Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4225results about "Gymnasium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

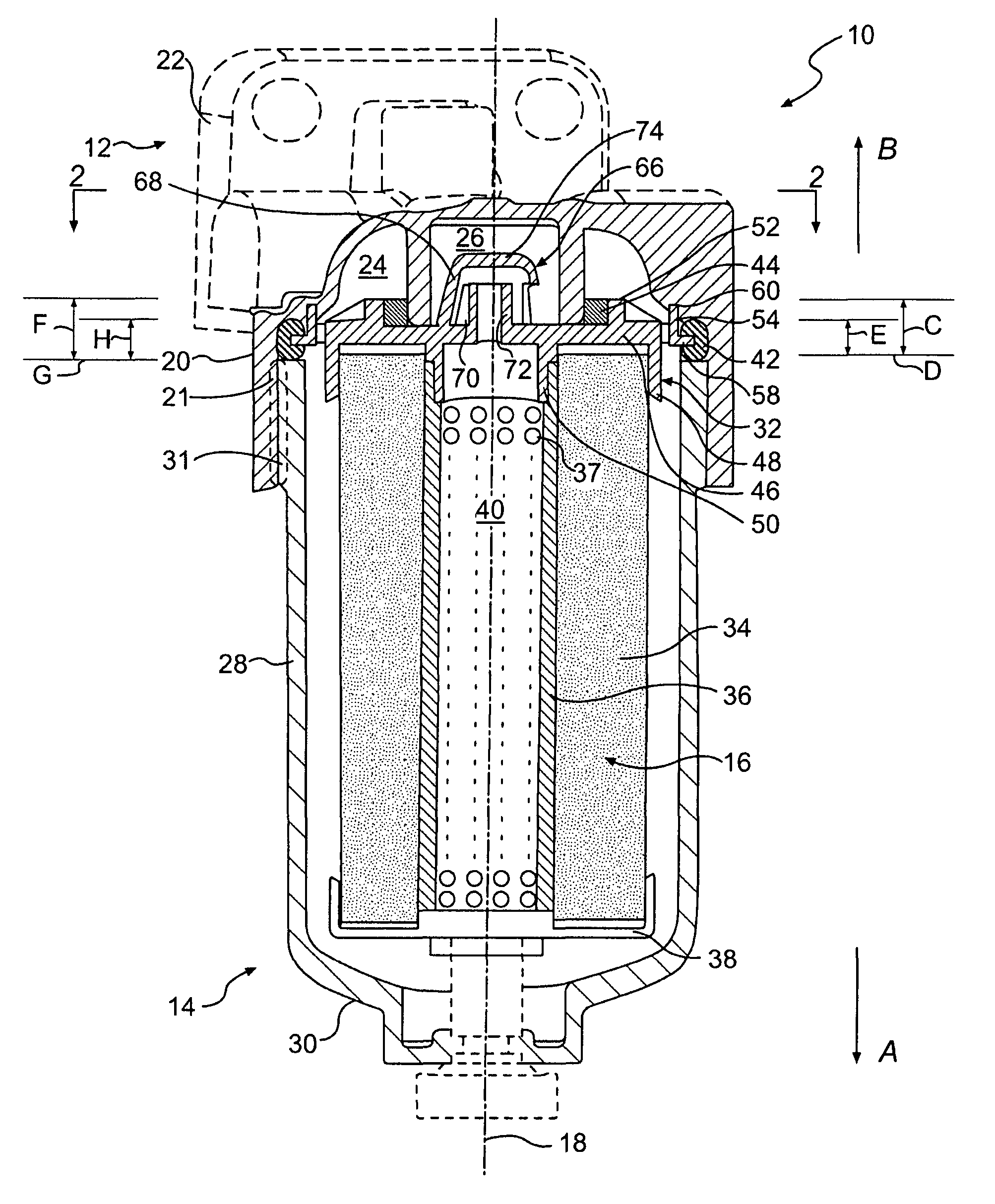

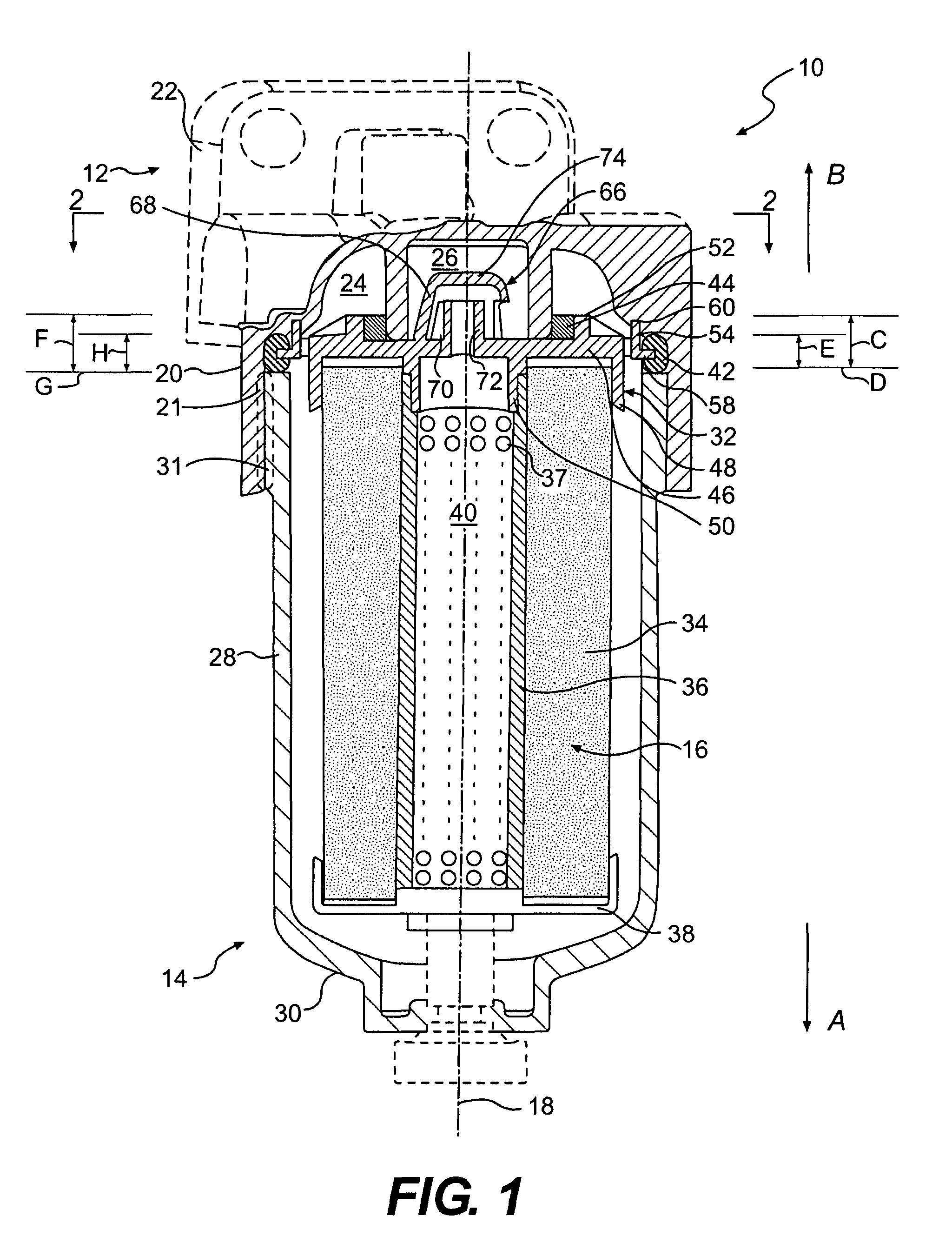

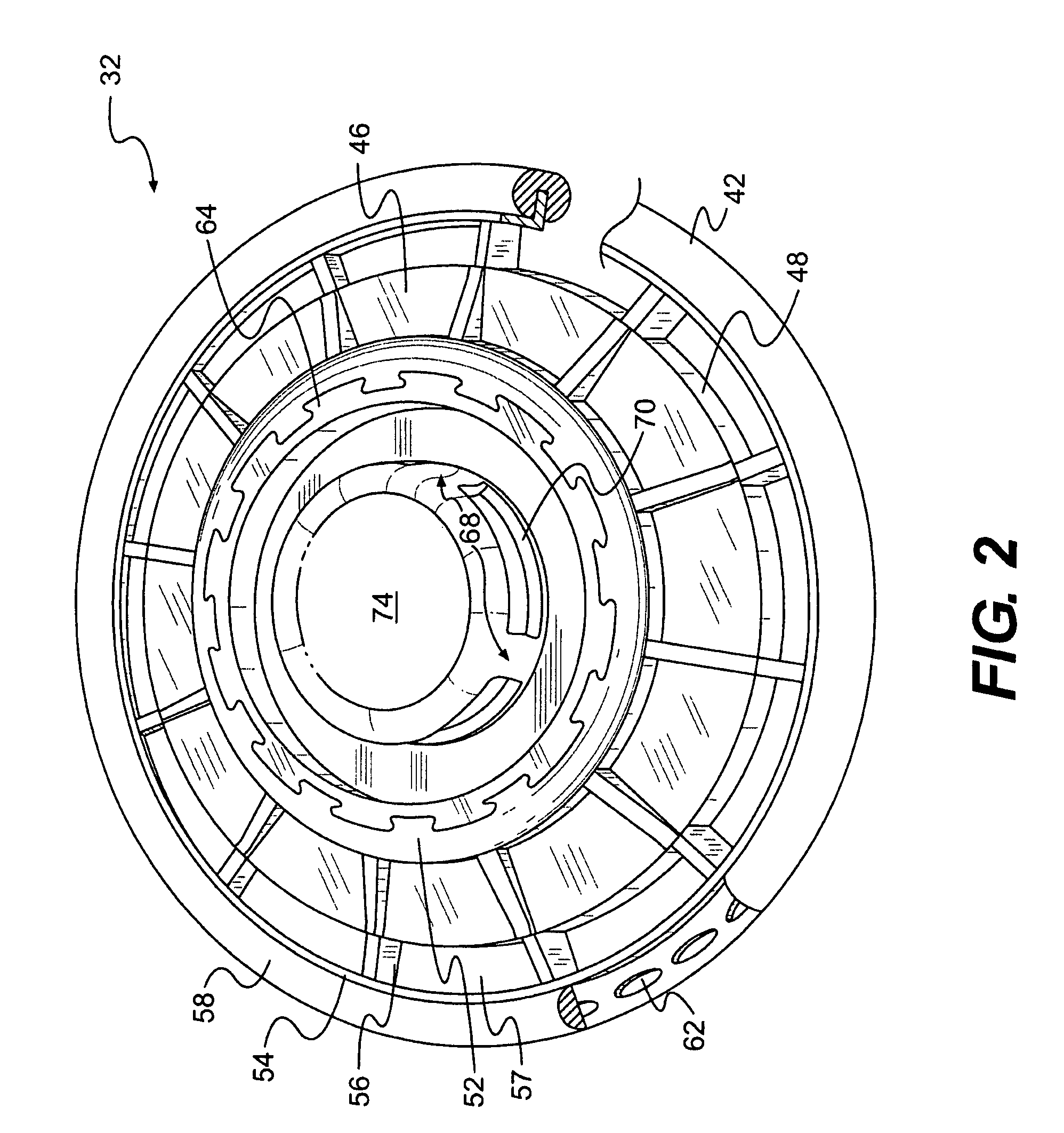

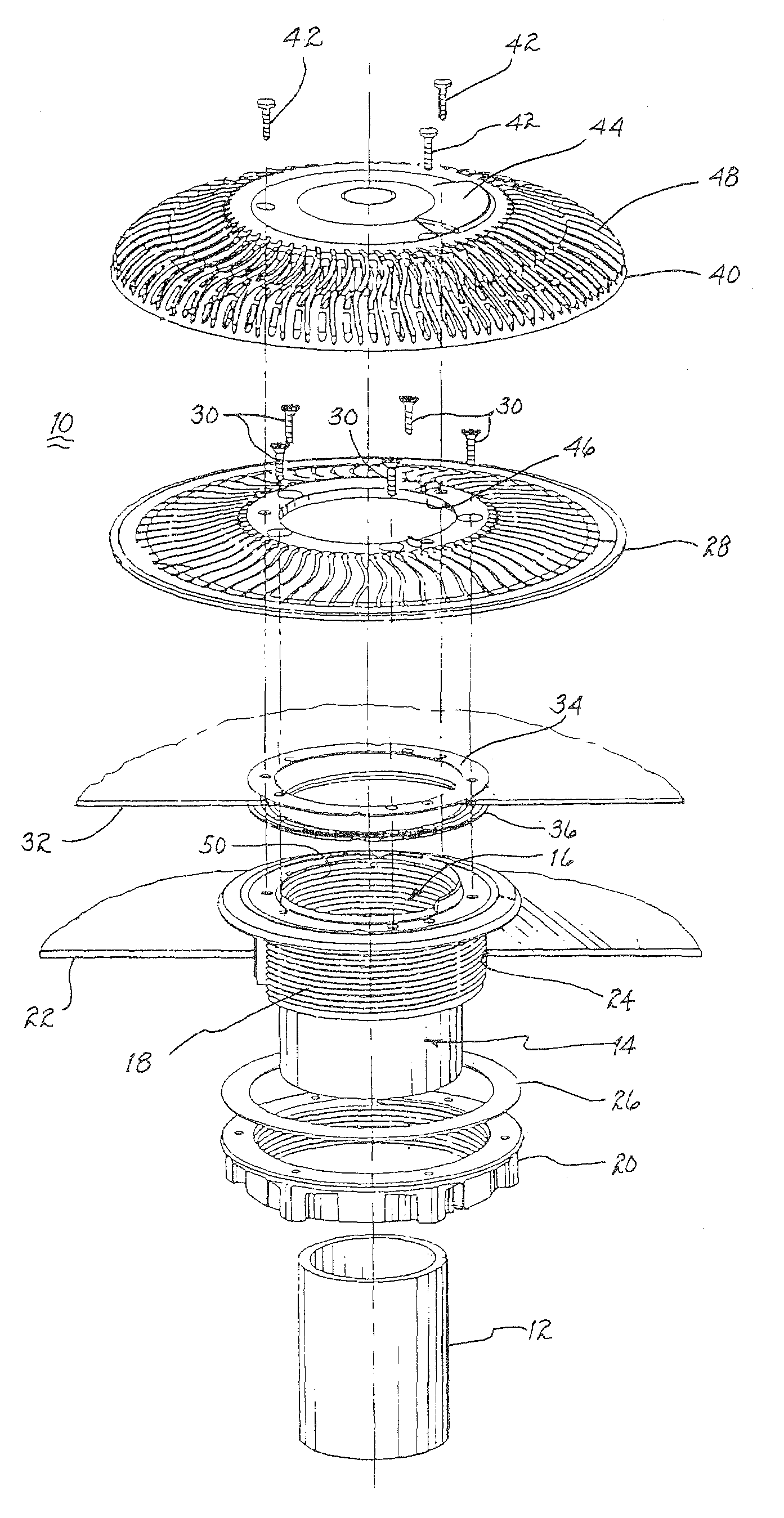

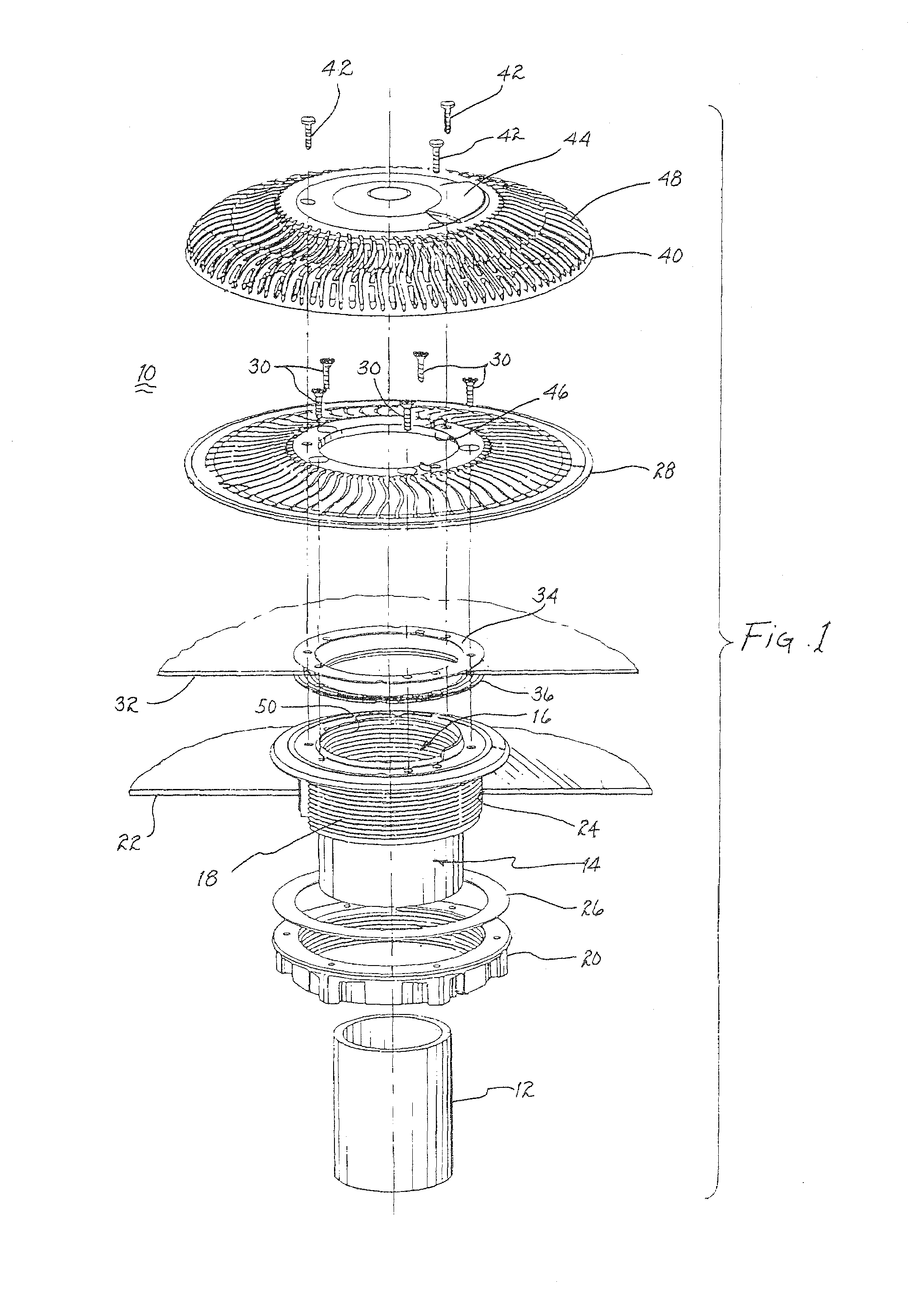

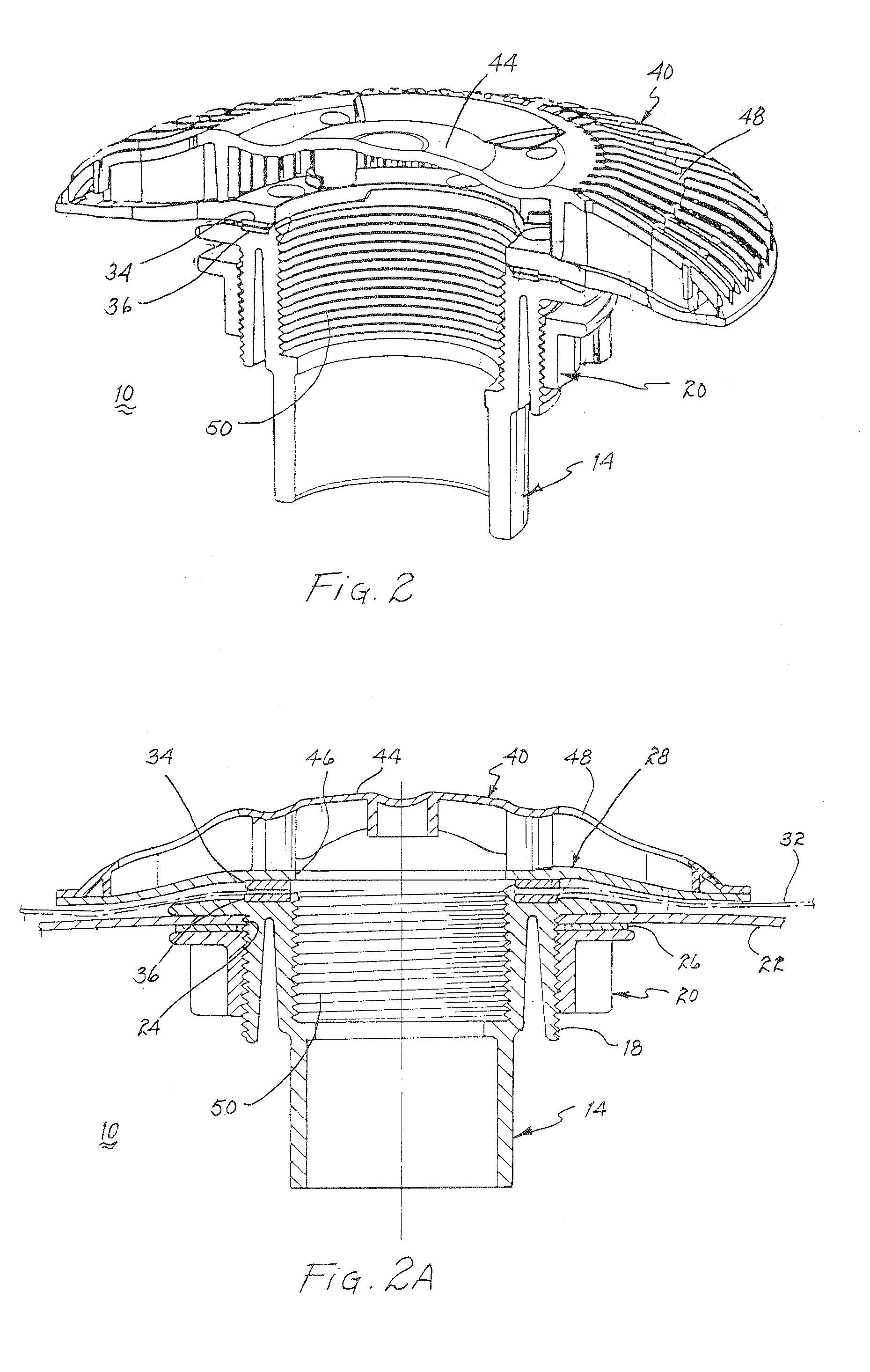

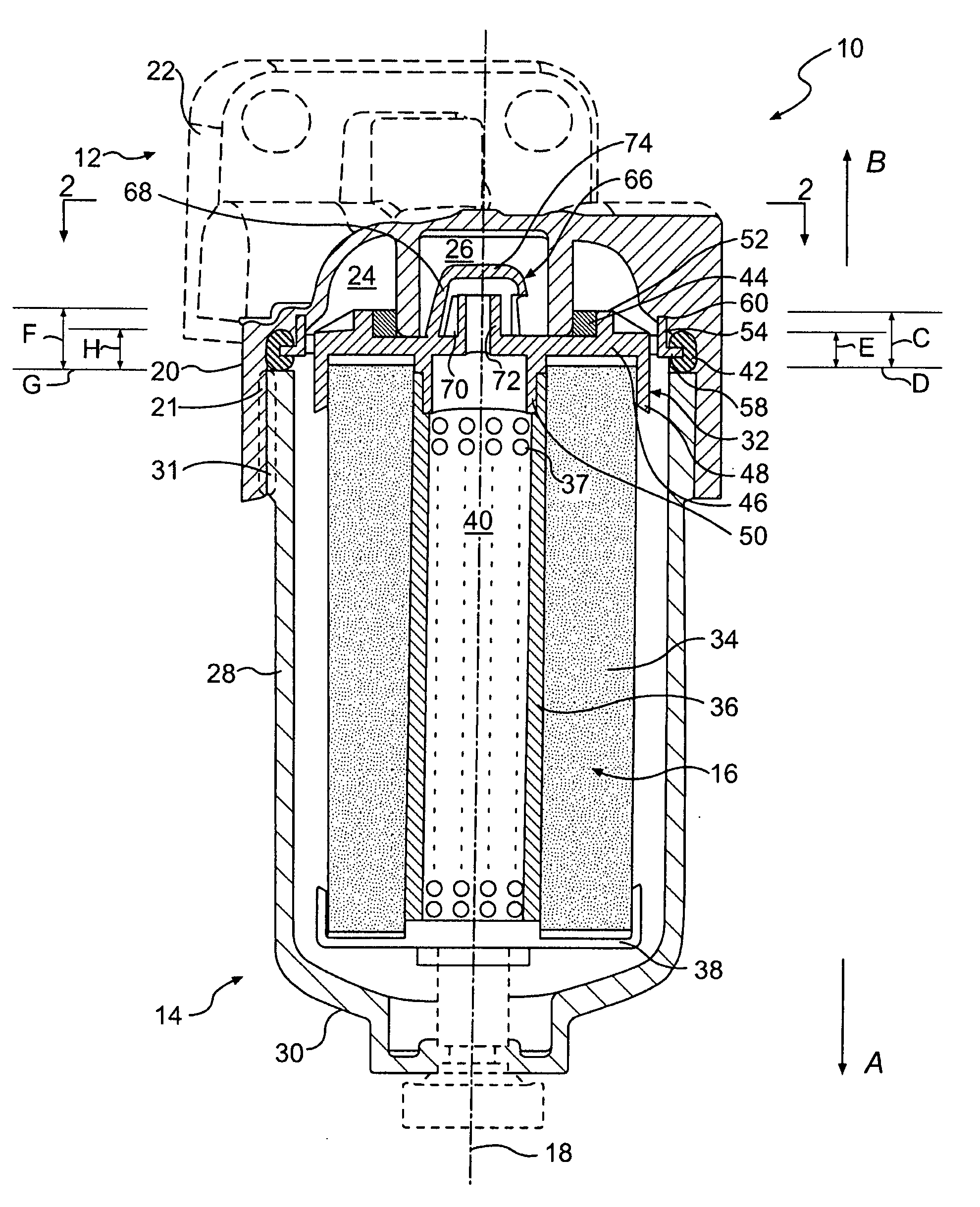

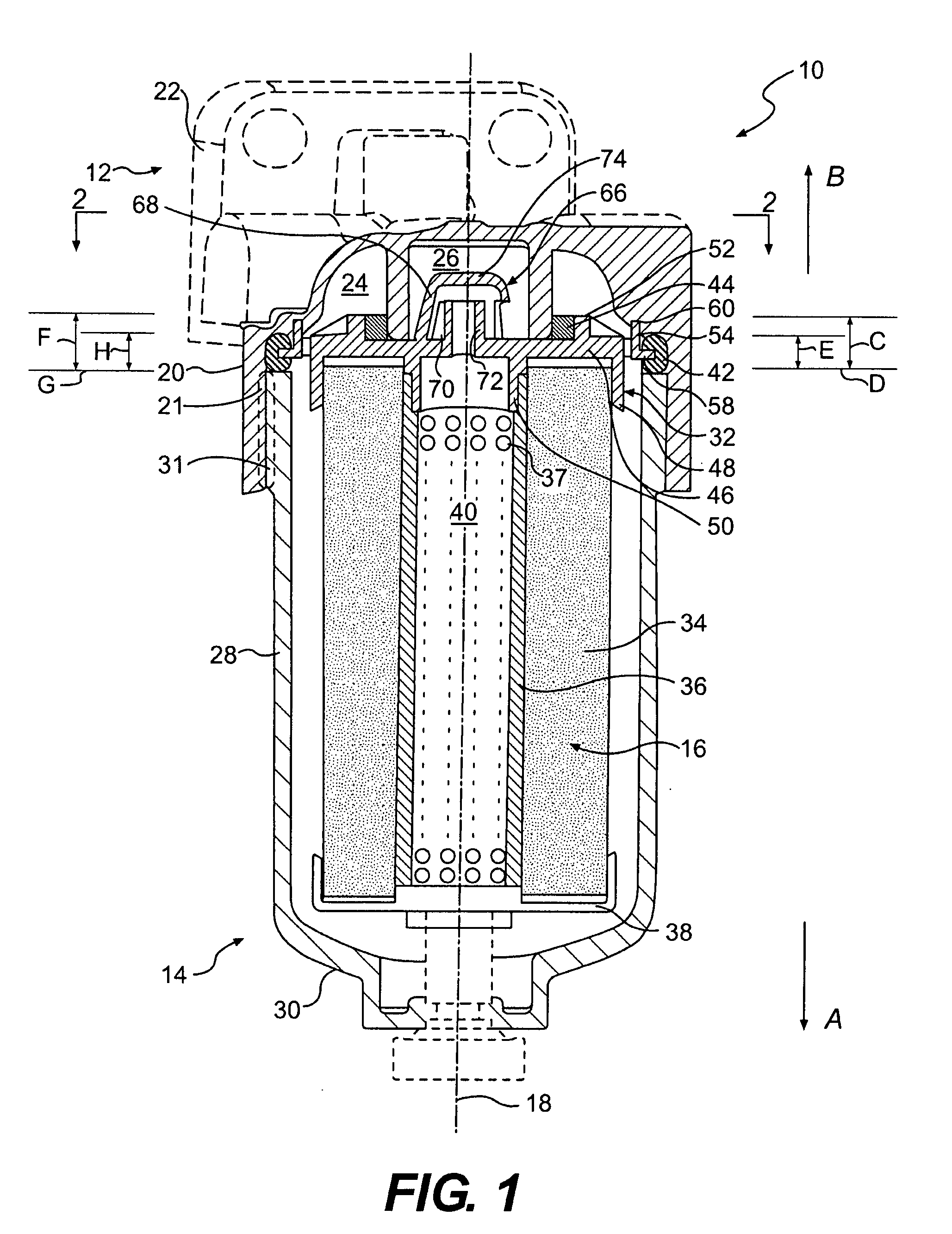

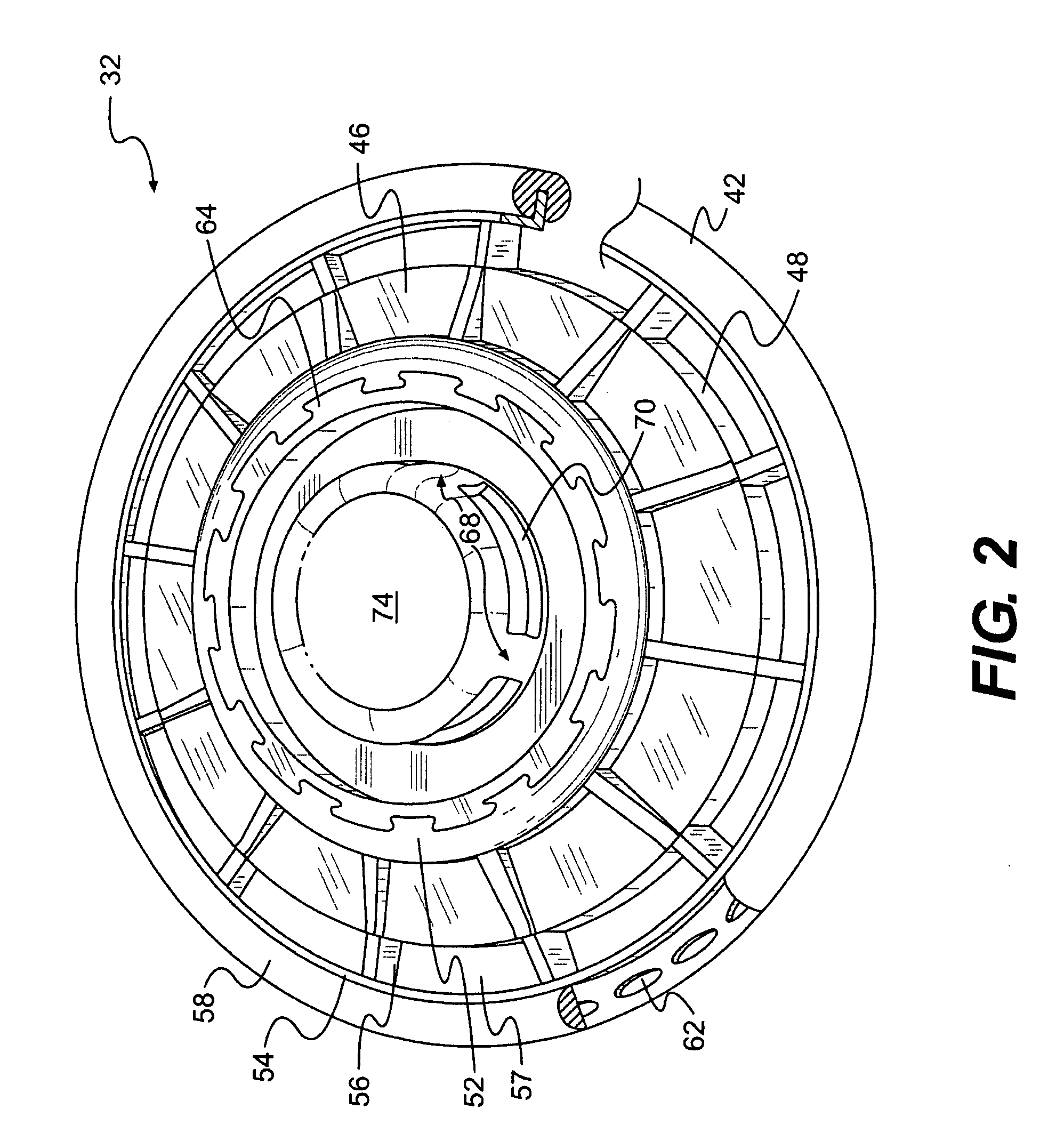

Fluid filter system

An endcap including a first plate member including a radial inner portion, a radial outer portion, and defining a longitudinal axis. The endcap also includes a flange disposed between the radial inner and outer portions of the first plate member and projecting axially along the longitudinal axis in a first direction. The endcap also includes a first seal member disposed adjacent the flange. The first seal includes a first portion thereof engaged with an axial facing surface of the first plate member and a second portion thereof engaged with a radially facing surface of the flange. The endcap further includes a second plate member disposed radially outward of the radial outer portion and a second seal member disposed adjacent the second plate member including at least a portion thereof axially spaced from the axially facing surface of the first plate member in a second direction along the longitudinal axis opposite the first direction.

