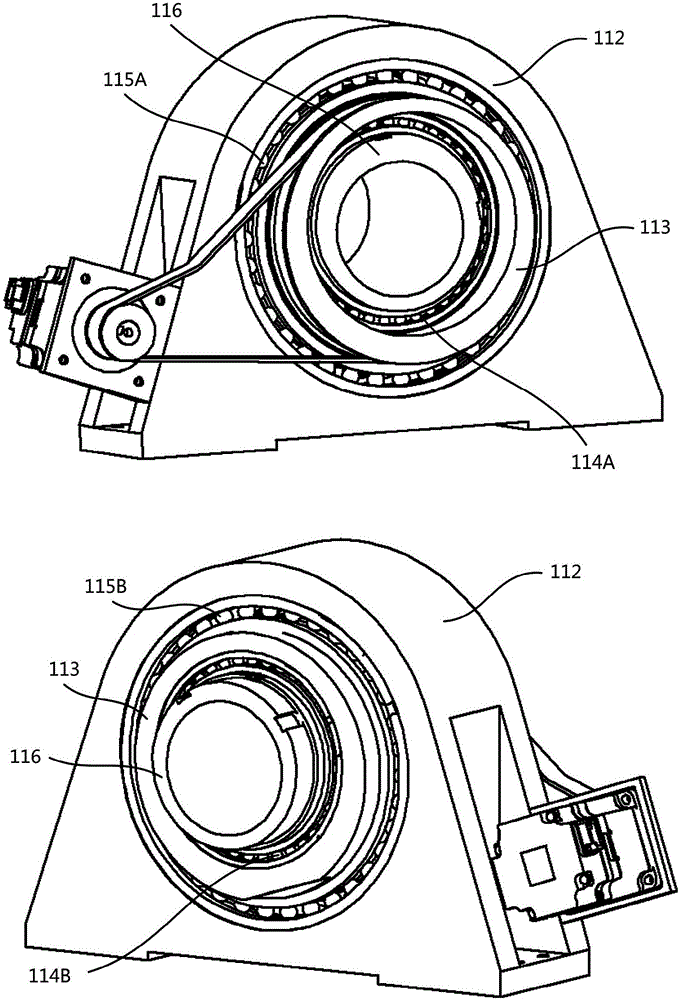

Drilling tail end actuator

ActiveCN103100734AFunctionalEasy to expose layoutBoring/drilling componentsBoring/drilling machinesButt jointActuator

The invention discloses a drilling tail end actuator which comprises a butt joint support assembly, a cutter revolution assembly arranged at one end of the butt joint support assembly in a rotation mode, a cutter rotation assembly arranged in the cutter revolution assembly in a rotation mode, an axial feeding assembly arranged at the other end of the butt joint support assembly and used for controlling axial feeding of a cutter, and a cutter deviation adjusting assembly arranged on the cutter revolution assembly and used for performing deviation adjustment on the cutter. The drilling tail end actuator has the advantages that the cutter deviation adjusting assembly is arranged so that the drilling tail end actuator clamps the cutter capable of machining various apertures, a cutter changing link is avoided, and drilling efficiency is improved. The cutter revolution assembly and the cutter rotation assembly are arranged so that double functions of drilling and milling holes in a screwed mode of the drilling tail end actuator are achieved. Externally exposed arrangement of the cutter deviation adjusting assembly is achieved so that transmission design among moving components is convenient, and the design difficulties of the drilling end tail actuator are reduced.

Owner:江苏欧亿德新材料科技有限公司

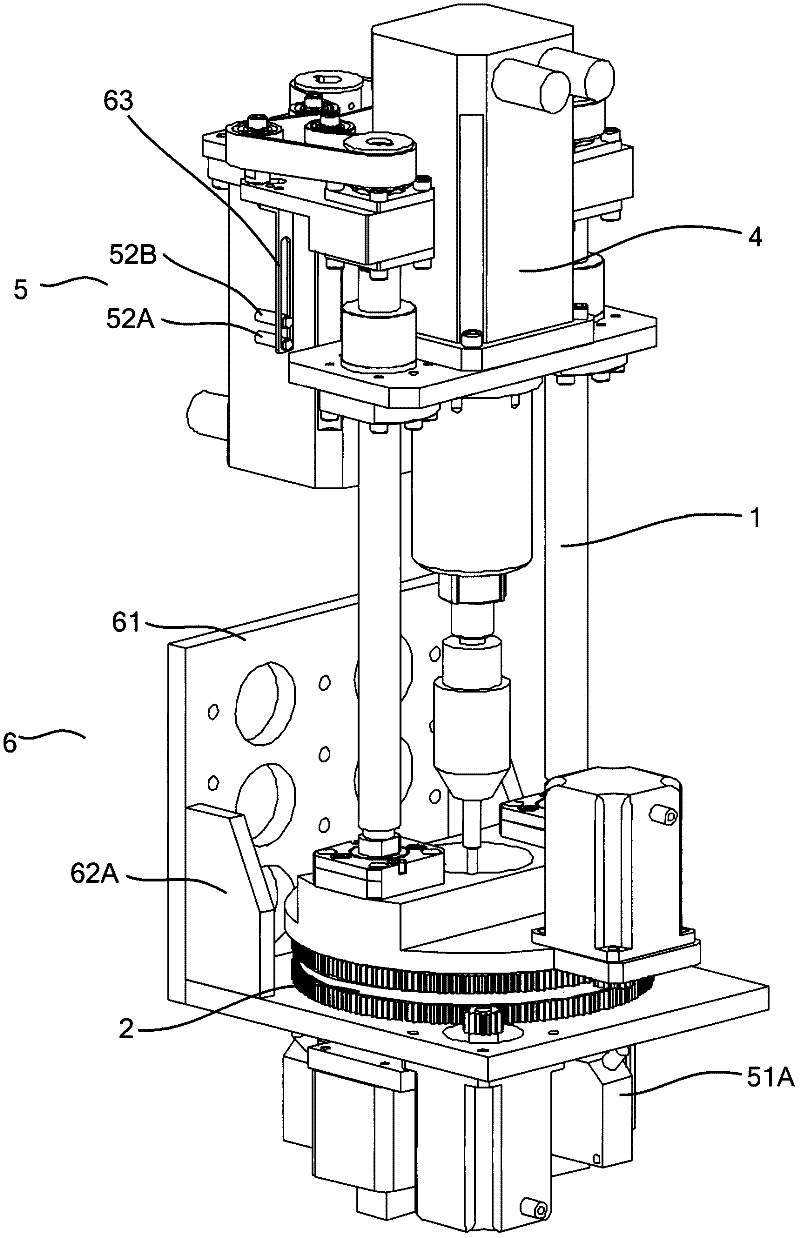

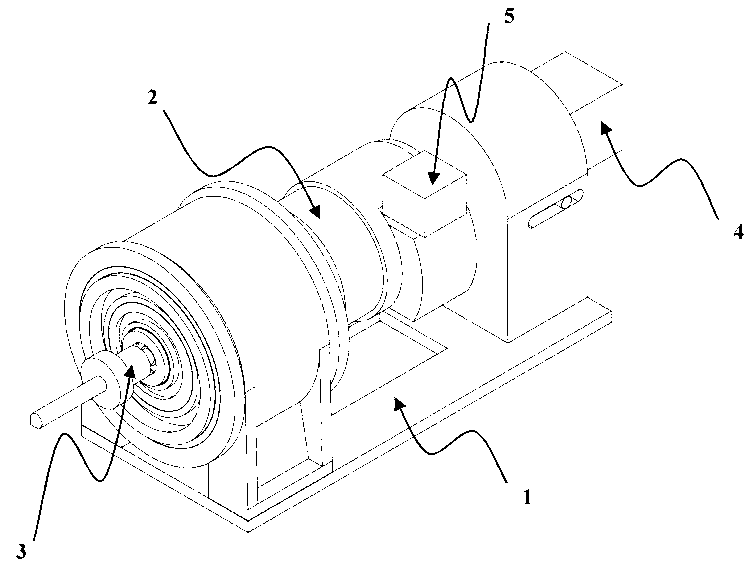

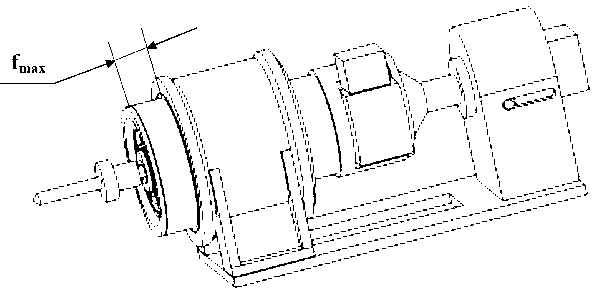

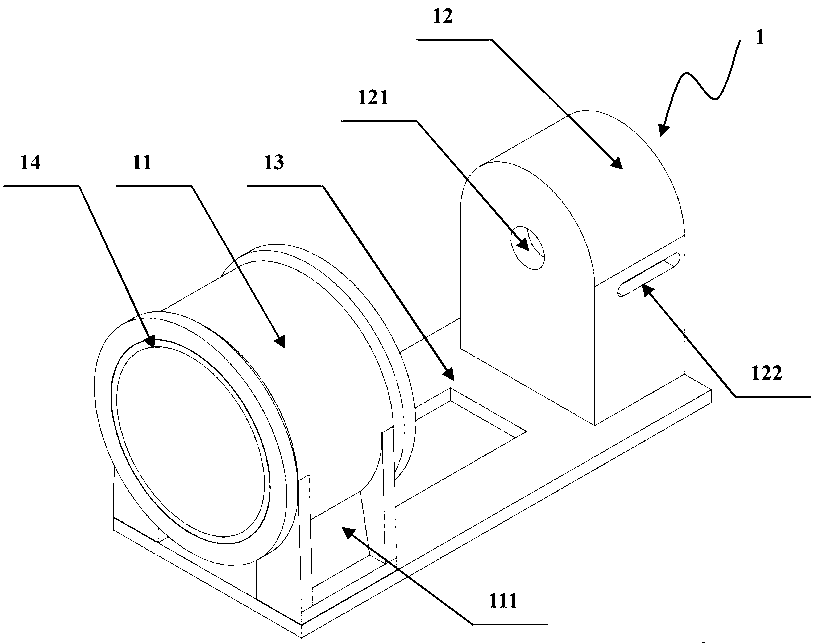

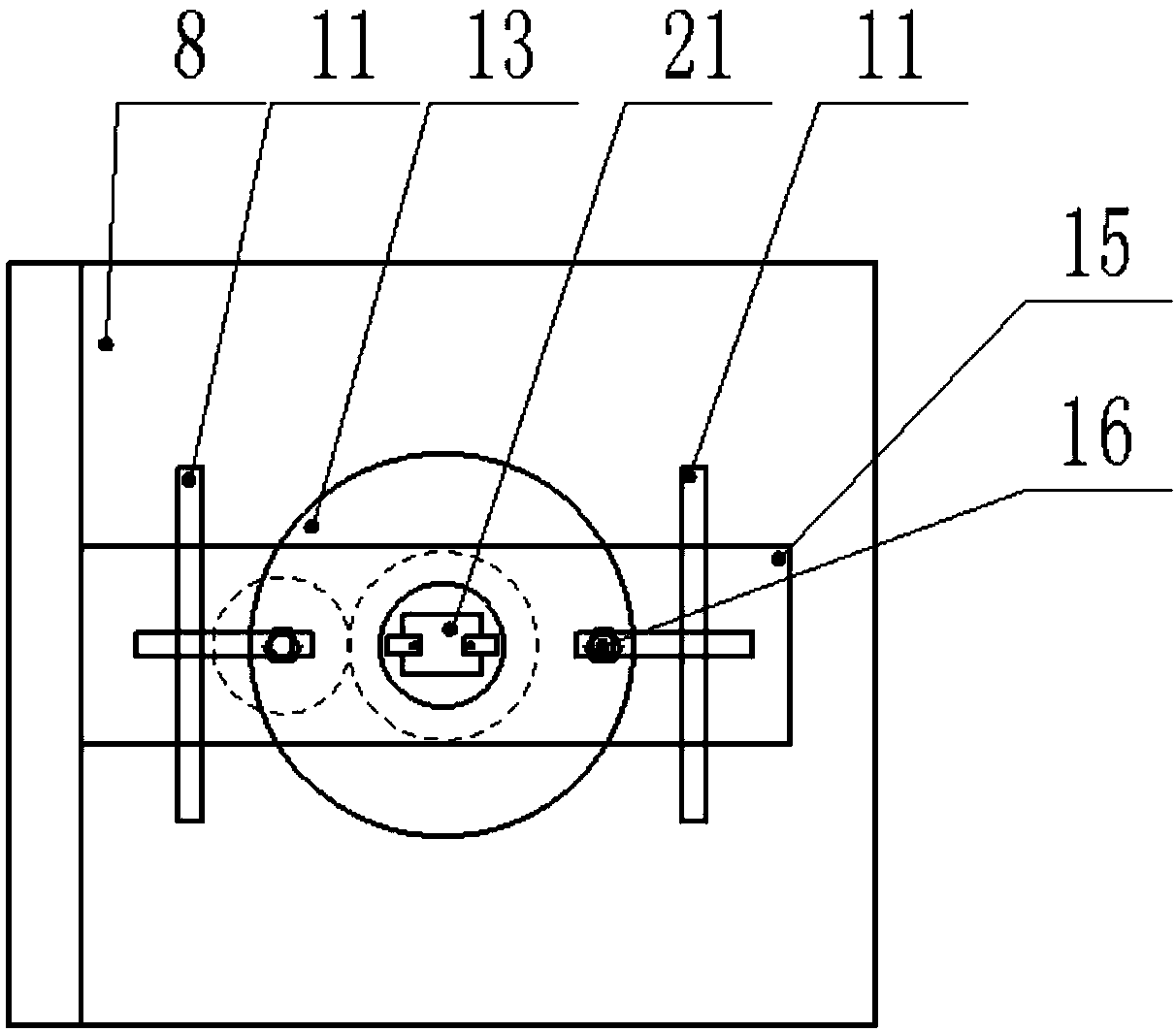

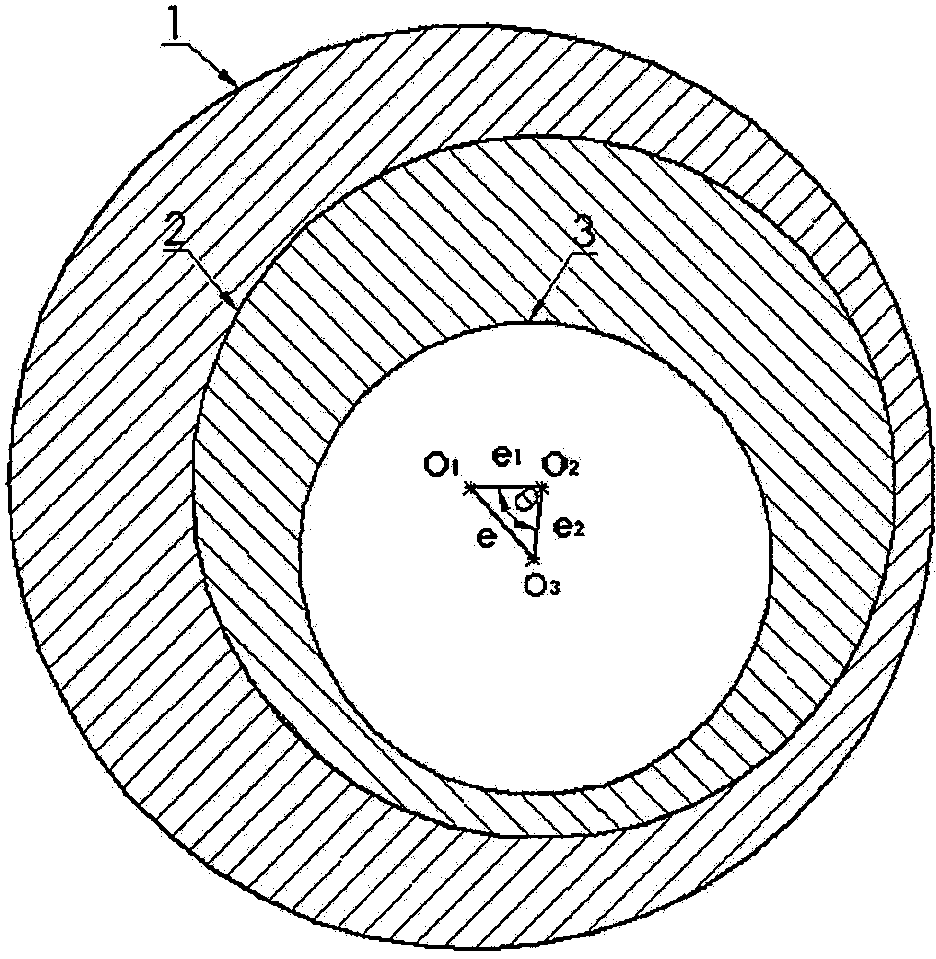

Hole helical milling device

ActiveCN102689040AImprove hole making efficiencyReduce processing costsMilling machinesNumerical controlMilling cutter

The invention provides a hole helical milling device, which comprises a frame, a main shaft system, a deviation regulating mechanism, a revolution system and an anti-winding mechanism. The main shaft system includes an electric main shaft and a milling cutter fixed to the free end of the electric main shaft, and the electric main shaft drives the miller cutter to rotate. The deviation regulating mechanism includes an inner cylinder and an outer cylinder, the inner cylinder surrounds the electric main shaft, the outer cylinder surrounds the inner cylinder, the inner circle and the outer circle of the outer cylinder are eccentrically arranged, and the inner circle and the outer circle of the inner cylinder are eccentrically arranged. The revolution system includes a driving motor, a pinion and a bull gear, the driving motor drives the pinion to drive the bull gear so as to realize revolution of the main shaft system, and an eccentric distance exists between the axial line of rotation of the milling cutter and the axial line of the revolution of the main shaft system. The device disclosed by the invention can be mounted on a mechanical arm, realizes accurate positioning of hole center and axial milling feeding by CNC (computer numerical control) during hole formation, is suitable for work occasions where a large number of series hole-diameter hole structures are rapidly manufactured.

