Aircraft assembly positioning method based on three-dimensional laser projection

A technology of aircraft assembly and positioning method, applied in aircraft assembly and other directions, can solve the problems of high cost of tooling positioning, failure to detect the quality of parts in key assembly areas in time, and repeated investment in tooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

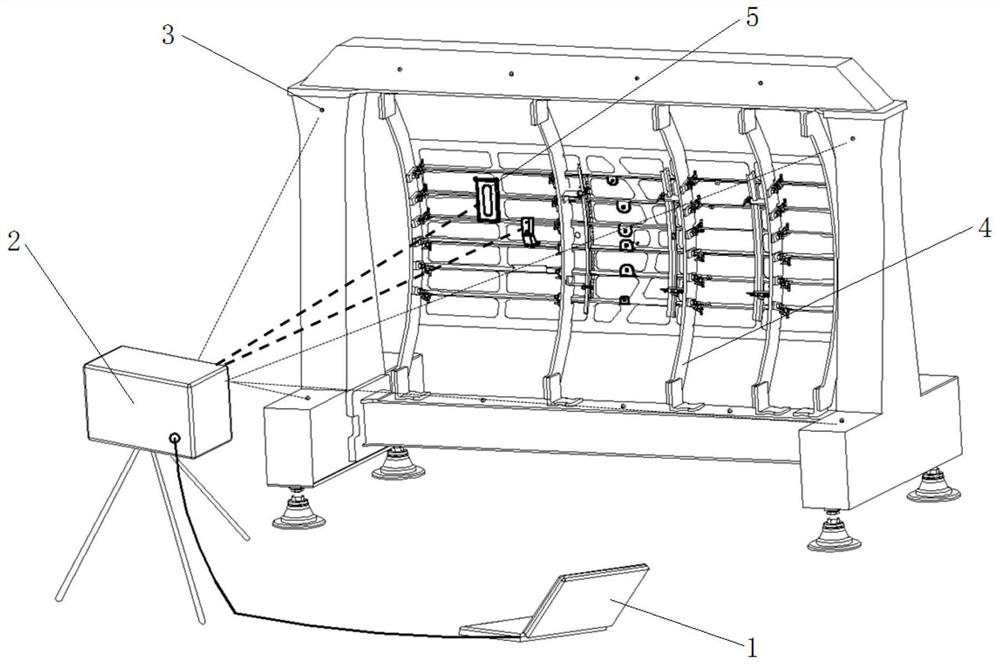

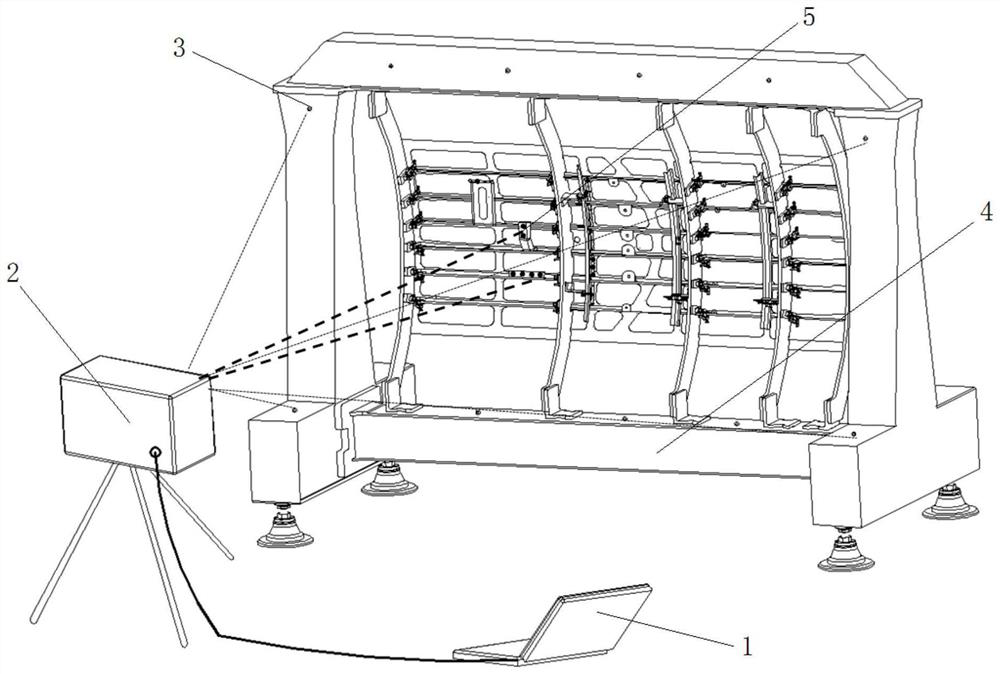

[0015] Referring to the accompanying drawings, the aircraft assembly positioning method based on three-dimensional laser projection is to input the design digital model of the first assembly part 4 and the second assembly part 5 into the control computer 1 of the projection device 2 to establish a simulated assembly relationship. In the coordinate system of the first assembly part 4, the three-dimensional outline of the second assembly part 5 or the center of the fastener hole is projected on the assembly position of the first assembly part 4 in the form of a laser line, instead of the tooling locator, the drilling The model, instead of the line drawing positioning method, completes part positioning, fastener hole position determination and assembly inspection.

[0016] After collecting the feature points on the entity of the first assembly 4 and correlating with the design digital model of the first assembly 4, the projection device 2 is connected to the aircraft coordinate sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com