Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1910results about How to "Guaranteed dimensional accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

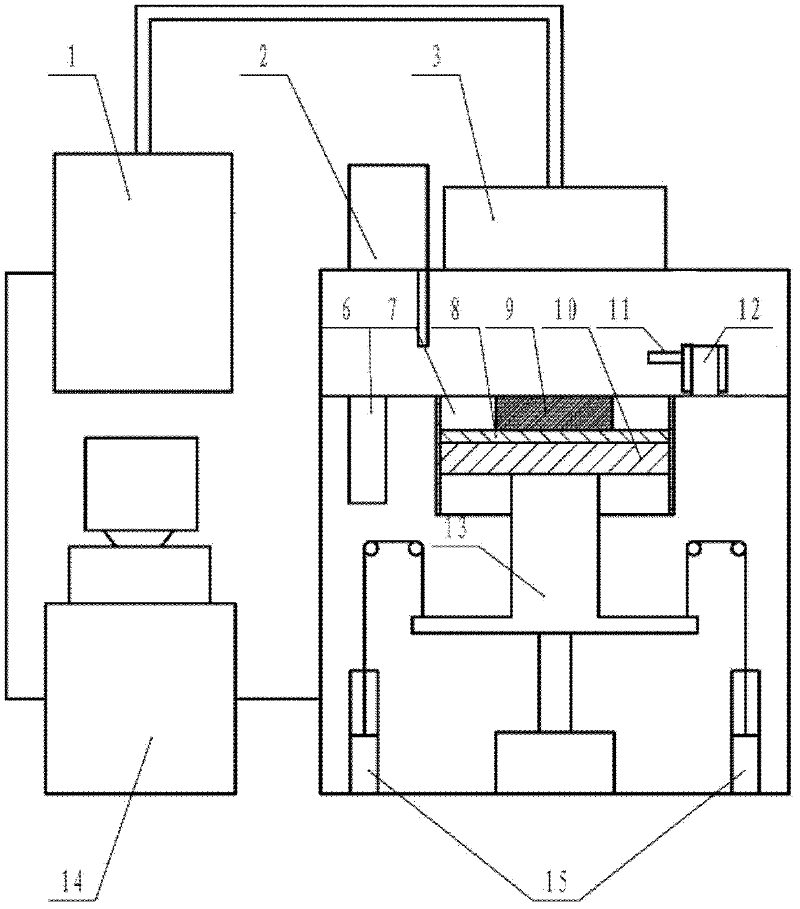

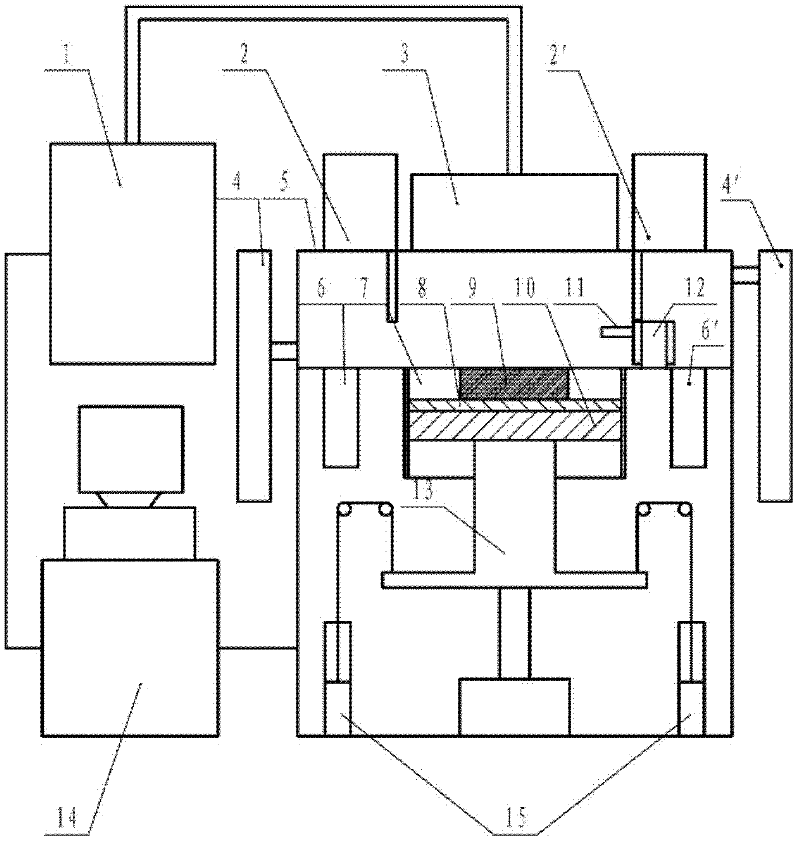

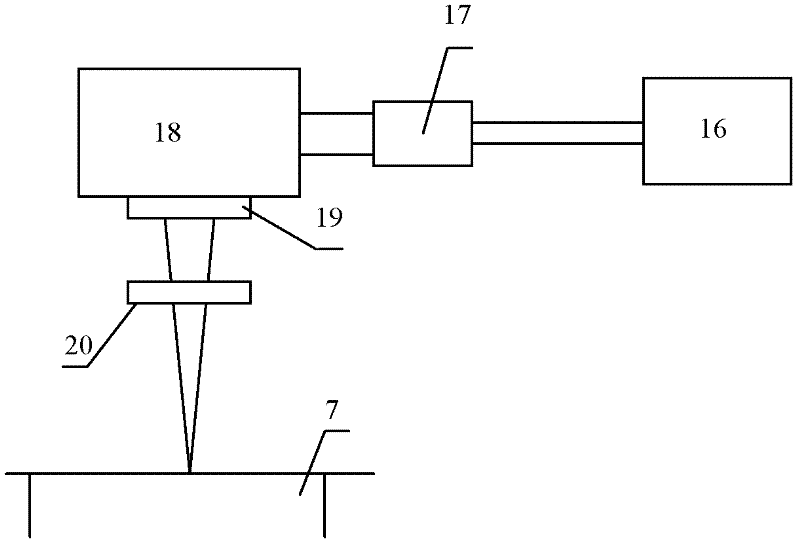

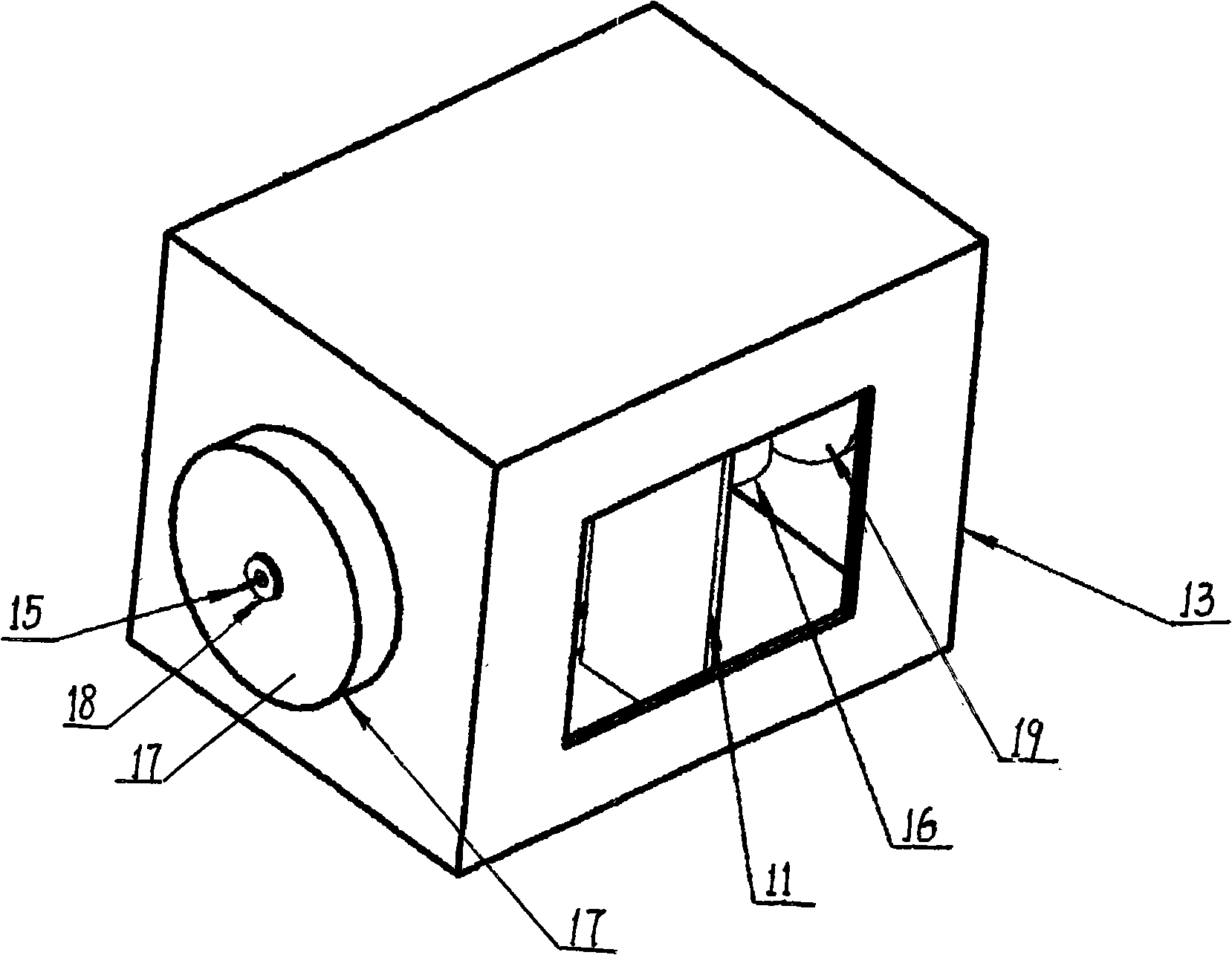

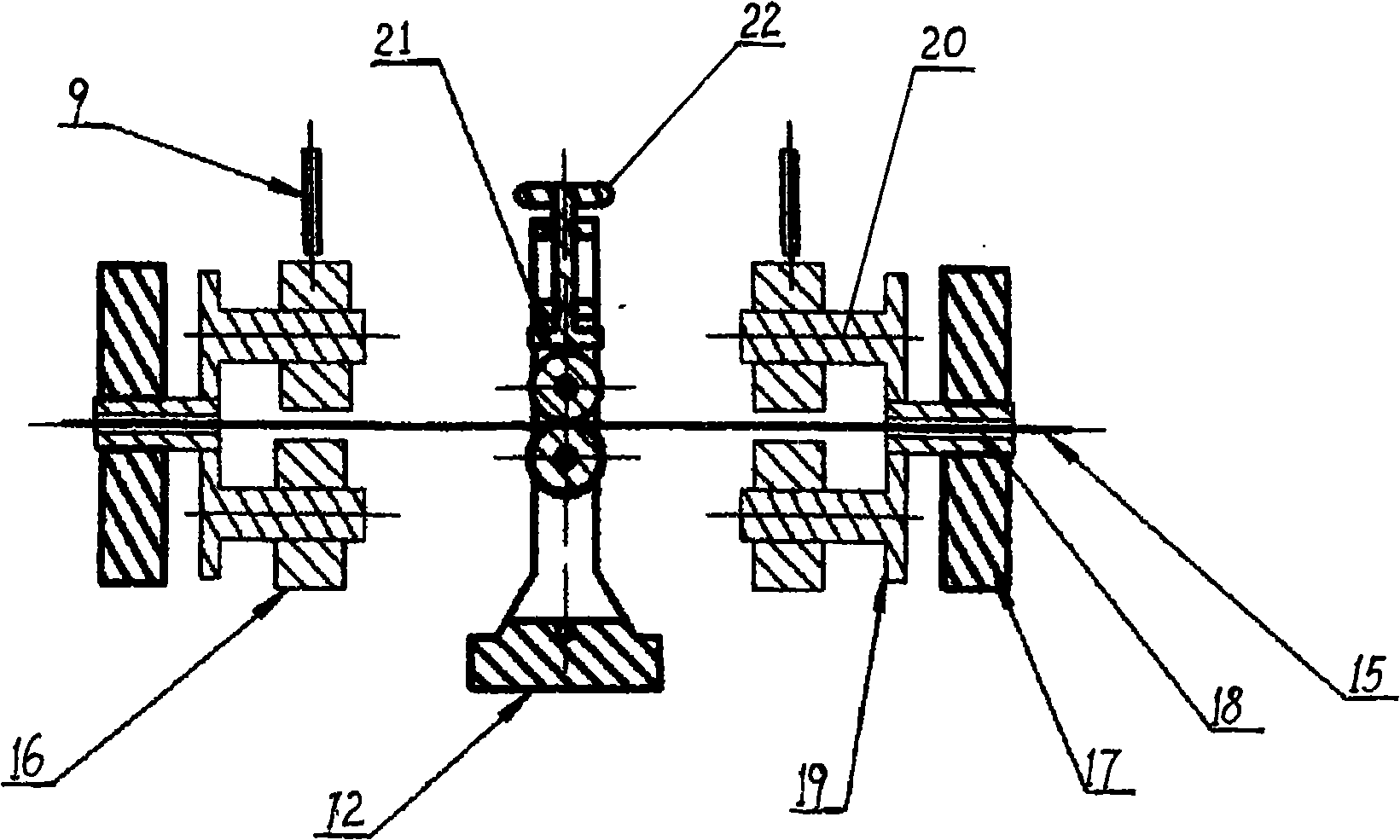

Selective laser melting rapid prototyping equipment for direct manufacturing of large parts

ActiveCN102266942AMeet the process requirementsReduce construction costsIncreasing energy efficiencySelective laser meltingLaser array

The invention discloses a selective laser melting rapid forming device for directly manufacturing large-size compact parts, which mainly comprises a laser array, an optical system array, a forming cylinder, a forming cylinder vertical sectional heating thermal-insulation structure, a forming cylinder weight balancing system, a substrate leveling device, a double-recovering cylinder, a double powder storing box, a double quantitative powder sending and discharging device, a powder paving device, a protective atmosphere cover, a gas purifying system and a control system, wherein an adopted optical system is composed of a plurality of optical system units and a mechanical moving platform, and the coverage area of the optical system can be randomly expanded or reduced. The size of the parts manufactured by using the selective laser melting rapid forming device provided by the invention is more than the size of the parts manufactured by using the existing national and foreign selective laser melting processes. The forming efficiency is multiplied while the forming precision, the parts complexity and the mechanical property are not changed.

Owner:TECH LASER TECH SHANGHAI CO LTD

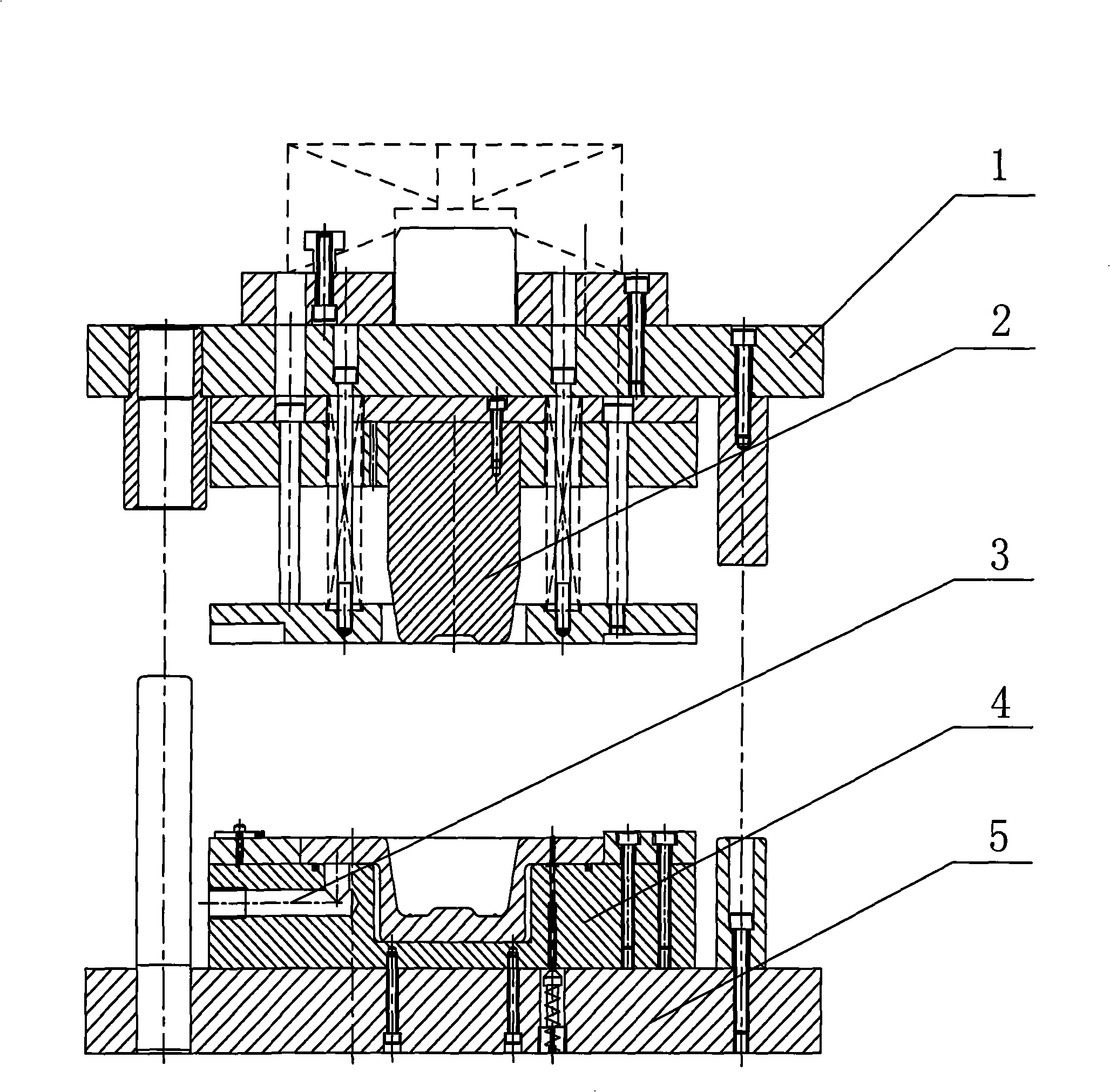

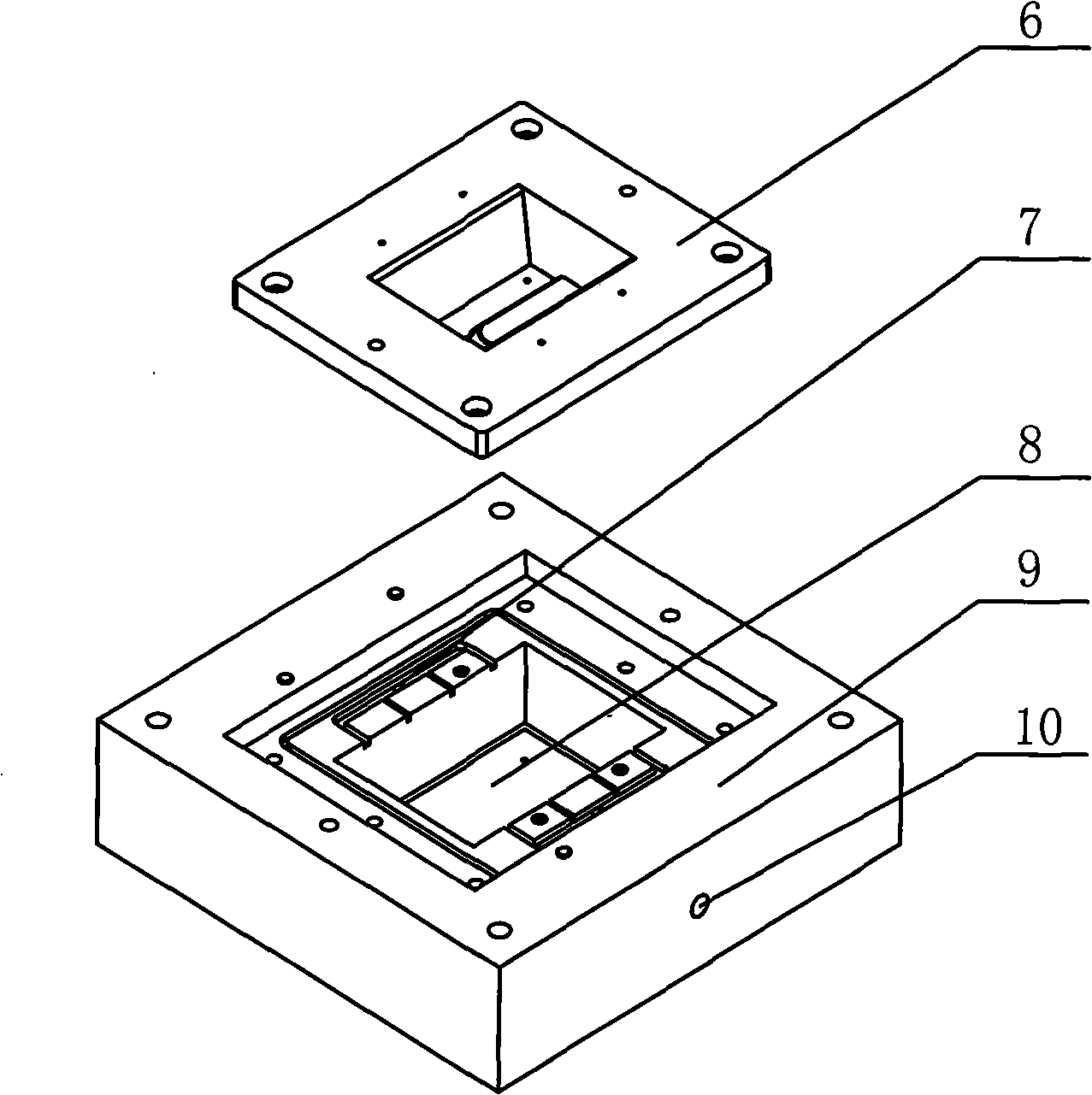

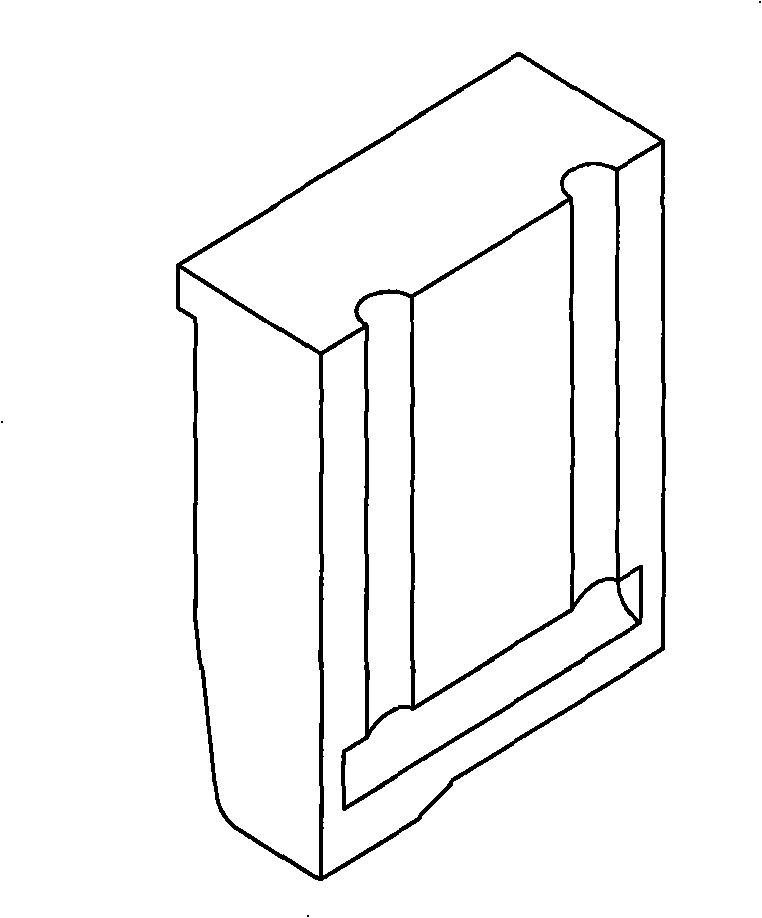

Ultra-high strength steel hot stamping forming die

The invention discloses an ultra-high strength steel plate thermal die cutting and forming die, comprising an upper die seat and a convex die which is fixed on the upper die seat, a lower die seat and a concave die that is fixed on the lower die seat; the concave die is internally provided with a cooling water passage which is connected with a cooling water circulation system. More particularly, the concave die is compose of a trough-shaped concave die seat and a cavity body; the concave die seat is provided with a water inlet and a water outlet; the cavity body is arranged in the concave trough of the concave die seat; a gap is arranged between the cavity body and the concave die seat; the gap is communicated with the water inlet and the water outlet. The die improves cooling speed, ensures the uniformity of cooling, has simple and practical structure, and fast cools the die and the punching parts in the die by the water cooling system of the die, so as to achieve the effect of quenching. As the process is completed under the pressure preservation process of the die, the workpiece has extremely small deformation and the dimension precision of the punching part can be excellently ensured.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD +1

