Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

548results about How to "Efficient suction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

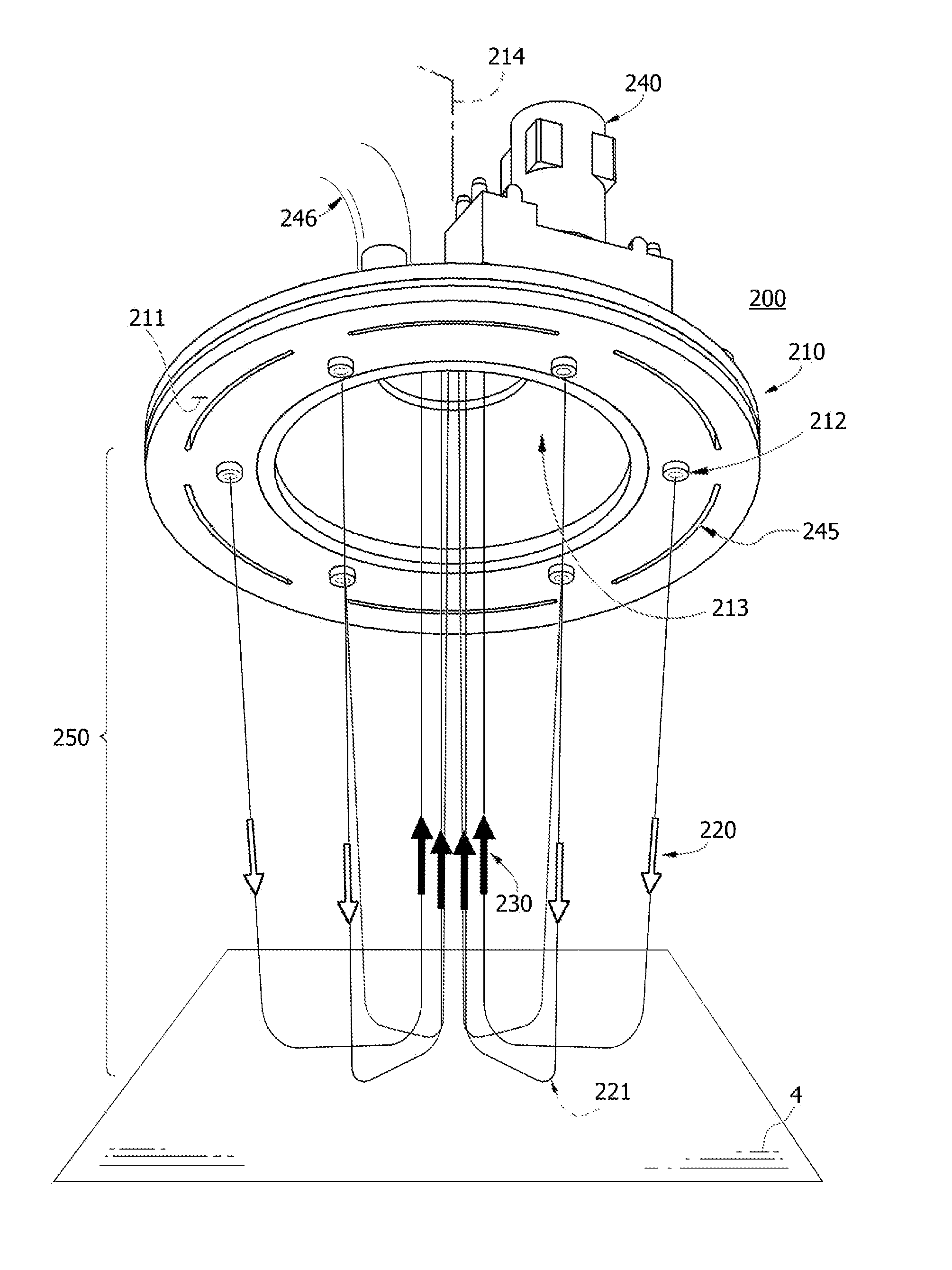

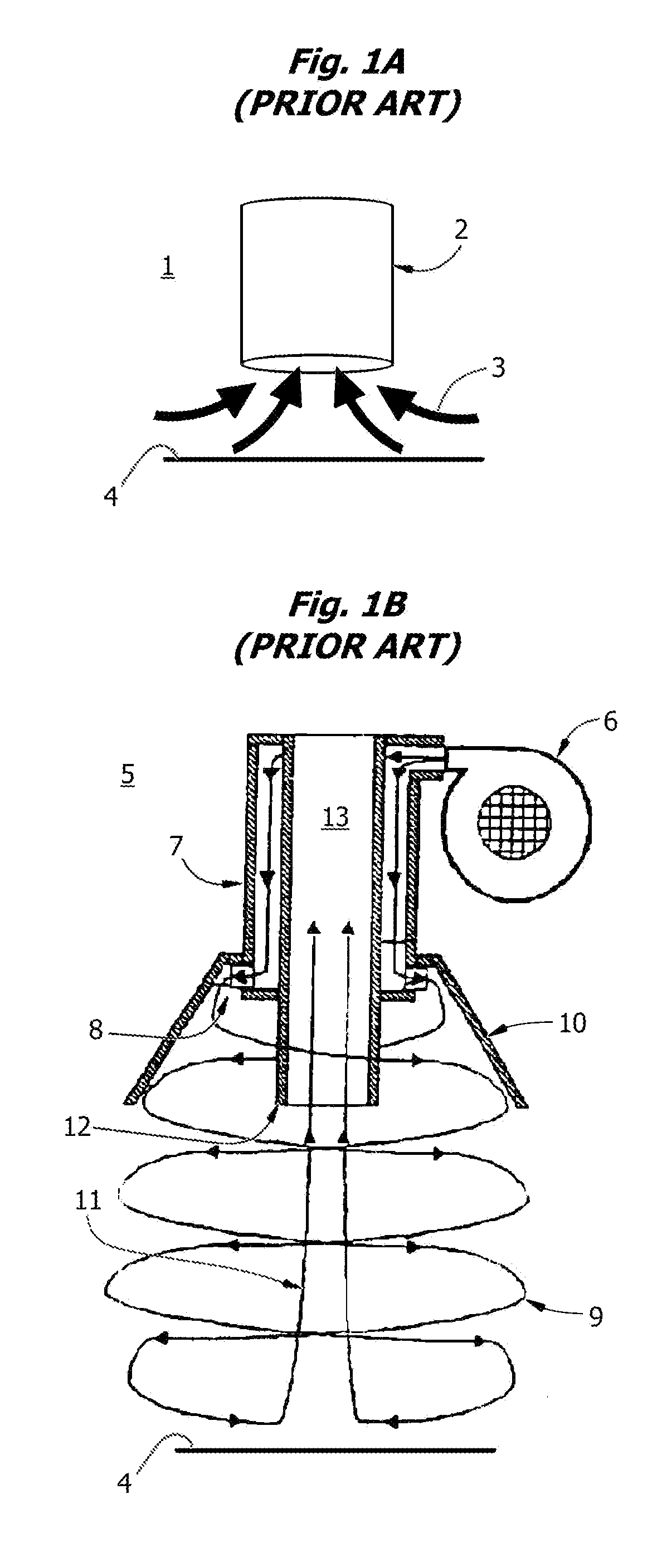

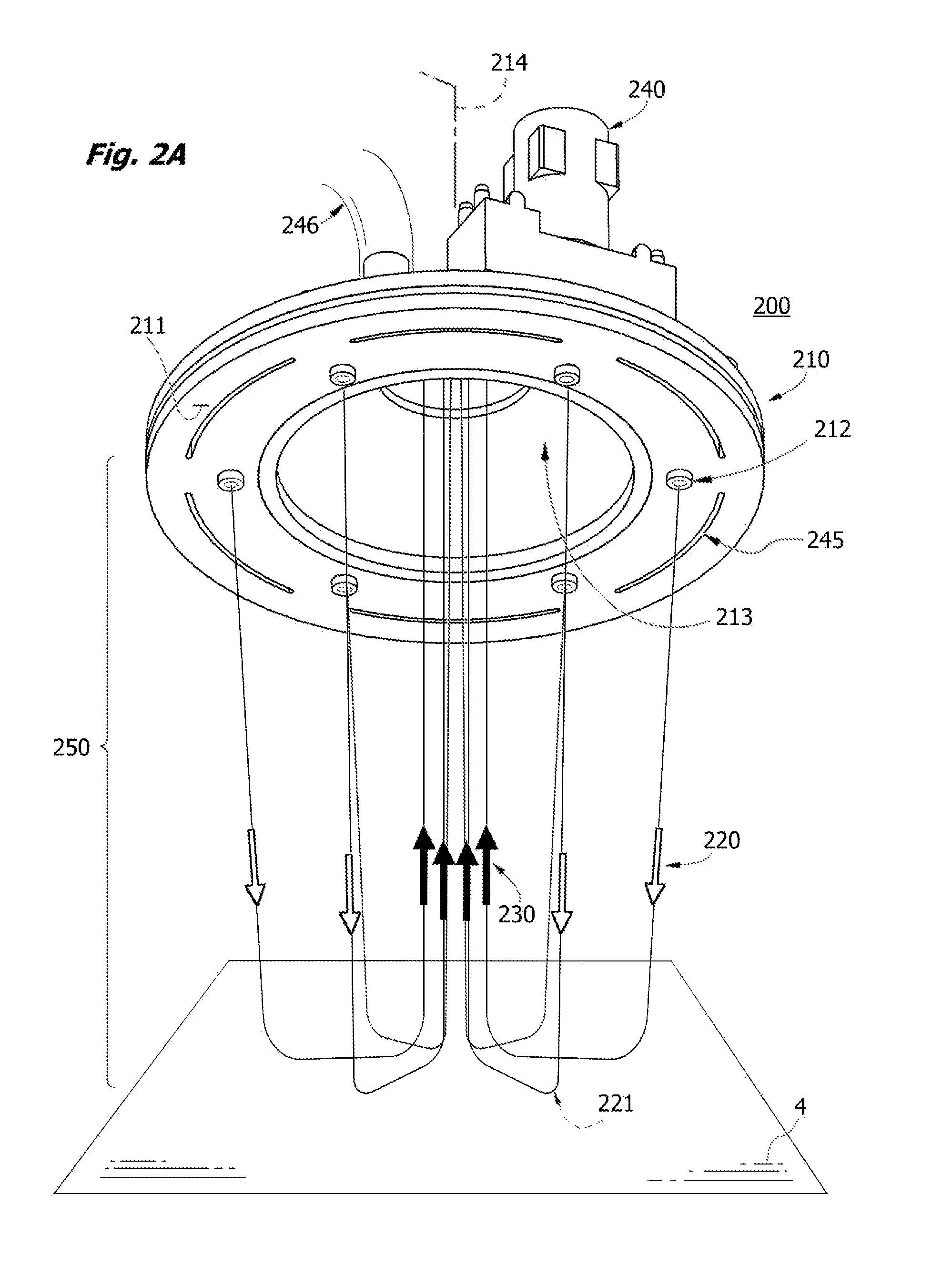

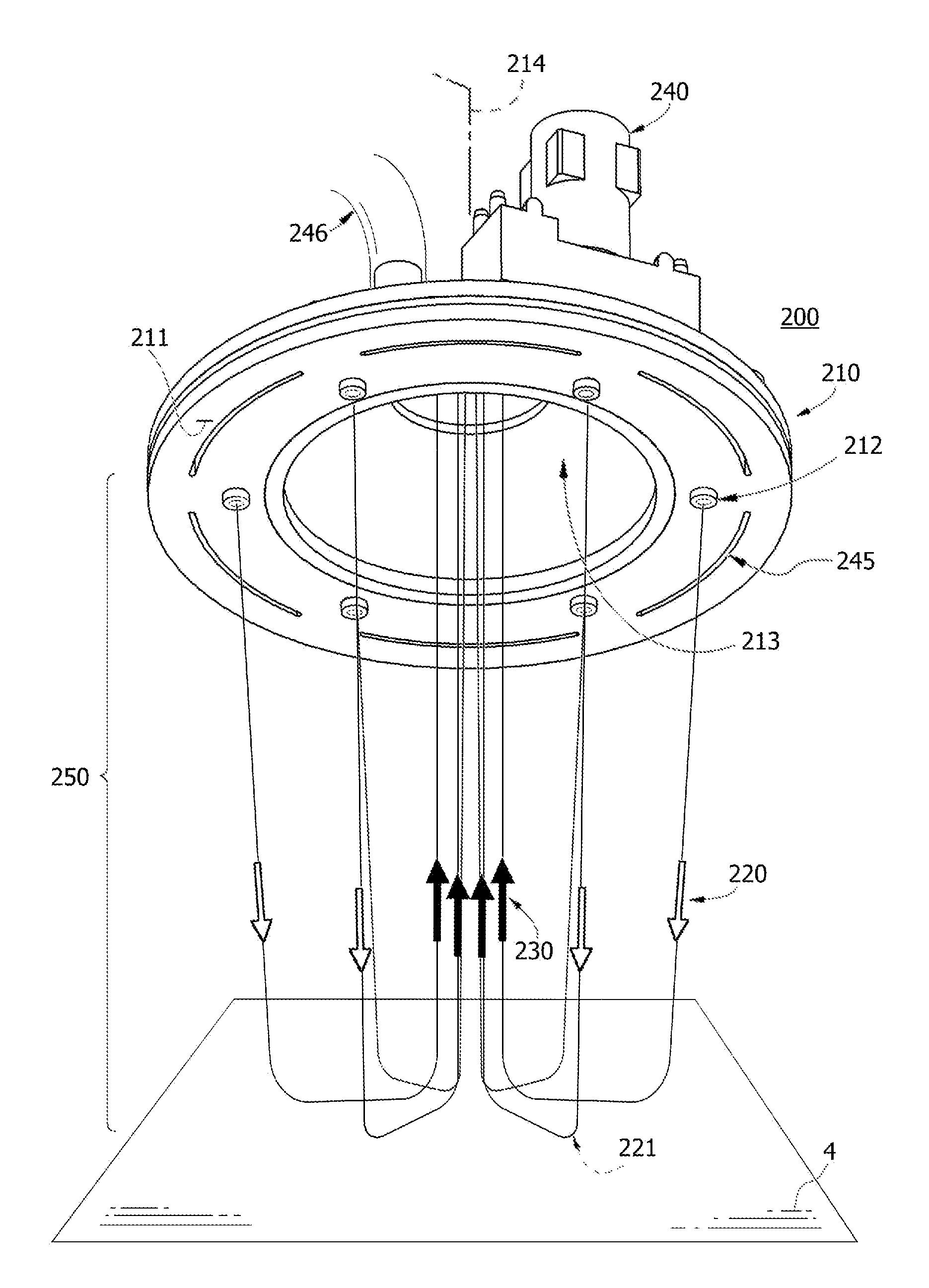

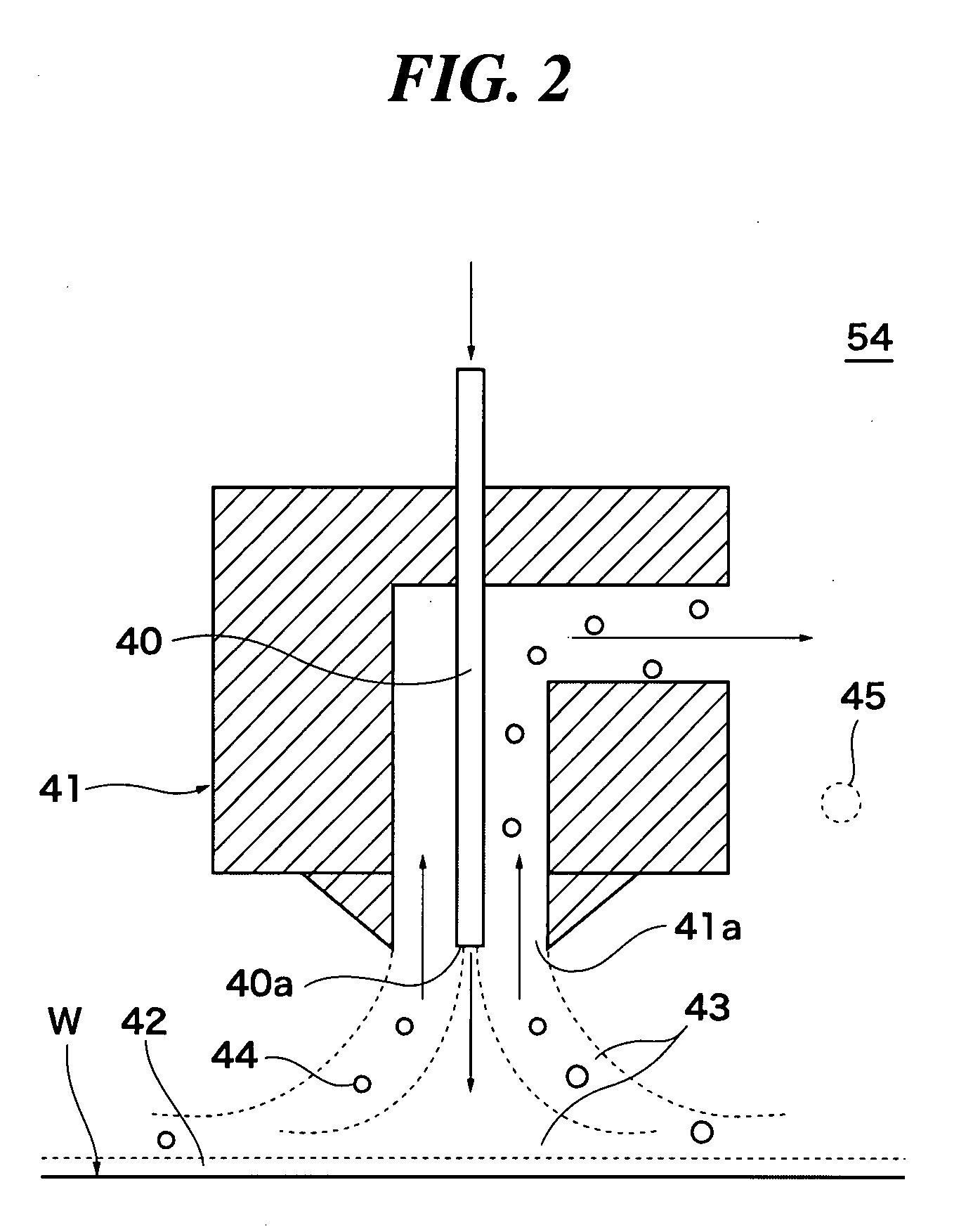

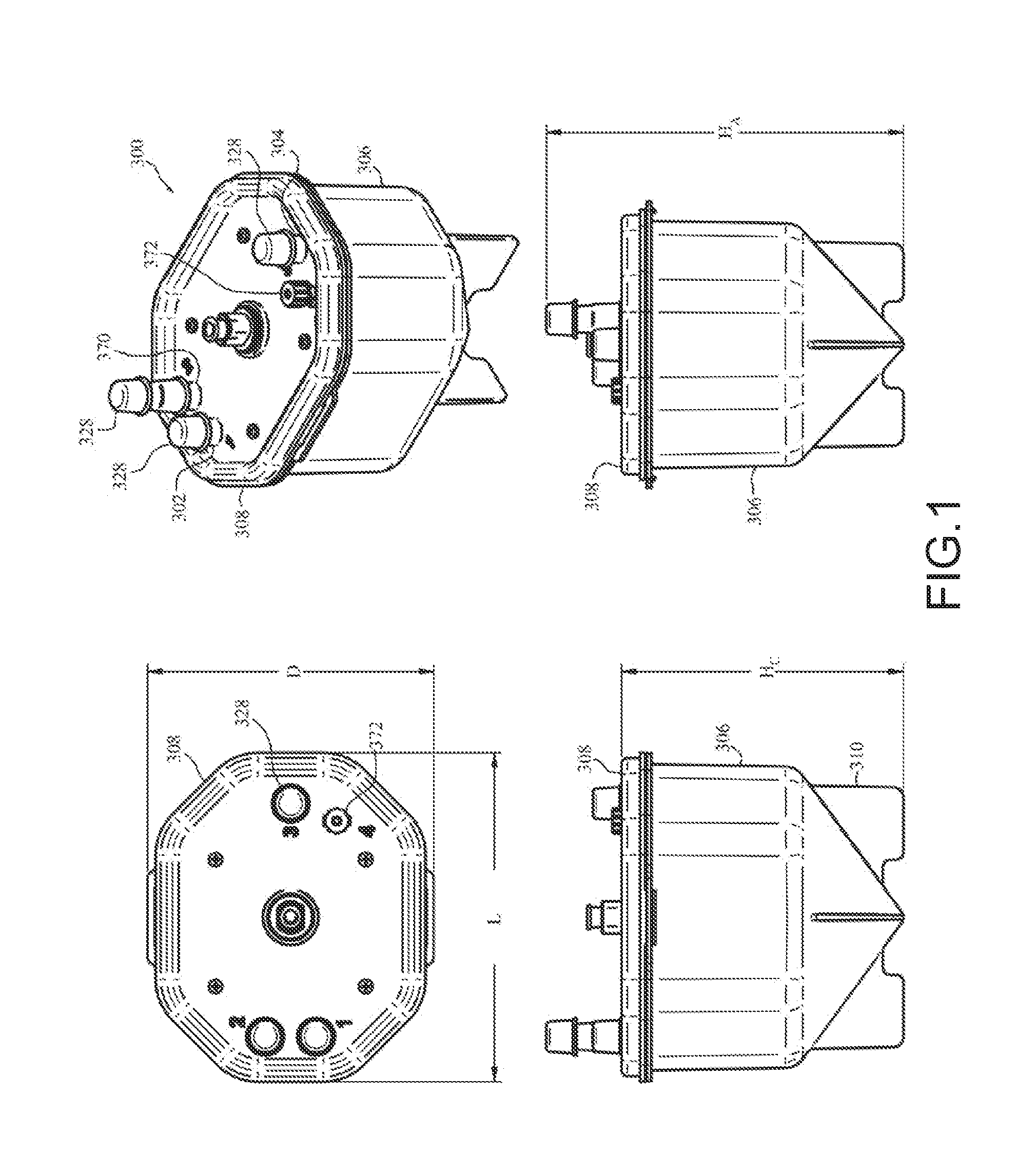

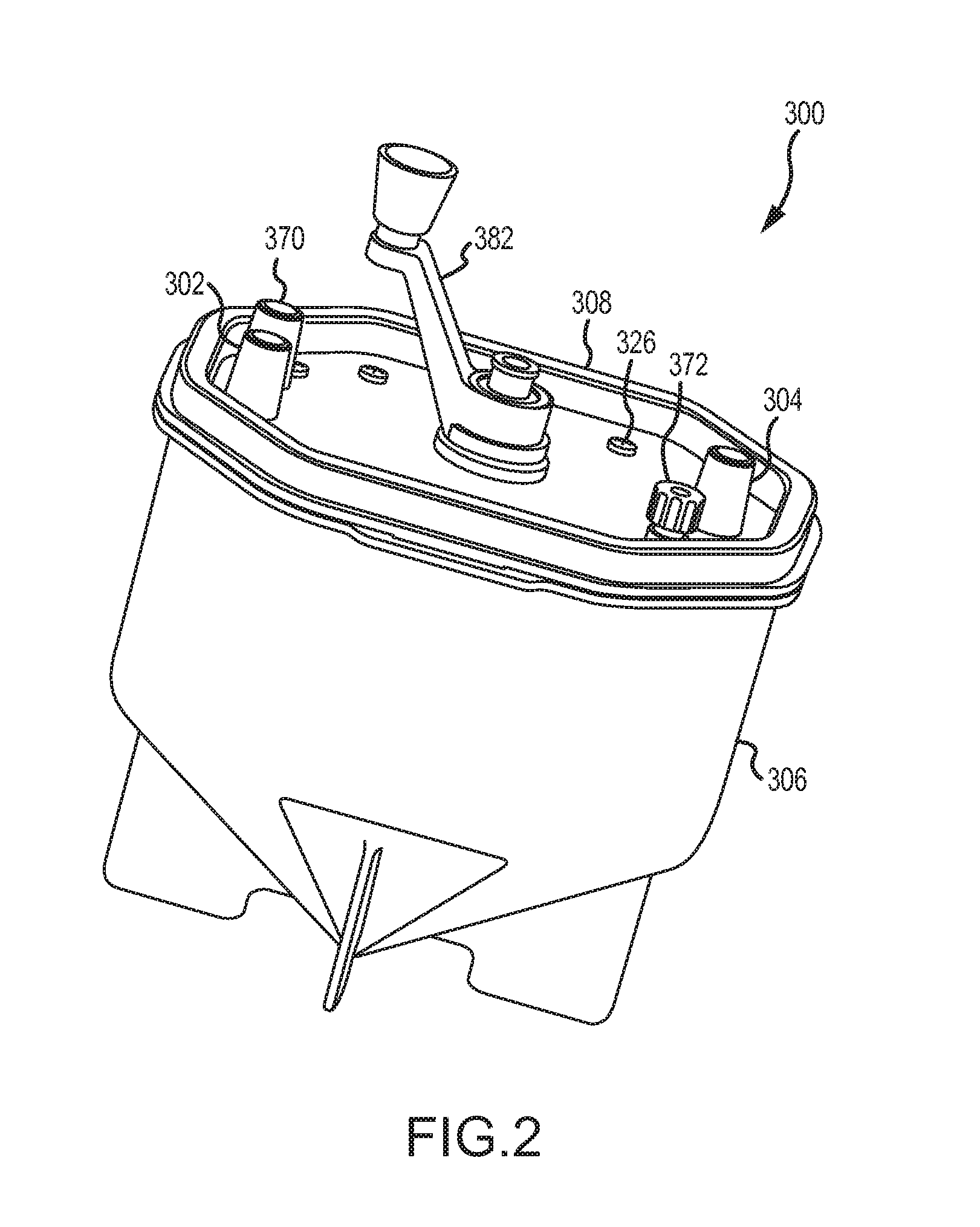

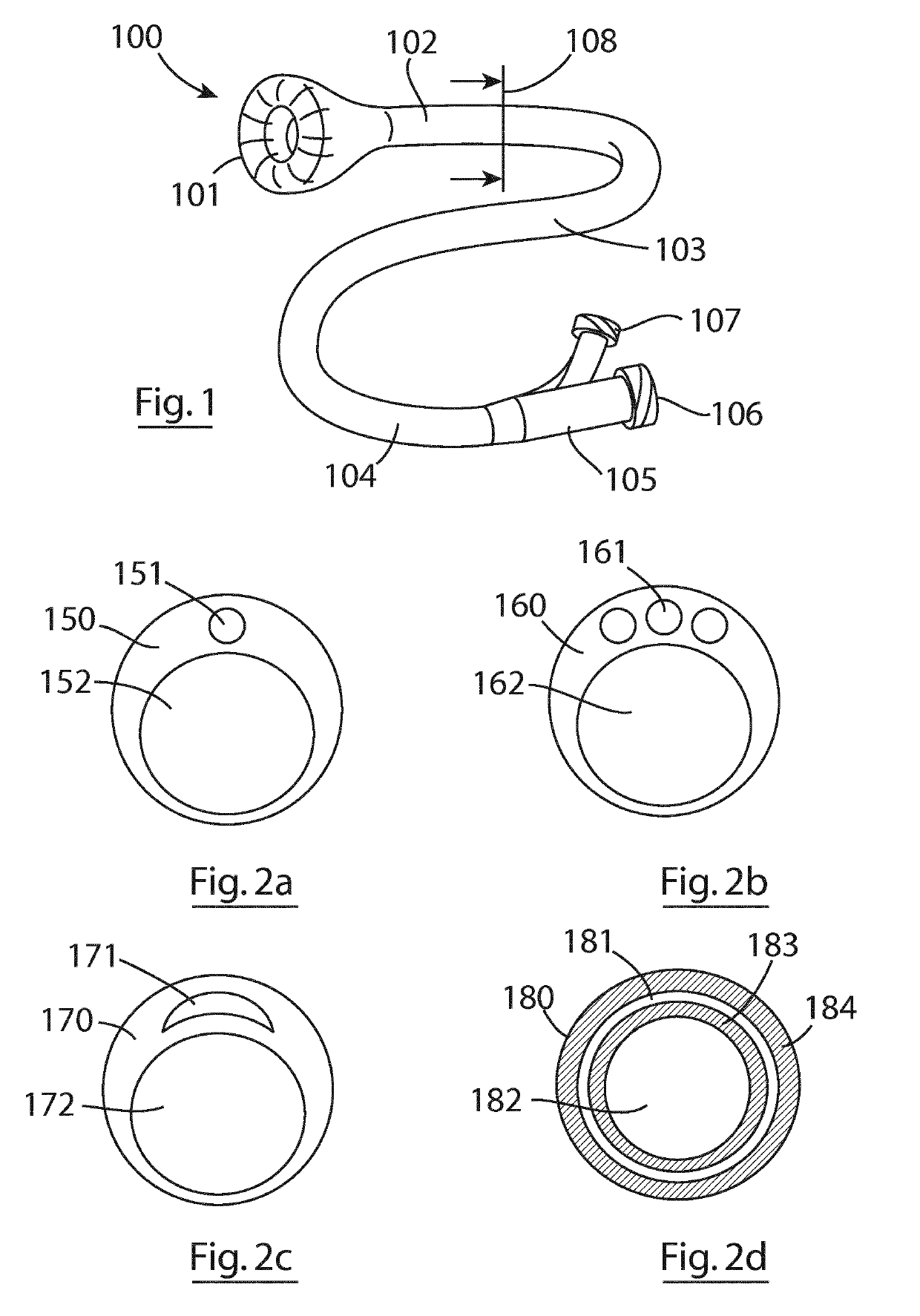

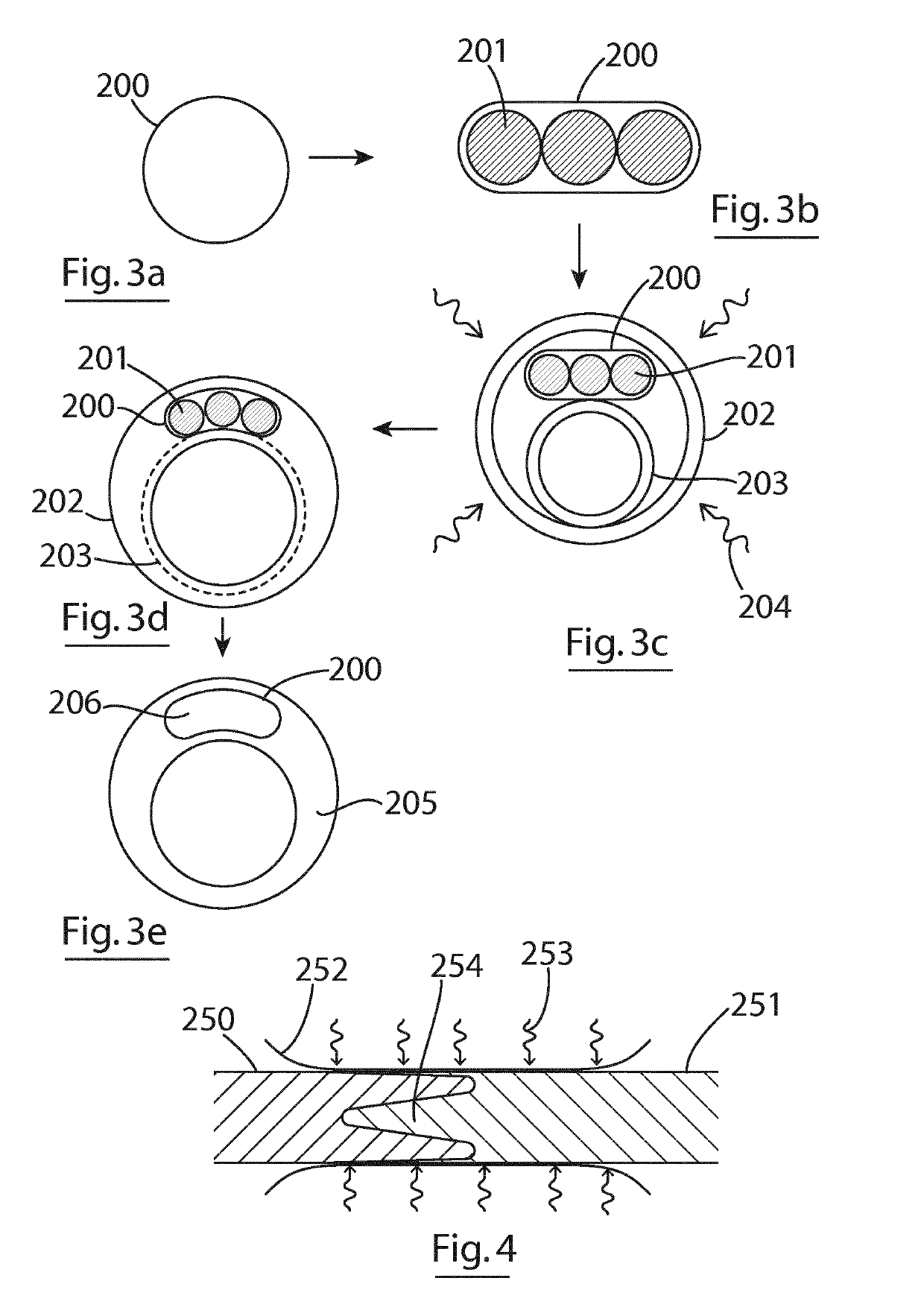

Particle Interrogation Devices and Methods

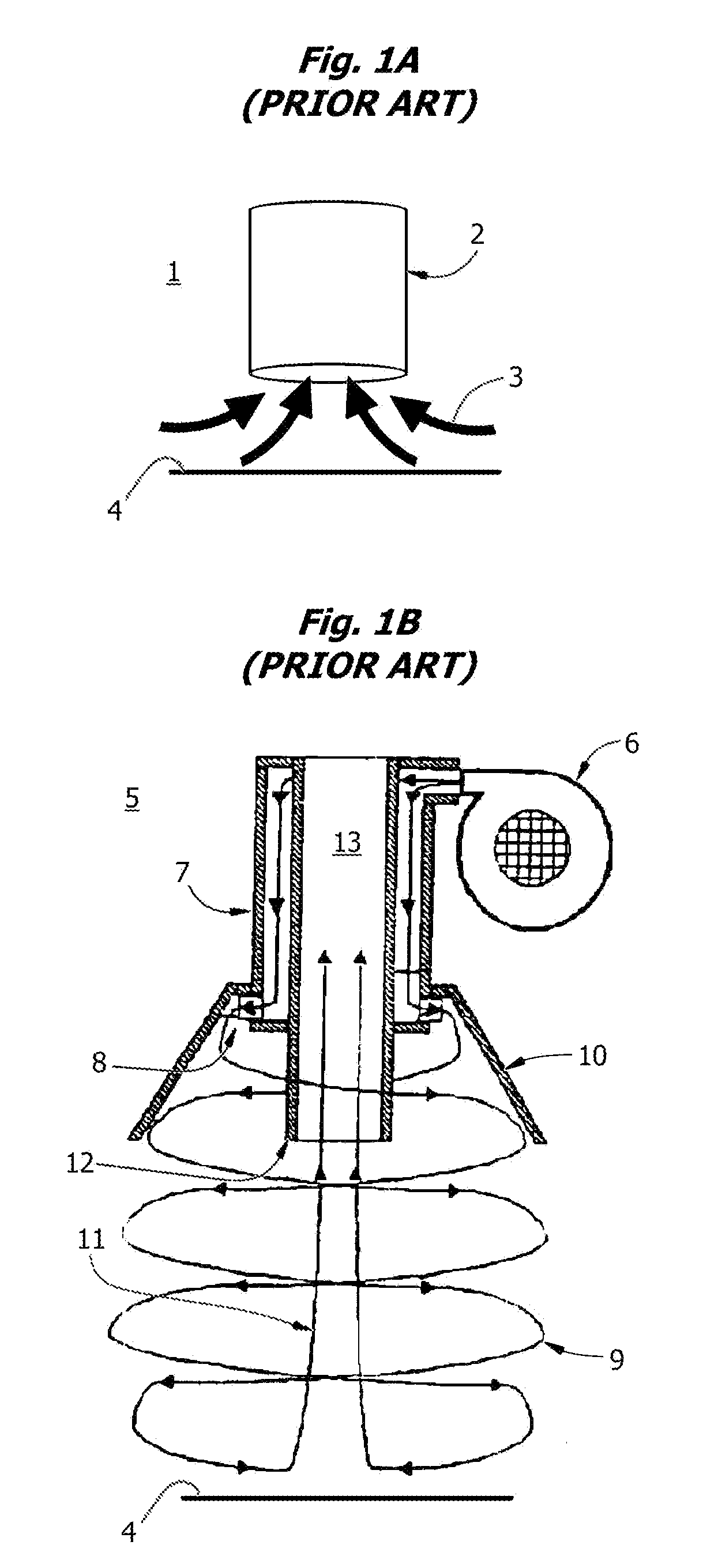

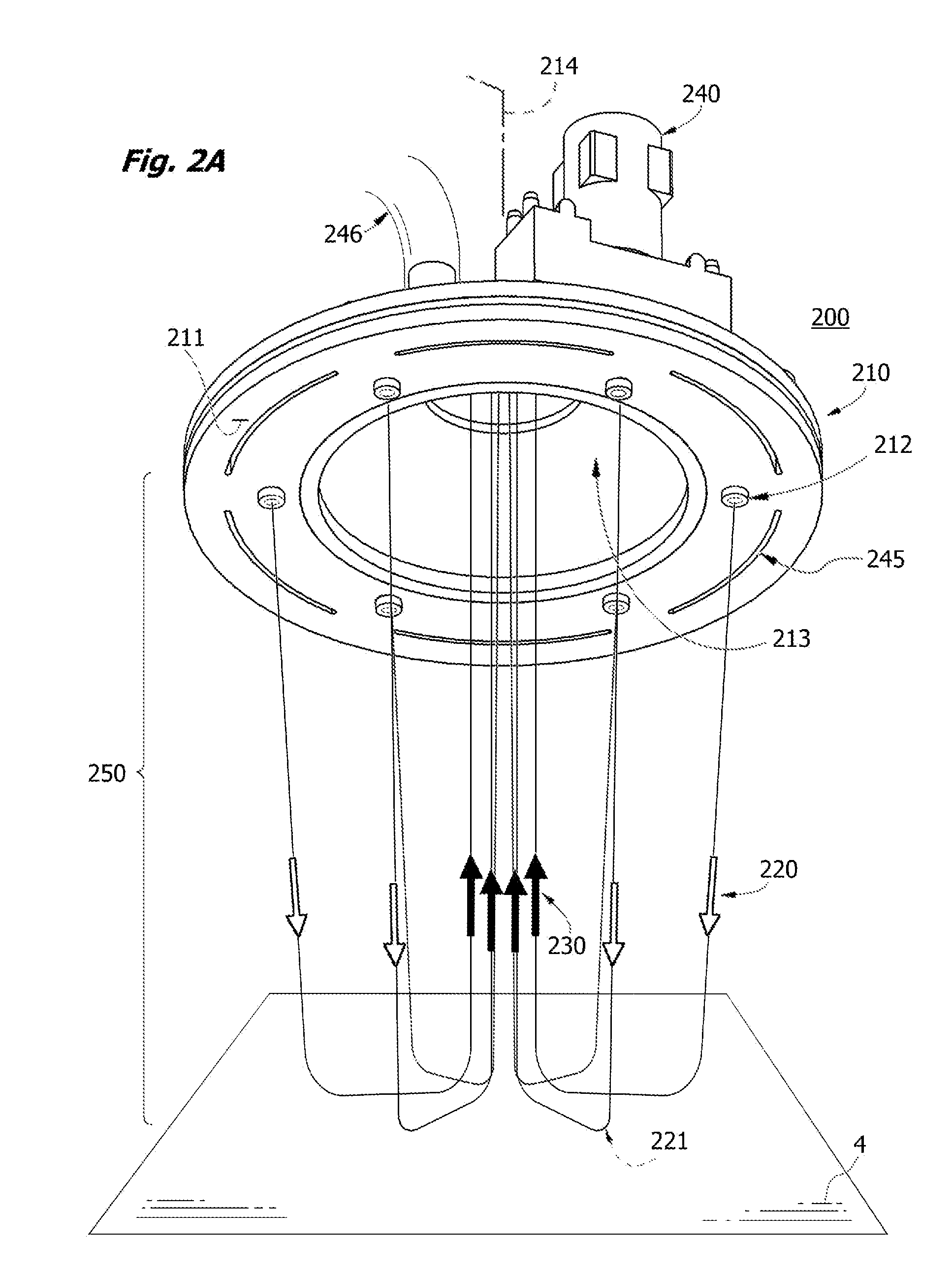

InactiveUS20110186436A1Reduce elutriative lossImprove sampling efficiencyOptical radiation measurementSludge treatmentParticle trappingEngineering

Devices, apparatus and methods are disclosed for non-contact pneumatic sampling and sampling of surfaces, persons, articles of clothing, buildings, furnishings, vehicles, baggage, packages, mail, and the like, for contaminating aerosols indicative of a hazard or a benefit, where the contaminating aerosols are chemical, radiological, biological, toxic, or infectious in character. In a first device, a central orifice for pulling a suction gas stream is surrounded by a peripheral array of convergingly-directed gas jets, forming a virtual sampling chamber. The gas jets are configured to deliver millisecond pneumatic pulses that erode particles from solid surfaces at a distance. In another aspect of the invention, a suction gas stream is split using an air-to-air concentrator so that a particle-enriched gas flow is directed to a particle trap and any particles immobilized in the particle trap (including any adsorbed vapors associated with the particles) are selectively analyzed to detect trace residues associated with explosives.

Owner:ENERTECHNIX

Particle Interrogation Devices and Methods

InactiveUS20110203931A1Efficient suctionReduce lossesOptical radiation measurementSludge treatmentParticle trappingEngineering

Devices, apparatus and methods are disclosed for non-contact pneumatic sampling and sampling of surfaces, persons, articles of clothing, buildings, furnishings, vehicles, baggage, packages, mail, and the like, for contaminating aerosols or vapors indicative of a hazard or a benefit, where the contaminating aerosols or vapors are chemical, radiological, biological, toxic, or infectious in character. In a first device, a central orifice for pulling a suction gas stream is surrounded by a peripheral array of convergingly-directed gas jets, forming a virtual sampling chamber. The gas jets are configured to deliver millisecond pneumatic pulses that erode particles and vapors from solid surfaces at a distance. In another aspect of the invention, a suction gas stream is split using an air-to-air concentrator so that a particle-enriched gas flow is directed to a particle trap and particles immobilized therein are selectively analyzed for explosives and explosives related materials under optimized conditions for analyzing particle-associated constituents and a bulk flow is directed to a vapor trap and free vapors immobilized therein are selectively analyzed for explosives and explosives related materials under optimized conditions for analyzing free vapors. Detection signals from the particle channel and the vapor channel are compared or integrated to detect trace residues associated with explosives.

Owner:ENERTECHNIX

Method for harvesting bone marrow and its medical apparatus

InactiveUS20090187116A1Efficiently aspirateLight burdenSurgical needlesVaccination/ovulation diagnosticsPuncturingTubular bone

