Electric vacuum cleaner

a vacuum cleaner and electric technology, applied in the field of electric vacuum cleaners, can solve the problems of increasing maintenance difficulty, reducing suction power, etc., and achieve the effects of reducing suction amount, clogging of filter, and increasing air passage resistance of the first air passage sid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

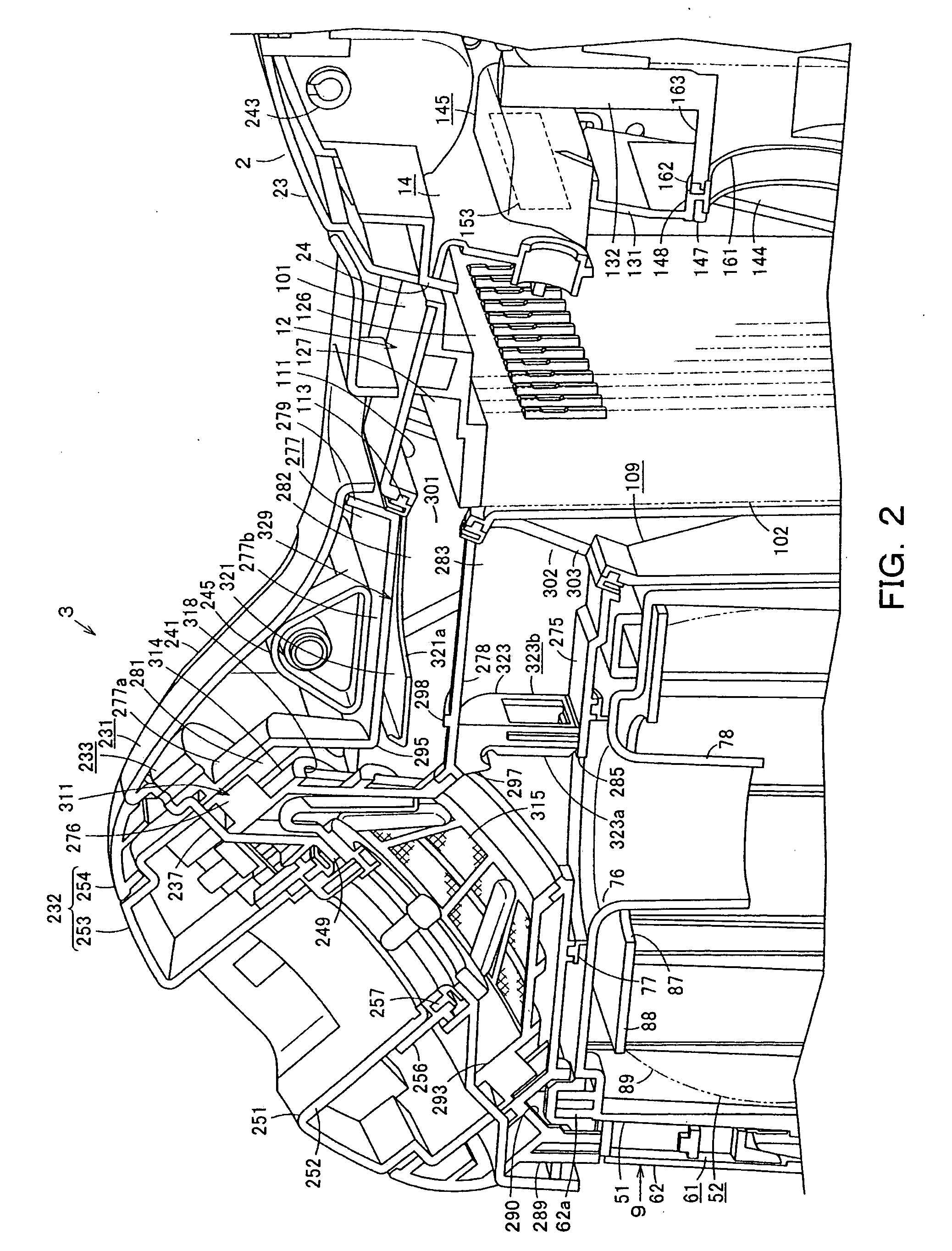

[0026]the present invention will be described below with reference to FIG. 1 to FIG. 10.

