Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about "Vacuum cleaner apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

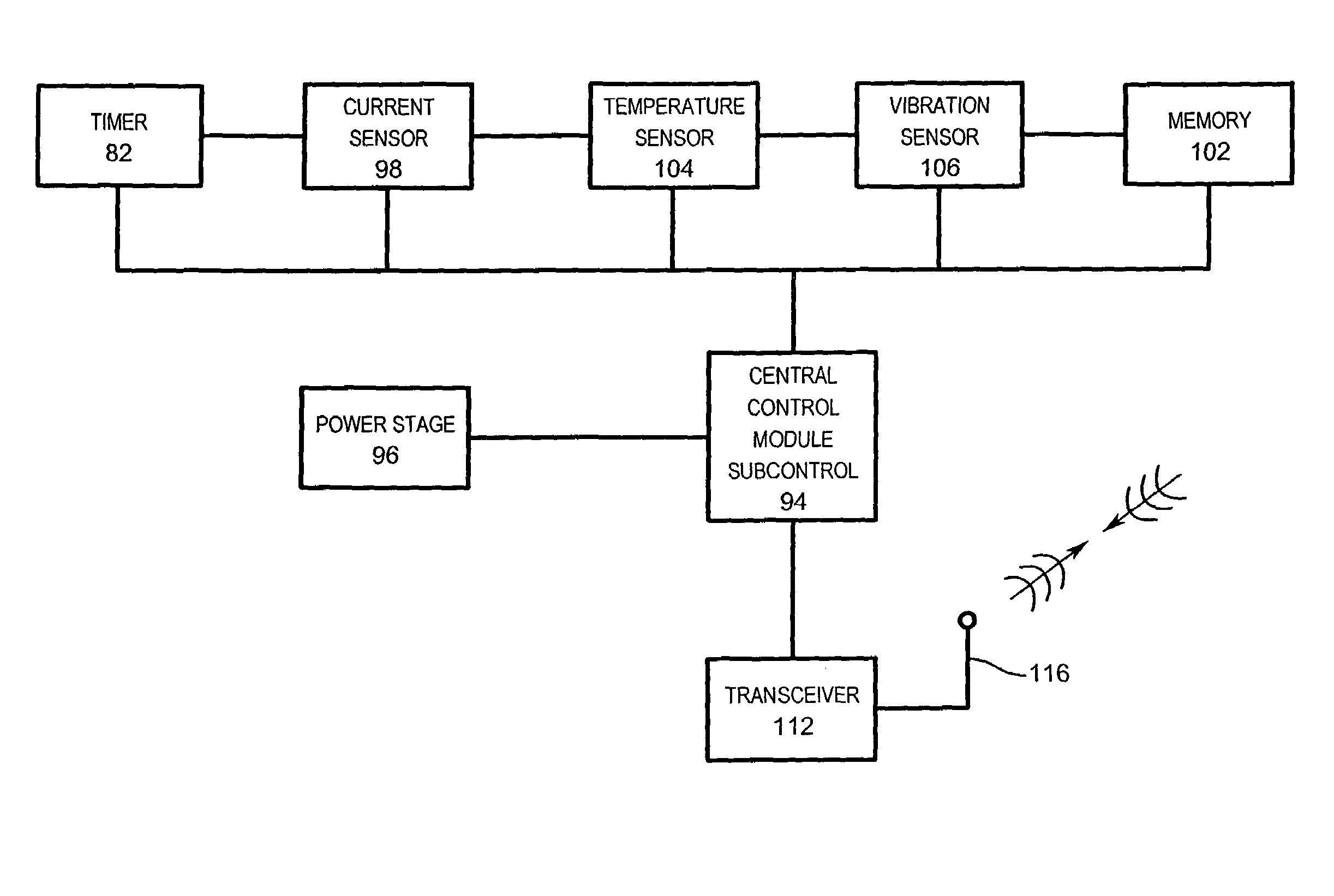

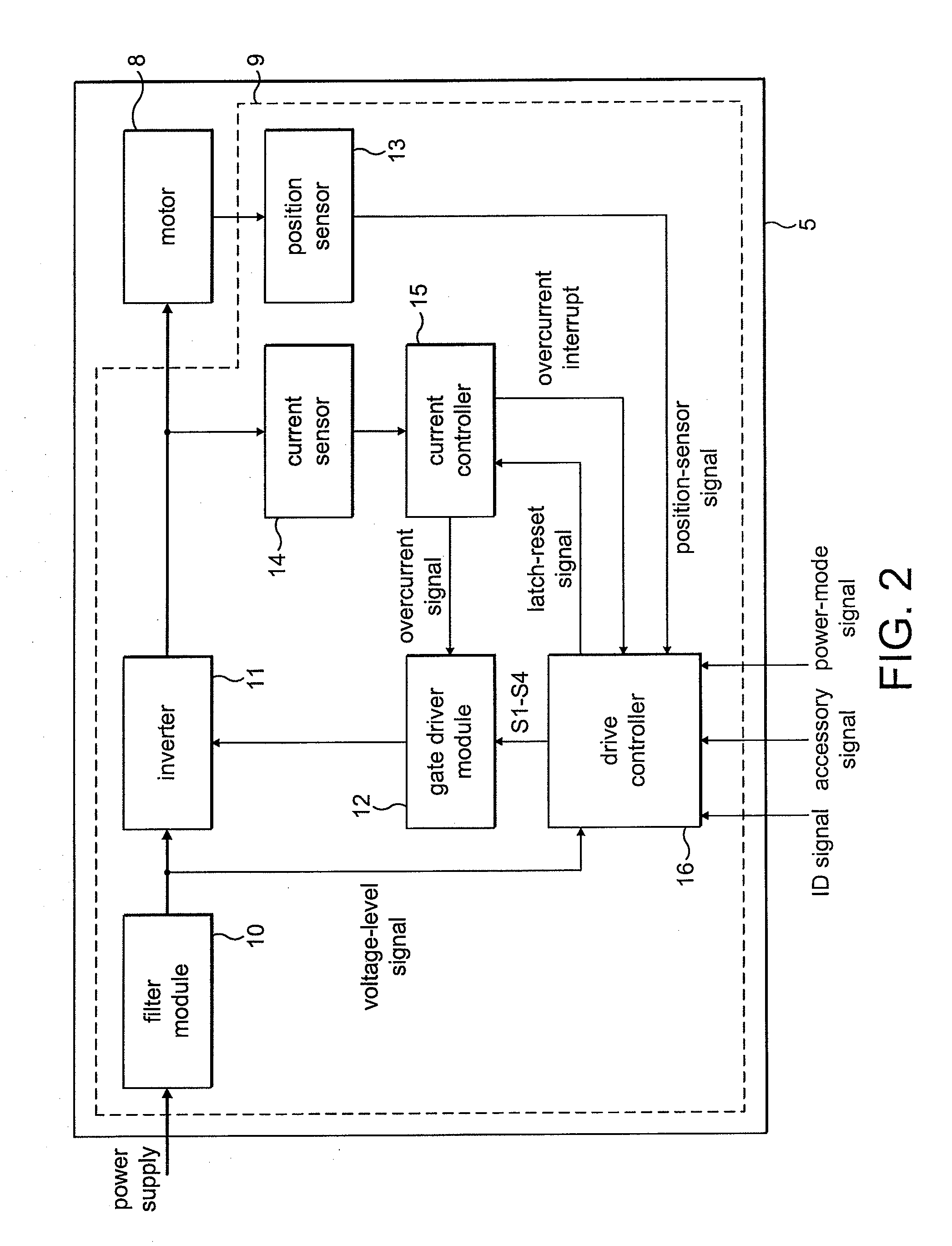

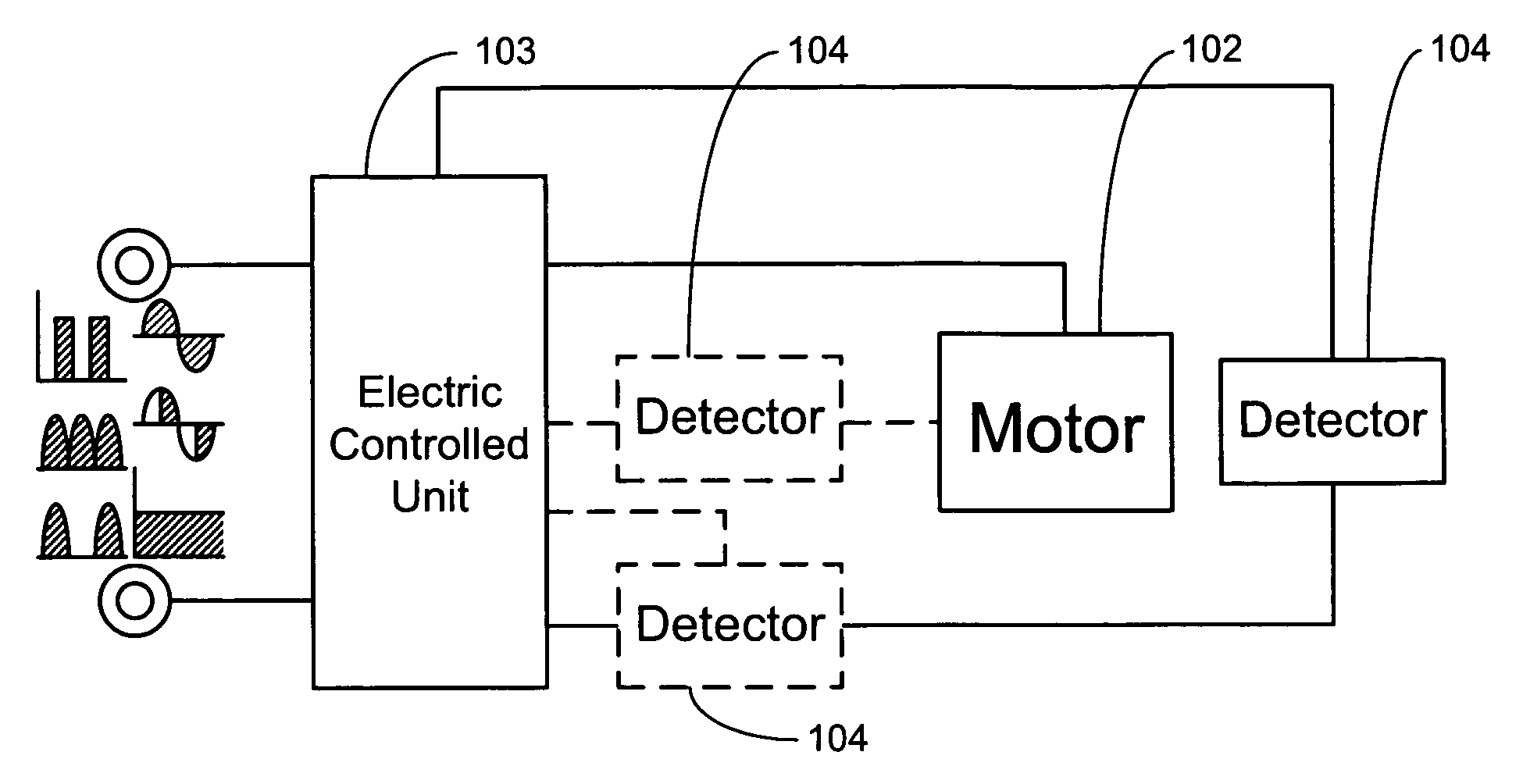

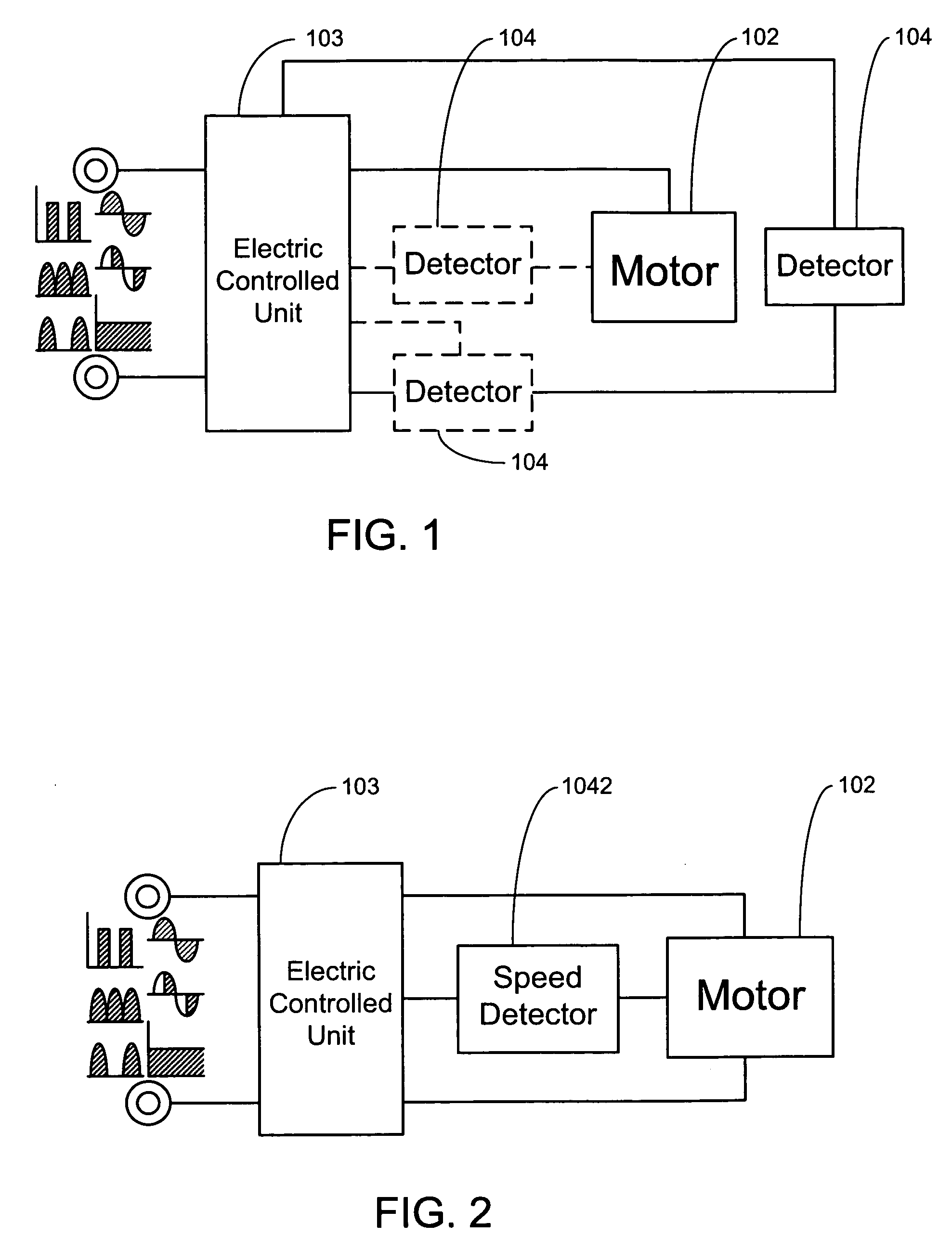

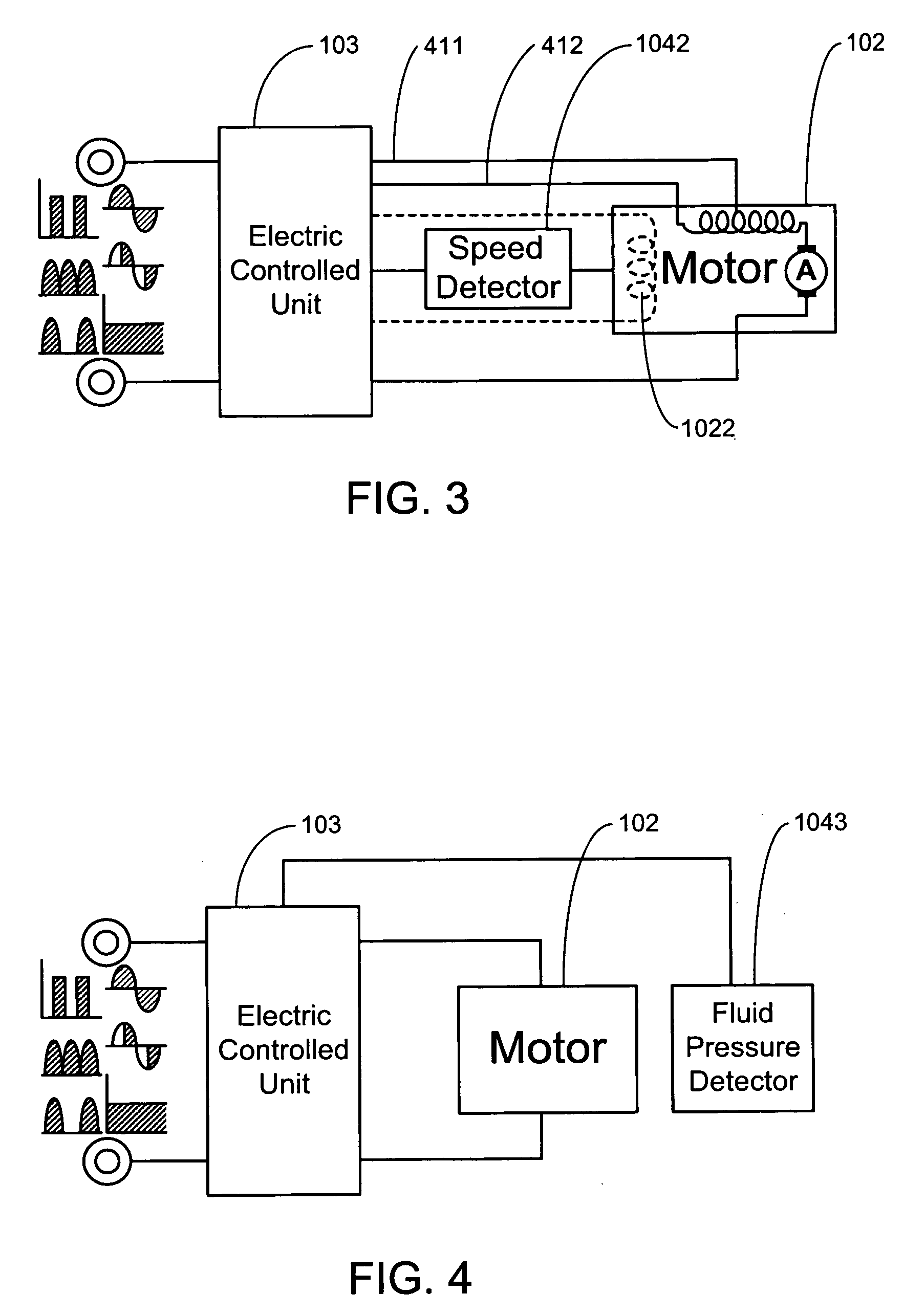

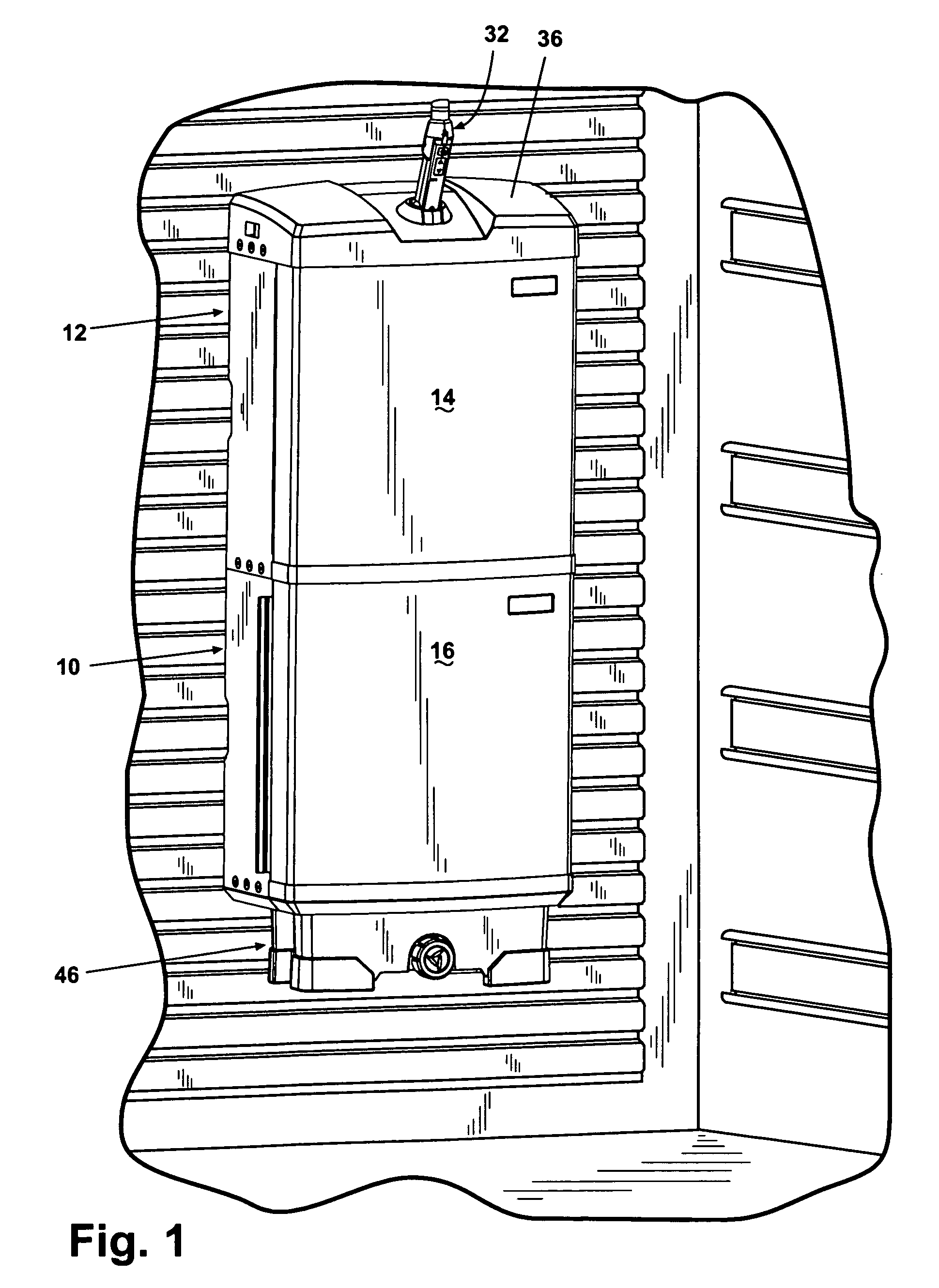

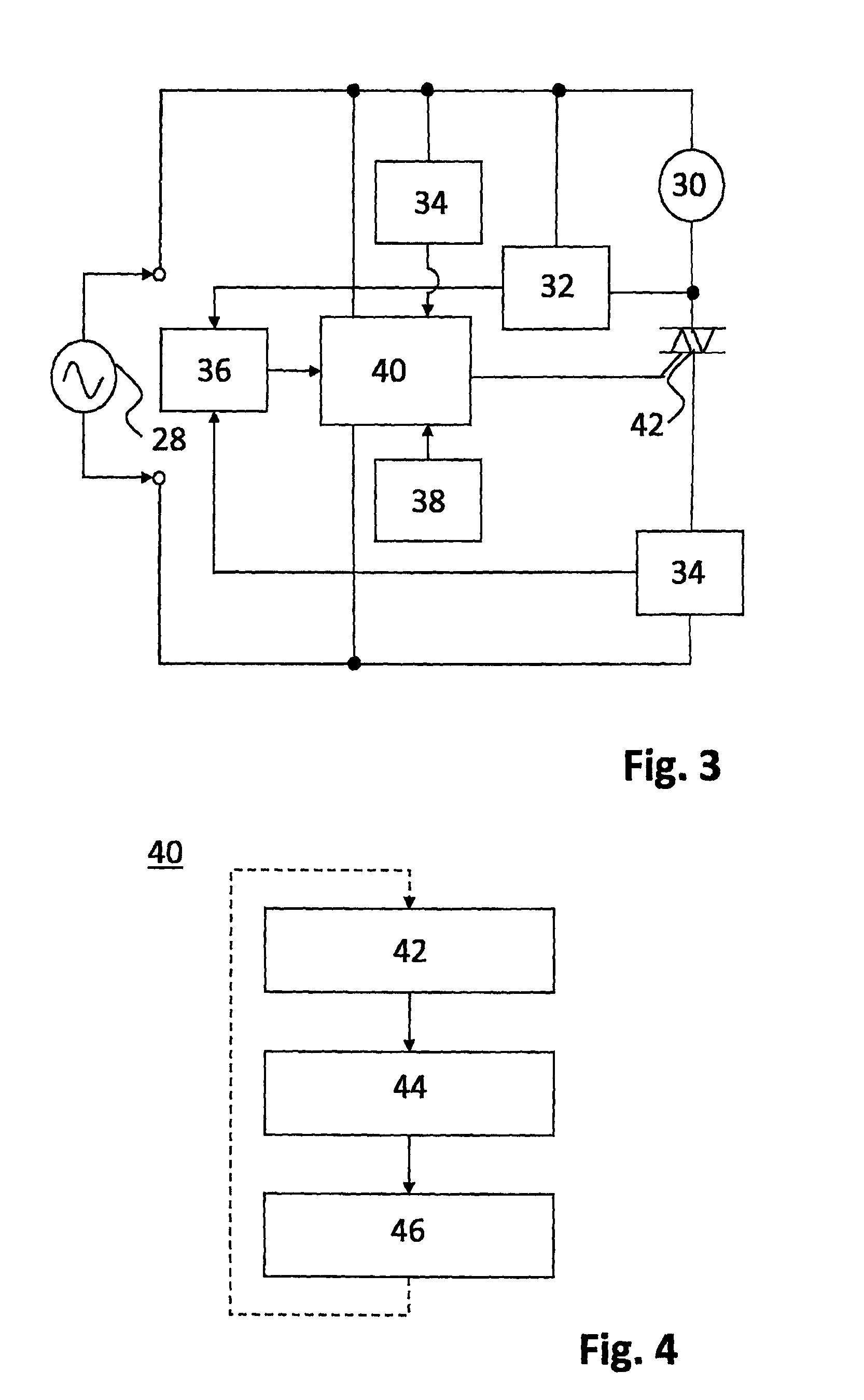

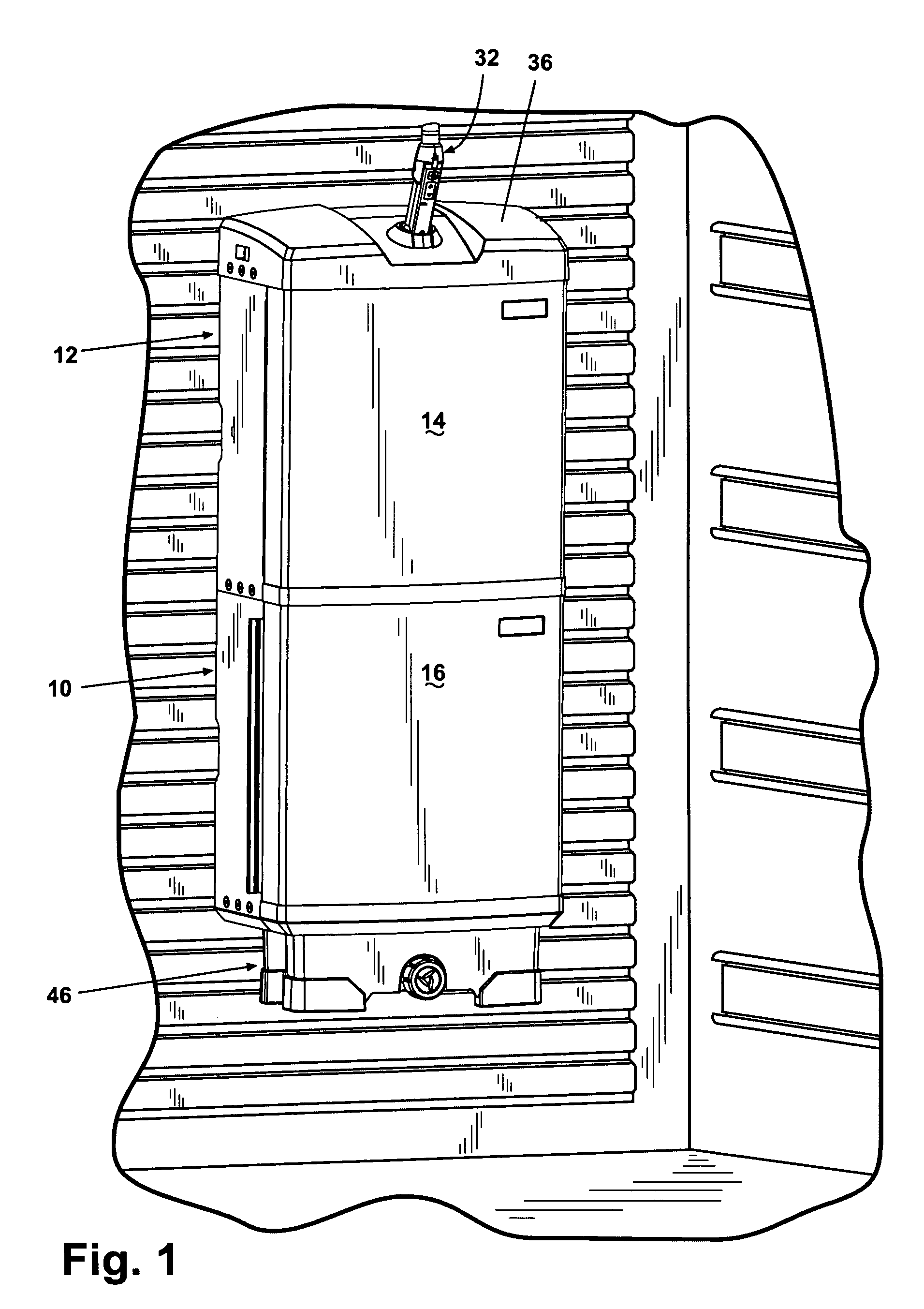

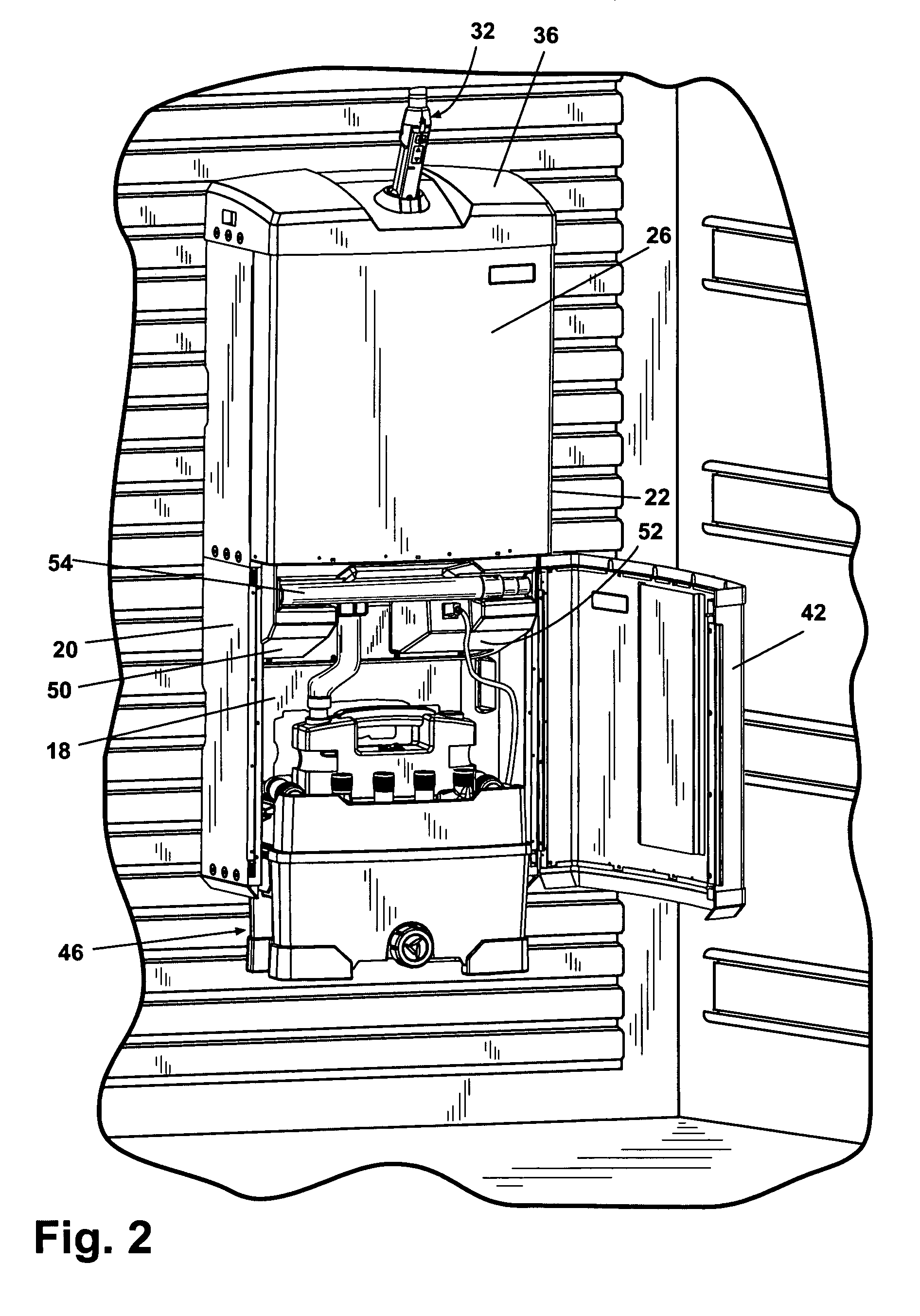

Central vacuum cleaning system control subsystems

InactiveUS7403360B2Coupling device detailsEmergency protective arrangements for automatic disconnectionControl powerTRIAC

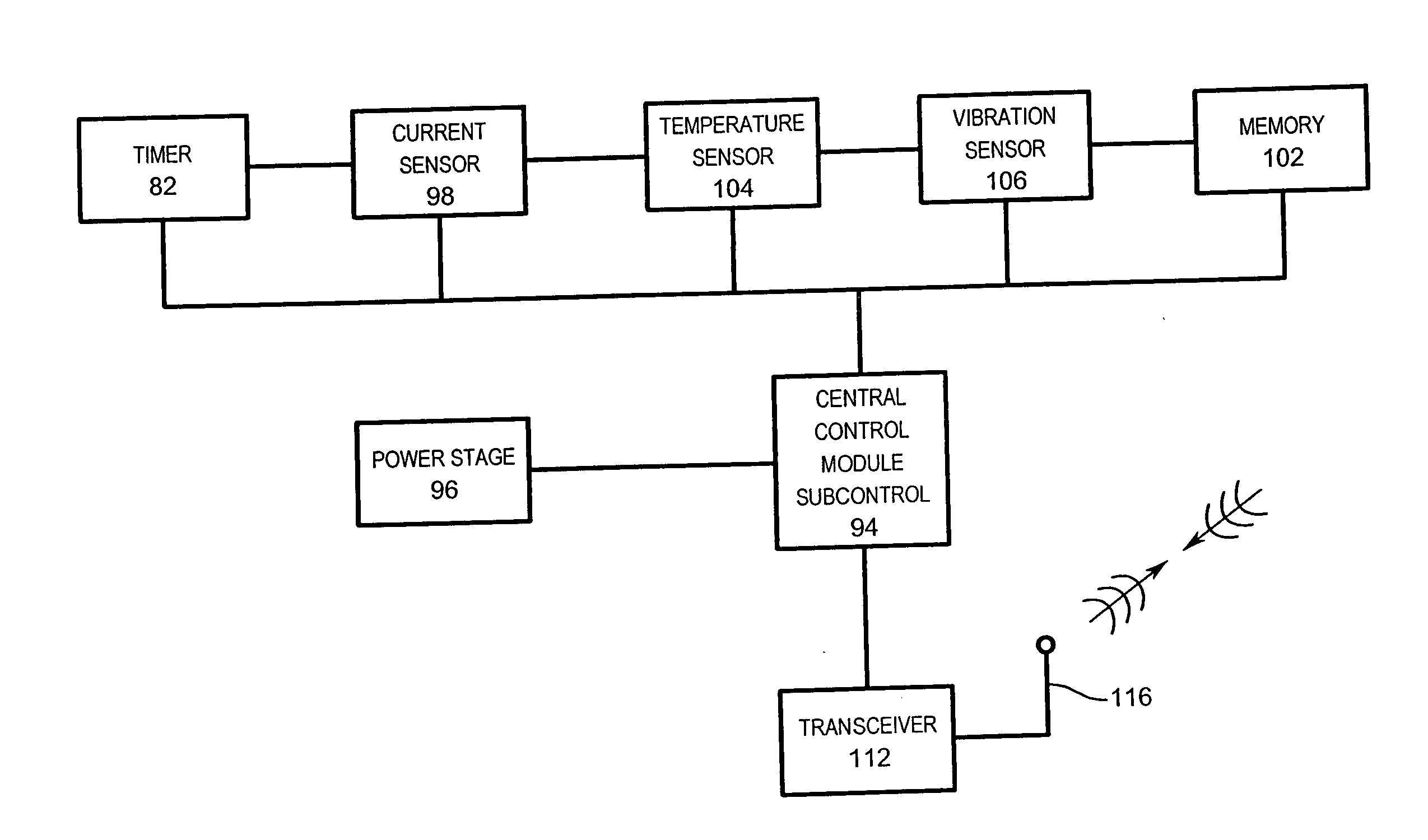

A central vacuum cleaning system control subsystem for use in a central vacuum cleaning system having a motor includes a central vacuum unit control module with a receiver for wirelessly receiving command signals, and a power stage for controlling the motor in accordance with command signals received through the receiver. The control module is stable in high ambient temperature. Current flowing to the motor is sensed, and motor overcurrent and undercurrent conditions are determined. The control module determines when the motor is in an overcurrent condition. Power stage has a triac for controlling power to the motor. The control module also has a microprocessor that compares the current sensed against a normal operating current to determine overcurrent condition. Power to motor ceases when overcurrent condition exists. A generator is powered by air flow in a cleaning system for production of electrical energy.