Owner:DONALDSON CO INC +2

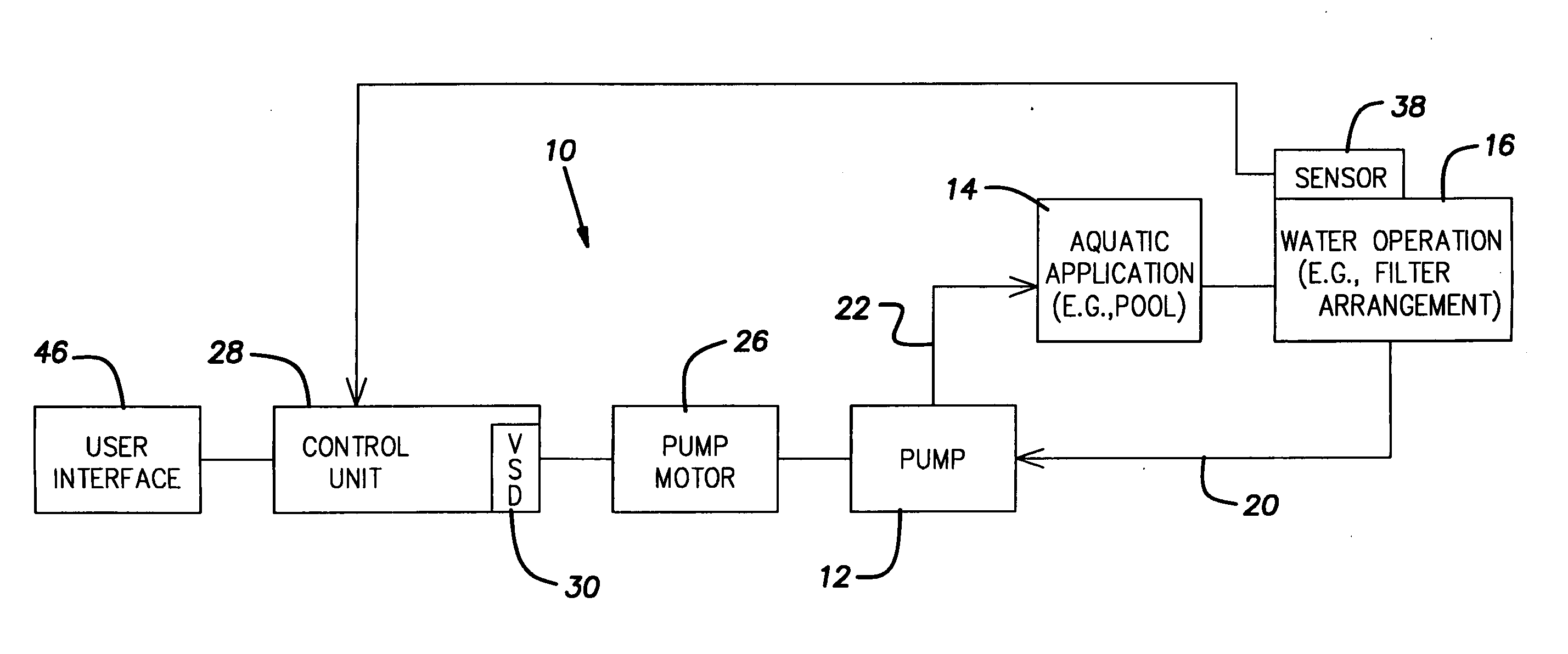

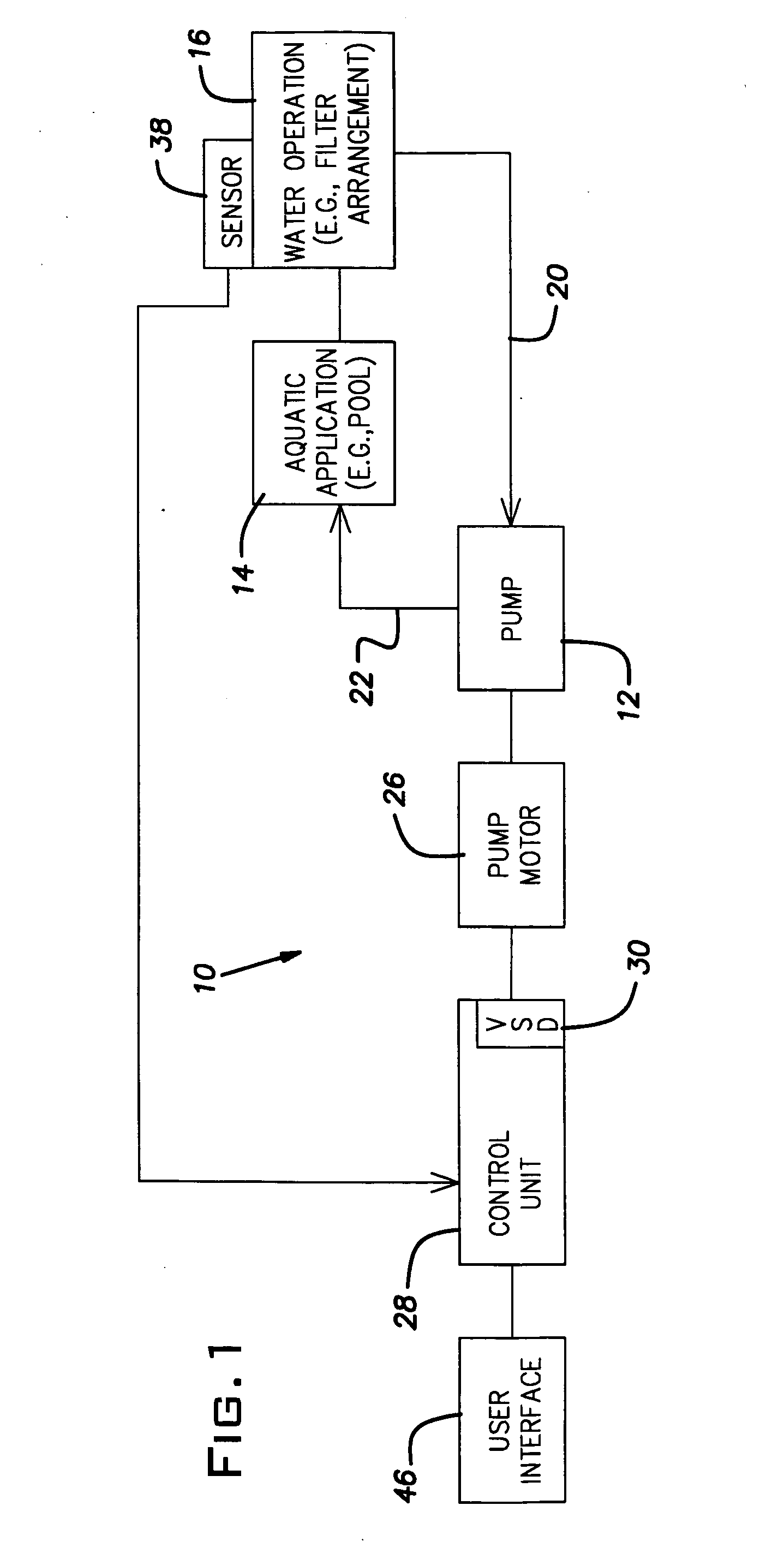

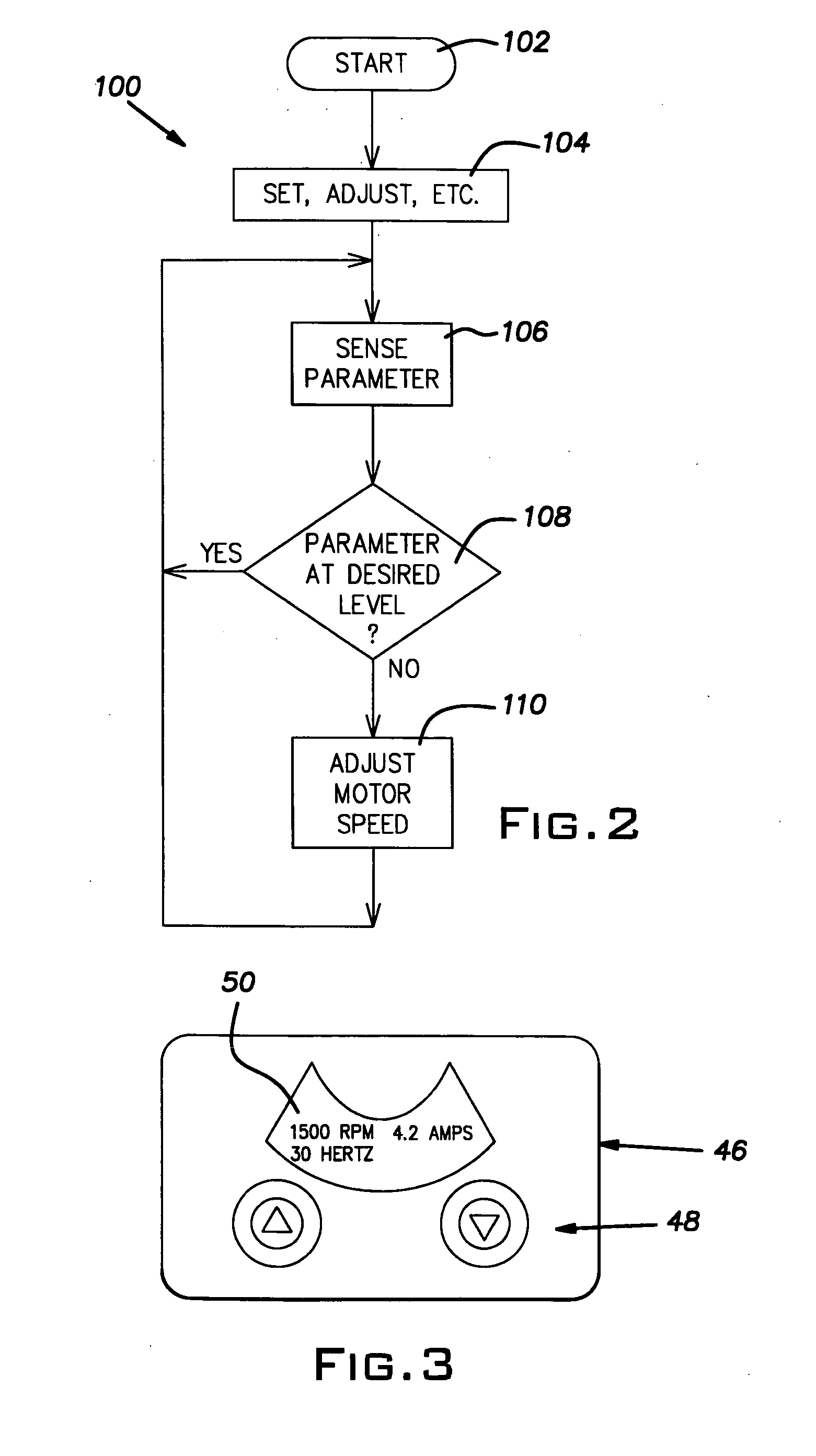

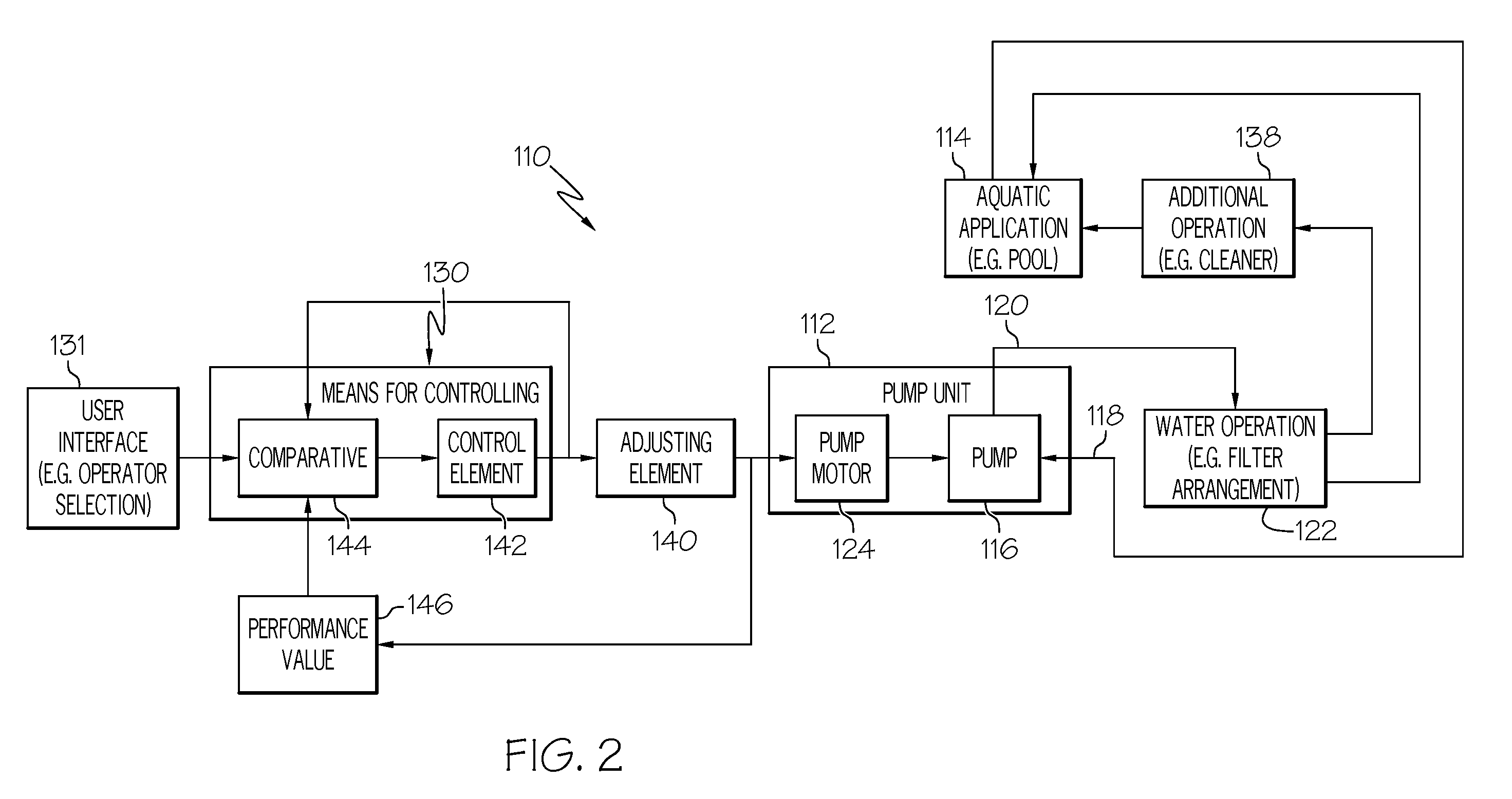

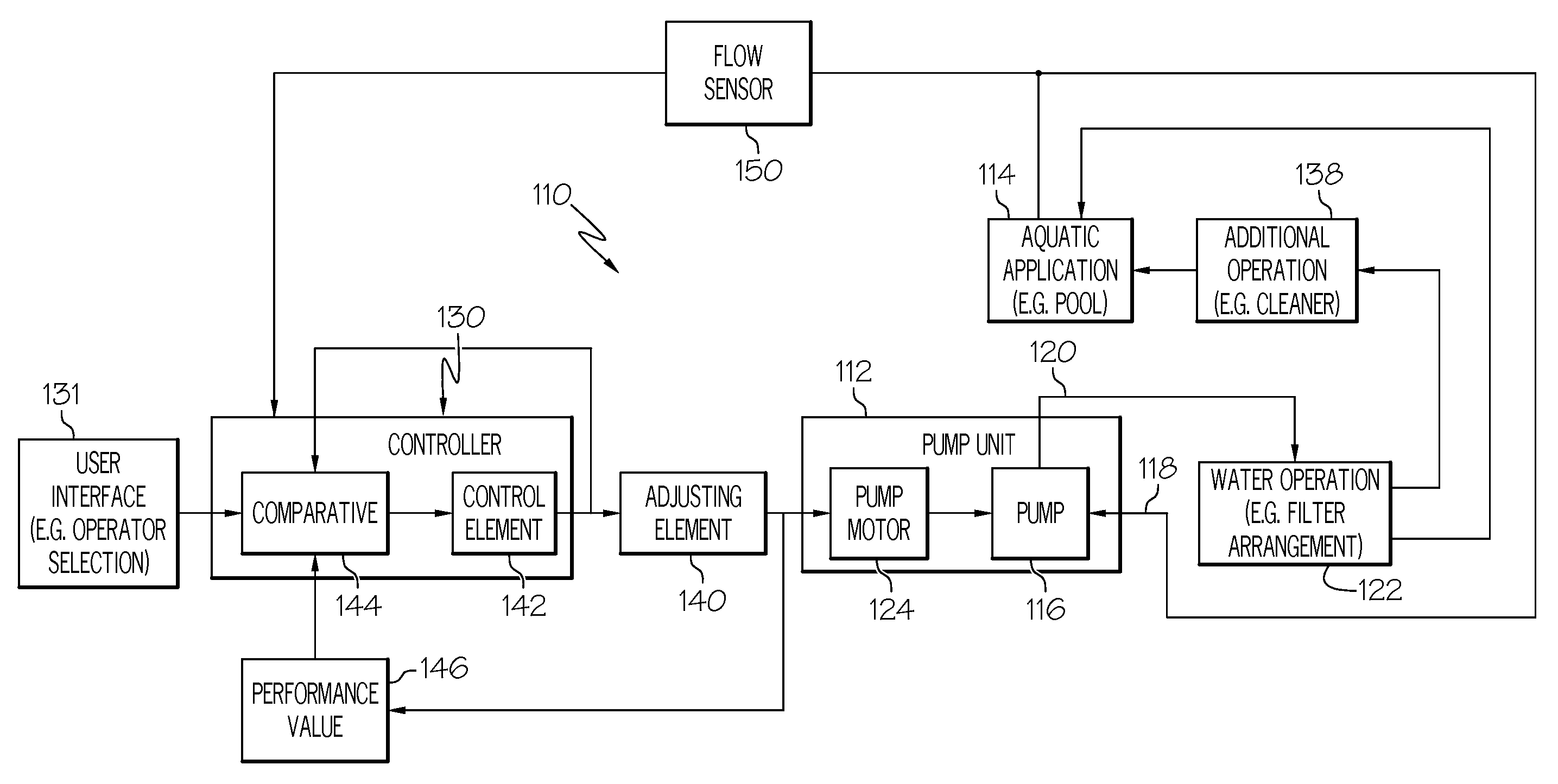

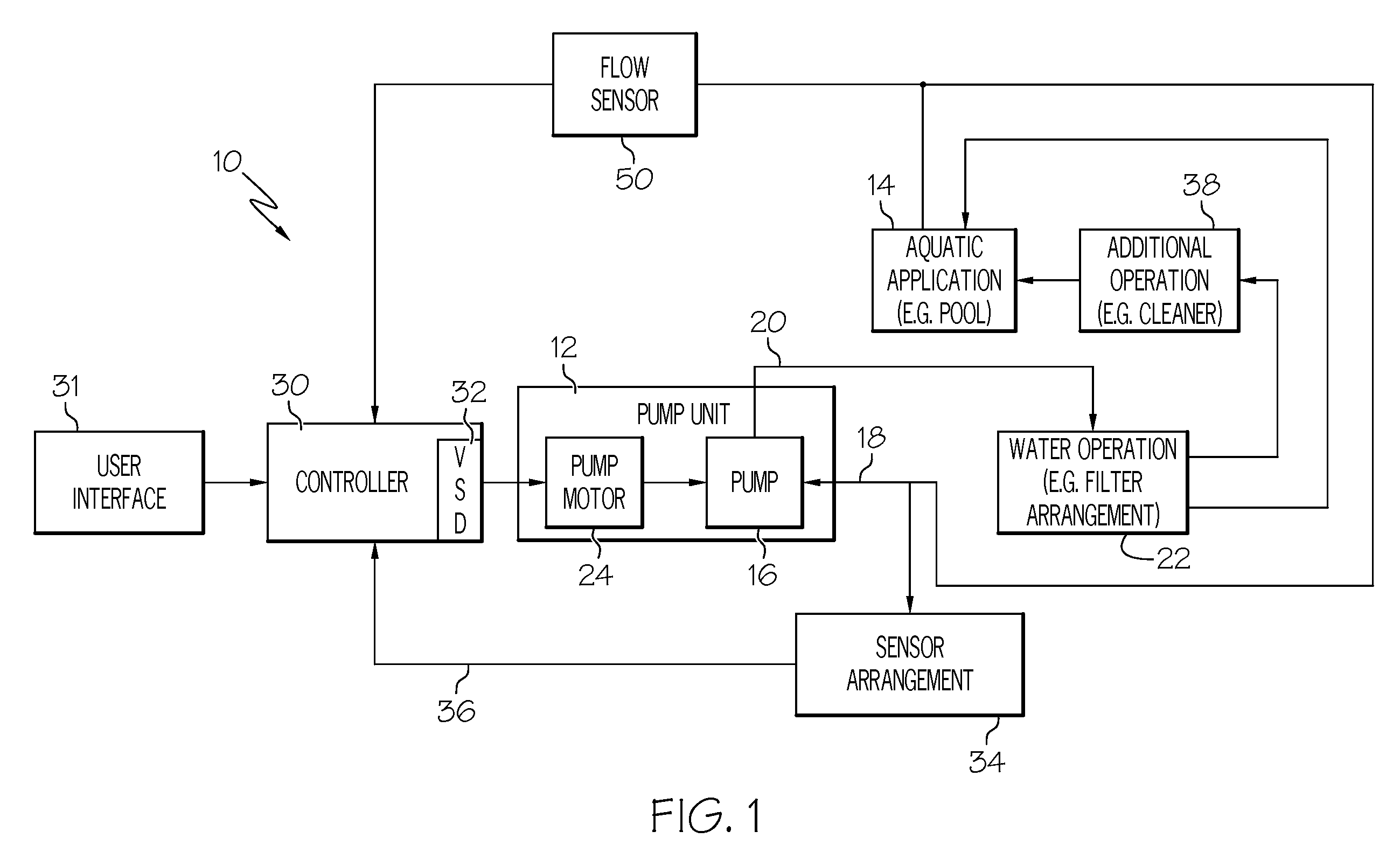

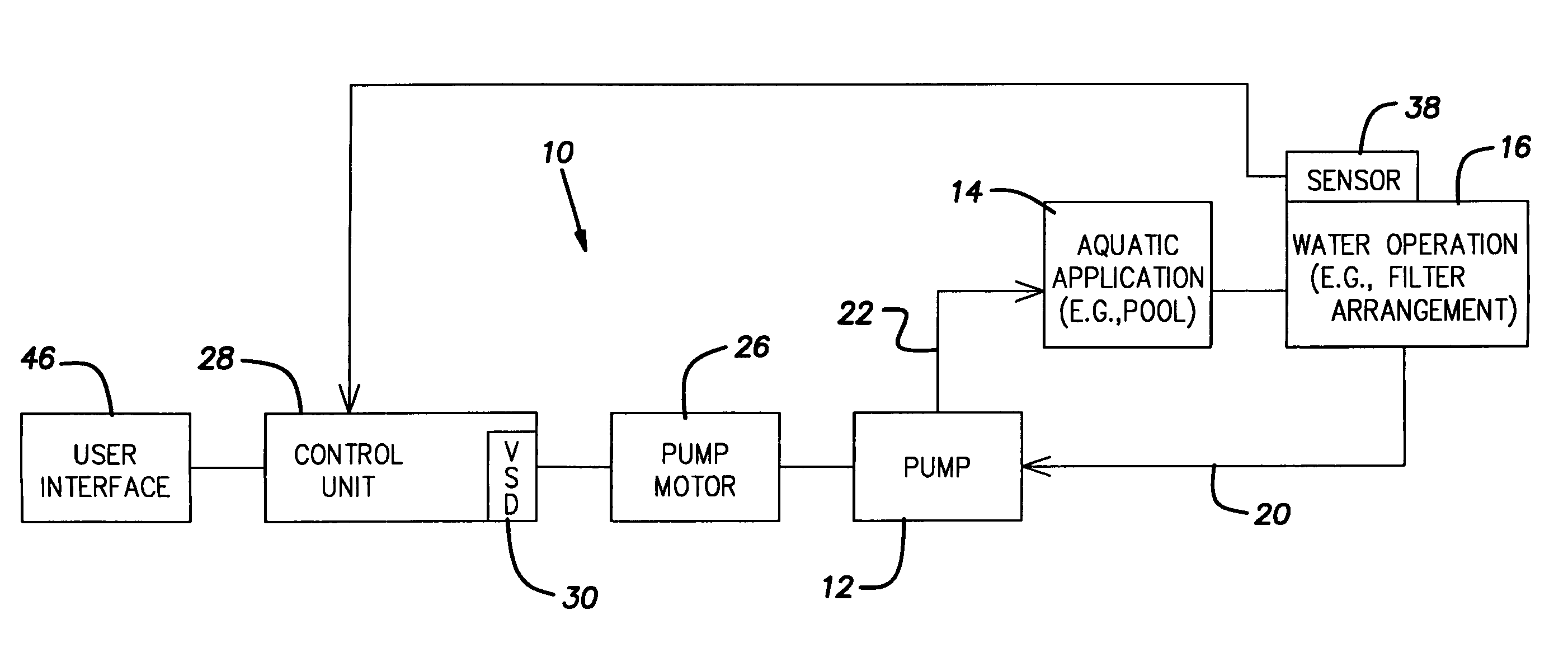

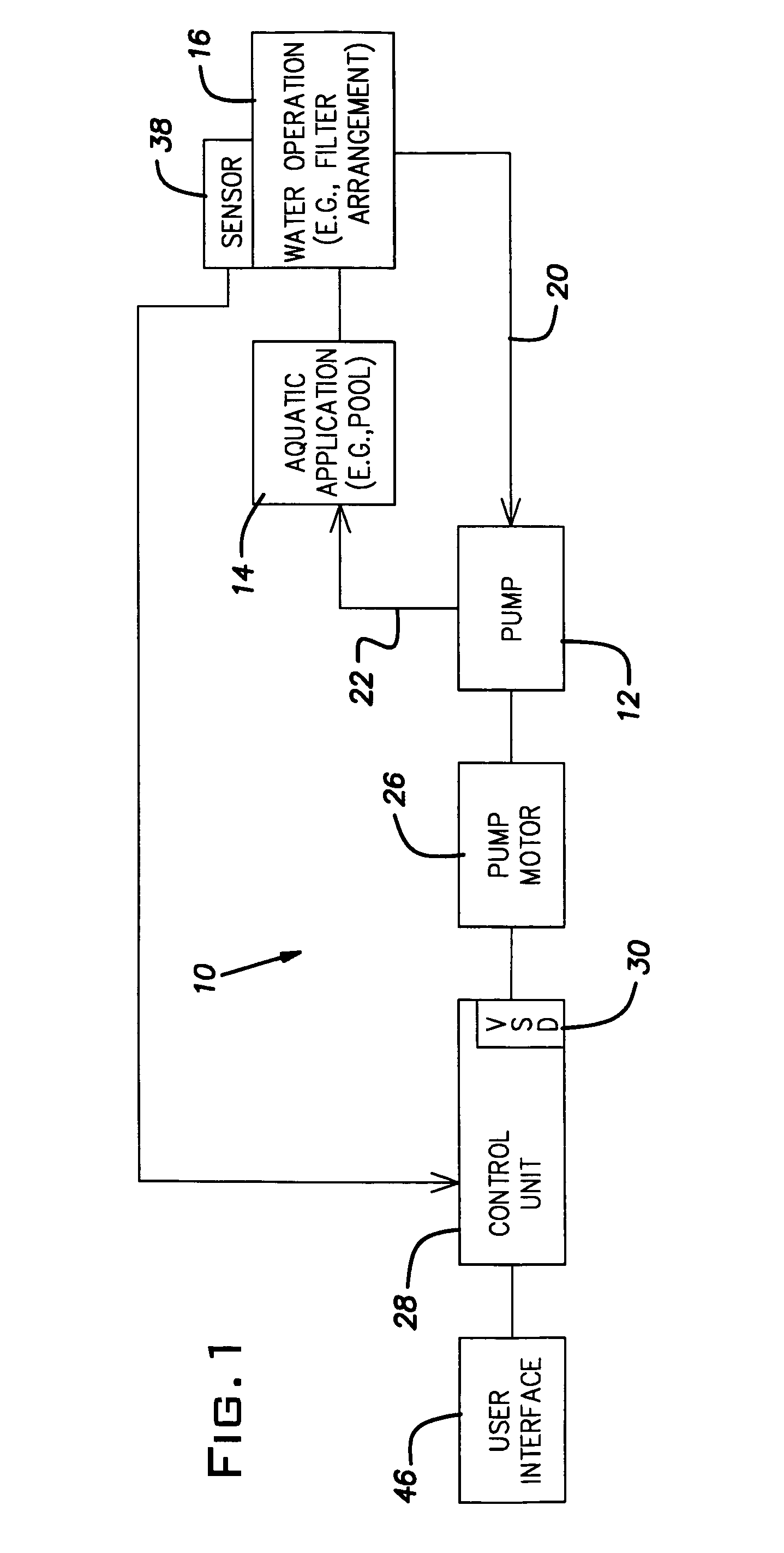

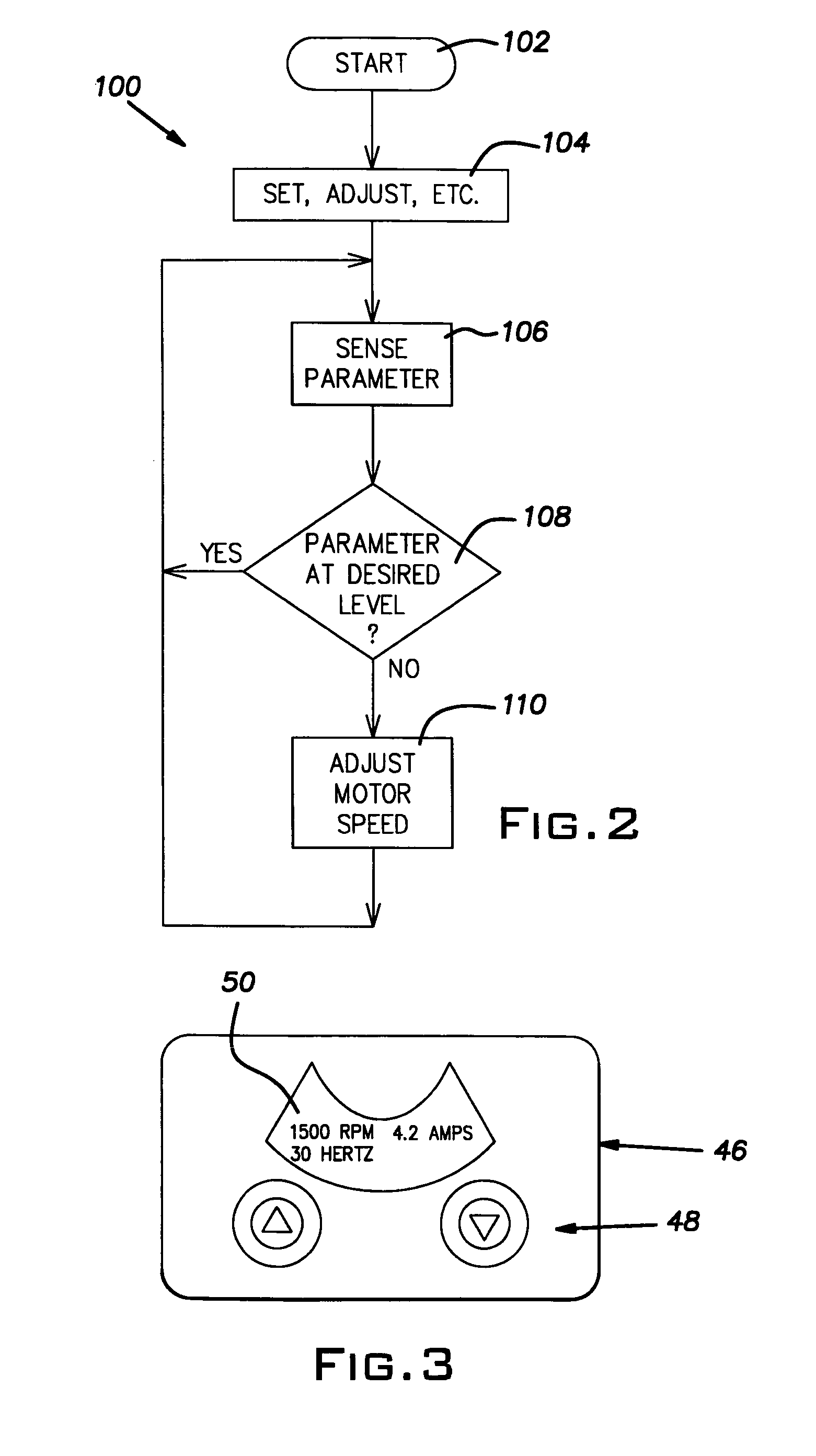

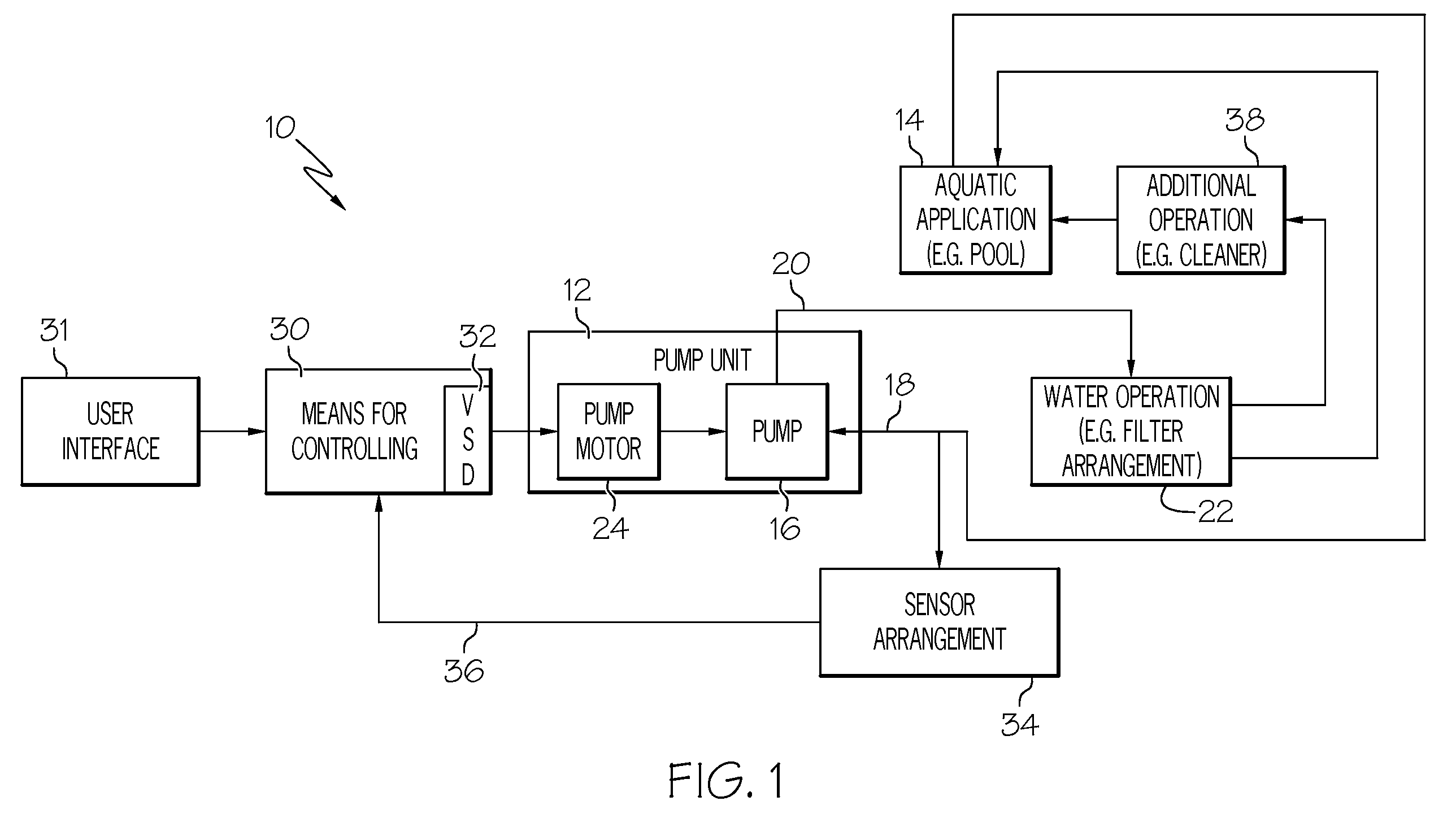

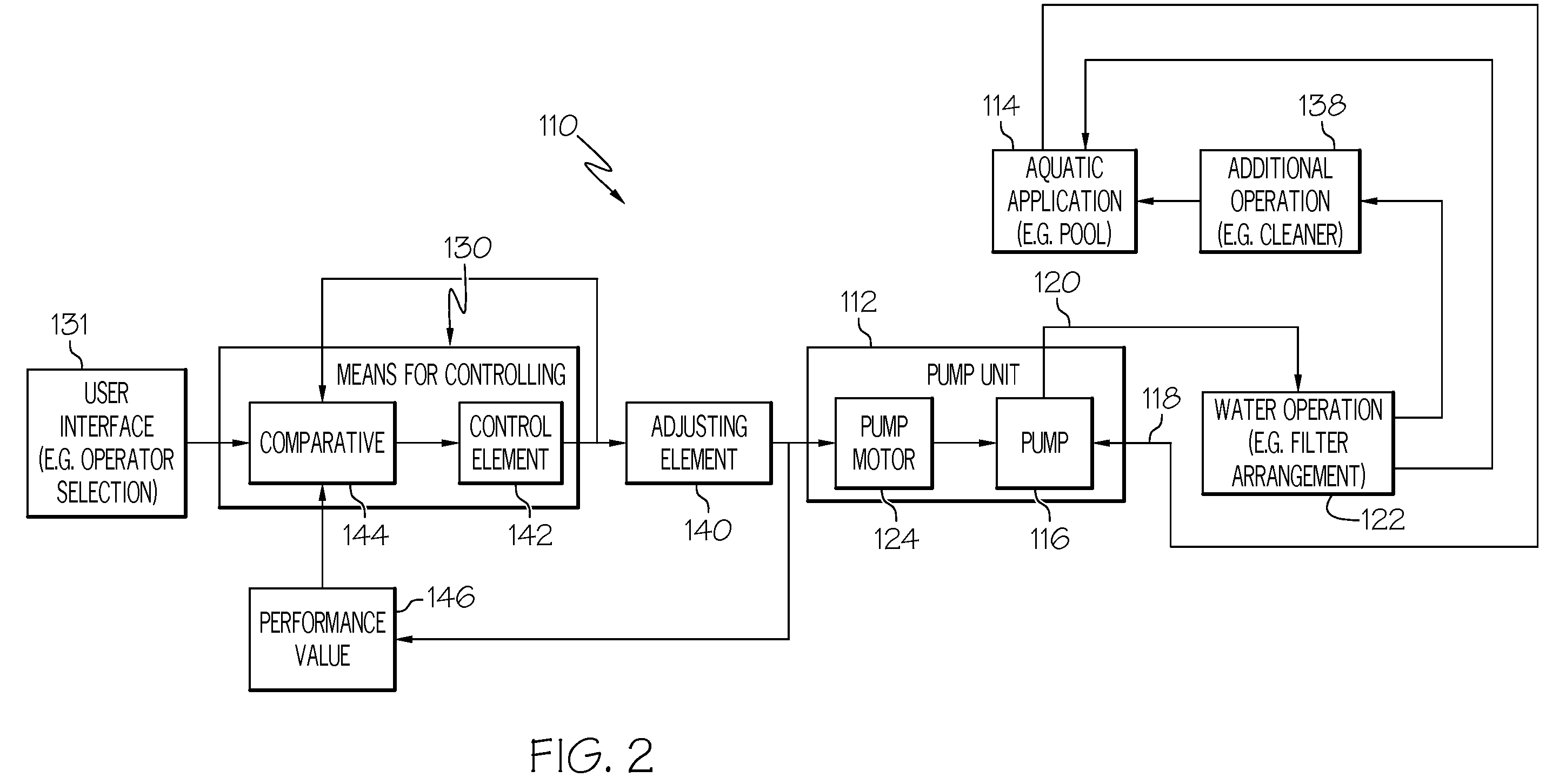

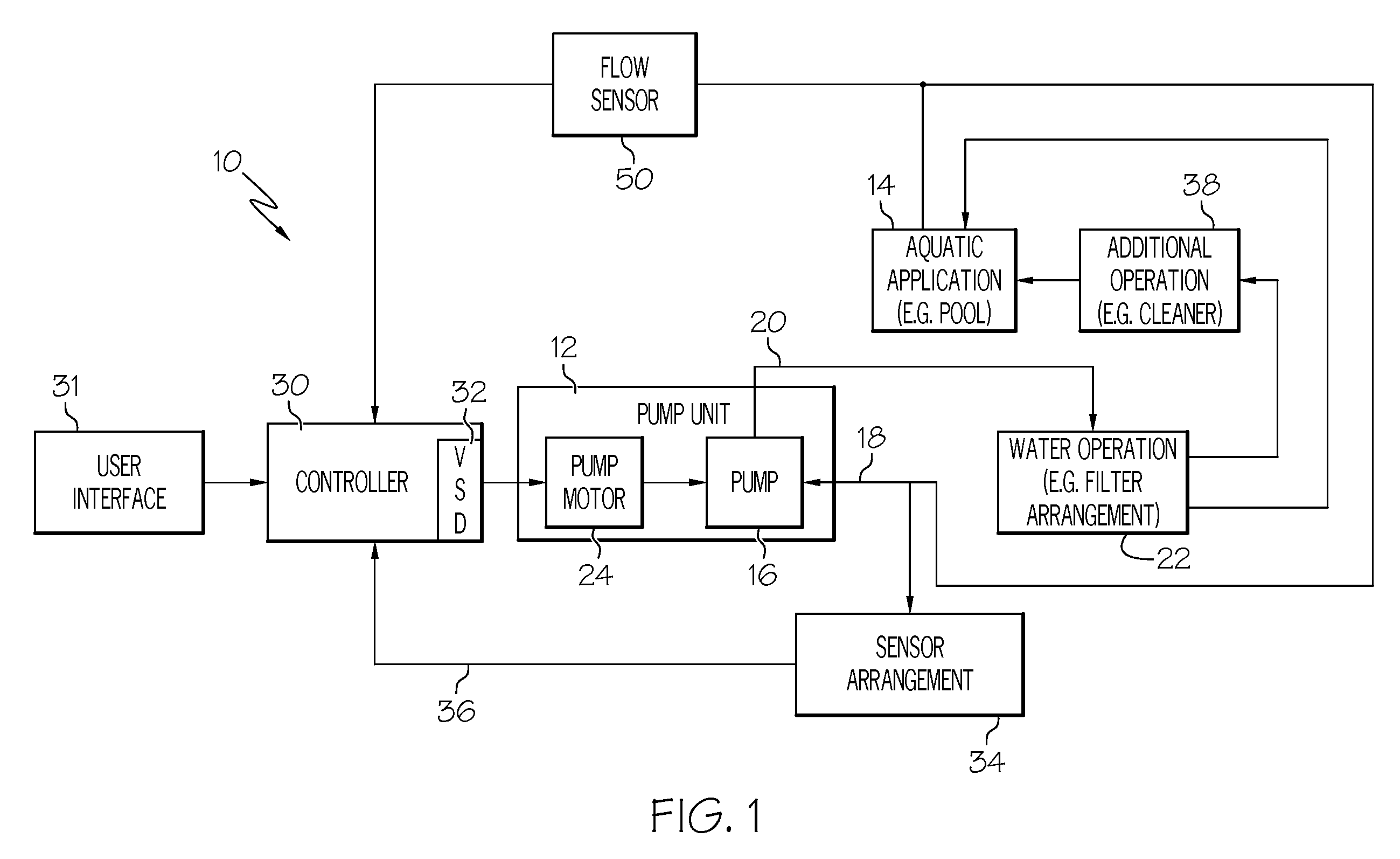

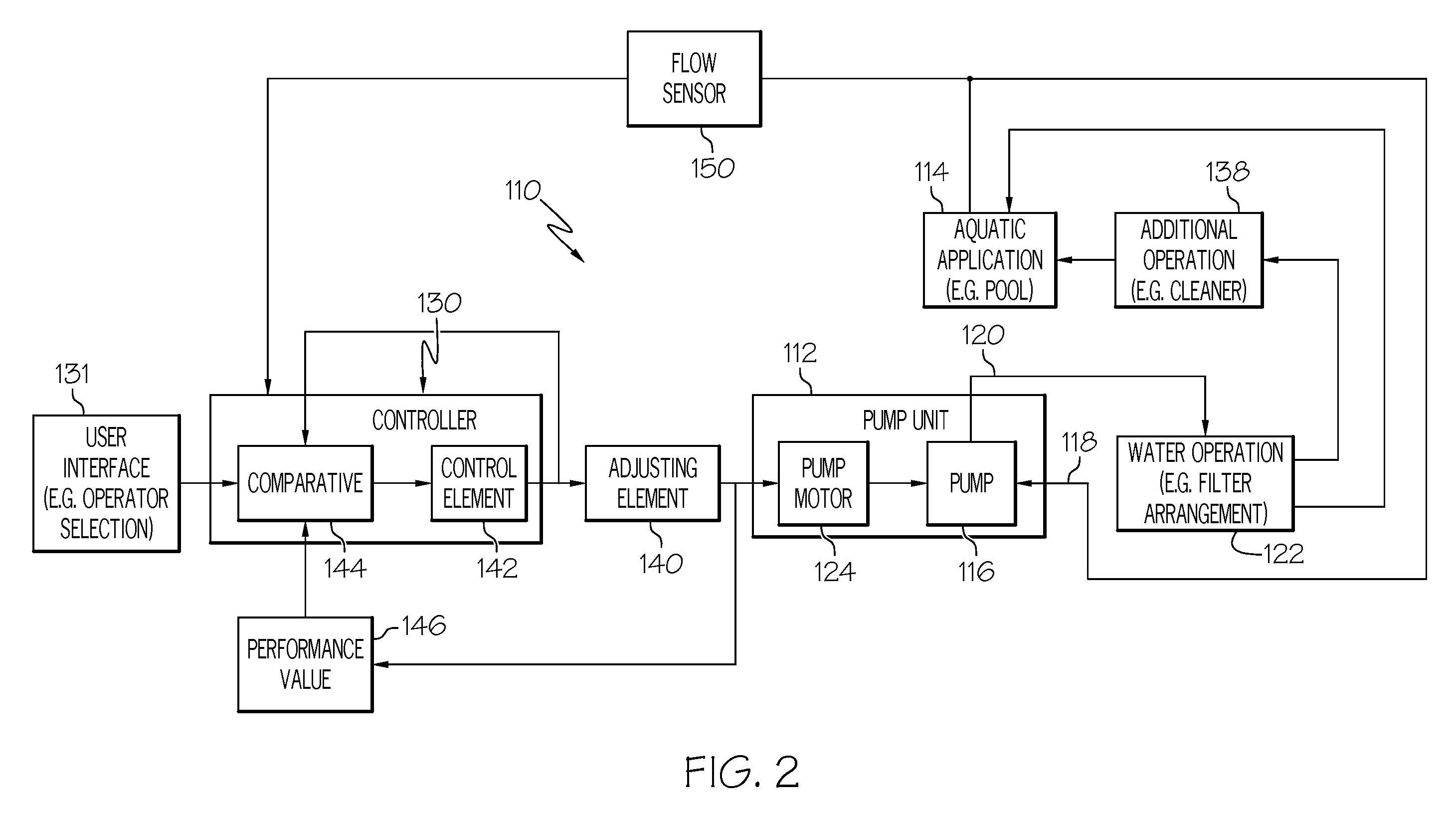

Variable speed pumping system and method

A variable speed pumping system and an associated method for moving water of an aquatic application. The variable speed pumping system includes a water pump for moving water in connection with performance of an operation upon the water. A variable speed motor is operatively connected to drive the pump. A sensor senses a parameter of the operation performed upon the water. A controller controls speed of the motor in response to the sensed parameter of operation.