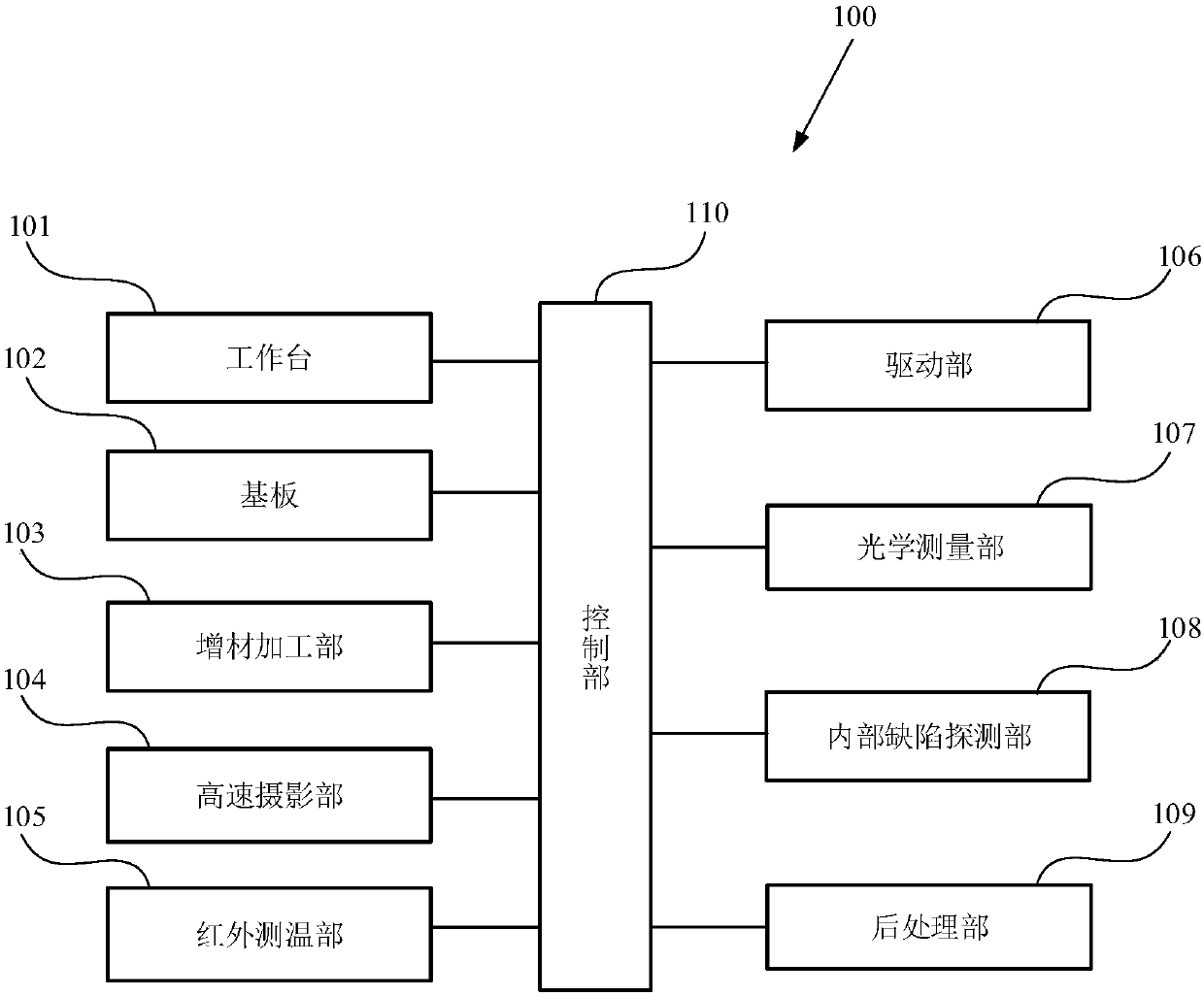

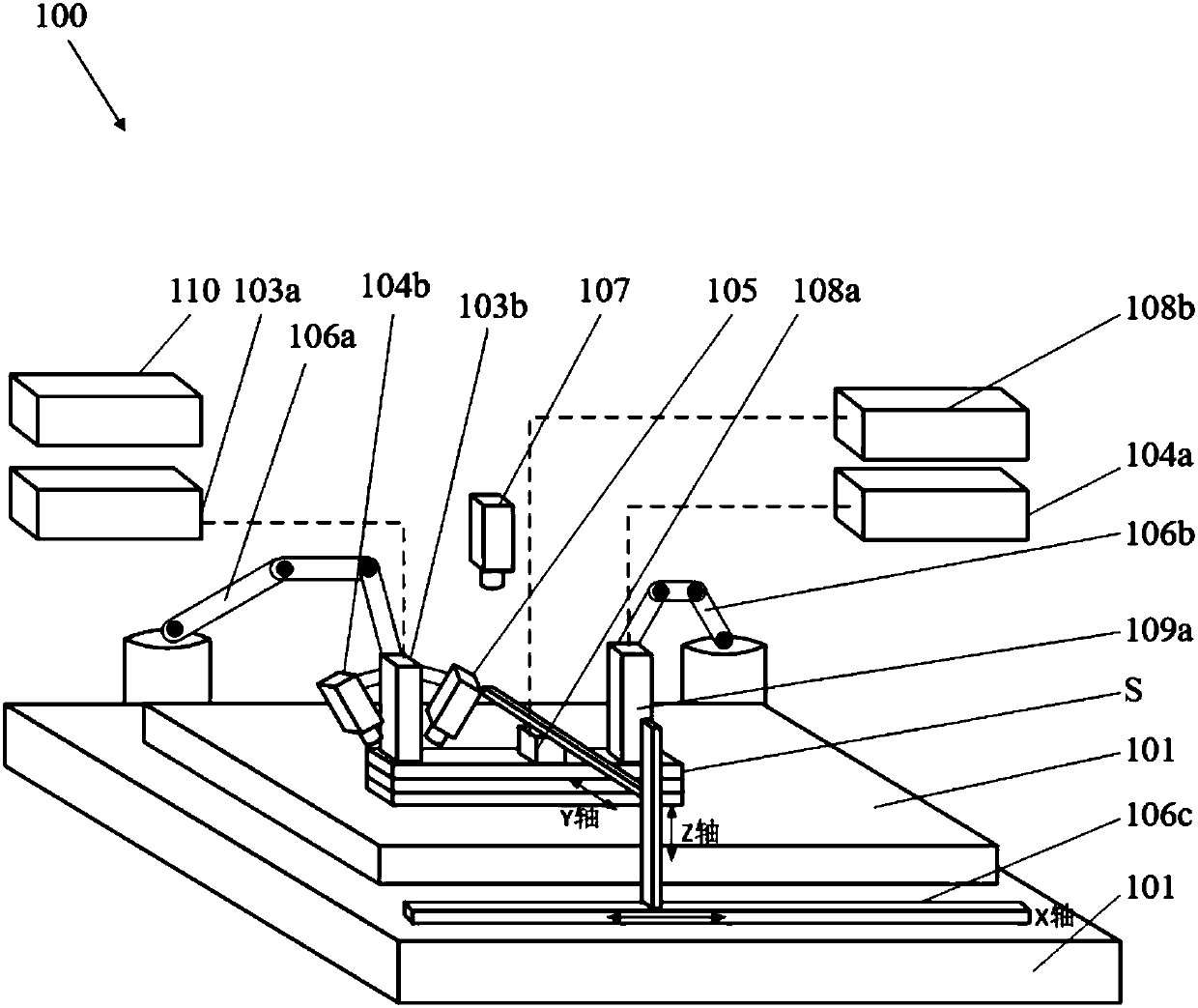

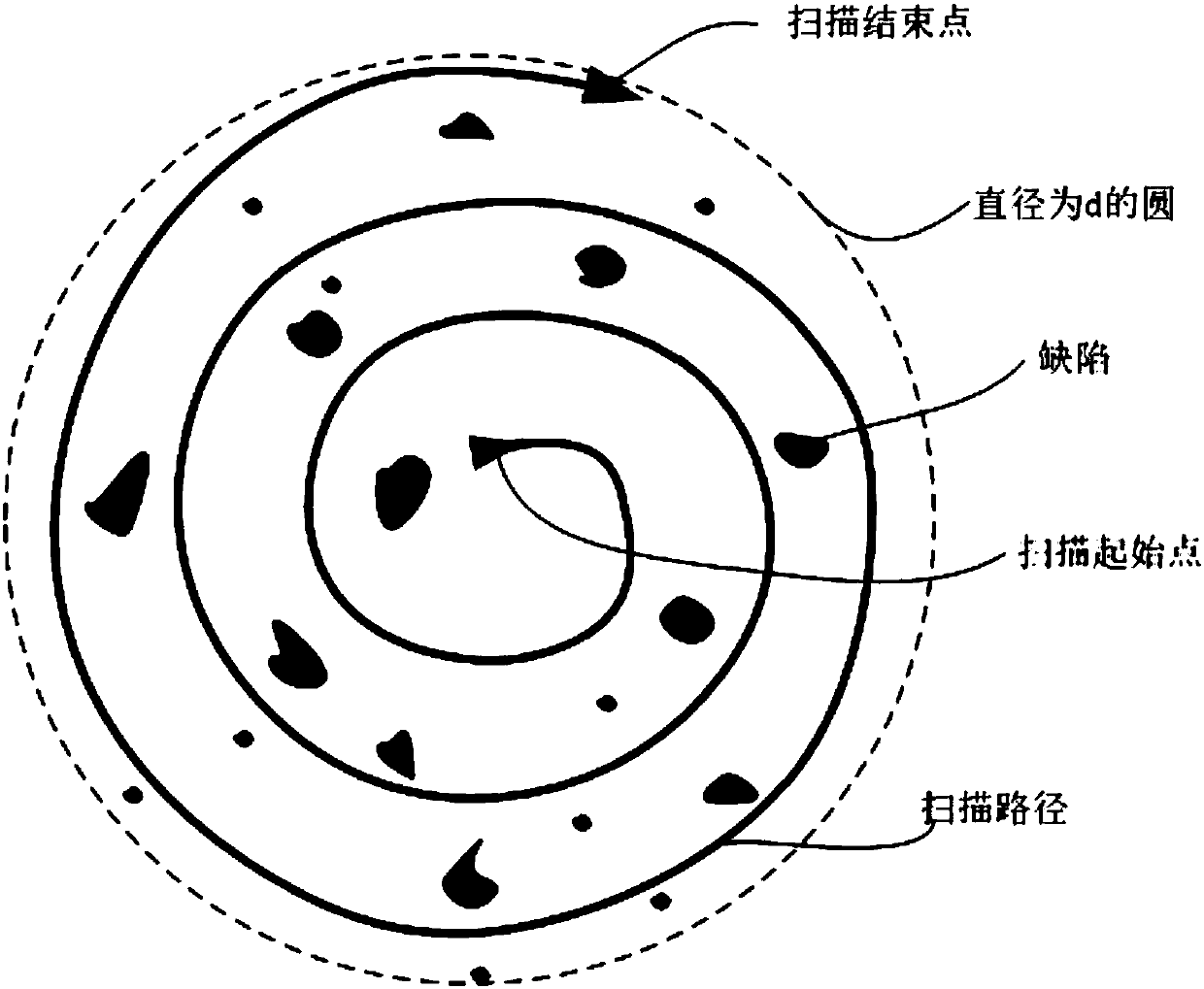

Added material manufacturing device and method

ActiveCN107671288AImprove yieldEliminate defectsAdditive manufacturing apparatusIncreasing energy efficiencyOptical measurementsEngineering

The invention provides an added material manufacturing device and a method. The device is characterized by comprising an added material machining part, a high-speed camera part, an infrared temperature measuring part, an optical measuring part, an internal defect detecting part, an aftertreatment part and a control part, wherein the high-speed camera part comprises a camera head, which moves withthe added material machining head at the same time to obtain material image information; the infrared temperature measuring part comprises a temperature measuring head, which moves with the added material machining head at the same time to obtain material temperature distribution information; the optical measuring part detects surface defects and forming sizes of materials to obtain detecting information; the internal defect detecting part comprises a detecting head and a detecting analyzer; the aftertreatment part treats material defect areas to eliminate defects by adopting corresponding aftertreatment modes; the aftertreatment modes comprise at least one of mechanical rolling treatment, laser shock reinforcement treatment and friction stir treatment; and the control part controls all the parts to operate to obtain various information, determines the defect treatment areas, aftertreatment paths and the aftertreatment modes based on the information, and controls the aftertreatment part to perform corresponding aftertreatments.

Owner:岳阳珞佳智能科技有限公司

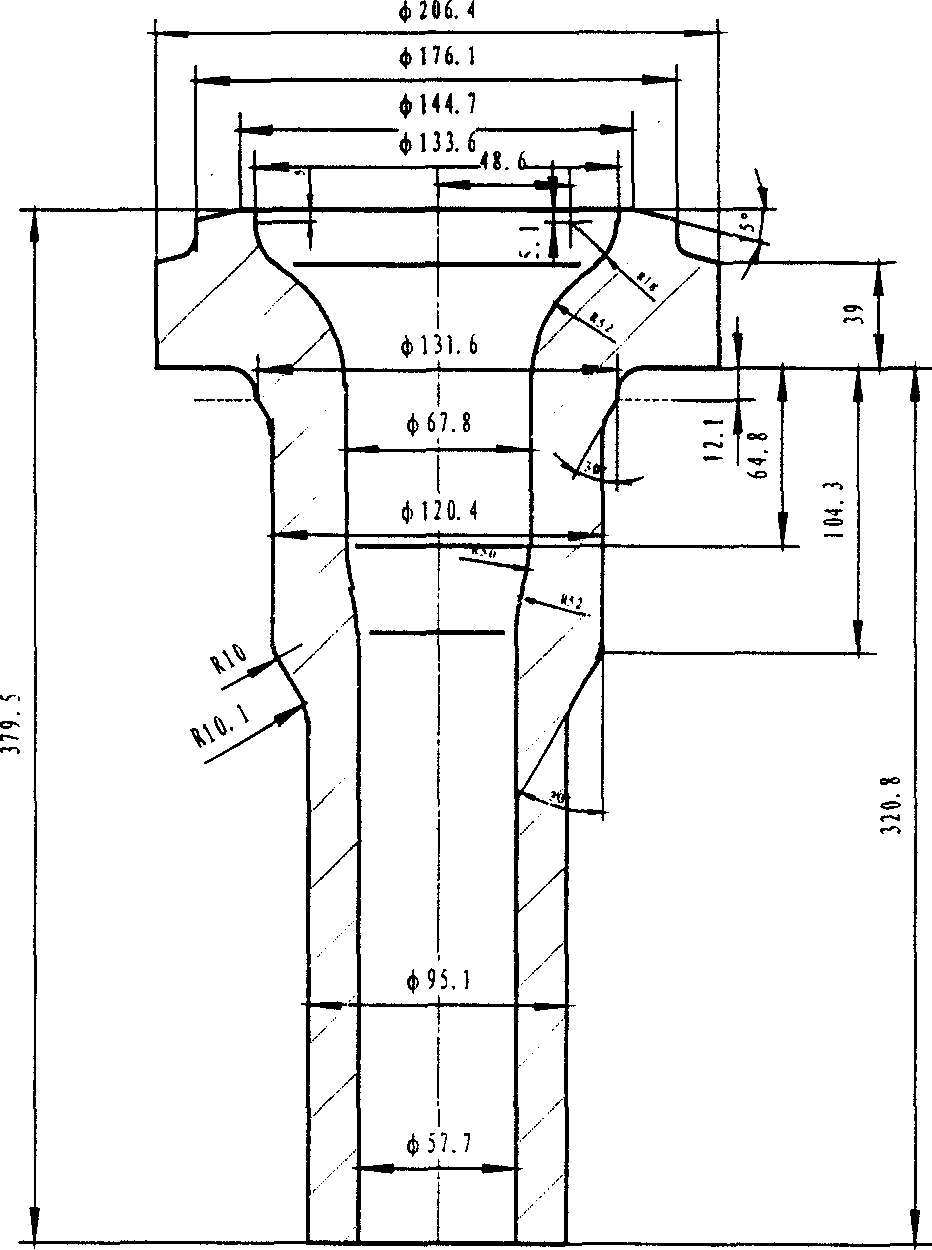

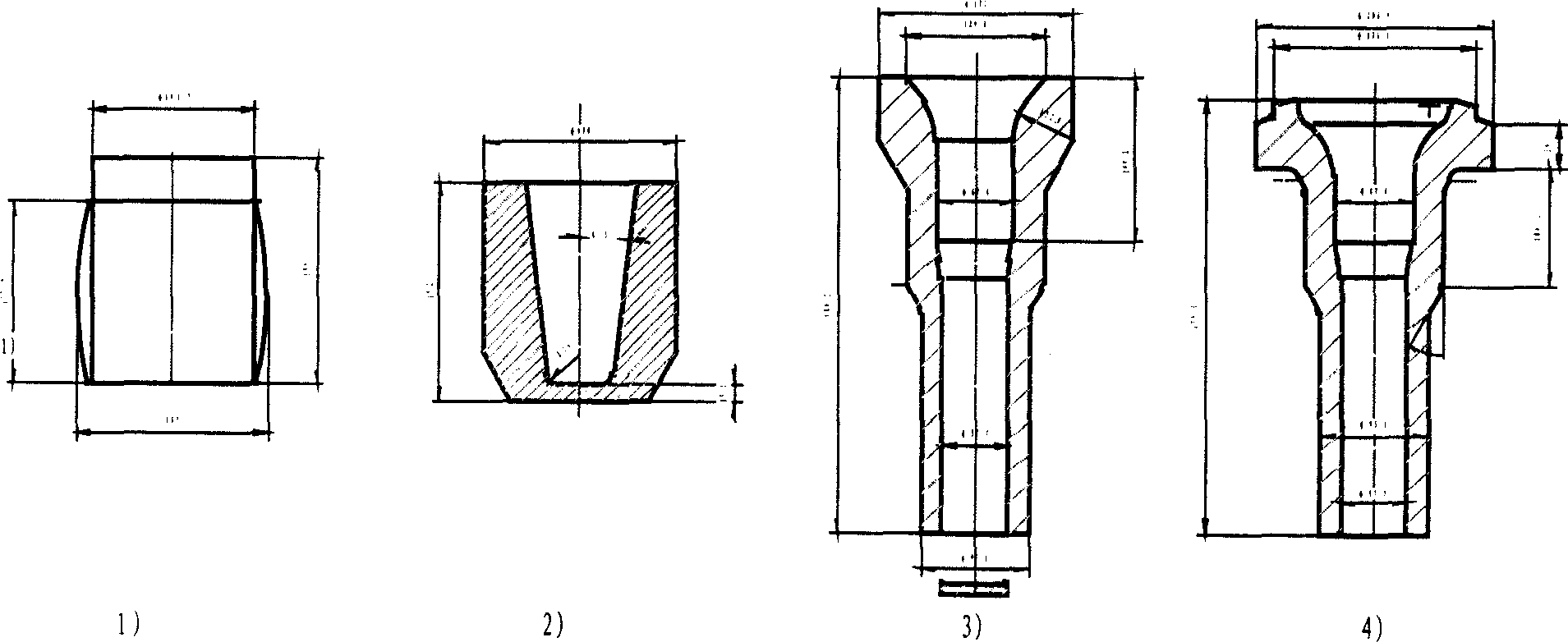

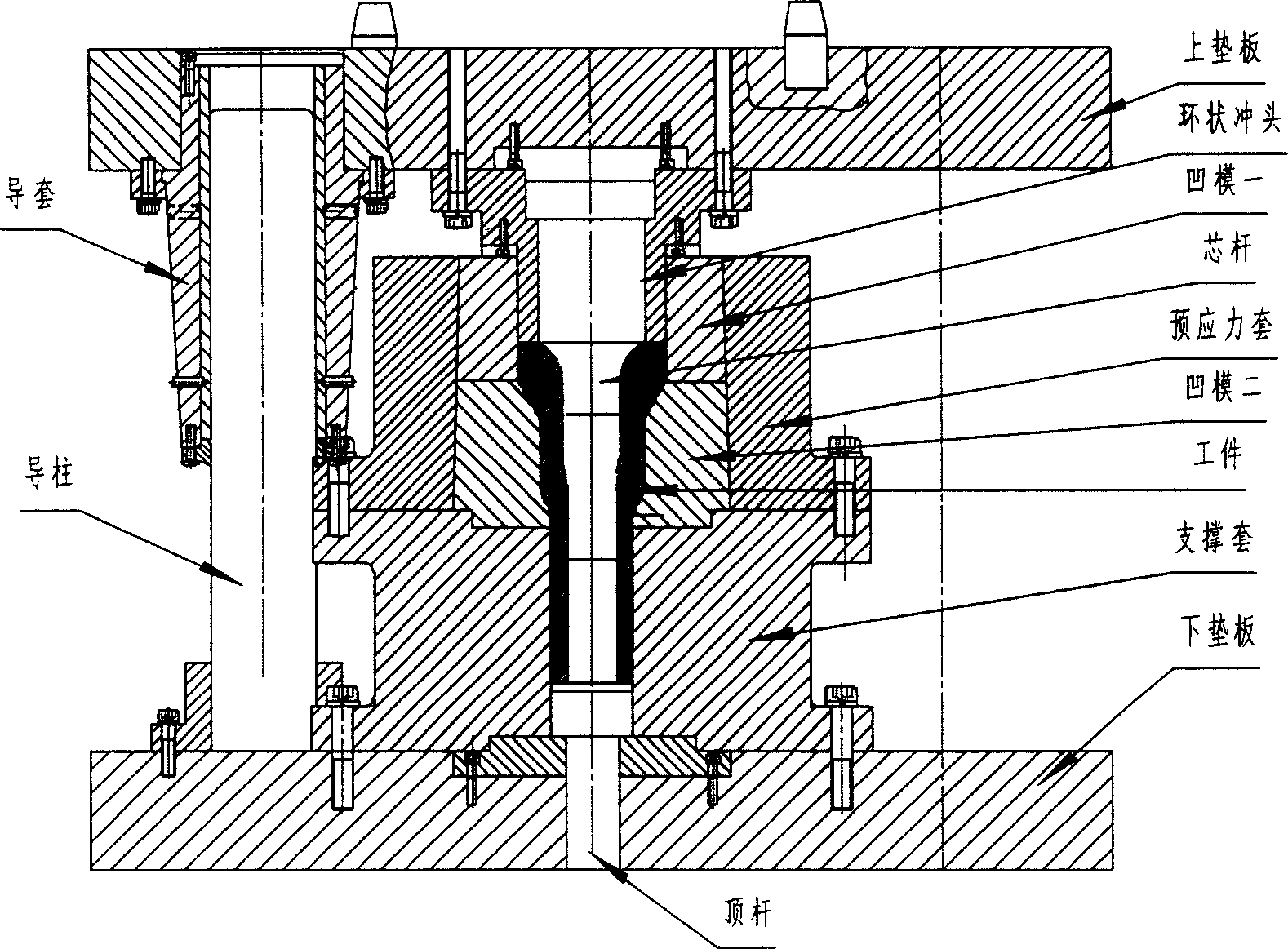

Fast precise semi-axle casing extruding formation process

InactiveCN1672863AImprove the state of stressGuaranteed dimensional accuracyMetal-working apparatusOther manufacturing equipments/toolsEngineeringMachining