Owner:SHANGHAI AIRCRAFT MFG +1

Aviation lamination material variable-parameter adaptive hole drilling system and method

ActiveCN104759658ARealize online monitoringAchieving Adaptive ControlAircraft componentsAutomatic control devicesAviationDrive motor

An aviation lamination material variable-parameter adaptive hole drilling system is characterized by comprising a, an end executor; b, a force sensor or a current detector; c, an adaptive controller; d, a control unit. An electric spindle transducer of the end executor controls the rotation of an electric spindle. The force sensor or the current detector is arranged on the electric spindle to be used for detecting the axial force or the current of the electric spindle. The adaptive controller communicates with the force sensor or the current detector and the control unit to be used for receiving feedback signals of the force sensor or the current detector to send instructions to the control unit, and the control unit controls the end executor to perform corresponding actions. A drive motor of the end executor comprises an encoder to be used for recognizing and feeding back tool feeding positions, and the adaptive controller communicates with the encoder and the control unit to be used for receiving the feedback signals of the encoder to send instructions to the control unit which controls the end executor to perform corresponding actions.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

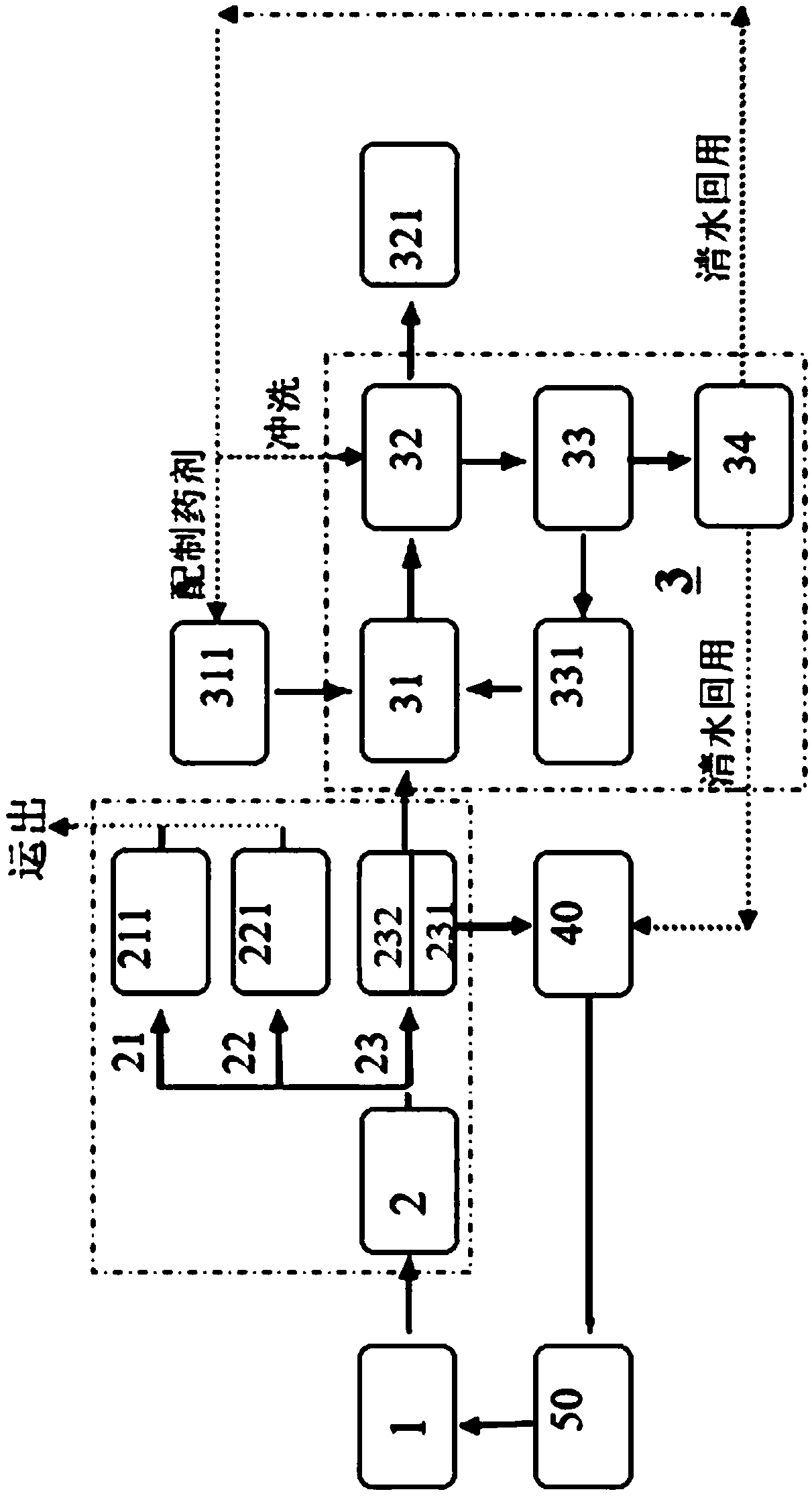

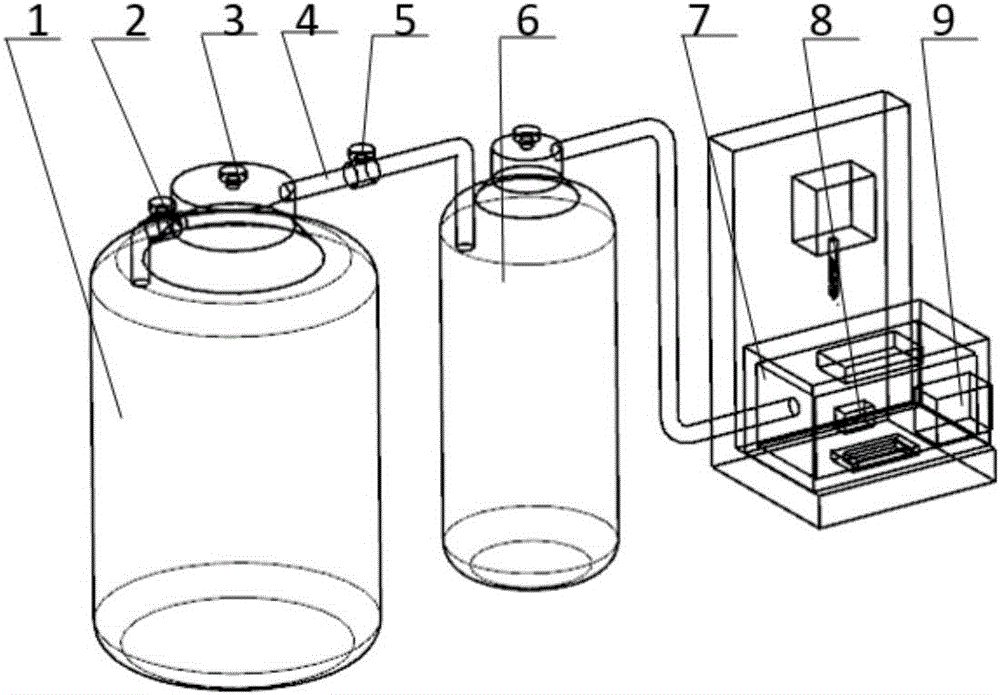

Purifying treatment method and system for cuttings-carrying slurry of bentonite

PendingCN107842330AReduce wear and tearAchieve the goal of energy saving and emission reductionFlushingFlocculationSlurry

The invention provides a purifying treatment method for cuttings-carrying slurry of bentonite. The purifying treatment method for the cuttings-carrying slurry of the bentonite comprises the steps thatmud-water separating treatment is conducted, specifically, a multistage sieving device is used for conducting separating treatment on the input cuttings-carrying slurry, sandstone which does not conform to a slurry system is sorted out, then the slurry is subjected to concentrating and dewatering, and concentrated slurry and a mud-containing water body are obtained; and purifying and recovery ofthe mud-containing water body are conducted and comprise the steps of flocculation filter pressing and flocculation sedimentation, specifically, according to the flocculation filter pressing step, first the mud-containing water body is adjusted to a predetermined solid content, a flocculant is added, then a mixture enters a filter press for filter pressing, a mud cake and filter water are obtained, and according to the flocculation sedimentation step, the filter water generated in the flocculation filter pressing step is sent into a sedimentation tank and is subjected to sedimentation and layering in the sedimentation tank, and the upper layer of clear water is sent into a clear water tank for storage. According to the purifying treatment method for the cuttings-carrying slurry of the bentonite, the cuttings-carrying slurry can be subjected to full purifying treatment, zero discharge of water is realized, and a large amount of bentonite and the cost for dumping the waste slurry are saved.