Owner:CUBE INVESTMENTS

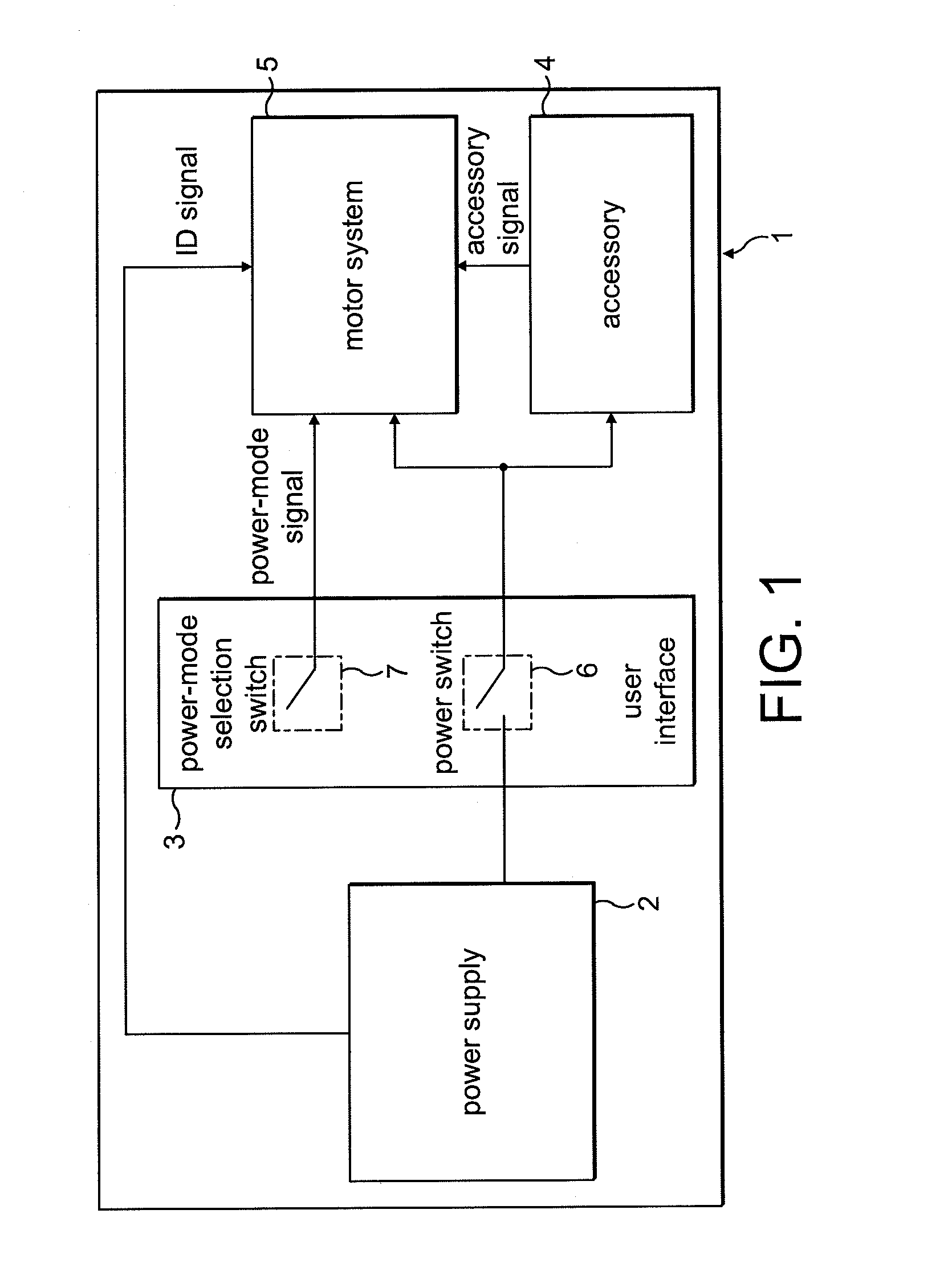

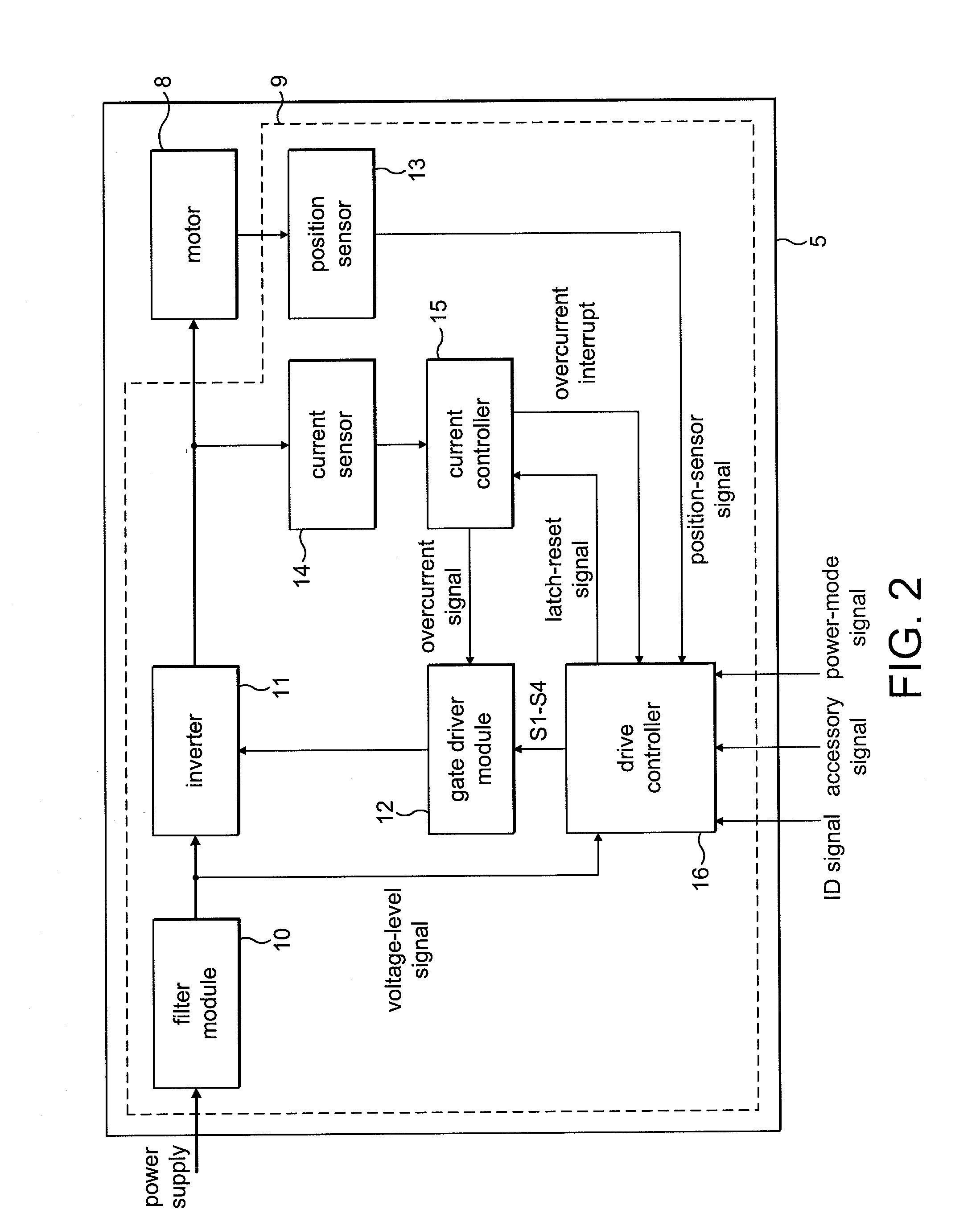

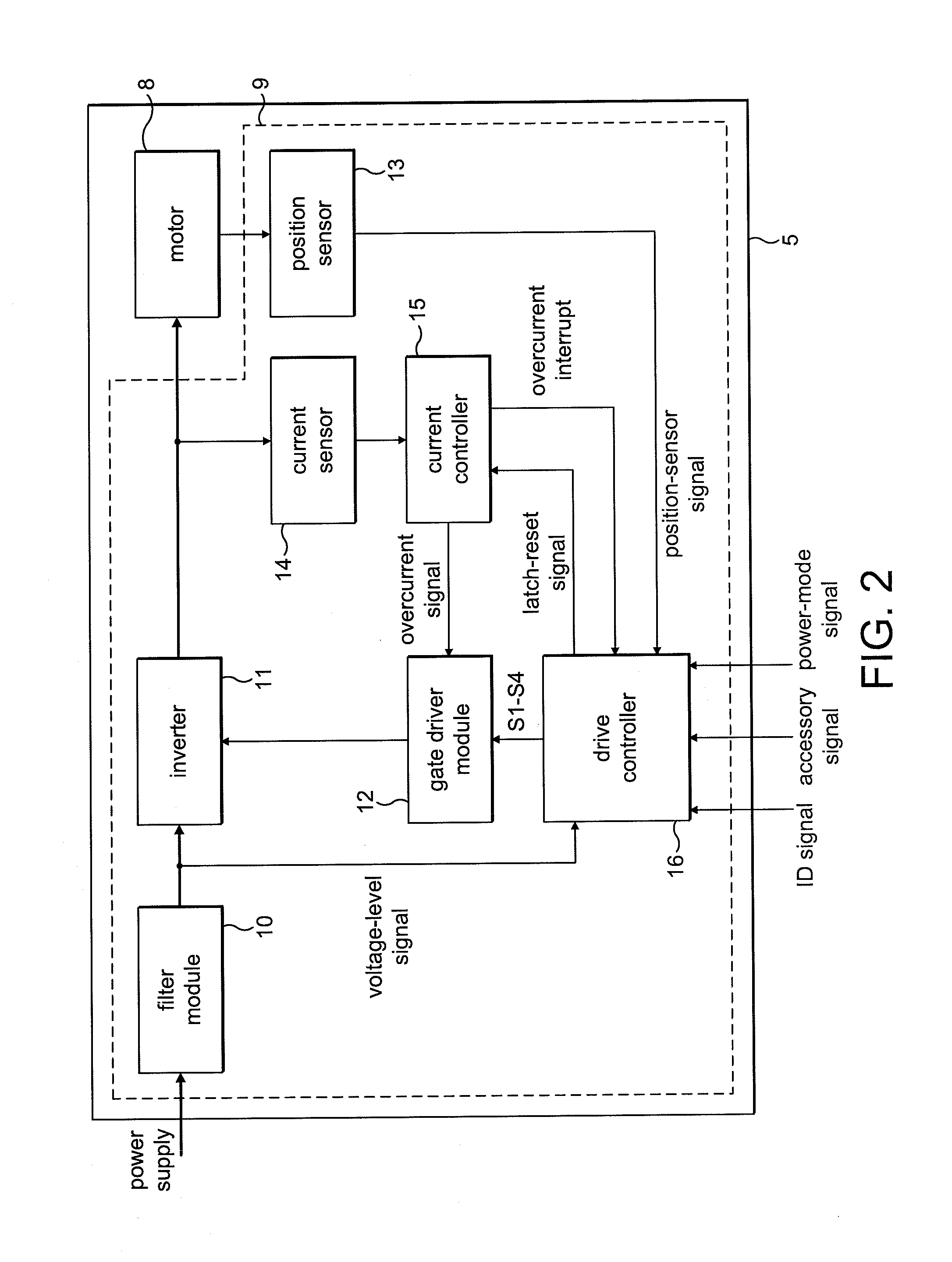

Control of an electric machine

ActiveUS20100253264A1Increase powerLess torqueTorque ripple controlMotor/generator/converter stoppersFreewheelControl system

A method of controlling an electric machine that includes sequentially exciting and freewheeling a winding of the electric machine. The winding is excited in advance of zero-crossings of back emf in the winding by an advance angle, and the winding is freewheeled over a freewheel angle. The method then includes varying the advance angle and the freewheel angle in response to changes in the speed of the electric machine. Additionally, a control system for an electric machine, and a product incorporating the control system and electric machine.

Owner:DYSON TECH LTD

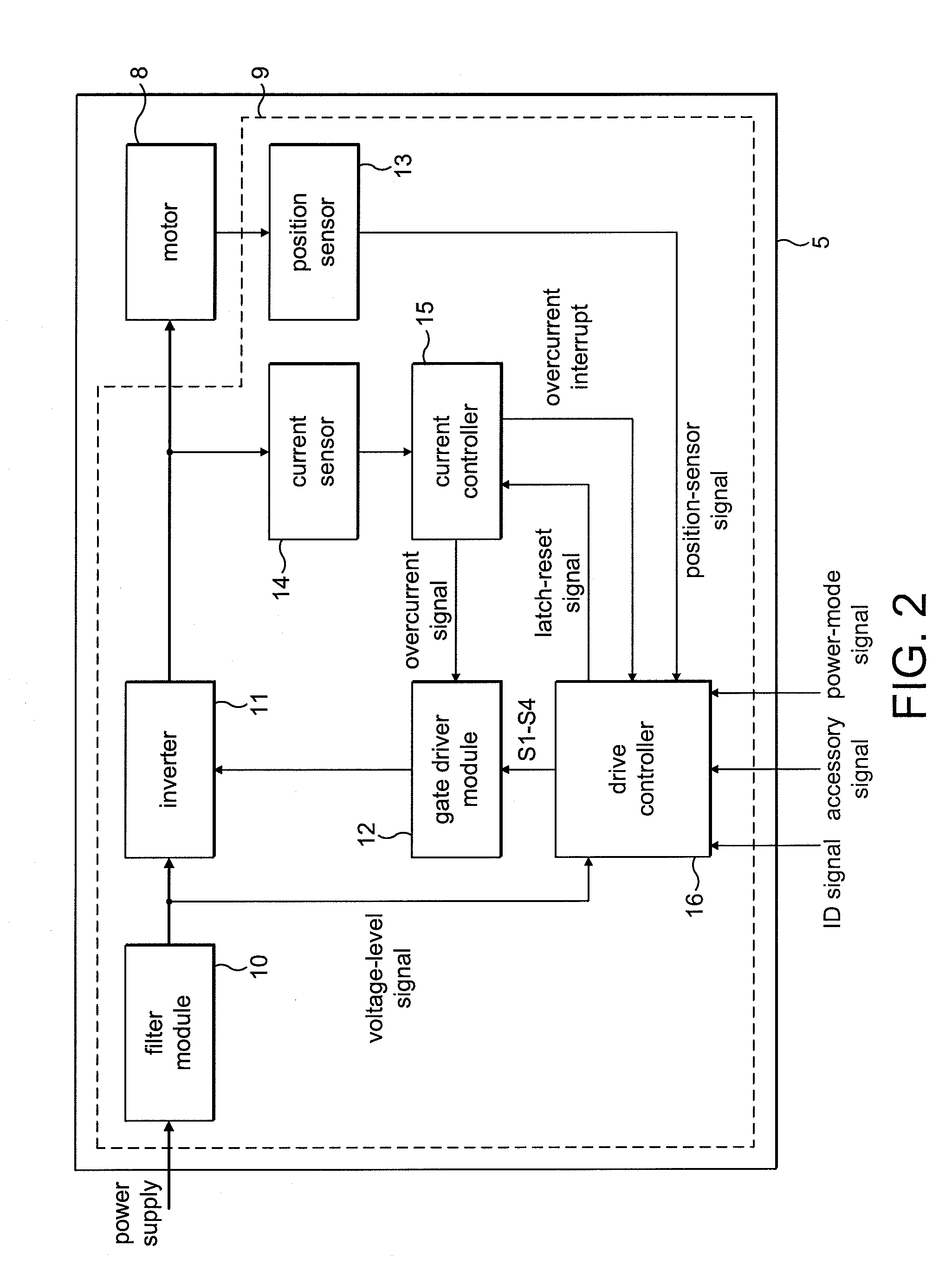

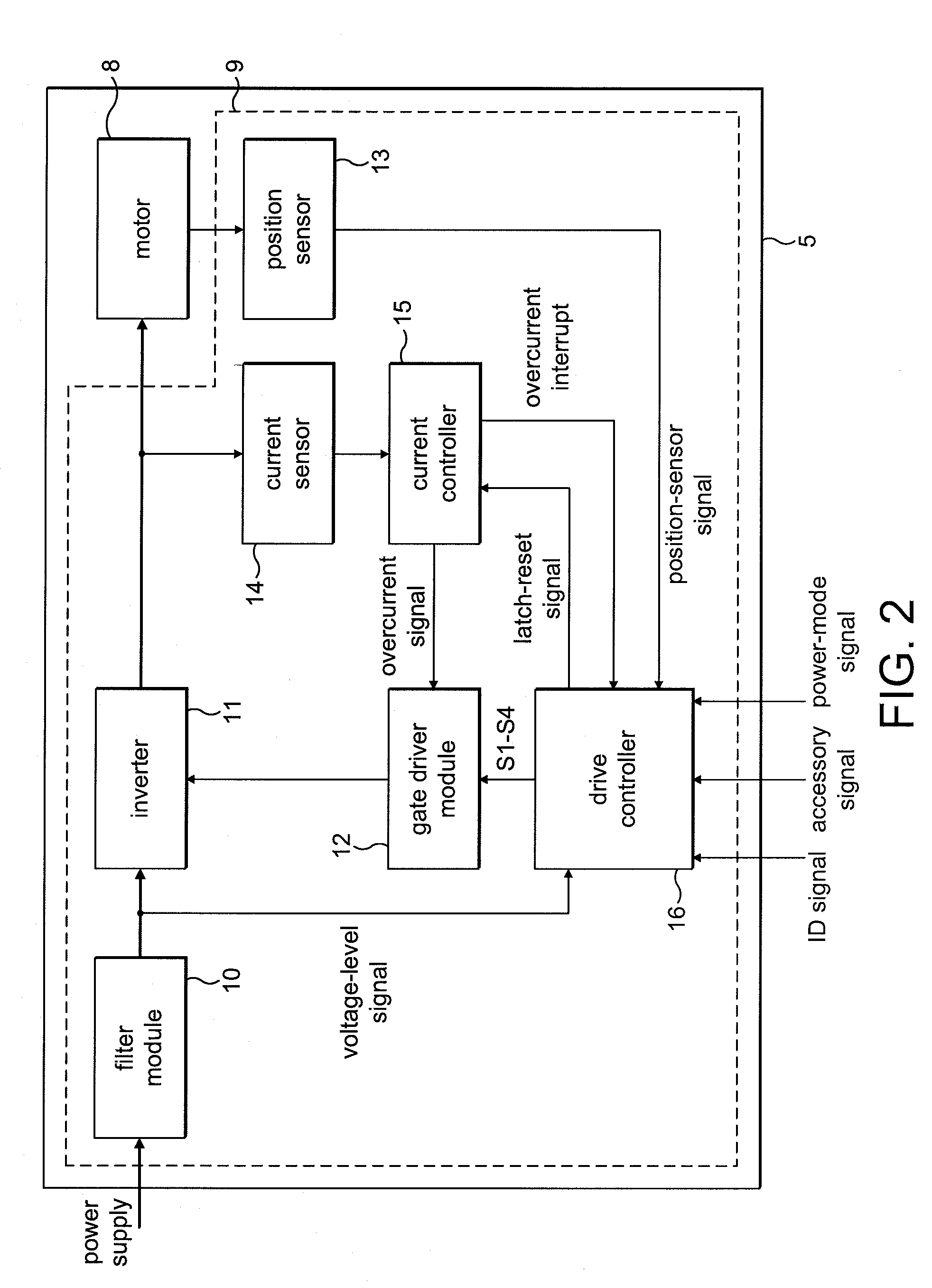

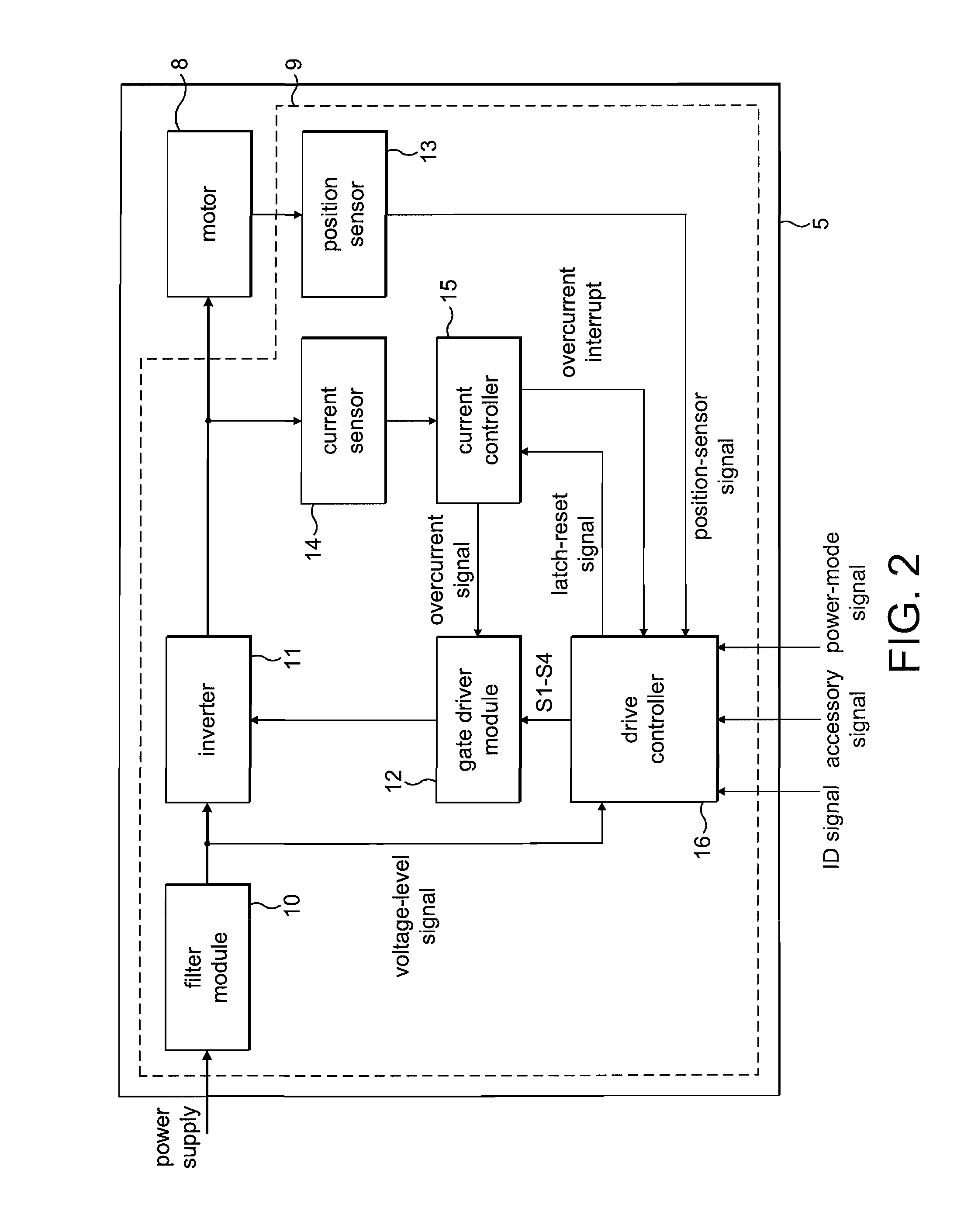

Electronic control system for a vacuum system

A programmable control unit for a vacuum cleaning system, such as central vacuum cleaning system. A control unit is programmed after manufacture to execute a particular control program for performing various diagnostic and operational functions including user interface, voltage level detecting, voltage monitoring, current monitoring, user interface, power supply control, temperature monitoring, AC line frequency detection, operation data recording, speed control program selection, expansion bus interface and service tool interface. Power control to the vacuum motor is facilitated by the control unit directly through a triode for alternating current (TRIAC). Manufacturing costs are reduced by producing a single programmable control unit that can be programmed with a control program corresponding to a variety of different vacuum cleaning devices across a manufacturer's product line.

Owner:ELECTROLUX HOME CARE PRODS

Control of an electric machine

ActiveUS20100253265A1Good control over powerConvenient power controlSynchronous motors startersVacuum cleaner apparatusFreewheelElectric machine

A method of controlling an electric machine that includes sequentially exciting and freewheeling a winding of the electric machine. The winding is excited in advance of zero-crossings of back emf in the winding by an advance angle, and the winding is freewheeled over a freewheel angle. The method then includes varying the advance angle and the freewheel angle in response to changes in the voltage used to excite the winding. Additionally, a control system for an electric machine, and a product incorporating the control system and electric machine.