The technological process of fast forming precise semi-axle casing with circular rod material heated to forging temperature includes four steps of upsetting, punching hole, perforating and positive extruding. The present invention realizes the fast formation of precise semi-axle casing in only four steps. Combined male die structure is adopted to simplify the technological process of extruding hollow rod, and the present invention has high production efficiency and raised material utilization.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

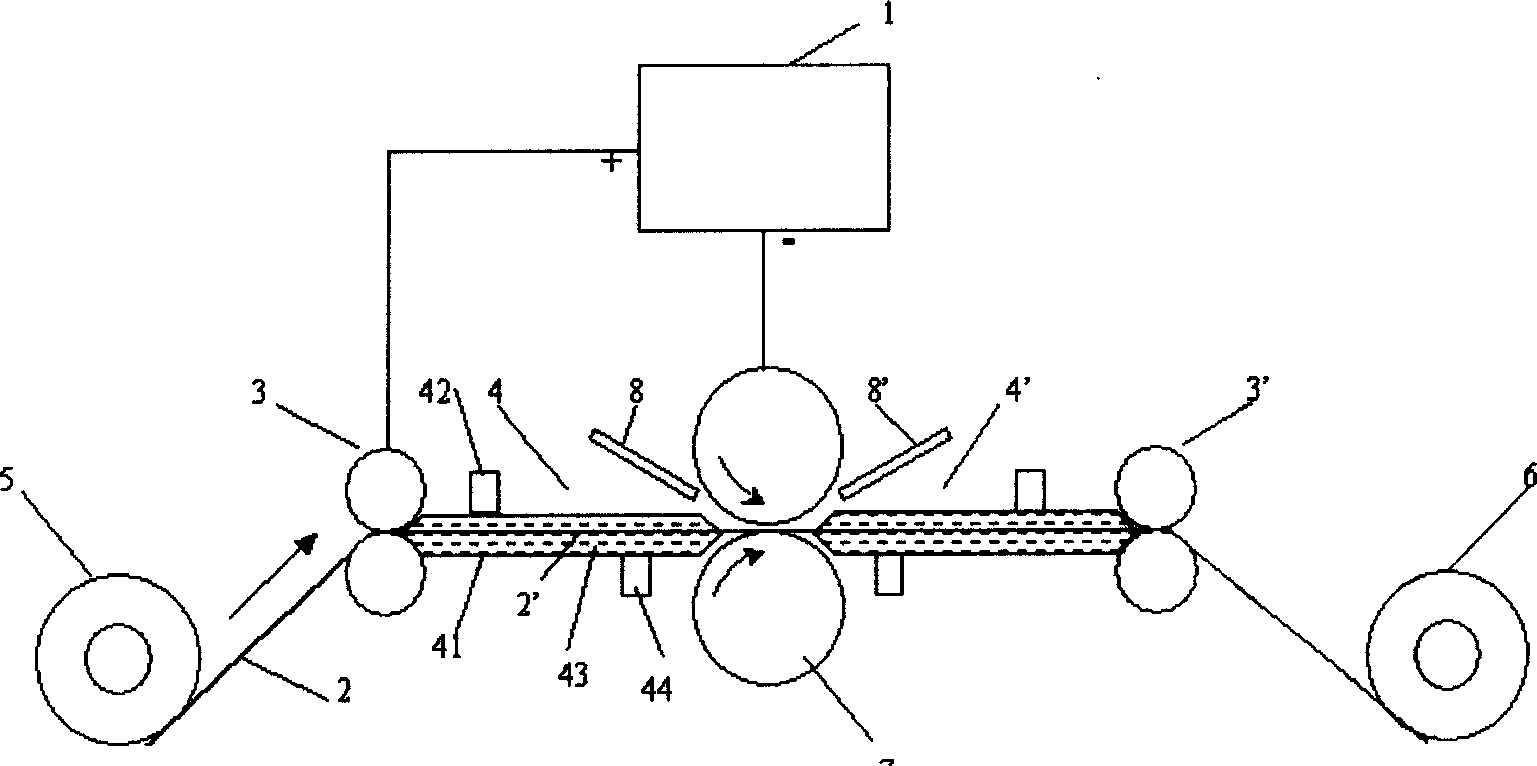

Electroplastic rolling method and apparatus for deformable magnesium alloy sheet, band and wire rod

This invention relates to an electro-plastic rolling method and a device for deformed Mg alloy thin plates, strips and wires including: inducing the deformed Mg alloy plates, strips and wires in single-way instant high energy continuous pulse current directly in the process of rolling, the current passes through a pair of electric contact devices with their distance adjustable to apply on the moving Mg materials, and the roller is the negative in it, necessary cooling and lubrication measures should be taken when rolling, this time, the rolling deformation ability of the Mg material is increased greatly and the resistance is reduced to avoid high temperature oxidation and poor accuracy in size.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

Direct light-curing fabrication method of hollow blade ceramic cast

The invention relates to a method for directly making a hollow blade ceramic mold based on a photo-curing process. The method is as follows: firstly, ceramic powder and pre-mix liquid are evenly mixed so as to make ceramic slurry; secondly, according to a hollow blade model, a hollow blade mold model containing a gating system is obtained, and the ceramic slurry is directly made into a ceramic mold biscuit on a photo-curing forming machine according to the hollow blade mold model; then, the ceramic mold biscuit is dewatered to obtain a dry ceramic mold; finally, the dry ceramic mold is placed in a high-temperature baking furnace so as to carry out degreasing and sintering, thereby making the hollow blade ceramic mold. The ceramic mold can be used in the casting of a hollow blade, and replaces a multi-layer ceramic shell and core manufacturing process adopted in the prior investment casting. The method does not need the processes of investment pattern making, slurry coating and sand spreading adopted in the prior process, and has the characteristics of simple process, short cycle, low cost and quick returns, etc.

Owner:XI AN JIAOTONG UNIV

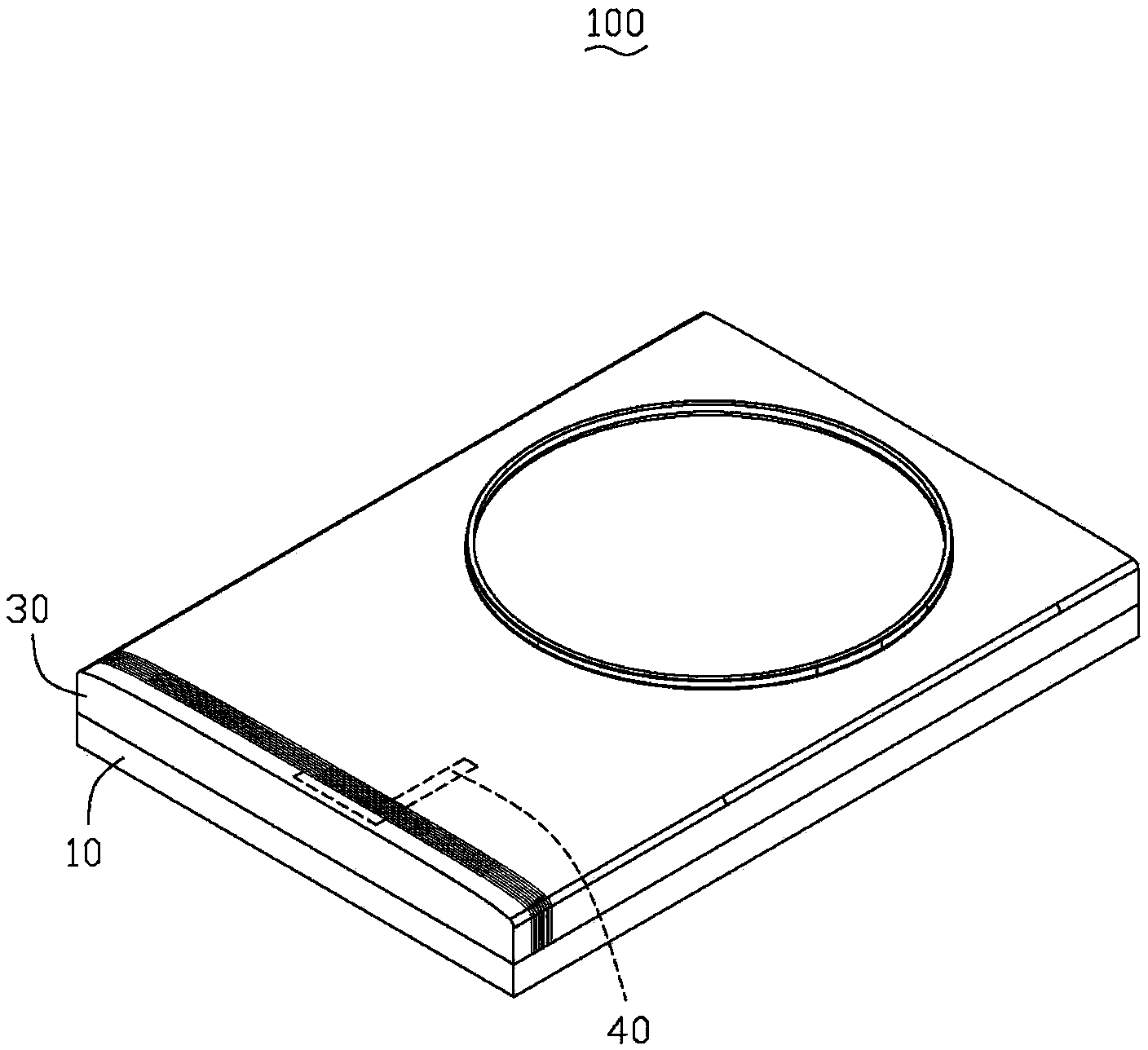

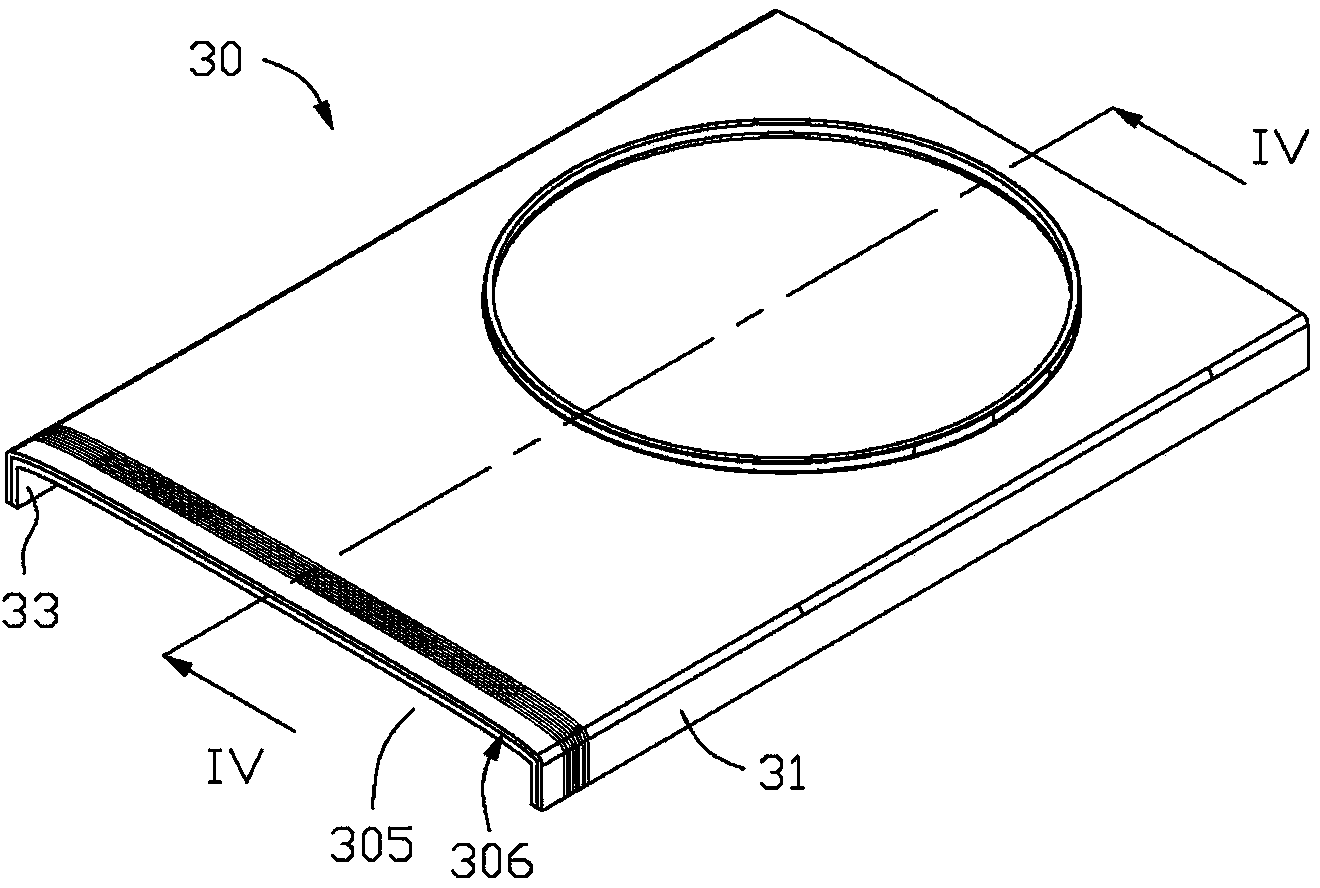

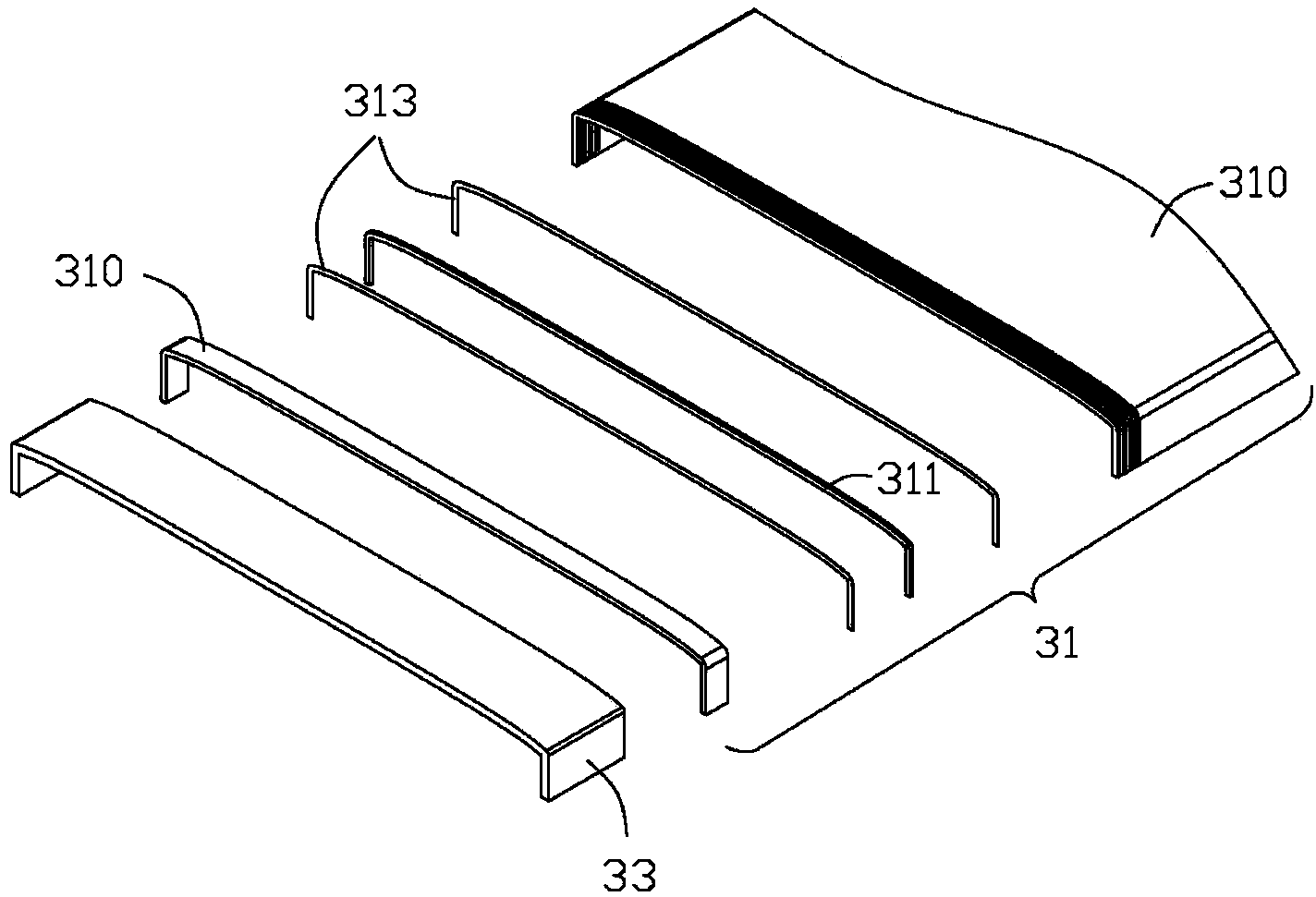

Shell, electronic device employing the shell and manufacturing method of the shell

ActiveCN104168730ADoes not affect appearanceImprove bindingDigital data processing detailsCasings/cabinets/drawers detailsIsolation layerMetal sheet

A shell comprises a substrate and a reinforcing layer formed on the inner surface of the substrate. The substrate comprises at least one body part, a plurality of metal sheets and a plurality of nonconductive isolation layers. The metal sheets and the isolation layers are arranged alternately, and the metal sheets are fixedly connected by the isolation layers. The at least one body part is fixedly connected through the isolation layers with a component formed by alternately arranging the metal sheets and the isolation layers. The invention further provides an electronic device employing the shell and a manufacturing method of the shell. According to the shell, the electronic device employing the shell and the manufacturing method of the shell, the metal sheets and the isolation layers are arranged alternately, and the binding force of the metal sheets, the isolation layers and the substrate is enhanced by the reinforcing layer. Therefore, signal shielding is avoided, the dimensional accuracy is ensured, and the appearance of the shell is not affected.

