Method and equipment for removing oxidizing layer of titanium and titanium alloy wire material

A technology for titanium alloys and oxide layers, applied in the field of removing oxide layers from titanium and titanium alloy wires, can solve the problems of difficulty in ensuring safe production, easy combustion, low tension, etc., to ensure consistency and uniformity, and purify the working environment. , to ensure the effect of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

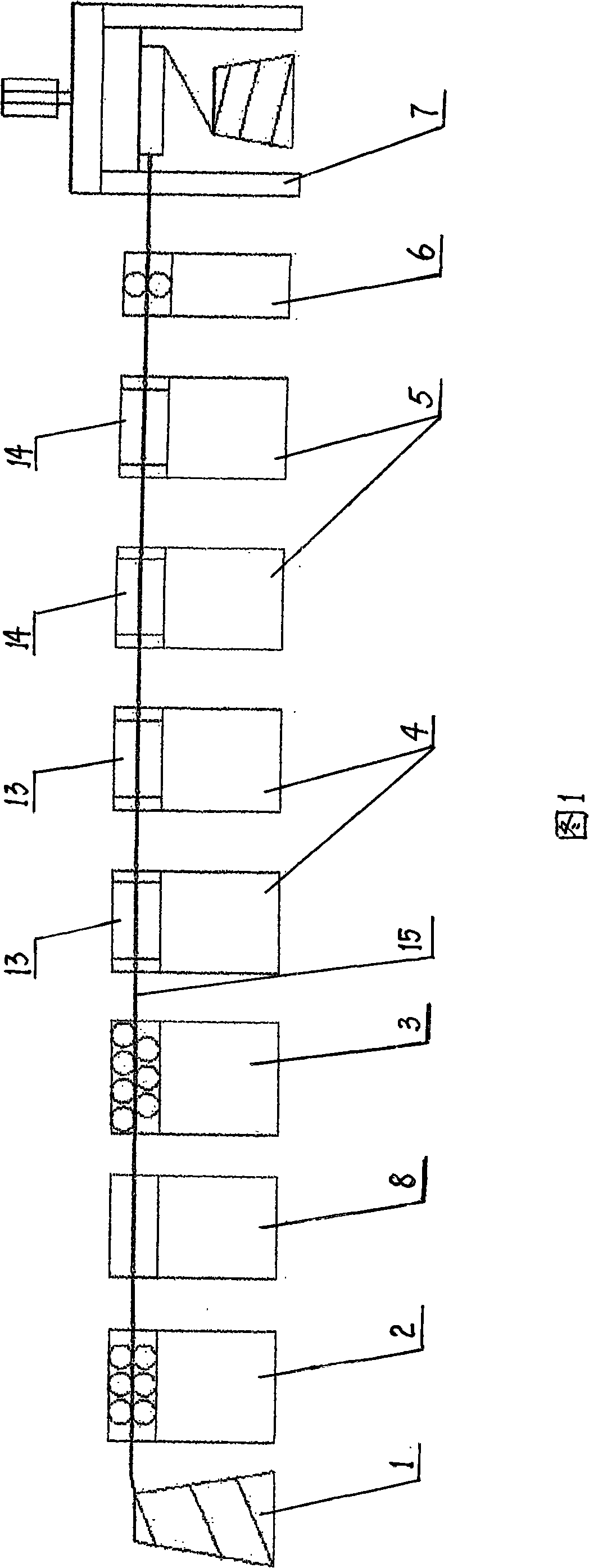

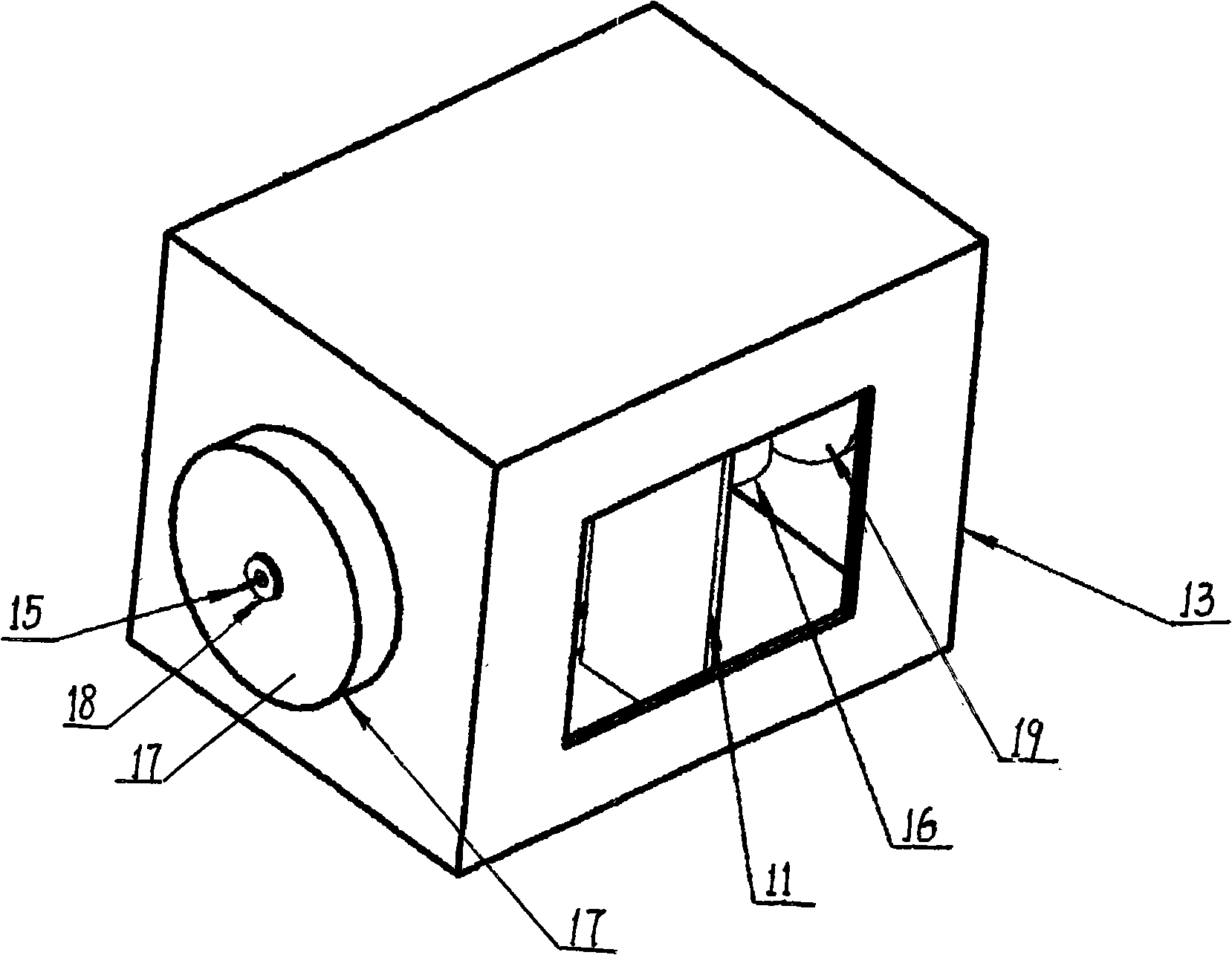