Owner:PENTAIR WATER POOL & SPA INC

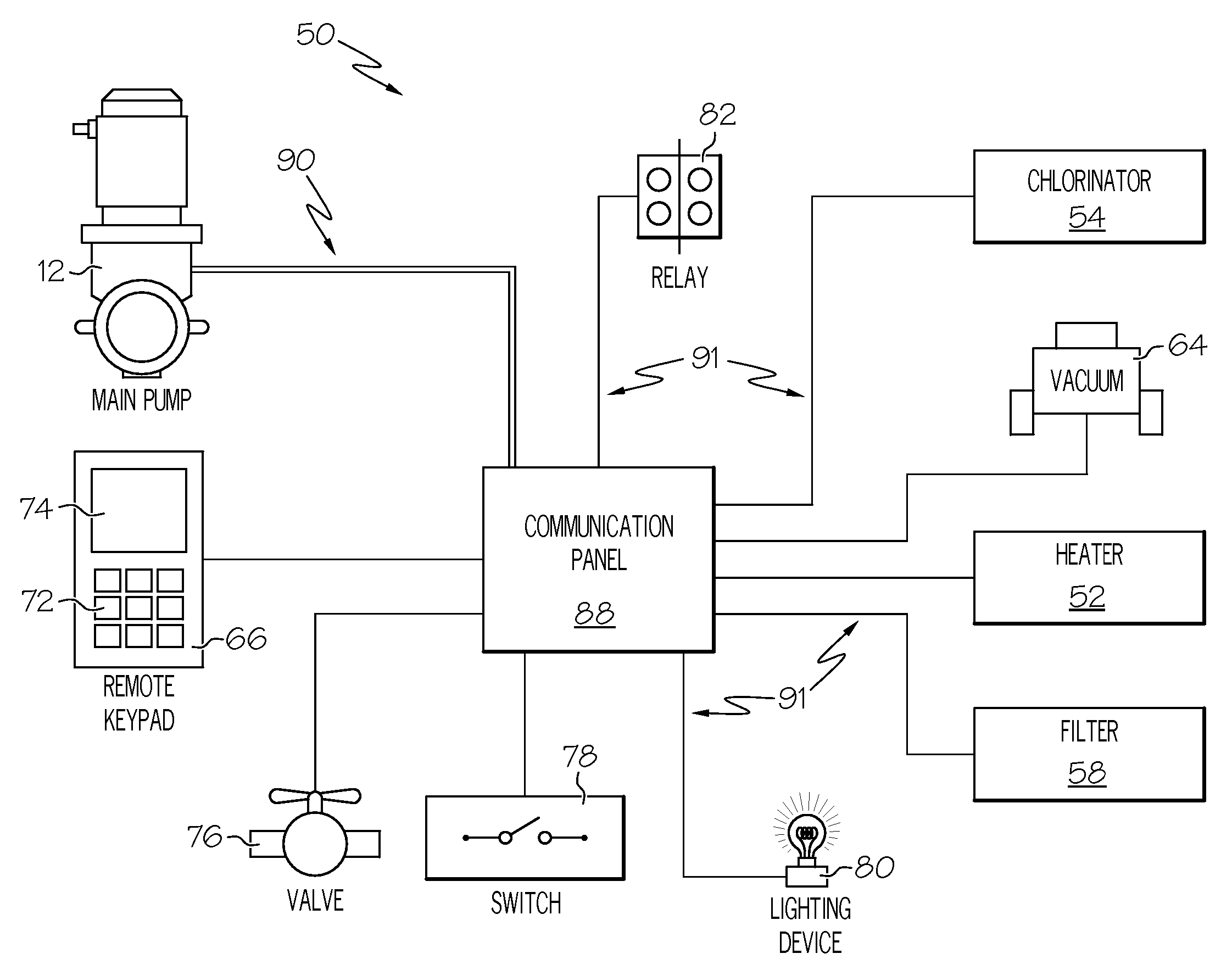

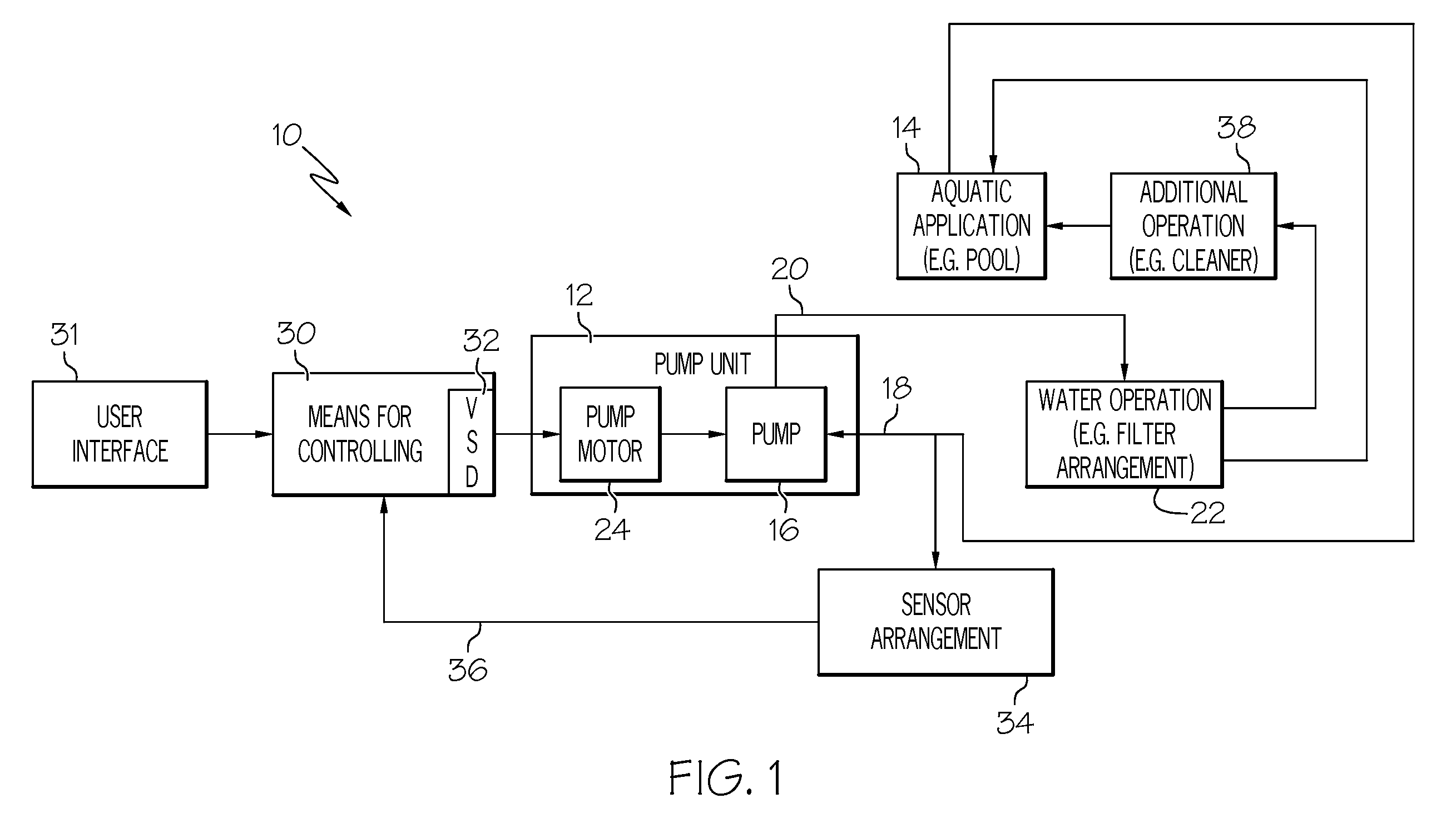

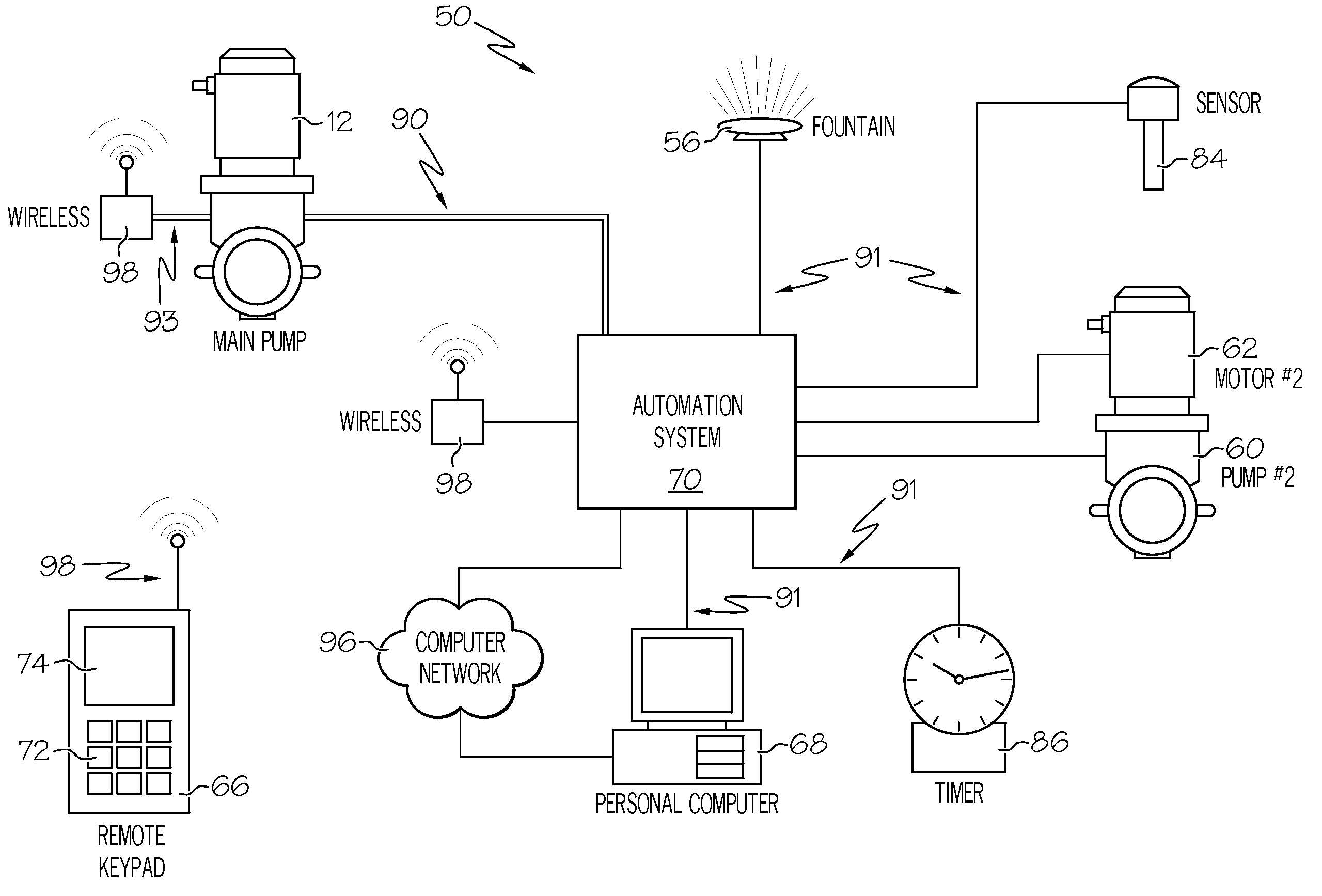

Pumping system with two way communication

A pumping system for moving water of a swimming pool includes a water pump, a variable speed motor, and an arrangement for controlling the variable speed motor. The pumping system further includes an auxiliary device operably connected to the arrangement for controlling, and an arrangement for providing two-way communication between the arrangement for controlling and the auxiliary device. The arrangement for controlling is capable of receiving a parameter from the auxiliary device through the arrangement for providing two-way communication. In one example, the arrangement for controlling is capable of independently controlling the variable speed motor without receipt of a parameter from the auxiliary device. In addition or alternatively, the arrangement for controlling is operable to selectively alter operation of the motor based upon the parameter. In addition or alternatively, the arrangement for controlling is configured to optimize a power consumption of the variable speed motor over time based upon the parameters received. A method for controlling the pumping system is also provided.

Owner:PENTAIR WATER POOL & SPA INC +1

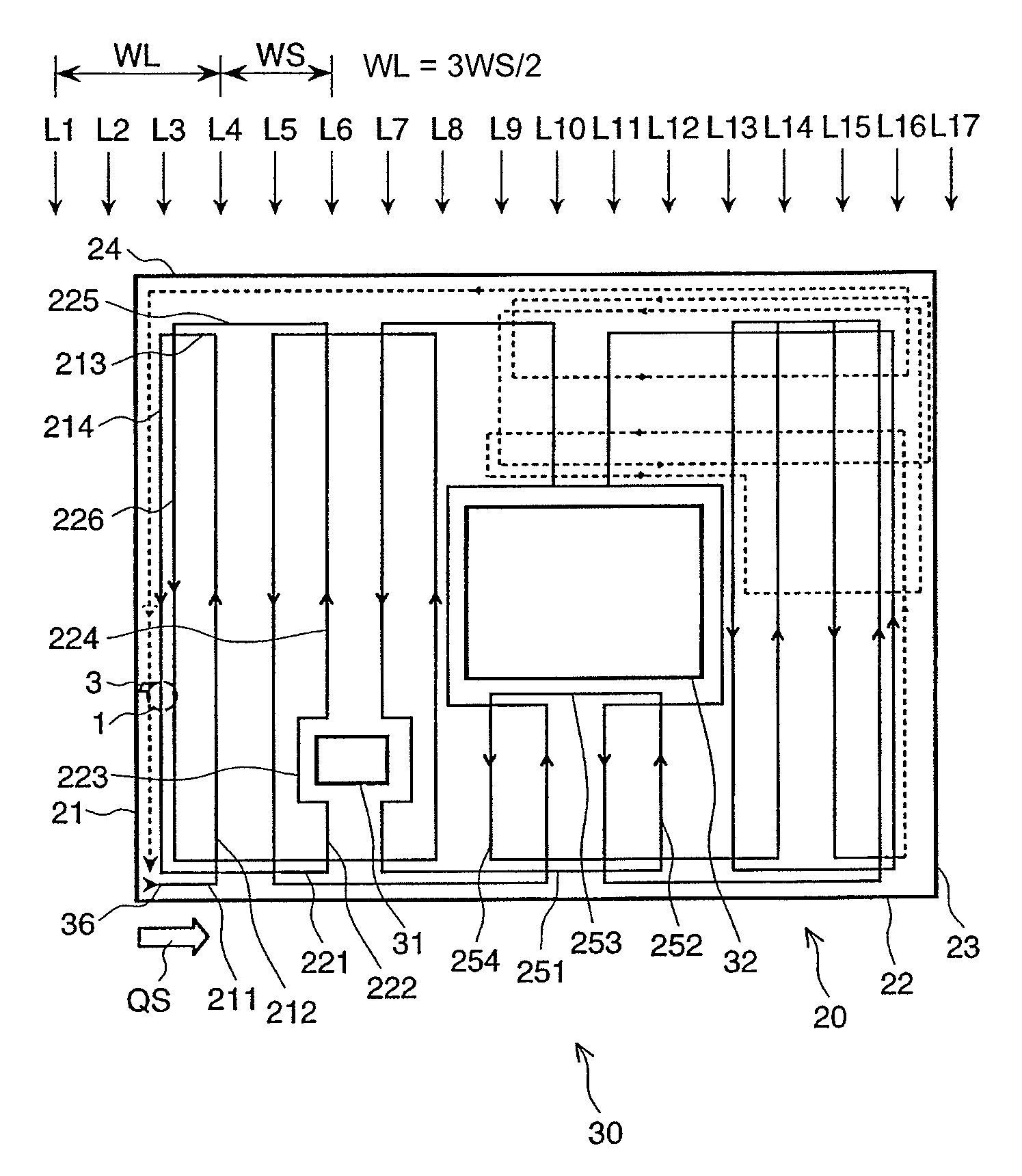

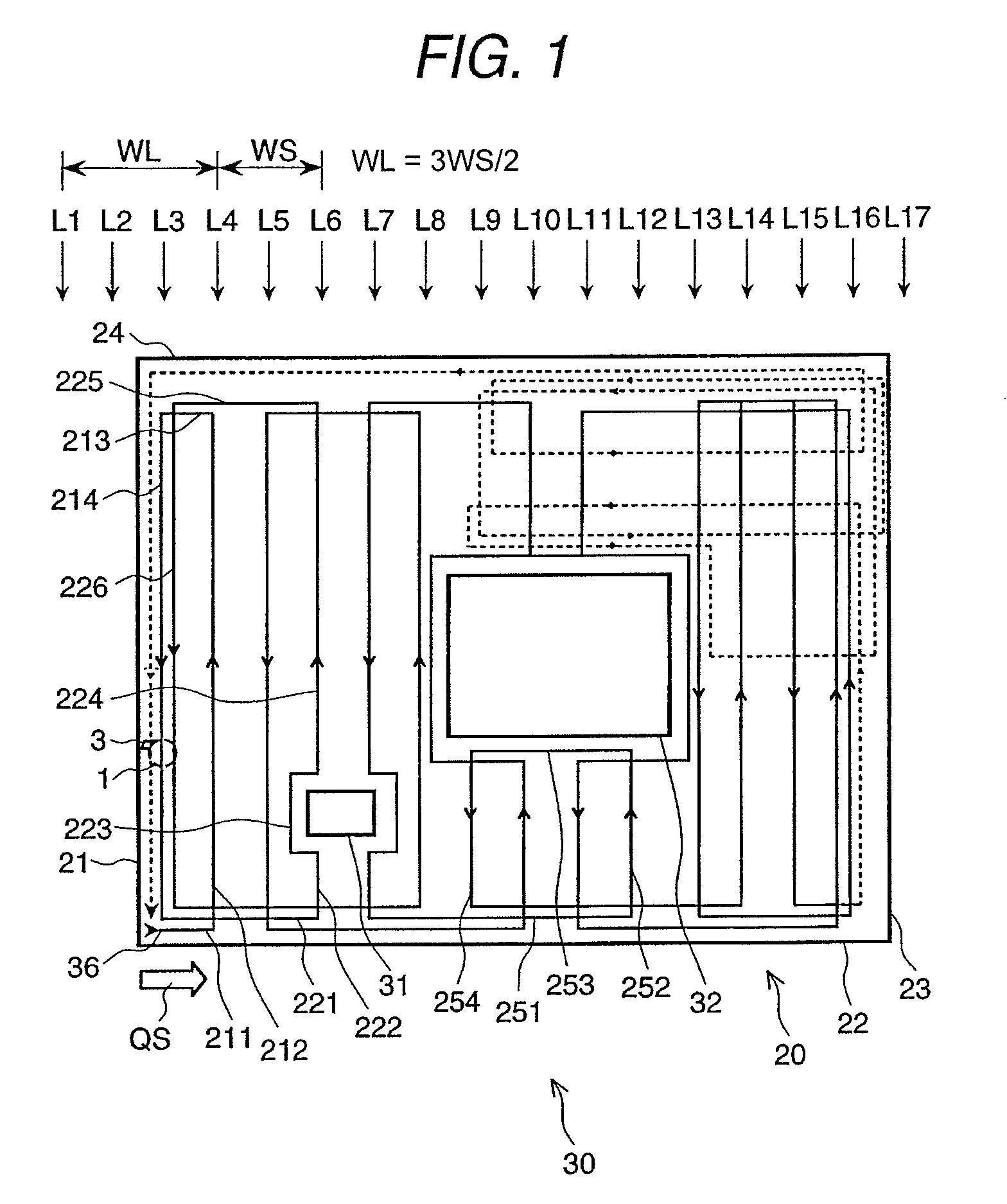

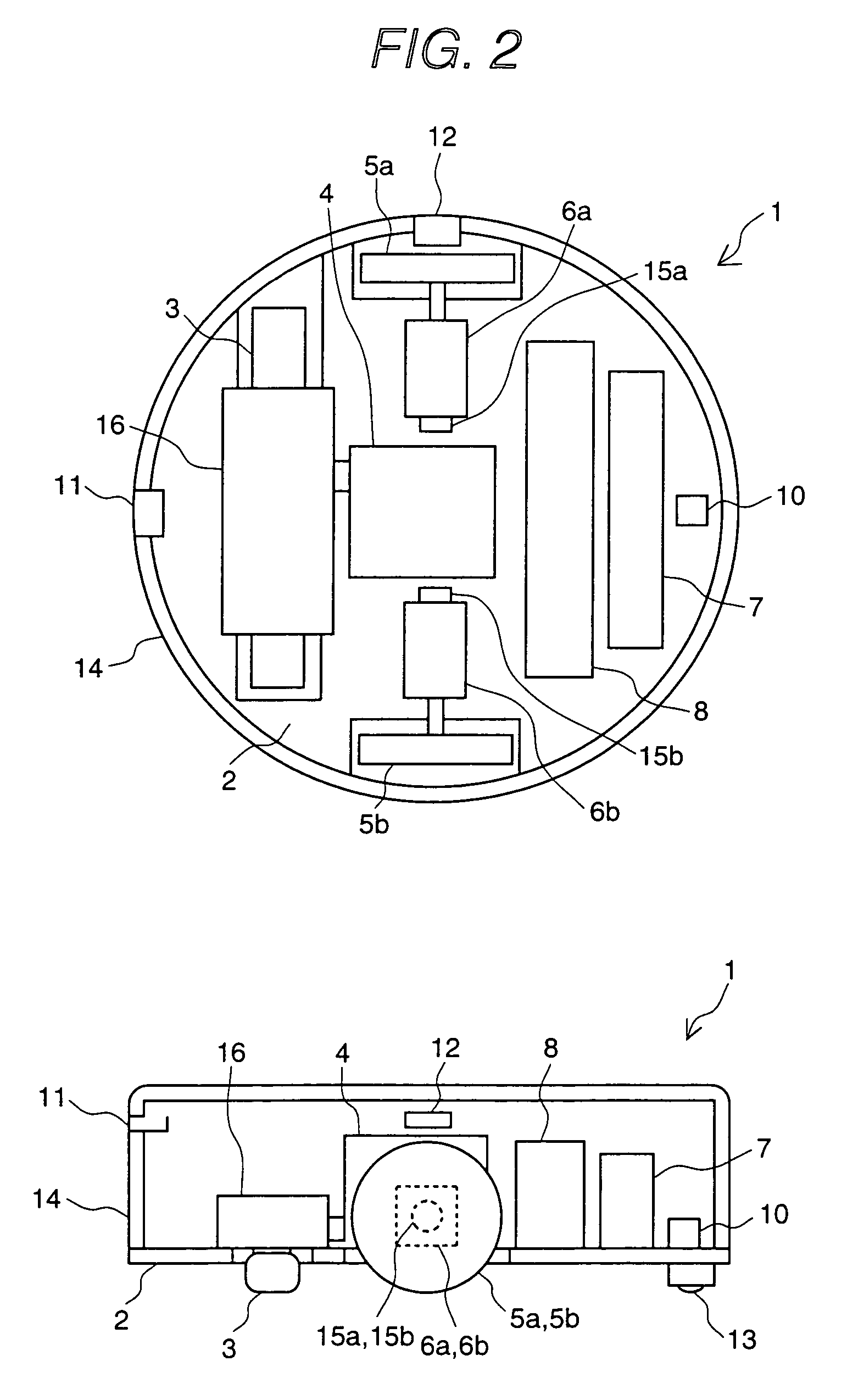

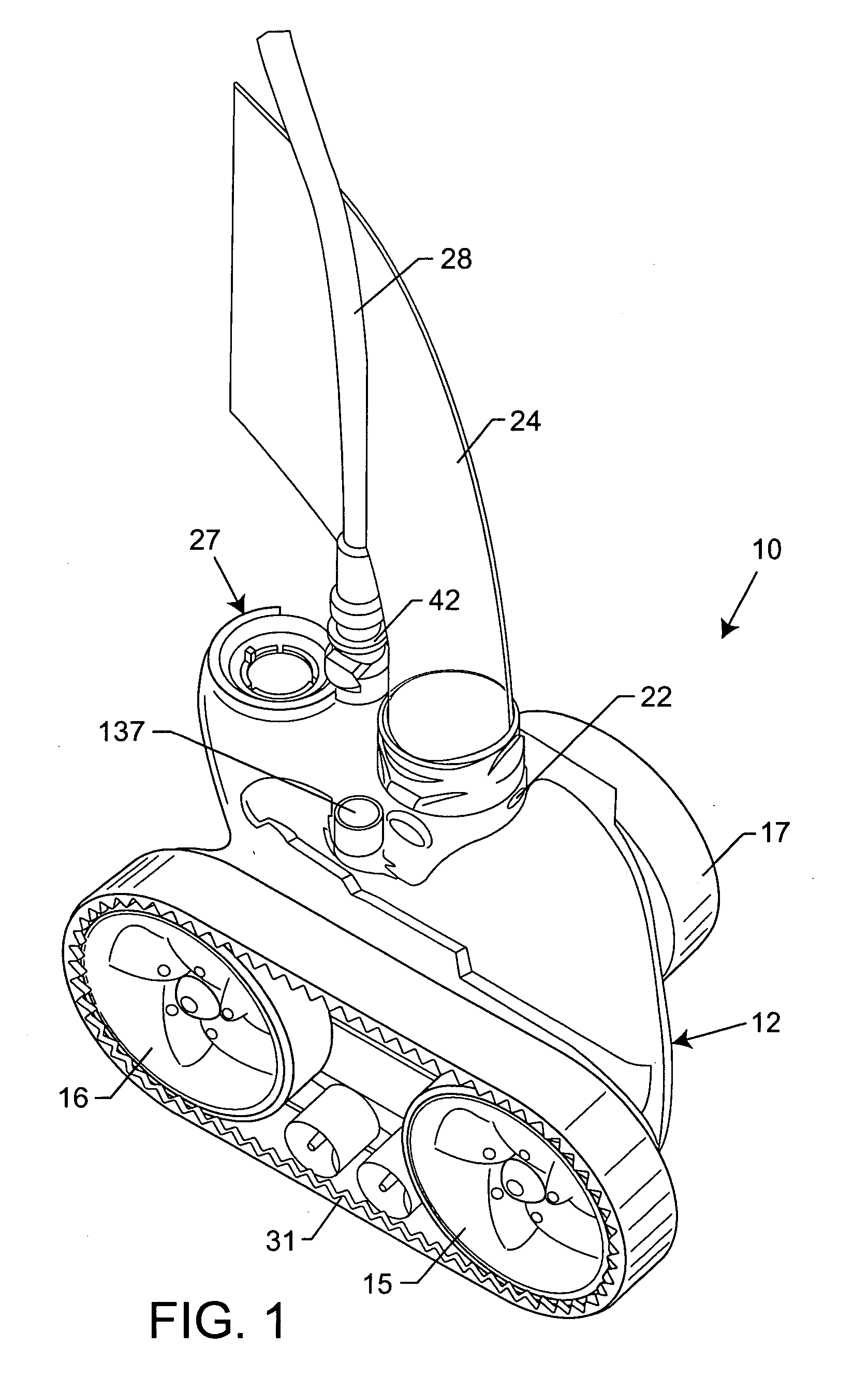

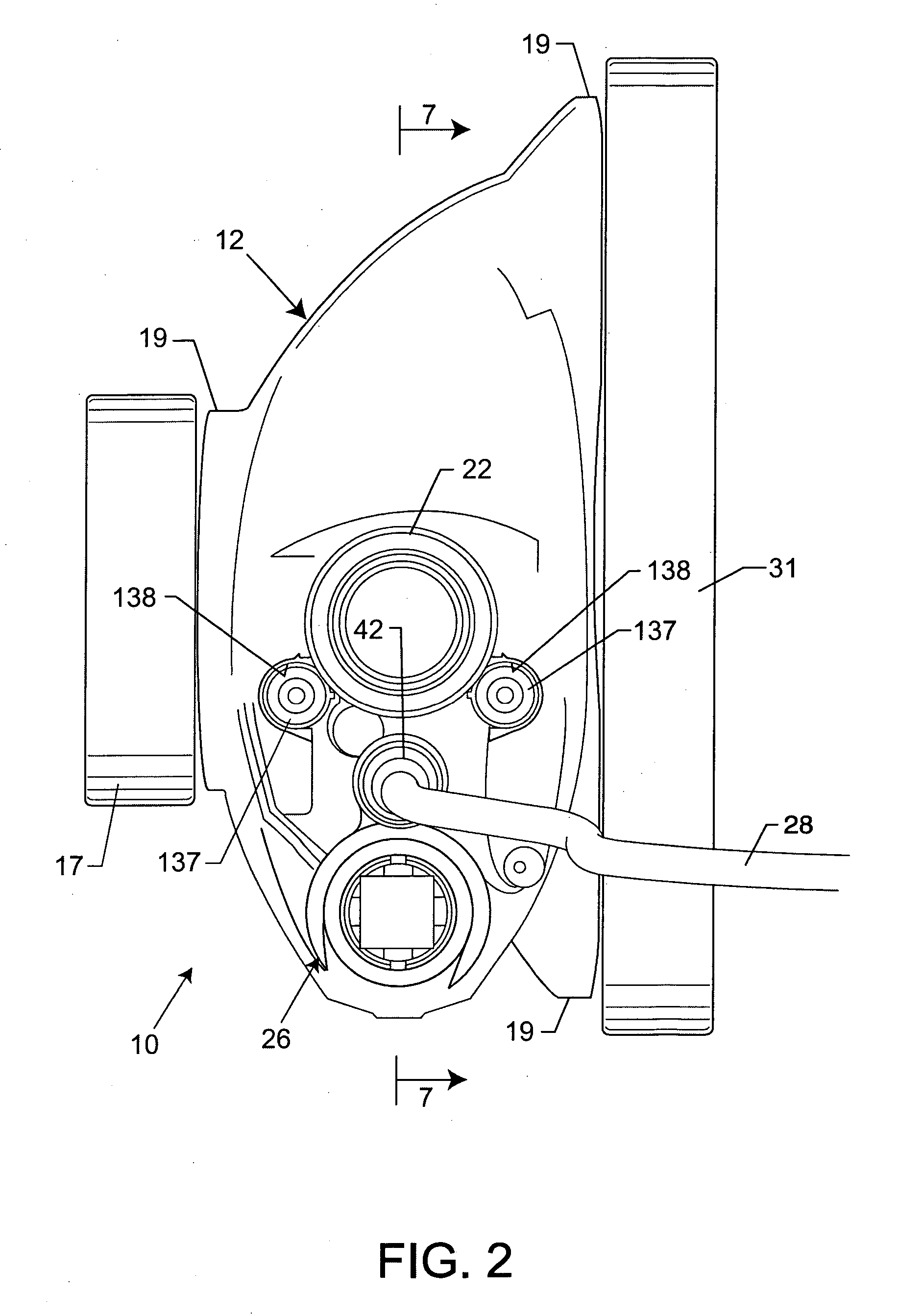

Self-propelled cleaning device and method of operation thereof

InactiveUS7515991B2Quick cleanAutomatic obstacle detectionTravelling automatic controlGyroscopeEngineering