Using a bended puncturing needle, a through hole from the greater trochanter of a long tubular bone to the bone marrow cavity is formed, the catheter 61a, 61b is passed into the through hole, a physiological salt solution is injected from one of the catheter 61b, and the physiological salt solution and the bone marrow is stirred by the stirring wire 68, the obtained mixed liquid is aspirated and harvested by another catheter 61a, thereby a large amount of the bone marrow is harvested. A method enabling easy and a large amount harvesting of the bone marrow from long tubular bones such as femurs, in which a multi-lumen catheter can also be used as a catheter.

Owner:HI-LEX CORPORATION +1

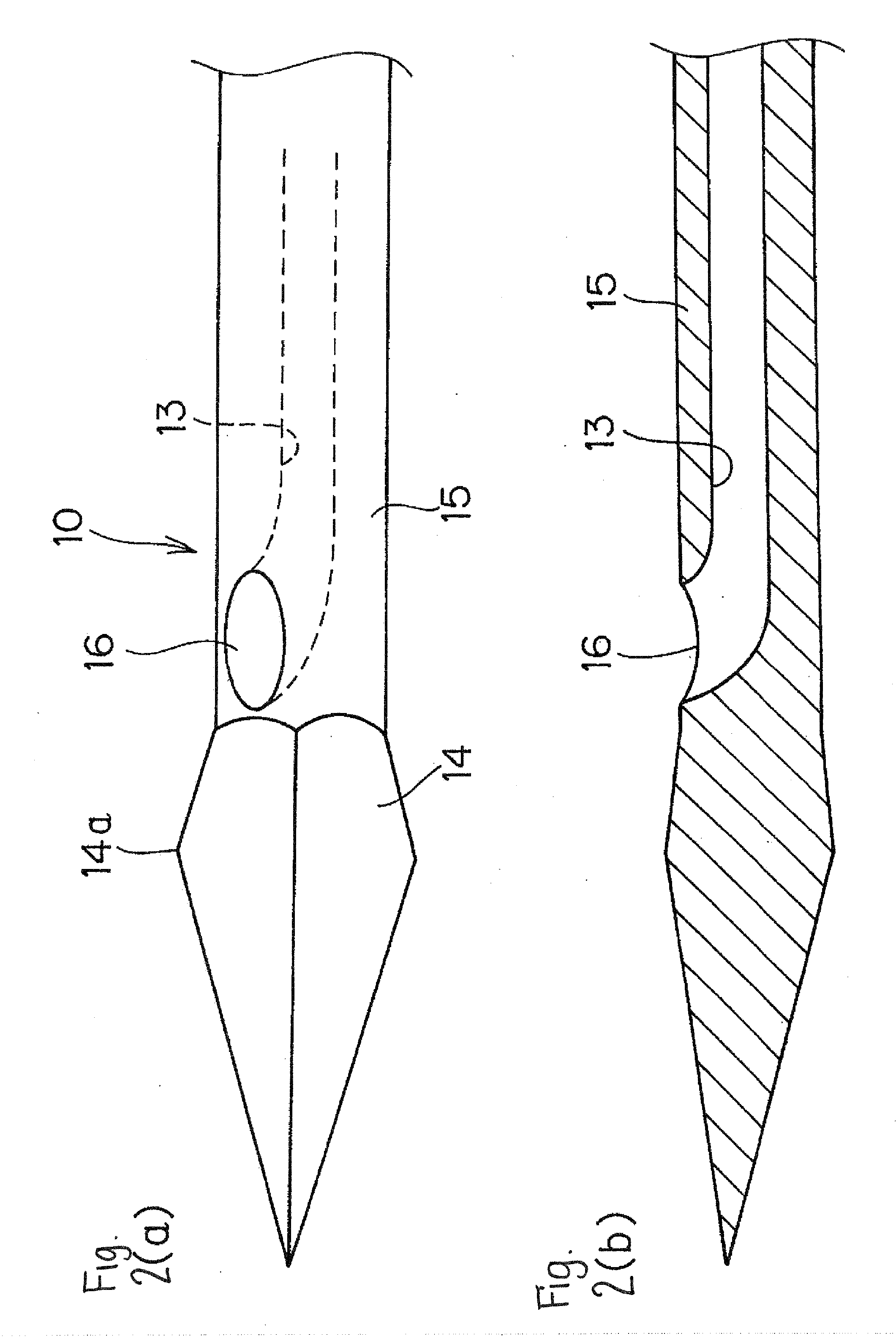

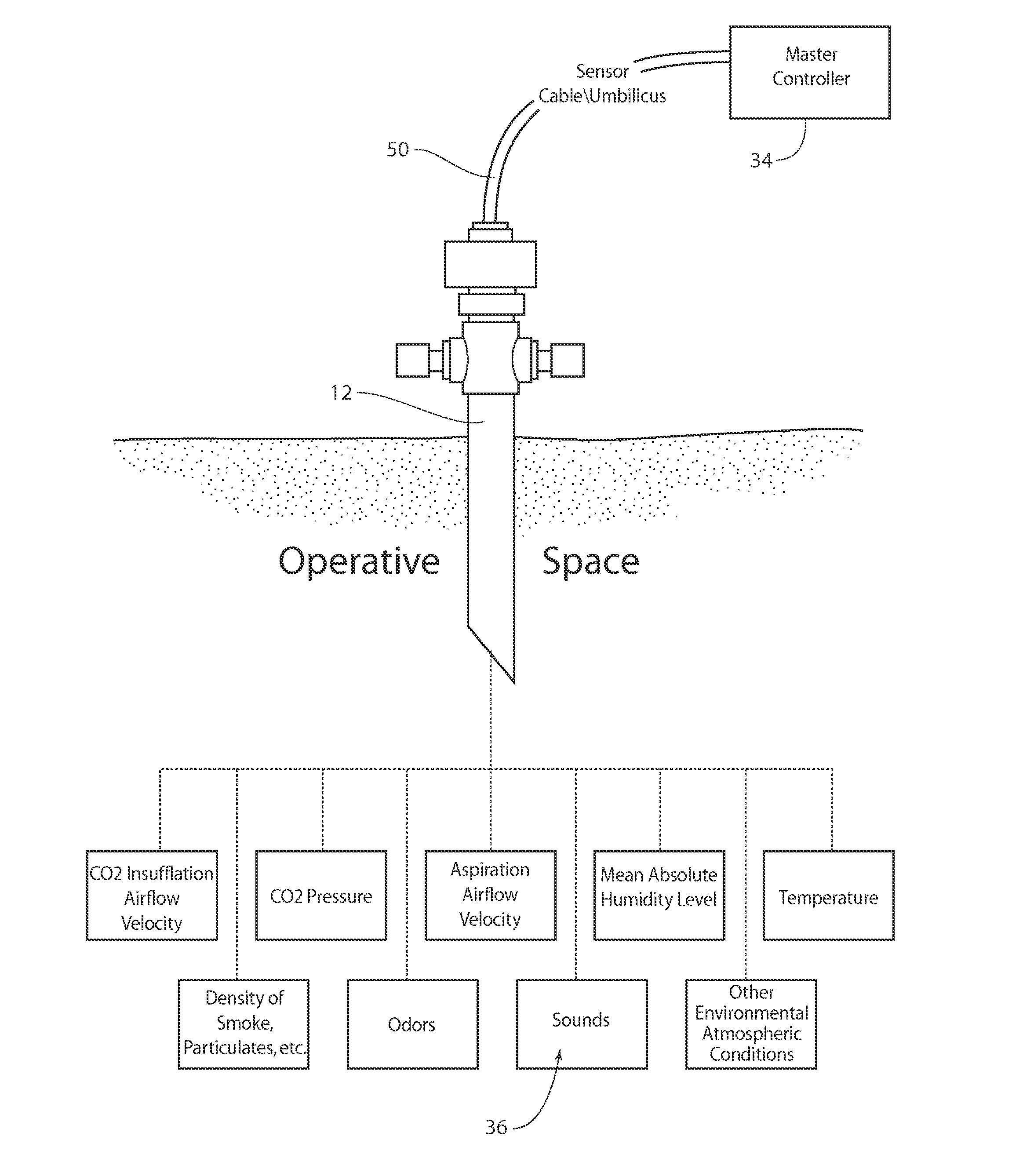

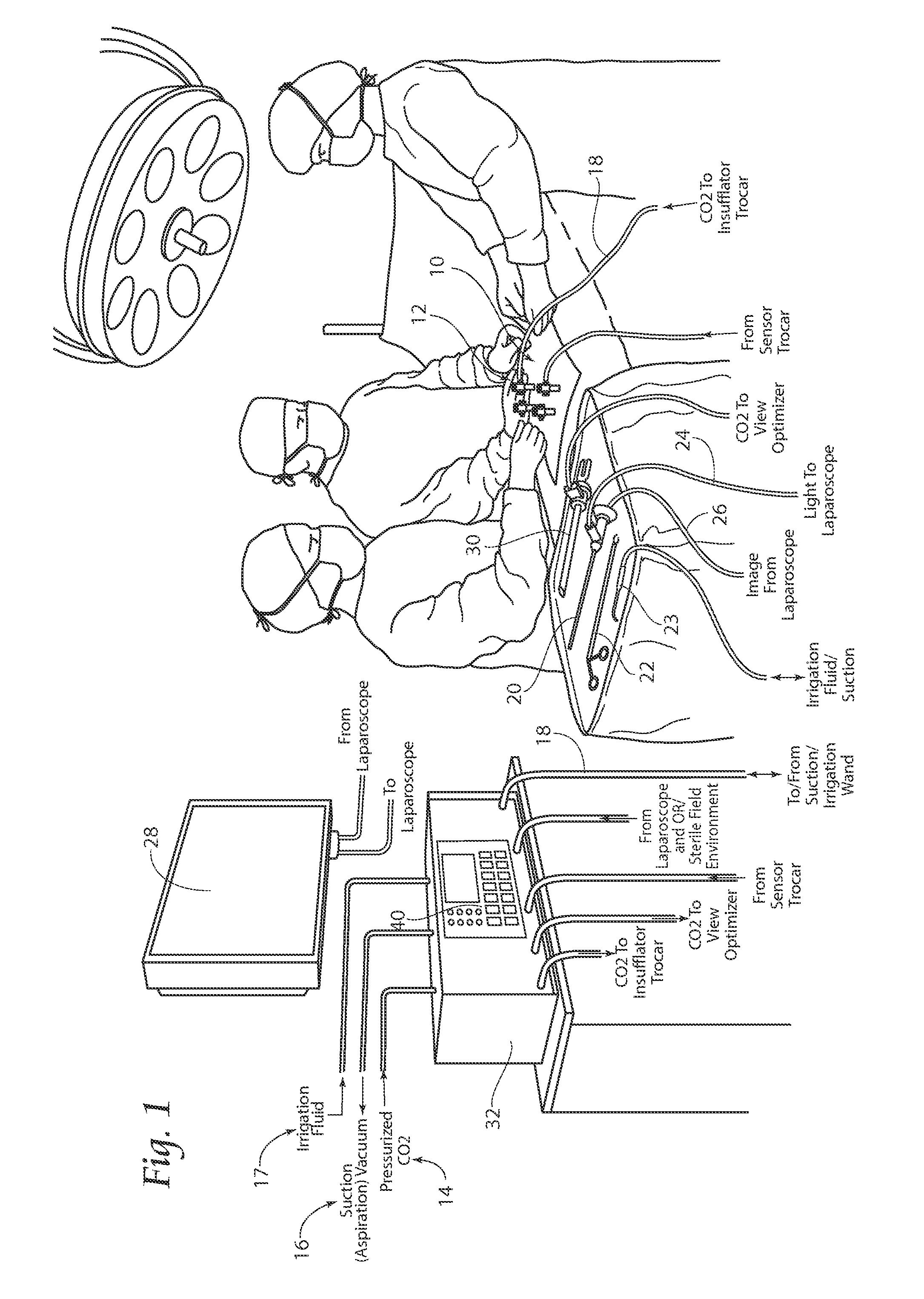

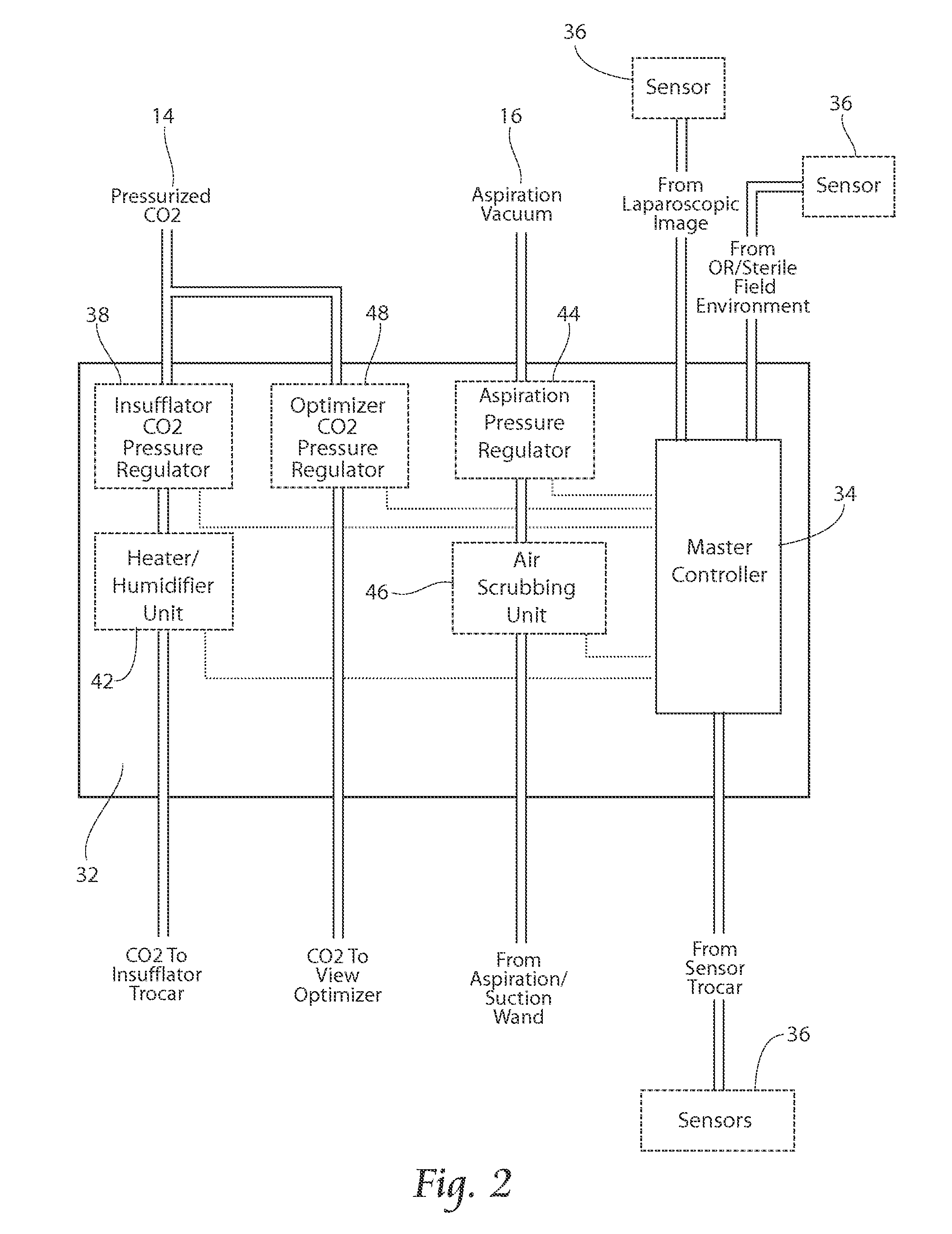

Integrated systems and methods for maintenance and management of an intra-abdominal gas environment during laparoscopic surgery

InactiveUS20120184897A1Improve clarityEfficient suctionRespiratorsEndoscopesParticulatesAir management

Air management control systems and methods maintain and manage an intra-abdominal gas environment during laparoscopic surgery. The systems and methods locate a plurality of in vivo sensors to monitor different environmental conditions within the operative space insufflated with pressurized CO2, e.g., CO2 insufflation airflow velocity, CO2 pressure, aspiration airflow velocity, and at least one of humidity level, temperature, density of smoke / particulates, odors, and sound within the operative space. The systems and methods couple the plurality of in vivo sensors to a master controller. The master controller implements pre-programmed rules to generate control commands that govern the delivery of pressurized CO2 and aspiration pressure into and out of the operative space in response, at least in part, to the different environmental conditions monitored by the in vivo sensors.

Owner:FLOSHIELD INC

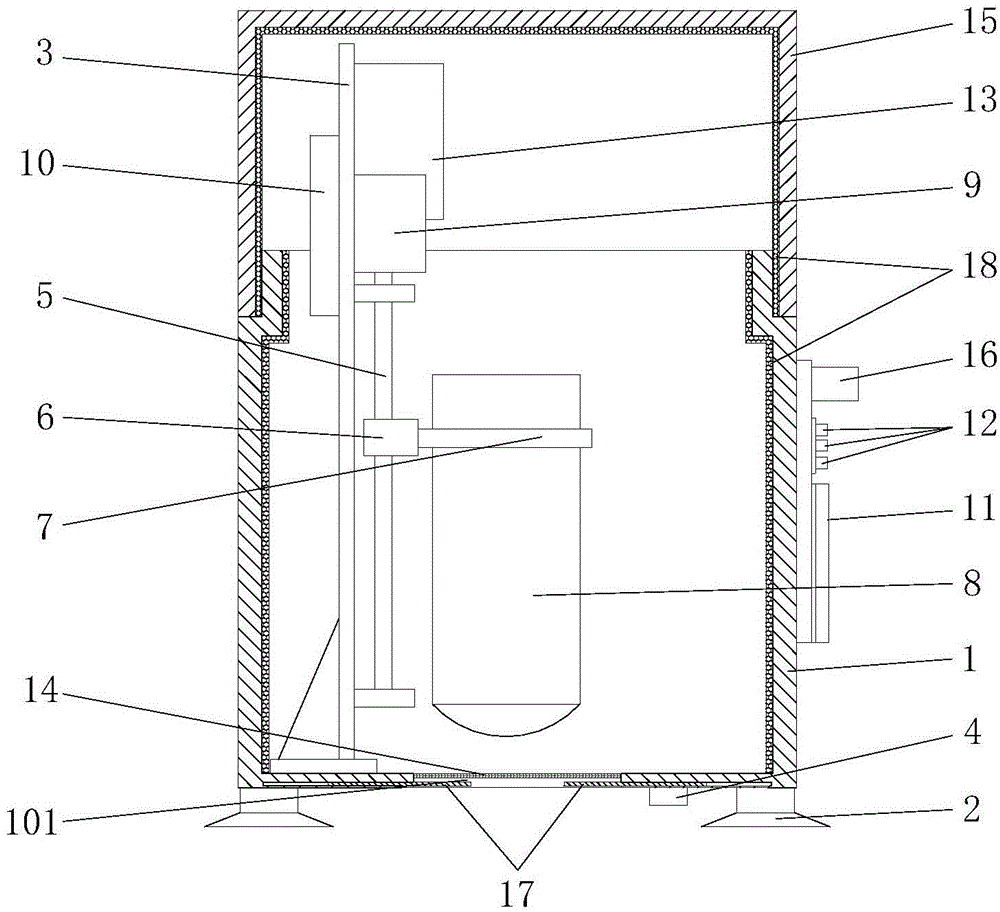

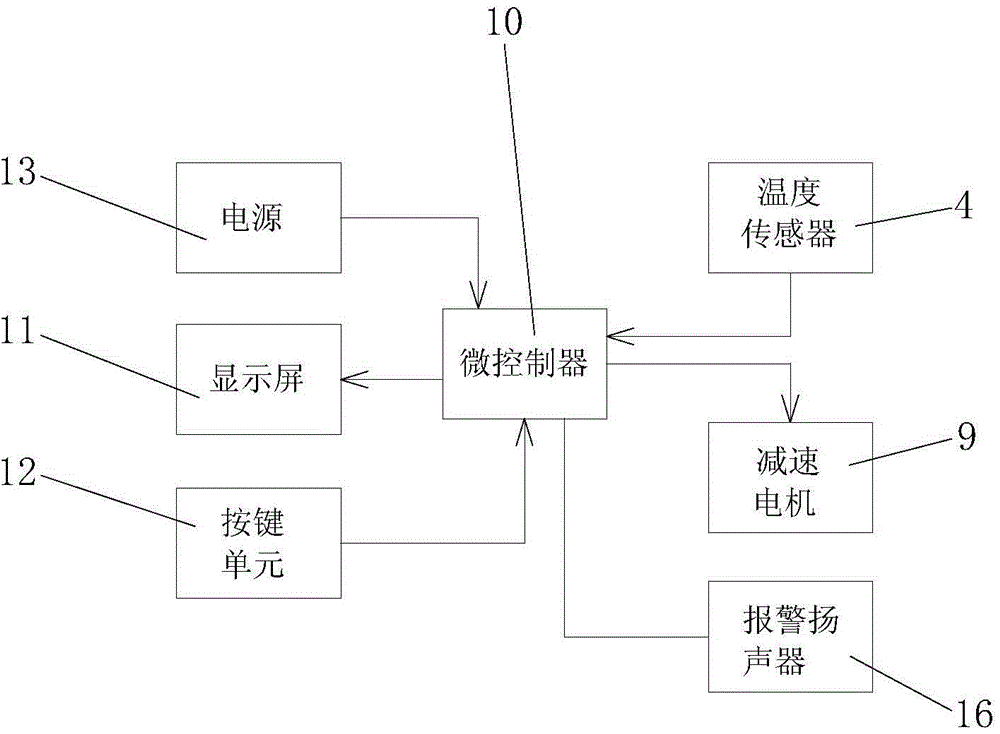

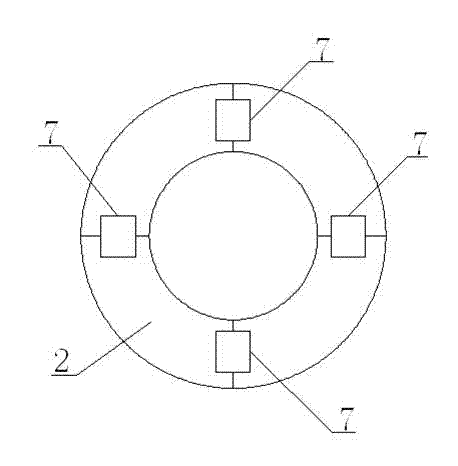

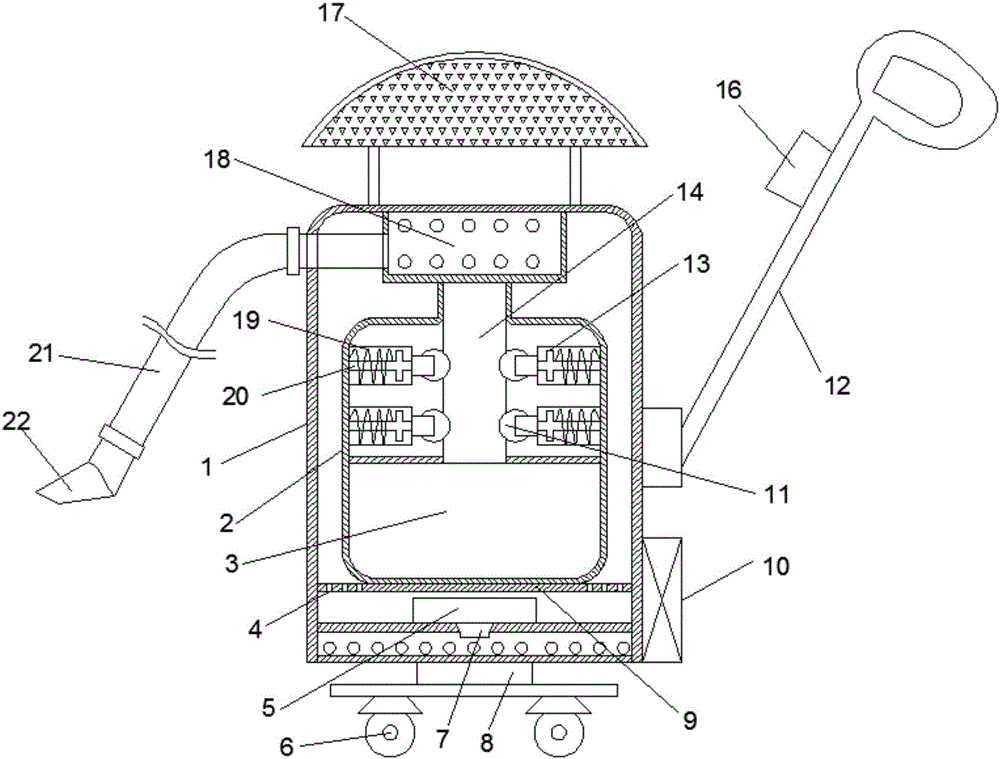

Novel temperature control moxibustion device

InactiveCN103550062AMaintain a constant temperatureKeep the moxibustion process temperature at the best constant temperatureDevices for heating/cooling reflex pointsTemperature controlTreatment effect

The invention discloses a novel temperature control moxibustion device which comprises a cylindrical moxibustion box and a box cover, wherein a moxibustion hole is formed in the bottom of the moxibustion box, and a detachable dust stop screen is arranged on the moxibustion hole. The temperature control moxibustion device further comprises a support frame and a temperature sensor, the support frame is fixed in the moxibustion box, and the temperature sensor is fixed on the bottom surface of the moxibustion box; a screw rod perpendicular to the bottom surface of the moxibustion box is arranged at the lower part of the support frame, a nut seat is in bolted connection with the screw rod, and a fixing ring corresponding to the moxibustion hole is fixed on one side of the nut seat and used for inserting moxa sticks; and the screw rod is driven by a reducing motor fixed on the support frame to rotate. According to the novel temperature control moxibustion device, the therapeutic temperature is regulated by controlling a distance between a moxa stick fire point and a moxibustion acupuncture point, the constant temperature of the moxibustion acupuncture point of a human body is maintained, and the whole device is portable and flexible, so that the temperature of the moxibustion acupuncture point of the human body can be accurately controlled, and an optimal curative effect is achieved.

