Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Increase suction power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

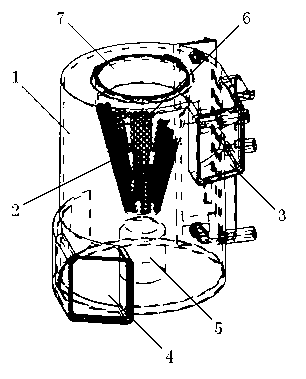

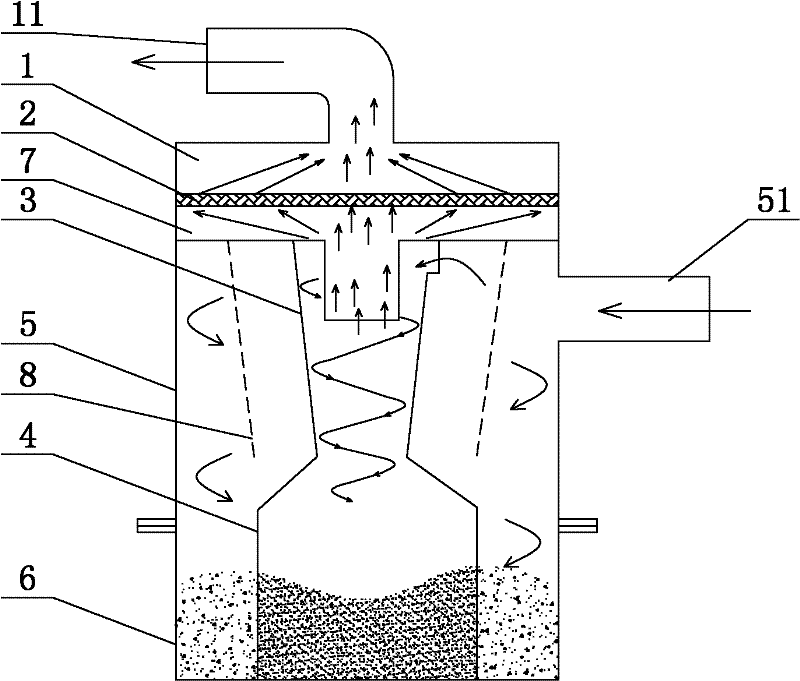

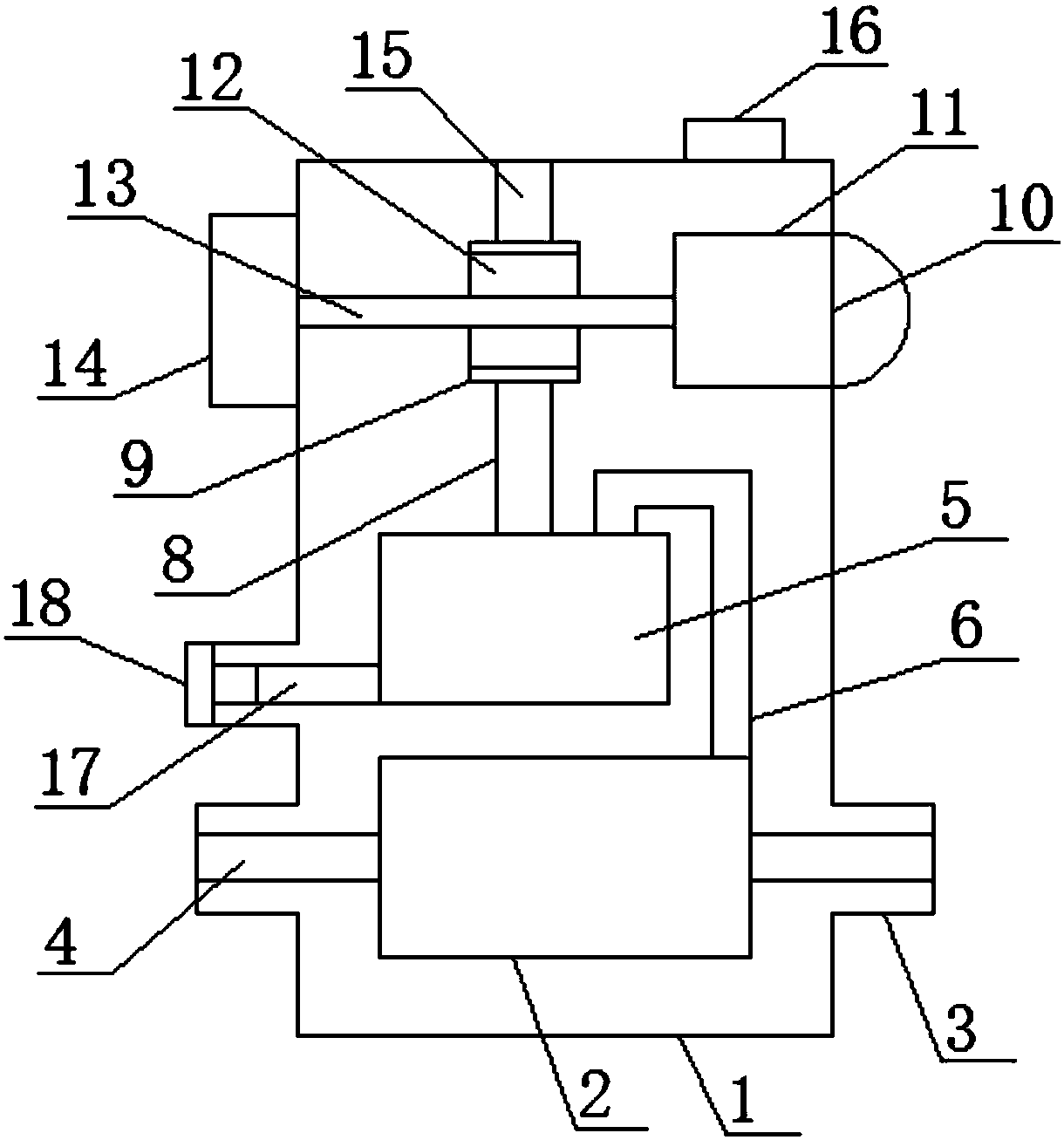

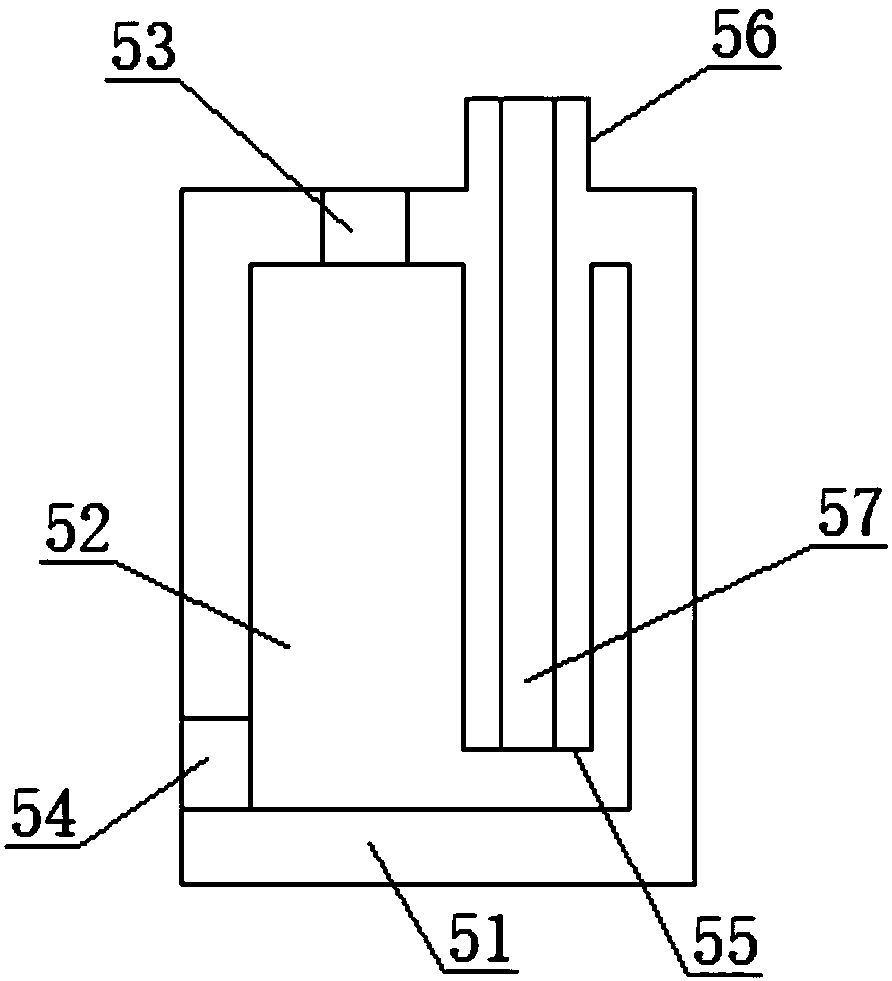

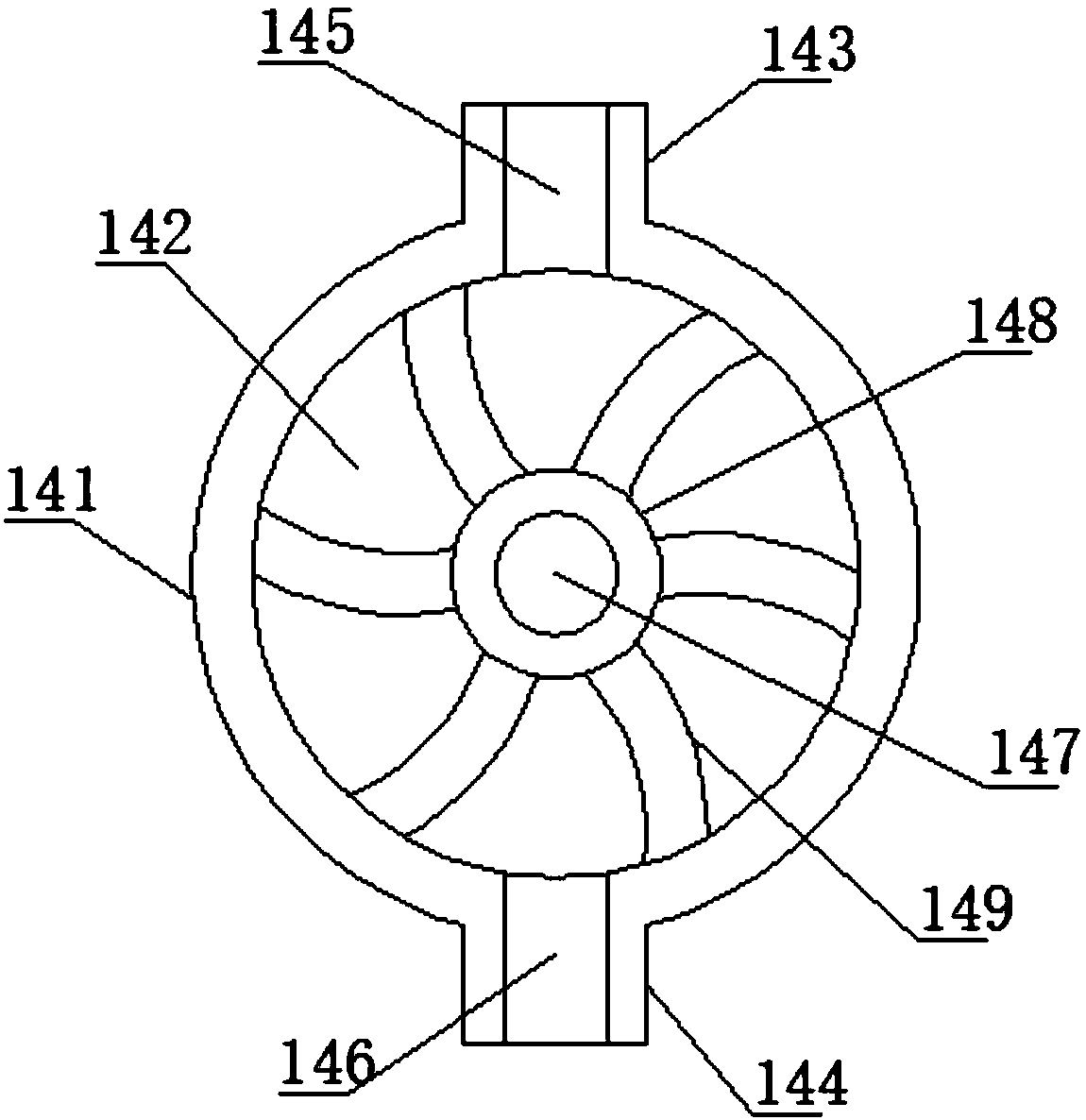

Efficient cyclone separation device for dust remover

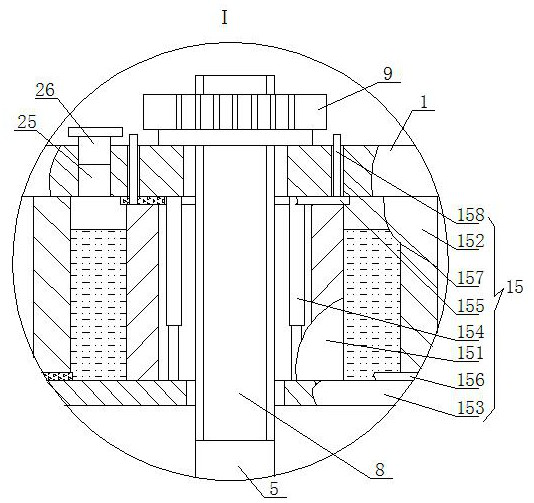

InactiveCN103181741AReduce energy lossGreat suctionSuction filtersCycloneElectrical and Electronics engineering

The invention discloses an efficient cyclone separation device for a dust remover, which comprises a barrel body and a filter arranged inside the barrel body, wherein an air inlet communicated with the inside of the barrel is formed on one side of the upper end of the barrel body in tangential direction of the outer wall; the cross section of the outer wall of an air intake way at the upper end of the barrel body, communicated with the air inlet, is helical; and a plurality of air intake guide vanes are evenly arranged inside the air intake way in the circular direction. According to the efficient cyclone separation device for the dust remover, the cross sectional area is gradually reduced from the air inlet to the inside to facilitate the increasement of the tangential speed of the airflow inside the air intake way along with the reduction of the cross sectional area, so as to increase the separation efficiency of an outer eddy side; the air intake guide vanes are arranged inside the air intake way and evenly distributed in the circular direction to facilitate the conversion of the axial speed of the airflow to the tangential speed, reduce the loss of energy of axial downwards speed of an inner eddy and improve the suction power of the dust remover; and therefore, the efficient cyclone separation device for dust remover has the advantages of high efficiency and less power loss and can effectively improve the suction power of a dust remover motor.

