Drilling dust collection auxiliary tool and method

An auxiliary tool and round hole technology, which is applied in metal processing and other directions, can solve the problems that drilling operators cannot take into account the vacuuming operation and consume labor, and achieve the effect of reducing the possibility of inhaling dust, saving labor, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

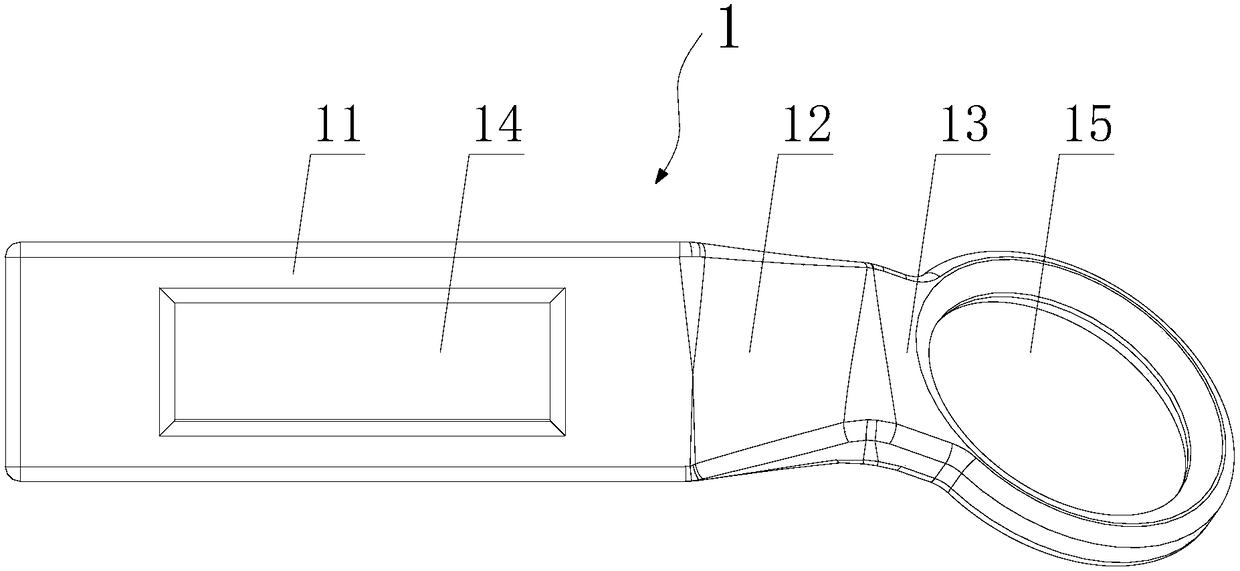

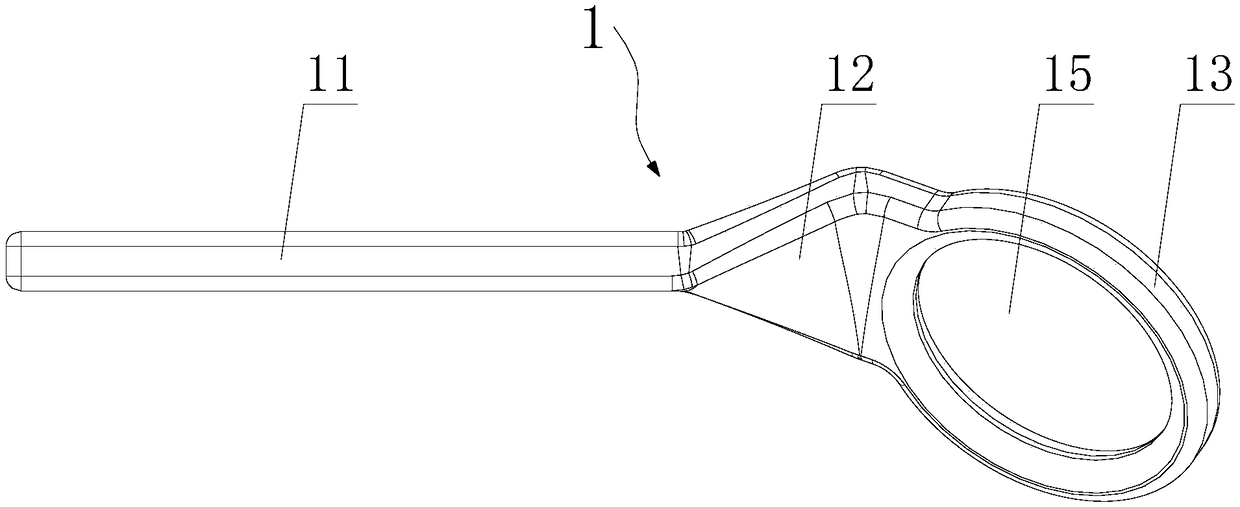

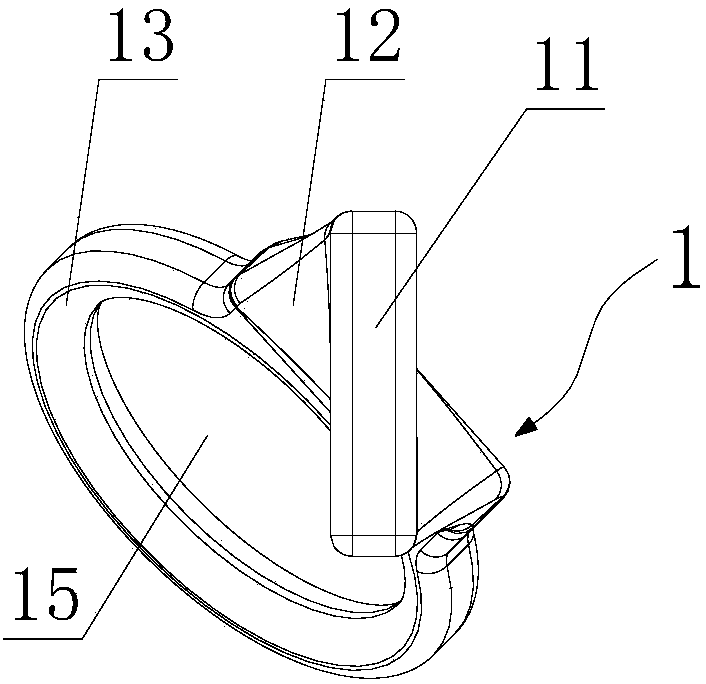

[0022] Such as Figures 1 to 3 As shown, the auxiliary tool for drilling and vacuuming of the present invention includes a fixing part 11, a connecting part 12 and a collar part 13, and the fixing part 11, the connecting part 12 and the collar part 13 are integrated. The drilling and vacuuming auxiliary tool 1 is made of 3D printing of PLA or ABS material to ensure the strength requirement.

[0023] The fixed part 11 is plate-shaped, and a rectangular hole 14 is arranged on the fixed part 11. The rectangular hole 14 is used for inserting the handle of the handle drilling jig, so the size of the rectangular hole 14 matches the size of the handle of the handle drilling jig, ensuring Among them, the auxiliary tool for drilling and vacuuming can be stuck on the handle drilling template by its own gravity. The connecting portion 12 is twisted, one end of the connecting portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com