Owner:HITACHI LTD +1

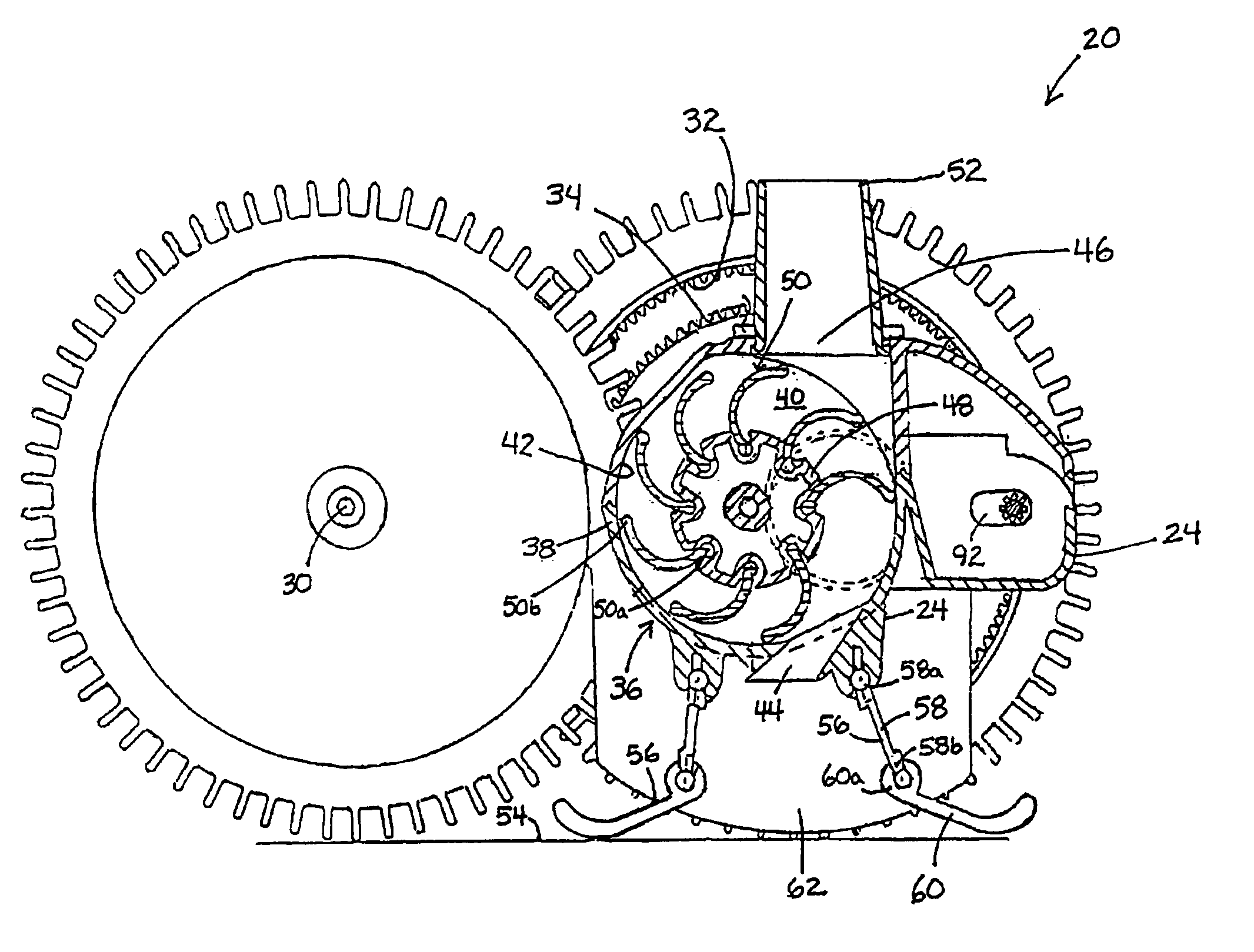

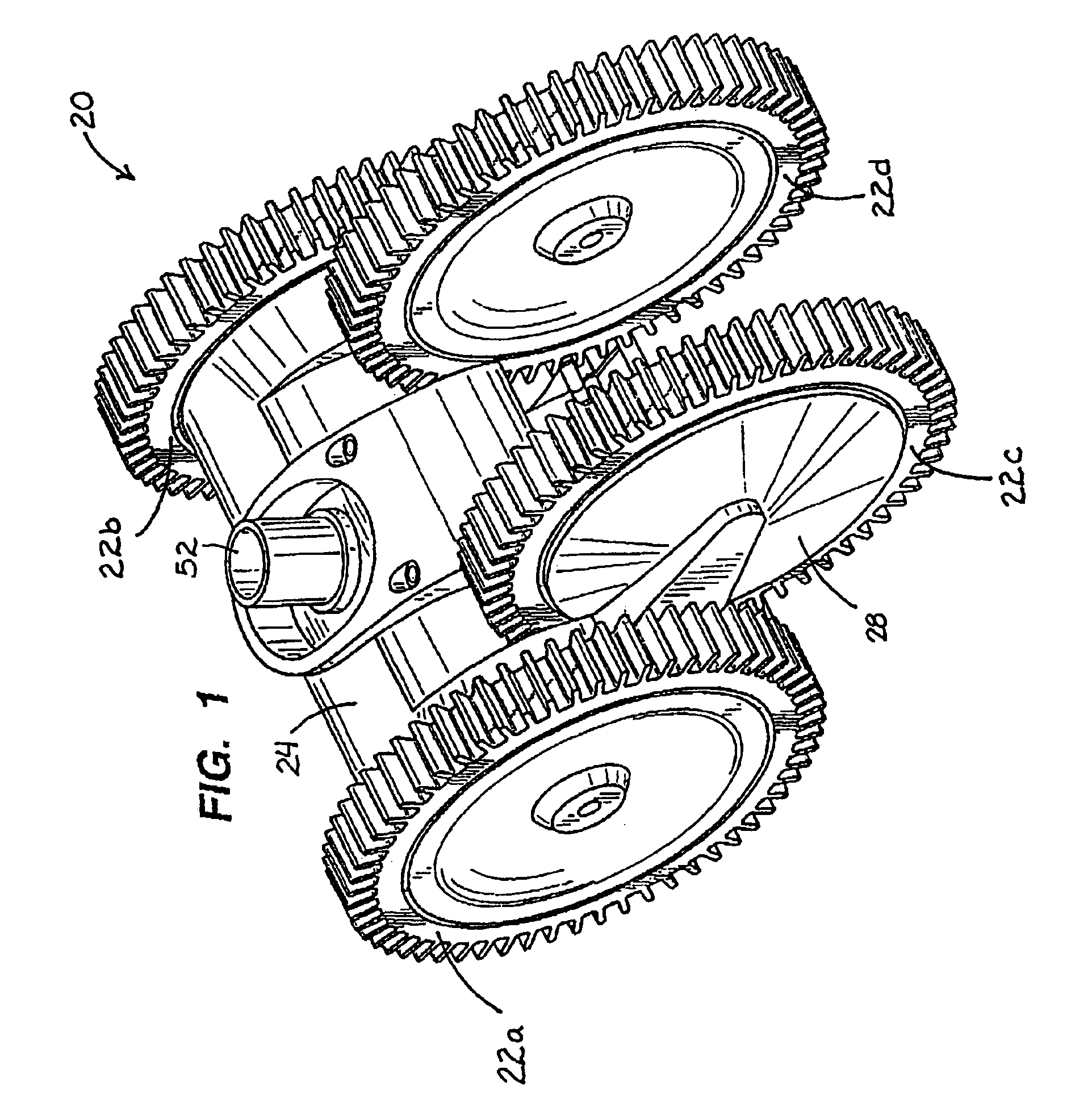

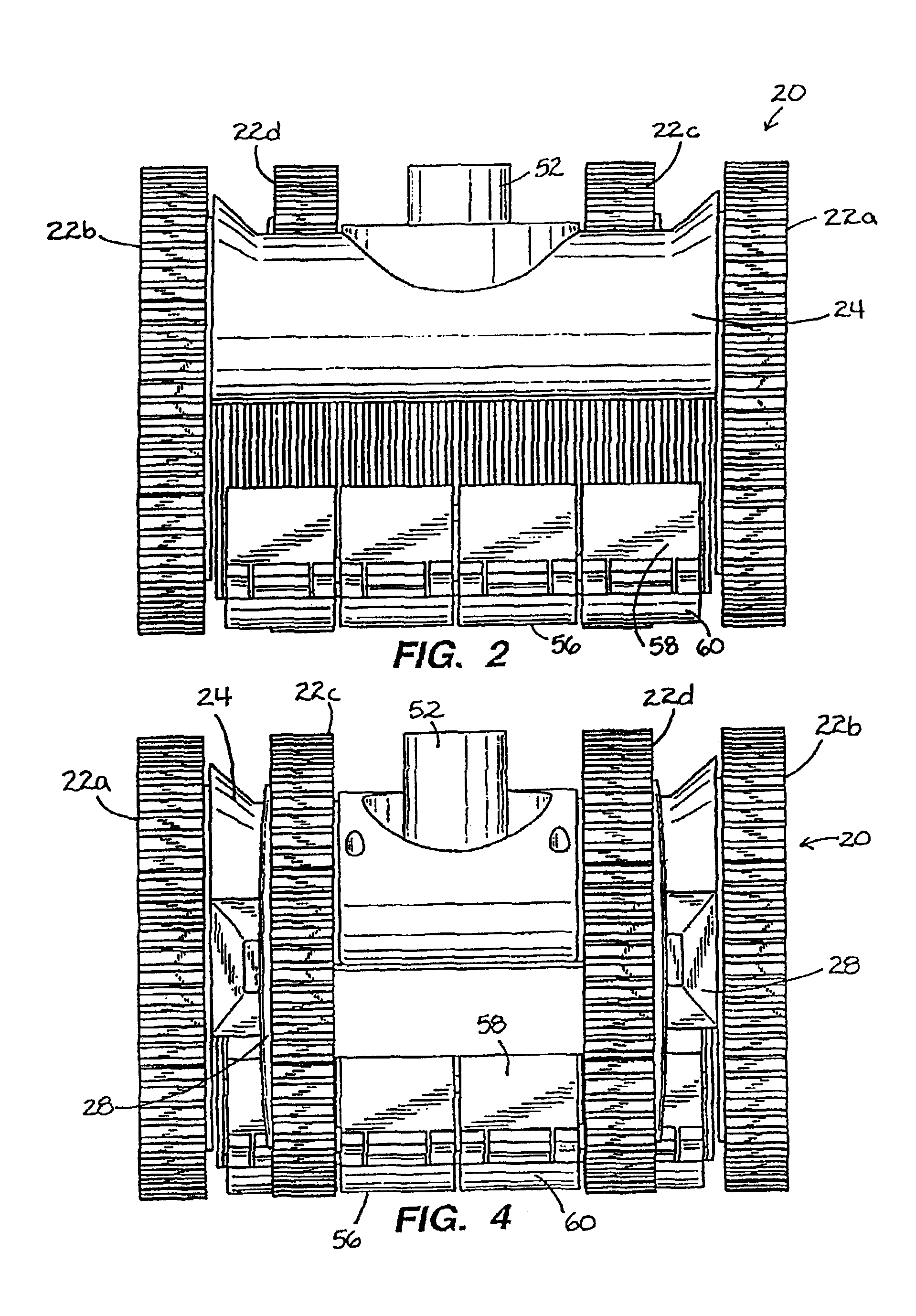

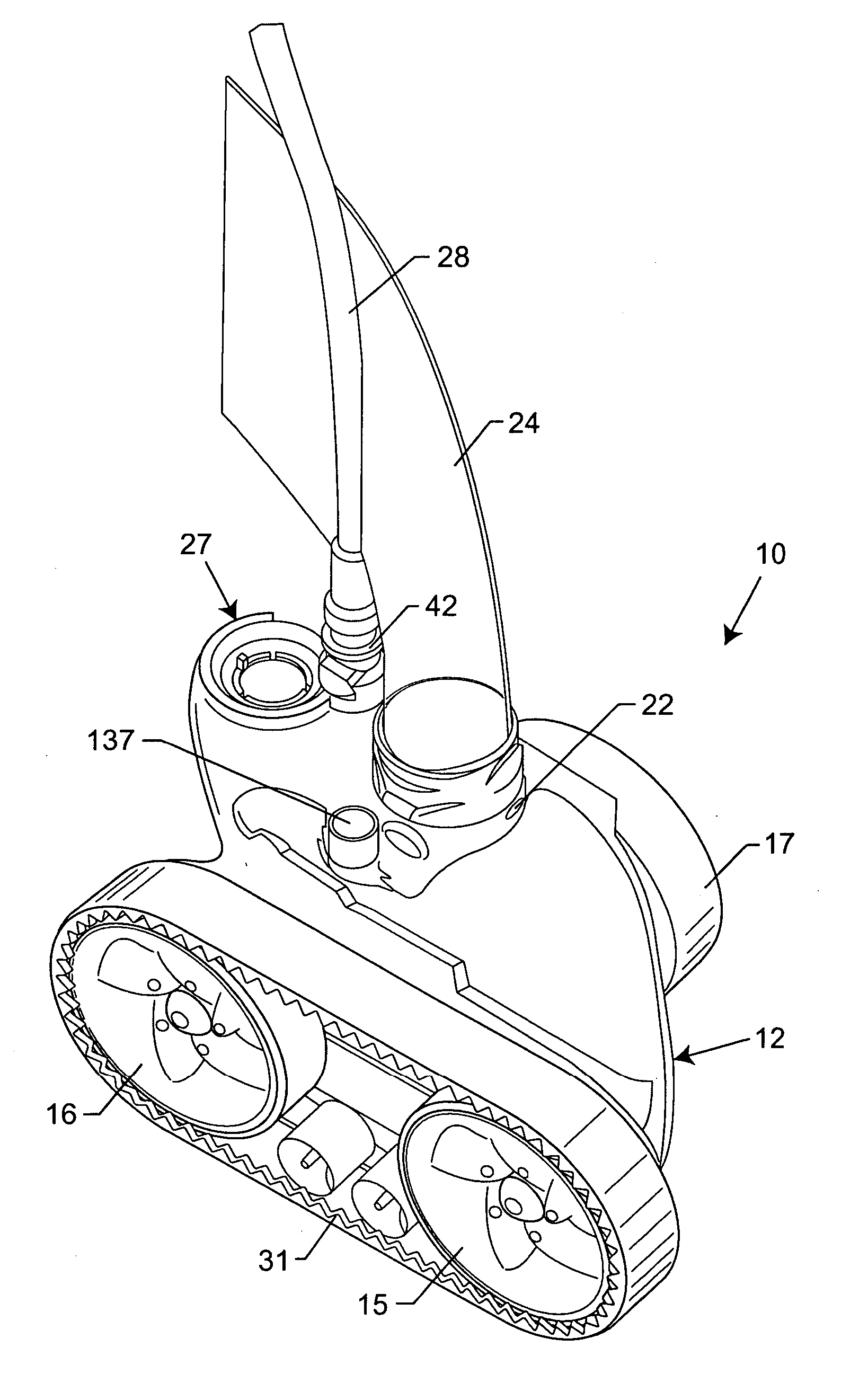

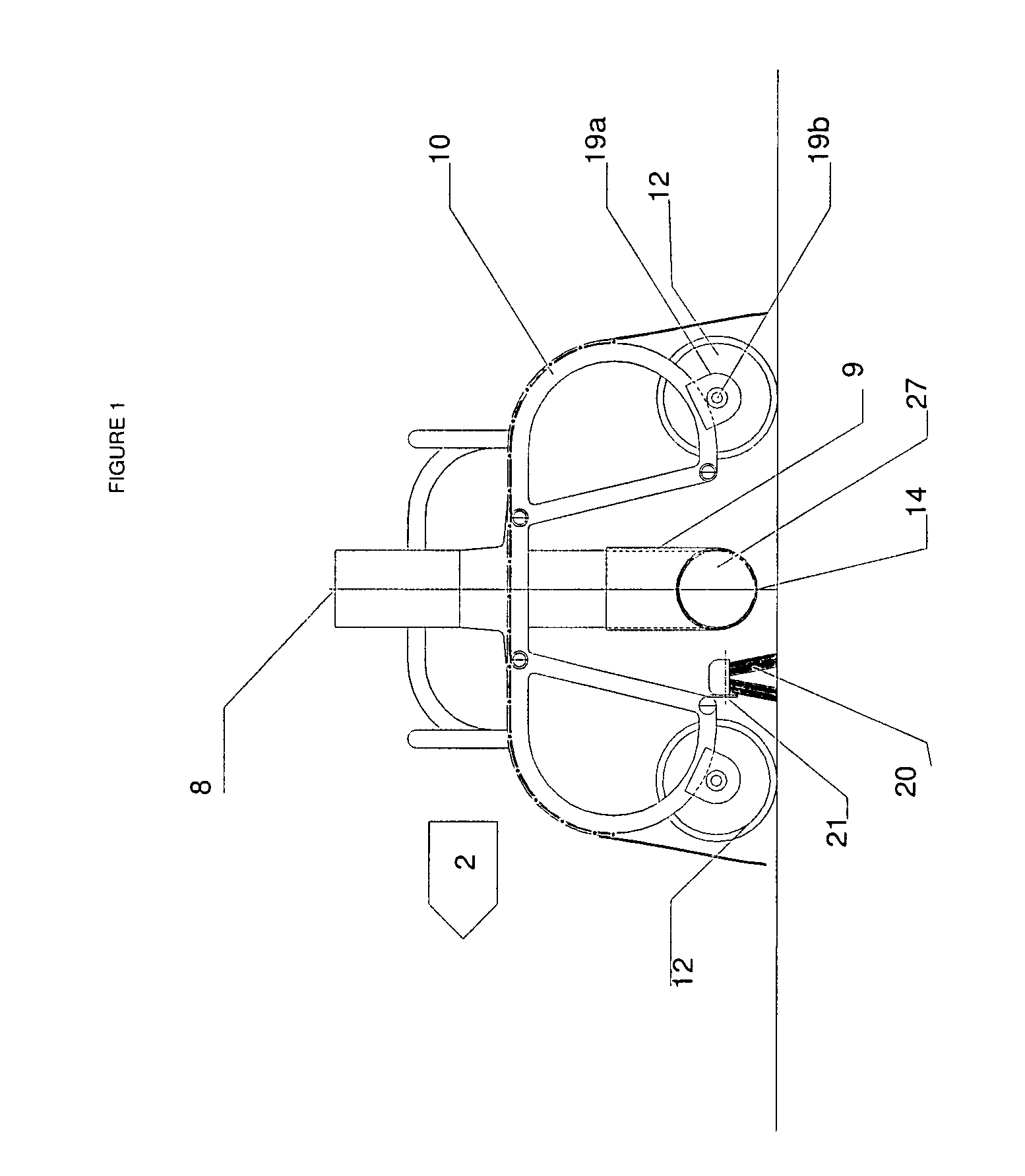

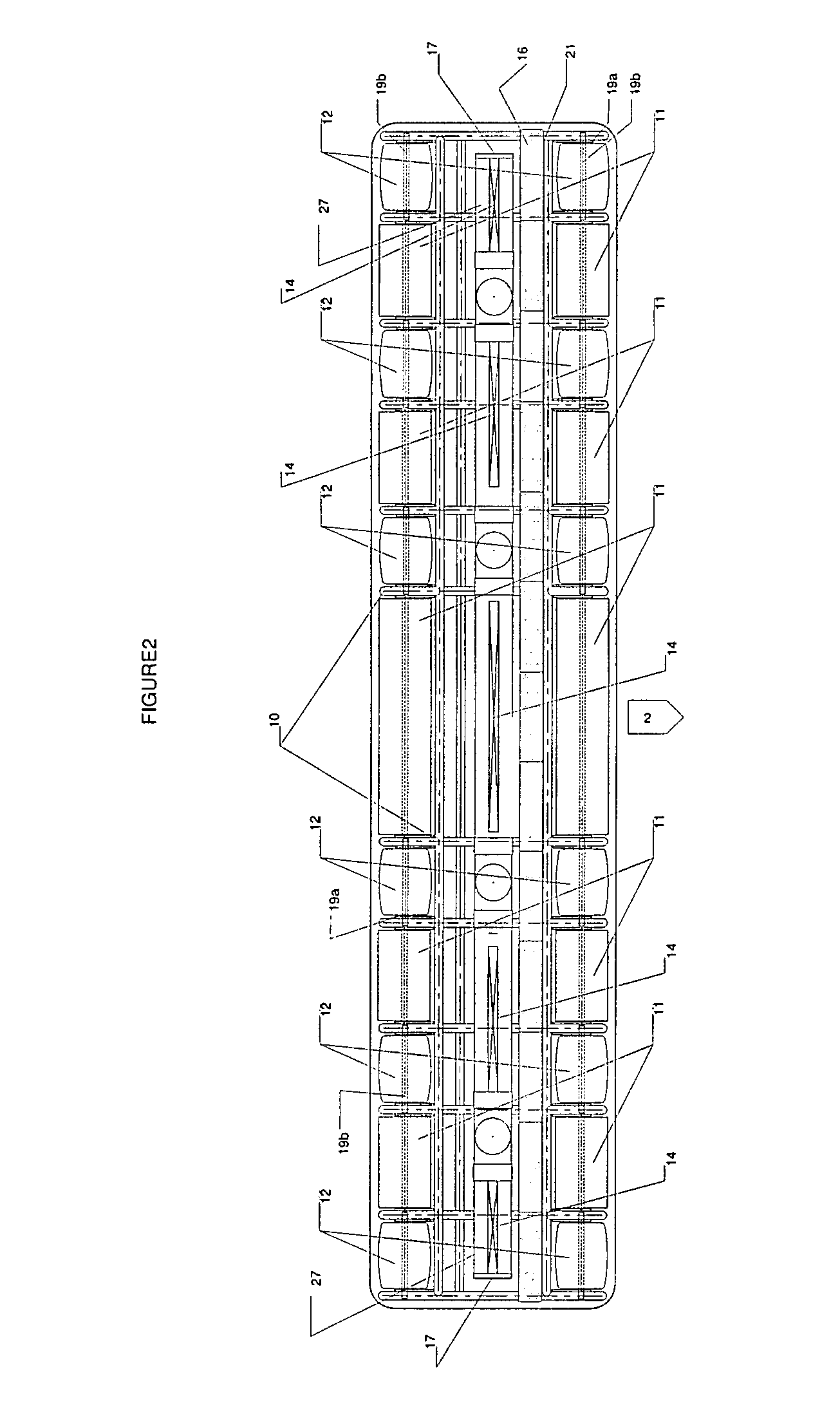

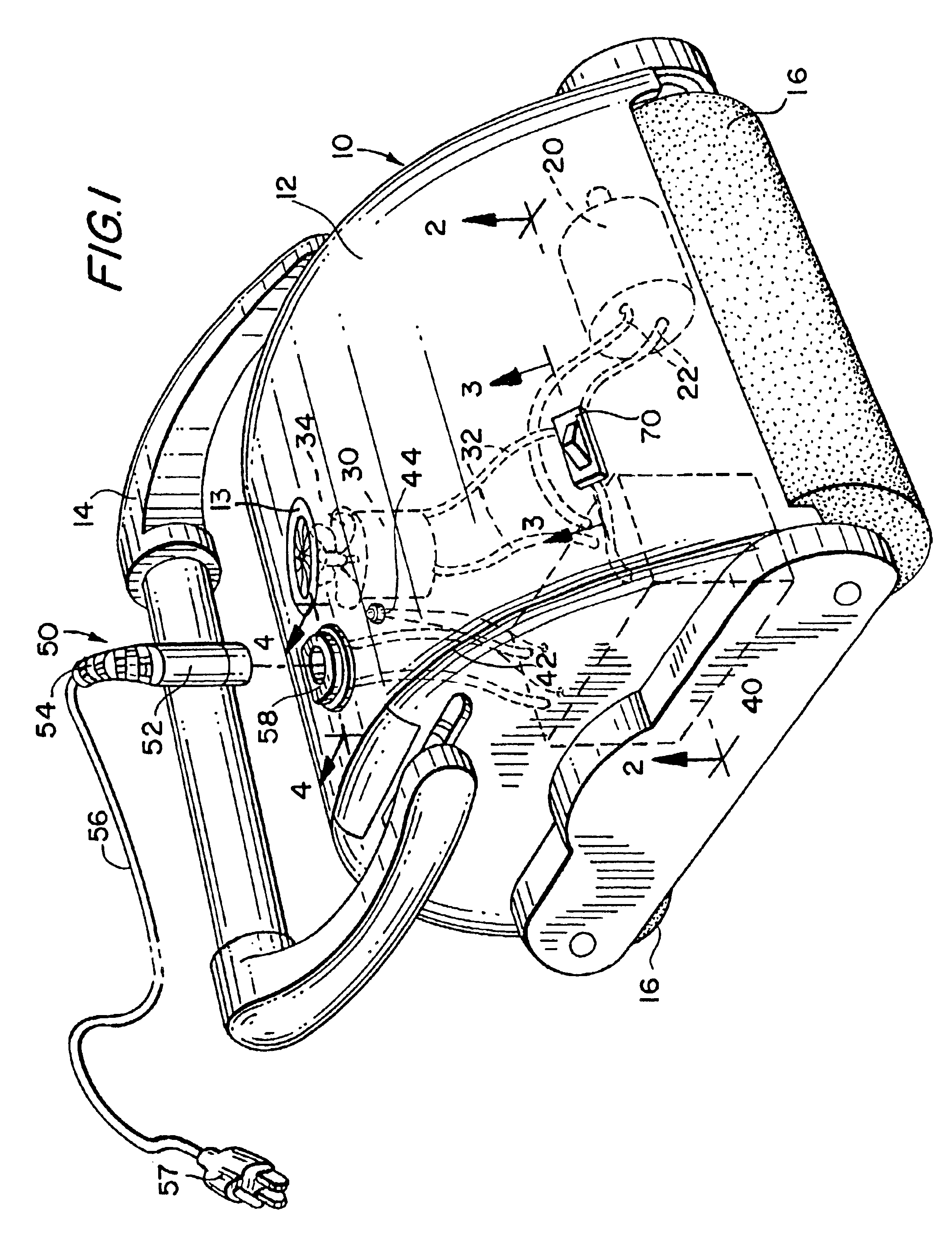

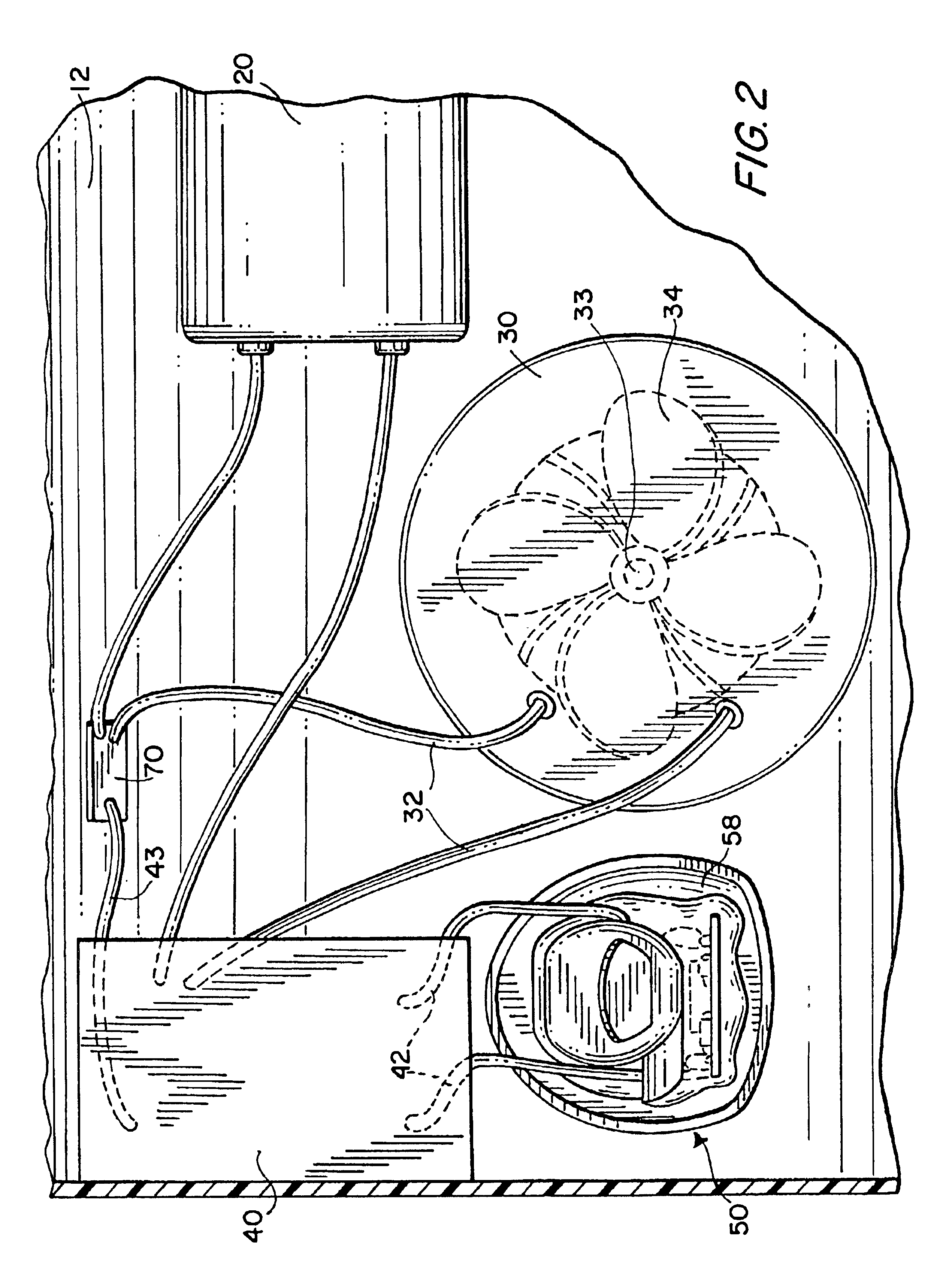

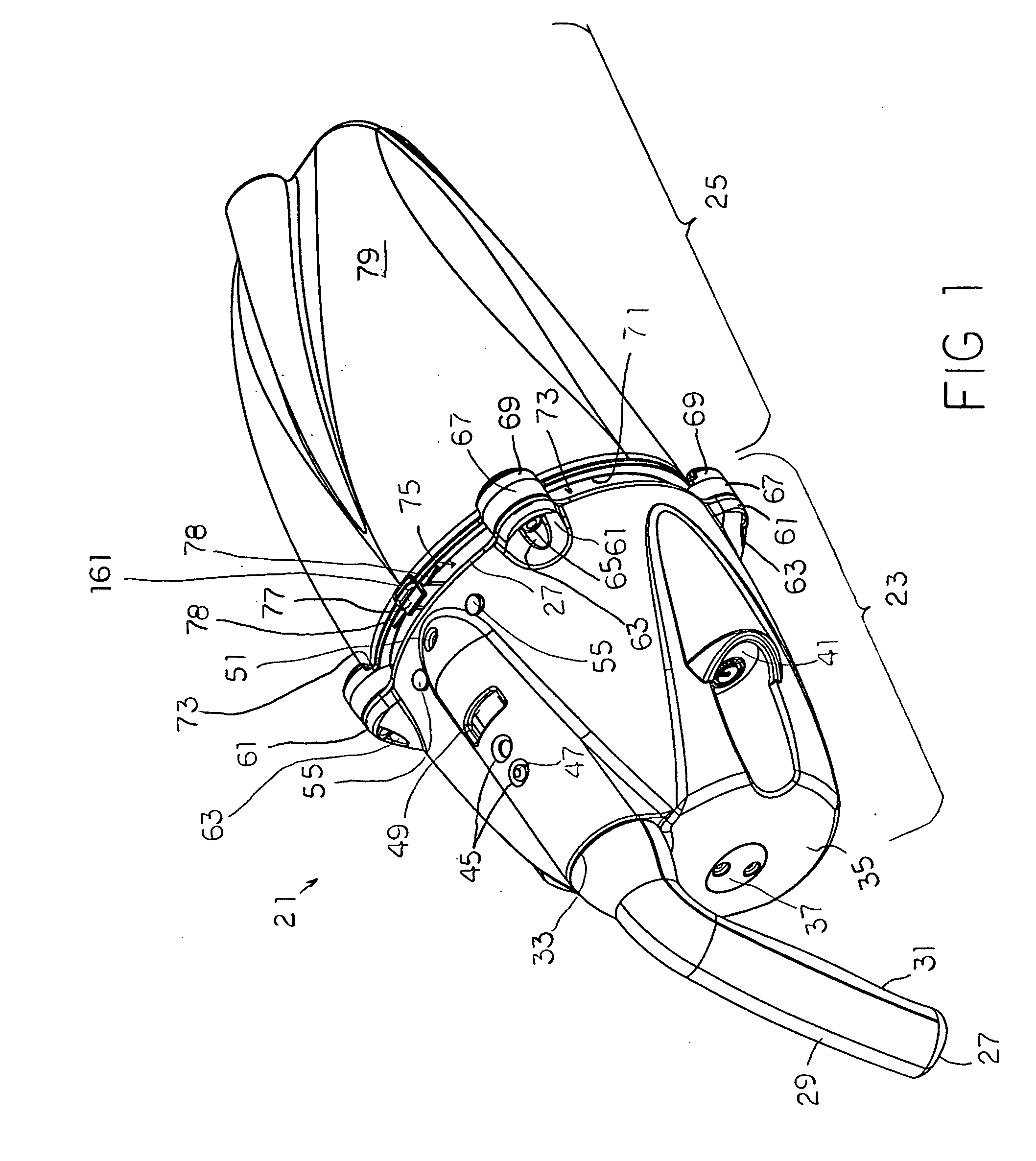

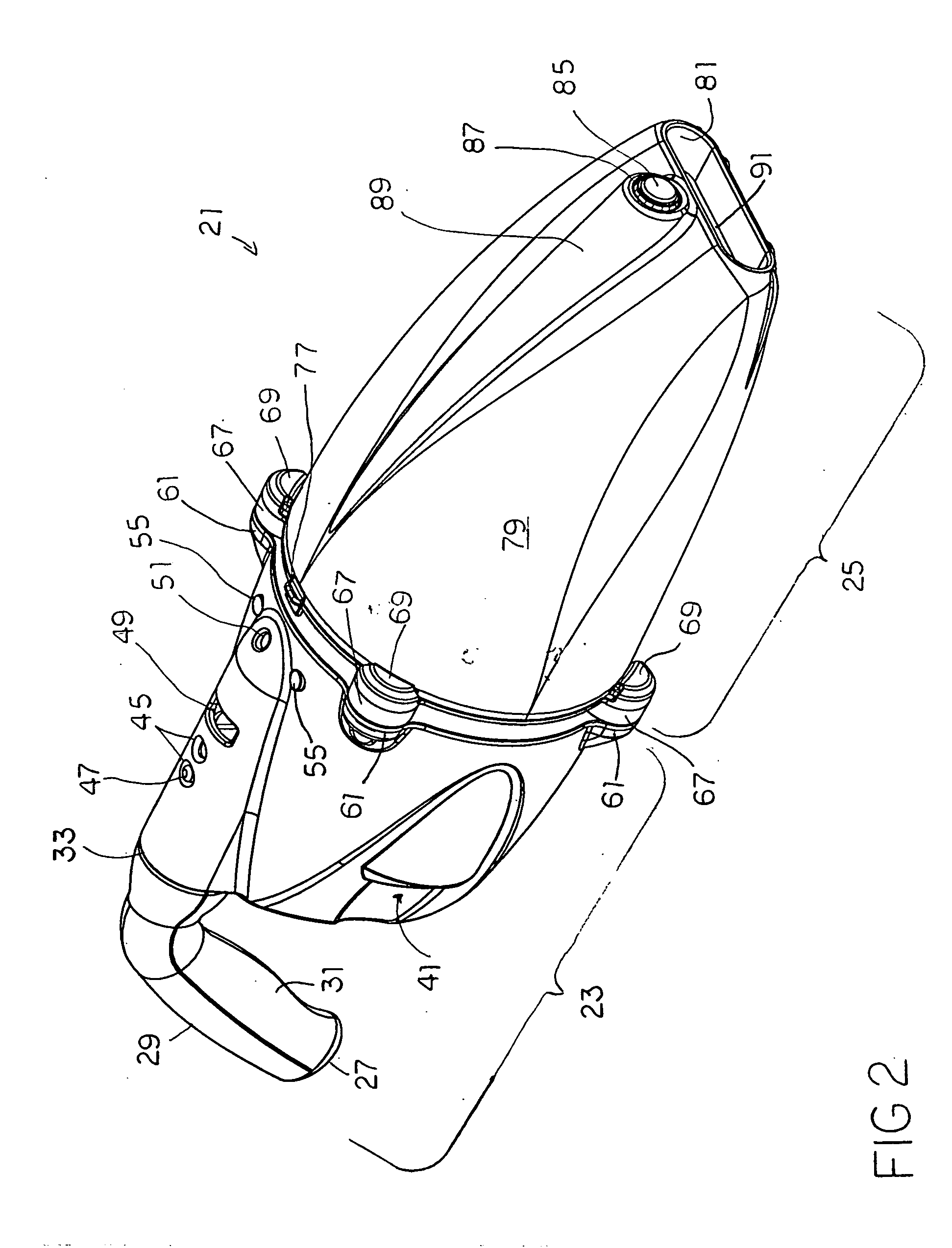

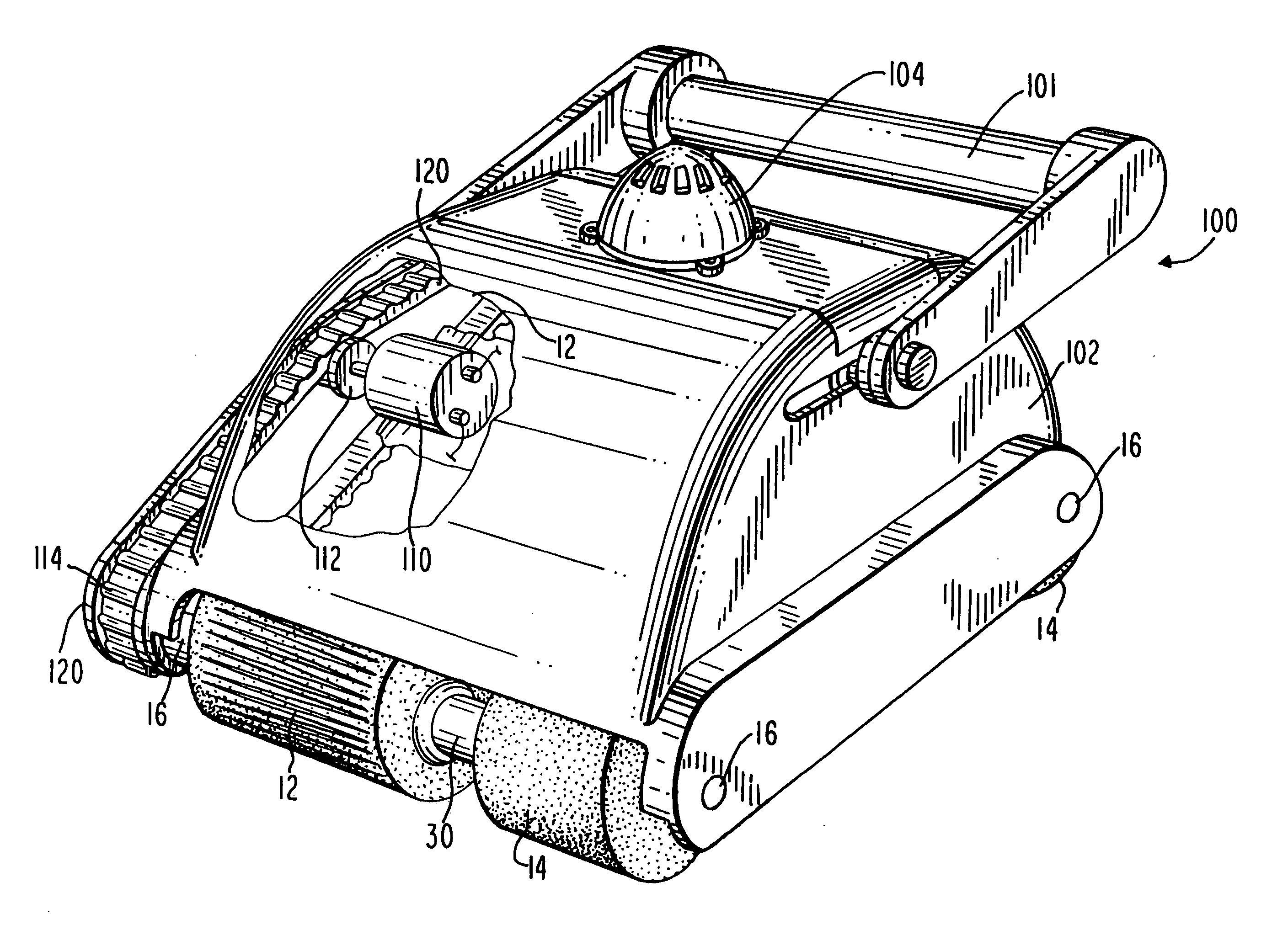

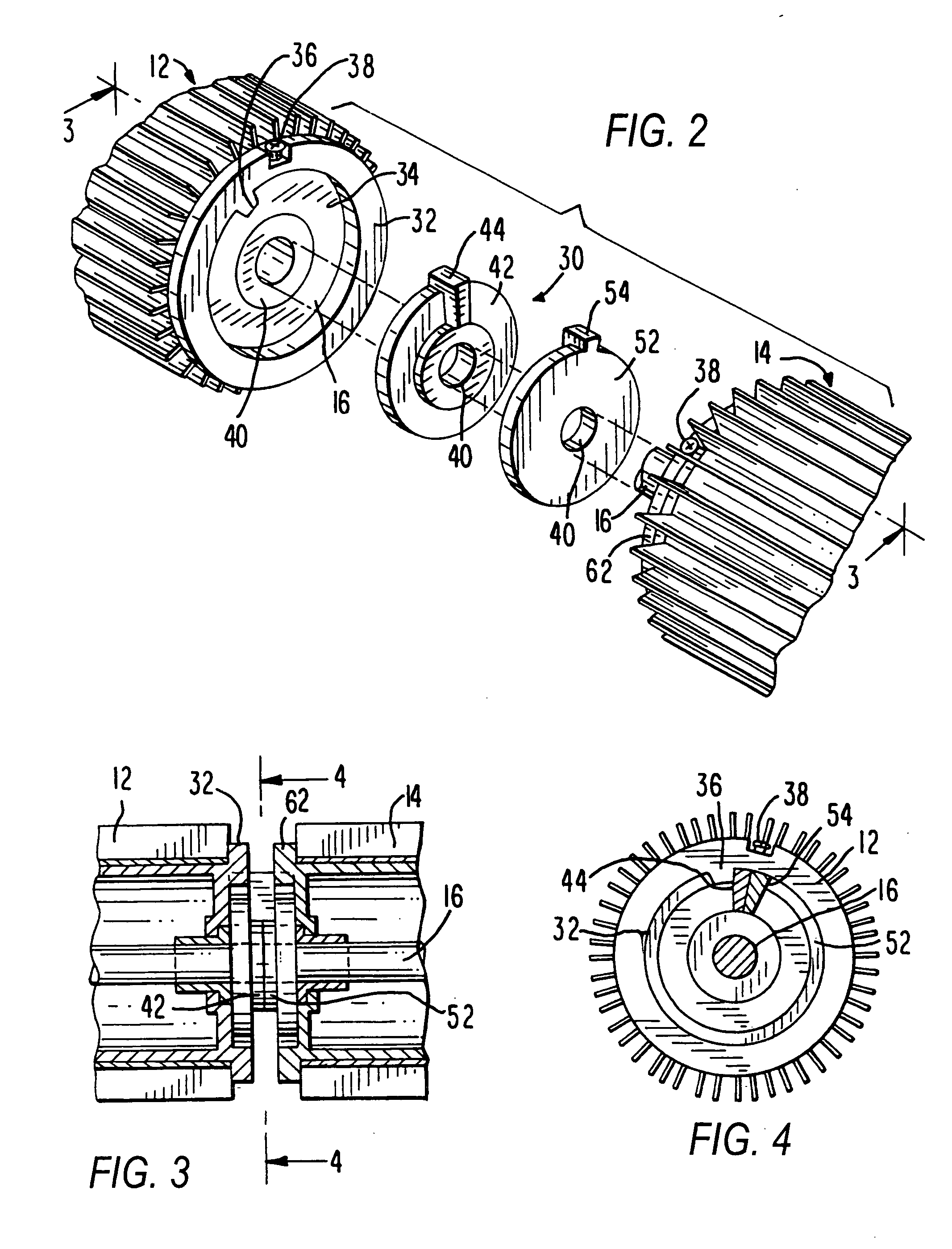

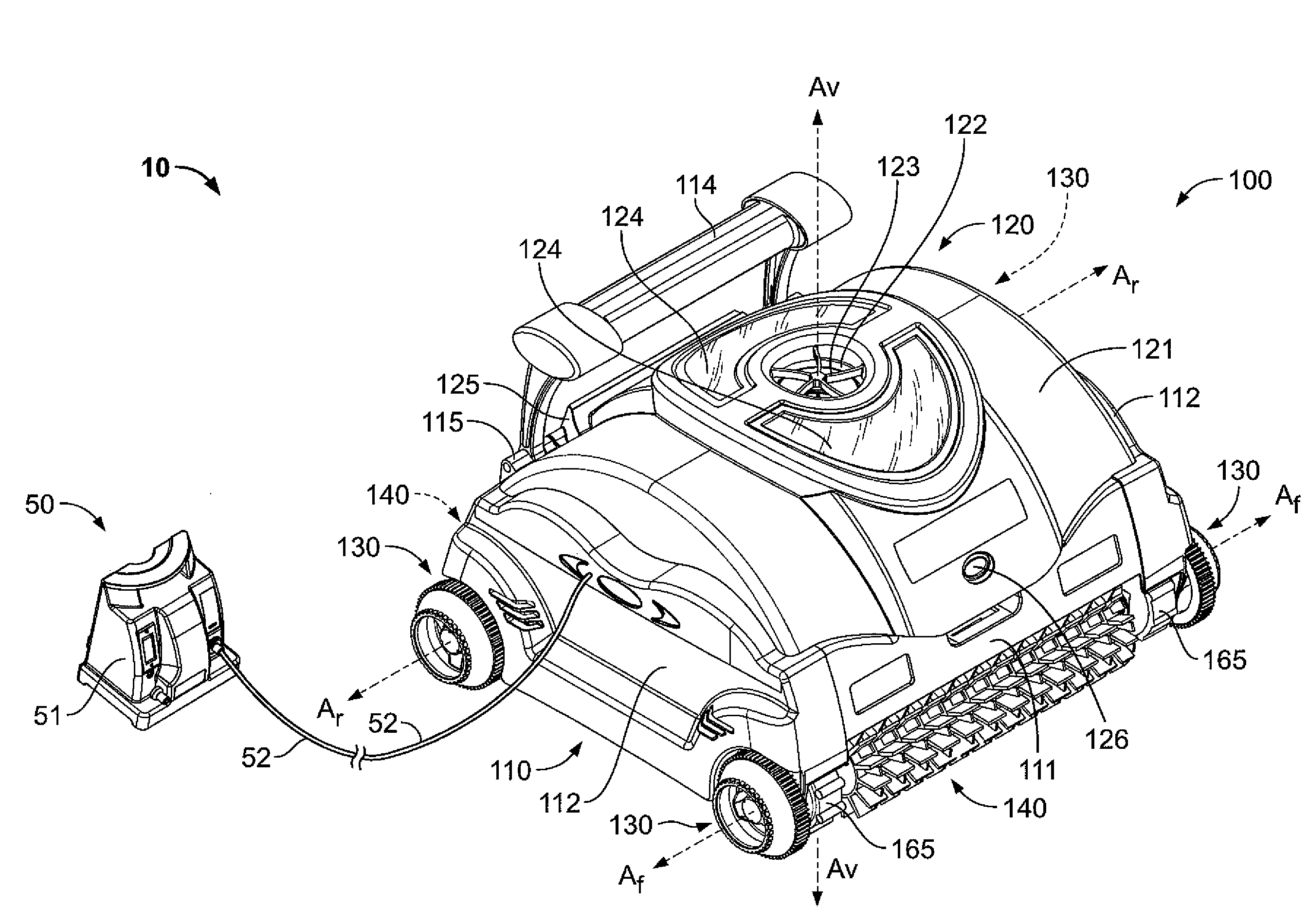

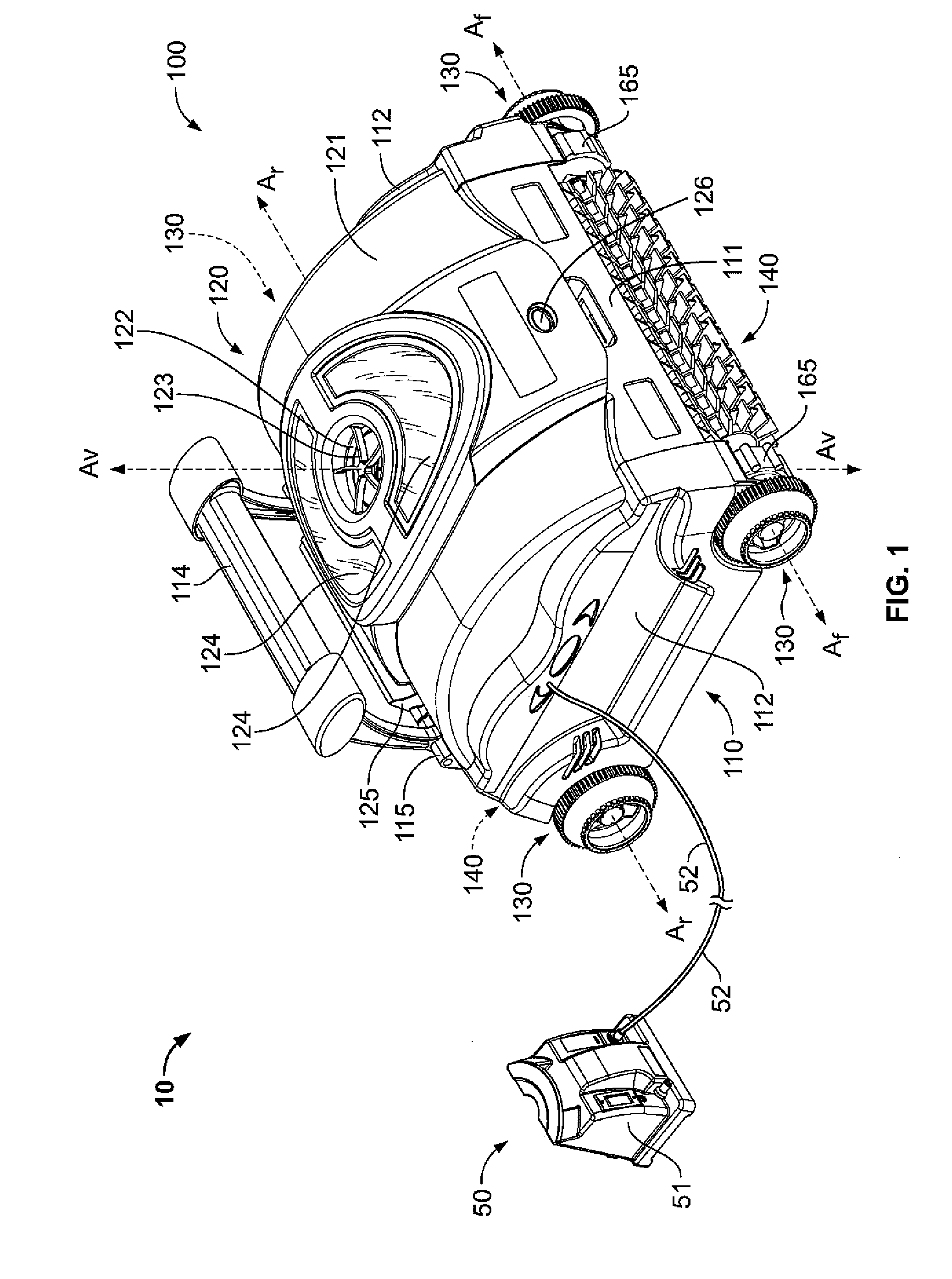

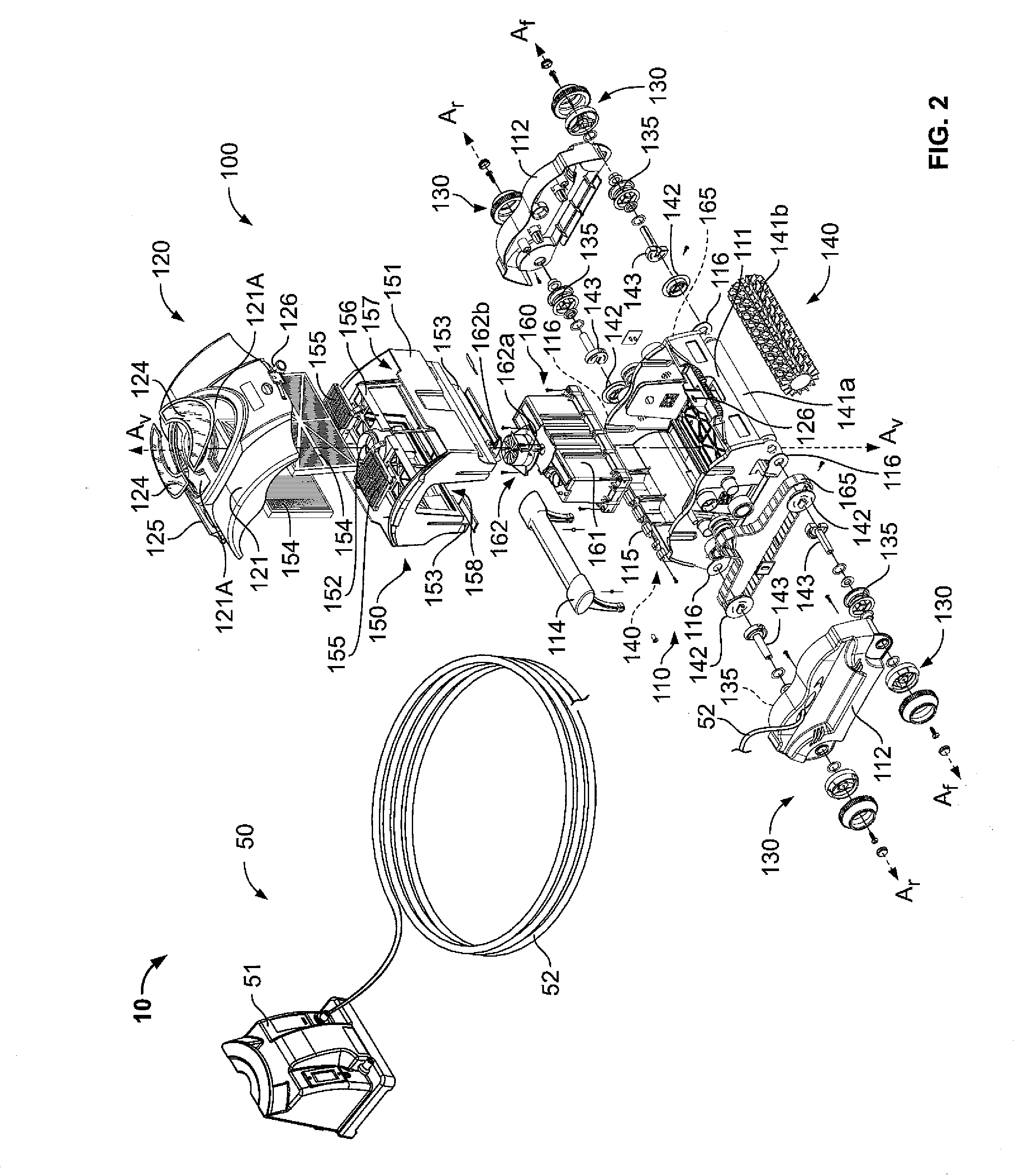

Four-wheel-drive automatic swimming pool cleaner

InactiveUS6854148B1Great tractionExcellent ability to traverse pool surfaceGymnasiumSwimming poolsDrive shaftWater flow

A four-wheel pool cleaner (20) motivated by water flow to move along a pool surface, and having: a body (24); the four wheels rotatably mounted thereon and including two sets of two wheels (22) each, one wheel of each set on each side; a drive mechanism (36) in position to be moved by water flow and having a rotatable drive member (76); a drive train extending to the first wheel set (22a, b) and to the second wheel set (22c, d), to drive all four wheels. Preferred embodiments include: wheel-to-wheel drive links (88) along the side; a turbine (36) as drive mechanism; a pair of spaced wheelgears (32, 34), preferably integrally formed with the wheel, facilitating drive linkages and steering; a pair of end-to-end drive shafts (80, 82) joined by a coupler (84c), one shaft end (80a) being a ball joint allowing fore-and-aft movement of a drive-shaft distal end; a spring (102) and cam (100) for alternately moving that distal end between a driving position engaging one of the spaced wheelgears (32), and a steering position engaging the other of the spaced wheelgears (34); wheel treads (108) with radial fingers (110), some (110a-c) of longer length; and a segmented articulated skirt (56) to help enclose a plenum beneath the pool cleaner.

