Section port body and vacuum cleaner

A suction port and mouth body technology, applied in vacuum cleaners, suction nozzles, cleaning equipment, etc., can solve the problems of inability to suction wall dust, low dust suction efficiency, and inability to effectively suction dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the suction port body and the vacuum cleaner using the suction port body according to the present invention will be described in detail with reference to the drawings.

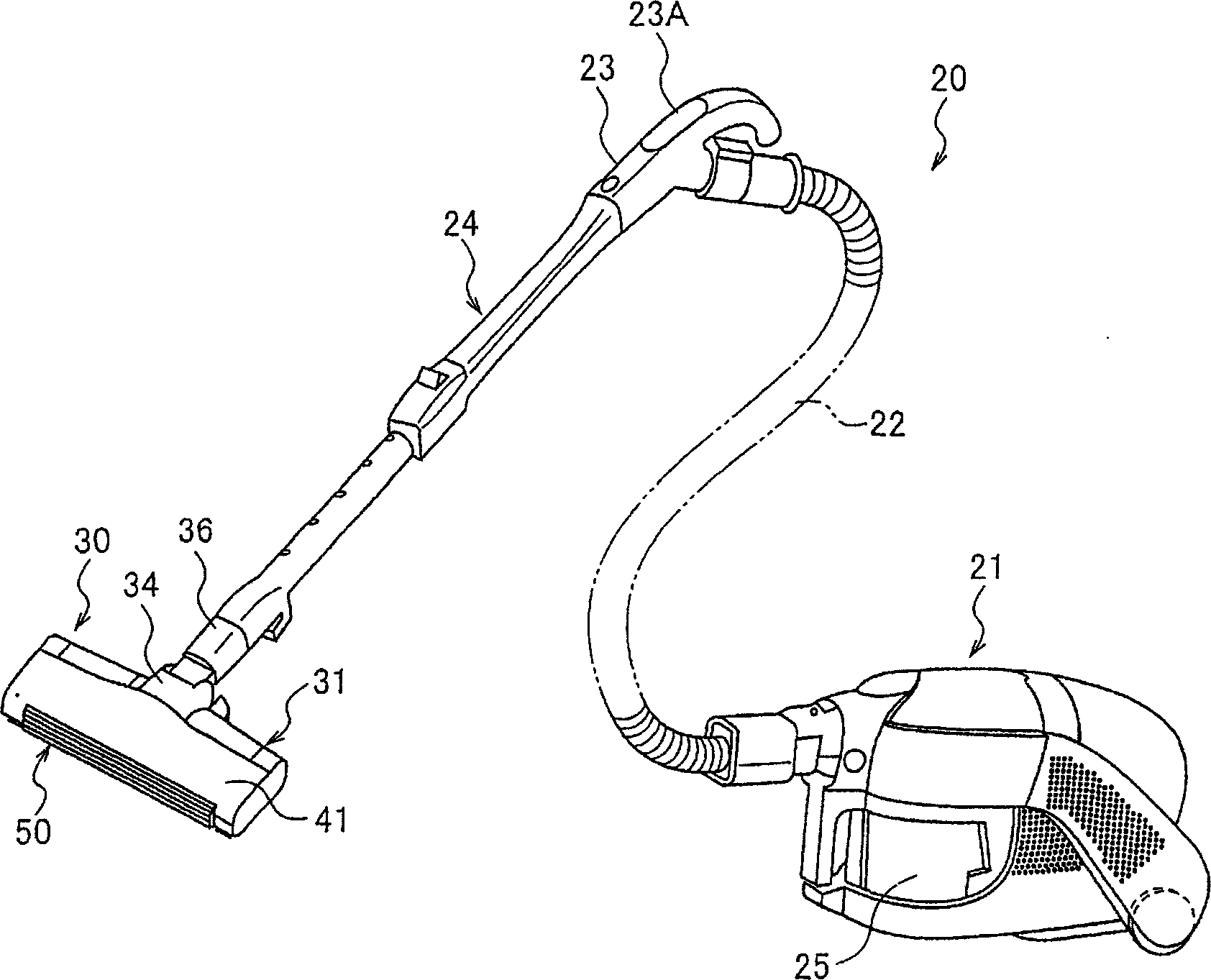

[0027] figure 1 It shows the vacuum cleaner 20 to which the suction port body 30 of this invention was applied. The vacuum cleaner 20 has: a vacuum cleaner main body 21; a hose 22, one end of which is connected to the vacuum cleaner main body 21 in a detachable manner; and an extension pipe 24, which is arranged on the other end of the hose 22 in a detachable manner The manual operation tube 23 is connected. The suction port body 30 is detachably connected to the front end portion of the extension pipe 24 .

[0028] The operation part 23A is provided on the manual operation pipe 23, has operation switches, operation buttons, etc. (not shown), and is used to operate the vacuum cleaner.

[0029] The vacuum cleaner main body 21 is provided with a dust collection container 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com