Owner:FUJIAN UNIV OF TRADITIONAL CHINESE MEDICINE

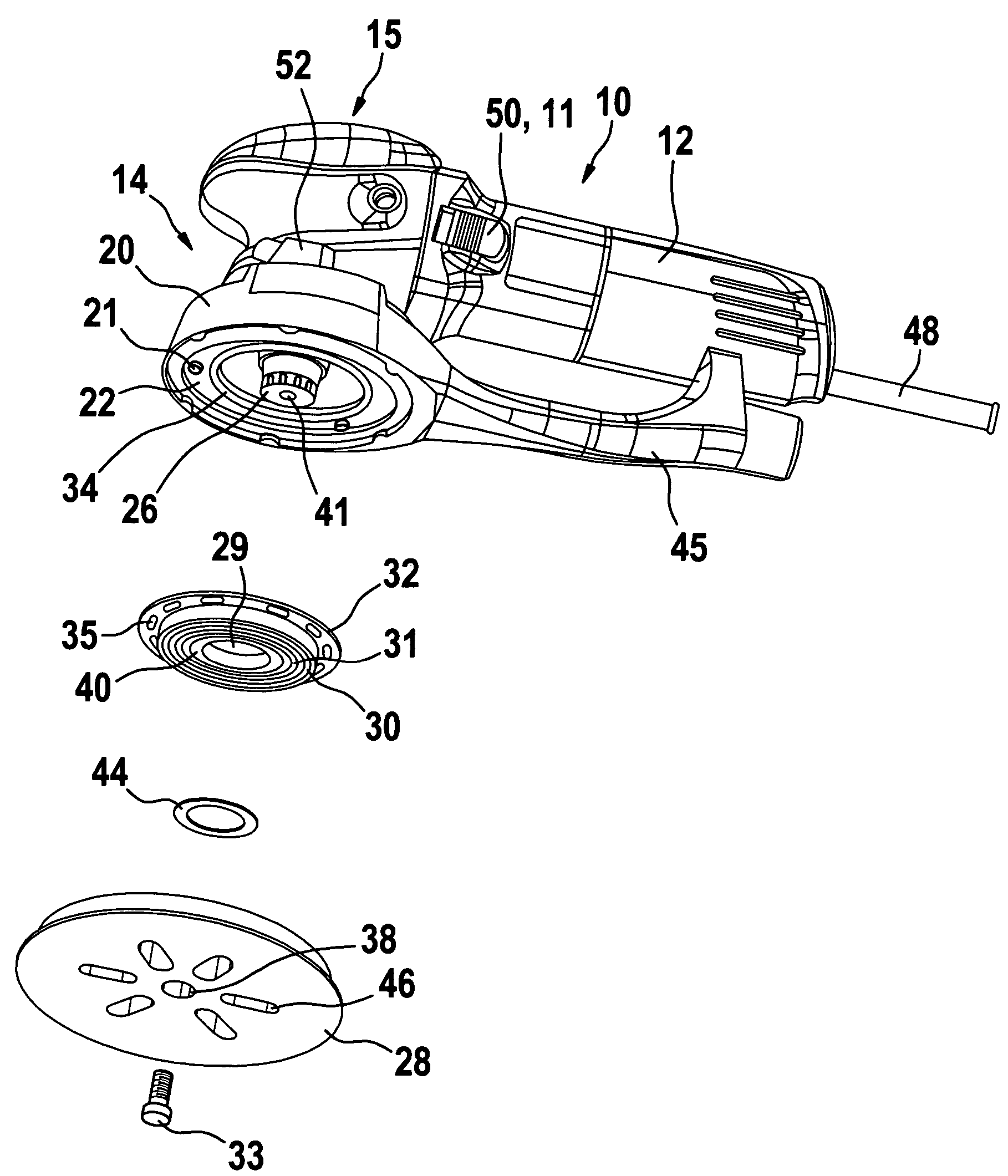

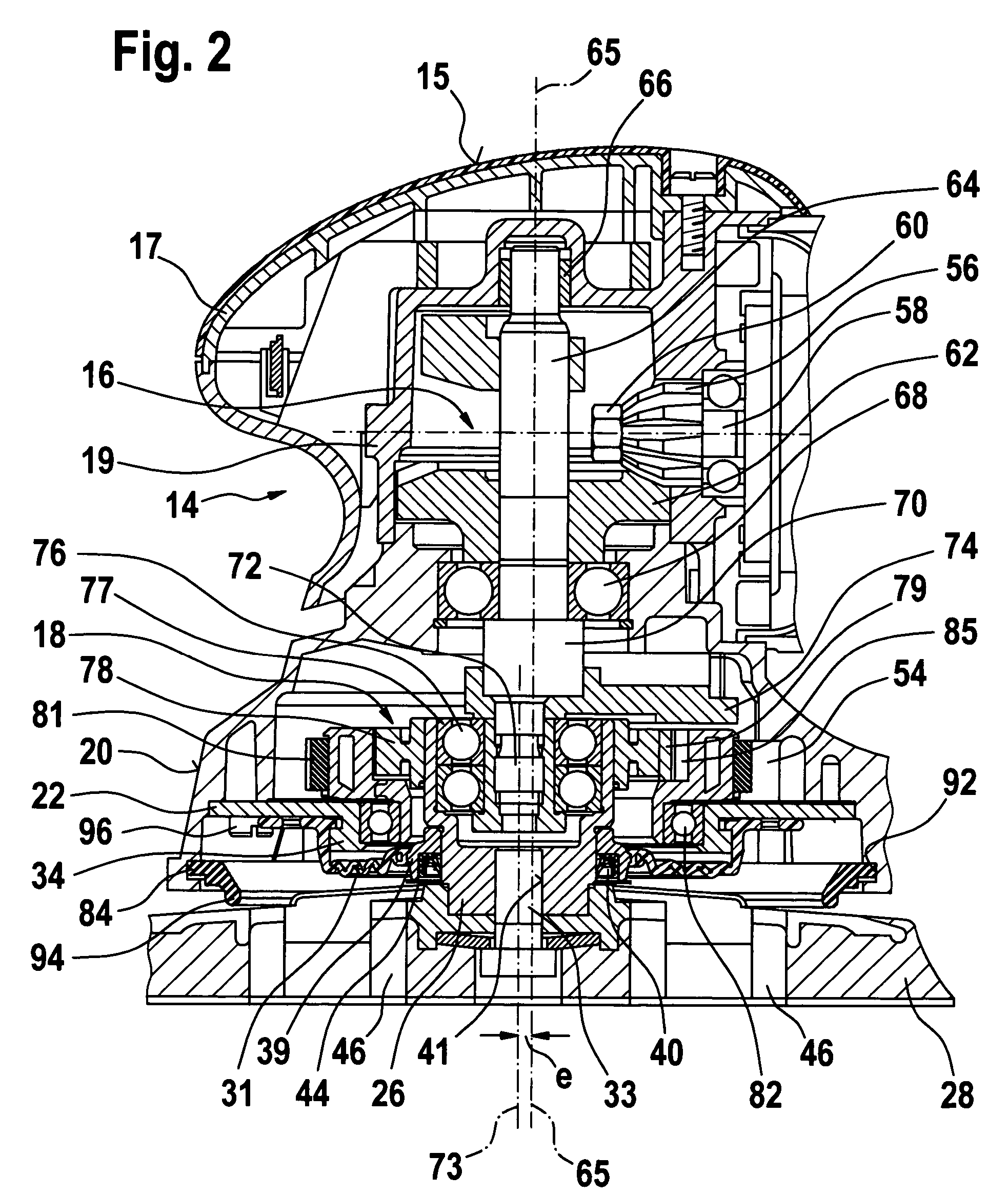

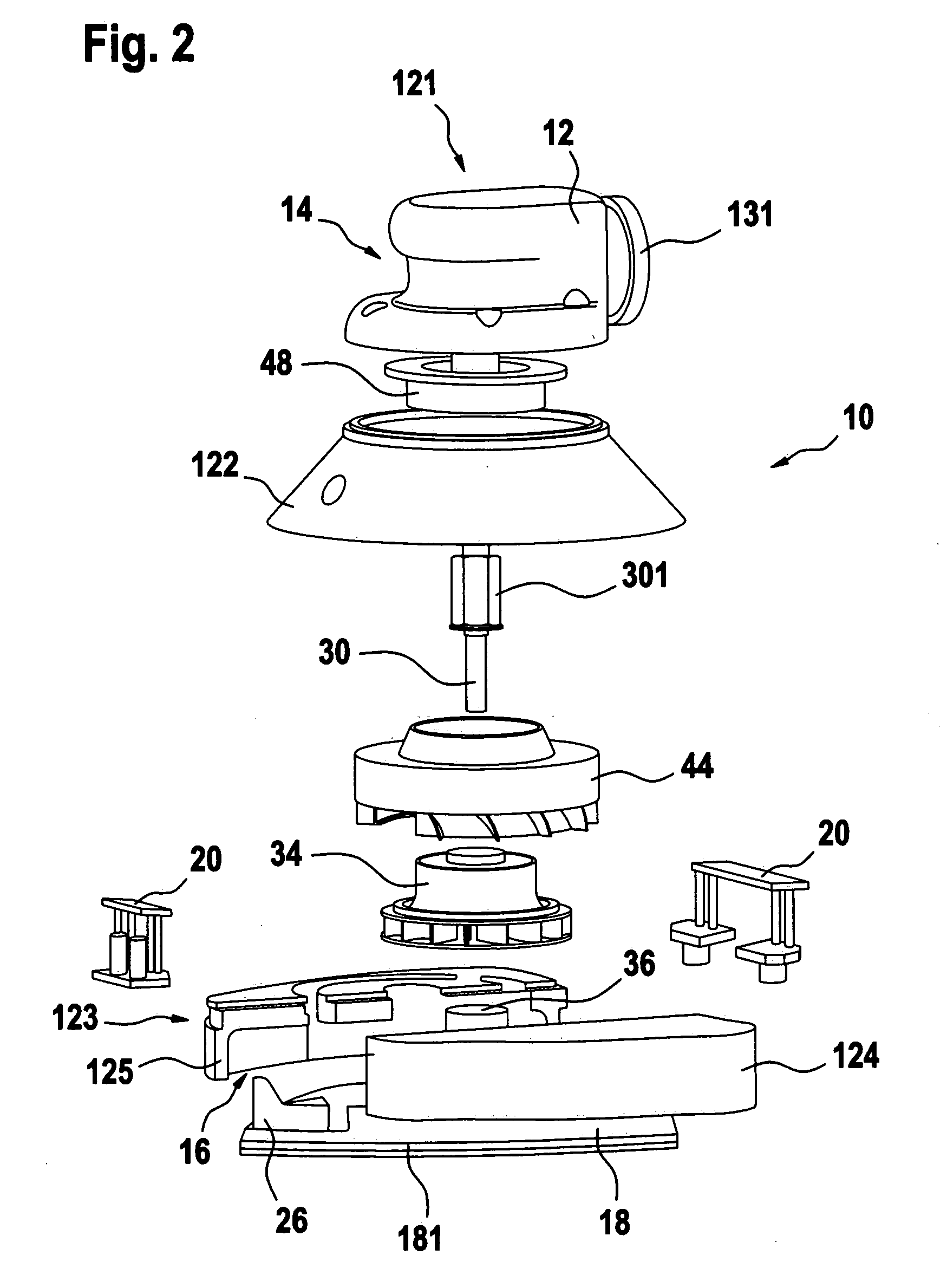

Eccentric grinding hand power tool

InactiveUS7077734B2Timing is simpleDeposit of the grinding dust there is preventedPortable grinding machinesEngineeringHand tool

An eccentric grinding hand power tool has a housing, a grinding plate unit supported on the housing and being eccentrically driven, an elastic seal that dust-tightly seals the housing with respect to the grinding plate unit, the elastic seal being held on the housing both in a form-locking, positive manner and in a force-transmitting, non positive manner without separate elements but with integrated securing elements.

Owner:ROBERT BOSCH GMBH

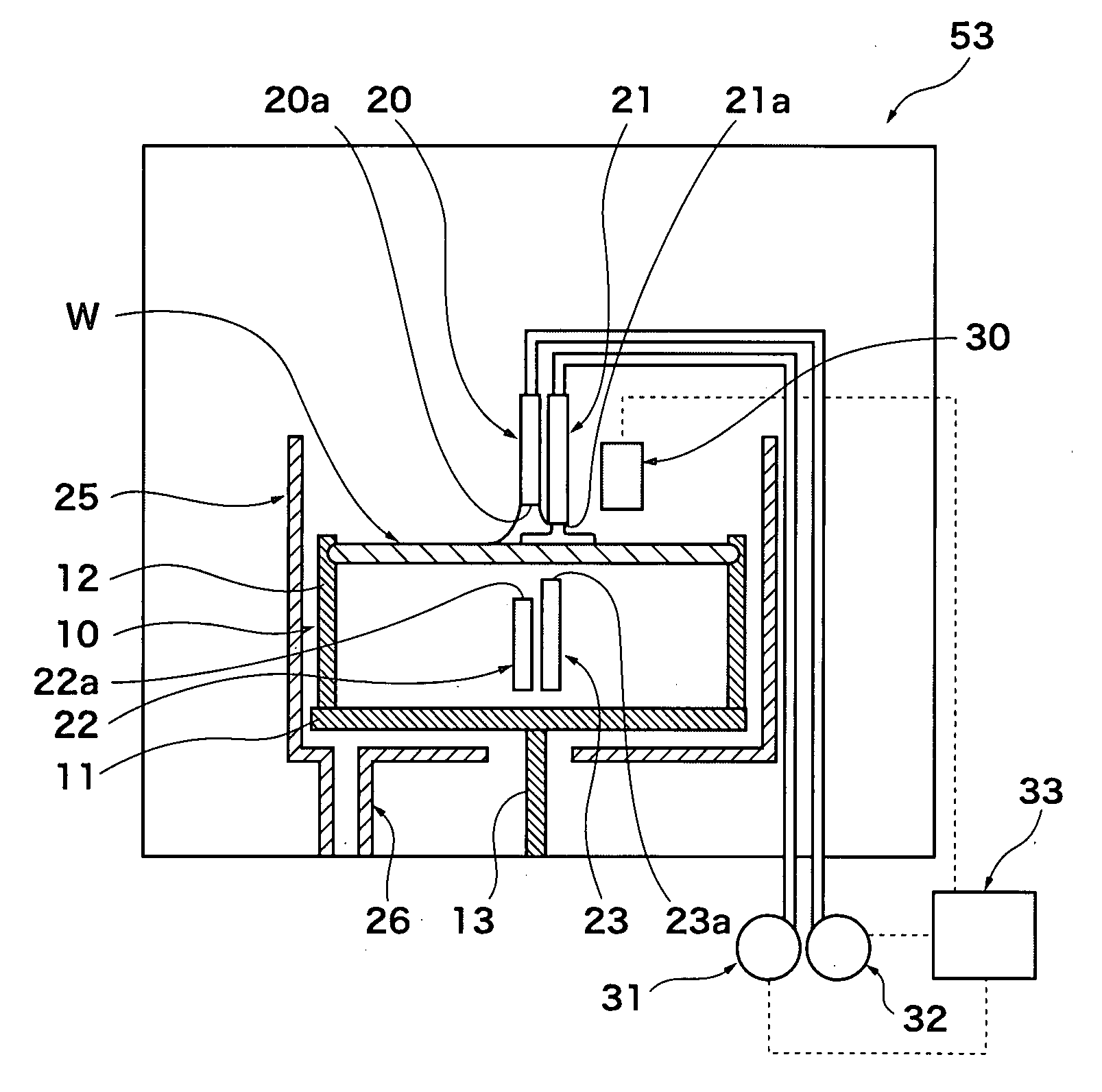

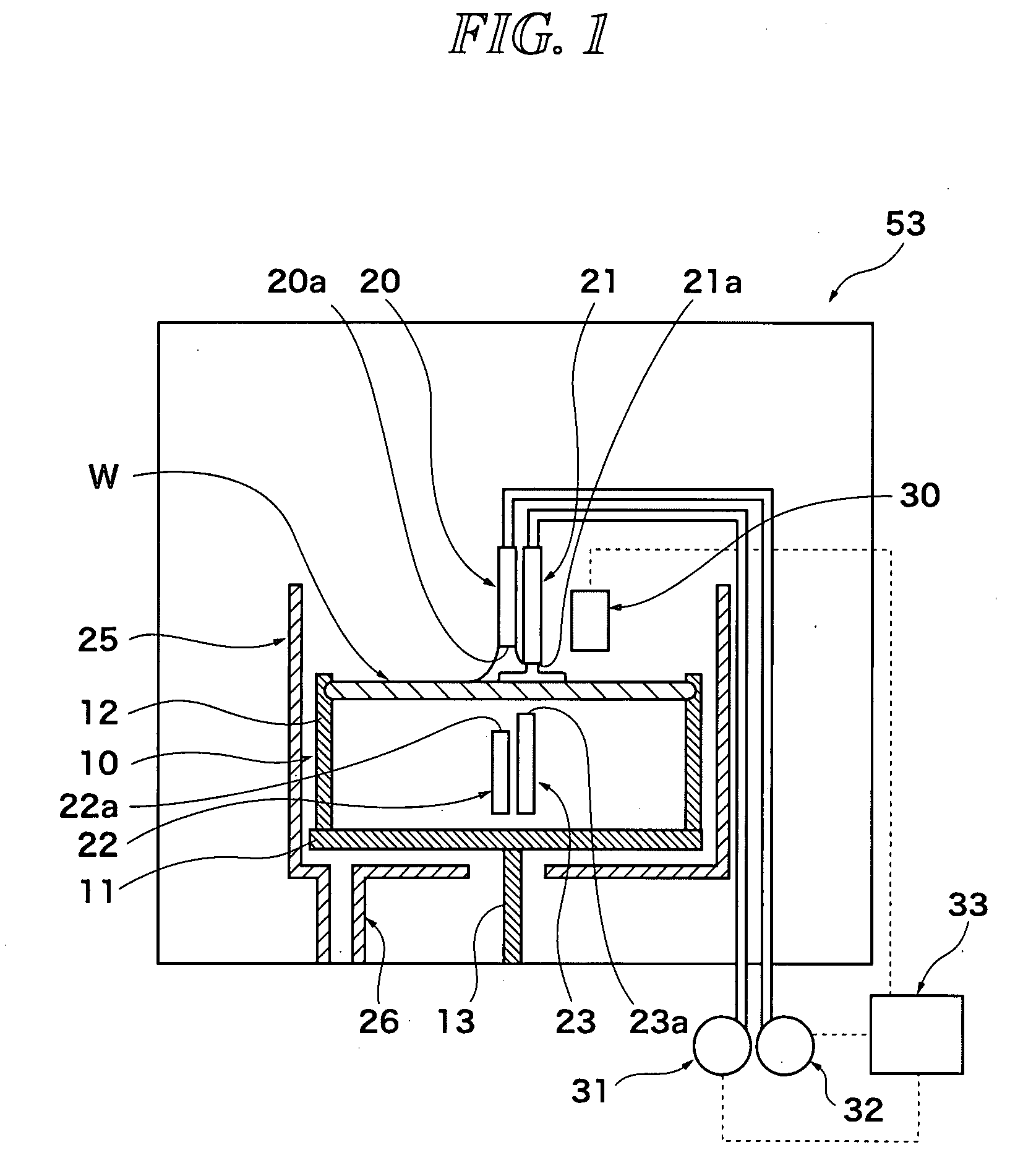

Substrate processing apparatus and substrate processing method

InactiveUS20090081810A1Effectively suctionEliminate possibilitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringBiomedical engineering

A substrate processing apparatus has a fluid supply means 20 for supplying fluid to a substrate W and a fluid collection means 21 for collecting the fluid in the vicinity of the substrate W, the fluid supply means 20 having a fluid spurt section 20a, the fluid collection means 21 having a fluid suction section 21a opening in the vicinity of the fluid spurt section 20a. Since the fluid collection means 21 suctions and collects the fluid floating around the substrate W as a result of the liquid having been supplied from the fluid spurt section 20a to the substrate W, it is possible to prevent the substrate W from being contaminated after the substrate W being processed with the fluid supplied from the fluid supply means 20.

Owner:EBARA CORP

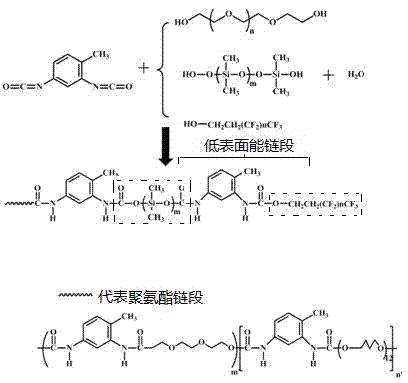

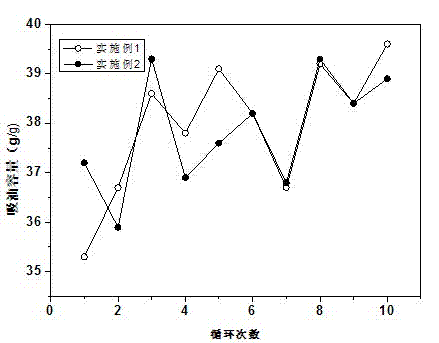

Super-hydrophobic/super-oleophylic polyurethane oil-absorption sponge and preparation method thereof

InactiveCN104231211AEasy to prepareEasy to operateOther chemical processesPtru catalystEmergency treatment

The invention belongs to the technical field of functional polymer materials, and in particular relates to a super-hydrophobic / super-oleophylic polyurethane oil-absorption sponge and a preparation method thereof. According to the technical scheme, the super-hydrophobic / super-oleophylic polyurethane oil-absorption sponge is prepared from the following components in parts by weight: 10-50 parts of polyisocyanates, 20-60 parts of a chain extender, 0.05-1.5 parts of a catalyst, 1-4 parts of a chemical foaming agent, 1.0-8.0 parts of a physical foaming agent, 0.5-3 parts of a cross-linking agent and 2-20 parts of other additives. The invention further provides the preparation method of the super-hydrophobic / super-oleophylic polyurethane oil-absorption sponge. The oil-absorption sponge provided by the invention has the advantages of super-hydrophobicity, super-oleophylicity, large specific surface area, porous polymolecular layers, capillary agglutination super oil-absorption property, environment inertia and the like, and is a high-efficiency rapid separation material which can be applied to emergency treatment on ocean oil overflowing pollution accidents.