Owner:NANJING LG PANDA APPLIANCES

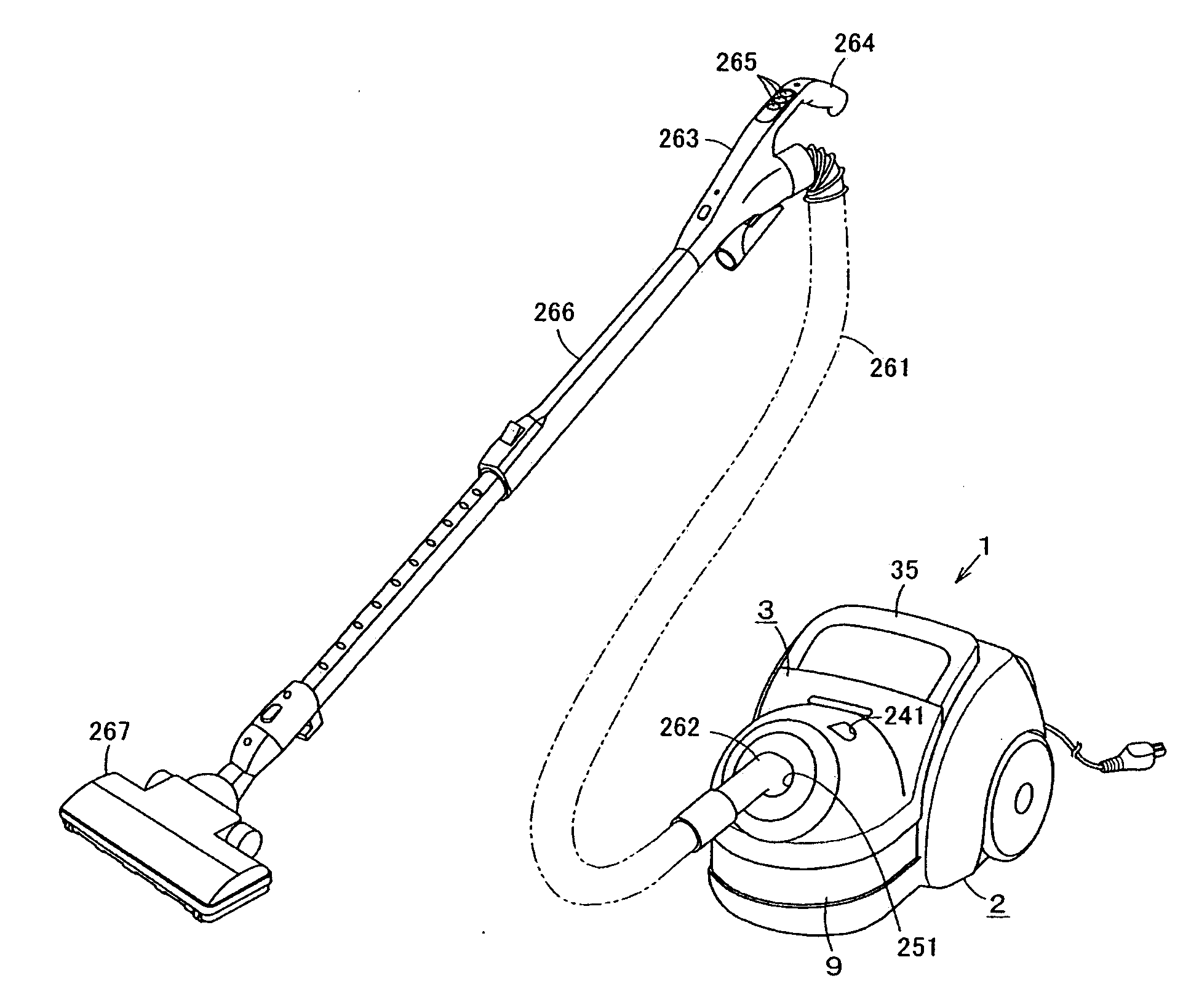

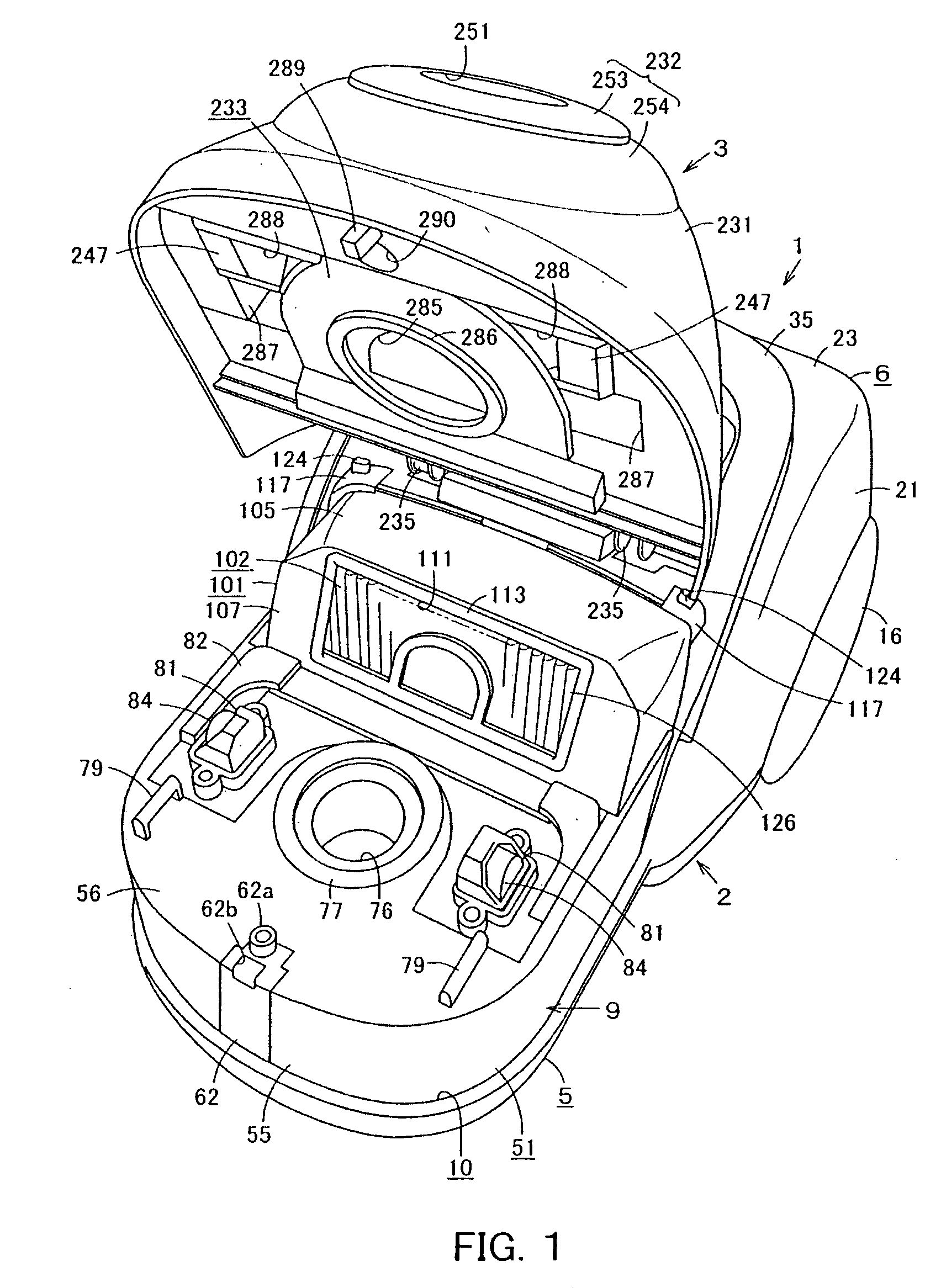

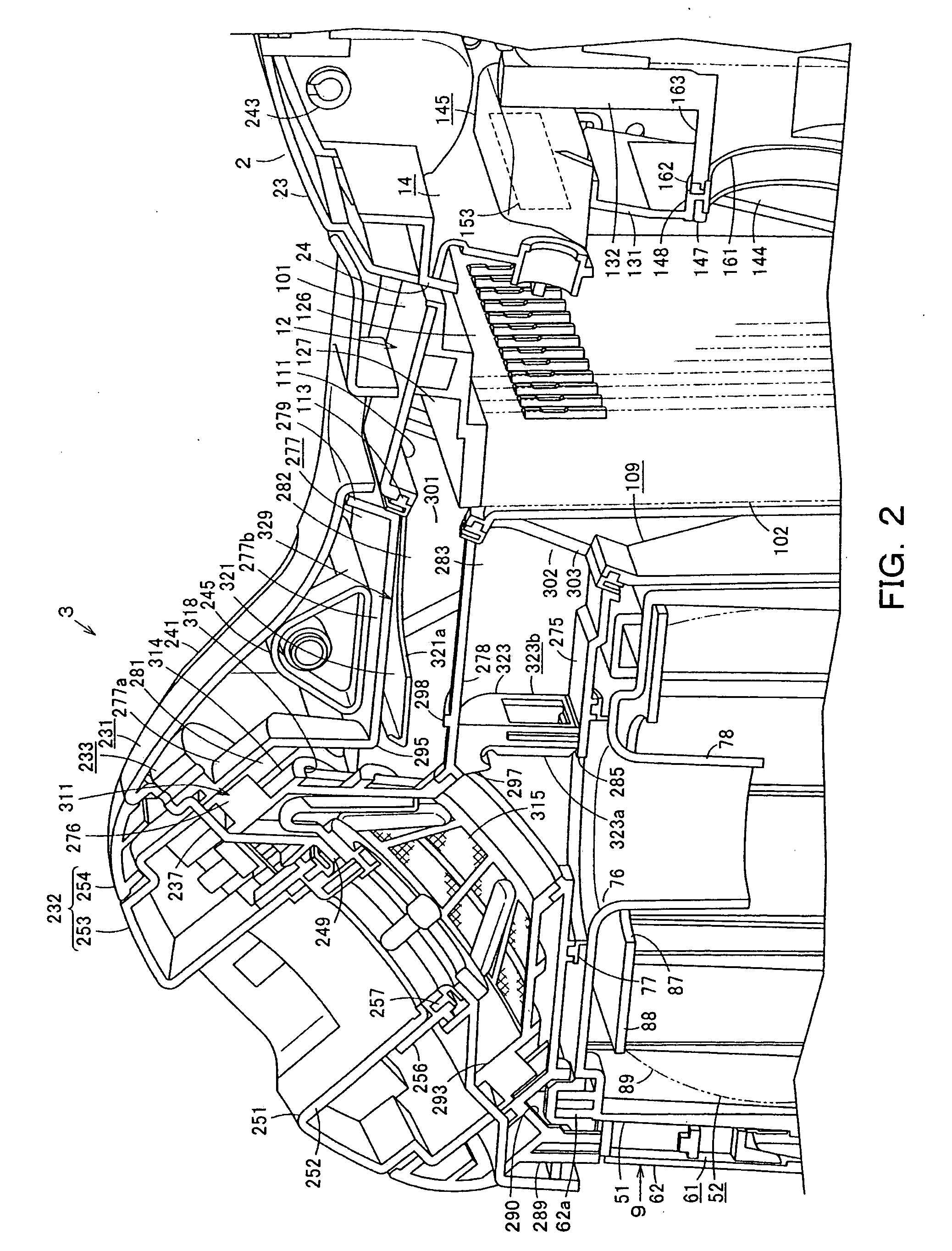

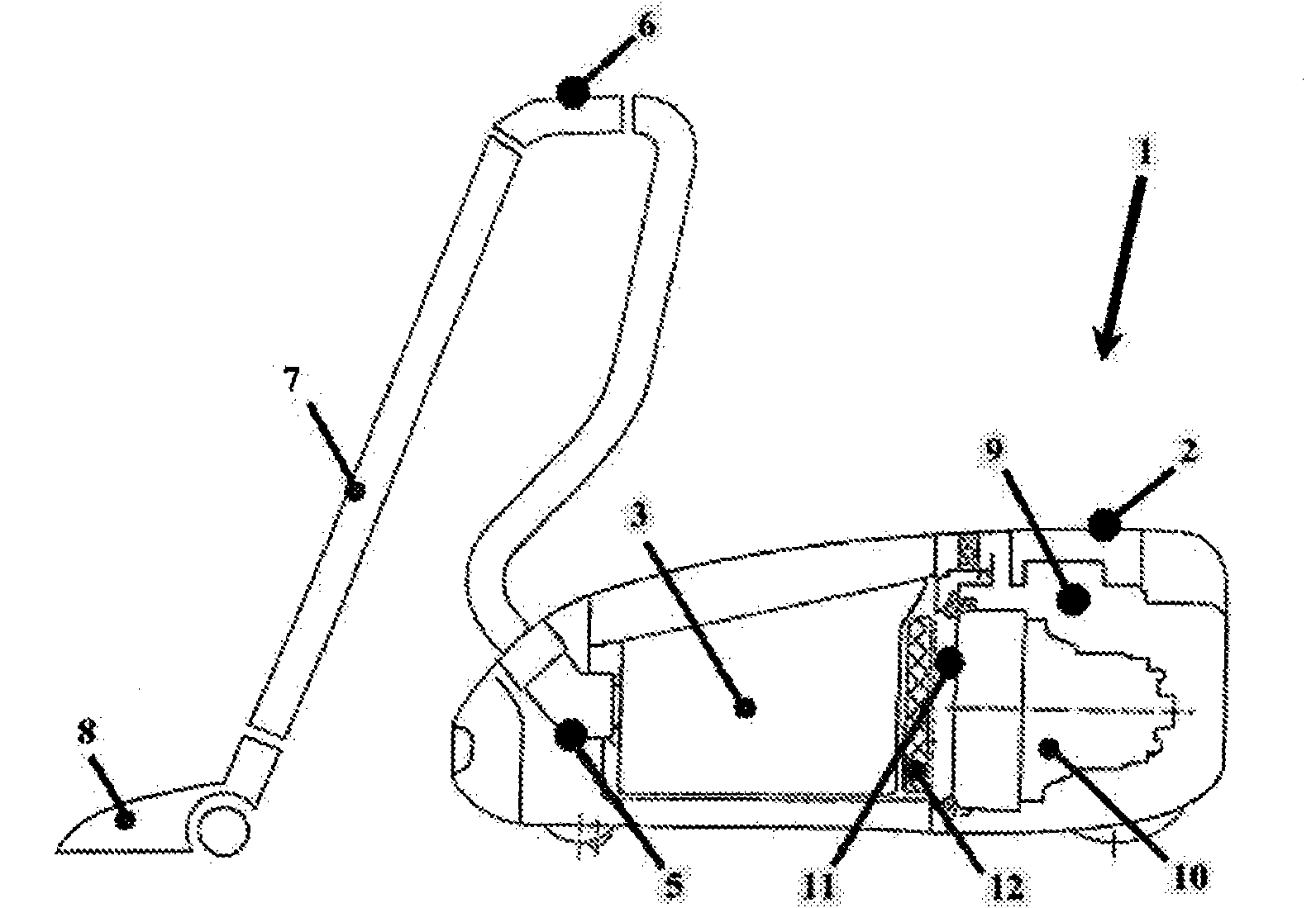

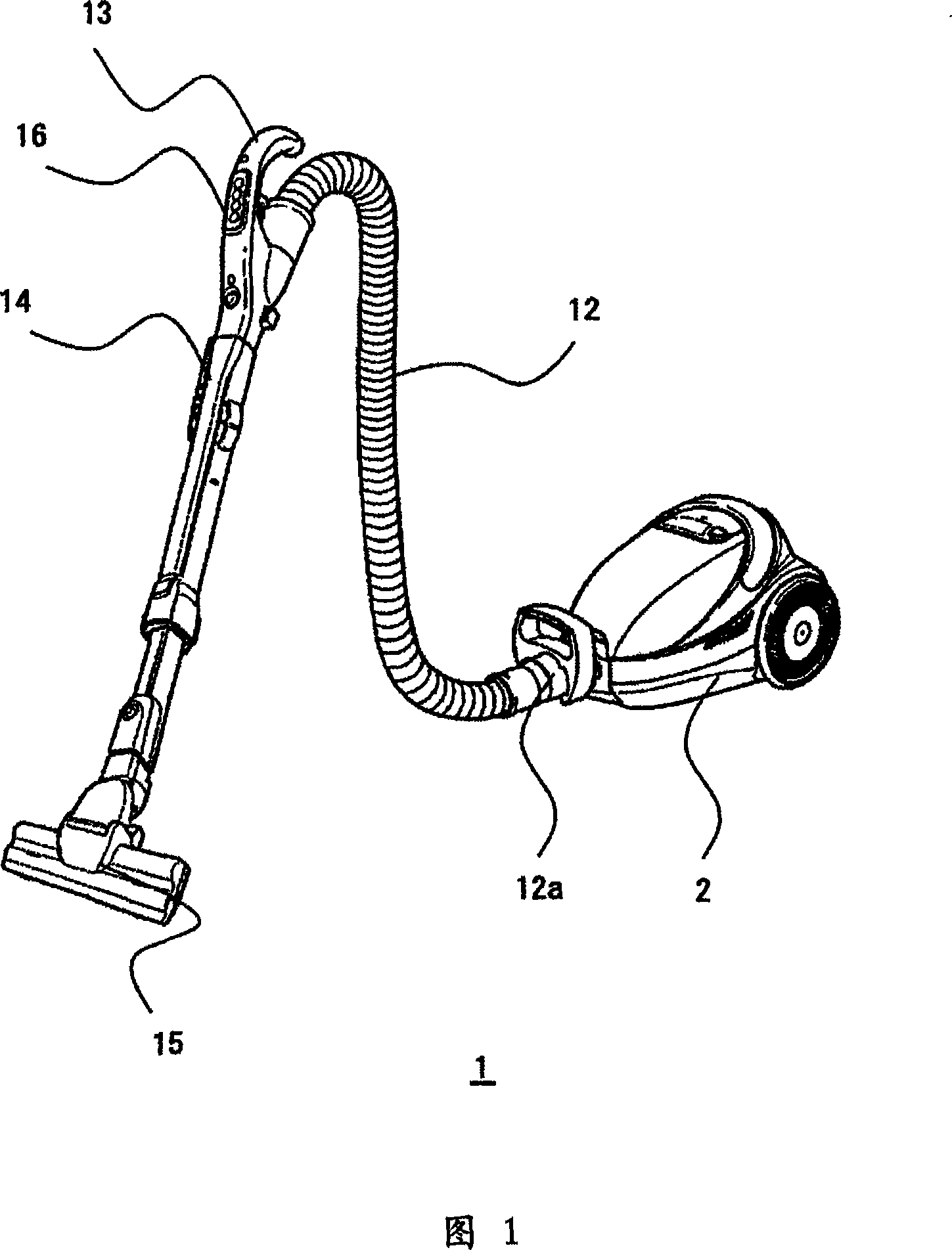

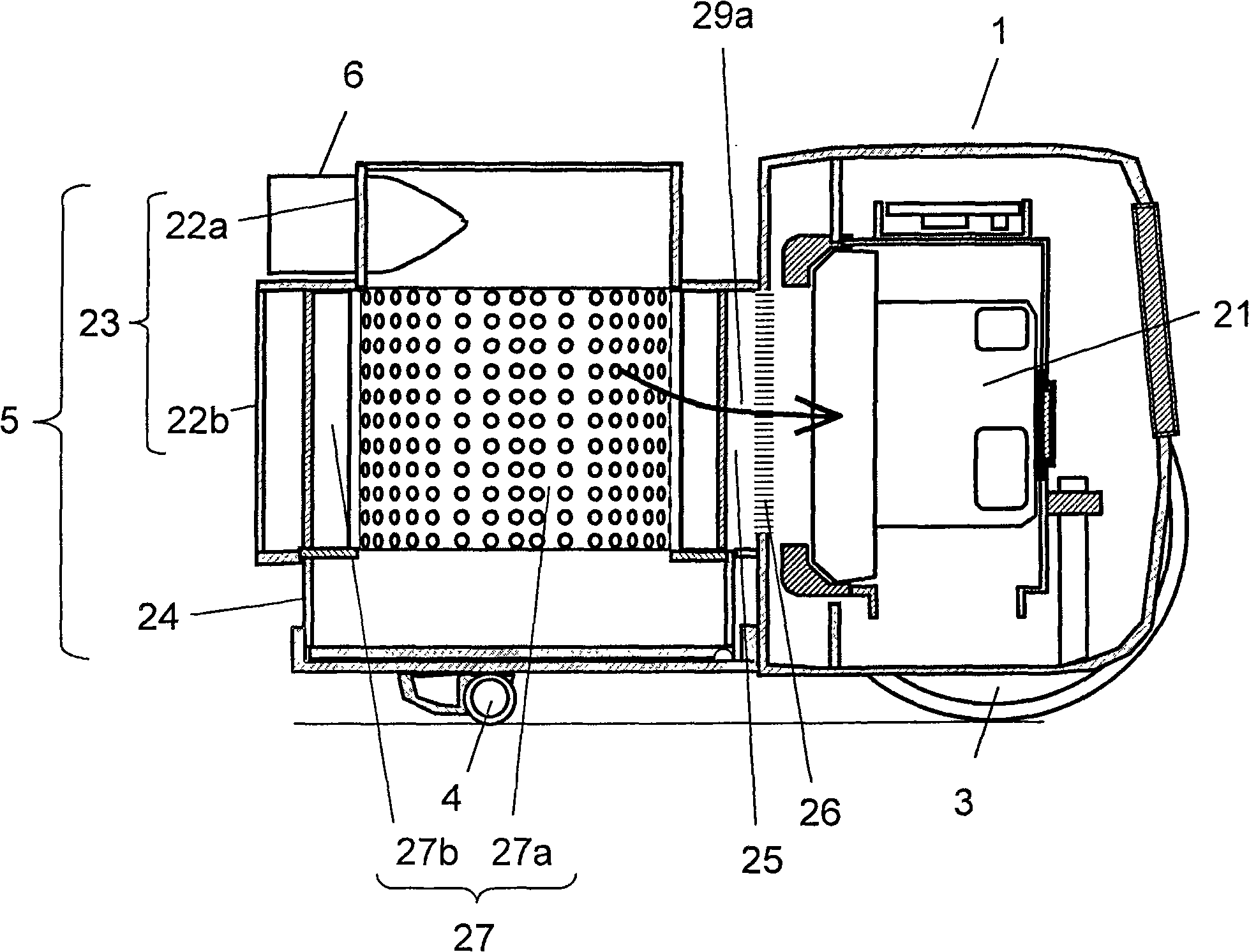

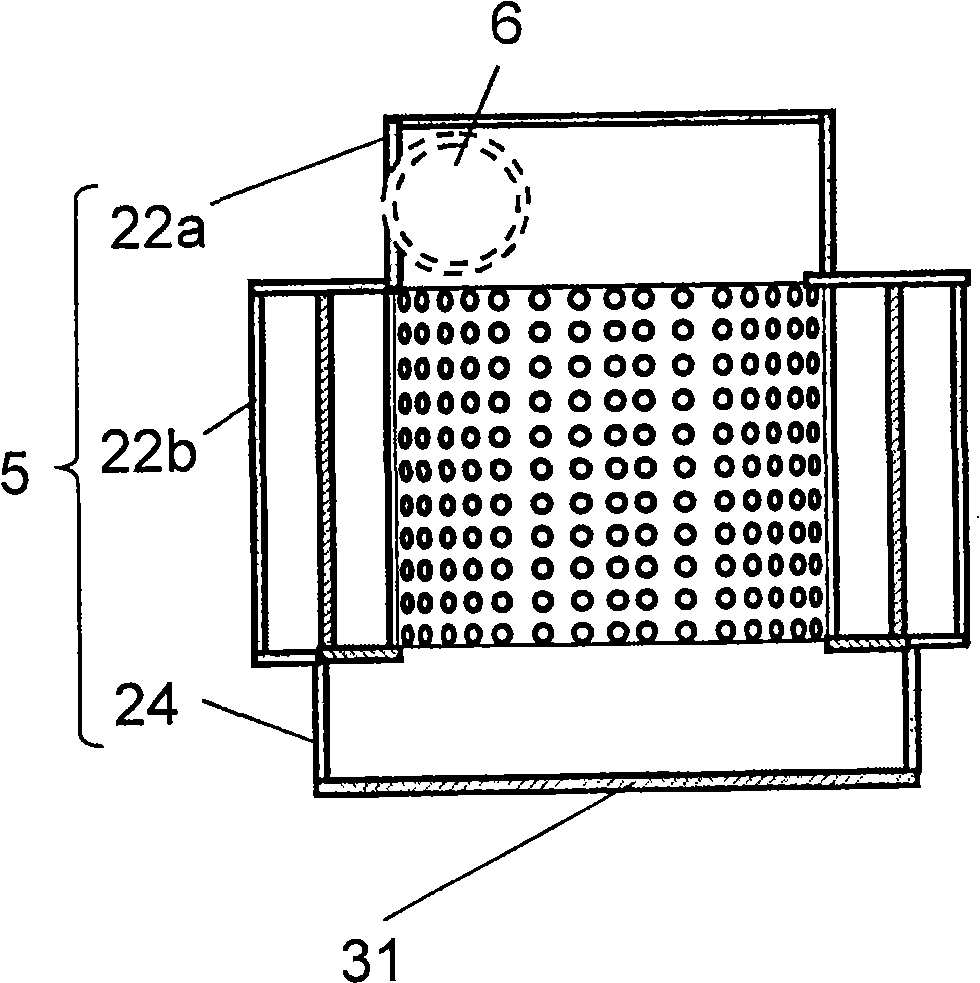

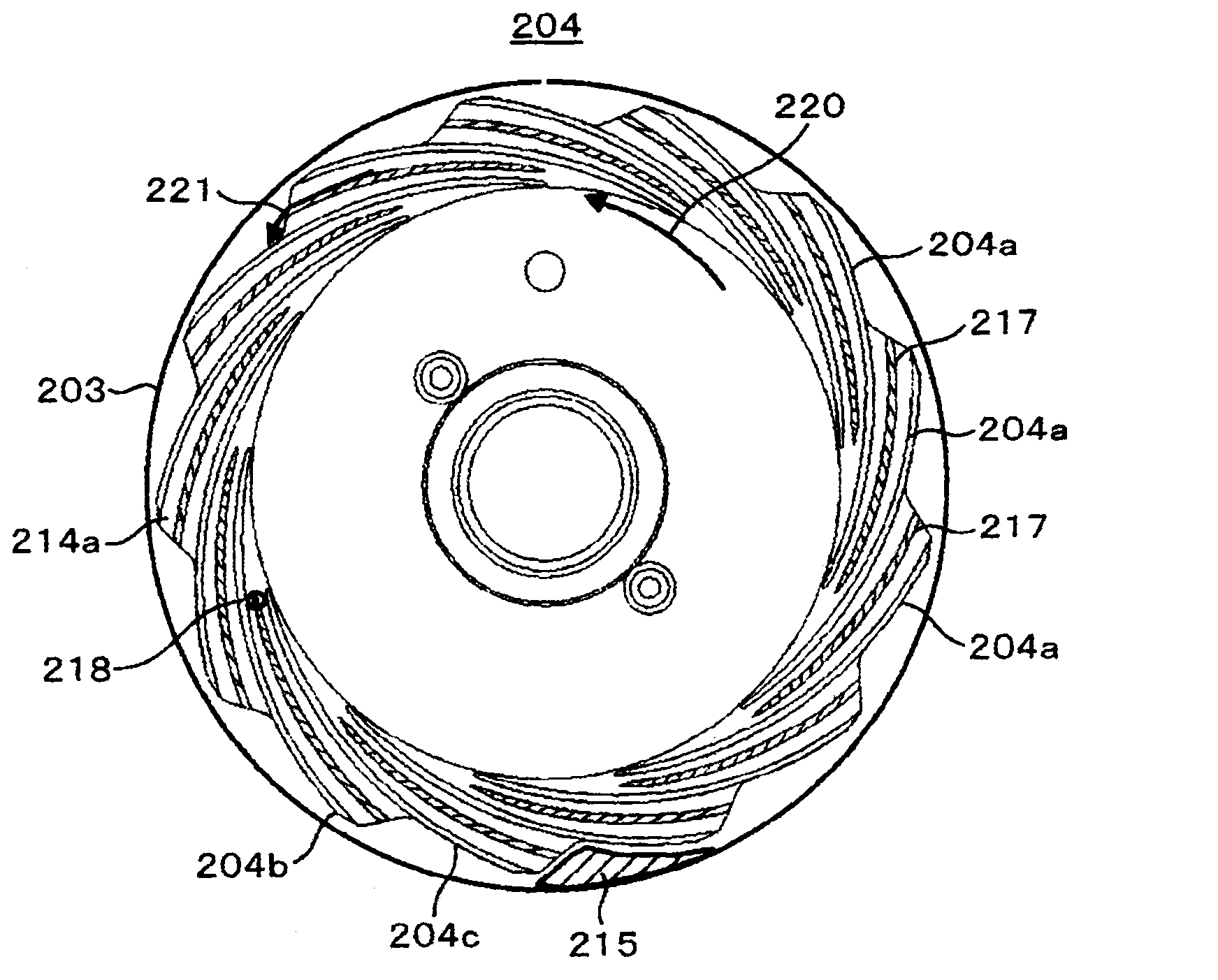

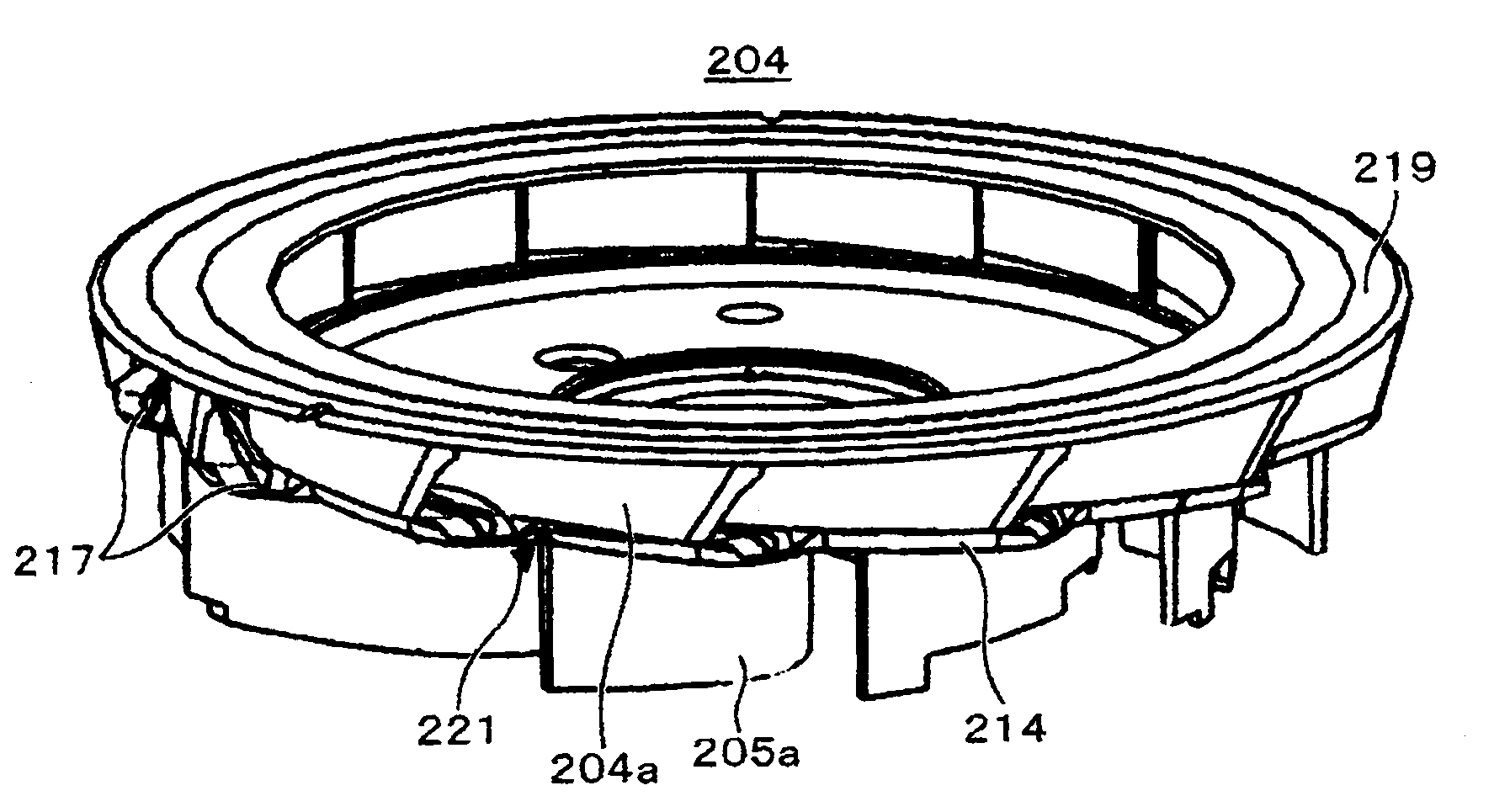

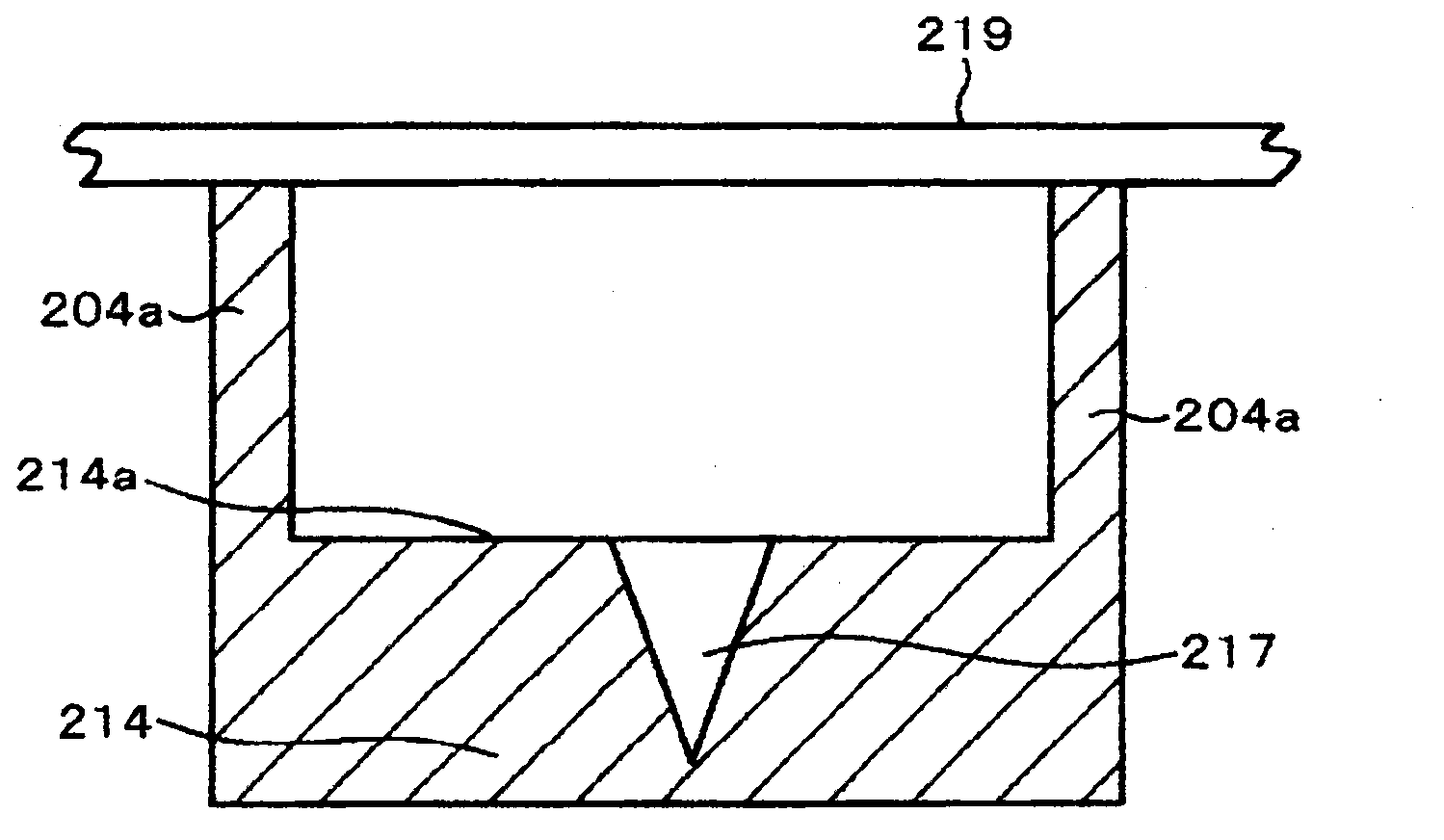

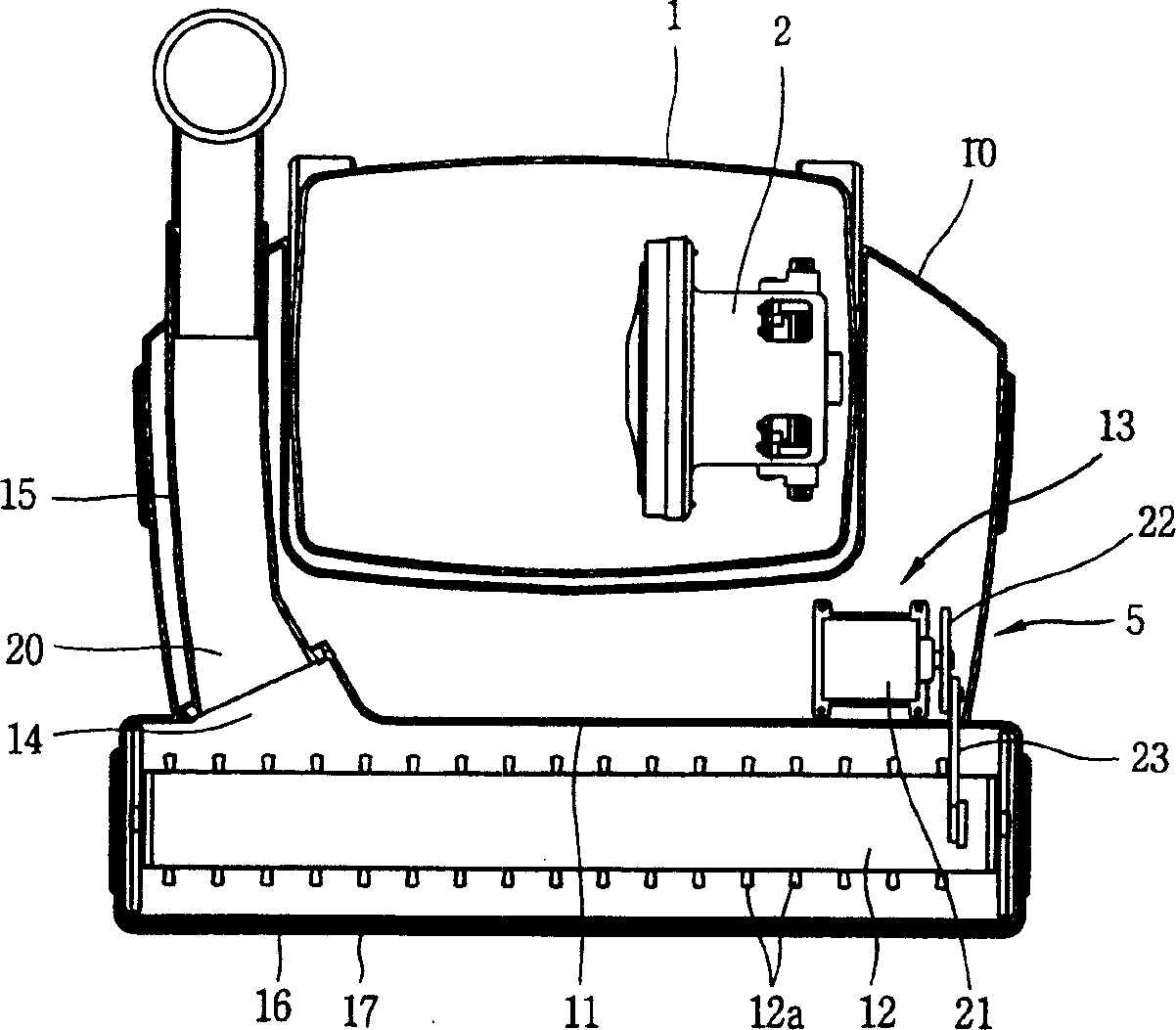

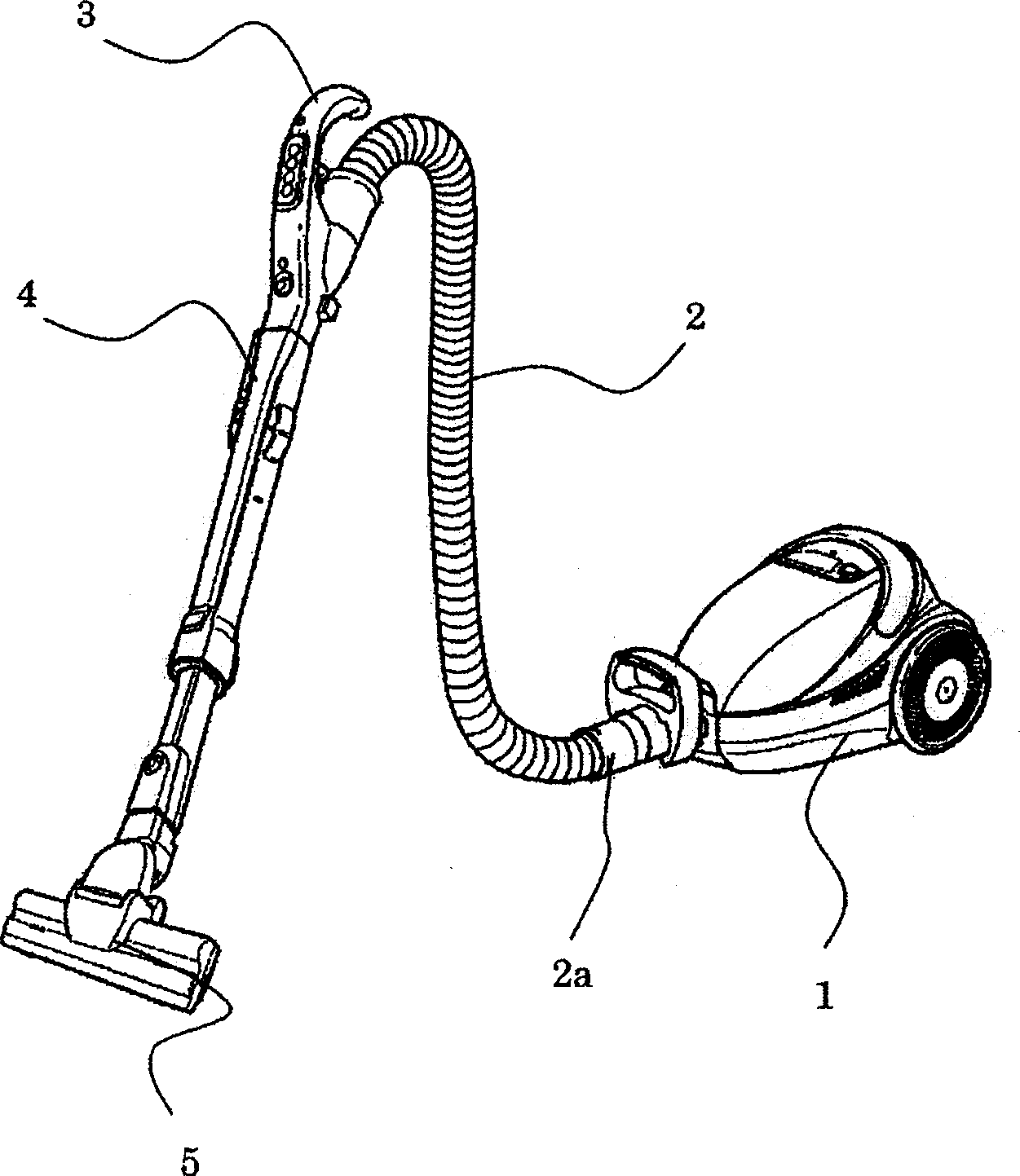

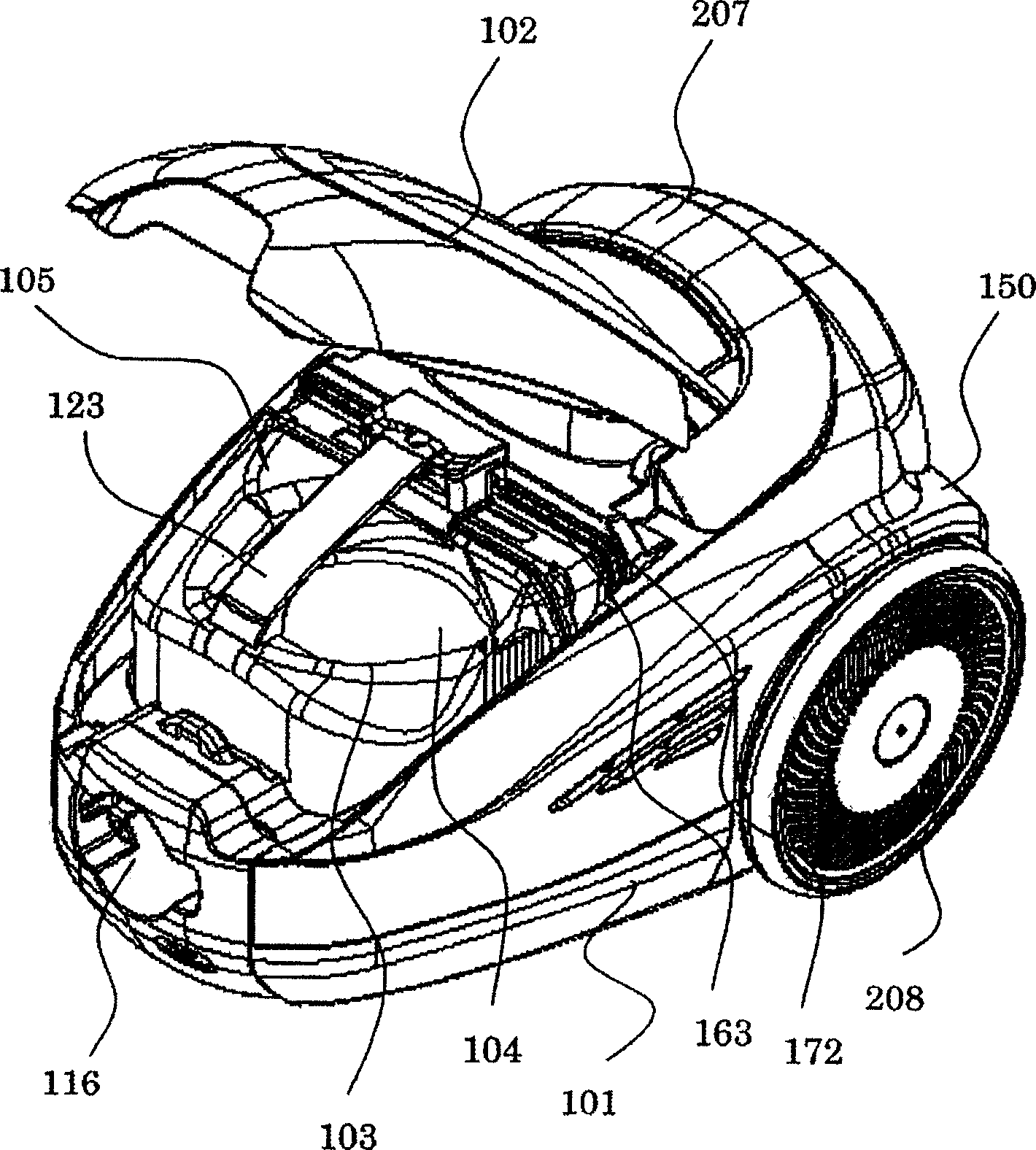

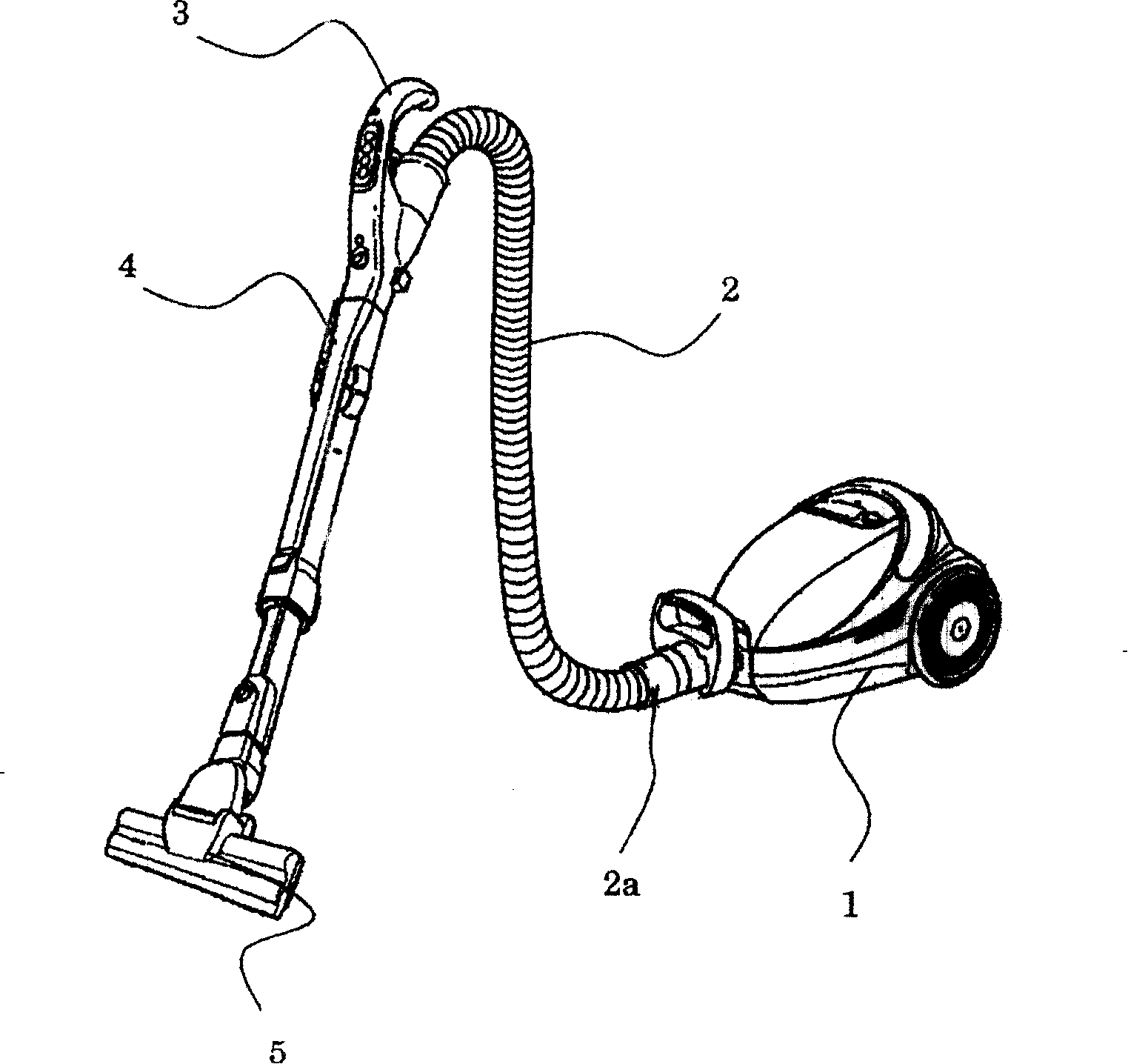

Electric vacuum cleaner

InactiveUS20080235901A1Reduction in suction amount is suppressedIncrease in air passage resistance of air passageCleaning filter meansSuction filtersSuction forcePower over

In a suctioning state, even if the amount of dust trapped in a dust collecting unit in a main air passage is increased, air suctioned from a hose connection port is branched into a first half passage and reduction in the suction air amount can be suppressed. When the suctioning state is switched to a dust moving state by switch means, the dust trapped in a pleated filter is moved to the dust collecting unit, increase in the air passage resistance at the first half passage side caused by clogging of the pleated filter can be suppressed, and reduction in suction power over time can be suppressed. Since an upper air passage and lower air passage are provided in the lid body, the dust collecting unit is exposed with the lid body opened, whereby maintenance performance of the dust collecting unit is improved.

