Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

192results about How to "Purify the working environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

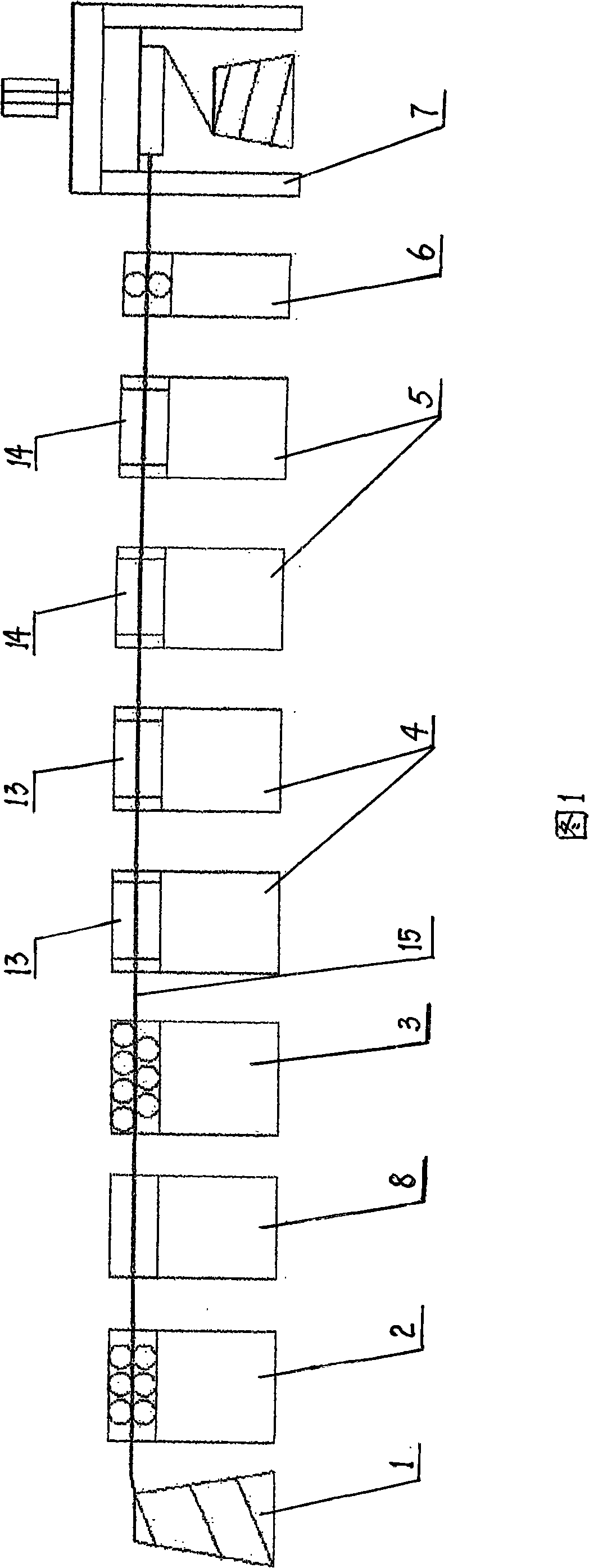

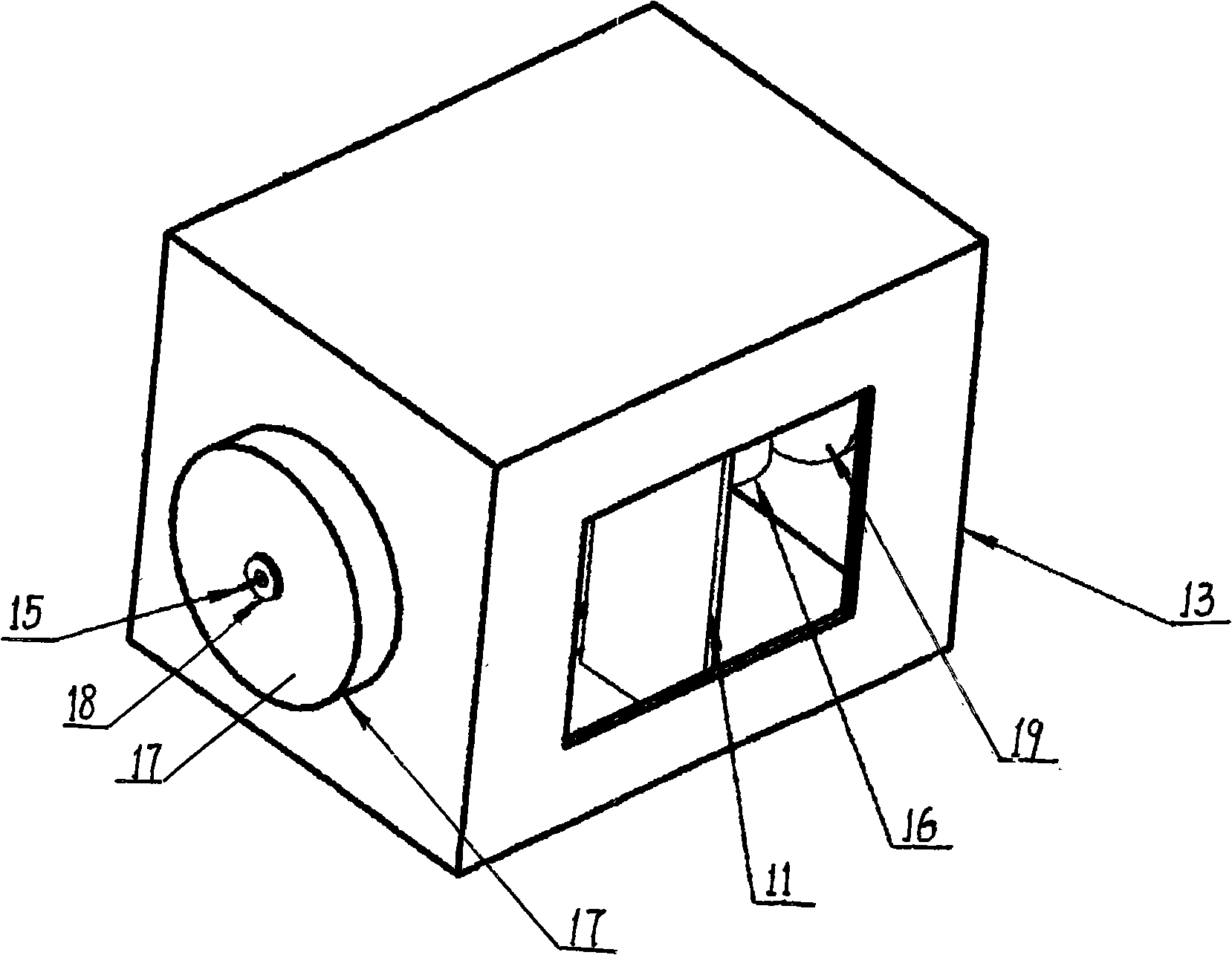

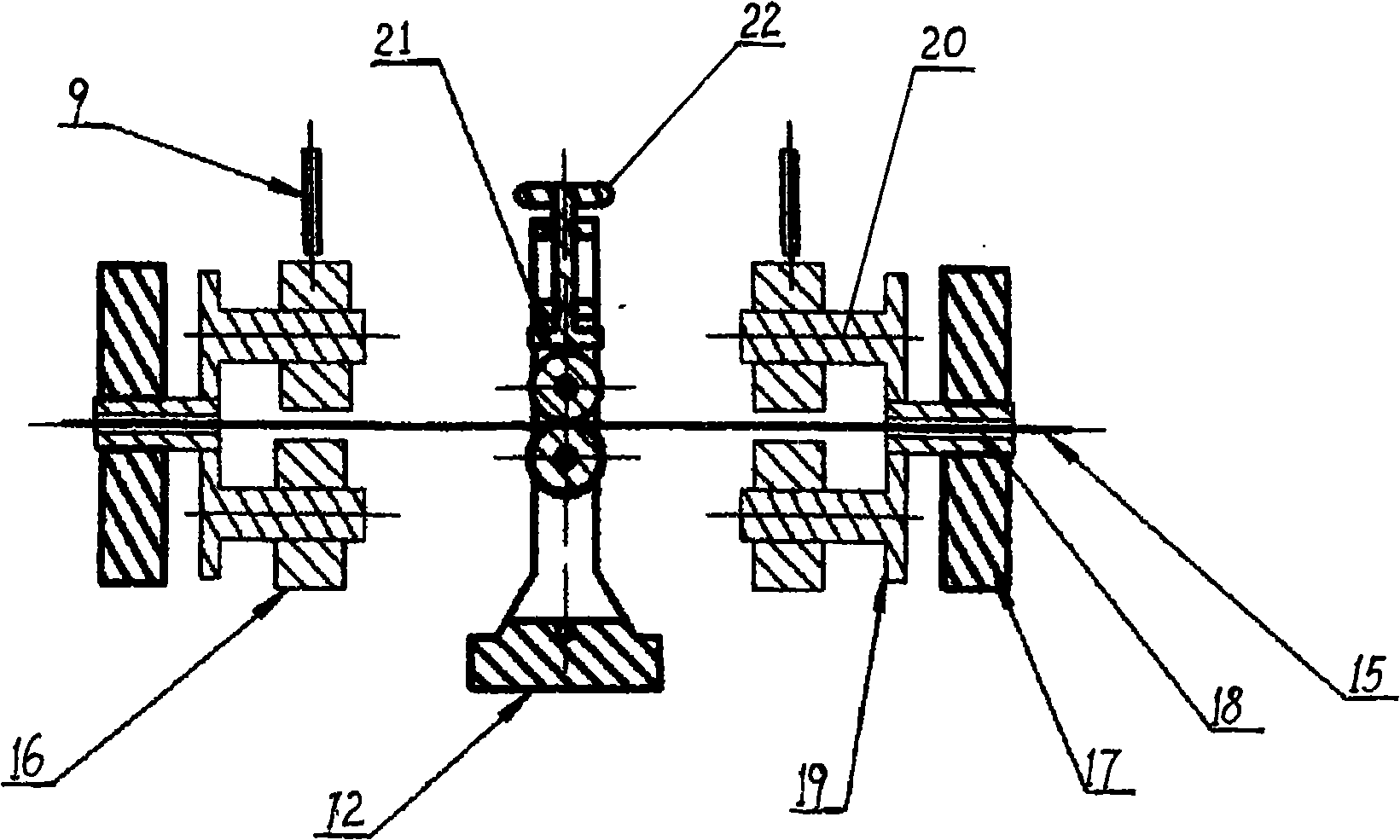

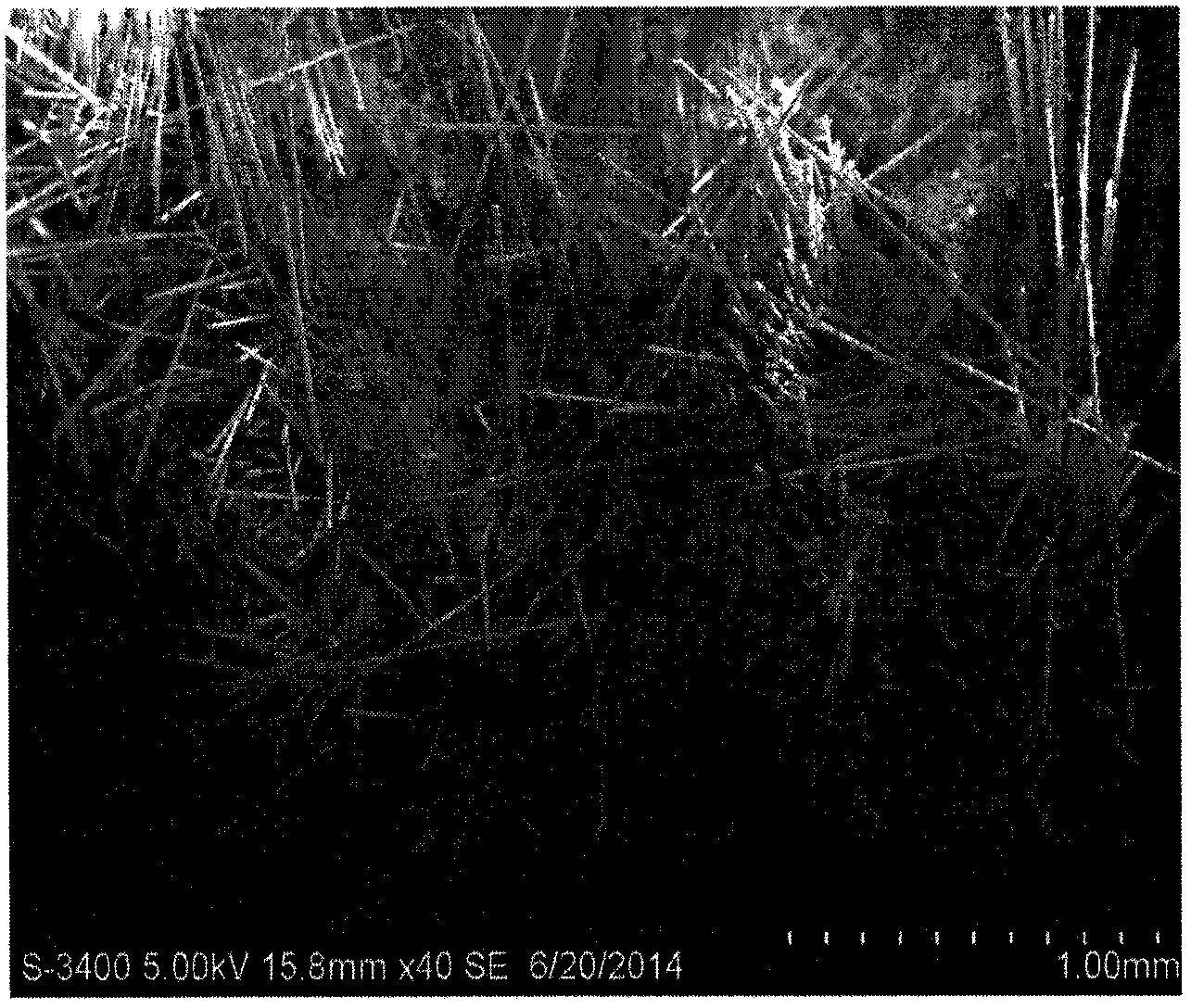

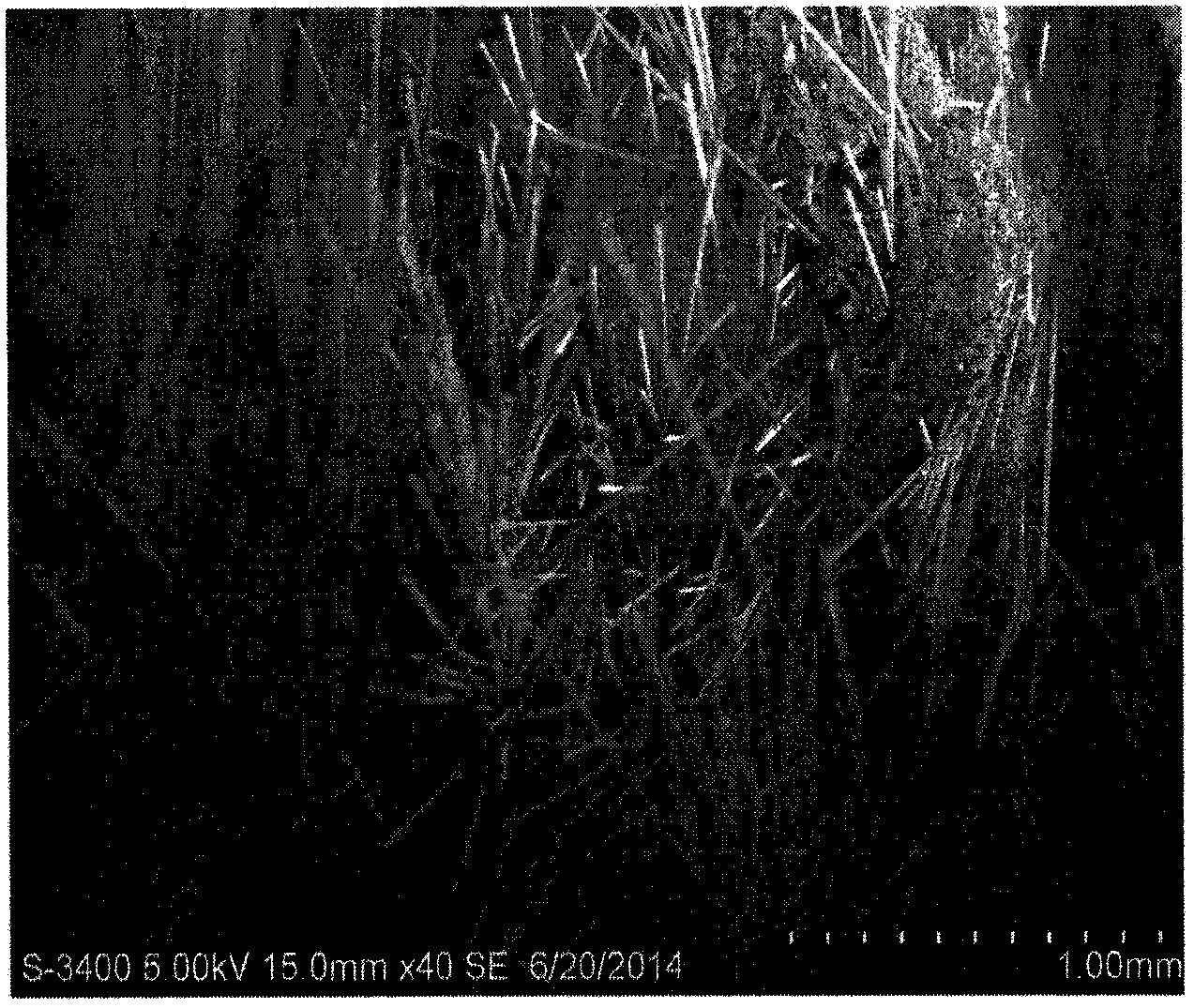

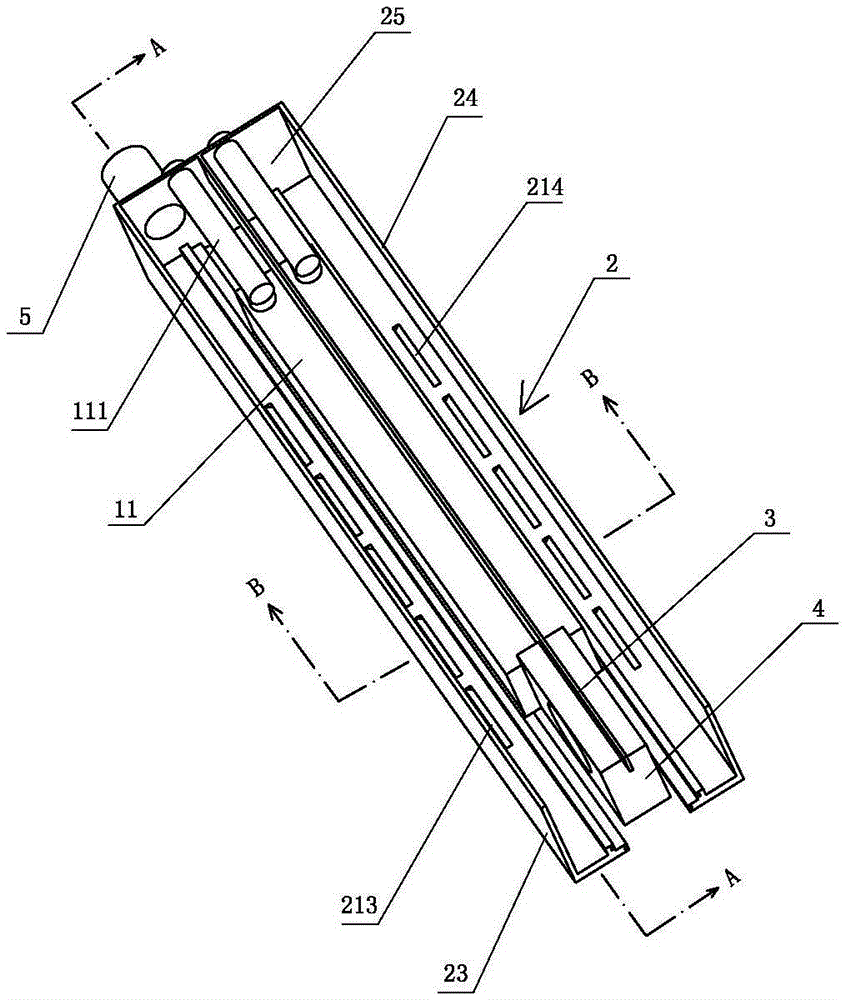

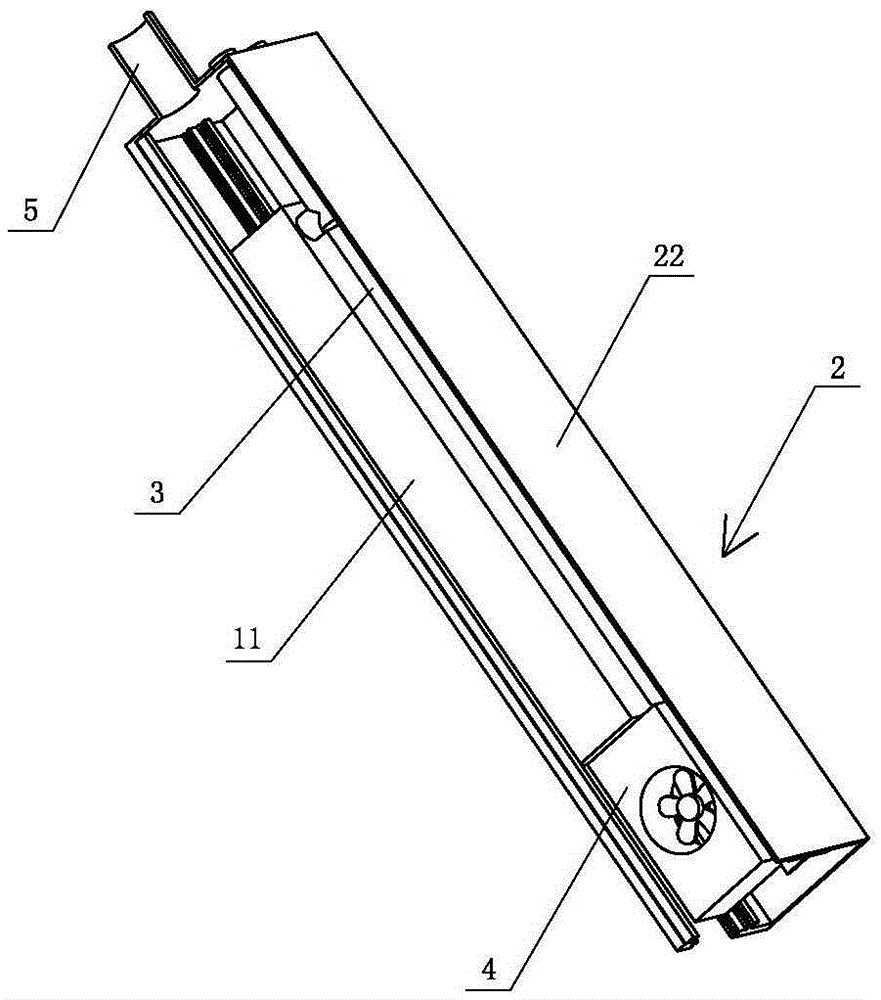

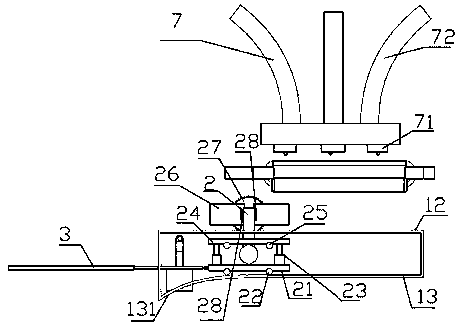

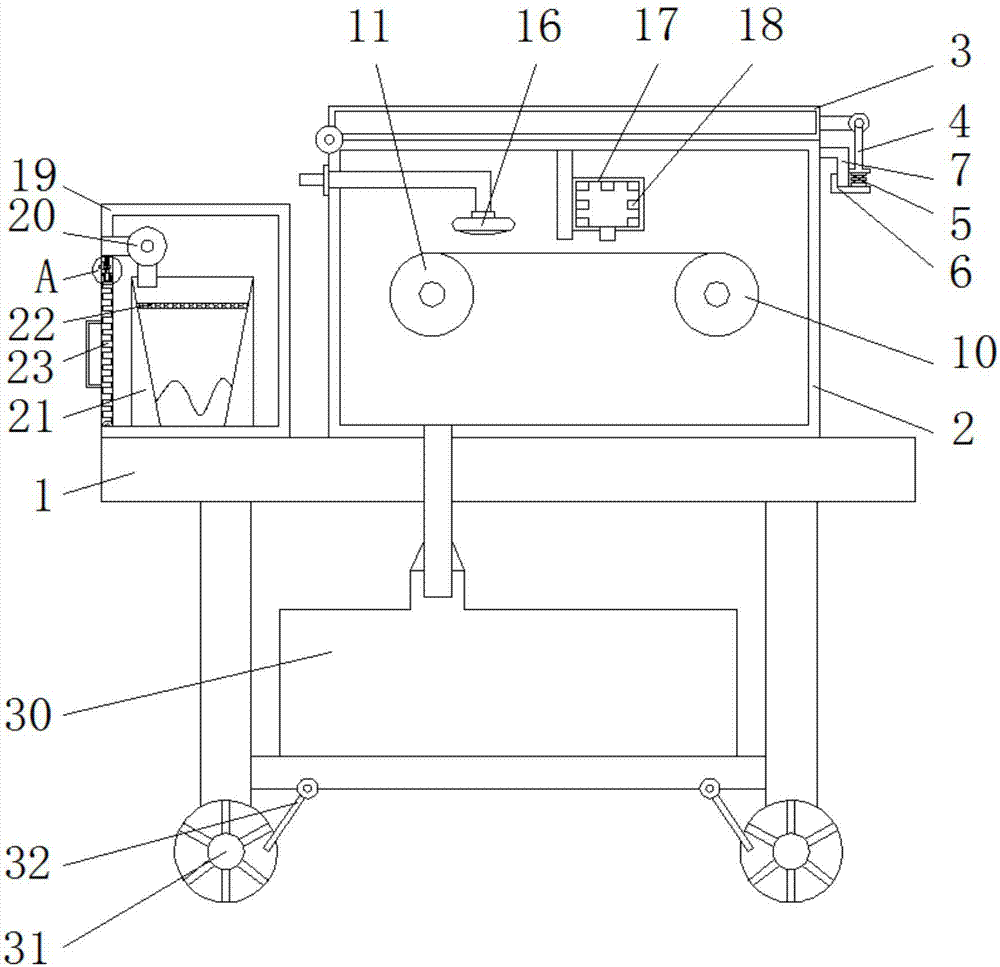

Method and equipment for removing oxidizing layer of titanium and titanium alloy wire material

ActiveCN101269397AEnsure consistencyGuaranteed uniformityWire articlesBurnishing machinesProduction lineTitanium

The invention relates to a method for removing an oxidation layer on titanium and titanium alloy wires and a device thereof. The method includes the following steps: 1. straightening: a straightening machine is used for straightening the titanium and titanium alloy wires; 2. phosphorus removal: a steel wheel phosphorus removal machine is used for removing the oxidation layer on the surface of the titanium and titanium alloy wires; 3. polishing: a sand belt wheel polisher is used for polishing the surface of the titanium and titanium alloy wires. The device is sequentially provided from left to right with a pay-off stand (1), a clamping device (2), a heating device (8), a straightening device (3), two steel wheel phosphorus removal machines (13), sand belt wheel polishers (14), a guide and guard (6) and a vertical down drawing machine (7). On the basis of the present steel wheel phosphorus removal machine, the method is additionally provided with a heating device, a phosphorus removing and polishing machine, a cooling device, a dust removing device and a tension device, thereby forming a production line for removing the oxidation layer on a large and heavy titanium alloy wire, so as to reach the purpose of removing the oxidation layer and polishing.

