Method for separating oil and water of and circularly using degreasant tank-liquor using ultrafiltration technology

A technology of oil-water separation and degreasing tank, which is applied in the direction of separation method, filtration separation, immiscible liquid separation, etc. It can solve the problems of short tank liquid renewal cycle, affecting the working environment, and poor oil-water separation effect, so as to improve the efficiency of oil-water separation , The effect of purifying the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

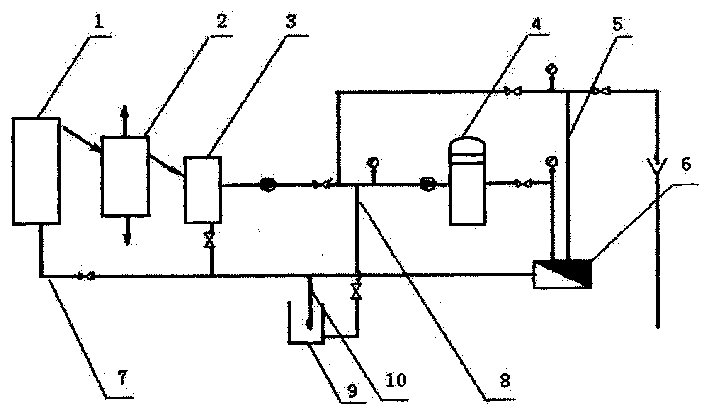

[0007] Below is 30m of steel plate to be processed 3 Taking the degreasing tank as an example, the present invention will be described in detail in conjunction with the accompanying drawings.

[0008] Such as figure 1 As shown, the entire working process is composed of a degreasing tank 1, a settling tank 2, a circulation tank 3, a pre-filter 4, a pipeline 5, an ultrafilter 6, a pipeline 7, a pipeline 8, a cleaning tank 9, and a pipeline 10. Put the steel plate to be processed into the degreasing tank 1 for degreasing, and the upper part of the degreasing tank 1 contains more oily tank liquid into the settling tank 2, and after a certain period of natural standing, the floating oil in the upper part and the sediment in the lower part are removed. The bath liquid flows into the circulation tank 3, and then enters the pre-filter 4 through the circulation pipeline for pre-filtration, the pre-filtered bath liquid enters the ultra-filter 6 through the pipeline, and the ultra-filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com