Owner:KK TOSHIBA +2

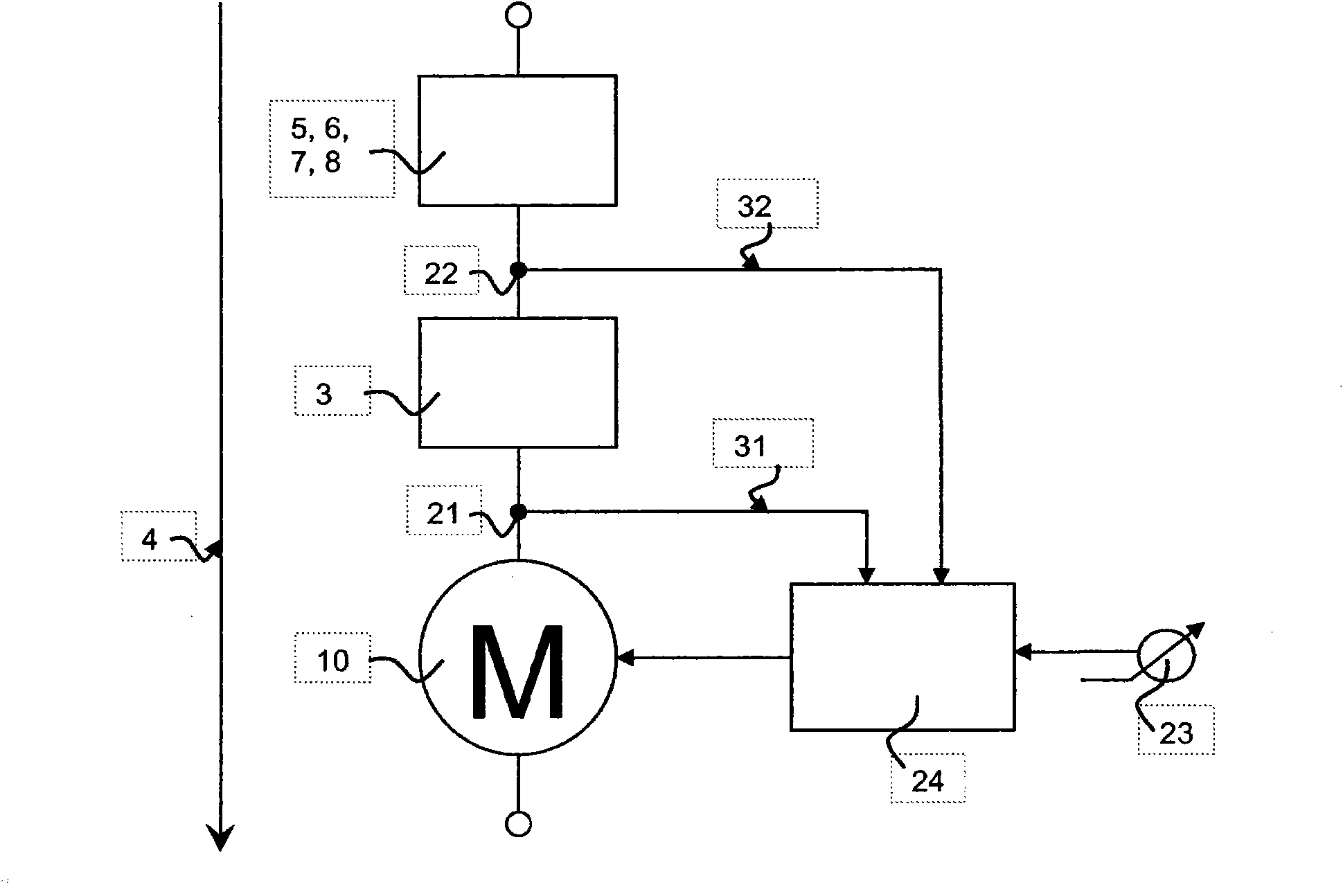

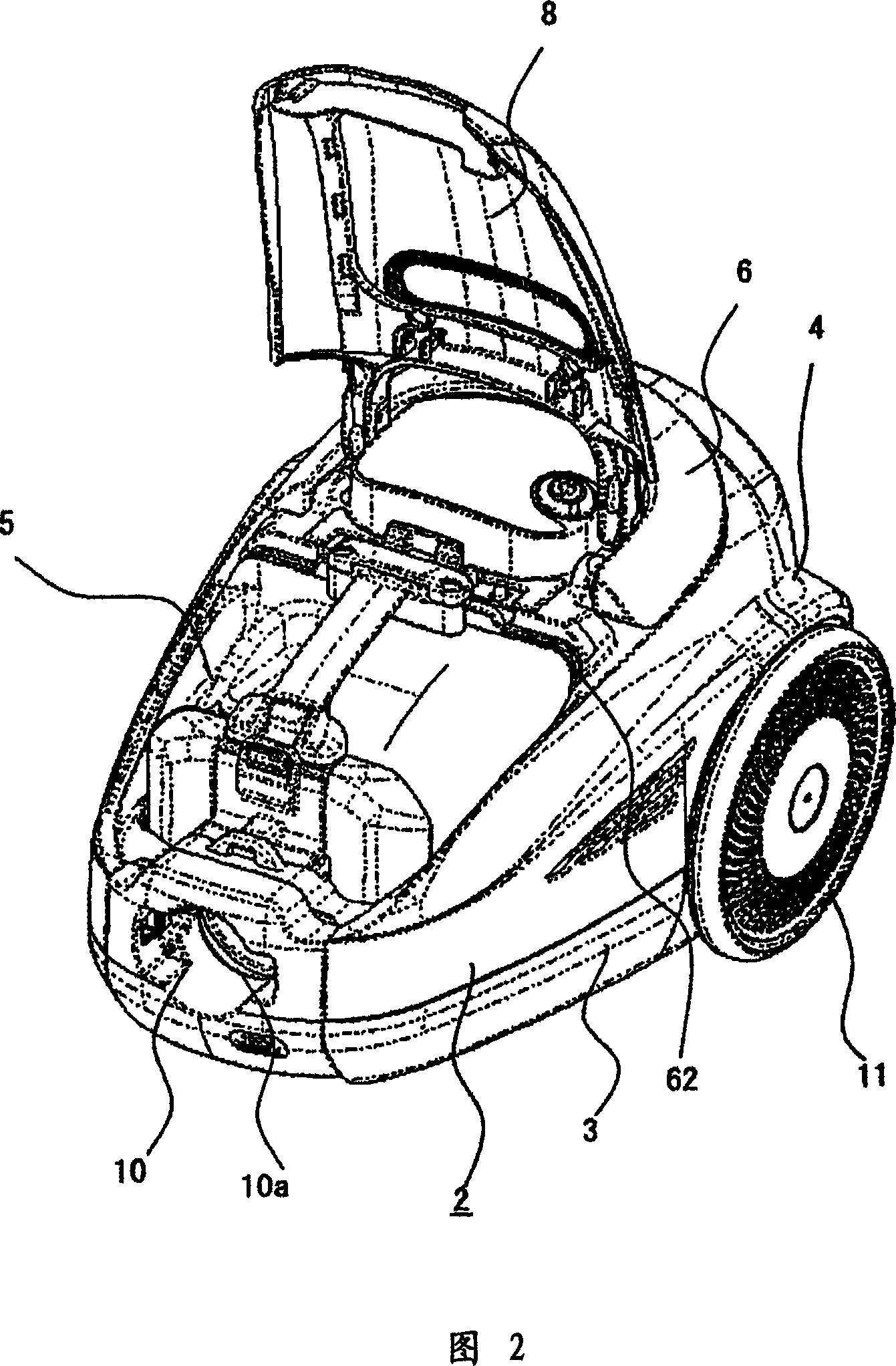

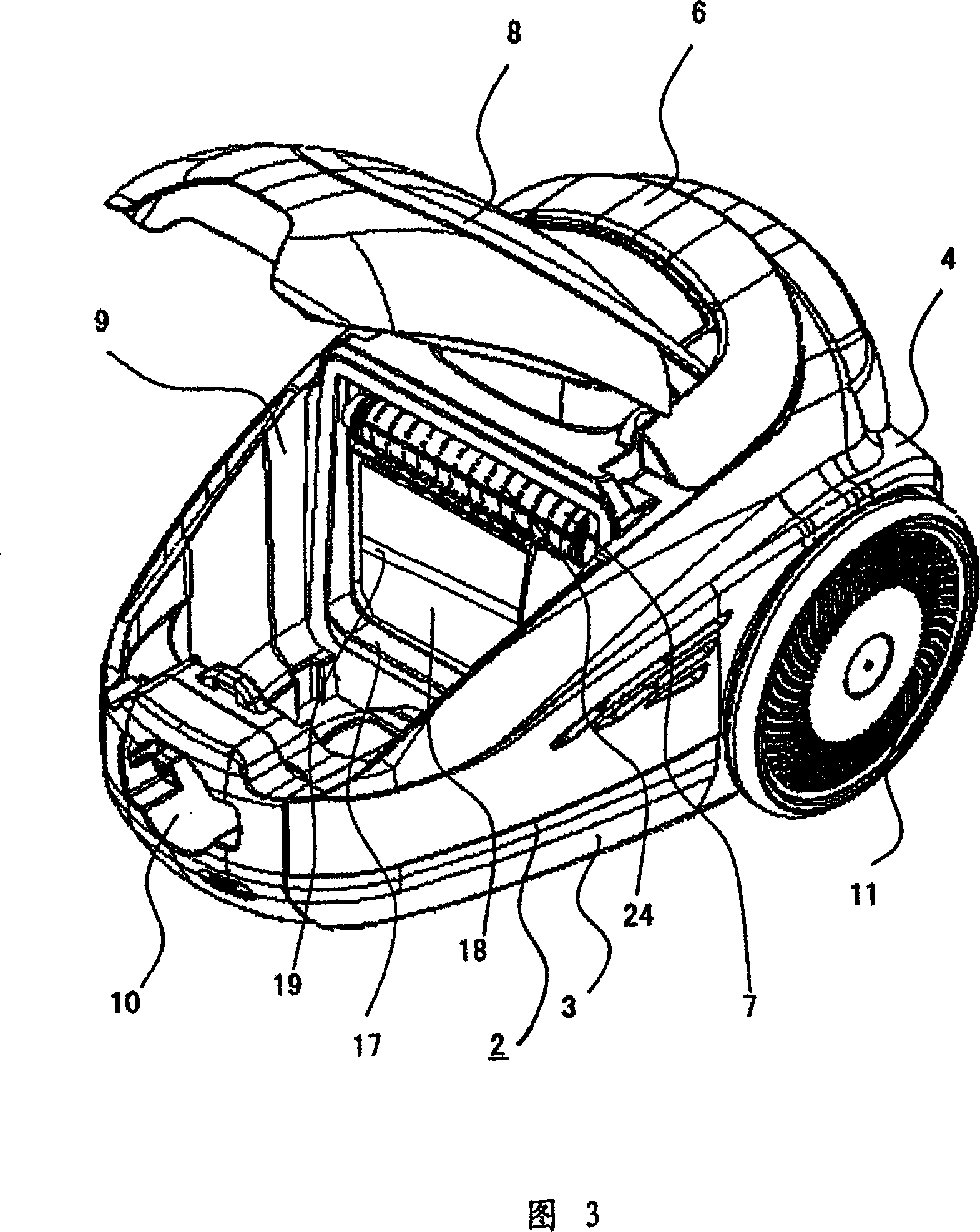

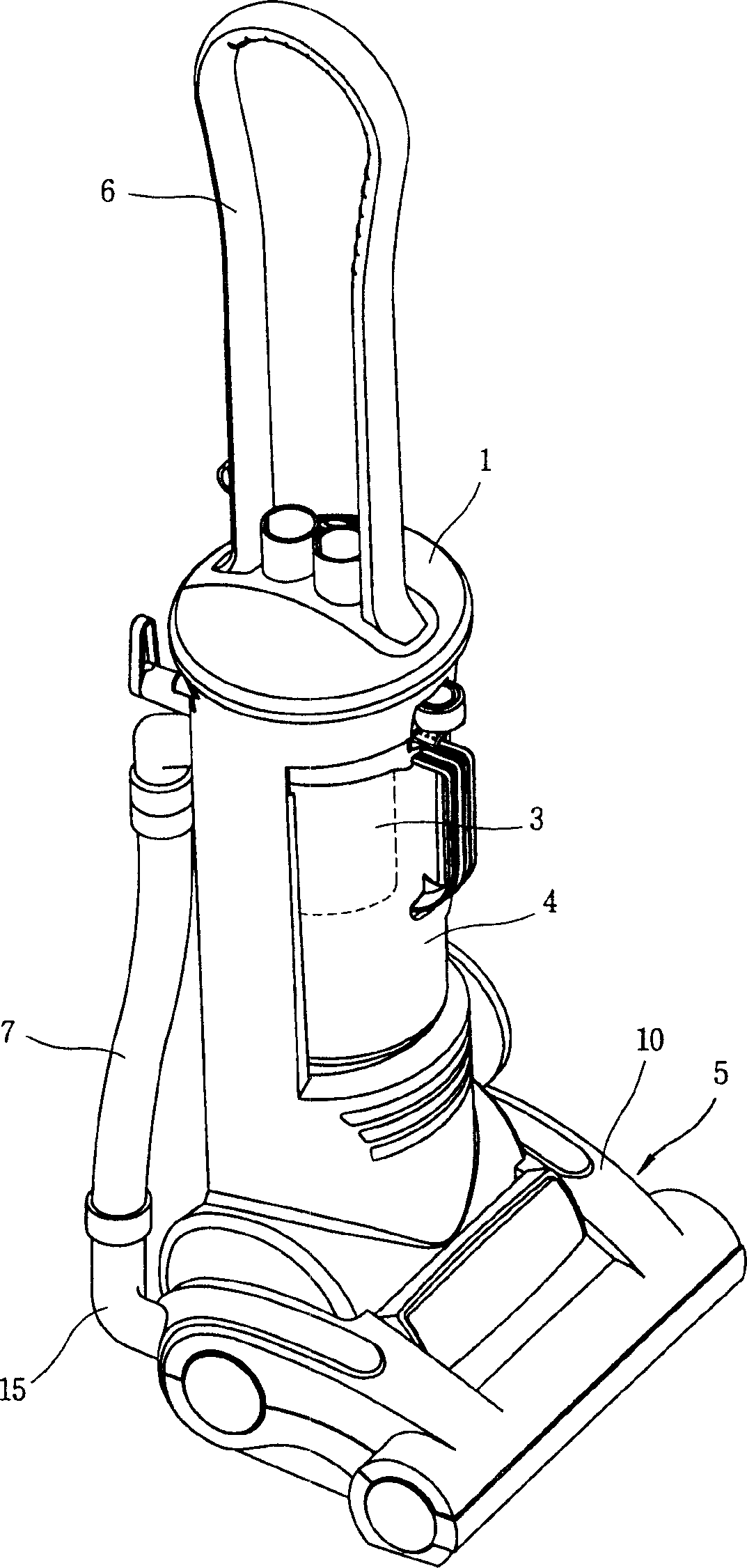

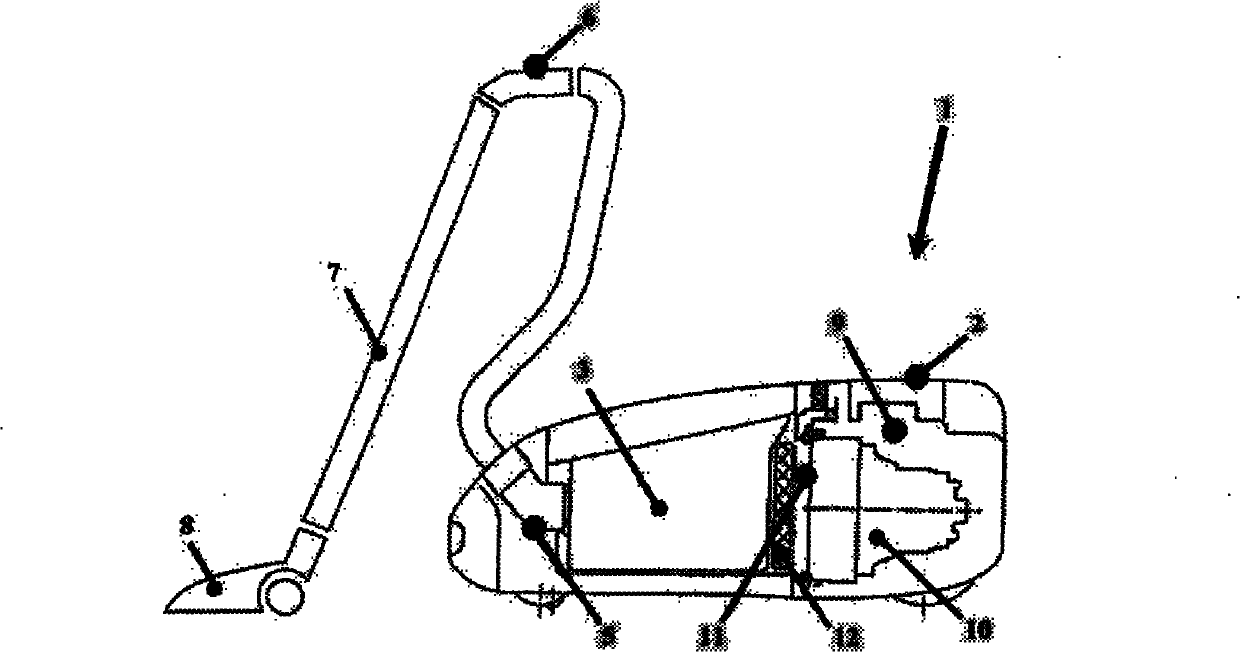

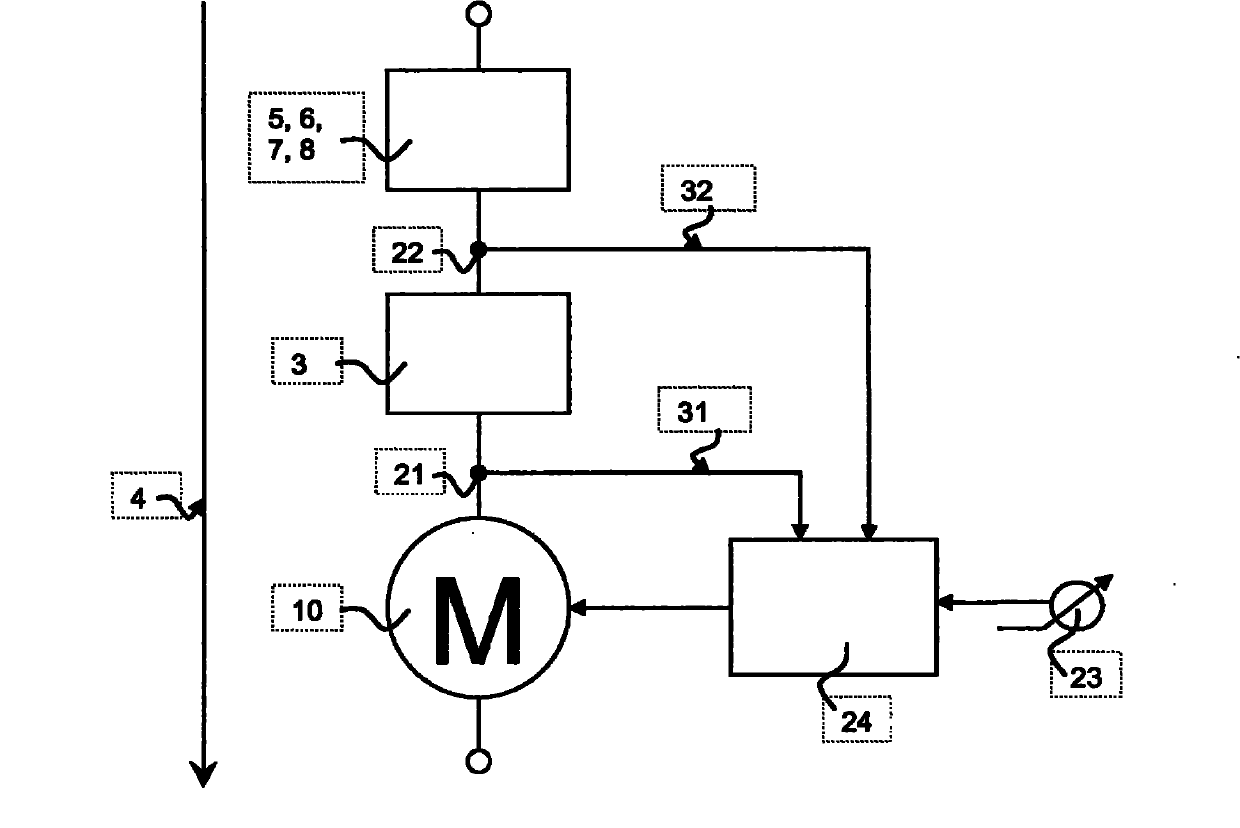

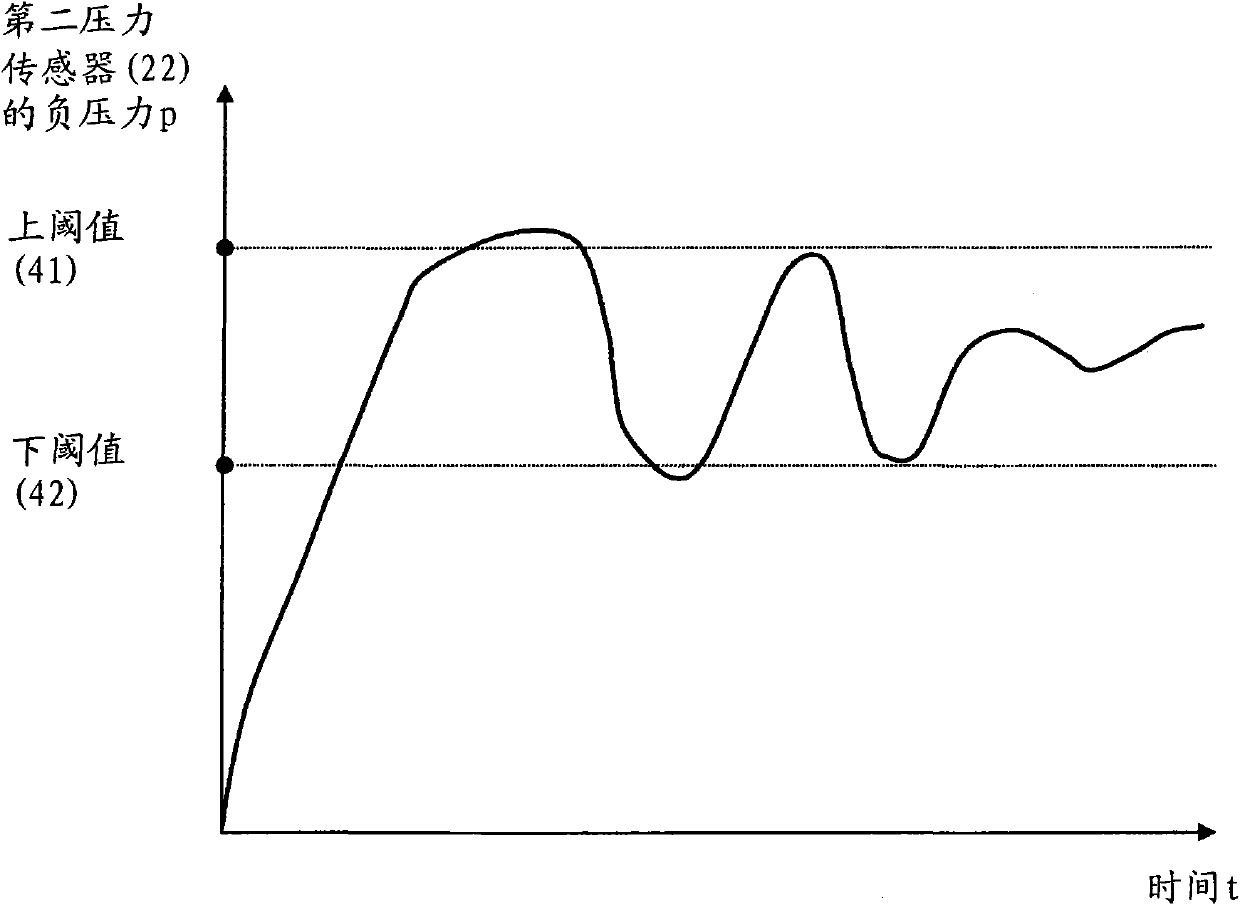

Device for the automatic suction power regulation of a vacuum cleaner

InactiveCN101945607AReduce suction powerIncrease suction powerVacuum cleaner apparatusElectric equipment installationVacuum cleanerPower regulation

The invention relates to a device for a vacuum cleaner (1). Said device only supplies as much electrical power to the motor / fan unit (10) as is necessary for the optimal cleaning of the floor surface to be cleaned and required by the respective operating states of the vacuum cleaner (1), thereby ensuring an energy-efficient use of the vacuum cleaner. Said device thereby ensures a constant cleaning action over the usable life of the vacuum cleaner (1). As the suction nozzle has a constant suction power, dust and dirt particles are always sucked up with a consistently applied suction power and supplied to a dust collection unit (3). The invention also protects the surfaces to be cleaned from being subjected to too much cleaning.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

