Efficient cyclone separation device for dust remover

The technology of a cyclone separation device and a vacuum cleaner, which is applied to the suction filter and other directions, can solve the problems that the small particle dust is not easily separated, the separation efficiency is reduced, and the system resistance is high, and the effect of improving the suction force, reducing the capacity loss and improving the suction power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the drawings and examples. The same symbols are used for the same components in the present invention as in the prior art.

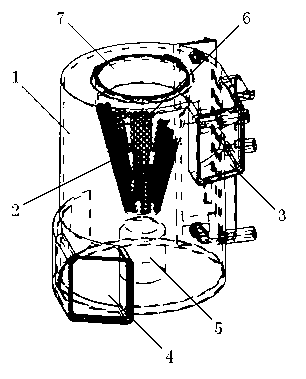

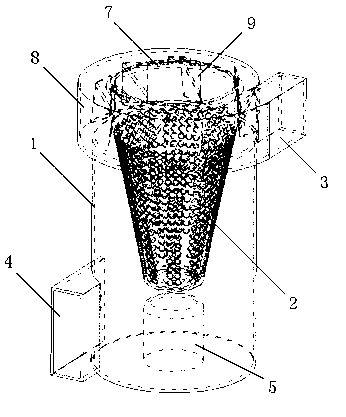

[0035] image 3 It is a perspective view of the vacuum cleaner cyclone separation device of the present invention. Such as image 3 As shown, the high-efficiency cyclone separation device for a vacuum cleaner of the present invention includes a barrel body 1 and a filter 2 disposed inside the barrel body with openings at both ends. The filter 2 has a large opening at the upper end and a small opening at the lower end, and the whole body is covered with filter holes 6 . An air inlet 3 communicating with the barrel is formed on one side of the upper end of the barrel body 1 along the tangential direction of the outer wall, and a dust removal port 4 of the barrel body 1 communicating with the barrel is formed in the tangential direction of the lower outer wall on the side op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com