Owner:DYSON TECH LTD

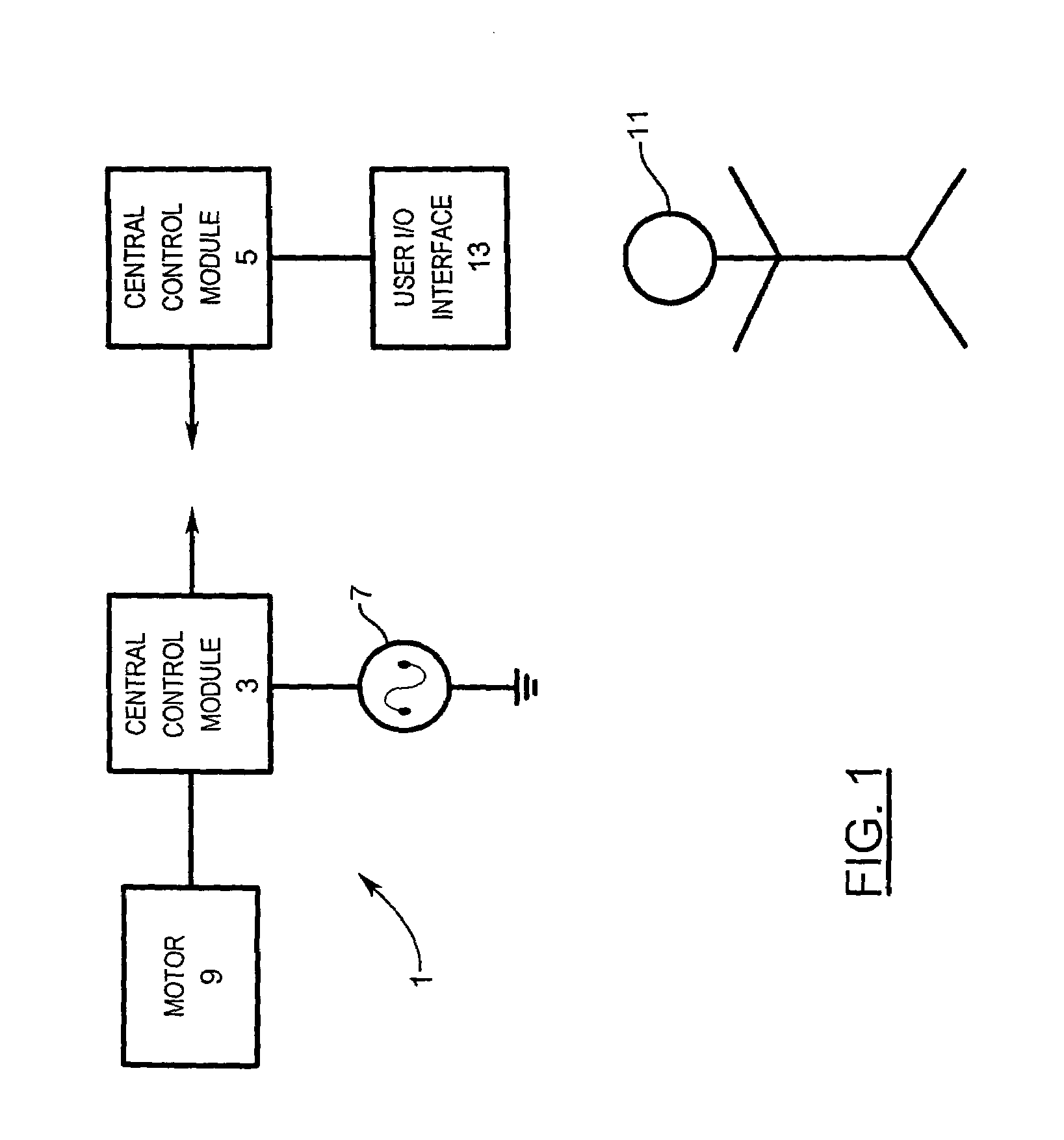

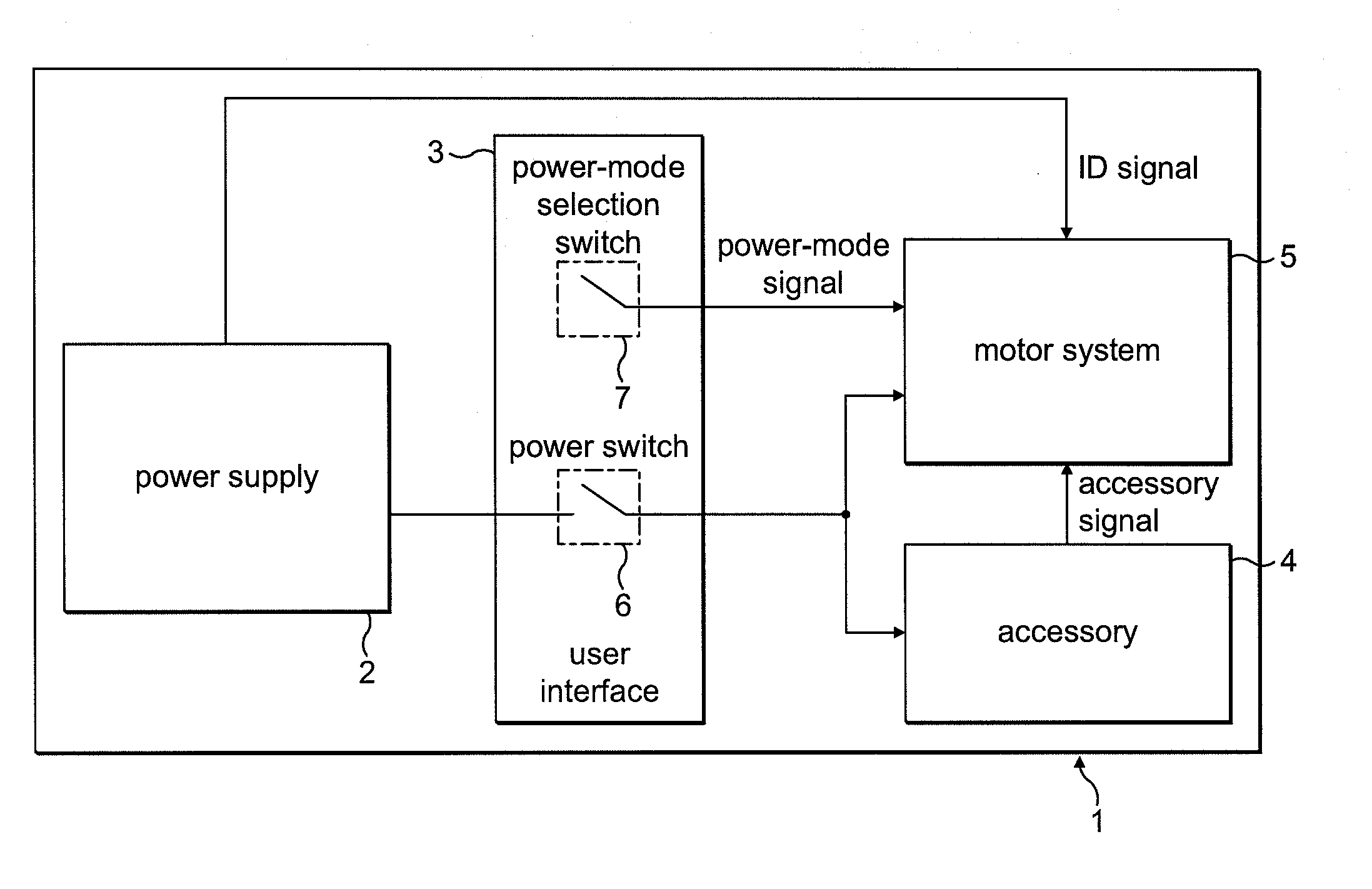

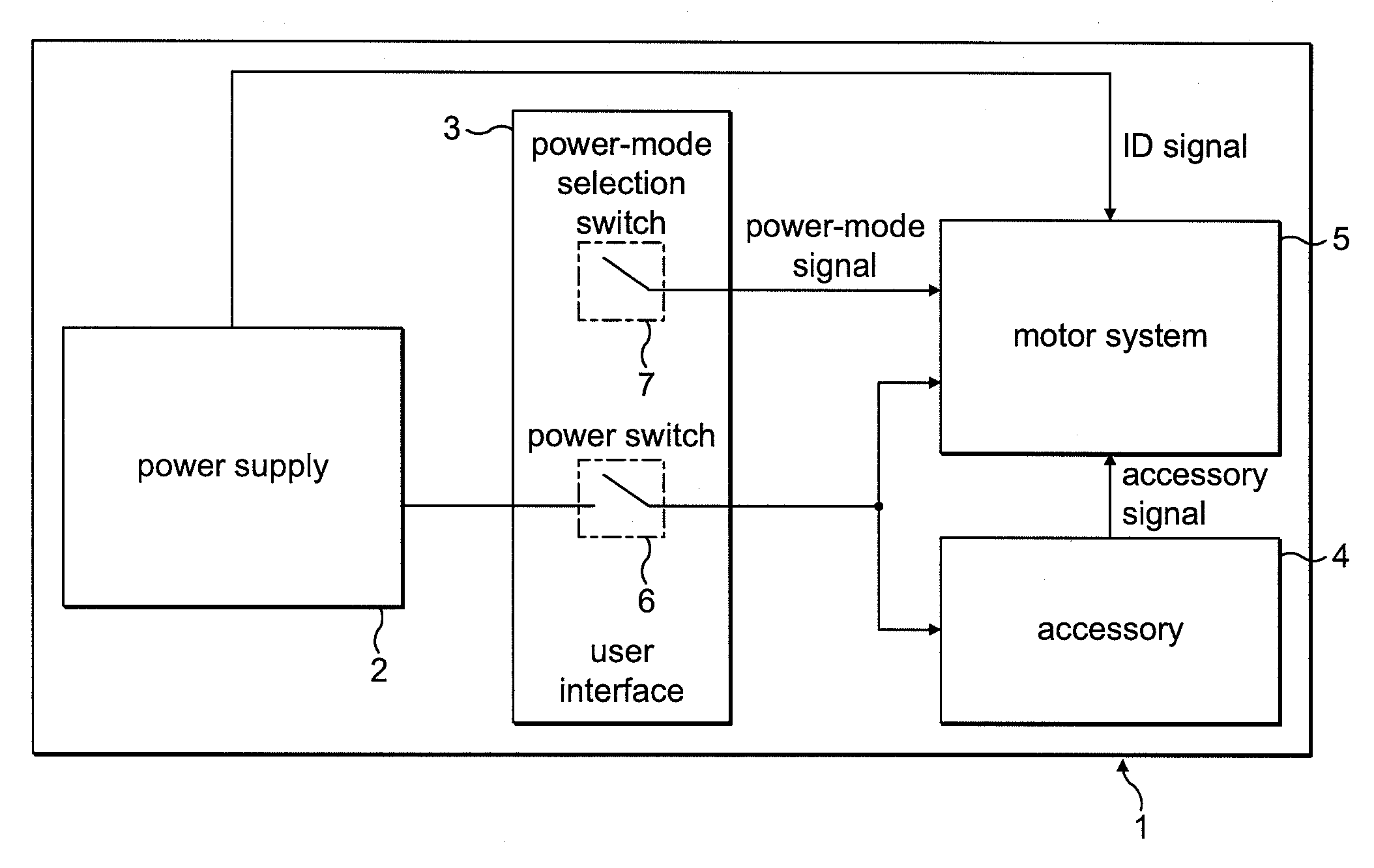

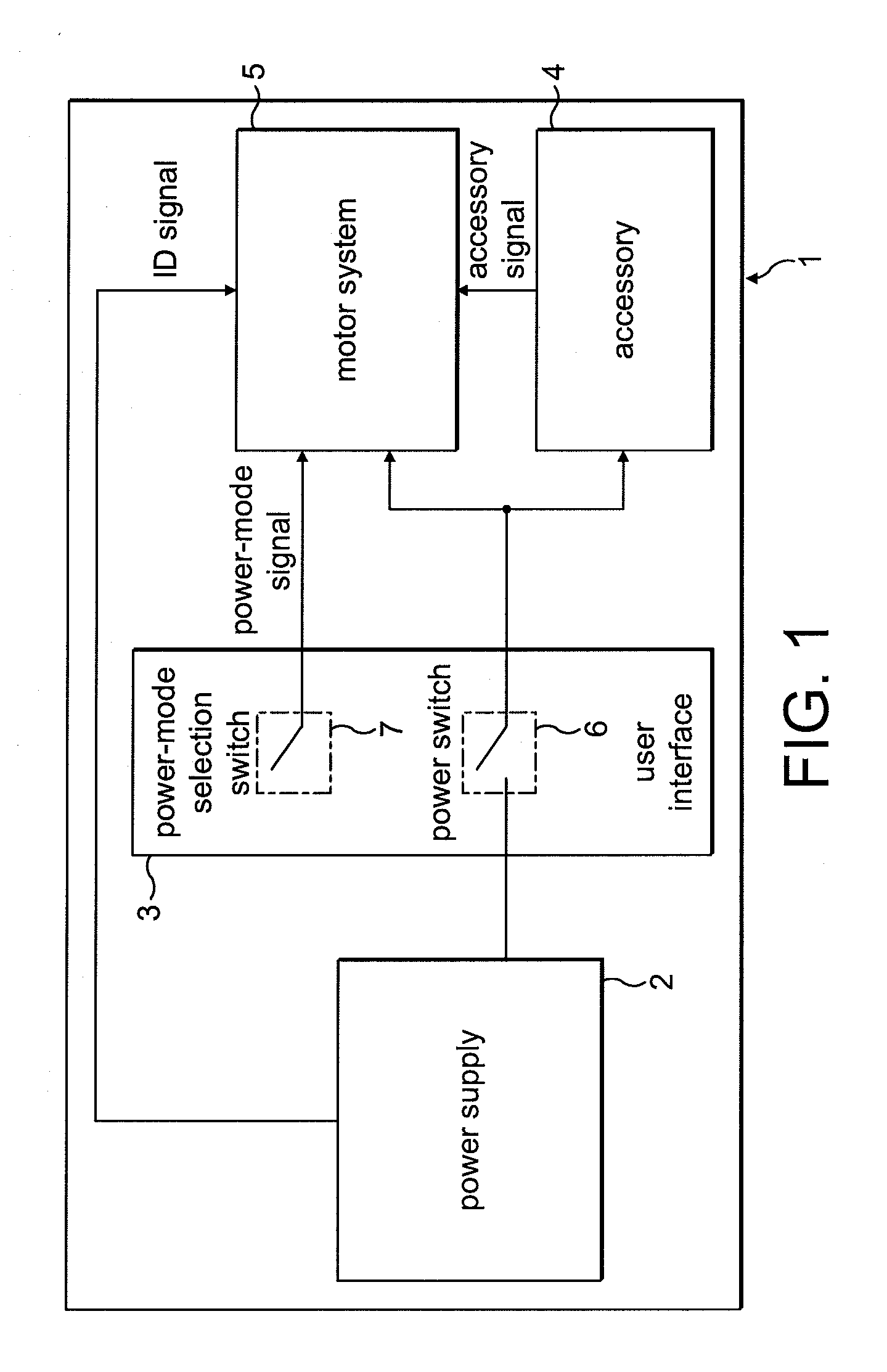

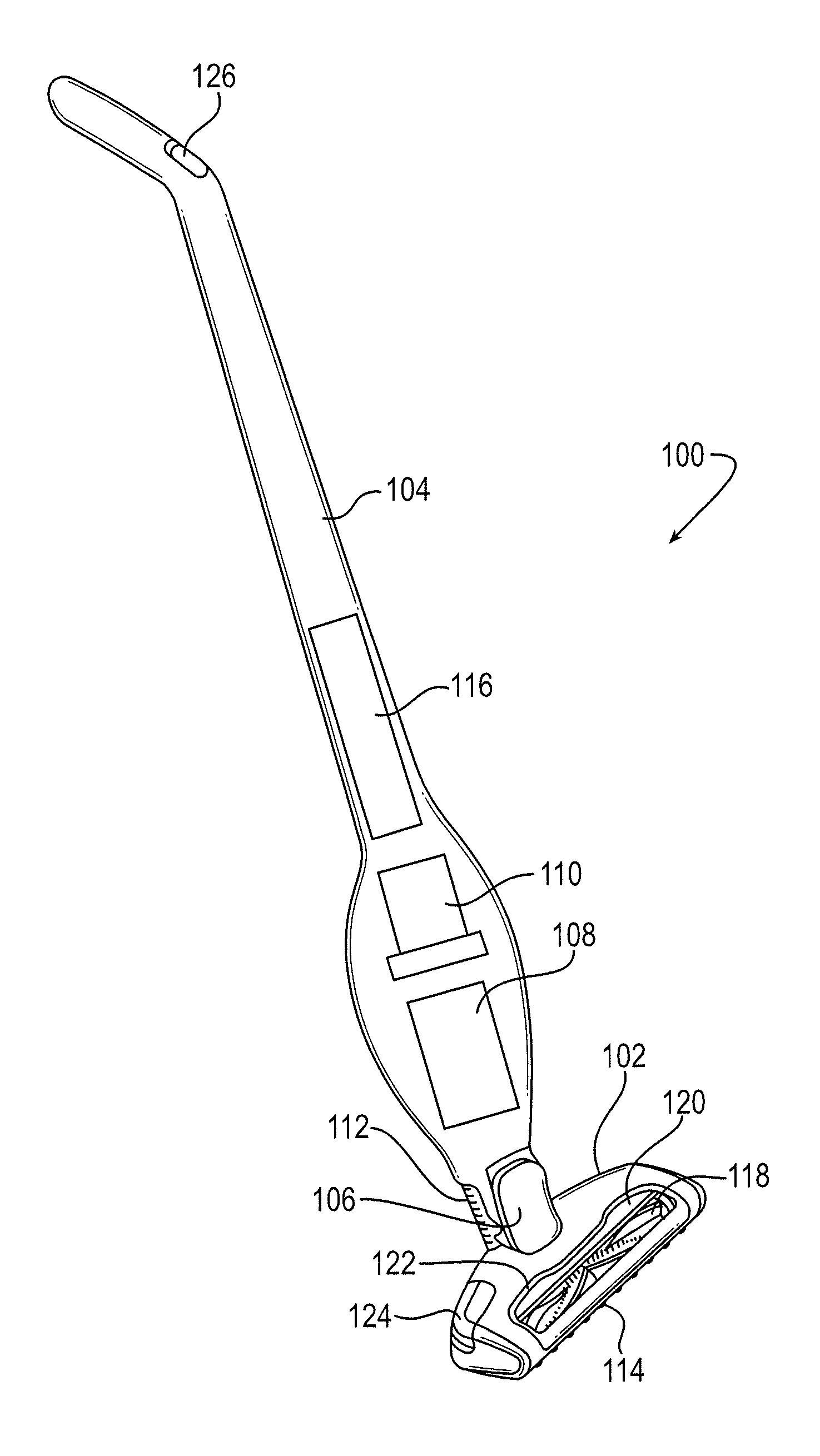

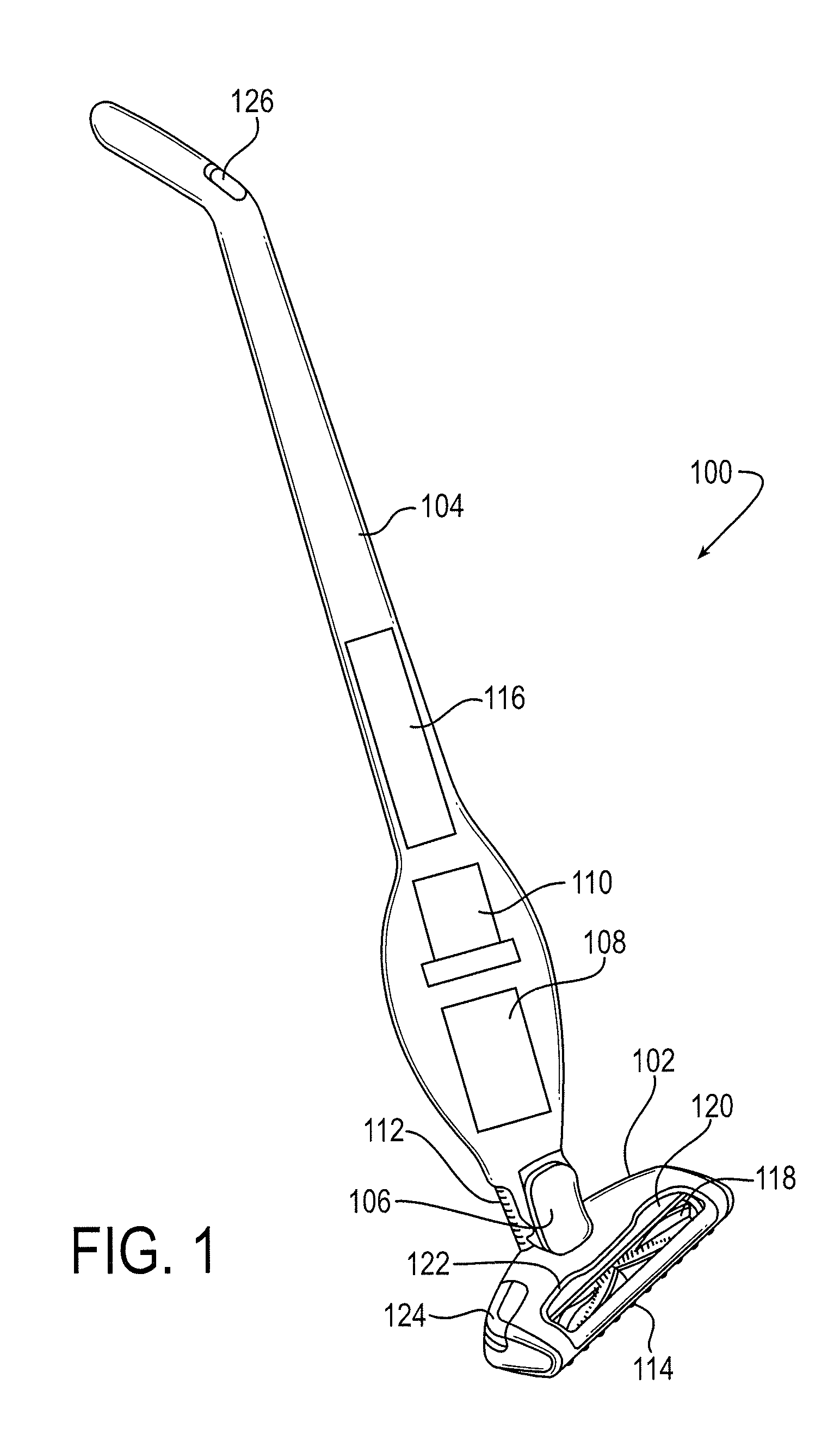

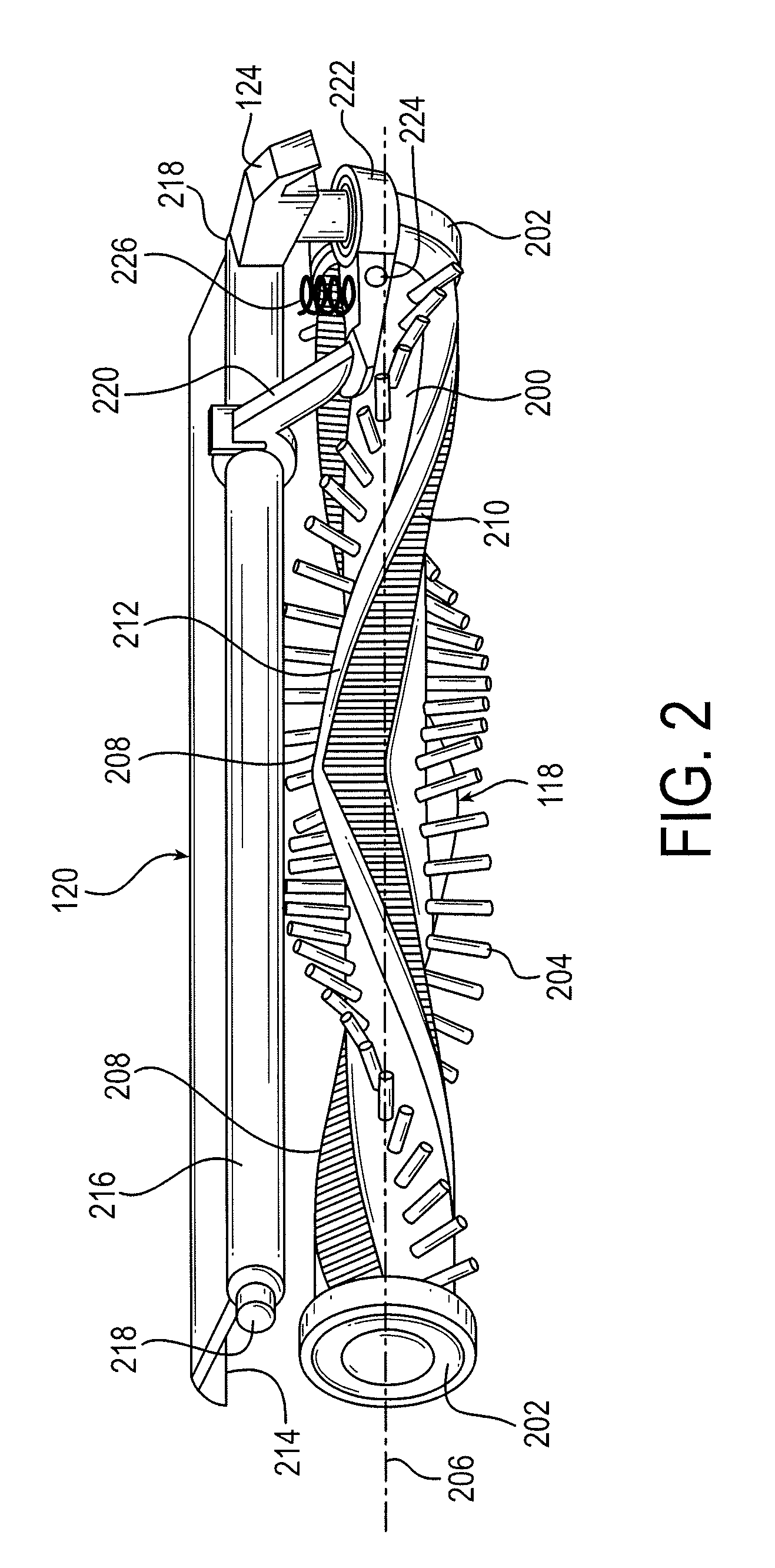

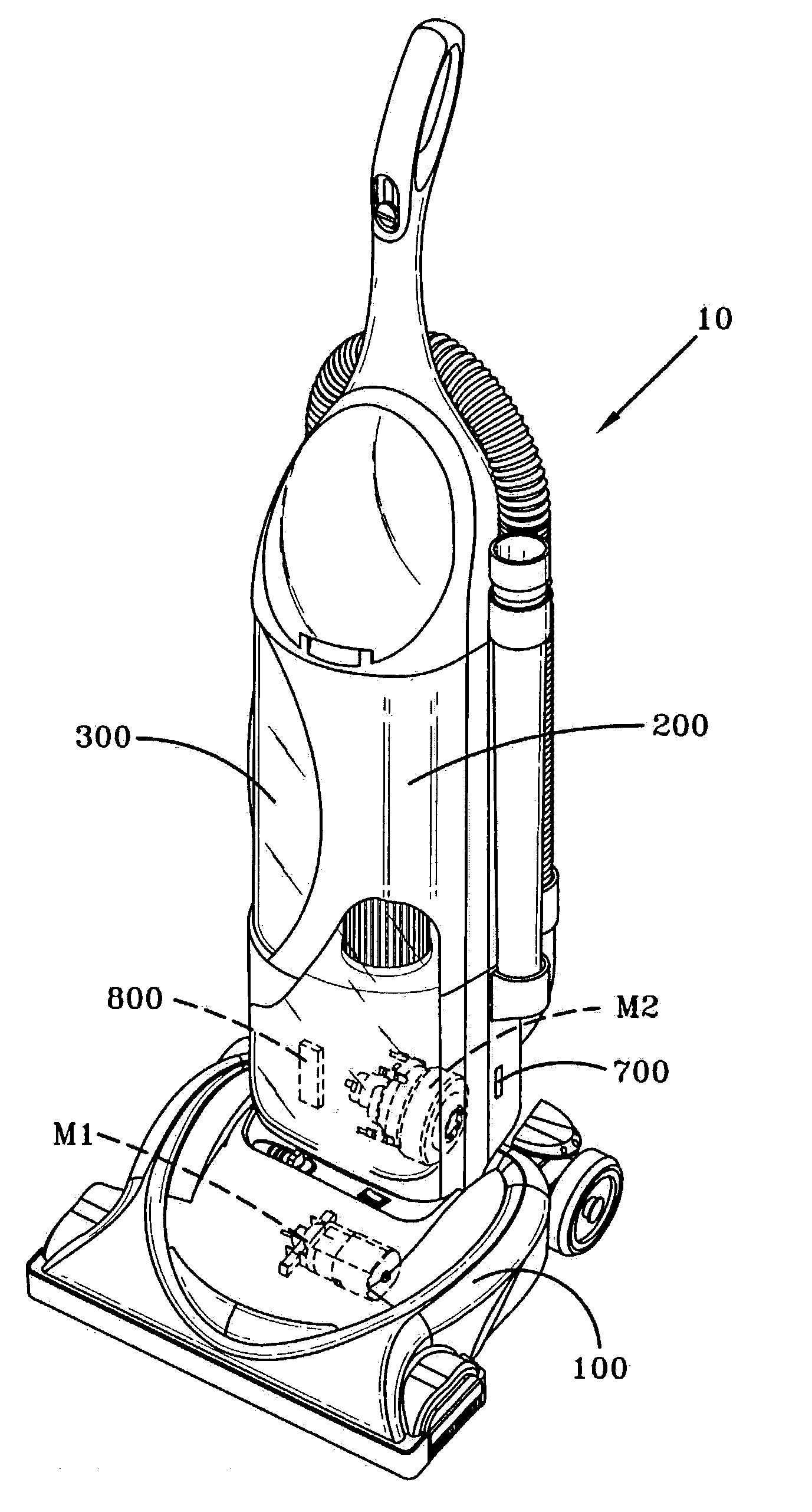

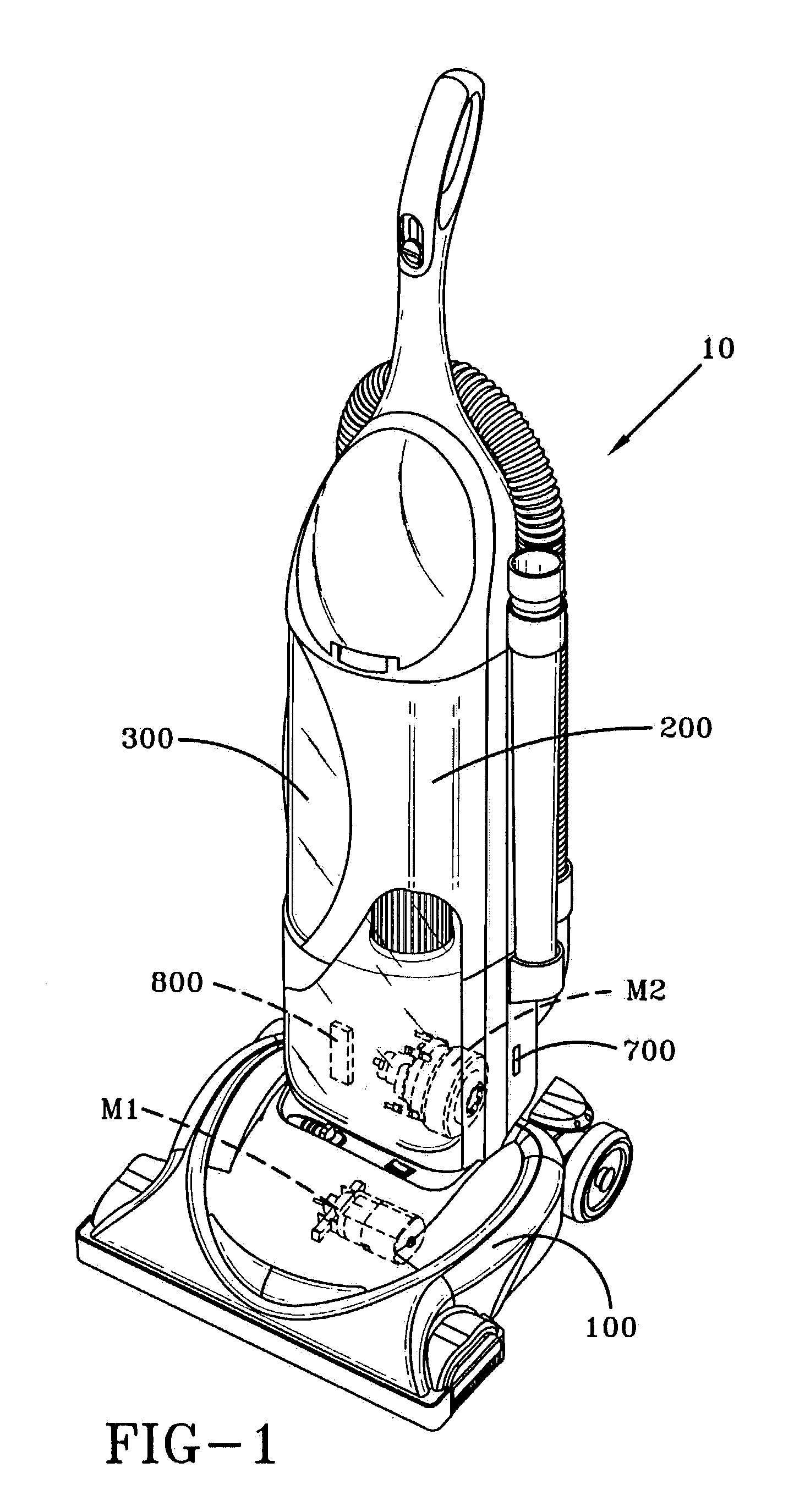

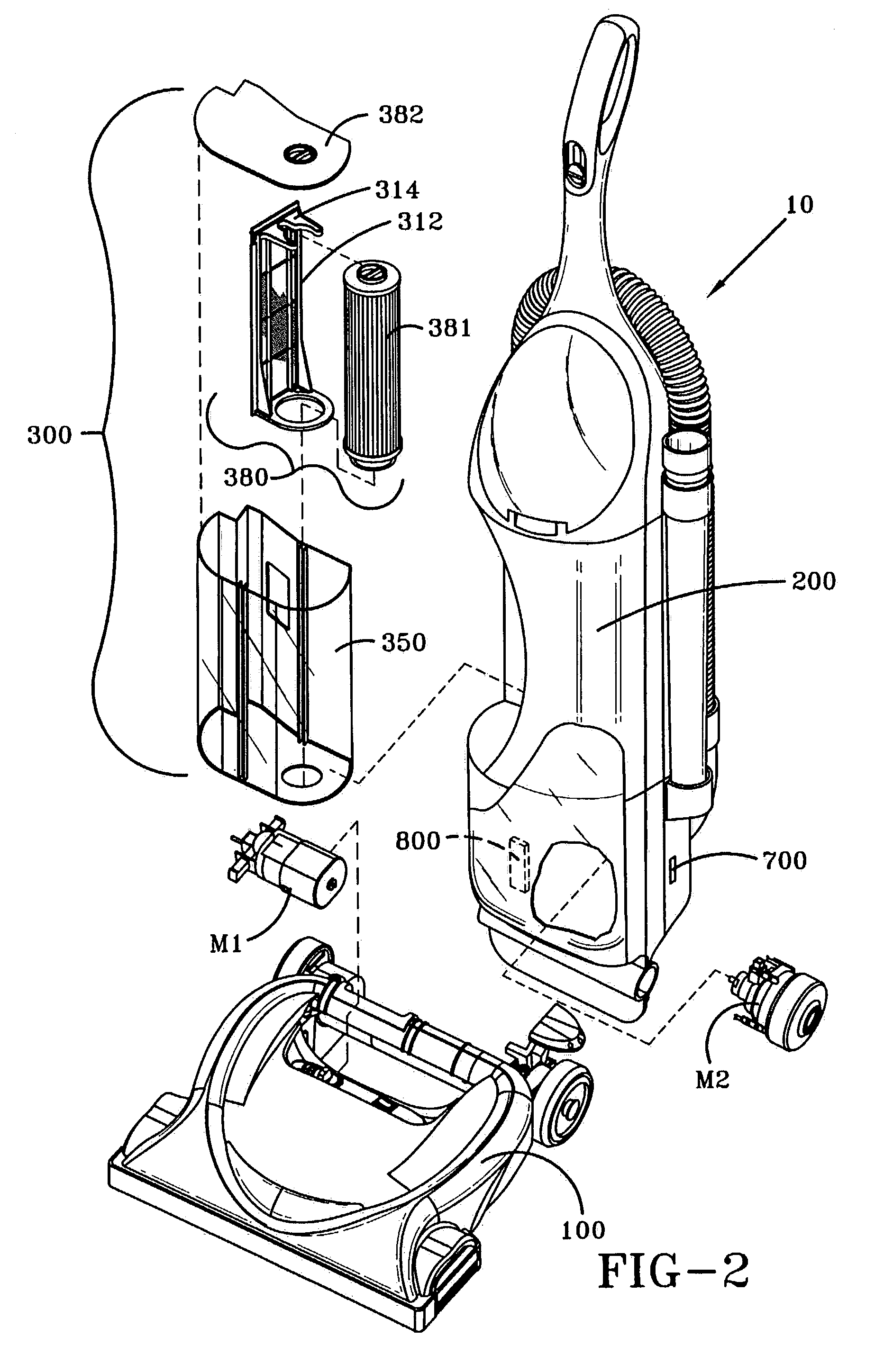

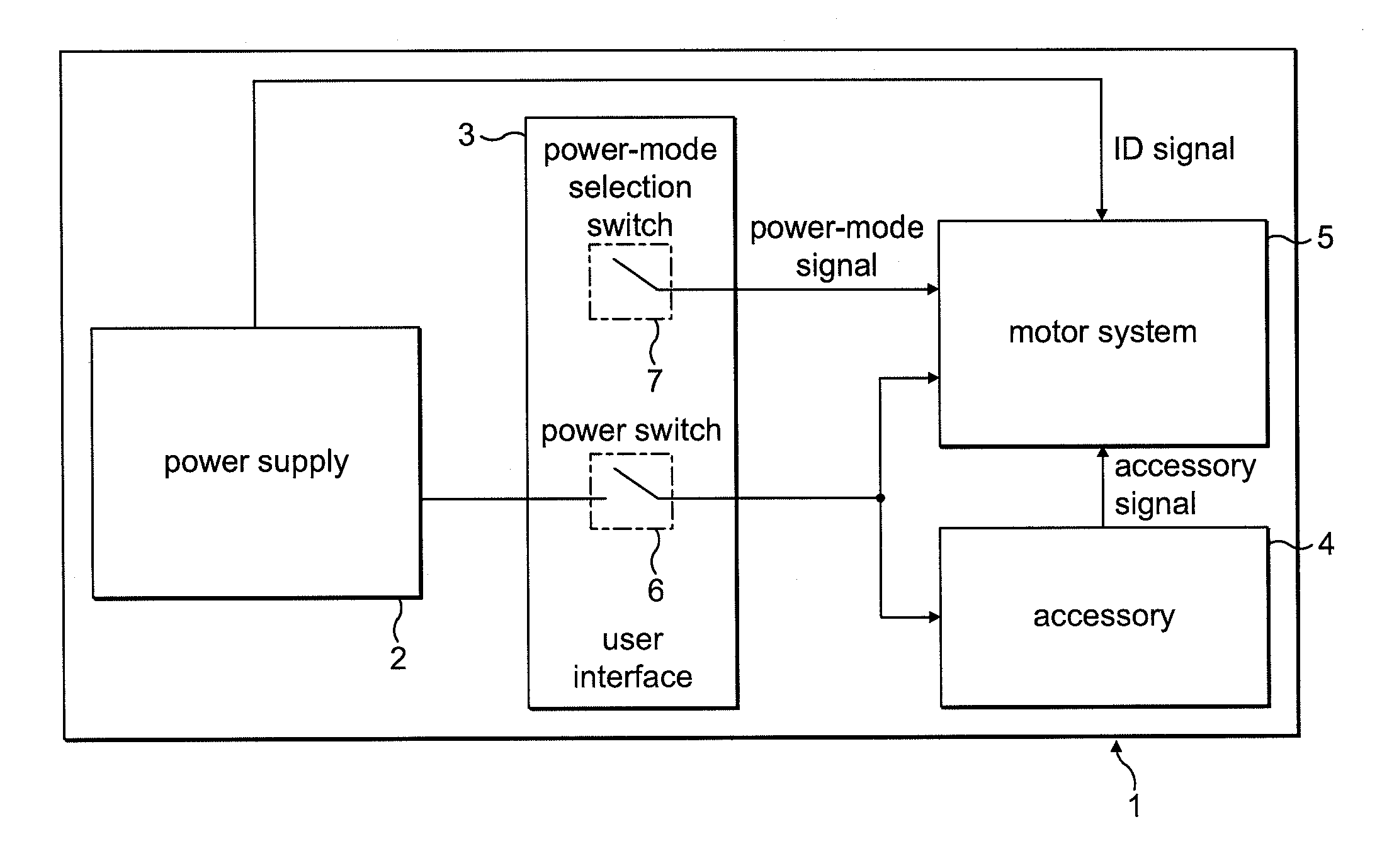

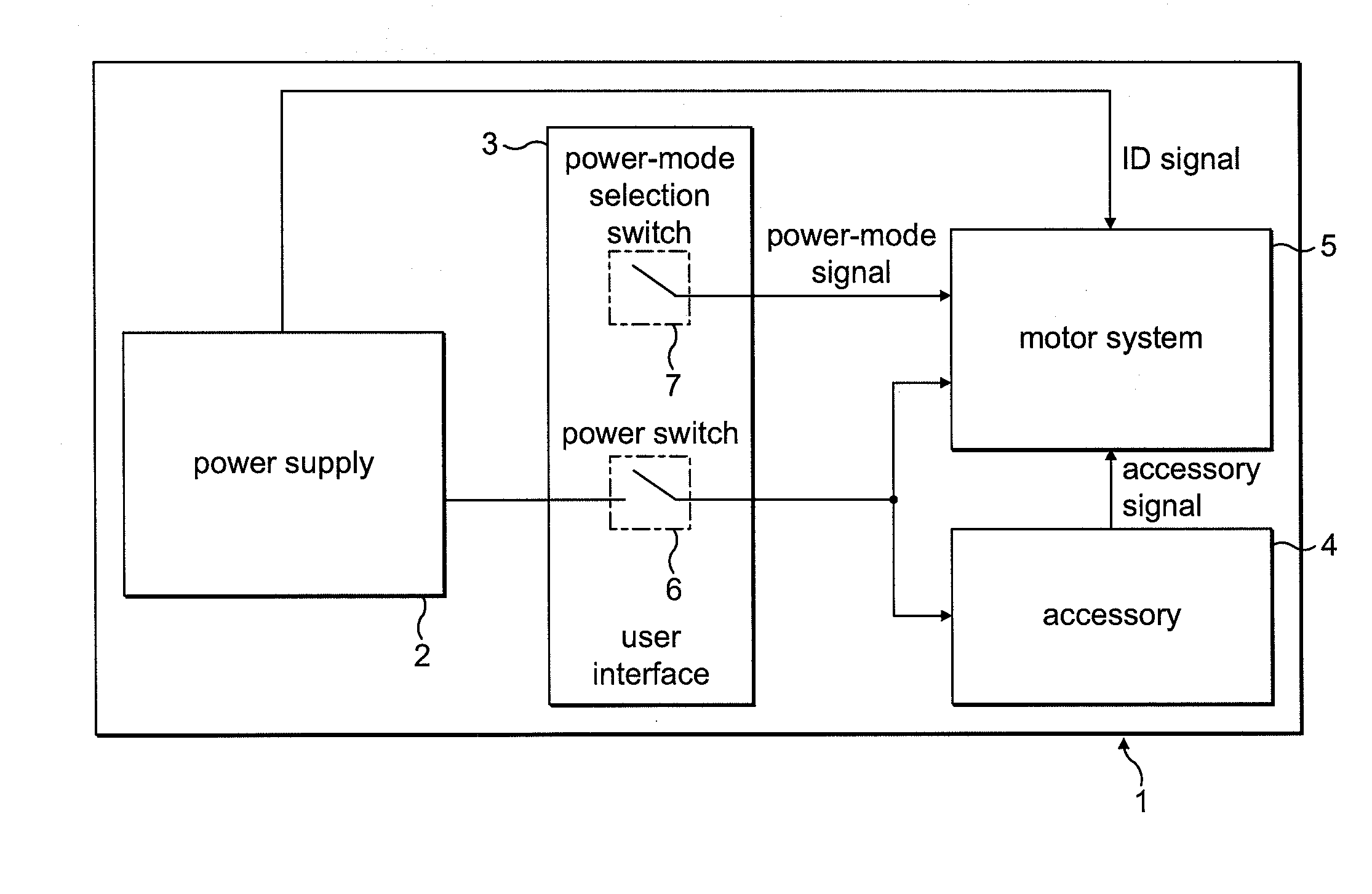

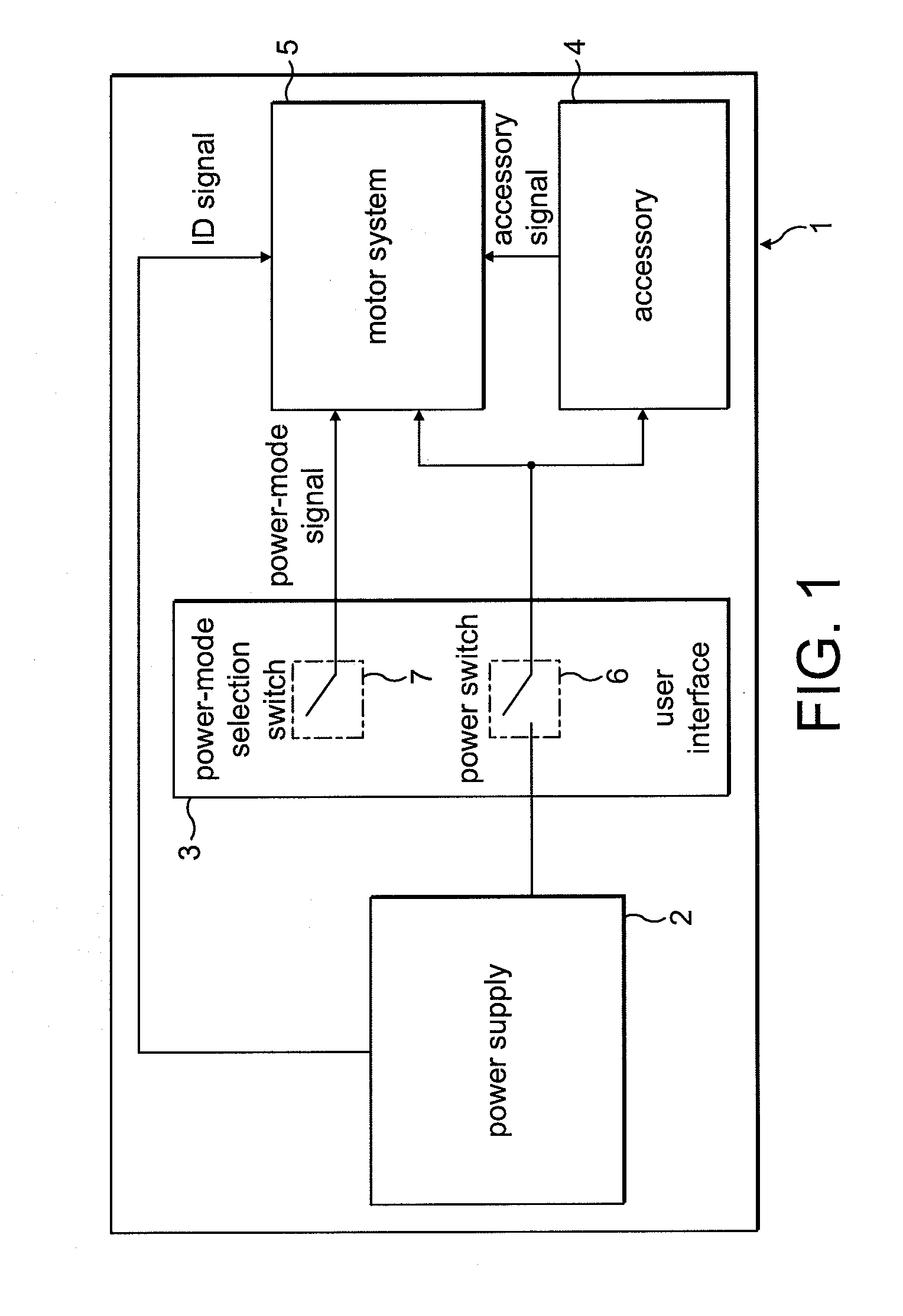

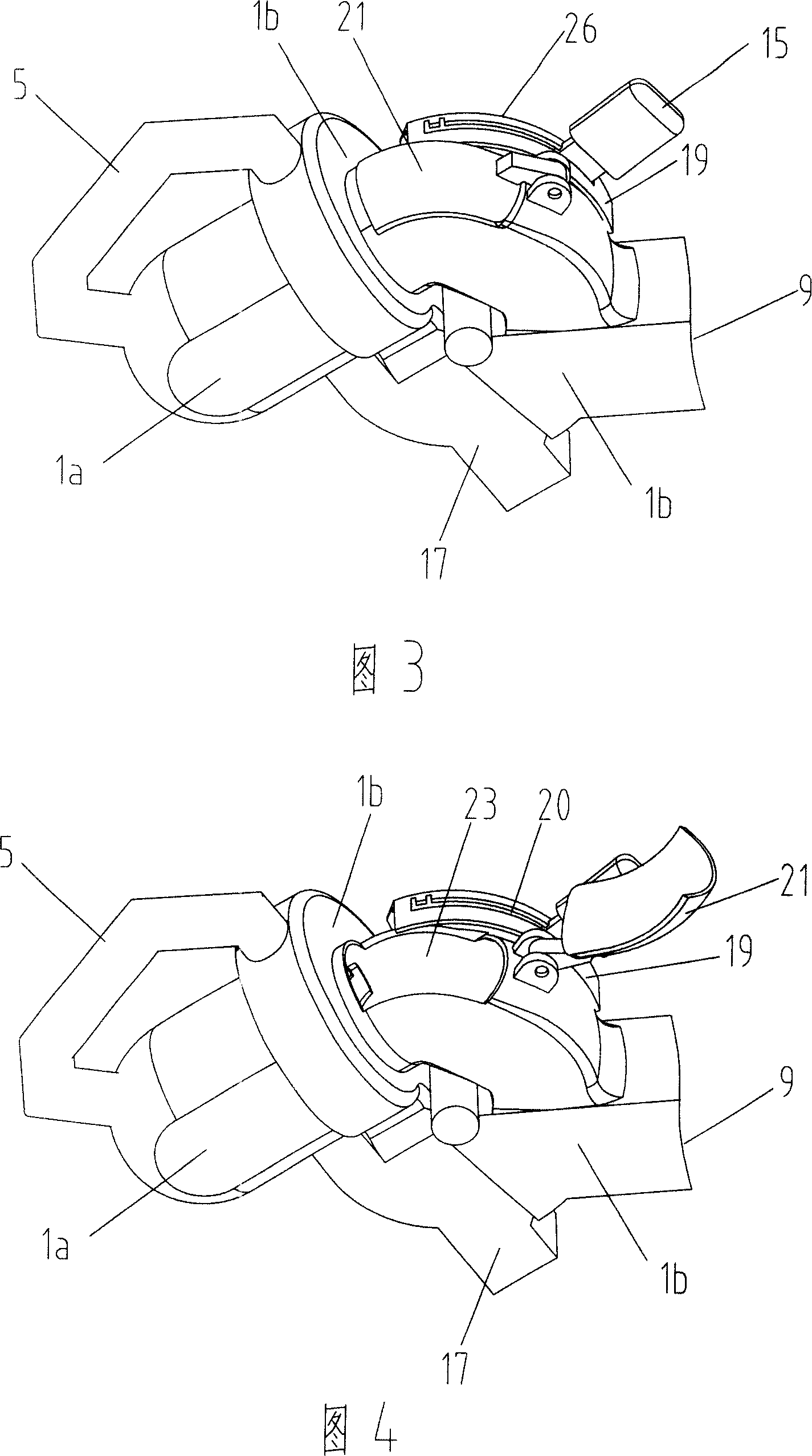

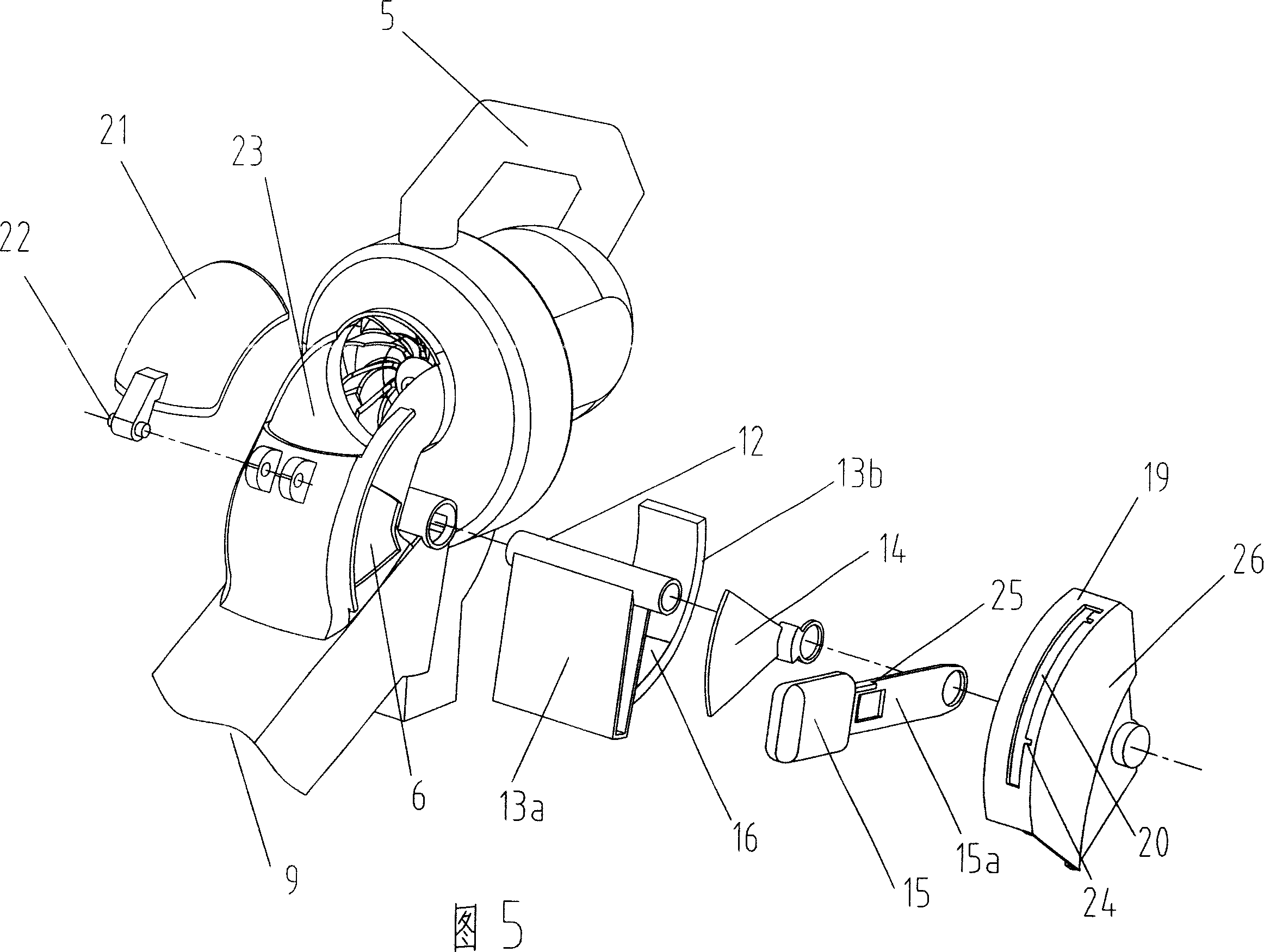

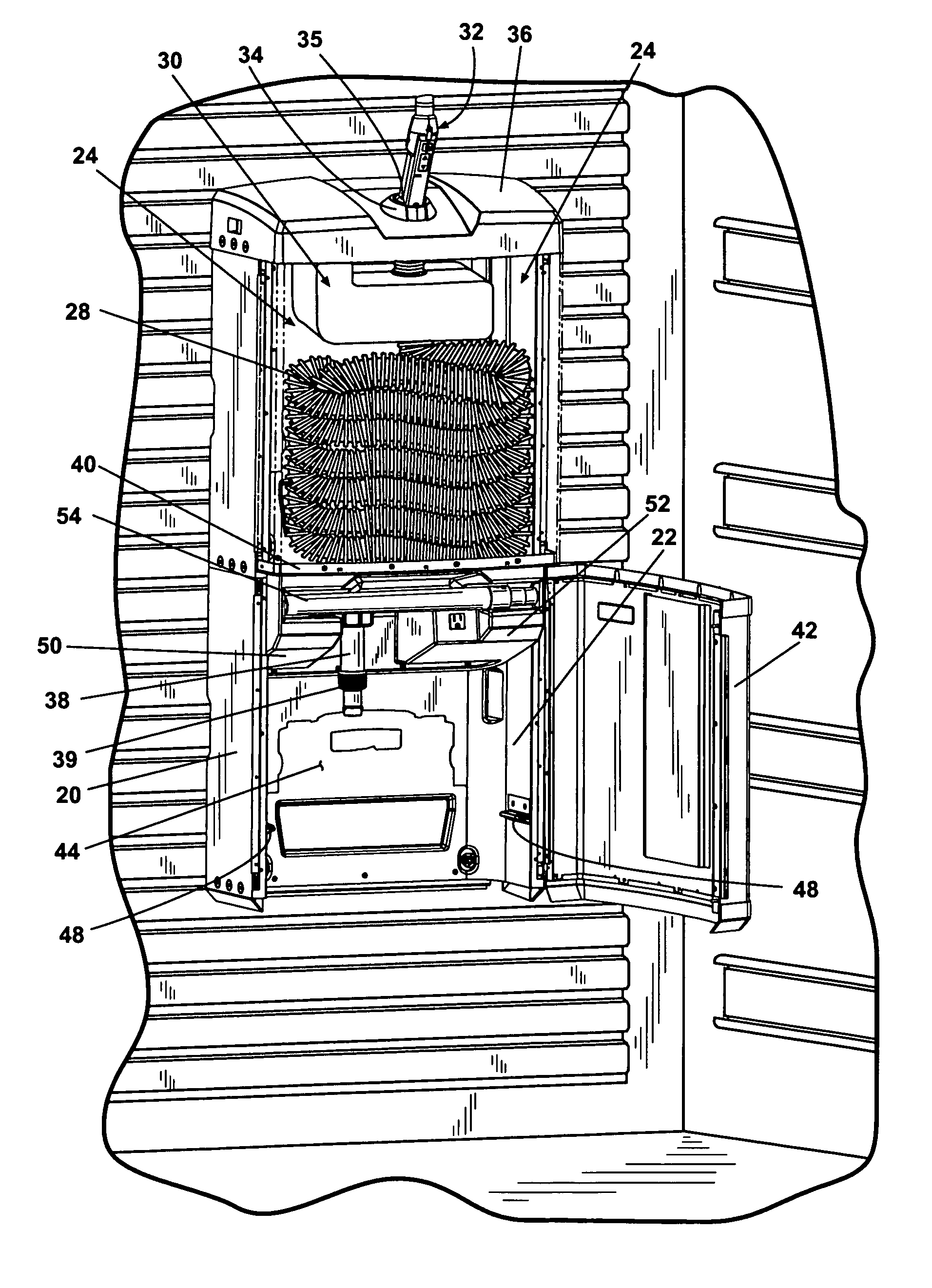

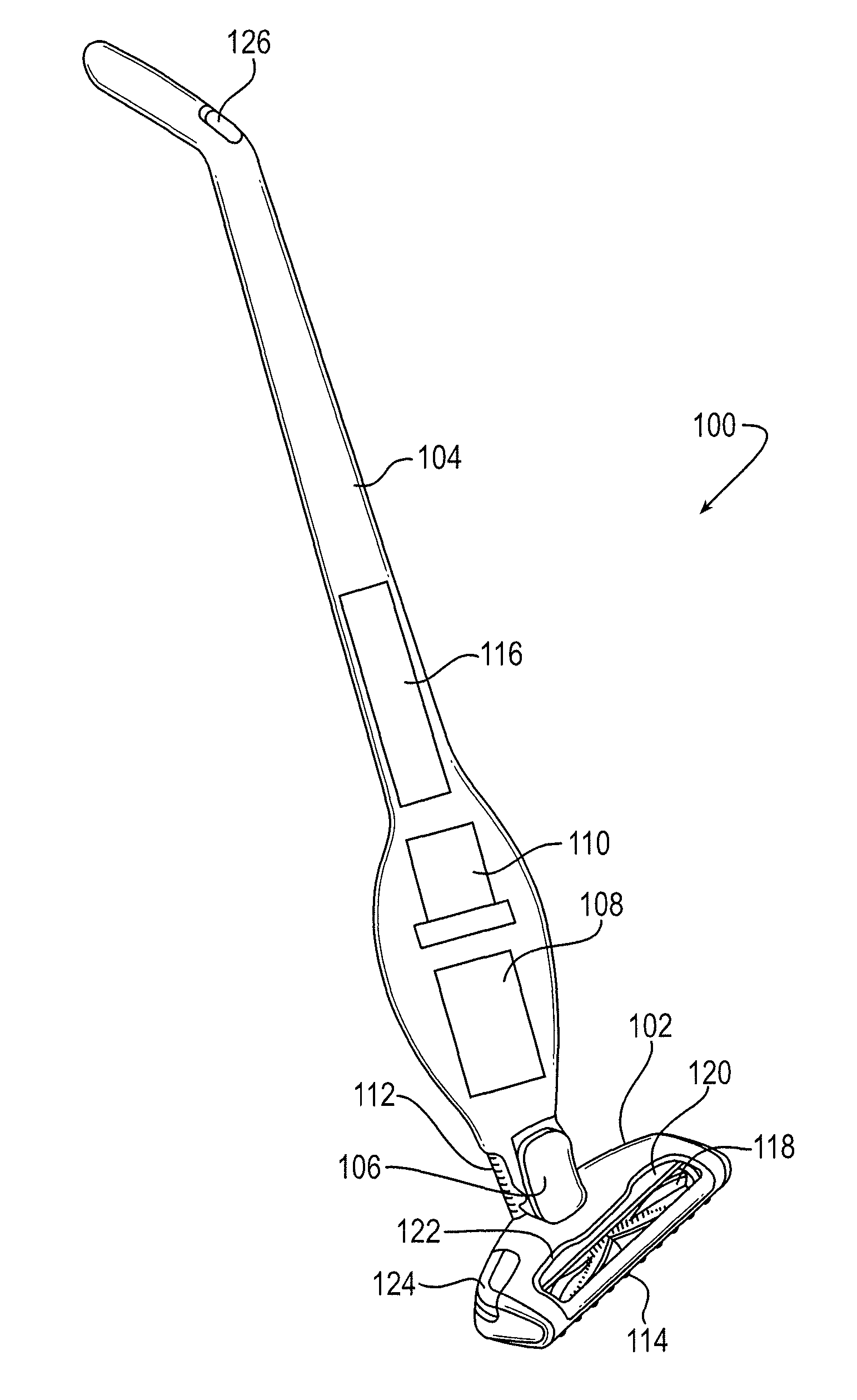

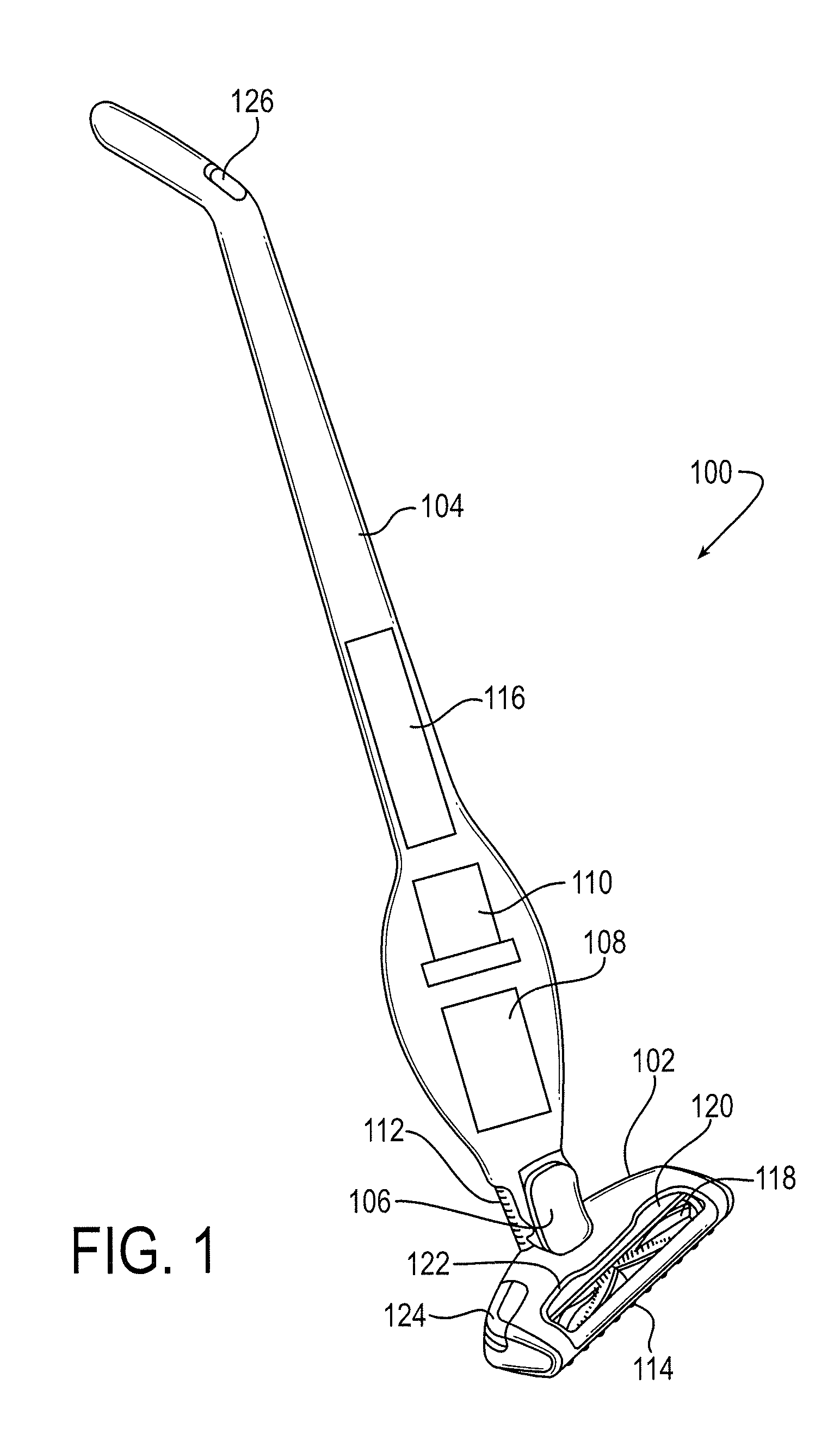

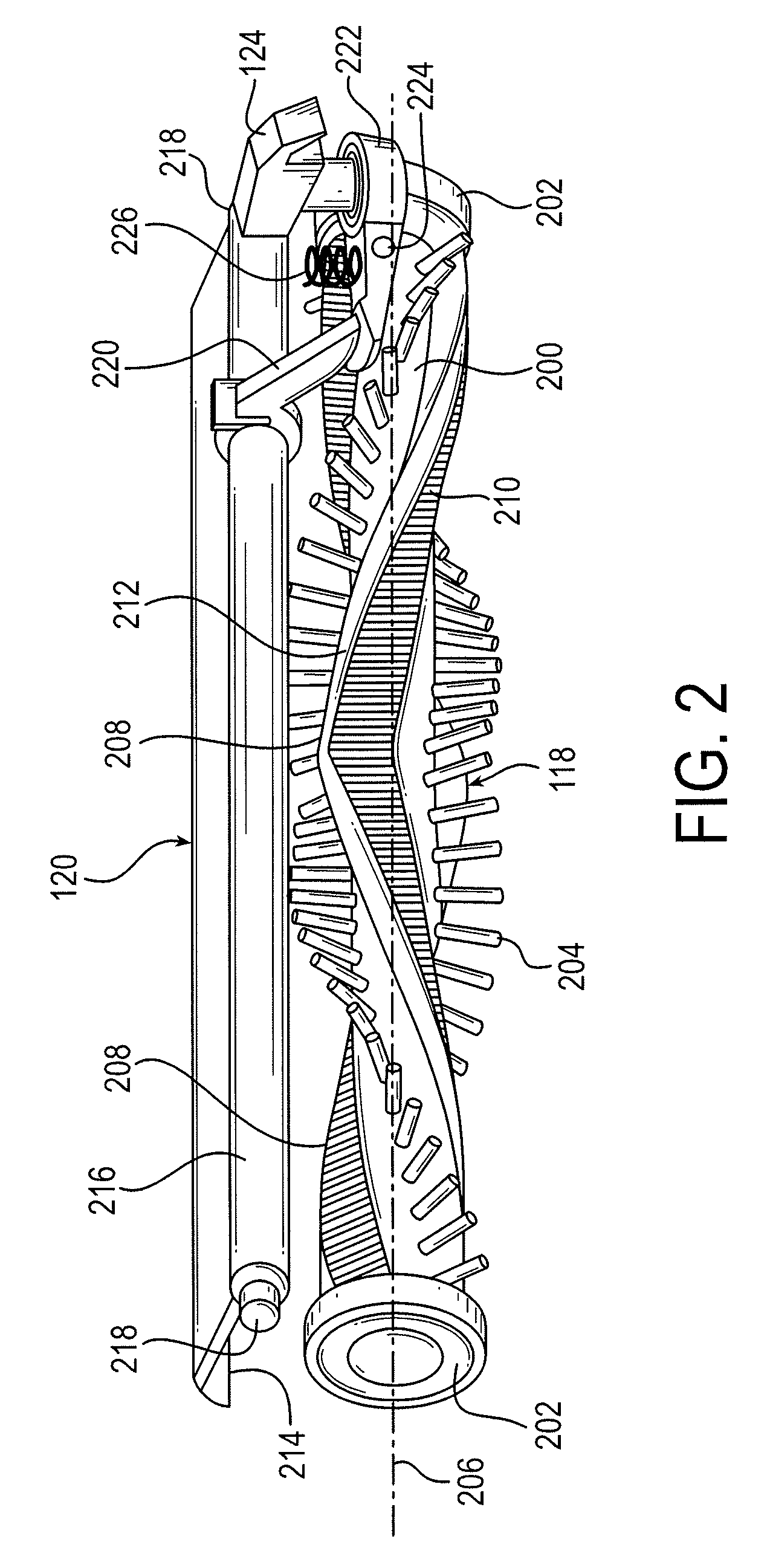

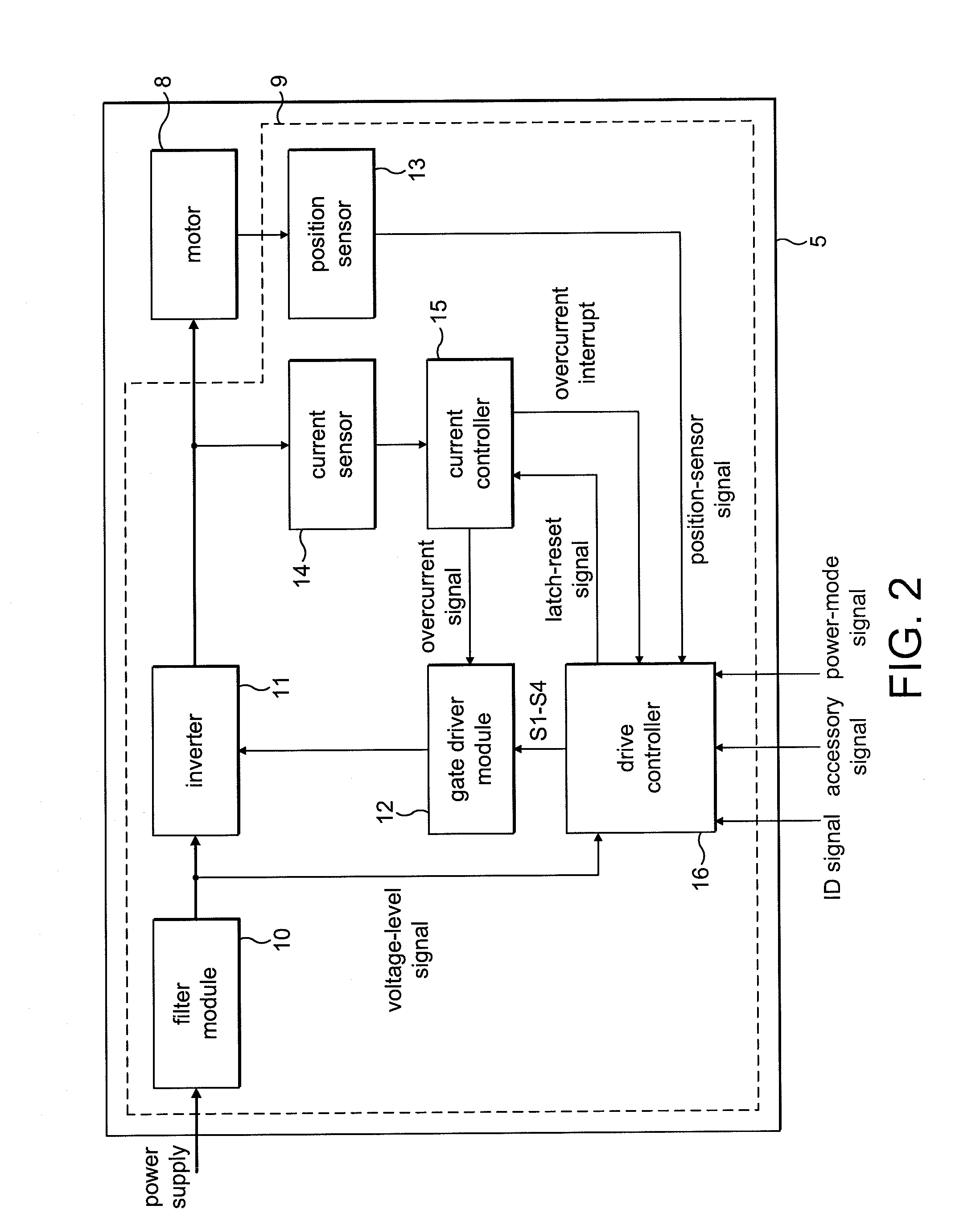

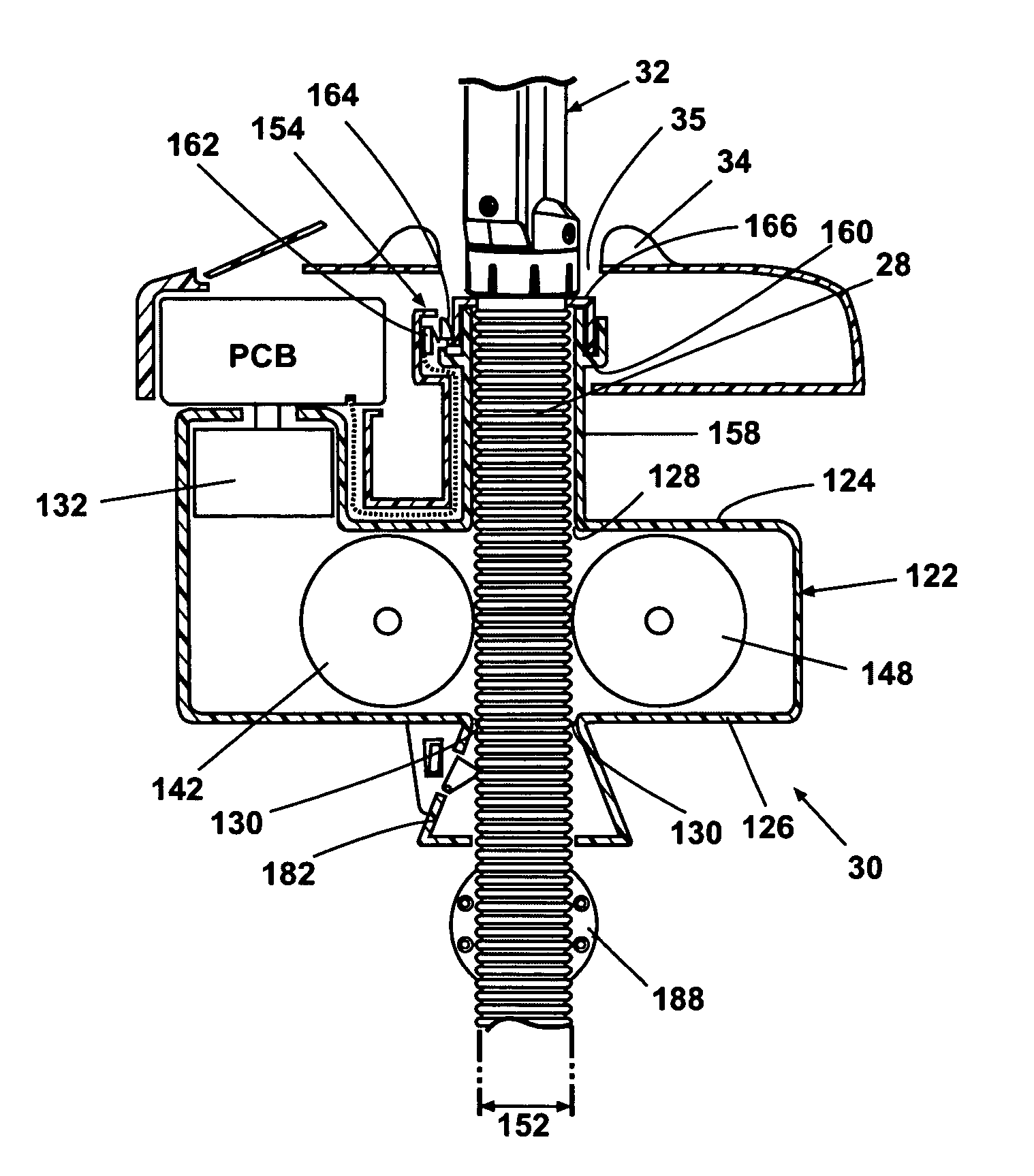

Vacuum cleaner agitator cleaner with power control

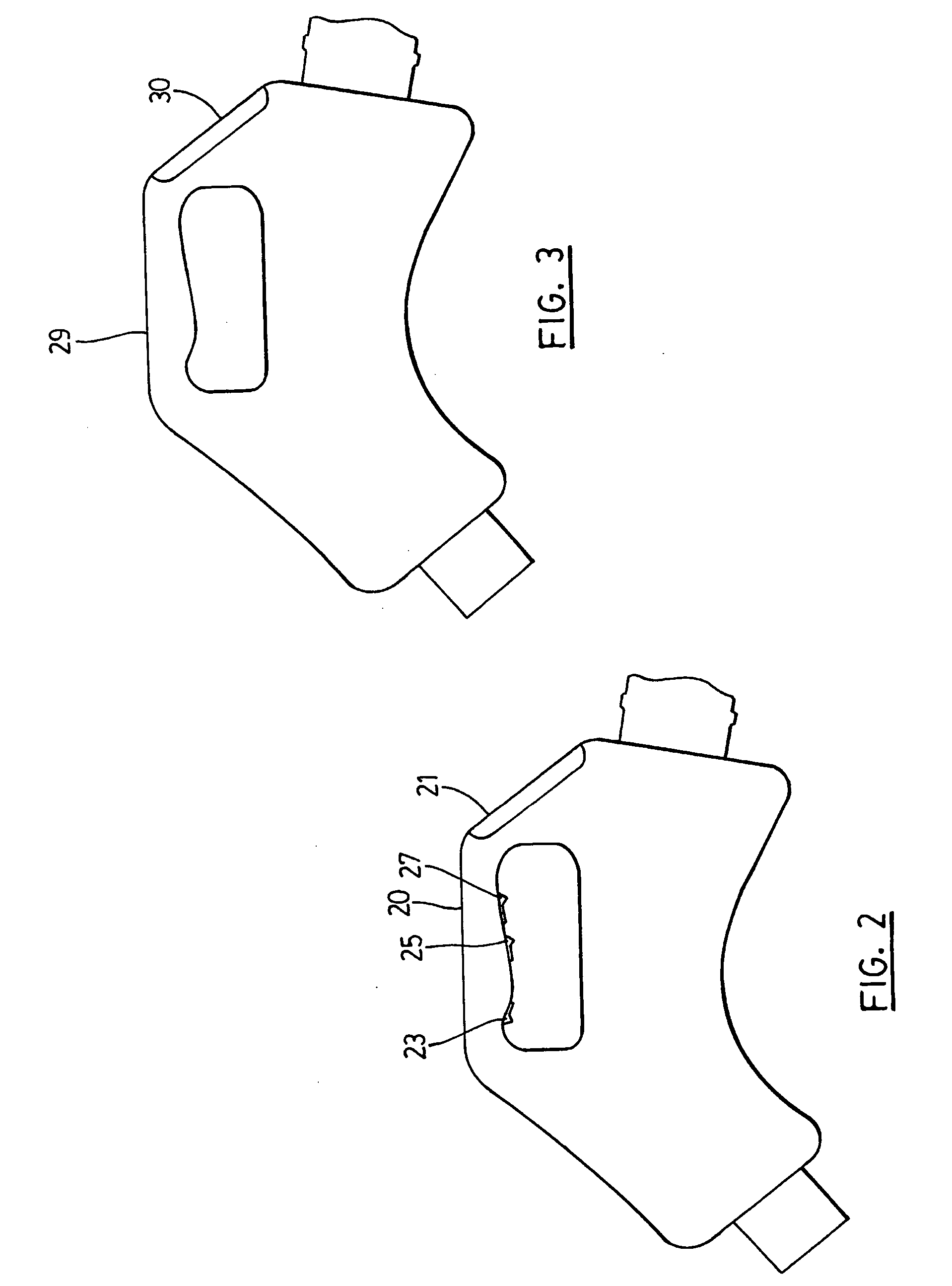

A vacuum cleaner agitator system having an agitator, an electric motor to rotate the agitator, a power source, and an agitator cleaner. The cleaner moves between a first position in which it is spaced from the agitator and a second position in which it engages the agitator to remove debris while the agitator rotates. The system also has a detector configured to indicate when the cleaner is in the second position. A drive control system connects the electric motor, electric power source, and agitator cleaning detector. The drive control system