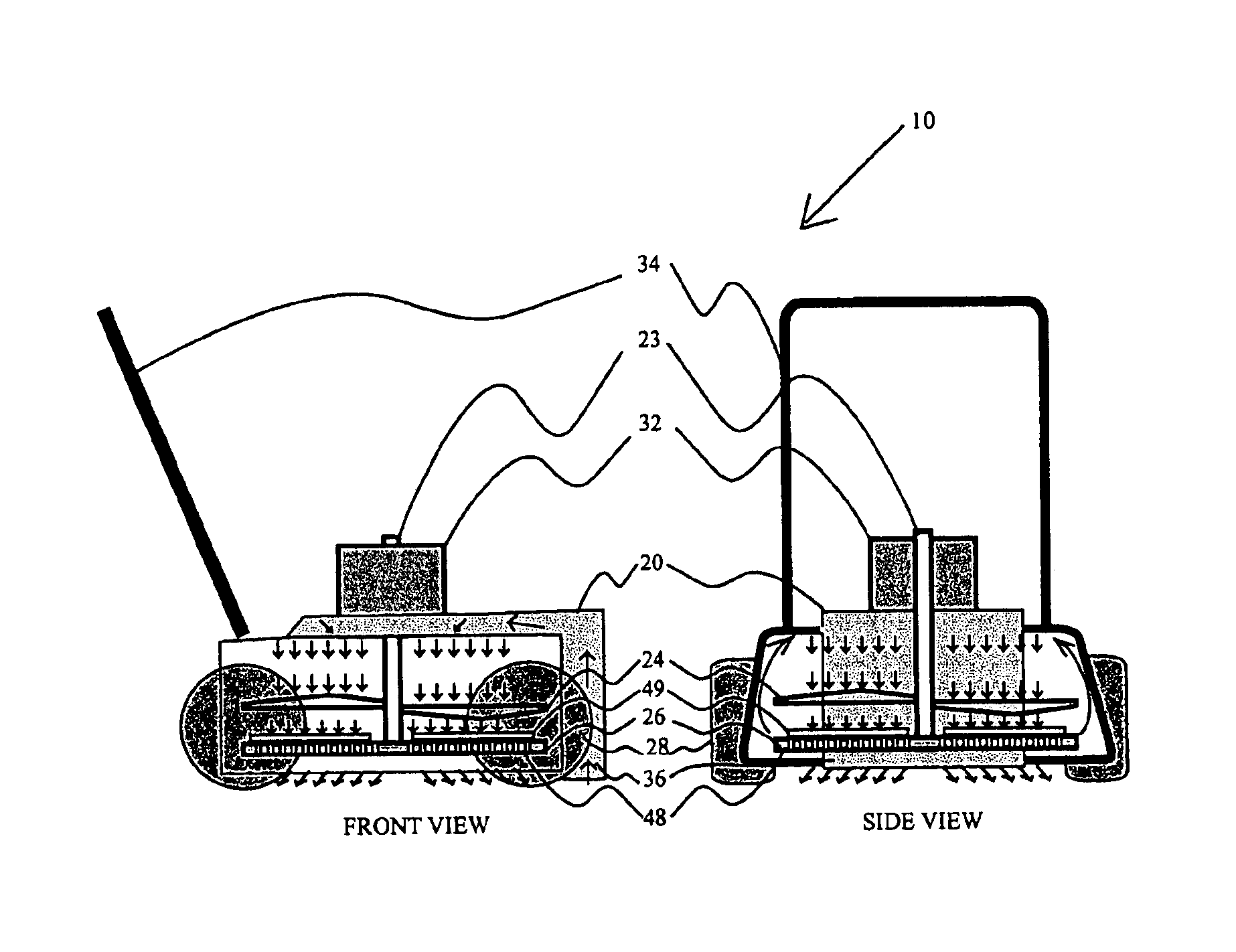

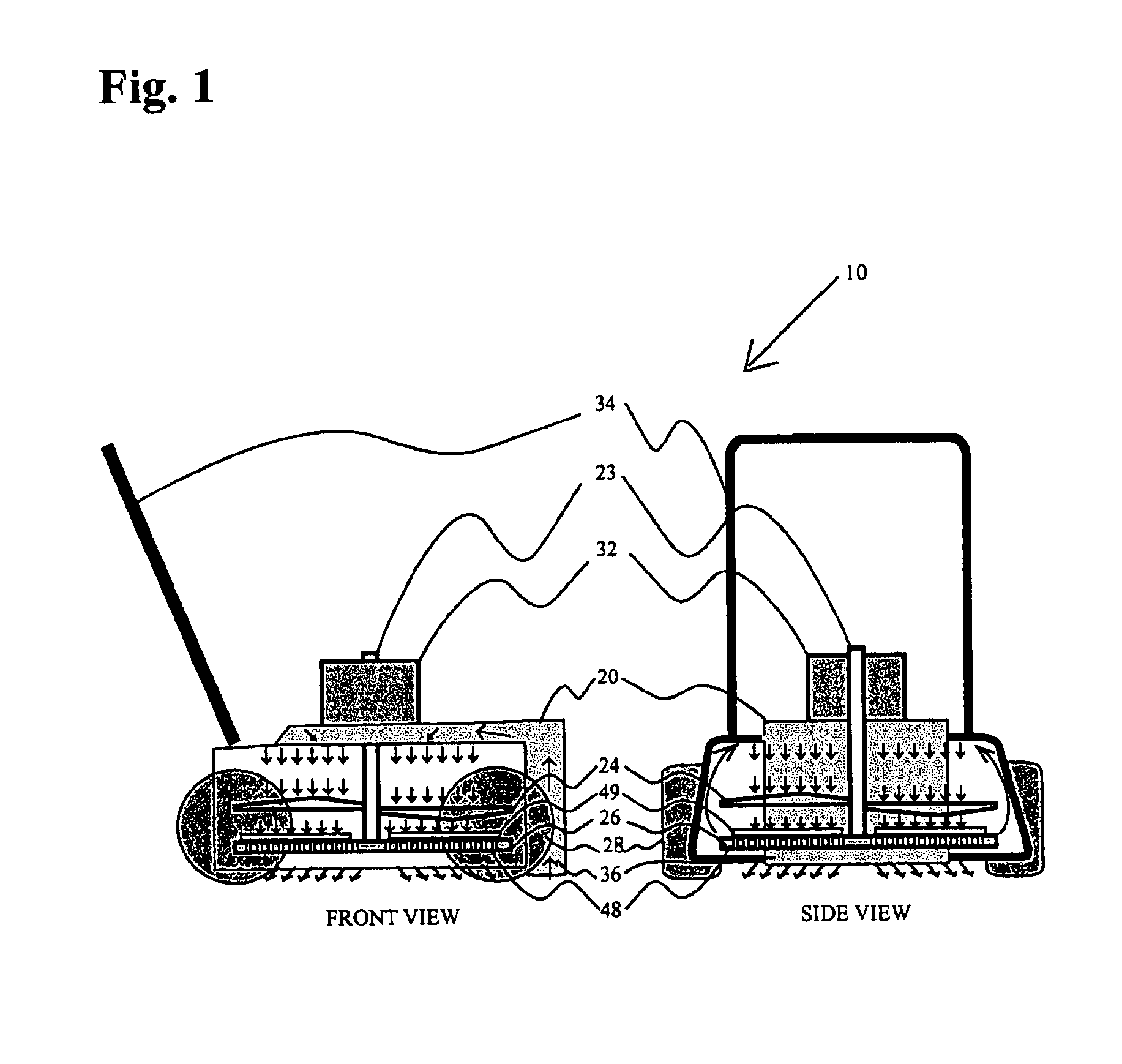

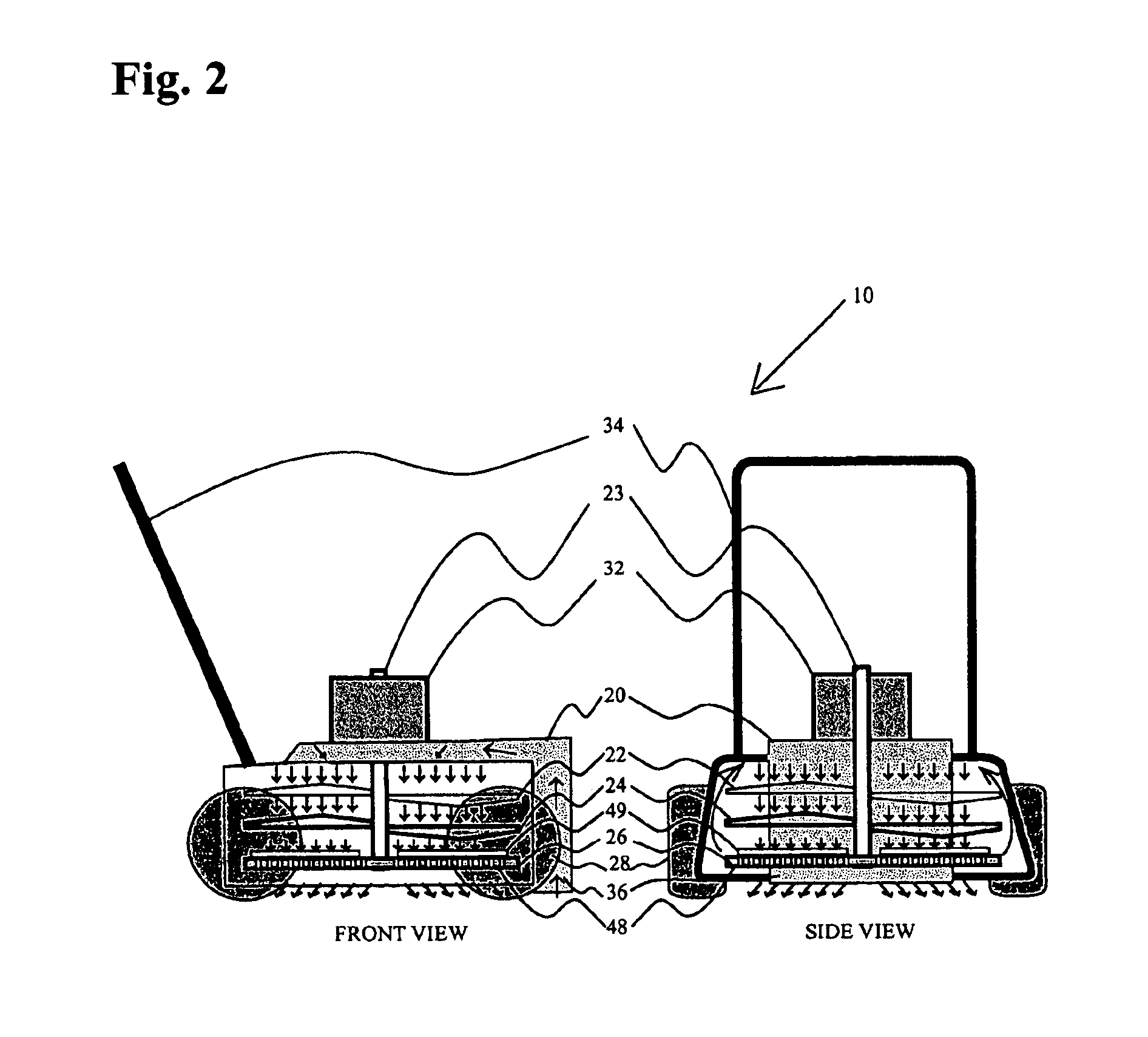

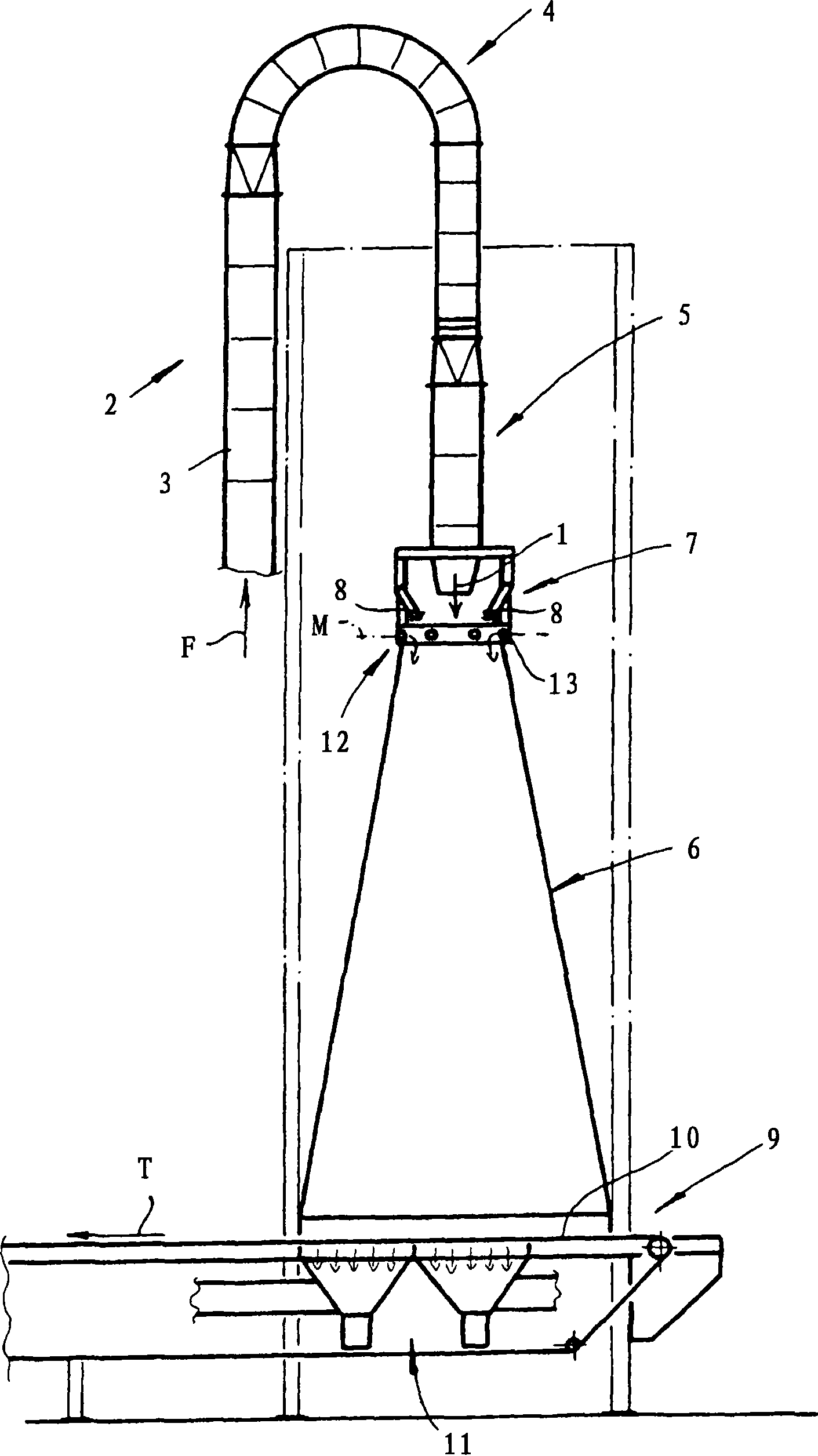

Apparatus for fine pulverization of dry leaves and garden debris

InactiveUS6928799B2Cheap constructionGuaranteed uptimeCrop conditionersLawn-mowersImpellerDrive shaft

An apparatus for finely pulverizing lawn debris has a central drive shaft driven by a gasoline or electrical power source. Lawn debris is drawn into a suction and grinding chamber by the rotation of a distribution plate which has a plurality of curved impeller blades permanently attached to a perforated plate. A grinding blade with a plurality of blade elements is mounted on the central drive shaft above the distribution plate and effects pulverization of the debris. The distributing plate apertures dispense the pulverized debris uniformly over a lawn. Optionally, additional fan impeller blades may be mounted on the central drive shaft to draw and initiate pulverization of the debris. In this case, the rotation of the distributing plate may be stopped by disengaging a clutch mounted on the central shaft to direct pulverized debris to a side collection chamber, which is periodically emptied through a bottom discharge gate.

Owner:NWOSU MICHAEL U +1

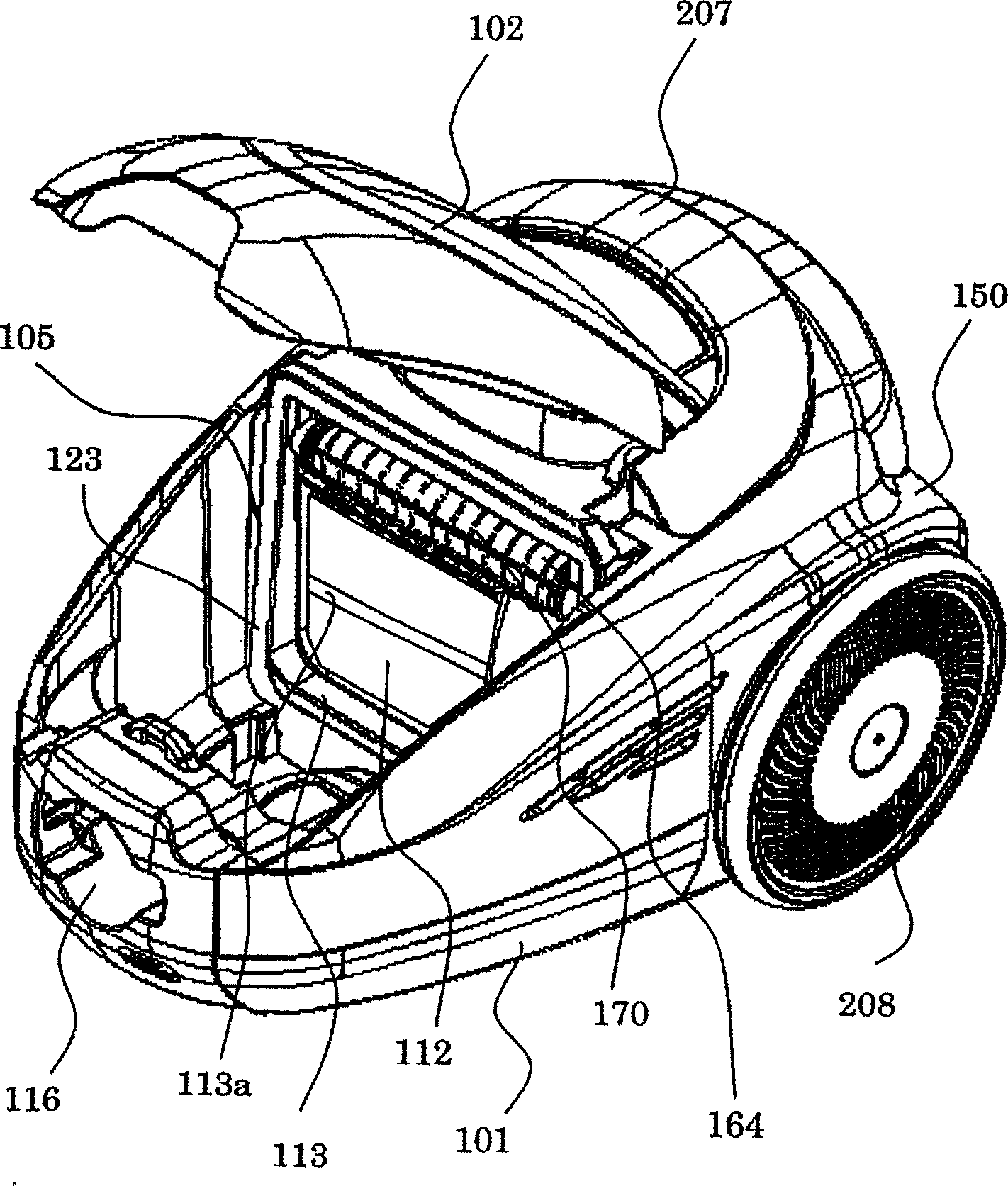

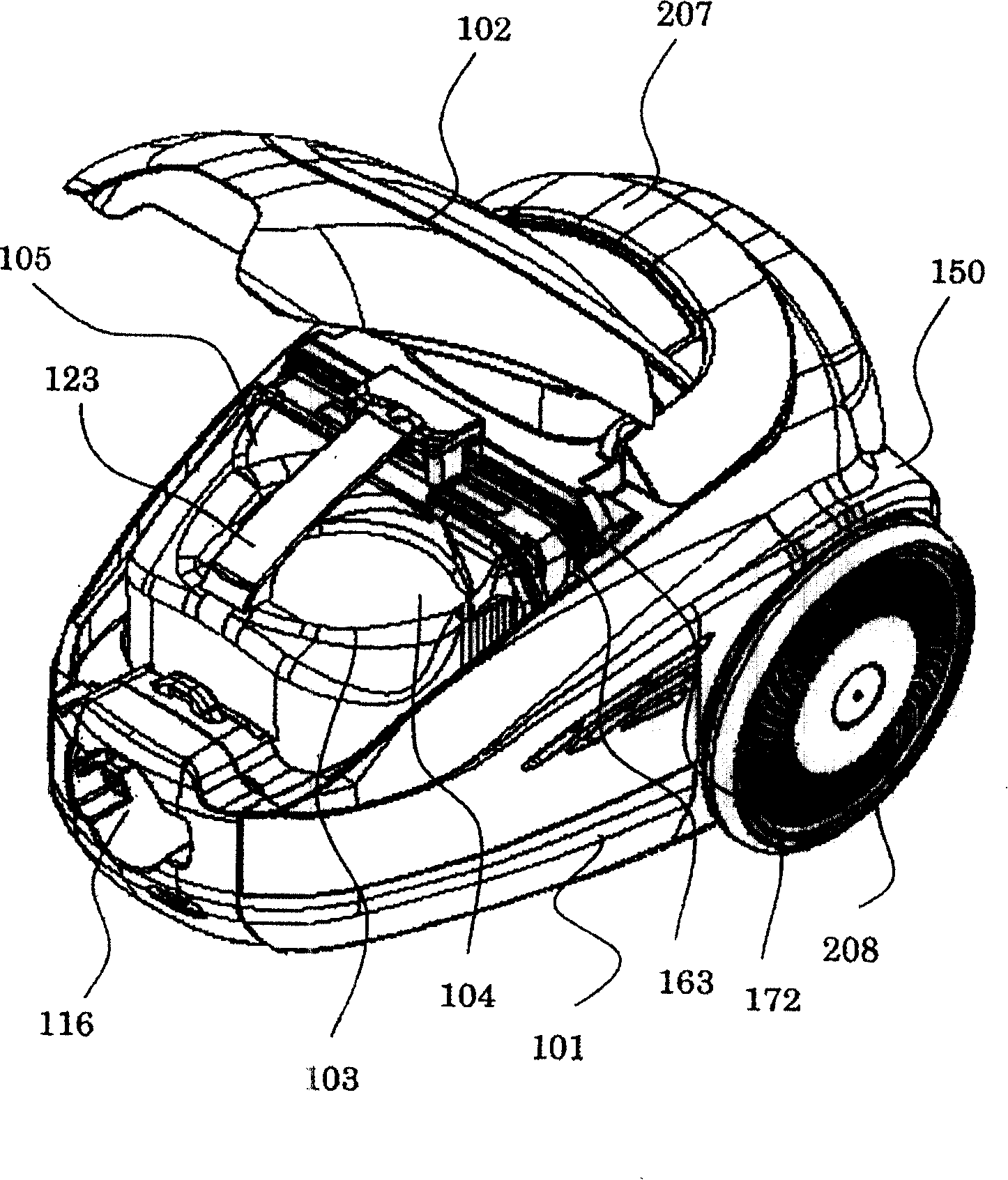

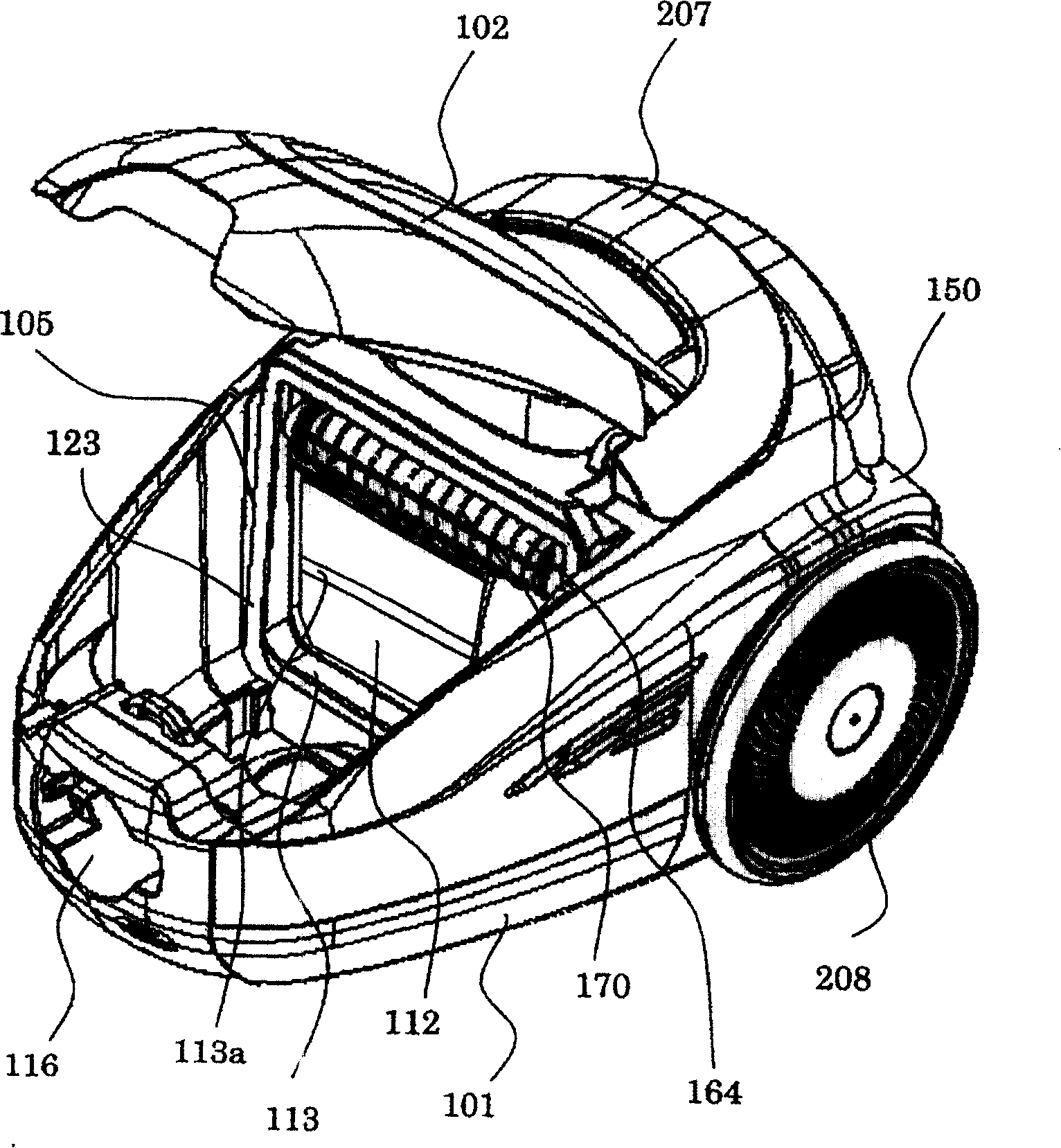

Electric dust collector

ActiveCN101091635ASmall ventilation lossIncrease suction powerSuction filtersElectric driveEngineering

The present invention provides an electric dust cleaner which can easily and wholesomely discharge the collected dust and the ventilating loss lost is small namely high sucking power. It is provided with a vacuum cleaner main body which is installed with an electric driven blower at the inner side and a dust collecting box which is detachably arranged on the vacuum cleaner main body, an ash accommodating component which accommodates the ash is arranged in the dust collecting box, and the flow circuit which is formed by the dust accommodating component and the inner wall of the dust collecting box is formed that it extends from the upriver side to the downriver side.

Owner:日立グローバルライフソリューションズ株式会社

Electric cleaner

InactiveCN101309624AIncrease suction powerThe suction power is not easy to decreaseCleaning filter meansSuction filtersEngineeringAirflow

Owner:PANASONIC CORP

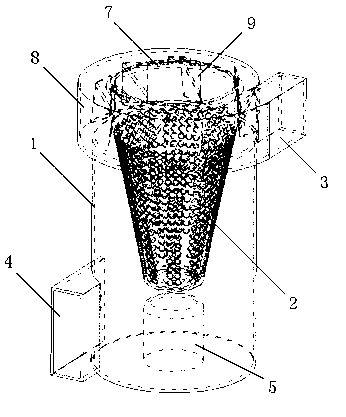

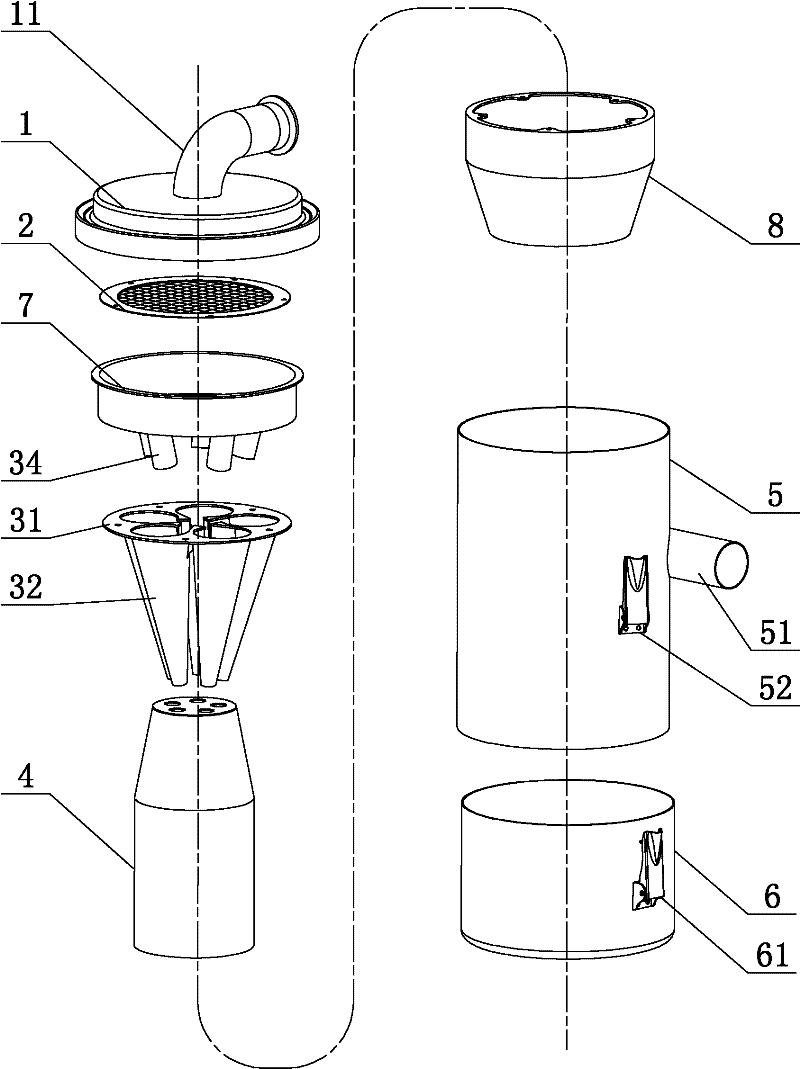

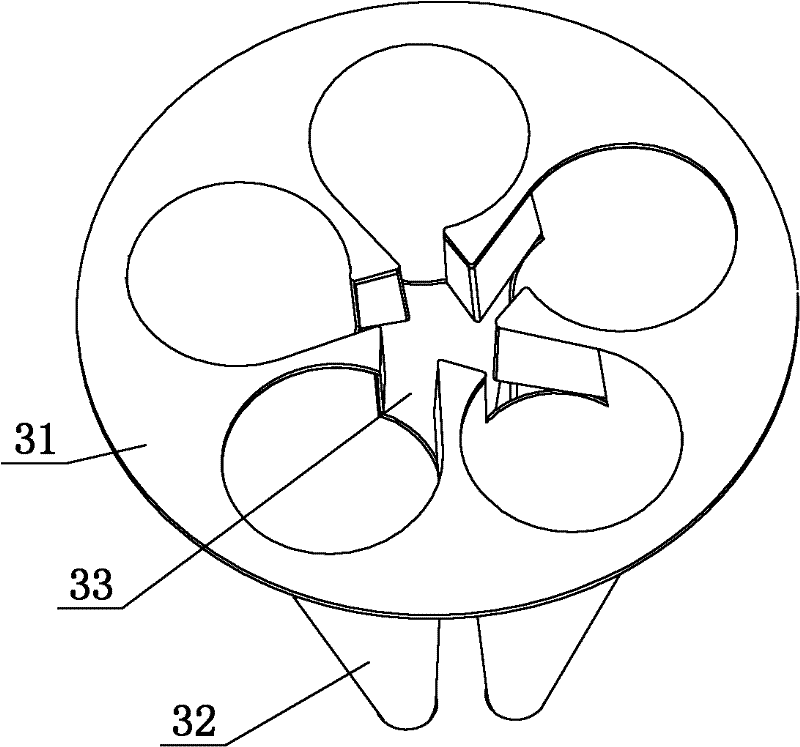

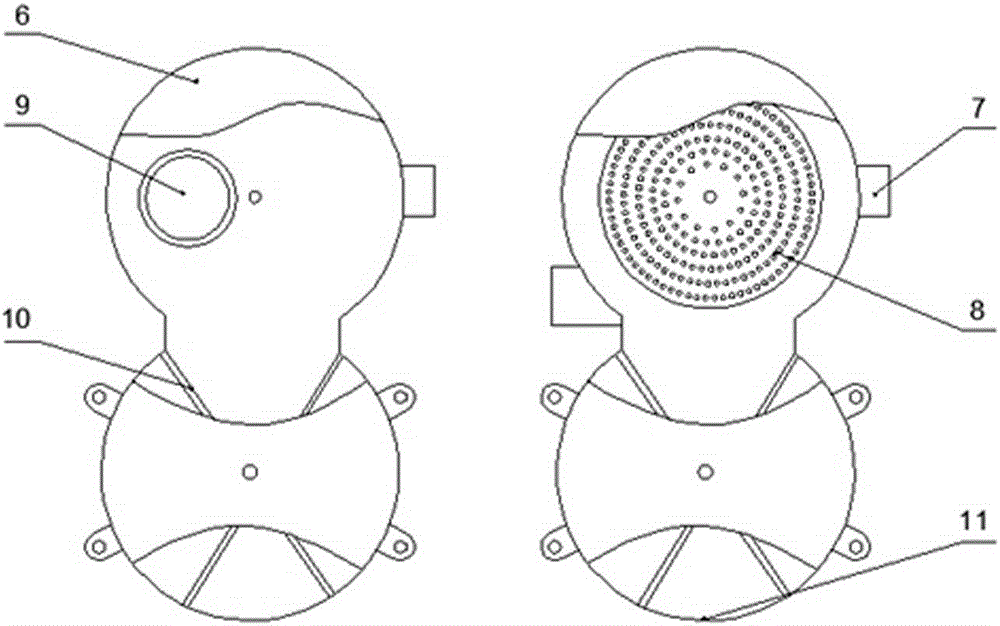

Multi-cyclone separation filter equipment

The invention discloses multi-cyclone separation filter equipment comprising a filter bung, a filter screen device, a filter screen pedestal, an inner cyclone device, an inner dust bucket, a filter bucket, an outer dust bucket, with the filter bucket covered by the filter bung and the outer dust bucket disposed at the bottom of the filter bucket. The filter bung is provided with an outtake pipe, and an intake pipe is installed on the side wall of the filter bucket. And the inside of the filter bucket is equipped orderly with the filter screen device, the filter screen pedestal, the inner cyclone device and the inner dust bucket from top to bottom. According to the invention, filtered by multi-cyclone, the intake air rotates repeatedly, so that dust or stive in the air can fall into the dust buckets and the tiny stive and harmful substances can be filtered out. The equipment of the invention is fast and convenient for cleaning, without the problem of a blocked filter screen.