Owner:重庆市环境科学研究院

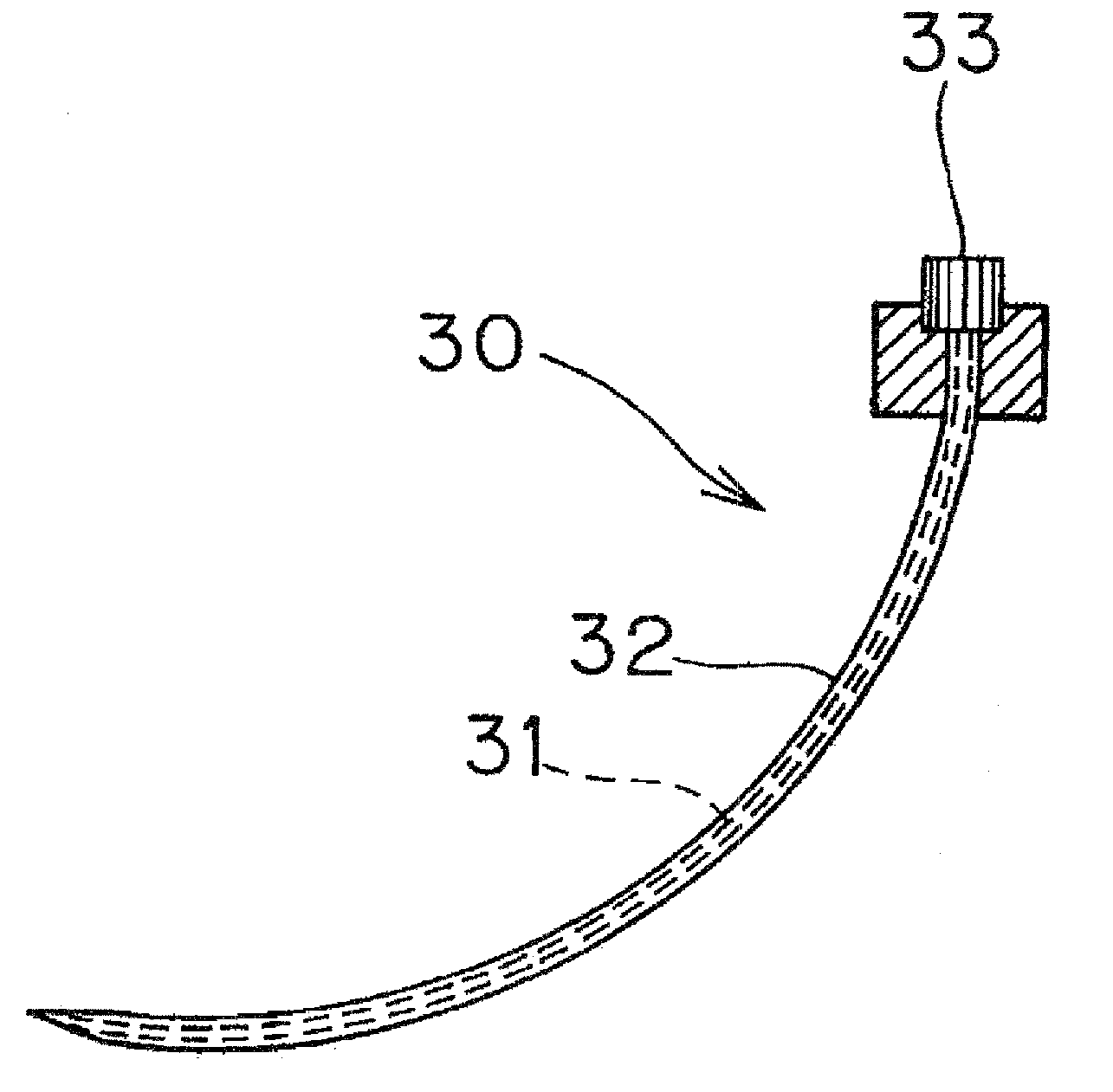

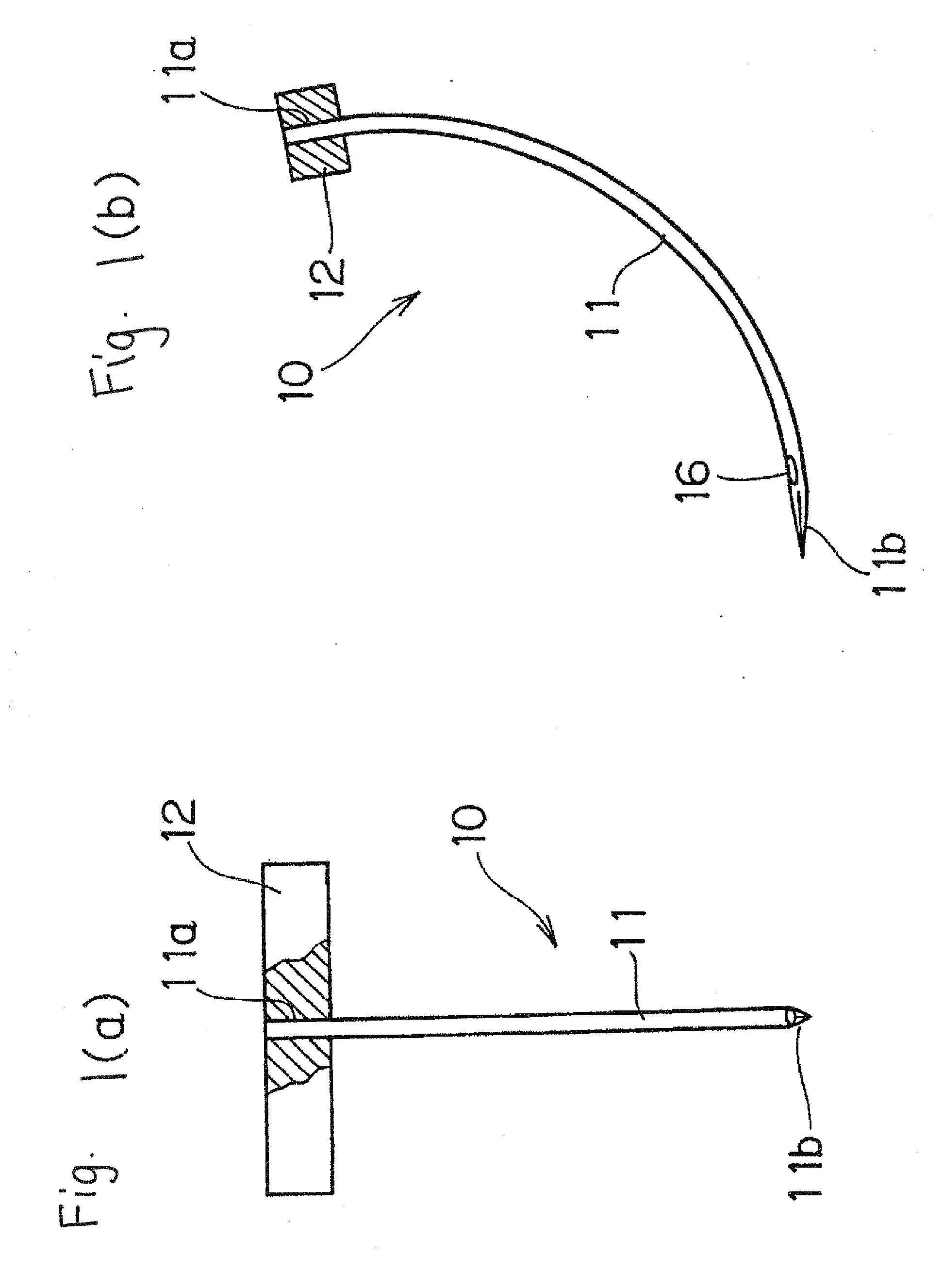

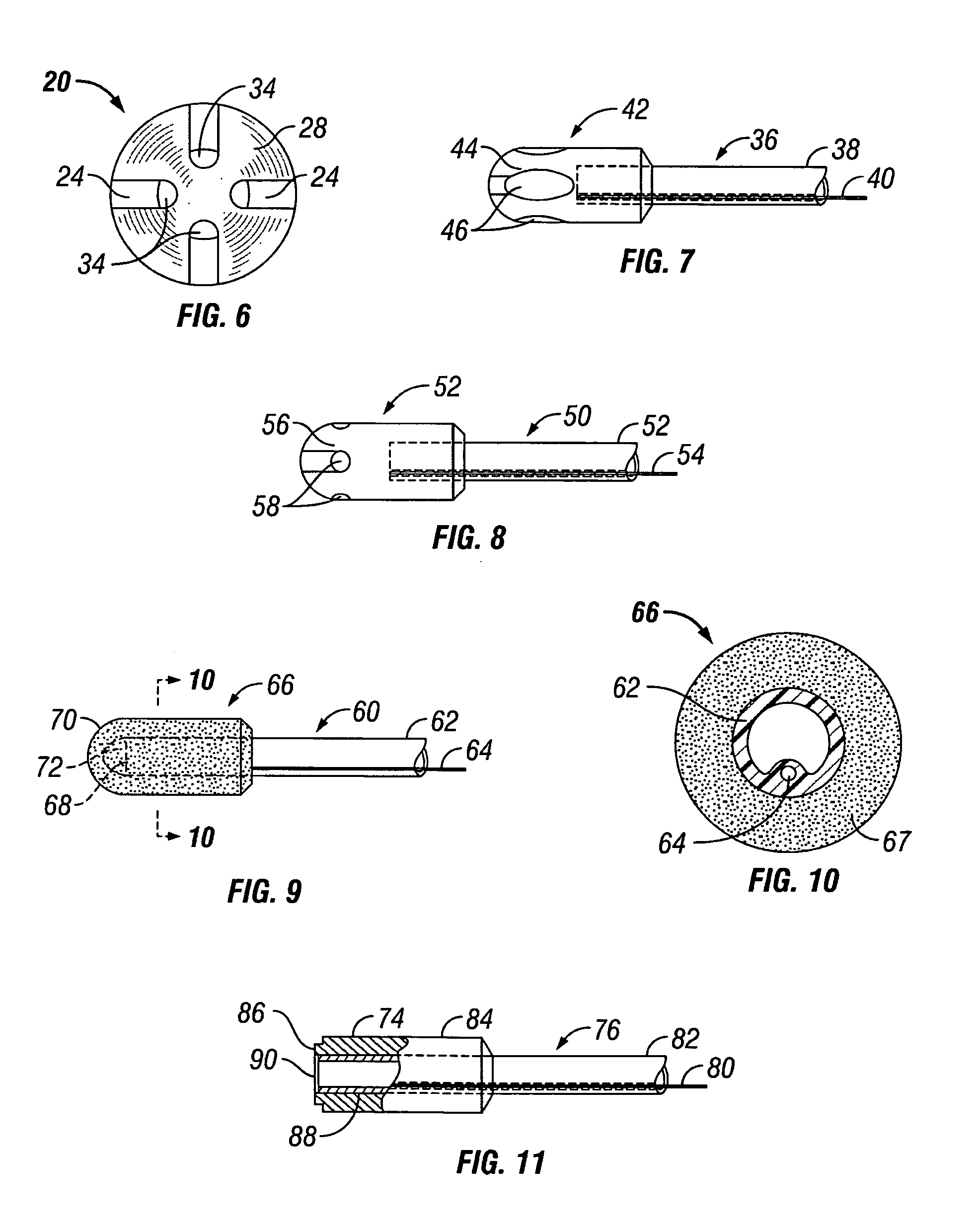

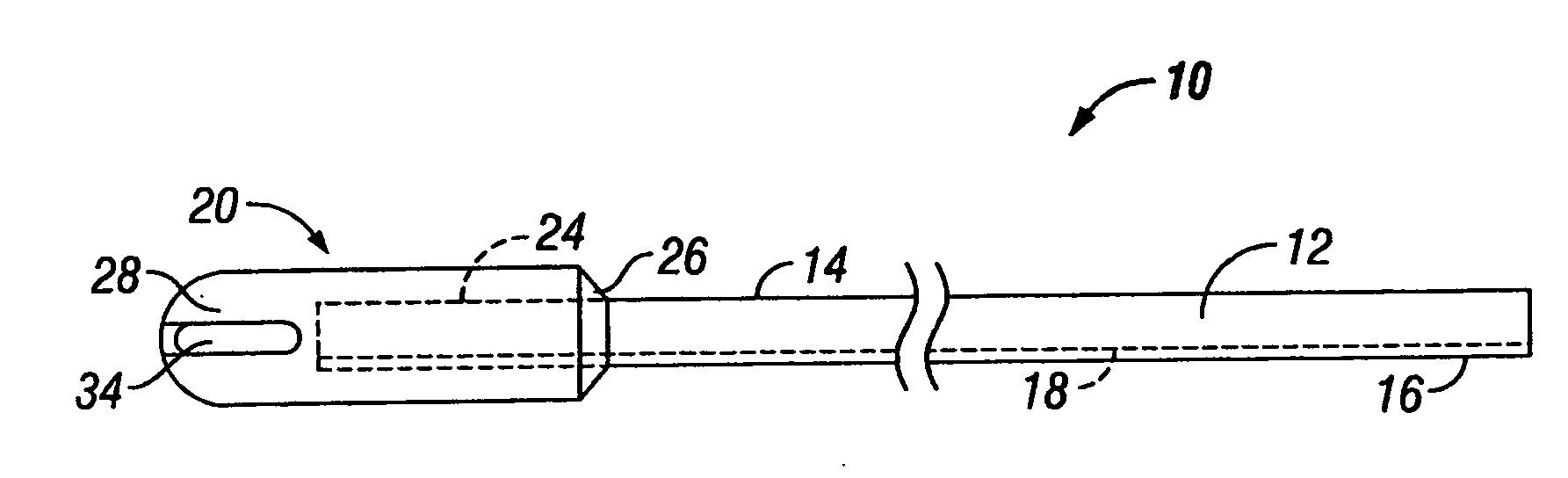

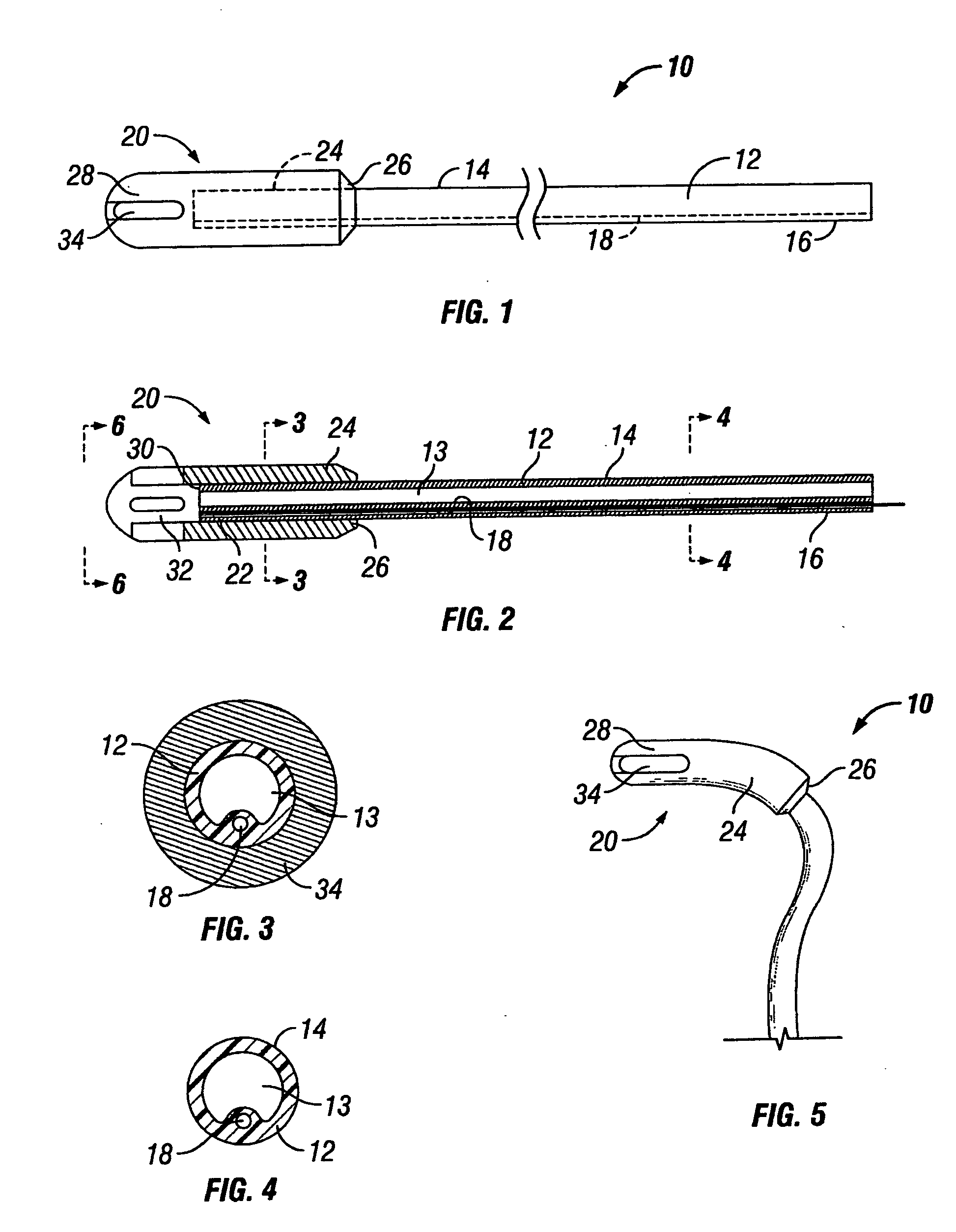

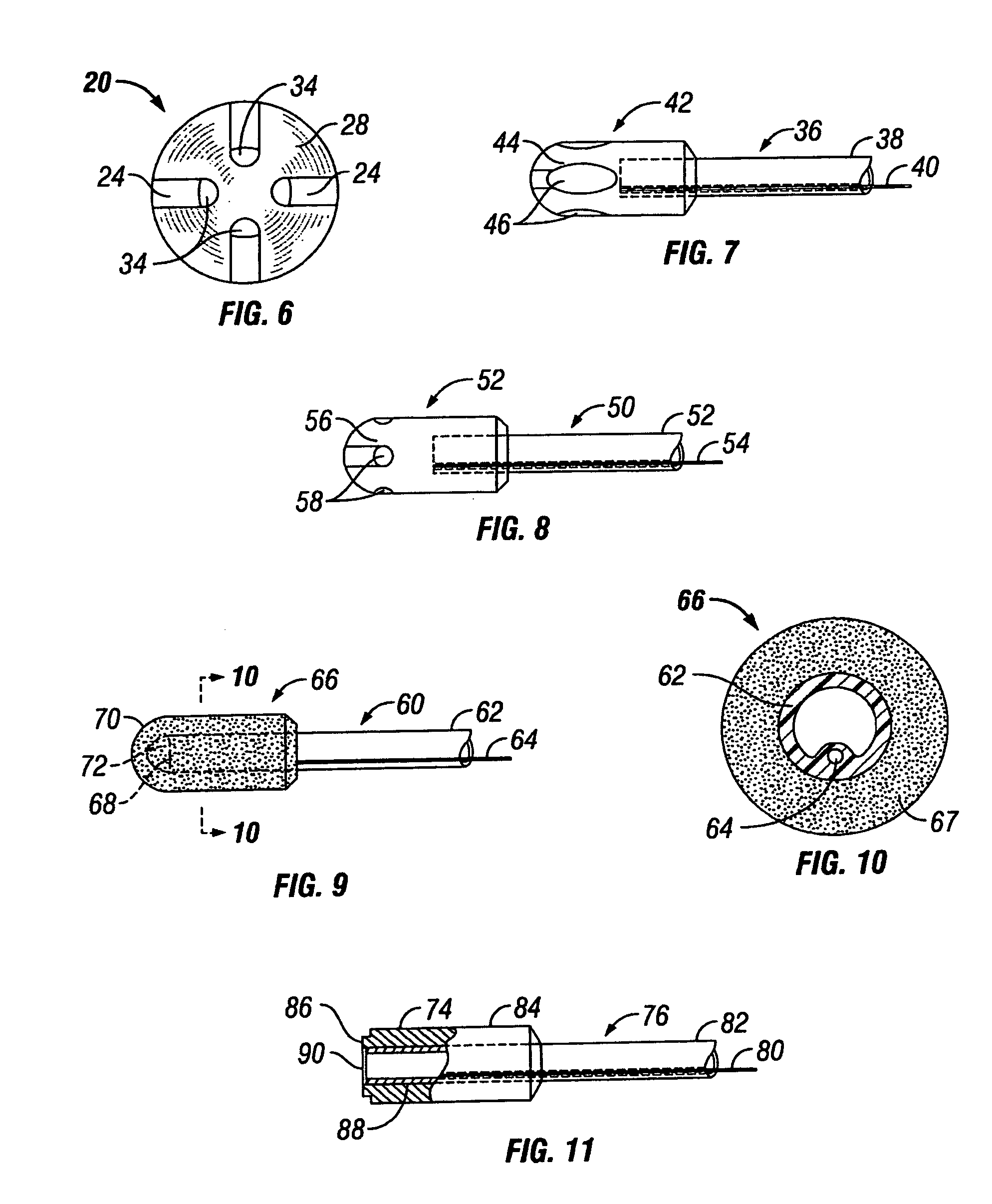

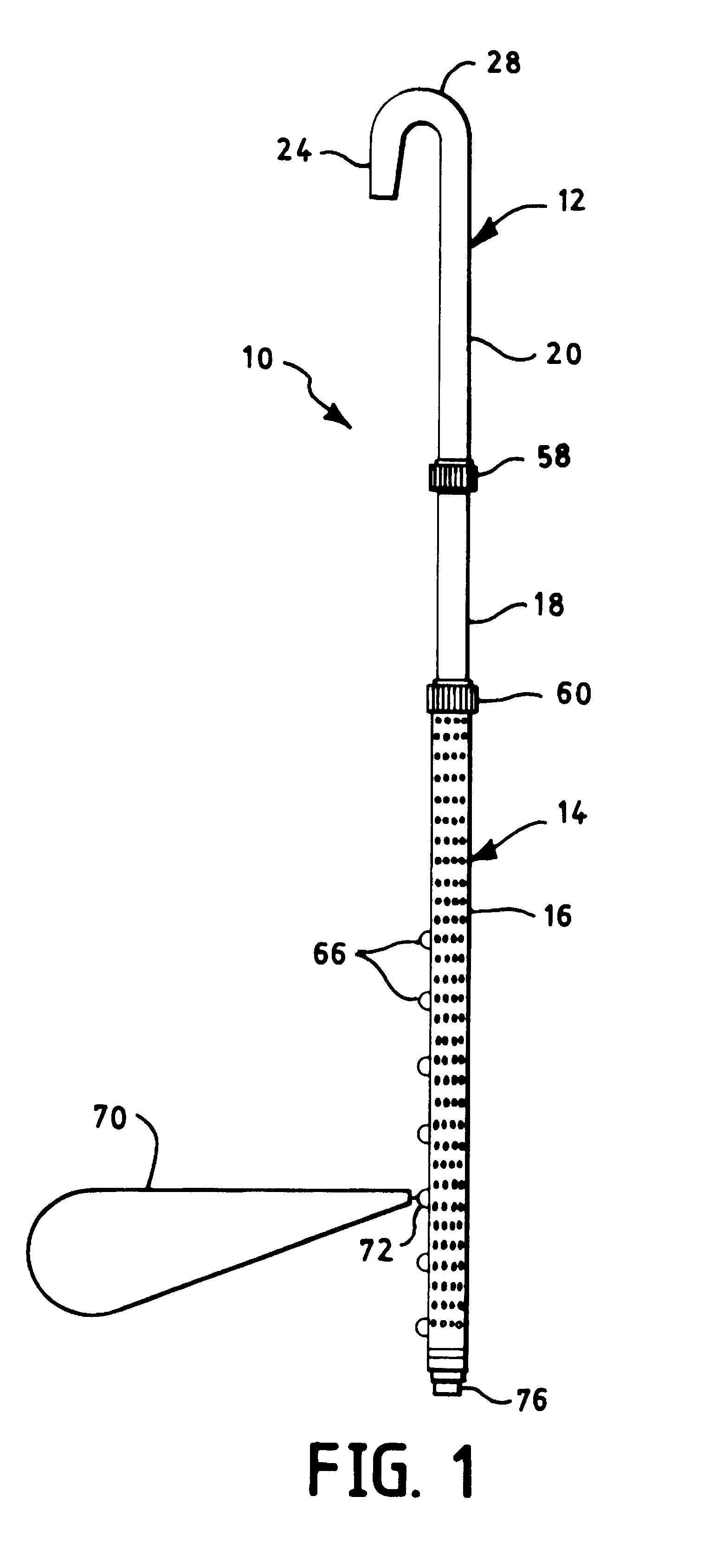

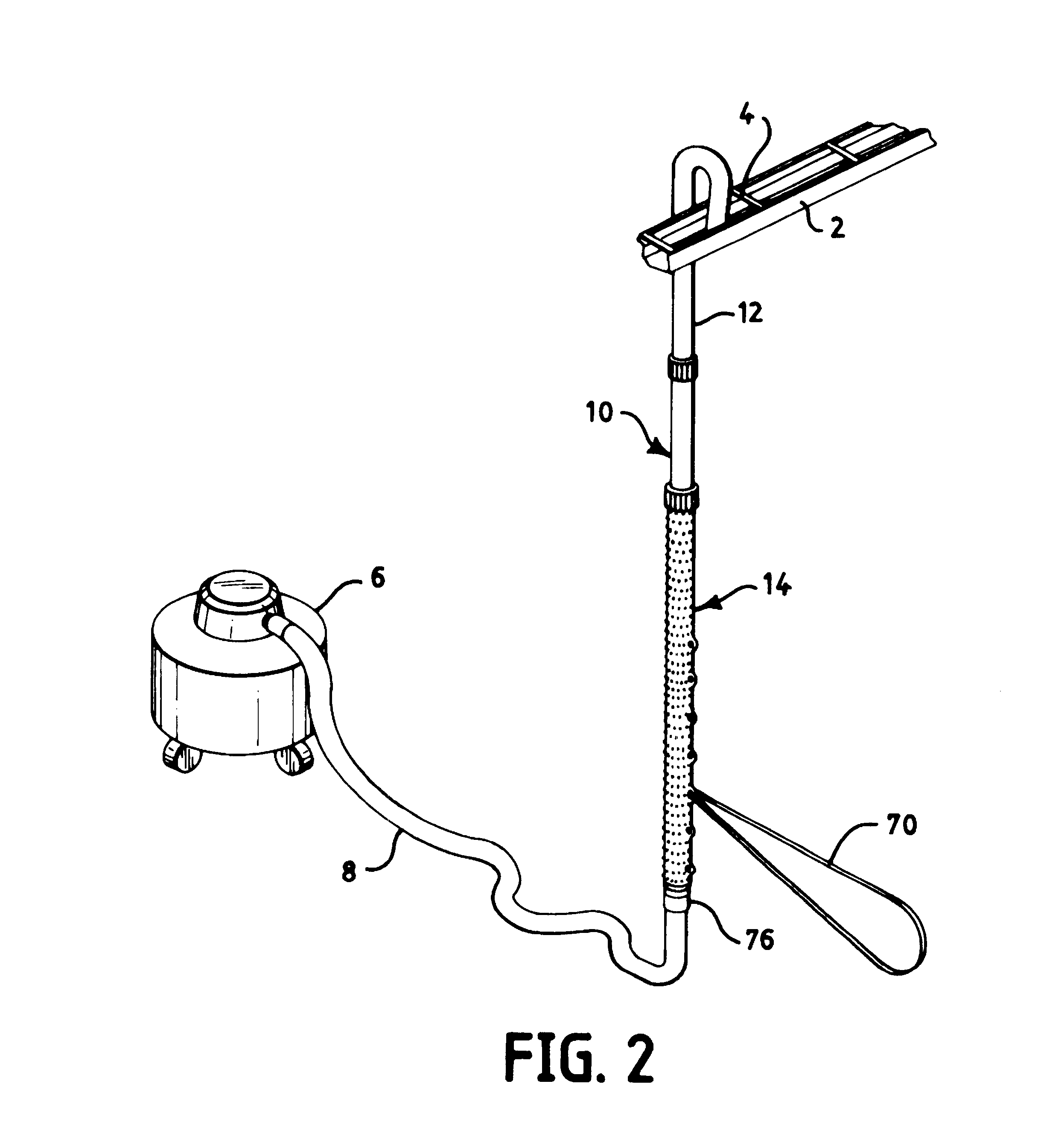

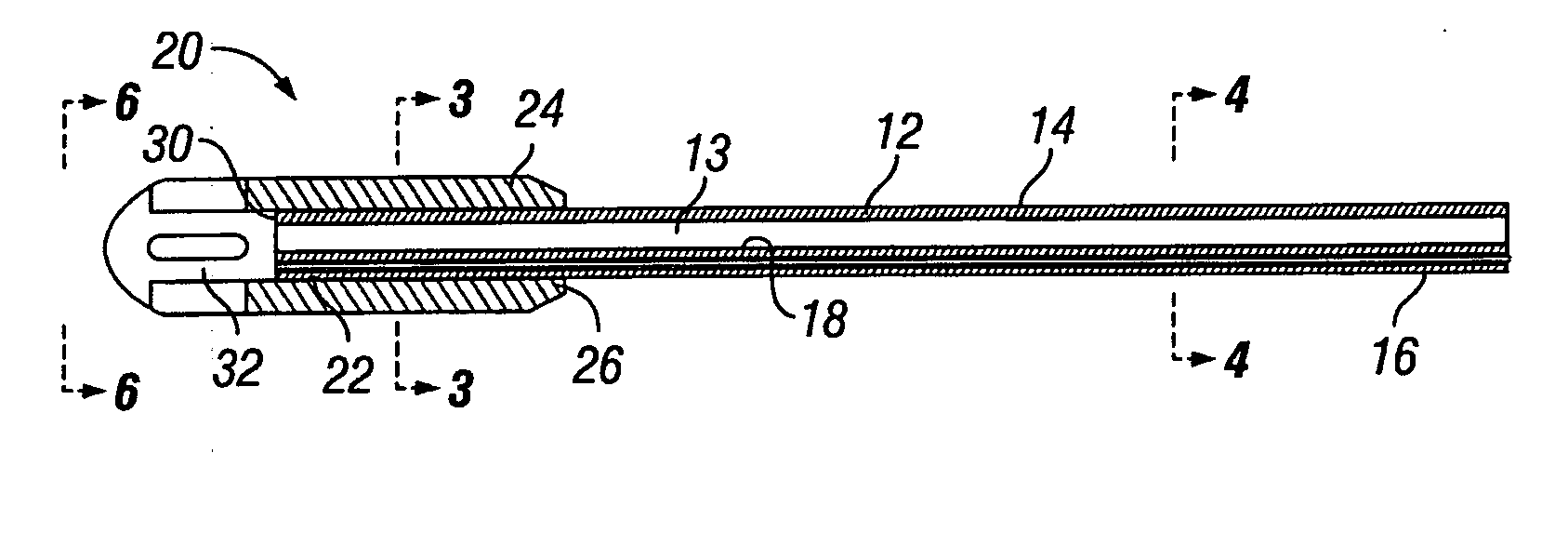

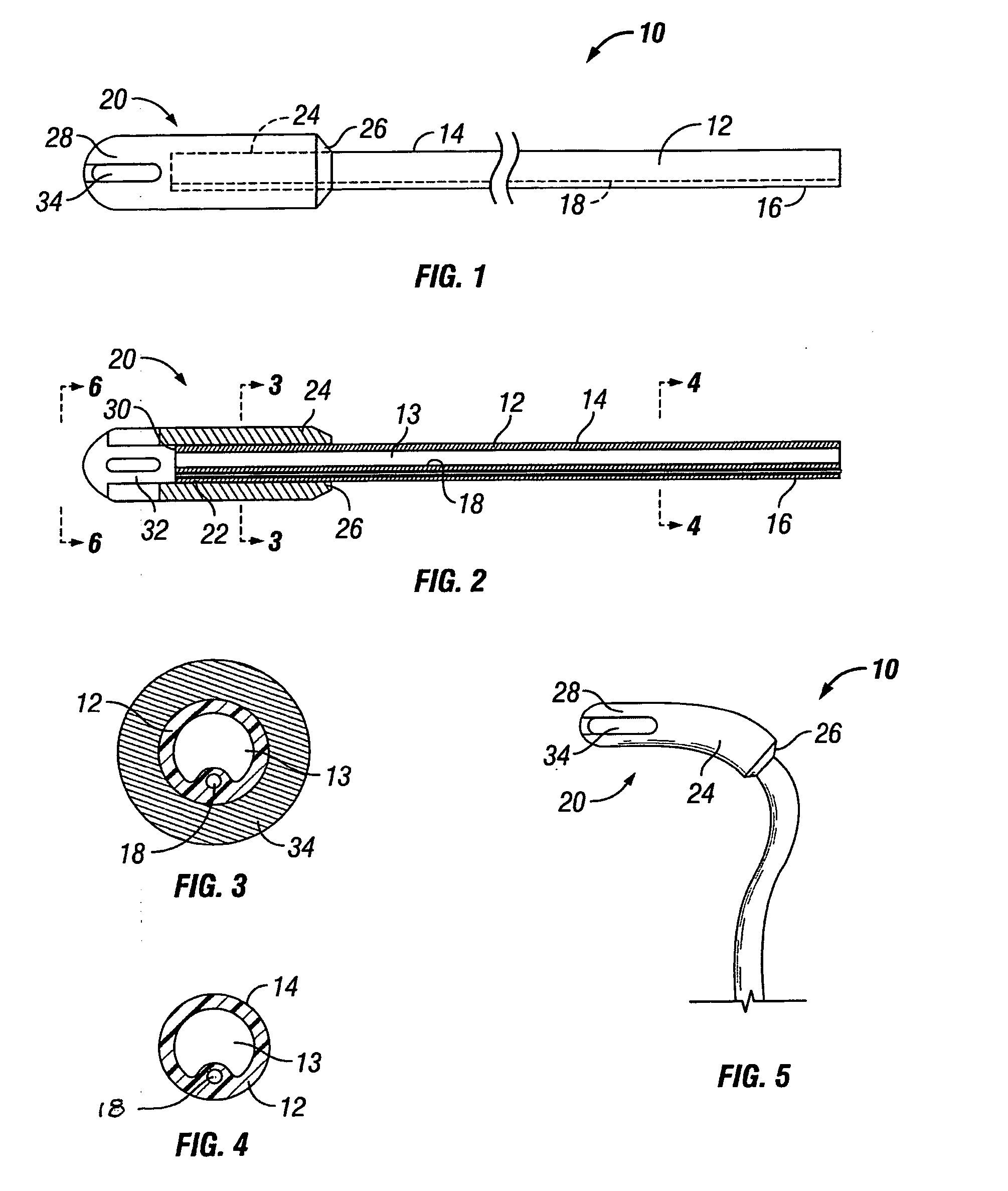

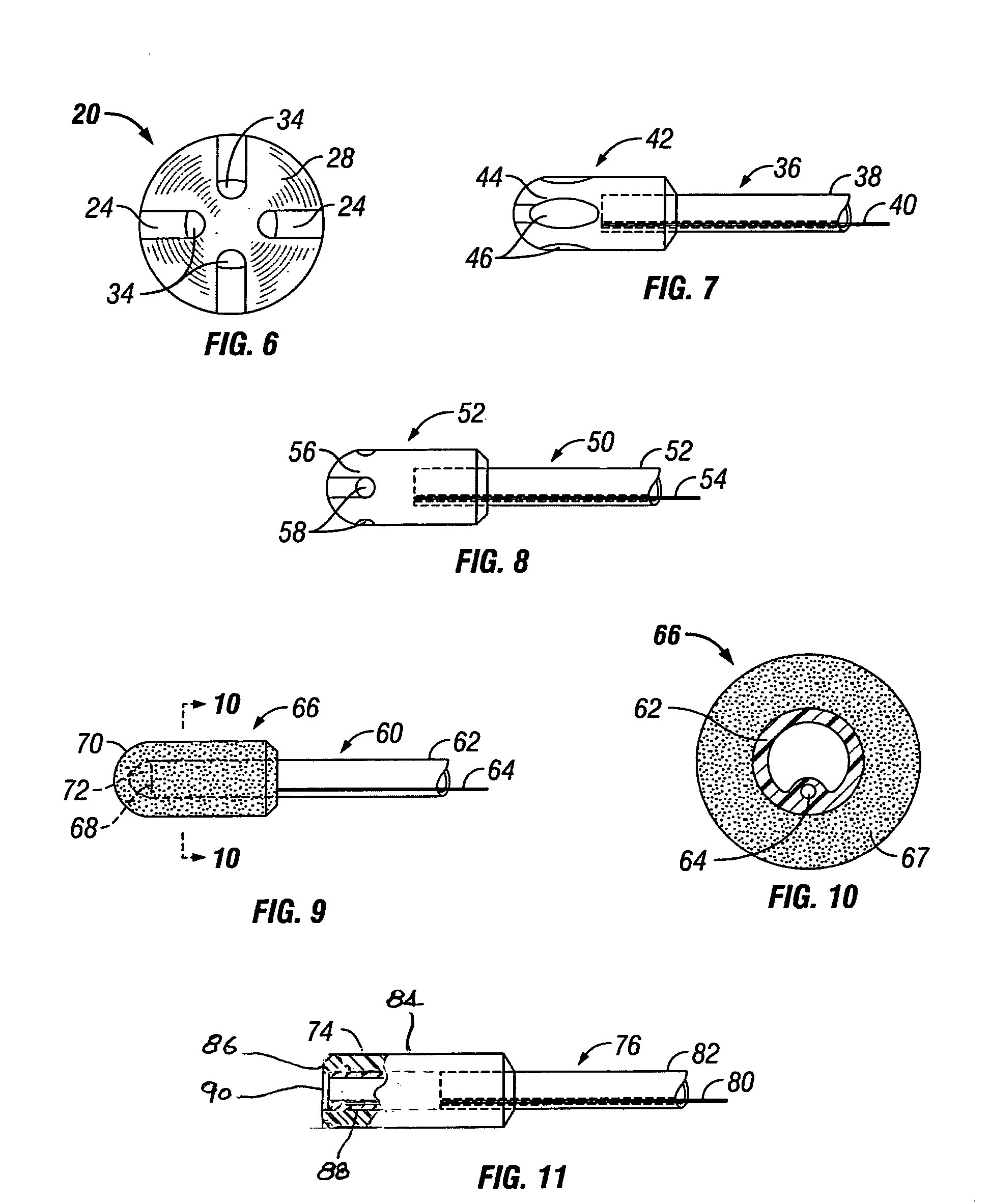

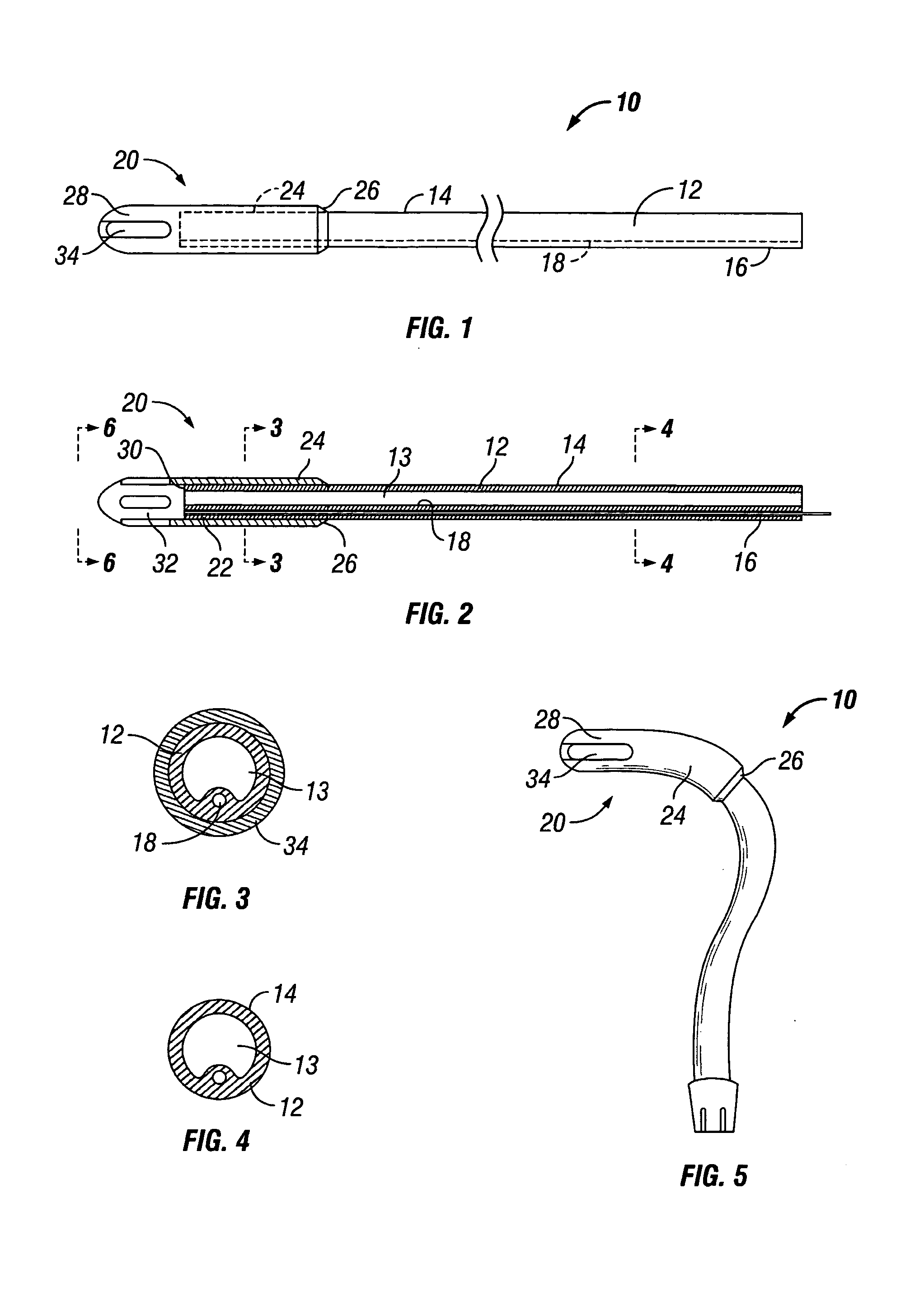

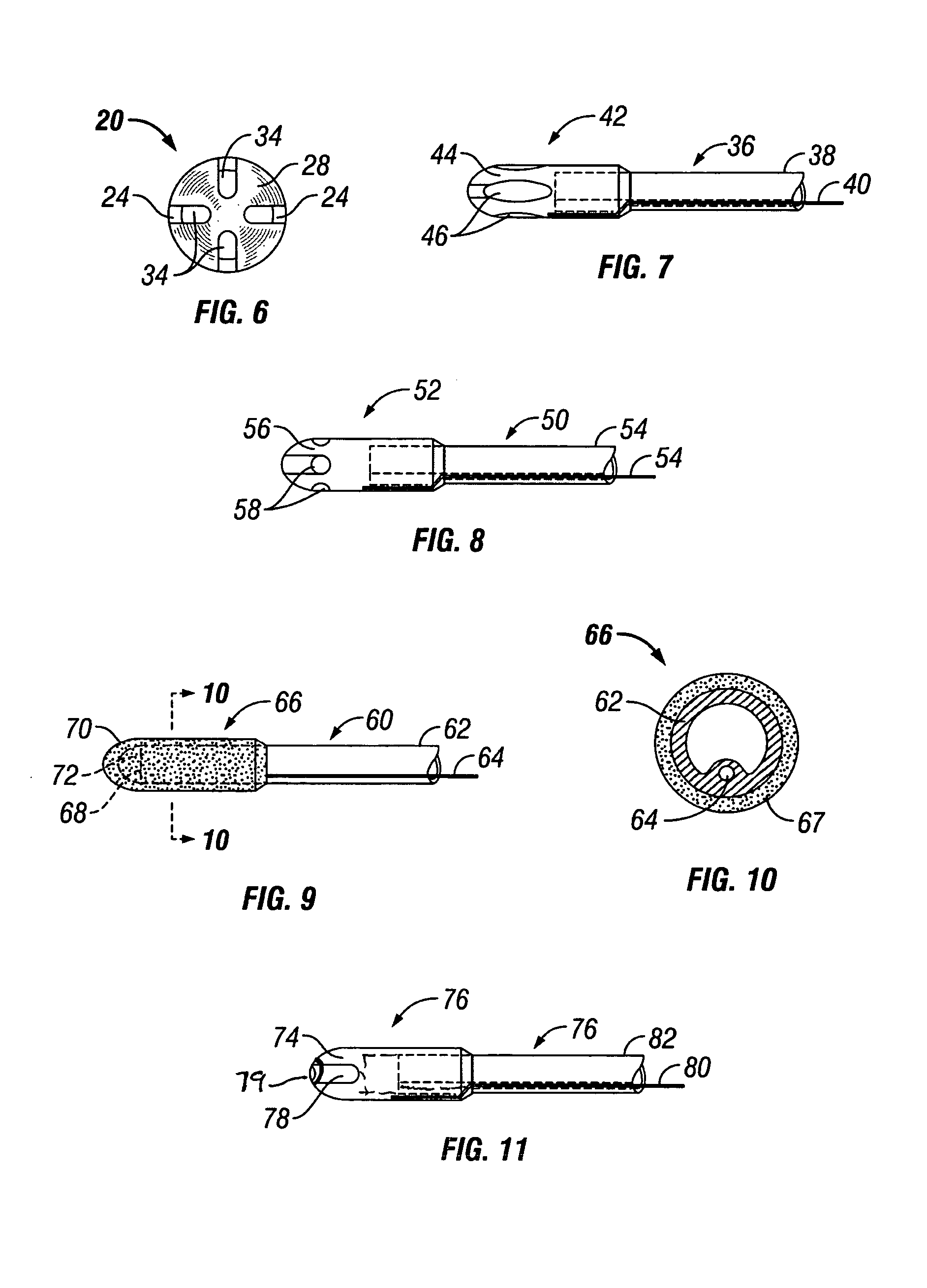

Aspirator having a cushioned and aspiration controlling tip

Owner:MAHLMANN LEE A

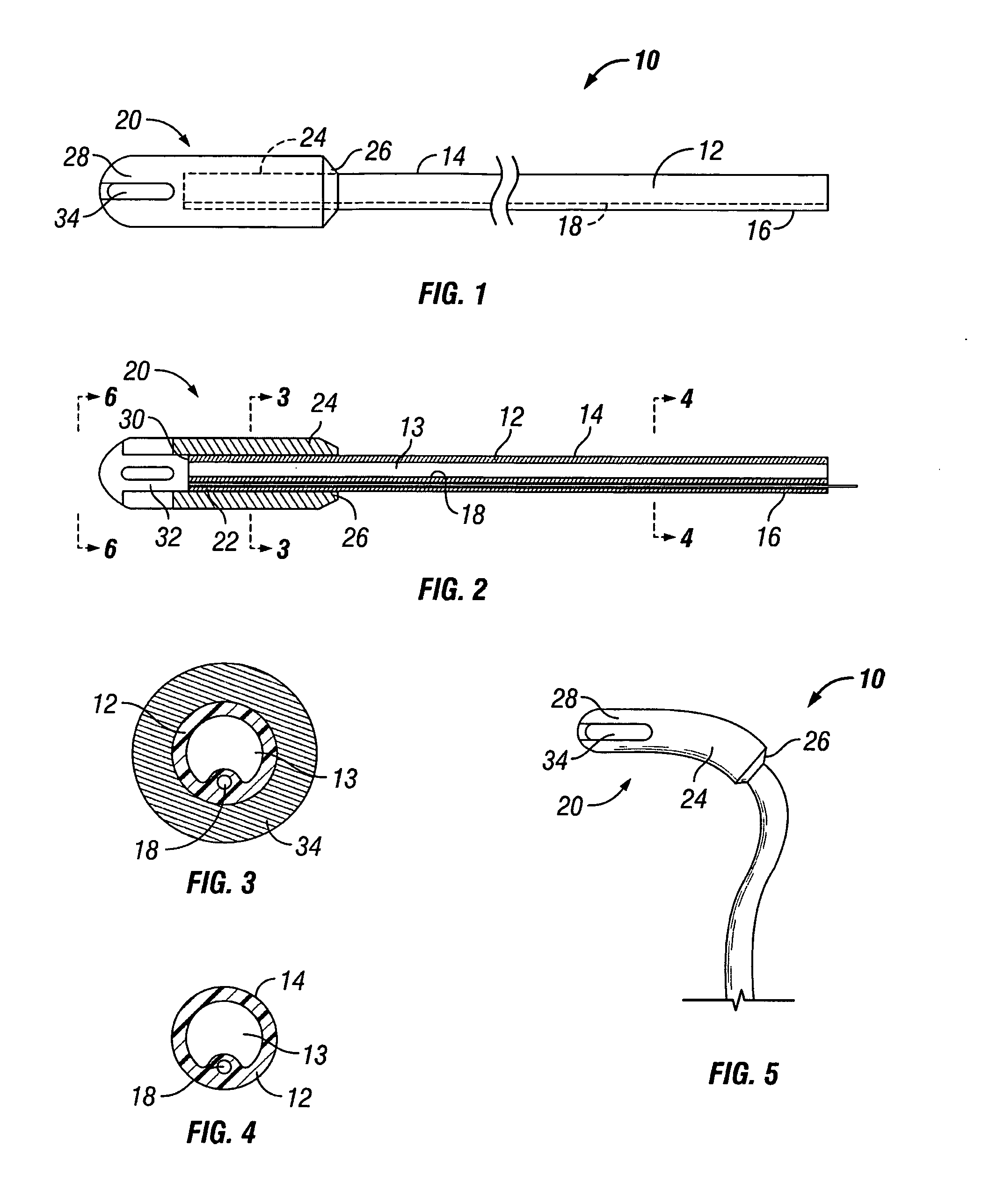

Aspirator having a cushioned and aspiration controlling tip

ActiveUS20060199147A1Minimize potentialEfficient suctionTeeth fillingCatheterMedical procedurePolymer

A disposable cushioned aspirator which forms part of a dental or medical aspirating system. The disposable cushioned aspirator appliance described herein is intended principally to be used in dental and medical procedures where body fluids and rinse water is evacuated from the site of a procedure. An elongate tubular element has a connection end and a patient end. The patient end is exteriorly lined with a layer of soft cushioning material such as a soft thermoplastic elastomers, styrene based polymers, rubber or a porous polymer foam material to define an aspirator tip that protects the soft tissues in and around the mouth of a patient. The soft aspirator tip has external longitudinal pressure relief channels and recessed aspiration openings within the channels for control of aspiration characteristics. The aspirator tube is capable of