has a first drive mode to drive the electric motor at a first power level, and a second drive mode, activated upon receiving an indication from the detector that the cleaner is in the second position, to drive the electric motor at a second power level that is greater than the first power level.

Owner:AB ELECTROLUX

Central vacuum cleaning system control subsystems

InactiveUS20050254185A1Coupling device detailsEmergency protective arrangements for automatic disconnectionTRIACControl theory

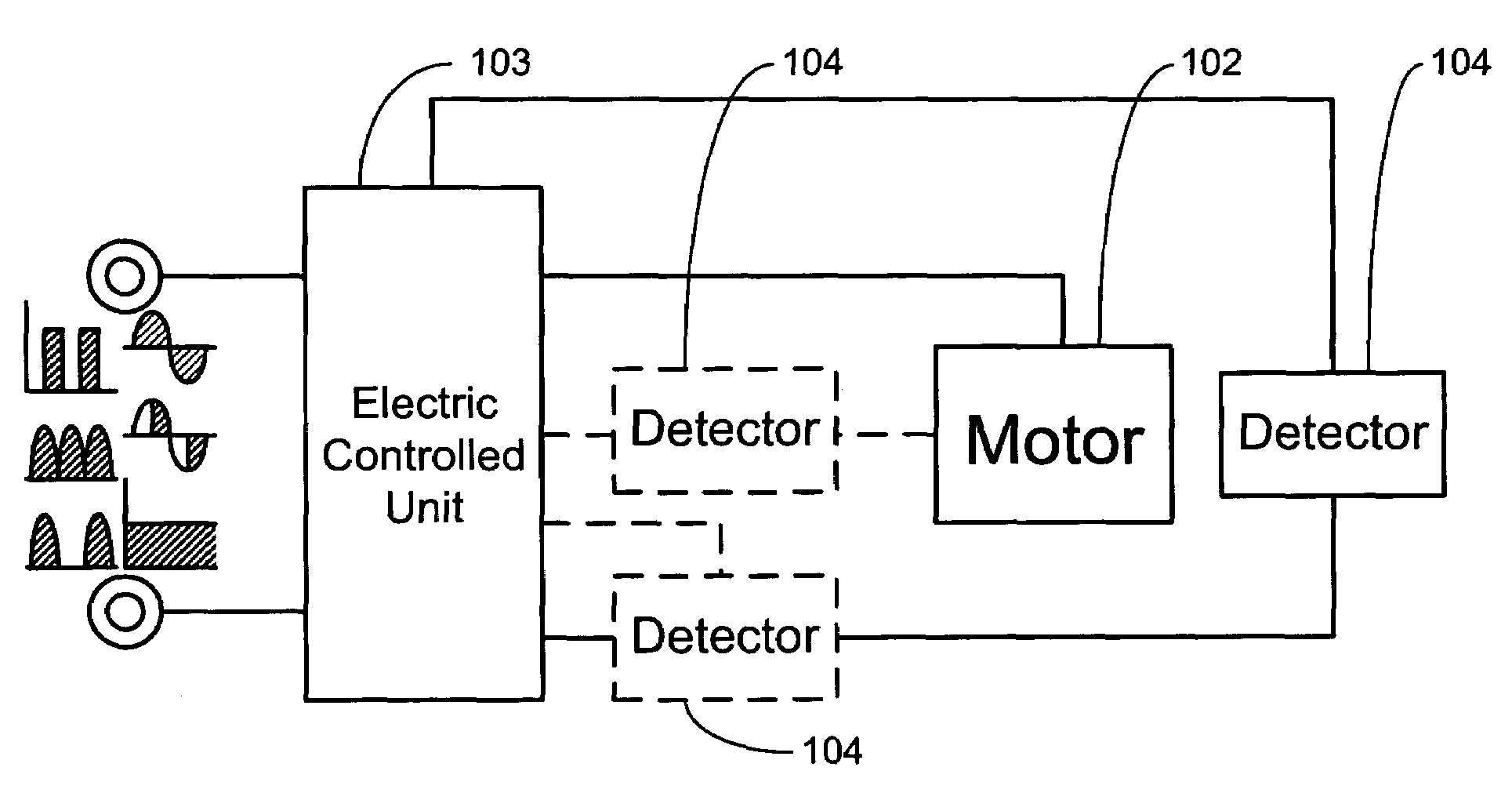

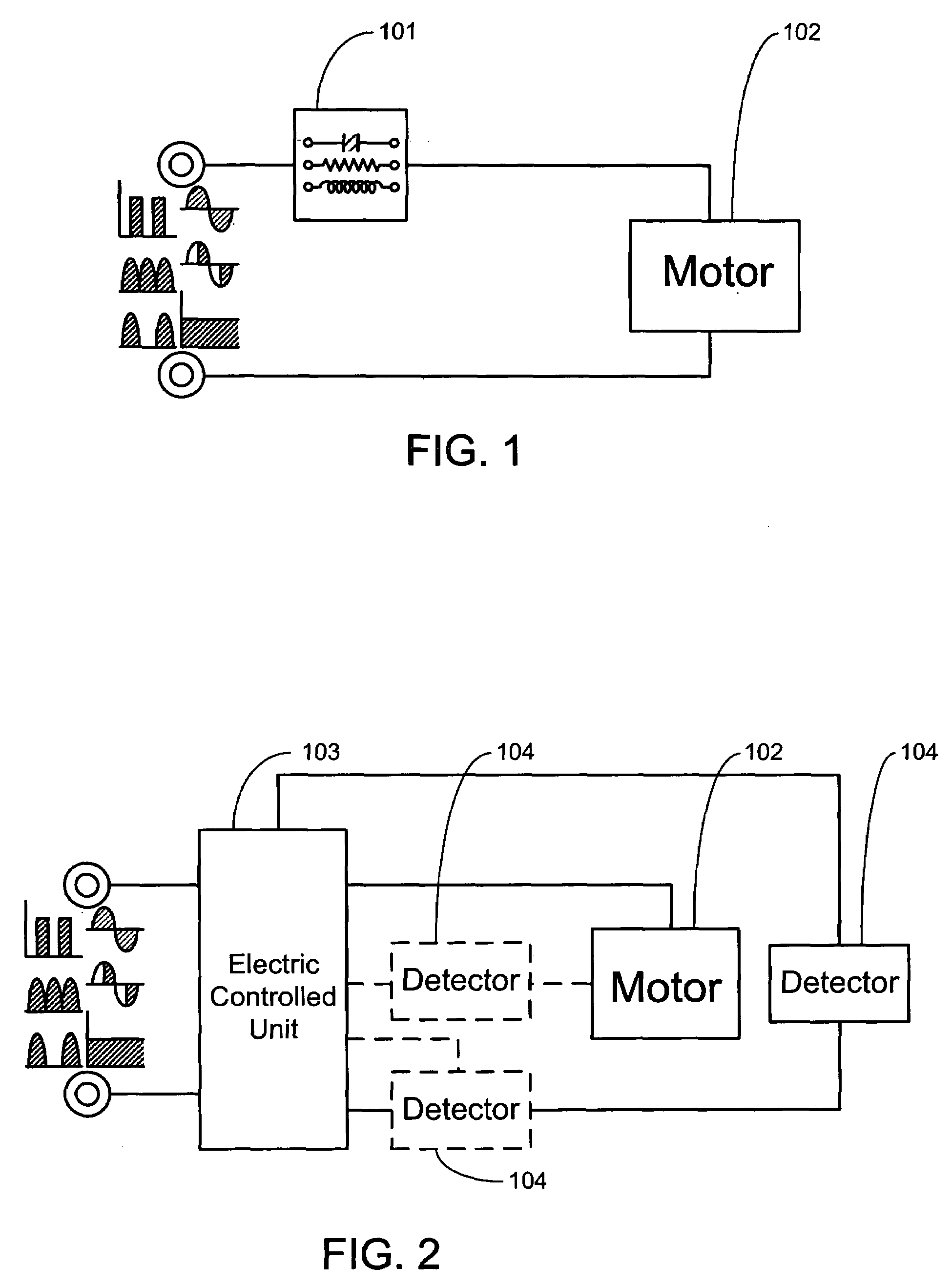

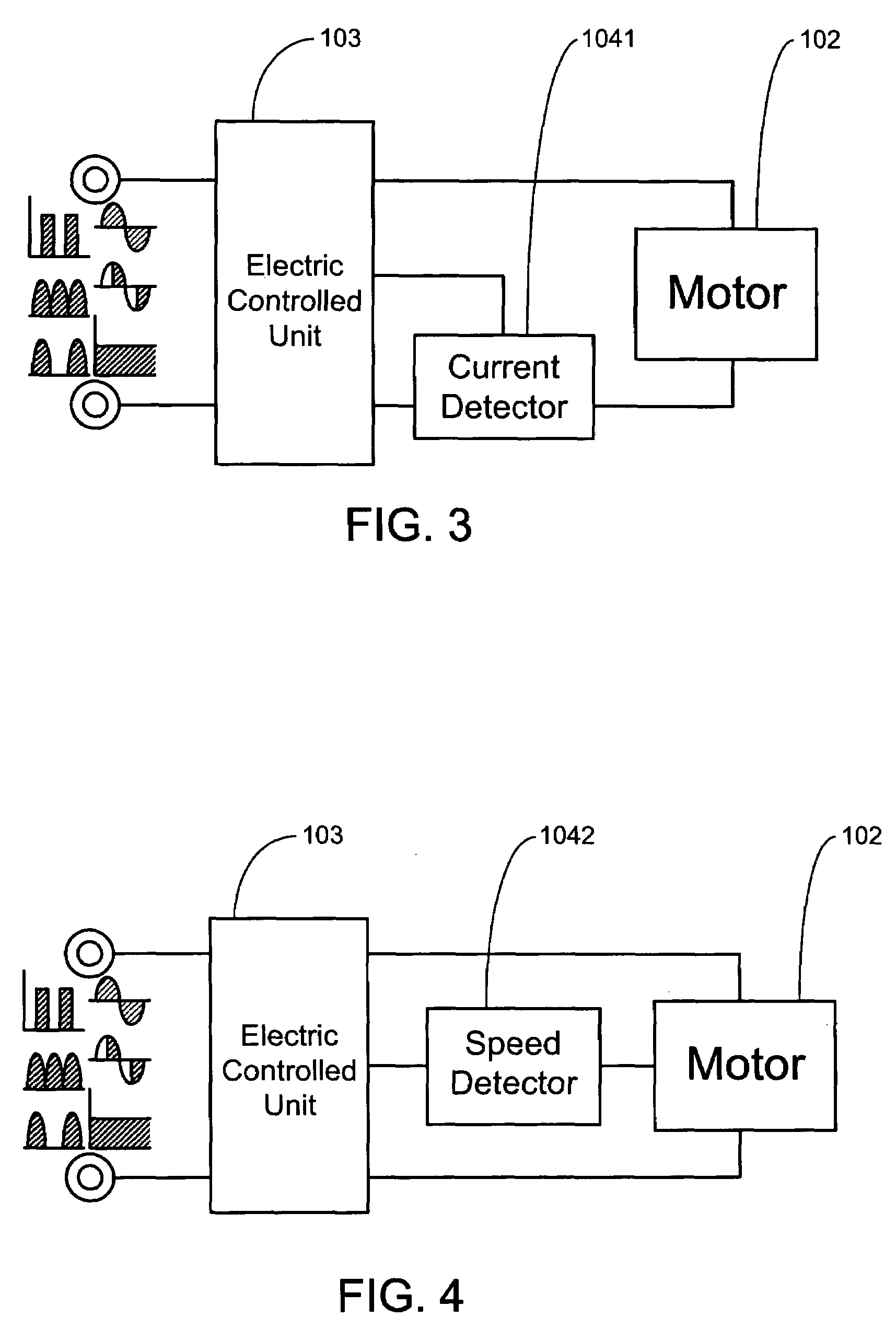

A central vacuum cleaning system control subsystem for use in a central vacuum cleaning system having a motor includes a central vacuum unit control module with a receiver for wirelessly receiving command signals, and a power stage for controlling the motor in accordance with command signals received through the receiver. The control module is stable in high ambient temperature. Current flowing to the motor is sensed, and motor overcurrent and undercurrent conditions are determined. The control module determines when the motor is in an overcurrent condition. Power stage has a triac for controlling power to the motor. The control module also has a microprocessor that compares the current sensed against a normal operating current to determine overcurrent condition. Power to motor ceases when overcurrent condition exists. A generator is powered by air flow in a cleaning system for production of electrical energy.