Owner:SHINI ELECTRIC HEATING MACHINERY

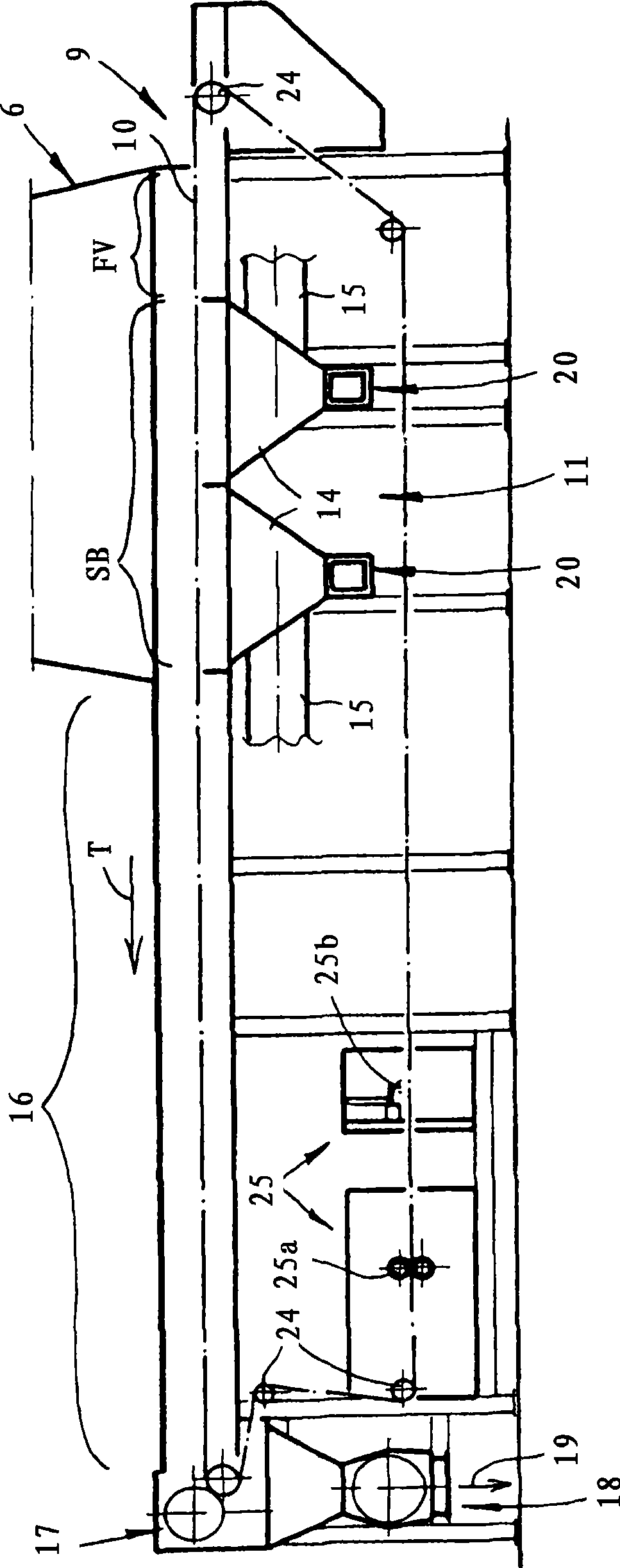

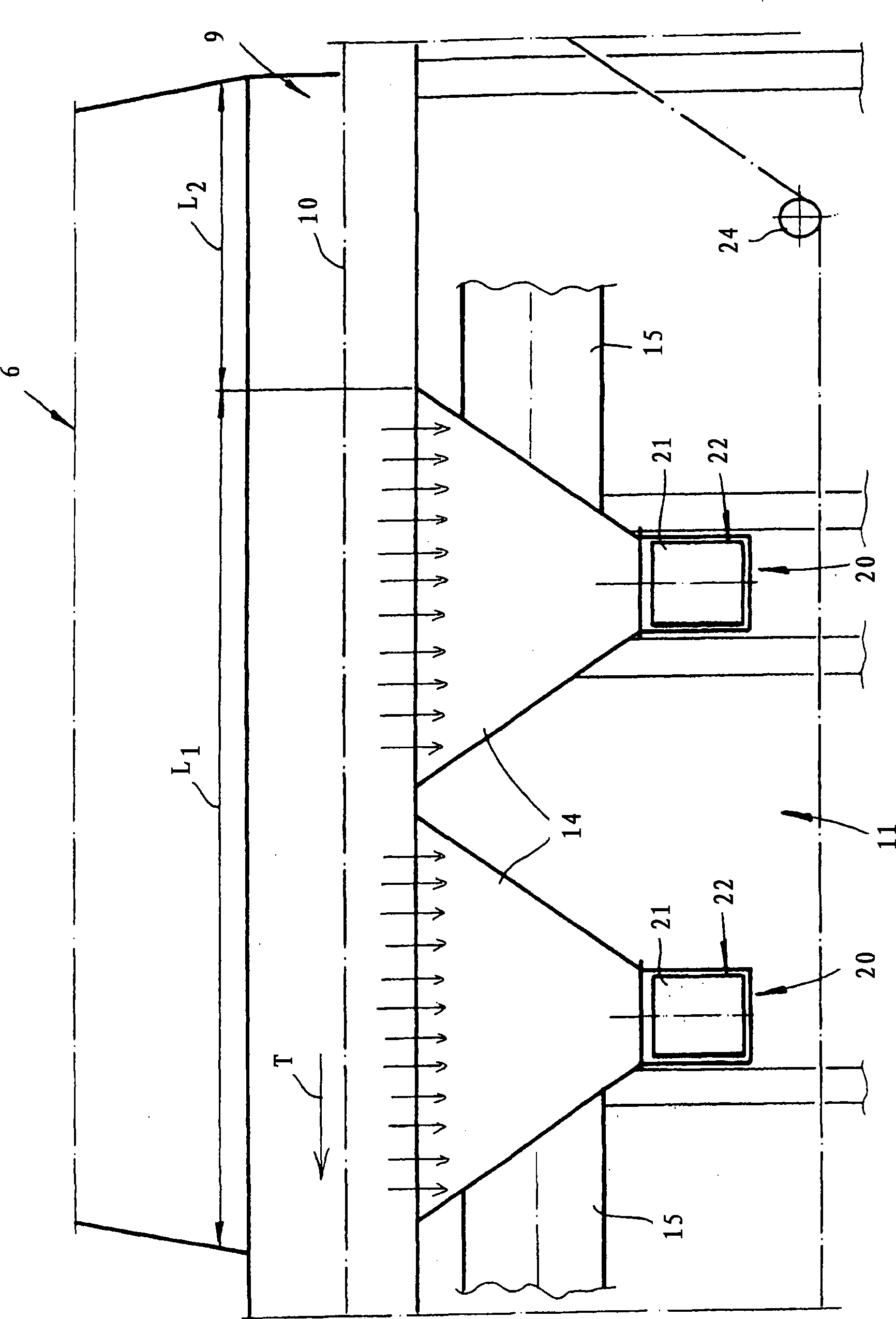

Installation for applying glue to fibers for the production of fiberboard

ActiveCN101466512AConvenience to workWork lessFlow mixersTransportation and packagingFiberSpray nozzle

The invention relates to an installation for applying glue to fibers for the production of fiberboard, especially MDF board or similar wood material board. Said installation comprises a fiber feed unit having at least one fiber feed conduit which opens into a fiber exit tube via a fiber deflection element and receives the air that is used to transport the fibers, a chute which is located downstream of the fiber exit tube, a glue application device which has spray nozzles for spraying the fibers that emerge from the fiber exit tube and enter the chute with drops of glue, and a collection device, located downstream of the chute and having an air-permeable transport belt for collecting and optionally carrying off the fibers and a suction device located below the transport belt for suctioning air from the chute through the transport belt, the suction device having one or more suction boxes to which one or more suction pipes are connected. The installation is characterized in that the suction boxes are configured as cleaning boxes having at least one cleaning device for removing fibers that enter the suction boxes through the transport belt.

Owner:SIEMPELKAMP MASCH & ANLAGENBAU GMBH & CO KG

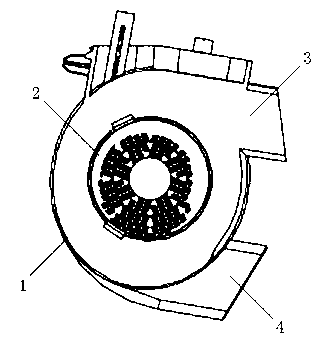

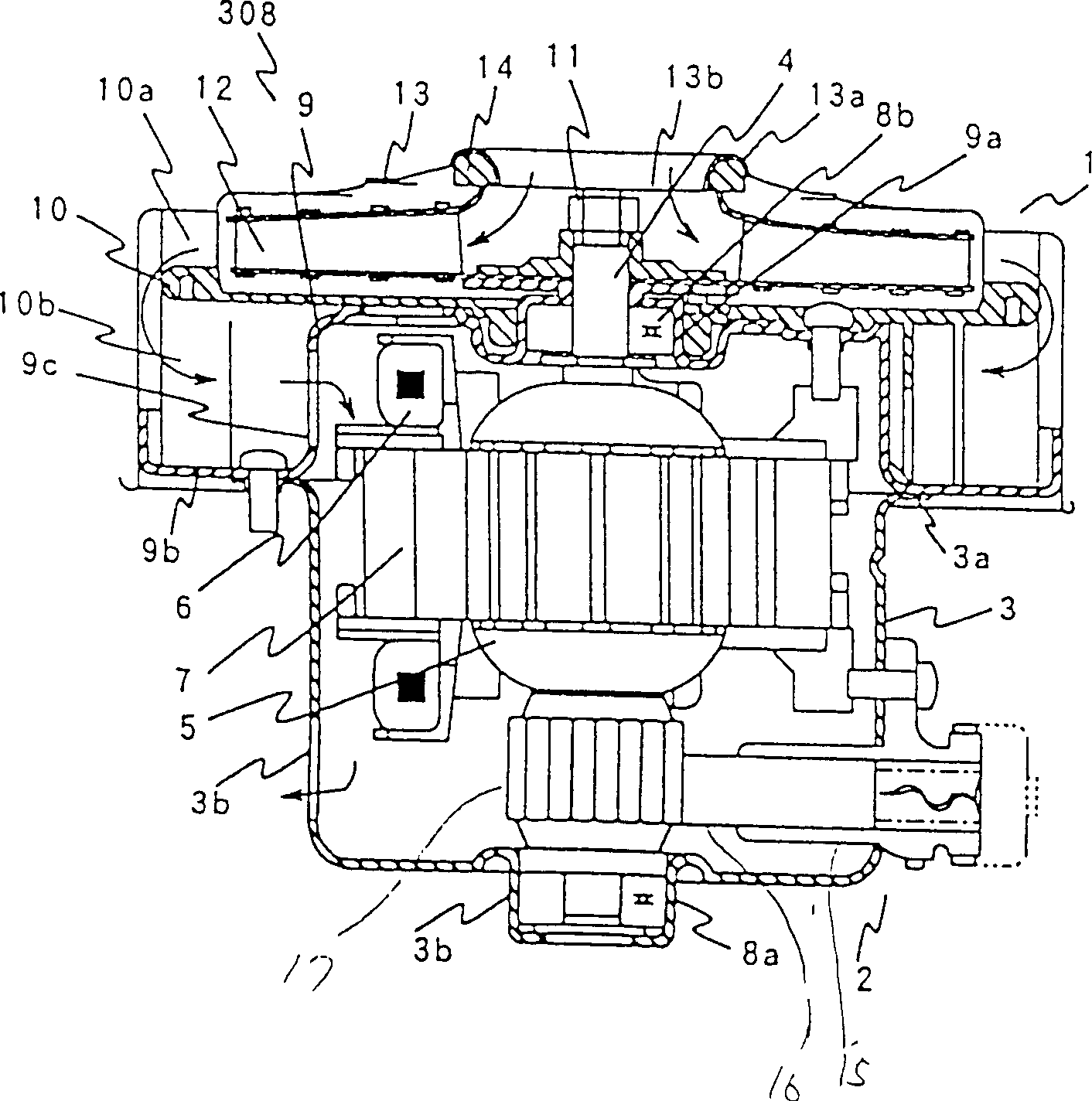

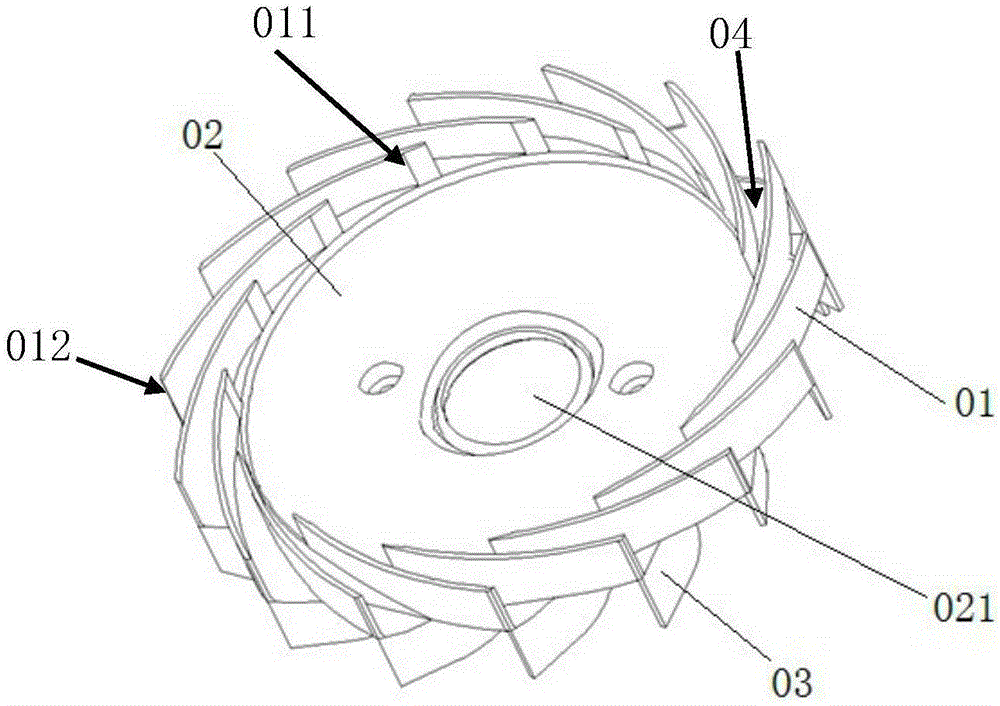

Electric blower and electric dust collector installed with the electric blower

ActiveCN102913474AIncreased static pressure recoveryImprove performancePump componentsPumpsEngineeringBend loss

The invention provides an electric blower and an electric dust collector installed with the electric blower. The efficiency of the electric blower is improved by reducing the flow rate at a bent portion from a diffuser to a ball returning device and turning the flow smoothly to reduce the bending loss. Further, by improving the efficiency of the electric blower, the sucking power, i.e. output, is enhanced. The electric blower is provided with a separation plate, a plurality of ball returning vanes disposed on one surface of the separation plate, a plurality of diffuser vanes disposed on the other surface of the separation plate, and an electric motor. The other surface of the separation plate is provided with a recess. Flow channels are disposed by adjacent diffuser vanes in the plurality of diffuser vanes and the separation plates. The recess portion is set to be an end portion from the flow channel to the outer peripheral of the separation plate.

Owner:HITACHI APPLIANCES INC

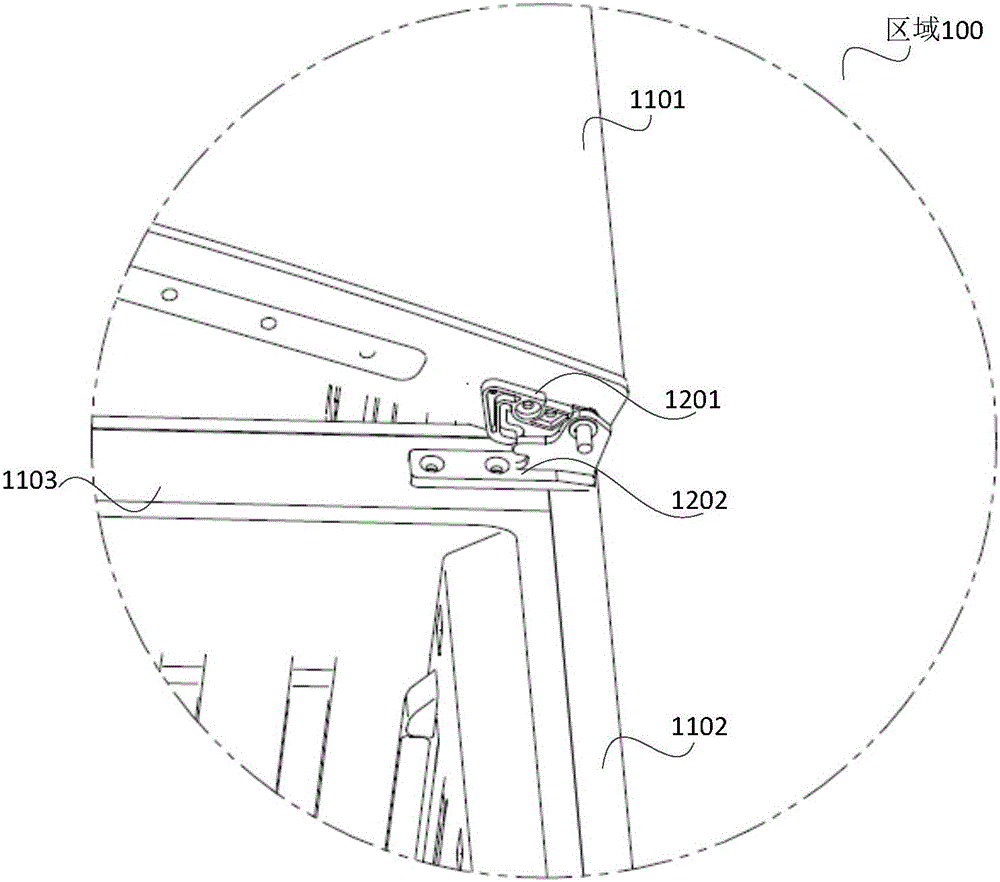

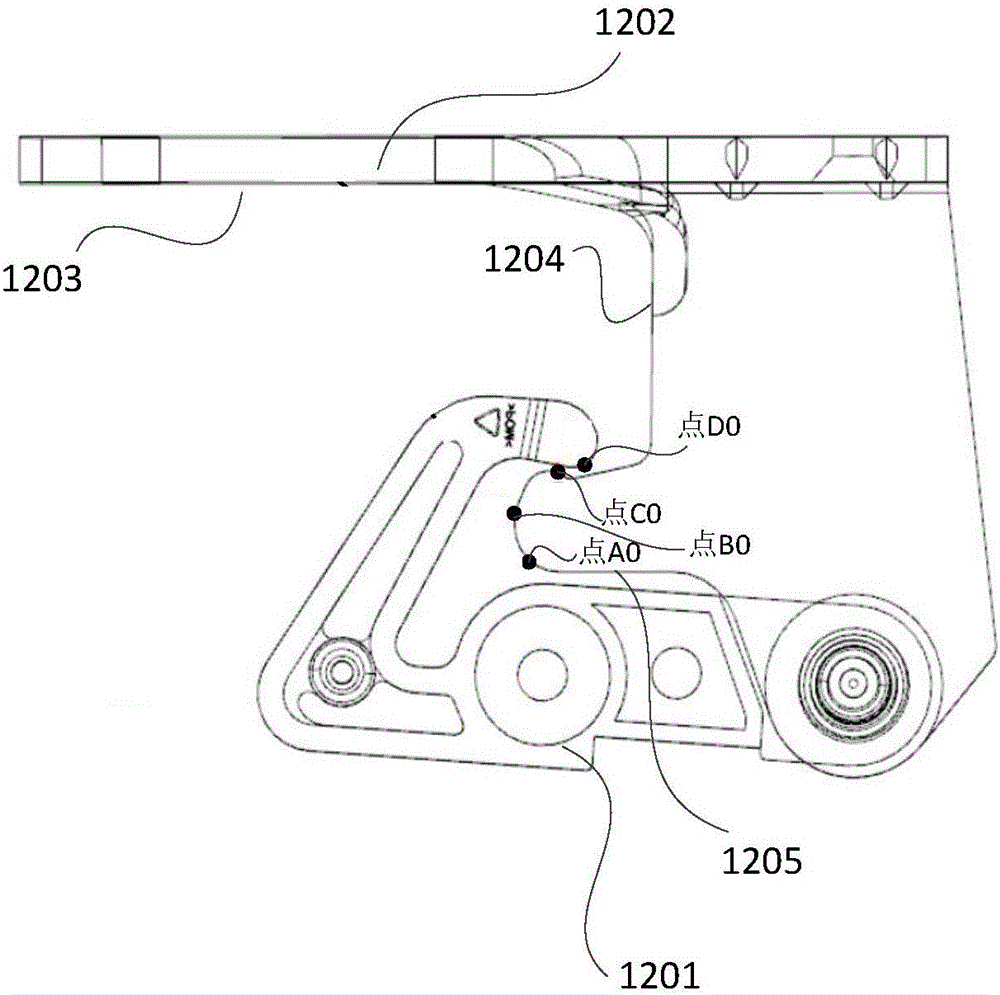

Door body suction assisting device and refrigerator

InactiveCN106123458AIncrease suction powerEnhance suction effectLighting and heating apparatusHingesEngineeringRefrigerated temperature

Owner:HISENSE RONGSHENG YANGZHOU REFRIGERATOR CO LTD

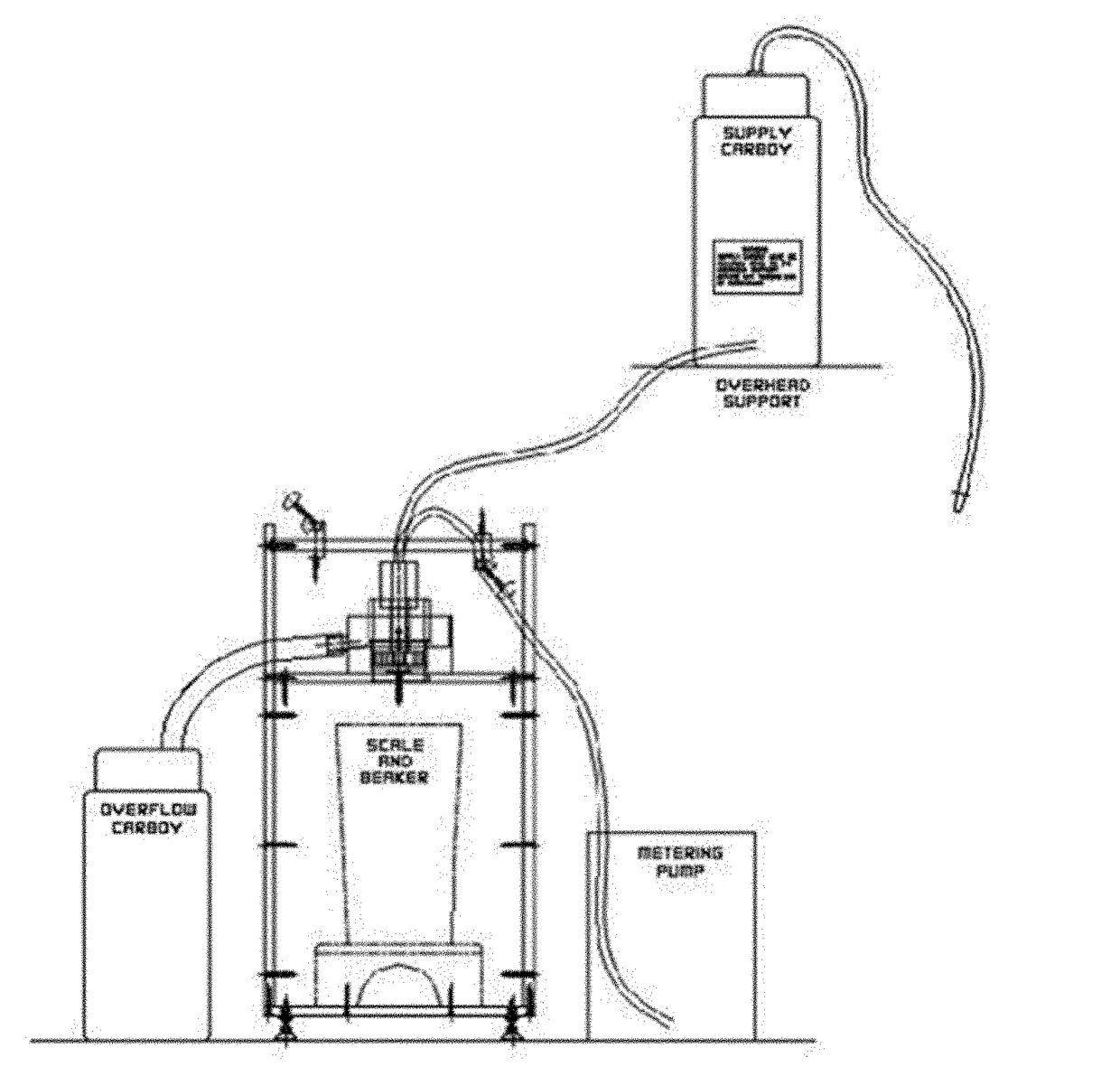

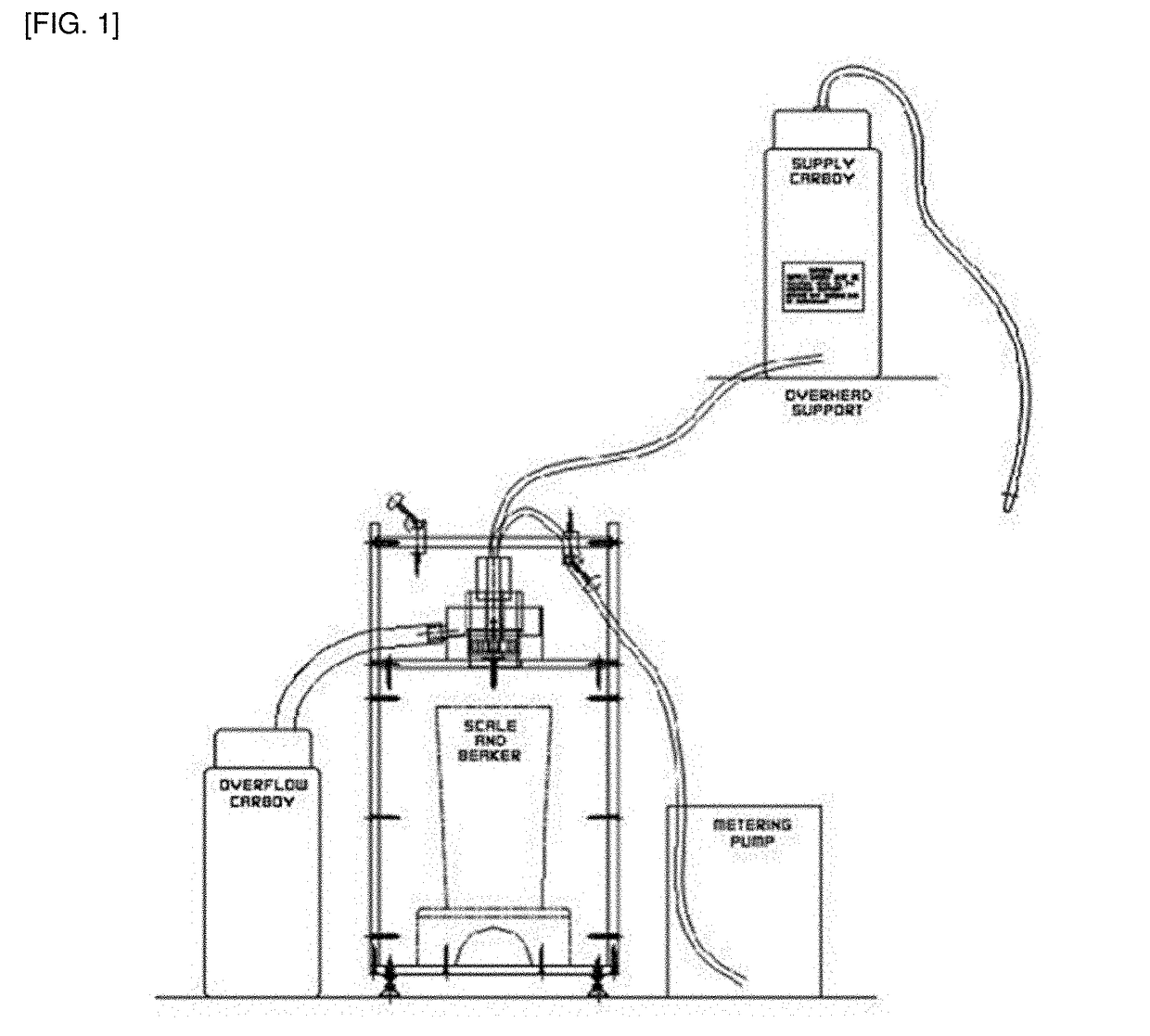

Method for preparing superabsorbent polymer

InactiveUS20180257059A1Great suctionEasy to wearOther chemical processesAbsorbent padsSuperabsorbent polymerPolymer science

The preparation method of superabsorbent polymer according to the present invention can increase suction power without degradation of other properties of superabsorbent polymer, and thus, the prepared superabsorbent polymer may be usefully used as material of hygienic goods such as a diaper.