Owner:河南小威环境科技有限公司

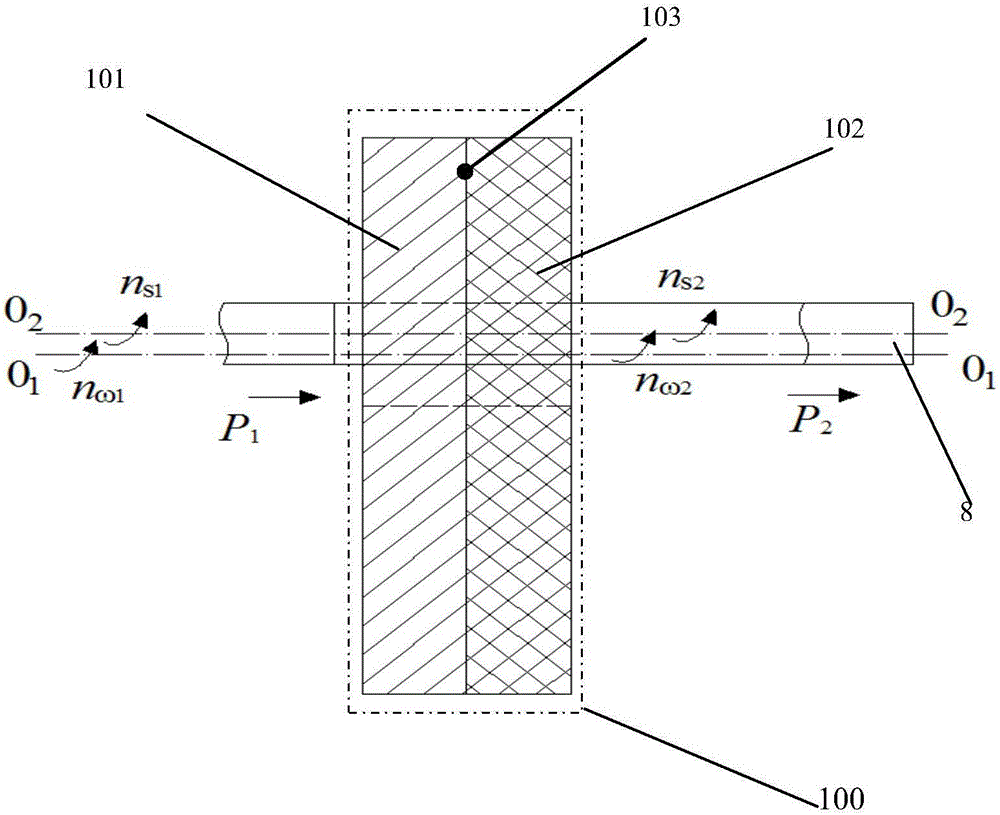

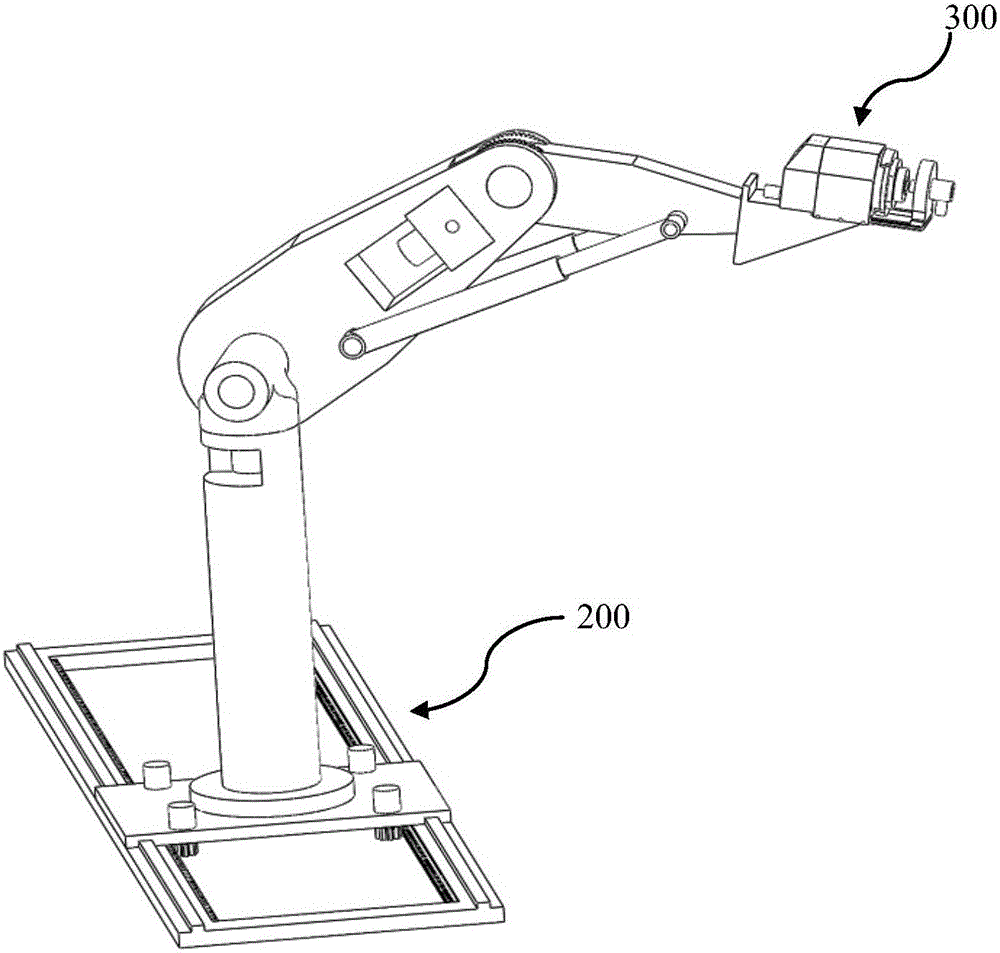

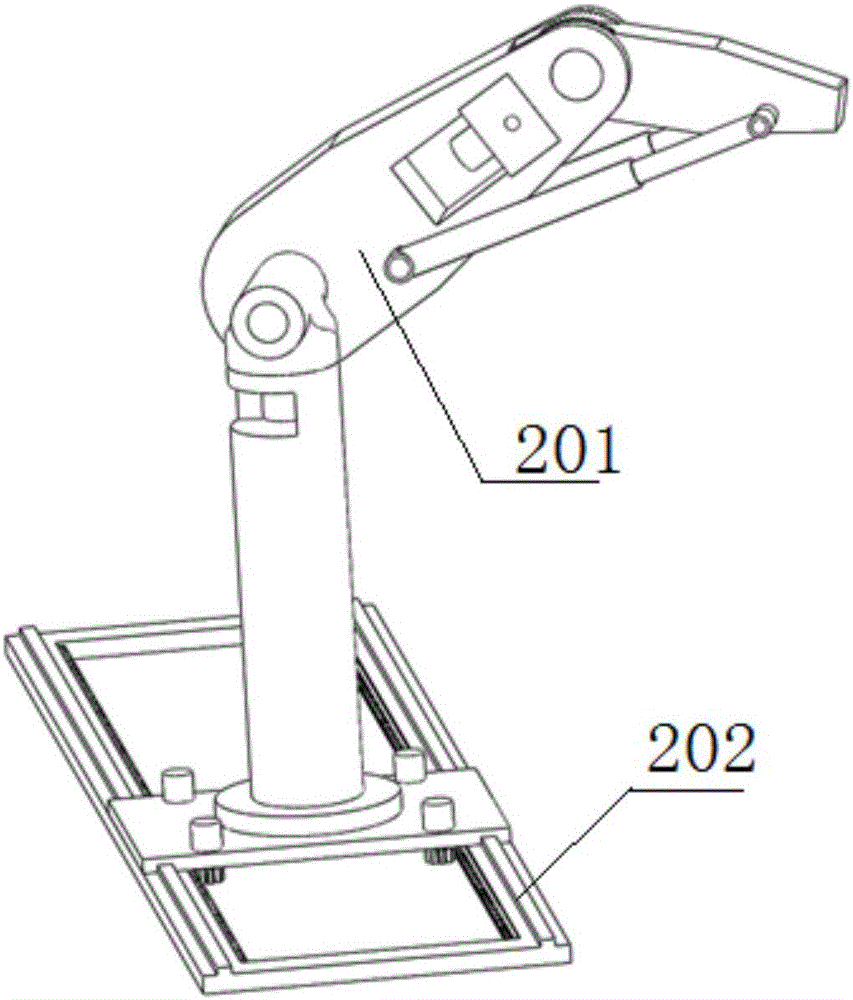

Robotized spiral drilling method and system for laminated structure of airframe

ActiveCN105728811AImprove hole making efficiencyQuality improvementWorkpiecesMilling equipment detailsEngineeringActuator

The invention discloses a robotized spiral drilling method and system for a laminated structure of an airframe. The robotized spiral drilling method comprises the steps of firstly, pressing a drilling region of the laminated layer of the airframe by using a pressing mechanism; then, spirally drilling a top-layer structural member at the high autoroatation speed ns1, low revolution speed nomega1 and large feeding pitch P1, matched with a top-layer structural member material, of a cutter; next, regulating the high autoroatation speed, low revolution speed and large feeding pitch of the cutter from ns1, nomega1 and P1 to ns2, nomega2 and P2 matched with a bottom-layer structural member material at an interface of the laminated layer; and finally, spirally drilling a bottom-layer structural member at ns2, nomega2 and P2. The system mainly comprises an industrial robot and a spiral drilling actuator, wherein the industrial robot is provided with a seventh shaft. The robotized spiral drilling method and system are beneficial to the reliable installation and connection of the spiral drilling actuator and a robot platform and can be used for remarkably increasing the spiral drilling efficiency and quality of the laminated structure.

Owner:NANJING COLLEGE OF INFORMATION TECH

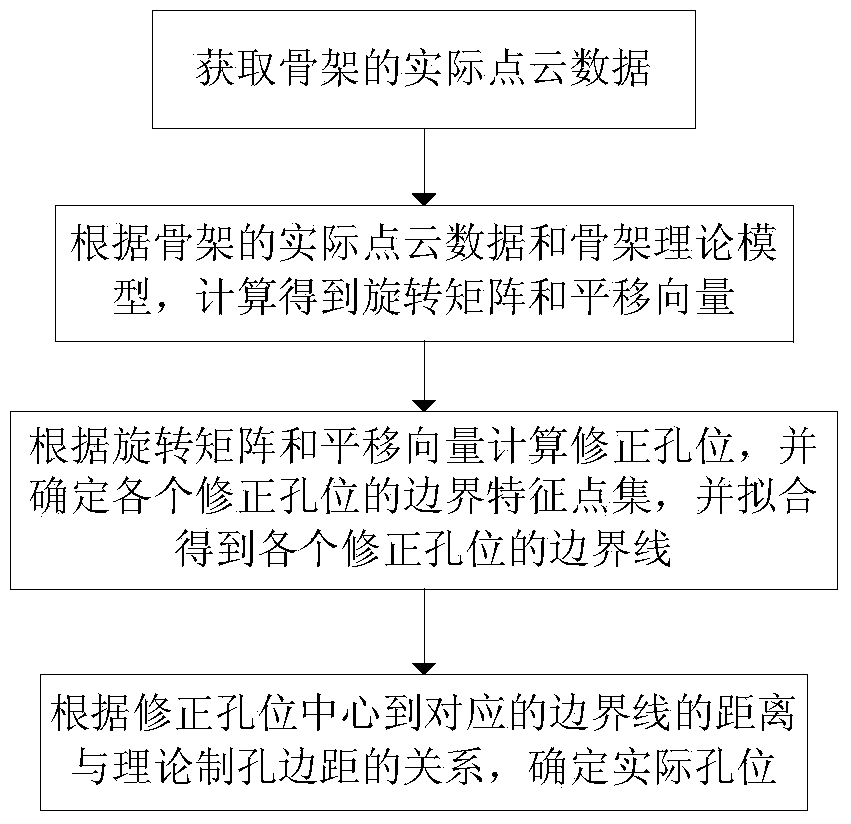

Method for correcting hole sites on basis of framework scanning measurement

ActiveCN103895877AEliminate inaccuraciesSolve the problem of unpredictable marginsAircraft assemblyPoint cloudComputer science

The invention provides a method for correcting hole sites on the basis of framework scanning measurement. The method for correcting the hole sites includes computing rotation matrixes and translation vectors according to actual point cloud data and theoretical models of frameworks; correcting theoretical hole sites on the frameworks by the aid of the rotation matrixes and the translation vectors to obtain corrected hole sites; determining boundary lines of the various corrected hole sites; utilizing distances from the centers of the corrected hole sites to the boundary lines as corrected hole drilling edge distances. The method has the advantages that the problem of difficulty in measuring edge distances of closed structures can be solved; integral procedures are implemented on the basis of digitalization, accordingly, manual measurement can be omitted, and technological processes can be simplified; the problem of hole site inaccuracy due to the fact that hole sites are manually corrected after involution is performed by the aid of an existing method can be solved, and the automatic hole drilling precision can be guaranteed; the hole sites are firstly corrected before the hole drilling edge distances are determined, and the corrected hole sites can be acquired, so that hole site inaccuracy due to deformation, positioning and coordination can be eliminated, and the automatic hole drilling precision can be guaranteed.

Owner:ZHEJIANG UNIV

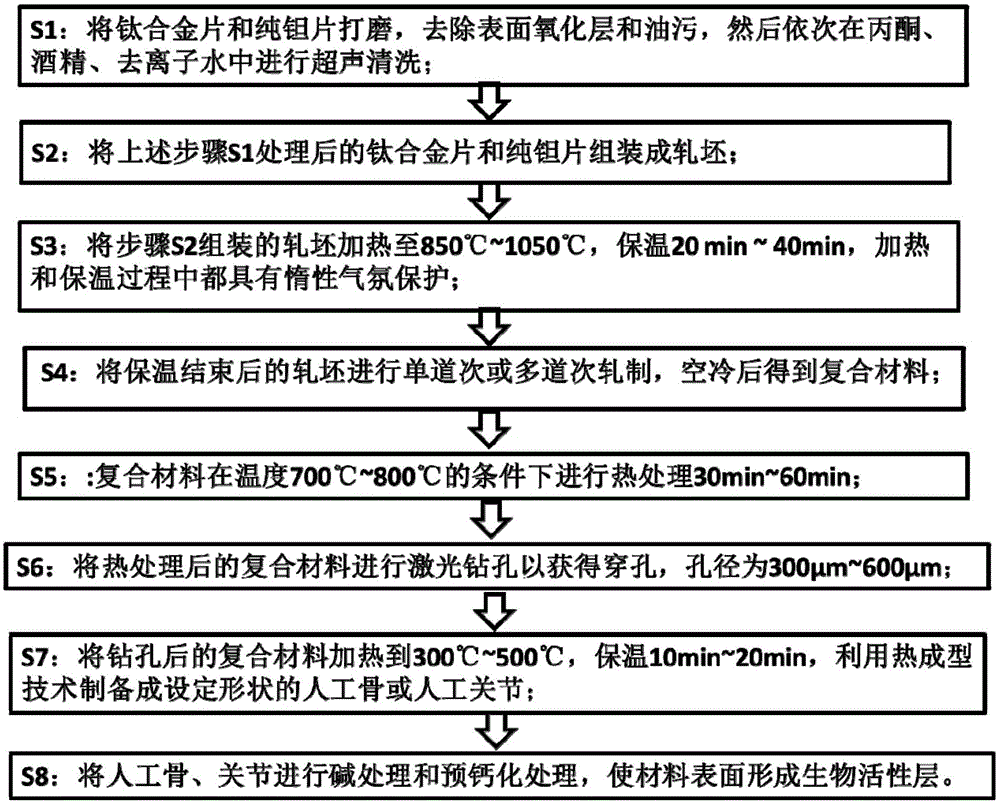

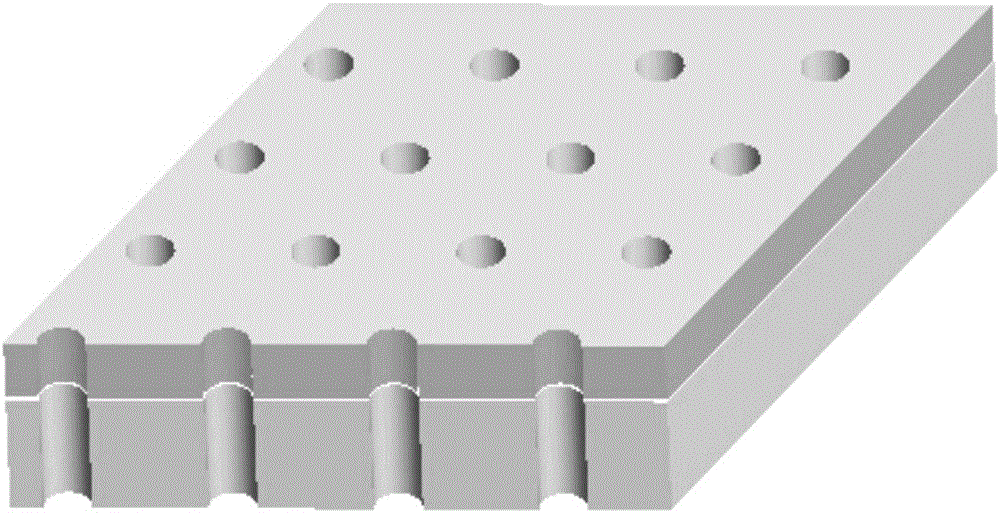

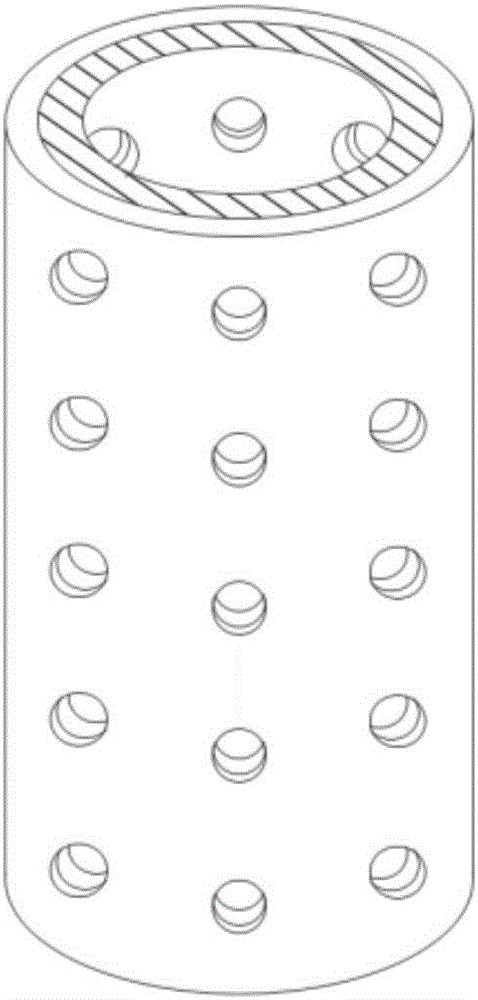

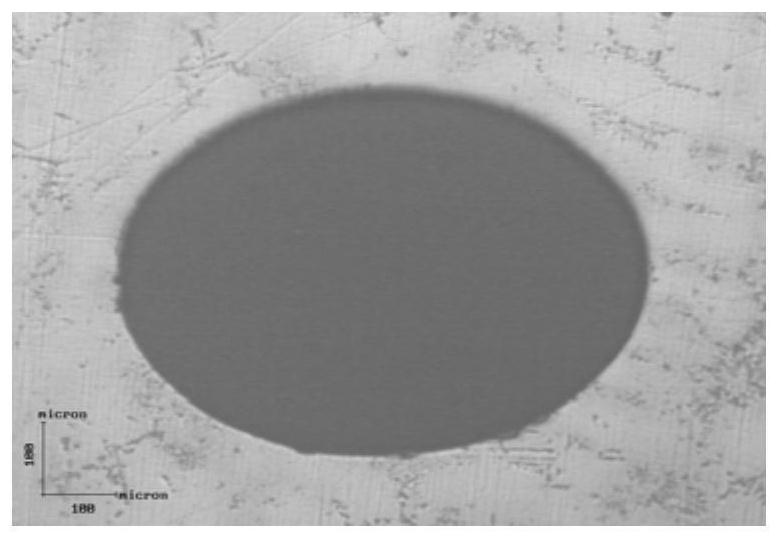

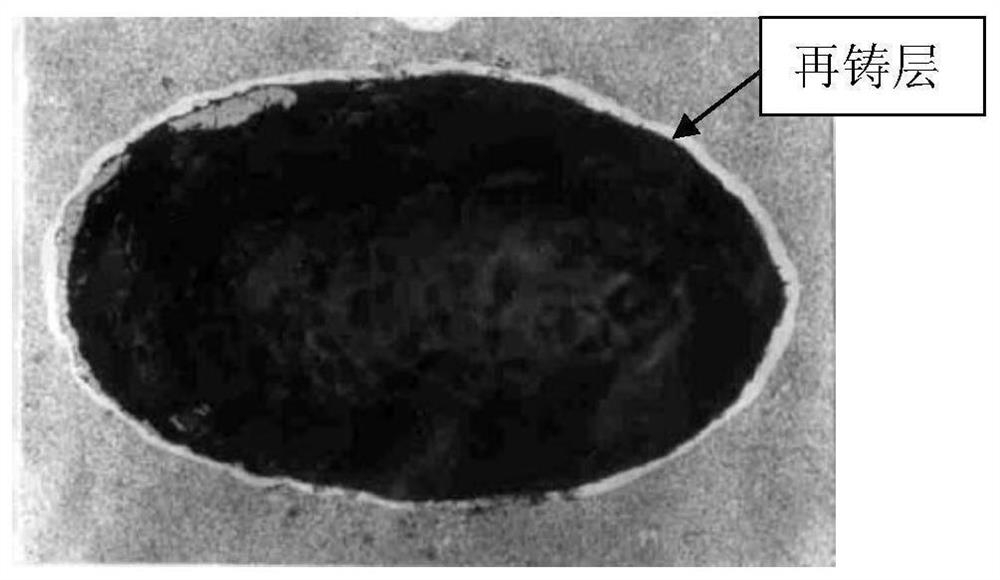

Method for preparing medical porous titanium-tantalum artificial bone and artificial joint, and products thereof

ActiveCN106693069AGuaranteed bonding qualityReliable workmanshipPharmaceutical delivery mechanismTissue regenerationBiocompatibility TestingArtificial bone

The invention discloses a method for preparing porous titanium-tantalum artificial bone and joint and products thereof, and belongs to the field of biological materials. The method comprises the following steps: S1, grinding to-be-bonded surfaces of a titanium alloy sheet and a tantalum sheet, and performing ultrasonic washing sequentially with acetone, alcohol and deionized water; S2, fitting the titanium alloy sheet and the tantalum sheet, heating to 850-1050 DEG C, insulating for 20-40 minutes, pressurizing to perform plastic deformation, and air-cooling to room temperature to form metallurgic bonding between the two materials; S3, quickly preparing pores having a pore size of 300-600mu m in a compound plate by utilizing a solid laser; S4, preparing various artificial bones and joints from the titanium-tantalum compound plate by utilizing a thermal forming technology; and S5, performing alkali and pre-calcifying treatment to improve the biocompatibility of the compound material. Compared with a traditional explosive compound method, the hot-rolling compound method is safer, controllable, convenient and firm in bonding. The product has relatively high biocompatibility.