Owner:FIH PRECISION ELECTRONICS LANG FANG CO LTD

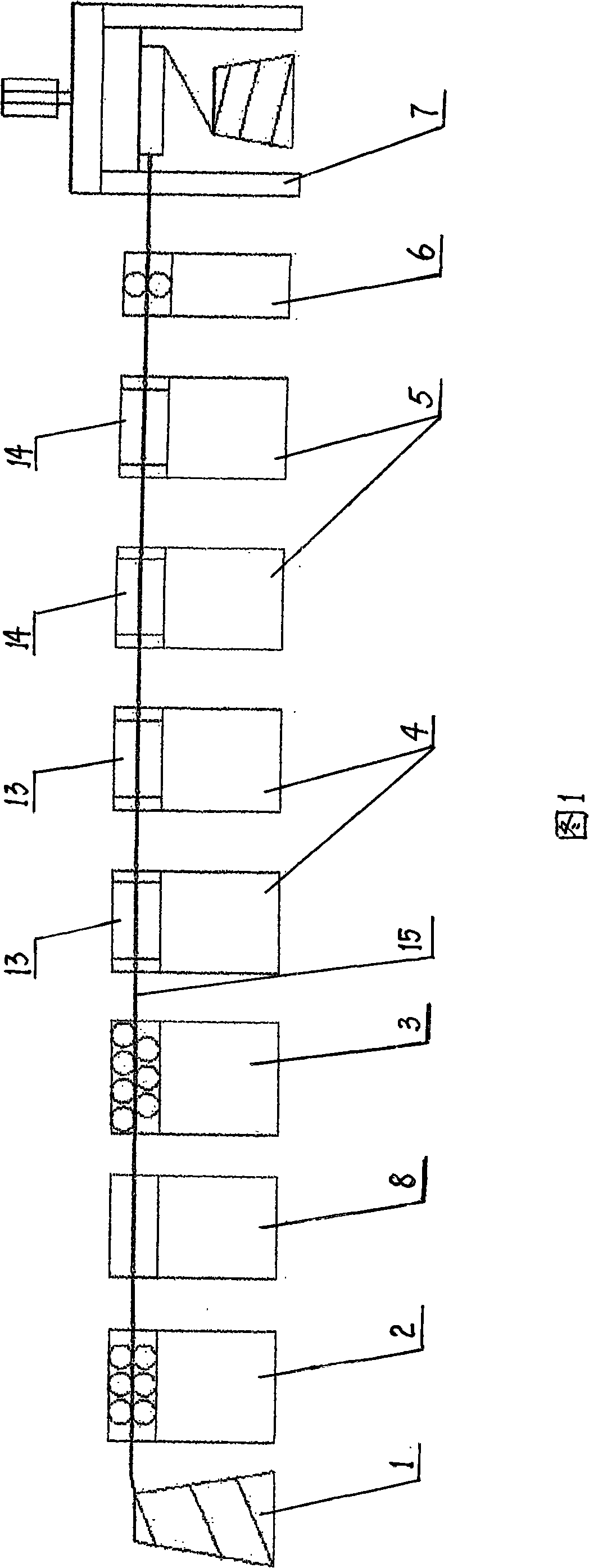

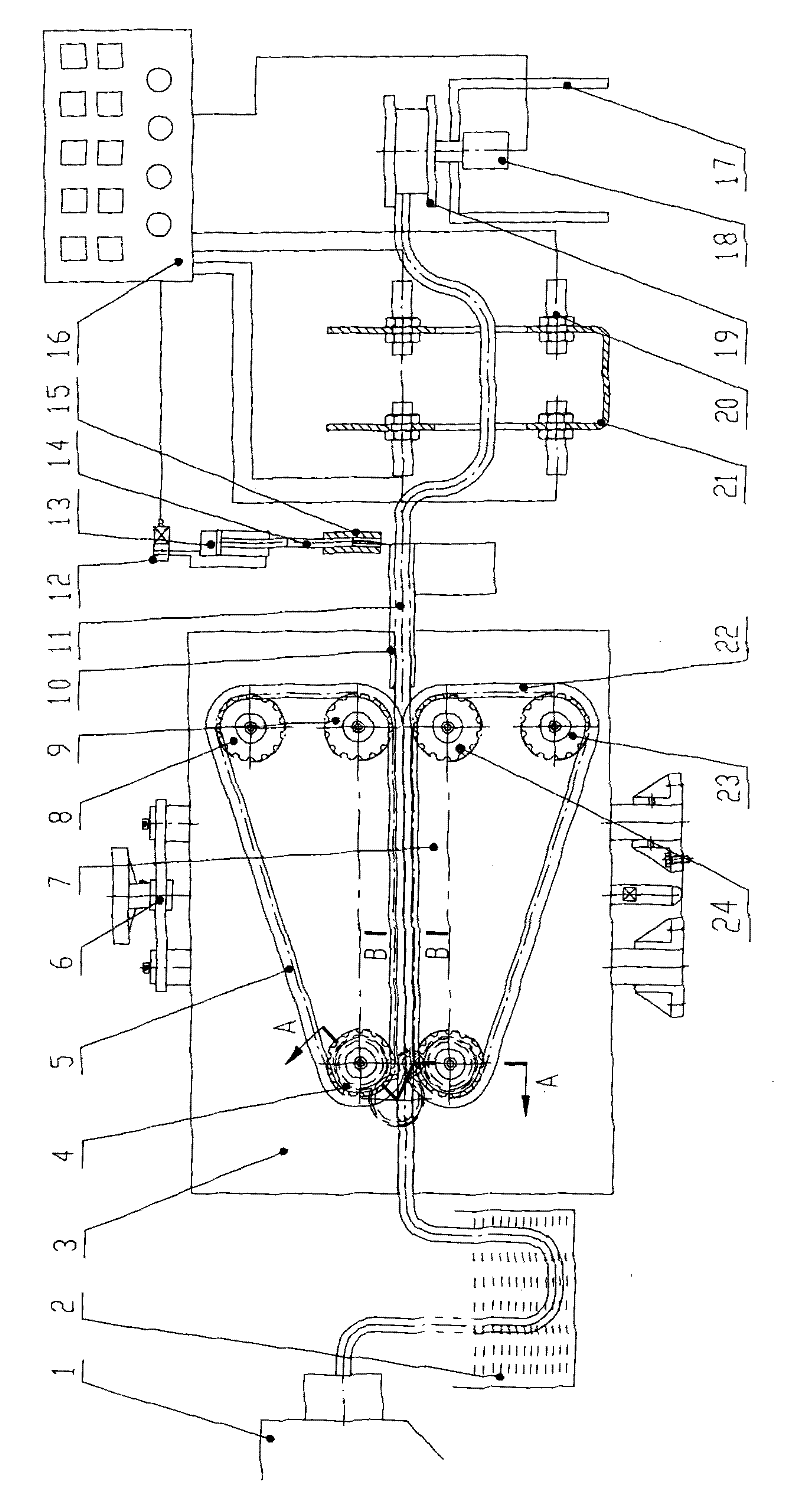

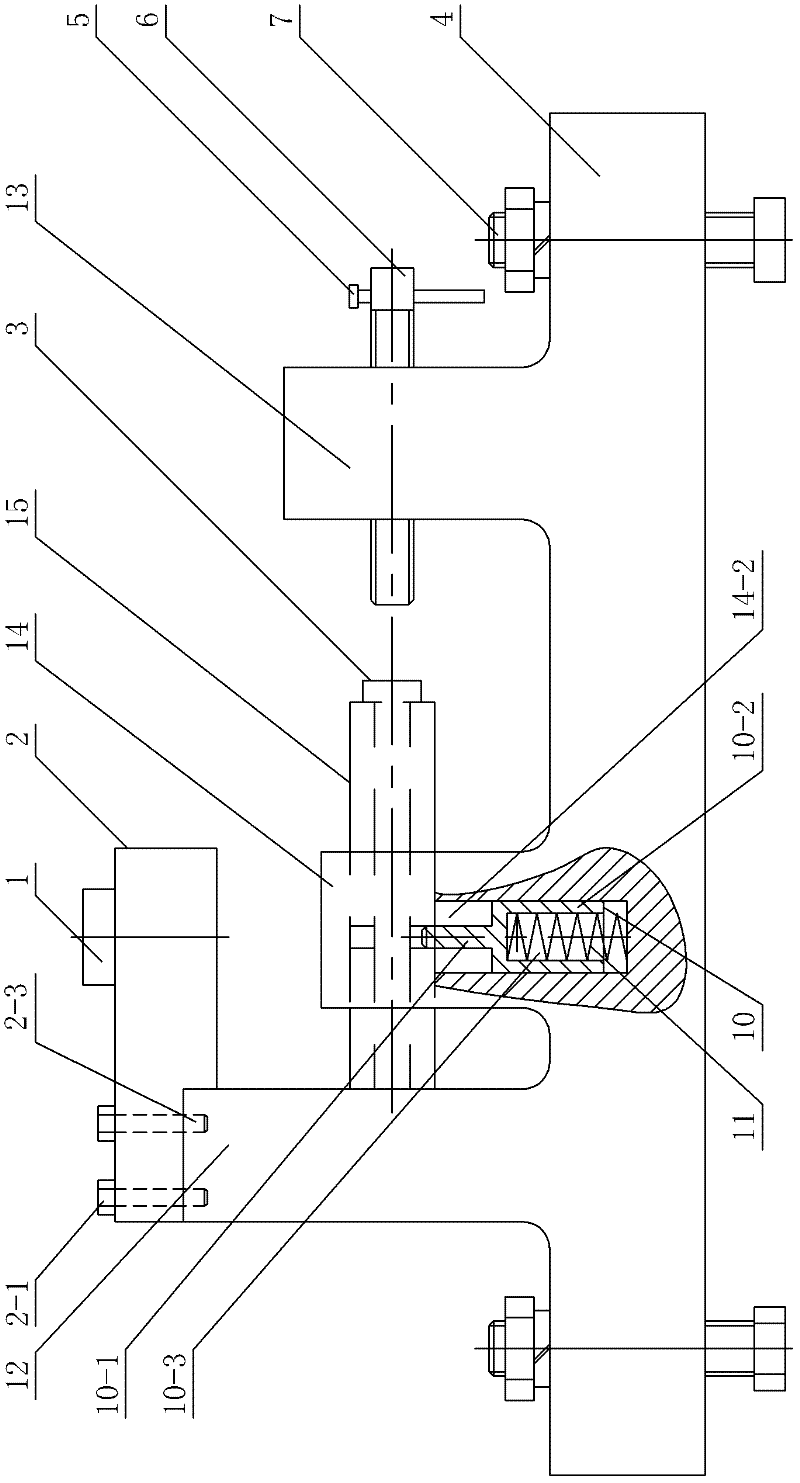

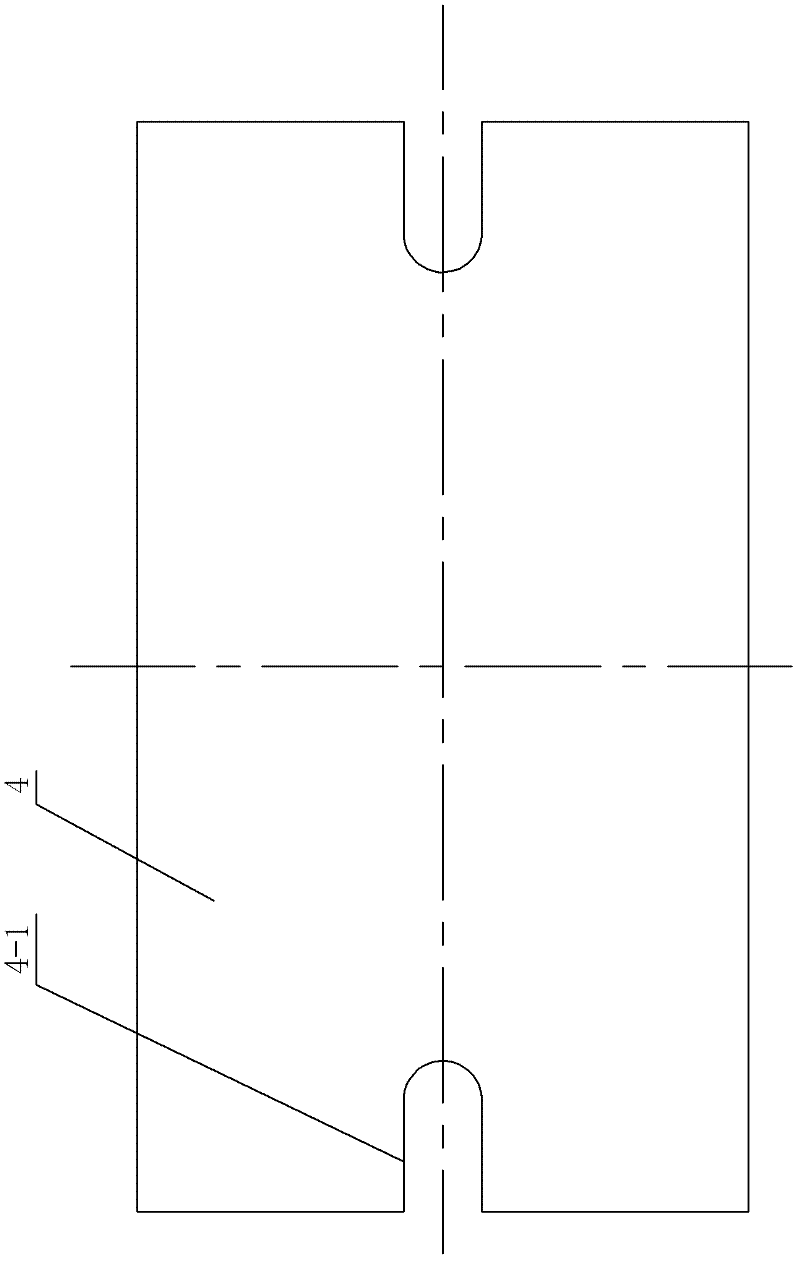

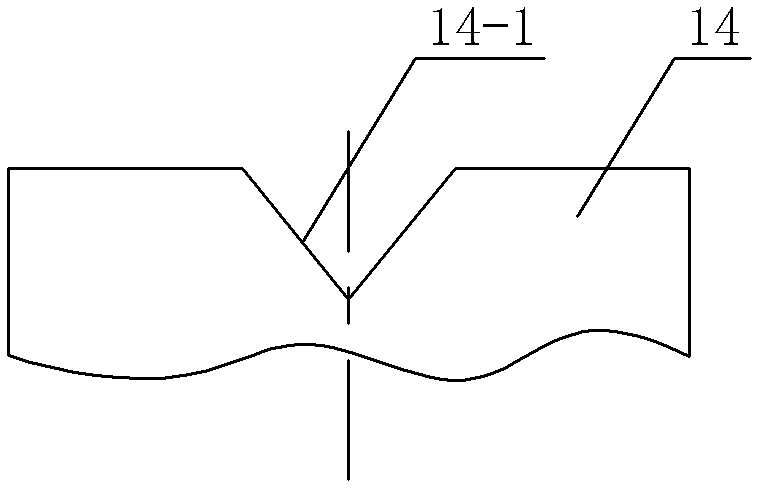

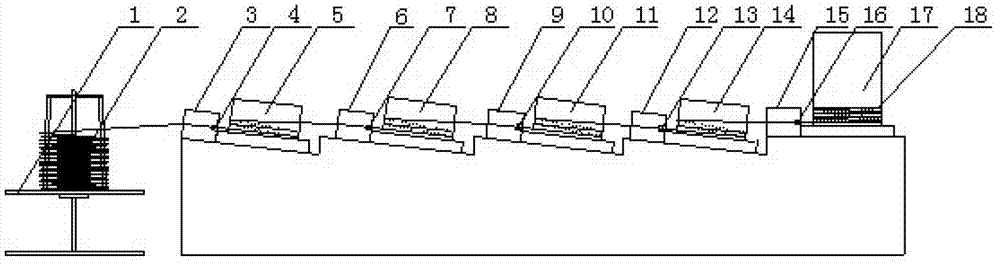

Method and equipment for removing oxidizing layer of titanium and titanium alloy wire material

ActiveCN101269397AEnsure consistencyGuaranteed uniformityWire articlesBurnishing machinesProduction lineTitanium

The invention relates to a method for removing an oxidation layer on titanium and titanium alloy wires and a device thereof. The method includes the following steps: 1. straightening: a straightening machine is used for straightening the titanium and titanium alloy wires; 2. phosphorus removal: a steel wheel phosphorus removal machine is used for removing the oxidation layer on the surface of the titanium and titanium alloy wires; 3. polishing: a sand belt wheel polisher is used for polishing the surface of the titanium and titanium alloy wires. The device is sequentially provided from left to right with a pay-off stand (1), a clamping device (2), a heating device (8), a straightening device (3), two steel wheel phosphorus removal machines (13), sand belt wheel polishers (14), a guide and guard (6) and a vertical down drawing machine (7). On the basis of the present steel wheel phosphorus removal machine, the method is additionally provided with a heating device, a phosphorus removing and polishing machine, a cooling device, a dust removing device and a tension device, thereby forming a production line for removing the oxidation layer on a large and heavy titanium alloy wire, so as to reach the purpose of removing the oxidation layer and polishing.

Owner:BAOJI TITANIUM IND

Machining process of axial-flow type turbine blade

The invention discloses a machining process of an axial-flow type turbine blade. The machining process of the axial-flow type turbine blade comprises the following steps that two side faces are machined on a square blank stock through an end face end mill on an ordinary milling machine through two process of rough milling and finish milling, another two side faces are machined with the two machined side faces as base planes, and then the two end faces are machined through the end face end mill; a steam outlet side face is machined on one side face through two process of rough milling and finish milling, the position, close to the steam outlet side face, of the blade root end face is marked as C, a face which forms an acute angle with the steam outlet side face and is adjacent to the steam outlet side face is marked as N and is the inner radial surface, and the other three side faces are machined to be a parallelogram through rough milling and finish milling; central holes are drilled in the blade root end face and the blade crown end face; the blade type is roughly milled through the end face end mill, the blade root is roughly milled, and finally the blade crown is roughly milled; then the blade is installed on a five-axis numerical control machining center for alignment and is machined in a finish mode; a process head at the blade root end face is roughly sawn through a sawing machine; the turbine blade is detected according to the requirements of a drawing.

Owner:南京赛达科技有限公司

Manufacturing method of nuclear nickel-base high-temperature alloy GH 4145 wire

The invention provides a manufacturing method of a nuclear nickel-base high-temperature alloy GH 4145 wire and belongs to the technical field of high-temperature alloy wire machining. The method includes the steps that after being blended according to the mass percent, raw materials are subjected to vacuum induction and vacuum consumption duplex smelting and cast into an alloy ingot; the alloy ingot is homogenized so as to be forged into an alloy ingot blank, and the alloy ingot blank is then subjected to flaw detection and finishing and hot-rolled into a wire rod with the diameter phi ranging from 8 mm to 12 mm; the wire rod is subjected to solution treatment and is rounded, peeled and coated with a film; drawing and annealing are performed sequentially, the wire rod is pulled into the alloy wire with the required diameter, and the GH 4145 alloy wire is obtained. By the adoption of the nuclear nickel-base high-temperature alloy wire, the whole process is free of acid pickling, the special nuclear requirement is met, and meanwhile the finished wire is high in size accuracy, good in surface quality, even in component and structure and excellent in mechanical performance and processing performance. The method can be widely applied to the machining field of the nuclear nickel-base high-temperature alloy wire.

Owner:CENT IRON & STEEL RES INST

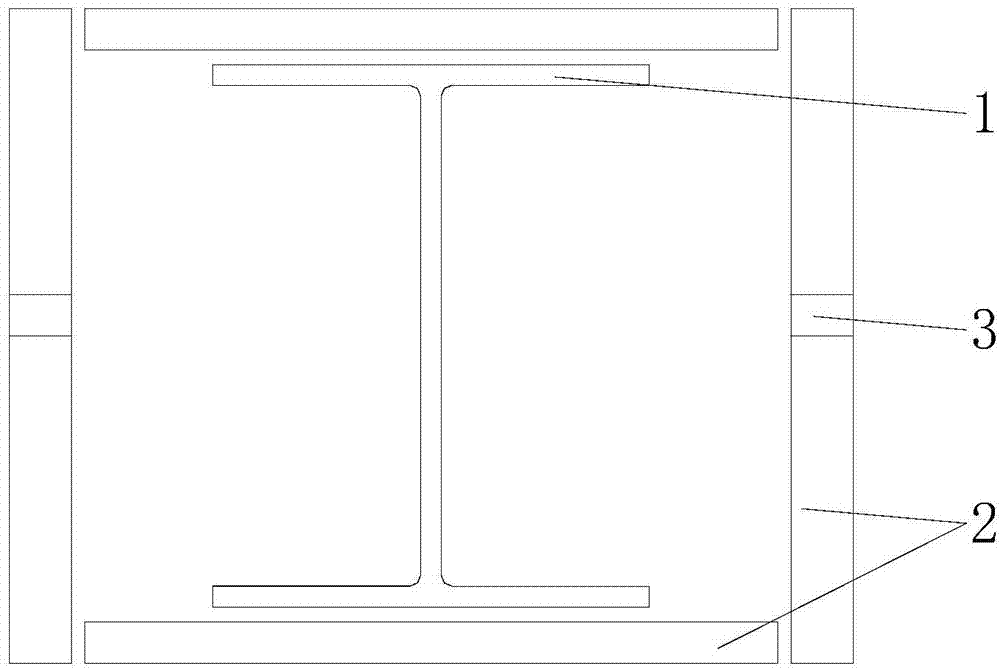

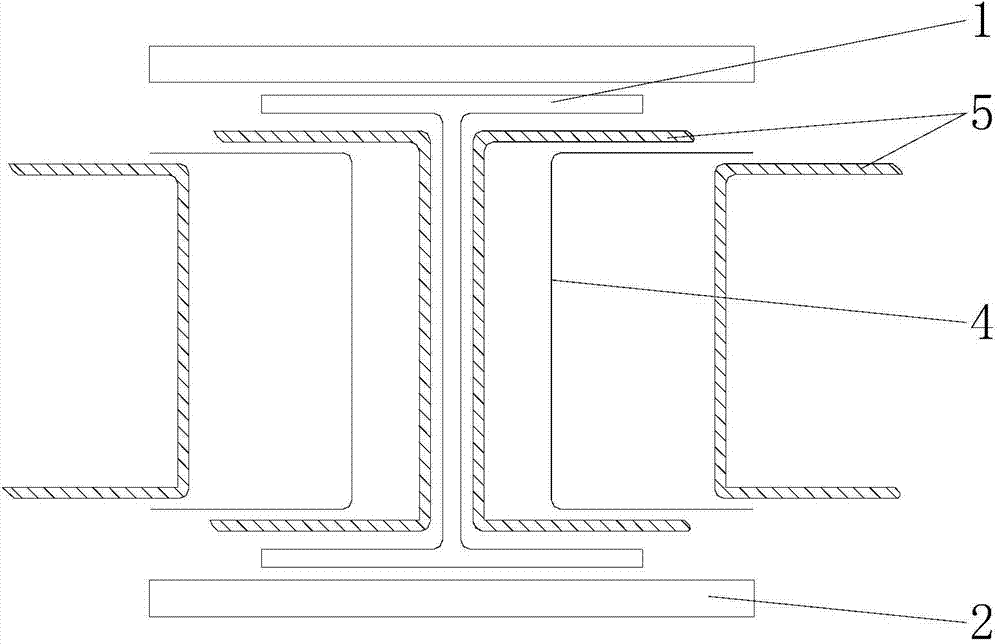

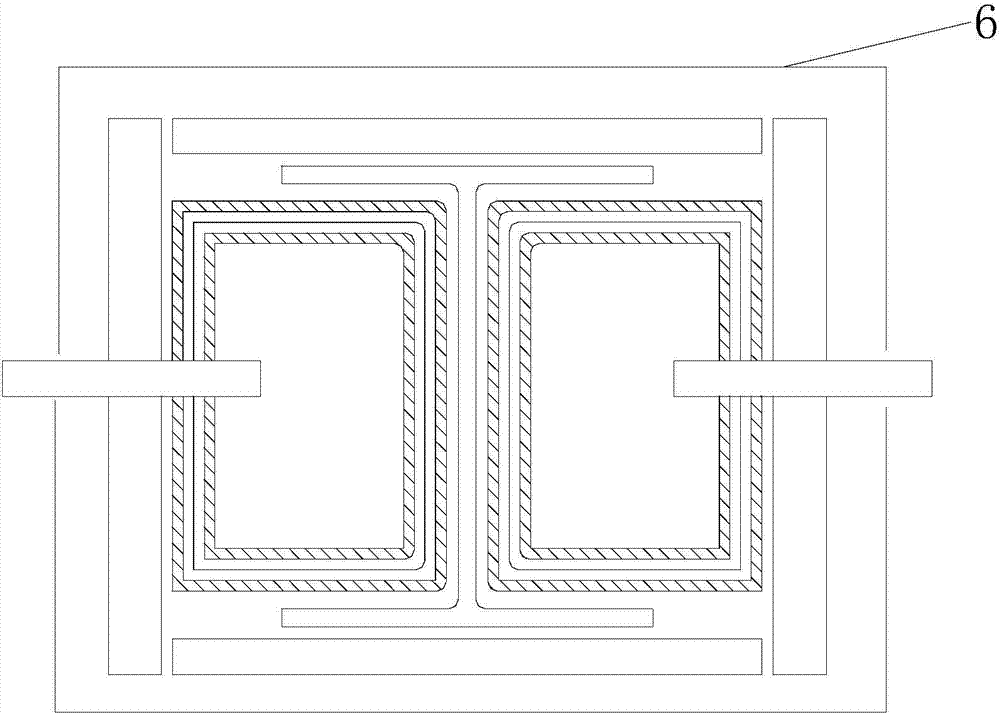

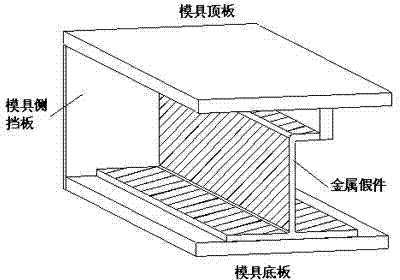

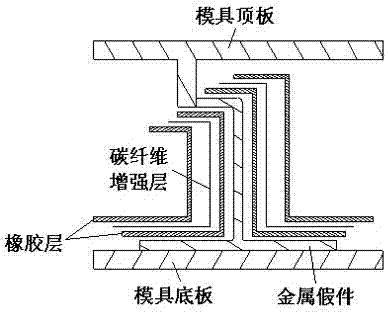

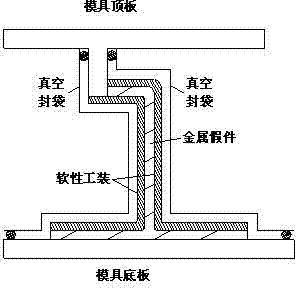

Molding method for composite material structural member with I-shaped section

The invention discloses a molding method for a composite material structural member with an I-shaped section. The composite material structural member is molded by taking a metal fake member and a molding mould to mould a glass fiber enhanced silicone rubber airbag and taking the airbag as a core mould to be combined with the molding mould. The molding method has the advantages that with the adoption of a silicone rubber airbag molded structural member, firstly, the wall of the airbag is thin, the heat transferring performance is good, the temperature gradient of the structural member and the edge is small, and the inner quality of the molded structural member is guaranteed; secondly, silicone rubber on the surface of the airbag is elastic so as to have the effect of a pressure equalizing cushion; the surface quality of a molded part is good; thirdly, the silicone rubber airbag is combined with a box-shaped structure of the airbag; meanwhile, the two ends of the I-shaped structural member are connected by the silicone rubber, the structural rigidity of the airbag is great and the molding position and the size precision of a web are guaranteed; fourthly, the airbag can be used repeatedly and can be manufactured conveniently again so that the production cost is reduced effectively; the whole molding method can uniformly apply a pressure to the web and an edge strip of the structural member and the pressure is equal to a tank pressure.