Owner:LG CHEM LTD

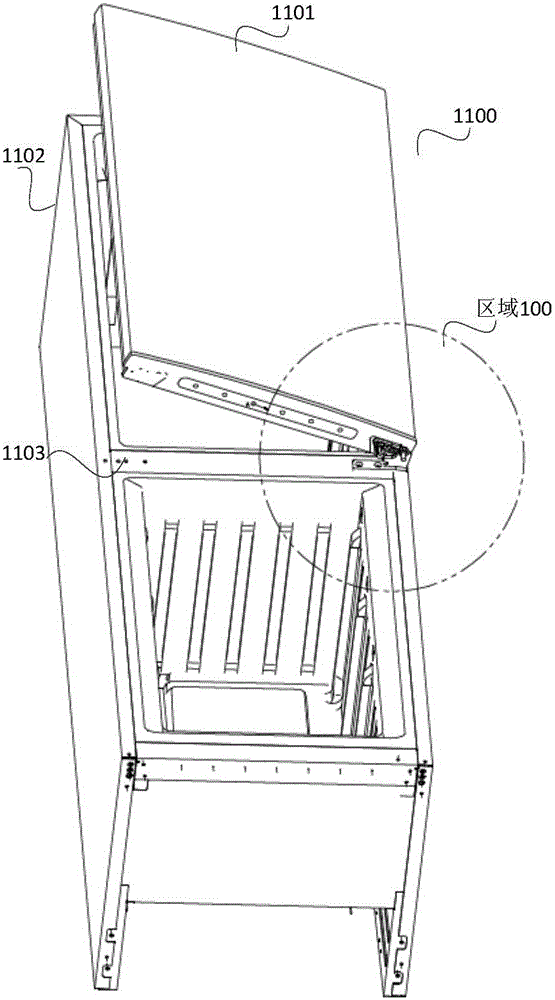

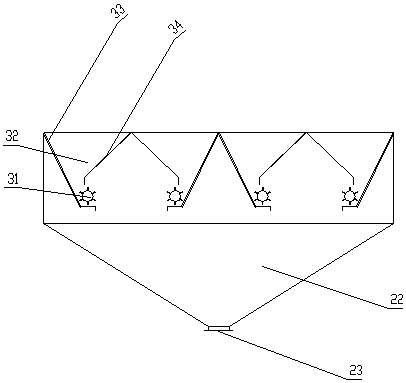

Kitchen ventilator and kitchen ventilator and cooker integrated machine

PendingCN108954454AImprove suction and purification effectReduce escapeDomestic stoves or rangesLighting and heating apparatusEngineeringCooker

The invention provides a kitchen ventilator and a kitchen ventilator and cooker integrated machine and relates to the technical field of purification equipment. The kitchen ventilator comprises a fumecollecting hood and a wind shield. A fume collecting panel of the fume collecting hood is provided with an air inlet. The fume collecting hood is provided with a driving device. The driving end of the driving device is connected with the wind shield and used for driving the wind shield to extend, contract and rotate relative to the air inlet. The wind shield and the fume collecting panel form a left fume gathering cavity and / or a right fume gathering cavity. The kitchen ventilator and cooker integrated machine comprises a cooker and the kitchen ventilator. A panel of the cooker is sequentially provided with a left burner and a right burner from left to right. The kitchen ventilator is arranged between the left burner and the right burner. An opening of the left fume gathering cavity of the kitchen ventilator faces the left burner, and an opening of the right fume gathering cavity of the kitchen ventilator faces the right burner. The wind shield of the kitchen ventilator is applicableto three conditions to be adjusted into three fume gathering forms, wherein the first condition is that a user uses the left burner and the right burner at the same time, the second condition is thatthe user only uses the left burner, and the third condition is that the user only uses the right burner; and thus, the fume gathering effect of the kitchen ventilator is improved, and furthermore, thepurification effect of the kitchen ventilator is improved.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Method for detection of ink residual, ink residual detection mechanism, ink supply system and ink jet printer

ActiveCN106142871AImprove accuracyIncrease suction powerOther printing apparatusEngineeringComputer printing

The present invention relates to a method for detection of ink residual, an ink residual detection mechanism, an ink supply system and an ink jet printer. The method is configured to detection whether there is ink or not. The method comprises the following steps: 1, setting a presetting value having larger suction power than the normal suction power; 2, detecting whether the position has ink or not through an ink residual detection part, and if the position has no ink, entering the step 3; 3, comparing the real-time suction power to the presetting value, if the real-time suction power is smaller than the presetting value, performing the step 4, and on the contrary, turning the step 5; 4, adding the suction power, and entering the step 2; and 5, prompting that the ink is exhausted. After the ink residual detection part detects that the position has no ink, and the suction power of an ink suction needle is increased to allow the ink remained in an ink box to be pumped out until the power to be sucked reaches the presetting value and the ink residual detection part detects that the position has no ink, the printer prompts that the ink is exhausted. The method for detection of ink residual, the ink residual detection mechanism, the ink supply system and the ink jet printer can accurately detect the ink residual in the ink box to allow the ink residual in the ink box to reach the minimum and avoid the damaging caused by the air suction of the ink suction needle.

Owner:ZHUHAI NINESTAR MANAGEMENT CO LTD

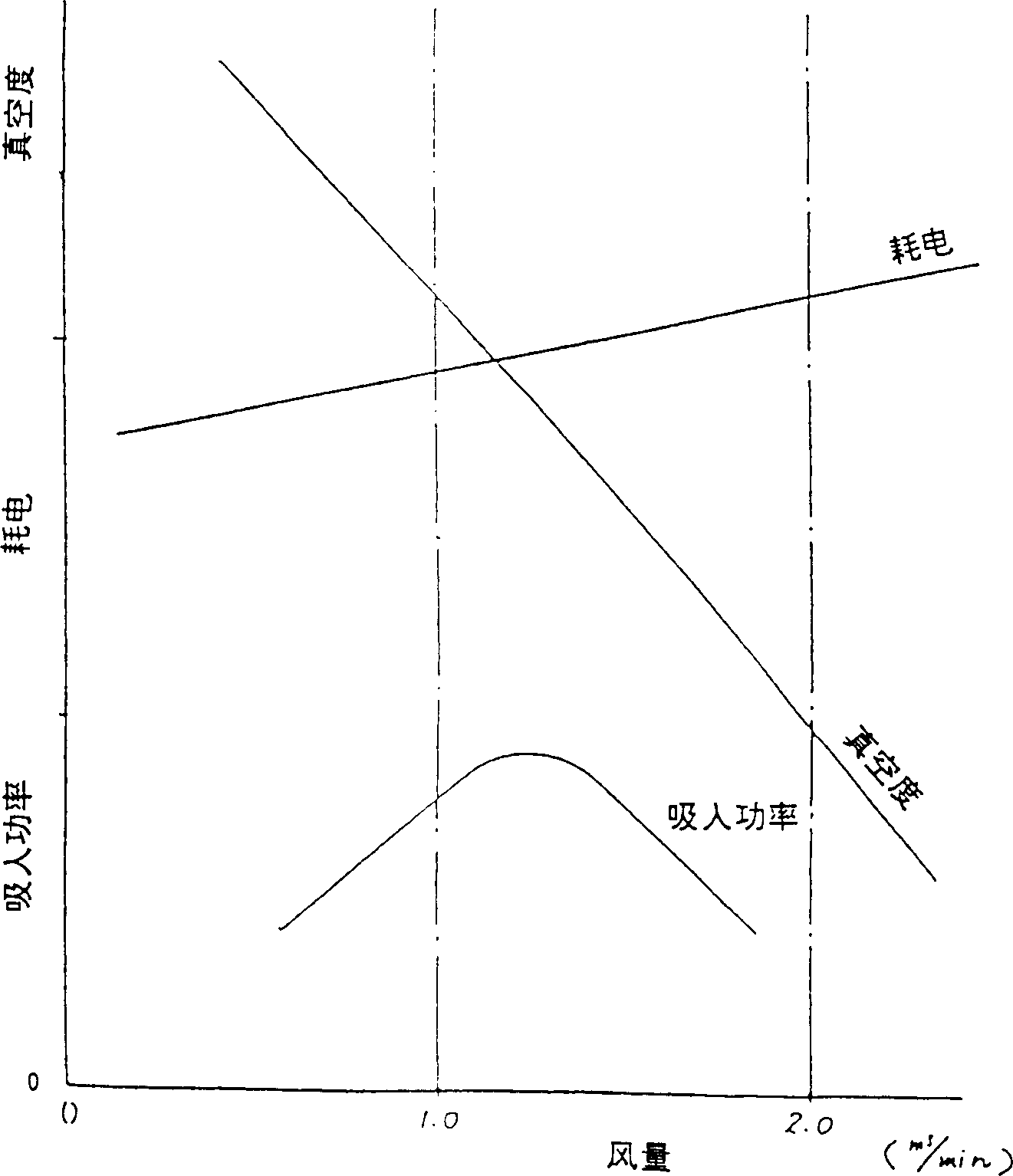

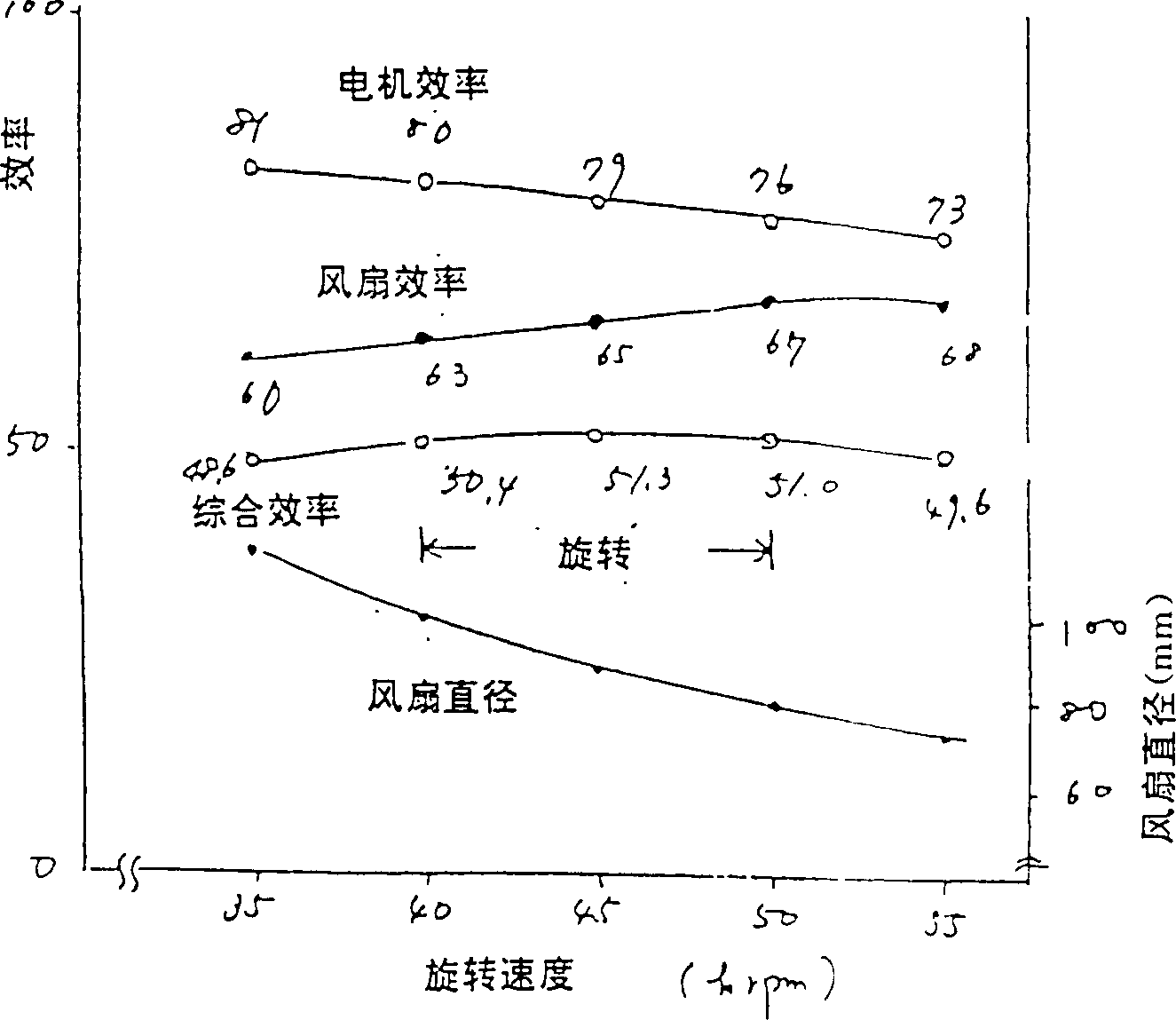

Electric dust collector

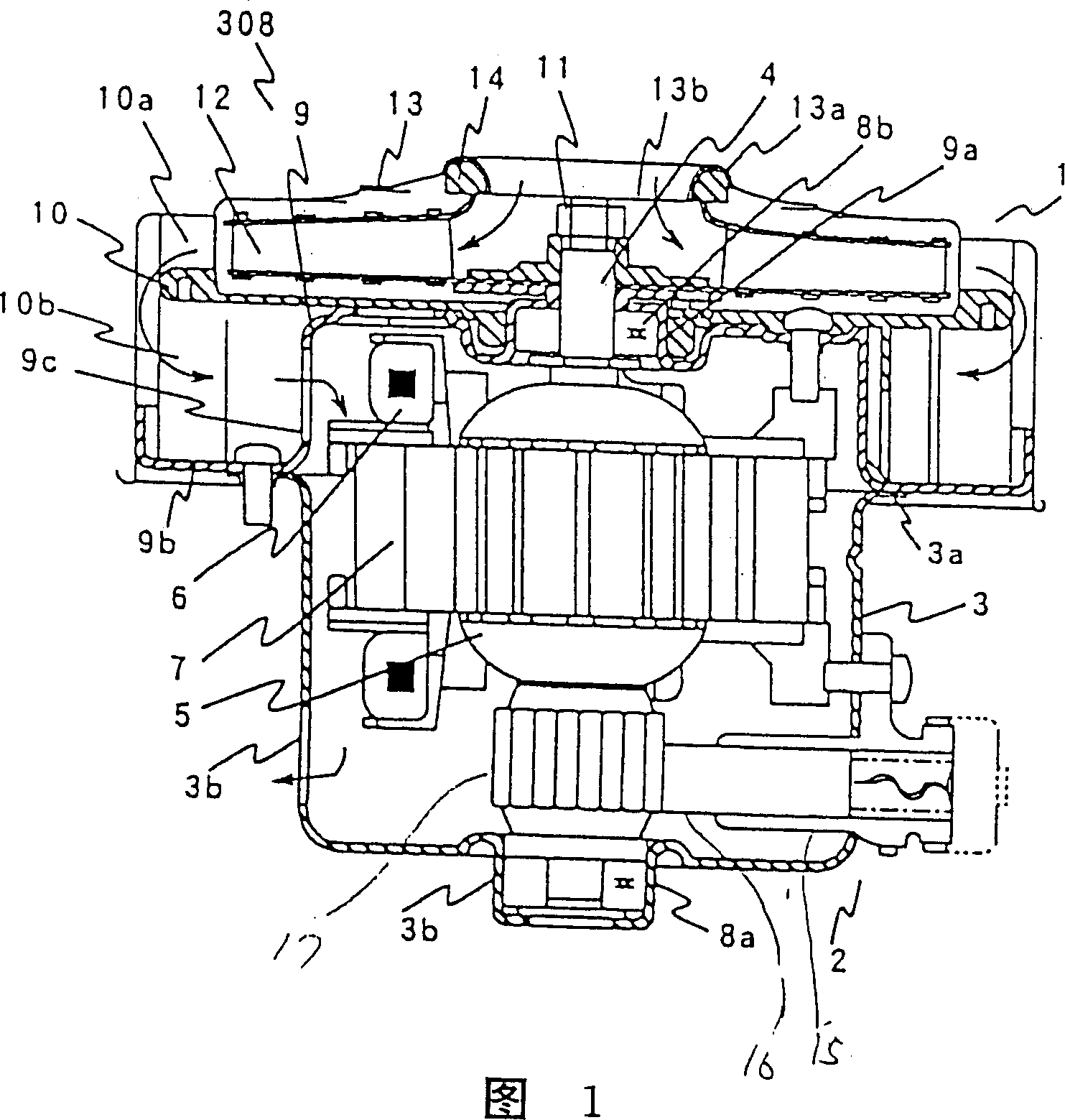

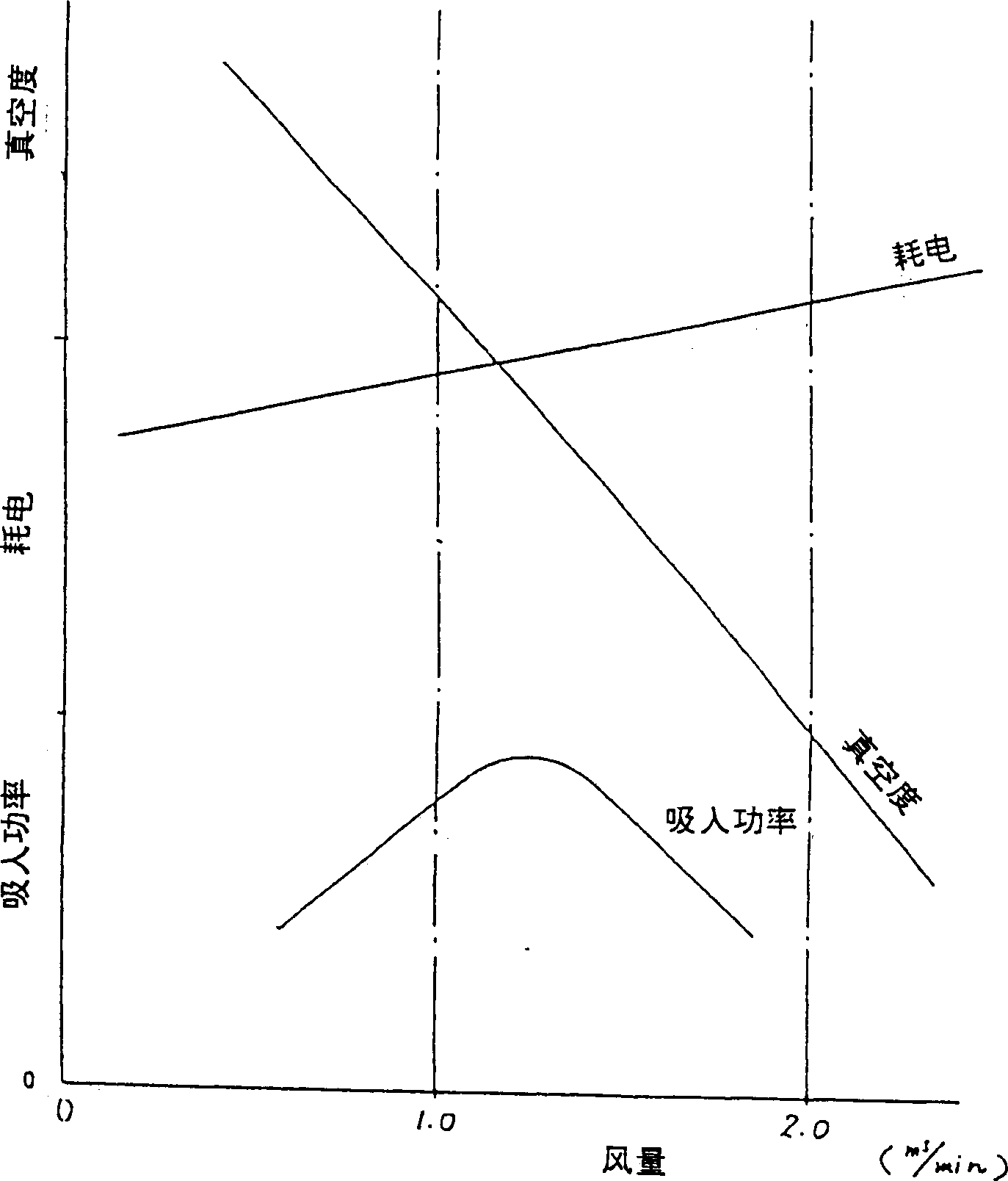

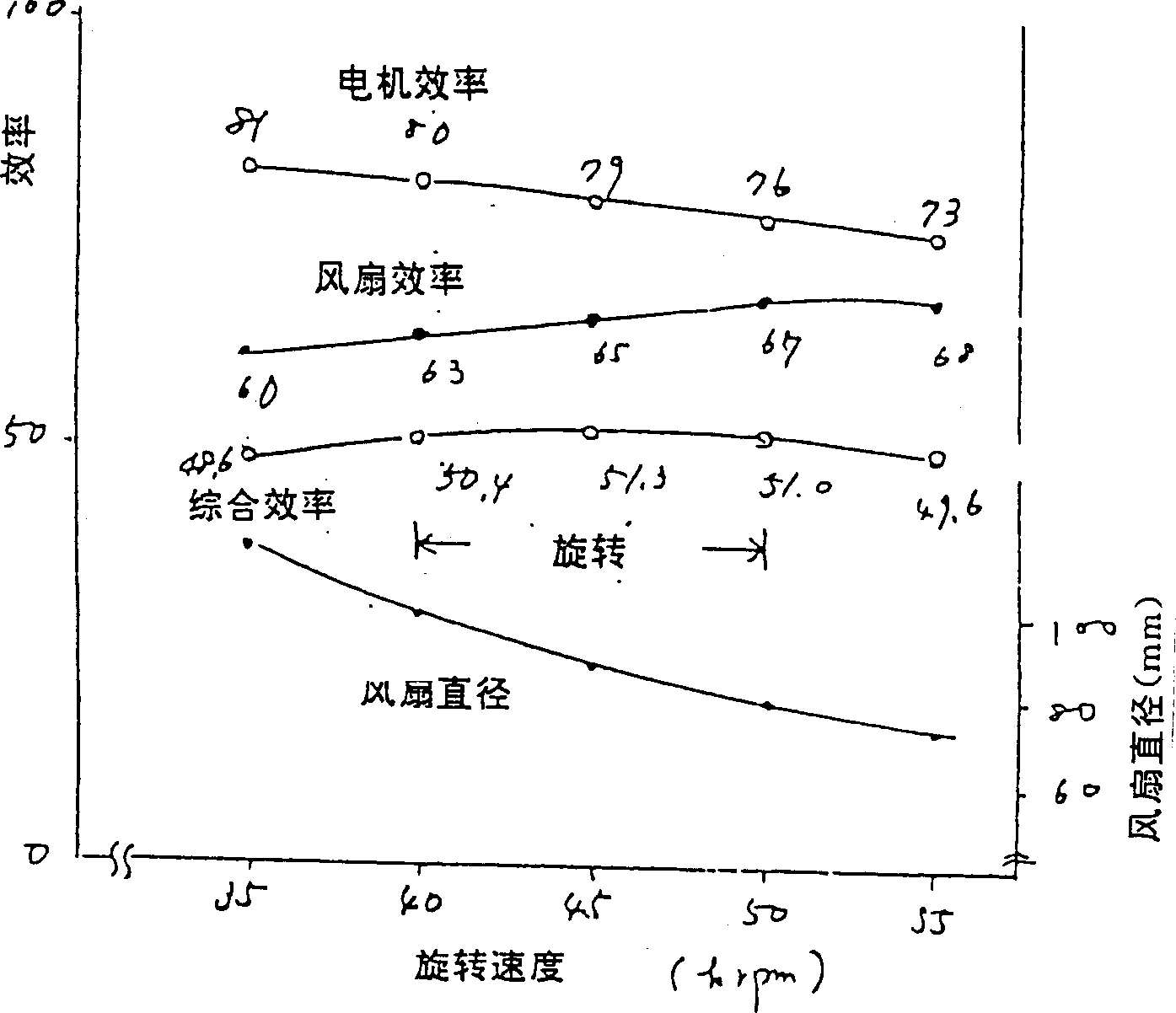

InactiveCN1108138CIncrease suction powerAdjust load characteristicsPump componentsOther chemical processesImpellerAir volume

The invention discloses an electric cleaner which has an air volume above 1.0 cubic meter per minute. The rotation number of the electric blower is arranged between the range from 40000 to 50000 rpm; area ratio of the co-adjacent hypothetic circle area of the front end of the blade center in the centrifugal impeller to the entrance area of the centrifugal impeller is arranged between 1.0 to 1.4; the dimension ratio of the blade external periphery outlet width to the external diameter is above 0.07; the sectional area ratio of the blade internal periphery flow route to the external one is blow 0.74; the dimension ratio of the blade inlet width to the outlet width is below 2.0; the ratio of the fillet curvature radius to the blade inlet width is from 0.6 to 0.9.

Owner:HITACHI LTD

Electric dust collector

InactiveCN1389174AImprove suction powerImprove operability and usabilityOther chemical processesPump componentsImpellerEngineering

The present invention discloses an electric dust collector with a wind volume more than 1.0 m<3> / min. The rotating number of an electric blower is set between 40000-50000rpm. A ratio between the area of a virtual annulus ring to interconnect the front ends on the central side of the blades of a centrifugal impeller and the inlet area of the centrifugal impeller is set to a range of 1.0-1.4. A ratio between the width size at the outer circumferential outlet of the blade and the outer diameter size is set to more than 0.07. A ratio between the flow path section area of the inner circumferential side of the blade and the flow path section area of the outer circumferential side is set to below 0.74. A ratio between the inlet width size of the blade and the outlet width size is below 2.0, and a ratio between the curvature radius of the round corner and the inlet width size of the blade is set to a range of 0.6-0.9.

Owner:HITACHI LTD

Underwater cleaner

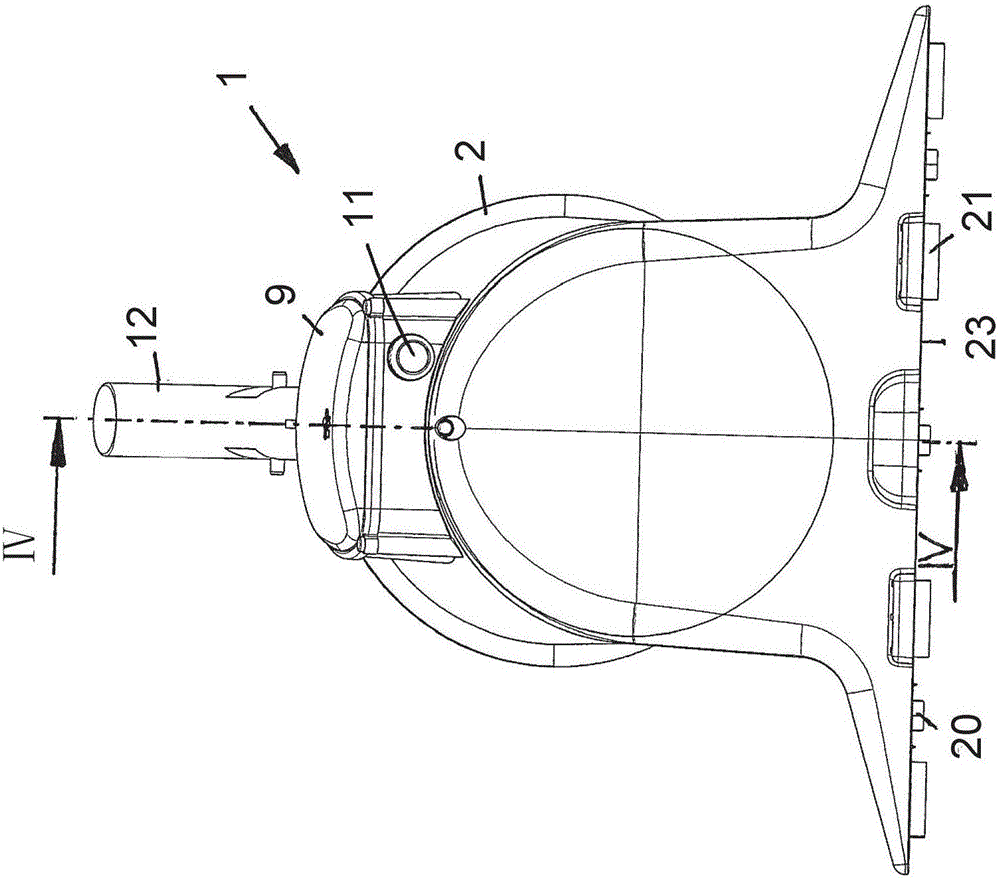

The invention relates to an underwater cleaner, in particular for a swimming pool, comprising a housing in which is arranged an especially battery - operated pump with an electric motor and an impeller and a second channel section, which accommodates the impeller, the second channel section having a first channel section, the first channel section is arranged inclined relative to the first channel section, and the impeller axis is arranged inclined to a normal on the opening cross section of the inlet opening. The ratio A / B of a first cross-sectional area A to a second cross-sectional area B is less than 2.8, the first cross-sectional area A being defined by the smallest cross-section of flow in the first channel section 13 and the second cross-sectional area B by the smallest cross-section of the second channel section is defined directly at the pump inlet. In order to obtain a very simple and productive underwater cleaner and to realize high suction effects with relatively little flow losses in the case of wheels with relatively large diameters, the first channel section transits into the second channel section.