Owner:HAYWARD IND INC

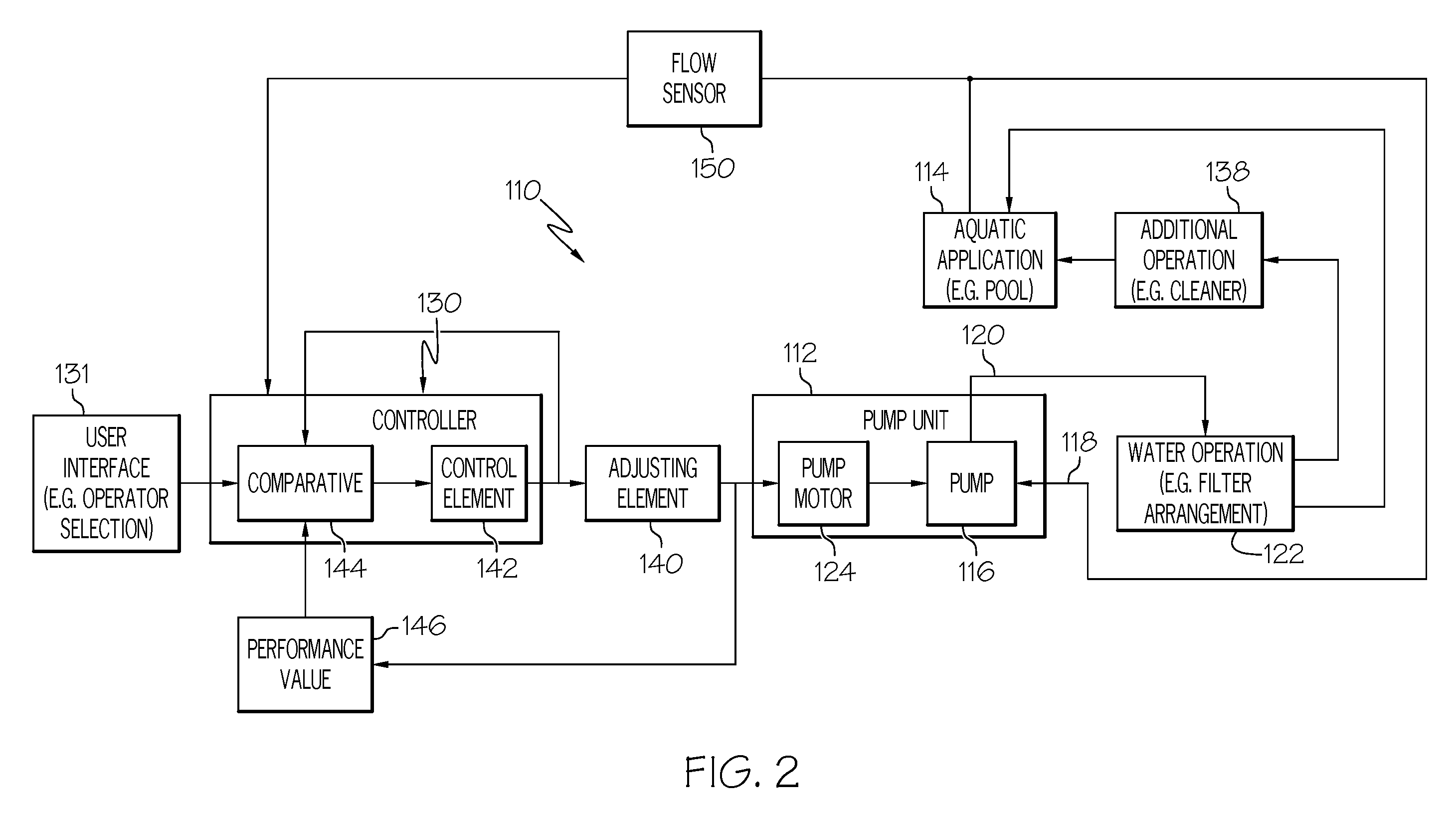

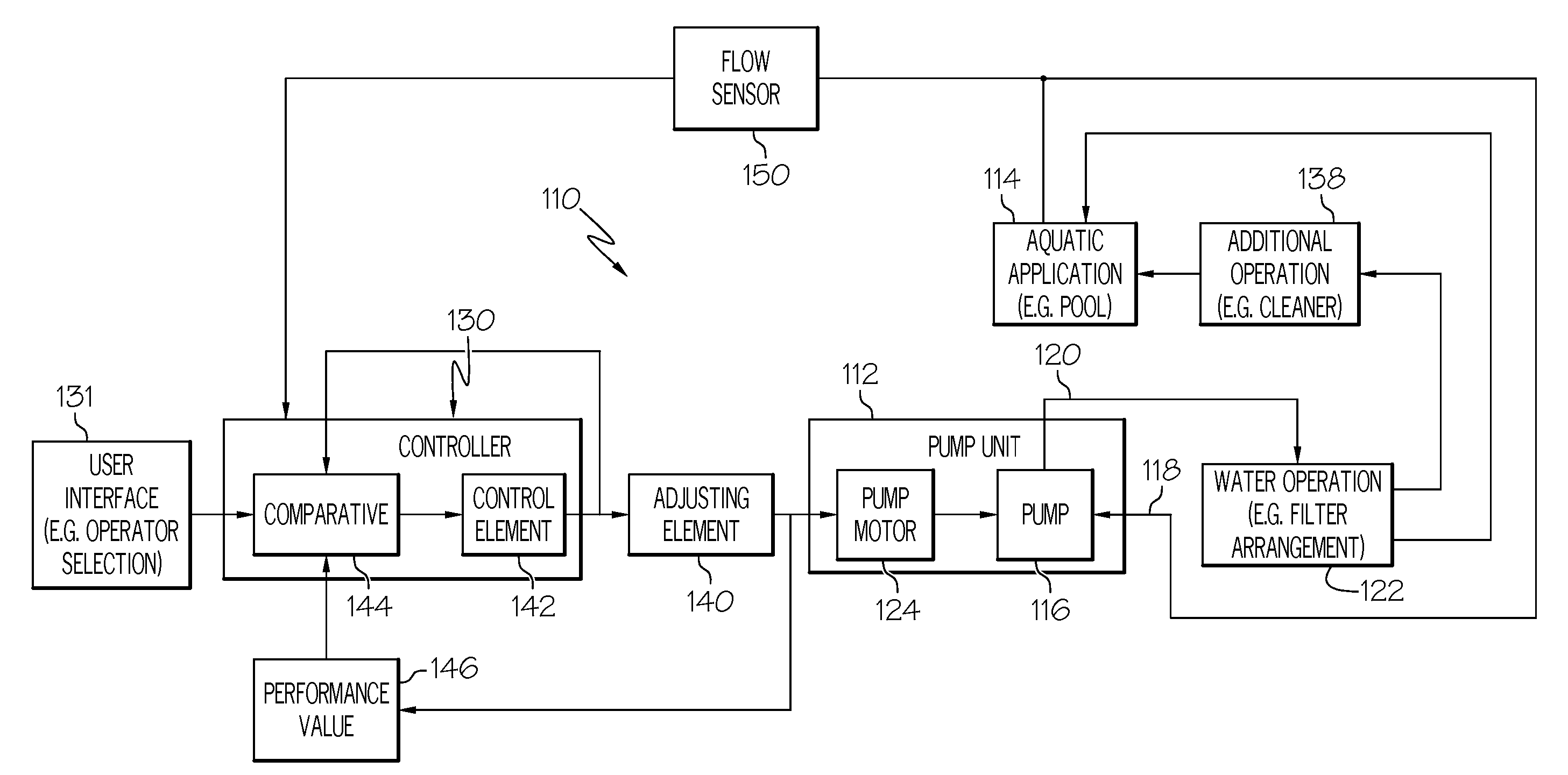

Pumping system with power optimization

The present invention provides a pumping system for moving water of a swimming pool, including a water pump and a variable speed motor. In one example, a target volume amount of water and an operational time period is provided, and the operational time period is altered based upon a volume of water moved. In another example, operation of the motor is altered based upon the volume of water moved. In addition or alternatively, a target flow rate of water to be moved by the water pump is determined based upon the target volume amount and a time period. In addition or alternatively, a plurality of operations are performed on the water, and a total volume of water moved by the pump is determined. In addition or alternatively, an optimized flow rate value is determined based upon power consumption.

Owner:DANFOSS POWER ELECTRONICS AS +1

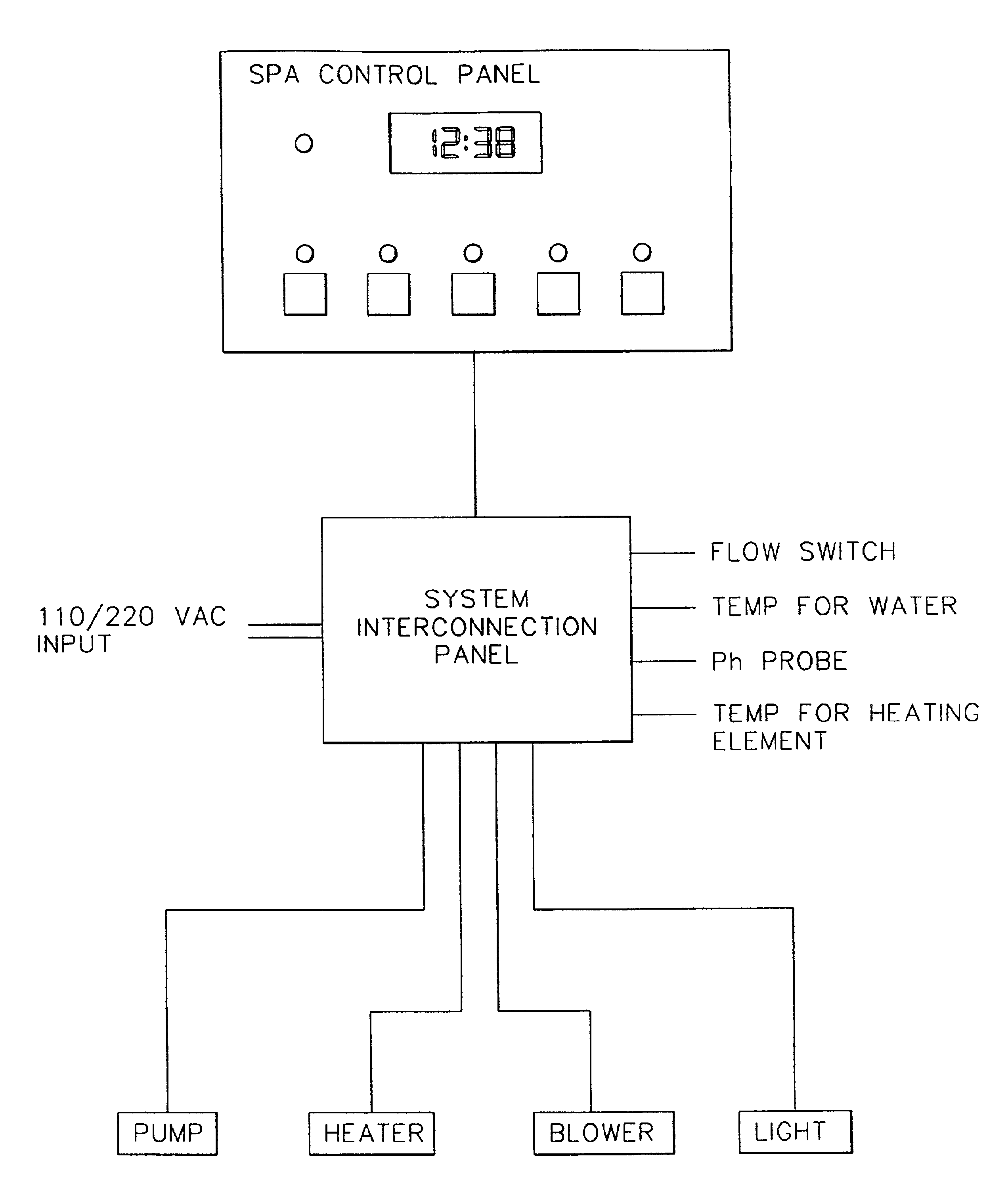

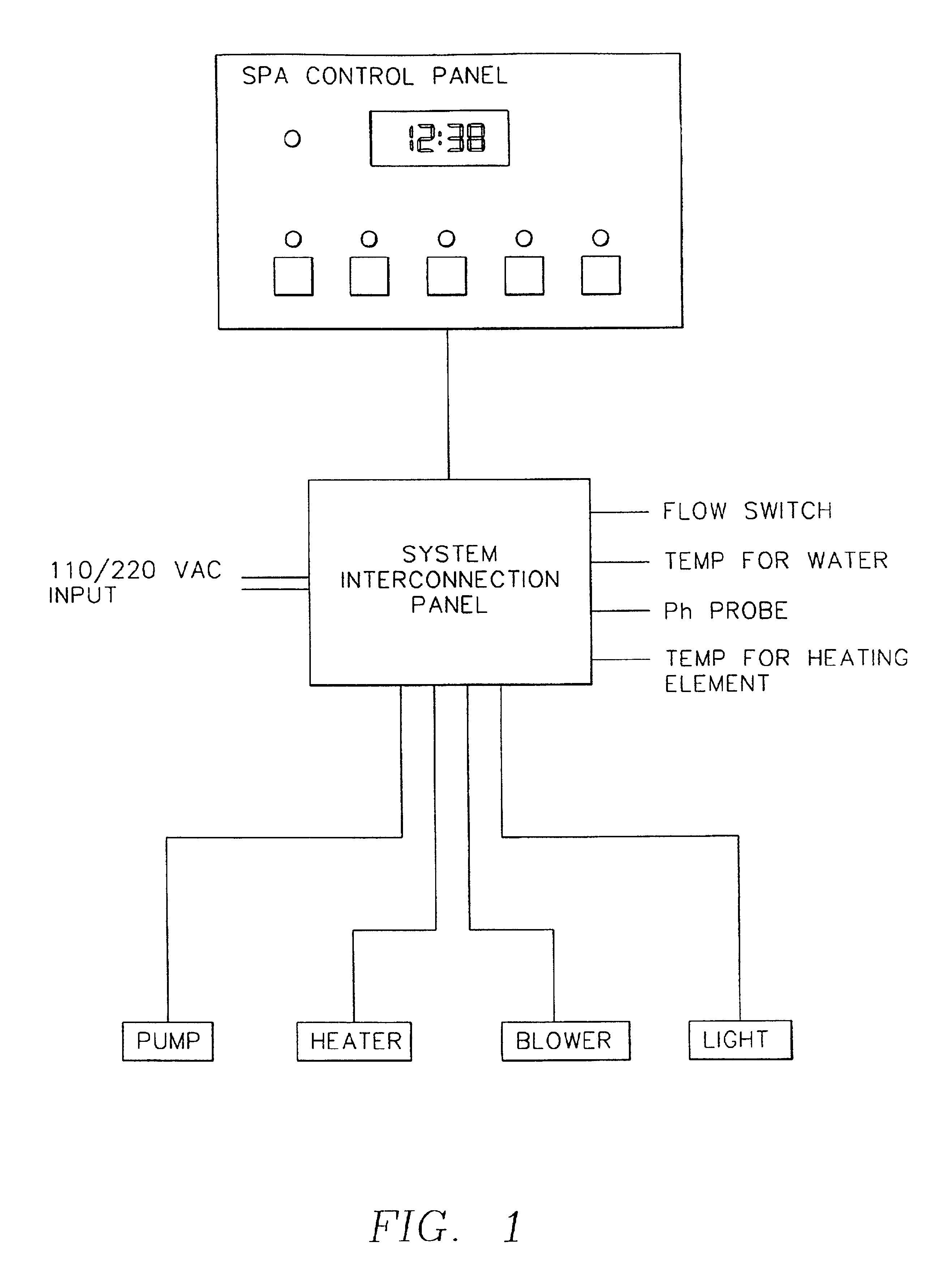

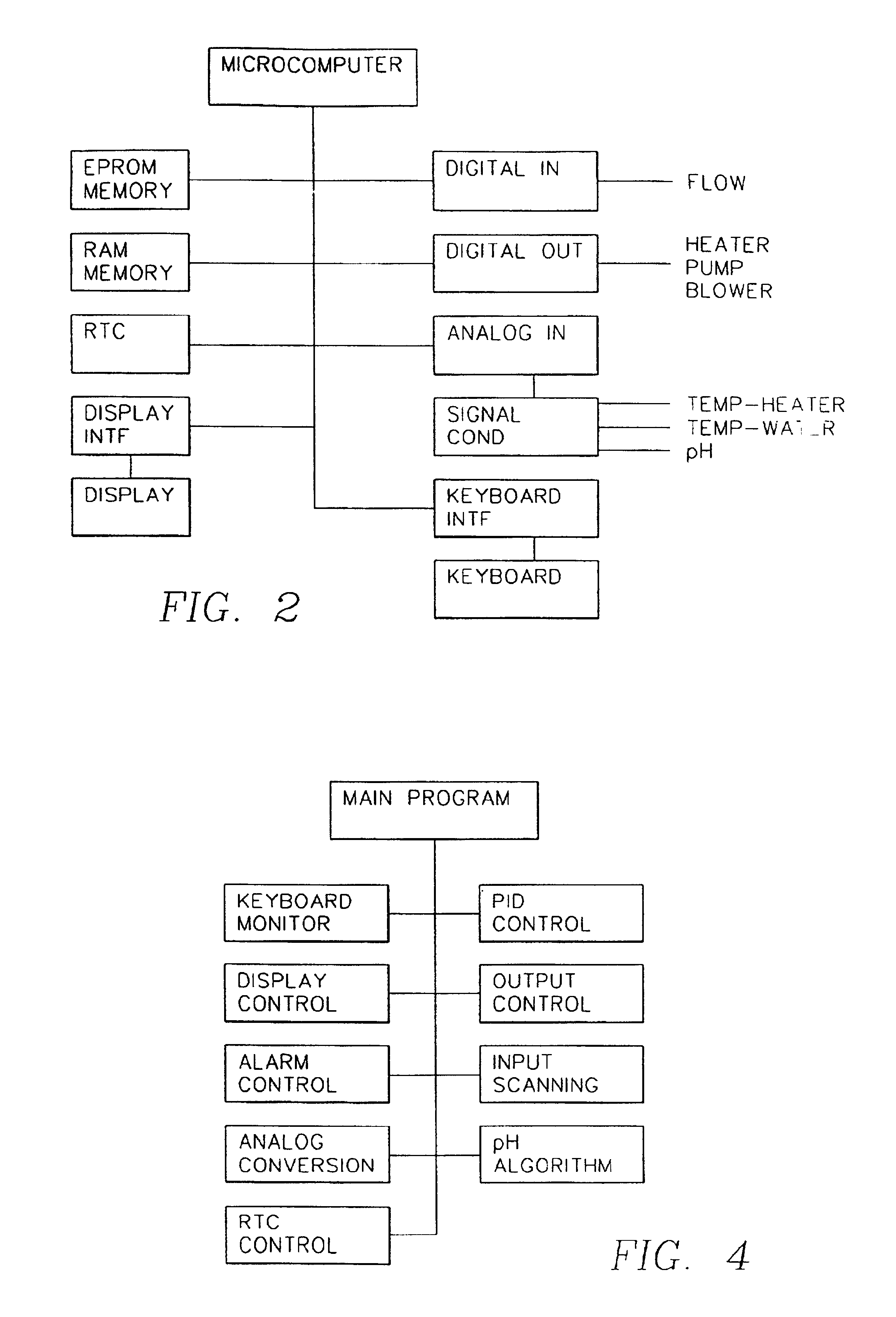

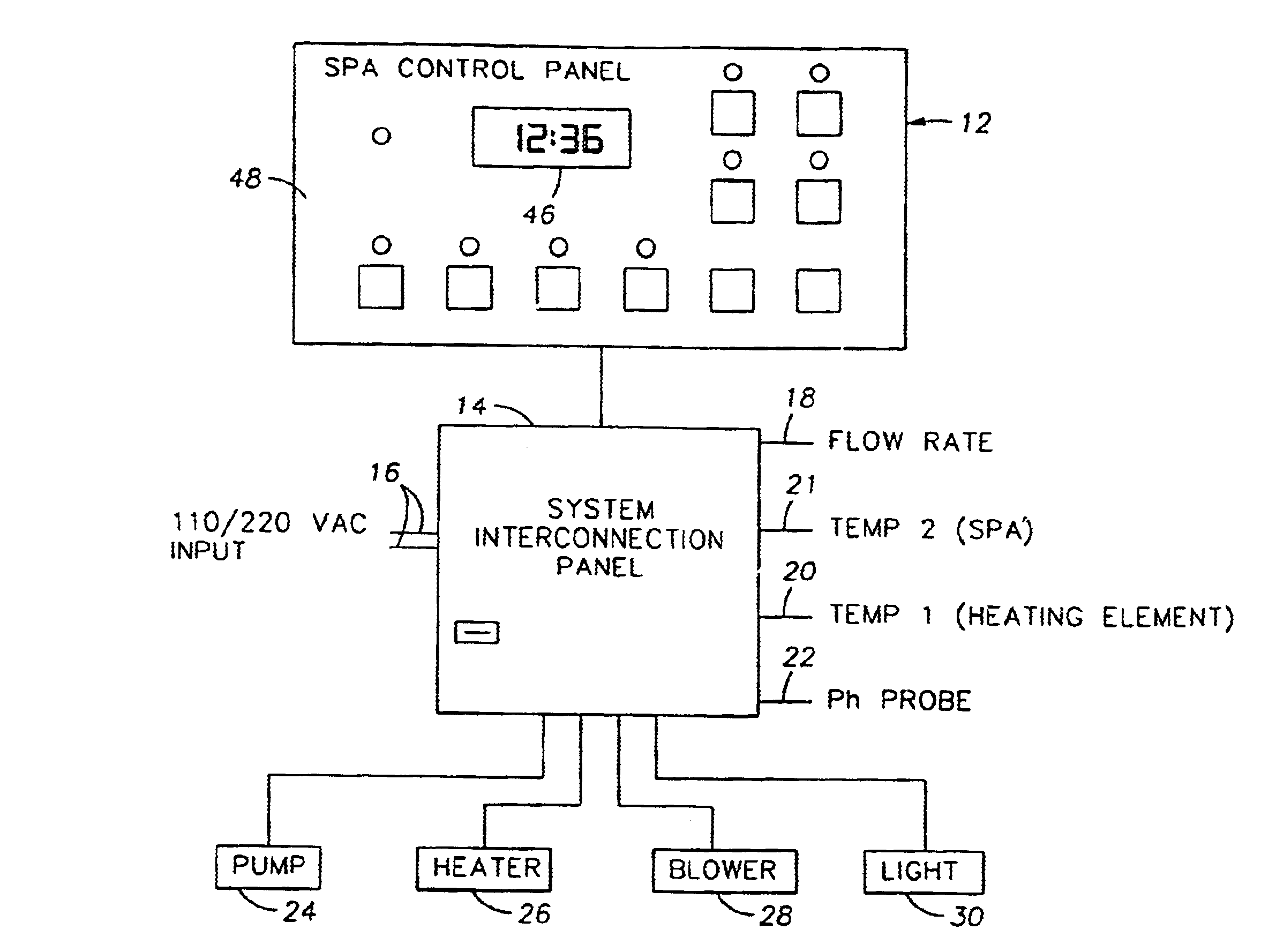

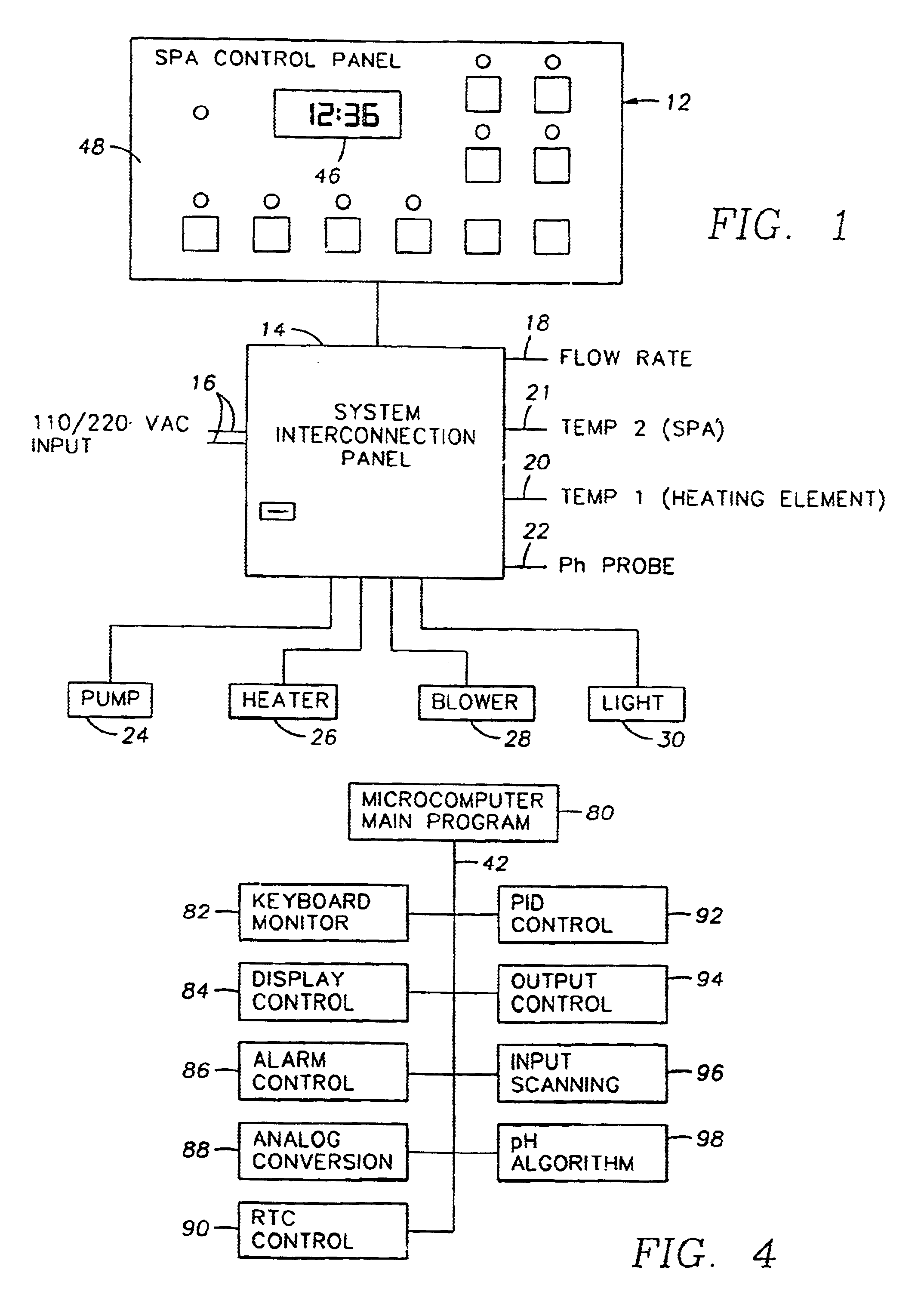

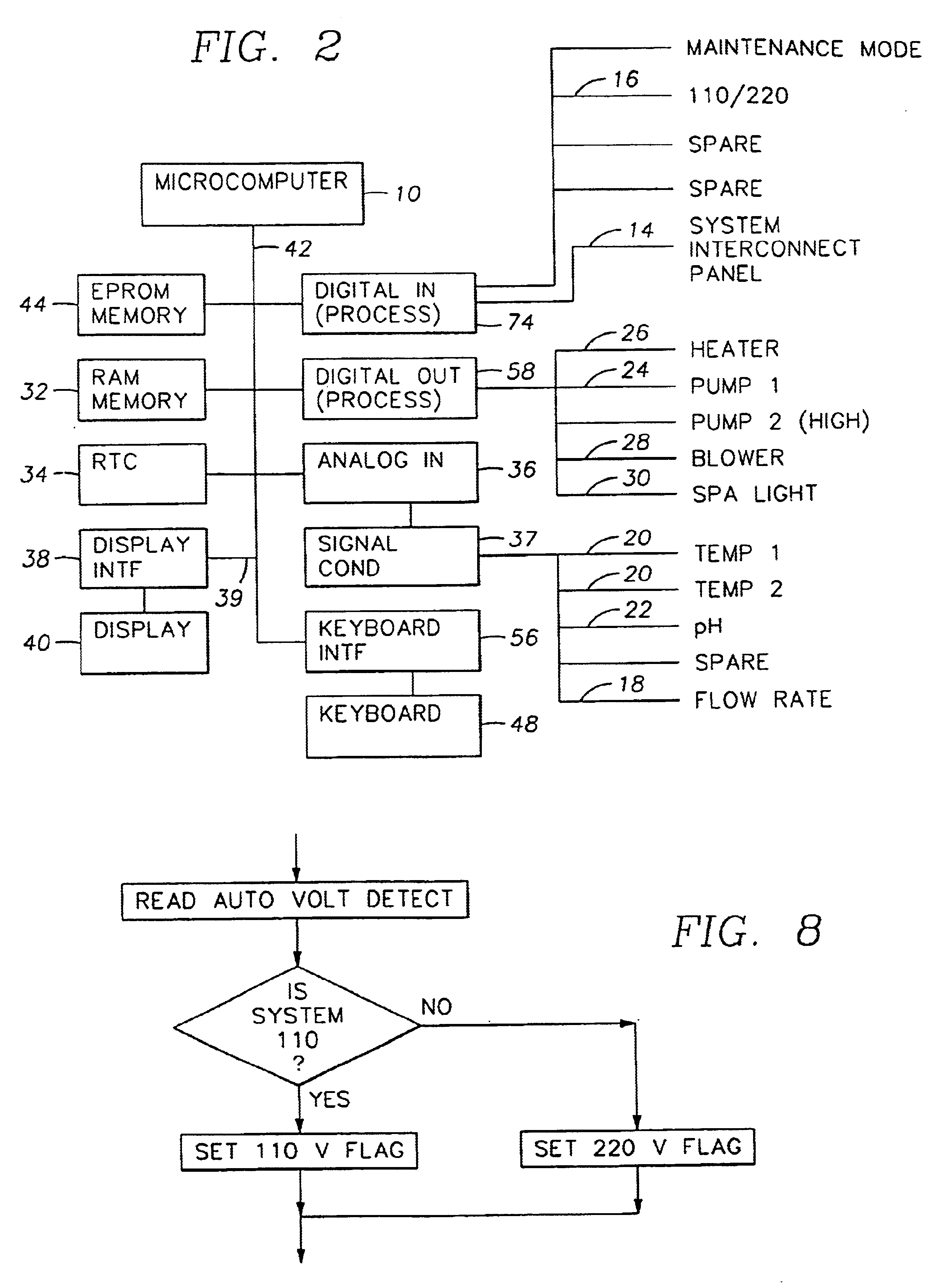

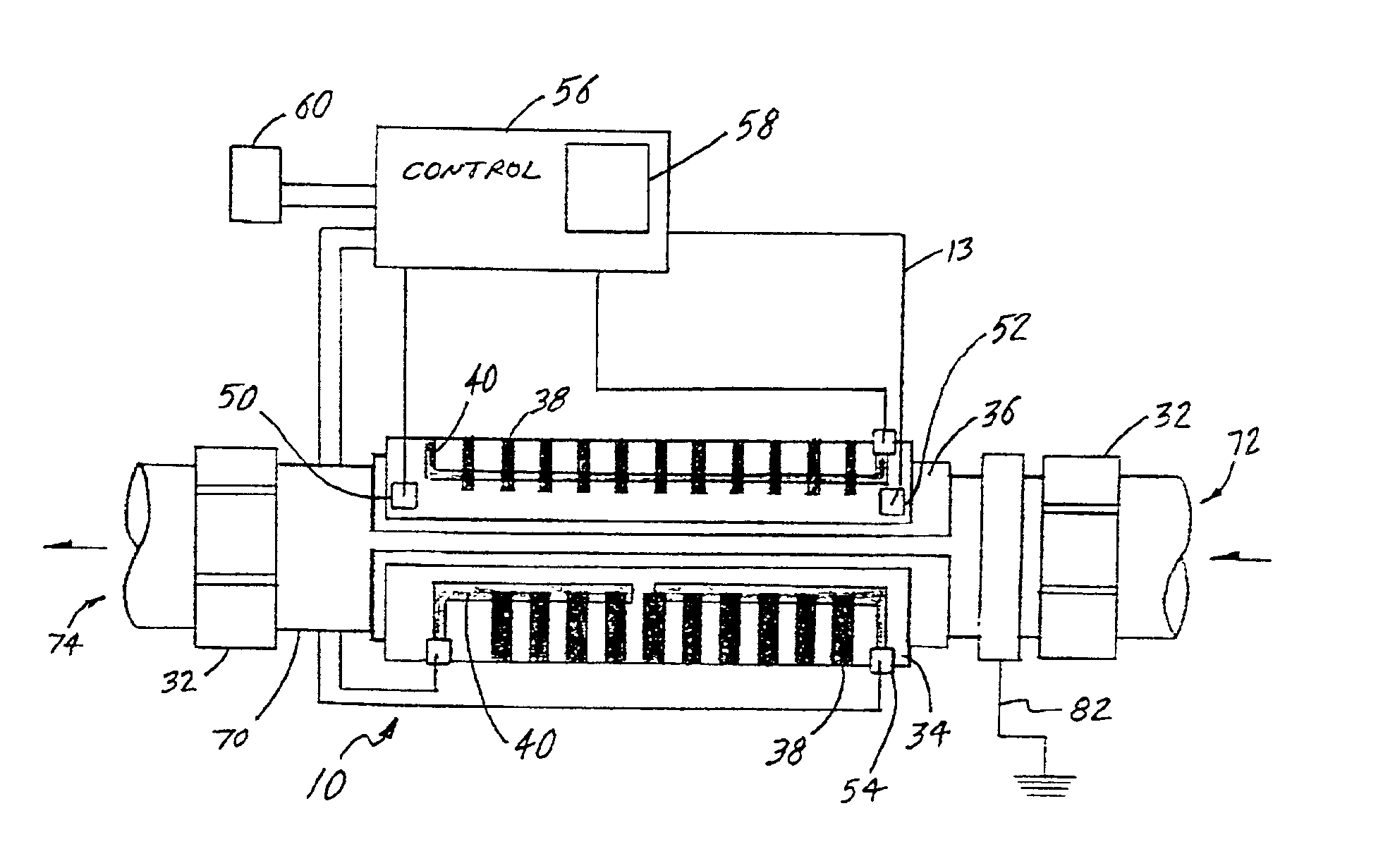

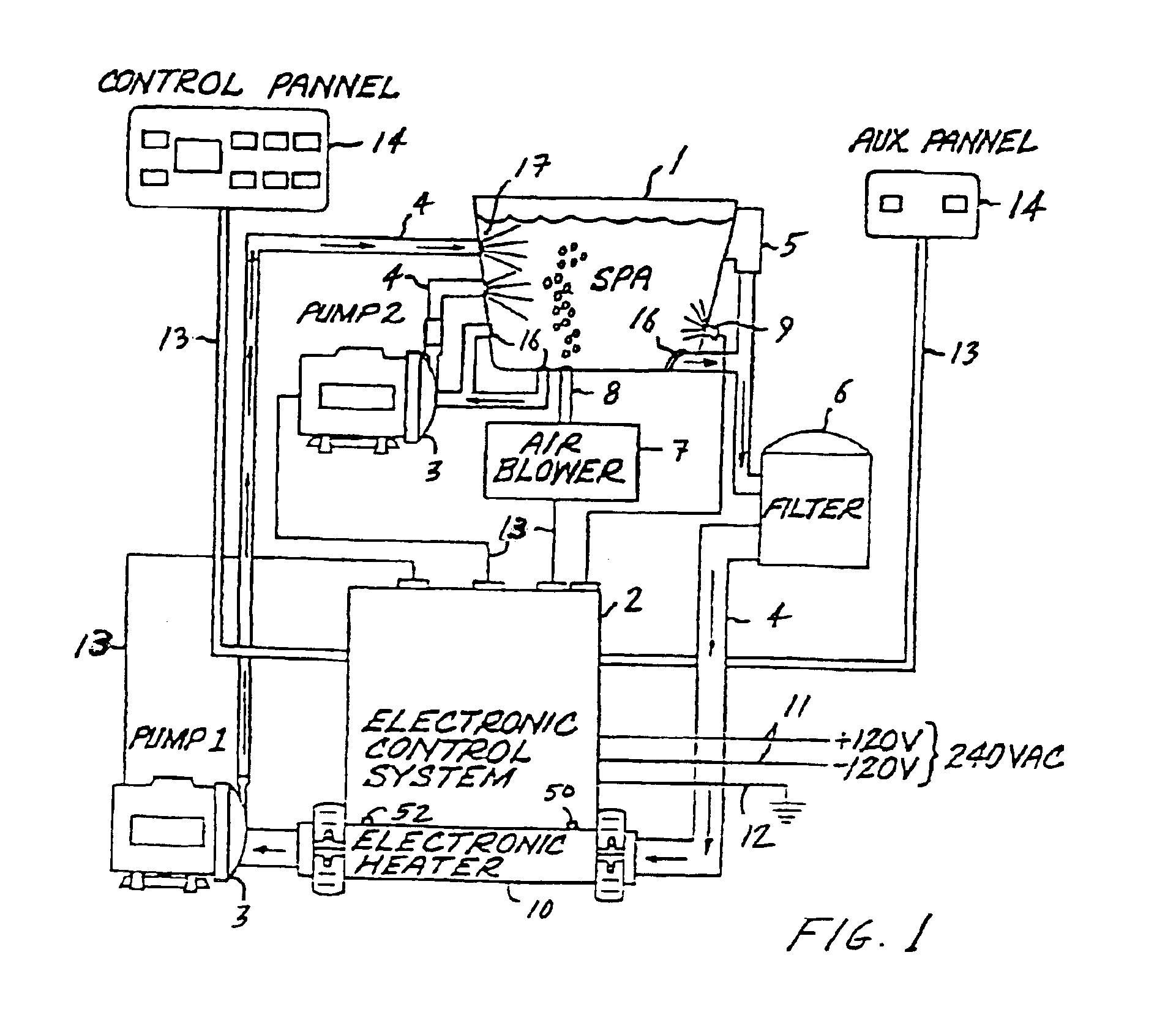

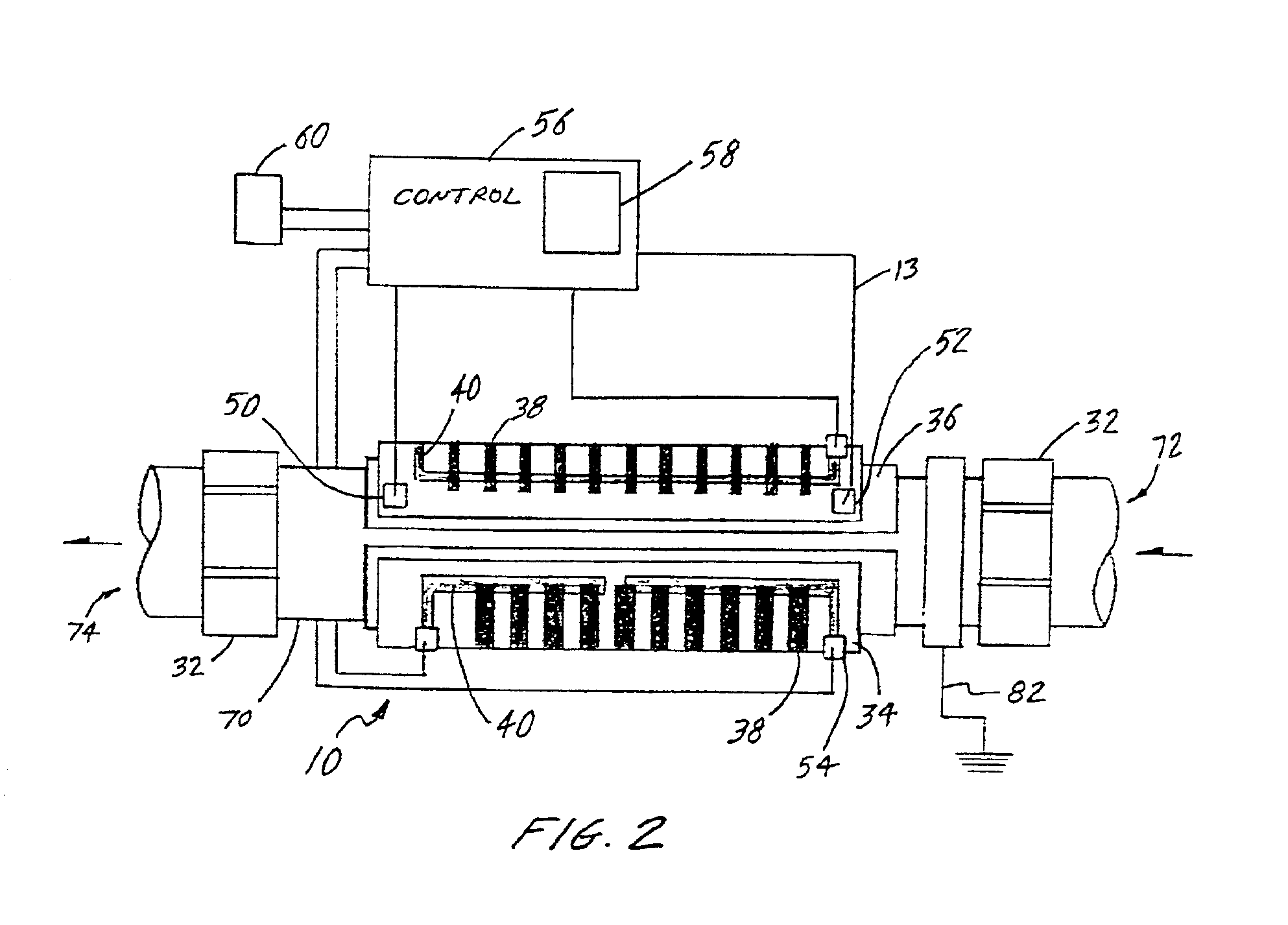

Spa control system

InactiveUS6976052B2Accurately and efficiently controls operationNot adversely affectedTemperatue controlWater/sewage treatmentControl systemWater flow

An improved spa control system is disclosed. The invention describes a spa control system which calculates the time required to heat the water in the spa system to a desired temperature. From that information, the heating rate of the spa system can be determined, and the heating element of the spa system can be activated at the proper time to raise the temperature of the water to a selected temperature by a desired time. The spa system also monitors information which might show errors in the operation of the spa system such as a blockage in the flow of water over the heating element in the spa system.

Owner:DYMAS FUNDING COMPANY +1

Spa control system

InactiveUS6965815B1Accurately and efficiently controls operationNot adversely affectedTemperature control using digital meansBathsControl systemWater flow

An improved spa control system is disclosed. The invention describes a spa control system which calculates the time required to heat the water in the spa system to a desired temperature. From that information, the heating rate of the spa system can be determined, and the heating element of the spa system can be activated at the proper time to raise the temperature of the water to a selected temperature by a desired time. The spa system also monitors information which might show errors in the operation of the spa system such as a blockage in the flow of water over the heating element in the spa system.

Owner:DYMAS FUNDING COMPANY +2

Variable speed pumping system and method

A variable speed pumping system and an associated method for moving water of an aquatic application. The variable speed pumping system includes a water pump for moving water in connection with performance of an operation upon the water. A variable speed motor is operatively connected to drive the pump. A sensor senses a parameter of the operation performed upon the water. A controller controls speed of the motor in response to the sensed parameter of operation.