Owner:CUBE INVESTMENTS

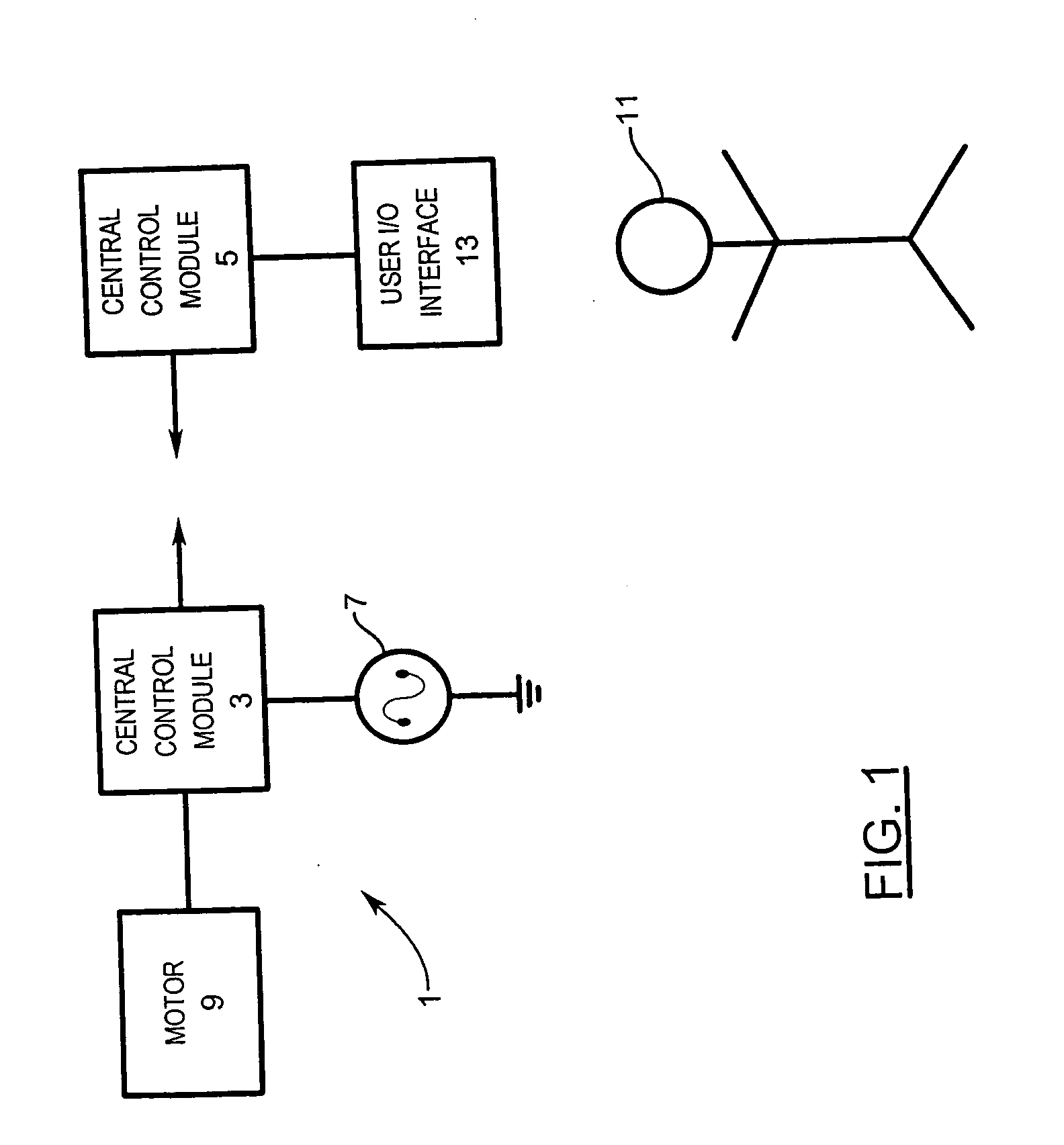

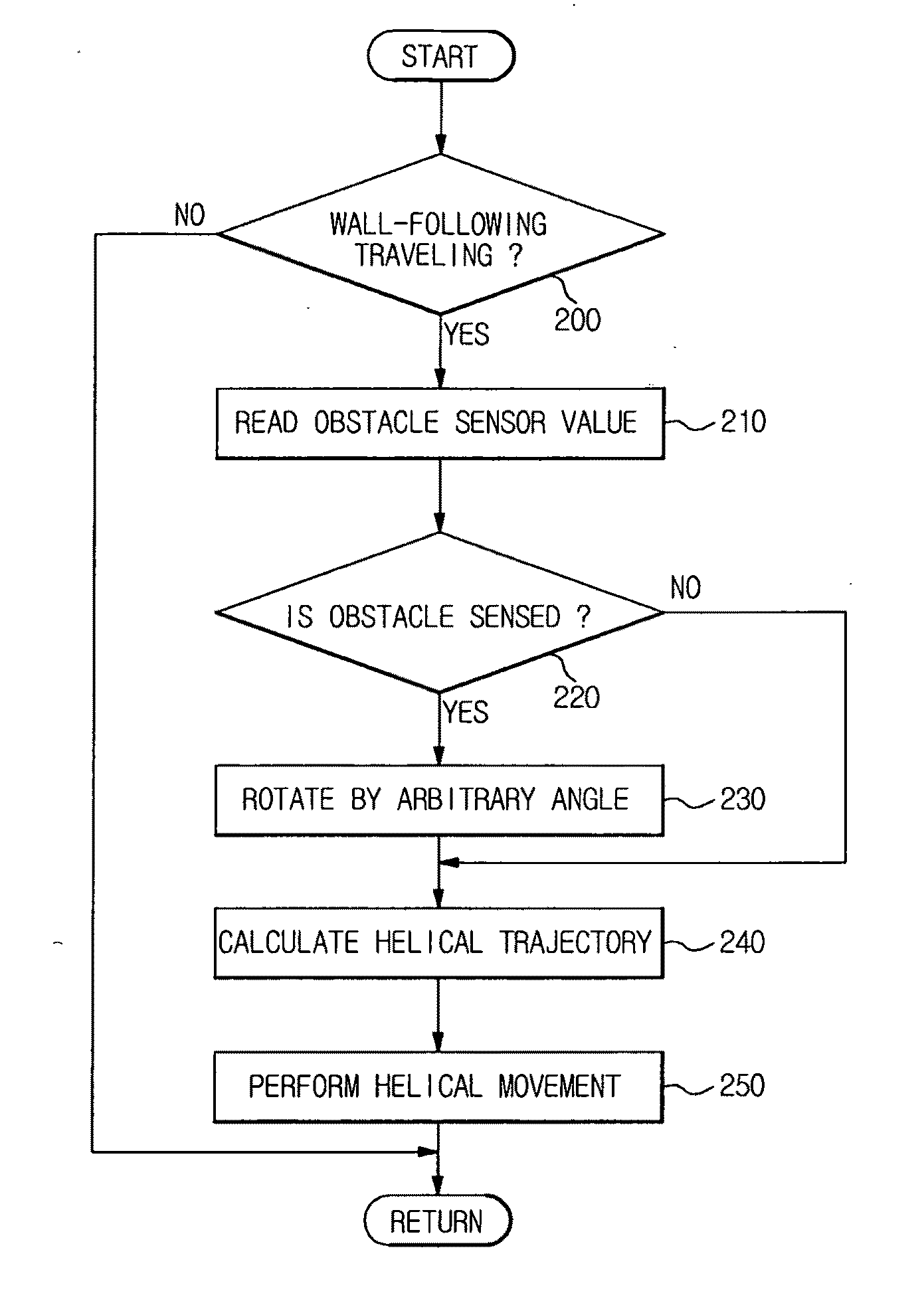

Control method of performing rotational traveling of robot cleaner

ActiveUS20110118928A1Keep distanceReduce travel timeAutomatic obstacle detectionTravelling automatic controlControl theoryRobot

Disclosed herein is a control method of a robot cleaner in which a robot cleaner is moved at an arbitrary starting angle along a rotation trajectory having an arbitrary rotational center and rotation radius during obstacle-following traveling, whereby an obstacle-following traveling time is reduced and consequently, a movement time of the robot cleaner is reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

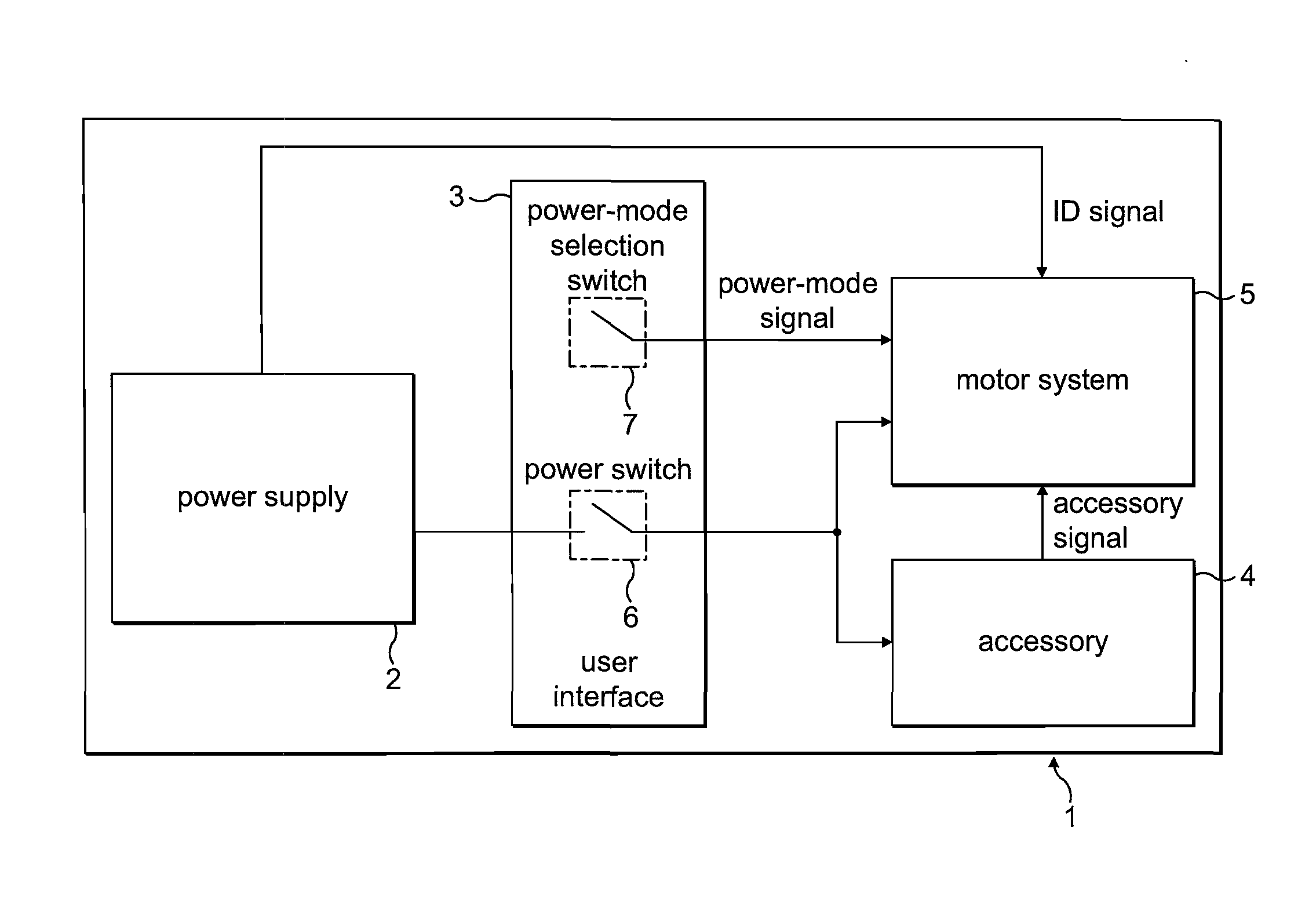

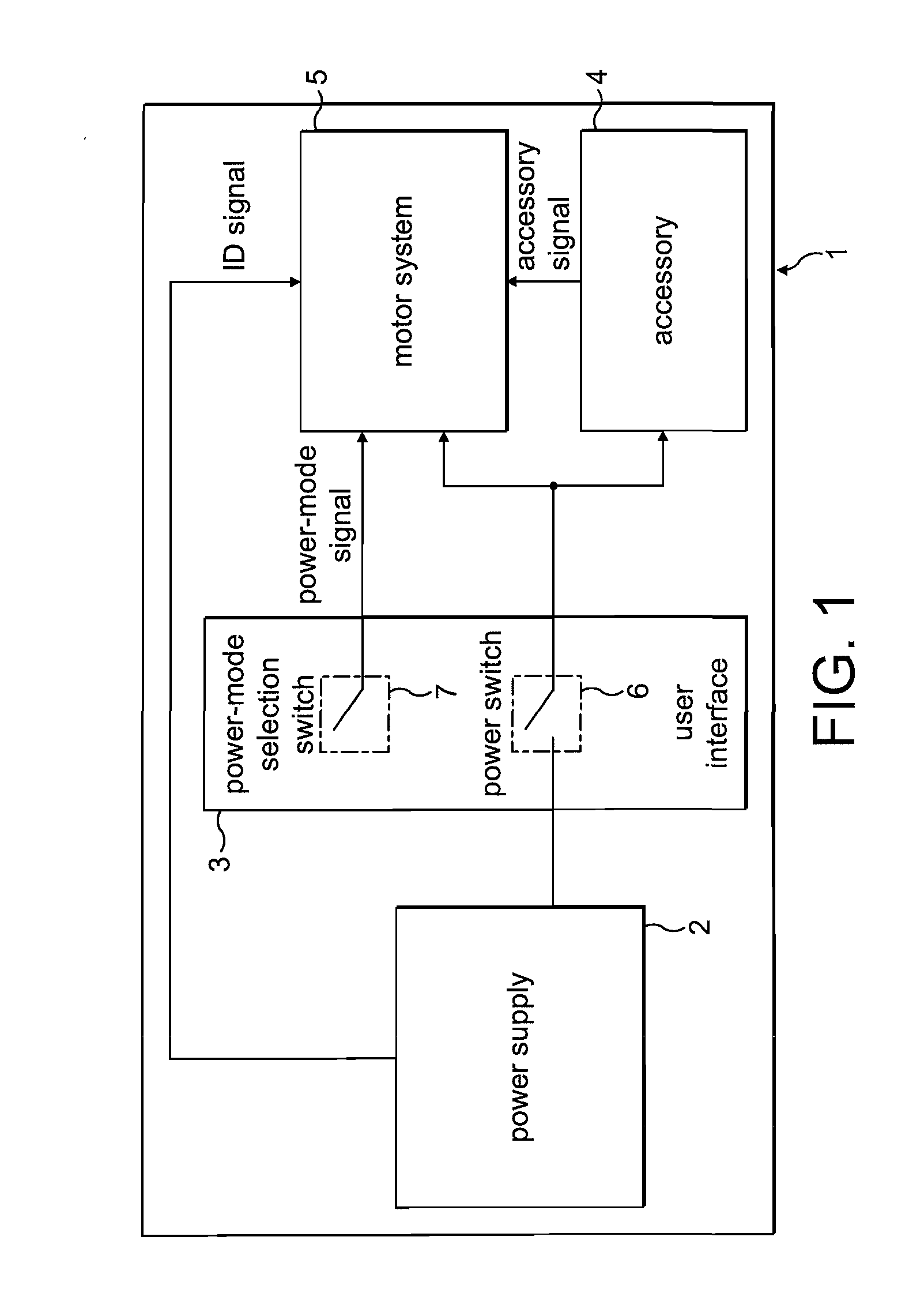

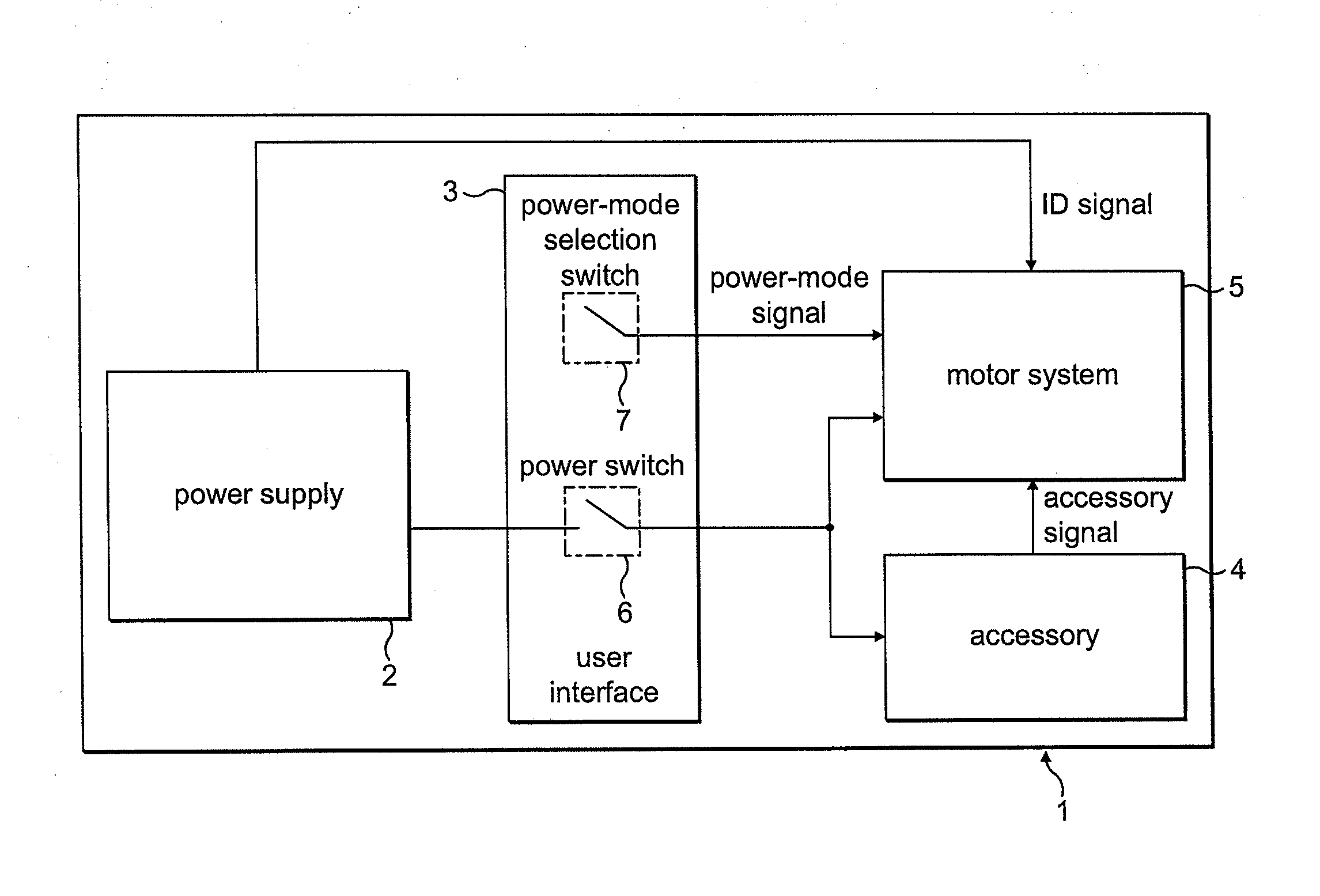

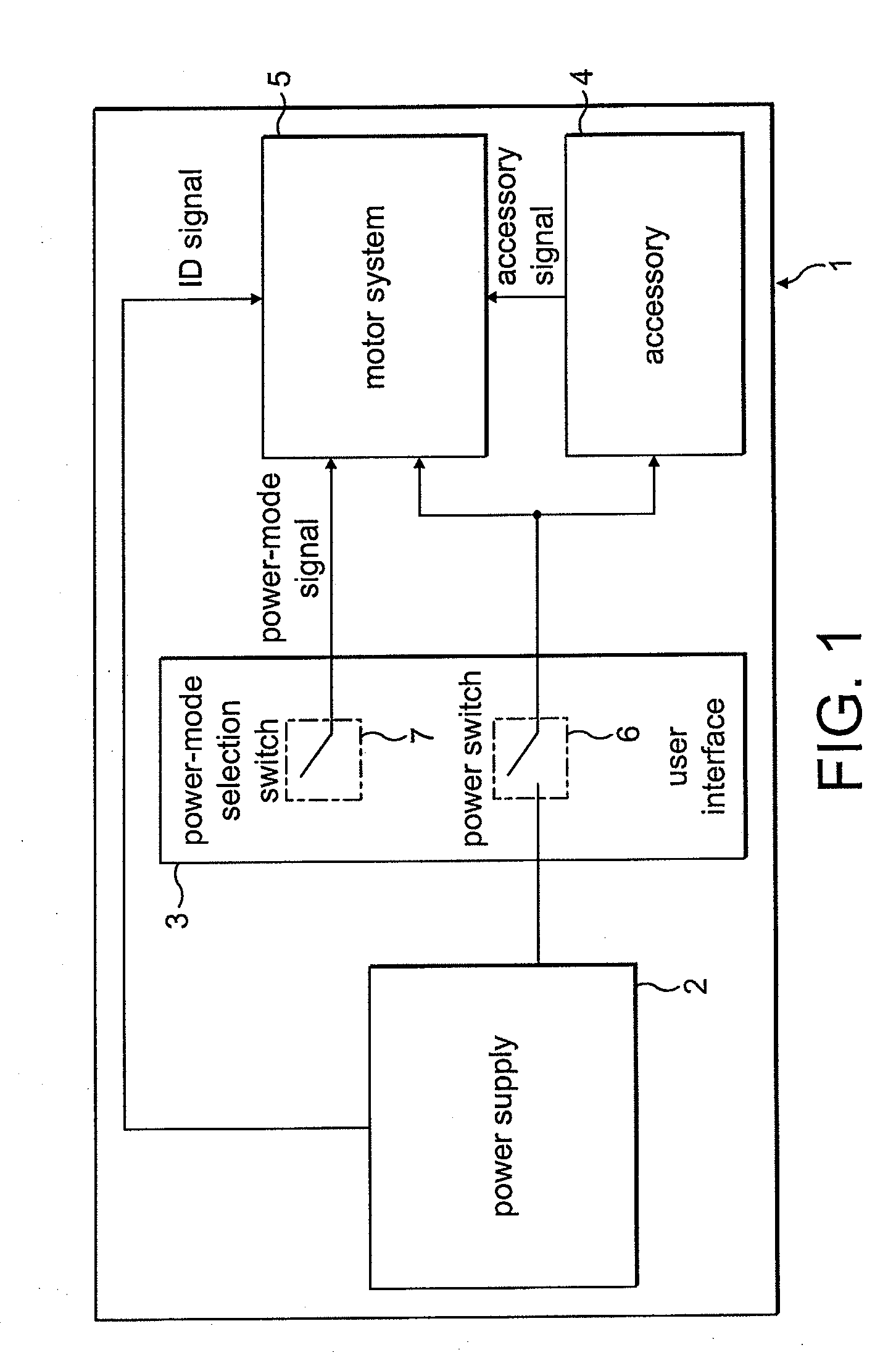

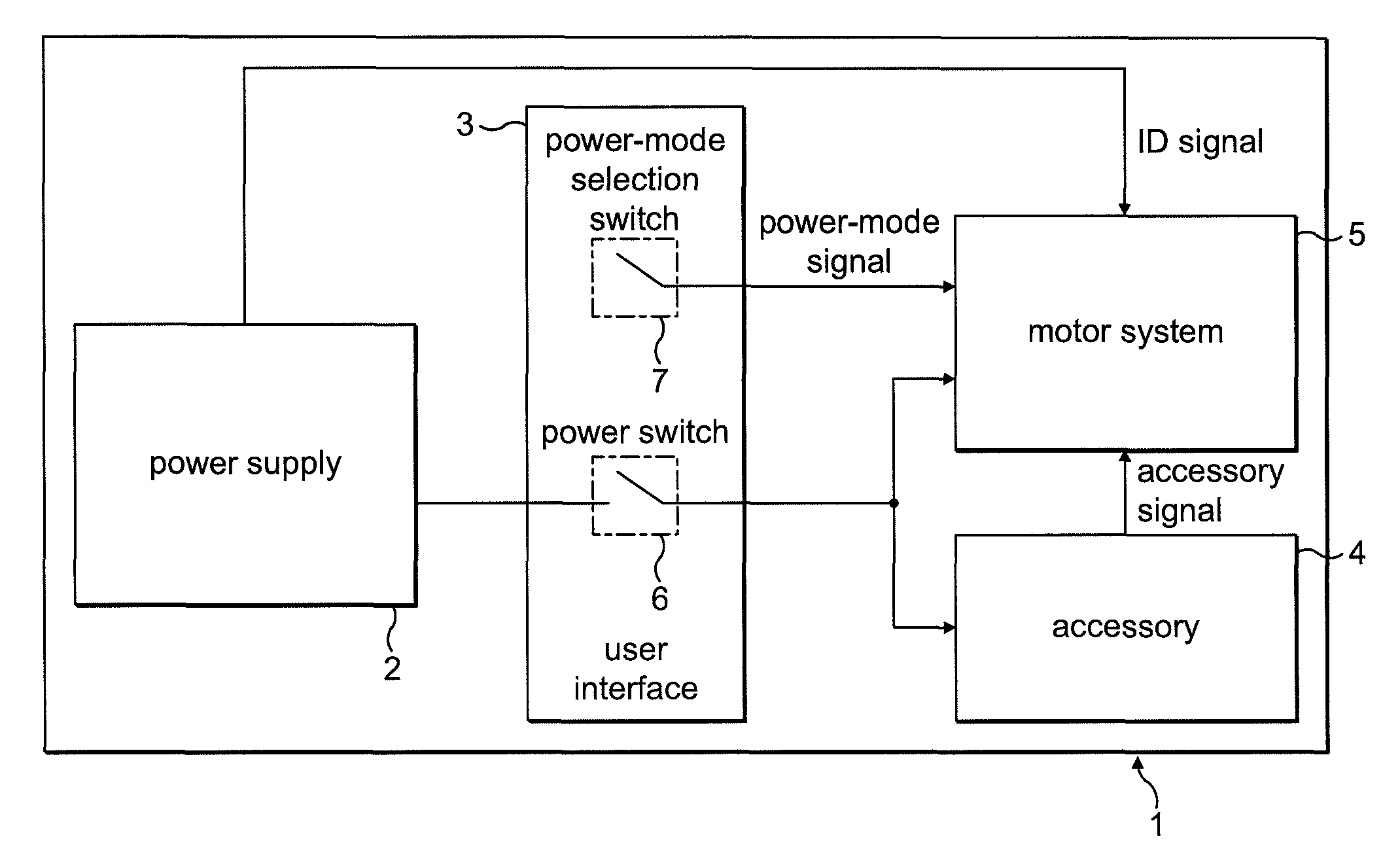

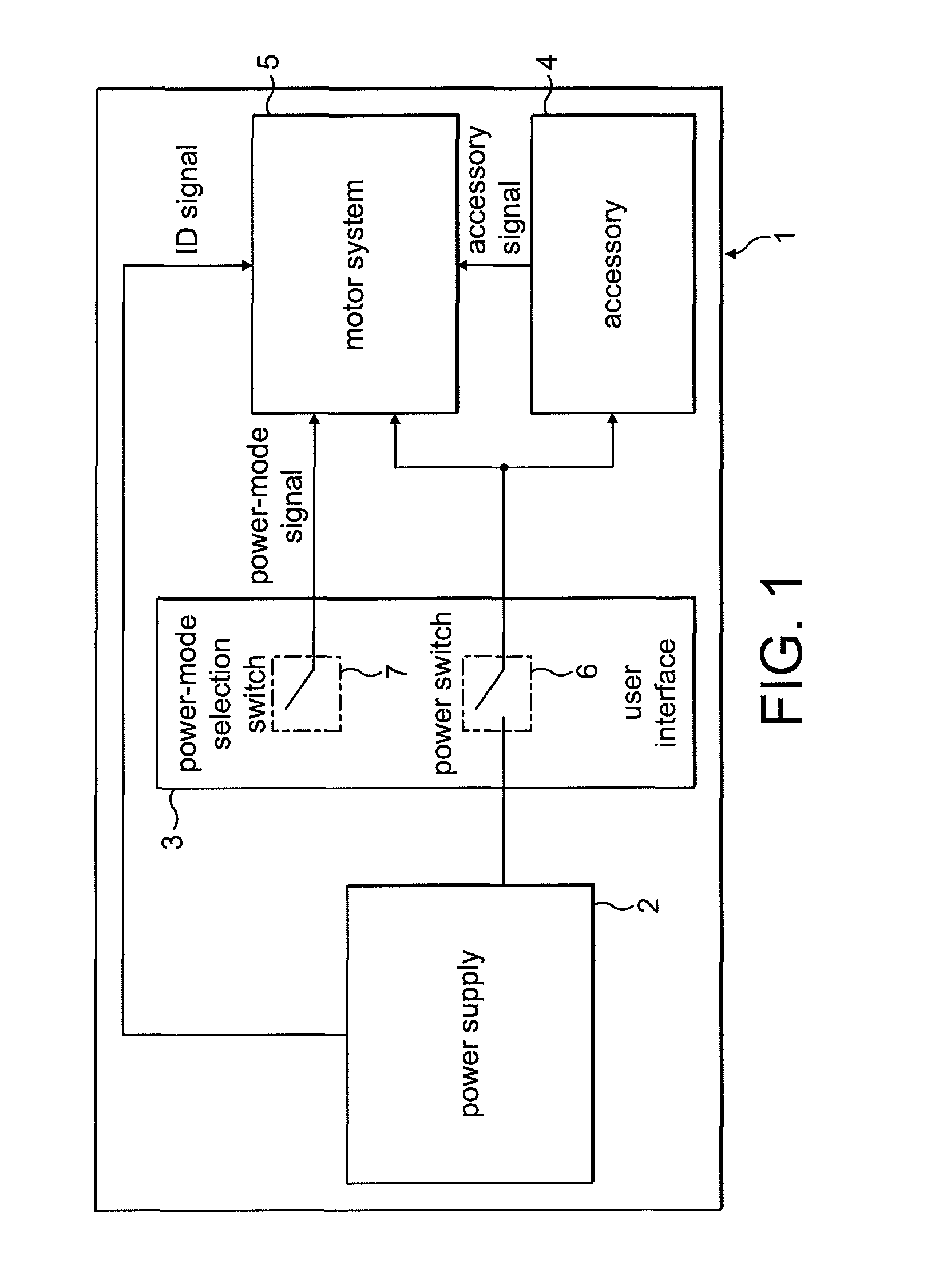

Power management system for a floor care appliance

A floor care appliance is provided with an improved power management system for controlling the total amount of current provided to at least a first and a second load device of an appliance. The power management system is comprised of a microprocessor, an alternating current voltage source, a voltage regulating circuit, a clamping circuit, at least two load devices, and a MOC and a triac for each of the at least two load devices. The clamping circuit outputs a fixed voltage of 5.7 volts during the positive portion of the ac cycle and a fixed voltage of −0.7 volts during the negative portion of the ac cycle. The fixed voltages are input to a microprocessor which utilizes these inputs to control the average voltage and the amount of time the current is turned on to each of the at least first and second load devices. A current sensing circuit is used to monitor the current to one of the at least two load devices to provide feedback to the microprocessor so that the microprocessor can adjust the average voltage and current to the at least two load devices so that the total current consumed does not exceed a pre-determined level.

Owner:HOOVER LIMITED

Control of a permanent-magnet motor

ActiveUS20100251511A1Less torqueEfficient processSynchronous motors startersMultiple motor speed/torque controlControl systemPermanent magnet motor

A method of controlling a permanent-magnet motor that includes sequentially exciting and freewheeling a winding of the motor. The method includes varying the angle over which the winding is freewheeled in response to changes in speed of the motor. Additionally, a control system for a permanent-magnet motor, and a product incorporating the control system and motor.

Owner:DYSON TECH LTD

High-speed electric system

ActiveUS20100251509A1Improve efficiencyConstant output powerSynchronous motors startersMultiple motor speed/torque controlElectric machineControl system

An electric system that includes a single-phase permanent-magnet electric machine and a control system for driving the electric machine under load at speeds in excess of 60 krpm. Additionally, a product that includes the electric system.

Owner:DYSON TECH LTD

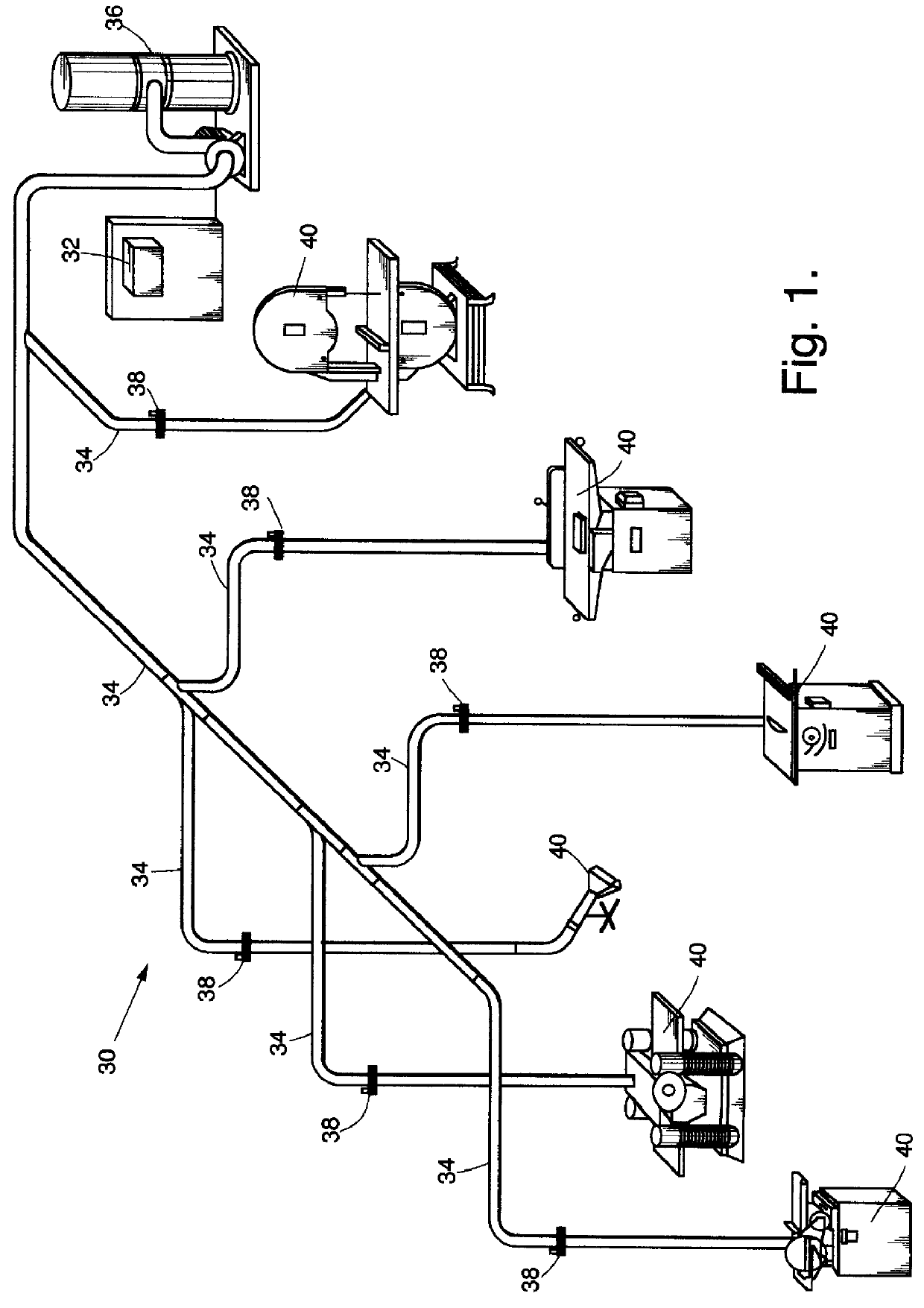

Refuse vacuum system for machine shops

InactiveUS6012199AInexpensiveEfficient mannerMetal sawing accessoriesLighting and heating apparatusParticulatesMachine shop

A vacuum system for machine shop dust, particulate matter, and the like. Blast gates control the flow of vacuum generated by a dust collector to individual machines that may or may not accommodate vacuum ductwork and the like. The blast gate has a rotating blade inside a chassis with a DC motor effectively using a slip clutch or an increased current feedback system to limit the rotation driving of the rotating blade. Importantly, a small aperture serves to allow air flow into the chassis gap through which the rotating blade rotates in order to ensure the particular matter does not lodge inside the chassis thereby preventing the proper operation of the rotating blade. A central controller having a microprocessor or the like may be programmed or programmable and serve to individually control a selected number of blast gates based upon a feedback mechanism. A piezoelectric sensor or the like senses the vibration arising from the turning on of the associated machinery, indicating the demand for vacuum power to collect particulate matter. In response to the piezoelectric sensor's signal, the blast gate is opened and the dust collector is either turned on or stepped up to accommodate the increase load upon the vacuum system. The reverse situation occurs when the machinery is turned off. The piezoelectric sensor ceases signalling the central controller of the machine "on" condition. The central controller then steps down the dust collector / vacuum system and closes the associated blast gate. Alternative embodiments are set forth whereby additional features provide for enhanced utility, including a computer operation, control, monitoring, and feedback.

Owner:LITOMISKY PETR +1

Control of an electric machine

ActiveUS20100253263A1Convenient power controlDecreasing freewheel angleMotor/generator/converter stoppersSynchronous motors startersFreewheelFree rotation

A method of controlling an electric machine that includes sequentially exciting and freewheeling a winding of the electric machine. The winding is excited by an excitation voltage and is freewheeled over a freewheel angle. The method then includes varying the freewheel angle in response to changes in the excitation voltage. Additionally, a control system for an electric machine, and a product incorporating the control system and electric machine.

