Installation for applying glue to fibers for the production of fiberboard

A technology for manufacturing fibers and fibers, which is applied in the field of a fiber conveying device, can solve problems such as the inability to develop further, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

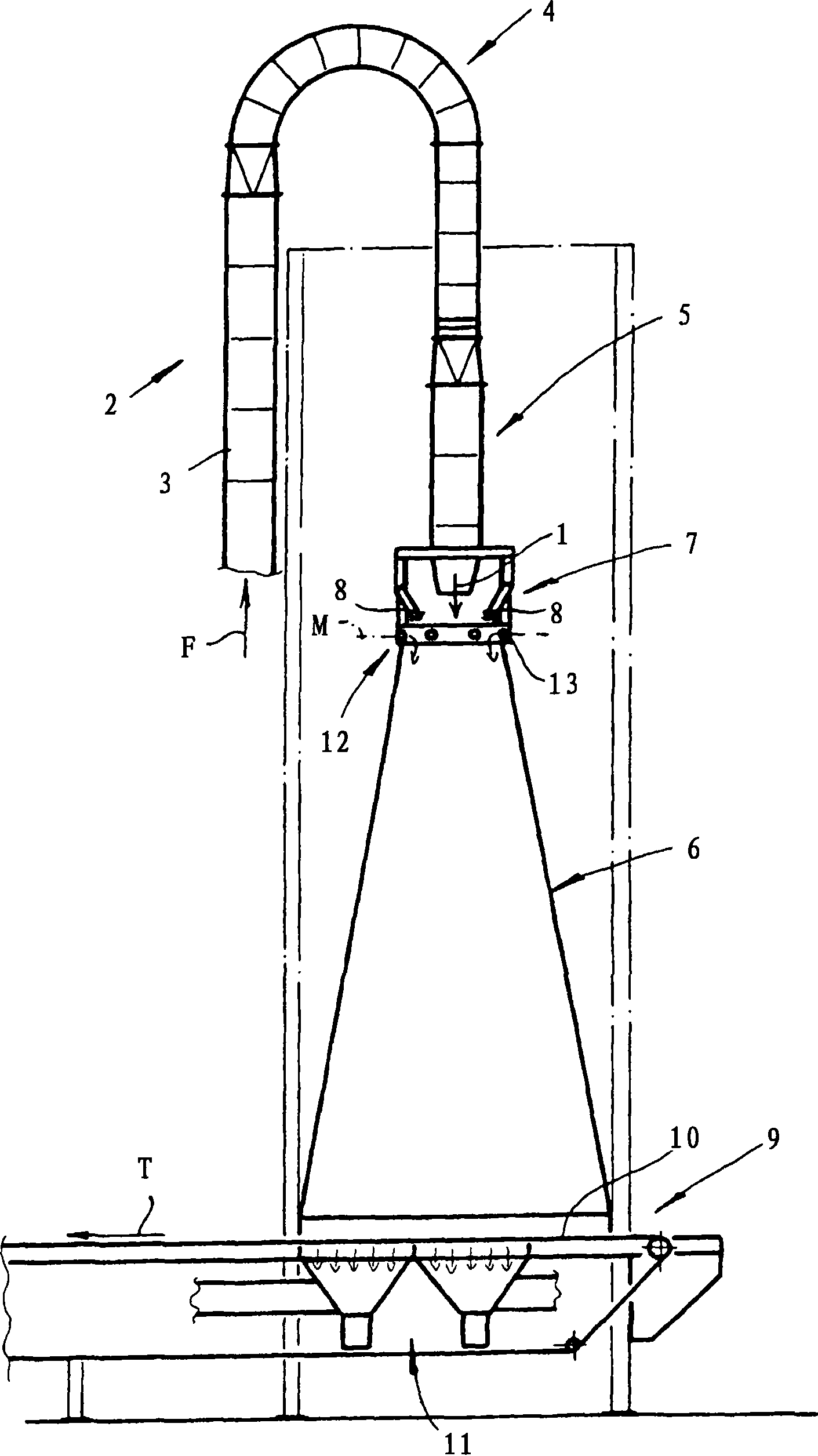

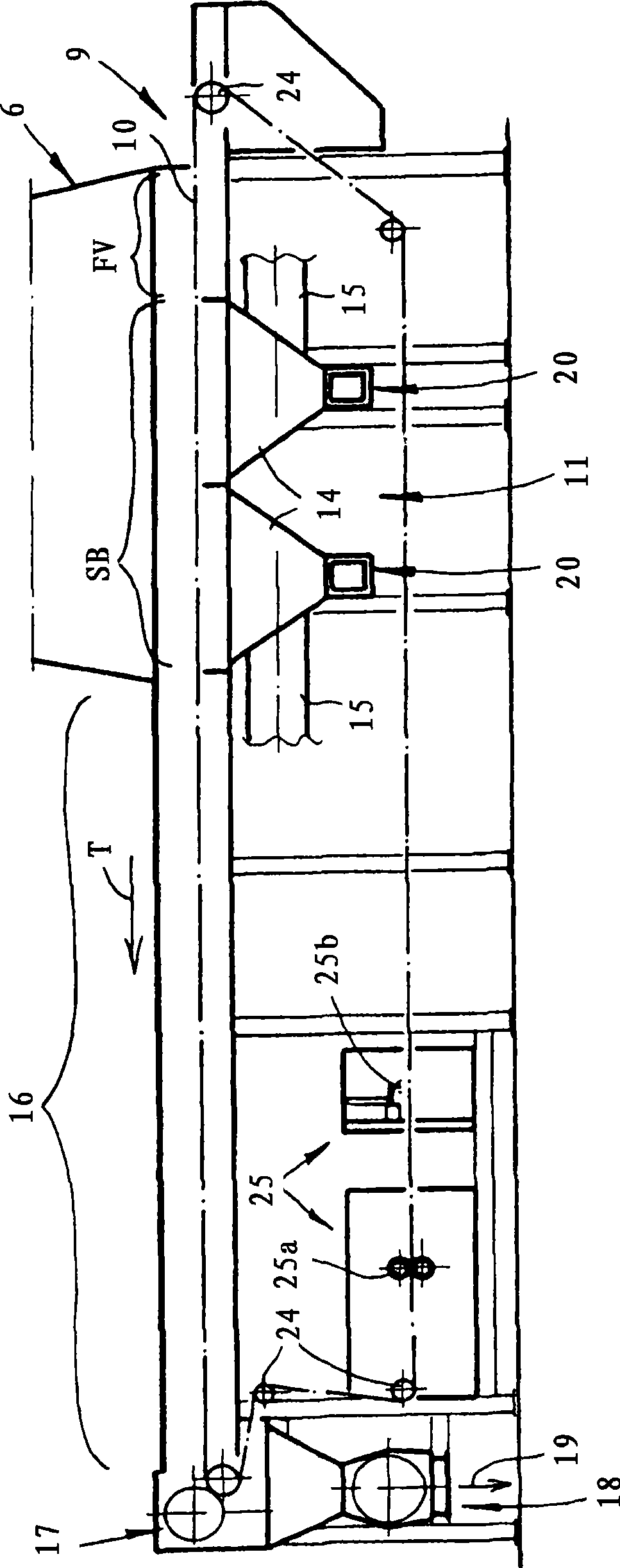

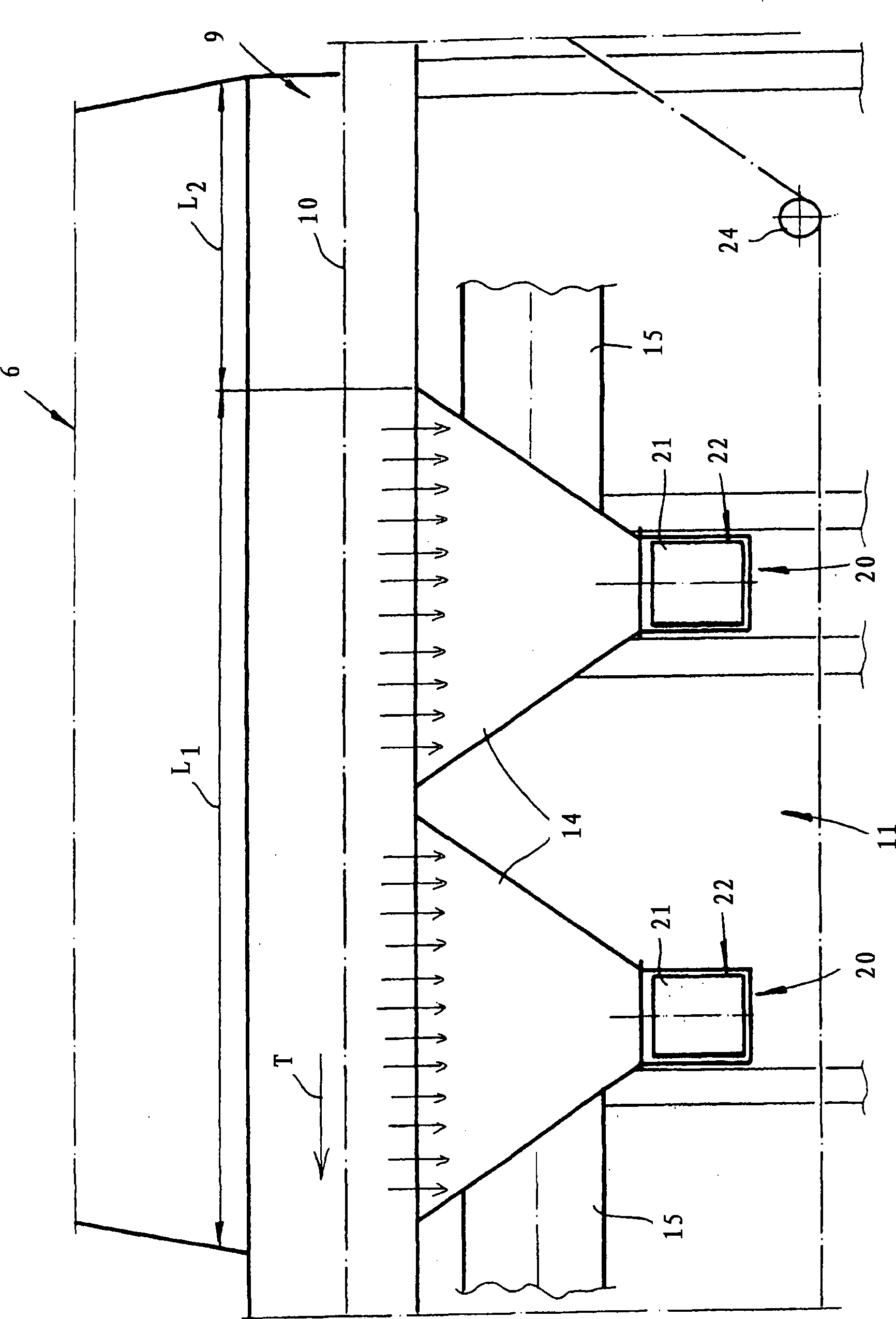

[0016] A plant for gluing fibers for the manufacture of fibreboards, in particular MDF boards, is shown in the drawing. The device is designed for continuous operation and has a fiber feed device 2 comprising at least one fiber feed line 3 to which feed air F can be applied for the fiber feed. This vertically arranged fiber supply line 3 opens via an arcuate 180° fiber deflection line 4 into a likewise vertically oriented fiber discharge line 5 . Arranged downstream of the fiber discharge pipe 5 is a descending shaft 6 which is likewise oriented vertically and has a cross section that widens downwards and thus widens in the direction of descent. A gluing device 7 is arranged between the fiber discharge pipe 5 and the descending shaft 6 and has a nozzle 8 for spraying glue droplets on the fibers 1 exiting the fiber discharging pipe 5 and entering the descending shaft 6 . For this purpose, a plurality of, for example 10 to 20, nozzles are arranged on the nozzle ring which surro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com