Owner:航天海鹰(镇江)特种材料有限公司

Automatic fixed-length cutting machine for soft rubber hose

ActiveCN102501260AGuaranteed dimensional accuracyAvoid economic lossMetal working apparatusEngineeringFixed length

The invention discloses an automatic fixed-length cutting machine for a soft rubber hose. The automatic fixed-length cutting machine comprises a regulating part, a transmitting part, a rapid cutting part, a controlling part and a pipe reeling part which are sequentially arranged along the motion direction of the soft rubber hose, wherein the transmitting part is arranged on the regulating part; amatched cavity matched with the soft rubber hose is arranged between a pair of special synchronous belts in the transmitting part; an inlet of a rubber hose guide sleeve in the rapid cutting part is opposite to an outlet of the matched cavity between the pair of the special synchronous belts; a cutter of the rapid cutting part is positioned right above the soft rubber hose and close to a tail endoutlet of the rubber hose guide sleeve; a monitoring region is formed between two pairs of correlation pipes in the controlling part; and a coiling motor in the pipe reeling part is synchronously matched with a servo motor in the transmitting part in the working process. According to the invention, the automatic fixed-length cutting can be realized; the size precision of the soft rubber hose is ensured; the automatic fixed-length cutting machine is convenient and safe to operate, has high automation degree, high working efficiency and low labor intensity; the economic loss of manufacturers can be avoided; and the production cost is reduced.

Owner:莱州市得利安数控机械有限公司

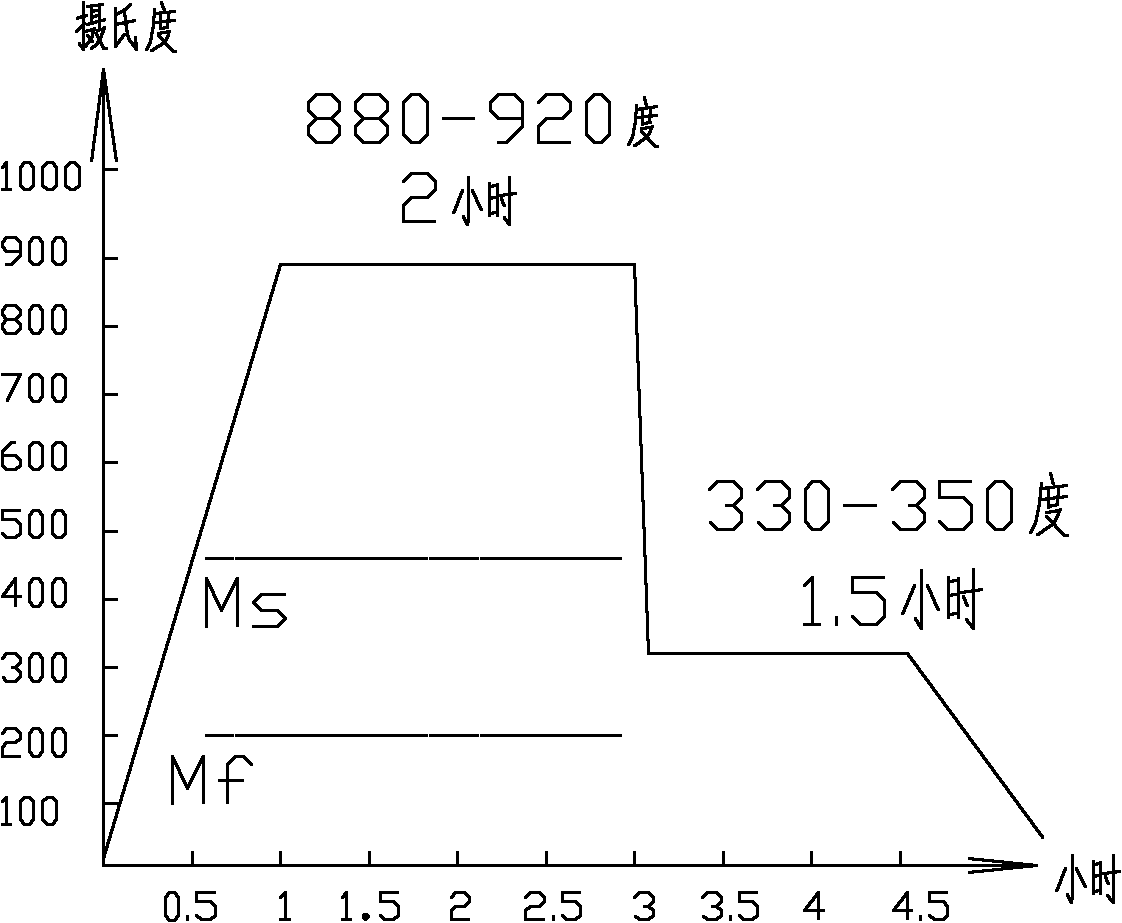

Method for manufacturing austempered ductile iron (ADI) front axle of heavy truck by sand casting

InactiveCN102218504AImprove integrityImprove fatigue lifeFoundry mouldsFurnace typesVolumetric Mass DensityQuenching

The invention discloses a method for manufacturing an austempered ductile iron (ADI) front axle of a heavy truck by sand casting. By the method, nickel molybdenum copper austempered ductile iron (ADI) front axle of the heavy truck is produced by a furane resin sand molding process, and the problems that the internal density and the performance reliability of ADI products are difficult to guarantee and the mechanical properties of the ADI products are low are solved. The method has the following steps of: firstly, casting a blank of the nickel molybdenum copper alloyed spheroidal graphite cast iron front axle by the furane resin sand molding process; secondly, performing the surface shot peening strengthening and isothermal quenching heat treatment; and finally machining the front axle parts. By the method, casting is replaced by forging, and the iron is replaced by steel, the comprehensive mechanical properties are obviously higher than those of common spheroidal graphite cast iron and forged steel, the weight of truck parts is reduced, the investment of heavy forging equipment and dies is saved, the cost is reduced, the production cycle is shortened, energy is saved, the emission is reduced, and the economic benefit and the social benefit are obvious.

Owner:DALIAN XINZHONG GRP +1

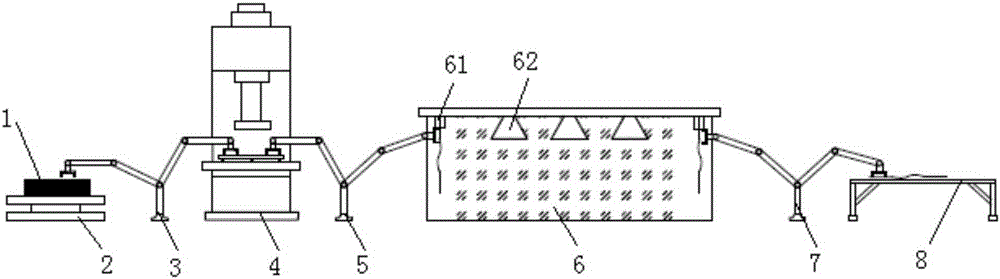

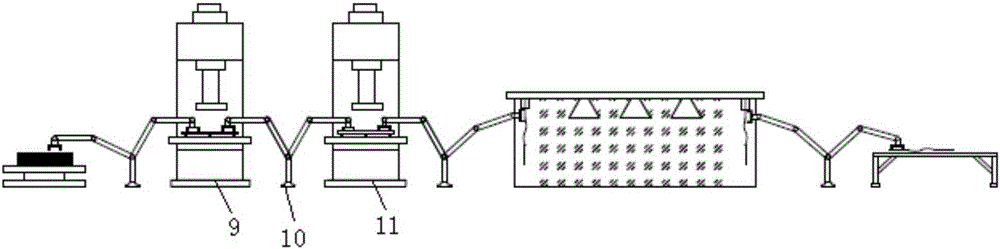

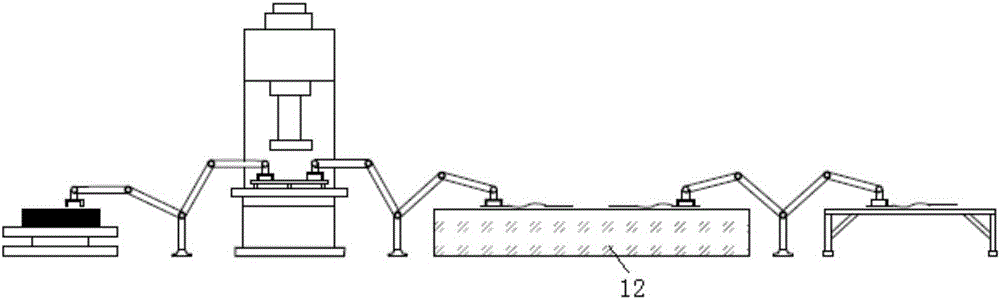

Multi-station continuous hot stamping production line and method

ActiveCN105215160AGuaranteed surface qualityReduce lossesShaping toolsMetal-working feeding devicesHot stampingProduction line

The invention discloses a multi-station continuous hot stamping production line and method. The production line comprises a material loading table, a feeding robot, a press unit, a material conveying robot, a quenching device, a material unloading robot and a conveyor belt which are arranged in sequence. The press unit comprises a heating device, a mould device and at least one press used for installation of the mould device; the heating device is used for wholly or locally heating a prefabricated blank to obtain a hot blank, and the mould device is used for conducting stamping forming, pressure maintaining setting and trimming and punching on the hot blank to obtain a hot stamped part. The rapid heating, stamping forming, pressure maintaining setting, trimming and punching and quenching can be continuously completed, so that the heating efficiency is improved, and the transportation process before punching of the hot blank is also avoided. For steel plates, stamped parts are blanked at a high temperature, increasing of cutting difficulty caused by generation of a martensitic structure at normal temperature is avoided, the blanking force is reduced, and the optimal blanked edge can be obtained.

Owner:WUHAN UNIV OF TECH

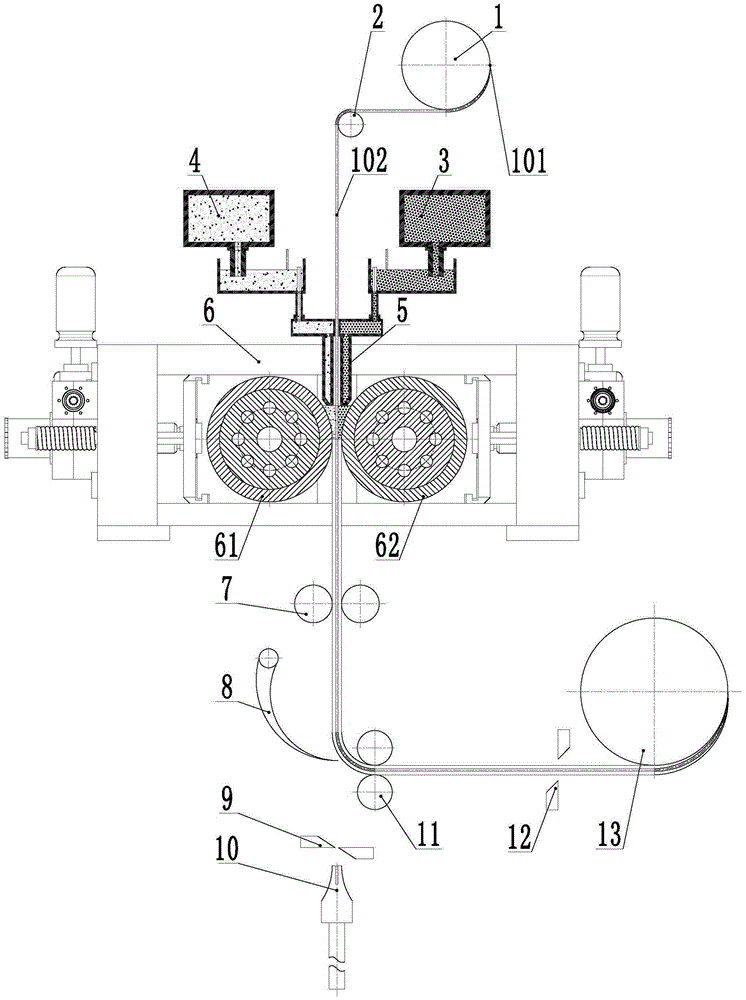

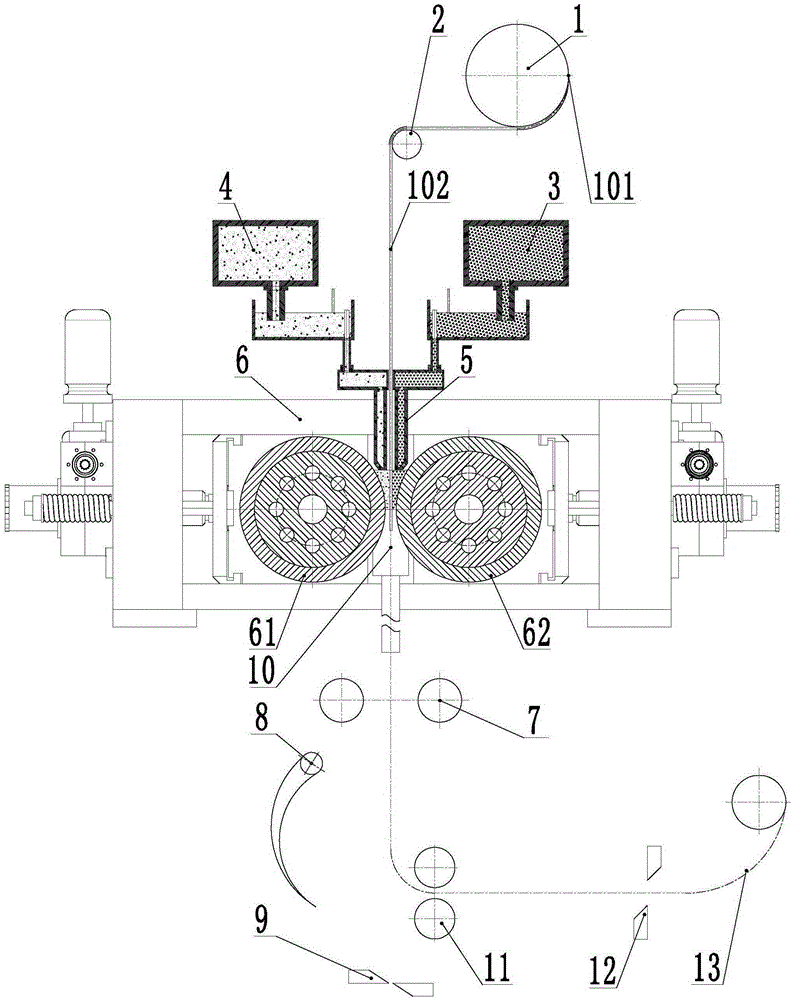

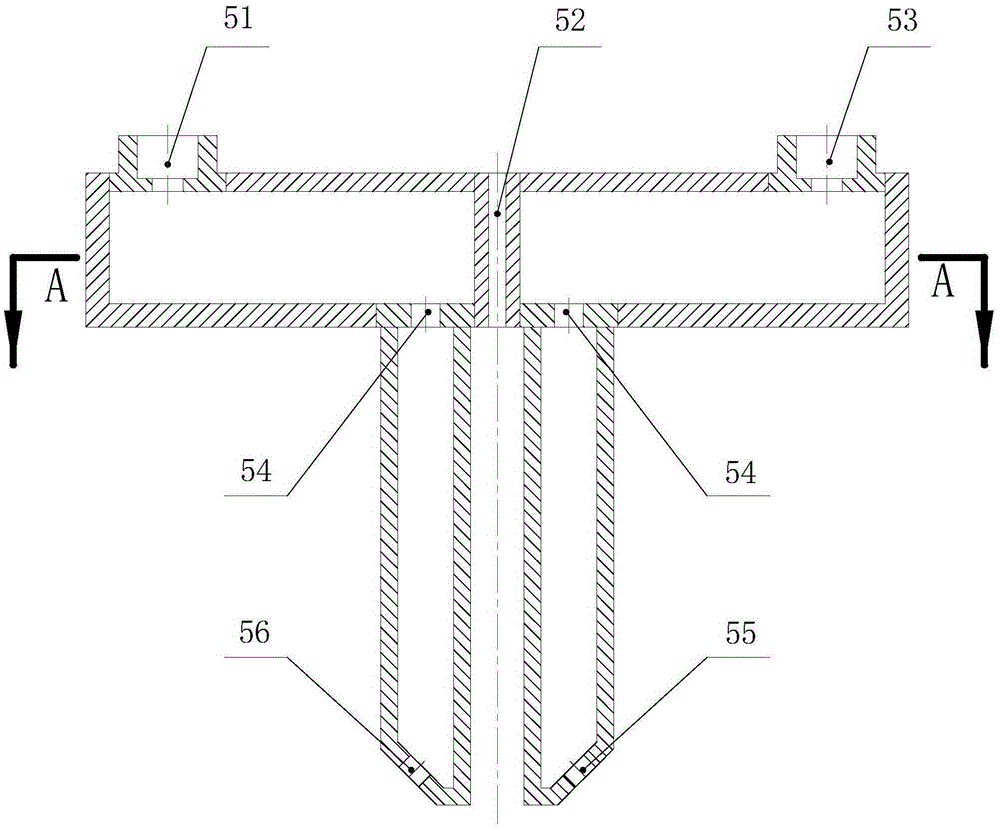

Solid-liquid cast-rolling compounding device and method for producing reticular reinforcement interlayer composite material

ActiveCN105290352ASolve problems such as continuous productionImprove efficiencyMetal rolling arrangementsIngotPre treatment

The invention provides a solid-liquid cast-rolling compounding device for producing a reticular reinforcement interlayer composite material. The solid-liquid cast-rolling compounding device comprises an uncoiler, a steering roll, a molten metal pouring device and a cast-rolling machine. The molten metal pouring device comprises a first pouring unit for containing first molten metal and a second pouring unit for containing second molten metal. The first pouring unit and the second pouring unit are arranged on the two sides of the reticular material respectively in parallel. The invention further provides a continuous cast-rolling compounding method for producing the reticular reinforcement interlayer composite material. The reticular material is fed into a cast-rolling region after being subjected to surface pretreatment, through dummy ingot flow blockage and seam thickness pre-distribution control, the surface treatment technology, the quick solidification technology and the rolling compounding technology are combined, the interface is compounded reliably, and the device and the method have the beneficial effects that the manufacturing procedure is short, efficiency is high, cost is low and the types of products are various.