Owner:DYSON TECH LTD

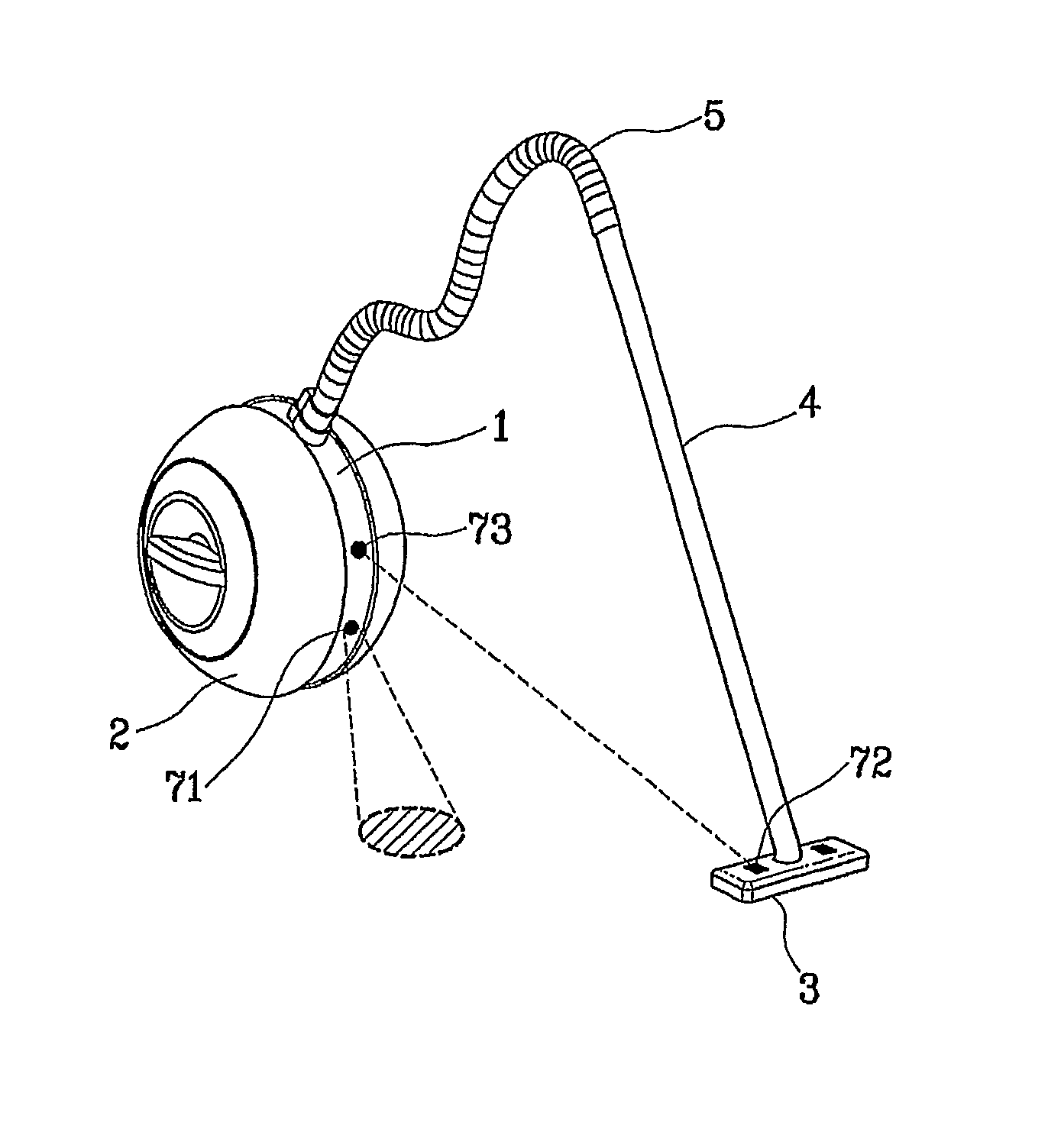

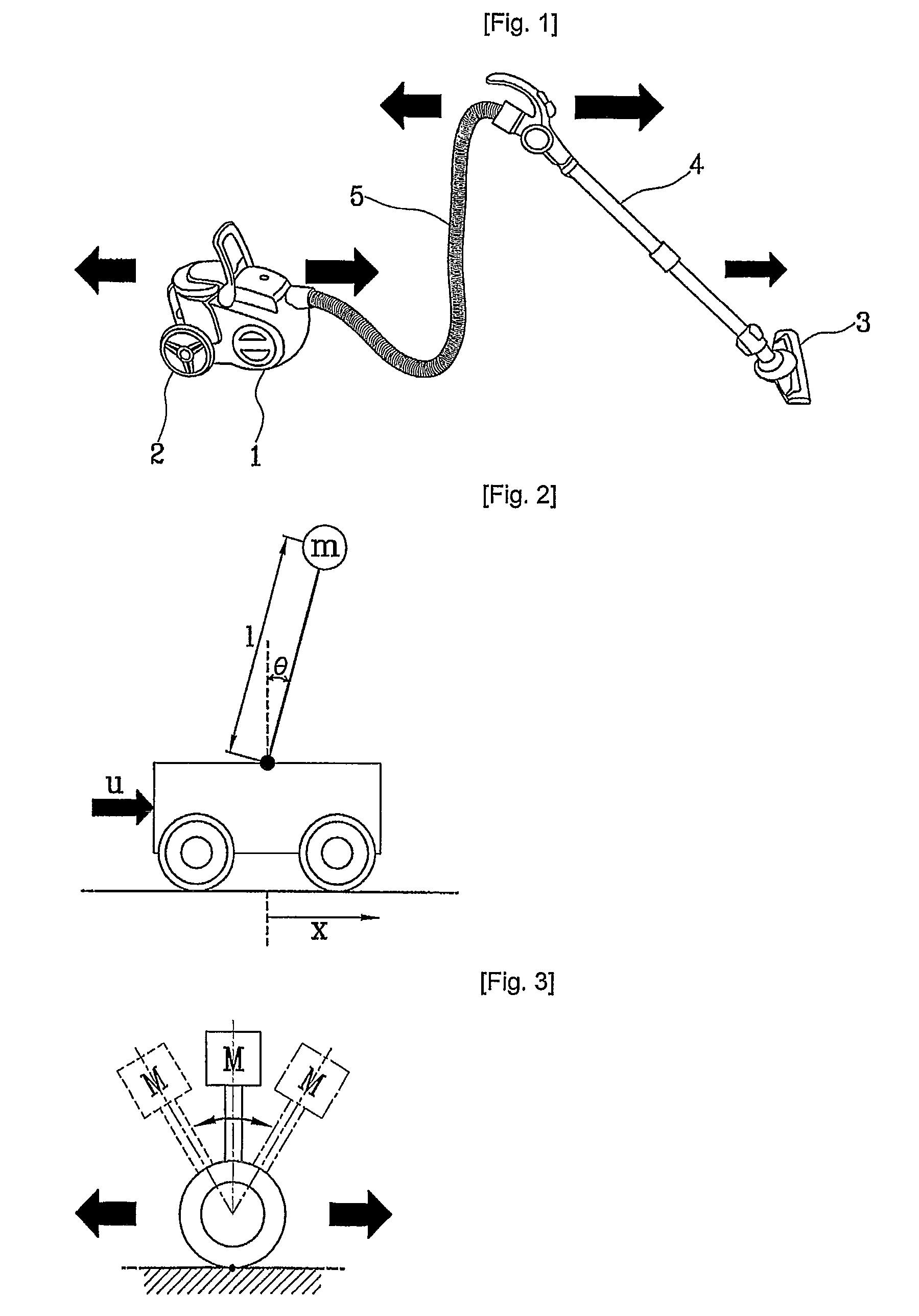

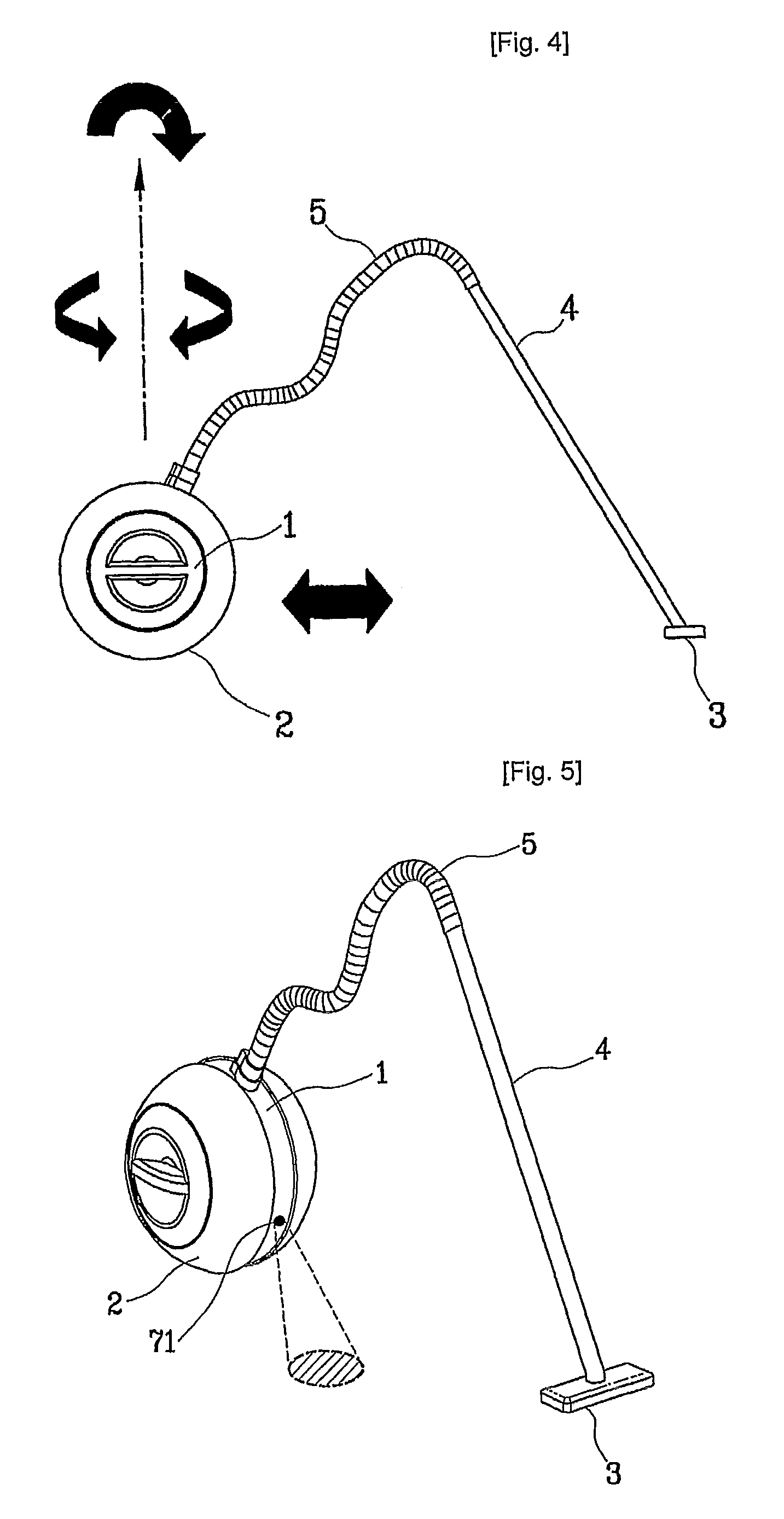

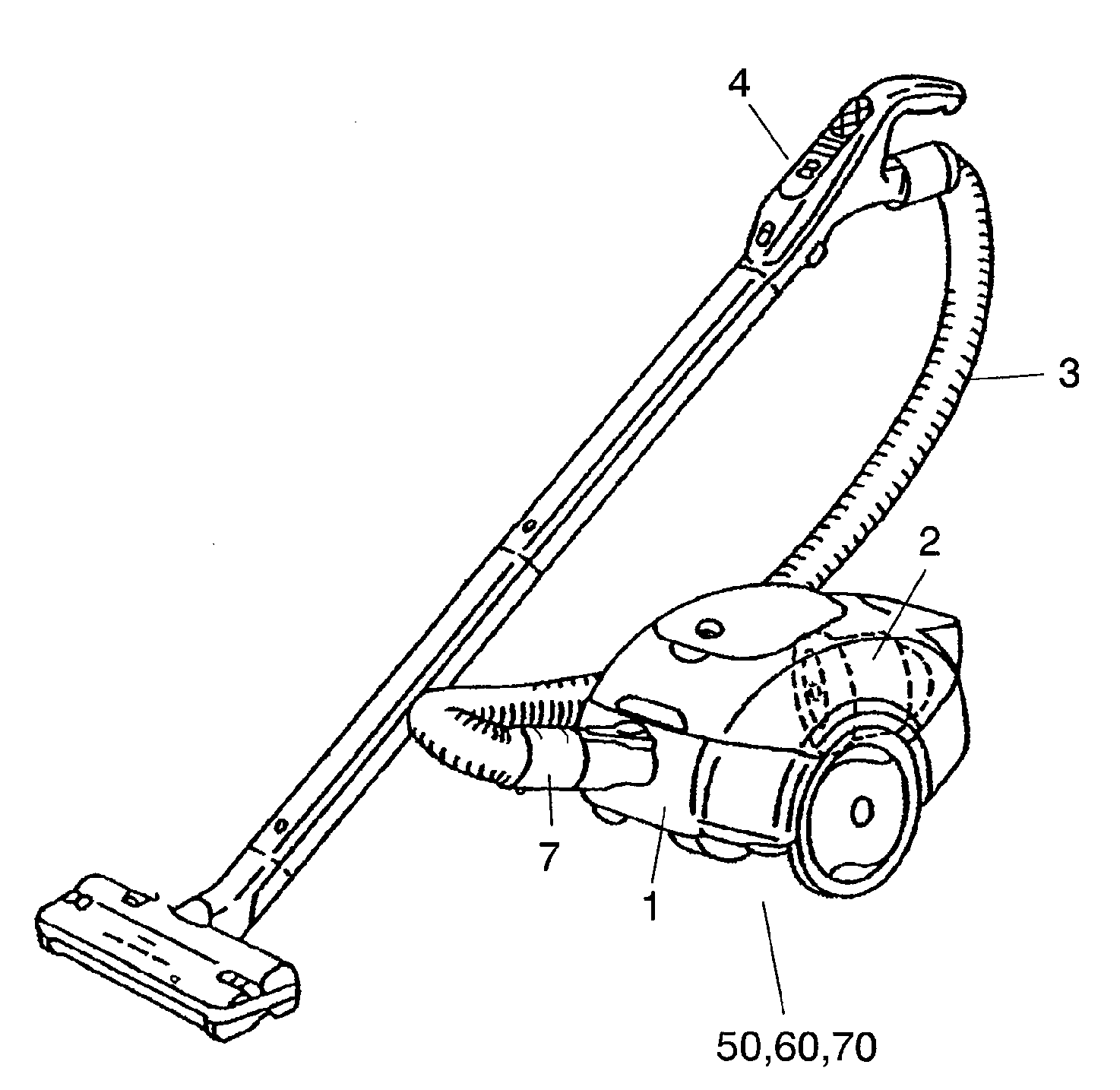

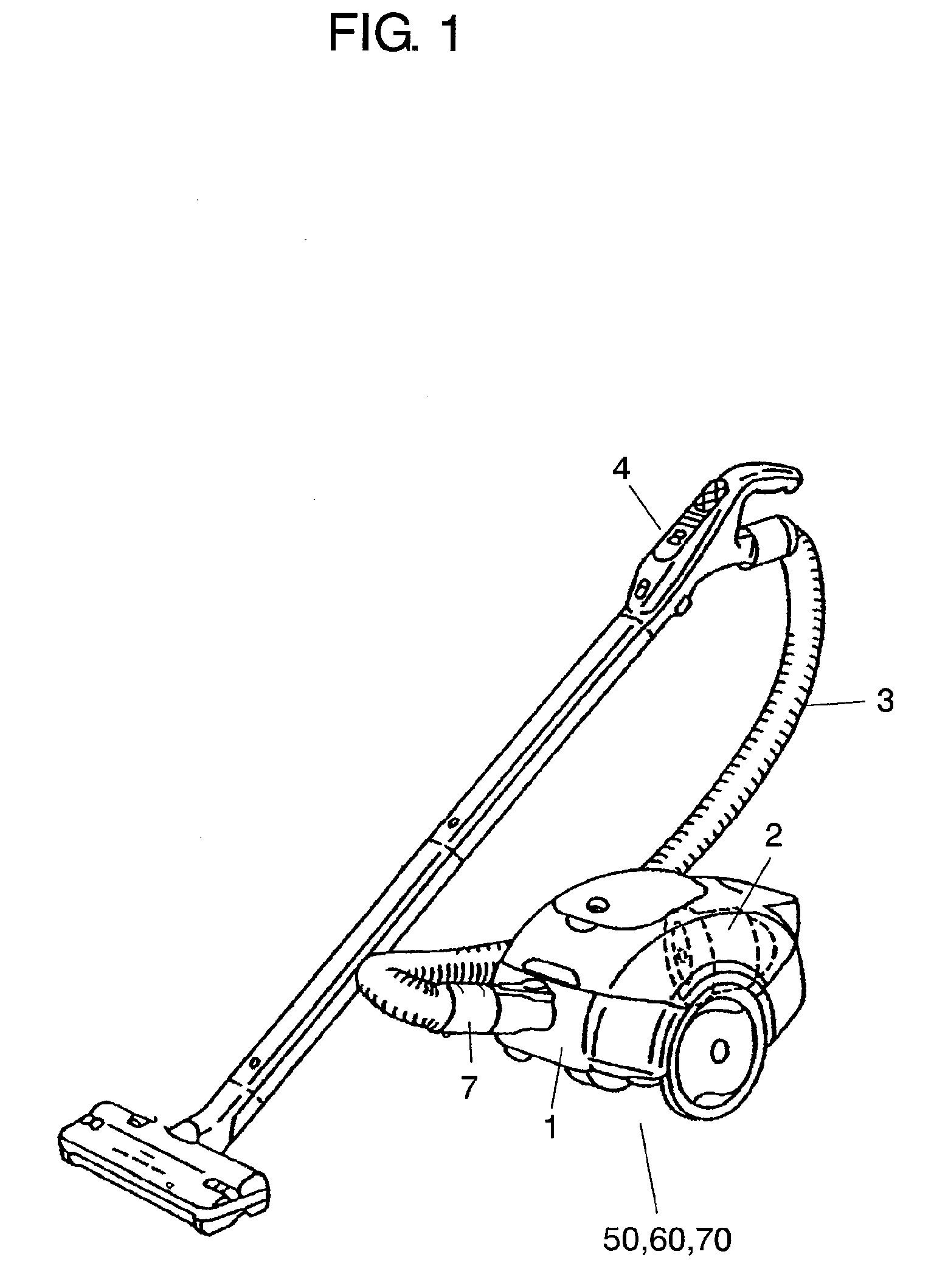

Vacuum cleaner having abilities for automatic moving and posture control and method of controlling the same

The present invention discloses a vacuum cleaner including a main body (1) of the vacuum cleaner, a wheel (2) rotatably mounted at the body, a driving unit for driving the wheel (2), a sensor (71) positioned at the main body, for sensing an inclined direction of the main body (1), and a control unit for controlling the driving unit according to the inclined direction of the main body (1) sensed by the sensor (71). In this configuration, the posture of the main body (1) of the vacuum cleaner can be controlled according to the inverted pendulum control theory. Therefore, the main body (1) of the vacuum cleaner can maintain the posture thereof not to fall down.

Owner:LG ELECTRONICS INC

Constant-power electric system

ActiveUS20100251510A1Easy to controlKeep for a long timeSynchronous motors startersSingle motor speed/torque controlConstant powerControl system

An electric system that includes a single-phase permanent-magnet electric machine and a control system for driving the electric machine. The control system sequentially excites and freewheels a winding of the electric machine so as maintain substantially constant power over an operating speed range spanning at least 10 krpm and / or an excitation voltage range extending between a minimum voltage and a maximum voltage, the minimum voltage being less than 80% of the maximum voltage. Additionally, a product comprising the electric system.

Owner:DYSON TECH LTD

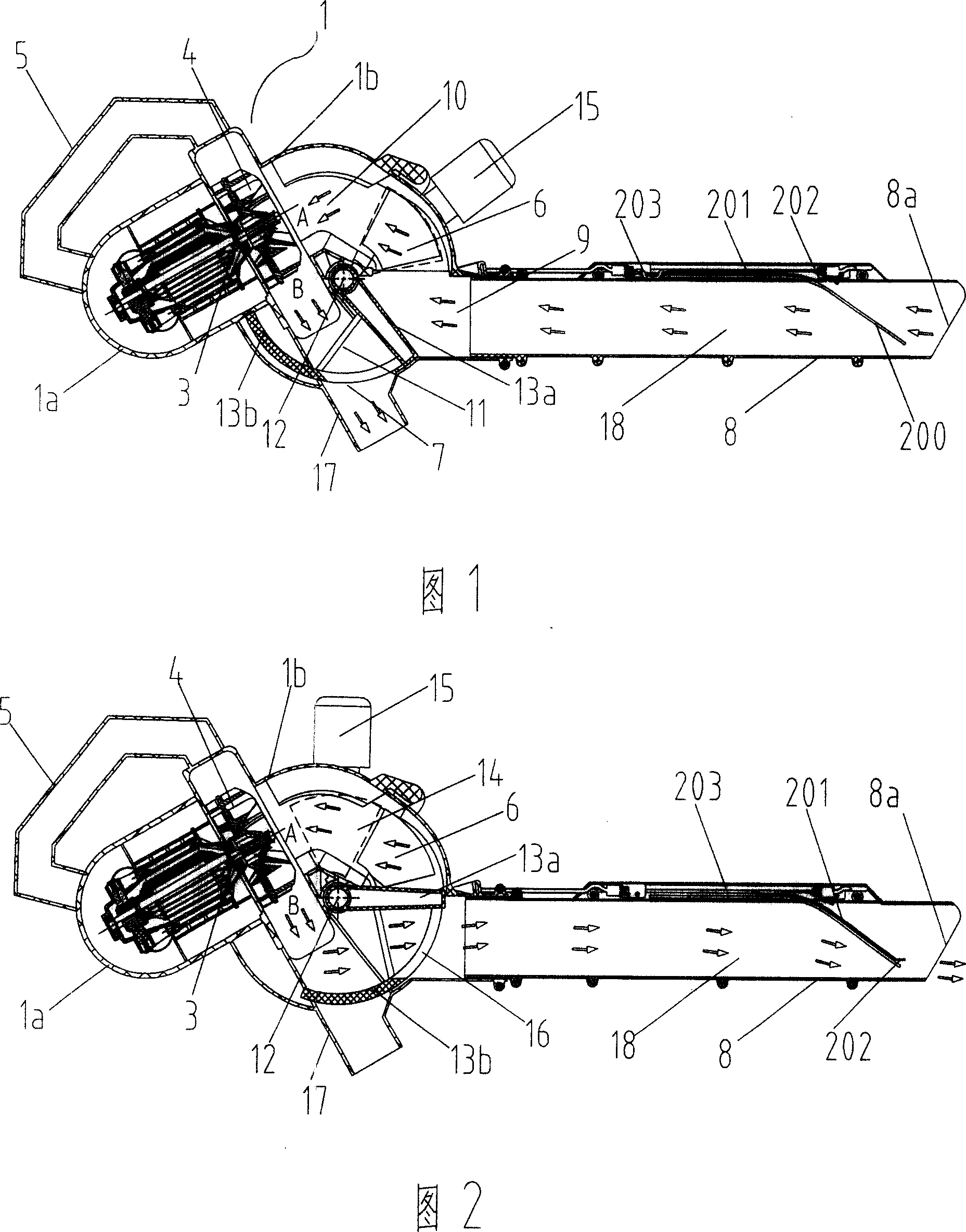

Blowing and sucking machine

The blowing and sucking machine as gardening apparatus consists of one casing, one motor, one motor rotated fan, and one blowing / sucking function converting mechanism. The casing has one air inlet and one dust outlet; and the blowing / sucking function converting mechanism has one controller for controlling the mode conversion between blowing mode and the sucking mode. The casing is also provided with one single cavity port to communicate optionally to the air inlet or the dust outlet, so that the blowing and sucking machine can operate in a blowing mode or a sucking mode separately.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

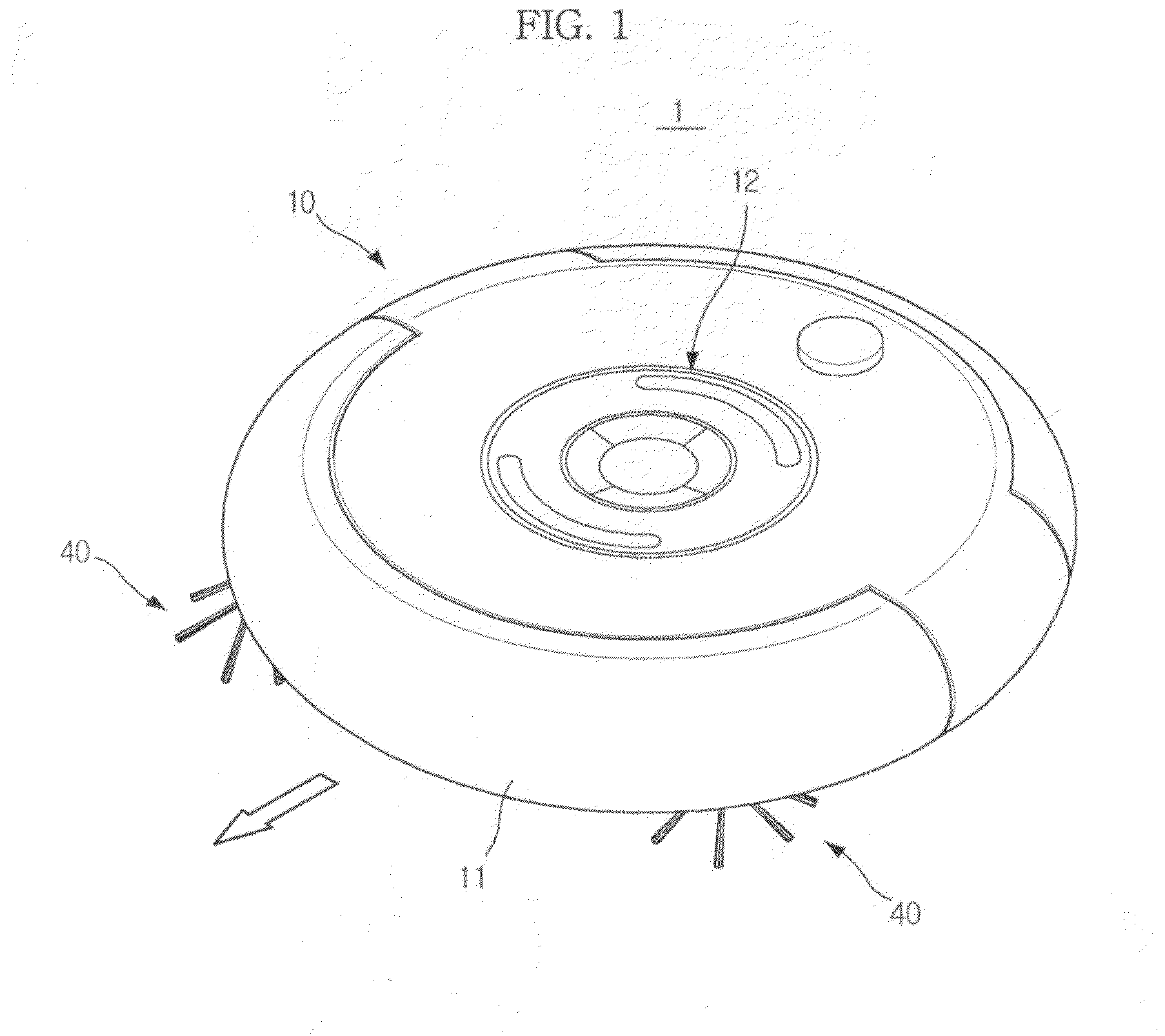

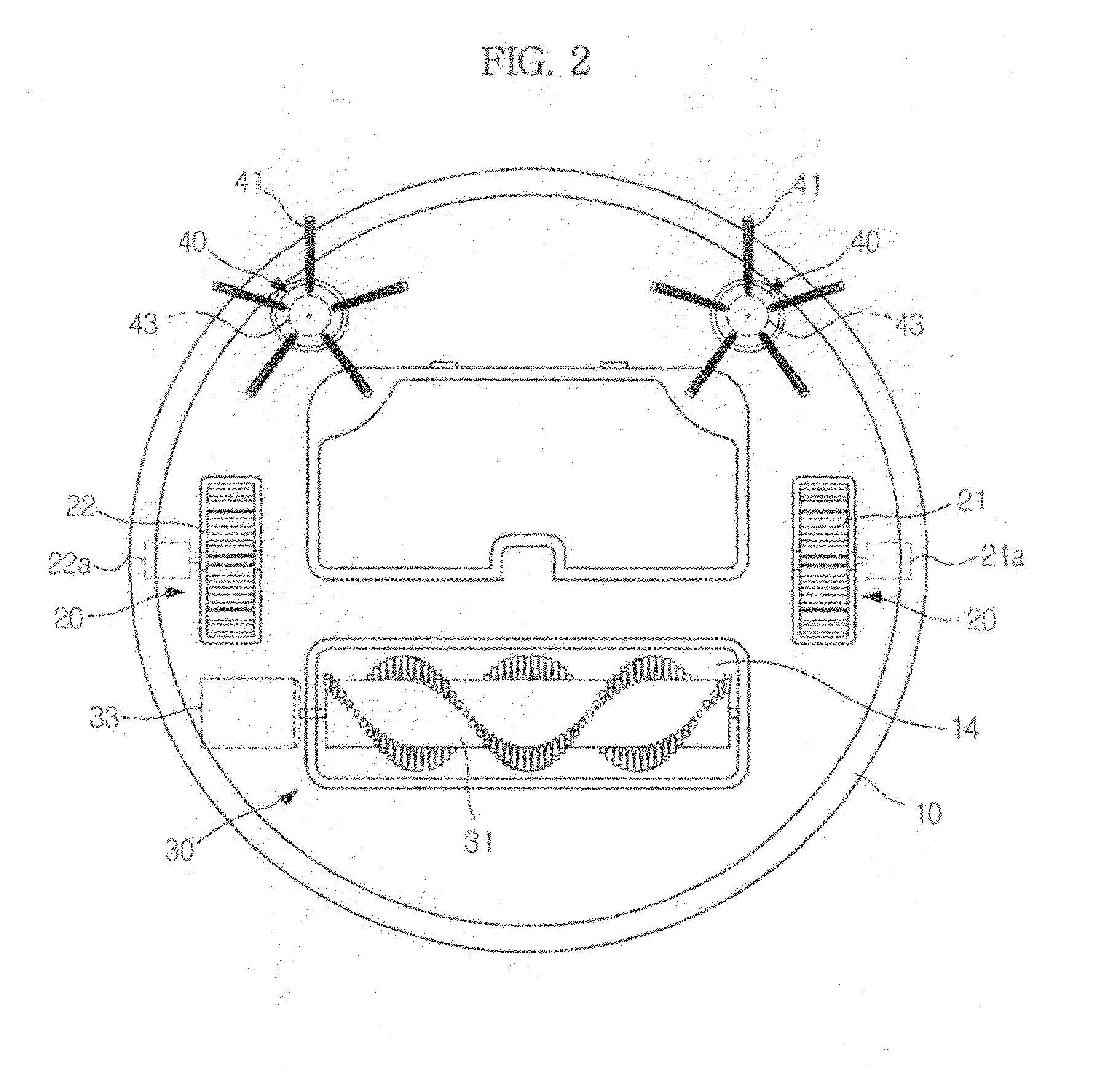

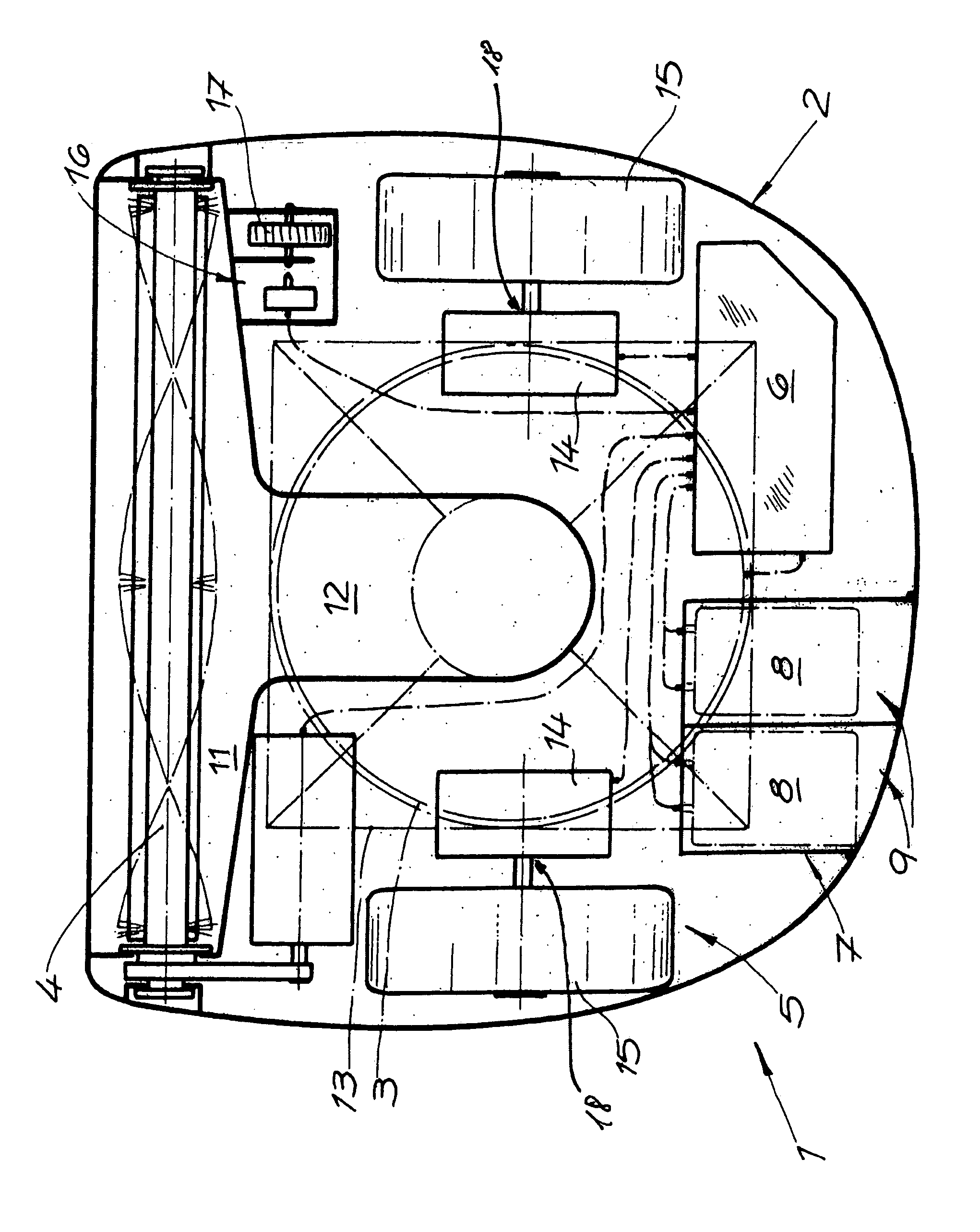

Self-propelled vacuum-cleaning device

ActiveUS8127399B2Acceptable cleaning capacityQuick refillSuction cleanersSecondary cellsControl electronicsEngineering

A self-propelled vacuum-cleaning device for cleaning smooth and textile floor coverings, particularly in the private home sector. The device has a housing, a vacuum blower, an electrically driven cleaning roller, an electrical drive mechanism, control electronics, and a power source. The maximal electric power of the self-propelled vacuum-cleaning tool lies between 150 watts and 300 watts during cleaning operation, whereby between 120 watts and 220 watts are allocated to the vacuum blower, between 10 watts and 40 watts are allocated to the electrical roller drive for the cleaning roller, and between 5 watts and 40 watts are allocated to the drive mechanism, and whereby the control electronics have a power demand of less than 5% of the maximal electric power.

Owner:WESSEL WERK

Off-load reduced input power energy saving low noise air vacuum cleaner

InactiveUS20080034532A1Reduce investmentReduce noiseVacuum cleaner apparatusElectric equipment installationLow noiseNoise level

An off-load reduced input power energy saving low noise air vacuum cleaner by detecting the operation status of the cleaner to control the size of the electricity inputted to an air pump drive motor, or exercise the control of power delivery or power cut off; normal rated voltage being inputted when the cleaner is in normal working status; or the power outputted to the air pump drive motor being reduced or cut off when the cleaning tool of the cleaner clears away from its working area to render the cleaner in full load operation status as were a blower to increase both noise level and power consumption for reduced noise level and energy saving.

Owner:YANG TAI HER

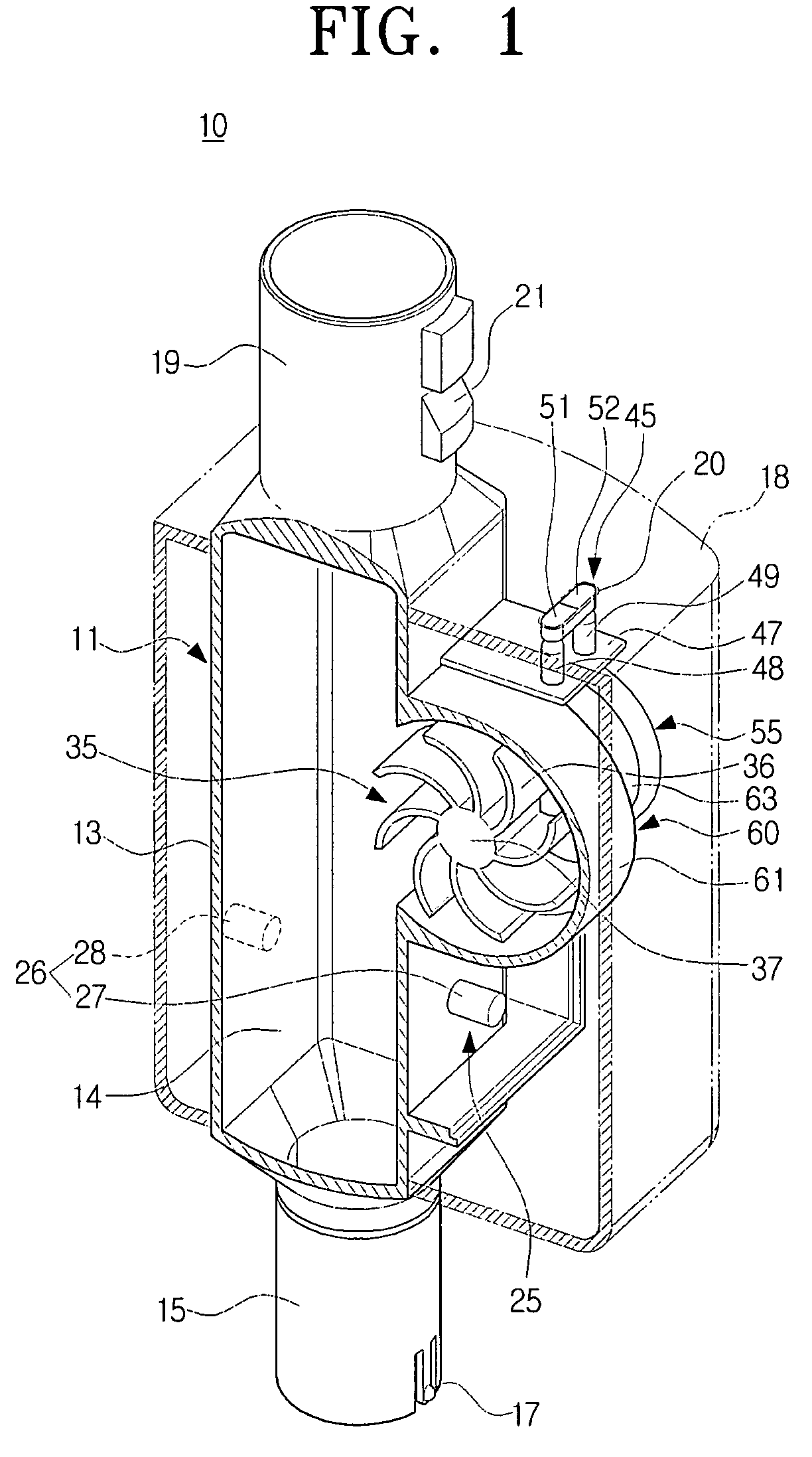

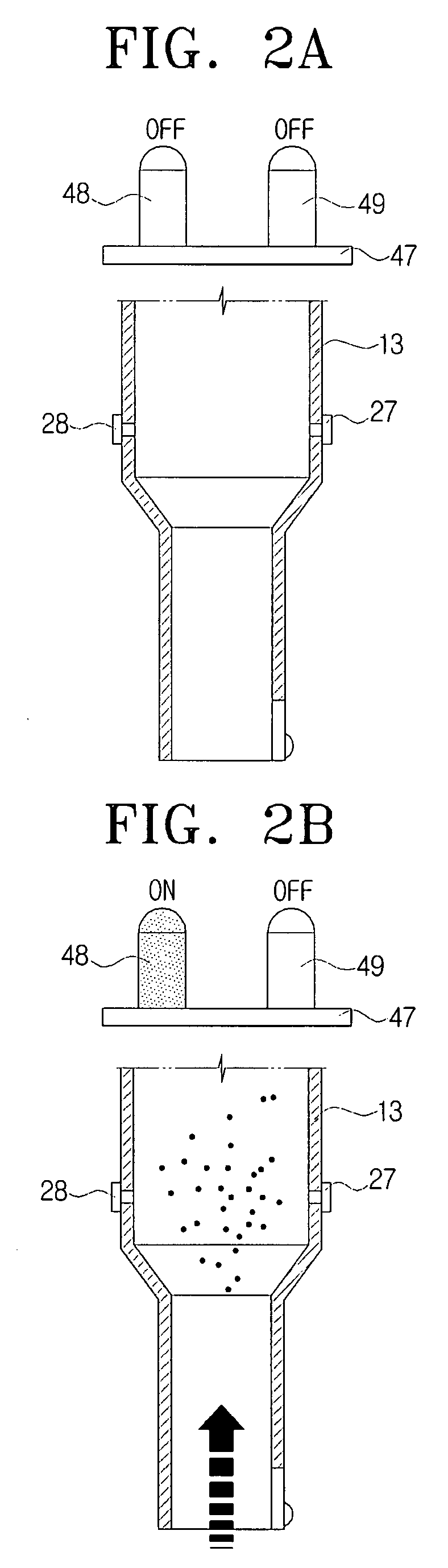

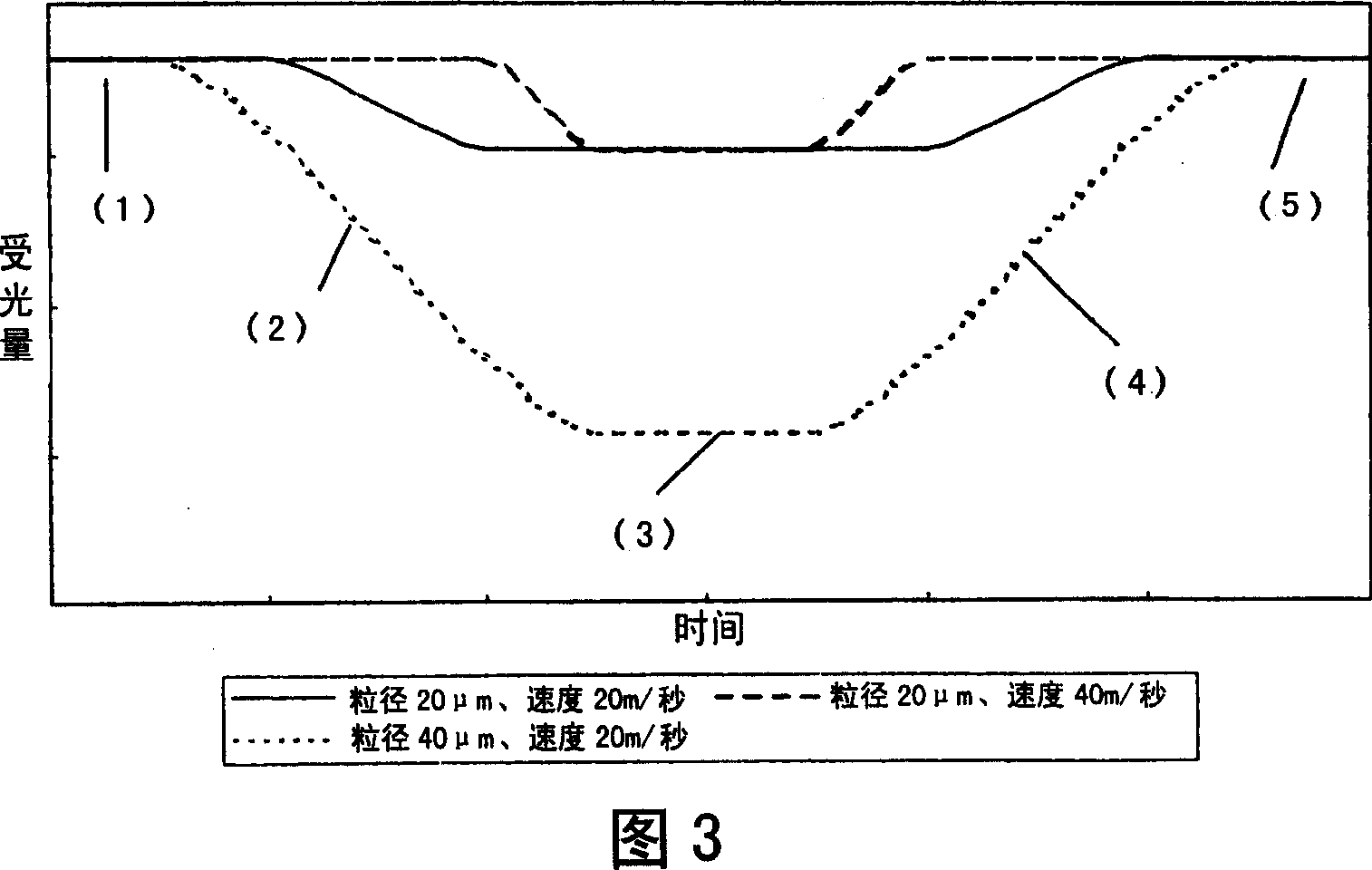

Dust sensing unit for use in vacuum cleaner

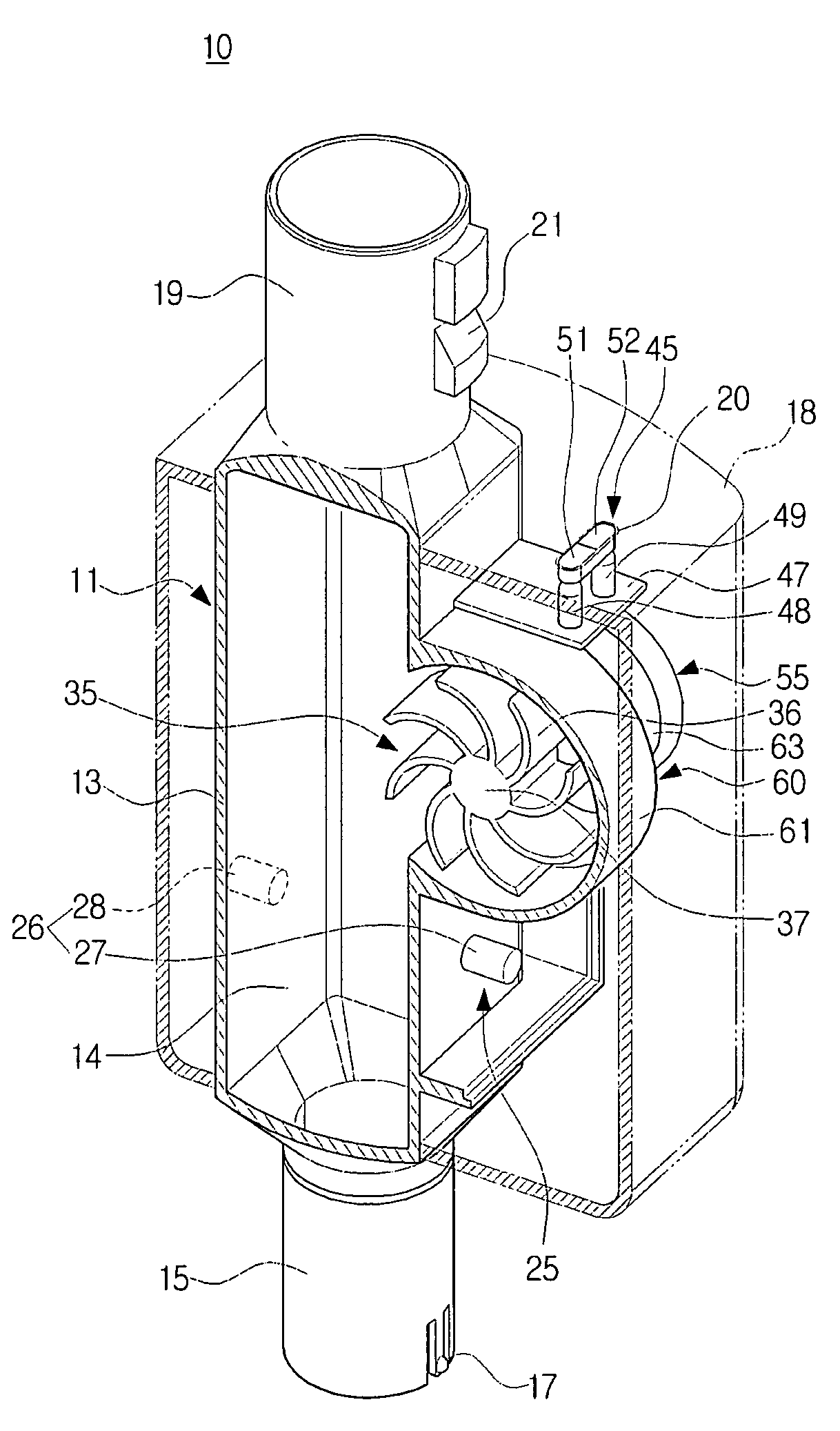

InactiveUS7562414B2Reduce maintenance costsExtend your lifeCleaning filter meansSuction filtersElectric powerElectric generator

A dust sensing unit for use in a vacuum cleaner, which can detect whether there is dust or dirt on a surface to be cleaned and inform a user of the detected result in cleaning, is disclosed. The dust sensing unit includes a body having an air flowing passage therein to move air laden with dust or dirt drawn in through a suction nozzle, a detecting sensor disposed on the air flowing passage to detect whether the dust or dirt is passing through the air flowing passage, a lamp part to operate according to a signal outputted from the detecting sensor, a rotating part disposed to the body to rotate by air flowing through the air flowing passage, and an electric generator rotated by the rotating part to generate an electric power.