being manually bent to a desired configuration and has an embedded structural member such as wire extending along its length and being pliable to permit bending and yet of sufficient structural integrity to maintain the aspirator in the desired configuration during use.

Owner:MAHLMANN LEE A

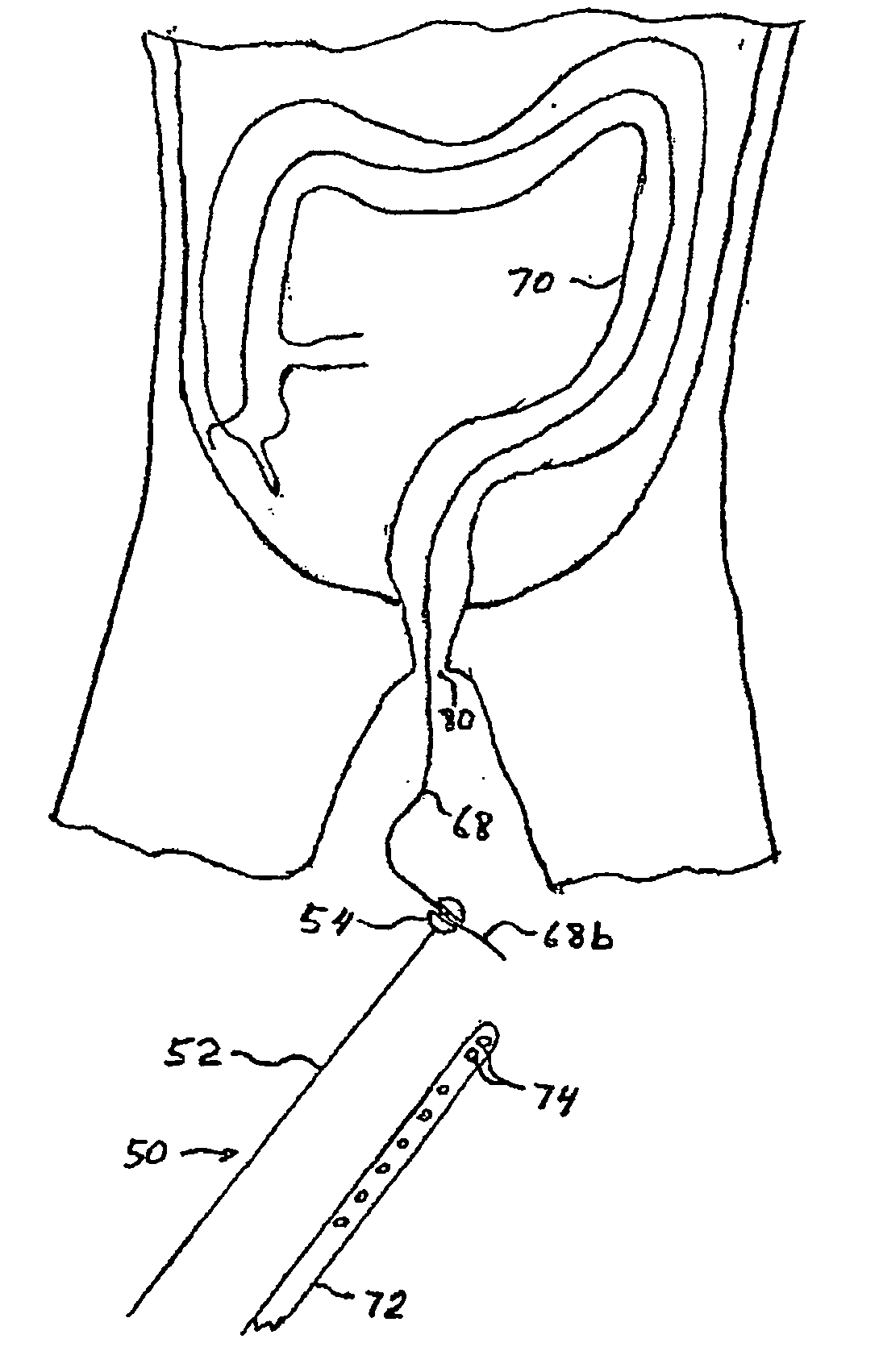

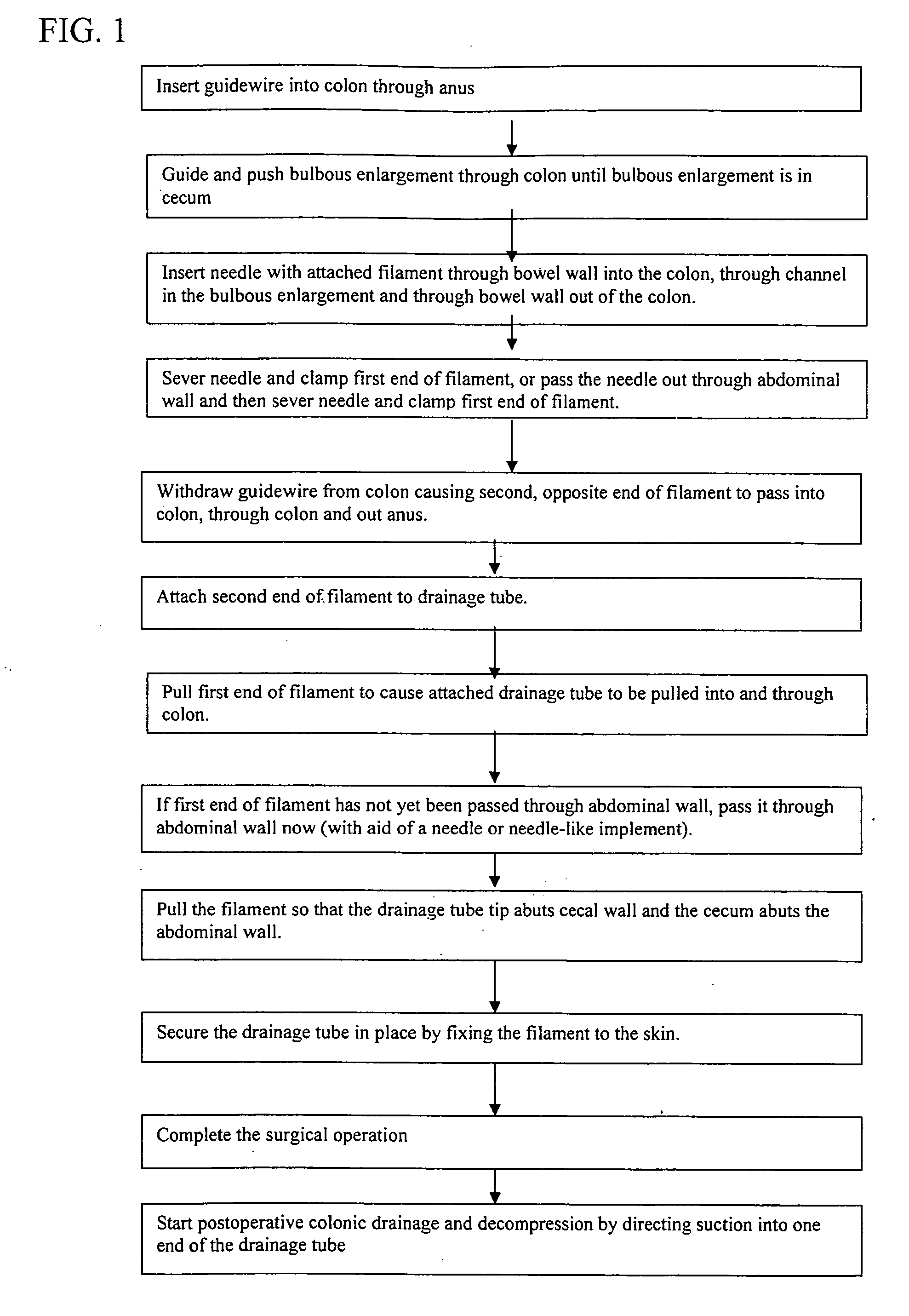

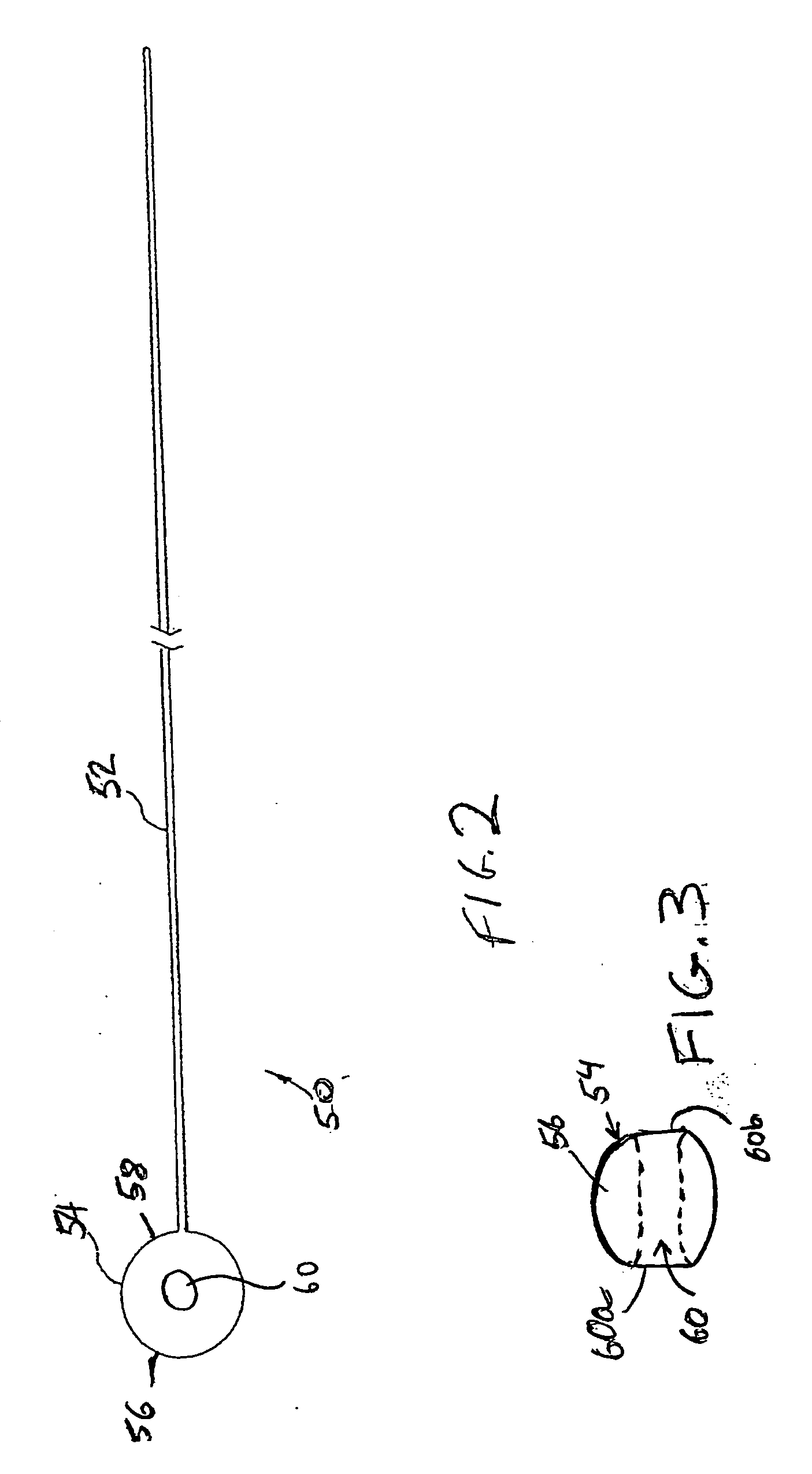

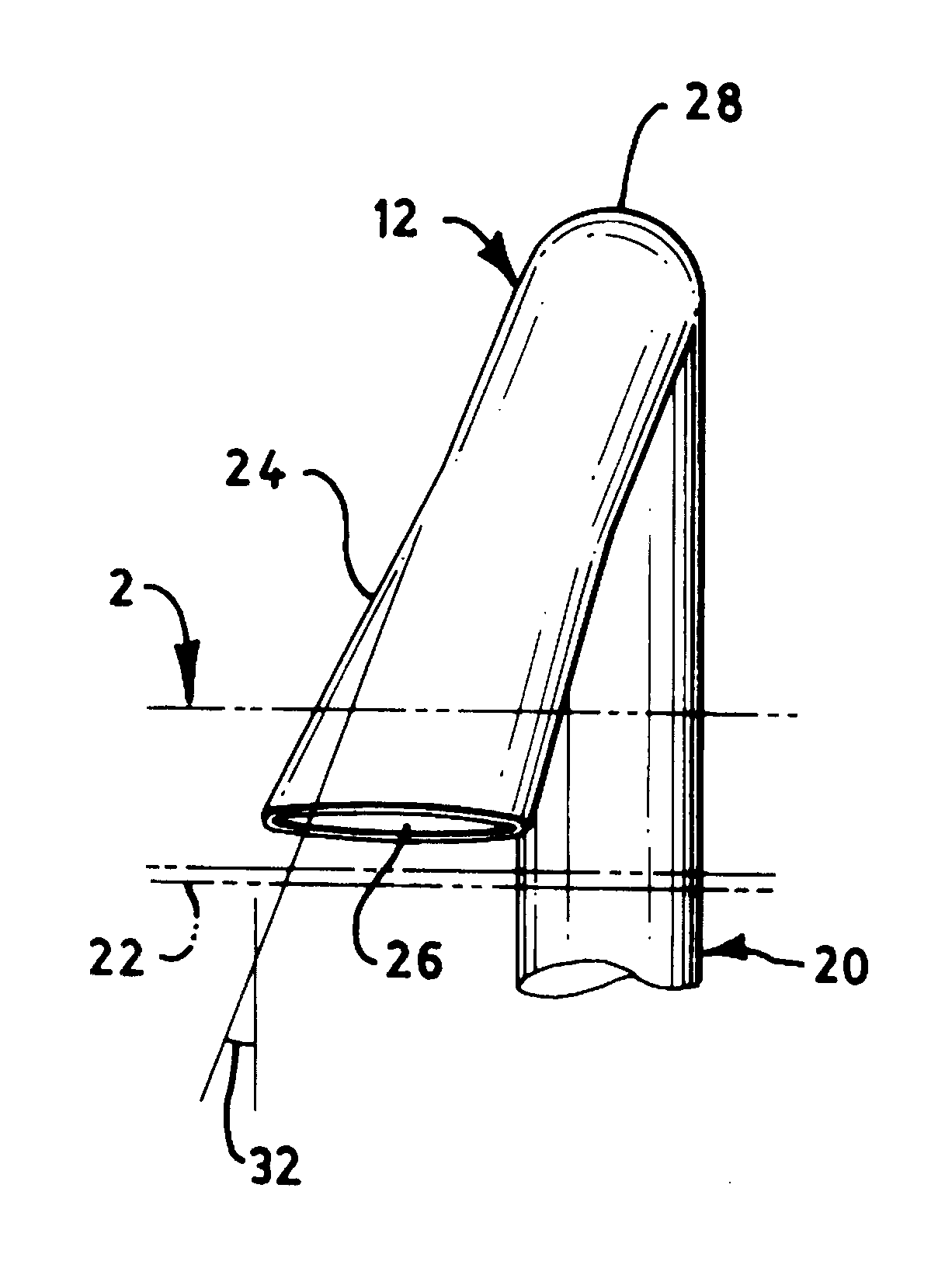

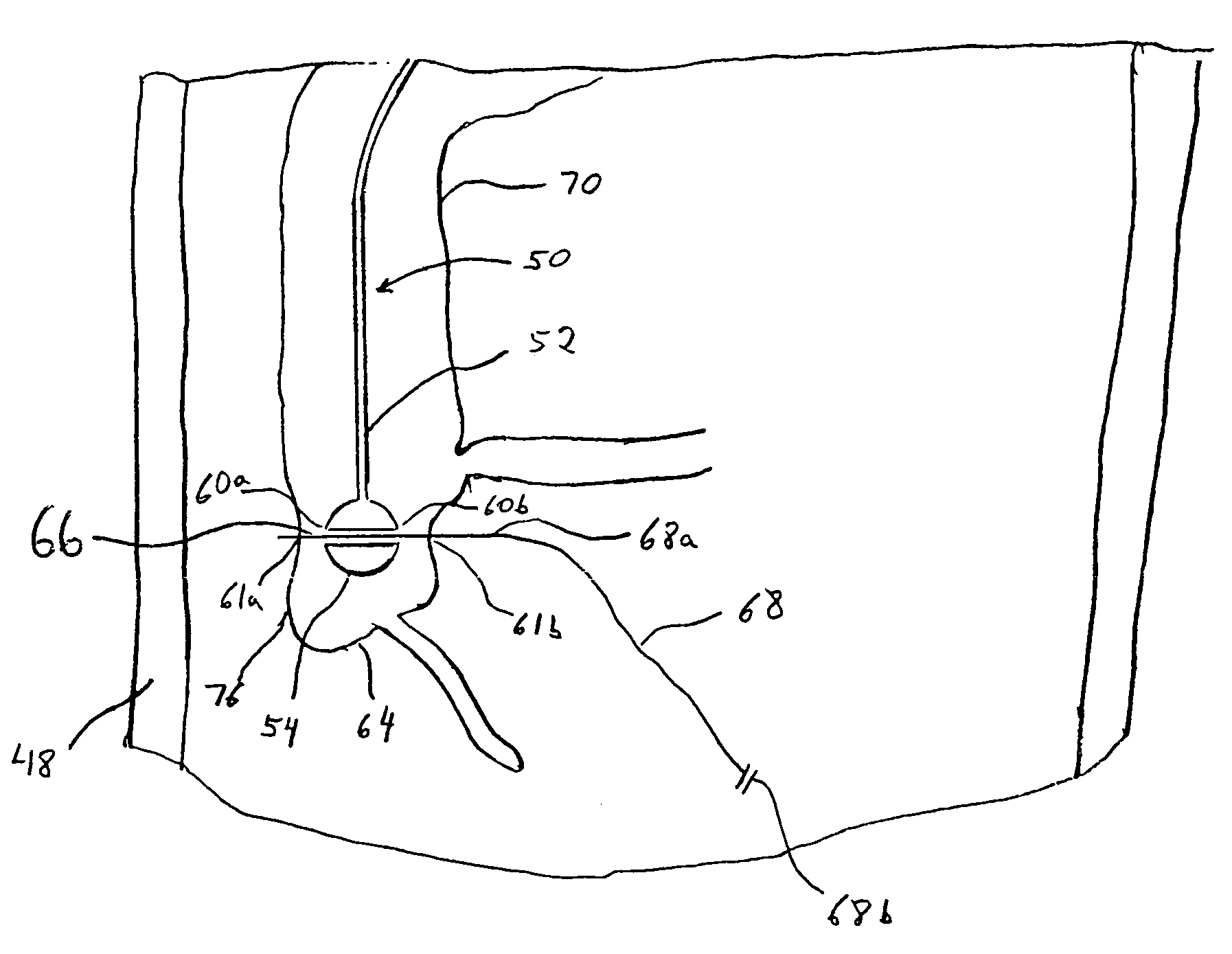

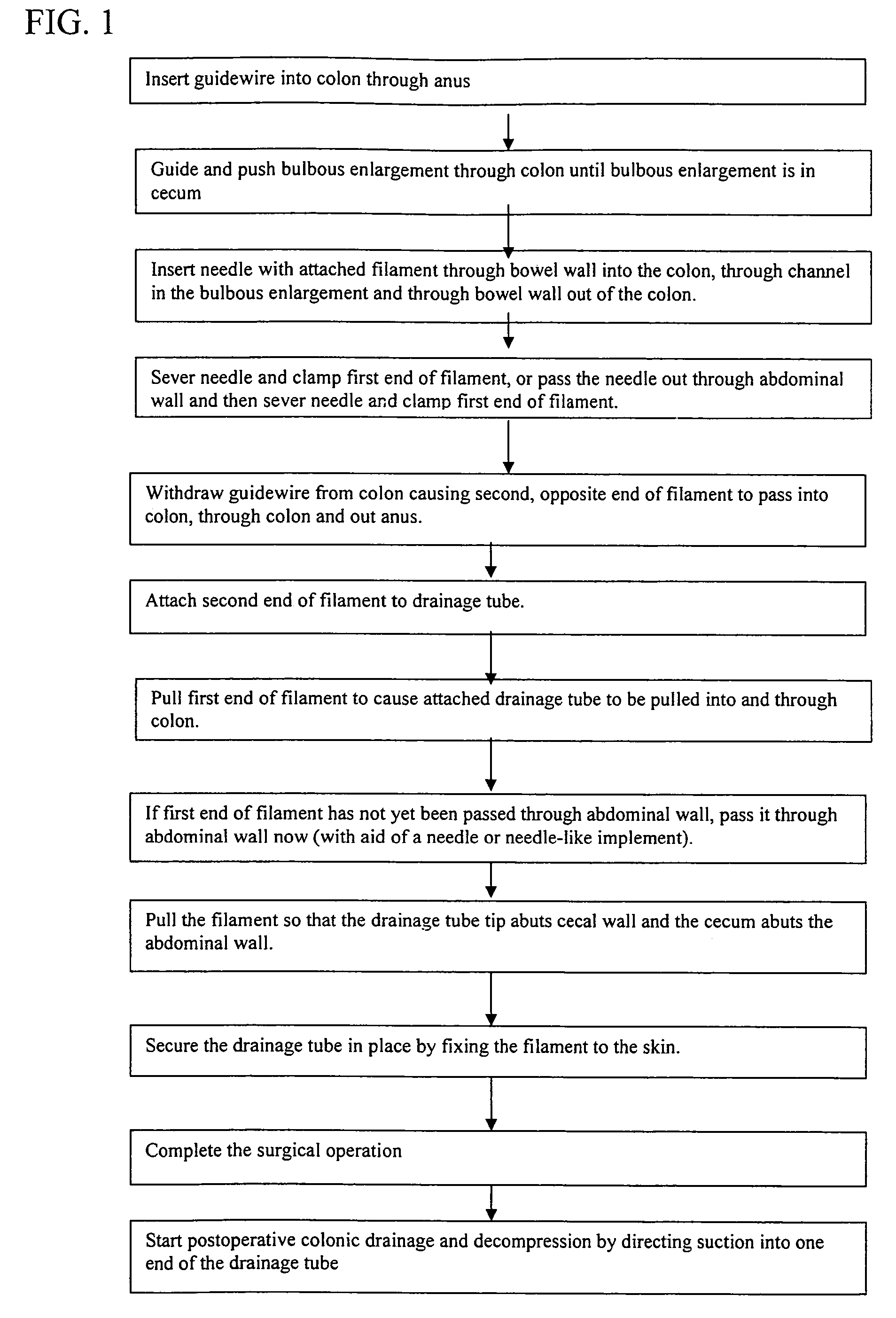

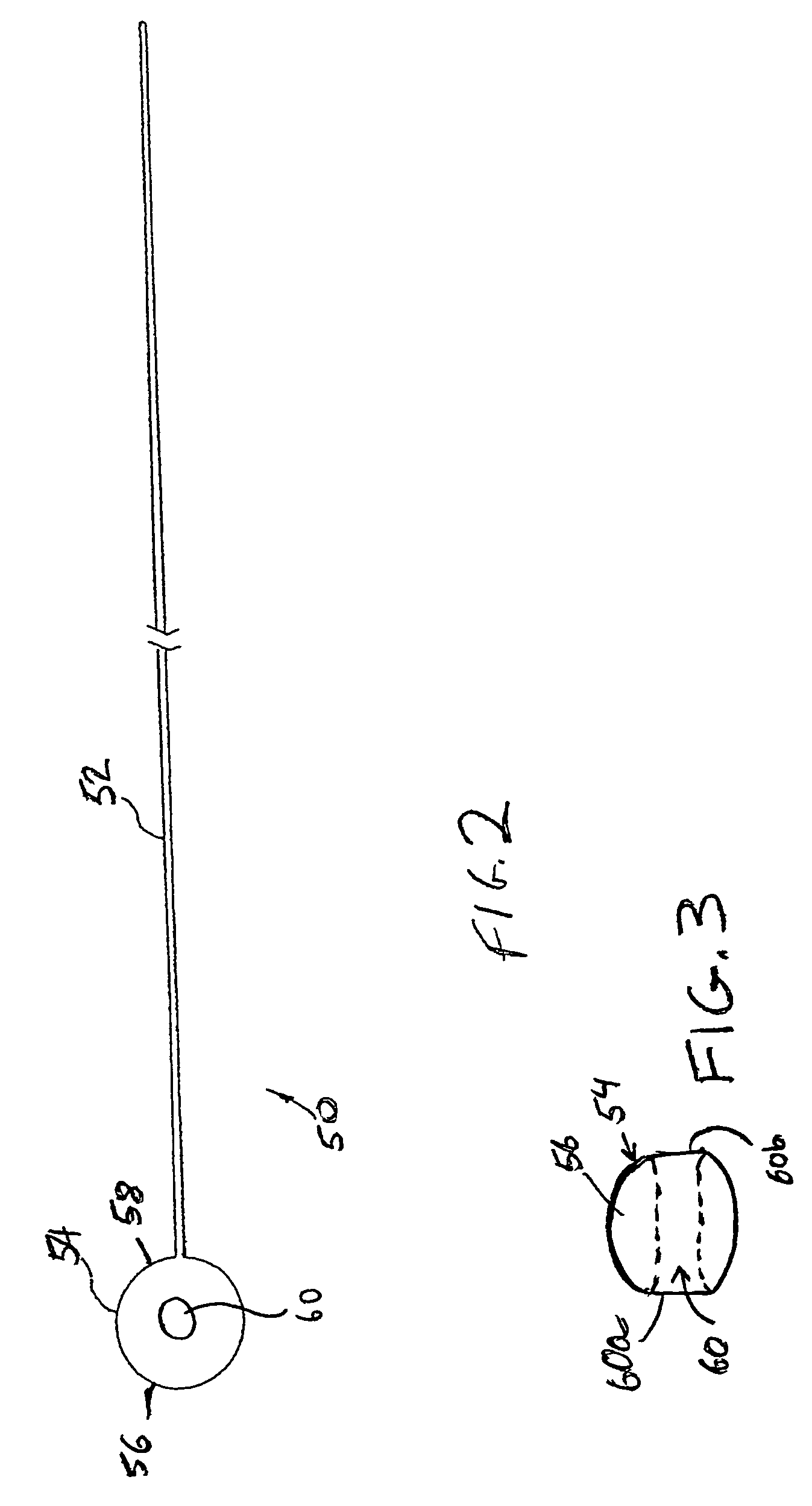

Tubular apparatus for drainage of the colon and method and guidewire for colonic intubation

InactiveUS20050228363A1Efficient suctionDiverting fecal matterInfusion syringesWound drainsEntire colonDrainage tubes

Method for draining and decompressing a colon in which a drainage tube is inserted through the anus into the colon to extend through the entire colon. The drainage tube is fixed in position and suction is applied therethrough to cause fecal matter to pass therein through apertures and be withdrawn from the colon. The drainage tube is inserted by inserting a guidewire into the colon through the anus, manipulating and pushing the guidewire to the cecum, passing a filament through the colon wall to engage the guidewire, pulling the guidewire out of the colon and anus to draw the filament through the colon and out of the anus, attaching the drainage tube to the filament and drawing the filament with attached drainage tube through the anus into the colon. The invention also relates to constructions of the guidewire, the drainage tube and methods for inserting drainage tubes using guidewires.