Owner:HUAZHONG UNIV OF SCI & TECH

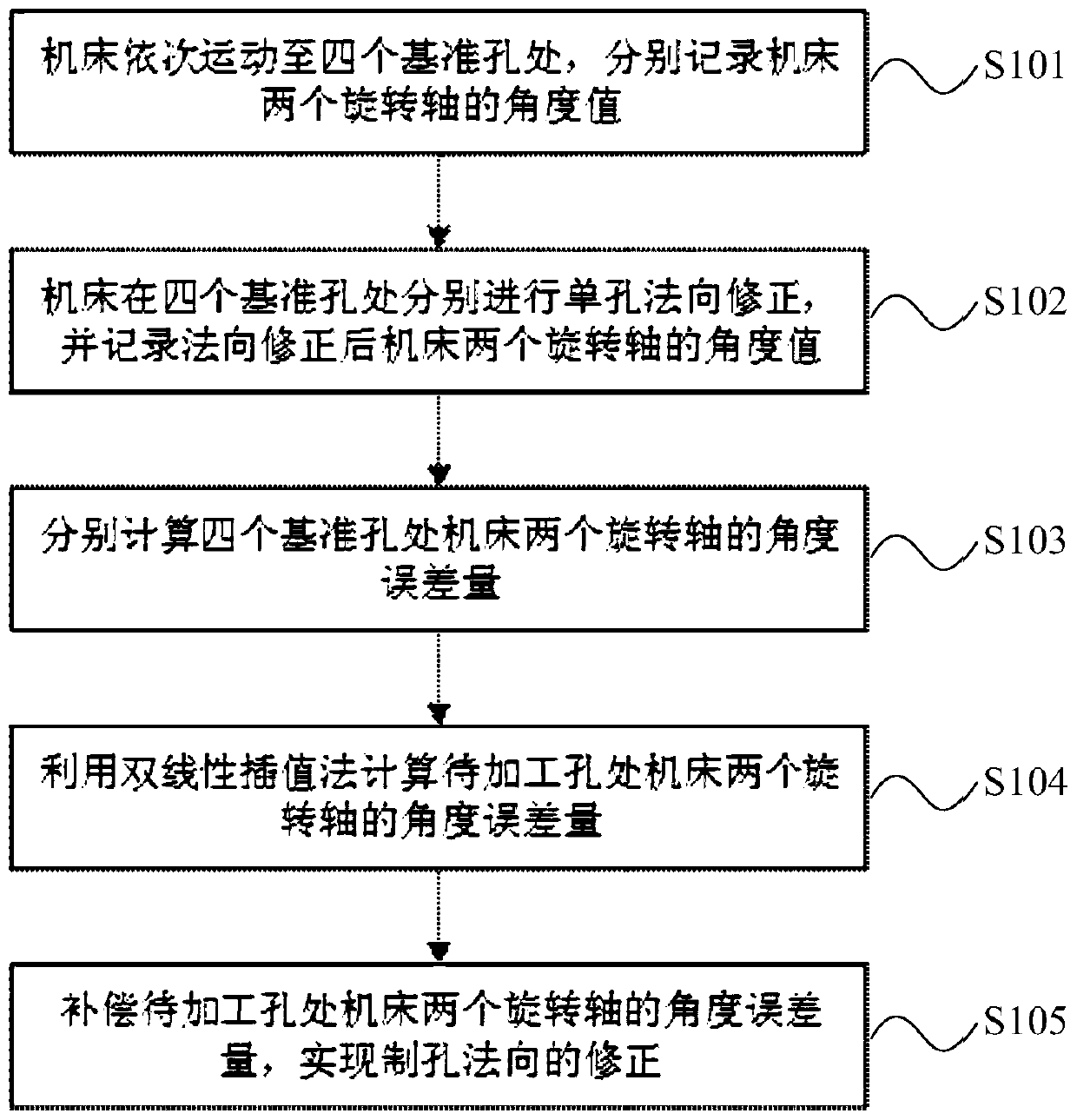

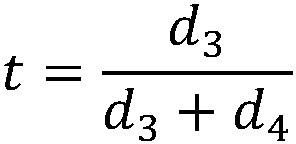

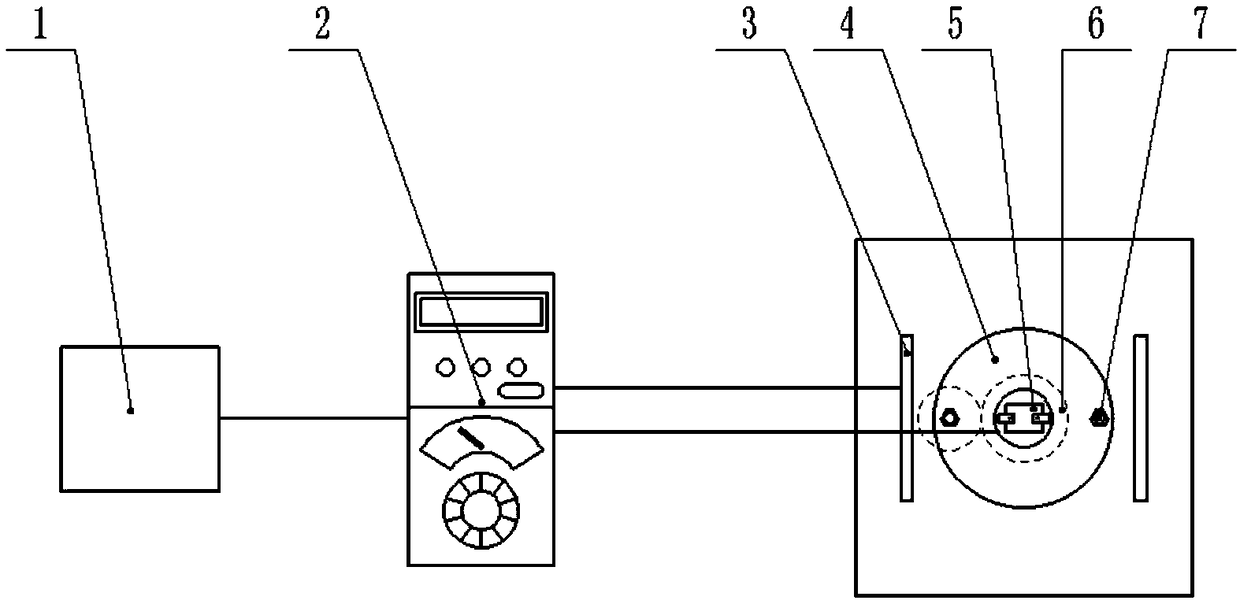

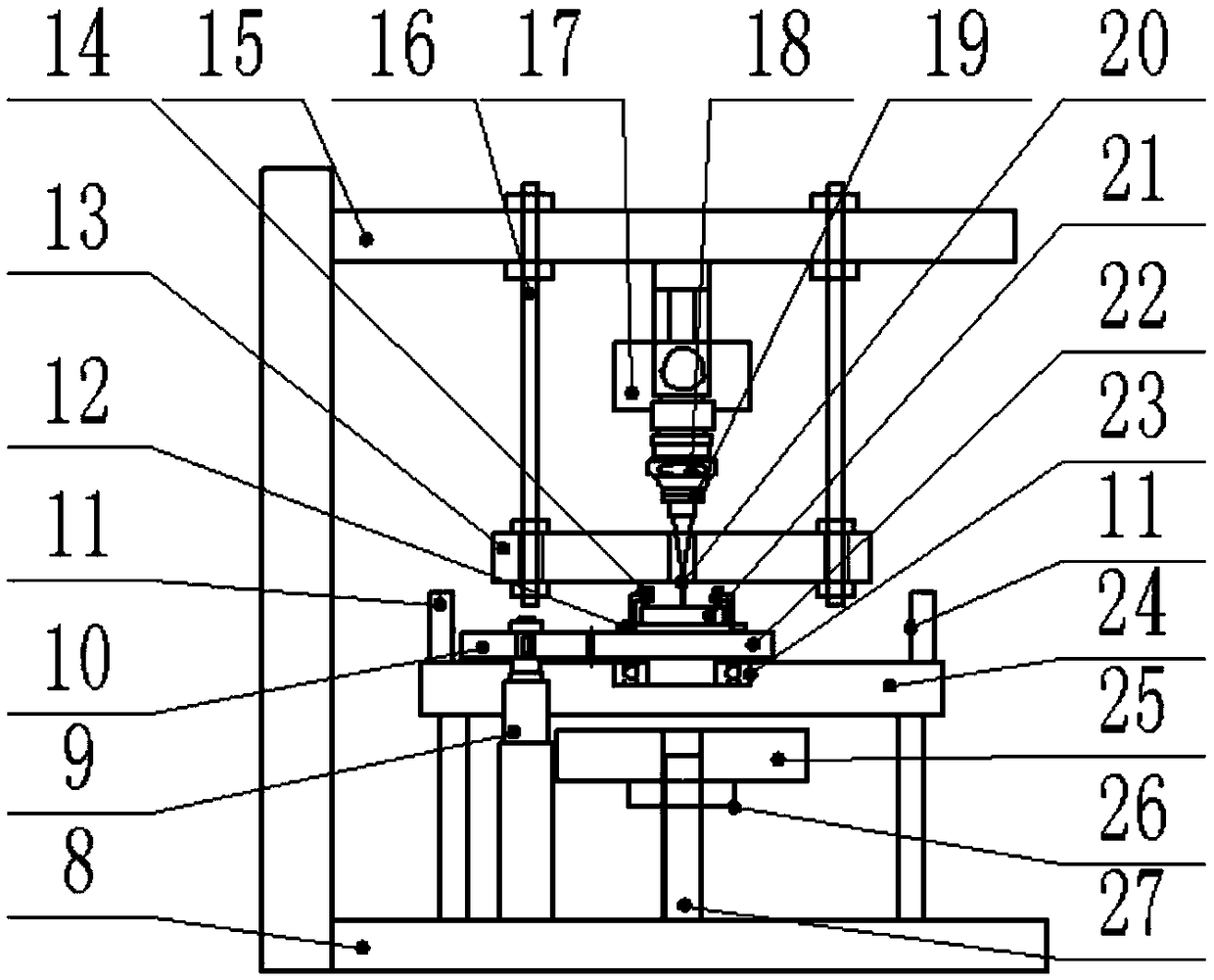

Hole making normal interpolation correction method for five-axis numerical control hole making machine tool

ActiveCN109884988AImprove hole making efficiencySolve the problem that the normal measurement is inaccurate and cannot be correctedProgramme controlComputer controlNumerical controlCorrection method

The invention discloses a hole making normal interpolation correction method for a five-axis numerical control hole making machine tool, and belongs to the field of automatic hole making in aircraft digital assembly. The hole making normal interpolation correction method includes the steps that firstly, the angle error amount of two rotary axes (the A axis and the B axis) of the machine tool before and after normal correction at four reference holes in a hole making area is calculated, then the angle error amount of the two rotary axes of the machine tool at to-be-machined holes is calculatedthrough a bilinear interpolation method, and finally, the angle error is compensated to correct a hole making normal. According to the hole making normal interpolation correction method for the five-axis numerical control hole making machine tool, the hole making normal precision can be guaranteed, and the problems that the single hole normal correction efficiency is low, and part of the hole location normal is difficult to correct when hole location distribution is dense can also be solved.

Owner:ZHEJIANG UNIV +1

Laser hole-making device based on direct-current electric field and axial magnetic field

The invention provides a laser hole-making device based on a direct-current electric field and an axial magnetic field. The laser hole-making device comprises an electric field generating unit, a magnetic field generating unit and a workpiece rotating unit. The electric field generating unit comprises two electrode plates located on the left and right sides of a workpiece. The magnetic field generating unit comprises a first magnet located above the workpiece and a second magnet located below the workpiece and further comprises a lifting device controlling the heights of the first magnet and the second magnet. Whether the workpiece is driven by the workpiece rotating unit to rotate in the hole-making process or not is selected according to the need, while laser hole-making is conducted, the magnetic field generating unit generates the magnetic field perpendicular to the workpiece, the electric field generating unit generates the electric field in the horizontal direction, and a coupling energy field generated by the magnetic field generating unit and the electric field generating unit acts on the workpiece. According to the laser hole-making device, motion, forms, density and distribution of plasmas in the laser hole-making process are influenced through the additional electric-magnetic coupling energy field, thus the hole-making quality is improved, and the hole-making efficiency is improved.

Owner:JIANGSU UNIV

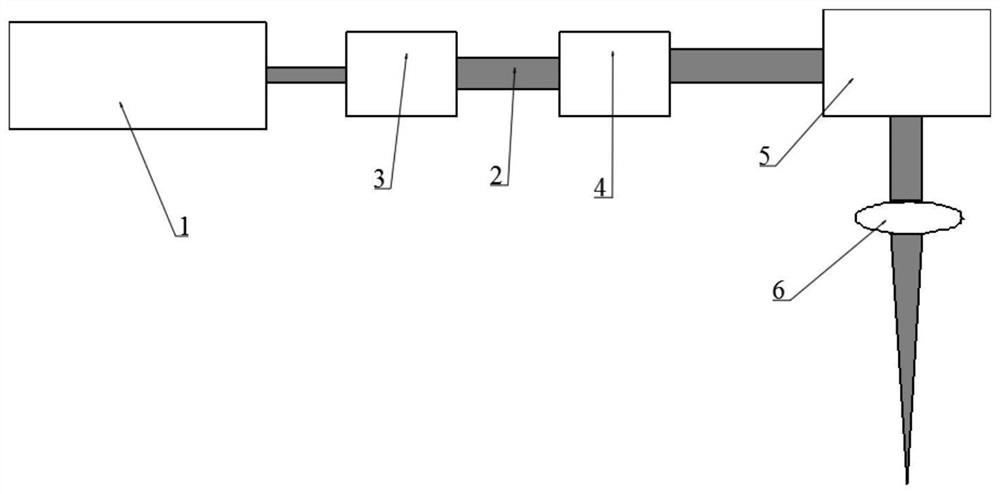

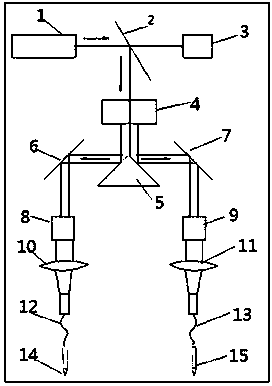

Laser hole making device and method

InactiveCN111790982ADifferent processing effectsReduce hole taperLaser beam welding apparatusBeam expanderGalvanometer

The invention relates to a laser hole making device and method. The hole making device comprises a laser source, a beam expander group, a laser self-rotating device and a scanning galvanometer device,wherein the laser source is used for outputting laser beams along a center axis of a conduction light path; the beam expander group comprises a convex lens and a concave lens, the separation distanceof which can be adjusted, and the laser beams passing through the beam expander group are incident to the laser self-rotating device; the laser self-rotating device is used for deviating the laser beams at an adjustable deviation radius to the center axis of the conduction light path to form a round ring facula, and the round ring facula is incident to the scanning galvanometer device; the scanning galvanometer device is used for rotating the round ring facula around the center axis of a focusing lens to form a plurality of concentric tracks, the focused tracks are used for scanning a processed hole to a target bore diameter after focusing, and the target bore diameter is preset. The laser hole making device can reduce the hole making tamper to improve the hole making efficiency and further can reduce influence of change of a focal position or a wall thickness to consistence of the bore diameter.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