Owner:INTELLECTUAL DISCOVERY CO LTD +1

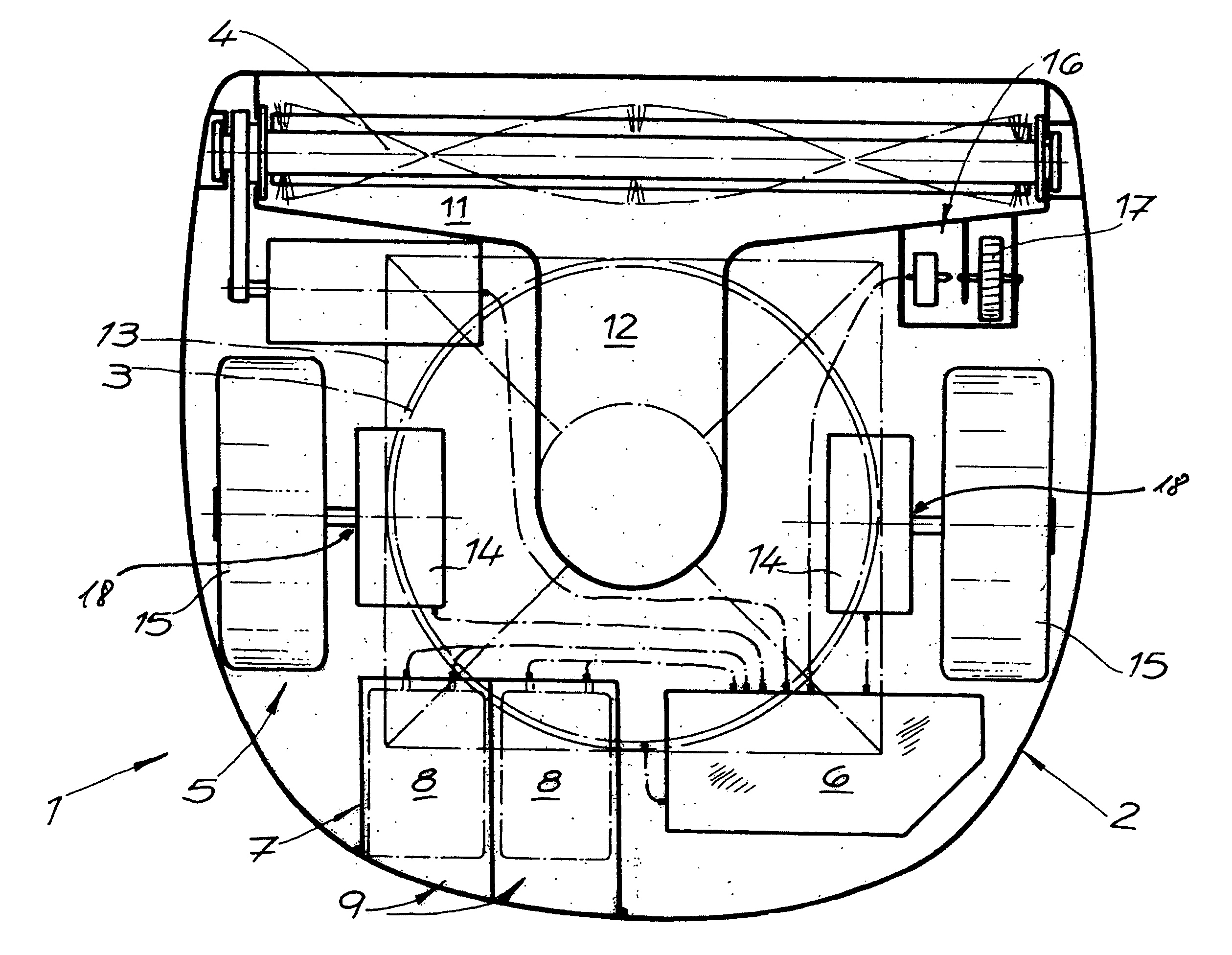

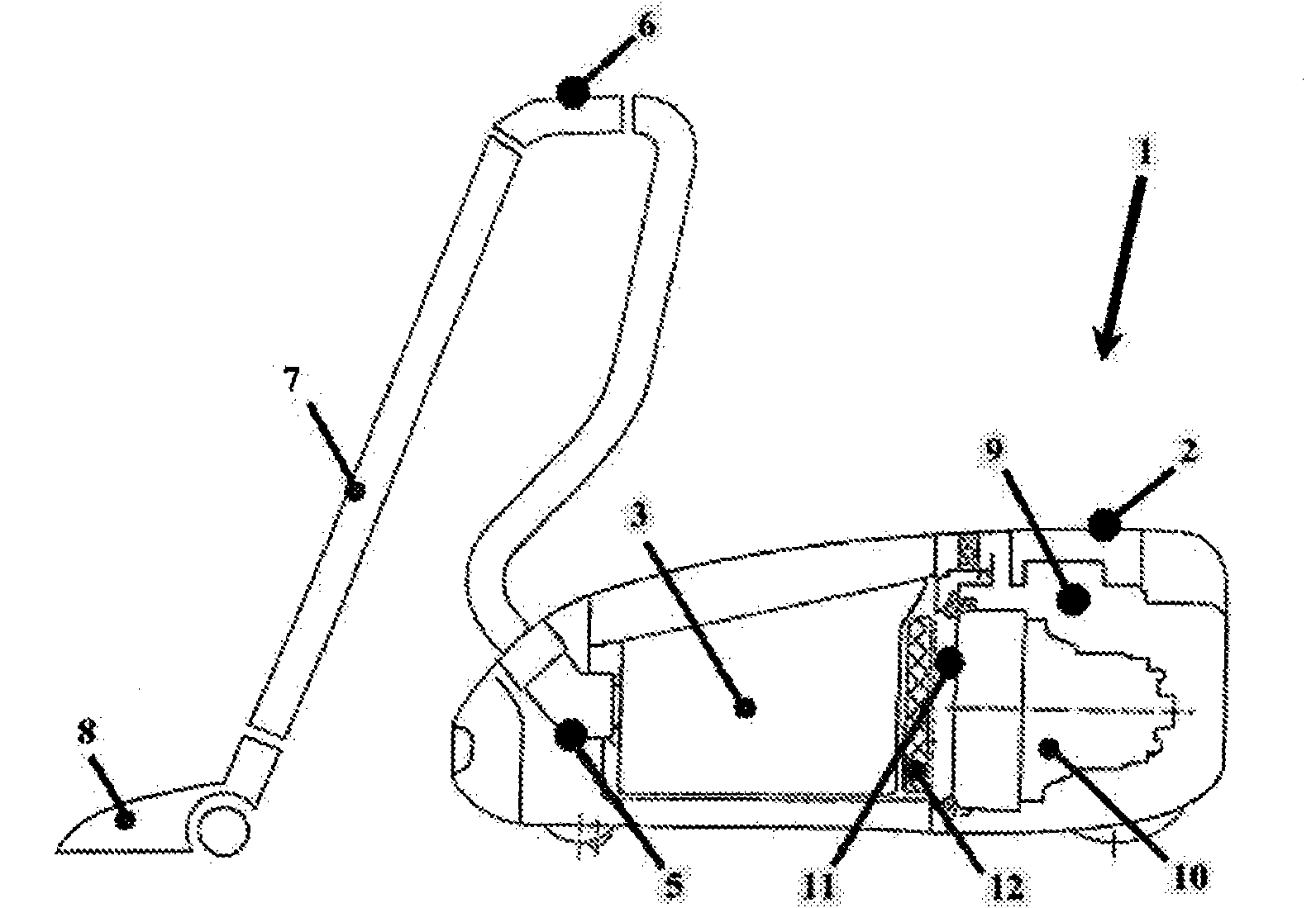

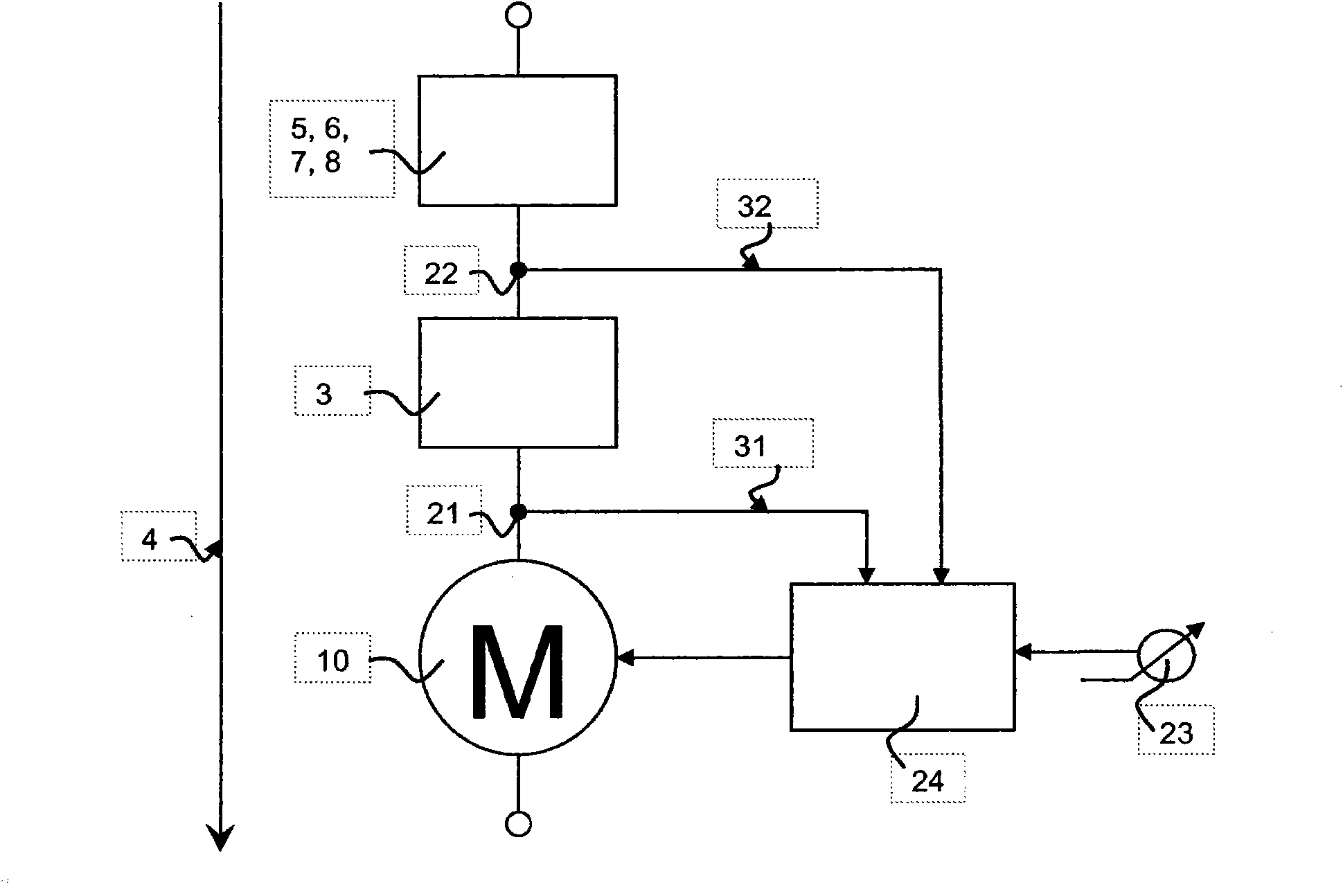

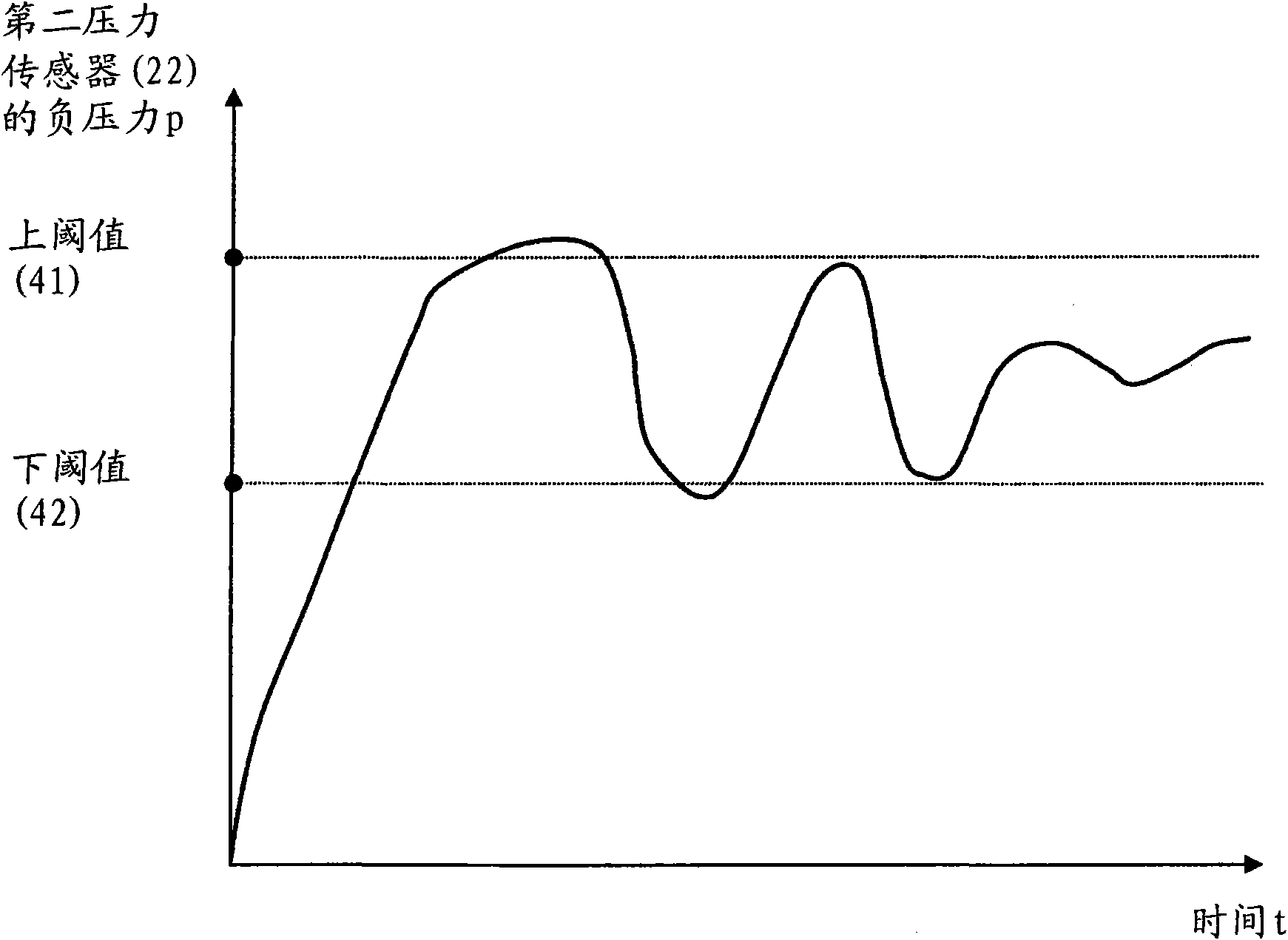

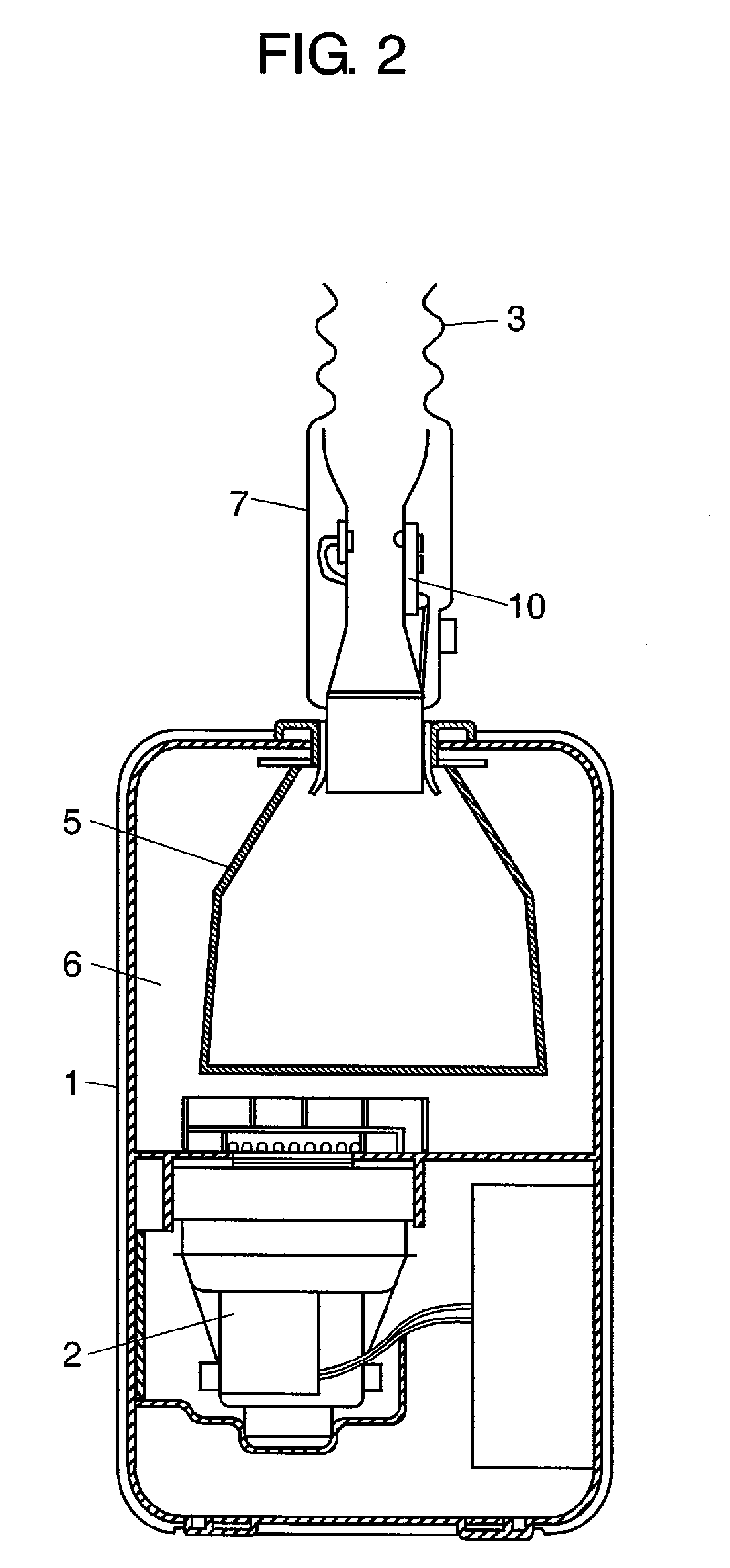

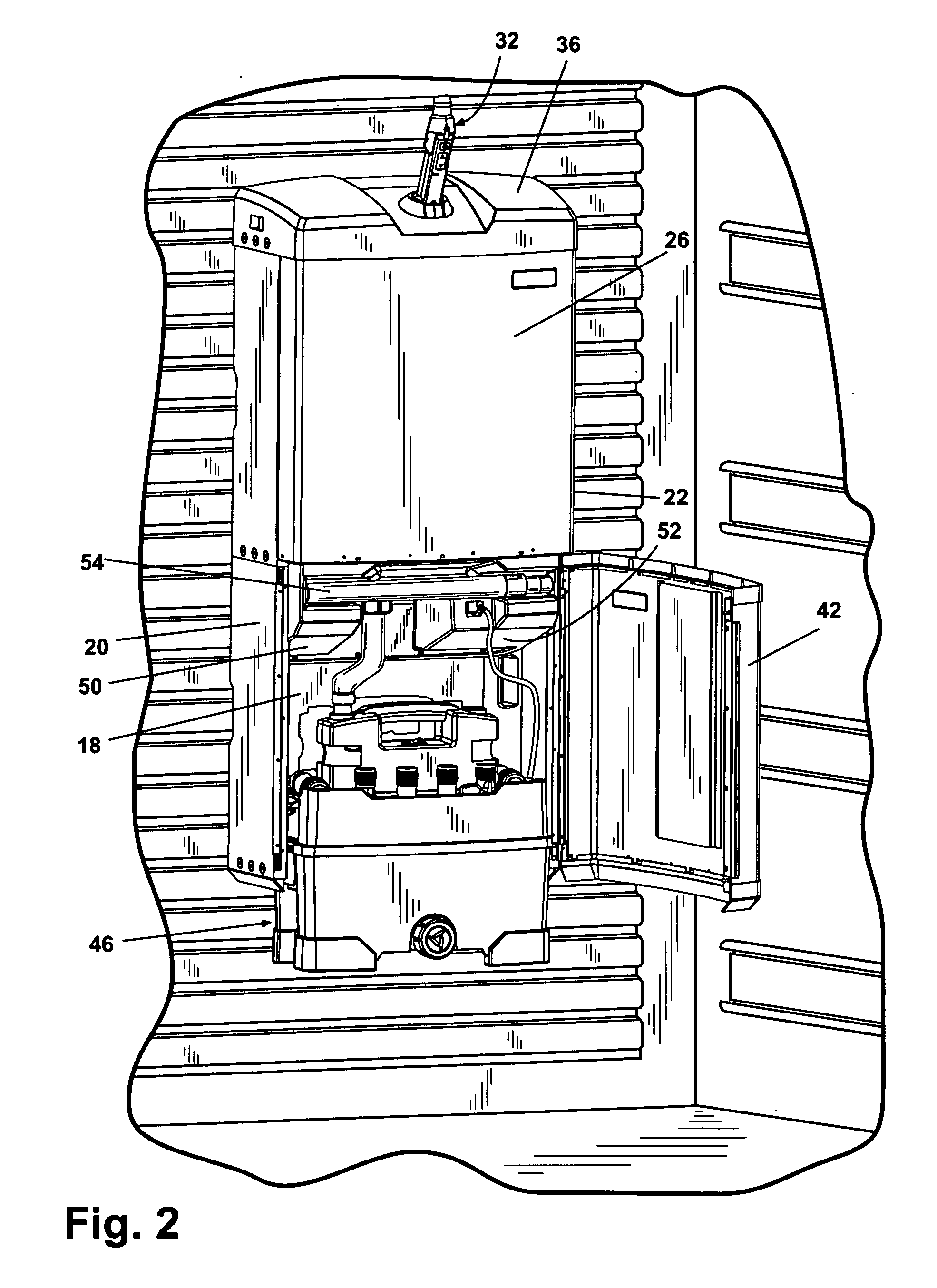

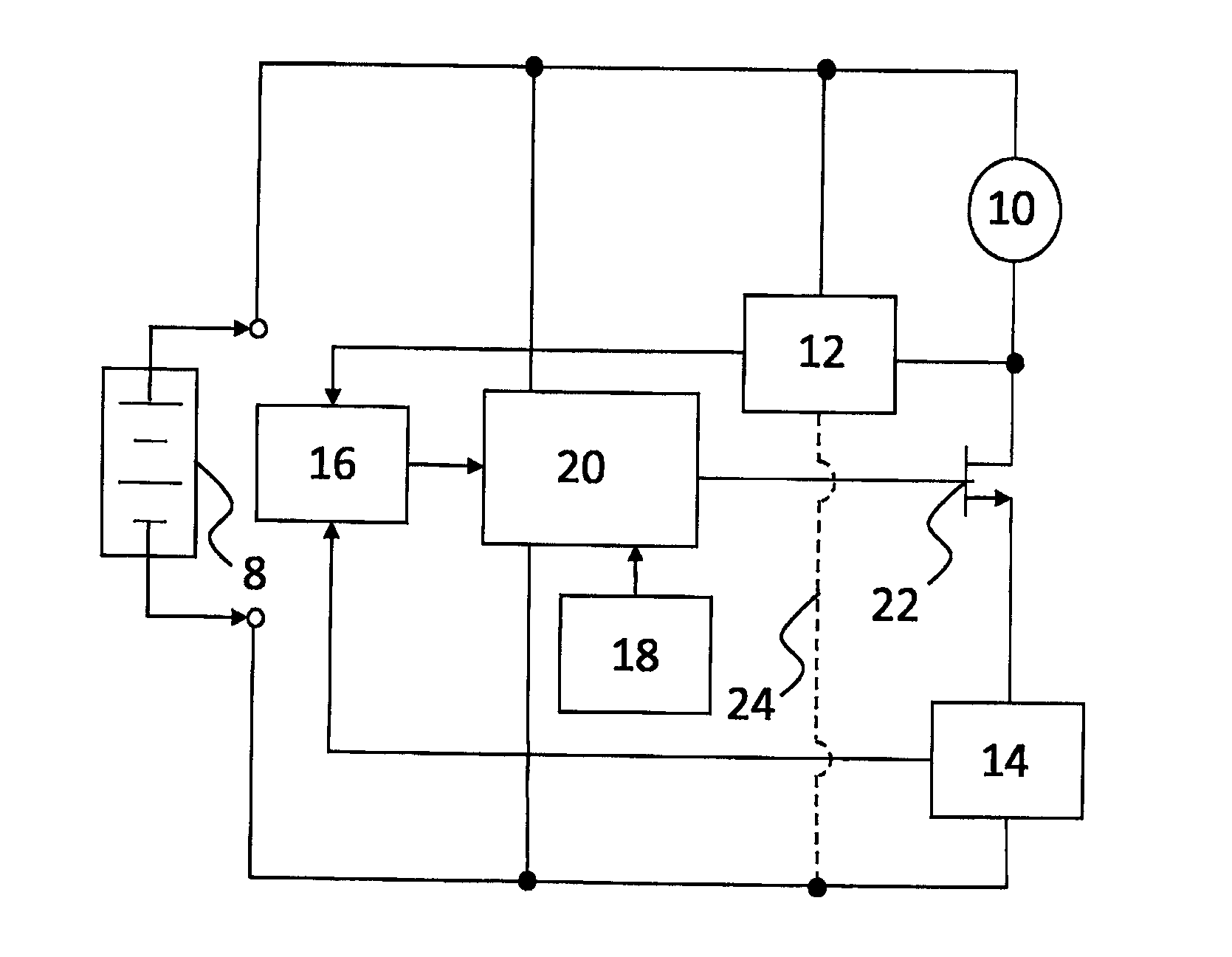

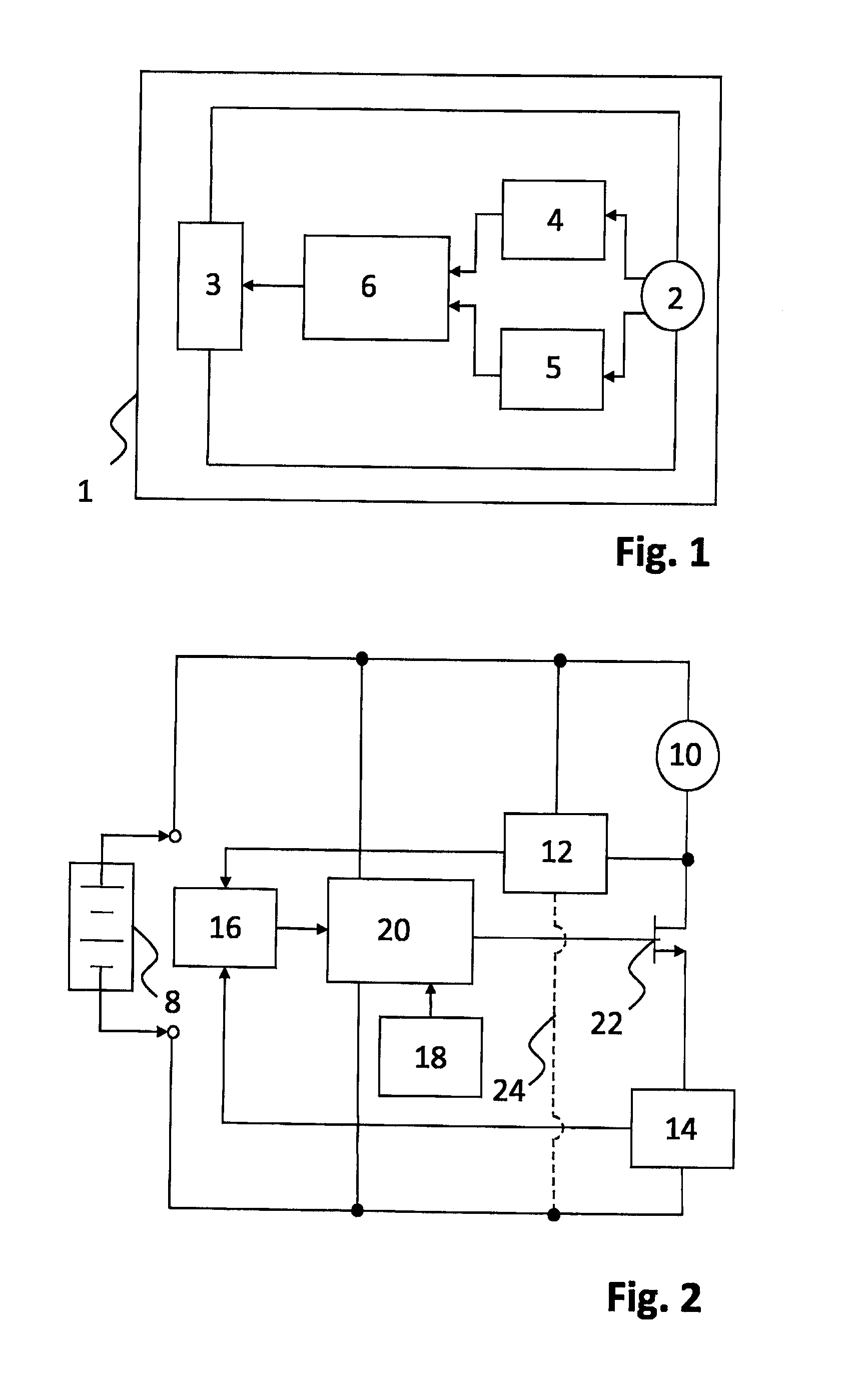

Device for the automatic suction power regulation of a vacuum cleaner

InactiveCN101945607AReduce suction powerIncrease suction powerVacuum cleaner apparatusElectric equipment installationVacuum cleanerPower regulation

The invention relates to a device for a vacuum cleaner (1). Said device only supplies as much electrical power to the motor / fan unit (10) as is necessary for the optimal cleaning of the floor surface to be cleaned and required by the respective operating states of the vacuum cleaner (1), thereby ensuring an energy-efficient use of the vacuum cleaner. Said device thereby ensures a constant cleaning action over the usable life of the vacuum cleaner (1). As the suction nozzle has a constant suction power, dust and dirt particles are always sucked up with a consistently applied suction power and supplied to a dust collection unit (3). The invention also protects the surfaces to be cleaned from being subjected to too much cleaning.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Low noise and energy saving air vacuum cleaner

InactiveUS20080180049A1Reduce noiseSave energyDC motor speed/torque controlAsynchronous induction motorsLow noiseNoise level

A low noise and energy saving air vacuum cleaner by detecting the operation status of the cleaner to control the size of the electricity inputted to an air pump drive motor, or exercise the control of power delivery or power cut off; normal rated voltage being inputted when the cleaner is in normal working status; or the power outputted to the air pump drive motor being reduced or cut off when the cleaning tool of the cleaner clears away from its work area to render the cleaner in full load operation status as were a blower to increase both noise level and power consumption, or when the cleaning tool is blocked due to excessive packing against the work area for reduced noise level and energy saving.

Owner:YANG TAI HER

Self-propelled vacuum-cleaning device

ActiveUS20070136981A1Acceptable cleaning capacityQuick refillSuction cleanersSecondary cellsControl electronicsEngineering

A self-propelled vacuum-cleaning device for cleaning smooth and textile floor coverings, particularly in the private home sector. The device has a housing, a vacuum blower, an electrically driven cleaning roller, an electrical drive mechanism, control electronics, and a power source. The maximal electric power of the self-propelled vacuum-cleaning tool lies between 150 watts and 300 watts during cleaning operation, whereby between 120 watts and 220 watts are allocated to the vacuum blower, between 10 watts and 40 watts are allocated to the electrical roller drive for the cleaning roller, and between 5 watts and 40 watts are allocated to the drive mechanism, and whereby the control electronics have a power demand of less than 5% of the maximal electric power.

Owner:WESSEL WERK

Electric cleaner

InactiveUS20090119867A1Improve accuracyVacuum cleaner apparatusElectric equipment installationDriver/operatorElectric power

An electric vacuum cleaner includes an electric blower, a driver for driving the electric blower, a determination controller for controlling the electric power supply to the electric blower by transmitting a signal to the driver, and a dust amount sensor for sensing the amounts of dusts of different sizes. The determination controller controls the electric power supply to the electric blower based on the amounts of dusts of the different sizes sensed by the dust amount sensor.