Owner:YANSHAN UNIV

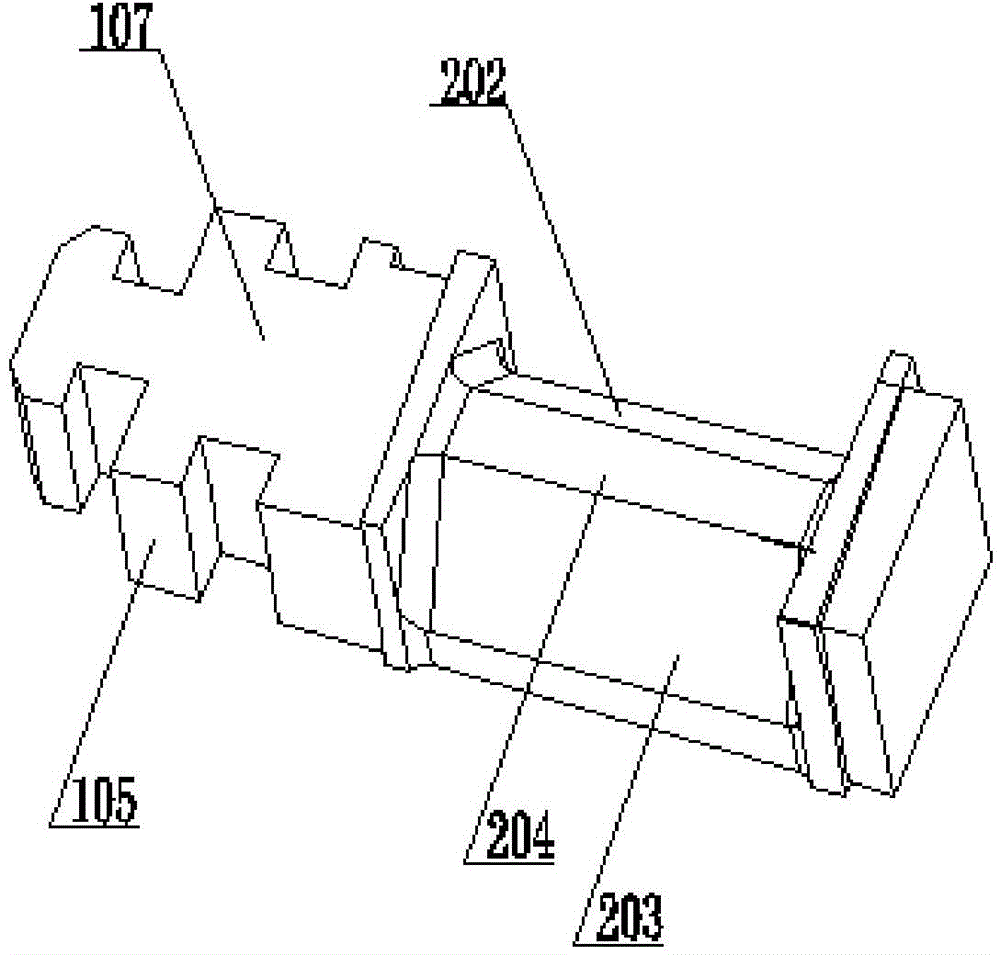

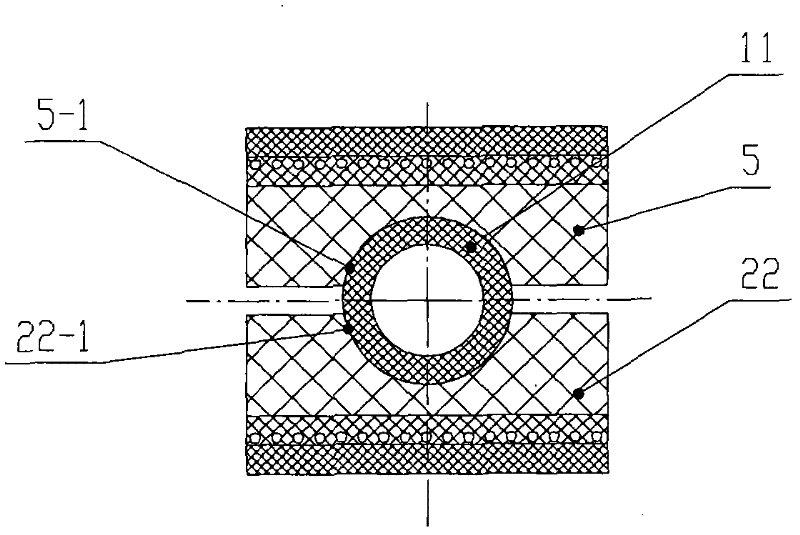

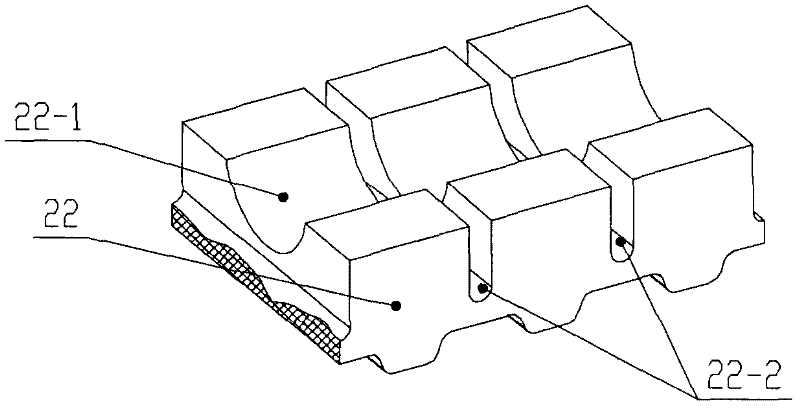

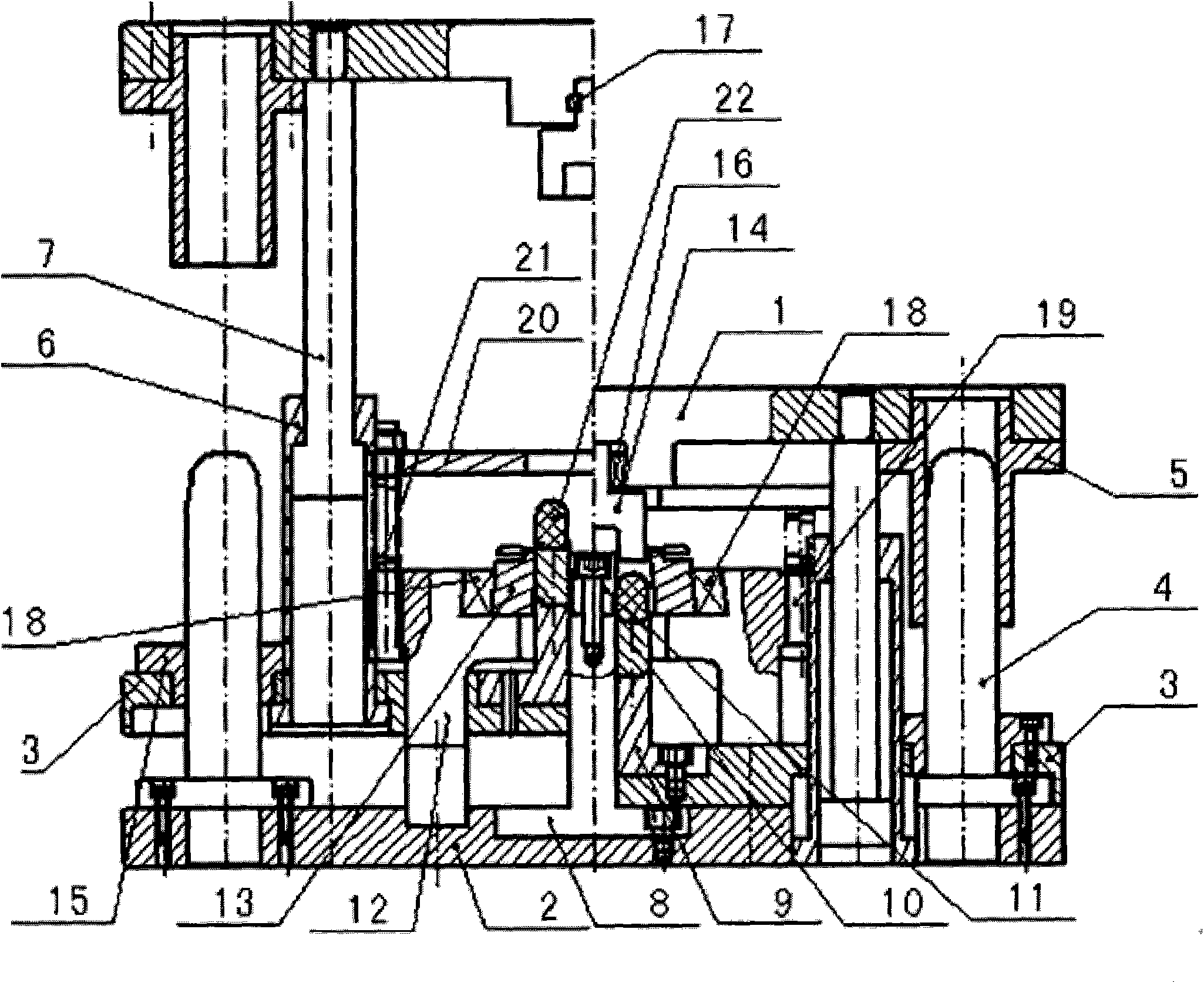

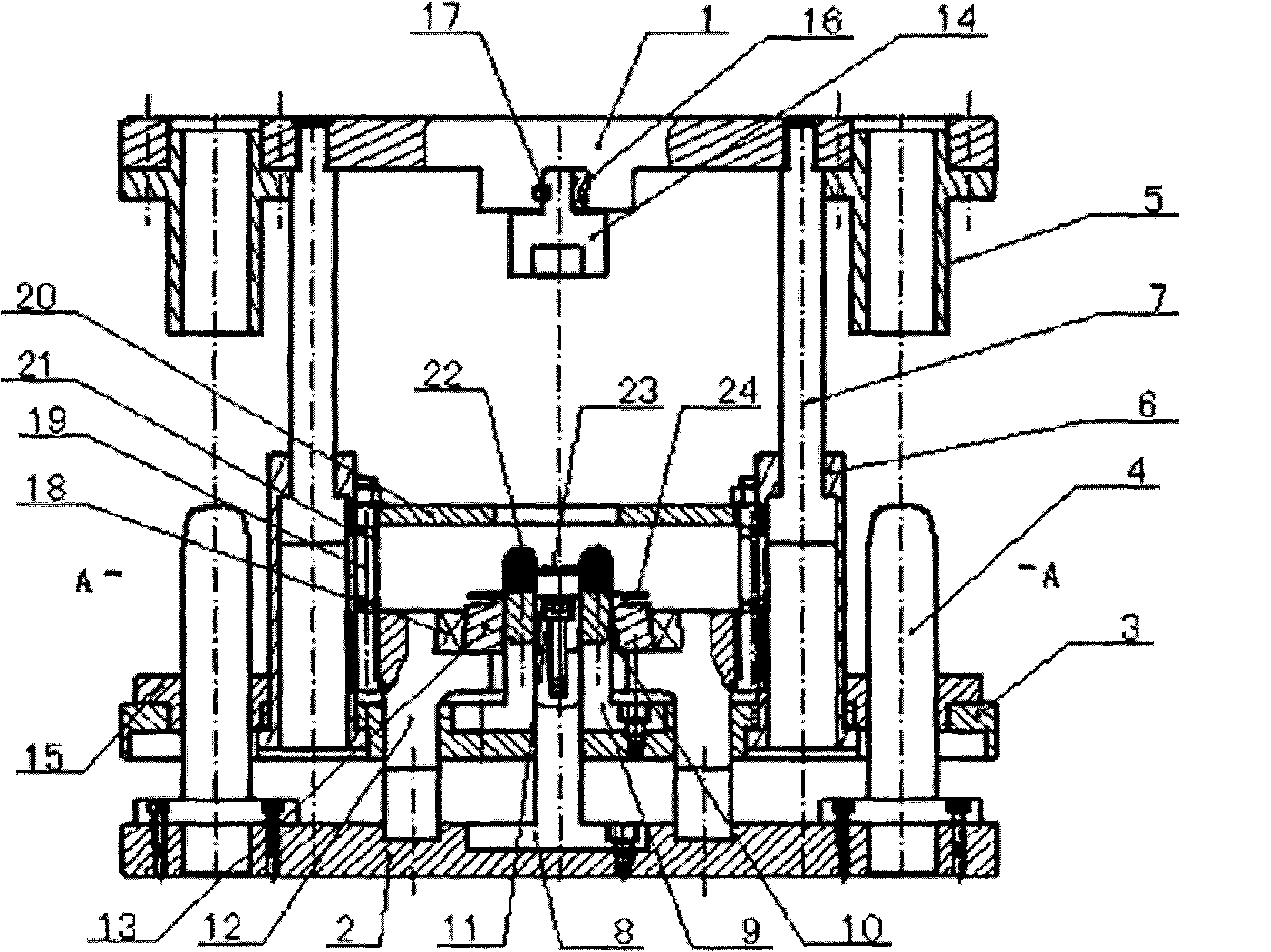

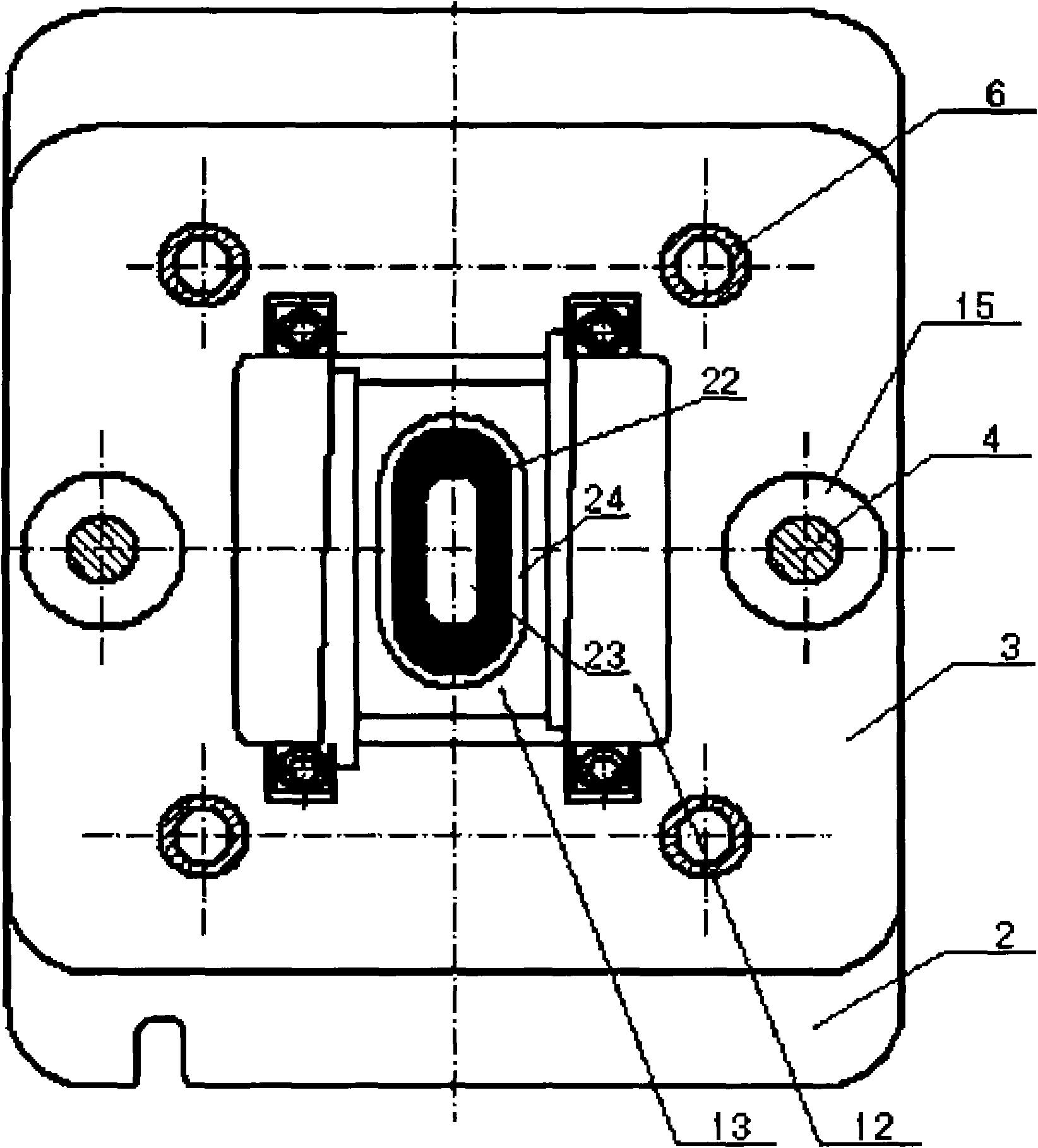

Ring forge piece punching and cutting composite type mould

ActiveCN102029323ACompact structureReasonable structureShaping toolsPerforating toolsPunchingEngineering

The invention relates to a ring forge piece punching and cutting composite type mould which is used on a mechanical press, in particular to the ring forge piece punching and cutting composite type mould. In the conventional mechanical manufacturing industry, inner hole punching and outer edge cutting in a forging and forming process of a forging ring of a transmission chain are performed in two steps, the production efficiency is low and the cost is high. The mould consists of an upper mould, an ejector, a lower mould and a material returning and outer burr removing part, wherein an upper mould plate is provided with a guide sleeve, connecting rods and an edge cutting punch head; a lower mould plate is provided with guide posts, an edge cutting female die seat, an edge cutting female die, a punching punch head seat and a punching punch head; a movable plate is provided with a connecting sleeve, an ejector seat and an ejector head and positioned and guided by two guide posts and the guide sleeve; and four connecting rods drive the connecting sleeve, the movable plate and the ejector part to rise so as to eject a finished punched workpiece. The composite mould is matched with a guide post guide sleeve structure, so accurate positioning of the upper mould, the lower mould and the ejector part is realized, the dimensional accuracy of a product is guaranteed, and the mould is suitable for simultaneous edge cutting and punching of a ring forge piece.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

