Electric cleaner

A vacuum cleaner and electric technology, which is applied to the installation of vacuum cleaner equipment, electrical equipment, and improvement of the efficiency of home appliances, etc., can solve the problems of difficult calibration and large width difference, and achieve the effect of improving control accuracy and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A first embodiment of the present invention will be described below with reference to FIGS. 1 to 6 . Wherein, for the components that are the same as those in the above-mentioned conventional vacuum cleaner, only the same symbols are attached here, and repeated descriptions thereof are omitted.

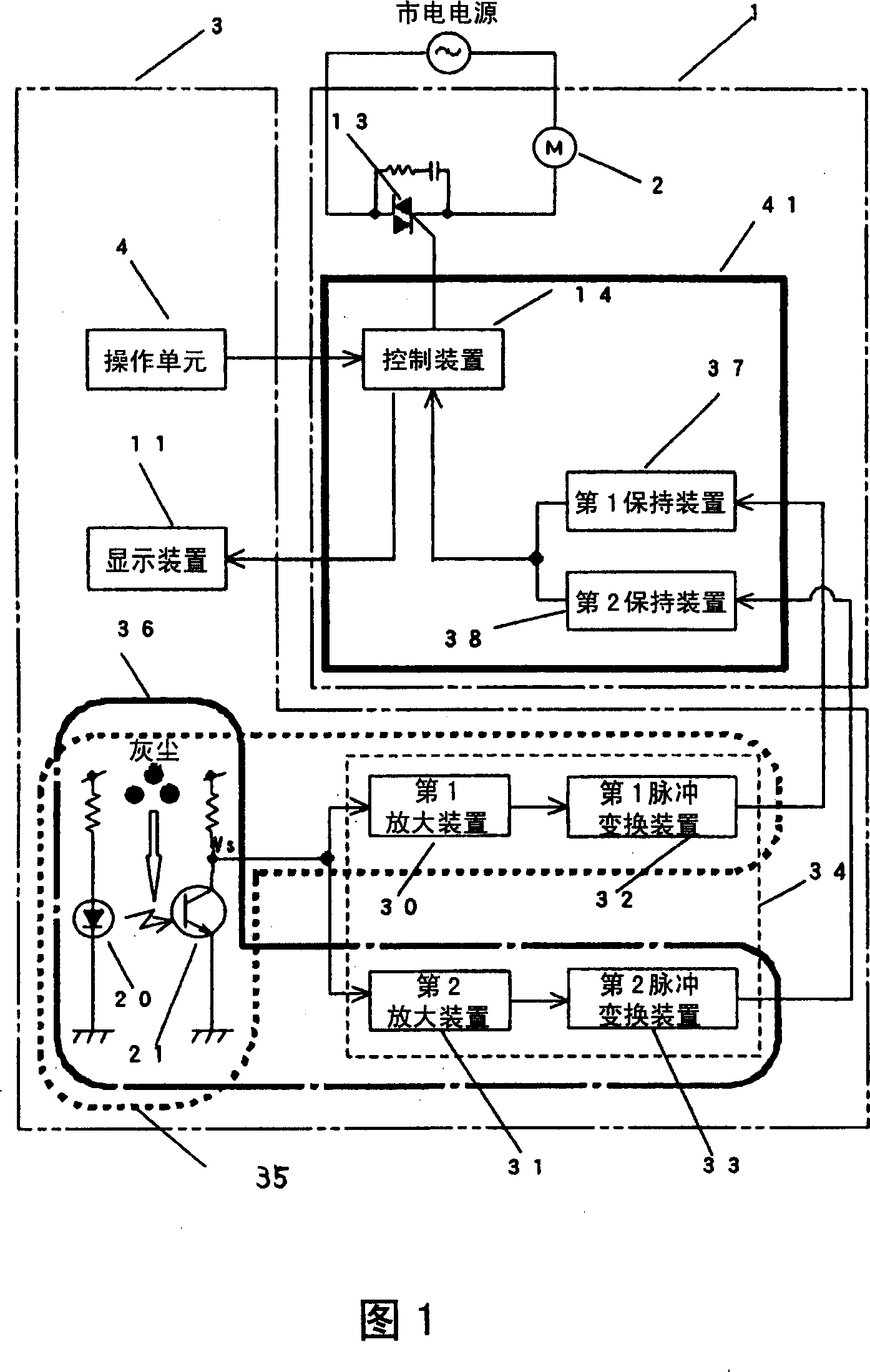

[0039] FIG. 1 is a block diagram of a control circuit of a dust display device for an electric vacuum cleaner in Embodiment 1 of the present invention.