Owner:PANASONIC CORP

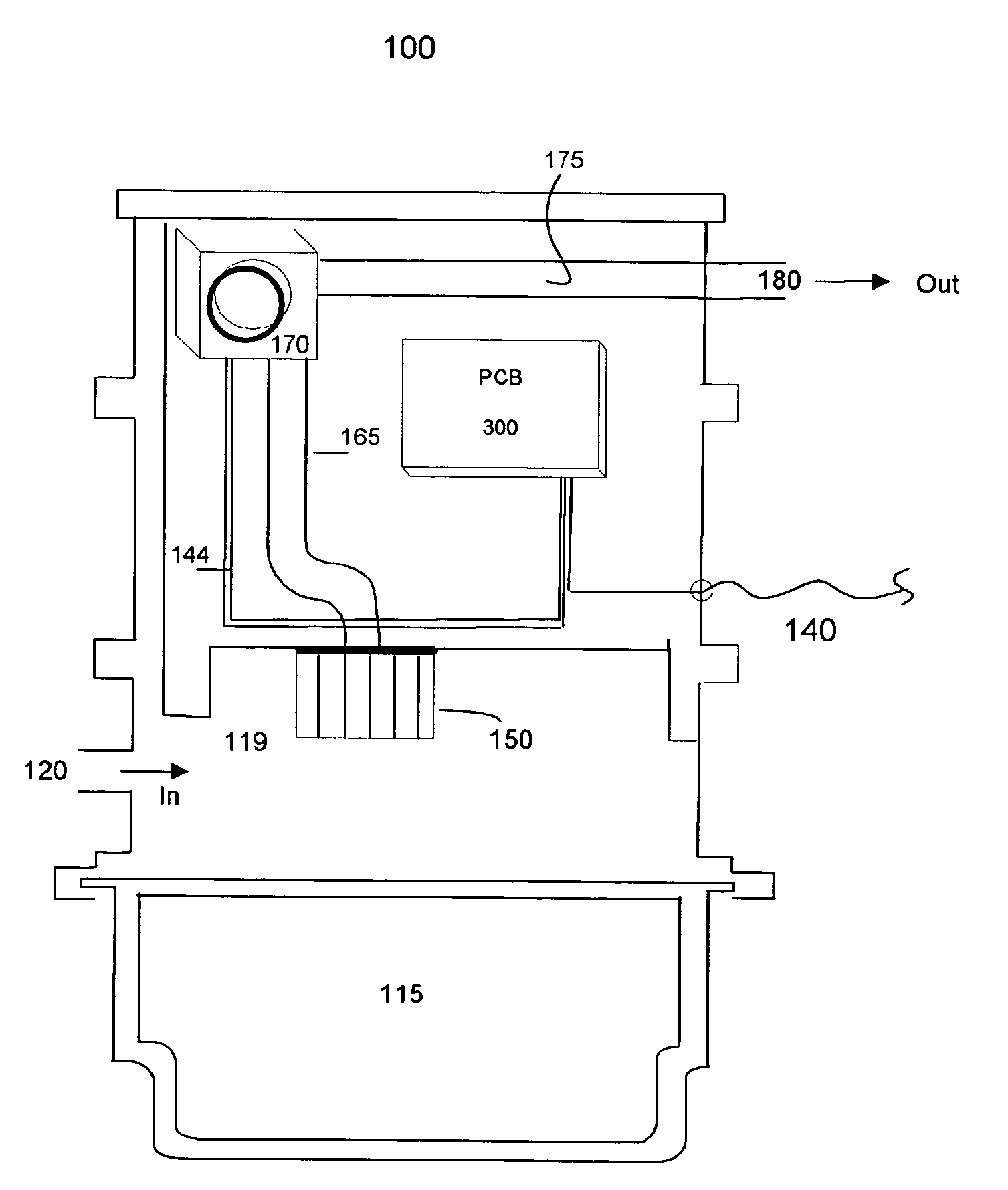

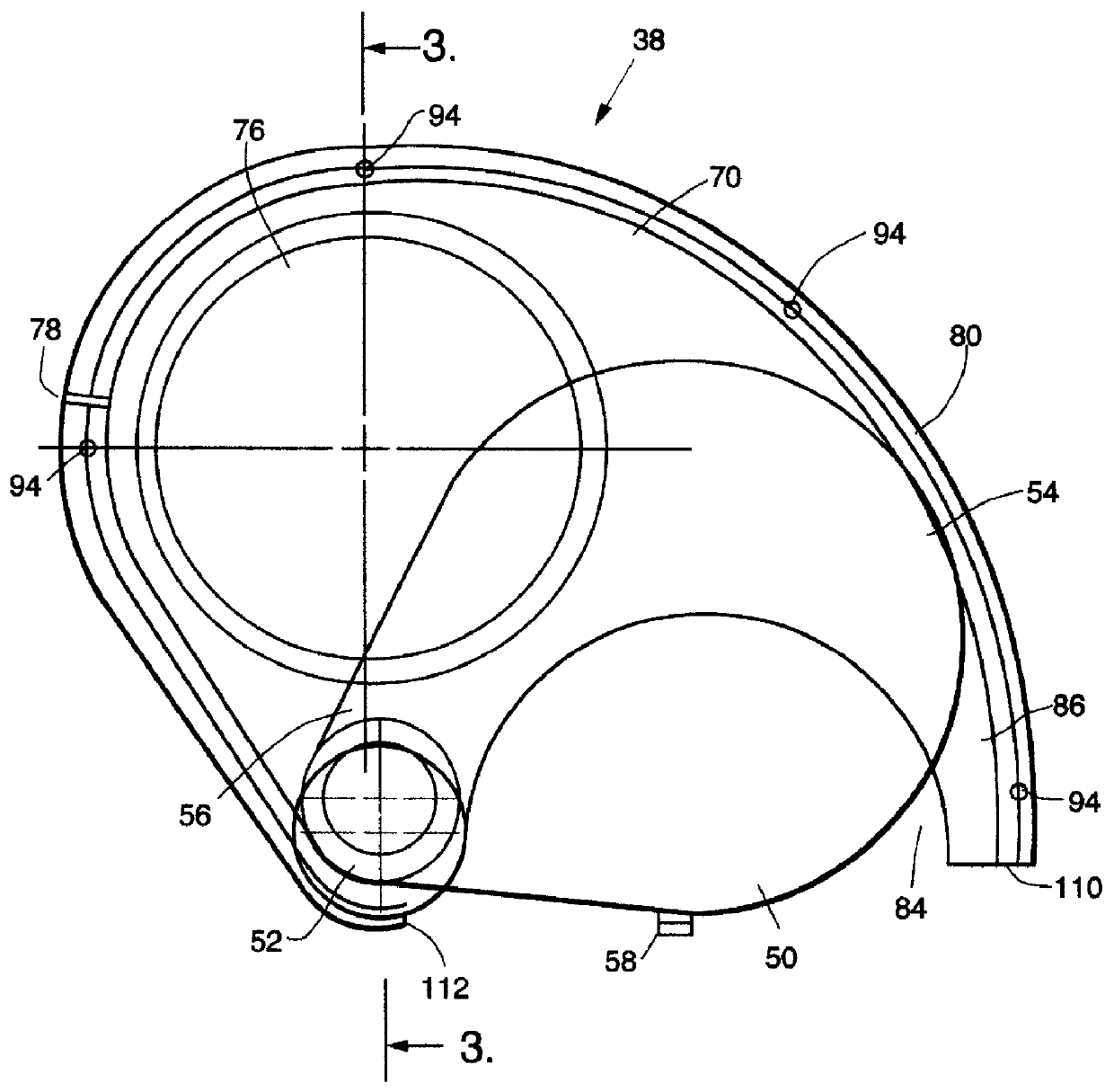

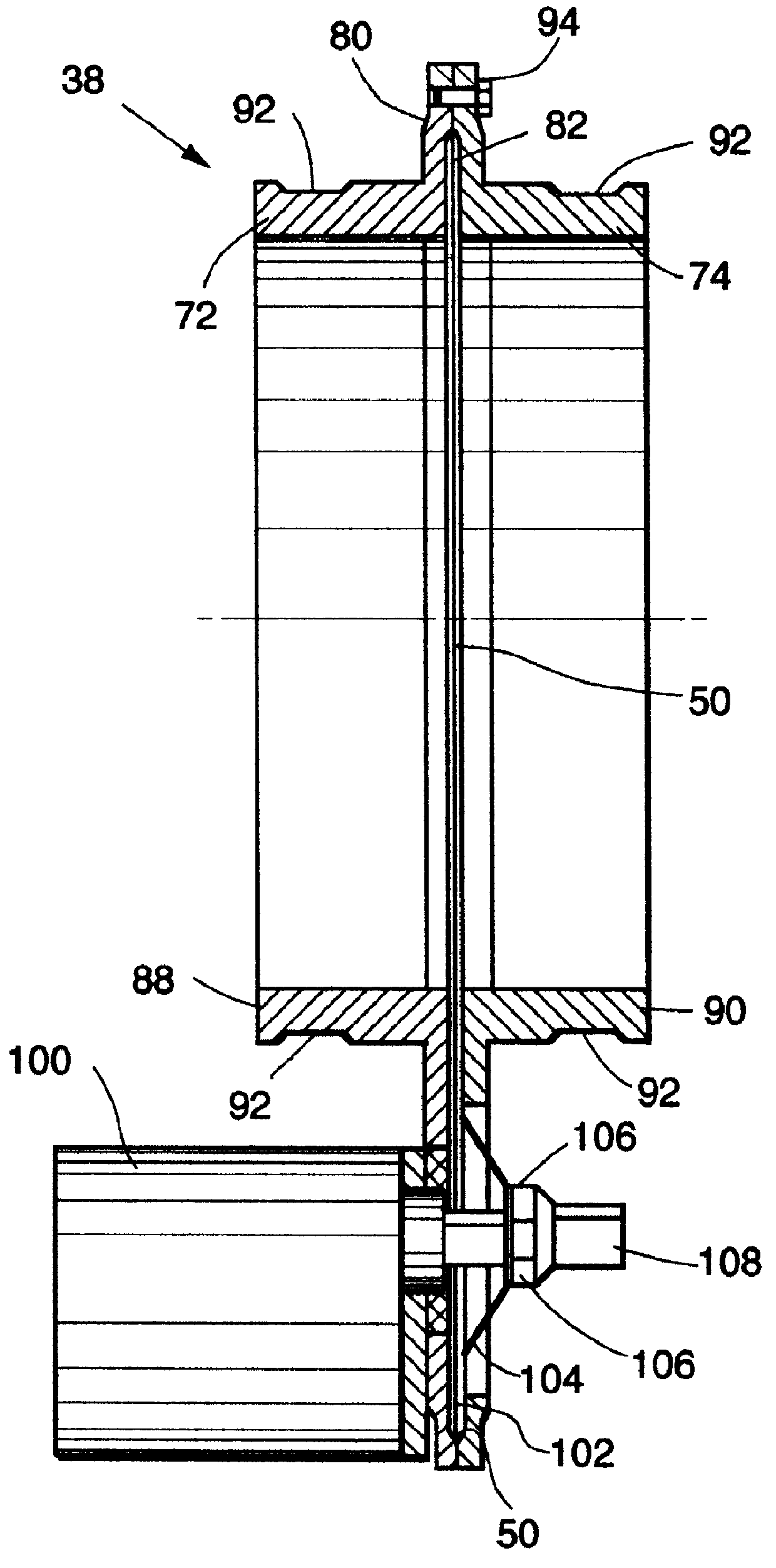

Convertible vacuum system

InactiveUS20070017057A1Vehicle cleaningTableware washing/rinsing machinesElectric powerElectrical and Electronics engineering

A vacuum system has a cabinet that can be mounted to a wall. The cabinet includes a hose extendable form the cabinet between retracted and extended positions. A portable vacuum unit can be removably docked to the cabinet and has a tank and inlet port in fluid communication with the tank. It also has an electrically operated vacuum source. The cabinet has a controller for selectively delivering power to a socket in the cabinet. When the portable vacuum unit is docked to the cabinet with the proximal end connected to the inlet port, and when the controller delivers power to the socket, the hose can be used to vacuum waste into the tank.

Owner:WHIRLPOOL CORP

Vacuum cleaner and method for controlling an electric motor

ActiveUS20120112670A1Easy to controlSufficient suction powerMotor/generator/converter stoppersAC motor controlElectric powerMotor power

A vacuum cleaner and a method for controlling the motor power of a vacuum cleaner are disclosed. The vacuum cleaner comprises an electric motor and an electric power supply for providing electric power to the electric motor. Furthermore, a voltage measuring means for measuring a motor voltage over the electric motor and a current measuring means for measuring a motor current flowing through the electric motor are provided. The vacuum cleaner further comprises a control means for controlling, based on the measured voltage and the measured current, the electric power provided to the electric motor from the electric power supply towards a target motor power value.

Owner:AB ELECTROLUX

Vacuum cleaner agitator cleaner with power control

A vacuum cleaner agitator system having an agitator, an electric motor to rotate the agitator, a power source, and an agitator cleaner. The cleaner moves between a first position in which it is spaced from the agitator and a second position in which it engages the agitator to remove debris while the agitator rotates. The system also has a detector configured to indicate when the cleaner is in the second position. A drive control system connects the electric motor, electric power source, and agitator cleaning detector. The drive control system has a first drive mode to drive the electric motor at a first power level, and a second drive mode, activated upon receiving an indication from the detector that the cleaner is in the second position, to drive the electric motor at a second power level that is greater than the first power level.

Owner:AB ELECTROLUX

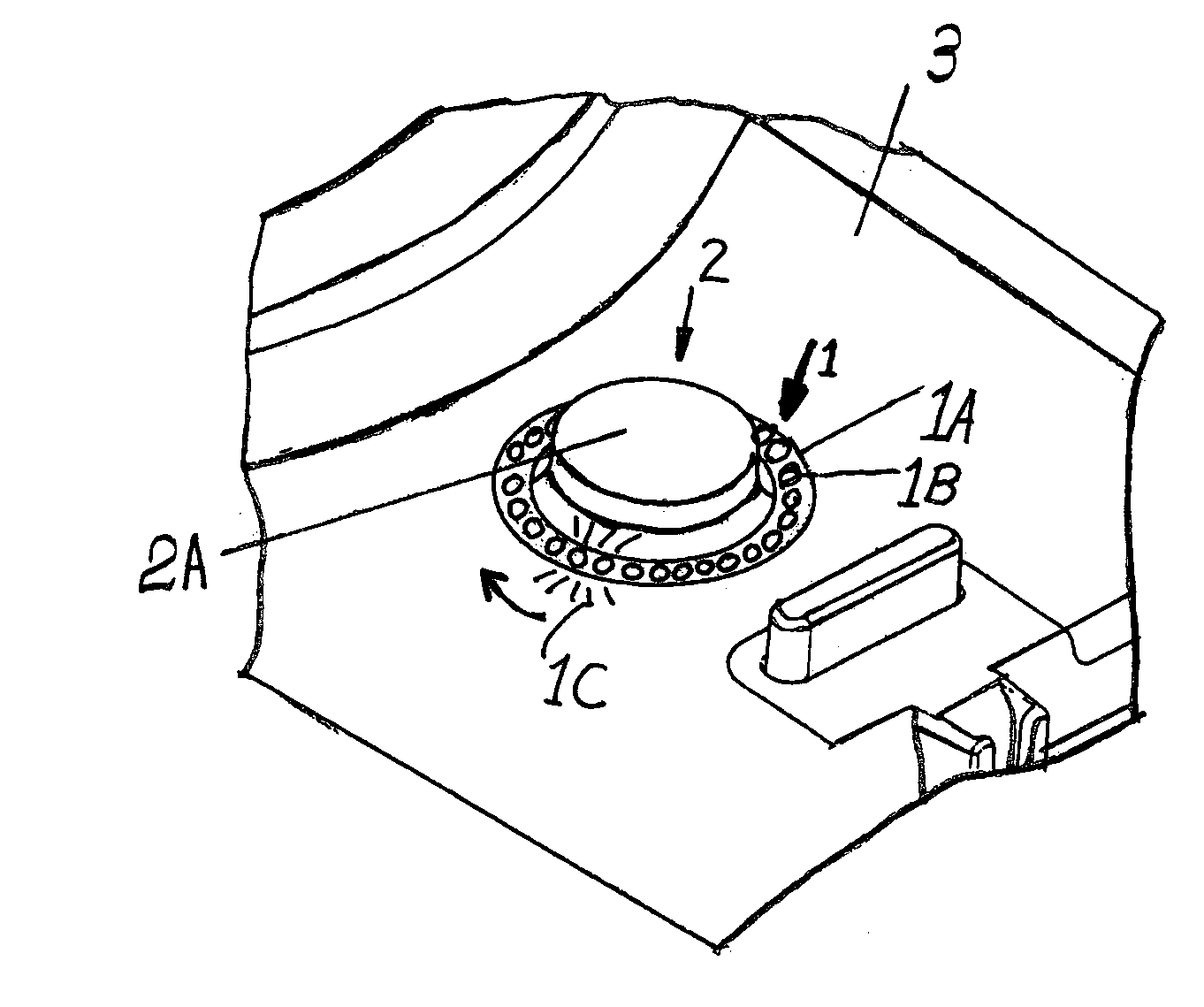

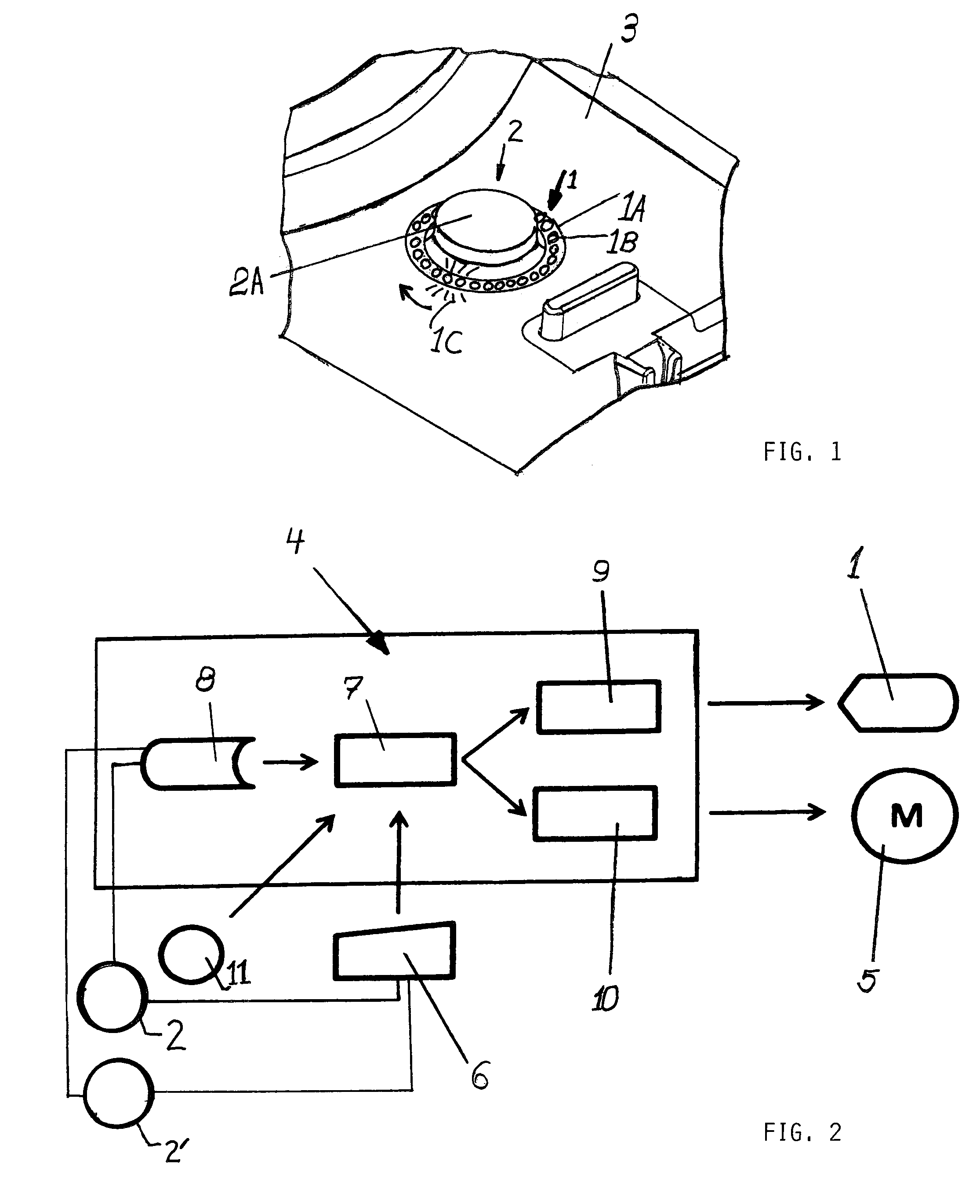

Vacuum Cleaner With Motor Speed Indicator

ActiveUS20110232687A1Easy detectionGreat suctionElectrical apparatusElectroluminescent light sourcesMotor speedElectric machine

A vacuum cleaner includes a variable speed suction motor and an illuminatable motor speed indicator having plural lights arranged in a circular pattern or annular ring pattern, for example around a motor speed control switch. A control unit includes an indicator controller and a motor controller that respectively control the illuminatable indicator and the motor, based on inputs from the motor speed control switch and optionally at least one sensor that senses operating conditions of the vacuum cleaner. The lights are successively activated and deactivated to create a visible light spot that appears to rotate around the circular or annular ring pattern at a light rotation rate related to and indicative of the motor rotation speed. Thereby the indicator allows the vacuum suction power to be visually monitored.

Owner:STEIN

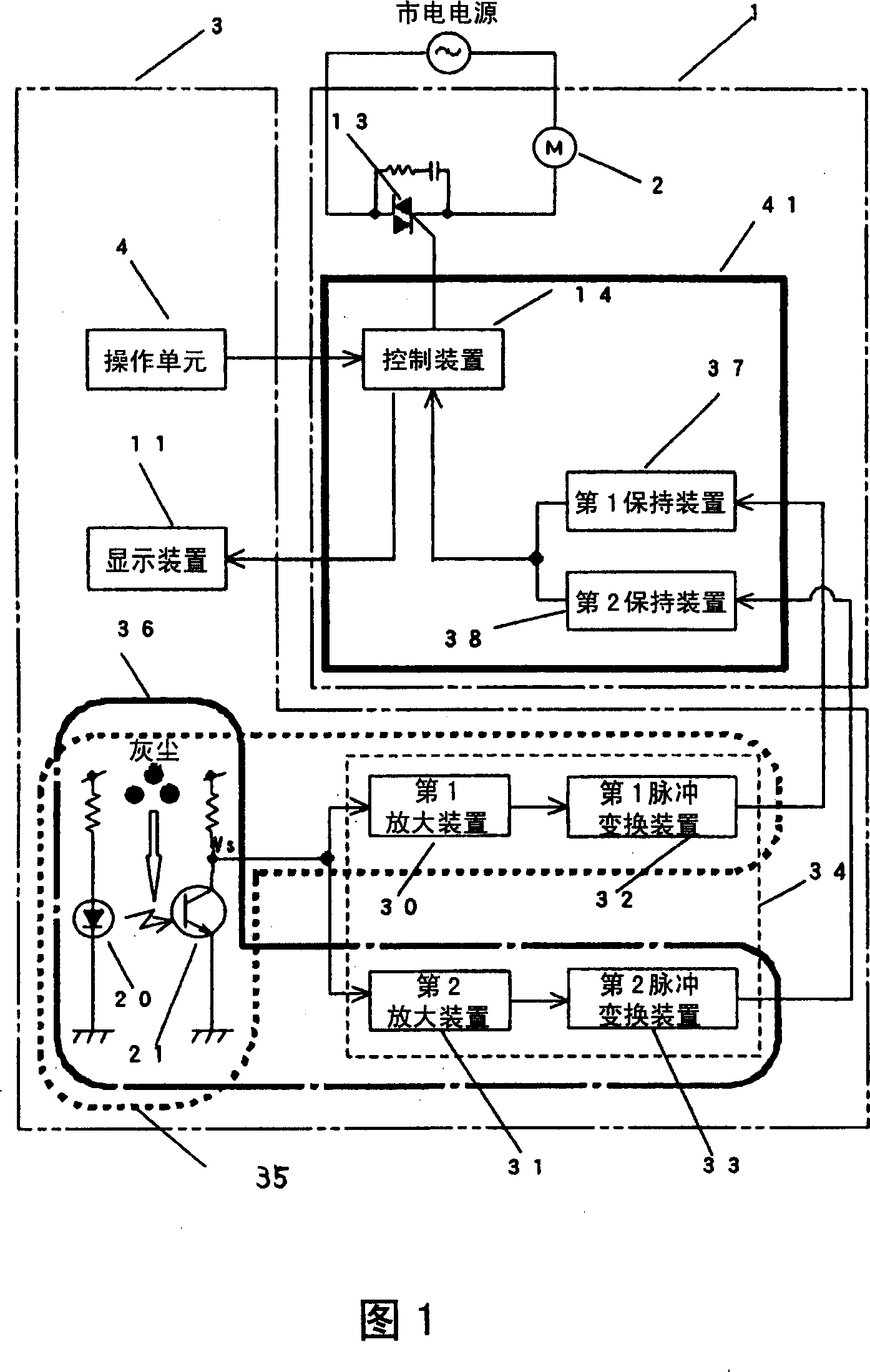

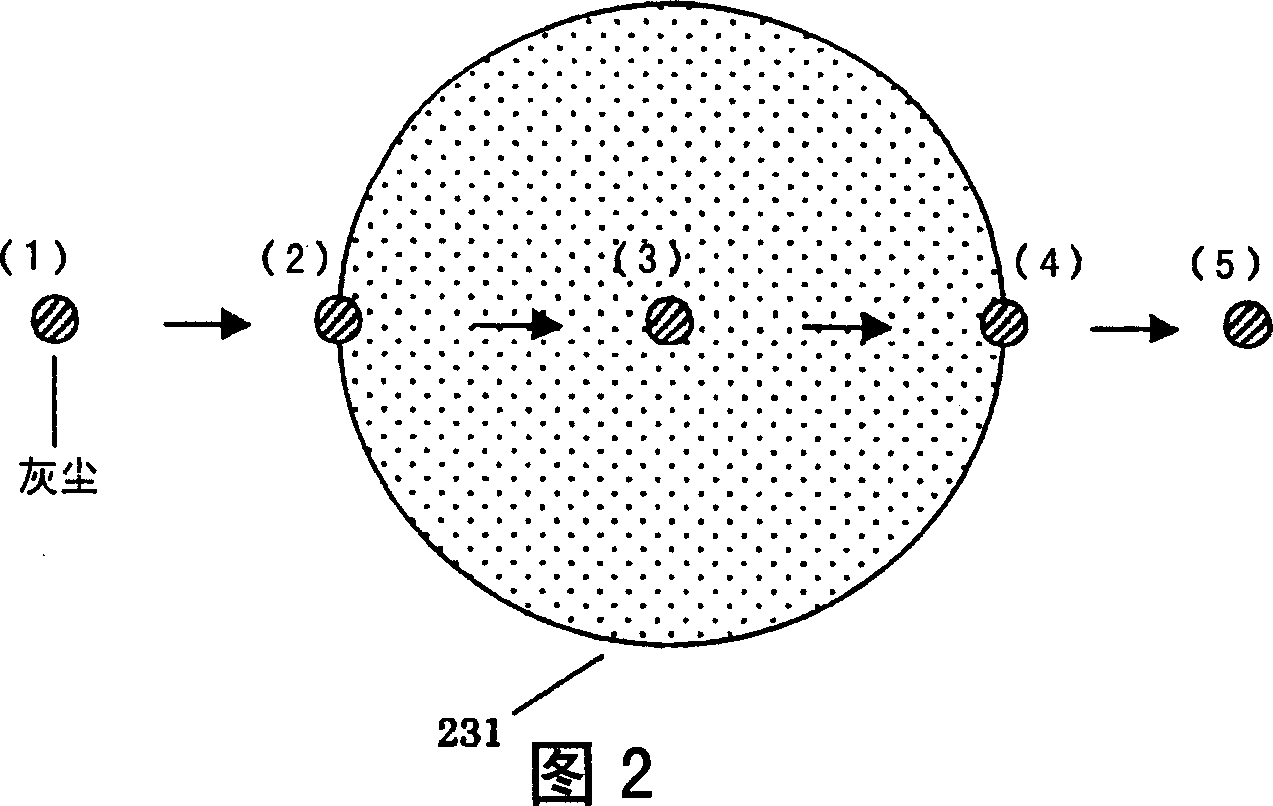

Electric cleaner

ActiveCN1954766AHigh control precisionAttractiveVacuum cleaner apparatusElectric equipment installationEngineeringDust collector

The present invention provides an electric dust collector capable of always keeping optimal attractive force for various kinds of dust, thereby improving the control precision and efficiency of the power supplied to the electric blower fan. The electric dust collector of the present invention comprises a first dust detecting device(35); a second dust detecting device(36); a first holding device(37)for giving holding time to each signal and outputting a first holding signal based on the first dust detecting signal detected by the first dust detecting device; a second holding device(38)for giving holding time to each signal and outputting a second holding signal based on the second dust detecting signal detected by the second dust detecting device; and a display control device(14)for controlling the power supplied to the electric blower fan based on the first holding signal and the second holding signal. Thus, the dust of different sizes can be detected according to various sizes of the dust respectively so as to improve the control precision of the power according to the size, the kinds and the quantity of dust.

Owner:PANASONIC CORP

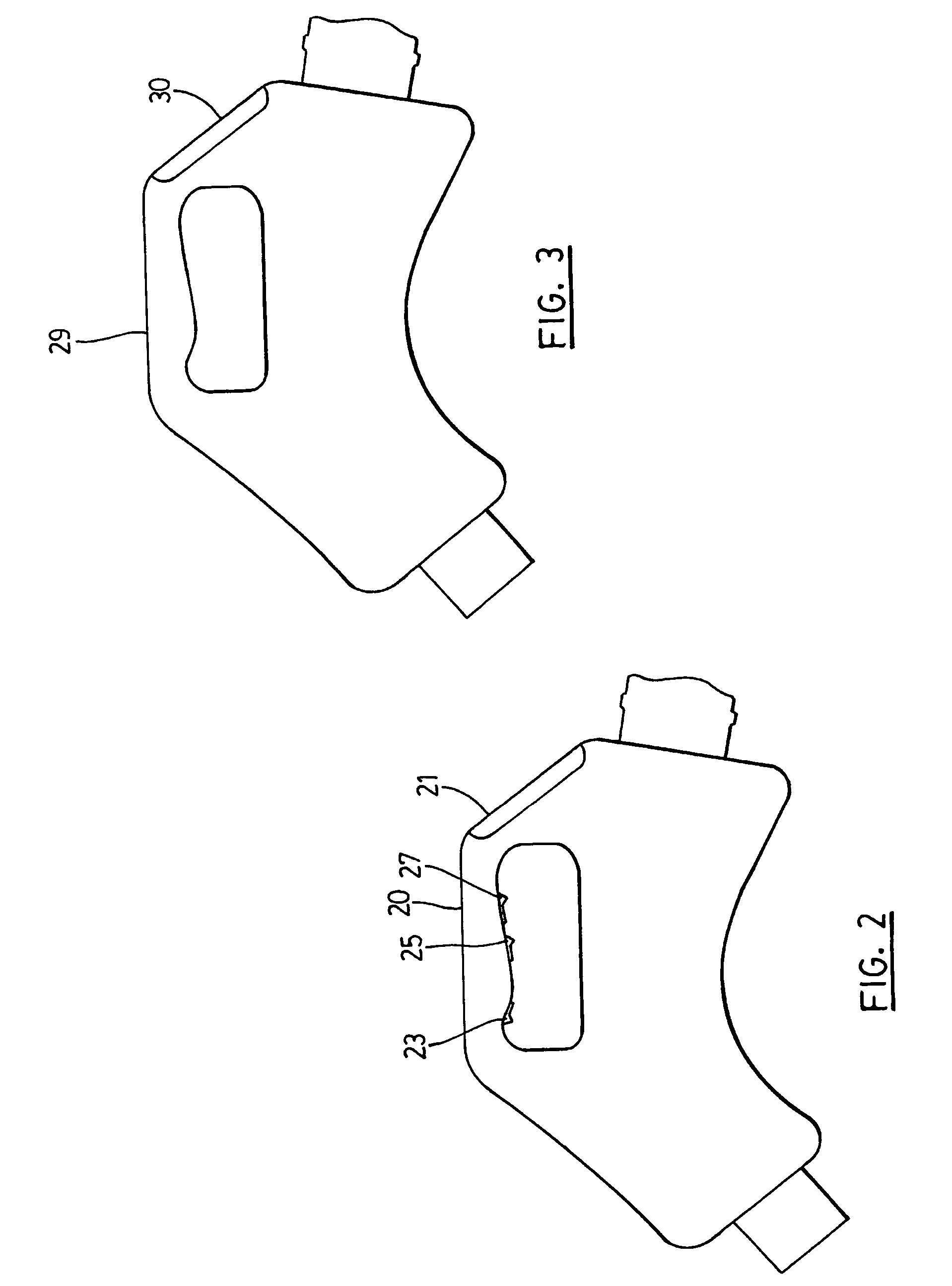

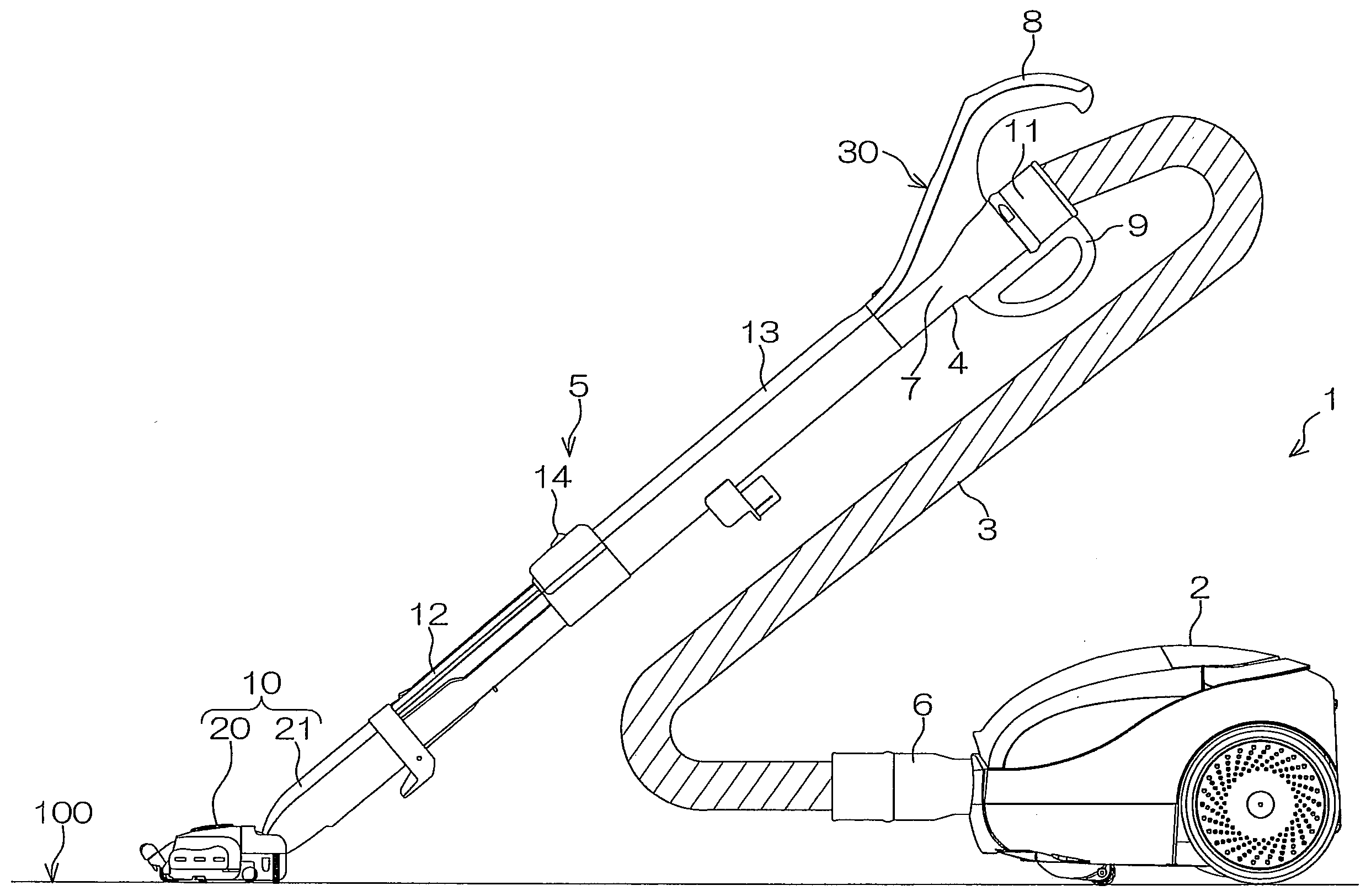

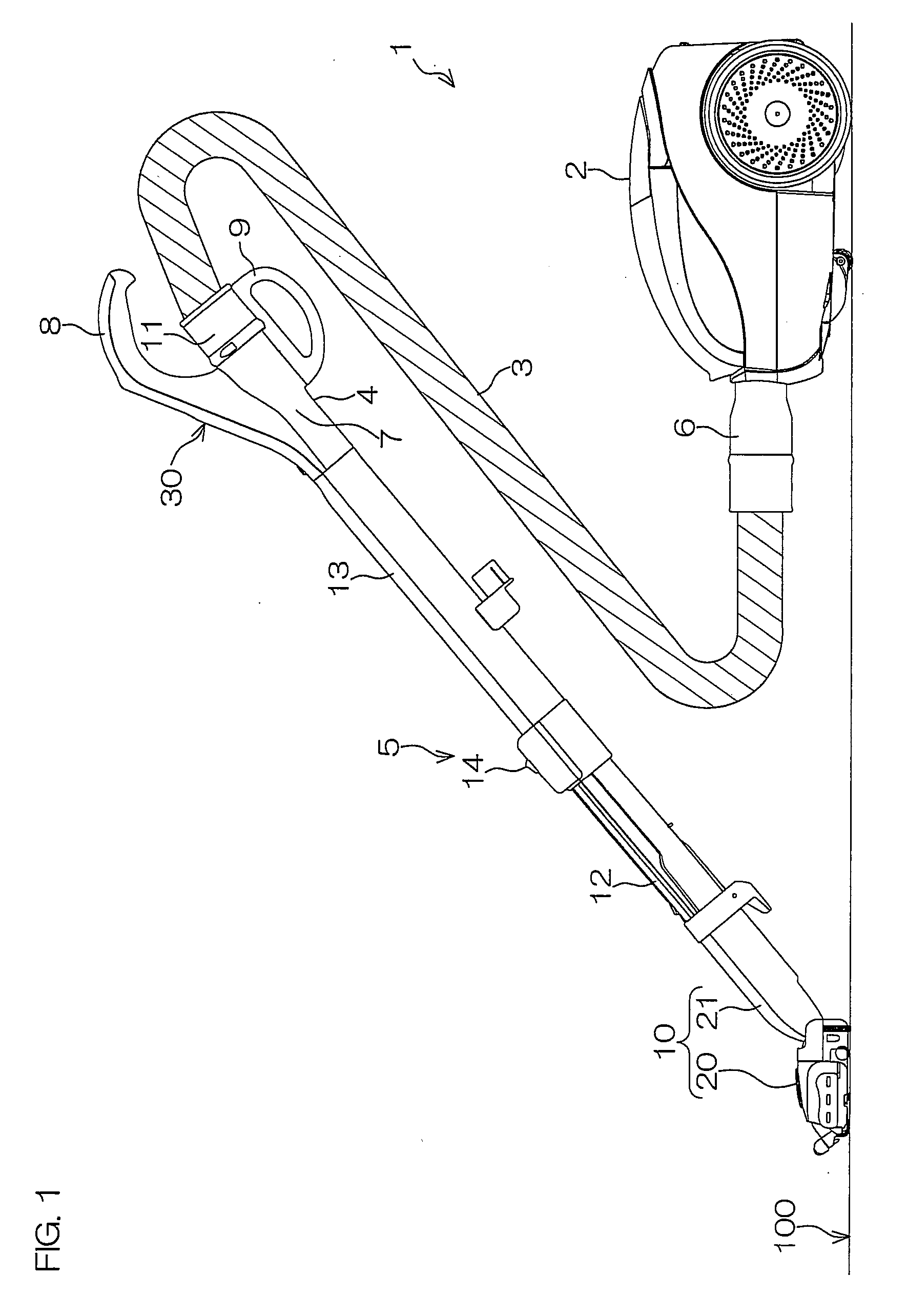

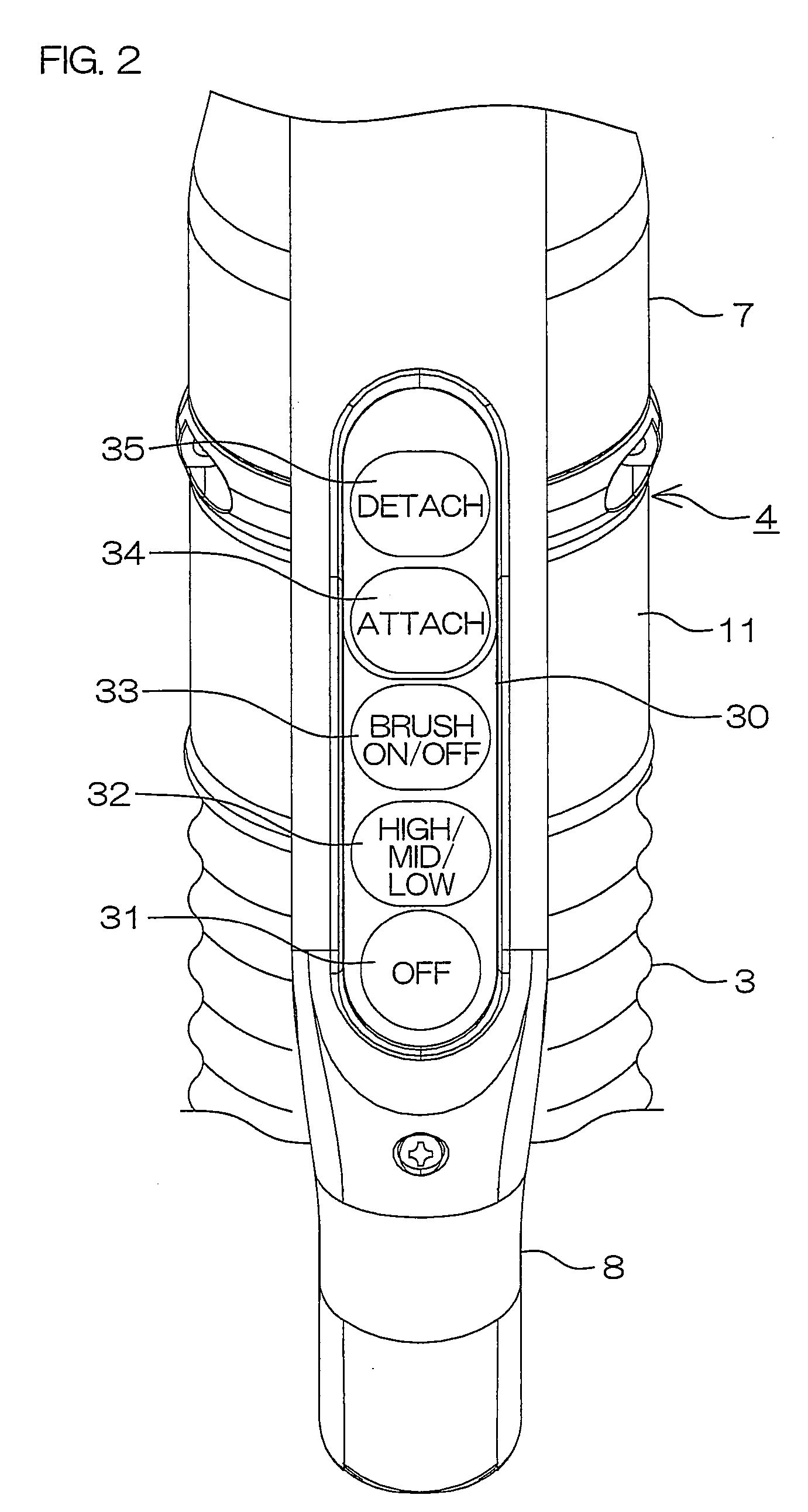

Electric vacuum cleaner

InactiveUS20080201897A1Easy to operateGreat suctionMechanical cleaningPressure cleaningSuction forceEngineering

An electric vacuum cleaner (1) of the invention is adapted for wipe off cleaning using a sheet wound about a rotary brush (25) incorporated in a suction device (10). In order to wind a sheet (50) around a periphery of the rotary brush (25), a brush motor (44) rotates the rotary brush (25) in a predetermined direction at a predetermined rotational speed. At the same time, suction force of an electric blower fan (42) is set to the lowest level. This achieves the following advantage in a case where a wet sheet is used as the sheet (50). During sheet winding, water and alcohol released from the wet sheet (50) can be prevented from being scattered on a surface (100) to be cleaned. Further, the released water and alcohol do not adversely affect the electric blower fan (42).

Owner:SANYO ELECTRIC CO LTD

High-speed electric system

ActiveUS8432114B2Less torqueEfficient electric machineSynchronous motors startersMultiple motor speed/torque controlControl systemElectric machine

Owner:DYSON TECH LTD

Anti jamming device for a vacuum hose

Owner:WHIRLPOOL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com