Owner:BAOJI TITANIUM IND

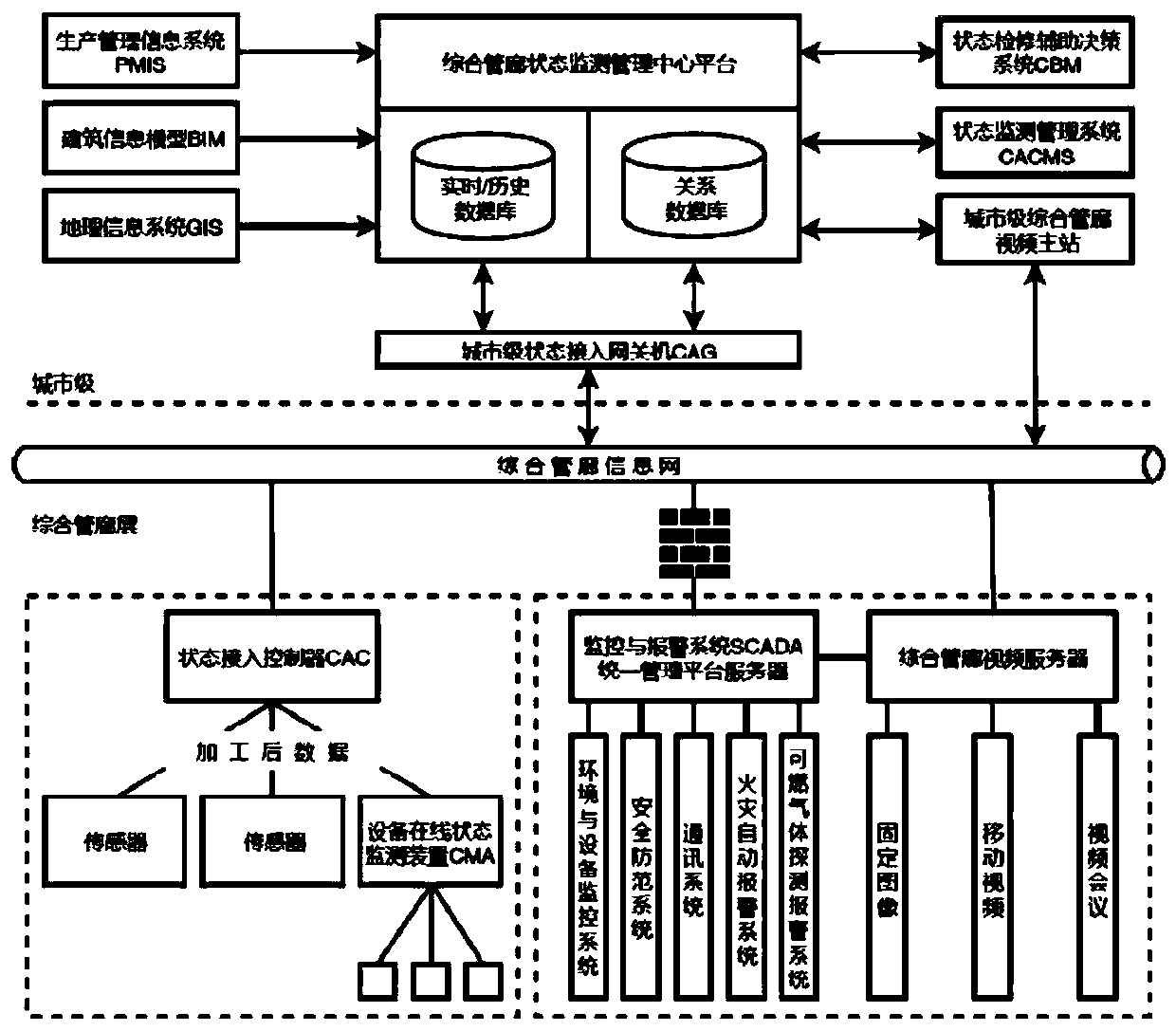

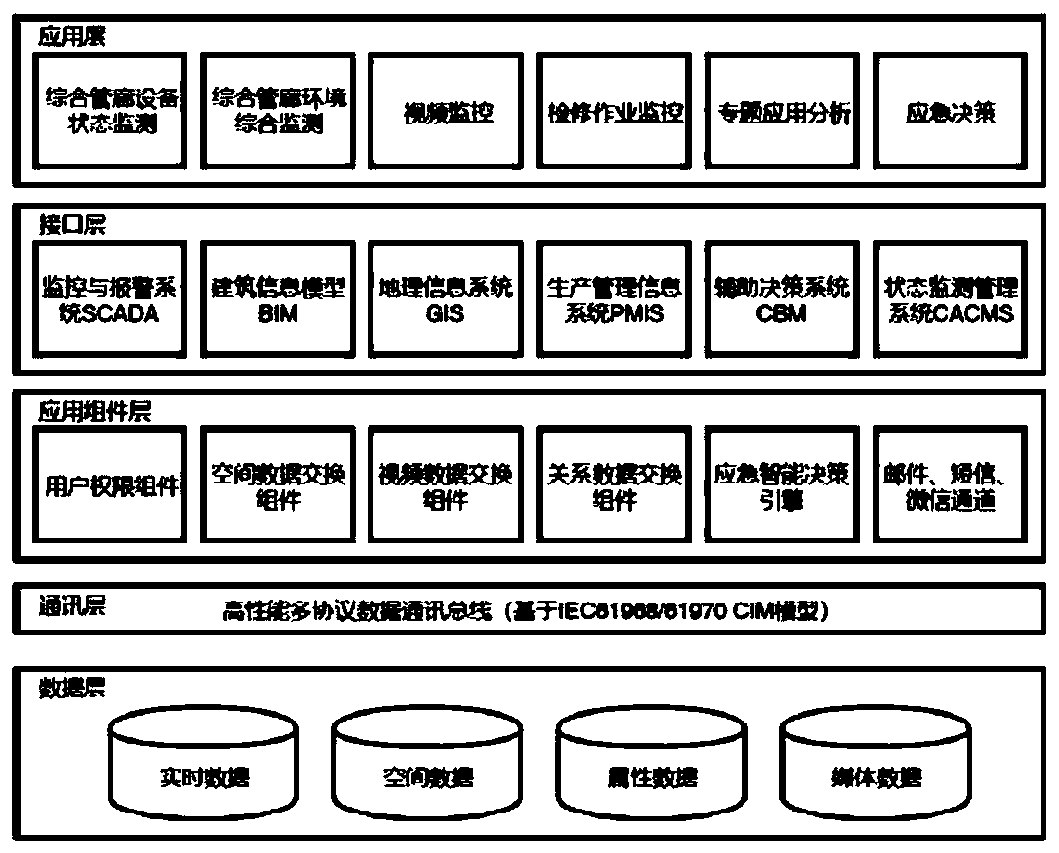

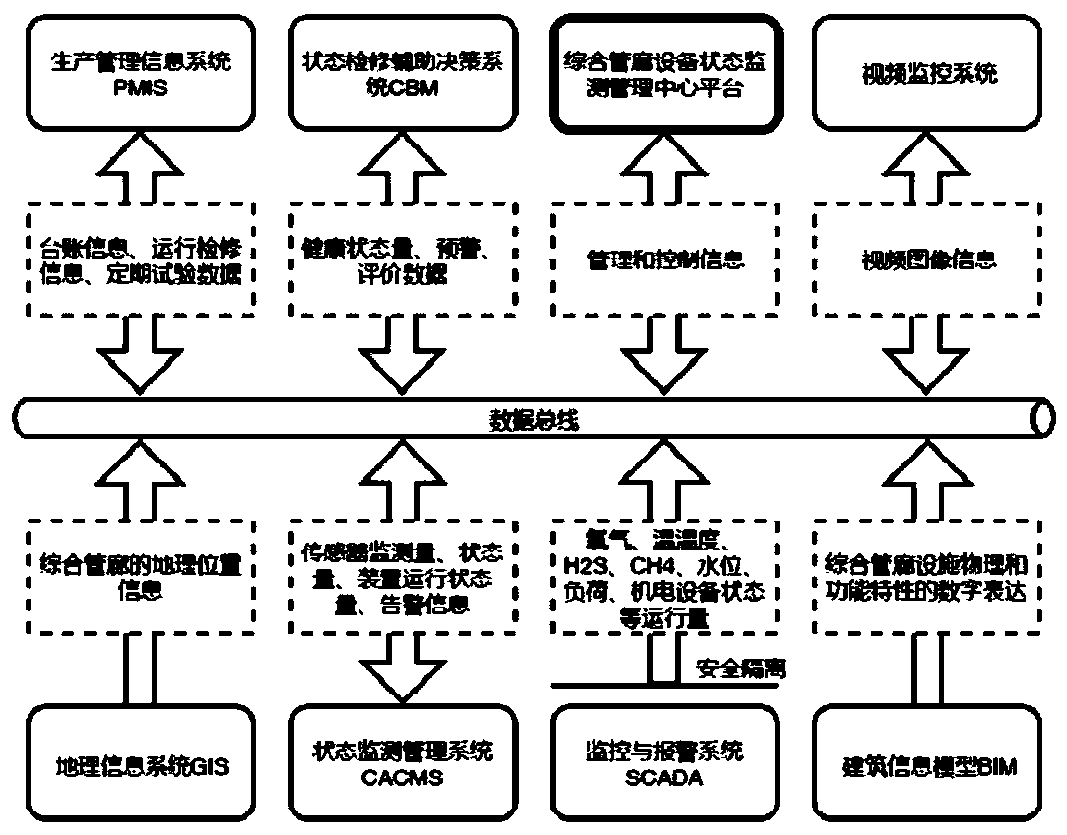

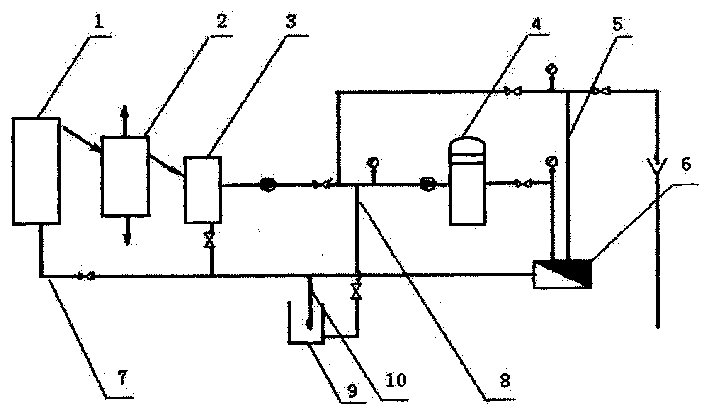

Comprehensive pipe gallery equipment state monitoring and management system

PendingCN110428135AComprehensive and timely information serviceImprove operational efficiencyRegistering/indicating working of machinesHardware monitoringTime informationData warehouse

The invention discloses a comprehensive pipe gallery equipment state monitoring and management system which is characterized by comprising a comprehensive pipe gallery layer system and a city-level system. According to the invention, a real-time database, a data warehouse and an intelligent platform tool are used as key technical means; a centralized and unified integration and sharing platform isprovided for various real-time information and production management information; a comprehensive pipe gallery equipment state unified centralized monitoring system is established; real-time information and business information based on manual work are effectively collected, converted, integrated, loaded and displayed, and more comprehensive and timely information services are better provided forvarious business fields such as comprehensive pipe gallery production operation commanding, emergency disposal, gallery entry professional pipeline operation management and state maintenance.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP +1

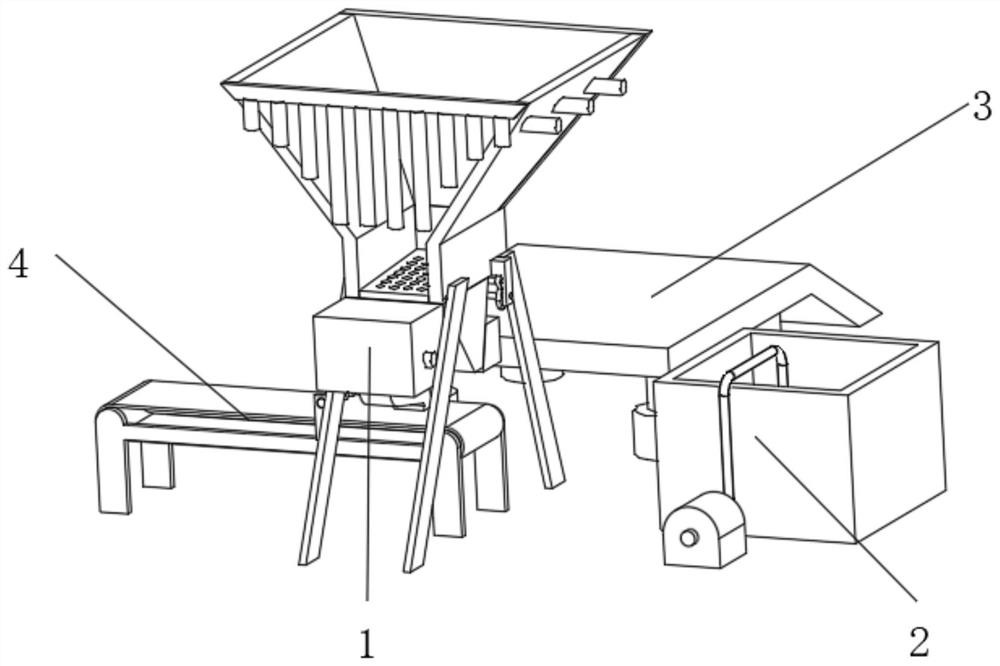

Separation device of plastic particles and dust by negative-pressure air power

InactiveCN101797561AEliminate the sorting processAvoid flyingGas current separationWorking environmentEngineering

The invention discloses a separation device of plastic particles and dust by negative-pressure air power, which comprises a separator (1), a draft fan (2) and a dust-collecting bag (3). The device comprising the separator (1), the draft fan (2) and the dust-collecting bag (3) adopts the technical scheme of sucking dust and separating plastic particles and dust by utilizing negative-pressure air power and overcomes the problems and the defects of great dust danger, high labor cost for secondary separation and low production efficiency of the prior art. The device is arranged at a discharging hole of a plastic pulverizer, finishes the crushing and separating procedures of plastics by one step and blows the dust into the dust-collecting bag to prevent the dust from flying, and the production of crushing and recycling plastics reaches the aims of no dust escape, working environment purification, procedure simplification, labor cost reduction and production efficiency improvement.

Owner:NINGHAI XINCHENG AUTOMOBILE PARTS CO LTD

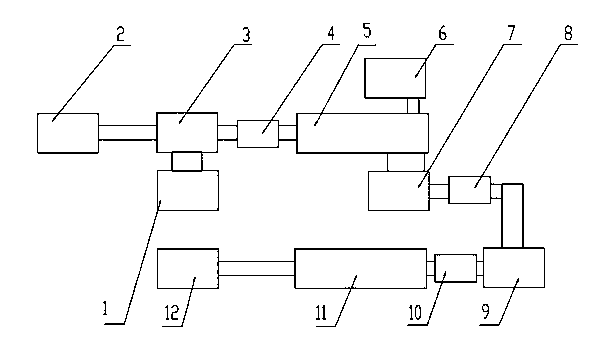

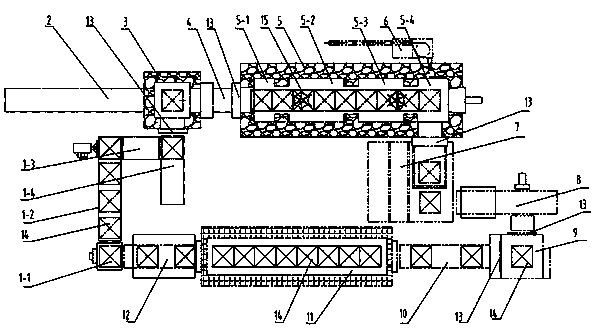

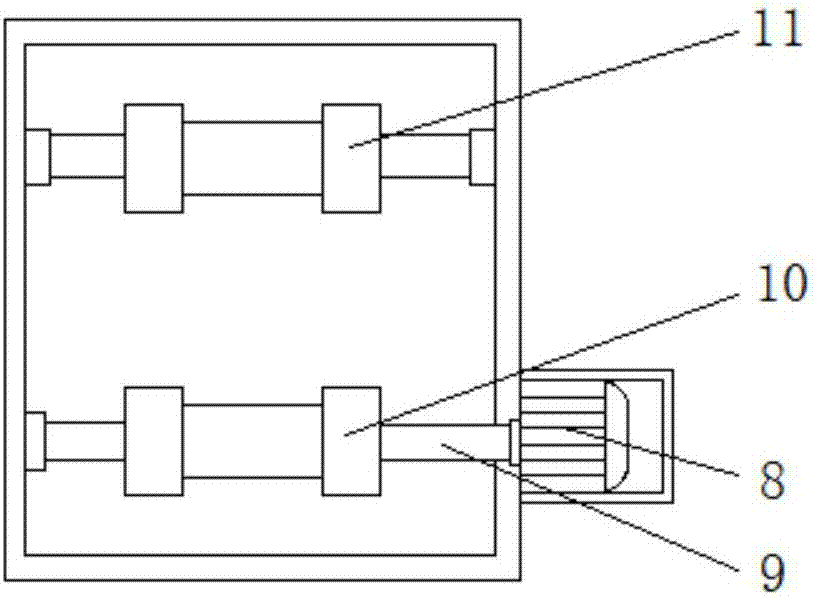

Automatic production line for saw blade heat treatment

InactiveCN103146902AGuarantee the environmentGuaranteed atmosphereFurnace typesHeat treatment furnacesProduction lineEngineering

The invention discloses an automatic production line for saw blade heat treatment, and belongs to the technical field of work piece heat treatment. The automatic production line for the saw blade heat treatment is characterized by comprising a feed mechanism, a feeding tray stepping advancing mechanism, a heat preserving furnace, a carbon-nitrogen furnace, a quenching mechanism, a cleaning machine, a tempering furnace and feeding tray conveying mechanisms, wherein the feed mechanism, the feeding tray stepping advancing mechanism, the heat preserving furnace, the carbon-nitrogen furnace, the quenching mechanism, the cleaning machine, the tempering furnace are sequentially arranged according to a manufacturing process order, and the feeding tray conveying mechanisms are arranged between each two adjacent devices. The feeding tray conveying mechanisms comprise a transition cylinder, a carbon-nitrogen furnace discharging advancing device, a quenching discharging advancing device, a tempering furnace feeding advancing device and a tempering furnace discharging advancing device, wherein the transition cylinder is arranged between the heat preserving furnace and the carbon-nitrogen furnace, the carbon-nitrogen furnace discharging advancing device is arranged on one side of the carbon-nitrogen furnace, the quenching discharging advancing device is arranged between the quenching mechanism and the cleaning machine, the tempering furnace feeding advancing device is arranged between the cleaning machine and the tempering furnace, and the tempering furnace discharging advancing device is arranged at an outlet of the tempering furnace. The automatic production line for the saw blade heat treatment has the advantages of improving production efficiency and energy use rates of the devices, ensuring heat treatment quality of saw blades due to continuous production, achieving automation operation of the whole production line and being small in number of employed workers and good in labor environment.

Owner:烟台金都锯业有限公司

Silane coupling agent modified friction material and friction plate made of friction material

InactiveCN104356590ALiquidInfiltratingOther chemical processesFriction liningUltimate tensile strengthShear strength

The invention discloses a silane coupling agent modified friction material and a friction plate made of the friction material. The friction material comprises components in a frictional material formula and a processed silane coupling agent. A method for preparing the friction material comprises steps as follows: raw materials are prepared according to the friction material formula, the components of the friction material are uniformly mixed through a mixing process, and the processed silane coupling agent is sprayed into mixing equipment through the mixing process. The silane coupling agent modified friction material and the friction plate made of the friction material have the benefits as follows: the problem about compatibility of raw materials in a friction product is solved, then one friction product is provided, the friction product improves impact strength and inner shearing strength while the friction coefficient and performance are not damaged under the same condition, the wearing is reduced, and the friction plate made of the friction material can be applied to the harsh working condition.