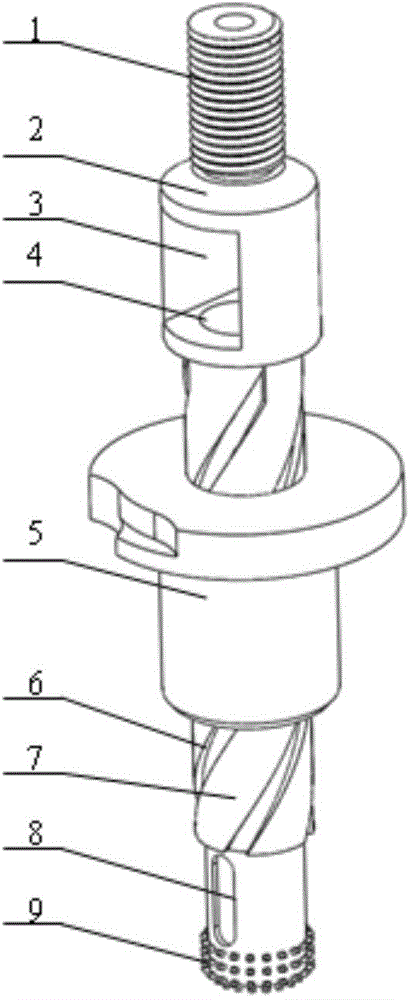

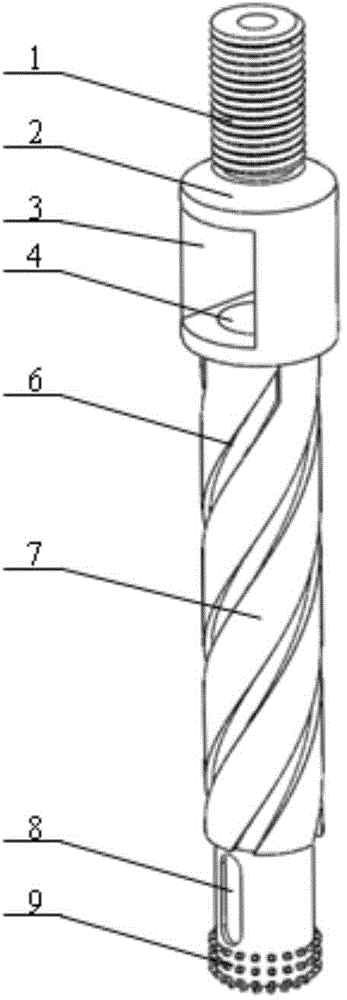

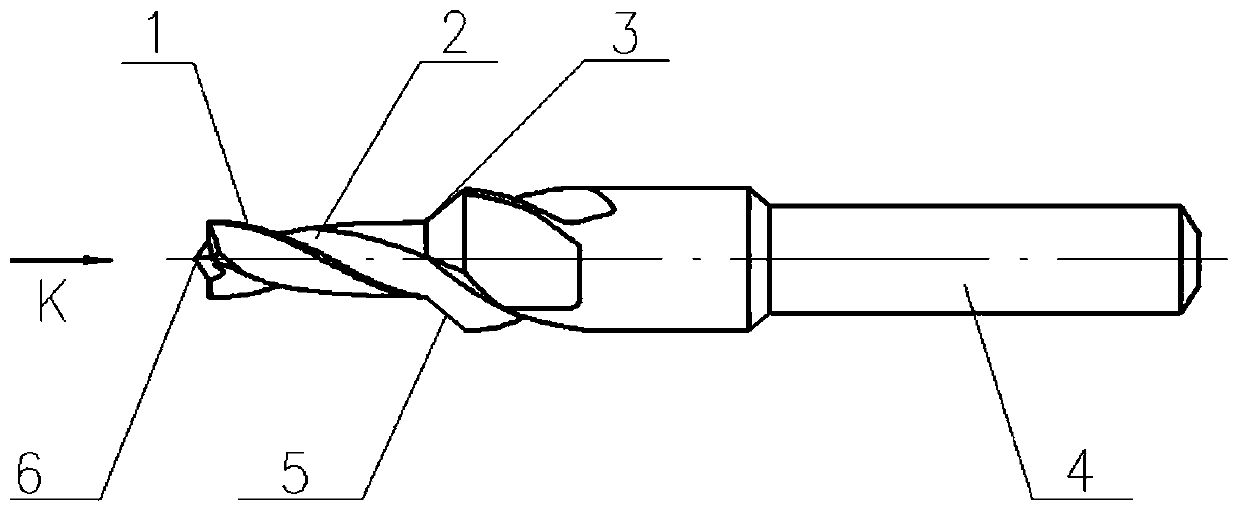

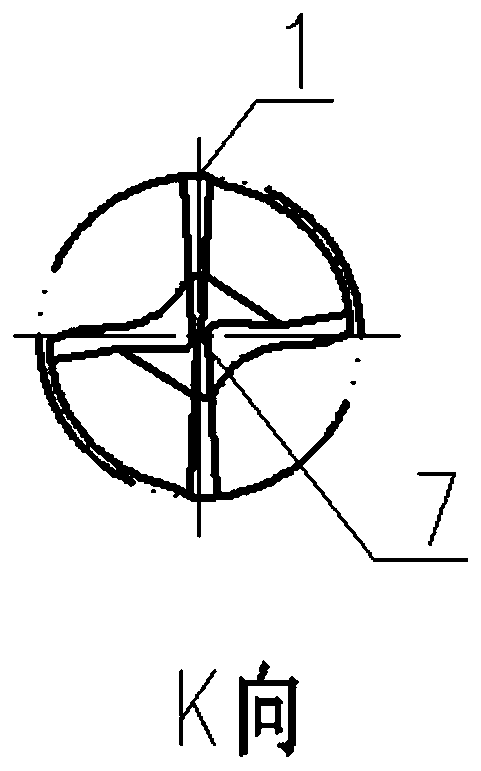

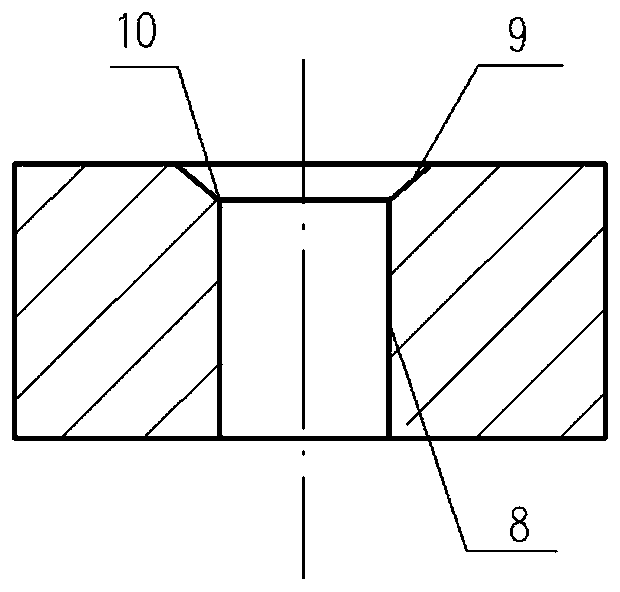

Diamond sleeve grinding cutter suitable for drill sleeve guide

ActiveCN104475826APrevent sticking sleeveReduce wearDrilling/boring measurement devicesTransportation and packagingEngineeringScrew thread

A diamond sleeve grinding cutter suitable for drill sleeve guide comprises a circular drill rod and a guide drill sleeve. The guide drill sleeve is positioned on the middle lower portion of the drill rod and connected with a drill template, the drill rod comprises a threaded handle (1), a 120-degree positioning conical surface (2), a core discharging port (3), a core discharging guide hole (4), a dust chip discharging spiral groove (6), a spiral guide surface (7), a dust chip discharging straight groove (8) and a cutter cutting edge (9) from top to bottom, double cylindrical surfaces are combined to from the guide drill sleeve, and a through hole is formed in a core, so that the drill rod conveniently penetrates the through hole. The diamond sleeve grinding cutter is an integrated cutter, the quality of a machined hole is fine, defects are fewer, hole forming efficiency is high, a composite hole with a large diameter can be machined once, dust cuttings are fewer and almost discharged in the form of material cores, environmental pollution is low, and materials can be repeatedly used.

Owner:BEIHANG UNIV +1

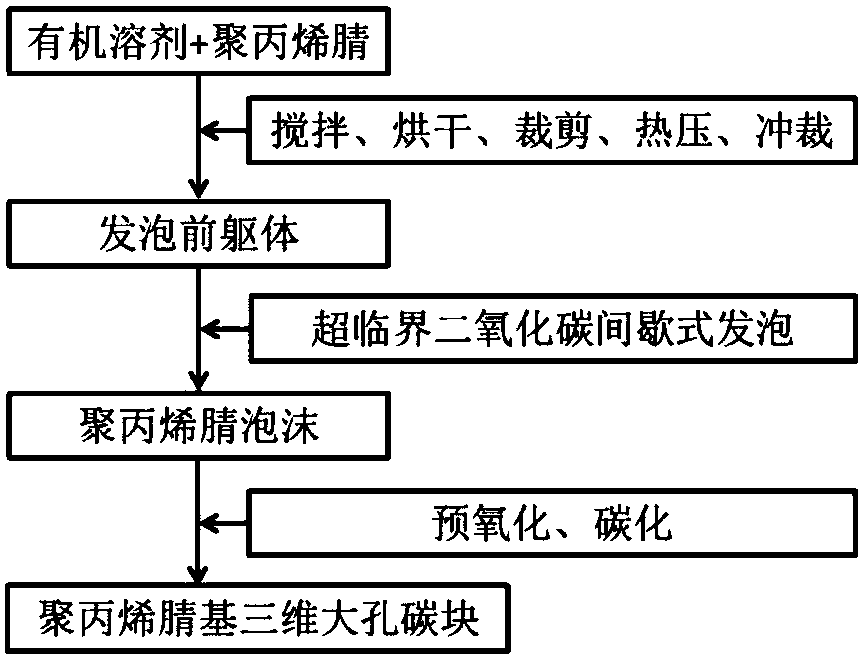

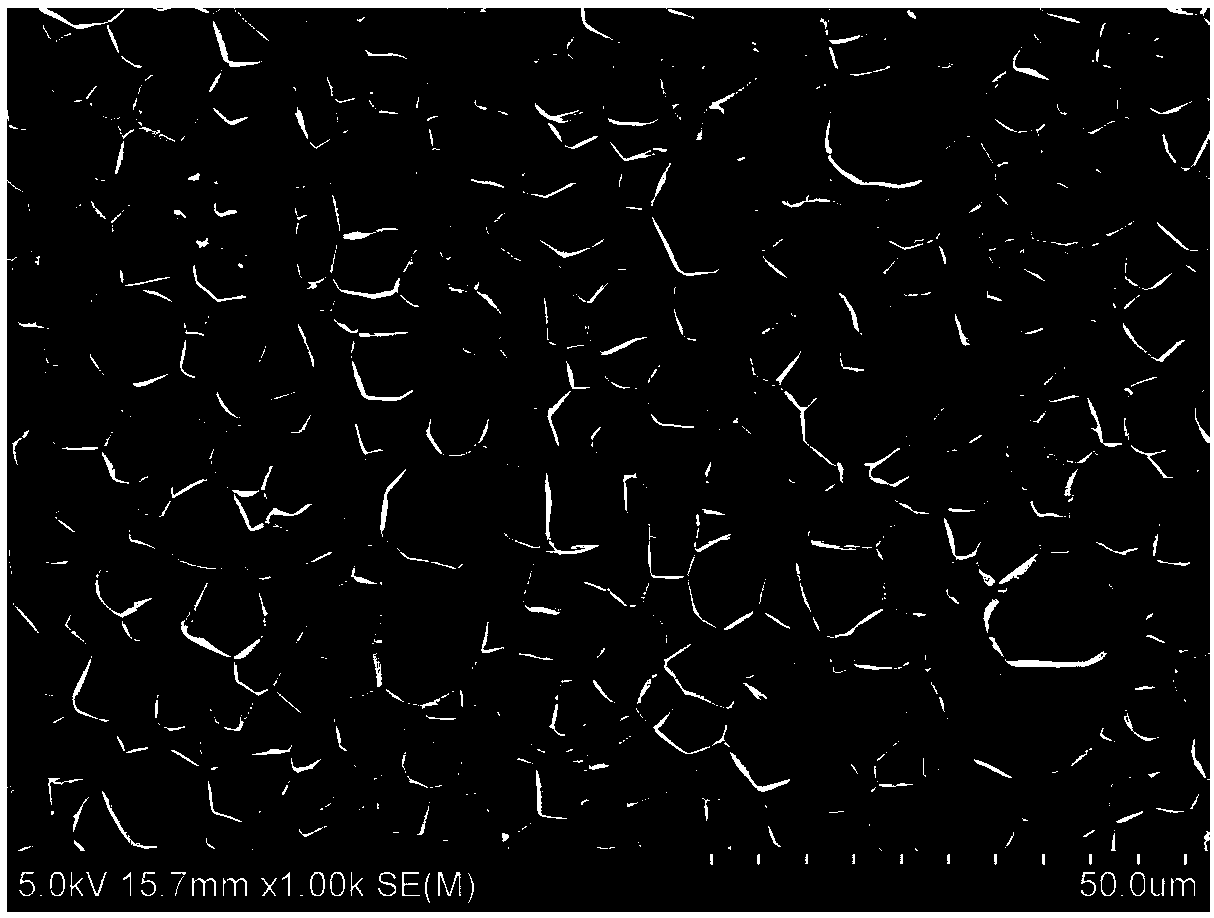

Preparation method of polyacrylonitrile based three-dimensional macroporous carbon block

ActiveCN108383101AUniform pore structurePore structure can be adjustedCarbon preparation/purificationOrganic solventCarbonization

Owner:SHANDONG UNIV

Fiber composite material/metal laminated structure low-temperature hole production device and method

ActiveCN106475591AReduce hole making defectsImprove processing efficiencyWorkpiecesTurning toolsClosed loopFibrous composites

The invention discloses a fiber composite material / metal laminated structure low-temperature hole production device and a method for solving the technical problem of low machining efficiency in traditional carbon fiber composite material and metal material laminated assembly hole production method and device. Under constant feeding speed and main shaft rotating speed, liquid nitrogen is used as a cooling medium; the generation quantity of low-temperature gas is controlled through controlling the volatilizing quantity of the liquid nitrogen; and the closed-loop control is performed for the temperature of a machining area to realize adjustment and constant keeping of the temperature of the machining area along with workpiece materials, so that the hole production defects caused by different material properties are reduced, and the machining efficiency is improved when realizing high-quality hole production of a fiber composite material / metal laminated structure.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