Owner:安德烈斯弗兰克尔

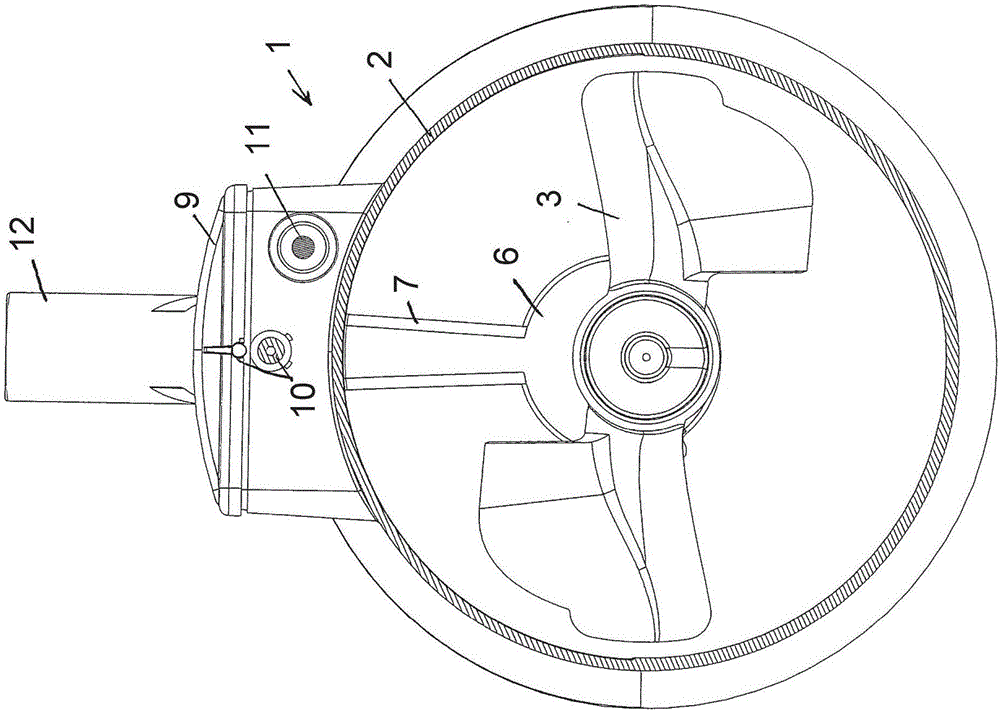

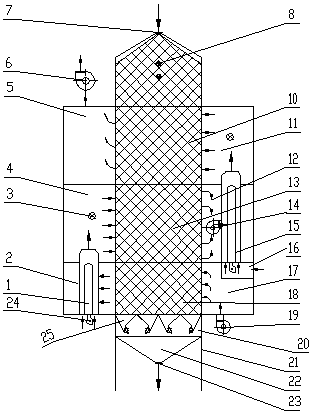

Multistage built-in heat source and multistage waste heat recycling type cereal drying tower

PendingCN111023728AReduce consumptionReduce drying costsFood processingClimate change adaptationEngineeringMechanics

A multistage built-in heat source and multistage waste heat recycling type cereal drying tower comprises a tower body and a plurality of air chambers. A cereal storage section, a multistage drying section, a cooling section, a cereal discharging section and a cereal discharging hopper are sequentially arranged in the tower body from top to bottom. The air chambers matched with the multistage drying section and the cooling section are arranged at the positions, on the tower body, of the left side and the right side of the multistage drying section and the cooling section from top to bottom. Theair chambers are divided into waste gas chambers, hot air chambers and cold air chambers according to functions, and the air chambers located on the left side are alternately and sequentially arranged from the waste gas chamber and the hot air chamber. The cold air chamber is arranged on the lowermost layer of the air chambers located on the right side, and the waste gas chamber and the hot air chamber are alternately and sequentially arranged above the cold air chamber. A hot blast heater is arranged in the vertically adjacent waste gas chamber and hot air chamber of the cereal discharging section, the hot blast heater is one or more of upright direct-fired hot blast heaters, an air outlet of the hot blast heater is formed in the hot air chambers, and an air inlet of the hot blast heateris formed in the waste gas chambers. The multistage built-in heat source and multistage waste heat recycling type cereal drying tower can achieve the aims of reducing energy consumption and reducingemission pollution.

Owner:ZHENGZHOU WANGU MACHINERY

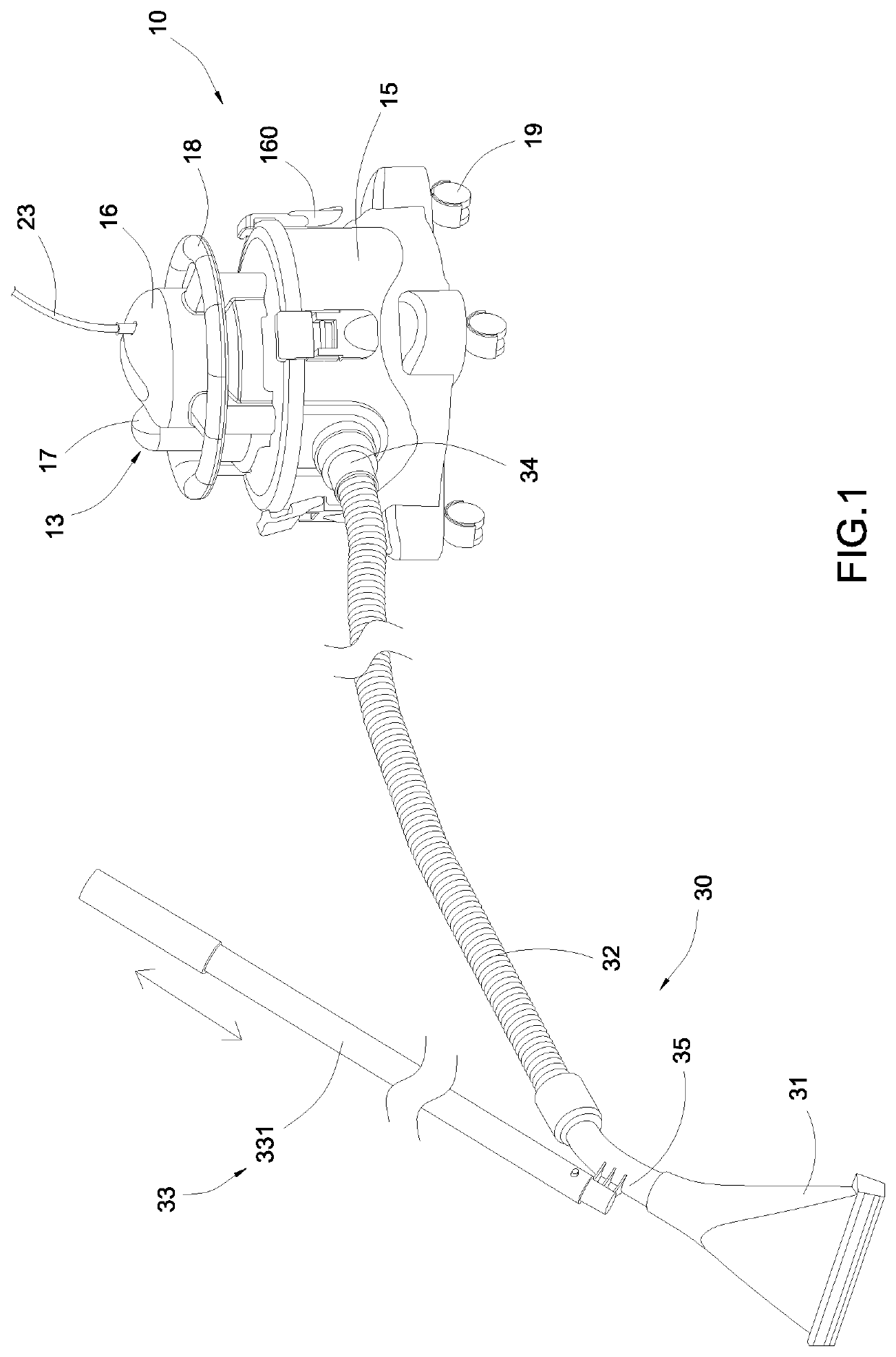

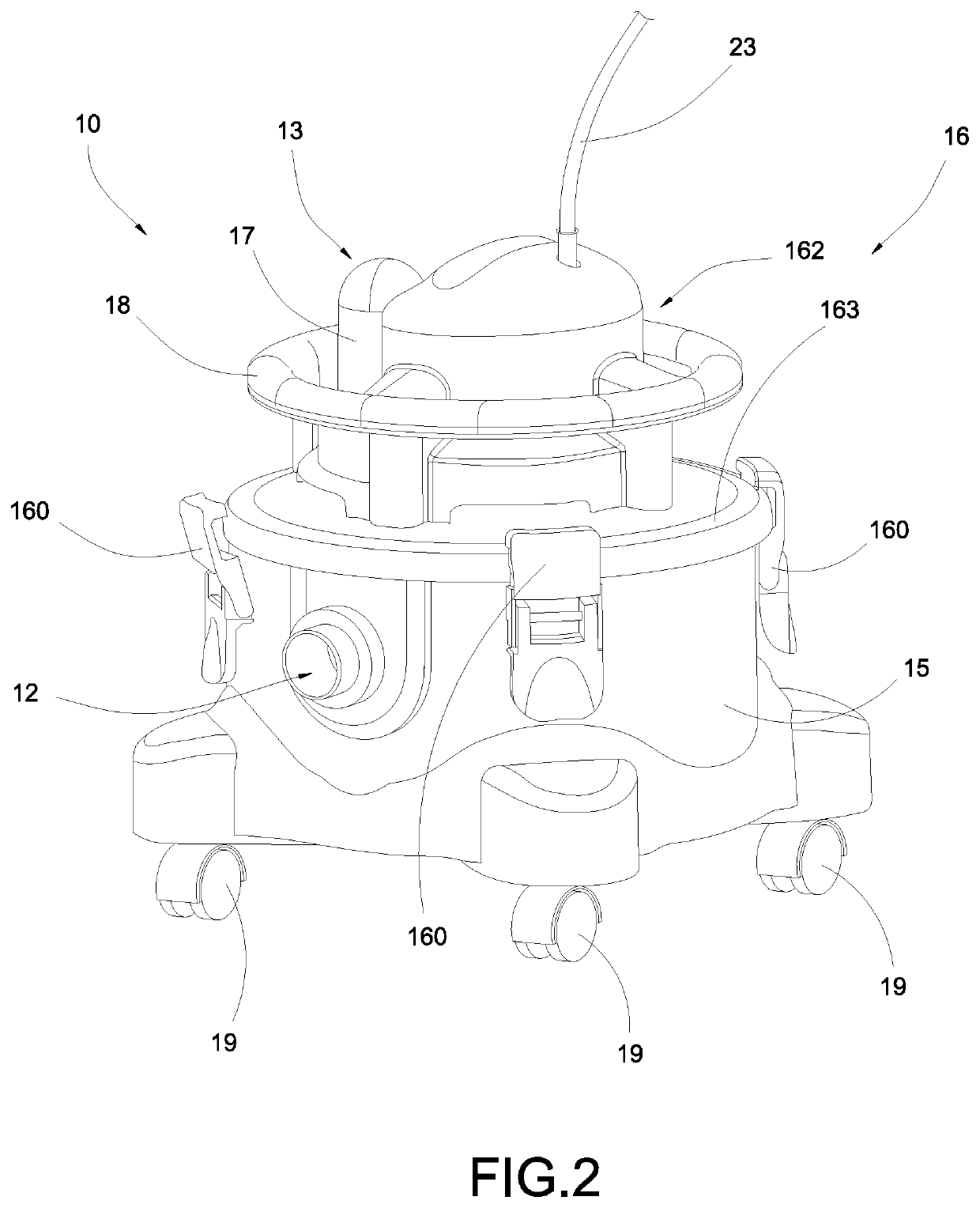

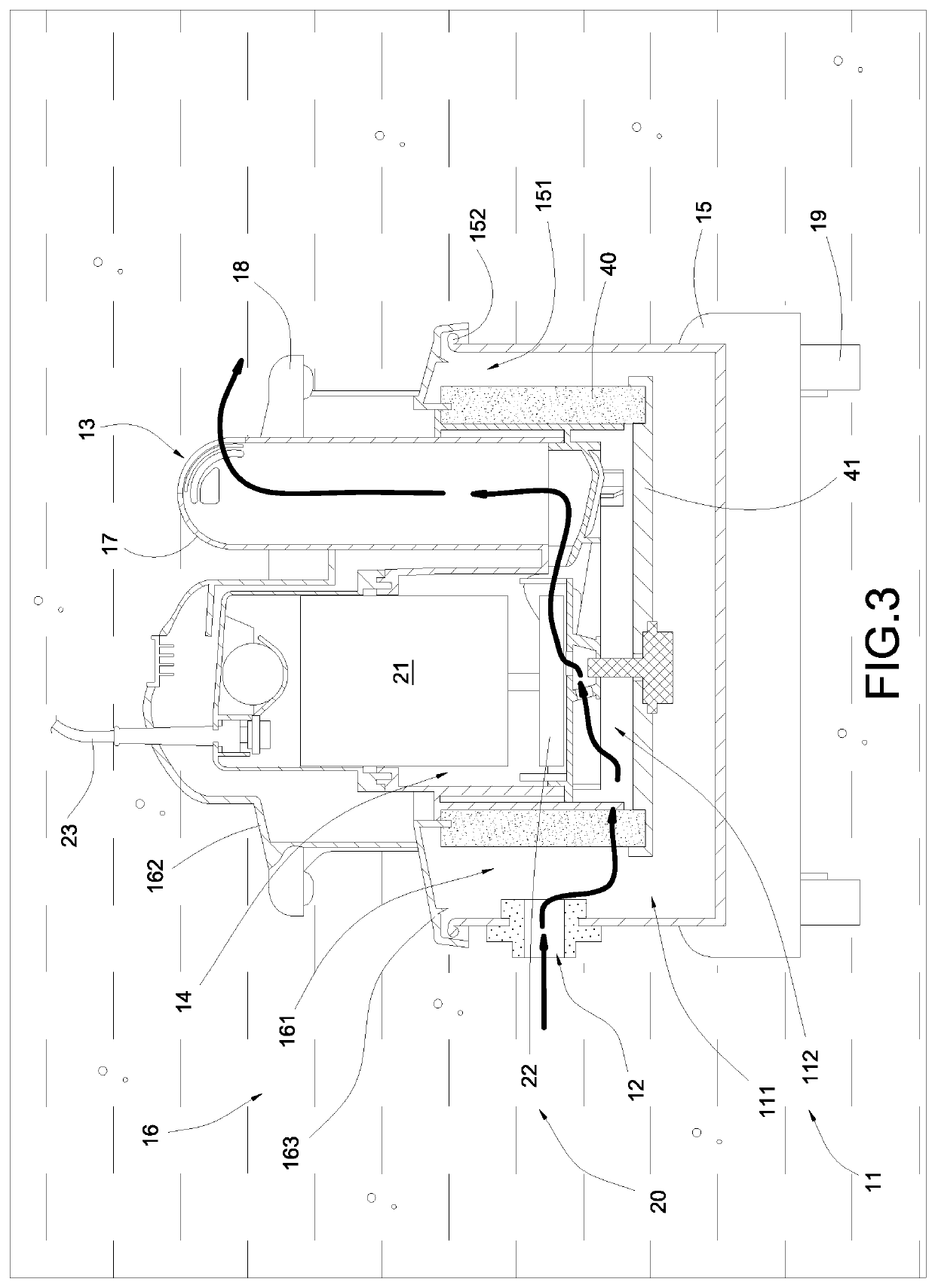

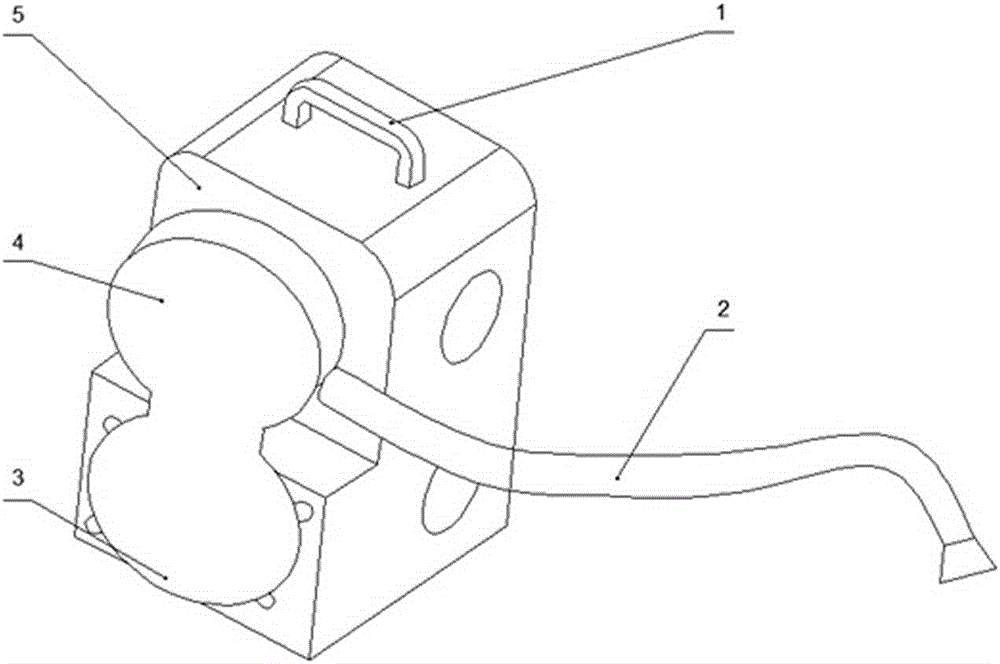

In-Water Suction Cleaner

ActiveUS20200087940A1Increase suction powerEnhance portabilityGymnasiumSwimming poolsPumping vacuumWater tanks

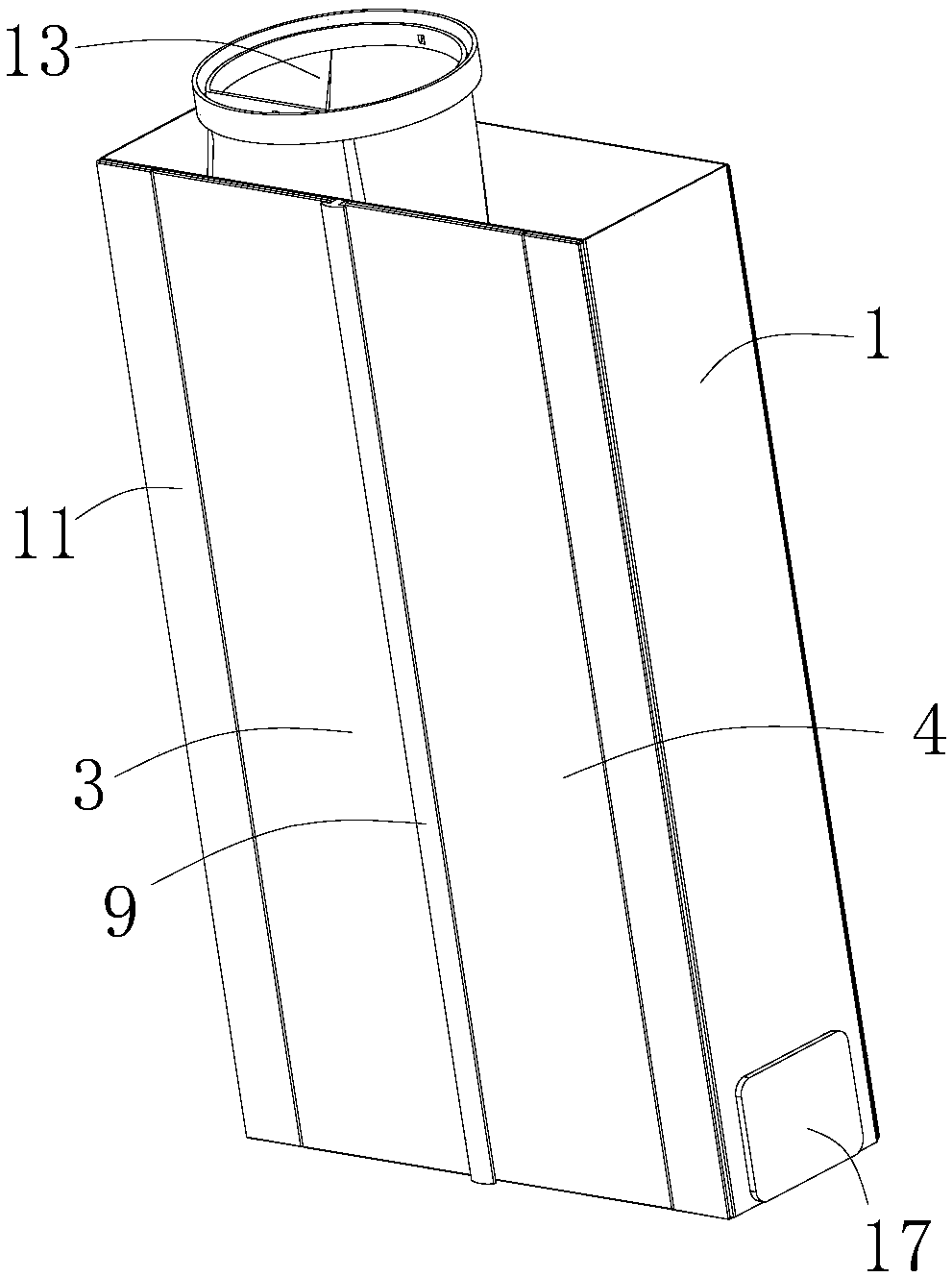

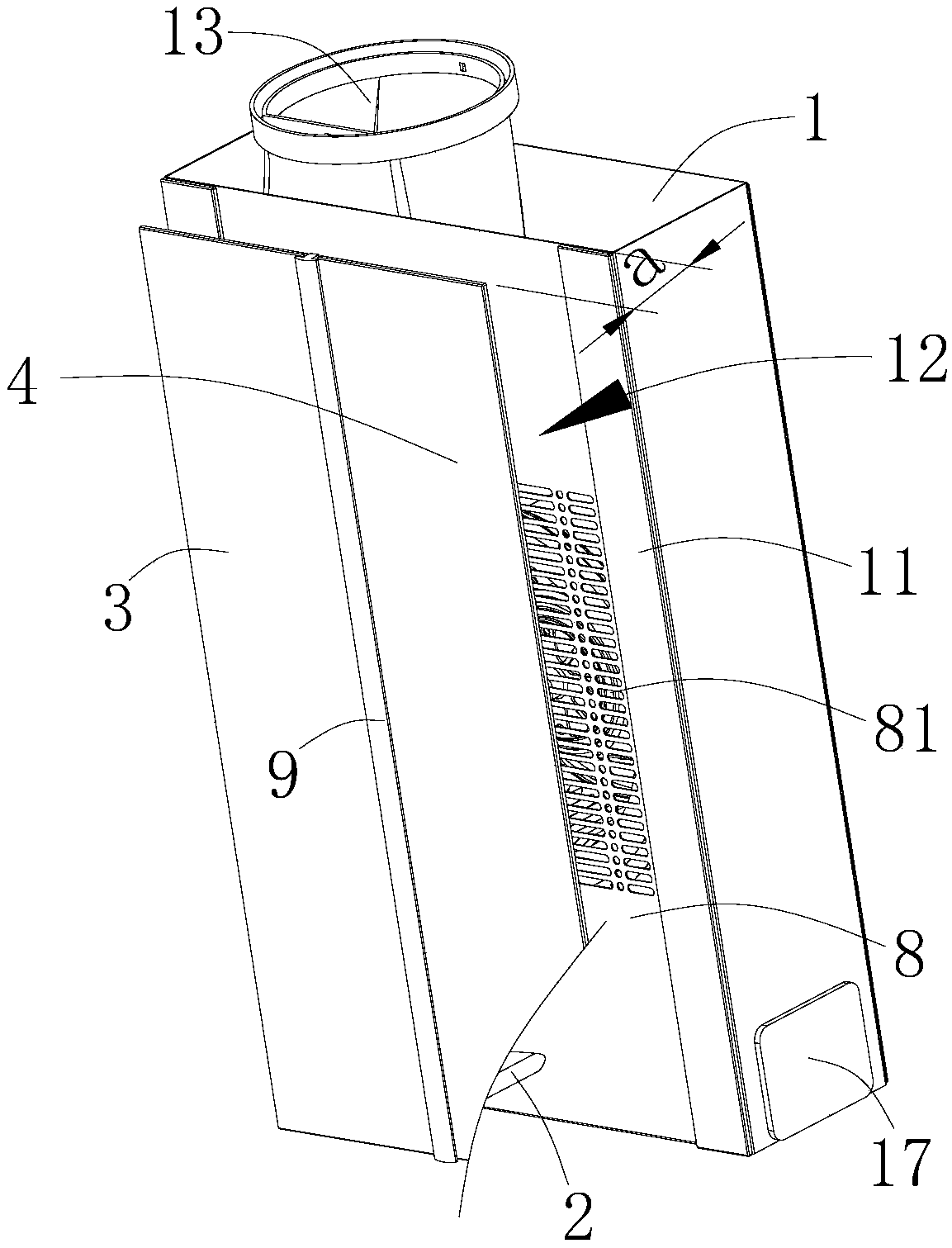

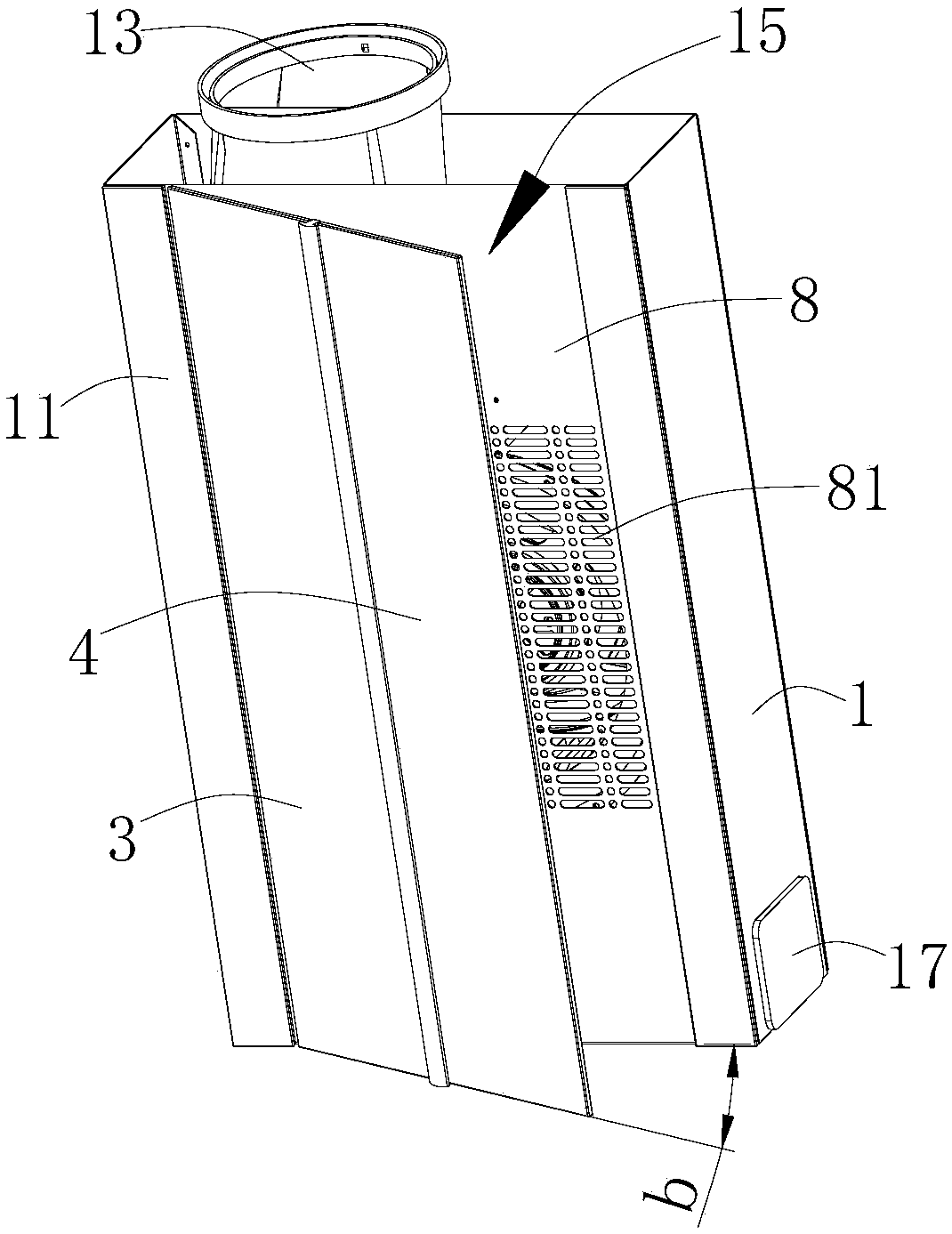

An in-water suction cleaner includes a portable housing for disposing at water of a pool or tank, a motorized unit supported in the portable housing for vacuuming a suction cavity of the portable housing to suck the water in the suction cavity out of the portable housing through a fluid outlet of the portable housing so as to create a suction at a fluid inlet of the portable housing, a manual scrubbing arrangement detachably coupled at the fluid inlet of the portable housing for scrubbing pool or tank surfaces and for sucking the water into the suction cavity at the same time, and a filtering element replaceably disposed in the suction cavity for filtering the water from the fluid inlet to the fluid outlet through the suction cavity so as to ensure the water after filtered being discharged back to the pool or tank via the fluid outlet.

Owner:XU QIANG

Ventilating and dedusting device for underground coal mining

InactiveCN107630714AReduce contentIncrease suction powerUsing liquid separation agentMachines/enginesAir filterLiquid water

The invention discloses ventilating and dedusting equipment for underground coal mining. The ventilating and dedusting equipment comprises a tubular hollow shell, wherein an air entering space is arranged at the inner part of the bottom part of the tubular hollow shell; multiple main air inlet pipelines in an integrated structure with the tubular hollow shell are arranged at the bottom part of thetubular hollow shell; main air inlet holes for communicating the exterior with the air entering space are formed in the main air inlet pipelines; an air filter mechanism is arranged at the inner partof the tubular hollow shell and is located above the air entering space; a main air vent for communicating the top part of the air entering space with the top part of the air filter mechanism is formed in the tubular hollow shell. The ventilating and dedusting equipment disclosed by the invention is used for air exhausting during underground coal mining, can be placed in a safety zone and can work through a pipeline; in addition, the ventilating and dedusting equipment is capable of filtering exhausted air through liquid water, so that the content of flammable matters in air can be effectively reduced; in addition, the ventilating and dedusting equipment is provided with a turbo charging mechanism, so that the air suction power can be increased.

Owner:吴舒雨

Cotton picker

InactiveCN106717539AIncrease suction powerReasonable structurePicking devicesGear wheelReduction drive

The invention provides a cotton picker. The cotton picker comprises a cotton picking handle, a hose, a cotton-air separation box, a centrifugal fan and a case. A handle is arranged on the case, and the handle is arranged on the upper portion of the case. One end of the cotton picking hose is connected with a separation box shell, and a suction head is arranged at the other end of the cotton picking hose. A wind closing wheel is arranged on the lower portion of the separation box, and cotton is conveyed to a cotton outlet. A cotton collecting bag is arranged on the outlet. A motor is arranged on the lower portion in the case, the motor transmits torque to a rotary shaft of the wind closing wheel through a gear reducer, a large belt wheel is arranged on the rotary shaft of the wind closing wheel, a small belt wheel is arranged on a rotary shaft of a screen, rotational motion of the wind closing wheel is also transmitted to the screen through belt drive, the rotating speed of the screen is far higher than that of the wind closing wheel, and large centrifugal force is generated. The cotton picker is high in suction power and more reasonable in structure, the cotton hull separation rate is high, and cotton and cotton seed separation rate is higher.