Owner:HUBEI FEILONG FRICTION & SEALING MATERIALS

Metal cutting machine tool with metal chip collecting function

InactiveCN107825215AQuick disassemblyEasy to clean and replaceMaintainance and safety accessoriesWorking environmentPulp and paper industry

The invention discloses a metal cutting machine tool with the function of collecting metal shavings, comprising a machine tool body, the machine tool body is a hollow structure, a workbench is fixedly installed inside the machine tool body, and a collection box with an opening at the top is arranged under the workbench , both sides of the collection box are welded with connecting blocks, both sides of the machine body are welded with fixed blocks, the inner walls of both sides of the machine body are provided with first through holes, and the fixed blocks are provided with second through holes, the first The through hole communicates with the second through hole, the same slide bar is slidably installed in the first through hole and the second through hole, and both ends of the slide bar extend outside the first through hole and the second through hole. The present invention is simple in structure, easy to use, adds the function of collecting metal shavings to the metal cutting machine tool, and the collection box is convenient to clean and replace, purifies the working environment, is easy to operate, and improves work efficiency.

Owner:湖州南浔昊骏金属制品厂

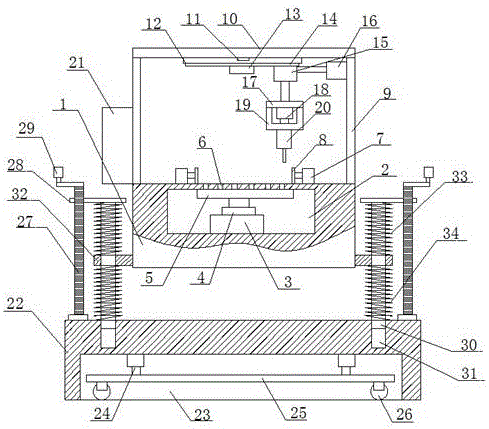

Multi-direction cutting plate shearing machine adjustable in damping performance

InactiveCN106541505AProtect your healthProtective elastic forceWorking accessoriesStone-like material working toolsMachiningAerospace engineering

The invention discloses a multi-direction cutting plate shearing machine adjustable in damping performance. The multi-direction cutting plate shearing machine comprises a workbench and a base. A cavity is formed in the workbench. A dust collecting box is arranged at the bottom of the cavity. A dust suction device is arranged on the upper side of the dust collecting box and connected with a dust suction hopper through a pipeline. Multiple dust suction openings are formed in the upper side of the workbench. A first longitudinal guide rail is arranged on the lower side of an installing plate and provided with a moving plate. A first air cylinder is arranged at the rear end of the upper side of the installing plate. The front end of the first air cylinder is connected with the rear side of the moving plate. A second longitudinal guide rail is arranged on the lower side of the moving plate, and a second air cylinder is arranged on the lower side of the second longitudinal guide rail. A third air cylinder is arranged at the right end below the installing plate. The left end of the third air cylinder is connected with the right end of the second air cylinder. A connecting plate is arranged at the lower end of the second air cylinder. A motor is arranged on the lower side of the connecting plate, and the output end of the motor is connected with a rotation support. The multi-direction cutting plate shearing machine is simple in structure and convenient to use, multi-direction machining can be achieved, and the function of dust suction is achieved as well.

Owner:江苏言诺机械科技有限公司

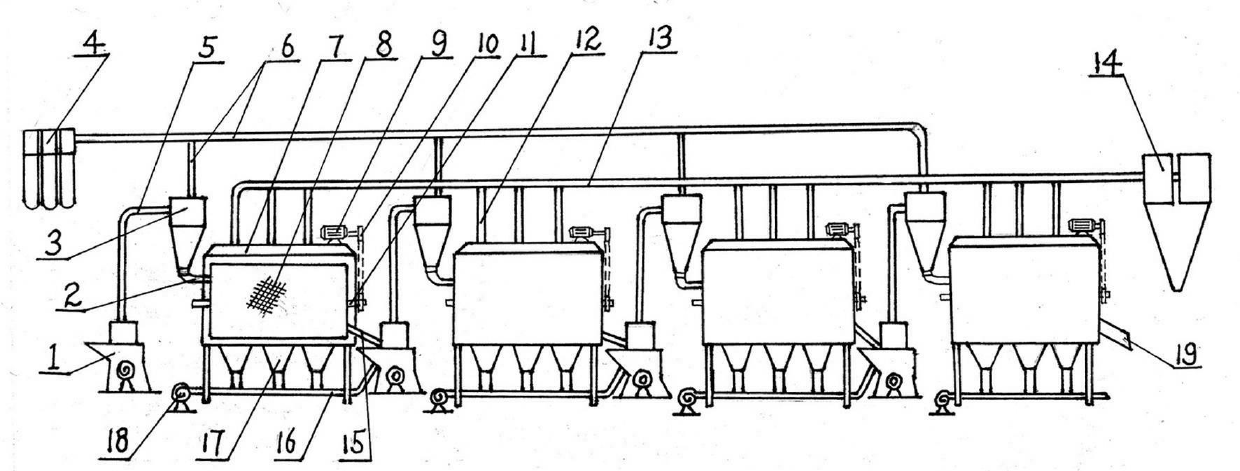

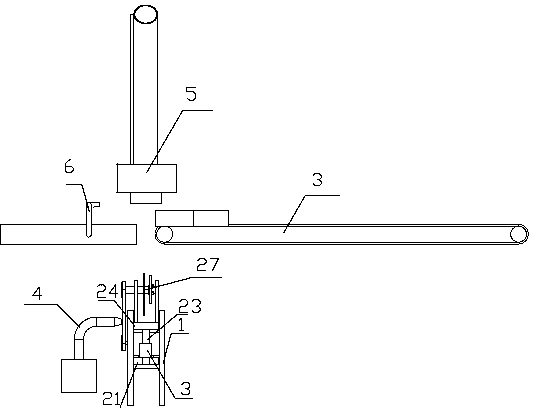

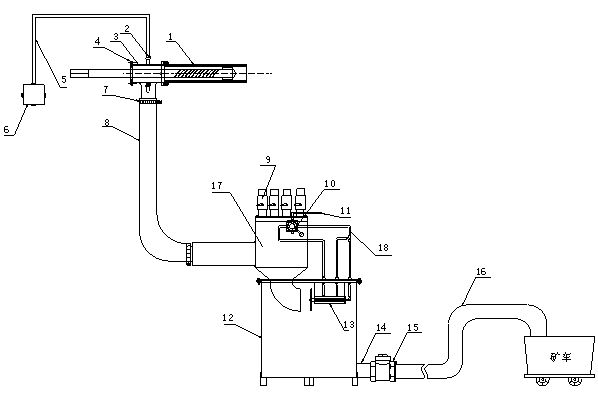

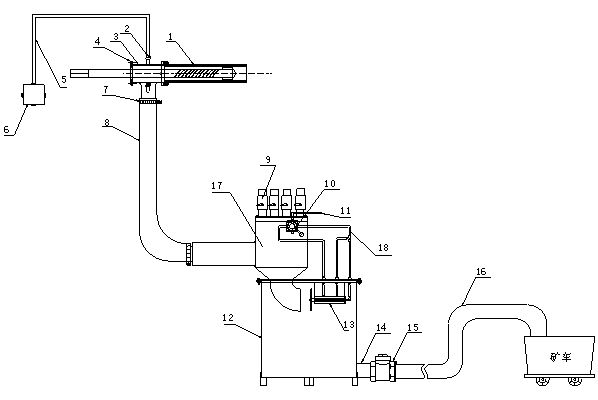

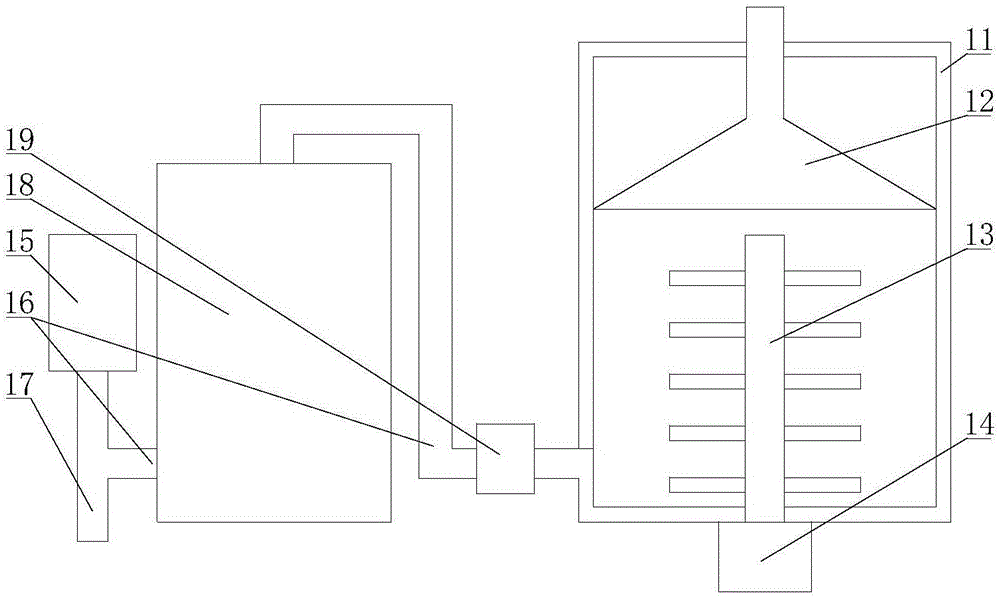

Negative-pressure dustless moxa extracting equipment and production process thereof

ActiveCN102560691AHigh purityImprove automationMechanical fibre separationWorking environmentProcess engineering

The invention relates to negative-pressure dustless moxa extracting equipment and a production process thereof. The negative-pressure dustless moxa extracting equipment comprises a fine fleece collector, a dust collector and four moxa extracting devices, wherein the four moxa extracting devices are connected in sequence. Each moxa extracting device consists of a grinder, a separator and a moxa remover, the grinder is sequentially connected and communicated with the separator and the moxa remover through conveying pipelines, the moxa remover is connected with the fine fleece collector through a negative-pressure moxa suction pipe and a fine fleece conveying pipeline, and the separator is communicated with the dust collector through a dust collecting pipeline. The negative-pressure dustless moxa extracting equipment is applicable to large-scale industrialized continuous production of moxa extraction, is capable of extracting high-purity moxa in a short time and simplifying production process, and simultaneously guaranteeing product quality reliably, improving working environment and reducing waste of folium artemisiae argyi.

Owner:南阳仙草健康集团有限公司

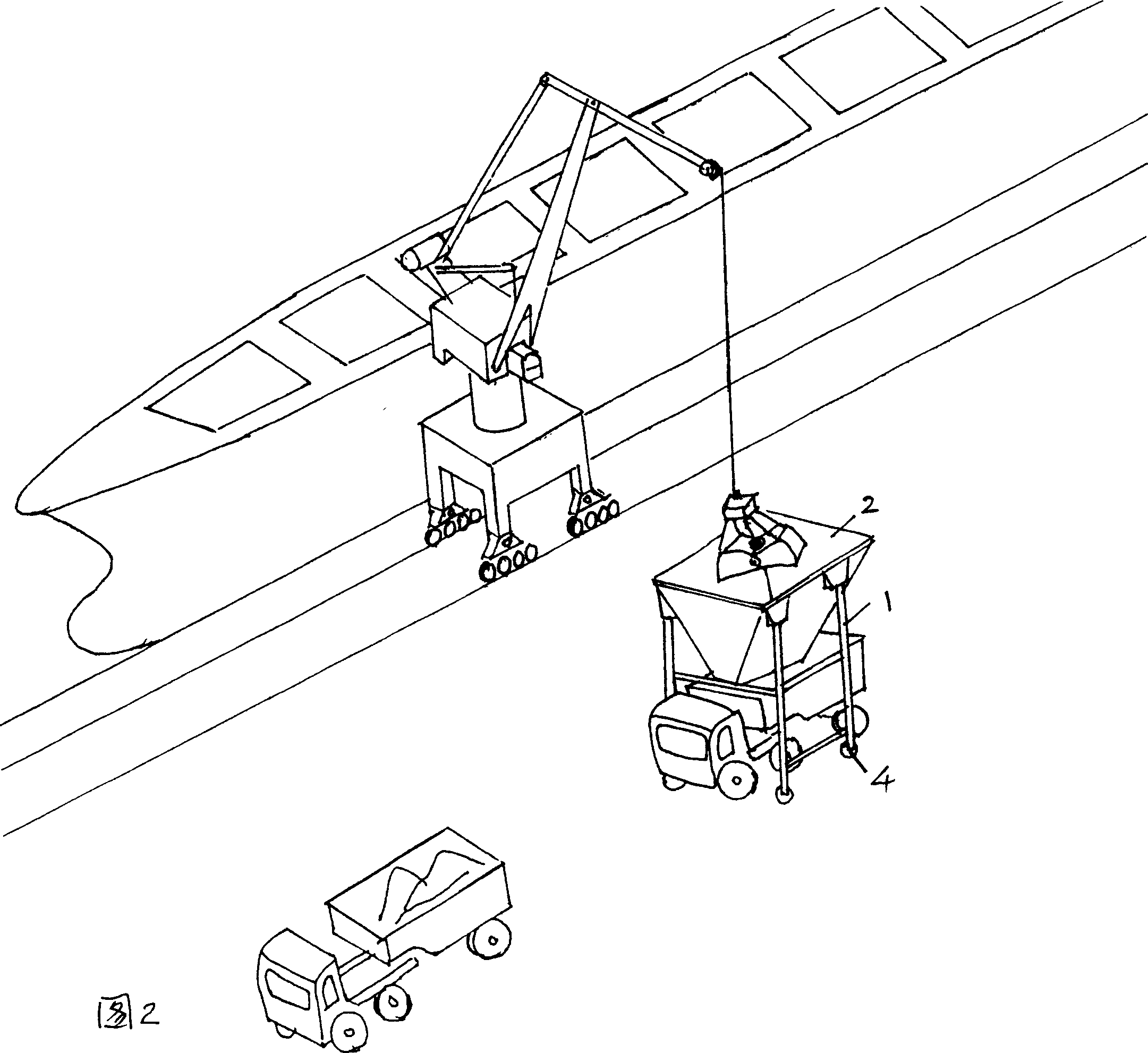

Technical method and facilites for loading and unloading goods at berth in hundred thousand tunnage

InactiveCN1498834AEasy to operateEliminates the need for stockpiling in the dock front yardLarge containersTrolley cranesQuality of workTruck

A loading and unloading method for the one hundred thousands tons class of dock features that the cargo is transported from ship's cabin into a greater hopper with guide plate at its lower opening by the grab bucket of greater hoist, and then loaded in a truck under said greater hopper. Its apparatus is composed of a 4-column supporting frame, and a greater hopper installed on said supporting frame. Its advantages are high efficiency and quality of unloading and loading and less loss.