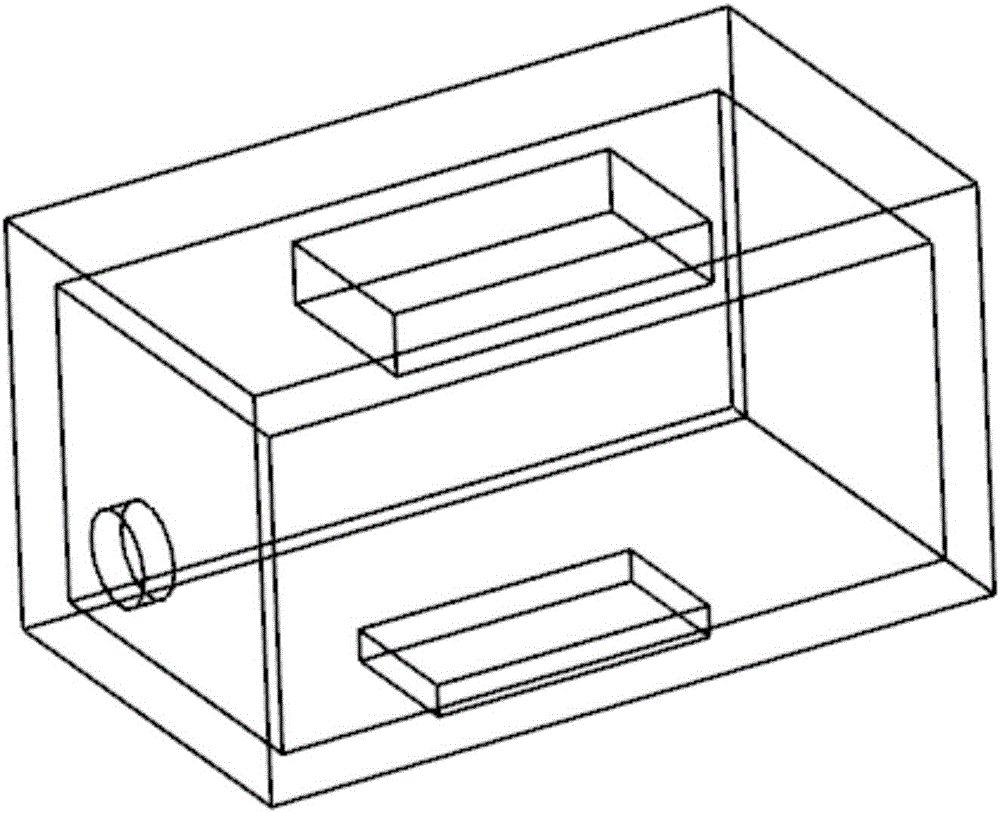

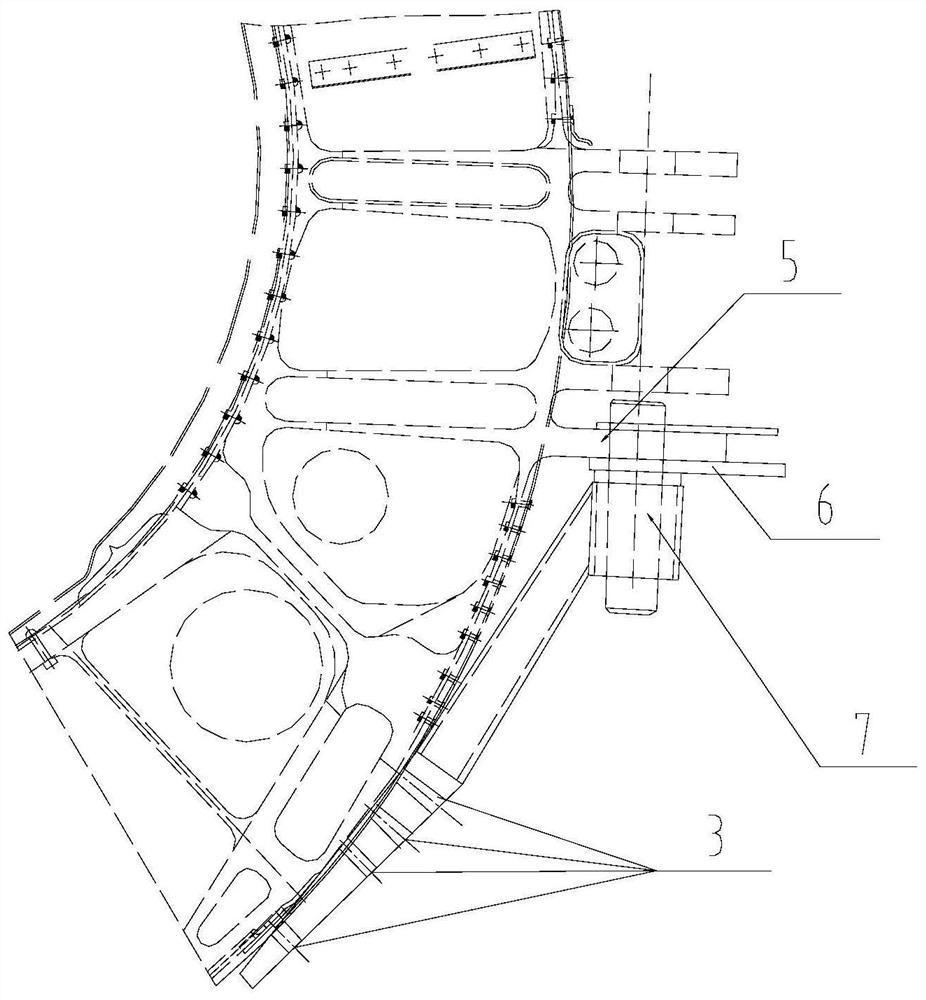

Compact hole-forming end executer for shared guide rails of electric spindle and pressure foot

InactiveCN108081281ARealize quick changeReduce downtime preparation timeGripping headsComputer moduleEngineering

The invention discloses a compact hole-forming end executer for shared guide rails of an electric spindle and a pressure foot. The compact hole-forming end executer comprises an installation base, a hole-forming unit, a compression unit and a normal detection unit. A flange connection plate connected with a robot end is installed on the upper surface of an installation base, two parallel guide rails are erected on the end parts of the two sides of the lower surface of the installation base, and the central axes of the two guide rails are superposed with the central axis of the lower surface ofthe installation base. The hole-forming unit and the compression unit are arranged on the two guide rails in parallel in the central axis direction through slide blocks, and the normal detection unitis installed on the compression unit. Rapid switchover with regard to different part surface compression functions can be realized through rapidly changing a pressing sleeve. According to the compacthole-forming end executer disclosed by the invention, the electric spindle of a hole-forming module and the pressure foot of a pressure foot module share one set of guide rails, and one transmissiondevice is reduced, so that the weight of the end executer is greatly reduced.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

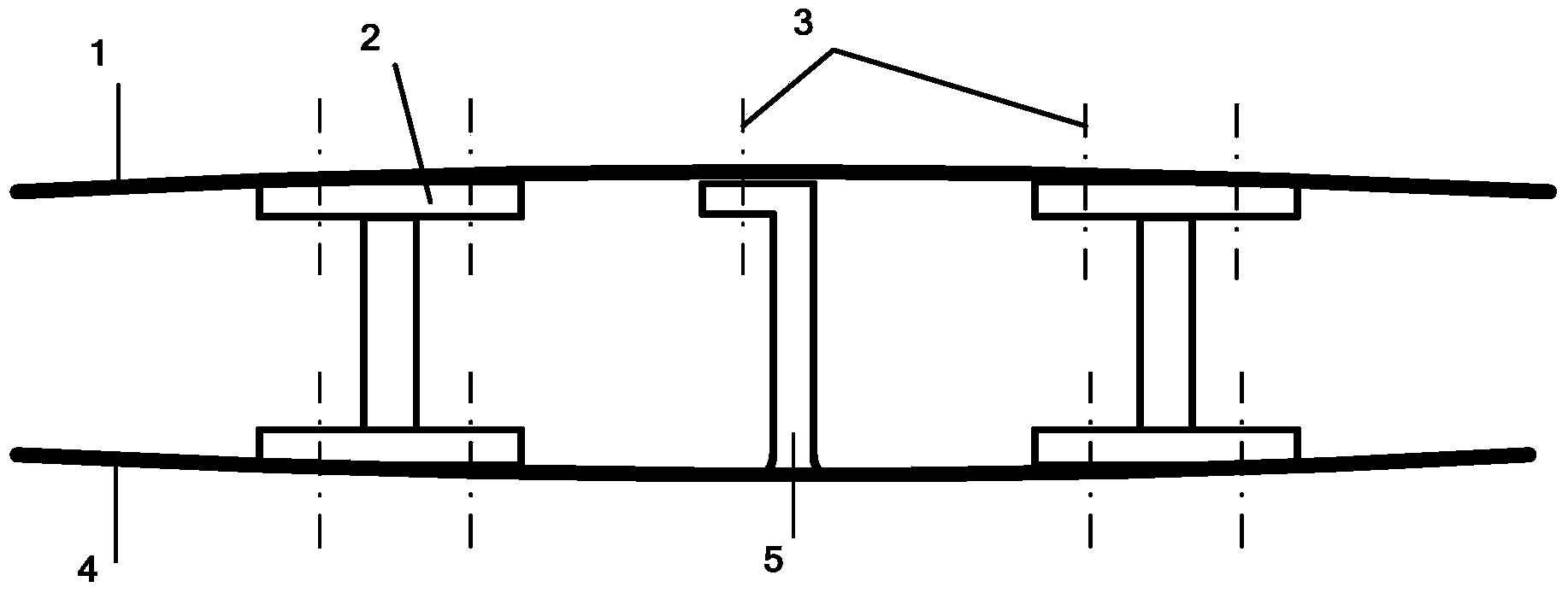

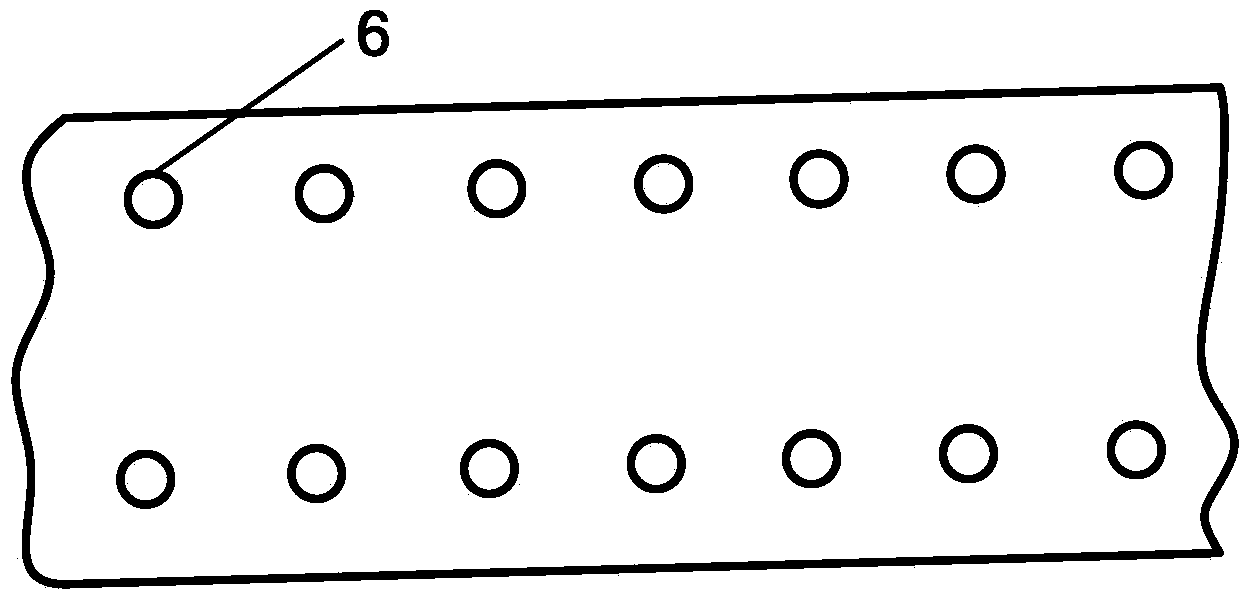

A method for manufacturing a metal silenced honeycomb structure

InactiveCN109204845AAvoid pluggingImprove hole making efficiencyAircraft power plant componentsFuselage insulationBeam splitterOptoelectronics

The invention relates to a method for manufacturing a metal silenced honeycomb structure. The metal honeycomb structure obtained by brazing the panel and the honeycomb core body adopts the laser to drill the metal silencing hole, and adopts a single-stage or multi-stage beam splitter system to separate the single beam laser light source into a plurality of laser beam streams when the laser drillsthe hole, so as to simultaneously drill the metal silencing hole by the plurality of laser beam streams. On the basis of avoiding hole blocking in the brazing process of metal muffler honeycomb and ensuring the muffler performance, the method solves the problem of low machining efficiency when drilling holes one by one with single laser beam, and improves the drilling efficiency of metal muffler honeycomb.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

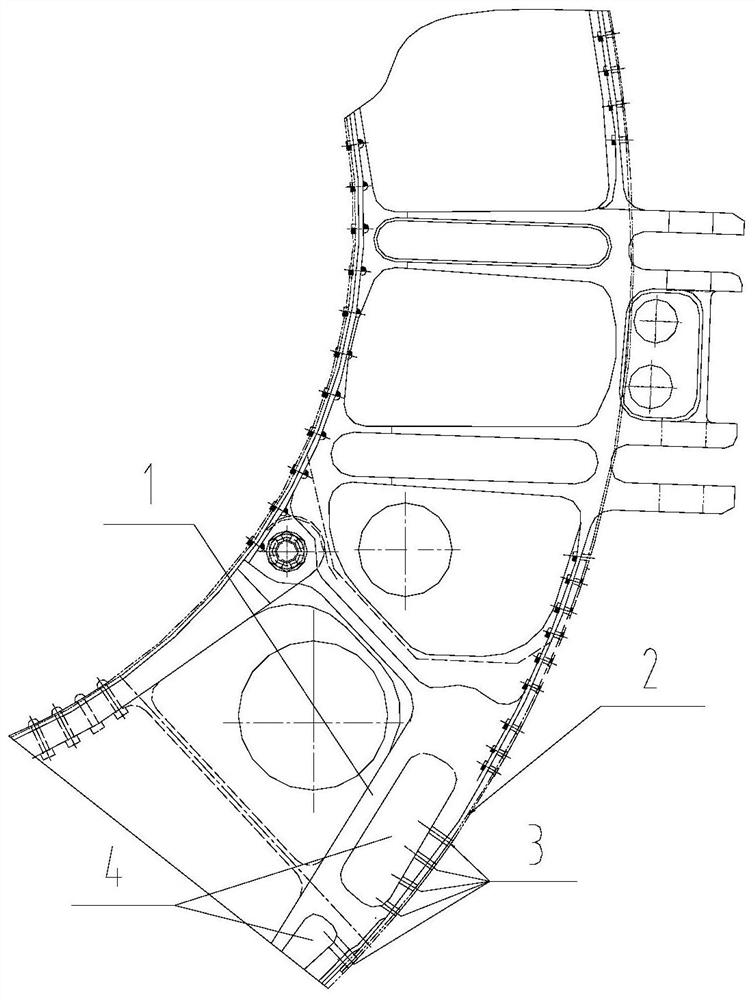

Flexible clamping tool applicable to metal plate supports

ActiveCN108673182AImprove positioning efficiencyImprove clamping efficiencyPositioning apparatusMetal-working holdersWedge angleEngineering

The invention relates to a flexible clamping tool applicable to metal plate supports, in particular to a structure form and a technology for pressing, locating and angle adjusting of thin-wall components with different wedge angles, and belongs to the technical field of clamping and locating. The flexible clamping tool applicable to the metal plate supports is applicable to fast locating and clamping of thin-wall component products of multiple specifications. The tool aims at the situations that the metal plate supports of various sizes and with different shapes exist on metal shells of guidedmissile weapons at the present stage, the specification and the number of metal plate parts with holes needing to be made are many correspondingly, these metal plate supports are in a wedge structure, and the wedge angles are different and range from 0 to 5 degrees. When the tool is used for carrying out hole making on the metal plate supports, the situations that corresponding locating and clamping tools are designed and manufactured for the different product shapes and the hole making requirements, waste of the tools is caused can be avoided. The tool can achieve fast locating and fast clamping for metal plates with the different shape sizes and wedge angles.

Owner:CAPITAL AEROSPACE MACHINERY +1

Hole-making device for adjusting hole diameter on-line

ActiveCN103659403BRealize processingSolve the entanglementFeeding apparatusLarge fixed membersFrequency changerEngineering

The invention discloses a hole forming device capable of adjusting the aperture of a formed hole on line. The hole forming device comprises an eccentric hole-forming machine head component, an eccentric head feeding platform component, an aperture adjusting driving component, a main shaft cable winding-preventing component and a pressing foot component. According to the hole forming device, an inner eccentric sleeve and an outer eccentric sleeve are used for achieving high-speed self rotating of a tool and revolution of the tool around a changeable center in a hole forming process, and then compound motion needed by tool eccentric hole forming is provided. The self-rotating speed of the tool is achieved by the fact that an outer frequency changer controls the frequency of an electric main shaft. Aperture adjusting, tool revolution speed and tool axial feeding speed can be accurately controlled by programs through servo control motors. The hole forming device can achieve on-line formed hole aperture adjusting, hole forming efficiency is improved, meanwhile, machining of taper hole can be achieved, the problem of cable winding during main shaft high-speed rotating is avoided through a main shaft cable winding-preventing mechanism, and the stability and the safety of the whole hole forming device are improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Hole helical milling device

ActiveCN102689040BImprove hole making efficiencyReduce processing costsMilling machinesNumerical controlMilling cutter

Owner:SHANGHAI AIRCRAFT MFG +1

Automatic reaming and counterboring cutter applicable to weakly rigid equipment

InactiveCN111360301AImprove hole finishAvoid contactTransportation and packagingTrepanning drillsEngineeringStructural engineering

The invention provides an automatic reaming and counterboring cutter applicable to weakly rigid equipment. The cutter comprises a cutter body used for performing machining and a cutter clamping handleportion. The cutter body is provided with a drilling portion and a counterboring portion from top to bottom in sequence. The drilling portion, the counterboring portion and the cutter clamping handleportion are integrally formed. The drilling portion comprises a drilling tip and a cutting edge. A spiral groove and a counterboring edge are formed on the counterboring portion. A transition filletis arranged between the spiral groove and the counterboring edge. The cutting edge comprises a ridge, a transverse edge body and a main cutting edge body. The drilling tip reams a product, the counterboring edge performs counterboring on the reamed product, and the central axes of the drilling tip and the counterboring edge are located on the same straight line. The design of the cutter provided by the invention is oriented to the weakly rigid equipment, the centering ability is improved, the pore diameter precision is improved, vibration during drilling is reduced, the inverted cone design ofthe cutter effectively prevents contact between the cutter and a pore wall, and the pore wall degree of finish is increased.