Owner:LEIBOFF ARNOLD R

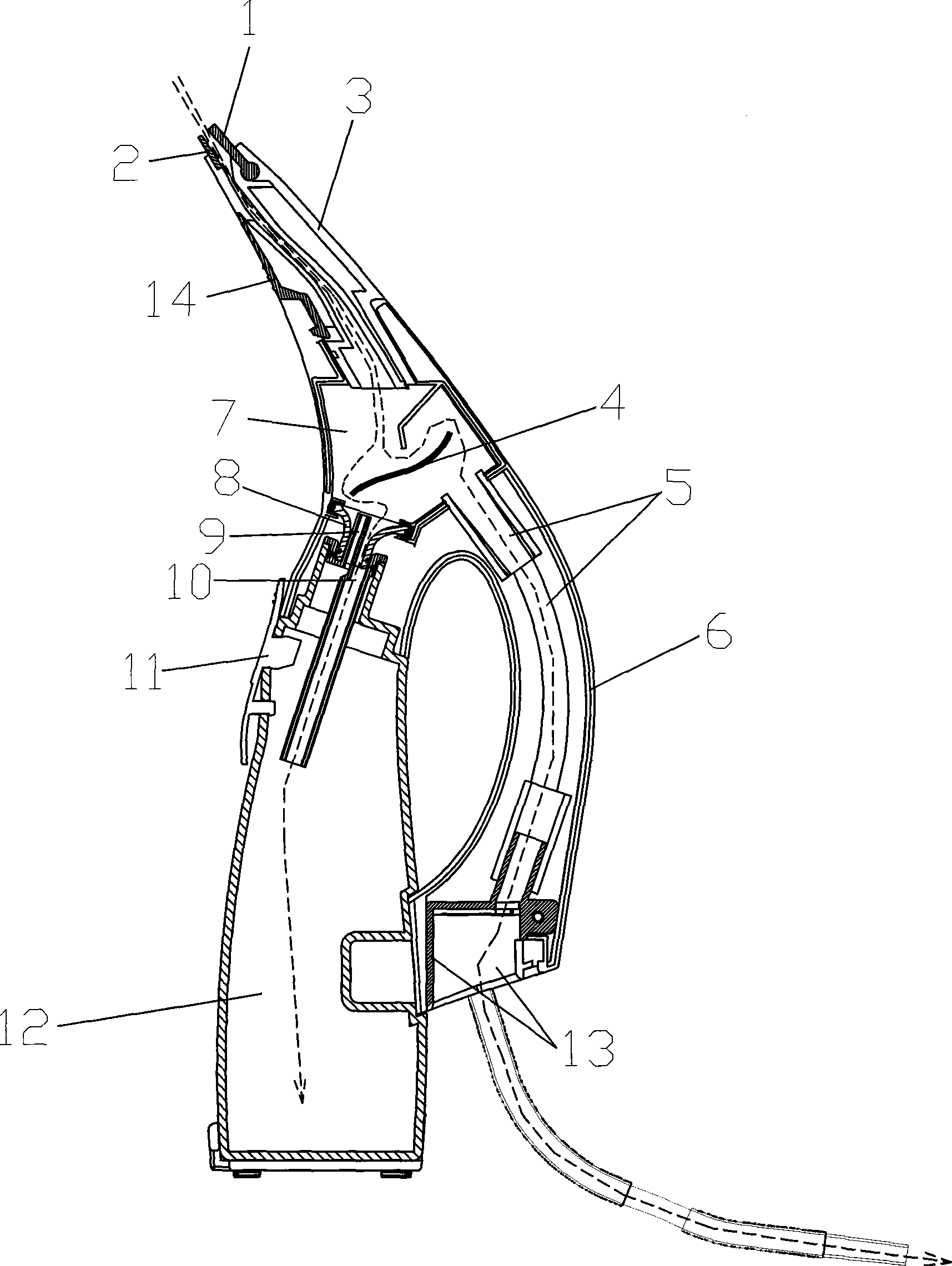

Gutter cleaner

InactiveUS6519809B2Easy to reachReduce chanceCarpet cleanersSuction hosesEngineeringOrthogonal plane

A gutter cleaner having a head and a handle. The head is tubular and has a bend and a nozzle. The bend curves in two orthogonal planes, through an angle of 135.degree. to 195.degree. in one plane and through an angle of 15.degree. to 60.degree. in the other plane. The nozzle has an egress with one dimension being narrower than the other. The head and handle slidably fitting together and are secured to fix their relative positions. The lower end of the handle is adapted to attach to a vacuum source. The handle has a textured surface for gripping and eyelets for removably attaching a shoulder strap. Optionally, the handle has two sections that are slidably fitted together and that can be secured relative to each other.

Owner:LEUPOLD & STEVENS

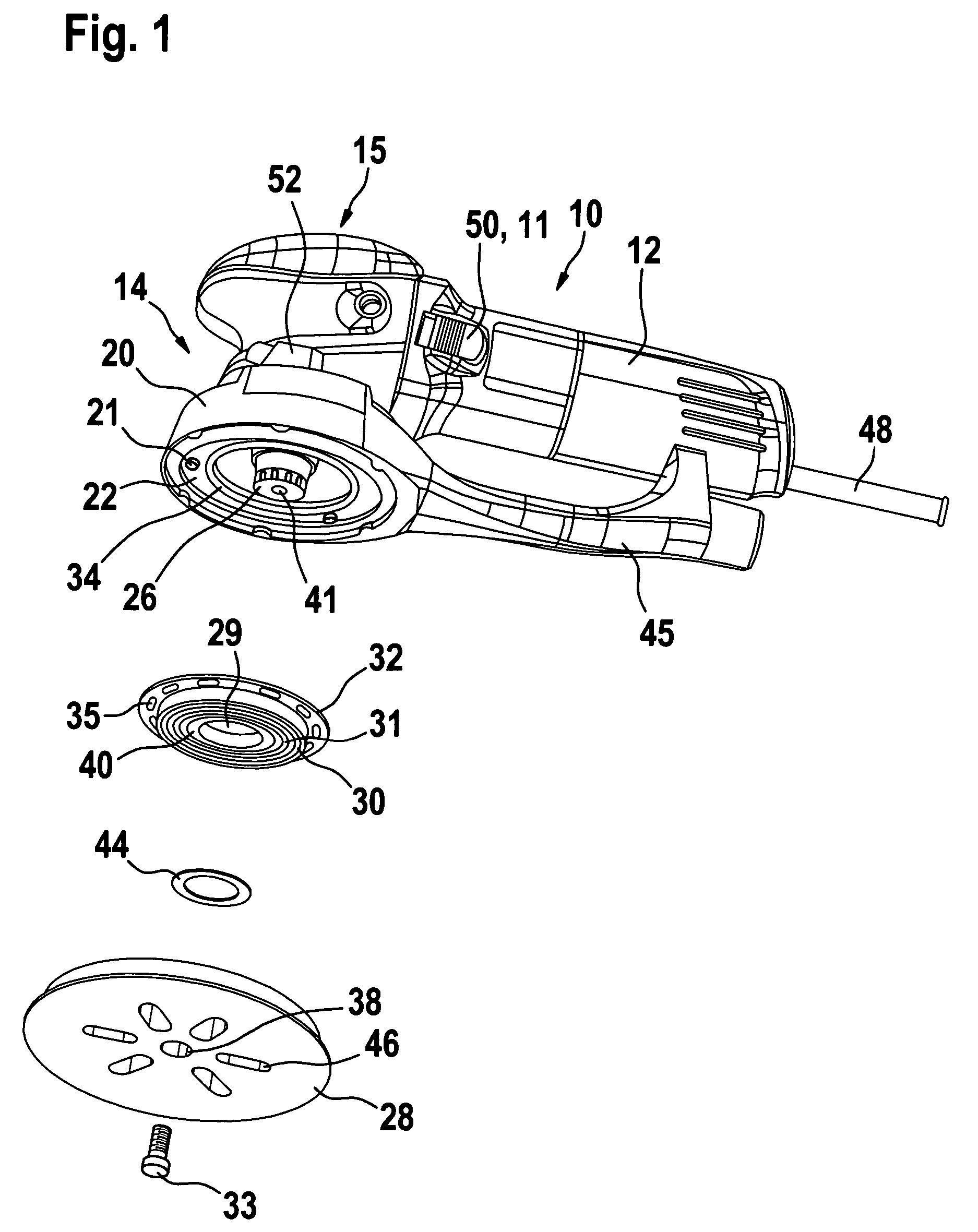

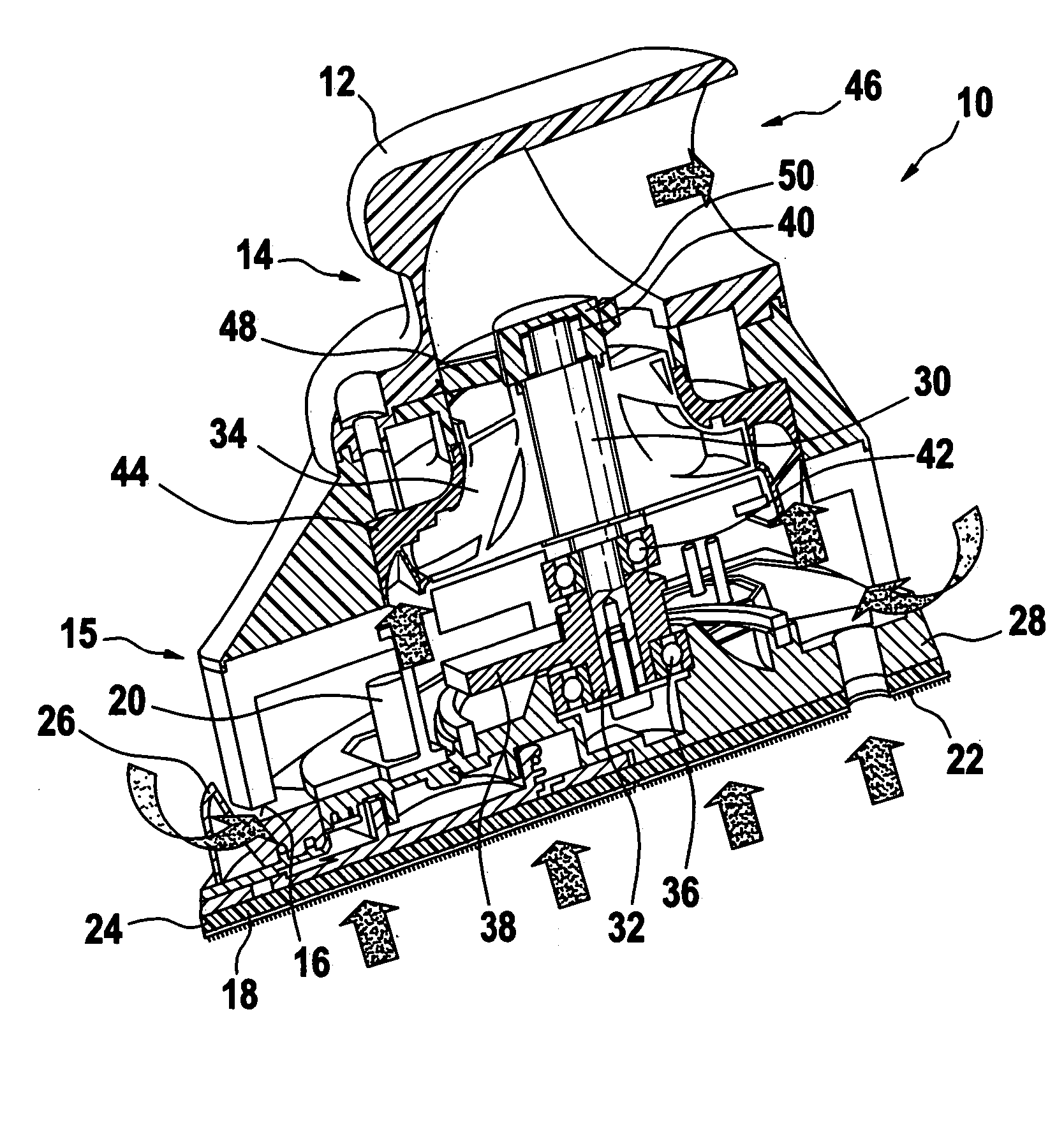

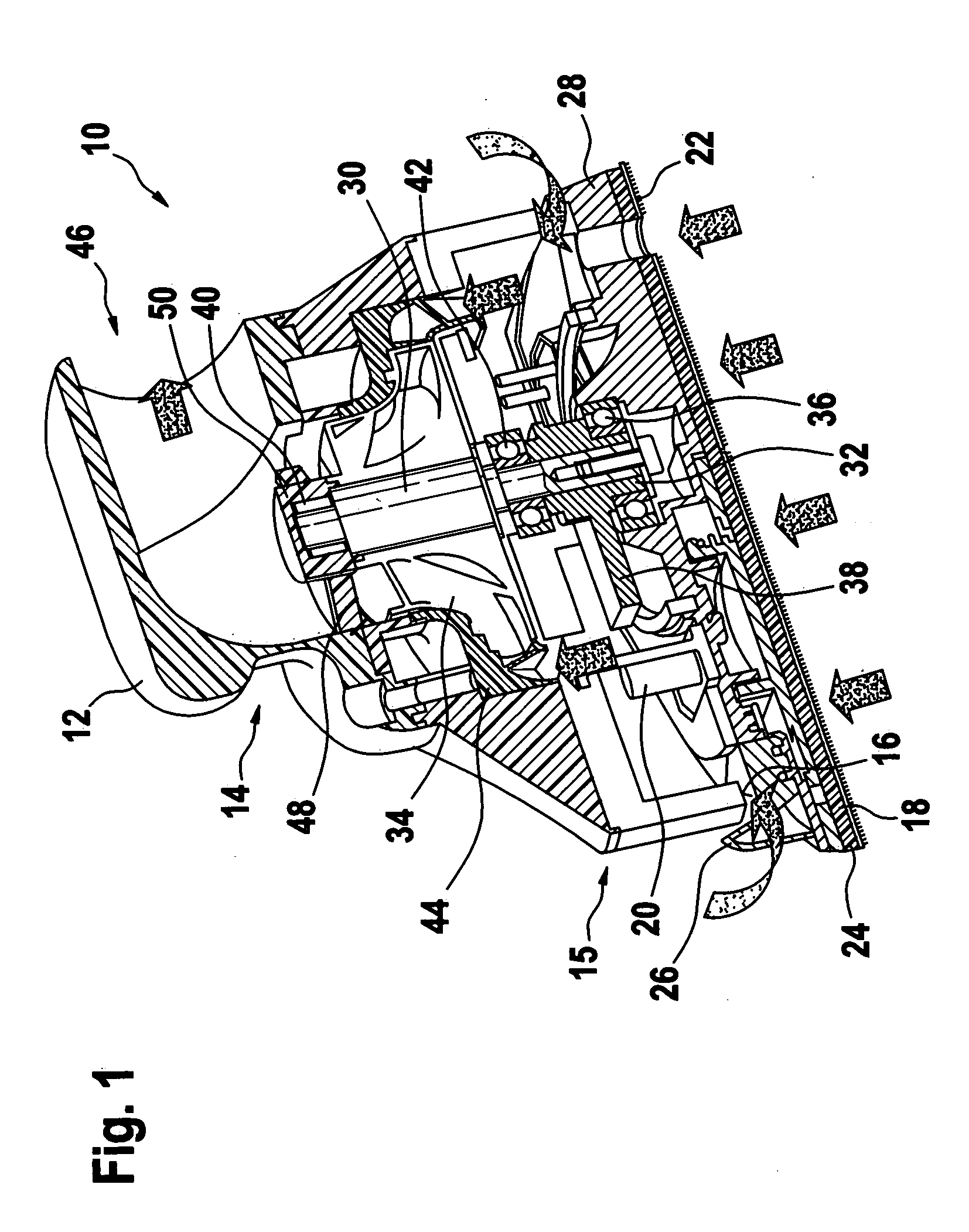

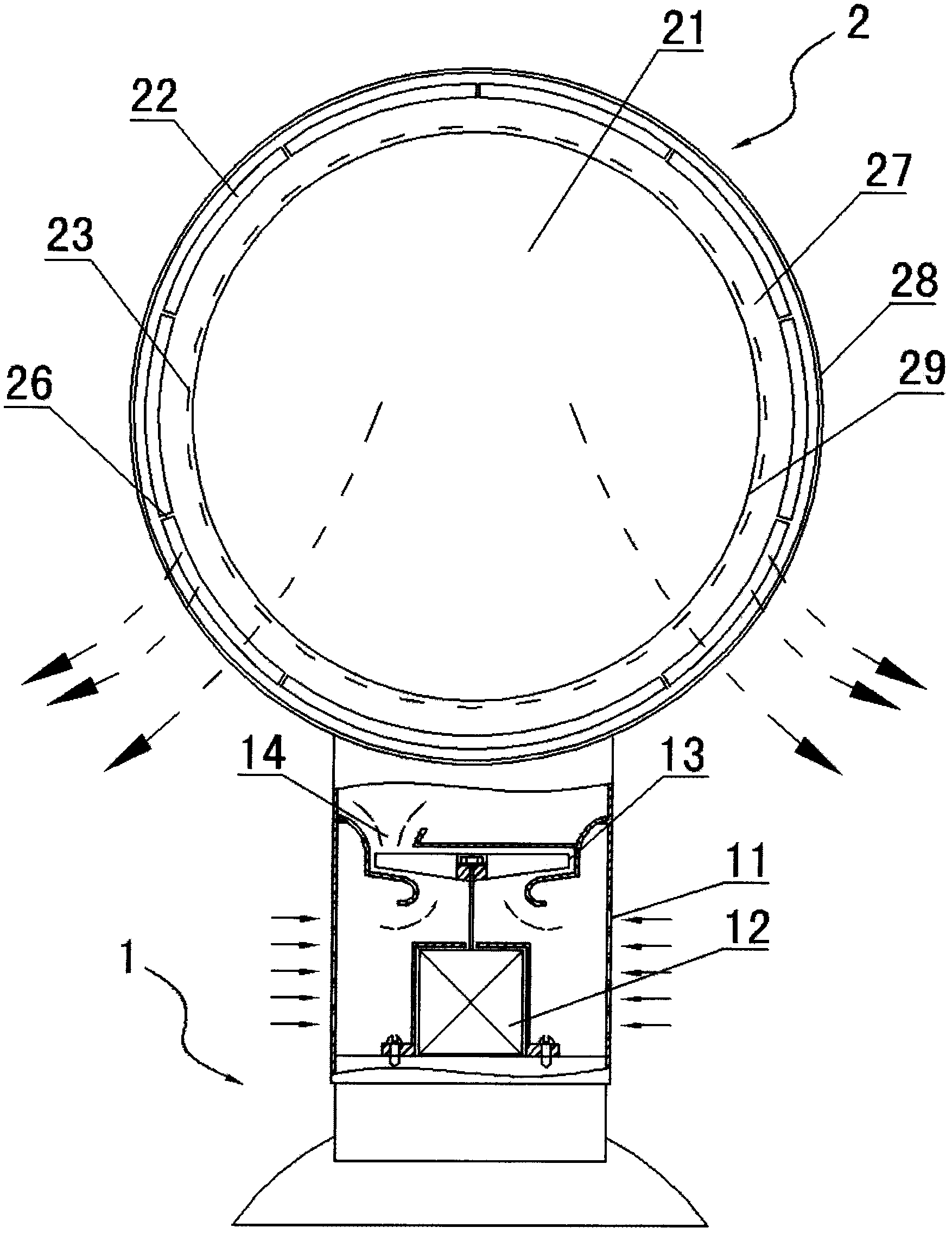

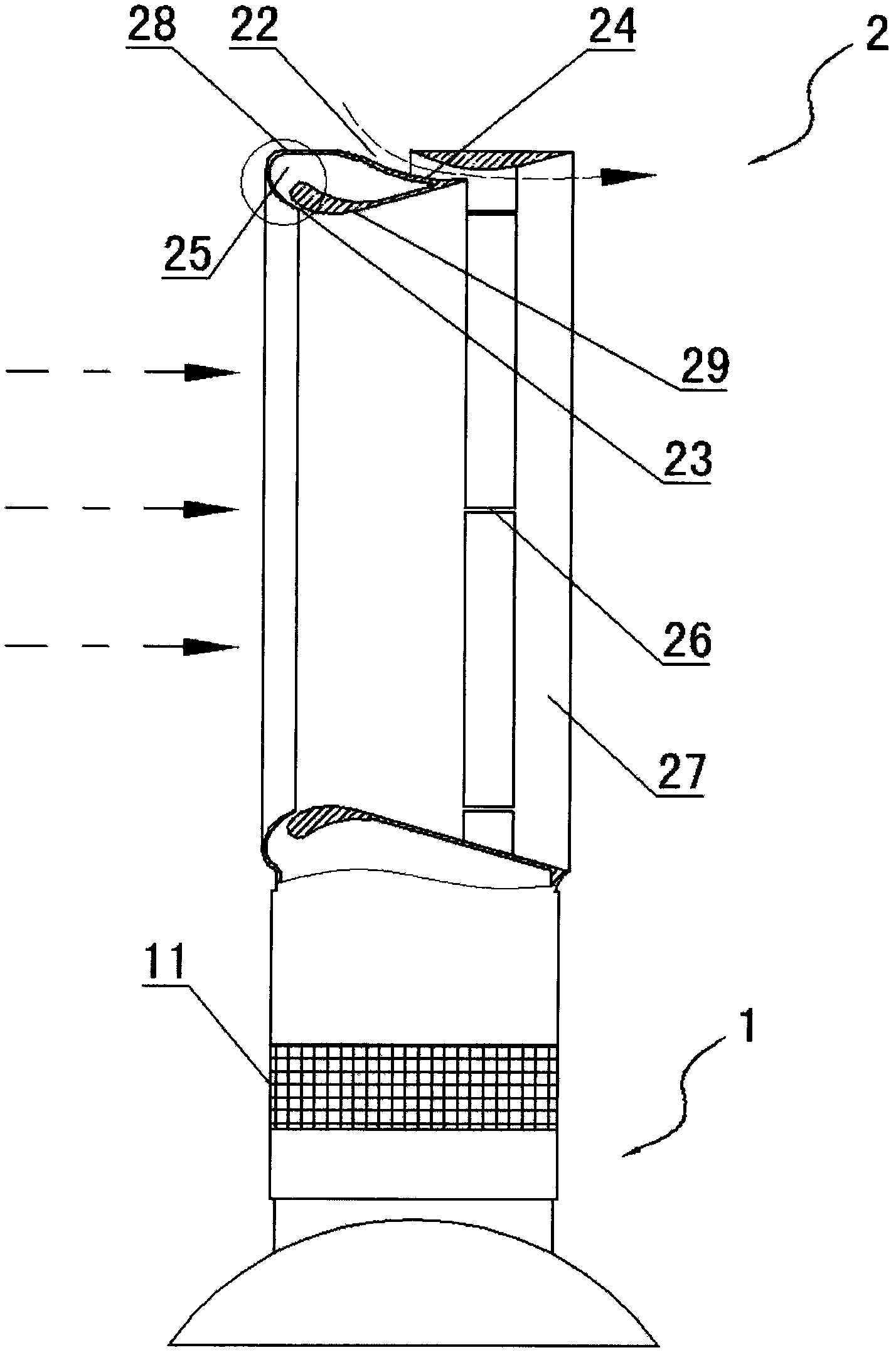

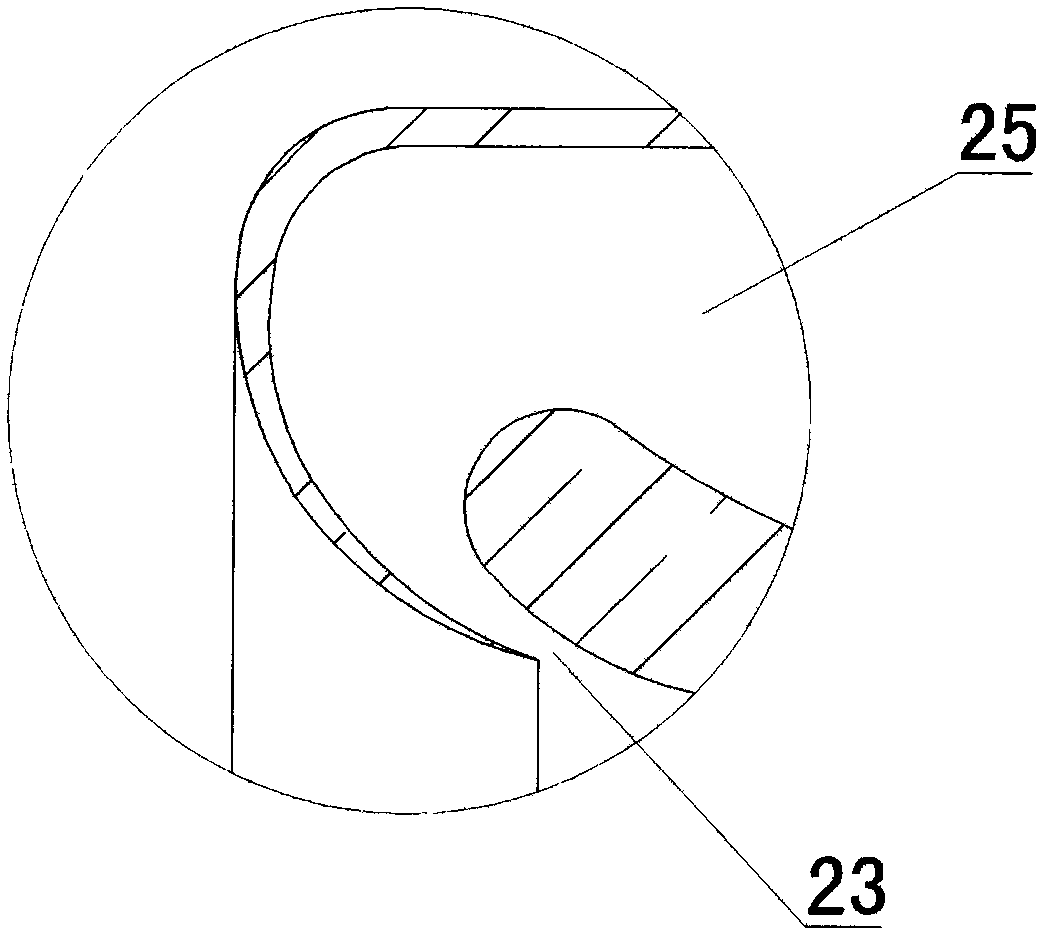

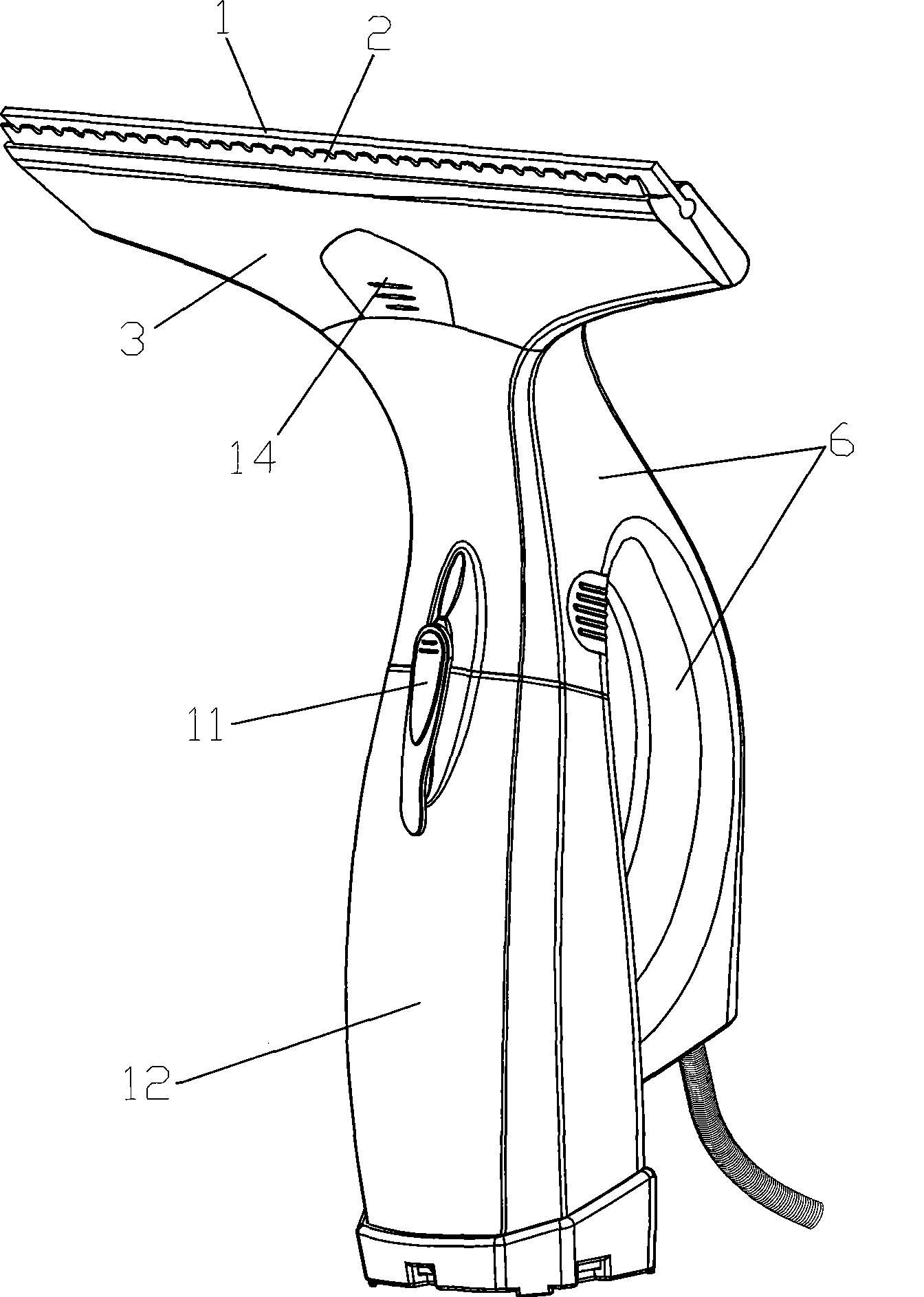

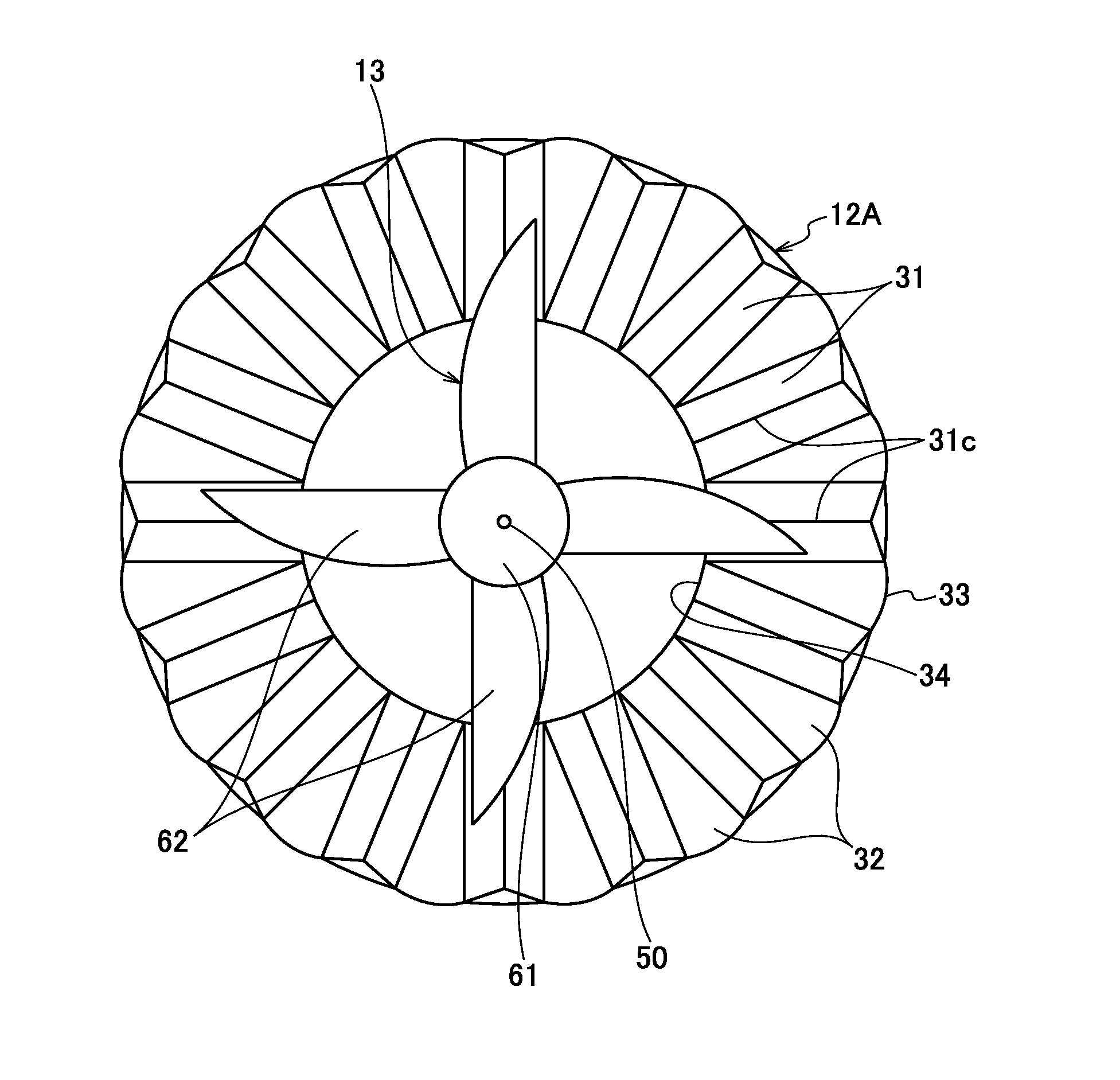

Power tool

InactiveUS20050221739A1Improve efficiencyEasy to operateGrinding drivesBelt grinding machinesImpellerAs Directed

A power tool with a housing (12) and a tool (18, 22) located thereon such that it is capable of being driven in a rotating and / or oscillating manner, the tool being operable as directed using vacuum flow, in particular using a vacuum cleaner. The power tool is made particularly powerful by the fact that a radial turbine wheel (34) with forward-guiding and rearward-guiding vane rows (44, 48) functions as the drive.