Owner:天津港第五港埠有限公司

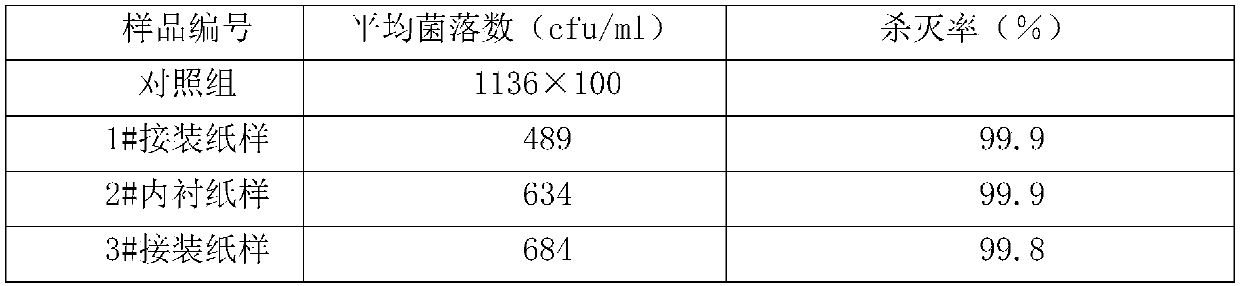

LED UV printing and curing device

ActiveCN105398205AReduce pollutionPurify the working environmentPrinting press partsWorking environmentEngineering

The invention discloses an LED UV printing and curing device and belongs to the technical field of printing devices. The LED UV printing and curing device comprises an LED lamp bead substrate with a cooling device, and a shell, wherein a longitudinal opening is formed in the middle of the bottom wall of the shell; the LED lamp bead substrate is arranged on the longitudinal opening; a partition board is arranged between the top end of the cooling device of the LED lamp bead substrate and the top wall of the shell; an inner cavity of the shell is divided into a left part and a right part by the partition board; the left part is an air sucking chamber; the right part is an air spraying chamber; an air sucking hole and an air spraying hole are respectively formed in the bottom wall of the shell on two sides of the LED lamp bead substrate; the air sucking hole and the air spraying hole are respectively communicated with the air sucking chamber and the air spraying chamber. The LED UV printing and curing device has the advantages that the air sprayed by the air spraying chamber is blown to the UV ink, so that the curing speed is improved; the air sucking chamber is used for sucking the volatile UV ink and solvents of the UV ink; the volatile UV ink and solvents of the UV ink are discharged out of the room through an air outlet through hole and an air extracting device; the working environment is greatly purified; the air pollution is reduced; operators can work with physical and mental pleasure; the working efficiency is improved.

Owner:QINGDAO LAIYIDI PHOTOELECTRIC SCI & TECH CO LTD

Cement compound type grinding aid

The invention provides a cement compound type grinding aid which is high-efficient cement grinding aid integrating grinding and enhancement. The cement compound type grinding aid comprises the following compositions in percentage by weight: 10-20% of modified triethanolamine, 10-15% of triethanolamine, 20-30% of triisopropanolamine, 10-15% of glycerinum, 10-15% of sodium humate, 1% of low-molecular-weight fatty salt and 20-30% of clean water. According to the cement compound type grinding aid, the grinding efficiency of a cement grinding technology and the purification of the working environment in a manufacturing shop can be effectively improved, and the cement compound type grinding aid has the characteristics of lowering the production cost and effectively optimizing the properties of cement.

Owner:湖南润攸科技发展有限公司

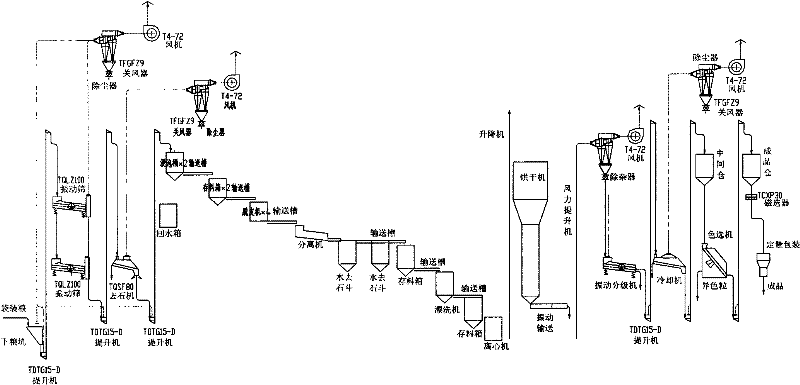

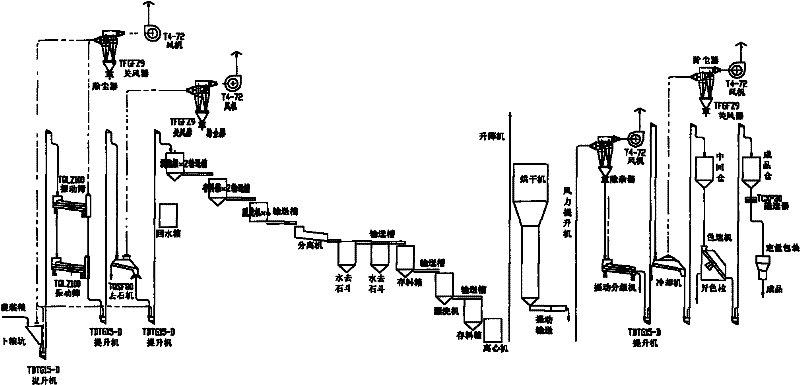

Process for washing sesame with water

InactiveCN102240653AReduce turnover timesEasy to separateCleaning processes and apparatusGeneral screeningEngineering

The invention discloses a process for washing sesame with water. The process comprises the following steps of: removing and separating impurities and stones from the sesame at first; then immersing and washing the sesame with water, stripping the sesame and separating the sesame; drying, performing color selection and magnetic separation; and finally, finishing a process of manufacturing qualified sesame meat. The whole process is extremely smooth and the transferring frequency of the sesame is low, so the production efficiency is improved greatly; various measures, such as general screening, color selection, magnetic separation and the like, are used together, so cleaning and grading can be performed simultaneously; and the later targeted deep processing of the sesame is facilitated.

Owner:NANTONG GRAIN MACHINERY

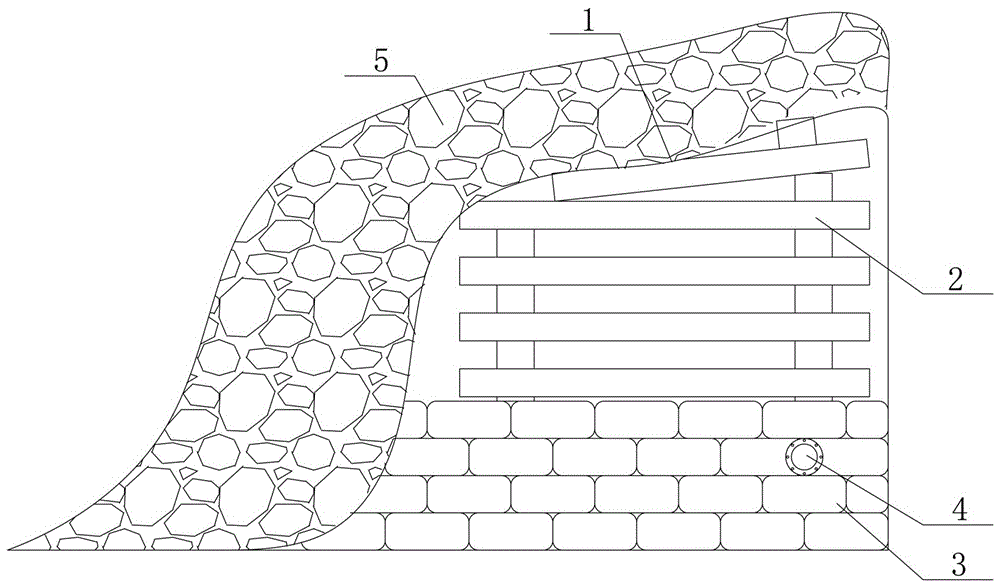

Down coal face goaf water dredging structure and dredging method thereof

InactiveCN106640187AAvoid flooding the roadwayEliminate hidden dangers in production safetyMining devicesDrainageCoalOperating environment

The invention relates to a down coal face goaf water dredging structure. The structure includes a fish scale net covering a collapsed top plate, after top plate gangue collapses, a goaf is no longer filled freely, and the fish scale net is used for covering to achieve the effects of protecting the top plate and catching the gangue; a nog shaped like a Chinese character 'Jing' is erected below the collapsed top plate and used for supporting the collapsed top plate; a water-retaining wall is built at the lower side of the nog shaped like a Chinese character 'Jing', and the goaf and the water-retaining wall are used for building a weir to form a water sump. The structure further includes a water discharge pipe, the water-retaining wall is provided with at least one water discharge pipe to connect space outside the water-retaining wall and the water sump. The invention further provides a down coal face goaf water dredging method. The down coal face goaf water dredging structure has the advantages that water dredging is conducted from a source, water and coal are separated, water blasting of a tunnel is avoided, and the production security hidden danger is eliminated; the discharged water is few in impurity, damage to a drainage system is reduced, and the electric charge is saved; the dredging project is reduced, manpower is reduced, and the work efficiency is improved; the operating environment is purified, and the production efficiency and the quality standardization level are improved.