Owner:SHANGHAI TOPNC NUMERICAL CONTROL TECH CO LTD

Precise hole leading method for machining training plane skin

ActiveCN112935349AImprove hole making precisionImprove hole making efficiencyAircraft assemblyDrill jigsStructural engineeringDrill

The invention discloses a precise hole leading method for machining a training plane skin. The method comprises the following steps that firstly, according to a structural form of the position where hole leading is needed, a proper and reliable airplane training plane structure frame plate piece or part is selected as a mounting point, a hole leading drill jig is designed and manufactured, the mounting position of the hole leading drill jig is adjustable, and the hole leading drill jig is coordinated and consistent with the position of a hole needing to be led out; an aircraft skin is assembled on an aircraft structure frame plate, and before installation, the hole leading drill jig is installed on an aircraft structure lug hole in an aircraft structure lug, so that the position of an aircraft structure lug drilling jig hole is consistent with that of a bolt hole needing to be led out; after the aircraft skin is backfit and assembled, it is guaranteed that the positions of the hole leading drill jig are consistent before and after the aircraft skin is installed; the hole in the aircraft skin and the bolt hole in the structural frame plate of the aircraft structure frame plate are coordinated and consistent in position. According to the precise hole leading method for machining the training plane skin, the hole forming precision can be greatly improved, the labor intensity is reduced, the expansibility is high, and the method can be popularized and used and applied to hole forming in narrow spaces of other parts.

Owner:AVIC GUIZHOU AIRPLANE

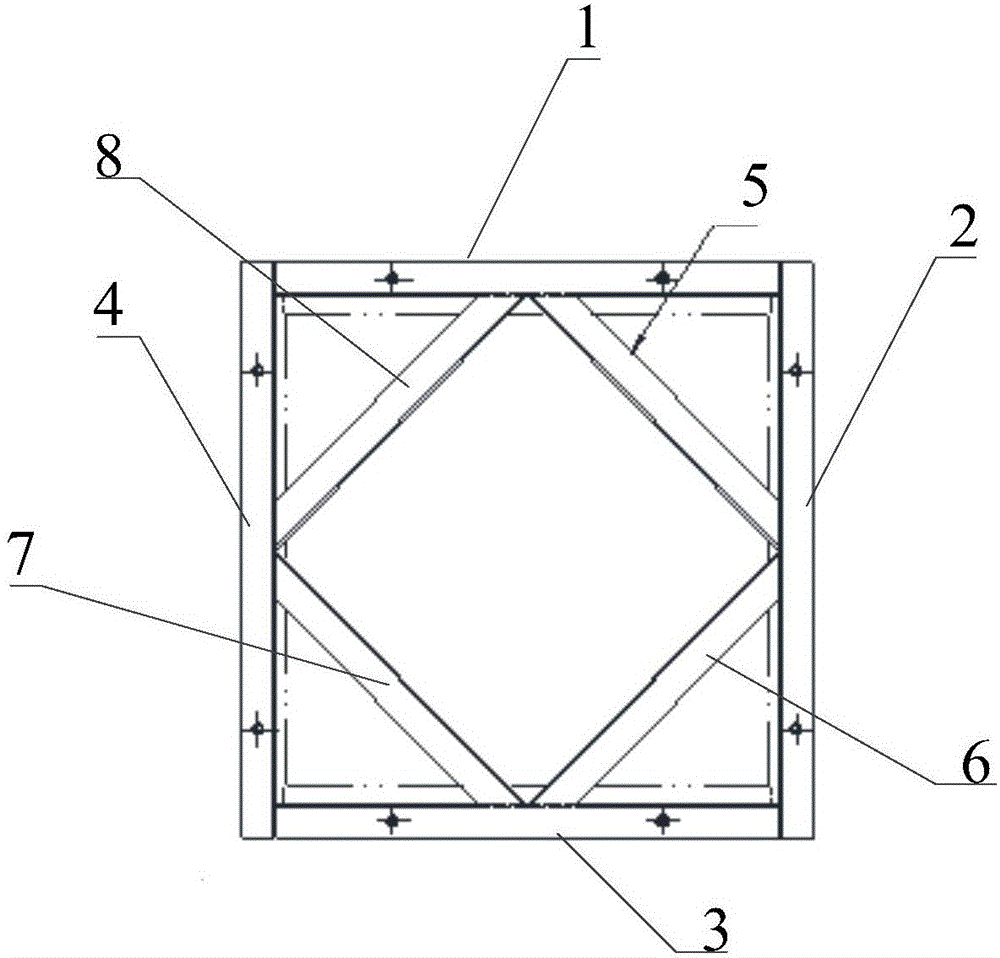

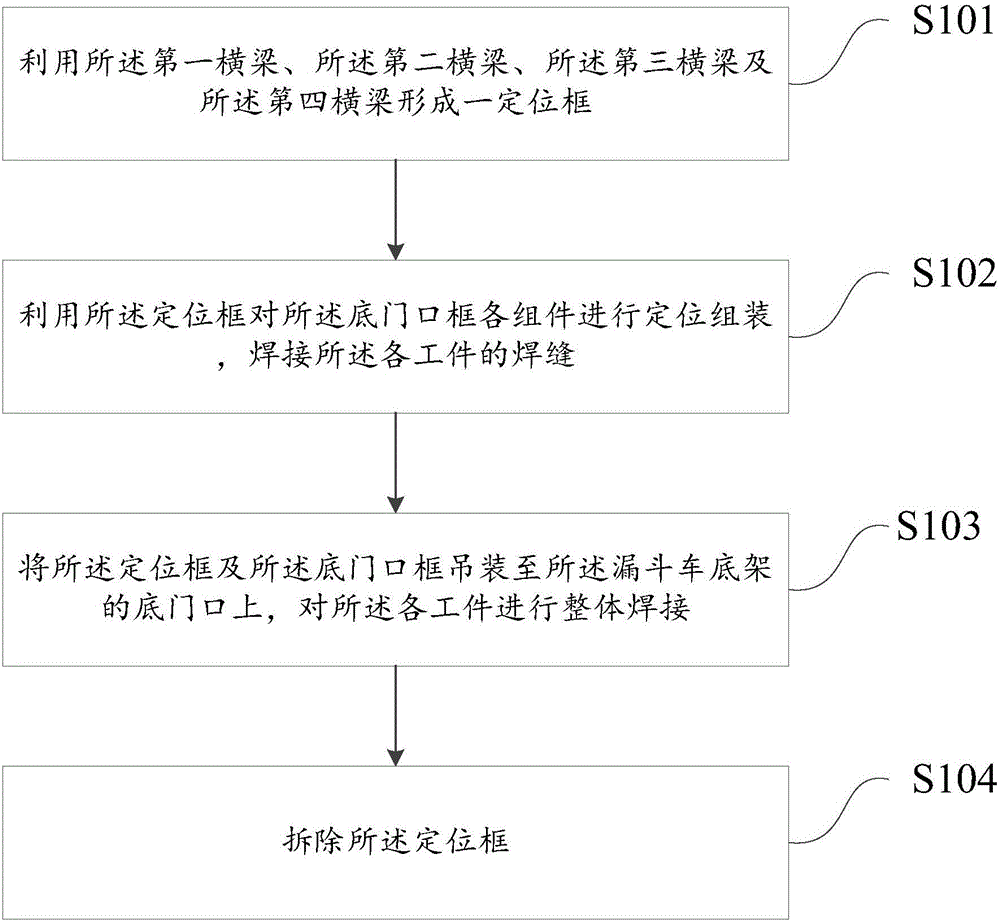

Assembling fixture and assembling method

InactiveCN106624481AImprove hole making efficiencyReduce processing costsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringProcessing cost

The invention provides an assembling fixture and an assembling method. The fixture comprises a first cross beam, a second cross beam, a third cross beam and a fourth cross beam; wherein the first cross beam, the second cross beam, the third cross beam and the fourth cross beam are connected in sequence to form an aligning frame; the aligning frame is used for a bottom door frame of a positioning hopper car, the size of the aligning frame is consistent with the size of a bottom door of a bottom frame of the hopper car; a positioning hole is arranged on the aligning frame, the size and the location of the positioning hole are consistent with the size and the location of a screw bolt hole on the bottom door frame and are consistent with the size and the location of the screw bolt hole on the bottom door; in this way, every component on the bottom door frame is separately drilled holes by firstly using mini type equipment, then every component is fixed-position welded by utilizing the aligning frame, the separate drilling for every component in such a way not only enables the drilling efficiency to be increased but also makes it possible to lower the processing cost.

Owner:CRRC YANGTZE CO LTD

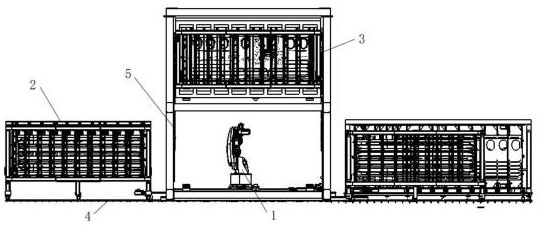

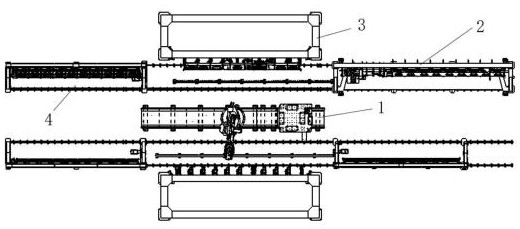

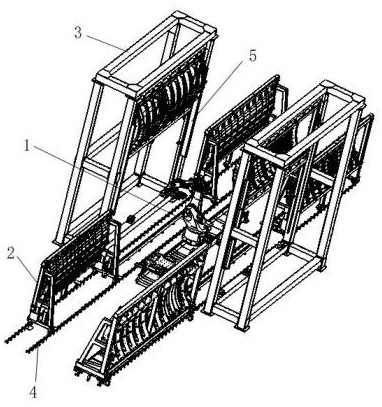

Three-dimensional cluster type aircraft panel automatic assembly production line and planning control method thereof

ActiveCN111737827AReduced range of movementSmall footprintGeometric CADResourcesLogic modelingWorkstation

The invention relates to a three-dimensional cluster type aircraft panel automatic assembly production line and a planning control method thereof. The three-dimensional cluster type aircraft panel automatic assembly production line is provided with a drilling system and a fixture tool used for positioning a panel. The hole making system is a robot hole making system; the fixture tool is mounted onthe left-right translation module in a sliding manner; the two left-right translation modules are arranged on the two sides of the robot drilling system in parallel. The method comprises the following steps: firstly, determining a single wallboard assembly operation sequence to form a preliminary single wallboard assembly process flow time sequence diagram; analyzing the time and space consumption of the operation process; analyzing a plurality of wallboard operation tasks and a coupling relationship between a multi-station in-out frame and a logistics transportation channel, and designing aproduction takt for assembly operation; carrying out logic modeling on operation of the multiple wallboard assembly production lines, carrying out production line material layout planning, and finallycarrying out verification and examination. A robot hole forming station is located in the middle, and modular tools horizontally move left and right or move up and down to hole forming stations fromrespective work stations.