Owner:PENTAIR WATER POOL & SPA INC

Automatic pool cleaner

ActiveUS20070094817A1Prevent movementEfficient vacuumingGymnasiumSwimming poolsPower cableMarine engineering

An automatic pool cleaner is provided of the type for random travel over submerged floor and side wall surfaces of a swimming pool or the like to dislodge and collect debris. The pool cleaner includes an electric-powered traction drive system for rotatably driving cleaner wheels, and an electric-powered water management system including a water supply pump and related manifold unit for venturi-vacuuming and collection of settled debris within a porous filter bag. A directional control system including an on-board compass monitors turning movements of the pool cleaner during normal random travel operation, and functions to regulate the traction drive system in a manner to prevent, e.g., excess twisting of a conduit such as a power cable tethered to the pool cleaner.

Owner:ZODIAC POOL SYST LLC

Anti-entrapment drain

A drain for swimming pools, spas, whirlpool baths, etc., includes a plurality of first orifices in communication with corresponding serpentine passageways to minimize hair or a body part from covering and entering the first orifices to a degree sufficient to entrap a bather. A plurality of second orifices independent of the first orifices and in fluid communication with one another through a peripheral passageway provide a flow of water from the peripheral passageway into the serpentine passageways to create an alternate water inflow path and reduce the pressure differential and possible entrapment that might occur should a body part or hair come in contact with or enter the first orifices. Moreover, a plurality of ridges are attendant the first orifices to reduce the likelihood of direct contact with the first orifices by a body part or hair.

Owner:HAYWARD IND INC

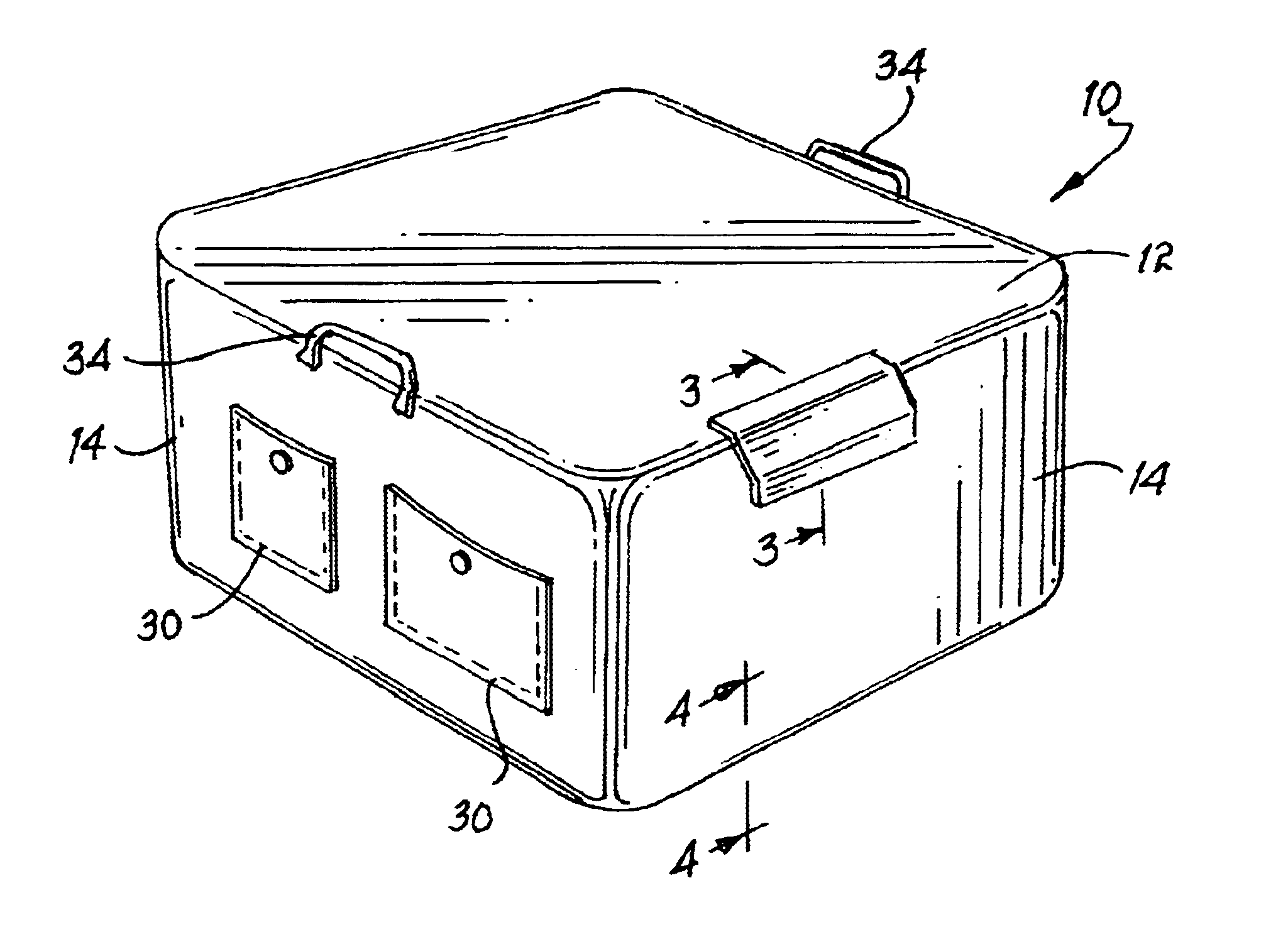

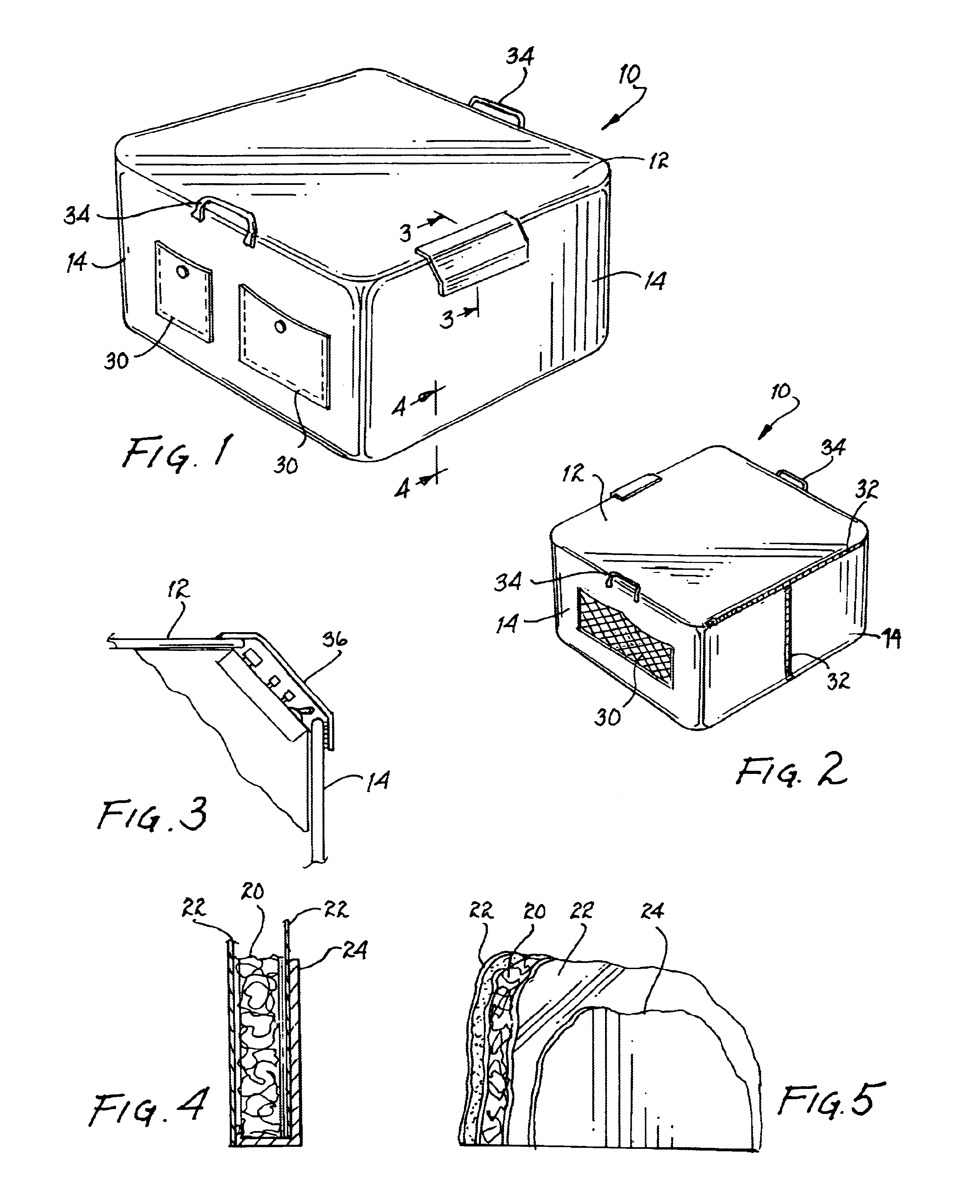

Lightweight insulated spa cover and method therefor

A lightweight insulated cover which may be easily installed and removed from an above ground spa has a top section and four side walls coupled to the top section. The top section and the four side walls comprised of an insulated layer, and a second layer coupled to a front and back surface of the insulated layer for protecting the insulated layer from moisture generated from the above ground spa and external weather conditions.

Owner:MINNICK JEFF F

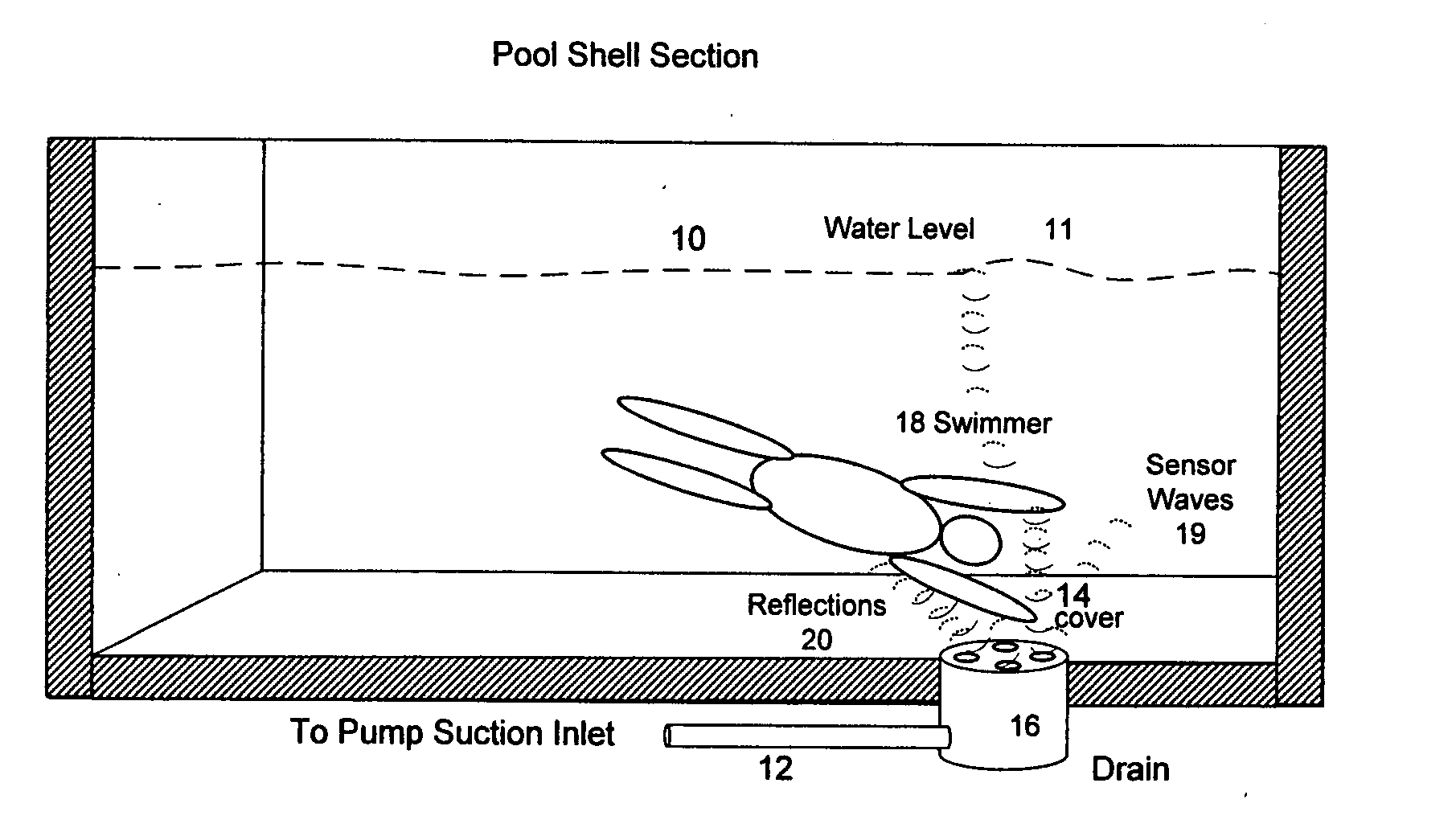

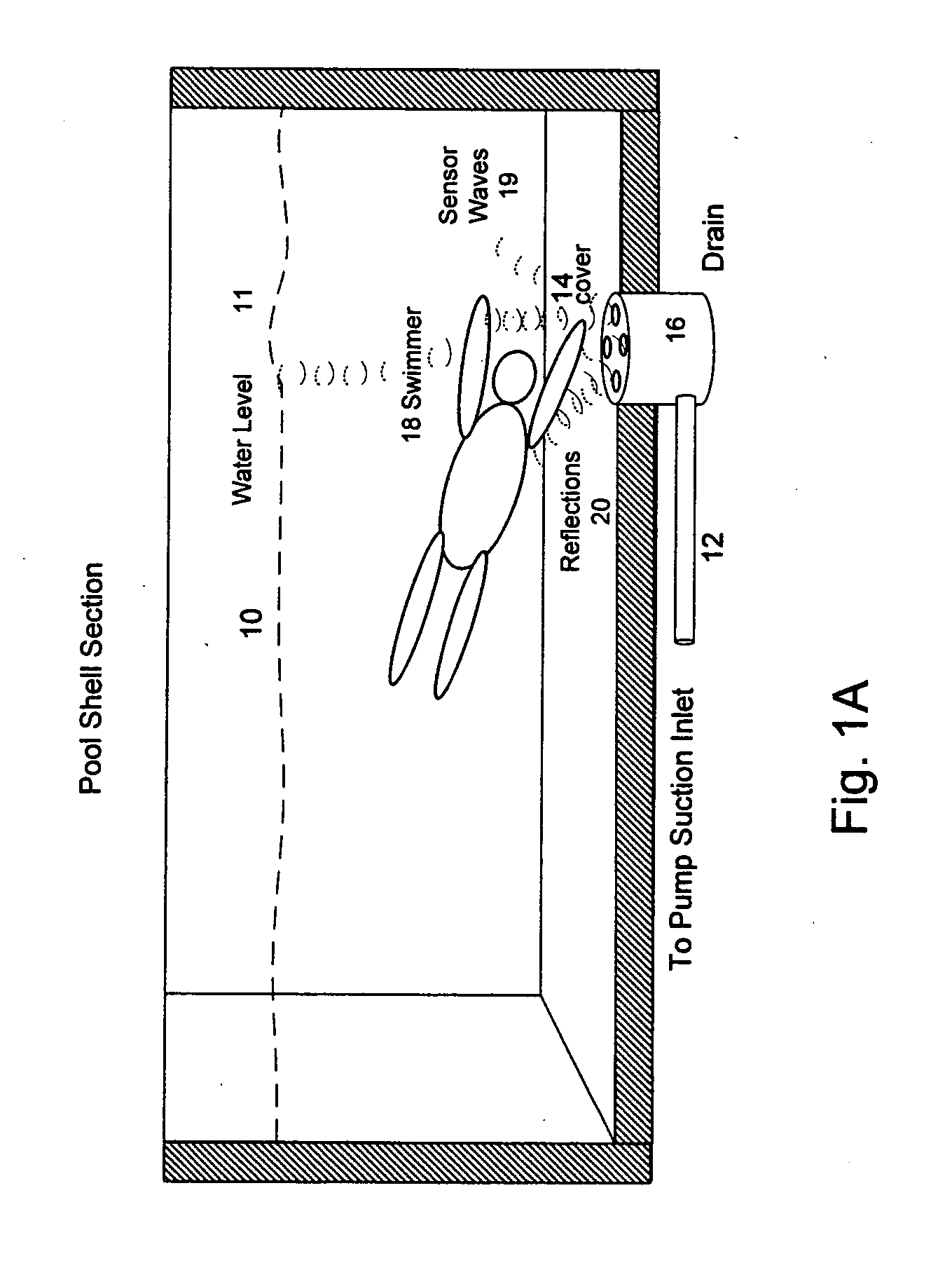

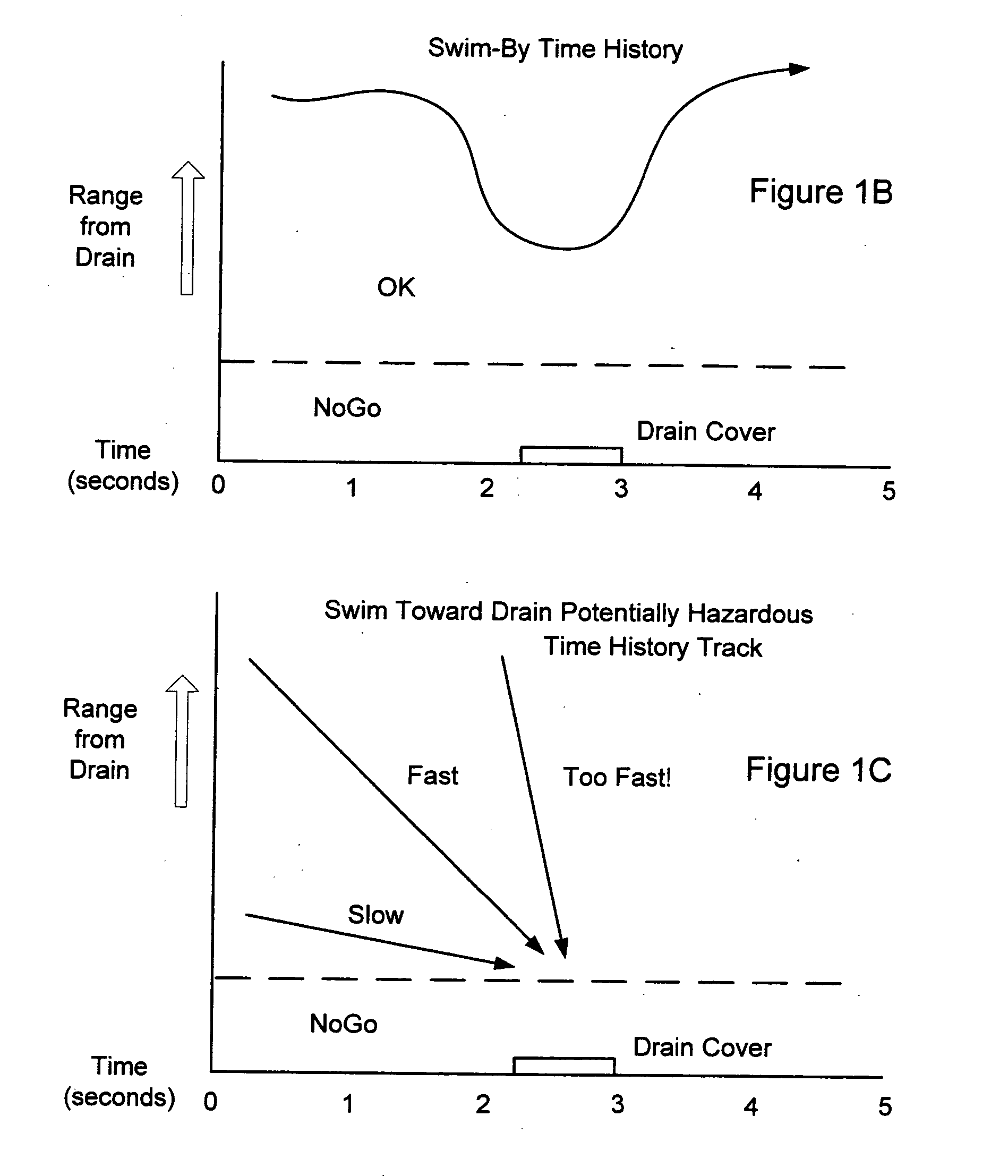

Machine for anticipatory sensing and intervention to avoid swimmer entrapment

A machine for anticipatory sensing and intervention to avoid swimmer entrapment, with an active pre-entrapment sensor (e.g. ultrasonic) that assesses the relative hazard based on swimmer proximity to the drain cover. An Ultrasonic Transducer launches waves into the suction piping and / or drain system, and to receive echoes from the drain cover, swimmer limbs, hair or body, and the water surface parellel to the drain cover. A Transmitter / Pulser electrically energizes the ultrasonic transducer to launch waves into the suction piping and / or drain system, A Receiver / Processor detects the echoes electrical signals from the the ultrasonic transducer and to receive echoes from objects of interest beyond the pool drain. A Logic and Control element converts the detected signals into reliable information regarding a swimmer safety / hazard status. An Output provides a pump shutdown command when required. Solutions for both new construction and retrofit are described.

Owner:WOLFE MICHAEL LAWRENCE

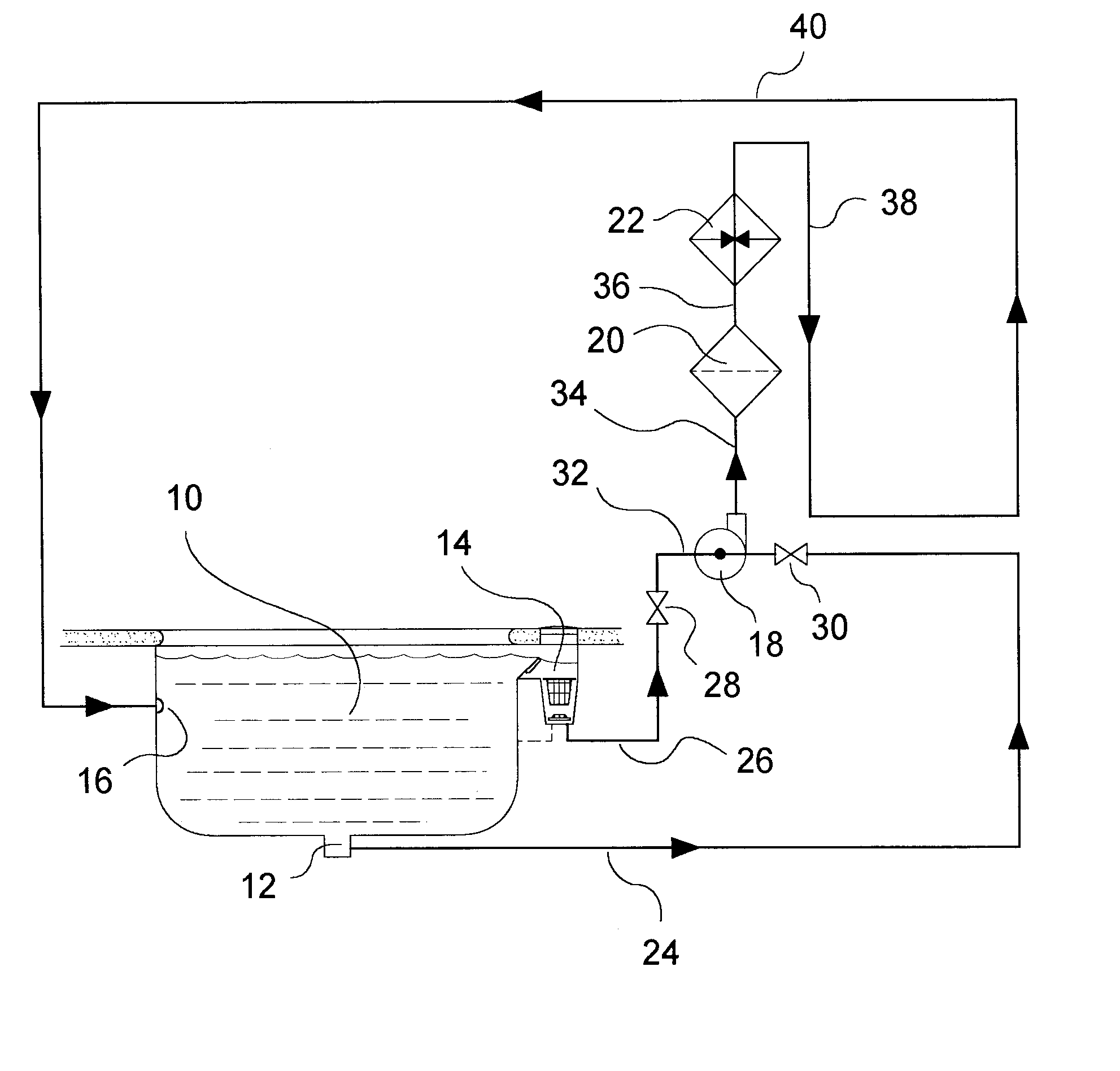

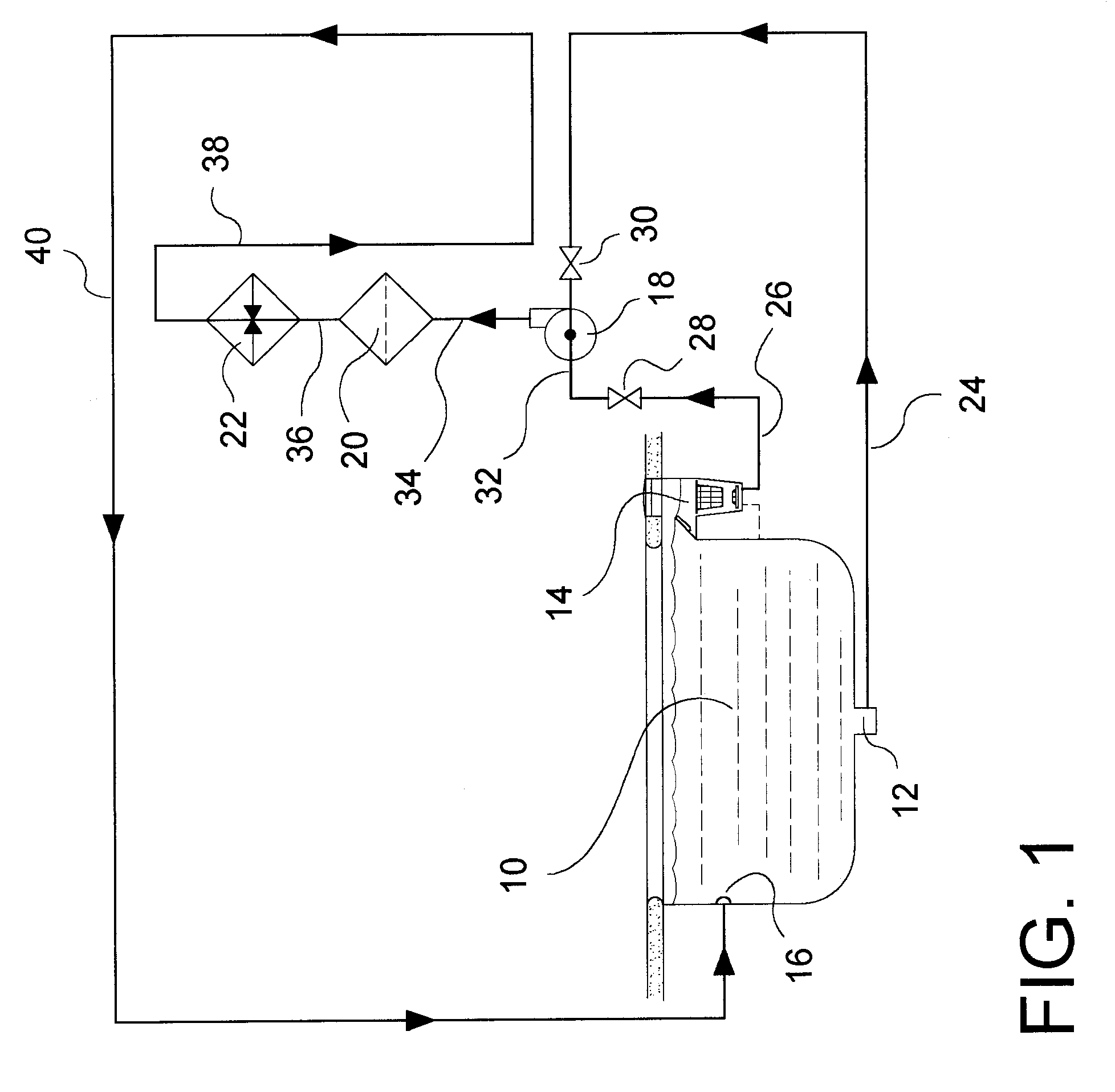

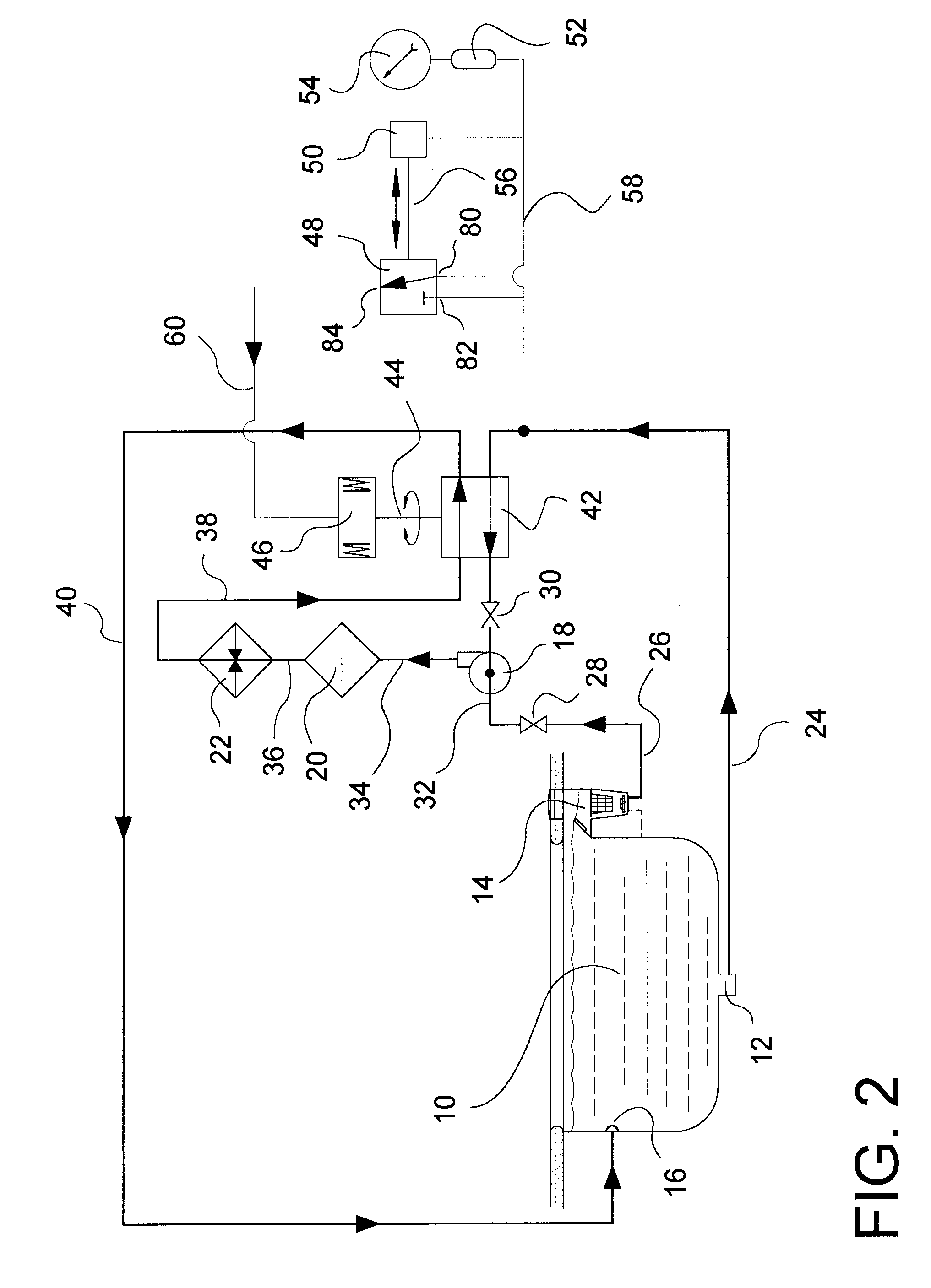

Propulsion-Release Safety Vacuum Release System

InactiveUS20030106147A1Reliably release and push awayNew designGymnasiumSwimming poolsPositive pressureFiltration

Abstract of Disclosure A propulsion-release safety vacuum release system (SVRS) for swimming pools monitors vacuum level in a suction pipe and reverses flow within the suction pipe if vacuum level exceeds a predetermined level. Thus, if a bather becomes entrapped on a suction outlet such as the pool main drain, the SVRS system not only releases the vacuum but also pushes away the suction-entrapped bather. In response to an elevated vacuum level, a vacuum-monitoring device actuates an automatic valve, which reverses fluid communications between the influent and effluent conduits of the pump and filter system. In this process, the suction pipe is converted from vacuum (negative pressure) to positive pressure. Thereafter, the automatic valve system automatically resets the SVRS to the original or normal flow configuration. The SVRS functions without interrupting operation of the swimming pool filtration system.

Owner:COHEN JOSEPH D +1

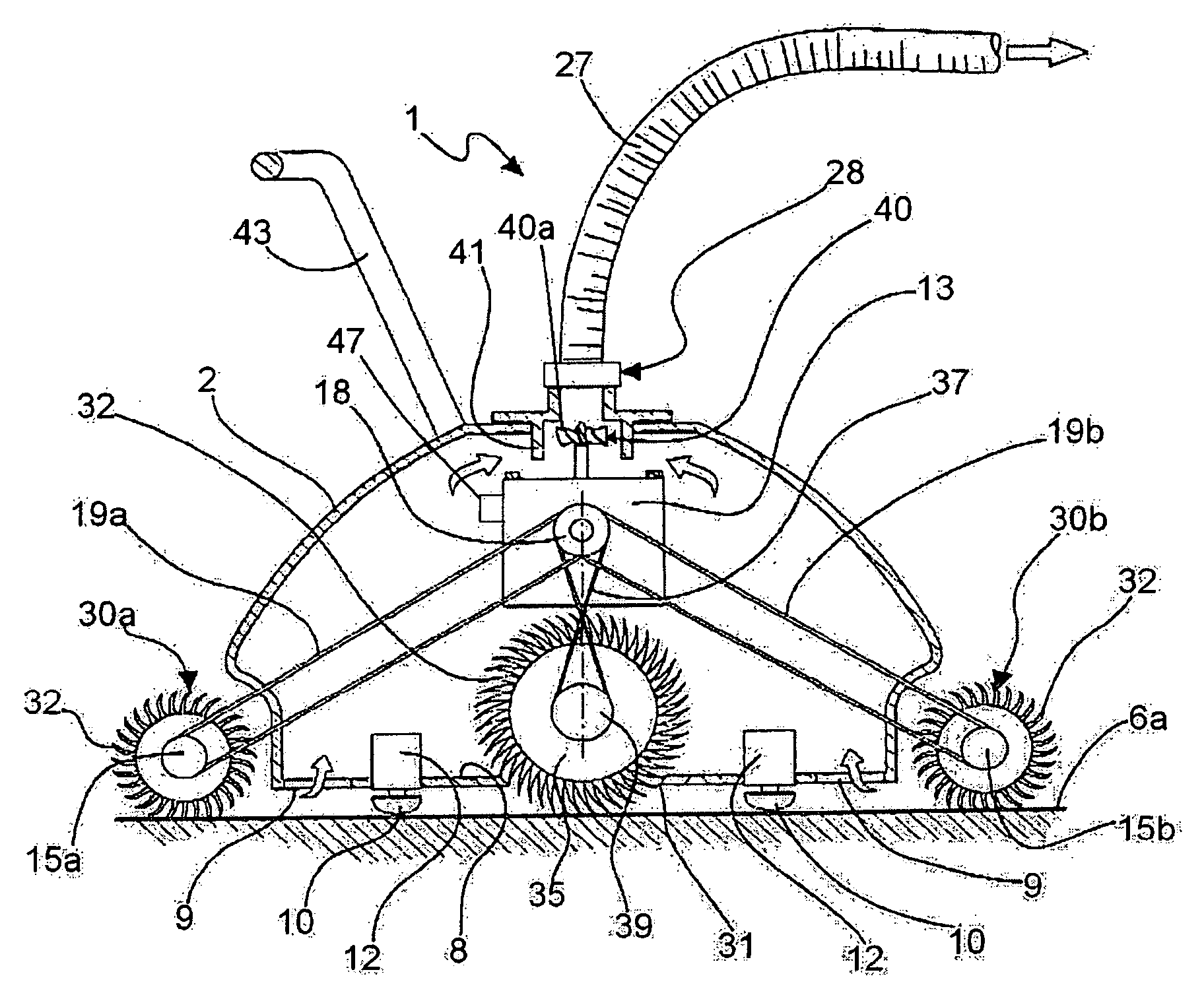

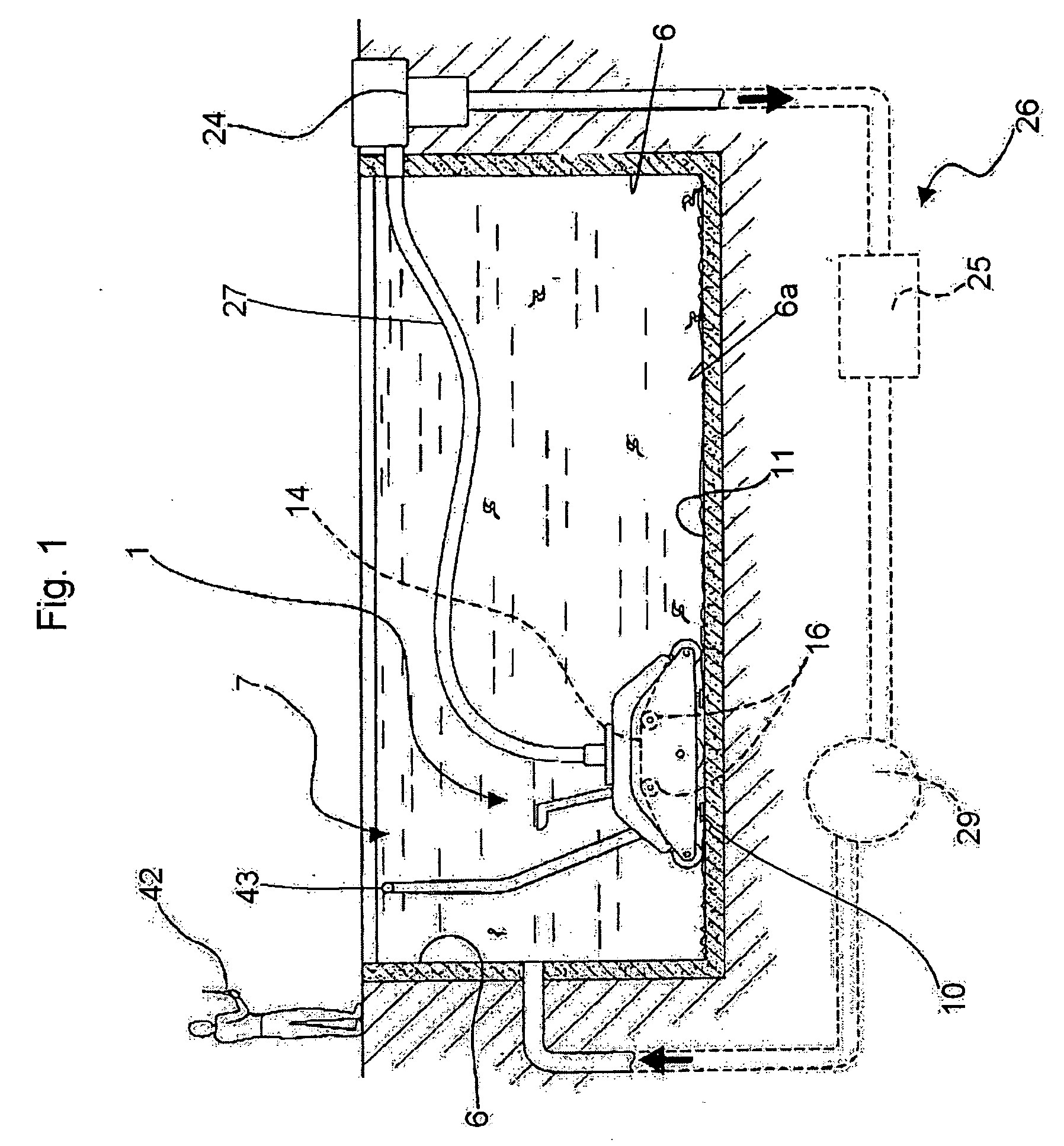

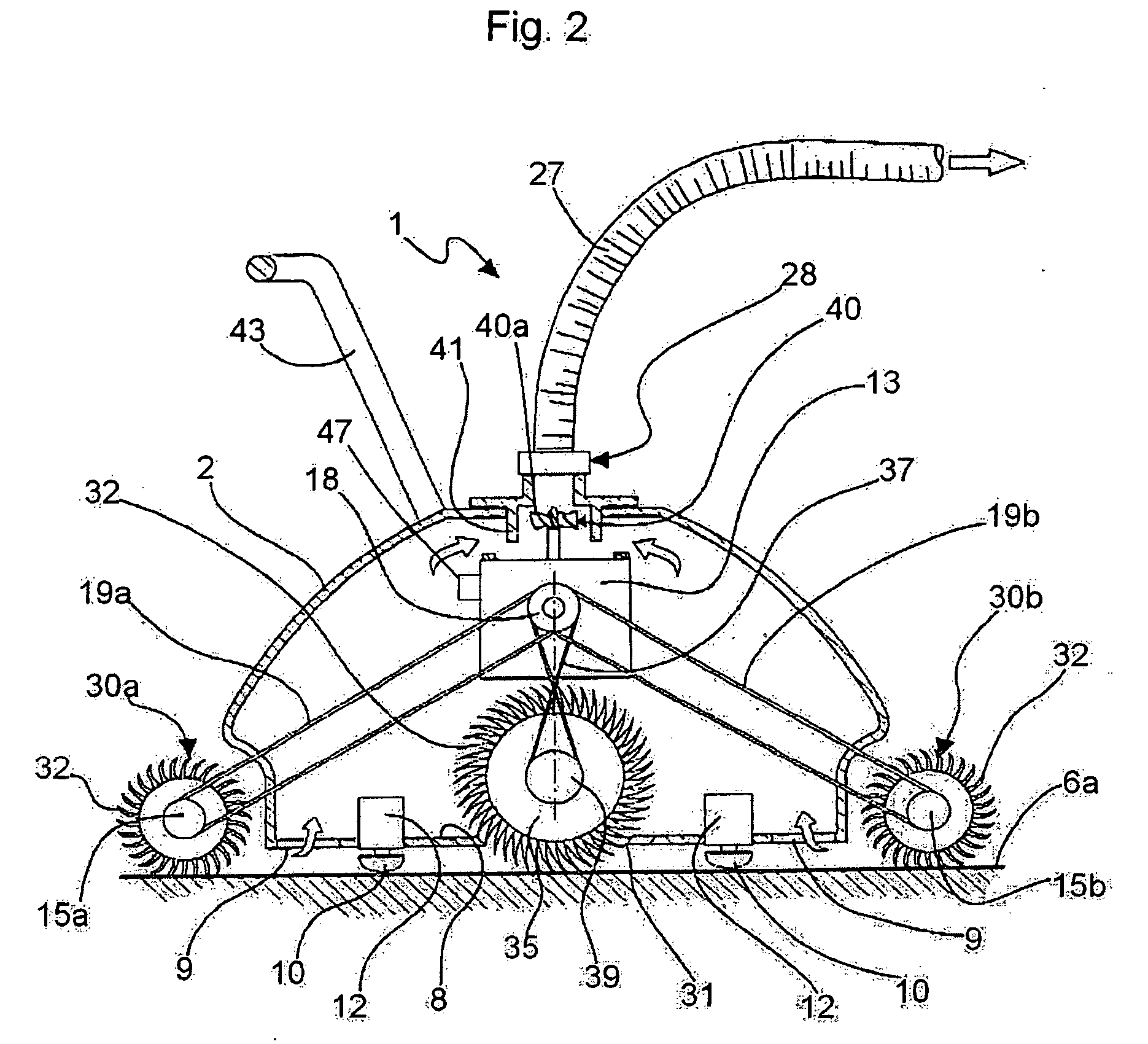

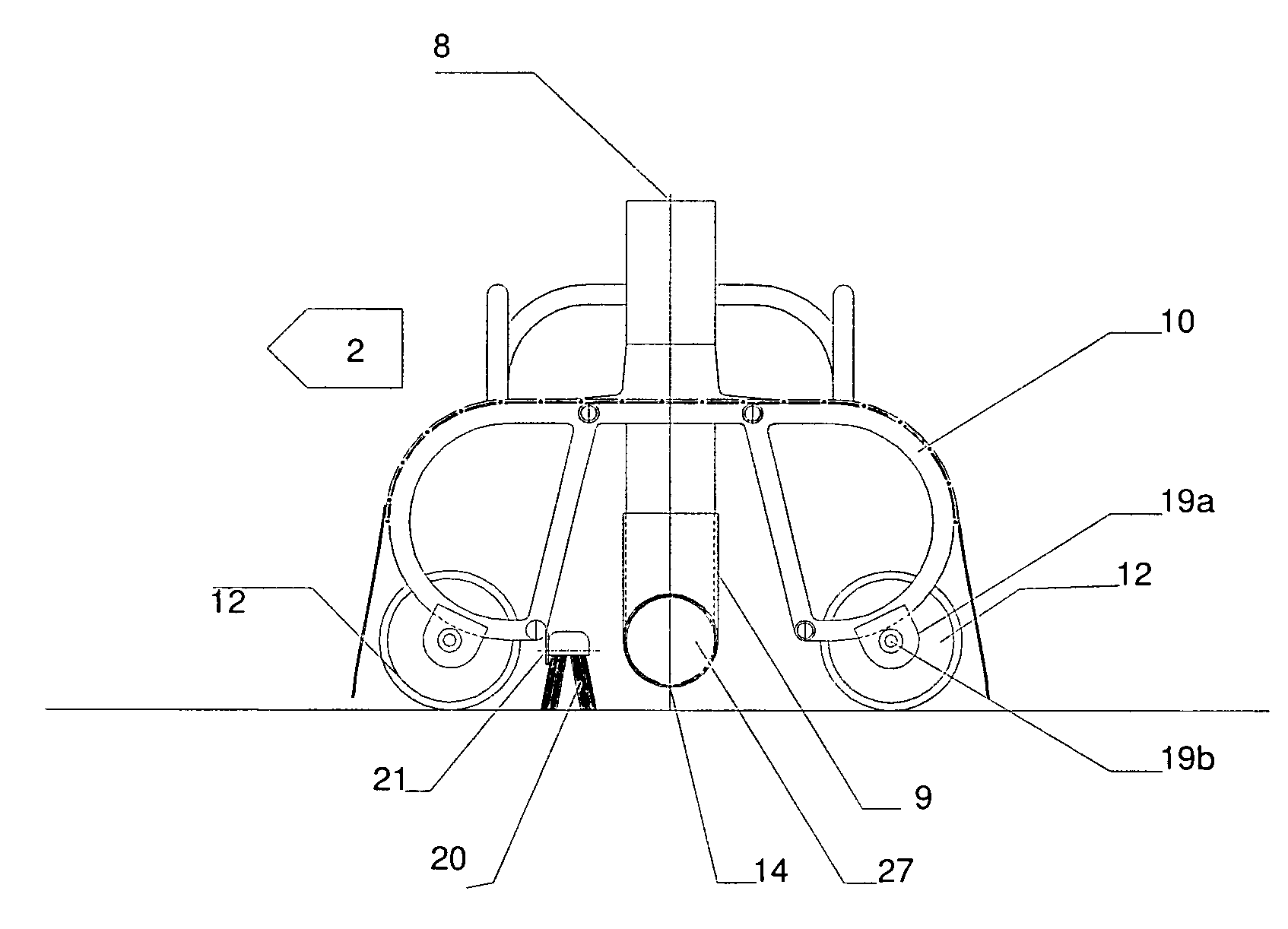

Swimming pool cleaning device

ActiveUS20060174430A1Eliminating or substantially reducing the above mentioned drawbacksGood removal effectBrush bodiesSuction cleanersMarine engineeringMechanics