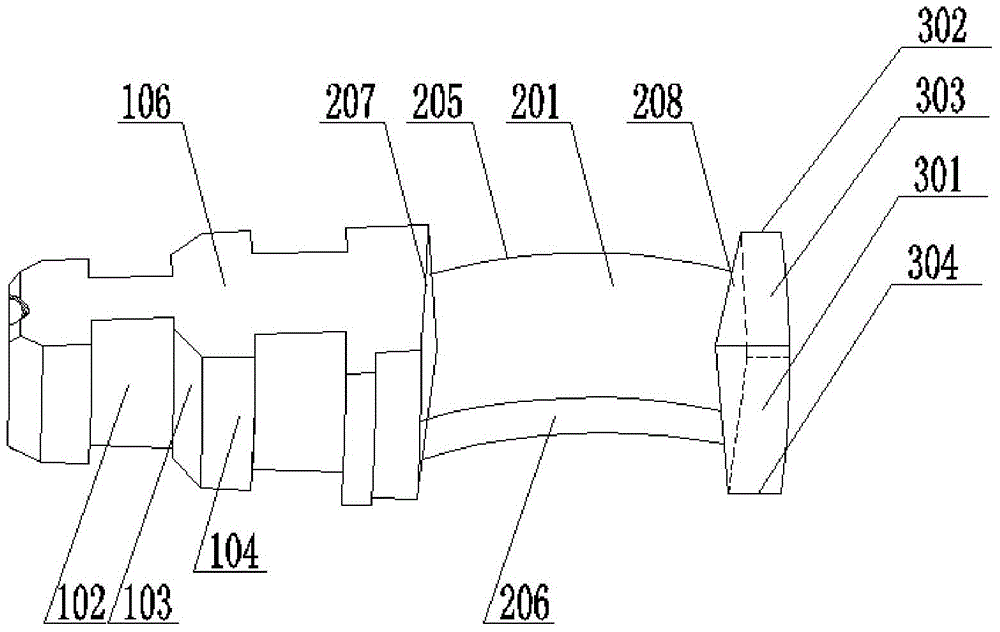

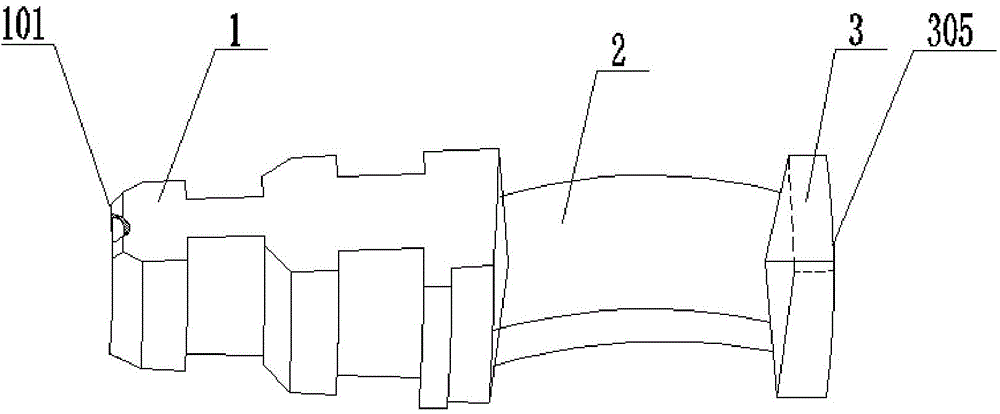

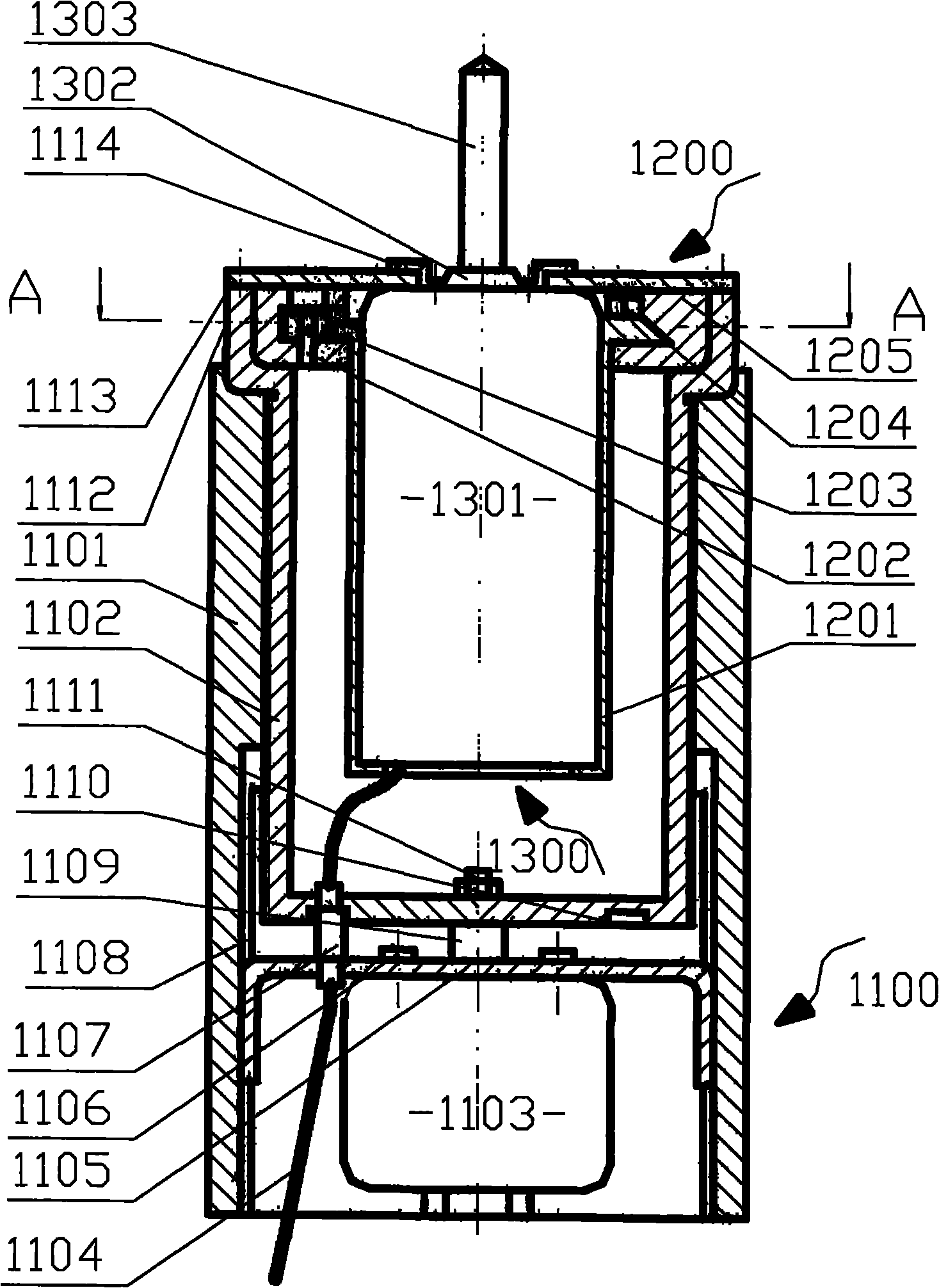

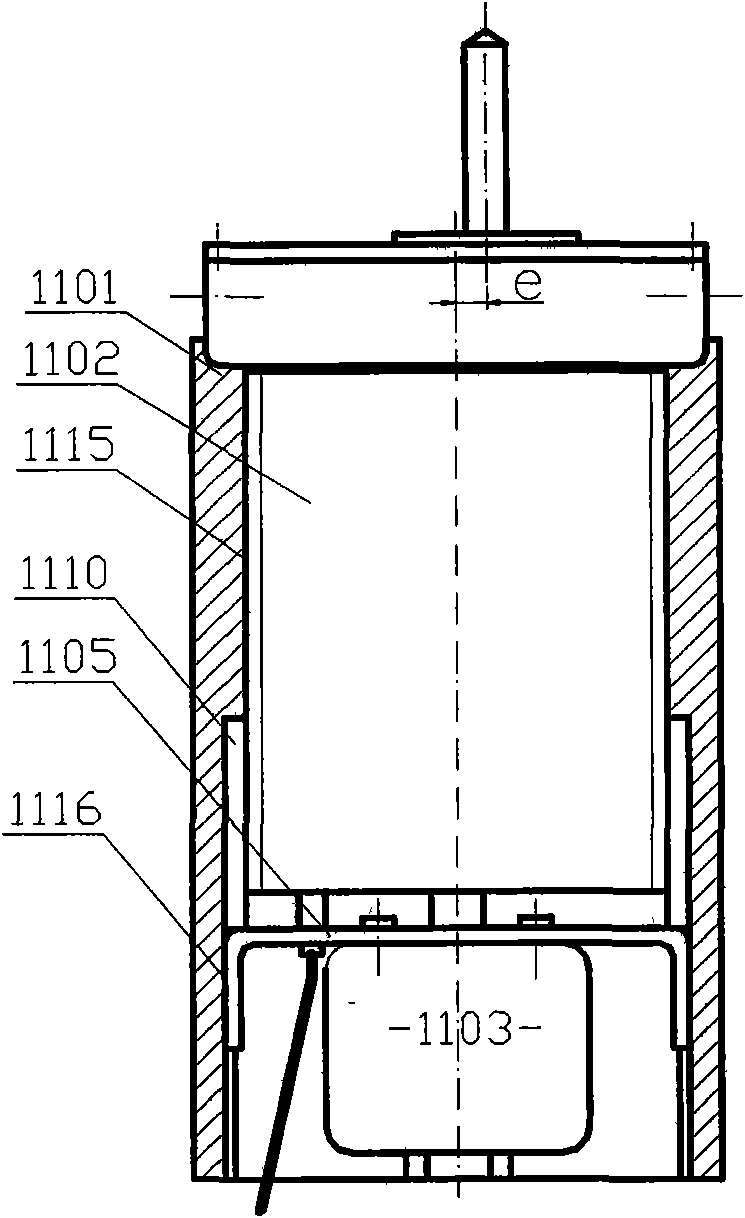

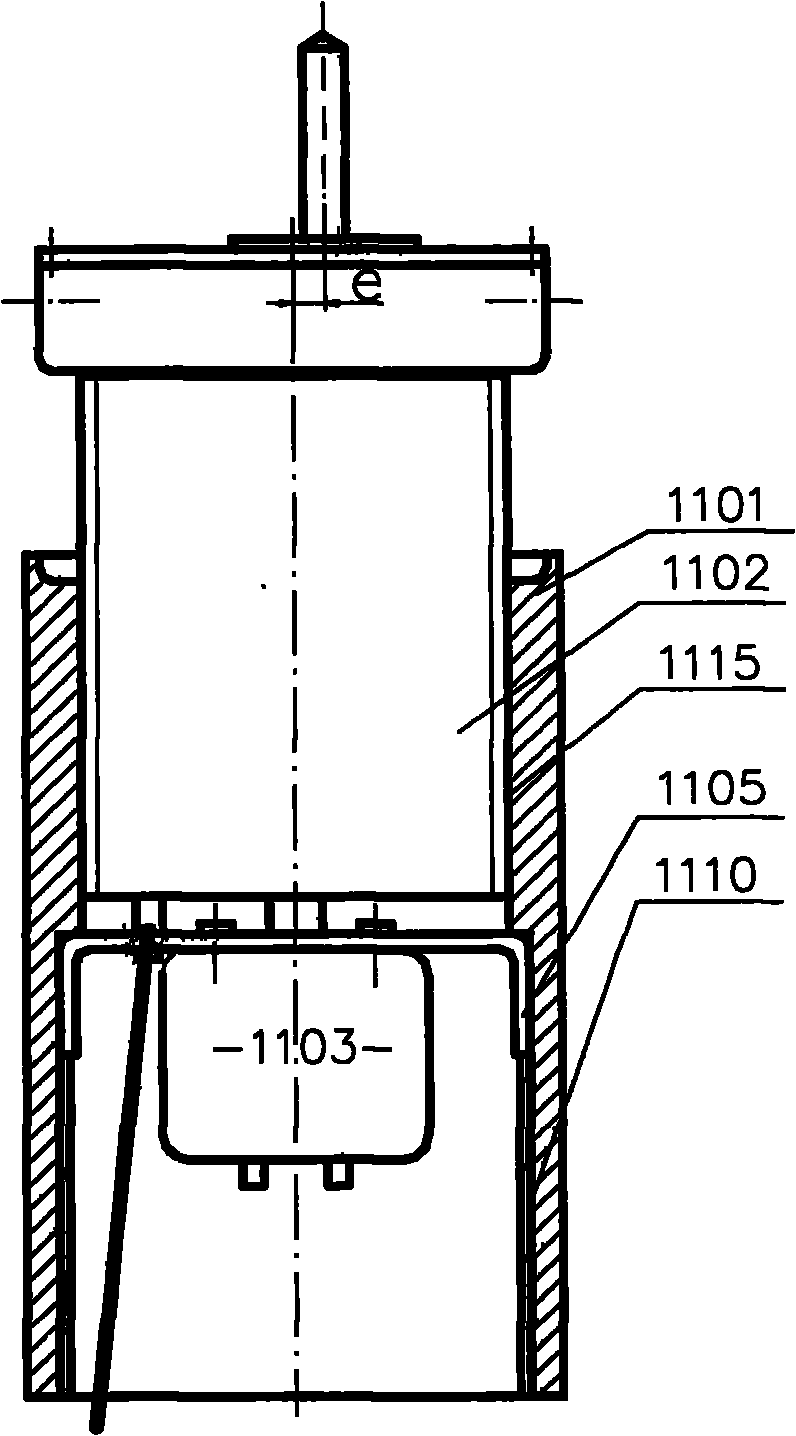

Helical milling device and method

InactiveCN101786180ASimple structureReduce weightFeeding apparatusMilling equipment detailsEngineeringRadial deviation

The invention relates to a helical milling device and a helical milling method, and belongs to the technical field of machining. The device mainly comprises a helical feed mechanism (1100) used for realizing the axial feeding and revolution of a cutter (1303), a radial deviation mechanism (1200) used for adjusting the revolution radius of the cutter (1303) relative to axes of pores and a rotation mechanism (1300) used for driving the cutter to rotate. The device and the method of the invention can greatly improve the manufacturing quality and machining efficiency of complex pore series on surfaces of large-scale workpieces.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

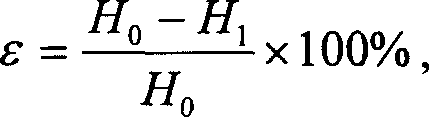

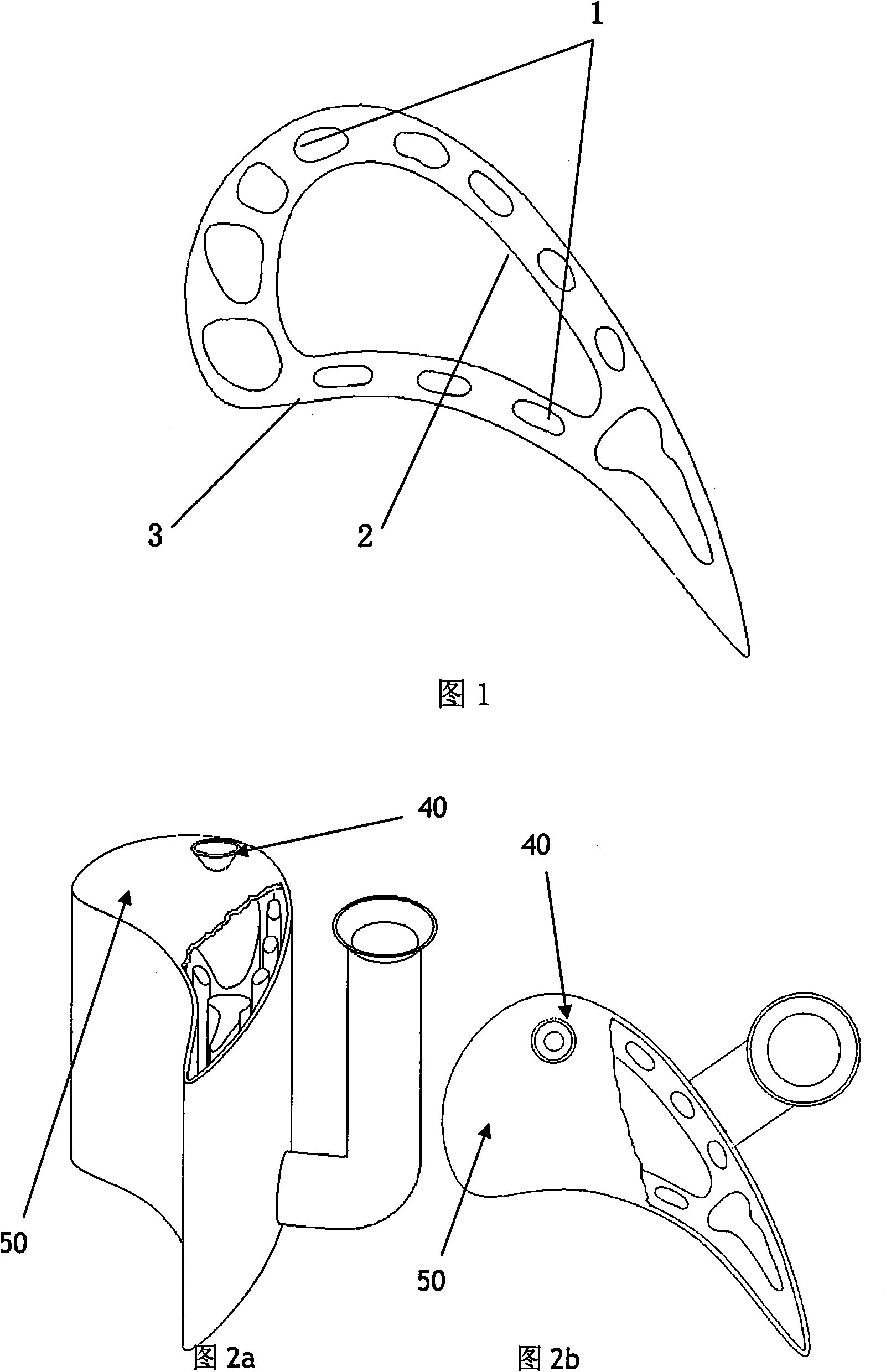

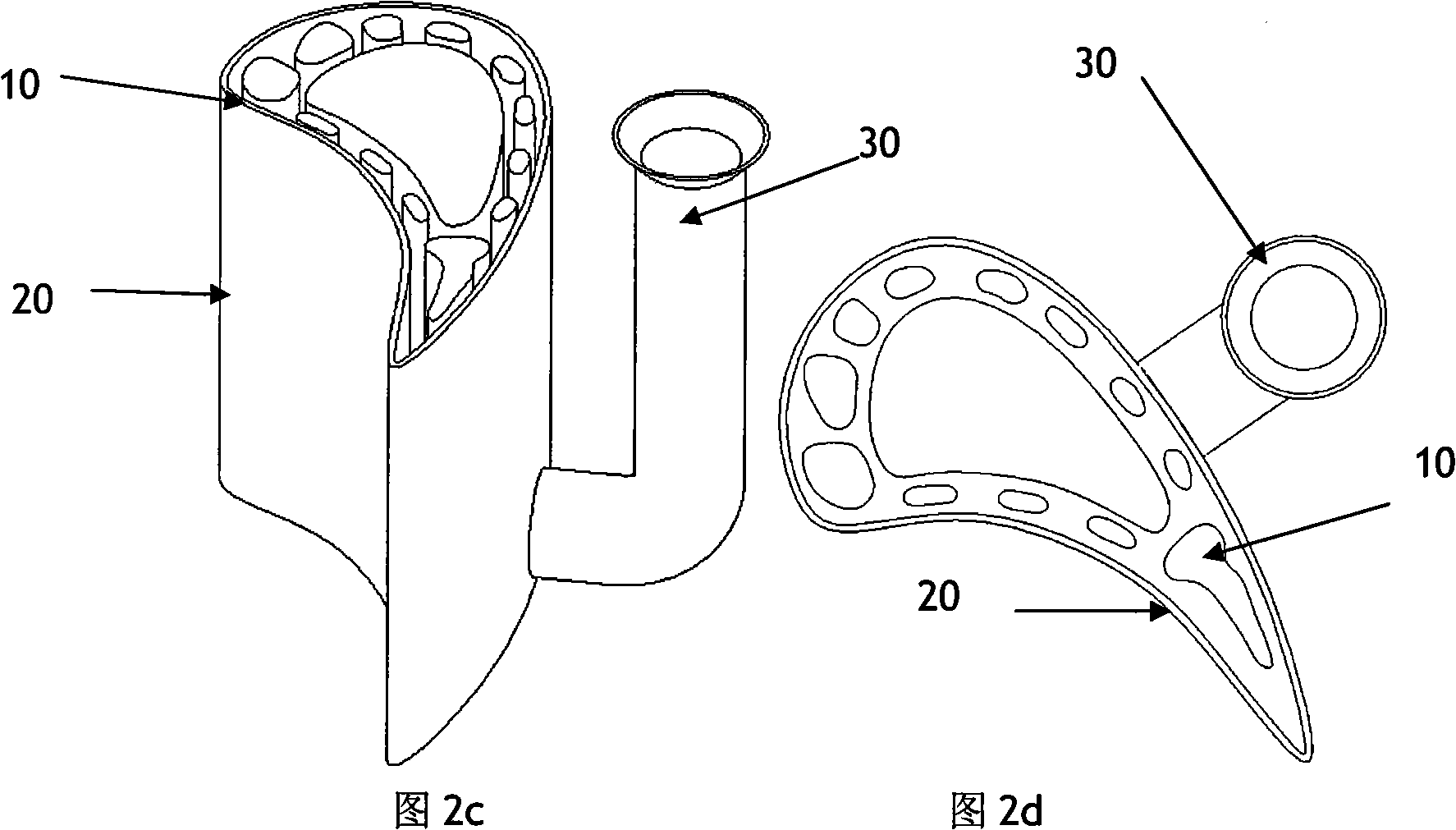

Preparation of multilayer semitransparent zirconia full-porcelain dental repair material

InactiveCN103121840AHigh molding densitySmall sintering shrinkageChemical compositionRepair material

The invention belongs to the field of porcelain materials and preparation thereof, and in particular relates to a multilayer semitransparent zirconia full-porcelain dental repair material and a preparation method thereof. The material comprises the chemical ingredients such as magnesium oxide and part stable square-phase zirconia, wherein the molecular contents of the magnesium oxide and the zirconia are respectively 2-10% and 90-98%; the part stable square-phase zirconia is added with a modifying agent to be modified, wherein the molar ratio of the modifying agent and the part stable square-phase zirconia is 1: (0.01-0.1); and a coloring agent is added into the modified zirconia repair material, and the coloring agent and the modified zirconia repair material respectively account for 0.1-1% and 99-99.9%. The method comprises the following steps of power preparing, mixing and granulating, two-step forming, plastic discharging and sintering. Compared with the prior art, the material has the advantages of good producing technology repeatability, stable quality, reliable performance and convenience in production.

Owner:ZXTGY BEIJING TECH

Low shrinken, fireproof, high leakage resisted material of duct piece for shield tunnel, and preparation method

ActiveCN101003428AImprove volume stabilityImprove waterproof and anti-seepage performanceSolid waste managementCeramicwareFiberPolymer science

This invention relates to a method for preparing ireproof shield tunnel segment material with low shrinkage and high impermeability. The material is prepared from: cement 360-400kg / m3, fly ashes 80-120 kg / m3, fine aggregate 690-720kg / m3, coarse aggregate 1100-1180 kg / m3, humidity supplementary medium 50-150 kg / m3, fibers 0.8-2 kg / m3, expanding agent 20-30 kg / m3, water (the water / colloid is 0.29-0.32), and high-performance naphthalene-based water reducer (the amount is 1.3-1.6 wt.%). The material has such advantages as good durability, high size stability, and good fireproof performance.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Thin-wall aluminum alloy material tube-shell part cutting processing heat treatment process

InactiveCN104233125AImprove cutting performanceGuaranteed processing deformationSolution treatmentMachine parts

The invention relates to a thin-wall aluminum alloy material tube-shell part cutting processing heat treatment process which comprises the following steps: carrying out quenching and aging solution treatment by adopting a blank; improving the cutting property of a material; relieving stress by adopting aging heat treatment after rough machining; carrying out semi-finishing, and then carrying out the aging heat treatment to further relieve machining stress so as to ensure the stress inside a machined part is completely released; after turning is completed, carrying out low-temperature heat treatment for stabilizing machining size for the last time. Practices indicate that the heat treatment process method can be used for achieving the purposes of eliminating the machining deformation of the part and stabilizing the machining size and ensuring that the size accuracy and form and location tolerance of the part meet the technical requirements.

Owner:无锡市森信精密机械厂

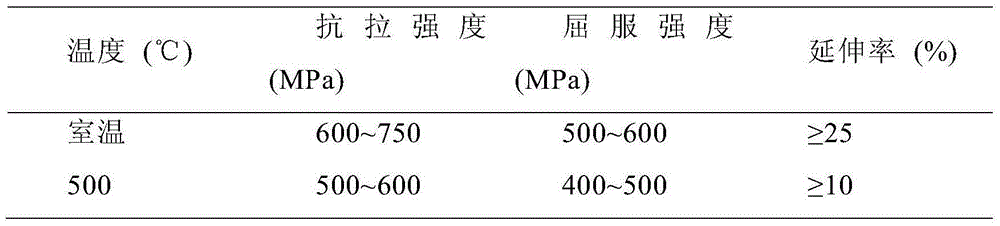

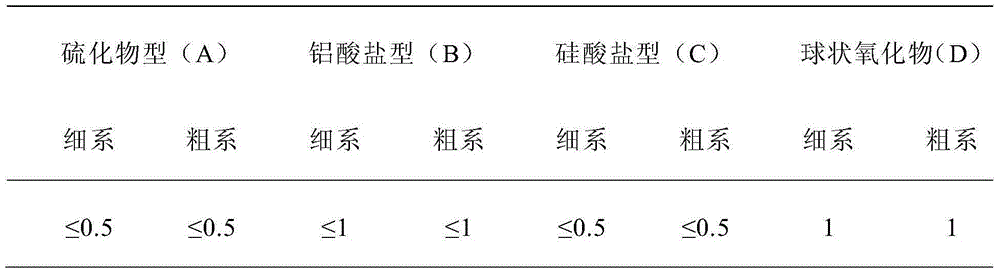

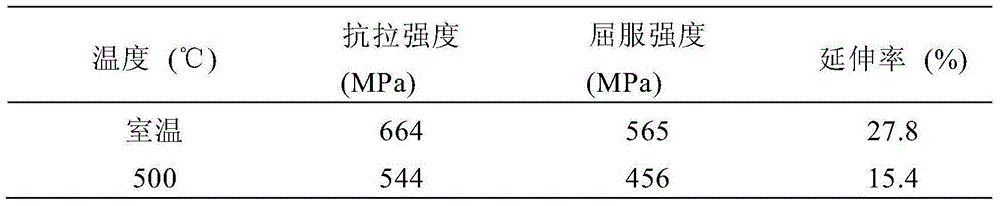

Austenitic stainless steel jacketing pipe for lead-bismuth fast reactor and preparation method of austenitic stainless steel jacketing pipe

ActiveCN105112811APrecise controlLow content of impurity elements and inclusionsQuenchingAustenitic stainless steel

The invention discloses an austenitic stainless steel jacketing pipe for a lead-bismuth fast reactor and a preparation method of the austenitic stainless steel jacketing pipe. The austenitic stainless steel jacketing pipe comprises, by weight, 0.06%-0.1% of C, 0.5%-1.0% of Si, 14%-16% of Ni, 14%-16% of Cr, 0.3%-0.6% of Ti, 1.5%-2.0% of Mn, 1.2%-1.8% of Mo, smaller than or equal to 0.03% of P, smaller than or equal to 0.05% of Co, smaller than or equal to 0.05% of Al, smaller than or equal to 0.01% of B, smaller than or equal to 0.02% of N, and the balance Fe. The method for preparing the jacketing pipe through the materials includes the steps of smelting, forging, hot working, solution treatment, cold rolling and intermediate annealing, final heat treatment, final cold working, straightening, cleaning, finished product inspection, identification, packaging and the like. In the final heat treatment step, quenching is conducted in a high-pressure nitrogen cooling mode, and in the cleaning process, an acidic degreasing agent is prohibited.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

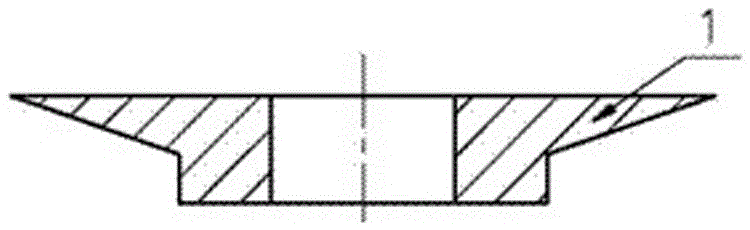

Manufacturing method of hub type electroplated ultrathin diamond abrasive cutting wheel

ActiveCN106637359AReduce stressStress reliever for low micro stressElectrolytic coatingsChemical platingGrinding wheel