Owner:XIAOYUN COAL MINE JINING MINING IND GRP CO LTD

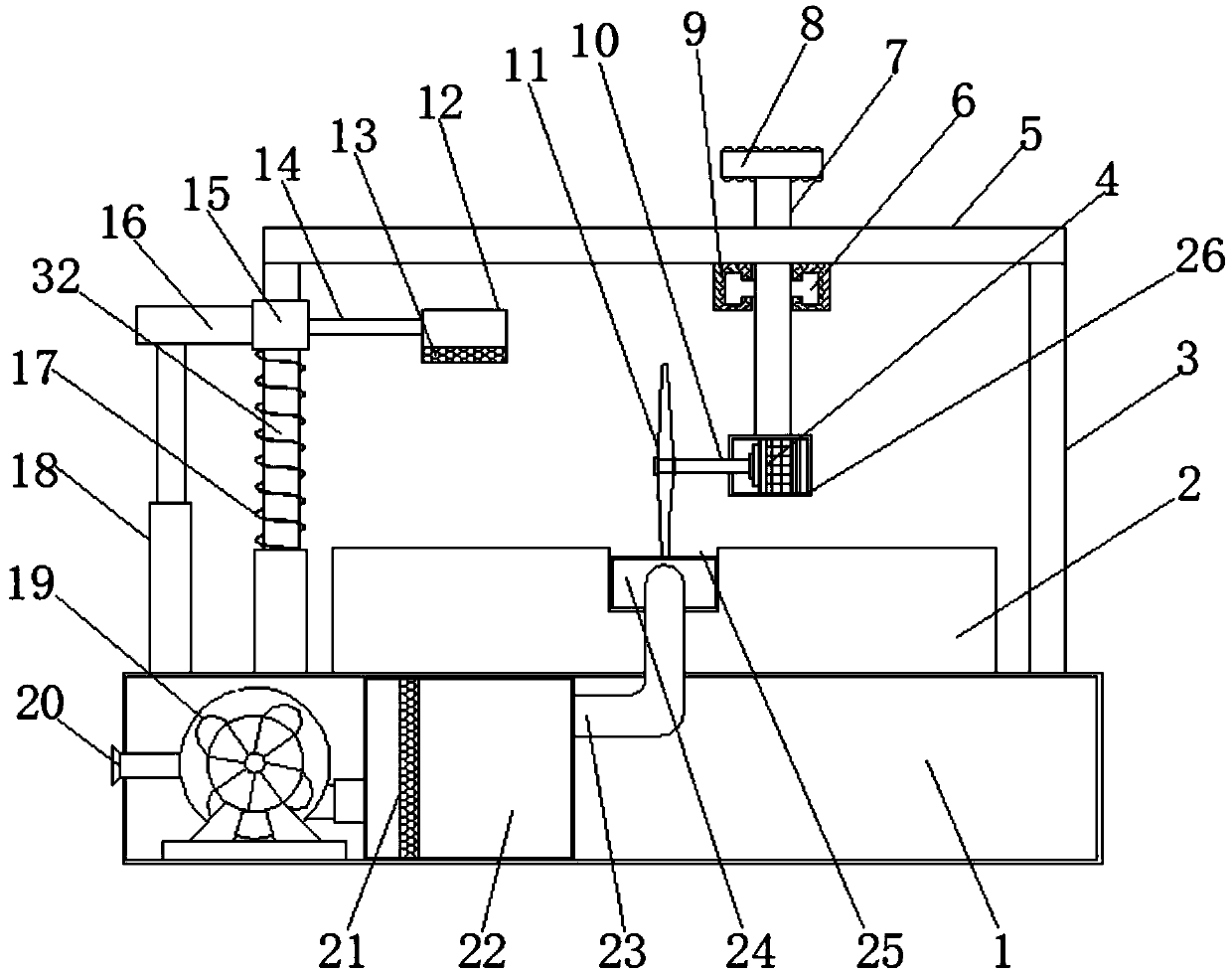

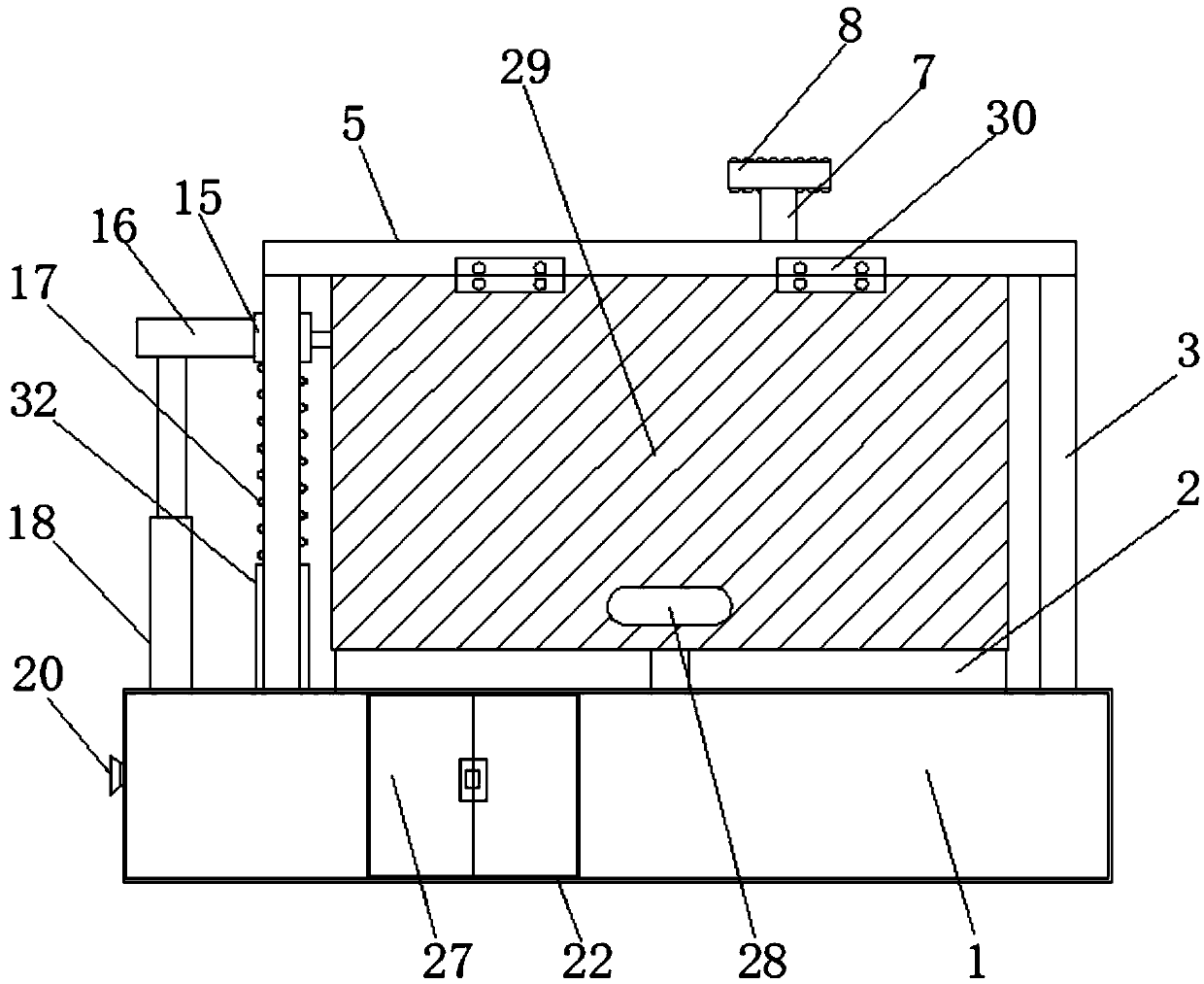

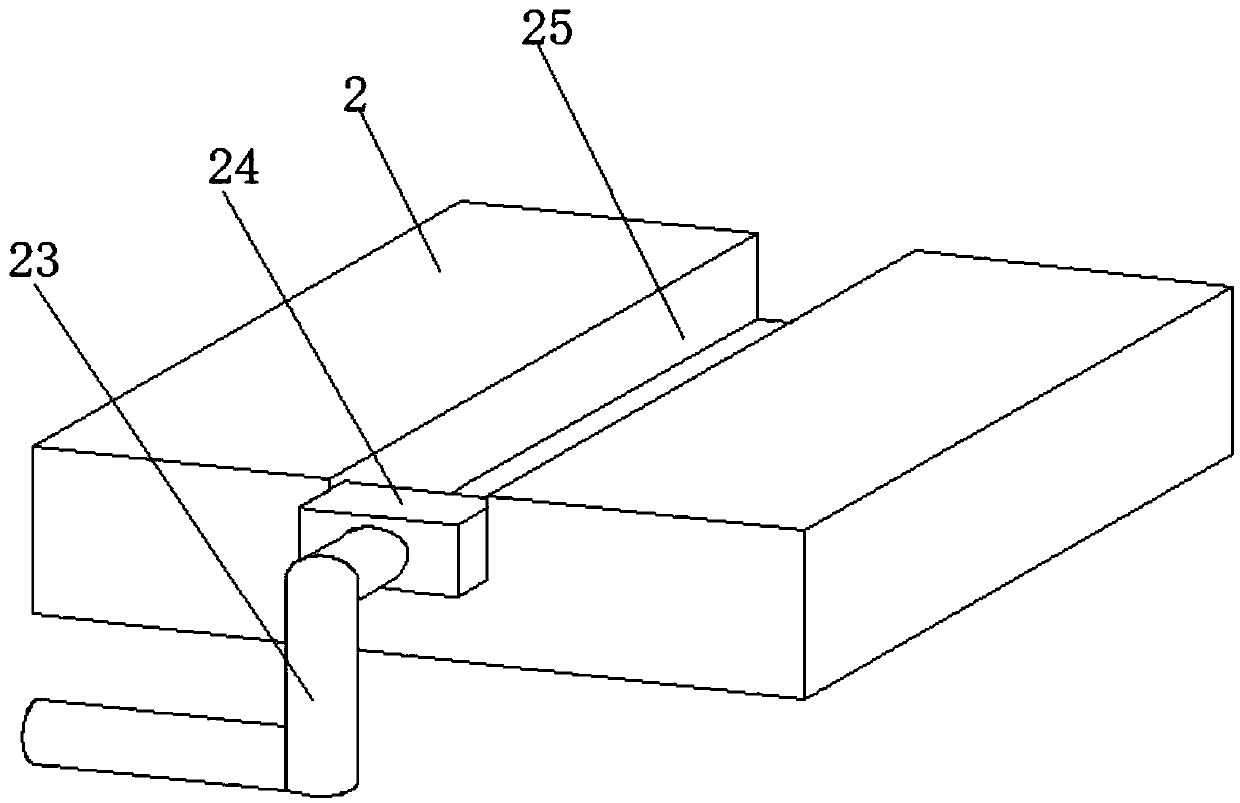

Computer accessory processing equipment

InactiveCN108673596APrevent looseningPurify the working environmentDispersed particle filtrationMetal working apparatusEngineeringWorking environment

The invention discloses computer accessory processing equipment, which comprises a base, wherein upright posts are fixed in four corner positions of the top of the base; a top plate is fixed on the tops of the upright posts; a cutting table is arranged on the top of the base; a groove is formed in the middle position of the top of the cutting table; a support rod is fixed in a position, positionedat one side of the cutting table, of the top of the base; an air cylinder is arranged at one side, far away from the cutting table, of the support rod; the air cylinder is fixed on the top of the base; and the output end of the air cylinder is connected with a second connecting rod. The air cylinder drives the second support rod to downwards move; under the effects of an installed sleeve, a spring and the first support rod, a press block downwards moves, so that a circuit board to be cut is fixed; the phenomenon of nonuniform cutting due to occurrence of looseness during the cutting is avoided; through an installed draft fan, a collection cabin and an air suction cover, fragments falling into the groove during the cutting can be collected; the work environment is purified; and the resource waste is avoided.

Owner:广东鑫城绿美陶瓷有限公司

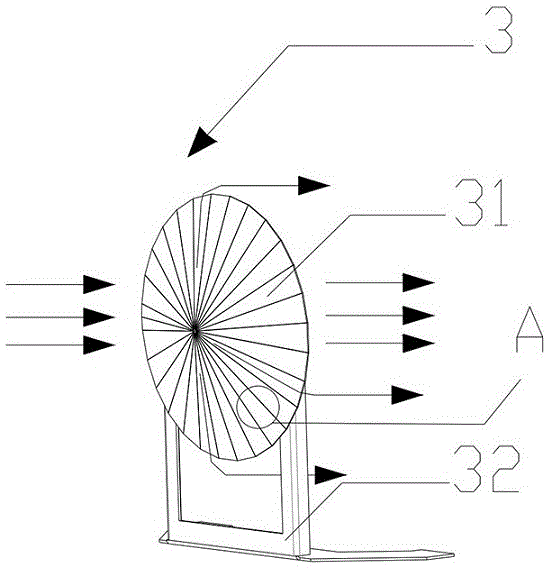

Oil mist recycling machine

PendingCN106823595AAvoid damagePurify the working environmentCombination devicesDispersed particle filtrationWorking environmentOil mist

The invention relates to the technical field of oil mist filtering equipment and in particular relates to an oil mist recycling machine. The oil mist recycling machine comprises a rack, wherein the rack is provided with a shell body; an inlet is formed in one side of the shell body; the shell body is internally provided with a first-grade filtering device for carrying out first-grade filtering on oil mist, a second-grade filtering device for carrying out second-grade filtering on the oil mist, a third-grade filtering device for carrying out third-grade filtering on the oil mist and a driving mechanism; the driving mechanism is in driving connection with the third-grade filtering device; a collection device is arranged at the lower end of the third-grade filtering device. According to the oil mist recycling machine provided by the invention, the effects of filtering the oil mist for a plurality of times, carrying out odor removal treatment and cooling, liquefying and recycling the oil mist can be realized through the first-grade filtering device, the second-grade filtering device and the third-grade filtering device. An external working environment is effectively purified and corrosion damages, caused by the oil mist, to the equipment are reduced; damages, caused by the oil mist, to human bodies are reduced; the atmospheric environment is protected.

Owner:TANGXIA BRANCH VISION TOOL & MOLD

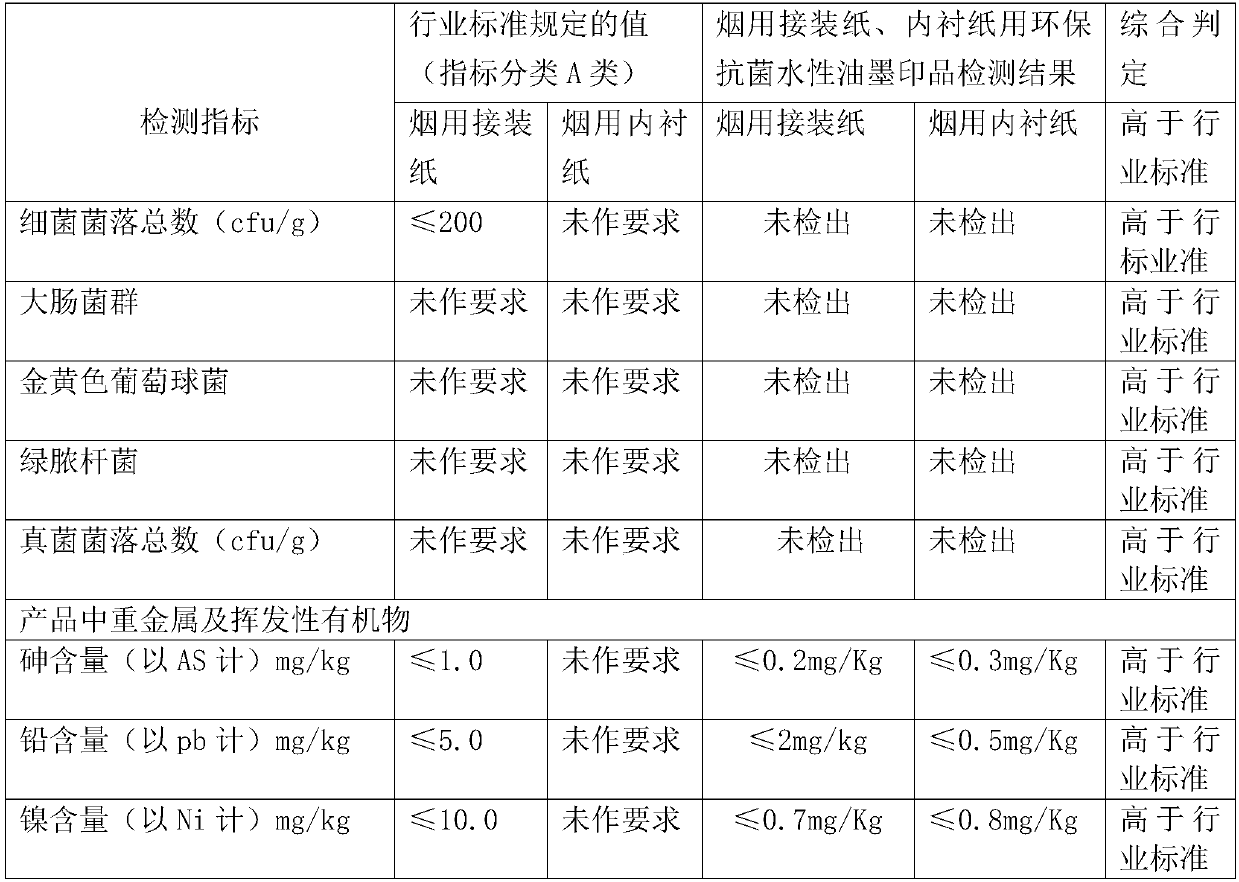

Environment-friendly antibacterial aqueous ink for tipping paper and lining paper for cigarettes and preparation method of ink

The invention discloses environment-friendly antibacterial aqueous ink for tipping paper and lining paper for cigarettes. The ink is prepared from, by weight, 12-18% of a water-soluble resin liquid, 35-45% of a solvent, 25-35% of a compound antibacterial filler, 8-20% of pigment and 0-3% of an auxiliary; the composite antibacterial filler comprises nano titanium dioxide, a silver ion antibacterialagent, a chitosan-copper complex and soybean powder. The invention further provides a preparation method of the aqueous ink. The environment-friendly antibacterial aqueous ink greatly eliminates damage caused by volatile organic compounds such as benzene, methylbenzene, ethylbenzene, xylene and n-butyl acetate and harmful metals such as arsenic, mercury, lead, cadmium, nickel and chromium and hasthe good antibacterial effect, and the sterilizing effect on bacillus, escherichia coli and staphylococcus aureus can reach 99% or above.

Owner:楚雄市华丽包装实业有限责任公司

Straight-edge machine suitable for bamboo and wood products

ActiveCN104260152APurify the working environmentAffectWood mortising machinesCircular sawsPulp and paper industryWood product

The invention relates to the field of gluing devices, in particular to a straight-edge machine suitable for bamboo and wood products. According to the technical scheme, the straight-edge machine suitable for the bamboo and wood products comprises a rack, a conveying table and a cutting device, the cutting device can move on the rack and cut the bamboo and wood products on the conveying table, an air-breathing device is arranged above a material cut position on the conveying table, a first baffle and a second baffle used for containing wood scraps that are generated during cutting are mounted on the conveying table, the straight-edge machine further comprises an oil spraying device, and a track system which is provided for the cutting device to slide is disposed on the rack. The invention aims to provide the straight-edge machine suitable for the bamboo and wood products. The straight-edge machine suitable for the bamboo and wood products has the advantages that the structure is simple, the implementation is facilitated, whole cutting or slotting process is automatic, single-time contact is merely performed, double-channel slots due to errors are avoided, protective measures are applied during slotting so as to avoid excessively deep slotting, and produced dust and wood scraps can be cleaned to a certain degree.

Owner:NANTONG TONGZHOU YIDA PORT MACHINERY

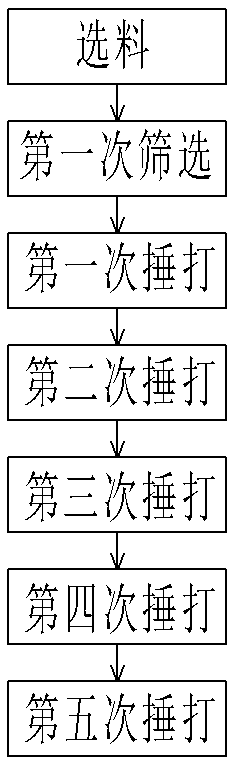

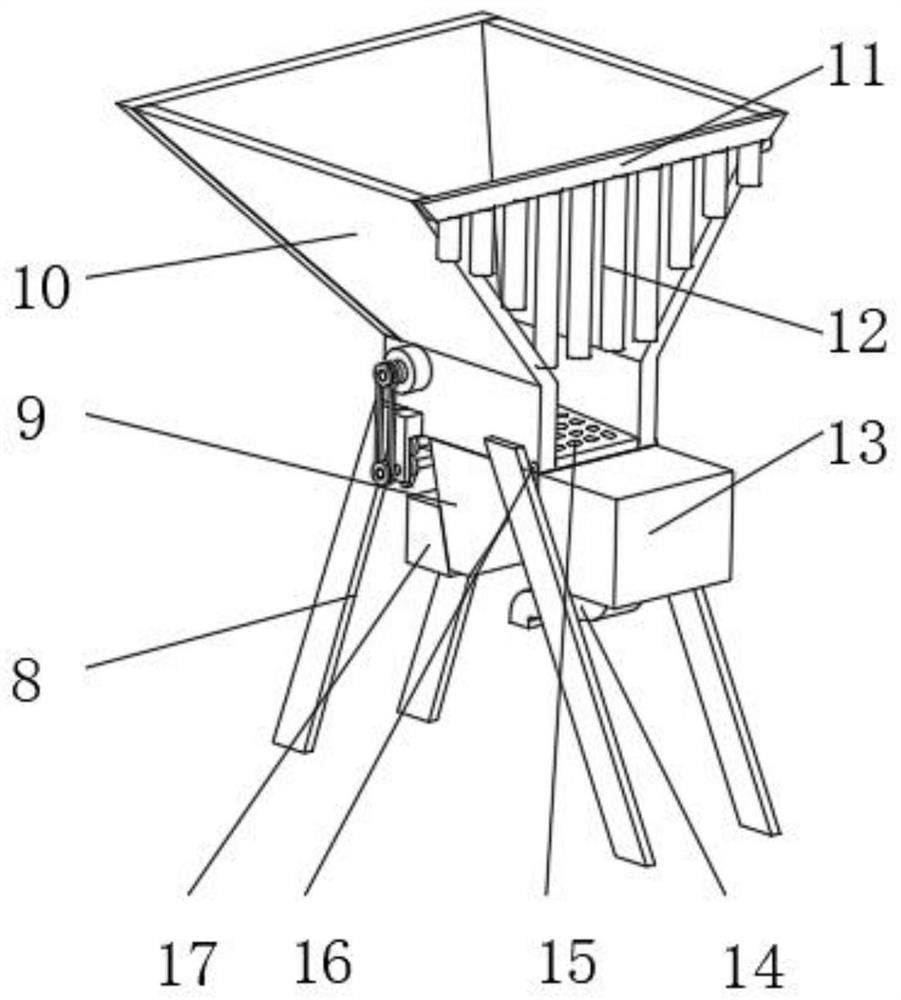

Process for utilizing moxa making machine to make moxa

InactiveCN107669480AFast thrashingBeating smoothlyDevices for heating/cooling reflex pointsPlant ingredientsWorking environmentPulp and paper industry

The invention provides a process for utilizing a moxa making machine to make moxa. The process comprises the following steps of 1, material selection, wherein aged folium artemisiae argyi at the age of more than 3 years is selected for use, and folium artemisiae argyi is harvested before or after the dragon boat festival and subjected to moisture-proof drying in the shade indoors; 2, first screening; 3, first beating; 4, second beating; 5, third beating; 6, fourth beating; 7, fifth beating. By means of the process for utilizing the moxa making machine to make the moxa, cutting is not needed, folium artemisiae argyi can be beaten quickly and more stably and smoothly, the manpower is saved, the working efficiency is improved, the dust hazards are reduced, the working environment is purified,the loss of effective components in the process of making the moxa is reduced, and the high-quality moxa is made.