Owner:ROBERT BOSCH GMBH

Bladeless fan

The invention discloses a bladeless fan. The bladeless fan consists of a base and an air flow jetting device which is positioned above the base, wherein an air inlet is formed on the shell of the base; the air flow jetting device has a hollow ring-shaped structure; a hollow part is a first air flow channel; and a ring-shaped second air flow channel and a ring-shaped air outlet are formed on the air flow jetting device. The bladeless fan is provided with the first air flow channel which is the same as that of the common bladeless fan, and is also provided with the second air flow channel, and air on the back side and the lateral sides of the fan can be extracted effectively, so that the fan has larger air volume and a more obvious effect.

Owner:王瑛

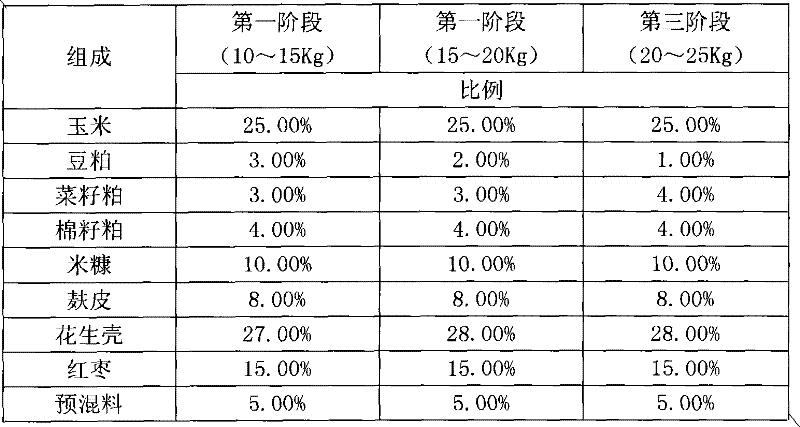

Lamb fattening complete pellet feed

ActiveCN101744107ASimple processing technologyLow costFood processingAnimal feeding stuffAnimal ForagingAnimal science

The invention provides lamb fattening complete pellet feed, which belongs to the field of feed processing in animal husbandry and applies to the intensive complete-barn-feeding production of mutton sheep. According to the nutritional need of lambs in different fattening periods, three types of complete pellet feed are prepared and processed through three formulations in order to satisfy the balanced nutrition supply for weight increase and other aspects except water drinking in a 10 to 15 kg stage, a 15 to 20 kg stage and a 20 to 25 kg stage in a fattening period respectively, so that the factory production of fattening sheep without depending on the conditions of forage grass resources is realized. Due to abundant raw material sources, simple processing technique and low production cost, the pellet feed is beneficial to large-scale commercial production. After application, the pellet feed can ensures that the production of fattening sheep is not restricted to the conditions of natural feed and forage grass resources, and production scale can be adjusted in time according to market demand. Meanwhile, as only one type of pellet geed is used in one fattening stage, more simplified and scientific production process, reliable fattening effect, high production efficiency and low comprehensive cost are ensured.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Tubular apparatus for drainage of the colon and method and guidewire for colonic intubation

InactiveUS7338478B2Efficient suctionDiverting fecal matterInfusion syringesWound drainsEntire colonDrainage tubes

Method for draining and decompressing a colon in which a drainage tube is inserted through the anus into the colon to extend through the entire colon. The drainage tube is fixed in position and suction is applied therethrough to cause fecal matter to pass therein through apertures and be withdrawn from the colon. The drainage tube is inserted by inserting a guidewire into the colon through the anus, manipulating and pushing the guidewire to the cecum, passing a filament through the colon wall to engage the guidewire, pulling the guidewire out of the colon and anus to draw the filament through the colon and out of the anus, attaching the drainage tube to the filament and drawing the filament with attached drainage tube through the anus into the colon. The invention also relates to constructions of the guidewire, the drainage tube and methods for inserting drainage tubes using guidewires.

Owner:LEIBOFF ARNOLD R

Tissue processing apparatus and method for processing adipose tissue

ActiveUS20150118752A1High viscosityLow viscosityCell dissociation methodsBioreactor/fermenter combinationsLipoplastiesTissue Collection

A portable apparatus useful for collection and processing of human biological material containing adipose, such as extracted during a lipoplasty procedure to prepare a concentrated product (e.g., stromal vascular fraction) or a fat graft composition. The apparatus has a container with a containment volume with a tissue retention volume and a filtrate volume separated by a filter and with a tapered portion to a collection volume for collecting concentrate product. Inlet and suction ports provide access to the tissue retention volume and filtrate volume, respectively, and an extraction port provides versatile access for removal of target processed concentrate material or fat graft material, which access may be via a lumen through a rotatable mixer shaft. Access ports may be configured for access only from above the container. The apparatus may include a tissue collector disposed in the disuse retention volume to engage and collect collagen or other stringy tissue. A method of processing adipose tissue to concentrate leuko stromal vascular cells includes multi-step processing using a portable container.

Owner:THE GID GROUP

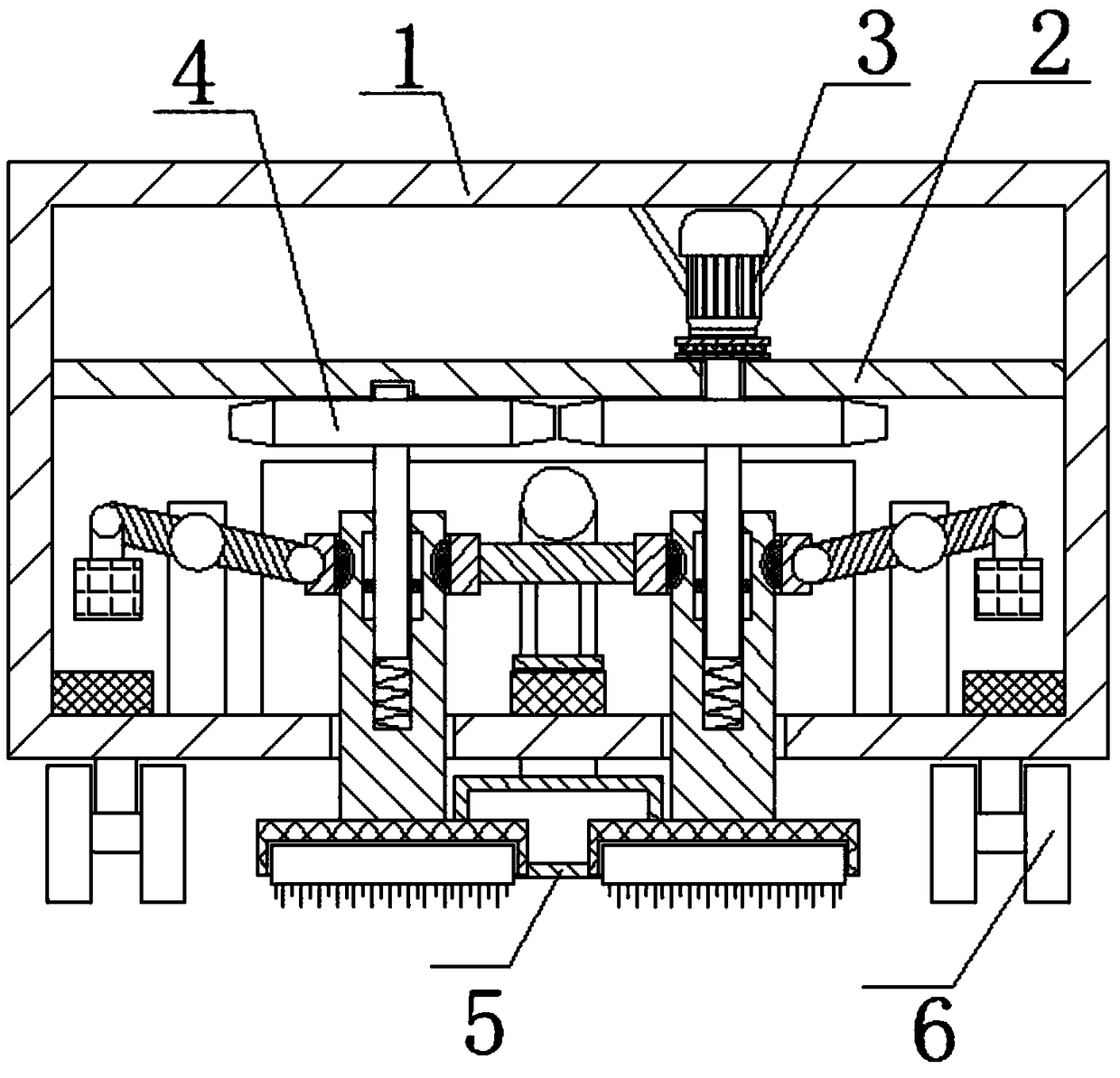

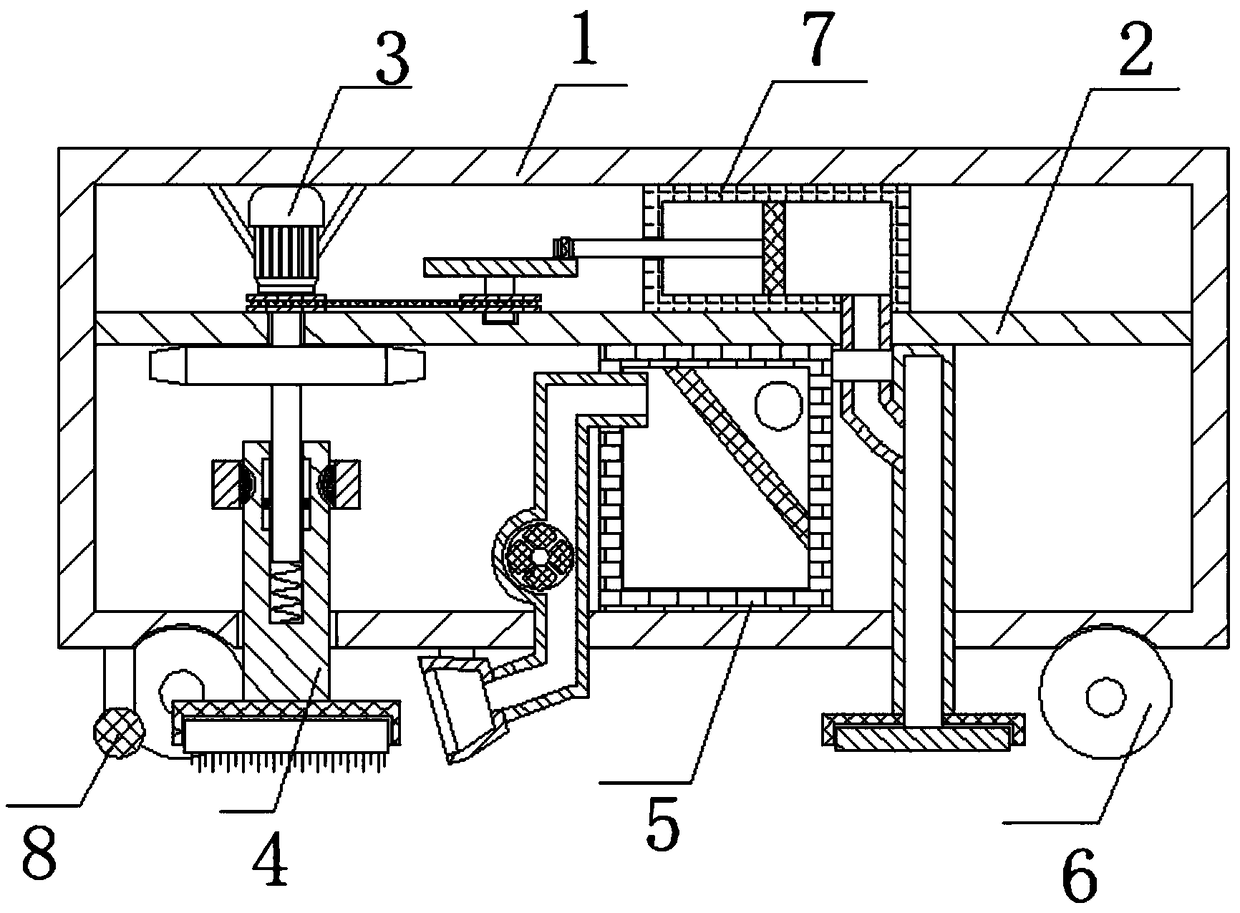

Household intelligent floor trailer

ActiveCN109157165AImprove cleaning efficiencyShorten cleaning timeCarpet cleanersFloor cleanersStopped workElectric machinery

A household intelligent floor trailer includes a housing and a baffle, the inner side wall of the shell is fixedly connected with a baffle plate, the inner top wall of the shell is fixedly connected with a servo motor through a bracket, and the output end of the servo motor penetrates the baffle plate and is vertically connected with a cleaning device, the front end of the cleaning device is provided with a water level detecting mechanism, the rear end of the cleaning device is provided with a dust suction device, the lower end of the shell is rotatably connected with four traveling wheels, and the rear end of the traveling wheels is connected with a rotating shaft on the traveling motor. The invention overcomes the shortcomings of the prior art, Reasonable design, compact structure, combination of floor sweeping and floor mopping to improve cleaning efficiency, sweeping and floor mopping at the same time, when encountering stagnant water, cleaning device can rise without contact withstagnant water, suction fan can stop working to avoid stagnant water into the interior of the trailer to affect machine work, cleaning cloth suction stagnant water, improve cleaning efficiency.

Owner:HEFEI MENGLONG ELECTRONICS TECH

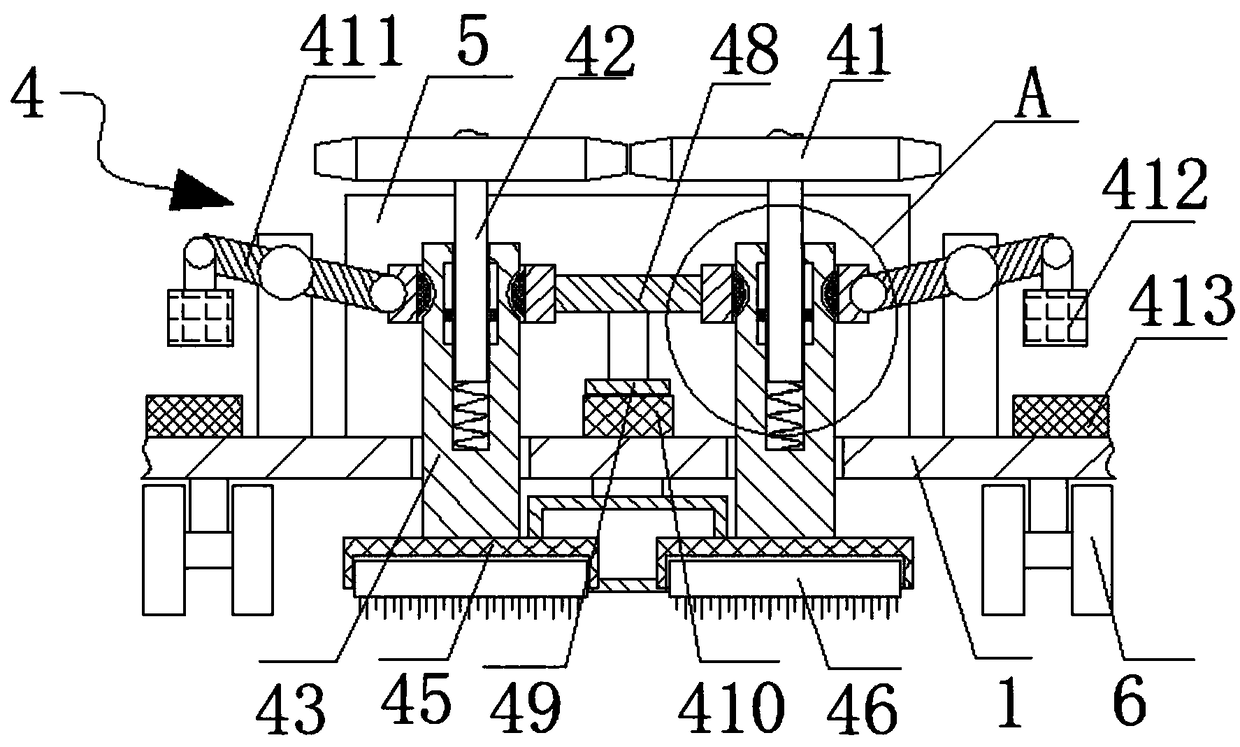

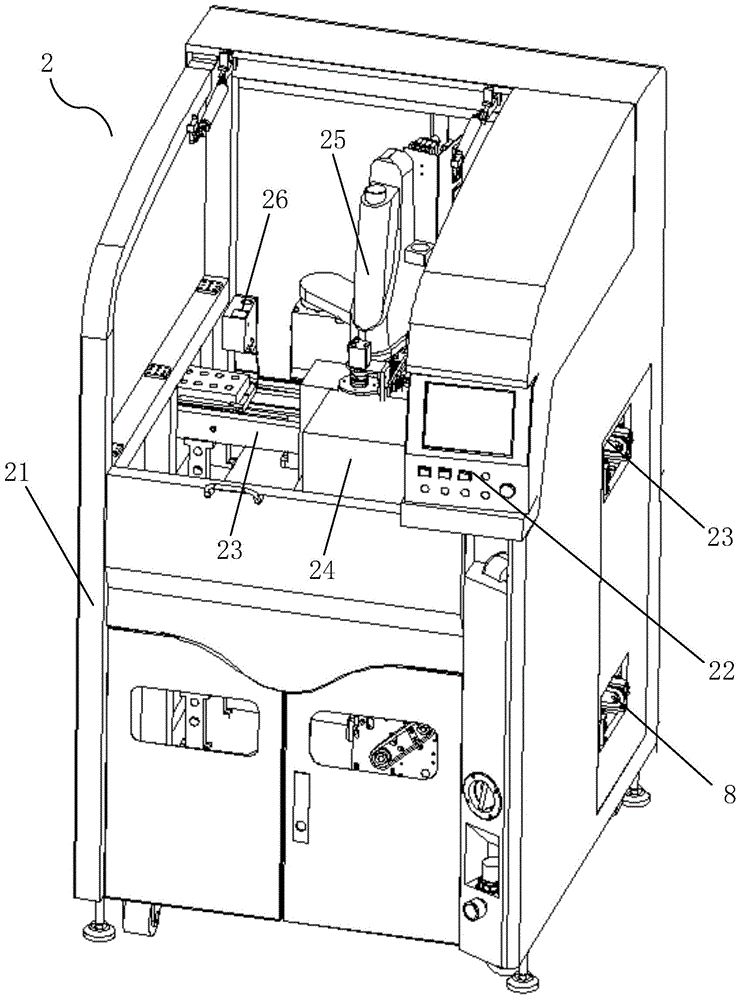

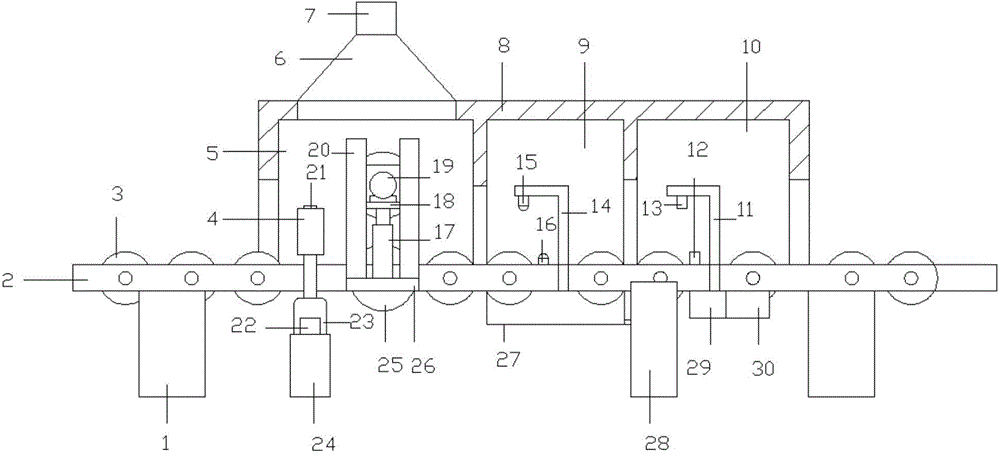

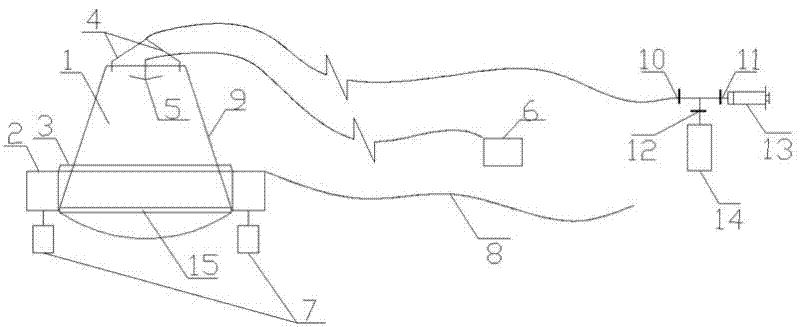

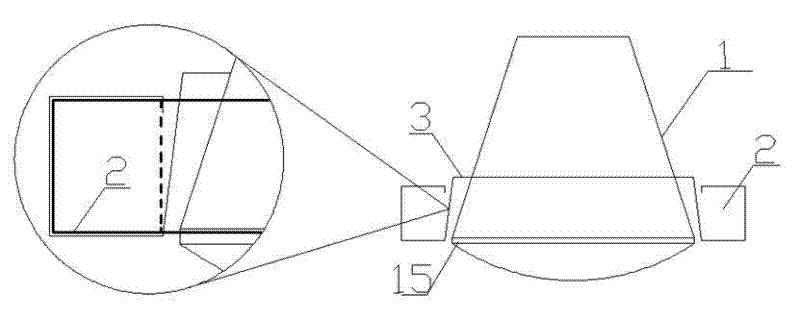

Novel multifunctional PCB production automation system

ActiveCN104822230AReduce labor intensityReduce in quantityLiquid surface applicatorsInsulating layers/substrates workingAdhesiveEngineering

The invention relates to a novel multifunctional PCB production automation system, comprising an automatic feeding system, a fully-automatic two-dimensional code sticking system, a height measuring system, an automatic adhesive dispensing curing system, an online automatic board-splitting cutting system, and a finished product sorting recovery system. The input ends and output ends of the above systems are connected in sequence. Control centers disposed on the above systems are connected with each other. The input end of the automatic feeding system is also provided with a large PCB feeding device. The large PCB feeding device is connected with the control center of the automatic feeding system. Thus, two-dimensional code marking on each PCB unit on a large PCB can be automatically completed, and good product detection, and cutting of the large PCBs can be automatically completed. The system can automatically complete finished products of PCB units, and the system is powerful in functions, high in automation degree, high in production efficiency, low in labor intensity, low in production cost, and high in qualified rate, and has assurance in product quality. A reversed design is used, thereby effectively preventing dusts generated in a cutting process from falling on the PCB, so the finished products are clean.