The invention discloses a manufacturing method of a hub type electroplated ultrathin diamond abrasive cutting wheel. The method comprises the steps that a high-precision aluminum alloy matrix is subjected to chemical plating treatment and placed into an electroplating solution containing diamond abrasive materials, the evenly-suspended diamond abrasive materials are wrapped by a plating layer during reduction of a cathode of anode nickel ions under the effect of a direct current electric field, and a composite plating layer with the needed thickness is formed after uniform codeposition is kept for a certain period of time; and the hub type electroplated ultrathin diamond abrasive cutting wheel with the blade thickness of 0.010-0.150 mm is manufactured through the plating layer surface precise grinding, external circle grinding and blade reverse face microcorrosion treating processes. By the adoption of the phosphorous nickel aminosulfonate electroplating solution, by means of the hardness increasing effect of a hardening agent and the microstress effect of a stress removing agent, a low-stress high-hardness novel nickel-based binding agent is obtained, a blade of a cuter of the hub type electroplated ultrathin diamond abrasive cutting wheel has extremely low stress and high strength, and the problem that the cutter of the abrasive wheel is broken due to stress deformation or too low strength in practical application is avoided.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

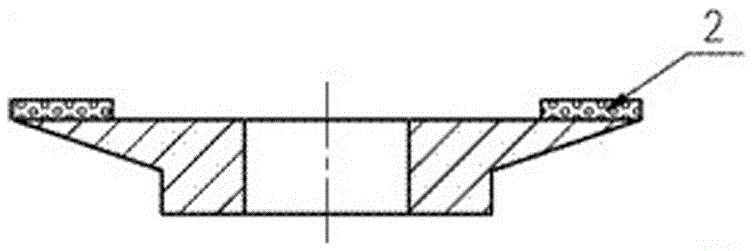

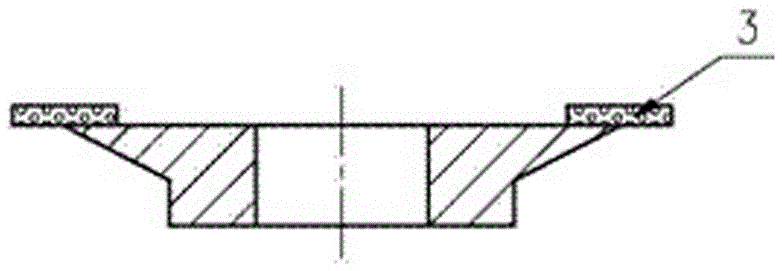

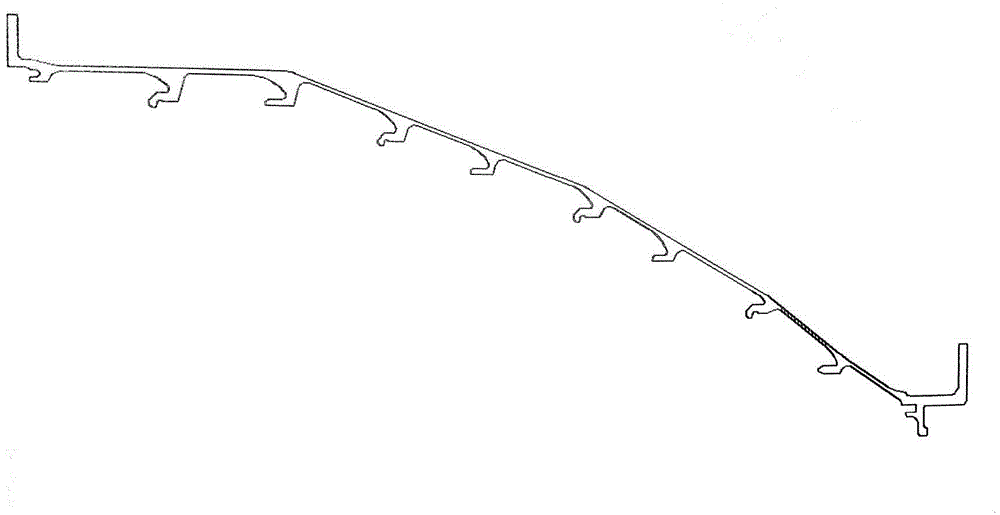

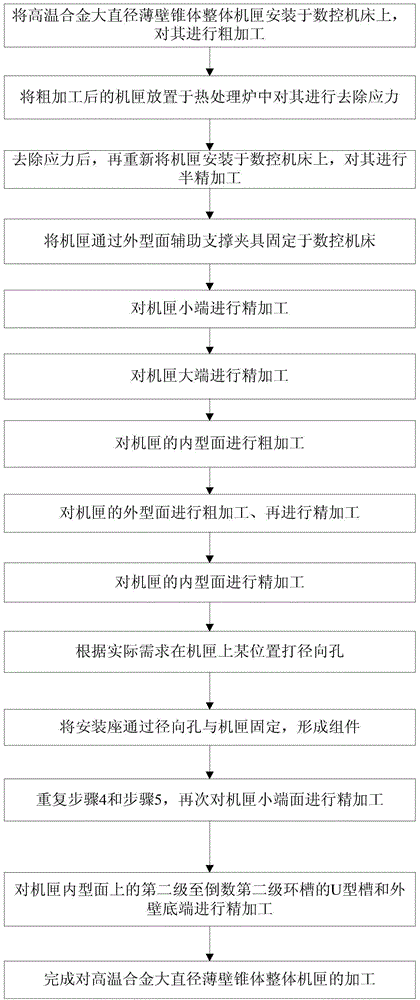

High-temperature alloy large-diameter thin-wall pyramidal integral casing machining method

InactiveCN104476112AGuaranteed pick-up requirementsGuaranteed dimensional accuracyMachines/enginesEngine componentsSuperalloyScrew thread

The invention discloses a high-temperature alloy large-diameter thin-wall pyramidal integral casing machining method and belongs to the machine manufacturing field. The machining method changes a former machining mode that an internal profile and an external profile are machined in different procedures, the remaining is not uniform in distribution, and the size is difficult to guarantee, guarantees parts being delivered in a qualified mode and a knife connecting requirement between a single part and an assembly and finally forms into a technological process with three-time lathing of the single part, one-time lathing of the assembly and boring machining. According to the high-temperature alloy large-diameter thin-wall pyramidal integral casing machining method, the factor that a thin-wall casing is easy to deform and the parts are avoided from vibrating through different auxiliary bearing modes in finish turning and hole boring; selection of finish turning tools, a moving path and parameters are optimized; high-temperature alloy small-diameter threaded hole manual tapping is replaced by the screw thread milling machining technology; the size accuracy of parts is guaranteed, high quality and efficiency and low costs are achieved, and the market application prospect is wide.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

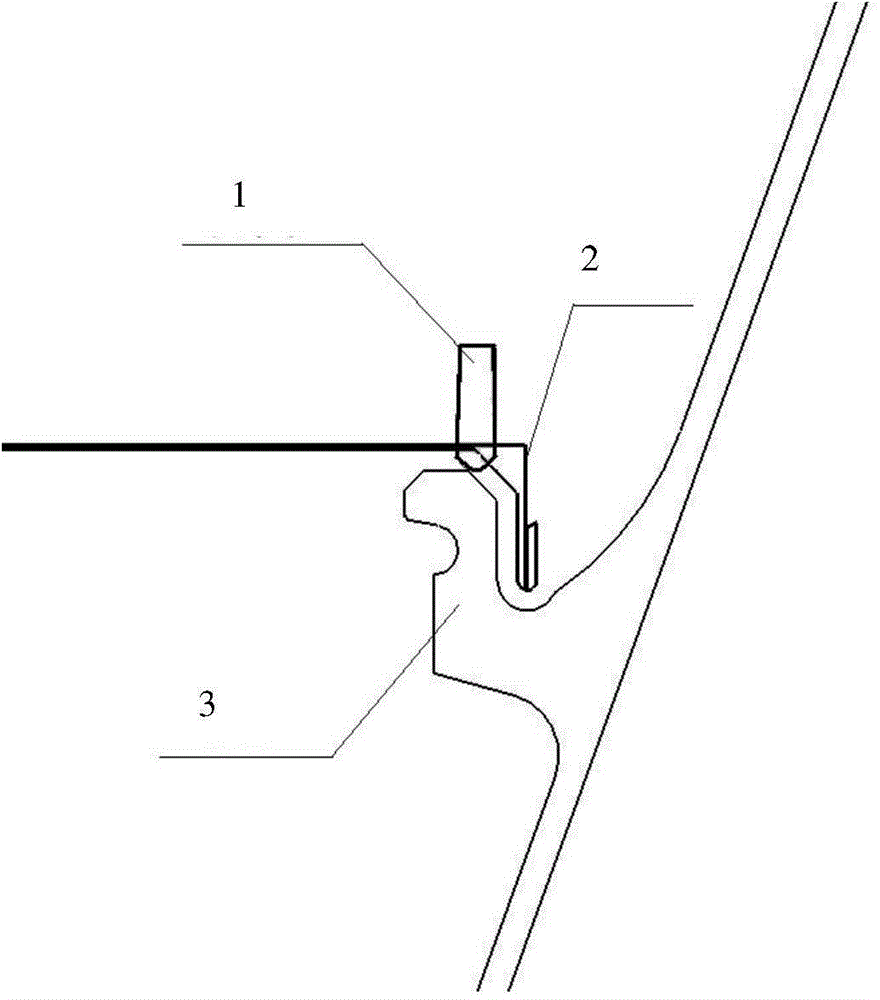

Method for forming J-shaped beam structure composite workpiece by open type soft tooling

The invention discloses a method for forming a J-shaped beam structure composite workpiece by open type soft tooling; fiber-reinforced rubber open type soft tooling can be formed by a metal mold, the formed soft tooling can be one part of a formed mold for completing the forming process of the composite produced part. Compared with a traditional core mold forming method, the soft tooling can uniformly and accurately transmits pressure applied by an autoclave, out-of-tolerance of thickness of the composite workpiece can be avoided, the soft tooling is thinner in wall thickness, thermal hysteresis effect can be avoided, the forming quality of the workpiece can be effectively guaranteed by the above two points, and the qualified rate and the efficiency of production can be improved. The soft tooling can be used repeatedly, the reproduction is also more convenient, and the production cost and the manufacturing cycle are effectively reduced, and the production efficiency is improved.

Owner:航天海鹰(镇江)特种材料有限公司

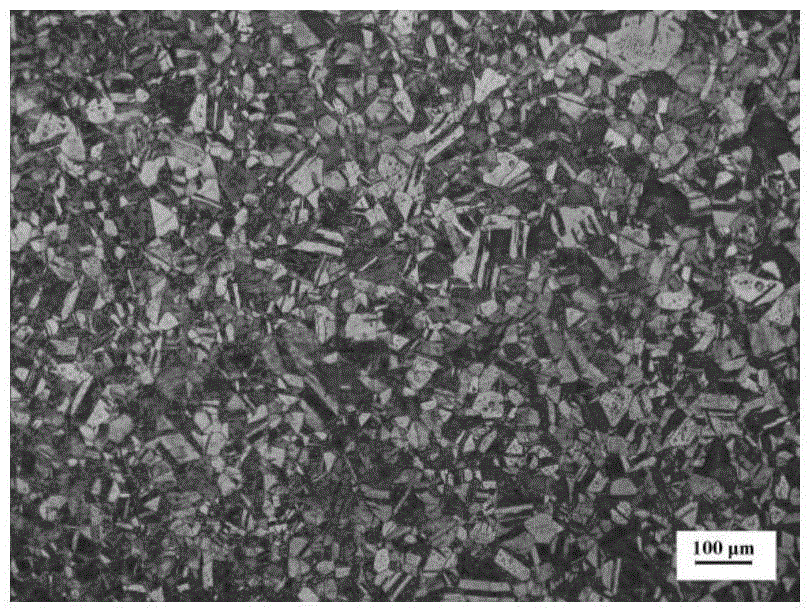

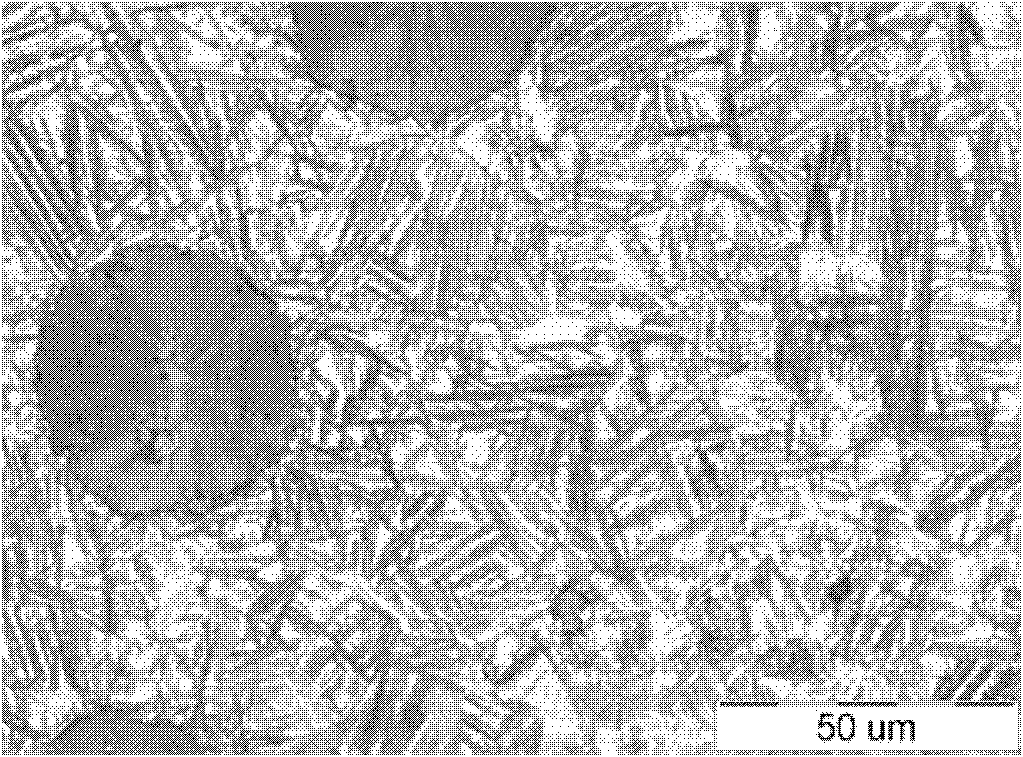

Preparation method of tubular niobium target for magnetron sputtering

The invention discloses a preparation method of a tubular niobium target for magnetron sputtering. The method comprises the following steps of: forging a niobium casting ingot into a cylindrical niobium blank; drilling a through hole at the center of the cylindrical niobium blank to obtain a tubular niobium blank, and then uniformly coating anti-oxidization coatings on the surfaces of the inner and outer walls of the tubular niobium blank; extruding the tubular niobium blank coated with the anti-oxidization coatings to obtain a niobium tube blank; sequentially carrying out sand spraying, acid washing and machining on the niobium tube blank to obtain a semi-finished product of the tubular niobium target; and carrying out vacuum heat treatment on the semi-finished product of the tubular niobium target to obtain the tubular niobium target for the magnetron sputtering. The tubular niobium target prepared by the method disclosed by the invention has a good structure property; and crystal grains along the wall thickness direction of the target are uniform and can reach the grade of 4-6, the size of the crystal grains is not more than 100 mu m, and the re-crystallization rate of the grains is not less than 90%, so that the uniform consistency of a coating film in the magnetron sputtering is guaranteed.

Owner:西安方科新材料科技有限公司

Special through-hole drilling fixture for cylindrical part

ActiveCN102335772AGuaranteed dimensional accuracyGuaranteed positioning accuracyDrilling/boring measurement devicesPositioning apparatusEngineeringScrew thread

The invention provides a special through-hole drilling fixture for a cylindrical part, and relates to a drilling fixture for a cylindrical part, which is used for solving the problems such as poor size and position precision of the hole and easy rupture of a drill bit caused by no machining plane, difficult drill bit localization and greater vibration when the through hole is drilled on the outer side wall of the cylindrical part. In the invention, a high vertical plate, a low vertical plate and a support vertical plate are fixedly connected on a base, wherein, the support vertical plate is positioned between the high vertical plate and the low vertical plate; a V-shaped groove is machined at the middle part of the upper end surface of the support vertical plate; a screw is in threaded connection with a threaded through hole of the low vertical plate; a first blind hole is machined on the bottom of the V-shaped groove; a pressure plate and the high vertical plate are located by two second locating pins; a locating block is composed of a large-diameter cylinder and a small-diameter cylinder which are integrated together, and the small-diameter cylinder is matched with an inner hole of the part; and a first locating pin is composed of a large-diameter pin and a small-diameter pin which are integrated into a whole, the first locating pin is arranged in the first blind hole of the support vertical plate, and a spring is arranged in a second blind hole of the first locating pin. The special through-hole drilling fixture provided by the invention is used for localization when the through hole is drilled on the cylindrical part.

Owner:HARBIN JIANCHENG GRP

Austenitic stainless steel thin-walled pipe machining method

InactiveCN105522341AGuaranteed quality and accuracyGuaranteed dimensional accuracyThin walledAustenitic stainless steel

The invention relates to the field of machining, in particular to an austenitic stainless steel thin-walled pipe machining method. The method comprises the following steps: rough turning, including turning excircles and step end surfaces with machining allowances 2 mm, and erecting a central frame at a right end; clamping, including machining a left end screw hole, which is matched with a left end choke plug, in a workpiece; heat treatment and aging treatment, wherein a right end choke plug rather than the left end choke plug needs to be demounted during aging heat treatment; and semi-fine turning, including clamping the excircle of the left end choke plug with a four-jaw chuck, supporting a right end inner hole with a four-jaw chuck tool on a tailstock with alignment within 0.05 mm, dismounting the four-jaw chuck tool of the tail stock, turning the right end inner hole with an allowance 0.4-0.5 mm, propping the tail stock, dismounting the central frame, and turning all the excircles and end surfaces, with the excircles remaining machining allowances 0.4-0.5 mm; heat treatment and aging treatment; secondary semi-fine turning; fine milling; fine turning; and grinding. The method is simple in machining process, facilitates manufacturing, can ensure the machining quality and dimensional precision of the workpiece, reduces the machining difficulty and the production cost and improves the machining efficiency.

Owner:SHAANXI YIPINDA PETROCHEM CO LTD

Titanium alloy wire production method

The invention discloses a titanium alloy wire production method. A titanium alloy wire is prepared by carrying out multi-die continuous cold-drawing on a titanium alloy wire blank by using a polycrystalline wire drawing die or high-crystalline wire drawing die, wherein calcium-based wire drawing powder or sodium-based wire drawing powder is used as a lubricating agent. By using the titanium alloy wire production method, the size precision and the surface quality of a finished product of the titanium alloy wire are ensured, the production efficiency is increased, and the environment of a working site is improved.

Owner:BAOJI TITANIUM IND CO LTD

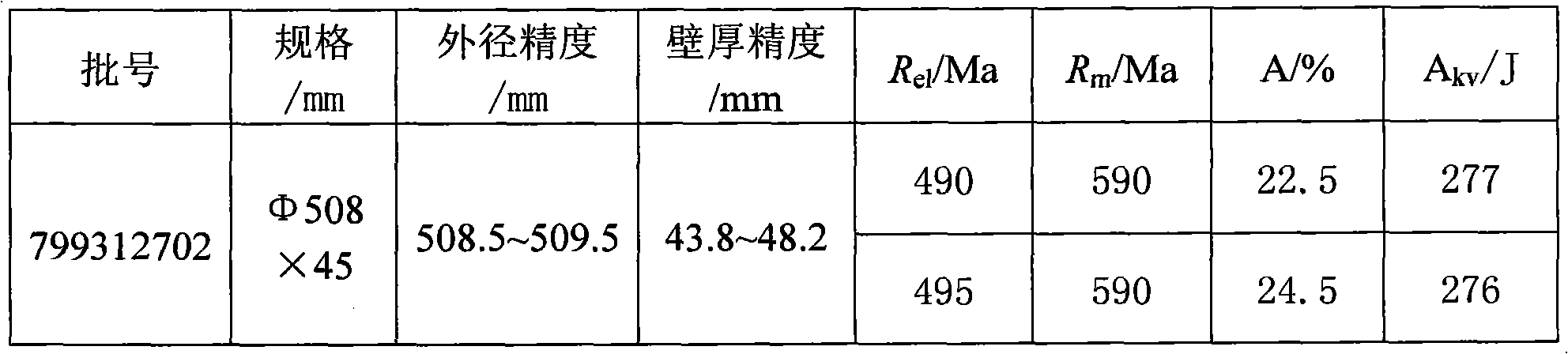

Production method of large-caliber high-pressure boiler tube

InactiveCN101890432AImprove internal and external qualityGuaranteed dimensional accuracyMetal rolling arrangementsPunchingEddy current

The invention provides a production method of a large-caliber high-pressure boiler tube, comprising the following steps: inspecting blank; saw cutting blanking; heating by an annular furnace; punching by a Mannesmann punching machine or punching by hydraulic pressure and punching by utilizing the Mannesmann punching machine; pre-punching a mandril; rolling by a pilger mill; carrying out hot-sawing on pilger heads; reheating by a walking beam furnace; externally descaling by high pressure water; sizing by a sizing mill; cooling by a cooling bed; carrying out thermal treatment; sampling; passing physical and chemical inspection; straightening; cutting head and end parts; carrying out manually initial check; polishing an inner surface and an outer surface or internally boring and externally raking; blowing soot; carrying out ultrasonic and eddy-current combination detection; manually rechecking; carrying out spectral inspection; measuring length and weighing; jet-printing; and finally packaging and warehousing. In the method, a steel billet is heated in the annular furnace, which comprises three processes of preheating, heating and soaking; and heating temperature and time in each process are rationally distributed to prevent heating unevenness and heating defects. During the tube rolling process, the feeding system of the pilger mill completes feeding release with the feeding quantity less than 0.5mm, thus achieving uniform and accurate feeding quantity in each rolling cycle.

Owner:HENGYANG VALIN STEEL TUBE

Liquid die forging and rolling compound formation method for GH4033 high-temperature alloy irregular-section large ring piece

The invention relates to a liquid die forging and rolling compound formation method for a GH4033 high-temperature alloy irregular-section large ring piece. The method comprises the following steps of: 1) smelting; 2) performing liquid die forging, namely fixing a liquid die forging mold on an indirect extrusion casting machine, pouring a quantitative amount of alloy solution into the liquid die forging mold at the pouring temperature of between 1350 and 1450 DEG C, pressurizing at the speed of 40 to 50 mm / s, filling for 1 to 6 seconds at the specific pressure of 300 to 400 MPa, keeping the pressure for 50 to 90 seconds, and thus obtaining a similarly final section ring blank; 3) homogenizing; 4) performing afterheat isothermal rolling, namely cooling the homogenized similarly final section ring blank to the temperature of between 1100 and 1140 DEG C, and performing afterheat isothermal rolling on a radial shaft compound ring rolling machine; 5) performing thermal treatment, namely performing solid solution instant thermal treatment, keeping the ring blank at the temperature of between 900 and 1000 DEG C for 1 to 2 hours, performing air cooling, then heating to the temperature of 1080 DEG C, keeping the temperature for 8 hours, performing air cooling to the temperature of 750 DEG C, keeping the temperature for 16 hours, and performing air cooling; and 6) finishing.

Owner:SOUTHWEST UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com