Owner:郭洪

Dust collector suction nozzle

The invention provides a sucker header of dust collector comprising a cover of header, an inlet tube, a mouth of inlet tube, a swinging brush, a front inlet flow circuit and a back inlet flow circuit. Wherein, a plurality of guide ribs are arranged with certain space on the inner side surface of mouth of inlet tube to form a channel, for generating the suction flow from the opposite side of back inlet to the back inlet. The invention arranges the sucker of dust collector on the inner side of mouth of inlet tube and forms several channels via arranging the guide ribs in certain space to generate the flowing effect inside said channels. And the opposite side of back inlet can generate higher suction force with the increase of flowing speed to guide the sucked dust or foreign matter to the back inlet, therefore, the uniform cleaning effect can be realized.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

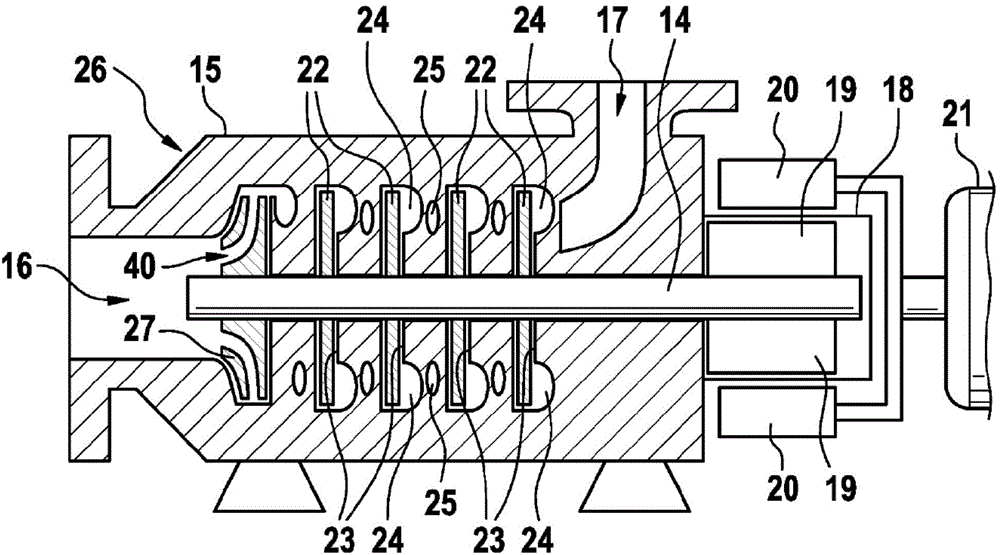

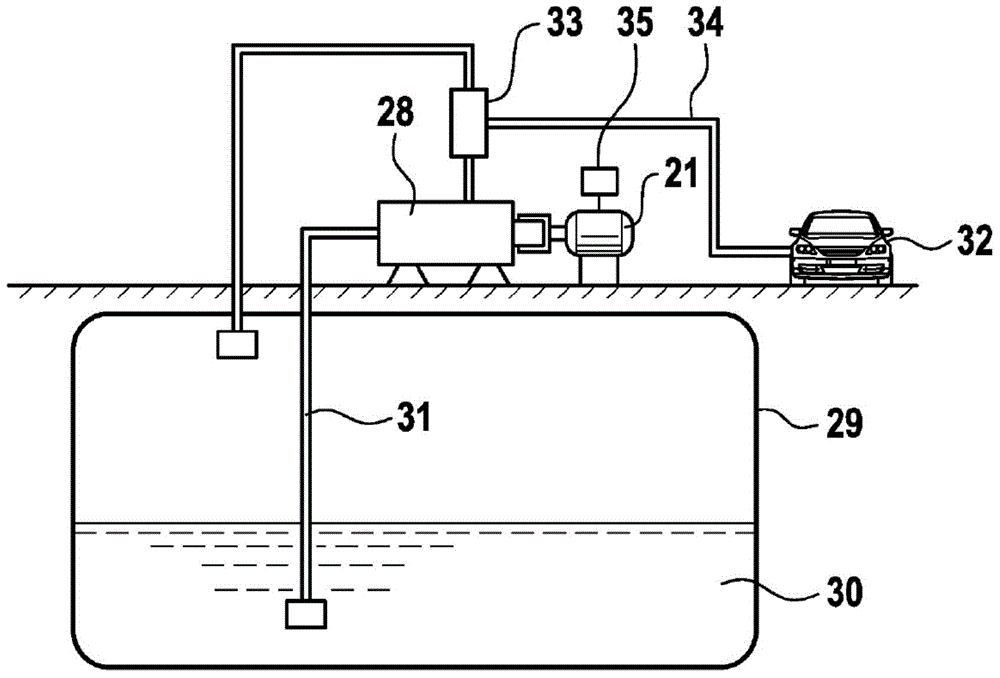

Side-channel pump, and method for operating a side-channel pump

ActiveCN104619989AIncrease suction powerEvenly distributedCircumferential flow pumpsPump componentsImpellerEngineering

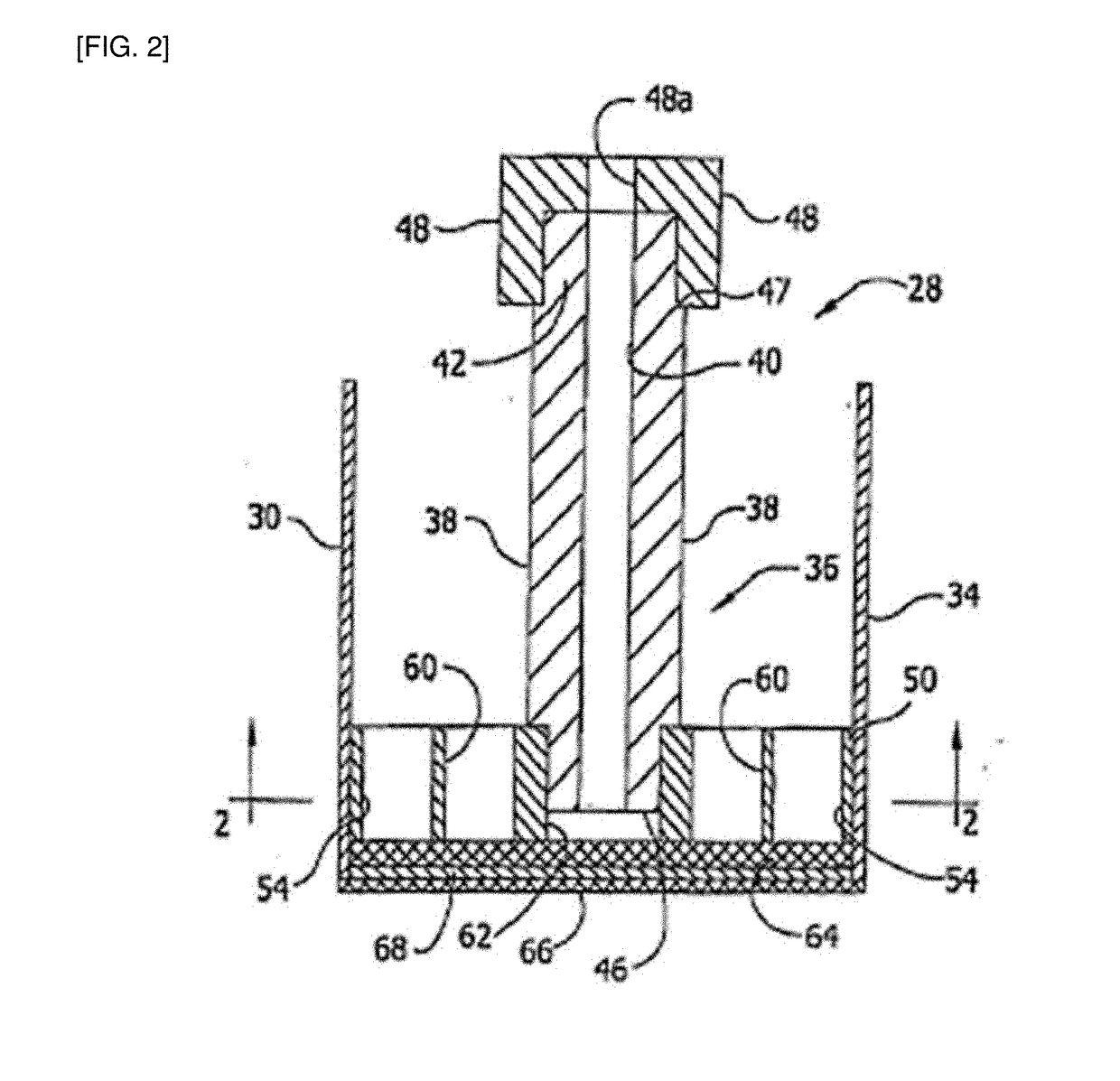

The invention relates to a side-channel pump (28) and to a method for operating a side-channel pump (28) in which an impeller (22) rotates in a working chamber (23) provided with a side channel (24). According to the invention, the pump (28) is operated at an overspeed with a gas-filled working chamber (23) in a first step. The speed is then reduced to an operating speed in order to pump a liquid. The pump according to the invention has a high suction power as a result of the overspeed, but only gas is drawn initially.

Owner:STERLING IND CONSULT GMBH

Monitoring system for a central vacuum assembly

InactiveUS20180106653A1Great suctionMarginally effectiveSuction filtersVolume/mass flow measurementMonitoring systemEngineering

A service network, and associated methods, for monitoring central vacuum assemblies at distinct sites that include one or more air flow meters at each distinct site, each air flow meter respectively positioned and adapted to measure an indicia of air flow in connection with a particular central vacuum assembly within the service network; interfaces at the distinct sites associated with each air flow meter to relay an abnormal result from the respective air flow meter; and an off-site service center in communication with the interfaces at the distinct sites to register the abnormal result and identify the site of the abnormal result.

Owner:RAVE SYST INC

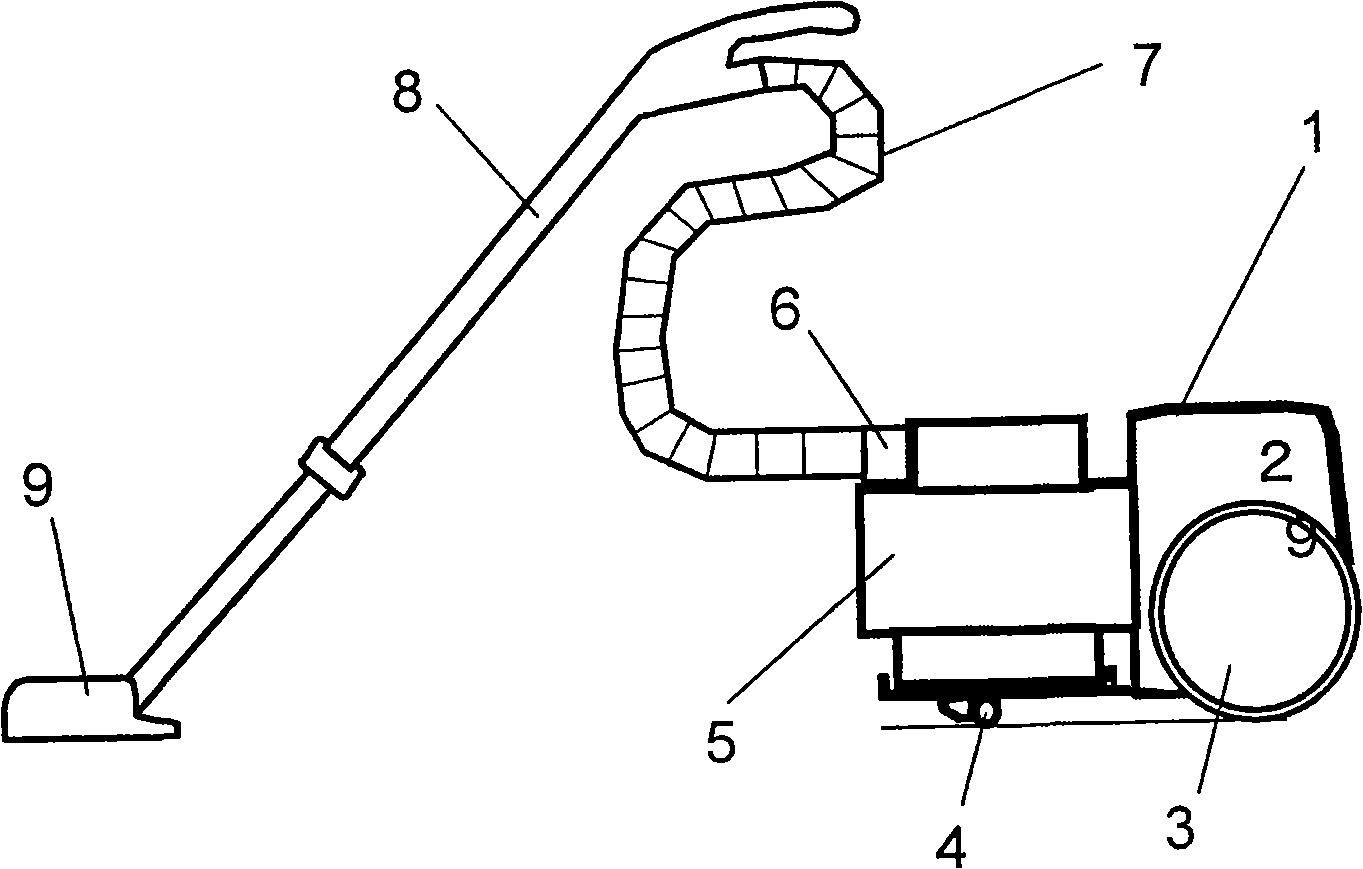

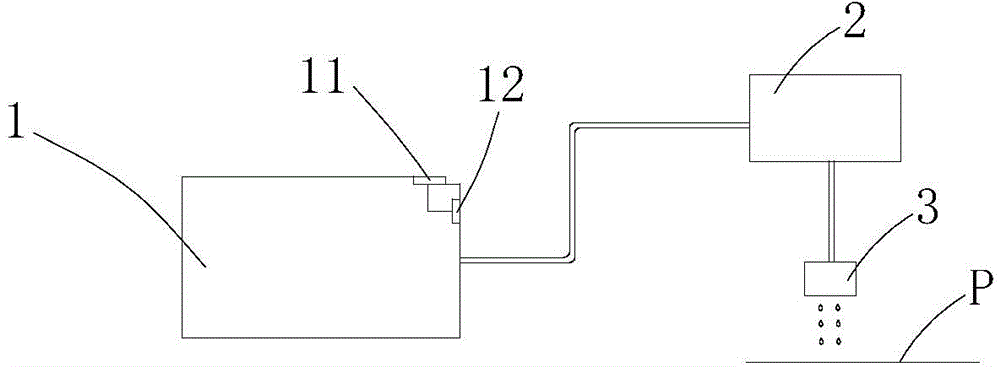

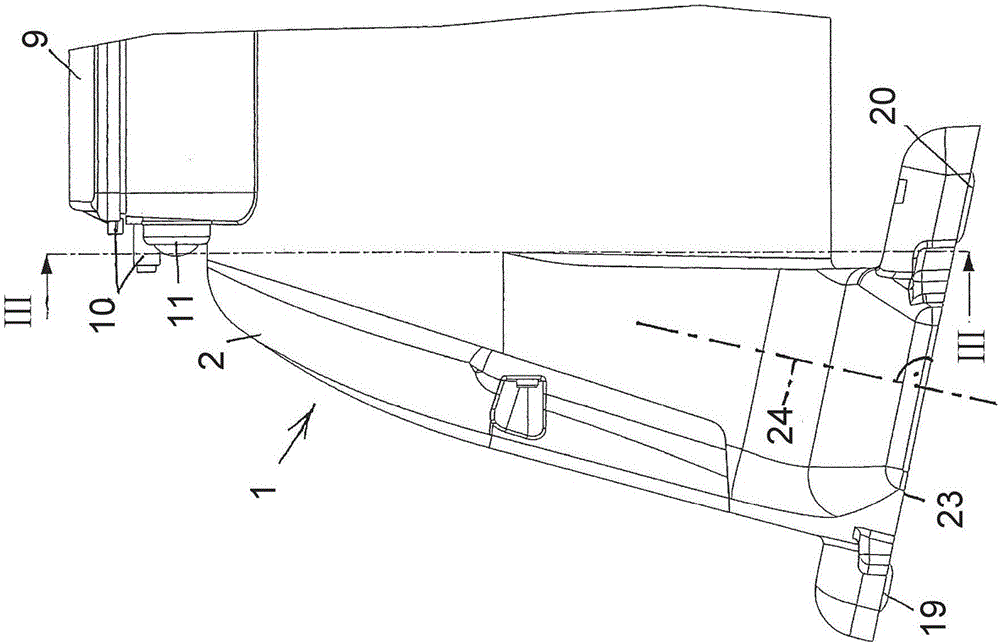

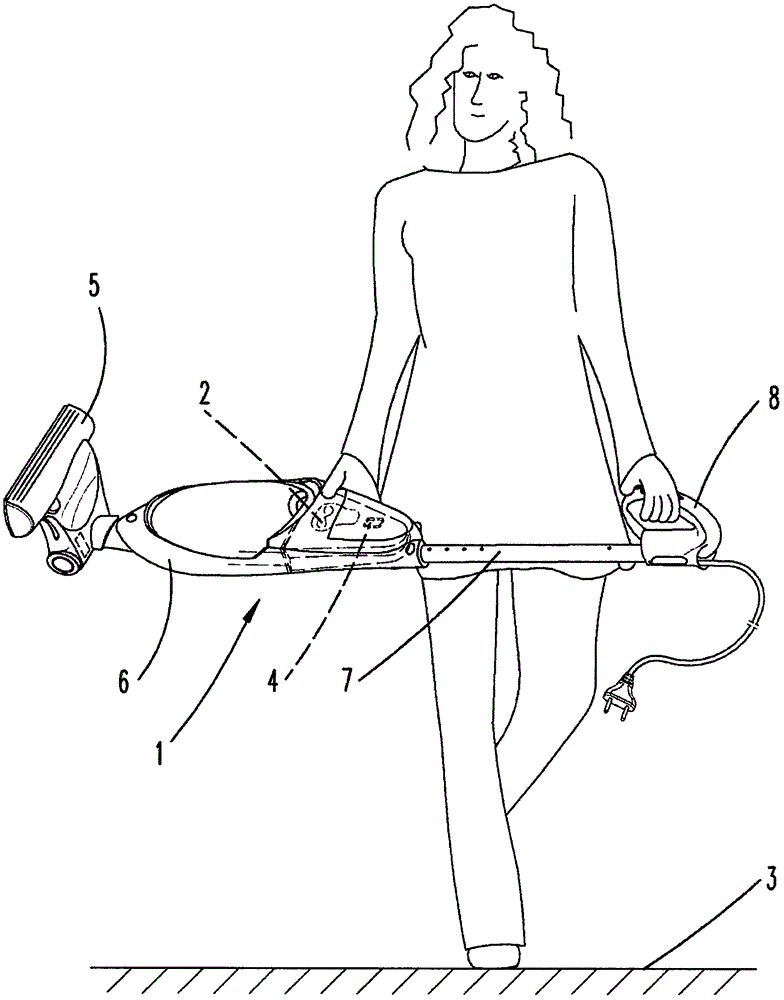

Cleaning device and method for operating cleaning device

InactiveCN106798523AIncrease suction powerEasy to cleanElectric equipment installationEngineeringElectrical and Electronics engineering

The invention relates to a cleaning device (1), particularly a household vacuum cleaner, with a blower (2) and an evaluation and control device (4) for varying a suction power of the blower (2) in response to a determined allocation state of the cleaning device (1) to a surface (3), namely a contact state in which the cleaning device (1) is placed on the surface (3), or a non-contact state in which the cleaning device (1) is lifted from the surface (3). In order to provide a cleaning device (1) with which a surface remote cleaning task can be carried out successfully, it is proposed that the evaluation and control device (4) arranged to set the suction power upon detection of the non-contact state at a higher level than upon detection of a contact state. Furthermore, the invention relates to a method of operating the cleaning device (1).

Owner:VORWERK & CO INTERHOLDING GMBH

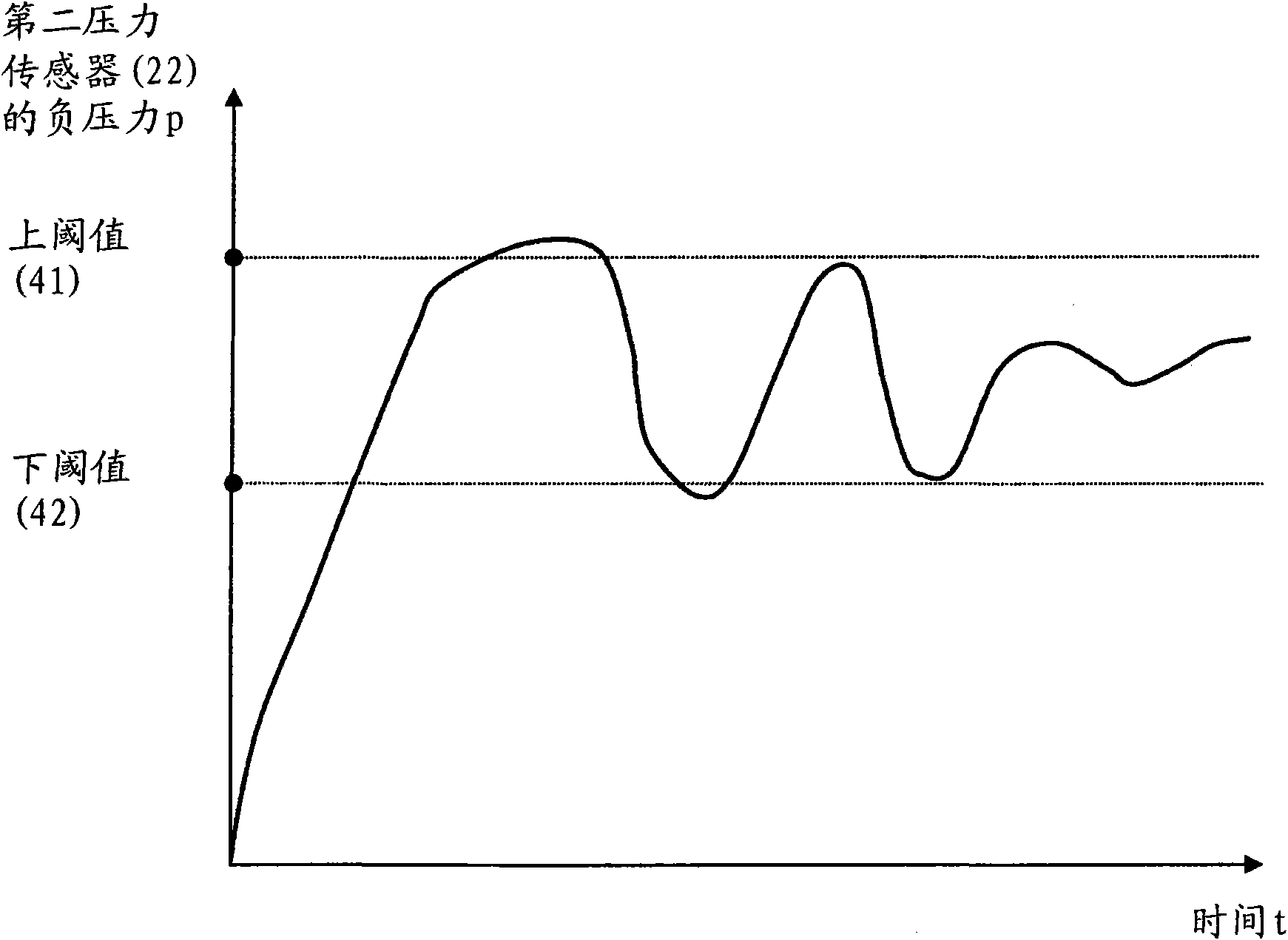

Device for the automatic suction power regulation of a vacuum cleaner

InactiveCN101945607BReduce suction powerIncrease suction powerVacuum cleaner apparatusElectric equipment installationVacuum cleanerPower regulation

The invention relates to a device for a vacuum cleaner (1). Said device only supplies as much electrical power to the motor / fan unit (10) as is necessary for the optimal cleaning of the floor surface to be cleaned and required by the respective operating states of the vacuum cleaner (1), thereby ensuring an energy-efficient use of the vacuum cleaner. Said device thereby ensures a constant cleaning action over the usable life of the vacuum cleaner (1). As the suction nozzle has a constant suction power, dust and dirt particles are always sucked up with a consistently applied suction power and supplied to a dust collection unit (3). The invention also protects the surfaces to be cleaned from being subjected to too much cleaning.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Fixed impeller and motor using same

InactiveCN105201906ANoise decibel reductionImprove comfortPump componentsSuction cleanersImpellerNoise reduction

The invention discloses a fixed impeller which comprises an air deflector and a substrate, wherein the air deflector is provided with a toothed structure. The invention also discloses a motor which comprises the fixed impeller. The motor has favorable noise reduction effect under the condition of not adding muting cotton or taking other muting measures; and meanwhile, the air properties of the motor are enhanced.

Owner:KINGCLEAN ELECTRIC

Electric cleaner

The present invention provides an electric vacuum cleaner having a small and easy-to-operate cyclone-type dust collecting section. It has: an inflow part (115) that flows into the dust-laden air; a separation chamber (104) that separates dust from the dust-laden air that flows in from the inflow part; Part (105a); the first communication port (117) that communicates the first dust containing part with the separation chamber; the first exhaust port (144) that discharges the air stream discharged from the separation chamber; is arranged in the first dust containing part of the second exhaust port (146); accommodate dust, and separate from the first dust containing part 105a set second dust containing part (105b); communicate with the second dust containing part and the separation chamber, and with the first communication port The second communication port (118) provided separately, and the third exhaust port (147) for discharging the air discharged from the second dust containing part.

Owner:HITACHI APPLIANCES INC

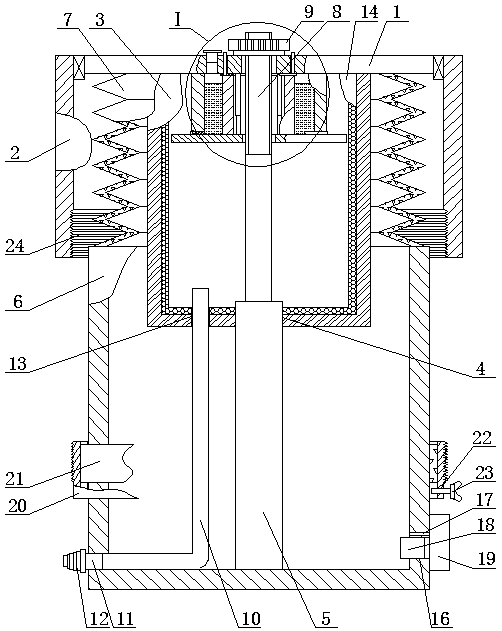

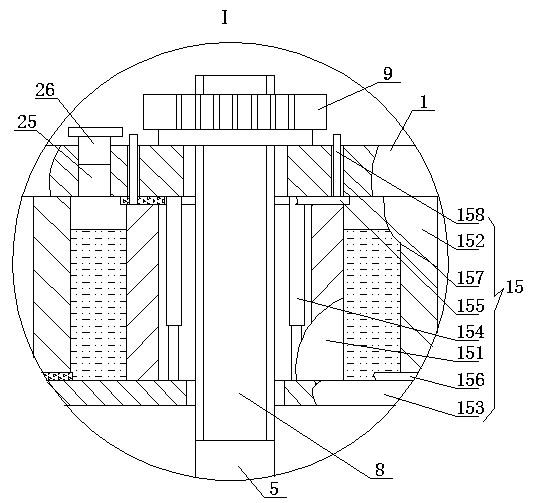

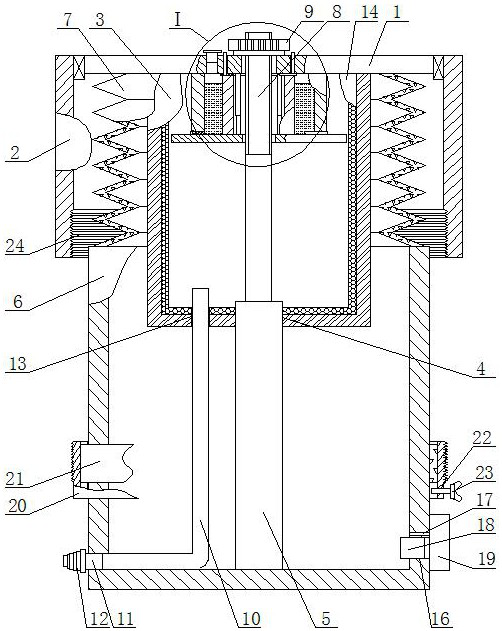

Emergency ventilator

An emergency ventilator comprises a top plate, the top plate is an annular horizontal plate, the outer peripheral bearing of the top plate is connected to the upper end of the inner wall of a sleeve,the middle part of the bottom side of the top plate is fixedly connected with the top side of a filter screen, the filter screen is a circular barrel with an open upper end and a closed lower end, a first through hole is arranged in the middle of the bottom side of the filter screen, a first spring rod is movably mounted in the first through hole, and the outer periphery of the first spring rod isin sliding contact fit with the inner wall of the first through hole. The emergency ventilator has the advantages of compact structure, small size, convenience in folding and unfolding, portability,increase of the inspiration power of an airbag through using the spring rod to assist the airbag, avoiding of the airbag from being pressed in an offset manner through the direction guiding effect ofthe spring rod, avoiding of the airbag from being accidentally damaged by the external environment through arranging the airbag in the sleeve, and realization of continuous air inspiration and no affection of the normal use of the ventilator under a damaged airbag condition.

Owner:QINGDAO MUNICIPAL HOSPITAL

emergency respirator

InactiveCN109513087BEasy to breatheGood orientationRespiratorsPhysical medicine and rehabilitationEngineering

An emergency ventilator comprises a top plate, the top plate is an annular horizontal plate, the outer peripheral bearing of the top plate is connected to the upper end of the inner wall of a sleeve,the middle part of the bottom side of the top plate is fixedly connected with the top side of a filter screen, the filter screen is a circular barrel with an open upper end and a closed lower end, a first through hole is arranged in the middle of the bottom side of the filter screen, a first spring rod is movably mounted in the first through hole, and the outer periphery of the first spring rod isin sliding contact fit with the inner wall of the first through hole. The emergency ventilator has the advantages of compact structure, small size, convenience in folding and unfolding, portability,increase of the inspiration power of an airbag through using the spring rod to assist the airbag, avoiding of the airbag from being pressed in an offset manner through the direction guiding effect ofthe spring rod, avoiding of the airbag from being accidentally damaged by the external environment through arranging the airbag in the sleeve, and realization of continuous air inspiration and no affection of the normal use of the ventilator under a damaged airbag condition.

Owner:QINGDAO MUNICIPAL HOSPITAL

Electric cleaner

The invention discloses an electric cleaner with small-sized and operational cyclone separating dust collection part, which comprises the following parts: inflow part (115) to flow air with dust, separating chamber (104) to separate dust in the air, first dust containing part (105a) to contain dust from separating chamber, first interconnecting hole (117) to connect the first dust containing part and separating chamber, first vent (144) to drain air from separating chamber, second vent (146) at the position of first dust containing part, second dust containing part (105b) to contain dust away from the first dust containing part (105a), second connecting hole (118) to connect second dust containing part and separating chamber at the position of first connecting hole, third vent (147) to drain air out of the second dust containing part.

Owner:HITACHI APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com