Owner:ZHUHAI ZHIXIN AUTOMATIC TECH CO LTD

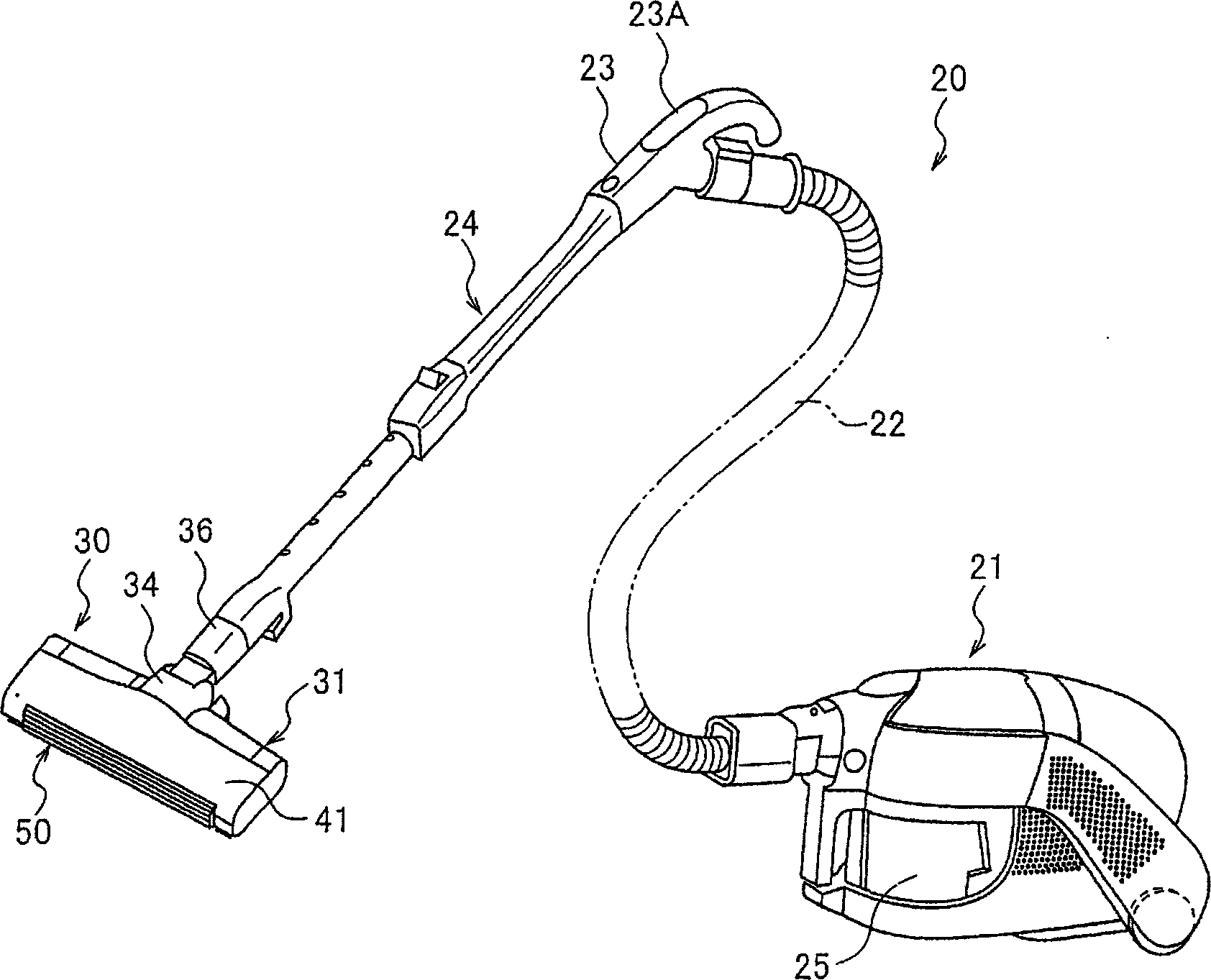

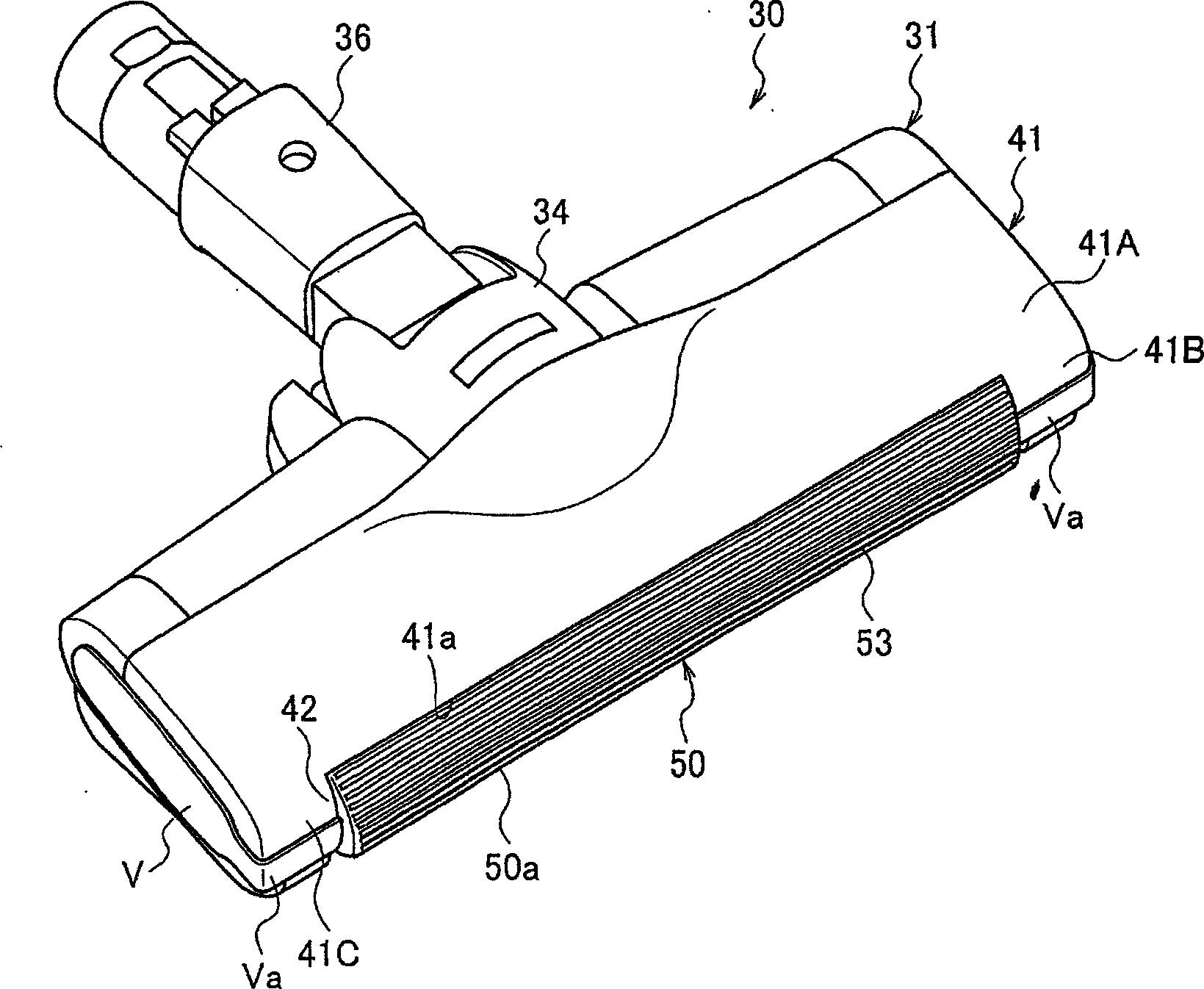

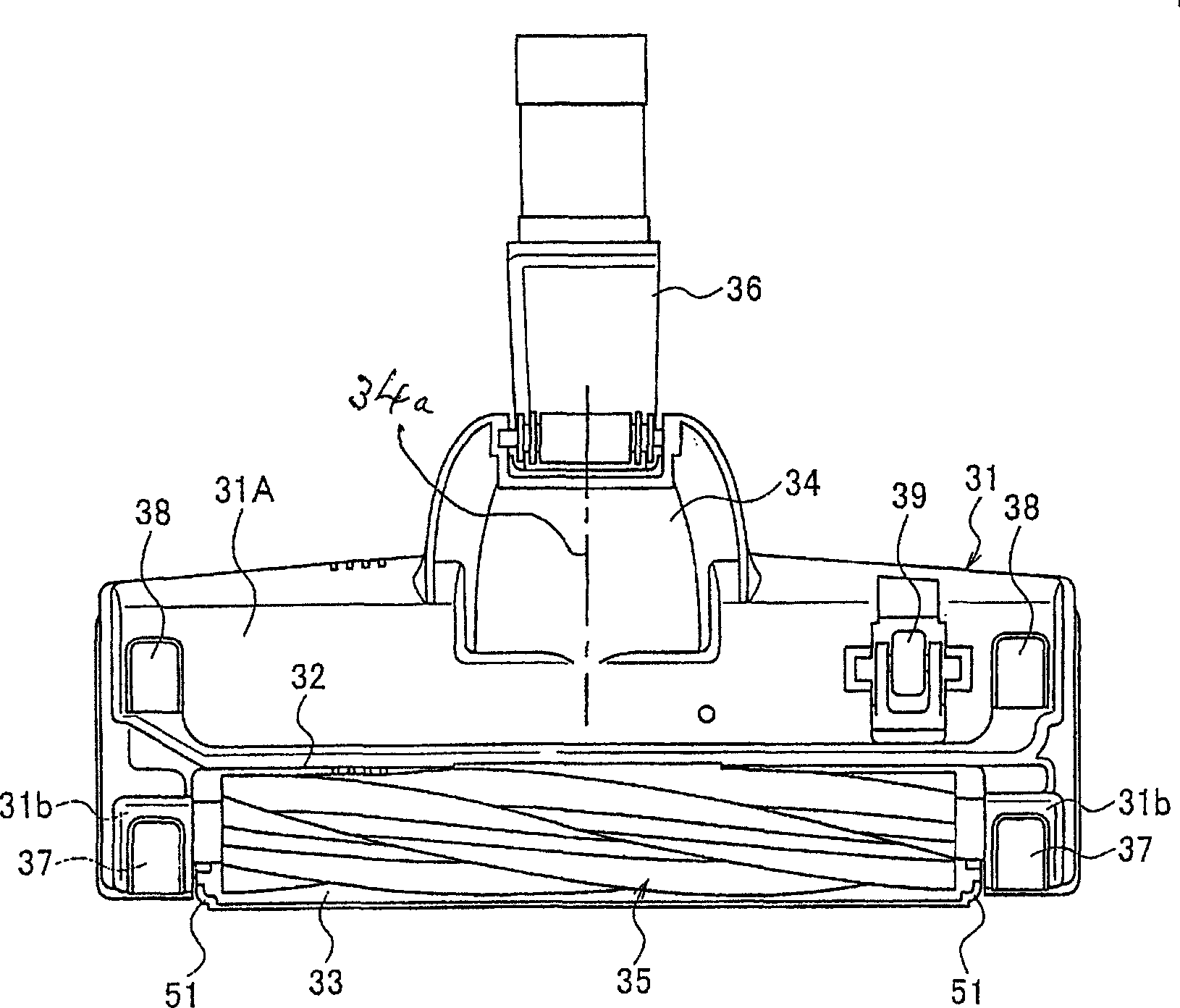

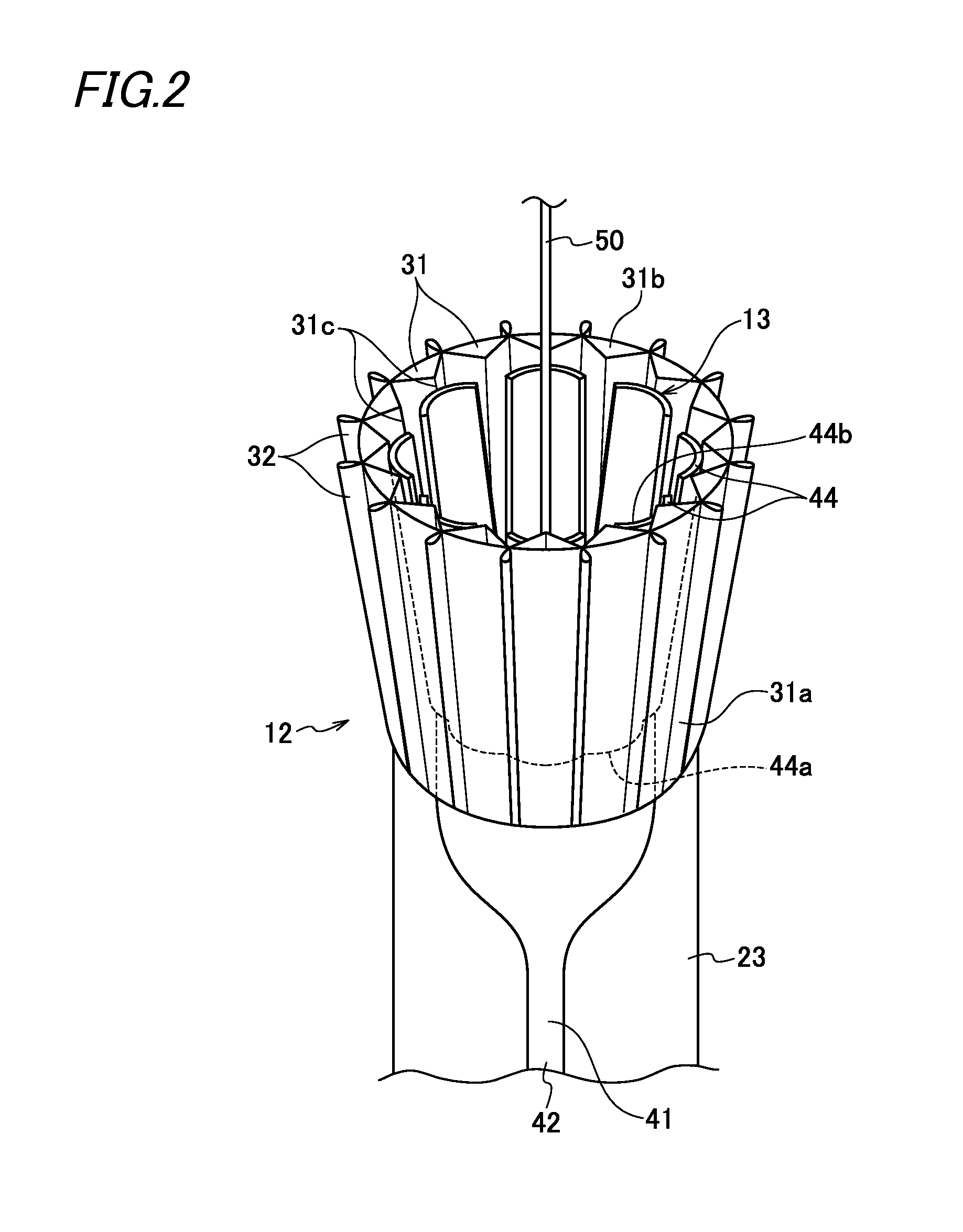

Section port body and vacuum cleaner

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

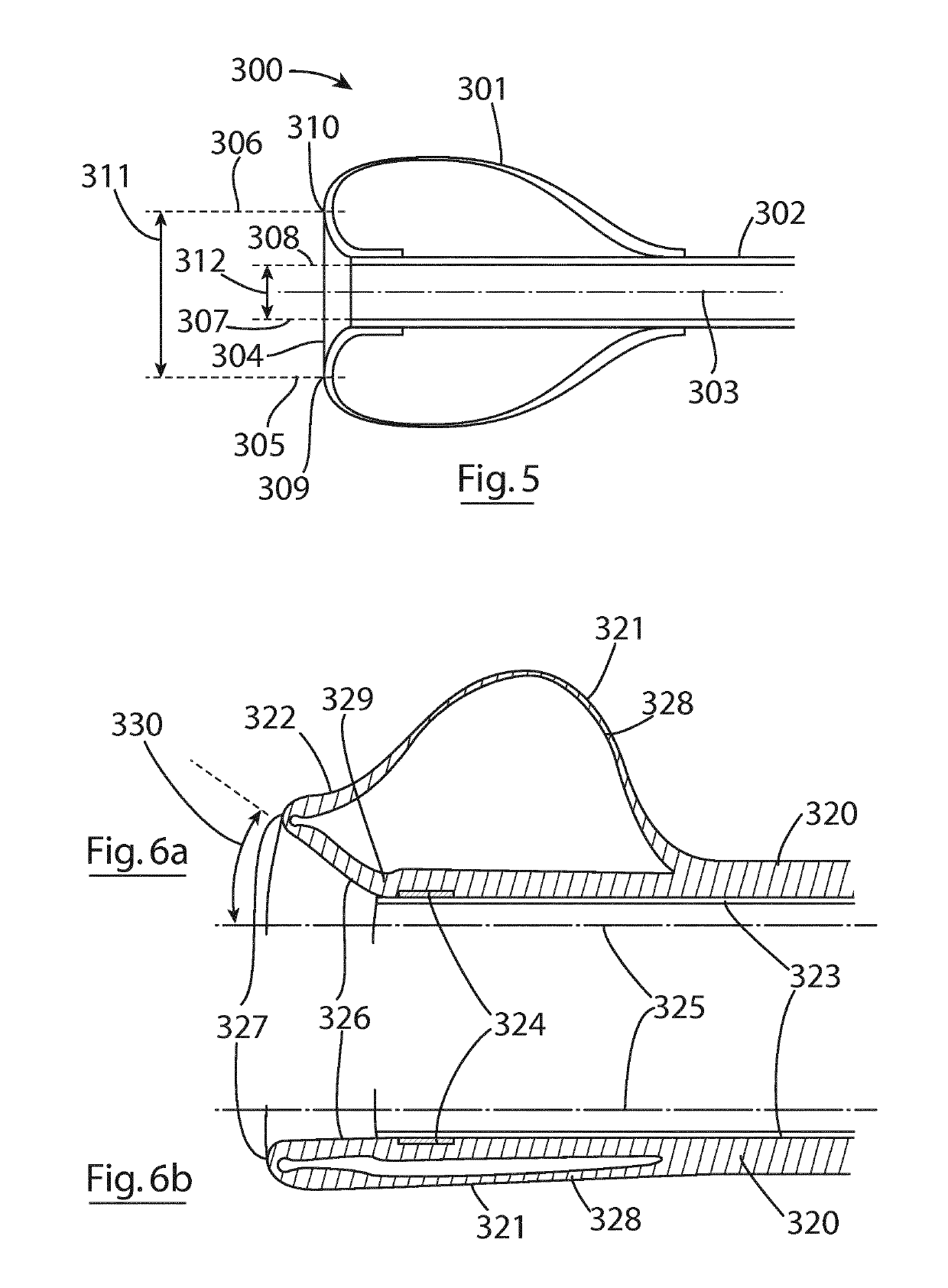

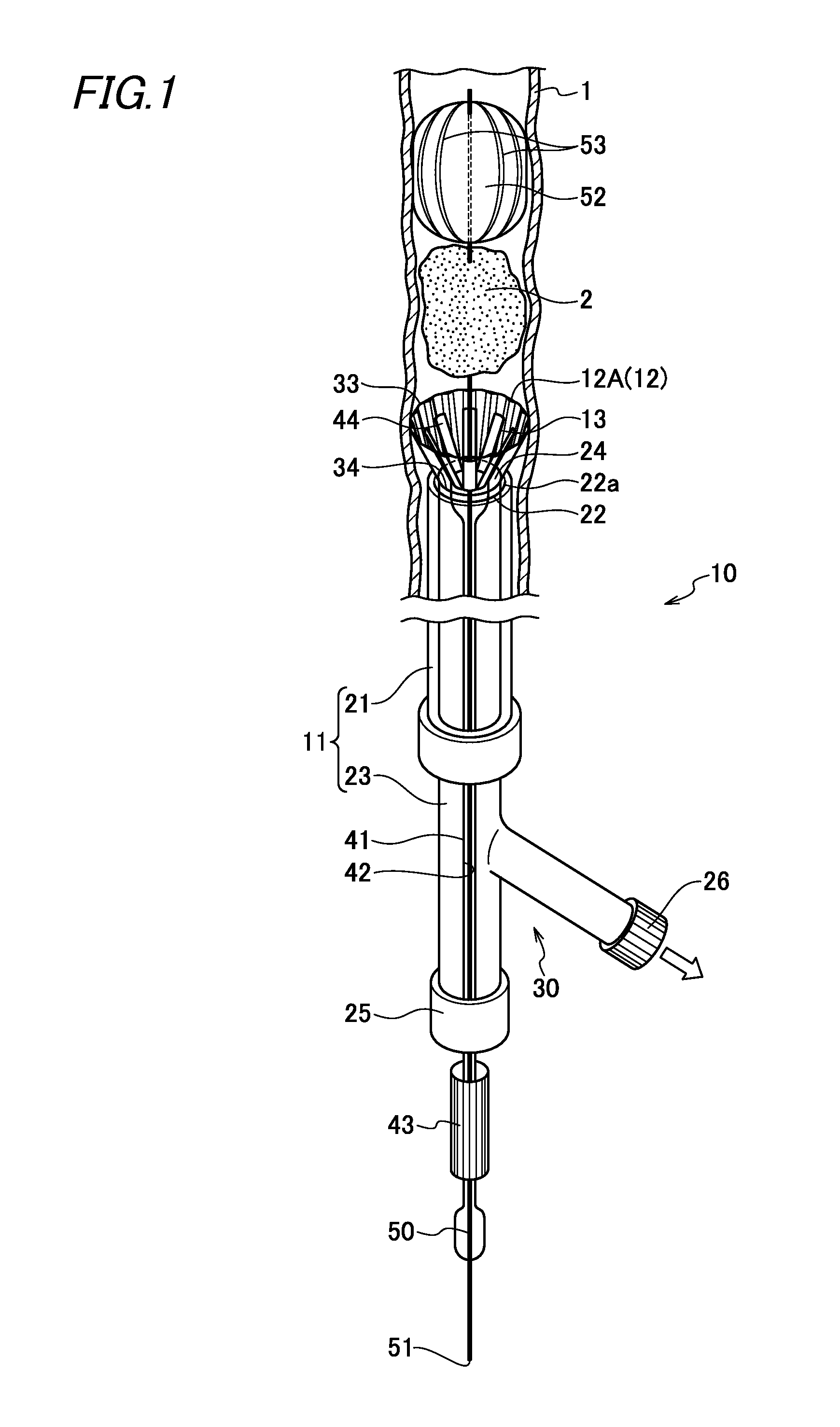

A clot retrieval system for removing occlusive clot from a blood vessel

ActiveUS20190167287A1Minimizes shear forceFacilitate easy entryStentsBalloon catheterBlood vessel spasmBlood vessel

A clot capture catheter comprises an elongate tubular shaft having a proximal end, a distal end and an inflatable expansile member at the distal end. The expansile member is inflatable from a collapsed delivery configuration to an expanded configuration. In the expanded configuration, the expansile member extends to define a funnel shape having an enlarged distal clot entry mouth at the distal-most end of the catheter. In the expanded configuration, the expansile member may extend distally beyond the distalmost tip of the shaft. The expansile member may be integral with the distal tip of the catheter shaft.

Owner:NEURAVI

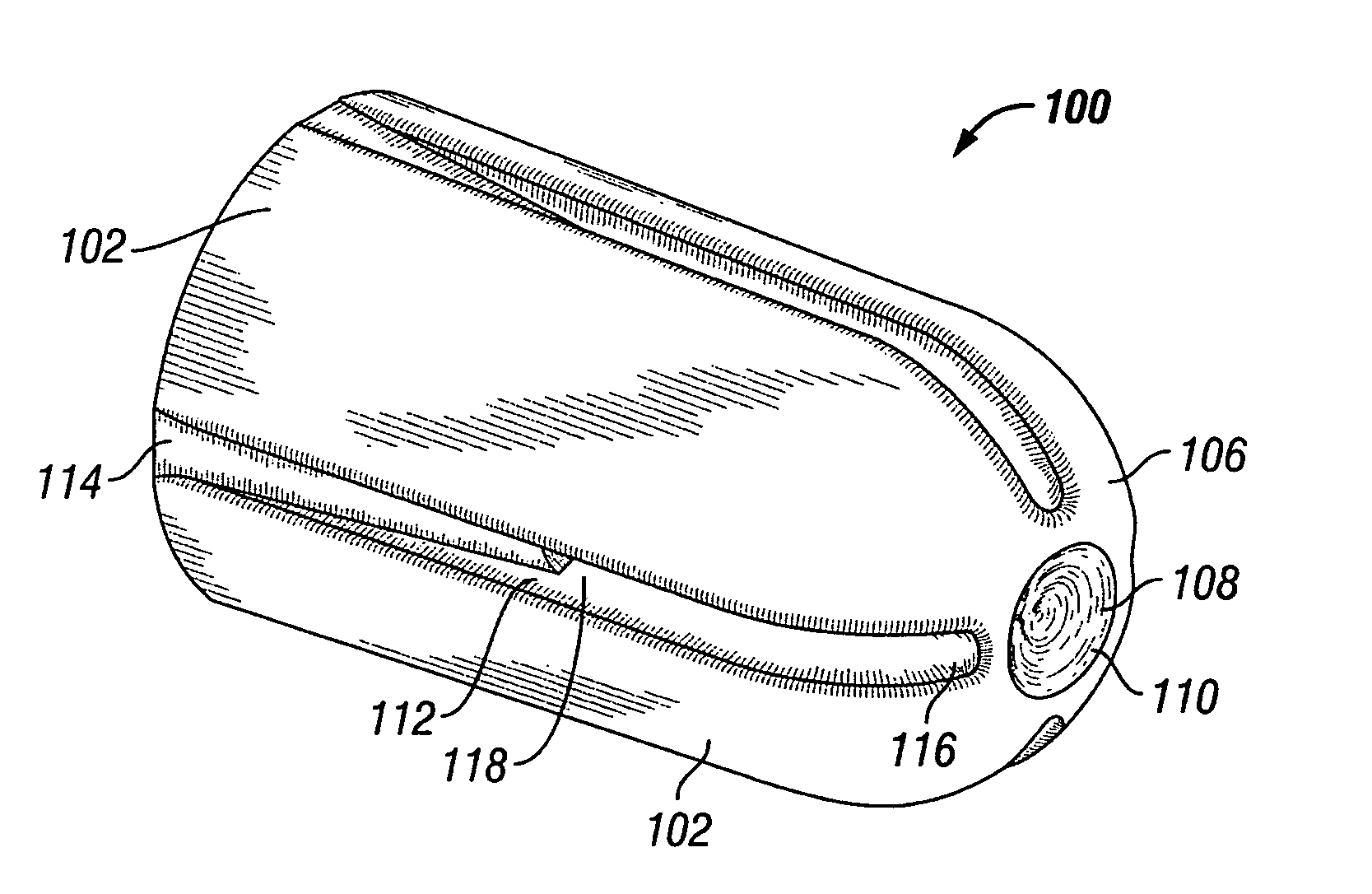

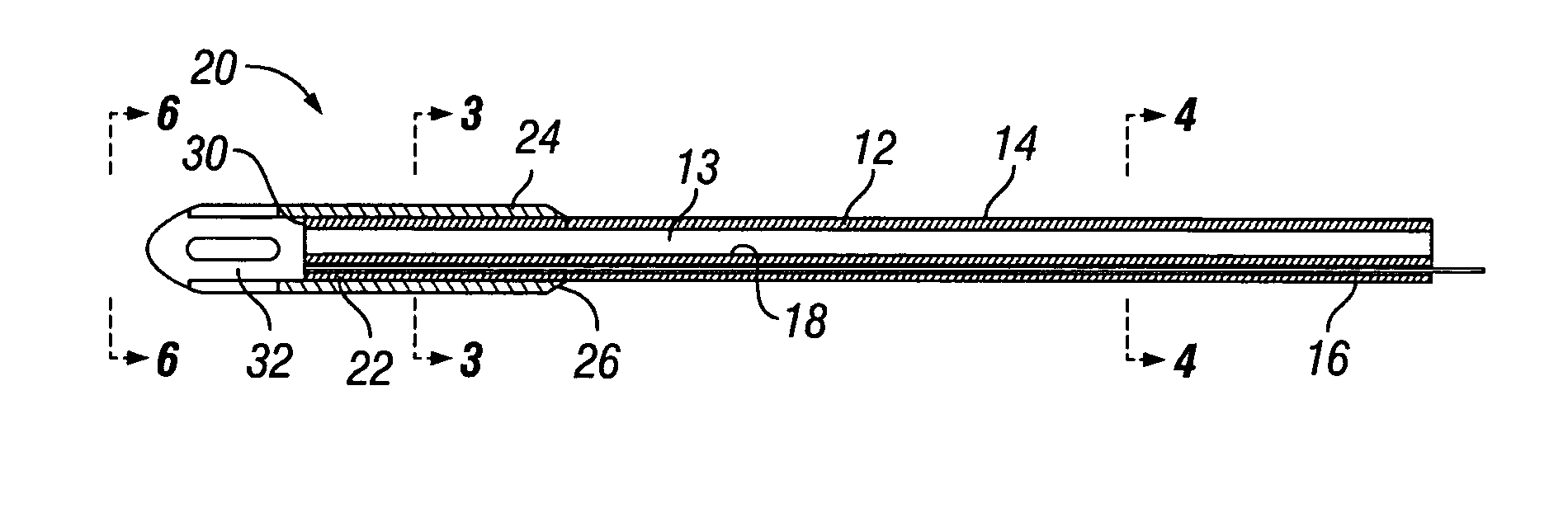

Aspirator having cushioned tip

InactiveUS20060024641A1Eliminate the problemEffective fluid transferSaliva removersCushioningRinse water

A disposable cushioned aspirator which forms part of a dental or medical aspirating system. The disposable cushioned aspirator appliance described herein is intended principally to be used in dental procedures where bodily fluids and rinse water is evacuated from a patient's mouth, but the invention has application in medical procedures and various other applications as well. An elongate tubular element having a patient end and a connection end is exteriorly lined with a layer of soft cushioning material such as a soft polymer material, rubber or a porous foam material to protect the soft tissues in and around the mouth of a patient. The elongate tubular aspirator is capable of being manually bent from an initially straight configuration to a curved or other desired configuration and is provided with a structural member extending along its length and being pliable to permit bending and yet of sufficient structural integrity to maintain the aspirator in the desired configuration during use. The structural member is preferably a wire element which is embedded within or attached to the elongate tubular element.

Owner:MAHLMANN LEE A

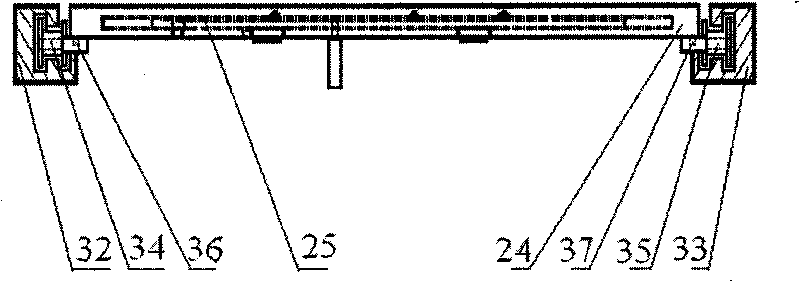

Modified section cleaning device

InactiveCN105478399AImprove work efficiencyPrecipitation is effectiveEdge grinding machinesDirt cleaningEngineeringMechanical engineering

The invention relates to a modified section cleaning device. The modified section cleaning device comprises brackets, a transmission roller way, a cover body, a burr cleaning mechanism, a cleaning mechanism and a drying mechanism, wherein the transmission roller way is embedded on the brackets; a plurality of transmission rollers are distributed in the transmission roller way, and the cover body covers the transmission roller way; a burr cleaning cavity, a cleaning cavity and a drying cavity are separately formed in the cover body from the input end to the output end, and the burr cleaning mechanism is arranged in the burr cleaning cavity; the burr cleaning mechanism comprises an upper brush roller, a lower brush roller, and a group of side brush rollers symmetrically arranged relative to the transmission roller way; the lower brush roller is embedded in the middle of the transmission roller way, and the upper brush roller with adjustable height is arranged right above the lower brush roller; the side brush rollers are arranged on a pedestal at the side end of the transmission roller way, a dust sucking device communicates with the top of the burr cleaning cavity, and the cleaning mechanism is arranged in the cleaning cavity; and the drying mechanism is arranged in the drying cavity. The modified section cleaning device disclosed by the invention is simple in structure, can be adaptive to cleaning operation of the surfaces of sections with different dimensions, and is simple in structure and high in working efficiency.

Owner:TIANJIN FUDACHANG TECH

Waste circuit board hook pulling and dismounting device

InactiveCN101733631AImprove dismantling rateAvoid damageSolid waste disposalMetal working apparatusCratePrinted circuit board

The invention discloses a waste circuit board hook pulling and dismounting device, belonging to the technical field of waste recovery and reuse. The waste circuit board hook pulling and dismounting device comprises a crate, a heating system, a double-chain delivery mechanism, a hook pulling mechanism and a double-rolling brush mechanism, wherein the heating system divides the crate into a pre-heating region and a high temperature region; and a circuit board is arranged on the double-chain delivery mechanism, is preheated by the preheating region, and is subjected to dismounting of components and solder by the hook pulling mechanism and the double-rolling brush mechanism in the high temperature region. The air-out inclined planes of two lower high temperature bellows arranged at the lower part of the high temperature region inclines at a large angle facing to the center of the high temperature region, extension type hot air nozzles on the air-out inclined planes are a group of hot air spray pipes, the diagonal fault planes of the hot air spray pipes inclining upwards and the spray pipe outlets not only enable the circuit board to be heated evenly and rapidly, but also can ensure that all dismounted components and solder can enter collection trays of components and solder without entering the spray pipe outlets. The invention is a device which can pull and dismount the components from the printed circuit board with no damage and integrity, and is used for waste recover and reuse enterprises in electronic industry.

Owner:TSINGHUA UNIV

Collecting device of greenhouse gases released by lake and reservoir water bodies and analysis method of release rate

InactiveCN102507272AReduce device weightPrevent local overheatingComponent separationWithdrawing sample devicesGreenhouse gasCollection system

The invention belongs to the field of laboratory instrument equipment, and discloses a device for collecting greenhouse gases released by lake and reservoir water bodies and an analysis method of release rate. The device comprises an overwater gas collecting system and a gas sample collecting system, wherein the overwater gas collecting system is composed of a PVC (Polyvinyl Chloride) and a buoy; the PVC barrel is inverted in the buoy, and the barrel port of the PVC barrel is coincided with the lower edge of the buoy; the gas collecting system comprises a gas collecting pipe, a tee valve, a gas sucking plastic needle cylinder and an aluminum foil vacuum bag; one end of the gas collecting pipe is communicated with the top of the PVC barrel; and the other end of the gas collecting pipe, the gas sucking plastic needle cylinder and the aluminum foil vacuum bag are respectively communicated with a valve I, a valve II and a valve III of the tee valve. By adopting the device disclosed by the invention, the problem that the greenhouse gases in the lake and reservoir are difficultly collected is solved; and the device is simple and convenient in structure, easy to operate and is high in experiment precision.

Owner:NANJING UNIV

Glass vacuum cleaning brush

The invention discloses a vacuum glass cleaning brush for cleaning glass. The vacuum glass cleaning brush comprises a brush head and a main body communicated with each other through inner cavities thereof, wherein the brush head is connected with a splitting cavity section of the main body; a diversion water pipe and a main inner cavity communicated with each other are respectively arranged on opposite sides of the splitting cavity and the brush head; the diversion water pipe is connected with a bottle body; a connection head for connecting a vacuum dust collector is arranged on the other end of the main inner cavity; and a spoiler for spoiling the air current is also arranged at the middle part of the splitting cavity. The vacuum glass cleaning brush is improved based on the ground cleaning brush of the prior vacuum dust collector to effectively collect dusts and water on the glass through the brush, the splitting cavity and the bottle body, and can collect water in the bottle body in a splitting manner to prevent the vacuum dust collector from being damaged by the water. The vacuum glass cleaning brush has the advantages of reliable structure and convenient use.

Owner:黄有光

Power tool

InactiveUS7040972B2Level of efficiencyHigh degreeGrinding drivesBelt grinding machinesImpellerAs Directed

A power tool with a housing (12) and a tool (18, 22) located thereon such that it is capable of being driven in a rotating and / or oscillating manner, the tool being operable as directed using vacuum flow, in particular using a vacuum cleaner. The power tool is made particularly powerful by the fact that a radial turbine wheel (34) with forward-guiding and rearward-guiding vane rows (44, 48) functions as the drive.

Owner:ROBERT BOSCH GMBH

Catheter for removing foreign body in blood vessel

InactiveUS20150150589A1Effectively nodulizedEfficient removalCannulasExcision instrumentsCatheterBiomedical engineering

A capturing unit provided on a distal end of a second tube can be deformed into a contracted state and an expanded state, in which the capturing unit is deployed to form a capturing chamber. The capturing chamber has an opening area decreased as it goes from a distal end opening of the capturing chamber toward a proximal end opening of the capturing chamber. A third tube rotatable relative to the second tube and a cutting unit provided on a distal end of the third tube for cutting a foreign substance are arranged in a second lumen. In the expanded state of the capturing unit, the cutting unit is arranged more toward the proximal end opening of the capturing chamber than the distal end opening.

Owner:KAWASUMI LABORITORIES INC +1

Outdoor tennis ball-collecting machine

The invention discloses an outdoor tennis ball-collecting machine which comprises a machine body and a ball storage chamber, wherein a ball entering channel is connected with the upper end of the ball storage chamber; cleaning brushes are arranged at the two ends of the ball entering channel; moveable rods are connected with the two ends of the cleaning brushes; reset springs are sleeved on the moveable rods; a ball-absorbing chamber is arranged at the upper end of the ball entering channel; a ball-absorbing pipe is connected with the left end of the ball-absorbing chamber; a ball-absorbing cover is connected with the front end of the ball-absorbing pipe; a flow guide plate is arranged at the lower end of the ball storage chamber; the air vents are arranged at the two ends of the flow guide plate; an axial flow fan is arranged at the lower end of the flow guide plate; an air outlet is connected with the lower end of the axial flow fan; a rotating table is connected with the lower end of the machine body; a solar power generation panel is arranged at the upper end of the machine body; a storage battery is arranged at the lower end on the right side of the machine body; a push rod is connected with the middle part at the right end of the machine body; a controller is arranged at the upper end of the push rod. The outdoor tennis ball-collecting machine has the advantages of simple structure, novel design, high practicability and capabilities of realizing efficient ball absorption for tennis, preventing workers from picking up the balls by bending down and effectively cleaning the picked balls.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

Aspirator having a cushioned and aspiration controlling tip

InactiveUS20060110702A1Eliminate the problemEffective fluid transferSaliva removersElastomerMedical procedure

A disposable cushioned aspirator which forms part of a dental or medical aspirating system. The disposable cushioned aspirator appliance described herein is intended principally to be used in dental and medical procedures where body fluids and rinse water is evacuated from the site of a procedure. An elongate tubular element has a connection end and a patient end. The patient end is exteriorly lined with a layer of soft cushioning material such as a soft thermoplastic elastomers, styrene based polymers, rubber or a porous polymer foam material to define an aspirator tip that protects the soft tissues in and around the mouth of a patient. The soft aspirator tip has external longitudinal pressure relief channels and recessed aspiration openings within the channels for control of aspiration characteristics. The aspirator tube is capable of being manually bent to a desired configuration and has an embedded structural member such as wire extending along its length and being pliable to permit bending and yet of sufficient structural integrity to maintain the aspirator in the desired configuration during use.

Owner:MAHLMANN LEE A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com