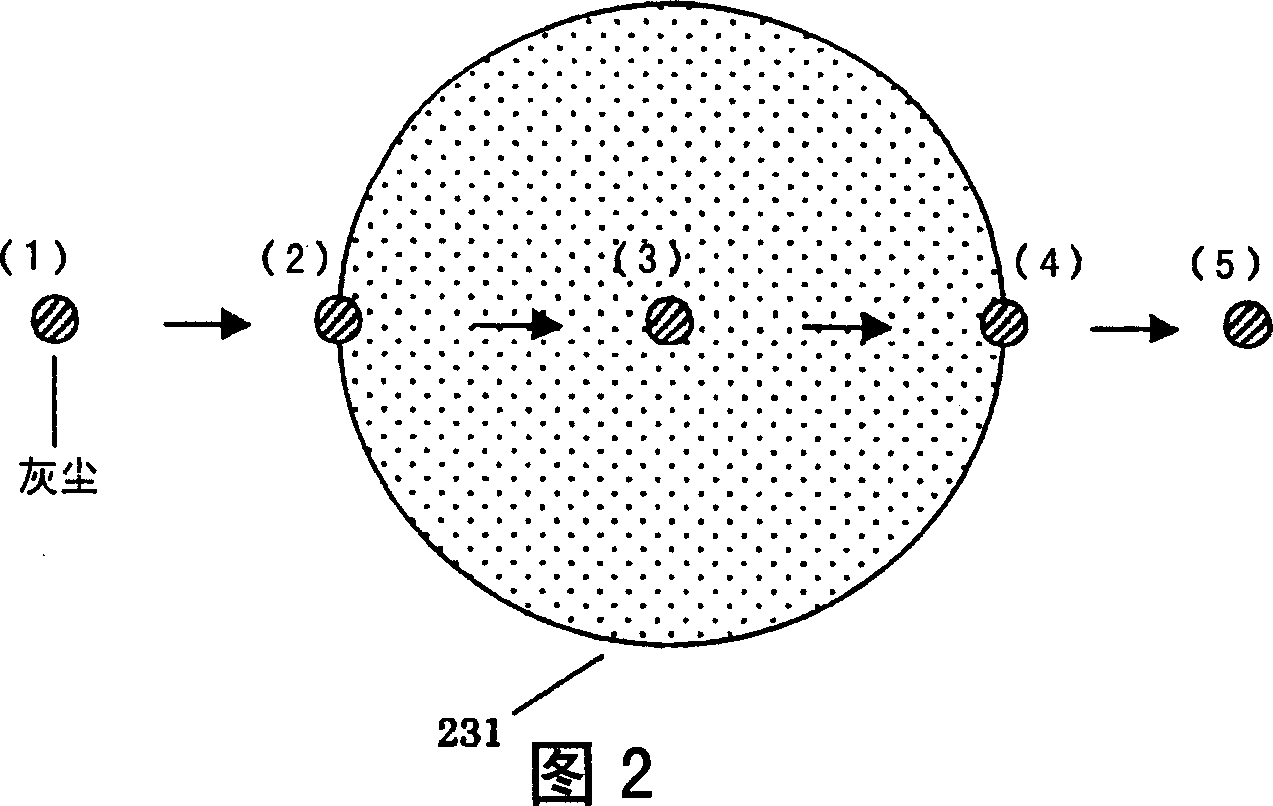

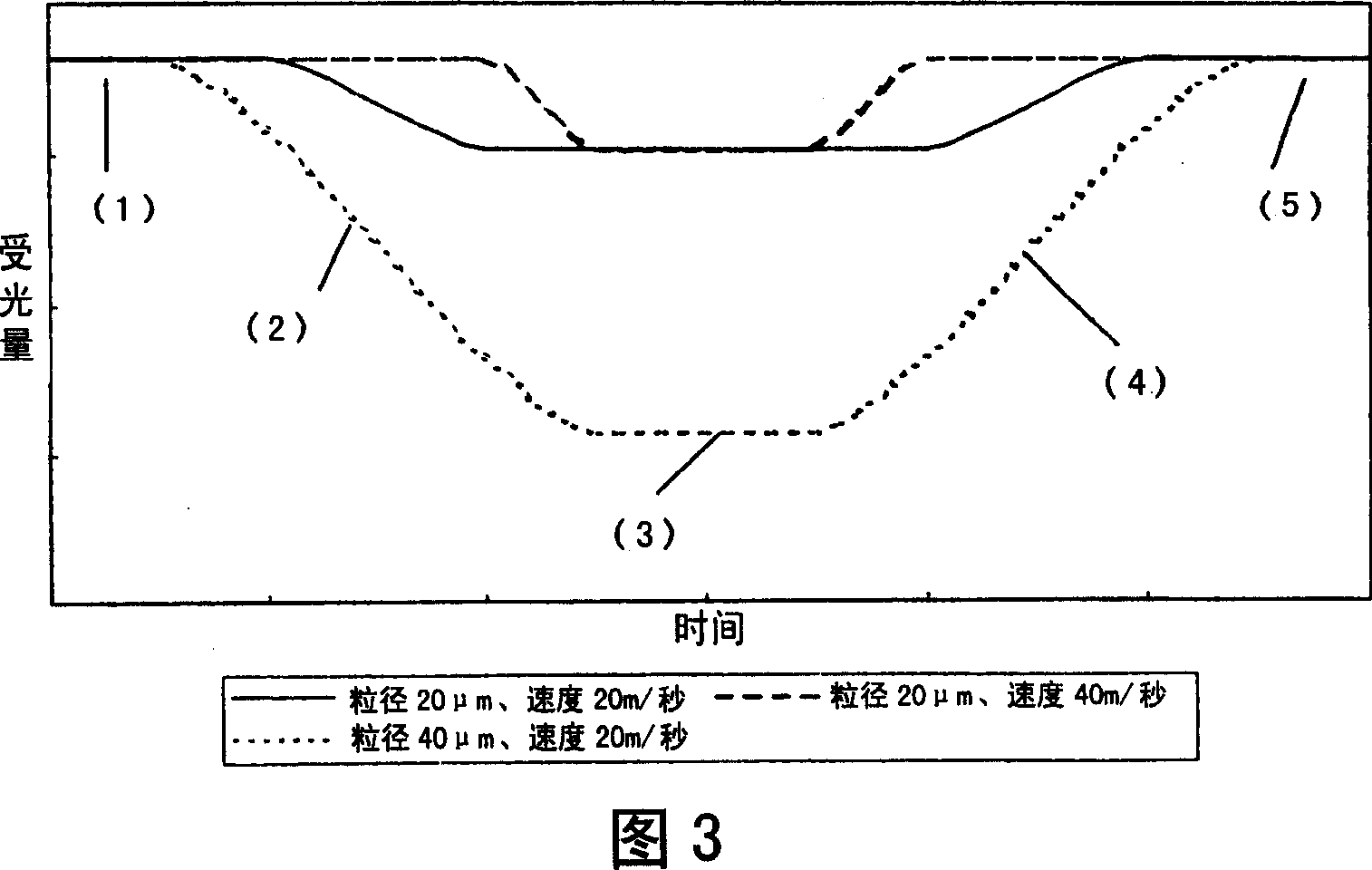

[0040] In Fig. 1, 20 is a light-emitting unit composed of infrared light-emitting diodes, etc., and 21 is a light-receiving unit composed of photosensitive tubes, etc. When dust passes between the two, a signal Vs corresponding to the dust will be output. 30 is a first amplifying device composed of an operational amplifier, etc., which amplifies the signal Vs output by the detection unit 22 with a specified first amplification factor. The first amplifying device 30 has amplification and filtering functions, and only outputs a ...

Embodiment 2

[0080] Next, a second embodiment of the present invention will be described using FIG. 7 . Wherein, for the same components as those in the previous existing vacuum cleaner, only the same symbols are attached here, and the detailed description thereof is omitted.

[0081] Fig. 7 is a control block diagram of the dust display device of an electric vacuum cleaner in Embodiment 2 of the present invention. The difference between Embodiment 3 and Embodiment 1 is that a third holding device 50 is provided, and the first dust detection signal and the second dust detection signal It is input to the third holding device 50, and the third holding device 50 outputs a first holding signal corresponding to the first dust detection signal and a second holding signal corresponding to the second dust detection signal based on these two signals.

[0082] The third holding device 50 first judges each degree of dirtiness according to the number of pulses generated by the first dust detection sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com