Owner:郑州康容健康管理有限公司

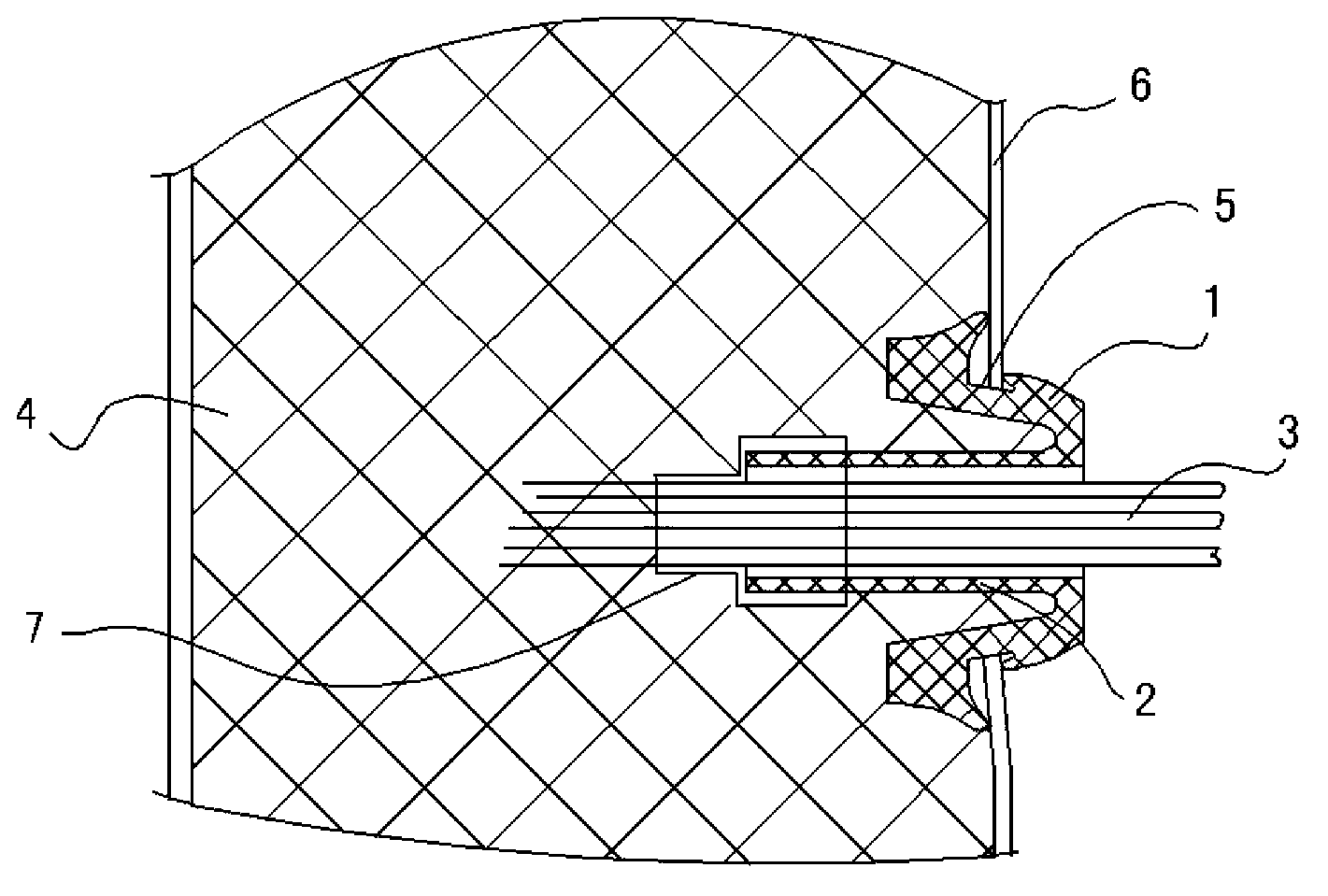

Refrigerator container threading structure

ActiveCN103017464AEliminate agingOptimize process flowDomestic cooling apparatusLighting and heating apparatusWorking environmentRefrigerated temperature

The invention discloses a refrigerator container threading structure. The refrigerator container threading structure is characterized in that a section of extended harness sleeve is integrally arranged in an external sleeve; a wiring harness penetrates through central holes of the harness sleeve; the harness sleeve is parallel and level, and connected with the external sleeve at the external end; and the inner end of the harness sleeve is pre-buried in a foaming layer of the refrigerator. By the refrigerator container threading structure, the threading structure is more reasonable; the technological process is simplified, the working efficiency is improved, the aging problem caused by using 502 glue is eliminated, and the working environment of operators is purified.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

Blowout prevention and dust prevention device

ActiveCN102102497AImprove progressRealize parallel operationConstructionsDust removalEngineeringMethane gas

The invention discloses a blowout prevention and dust prevention device. The device comprises a spraying system, a wind pressure system and an embedded pipe, wherein the outer end part of the embedded pipe is connected with a dust prevention housing; the upper part of the dust prevention housing is provided with a spraying head which is connected with the spraying system, and the lower part of the dust prevention housing is provided with a gas-residue separator which is connected through a conduit; the gas-residue separator comprises a material guide cylinder and a residue discharger; the material guide cylinder is provided with a negative pressure port and a pneumatic reversing valve; the residue discharger comprises a sealed cylinder body; an elbow pipe which is connected with a funnel port of the material guide cylinder is fixed on the inner side of a top cover of the sealed cylinder body; the port of the elbow pipe is provided with a control cylinder; the lower part of the sealed cylinder body is provided with a residue discharge port; and the residue discharge port is provided with a check valve. Through the device, single-roadway multi-drill parallel work can be realized; water, ash and residue in the sealed cylinder body are discharged under the action of pneumatic pressure; harmful gases such as gas and the like are extracted and discharged to a specific position through the negative pressure pipe; the progress of mine floor layer-crossing hole-drilling construction is greatly improved; and the device has the characteristic of controlling dust for hole drilling anddry hole drilling at explosive dangerous places with methane gas, toxic gas and the like.

Owner:ANHUI CHUANGQI MONITORING EQUIP

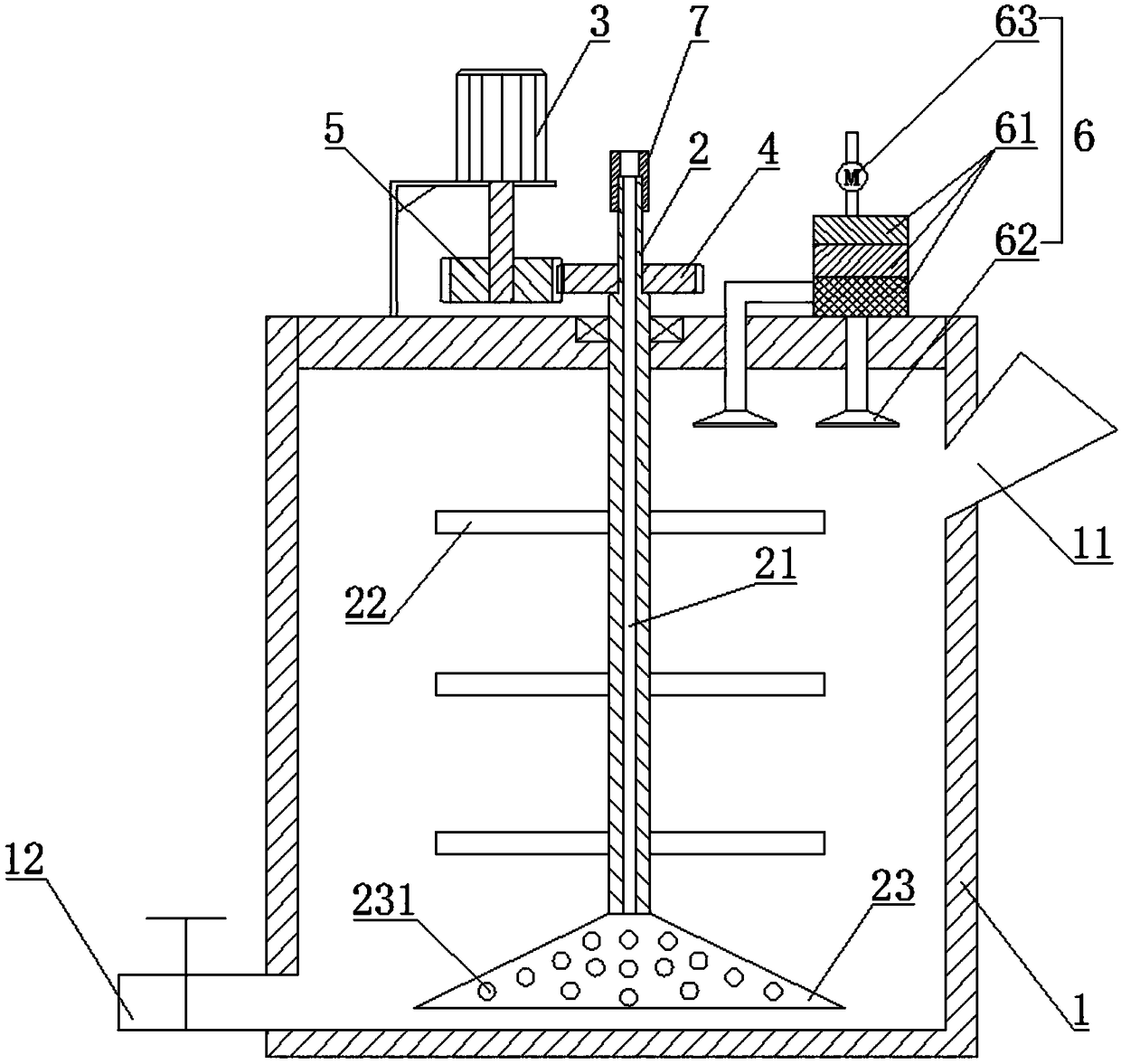

Paint stirring device with multiple stirring functions

InactiveCN108159952AWith multiple stirring functionsImprove mix qualityRotary stirring mixersTransportation and packagingGas passingEngineering

The invention discloses a paint stirring device with multiple stirring functions. The paint stirring device comprises a material barrel, a rotating shaft and a motor, wherein the rotating shaft is vertically arranged in the material barrel, the upper end of the rotating shaft and the top of the material barrel are in rotary connection, a driven gear is arranged on the rotating shaft in a sleevingmode and on the outer side of the top of the material barrel, the motor is fixed to the top of the material barrel, a driving gear is arranged on an output shaft of the motor, the driving gear and thedriven gear are mutually meshed with each other, a stirring blade is sleeved on the rotating shaft and in the material barrel, a through air channel is arranged on the rotating shaft along the central axis, a conical body is fixedly arranged at the bottom end of the rotating shaft, a sealed cavity is arranged in the conical body, the air channel is communicated with the cavity, air holes are arranged on the surface of the conical body, and the air holes are communicated with the cavity. According to the paint stirring device disclosed by the invention, a traditional stirring blade is used forstirring; meanwhile, air is fed into the material barrel, and the air can turn paint up and down through the air holes at the bottom of the material barrel; thus, paint mixing quality is improved; furthermore, inflated gas can be absorbed by an air purifying device.

Owner:SUZHOU WUZHONG DISTRICT SHUANGLONG PAINT CO LTD

Low-density propping agent taking flint clay as raw material and preparation method thereof

ActiveCN103756665ALow densityEasy to GrindFluid removalDrilling compositionWorking environmentMullite

The invention discloses a low-density propping agent taking flint clay as a raw material and a preparation method thereof. The propping agent is prepared by simply compounding raw flint clay, underburnt flint clay and easily ground sandstone, adding a small amount of aids, performing wet-process ball-milling, ageing, drying, granulating, performing stoving and sintering, and polishing. A mode that materials and dry hot air are fed from the bottom is adopted during drying, and a drying process of an internal grinding device is added, so that spray-drying and pulverizing machines are removed, the investment is saved, and the working environment is purified; the raw flint clay and the processed flint clay are compounded and can bring the respective advantages into full play; the raw flint clay is easily subjected to ball milling, and the burning loss components of the raw flint clay form pores to reduce the density of the propping agent; mullite formed in underburnt flint clay tailings is utilized to disperse a glass phase and achieve an enhancement effect; SiO2 is introduced by the sandstone to react with aluminum oxide in the raw flint clay to produce the glass phase, which is favorable for improving the bonding capability of a mullite phase and sealing the pores formed by the burning loss of the flint clay.

Owner:JINGANG NEW MATERIALS

Efficient lime powder sprayer

ActiveCN106166508AAvoid reverse flowCreate pollutionGrain treatmentsElectrostatic chargesSprayerDrive motor

The invention discloses an efficient lime powder sprayer, belongs to powder sprayers in the technical field of powder spraying and aims to provide an efficient lime powder sprayer. The efficient lime powder sprayer comprises a material barrel, a feeding adjusting hopper is arranged in an inner cavity of the material barrel, a feeding port of the feeding adjusting hopper penetrates out of the top of the material barrel, the bottom of the material barrel is connected with a driving motor, and a vibration stirring device is arranged in the material barrel and connected with the driving motor. One end of the bottom of the material barrel is connected with a discharging pipe, one end of the discharging pipe is communicated with a blowdown pipe, the middle of the blowdown pipe is communicated with the discharging pipe, and the other end of the blowdown pipe is connected with a fan. A secondary smashing device for protecting high-speed air flow from reverse flowing is further arranged between the material barrel and the blowdown pipe, the two ends of the secondary smashing device are communicated with the material barrel and the blowdown pipe through the discharging pipe, and the discharging pipe between the secondary smashing device and the material barrel is connected with an air inlet adjusting valve.

Owner:MIANYANG TIANHONG SILK CO LTD

Dyeing machine with dedusting function

InactiveCN107326591AUniform colorImprove dyeing qualityTextile treatment containersUsing liquid separation agentPropellerWater tanks

The invention discloses a dyeing machine with a dust removal function, which comprises a support platform, a dyeing box is welded on one side of the top of the support platform, a servo motor is fixedly installed on the rear side of the dyeing box, and one end of the servo motor shaft is connected through a shaft coupling. There is a transmission shaft, one end of the transmission shaft extends to the inside of the dyeing box and is fixedly connected with a first roller, one side of the first roller is provided with a second roller, and the other side of the top of the support table is welded with an outer box, the outer box is The air inlet on the inner wall of the box is fixedly connected with a blower, and the bottom of the inner cavity of the outer box is provided with a dust removal water tank, and the bottom end of the blower extends to the inside of the dust removal water tank. By setting the blower, the flying dust in the factory can be sucked into the dust removal water tank, and the inhaled dust can be adsorbed by the water in the dust removal water tank, so that it can achieve the effect of dust removal, and then the working environment in the factory can be purified, so that the staff Able to work in a good working environment.