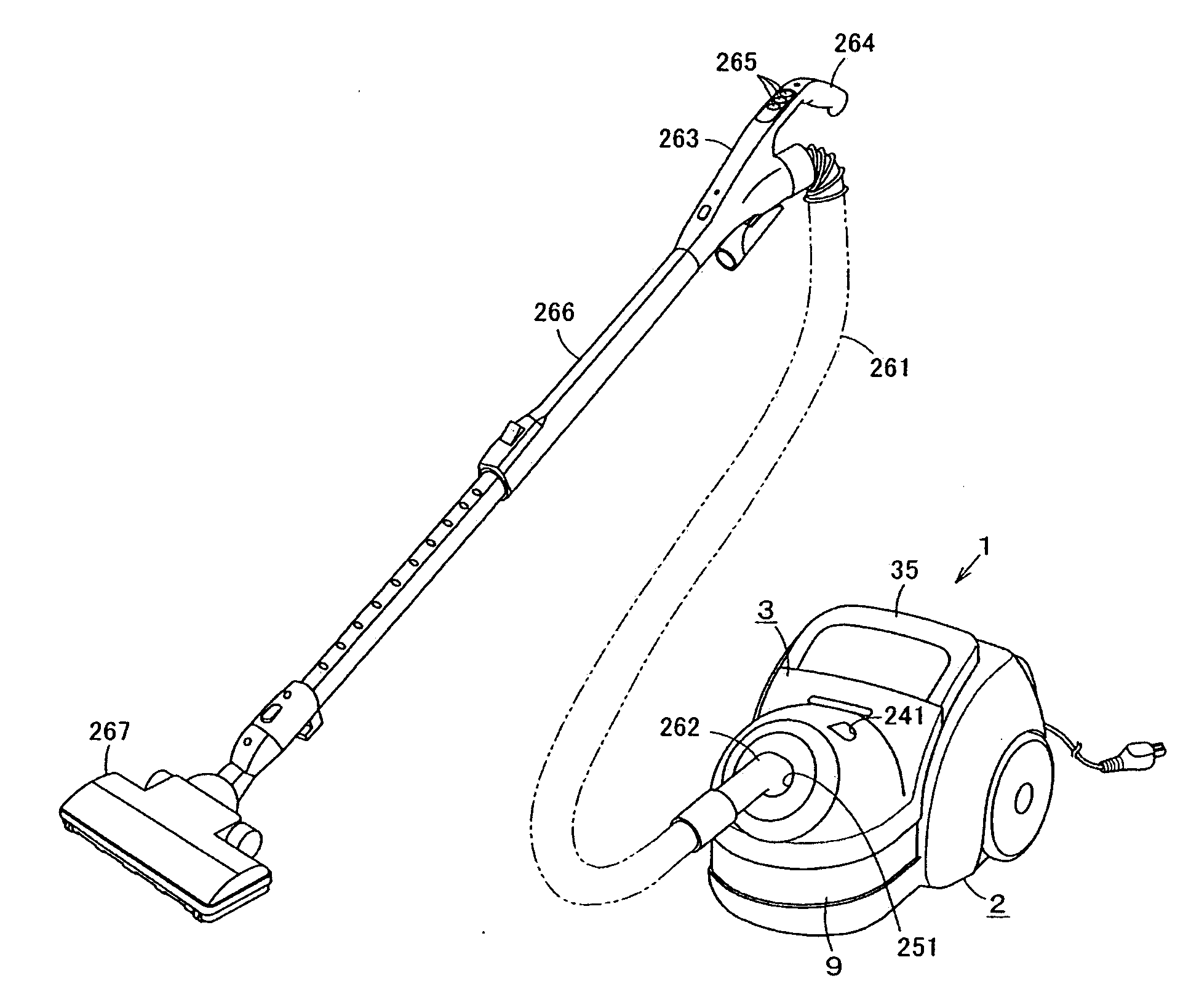

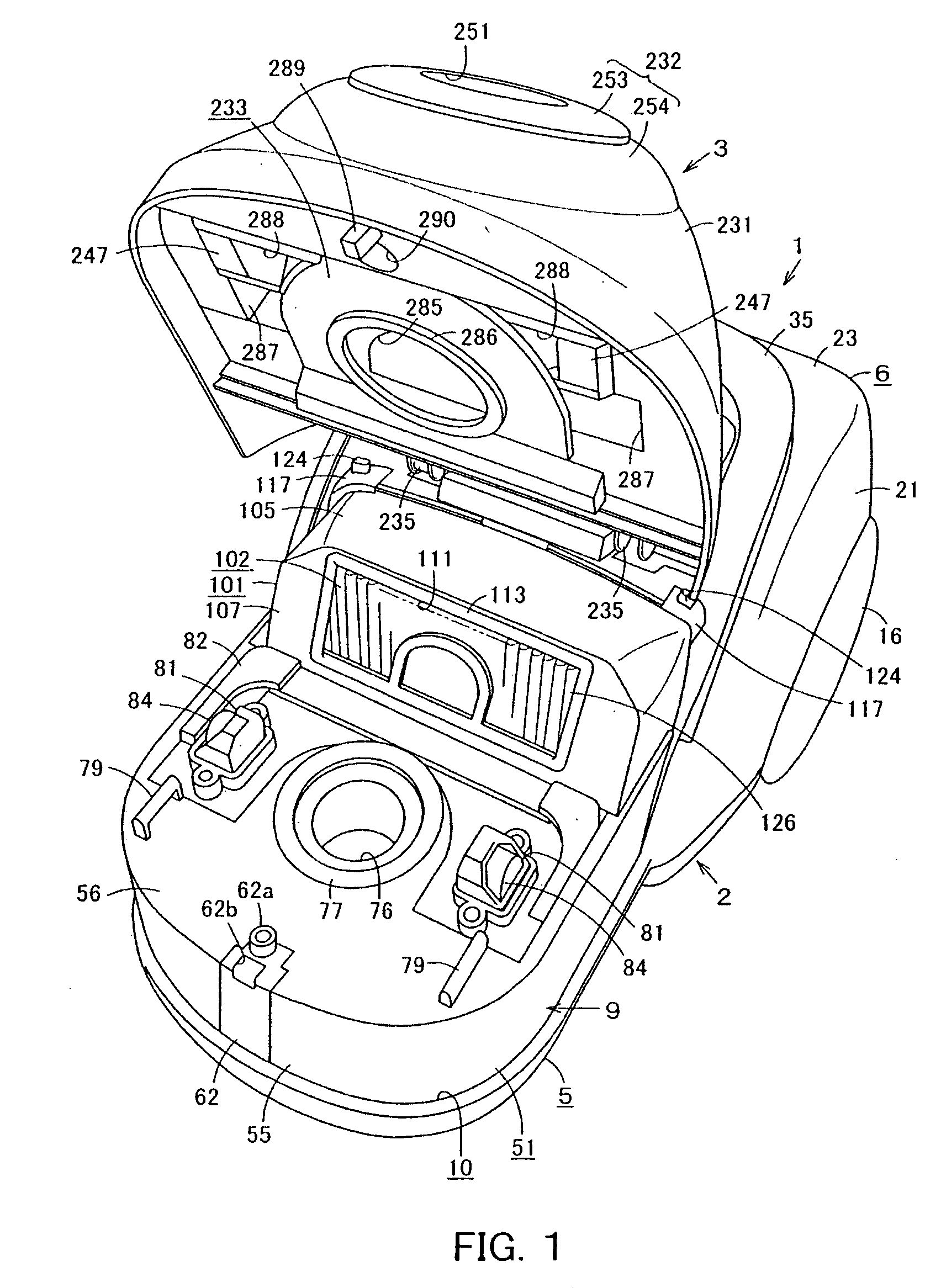

[0027]In FIG. 1, FIG. 3, FIG. 4 and FIG. 10, the reference numeral 1 denotes a vacuum cleaner main body, and the vacuum cleaner main body is a so-called canister type electric vacuum cleaner. The vacuum cleaner main body 1 has a main body case 2 and an openable / closable lid body 3 provided on the main body case 2.

[0028]The main body case 2 includes a lower case 5 formed in a long shape in a front and rear direction, and an upper case 6 provided to the upper side of the lower case 5. An electric blower chamber 8 with an electric blower 7 housed therein is formed at the rear portion of the main case body 2, and a recessed mount part 10 is formed at the front portion thereof, the recessed mount part 10 being a dust collecting unit attachment part on which a dust collecting unit 9 as a dust collecting unit being a main dust collecting unit is detachably mounted. A space 13, with which a filter 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com