Owner:SHANGHAI SHANGFEI AIRCRAFT EQUIP MFG

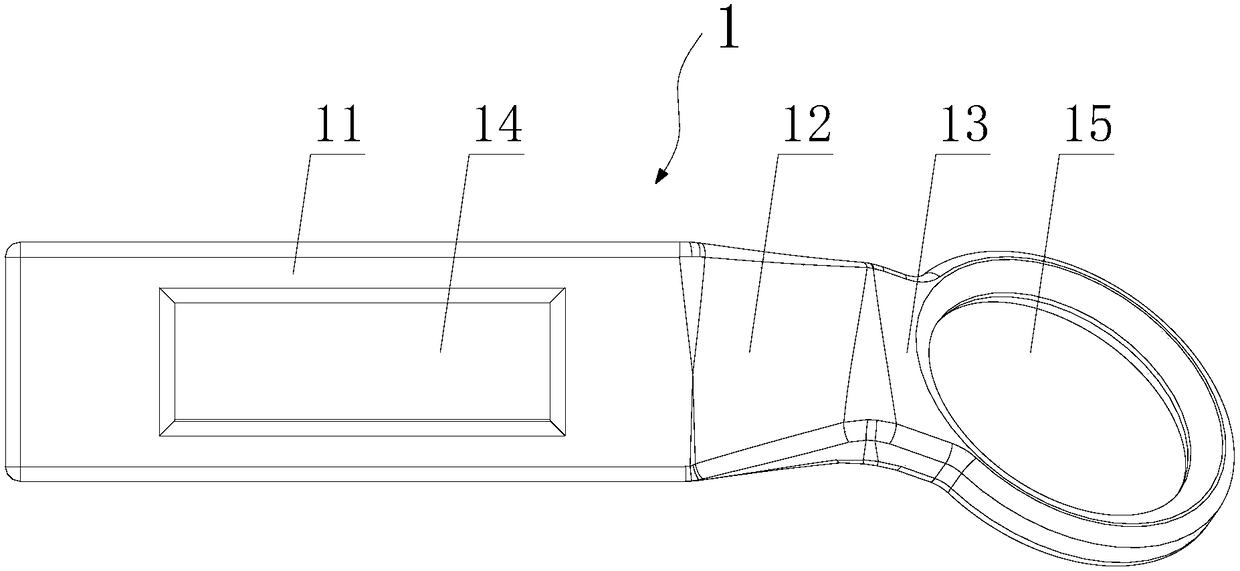

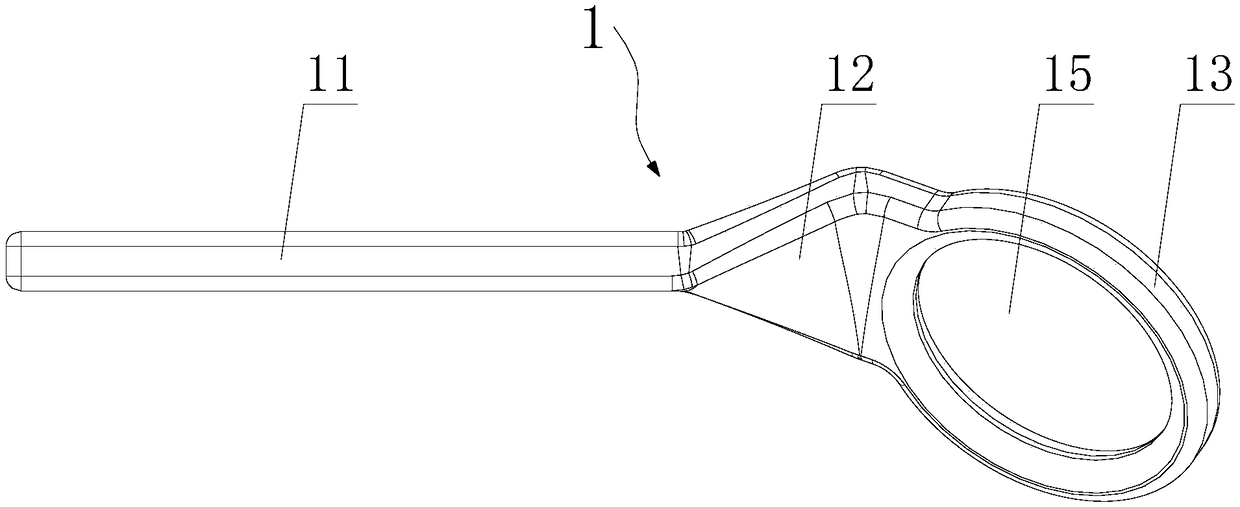

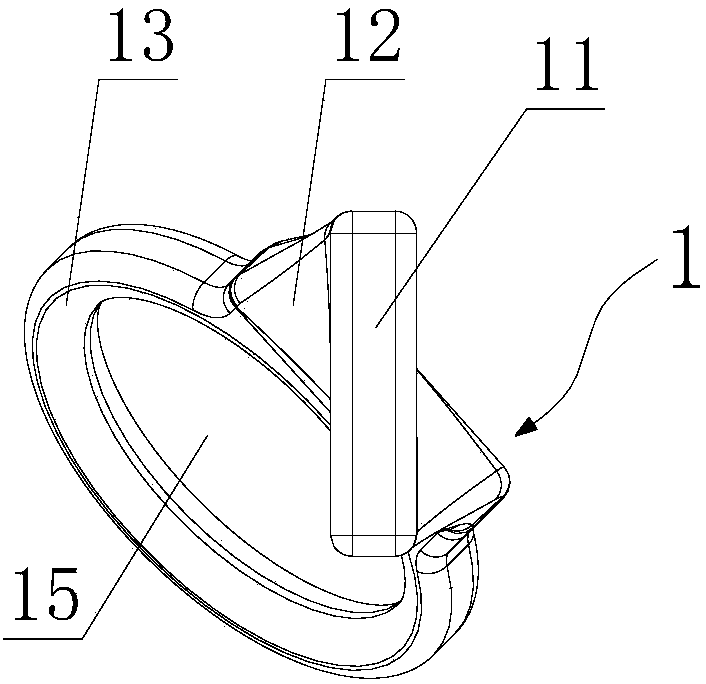

Drilling dust collection auxiliary tool and method

The invention discloses a drilling dust collection auxiliary tool and method and relates to the technical field of drilling. Through the drilling dust collection auxiliary tool, the problem that drilling operators cannot conduct dust collection operation during drilling in existing drilling modes is solved. According to the adopted scheme, the drilling dust collection auxiliary tool comprises a fixing part, a connecting part and a clamping ring part; the fixing part and the clamping ring part are connected through the connecting part; a rectangular hole is formed in the fixing part; the connecting part is in a twisted shape; and the clamping ring part is provided with a circular hole. Through the drilling dust collection method, the problem that the drilling operation and auxiliary dust collection cannot be conducted by one person in existing drilling modes is solved. According to the drilling dust collection method, firstly, a handle of a handle drilling jig penetrates into the rectangular hole of the fixing part and is clamped, and a dust collection pipe penetrates into the circular hole of the clamping ring part and is clamped; secondly, the handle drilling jig is arranged at the drilling position, and the end of the dust collection pipe is located on the back face of the drilling position; and finally, a gun driller is used for drilling and dust collection. Through the drilling dust collection method, single-person operation is achieved, dust intake is reduced, and the drilling efficiency is improved.

Owner:AVIC CHENGFEI COMML AIRCRAFT COMPANY

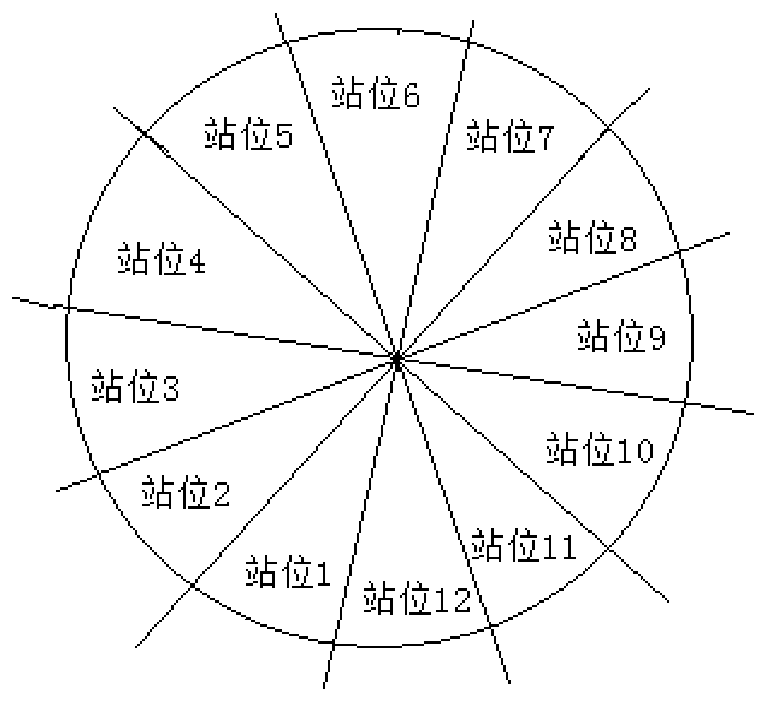

Hole making method of butt joint surface structure of large aircraft body

The invention discloses a hole making method of a butt joint surface structure of a large aircraft body. According to the hole making method, annular rail automatic hole making equipment is used, holes are made in the butt joint surface structure of the aircraft body, an arc-shaped rail arc length on the annular rail automatic hole making equipment is divided into a plurality of station positionsaround the butt joint surface of a machine body, so that each station can have the largest number of holes, a long truss joint and a butt strap plate are arranged on the butt joint surface, process screws are installed, the position of the process screws serves as a hole making reference, and the station positions are built by using the reference hole process screws. A hole making program is corrected, and hole making and counter sinking in the station butt joint surface structure are carried out. The arc-shaped rail is rotated to the next station position until the hole making of the joint surface structure of the machine body at all stations is completed.

Owner:XIAN AIRCRAFT IND GROUP

Aircraft assembly positioning method based on three-dimensional laser projection

The invention relates to an aircraft assembly positioning method based on three-dimensional laser projection. The method comprises the following steps: inputting design digital-analog of a first assembly part and a second assembly part into a control computer of projection equipment to establish a simulation assembly relationship; in the coordinate system of the first assembly part, the three-dimensional contour of the second assembly part or the center of the fastener hole is projected on the assembly position of the first assembly part in a laser line mode, a tool positioner and a drilling sample plate are replaced, a line drawing positioning mode is replaced, and part positioning, fastener hole position determination and assembly inspection are completed.

Owner:中航西飞民用飞机有限责任公司

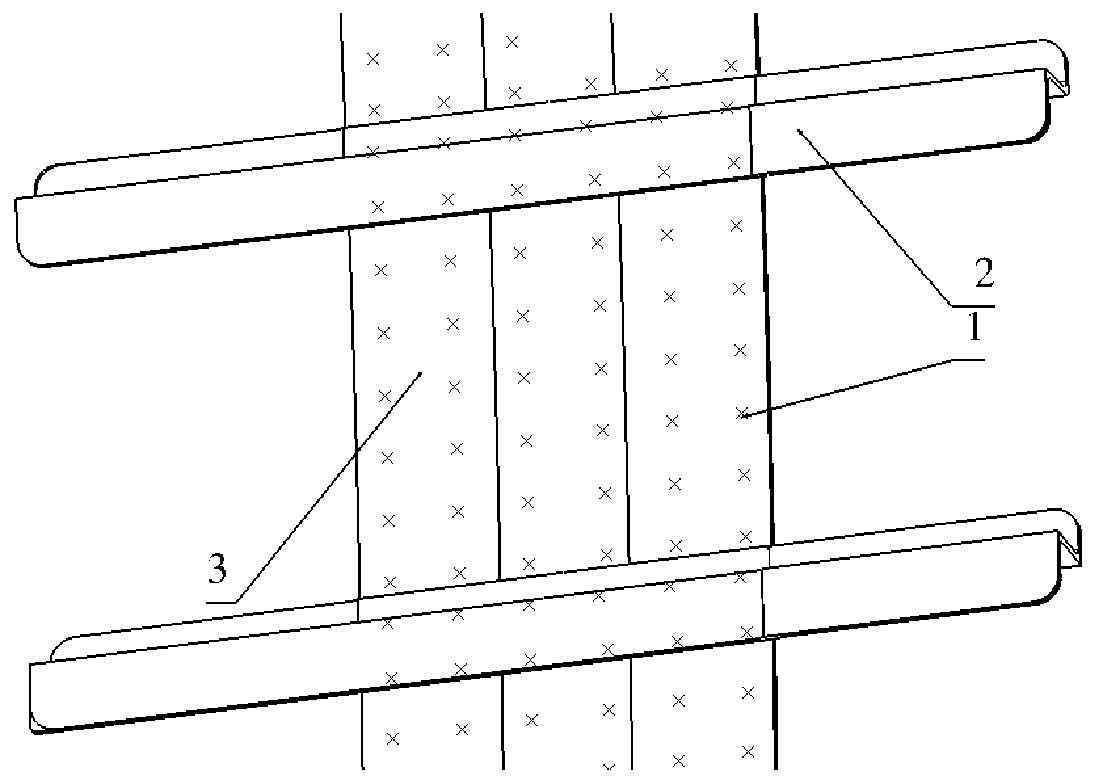

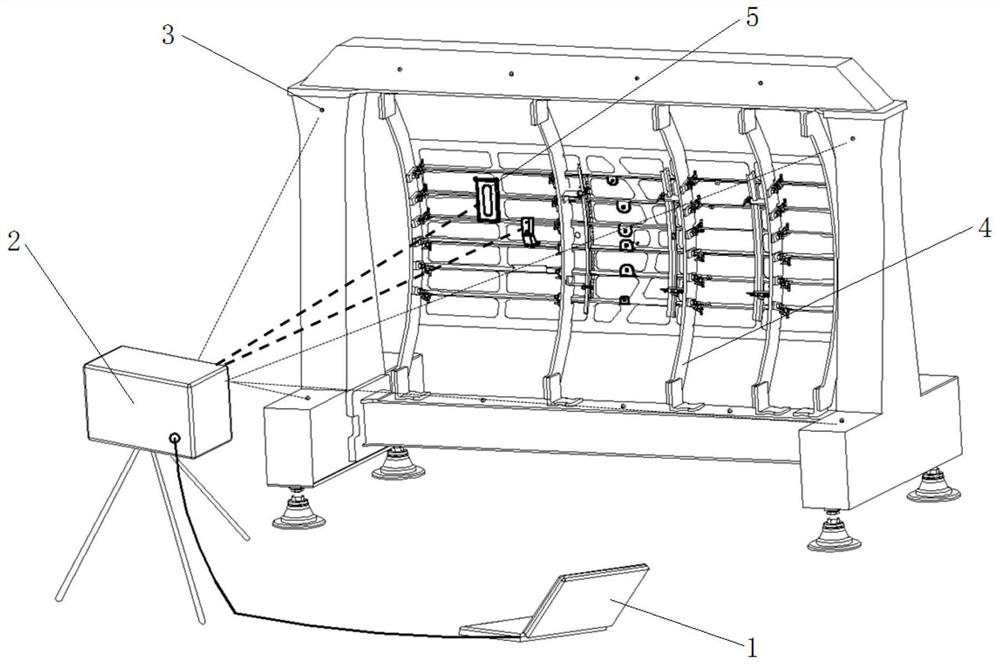

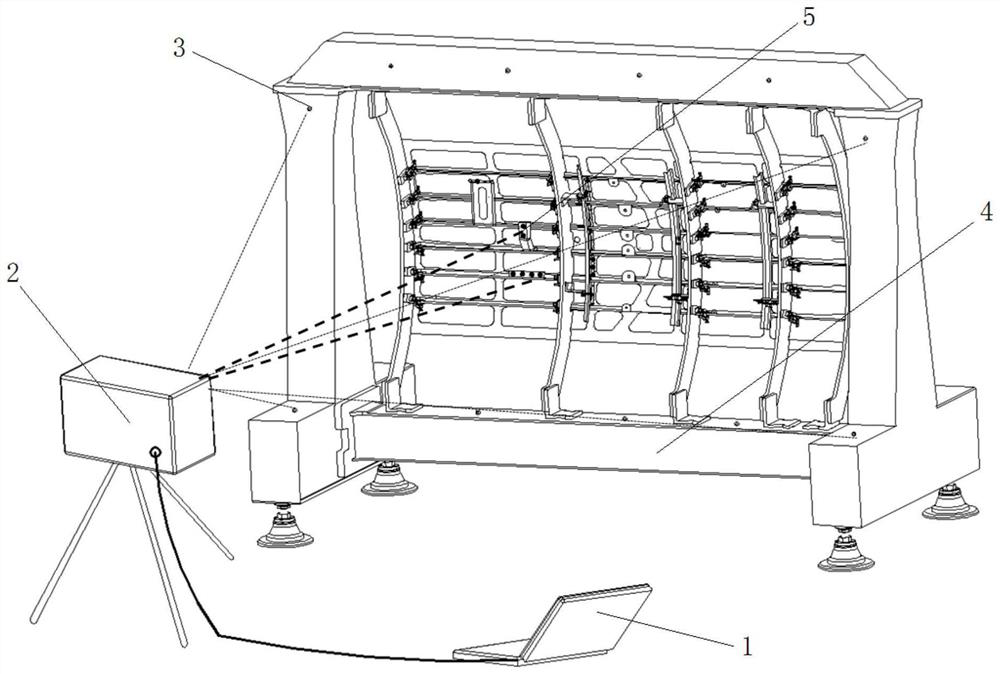

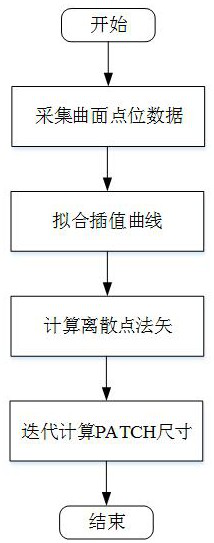

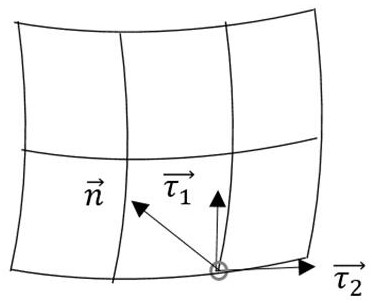

PATCH design method for machining group holes in curved surface of aviation structural member

PendingCN114266148AGuarantee processing qualityControl hole position normal vector deviationGeometric CADDesign optimisation/simulationAviationStructural engineering

The invention relates to the field of aviation part machining, in particular to a PATCH design method for machining group holes in a curved surface of an aviation structural part, which comprises the following steps: collecting point location data of the curved surface; fitting an interpolation curve according to the point location data; fitting discrete point location data for the discrete point data by using a cubic spline curve in each direction, and solving an equation of an interpolation curve; tangent vectors of the discrete points in the two directions are calculated, and normal vectors of the discrete points are solved through cross multiplication, so that normal vector information of the whole curved surface is obtained; and with the normal vector angle deviation of the drilling hole site as a constraint condition, iteratively calculating the size of the drilling matrix unit PATCH in the warp direction and the weft direction in sequence. According to the method, in the machining process of the free-form surface high-order-of-magnitude group holes, the geometric features of the curved surface are matched, the normal vector deviation of the hole site is controlled, high-order-of-magnitude batch rapid hole forming on the free-form surface by the gang drill is achieved, the hole forming efficiency can be improved, and the group hole machining quality is guaranteed.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Robotic hole making end effector

InactiveCN103639471BImprove hole qualityImprove hole making efficiencyMeasurement/indication equipmentsFeeding apparatusEngineeringActuator

The invention discloses a drilling end actuator suitable for an industrial robot. The drilling end actuator comprises a cutting unit, a connecting unit, a feeding unit, a pressing unit and a measuring unit. The cutting unit mainly comprises a motorized spindle, a cutter handle, a cutter, a servo motor and a cutting transmission assembly and is used for achieving planetary drilling and cutting; the connecting unit mainly comprises a connecting plate and tool fast-switching devices and is used for achieving three installation modes and fast switching between the different installation modes; the feeding unit mainly comprises a lead screw nut pair, a feed motor and a feed transmission assembly and is used for achieving feed movement of planetary drilling and cutting; the pressing unit mainly comprises an air cylinder, a pressing plate, a pressing pipe and a pressing head and is used for pressing a workpiece; the measuring unit comprises a photoelectricity distance sensor and a force sensor and is used for detecting the perpendicularity of the cutter before and after pressing and monitoring the state of the cutter during the drilling process in real time. The drilling end actuator can form a flexible drilling system when used in cooperation with the industrial robot, and precise drilling of stacked materials can be achieved.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com