Owner:姚飞

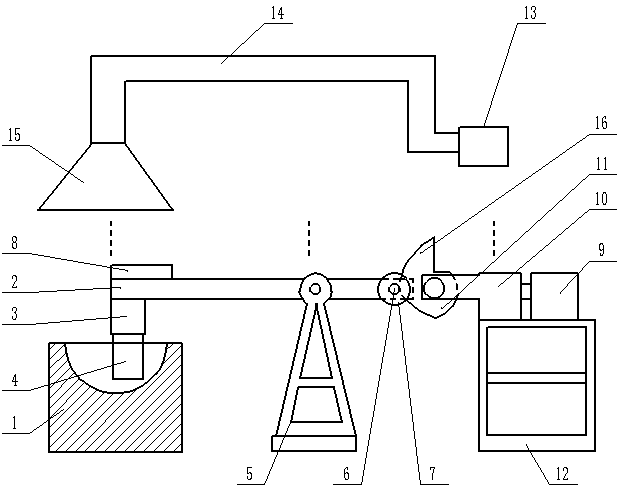

Automatic lubricating powder recovery device

ActiveCN102172651AAvoid flyingKeep healthyWork treatment devicesMetal rolling arrangementsProduction lineMetallurgy

The invention discloses an automatic lubricating powder recovery device which comprises a lubricating powder recovery cylinder, a valve body and a valve clack, wherein the two ends of the lubricating powder recovery cylinder are provided with a through hole allowing a steel bar to penetrate therethrough; the bottom of the lubricating powder recovery cylinder is communicated with an opening at theupper end of the valve body; the upper part of the inner side of the valve body is provided with a powder discharge hole communicated with the lubricating powder recovery cylinder as well as a valve clack for opening / closing the powder discharge hole; and the lower part of the inner side of the valve body is provided with an air inlet and a powder discharge port, wherein the air inlet is connected with an air source, and the powder discharge port is communicated with a lubricating powder device. The automatic lubricating powder recovery devicedisclosed by the invention overcomes the shortcomings of the prior art, avoids flying of the lubricating powder in the production line of rolled steel bar, purifies the operation environment, guarantees health of operators, can recover the lubricating powder, saves resources and protects the production equipment perfectly. The automatic lubricating powder recovery device disclosed by the invention has the advantages of simple structure, low processing cost and the like, and is simple and easy to operate and convenient to maintain.

Owner:TJK MACHINERY TIANJIN

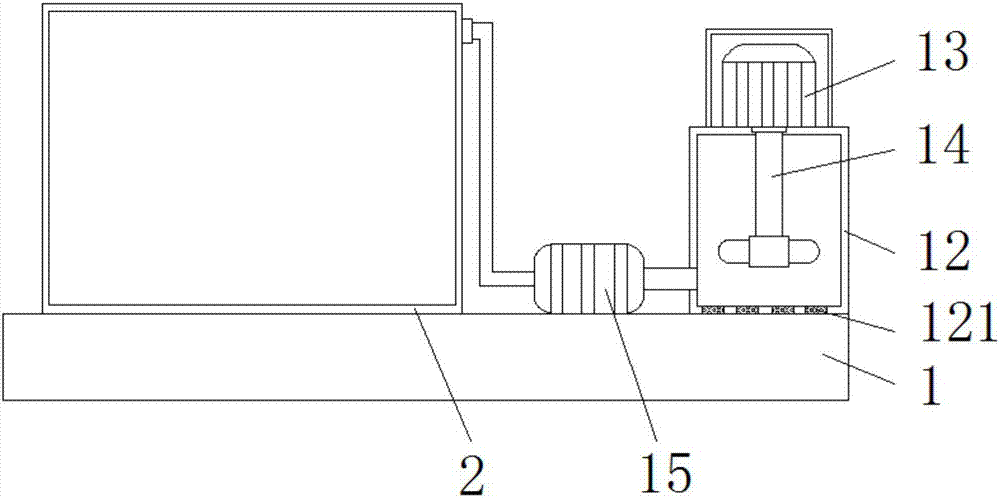

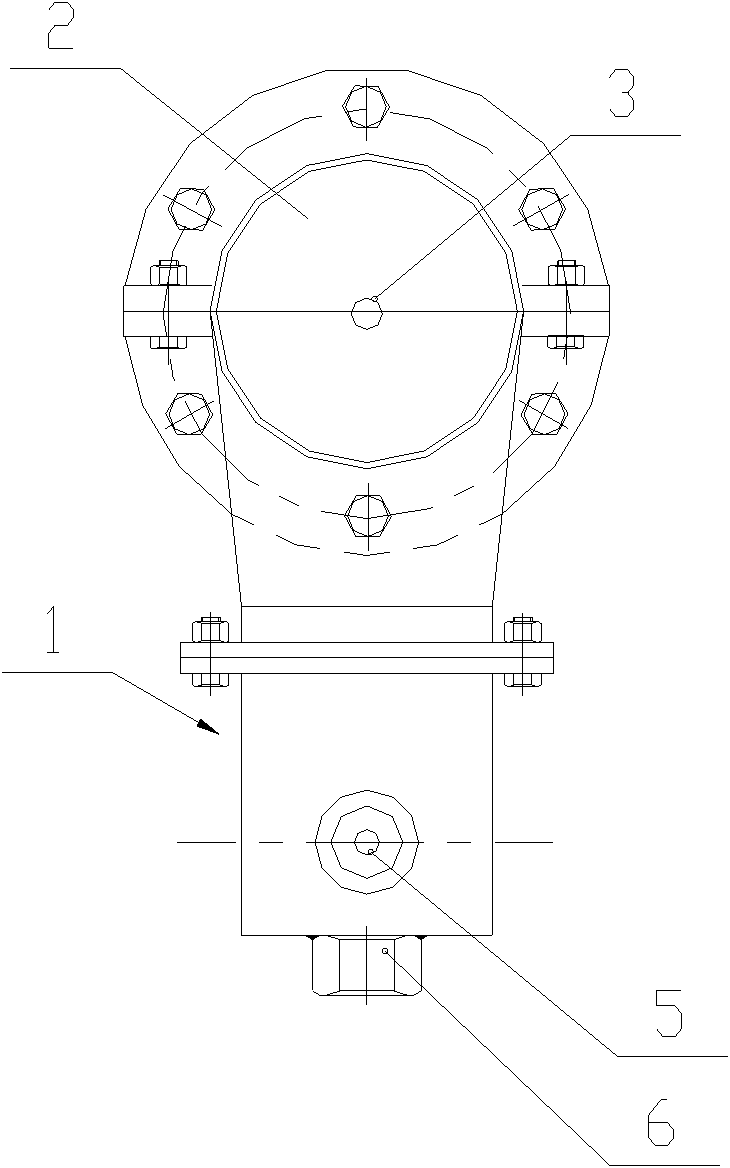

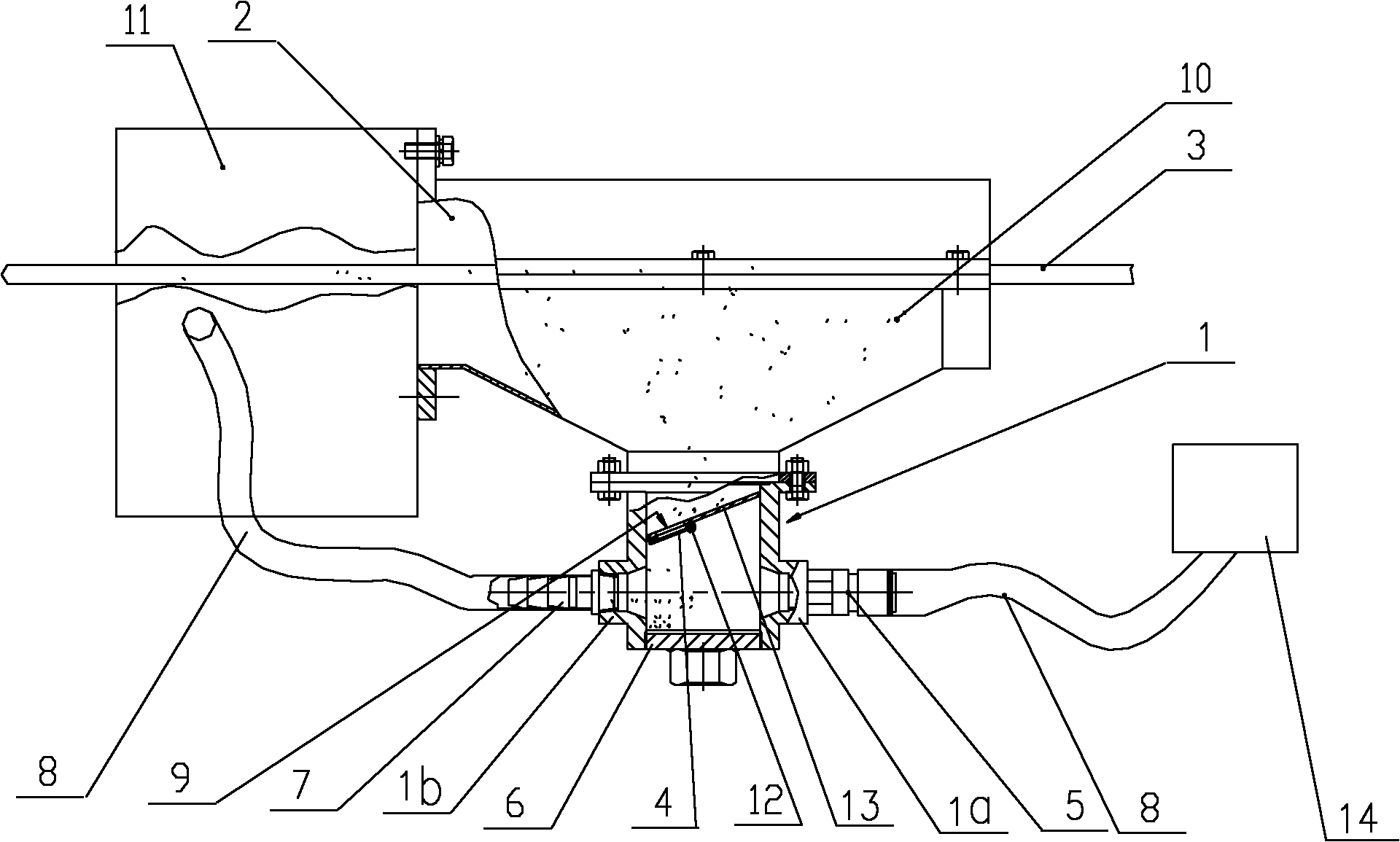

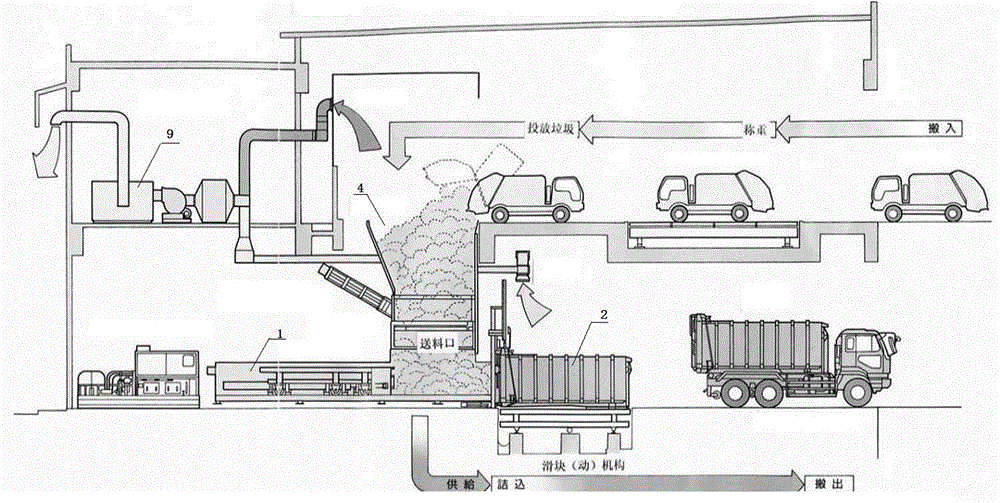

New garbage treatment method

InactiveCN106241148ANo pollutionImprove work efficiencyRefuse transferringLoading/unloadingButt jointReciprocating motion

The invention discloses a new garbage treatment method. The new garbage treatment method comprises the steps that garbage collected by a garbage collecting vehicle is transferred to a garbage transfer station and poured into a material receiving tank, a container body for transferring the garbage is moved to a loading device, a push plate on the loading device and a sealing plate on a container are in butt joint into a whole, and a composite push head is formed; the garbage in the material receiving tank is pushed into a compression cavity of the loading device, the composite push head is driven to reciprocate, and the garbage is compressed for volume reduction and pressed into a garbage container; after the garbage container is fully loaded, the sealing plate and the push plate are separated, and the sealing plate is fixed to an unloading door of the garbage container; and then the garbage with which the garbage container is loaded is transferred to a garbage treatment plant to be treated. By means of the method, rapid and efficient transferring of the garbage in the transfer station can be achieved, and secondary pollution of the garbage to the environment is prevented.

Owner:CHONGQING ENDURANCE & SHINMAYWA IND

Method for separating oil and water of and circularly using degreasant tank-liquor using ultrafiltration technology

InactiveCN1500541AImprove separation efficiencyExtend update cycleUltrafiltrationFiltration circuitsUltrafiltrationWorking environment

In the ultrafiltration of degreasing tank liquid for oil-water separation and reusing, ultrafiltration membrane in certain specification is selected to intercept emulsified oil part of the tank liquid based on the size of the oil drops. Contaminated degreasing tank liquid is first processed in the deposition tank and circulating tank, then pre-filtered in the pre-filter and finally ultrafiltered in the ultrafilter before returning to degreasing tank for re-use. The intercepted liquid in the ultrafilter may be returned via pipeline to the pre-filter for re-filtering. The present invention has also one ultrafiltration membrane cleaning tank, cleaning liquid is injected via pipeline and the effluent is made to return into the pre-filter. The present invention has the features of saving in energy, saving in water, clean work environment, high oil-water separating rate, etc. The tank liquid has an updating period as long as three months.

Owner:FAW GROUP

Environmentally-friendly organic fertilizer

InactiveCN105565996APromote growthBright colorBio-organic fraction processingExcrement fertilisersDiseasePotassium

The invention discloses an environmentally-friendly organic fertilizer. The environmentally-friendly organic fertilizer is prepared from, by mass, 65-70 parts of mixed sheep rabbit manure, 120-130 parts of rice washing water, 1-3 parts of traditional Chinese medicine liquid, 6-10 parts of tobacco powder, 5-8 parts of tea seed cakes, 3-6 parts of vinegar residues and 1-3 parts of a strain. The environmentally-friendly organic fertilizer adopts a modern scientific and technological biotechnology, the selected raw materials are scientifically configured, are green, are environmentally-friendly and are low in cost, and the produced fertilizer contains multiple trace elements including nitrogen, phosphorus, potassium and the like required by fruit growth, is added with the traditional Chinese medicine liquid, is prepared by adopting an unique method, can promote the balance of fruit plants, comprehensively absorb the trace elements and promote the growth and root system development of the fruit plants, can perform soil sterilization and disinfection and prevent the occurrence of physiological diseases, uses the rice washing water to replace rain water or pure water, is high in nutrient, good in absorbability and is more advantageous to the growth of fruits. When the organic fertilizer is used, 50-60 kg of the organic fertilizer is applied per mu, mainly adopts centralized application modes, such as furrow application and hole application, is covered with soil after application and enables growing fruits to be bright in color and luster, good in taste and good in disease resistance capability, be completely full and be resistant to storage and transportation.

Owner:周紫阳

Crushing, lifting, hoisting and transporting equipment for ore production and with dust removal function

InactiveCN111604159APurify the working environmentCreate pollutionSievingUsing liquid separation agentMining engineeringStructural engineering

Owner:黄松檀

Coal ash bulk device

InactiveCN107253620AAvoid dust phenomenonPurify the working environmentLoading/unloadingBaghouseWorking environment

The invention relates to a coal ash bulk device. The coal ash bulk device comprises a base, a bulk machine body, a telescopic pipe and a cloth bag dust remover. The bulk machine body is fixed on the base, the telescopic pipe is arranged under the base and connected with the bulk machine body, and the bulk machine body is connected with the cloth bag dust remover through a first pipeline; a manual butterfly valve is arranged on the first pipeline, a lower box body of the cloth bag dust remover is connected with the bulk machine body through a second pipeline, and a pneumatic gate valve is arranged on the second pipeline; a vibrator is arranged on the lower box body, the telescopic pipe is a double sleeving pipe, and a material detaching head is arranged at the bottom of the telescopic pipe. According to the coal ash bulk device, a problem of dust raising generated during ash unloading of an ash bin is solved, working environment of a loading area is purified, and running and maintaining cost are reduced.

Owner:JIANGSU ZHONGNENG POWER EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com