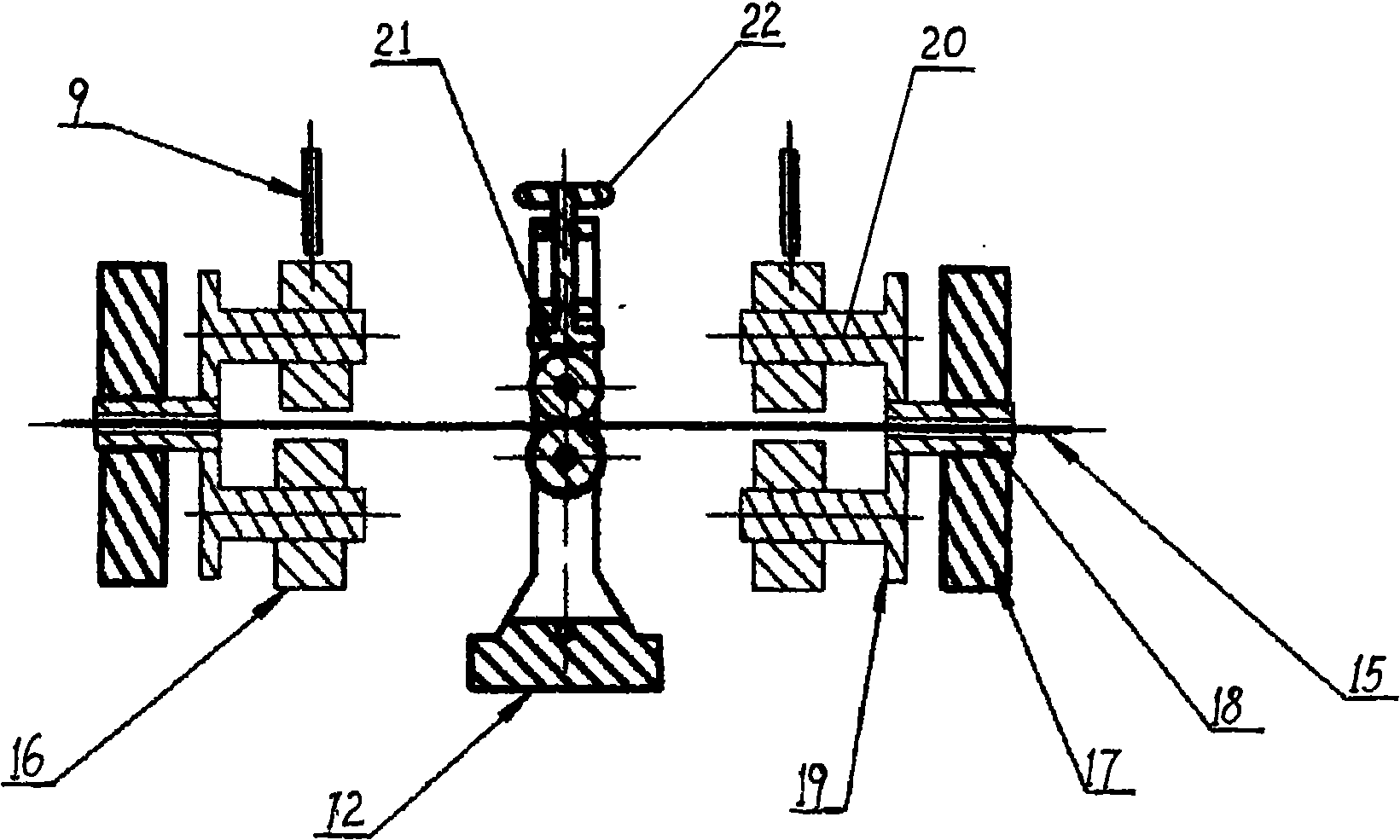

[0032] An embodiment of the present invention will be described with reference to accompanying drawings 1, 2, 3, 4, and 5.

[0033] 1. Method for removing oxide layer of titanium and titanium alloy wire:

[0034] ①Straightening: first heat the titanium and titanium alloy wire to 500℃-800℃, and then straighten the titanium and titanium alloy wire with a straightening machine;

[0035] ② Phosphorus removal: first use a set of thick steel wire wheels to remove the oxide layer on the surface of titanium and titanium alloy wires, and then use a set of thin steel wire wheels to remove the remaining oxide layer on the surface of the titanium and titanium alloy wires;

[0036] ③ Polishing: first use three sets of abrasive belt wheels to rough polish the surface of titanium and titanium alloy wire, and then use a set of polishing wheels to finish polishing the surface of titanium and titanium alloy wire, and the three sets of abrasive belt wheels are used alternately. After one set of abra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com