The present invention relates to a swimming pool cleaning assembly comprising at least one ultrasonic generating means (10; 46b). Advantageously the swimming pool cleaning assembly comprises a swimming pool cleaning machine including a support frame (4), a housing shell (2) provided with a bottom wall (8) and arranged around the support frame (4), driving means (3) located in said housing shell (2), advancing means (5) supported by said frame (4) and arranged to be placed, in use, on a surface to be cleaned (6, 6a) of a swimming pool (7) and driven by said driving means (3), at least one water suction opening (9) provided in the bottom surface (8) of said housing shell (2), which is designed to be put in fluid communication with water suction means, said driving means (3) being tight sealed in the housing shell (2) and electrically connectable to supply means, said ultrasonic generating means (10) being arranged at said bottom wall (8) facing, in use, said surface to be cleaned (6, 6a).

Owner:PARETI VITTORIO

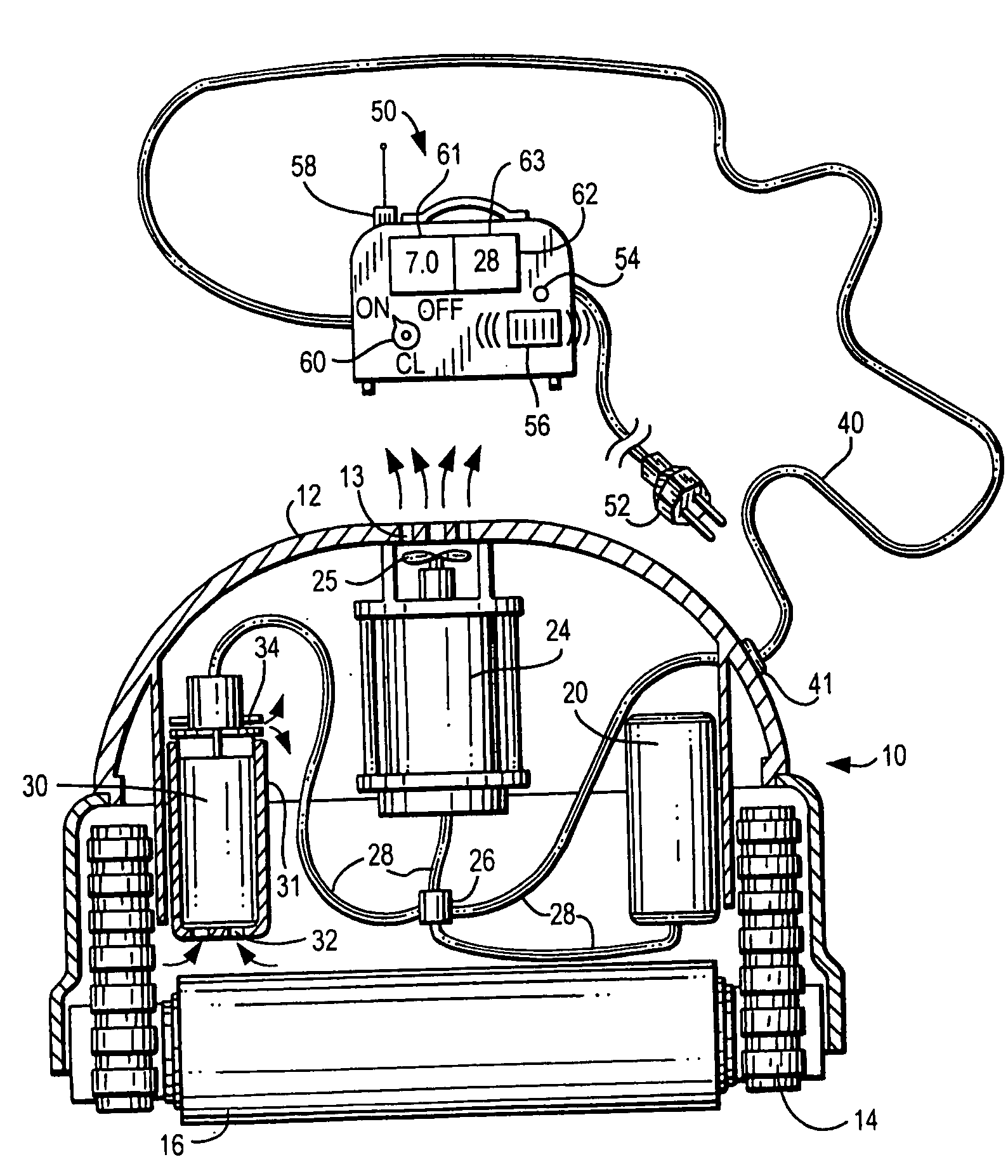

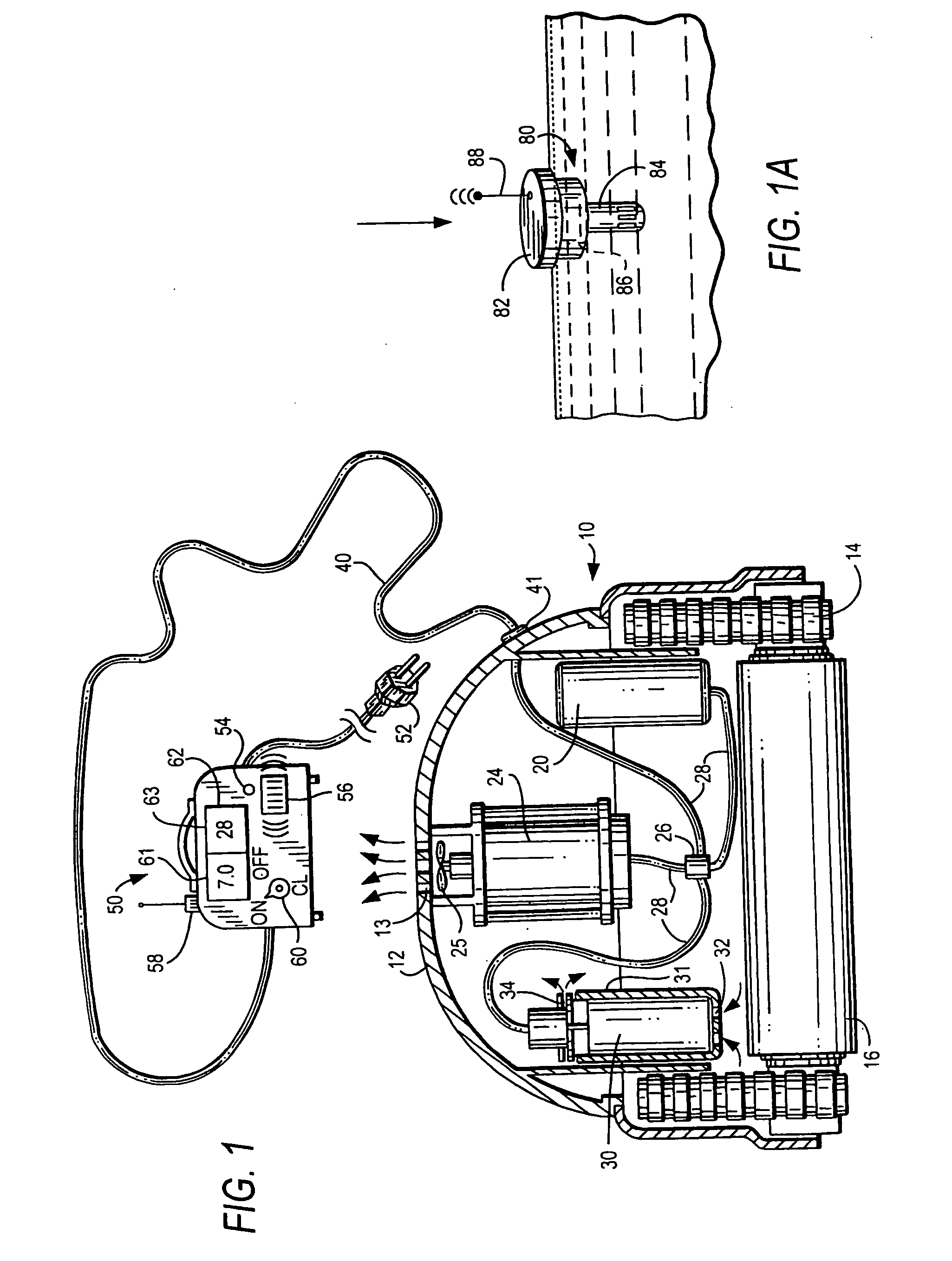

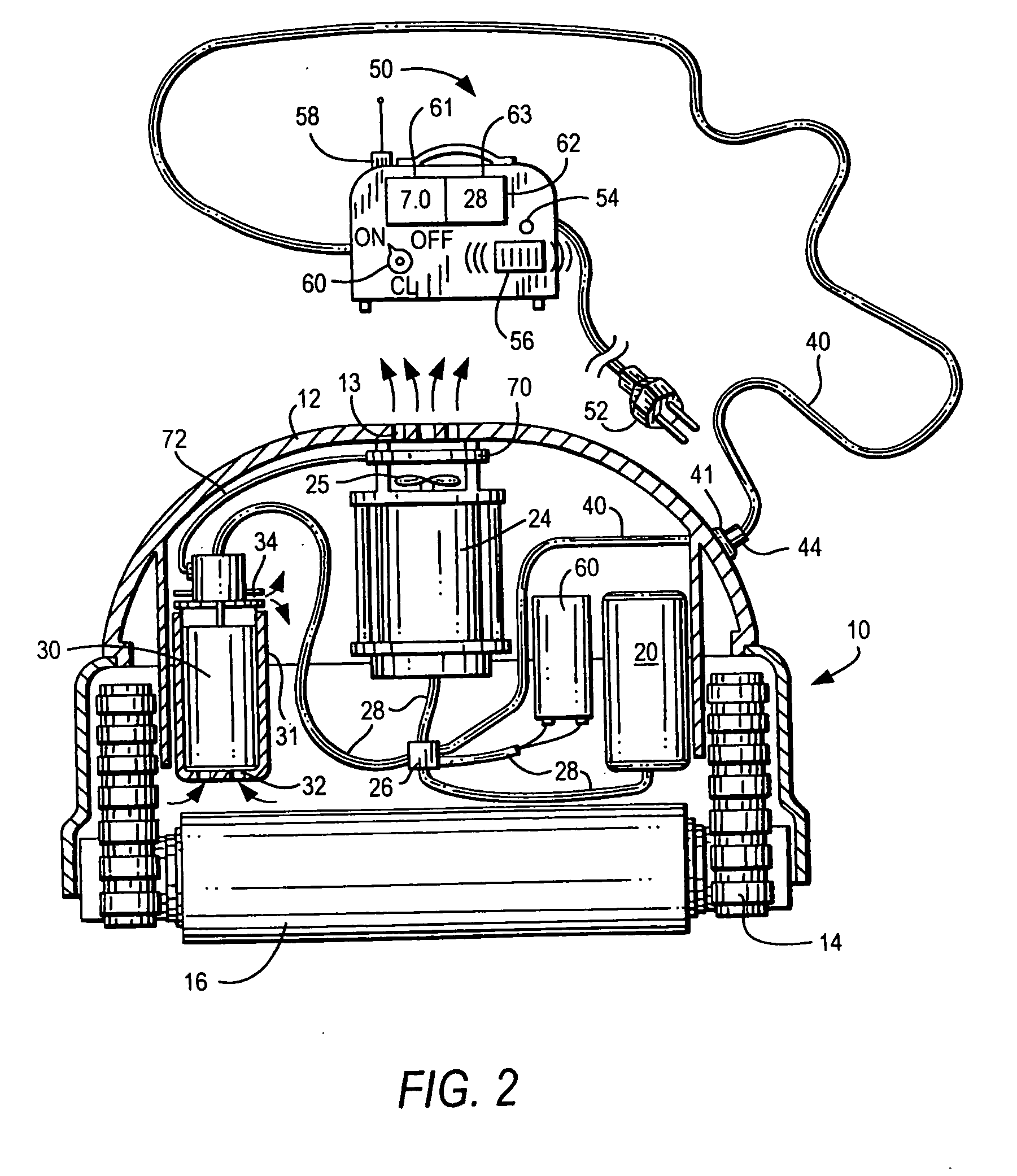

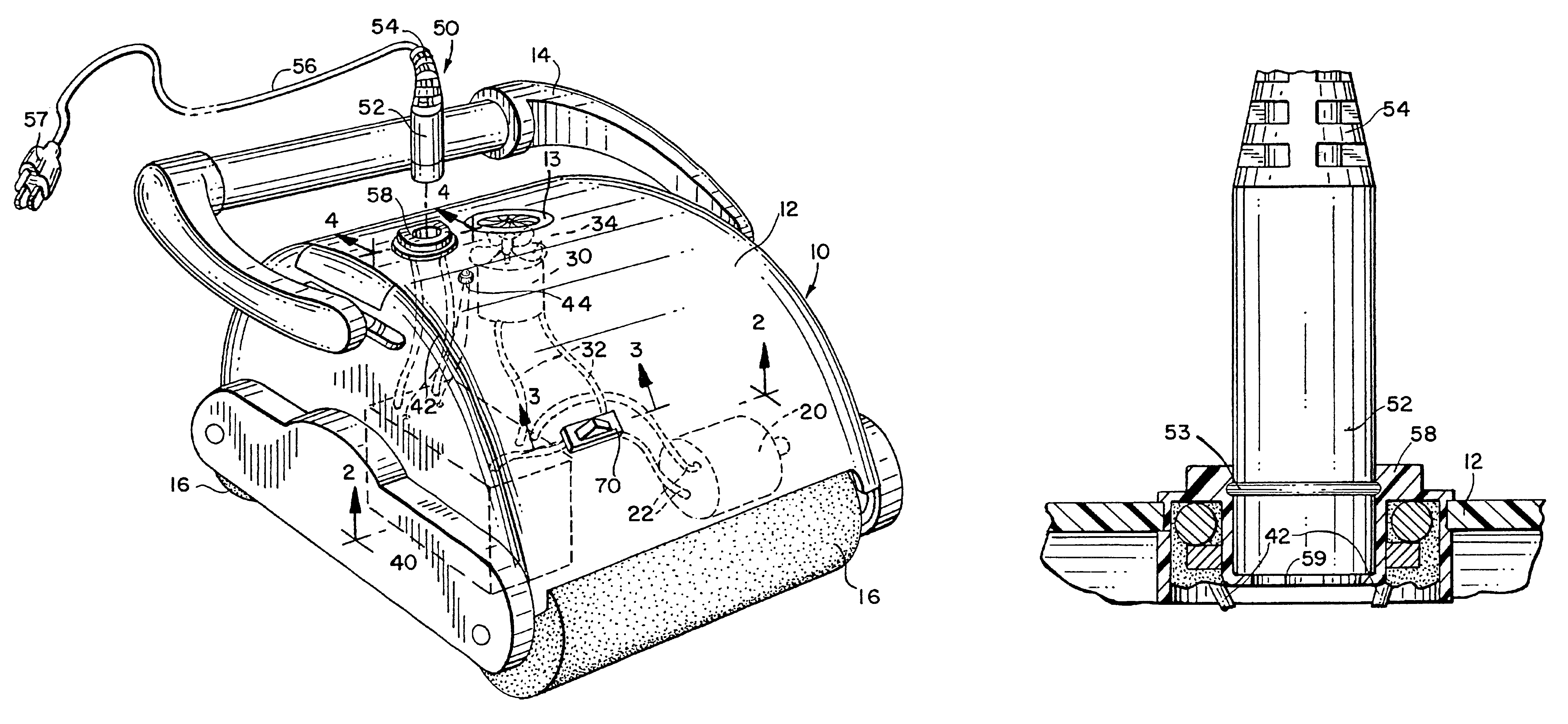

Method and appartus for operation of pool cleaner with integral chlorine generator

ActiveUS20090282627A1Efficiently and effectively distributesUniform concentrationCellsPhotography auxillary processesTime segmentElectrical battery

An automated self-propelled pool cleaner having a housing, a water pump for moving water through the housing, drive means for moving the pool cleaner over the surface of the salt water pool to be cleaned, and an integral electrochemical chlorine generator mounted in the housing, includes a processor / controller that is programmed to activate the chlorine generator, the pump and drive means in predetermined operational sequences that minimize wear and tear on the water pump and drive means, while at the same time distribute and maintain a safe level of sanitizing chlorine in the pool, to thereby obviate the need for an in-line chlorinator or other chemical additive treatments; an optional automated sensor device can be provided to activate a secondary maintenance program which enables the pool cleaner to operate over prolonged periods of time as the sole means for filtering and sanitizing the pool water. An electrochemical cell manual mounting system permits the cell to be secured in place for operation and manually removed for maintenance, repair or replacement by the user without special tools or training.

Owner:AQUA PRODS

Process to obtain water bodies larger than 15,000 m3 for recreational use with color, transparency and cleanness characteristics similar to swimming pools or tropical seas at low cost

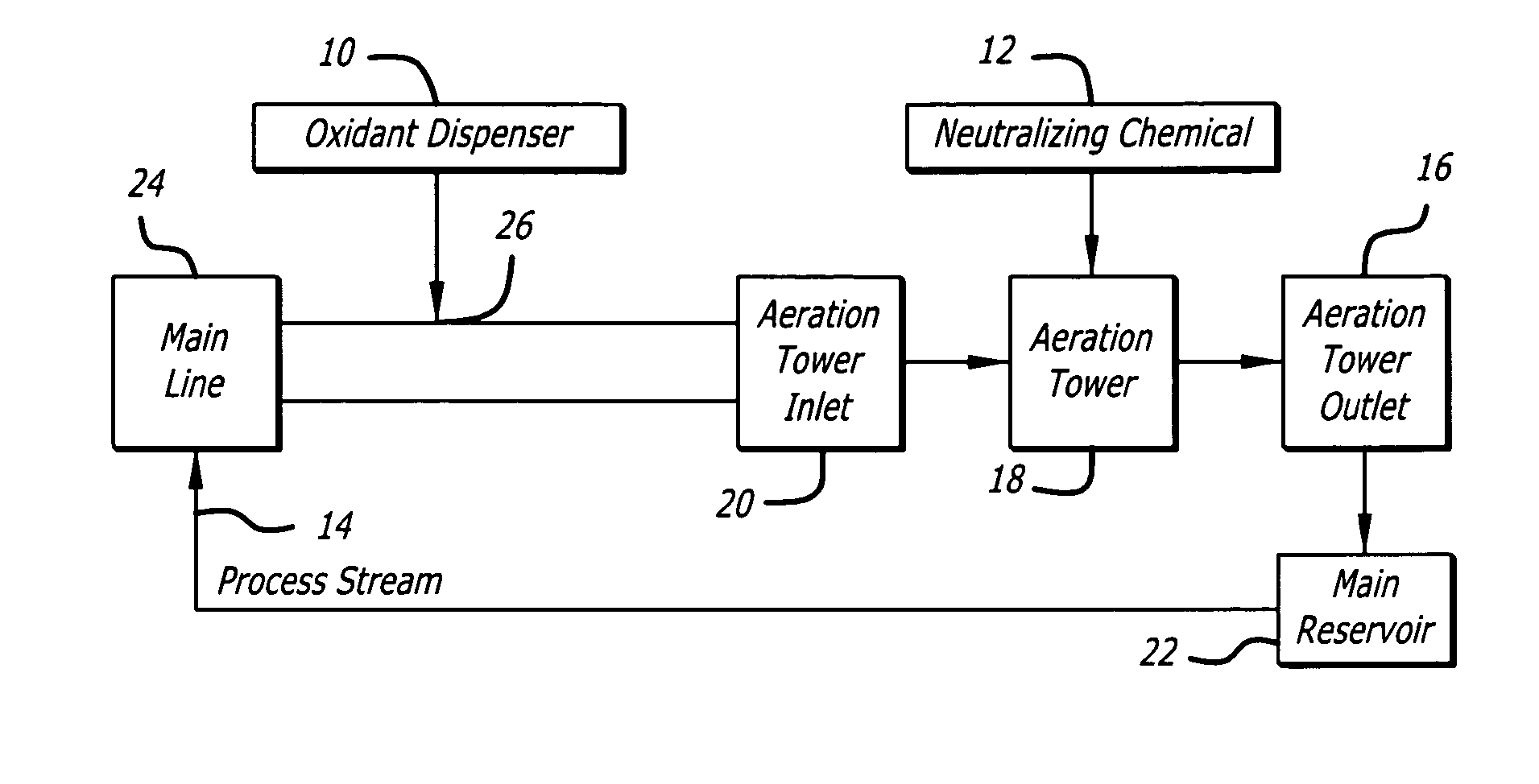

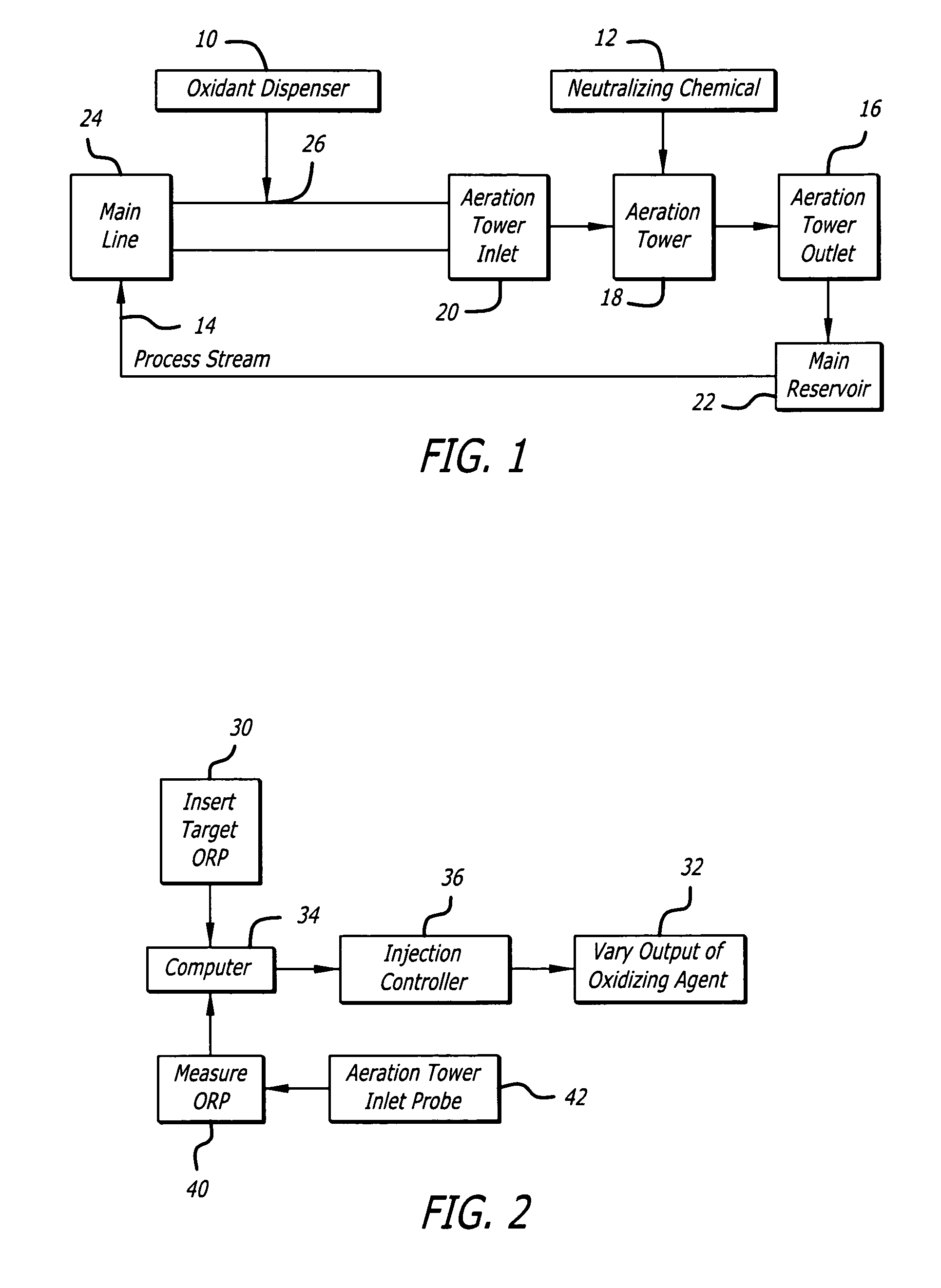

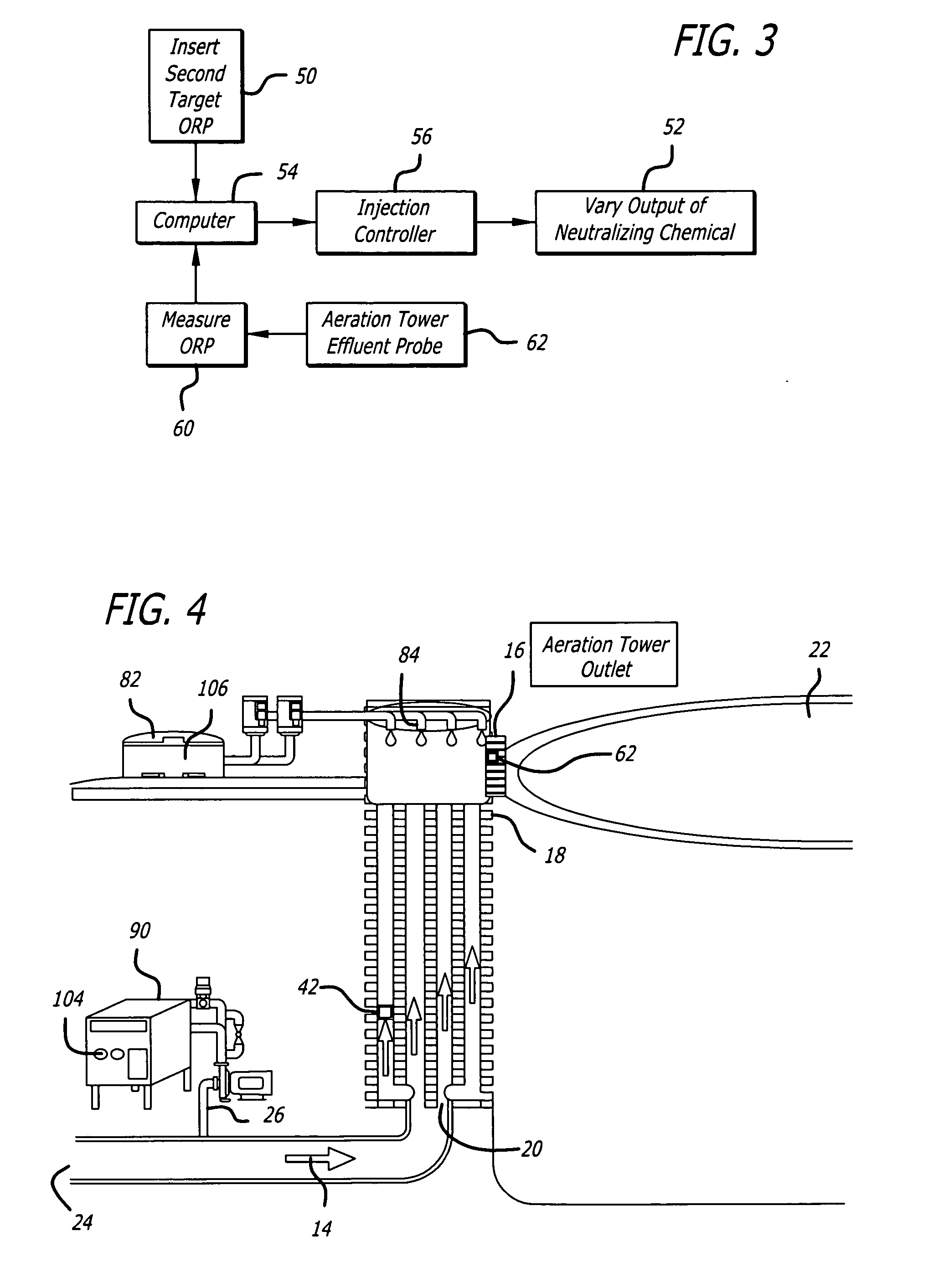

The invention discloses a process to implement and maintain water bodies larger than 15,000 m3 for recreational use, such as lakes or artificial lagoons, with excellent color, transparency and cleanness properties at low cost, which comprises the following steps:a.—providing a structure able to contain a large water body larger than 15,000 m3;b.—feeding the structure of step (a) with inlet water having iron and manganese levels lower than 1.5 ppm and turbidity lower than 5 NTU;c.—measuring water pH, ideally it should be within a range lower than 7.8;d.—adding an oxidizing agent to the water contained in the structure of step (a), with which a 600 mV minimal ORP is controlled in water for a minimal period of 4 hours and in maximal cycles of 48 hours;e.—adding a flocculating agent in concentrations within 0.02 and 1 ppm with maximal frequencies of 6 days and cleaning the bottom of the structure of step (a) with a suction device to remove precipitated impurities from the bottom of said structure, together with the additional flocculants and;f.—generating a displacement of surface water containing impurities and surface oils by means of the injection of inlet water according to step (b), which generates said displacement in such a way to remove said surface water by means of a system for impurities and surface oils removal arranged in the structure of step (a), which together with step (e) replaces traditional filtering.The present invention also discloses a structure to contain large water bodies comprising a system for the removal of impurities and surface oils by means of skimmers and the suction device to clean said structure.

Owner:CRYSTAL LAGOONS TECH INC

Pumping system with two way communication

A pumping system for moving water of a swimming pool includes a water pump, a variable speed motor, and an arrangement for controlling the variable speed motor. The pumping system further includes an auxiliary device operably connected to the arrangement for controlling, and an arrangement for providing two-way communication between the arrangement for controlling and the auxiliary device. The arrangement for controlling is capable of receiving a parameter from the auxiliary device through the arrangement for providing two-way communication. In one example, the arrangement for controlling is capable of independently controlling the variable speed motor without receipt of a parameter from the auxiliary device. In addition or alternatively, the arrangement for controlling is operable to selectively alter operation of the motor based upon the parameter. In addition or alternatively, the arrangement for controlling is configured to optimize a power consumption of the variable speed motor over time based upon the parameters received. A method for controlling the pumping system is also provided.

Owner:PENTAIR WATER POOL & SPA INC +1

Water heater

InactiveUS6943325B2Eliminate riskEliminate the risk of corrosionBathsDouchesWater useElectronic controller

An improved water heater for use in spas, hot tubs, pools, hydrotherapy pools, bath tubs, and similar bodies of water used indoors, outdoors, or both indoors and outdoors are used for both therapeutic and recreational purposes. The water heater uses heating element technology know as thick film on substrate comprising resistive elements bonded to the outer dry surface of a pipe to heat the pipe which in turn heats the water flowing therethrough. The heater is highly efficient due to the direct contact of the wet heating surface with the water and provides a smooth seamless inner heating surface by eliminating the need to pass electrical leads into the wet region of the heater. This virtually eliminates the risk of leaks in the water heater due to bulkhead fittings. The invention further eliminates the need for a heating element to be contained in the inner wet region of a spa heater, thereby reducing the risk of corrosion. The water heater is used in combination with an electronic controller having a microprocessor to control and regulate the operation of the water heater. The water heater can be used with electrical, electro-mechanical, and mechanical control systems for spas and can be retrofitted into existing spa applications.

Owner:DYMAS FUNDING COMPANY

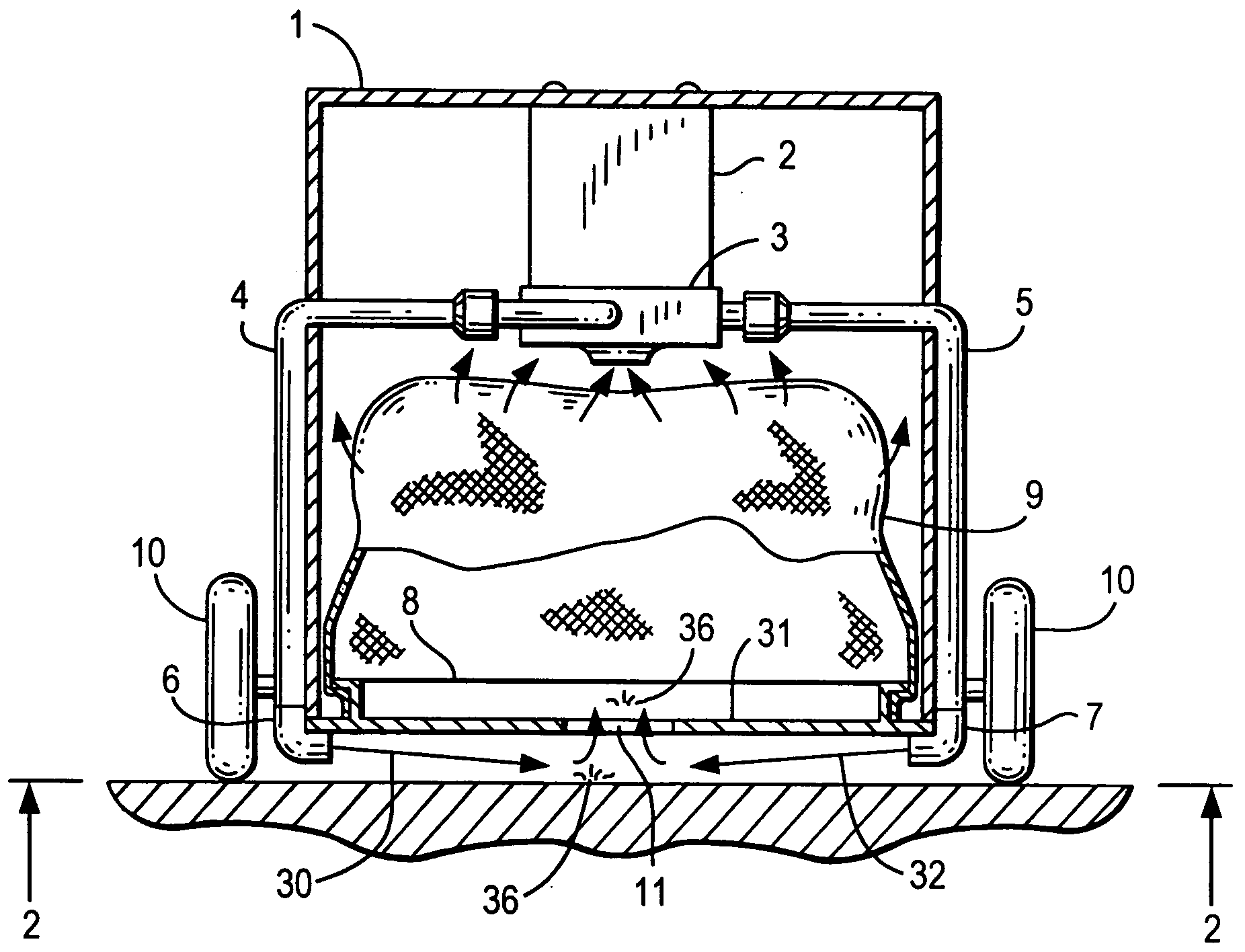

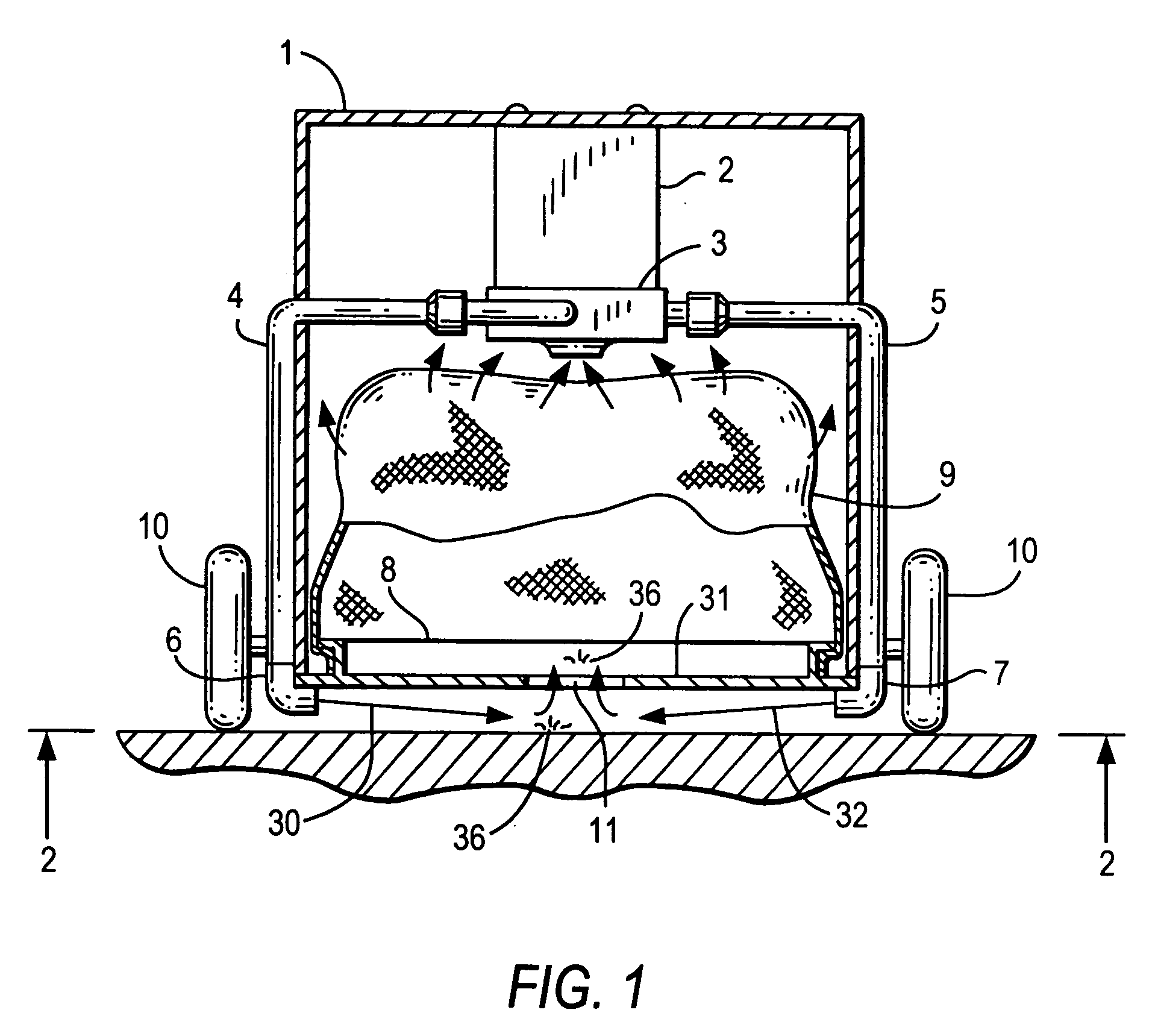

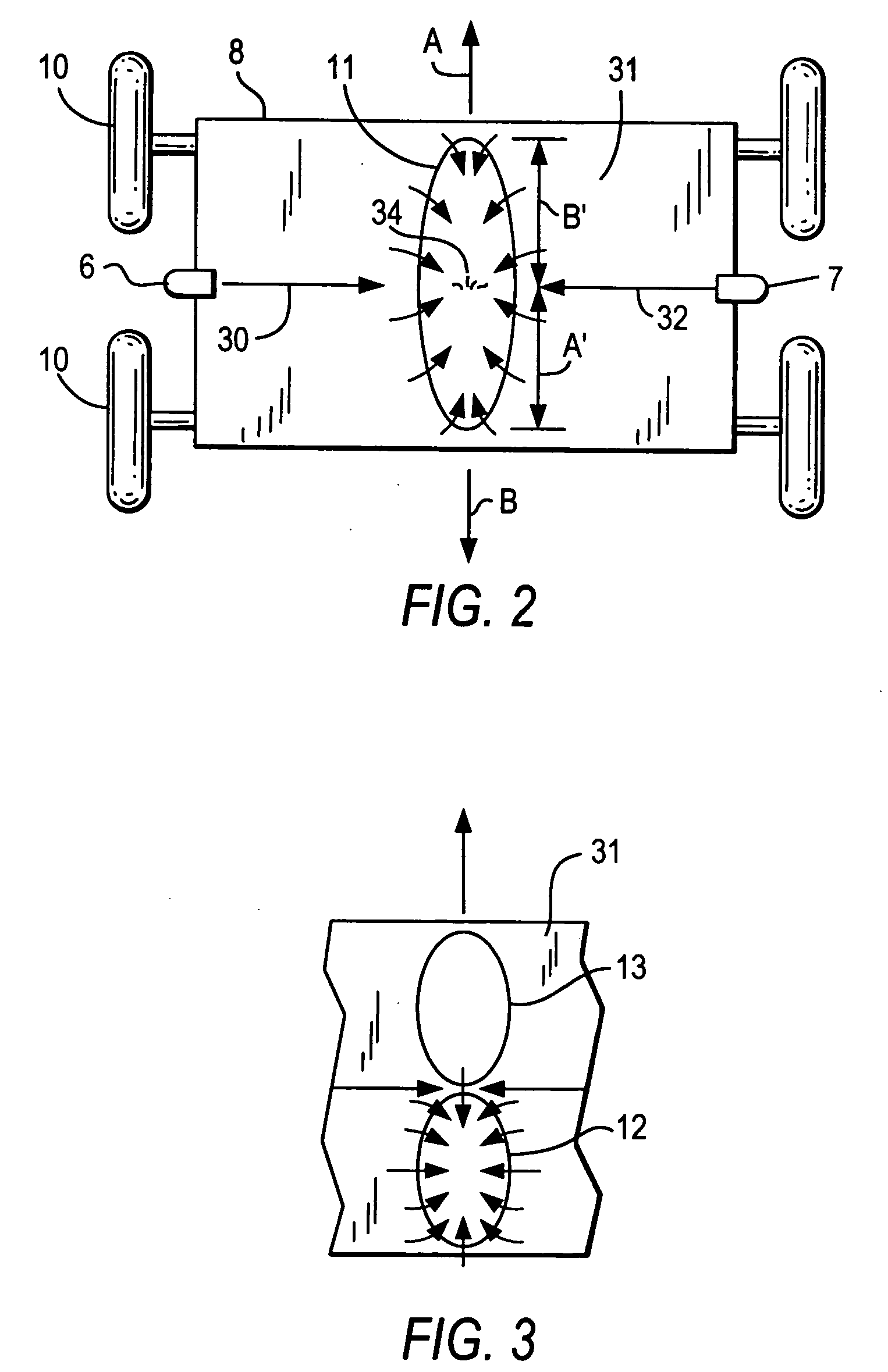

Pool cleaner with high pressure cleaning jets

InactiveUS20080236628A1Easy to cleanKeep for a long timeGymnasiumCleaning using gasesHigh pressureJet stream

A pool cleaning apparatus includes a housing and a pump for drawing water and debris through an intake port into a filter. A jet-valve housing having a jet valve flap is mounted over the pump to direct a propulsion jet stream from the pump to move the cleaner in a forward direction. A cleaning nozzle is mounted over each of the front and rear portions of the housing, and a pressurized water jet stream is directed at a first pool surface beneath the cleaner through the front end nozzle while moving in a forward direction. When the cleaner engages a second pool surface substantially perpendicular to the first surface, propulsion outlets of the jet valve housing are partially closed to redirect a portion of the propulsion jet stream to the front-end nozzle to lift the front end of the cleaner off the first surface. When the front end of the cleaner disengages from contact with the second surface, the propulsion outlets open to permit the propulsion jet stream to propel the cleaner along the second surface.

Owner:AQUA PRODS

Submersible pool cleaner with integral rechargeable battery

InactiveUS6842931B2Power is requiredReduce frictionGymnasiumConnectionsMotor driveElectrical battery

A submersible robotic pool cleaner is provided with an integral sealed rechargeable battery and an inductive charging assembly, a first portion of which is mounted in the pool cleaner housing and during the charging, receives a second separate portion that is connected by a cable to a conventional power source. The pump motor drive shaft is treated with a specialized anti-friction lubricant composition to minimize frictional energy losses where the shaft contacts the seal(s) and any shaft bearing(s), to maximize efficiency and minimize the power consumption of the pump motor assembly and permit the pool cleaner to completely traverse the surfaces to be cleaned within the fully-charged power capacity of the battery.

Owner:ZODIAC POOL SYST LLC

Pumping system with power optimization

The present invention provides a pumping system for moving water of a swimming pool, including a water pump and a variable speed motor. In one example, a target volume amount of water and an operational time period is provided, and the operational time period is altered based upon a volume of water moved. In another example, operation of the motor is altered based upon the volume of water moved. In addition or alternatively, a target flow rate of water to be moved by the water pump is determined based upon the target volume amount and a time period. In addition or alternatively, a plurality of operations are performed on the water, and a total volume of water moved by the pump is determined. In addition or alternatively, an optimized flow rate value is determined based upon power consumption.

Owner:DANFOSS POWER ELECTRONICS AS +1

Process control oxidation

InactiveUS20060006122A1Reduce pointsSeawater treatmentSolid sorbent liquid separationProcess controlChemistry

Owner:DISNEY ENTERPRISES INC

Pool vacuum

ActiveUS20080109972A1Impairs visibilityDrain fastCleaning filter meansSuction filtersImpellerEngineering

An improved pool vacuum includes a filter cone and poppet valve combination which enables quick drainage of water which has passed through and been cleaned by the cleaner's filter. A charging circuit is provided with isolation so that the pool vacuum can be used in an electrolytic environment without battery drainage. A combination charger and hang bracket enables the pool vacuum to be stored in a vertical position to both drain and charge simultaneously. An interstitial open exhaust gap between a rear body and nose-cone shaped front section provides a low pressure drop free exhaust area for an impeller. An optionally obstructed bottom gap portion helps to produce a net downward thrust to assist in using the vacuum in deep pools from a long pole structure.

Owner:WATERTECH

Fluid filter system

An endcap including a first plate member including a radial inner portion, a radial outer portion, and defining a longitudinal axis. The endcap also includes a flange disposed between the radial inner and outer portions of the first plate member and projecting axially along the longitudinal axis in a first direction. The endcap also includes a first seal member disposed adjacent the flange. The first seal includes a first portion thereof engaged with an axial facing surface of the first plate member and a second portion thereof engaged with a radially facing surface of the flange. The endcap further includes a second plate member disposed radially outward of the radial outer portion and a second seal member disposed adjacent the second plate member including at least a portion thereof axially spaced from the axially facing surface of the first plate member in a second direction along the longitudinal axis opposite the first direction.

Owner:DONALDSON CO INC +2

Directional control for dual brush robotic pool cleaners

A method and apparatus for accurately controlling the directional and turning movement of a self-propelled robotic pool cleaner having at least one pair of rotational support members for propelling and cleaning along a surface of a pool or tank include accelerating at least one pair of the rotational support members from a stopped position to a first predetermined rotational rate for a first predetermined time period to propel the pool cleaner in a first direction along the pool surface, continuing the rotation at the first rotational rate for a second predetermined time period; and increasing to a second higher rotational rate, such that the cleaner is propelled at a maximum normalized rate during straight-line movement for cleaning the pool. The duration of straight-line movement is incrementally advanced by a signal that is manually generated by a user switch or a magnet that is brought into proximity of a reed switch mounted inside the cleaner's housing.

Owner:ZODIAC POOL SYST LLC

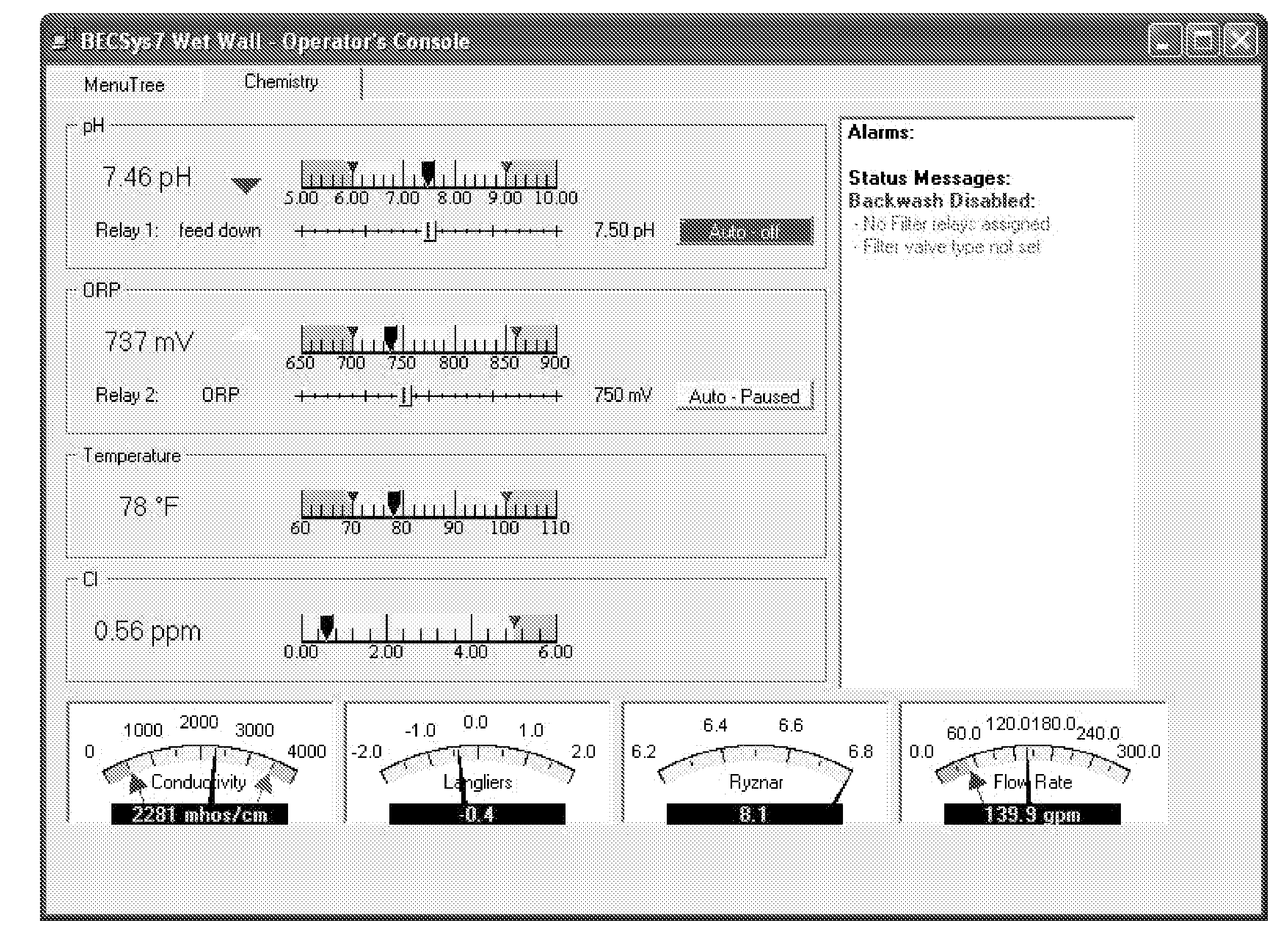

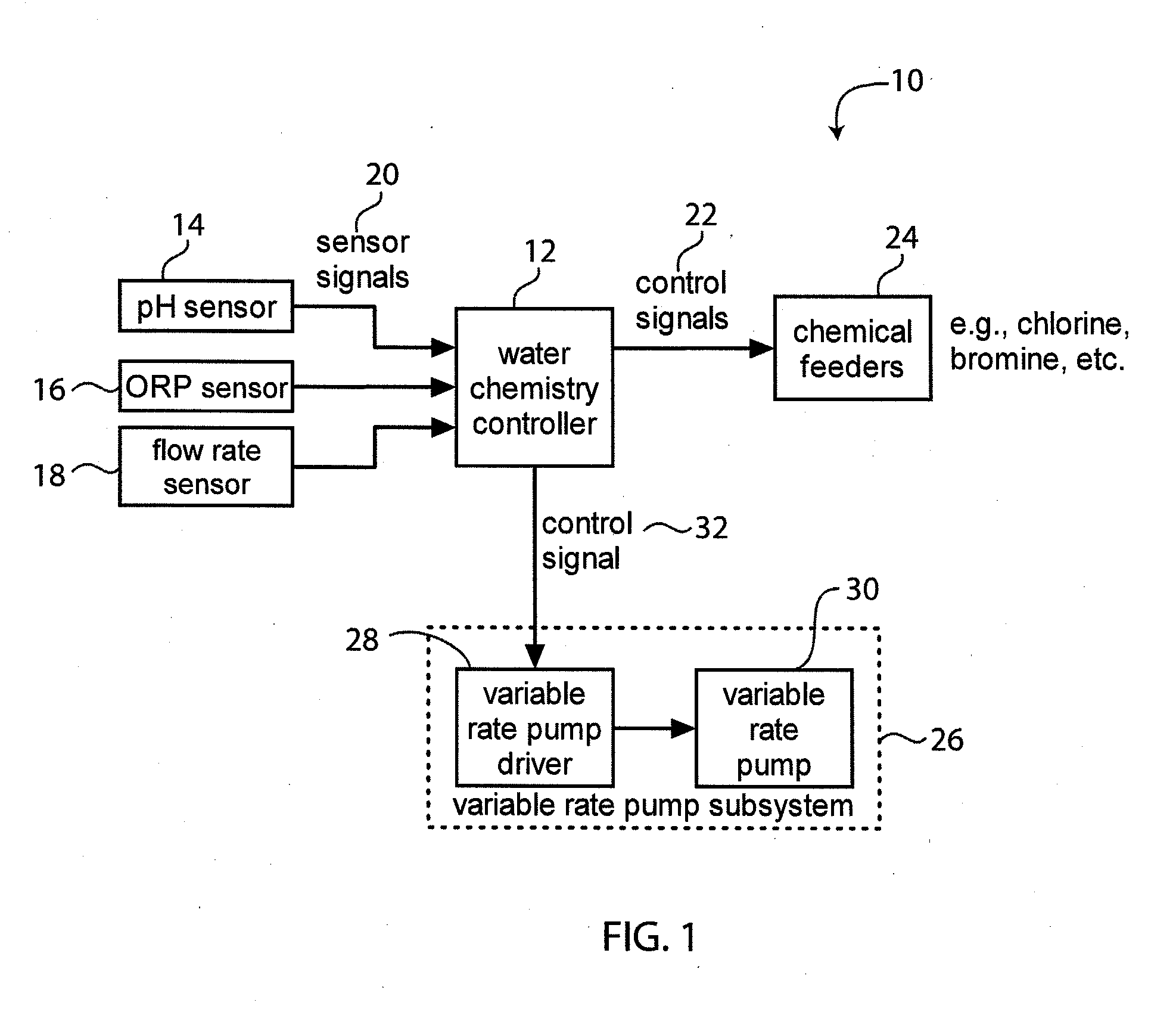

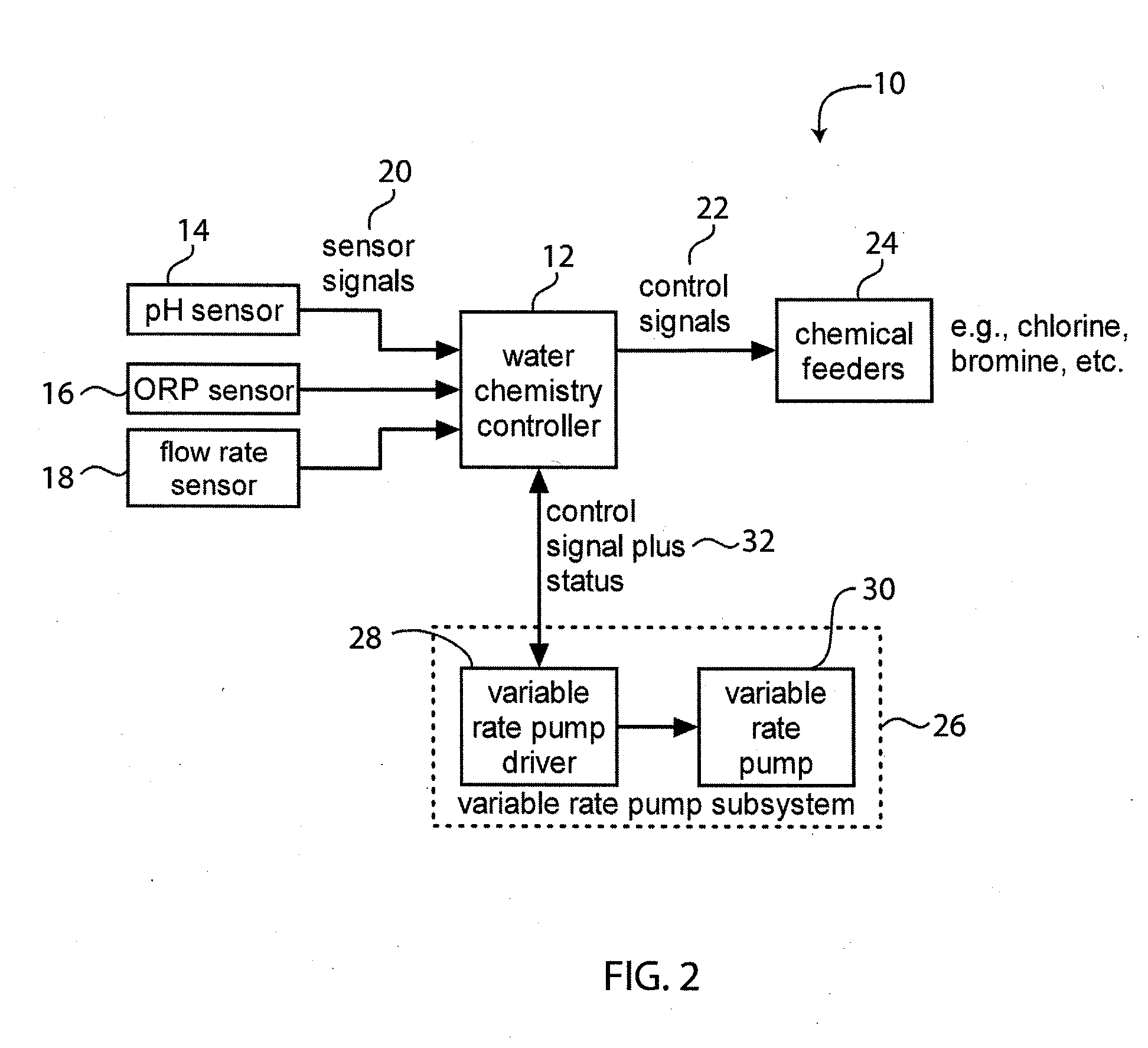

System for Controlling Water in an Aquatic Facility

InactiveUS20090200245A1GymnasiumWater/sewage treatment by oxidationMotor driveEnvironmental engineering

A system for controlling water within an aquatic facility includes a water chemistry controller, a variable rate water pump adapted to move water in the facility, and a variable rate motor driver operationally coupled to the water pump for variably energizing the water pump. The variable rate motor driver is coupled to the water chemistry controller to allow the water chemistry controller to manage the operation of the water pump.

Owner:BECS TECH

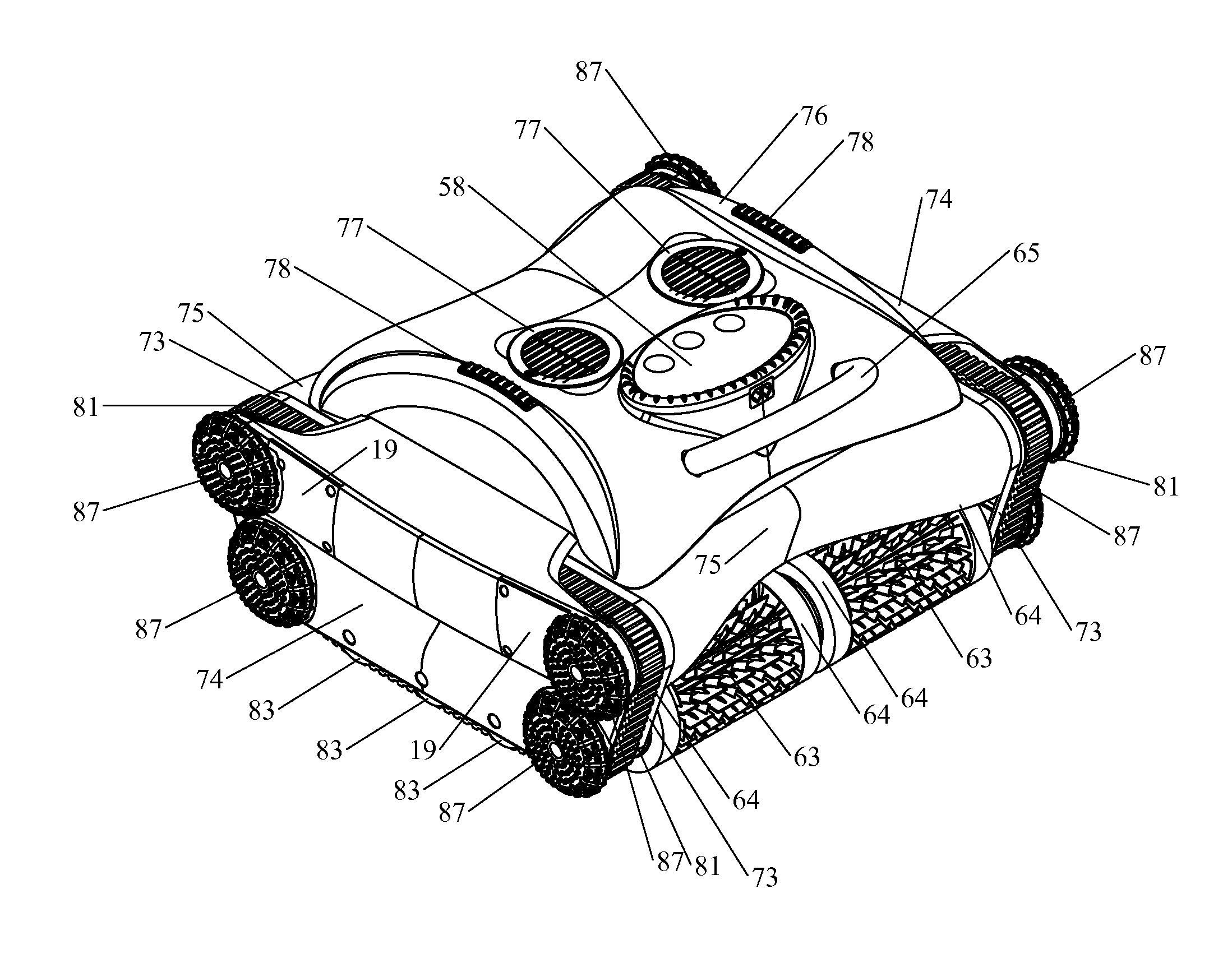

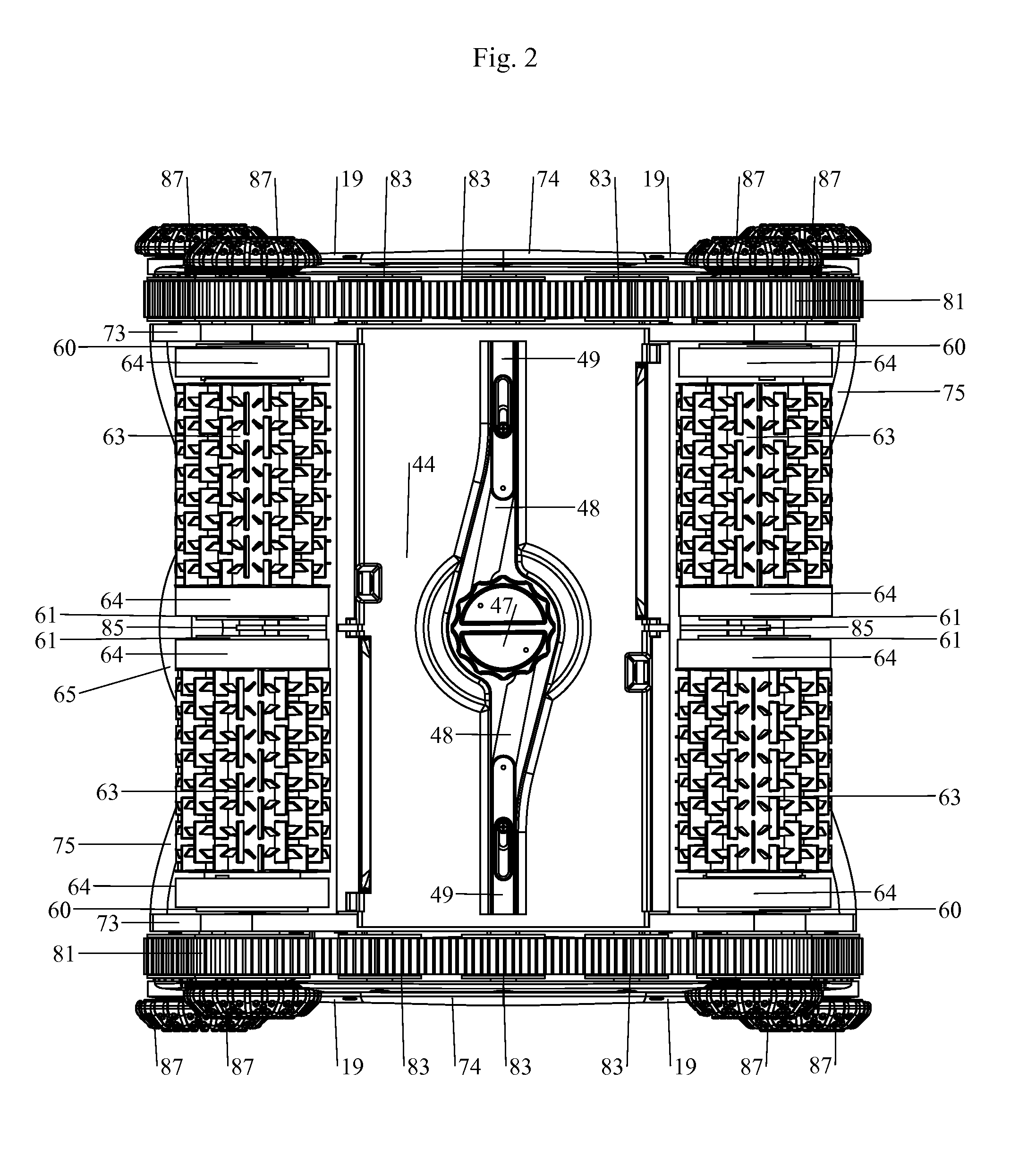

Robotic pool cleaning apparatus

Robotic apparatus cleans swimming pools and has road and pulley wheels with belts thereon, on opposite sides and drive motors that rotate a wheel on each side to move the frame along a pool surface. Pairs of outside wheels have friction surfaces to engage pool surfaces to also moving the frame. Forward and rearward brush assemblies are driven to brush the pool surface. Oppositely facing and angled duck bill valves allow water into free volumes in the frame and are covered by a filter bag for filtering out debris under the action of a dual pump assembly that pumps water out through a pair of outlet opening in a top of the frame. A computer processor controls the drive motors and pump assembly to move the frame along programmed paths and rechargeable batteries power the drive motors, pump assembly and computer processor.

Owner:FLUIDRA

Apparatus For Facilitating Maintenance Of A Pool Cleaning Device

ActiveUS20100065482A1Easy accessEasy to seeWater/sewage treatmentLoose filtering material filtersFast releaseBiomedical engineering

Advantageous apparatus, are provided for facilitating maintenance of a automated pool cleaning device. More particularly, an improved automated pool cleaning device is provided, according to the present disclosure. The device, generally, includes a facially accessible quick-release roller assembly, a bucket-type filter assembly, and a windowed top access lid assembly. The improved roller assembly and filter assembly are easily accessible for maintenance purposes. Furthermore, the windowed lid assembly provides visual feedback as to when the filter assembly needs to be cleaned.

Owner:HAYWARD IND INC

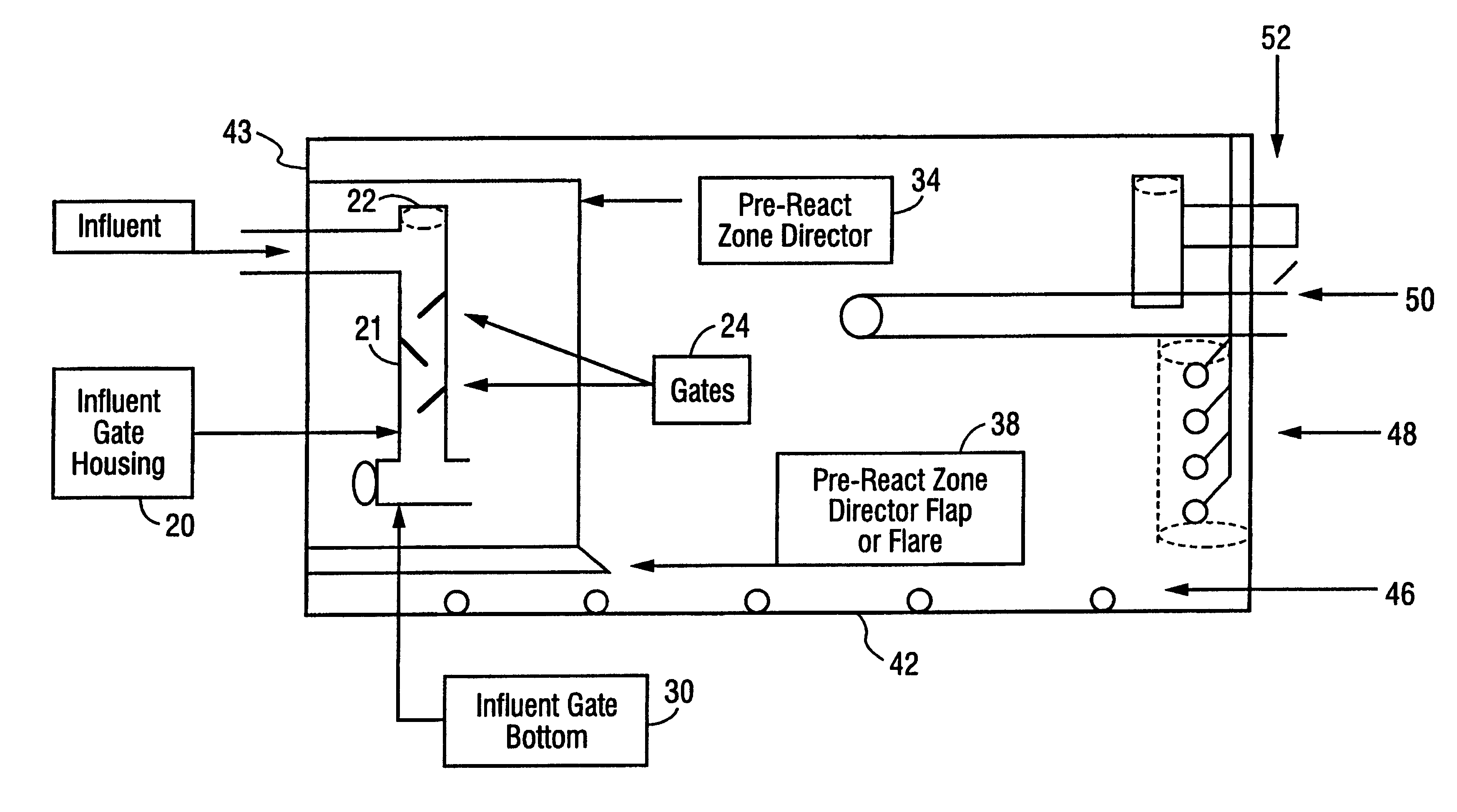

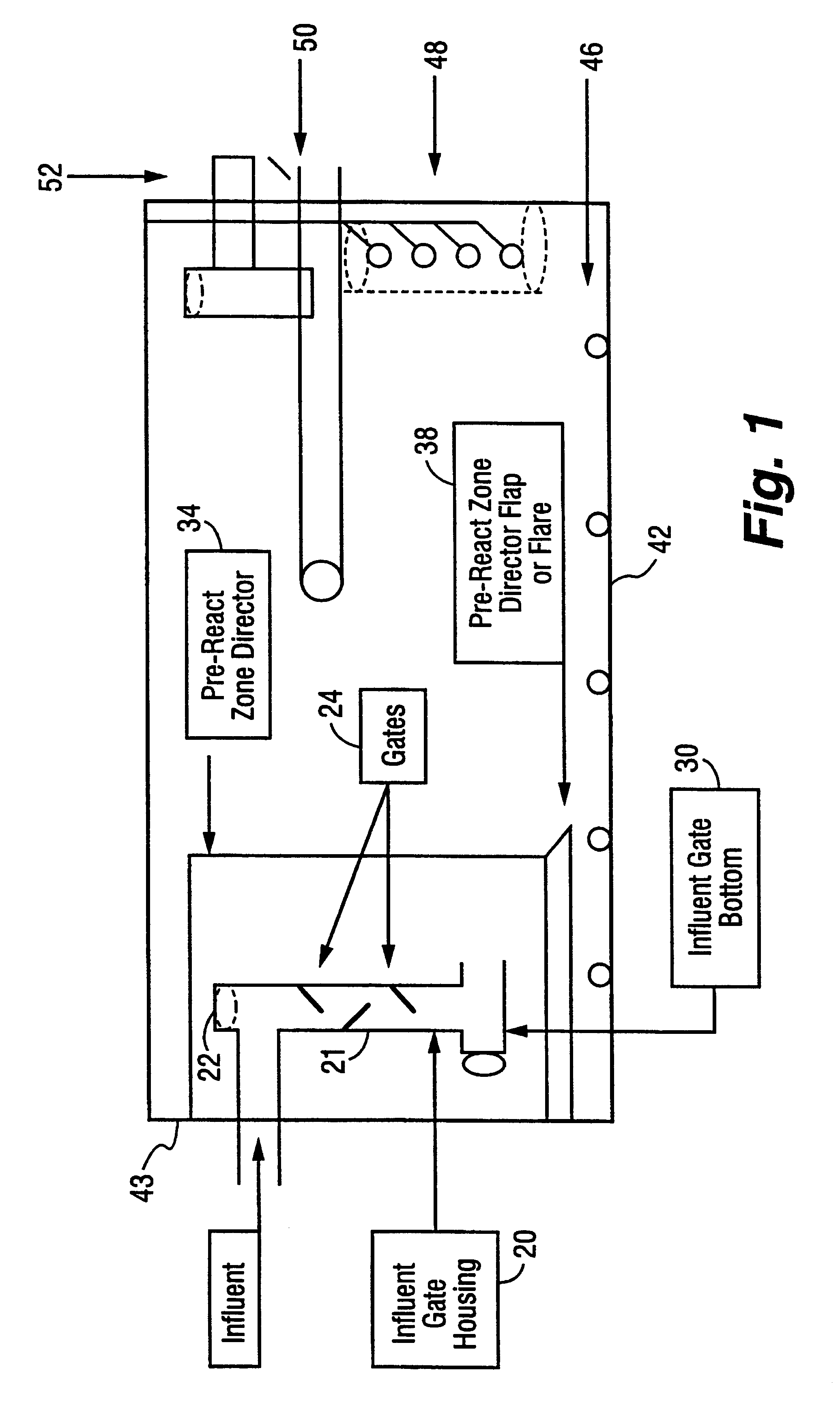

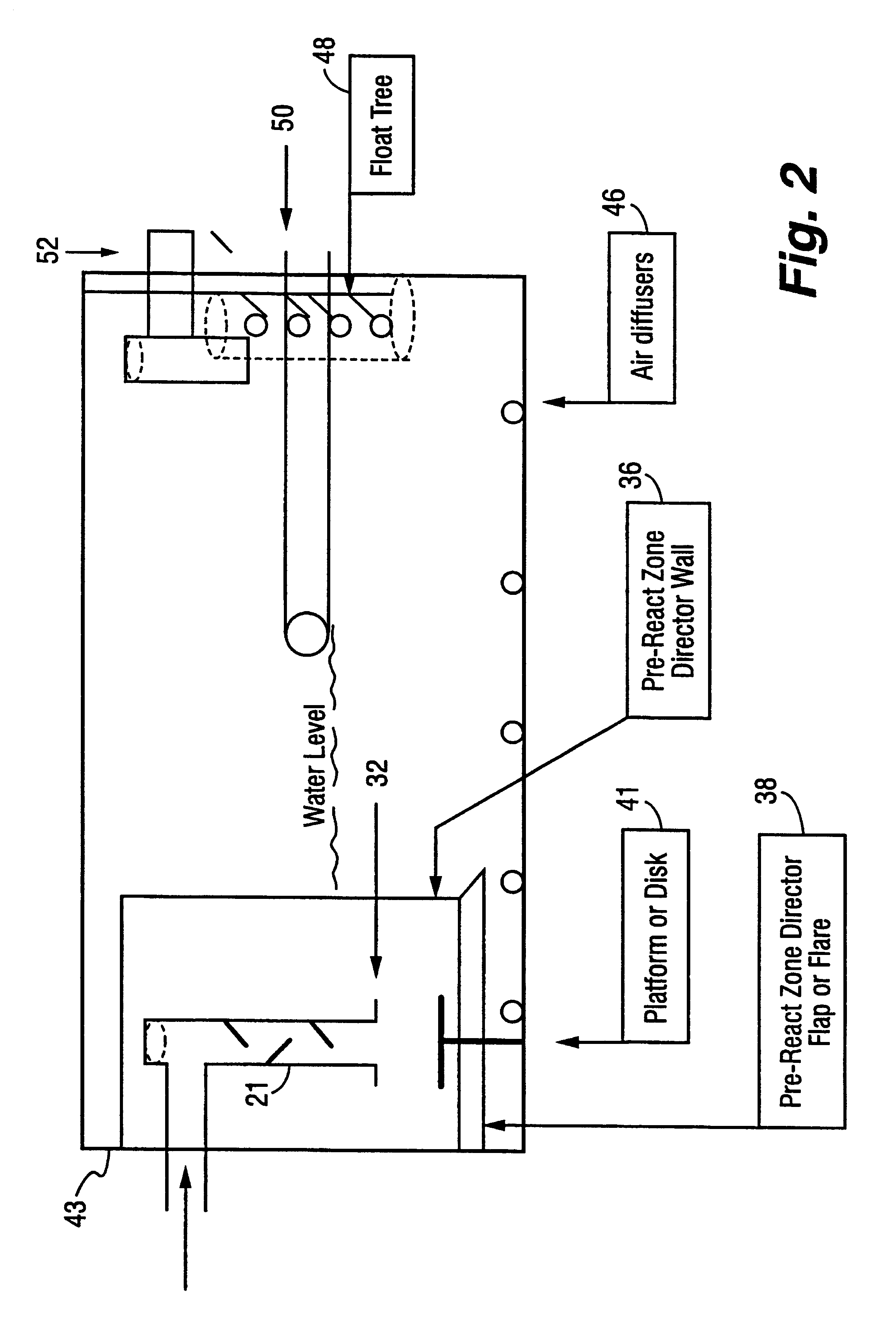

Wastewater treatment tank with influent gates and pre-react zone with an outwardly flared lower portion

InactiveUS6303026B1Reduce flow rateAvoid interferenceWater treatment parameter controlTreatment using aerobic processesSludgeBiological filter

A wastewater treatment tank with influent gates (24) and pre-react zone with an outwardly flared lower portion. Influent passes over influent gates (24), which introduce turbulence, causing aeration, and reducing flow velocity. As influent flows out of the influent gate housing (20), flow velocity is further reduced by contact with the surface of the wastewater in the basin and influent flow is directed laterally by an influent gate bottom (30). A pre-react zone director (34) spaced apart from the bottom (42) of the basin encloses the influent gate housing (20) and utilizes an outwardly flared lower portion, or flap (38), to further reduce flow velocity and enhance laminar flow. This results in minimal disturbance of settled sludge blanket, allowing it to act as a natural biological filter, which in turn results in a superior supernatant.

Owner:LINDBO GLEN D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com